Page 1

LG

BNU-LW(Lonworks Gateway)

Owner's / Installation Manual

LG

IMPORTANT

• Please read this Installation Manual carefully and

thoroughly before installing and operating your room air

conditioner.

• Please retain this Installation Manual for future reference

after reading it thoroughly.

Page 2

2 Lonworks Gateway

BNU-LW (Lonworks Gateway)

TABLE OF CONTENTS

■ Safety Precautions

..............................................................................

3

■ BNU-L W Configur ation

.......................................................................

7

• BNU-L W Accessory P arts

................................................................

7

• Name of each part

............................................................................

8

■ System Structure

................................................................................

9

■ Address of the indoor unit connected to the BNU-LW

(LonWorks Gateway)

.......................................................................

10

■ Communications Wire Specifications

...............................................

11

■ General Specifications

......................................................................

12

■ Installation procedure of the BNU-LW(Lonworks gatewa y)

.............13

■ Wiring procedure of the BNU-L W

.....................................................

14

■ Appendix

...........................................................................................

15

■ The relationship between indoor unit address

and network variable

........................................................................

16

■ Network V ariables

.............................................................................

16

Page 3

Safety Precautions

Installation Manual 3

Do not operate or stop

the unit by inserting or

pulling out the power

plug.

• It will cause electric shock

or fire due to heat

generation.

Ask for Product

equipment at the service

center or establishment

certainly at the specialty

store.

• It can cause an accident,

electric shock, explosion

or injury.

Use standard parts.

• Use of non standard parts

can cause electric shock,

explosion, injury,

breakdown.

■ Operation

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

WARNING

WARNING

CAUTION

BNU-LW

BNU-LW

Standard Parts

Page 4

Safety Precautions

4 Lonworks Gateway

If water enters the product, turn the power

switch of the main body of appliance off.

• After taking the power-plug out from the

socket, contact the service center.

Keep the product away from the places

which can have moisture.

• Water may enter the unit and degrade the

insulation. It may cause an electric shock.

BNU-LW

■ During usage

While re-installing the

established product, notify

the service center or

establishment specialty

store.

• It can cause an accident,

electric shock, explosion,

injury.shock.

Do not use the power cord

near Flammable gas or

combustibles, such as

gasoline, benzene, thinner,

etc.

• It may cause an explosion

or fire

Do not disjoint randomly or

repair and remodel the

product.

• It may cause fire and

electric shock

BNU-LW

BNU-LW

Do not change or extend the

conductor at random.

• It can cause fire and

electric shock.

Do not use concert with in

the octopus-like legs way.

• It can cause fire and

electric shock

Unplug the unit if strange

sounds, smell, or smoke

comes from it.

• It may cause fire and

electric shock accident.

BNU-LW

BNU-LW

BNU-LW

Thinner

Wax

Page 5

Safety Precautions

Installation Manual 5

Do not put firearms near

product.

• It can cause fire.

Do not put an electric heater

or conductor near to the

product.

• It can cause fire and

electric shock.

Do not spill water inside

product.

• It can cause electric

shock and breakdown.

BNU-LW

BNU-LW

BNU-LW

Do not place heavy goods

on wire.

• It can cause fire and

electric shock.

Hold the plug by the head of

the power plug when taking

it out.

• It may cause electric

shock and damage.

Do not place heavy goods

on product.

• It can cause product

breakdown.

BNU-LW

BNU-LW

That increase in case of

product was been flood

certainly in the service

center or establishment

specialty store commit .

• I am responsible for fire

and electric shock.

Protect the product from

handling by a children.

• It can cause accident and

product breakdown.

Do not apply shock to

product.

• I am responsible for

breakdown in case of

shock to product.

BNU-LW

BNU-LW

BNU-LW

Page 6

Safety Precautions

6 Lonworks Gateway

■ During usage

CAUTION

Clean by soft hands using a

cleaning material like a soft

cloth.

• It can result in fire and

product transformation.

Use touch screen with a pen

that product offers.

• Otherwise, there can be

breakdown and damage

to the product.

Do not place any live part on

the surface having water.

• It can cause product

breakdown.

BNU-LW

Wax

Thinner

BNU-LW

BNU-LW

Use recommended Adapter.

• Otherwise it can result in

product breakdown

Avoid contact to the metallic

goods such as necklace,

coin, key, a watch which

may touch the battery even

for a short-time.

