Page 1

PDP MONITOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MP-00MB

MODEL : MT/MZ-40PA10/G/S

MODEL : MT/MZ-40PA20/G/S

MODEL : R4018PDP

MODEL : R40PDP28

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

Contents ................................................................................................................. 2

Safety Precautions ............................................................................................3

Specifications ..................................................................................................... 4

Control Descriptions ........................................................................................ 5

Adjustment Instructions ............................................................................... 8

Block Diagram .................................................................................................... 12

Wiring Diagram ................................................................................................. 14

Exploded View ............................................................................................ 16,18

Exploded View Parts List ........................................................................17,19

Replacement Parts List ............................................................................... 20

SVC. Sheet ................................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

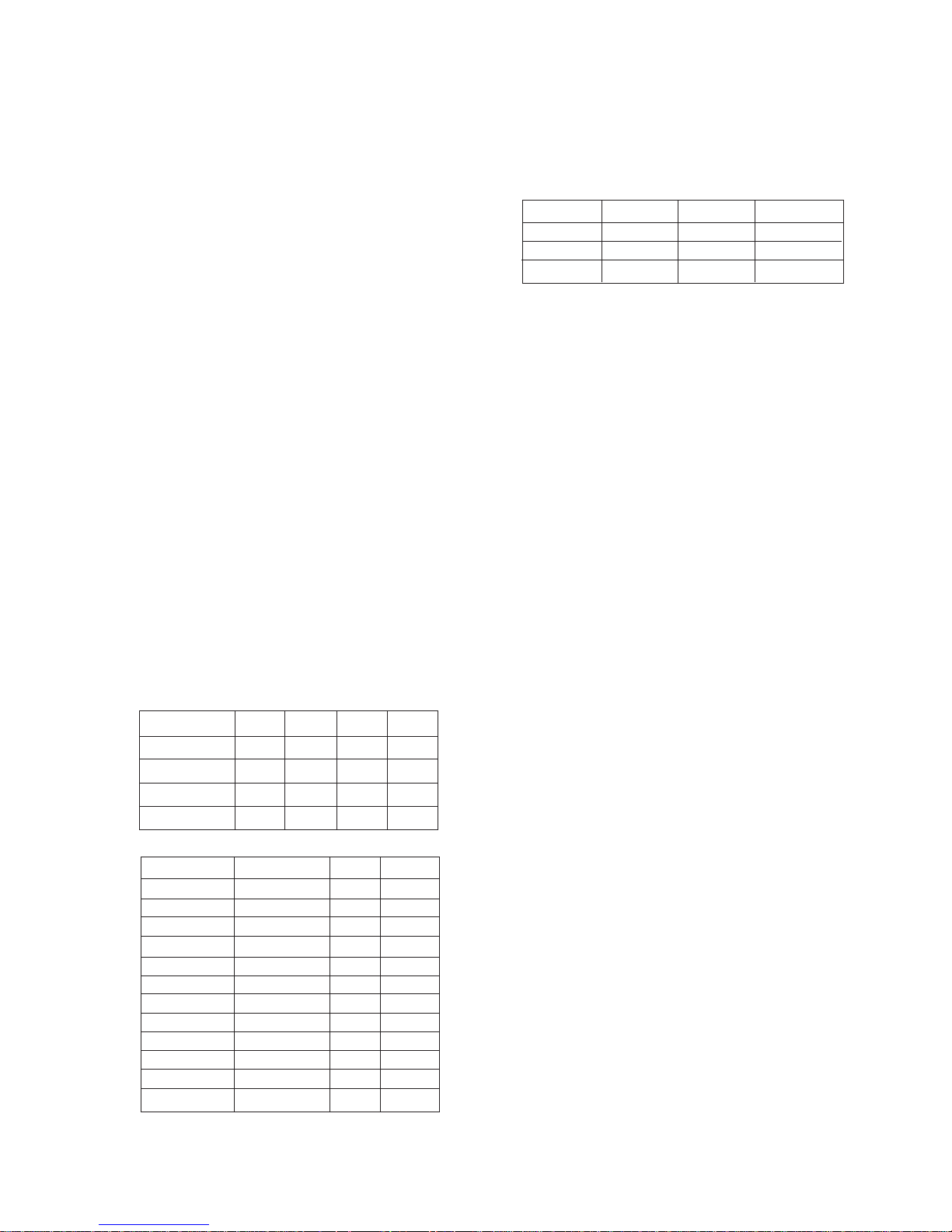

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

O MONITOR

O Video receiving system:

PAL

SECAM

NTSC

VGA

SVGA

O Input Voltage : AC 110~240V, 50/60Hz

O Power consumption : Max 330W

Stand-By : 5W

O PDP Module : PDP40NVVDN4

O Speaker Impedance : 8 ohm

O Sound output : 20W max

O Feature : AV Input (Bottom)

Component Input (Bottom)

RGB Input (Bottom,D-Sub 15pin)

External SPK Out (Bottom,SPK Jack)

STB Control Input (Bottom)

STB Audio Input (D-Sub 25pin)

O Funtion : PSM

SSM

Child Lock

Auto Sleep

O External Interface

AV/COMPONENT Output

COMPONENT Mode ( Y,Cb/Pb,Cr/Pr)

OSET TOP BOX

O Video receiving system:

PAL-BG/DK/I

NTSC M

O Input Voltage : AC 110~250V, 50/60Hz

O Tuning System : FVS 100 Program

O Power consumption : Max 35W

Stand-By : 5W

O Available Channel : VHF : E2~E12(L/L’:B,C,D)

UHF : E21~E69

CATV : S1~S20(HYPER:S21~S41)

O Feature : AV In/out(RCA) : AV1(With RGB in/TV out)

AV In/out(RCA) : AV2(Monitor out)

AV In : AV3(Rear,CVBS)

S-Input : S-Input

Y,Pb,Pr Input : Component(Rear,480I,480P)

RGB Input : RGB-PC(Rear,D-Sub 15pin)

Audio-Input : Component/RGB- PC

RGB out : RGB-PC(Rear,D-Sub 15pin)

RGB out/Control :

PDP MNT connection:RGB,Control

AUDIO out :

PDP MNT connection:L,R(D-Sub 25pin)

Woofer out :

Woofer Speaker

O Funtion : PSM

SSM

Teletext

Auto Sleep

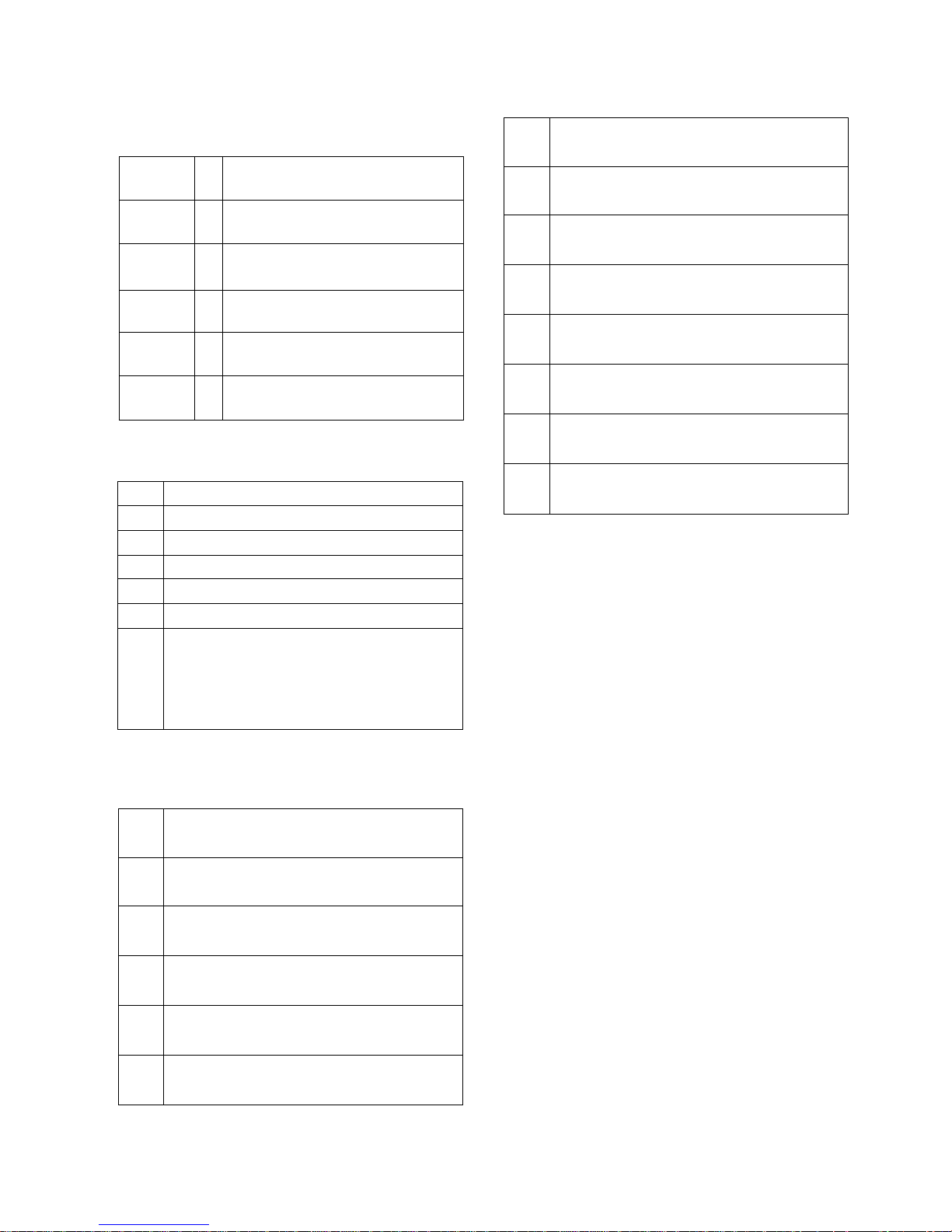

ITEM

AV Video out

AV SYNC out

AV Burst out

AV Audio Out

MIN

0.85

0.25

0.15

0.40

TYP

1.00

0.30

0.30

0.50

MAX

1.15

0.35

0.35

0.60

UNIT

Vpp

Vpp

Vpp

V

PIn Name

R

G

B

GND

H.Sync

V.Sync

STB-DET

SCL

SDA1 out

SDA1 in

SDA2 out

SDA2 in

Spec.

0.7Vpp

¡ 0.05

0.7Vpp¡ 0.05

0.7Vpp¡ 0.05

Case Common

4.0Vpp¡ 0.5

3.0Vpp¡ 0.5

High/Low

3.0~4.5Vpp

3.0~4.5Vpp

3.0~4.5Vpp

3.0~4.5Vpp

3.0~4.5Vpp

Pin

VSC-Det

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

No.

