LG MH-1357M, MH-1356M, MH-1355M Service Manual

MICROWAVE OVEN

SERVICE MANUAL

MODEL: MH-1355M

MH-1356M

MH-1357M

CAUTION

BEFORE SERVICING THE UNIT, READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Website: http://biz.lgservice.com

P/NO : 3828W5S6174

July, 1998

Printed in Korea

– 2 –

SAFETY PRECAUTIONS

This device is to be serviced only by properly qualified service personnel.

Consult the Service Manual for proper service procedures to assure continued safety operation and for

precautions to be taken to avoid possible exposure to excessive microwave energy.

— Proper operation of the microwave ovens requires that the magnetron be assembled to the wave guide and

cavity. Never operate the magnetron unless it is properly installed.

— Be sure that the magnetron gasket is properly installed around the dome of the tube whenever installing the

magnetron.

— Routine service safety procedures should be exercised at all times.

— Untrained personnel should not attempt service without a thorough review of the test procedures and safety

information contained in this manual.

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE

ENERGY

A) Do not operate or allow the oven to be operated with the door open.

B) Make the following safety checks on all ovens to be serviced before activating the magnetron

or other microwave source, and make repairs as necessary; (1) interlock operation, (2) proper

door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or

loosening of hinges and latches, (5) evidence of dropping or abuse.

C) Before turning on microwave power for any service test or inspection within the microwave

generating compartments, check the magnetron, wave guide or transmission line, and cavity

for proper alignment, integrity, and connections.

D) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures

described in this manual before the oven is released to the owner.

E) A microwave leakage check to verify compliance with the Federal Performance Standard

should be performed on each oven prior to release to the owner.

– 3 –

TABLE OF CONTENTS

SPECIFICATIONS

-----------------------------------------------------------------------------------------------------------------------

4

CAUTIONS

---------------------------------------------------------------------------------------------------------------------------------

5

INSTALLATIONS

-------------------------------------------------------------------------------------------------------------------------

6

FEATURE DIAGRAM

-------------------------------------------------------------------------------------------------------------------

7

CONTROL PANEL

-----------------------------------------------------------------------------------------------------------------------

8

HOW THE MICROWAVE/CONVECTION OVEN WORKS

-----------------------------------------------------------------

10

COOKING FLOW CHART

-----------------------------------------------------------------------------------------------------------

11

OPERATING INSTRUCTIONS

-----------------------------------------------------------------------------------------------------

12

SCHEMATIC DIAGRAM

-------------------------------------------------------------------------------------------------------------

15

CIRCUIT DESCRIPTION

-------------------------------------------------------------------------------------------------------------

18

DESCRIPTION AND FUNCTION OF COMPONENTS

---------------------------------------------------------------------

20

NECESSARY TOOLS AND MEASURING INSTRUMENTS

--------------------------------------------------------------

22

INSTALLATION AND ADJUSTMENT OF THE INTERLOCK SYSTEM

----------------------------------------------

23

INTERLOCK CONTINUITY TEST

-------------------------------------------------------------------------------------------------

25

DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE

---------------------------------------------------------

26

TROUBLESHOOTING

----------------------------------------------------------------------------------------------------------------

30

COMPONENT TEST PROCEDURE

----------------------------------------------------------------------------------------------

36

PROCEDURE FOR MEASURING MICROWAVE ENERGY LEAKAGE

----------------------------------------------

42

EXPLODED VIEW AND PARTS LIST

-------------------------------------------------------------------------------------------

44

INTRODUCTION

-------------------------------------------------------------------------------------------------------------------

44

1. DOOR PARTS

-----------------------------------------------------------------------------------------------------------------

45

2. CONTROL PANEL PARTS

------------------------------------------------------------------------------------------------

46

3. OVEN CAVITY PARTS

------------------------------------------------------------------------------------------------------

47

4. OVEN INTERIOR PARTS (1)

---------------------------------------------------------------------------------------------

48

5. OVEN INTERIOR PARTS (2)

----------------------------------------------------------------------------------------------

49

6. LATCH PARTS

----------------------------------------------------------------------------------------------------------------

50

7. BASE PLATE PARTS

-------------------------------------------------------------------------------------------------------

51

8. WIRING HARNESS PARTS

-----------------------------------------------------------------------------------------------

52

9. CIRCUIT BOARD

-------------------------------------------------------------------------------------------------------------

53

10. CIRCUIT BOARD SCHEMATIC DIAGRAM

-------------------------------------------------------------------------

54

REPLACEMENT PARTS LIST

-------------------------------------------------------------------------------------------------

55

– 4 –

SPECIFICATIONS

Power Supply

---------------------------------------------------

120 VAC, 60 Hz

Power Consumption

------------------------------------------

1400 Watts (Microwave), 12A

1580 Watts (Convection), 13.2A

Output

--------------------------------------------------------------

*850 Watts (Microwave)

