Page 1

LCD Projection Monitor

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : RE-01JB

MODEL : MW-60SZ12

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Servicing Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrostatically Sensitive (ES) Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Correction of Screen Tilt & Keystone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Replacing the Lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Description of each Block Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Description of Micom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Exploded View Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- 2 -

Contents

Page 3

Safety Precautions

- 3 -

1. Before returning an instrument to the customer, always make a safety check

of the entire instrument, including, but not limited to, the following items:

a. Be sure that no built-in protective devices are defective and/or have been

defeated during servicing. (1) Protective shields are provided on this chassis to protect both the technician and the customer. Correctly replace all

missing protective shields, including any removed for servicing convenience. (2) When reinstalling the chassis and/or other assemblies in the

cabinet, be sure to put back in place all protective devices, including, but

not limited to, nonmetallic control knobs, insulating fishpapers, adjustment

and compartment covers/shields, and isolation resistor/capacitor networks.

Do not operate this instrument or permit it to be operated without all

protective devices correctly installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or child

might be able to insert their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, (1) spacing between the picture

tube and the cabinet back, (2) excessively wide cabinet ventilation slots,

and (3) an improperly fitted and/or incorrectly secured cabinet back cover.

c. Antenna Cold Check-With the instrument AC plug removed from any AC

source, connect an electrical jumper across the two AC plug prongs. Place

the instrument AC switch in the on position. Connect one lead of an ohmmeter to the AC plug prongs tied together and touch the other ohmmeter

lead in turn to each tuner antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the measured resistance is less than

1.0 megohm or greater than 5.2 megohm, an abnormality exists that must

be corrected before the instrument is returned to the customer. Repeat this

test with the instrument AC switch in the off position.

d. Leakage Current Hot Check-With the instrument completely reassembled,

plug the AC line cord directly into a 120 V AC outlet.

(Do not use an isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 Leakage Current for Appliances and Underwriters

Laboratories (UL) 1410, (50.7). With the instrument AC switch first in the on

position and then in the off position, measure from a known earth ground

(metal waterpipe, conduit, etc.) to all exposed metal parts of the instrument

(antennas, handle bracket, metal cabinet, screwheads, metallic overlays,

control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any current measured must not exceed 0.5

milliamp. Reverse the instrument power cord plug in the outlet and repeat

the test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE CUSTOMER.

e. X-Radiation and High Voltage Limits-Because the picture tube is the pri-

mary potential source of X-radiation in solid-state TV receivers, it is specially constructed to prohibit X-radiation emissions. For continued X-radiation

protection, the replacement picture tube must be the same type as the original. Also, because the picture tube shields and mounting hardware perform

an X-radiation protection function, they must be correctly in place.

High voltage must be measured each time servicing is done that involves

B+, horizontal deflection, or high voltage. Correct operation of the X-radiation protection circuits also must be reconfirmed each time they are serviced. (X-radiation protection circuits also may be called “horizontal disable”

or “hold-down.”) Read and apply the high voltage limits and, if the chassis is

so equipped, the X-radiation protection circuit specifications given on instrument labels and in the Product Safety & X-radiation Warning note on the

service data chassis schematic.

High voltage is maintained within specified limits by close-tolerance safetyrelated components/adjustments in the high-voltage circuit.

If high voltage exceeds specified limits, check each component specified on

the chassis schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside the

receiver cabinet, on the receiver chassis, or on the picture tube.

3. Design Alteration Warning- Do not alter or add to the mechanical or electrical design of this TV receiver. Design alterations and additions, including,

but not limited to, circuit modifications and the addition of items such as

auxiliary audio and/or video output connections, might alter the safety characteristics of this receiver and create a hazard to the user. Any design alterations or additions will void the manufacturer’s warranty and will make you,

the servicer responsible for personal injury or property damage resulting

therefrom.

4. Picture Tube Implosion Protection Warning-The picture tube in this

receiver employs integral implosion protection. For continued implosion protection, replace the picture tube only with one of the same type and number. Do not remove, install, or otherwise handle the picture tube in any

manner without first putting on shatterproof goggles equipped with side

shields. People not so equipped must be kept safely away while picture

tubes are handled. Keep the picture tube away from your body. Do not handle the picture tube by its neck. Some “in-line” picture tubes are equipped

with a permanently attached deflection yoke; because of potential hazard,

do not try to remove such “permanently attached” yokes from the picture

tube.

5. Hot Chassis Warning-a. Some TV receiver chassis are electrically connected directly to one conductor of the AC power cord and may be safely

serviced without an isolation transformer only if the AC power plug is inserted so that the chassis is connected to the ground side of the AC power

source. To confirm that the AC power plug is inserted correctly, with an AC

voltmeter measure between the chassis and a known earth ground. If a

voltage reading in excess of 1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again measure the voltage potential

between the chassis and a known earth ground. b. Some TV receiver chassis normally have 85 V AC (RMS) between chassis and earth ground

regardless of the AC plug polarity. These chassis can be safely serviced

only with an isolation transformer inserted in the power line between the

receiver and the AC power source, for both personnel and test equipment

protection. c. Some TV receiver chassis have a secondary ground system

in addition to the main chassis ground. This secondary ground system is

isolated from the AC power line. The two ground systems are electrically

separated by insulating material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead dress in

the following areas: a. near sharp edges, b. near thermally hot parts- be

sure that leads and components do not touch, c. the AC supply, d. high

voltage, and e. antenna wiring. Always inspect in all areas for pinched, outof-place, or frayed wiring. Do not change spacing between components,

and between components and the printed circuit board. Check the AC

power cord for damage.

7. Components, parts, and/or wiring that appear to have overheated or are

otherwise damaged should be replaced with components, parts, or wiring

that meet original specifications. Additionally, determine the cause of overheating and/or damage and, if necessary, take corrective action to remove

any potential safety hazard.

8. PRODUCT SAFETY NOTICE

Some electrical and mechanical parts have special safety related characteristics which are often not evident from visual inspection, nor can the protection they give necessarily be obtained by replacing them with components

rated for higher voltage, wattage, etc. Parts that have special safety characteristics are identified by shading, by a

*

, or by on schematics and

parts lists. Use of a substitute replacement that does not have the same

safety characteristics as the recommended replacement parts might create

shock, fire, and/or other hazards. Product safety is under review continuously and new instructions are issued whenever appropriate.

AC Leakage Test

DEVICE

UNDER

TEST

TEST ALL

EXPOSED MET AL

SURFA CES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

+ -

(READING SHOULD

NO T BE ABOVE

0.5mA)

EAR TH

GROUND

Page 4

Servicing Precautions

- 4 -

CAUTION: Before servicing instruments covered by this service manual and

its supplements, read and follow the SAFETY PRECAUTIONS section of this

manual. Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. a. Always unplug the instrument AC power cord from the AC power source

before: (1) removing or reinstalling any component, circuit board, module,

or any other instrument assembly. (2) disconnecting or reconnecting any

instrument electrical plug or other electrical connections. (3) connecting a

test substitute in parallel with an electrolytic capacitor in the instrument.

Caution: Awrong part substitution or incorrect polar-ity installation of

electrolytic capacitors may result in an explosion hazard.

b. Do not defeat any plug/socket B+ voltage interlocks with which instru-

ments covered by this service manual might be equipped.

c. Do not apply AC power to this instrument and/or any of its electrical

assemblies unless all solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead to the instrument chassis

ground before connecting the test instrument positive lead.

Always remove the test instrument ground lead last.

Note: Refer to the Safety Precautions section of this manual.

2. The service precautions are indicated or printed on the cabinet, chassis, or

components. When servicing, follow the printed or indicated service precautions and service materials.

3. The components used in the unit have a specified flame resistance and

dielectric strength. When replacing any components, use components

which have the same ratings. Components identified by shading, by

*

, or

by in the circuit diagram are important for safety or for the characteristics

of the unit. Always replace with the exact replacement components.

4. An insulation tube or tape is sometimes used and some components are

raised above the printed wiring board for safety. The internal wiring is sometimes clamped to prevent contact with heating components. Install them as

they were.

5. After servicing, always check that the removed screws, components, and

wiring have been installed correctly and that the portion around the service

part have not been damaged. Further, check the insulation between the

blades of the attachment plug and accessible conductive parts.

INSULATION CHECKING PROCEDURE

Disconnect the attachment plug from the AC outlet and turn the power on.

Connect the insulation resistance meter (500 V) to the blades of the attachment plug. The insulation resistance between each blade of the attachment

plug and accessible conductive parts (Note 1) should be more than 1 Mohm.

