Page 1

P/NO : MFL62049603

www.lg.com

INSTALLATION MANUAL

AIR CONDITIONER

• Please read this installation manual completely before installing the product.

• Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this installation manual for future reference after reading it

thoroughly.

TYPE : AHU EXPANSION KIT

Models : PATX13A0E PATX20A0E PATX25A0E

PATX35A0E PATX50A0E

ENGLISH

Page 2

2 AHU EXPANSION KIT

AHU EXPANSION KIT Installation Manual

TABLE OF CONTENTS

n Safety Precautions.............................................................3

n Installation Scene...............................................................5

n Supplies..............................................................................6

n EXPANSION KIT Installation .............................................7

n Mechanical installation ...............................................................................7

n Brazing work .............................................................................................10

n Pipe cutting work ......................................................................................11

n Thermistor connection..............................................................................12

n Leakage and vacuum test ...............................................15

n Leakage test.............................................................................................15

n Vacuum test..............................................................................................15

n

Superheat Adjustment ...............................................................

16

n

EXPANSION KIT installation confirmation plate preparation ...

17

Page 3

Safety Precautions

Installation Manual 3

ENGLISH

n Installation

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

n Meanings of symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

WARNING

Do not use the existing manifold gauge for

R22 refrigerant.

• To charge the refrigerant stably, always

use the manifold gauge for high pressure

(R410A).

Install the air conditioner at a designated

location using the designated material.

• Heat exchanger inlet/outlet pipe location.

Do not store or use

flammable gas or volatile

substance near the air

conditioner.

• It can cause a fire or problem

to the product.

Do not mix existing R22 pipe

and installation products for

the installation.

• When you mix the mineral oil

of R22 and R410A oil (PVE), it

can decompose with water to

cause problems to the product.

Do not mix other refrigerant

with the designated

refrigerant (R410A) during

the installation or moving

the air conditioner.

• When other refrigerant is

mixed with the original

refrigerant, it can cause a

problem in the refrigerant cycle

and damage the product.

System air conditioner can

only be installed by

specialized service provider

with air condition

installation certifications.

• Inappropriate installation can

cause leakage, fire and

electric shock.

When moving or reinstalling

the air conditioner, please

contact the

MULTI VTM AHU

installation service provider.

• Inappropriate installation can

cause leakage, fire and

electric shock.

Do not disassemble, repair

or reconfigure the product

arbitrarily.

• It can cause a fire and electric

shock.

Page 4

Safety Precautions

4 AHU EXPANSION KIT

n Operation

n Installation

Do not install the air conditioner outdoors.

• If installed outdoor inevitably, consult Multi

VTM

AHU installation service provider.

Do not let any worker or user climb on top of

the product.

• The person can get seriously injured.

Make sure that water does

not get inside the product

(Controller). Especially, do

not clean the product with

water.

• It can cause electric shock and

problems.

When the air conditioner is

submersed in water, always

consult

MULTI VTM AHU

installation service provider.

• It can cause a fire and electric

shock.

Do not keep any heating

devices near the product.

• It can cause a fire.

After the product installation

and repair, always check for

gas leakage.

• It can cause problems in the

product.

When installing the product,

always make sure to level to

the product.

• It can cause vibration and

leakage.

Do not install the product

where flammable gas leaks.

• It can cause a fire and

problems to the product.

n Operation

If the refrigerant leaked while installing the product, always ventilate the room.

• The refrigerant gas can react with the fire to turn into hazardous gas to cause an accident.