1500 Watts (Convection)

Microwave Frequency

---------------------------------------

2450 MHz ± 50 MHz

High Voltage Capacitor

--------------------------------------

0.91µF, 2100V AC

High Voltage Diode

-------------------------------------------

HVR-IX

Oven Lamp

-------------------------------------------------------

125V, 25W

Timer

---------------------------------------------------------------

99 mim. 99 sec. (Microwave, Convection and Combination)

Power Control

---------------------------------------------------

MICOM

Outer Dimension

-----------------------------------------------

15" x 22

1

/4" x 1913/16" (H x W x D)

Cavity Dimension

----------------------------------------------

103/16" x 149/16" x 1411/16" (H x W x D)

Safety Device

---------------------------------------------------

Primary Interlock Switch, Secondary Interlock Switch

Monitor Switch

Fuse 15 Amp

Magnetron Thermostat

Open at 145°C ± 6°C

Close at 60°C ± 15°C

Oven Thermostat:

Open at 130°C ± 6°C

Close at 60°C ± 15°C

✽

IEC60705 Rating Standard.

✽

Specifications are subject to change without notice.

– 5 –

• DO NOT operate on a 2-wire extension cord during

repair and use.

• NEVER TOUCH any oven components or wiring

during operation.

• BEFORE TOUCHING any parts of the oven, always

remove the power plug from the outlet.

• For about 30 seconds after the oven stops, an

electric charge remains in the high voltage

capacitor. When replacing or checking, you must

discharge the high voltage capacitor by shorting

across the two terminals with an insulated

screwdriver.

• Remove your watches whenever working close to or

replacing the Magnetron.

• NEVER operate the oven with no load.

• NEVER injure the door seal and front plate of the oven

cavity.

• NEVER put iron tools on the magnetron.

• NEVER put anything into the latch hole and the

interlock switches area.

• Proper operation of the microwave oven requires

that the magnetron be assembled to the waveguide

and cavity. Never operate the magnetron unless it is

properly installed.

• Be sure that the magnetron gasket is properly

installed around the dome of the tube whenever

installing the magnetron.

CAUTIONS

Unlike other appliances, the microwave oven is

high-voltage and high-current equipment.

Though it is free from danger in ordinary use,

extreme care should be taken during repair.

THE OVEN IS TO BE SERVICED ONLY

BY PROPERLY QUALIFIED SERVICE

PERSONNEL.

MICROWAVE RADIATION

Personnel should not be exposed to the

microwave energy which may radiate from the

magnetron or other microwave generating

device if it is improperly used or connection.

All input and output microwave connections,

waveguide, flange and gasket must be secure

never operate the device without a microwave

energy absorbing load attached.

Never look into an open waveguide or antenna

while the device is energized.

Gasket

ANTENNA

COOLING FIN

MAGNETRON

CHASSIS GROUND

FILAMENT

TERMINALS

MAGNETRON

– 6 –

INSTALLATIONS

INSTALLING

1. Empty the microwave oven and clean inside it with

a soft, damp cloth. Check for damage such as

misaligned door, damage around the door or dents

inside the cavity or on the exterior.

2. Put the oven on a counter, table, or shelf that is

strong enough to hold the oven and the food and

utensils you put in it. (The control panel side of the

oven is the heavy side. Use care when handling.)

3. Do not block the vent and the air intake openings.

Blocking vent or air intake openings can cause

damage to the oven and poor cooking results.

Make sure the microwave oven legs are in place to

ensure proper air flow.

4. The oven should not be installed in any area where

heat and steam are generated, because they may

damage the electronic or mechanical parts of the

unit.

Do not install the oven next to a conventional

surface unit or above a conventional wall oven.

5. Use microwave oven in an ambient temperature

less than 104°F(40°C).

6. Place the microwave oven on a sturdy and flat

surface at least 10 cm(4 inches) from the wall.

7. Place the microwave oven as far away as possible

from TV, RADIO, COMPUTER, etc., to prevent

interference.

8. This oven must be plugged into a 15A outlet.

9. Do not touch the front glass during or after cooking

of the Grill and Combination mode.

This glass is very hot during heater operating.

10. Do not operate the oven at microwave and

combination mode with Grill rack placed in the

cavity when the oven is empty.

EARTHING INSTRUCTIONS

This microwave oven is designed to be used in a fully

earthed condition.

It is imperative, therefore, to make sure it is properly

earthed before servicing

WARNINGTHIS APPLIANCE

MUST BE EARTHED

IMPORTANT

As the colors of the wires in the mains lead of this

appliance may not correspond with the colored

markings identifying the terminals in your plug,

proceed as follows.

The wire which is colored green-and-yellow must be

connected to the terminal in the plug which is marked

with the letter E or by the earth symbol ( ) or

colored green or green-and-yellow.

The wire which is colored blue must be connected to

the terminal in the plug which is marked with the letter

N or colored black.

