Page 1

SERVICE MANUAL

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Internal Use Only

Mini Hi-Fi AUDIO

MAY, 2016P/NO : AFN77483264

MODEL: OM5560

MODEL: OM5560

Page 2

ÍNDICE

SECCIÓN 1 ........RESUMEN

SECCIÓN 2 ........

SECCIÓN 3 ........COMPONENTES ELÉCTRICOS

SECCIÓN 4 ........MECANISMO (DM19AC)

SECCIÓN 5 ........LISTA DE RECAMBIOS

CARCASA Y ARMAZÓN PRINCIPAL

1-1

Page 3

SECCIÓN 1

RESUMEN

ÍNDICE

MEDIDAS DE PRECAUCIÓN DURANTE LAS TAREAS DE CUIDADO Y MANTENIMIENTO ...................... 1-3

MEDIDAS DE PRECAUCIÓN ESD ................................................................................................................... 1-5

MODO TECLA OCULTA ................................................................................................................................... 1-6

GUÍA DE DESCARGA DE PROGRAMAS ........................................................................................................ 1-7

ESPECIFICACIONES ...................................................................................................................................... 1-10

1-2

Page 4

MEDIDAS DE PRECAUCIÓN DURANTE

LAS TAREAS DE CUIDADO Y MANTENIMIENTO

NOTAS RELACIONADAS CON LA MANIPULACIÓN DEL LECTOR

1. Notas de transporte y almacenamiento

1) El lector deberá permanecer en su bolsa conductora hasta el momento inmediatamente previo al uso.

2) El lector no debe ser expuesto a presiones externas o golpes.

Almacenamiento en bolsa conductora

2. Notas de reparación

1) El lector incluye un imán de gran tamaño, y no debe acercarse nunca a materiales magnéticos.

2) El lector debe ser manipulado correctamente y con cuidado, teniendo cuidado de evitar

presiones externas y golpes. Si así fuera, el resultado podría ser una avería operativa o daños

en la placa de circuito impreso.

3) Cada uno de los captadores ha sido ya ajustado individualmente a un alto nivel de precisión,

motivo por el que el punto de ajuste y los tornillos de instalación no deben tocarse nunca.

4) ¡El haz del láser puede dañar los ojos!

¡No mire nunca directamente al haz del láser! Igualmente, no encienda NUNCA

la alimentación de la pieza de salida láser (lente, etc.) del lector si estuviera dañado.

No mire NUNCA directamente al haz del láser, y no lo toque con

los dedos u otras partes expuestas de su cuerpo.

5) Limpieza de la superficie de la lente

Si hubiera polvo en la superficie de la lente, límpielo mediante un pulverizador (como los

empleados para limpiar las lentes de las cámaras). La lente está sujeta por un delicado soporte.

Por lo tanto, al limpiar la superficie de la lente, utilice un bastoncillo de algodón con cuidado de

Impacto por caída

Presión

Imán

Cómo sujetar el lector

Lámina

conductora

Bastoncillo de algodón

6) Nunca intente desmontar el resorte del lector ejerciendo una presión excesiva. Si la lente

estuviera extremadamente sucia, aplique alcohol isopropílico al bastoncillo de algodón. (No

utilice ningún otro limpiador líquido, ya que podría dañar la lente.) Tenga cuidado de no aplicar

demasiado alcohol en el bastoncillo, y no permita que el líquido entre en el interior del lector.

1-3

Presión

Page 5

NOTAS RELACIONADAS CON LA REPARACIÓN DE REPRODUCTORES DE CD

1. Preparación

1) Los reproductores de CD incorporan un gran número de CIs, así como un lector (diodo láser).

Estos componentes son muy sensibles y se ven fácilmente afectados por la electricidad estática. En el

caso de electricidad estática de alta tensión los componentes podrían resultar dañados, motivo por el que

deben manipularse con cuidado.

2) El lector está compuesto de numerosos componentes ópticos y otros de gran precisión.

Por lo tanto, tenga cuidado de evitar realizar labores de reparación o almacenamiento cuando la

temperatura o humedad son altas, en presencia de fuerte magnetismo o grandes cantidades de polvo.

2. Notas de reparación

1) Antes de reemplazar una pieza o componente, desconecte primero el cable de alimentación de la unidad.

2) Todo el equipamiento, instrumentos de medición y herramientas deben estar correctamente puestos a

tierra.

3) Debe cubrir su mesa de trabajo con una lámina conductora puesta a tierra. Al extraer el

lector láser de su bolsa conductora, no lo coloque sobre ésta. (El motivo es la posibilidad

de daños a causa de la electricidad estática.)

4) Para evitar la fuga de CA, la parte metálica del soldador deberá estar puesta a tierra.

5) Todos los trabajadores deberán tener conexión a tierra por medio de un brazalete especial (1 M)

6) Tenga cuidado de no permitir que el lector láser entre en contacto con la ropa, a fin de

evitar que la electricidad estática de sus prendas escape por el brazalete.

7) El haz láser del lector NUNCA debe ser dirigido hacia los ojos o la piel desnuda.

Brazalete

Resistencia

(1 M)

Resistencia

(1 M)

Lámina

conductora

1-4

Page 6

MEDIDAS DE PRECAUCIÓN ESD

Dispositivos electrostáticamente sensibles (ESD)

Ciertos dispositivos semiconductores (estado sólido) pueden resultar fácilmente dañados por la electricidad

estática. Normalmente tales componentes son conocidos comúnmente como Dispositivos electrostáticamente

sensibles (ES) Ejemplos de dispositivos ESD

típicos son los circuitos integrados y algunos transistores de efecto campo y componentes de chips semiconductores. Debe utilizar las siguientes técnicas para ayudarle a reducir las incidencias de daños en los componentes

causados por la electricidad estática.

1. Inmediatamente antes de manipular cualquier componente semiconductor o montaje equipado a tal efecto,

elimine cualquier carga electroestática presente en su cuerpo tocando una puesta a tierra segura.

Opcionalmente, obtenga y vista un dispositivo de muñequera de descarga disponible en el mercado, que

deberá retirar antes de aplicar potencia a la unidad bajo prueba a fin de evitar riesgos potenciales de descarga

eléctrica.

2. Después de retirar un montaje eléctrico equipado con dispositivos ESD, coloque el montaje sobre una superfi-

cie conductora, como papel de aluminio, para evitar la acumulación de cargas electroestáticas o la exposición

del montaje.

3. Utilice únicamente un soldador con puesta a tierra para soldar o eliminar soldaduras en los dispositivos ESD.

4. Utilice únicamente un dispositivo de eliminación de soldaduras antiestático. Ciertos dispositivos de eliminación

de soldaduras, no clasificados como “antiestáticos” pueden generar cargas eléctricas suficientes como para

dañar los dispositivos ESD.

5. No utilice productos químicos que incluya freón. Estos pueden generar cargas eléctricas suficientes como

para dañar los dispositivos ESD.

6. No saque un dispositivo ESD de repuesto de su embalaje protector hasta inmediatamente antes de su

instalación. (La mayor parte de los dispositivos ESD de repuesto están embalados con cables cortocircuitados

eléctricamente entre sí mediante espuma conductora, papel de aluminio o materiales conductores similares).

7. Inmediatamente antes de retirar el material protector de los cables de un dispositivo ESD de repuesto,

ponga en contacto el material protector y el armazón o montaje decir cuitos en los que se instalará el dispositivo.

PRECAUCIÓN: ASEGÚRESE DE QUE EL CHASIS O CIRCUITO NO RECIBE ALIMENTACIÓN LÉCTRICA,

Y RESPETE TODAS LAS PRECAUCIONES DE SEGURIDAD.

8. Minimice los movimientos corporales durante el manejo de dispositivos ESD de repuesto ya desempaqueta-

dos. (De lo contrario el movimiento inofensivo de, por ejemplo, el roce de su ropa o levantar los pies de un

suelo enmoquetado, puede generar la electricidad estática suficiente para dañar un dispositivo ESD).

PRECAUCIÓN. SÍMBOLOS GRÁFICOS

EL SÍMBOLO DEL RELÁMPAGO CON FLECHAS DENTRO DE UN TRIÁNGULO EQUILÁTERO

ESTÁ PENSADO PARA ALERTAR AL PERSONAL DE SERVICIO DE LA PRESENCIA DE

“TENSIONES PELIGROSAS” NO AISLADAS, Y QUE PUEDEN TENER LA MAGNITUD

SUFICIENTE COMO PARA CONSTITUIR UN RIESGO DE DESCARGA ELÉCTRICA.

EL SIGNO DE EXCLAMACIÓN DENTRO DE UN TRIÁNGULO EQUILÁTERO ESTÁ PENSADO

PARA ALERTAR AL PERSONAL DE SERVICIO DE LA PRESENCIA DE INFORMACIÓN

IMPORTANTE DE SEGURIDAD EN LA DOCUMENTACIÓN DE SERVICIO.

1-5

Page 7

MODO TECLA OCULTA

Presione a la vez durante 5 segundos la tecla frontal y RCU a fi n de activarlo.

1. Compruebe el código de versión y opción

Tecla frontal: PARAR

Tecla RCU: REPRODUCIR/PAUSA

Puede cambiar [Versión MCU audio <-> Versión controlador CD <-> opción EEPROM] mediante SALTAR+/-.

2. Borrar EEPROM

Tecla frontal: PARAR

Tecla RCU: SALTAR- (modelo CD), 0 (modelo DVD)

1-6

Page 8

GUÍA DE DESCARGA DE PROGRAMAS

1. PROGRAMA DE AUDIO

El nombre del archivo del programa a descargar debe ser MICOM_OM5560_YYMMDDX.HEX

Si el programa de seguridad (Water Wall) está activado en la PC, debe guardar el archivo en el dispositivo de

almacenamiento USB y desactivar el software de seguridad; A continuación, descargue el archivo al aparato.

La descarga del archivo procede en la misma forma para la función USB1 y USB2.

Precaución:

Durante la descarga del archivo, no desconecte el dispositivo USB, no cambie a otra función y no

apague el aparato. El dispositivo USB debe desconectarse cuando haya finalizado el proceso de

descarga.

EN LA PANTALLA VFD

NO USB

Conectar un dispositivo USB en función USB.

SEARCH

MICOM UP

FINISH

1) Formato (Rápido) de la memoria USB.

2) Copia el archivo de firmware a la memoria USB.

AUTO POWER OFF

1-7

Page 9

2. PROGRAMA DE CD

El nombre del archivo del programa a descargar debe ser HG690_OM5560_YYMMDDX.bin

Si el programa de seguridad (Water Wall) está activado en la PC, debe guardar el archivo en el dispositivo de

almacenamiento USB y desactivar el software de seguridad; A continuación, descargue el archivo al aparato.

La descarga del archivo procede en la misma forma para la función USB1 y USB2.

Precaución:

Durante la descarga del archivo, no desconecte el dispositivo USB, no cambie a otra función y no

apague el aparato. El dispositivo USB debe desconectarse cuando haya finalizado el proceso de

descarga.

EN LA PANTALLA VFD

NO USB

Conectar un dispositivo USB en función USB.

SEARCH

FIRMWARE

FINISH

1) Formato (Rápido) de la memoria USB.

2) Copia el archivo de firmware a la memoria USB.

AUTO POWER OFF

1-8

Page 10

3. PROGRAMA DE EQ

El nombre del archivo del programa a descargar debe ser EQ_PRG.BIN

Si el programa de seguridad (Water Wall) está activado en la PC, debe guardar el archivo en el dispositivo de

almacenamiento USB y desactivar el software de seguridad; A continuación, descargue el archivo al aparato.

La descarga del archivo procede en la misma forma para la función USB1 y USB2.

Precaución:

Durante la descarga del archivo, no desconecte el dispositivo USB, no cambie a otra función y no

apague el aparato. El dispositivo USB debe desconectarse cuando haya finalizado el proceso de

descarga.

EN LA PANTALLA VFD

NO USB

Conectar un dispositivo USB en función USB.

SEARCH

EQ UP

FINISH

1) Formato (Rápido) de la memoria USB.

2) Copia el archivo de firmware a la memoria USB.

AUTO POWER OFF

1-9

Page 11

ESPECIFICACIONES

GENERAL

Requerimientos de energía Consulte la etiqueta principal de la unidad

Consumo de Energía Consulte la etiqueta principal de la unidad

Red en espera: 0,5 W (Si todos los puertos de red están activos.)

Dimensiones (An x Alt x P) Aprox. 330 mm x 715 mm x 302 mm

Peso neto Aprox. 13 kg

Temperatura de Operación 5 °C a 35 °C (41 °F a 95 °F)

Humedad de Operación 60 %

Suministro de energía del puerto 5 V 500 mA

ENTRADAS

Entrada de audio analógica (AUX IN)

Salida de audio analógica (AUX OUT)

Entrada portátil (PORT. IN) 1,4 Vrms (toma estéreo de 3,5 mm) x 1

Micrófono (MIC 1/2) Sensibilidad 20 mV (1 kHz), 2 tomas de 6,3 mm

SINTONIZADOR

Rango de sintonización FM 87,5 a 108,0 MHz u 87,50 a 108,00 MHz

Rango de sintonización AM 522 a 1,620 kHz, 520 a 1,710 kHz u 522 a 1,710 kHz

SISTEMA

Respuesta de frecuencia Response 40 a 20 000 Hz

Relación señal-ruido Más de 75 dB

Rango dinámico Más de 80 dB

Suministro de energía del puerto (USB) 5 V 500 mA

2,0 V raíz cuadrático medio (1 kHz 0 dB), 600 Ω conector RCA (L, R)

2,0 V raíz cuadrático medio (1 kHz 0 dB), 600 Ω conector RCA (L, R)

AMPLIFICADOR (potencia de salida valor cuadrático medio total)

Salida total RMS 500 W

ALTA 160 W × 2 (4Ω a 1KHz, 10% THD)

BAJA 180 W × 1 (4Ω a 200Hz, 10% THD)

El diseño y especificaciones están sujetos a cambios sin previo aviso.

