Page 1

X

MUL

TI

MUL

F

F

TI

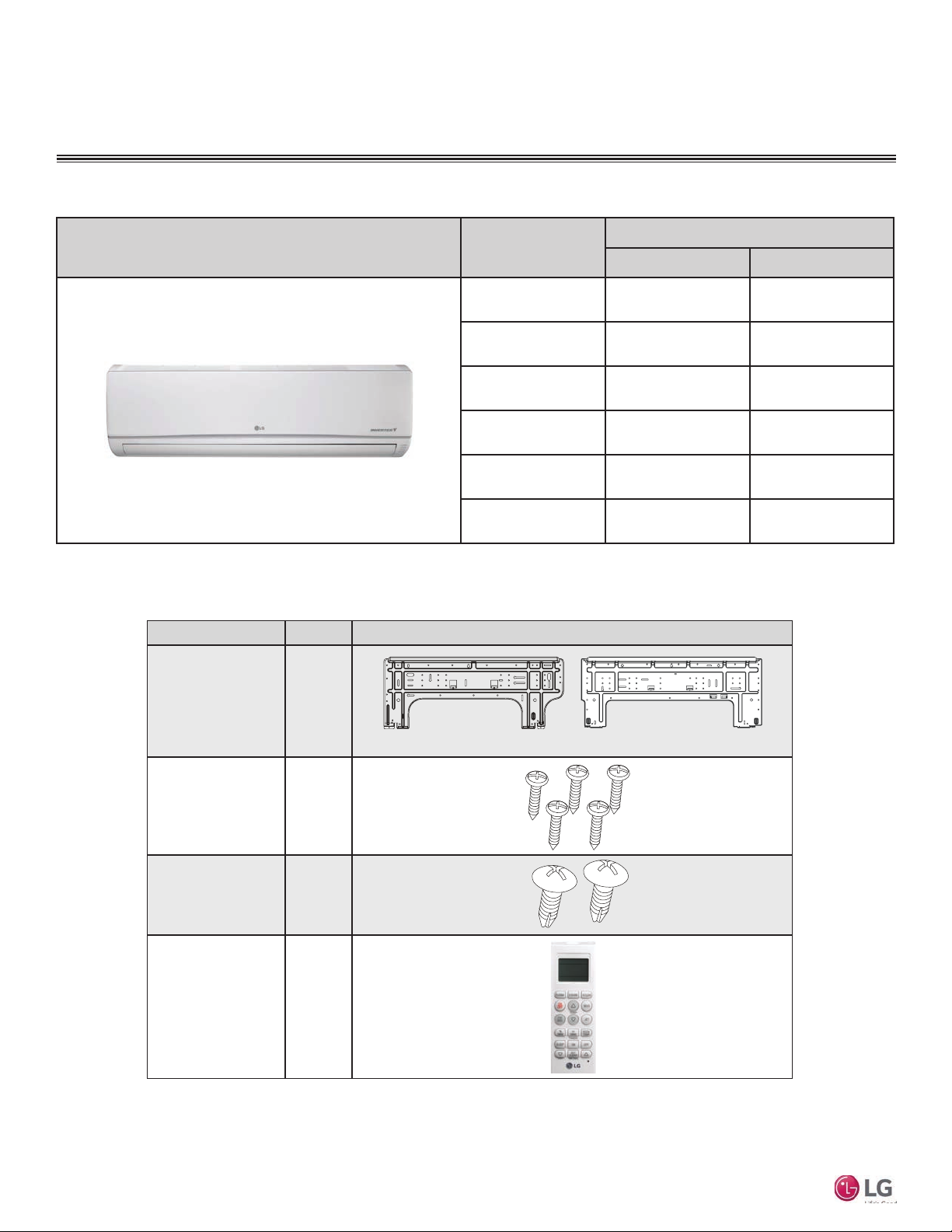

STANDARD WALL-MOUNTED INDOOR UNIT

INSTALLATION MANUAL

MA

• LMN078HVT 7 kBtu

• LSN090HSV4 9 kBtu

• LSN120HSV4 12 kBtu

• LMN158HVT 15 kBtu

• LSN180HSV4 18 kBtu

• LMN248HVT 24 kBtu

Page 2

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information, and other

materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc., only in confidence.

Do not throw away, destroy, or lose this manual.

Please read carefully and store in a safe place for future reference.

Content familiarity required for proper installation.

The instructions included in this manual must be followed to prevent prod-

uct malfunction, property damage, injury, or death to the user or other

people. Incorrect operation due to ignoring any instructions will cause

harm or damage. A summary of safety precautions begins on page 4.

For more technical materials such as submittals, engineering

databooks, and catalogs, visit www.lghvac.com.

IM_MultiF_StdWallMount_11_15

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

©LG Electronics U.S.A., Inc.

This document, as well as all reports, illustrations, data, information, and other materials are the property of LG Electronics U.S.A., Inc.

Page 3

X

MUL

TI

MUL

F

F

TABLE OF CONTENTS

TI

MA

CONTENTS

Safety Instructions ..............................................................................................................4

Introduction .........................................................................................................................9

Unit Nomenclature ............................................................................................................11

General Data ....................................................................................................................12

Specications .............................................................................................................................13

Typical Multi F/Multi F Max Systems ..........................................................................................15

Refrigerant Piping Requirements ...............................................................................................17

General Installation Guidelines .........................................................................................18

Location Selection ...................................................................................................................... 18

Inspection ................................................................................................................................... 19

Install Wall-Mounted IDU Chassis ..............................................................................................20

Refrigerant Piping ....................................................................................................................... 22

Piping Materials and Handling .................................................................................................... 30

Piping Preparation ...................................................................................................................... 31

Installation Manual

Piping Connections ...........................................................................................................32

IDU to ODU ................................................................................................................................32

Piping Insulation ......................................................................................................................... 35

Drain Piping ................................................................................................................................ 37

Electrical Wiring ................................................................................................................38

Power Wiring Specications and Best Practices ........................................................................ 39

Controller Options .......................................................................................................................40

Indoor Unit Electrical Connections Guidelines ...........................................................................41

Indoor Unit Electrical Connections Procedure ............................................................................ 42

Self Diagnosis Functions ........................................................................................................... 44

LG SIMS - Self Diagnosis Functions ......................................................................................... 46

Optional Wall-Mounted Sensor and Controller ...........................................................................48

Troubleshooting ................................................................................................................49

Error Codes ............................................................................................................................... 49

Cautions for Refrigerant leaks ..........................................................................................50

Refrigerant Leaks ....................................................................................................................... 50

Installation Checklist .........................................................................................................51

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

Page 4

X

MUL

MUL

F

SAFETY INSTRUCTIONS

WARNING

DANGER

WARNING

CAUTION

DANGER

TI

F

TI

The instructions below must be followed to prevent product malfunction, property damage, injury or death to the user or other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the symbols below.

MA

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Note:

This symbol Indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

INSTALLATION

Don’t use or store ammable gas or combustibles near the unit.

There is risk of re, explosion, and physical injury or death.

Do not install, remove, or re-install the unit by yourself

(end-user). Ask the dealer or an LG trained technician to

install the unit.

Improper installation by the user may result in water leakage, re,

explosion, electric shock, physical injury or death.

For replacement of an installed unit, always contact an

LG trained service provider.

There is risk of re, electric shock, explosion, and physical injury or death.

Multi F Standard Wall-Mounted Indoor Unit

The outdoor unit is shipped with refrigerant and the service

valves closed. Do not open service valves on the unit until

all non-condensibles have been removed from the piping

system and authorization has been obtained from the commissioning agent.

There is a risk of physical injury or death.

Do not run the compressor with the service valves

closed.

There is risk of explosion, physical injury, or death.

Periodically check that the outdoor unit is not damaged.

There is risk of explosion, physical injury, or death.

Replace all control box and panel covers.

If cover panels are not installed securely, dust, water and animals may

enter the unit, causing re, electric shock, and physical injury or death.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Exposure to high concentration levels of refrigerant gas may lead to

illness or death.

4

Do not install the unit using defective hanging, attaching,

or mounting hardware.

There is risk of physical injury or death.

Wear protective gloves when handling equipment.

Sharp edges may cause personal injury.

Dispose of the packing materials safely.

• Packing materials, such as nails and other metal or wooden parts

may cause puncture wounds or other injuries.

• Tear apart and throw away plastic packaging bags so that children

may not play with them and risk suffocation and death.

Do not install the unit in any location exposed to open

ame or extreme heat. Do not touch the unit with wet hands.

There is risk of re, electric shock, explosion, and physical injury or death.

Install the unit considering the potential for earthquakes.

Improper installation may cause the unit to fall, resulting in physical

injury or death.

Do not change the settings of the protection devices.

If the pressure switch, thermal switch, or other protection device is

shorted and forced to operate improperly, or parts other than those

specied by LG are used, there is risk of re, electric shock, explosion,

and physical injury or death.

If the air conditioner is installed in a small space, take measures to prevent the refrigerant concentration from exceeding safety limits in the event of a refrigerant leak.

Consult the latest edition of ASHRAE (American Society of Heating,

Refrigerating, and Air Conditioning Engineers) Standard 15. If the refrigerant leaks and safety limits are exceeded, it could result in personal

injuries or death from oxygen depletion.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 5

X

MUL

TI

MUL

F

CAUTION

F

SAFETY INSTRUCTIONS

TI

MA

INSTALLATION – CONTINUED

Be very careful when transporting the product.

• Do not attempt to carry the product without assistance.

• Some products use polypropylene bands for packaging. Do not use polypropylene bands to lift the unit.

• Suspend the unit from the base at specified positions.

• Support the unit at a minimum of four points to avoid slippage from rigging apparatus.

• Failure to follow these directions may result in minor or moderate physical injury.

Note:

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated pipe can generate condensate that may

drip and cause a slippery oor condition and/or water damage to walls.

When installing the unit in a hospital, mechanical room, or

similar electromagnetic eld (EMF) sensitive environment,

provide sufcient protection against electrical noise.

Inverter equipment, power generators, high-frequency medical equipment, or radio communication equipment may cause the air conditioner to

operate improperly. The unit may also affect such equipment by creating

electrical noise that disturbs medical treatment or image broadcasting.

Do not use the product for special purposes such as preserving foods, works of art, wine coolers, or other precision

air conditioning applications. This equipment is designed to

provide comfort cooling and heating.

There is risk of property damage.

Do not make refrigerant substitutions. Use R410A only.

If a different refrigerant is used, or air mixes with original refrigerant, the

unit will malfunction and become damaged.

Do not install the unit in a noise sensitive area.

When connecting refrigerant tubing, remember to allow for

pipe expansion.

Improper piping may cause refrigerant leaks and system malfunction.

Take appropriate actions at the end of HVAC equipment life

to recover, recycle, reclaim or destroy R410A refrigerant according to applicable U.S. Environmental Protection Agency

(EPA) rules.

Periodically check that the outdoor unit is not damaged.

There is a risk of equipment damage.

Install the unit in a safe location where no one can step on or

fall onto it.

attaching, or mounting hardware.

There is risk of unit and property damage.

Install the drain hose to ensure adequate drainage.

There is a risk of water leakage and property damage.