13

14

15

16

17

18

19

20

21

22

23

24

REsolution

640*480

640*480

704*480

H-Freq(Khz)

15.73

15.63

31.47

V-Freq(hz)

60

50

59.94

Proposed

SDTV,DVD 480I

SDTV,DVD 480I

SDTV 480P

RGB/HV Control Signal In/Out(D-Sub 25pin Cable)

Page 5

- 5 -

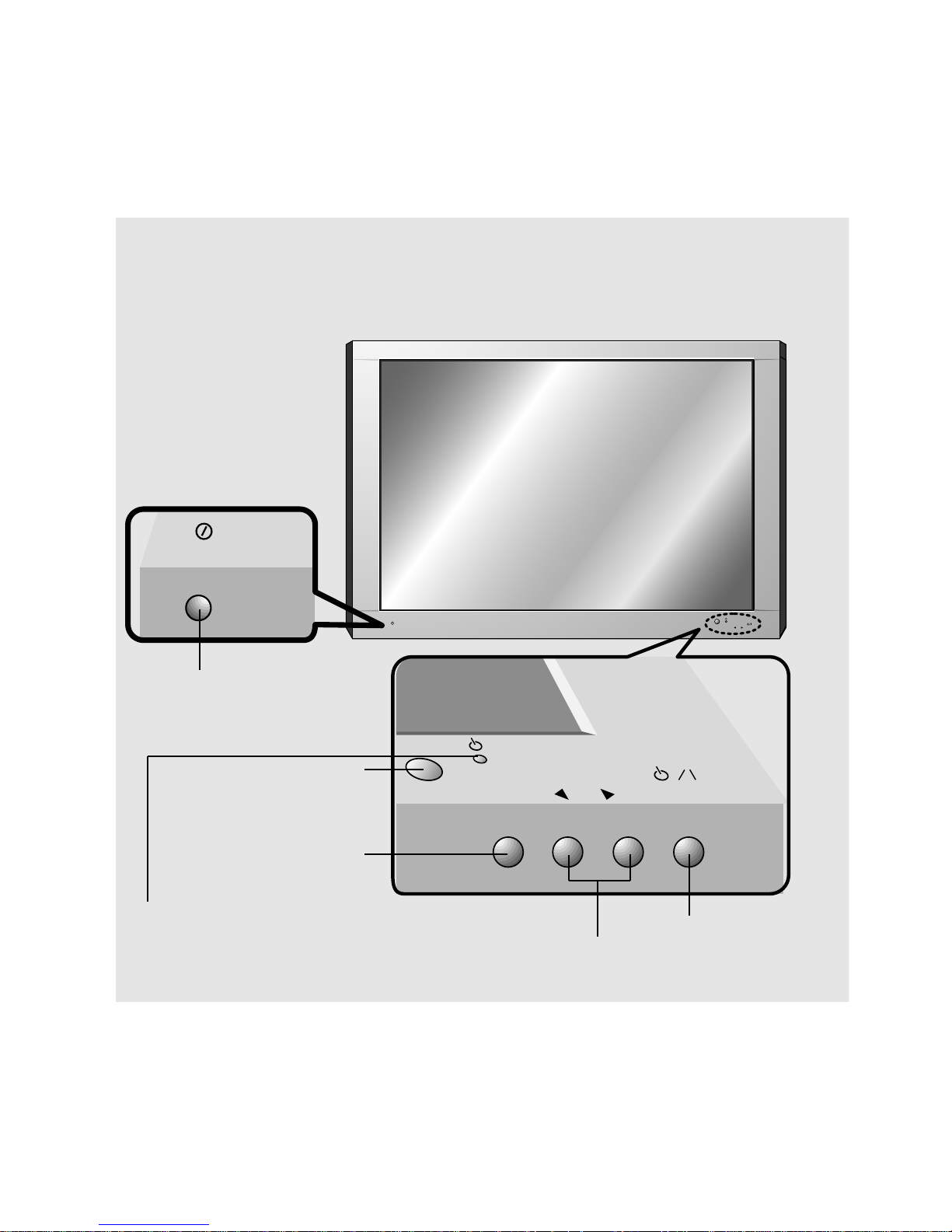

CONTROLS DESCRIPTION

ON/OFF

VOLUME

INPUT

SELECT

ON/OFF

INPUT

VOLUME

SELECT

<Front Panel>

MAIN POWER BUTTON

INPUT SELECT BUTTON

REMOTE CONTROL SENSOR

POWER/STANDBY INDICATOR

Illuminates red in standby

Illuminates green when the Monitor is switched on

POWER BUTTON

VOLUME (FF,GG) BUTTON

Page 6

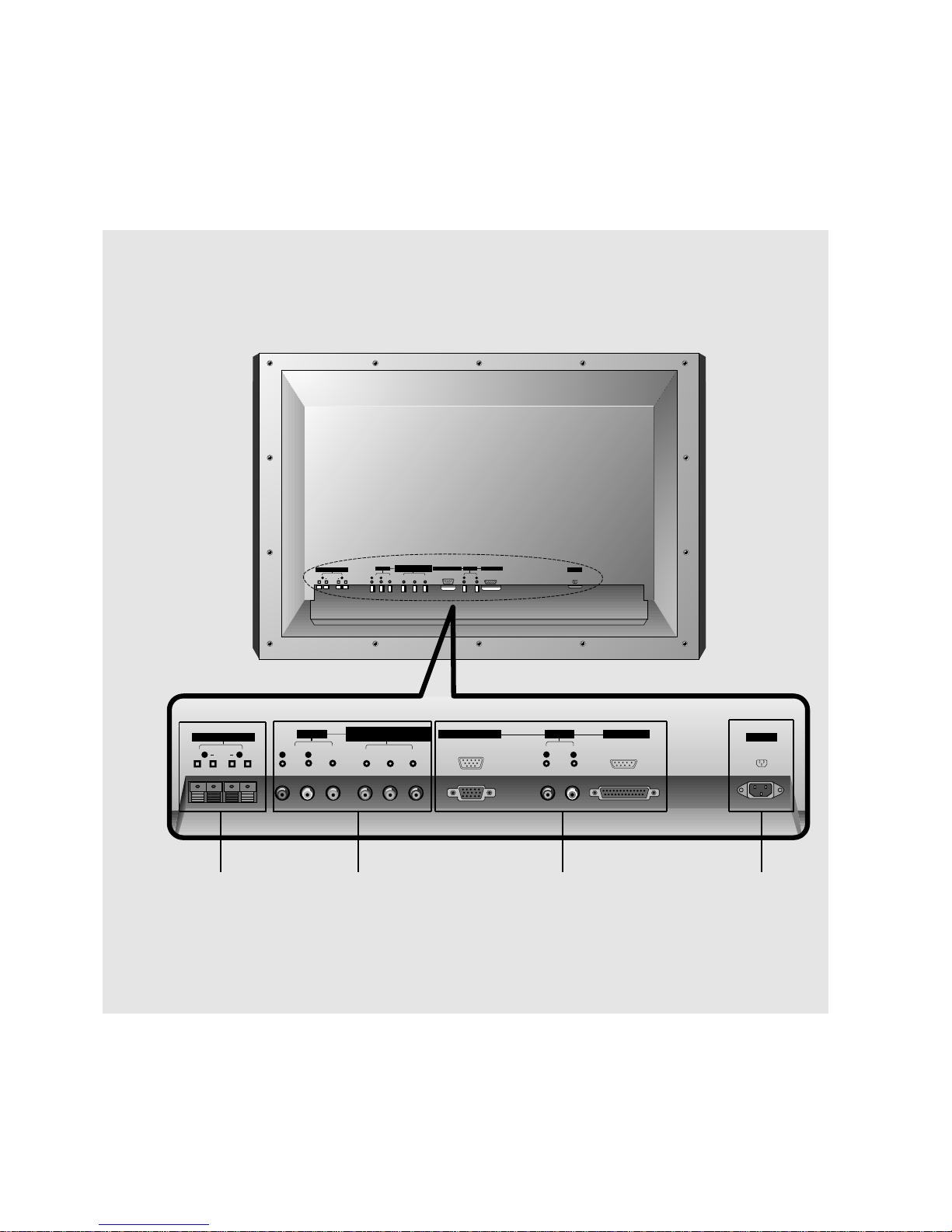

- 6 -

P

B R

Y P

(+) ( ) (+)( )

AC INPUT

EXTERNAL SPEAKER (8Ω)

AV INPUT

RGB-PC INPUT(VGA/SVGA)

R RL L R

AUDIO INPUT RGB INPUT/CONTROL

L

AUDIO

(MONO)

VIDEO

COMPONENT (480i/480p)

(DVD INPUT)

PBY

R

P

(+) ( ) (+)( )

AC INPUT

EXTERNAL SPEAKER (8Ω)

AV INPUT

(DVD INPUT)

COMPONENT (480i/480p)

RRL

L

R

AUDIO INPUT RGB INPUT/CONTROL

L

AUDIO VIDEO

(MONO)

RGB-PC INPUT(VGA/SVGA)

<Back Panel>

EXTERNAL

SPEAKER (8Ω)

KNOBS

AV INPUT /

COMPONENT (480i/480p)

DVD INPUT SOCKETS

RGB-PC INPUT (VGA/SVGA) /

AUDIO INPUT /

RGB INPUT/CONTROL SOCKETS

POWER INPUT

SOCKET

This Monitor operates

on an AC mains supply,

the voltage is as indicated as inside back cover

of this manual. Never

apply DC power to the

Monitor.