1-10

Page 12

SECCIÓN 2

CARCASA Y ARMAZÓN PRINCIPAL

ÍNDICE

INSTRUCCIONES DE DESEMSAMBLE ........................................................................................................... 2-2

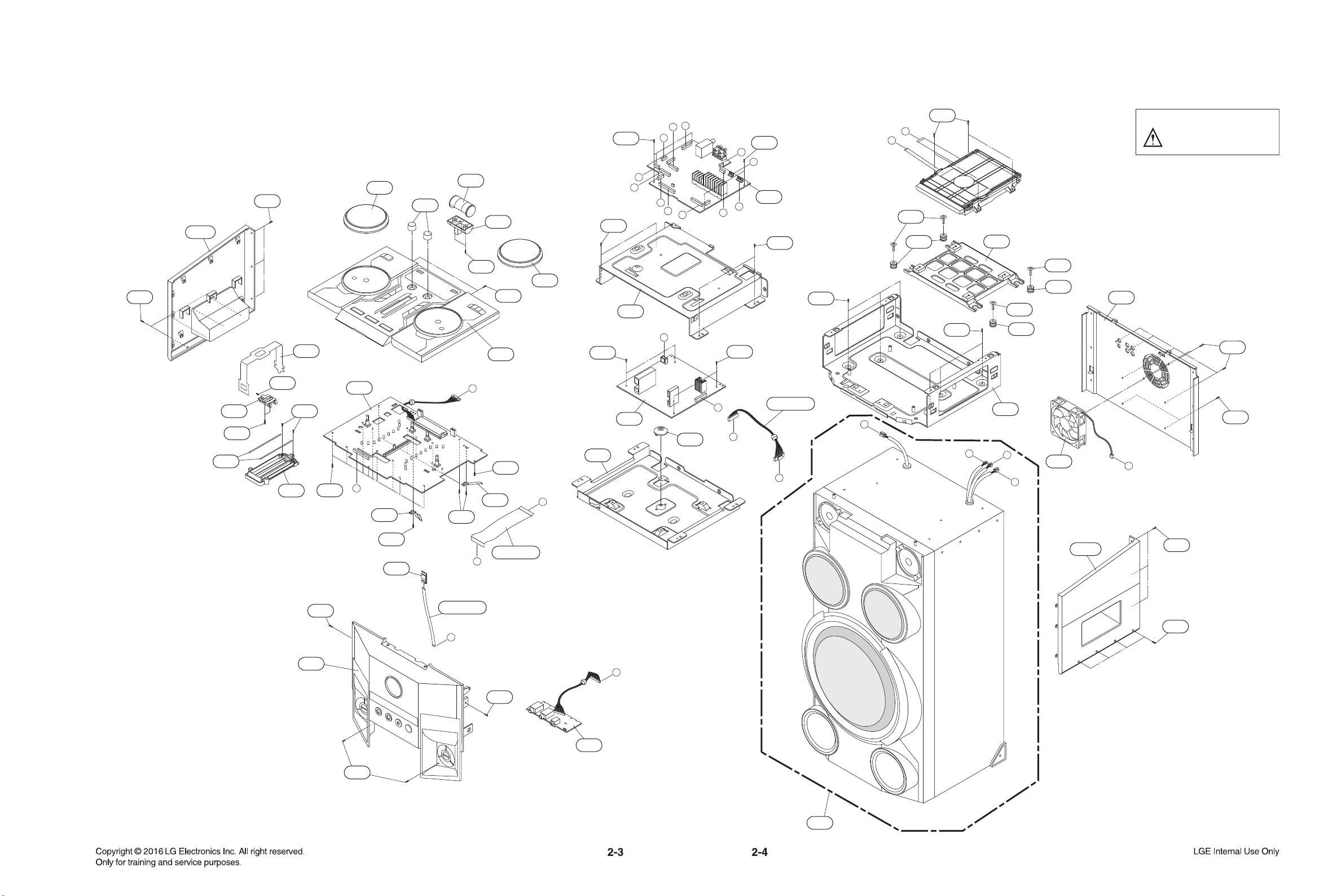

VISTAS AMPLIADAS ........................................................................................................................................ 2-3

1. SECCIÓN DEL GABINETE Y LA ESTRUCTURA PRINCIPAL ................................................................ 2-3

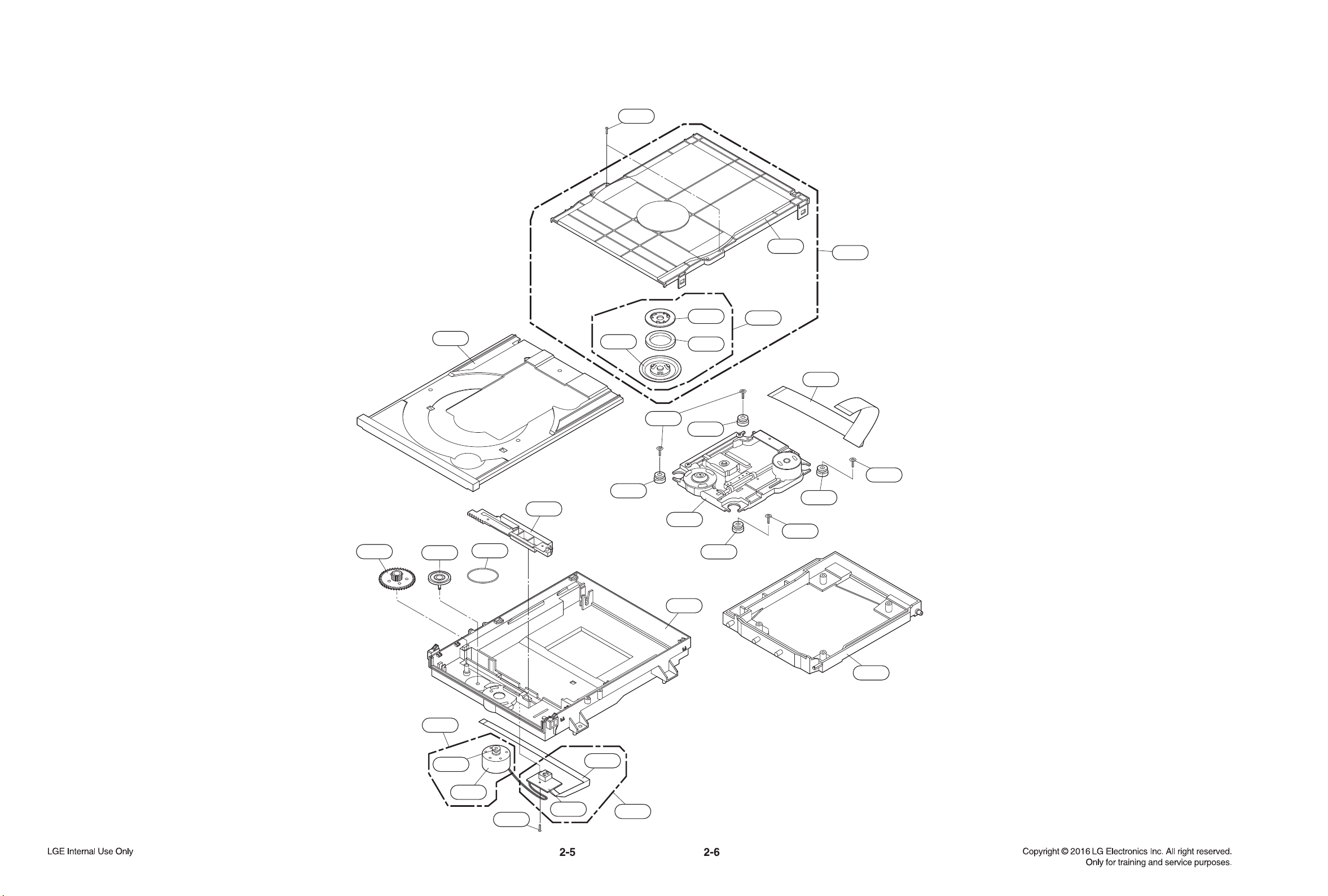

2. SECCIÓN DEL MECANISMO DE LA UNIDAD (DM19AC) ...................................................................... 2-5

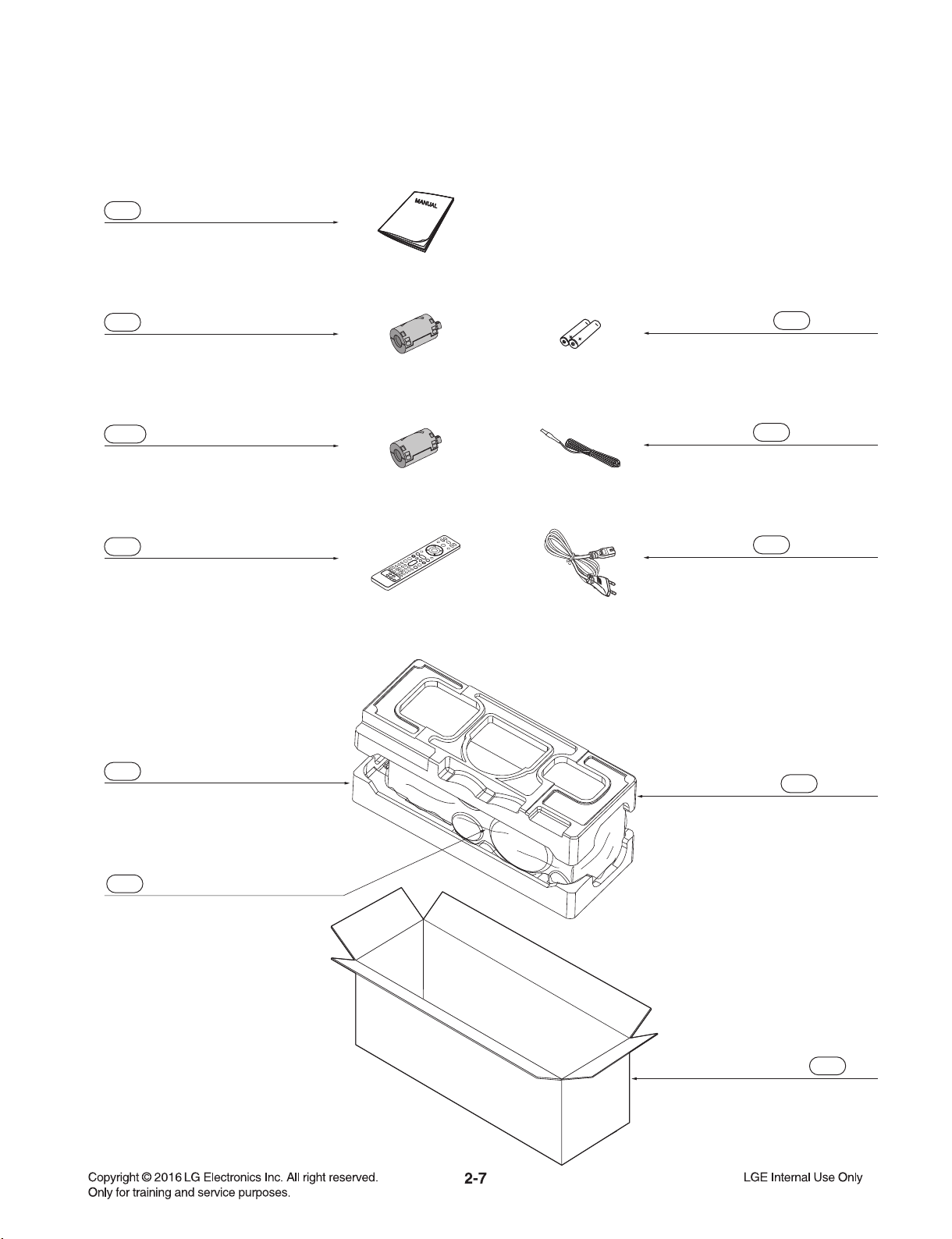

3. SECCIÓN DE ACCESORIOS DE EMBALAJE ......................................................................................... 2-7

2-1

Page 13

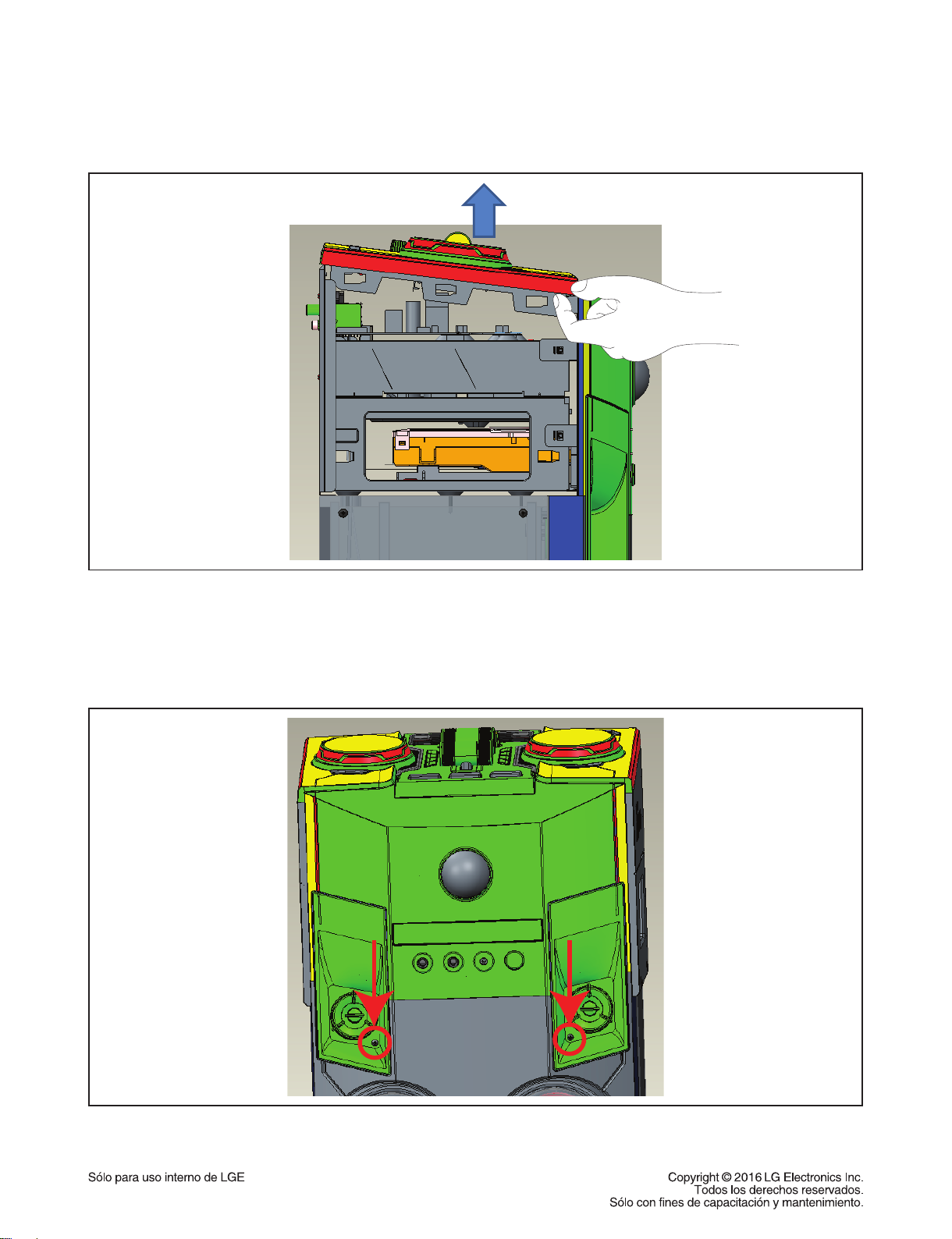

INSTRUCCIONES DE DESEMSAMBLE

1) Para desmontar la parte superior no gire y desmonte tirando hacia arriba.

