Page 1

LG inverter modification “II”

Ref. nr. SCC_73709

Doc. version 1.2

October 30, 2009

Page 2

SCC_73709

COMPONENT KIT (996500095005)

The Component Kit includes the following components (for Master & Slave) :

• TVS zener diode (33 V) x 2

• MLCC capacitor (100 pF) x 2

• Resistor (DIP type or SMD) 4.7 Ω x 4

2

Page 3

SCC_73709

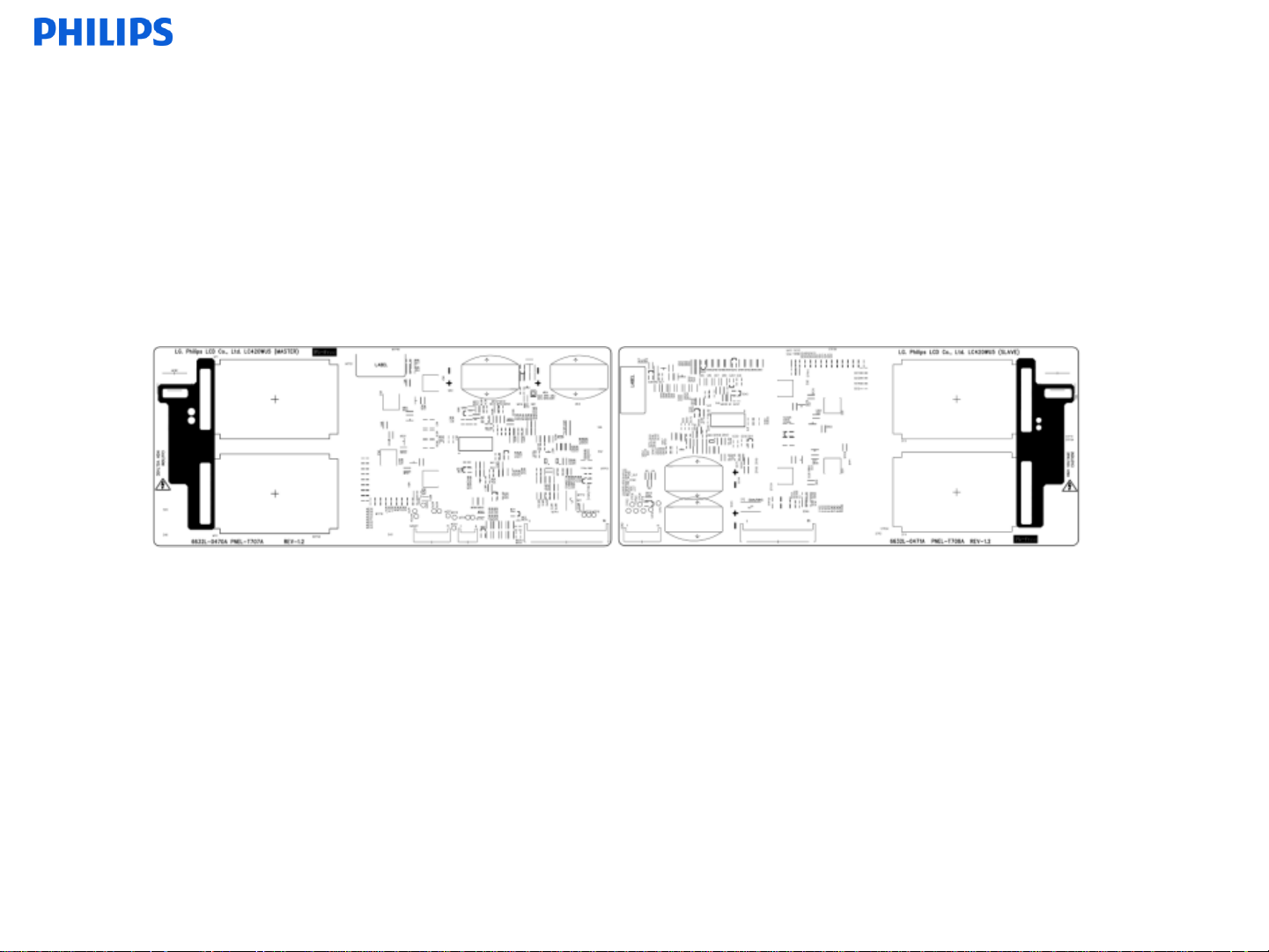

STEP 1

Confirm Inverter model name:

•PNEL-T707A(MASTER),

•PNEL-T708A(SLAVE).

