Page 1

ENGLISH ITALIANO ESPAÑOL FRANÇAIS DEUTSCH CHINESE

LG

BNU-LW(Lonworks Gateway)

Installation Manual

LG

IMPORTANT

• Please read this Installation Manual carefully and

thoroughly before installing and operating your room air

conditioner.

• Please retain this Installation Manual for future reference

after reading it thoroughly.

Page 2

2 Lonworks Gateway

BNU-LW (Lonworks Gateway)

TABLE OF CONTENTS

Safety Precautions.................................................................................................3

Overall system diagram.........................................................................................7

External wiring diagram ........................................................................................8

How to set the address for the central controller of the indoor unit

connected to BNU-LW (Lonworks Gateway).......................................................8

Communication line specification .......................................................................9

Name of each part................................................................................................10

Installation order..................................................................................................11

BNU-LW wiring order...........................................................................................12

Air conditioner/ventilation function table..........................................................13

Air conditioner indoor unit function ...................................................................13

Ventilation indoor unit function..........................................................................14

BNU-LW remote diagnosis function...................................................................15

Setting method..................................................................................................15

Configuration ....................................................................................................16

Setting the indoor unit address..........................................................................18

Setting the indoor unit address .........................................................................18

Interfacing with simple central controller..........................................................19

Appendix...............................................................................................................20

A/C Objects.......................................................................................................20

Air conditioner control/monitoring point ............................................................21

Ventilation control/monitoring point...................................................................22

Network variables .............................................................................................23

Page 3

Safety Precautions

Installation Manual 3

ENGLISH

Do not operate or stop

the unit by inserting or

pulling out the power

plug.

• It will cause electric shock

or fire due to heat

generation.

Ask for Product

equipment at the service

center or establishment

certainly at the specialty

store.

• It can cause an accident,

electric shock, explosion

or injury.

Use standard parts.

• Use of non standard parts

can cause electric shock,

explosion, injury,

breakdown.

■ Operation

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

WARNING

Standard Parts

WARNING

CAUTION

BNU-LW

BNU-LW

Page 4

Safety Precautions

4 Lonworks Gateway

If water enters the product, turn the power

switch of the main body of appliance off.

• After taking the power-plug out from the

socket, contact the service center.

Keep the product away from the places

which can have moisture.

• Water may enter the unit and degrade the

insulation. It may cause an electric shock.

BNU-LW

■ During usage

While re-installing the

established product, notify

the service center or

establishment specialty

store.

• It can cause an accident,

electric shock, explosion,

injury.shock.

Do not use the power cord

near Flammable gas or

combustibles, such as

gasoline, benzene, thinner,

etc.

• It may cause an explosion

or fire

Do not disjoint randomly or

repair and remodel the

product.

• It may cause fire and

electric shock

BNU-LW

BNU-LW

Do not change or extend the

conductor at random.

• It can cause fire and

electric shock.

Do not use concert with in

the octopus-like legs way.

• It can cause fire and

electric shock

Unplug the unit if strange

sounds, smell, or smoke

comes from it.

• It may cause fire and

electric shock accident.

BNU-LW

BNU-LW

BNU-LW

Thinner

Wax

Page 5

Safety Precautions

Installation Manual 5

ENGLISH

Do not put firearms near

product.

• It can cause fire.

Do not put an electric heater

or conductor near to the

product.

• It can cause fire and

electric shock.

Do not spill water inside

product.

• It can cause electric

shock and breakdown.

BNU

-LW

BNU-LW

BNU-LW

Do not place heavy goods

on wire.

• It can cause fire and

electric shock.

Hold the plug by the head of

the power plug when taking

it out.

• It may cause electric

shock and damage.

Do not place heavy goods

on product.

• It can cause product

breakdown.

BNU-LW

BNU-LW

That increase in case of

product was been flood

certainly in the service

center or establishment

specialty store commit .

• I am responsible for fire

and electric shock.

Protect the product from

handling by a children.

• It can cause accident and

product breakdown.

Do not apply shock to

product.

• I am responsible for

breakdown in case of

shock to product.

BNU-LW

BNU-LW

BNU-LW

Page 6

Safety Precautions

6 Lonworks Gateway

■ During usage

CAUTION

Clean by soft hands using a

cleaning material like a soft

cloth.

• It can result in fire and

product transformation.

Do not place any live part on

the surface having water.

• It can cause product

breakdown.

Use recommended Adapter.

• Otherwise it can result in

product breakdown

BNU-LW

Wax

Thinner

BNU-LW

BNU-LW

Avoid contact to the metallic

goods such as necklace,

coin, key, a watch which

may touch the battery even

for a short-time.

• It may cause product

breakdown and injury.

Hold the plug by the head of

the power plug when taking

it out.

• It may cause electric

shock and damage.

BNU-LW

Page 7

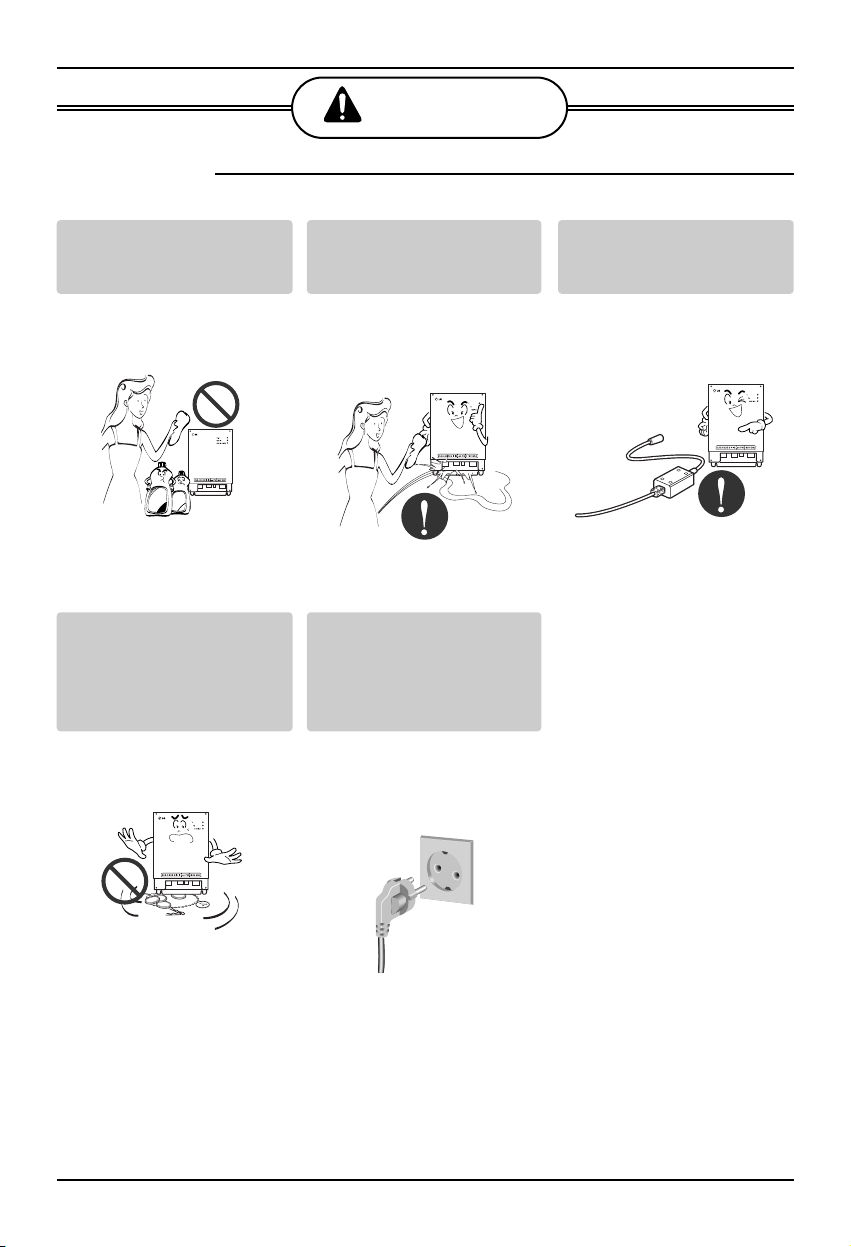

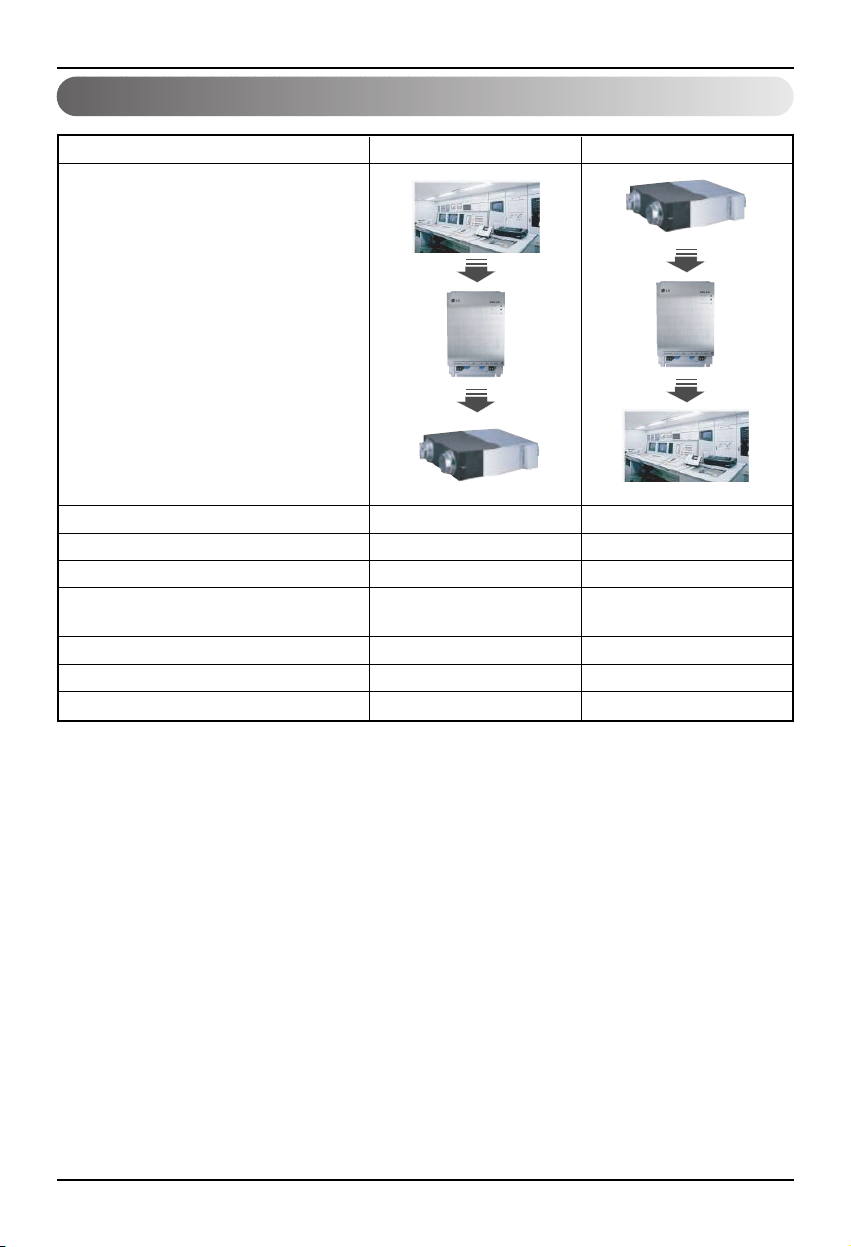

Overall system diagram

Installation Manual 7

ENGLISH

Overall system diagram

* PNF-B16A1 (Lon Gateway) can be used in connection with the simple central

controller.

* Can be connected to 64 indoor units (Ventilation+Air conditioner)

Simple central

controller

485 communication

Ventilation A/C

Page 8

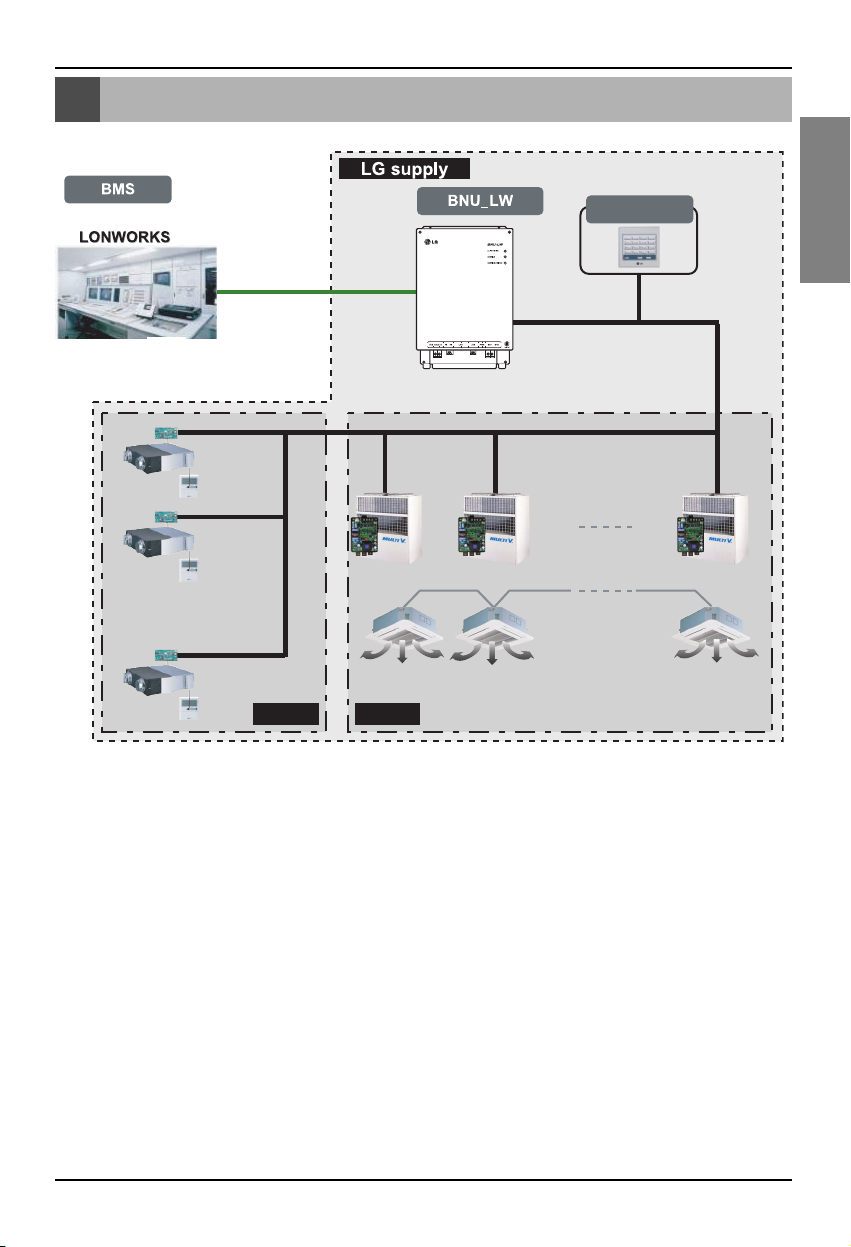

External wiring diagram

8 Lonworks Gateway

• When the address of the indoor unit of the air conditioner is duplicated with that of the ventilation

unit, it will not operate normally.

