LG PAHCNM000 Owner’s Manual

OWNER’S &

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by

authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

Applied(AHU)

AHU CONTROL KIT

Original instruction

[Representative] LG Electronics Inc. EU Representative : LG Electronics

European Shared Service Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro,

Seongsan-gu, Changwon-si, Gyeongsangnam-do, KOREA

www.lg.com

Copyright © 2019 - 2021 LG Electronics Inc. All Rights Reserved.

MFL71386003

Rev.04_040821

ENGLISH

ESPAÑOL FRANÇAIS DEUTSCH

PORTUGUÊS

SAFETY INSTRUCTIONS

2

ENGLISH

SAFETY INSTRUCTIONS

The following safety guidelines are intended to prevent unforeseen

risks or damage from unsafe or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as

described below.

This symbol is displayed to indicate matters and operations

!

that can cause risk.

Read the part with this symbol carefully and follow the

instructions in order to avoid risk.

WARNING

!

This indicates that the failure to follow the instructions can

cause serious injury or death.

CAUTION

!

This indicates that the failure to follow the instructions can

cause the minor injury or damage to the product.

WARNING

!

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual

can result in equipment malfunction, property damage, personal

injury and/or death.

Installation

• For installation of the product, always contact the service center

or a professional installation agency.

- Otherwise, it may cause fire, electrical shock, explosion or

injury.

SAFETY INSTRUCTIONS

3

• Securely attach the electrical part cover to AHU Communication

Kit.

- If the electric part cover of AHU Communication Kit is not

attached securely, it could result in a fire or electric shock due

to dust, water, etc.

• Do not keep or use flammable gases or combustibles near the

equipment.

- Otherwise, it may cause a fire or the failure of product.

• Do not install, remove or reinstall the unit by yourself.

- Otherwise, it may cause a fire, electrical shock, explosion or

injury.

• Do not disassemble or repair the product randomly.

- It will cause a fire or electrical shock.

• Do not install the product in a place where there is the concern of

falling down.

- Otherwise, it may result in personal injury.

• Use caution when unpacking and installing.

- Sharp edges may cause injury.

• Always ground the product.

- There is risk of fire or electric shock.

• Do not install the product on a non-parallel or defective

installation stand.

- It may cause injury, accident, or damage to the product.

ENGLISH

Operation

• Keep flames away.

- Otherwise, may occur a fire.

• Do not use the power cord near the heating tools.

- Otherwise, it may cause a fire and electrical shock.

• Do not allow water to run into electrical parts.

- Otherwise, it may cause the failure of machine or electrical

shock.

• Be cautious that water could not enter the product.

- Otherwise, it may cause a fire electrical shock or product

damage.

ENGLISH

SAFETY INSTRUCTIONS

4

• Do not place a heavy object on the power cord.

- Otherwise, it may cause a fire or electrical shock.

• When the product is submerged into water, always contact the

service center.

- Otherwise, it may cause a fire or electrical shock.

CAUTION

!

Installation

• Do not install the product direct sunlight.

• Do not insert a drain hose in drain or soil pipe.

- Bad smells can occur and it results in a corrosion of a heat

exchanger or pipe.

Operation

• If anyone other than a licensed Professional installs, repairs, or

alters LG Electronics Air Conditioning Products, the warranty is

voided.

- All costs associated with repair are then the full responsibility of

the owner.

• This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety.

- Children should be supervised to ensure that they do not play

with the appliance.

