LG MW-30LZ10 Owner's Manual

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

LCD

MONITOR

SERVICE

SERVICING

THE

:

MF-02HA

SAFETY

:

MW-30LZ10

THE

PRECAUTIONS

CHASSIS

MODEL

CAUTION

BEFORE

READ

CHASSIS,

MANUAL

IN

THIS

MANUAL.

P/NO

:

3828VD0120B

2002

Aug.,

PrintedinKorea

CONTENTS

Contents

Safety

Adjustment

..................................................................................................

Precautions

Instruction

Troubleshooting

Printed

Block

Exploded

Exploded

Circuit

Diagram.........................................................................................11

View

View

Replacement

2

..................................................................................3

............................................................................4

.......................................................................................6

Board

......................................................................................

Parts

Parts

...............................................................................7

16

.......................................................................17

List

........................................................................

List

18

SVC.

Sheet

.................................................................................................

-2-

SAFETY

PRECAUTIONS

electrical

Many

the

Schematic

It

is

essential

not

lsolation

servicing

AC

this

will

also

X-RADIATION,

modify

Guidance

power

protects

injury

protect

by

prevent

Do

General

An

the

the

as

personal

It

damaged

inadvertently

If

fuse

any

it

replace

When

Resistor,

Keep

Due

extreme

Do

Before

always

metallic

to

electrical

with

replacingahigh

over

wires

to

high

care

lift

not

the

returning

perform

parts

be

sure

shock.

and

Diagram

that

the

Transformer

of

a

line.

from

accidental

introduced

Fusible

(or

the

1W),

away

vacuum

should

Picture

an

of

the

set

mechanical

and

these

Shock,

original

receiver

Use

a

the

technician

electrical

the

receiver

during

Resistor)

specified.

wattage

the

keep

from

high

and

be

tubebyit's

the

AC

leakage

the

cabinet,

is

safe

parts

Replacement

special

safety

Fire,

without

design

should

whose

chassis

transformer

from

shocks.

and

shorts

of

the

service

in

resistor

resistor

voltageorhigh

surface

large

in

used

receiver

current

such

to

handling

Neck.

as

operate

IMPORTANT

in

this

chassis

Parts

List.

should

parts

or

other

Hazards.

permission

always

of

it's

components

the

thisTVreceiver

10mm

to

the

antennas,

be used

is

not

adequate

accidents

circuitary

operation.

(Oxide

away

temperature

area

of

the

Picture

customer,

check

on

without

have

be

of

isolated

power

resulting

from

that

may

is

Metal

from

PCB.

picture

the

exposed

terminals,

damage

SAFETY

special

replaced

manufacturer.

during

from

rating

in

being

be

blown,

Film

parts.

tube,

Tube.

etc.,

of

NOTICE

same

Current

the

instrument

an

the

AC

terminals,

exposed

resistance

the

exposed

must

abnormality

Current

use

1.5K/10watt

a

known

exposed

the

with

plug

measurements

measured

any

of

before

Current

characteristics.

components

electrical

switchinthe

to

the

AC

in

lead

phone

metallic

be

infinite.

directly

a

line

good

metallic

AC

1000

the

AC

to

0.5mA.

measurement

shock

it

is

safety-related

with

the

Leakage

With

connect

Place

ohm-meter

ohm-meter

antenna

If

the

measured

When

reading

An

other

receiverisreturnedtothe

Leakage

theACcord

Plug

Do

not

Connect

between

and

the

Measure

voltmeter

Reverse

voltage

voltage

corresponds

In

case

possibility

repaired

Leakage

These

as

recommended

Cold

Check(Antenna

AC

plug

to

across

on

prongs

each

jumper

plug

turn

jacks,

has

part

shouldbebetween

metal

has

no

exists

that

customer.

Hot

Check

into

theACoutlet.