Figura 1

2) Para desmontar el panel frontal, suelte los dos tornillos y proceda.

Figura 2

2-2

Page 14

RMC

TOP

E

D

H

P

J

A

C

O

I

K

L

G

K

L

B

E

D

J

I

F

G

N

N

P

H

C

A

B

O

260L

476

475

251

255

254

464

252

464

253

256

258

259

464

475

256

A50

475

270

475

A51

A41

475

475

475

475

263

475

475

275

264

476

475

260R

265

476

476

267

521

475

475

521

521

262

475

269

266

266

266

475

475

270

257

CABLE4

CABLE1

CABLE3

A44

A43

464

A60

464

464

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

MAIN

A46

SMPS

A47

Page 15

1439

A001

1002

1005

1001

1003

1004

1026

1043

A005

1016

1013

1015

1020

1439

1018

1019

1012

A006

1045

1049

1437

1437

1024

1024

1024

1024

1437

1011

1030

2. MECHANISM DECK SECTION (DM19AC)

Page 16

3.3. PACKING ACCESSORY SECT

801 Owner’s manual

826 Filter, Ferrite core

826A Filter, Ferrite core

900 Remote control

803 Packing

808 Batteries

825 FM antenna

300 Power Cord

803 Packing

804 Bag

802 Box

Page 17

2-8

Page 18

SECTION 3 ELECTRICAL

ONE POINT REPAIR GUIDE ............................................................................................................................ 3-2

CONTENTS

1. NO POWER ............................................................................................................................................ 3-2

2. NO BOOTING WHEN POWER ON THE SET........................................................................................ 3-3

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET ..................................................................... 3-4

4. NO BOOTING (IN CD/USB FUNCTION) ................................................................................................ 3-5

5. NO OPERATION OF MD ........................................................................................................................ 3-9

6. NO SOUND ........................................................................................................................................... 3-14

ELECTRICAL TROUBLESHOOTING GUIDE ................................................................................................. 3-22

1. POWER (SMPS) ................................................................................................................................... 3-22

2. MCS PART CHECK .............................................................................................................................. 3-25

3. FLD DISPLAY CHECK ......................................................................................................................... 3-26

4. PWM MODULATION CHECK ............................................................................................................... 3-27

5. POWER AMP PART CHECK ............................................................................................................... 3-28

6. TUNER / AUX FUNCTION CHECK ...................................................................................................... 3-29

7. TUNER FUNCTION CHECK................................................................................................................. 3-30

8. CD FUNCTION CHECK ........................................................................................................................ 3-31

9. DOUBLE USB FUNCTION ................................................................................................................... 3-32

WAVEFORMS OF MAJOR CHECK POINT .................................................................................................... 3-33

1. DSP (IC501) .......................................................................................................................................... 3-33

2. SDRAM (IC502) .................................................................................................................................... 3-34

3. SERVO (IC401) ..................................................................................................................................... 3-35

4. MOTOR DRIVER (IC400) ..................................................................................................................... 3-36

5. ADC (IC201) .......................................................................................................................................... 3-37

6. USB (CN502) ........................................................................................................................................ 3-37

7. BLUETOOTH (CN504) .......................................................................................................................... 3-38

WIRING DIAGRAM .......................................................................................................................................... 3-39

BLOCK DIAGRAMS ........................................................................................................................................ 3-41

1. SYSTEM BLOCK DIAGRAM ................................................................................................................ 3-41

2. POWER BLOCK DIAGRAM ................................................................................................................. 3-43

3. AUDIO PATH BLOCK DIAGRAM ......................................................................................................... 3-45

CIRCUIT DIAGRAMS ...................................................................................................................................... 3-47

1. SMPS CIRCUIT DIAGRAM .................................................................................................................. 3-47

2. MAIN - CD DSP CIRCUIT DIAGRAM ................................................................................................... 3-49

3. MAIN - SUB MICOM CIRCUIT DIAGRAM ...........................................................................................3-51

4. MAIN - POWER PART CIRCUIT DIAGRAM ........................................................................................ 3-53

5. MAIN - ADC/ DAC/ PWM CIRCUIT DIAGRAM .................................................................................... 3-55

6. MAIN - RF SERVO CIRCUIT DIAGRAM .............................................................................................. 3-57

7. MAIN - PWM/ AMP CIRCUIT DIAGRAM .............................................................................................. 3-59

8. MAIN - FAN & LED LIGHTING CIRCUIT DIAGRAM ........................................................................... 3-61

9. TOP FRONT CIRCUIT DIAGRAM ........................................................................................................ 3-63

10. JACK/ RMC CIRCUIT DIAGRAM ......................................................................................................... 3-65

CIRCUIT VOLTAGE CHART ........................................................................................................................... 3-67

1. IC INPUT VOLTAGE ............................................................................................................................. 3-67

2. CAPACITOR VOLTAGE ....................................................................................................................... 3-68

3. CONNECTOR VOLTAGE ..................................................................................................................... 3-69

PRINTED CIRCUIT BOARD DIAGRAMS ....................................................................................................... 3-73

1. SMPS P.C.BOARD ............................................................................................................................... 3-73

2. MAIN P.C.BOARD ................................................................................................................................ 3-75

3. TOP FRONT P.C.BOARD .................................................................................................................... 3-79

4. JACK/ RMC P.C.BOARD ...................................................................................................................... 3-83

3-1

Page 19

ONE POINT REPAIR GUIDE

1. NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following guide.

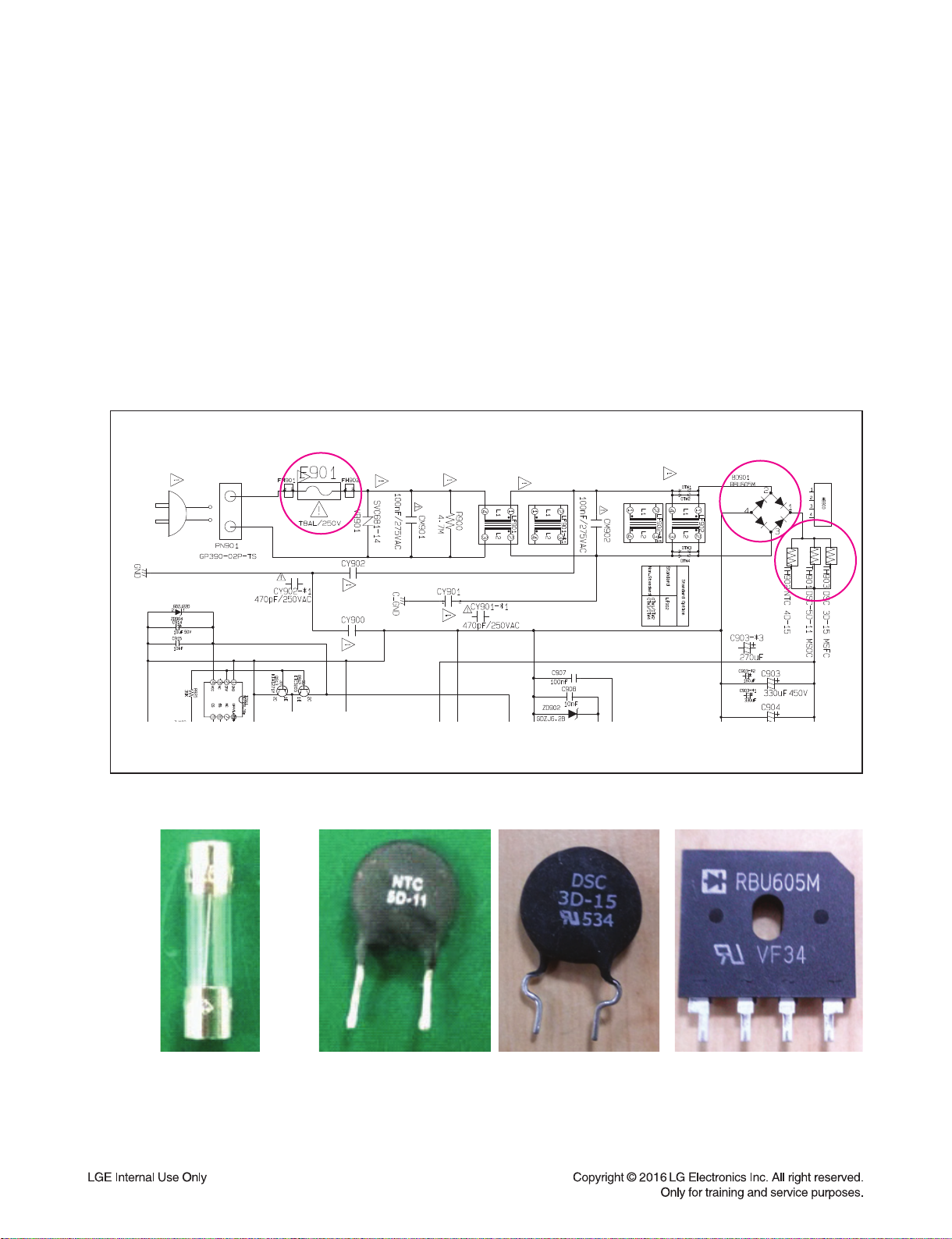

1-1. FUSE/ THERMISTOR/ BRIDGE DIODE

1-1-1. Solution

Please check and replace F901, TH901 or TH903, BD901 on SMPS board.

1-1-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F901 is open or short-circuit.

2) Check if the NTC thermistor TH900 or TH903 is normal or open.

3) Check if the bridge diode BD901 is short-circuit by over current with a digital multi-meter.

1-1-3. Service hint (Any picture/ Remark)

< F901 >

If F901 is not short-circuit,

replace it with a same

specifi cations one.

<TH901 or TH903 >

If TH901 or TH903 is open,

replace it with a new one.

3-2

< BD901 >

If BD901 is short-circuit,

replace it with a new one.

Page 20

ONE POINT REPAIR GUIDE

NO POWER

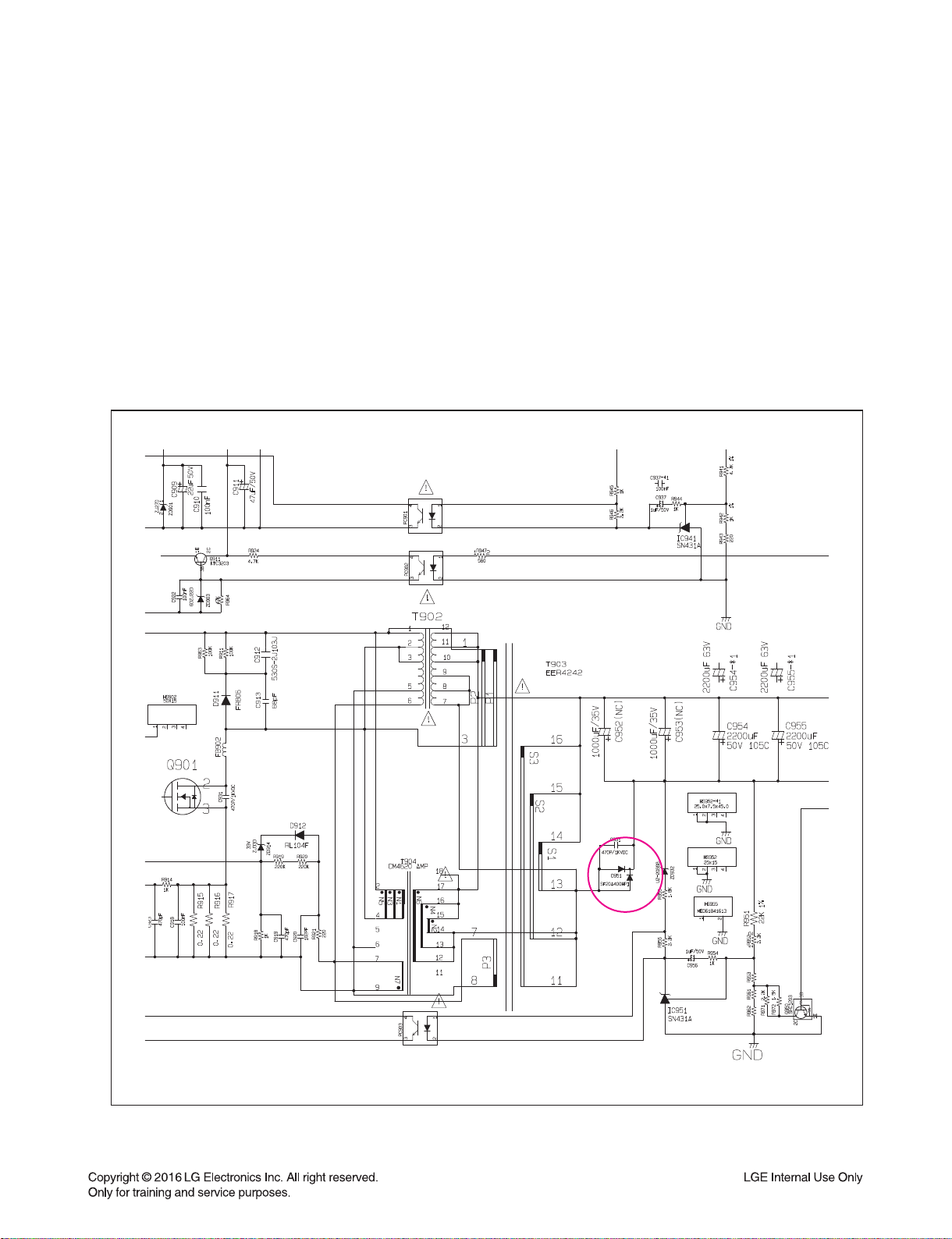

If the unit doesn’t work by no PVDD problem, repair the set according to the following guide.