The wire which is colored brown must be connected

to the terminal in the plug which is marked with the

letter L or colored red.

BEFORE YOU BEGIN, READ THE FOLLOWING INSTRUCTIONS COMPLETELY AND CAREFULLY.

The wires in this mains lead are colored in

accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

– 7 –

FEATURE DIAGRAM

Remove your Microwave/Convection Oven and all material from the shipping carton.

Your oven will be packed with the following material:

Turntable

---------------------------------------

1 Each

Rotating Ring Asm

--------------------------

1 Each

Convection Rack

-----------------------------

1 Each

Cookbook

---------------------------------------

1 Each

Owner’s Manual

------------------------------

1 Each

Do not use this Microwave/Convection Oven for commercial purposes.

This Microwave/Convection Oven is made for household use only.

SAFETY

INTERLOCK SYSTEM

CONVECTION RACK

TURNTABLE

ROTATING RING ASM

SEE-THROUGH

DOOR

AIR VENTS

CONTROL PANEL

Fig. 3

– 8 –

CONTROL PANEL

INDICATOR LIGHTS-

When cooking operations

are set, lights will go on

indicating the cycle in which

your oven is cooking.

DISPLAY WINDOW-

Used to show:

• Time of day.

• Cooking time.

• Cooking power level.

• Cooking temperature.

• It also functions as a

countdown timer or

temperature indicator

when cooking.

COMBINATION HIGH/LOW-

Used in setting combination

high or low cooking.

AUTO COOK- Used in

setting weight combination

cooking. Auto Combination

Guide is next to the pad.

DEFROST-

Used in setting

Auto Defrost.

POPCORN- Used to pop

pack aged popcorn.

PLUS TIME-

Used to cook

food for a longer time

after cooking end.

HOLD WARM- Used to

keep the food warm.

NUMBERS-

Used to enter the:

• Time of day.

• Cooking times.

• Cooking powers.

• Cooking temperatures.

• Weight for Auto

Combination cooking.

START-

Starts the oven.

NOTE: A “beep tone” sounds when a “pad” on the control panel is touched,

to indicate a setting has been entered.

CONVECTION-

Used in setting

convection cooking

or pre-heat.

REHEAT- Used to reheat

foods easily. Reheat Guides

is next to the pad.

COOK- Used to cook

foods easily. Cook

guide is next to the pad.

MICRO TIME- Used in

setting microwave

cooking time.

MICRO POWER-

Used to select cooking

power levels.

CLOCK- Used

to set the time of day.

STOP/CLEAR- Stops the

oven and Clears all entries

except TIME OF DAY. Once

cooking has begun, however,

CLEAR will function only after

STOP has been touched.

– 9 –

NOTE:

1. Beep Sound

The beep sound is activated under the following conditions.

Conditions Beep Sound Signal

• When the control key is touched,

• When the cooking stage is changed,

• When the preheat is ended and the holding time is begun,

• When cooking is ended,

• When an error occurs,

• When foods need to be turned over during auto weight defrost or

auto weight combination operation.

2. Microwave Cooking Power

Microwave cooking power can be chosen from one of the 10 cooking powers listed below. If cooking power is

not programmed, the oven operates at cooking power HI.

3. Digital Readout Display

Numbers

of

Touch Pads

Cooking

Power

Time

(Example: 99 min

and 99 sec)

%

Microwave

Emission Time

(sec/cycle)

ON OFF

1

2

3

4

5

10

20

30

40

50

10

20

30

40

50

4

6

8

10

12

18

16

14

12

10

Numbers

of

Touch Pads

Cooking

Power

%

Microwave

Emission Time

(sec/cycle)

ON OFF

6

7

8

9

60

70

80

90

HI

60

70

80

90

100

14

16

18

20

22

8

6

4

2

0

9 9 : 9 9

Time

(Example: 2 hours

and 30 min)

2 h 3 0

Temperature

(Example: 300°F)

3 0 0 f

Clock

(Example: 12 hours

and 30 min)

1 2 : 3 0

Cooking Power

(Example: cooking

power 50)

p - 5 0

Weight

(Example: 4.5 lbs)

4 . 5

End Error

e

– 10 –

HOW THE MICROWAVE/

CONVECTION OVEN WORKS

MICROWAVE COOKING

Using microwave energy only, food is cooked quickly

without altering its color or shape. The food is evenly

cooked on a rotating turntable as the microwaves are

produced by the magnetron. Power Control can be

adjusted in 10 steps, enabling the various kinds of foods

to cook at most desirable cooking power for the best

results.

CONVECTION COOKING

This is a way of cooking with hot air from the convec-tion

heater on the back side of the unit. This method allows

food to be browned evenly without losing any of the

juices. Heated air is circulated in the oven by a fan to

enable the heating and cooking of food. Since hot air

remains in the oven as it circulates, cooking is very

efficient. The temperature inside the oven can be controlled according to the type of food being cooked.

