LG PAHCMR000 INSTALLATION INSTRUCTIONS

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by

authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

[

Representative] LG Electronics Inc. EU Representative : LG Electronics

European Shared Service Center B.V. Krijgsman 1, 1186 DM Amstelveen,

The Netherlands

[

Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro,

Seongsan-gu, Changwon-si, Gyeongsangnam-do, KOREA

MFL69940001

Rev.02_020420

Applied(AHU)

AHU CONTROLLER

Original instruction

www.lg.com

Copyright © 2017 - 2020 LG Electronics Inc. All Rights Reserved.

ENGLISH ITALIANO ESPAÑOL

FRANÇAIS

DEUTSCH

PORTUGUÊS

SAFETY INSTRUCTIONS

2

ENGLISH

SAFETY INSTRUCTIONS

The following safety guidelines are intended to prevent unforeseen

risks or damage from unsafe or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as

described below.

This symbol is displayed to indicate matters and operations

!

that can cause risk.

Read the part with this symbol carefully and follow the

instructions in order to avoid risk.

WARNING

!

This indicates that the failure to follow the instructions can

cause serious injury or death.

CAUTION

!

This indicates that the failure to follow the instructions can

cause the minor injury or damage to the product.

WARNING

!

• Installation or repairs made by unqualified persons can result in

hazards to you and others.

• The information contained in the manual is intended for use by a

qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual

can result in equipment malfunction, property damage, personal

injury and/or death.

Installation

• For installation of the product, always contact the service center or

a professional installation agency.

- Otherwise, it may cause fire, electrical shock, explosion or injury.

SAFETY INSTRUCTIONS

3

• Securely attach the electrical part cover to AHU Comm. Kit.

- If the electric part cover of AHU Comm. Kit is not attached

securely, it could result in a fire or electric shock due to dust,

water, etc.

• Do not keep or use flammable gases or combustibles near the

equipment.

- Otherwise, it may cause a fire or the failure of product.

• Do not install, remove or reinstall the unit by yourself.

- Otherwise, it may cause a fire, electrical shock, explosion or

injury.

• Do not disassemble or repair the product randomly.

- It will cause a fire or electrical shock.

• Do not install the product in a place where there is the concern of

falling down.

- Otherwise, it may result in personal injury.

• Use caution when unpacking and installing.

- Sharp edges may cause injury.

• Always ground the product.

- There is risk of fire or electric shock.

• Do not install the product on a non-parallel or defective installation

stand.

- It may cause injury, accident, or damage to the product.

ENGLISH

Operation

• Keep flames away.

- Otherwise, may occur a fire.

• Do not use the power cord near the heating tools.

- Otherwise, it may cause a fire and electrical shock.

• Do not allow water to run into electrical parts.

- Otherwise, it may cause the failure of machine or electrical

shock.

• Be cautious that water could not enter the product.

- Otherwise, it may cause a fire electrical shock or product

damage.

SAFETY INSTRUCTIONS

4

ENGLISH

• Do not place a heavy object on the power cord.

- Otherwise, it may cause a fire or electrical shock.

• When the product is submerged into water, always contact the

service center.

- Otherwise, it may cause a fire or electrical shock.

• The Ingress Protection Marking given in this manual as IP20

restricts installation location, LG Electronics is not responsible for

installation locations non-compliant to IP20.

CAUTION

!

Installation

• Do not install the product in direct sunlight.

• If anyone other than a licensed professional installs, repairs, or

alters LG Electronics air conditioning products, the warranty is

voided.

- All costs associated with repair are then the full responsibility of

the owner.

• Do not insert a drain hose in drain or soil pipe.

- Bad smells can occur and it results in a corrosion of a heat

exchanger or pipe.

Operation

• This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety.

- Children should be supervised to ensure that they do not play

with the appliance.

- Appliances not accessible to the general public.

• This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved. Children shall not

play with the appliance. Cleaning and user maintenance shall not

be made by children without supervision.

TABLE OF CONTENTS

TABLE OF CONTENTS

2 SAFETY INSTRUCTIONS

6 INSTALLATION LAYOUT

7 TECHNICAL SPECIFICATION

8 CONTROLLER MODULE

9 COMMUNICATION KIT

9 Mechanical installation

11 THERMISTORS INSTALLATION

12 RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

12 DIP SW

21 DISCHARGE AIR TEMPERATURE CONTROL

(PAHCMS000)