CAUTION

Page 5

Installation Manual 5

ENGLISH

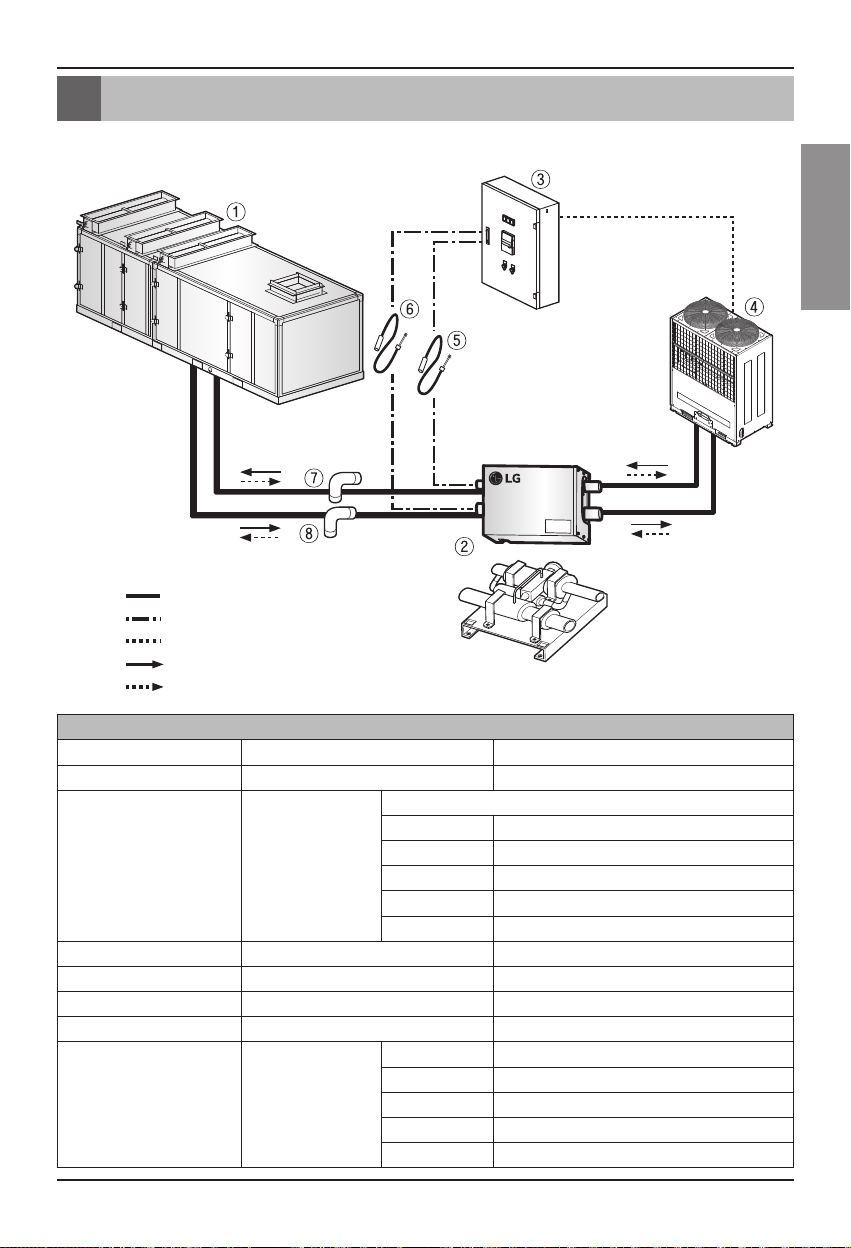

Installation Scene

Installation Scene

Liquid pipe

Gas pipe

Refrigerant pipe

Thermistor

Communication line

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

This EXPANSION KIT is the product connecting AHU and Outdoor unit configured as follows.