Isolation

voltage

ohms/volt

must

hazard

returnedtothe

Hot

resistor

earth

parts.

cord

for

not

is

Check

Transformer

in

ground

across

into

each

exceed

out

and

parts

removed

the

positioin,

tied

together

exposed

etc.

a

return

return

must

below

(See

parallel

(Water

the

or

more

the

AC

esposed

of

the

the

set

customer.

circuit

are

identified

in

this

Cold

from

two

AC

connect

and

metallic

to

the

path

1MΩ

and

to

path

be

the

corrected

Figure)

during

with

a

0.15uF

Pipe,

resistor

sensitivity.

outlet

and

metallic

0.75

volt

limits

sepcified,

must

be

manual

Check)

AC

plug

one

touch

parts

chassis,

5.2MΩ.

chassis

before

this

Conduit,

using

repeat

RMS

checked

in

by

to

source,

prongs.

lead

other

such

the

the

the

check.

capacitor

etc.)

AC

AC

part.

Any

which

there

and

of

as

is

is

-3-

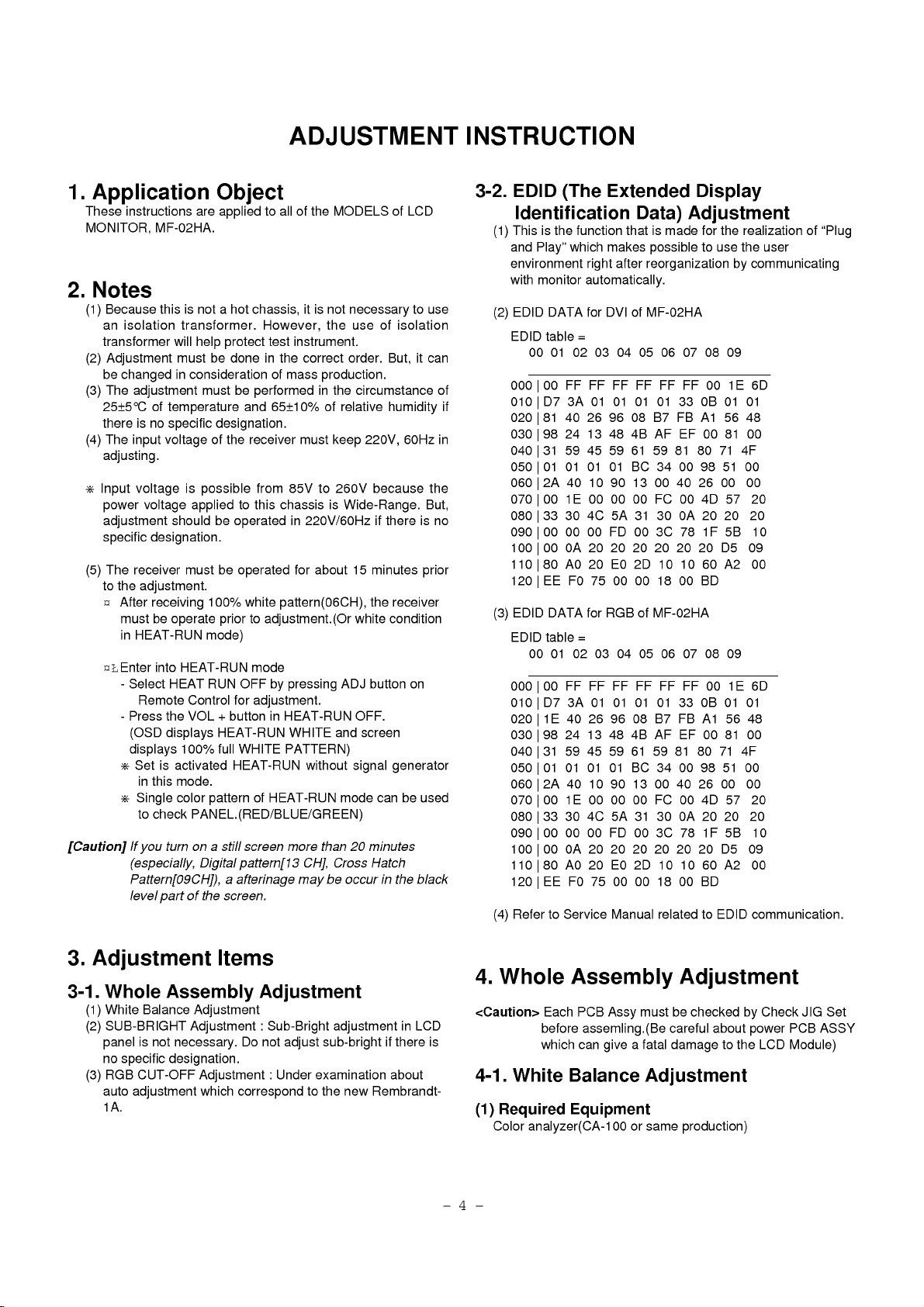

To

Instrument's

exposed

METALLIC

PARTS

AC

1.5

Volt-meter

0.15uF

Kohm/10W

Good

Earth

suchasWATER

CONDUIT

etc.

Ground

PIPE,

1.

Application

These

instructions

MONITOR,

2.

Notes

Because

(1)

an

isolation

transformer

(2)

Adjustment

be

changed

The

(3)

(4)

25±5°C

there

The

adjustment

is

input

adjusting.

[

Input

voltageispossible

power

voltage applied

adjustment

specific

The

to

¤

¤Ł

the

After

must

in

Enter

-

-

receiver

adjustment.

HEAT-RUN

Select

Remote

Press

(5)

(OSD

displays

[

Setisactivated

in

[

Single

to

[Caution]

If

you

(especially,

Pattern[09CH]),aafterinage

level

Object

are

is

not

transformer.

will

help

must

be

in

consideration

must

applied

a

hot

protect

doneinthe

be

designation.

of

the

be

operated

MF-02HA.

this

of

temperature

no

specific

voltage

should

designation.

must

be

operate

100%

priortoadjustment.(Or

receiving

be

mode)

into

HEAT-RUN

HEAT

RUN

Control

for

the

VOL+buttoninHEAT-RUN

displays

this

check

turn

HEAT-RUN

full

100%

HEAT-RUN

mode.

color

pattern

PANEL.(RED/BLUE/GREEN)