Don’t store or use ammable gas / combustibles near the

unit.

There is risk of product failure.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Low refrigerant levels may cause product failure

The unit is shipped with refrigerant and the service valves

closed.

non-condensibles have been removed from the piping system and authorization to do so has been obtained from the

commissioning agent.

There is a risk of refrigerant contamination, refrigerant loss and equipment damage.

Do not install the unit with defective hanging,

Do not open service valves on the unit until all

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

5

Page 6

X

MUL

MUL

F

SAFETY INSTRUCTIONS

DANGER

WARNING

TI

F

WIRING

High voltage electricity is required to operate this system.

Adhere to the National Electrical Codes and these

instructions when wiring.

Improper connections and inadequate grounding can cause accidental

injury or death.

Always ground the unit following local, state, and National

Electrical Codes.

The information contained in this manual is intended for use

by an experienced, trained electrician familiar with the U.S.

National Electric Code (NEC) who is equipped with the proper

tools and test instruments.

Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury or

death.

Ensure the unit is connected to a dedicated power source

that provides adequate power.

If the power source capacity is inadequate or the electric work is not per-

formed properly, it may result in re, electric shock, physical injury or death.

TI

Turn the power off at the nearest disconnect before servicing

the equipment.

Electric shock can cause physical injury or death.

Properly size all circuit breakers or fuses.

There is risk of re, electric shock, explosion, physical injury or death.

Refer to local, state, and federal codes, and use power wires

of sufcient current capacity and rating.

Wires that are too small may generate heat and cause a re.

Secure all eld wiring connections with appropriate wire

strain relief.

Improperly securing wires will create undue stress on equipment power

lugs. Inadequate connections may generate heat, cause a re and

physical injury or death.

Properly tighten all power connections.

Loose wiring may overheat at connection points, causing a re, physical

injury or death.

MA

Note:

Do not cut, lengthen or shorten the communications and

power cable between any dry contact unit and its connected

indoor unit. Do not install the unit in a location where the communications and power cable cannot be safely and easily connected between the two units. Do not allow strain on this cable.

Poor cable connections can cause equipment malfunction.

Multi F Standard Wall-Mounted Indoor Unit

6

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 7

X

MUL

TI

MUL

F

DANGER

WARNING

CAUTION

F

SAFETY INSTRUCTIONS

TI

MA

OPERATION

Do not provide power to or operate the unit if it is ooded

or submerged.

There is risk of re, electric shock, physical injury or death.

Use a dedicated power source for this product.

There is risk of re, electric shock, physical injury or death.

Do not operate the disconnect switch with wet hands.

There is risk of re, electric shock, physical injury or death.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Avoid excessive cooling and periodically perform ventilation

to the unit.

Inadequate ventilation is a health hazard.

Do not touch refrigerant piping during or after operation.

It can cause burns or frostbite.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

The rotating, hot, cold, and high-voltage parts of the unit can cause

physical injury or death.

Periodically check power cable and connection for damage.

Cable must be replaced by the manufacturer, its service agent, or similar

qualied persons in order to avoid physical injury and/or electric shock.

Securely attach the electrical cover to the unit.

Non-secured electrical covers can result in burns or electric shock due to

Periodically verify the hanging bolts and other hardware

securing the unit have not deteriorated.

If the unit falls from its installed location, it can cause property damage,

product failure, physical injury or death.

If refrigerant gas leaks out, ventilate the area before operating the unit.

If the unit is mounted in an enclosed, low-lying, or poorly ventilated area

and the system develops a refrigerant leak, it may cause re, electric

shock, explosion, physical injury or death.

dust or water in the service panel.

Do not open the inlet grille of the unit during operation.

Do not operate the unit with the panels or guards removed.

Do not insert hands or other objects through the inlet or

outlet when the unit is powered. Do not touch the electro-

static lter, if the unit includes one. The unit contains sharp,

rotating, hot, and high voltage parts that can cause personal

injury and/or electric shock.

Ensure no power is connected to the unit other than as

directed in this manual. Remove power from the unit before

removing or servicing the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Do not open the inlet grille of the unit during operation.

Do not operate the unit with the panels or guards removed.

Do not insert hands or other objects through the inlet or outlet with the unit is plugged in. Do not touch the electrostatic

lter, if the unit includes one.

The unit contains sharp, rotating, hot, and high voltage parts that can

cause personal injury and/or electric shock.

Installation Manual

To avoid physical injury, use caution when cleaning or

servicing the air conditioner.

Note:

Clean up the site after installation is nished, and check

that no metal scraps, screws, or bits of wiring have been left

inside or surrounding the unit.

purpose applications such as preserving foods, works of art,

wine coolers or refrigeration. This equipment is designed to

provide comfort cooling and heating.

Provide power to the compressor crankcase heaters at least

six (6) hours before operation begins.

Starting operation with a cold compressor sump(s) may result in severe

bearing damage to the compressor(s). Keep the power switch on during

the operational season.

Do not use this equipment in mission critical or special-

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Do not block the inlet or outlet.

Unit may malfunction.

Securely attach the electrical cover to the indoor unit. Non-

secured covers can result in re due to dust or water in the

service panel.

Periodically verify the equipment mounts have not deteriorated.

If the base collapses, the unit could fall and cause property damage or

product failure.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure.

7

Page 8

X

MUL

TI

MUL

F

F

TI

MA

Multi F Standard Wall-Mounted Indoor Unit

8

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 9

X

MUL

TI

MUL

F

WARNING

F

INTRODUCTION

TI

MA

Multi F and Multi F MAX Standard

Wall-Mounted Units

This manual describes how to install the LG Multi F and Multi F MAX

(Multi Zone) Standard Wall-Mounted Indoor Units (IDU) for Multi

F heat pump systems. Table 1 lists the available models. Refer to

LG’s Multi F Indoor Unit Engineering Manual for complete detailed

engineering data and selection procedures.

Safety

Safety of personnel is the primary concern during all

procedures. Read and understand the safety summary at the front of this manual. Read and understand

this installation procedure before beginning installation. Use the appropriate tools and accessories

during installation. Plan your work and do not work

alone, if possible. Know how to obtain emergency

medical and firefighting assistance.

Installation Personnel

This equipment is intended for installation by personnel trained

in the required construction, mechanical, electrical, and/or other

disciplines.

Applicable Codes

Personnel must be familiar with and follow the applicable national,

state, and/or local codes.

Figure 1: Typical Multi F Standard Wall-Mounted Indoor Unit

Installation Manual

Installation work must be performed by trained personnel and in

accordance with national wiring standards and all local or other

applicable codes. Improper installation can result in re, electric shock,

physical injury, or death.

Note:

Please read all instructions before installing this product. Become familiar

with the unit’s components and connections, and the order of installation.

Incorrect installation can degrade or prevent proper operation.

Required Tools (field provided)

Required Parts (field provided)

• Level

• Screwdriver

• Electrical lineman pliers

• Electric drill

• Hole saw

• Connecting cable (power and control)

• Pipes - vapor line and liquid line, with

insulation

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

• Drill

• Flaring tool set

• Tubing cutter

• Tube/pipe reamer

• Torque wrenches

• Insulated drain hose

• Additional drain hose

• Allen wrench

• Gas-leak detector

• Thermometer

9

Page 10

X

MUL

MUL

F

INTRODUCTION

TI

F

Table 1: Multi F Standard Wall-Mounted Indoor Units

Typical Unit Model Number

LMN078HVT 7,000 8,100

LSN090HSV4 9,000 10,400

LSN120HSV4 12,000 13,800

LMN158HVT 14,300 16,500

LSN180HSV4 18,000 20,800

LMN248HVT 24,000 27,000

TI

Nominal Capacity

Cooling (Btu) Heating (Btu)

MA

Part Quantity Image

Installation Plate One (1)

Type “A” Screws Five (5)

Multi F Standard Wall-Mounted Indoor Unit

Type “B” Screws

(M4 x 12L)

Wireless

Controller with Holder

HVT: AKB73635606

HSV: AKB73835312

Two (2)

One (1)

Table 2: Included Items

7,000 ~ 15,000 Btu/h Indoor Units

18,000 and 24,000 Btu/h Indoor Units

10

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 11

X

MUL

TI

MUL

F

F

UNIT NOMENCLATURE

TI

MA

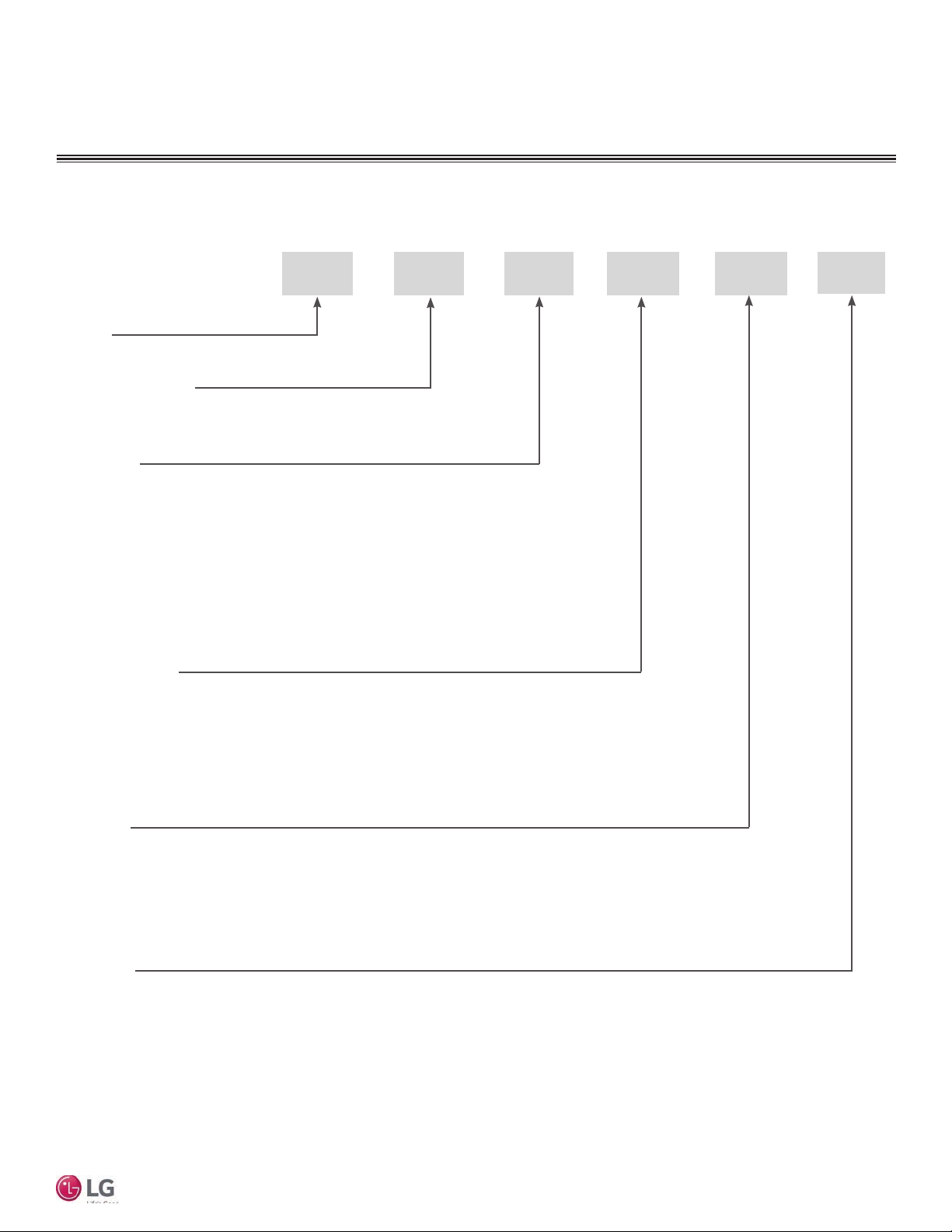

Multi F Multi-Zone Systems — Indoor Units

L

L = LG

Type: M = Multi-Zone

A/S = Single Zone (Gen 4 Single Zone units also compatible with Multi Zone)