COMBINATION COOKING

With microwave energy and hot air, this solid-state

control can cook alternately according to the cycles

programmed between microwave and hot air to pro-vide

efficient cooking fully utilizing the advantages of

two functions. Convection rack is also used in Combination Cooking.

Fig. 5

Magnetron

Convection Heater

Convection Rack

Circulation

Motor

Convection Heater

Convection Rack

Circulation

Motor

– 11 –

COOKING FLOW CHART

Cooking procedure have five sequential programs.

AUTO WEIGHT DEFROST STAGE 1 STAGE 2 STAGE 3 HOLD WARM

Cooking program can be partially and independently selected.

Example:

AUTO WEIGHT DEFROST STAGE 1 STAGE 2 STAGE 3 HOLD WARM

AUTO WEIGHT DEFROST STAGE 1 STAGE 2 STAGE 3

AUTO WEIGHT DEFROST STAGE 1 STAGE 2 HOLD WARM

AUTO WEIGHT DEFROST STAGE 1 STAGE 2

AUTO WEIGHT DEFROST STAGE 1 HOLD WARM

AUTO WEIGHT DEFROST STAGE 1

AUTO WEIGHT DEFROST HOLD WARM

AUTO WEIGHT DEFROST

STAGE 1 STAGE 2 STAGE 3 HOLD WARM

STAGE 1 STAGE 2 STAGE 3

STAGE 1 STAGE 2 HOLD WARM

STAGE 1 STAGE 2

STAGE 1 HOLD WARM

STAGE 1

HOLD WARM

AUTO WEIGHT COMBINATION

REHEAT

POPCORN

START

REHEAT

AUTO

WEIGHT

DEFROST

AUTO

WEIGHT

COMBINATION

STAGE 1 STAGE 3

HOLD

WARM

STAGE 2

CLOCK

POPCORN

– 12 –

OPERATING INSTRUCTIONS

TO SET THE TIME OF DAY

1. When the oven is plugged in, the display window will

show zero( :0)

2. Touch CLOCK.

3. Touch numbers for correct time of day.

4. Touch CLOCK again.

NOTE:

• If your oven does not operate properly, unplug the

oven from the 120-volt household outlet and then

plug it back in.

• To reset the time of day in the display window, touch

CLOCK again.

The colon will disappear. Enter the correct time of day

by following the above procedure.

• Oven will operate even though the TIME OF DAY is

not set.

• If the TIME OF DAY is not set, nothing will show in

the display window when STOP/CLEAR is touched.

• The TIME OF DAY can be set only from 1 : 00 to 12

: 59. At invalid setting, “E” will appear in the display

window with two short and one long beep sounds.

Only STOP/CLEAR can be operated while an error

condition exists.

• If you accidentally touch more than 4 numbers, the

last 4 numbers you have touched will appear in the

display window.

• If a momentary power failure occurs, the clock display

returns to zero ( : 0). If this occurs, please reset the

clock.

• If STOP/CLEAR is touched or door is opened after

cooking, the TIME OF DAY will appear in the display

window.

• If you don't set the time of day, the display counts

up per minute.

REGULAR TIMER

1. Touch MICRO TIME.

2. Touch numbers for desired time.

3. Touch MICRO POWER.

4. Touch “0”

5. Touch START.

“MICRO TIME” COOKING

1. Touch MICRO TIME.

2. Touch numbers for desired cooking time.

3. Touch MICRO POWER.

4. Touch number for desired cooking power.

5. Touch START.

“CONVECTION” COOKING

To Preheat

1. Touch CONVECTION.

2. Touch number for desired preheating temperature.

3. Touch START.

NOTE:

• After oven temperature reached the selected

temperature, the oven will automatically begin to hold

operation at the preheat temperature for 30 minutes.

To Cook

1. Touch CONVECTION.

2. Touch number for desired oven temperature.

3. Touch numbers for desired cooking time.

4. Touch START.

NOTE:

• Convection cooking temperatures range from 225°F

to 450°F.

• When oven doesn't reach selected temperature, oven

temperature will appear in the display window.

Current temperature of oven will be displayed in rising

5°F increments. If oven temperature is lower than

200°F, the display window will show "LO F" until

oven temperature reaches 200°F.

– 13 –

“COMBINATION” COOKING

1. Touch COMBINATION HIGH or LOW.

2. Touch numbers for desired cooking time.

3. Touch START.

NOTE:

• Output is fixed as follows.

“AUTOMATIC DEFROST BY WEIGHT”

1. Touch MEAT, POULTRY or FISH of AUTO WEIGHT

DEFROST.

2. Touch numbers for desired weight.

3. Touch START.

NOTE:

• If you input over the acceptable weight, "E" will show

in the display window. It means error and the oven

does not operate.