21 Main Module DIP SW

5

ENGLISH

31 EXTERNAL CONNECTION DIAGRAM

31 Return air temperature control

35 BMS PROTOCOL

35 BACnet points of PAHCMR000 (Return air temperature control)

41 CONNECTION & SETTING GUIDE

44 COMMUNICATION MODULE &

EEV KIT CONNECTION GUIDE

INSTALLATION LAYOUT

6

ENGLISH

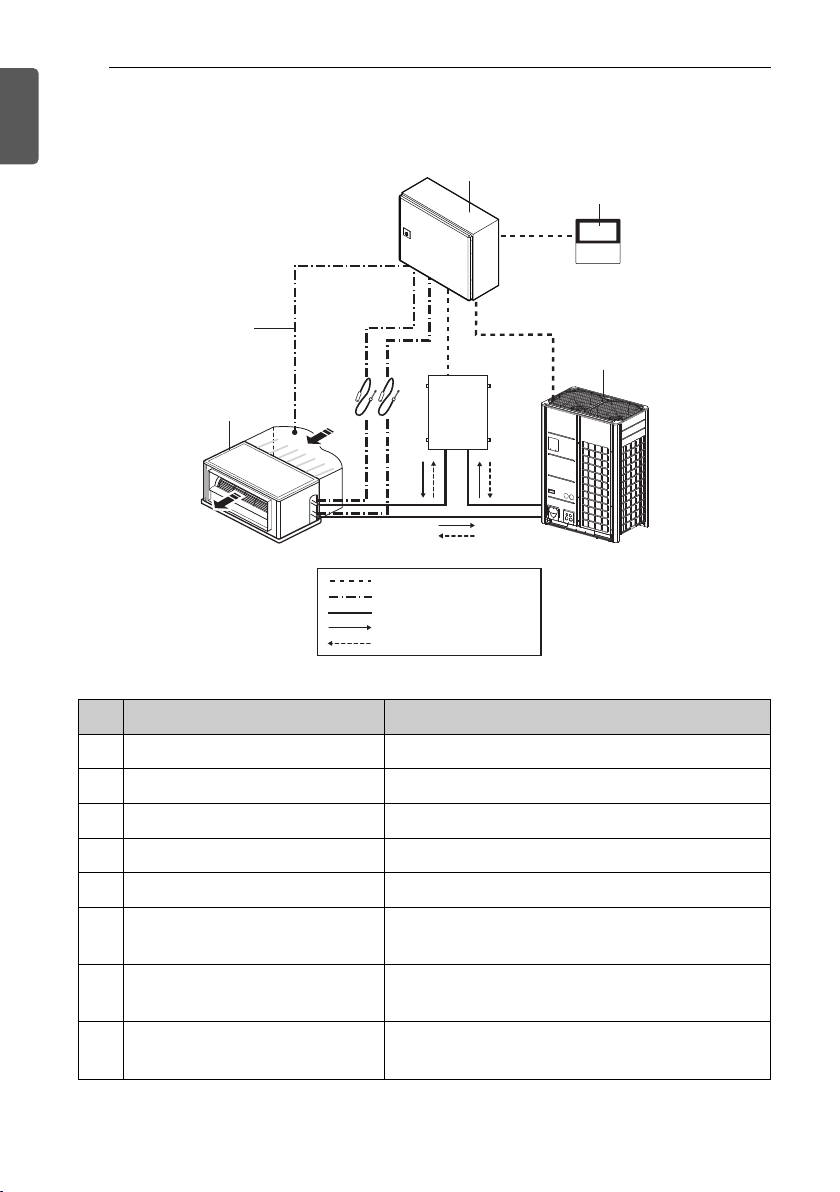

INSTALLATION LAYOUT

Δ

Ύ

Ώ

ΒΓ

Control Signal (field supplied)

Thermistor Signal

Pipe

Refrigerant flow (cooling)

Refrigerant flow (heating)

Α

ΐ

No. Item Specification

①

②

③

④

⑤

⑥

AHU(Air Handling Unit) Local supply

AHU Communication kit PAHCMS000/PAHCMR000

Remote controller LG wired remote controller(Optional)

Outdoor unit MULTI V

EEV Kit PRLK048A0/PRLK096A0/PRLK396A0/PRLK594A0

Pipe in(Liquid) thermistor

Sensor : Ø 5(NTC 5 kΩ)

length : 5 m, Cable color : Black

⑦

⑧

Pipe out(Gas) thermistor

Room(Return) thermistor

Sensor : Ø 7(NTC 5 kΩ)