1-2. FUSE/ FET

1-2-1. Solution

Please check and replace F901, Q901 on SMPS board.

1-2-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F901 is open or short-circuit.

2) Check the anode-cathod voltage of D951 with a digital multi-meter, it is normally 0.2 ~ 0.3 V.

If it doesn’t have any voltage, it’s destroyed. Replace it with a new one.

1-2-3. Service hint (Any picture/ Remark)

< SMPS circuit >

3-3

Page 21

ONE POINT REPAIR GUIDE

X500

(24 MHz)

X501

(32.768 kHz)

KEY1

(R518)

PWR_CTRL

R559

2. NO BOOTING WHEN POWER ON THE SET

The set doesn’t work when press the power button on the top board or the remote control.

2-1. IC501

2-1-1. Solution

Replace IC501 on MAIN board.

2-1-2. How to troubleshoot (Countermeasure)

1) Check the +12 VA (CN202) and 3.3VA (IC503) in standby mode.

If there is no 12 VA, check the SMPS and if doesn’t appear 3.3 VA, check IC503.

2) Check +12 VA, +5.1 VA, 3.3 VA, DVCC_5V and DVCC_3.3V when power on the set.

If the set doesn’t work regardless of what the KEY1 changes high to low while pressing the power button.

-

X500 and X501 work normally but, if you can not power on the set, replace the IC501 with a new one

on the main board.

2-1-3. Service hint (Any picture/ Remark)

X501

(32.768 kHz)

KEY1

(R518)

X500

(24 MHz)

< MAIN board top view >

PWR_CTRL

R559

< MAIN board bottom view >

3-4

Page 22

ONE POINT REPAIR GUIDE

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET

When power on the set, any icons or characters on VFD are not displayed.

3-1. VFD (VFD301)

3-1-1. Solution

Please check and replace VFD301 on TOP FRONT board.

3-1-2. How to troubleshoot (Countermeasure)

1) Check if VFD_12V, DVCC_3.3V and VCC_5V are output from SMPS to VFD via the main board.

2) Check if the IC501 outputs VFD_CLK, VFD_STB, and VFD_DAT to the top board.

3) Check if the VFD grid current amplifier circuit on the top board.

Check the drive signal to the transistor’s(Q801,2) base.

If the control signals from VFD (DGND, VDD) isn’t output, replace VFD with a new one.

3-1-3. Service hint (Any picture/ Remark)

R812(TP 841)

Q801 Emitte r

< Waveform of the grid current driver>

about

30 Vp-p

< TOP FRONT circuit >

3-5

Page 23

ONE POINT REPAIR GUIDE

IC505

IC202

IC205

4. NO BOOTING (IN CD/USB FUNCTION)

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

4-1. NO DVCC_3.3V, 1.2 VA

4-1-1. Solution

Please check and replace IC202, IC205 on MAIN board.

4-1-2. How to troubleshoot (Countermeasure)

1) Check Voltage of IC202 pin3 on MAIN board.

If IC202 pin3 (about 5.1 V) & pin1 Input 12 VA doesn’t come out, check +12 VA from SMPS board.

2) If IC202 pin3 (about 5.1 V) is normal, check voltage of IC205 pin3 (about 1.2 VA), pin6 (about 3.3 VA).

If IC205 pin3 (about 1.2 VA), pin6 (about 3.3 VA) doesn’t come out, check R253, R254, R256 and R260, R261, R262.

If there’s no defective component then replace IC205.

3) PWR_CTRL is high, check R512 and if there’s no defective component then replace IC505.

PWR_CTRL (IC505 pin3) is high (about 3.2 V)

If PWR_CTRL isn’t high, check pin D11 of IC501 & R512, R513

4) If PWR_CTRL is high, check R559 and if there’s no defective component then replace IC505.

4-1-3. Service hint (Any picture/ Remark)

IC205

< MAIN board top view >

IC505

< MAIN board bottom view >

IC202

3-6

Page 24

ONE POINT REPAIR GUIDE

XI

XO

IC501

X500

NO BOOTING (IN CD/USB FUNCTION)

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

4-2. CRYSTAL (X500)

4-2-1. Solution

Replace X500 on MAIN board.

4-2-2. How to troubleshoot (Countermeasure)

1) If 3.3 VA & 1.2 VA is normal, check reset ‘High’ of IC501 pin T12 on MAIN board.

If MAIN_RESET isn’t high, check MICOM (IC101) pin40.

2) If MAIN_RESET is high, check the soldering status of 24 MHz crystal (X500).

3) If the crystal (X500) doesn’t oscillate, check R508, C502, C503 around crystal (X500).

If there’s no defective component, then replace X500.

4-2-3. Service hint (Any picture/ Remark)

IC501

X500

< MAIN board top view >

X

X500

< Signal waveform >

3-7

Page 25

ONE POINT REPAIR GUIDE

VCC

CLK

DO

CS#

IC503

NO BOOTING (IN CD/USB FUNCTION)

After you turn on power key and displayed message in the following order (HELLO VOL XX

CD or USB) on VFD, it will not display other message on VFD, and it will not boot-up normally.

4-3. SERIAL FLASH (IC503)

4-3-1. Solution

Please check and replace IC503 on MAIN board.

4-3-2. How to troubleshoot (Countermeasure)

1) If the crystal (X500) does oscillate, check serial flash (IC503) on MAIN board.

Check pin8 (VCC), pin6 (CLK), pin1 (CS), pin2 (DO), pin5 (DI) of below waveform.

2) If pin1, 2, 5, 6 doesn’t come out, check registers (R563, R564, R534, R535, R536, R5E4) of IC503.

If registers of IC503 is OK, then replace IC503. (it need to download program.)

3) After change IC503, if It is still not below waveform, check IC501 (DSP IC).

4-3-3. Service hint (Any picture/ Remark)

IC503

< MAIN board bottom view >

< Signal waveform >

3-8

Page 26

ONE POINT REPAIR GUIDE

SP+: pin18

SP-: pin19

IC400

5. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the SPINDLE MOTOR among

them.

5-1. SPINDLE MOTOR

5-1-1. Solution

Replace IC400 on MAIN board.

5-1-2. How to troubleshoot (Countermeasure)

1) Check the SPDO signal from pin16 of IC401.

If no signal, check DVCC_3.3V and DV 3.3V (RF) and X400.

2) Check the SPIN+ & SPIN- from IC400 to CN401 for driving SPINDLE motor. It is about 3.6 Vp-p.

If no signal, check M_5 V for IC400.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the spindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Please check the function after changing another MD.

5-1-3. Service hint (Any picture/ Remark)

< Waveform of SP- & SP+

for driving SPINDLE motor >

SP+: pin18

SP-: pin19

< MAIN board top view >

IC400

3-9

Page 27

ONE POINT REPAIR GUIDE

SLED+: pin11

SLED-: pin12

IC400

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the SLED MOTOR among

them.

5-2. SLED MOTOR

5-2-1. Solution

Replace IC400 on MAIN board.

5-2-2. How to troubleshoot (Countermeasure)

1) Check the SLDO signal from pin15 of IC401.

If no signal, check DVCC_3.3V and DV 3.3V(RF) and X400.

2) Check the SPED+ & SLED- from IC400 to CN401 for driving SPINDLE motor. It is about 2.9 Vp-p.

If no signal, check M_5 V for IC400.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the spindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Please check the function after changing another MD.

5-2-3. Service hint (Any picture/ Remark)

SP+

SP-

< Waveform of SLED- & SLED+

for driving SLED motor >

SLED+: pin11

SLED-: pin12

< MAIN board top view >

IC400

3-10

Page 28

ONE POINT REPAIR GUIDE

MOT_CLOSE: pin6

MOT_OPEN: pin7

LOAD+: pin9

LOAD-: pin10

IC400

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the servo motors in MD don’t work. This step is for checking the TRAY OPEN / CLOSE

MOTOR among them.

5-3. TRAY OPEN/ CLOSE MOTOR

5-3-1. Solution

Replace IC400 on MAIN board.

5-3-2. How to troubleshoot (Countermeasure)

1) Check MOT_OPEN & MOT_CLOSE signals from pin P5, L4 of IC501 to IC400.

If no signal, check M_5V to IC400.

2) Check LOAD± from IC400 to CN401 for driving the tray open / close motor. It is about 3.85 Vp-p.

If no signal, check M_5V to IC400. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the tray motor is sort-circuit or has any trouble, it can not open or close the tray.

Please check the function after changing another MD.

5-3-3. Service hint (Any picture/ Remark)

LO-

LO+(RED)

MOT_OP EN

MOT_ CL OSE

< Waveform

for driving tray open/ close motor >

MOT_CLOSE: pin6

MOT_OPEN: pin7

LOAD+: pin9

LOAD-: pin10

< MAIN board top view >

IC400

3-11

Page 29

ONE POINT REPAIR GUIDE

TR+: pin16

TR-: pin15

IC400

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the pickup module in MD doesn’t work. This step is for checking the LASER TRACKING

ACTUATOR.

5-4. LASER TRACKING ACTUATOR

5-4-1. Solution

Replace IC400 on MAIN board.

5-4-2. How to troubleshoot (Countermeasure)

The tracking actuator makes the laser beam be positioned in the center of a track on CD disc.

1) Check the TRD signal from pin14 of IC401.

If no signal, check DVCC_3.3V & DV_3.3V (RF) and X400.

2) Check TR- & TR+ from IC400 to CN400 for driving the tracking actuator.

If no signal, check M_5V for IC400.

3) Check if the FFC cable is solidly connected between CN400 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Please check the function after changing another MD.

5-4-3. Service hint (Any picture/ Remark)

< Waveform of TR±

for driving tracking actuator >

TR+: pin16

TR-: pin15

< MAIN board top view >

IC400

3-12

Page 30

ONE POINT REPAIR GUIDE

F+: pin14

F-: pin13

IC400

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD

disc if the pickup module in MD doesn’t work. This step is for checking the LASER FOCUSING

ACTUATOR.

5-5. LASER FOCUSING ACTUATOR

5-5-1. Solution

Replace IC400 on MAIN board.

5-5-2. How to troubleshoot (Countermeasure)

The focusing actuator makes the laser beam keep a regular interval with the surface of a CD disc.

1) Check the FDO signal from pin13 of IC401.

If no signal, check DVCC_3.3 & DV_3.3V(RF) and X400.

2) Check F- & F+ from IC400 to CN400 for driving the focusing actuator.

If no signal, check M_5V for IC400.

3) Check if the FFC cable is solidly connected between CN400 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

5-5-3. Service hint (Any picture/ Remark)

< Waveform of F±

for driving focusing actuator >

F+: pin14

F-: pin13

< MAIN board top view >

IC400

3-13

Page 31

ONE POINT REPAIR GUIDE

IC701

L703

L702

L701

L704

IC702

IC601

6. NO SOUND

There is no sound output by DIGITAL AUDIO AMP DAMAGE, repair the set according to the

following guide.

6-1. DIGITAL AUDIO AMP DAMAGE

6-1-1. Solution

Replace IC701, IC702 on MAIN board.

6-1-2. How to troubleshoot (Countermeasure)

1) Check PWM_FL±, PWM_FR± & PWM_SW± signals from IC601 to IC701 & 702 each input function.

If no signal, check if I2S audio signals are entered to IC601.

2) Check PVDD.

If PVDD is abnormal, check the SMPS.

3) Check AMP_12V for driving the gate of AMP IC.

a. All the powers are normal, but if AMP_12V is low, there is possible for AMP IC to be damaged.

b. Remove L701, L702, L703 and L704 one by one.

When removed a inductance, if AMP_12V is recovered, the IC connected to it was damaged.

c. Replace the IC with a new one.

4) Check the impedance between IC701/IC702_OUT_A/OUT_B & GND.

a. If the impedance is 0 Ω, the IC must be damaged.

b. After removing the heat sink, replace it with a new one.

6-1-3. Service hint (Any picture/ Remark)

L703

IC701

L701

L704

IC702

IC601

L702

< MAIN board top view >

3-14

Page 32

ONE POINT REPAIR GUIDE

IC501

R503

NO SOUND

There is no sound output in the CD FUNCTION, repair the set according to the following guide.

6-2. CD FUNCTION

6-2-1. Solution

Replace IC501 on MAIN board.