REMARK 1

• It does not matter if the zener diode (modification “I”) exists or not for

inverter modification “II”.

3

Page 4

SCC_73709

STEP 2.1

Cut tracks:

- Cut the SW1 & SW2 tracks on both inverters.

- Confirm that there are no short circuits with metal

pieces of tracks, and there is no damage to other tracks !

PNEL-T707A

PNEL-T708A

4

Page 5

SCC_73709

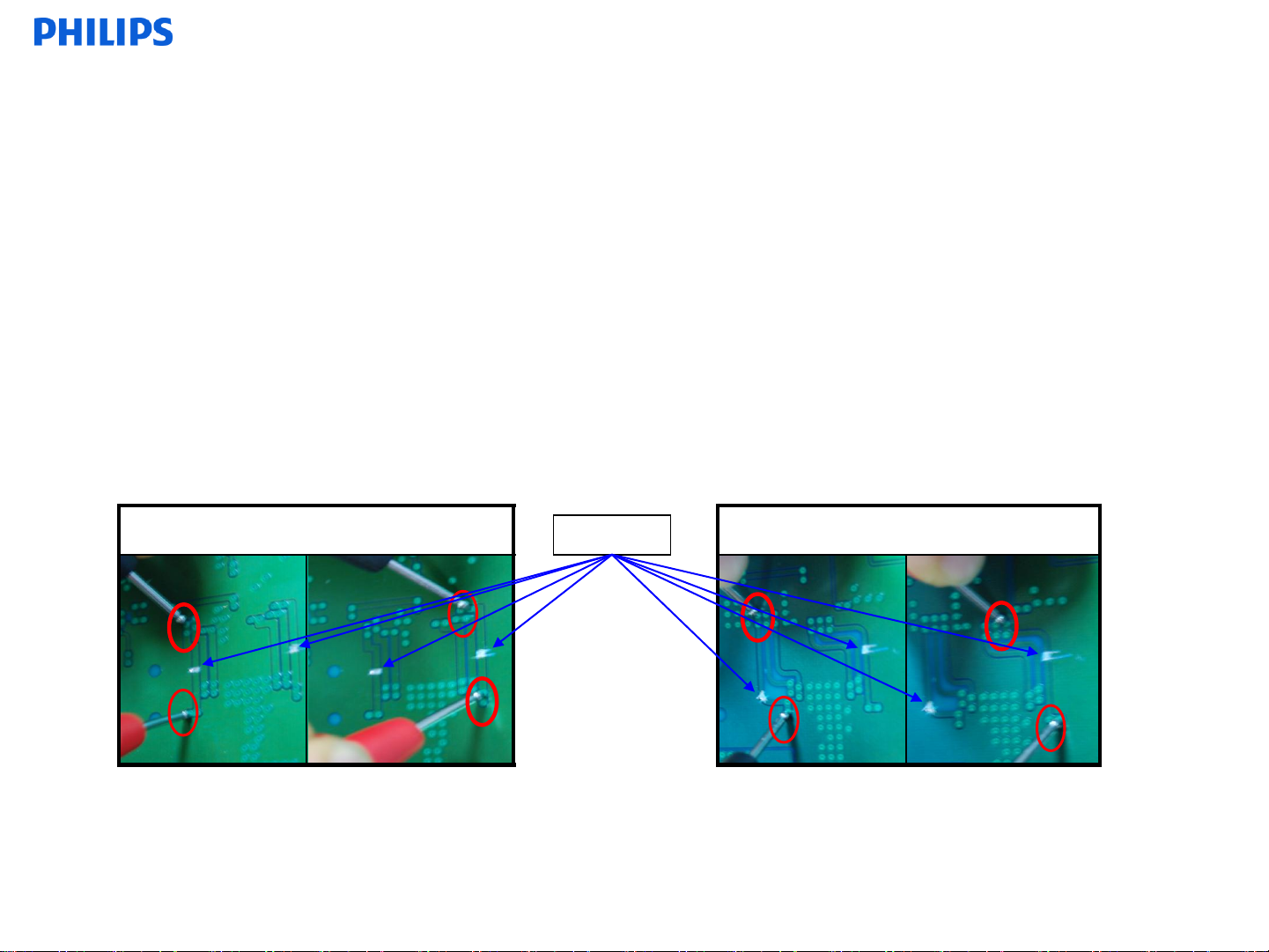

STEP 2.2

1. Check the secure cut line (SW1 & SW2) by visual inspection first:

Visual inspection to verify if cut well and not damaged.