• Maximum of 64 units of the indoor unit (Air conditioner+Ventilation) can be connected to the BNULW.

• It is recommended to connect 16 units of PI485 and maximum of d32 PI485 units to the BNU-LW.

• Ventilation products cannot be interfaced with the simple central controller.

External wiring diagram

How to set the address for the central controller of

the indoor unit connected to BNU-LW (Lonworks Gateway)

LON protocol

BMS system

<Maximum number of connected indoor unit: 64 units>

Air conditioner

RS485

BNU-LW

RI485 Central controller address(0.0) (0.1) ............(0.F)

RI485

Central controller

address(2.0)

Central controller

address(2.4)

Central controller address(1.0)

(2.1) (2.2) (2.3)

(2.5) (2.6) (2.7)

(1.1)............(1.F)

Page 9

External wiring diagram

Installation Manual 9

ENGLISH

1. RS-485 communication line specification: 0.75mm2or above 2C shield, product to product: 200M,

total length: 1km

2. FT-10 communication line: Refer to the following table.

* Nod to node distance (max): 250m, maximum distance: 450m

* AWG: American Wire Gauge

Cable Type Line thickness (AWG) Diameter

TIA 568A Category 5 cable 24 0.5mm

Belden 88471 (PVC jacket) or 16 1.3mm

equivalent cable

Belden 85102(Tefzel jacket) or 16 1.3mm

equal cable

Level IV cable 22 0.65mm

JY(st)Y 2x2x0.8 20.4 0.8mm

Communication line specification

Page 10

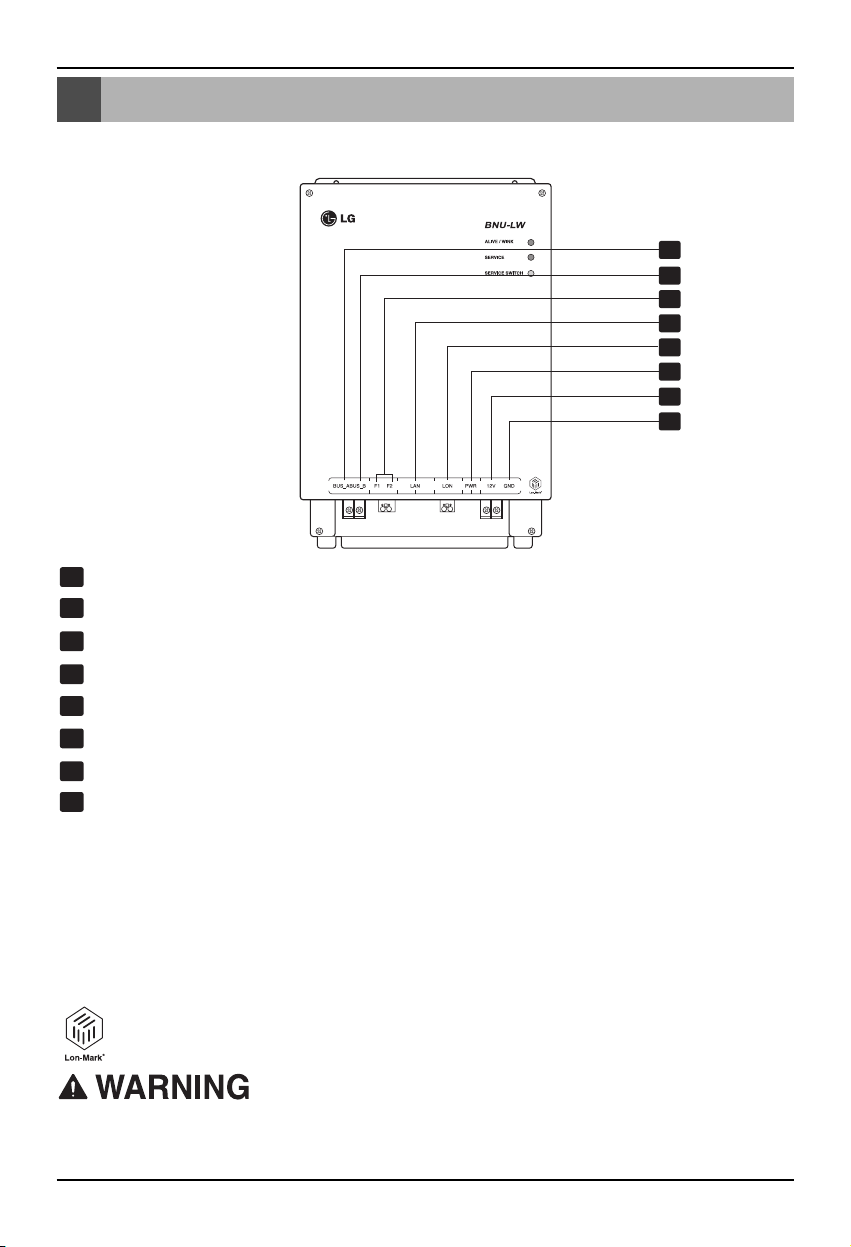

Name of each part

10 Lonworks Gateway

Name of each part

1

2

3

4

5

6

7

8

BUS_A: 485 communication line A (+)

BUS_B: 485 communication line B (-)

F1, F2: Fire detection function (external device) contact point connection

LAN: LAN port necessary for web function

LON: TP/FT-10 communication line (Lonworks system communication line) non-polarity

PWR: Connection to DC 12V power adapter

12V: Connection when not using DC 12V power adapter

GND: Connection when not using GNS adapter

ALIVE/WINK: It flashes every 1 second when it is normal

It flashes 5 times when receiving WINK command from Lonworks system

(Green)

SERVICE: It is turned off when it is normal and flashes when it is not connected to the

Lonworks system. It is turned on when the service switch is pressed.

SERVICE SWITCH: When you press the switch the Neuron ID is transmitted to the

Lonworks system, and the service LED is turned on.

BNU-LW (PNF-B16A1) product is a product certified of LON-MARK, an international

standard. (Lon Mark Version 3.3)

1

8

2

3

4

5

6

7

LONWORKS GATEWAY

No. 6 and No. 7,8 are all for power supply. Therefore, only one of two combinations should be used.

When DC 12V is used for the power, Connect No. 6 to the power (not necessary to use No. 7,8.)

When DC 12V is NOT used for the power, Connect No. 7, 8 to the power (not necessary to use No. 6.)

Page 11

Installation order

Installation Manual 11

ENGLISH

Installation order

1. Install the product according to the setting of the central controller address of the indoor unit and the

DIP S/W of PI485. (Set the DIP switch No. 4 to ON.)

(Refer to the PI485 installation manual for details.)

2. Connect BUS_A and BUS_B (485 communication line) while paying attention to the connecting

polarity. (Refer to the next page.)

3. LON (TP/FT-10 line‡Lonworks Gateway communication line connection) TP/FT-10 communication

line does not have polarity. Connect the 2 communication lines to BMS.

4. PWR (Power supply)

You can select either one of the two for the power supply.

Use DC 12V power adapter

Connect to No. 6 in name of each part.

When separate DC12 can be supplied

Connect 12V and GND to No. 7 and 8 terminals.

5. When you press the service switch after connecting to the Lonworks system, the service LED is

turned on and the neuron ID is automatically transmitted to the Lonworks system.

6. Check whether the service LED is in normal condition (OFF condition) within 10 minutes. If the

service LED is in normal condition, the installation has been done normally.

7. When using the fire detection port, connect the two terminals of the fire diction sensor to F1 and F2.

(Fire detection sensor must be used for DC output of 12V or below.)

8. After the installation, connect the LAN cable between the PCs to use the web server so that you

can check whether the LG product has been installed normally. – Refer to the remote diagnosis

function part (page 16) for details.

When connecting the signal line to the terminal of Lonworks Gateway, always use a

manual driver.

(Careful attention is required not to damage the terminal block and PCB.)

Page 12

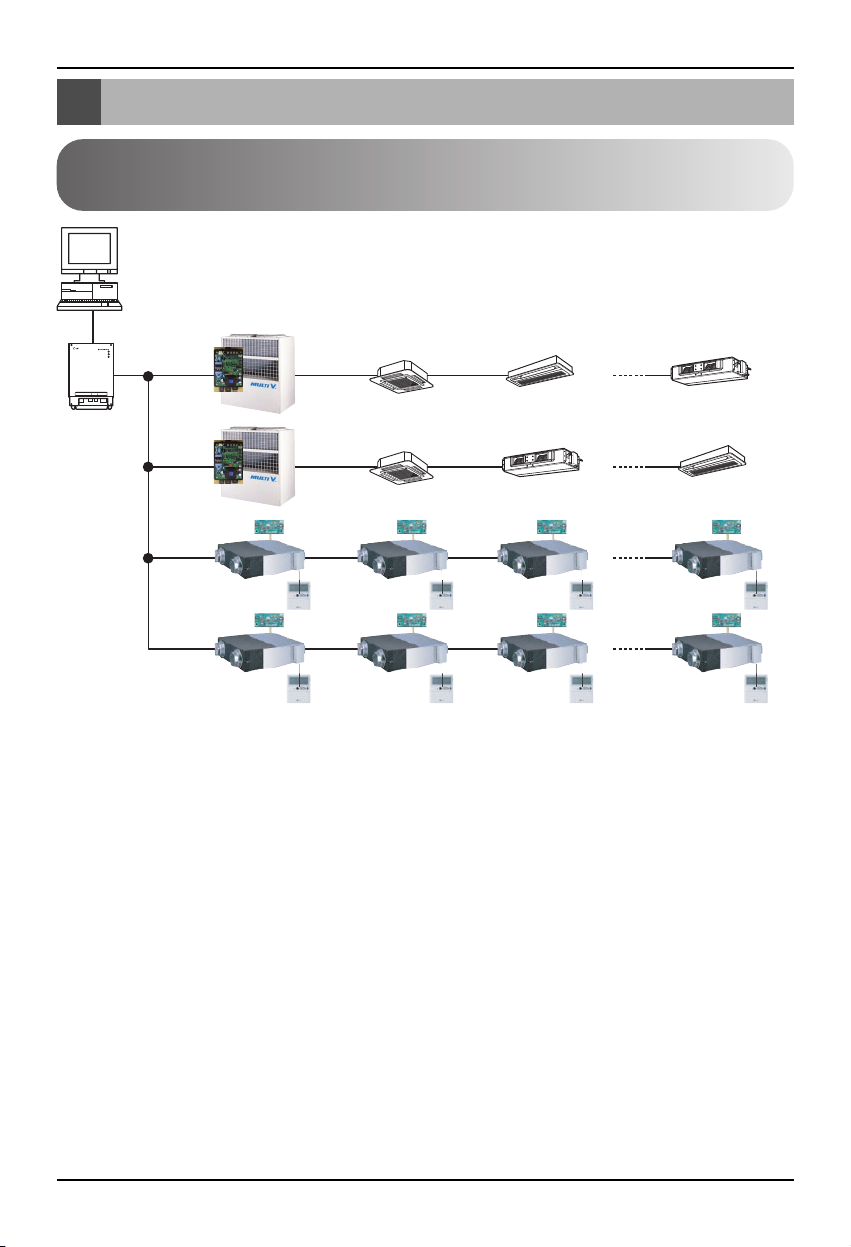

BNU-LW wiring order

12 Lonworks Gateway

BNU-LW wiring order

[Wiring sequence]

1. Connect 485 communication line

- Pay attention to BUS A and BUS B polarity

(Refer to the G/W manual for DIP S/W

information for 485 G/W.)

2. Connect the Lonworks communication line

(TP/FT-10)

- No polarity.

3. Power supply (Select one from No. 1 or 2)

Use DC 12V adapter

- Connect to No. 6 jack from name of each

part.

Supply DC 12V to installation site

- Connect 12V and GND to No. 7 and 8

terminals.

4. Interface with simple central controller

- Set the DIP S/W No. 2 of the simple central

controller to ON and configure the setting

according to the rotary S/W address. (Refer

to setting part when connection to simple

central controller (page 20) for details.)

5. Connect fire detection sensor

- When the signal of DC 12 or below is

transmitted in case of a fire, the indoor unit

and ventilation product that is connected to

BNU-LW will all be turned off.

