LG LSU243HLV Extended Piping, LSN363HLV, LS243HLV, LS303HLV, LS363HLV Engineering Manual

...

SINGLE ZONE WALL MOUNTED

EXTENDED PIPING ENGINEERING MANUAL

Single Zone Wall Mount Systems

2 to 2-3/4 Tons

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information,

and other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc. only in confidence.

This document is for design purposes only.

A summary list of safety precautions is on page 4.

For more technical materials such as submittals, catalogs, installation,

owner’s, and service manuals, visit www.lghvac.com.

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

© LG Electronics U.S.A., Inc.

About LG Electronics, Inc.

LG Electronics, Inc. is a global leader and technology innovator

in consumer electronics, mobile communications, and home

appliances. LG Electronics, Inc. comprises five business units—

Home Entertainment, Mobile Communications, Air Conditioning,

Business Solutions, and Home Appliance. LG is one of the world’s

leading producers of flat panel televisions, audio and video products,

mobile handsets, air conditioners, and washing machines. LG’s

commercial air conditioning business unit was established in 1968

and has built its lineup of residential and commercial products to

include VRF, Multi F, duct-free split systems, packaged terminal air

conditioners (PTACs), and room air conditioners. In 2011, the air

conditioning and energy solutions business unit grew to include LED

lighting and solar products. For more information, visit www.lg.com.

Duct Free Split (DFS) Technology

LG HVAC systems offer a range of solutions that are cost efficient,

quiet and attractive. Duct-Free Split (DFS) systems are “split” into

indoor and outdoor units, and provide a smart alternative to both

central HVAC and window-mounted air conditioners. These inverter

heat pump systems are available in a variety of configurations to suit

different cooling and heating situations. Installation by a qualified

HVAC contractor is safe and easy – little to no duct work or sheet

metal is required.

Inverter Systems

LG Single Zone Wall Mounted Extended Piping air-source systems

offer the opportunity to minimize ductwork in the same configuration.

The systems offer zoning without the need for zone damper systems.

LG Single Zone Wall Mounted Extended Piping systems’ advanced

controls provide exceptional building dehumidification and temperature control, and can rapidly adapt system operating parameters

to the ever changing building load. LG Single Zone Wall Mounted

Extended Piping systems are easy to design, install, and maintain.

The modular design allows occupants to control their environmental

condition, providing individualized control of the setpoint temperature

and allowing occupants to condition only the occupied zones.

Quality Commitment

LG is committed to the success of Duct-Free Split projects. We

provide industry leading technical support during installation and

commissioning. LG offers a variety of classes designed for installers

and servicers to ensure that every system installation is completed

successfully.

Classes are conducted at LG’s training centers and in field locations

at various times throughout the year and upon special request.

Introduction

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG” is a registered tra demark of LG Corp.

©

3

TABLE OF CONTENTS

DANGER

CAUTION

Introduction ..................................................................................................................................................................................................5

Architectural Appeal .....................................................................................................................................................................................6

Product Data ............................................................................................................................................................................................7-24

Product Features and Benefits ....................................................................................................................................................................8

Unit Nomenclature ......................................................................................................................................................................................9

General Data .......................................................................................................................................................................................10-11

Electrical Data ..........................................................................................................................................................................................12

Functions, Controls, Options .....................................................................................................................................................................13

Outdoor Unit Dimensions ..........................................................................................................................................................................14

Outdoor Unit Center of Gravity / Corner Weight .........................................................................................................................................15

Indoor Unit Dimensions .............................................................................................................................................................................16

Acoustic Data ......................................................................................................................................................................................17-18

Refrigerant Flow Diagrams ...................................................................................................................................................................19-20

Indoor Unit Wiring Diagrams .....................................................................................................................................................................21

Outdoor Unit Wiring Diagrams ..............................................................................................................................................................22-23

Accessories ..............................................................................................................................................................................................24

Performance Data ..................................................................................................................................................................................25-37

Cooling Capacity ..................................................................................................................................................................................26-27

Heating Capacity .................................................................................................................................................................................28-29

Maximum Heating Capacity ..................................................................................................................................................................30-31

Air Flow and Temperature Distributions Graphs .................................................................................................................................... 32-37

Application Guidelines ..........................................................................................................................................................................38-44

Equipment Selection Procedure ................................................................................................................................................................39

Building Ventilation Design Guide ........................................................................................................................................................40-41

Placement Considerations ...................................................................................................................................................................42-44

Refrigerant Piping Design & Layout Best Practices ............................................................................................................................45-53

Refrigerant Piping Design .........................................................................................................................................................................46

Installation & Best Layout Practices .....................................................................................................................................................48-52

Electrical Connections ..............................................................................................................................................................................53

Technical Data .......................................................................................................................................................................................54-56

Mechanical Specifications .........................................................................................................................................................................55

Acronyms ..................................................................................................................................................................................................56

Single Zone High Wall Mounted Extended Piping Engineering Manual

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action should not be completed.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG” is a registered tra demark of LG Corp.