Component:

AN: Art Cool™ Wall-Mounted Indoor Unit

N: Standard Wall-Mounted Indoor Unit

CN: Four-Way Ceiling-Cassette Indoor Unit

DN: Ceiling-Concealed Duct (Low Static) Indoor Unit

HN: Ceiling-Concealed Duct (High Static) Indoor Unit

VN: Vertical-Horizontal Air Handling Indoor Unit

M

N 158 HVT

Installation Manual

Nominal Capacity

(Nominal cooling capacity in Btu/h):

078 = 7,000

090 = 9,000

120 = 12,000

Features:

H = Heat Pump

V = Inverter

T = High Wall-Mounted Indoor Unit

P = Art Cool Gallery Indoor Unit

Generation

3 = Third (also Third Gen if no number in this position)

4 = Fourth

• Voltage for all equipment is 208-230V, 60 Hz, 1-phase.

• All indoor units are compatible with wired controllers

158 = 15,000

180 = 18,000

248 = 24,000

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

11

Page 12

X

MUL

MUL

F

GENERAL DATA

WARNING

TI

F

TI

MA

R410A Refrigerant

R410A refrigerant has a higher operating pressure in comparison to R22 refrigerant. All piping system materials installed must have

a higher resisting pressure than the materials traditionally used in R22 systems.

R410A refrigerant is an azeotrope of R32 and R125, mixed at 50:50. The ozone depletion potential (ODP) is 0.

• Do not place refrigerant cylinder in direct sunlight. Refrigerant cylinder may explode causing severe injury or death.

Note

• Because R410A is a combination of R32 and R125, the required additional refrigerant must be charged in its liquid state. If the

refrigerant is charged in its gaseous state, its composition changes and the system will not work properly.

• Do not heat piping more than necessary during installation. Piping may become soft and fail when pressurized.

• Do not use any piping that has not been approved for use in high-pressure refrigerant systems. Piping wall thickness must comply

with the applicable local, state, and federal codes for the 551 psi design pressure of R410A. Inadequate piping may fail when

pressurized.

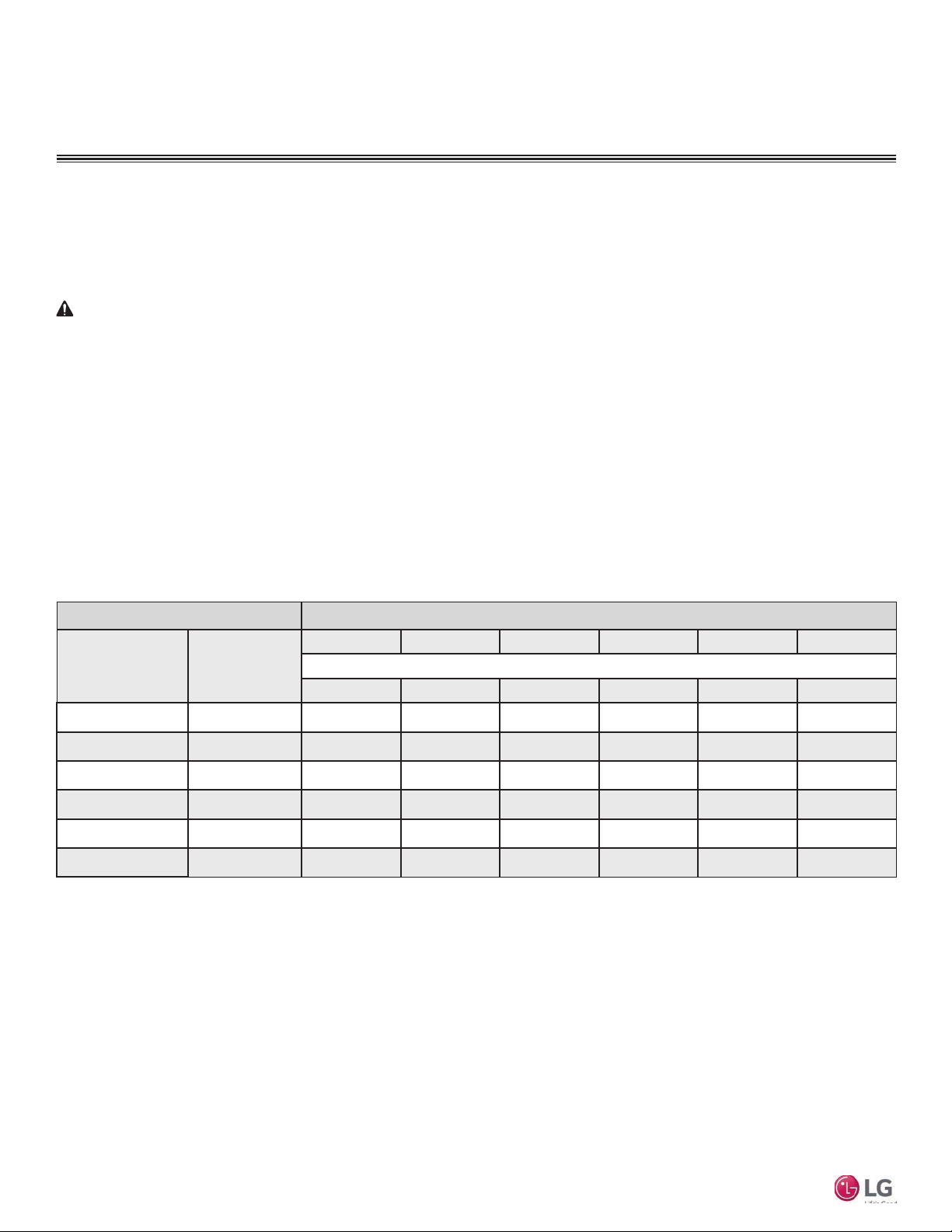

Allowable Indoor Unit to Outdoor Unit Connections

In Multi F/Multi Zone systems, the standard wall-mounted IDUs can be connected to the Multi F outdoor units (ODUs) listed in Table 3.

Table 3: Allowable Indoor Unit to Outdoor Unit Connections.

Indoor units Outdoor units

Model Number

LMN078HVT 7,000 O O O O O O

LSN090HSV4 9,000 O O O O O O

LSN120HSV4 12,000 O O O O O O

LMN158HVT 15,000 O O O O O O

Indoor Unit Nominal

Capacity (Btu/h)

LMU18CHV LMU24CHV LMU30CHV LMU36CHV LMU480HV LMU540HV

2 3 4 4 8 8

Multi F Standard Wall-Mounted Indoor Unit

LSN180HSV4 18,000 – O O O O O

LMN248HVT 24,000 – O O O O O

connection allowed: O

connection not allowed: –

Device Connection Limitations

• The minimum number of connected and operating indoor units to Multi F / Multi F MAX systems is two.

• The maximum number of indoor units for each Multi F / Multi F MAX heat pump system is:

LMU18CHV = 2 LMU24CHV = 3 LMU30CHV = 4

LMU36CHV = 4 LMU480HV = 8 LMU540HV = 8

Maximum No. of Connectable Indoor Units

• The maximum allowable total indoor unit capacity (Btu/h) for each Multi F / Multi F MAX heat pump system is:

LMU18CHV = 24,000 LMU24CHV = 33,000 LMU30CHV = 40,000

LMU36CHV = 48,000 LMU480HV = 65,000 LMU540HV = 73,000

• Refer to the Multi F Engineering Manual to properly determine total indoor unit connected capacity.

12

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 13

X

MUL

TI

MUL

F

F

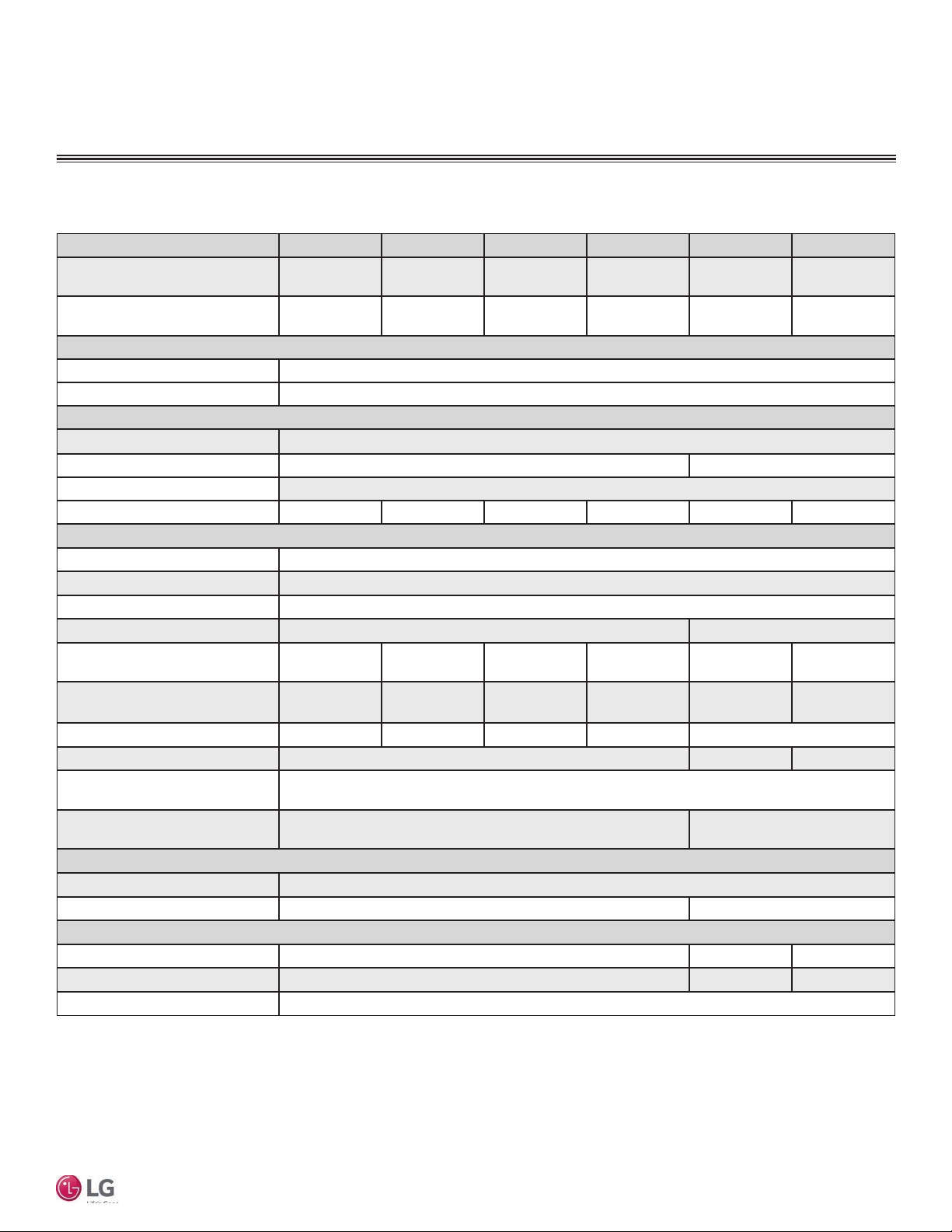

GENERAL DATA

TI

Nominal Cooling Capacity

(Btu/h)

Nominal Heating Capacity

(Btu/h)

Operating Range

Cooling (°F WB)

Heating (°F DB)

Fan

Type

Motor Output (W) x Qty.