length : 5 m, Cable color : Red

Sensor : NTC 10 kΩ

length : 5 m, Cable color : Black

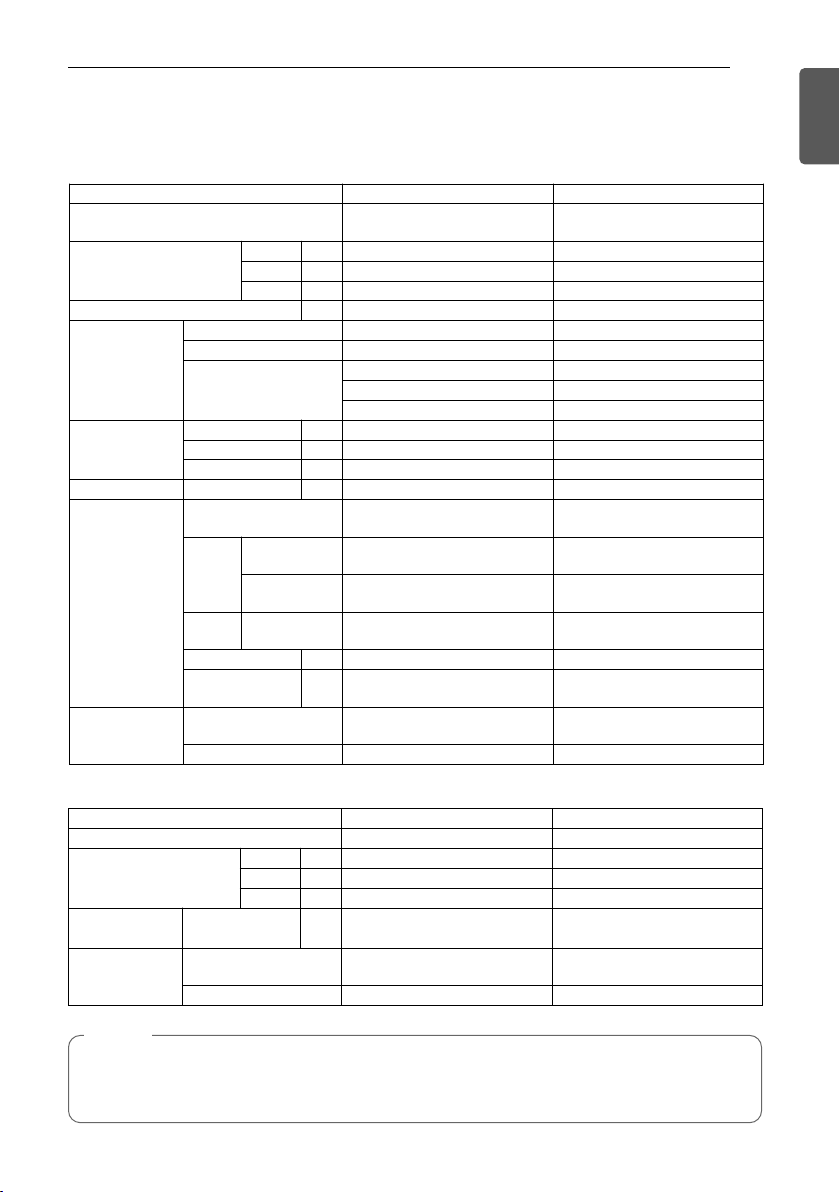

TECHNICAL SPECIFICATION

TECHNICAL SPECIFICATION

1. COMMUNICATION KIT

Model PAHCMR000 PAHCMS000

Application Return air temperature control

Dimensions

Net Weight kg 6.0 7.3

Casing

Power Supply

Current Rated A 0.1 0.1

Composition

Product

Environment

Operation Range

Color RAL 7035 RAL 7035

Material Steel Steel

Certification Degree of

Protection

Voltage V 220-240 220-240

Frequency Hz 50/60 50/60

Phase Ø 1 1

Controller Communication Module : 1 EA

Terminal

Block

Temp.

Sensor

Key EA 1 1

Installation Manual EA 1 1

Ambient Temperature - 20 ~ 65 °C DB - 20 ~ 65 °C DB

Humidity 0 ~ 98 % 0 ~ 98 %

Width mm 300 380

Depth mm 155 155

Height mm 300 300

IP 66 (EN 60529) IP 66 (EN 60529)

UL 508 Type 4 / NEMA 4 UL 508 Type 4 / NEMA 4

IK 08 (EN 50102) IK 08 (EN 50102)

Power Supply Screw type (L / N, Ring type) Screw type (L / N, Ring type)

Communication Spring push type (Pin type, JOBN153) Spring push type (Pin type,JOBN153)

Air (Room) Q’ty : 1 EA (Pin type, 5m, Black) Q’ty : 1 EA (Pin type, 5m, Black)

Discharge(supply)

air temperature control

Main Module : 1 EA

Communication Module : 1 EA

7

ENGLISH

2. CONTROLLER MODULE

Application Main module Communication module

Dimensions

Power Supply Voltage V DC 12 V DC 12 V

Product

Environment

Operation Range

Model PAHCMM000 PAHCMC000

Width mm 162 108

Depth mm 61 61

Height mm 90 90

Ambient Temperature - 20 ~ 65 °C DB - 20 ~ 65 °C DB

Humidity 0 ~ 98 % 0 ~ 98 %

NOTE

• Maximum connectable PAHCMR000(Communication Module) to Discharge air temperature

control(PAHCMS000) AHU Communication Kit is less or equal than 3, i.e.

‘PAHCMS000 x 1 + PAHCMR000 x 3 system’ can control 4 circuits of the DX coil.