TABLE OF CONTENTS

2 SAFETY INSTRUCTIONS

6 INSTALLATION LAYOUT

6 Installation composition diagram

6 Caution on installation layout

7 PRODUCT DIMENSION

7 Product Measurements

8 PARTS LAYOUT

9 WIRING DIAGRAM

10 AHU CONTROL KIT INSTALLATION

10 Determining the product's mounting location

11 Things to keep in mind when installing outdoors

12 Sensor Cover Installation (outdoors)

13 AHU CONTROL KIT SETTINGS

13 Check Module Configuration

15 PIPE THERMISTOR CONNECTION

TABLE OF CONTENTS

5

ENGLISH

16 OUTDOOR UNIT COMMUNICATION LINE CONNECTION

16 Cautions on connecting the EEV module (communication module) with outdoor unit

16 Capacity Control Communication Cable Connection

17 INSTALLATION AND WIRING METHOD (OPTIONAL)

17 Installation method when adding EEV module

17 Wiring method when adding EEV module.

18 AHU SENSOR SPECIFICATION

20 AHU SENSOR CONNECTION

20 Sensor connection

25 Electrical Wiring (if using a belt driven fan)

26 Connect the electric wires

27 Things to keep in mind when installing the Control Kit on site

28 HMI SETTINGS

28 HMI Settings

45 Self-Diagnosis

INSTALLATION LAYOUT

6

ENGLISH

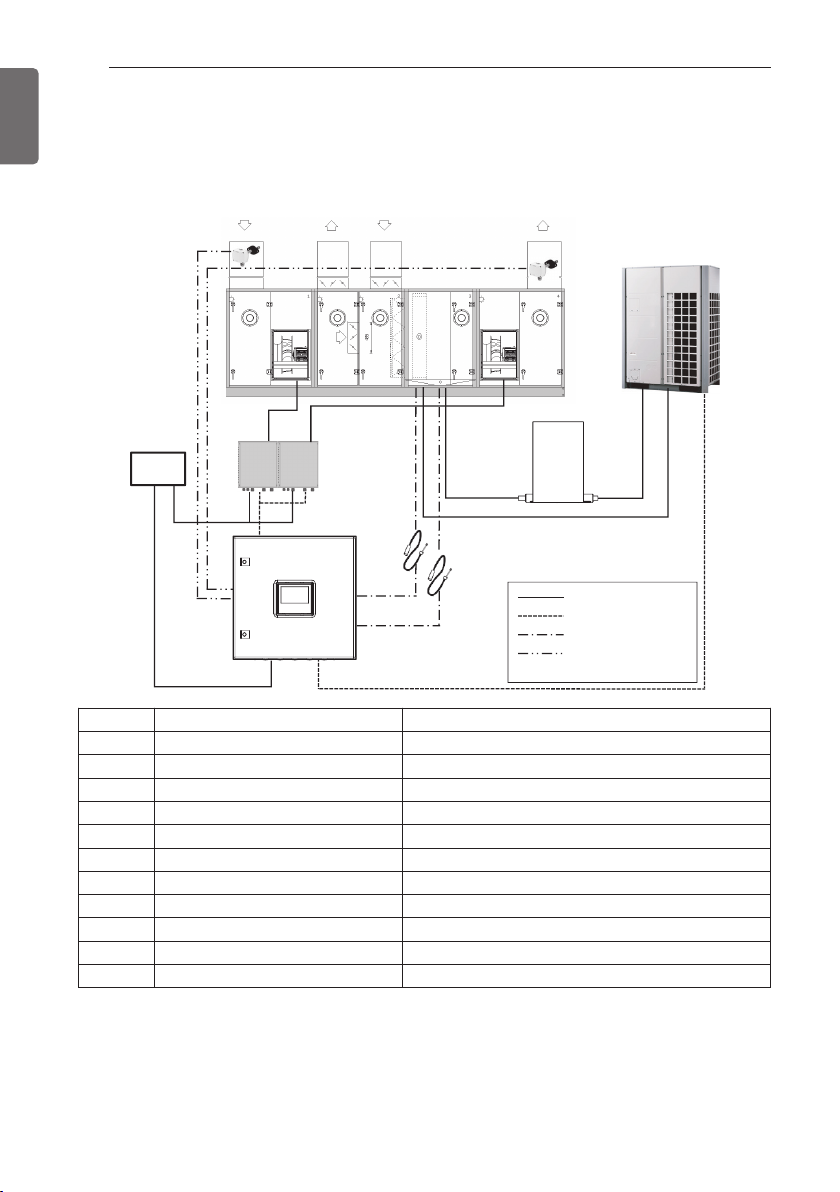

INSTALLATION LAYOUT

Installation composition diagram

RA

ῧ-1

Ῡ-1ῪῩ-2

MCC

ῢ

No. Item Applied Standards

①

②

③

④

⑤

⑥

⑦-1, 2

⑧-1, 2

⑨-1, 2

⑩

⑪

AHU CONTROL KIT PAHCNM000

Expansion kit -

Outdoor unit MULTI V

Pipe in Thermistor(Liquid)

Pipe out Thermistor(Gas)

Temperature/humidity sensor RA, SA Optional

Ventilation Fan, Supply Fan -

Inverter drive kit -

Main power switch board MCC switch board panel

EA OA SA

ῧ-2

Ῠ-1 Ῠ-2

ῥ

ῦ

Ύ

AHU -

Sensor : Ø 5(NTC 5 kΩ), Length : 5 m, Cable color : Black

Sensor : Ø 7(NTC 5 kΩ), Length : 5 m, Cable color : Red

HMI -

ῡ

Power cable

Communication cable

Thermistor signal

Temperature /

humidity sensor

ῤ

Caution on installation layout

- MCC is part of the installation construction to be performed by the equipment supplier, so

confer with the supplier before installing the product.

- Temperature/humidity sensors must be installed on the SA (supply)/RA(ventilation) ducts before

the product can run normally.

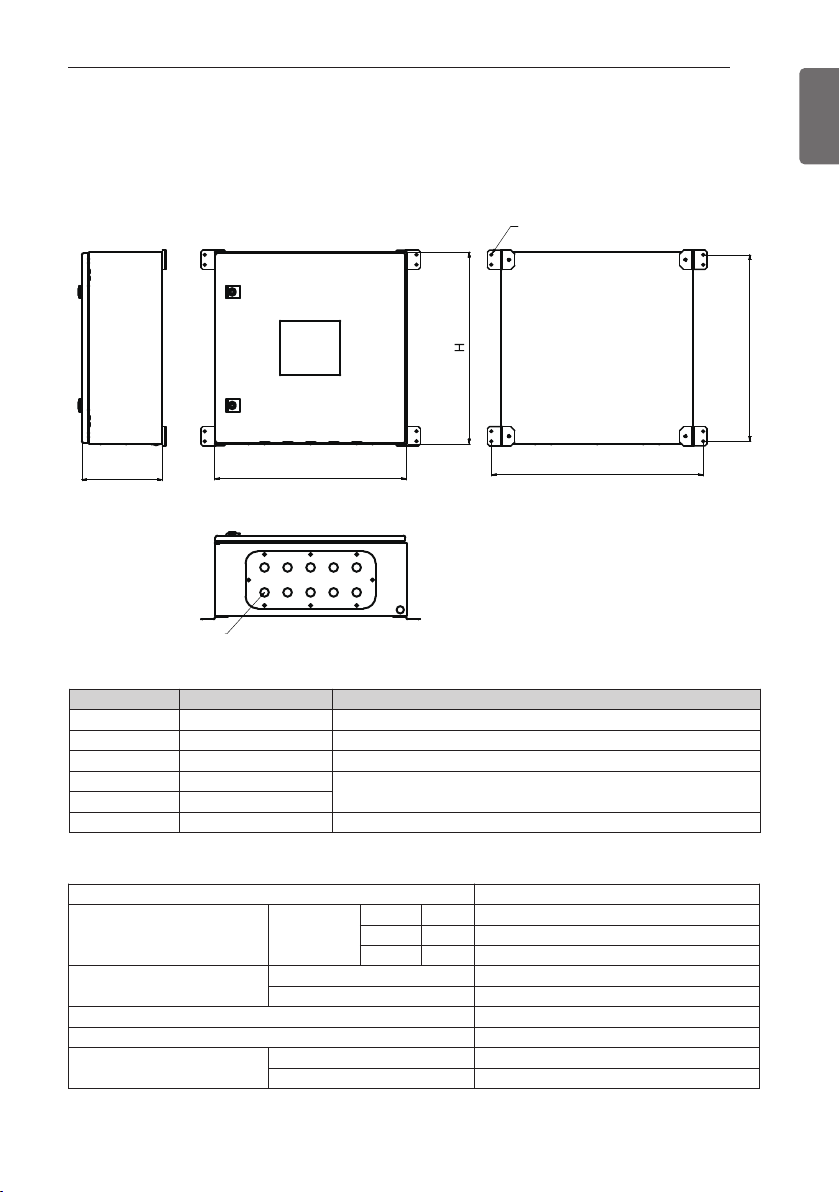

PRODUCT DIMENSION

Product Measurements

PRODUCT DIMENSION

8-Ø7 Holes

7

ENGLISH

B

DW

(Front)(Side) (Back)