LG does NOT supply this section ( Connection and Installation)

LonWorks

Adaptor

TP/FT-10

F1 F2 LAN LON PWR 12V GND

Fire detection sensor

(Use DC 12V or below)

BMS Control (PC)

A

B

+10V

GND

PI485

terminal

Central

controller

VOC

GND

C

D

PI485

10V

GND

BUS_A

BUS_B

LG supply

Power

Page 13

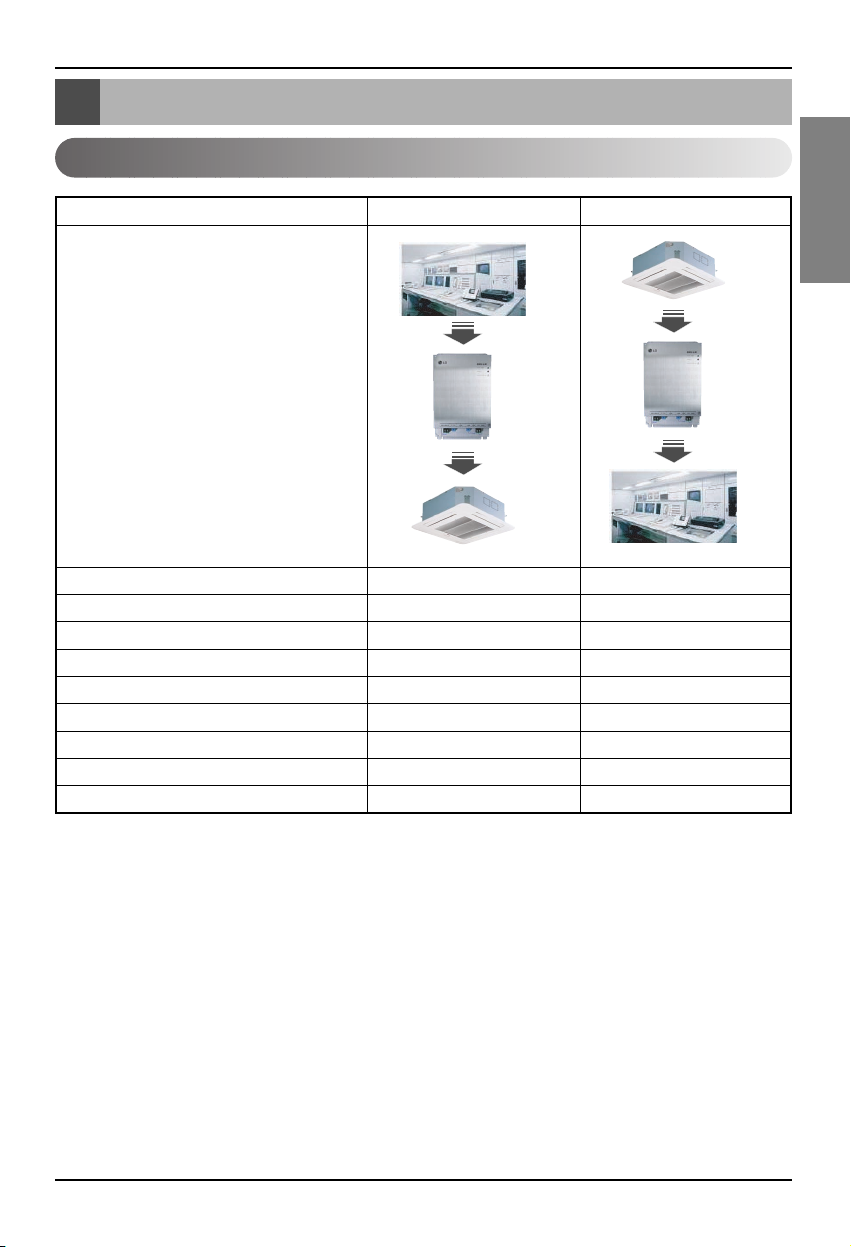

Air conditioner/ventilation function table

Installation Manual 13

ENGLISH

Air conditioner/ventilation function table

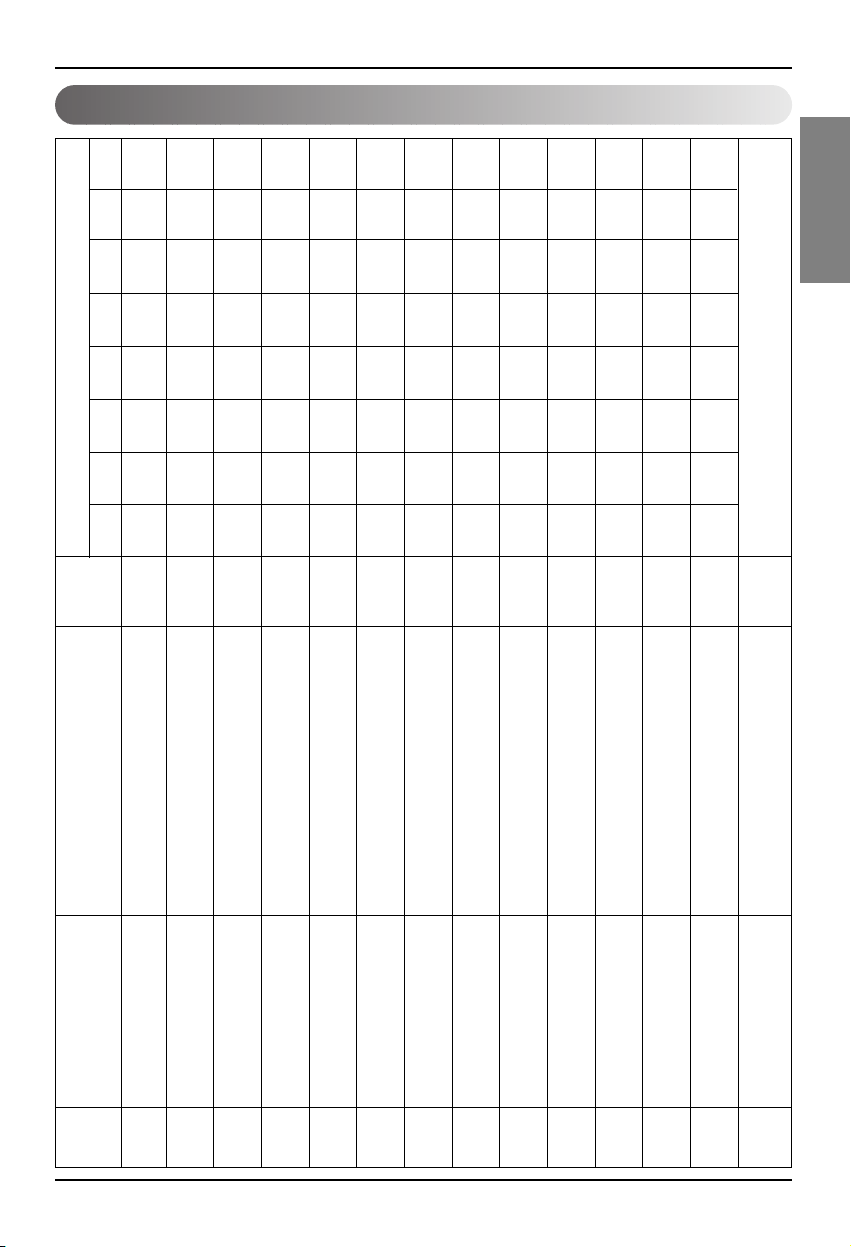

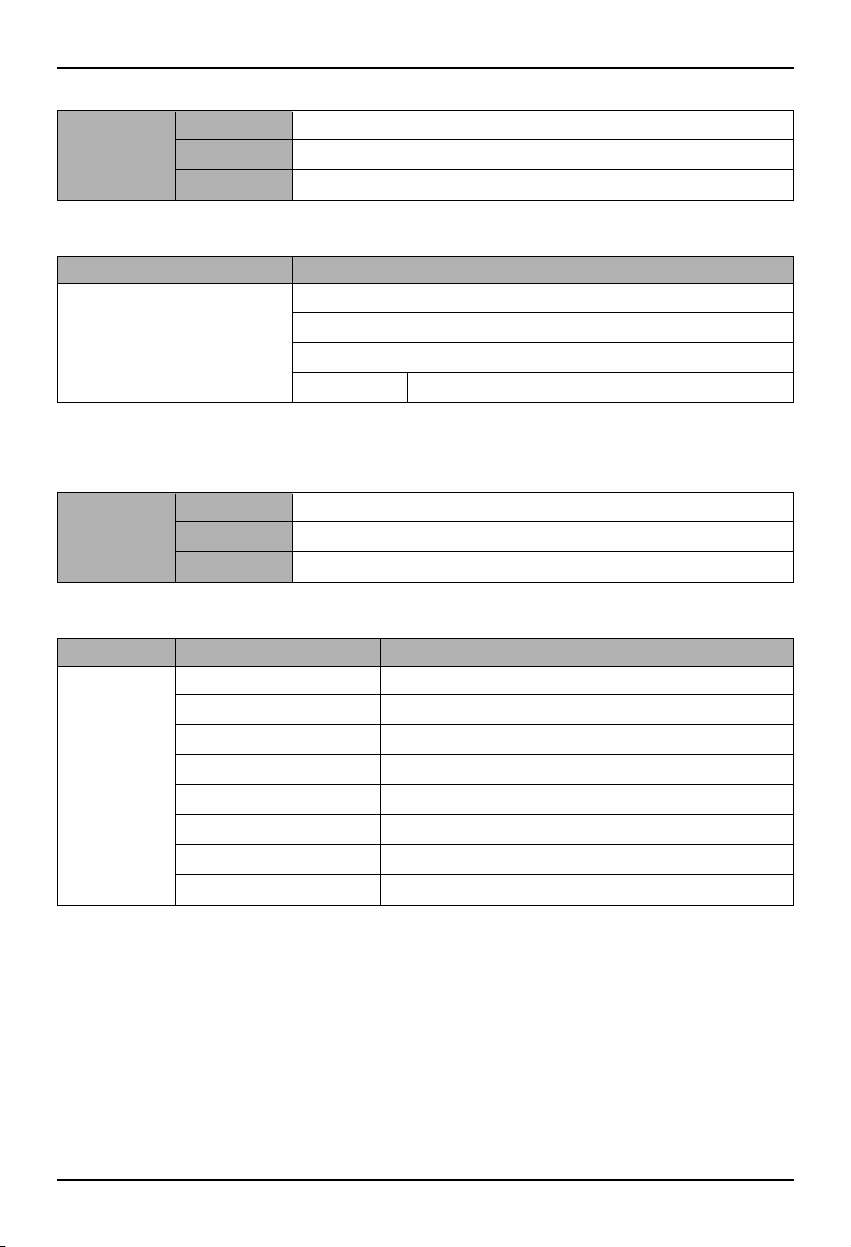

Air conditioner indoor unit function

Indoor unit individual control O O

Operating mode change O O

Fan level change O O

Temperature adjustment function O O

Lock function O O

Automatic fan direction O O

Indoor unit temperature check X O

Error check X O

Simultaneous operation/stop O X

Function

BMS

BNU-LW

Air conditioner

BMS

BNU-LW

Air conditioner

Classification Control Monitoring

Binding (connection) function: Binding function refers to the case when the output of a unit has been

bound to the input of another unit and the process of input change from

the output change. The binding function is possible with Lon unit of

other manufacturer.

Ex) When the ON/OFF output of the indoor unit No. 1 is bound to ON/OFF input of indoor unit of No. 2

and when the indoor unit No. 1 is turned on, the indoor unit No. 2 also gets turned on from

receiving the signal.

Page 14

Air conditioner/ventilation function table

14 Lonworks Gateway

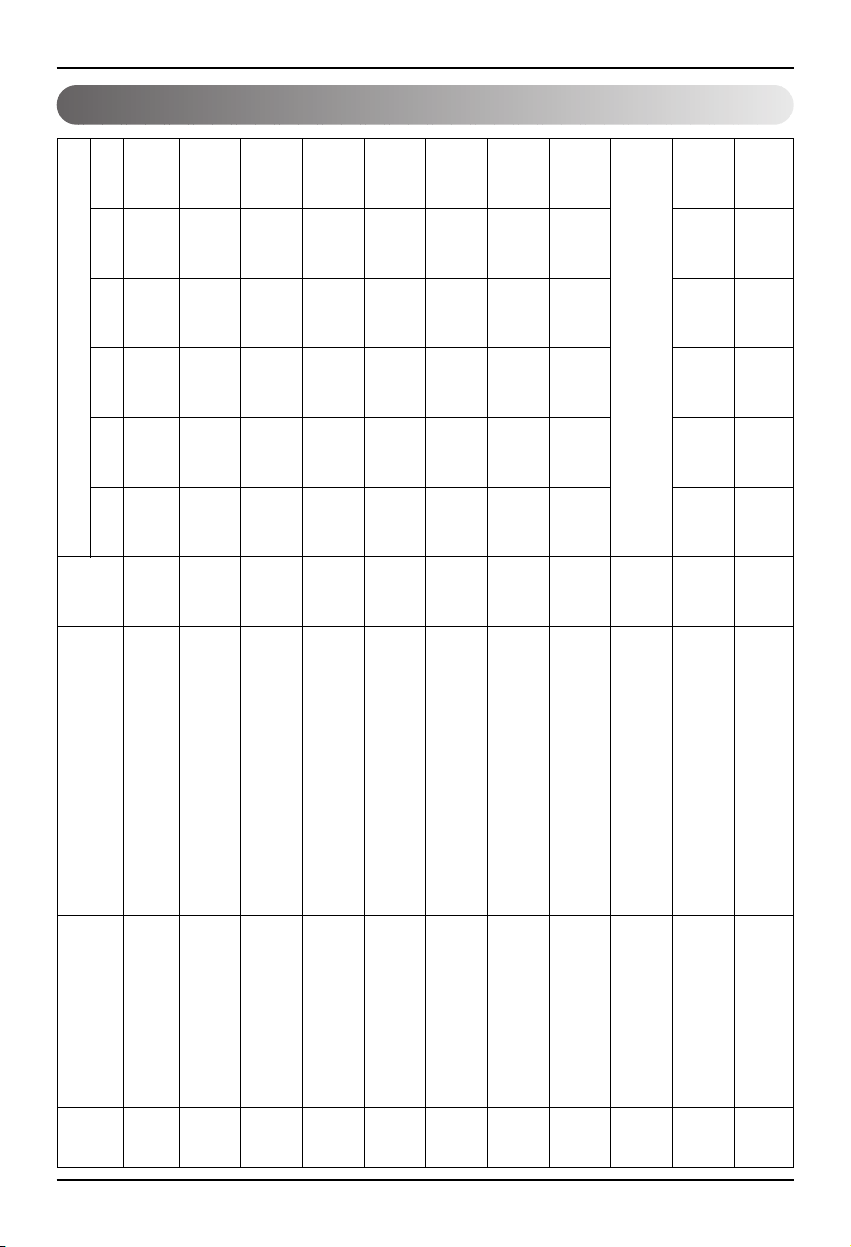

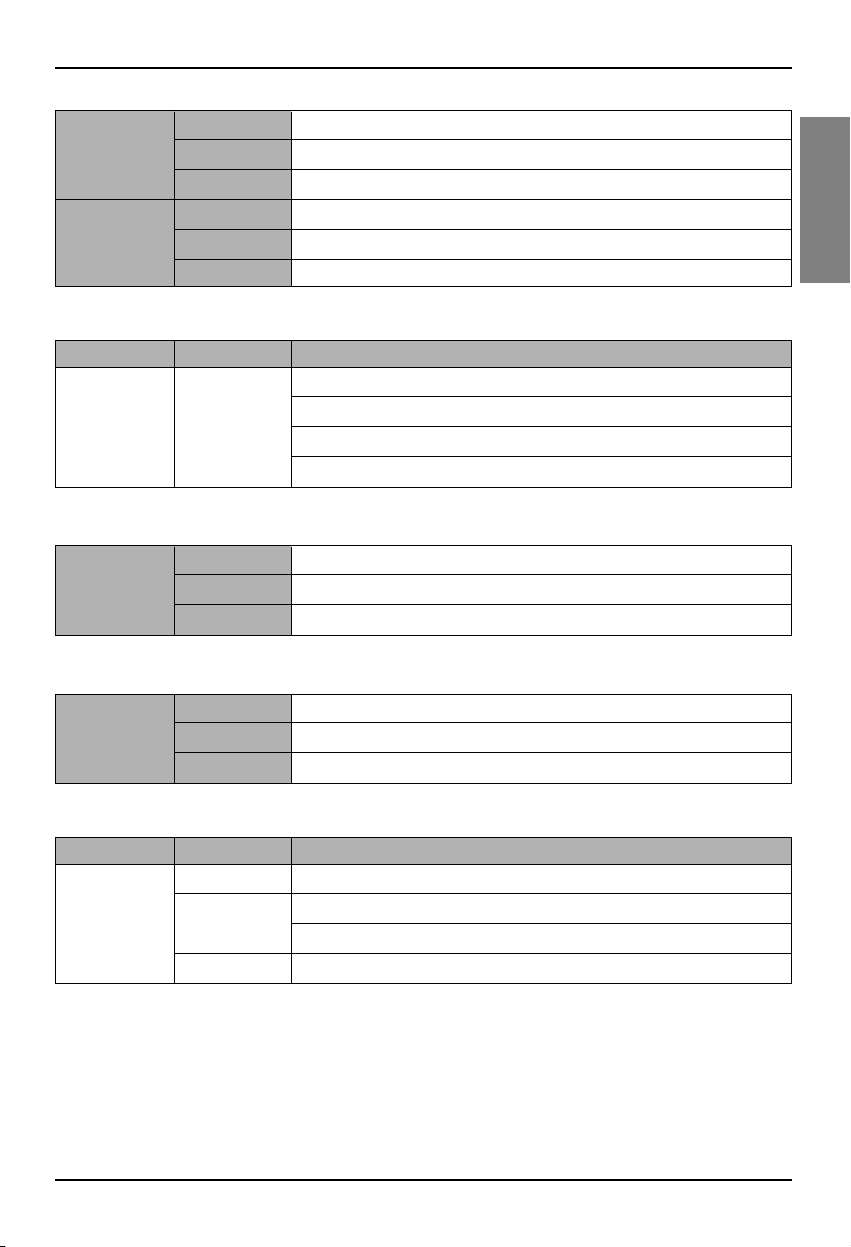

Ventilation indoor unit function

Indoor unit individual control O O

Operating mode change O O

Fan level change O O

User operation mode

OO

(Quick ventilation, power save, heating)

Lock function O O

Error check X O

Simultaneous operation/stop O X

Function

BMS

BNU-LW

Ventilation

BMS

BNU-LW

Ventilation

Classification Control Monitoring

Binding (connection) function: Binding function refers to the case when the output of a unit has been

bound to the input of another unit and the process of input change from

the output change. The binding function is possible with Lon unit of

other manufacturer.