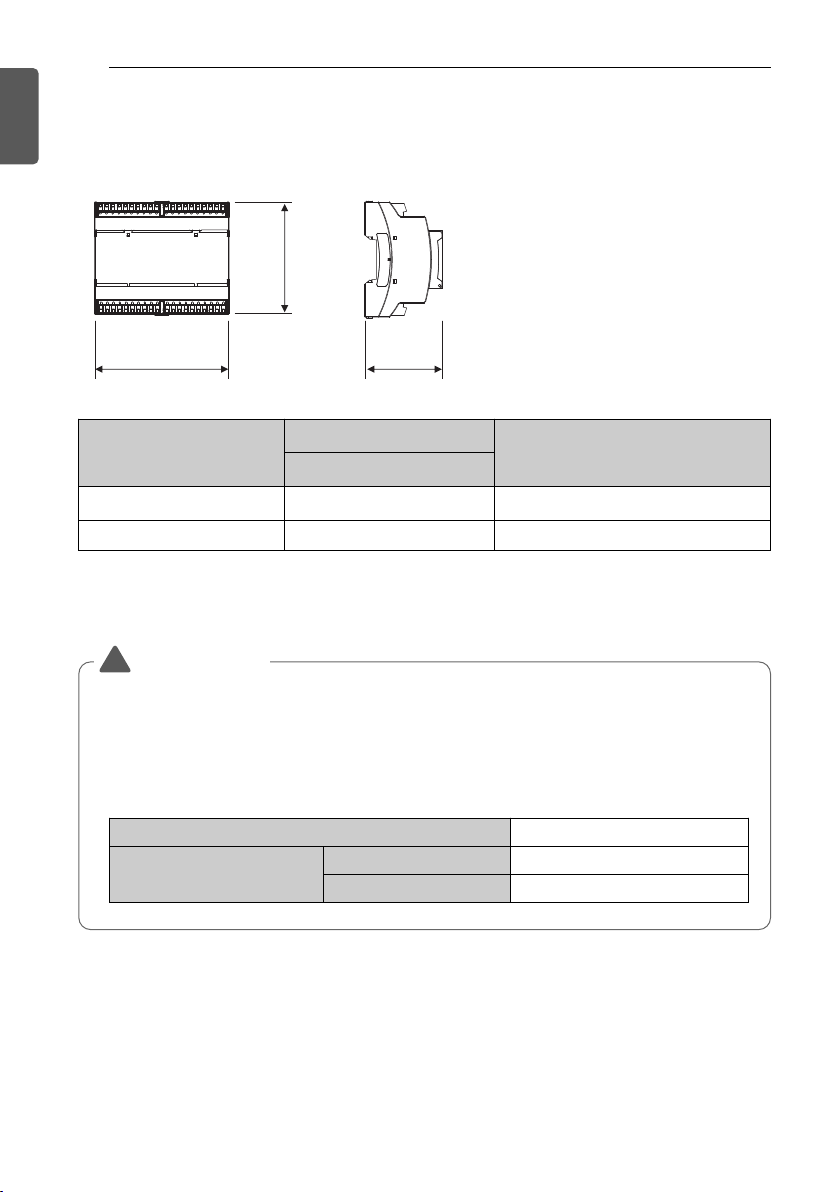

CONTROLLER MODULE

8

ENGLISH

CONTROLLER MODULE

90

Unit(mm)

61A

Model

PAHCMM000

PAHCMC000

1) PAHCMM000 Model refer for Main module.

2) PAHCMC000 Model refer for Communication module.

CAUTION

!

• This model requires DC12 V ~ external power supply. (Select an insulating transformer

that complies with IEC61558-2-6 and NEC Class 2.)

• Please check the Product operation range below.

• The Ingress Protection Marking given in this manual as IP20 restricts installation location,

LG Electronics is not responsible for installation locations non-compliant to IP20.

Product operation range

1)

2)

Power supply DC 12 V

Size (mm)