C

(Bottom)

Classification Spec Description

W (mm) 500 Width

H (mm) 500 Height

D (mm) 210 Depth

A (mm) 552

B (mm) 486

C 22.5Ø Hole(10 EA) Power cable, Sensor/Communication line insert part

Use the appropriate flexible tubing and connectors for the corresponding holes.

Model PAHCNM000

Size Product

Enclosure

Power 220-240 V~, 50/60 Hz

Rated current 0.2 A

Product Operating

Environment Conditions

Operating Temperature -20 ~ 65 °C DB

Distance between wall mounting brackets

W mm 500

D mm 210

H mm 500

Color RAL 7035

Material Steel

Humidity 0 ~ 98 %

A

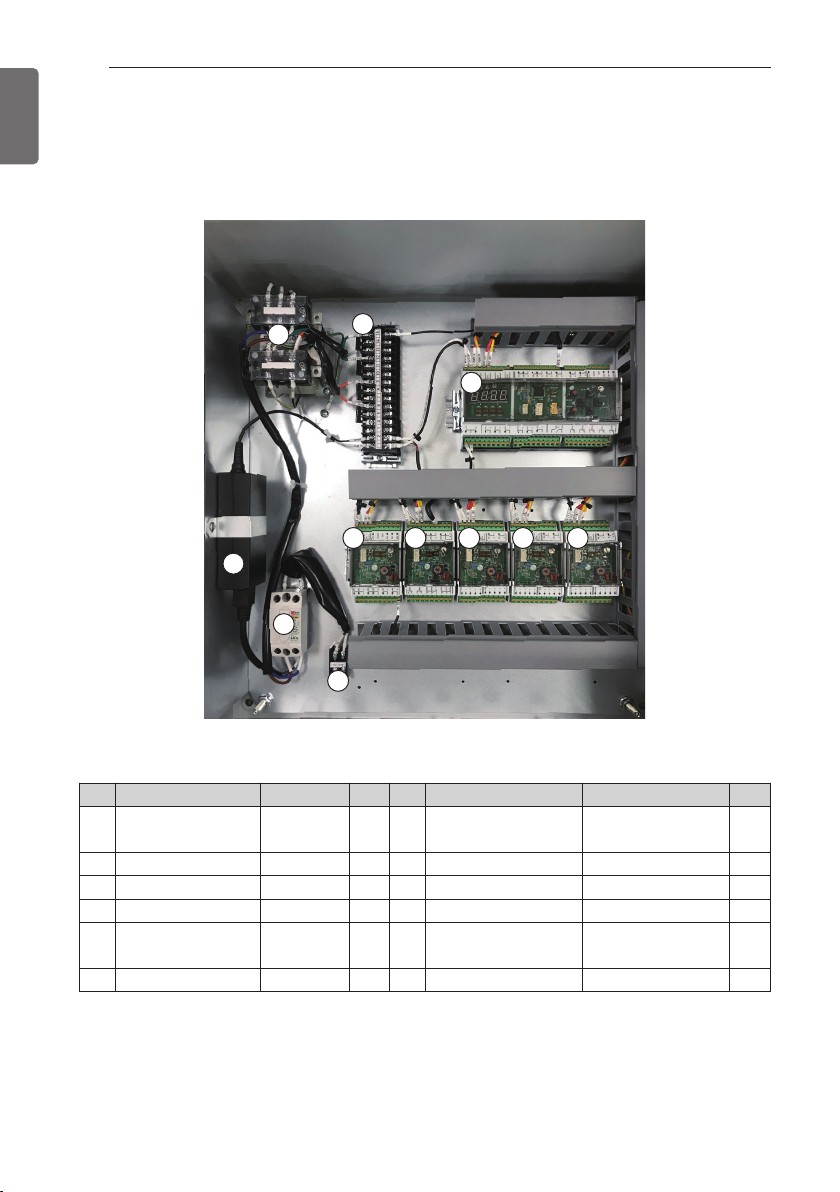

PARTS LAYOUT

10

1

8

7

11

2 3 4 5 6

9

8

ENGLISH

PARTS LAYOUT

• PAHCNM000

No. Main module Spec Qty. No. Main module Spec Qty.

①

②

③

④

⑤

⑥

Main module DC 12 V 1

UI module DC 12 V 1

UO module DC 12 V 1

EEV module #1 DC 12 V 1

EEV module #2 DC 12 V 1

EEV module #3 DC 12 V 1

NFB(No Fuse

⑦

⑧

⑨

⑩

⑪

Breaker)

