Page 1

MODEL: MDT355(MDS355V/MDS355W)SERVICE MANUAL

Internal Use Only

Website http://biz.lgservice.com

DVD Mini Hi-Fi System

SERVICE MANUAL

P/NO : AFN75496339 JUNE, 2011

MODEL: MDT355(MDS355V/MDS355W)

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Page 2

CONTENTS

SECTION 1 ........ SUMMARY

SECTION 2 ........ CABINET & MAIN CHASSIS

SECTION 3 ........ ELECTRICAL

SECTION 4 ........ REPLACEMENT PARTS LIST

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

SERVICING PRECAUTIONS ................................................................................................................... 1-3

ESD PRECAUTIONS .................................................................................................................................. 1-5

SERVICE INFORMATION FOR EEPROM .......................................................................................... 1-6

SOFTWARE UPGRADE PROCESS ..................................................................................................... 1-7

SPECIFICATIONS ....................................................................................................................................... 1-8

1-2

Page 4

SERVICING PRECAUTIONS

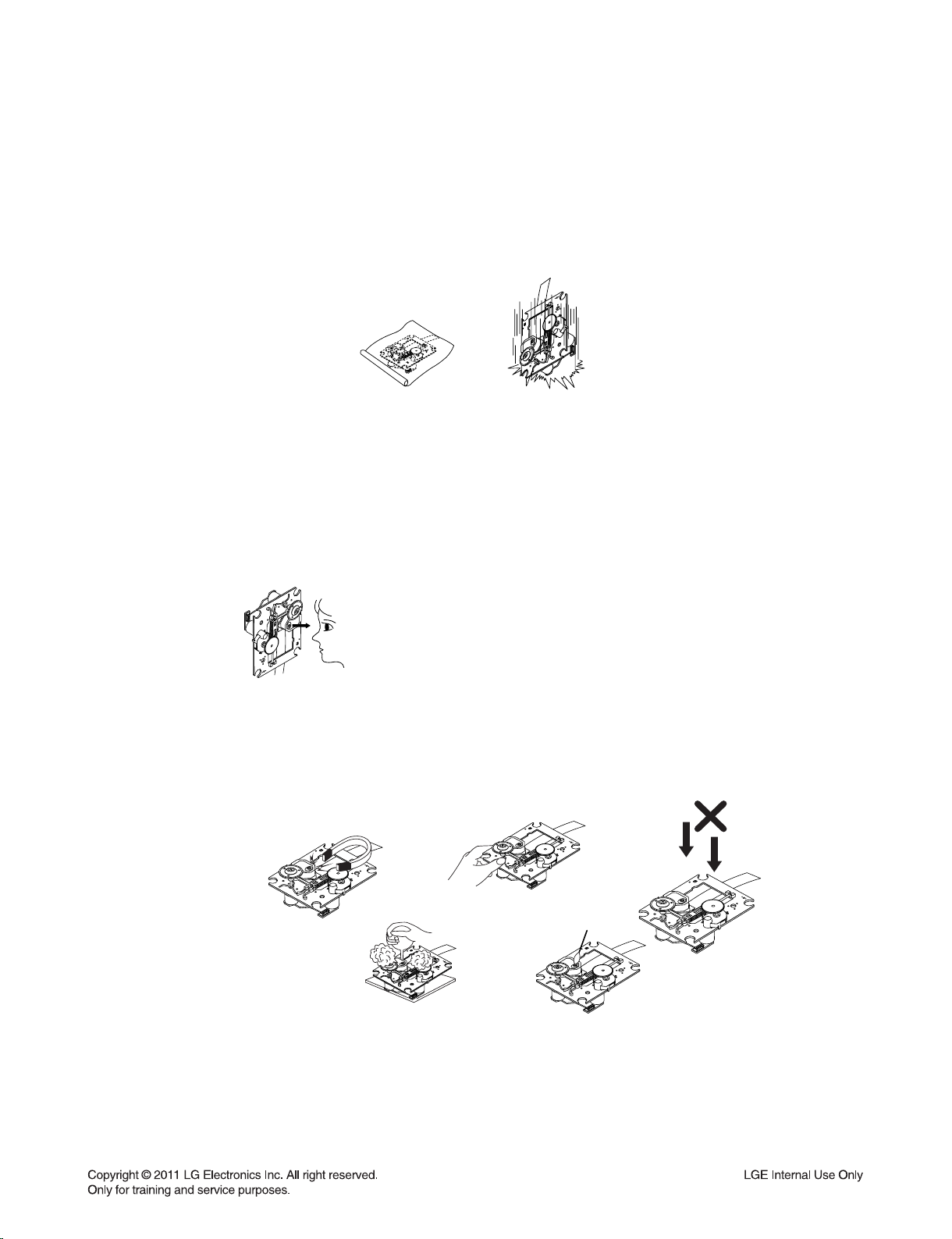

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

Storage in conductive bag

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton

swab should be used, taking care not to distort lens.

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

Drop impact

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-3

Pressure

Page 5

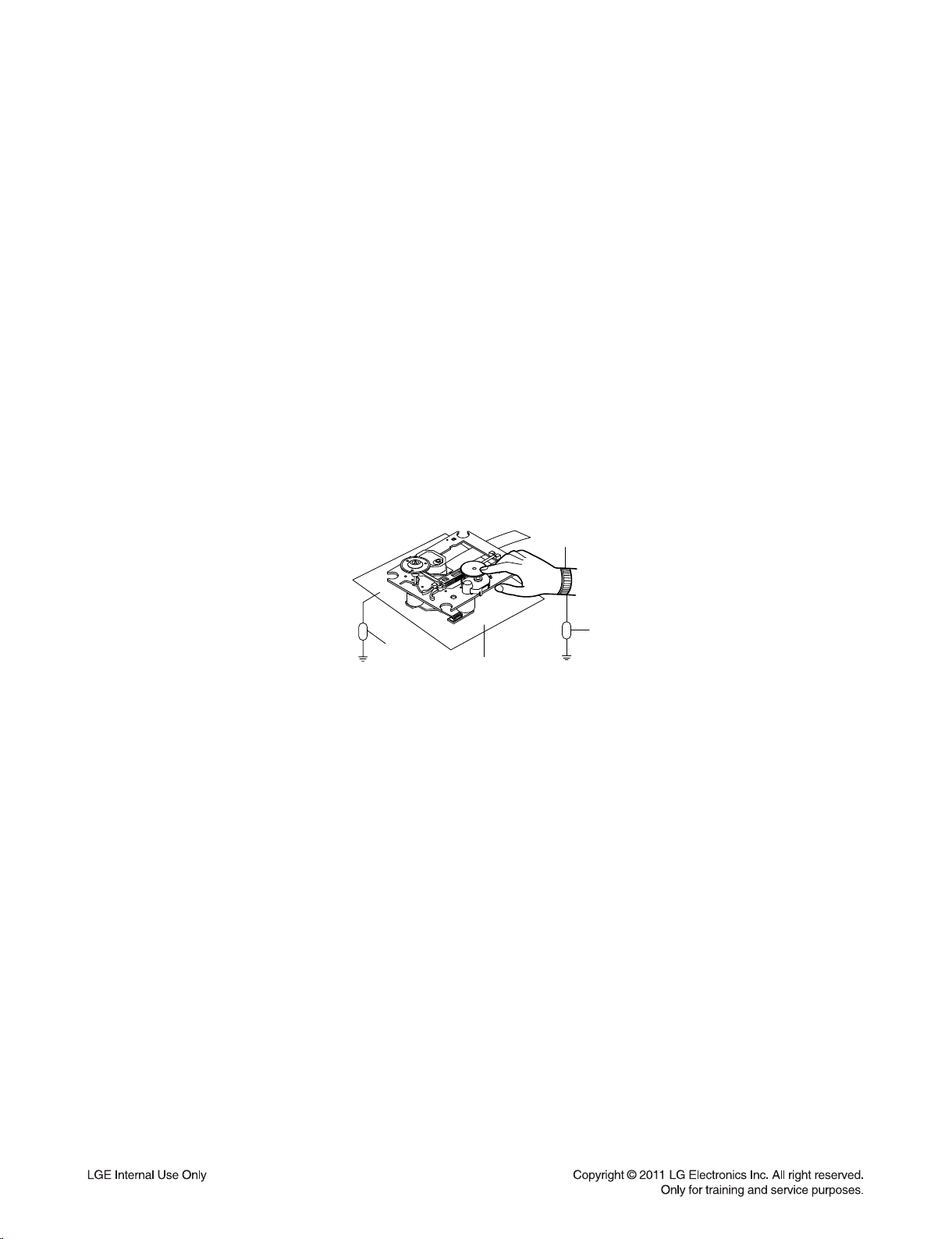

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1 MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Resistor

(1 MΩ)

Resistor

(1 MΩ)

Conductive

Sheet

1-4

Page 6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

Page 7

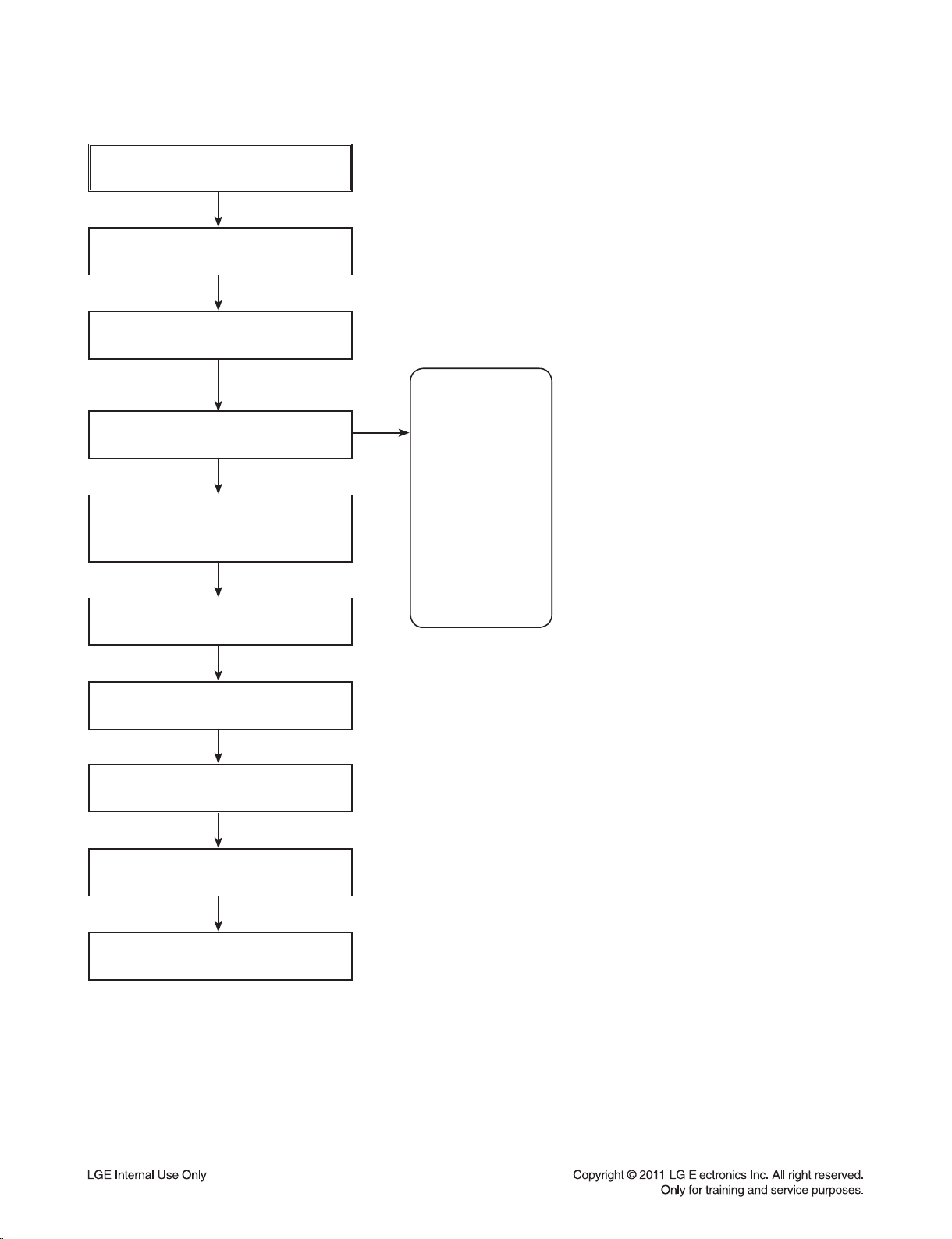

SERVICE INFORMATION FOR EEPROM

POWER ON

FLD no disc status

Remote control ‘2’ + Front ‘STOP’

push same timing during 5s

FLD ‘OP-0….