Note: Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any electrostatic charge on the body by touching a known earth ground.

Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install

t.(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil, or

comparable conductive material.)

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will

be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replace

ment ES devices. (Otherwise, seemingly harmless motion,

such as the brushing together of your clothing or the lifting of

your foot from a carpeted floor, can generate static electricity

sufficient to damage an ES device.)

Page 5

- 5 -

Description of Controls

Main Body

Main Body

ON/OFF

ON/OFF

ON/OFF Button

SOURCE MENU VOLENTER

MENU Button

SOURCE Button ENTERA / Button

/

VOL

F, G Button

Indicators

E, D Button

* Temperature indicator, lamp Indicator and operation indicator at the front of the monitor show the user the

operating status of the monitor.

Orange Standby.

Green(flashing) Lamp cooling untill the lamp turn on.

Operation Indicator

Lamp Indicator

Temperature Indicator

“ ”

is the warning message on screen.

Green On operation.(Turn on the lamp)

Orange(flashing) Monitor lamp is cooling as power out(1 minutes)

Off Power off.

Red to be replaced with a new lamp.(over 10000 hours)

Red(flashing)

Green(flashing) The lamp cover is not closed.

Red

Red(flashing) Power has turned off due to problem with the

Green(flashing) internal cooling fans. Contact your service center.

(for 25 seconds)(Refer to P.18)

Monitor lamp is reaching the end of its life and needs

“Replace the Lamp”

The monitor has trouble in the lamp or around it.

Contact the service center.

The monitor is turned off due to its high temperature.

Contact your service center.

Page 6

- 6 -

Rear Connecting Part

Rear Connecting Part

RGB IN3(DVI-I)

(12V/0.5A)

RGB IN1 RGB IN2 RGB OUT

DC OUT

RGB IN3

(DVI-I)

VIDEOS-VIDEO

RS-232C

RS-232C

PONENT

COM-

YPBPR

RL

MOUSE

MIC

RGB IN1

RGB IN2

RGB OUT

MOUSE

RS-232C

RGB IN1 RGB IN2 RGB OUT

RGB IN3(DVI-I)

(12V/0.5A)

VIDEOS-VIDEO

RS-232CRGB IN3(DVI-I)

PONENT

MOUSE

MIC

DC OUT

COM

R L

MIC

DC OUT(12V/0.5A)

*Use this jack when

connecting the

wireless receiver to

the monitor.

S-VIDEO

VIDEO

YPBPR

COMPONENT

B, PR)

(Y, P

R, L

Page 7

- 7 -

POWER

SOURCE

MENU

L

R

ZOOM

MUTE

LASER

Remote Control

MOUSE DRAG

VOL.

STILL

ARC

AUTO

AVL

DASP

APC

MIC

Remote Control

POWER Button

SOURCE Button

MENU Button

MOUSE DRAG

L MOUSE Button

(Zoom-out Button)

ENTERA Button

ZOOM Button

LASER Button

R MOUSE Button

(Zoom-in Button)

POINTER Button

MUTE Button

* Switches the sound

on or off.

Button

VOL. +, - Button

STILL Button

ARC Button

AUTO Button

AVLButton

DASP Button

APC Button

MIC Button

Button

Button

Function

Function

POWER Button Selects ON/OFF of power.

SOURCE Button Switches to RGB1/2/3, Video, S-Video, Component mode.

MENU Button Displays or hides the menu.

L MOUSE Button * Corresponds to the Left - Click of PC Mouse.

(Zoom-out Button) * Downsizes the screen on the zoom function.

R MOUSE Button * Corresponds to the Right - Click of PC Mouse.

(Zoom-in Button) * Enlarges the screen size on zoom function.

POINTER Button * After selecting menus, controls selecting and adjusting

functions with the direction of up, down, left, right.

* Moves the screen with the direction of up, down, left, right

on zoom function.

* Moves and releases the selected icon on PC screen.

MOUSE DRAG Button Uses to select and drag an icon in PC mode.

ENTERA Button Checks the present mode and sets the change of functions.

ZOOM Button Refer to page 34.

MUTE Button Cuts off audio.

VOL.(+, -) Button Adjusts volume level.

STILL Button

ARC Button

AUTO Button

AVL Button

DASP Button

APC Button

MIC Button

LASER Button Projects a bright red laser point on to the screen for indication

purposes.

(Don’t look at laser beam directly as it will cause eye

damage.)

Page 8

- 8 -

Accessories

Accessories

POWER

MENU

SOURCE

L

R

ZOOM

MUTE

LASER

Remote Control

1.5V

1.5V

Batteries 2 (size AA)

Audio/Video Cable

DVI cable

Computer Cable

Mouse Connecting Cables

PS/2 Mouse Cable

(IBM PC or Compatible)

Optional Extras

* Contact your dealer for buying these items.

* Contact your dealer for replacing a new lamp.

S-Video Cable

Lamp

Operating guide

MAC Serial Mouse Cable

Page 9

1. Application Object

This instruction is for the application to the LCD projection Monitor.

2. Notes

(1) The power source insulation of this LCD Projection TV is

not charging type and you may not use the transformer for

insulation. But you better adjust the set after operating it

with insulation transformer between power supply cable

and input part of the set for protecting the adjusting equipment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25!5°C of temperature and 65!10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

(5) The set must be operated for 5 minuets preliminarily

before adjustment if there is no specific designation.

The preliminary operation must be performed after receiving 100% white pattern, but reception of the moving picture may also be possible in unavoidable case.

3. DRIVER Voltage Adjustment

All adjustment mode are entered by pressing the IN-START

key on the remote control, after adjustment press the ENTER

key to come out.

(1) Required Test Equipment

1) Output voltage measurement Jig : 1EA

2) PC Patteren generator : 1EA

3) Aremote control for adjustment

(2) Setting of Devices

(3) Preparation for Adjustment

1) Connect the PC pattern Generator with the RE-01JB set

as Fig.1

2) Adjust the PC pattern generator to XGA60Hz.

3) Press the INPUT SELECTION key(TV/AV) to select the

RGB1 input.

4) Install the Main Board of RE-01JB to the set JIG.

(4) Sequence of Adjustment (VREF&VMID)

1) Turn the set on.

2) Use the IN-START key on the R/C for adjustment to select

'Drive LCCOM Adjust' in adjustment menu.

3) Adjust voltage of VREF and VMID for each R,G,B. ( SEE a

Table below)

4) Press the ENTER key on the R/C for adjustment to store

the adjustment value when adjustment is finished.

4. EPLD Programming

(1) Required Test Equipment

1) Byteblaster

2) PC (or Notebook): 1EA

3) EPLD Program

(2) Sequence of Adjustment

1) Connect one port of Byteblaster to the Parallel Port and

connect another port of Byteblaster to P1201 of Sound

Board.

2) Turn the SET and PC on.

3) Operate an EPLD program of PC(or Notebook).

5. Signal adjustment of LCD control

5-1. LCCOM ADJUSTMENT

(1) Required Test Equipment

1) Pattern generator which can generate each R,G,B signal

of fined horizontal bar pattern.

2) Aremote control for adjustment : 1EA

(2) Sequence of Adjustment

1) Turn on the power supply of JIG for adjustment.

2) Adjust the PC pattern generator to XGA60Hz and fined

horizontal bar pattern and then connect to the SET.

3) Press the INPUT SELECTION key on the R/C to select

RGB.

4) Press IN-START key on the R/C for adjustment to enter

adjustmet mode.

5) Select LCCOM adjustment menu.

6) Use the VOLUME key to make the fewest screen FLICKER with watching screen. (Adjust individually after

inputting each RGB input signal.)

7) Press the ENTER key to come out of adjustment mode

when adjustment is finished.

5-2. NRS ADJUSTMENT

(1) Required Test Equipment

1) PC Pattern generator : 1EA

2) Aremote control for adjustment : 1EA

(2) Sequence of Adjustment

1) Turn the Power supply on.

2) Adjust the PC pattern generator to XGA60Hz and 16Gray

pattern and then connect the PC pattern generator to SET.

3) Press the INPUT SELECTION key on the R/C to select

RGB.

Adj.Value

The minimum value which is over 9.5V

7.0V

VREF

VMID

IC1808 PIn 14

IC1808 PIn1

- 9 -

Adjustment Instructions

R G B

(fig. 1) Voltage adjustment Set

MONITOR

Voltage

measurement

JIG

RGB

Board

SET JIG

PC Pattern

Generator

Page 10

4) Press the IN-START key on the R/C for adjustment to

enter adjustment mode.