Motor/Drive

Airflow Rate CFM (H/M/L)

Unit Data

Refrigerant Type

Refrigerant Control

Power Supply V, Ø, Hz3

Rated Amps (A)

Sound Pressure Level ±3 dB(A)

(H/M/L)4

Dimensions (W x H x D, in.)

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Power Wiring / Communications

Cable (No. x AWG)5

Heat Exchanger (Row x Column

x Fin / inch) x Number

Pipe Size

Liquid (in.)

Vapor (in.)

Connection Size

Liquid (in.)

Vapor (in.)

Drain O.D. / I.D. (in.)

1

Nominal capacity is rated 0 ft. above sea level with corresponding refrigerant piping

length in accordance with standard length of each outdoor unit and a 0 ft. level difference

between outdoor and indoor units. All capacities are net with a combination ratio between

95 – 105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb

(DB) and 67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and

75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb

(DB) and 60ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and

43ºF wet bulb (WB).

MA

Table 4: Multi F Multi Zone Standard Wall-Mounted Indoor Unit Specications

Model Name LMN078HVT LSN090HSV4 LSN120HSV4 LMN158HVT LSN180HSV4 LMN248HVT

1

1

2

7,000 9,000 12,000 14,300 18,000 24,000

8,100 10,400 13,800 16,500 20,800 27,000

198 / 177 / 162 247 / 230 / 212 335 / 318 / 300 371 / 318 / 247 572 / 501 / 434 720 / 600 / 466

33 / 30 / 26 33 / 30 / 27 39 / 36 / 31 43 / 39 / 34 37 / 33 / 28 42 / 39 / 36

35-1/4 x 11-3/8

x 8-9/32

23 20 20 23 31

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

34-13/16 x 11-1/4

x 8-1/4

(2 x 16 x 23) x 1 (3 x 18 x 22) x 1

Specications

57-77

59-81

Cross Flow

14.4 x 1 76.0 x 1

Brushless Digitally Controlled / Direct

R410A

Electronic Expansion Valve (EEV)

208-230, 1, 60

0.2 0.3

34-13/16 x 11-1/4

x 8-1/4

26 36 37

3/8 1/2

1/4 3/8 1/4

3/8 5/8 1/2

2

This unit comes with a dry helium charge.

3

Acceptable operating voltage: 187V-253V.

4

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and

are the same in both cooling and heating mode. These values can increase due to ambient

conditions during operation.

5

All power wiring / communications cable to be minimum 18 AWG, 4-conductor, stranded,

shielded, and must comply with applicable local and national codes.

35-1/4 x 11-3/8

4 x 18

1/4

27/32, 5/8

x 8-9/32

40-9/16 x 12-13/16

x 9-13/16

40-9/16 x 12-13/16

x 9-13/16

Installation Manual

13

Page 14

X

MUL

MUL

F

GENERAL DATA

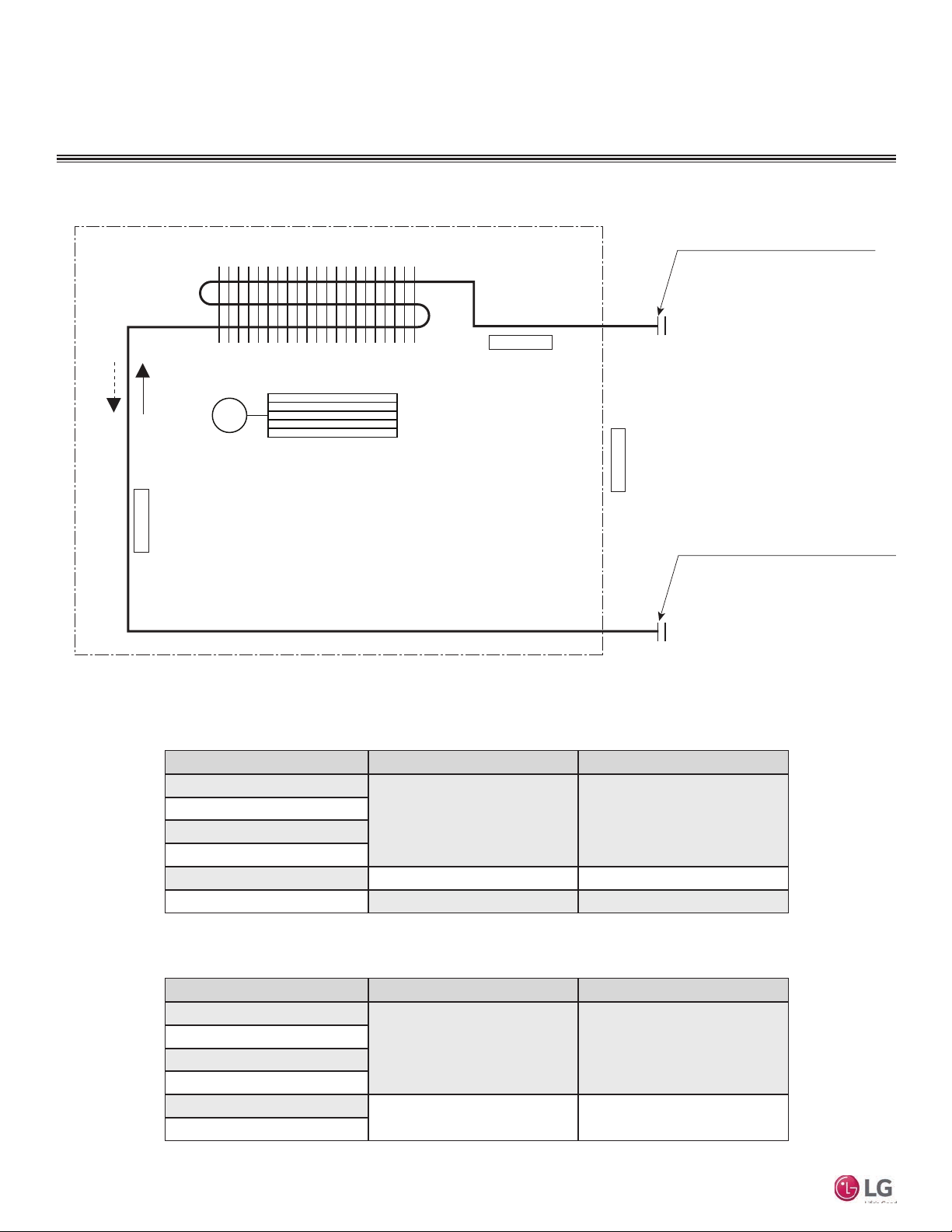

Gas pipe connection port

TI

F

Refrigerant Piping

Cross Flow Fan

Heating

Cooling

Evaporator Inlet Temperature

Thermistor for

M

Heat Exchanger

Thermistor for Evaporator

Outlet Temperature

TI

(flare connection)

Indoor Air Temperature

Thermistor for

Liquid pipe connection port

(flare connection)

MA

Table 5: Multi F Multi Zone Standard Wall-Mounted Indoor Unit Refrigerant Pipe Connection Port Diameters

Multi F Standard Wall-Mounted Indoor Unit

14

Model No. Vapor (inch) Liquid (inch)

LMN078HVT

LSN090HSV4

LSN120HSV4

LMN158HVT

LSN180HSV4 Ø5/8 Ø3/8

LMN248HVT Ø1/2 Ø1/4

Table 6: Multi F Multi Zone Standard Wall-Mounted Indoor Unit Refrigerant Pipe Sizes

Model No. Vapor (inch, OD) Liquid (inch, OD)