Move to appropriate position

and make changes

with Rmc ‘skip, mode, play’ key.

Press STOP key

FLD ‘write ok’

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME

OPT 0

OPT 1

OPT 2

OPT 3

OPT 4

OPT 5

OPT 6

OPT 7

OPT 8

OPT 9

HEX

F5

00

A4

DD

00

09

81

20

50

00

Remote control ‘Fwd skip’ +

Front ‘STOP’ push same timing

FLD ‘E2P CLR’

Completed

1-6

Page 8

SOFTWARE UPGRADE PROCESS

Important Notice :

When ugrade the software running. Do not shunt down the power, it tmay damage the unit.

1. MICOM UPGRADE

1) Copy the software file into USB flash, as the file name is LG_MDT355__XXXXXXX.HE

2) Insert the USB flash into USB host.

3) Set Function to USB position.

Appear onto VFD

UPGRADE

4) After finish, Set will automatically power off.

2. FLASH MEMORY UPGRADE

1) Copy the software file into USB flash, As the file name is LG_MDT355__XXXXXXX.RO

2) Insert the USB flash into USB host.

3) Set Function to USB position.

Appear onto VFD

CODE 00

NO USB

4) Manual Power off and Power on is finish.

1-7

Page 9

SPECIFICATIONS

• GENERAL

Power supply Refer to main label.

Power consumption Refer to main label.

Net Weight 5.27 kg

External dimensions (W x H x D) ( 272 x 334 x 381 ) mm

Operating conditions Temperature 5 °C to 35 °C, Operation status: Horizontal

Operating humidity 5 % to 85 %

Laser Semiconductor laser, wavelength, 760 to 800 nm

• TUNER FM/AM [MW]

FM Tuning Range 87.5 to 108.0 MHz or 87.50 to 108.00 MHz

FM Intermediate Frequency 128 kHz

AM Tuning Range 522 to 1 620 kHz, 520 to 1 710 kHz or 522 to 1 710 kHz

AM Intermediate Frequency 45 kHz

• AMPLIFIER

Output Power Front : 100 W x 2

SUB Woofer : 150 W

• USB

Bus Power Supply (USB) DC 5 V 500 mA

USB Version USB 2.0 or USB 1.1

• CD

Frequency Response 40 to 20 000 Hz

Signal-to-noise ratio More than 60 dB

Dynamic range More than 50 dB

• TAPE

F.F/REW Time 120 sec (C-60)

Frequency Response 250 to 8 000 Hz

Signal to Noise Ratio 40 dB

Channel Separation 45 dB (P/B) / 40 dB (R/P)

Erase Ratio 50 dB (MTT-5511)

• SPEAKERS

FRONT SUBWOOFER

Speaker name MDS355V MDS355W

Type 2 Way 2 Speaker 1 Way 1 Speaker

Impedance 4 Ω 3 Ω

Rated Input Power 100 W 150 W

Max. Input Power 200 W 300 W

Net Dimensions (W x H x D) ( 222 x 342 x 276 ) mm ( 272 x 334 x 332 ) mm

Net Weight 4.75 kg 5.3 kg

1-8

Page 10

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS ..................................................................................................................................... 2-3

1. CABINET AND MAIN FRAME SECTION (MDT355) ................................................................................ 2-3

2. TAPE DECK MECHANISM SECTION ...................................................................................................... 2-5

3. SPEAKER SECTION ................................................................................................................................ 2-7

4. PACKING ACCESSORY SECTION ......................................................................................................... 2-9

2-1

Page 11

MEMO

2-2

Page 12

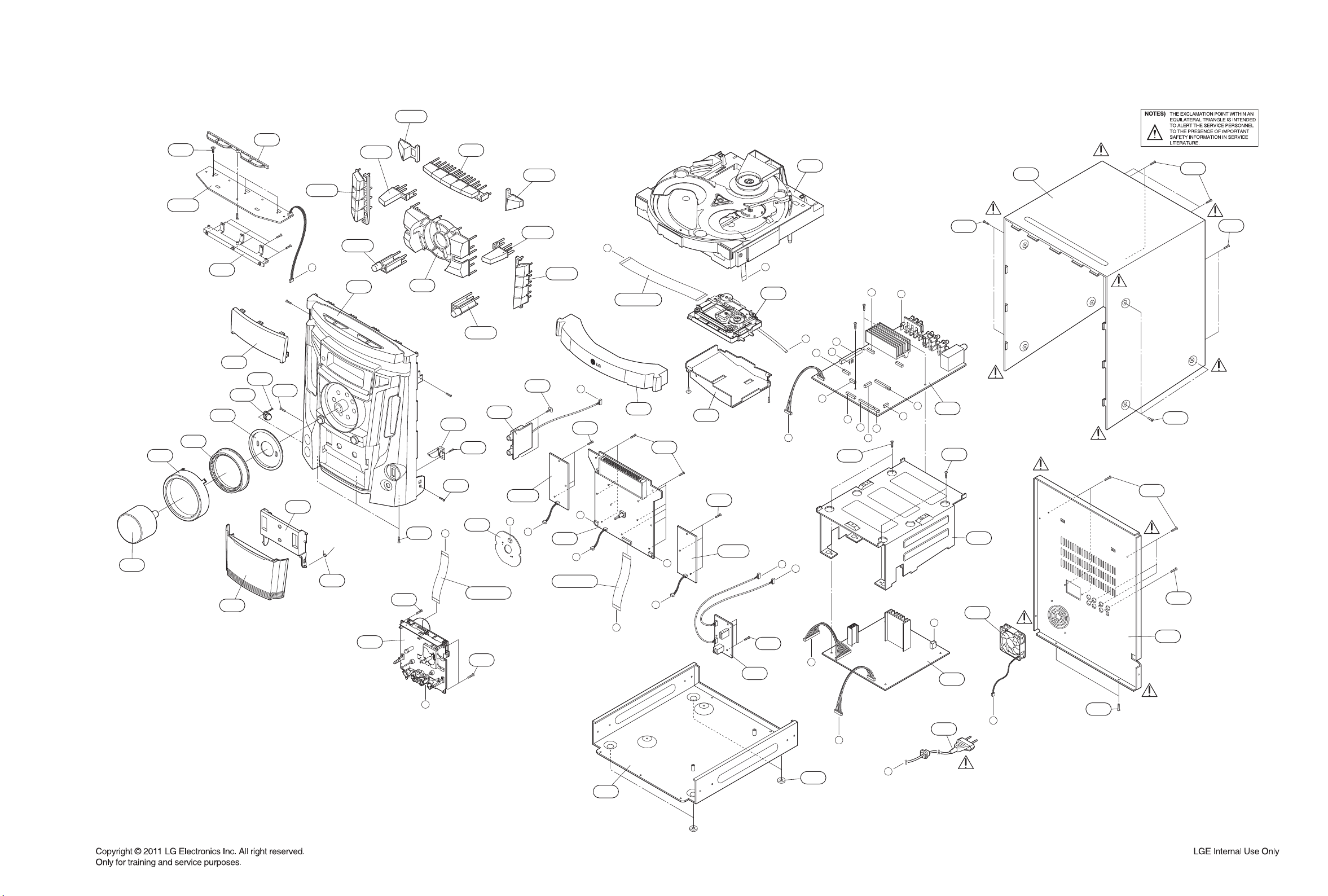

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION (MDT355)