5) Select NRS adjustment menu.

6) Use the VOLUME key to make the fewest vertical lines on

the screen with watching screen.

7) Press the ENTER key to come out of adjustment mode

when adjustment is finished.

6. Factory Default&RGB Gain/Offset

Adjustment

(1) Required Test Equipment

1) Pattern generator : 1EA

2) Aremote control for adjustment : 1EA

(2) Sequence of Adjustment

1) Adjust the pattern generator to white/black window as Fig.

Below and connect to RGB1 Input terminal of the set.

2) Select RGB1 as Input signal.

3)Press the IN-START key on the R/C for adjustment to enter

adjustment mode and select Factory Default in adjustment

mode.

4) Press the ENTER key to operate Factory Default and enter

adjustment mode again and then select AutoGain in

adjustment menu.

5) Press the ENTER key to operate AutoGain and press the

Enter key to store AutoGain when adjustment is finished.

7. Screen Position Adjustment

(1) Required Test Equipment

1) Pattern generator : 1EA

2) Aremote control for adjustment : 1EA

(2) Sequence of Adjustment

1) Connect a power source with TV Set and turn TV Set on.

2) Do heat run for 5 min and over before adjustment.

3) Input the farthest outer pattern signal into pattern genera-

tor except DTV signal (Hat or Hatch pattern which has the

farthest line) and connect to RGB1 and then select Input

signal of set to RGB1.

4) Press IN-START key on the remote control to enter the

adjustment mode.

5) Select POSITION CONTROL of adjustment menu and

then select the H POSITION in SUB Menu.

6) Adjust H-Position so that the farthest line is shown and to

be symmetrical on the end of right/left screen.

7) Select the V POSITION in Menu.

8) Adjust V POSITION so that the farthest line is shown and

to be symmetrical on the end of top/bottom screen.

9) When finishing the adjustment, get out of adjustment mode

by pressing ENTER button on Remote Control.

7. White Balance &Gamma Adjustment

(1) Required Test Equipments

1) Illuminometer (name of model : CA-100) : 1EA —>

Measure color of projecting screen center

2) Pattern Generator : 1EA —> 16 step Gray Pattern, 64 step

Gray Pattern

3) Aremote control for adjustment : 1EA

(2) Setting of Devices

7-1 Sequence of Gamma manually adjustment

1) Prepare the PC Pattern Generator which is possible to output R/G/B of 16 step and 64 step Gray Pattern.

2) Equipment composition : Follow Fig. 3.

3) Turn on the Jig for adjustment.

4) Select the RGB 1 by pressing the input select button on

Remote Control.

5) Output the 16 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

W/B is right about each Gray.

If it’s not, press the IN-START button on Remote Control

and then adjust the level data of each step manually in

sub menu of Gamma RGB.

6) Output the 64 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

W/B is right about each Gray or whether there is Gamma

noise.

If there’s any problem, press the IN-START button on

Remote Control and then adjust the level data of each

step manually in sub menu of Gamma RGB.

7) After finishing adjustment, exit adjustment mode by using

ENTER button on Remote Control.

7-2 Sequence of Gamma Auto Adjustment

1) Display the biggest WHITE PATTERN on screen and

change the 7050 R/G/B CONTRAST ( or 16th Gamma 1

R/G/B) data value of adjustment mode so that the white

balance of illumination system or illuminometer to be

x:283, y: 297(D9300K).

2) Measure the luminance value with changed data value in

clause 1.

3) Seek the luminance of each step so that each Gamma

value of 16 step to be 2.5 curve on a basis of luminance

value measured in clause 2. ( Maximum luminance *

(n1/16)** Maximum luminance : luminance measured

in clause 2)

N 1 : Each step unit (1.2.3.4,------15) when classify the signal level to 16 step.

4) Input the Gray pattern corresponding to the first luminance

and change the first adjustment mode R/G/B data value so

that the R/G/B data value to be same white balance with

1) above and luminance with 3) above.

- 10 -

PC Pattern

Generator

MW-60SZ12

Page 11

- 11 -

5) Input the Gray pattern corresponding to the second luminance and change the second adjustment mode R/G/B

data value of Gamma adjustment item so that the R/G/B

data value to be same white balance with 1) and right to

the second luminance (measured in clause 3)

6) Input pattern signal with same method above and change

the Gamma R/G/B data value of corresponding level and

make same luminance with 3) and white balance with 1).

9. Uniformity Adjustment

(1) Required Test Equipments

1) Uniformity measurement equipment

2) ARemote Control for Adjustment

3) PC Pattern Generator : 1EA

(2) Setting of Devices

(3) Sequence of Adjustment

1) Adjust the screen coordinates as shown below.

2) Output the 17th VDP Test Pattern signal(7050 MAX 640) of

No. 4 sub adjustment item maximum adjustment.

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color uniformity of max point.

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

3) Output the 16th VDP Test Pattern signal(7050 MID 570) of

No. 4 sub adjustment item(middle adjustment).

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color uniformity of mid point.

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

4) Output the 15th VDP Test Pattern signal(7050 MIN 360) of

No. 4 sub adjustment item(min adjustment).

Read the white coordinate and communicate with ET7050

IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color unifor-

mity of miner point.

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

5) White the miner, middle, maximum data for each point to

confront to each MICOM address.

10. Video Gain Adjustment

(1) Required Test Equipments

1) TV

2) ARemote Control for Adjustment

(2) Sequence of Adjustment

1) Press the INPUT SELECTION key on the R/C to select

VIDEO input.

2) Input the NTSC 13CH signal into Video input.

3) Set the set input to video (AV input).

4) Press the IN-START key on R/C for adjustment to select

'2101 Color Control1' in adjustment menu.

5) Raise the 2101 picture value to the maximum(63).

6) Use the 2101 subbright value and adjust upper 3 gradation

of Gray bar not to be distinguished.

7) Set the video channel to NTSC 6CH.

8) Press the IN-START key on R/C for adjustment again to

select '2101 Color Control1' in adjustment menu.

9) Raise the Driver G Gain to the maximum(63) and then

stop the Driver G Gain when the US 6CH is visible.

10) Make the Driver B value same with Driver G value and

make the Driver R value higher(2) than Driver G.

11) Press the ENTER key on R/C for adjustment to store the

adjustment value when the adjustment is finished.

0 1 2 3 ............xx..........15 16

1

.

yy

.

11

12

Adj.Jig

Camera

MW-60SZ12

PC Pattern

Generator

Adjust 3 gradations

not to be

distinguished.

Color Bar

Gray Bar

Adjust the these

letters not to

be saturated.

US 6CH

Page 12

11. Component Gain Adjustment

(1) Required Test Equipments

1) Signal(DTV Signal 31-3)

2) SET-TOP box( or an equipment which can generate YPbPr

output receiving DTV signal)

3) ARemote Control for Adjustment

(2) Sequence of Adjustment

1) Press the TV/AV key on the R/C for adjustment to select

component input.

2) Input DTV signal 31-3 into component input.

3) Press the IN-START key on the R/C for adjustment to

select '2101 color control1' in menu.

4) Raise the 2101 picture value to the maximum.

5) Use the 2101 subbright value and adjust lower 2 gradation

of Gray bar not to be distinguished.

6) Press the IN-START key on R/C for adjustment again to

select '2101 color control2' in adjustment menu.

7) Use the Driver G Gain and adjust 2101 G Gain so that all

gradation(11gradation) of upper Gray bar are distinguished.

8) Make the Driver B value same with Driver G value and

make the Driver R value higher(2) than Driver G.

9) Press the ENTER key on R/C for adjustment to store the

adjustment value when the adjustment is finished.

12. EDID Data INput

(1) Required Test Equipments

1) AJIg for adjusting PC,DDC.(PC serial to D-sub.connection

equipment)

2) SW for writing DDC(EDID data write & read)

3) D-sub terminal

4) D-sub /DVI conversion connector

(2) Setting of Devices

(3) Preparation for Adjustment

1) Set devices as above and turn the PC,jig on.

2) Put the S/W for writing DDC(EDID datawrite&read)into

operation.(Operated in DOS mode.)

(4) Sequence of Adjustment

1) Turn the set on and set the input to RGB1 and then connect D-sub to RGB1 input terminal.

2) nput the product code, production week/year, serial number (if it is not input, write "01") to the S/W for writing DDC.

3) Select '60RPM_A' out of DDC file.