• When five short beeps sound during Auto Weight

Defrost, please turn over foods.

• Each category can defrost food with the weight of the

defrosting food input. The cooking power will

automatically be fixed in proportion to the time.

Categories for Auto Weight Defrost and the maximum

weights are 9.9 lbs.

“AUTOMATIC COMBINATION”

COOKING

1. Touch AUTO COOK.

2. Touch number for desired category.

3. Touch numbers for desired cooking weight.

4. Touch START.

NOTE:

• If you input over the acceptable weight, "E" will show

in the display window. It means error and the oven

does not operate.

• When five short beeps sound during cooking, please

turn over foods.

• Don't cook with plugging in the temperature probe.

• If you touch Auto Weight Combination Cook key, the

cooking data input already in each stage is cancelled.

• If you are going to reprogram a certain cooking

function after programming Auto Weight Combination

data, STOP/CLEAR must always be touched before.

• Weight can be programmed in pounds and tenths of

a pound. Categories for Auto Weight Combination

Cooking and the maximum weights are 5.9 lbs.

“REHEAT”

1. Touch REHEAT.

2. Touch REHEAT repeatedly for desired category of

Reheat. (Touch 1. or 2)

3. Touch START.

NOTE:

• If you touch Reheat key, the cooking data input

already in each stage is cancelled.

• If you reprogram a certain cooking function after

programming Reheat data, STOP/CLEAR must

always be touched before.

“HOLD WARM”

1. Touch HOLD WARM.

2. Touch START.

NOTE:

• The time of HOLD WARM is 60 minutes.

• With temperature probe foods will be held at

120°F.

• Take care that the temperature probe is not removed

from foods.

MICROWAVE

COOKING TIME

COMBI-HIGH

COMBI-LOW

8 Sec

8 Sec

14 Sec (375°F)

14 Sec (350°F)

CONVECTION

COOKING TIME

– 14 –

“POPCORN”

1. Put a micro-proof rack on the turntable.

2. Touch POPCORN.

3. Touch START.

NOTE:

• If additional time is required, micro HI power in

increments of 20 sec.

• Elevate popcorn packages on a micro-proof rack.

• Do not leave oven unattended while popping corn.

• This feature can only be used for popping

packaged.

CHILD LOCK

To Set Child Lock

1. Touch “0” more than 2 seconds.

NOTE:

• When Child Lock is selected STOP/CLEAR must

always be touched before selection.

• At this time, the oven will operate normally but Micro

Power and Heater Power will be zero and cooking

can not take place.

• At this time, if you start to cook “L” will appear in the

display window for 1 sec at first.

.

To Cancel Child Lock

1. Touch “0” more than 2 seconds.

NOTE:

• When you cancel Child Lock, STOP/CLEAR must

always be touched before selection.

MULTI-STAGE COOKING

Let’s start to cook with a first stage 4 minutes at the

cooking power HI followed by a second stage of 10

minutes at cooking power 60.

1. Touch MICRO TIME.

2. Touch “4”, “0” and “0” in sequence.

3. Touch MICRO TIME.

4. Touch “1”, “0”, “0” and “0” in sequence.

5. Touch MICRO POWER.

6. Touch “6”.

7. Touch START.

NOTE:

• There are three memory stages.