6-2-2. How to troubleshoot (Countermeasure)

1) Check CD_BCK, CD_LRCK, & CD_DATA signals from IC501 to IC401.

If no signal, check if the RF & servo signals from MD is entered to IC401.

Refer to the “No operation of MD” guide on Item 5.

2) Check the following I2S signal flow. < I2S audio signal Interface >

- MCS_BCK : IC501_pin E1 --> IC601_pin23

- MCS_LRCK : IC501_pin D1 --> IC601_pin22 (44.1 kHz)

- MIX_DATA0_OUT : IC501_pin E2 --> IC601_pin24

- MCS_MCLK : IC501_pin D2 --> IC201_pin44

If there is any trouble, check the power for each IC.

The power is normal but, if the signal waveform to the IC is distorted or no signal,

replace it with a new one.

6-2-3. Service hint (Any picture/ Remark)

< Waveform of I2S audio interface signals >

< MAIN - CD DSP circuit >

IC501

R503

< MAIN board top view >

3-15

Page 33

ONE POINT REPAIR GUIDE

D+

D-

CN502

NO SOUND

There is no sound output in the USB Function, repair the set according to the following guide.

6-3. USB FUNCTION

6-3-1. Solution

Replace IC204 on MAIN board.

6-3-2. How to troubleshoot (Countermeasure)

1) Check +5V_USB to USB board.

If the USB LED are turned on, the voltage is okay, if so not, check USB_5V to pin5, 6 of CN803.

2) Check USB D1± or USB D2± from MAIN board to TOP board.

a. Check 2.0_D1±signals(pin U7, U8 ) or 1.1_D1± signals(pin A7, A8 ) to IC501.

b. Check USB± signals to CN502(pin1, 2, 8, 9).

If there is any trouble, check the power for IC204.

The power is normal but, if the signal waveform to the IC is distorted or no signal,

replace it with a new one.

3) Check if “Digital audio AMP block” on item 6-1 is normal.

6-3-3. Service hint (Any picture/ Remark)

D

USB D-/D+ (CN502 pin1, 2 & pin8, 9)

< Waveform of USB D± signal >

CN502

< MAIN board top view >

3-16

Page 34

ONE POINT REPAIR GUIDE

MCS_BCK: pin42

MCS_LRCK: pin43

MCS_MLCK: pin44

IC201

NO SOUND

There is no sound output in the AUX Function, repair the set according to the following guide.

6-4. AUX FUNCTION

6-4-1. Solution

Replace IC201 on MAIN board.

6-4-2. How to troubleshoot (Countermeasure)

1) Check AUX_L/R signals to IC201 (pin23, 24).

2) Check if MCS_BCK, MCS_LRCK & MCS_MCLK are entered from IC501 to IC201.

3) Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check DVCC_5V & DVCC_3.3V (ADC) for IC201. If is NG, replace it a new one.

4) Check the following I2S signal flow from IC501 to IC601. (Refer to Item 6-2.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform

to the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 6-1.

If AMP is damaged, replace it with a new one.

6-4-3. Service hint (Any picture/ Remark)

MCS_BCK: pin42

MCS_LRCK: pin43

MCS_MLCK: pin44

IC201

< AUX function signal fl ow >

< MAIN board bottom view >

3-17

Page 35

ONE POINT REPAIR GUIDE

TUNER_L: pin26

TUNER_R: pin27

IC201

NO SOUND

There is no sound output in the TUNER function, repair the set according to the following guide.

6-5. TUNER FUNCTION

6-5-1. Solution

Replace IC201 on MAIN board.

6-5-2. How to troubleshoot (Countermeasure)

1) Check if TUNER_LR is entered from pin1, 3 of TU500 to IC201 (pin26, 27).

If no signals, check DVCC_3.3V for tuner power.

Check if the tuner control signals (CLK, DAT, CE, RST, SLT) are entered from IC501 to TU500.

If it doesn’t work, replace TUNER with a new one.

2) Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC501 to IC201.

3) Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check DVCC_5V & DVCC_3.3V (ADC) for IC201. If is NG, replace it with a new one.

4) Check the following I2S audio signal flow from IC501 to IC601. (Refer to Item 6-2.)

If there is any trouble, check the power for each IC.

The power is normal but, if the signal waveform to the IC is distorted or no signal,

replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 6-1.

If AMP is damaged, replace it with a new one.

6-5-3. Service hint (Any picture/ Remark)

TUNER_L: pin26

TUNER_R: pin27

IC201

< TUNER function signal fl ow >

< MAIN board bottom view >

3-18

Page 36

ONE POINT REPAIR GUIDE

PT_L: pin9

PT_R: pin10

IC201

NO SOUND

There is no sound output in the PORTABLE Function, repair the set according to the following guide.

6-6. PORTABLE FUNCTION,

6-6-1. Solution

Replace IC201 on MAIN board.

6-6-2. How to troubleshoot (Countermeasure)

1) Check if PT_LR signals to IC201 (pin9, 10).

2) Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC501 to IC201.

3) Check if ADC_DATA is entered from IC201 to IC501.

If no signal, check DVCC_5V & DVCC_3.3V (ADC) for IC201. If is NG, replace it with a new one.

4) Check the following I2S audio signal flow from IC501 to IC601. (Refer to Item 6-2.)

If there is any trouble, check the power for each IC.

The power is normal but, if the signal waveform to the IC is distorted or no signal,

replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 6-1.

If AMP is damaged, replace it with a new one.

6-6-3. Service hint (Any picture/ Remark)

IC201

PT_L: pin9

PT_R: pin10

< PORT. IN function signal fl ow >

< MAIN board bottom view >

3-19

Page 37

ONE POINT REPAIR GUIDE

IC206

ADC/ MIC_DATA: pin9

MCS_BCK: pin8

MCS_LRCK: pin7

MCS_MCLK: pin6

NO SOUND

There is no sound output in the MIC IN function, repair the set according to the following guide.

6-7. MIC IN function

6-7-1. Solution

Replace IC206 on MAIN board, ICA301 on TOP FRONT board.

6-7-2. How to troubleshoot (Countermeasure)

1) Check MIC_SI & MIC_S2 signal to pin5 & 6 of CN201.

If no signal, Check the signals to pin6 & 8 of CNA301 on the FRONT board.

Check if the signal is entered from pin 6 & 8 of CNA301 to pin 5 & 6 of CN201.

2) Check if MIC_SIG is entered from pin 6 of JK302 & JKA303 to pin2, 13 to ICA301 (PRE AMP).

3) Check if the amplified signal comes out from pin3 &12 of ICA301.

If no signal output, check DVCC_3.3V for ICA301, replace ICA301 with a new one if it has a problem.

4) Check if MCS_BCK, MCS_MLCK & MCS_LRCK is entered from IC501 to IC206.

Check if MIC_DATA_IN is entered from pin9 of IC206 to pin T1of IC501.

If no signal, check DVCC_5V & DVCC_3.3V for IC206.

If it is abnormal, change replace it a new one.

5) Check the following I2S signal flow from IC206 to IC501.

If there is any trouble, check the power for each IC.

If the signals are abnormal, replace it a new one.

6) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on item 6-1.

If AMP is damaged, replace it with a new one.

6-7-3. Service hint (Any picture/ Remark)

ADC/ MIC_DATA: pin9

MCS_BCK: pin8

MCS_LRCK: pin7

MCS_MCLK: pin6

IC206

< MAIN board bottom view >

3-20

Page 38

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the Bluetooth function, repair the set according to the following guide.

6-8. BLUETOOTH FUNCTION

6-8-1. Solution

Replace IC501 on the MAIN board or bluetooth module on the FRONT Panel.

6-8-2. How to troubleshoot (Countermeasure)

1) Check BT_RX, BT_TX signal to pin6, 4 of CN504.

If no signal, check the signal to pin4, 6 and pin10 (BT_3.3V) of on the Bluetooth module

and cable connection state.

If there are no signal out from module, replace new module.

2) Check if BT_RX/TX is entered from pin6, 4 of CN504 to pin L1,K1 to IC501 (DSP).

3) Check if MCS_BCK, MCS_LRCK & MIX_DATA IN is entered from IC501 to IC601.

If no signal, check +3.3 VA & +1.2 VA for IC501.

If it is abnormal, change replace it a new one.

4) Check the following I2S signal flow from IC501 to IC601.

If there is any trouble, check the power for each IC.

If the signals are abnormal, replace it a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on item 6-1.

If AMP is damaged, replace it with a new one.

6-8-3. Service hint (Any picture/ Remark)

B/T Module

BT_RX,

BT_TX

IC501

MLC3730

IC601

TPS5548DGG

MCS_BCK

MCS_LRCK

MIX_DATA0_OUT

PWM

TPS5631B

AMP

< Bluetooth function signal fl ow >

< MAIN board bottom view >

3-21

Page 39

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER (SMPS)

No 12 VA

YES

F901 normal?

YES

BD901 normal?

YES

TH901(TH903) normal?

YES

Is Vcc

(10 V ~ 18 V) supplied to

IC901 pin7?

YES

D933 normal?

NO

Replace F901 (Use the same fuse).

NO

Replace BD901.

NO

Replace TH901.

NO

D902 normal?

NO

Check or replace D902.

NO

Replace D933.

YES

Is there

about 2.5 V at

IC941 pin1?

YES

D951 normal?

YES

ZD932 normal?

YES

Power line of main PCB is short.

NO

Replace IC941.

NO

Replace D951.

NO

Replace ZD932.

3-22

Page 40

ELECTRICAL TROUBLESHOOTING GUIDE

No PVDD

YES

F901 normal?

YES

BD901 normal? Replace BD901.

YES

TH901(TH903) normal?

YES

NO

NO

NO

Replace F901 (Use the same fuse).

Replace TH901.

(10 V ~ 18 V) supplied to

Is Vcc

IC911 pin4?

YES

Q901 normal? Replace Q901.

YES

D951 normal?

NO

NO

NO

D903 normal?

YES

Q911 base HIGH?

YES

Check or replace Q911.

Replace D951.

NO

Check or replace D903.

NO

•

Check P_CTRL HIGH signal from MCS.

• Check PC902.

YES

Is there about 2.5 V

at IC951 pin1?

YES

Power line of main PCB is short.

NO

Replace IC951.

3-23

Page 41

ELECTRICAL TROUBLESHOOTING GUIDE

No LED

YES

Is Vcc (DVCC_3.3V)

supplied to IC103?

YES

Is LED_5V & F_LED_12V is normal?

YES

Check or replace IC931.

No VFD

YES

VFD_12V is normal?

NO

NO

NO

Check or replace IC505

Check or replace IC207, Q210 & Q209.

Check or replace Q209, Q210.

YES

DVCC_5V & 3.3V is normal?

YES

VFD_CLK, STB, DO is normal?

YES

Check or replace VFD.

NO

NO

3-24

Check or replace Q204 & Q205, IC505.

Check or replace R808, R811, R814.

Page 42

ELECTRICAL TROUBLESHOOTING GUIDE

2. MCS PART CHECK

MCS PART CHECK

YES

Check if voltage

of CN202 pin1, 2: 12 V.

YES

Check if IC205

have 3.3 VA & 1.2 VA output.

YES

Check if IC505

have DVCC_3.3V output.

YES

X501: 32.768 kHz, X500: 24 MHz

Check the operation.

YES

NO

Refer to SMPS troubleshooting.

NO

Check and change IC205.

NO

Check and change IC505.

OK

3-25

Page 43

ELECTRICAL TROUBLESHOOTING GUIDE

3. FLD DISPLAY CHECK

FLD DISPLAY CHECK

YES

CN202 pin1, 2: 12 V input

of FL+, FL- are over 1.85 V

connection and DVCC_3.3V of

Check

voltage.

YES

Check

if both end voltage

VH : over 29 V.

YES

Check CN804

VDD(C806+).

YES

Check

IC501 -> VFD801

data communication

STB/ DATA/ CLK.

YES

FLD light on?

NO

NO

NO

NO

Refer to SMPS/MPEG

troubleshooting.

Check

DVCC_5V(Q205 & Q204)

VH : Q801, Q802, D801~D804.

Check CN804 connection.

Check data

IC501 pin C2, B3, B1.

NO

Check each pin voltage.

OK

YES

3-26

Page 44

ELECTRICAL TROUBLESHOOTING GUIDE

4. PWM MODULATION CHECK

PWM MODULATION PART

CHECK

YES

Check CN202

pin1, 2: 12 V.

YES

• Check IC601(TAS5548) 3.3 V - pin9, 14, 35, 50.

• Check X601 (12.288 MHz).

YES

Check

X601(12.288 MHz)

operation.

YES

Check IC601 pin21 CLK input.

YES

Check IC501 (MLC3730)

pin U13: RESET, pin L14: SDA

pin L13: SCL output.

NO

NO

NO

SMPS troubleshooting.

Refer to

Check X601

(12.288 MHz).

YES

OK

Check line resistor output

RST: R5T1, SCL: R550,

SDA: R595.

NO

NO

Replace X601(12.288 MHz).

Replace R5T1, R559, R550.

YES

IC601(TAS5548) input data

FL: Pin48(-),49(+). FR: Pin46(-),47(+).

Check

pin24 PWM wave.

Check

PWM modulator output

Other output

check.

YES

NO

YES

OK

Check

CD Assy communication

Pin22, 23, 24.

YESYES

Check IC601

input data.

YES

OK

Check IC601.

YES

NONO

NO

NO

Refer to

CD troubleshooting.

Check each line resistor output.

Replace IC601.

OK

OK

3-27

Page 45

ELECTRICAL TROUBLESHOOTING GUIDE

5. POWER AMP PART CHECK

POWER AMP PART CHECK

YES

Check CN202 pin1, 2: 12 V,

pin8, 9, 10: 48.5 V (35.5 V).

YES

Check IC701, IC702

Pin51, 52, 42, 43, 38, 39, 30, 31 input voltage.

YES

Check IC701, IC702

pin64: AMP_12V input.

YES

Check PWM modulator input

IC701 pin4, 5/ IC702 pin4, 5, 10, 11.