on

a

still

Digital

of

the

part

screen.

ADJUSTMENT

to

allofthe

chassis,

However,

test

of

mass

performed

and

65±10%

receiver

from

85V

to

this

chassis

operated

white

pattern(06CH),

mode

OFF

by

pressing

adjustment.

WHITE

WHITE

pattern[13

screen

of

PATTERN)

HEAT-RUN

more

it

is

not

the

instrument.

correct

production.

in

of

must

to

in

220V/60Hz

for

about

without

than20minutes

CH],

be

may

MODELS

necessary

use

order.

the

circumstance

relative

220V,

keep

260V

is

Wide-Range.

15

minutes

the

white

ADJ

button

OFF.

and

screen

signal

mode

Cross

Hatch

occur

of

of

But,

humidity

because

if

there

receiver

condition

generator

can

in

the

LCD

to

use

isolation

it

can

60Hz

But,

is

prior

on

be

used

black

INSTRUCTION

3-2.

of

if

in

the

no

EDID

(The

Extended

Identification

Thisisthe

(1)

and

environment

with

EDID

(2)

EDID

00010203040506070809

_________________________________

000|00FFFFFFFFFFFF001E6D

010|D73A01010101330B0101

020|8140269608B7FBA15648

030|982413484BAFEF008100

040|3159455961598180714F

050|01010101BC3400985100

060|2A401090130040260000

070|001E000000FC004D5720

080|33304C5A31300A202020

090|000000FD003C781F5B10

100|000A202020202020D509

110|80A020E02D101060A200

120|EEF07500001800BD

EDID

(3)

EDID

00010203040506070809

__________________________________

000|00FFFFFFFFFFFF001E6D

010|D73A01010101330B0101

020|1E40269608B7FBA15648

030|982413484BAFEF008100

040|3159455961598180714F

050|01010101BC3400985100

060|2A401090130040260000

070|001E000000FC004D5720

080|33304C5A31300A202020

090|000000FD003C781F5B10

100|000A202020202020D509

110|80A020E02D101060A200

120|EEF07500001800BD

RefertoService

(4)

Play"

monitor

DATA

table

DATA

table

function

which

makes

right

automatically.

for

DVIofMF-02HA

=

for

RGB

=

Manual

Display

Data)

thatismade

after

of

Adjustment

for

the

realization

to

use

possible

the

reorganizationbycommunicating

MF-02HA

relatedtoEDID

communication.

user

of

"Plug

3.