4 | INTRODUCTION

©

INTRODUCTION

“Architectural Appeal” on page 6

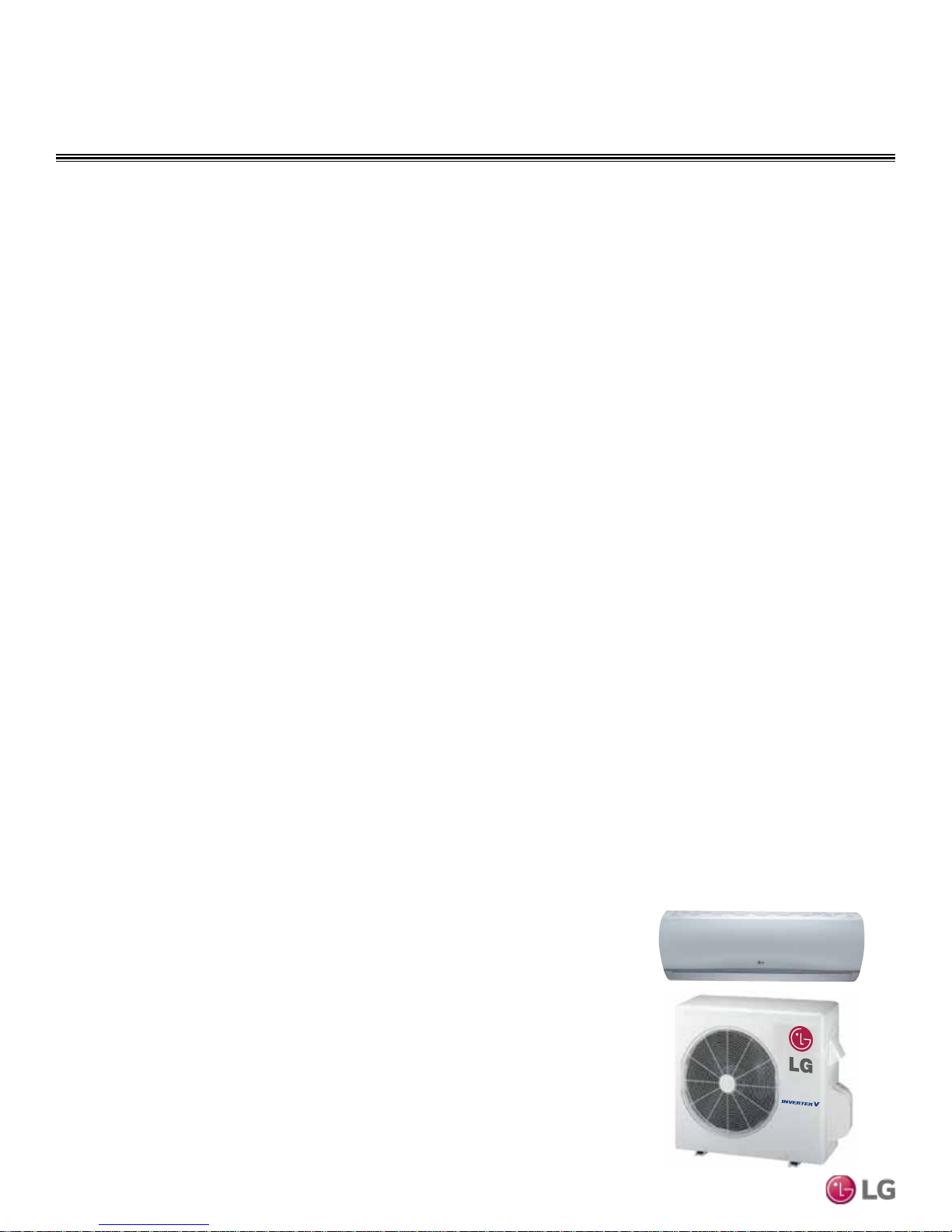

ARCHITECTURAL APPEAL

Convergence of Technological Innovation with Flexibility and Style

Single Zone Wall

Benefits of Single Zone Wall

Mounted Extended Piping Systems

• Available from 22,000 - 33,000 Btu/h

• Inverter technology

• All season use - heat pump models for both

cooling and heating capabilities

• Operating range for outdoor units of 14°F to

118°F (DB) in cooling and -4°F to 75°F (WB)

in heating

• Operating range for indoor units of 53°F to

75°F in (WB) cooling and 60°F to 86°F (DB)

in heating

• Quiet operation inside and outside

• Duct-free split system

Mounted Extended

Piping Systems

Single zone wall mounted extended piping

systems are among the industry’s best

air-conditioning units. Choosing an LG

single zone wall mount product provides

a system designer an edge to engineer a

system with individual control, and design

flexibility with advanced controls.

Single zone systems are available in a

nominal capacity range of 2 to 2-3/4 tons.

These are best suited for applications

with zones that require heating or cooling,

such as residential, and small business

office buildings. Single zone wall mount

outdoor and indoor units are available in

208–230V/60Hz/1Ph.

Adaptable and Flexible

Single zone wall mounted extended piping

systems allow cooling or heating for the

entire residence or just a single room

without the need for evasive ductwork.

There is no tearing down of walls or altering the homes appearance. Long refrigerant piping lengths allow for extra design

flexibility in indoor unit installation.

These units may be used for a number of

residential or commercial environments

such as:

• Older homes

• New home construction

• Office buildings

• Restaurants

• Hospitals / Medical facilities

• Schools

• Nursing homes

• Retail establishments

• Place of worship

Single Zone High Wall Mounted Extended Piping Engineering Manual

Inverter Technology

Inverter variable-speed DFS systems are

measurably quieter and consume less

energy than conventional air conditioners. The inverter compressor ramps up or

down to match the required room capacity

and maintain the comfort level. When the

selected temperature is reached, the inverter compressor operates at low speed

to maintain that comfort level, thereby

using less energy.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG” is a registered tra demark of LG Corp.

6 | INTRODUCTION

©

PRODUCT DATA

“Product Features and Benefits” on page 8

“Unit Nomenclature” on page 9

“General Data” on page 10

“Electrical Data” on page 12

“Functions, Controls, Options” on page 13

“Outdoor Unit Dimensions” on page 14

“Outdoor Unit Center of Gravity / Corner Weight” on page 15

“Indoor Unit Dimensions” on page 16

“Acoustic Data” on page 17

“Refrigerant Flow Diagrams” on page 19

“Indoor Unit Wiring Diagram” on page 21

“Outdoor Unit Wiring Diagrams” on page 22

“Accessories” on page 24

PRODUCT FEATURES AND BENEFITS

Single Zone Systems

Single zone wall mounted extended piping

systems are equipped with inverter components that offer superior load matching

and long piping installation. The product

works for optimizing power consumption in

residential and small office buildings. Utilizing multiple indoor wall mount units each

with custom temperature controls allow for

precise temperature settings in each zone

of the building. Single zone systems allow

flexibility in interior design and complement

any decor.

Inverter Driven

The twin rotary compressors are optimized

to maximize compressor efficiency, which

reduces power consumption and monthly

utility bills. This latest inverter technology

allows single zone system outdoor units to

vary the compressor motor shaft speed to

deliver an appropriate amount of cooling to

the indoor unit. Precise refrigerant volume

delivery translates into long periods with coil

surface temperatures below dew point and

minimizes compressor and fan component

run time. Occupants remain comfortable

while utility costs are reduced.

Low Sound Levels

When outdoor units operate fully loaded,they

have one of the quietest sound levels in

the industry. Sound is almost undetectable

during off-peak operation. To promote a

quiet, comfortable environment, the single

zone system indoor units operate at sound

levels as low as 37 dB(A) and outdoor units

as low as 55 dB(A) at full load. LG customers often ask if the outdoor unit is running

after commissioning is complete. All rotating

components are soft-started by the controller using digitally controlled inverters, which

reduce undesirable noise caused by fans

and compressors cycling on and off.

Comfort Control at Its

Best

Tight temperature control through precise

load matching maximizes the time that

the indoor units remove moisture. Unlike

traditional air conditioning control systems,

which use thermostatic controls to maintain

room temperatures, LG single zone Inverter

controls continuously adjust the indoor unit

fan speed and refrigerant flow, indirectly providing lower and more consistent humidity

levels in the conditioned space. The longer

Single Zone Wall Mounted Extended Piping Engineering Manual

the indoor coil temperature is below the

dew-point of the room in conjunction with air

movement across the coil, the space humidity level will vary little, compared to technologies that cycle fans and compressors on and

off multiple times per hour. The outdoor unit

responds by varying the compressor speed

and outdoor fan motors as needed to maintain system operating pressure. As a result,

the single zone systems deliver precise

space temperature control.

Simplified Installation

Cooling and heating applications that use

single zone systems simplify and reduce

the mechanical and control system design

time. The designer no longer has to be

concerned with interconnecting chilled and

condenser water piping, air-distribution duct

systems,matching and selecting chillers,

towers,pumps, coils, fans, air handlers, or

Variable Air Volume (VAV) boxes.

Operating Range

Single zone systems have a nominal capacity range of 2 to 2-3/4 tons (depending on

outdoor/indoor units).

Operating ranges for single zone systems:

Cooling: 14°F DB to 118°F DB

Heating: -4°F WB to 65°F WB

Installing an optional Low Ambient Wind

Baffle Kit will allow operation down to 0°F in

cooling mode for all single zone systems.

Compact Size

Single zone outdoor units have the following

footprints:

LSU243HLV, LSU303HLV, LSU363HLV

(WxHxD (in)) 34-1/4 x 31-1/2 x 12-5/8.

Fin Design with GoldFin™ Coating

All single zone outdoor units are provided

with large surface coils made of copper

tubes with louvered aluminum fins designed

to maximize unit operating efficiency over a

wide range of ambient conditions.