YES

Check IC701, IC702

pin28, 29, 36, 37, 44, 45, 52, 53.

NO

Refer to SMPS troubleshooting.

NO

Check each line resistor output voltage.

YES

Check output line coil.

YES

OK

NO

Replace the coil.

3-28

Page 46

ELECTRICAL TROUBLESHOOTING GUIDE

6. TUNER / AUX FUNCTION CHECK

FUNCTION CHECK

YES

Check

IC201 (CS5346)

pin23, 24, 26, 27

input.

YES

Check IC201

(CS5346) pin41 output

data.

YES

Check

IC501(MLC3730)

input data.

YES

IC501(MLC3730)

output data.

YES

OK

NO

NO

NO

Check JK200, TU500.

Check IC201

Pin5: DVCC_3.3V

Pin14: DVCC_5V.

YES

Check IC201

Pin5: DVCC_3.3V,

Pin6: High, Pin14: DVCC_5V.

NO

NO

Check CN202 pin1, 2: 12 V.

Check IC201

pin41: SDOUT, pin42: SLCK,

pin43: LRCK, pin44: MCLK.

YES

Replace IC201.

3-29

Page 47

ELECTRICAL TROUBLESHOOTING GUIDE

7. TUNER FUNCTION CHECK

TUNER FUNCTION CHECK

YES

tuner module (TU500)

Check

operation.

YES

YES

Refer to function check.

NO

Check tuner module voltage (pin4: DVCC_3.3V).

NO

Check tuner module data.Check IC501 Pin P7, P8, P10, P11.

3-30

Page 48

ELECTRICAL TROUBLESHOOTING GUIDE

8. CD FUNCTION CHECK

CD FUNCTION

YES

Can the

disc insert?

YES

Disc reading

is ok?

YES

Is no signal at speaker?

NO

NO

Is load +,- ok?

YES

Is motor ok? (about 12 Ω)

IM driving

(Focus and tracking) is ok?

NO

NO

NO

Is motor_open/close ok?

(IC400 pin6, 7)

YES

Check IC400.

Check loading motor.

Check IC400 (Motor drive IC).

NO

Focus,

tracking, sled signal

is ok?

YES

Is the MD (PN401 pin22)

about 190 mV?

YES

Check

the signal of IC401.

YES

Check

the signal (16.9344 MHz)

at IC401 pin49.

YES

Check IC501

input/output and

control line.

YES

Refer to function check.

NO

NO

NO

Check Vcc of IC401.

Check cristal (X400).

Replace IC501.

3-31

NO

NO

Check MD (pick-up).

Replace cristal (X400).

Page 49

ELECTRICAL TROUBLESHOOTING GUIDE

9. DOUBLE USB FUNCTION

USB FUNCTION

YES

Plug-in USB device.

YES

Display “NO USB”.

YES

Display “READ”.

YES

Display “NO FILE”.

YES

Check USB audio file in USB device

(MP3, WMA file is playable)

NO

Check USB_5V.

YES

Check USB_D+, D-

(R573, R574, C573, C574

D501, D502).

YES

Check IC501

(pin U7, U8/ A7, A8).

NO

NO

NO

Check CN502.

Check USB jack

(CN801, CN802).

Replace IC501.

3-32

Page 50

WAVEFORMS OF MAJOR CHECK POINT

XI

XO

XI

XO

1. DSP (IC501)

X

1

2

Fig 1-1. X501: Crystal of RTC 32.768 MHz

(R5D6 both side)

X

3

4

Fig 1-2. X500: Crystal of system 24 MHz

( MAIN DSP : R508, C503 )

3 4

1

2

3-33

Page 51

2. SDRAM (IC502)

5

6

7

8

Fig 2. SDRAM

8

6

5

7

3-34

Page 52

3. SERVO (IC401)

XI

XO

X

9

10

11

Fig 3-1. X400: Crystal 16.9344 MHz

Fig 3-2. CD-16M

(IC401 pin31)

10

9

11

3-35

Page 53

4. MOTOR DRIVER (IC400)

12

16

13

14

15

18

19

Fig 4-1.

LO- & LO+ / MOT_OPEN &MOT_CLOSE

for Driving TRAY Motor

(IC400 Pin6, 7, 9, 10)

17

Fig 4-2. SL- & SL+ for Driving SPINDLE Motor

(IC400 Pin11, 12)

Fig 4-3. SP- & SP+ for Driving SPINDLE Motor

(IC400 Pin17, 18)

15

13

14

12

16

17

19

18

3-36

Page 54

5. ADC (IC201) 6. USB (CN502)

20

21

23

22

24

Fig 5. ADC I2S

(IC201 Pin42, 43,44)

Fig 6. USB D+/D-

(CN502 Pin1, 2, 8, 9)

23

20

21

24

22

3-37

Page 55

7. BLUETOOTH (CN504)

BT_TX

BT_RX

BT_RST

BT_TX

BT_RX

BT_RST

BT_TX

BT_RX

BT_RST

25

26

27

B

Fig 7. BT_TX / BT_RX / BT_RST

26

27

25

3-38

Page 56

3-39 3-40

IC501

MLC3730

IC401

RF IC

BU9546

IC601

PWM

TAS5548

IC101

MICOM

R5F100G

IC201

ADC

CS5346

IC206

ADC

PCM1808

IC503

F/S 16M

W25Q18

IC502

SDRAM

W9825G6KH

ICA301

MIC AMP

DRV632

IC400

Motor DR

AM5890

IC103

EXPENDER

TLC5928

IC602

DRV632

Tuner

MIC

2

MIC

1

PTB

33pin

33pin

10pin

10pin

10pin 23pin

23pin

USB1 USB2

TOP

Control

Board

MAIN Board

Front Board

10pin

BT

module

AUX IN/OUT

BB Light

LED

IC701

TAS5631B

12pin

12pin

5pin

SMPS

Harness

FFC

FL/FR

W1

L707

L718 L705

L706

MD

RMC

12pin

12pin

10pin

SPK

LED

6

pin

77560 Only

TOP

BOTTOM

IC504

F/S 1M

W25Q80

IC702

TAS5631B

3pin

F

A

N

WIRING DIAGRAM

Page 57

3-41 3-42

BLOCK DIAGRAMS

1. SYSTEM BLOCK DIAGRAM

ڤڤڞڐڋڌٻ

ڨڧڞڎڒڎڋٻ

ڨڼۄۉٻڟڮګٻ

ٻ

ٻٻ

ڃچڎډڎڱںڞڟڇٻڱڞڞڌډڍڄٻ

ڟڠڞڦٻٻٻ

ڨڠڞڣڜکڤڮڨٻ

ڨٻ

ګڊڰګٻ

ڃڱڞڞڐڋڄٻ

ٻ

ٻ

گڪګٻ

ڝڧڪڞڦٻ

ڱۊۇېۈۀڊٻ

ڦۀ۔ڊێےۄۏھۃٻ

ڃچڎډڎڱڜڇڐڱڇچڌڍڱڄٻ

ڎڍڨڝٻ

ڮڟڭڜڨٻٻ

ڌڑڨڝٻ

ڡۇڼێۃٻ

ڤڞڏڋڌٻ

ڜڨڐړڔڋٻ

ڨۊۏۊۍٻڟۍۄۑۀٻ

ڰڮڝڌٻ

ڰڮڝڍٻ

ڤڞڏڋڋٻٻ

ڮڠڭڱڪٻڝڰڔڐڏڑٻ

ڃڏⵤ㋁ڄٻ

ڤڞڍڋڌٻ

ڜڟڞٻ

ڞڮڐڎڏڑٻ

ڟڭڨںڲڠکڊڞڜڮڊٻ

ڭڜڮڊڮڠڧڊڞڧڦڊڞڦڠٻ

ڲۊۊہۀۍٻڮۋۀڼۆۀۍٻ

ڧۄۂۃۏۄۉۂٻ

ڜڟڞںڟڜگڜٻ

ڨڞڮںڝڞڦڊڧڭڞڦڊڨڞڧڦٻ

ڡڭڪکگڃڝگڧڄٻ

ڨڋڋںڌڐٻ

ڜڋڋںڌڑٻ

ڮڡںڟڤڊڟڪٻ

ڮڡںڞڮڊڮڞڦٻ

ڱڡڟںڮگڝڊڞڧڦڊڟڪڊڭڮگڇٻ

ڨڜڤکٻڱڪڧںڜڊڝڇٻ

ڦڠڴٻڌڊڍٻ

ڎڍڋڲٻ

ڪګںڮڲڇڞڧںڮڲڇڰګںڮڲڇڟکںڮڲڇڟںڮڠکڮڠٻ

ڨڪگںڨڰگڠڇڞڧڪڮڠڇڪګڠکٻ

ڜڇڝڇڞڇڟڇڠڇڡڇګڟٻٻٻ

ڧڟٻ

ڮګڟڪڊڮڧڟڪٻ

ڊڡڪڟڊگڭڟٻ

ڧڪڜڟڇڮڧڠڟڇٻ

ڮګڤکڇگڭڇڡٻ

ڟڍڮچڊڈٻ

ګڲڨںڧڭڞڦڊڝڞڦڊڟڜگڜٻ

ڞڟںڭڲڊڨڞڧڦڊڧڭڞڦڊڝڞڦڇٻ

ڞڟںڟڜگٻ

ڞڟںڭڮگٻ

ڰڜڭگںڭڳڊگڳٻ

[OM7560 : Total 1000W]

WOOFER : 360W X 1CH

FRONT : 320W X 2CH

ڡۊۍٻڜڰڳٻ

ڡۊۍٻڨڤڞٻ

ڌډڌٻڍډڋٻ

ڤڞڌڋڌٻ

ڮېڽٻڨۄھۊۈٻ

ڃٻڭڠکڠڮڜڮٻڄٻ

ګڞڨڌړڋړٻ

ڮڞڭڜگڞڣٻڜڊڝڇٻٻ

ڨںڱڪڧںڜڊڝڇٻ

ڡڜکںڞگڭڧٻڊڍڇٻ

ڟڥٻڠہہۀھۏٻڮھۍڼۏھۃڊڧۀۑۀۇٻ

ڮڲڃګڝگڧڄٻ

ڎڍڋڲٻ

ڎڑڋڲٻ

ڌڨڝٻ

ڮڊڡۇڼێۃٻ

ڮڡںڟڤڊڟڪٻ

ڮڡڍںڞڮڊڮڞڦٻ

ڜڰڳٻڤکٻ

گڰکڠڭٻ

ڃڡڨڊڜڨڄٻ

ګگڝٻ

ڨڤڞٻڌٻ

ڨڤڞٻڍٻ

ڧګڡٻ

ڜڨګٻ

گڜڮڐڑڎڌٻ

ڝګڣڟٻ

ګڲڨٻ

گڜڮڐڐڏړٻ

ڡڭڪکگڃڝگڧڄٻ

ڪګٻڜڨګٻ

ڟڭڱڑڎڍٻ

ࣽࣜࣜࣜࣜࣾࣜ

ګڲڨںڧڊڭٻٻٻ

ڟڌچڊڈٻ

ڡڨڊڜڨٻ

ڝڪڪڨٻڝڪڪڨٻ

ڧۄۂۃۏۄۉۂٻ

ڠڳګںڟڜگڜٻڊٻڠڳګٻڞڧڦٻ

ڟڭڱڑڎڍٻ

ڤڭٻٻ

ڭۀھۀۄۑۀۍٻٻ

ࣜࣧࣜࣽࣜࣜࣾࣜ

ࣜ

ࣾࣜ

ڠڳګںڟڜگڜٻڊٻڠڳګٻڞڧڦٻ

ڭڨڞٻٻڤکٻ

ڧڠڟٻ

ڧۄۂۃۏۄۉۂٻ

ڱڡڟٻ

ࣽࣽࣜࣜࣾࣜ

ࣜࣾࣜ

ڞکڏڋڋٻ

ڞکڏڋڌٻ

ڞکڐڋڏٻ

ڞکڐڋڍٻ

گڰڐڋڋٻ

ڞکڑڋڐٻ

Page 58

3-43 3-44

2. POWER BLOCK DIAGRAM

SMPS

+12VA

PVDD_46V

SN1501019

[3A]

TR Switching

12V

TR Switching

12V

TR Switching

12V

VFD

FAN

TR Switching

VCC_5V

MOTO DRIVE

AM5890

CD PICK UP

+5.1VA

DVCC_5V

USB1

USB2

MP2122

[Dual 2A]

MAIN DSP

MLC3730

1.2VA

3.3VA

BD2242G

CS5346

VFD

CS5346

MIC ADC

PCM1808

MIC AMP

DRV632

MIC ADC

PCM1808

TUNER

TAS5548

VCC3.3

BT MODULE

3.3VA

TAS5631B

TAS5631B

12V

12V

RMC

150mA

20mA

VCC3.3

163mA

500mA

500mA

28mA

40mA

50mA

300mA

80mA

350mA

11mA

25mA

RF IC BU9546

5mA

10mA

45mA

MICOM R5F100G

EXPENDER

SPK LED

11mA

60mA

EXPENDER

Space LED

11mA

LINE OUT

DRV632

25mA

10mA

SPK LED

135mA

BOOM B LED

300mA

F/S + SDRAM

105mA

32mA

0.7mA

RESET IC

1mA

70mA

VFD F+/ -

150mA

25mA

IC203

SN1501019

[3A]

P-SENSE

46V

12V

LED_5V

+12V

USB_5V

BD2242G

[2.1]

351mA

395mA

553.7mA

1000mA

785mA

330mA

491mA

351mA

1842mA

979mA

70mA

200mA

300mA

1964mA

EXPENDER

Front LED

25mA

54mA

TR Switching

12V

110mA

LED

110mA

200mA

46V

12V

12V

Page 59

3-45 3-46

3. AUDIO PATH BLOCK DIAGRAM

MLC3730

Main DSP

SERVO

BU9546KV

(4-speed)