Adaptor

Trans

Terminal Block 15 PIN 1

Terminal Block

15 A 1.5 kA 1

220 V → DC 12 V

220 V → AC 24 V

Single phase

220 V~, 60 Hz

1

1

1

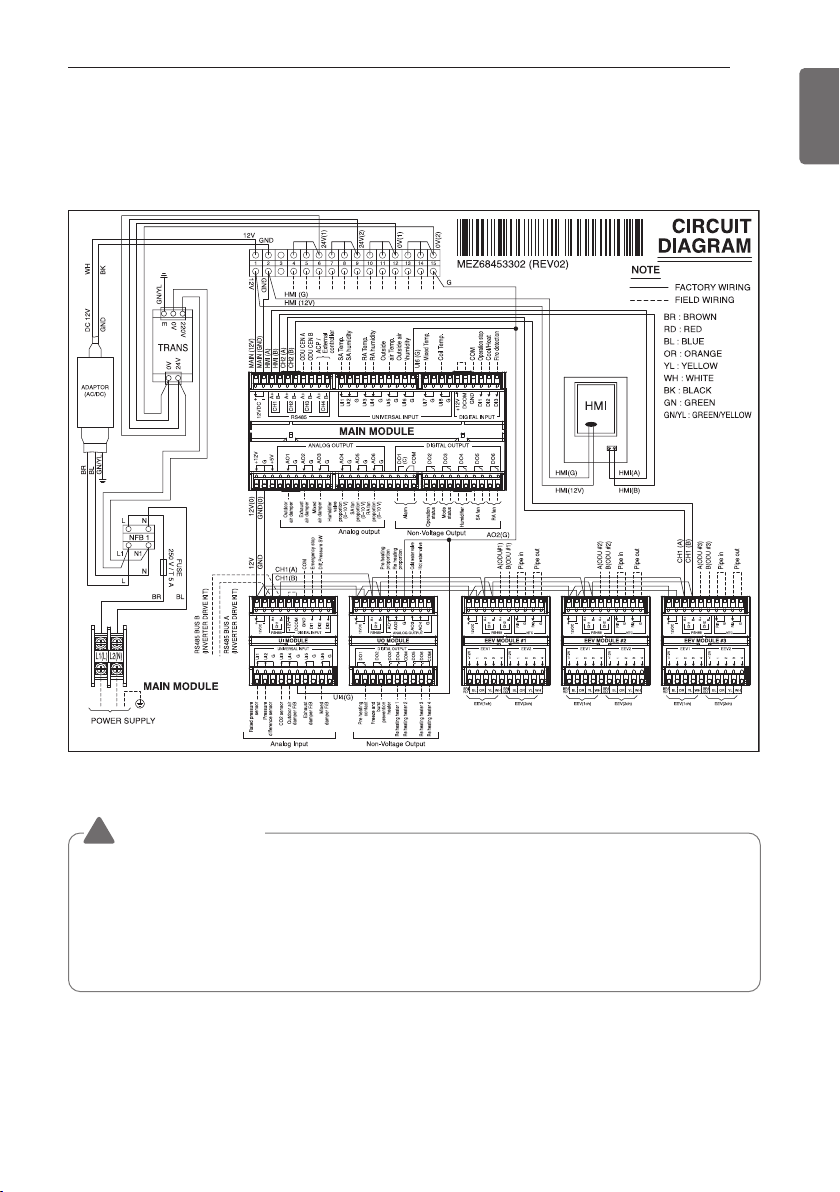

WIRING DIAGRAM

• PAHCNM000

WIRING DIAGRAM

9

ENGLISH

CAUTION

!

• In order to use the main module's shutdown, heating/cooling, and fire detection functions,

the main module's +12V terminal should be connected to the DCOM terminal. Failure to

do so could result in the malfunctioning of the product.

• In order to use the UI module's emergency shutdown and differential pressure switch

functions, the UI module's +12V terminal should be connected to the DCOM terminal.

Failure to do so could result in the malfunctioning of the product.

AHU CONTROL KIT INSTALLATION

10

ENGLISH

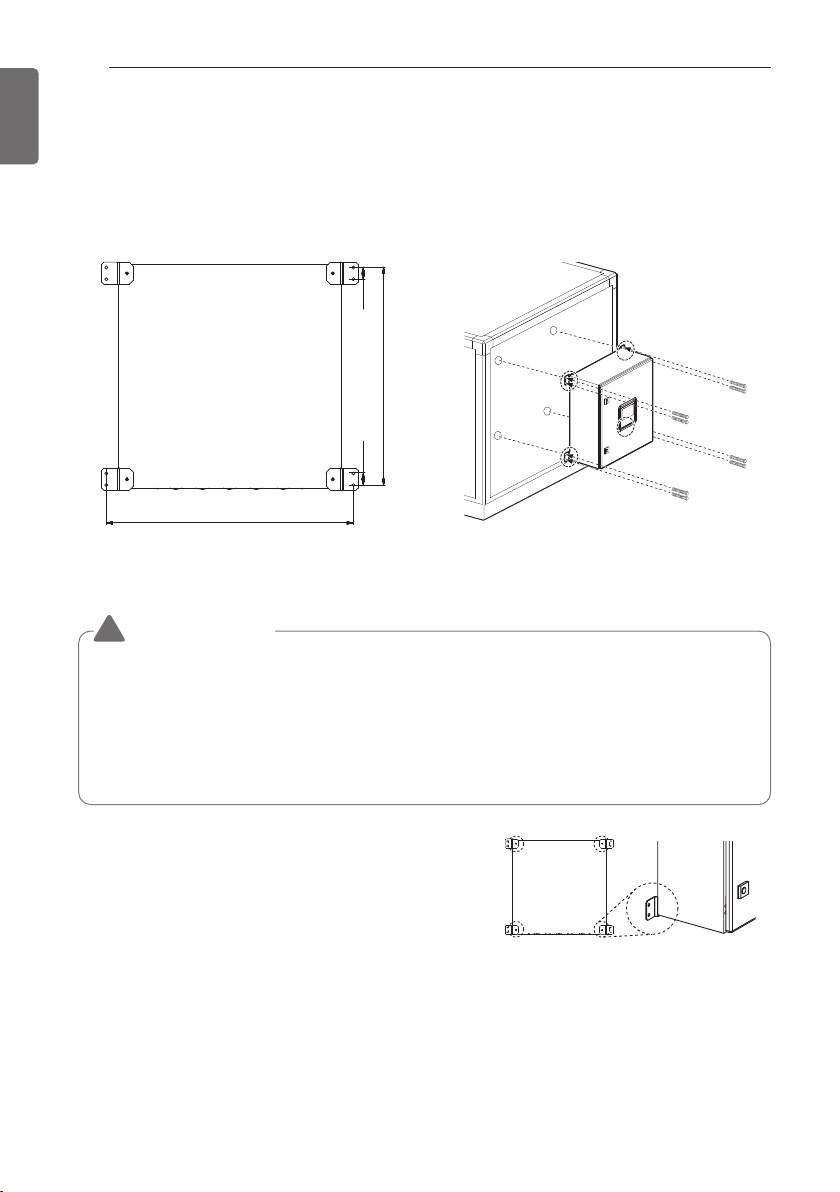

AHU CONTROL KIT INSTALLATION

Determining the product's mounting location

- The control kit's mounting location should be determined based on the conditions on site.