Installation components

No. Name Remarks

①

Air Handling Unit

-

②

EXPANSION KIT

Connectable outdoor unit capacity

PATX13A0E 8 ~ 16 HP

PATX20A0E 18 ~ 26 HP

PATX25A0E 28 ~ 36 HP

PATX35A0E 38 ~ 46 HP

PATX50A0E 48 ~ 56 HP

③

AHU control box -

④

Outdoor unit

Multi-VTM

⑤

Thermistor IN Sensor: Ø5, Length: 10m, Line color: Black

⑥

Thermistor OUT Sensor: Ø7, Length: 10m, Line color: Red

⑦

⑧

90° Elbow

PATX13A0E

⑦: Ø15.88 ⑧: Ø22.22

PATX20A0E

⑦: Ø22.2 ⑧: Ø28.58

PATX25A0E

⑦: Ø28.58 ⑧: Ø34.92

PATX35A0E

⑦: Ø34.92 ⑧: Ø41.3

PATX50A0E

⑦: Ø34.92 ⑧: Ø41.3

Page 6

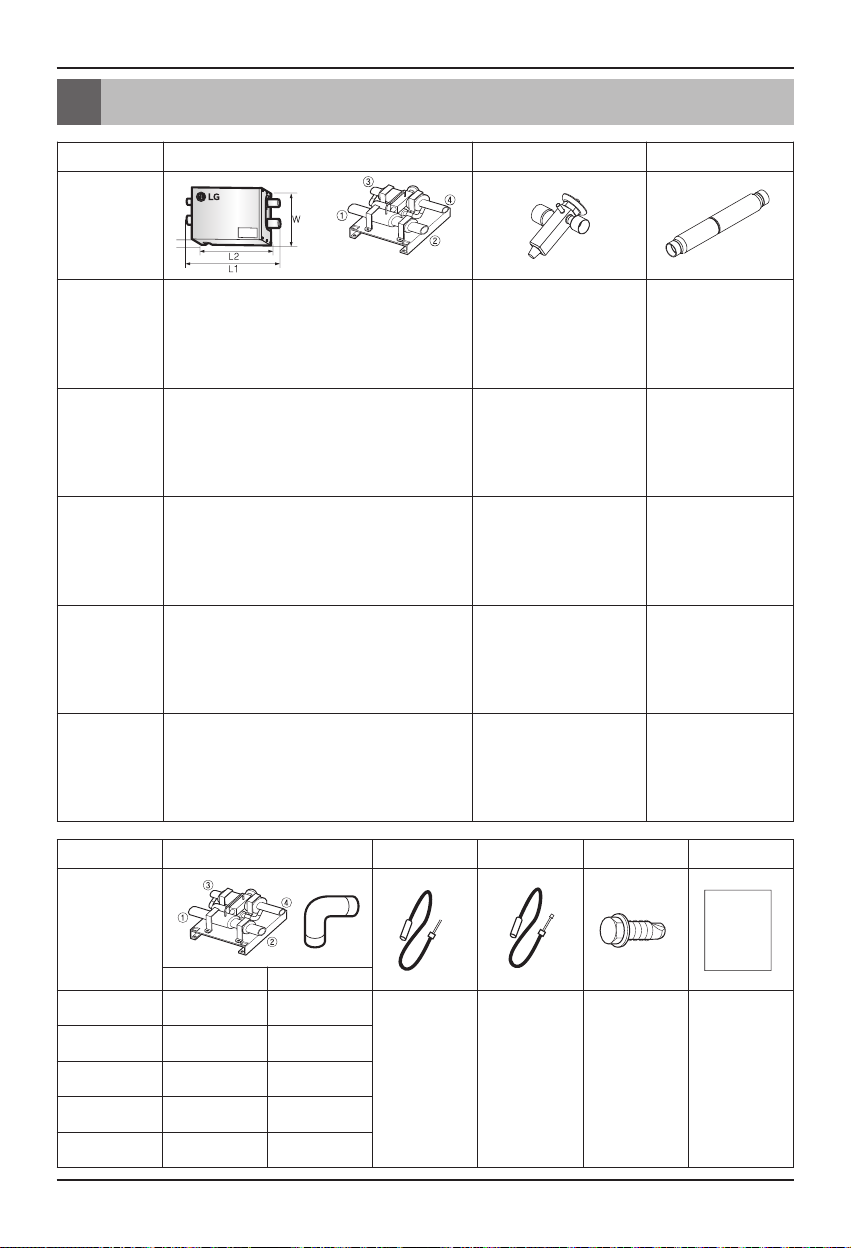

6 AHU EXPANSION KIT

Supplies

Supplies

q

EXPANSION KIT

TXV V/V CHECK V/V

Model naame

PATX13A0E

- Pipe diameter (mm) ①②:22.2

③ : 15.88

④ : 15.88

- L1 x L2 x W x H(mm) : 491 x 331 x 238 x 174

- Weight (NET/GROSS, kg): 5.6/6.9

- Norminal capacity : 20RT

- Applied Outdoor unit

capacity : 18~26HP

- Flow rate : 37l /min

PATX20A0E

- Pipe diameter (mm) ①②:28.58

③ : 22.2

④ : 15.88

- L1 x L2 x W x H(mm) : 491 x 331 x 238 x 174

- Weight (NET/GROSS, kg): 5.8/7.1

- Norminal capacity : 20RT

- Applied Outdoor unit

capacity : 18~26HP

- Flow rate : 37l /min

PATX25A0E

- Pipe diameter (mm) ①②:34.92

③ : 28.58

④ : 22.22

- L1 x L2 x W x H(mm) : 491 x 331 x 238 x 174

- Weight (NET/GROSS, kg): 6.0/7.3

- Norminal capacity : 25RT

- Applied Outdoor unit

capacity : 28~36HP

- Flow rate : 59l /min

PATX35A0E

- Pipe diameter (mm) ①②:41.3

③ : 34.92

④ : 28.58

- L1 x L2 x W x H(mm) : 491 x 331 x 238 x 174

- Weight (NET/GROSS, kg): 6.2/7.5

- Norminal capacity : 35RT

- Applied Outdoor unit

capacity : 38~46HP

- Flow rate : 59l /min

PATX50A0E

- Pipe diameter (mm) ①②:41.3

③ : 34.92

④ : 28.58

- L1 x L2 x W x H(mm) : 561 x 331 x 291 x 192

- Weight (NET/GROSS, kg): 8.5/10

- Norminal capacity : 50RT

- Applied Outdoor unit

capacity : 48~56HP

- Flow rate : 85l /min

90° Elbow

Thermistor IN

Thermistor OUT

Installation screw

Installation manual

Model name

Installation

manual