IC201

ADC

CS5346

LINE

OUT

DRV632

TAS5548

PWM

MCLK

BCK

LRCK

ADC_DATA_IN

147

100

100

33

33

33

33

100

MIC_DATA_IN

33

BCK

LRCK

33

33

PWM_ R_IN

33

MIX_DATA0

MIX_SDIN1

33

330

470

470

470

CD_16M

CD_BCK

CD_LRCK

CD_DATA

22pF

33pF

MIC

PRE,AMP

DRV632

PCM1808

33

100

100

PWM – RCH

PWM – LCH

PWM_ L_IN

33

AMP

TAS5631

PWM – FLCH

PWM –FRLCH

PWM –WCH

47

47

47

47

47

47

AUX_DATA

AUX_SDIN2

33

33

Page 60

CIRCUIT VOLTAGE CHART

1. IC INPUT VOLTAGE 2. CAPACITOR VOLTAGE

3-67 3-68

Locaton/ Parts Parts Name Specifi cation (V, mV)

110V/60Hz-10% 230V/50Hz+10%

Voltage (V) Voltage (V)

IC101

Microcontrollers

R5F100GEAFB#30 VDD : -0.5~+6.5V VDD : 3.3V VDD : 3.3V

IC102

Voltage Detector

APX809-29SR VIN:1.1~5.5V Vin : 3.3V Vin : 3.3V

IC103

LED Driver

TLC5928PW VIN : 3.0 ~ 5.5V VDD : 3.3V VDD : 3.3V

IC201

Stereo Audio ADC

CS5346-CQZR

VA : 4.75~5.25V

VD : 3.13~3.47V

VLS : 3.13~5.25V

VLC : 3.13~5.25V

VA : 5.04V

VD : 3.36V

VLS :3.36V

VLC :3.36V

VA : 5.04V

VD : 3.36V

VLS : 3.36V

VLC : 3.36V

IC202

DC,DC Converter

SN1501019 VIN : 4.5~17V Vin : 12V, Vout : 5.1V Vin : 12V, Vout : 5.1V

IC203

DC,DC Converter

SN1501019 VIN : 4.5~17V Vin : 12V, Vout : 5V Vin : 12V, Vout : 5V

IC204

Analog Switch

BD2242G Vin : 2.8~5.5V Vin : 5.1V Vin : 5.1V

IC205

Dual, SYNC Buck

Regulator

MP2122 VIN:2.7~6V

Vin : 5.1V

Vout : 3.3V, 1.2V

Vin : 5.1V

Vout : 3.3V, 1.2V

IC206

A/D Converter

PCM1808

Vcc : 4.5~5.5V (Analog)

Vdd : 2.7~3.6V (Digital)

Vcc : 5V (Analog)

Vdd : 3.3V (Digital)

Vcc : 5V (Analog)

Vdd : 3.3V (Digital)

IC400

Motor Driver

AM5890 5ch dvd-p

VCC1 : 4.3~13.2V

VCC2 : 4.3~VCC1

VCC1 : 4.96V

VCC2 : 4.96V

VCC1 : 4.96V

VCC2 : 4.96V

IC401

digital servo signal

processing

BU9546KV

VDD1 : 2.7~3.6V (Analog)

VDD_CORE : 1.4~1.65V

Vcc : 3.3V Vcc : 3.3V

IC501

IC,Digital Signal

Processors

MLC3730SL

Digital Power 3.3V or 1.2V

3.3V, 1.2VA 3.3V, 1.2VA

IC502

SDRAM

W9825G6KH-6 VDD : 3.0~3.6V VCC : 3.3V VCC : 3.3V

IC503

Serial Flash Memory

W25Q128FVSIG VCC : -0.6~VCC+0.4V VCC : 3.3V VCC : 3.3V

IC504

Serial Flash Memory

W25Q80DVSSIG VCC : -0.6~VCC+0.6V VCC : 3.3V VCC : 3.3V

IC505

Analog Switch

BD2242G Vin : 2.8~5.5V Vin : 3.3V Vin : 3.3V

IC601

Sound/Audio Processor

TAS5548DGG

DVDD : 3~3.6V(Digital)

AVDD_PLL : ~3.6V(Analog)

VCC : 3.3V VCC : 3.3V

IC602

Line Driver

DRV632 VDD:3~3.6V VDD : 3.31V VDD : 3.31V

IC701

Audio Amplifi er

TAS5631BPHD

PVDD : 25~52.5V

VDD : 10.8~13.2V

PVDD : 46V

VDD : 12V

PVDD : 46V

VDD : 12V

IC702

Audio Amplifi er

TAS5631BPHD

PVDD : 25~52.5V

VDD : 10.8~13.2V

PVDD : 46V

VDD : 12V

PVDD : 46V

VDD : 12V

IC851

LED Driver

TLC5928PW VIN : 3.0 ~ 5.5V VDD : 3.3V VDD : 3.3V

ICA301

Line Driver

DRV632 VDD:3~3.6V VDD:3.31V VDD:3.31V

Location

88 V, 60 Hz 288 V, 60 Hz

Voltage (V) Current (mV) Voltage (V) Current (mV)

C231 4.95 0.00 4.95 0.00

C242 11.82 0.00 11.82 0.00

C272 1.22 0.00 1.22 0.00

C288 3.39 0.00 3.39 0.00

C293 12.02 0.00 12.02 0.00

C402 5.06 0.00 5.06 0.00

C404 3.28 0.00 3.28 0.00

C409 3.28 2.88 3.28 2.88

C416 1.63 0.00 1.63 0.00

C418 1.63 1.63 1.63 1.63

C427 5.07 0.00 5.07 0.00

C501 2.97 0.00 2.97 0.00

C5E4 5.11 0.00 5.11 0.00

C614 3.26 0.00 3.26 0.00

C713 11.87 0.00 11.87 0.00

C714 11.87 0.00 11.87 0.00

C748 43.60 0.00 43.60 0.00

C749 43.60 0.00 43.60 0.00

C752 43.60 0.00 43.60 0.00

C753 43.60 0.00 43.60 0.00

Page 61

3. CONNECTOR VOLTAGE

3-69 3-70

Location

Connector

Name

Pin No. Pin Name Voltage(V)

CN109 MICOM DEBUG1

1 3.3VA 3.29

2 GND 0.00

3 NC 0.00

4 NC 0.00

5 UART_RX 0.12

6 UART_TX 3.29

CN201

MAIN MIC

SMW200-H12G

1 DVCC_3.3V 3.26

2 3.3VA 3.29

3 DGND 0.00

4 RMC_SIG 3.17

5 MIC_DET 3.24

6 MIC_SIG1 0.00

7 DGND 0.00

8 MIC_SIG2 0.00

9 PT_DET 3.26

10 PT-RCH 0.00

11 PTGND 0.00

12 PT-LCH 0.00

CN202

MAIN SMPS

1 12V 12.01

2 12V 12.01

3 DGND 0.00

4 P_CTRL 2.84

5 DGND 0.00

6 DGND 0.00

7 DGND 0.00

8 PVDD 43.80

9 PVDD 43.80

10 PVDD 43.80

11 GND 0.00

12 PVDD CTRL 0.00

CN400

MAIN MD

1 NC/FHM-VCC 4.92

2 RF 2.28

3 DVD_LD 0.01

4 MON(COM)/5V 0.00

5 DVD_VR 0.20

6 GND 0.00

7 VREF/VC 1.62

8 VCC 4.92

9 F 1.85

10 E 1.85

11 A 1.78

12 D 1.82

13 C 1.71

14 B 1.68

15 F(+) 2.69

16 T(+) 2.45

17 T(-) 2.50

18 F(-) 2.26

19 SW_PDIC 4.57

20 GND 0.00

21 CD_LD 1.77

22 MON_MPD 0.21

23 CD_VR 0.00

Location

Connector

Name

Pin No. Pin Name Voltage(V)

CN601 NC_PWM JIG

1

CLK_FORM UCOM

3.29

2

DAT_FORM UCOM

3.29

3 CLK_TO PWM 3.29

4 DAT_TO PWM 3.29

5 DGND 0.00

CN602

MAIN

WOOFER

SPK LED

1 WHITE 4.94

2 GND 0.00

3 WOOFER_R 5.01

4 WOOFER_G 2.04

5 WOOFER_B 0.77

CN604

MAIN FAN

CONTROL

1 VCC 11.98

2 GND 0.00

3 FG 0.32

4 PWM 0.74

CN605

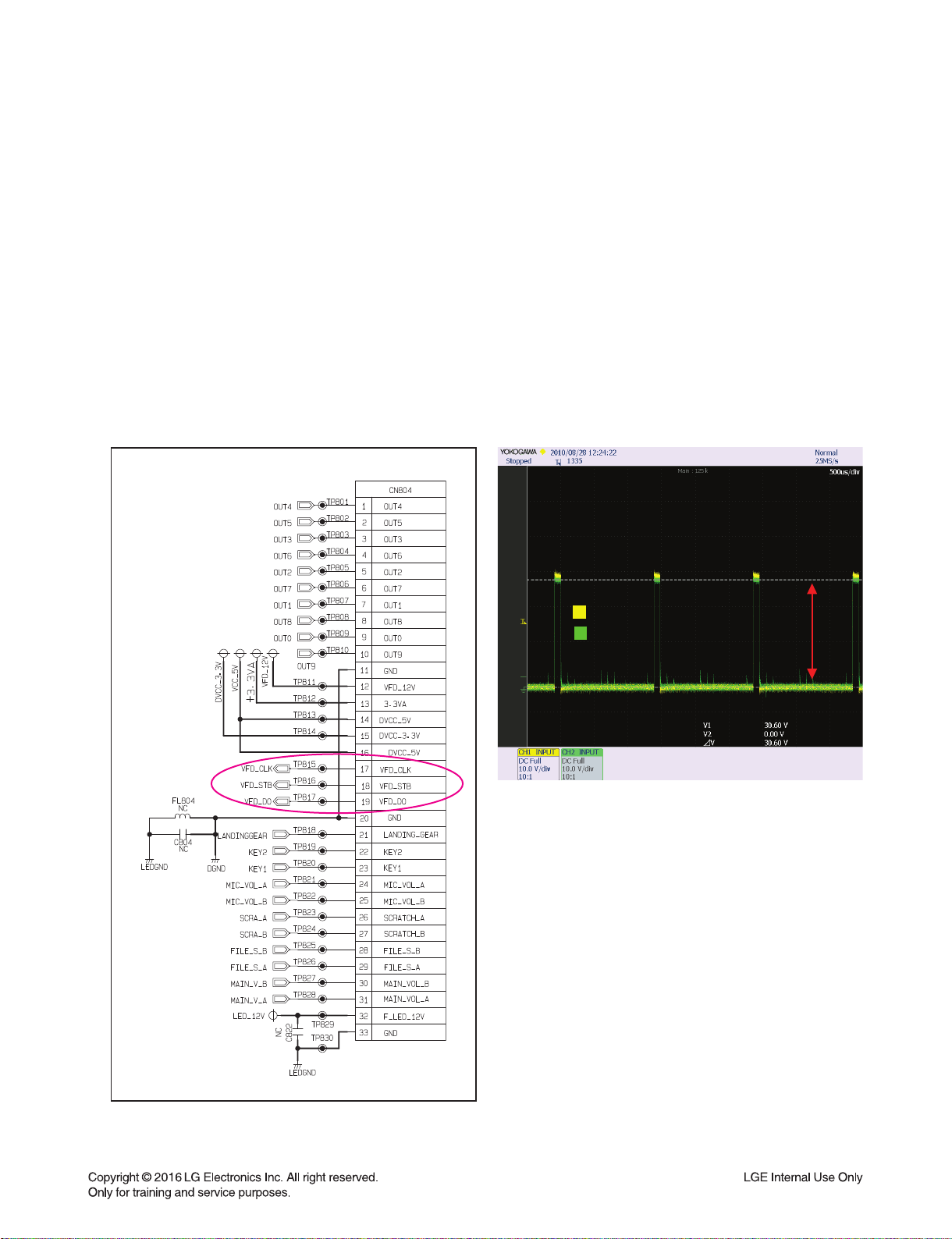

MAIN FRONT

12511HS-25SS-K

1 OUT4 0.18

2 OUT5 0.18

3 OUT3 0.18

4 OUT6 0.18

5 OUT2 0.18

6 OUT7 0.18

7 OUT1 0.18

8 OUT8 0.19

9 OUT0 0.18

10 OUT9 0.19

11 GND 0.00

12 VFD_12V 11.95

13 3.3VA 3.31

14 DVCC_5V 4.90

15 DVCC_3.3V 3.26

16 DVCC_5V 4.91

17 VFD_CLK 3.26

18 VFD_STB 3.10

19 VFD_DO 3.09

20 GND 0.00

21 LANDING_GEAR 1.96

22 KEY2 3.29

23 KEY1 3.29

24 MIC_VOL_A 3.26

25 MIC_VOL_B 3.26

26 SCRATCH_A 3.25

27 SCRATCH_B 0.00

28 FILE_S_B 3.26

29 FILE_S_A 0.00

30 MAIN_VOL_B 3.29

31 MAIN_VOL_A 3.29

32 F_LED_12V 11.80

33 GND 0.00

CN701

MAIN SPK

1 FL+ 22.15

2 FL- 22.15

3 FR+ 22.08

4 FR- 22.10

CN704

MAIN SPK

1 SW+ 22.19

2 GND 0.00

3 SW- 22.17

Location

Connector

Name

Pin No. Pin Name Voltage(V)

CN401

MAIN MD

1 OPEN_SW 3.25

2 LO- 0.01

3 CLOSE_SW 3.25

4 LO+ 0.01

5 GND 0.00

6 SP+ 3.40

7 SL+ 2.59

8 SP- 1.56

9 SL- 0.00

10 NC 0.00

CN501 Debug_MCS

1 VDD 3.29

2 NTRST 2.55

3 TDI 3.28

4 TMS 3.28

5 TCK 3.28

6 TDO 0.83

7 RESET 2.89

8 GND 0.00

9 RTCK 3.29

CN502

VOLUME(USB)