263L

255

460

A41A

256

283

257

259

258

282

KEY3

451

452

266L

H

267L

250

264L

265

261

262

267R

451

A49

MIC

263R

264R

459

266R

KEY2

B

454

J

CABLE3

268

454

281

C

A26

A01

D

272

455

I

R

A

B

C

455

455

MAIN

D

E

F

O

H

G

456

J

K

A46

455

456

251

252

254

253

A00

453

452

G

452

A48

LED

A41L

Q

454

L

L

A43

Q

VFD

M

KEY1

A41R

271

I

K

458

CABLE2

CABLE1

M

F

USB

N

274

453

453

A

A45

O

SMPS

A47

456

R

457

273

300

E

270

N

269

2-3 2-4

Page 13

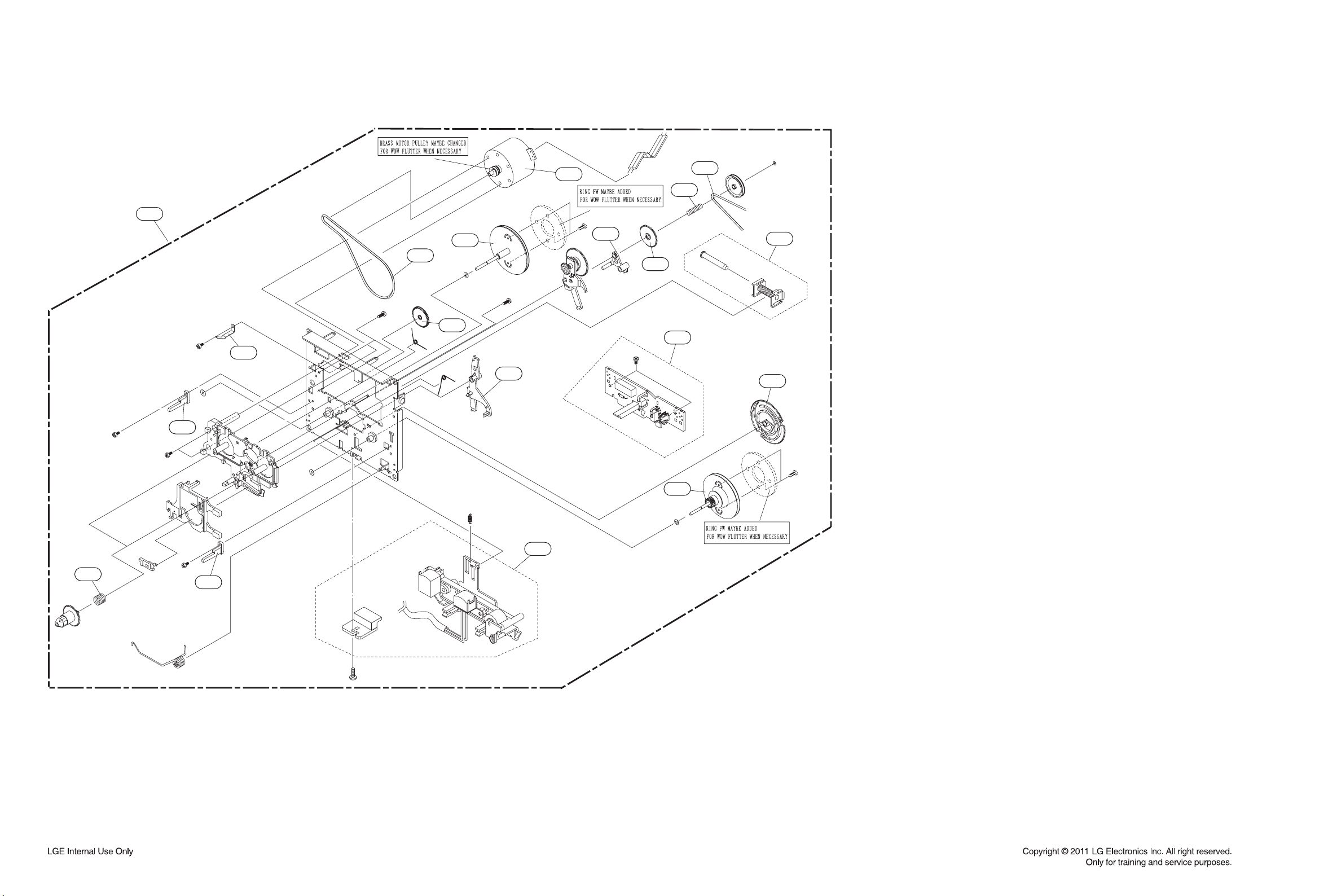

2. TAPE DECK MECHANISM SECTION

A00

009

003

001

007

037

015

006

017

020

019

022

018

A01

023

025

011

A02

009

2-5 2-6

Page 14

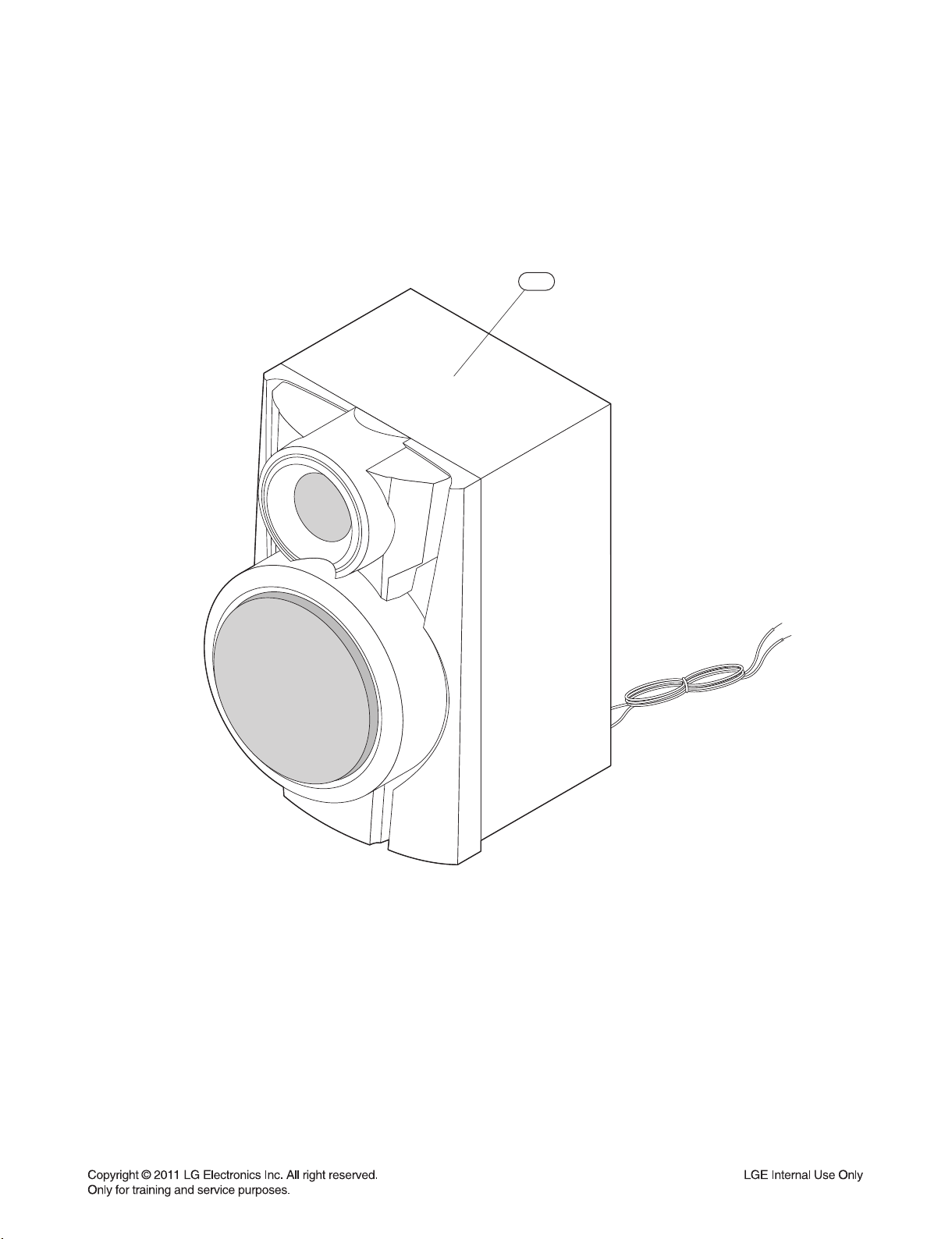

3. SPEAKER SECTION

3-1. LEFT/RIGHT SPEAKER (MDS355V)

A60

2-7

Page 15

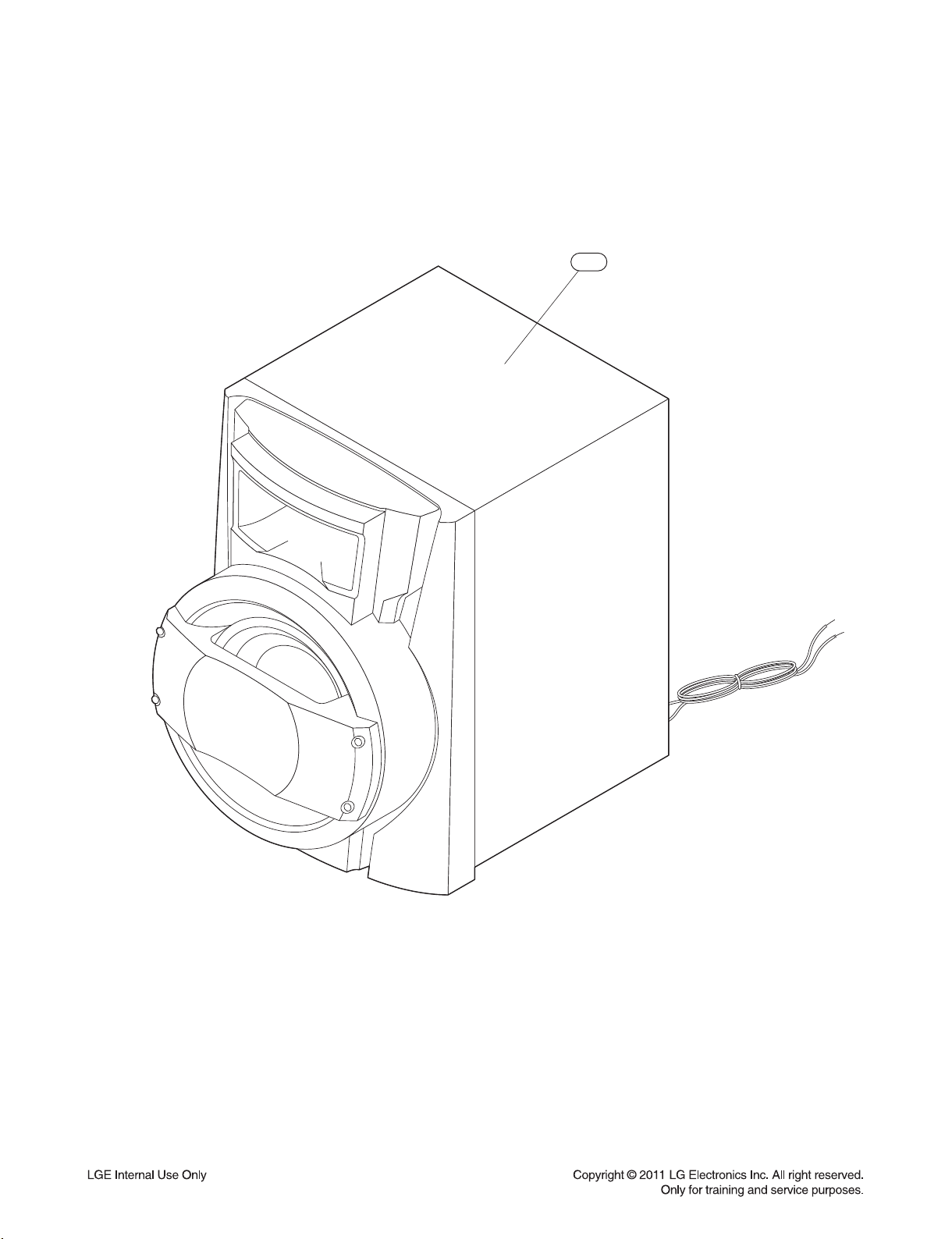

3-2. SUBWOOFER (MDS355W)

A90

2-8

Page 16

4. PACKING ACCESSORY SECTION

824 AM antenna

Remote controller900

Packing803T

825 FM antenna

Battery808

Instruction Ass'y801

Bag804

803B

Packing

Box802

2-9

Page 17

MEMO

2-10

Page 18

SECTION 3

ELECTRICAL

CONTENTS

ONE POINT REPAIR INSTRUCTION ................................................................................................... 3-2

1. NO POWER PROBLEM ......................................................................................................................... 3-2

2. VFD DOESN'T DISPLAY ........................................................................................................................ 3-4

3. THE DISC TRAY DOESN'T WORK ....................................................................................................... 3-5

4. NO BOOTING WHEN YOU TURN THE UNIT ON ................................................................................ 3-9

5. SPEAKER NO OUTPUT WHEN YOU TURN THE UNIT ON .............................................................. 3-13

6. VFD HAVEN'T SHOW WHEN YOU TURN THE UNIT ON .................................................................. 3-15

MAJOR WAVEFORMS ............................................................................................................................ 3-16

1. IC1 MICOM INTERFACE WAVEFORM ............................................................................................... 3-16

2. IC100 MICOM INTERFACE WAVEFORM ........................................................................................... 3-17

3. SLED DRIVE AND MOTOR WAVEFORM ........................................................................................... 3-18

4. SPINDLE DRIVE AND MOTOR WAVEFORM ..................................................................................... 3-19

5. RF, FOCUS AND TRACKING ERROR WAVEFORM .......................................................................... 3-20

WIRING DIAGRAM ................................................................................................................................... 3-21

BLOCK DIAGRAM .................................................................................................................................... 3-23

CIRCUIT DIAGRAMS ............................................................................................................................... 3-25

1. SMPS - POWER CIRCUIT DIAGRAM ................................................................................................. 3-25

2. MAIN - DVD MPEG CIRCUIT DIAGRAM ............................................................................................. 3-27

3. MAIN - MCU CIRCUIT DIAGRAM ........................................................................................................ 3-29

4. MAIN - SERVO CIRCUIT DIAGRAM ................................................................................................... 3-31

5. MAIN - D/AC CIRCUIT DIAGRAM ....................................................................................................... 3-33

6. MAIN - AMP CIRCUIT DIAGRAM ........................................................................................................ 3-35

7. AUDIO DECK SYSTEM CIRCUIT DIAGRAM ...................................................................................... 3-37

8. MIC / USB / KEY / VFD CIRCUIT DIAGRAM ...................................................................................... 3-39

CIRCUIT VOLTAGE CHART ................................................................................................................. 3-41

PRINTED CIRCUIT BOARD DIAGRAMS ......................................................................................... 3-45

1. MAIN P.C.BOARD ................................................................................................................................ 3-45

2. SMPS P.C.BOARD ............................................................................................................................... 3-49

3. FRONT P.C.BOARD ............................................................................................................................. 3-51

3-1

Page 19

2

W

7

V

F

C

-

ONE POINT REPAIR INSTRUCTION

1. NO POWER PROBLEM

No power problem occurs when you power on the unit.