①(mm) ③(mm)

PATX13A0E 22.2 15.88

- Quantity: 1 unit

- Sensor: Ø5

Length: 10m

- Line color: Black

- Quantity: 1 unit

- Sensor: Ø7

Length: 10m

- Line color: Red

- Quantity:

4 screws

- Self drilling

screw (Direct

screw)

- 20mm

- Quantity:

1 unit

PATX20A0E 28.58 22.2

PATX25A0E 34.92 28.58

PATX35A0E 41.3 34.92

PATX50A0E 41.3 34.92

Page 7

Installation Manual 7

ENGLISH

EXPANSION KIT Installation

Mechanical installation

1. Unscrew the 4 screws on the side cover of

EXPANSION KIT.

2. Disassemble the side cover.

3. Unscrew the 2 screws on the top cover.

4. Disassemble the top cover.

5. Check the location and direction to install

EXPANSION KIT on the AHU.

EXPANSION KIT Installation

Page 8

8 AHU EXPANSION KIT

EXPANSION KIT Installation

-

You have to install EXPANSION KIT according to the installation location and direction provided in

the upper table according to the heat exchanger pipe and checking door direction of AHU.

Installation location of EXPANSION KIT

Installation direction of EXPANSION KIT

Left side Left side Left side Horizontal installation

Left side Right side Left side Horizontal installation

Right side Left side Right side Horizontal installation

Right side Right side Right side Vertical installation

AHU

EXPANSION KIT

Heat exchanger

pipe direction

Checking door

direction

Installation

location

Installation

direction

n You must install the Expansion Kit exactly as

shown in the above diagram. Otherwise, it will

cause failure. (Do not install with the header

directing downward.)

CAUTION

Right side

Left side

Gas pipe

Header

Liquid pipe

Gas pipe

Liquid pipe

<Horizontal installation> <Vertical installation>

Outdoor unit side

Liquid pipe Gas pipe

Liquid pipe Liquid pipe

AHU side

Gas pipe

Refrigerant flowing direction based on cooling

Outdoor unit side

Gas pipe

Liquid pipe

Gas pipe

AHU side

Page 9

Installation Manual 9

ENGLISH

EXPANSION KIT Installation

6. Use the installation component 90° elbow to

connect AHU and EXPANSION KIT.