• It may cause product

breakdown and injury.

Hold the plug by the head of

the power plug when taking

it out.

• It may cause electric

shock and damage.

BNU-LW

BNU-LW

Page 7

BNU-LW Configuration

Installation Manual 7

BNU-LW Configuration

BNU-LW Accessory Parts

BNU-LW

BNU-LW Front view

Power Supply External S.M.P.S Power : 100~250 VAC

50/60 Hz Input

Page 8

BNU-LW Configuration

8 Lonworks Gateway

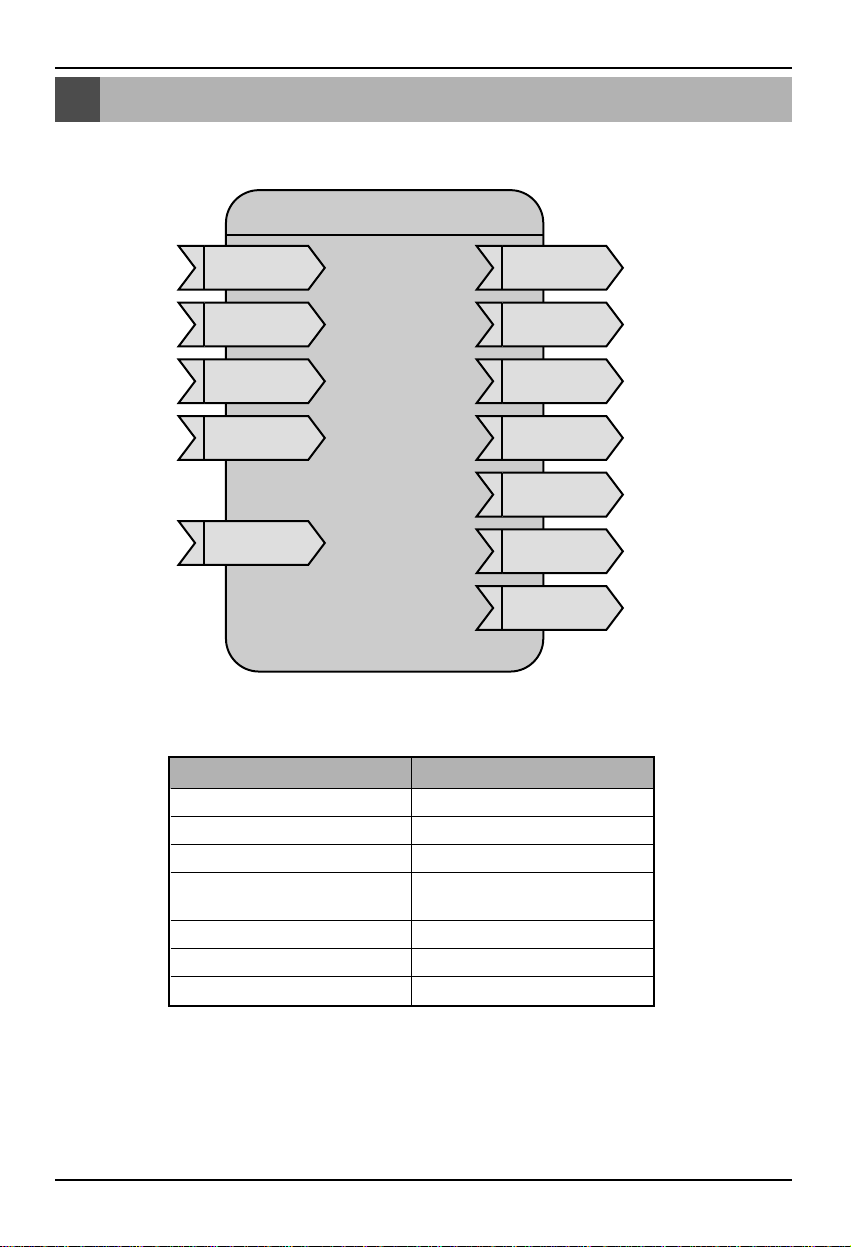

Name of each part

BUS_A: RS485 Communications cable

A (+)

BUS_B: RS485 Communications cable

B (-)

T1, T2: For reserve(not use)

LON: TP/FT-10 Communications wire

(no polarity)

- LonWorks system

communications wire

PWR: Connect to DC 12V power

adapter

12V: Connect when not using the DC

12V power adapter

GND: Connect when not using the DC

12V power adapter

WINK: It flashes 5 times when receiving

the WINK command from the

LonWorks system. (Green)

Service: It will stay off for normal status

and flash when it is not

connected to the LonWorks

system (Red)

It will be turned on when you

press the service switch.