1-1. F1, D2 and D6

1-1-1. Solution

Replace F1, D2, D6 on SMPS board.

1-1-2. How to troubleshoot (Countermeasure)

1) Look at the physical of fuse F1(Ft5a_250 V).

2) Check the bridge diode of D2(DF06M), D6(GBU6J).

D2

DF06M

2

2

3

3

SQE2930

RT1

NTC 4D-15

t

C19 104/275V

C23 102/400V

SQE2930

C25 104/275V

RV1 471

1

1

- +

4

4

1

D6

GBU6J

1

-+

4

4

12

56

7

8

34

LF1

C24 102/400V

12

5

6

8

7

34

LF2

1 2

W17 Jumper

C1

68uF/450V

3

3

C3

103/630V

330uF/

450V

C9

2

2

5

2

4

1

D19

RL104F

22uF/50V

U3

Vstr

Vcc

Ipk

GND

FSFM260

C21

DRAIN

DRAIN

DRAIN

Vfb

C14

47uF/50V

8

7

6

3

D11

RL104F

C20

272

R

56k/2

1-1-3. Service hint (Any picture / Remark)

D5

UF40

R4

10

R10

10

Check with ohm meter is short!

W10 Jumper

1 2

LTV

P

C26

472

R17

47k

R20 1.5M/0.5W

F1

250V/5A

2

R21

47k

Q7

KTA1268

1

10

R24

W12 Jumper

C33

U

3

4

1

2

Check with ohm meter is open!

3-2

Page 20

e

1 2

ONE POINT REPAIR INSTRUCTION

No power problem occurs when you power on the unit.

1-2. C29, C30 and C31

1-2-1. Solution

Replace C29, C30, C31 on SMPS board.

1-2-2. How to troubleshoot (Countermeasure)

1) Check all of voltage.

PC1

LTV-817

1

5

33

C32

561/1kV

C36

102

R16

2.7k

W11 Jumper

1 2

W16 Jumper

1

2

R31

1.5k

D22

RL104F

T2

7

6

8

9

5

4

13

14

15

3

16

2

17

18

10

11

1

12

EER4242/3335

PC3

LTV-817

R15 56

C15 470pF/1kV

1

1

2

3

3

D21

20A/200V

4

4

3

3

C37 102/400V

1

2

2

1

2

C29

2200uF

R32 470

/50V

C30

2200uF

HS2

15*10

/50V

1

2200uF

C31

R34

1k

/50V

R14

R25

33k

560

W15 Jumper

R27

33k

R28

33k

R26

33k

R18 18k

1 2

C27 2.2uF/50V

U5

KA431/TO

Danger if fuse is incorrectly replaced.

Replace only with the type identical to fuse rating

and(or) model name described in main label.

R22

1.2k

R29

82

CAUTION:

C28 2.2uF/50V

U6

KA431/TO

R19

2.7k

R23

2k

R30

150

Warn

Parts

resp

1-2-3. Service hint (Any picture / Remark)

3-3

&&&

Page 21

ONE POINT REPAIR INSTRUCTION

2. VFD DOESN'T DISPLAY

Timer doesn't work(abnormal display).

2-1. D10

2-1-1. Solution

Replace D10 on SMPS board.

2-1-2. How to troubleshoot (Countermeasure)

1) Check J1 pin3 Ö -26 V at power.

2

uF/50V

C7

1000uF/25V

1 2

W13

Jumper

1 2

W14

Jumper

100uF/25V

Q5

KTC3205

U2 78R12

3

1

U4 278R33

IN1OUT

GND3CON

C13

L1 2 2uH

GND

IN

R8 1k

C22

330uF/16V

1000uF/16V

CON

OUT

2

4

R12

36k

C5

4

2

R7 4.7k

C11

100uF/6.3V

1k

Q6

KTA1273

R6

R3

18k

3

U1 78R05

IN1OUT

CON

GND

C8

100uF/16V

KTA1268

W18Jumper

Q4

2

4

C6

100uF/6.3V

1 2

KTC3205

R9

1k

R1 4.7 k

R14

Q2

R11

4.7k

560

R5 4.7 k

W8 Jumper

1 2

C18

47uF/10V

W1 Jumper

1

2

D9

3V

W2 Jumper

1 2

D10

3V

W3 Jumper

2

1

D25

1N4148

W7 Jumpe r

1 2

D26

1N4148

W6

12

Jumper

W4

12

Jumper

12

W5

Jumper

12

12

8P

8

7

6

5

4

3

2

1

J1

W19

Jumper

W9

Jumper

8.GND

7.CD_CTRL

6.PWR_CTRL

5.PWR_SENS

4.5.6V

3.VKK

2.FL-

1.FL+

1.GND

J2

2.GND

3.GND

1

4.-12V

2

3

5.+12V

4

6.+12V

5

7.5V

6

8.5.9V

7

9.3.3V

8

9

10.3.3V

10

11.GND

11

12.GND

12

13.36V

13

14.36V

14

15.36V

15

15P

2-1-3. Service hint (Any picture / Remark)

3-4

Page 22

ONE POINT REPAIR INSTRUCTION

3. THE DISC TRAY DOESN'T WORK

When you turn on the set, the disc tray won't work.

3-1. U1

3-1-1. Solution

Replace U1_KA78R05 on SMPS board.

3-1-2. How to troubleshoot (Countermeasure)

1) Check all of voltage.

2) 5 V unnormal.

W1 Jumper

1

22uH

1000uF/16V

12

CON

OUT

3

2

4

R12

36k

1k

C5

4

2

R7 4.7 k

C11

100uF/6.3V

1k

Q6

KTA1273

2

U1 78R05

1

IN

OUT

3

R6

R3

18k

GND

100uF/16V

CON

C8

W18Jumper

Q4

KTA1268

2

4

C6

100uF/6.3V

1 2

KTC3205

R9

1k

R1 4.7 k

Q2

R11

4.7k

R5 4.7 k

W8 Jumper

1 2

C18

47uF/10V

D9

3V

W2 Jumper

1 2

D10

3V

W3 Jumper

2

1

D25

1N4148

D26

1N4148

W6

12

Jumper

W4

12

Jumper

12

W5

Jumper

12

12

8P

8

7

6

5

4

3

2

1

J1

W19

Jumper

W9

Jumper

8.GND

7.CD_CTRL

6.PWR_CTRL

5.PWR_SENS

4.5.6V

3.VKK

2.FL-

1.FL+

1.GND

J2

2.GND

3.GND

1

4.-12V

2

3

5.+12V

4

6.+12V

5

7.5V

6

8.5.9V

7

9.3.3V

8

3-1-3. Service hint (Any picture / Remark)

3-5

Page 23

0

R

1

m

2

ONE POINT REPAIR INSTRUCTION

When you turn on the set, the disc tray won't work.

3-2. U4 and D8

3-2-1. Solution

Replace U4_278R33 and D8 on SMPS board.

3-2-2. How to troubleshoot (Countermeasure)

1) Check all of voltage.

2) 3.3 V abnormal.

5

2

4

1

D19

RL104F

U3

Vstr

Vcc

Ipk

GND

FSFM260

DRAIN

DRAIN

DRAIN

Vfb

C14

47uF/50V

C3

103/630V

8

7

6

3

D11

RL104F

C20

R2

56k/2W

D5

UF4007

R4

10

R10

10

1

1

3

3

2

2

4

4

5

5

10

9

8

7

12

13

11

15

10

D3 SB360

1000uF/16V

9

D7 UG 2D

8

D8 SB360

7

12

13

D14 RL104F

11

D17 RL104F

15

1000uF/16V

100uF/50V

3-2-3. Service hint (Any picture / Remark)

C4

C10

C12

C7

1000uF/25V

1 2

W13

Jumper

KTC3205

1 2

3

1

1

IN

GND3CON

C13

100uF/25V

Q5

U2 78R12

CON

GND

IN

U4 278R33

OUT

R8 1k

1000uF/16V

OUT

2

4

R12

36k

C5

4

2

R7 4. 7k

C11

100uF/6.3V

1k

Q6

KTA1273

1

IN

3

GND

100uF/16V

R6

R3

18k

OUT

CON

C8

W18 Ju

Q4

KTA1268

2

4

10

1

3-6

Page 24

_

D

R

V

L

E

L

P

P

ONE POINT REPAIR INSTRUCTION

When you turn on the set, the disc tray won't work.

3-3. IC401

3-3-1. Solution

Replace IC401_IP9011 on main board.

3-3-2. How to troubleshoot (Countermeasure)

1) Check 5 VM voltage.

2) Check IC401 pin15,16,17,18 1.5 V?

3) All of normal, please check R404,R444,R424,R410, also replace IC401.

5VM

R4A1

27K

C413

GND

C428

104P

R4A2

9K1

220uF

C409

10V

104P

3

1DO1-

2DO1+

3DO2-

4DO2+

5VCC1

6IN2

7IN1

2PGND

8MUTE

9CTL3

10 REV3

11 FWD3

12 SVCC

13 DO3+

41DO4-

C408

220uF

10V

_MUTE

SE

N

D+

D-

R432

C438

100P

56K

R447

R422

1K

1K

R408

3K3

C188

C421

103P

C439

100P

L408

FB2500

C419

473P

R444

9K1

C414

R404

C425

20K

104P

103P

R452

DNGDNG

100R

GND

NC

GND

3-3-3. Service hint (Any picture / Remark)

R4A3

33K

V2.3V45.

R4A0

9K1

C402

C451

104P

R424

R410

R499

1K8

8K2

5K1

GND

C404

100uF

10V

C423

474P

28DO6-

DO6+

27

FWD5

26

REV5

25

CTL5

24

BIAS

DO5-

DO4+

23

22GND

03DNGP9

21IN4

IN5

20

19VCC2

18DO5+

17

16

1

5

R409

1K8

IC401

IP9011

3OD

-

C440

104P

C420

474P

R445

10K

XX

R402

1K2

R448

1K2

C435

104P

R417

33R

SPNN

TURD

TUR

GND

SPIND

TU

TU

S

SL

S

S

SP

S

IC401(IP9011)

3-7

R404, R444

R424, R410

Page 25

ONE POINT REPAIR INSTRUCTION

When you turn on the set, the disc tray won't work.