Standard from the factory, every single zone

outdoor unit coil fin surface is coated with

LG’s exclusive GoldFin™ anti-corrosive

coating designed to prevent natural surface

corrosion of the aluminum fins. This maintains heat transfer properties of the coil for

an extended time.

A hydrophilic coating is applied to the

outdoor unit coil fin surface over the GoldFin

coating. This coating enhances the development of heavier water droplets gathering

on the fin surface. As a result, the droplets

roll off the fin surfaces, delaying the point

when frost forms on the coil surface during

heating operation. This coating also makes it

possible to easily clean the outdoor unit coil

using a mild soap.

Other Features

• Inverter variable speed compressor

• Jet Cool / Jet Heat

• Dehumidifying mode

• Chaos Wind

• Auto restart

• Auto operation

• Self-cleaning indoor coil

• Condensate sensor connection

• Cooling only function

• Precision load matching

• Meets AHRI 210/240

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

8 | PRODUCT DATA

©

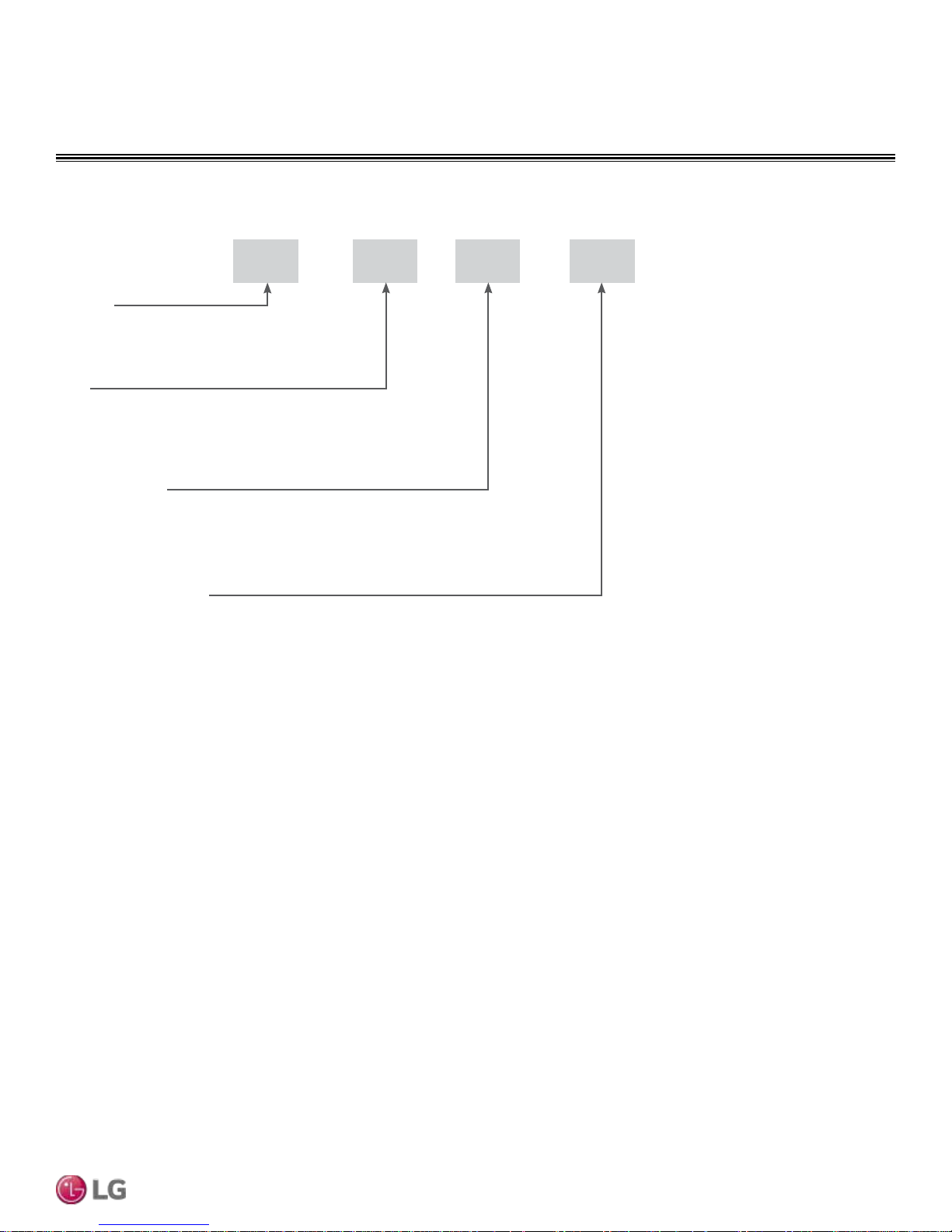

Single Zone Indoor and Outdoor Units

LS N 243 HLV

Family

LS = Wall Mounted

Type

N = Indoor Wall Mount Unit

U = Outdoor Heat Pump Unit

Nominal Capacity

(Nominal cooling capacity in Btu/h)