Service switch: When you press the

switch, the Neuron ID

will be transmitted to

the LonWorks system

and the service LED will

be turned on.

1

2

3

4

5

6

7

8

BNU-LW

1

8

2

3

4

5

6

7

Both 5 and 6/7 are for power supply and only one of the two needs to be connected.

When connecting 5, do not use 6/7.

When connecting 6/7, do not use 5.

WARNING

Page 9

System Structure

Installation Manual 9

System Structure

LonWorks Gateway can be connected to maximum of 64 indoor units.

BNU-LW(LonWorks Gateway) cannot be connected to I-gateway (CNU), PC central controller, Deluxe

central controller and simple central controller at the same time.

ON

L1 2 3 4

KSDO4H ON

L1 2 3 4

KSDO4H

LonWorks* Network

Max. 64 indoor & 8 outdoor

LonWorks* Gateway

RS485

PI485

PI485

LonWorks-compatible

BMS

Page 10

Address of the indoor unit connected to the BNU-LW(LonWorks Gateway)

10 Lonworks Gateway

Address of the indoor unit connected to the BNU-LW(LonWorks Gateway)

Indoor unit address can be from (0,0) to (3,F) as shown at figure.

ON

L1 2 3 4

KSDO4HON

L1 2 3 4

KSDO4HON

L1 2 3 4

KSDO4HON

L1 2 3 4

KSDO4H

LonWorks-compatible

BMS system

(Indoor units: Maximum of 64 units)

LonWorks*

Gateway

RS485

PI485

A/C No.

12 3

(0.0) (0.1) (0.F)

17 28 32

(1.0) (1.1) (1.F)

33 34 48

(2.0) (2.1) (2.F)

49 50 64

(3.0) (3.1) (3.F)

address

A/C No.

address

A/C No.

address

A/C No.

address

PI485

PI485

PI485

Page 11

Communications Wire Specifications

Installation Manual 11

Communications Wire Specifications

1. RS485 Communications Wire spec : 0.75 mm2 2C Shield, product to product : 200M, Total

Length : 1kM

2. FT-10 Communications Wire spec : see below table

*Node to node distance(max) : 200M, Total length : 450M

Cable Type AWG Diameter

TIA 568A Category 5 cable 24WAWG 0.5mm

Belden 88471 (PVC jacket) or 16AWG 1.3mm

equivalent cable

Belden 85102(Tefzel jacket) or equal 16AWG 1.3mm

cable

Level IV cable 22AWG 0.65mm

JY(st)Y 2x2x0.8 20.4WG 0.8mm

Page 12

General Specifications

12 Lonworks Gateway

General Specifications

Item Description

Neuron Chip FT3150 Smart Transceiver / 10 MHz

Supply Voltage DC 9 ~ 12V

Network Transceiver FT-X1 Communication Transformer (Free Topology 78kbps)

RS485 Connector LG-Net(connects to PI485)

LonWorks FT-10 Connector (connects to BMS)

Channel Type FT-10

Dimension(W H D) 178mm 237mm 50mm

Power LED

Service LED

LED Indicator Wink LED

LG-Net TX/RX LED

LonWorks TX/RX LED

Switch Service Pin(switch)

XIF File

See technical support part at http://www.lge.com/airconditioner

See network solution part at http://www.systemaircon.com

Page 13

Installation procedure of the BNU-LW(Lonworks gateway)

Installation Manual 13

General Specifications

Installation procedure of the BNU-LW(Lonworks gateway)

1. Setup the central controller address of the indoor unit and the DIP S/W of PI485 accordingly to the

product.(Refer to the PI485 installation manual for details.)

- Fourth Dip s/w of PI485 must be OFF.

2. Connect BUS_A and BUS_B (485 Communications cable) while properly checking the connecting

polarity. (Refer to next page)

3. LON (Connect TP/FT-10 cable to LonWorks Gateway communications cable) TP/FT-10

communications cable does not have the polarity.

Connect 2 communications cables to Lonworks System.

4. PWR (Power supply)

For the power, select one of the two following options.

When you are using DC 12V power adapter

Connect to 5 in Name of each part.