3-4. IC1

3-4-1. Solution

Replace IC1 ESS8390 on main board.

3-4-2. How to troubleshoot (Countermeasure)

1) Check 5 V CD voltage.

2) Check 3.3 V.

3) Check X501, X100.

4) Check IC100 to IC1 communication resistor R84, R109, R110, R581.

5) Check IC1 to IC502 communication resistor R83, R541, R542.

6) Check ESS8390 SERVO voltage 1.5 V up to snuff instead IC501.

3-4-3. Service hint (Any picture / Remark)

,&

,&

;

,&

;

,&

3-8

Page 26

ONE POINT REPAIR INSTRUCTION

4. NO BOOTING WHEN YOU TURN THE UNIT ON

When you turn on the set, it will show 'welcome' message continuously on the front

panel. And it will not boot-up normally.

4-1. IC503(W25Q16A), IC3(SN74LV00A)

4-1-1. Solution

Replace IC503,IC3 on main board.

4-1-2. How to troubleshoot (Countermeasure)

1) If 3.3 V haven't on main board of P1, please check P-SENS 5V come out or not?

Please check D1 or replace D1 on SMPS.

2) Check or replace L509.

4-1-3. Service hint (Any picture / Remark)

,&

,&

/

3-9

Page 27

ONE POINT REPAIR INSTRUCTION

When you turn on the set, it will show 'welcome' message continuously on the front

panel. And it will not boot-up normally.

4-2. IC100 (LC87F5NC8A)

4-2-1. Solution

Replace IC100 on main board.

4-2-2. How to troubleshoot (Countermeasure)

1) If 3.3 V haven't on main board of P1, please check P-SENS 5V come out or not?

Please check D1 or replace D1 on SMPS.

2) If 5V normal, first check R100, R101, R102; OK!

Check the IC101 out and check the zener diode ZD101 voltage if between 4.18 ~ 4.3 V(main pcb).

3) After changging it, the SET is still not booting, please check 5.6 VA at P7904 come out?

Please check or replace diode D3 or L1 on the SMPS board;

Other check the main MCU reset IC U101_KIA7027 of replace it, check or replace D101,D102(main PCB bottom )

4) All of changed the SET still boot-up, please check or replace IC100_LC87F5NC8A(main pcb).

4-2-3. Service hint (Any picture / Remark)

'

3

'

='

,&

,&

3-10

Page 28

ONE POINT REPAIR INSTRUCTION

When you turn on the set, it will show 'welcome' message continuously on the front

panel. And it will not boot-up normally.

4-3. X100

4-3-1. Solution

Replace X100_9.8304 MHz on main board.

4-3-2. How to troubleshoot (Countermeasure)

1) If 5.6 V normal? Please check D101, D102.

2) Check X100 pin1, 2 voltage is 2.46 V or not replace it.

4-3-3. Service hint (Any picture / Remark)

'

'

;

3-11

Page 29

ONE POINT REPAIR INSTRUCTION

When you turn on the set, it will show 'welcome' message continuously on the front

panel. And it will not boot-up normally.

4-4. X101

4-4-1. Solution

Replace X101_32.768 kHz on main board.

4-4-2. How to troubleshoot (Countermeasure)

1) If 5.6 V normal? Please check D102, D102.

2) Check X101 pin1, 2 voltage is 2.26 V or not then replace it.

4-4-3. Service hint (Any picture / Remark)

;

'

'

3-12

Page 30

ONE POINT REPAIR INSTRUCTION

5. SPEAKER NO OUTPUT WHEN YOU TURN THE UNIT ON

When you turn on the SET, it will show 'welcome' message continuously on the

front panel. And speaker have noise output.

5-1. IC604

5-1-1. Solution

Replace IC604_PS9831 on main board.

5-1-2. How to troubleshoot (Countermeasure)

1) Check 3.3 V.

2) Check X601 crytal operation.

3) Check IC604 to IC700 communication resistor R798, R703, R704, R709, R719, R708.

4) Check PWM waveform at R799, R731, R732, R736, R737, R746.

5) If check all of OK, please replace IC604.

5-1-3. Service hint (Any picture / Remark)

,&

;

3-13

Page 31

ONE POINT REPAIR INSTRUCTION

When you turn on the SET, it will show 'welcome' message continuously on the

front panel. And speaker have noise output.

5-2. IC700, IC701

5-2-1. Solution

Replace IC700, IC701 on main board.

5-2-2. How to troubleshoot (Countermeasure)

1) Check +12 V, +36 V.

2) Check IC700 / IC701 +12 V power supply resistor R701, R702, R724, R727, R726, R729, R730, R787, R753.

3) Check signal out at L709, L708, L710, L716, L715, L711, L707, L712.

4) Check all of OK, please replace IC700, IC701.

5-2-3. Service hint (Any picture / Remark)

/

/

/

,&

/

/

/

/

/

,&

3-14

Page 32

ONE POINT REPAIR INSTRUCTION

6. VFD HAVEN'T SHOW WHEN YOU TURN THE UNIT ON

When you turn on the SET, it will show 'welcome' message continuously on the

front panel. And speaker have noise output.

6-1. U901 (PT6324)

6-1-1. Solution

Replace PT6324 on VFD display board.

6-1-2. How to troubleshoot (Countermeasure)

1) Check F+_-22V, F-_-25V, VKK_-26V, VDD_+5.6V.

2) Check IC100 to U901 communication resistor R912, R913, R914.

3) Check FB914, FB907, FB906, FB918, FB908, FB910, FB911.

4) If check all of OK, please replace U901.

6-1-3. Service hint (Any picture / Remark)

37

3-15

Page 33

MAJOR WAVEFORMS

1. IC1 MICOM INTERFACE WAVEFORM

1) During power on 2) During normal play

1

2

3

IC1 Pin33 DVD_CE

IC1 Pin72 RESET

IC1 Pin34 DVD_DO

IC1 Pin35 DVD_DI

4

1

2

3

4

IC1 Pin35 DVD_DI

IC1 Pin33 DVD_CE

IC1 Pin72 RESET

IC1 Pin34 DVD_DO

FIG. 1-1 FIG. 1-2

CVBS

C198 10P

C127 10P

C128 10P

XOUT

R5A9

MRST

R5B2

750R

MCLK

FB600

C196

C195

103

103

GND

UP_SW

TURO+

TURO-

SENSOR

DOWN_SW

DALRCK

ADC_BCK

ADC_DATA

IN_SW

L21

FB600

OUT_SW

OPT_OUT

SPI_DO

SPI_DI

SPI_CLK

SPI_CLK_4MB

COREVCC

CLK/TDMCLK/RBCK

2

AUX3[0]/CAMIN0

IC1

ESS8390/8391SCC

AUX3[1]/CAMIN1

AUX3[2]/CAMIN2

AUX3[3]/CAMIN3

AUX3[4]/CAMIN4

AUX3[5]/CAMIN5

AUX3[6]/CAMIN6

AUX3[7]/CAMIN7

AUX15/656CLK

AUX14/TBCK/TXD1

AUX13/RWS/TDMFS

AUX12/RBCK/TDMCLK

AUX11/RSD/TDMDR

AUX10/TSD[3]

AUX9/HSYNC/TXD2

AUX8/VSYNC/RXD2

31 4

DWE/SEL_PLL19DSCK10DQM11DB712DB613DB514VD3315VS3316VDD17DB418DB319DB220DB121DB022DB823DB924DB1025DB1126DB1227DB1328DB1429VS3330VD3331DB1532AUX733AUX634AUX535AUX436VD3337VS3338VDD39AUX340AUX241AUX142AUX043SPI_CS244SPI_CS3

8

VDAC/YUV6

FDAC/YUV7

RESET/YUV4

COMP/YUV3

RESET

SPDIF_OUT

SPDIF_IN

SPI_DO

SPI_DI

SPI_CLK

80

R5A0

C90

79

390 1%

104

78

77

VREF

76

VD33

75

VS33

74

73

72

MCLK

71

70

69

VDD

68

VS33

67

VD33

66

65

64

63

62

61

60

59

58

57

56

55

54

53

VD33

52

VS33

51

50

49

48

47

46

45

C129

10P

C89

104

C81

104

R551

R5B4

750R

FB600

C182

330P

104

C540

C551

104

TP1

R558 FB272

R554 FB272

R5A8 FB272

R5B8 10R

C550

104

R5B7 FB600

Intel Flash Option

R5B6 NC

R5B9 0R

104

468

DB9

C535

C79

C541

104

468

12357

R5A7

R581 33R

10R

DVD_CLK

DB15

DB14

DB13

DB12

DB11

DB10

MCLK

DALRCK

ADC_DATA

ADC_BCK

104

R84 33R

R109 100R

R110 33R

L24 FB272

C186

GND

100P

V_MUTE

DVD_DI

DVD_DO

DVD_CB

PWMMUTE

DADATA_0

DADATA_1

DADATA_2

DADATA_3

R-X

NC

R43 33R

R543 33R

R566 33R

PWM_MUTE

SPI_CS3

I2C_DATA

I2C_CLK

104

C539

468

12357

R83 33R

R541 33R

R542 33R

DB5

DB6

DB7

DQM

DSCLK

WE

104

C542

468

R5A1

R5A4

10R

10R

12357

12357

R5A5 10R

DB8

DB1

DB0

DB2

DB3

DB4

220uF

C78

C549

16V

104

3-16

Page 34

2. IC100 MICOM INTERFACE WAVEFORM

1) During power on 2) During normal play

5

5

IC100 Pin25 DVD_CLK

IC100 Pin25 DVD_CLK

IC100 Pin29 DVD_RST

6

IC100 Pin29 DVD_RST

6

FIG. 2-1 FIG. 2-2

MIC_SENS

380_DSP_RST

R100

4K7

5V1

370_BQ_STB

360_ADC_RST

35

34

33NC

32I_VOL_A

31I_VOL_B

R101

4K7

ZD101

TP112

TP210

TP211

PWR_SENS

IC100

LC87F5NC8A

0_BQ_RST

0_PWM_RST

65

18 I_MIC_SENSE

19 I_SPBANA

20 I_DECK_LBAF_A

21 I_DECK_LBAF_B

22 I_HALL_A

23 0_DVD_DO

24 I_DVD_DI

25 I_DVD_CLK

26 0_VFD_DO

27 0_VFD_STB

28 0_VFD_CLK

29 0_DVD_RST

30 0_HP_MUTE

R166 100R

HP_MUTE

DVD_RST

VFD_CLK

VFD_STB

VFD_DO

DVD_CLK

DVD_DI

DVD_DO

LBAF-B

SPBANA

OUT

DGND

IN

R102

680R(2)