Page 7

- 7 -

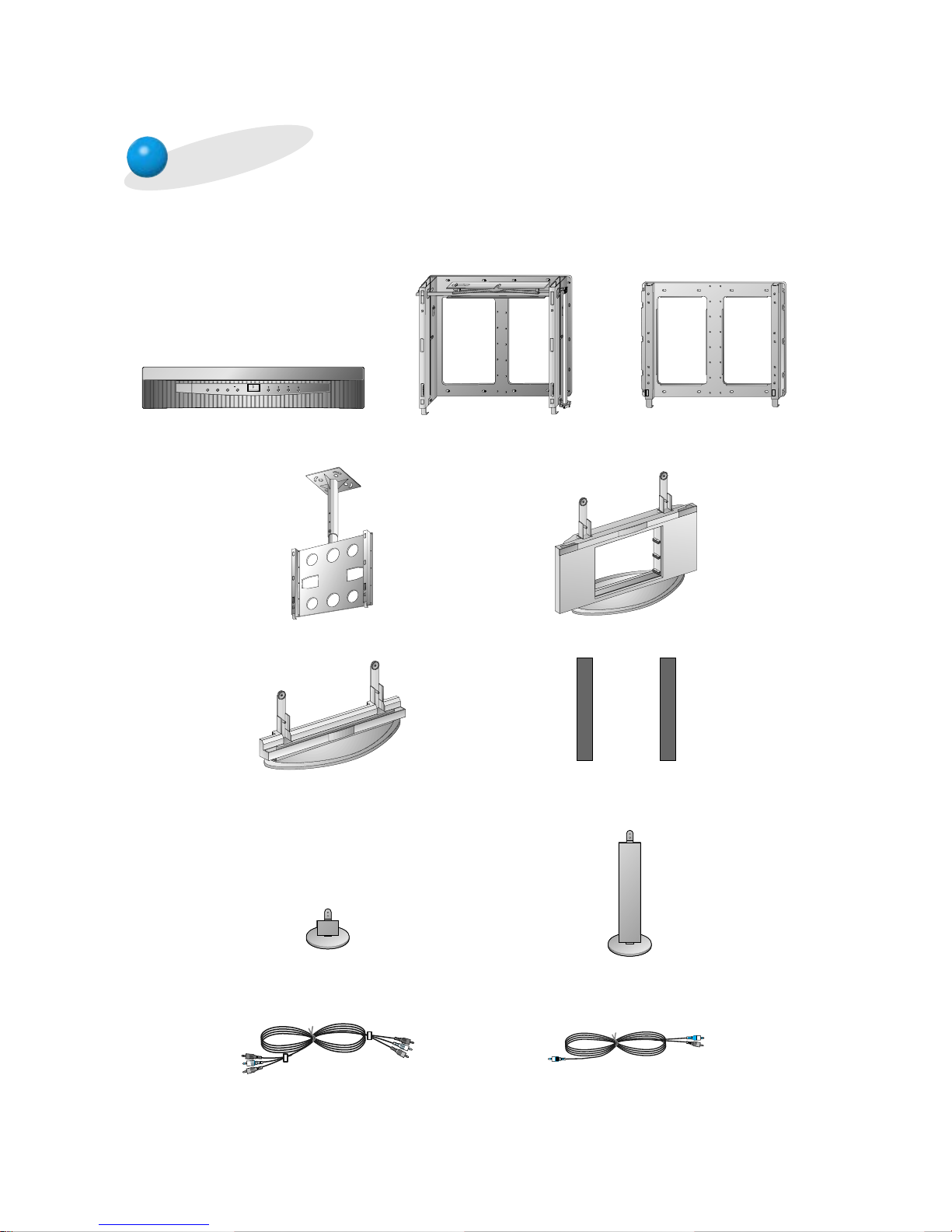

AP-40/42WA20M

(Tilt wall mounting bracket)

AP-40/42WA10

(Wall mounting bracket)

MULTIMEDIA

ON/OFF

TV/VIDEO MENU ENTER

VOL CH

RT/RZ-BA10 (PDP Tuner)

Optional Extras

- Optional extras can be changed or modified for quality improvement without any notification new

optional extras can be added.

- Contract your dealer for buying these items.

AP-40/42CA10 (Ceiling mounting bracket)

AP-40/42FA10 (Floor type stand)

AP-40/42DA10 (Desktop stand)

AP-40/42SA10 (Speakers)

AP-40/42SA10D

(Speaker stand)

AP-40/42SA10F

(Floor type speaker stand)

Video cables

Audio cables

Page 8

- 8 -

1. Application Object

These instructions are applied to all of the PDP monitor, MP00MB.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220/230V,

50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

¤ŁEnter into HEAT-RUN mode

- Select the HEAT-RUN OFF by pressing ADJ button on

Remote Control for adjustment.

- Press the VOL + button in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% full WHITE PATTERN)

¤ØSet is activated HEAT-RUN without SET TOP BOX or

signal generator in this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterinage may be occur in the black level part of the

screen.

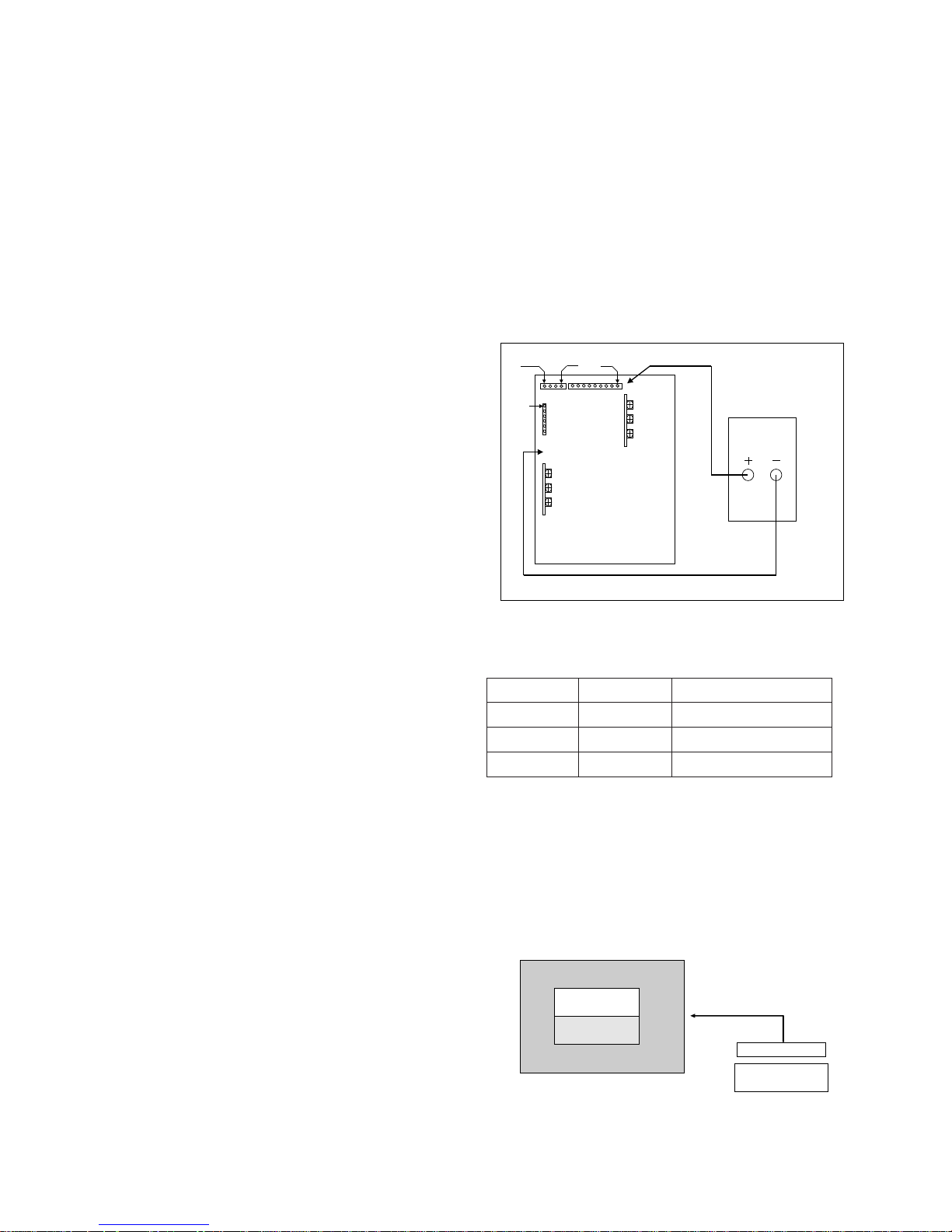

3. POWER PCB Assy Voltage Adjustment

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

3-1. Test Equipment

D.M.M 1EA

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method

(1) Va Adjusment(Address Voltage Adjusment)

¤ Connect pin 1 of P806 or P811 to (+) jack of D.M.M.

¤ŁAfter turning the VR803(Va Adj), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/bottom.(Deviation : ±0.5V)

(2) Vs Adjustment

¤ Connect pin 9 of P803 to (+) jack of D.M.M.

¤ŁAfter turning the VR804(Vs Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

(3) VSC Adjustment

¤ Connect pin 4 of P802 to (+) jack of D.M.M.

¤ŁAfter turning the VR806(VSC Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

(4) VSETUP Adjustment

¤ Connect pin 1 of P802 to (+) jack of D.M.M.

¤ŁAfter turning the VR805(VSETUP Adj),voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

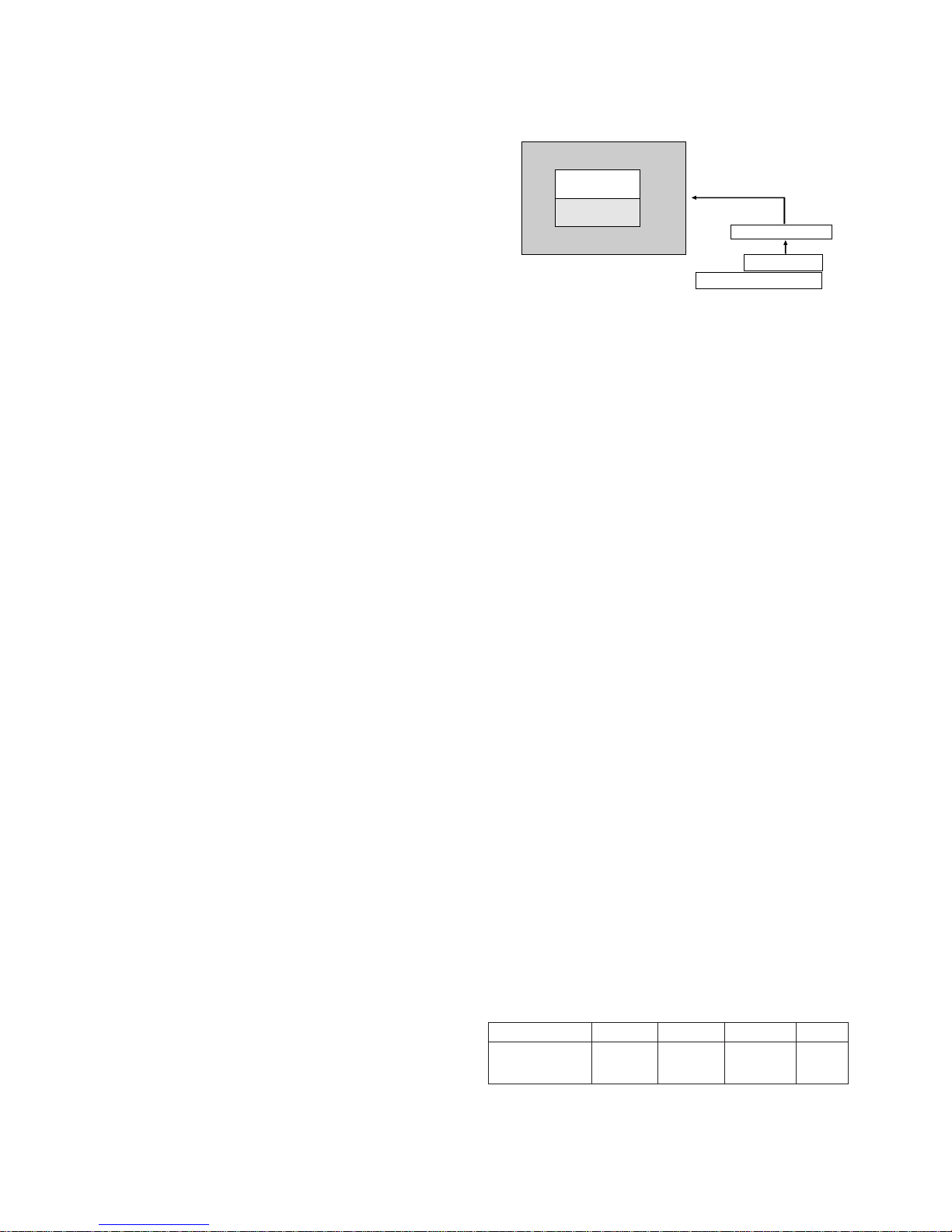

4. Adjustment of RGB Cut-off and

White Balance

4-1. Required Equipment

Color analyzer(CA-100 or same production)

4-2. Connection Diagram of Equipment for

Measuring

ADJUSTMENT INSTRUCTIONS

VSETUP

VR806

VR805

VR804

DMM

VSC

VA

VSC CTL

V

A CTL

P814

VR803

GND

V

SETUP CTL

V

S CTL

V

S

<Fig 1> Connection Diagram of Power Adjustment for Measuring

Refer to Typical Voltage

Va

Vs

Vsc

Vsetup

70V

182V

75V

225V

Address Voltage

Sustain Voltage

Scan Voltage

Setuo Voltage

COLOR

ANALYZER

TYPE; CA-100

Window Pattern

CVBS Signal Input

High Light

120±5cd/m2

Low Light

6±1cd/m2

PDP MONITOR

MSPG-2100 or

MSTG-5200

<Fig 2> Connection Diagram of Automatic Adjustment

Page 9

- 9 -

4-3. Adjustment of RGB CUT OFF

(1) Select A/C SRT (cut-off automatic adjustment ) by

pressing SVC button on Remote Control for adjustment.