243 = 22,000 303 = 30,000 363 = 33,000

UNIT NOMENCLATURE

Product Data

Indoor/Outdoor Product

HLV - Extended Piping

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

PRODUCT DATA | 9

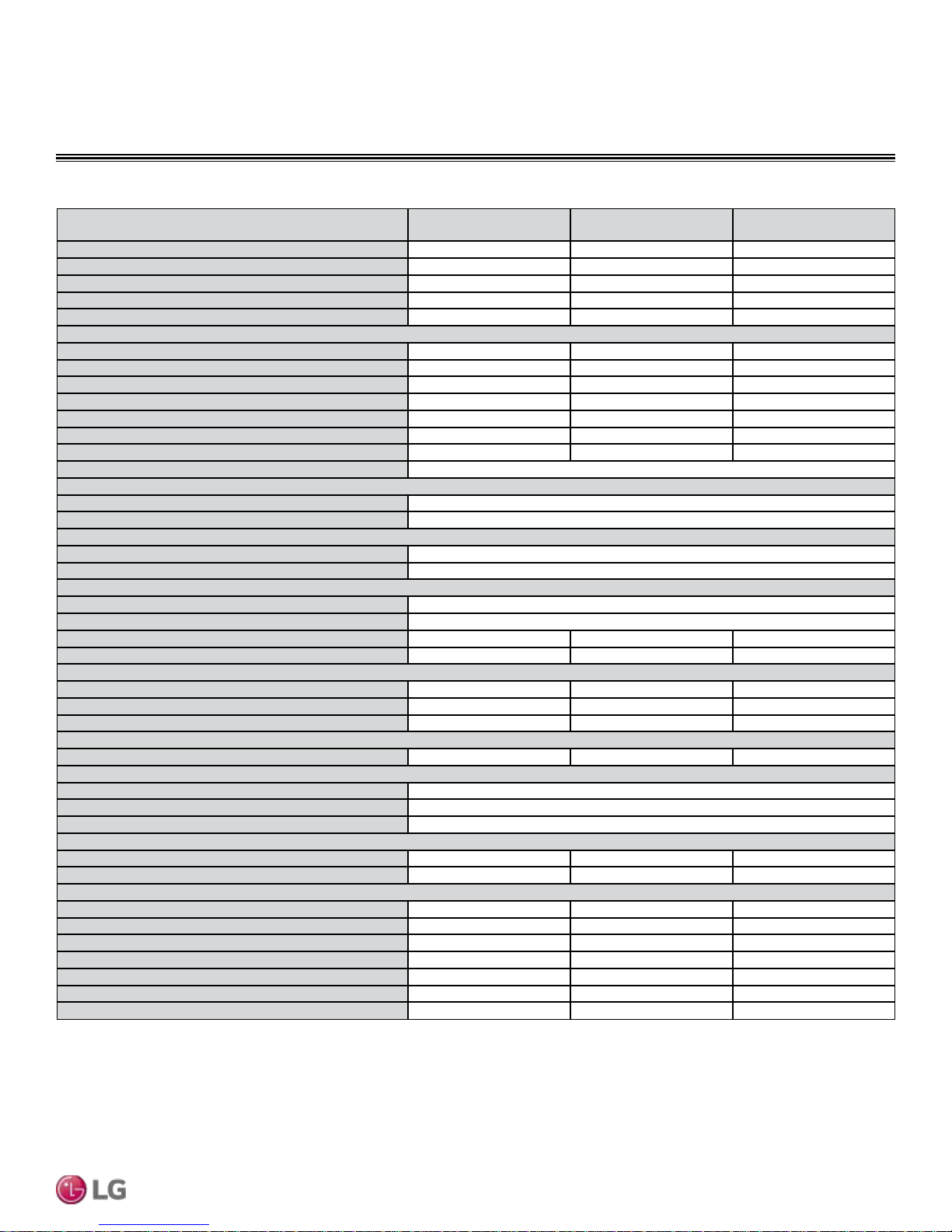

GENERAL DATA

Single Zone Wall Mounted Extended Piping System Pairing Table

The following tables show the available outdoor and indoor units, along with the factory provided controllers.

Table 1: Single Zone Wall Mounted Extended Piping System Pairing Table

Outdoor Unit Model Indoor Unit Model Controller

LSU243HLV

LSU303HLV

LSU363HLV

LSN243HLV

LSN303HLV

LSN363HLV

AKB74955602

Single Zone Wall Mounted Extended Piping Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

10 | PRODUCT DATA

©

Table 2: Single Zone Wall Mounted Extended Piping Specications.

System (Model) (Indoor Unit / Outdoor Unit)

Cooling Capacity

1

(Min/Rated/Max) (Btu/h)

Cooling Power Input1 (Rated) (kW)

Heating Capacity (Min/Rated/Max) (Btu/h)

Heating Power Input1 (Rated) (kW)

COP

Maximum Heating Capacity (Btu/h)

Outdoor 17°F (WB)/Indoor 70°F (DB)

Outdoor 5°F (WB)/Indoor 70°F (DB)

Outdoor 0°F (WB)/Indoor 70°F (DB)

Outdoor -4°F (WB)/Indoor 70°F (DB)

EER

SEER

HSPF

Power Supply V, Ø, Hz2

Outdoor Unit Operating Range

2

Cooling (°F DB)

Heating (°F WB)

Indoor Unit Operating Range

2

Cooling (°F WB)

Heating (°F DB)

Unit Data

Refrigerant Type

3

Refrigerant Control

IDU Sound Pressure Level dB(A) (H/M/L/SL)4

ODU Sound Pressure Level dB(A)

4

Unit Weight (lbs.)

IDU (Net/Shipping)

ODU (Net/Shipping)

Power Wiring / Communications Cable (No. x AWG)

Compressor

Compressor (Qty.)

Fan

IDU Type x Qty.

ODU Type x Qty.

Motor / Drive

Airflow Rate

IDU (H / M / L [CFM])

ODU (Max. [CFM])

Piping

Liquid (in.)

Vapor (in.)

Condensate Drain O.D. / I.D. (in.)

Additional Refrigerant Charge (oz./ft.)

Pipe Length5 (Minimum/ Maximum) (ft.)

Piping Length5 (no add’l refrigerant, ft.)

Max. Elevation Difference (ft.)

EEV: Electronic Expansion Valve IDU: Indoor Unit ODU: Outdoor Unit

Cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF wet

bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 59ºF wet

bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

This data is rated 0 ft above sea level with 24.6 of refrigerant line per indoor unit and a 0 ft level

difference outdoor and indoor units.

This unit comes with a dry helium charge.

Power wiring to the ODU is field supplied, solid or stranded, and must comply with the applicable local

and national codes

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

GENERAL DATA

Single Zone Wall Mounted Extended Piping Specications

LS243HLV

(LSN243HLV/LSU243HLV)

3,070 ~ 22,000 ~ 29,515 3,070 ~ 30,000 ~ 34,000 3,070 ~ 33,000 ~ 34,000

1.76 3.0 4.04

3,070 ~ 27,000 ~ 38,898 3,070 ~ 32,000 ~ 38,898 3,070 ~ 35,200 ~ 38,898

2.38 3.1 3.84

11.34 10.32 9.17

27,410 (102%) 32,490 (102%) 35,740 (102%)

23,690 (88%) 28,080 (88%) 30,890 (88%)

22,090 (82%) 26,180 (82%) 28,800 (82%)

20,580 (76%) 24,390 (76%) 26,820 (76%)

12.50 10.00 8.18

21.50 19.00 17.50

11.0 10.0 10.0

49/44/40/37 49/44/40/37 49/44/40/37

55 55 55

39.7/45.2 39.7/45.2 39.7/45.2

2

124.6/132.3 124.6/132.3 124.6/132.3

4 x 18 4 x 18 4 x 18

Twin Rotary (1) Twin Rotary (1) Twin Rotary (1)

Brushless Digitally Controlled/Direct

953/848/706/530 953/848/706/530 953/848/706/530

2,119 2,119 2,119

3/8 3/8 3/8

5/8 5/8 5/8

27/32 / 5/8 27/32 / 5/8 27/32 / 5/8

0.38 0.38 0.38

9.8/164 9.8/164 9.8/164

24.6 24.6 24.6

98.4 98.4 98.4

1

Power Input is rated at high speed.

2

Low Ambient Wind Baffle Kit allows operation down to 0°F in cooling mode.

3

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or destroy

R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F) under section 608

of CAA.

4

Sound Pressure levels are tested in an anechoic chamber under ISO Standard 1996.

5

All power/communication cables to be minimum 18 AWG, 4-conductor, stranded, shielded and must

comply with applicable and national code.

6

Piping lengths are equivalent.