BQ_RST

PWM_RST

3

2

1

KIA7042AF

BQ_STB

VOL_A

VOL_B

IC101

3-17

Page 35

3. SLED DRIVE AND MOTOR WAVEFORM

1) When focus search 2) During normal play

IC401 Pin18 SLED+ IC401 Pin18 SLED+

7

7

8

IC401 Pin15 SPIN+ IC401 Pin15 SPIN+

8

FIG. 3-1 FIG. 3-2

D

B

F0D

TRD

SLD

SPINDLBD

CD_DVD_SLCT

DRV_MUTE

CDLD

DVDLD

DVDMDI

VC

SVREF

OPEN

CLOSE

OUT_SW

IN_SW

UP_SW

DOWN_SW

SPNN

SPNP

PU_DET

SENSOR

TURO+

TURO-

IC401

IP9011

B

F0D

C402

C440

104P

C420

474P

XX

R417

33R

C435

104P

R402

1K2

R448

1K2

28DO6-

DO6+

27

FWD5

26

REV5

25

CTL5

24

BIAS

23

22GND

PGND

03

21IN4

20IN5

DO5-

DO4+

19VCC2

18DO5+

17

16

51DO4-

7

C451

104P

R424

8K2

R410

5K1

C404

100uF

10V

C423

474P

TURD_N+

TURD_N-

TURO+

TURO-

SVREF

GND

SPINDLBD

SLED+

SLED-

SPIN-

SPIN+

TRD

SLD

SPINDLBD

CD_DVD_SLCT

DRV_MUTE

CDLD

DVDLD

DVDMDI

VC

SVREF

OPEN

CLOSE

OUT_SW

IN_SW

UP_SW

SLD

DOWN_SW

SPNN

SPNP

PU_DET

SENSOR

TURO+

TURO-

8

3-18

Page 36

4. SPINDLE DRIVE AND MOTOR WAVEFORM

1) When focus search failed or there is no disc on tray

IC401 Pin6 FOD

9

IC401 Pin3 F+

10

FIG. 4-1

TR+

TR-

F+

F-

F0D

TRD

DRV_MUTE

CLOSE

OPEN

LOAD+

LOAD-

C438

100P

R447

R422

1K

R408

C188

1K

3K3

C421

103P

C439

100P

1DO1-

2DO1+

3DO2-

GND

C408

220uF

10V

4DO2+

5VCC1

6IN2

7IN1

2

8MUTE

9CTL3

10 RE V3

11 FWD3

12 SV CC

13 DO3+

41

C419

473P

R444

9K1

C413

C428

104P

C409

220uF

10V

104P

C414

R404

C425

20K

R452

100R

GND

104P

DNGDN

103P

G

NC

GND

10

9

IC401

IP9011

DNGP9

3OD

-

3-19

Page 37

5. RF, FOCUS AND TRACKING ERROR WAVEFORM

1) During normal play 2) When TOC reading

11

12

13

11

IC1 Pin136 RF

IC1 Pin136 RF

12

IC1 Pin120 TE

IC1 Pin121 FE

13

FIG. 5-1 FIG. 5-2

VC

MN

CDLD

SVREF

DVDLD

DVDMDI

C96 NC

C97 NC

C98 223

C585 472

R5B0 10K

123PI124

125

126

127

128

REX

VBO

COLD

V1650

DVDLD

DVDPD

1213

ESS8390/8391SCC

REFD

RF

A

B

C

D

E

F

VC

MN

SPINDLBD

F0D

SLD

TRD

DVDMDI

REFD

VD33RF

FB2500

C15

100uF

16V

C508

100uF

16V

C543

SPNP

+3.3VD

VD33RF

L3

C16

104

R82

4.7K

C76

C5C9

104

104

L511

FB252

C77

C5C1

680p

680p

C5A7

104

C5A1

104

104

C5A2

104

SPNN

C99 102

C100 100p

C184 NC

132

131

130

129

AGC1

AGC2

VPA

133

SPNN/MNTRN

VGA

134

SPNP/MNTRP/IMSR

DRFN

135

DRFP

136

A

137

11

B

138

C

139

D

140

E

141

F

142

G

143

H

144

MIN

145

SLV

146

DMO

147

FDO

148

SLO

149

TRO

150

CDPD

151

REFD

152

AVD33

153

AVS33

154

DVCC

155

VD33

156

C94 154

C95 102

117MP118DB119MB120TE121FE122

IC1 Pin120 TE

IC1 Pin121 FE

OPEN

CLOSE

C75 104

C69 NC

112

113

114

115

116

VPB

VGB

OPEN

CLOSE

OPENSW

IC1

PU_DET

DRV_MUTE

CD_DVD_SLCT

110

111

AMPSTBY

CLOSESW

XIN

XOUT

DADATA_1

DADATA_2

C92 104

C93 104

105

106

107

108

109

VS33

VD33

LDCO

VID_XI

VID_XO

C91 104

R198 33R/HB-121

R220 33R/HB-121

100

101

102

103

104

VDD

VS33

TBCK/PWM_01R/DAC_01R

TWD2/PWM_03L/DAC_03L

TWD3/PWM_03R/DAC_03R

3-20

Page 38

WIRING DIAGRAM

MDT355 SMPS_350W

LEFT

RIGHT

2P

FAN

MIC PCB

CN905

P7708

SIP1

Y/U/V/VIDEO OUT PUT AUX IN PUT

WOOFER

4p

P7709

FM ANTENNA

5p

AM ANTENNA

CN901

CN904

USB+PHONE PCB

MAIN BOARD PCB

Shief cable

3p

P1

SIP2

P406

15P

9p

J2

J1

LOGIC DECK

CRP42602

EAZ35771501

6p 7p

CN3

CN1

P33

P7904

P400

FFC

9P

P7905

FFC 23P

Connector

MAIN PCB TO USB PHONE PCB

3 DISC DVD DECK

CMS-S79RFVC

MAIN PCB TO 3DISC DECK

MAIN PCB TO MIC PCB

MAIN PCB TO LOGIC DECK

SMPS PCB TO MAIN PCB

5P

MAIN PCB TO KEY3 PCB

MAIN PCB TO DISPLAY PCB

P7709

DISPLAY PCB TO KEY1 PCB

DISPLAY PCB TO KEY2 PCB

P7906

MAIN PCB TO FAN

T

EA

1LOTA

2

2

1

2

2

1

1

1

1

1

4

CON901

FFC 23P

3P

2P

CN902

CN906

KEY3 PCB

KEY2 PCB

8P

CN903

2P

CON903 CO N9 0 2

DISPLAY +KEY BOARD

KEY1 PCB

IR

Controller

VFD

3-21 3-22

Page 39

BLOCK DIAGRAM

6/

(')7

63,1'/(

ZjkGjohunly

DVD PICKUP

CMS-S77CFS

M

SOL_CONT,MOTOR_CONT,MODE,REC

6

Disc Select

OPEN/CLOSE

VIDEO +COMPONENTS

OUT RCA JACK

FT24C02

IP9011

A,B,C,D,E,F,RF

EEPROM 2K

MOTOR

DRIVER

ESS8390SCC

FT24C16

EEPROM 16K

IR

LC87F5NC8A

MCU

M12L128168A-6TG

SDRAM 128M

W25Q16A

FLASH 16M

CLK, DI,D0,CE,

MPEG DSP

PHOTO_OUT,HALF_SW

Logic Deck

Control circuit

R/P SWITCH

CRP42602

LOGIC DECK

BA3216

KIA6225

P/B AMP

BA3308S

REC AMP

MIC

Jack

L /R

L / R

R / Key

Control

TU_SDA,SCLK,RESET

VFD SC,CLK,DO

PT6324

VFD

DRIVER

4052_A,B

BU4052

SWITCH

AM / FM

Tuner

Module

YST996

VFD

DISPLAY

D4558

OP Amp

Portable

In

KEY0,KEY1,KEY2

Front

Key

Control

CD L / R

WM8738

L /R

ADC

D4558

HP Amp

L / Key

Control

PS9831

PWM

SOUND PROCESSOR

S4308

Mic Amp ALC

D+, D-

HP

Jack

USB Host

POWER AMP

TAS5342A

PWM

100WX2

POWER AMP

TAS5342A

150WX1

P Sense

-12V

+12V

USB+5V

+3.5V

V

+12V

MDT355

SMPS

MULTI VOLTAGE

FL

4ΩX2

FR W

3Ω

+31.5

P Cont

FL+

FL-

VKK

3-23 3-24

Page 40

CIRCUIT DIAGRAMS

1. SMPS - POWER CIRCUIT DIAGRAM

U3

5

Vstr

2

Vcc

4

Ipk

1

GND

FSFM260

C21

22uF/50V

C26

472

R21

47k

Q7

KTA1268

1 2

W17 Jumper

DRAIN

DRAIN

DRAIN

Vfb

C14

47uF/50V

R17

47k

C34

47uF/50V

103/630V

8

7

6

3

D11

RL104F

R24

1 2

1

12

DF06M

2

D2

2

11

10

3

3

W10 Jump er

1

- +

4

4

1

D6

GBU6J

1

-+

4

4

C1

68uF/450V

3

3

450V

330uF/

C9

2

2

9

LF1 SQE2930_4p

12

4

3

8

RT1

NTC 4D-15

t

7

471/400V

C23

6

5

471/400V

C24

C19 104/275V

LF2SQE2930_4p

12

4

3

C25 104/275V

RV1 471

D19

RL104F

4

R20 1.5M/0.5W

F1

3

2

1

T5.0AL250V

2

CONN FLEX 2

JR5 MT_HOLE

1

1

1

J3

JR6 MT_HOLE

1

1

C3

56k/2W

D5

UF4007

C20

272

10

3

W12 Jumper

1 2

C33

224

EER2828(MULTI)

1

R2

3

2

R4

4

10

R10

5

1

6

3

3

4

4

3

LTV-817

3

PC2

4

4

HS1 47*17

1

U7 FSCQ1265RT

DRAIN

Vcc

F/B4Sync

GND

2

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES IDENTICAL

TO THOSE IN THE ORIGINAL CIRCUIT. SPECIAL

D1 RL104F

T1

10

10

1

3

2

4

5

6

2

1

2

1

2

R33

1k

2

1

2

1

1

5

9

8

7

12

13

11

15

14

PC1

LTV-817

561/1kV

C36

102

D3 SB360

1000uF/16V

9

D7 UG 2D

8

D8 SB360

7

12

13

D14 RL104F

11

D17 RL104F

15

D20 SR140

14

R16

2.7k

C32

1000uF/16V

100uF/50V

C4

C10

C12

W16 Jumper

R31

1.5k

C2

2.2uF/50V

C7

1000uF

1

2

/25V

1 2

W13

Jumper

1 2

W14

Jumper

D22

RL104F

100uF/25V

Q5

KTC3205

U2 7 8R12

3

GND

1

IN

U4 278R33

1

IN

GND3CON

C13

C22

330uF/16V

T2

6

5

4

13

14

15

3

16

17

2

18

10

11

1

12

EER4242/3335

LTV-817

L1 22uH

OUT

R8 1k

R15 56

7

8

9

PC3

C37 222/400V

C5

1000uF/16V

4

CON

2

OUT

2

4

100uF/6.3V

R12

36k

KTA1273

C15 470pF/1kV

1

1

2

3

3

D21

20A/200V

1

4

4

3

2

3

R7 4.7 k

C11

1k

Q6

2

2200uF/50V

1

2

1

R6

R3

18k

C29

R32 470

U1 78R05

OUT

IN

GND3CON

C8

100uF/16V

KTA1268

HS2

15*10

C30

2200uF/50V

2

4

100uF/6.3V

W18Jumper

1 2

Q4

1

C31

2200uF/50V

R34

1k

C6

KTC3205

R9

1k

R1 4. 7k

R14

R25

33k

Q2

R11

10k

560

R5 4. 7k

W8 Jumper

C18

47uF/10V

R26

33k

COMPONENTS ARE SHADED ON THE SCHEMATIC

FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

W1 Jumper

1

1

R27

33k

2

2

W15 Jump er

R28

33k

D9

open

1 2

W2 Jumper

1

2

W3 Jumper

1

2

D25

1N4148

D10

3V

W7 Jumper

2

1

R18 18k

C27 2.2uF/50V

U5

KA431/TO

Danger if fuse is incorrectly replaced.

