LG LS-C1260HD, LS-C1120CM, LS-C1420CM, LS-C1420CN, LS-C1260CD Service Manual

...

K

M

K

M

Room Air Conditioner

SERVICE MANUAL

MODEL : LS-B0760CM/B0760HM

LS-B0960CM/B0960HM

LS-B0962CM/B0962HM

LS-B0962CD/B0962HD

LS-B0960CD/B0960HD

LS-C1260CM/C1260HM

LS-C1260CD/C1260HD

LS-C1120CM/C1420CM

LS-C1420CN

CAUTION

BEFORE SERVICING THE UNIT,

READ THE "SAFETY PRECAUTIONS" IN THIS MANUAL.

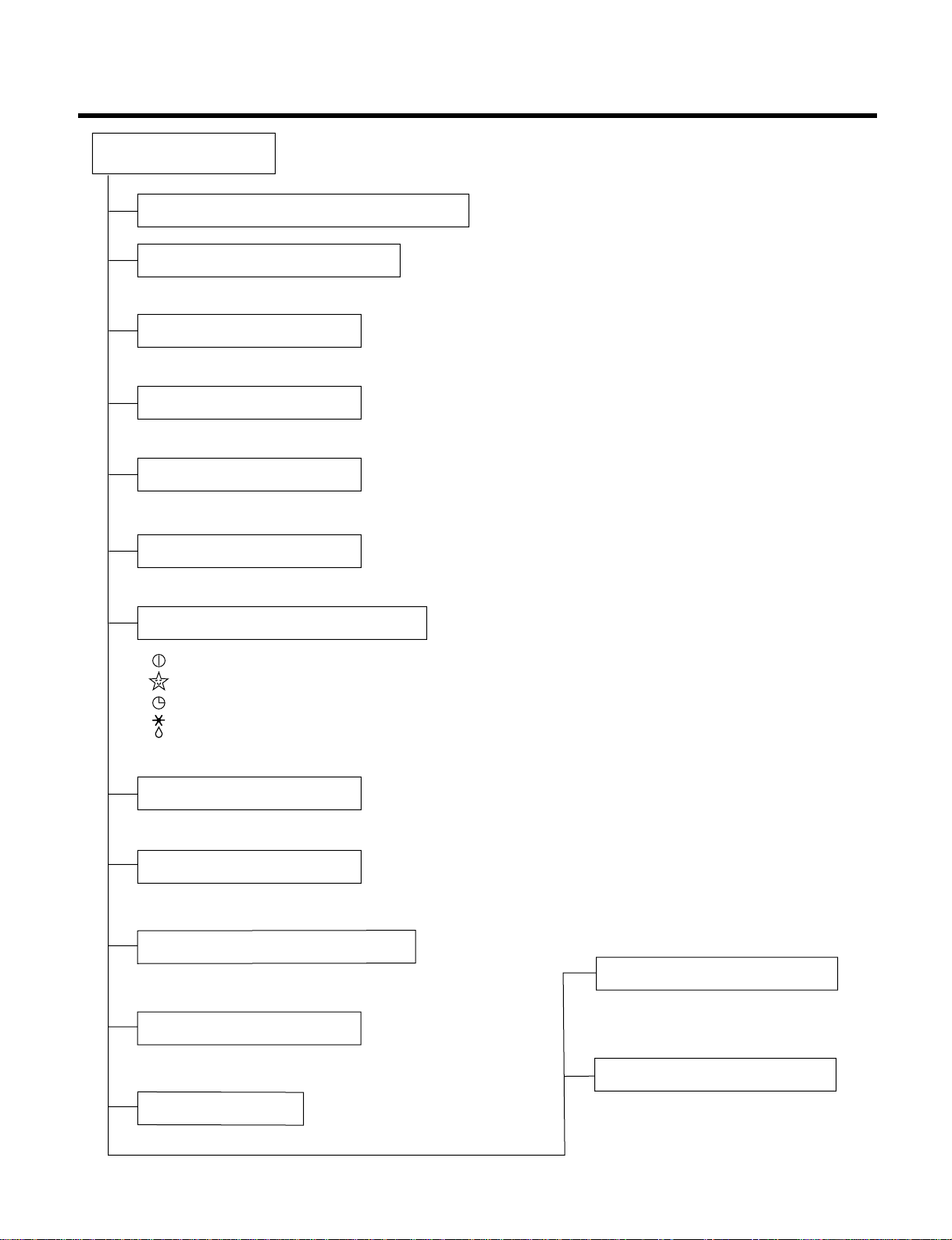

Functions

......................................................................................................................................

3

Product Specifications (Cooling Only)

......................................................................................

5

Product Specifications (Cooling & Heating)

..............................................................................

6

Dimensions

...................................................................................................................................

7

Maximum Length of Pipe and Freon Extra Charge

...................................................................

9

Refrigeration Cycle Diagram

.....................................................................................................

10

Wiring Diagram

..........................................................................................................................

11

Operation Details

.......................................................................................................................

13

Display Function

........................................................................................................................

20

Self-diagnosis Function

............................................................................................................

20

Installation

..................................................................................................................................

21

Operation

....................................................................................................................................

39

Disassembly of the parts(Indoor Unit)

.....................................................................................

41

2-way, 3-way V alve

.....................................................................................................................

44

Cycle Troubleshooting Guide

...................................................................................................

51

Electronic Parts Troubleshooting Guide

..................................................................................

52

Electronic Control Device

.........................................................................................................

56

Schematic Diagram

....................................................................................................................

59

Exploded View & Replacement Parts List

...............................................................................

61

- 2 -

Contents

- 3 -

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

Sleep Mode Auto Control

Auto Air Control by CHAOS Logic

Airflow Direction Control

AUTO Wind

Deice(defrost) control(Heating)

Hot-start Control(Heating)

• Room temperature sensor(THERMISTOR).

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, Chaos or Auto

• Intermittent operation of fan at low speed

• The louver can be set at the desired position or swing up

and down, right and left (not on all models) automatically.

• The fan speed is automatically switched from high to low speed.

• Both the indoor and outdoor fan stops

during deicing.

• Hot start after deice ends.

• The indoor fan stops until the

evaporator piping temperature will be

reached at 28°C.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation.

• The fan speed is automatically switched from high to low speed.

--- Lights up in Operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Deice Mode or Hot Start Mode (only Heating Model)

--- Lights during in compressor running (for Cooling Model)