4) Operate the EDID write command and check the

60RPM_A is writed well through the Read command.

5) Connect the DVI conversion connector to D-sub and

RGB3(DVI) input terminal of set.

6) Set the Input selection to RGB3.

7) Select '60RPM_D' out of DDC file.

8) Operate the EDID Write command and check the

60RPM_D is writed well through the Read command.

- 12 -

Adjust 2101 G Gain

so that all lumination

are distinguished.

Adjust subbright

so that 2 lumination

are not to be

distinguished.

PC

JIG

Page 13

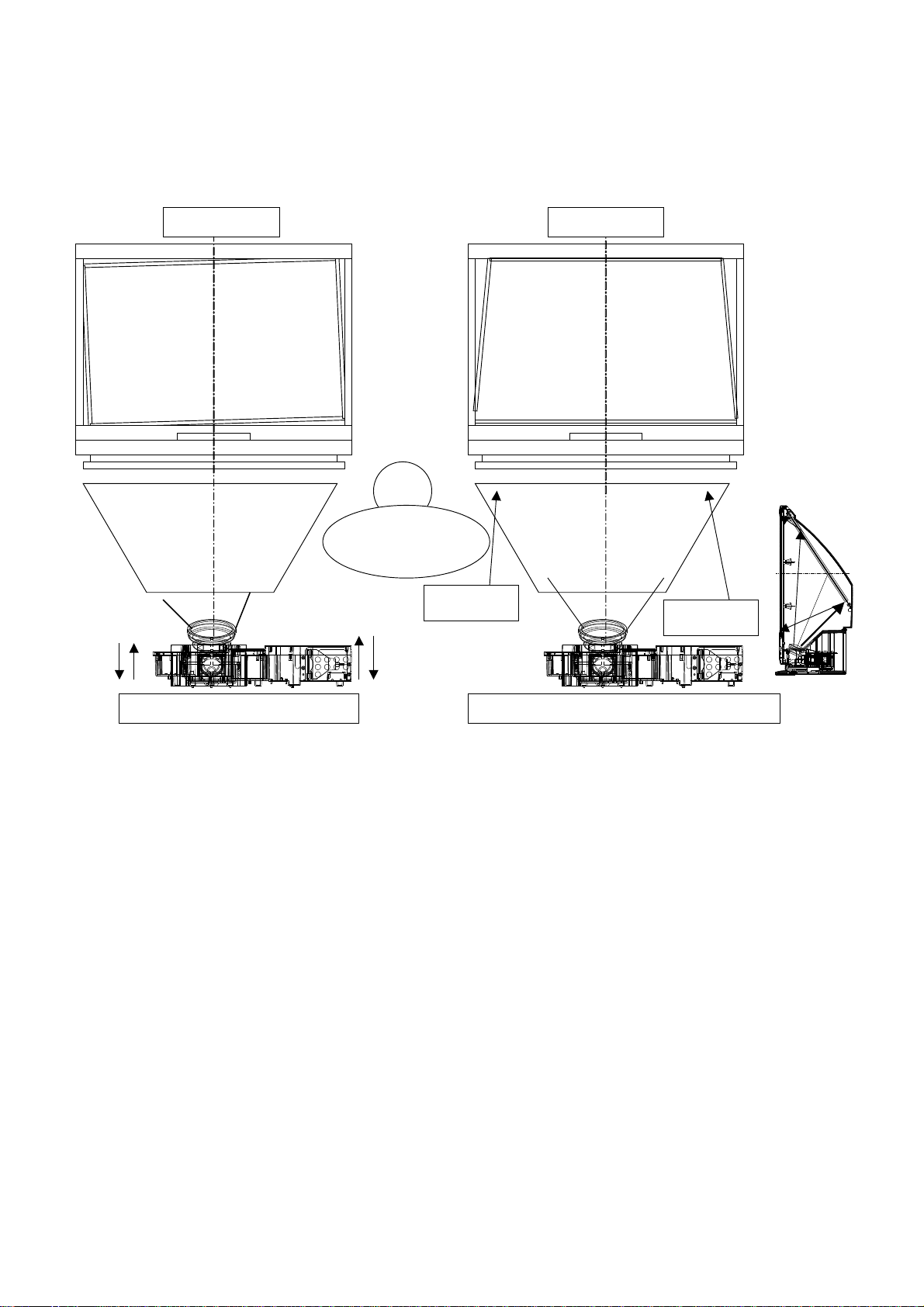

1. Screen Tilt and Keystone cause of occurrence

When the whole engin is leaned, Tilt occur and Keystone occur because of changing TCL

when projection angle of engine is different or Mirror angle is different.

- 13 -

Correction of Screen Tilt & Keystone

TILT-Up and down operation necessity

of the whole engine

Rotation and side angle operation necessity

of the whole engine

KEYSTONE-TLC is

shorter than down

KEYSTONE-TLC is

shorter than down

Mirror angle

Engine projection angle

Comm

-onness

TILT KEYSTONE

Page 14

2. New Mechanism for Adjustment

The axis of rotation of engine sets back and the whole engine enable left and right rotation, up and down, left and right angle

movement.

When turning adjustment Knob of left/right in front, engine will move.

When moving the engine base with left and right direction in front, engine will rotate.

- 14 -

Rota

-tion

Fixing Boss

Adjustment Knob

Adjustment Knob

Locking Knob

engine

engine

supporter

engine base

engine base For calculation : When

projection lens 0.2c leans,

Keystone occurs 5mm.

engine base

The axis of rotation

The axis of rotation

Side angle

Left/Right

angle

pole

Page 15

3. Working Method and Improvement for Correction Mechanism of Tilt and Keystone

3.1 Working Method

(1) Put the 3t spacer on back of down parts of Mirror to correcting the Mirror angle of down parts

- To correct difference between Mirror angle of C/Aand JIG angle of lighting parts.

(2) Looking at the screen, push the engine base for left/right direction in front of engine. At this time,

check the screen Keystone condition.

(3) Adjust engine angle by turning the adjustment Knob on the down part.

(4) If Tilt and Keystone is [MAX-MIN] # 4mm, lock the locking Knob of left/right in front part and then fix

the fixing boss with screw.

3.2 Improvement

When turning left and right rotation, because an engine construction structure is tuched a construction

structure of cabinet, shield case will be correction. When turning adjustment Knob, operation is bad

because you cann’t input a hand to turning or adjustment Knob is tight.

Continously consult with the production department for improving adjustment operation. (A special

Driber for adjustment and so on)

- 15 -

3t spacer

engine base

engine

Fixing Boss

Adjustment Knob Adjustment Knob

Page 16

* Connect your dealer or LG service center for replacing of new lamp.

You must replace the lamp when:

¯ The projector image get darker or start to be deteriorated.

¯ The lamp indicator is red(red, flashing alternately).

¯ The massage “LAMP REPLACE“ appears on the screen when turning the projec-

tor lamp on.

* Replace the lamp as below sequence

1. Turn off the projector and unplug the power cable.

(Cool the lamp for more than 1 hour.)

2. Remove the four retaing screws on the lamp cover with a screwdriver of “+“ type

and then lift off the lamp cover.

3. After lifting the lamp cover off, remove the two retaing screw on lamp case with

screwdriver of “-“ type. (refer to fig.2)

4. Lift up the fixed wire handle of the lamp. (refer to fig.3)

5. Pull out the handle slowly and remove the lamp case.

6. Insert the new lamp gently into the correct position. Make sure it is inserted correctly.

7. Tighten the screw you removed in step 3.

8. Replace the lamp cover and tighten the cover screws.(Make sure the almp cover

is securely fastend. If lamp cover is open, the lamp indicator flashes green and

the projector is not turn on.)

* Resetting the lamp time

After pressing the “?“ key on the remote control in Stand-By mode, press the “9876“

and press the “OK“ button.

And then three LED in the front is stop after flashing for a moment.

* Lamp Life Time Confirmation

1. Method1 : Enter ADJ mode with using the remote control. You can be confirmed

because “ Lamp Life Time XX hr“ is appeared.

2. Method2 : With using the remote control offerd to consumer if you press the

menu button continuously, OSD menus will disappear then press the “9876“ and

press the “OK“ button to enter ADJ mode you can see “Lamp Life Time XX hr“

- 16 -

Replacing the Lamp

< Fig. 1>

< Fig. 2>

< Fig. 3>

Page 17

1. Power Block

Circuit is to use the FLYBACK CONVERTER way for insulation basically and composed of HYBRID IC STR F6658B for

switching power, which has a POWER MOSFET within, and

STR G6153 as the circuit for stand-by. And it is operated by

the ERROR AMP (IC802, SE105) which transfers electric signal in output part to the primary part with insulating primary

and secondary part.