When you can supply another DC 12V power at your site(building)

Connect 12V and GND to 6 and 7 connector respectively.

5. If you press the Service Switch after connecting to the LonWorks system, the Service LED would

light up and the Neuron ID will automatically be transmitted to LonWorks system.

6. Check whether the Service LED turns to normal status (off) within 10 minutes.

If the Service LED turns to normal status, it the installation has been completely normally.

7. Appendix is the necessary information to BMS company using Lonworks system.

Function Remark

ON/OFF command/monitoring

SetTemp command/monitoring

SetMode command/montioring

SetFanSpeed command/monitoring

Lock command/monitoring

Error Code monitoring

All Off/All On command/monitoring

ON/OFF command(nviOnOff)

All Off/All On command(nviAllOnOff)

Other command(nviSetTemp,Mode)

Monitoring

possible

Control &

Monitoring

Directly

Binding

Function

Keep aware of connecting terminal block(Do not use the automatic driver)

WARNING

Set HeartBeat = O when binding connection between other Lonworks device output and indoor unit input.

Otherwise you cannot control the indoor unit by remote controller(wired/wireless).

Page 14

Wiring procedure of the BNU-LW

14 Lonworks Gateway

Wiring procedure of the BNU-LW

A

B

+10V

GND

PI485

RS -485

TP/FT-10

(Twisted Pair Cable)

LonWorks

Adapter

Pow er

BMS Control (PC)

[Wiring sequence]

1. Connect the 485 communications cable.

- Be careful of the polarity

2. Connect the LonWorks communications wire (TP/FT-10)

- No polarity

3. Power supply

Select one of the two options.

Use DC 12V adapter

- Connect to 5 connector in Name of each part.

Supply DC 12V at installation site

- Connect 12V and GND to 6 and 7 connector respectively.

Page 15

Appendix

Installation Manual 15

Appendix

• You can control and monitor as shown in the figure for one air

conditioner.

• Network variable can be different from real value.

Refer XIF file at the company website for detail information.

Air conditioner

Control network variable

Air conditioner

Status monitoring network variable

The appendix is not needed for the actual installation but includes necessary information for BMS

operation.

Indoor_nn (nn : 00~63)

nviOnOff_nn

SNVT_switch

ID : 95

nvoOnOff_nn

SNVT_switch

ID : 95

nvoMode_nn

SNVT_hvac_mode

ID : 108

nvoFanSpeed_nn

SNVT_switch

ID : 95

nvoLock_nn

SNVT_switch

ID : 95

nvoRoomTemp_nn

SNVT_temp_p

ID : 105

nvoSetTemp_nn

SNVT_temp_p

ID : 105

nvoError_nn

SNVT_count

ID : 8

nviMode_nn

SNVT_hvac_mode

ID : 108

nviFanSpeed_nn

SNVT_switch

ID : 95

nviLock_nn

SNVT_switch

ID : 95

nviSetTemp_nn

SNVT_temp_p

ID : 105

Controlling items Monitoring items

ON/OFF Command ON/OFF Status Report

Operation Mode Setting Operation Mode Status Report

Fan Speed Setting Fan Speed Status Report

Lock Setting

Lock Setting Report(Remote

Controller)

Temperature Setting Temperature Setting Report

Room Temperature Report

Error Code Report

Page 16

The relationship between indoor unit address and network variable

16 Lonworks Gateway

Network Variables

The relationship between indoor unit address and network variable

Refer PI485 manual for indoor unit address.

All On Off

nviAIIOnOff

SNVT_switch

ID : 95

A/C Object NV Name (Example : nviONOFF)

01~16 (0-0 ~ 0-15) Indoor_00 ~ Indoor_15 nviONOFF_01 ~ nviONOFF_16

17~32 (1-0 ~ 1-15) Indoor_16 ~ Indoor_31 nviONOFF_17 ~ nviONOFF_32

33~48 (2-0 ~ 2-15) Indoor_32 ~ Indoor_47 nviONOFF_33 ~ nviONOFF_48

49~64 (3-0 ~ 3-15) Indoor_48 ~ Indoor_63 nviONOFF_49 ~ nviONOFF_64

indoor unit address

Controlling items

All On and All Off(Command)