OUT

DOOR

- 4 -

TEMPERATURETEMPERATURE

LOWLOW

HIGHHIGH

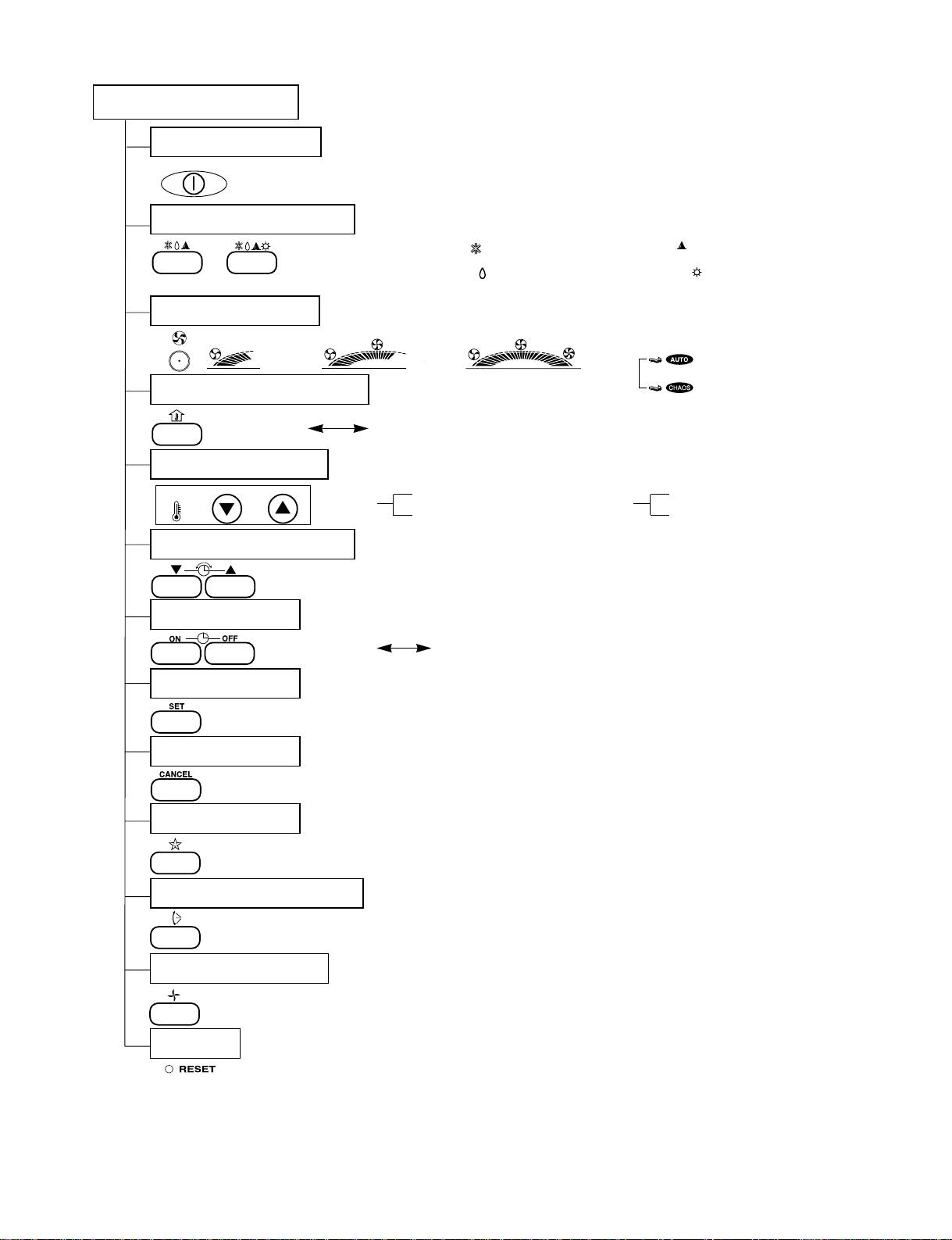

Remote Controller

Operation ON/OFF

(Cooling model only)

(Heatling model only)

Cooling Operation Mode ( )

Soft Dry Operation Mode ( )

(Low)

(Med)

(High)

(AUTO WIND)

(CHAOS)

: High: 39°C LOW : 11°C

Down to 18°C

Up to 30°C,

Cooling

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Auto Operation Mode ( )

Heating Operation Mode ( )

Operation Mode Selection

Fan Speed Selection

Room, Temperature Display

Temperature Setting

Setting the Time or timer

Timer Selection

Timer Setting

Timer Cancel

Sleep Operation

Airflow Direction Control

Fan Operation Mode

Reset

Down to 16°C

Up to 30°C,

Heating

Cooling Capacity BTU/h(kcal/h)

Moisture Removal ℓ/h

Power Source Ø, V, Hz

Air Circulation m3/min

Noise Level dB(A)

Input W

Runnig Current A

E.E.R. BTU/h-W

Motor Output W

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control (Up & Down)

Remocon type

Service valve

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

- 5 -

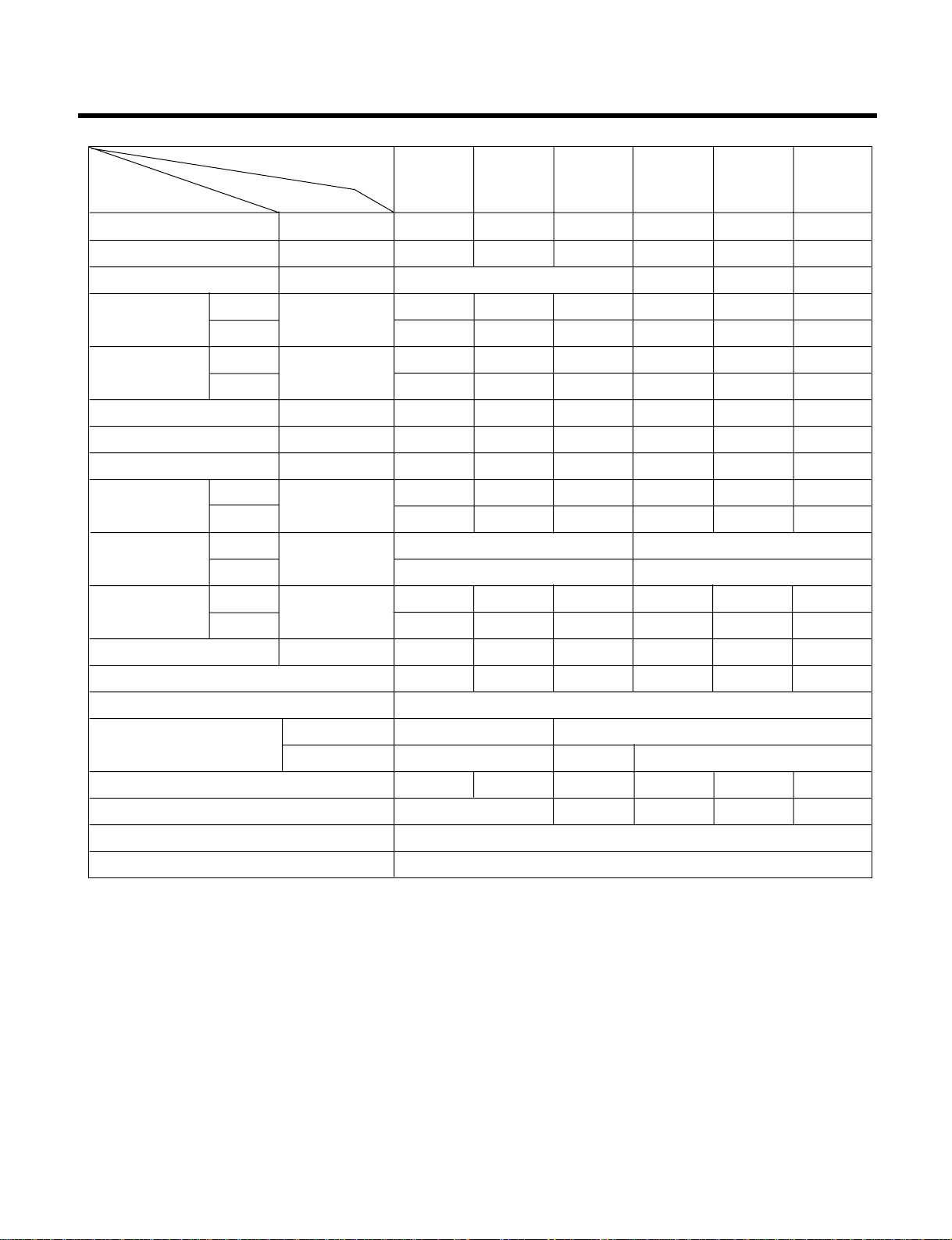

Product Specifications (Cooling Only)

7,300(1,840) 8,700(2,190) 8,700(2,190) 11,000(2,770) 12,000(3,020) 14,000(3,528)