Ex) When the ON/OFF output of the indoor unit No. 1 is bound to ON/OFF input of indoor unit of No. 2

and when the indoor unit No. 1 is turned on, the indoor unit No. 2 also gets turned on from

receiving the signal.

Page 15

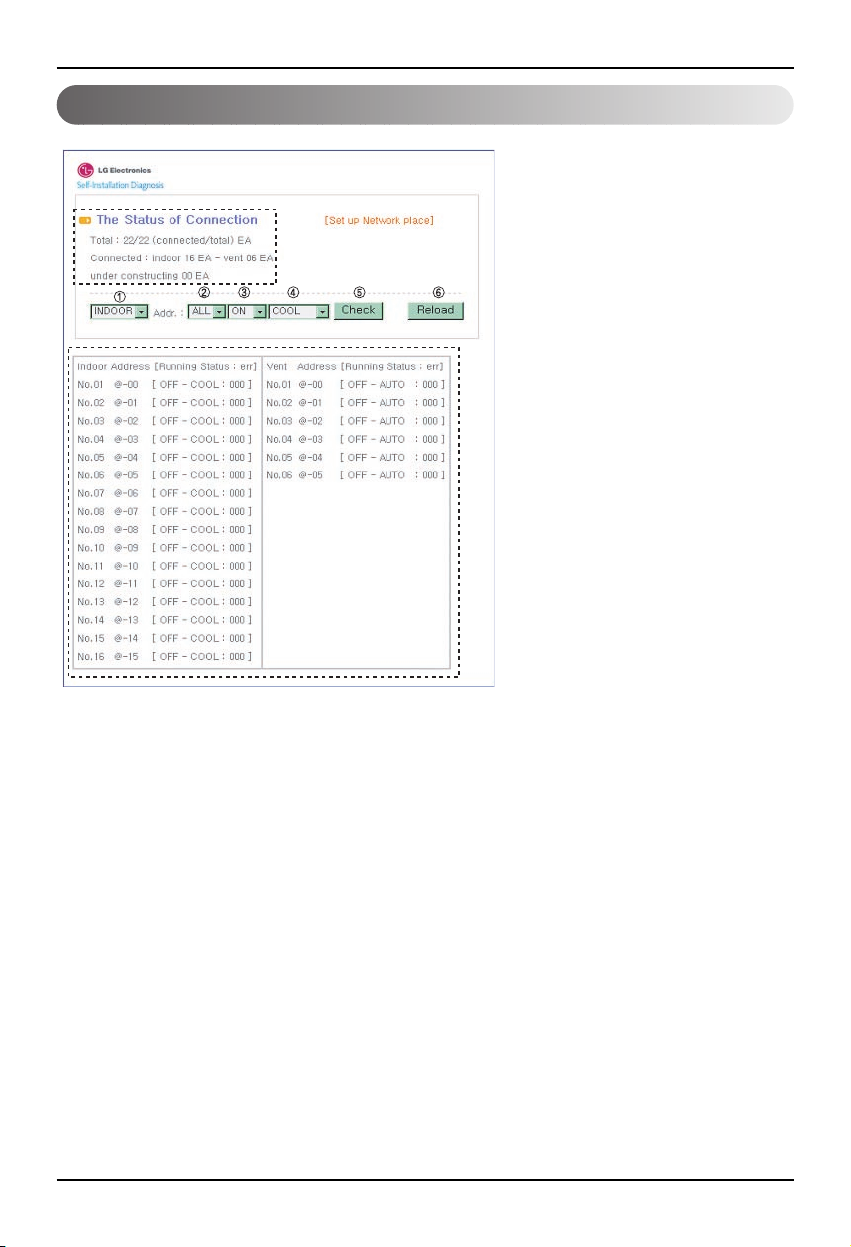

BNU-LW remote diagnosis function

Installation Manual 15

ENGLISH

1. Connect the LAN line between the PC

and the LAN port of the BNU-LW.

2. Set the network IP of the used PC to

192.168.1.xxx (except 101).

3. Enter 192.168.1.101 in the Internet

Explorer.

4. The above picture is shown when

connected normally.

• Initial ID: lonwork

• Initial password: lonwork

• Enter the total number of connected

indoor units in the Total Unit block.

BNU-LW remote diagnosis function

Setting method

LAN(cross cable)

Page 16

BNU-LW remote diagnosis function

16 Lonworks Gateway

Configuration

• After entering the ID and password,

the air condition and ventilation

products currently connected are

displays as shown in the picture.

• “A” part displays the number of air

condition and ventilation products

are currently connected.

• When you would like to control a

product ➀ Select the product – ➁

Set the address – ➂ Command

ON/OFF – ➃ Select the mode – ➄

Click on check to control the

product.

• When you would like to check the

current status ➅ Click on Reload

and you will be able to check the

current indoor unit status in the “B”

part.

• When you would like to change the

IP, click on [Set up Network place]

to change the IP.

"A"

"B"

Page 17

BNU-LW remote diagnosis function

Installation Manual 17

ENGLISH

A

B

C

D

A: It displays the current IP, Gateway,

Subnet mask information.

When you would like to use the

SVCnet Server, it displays the

SVCnet Server information.

It displays the MAC address

information.

It displays the current version

information of the BNU-LW.

B: When you would like to change the IP

and Gateway, Subnet mask

information, press the Edit button next

to the information you would like to

change.

C: This is the space to enter the SVCnet

Server information to connect.

SVCnet Server is the service that

monitors the air conditioner status

connected to BNU-LW through the

LAN in the future by the LG

Electronics Service Center to provide

early notification in case of a problem.

D: In order to prevent the network or

arbitrary change, a security function

has been applied for you to enter the

initial login password to change the

network setting.

Page 18

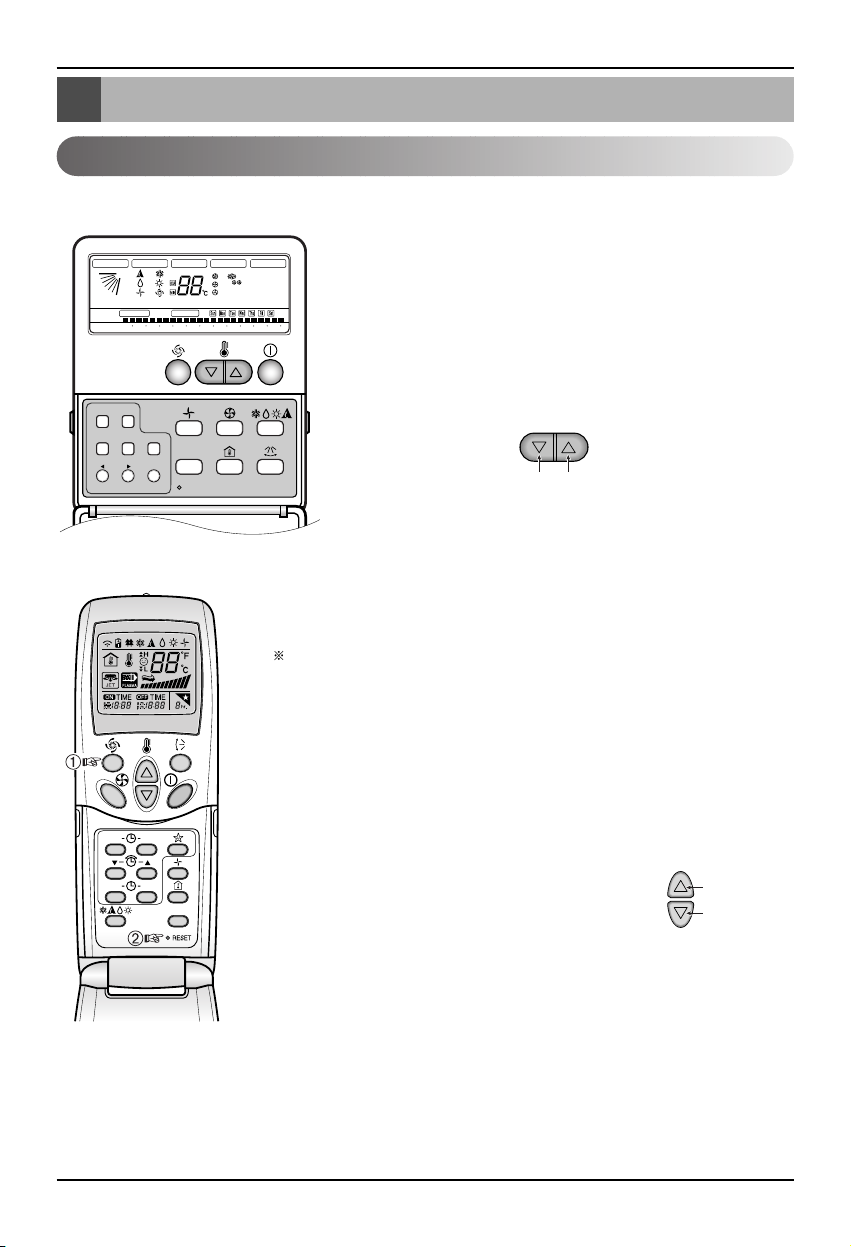

Setting the indoor unit address

18 Lonworks Gateway

Setting the indoor unit address

Setting the indoor unit address

When using the wired remote controller

When using the wireless remote controller

Timer Cancel

Program Week

Hour Min

Holiday

Set/Clr

RESET

ZONE

1234

Operation unit

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

Plasma

ON OFF

SET

CANCEL

PLASMA

Group No. Indoor unit No.

Temperature adjustment

1. Press the week day and reservation set/cancel buttons

simultaneously for 3 seconds.

2. By using the temperature adjustment button, set the indoor unit

address.

Setting range: 00~FF

3. When you press the week day and reservation set/cancel

buttons simultaneously for 3 seconds, the address setting is

completed.

Address setting mode

1. ➀ Press the top left button for more than 3 seconds. ➁ While the top left

button pressed, press the Reset button .

The wireless remote controllers have different shapes according to

the model.

2. By using the temperature adjustment button, set the indoor unit address.

Setting range: 00~FF

3. After setting the address, press the ON/OFF button toward the indoor

unit 1 time.

4. The indoor unit will display the set address to complete the address

setting. (The address display time and method can differ by the indoor

unit type.)

5. Reset the remote controller to use the general

operation mode.

Address check mode

1. With the top right button pressed, press the Reset

button.(Press the left button for more than 3

seconds.)

2. Press the ON/OFF button toward the indoor unit 1 time, and the indoor

unit will display the set address in the display window. (The address

display time and method can differ by the indoor unit type.)

3. Reset the remote controller to use the general operation mode.

❈ The above function might not work for some remote controllers depending on the manufactured

date of the wired/wireless remote controller.

It is not relevant for the consumer use and you can set the address with a remote controller that has

the address setting functionality during the installation.

Group No.

Indoor unit No.

Temperature

adjustment

Page 19

Interfacing with simple central controller

Installation Manual 19

ENGLISH

Interfacing with simple central controller

How to interface with simple central

controller

• When interfacing with simple central controller, turn the DIP

S/W No. 2 of the simple central controller ON.

• Set the rotary S/W to the group address of the indoor unit you

would like to control.

How to set PI-485

How to set PI-485

• BNU-LW uses LGAP communication protocol.

You can set the DIP S/W No. 1 and No. 4 of PI-485 ON.