7. Use the installation screw to tighten 4 locations of

the AHU casing and EXPANSION KIT.

8. Weld 4 connecting locations of AHU heat

exchanger pipe and 90° elbow and EXPANSION

KIT pipe.

9. Weld the connecting pipe (Field supply)

connected to the side of the outdoor unit.

10. When connecting the pipe on Outdoor unit and

EXPANSION KIT, always use the socket (Field

supply) that fits the specification.

11. As the size of the pipe connected to

Outdoor unit and EXPANSION

KIT can differ, always use the

socket Field supply that fits the

specification.

12. During all welding, always follow the

precautions. Always have the nitrogen gas flow

through as shown in the following figure during

all welding processes.

[Connection to outdoor unit]

[Connection to AHU]

Pipe connecting

to outdoor unit

(Field supply)

Connecting socket

(Field supply)

Page 10

10 AHU EXPANSION KIT

EXPANSION KIT Installation

n Be sure to carry out a nitrogen blow when brazing.

Brazing without carrying out nitrogen replacement or releasing nitrogen into the piping will

create large quantities of oxidized film on the inside of the pipes, adversely affecting

valves and compressors in the refrigerating system and preventing normal operation.

n When brazing while inserting nitrogen into the piping, nitrogen must be set to 0.02 MPa

with a pressure-reducing valve(just enough so that it can be felt on the skin).

CAUTION

n The leakage test is executed by pressurizing nitrogen gas up to 3.8MPa(38.7kgf/cm2)

(The test must be done with the service valve of the outdoor unit closed and the gas must

be pressurized at the liquid pipe, gas pipe and high/low pressure common pipe of the

outdoor unit), and the pressure of the nitrogen gas must not drop for 24 hours.

n For more details, refer to the manual of the outdoor unit.

a Refrigerant piping b Part to be brazed

c Taping d Hands valve

e Pressure-reducing valve f Nitrogen

Brazing work

a b

c

e

d

brazing

f

f

Page 11

Installation Manual 11

ENGLISH

1. Always use the copper pipe cutter when cutting the pipe.

2. Always remove the burr.

(Keep the end of the pipe facing down during the work and make sure that the burr does

not get inside the pipe.)

EXPANSION KIT Installation

n Always cut in a straight

line for the cut part.

CAUTION

n If the burr gets inside, it can cause leakage of refrigerant. Therefore always

remove the burr with a reamer.

n Cut pieces can cause problems when they go inside the pipe.

CAUTION

n Always make sure that the refrigerant is not leaking during the welding.

n When the refrigerant is burnt, it generates a toxic gas hazardous to the human

body.

n Do not proceed the welding work in a closed location.

n After the pipe welding, always do a leakage test.

WARNING

n When welding the part, always pass it through nitrogen. If not, the compressor

may not work or can be damaged.

n Before/After the welding, wrap the area with a wet water cloth. If not, the part

can be damaged.

n Use a protective panel or pay special attention so that the welding torch flame

does not directly touch AHU casing.

n After the welding, always do a leakage test.

CAUTION

Pipe cutting work

Copper

pipe cutter

Pipe

Pipe

Reamer

Pipe

Cut pieces

Tilted Rough

Reamer

Page 12

12 AHU EXPANSION KIT

EXPANSION KIT Installation

Thermistor connection

1. Insert the Thermistor IN/OUT to the correct

location on the sensor holder.

2. Set the same inserting location of the

Thermistor as shown in the picture.

3. Insert the Thermistor so that it is inserted to

the end of the sensor holder.

4. After the Thermistor is inserted, insulate the

welded part with insulation material (15T or

above).

5. Assemble the Top cover of EXPANSION KIT

and tighten 2 screws.

6. Use the flexible pipe and connector for the 2

types of connected Thermistor to pull them

out of EXPANSION KIT.

7. Always pull the Thermistor using the

flexible pipe and use specified product

(Ø16) for the flexible pipe and connector.

8. Assemble the side cover of EXPANSION KIT

and screw the 4 screws.