LMN078HVT

LSN090HSV4

LSN120HSV4

LMN158HVT

LSN180HSV4

LMN248HVT

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Ø3/8 Ø1/4

Ø3/8 Ø1/4

Ø1/2 Ø1/4

Page 15

X

MUL

TI

MUL

F

Max. 49.2 feet

Max. 24.6 feet

A

B

C

D

ODU

F

GENERAL DATA

TI

MA

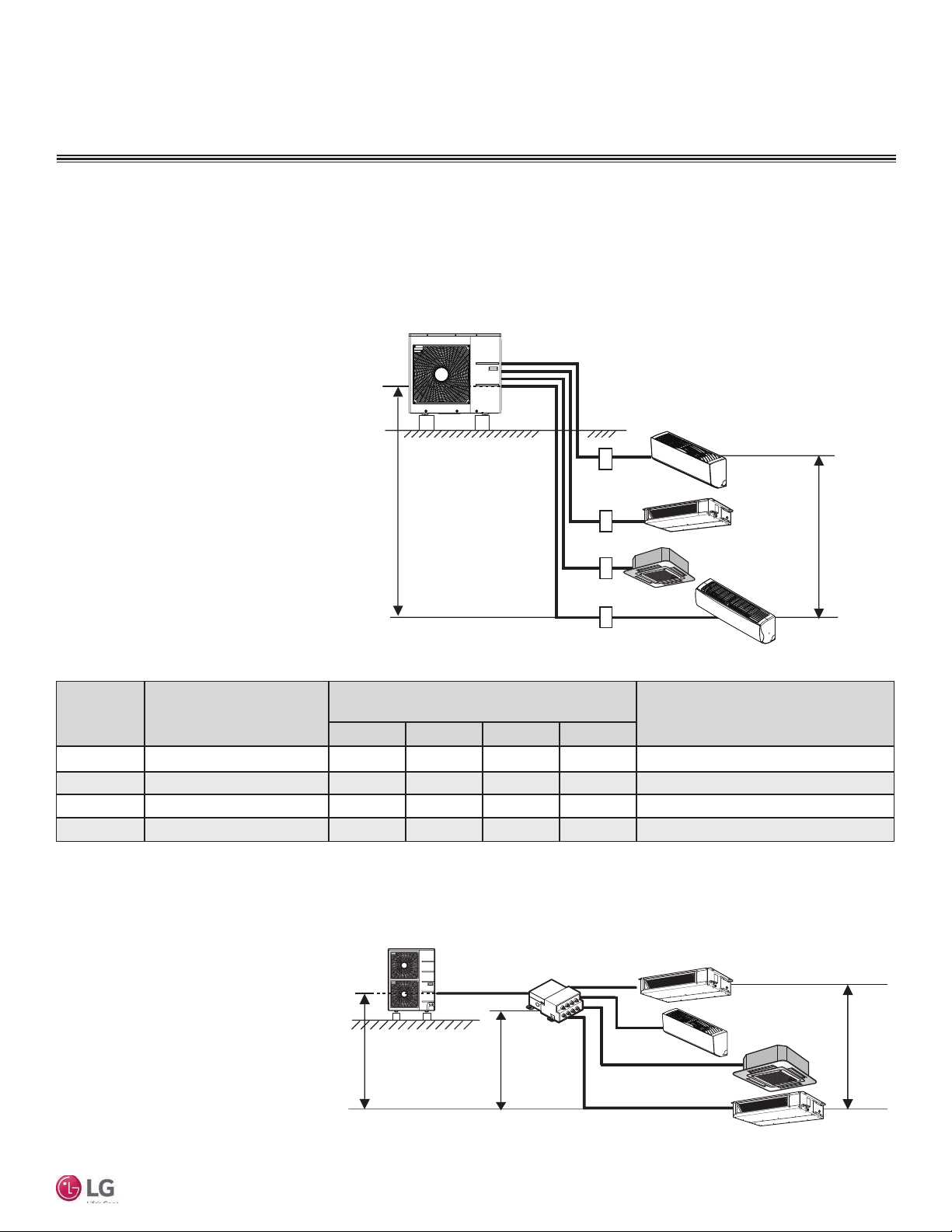

Typical Multi F/Multi F Max Systems

Major System Components

A typical Multi F system consists of an outdoor unit (ODU), refrigerant piping, and two to four indoor units (IDUs). The standard

wall-mounted units described in this manual are one of the types of IDUs that can be connected to a Multi F system.

A typical Multi F Max system consists of an ODU, refrigerant piping, one or two branch distribution units (BDU), and two to eight

IDUs. The standard wall-mounted units described in this manual are one of the types of IDUs that can be connected to a Multi F

Max system.

Typical Multi F System

Example: LMU36CHV outdoor unit with four (4)

indoor units connected.

ODU: Outdoor Unit.

IDU: Indoor Unit.

A, B, C, D: Piping from Outdoor Unit to Indoor Unit.

Installation Manual

Table 7: Multi F Outdoor Unit Refrigerant Piping System Limitations.

Outdoor

Unit

LMU18CHV 9.8 82 82 - - 164

LMU24CHV 9.8 82 82 82 - 246.1

LMU30CHV 9.8 82 82 82 82 246.1

LMU36CHV 9.8 82 82 82 82 246.1

Minimum Length for Each

Pipe Segment (ft.)

Maximum Equivalent Pipe Length

to Each Indoor Unit (ft.)

A B C D

Maximum Equivalent Pipe Length

for Each System (ft.)

Typical Multi F MAX System with One Branch Distribution Unit

Example: LMU540HV outdoor unit with four

(4) indoor units, and one (1) branch distribution unit connected.

ODU: Outdoor Unit.

IDU: Indoor Unit.

BDU: Branch Distribution Unit.

A: Main Piping.

B: Branch Piping (Branch Distribution Unit to

Indoor Unit[s]).

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

h1 ≤ 98.4 feet

A

BDU

h3 ≤ 32.8 feet

IDU

B

B

B

B

IDU

h2 ≤ 49.2 feet

IDU

IDU

15

Page 16

X

MUL

MUL

F

GENERAL DATA

ODU

TI

F

Typical Multi F/Multi F Max Systems

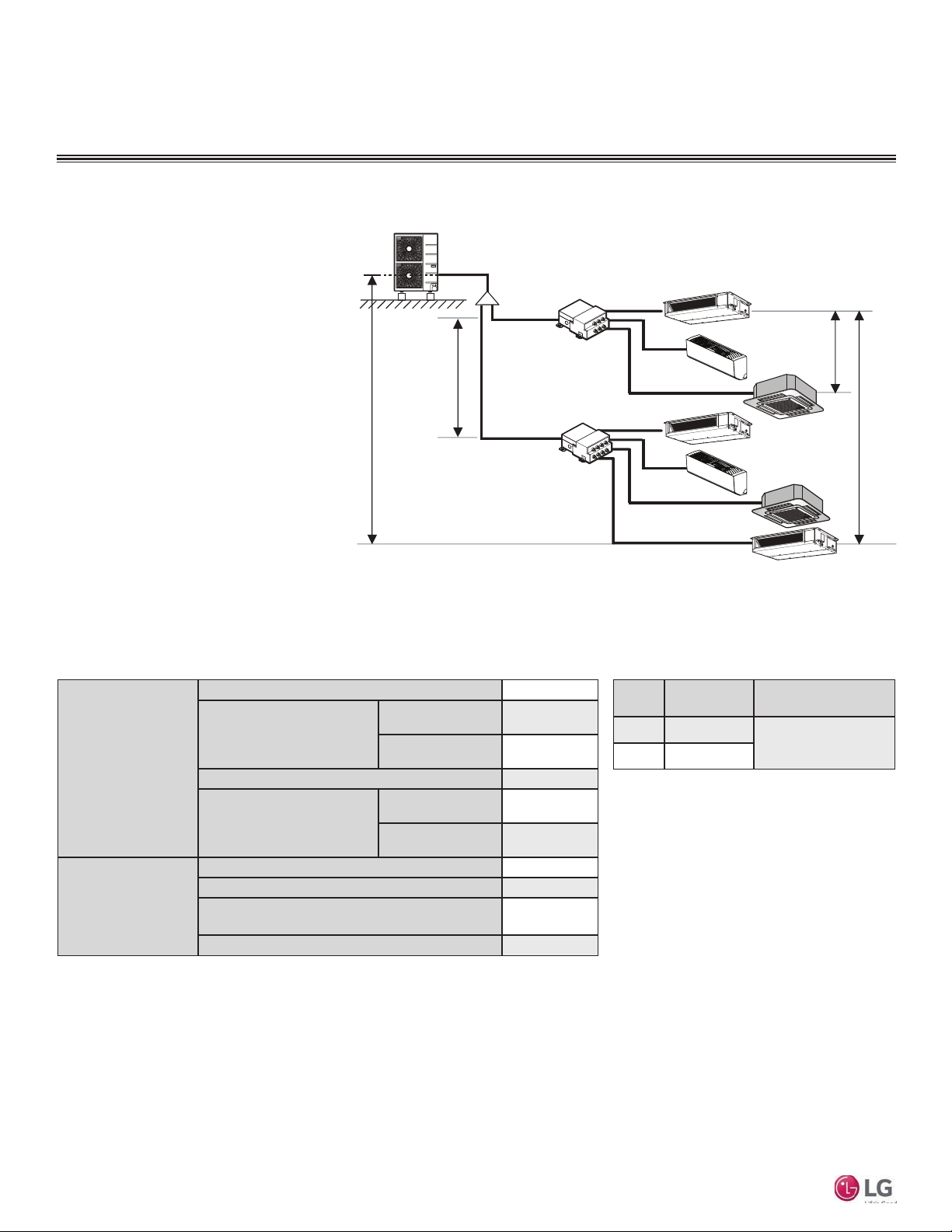

Typical Multi F MAX System with Two Branch Distribution Units

Example: LMU540HV outdoor unit with seven

(7) indoor units, and two (2) branch distribution units connected.

ODU: Outdoor Unit.

IDU: Indoor Unit.

BD: Branch Distribution Unit(s).

ΣA: Main Piping.

ΣB: Branch Piping (Branch Distribution Unit[s]

to Indoor Unit[s]).

h4 ≤ 49.2 feet

h1 ≤ 98.4 feet

A

BDU Y-Branch

A

A

BDU

B

B

B

B

B

B

B

IDU

IDU

IDU

IDU

TI

IDU

IDU

MA

h3 ≤ 32.8 feet

h2 ≤ 49.2 feet

Table 8: Multi F MAX Outdoor Unit Refrigerant Piping System Limitations.

Pipe Length

(ELF = Equivalent

Length of pipe

in Feet)

Multi F Standard Wall-Mounted Indoor Unit

Elevation Differential

(All Elevation

Limitations are

Measured in

Actual Feet)

(Outdoor Unit to Branch

Distribution Units: ΣA)

(Branch Distribution Units

to Indoor Units: B)

If outdoor unit is above or below indoor unit (h1)

Between the farthest two indoor units (h2)

Between branch distribution unit and farthest

Between branch distribution units (h4)

Total piping length (ΣA + ΣB)

Main pipe

Total branch piping length (ΣB)

Branch pipe

connected indoor unit(s) (h3)

Minimum

Maximum

Minimum

Maximum

≤475.7 feet

9.8 feet

≤180.4 feet

≤295.3 feet

9.8 feet

≤49.2 feet

≤98.4 feet

≤42.9 feet

≤32.8 feet

≤42.9 feet

Table 9: Multi F MAX Piping Sizes.

Piping

Liquid Ø3/8

Main Pipe A

(inch)