1.0 1.2 1.2 1.2 1.7 1.7

1Ø, 220-240V, 50Hz

1Ø, 220V~,60Hz

1Ø, 220-240V,50Hz

1Ø, 220V~,60Hz

4.85 5.3 5.3 8.5 10.2 9.5

25 25 25 25 25 25

36±339±338±339±341±341±3

47±349±349±349±350±350±3

755 920 920 1,050 1,140 1,270

3.2 4.0 4.0 4.9 5.0 5.9

9.7 9.5 9.5 10.5 10.5 11

7 1010101515

25 25 25 25 25 25

810 x 220.5 x 152 900 x 290 x 183

660 x 540 x 260 801 x 555 x 262

6.5 6.5 6.5 10 10 10

27 27 27 33 33 35

540 670 690 1,080 840 980

OOOOOO

L.C.D Wireless

1/4"(6.35) 1/4"(6.35)

3 /8"(9.52) 3/8"(9.52) 1/2"(12.7)

OOOOOO

O OOOO

1.0mm

2

1.0mm

2

Model Name

Unit

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Dimensions

(W x H x D)

Item

LS-B0760CM

LS-B0960CD

LS-B0960CM

LS-B0962CD

LS-B0962CM

LS-C1120CM

LS-C1260CD

LS-C1260CM

LS-C1420CM

LS-C1420CN

- 6 -

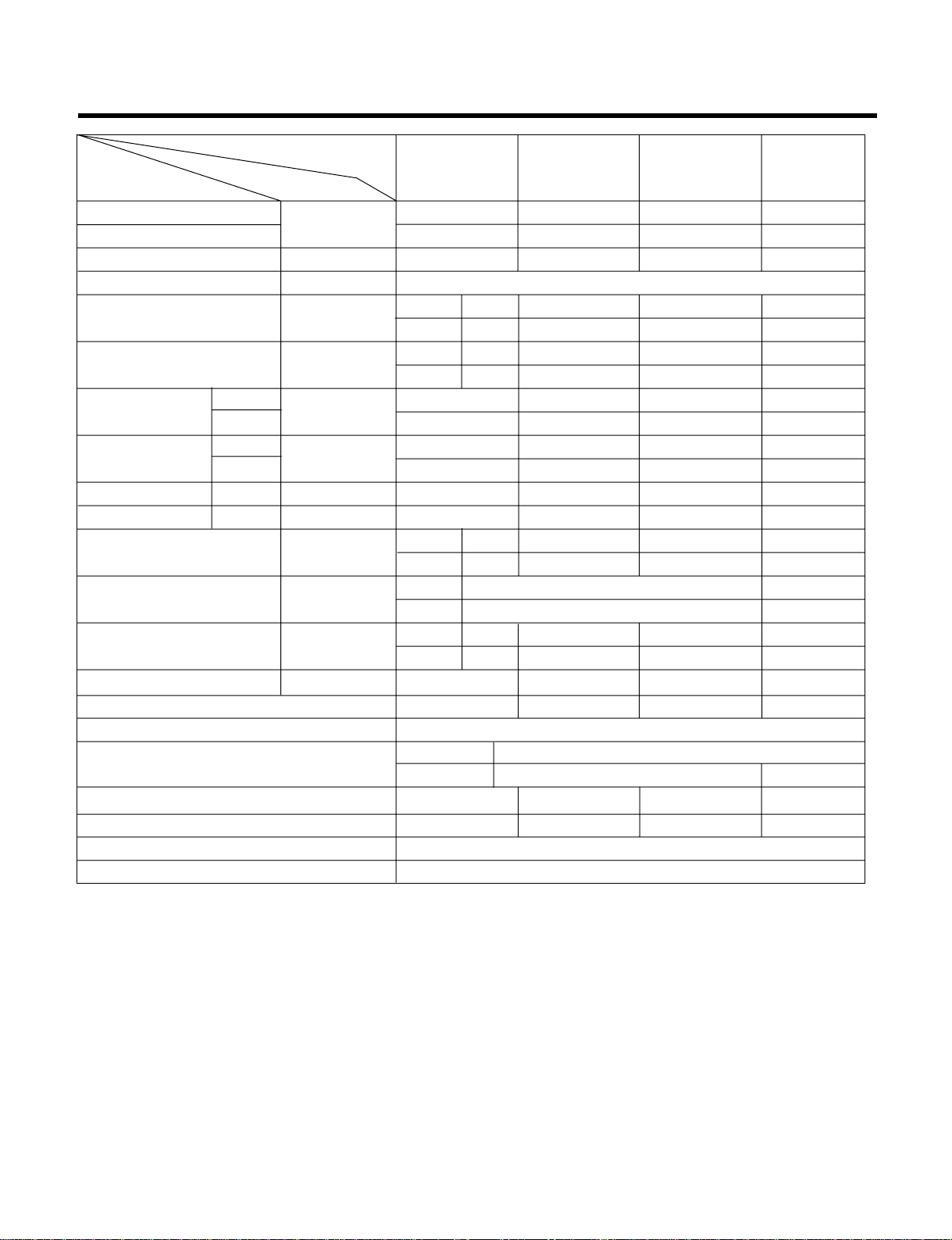

Product Specifications (Cooling & Heating)

Cooling Capacity

Heating Capacity

Moisture Removal ℓ/h

Power Source Ø, V, Hz

Air Circulation m3/min

Noise Level dB(A)

Input W

Runnig Current

A

E.E.R. BTU/h·W

C.O.P W/W

Motor Output W

mm

Net. weight kg

Refrigerant(R-22) g

Airflow Direction Control (Up & Down)

Remocon Type

Service Valve

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

7,000(1,764) 8,500(2,142) 8,500(2,142) 12,000(3,020)

7,500(1,890) 9,500(2,394) 9,500(2,394) 12,500(3,150)

1.0 1.2 1.2 1.7

1Ø, 220-240V, 50Hz

4.85 5.3 5.6 10.2

25 25 25 25

36±339±340±141±3

47±349±350±151±3

760 940 895 1,250

780 1,030 950 1,100

3.2 4.1 3.8 5.5

3.3 4.4 4.1 4.8

9.2 9.0 9.5 9.6

2.82 2.7 2.76 3.3

710 10 15

25 25 25 25

810 x 220.5 x 152

900 x 290 x 183

660 x 540 x 260

810 x 555 x 262

6.5 6.5 6.5 10

30 30 30 35

590 690 720 810

OOOO

L.C.D Wireless

1/4"(6.35)

3/8"(9.52) 1/2"(12.7)

OOOO

OOOO

1.0mm

2

1.0mm

2

Model Name

Unit

Indoor

Outdoor

Indoor

Outdoor

Cooling

Heating

Cooling

Heating

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Dimensions

(W x H x D)

Item

LS-B0760HM

LS-B0960HD

LS-B0960HM

LS-B0962HD

LS-B0962HM

LS-C1260HD

LS-C1260HM

BTU/h(kcal/h)