(2) Press the VOL + or VOL - button.

(3) It displayed all of the black on the screen and then

adjustment is started.

(4) If adjustment is finished, exit from adjustment mode by

pressing A/V button.

4-4. Adjustment of White Balance

• White Balance should be done after RGB cut-off become

adjustment.

• Operate the Zero-calibration of the CA—100, then stick

sensor to PDP module surface when you adjust.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

SVC button on Remote Control for adjustment then

operate HEAT RUN more than 15 minute.

(2) Supply window Signal in pattern generater.

[ When adjustment is operated manually, perate process (3)

to (6) regular sequence, when adjustment is operated

automatically perate process (1)~(2).

(3) To adjust Low Light, stick sensor to pattern(Dark), select

the R cut/B cuby pressing SVC button on Remote Control

for adjustment and adjust it until color coordination

becomes X=0.280±0.003, Y=0.310±0.003 and color

temperature becomes 8.800

cK ± 500cK by pressing VOL+,

- button. (G-cut fixation)

(4) To adjust High Light, stick sensor to pattern(White).

Select the R Gain/G Gain(adjustment 6) by pressing SVC

button on Remote Control for adjustment and adjust R

Gain/G Gain until color coordination becomes

X=0.280±0.003, Y=0.310±0.003 and color temperature

becomes 8.800cK ± 500cK.(B-Gain fixation)

(5) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(6) Exit adjustment mode using AV button.

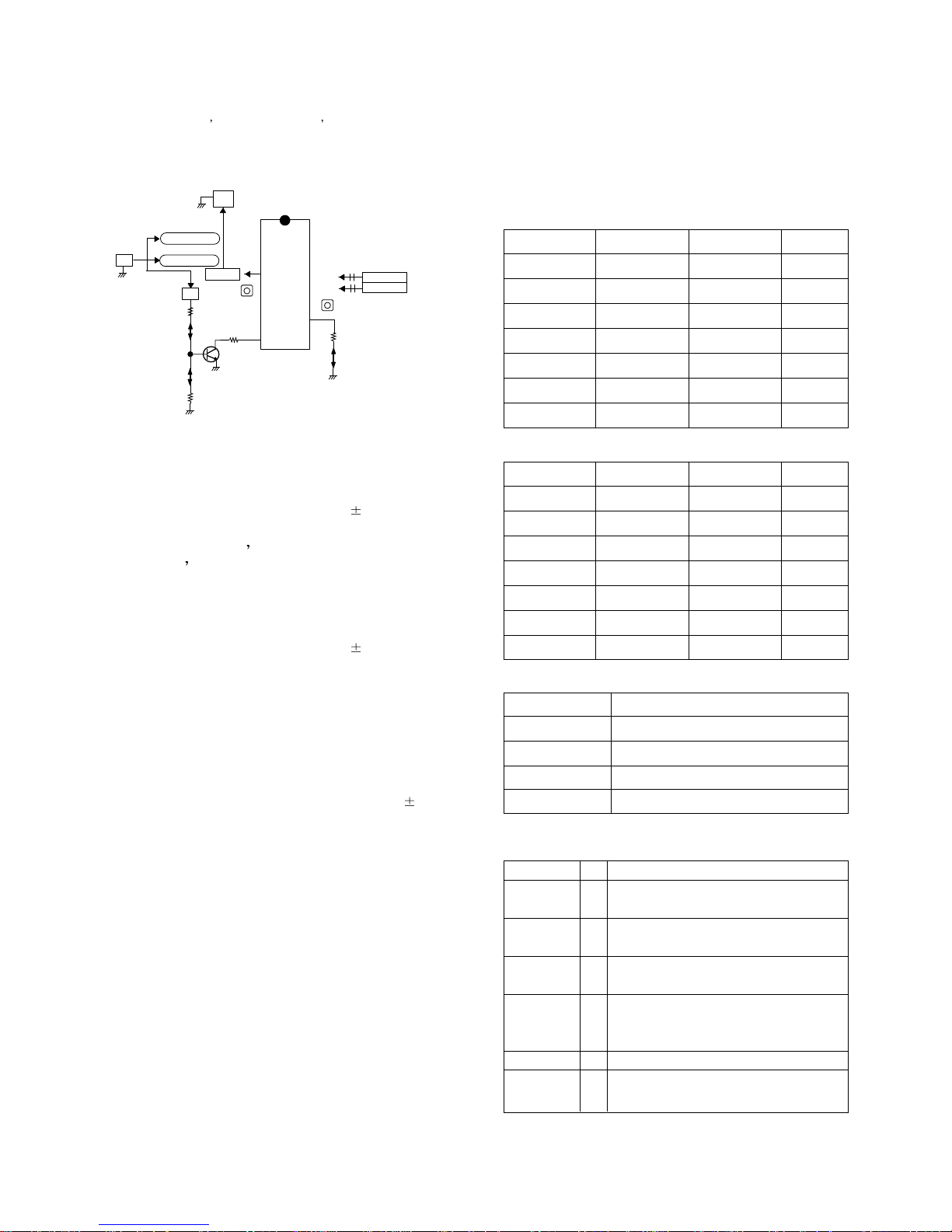

5. Color Temperature of STB

White Balance Adjustment

5-1. Required Equipment

Color Analyzer(CA-110, CA-100 or same production)

5-2. Connection diagram of equipment for

measuring

(1) To adjust the deviation of the STB signal output.

(2) Use regular PDP Monitor(JIG).

5-3. Adjustment Method

• Connect the STB to regular PDP Monitor.

• Operate the zero-calibration of the CA-100, then stick

sensor to surface of PDP module when you adjust.

(1) Select ITE PATTERN of HEAT RUN mode by pressing

SVC button on Remote Control for adjustment, then

operate HEAT RUN more than 15 minute.

(Operate the HEAT RUN to adjust the STB at first, then if

OFF hour don’t keep more than 3 minutes, operate next

adjustment of the STB without HEAT RUN.)

(2) Supply window Signal to TD-710 in pattern generator.

[ When adjustment is operated manually, perate process (3)

to (7) regular sequence, when adjustment is operated

automatically perate process (1) to (2).

(3) Select STB CXA2101 by pressing SVC,ADJUST button on

Remote Control for adjustment.

(4) To adjust Low Light, stick sensor to 9th pattern(Dark).

Select the B Cut/R Cut, then adjust the B Cut/R Cut until

color coordination becomes X=0.280±0.003,

Y=0.310±0.003 and color temperature becomes 8.800cK ±

500cK by pressing VOL+, - button. (Adjust in B Cut 10±1,

R Cut 6±1)

(5) To adjust High Light, stick sensor to 2th pattern(White).

Select the R Gain/G Gain, then adjust the R Gain/G Gain

until color coordination becomes X=0.280±0.003,

Y=0.310±0.003 and color temperature becomes 8.800cK

±500cK. (B-Gain fixation)

(6) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(Expectation average adjustment data : B-Cut & RCut=6±2, R-Gain/G-Gain=25±3)

(7) Exit adjustment mode using A/V button.

6. Adjustment of VIF-VCO COIL

6-1. Preparation for Adjustment

(1) Connect the equipment for measuring as below.

(2) Setting equipment for measuring.

RF Signal generator

COLOR

ANALYZER

TYPE; CA-100

CVBS Signal Input

PDP MONITOR

RT-BA10(STB)

Window Pattern

MSPG-2100 or MSTG-5200

High Light

120±5cd/m2

Low Light

6±1cd/m2

<Fig 3> Connection Diagram of STB Automatic Adjustment

ADJ.Point

X106

VR101

System

B/G,D/K/I,SECAM-L

SECAM-L’

Frequency

38.9

34.25

Modulation

OFF

OFF

Level

80dBuV

80dBuV

Page 10

* If any model don t have SECAM-L/L System, you should not

operate adjustment of VR101.

* Output of Power Supply = DC 5V

* Oscilloscope range = set 0.5V/div., 5msec/Div.(using scope)

6-2. Adjustment 38.9MHz IF(B/G, D/K, I, L, M)

(1) Input the signal of the signal generater(38.9MHz) to

TP105(IC102 pin 7) through 0.01uF(103) capacitor.

(2) S1 : OFF, S2 : IN, S3 : OFF

(3) Adjust voltage of the TP103 to 2.5

0.1V by adjusting

X106.

6-3 Adjustment L VCO(Adjustment

SECAM-L ) --> Only SECAM L model

(1) After changing the signal of the signal generater to

34.25MHz, input the signal to TP102(IC102 pin 11) through

0.01uF(103) capacitor.

(2) S1 : on, S2 : off, S3 : ON

(3) Adjust voltage of the TP103 to 2.5

0.1V by adjusting

VR101.

7. Adjustment AGC

7-1 Preparation for Adjustment

(1) Connect the signal of PAL-B/G 05ch. to Antenna jack.

(2) Connect Multi meter to point(J150) of AGC adjustment.

7-2 Adjustment

Adjustment the voltage of Multi meter to 2.3 0.1V by

changing VR102.

8. OPTION TABLE

8-1 Funtion of Line Service

(1) • Enter to SVC mode by using SVC button on the remote

control.

•To enter to the SVC mode,press the “OK” button on RTBA10 local key ond “OK” button on the remote control

simultaneously.

• In MT-BA10 only,press the “INPUT” button and “OK” button

on remote control to enter to SVC mode.

(2) Select the item by using the Quick View(Yellow) button.

(3) After adjusting,restore adjusted item in EEPROM by using

“OK” button and use the CYAN button to cancel the

adjusted condition.

(4) Select the program directly and input the data of option by

using the number button.