1.1 Block Diagram (STR F6668B)

1.2 Pin Description

1.3 Others

1.4 Function & Description of each terminals

(1) Vin terminal (4 PIN), Start circuit

The Start circuit performs the operation start and stop of control IC by voltage of Vin terminal (4 PIN).

In power start, C2 is charged through the start resistor Rs.

If the Vin terminal voltage reaches 16V (TYP), control IC

starts operating and current increases by the operation of

Start circuit. If this voltage decreases and reaches lower than

10V (TYP), the control IC stops and returns initial states by

the operation of UVLO (operation stop circuit).

The control circuit gains power by rectifying the trans wire

wound D after operation.

As the voltage of trans wire wound doesn’t go up to the set

voltage just after operation, the Vin terminal voltage begins to

decrease. But as the voltage of operation stop is set to 11V

(Max), the voltage of trans wire wound reaches the set value

and control IC keeps operating while the Vin terminal voltage

decreases to the voltage of operation stop.

The Vin Start voltage (Terminal 4) is 16V (TYP), the voltage

of operation stop is 10V (TYP) and the Vovp voltage is 22.5V

(TYP).

(2) OCP / FB terminal (Terminal 1), Oscillator

and Constant voltage control circuit

The oscillator is to use charge or discharge of internal condensor C1 and to select PRC (Pulse Ratio Control) which

fixes off time of MOSFET and changes on time of it.

The voltage regulator Vr4, which is generated when the FB

current through Photo Coupler flows in R4, is approved by

Vr5. Because of this, Comp. 1 reverses and needed voltage

value of Vr5 (peak value of Id) is supplied from Vr4(FB current). Like this Output control is current mode control.

(3) OCP / FB terminal (Terminal 1) and OCP circuit

OCP circuit is the Protection circuit against over-current

which selects the pulse by pulse way. This way is to reverse

oscillator output by detecting peak value of MOSFET drain

current every pulse.

Detecting MOSFET drain current is done by connecting R5

with MOSFET source terminal (Terminal 2) and GND terminal

(Terminal 3) and by inputting regulated voltage to OCP/FB

terminal. The threshold voltage Vth (1) of OCP terminal is

about 0.73V compared with GND. External components R4

and R5 are Filter circuit to protect malfunction by surge current which is generated in MOSFET On.

- 17 -

Description of each Block Circuits

1

2

3

4

5

O.C.P/F.B

S

D

Vin

GND

No.

Symbol Name Function

Input signal of detecting

over-current & to input

signal for controlling constant voltage.

Over-current

/Feed-Back

terminal

MOSFET sourceSource

terminal

MOSFET drainDrain

terminal

Input control circuit powerVoltage input

terminal

GroundGround

terminal

Symbol Function

O.V.P Internal Protect circuit against over-voltage

T.S.D Internal Protect circuit against overheat

Start Circuit Vin terminal voltage waveform

Vcc

5

START

Internal Bias

Reg1 (9.4V)

Reg2 (7.2V)

Reg3 (7.2V)

TSD

Internal Bias

Internal Bias

Counter

OVP

OSC

Mirror

FB Current

Detector

4

FB

Latch

S

R

Q

FB OCP

Drive

Buffer

Amp.

1

D

2

OCP

3

GND

Vcc

5pin)

Internal Bias

Reg.

Icc

15mA(TYP)

13mA(TYP)

70µA(MAX)

20VVcc(ON)Vcc(OFF) 15V

Vcc

Page 18

In light load, if output voltage decreases, the trans wire

wound voltage in primary part also decreases proportionately

and the Vin terminal voltage in primary part reaches lower

than operation stop volate so that OCP circuit stops operating. In this case, the circuit current decreases so that the Vin

terminal voltage increases in proportion to charge current by

start resistance Rs again and intermittent operation occurres

which restarts in operation start voltage.

The advantage of adding the Protection circut against overcurrent is as follows. When input voltage is high, the surge

voltage becomes low by controlling MOSFET drain current

low and stress of voltage in MOSFET becomes less in start

and overload.

And stress of current in secondary Diode can be also less by

controlling output voltage regular.

(4) Latch circuit

Latch circuit is to stop power circuit operating by keeping the

output of oscillator low in operating of two circuits (OVP &

TSD) which protect Over-voltage and overheat.

Latch circuit is to protect malfunction caused by noise etc..

And this circuit starts to function when OVP and TSD operates for more than 8 seconds. In this case, delay time is set

by timer circuit in control IC.

Though Latch circuit operates, Constant voltage power (Reg)

circuit in control IC is also operating and the circuit current is

high. So the Vin terminal voltage decreases rapidly.

If the Vin terminal voltage becomes lower than operation stop

voltage 10V (TYP), circuit current becomes below 400uA and

the Vin terminal voltage begins to increase. On the contrary, if

the Vin terminal voltage reaches operation start voltage 16V

(TYP), circuit current begins to increase and the Vin terminal

voltage begins to decrease.

In other words, the Vin terminal voltage rises and falls

between 10V (TYP) and 16V (TYP).

Like this, the latch circuit protects the Vin terminal voltage

from increasing abnormally.

Releasing latch circuit is done by making the Vin terminal

voltage lower than 6.5V and generally latch circuit is restarted

after cutting AC input.

(5) Protect circuit against overheat

This circuit lets latch circuit operate when the frame temperature of Hybrid IC is above 140°C(Min).

Actual temperature is detected by control circuit element. This

is to protect MOSFET from overheat which is caused by the

system that MOSFET and control circuit element are on the

same frame.

(6) Protect circuit against over-voltage

This circuit lets latch circuit operate when the Vin terminal

voltage exceeds 22.5V (TYP) and this is used to protect the

Vin terminal in control circuit from over-voltage.

Commonly the Vin terminal is supplied with subsidiary wire

wound of Trans and this voltage is in proportion to output

voltage so that this Protect circuit against over-voltage operates in over-voltage output in secondary part when the circuit

of detecing voltage is open.

1.5 STR G6153T(ST-BY STR)

(1) Description of each terminals

Others

(2) Operation stop circuit (UVLO)

This begins operation control if voltage is supplied to low subsidiary current terminal (Vcc) 5PIN.

If the supplied voltage in the same terminal reaches operation

start current voltage (Vcc), 17.5V (TYP), current is supplied to

circuits within IC and then the operation stop circuit (UVLO)

begins operaiton control and high impedence is sustained

until the supplied voltage reaches the same voltage. In this

time, the supplied current is circuit current (Icc) in not operating and it is 70Ua (Max).

If the operation stop circuit begins operation control, circuit

current (Icc) in operation, about 15mA flows in the same terminal. In controlling operation, if the supplied voltage in this

terminal goes below operation stop current voltage (Vcc),

11.5V (TYP), IC stops functioning.

Like this, this terminal plays a roll to detect supplied voltage

and to control operation start in low voltage input.

(3) Internal Oscillator (OSC)

Condernsor to determine oscillation frequency : Ct

If IC begins operating, Ct is charged from internal power by

constant current I1. At this moment, both SW1 and SW2

become open.

If electric potential of charge reaches about 4V, comparator

reverses, and SW1 and SW2 are on simultaneously.

If setting the state that I1 is lower than I2, SW1 becomes on,

Ct gets discharged and Vt decreases.

Oscillation is made by these operations.

Maximum Duty cycle of oscillator is set to 80% (TYP) and frequency is set to 100KHz (TYP). Globular shaped wave output

of Comparator is used as timing clock in internal circuit and

triangle shaped wave output is used as standard signal for

transforming pulse width which will be mentioned later.

- 18 -

1

2

3

4

5

D

OCP

GND

FB

Vcc

No.

Symbol Name Function

MOSFET drainDrain

terminal

Input signal of detecting

over-current in primary

part

Over-current

terminal

Ground

Ground

terminal

Input signal of controlling

constant voltage

Feed-Back

terminal

Input control circuit power

Power

terminal

Symbol Function

OVP Protect circuit against over-voltage

OLP Protect circuit against overload

TSD Protect circuit against overheat

SS Soft start function

Page 19

(4) Control mode (PWM Latch / Feed Back)

Control mode of IC uses MIX Mode which is switched to the

voltage control mode in lightload and and current control

mode in heavyload linearly according to load.