- 7 -

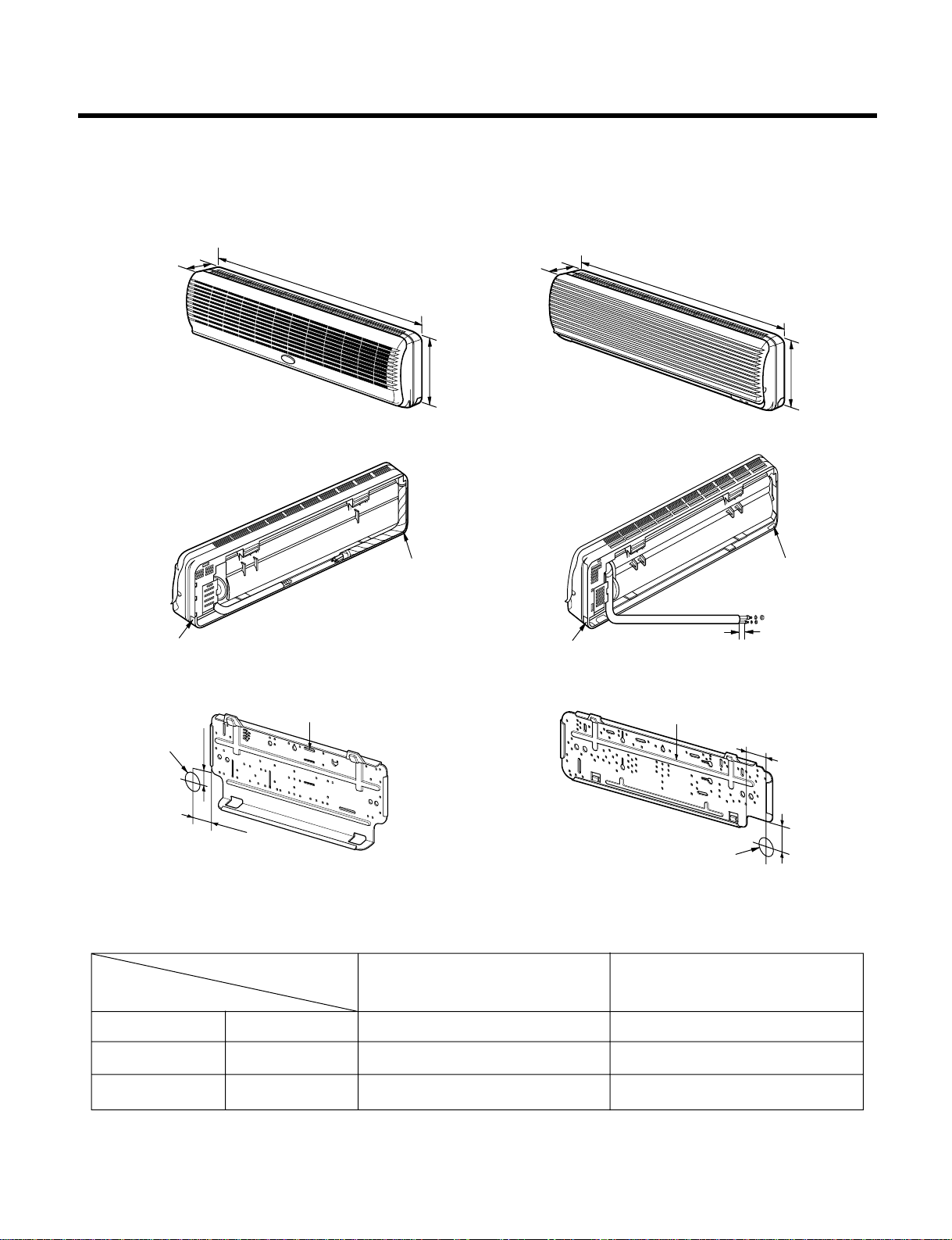

Dimensions

(1) Indoor Unit

4.5cm

4cm

50

8cm

2cm

W

W

D

D

H

H

Installation plate

Tubing hole cover

Tubing hole cover

Tubing hole cover

Tubing hole cover

Installation plate

Hole for piping

Hole for piping

(7K, 9K)

(11K, 12K, 14K)

MODEL 7K, 9K BTU 11K, 12K, 14K BTU

DIM Series Series

W mm 810 900

H mm 220.5 290

D mm 152 183

- 8 -

W

D

L1

L2

H

L3

L4

L5L6 L7 L8

L9

L10

Liquid side

2-way valve

Gas side

3-way valve

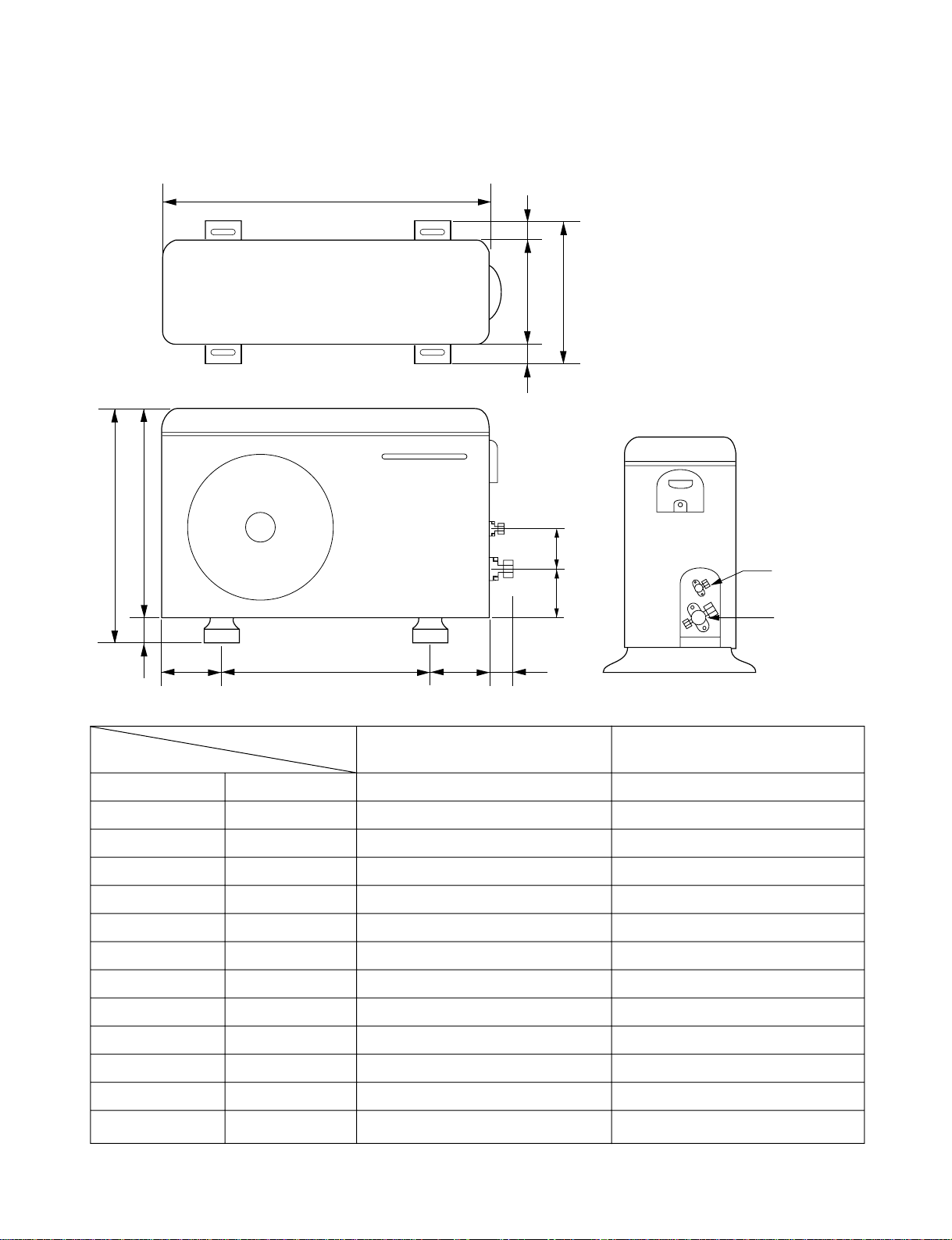

(2) Oudoor Unit (7K, 9K, 11K, 12K, 14K)