(5) Line SVC-0(Hitrun&W/B Adj.mode)=> VSC EEPROM

• H/T RUN:OFF,WHITE,RED,GREEN,BLUE,OFF

• A/C SRT:Auto Cutoff

• R/G/B Fine 16,R/G/B Gain 3,R/G/B Cutoff 100

(6) Line SVC-1(Phase&Position Adj.mode)=> VSC EEPROM

• Phase 15,H-Pos 32,V-Pos 32,Auto Position

(7) VSC CXA2101 Adj.mode)=> VSC EEPROM

(8) STB CXA2101 Adj.mode)=> STB EEPROM

(9) SOUND Adj.mode => VSC EEPROM

(10) Option 1 Adj.mode => VSC EEPROM

• Select it directly by using Teletext Size button.

- 10 -

IC102

TDA4474

TP103

ST-BY 5V:P001

24

7

13

15

1

0.01uF

TP105

X106

(VCO)

5V

PowerSupply

V Multimeter or Oscilloscope

TP110

38.9MHz

34.25MHz

(B/G,D/K,I,L)

(SECAM-L')

100 ohm

S1

5V

4.7 Kohm

S3

Q122

VR122

R144

16

TP112(IF VCC)

S2

TP111

100 ohm

11 TP102

VR102(AGC)

(STB MAIN)

BC 7

RC 7

RG 10

GG 10

BG 10

SUB-CON 3

SUB-BRI 54

SUB-COL 0

SUB-HUE 14

SUB-SHP 3

CTI 0

RYR 6

GYR 10

RYB 9

GYB 5

GMM 5

BLK 15

PRE 1

DCT 1

DPI 2

VTC 3

HWI 1

DCO 1

HDT 0

SFO 1

BC 7

RC 7

RG 31

GG 31

BG 31

SUB-CON 3

SUB-BRI 54

SUB-COL 0

SUB-HUE 7

SUB-SHP 0

CTI 0

RYR 6

GYR 10

RYB 9

GYB 5

GMM 0

BLK 15

PRE 1

DCT 0

DPI 0

VTC 3

HWI 1

DCO 0

HDT 0

SFO 1

CON 25

BRI 31

COL 31

HUE 31

SHP 31

FP

NP

SP

SC VOL

STB VOL

14

80

25

83

118

System

Aus/China

ACMS

TOP

A2MONO

TXT LAN

Language

2

0

1

0

0

6

6

0:BG/I/DK 1:BG/I/DK/L 2:BG/I/DK/M

0:CCIR BG/OIRT DK

1:Australia BB/China DK

0:

1:Channel Name Labeling

0:TOP=>SIMPLE

1:TOP

0:Sound treatment normally

1:Don’t recognize the Stereo(NICAM

treatment normally) => A part of AFRICA

0:E only,1:EU5,2:NON,3:China,4:Arabic

5:Parsi,6:All

Page 11

(10) Option 2 Adj.mode

• Select it directly by using Teletext Hold button.

8-2 OSD LANGUAGE

( Select a one among Option in SVC Mode-Language item.)

8-3 TXT LANGUAGE

( Select a one among Option in SVC Mode-TXT LAN item.)

- 11 -

Turbo

I/II save

Woofer

TEXT

Vol Curve

PIP

0

1

0

0

1

0

0:NORMAL Search

1:Turbo Search not use

0:EU

1:NON EU

0:Without Woofer

1:With Woofer

0:Without TEXT

1:With TEXT

0:EU Curve

1:Non EU Curve

0:Without PIP

1:With PIP

0

1

2

3

4

5

6

E Only(English)

EU5(Enlish,German,French,Italian,Spanish)

NON 12

CHINA(English,Chinese)

ARAB(English,French,Arabic,Urdu)

PARSI(English,Parsi)

ALL(Enlish,Norwegian,Czech,German,Danish,Ru

ssian,French,Finish,Chinese,Italian,Portuguess,

Arabic,Spanish,Rumanian,Urdu,Dutch,Polish,

Persian,Swedish,Hungarian)

6

38

40

55

70

128

English,French,SWedish,Czech,German,

Spanish,Italian

Polish,French,SWedish,Czech,German,Spanish,

Italian,English

English(US),French,SWedish,Czech,German,

Spanish,Italian,English(TPU3050 US)

English,French,SWedish,Turkish,German,

Spanish,Italian,English(TPU3050 Turkish)

English(US),Slovakian,Hungarian,Serbian,

Albanian,Polish,Turkish,Rumanian

Polish,Cylrillic,Estonia,Estonia,Estonia,Estonia,

Estonia,Estonia(TPU3051)

128

129

129

130

130

131

131

132

English,French,French,French,French,French,

French,Arabic(TPU3052)

Polish,Cylrillic,SWedish,Czech,Estonia,Estonia,

Estonia,Estonia(TPU3051)

Hebrew,Hebrew,Hebrew,Hebrew,Hebrew,

Hebrew,Hebrew,Arabic(TPU3052)

English,French,SWedish,Turkish,German,

Spanish,Italian,Greek(TPU3051)

English,French,French,Turkish,French,French,

French,Italian(TPU3052)

English,Turkish,Turkish,Turkish,German,Turkish,

Turkish,Greek(TPU3051)

French,French,French,Turkish,French,French,

French,Italian(TPU3052)

English,French,French,French,French,French,

Arabic(TPU3052)

Page 12

- 12 -

BLOCK DIAGRAM

1. VSC Board

Chip for flat panel display application

VGA XGA scale up/down

Triple 8Bit, 80MSPS, 3.3V Video&Graphic Digitizer

with Digital PLL

Analog R/G/B Input to 3X8 Digital R/G/B Output

Display Processor & Scan Rate Converter

(Format Converter)

Interlace to Progressive

15KHz 31KHz(2H X 1V)

Comb Filter Video Process

CVBS(Composite Video Baseband

Signal) Input to Y/C(Y,U,V) Output

P101

V/R/L

P102

DVD

DS102

DS101

IC203

VPC3230

Decoder

80Pin

3

Y,Cb,Cr

CVBS

(A)

1

IC204

SDA9410

Deinterlace &

D/A

100Pin

&

8 LU0-7

8

CHR0-7

IC303

Video&Chroma

CXA2101AQ

80Pin

STB-R/G/B/HS/VS(A)

5

PC-R/G/B/HS/VS (A)

5

DTV-Y/Pb/Pr (A)

3

TV-Y/U/ V/HS/VS

(A)

5

THS8083

100Pin

IC304

3 CXA-R/G/B(A )

MX88L284

3X2M

Scan converter

208Pin

IC401

IC001

M37270

Micro-Com

IC403

2M

SDRAM

IC402

2M SDRAM

(R/G/B)(D)

CAX-HS/VS

2

16

D0-16

A0-10

D16-31

11

16

OSD_R/G/B/YS

4

IC501

74F541

IC502

74F541

IC503

74F541

Buffer

IC504

74F541

OSD_HS/VS

2

HS/VS/Black/Clk

4

8

DOR0-7

8

DOG0-7

8

DOB0-7

STB-POWER

VSC DET/POWER

HDSTB_DET

STB_SCL/SDA

ANA_STB_DET

7

PVS/PHS

Black/Clk

4

PAR0-7

8

PAG0-7

8

PAB0-7

8

PD501

(41Pin)

PDP Module

(D)

3X8

Multi-Component Processor

(Baseband Video Signal Processor)

STB, PC, DTV, TV signals Input to Analog R/G/B Output

D-sub

25

D-sub

15

IC604

LA7222

(Audio S/W)

(A)

P601

L/R

RGB-PC

AV/DVD/COMPONENT

IC602

CXA2022S

(Tone Control)

IC603

LA4282

Audio Amp.

(12Wx2)

L/R

P007A

(Spk. Jack)

I C

IC203,204,303,304,407

IC002

24C16

IC407

SC786102DW

OSD IC

2 22

L/R

L/R

HS/VS

SDA2

SCL2

LLC1/2

2

VS

PLL HS/

CLK

2

Page 13

- 13 -

2. STB Main

TUNER

CXA2069Q

A/V SW

DC 12V

V, L/R

CVBS

(RCA JACK)

V, L/R

* SCART2 : HALF

* RCA Jack

Common Use

*PCB LayOut)

V, L/R

TV, L/R

(SCART1: FULL)

Y / C

AUDIO

COMMON USE

MSP3411G

Sound

Processor

DC 8V

2 nd

SIF

L/R(TV)

L/R

(RCA JACK)

L/R

CVBS1/Y

TPU3052S

TELETEXT

DC5V

VPC3230D

MAIN

[ADDR: 47]

Video

Processor

DC 6V

C

DVD Y/Cr/Cb

(A)

VPC3230D

SUB

Processor

DC6V

[ADDR: 44]

Video

SDA9410

1H/1V=> 2H/ 1V

DW / PIP / MPIP

DC 3.3V

L / R OUT

CXA2101AQ

RGB

Processor

DC9V

DTV Y, Pb, Pr (A)

H V

R/G/B/HS/VS(A)

CVBS2/Y

R/G/B

HS/VS(A)

R/G/B

HS/VS(A)

IF IC

TDA4474

DC5V

FB

CVBS.3

RGB

C

EXT_RGB

BA7657F

RGB

S/W

DC 5V

R/G/B

HS/VS(A)

81

FIFO

Memory

V04160

RE

WE

RF

SVHS

AV3

AV2

MNT

OUT

DVD/DTV

TV

OUT

AV1

P801

7PIN

Y/ C/HS/VS (D)

M37272

u-COM

IC 001

KEY-1

K

IN

K

OUT

I

2

C

SCL-A

SDA-A

I

2

C

SCL-A

SDA-A

I

2

C

SCL-A

SDA-A

I

2

C

SCL-A

SDA-A

I

2

C

SCL-D

SDA-D

I

2

C

SCL-D

SDA-D

DS 701

(25Pin

Cable)

SCL-A/D

SDA-A/D

9

10

PC- IN

PC- OUT

PC Audio(Stereo)

Page 14

- 14 -

WIRING DIAGRAM

P15

P004B

P004A

P14

PD501

P100

P802

P803

P802

P801

P006A

P810

P811

P806

P801

P809

P815

P005A

P003A

P304

P007B

P007A

P302

P301

P303

P807

P805

P804

P102

Page 15

MEMO

- 15 -

Page 16

- 16 -

EXPLODED VIEW (MONITOR)

300

301

303

305

302

200

201

202

203

204

205

206

210

207

209

208

400

401

550

551

530

570

540

520

560

211

212

Page 17

- 17 -

EXPLODED VIEW PARTS LIST

200 6348Q-A002A PDP,40” 4:3 640*480 DOUBLE SCAN

201 6871VSN168A X RIGHT TOP B/D ASSY

202 6871VSN168B X LEFT TOP B/D ASSY

203 6871VSN168C ZCNT TOP B/D ASSY

204 6871VSN168D ZSUS B/D ASSY

205 6871VSN168E ZCNT BOTTOM B/D ASSY

206 6871VSN168F X LEFT BOTTOM B/D ASSY

207 6871VSN168G X RIGHT BOTTOM B/D ASSY

208 6871VSN168H YDRU B/D ASSY

209 6871VSN168J YSUS B/D ASSY

210 6871VSN168K CTRL B/D ASSY

211 4980V00164B SUPPORTER,VERTICAL

212 4980V00164B SUPPORTER,VERTICAL

300 3091V00288C CABINET ASSY LG

3091V00288H CABINET ASSY (SILVER, GREAT WALL)

3091V00288F CABINET ASSY (GOLD)

3091V00A26A CABINET ASSY (40PA20S,LG)

3091V00A26H CABINET ASSY (40PA20S,NO BRAND)

301 4980V00183B SUPPORTER,FILTER(TOP)

302 4980V00180B SUPPORTER,FILTER(BOTTOM )

303 4980V00181B SUPPORTER,FILTER(SIDE)

305 3790V00287A WINDOW FILTER

400 3809V00212C BACK COVER ASSY

3809V00212H BACK COVER ASSY (SILVER, GREAT WALL)

3809V00212F BACK COVER ASSY (GOLD)

401 3301V00005A PLATE ASSY,REAR A/V

3301V00005E PLATE ASSY,REAR A/V (SILVER)

3301V00005D PLATE ASSY,REAR A/V (GOLD)

520 6871VMM704A PWB ASSY,MAIN VSC

530 3501V00028A BOARD ASSY,PDP POWER LINE FILTER

540 6871VSM689A PWB ASSY,CONT

550 6871VSM690A PWB ASSY,PSW

551 5020V00445A BUTTON,POWER

560 6871VSM692A PWB ASSY,AUDIO

570 3501V00027E BOARD ASSY,PDP POWER

No.