When mounting the control kit, use Ø 6 direct screws (8 EA).

2626

486

552

<Back Side of Control Kit>

CAUTION

!

• When installing the control kit, make sure to leave at least 900 mm between the wall and

the product case so there is enough room for servicing and installation.

• After mounting the product, check whether it is properly affixed.

• If the control kit has to be installed outdoors, be sure to also install an enclosure.

• When installing load devices such as AHU sensors and dampers outdoors, fitted covers

must also be mounted to protect them from the effects of the external environment.

- When using wall mount brackets, fasten the brackets to

the four holes on the rear of the enclosure.

- Please use the provided bolts, nuts, and washers to

fasten the brackets.

AHU CONTROL KIT INSTALLATION

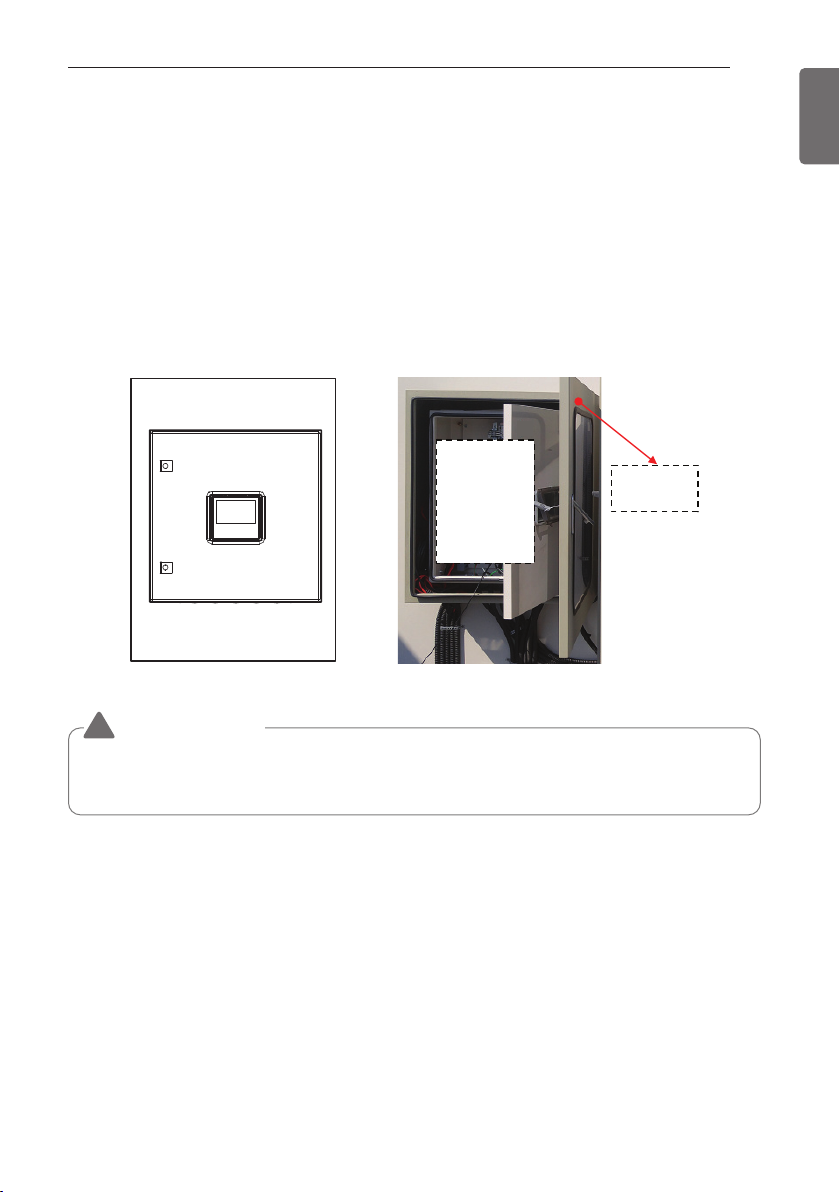

Things to keep in mind when installing outdoors

- Enclosures should be purchased separately if needed.

- After mounting the product, check the tightness of the connection between the AHU and the

enclosure.

If the connection is not airtight, moisture or dust could contaminate the product.

- When installing the AHU outdoors, be sure to use an enclosure to protect the control kit.

- The enclosure should be made of SUS or painted sheet metal to prevent corrosion.

- Make the structure so that it is easy to perform wiring tasks.

- The installation form and location may vary by site.

- Panels installed outdoors must be installed in a place that is not exposed to direct sunlight.

11

ENGLISH

AHU

Control

kit

CAUTION

!

Exposure to direct sunlight could raise the temperature inside the control kit and cause the

unit to malfunction.