– 15 –

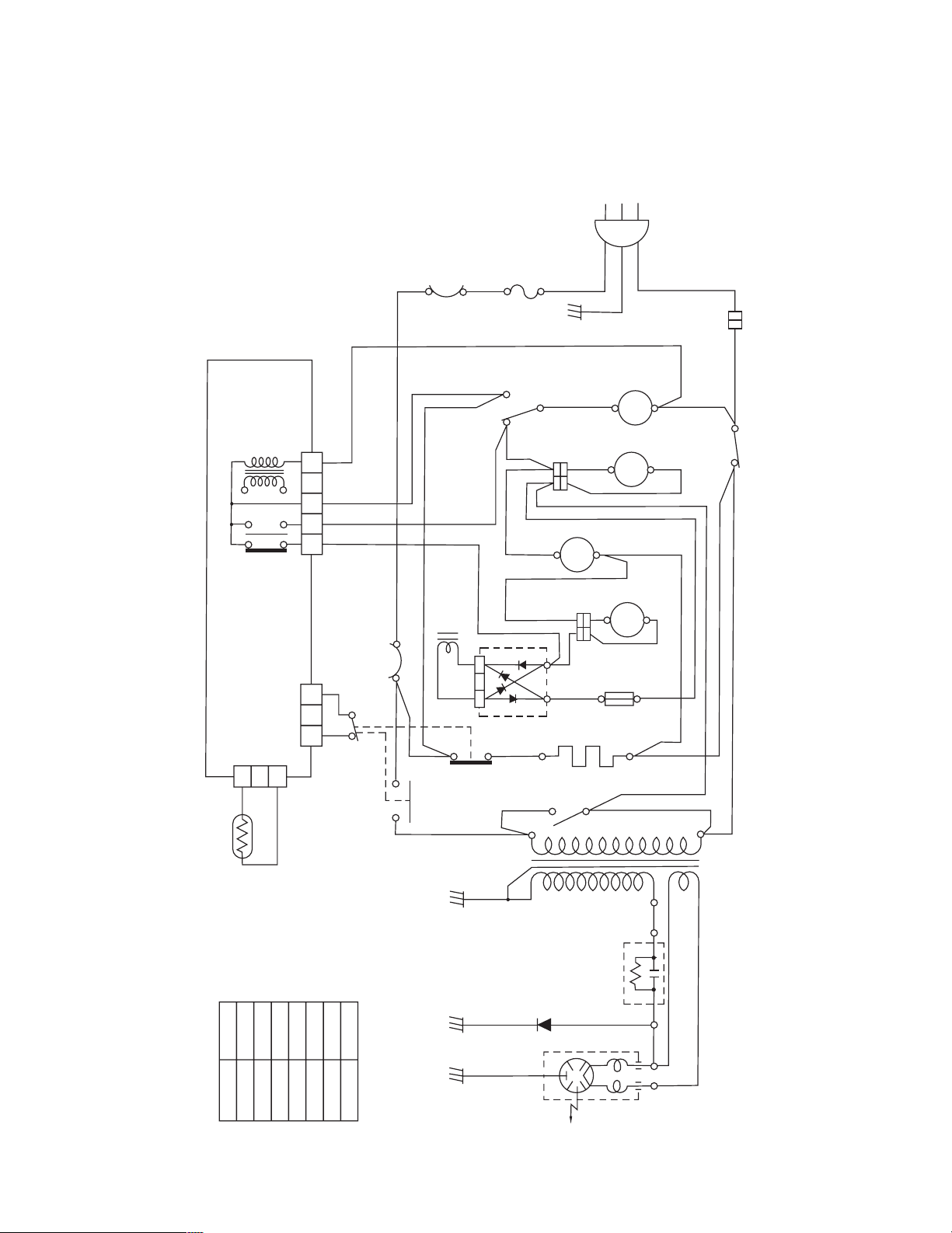

SCHEMATIC DIAGRAM

SYSTEM 1: STAND-BY CONDITION

Set up: Door is opened. Oven power cord is plugged into standard 120 volt ground outlet.

Normal operation

• Oven light turns on.

POWER

T

R

ANS

CN 1

1 2 3 4 5

WH B L R D YL

REL A Y 3

REL A Y 4

P. C.B.

1 2 3

THERMOSTAT

( M AGNE TR ON )

SOLENOID

WH

WH

WH

WH

WH

RD

RD

RD

RD

RD

RD RD

YL

YL

YL

RD

RD

RD

RD

OVEN

LAMP

SWITCH

NC

YL

NO

COM

BL

WH

WH

WH

WH

AC 120V

60Hz

THERMOSTAT

(OVEN)

FUSE

GN

OVEN LAMP

O. L

TURNTABLE MOTOR

T. T. M

FAN MOTOR

F.M.

C.M.

CIRCULATION MOTOR

RECTIFIRE FU SE

CONVECTION HEA TER

REL AY 2

MONI TOR SWITCH

REL A Y1

NOTE: 1. DOOR IS CLOSED.

2. COOK OFF.

3.CIRCUIT BE SUB JECT TO

CH A NGE WITHOU T NO TICE.

SYM B OL COLOR

WH WHI TE

BK BL A CK

BL BL UE

RD RED

YL YEL L OW

PK PINK

BN BROWN

HIGH VOL TAGE

DIODE

MAGNETRON

HIGH VOL TAGE

HIGH VOL TAGE

CAPACITOR

TRA N SFORM ER

1 2 3

SECONDARY

SWITCH

WH

WH

THERMI S TOR

PRIMAR Y

SWITCH

Fig. 6

– 16 –

SYSTEM 2: MICROWAVE COOKING CONDITION

Set up: Door is closed. START is touched.

Normal operation

• Oven light turns on.

• Turntable operates.

• Fan motor operates.

POWER

T

R

ANS

CN 1

1 2 3 4 5

WH B L R D YL

REL A Y 3

REL A Y 4

P. C.B.

1 2 3

THERMOSTAT

( M AGNE TR ON )

SOLENOID

WH

WH

WH

WH

WH

RD

RD

RD

RD

RD

RD RD

YL

YL

YL

RD

RD

RD

RD

OVEN

LAMP

SWITCH

NC

YL

NO

COM

BL

WH

WH

WH

WH

AC 120V

60Hz

THERMOSTAT

(OVEN)

FUSE

GN

OVEN LAMP

O. L

TURNTABLE MOTOR

T. T. M

FAN MOTOR

F.M.

C.M.