MIX control mode operates PWM control comparing standard

triangle shaped wave with current waveform piled up on DC

FB voltage. So input voltage difference of PWM Comparator

in waveform cross becomes bigger and as a result, stable

PWM signal is gained.

In MIX control mode, enough noise margin can be obtained

with changing voltage PWM of standard triangle shaped

wave. Also,even in continuation inductor mode in which On

Duty is over 50%, Sub-harmonic phenomenon is suppressed

and every essential part of internal oscillator becomes optimum.

(5) Protect circuit, Protect circuit against over-voltage,

Protect circuit against overheat (OLP/OVP/TSD)

1) Protect circuit against overload

This IC has protect circuit against over-current which

detects over-current every pulse.

In over-current, FB system cuts Photo Coupler for FB off

because output voltage doesn’t reach set voltage.

If detecting “Over-current Detector” signal and the “FB

Current Mirror Detector” signal, internal timer count starts

operating 655ms later after detection.

Just after overflow, the “Count Out” signal is output and at

the same time previous operation is stopped. In this state,

main switch is fixed to off and latch circuit starts operating.

Also, in latch operation, latch circuit needs 400uA (Max)

for maintenance and this current is influenced by the electric potential of Vcc terminal.

If the supplied voltage in Vcc terminal goes below power

voltage for releasing latch circuit, 8.7V (TYP), latch operation can be released. When this latch operation is

released, this IC begins start operation from Soft Start.

2) Protect circuit against over-voltage

If the supplied voltage in subsidiary power terminal (Vcc)

of this IC exceedes 22.2V (TYP), oscillation operation is

stopped by the protect circuit against over-voltage, and in

this state, main switch is fixed to off and latch operation

begins.

* power voltage Vcc(ovp) for OVP operation = 22.2V (TYP)

3) Protect circuit against overheat

When the temperature of internal chip reaches 150°C

(TYP), oscillation operation stops. In this state, main

switch is fixed to off and latch operation begins.

(6) Soft Start, Protect circuit against over-current

1) Protect circuit against over-current

In main switch’s on, drain current is monitored. If drain current over standard value is detected, main switch is

switched to off immediately. This drain current detection is

performed every time main switch is on. The standard voltage in OCP terminal is 0.75V (TYP).

2) Soft Start function

Aa this IC has Soft Start function which is Timer way,

external condensor for Soft Start is unnecessary.

Soft Start function is performed by increasing standard

voltage for detecting over-current step by step and by controlling current in main switch.

There are 4 steps and voltage level and continuant time of

each steps are fixed inside. Table SS(1) ~ SS(4) shows

this.

- 19 -

Symbol

Vss(1)

Vss(2)

Vss(3)

Vss(4)

MIN

0.16

0.35

0.51

0.63

TYP

- -

- -

- -

- -

MAX

0.35

0.54

0.68

0.75

Page 20

2 MSP3410G : Sound Block

(1) Introduction

The MSP 3410G family of single-chip Multistandard Sound

Processors covers the sound processing of all analog TVStandards worldwide. The full TV sound processing, starting

with analog sound IF signal-in, down to pro-cessed analog

AF-out, is performed on a single chip.

Figure shows a simplified functional block diagram of the

MSP 3410G.

Surround sound can be reproduced to a certain extent with

two loudspeakers.

These TV sound processing ICs include versions for processing the multichannel television sound (MTS) signal conforming to the standard recommended by the Broadcast

Television Systems Committee (BTSC).

The DBX noise reduction, or alternatively, MICRONAS Noise

Reduction (MNR) is performed alignment free.

The MSP 3410G has built-in automatic functions: The IC is

able to detect the actual sound standard automat-ically

(Automatic Standard Detection). Furthermore, pilot levels and

identification signals can be evaluated internally with subsequent switching between mono/stereo/bilingual; no I

2

C inter-

action is necessary (Auto-matic Sound Selection).

(Fig Simplified functional block diagram of the MSP 3410G)

(2) Features

• Automatic Standard Detection of terrestrial TV standards

• All NICAM standards

• All Analog FM-Srereo A2 standards

• Simultaneous demodulation of high-deviation FM-Mono and

NICAM (China)

• Very high-deviation FM-Mono mode(China,Eutelast,etc.)

• FM demodulation of all analog satellite standards.

• ADAPTIVE deemphasis for satellite(According to ASTRA

specification)

• ASTRADigital Radio(ADR) together with DRP3510A.

(3) Sound IF Processing

1) Analog Sound IF Input

The input pins ANA_IN1+, ANA_IN2+, and ANA_IN-offer

the possibility to connect two different sound IF(SIF)

sources to the MSP 3440G. The analog-to-digital conversion of the preselected sound IF signal is done by an A/Dconverter. An analog automatic gain circuit(AGC) allows a

wide range of input levels. The high-pass filters formed by

the coupling capacitors at pins ANA_IN1+ and ANA_IN2+.

2) Demodulator: Standards and Features

The MSP 3440G is able to demodulate all TV-sound standards worldwide including the digital NICAM system.

Very high deviation FM-Mono: Detection and robust

demodulation of one FM carrier with a maximum devi-ation

of 540 kHz.

- 20 -

Page 21

(3) Block Diagram

- 21 -

Fig Signal flow block diagram of the MSP 3410G(input and output names correspond to pin names)

Page 22

3. LCD Driver Part

3.1 E07050K0A : Video Signal Processor IC for TFT-LCD

(1) Scope

These specifications apply to the E07050K0A CMOS IC.

<Feature>

1) Operation clock frequency Max. 85 MHz

2) RGB swap function (RGB three-system set's video signals can be swapped via external settings)

3) Contrast and brightness adjustment functions

4) Ten-bit digital gamma correction function (look-up table type with interpolation process)

5) Image quality improvement function

(Vertical stripes correction, ghost image correction, horizontal crosstalk correction)

6) Built-in OSD function (2 bits • 3 systems, 1 control pin)

7) Output masking of video signals is enabled

8) Color uniformity correction function (look-up table type with interpolation process)

Enables setting of correction data for three brightness levels or four brightness levels.

Two types of screen correction segments (32 horizontal segments • 24 vertical segments or 16

horizontal segments • 12 vertical segments).

9) Enables insertion of reference signal in video signal.

10) Outputs drive signal for panel

11) Data is set via three-wire serial interface

12) Built-in boundary scan function

13) 176-pin (24 mm • 24 mm) QFP package

(2) Block Diagram

- 22 -

rect

ROUT(9:0)

GOUT(9:0)

BOUT(9:0)

HPLL

HRESETO

VRESETO

ENBY1 - 2

DXOUT(R:G:B)

ENBX3(R:G:B)

ENBX4(R:G:B)

ENBX1(R:G:B)

ENBX2(R:G:B)

DYOUT

CLXOUT(R:G:B)

CLYOUT

FRP(R:G:B)

SHCLK(R:G:B)

XFR(R:G:B)

STSQE(R:G:B)

STSQO(R:G:B)

NRG

CLP 1~2

10bit

RIN[9:0]

Reference

voltage

Color

Uniformit y

correct

correct

Picture

quality

V. line cor

H. crosstalk

Ghost

Video

mask

Gamma

cor-

Contrast

Bright

OSD

10bit

10bit

BIN[9:0]

GIN[9:0]

OSDBIN[1:0]

OSDRIN[1:0]

OSDGIN[1:0]

OSDSW

Timing

generator

Range of Video p rocessingUnitdescribed in Chapter8.

Serial

interface

SCS

SCLK

SDATA

HSYNC

VSYNC

DCLK

SELECT

Page 23

3-2 E06070D0A : Video signal conversion IC

for TFT-LCD

(1) Scope

The E06070D0A provides a fast, 10bit latched decimating

digital input, which drives 6

channel high voltage drive outputs. Flexible digital input formats, allow several

L3E06070D0As to be used in parallel for higher resolution

displays.