Additional

enclosure

AHU CONTROL KIT INSTALLATION

12

ENGLISH

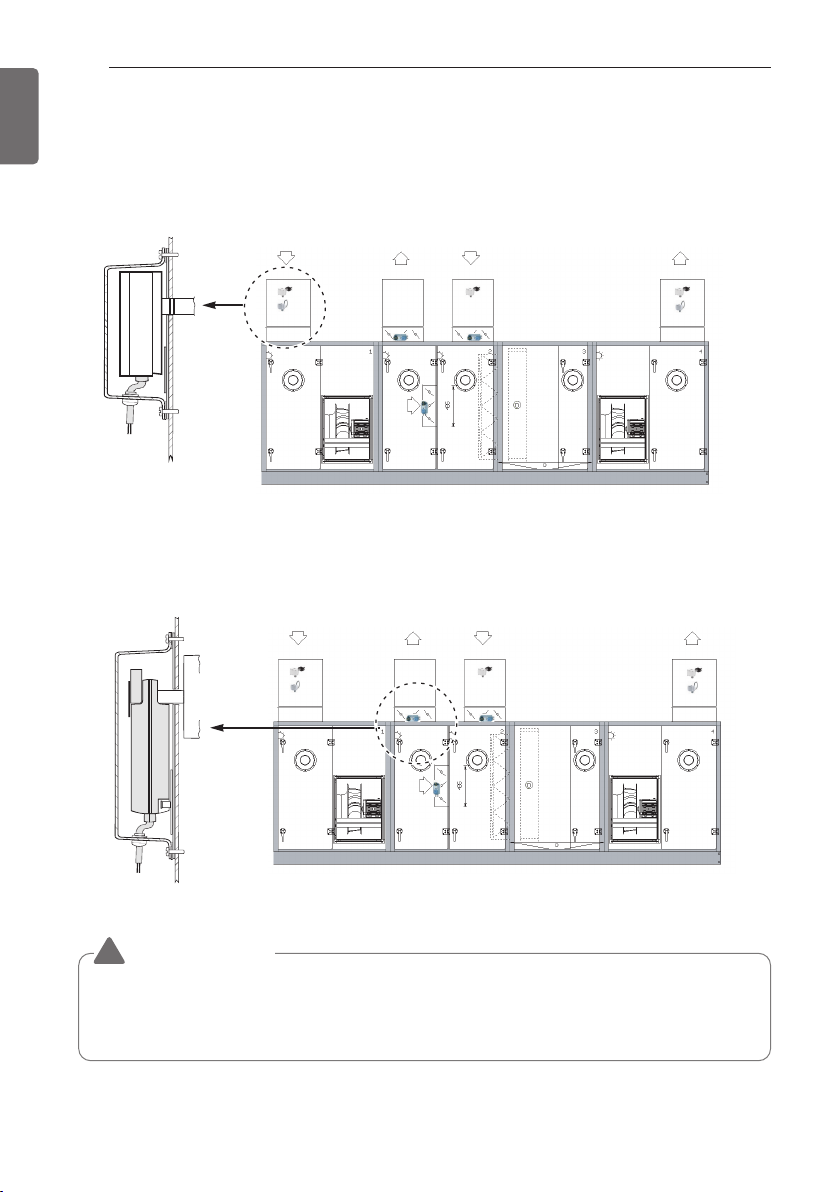

Sensor Cover Installation (outdoors)

When installing the AHU outdoors, make sure to install the protection box as shown below.

Ex: Installation of a temperature and temperature/humidity sensor covers.

RA EA OA

Ex: Installation of a damper actuator cover.

RA SA

EA OA

SA

CAUTION

!

• When installing a sensor outdoors, make sure to install the protective cover, at which time

the Safety Grade must be IP 56 or higher. If the cover is not installed, rainwater can flood

the sensor, causing it to malfunction.

AHU CONTROL KIT SETTINGS

AHU CONTROL KIT SETTINGS

Check Module Configuration

13

ENGLISH

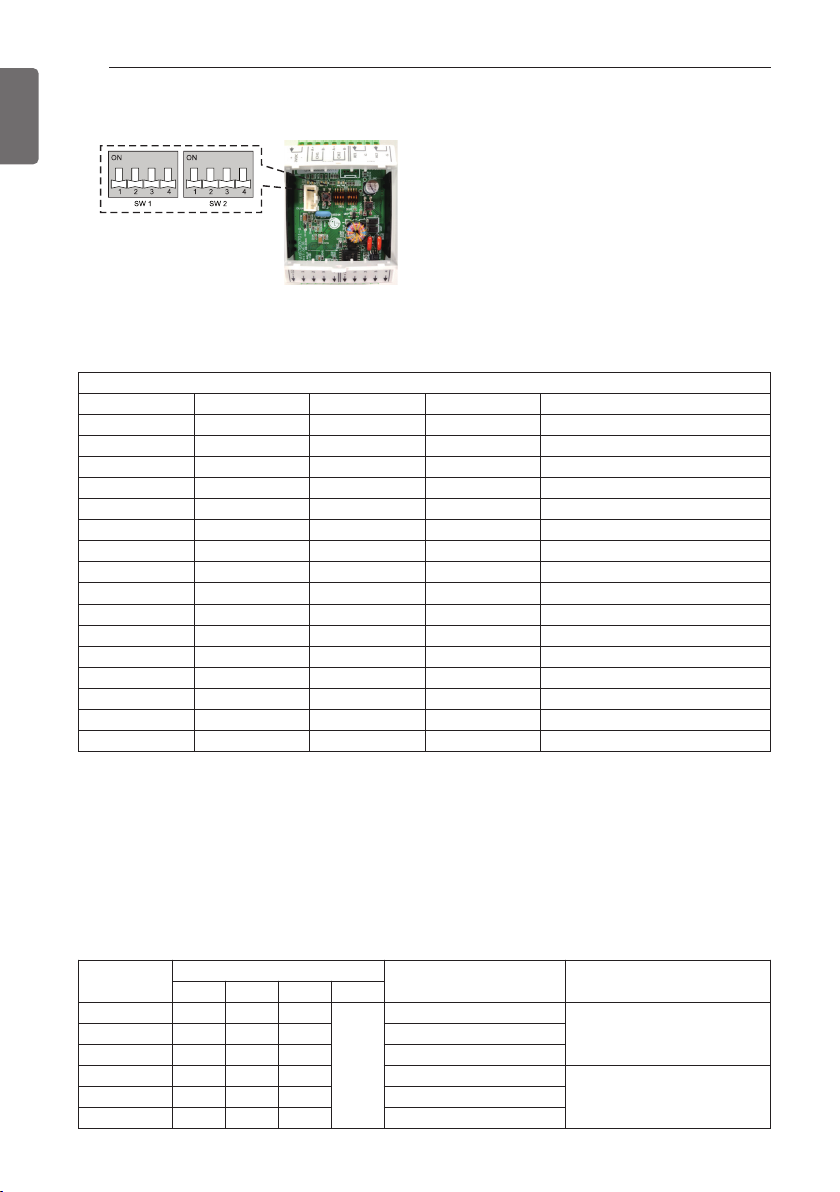

- After installing the Control Kit, the first thing

you should do is check the module settings

inside the Control Kit.