9. Fixate the flexible pipe inserted with the

Thermistor to the AHU external casing, and

connect it all the way to the AHU control box.

Thermistor

IN

Thermistor

OUT

Insulate 4 location of the connecting part

Flexible pipe and connector:

Ø16 (Field supply)

Thermistor IN

Thermistor OUT

Sensor

holder

Page 13

Installation Manual 13

ENGLISH

EXPANSION KIT Installation

[COMMUNICATION PCB CONFIGURATION]

10. Distinguish and connect the IN and OUT on the Thermistor terminal on the

communication PCB inside AHU CONTROL KIT.

11. Check the rotary switch number and write the installation confirmation plate of

EXPANSION KIT.

The error number displayed on AHU Controller in case of an error is displayed

for the rotary switch number, and error on Outdoor unit can be easily

estimated during the service.

n 2 EXPANSION KIT and Outdoor unit are connected to one communication PCB,

and each is classified and connected.

Ex) EXPANSION KIT A, Outdoor unit A, outdoor communication line A, thermistor

A IN, thermistor A OUT

‘ All connected to A circuit

EXPANSION KIT B, Outdoor unit B, outdoor communication line B, thermistor

B IN, thermistor B OUT

‘ All connected to B circuit

CAUTION

Thermistor #B OUT

Rotary switch #B

Thermistor #B IN

Outdoor unit communication line #B

Thermistor #A OUT

Outdoor unit communication line #A

Thermistor #A IN

Rotary switch #A

confirmation plate

Installation

Page 14

14 AHU EXPANSION KIT

EXPANSION KIT Installation

[INSTALLATION CONFIGURATION EXAMPLE]

Thermistor

[AHU control box]

Thermistor

A (Outdoor unit 1)

Liquid pipe

Gas pipe

Refrigerant flow direction

based on cooling

B (Outdoor unit 2)

Liquid pipe

Gas pipe

Refrigerant flow direction

based on cooling

Communication PCBAHU Controller

Refrigerant pipe

AHU communication line

Thermistor

Page 15

Installation Manual 15

ENGLISH

Leakage and vacuum test

Leakage and vacuum test

Leakage test

Execute the leakage test in the same criteria as MULTIVTM leakage test.

Leakage test is done by apply nitrogen gas at 3.8MPa (38.7kgf/cm

3

). Refer to the following

picture for the test method. (Test with the service valve closed and pressurize the liquid and gas

pipe.)

After the nitrogen gas is pressurized, the pressure must not drop for 24 hours.

Ⓐ Nitrogen gas

Ⓑ Indoor unit direction

Ⓒ Manifold gauge

Ⓓ Low pressure side handle

Ⓔ High pressure side handle

Ⓕ Service valve

Ⓖ Gas pipe

Ⓗ Liquid pipe

Ⓘ Outdoor unit

Ⓙ Service port

Vacuum test

Ⓐ Manifold gauge

Ⓑ

Low pressure side handle

Ⓒ

High pressure side handle

Ⓓ Service valve

Ⓔ Liquid pipe

Ⓕ Gas pipe

Ⓖ Service port

Ⓗ 3 way joint

Ⓘ Valve

Ⓙ Valve

Ⓚ R410A cylinder

Ⓛ

Weight: Use a

gravitational weight

(Use one that can

measure up to 0.1kg)

If you cannot get a

high precision

weight, you can also

use the charging

cylinder.

Ⓜ Vacuum pump

Execute the vacuum test in the same criteria as MULTIVTM vacuum test.

As shown in the below picture, close the service valve of the outdoor unit with the vacuum pump and execute the

vacuuming process on the connecting pipe and AHU from the service port of the stop valve. (Liquid and gas pipe

must always be vacuumed from the service port.)

When the vacuum level reaches 5 Torr, additionally vacuum for 1 hour, and the vacuum level must not change for 1 hour.

(If there is any change, there should be moisture or leakage within the pipe.)

If there is a possibility of moisture within the pipe, vacuum for 2 hours and insert the nitrogen gas at 0.05Mpa

(0.5kgf/cm

3

).