Gas Ø3/4

Depends on the size

of the indoor unit piping

IDU

Branch Pipe B

16

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 17

X

MUL

TI

MUL

F

F

GENERAL DATA

TI

MA

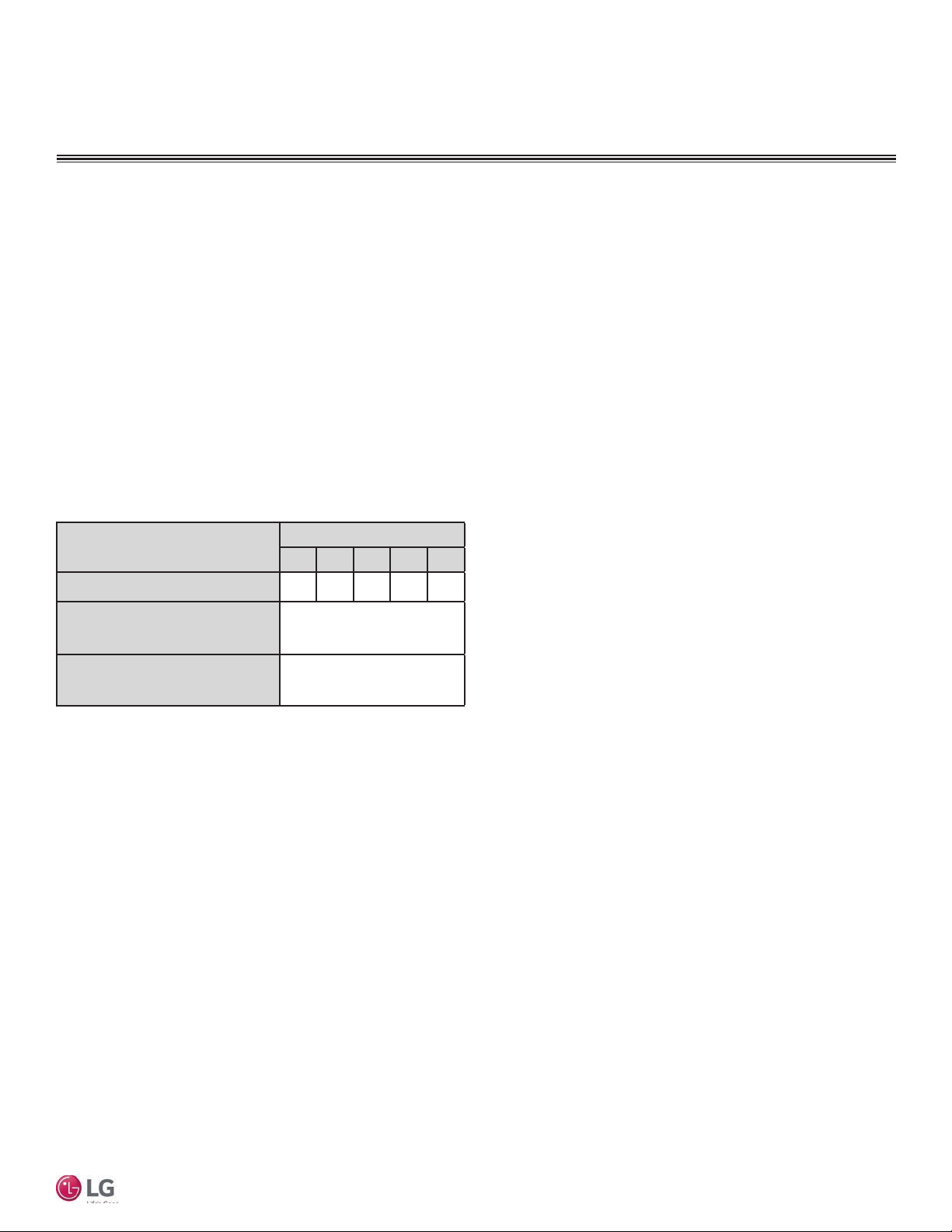

Refrigerant Piping Requirements

Field Supplied Refrigerant Piping

Type ACR copper is the only approved refrigerant pipe material for use with LG Multi F air conditioning

products. ACR rated tubing is the only type that ships with yellow caps. Approved tubing for use with

Multi V products will be marked “R410 RATED” along the length of the tube. Tube wall thickness should

meet local code requirements and be approved for a maximum operating pressure of 551 psi.

Refer to the refrigerant piping section (starting on page 22) of the General Installation Guidelines for

more information on piping.

Using Refrigerant Components

Field-supplied elbows are allowed if they are long radius and designed for use with R410A refrigerant. Be

sure to account for the additional pressure losses in equivalent pipe length calculations for each elbow,

y-branch, and branch distribution unit. The equivalent pipe length of each elbow, Y-branch, and/or branch

distribution unit must be added to each pipe segment to ensure maximum lengths are not exceeded.

Table 10: Equivalent Piping Length for Elbows,

Y-branches, and Branch Distribution Units.

Component

Size (Inches)

1/4 3/8 1/2 5/8 3/4

Installation Manual

Elbow (ft.)

Y-Branch Kit (ft.)

(Multi F MAX systems only)

Branch Distribution Unit (ft.)

(Multi F MAX systems only)

1

Kit contains two Y-branches: one for liquid and one for vapor.

0.5 0.6 0.7 0.8 1.2

1

1.6

8.2

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

17

Page 18

X

MUL

MUL

F

DANGER

GENERAL INSTALLATION GUIDELINES

>4 inches

Recommended height

>6-1/2 feet from floor

>4 inches

HVT; 9/12k HSV4 Units: ≥5 inches

LSN180HSV4 Units: ≥8 inches

TI

F

Location Selection

To avoid the possibility of re, do not install the unit in an area where combustible gas may generate, ow, stagnate, or leak. Failure to do so will

cause serious bodily injury or death. Before beginning installation, read the safety summary at the beginning of this manual.

Select a location for installing the wall-mounted indoor unit (IDU) that meets the following conditions:

• Where there is enough structural strength to bear the weight of the unit

• Where air circulation will not be blocked

• Where noise prevention is taken into consideration

• Ensure there is sufcient space from the ceiling and oor

• Locate the indoor unit in a location where it can be easily connected to the outdoor unit/branch distribution unit

• Include space for drainage to ensure condensate ows properly out of the unit when it is in cooling mode

• Use a level indicator to ensure the unit is installed on a level plane

Note:

The unit may be damaged, may malfunction, and/or will not operate as designed if installed in any of the following conditions:

Do not install the unit where it will be subjected to direct thermal radiation from other heat sources.

Do not install the unit in an area where combustible gas may generate, flow, stagnate, or leak.

TI

MA

Do not install the unit in a location where acidic solution and spray (sulfur) are often used.

Do not use the unit in environments where oil, steam, or sulfuric gas are present.

Do not install additional ventilation products on the chassis of the unit.

Do not install the unit near high-frequency generator sources.

Do not install the unit near a doorway.

Installing in an Area Exposed to Unconditioned Air

In some installation applications, areas (floors, walls) in some rooms may be exposed to unconditioned air (room may be above or next to an

unheated garage or storeroom). To countermeasure:

• Verify that carpet is or will be installed (carpet may increase the temperature by three degrees).

• Add insulation between the oor joists.

Multi F Standard Wall-Mounted Indoor Unit

• Install radiant heat or another type of heating system to the oor.

Required Clearances

Figure 6 shows required clearance distances around a typical installed wall-mounted unit.

Figure 2: Required Clearances Around Typical Installed Unit

18

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 19

X

MUL

TI

MUL

F

CAUTION

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Unpack and Inspect for Freight Damage

Shipping and net weights of the wall-mounted units are listed in Table 4. To help avoid injury to personnel and

damage to the unit, use two people when carrying a unit by hand.

Note:

Do not unpack the unit and remove the protective materials until ready to install. Before unpacking,

carefully move the packaged unit to a work area near the installation location.

After opening, if the unit is damaged, repack the unit as it was shipped to you. RETAIN ALL PACKING

MATERIALS. In general, freight damage claims will be denied if the original packing materials are not

retained for the claims adjustor to inspect. Contact your supervisor on how to proceed with filing a freight

claim and to order a replacement unit.

Note:

Before opening the shipping container, check the container labeling to verify the unit received is the correct

unit. Verify the unit capacity, type, and voltage. Refer to the chart on “Dimensions of the Flare” on page 29.

1. Before opening the shipping container, verify you have the correct unit as described in the Note

above.

2. Place the box on a solid surface right side up.

3. Cut the reinforced nylon straps.

4. Open the top of the box and fold back all four flaps.

5. Remove the protective cardboard/Styrofoam® top sheet and place to the side.

6. The walls and top panels are not attached to the bottom of the box. Lift the cardboard carton by the

flaps and remove the box walls and top and place it to the side.

7. Remove the moisture barrier plastic bonnet.

8. Check the unit nameplate data and model number. Verify the unit voltage, and capacities are correct

before proceeding.

9. Locate and retain the piping/condensate accessory kit located in the bottom of the box under the

refrigerant pipe stubs.

10. Using two people, carefully lift the unit and inspect for freight damage. DO NOT lift by the refrigerant

piping or drain pipe stub. Lift by the hangar brackets or chassis frame only. If damage is found, repack

the unit as it was received in the original container.

11. If the unit is undamaged, remove and retain the installation manual. It is located under or on top of

the unit.

Inspection

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

19

Page 20

X

MUL

MUL

F

GENERAL INSTALLATION GUIDELINES

Frame

Hooks

Ø2-3/4 inches

Place a level on raised tab

Right rear piping

Left rear piping

TI

F

Install Wall-Mounted IDU Chassis

WARNING

• Mounting hardware must be securely installed to prevent the chas-

sis falling from its installation location. There is risk of personnel

injury or property damage from falling equipment.

• When choosing a location for the wall mount plate, be sure to take

into consideration routing of wiring for power outlets within the wall.

Touching wiring can cause serious bodily injury, or death.

• Installation work must be performed by trained personnel and in

accordance with all local or other applicable codes. There is risk of

injury to personnel from incorrect installation.

Note:

• Ensure the unit is properly installed. Incorrectly installed units can

result in degraded performance or an inoperative unit/system.

• Use a level indicator to ensure the installation plate and chassis

are installed on a level plane.

• If the unit is installed near a body of water, certain components

are at risk of being corroded. Appropriate anti-corrosion methods

should be taken for the unit and all components.

Mounting the Installation Plate

The mounting wall should be strong and solid enough to protect the

unit from vibration. It should securely hold the installation plate and

the weight of the chassis.

TI

Figure 3: Installation Plate for LMN078HVT, LSN090HSV4,

LSN120HSV4, and LMN158HVT Units.

Unit Outline

Ø2-9/16

5-3/16 3-11/16

6-7/8

Figure 4: Installation Plate for LSN180HSV4 and LMN248HVT Units.

Unit Outline

18-1/8 inches 22-7/16 inches

Place a level on raised tab

17-3/8 17-3/8

5

MA

Ø2-9/16

8-1/2

1. Determine the installation location.

2. Refer to Figure 3 or Figure 4 for the appropriate mounting

diagram.

3. Mount the installation plate on the wall using the Type “A” screws.

If mounting the unit on concrete, consider using anchor bolts.

Use a level to ensure the plate is level.

4. Always mount the installation plate horizontally. Measure the wall

and mark the centerline using thread and a level.

Multi F Standard Wall-Mounted Indoor Unit

Installation Plate

Left rear

piping

2-23/32 inches

4-1/8 inches

Figure 5: Installation Plate Attaching Screw Placement.

Type "A" Screws

Installation Plate

Measuring Tape

Measuring Tape Hanger

A-Type

B-Type

Ø2-3/4 inches

Right rear

piping

2-7/32 inches

8-5/32 inches

20

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 21

X

MUL

TI

MUL

F

(3/16"~5/16")

Installation plate

Tubing Clamp

Right

Tubing Clamp

Down

Left

Back

Frame Cover

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Drilling Piping Hole in the Wall

Use caution when drilling holes through walls. Drilling into power wiring in the wall can

cause serious bodily injury or death.

Follow the left or right piping clearance recommendations in Figure 3 or Figure 4.

1. Using a 2-5/8 (ø 65mm) inch hole core drill bit, drill a hole at either the right or

left side of the wall mounting (Figure 6). The hole should slant 3/16” to 5/16” from

level (upward on the indoor unit side and downward on the outdoor unit side).

2. Finish off the newly drilled hole as shown with bushing and sleeve covering.

Sleeve and bushing prevents damage to the tubing/bundling of the piping.

Hanging the Indoor Unit Chassis

1. Attach the three (3) hooks on the top of the indoor unit to the top edge of

the installation plate. Verify the hooks are properly attached to the installation plate by gently shaking the indoor unit from side to side.

2. Unlock the tubing clamp from the indoor unit frame. For easier access between the bottom of the indoor unit and the wall, prop the clamp between

the indoor unit frame and installation plate.

3. Remove the screw covers at the bottom of the indoor unit, unscrew the

two (2) screws, remove the frame cover, remove the piping connection

cover, and position the piping for installation (down, back, left, or right).

Install Wall-Mounted IDU Chassis

Figure 6: Drilling Piping Hole

WALL

Indoor

Core Drill

Bushing

Sleeve

Figure 7: Locking the Indoor Unit onto the Installation Plate.