CIRCULATION MOTOR

RECTIFIRE FU SE

CONVECTION HEA TER

REL AY 2

MONI TOR SWITCH

REL A Y1

NOTE: 1. DOOR IS CL OSED.

2. COOK OFF.

3.CIRCUIT BE SUB JECT TO

CH A NGE WITHOU T NO TICE.

SYM B OL COLOR

WH WHI TE

BK BL A CK

BL BL UE

RD RED

YL YEL L OW

PK PINK

BN BROWN

HIGH VOL TAGE

DIODE

MAGNETRON

HIGH VOL TAGE

HIGH VOL TAGE

CAPACITOR

TRA N SFORM ER

1 2 3

SECONDARY

SWITCH

WH

WH

THERMI S TOR

PRIMAR Y

SWITCH

Fig. 7

– 17 –

SYSTEM 3: CONVECTION COOKING CONDITION

Set up: Door is closed. START is touched.

Normal operation

• Oven light turns on.

• Turntable operates.

• Fan motor and circulation motor operate.

POWER

T

R

ANS

CN 1

1 2 3 4 5

WH B L R D YL

REL A Y 3

REL A Y 4

P. C.B.

1 2 3

THERMOSTAT

( M AGNE TR ON )

SOLENOID

WH

WH

WH

WH

WH

RD

RD

RD

RD

RD

RD RD

YL

YL

YL

RD

RD

RD

RD

OVEN

LAMP

SWITCH

NC

YL

NO

COM

BL

WH

WH

WH

WH

AC 120V

60Hz

THERMOSTAT

(OVEN)

FUSE

GN

OVEN LAMP

O. L

TURNTABLE MOTOR

T. T. M

FAN MOTOR

F.M.

C.M.

CIRCULATION MOTOR

RECTIFIRE FU SE

CONVECTION HEA TER

REL AY 2

MONI TOR SWITCH

REL A Y1

NOTE: 1.DOOR IS CLOSED.

2. COOK OFF.

3.CIRCUIT BE SUB JECT TO

CH A NGE WITHOU T NO TICE.

SYM B OL COLOR

WH WHI TE

BK BL A CK

BL BL UE

RD RED

YL YEL L OW

PK PINK

BN BROWN

HIGH VOL TAGE

DIODE

MAGNETRON

HIGH VOL TAGE

HIGH VOL TAGE

CAPACITOR

TRA N SFORM ER

1 2 3

SECONDARY

SWITCH

WH

WH

THERMI S TOR

PRIMAR Y

SWITCH

Fig. 8

– 18 –

CIRCUIT DESCRIPTION

• The low voltage transformer supplies the necessary

voltage to the micom controller when power cord is

plugged in.

• As the door is opened, the contact of MONITOR

SWITCH short. This switch creates the short circuit

to blow 15 A fuse during operation under abnormal

condition. (i.e. should the contacts of primary switch

and relay and/or secondary switch fail to open the

circuit).

WHEN COOKING POWER AND COOKING TIME

ARE SET BY TOUCHING THE TIME AND THE

POWER PAD

• The micom controller memorizes the function you

set.

• The time or cooking power you set appears in the

dispaly window.

• Each indicator light turns on to indicate that stage

has been set.

WHEN TOUCHING THE START PAD WITH THE

MICROWAVE FUNCTION SELECTED.

• The oven lamp, fan motor and turntable motor operate by closing the relay 3 and primary switch.

• The 120 Volts AC is supplied to the high voltage

transformer through the contact of the relay 1 and

primary switch. 3.5 Volt AC generated from the filament (winding of the high voltage transformer

applied to the magnetron to heat magnetron filament) through two noise suppression chock coils.

A high voltage 2100 Volts AC is generated in the

secondary winding of the high voltage transformer

and this secondary voltage is increased by action of

the diode and charging of the high voltage capacitor.

This resultant is then applied to the magnetron via

the filament.

• The disturbance wave generated by the magnetron

is suppressed by the choke coils, filter capacitors

and the magnetron shielded case, so that TV and

RADIO programs are not impaired by noise.

WHEN TOUCHING THE START PAD WITH THE

CONVECTION COOKING FUNCTION SELECTED.

• Relay 2 is closed to provide a current path to the

Convection Heater.

• The microwave does not emit with Relay 1 open.

• The Relay 3, 4 and primary switch are closed to

provide a current path to the oven lamp, the turntable motor, the fan motor and the circulation motor.

WHEN THE OVEN IS SET AT SOME COOKING

POWER EXCEPT MAX. COOKING POWER.

• Micom controller controls the ON-OFF time of the

RELAY by the applied gets signal to vary the average output power of microwave oven from “COOKING POWER 10” to “COOKING POWER HI”.

• One complete cycle of Relay is 22 seconds.

WHEN THE DOOR IS OPENED DURING COOKING.

• Both primary switch and relay open to cut off

primary winding voltage to the high voltage transformer.