Remark

A

162 Main module

108 Communication module

Ambient Temperature -20 ~ 65 °C DB

Humidity 0 ~ 98 %

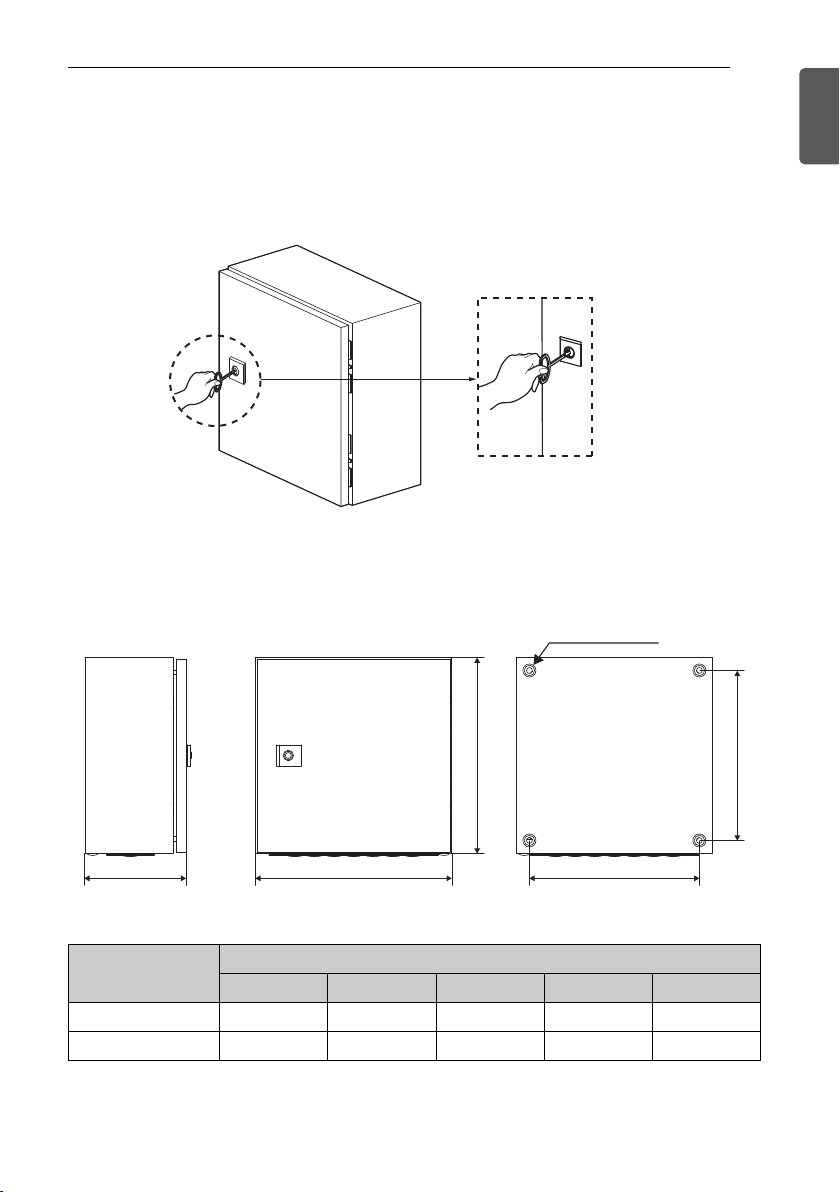

COMMUNICATION KIT

COMMUNICATION KIT

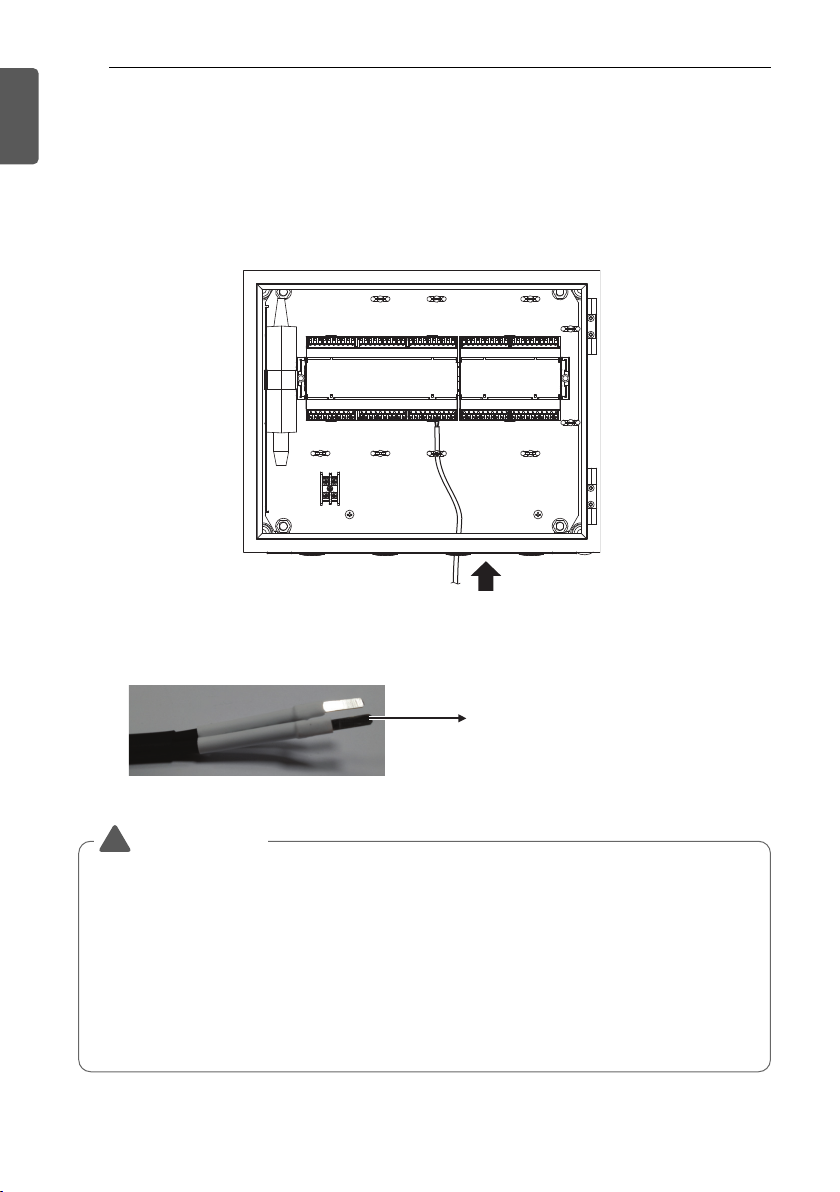

Mechanical installation

1 Open the door using the key.

2 Drill 4 holes on correct position and fix the Communication Kit box securely with 4 screws

(Field supply) through the holes Ø 9 mm(11/32 inch).

4-9 HOLES

9

ENGLISH

+

$:'

<Side> <Front> <Rear>

Model

PAHCMR000 300 155 300 260 260

PAHCMS000 380 155 300 340 260

W D H A B

Size (mm)

%

COMMUNICATION KIT

10

ENGLISH

Connection of the wires

1 For connection to outdoor unit and to controller (Field supply) :

Pull the wires inside through the cable gland and close the nut firmly in order to ensure a

good pull relieve and water protection.

2 The wires require an additional pull-relief. Strap the wire with the support tie wrap.

&DEOHLQVHUW

3 For the wired remote controller wire and outdoor unit communication wire, use the Pin type

(JOBN153) to connect to the terminal block.

Pin type (JOBN153)

CAUTION

!

• All field supplied parts and materials and electric works must be conform to local codes.

• Use copper wire only.

• All wiring must be performed by an authorized electrician.

• A main switch or other means for disconnection, having a contact separation in all poles,

must be incorporated in the fixed wiring in accordance to relevant local and national

legislation.

• Refer to the installation manual attached to the outdoor unit for the size of power supply

electric wire connected to the outdoor unit, the capacity of the circuit breaker and switch,

wiring and wiring instructions.