The DIP switches for the main module, UI

module, and UO module are configured in

the following order.

- The default setting of the DIP switches for

the main module, UI module, and UO

module is OFF. Do not change the settings

arbitrarily.

Main Module

UI Module

UI Module

(Main Module)

Main Module

UO Module

EEV Module

(UI Module)

UO Module

(UO Module)

The default setting for all DIP switches is OFF. (factory condition)

AHU CONTROL KIT SETTINGS

14

ENGLISH

EEV Module

Capacity Settings

Use DIP switch SW1 to set the capacity.

1234Capacity [kW (kBtu/h)]

OFF OFF OFF OFF 2.1 (7)

OFF OFF OFF ON 2.5 (9)

OFF OFF ON OFF 3.5 (12)

OFF OFF ON ON 5.6 (18)

OFF ON OFF OFF 7.1 (24)

OFF ON OFF ON 8.2 (28)

OFF ON ON OFF 10.6 (36)

OFF ON ON ON 12.3 (42)

ON OFF OFF OFF 14.1 (48)

ON OFF OFF ON 22.4 (76)

ON OFF ON OFF 28.0 (96)

ON OFF ON ON 33.6 (115)

ON ON OFF OFF 39.2 (134)

ON ON OFF ON 44.8 (153)

ON ON ON OFF 50.5 (172)

ON ON ON ON 56.4 (192)

(EEV Module)

SW1

* When connecting a high-capacity EEV kit (PRLK396A0, PRLK594A0), set the capacity to

56.4 kW.

Address Setting

DIP switch SW2 is the address setting function. When the product is shipped from the factory,

the addresses are set as follows.

EEV #1,2,3 are included and EEV #4,5,6 are optional.(After purchasing separately, additional

setting required.)

Sequence

EEV #1 OFF OFF OFF

EEV #2 OFF OFF ON Internal address 1

EEV #3 OFF ON OFF Internal address 2

EEV #4 OFF ON ON Internal address 3

EEV #5 ON OFF OFF Internal address 4

EEV #6 ON OFF ON Internal address 5

1 2 3 4

SW2

OFF

Address Remark

Internal address 0

EEV #4,5,6 Optional :

Additional setting required

EEV #1,2,3

Included

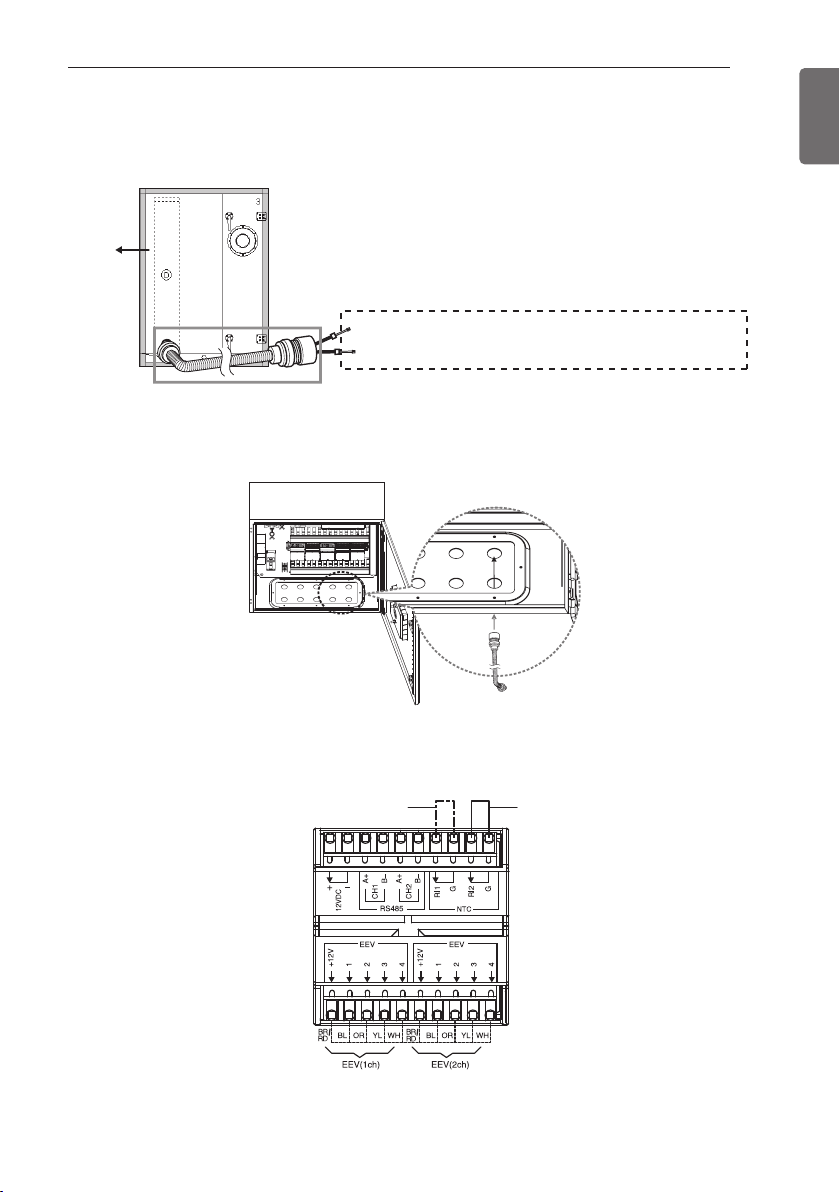

PIPE THERMISTOR CONNECTION

PIPE THERMISTOR CONNECTION

- Check the IN/OUT of the pipe thermistor connected to the AHU

15

ENGLISH

AHU

- Connect the flexible tube and connector (Ø16, installed on the site) from the AHU to the Control

Kit.