LS303HLV

(LSN303HLV/LSU303HLV)

208-230/60/1

14 to 118

-4 to +65

53 to 75

60 to 86

R410A

EEV

Cross Flow Fan (1)

Propeller (1)

LS363HLV

(LSN363HLV/LSU363HLV)

PRODUCT DATA | 11

Product Data

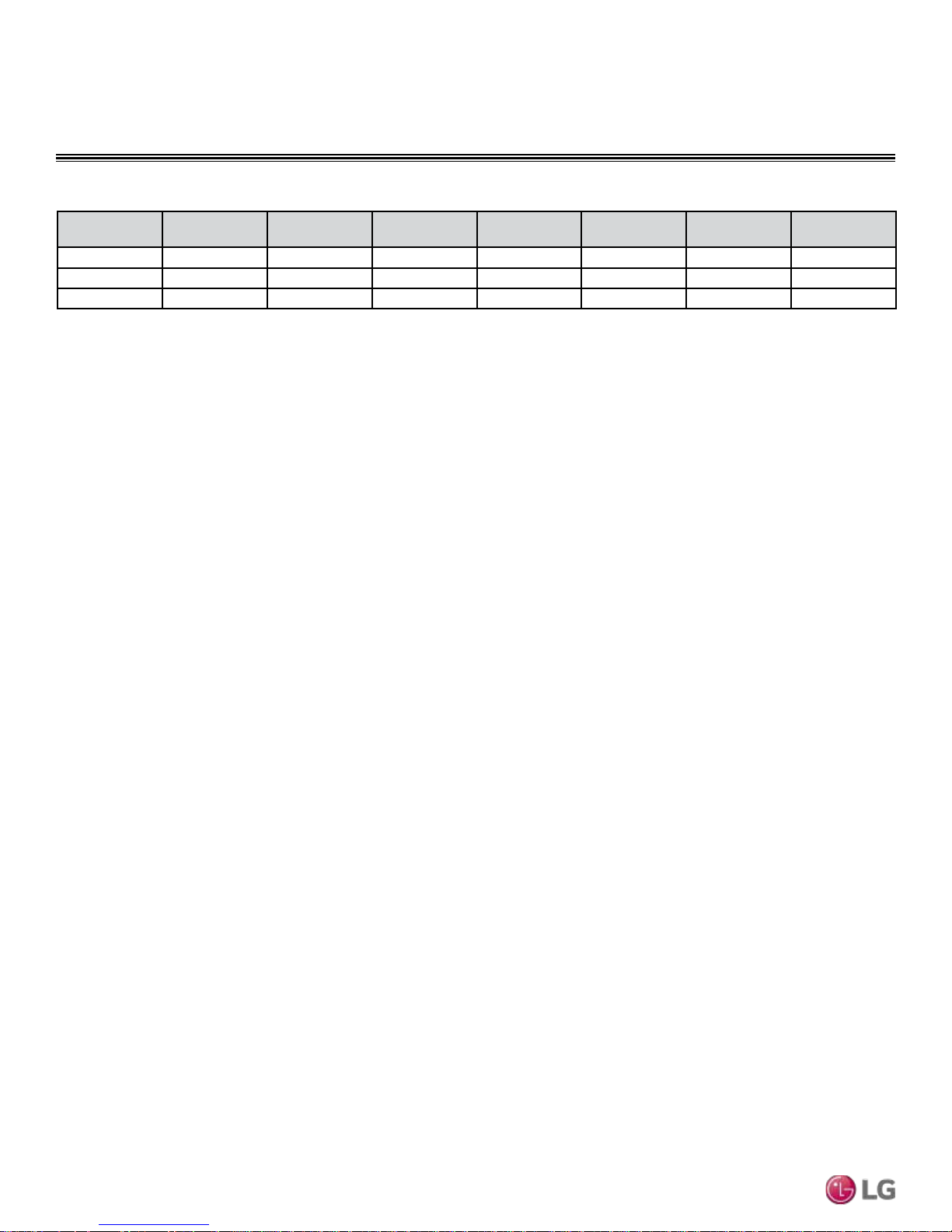

ELECTRICAL DATA

Table 3: Single Zone Wall Mounted Extended Piping Electrical Data

Model Number Nominal Tons Compressor Qty

LS243HLV

LS303HLV

LS363HLV

Voltage tolerance is ±10%.

Maximum allowable voltage unbalance is 2%.

RLA = Rated Load Amps.

2 1 14.6/14.6 1 0.25 19 30

2-1/2 1 14.6/14.6 1 0.25 19 30

2-3/4 1 14.6/14.6 1 0.25 19 30

Compressor (A)

Cool / Heat

MCA = Minimum Circuit Ampacity.

Maximum Overcurrent Protection (MOP) is calculated as follows:

(Largest motor FLA x 2.25) + (Sum of other motor FLA) rounded down

to the nearest standard fuse size.

Fan Qty

Outdoor Unit

Fan (A)

Recommended fuse size: 25A.

MCA (A) MOP (A)

Single Zone Wall Mounted Extended Piping Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

12 | PRODUCT DATA

©

Table 4: Indoor Units—Functions, Controls and Options.

Indoor Unit Type LS243HLV LS303HLV LS363HLV

Air supply outlet

Airflow direction (left/right)

Airflow direction (up/down)

Auto swing (left/right)

Auto swing (up/down)

Airflow steps (fan/cool/heat)

Airow

Auto swing

Auto wind

Jet-cool/heat

Comfort air

Washable anti-fungal

1

Deodorizing filter

2

Plasma

3M Micro Dust filter

Air Purifying

3M Micro Protection filter

2

Drain pump

Electric heater

Defrost

Low ambient

Hot start

Self diagnostics

Outdoor Unit Drain Pan Heater

Dry (Dehumidification operation)

Auto changeover

Auto clean (coil dry)

Functions

Auto restart

Child lock (applicable with wired controller)

Forced operation

Sleep mode

Timer (24hr on/off)

Weekly timer (applicable with wired controller)

Two thermistor control (applicable with wired controller)

Energy saving

Wireless Remote Controller

Simple Controller with Mode Selection

Simple Controller without Mode Selection

LG Programmable Thermostat

Dry contact

Controllers

Central control (LGAP)

PI 485

FUNCTIONS, CONTROLS, OPTIONS

1 1 1

5 Steps 5 Steps 5 Steps

6 Steps 6 Steps 6 Steps

√ √ √

√ √ √

6 / 6 / 6 6 / 6 / 6 6 / 6 / 6

√ √ √

√ √ √

√ / √ √ / √ √ / √

X X X

√ √ √

X X X

X X X

X X X

√ √ √

X X X

X X X

√ √ √

√ √ √

√ √ √

√ √ √

X o o

√ √ √

√ √ √

√ √ √

√ √ √

o o o

√ √ √

√ √ √

√ √ √

o o o

o o o

√ √ √

o o o

o o o

o o o

o o o

o o o

o o o

Product Data

Wi-Fi Module

Water level sensor connection (for optional AG-9300-LG)

Wind baffle kit

Special Function Kit

1

Primary washable filters.

2

Secondary filters.

√ = Standard feature

o = Optional accessory (must be purchased separately)

X = Not available

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

√ √ √

o o o

ZLABGP02A ZLABGP02A ZLABGP02A

• When Dry Contact Mode active, Wi-Fi Function can not be used.

• When changing from Wi-Fi mode to dry contact mode, normal operation resumes in approximately 3 minutes.