Outdoor

Installation Manual

Figure 8: Accessing the Back of the Indoor Unit.

Figure 10: Exterior Back View of Indoor Unit. Figure 11: Piping Installed to the Left.

Figure 9: Removing the Frame Cover.

Tape

Connecting

pipe

Drain hose

Figure 12: Piping Installed to the Right.

Tape

Connecting

pipe

Drain hose

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

21

Page 22

X

MUL

MUL

F

GENERAL INSTALLATION GUIDELINES

3X

Minimum

TI

F

Refrigerant Piping

TI

MA

Preparing for Piping Installation to the Indoor Unit

Note:

Do not bend the piping / drain hose from side to side, it may damage the components.

Prepare the refrigerant piping and drain hose (indoor unit piping) for installation through the wall. Press on the top of the tubing clamp

and slowly guide the piping/hose down (depending on installation requirements, then to the left or right). Relock the tubing clamp after

the piping/hose are released.

No Pipe Size Substitutions

Use only the pipe size selected by the LATS Multi F pipe system design software or as conveyed in the product installation instructions.

Using a different size is prohibited and may result in a system malfunction or failure to work at all.

Pipe Slope

The horizontal pipe slope cannot exceed 10° up or down. Y-branches have additional restrictions described below.

In-line Refrigeration Components

Components such as oil traps, solenoid valves, filter-dryers, sight glasses, tee fittings, and other after-market accessories are not permitted on the refrigerant piping system between the outdoor units and the indoor / branch distribution units.

Multi F/Multi F Max systems have redundant systems that ensure oil is properly returned to the compressor. Sight-glasses and solenoid

valves may cause vapor to form in the liquid stream.

Note:

Over time, dryers may deteriorate and introduce debris into the system. The designer and installer should verify the refrigerant piping system is

free of traps, sagging pipes, sight glasses, lter dryers, etc.

Field-Provided Isolation Ball Valves

LG recommends installing field-supplied ball valves with Schrader ports at each indoor unit. Full-port isolation ball valves with Schrader

ports (positioned between valve and indoor unit) rated for use with R410A refrigerant should be used on both the liquid and vapor lines.

For Multi F MAX systems, position valves with a minimum distance of three (3) to six (6) inches of pipe on either side of the valve, and

Multi F Standard Wall-Mounted Indoor Unit

between six (6) and twelve (12) inches from the first upstream Y-branch or branch distribution unit. If ball valves are installed away from

the first Y-branch and/or branch distribution unit and closer to the indoor unit, oil may accumulate where it cannot be returned to the

outdoor unit and may cause a shortage of oil in the compressor.

Valves should be easily accessible for service. If necessary, install drywall access doors or removable ceiling panels, and position the

valves to face the access door or ceiling panel opening. Mount valves with adequate space between them to allow for placement of

adequate pipe insulation around the valves.

Obstacles

When an obstacle, such as an I-beam or concrete T, is in the

path of the planned refrigerant pipe run, it is best practice to

route the pipe over the obstacle. If adequate space is not available to route the insulated pipe over the obstacle, then route

the pipe under the obstacle. In either case, it is imperative the

horizontal section of pipe above or below the obstacle be a

minimum of three (3) times greater than the longest vertical rise

(or fall) distance.

Figure 13: Installing Piping Above and Below an Obstacle.

Above an obstacle.

Below an obstacle.

22

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 23

X

MUL

TI

MUL

F

Viewed from A in direction of arrow

Horizontal

plane

Within ±5

°

A

Vertical Up Configuration

Within ± 3°Within ± 3°

Vertical Down Configuration

Liquid and Gas

Pipe Joints

Y-Branch Kit Insulation

Insulation for

Field-Installed Piping

Field-Supplied Insulation Tape

A

B

X

Y

1

2

3

1

2

3

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Refrigerant Piping

Multi F MAX Y-Branch Kit PMBL5620

The LG supplied Y-Branch Kit PMBL5620 MUST be used when two branch distribution units are connected to one Multi F MAX system.

Field-supplied fittings are not permitted. Each Y-Branch kit comes with two (2) Y-branches (one for the liquid line and one for the vapor line)

and insulation covers.

Y-branches may be installed in horizontal or vertical configurations. When installed vertically, position the Y-branch so the straight-through

leg is ±3° of plumb. When installed horizontally, position the Y-branch so the take-off leg is level and shares the same horizontal plane as the

straight-through leg ±5° rotation.

Y-branches should always be installed with the single port facing the outdoor unit and the two-port end facing the branch distribution units.

Do not install Y-branches backwards as refrigerant flow cannot make U-turns. The Y-branch kit must be located at least three (3) feet from

the outdoor unit. Provide a minimum of 20 inches between a Y-branch and the branch distribution unit.

Figure 14: Y-Branch Port Identication and Dimensions.

Table 12: Multi F MAX Y-Branch Connection Diameters.

Model

PMBL5620

Y-Branch

Type

Liquid Ø3/8 Ø3/8 Ø3/8

Vapor Ø3/4 Ø3/4 Ø3/4

Y-Branch

Type

Liquid 13.80 3.24

Vapor 12.48 3.02

Port Identier (inch)

1 2 3

Dimensions (inch)

X Y

Installation Manual

A = To Outdoor Unit

B = To Branch Distribution Unit

Figure 15: Y-branch Horizontal Installation Alignment.

Y-Branch Kit Insulation

Each Y-branch kit comes with clam-shell type peel-andstick insulation jackets molded to fit the Y-branch fittings—

one for the liquid line, one for the vapor line.

Table 11: Insulation Jacket Properties.

Material

UL94 Flame Classication

Density

Thermal Conductivity

Thickness

Polyolefin Foam

1.84 lbs./ft.

.0208 Btu/h/ft. ºR

Figure 16: Y-branch Vertical Installation Alignment.

Figure 17: Y-Branch Insulation Jacket Diagram.

HF-1

1/2 inch

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

Due to our policy of continuous product innovation, some specifications may change without notification.

23

Page 24

X

MUL

MUL

F

GENERAL INSTALLATION GUIDELINES

TI

F

Refrigerant Piping

TI

MA

Selecting Field-Supplied Copper Tubing

Copper is the only approved refrigerant pipe material for use with Duct Free System products, and LG recommends seamless phosphorous

deoxidized ACR type copper pipe, hard-drawn rigid type “K” or “L”, or annealed-tempered, copper pipe.

• Drawn temper (rigid) ACR copper tubing is available in sizes 3/8 through 2-1/8 inches (ASTM B 280, clean, dry, and capped).

• Annealed temper (soft) ACR copper tubing is available in sizes 1/4 through 2-1/8 inches (ASTM B 280, clean, dry, and capped).

Tube wall thickness should meet local code requirements and be approved for an operating pressure of 551 psi. If local code does not

specify wall thickness, LG suggests using tube thickness per table below. When bending tubing, try to keep the number of bends to a minimum, and

use the largest radii possible to reduce the equivalent length of installed pipe; also, bending radii greater than ten (10) pipe diameters can minimize

pressure drop. Be sure no traps or sags are present when rolling out soft copper tubing coils.

Table 13: ACR Copper Tubing Material

Type Seamless Phosphorous Deoxidized

Class UNS C12200 DHP

Straight Lengths H58 Temper

Coils O60 Temper

Table 14: Piping Tube Thicknesses

OD (in) 1/4 3/8 1/2 5/8 3/4 7/8 1-1/8 1-3/8 1-5/8

Material Rigid Type “K” or “L” and Soft ACR Acceptable Rigid Type “K” or “L” Only

Min. Bend

Radius (in)

Min. Wall

Thickness (in)

Nominal Pipe

Outside

Diameter (in)

Multi F Standard Wall-Mounted Indoor Unit

1/4 0.250 -- -- -- 0.030 0.081 .00020

3/8 0.375 0.030 0.126 .00054 0.032 0.134 .00053

1/2 0.500 0.035 0.198 .00101 0.032 0.182 .00103

5/8 0.625 0.040 0.285 .00162 0.035 0.251 .00168

3/4 0.750 0.042 0.362 .00242 0.042 0.362 .00242

7/8 0.875 0.045 0.455 .00336 0.045 0.455 .00336

1-1/8 1.125 0.050 0.655 .00573 0.050 0.655 .00573

1

All dimensions provided are in accordance with ASTM B280 – Standard.

2

Design pressure = 551 psig.

3

ACR Tubing is available as hard drawn or annealed (soft) and are suitable for use with R410A refrigerant.

4

The Copper Tube Handbook, 2010, Copper Development Association Inc., 260 Madison Avenue, New York, NY 10016.

.563 .9375 1.5 2.25 3.0 3.0 3.5 4.0 4.5

.03 .03 .035 .040 .042 .045 .050 .050 .050

1-4

Weight (lb/ft)

Actual Outside

Diameter (in)

Table 15: ACR Copper Tubing Dimensions and Physical Characteristics

Drawn Temper Annealed Temper

Nominal Wall

Thickness (in)

Weight (lb/ft)

Cubic ft per

Linear ft

Nominal Wall

Thickness (in)

Cubic ft per

Linear ft

• Commercially available piping often contains dust and other materials. Always blow it clean with a dry, inert gas.

• Prevent dust, water or other contaminants from entering the piping during installation. Contaminants can cause mechanical failure.

24

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 25

X

MUL

TI

MUL

F

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Refrigerant Piping

No Pipe Size Substitutions

Note:

Use only the pipe size recommended by this installation manual. Using a different size is prohibited and may result in system malfunction or failure.

Copper Expansion and Contraction

Under normal operating conditions, the vapor pipe temperature of a

Duct Free System can vary as much as 280°F. With this large variance in pipe temperature, the designer must consider pipe

expansion and contraction to avoid pipe and fitting fatigue failures.

Refrigerant pipe along with the insulation jacket form a cohesive unit that

expands and contracts together. During system operation, thermal heat

transfer occurs between the pipe and the surrounding insulation.

If the pipe is mounted in free air space, no natural restriction to

movement is present if mounting clamps are properly spaced and

installed. When the refrigerant pipe is mounted underground in a

utility duct stacked among other pipes, natural restriction to linear

movement is present. In extreme cases, the restrictive force of

surface friction between insulating jackets could become so great

that natural expansion ceases and the pipe is “fixed” in place. In this

situation, opposing force caused by change in refrigerant fluid/vapor

temperature can lead to pipe/fitting stress failure.

The refrigerant pipe support system must be engineered to allow

free expansion to occur. When a segment of pipe is mounted

between two fixed points, provisions must be provided to allow pipe

expansion to naturally occur. The most common method is the

inclusion of expansion Loop or U-bends. Each segment of pipe has

a natural fixed point where no movement occurs. This fixed point is

located at the center point of the segment assuming the entire pipe

is insulated in a similar fashion. The natural fixed point of the pipe

segment is typically where the expansion Loop or U-bend should be.

Linear pipe expansion can be calculated using the following formula:

LE = C x L x (T

LE = Anticipated linear tubing expansion (in.)

C = Constant (For copper = 9.2 x 10

L = Length of pipe (ft.)

T

R

T

a

12 = Inches to feet conversion (12 in./ft.)