After this vacuum for another 1 hour to reach 5 Torr. Maintain the vacuum for 1 hour and check for changes in vacuum gauge.

* Never purge the air with the refrigerant.

* Always execute the vacuuming with the vacuum pump with vacuum gauge attached.

Low

pressure

High

pressure

Low

pressure

High

pressure

Page 16

16 AHU EXPANSION KIT

Leakage and vacuum test

- Add the accurate amount of refrigerant after the calculation.

- If the amount of refrigerant is not accurate, it can cause problems to the product.

- If the additionally inserted amount of refrigerant exceeds ±10%, the compressor can be

burnt and the indoor unit can underperform.

n Pipe to vacuum: Gas pipe and liquid pipe

n When moving the product to a different location, do not charge a different

refrigerant than the regulated refrigerant (R410A).

n If other refrigerant is mixed to the original refrigerant, it can cause a malfunction in

the refrigerant cycle to cause damages.

n As the refrigerant composition of R410A changes when inserted in gas condition,

always insert the refrigerant in liquid condition.

CAUTION

1. After removing the cap nut, turn the stem clockwise to increases superheat / decreases

refrigerant flow.

2. Superheat change per 1 turn of adjustment stem according to the evaporator temperature.

* Factory setting on preset valves is 9°F / 5°C static superheat.

* Even if the superheat adjustment, system operates according to the logic to meet the target low

pressure.

Superheat Adjustment

Evaporator Temperature +32°F / 0° C +41°F / +5° C

Superheat change / turn 2.52°F / 1.4°C 2.16°F / 1.2°C

<View of Adjustment Stema>

Counter-Clockwise

increase SH

Clockwise

decrease SH

stem

cap nut

Page 17

Installation Manual 17

ENGLISH

EXPANSION KIT installation confirmation plate preparation

EXPANSION KIT installation confirmation plate preparation

When the installation of EXPANSION KIT is completed, prepare the installation confirmation plate.

Site name

EXPANSION

KIT

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

EXPANSION

KIT

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

EXPANSION

KIT

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

Model name

Outdoor unit capacity

No.

Model name

Installation location

AHU side

Outdoor unit side

Site name

Model name

Outdoor unit capacity

No.

Model name

Installation location

AHU side

Outdoor unit side

Site name

Model name

Outdoor unit capacity

No.

Model name

Installation location

AHU side

Outdoor unit side

Site name

EXPANSION

KIT

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

Gas pipe:

Gas pipe:

Gas pipe:

Gas pipe:

Gas pipe:

Gas pipe:

Model name

Outdoor unit capacity

No.

Model name

Installation location

AHU side

Outdoor unit side

PATX13A0E

8 ~ 16 HP

22.22 /

Liquid pipe:

22.22 /

Liquid pipe:

PATX25A0E

28 ~ 36 HP

34.92 /

Liquid pipe:

34.92 /

Liquid pipe:

PATX50A0E

48 ~ 56HP

41.3/

Liquid pipe:

41.3 /

Liquid pipe:

15.88

15.88

28.58

22.22

34.92

28.58

PATX13A0E

8 ~ 16 HP

Gas pipe:

22.22 /

Liquid pipe:

Gas pipe:

22.22 /

Site name

EXPANSION

KIT

Outdoor unit capacity

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

Site name

EXPANSION

KIT

Outdoor unit capacity

Outdoor

unit

Communication PCB rotary S/W No.

Connecting

pipe size (mm)

15.88

Liquid pipe:

15.88

Model name

No.

Model name

Installation location

AHU side

Outdoor unit side

Model name

No.

Model name

Installation location

AHU side

Outdoor unit side

Gas pipe:

Gas pipe:

Gas pipe:

Gas pipe:

PATX20A0E

18 ~ 26 HP

28.58 /

Liquid pipe:

28.58 /

Liquid pipe:

PATX35A0E

38 ~ 46HP

41.3/

Liquid pipe:

41.3 /

Liquid pipe:

22.22

15.88

34.92

28.58

Page 18

18 AHU EXPANSION KIT

Page 19

Loading...

Loading...