PRODUCT DATA | 13

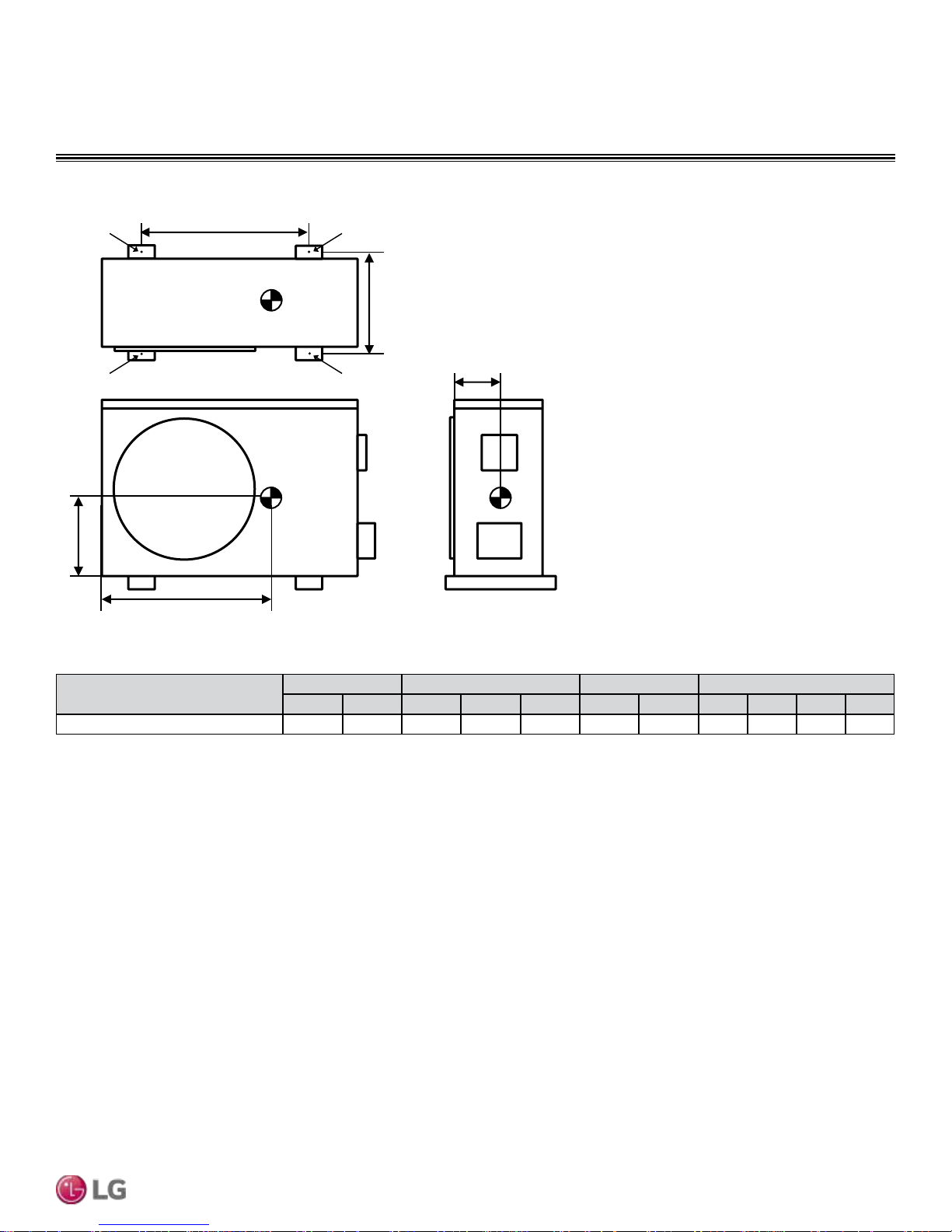

OUTDOOR UNIT DIMENSIONS

LSU243HLV, LSU303HLV, LSU363HLV

Drain Hole 2-Ø13/16

6-15/32 21-1/2

14-3/16

13-13/32

29/32

13-3/32

15-3/32

34-1/4

3-5/32

4

21-1/2

7/8

1

17/32

31-1/2

2

3

Unit : inch (mm)

Single Zone Wall Mounted Extended Piping Engineering Manual

12-19/32

5-7/8

1-25/32

25°

14°

6-25/32

6-29/32

Air Discharge Grille 1

Gas Pipe Connection Port

2

3

Liquid Pipe Connection Port

Control Box

4

2-3/4

20-27/32

7-11/16

4-7/32

Part Name RemarkNo

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

14 | PRODUCT DATA

©

d

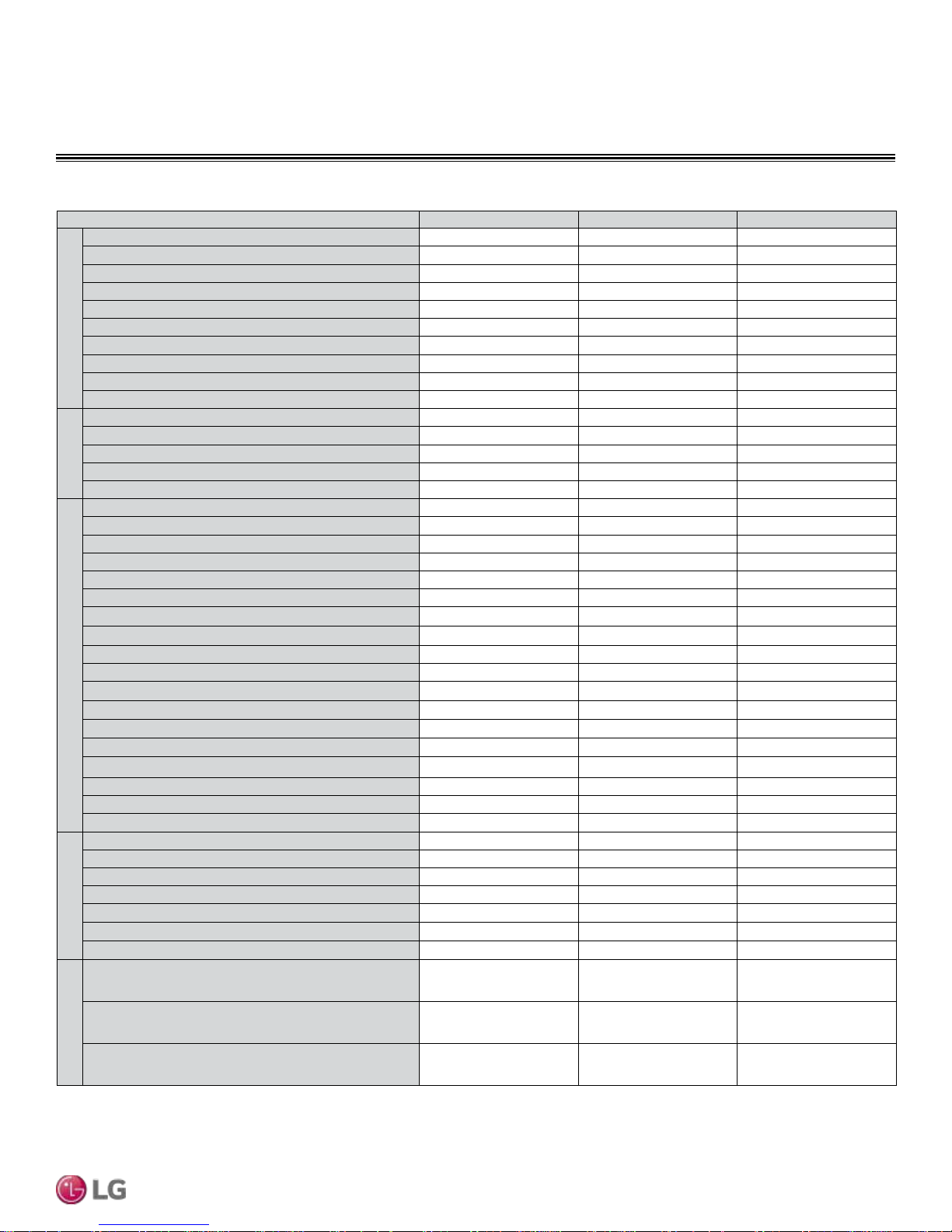

OUTDOOR UNIT CENTER OF GRAVITY /

Figure 1: Center of Gravity and Corner Weight Dimensions Diagram.