MODEL

7K, 9K, 11K BTU Series 12K, 14K BTU Series

DIM

W mm 660 801

H mm 540 555

D mm 260 262

L1 mm 297 339

L2 mm 18.5 37

L3 mm 523 543.6

L4 mm 17 11.4

L5 mm 447 591

L6 mm 76.5 105

L7 mm 76.5 105

L8 mm 66 72.5

L9 mm 82 86.4

L10 mm 77 77

- 9 -

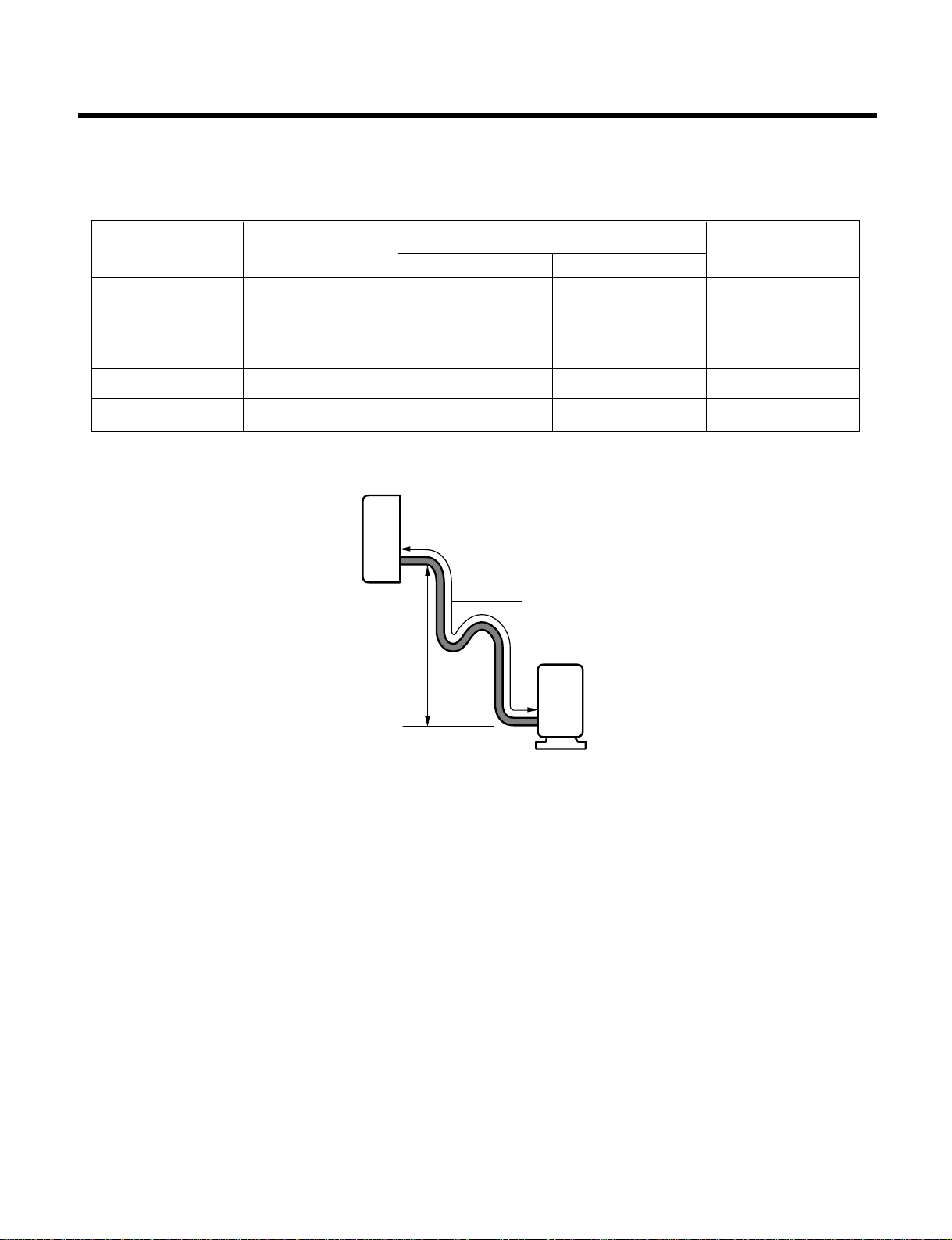

Maximum Length of Pipe and Freon Extra Charge

Charge amount per 1m

A

B

Oil trap

Outdoor unit

Indoor unit

Capacity STANDARD

MAXIMUM LENGTH Charge amount (g)

(Btu/h) LENGTH(m)

AB

per 1m

~7000 4 7 15 20

~9000 4 7 15 20

~12000 4 7 15 20

~18000 5 15 30(25) 40

~24000 5 15 25 40

* A, B mean indoor unit higher located than outdoor unit

* Capicity is based on standard length and maximum allowance length is the basis of relia-

bility.

* Oil trap should be installed per 10 meters.

* Numerical value in "( )" is for Rotary Comp. model.