Page 20

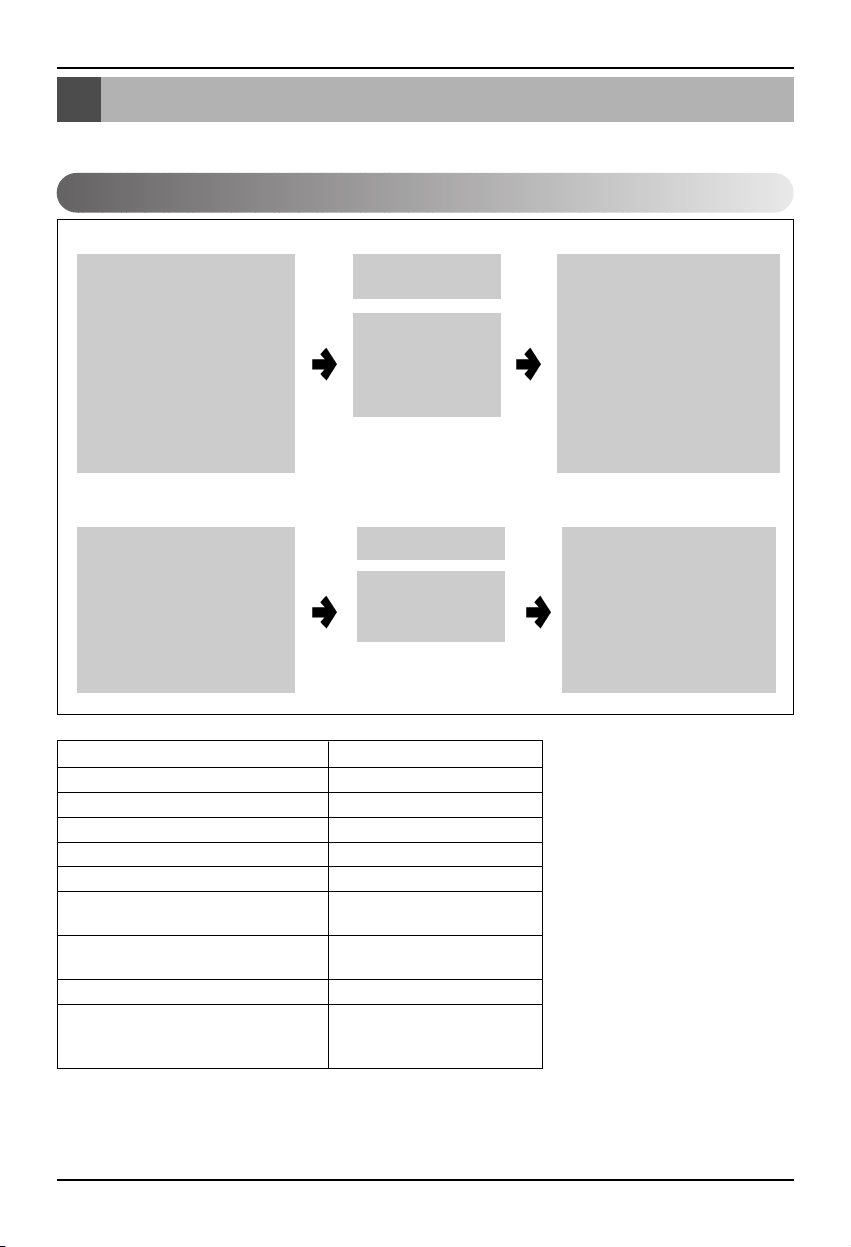

Appendix

20 Lonworks Gateway

Appendix

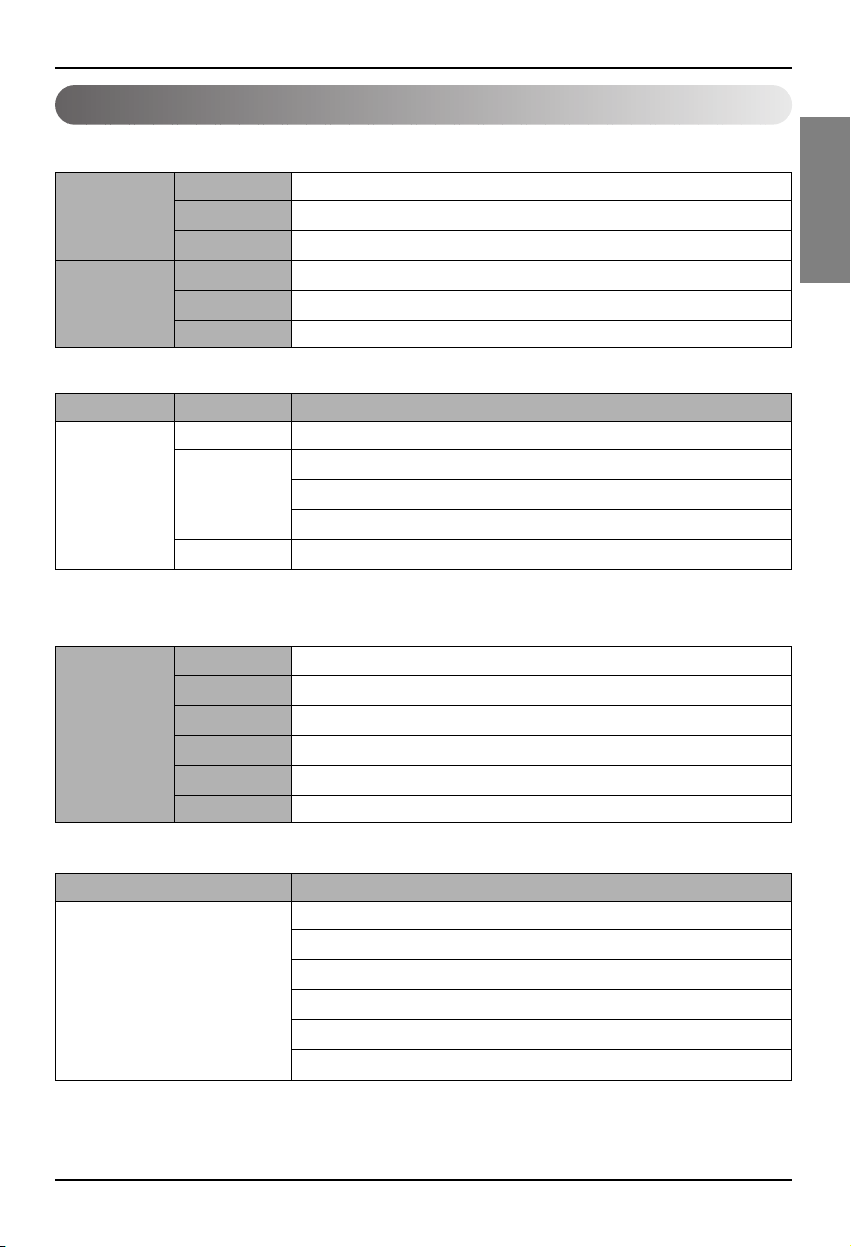

A/C Objects

• The appendix carries information necessary for interfacing with BMS and not necessary for actual

installation.

Standard Fundtion Block

SCC(8500)FB

Indoor/

Ventilator unit

Network Varlables

SNVT

_

switch nviOnOff

SNVT_hvac_mode nviHeatCool

SNVT_switch nviFanSpeedcmd

SNVT_switch nviLock

SNVT

_

switch nviSwing

SNVT_switch nviSetPoint

SNVT_switch nviUser

SNVT_switch nviSpaceTemp

SNVT

_

switch nvoOnOff

SNVT_hvac_mode nvoHeatCool

SNVT_switch nvoFanSpeed

SNVT_switch nvoLock

SNVT

_

switch nvoSwing

SNVT_temp_P nvoSetPoint

SNVT_hvac_status nvoUnitStatus

SNVT_count nvoUser

SWITCH(3200)FB

Total

Control

SNVT_switch

nviTotalOnOff_Indoor

SNVT_switch

nviTotalOnOff_Vent

SNVT_switch nvoSwitch

• You can enable control and monitoring as shown in the figure for one air conditioner/ventilation unit.

• The network variable can differ from the actual.

(Refer to the XIF file for correct network variable.)

Control Monitoring

On/Off command

Mode selection command

Fan level selection command

Indoor unit lock command

Fan direction command

Temperature setting command

Ventilation additional function command

(Only applies for ventilation product)

Air conditioner total On/Off control

Ventilation total On/Off control

On/Off status monitoring

Mode status monitoring

Fan level status monitoring

Lock status monitoring

Fan direction status monitoring

Temperature setting status

monitoring

Current temperature monitoring

Error display

Ventilation additional function

status monitoring (Only applies

for ventilation product)

Page 21

Appendix

Installation Manual 21

ENGLISH

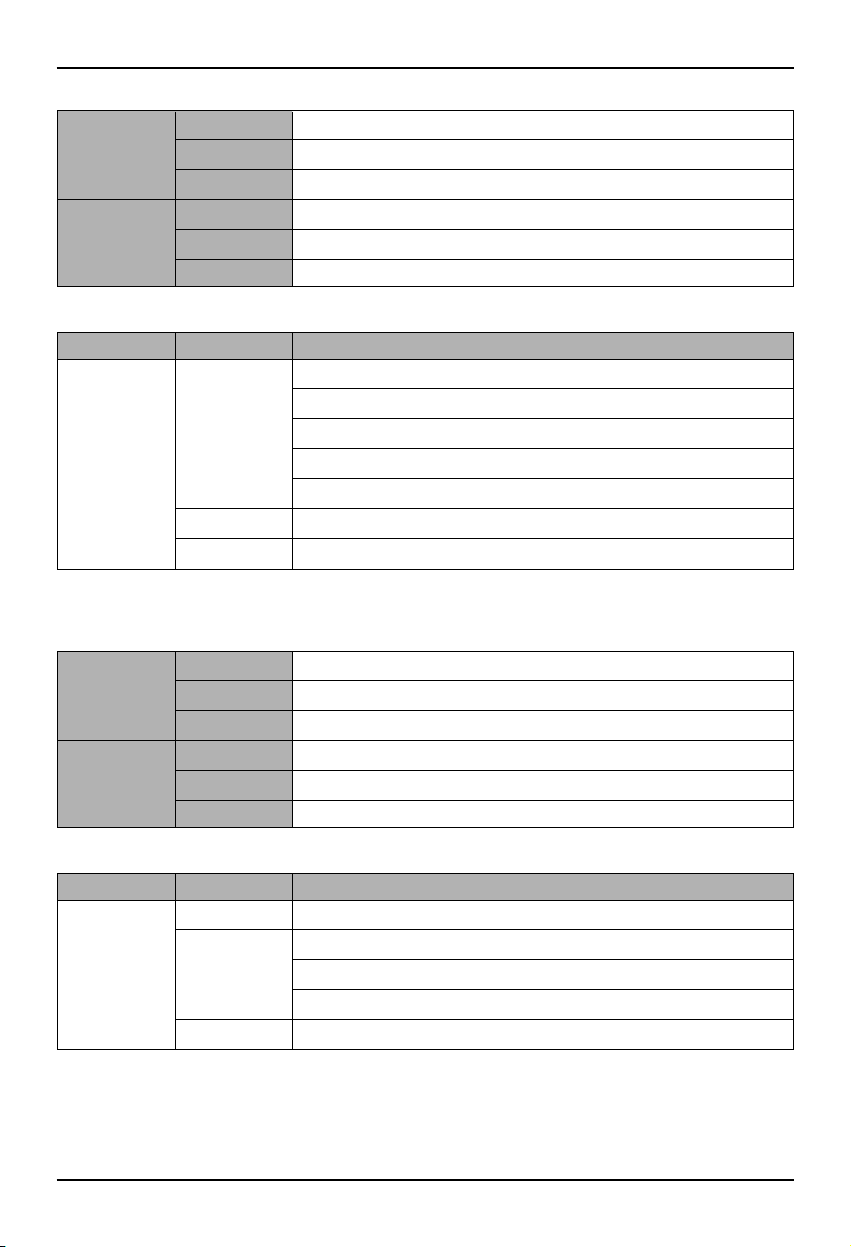

Air conditioner control/monitoring point

1 ON/OFF (setting) SNVT_switch nviOnOff_nn input Stop

Operation

2 ON/OFF (status) SNVT_switch nvoOnOff_nn output Stop

Operation

3 Lock (setting) SNVT_switch nviLock_nn input Cancel Setting

4 Lock (status) SNVT_switch nvoLock_nn output Cancel Setting

5 Operation Mode (setting) SNVT_hvac_modenviHeatCool_nn input Auto Heating Cooling Fan Dry

6 Operation Mode (status) SNVT_hvac_mode nviHeatCool_nn output Auto Heating Cooling Fan Dry

7 Swing(setting) SNVT_switch nviSwing_nn input Cancel Setting

8 Swing(status) SNVT_switch nvoSwing_nn output Cancel Setting

9 Fan speed(setting) SNVT_switch nviFanSpeedCmd_nn input Low Med High Auto

Super Low

10 Fan speed(status) SNVT_switch nvoFanSpeed_nn output Low Med High Auto

Super Low

11 Set Room Temperature SNVT_temp_p nviSetPointCmd_nn input °C

12 Set Room Temperature SNVT_temp_p nvoSetPoint_nn output °C

13 Room Temperature SNVT_temp_p nvoSpaceTemp_nn output °C

14 Error Code SNVT_hvac_status nvoUnitStatus_nn output no errorRefer to the LG Air Conditioner Error Code.

Point

No.

Name

Object

Type

Unit

code 0 code 1 code 2 code 3 code 4 code 5 code 9 code

14

Object Name

(nn: Air conditioner and ventilation

group/indoor unit address)

Page 22

Appendix

22 Lonworks Gateway

Ventilation control/monitoring point

1 ON/OFF (setting) SNVT_switch nviOnOff_nn input Stop Operation

2 ON/OFF (status) SNVT_switch nvoOnOff_nn output Stop Operation

3 Lock (setting) SNVT_switch nviLock_nn input Cancel Setting

4 Lock (status) SNVT_switch nvoLock_nn output Cancel Setting

5 Operation Mode (setting) SNVT_hvac_modenviHeatCool_nn input Auto

Heat exchange

Normal

6 Operation Mode (status) SNVT_hvac_mode nviHeatCool_nn output Auto

Heat exchange

Normal

7 Fan speed(setting) SNVT_switch nviFanSpeedCmd_nn input Low High Very high

8 Fan speed(status) SNVT_switch nvoFanSpeed_nn output Low High Very high

9 Error Code SNVT_hvac_status nvoUnitStatus_nn output Refer to the LG Air Conditioner Error Code.

10 User Mode(setting) SNVT_count nviUser_nn output Quick

Power save

heat

11 User Mode(status) SNVT_count nvoUser_nn output Quick

Power save

heat

Point

No.

Name

Object

Type

Unit

code 0 code 1 code 2 code 3 code 5 code 9

Object Name

(nn: Air conditioner and ventilation

group/indoor unit address)

Page 23

Appendix

Installation Manual 23

ENGLISH

Network variables

1) Individual operation/stop input/output (Air conditioner/ventilation)

Valid Range

SNVT_switch

( Index : 95 )

NV Filed Operation

Function Operation/stop input

Input Using NV Network input variable : SNVT_switch nviOnOff_n

Operation It controls the operation/stop of each product (air conditioner/ventilation)

Function Operation/stop status display

Output Using NV Network output variable : SNVT_switch nvoOnOff_n

Operation It monitors the operating status of each product (air conditioner/ventilation)

2) Operating mode input/output (Air conditioner/ventilation)

Function Operating mode command input

Input Using NV Network input variable : SNVT_hvac_mode nviHeatCool_n

Operation It controls the operating mode of each air conditioner/ventilation product.

Function Operating mode status display

Output Using NV etwork output variable : SNVT_hvac_mode nvoHeatCool_n

Operation It monitors the operating status of each air conditioner/ventilation product.

value not used (set in 0% usually)

0 = Air conditioner/ventilation product OFF

state 1 = Air conditioner/ventilation product ON

Default Value

HVAC_AUTO : 0 = AUTO mode(air conditional), Auto (ventilation)

HVAC_HEAT : 1 = Heat mode(air conditional), heat exchange(ventilation)

HVAC_COOL: 3 = Cool mode (cool)

HVAC_FAN_ONLY: 9 = Fan mode (fan) normal ventilation

HVAC_DEHUMID:14=Dry Mode (dehumidication)

Default Value

Valid Range

SNVT_hvac_mode

( Index : 108 )

NV Operation

Page 24

Appendix

24 Lonworks Gateway

1: Air conditioner, ventilation low fan

2: Air condition med fan, ventilation high fan

value 3: Air condition high fan, ventilation very high fan

4: Air condition, ventilation auto fan

5. Air conditioner super low fan

state 0: Product not applied, 1: Product applied

Default Value

3) Fan level command input/output (Air conditioner/ventilation)

Valid Range

SNVT_switch

( Index : 95 )

NV Filed Operation

Function Fan level command input

Input Using NV Network input variable : SNVT_switc nviFanSpeedCmd_n

Operation It controls the fan level of each indoor unit.