Part No.

Description

Page 18

- 18 -

EXPLODED VIEW (SET TOP BOX)

400

174

410

530

300

550

315

320

330

316

311

310

520

540

Page 19

- 19 -

EXPLODED VIEW PARTS LIST

174 174-322G POWER CORD VDE 2400MM HOUSING BLAC

300 3110V00101B CASE ASSY,BOTTOM

310 5020V00443A BUTTON,CONTROL 4KEY

311 5020V00448A BUTTON,CONTROL 4KEY

315 3720V00079A PANEL,FRONT

316 3720V00080B PANEL,CONTROL

320 320-062H SPRING,COIL

330 5020V00444B BUTTON,POWER

400 3110V00102A CASE ASSY,TOP

410 3110V00111C CASE ASSY,REAR

520 6871VMM677A PWB ASSY,MAIN RT-BA10(TPU3052)(PH+PH)

6871VMM677B PWB ASSY,MAIN RT-BA10(TPU3050)(PH+PH)

6871VMM677C PWB ASSY,MAIN RT-BA10(TPU3051)(PH+PH)

530 6871VPM062A PWB ASSY,SMPS MP-00MB STB(TD-711)

540 6871VSM658A PWB ASSY,A/V

550 6871VSM718A PWB ASSY,CTL

No.

Part No.

Description

Page 20

- 20 -

REPLACEMENT PARTS LIST(MONITOR)

LOCA. NO PART NO DESCRIPTION

D401

D402

D601

D602

D603

D604

D605

D606

LD001

LED002

LED003

IC006

IC007

Q001

Q001

Q002

Q002

Q020

Q021

Q102

Q103

Q104

Q105

Q106

Q107

Q108

Q109

Q110

Q111

Q201

Q202

Q301

Q302

Q303

Q601

Q603

C001

C002

C003

C008

C011

C016

C022

C026

C038

C045

C105

C107

C109

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DL200000CA

0DL112100AA

0DL112100AA

0TR830009BA

0TR830009BA

0TR319809AA

0TR387500AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0CN1040K949

0CE476DD618

0CE108BF618

0CE108BF618

0CE108BF618

0CE108BF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE476DF618

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING KDS184S CHIP 85V 300MA KEC TP

DIODE,SWITCHING KDS184S CHIP 85V 300MA

KEC TP

DIODE,SWITCHING KDS184S CHIP 85V 300MA KEC TP

DIODE,SWITCHING KDS184S CHIP 85V 300MA KEC TP

DIODE,SWITCHING KDS184S CHIP 85V 300MA KEC TP

LED,SAM5670(DL-2LRG) BK Y-GREEN -

LED,SR3411(DL-11S2RN1) BK RED -

LED,SR3411(DL-11S2RN1) BK RED -

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,KTC3198-TP-Y (KTC1815)KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,KTC3198-TP-Y (KTC1815)KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

0.1M 50V Z F TA52

47UF STD 10V 20% FL TP 5

1000UF KME 16V M FL TP5

1000UF KME 16V M FL TP5

1000UF KME 16V M FL TP5

1000UF KME 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

47UF STD 16V M FL TP5

LOCA. NO PART NO DESCRIPTION

IC001

IC002

IC003

IC004

IC005

IC101

IC102

IC201

IC202

IC203

IC204

IC301

IC302

IC303

IC304

IC401

IC402

IC403

IC404

IC406

IC407

IC501

IC502

IC503

IC504

IC601

IC602

IC604

D002

D003

D004

D005

D006

D009

D010

D011

D012

D013

D101

D102

D103

D104

D105

D106

D107

D201

D202

D301

D302

0IZZVA0025A

0IAL241600B

0IFA753307A

0IFA754207A

0IFA754207A

0IPH827150A

0IKE780500D

0ISH323422A

0ISH323422A

0IIT323000D

0ISM941000A

0ISH092100B

0ISH323422A

0ISO210100B

0ITI808300B

0IMR882840B

0IEB121616A

0IEB121616A

0ISH323422A

0ISH323422A

0ICTMMO003A

0IPH745410A

0IPH745410A

0IPH745410A

0IPH745410A

0ISH092100B

0ISO202200A

0ISA722200A

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

IC,CXP750010 64 BK MT-40PA10 VSC

IC,AT24C16-10PC 8D EEPROM 16K

IC,KA75330ZTA(KA7533ZTA) 3P,TO-92

IC,KA75420ZTA(KA7542ZTA) 3P,TO-92

IC,KA75420ZTA(KA7542ZTA) 3P,TO-92

IC,P82B715T 8SOP R/TP IIC EXTENDE

IC,KIA7805P(KIA78005AP),KEC

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,VPC3230D QA B4 80P QFP TRAY SO

IC,SDA9410 100QFP BK SCAN CONVERT

IC,PQ09RD21 4SIP

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,CXA2101AQ 80P,QFP BK VIDEO SIG

IC,THS8083 100QFP BK ADC IC PD-40

IC,MX88L284-V 208QFP BK SCALE MF0

IC,M12L16161A-7T 50P TSOP ST 16M(

IC,M12L16161A-7T 50P TSOP ST 16M(

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,SC786107DWR2 MOTOROLA

IC,74F541 20P SOT BK BUFFER MXIC

IC,74F541 20P SOT BK BUFFER MXIC

IC,74F541 20P SOT BK BUFFER MXIC

IC,74F541 20P SOT BK BUFFER MXIC

IC,PQ09RD21 4SIP

IC,CXA2022S 30P SDIP ST TONE CONT

IC,LA7222 (1280 AUDIO)