• ON-OFF of relay is coupled electrically with open

and close of secondary switch.

• When the door is opened, secondary switch is

closed and when the door is closed, secondary

switch is opened.

• Function indicator light and colon turn off and display stops counting down.

• Relay stops functioning.

• As the door is opened, if the contact of primary

switch and relay and/or secondary switch fail to

open, the 15 A fuse opens due to the large current

surge caused, by the monitor switch activation and

then stops magnetron oscillation.

– 19 –

MAGNETRON TUBE

• The magnetron tube is the heart of the microwave

oven. It is basically a diode with the addition of a

magnetic field. The magnetron tube assembly consists of cylindrical cathode (negative) terminal,

enclosed within a cylindrical anode (positive) terminal, evacuated of all air, and surrounded by a permanent magnet.

• In order to create an electron flow from cathode to

anode, the cathode must be heated and a potential

difference must exist between the two. This is

accomplished by heating the cathode with 3.15 VAC

(from the filament winding of the high voltage transformer), and applying a negative 4000 VDC (from

the voltage doubler circuit) to the cathode.

• Originally, the electrons would travel in a straight

line from the cathode to the anode (see Fig. 9).

However, with the addition of a permanent magnet

surrounding the anode creating a magnetic field, the

electrons travel an orbital path between the cathode

and anode (see Fig. 10). As the electrons approach

the anode, their orbital path takes them past small

resonant cavities that are part of the anode. The

passing notion of the electrons induces electron current to oscillate in the resonant cavities at the very

high frequency or 2,450 megahertz. This RF energy

is then transferred to the antenna.

TESTING MAGNETRON TUBE

• Disconnect power, remove the wrapper, and discharge the capacitor.

• Remove the two leads from the magnetron terminals.

• Connect the ohmmeter between one terminal of the

magnetron and the outer case of the magnetron. If

the ohmmeter reads infinity, go to below. If the ohmmeter reads less than infinity, the magnetron is

shorted.

• Connect an ohmmeter across the terminals of the

magnetron. The ohmmeter should read less than

one ohm. If the ohmmeter reads over one ohm or

infinity, the tube is defective.

MAGNETRON WITHOUT MAGNETIC FIELD

MAGNETRON WITH MAGNETIC FIELD

ANTENNA

ANTENNA

PERMANENT

MAGNET

CATHODE

CATHODE

2,450 MHz.

ELECTRONS

ELECTRONS

ANODE

ANODE

Fig. 9

Fig. 10

– 20 –

DESCRIPTION AND FUNCTION OF COMPONENTS

OVEN LAMP

The oven lamp illuminates the interior of the oven

during cooking so that food can be seen without

opening the door.

The oven lamp will turn off when the cooking time is

ended.

TURNTABLE MOTOR

The turntable motor rotates the turntable located on

the bottom of the oven cavity during the cooking

operation to cook the foods evenly.

Turntable will rotate in either direction.

OVEN THERMOSTAT

The oven thermostat located on the insulator-T, is

designed to prevent damage to the components and

acts when heater overheats to abnormally high temperatures. Under normal convection operation, the

heater thermostat remains closed. However, when

abnormal condition within the convection chamber

approaches a critical level (130°C), the oven thermostat will open and interrupt the circuit to the oven,

causing it to shut down.

MAGNETRON THERMOSTAT

The magnetron thermostat located on the magnetron,

is designed to prevent damage to the magnetron if an

overheated condition develops in the tube due to

abnormal state.

The magnetron thermostat remains closed under normal operation, but the magnetron thermostat opens

when abnormal high temperatures within the magnetron approach a critical level (145°C), causing oven to

shut down.

DOOR OPENING MECHANISM

The door can be opened by pushing button and lifting

the latch as a result of action by the latch spring, latch

and latch board jaw. The latch is released from the

latch board and the door can be opened.

PRIMARY AND SECONDARY INTERLOCK

SWITCHES (FIG. 11)

The primary interlock switch is mounted in the latch

board-U and secondary interlock switch is mounted in

the latch board-L.

When the door is closed, the switches are activated by

the latch on the door. When the door is opened, the

switches interrupt the circuit to all components except

the oven lamp.

MONITOR SWITCH (FIG. 11)

The monitor switch, mounted on the latch board-L with

the oven lamp switch, is activated by a latch on the

door while the door is closed.

If the door is opened and the primary and secondary

interlock switch contacts fail to open, this switch is

intended to render the oven inoperative by means of

fuse failure, simultaneously with the closing of monitor

switch contacts.

OVEN LAMP SWITCH (FIG. 11)

The oven lamp switch mounted on the latch board-L

with monitor switch, is activated by latch on the door

while the door is closed.

OVEN LAMP

SWITCH

MONITOR

SWITCH

SECONDARY

SWITCH

PRIMARY SWITCH

Fig. 11

Loading...

Loading...