- Connect the pipe IN and OUT Thermistor in the EEV module connector.

AHU

Pipe Temperature Sensor IN : Ø 5, Length: 5m, Color: Black

Pipe Temperature Sensor OUT : Ø 7, Length: 5m, Color: Red

Flexible Tube and Connector: Ø 16 (supplied on the site)

Pipe out Thermistor

Pipe in Thermistor

OUTDOOR UNIT COMMUNICATION LINE CONNECTION

16

ENGLISH

OUTDOOR UNIT COMMUNICATION LINE

CONNECTION

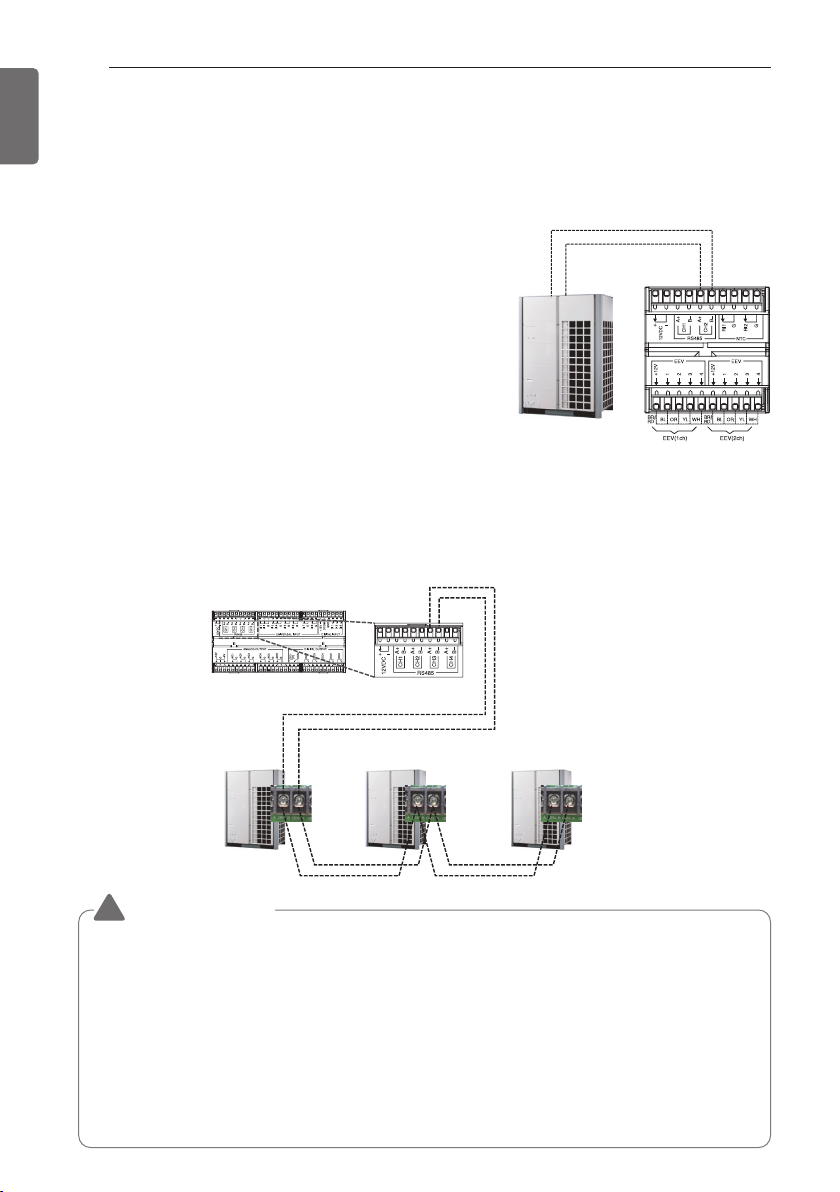

Cautions on connecting the EEV module (communication

module) with outdoor unit

- The Control Kit comes mounted with three EEV modules,

and each EEV module can be connected to one Expansion

Kit.

If additional EEV modules are required depending on the

number of outdoor units, they must be purchased

separately and installed.

- Make sure the communication cables of each outdoor unit

and pipe thermistor wires of Expansion Kit are not mixed

when connecting the outdoor units.

Capacity Control Communication Cable Connection

-

In order to control the SA temperature in the control kit, the central control communication line

must be additionally connected. Please refer to the wiring diagram and the figure below for details.

- For models without a central control communication modem, a central control communication

modem must be installed separately to control the supplied air's temperature.

CH3 A+

CH3 B-

IDU B

IDU A

CH2 B-

CH2 A+

<Main module>

CAUTION

!

Connect

CEN B, CEN A

Outdoor

Unit #1

Connect

CEN B, CEN A

Outdoor

Unit #2

Connect

CEN B, CEN A

Outdoor

Unit #3

• The AHU Control Kit can control the temperature of the supply air by connecting to up to three

outdoor units. When connecting outdoor units, the communication addresses should be set

from 1 to 3, sequentially.

Otherwise, the supply air temperature control function may not work properly.

• Make sure the polarity of the power supply connector is correct when connecting the

communication cable between the Control Kit and outdoor unit.

• DIP SW 3 of the outdoor unit must be turned off in order to ensure communication between the

control kit and the outdoor unit.

• When connecting to Multi V Super 5, Function FN39 must be set to Option1. (Dip switch No.5

ON → FUNC → FN39 → OP1) Please refer to the Multi V manual for details on Multi V Function

settings. (Applicable to both ventilation temperature control and supply air temperature control)

Loading...

Loading...