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

IC

TRANSISTOR

DIODE

CAPACITOR

Page 21

- 21 -

LOCA. NO PART NO DESCRIPTION

C111

C112

C115

C118

C124

C201

C203

C206

C207

C212

C225

C229

C231

C233

C235

C238

C240

C241

C242

C243

C244

C245

C279

C306

C318

C325

C326

C330

C338

C340

C343

C347

C349

C351

C353

C355

C357

C360

C401

C412

C414

C415

C418

C420

C424

C433

C445

C453

C457

C470

C502

C601

0CE476DF618

0CE476DF618

0CE476DF618

0CE476DF618

0CQ3331N509

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CK224DF56A

0CE107DF618

0CE476DF618

0CE107DF618

0CE107DF618

0CE476DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE476DF618

0CE476DF618

0CE105DK618

0CE107DF618

0CE477DF618

0CE476DF618

0CE106DF618

0CE106DF618

0CE476DF618

0CE107DF618

0CE107DF618

0CE477DD618

0CE106SF6DC

0CE106SF6DC

0CE107DF618

0CE107DF618

0CE107DF618

0CE476DF618

0CE107DF618

0CE107DF618

0CE477DD618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE107DF618

0CE477DD618

0CE107DF618

0CE107DF618

0CE106DF618

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

0.033U 100V K POLY TP

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

220000PF 2012 16V 10% R/TP X7R

100UF STD 16V M FL TP5

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

1UF STD 50V M FL TP5

100UF STD 16V M FL TP5

470UF STD 16V 20% FL TP 5

47UF STD 16V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

470UF STD 10V M FL TP5

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

470UF STD 10V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

470UF STD 10V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

10UF STD 16V M FL TP5

LOCA. NO PART NO DESCRIPTION

C602

C603

C604

C605

C606

C607

C608

C609

C610

C611

C612

C613

C614

C615

C616

C617

C618

C619

C620

C621

C622

C623

C624

C625

C626

C630

C631

C634

C635

C641

C643

C644

C645

C646

C647

C650

C651

C653

C654

C655

C656

C659

C660

C660

C663

C664

C665

JP1

P101

P102

0CE106DF618

0CE104DK618

0CQ4721N519

0CE475DK618

0CE475DK618

0CE475DK618

0CE475DK618

0CE475DK618

0CE106DF618

0CQ4721N519

0CE106DF618

0CE104DK618

0CE475DK618

0CE104DK618

0CQ2231N509

0CQ4721N519

0CQ8221N519

0CE106DF618

0CE475DK618

0CQ8221N519

0CQ1041N509

0CE476DK618

0CQ4721N519

0CE104DK618

0CE107DF618

0CE108BF618

0CE106DK618

0CE107DF618

181-007T

0CE106DK618

0CE477DK618

0CE477DK618

0CE106DF618

0CE106DF618

0CE476DK618

0CE106DF618

0CE106DF618

0CE477DK618

0CE477DK618

0CE477DK618

0CE477DK618

181-120K

0CE107DF618

181-120K

0CE107BH618

0CE107BH618

0CE107BH618

6612VLH002A

380-389N

380-389P

10UF STD 16V M FL TP5

0.1000UF STD 50V M FL TP5

0.0047U 100V K POLY NI TP

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

10UF STD 16V M FL TP5

0.0047U 100V K POLY NI TP

10UF STD 16V M FL TP5

0.1000UF STD 50V M FL TP5

4.7UF STD 50V 20% FL TP 5

0.1000UF STD 50V M FL TP5

0.022U 100V K POLY TP

0.0047U 100V K POLY NI TP

0.0082U 100V K POLY NI TP

10UF STD 16V M FL TP5

4.7UF STD 50V 20% FL TP 5

0.0082U 100V K POLY NI TP

0.1U 100V K POLY TP

47UF STD 50V M FL TP5

0.0047U 100V K POLY NI TP

0.1000UF STD 50V M FL TP5

100UF STD 16V M FL TP5

1000UF KME 16V M FL TP5

10UF STD 50V M FL TP5

100UF STD 16V M FL TP5

MPE ECQ-V1H105JL3(TR), 50V 1.0

10UF STD 50V M FL TP5

470UF STD 50V 20% FL TP 5

470UF STD 50V 20% FL TP 5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

47UF STD 50V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

470UF STD 50V 20% FL TP 5

470UF STD 50V 20% FL TP 5

470UF STD 50V 20% FL TP 5

470UF STD 50V 20% FL TP 5

2200PF 4KV M E FMTW LEAD 4.5

100UF STD 16V M FL TP5

2200PF 4KV M E FMTW LEAD 4.5

100UF KME 25V M FL TP5

100UF KME 25V M FL TP5

100UF KME 25V M FL TP5

JACK,RCA,SP026B 4P RD/BK/BK/R

JACK,RCA,S-456S-N A/V 3P RD-W

JACK,RCA,S-456S-P A/V 3P GR-B

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

JACK

Page 22

- 22 -

LOCA. NO PART NO DESCRIPTION

P601

L001

L113

L211

DS101

DS102

P002A

P003A

P004A

P004B

P005A

P006A

P007A

P007B

PD501

R001

R002

R003

R006

R007

R225

R226

R431

R618

R619

R655

R656

SW001

SW002

SW003

SW004

F601

F602

L001

L002

L104

L105

L106

L107

L201

L202

L203

6612VJH018A

0LA0102K119

6140VB0006A

0LA0102K119

6630VGA002B

6630VGA001C

366-932E

387-A07B

366-921F

366-922F

387-A15B

366-932C

366-932C

387-A04E

6602T10002A

0RD3302F609

0RD1002F609

0RD3001F609

0RD4700F609

0RD5100F609

0RN5602F409

0RN2202F409

0RH0000D622

0RS0221H609

0RS0221H609

0RD4700H609

0RD4700H609

140-315A

140-315A

140-315A

140-315A

6200VJS001A

6200VJS001A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0005A

JACK,RCA,PJ6058C-A A/V 2P MON

INDUCTOR,10UH K

COIL,CHOKE 12UH 0.3PHY,PHY 15.5TURN

INDUCTOR,10UH K

CONNECTOR,D-SUB 68108_2521 MOLEX_KOR 25 PIN

CONNECTOR,D-SUB 68114-1521 MOLEX 15PIN 2.29MM

CONNECTOR,WAFER 2.5MM 6P GIL-G LG CABLE S

CONNECTOR ASSY,7P 150MM H-H UL 1007

CONNECTOR (CIRC),2.5MM 7P GIL-G LG CABLE

CONNECTOR (CIRC),2.5MM 7P GIL-G LG CABLE

CONNECTOR ASSY,12P(L=150)

CONNECTOR (CIRC),2.5MM 4P GIL-G LG CABLE

CONNECTOR (CIRC),2.5MM 4P GIL-G LG CABLE

CONNECTOR ASSY,4P (L=300)

CONNECTOR (CIRC),DF9B-41P-1V HIROSE 1.0MM LB570

33K OHM 1/6 W 5.00% TA52

10K OHM 1/6 W 5.00% TA52

3K OHM 1/6 W 5.00% TA52

470 OHM 1/6 W 5.00% TA52

510 OHM 1/6 W 5.00% TA52

56K OHM 1/6 W 1.00% TA52

22K OHM 1/6 W 1.00% TA52

0 OHM 1 / 10 W 2012 5.00% D

2.2 OHM 1/2 W 5.00% TA52

2.2 OHM 1/2 W 5.00% TA52

470 OHM 1/2 W 5.00% TA52

470 OHM 1/2 W 5.00% TA52

SWITCH,TACT SKHV17910B LG C&D NON 12V

SWITCH,TACT SKHV17910B LG C&D NON 12V

SWITCH,TACT SKHV17910B LG C&D NON 12V

SWITCH,TACT SKHV17910B LG C&D NON 12V

FILTER,EMI ZJY51R5-4P TDK DC 50VOLT 2A PD

FILTER,EMI ZJY51R5-4P TDK DC 50VOLT 2A PD

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

LOCA. NO PART NO DESCRIPTION

L204

L205

L206

L207

L208

L209

L210

L212

L301

L302

L303

L304

L305

L306

L401

L402

L403

L404

L405

L406

L407

L408

L410

L501

L601

L602

L603

RA301

RA302

RA303

RA304

RA305

RA306

RA401

RA402

RA403

RA404

RA405

RA406

RA407

RA408

RA409

RA410

RA411

RA412

RA413

RA414

RA415

RA416

RA417

RA418

RA419

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0006A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

150-F09A

6210VC0006A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC BK2125 HS 750 TAIYOYUDEN 2X1.2

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC SQE2222 7-14MH 0.37PHY 48TURN

FILTER,EMC FBMH3216 HM501NT TAIYOYUDEN 3.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

COIL

CONNECTOR

RESISTOR

SWITCH

FILTER & CRYSTAL

Page 23

- 23 -

LOCA. NO PART NO DESCRIPTION

RA420

RA421

RA422

RA423

RA424

X001

X201

X301

X401

A1

A2

A2

A2

B1

P801

P801

P801

P801

PA001

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

6210VC0004A

156-A02V

6202VDB007B

6202VDT002B

6202VDT002B

3828VA0233A

6710V00067G

6710V00067Q

6710V00067U

3890V01000A

3110V00145A

6210VH0004B

6600VM2006A

6410VBH003B

6410VEH003B

6410VWH005B

6410VCH001C

6726VH0001A

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

FILTER,EMC BK3216 4S600 TAIYOYUDEN 3.2X1.

RESONATOR,CRYSTAL DISHINKU RADIAL 16.200MH

RESONATOR,CRYSTAL SUNNY RADIAL 20.250MHZ

RESONATOR,CRYSTAL SUNNY RADIAL 14.318MHZ

RESONATOR,CRYSTAL SUNNY RADIAL 14.318MHZ

MANUAL,OWNERS MP00MA/B/C PDP LG EN 067 TX

REMOTE CONTROLLER,MP-00MB

REMOTE CONTROLLER GREAT WALL

REMOTE CONTROLLER 40PA20S

BOX,MT-40PA10.AMPLRA 40” NEW DWR2

CASE,SHIELD BOTTOM

FILTER,EMC ZCAT1518-0730-M-K TDK

SWITCH,PUSH SDDF3PATP011

POWER CORD,MP5004+V1625 VOLEX BSI 2800MM

POWER CORD,M251A VOLEX VDE/SEM

POWER CORD,SA16A+V1625

POWER CORD,MP5004+V1625

REMOTE CONTROLLER RECEIVER TSOP1238RF1 38KHZ

LOCA. NO PART NO DESCRIPTION

ACCESSORIES

MISCELLANEOUS

Page 24

- 24 -

LOCA. NO PART NO DESCRIPTION

ICX001

IC001

IC002

ICX002

IC003

IC101

IC102

IC201

IC202

IC301

IC302

IC306

IC303

IC304

IC305

IC307

IC501

IC502

IC503

IC604

IC605

IC606

IC608

IC609

IC701

IC702

IC703

IC704

IC705

IC706

IC707

IC801

IC802S

IC804S

IC851S

D801S

D802S

D803S

D804S

D805S

D806S

D807S

D808S

DD001

DDX001

DD002

DDX002

DD003

0IPH741400E

0IZZVA0020A

0IAL241610B

0IBB368200A

0IKE703300D

0ISH052100C

0ITF447400A

0ISO206900A

0ISH092100B

0IIT323000D

0IIT323000D

0ISH323422A

0IOK810416A

0ISH052100C

0ISH323422A

0ISM941000A

0ISH052100C

0IHY762567A

0IIT305200B

0IIT341120A

0IKE780500Q

0ISH122100B

0IKE780800J

0IKE704200B

0ISO210100B

0ISH092100B

0ISH052100C

0IRH765700B

0IPH827150A

0IPH827150A

0IBB368200A

0ISK655313A

0ISH817300B

0ISK012120A

0ISH052100C

0DD260000BD

0DR010009AA

0DD100009AM

0DD100009AP

0DD100009AU

0DD120000BB

0DD120000BB

0DD120000BB

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD181009AB

IC,74HC14D 14SOP TP SHITTER TRIGG

IC,M37272EFSP6 42 BK FD-36X30 STB

IC,AT24C16-10PC-2.7 8PIN DIP ST E

IC,OPA3682E 16P SOP ST BUFFER AMP

IC,KIA7033AP TO-92 TP 3.3V RESET

IC,PQ05RD21 4SIP ST REGULATOR

IC,TDA4474(VIF) - - - -

IC,CXA2069Q QFP64 BK I2C BUS AV S

IC,PQ09RD21 4SIP ST REGULATOR

IC,VPC3230D QA B4 80P QFP TRAY SO

IC,VPC3230D QA B4 80P QFP TRAY SO

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,MS81V04160 100QFP BK FIELD MEM

IC,PQ05RD21 4SIP ST REGULATOR

IC,PQ3RF23 4P(TO-220) 3.3V REGUL

IC,SDA9410 100QFP BK SCAN CONVERT

IC,PQ05RD21 4SIP ST REGULATOR

IC,GM76C256CLLFW-70 28 PIN ST 256

IC,TPU3052S-PO-A2 52P SDIP BK TEX

IC,MSP3411G-PO-A2 52DIP ST SOUND

IC,KIA7805API 3P TO-220 ST REGULA

IC,PQ12RD21 4SIP ST REGULATOR

IC,KIA7808API 3 ST REGULATOR .

IC,KIA7042P(AT) TO-92 4.2V RESET

IC,CXA2101AQ 80P,QFP BK VIDEO SIG

IC,PQ09RD21 4SIP ST REGULATOR

IC,PQ05RD21 4SIP ST REGULATOR

IC,BA7657F 24P,SOP TP INPUT SIG.