THERMISTORS INSTALLATION

Water

THERMISTORS INSTALLATION

11

ENGLISH

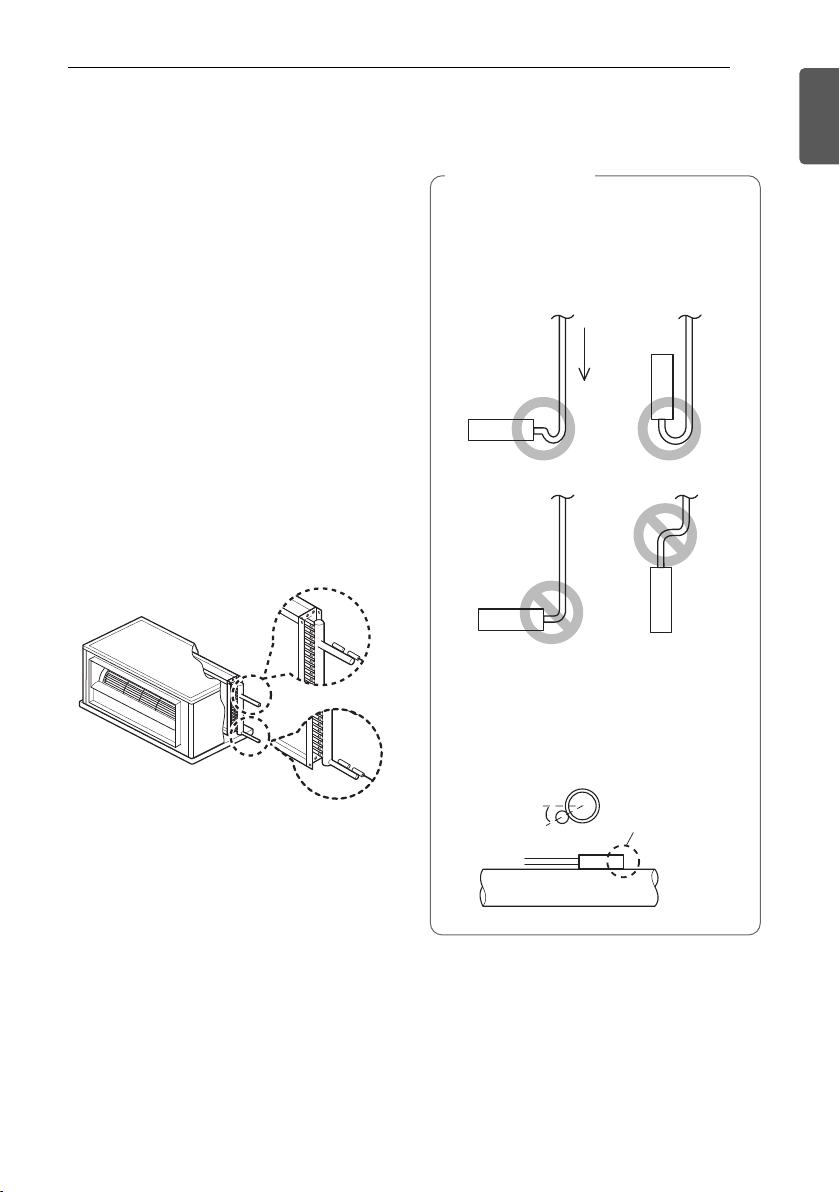

Pipe thermistors Installation

Location of the pipe thermistors

A correct installation of the thermistors is

required to ensure a good operation :

1 Pipe_In

: Install the thermistor behind the

distributor on the coldest pass the heat

exchanger

(contact your heat exchanger dealer).

2 Pipe_Out

: Install the thermistor at the outlet of the

heat exchanger as close as possible to

the heat exchanger.

Evaluation must be done to check if the

evaporator is protected against freeze-up.

Execute test operation and check for

freeze up.

Ø6.3

Ø8.2

INSTRUCTION

• To prevent condensation from

accumulating on the bottom of the pipe

sensor, install the sensor by lifting it up

as shown below.

1

• In order to detect the temperature of

2

the pipe well, install the sensing part so

that it can be attached to the pipe well

as shown below.

(Air handling unit)

45°

Most sensitive

point of the

thermistor

RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

12

ENGLISH

RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

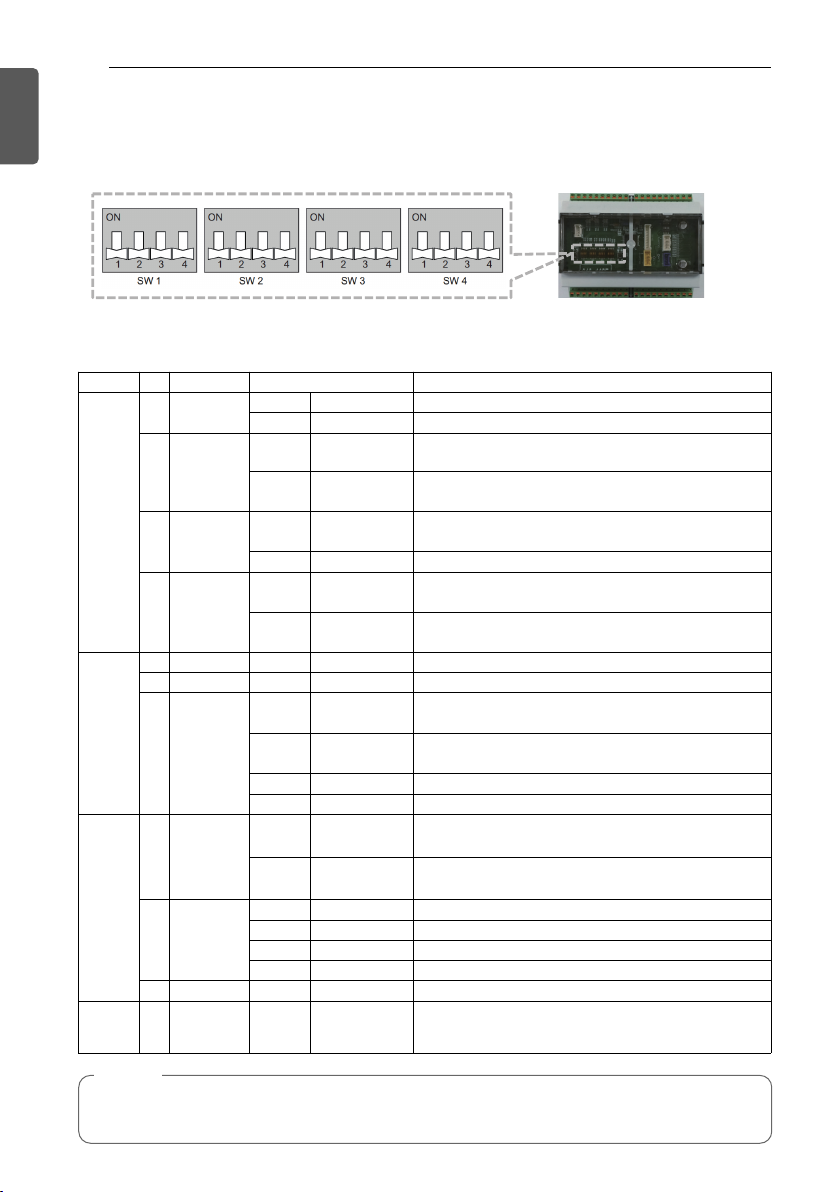

DIP SW

The default setting of all DIP switch is set “off”

<Communication Module>

n Table of SW1~SW3

SW name

No Item Setting Note

ON

1 ODU Type

2 Control Type

SW1

3 DO Type

4

1 Reserved

2 Reserved

SW2

3/4 UI Setting

1

SW3

2/3

4 Reserved

SW4 1~4

Fan Speed

(available when

SW1-3 ‘ON’)

Group

Master/Slave

(Return Air

only)

Operation

mode setting

Capacity

Index

Setting

Single Comm.