2. Check the resistance between two ‘via’ holes of the cut SW line:

Measure the resistance of the cutted SW1 & SW2 line through „via‟ holes

with a DVM (Digital Volt Meter).

Measure Point (Master) Measure Point (Slave)

Case 1 > Several tens of kΩ: Line cut well.

Case 2 > under 1 Ω: Line short.

※ After attaching the resistor, the resistance should be 4.2 ~ 5.2 Ω.

Cut Mark

5

Page 6

SCC_73709

STEP 2.3

Check pattern damage of parallel tracks

Cut Mark

PNEL-T707A PNEL-T708A

GND

Cut mark

GND

GND

SW2 Pattern

HN2 Pattern

SW1 Pattern

HN1 Pattern

GND

SW1 Pattern

HN1 Pattern

Case study for pattern damage of parallel tracks

Parallel tracks of SW line are HN1, HN2 and GND tracks.

- Case1> If cut the HN track by mistake Cause of Inverter malfunction.

Check : HN line‟s resistance should be under 0.5Ω when measured with DVM (resistance b.t.w. via holes of HN line).

- Case2> Damage on GND track by mistake No affect to Inverter function.

No damage on GND function because GND track is spread widely.

SW2 Pattern

HN2 Pattern

6

Page 7

SCC_73709

REMARK 2

• The kit of components can include the following resistors:

4 x DIP type resistors (4.7 Ω) with shrink tube (20 mm)

then go to step 3.1 and 3.2

OR

20mm

4 x SMD type resistors (4.7 Ω)

then go to step 3.3

7

Page 8

SCC_73709

STEP 3.1

Solder resistors on board PNEL-T708A:

- Remove the coating/varnish on solder point to reveal the copper pad.

- Solder resistor (DIP type resistors (4.7 Ω) with shrink tube (20 mm)) on solder points (red marks).

PNEL-T708A PNEL-T708A

8

Page 9

SCC_73709

STEP 3.2

Solder resistors on board PNEL-T707A:

- Remove the coating/varnish on solder point to reveal the copper pad.

- Solder resistor (DIP type resistors (4.7 Ω) with shrink tube (20 mm)) on solder points (red marks).

PNEL-T707A PNEL-T707A

9

Page 10

SCC_73709

REMARK 3

Front side of reworked inverter (DIP type resistor):

DIP type resistor (Front)

Side view dimension of implemented inverter

Take care that the height of the DIP type resistor is below the height of the transformer

because of the metal shielding on the inverter boards.

Shield Cover

3.5mm

Cover Bottom

11mm

Cap.

8mm

Resistor

1mm

Trans.

10.1mm

3.5mm

10

Page 11

SCC_73709

STEP 3.3

Solder SMD resistors on board PNEL-T707A and PNEL-T708A:

- Remove the coating/varnish on solder points to reveal the copper.

- Solder SMD resistor on created solder pads (red marks).

11

Page 12

SCC_73709

STEP 3.4

Solder capacitor (MLCC) on PNEL-T707A and PNEL-T708A:

-Solder capacitor MLCC (100 pF) on blue indicated position.

MLCC position

PNEL-T707A PNEL-T708A

PNEL-T707A PNEL-T708A

12

Page 13

SCC_73709

STEP 3.5

Solder zener diode (TVS) on PNEL-T707A and PNEL-T708A:

- Solder zener diode TVS (33 V) on red indicated position.

Classification Indication Attachment

Polarity Band mark on body Place band mark on assigned position

TVS position

PNEL-T707A PNEL-T708A

Non polarity No mark No need to distinguish the TVS direction

Polarity : Band mark position

Non-Polarity: No placing direction

PNEL-T707A PNEL-T708A

13

Page 14

14

Loading...

Loading...