MAIN

1 D2- 0.01

2 D2+ 0.07

3 DGND 0.00

4 USB_5V 5.07

5 USB_5V 5.07

6 USB_5V 5.07

7 DGND 0.00

8 D1- 0.03

9 D1+ 0.03

10 DGND 0.00

CN503 6630R-FB02D

1 RESET 3.28

2 VSS 0.00

3 DOWNLOAD 0.36

4 VDD 3.26

CN504

BT Moudle

MAIN

1 SDA 0.12

2 SCL 3.29

3 GND 0.00

4 TXD 3.29

5 GND 0.00

6 RXD 3.28

7 RTS 3.09

8 CTS 0.00

9 RESET 3.29

10 VDD 3.29

CN505

MAIN

SPACE

LIGHTING

1

SPACE_EXP_DAT

3.11

2

SPACE_EXP_CLK

0.00

3

SPACE_EXP_LAT

0.00

4 DVCC_3.3V 3.25

5 DGND 0.00

6 LED_5V_M 5.09

Page 62

CONNECTOR VOLTAGE

3-71 3-72

Location

Connector

Name

Pin No. Pin Name Voltage(V)

CN801 USB1 (2.0)

1 GND 0.00

2 D+ 0.07

3 D- 0.07

4 USB 5V 5.07

5 GND 0.00

6 GND 0.00

CN802 USB2 (1.1)

1 GND 0.00

2 D+ 0.22

3 D- 0.23

4 USB 5V 5.07

5 GND 0.00

6 GND 0.00

CN803

FROM TOP

MAIN

1 D2- 0.01

2 D2+ 0.07

3 DGND 0.00

4 USB_5V 5.07

5 USB_5V 5.07

6 USB_5V 5.07

7 DGND 0.00

8 D1- 0.03

9 D1+ 0.03

10 DGND 0.00

CN804

MAIN FRONT

1 OUT4 0.18

2 OUT5 0.18

3 OUT3 0.18

4 OUT6 0.18

5 OUT2 0.18

6 OUT7 0.18

7 OUT1 0.18

8 OUT8 0.19

9 OUT0 0.18

10 OUT9 0.19

11 GND 0.00

12 VFD_12V 11.95

13 3.3VA 3.31

14 DVCC_5V 4.90

15 DVCC_3.3V 3.26

16 DVCC_5V 4.91

17 VFD_CLK 3.26

18 VFD_STB 3.10

19 VFD_DO 3.09

20 GND 0.00

21 LANDING_GEAR 1.96

22 KEY2 3.29

23 KEY1 3.29

24 MIC_VOL_A 3.26

25 MIC_VOL_B 3.26

26 SCRATCH_A 3.25

27 SCRATCH_B 0.00

28 FILE_S_B 3.26

29 FILE_S_A 0.00

30 MAIN_VOL_B 3.29

31 MAIN_VOL_A 3.29

32 F_LED_12V 11.80

33 GND 0.00

Location

Connector

Name

Pin No. Pin Name Voltage(V)

CN851

MAIN

SPACE

LIGHTING

1

SPACE_EXP_DAT

3.11

2

SPACE_EXP_CLK

0.00

3 LAT 0.00

4 DVCC_3.3V 3.25

5 DGND 0.00

6 LED_5V_M 5.09

CNA301

MAIN FRONT

1 DVCC_3.3V 3.26

2 3.3VA 3.29

3 DGND 0.00

4 RMC_SIG 3.17

5 MIC_DET 3.24

6 MIC_SIG1 0.00

7 DGND 0.00

8 MIC_SIG2 0.00

9 PT-DET 3.26

10 PT-RCH 0.00

11 PTGND 0.00

12 PT-LCH 0.00

CNS501

MAIN

SPAKER

LIGHTING

1 WHITE 4.94

2 GND 0.00

3 WOOFER_R 5.01

4 WOOFER_G 2.04

5 WOOFER_B 0.77

Page 63

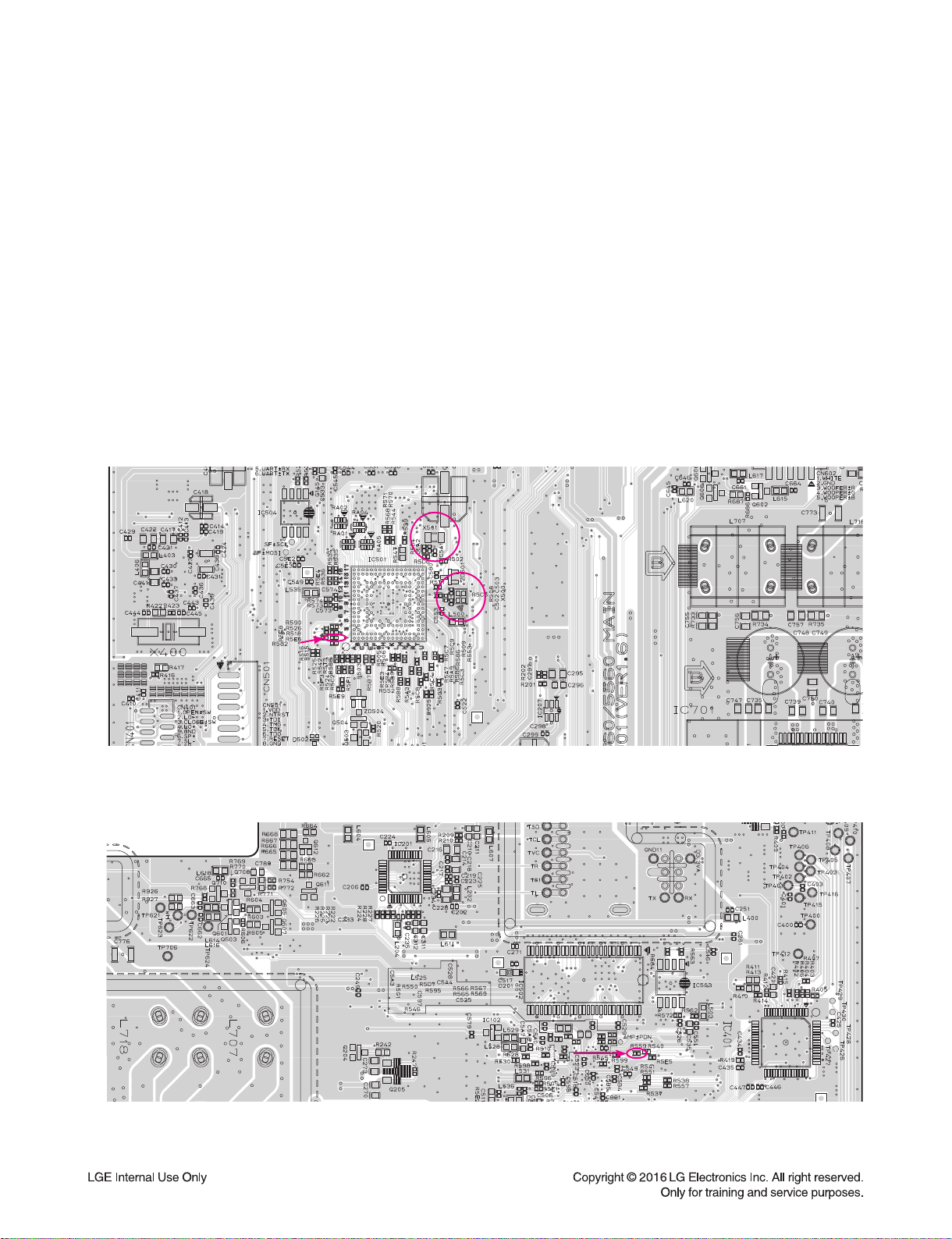

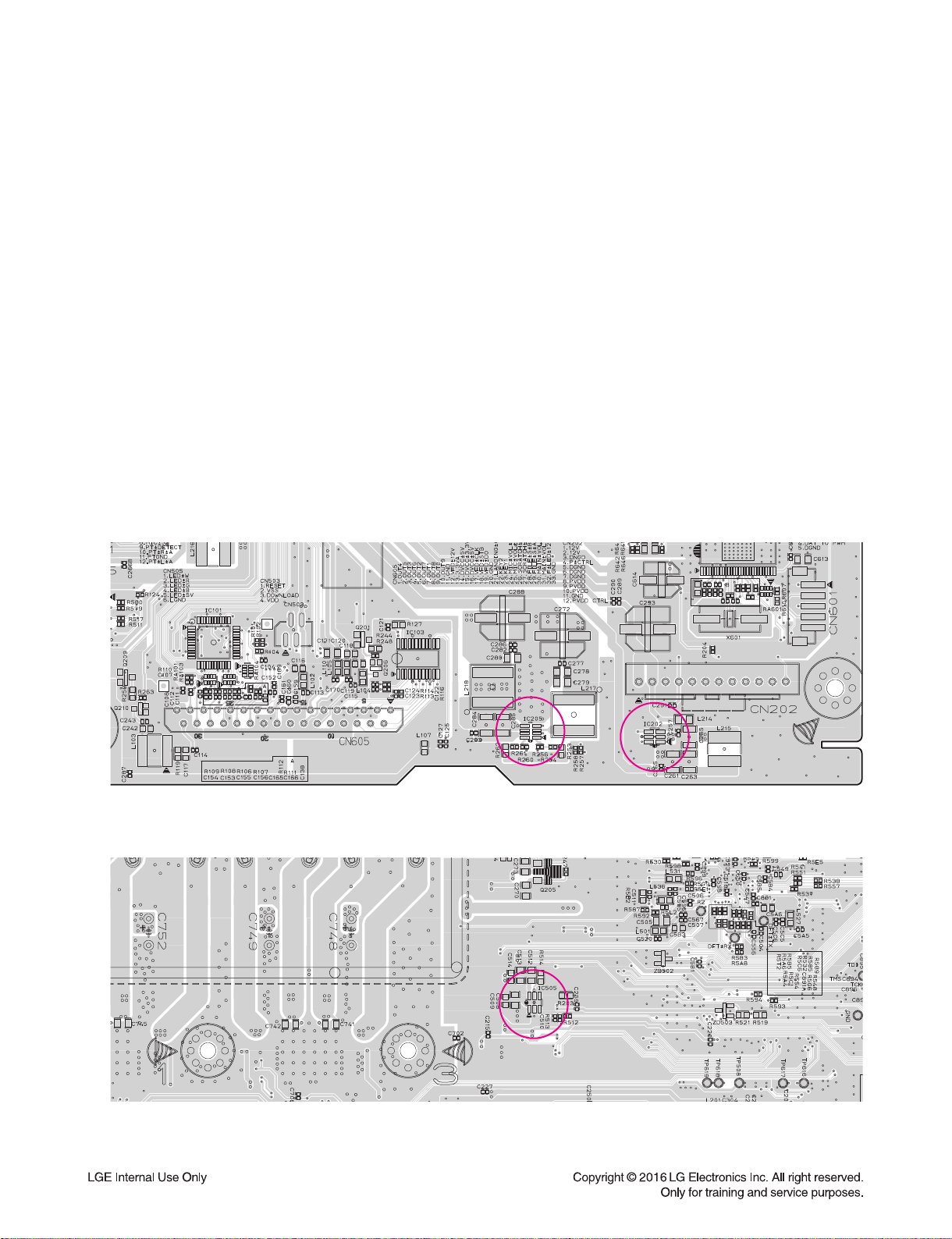

3-73 3-74

PRINTED CIRCUIT BOARD DIAGRAMS

1. SMPS P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

NOTE) Warning

Parts that are critical with respect to risk

of fire or electrical shock.

Page 64

3-75 3-76

2. MAIN P.C.BOARD

(TOP VIEW)

Page 65

3-77 3-78

MAIN P.C.BOARD

(BOTTOM VIEW)

Page 66

3-79 3-80

3. TOP FRONT P.C.BOARD

(TOP VIEW)

Page 67

3-81 3-82

TOP FRONT P.C.BOARD

(BOTTOM VIEW)

Page 68

3-83 3-84

4. JACK/ RMC P.C.BOARD

(TOP VIEW)

(BOTTOM VIEW)

Page 69

3-85 3-86

Page 70

SECTION 4

MECHANISM (DM19AC)

CONTENTS

DECK MECHANISM PARTS LOCATIONS

• Top View ................................................................................................................................................... 4-2

• Top View(without Tray Disc) ..................................................................................................................... 4-2

• Bottom View .............................................................................................................................................. 4-2

DECK MECHANISM PARTS LOCATIONS

1. Main Base ............................................................................................................................................... 4-3

1-1. Clamp Assembly Disc ........................................................................................................................ 4-3

1-1-1. Plate Clamp .................................................................................................................................. 4-3

1-1-2. Magnet Clamp .............................................................................................................................. 4-3

1-1-3. Clamp Upper................................................................................................................................. 4-3

2. Tray Disc ................................................................................................................................................. 4-3

3. Base Assembly Sled ............................................................................................................................... 4-4

3-1. Gear Feed .......................................................................................................................................... 4-4

3-2. Gear Middle ....................................................................................................................................... 4-4

3-3. Gear Rack .......................................................................................................................................... 4-4

4. Rubber Rear ............................................................................................................................................ 4-4

5. Frame Assembly Up/Down ..................................................................................................................... 4-5

6. Belt Loading ............................................................................................................................................ 4-5

7. Gear Pulley ............................................................................................................................................. 4-5

8. Gear Loading .......................................................................................................................................... 4-5

9. Guide Up/Down ....................................................................................................................................... 4-5

10. PWB Assembly Loading.......................................................................................................................... 4-5

11. Base Main ............................................................................................................................................... 4-5

DECK MECHANISM EXPLODED VIEW (DM19AC) ......................................................................................... 4-6

4-1

Page 71

DECK MECHANISM PARTS LOCATIONS

• Top View

• Top View(without Tray Disc)

Procedure

Starting No.

1