CORNER WEIGHT

A

B

b

a

Table 5: Center of Gravity and Corner Weight Dimensions.

Model

LSU243HLV, LSU303HLV, LSU363HLV 132.3 124.6 21-3/32 13-25/32 6-23/32 21-1/2 13-13/32 21.2 18.7 39.9 44.8

Shipping Net a b c d e A B C D

D

e

C

Weight (lb.) Center of Gravity (inch) Leg (inch) Corner Weight (lb.)

c

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

PRODUCT DATA | 15

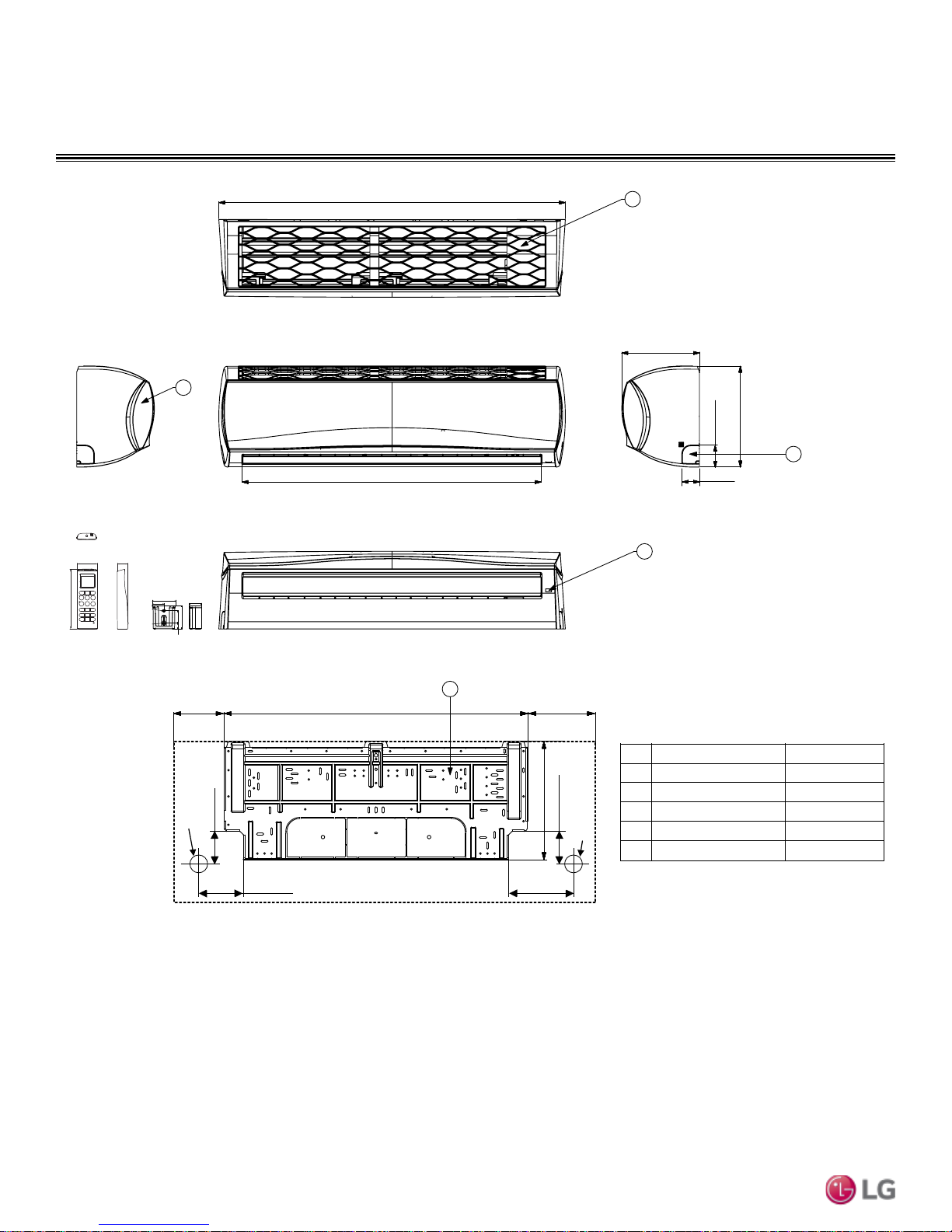

INDOOR UNIT DIMENSIONS

LSN243HLV, LSN303HLV, LSN363HLV

1-3/32

5-31/32

1-1/16

46-7/8

3

10-7/16

1

13-5/8

2-17/32

4

40-9/16

2-11/32

2

2-7/16

1-7/16

1-1/4

1/4 x 1/8

1-9/32

2-13/32

1/8 x 1/4

5/8

5

6-9/16

2-17/32Ø

1-11/16

4-23/32

33-25/32

Single Zone Wall Mounted Extended Piping Engineering Manual

4-23/32

6-9/16

13-3/16

1-11/16

2-17/32Ø

Part NameNo Remark

Front Panel 1

2

Display & Signal Receiver

3

Air Suction Grille

4

Knockout Hole For pipe and cable

5

Installation Plate

Unit: inch

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

16 | PRODUCT DATA

©

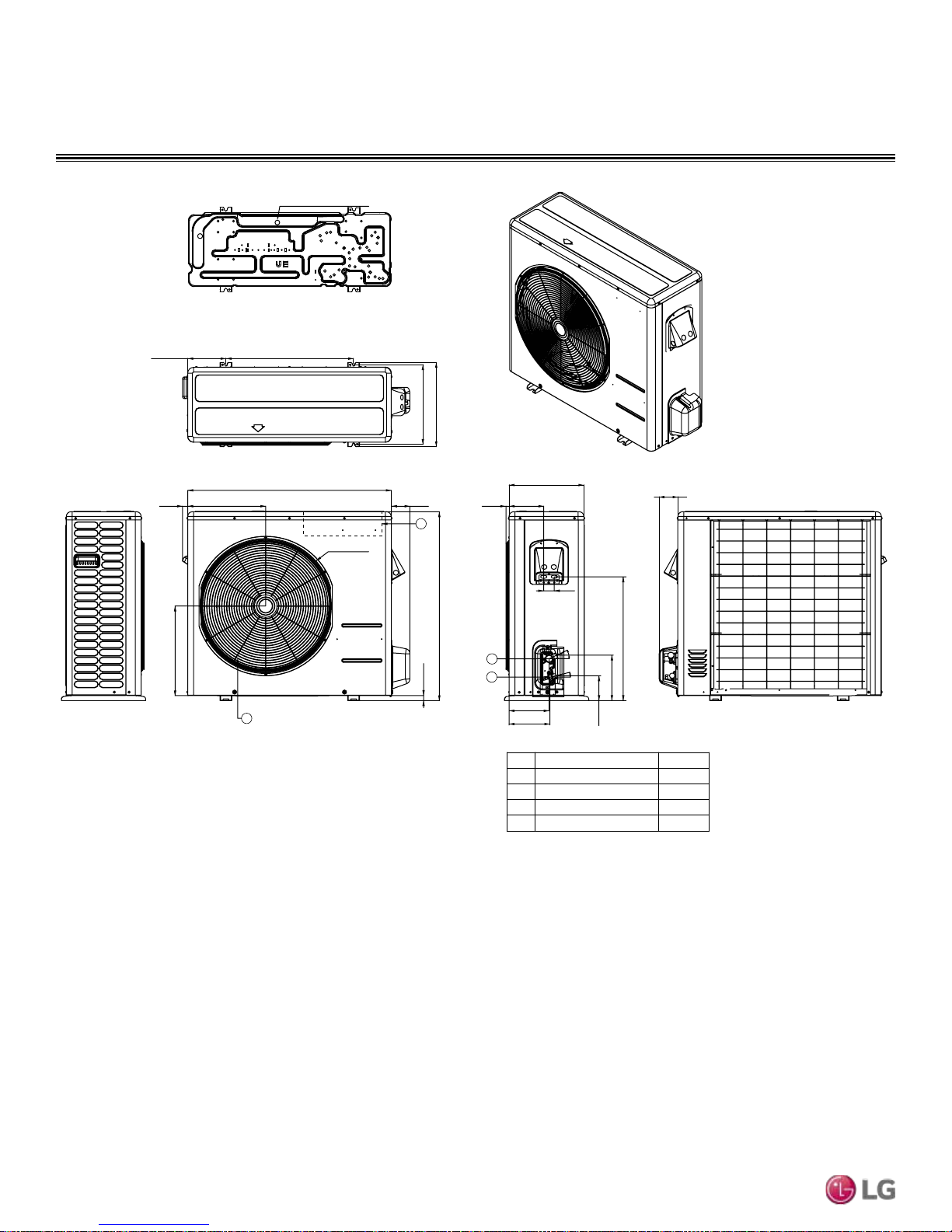

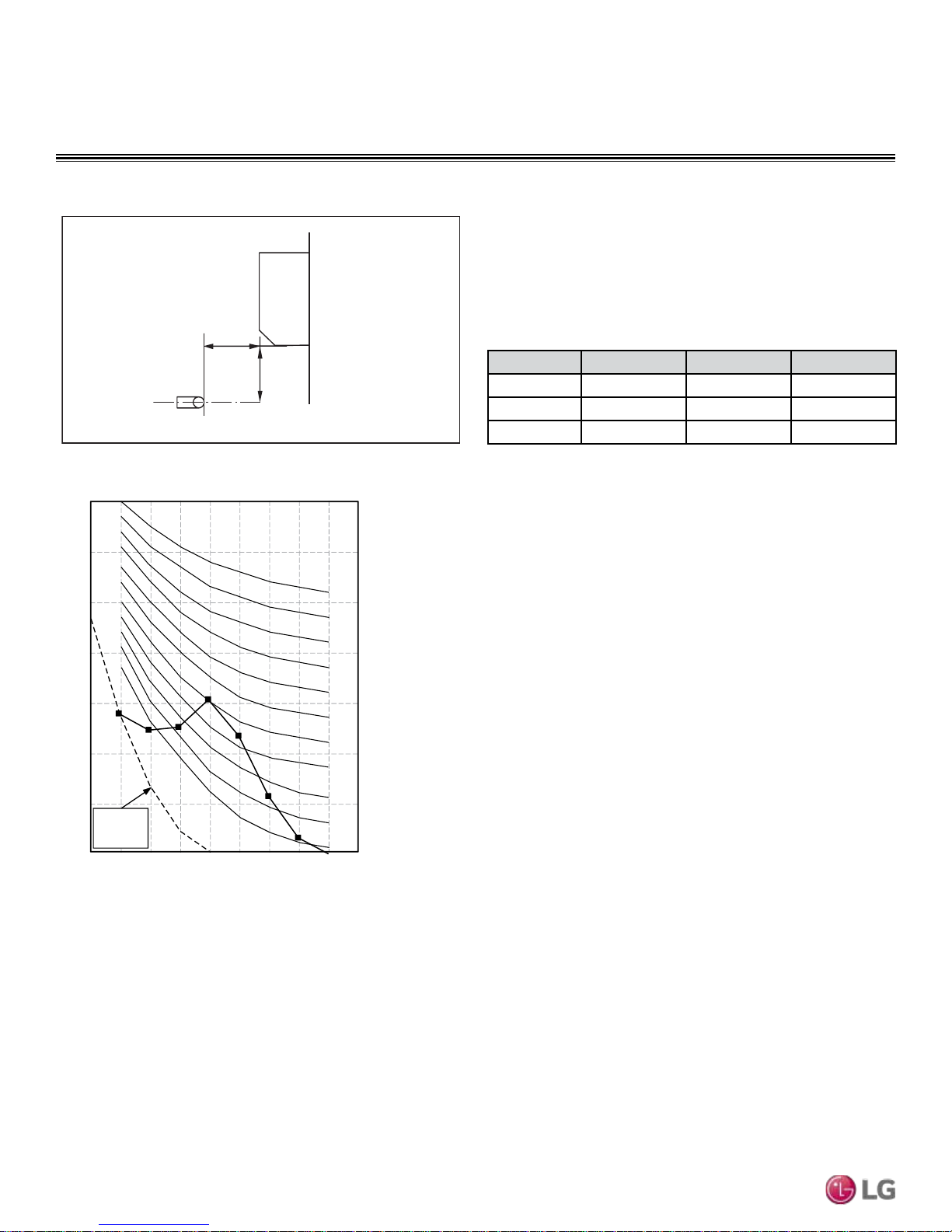

OUTDOOR UNIT ACOUSTIC DATA

3.28 ft

Center of

Outdoor Unit

Octave Band Sound Pressure Level (0dB = 20μPa)

Figure 2: Outdoor Unit Sound Levels

Figure 3: LSU243HLV, LSU303HLV, LSU363HLV

80

70

60

50

40

30

• Measurements are taken 3.28 ft away from the front of the unit.

• Sound pressure levels are measured in dB(A) with a tolerance of ±3.