Function ON/OFF Command Input

INPUT Using NV network input variable : SNVT_switch nviOnOff_n

Operation Control ON/OFF for each indoor unit

Function ON/OFF Status Output

OUTPUT Using NV network output variable : SNVT_switch nvoOnOff_n

Operation Monitor ON/OFF for each indoor unit

NV Field Operation

value not used (set in 0% usually)

0 = Indoor unit Off

state 1 = Indoor unit On

Else = Indoor unit Off

Default Value

1) ON/OFF Input/Output

Valid Range

SNVT_switch

( ID : 95 )

Page 17

Network Variables

Installation Manual 17

Function Mode Command Input

INPUT Using NV network input variable : SNVT_hvac_mode nviMode_n

Operation Control running Mode for each indoor unit

Function Mode Status Output

OUTPUT Using NV network output variable : SNVT_hvac_mode nvoMode_n

Operation Monitor running Mode for each indoor unit

NV Operation

HVAC_AUTO : 0 = Auto Mode

HVAC_HEAT : 1 = Heat Mode

HVAC_COOL : 3 = Cool Mode

HVAC_PRE_COOL : 5 = Dry Mode

HVAC_FAN_ONLY : 9 = Fan Mode

Else = Fan Mode

2) Mode Input/Output

Valid Range

SNVT_hvac_mode

( ID : 108 )

Default Value

Function Fan Speed Command Input

INPUT Using NV network input variable : SNVT_switch nviFanSpeed_n

Operation Control fan speed for each indoor unit

Function Fan Speed Status Output

OUTPUT Using NV network output variable : SNVT_switch nvoFanSpeed_n

Operation Monitor fan speed for each indoor unit

NV Field Operation

value 0 ~ 25 = Fan Speed Low

25.5 ~50 = Fan Speed Mid

50.5 ~ 100 = Fan Speed High

Else = Fan Speed High

state not used

Default Value

3) Fan Speed Input/Output

Valid Range

SNVT_switch

( ID : 95 )

Page 18

Network Variables

18 Lonworks Gateway

Function Lock Command Input

INPUT Using NV network input variable : SNVT_switch nviLock_n

Operation Control Lock setting(wired remote controller) for each indoor unit

Function LockStatus Output

OUTPUT Using NV network output variable : SNVT_switch nvoLock_n

Operation Monitor Lock status(wired remote controller) for each indoor unit

NV Field Operation

value not used (set in 0% usually)

0 = Indoor unit Lock Off

state 1 = Indoor unit Lock On

Else = Indoor unit Lock Off

Default Value

4) Lock Input/Output

Valid Range

SNVT_switch

( ID : 95 )

Function Set Temperature Command Input

INPUT Using NV network input variable : SNVT_temp_p nviSetTemp_n

Operation Control set temperature for each indoor unit

Function Set Temperature Status Output

OUTPUT Using NV network output variable : SNVT_temp_p nvoSetTemp_n

Operation Monitor set temperature for each indoor unit

NV Operation

At Cool mode : 18 ~ 30 C

At Heat mode : 18 ~ 30 C

At Dry mode and Fan mode : Not available

Default Value

5) Set Temperature Input/Output

Valid Range

SNVT_temp_p

( ID : 105 )

Page 19

Network Variables

Installation Manual 19

Function Room Temperature Status Output

OUTPUT Using NV network output variable : SNVT_temp_p nvoRoomTemp_n

Operation Monitor set temperature for each indoor unit

NV Operation

At Cool mode : -10 ~ 40 C

At Heat mode : -10 ~ 40 C

At Dry, Fan mode : Not available

Default Value

6) Room Temperature Output

Valid Range

SNVT_temp_p

( ID : 105 )

Function Error Status Output

OUTPUT

Using NV network output variable : SNVT_switch nvoError

Operation Monitor error code for each indoor unit

NV Field Operation

value

0 = No Error

Else = Error Code

state not used

Default Value

7) Error Output

Valid Range

SNVT_count

( ID : 8 )

• Refer product manual for error code

Function All Off Command Input

INPUT Using NV Network input variable : SNVT

_

switch nviAllOnOff

Operation Control ON/OFF for all indoor unit

NV Field Operation

value not used

state

1 : All ON indoor unit

0 : All OFF indoor unit

Default Value

8) All ON/OFF indoor unit

Valid Range

SNVT_switch

( ID : 95 )

Page 20

P/No.: 3828A20494E

After reading this manual, keep it in a place easily accessible to the user for future reference.

Printed in Korea

Loading...

Loading...