<Feature>

(1) Operation clock frequency :85 MHz

(2) 10-bit digital video signal input

(3) Digital serial parallel conversion (6-ch output)

(4) Built-in D/A converter (10 bit)

(5) Built-in amplifier for video signal polarity inversion

(6) High slew rate output: Typ. 265 V/µs (can drive a TFT

panel directly)

(7) Wide output dynamic range of 1.5 to 13.5 V

(8) Built-in function for switching scan direction

(9) Low power consumption

(10) 48-pin (7x7 mm 2 ) QFP package

(2) Pin Layout

(3) Block Diagram

- 23 -

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9(MSB)

CLK

47

48

1

2

3

4

5

6

7

8

9

10

11

12

141516171819202122

13

E/O

XFR

46

R/L

STSQ

45

INV

DGND

43

44

DVCC

AVCC(DAC

41

42

VREF

AGND(DAC

40

BYP

STBY

VMID

VMID

38

39

23

AGND1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

VID1

AVCC1,2

VID2

AGND2,3

VID3

AVCC3,4

VID4

AGND4,5

VID5

AVCC5,6

VID6

AGND6

CLK

STSQ

XFR

E/O

R/L

STBY

BYP

VREF

VMID

10

CHANNEL

SELECTOR

BIAS

SCALING

CONTROL

DB[0:9]

2-Stage

Latch

10 10

2-Stage

Latch

10 10

2-Stage

Latch

10 10

2-Stage

Latch

10 10

2-Stage

Latch

10 10

2-Stage

Latch

1010

DAC

DAC

DAC

DAC

DAC

DAC

VMIDINV

VID1

VID2

VID3

VID4

VID5

VID6

AGND(BIAS)

AVCC(BIAS)

Page 24

3.3 E01031F0A : TFT-LCD Level Shifter IC

(1) Scope

The L3E01031F0A is an interface IC for driving TFT active

matrix panels with built-in drivers. Its high

voltage circuit acts as an interface between the control IC

and the drivers on the LCD panel.

<Feature>

(1) Clock Frequency Max. 4.2 MHz

(Care is required to avoid exceeding the allowable power

dissipation for the package, which is 280mW.)

(2) Internal level shift circuit converts input to a signal capable

of driving a TFT panel.

(3) Built-in multiplex function to switch the panel auxiliary signal.

(4) CMOS Si-Gate process.

(5) 48-pin plastic flat package (lead pitch 0.5mm QFP).

(6) Does not feature radiation resistant or light and noise

resistant design.

(2) Pin Layout

- 24 -

(3) Block Diagram

Page 25

- 25 -

DESCRIPTION OF MICOM

1. Feature of MICOM Function

1-1. Signal Selection

(1) Input signal selection : RGB1(Analog)/RGB2(Analog)/RGB3(Analog/Digital)/Video/S-Video/Component

(2) A/V color standard automatic signal selection : NTSC/PAL/SECAM/NTSC 4.43/PAL M/PAL N/PAL 60

-> Automatic system detection

(3) Specification of PC input signal : Refer to “PC Input Specification Table”.

(4) Specification of Component input signal : 480I,480P,DVD 625Line,576P,720P,1080I 50Hz,1080I 60Hz

1-2. Video Interpolation Extension, Compression Support

You can control the correspondent IC like scaler after discrimination of input signal. If the resolution is lower than

XGA, you can extend it to the XGA scale. Or if it is higher than XGA, you can compress it to XGA scale.

* Resolution : Set the resolution lower than 1280x720 in order to adjust the picture of panel (resolution:1280x720) to the screen.

1-3. Judging No Signal

OSD,SOUND Mute

1-4. Video Signal Adjustment

(1) Analog RGB(PC) input : Contrast, Brightness, Color(R, G, B)

Clock, Phase, H Position, V Position

(2) Digital RGB (DVI) input : Contrast, Brightness, Colorr(R, G, B)

Clock, Phase, etc. are automatically adjusted on auto tracking mode, but noise can be included in the signal

owing to the IC specification and also they can’t be adjusted precisely according to the signal pattern.

So the manual to adjust Clock, phase, etc. manually.

1-5. Sound Signal Adjustment

Volume, Mute,DASP,AVL,MIC

1-6. Other Functions

Item

ARC(Aspect Ratio Control)

ZOOM

Checking Lamp Time

OSD Language Selection

Auto Tracking

Set ID

APC(Auto Picture Control)

Audio Input

Analog/Digital RGB :4:3,16:9 mode Toggle funtion

Video/S-Video/Component :4:3,16:9 ,zoom 1,zoom 2,zoom 3 mode Toggle funtion

Adjusting the magnification of zoom by shortened key.(+/- 25 level)

Checks used time to now and displayes the fact when replacing time gets.

Korean, English, French, German, Italian, Spanish, Chinese,Japanese

Automatically controlling CLOCK, PHASE

Characteristic number of set which is used to adjust the funtions of set with PC by

connecting RS-232C terminal(1~99).

When the Set ID specified in PC P/G accords with the set ID specified in the

set,the funtions of set can be controlled by using the menu of PC P/G.

By using this menu,you can select “clear”,”soft”,”comfortable” or “off” in Video,SVideo,Component.

By using this menu,make speaker output by selecting audio input R/L or Mic.

And you can use R/L by connecting the stereo output from DVDP or STB.

REF

1-7. Controlling Power

(1) ST-BY -> Power On key in -> Main Power On -> Fan Off -> Blue Background -> Lamp On

-> LOGO ON -> Video output or No signal

(2) Power Off key in -> Lamp Off -> Audio mute -> Fan Off -> Main Power Off -> ST-BY

1-8. Data Saving

EEPROM(24C256), EEPROM IIC BUS

Page 26

- 26 -

1-9. Warning OSD and Controlling LED

Operation indicator LED Orange 7 Stand-By

Orange(flashing)

Green 7 Run

Green(flashing)

Off

Lamp Indicator LED Red

Red(flashing)

Green(flashing)

Temperature indicator Red

LED Red(flashing)

Green(flashing)

7 lamp is cooling as power out(1 minutes),Ignore the power on input.

7 7 Sec. : Cooled for a minute before turning off the lamp.

7 25 Sec. : Didn’t cool the lamp for a minute while turning off the lamp.

7 Off (the state that AC S/W is off or the Power cable isn’t connected)

7 Warning the life of lamp, Needing to replace the lamp ( over 10000H)

7 Displaying OSD for lamp warning when power on.

7 Lamp on error. ( case of lamp isn’t on when power on )

7 Turn on the lamp and start the detect after 5 seconds.

When occuring error,turn off the lamp at once.

7 Warning of lamp case open

7 Power off forcedly, Not Power on

7 High temperature.Power off

7 Warning of fan1 malfunction. (Perceived after 20 ~ 60 seconds because it takes a

little time to check internally. )

7 Warning of fan2 malfunction. (Perceived after 20 ~ 60 seconds because it takes a

little time to check internally. )

1-10. Checking and Initiating the Lamp Time

Used lamp time is displayed on the menu.

(1) Over 10000 hours : Informs warning.(Red LED), Displaying warning OSD when power on.

If you don’t initializing the lamp,it is always display warning OSD on screen when turning on the lamp.

(2) Initiation : Used time must be initiated by the user after replacing the lamp.

You can move to the next service menu by pressing the “MENU” key,and when you press the “MENU” key

continuously,you can move to “LAMP TIME RESET” menu.

If you press the “+” key (VOL+) in this menu,the user lamp time is reset.And then press the “ENTER” key to come out

of service menu.

Caution : Changing the set value in other menus besides “LAMP TIME RESET” or input other keys besides “MENU” key can cause

serious problem to the lamp.Always use the “ENTER” key to cancel the service menu in “LAMP TIME RESET” menu.

1-11. Remote Mouse Control

(1) Funtion the mouse of PC.

(2) Apply the 16 directions and left,right click/drag.

(3) Apply the function of the PS/2,MAC Mouse.

1-12. DDC1/2B

Use the specified IC-24LC21 for DDC1/2B to write EDID table data on 24C21 through adjustment Zig.