Replace only with the type identical to fuse rating

and(or) model name described in main label.

R22

1.5k

R29

75

CAUTION:

D26

1N4148

C16

10uF/50V

NOTE :

1. Shaded(

2. Voltages are DC-measured with a digital voltmeter

W4

12

Jumper

W6

12

Jumper

C28 2.2uF/50V

U6

KA431/TO

) parts are critical for safety.

Replace only with specified part number.

during Play mode.

8P

8.GND

8

7.CD_CTRL

7

6.PWR_CTRL

6

5.PWR_SENS

5

4

4.5.6V

3

3.VKK

2

2.FL-

1

1.FL+

J1

W11

12

Jumper

W9

12

Jumper

W5

12

Jumper

J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15P

JR1 MT_HOLE

R19

2.7k

R23

2k

R30

150

Warning

Parts that are shaded are critical with

respect to risk of fire or electrical shock.

0

JR2 MT_HOLE

JR3 MT_HOLE

JR4 MT_HOLE

JR7 MT_HOLE

JR8 MT_HOLE

1.GND

2.GND

3.GND

4.-12V

5.+12V

6.+12V

7.5V

8.5.9V

9.3.3V

10.3.3V

11.GND

12.GND

13.36V

14.36V

15.36V

1

1

1

1

1

1

1

1

1

1

1

1

A

B C D E F G H I J K L M N O P Q R ST

3-25 3-26

Page 41

2. MAIN - DVD MPEG CIRCUIT DIAGRAM

R116

12

11

COMPOSITB

10

9

8

7

6

5

4

3

2

1

A

1M

X501

27MHz

C533

C536

27P

4.7K

R158

4.7K

R154

4.7K

R156

4.7K

R89

Q500

KTD1304S

Q503

KTD1304S

Q502

KTD1304S

Q501

KTD1304S

Q506

A1298Y

Q507

KTD1304S

FB600

R548

L504

220nH

C200

82P

C146

470P

L19

220nH

C126

82P

L25

220nH

C131

82P

R88

R118

10K

4.7K

27P

Y/G

PB/B

PR/R

+3.3VD

C3

104

+3.3V

R544

NC

DEBUG/NOMAL MODE

R555

4.7K

L23

R92

FB272

4.7K

R90

C193

4K7

104

GND

R91

4.7K

R93

4.7K

R596

4.7K

R95

4.7K

470nH

2.2UH

470nH

L31

L28

L20

470nH

XOUT

XIN

Y_G

R509

75R

CVBS

RF

R173

75R

FB272

10K

A

B

C

D

PB_B

E

F

R113

75R

VC

MN

SPINDLBD

PR_R

F0D

SLD

TRD

R155

DVDMDI

75R

REFD

VD33RF

L541

+12VA

C538

104

V_MUTE

DMA4

DMA5

DMA6

DMA7

C189

100P

DMA8

DMA9

DMA11

DMA3

DMA2

DMA1

DALRCK

DMA0

DMA10

BANK1

CAS

BANK0

VD33

WE

+3.3VD

C503

470P

L26

R515

R87

FB272

RASO

+3.3VD

OPT_OUT

SPI_CS3

DVD_CB

OPTION

L201

FB102K

L202

FB102K

L205

FB102K

L206

FB102K

+3.3VD

470uF

470uF

470uF

470uF

C217

10V

C216

10V

C218

10V

C219

10V

KDS226

Q11

1

KDS226

Q10

1

KDS226

Q12

1

KDS226

Q13

1

JK201

RGB&CVBS

3

2

1

2

3

4

5

6

GND

3

2

3

2

3

2

+3.3VD

VD33RF

L3

FB2500

C15

C16

100uF

104

16V

REFD

C508

100uF

16V

C5C1

680p

C543

104

+3.3V

NC

R534

GND

R96

R5A2 10R

R5A6

10R

L528

FB2500

C80

100uF

16V

COMPOSITB

Y/G

PB/B

PR/R

L511

FB252

C77

680p

C5A7

104

C5A1

104

C5A2

104

R132 4K7

NC

R5A3

10R

R82

4.7K

C76

C5C9

104

104

C5A3

104

R533 NC

C5A4

104

C548

104

+5VM

+5.6VA

C184 NC

VPA

133

VGA

134

DRFN

135

DRFP

136

A

137

B

138

C

139

D

140

E

141

F

142

G

143

H

144

MIN

145

SLV

146

DMO

147

FDO

148

SLO

149

TRO

150

CDPD

151

REFD

152

AVD33

153

AVS33

154

DVCC

155

VD33

156

VS33

157

VDD

158

SIN

159

SOUT

160

DMA4

161

DMA5

162

VD33

163

VS33

164

DMA6

165

DMA7

166

DMA8

167

DMA9

168

DMA11

169

DMA3

170

DMA2

171

DMA1

172

DMA0

173

DMA10

174

DRAS2

175

DRAS1

176

C534

104

C513

NC

R64

100R

R600

22K

VC

DVDMDI

128

DVDPD

MN

CDLD

SVREF

DVDLD

C96 NC

C97 NC

C98 223

C585 472

R5B0 10K

123PI124

125

126

127

REX

VBO

COLD

V1650

DVDLD

SPNP

SPNN

C99 102

C100 100p

132

131

130

129

AGC1

AGC2

SPNN/MNTRN

SPNP/MNTRP/IMSR

OPEN

CLOSE

C75 104

C94 154

C95 102

C69 NC

112

113

114

115

116

117MP118DB119MB120TE121FE122

VPB

VGB

OPEN

CLOSE

OPENSW

IC1

ESS8390/8391SCC

VD332VS333DSC14DSC05DRAS0/SEL_PLL26DCAS/SEL_PLL37DOE/SEL_PLL08DWE/SEL_PLL19DSCK10DQM11DB712DB613DB514VD3315VS3316VDD17DB418DB319DB220DB121DB022DB823DB924DB1025DB1126DB1227DB1328DB1429VS3330VD3331DB1532AUX733AUX634AUX535AUX436VD3337VS3338VDD39AUX340AUX241AUX142AUX043SPI_CS244SPI_CS3

1

C199

47P

1

CAS

RASO

CSO

KIA78R05P

IC951

34

R557 FB272

104

C539

468

12357

R83 33R

R541 33R

R542 33R

DB5

DB6

DB7

DQM

DSCLKWEDALRCK

2

C54

C55

100uF

104

25V

GND

104

C542

468

R5A1

R5A4

10R

10R

12357

R5A5 10R

DB1

DB0

DB2

DB3

DB4

4K7

R124

GND

USB_N

USB_P

R2C1 22R

R2C0 22R

R2A8

R2A9

15K

15K

PU_DET

DRV_MUTE

111

CLOSESW

468

12357

DB9

DB8

L208

FBS2545

C266

100P

XIN

XOUT

DADATA_1

DADATA_2

CD_DVD_SLCT

C93 104

104

105

106

107

108

109

110

AMPSTBY

VDD

VS33

VD33

LDCO

VID_XI

VID_XO

104

C535

DADATA_0

C92 104

C91 104

R198 33R/HB-121

R220 33R/HB-121

99

100

101

102

103

VS33

VD33

TBCK/PWM_01R/DAC_01R

TWD2/PWM_03L/DAC_03L

TWD3/PWM_03R/DAC_03R

468

12357

R5A7

10R

DB15

DB14

DB13

DB12

DB11

DB10

MCLK

DALRCK

ADC_DATA

1K

0R

R150

0R

RXXX

XXX

ADDATA

ADMCLK

ADLRCK

T+22

T+21

T+20

T+24

C267

C265

104P

100P

GND

R581 33R

DVD_CLK

ADC_BCK

0R

XXR

ADBCK

USB JACK

R84 33R

R109 100R

R110 33R

DVD_DI

DVD_DO

DVD_CB

PWMMUTE

0R

RXX

R304

PWM_MUTE

CN205

5

GND

4

5V_USB

3

D-

2

D+

1

GND

MIC_L

MIC_R

USB_P

DADATA_3

USB_N

C187 100P

GND

R86 33R/HB-121

R560 33R/HB-121

91

92

93

94

95

96

97

98

MIC_L

AVS33

MIC_R

USB_NO

ADC_BIAS

TWS/PWM_01L/DAC_01L

TWD0/PWM_02L/DAC_02L

TWD1/PWM_02R/DAC_02R

CLK/TDMCLK/RBCK

AUX3[0]/CAMIN0

AUX3[1]/CAMIN1

AUX3[2]/CAMIN2

AUX3[3]/CAMIN3

AUX3[4]/CAMIN4

AUX3[5]/CAMIN5

AUX3[6]/CAMIN6

AUX3[7]/CAMIN7

AUX14/TBCK/TXD1

AUX13/RWS/TDMFS

AUX12/RBCK/TDMCLK

AUX11/RSD/TDMDR

AUX9/HSYNC/TXD2

AUX8/VSYNC/RXD2

C79

C541

104

104

R43 33R

R543 33R

R566 33R

L24 FB272

C186

GND

100P

DADATA_2

DADATA_3

0R

0R

R_X

DADATA3

PWM_MUTE

I2C_DATA

I2C_CLK

V_MUTE

DADATA_0

DADATA_1

RX

0R

0R

R194

DADATA0

DADATA1

DADATA2

+3.3VD

C14

103P

89

90

AVD33

USB_PO

VS33PLL

VD33PLL

TDAC/YUV1

UDAC/YUV0

CDAC/YUV2

YDAC/YUV5

VS33DAC

VD33DAC

VDAC/YUV6

FDAC/YUV7

RESET/YUV4

COMP/YUV3

AUX15/656CLK

AUX10/TSD[3]

SPDIF_OUT

SPDIF_IN

SPI_CS3

RESET

SPI_DO

SPI_DI

SPI_CLK

470uF

GND

R85

33K

L519

FB2500

C516

C88 473

105

R540 22K

100uF

C591

16V

FB2500

+3.3VD

L524

L522

FB2500

0R

C87

C529

R272

88

87

86

85

84

83

82

104P

81

C68

80

R5A0

C90

79

390 1%

104

78

77

VREF

76

VD33

75

VS33

74

73

R5B4

72

MCLK

VDD

VS33

VD33

VD33

VS33

R-X

NC

C18

10V

FB600

71

70

104

69

C540

68

67

66

C551

65

104

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

RCHOUT

LCHOUT

IC501

NC

1.5V

2

3

1

104

C85

104

C89

104

C81

104

C182

330P

R558 0R

R554 FB272

R5A8 FB272

R5B8 10R

C550

104

R5B7 FB600

Intel Flash Option

R5B6 NC

R5B9 0R

C78

220uF

16V

COREVCC

100uF

16V

C86

104

PR_R

PB_B

Y_G

CVBS

C198 33P

C127 33P

C128 33P

R551

750R

TP1

XOUT

R5A9

MRST

R5B2

750R

MCLK

FB600

C196

C195

103

103

GND

UP_SW

TURO+

TURO-

SENSOR

DOWN_SW

DALRCK

ADC_BCK

ADC_DATA

IN_SW

L21

FB600

OUT_SW

OPT_OUT

SPI_DO

SPI_DI

SPI_CLK

SPI_CLK_4MB

COREVCC

C549

104

R203

270R(3)