IC,P82B715T 8SOP R/TP IIC EXTENDE

IC,P82B715T 8SOP R/TP IIC EXTENDE

IC,OPA3682E 16P SOP ST BUFFER AMP

IC,STR-F6553(LF1351) 3P,SIP BK PO

IC,PC817XF3 4D PHOTO COUPLER

IC,SE012N(LF12) 3P,TO-220 BK 12V

IC,PQ05RD21 4SIP ST REGULATOR

DIODE,BRIDGE D2SBA60 SHINDENKEN

DIODE,RECTIFIER EG01C TP 1000V 0.5A

DIODE,RECTIFIER EU1ZV(1) TP SANKEN

DIODE,RECTIFIER EG1ZV(1) TP SANKEN

DIODE,RECTIFIER EU1AV(1) TP SANKEN

DIODE,RECTIFIER FML-G12S

DIODE,RECTIFIER FML-G12S

DIODE,RECTIFIER FML-G12S

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS181 85V 300MA

LOCA. NO PART NO DESCRIPTION

DDX003

DDX004

DDX005

DDX006

DDX007

DDX008

DDX009

DD010

DDX010

DD011

DDX011

DD012

DDX012

DD013

DDX013

DD014

DDX014

DD015

DD101

DD104

DD210

DD211

DD212

DD213

DD214

DD216

DD217

DD218

DD221

DD222

DD223

DD224

DD225

DD226

DD227

DD228

DD229

DD230

DD231

DD232

DD301

DD302

DD303

DD501

DD601

DD602

DD701

DD702

DD703

DD704

DD705

DD706

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

REPLACEMENT PARTS LIST(SET TOP BOX)

IC

DIODE

Page 25

- 25 -

LOCA. NO PART NO DESCRIPTION

DD707

DD708

DD709

DD710

DD711

ZD001

ZD002

ZDX002

ZD101

ZD301

ZD302

IC308

IC309

IC310

IC311

IC312

IC313

Q010

Q011

Q104

Q105

Q108

Q110

Q111

Q112

Q202

Q203

Q204

Q205

Q206

Q207

Q208

Q209

Q210

Q211

Q212

Q220

Q221

Q301

Q302

Q303

Q304

Q305

Q306

Q307

Q421

Q422

Q423

Q490

Q491

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DZ510009DB

0DZ510009DB

0DZ620009BB

0DZ300009BB

0DZ511109AA

0DZ511109AA

0TR830009BA

0TR830009BA

0TR830009BA

0TR830009BA

0TR830009BA

0TR830009BA

0TR387500AA

0TR387500AA

0TR102009AG

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR102009AG

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,ZENER MTZJ5.1B TP ROHM-K DO34

DIODE,ZENER MTZJ5.1B TP ROHM-K DO34

DIODE,ZENER MTZJ6.2B TP ROHM-K DO34 0.5W

DIODE,ZENER MTZJ30B TP ROHM-K DO34 0.5W

DIODE,ZENER DTZ5.1BTT11(CHIP) TP ROHM

DIODE,ZENER DTZ5.1BTT11(CHIP) TP ROHM

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,BSS83 TP PHILIPS NON N-CHANNEL

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

LOCA. NO PART NO DESCRIPTION

Q501

Q601

Q602

Q605

Q606

Q607

Q608

Q701

Q702

Q703

Q707

Q708

Q709

Q710

QF01

QF02

QX003

QX004

QX005

QX006

QX007

QX008

QX009

QX010

QX011

QX012

QX013

QX014

QX015

QX016

C006

C007

C008

C009

C011

C017

C019

C023

C027

C035

C101

C104

C105

C107

C109

C114

C115

C119

C124

C126

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR319809AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0CE476DK618

0CE477DF618

0CE108DD618

0CE476DF618

0CE477DD618

0CE477DD618

0CE107DD618

0CE477DD618

0CE477DD618

0CE107DD618

0CE477DD618

0CE477DD618

0CE108DD618

0CE106DK618

0CE477DD618

0CE225DK618

0CE225DK618

0CE107SF6DC

0CE477DD618

0CE684DK618

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,KTC3198-TP-Y (KTC1815)KEC

TR,KTC3198-TP-Y (KTC1815)KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

47UF STD 50V M FL TP5

470UF STD 16V 20% FL TP 5

1000UF STD 10V M FL TP5

47UF STD 16V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

100UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

100UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

1000UF STD 10V M FL TP5

10UF STD 50V M FL TP5

470UF STD 10V M FL TP5

2.2UF STD 50V 20% FL TP 5

2.2UF STD 50V 20% FL TP 5

100UF MVG 16V M SMD R/TP

470UF STD 10V M FL TP5

0.68UF STD 50V 20% FL TP 5

TRANSISTOR

CAPACITOR

Page 26

- 26 -

LOCA. NO PART NO DESCRIPTION

C134

C135

C137

C142

C202

C215

C216

C217

C224

C227

C228

C233

C235

C239

C244

C247

C256

C257

C262

C283

C301

C302

C303

C310

C317

C321

C326

C334

C340

C350

C359

C364

C369

C371

C372

C377

C380

C381

C384

C385

C388

C389

C392

C410

C453

C454

C455

C482

C501

C504

C505

C508

0CE475WJ6DC

181-007H

0CE477DD618

0CE106SF6DC

0CE477DD618

0CE475WJ6DC

0CE475DK618

0CE477DD618

0CE475DK618

0CE475DK618

0CE105DK618

0CE105DK618

0CE475WJ6DC

0CE105DK618

0CE107DF618

0CE107DF618

0CE107DF618

0CE106DF618

0CE474DK618

0CE105CK636

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CK224DF56A

0CE107SF6DC

0CE476DF618

0CE107DF618

181-007H

181-007H

0CE476SF6DC

0CE107DF618

0CE477DD618

0CE477DD618

0CE477DD618

0CE107SF6DC

0CE477DD618

0CE477DD618

0CE477DD618

0CE476DF618

0CE476DF618

0CE476DF618

0CE477DD618

0CE477DD618

0CE107SF6DC

0CE477DD618

0CE476DD618

4.7UF MVK 35V 20% R/TP(SMD) SM

MPE ECQ-V1H474JL3(TR), 50V 0.4

470UF STD 10V M FL TP5

10UF MVG 16V 20% R/TP(SMD) SMD

470UF STD 10V M FL TP5

4.7UF MVK 35V 20% R/TP(SMD) SM

4.7UF STD 50V 20% FL TP 5

470UF STD 10V M FL TP5

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

1UF STD 50V M FL TP5

1UF STD 50V M FL TP5

4.7UF MVK 35V 20% R/TP(SMD) SM

1UF STD 50V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

10UF STD 16V M FL TP5

0.4700UF STD 50V M FL TP5

1UF SHL,SD 50V M FM5 BP(D) TP

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

MPE ECQ-V1H474JL3(TR), 50V 0.4

MPE ECQ-V1H474JL3(TR), 50V 0.4

47UF MVG 16V M SMD R/TP

100UF STD 16V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

100UF MVG 16V M SMD R/TP

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

47UF STD 16V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

100UF MVG 16V M SMD R/TP

470UF STD 10V M FL TP5

47UF STD 10V 20% FL TP 5

LOCA. NO PART NO DESCRIPTION

C509

C621

C622

C624

C626

C633

C635

C647

C648

C650

C656

C658

C661

C662

C670

C671

C701

C704

C710

C714

C721

C728

C731

C734

C738

C741

C742

C743

C744

C745

C746

C747

C755

C760

C761

C762

C763

C764

C765

C768

C769

C770

C771

C780

C801S

C802S

C803S

C804S

C805S

C807S

C808S

C810S

0CE106SF6DC

0CE106DF618

0CE106DF618

0CE227DF618

0CE335DK618

0CE107DF618

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE475WJ6DC

0CE476DF618

0CE107DF618

0CE107DF618

0CE107SF6DC

0CE475WJ6DC

0CE475WJ6DC

0CE107DF618

0CE107DF618

0CE107DF618

0CE105DK618

0CE107DF618

0CE106DF618

0CE106DF618

0CE226DF618

0CE477DD618

0CE107SF6DC

0CE106CF636

0CE106CF636

0CE106CF636

0CE106CF636

0CE106CF636

0CE106CF636

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE477DD618

0CE477DD618

0CE477DD618

0CE477DD618

0CQZVBK002D

0CQZVBK002C

181-033R

0CE104DK618

181-033R

0CEZVBK002B

0CBZVBK001C

0CE107DK618

10UF MVG 16V 20% R/TP(SMD) SMD

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

220UF STD 16V M FL TP5

3.3UF STD 50V 20% FL TP 5

100UF STD 16V M FL TP5

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

4.7UF MVK 35V 20% R/TP(SMD) SM

47UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF MVG 16V M SMD R/TP

4.7UF MVK 35V 20% R/TP(SMD) SM

4.7UF MVK 35V 20% R/TP(SMD) SM

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

1UF STD 50V M FL TP5

100UF STD 16V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

22UF STD 16V M FL TP5

470UF STD 10V M FL TP5

100UF MVG 16V M SMD R/TP

10UF SHL,SD 16V M FM5 BP(D) TP

10UF SHL,SD 16V M FM5 BP(D) TP

10UF SHL,SD 16V M FM5 BP(D) TP

10UF SHL,SD 16V M FM5 BP(D) TP

10UF SHL,SD 16V M FM5 BP(D) TP

10UF SHL,SD 16V M FM5 BP(D) TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF STD 10V M FL TP5

A.C 275V 0.47UF K (S=22.5)

A.C 275V 0.22UF K (S=22.5)

2KV B 102K TP7.5(TEMP.+85)

0.1000UF STD 50V M FL TP5

2KV B 102K TP7.5(TEMP.+85)

220000000F 0 500V M VNSN BULK

0.033UF 800V J M/PP NI FM7.5

100UF STD 50V M FL TP5

Page 27

- 27 -

LOCA. NO PART NO DESCRIPTION

C811S

C812S

C814S

C815S

C816S

C818S

C819S

C820S

C821S

C822S

C824S

C827S

C828S

C850S

C852S

CF01

CF02

CX004

CX005

CX008

CX019

CX020

CX021

CX022

CX023

CX024

CX025

CX027

CX029

CX031

CX037

CX038

CX039

CX041

CX046

CX060

F801S

F802S

F803S

F805S

JA801S

JX001

JX002

JX003

JX004

SCT201

SCT202

PAX001

0CK4710K515

181-120K

0CK47101515

0CK47101515

0CK47101515

0CE337DK618

0CE228DF618

0CE228BH61A

0CE108DF618

0CE108DH618

0CQ1042K439

0CN5610K519

0CN5610K519

0CE108DD618

0CE108DJ618

0CN1040K949

0CN1040K949

0CQ3332K439

0CE107SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE337DD618

0CE337DD618

0CE337DD618

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0FT4001B51C

131-096E

131-096E

131-096E

6612VJH018A

380-363D

380-389N

6612VJH018A

380-389P

6612VJH021A

6612VJH021A

380-068B

470PF 50V K B TR

2200PF 4KV M E FMTW LEAD 4.5

470P 1KV K B TS

470P 1KV K B TS

470P 1KV K B TS

330UF STD 50V M FL TP5

2200UF STD 16V M FL TP5

2200UF KME 25V M FL TP7.5

1000UF STD 16V M FL TP5

1000UF STD 25V M FL TP5

0.1000UF S 50V J M/PE NI TP

560P 50V K B TA52

560P 50V K B TA52

1000UF STD 10V M FL TP5

1000UF STD 35V M FL TP5

0.1M 50V Z F TA52

0.1M 50V Z F TA52

0.0330UF S 50V J M/PE NI TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

330UF STD 10V M FL TP5

330UF STD 10V M FL TP5

330UF STD 10V M FL TP5

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

FUSE,4000MA 250 V 5.2X20 CY/GL SEMK

FUSE,4000MA 125 V 2.5X7.6 CY/CE UL

FUSE,4000MA 125 V 2.5X7.6 CY/CE UL

FUSE,4000MA 125 V 2.5X7.6 CY/CE UL

JACK,RCA PJ6058C-A A/V 2P MON

JACK,DIN S-VHS(PJ 6046B-01)H=8.0,W/SW

JACK,RCA S-456S-N A/V 3P RD-W

JACK,RCA PJ6058C-A A/V 2P MON

JACK,RCA S-456S-P A/V 3P GR-B

JACK,RCA PPJ124A A/V 6P FOR S

JACK,RCA PPJ124A A/V 6P FOR S