Page 27

- 27 -

1-13. Micom Controlled IC’s

Chip Name

24LC256

MSM82C55

PW164

VPC3230D

FLI2200

ET7050

M62320

AD9884

M62352

AT24LC21

EEPROM

PORT EXPANSION IC

MICOM EMBEDDED

SCALER IC

VIDEO DECODER

VIDEO DEINTERLACE IC

TIMING GENERATOR

GAMMA/COLOR UNIFORMITY

I2C Controlled OUTPUT PORT

ADC

DA CONVERTER

DDC 1/2B

1-14. PC Input Specification Table

O HD sigal(D-Sub 15pin input)

(1) 280X720,60Hz/59.94Hz

(2) 1920X1080,Interface 60Hz/59.94Hz

Function

VGAEGA

PC98

(VGA Text)

VGA

Resolution

640 x 350

640 x 350

640 x 400

720 x 400

720 x 400

640 x 480

640 x 480

640 x 480

640 x 480

640 x 480

Vertical Frequency

70.090Hz

85.080Hz

85.080Hz

70.082Hz

85.039Hz

59.940Hz

72.800Hz

75.00Hz

85.008Hz

100.040Hz

Horizontal Frequency

31.468KHz

37.861KHz

37.861KHz

31.469KHz

37.927KHz

31.469KHz

37.861KHz

37.500KHz

43.269KHz

53.011KHz

Page 28

- 28 -

Resolution

Vertical Frequency

Horizontal Frequency

SVGA

XGA

SXGA

800 x 600

800 x 600

800 x 600

800 x 600

800 x 600

800 x 600

1024 x 768

1024 x 768

1024 x 768

1024 x 768

1024 x 768

1152 x 864

1152 x 864

1152 x 864

1152 x 864 *

56.250Hz

60.317Hz

72.188Hz

75.00Hz

85.061Hz

100.00Hz

43.479Hz

60.004Hz

70.069Hz

75.029Hz

84.997Hz

60.053Hz

70.016Hz

75.00Hz

85.057Hz

35.156KHz

37.879KHz

48.077KHz

46.875KHz

53.674KHz

64.016KHz

35.522KHz

48.363KHz

56.476KHz

60.023KHz

68.677KHz

54.348KHz

63.995KHz

67.500KHz

77.487KHz

1280 x 960

1280 x 960

1280 x 1024

MAC

HD

“*” : Only available to RGB1,2 mode.Not applied to RGB3 mode.

16¡–

19¡–

21¡–

1024 x 768

1024 x 768

1152 x 870

1920 x 1080i *

1280 x 720 *

1-15. AV Input Specification

Item

Video Input applicable

System

832 x 624

Specification

NTSC M

NTSC 4.43

PAL B,G,H,I

PAL M

PAL N

SECAM

PAL 60

60.00Hz

75.00Hz

60.020Hz

74.550Hz

60.004Hz

75.029Hz

75.062Hz

60.00Hz

60.00Hz

3.579545 / 60 Hz

4.433618 / 60 Hz

4.433618 / 50 Hz

3.575611 / 60 Hz

3.582056 / 50 Hz

4.286 / 50 Hz

4.433618 / 60 Hz

60.00KHz

75.00KHz

63.981KHz

49.725KHz

48.363KHz

60.023KHz

68.681KHz

33.750KHz

45.00KHz

Remark

Page 29

- 29 -

1-16. S-VIDEO Input Specification

: NTSC/PAL

Item

Video Input applicable

System

Specification

NTSC M

PAL B,G,H,I

3.579545 / 60 Hz

4.433618 / 50 Hz

1-17. Component(DVD/HD STB) Input Specification

Specification

No.

Resolution

1

2

3

4

5

6

7

8

640 x 480

640 x 480

704 x 480

720 x 576

720 x 576

1280 x 720

1280 x 720

1920 x 1080

H-Freq(KHz)

15.73

15.63

31.47

15.625

31.25

45.00

44.96

31.25

V-Freq(KHz)

60

59.94

59.94

50.00

50.00

60.00

59.94

50.00

Remark

Proposed

SDTV,DVD 480I

SDTV,DVD 480I

EDTV 480P

SD 576I(625 Line)

HDTV 576P

HDTV 720P

HDTV 720P

HDTV 1080 50I

10

9

1920 x 1080

1920 x 1080

33.75

33.72

60.00

59.94

HDTV 1080 60I

HDTV 1080 59.94I

Page 30

- 30 -

2. Block Diagram

IRRCVR0

IRRCVR1

PORTA0

PORTA1

PORTA2

PORTA3

PORTA4

PORTA5

PORTA6

PORTA7

EXTINT0

PW164

8255A

Parallel

Controller

EEPROM

24LC256

A2~A1

D15~D0

WE

RD

PORTB0

PORTB1

PORTB2

PORTB3

PORTB4

PORTB5

PORTB6

PORTB7

CS0

CS1

VPC3230D

FLI2200(Faroudja)

ET7050

M62352

1 st

CS

A1~A0

D7~D0

WE

RD

CS

PC

0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

P11

P12

P13

P14

P15

P16

VREF

VMID

RLCCOM

RNRSH

RNRSL

GLCCOM

GNRSH

GNRSL

BLCCOM

BNRSH

BNRSL

N.C

P1

7

P18

P19

P110

P111

P112

KEY_OUT1

KEY_OUT2

KEY_OUT3

SDAT

SCLK

ET7050_CSEL

M62352_CS

M62352_CS2

SCDT

N.C

TEMP_DET

LAMP_ON_DET

CASE_DET

PC_SEL2

WP

N.C

SDA

SCL

N.C

E_SDA

E_SCL

SDA_2

SCL_2

N.C

N.C

M62352

2nd

CS

P2

1

P22

P23

P24

P25

P26

N.C

MOUSE_RESET

UDI

LRI

COR_CON

N.C

N.C

MUTE

N.C

TEMP_REF

N.C

N.C

P2

7

P28

P29

P210

P211

P212

3503_CS

62352_CS1

SDAT5

SCLK5

N.C.

CASE_DET

POWER_KEY

LAMP_DET

FAN2-DET

KEY_IN1

V_480IP_DET

LAMP_DET

KEY_IN2

FAN_DET

N.C

KEY_IN3

2

16 8

M62320

(LED Control)

Page 31

- 31 -

2-1. Description of Control Part

No.

A19~A0

D15~D0

/RD

/WE

IRRCVR0

IRRCVR1

PORTA0

PORTA1

PORTA2

PORTA3

PORTA4

PORTA5

PORTA6

PORTA7

PORTB0

PORTB1

PORTB2

PORTB3

PORTB4

PORTB5

PORTB6

PORTB7

CS0

CS1

EXTINT0

EXTINT1

PA

0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

Symbol I/O Active Reset Function

IRRCVR0

IRRCVR1

SDA

SCL

NC

E_SDA

E_SCL

SDA_2

SCL_2

N.C

SCDT

N.C

TEMP_DET

LAMP_ON_DET

CASE_DET

PC_SEL2

WP

N.C

8255_CS

N.C

N.C

N.C

N.C

LAMP_ON

FAN_ON

POWER_ON

PC-VIDEO-SEL

PC_SEL1

ADDOWN

TMDSOE

FAN2_DET

KEY_IN1

V_480IP_DET

LAMP_DET

KEY_IN2

FAN_DET

O

I/O

O

O

O

O

I/O

O

O

O

O

I/O

I/O

O

I/O

I/O

O

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

L

L

I

I

H/L

H/L

H/L

H/L

H/L

H/L

H/L

H/L

H

I

H/L

H

I

H

I

H

I

H/L

H/L

H/L

L

H

H/L

H/L

H/L

H/L

H

H

L

L

L

H

L

H

I

I

I

I

I

I

7 Address Bus

7 Data Bus

7 Read Enable

7 Write Enable

7 Remote Control IR Signal : IR is NEC Format

Not Used

2

7 I

C Bus Clock & Data Line

7 AD9884, FLI2200, VPC3230D, CXA2101

Not Used

7 EEPROM I

7 EEPROM I

7 LED Control I

7 LED Control I

2

C Bus Data Line (EEPROM,24LC256)

2

C Bus Clock Line (EEPROM,24LC256)

2

C Bus Data Line (M62320)

2

C Bus Clock Line (M62320)

Not Connection

7 Sync detection from TFP401.

Not Connection

7 Temperature detect

7 Lamp On/Off status detect.

7 Lamp case open error detect.

7 Selection between RGB3 and RGB1,2 selection result.

7 EEPROM(24LC256)Write protection

Not Connection

7 MSM82C55A Chip Select(for IC Control using data bus)

Not Connection

Not Connection

Not Connection

Not Connection

7 Lamp ON/OFF (HIGH/LOW)

7 Fan ON/OFF (HIGH/LOW)

7 Main Power ON/OFF (HIGH/LOW)

7 Select PC or AV(From CXA1201) for AD9884 input.

7 Select between RGB1 or RGB2.

7 ADC(AD9884) power down for digital RGB3.

7 TFP401 digital RGB output enable for digital RGB3.

7 Fan2 operation error detect(High:fan error)

7 Inputs for KEY Scanning

7

Detect component input(480i or higher resolution->low:480i)

7 Lamp on/off status detect.(High:lamp error)

7 Inputs for KEY Scanning

7 FAN1 operation error detect.

Page 32

- 32 -

No.

Symbol I/O Active Reset Function

PB

PB7

PC0

PC1

PC2

PC3

PC4

PC5