- 10 -

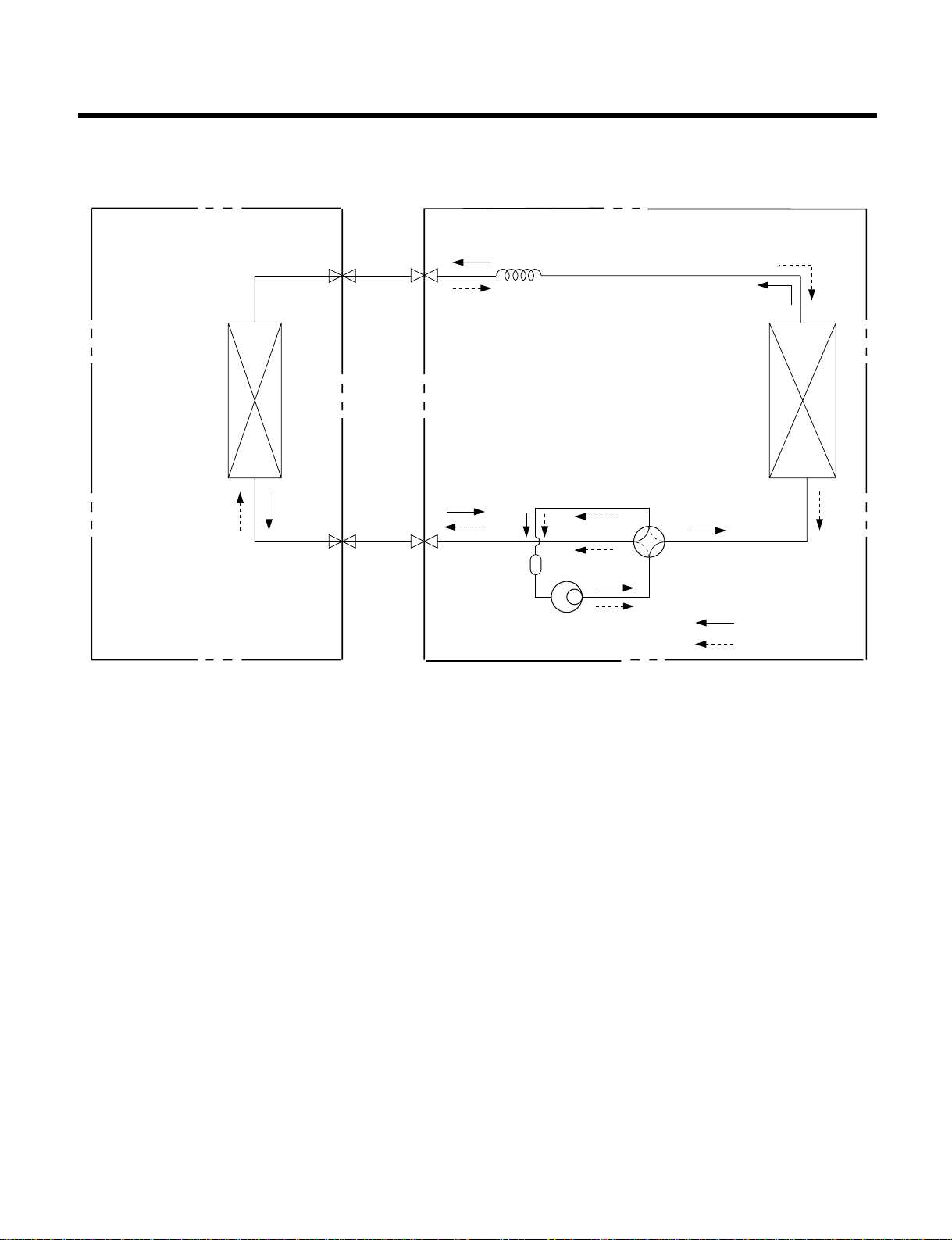

Refrigeration Cycle Diagram

INDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

COOLING

HEATING

ACCUMULATOR

REVERSING

VALVE

GAS SIDE

CAPILLARY TUBE

LIQUID SIDE

2-WAY VALVE

3-WAY VALVE

OUTDOOR UNIT

- 11 -

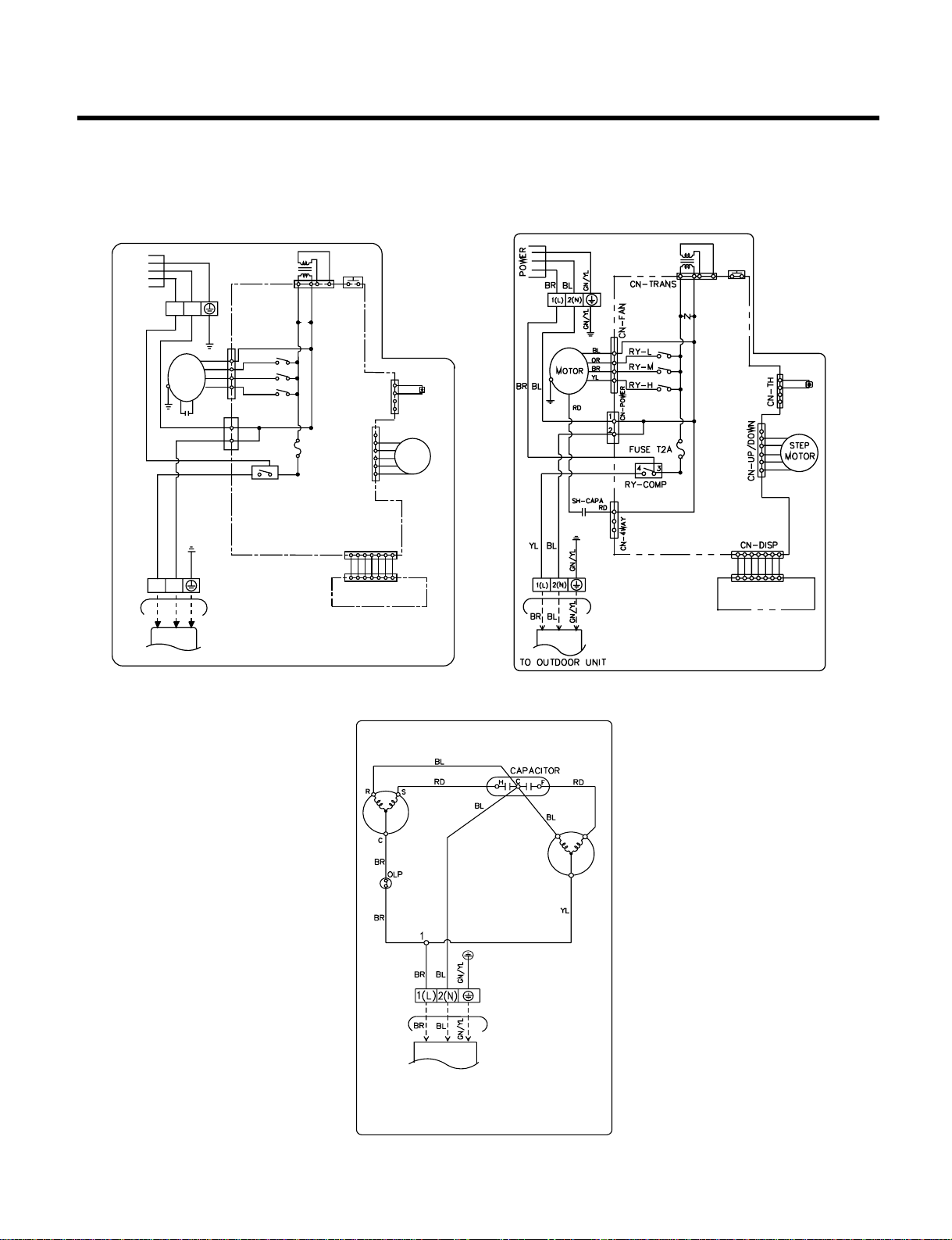

Wiring Diagram

(1) 7K, 9K, 11K, 12K, 14K BTU Cooling Only

1. Indoor Unit

2. Outdoor Unit

YL BL

YL

RD

SH-CAPA

OR

BR

BR

BR BL

GN/YL

POWER

BL

RY-L

RY-M

RY-H

MOTOR

STEP

MOTOR

GN/YN

PILLAR

TO OUTDOOR UNIT

CN-POWER

CN-FAN

CN-TRANS

CN-TH

THERMISTOR

RY-COMP

MAIN PCB

DISPLAY PCB ASM

ASM

CN-DISP

FUSE T2A

CN-UP/DOWN

1

2

43

TERMINAL

TRANS

FORCED

OPERATION

SWITCH

FORMER

N

INDOOR WIRING DIAGRAM

1

2

(N)(L)

1

2

(N)(L)

TRANS

FORMER

FORCED

OPERATION

SWITCH

THERMISTOR

PILLAR

TERMINAL

MAIN PCB

ASM

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

(7K, 9K, 12K)

(11K, 14K)