– Ta) x 12

r

= Refrigerant pipe temperature (°F)

= Ambient air temperature (°F)

-6

in./in.°F)

1. In Table 16 find the row corresponding with the actual length of

the straight pipe segment.

2. Estimate the minimum and maximum temperature of the pipe.

In the column showing the minimum pipe temperature, look up the

anticipated expansion distance. Do the same for the maximum

pipe temperature.

3. Calculate the difference in the two expansion distance values.

The result will be the anticipated change in pipe length.

Example:

A system is installed and the design shows that there is a 100 foot

straight segment of tubing between an indoor unit and the outdoor

unit. In heating, this pipe transports hot gas vapor to the indoor units

at 120°F. In cooling, the same tube is a suction line returning refrigerant vapor to the outdoor unit at 40°F. Look up the copper tubing

expansion at each temperature and calculate the difference.

Vapor Line

Transporting Hot Vapor: 100 ft. pipe at 120 °F = 1.40 in.

Transporting Suction Vapor: 100 ft. pipe at 40 °F = 0.40 in.

Anticipated Change in Length: 1.40 in. – 0.40 in. = 1.00 in.

Liquid Line

The liquid temperature remains relatively the same temperature; only

the direction of flow will reverse. No significant change in length of

the liquid line, therefore, is anticipated.

When creating an expansion joint, the joint height should be a

minimum of two times the joint width. Although different types of

expansion arrangements are available, the data for correctly sizing

an Expansion Loop is provided in Table 1010. Use soft copper with

long radius bends on longer runs or long radius elbows for shorter

pipe segments. Using the anticipated linear expansion (LE) distance

calculated, look up the Expansion Loop or U-bend minimum design

dimensions. If other types of expansion joints are chosen, design per

ASTM B-88 Standards.

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

25

Page 26

X

MUL

MUL

F

Large Tubing U-bend (>3/4 in.) Loop Small Tubing U-bend (<3/4 in.)

GENERAL INSTALLATION GUIDELINES

TI

F

Refrigerant Piping

See table below for precalculated anticipated expansion for various pipe sizes and lengths of refrigerant tubing.

To find the anticipated expansion value:

1. From the table below, find the row corresponding with the actual feet of the straight pipe segment.

2. Estimate the minimum and maximum temperature of the pipe.

3. In the column showing the minimum pipe temperature, look up the anticipated expansion distance corresponding to the segment length.

Do the same for the maximum pipe temperature.

4. Calculate the difference in the two expansion distance values. The result will be the change in pipe length.

Table 16: Linear Thermal Expansion of Copper Tubing in Inches

Pipe

1

Length

1

Pipe length baseline temperature = 0°F. "Expansion of Carbon, Copper and Stainless Steel Pipe," The Engineers' Toolbox, www.engineeringtoolbox.com.

35° 40° 45° 50° 55° 60° 65° 70° 75° 80° 85° 90° 95° 100° 105° 110° 115° 120° 125° 130°

10 0.04 0.04 0.05 0.06 0.06 0.07 0.08 0.08 0.09 0.09 0.10 0.10 0.11 0.11 0.11 0.12 0.13 0.14 0.15 0.15

20 0.08 0.08 0.10 0.12 0.13 0.14 0.15 0.16 0.17 0.18 0.19 0.20 0.21 0.22 0.22 0.23 0.26 0.28 0.29 0.30

30 0.12 0.12 0.15 0.18 0.20 0.21 0.23 0.24 0.26 0.27 0.29 0.30 0.32 0.33 0.32 0.35 0.39 0.42 0.44 0.45

40 0.16 0.16 0.20 0.24 0.26 0.28 0.30 0.32 0.34 0.36 0.38 0.40 0.42 0.44 0.43 0.46 0.52 0.56 0.58 0.60

50 0.20 0.20 0.25 0.30 0.33 0.35 0.38 0.40 0.43 0.45 0.48 0.50 0.53 0.55 0.54 0.58 0.65 0.70 0.73 0.75

60 0.24 0.24 0.30 0.36 0.39 0.42 0.45 0.48 0.51 0.54 0.57 0.60 0.63 0.66 0.65 0.69 0.78 0.84 0.87 0.90

Fluid Temperature °F

TI

MA

Figure 18: Coiled Expansion Loops and Offsets

L

R

Table 17: Radii of Coiled Expansion Loops and Developed Lengths of Expansion Offsets

Multi F Standard Wall-Mounted Indoor Unit

Anticipated Linear

Expansion (LE) (inches)

1/2

1

1-1/2

2

2-1/2

3

3-1/2

4

L

1

R

2

L

1

R

2

L

1

R

2

L

1

R

2

L

1

R

2

L

1

R

2

L

1

R

2

L

1

R

2

L

6 7 8 9

38 44 50 59

9 10 11 13

54 63 70 83

11 12 14 16

66 77 86 101

12 14 16 19

77 89 99 117

14 16 18 21

86 99 111 131

15 17 19 23

94 109 122 143

16 19 21 25

102 117 131 155

17 20 22 26

109 126 140 166

1/4 3/8 1/2 3/4

R

Nominal Tube Size (OD) inches

L

26

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 27

X

MUL

TI

MUL

F

Max. 12" Max. 12"

Max. 12"

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Inserts and Pipe Supports

Inserts

An insert can be installed into a floor or beam before the concrete sets so that fittings such as ducts,

pipes, or suspension bolts can be added at a later time. Decide where the inserts should be placed

before support installation.

Pipe Supports

Note:

The pipe system must be adequately supported to avoid pipe sagging. Sagging pipes become oil traps that

lead to equipment malfunction.

Pipe supports should never touch the pipe wall; supports should be installed outside

(around) the primary pipe insulation jacket. Insulate the pipe before installing the supports. Pipe supports are field-provided and must meet local code. If local codes do not

specify pipe support spacing, install pipe supports a maximum of 5 feet on center for

straight segments of pipe up to 3/4” outside diameter size.

Wherever the pipe changes direction, place a hanger within twelve (12) inches on one

side and within twelve to nineteen (12 to 19) inches of the bend on the other side. Support piping at indoor units as shown. Support Y-Branch fittings as shown.

Refrigerant Piping

Figure 19: Installing an Insert Into

a Concrete Beam.

Anti-vibration Material

Insert

Concrete Beam

Figure 20: Pipe Hanger Details.

Suspension Bolt

Nail

Installation Manual

Figure 21: Typical Pipe Support Location—Change

in Pipe Direction.

~ 12" – 19"

Figure 23: Pipe Support at Y-branch Fitting.

Max. 12"

Figure 22: Pipe Support at Indoor Unit.

A

A + B ~ 12" – 19"

B

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

27

Page 28

X

MUL

MUL

F

Bolt

PVC

PVC

Welding

Refrigerant Pipe

Insulated

Support Band

Insulated

Support Band

Down

Stop

Welding

Plate Nut

Hexagonal Nut

O-ring Band

GENERAL INSTALLATION GUIDELINES

TI

F

Refrigerant Piping

Examples of Supports

Figure 24: U-Bolt Support with Insulation. Figure 25: O-Ring Support with Insulation.

Insulation

Bolt

1.5t

Plate

Figure 26: Saddle-Type Support.

Support at Intervals Between 5 and 6-3/4 Feet

TI

Note:

Do not compress the insulation with the saddle-type support. If the insulation is compressed, it may tear open and allow condensation to

generate during product operation.

Figure 27: U-Bolt Support with an Insulated Pipe. Figure 28: O-Ring Band Support with an Insulated Pipe.

MA

To prevent

insulation from

pressing and

lagging, use a cover.

Sheathing

Multi F Standard Wall-Mounted Indoor Unit

Figure 29: One-Point Down-Stop Support (>441 lbs.).

O-Ring

Band

Lags

Sheathing

Figure 30: Two-Point Down-Stop Support.

28

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 29

X

MUL

TI

MUL

F

40 in40 in

A

B

D

F

G

B

G

D

B

H

I

J

A

E

B

I

A

B

D

C

Inside wall (concealed)

Floor (fire-resistance)

Area between fire-resistant

insulation and boundary wall

Roof pipe shaft

Outside wall

Outside wall (exposed)

Sleeve

Insulation

Lagging

Caulk

Band

Water-resistant layer

Sleeve with edge

Lagging

Mortar or other fire-resistant caulk

Fire-resistant insulation

When filling an access hole with mortar, cover the

area with steel plate so that the insulation will not

fall through. For this area, use fire-resistant

materials for both the insulation and cover. (Vinyl

cover should not be used.)

F

GENERAL INSTALLATION GUIDELINES

TI

MA

Pipe Sleeves at Penetrations

LG requires that all pipe penetrations through walls, floors, and

pipes buried underground be routed through a properly insulated

sleeve that is sufficiently sized to provide free movement of the pipe

and does not compress the insulation. Route underground refrigerant pipe inside a protective sleeve to prevent insulation deterioration. Follow federal, state, and local regulations and codes when

choosing a sleeve type.

Figure 31: Pipe Sleeve Options.

Refrigerant Piping

Note:

Pipe diameter plus insulation thickness determines wall

penetration diameter.

For example:

Diameter of Gas Piping: 1/2"

Diameter of Liquid Piping: 1/4"

Thickness of Gas Piping Insulation: 0.4" x 2

Thickness of Liquid Piping Insulation: 0.4" x 2

Surplus: 0.8"

Sleeve diameter (total): 3.1" minimum

Installation Manual

Underground Refrigerant Piping

Route refrigerant pipe installed underground inside a vapor tight protective sleeve to prevent insulation deterioration and water infiltration. Refrigerant pipe installed inside underground casing must be

continuous without any joints. Underground refrigerant pipe must be

located at a level below the frost line.

Liquid

Pipe

1/4 (1.0)

3/8 (1-1/8)

1

OD pipe diameter in inches; Values in parenthesis () indicate OD of pipe with insulation

jacket.

2

Diameter of pipe with insulation. Thickness of pipe insulation is typical. Actual required

thickness may vary based on surrounding ambient conditions and should be calculated

and specified by the design engineer.

3

Insulation thickness (value in parenthesis) = 3/8 inch.

4

Insulation thickness (value in parenthesis) = 1 inch.

5

Insulation thickness (value in parenthesis) = 3/4 inch.

1

3

3

Table 18: Utility Conduit Sizes.

Vapor Pipe

3/8 (1-1/8

2,3

) 1/2 (2.0

4 4 4 4

4 4 4 5

2,5

) 5/8 (2-1/8

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

1

Due to our policy of continuous product innovation, some specifications may change without notification.

2,5

) 3/4 (2-1/4

2,5

)

Figure 32: Typical Arrangement of Refrigerant Pipe

and Cable(s) in a Utility Conduit.

Figure 33: Underground Refrigerant Piping.

Vapor Line

Insulation Material

Liquid Line

Pipe Sleeve

Insulation

Material

Min. 18 Gauge

Power/Communication

Cable

29

Page 30

X

MUL

MUL

F

GENERAL INSTALLATION GUIDELINES

TI

F

Piping Materials and Handling

Piping Materials and Handling

Pipes used for the refrigerant piping system must include the specified thickness, and the

interior must be clean.