OFF

MULTI V Comm.

ON

Communication

Contact signal

OFF

ON

OFF

ON

OFF

OFF/OFF

OFF/ON

ON/OFF

ON/ON

ON

OFF

OFF/OFF

OFF/ON

ON/OFF

ON/ON

Fan Speed

Status DO1 : ON/OFF, DO2 : Defrost, DO3 : Alarm

Fixed

Change

-

-

UI Setting #1

UI Setting #2

Reserved Reserved -

Slave mode

Master mode

Heat Pump Cooling or Heating operation mode is available

Heating Only Operation mode is Heating only (Heating / Fan)

Cooling Only Operation mode is Cooling only (Cooling / Fan)

Reserved -

-

--

Using Single Split outdoor unit

Using MULTI V outdoor unit

Controlled by DDC Modbus or LG remote controllers & central controllers

Controlled by DDC through Contact signal

(LG Central controller can only monitor status)

DO1 : High, DO2 : Middle, DO3 : Low

(DO changes according to fan speed setting value)

The fan will always be running as set fan speed except defrost.

(During defrost, the fan speed will change as low fan speed.)

The fan speed will be changed according to TH on/off

For more detail please check ‘Digital Output – Fan Speed’

--

--

UI1 : Operation ON/OFF, UI2 : Heating/Cooling

UI3 : Forced Thermal ON/OFF, UI4 : Target air temperature

UI1 : Operation ON/OFF, UI2 : Cooling only/OFF

UI3 : Heating only/OFF, UI4 : Forced Thermal ON and OFF

Please see “Multiple module installation guide In the PDB” for more detail

Master mode is default for single AHU Controller installation.

Please see “Multiple module installation guide In the PDB” for more detail

--

According to ODU Type, you can setup the capacity index of MULTI V

or Single Split

NOTE

• Do not change the reserved switch(It may malfunction).

• To use the group control, length of group control cable is max 50 m.

RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

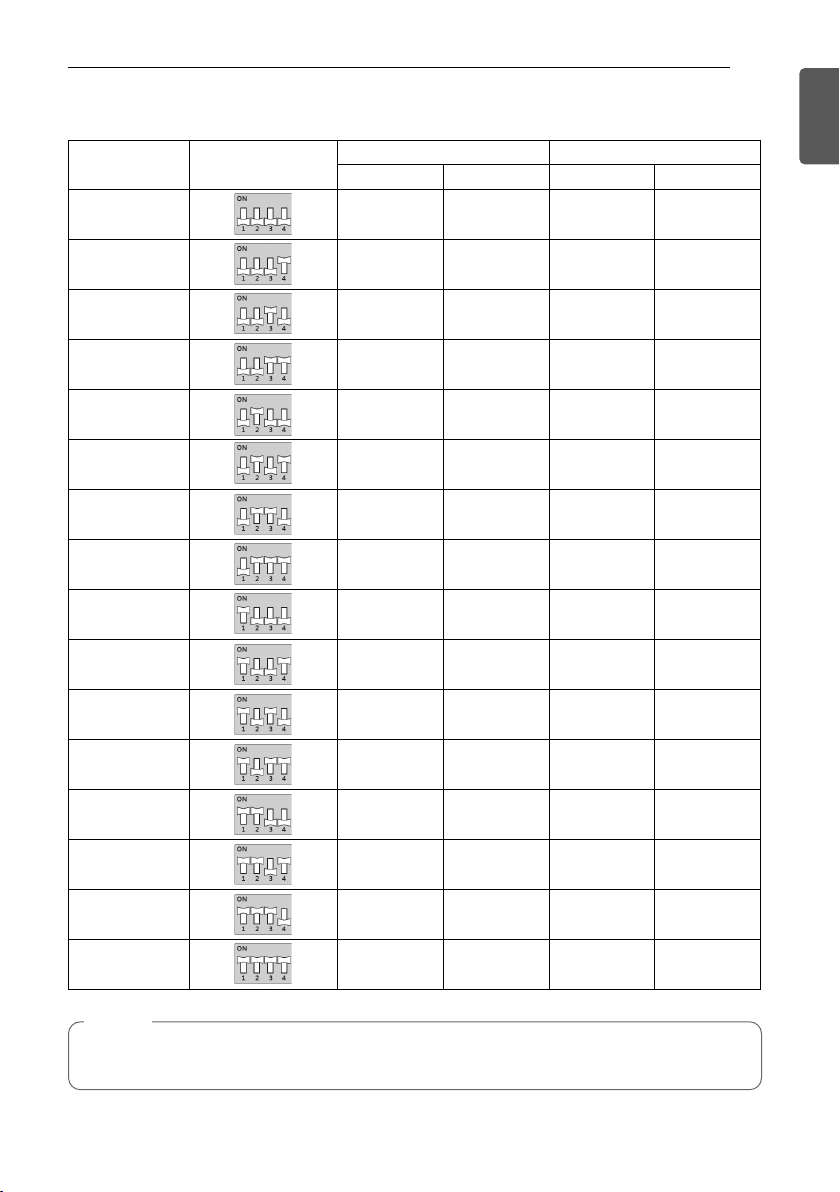

n Table of SW4 (Capacity Index Setting)