Function Fan level status display

Output Using NV Network output variable : SNVT_switch nvoFanSpeed_n

Operation It monitors the fan level of each product (air conditioner/ventilation)

value not used (set in 0% usually)

0 = Air conditioner/ventilation product lock OFF

state 1 = Air conditioner/ventilation product lock ON

Default Value

4) Lock input/output (Air conditioner/ventilation)

Valid Range

SNVT_switch

( Index : 95 )

NV Filed Operation

Function Lock setting command input

Input Using NV Network input variable : SNVT_switch nviLock_n

Operation It controls the lock status of each product (air conditioner/ventilation)

Function Lock status display

Output Using NV Network output variable : SNVT_switch nvoLock_n

Operation It monitors the lock status of each product (air conditioner/ventilation)

Page 25

Appendix

Installation Manual 25

ENGLISH

value not used (set in 0% usually)

0 = Fan direction fixed for air conditioner product

state 1 = Fan direction auto for air conditioner product

Default Value

5) Fan direction auto input/output (Only applies to air conditioner)

Valid Range

SNVT_switch

( Index : 95 )

NV Filed Operation

Function Fan direction auto command input

Input Using NV Network input variable : SNVT_switch nviSwing_n

Operation It controls the fan direction of each product (air conditioner/ventilation)

Function Fan direction auto status display

Output Using NV Network output variable : SNVT_switch nvoSwing_n

Operation It monitors the fan direction of each product (air conditioner/ventilation)

6) Temperature setting input/output (Only applies to air conditioner)

Function Set temperature range input

Input Using NV Network input variable : SNVT_switch nviSetPoint_n

Operation It controls the temperature setting of each product (air conditioner/ventilation)

Function Set temperature range status display

Output Using NV Network output variable : SNVT_switch nvoSetPoint_n

Operation It monitors the set temperature of each product (air conditioner/ventilation)

At Cool mode : 18 ~ 30°C

At Heat mode : 18 ~ 30°C

At Dry mode and Fan mode : Not available

Default Value

Valid Range

SNVT_switch

( Index : 95 )

NV Operation

Page 26

Appendix

26 Lonworks Gateway

7) Indoor temperature status display (Only applies to air conditioner)

Function Indoor temperature status display

Output Using NV Network output variable : SNVT_switch nvoSpaceTemp_n

Operation It monitors the indoor temperature.

8) Error output (Air conditioner/ventilation)

Function Error status display

Output Using NV Network input variable : SNVT_hvac_Status nvoUnitStatus_n

Operation It monitors the error status of each product (air conditioner/ventilation)

At Cool mode : 10 ~ 40°C

At Heat mode : 10 ~ 40°C

At Dry, Fan mode : Not available

Default Value

Valid Range

SNVT_switch

( Index : 95 )

NV Operation

Mode Currently operating mode display

Heat_output_primary Not used

Heat_output_Secondary Not used

Cool_output Not used

Cool_output Not used

Econ_output Not used

fan_output Not used

In_alarm Error code display

Valid Range

SNVT_switch

( Index : 112 )

NV Filed Operation

* Refer to the Error Code table of the product manual for the error code.

Page 27

Appendix

Installation Manual 27

ENGLISH

10) Total operation/stop air conditioner indoor unit

Function Total stop command input

Input Using NV Network input variable : SNVT_switch nviTotalONOFF_indoor

Operation It turns ON or OFF all the indoor units.

11) Total operation/stop ventilation indoor unit

Function Total stop command input

Input Using NV Network input variable : SNVT_switch nviTotalONOFF_indoor

Operation It turns ON or OFF all the ventilation units.

0 = Not used

value

1 = Quick mode

2 = Power save mode

3 = Heat

9) Ventilation function command (Only applies to ventilation product)

Valid Range

SNVT_count

( Index : 8 )

NV Filed Operation

Function Ventilation user operating mode input

Input Using NV Network input variable : SNVT_count nviUser_n

Operation It controls the product function of each ventilation product.

Function Ventilation user operating mode status

Output Using NV Network output variable : SNVT_count nvoUser_n

Operation It monitors the function status of each ventilation product.

value not used

state

1 = All ON indoor/Vent unit

0 = All OFF indoor/Vent unit

Default Value

Valid Range

SNVT_switch

( Index : 95 )

NV Filed Operation

Page 28

Memo

28 Lonworks Gateway

Page 29

ITALIANO

LG

BNU-LW(Lonworks Gateway)

LG

Importante

• Leggere per intero questo manuale

d'intallazione prima di installare il prodotto.

• Dopo aver letto interamente il manuale,

conservarlo per riferimento futuro

Manuale d'installazione

Page 30

2 Lonworks Gateway

BNU-LW (Lonworks Gateway).

SOMMARIO

Precauzioni per la sicurezza .................................................................................3

Schema generale del sistema...............................................................................7

Schema del cablaggio esterno .............................................................................8

Impostazione dell’indirizzo dell’unità di controllo centrale dell’unità interna

collegata al BNU-LW (Lonworks Gateway).........................................................8

Specifiche linea di comunicazione......................................................................9

Identificazione delle parti ....................................................................................10

Sequenza di installazione....................................................................................11

Ordine di cablaggio BNU-LW ..............................................................................12

Tabella delle funzioni condizionatore/ventilazione...........................................13

Funzionamento dell’unità interna del condizionatore intern .............................13

Funzionamento unità interna di ventilazione ....................................................14

Funzionamento diagnosi remota BNU-LW ........................................................15

Metodo di impostazione....................................................................................15

Configurazione..................................................................................................16

Impostazione dell’indirizzo dell’unità interna....................................................18

Impostazione dell’indirizzo dell’unità intern.......................................................18

Interfacciamento con l’unità di controllo centrale semplice............................19

Appendice.............................................................................................................20

Oggetti A/C .......................................................................................................20

Punto di monitoraggio/controllo condizionatore................................................21

Punto di monitoraggio/controllo ventilazione ....................................................22

Punto di monitoraggio/controllo ventilazione ....................................................23

Page 31

Precauzioni per la sicurezza

Manuale d'installazione 3

ITALIANO

Non avviare o arrestare

l’unità inserendo o

estraendo la spina

dell’alimentazione.

• Ciò causerà scosse

elettriche o incendio

dovuti alla generazione di

calore.

Rivolgersi al Servizio di

assistenza tecnica autorizzata

o al negozio specializzato per

informazioni sul prodotto e

sul suo utilizzo.

•

L'utilizzo improprio del

prodotto può causare

scosse elettriche, esplosioni

o lesioni personali.

Utilizzare solo

componenti standard.

• L'uso di parti diverse può

causare scosse elettriche,

esplosioni, lesioni alla

persona e guasti.

■ In funzionamento

Precauzioni per la sicurezza

Per evitare infortuni all'utente o a terzi e danni alla proprietà, attenersi alle seguenti istruzioni.

■ L’uso errato causato dalla mancata osservanza delle istruzioni può causare danni o lesioni.

L’importanza è classificata dalle seguenti indicazioni.

■ Il significato dei simboli utilizzati in questo manuale è spiegato di seguito.

Questo simbolo indica la possibilità di decesso o di grave infortunio.

Questo simbolo indica il rischio di lesioni alla persona o di danni alla proprietà.

Azione/operazione da non fare.

Attenersi alle istruzioni.

Attenzione

Componenti standard

Attenzione

Avvertenza

BNU-LW

BNU-LW

Page 32

Precauzioni per la sicurezza

4 Lonworks Gateway

In caso di ingresso di acqua nel prodotto,

spegnere l’interruttore di alimentazione del

corpo principale dell’apparecchio.

• Dopo avere rimosso il cavo dalla presa,

contattare il centro di assistenza.

Tenere il prodotto lontano da ambienti

umidi.

• L'eventuale ingresso di acqua nell'unità

potrebbe deteriorarne l’isolamento. Ciò

potrebbe causare scosse elettriche.

BNU-LW

■ Durante l’uso

Se è necessario reinstallare

il prodotto, informare il

centro di assistenza tecnica

o il rivenditore specializzato.

•

L'utilizzo improprio del

prodotto può causare scosse

elettriche, esplosioni o lesioni

personali.

Non utilizzare il cavo di

alimentazione in prossimità

di gas infiammabili o

combustibili, quali benzina,

benzene, solventi, ecc..

• Ciò potrebbe causare

l'insorgere di incendi o di

esplosioni.

Non smontare o riparare o

apportare modifiche al

prodotto.

•

Ciò potrebbe causare

incendi e scosse elettriche.

BNU-LW

BNU-LW

Non modificare o prolungare

il cavo di alimentazione.

• Ciò potrebbe causare

incendi e scosse

elettriche.

Non usare con cavi

intrecciati o sovrapposti.

• Ciò potrebbe causare

incendi e scosse

elettriche.

Scollegare l’unità in caso di

rumori, odori o fumo

anomali.

•

Ciò potrebbe causare

incendi e scosse elettriche.

BNU-LW

BNU-LW

Thinner

Wax

BNU-LW

Page 33

Precauzioni per la sicurezza

Manuale d'installazione 5

ITALIANO

Tenere lontano da armi da

fuoco.

• Ciò potrebbe causare

incendi.

Tenere il prodotto lontano

da riscaldatori e cavi

elettrici.

•

Ciò potrebbe causare

incendi e scosse elettriche.

Non far gocciolare acqua

all'interno dell'unità.

• Ciò potrebbe causare

scosse elettriche e guasti.

BNU

-LW

BNU-LW

BNU-LW

Non mettere oggetti pesanti

sul cavo di alimentazione.

• Ciò potrebbe causare

incendi e scosse

elettriche.

Estrarre il cavo di

alimentazione tenendolo per

la spina.

•

In caso contrario, potrebbero

verificarsi scosse elettriche o

danni al prodotto.

Non mettere oggetti pesanti

sul prodotto.

• Ciò potrebbe causare

guasti.

BNU-LW

BNU-LW

Se incautamente si versa acqua

sull'unità o se le parti interne del

prodotto si bagnano, rivolgersi

al centro di assistenza tecnica o

al rivenditore specializzato per

istruzioni in proposito.

•

Se ciò si verifica, l'utente è

responsabile del possibile verificarsi

di incendi o scosse elettriche.

Tenere il prodotto lontano

dalla portata dei bambini.

•

In caso contrario,

potrebbero verificarsi

incidenti o danni al prodotto.

Proteggere il prodotto da

forti impatti.

• L’utente è responsabile

del possibile verificarsi di

danni in caso di urto.

BNU-LW

BNU-LW

BNU-LW

Page 34

Precauzioni per la sicurezza

6 Lonworks Gateway

■ Durante l’uso

Avvertenza

Pulire delicatamente usando

un panno morbido.

•

L'uso di detergenti aggressivi

potrebbe causare incendi o

alterare le caratteristiche del

prodotto.

Tenere le parti sotto

tensione lontano da acqua o

da superfici bagnate.

• Ciò potrebbe causare

guasti.

Utilizzare solo il tipo di

adattatore raccomandato.

• In caso contrario,

potrebbero verificarsi

danni al prodotto.

BNU-LW

Wax

Thinner

BNU-LW

BNU-LW

Evitare che la batteria venga

a contatto con parti in

metallo, quali collane,

monete, chiavi, orologi.

• Ciò potrebbe causare

danni al prodotto e lesioni

alla persona.

Estrarre il cavo di

alimentazione tenendolo

per la spina.

•

In caso contrario,

potrebbero verificarsi

scosse elettriche o danni al

prodotto.

BNU-LW

Page 35

Schema generale del sistema

Manuale d'installazione 7

ITALIANO

Schema generale del sistema

* Il PNF-B16A1 (Lon Gateway) può essere utilizzato congiuntamente all’unità di

controllo centrale semplice.

Fornitura LG

Unità di controllo

centrale semplice

Comunicazione 485

* Può essere collegato a 64 unità interne (ventilazione+condizionatore)

Ventilazione

A/C

Page 36

Schema del cablaggio esterno

8 Lonworks Gateway

• Quando l’indirizzo dell’unità interna del condizionatore è duplicato di quello dell’unità di ventilazione,

si hanno dei malfunzionamenti.

• Alla BNU-LW possono essere collegate massimo 64 unità dell’unità interna

(condizionatore+ventilazione).

• Si raccomanda di collegare 16 unità di PI485 e un massimo di d32 PI485 unità alla BNU-LW.

• Non è possible interfacciare i prodotti di ventilazione all’unità di controllo centrale semplice.

Schema del cablaggio esterno

Impostazione dell’indirizzo dell’unità di controllo centrale

dell’unità interna collegata al BNU-LW (Lonworks Gateway)

Protocollo LON

Sistema BMS

<Numero massimo di unità interne collegate: 64 unità>

Condizionatore d'aria

RS485

BNU-LW

RI485

RI485

Indirizzo dell’unità di

controllo centrale(2.0)

Indirizzo dell’unità di

controllo centrale(2.4)

Indirizzo dell’unità di controllo centrale(0.0) (0.1).............(0.F)

Indirizzo dell’unità di controllo centrale(1.0)

(2.1) (2.2) (2.3)

(2.5) (2.6) (2.7)

(1.1).............(1.F)

Page 37

Schema del cablaggio esterno

Manuale d'installazione 9

ITALIANO

1. Specifica linea di comunicazione RS -485: schermo 0,75mm2 o oltre 2C, da prodotto a prodotto:

200M, lunghezza totale: 1km

2. Linea di comunicazione FT-10: fare riferimento alla tabella seguente

* Distanza da nodo a nodo (max): 250m, distanza massima: 450m

* AWG: American Wire Gauge

Tipo di cavo Spessore linea (AWG) Diametro

TIA 568A Category 5 cable 24 0.5mm

Belden 88471 (PVC jacket) or 16 1.3mm

equivalent cable

Belden 85102(Tefzel jacket) or 16 1.3mm

equal cable

Level IV cable 22 0.65mm

JY(st)Y 2x2x0.8 20.4 0.8mm

Specifiche linea di comunicazione

Page 38

Identificazione delle parti

10 Lonworks Gateway

Identificazione delle parti

1

2

3

4

5

6

7

8

BUS_A: 485 linea di comunicazione A (+)

BUS_B: 485 linea di comunicazione B (-)

F1, F2: Connessione punto di contatto funzione di rilevamento incendi (dispositivo esterno)

LAN: porta LAN necessaria per funzione Web

LON: non-polarità linea di comunicazione TP/FT-10 (linea di comunicazione sistema Lonworks)

PWR: collegamento ad adattatore di alimentazione CC 12V

12V: collegamento quando non si utilizza l’adattatore CC 12V

GND: collegamento quando non si utilizza l’adattatore GNS

ALIVE/WINK: lampeggia ogni secondo quando è normale lampeggia 5 volte alla

ricezione del comando WINK dal sistema Lonworks (verde)

SERVIZIO: spento quando è normale e lampeggiante quando non collegato al sistema

Lonworks. Acceso quando viene premuto l’interruttore di servizio.