Adjustment

3-1.

Whole

White

(1)

SUB-BRIGHT

(2)

panel

no

specific

RGB

(3)

auto

adjustment

1A.

Balance

is

not

CUT-OFF

Assembly

Items

Adjustment

Adjustment

Adjustment:Sub-Bright

necessary.

designation.

Do

Adjustment

which

correspond

not

:

Under

adjust

to

adjustment

sub-bright

examination

the

new

in

if

there

about

Rembrandt-

LCD

4.

Whole

<Caution>

is

4-1.

White

(1)

Required

Color

-4-

Assembly

Each

PCB

before

which

analyzer(CA-100

Assy

assemling.(Be

can

give

Balance

Equipment

Adjustment

must

be

checked

careful

a

fatal

damage

Adjustment

or

same

production)

about

to

the

by

power

Check

LCD

JIG

PCB

ASSY

Module)

Set

Connection

(2)

Measuring

(Fig.

Connect

Automatization

repairing

Only

adjust

GAIN/B-GAIN

Automatic

GAIN/G-GAIN/B-GAIN

balance

saves

data

White

(3)

↓

Operate

stick

↓

Devide

adjustment

↓

Manual

adjustment

Diagram

(Automatic

High

Light

450±70cd/m2

Connection

1)

RS-232C

operating

about

adjusting

HIGH

automatically.

adjustment

and

transmits

values.

Balance

Zero

CalibrationofCA-100

completely

Manual

by

adjustment

is

not

of

Equipment

Adjustment)

Diagram

to

Adjustment

LIGHT

equipment

by

them

of

Equipment

room

has

equipment.

and

RGB

decides

correcting

into

SET

Adjustment(Manual

to

the

surfaceofLCD

into

adjustment

the

following

is

a

correspondent.

AV/PC

sequence.

temporary

for

COLOR

ANALYZER

TYPE;CA-100

RGB

Signal

Input

LCD

MONITOR

Window

MASTER

QUANTUM

Automatic

in

input

color

Adjustment

and

chargeofmanaging

adjusts

the

valuesofR-

coordinates/white

and

finally

Adjustment)

and

Sensor

module

and

operate

method

when

or

DATA

SET.

R-GAIN/G-

the

SET

must

automatic

and

Key

GAIN

is

color

coordination

color

temperature

Gainisused

(R

and

X-coordinates

increased.

G

Gainisused

andY-coordinates

adjust

fixed)

it

until

color

:

X=0.283±0.003,

:

9,350°K

to

to

X-coordinates

adjust

couldbeshortened

Y-coordinates

adjust

couldbeshortened

coordination

±

500°K

becomes

Y=0.296±0.003

while

adjusting

whenRGain

while

adjusting

whenGGain

(B

is

is

increased.)

Exit

5)

adjustment

3.

Component

↓

Use

this

Pattern

↓

This

and

YPbPr

1)

Operate

adjustment

OffsetinAD9888.

adjustment

Select

2)

Ch.14

(480p~1080i)

When

3)

you

adjustment,

Window(right

be

4)

5)

mode.

In

this

with

of

Ch.14.

Exit

adjustment

condition,

'DTV B

mode

(480p~1080i)

adjustment

has

redorblue

is

used

the

adjustment

progress.

after

terminal

ADJ

press

the

SET

side)/Sub

adjust

OFFSET'

mode

using

when

connect

and

button

goes

based

using

Enter

Offset

Adjustment

the

Grayscale

while

producing

to

remove

after

PC/AV

DTV

STB

AV

terminal.

twiceonthe

to

DWI

Window(left

R

with

'DTVROFFSET'

on

Enter

button.

the

declination

White

to

condition

side)

'foundation

button.

out

of

Ch13.

set.

Balance

Component

R/C

for

and

are

set

color(Gray)'

Main

and

of

to

AV

B

1.

AV

W/B

Select

1)

pressing

then

2)

Supply

generator.