+12VA

4V7

ZD201

C201

4.7uF

50V

R201

91R

R202

C202

91R

4.7uF

50V

C204

C205

222P

222P

GND

B C D E F G H I J K L M N O P Q R ST

+3.3VD

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DQM

WE

CAS

RASO

CSO

BANK0

BANK1

DMA10

DMA0

DMA1

DMA2

DMA3

SPI_CS3

SPI_DI

L510

FB2500

C107

104

C110

104

C557

104

C5B8

104

330P

C558

C220

C221

47uF

103P

16V

GND

C225

103P

GND

IC502

M12L128168A-6TG

VDD1

1

DQ0

2

VDDQ3

3

DQ1

4

DQ2

5

VSSQ6

6

DQ3

7

DQ4

8

VDDQ9

9

DQ5

10

DQ6

11

VSSQ12

12

DQ7

13

VDD

14

LDQM40NC

15

/WE

16

/CAS

17

/RAS

18

/CS

19

BA0

20

BA1

21

A10/AP

22

A0

23

A1

24

A2

25

A3

26

VDD

27

C111

104

R5N0

R529

R94

4K7

0R

47K

FB272

1

2

3

4

L203

R97

10K

1

2

3

4

GND

W25Q16A

IC504

FT24C02

E0

VDD

E1

E2

SCL

VSS

SDA

+3.3VD

GND

R574

4.7K

CE

SD

WP

VSS5SI

IC503

8

WC

7

6

5

L215

FB272

DNG

VSS

DQ15

VSS

DQ14

DQ13

VDD

DQ12

DQ11

VSS

DQ10

DQ9

VDD

DQ8

VSS

UDQM

CLK

CKE

A11

VSS

C226

103P

9AVDD

10 AGND

11 NOHP

12 LR CLK

13 MCL K

14 DGND

NC

A9

A8

A7

A6

A5

A4

FB272

L509

HOLD

FB272

WM8738

C517

220uF

10V

BUS-DVD

C117

104

C118

104

C116

104

C192

104

I2C_DATA

C120

104

DSCLK

DMA11

DMA9

DMA8

DMA7

DMA6

DMA5

DMA4

+3.3VD

VD33D

SPI_CLK

SPI_DO

+3.3VD

I2C_CLK

UP_SW

DOWN_SW

DB15

SENSOR

TUROTURO+

DB14

CD_DVD_SLCT

DB13

DRV_MUTE

OPEN

DB12

CLOSE

OUT_SW

DB11

IN_SW

SVREF

DB10

CDLD

DVDLD

DB9

VC

DVDMDI

DB8

SPNN

SPNP

RF

F

DQM

E

A

B

C

D

F0D

TRD

SLD

SPINDLBD

PU_DET

DVD_CLK

MRST

DVD_DI

DVD_DO

DVD_CB

USB_N

USB_P

MIC_L

MIC_R

R197 10K

C149

10uF

GND

16V

C147

R193

10uF

51K

16V

C148

R196

10uF

51K

16V

VD33D

CD1

VCC

1

SPI_CLK_4MB

SPI_CLK

MRST

SPI_DO

SPI_DI

SPI_CS3

IC3 SN74LV00A

D1

2

CP1

3

SD1

4

Q15

5

Q16

6

GND

7

R108 NC

14

CD2

13

D2

12

CP2

11

SD2

10

Q29

9

Q28

8

54

53

52

51

50

49

48

47

46

45

44

43

42

41

39

38

37

36

35

34

33

32

31

30

29

28

C530

104

R530

10K

VDD

8

7

SCK

6

L508

R1451KR98

1K

CXX

CX

NC

NC

+3.3VD

+12VA

C223

47uF

10V

GND

7

RIN8LIN

6VREF

5CAP

FMT

4

3BCLK

2SDATO

1DVDD

IC201

C121

C123

C124

10uF

104P

C122

10uF

104P

R226 33R

R229 33R

G

DN

R151 33R

R175 100R

10V

10V

GND

ADBCK

ADDATA

ADMCLK

ADLRCK

C515

104

SPI_RST

SPI_DO

GND

UP_SW

DOWN_SW

SENSOR

TUROTURO+

CD_DVD_SLCT

DRV_MUTE

OPEN

CLOSE

OUT_SW

IN_SW

SVREF

CDLD

DVDLD

VC

DVDMDI

SPNN

SPNP

RF

F

E

A

B

C

D

F0D

TRD

SLD

SPINDLBD

PU_DET

DVD_CLK

DVD_RST

DVD_DI

DVD_DO

DVD_CB

USB_N

USB_P

MIC_SIG

DOWNLOAD & DEBUG

CN2 NC

1

GND

2

SPI_RST

3

SPI_DO

4

SPI_DI

5

SPI_CLK

6

SPI_CE

7

3.3V

+3.3VD

+12VA

LG-MDT355/MDD265/MDD65/MDD105

MAIN BOARD DVD MPEG(ESS8390)

3-27 3-28

Page 42

3. MAIN - MCU CIRCUIT DIAGRAM

P7708

CN/2PIN

2

TP184

C840

16V

VSS4

GND

R100

104P

C812

104P

C813

4K7

5V1

+5V_UCOM

C114

50

49D_REC_SW

48D_REC_BIAS

47D_SCL_B

46

45D_MOTOR

44

43I_DSP_ESY

42I_HP _SNS

41I_PORT_SNS

40VDD4

39

380_DSP_RST

37

360_ADC_RST

350_BQ_RST

34

33NC

32I_VOL_A

31I_VOL_B

R101

4K7

ZD101

FAN DC(6.5 11V)

1

GND

TP185

GOTO FAN

104P

GND

TP106

TP104

TP103

TP101

TP109

TP110

R199 4K7

104P

C112

TP112

TP210

TP211

OUT

DGND

R102

680R(2)

PWR_SENS

3

4

VSS

IN+

IC801

MC4580

1N+61N-7OUT8VCC

5

R816 20K

C807

R815 7K5

D102

IN4001

C57

100uF

16V

D_REC_MUTE

REC_BIAS

D_SCL_B

MOTOR

HP_SENSE

BQ_STB

BQ_RST

PWM_RST

VOL_A

VOL_B

3

2

1

IN

IC101

KIA7042AF

R808 7K5

C802

R809 20K

1

2

IN-

OUT

220P

220P

OTW

AMP_RST

AMP_SD

AMP_PROTECT

BQ_RST

BQ_STB

PWM/DSP_DAT

PWM/DSP_CLK

PWM_RST

SPBANA

HP_MUTE

HP_SENSE

EEPROM_DATA

EEPROM_CLK

X1

X2

XT1

XT2

D101

IN4001

RESET

D_REC_MUTE

PB_MUTE

REC_BIAS

D_SCL_B

MOTOR

HALL_B

LBAF-B

TAPE_L

TAPE_R

GND

C803

C805

DNG

G

D

N

+5.6V

R104

330K

104P

C109

220uF

C101

10V

R1A9

1K

R63

100R(FX)

R153 100R(FX)

+12VA

47P

C674

R683 47K(FX)

C675

R684 47K(FX)

R810

560R

4u7

GND

R817

560R

4u7

GND

R902 104

L5F1

C1F2

R105

4M7

X101

32.768KHz

C103

C104

30P

30P

R191 4K7

IC102

KIA7027

1

3

VCC

OUT

GND

2

FB613 FB2500

FB612

BBAD

FB611

BBAD

47P

C804

X(272)

C806

X(272)

104

104P

PWM/DSP_DAT

PWM/DSP_CLK

R107

1M

X100

9.8304MHz

33P

C105

C106

GNDGND

G

DN

DN

G

AMP_RST

AMP_SD

AMP_PROTECT

BQ_RST

BQ_STB

PWM_RST

SPBANA

HP_MUTE

HP_SENSE

33P

OTW

+5V_UCOM

104P

C108

REC_MUTE

PB_MUTE

REC_BIAS

B-SOL

MOTOR

TA+12V

LCHOUT

RCHOUT

HALL_B

LBAF-B

TAPE-L

TAPE-R

7NC

8VCC

1B0

2B1

TO PWM

R189 100R

R190 100R

C102

223P

6SCL

IC103

FT24C16A

3B2

4GND 5SDA

TO DECK

TO ADC IC

LG-MDT355/MDD265/MDD65/MDD105

MAIN BOARD MCU

12

23P/FFC

P7905

F+

11

10

9

8

C163

C157

C142

C139

C145

7

6

5

C144

C154

C166

C159

C143

C156

C136

C133

C138

C140

C141

C158

C155

C135

GND

C412

104P

C415

104P

C417

104P

DNG

F-

-VKK

VFD-STB

VFD-DATA

VFD-CLK

DGND

+5V6

REMOTE-INT

VOL+A

VOL-B

KEY1

KEY3

+12VA

DGND

VOL_LED7

TO FRON PCB BOARD

VOL_LED6

VOL_LED5

VOL_LED4

VOL_LED3

VOL_LED2

VOL_LED1

VOL_LED8

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

GND

DNG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

C190

C181

C177

C173

C172

C176

C194

C171

C178

C167

C180

C174

C165

C164

C175

C191

C162

C170

C160

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

104P

TP1A5

TPA16

TP1A7

TP134

GND

4

3

MIC_SENS

MIC OUT

TO MIC BOARD

2

1

A

B C D E F G H I J K L M N O P Q R ST

C873

104P

SIP2

+12VA

C874

GND

P7904

8P/2.0MM

FROM SMPS

104P

GND

1

2

3

4

FL+

FL-

VKK

12345

TP136

TP135

TP137

GND

C134

104P

C35

104P

R67 0R

R68 0R

JK554

AUX-IN

+5.6V

TP1A4

PWR_CTRL

PWR_SENS

678

TP138

TP139

FB2K7

DGND_CPU

CD_PWR_CTRL

TP140

TP141

GND

1

7

8

9

3

2

6

5

4

L2

GND

+12VA

R183 100R

R184 100R

R181 100R

R178 100R

R169 100R

R170 100R

R162 100R

R129 100R

R55 100R

R56 100R

R57 100R

R58 100R

R59 100R

R60 100R

DVD_CLK

DVD_RST

DVD_DI

DVD_DO

DVD_CB

TO DVD ESS8390

MIC_SIG

KEY3

KEY2

GND

P7906

3P/2.0MM

TO KARAOKE KEY BOARD

L13

2.2UH

L14

2.2UH

L15

2.2UH

P1

GND

GND

GND

VFD_DO

VOL_A

VOL_B

DVD_DI

DVD_DO

DVD_CB

MIC_SIG

POT_R

POT_L

15P/2.5MM

FROM SMPS

12345

-12VA

TP197

R117 100K

104P

C882

104P

GND

P7709

DBBUG0

DBBUG1

DBBUG2

432

5

TP196

TP195

R192 100K

R164 100K

+12VA

KEY1

DBBUG2

KEY3

DBBUG1

DBBUG0

R44

TP165

R1C7 100R

R114 100R

R136 100R

R182 100R

GND

FB9

FB2K5

FB8

FB2K5

R1C5 100R

R1D1 100R

C825

10uF

50V

TP186

R1C6 100R

R140 4K7

R127 4K7

R163 4K7

103P

103P

C28

C31

R18

100R

C826

104P

PWM/DSP_DAT

PWM/DSP_CLK

DBBUG2

DBBUG1

DBBUG0

EEPROM_DATA

EEPROM_CLK

TUNER_RST

KEY3

TUNER_CE

KEY2

TUNER_DAT

TUNER_CLK

TUNER_GP02

VFD_PWR

DVD_CB

REMOCON

R115

330K