INTERRUTTORE DI SERVIZIO: quando si preme l’interruttore, l’ID Neuron viene

trasmesso al sistema Lonworks e il LED di servizio si accende.

Il prodotto BNU-LW (PNF-B16A1) è certificato LON-MARK, uno standard

internazionale(Lon Mark versione 3.3).

1

8

2

3

4

5

6

7

Gateway Lonworks

No. 6 e No. 7, 8 sono tutti riservati all'alimentazione. Quindi, solo una delle due

combinazioni dovrebbe essere usata.

Se si usa DC 12V come alimentazione, connettere No. 6 all'alimentazione (non è

necessario usare No. 7 e No. 8)

Quando NON si usa DC 12V per l'alimentazione, connettere No. 7 e No. 8

all'alimentazione (non è necessario usare No. 6)

Attenzione

Page 39

Sequenza di installazione

Manuale d'installazione 11

ITALIANO

Sequenza di installazione

1. Installare il prodotto secondo l’impostazione dell‘indirizzo del controller centrale dell’unità interna e

del DIP S/W di PI485. (Impostare il DIP switch n. 4 su ON.)

(Fare riferimento al manuale di installazione del PI485 per maggiori dettagli.)

2. Collegare BUS_A e BUS_B (linea di comunicazione 485) facendo attenzione alla polarità di

connessione. (Fare riferimento alla pagina successiva.)

3. LON (Linea TP/FT-10 ‡connessione linea di comunicazione Lonworks Gateway) la linea di

comunicazione TP/FT-10 è priva di polarità.

Connettere le 2 linee di comunicazione al BMS.

4. PWR (alimentazione)

Si può selezionare una delle due per l’alimentazione.

Utilizzare l’adattatore di alimentazione CC 12V

Connettere al n.6 in identificazione delle parti.

In caso di separazione alimentare CC12

Collegare 12V e GND ai terminali n. 7 e 8.

5. Se si preme l’interruttore di servizio dopo aver collegato il sistema Lonworks, si accende il LED di

servizio e l’ID neuron viene trasmesso automaticamente al sistema Lonworks.

6. Accertarsi che il LED di servizio si trovi in condizioni normali (OFF) entro 10 minuti. Se il LED di

servizio si trova in condizioni normali, l’installazione è stata eseguita correttamente.

7. Se si utilizza la porta di rilevamento incendio, collegare i due terminali del sensore di rilevamento

incendio su F1 e F2.

(Il sensore di rilevamento incendio deve essere utilizzato per l’uscita CC di 12V o inferiore.)

8. Dopo l’installazione collegare il cavo LAN tra i PC per utilizzare il server web che permette di

verificare la corretta installazione del prodotto LG. – Fare riferimento al capitolo sul funzionamento

della diagnosi remota (pagina 16) per maggiori dettagli.

Quando si effettua il collegamento della linea di segnale al terminale di Lonworks

Gateway, utilizzare sempre un cacciavite.

(Prestare estrema attenzione a non danneggiare la morsettiera e la PCB).

Avvertenza

Page 40

Ordine di cablaggio BNU-LW

12 Lonworks Gateway

Ordine di cablaggio BNU-LW

[Ordine di cablaggio]

1. Collegare la linea di comunicazione 485

- Prestare attenzione alla polarità del BUS A e

del BUS B(Fare riferimento al manuale GW

per maggiori informazioni DIP S/W per 485

G/W.)

2. Collegare la linea di comunicazione Lonworks

(TP/FT-10)

- Assenza di polarità

3. Alimentazione (selezionare tra n.1 o 2)

Utilizzare l’adattatore di CC 12V

- Collegare la jack n. 6 dall’identificazione

di ogni parte.

Alimentare CC 12V per il luogo di

installazione

- Collegare 12V e GND ai terminali n. 7 e

8.

4. Interfaccia con l’unità di controllo centrale

semplice

- Impostare il DIP S/W n. 2 dell’unità di

controllo centrale semplice su ON e

configurare l’impostazione all’indirizzo del

S/W a rotazione.(Fare riferimento al capitolo

sull’impostazione durante il collegamento

dell’unità di controllo centrale (pagina 20) per

maggiori dettagli).

5. Collegamento del sensore di rilevamento

incendio

- Se in caso di incendio viene trasmesso il

segnale di CC 12 o inferiore, l’unità interna e

la ventilazione collegata al BNU-LW viene

spenta.

LG non fornisce questa sezione (connessione e installazione)

Adattatore

LonWorks

TP/FT-10

F1 F2 LAN LON PWR 12V GND

Alimentazione

Sensore di rilevamento incendio

(Utilizzare CC 12V o inferiore)

Controllo BMS (PC)

A

B

+10V

GND

PI485

terminale

Controller

centrale

VOC

GND

PI485

10V

GND

C

BUS_A

D

BUS_B

Fomltura LG

Page 41

Tabella delle funzioni condizionatore/ventilazione

Manuale d'installazione 13

ITALIANO

Tabella delle funzioni condizionatore/ventilazione

Funzionamento dell’unità interna del condizionatore interno

Controllo individuale unità interna O O

Cambio modalità di funzionamento O O

Cambio potenza ventilatore O O

Funzione di regolazione della temperatura

OO

Funzione di blocco O O

Direzione automatica del ventilatore O O

Controllo temperatura unità interna X O

Controllo errore X O

Funzionamento/arresto simultaneo O X

Funzione

BMS

BNU-LW

Air conditioner

BMS

BNU-LW

Air conditioner

Classificazione Controllo Monitoraggio

Funzione di collegamento (connessione): La funzione di collegamento si riferisce al caso in cui

l’output di una unità è stato collegato all’input di un’altra

unità ed il processo di input dipende dal cambio di output.

La funzione di collegamento è possibile con unità Lon di altri

produttori.

Es) Se l’output ON/OFF dell’unità interna n.1 è collegato all’input ON/OFF dell’unità interna n.2 e si

accende l’unità interna n.1, anche l’unità interna n. 2 si accende perchè riceve il segnale.

Page 42

Tabella delle funzioni condizionatore/ventilazione

14 Lonworks Gateway

Funzionamento unità interna di ventilazione

Controllo individuale unità interna O O

Cambio modalità di funzionamento O O

Cambio potenza ventilatore O O

Modalità di funzionamento utente (ventilazione

OO

rapida,

rapida, risparmio energetico, riscaldamento)

Funzione di blocco O O

Controllo errore X O

Funzionamento/arresto simultaneo O X

Funzione

BMS

BNU-LW

Ventilation

BMS

BNU-LW

Ventilation

Classificazione Controllo Monitoraggio

Funzione di collegamento (connessione): La funzione di collegamento si riferisce al caso in cui

l’output di una unità è stato collegato all’input di un’altra

unità ed il processo di input dipende dal cambio di output.

La funzione di collegamento è possibile con unità Lon di altri

produttori.

Es) Se l’output ON/OFF dell’unità interna n.1 è collegato all’input ON/OFF dell’unità interna n.2 e si

accende l’unità interna n.1, anche l’unità interna n. 2 si accende perchè riceve il segnale.

Page 43

Funzionamento diagnosi remota BNU-LW

Manuale d'installazione 15

ITALIANO

1. Collegare la linea LAN tra il PC e la

porta LAN del BNU-LW.

2. Impostare l’IP di rete del PC in uso

su 192.168.1.xxx (tranne 101).

3. Immettere 192.168.1.101 in Internet

Explorer.

4. Se la connessione è corretta appare

l’immagine precedente.

• ID iniziale: lonwork

• Password iniziale: lonwork

• Immettere il numero totale di unità

interne collegate nel blocco unità

totale.

Funzionamento diagnosi remota BNU-LW

Metodo di impostazione

LAN(cross cable)

Page 44

Funzionamento diagnosi remota BNU-LW

16 Lonworks Gateway

Configurazione

- Dopo aver inserito l’ID e la

password i condizionatori d’aria ed i

prodotti di ventilazione attualmente

collegati vengono visualizzati come

illustrato nell’immagine.

- La parte “A” mostra il numero di

condizionatori d’aria e prodotti di

ventilazione attualmente collegati.

- Se si desidera controllare un

prodotto ➀ Selezionare il prodotto –

➁ Impostare l’indirizzo – ➂

Accendere o spegnere (ON/OFF) –

➃ Selezionare la modalità – ➄ Fare

clic su verifica per controllo del

prodotto.

- Se si desidera controllare lo stato

corrente ➅ Fare clic su Reload per

poter controllare lo stato attuale

dell’unità interna nella parte “B”.

- Se si desidera modificare l’IP, fare

clic su [Set up Network place] per

modificare l’IP.

"A"

"B"

Page 45

Funzionamento diagnosi remota BNU-LW

Manuale d'installazione 17

ITALIANO

A

B

C

D

A: Mostra l’IP corrente, il gateway, le

informazioni sulla subnet mask.

Se si desidera utilizzare il server

SVCnet Server, vengono

visualizzate le informazioni sul

Server SVCnet.

Mostra le informazioni sull’indirizzo

MAC.

Visualizza le informazioni sulla

versione corrente di BNU-LW.

B: Se si desidera cambiare l’IP, il

gateway, le informazioni sulla subnet

mask premere il pulsante Edit accanto

alle informazioni che si desidera

modificare.

C: Questo è lo spazio per immettere le

informazione del server SVCnet per

collegarsi.

Il server SVCnet è il servizio che

permette di monitorare in futuro lo

stato del condizionatore d’aria

collegato al BNU_LW attraverso la

LAN dal centro di assistenza LG

Electronics per fornire informazioni

tempestive in caso di problemi.

D: Per impedire alla rete una modifica

arbitraria, è stata impostata una

funzione di sicurezza che consente di

modificare le impostazioni di rete dopo

aver digitato la password di accesso

iniziale.

Page 46

Impostazione dell’indirizzo dell’unità interna

18 Lonworks Gateway

Impostazione dell’indirizzo dell’unità interna

Impostazione dell’indirizzo dell’unità interna

Se si utilizza il telecomando cablato

Se si utilizza il telecomando senza fili

Timer Cancel

Program Week

Hour Min

Holiday

Set/Clr

RESET

ZONE

1234

Operation unit

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

Plasma

ON OFF

SET

CANCEL

PLASMA

N°. gruppo N°. unità interna

Regolazione della temperatura

1. Premere contemporaneamente i pulsanti del giorno della

settimana e imposta/annulla programmazione per 3 secondi.

2. Utilizzando il pulsante della regolazione della temperatura,

impostare l’indirizzo dell’unità interna.

Intervallo di impostazione: 00~FF

3. Quando si premono contemporaneamente i pulsanti del giorno

della settimana e di imposta/annulla programmazione,

l’impostazione dell’indirizzo è completata.

Modalità di impostazione indirizzo

1.

Premere il tasto sinistro per un periodo superiore a 3 secondi

Con il tasto sinistro superiore premuto, premere il pulsante di ripristino.

❈ I telecomandi wireless hanno forme diverse secondo il modello.

2. Utilizzando il pulsante della regolazione della temperatura, impostare

l’indirizzo dell’unità interna.

Intervallo di impostazione: 00~FF

3. Dopo aver impostato l’indirizzo premere il pulsante ON/OFF verso l’unità

interna 1 volta.

4. L’unità interna visualizzerà l’indirizzo impostato per completarne

l’impostazione. (Il tempo di visualizzazione dell’indirizzo ed il metodo sono

diversi a seconda del tipo di unità interna.)

5. Ripristinare il telecomando per utilizzare la

modalità di funzionamento generale.

Modalità controllo indirizzo

1. Premendo il pulsante in alto a destra, premere il

pulsante Reset.(Premere il pulsante a sinistra per oltre 3 secondi.)

2. Premere il pulsante ON/OFF verso l’unità interna 1 volta. Quest’ultima

visualizzerà l’indirizzo impostato nella finestra del display. (Il tempo di

visualizzazione dell’indirizzo ed il metodo sono diversi a seconda del tipo di

unità interna.)

3. Ripristinare il telecomando per utilizzare la modalità di funzionamento

generale.

❈ La funzione di cui sopra potrebbe non funzionare con alcuni telecomandi a seconda della data di

fabbricazione e del tipo di telecomando cablato/senza fili.

Non si tratta di una condizione fondamentale in quanto l’utente può impostare l’indirizzo con un

telecomando che svolge le funzioni di impostazione di indirizzo durante l’installazione.

N°. gruppo

N°. unità interna

Regolazione

della temperatura

Page 47

Interfacciamento con l’unità di controllo centrale semplice

Manuale d'installazione 19

ITALIANO

Interfacciamento con l’unità di controllo centrale semplice

Come avviene l’interfacciamento con

l’unità di controllo centrale semplice

• Nell’interfacciamento con l’unità di controllo centrale

semplice, spostare su ON il DIP S/W n. 2 dell’unità di

controllo centrale semplice.

• Impostare lo S/W rotante sull’indirizzo di gruppo dell’unità

interna che si desidera controllare.

Impostazione di PI-485

Impostazione di PI-485

• BNU-LW us ail protocollo di comunicazione LGAP.

Si può impostare il DIP S/W n. 1 e n. 4 di PI-485 su ON.

Page 48

Appendice

20 Lonworks Gateway

Appendice

Oggetti A/C

• Nell’appendice sono riportate le informazioni necessarie per l’interfacciamento con BMS ma non

essenziali per l’installazione effettiva.

Blocco funzioni standard

SCC(8500)FB

Indoor/

Ventilator unit

Network Varlables

SNVT

_

switch nviOnOff

SNVT_hvac_mode nviHeatCool

SNVT_switch nviFanSpeedcmd

SNVT_switch nviLock

SNVT

_

switch nviSwing

SNVT_switch nviSetPoint

SNVT_switch nviUser

SNVT_switch nviSpaceTemp

SNVT

_

switch nvoOnOff

SNVT_hvac_mode nvoHeatCool

SNVT_switch nvoFanSpeed

SNVT_switch nvoLock

SNVT

_

switch nvoSwing

SNVT_temp_P nvoSetPoint

SNVT_hvac_status nvoUnitStatus

SNVT_count nvoUser

SWITCH(3200)FB

Controllo

totale

SNVT_switch

nviTotalOnOff_Indoor

SNVT_switch

nviTotalOnOff_Vent

SNVT_switch nvoSwitch

• Si può abilitare il comando ed il monitoraggio come illustrato nella figura per un condizionatore

d’aria/un’unità di ventilazione.