Low

3)

4)Toadjust

select

button

After

Mode

Key

GAIN

color

color

Exit

5)

2.

PC

W/B

Select

1)

pressing

then

2)

Supply

generator.(RGB1

Low

3)

4)Toadjust

select

button

After

Mode

adjustment

WHITE

ADJ

operate

pattern

(AV

has

Light

High

and

adjust

on

Remote

select

theRGAIN

by

pressing

and

adjust

is

fixed)

coordination

temperature

adjustment

Adjustment

WHITE

ADJ

operate

pattern

has

Light

High

and

adjust

on

Remote

select

theRGAIN

by

pressing

PATTERN

buttononRemote

HEAT

signal

RUN

for

of

more

WB

INPUT)

no

special

adjustment.

stick

Light,

theAVGAIN

Control

and

ENTER

it

until

color

:

X=0.283±0.003,

:

9,350°K

mode

using

PATTERN

buttononRemote

HEAT

signal

RUN

for

of

more

WB

INPUT)

no

special

adjustment.

stick

Light,

thePCGAIN

Control

and

ENTER

HEAT

than15minute

adjustment

sensor

by

for

adjustment.

G

GAIN,

button

coordination

±

500°K

Enter

HEAT

than15minute.

adjustment

sensor

by

for

adjustment.

G

GAIN,

button

RUN

Control

to

2th

pressing

enter

and

press

Y=0.296±0.003

button.

RUN

Control

to

2th

pressing

enter

and

press

mode

by

for

adjustment

in

pattern

pattern(White),

INSTSRT

Adjustment

the

VOL

+/-

becomes

mode

for

in

(B

by

adjustment

pattern

pattern(White),

INSTSRT

Adjustment

the

VOL

+/-

-5-

TROUBLESHOOTING

open

of

rectying

of

output

error

of

output

error

of

output

error

of

of

of

Cause

circuit/EMI

terminal

parts

and

terminal

parts

and

terminal

parts

and

peripheral

peripheral

peripheral

Filter

circuits.

circuits.

circuits.

Check

1)

2)

1)

2)

3)

4)

1)

2)

BD801,

Check

BD801,

Check

the

Check

reverse

Check

R941~R944

U902isabnormal.

-

Replace

-

Check

Replace

Check

the

Check

reverse

3)NoInput

are

low.

-

Replace

error.

Check

1)

2)

3)

the

Check

reverse

Check

R937~R939

U903isabnormal.

-

Replace

-

Check

the

T803

of

(normal

the

Symptom

1.

No

2.

No

/+18V

3.

No

4.

No

power

power

power

power

from

from

from

from

all

outputs

+24V/+12V

+18V

+5VS

Fuse

1)

Error

2)

Short

1)

2)

Input

ErrorofU902

3)

ErrorofT803

4)

Short

1)

2)

Input

ErrorofU802

3)

Short

1)

2)

Input

ErrorofU903

3)

Check

Q801,

Q802,

L801,

L802,

second

side

parts

of

input

PH801,

when

(normal:

U902(FAN7554)

error

of

Q804

peripheral

parts

inputofD916(SB560)

L812

when

both

voltage:

U802(PQ1CG203)

peripheral

input

of

when

parts

D802,

(normal:

U903(FAN7554)

error

of

Q802

Point

Q804

TH800,

and

the

Pin

15V~25V)

parts

of

18V

terminal

+24V)

parts

of

5VS

CR801

the

Pin

15V~25V)

parts

Pattern

D916,

Bias

and

Bias

TH801

voltage

when

and

CR802

power

Pattern

Pattern

power

short

there

no7.

of

no7.

short.

C830

is

short.

of

no

of

5.

No

power

/+18Vin110VAC

from

+24V/+12V

Input

ErrorofT802

4)

1)

Drop

of

PFC

ErrorofT801

2)

of

output

circuit.

power

duetothe

error

4)

Replace

1)

Replace

2)

Replace

the

peripheral

-

Check

T802

U901(MC33368D)

parts.

the

error

of

Q801

T801

when

there

is

no

error

in

-6-

MAIN(TOP)

PRINTED

CIRCUIT

BOARD

-7-

Loading...

Loading...