13

ENGLISH

No SW4 DIP switch

Capacity [kBTU/hr] Capacity [kW]

MULTI V Single MULTI V Single

1 12 5 3.5 1.5

2

3

4

5

6

7

8

9

10

11

15 7 4.5 2.1

18 9 5.6 2.5

24 12 7.1 3.5

28 15 8.2 4.2

36 18 10.6 5.0

42 24 12.3 7.1

48 30 14.1 8.0

54 36 15.8 10.0

76 42 22.4 12.5

96 48 28.0 14.0

12

13

14

15

16

115 60 33.6 15.0

134 70 39.2 19.0

153 85 44.8 23.0

172 Reserved 50.4 Reserved

192 Reserved 56.0 Reserved

NOTE

If connecting expansion valve's capacity is bigger than 192 kBtu/h, set DIP switches 1, 2, 3, and 4

to ON.

RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

14

ENGLISH

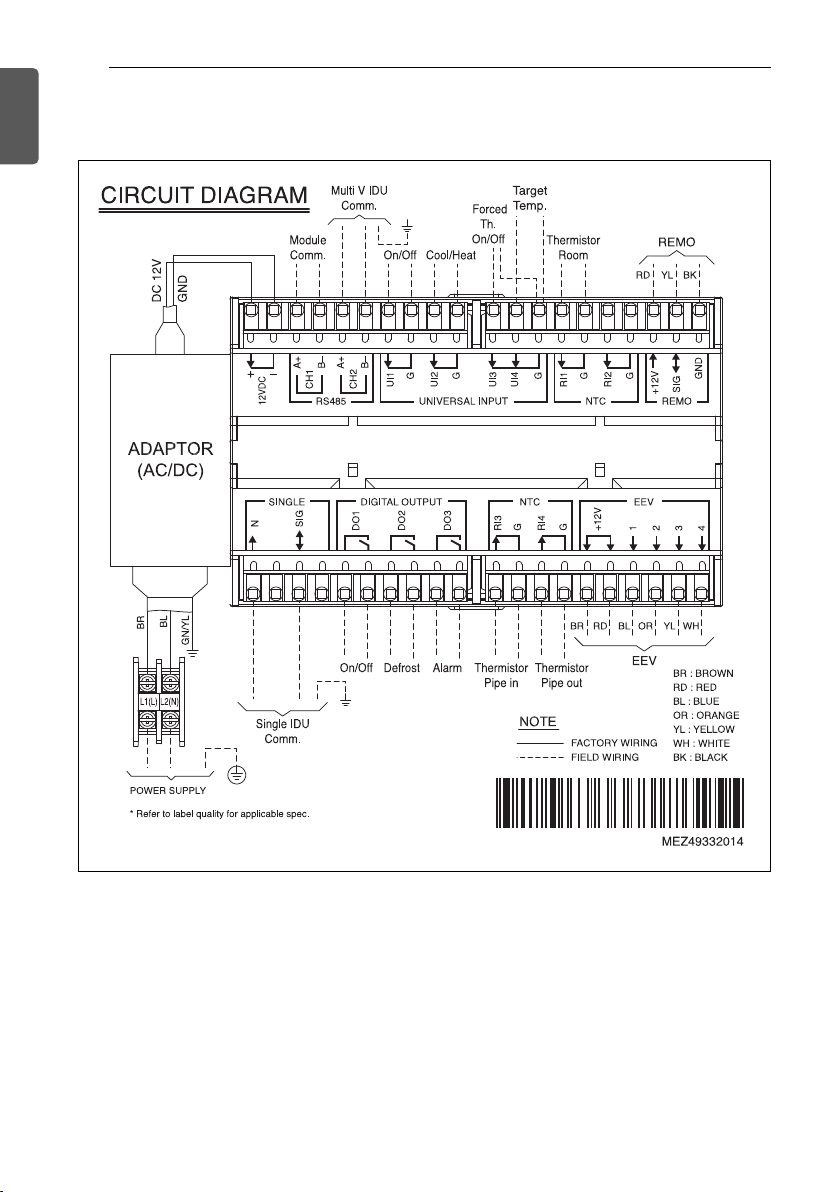

Electric Wiring Work (PAHCMR000)

RETURN AIR TEMPERATURE CONTROL (PAHCMR000)

Electric specification of port

n RS485/SINGLE Communication port

Name Port Contents Electrical Spec. Function

Module

Comm.

RS485 CH1

DDC(Modbus)

Comm.

Max 500 m,

2C x (1.0~1.5) mm

(shield wire)

Communication with

DDC or Main module of

2

PAHCMS000 model

through Modbus protocol

15

ENGLISH

MULTI V

IDU Comm.

Single IDU

Comm.

RS485 CH2 MULTI V IDU Comm.

SINGLE N/SIG Single IDU Comm.

Max 1 km,

2C x (1.0~1.5) mm

(shield wire)

Max 75 m,

2C x (1.0~1.5) mm

(shield wire)

Communication with

2

MULTI V Outdoor unit

Communication with

2

Single Split Outdoor unit

n NTC Thermistor

Name Port Contents Electrical Spec. Function

Thermistor

Room

Thermistor

Pipe in

Thermistor

Pipe out

NTC RI1/G

NTC RI3/G

NTC RI4/G

Room (Return) air

thermistor

Pipe in (Liquid)

thermistor

Pipe out (Gas)

thermistor

NTC 10 kΩ, 5 m

NTC 5 kΩ, 5 m

NTC 5 kΩ, 5 m

Return air temperature

sensor

Inlet pipe (Liquid) Temp.

sensor

Outlet pipe (Gas) Temp.

sensor

Loading...

Loading...