• La variabile di rete può essere differente da quella effettiva.

(Fare riferimento al file XIF per correggere la variabile di rete))

Controllo Monitoraggio

Comando On/Off

Comando selezione modalità

Comando selezione potenza ventilatore

Comando blocco unità interna

Comando direzione ventilatore

Comando impostazione temperatura

Comando funzionamento aggiuntivo ventilazione

(solo per prodotti di ventilazione)

Comando generale On/off condizionatore d’aria

Comando generale On/Off ventilazione

Monitoraggio stato On/Off

Monitoraggio stato modalità

Monitoraggio stato potenza ventilatore

Monitoraggio stato blocco

Monitoraggio stato direzione ventilatore

Monitoraggio stato impostazione temperatura

Monitoraggio temperature corrente

Visualizzazione errore

Monitoraggio stato funzione aggiuntiva

ventilazione (solo per prodotti di ventilazione)

Page 49

Appendice

Manuale d'installazione 21

ITALIANO

Punto di monitoraggio/controllo condizionatore

1 ON/OFF (impostazione) SNVT_switch nviOnOff_nn input Stop

Funzionamento

2 ON/OFF (stato) SNVT_switch nvoOnOff_nn output Stop

Funzionamento

3 Blocco (impostazione) SNVT_switch nviLock_nn input

Annulla Iniziale

4 Blocco (stato) SNVT_switch nvoLock_nn output

Annulla Iniziale

5

Modalità di funzionamento (impostazione)

SNVT_hvac_modenviHeatCool_nn input

Automatico

Riscaldamento

Bassa

Ventilatore

Deumidificazione

6

Modalità di funzionamento (stato)

SNVT_hvac_mode nviHeatCool_nn output

Automatico

Riscaldamento

Bassa

Ventilatore

Deumidificazione

7 Oscillazione (stato) SNVT_switch nviSwing_nn input

Annulla Iniziale

8

Oscillazione (impostazione)

SNVT_switch nvoSwing_nn output

Annulla Iniziale

9

Velocità ventola (impostazione)

SNVT_switch nviFanSpeedCmd_nn input Bassa Med Alta

Automatico

Debole

10 Velocità ventola (stato) SNVT_switch nvoFanSpeed_nn output Bassa Med Alta

Automatico

Debole

11

Imposta temperatura ambiente

SNVT_temp_p nviSetPointCmd_nn input °C

12

Imposta temperatura ambiente

SNVT_temp_p nvoSetPoint_nn output °C

13 Temperatura ambiente SNVT_temp_p nvoSpaceTemp_nn output °C

14 Codice errore SNVT_hvac_status nvoUnitStatus_nn output

Nessun errore Fare riferimento al Codice di errore del condizionatore d’aria LG.

.

N°.

punto

Nome

Tipo

oggetto

Unità

Codice

0

Codice

1

Codice

2

Codice

3

Codice

4

Codice

5

Codice

9

Codice

14

Nome oggetto

(nn: Condizionatore d’aria e gruppo di

ventilazione/indirizzo unità interna)

Page 50

Appendice

22 Lonworks Gateway

Punto di monitoraggio/controllo ventilazione

1 ON/OFF (impostazione) SNVT_switch nviOnOff_nn input Stop

Funzionamento

2 ON/OFF (stato) SNVT_switch nvoOnOff_nn output Stop

Funzionamento

3 Blocco (impostazione) SNVT_switch nviLock_nn input Annulla Iniziale

4 Blocco (stato) SNVT_switch nvoLock_nn output Annulla Iniziale

5

Modalità di funzionamento (impostazione)

SNVT_hvac_modenviHeatCool_nn input

Automatico

Riscaldamento

Normale

6

Modalità di funzionamento (stato)

SNVT_hvac_mode nviHeatCool_nn output

Automatico

Riscaldamento

Normale

7

Velocità ventola (impostazione)

SNVT_switch nviFanSpeedCmd_nn input Bassa Alta

Molto alta

8 Velocità ventola (stato) SNVT_switch nvoFanSpeed_nn output Bassa Alta

Molto alta

9 Codice errore SNVT_hvac_status nvoUnitStatus_nn output

Fare riferimento al Codice di errore del condizionatore d’aria LG.

10

Modalità utente (impostazione)

SNVT_count nviUser_nn output Quick

Power save

heat

11 Modalità utente (stato) SNVT_count nvoUser_nn output Quick

Power save

heat

N°.

punto

Nome

Tipo

oggetto

Unità

Codice

0

Codice

1

Codice

2

Codice

3

Codice

5

Codice

9

Nome oggetto

(nn: Condizionatore d’aria e gruppo di

ventilazione/indirizzo unità interna)

Page 51

Appendice

Manuale d'installazione 23

ITALIANO

Variabili di rete

1) Input/output funzionamento/arresto singolo (condizionatore d’aria/ventilazione)

Intervallo valido

Interruttore

SNVT

(indice: 95)

NV Campo Funzionamento

Funzione Input funzionamento/arresto

Input Uso di NV Variabile input di rete : SNVT_switch nviOnOff_n

Funzionamento

Serve per monitorare il funzionamento/l’arresto di ciascun prodotto (condizionatore d’aria/ventilazione)

Funzione Visualizzazione stato di funzionamento/arresto

Output Uso di NV Variabile output di rete : SNVT_switch nvoOnOff_n

Funzionamento

Serve per monitorare lo stato di funzionamento di ciascun prodotto (condizionatore d’aria/ventilazione)

2) Input/output modalità di funzionamento (condizionatore d’aria/ventilazione)

Funzione Input di comando modalità di funzionamento

Input Uso di NV Variabile input di rete : SNVT_hvac_mode nviHeatCool_n

Funzionamento

Serve per controllare la modalità di funzionamento di ciascun prodotto condizionatore d’aria/ventilazione

Funzione Display stato modalità di funzionamento

Output Uso di NV Variabile output di rete : SNVT_hvac_mode nvoHeatCool_n

Funzionamento

Serve per monitorare lo stato di funzionamento di ciascun condizionatore d’aria/prodotto di ventilazione.

Valore Non utilizzato (impostato di solito a 0%)

0 = Condizionatore d’aria/prodotto di ventilazione OFF

Stato 1 = Condizionatore d’aria/prodotto di ventilazione ON

Valore predefinito

HVAC_AUTO:0 = modalità automatico (auto), ventilazione automatica

HVAC_HEAT:1 = modalità riscaldamento (riscaldamento), ventilazione calda

HVAC_COOL: 3 = modalità raffreddamento (raffreddamento)

HVAC_FAN_ONLY:9 = modalità ventilatore (ventilatore), ventilazione normale

HVAC_DEHUMID:14 = modalità asciugatura (deumidificazione)

Valore predefinito

Intervallo valido

Modalità SNVT_hvac

(indice: 108)

NV Funzionamento

Page 52

Appendice

24 Lonworks Gateway

1: Condizionatore d’aria, ventilatore bassa ventilazione

2: Condizionatore d’aria ventilatore medio, ventilazione alta ventilatore

Valore 3: Condizionatore d’aria ventilatore alto, ventilazione molto alta ventilatore

4: Condizionatore d’aria, ventilatore ventilazione automatica

5. Condizionatore d’aria, ventilatore molto basso

Stato 0: Prodotto non applicato, 1: Prodotto applicato

Valore predefinito

3) Input/output comando potenza ventilatore (condizionatore d’aria/ventilazione)

Intervallo valido

Interruttore

SNVT

(indice: 95)

NV Campo Funzionamento

Funzione Input comando potenza livello ventilatore

Input Uso di NV Variabile input di rete : SNVT_switc nviFanSpeedCmd_n

Funzionamento Serve per controllare la potenza del ventilatore di ciascuna unità interna.

Funzione Display stato potenza ventilatore

Output Uso di NV Variabile output di rete : SNVT_switch nvoFanSpeed_n

Funzionamento

Serve per monitorare la potenza del ventilatore di ciascun prodotto (condizionatore d’aria/ventilazione)

Valore Non utilizzato (impostato di solito a 0%)

0 = blocco condizionatore d’aria/prodotto di ventilazione OFF

Stato 1 = blocco condizionatore d’aria/prodotto di ventilazione ON

Valore predefinito

4) Blocco input/output (condizionatore d’aria/ventilazione)

Intervallo valido

Interruttore

SNVT

(indice: 95)

NV Campo Funzionamento

Funzione Input comando impostazione blocco

Input Uso di NV Variabile input di rete : SNVT_switch nviLock_n

Funzionamento

Serve per controllare lo stato di blocco di ciascun prodotto (condizionatore d’aria/ventilazione)

Funzione Display stato di blocco

Output Uso di NV Variabile output di rete : SNVT_switch nvoLock_n

Funzionamento

Serve per monitorare lo stato di blocco di ciascun prodotto (condizionatore d’aria/ventilazione)

Page 53

Appendice

Manuale d'installazione 25

ITALIANO

Valore Non utilizzato (impostato di solito a 0%)

0 = direzione ventilatore fissa per prodotto condizionatore d’aria

Stato 1 = direzione ventilatore automatica per prodotto condizionatore d’aria

Valore predefinito

5) Input/output automatico direzione ventilatore (solo per condizionatori d’aria)

Intervallo valido

Interruttore

SNVT

(indice: 95)

NV Campo Funzionamento

Funzione Input comando automatico direzione ventilatore

Input Uso di NV Variabile input di rete : SNVT_switch nviSwing_n

Funzionamento

Serve per controllare la direzione del ventilatore di ciascun prodotto (condizionatore d’aria/ventilazione)

Funzione Display stato automatico direzione ventilatore

Output Uso di NV Variabile output di rete : SNVT_switch nvoSwing_n

Funzionamento

Serve per monitorare la direzione del ventilatore di ciascun prodotto (condizionatore d’aria/ventilazione)

6) Input/output impostazione temperatura (solo per condizionatori d’aria)

Funzione Input intervallo di temperatura impostato

Input Uso di NV Variabile input di rete : SNVT_switch nviSetPoint_n

Funzionamento

Serve per controllare l’impostazione della temperatura di ciascun prodotto (condizionatore d’aria/ventilazione)

Funzione Display stato intervallo temperature impostato

Output Uso di NV Variabile output di rete : SNVT_switch nvoSetPoint_n

Funzionamento

Serve per monitorare la temperatura impostata di ciascun prodotto (condizionatore d’aria/ventilazione)

In modalità raffreddamento : 18 ~ 30°C

In modalità riscaldamento: 18 ~ 30°C

In modalità essiccazione e in modalità ventola: non disponibile

Valore predefinito

Intervallo valido

Interruttore SNVT

(indice: 95)

NV Funzionamento

Page 54

Appendice

26 Lonworks Gateway

7) Display stato temperatura interna (solo per condizionatori d’aria)

Funzione Display stato temperature interna

Output Uso di NV Variabile output di rete : SNVT_switch nvoSpaceTemp_n

Funzionamento Serve per controllare la temperatura interna.

8) Output errore (condizionatore d’aria/ventilazione)

Funzione Display stato errore

Output Uso di NV Variabile input di rete : SNVT_hvac_Status nvoUnitStatus_n

Funzionamento

Serve per monitorare lo stato di errore di ciascun prodotto (condizionatore d’aria/ventilazione)

In modalità raffreddamento: 10 ~ 40°C

In modalità riscaldamento: 10 ~ 40°C

In modalità essiccazione e in modalità ventola: non disponibile

Valore predefinito

Valid Range

Interruttore SNVT

(indice: 95)

NV Funzionamento

Modalità Display modalità di funzionamento corrente

Primario_output_riscaldamento Non utilizzato

Secondario_output_riscaldamento Non utilizzato

Output_raffreddamento Non utilizzato

Output_raffreddamento Non utilizzato

Output_risparmio Non utilizzato

Output_ventola Non utilizzato

Output_in Display codice errore

Valid Range

Interruttore

SNVT

(indice: 112)

NV Campo Funzionamento

* Fare riferimento alla tabella del codice di errore riportata sul manuale del prodotto per il codice di

errore.

Page 55

Appendice

Manuale d'installazione 27

ITALIANO

10) Funzionamento/arresto generale unità interna condizionatore d’aria

Funzione Total stop command input

Input Uso di NV Network input variable : SNVT_switch nviTotalONOFF_indoor

Funzionamento It turns ON or OFF all the indoor units.

11) Funzionamento/arresto generale unità interna ventilazione

Funzione Input di comando arresto generale

Input Uso di NV Variabile input di rete : SNVT_switch nviTotalONOFF_indoor

Funzionamento Serve per spostare su ON o OFF tutte le unità interne.

0 = Non utilizzato

Valore

1 = Modalità rapida

2 = Modalità risparmio energetico

3 = Riscaldamento

9) Comando funzionamento ventilazione (solo per prodotti di ventilazione)

Intervallo valido

Conteggio_

SNVT

(indice: 8)

NV Campo Funzionamento

Funzione Input modalità di funzionamento ventilazione utente

Input Uso di NV Variabile input di rete : SNVT_count nviUser_n

Funzionamento Serve per controllare il funzionamento di ciascun prodotto di ventilazione.

Funzione Stato modalità di funzionamento ventilazione utente

Output Uso di NV Variabile output di rete : SNVT_count nvoUser_n

Funzionamento

Serve per monitorare lo stato di funzionamento di ciascun prodotto di ventilazione.

Valore Non utilizzato

state

1 = Tutto ON unità interna/ventola

0 = Tutto OFF unità interna/ventola

Valore predefinito

Intervallo valido

SNVT_switch

( Index : 95 )

NV Campo Funzionamento

Page 56

Note

28 Lonworks Gateway

Page 57

ESPAÑOL

LG

BNU-LW(Lonworks Gateway)

LG

Importante

• Lea completamente este manual de installación

antes de instalar el producto.

• Conserve este manual de instalación para

futuras consultas después de haberlo leído

completamente.

Manual de instalación

Page 58

2 Lonworks Gateway

BNU-LW (Lonworks Gateway)

CONTENIDO

Precauciones de seguridad ..................................................................................3

Diagrama general del sistema ..............................................................................7

Diagrama de cableado externo.............................................................................8

Cómo configurar la dirección del controlador central en la unidad interior

conectada a BNU-LW (Lonworks Gateway)........................................................8

Especificación de la línea de comunicaci ...........................................................9

Nombre de cada pieza .........................................................................................10

Orden de instalación............................................................................................11

Orden de cableado BNU-LW................................................................................12

Tabla de funciones aire acondicionado/ventilació ...........................................13

Función de la unidad interior de aire acondicionado ........................................13

Función de ventilación en la unidad interi.........................................................14

Función de diagnosis remota BNU-LW..............................................................15

Método de configuració ....................................................................................15