COMP

FAN

MOTOR

TO INDOOR UNIT

PILLAR

TERMINAL

OUTDOOR WIRING DIAGRAM

- 12 -

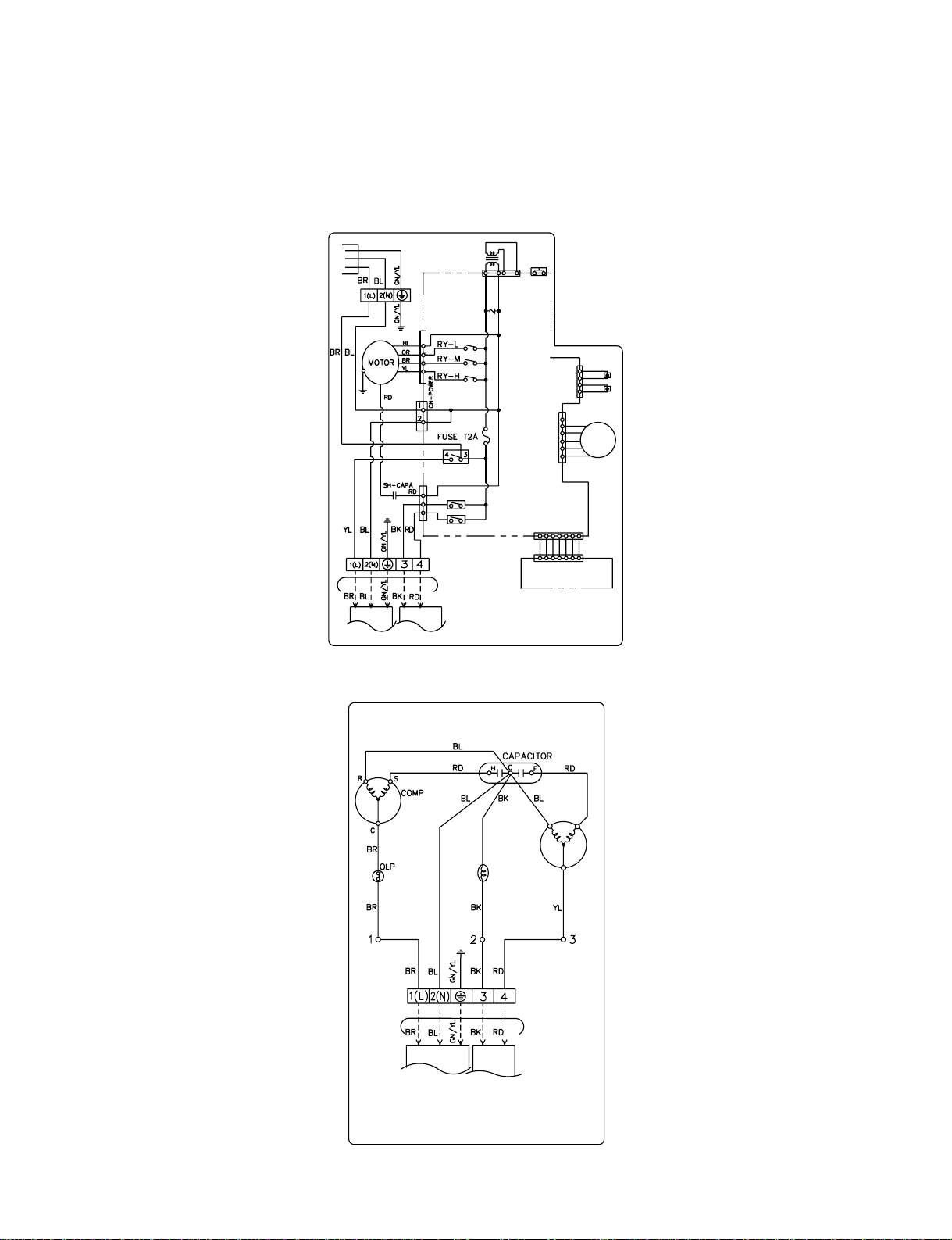

(2) 7K, 9K, 12K BTU Cooling & Heating

1. Indoor Unit

2. Outdoor Unit

POWER

CN-FAN

CN-TH

CN-UP/DOWN

TRANS

FORMER

THERMISTOR

CN-DISP

RY-FAN

RY-4W AY

CN-4WAY

RY-COMP

PILLAR

TERMINAL

TO OUTDOOR UNIT

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

MAIN PCB

ASM

STEP

MOTOR

CN-TRANS

FORCED

OPERATION

SWITCH

OUTDOOR WIRING DIAGRAM

TO INDOOR UNIT

PILLAR

TERMINAL

FAN

MOTOR

REVERSING

VALVE

1. Time Delay Safety Control

• 3min

...

The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 2sec

...

The indoor fan is ceased for 2sec. to prevent relay noise.

(Protection of fan relay and micro chip)

• 30sec

...

The 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode.

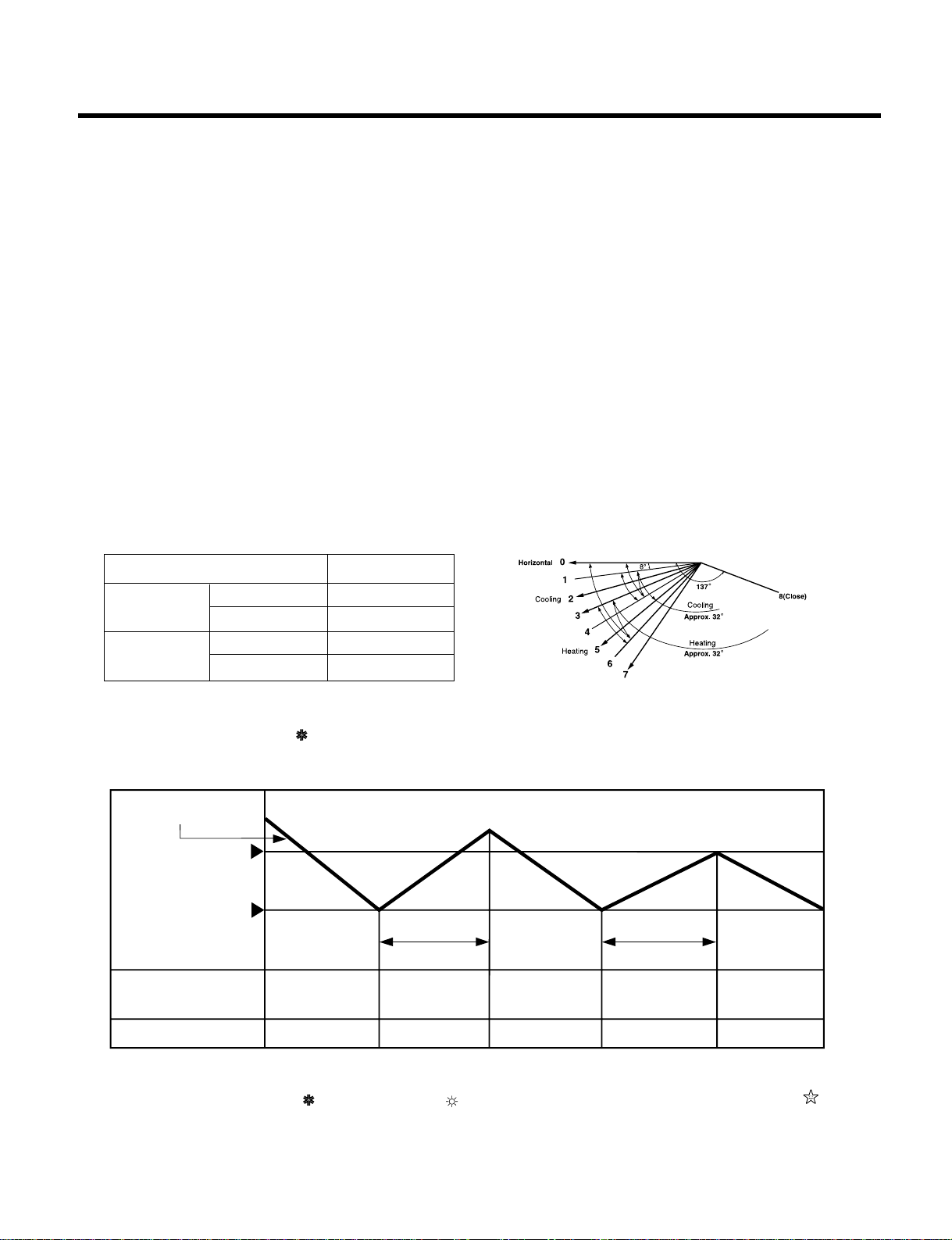

2. Airflow Direction Control

• This function is to swing the louver up and down automatically and to set it at the desired position.

• The procedure is as the following.

1st ;Press the ON/OFF Button to operate the product.

2nd ;Press the Airflow Direction Control Button to swing the louver up and down automatically.

3rd ;Repress the Airflow Direction Control Button to set the louver as the desired position.