• Sound pressure levels are tested in an anechoic chamber under

ISO Standard 3745.

• Sound level will vary depending on a range of factors including the

construction (acoustic absorption coefficient) of a particular room in

which the unit was installed.

Table 6: Outdoor Unit Sound Pressure Data

Model H

LSU243HLV 55

LSU303HLV 55

LSU363HLV 55

Product Data

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

NC-25

NC-20

NC-15

PRODUCT DATA | 17

INDOOR UNIT ACOUSTIC DATA

2.62 ft

3.28 ft

Microphone

Octave Band Sound Pressure Level (0dB = 20μPa)

Figure 4: Indoor Unit Sound Levels

Figure 5: LSU243HLV, LSU303HLV, LSU363HLV

80

70

60

50

40

30

• Measurements are taken 3.28 ft away from the front of the unit.

• Sound pressure levels are measured in dB(A) with a tolerance of

±3.

• Sound pressure levels are tested in an anechoic chamber under

ISO Standard 3745.

• Sound level will vary depending on a range of factors including the

construction (acoustic absorption coefficient) of a particular room in

which the unit was installed.

Table 7: Indoor Unit Sound Pressure Data

Model H M L

LSN243HLV 49 44 40

LSN303HLV 49 44 40

LSN363HLV 49 44 40

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

NC-25

NC-20

NC-15

Single Zone Wall Mounted Extended Piping Engineering Manual

18 | PRODUCT DATA

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Englewood Cl iffs, NJ. All r ights reserved. “LG ” is a re gistered trademark of LG C orp.

©

Loading...

Loading...