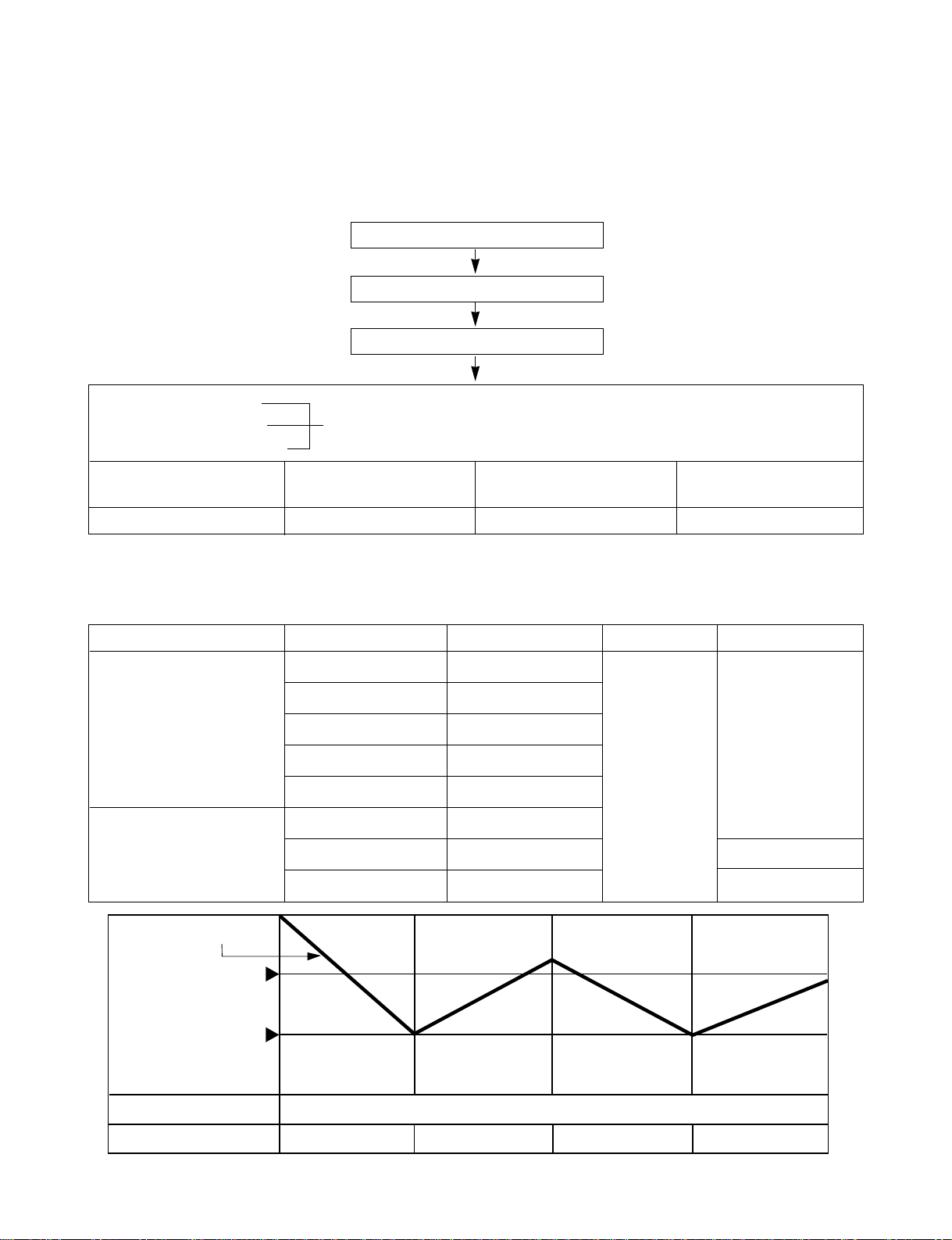

3. Cooling Mode Operation

• When selecting the Cooling ( ) Mode Operation, the unit will operate according to the setting by the remote controller and the operation diagram is as following.

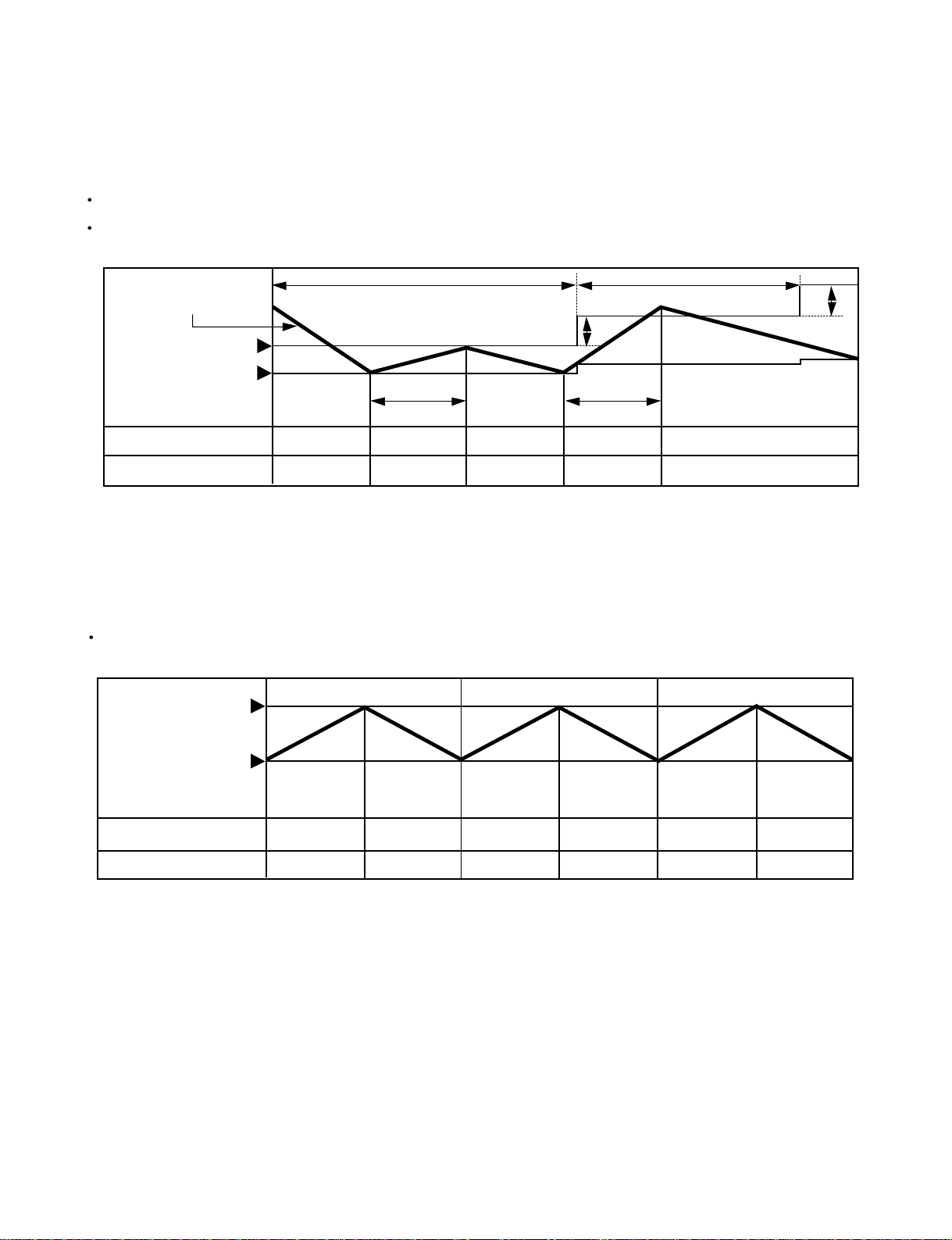

4. Cooling or Heating Mode with Sleep Mode Auto Operation

• When selecting the Cooling( ) or the Heating( ) combined with the Sleep Mode Auto Operation( ), the

operation diagram is as following.

- 13 -

Operation Details

Operating Mode Louver Position

Cooling

Start 2

Auto. Swing 1~4

Heating

Start 5

Auto. Swing 3~6

Selectig

fan speed

Intake Air temp.

More than

3 minutes

More than

3 minutes

Selecting

fan speed

Low

ON

OFF

ON ON

OFF

Low

Selectin

fan speed

COMP. ON

(SET TEMP.+0.5°C

COMP. OFF

(SET TEMP.-0.5°C

INDOOR FAN SPEED

COMPRESSOR

(1) The function of main control

- 14 -

• Cooling Mode with the Sleep Mode

The setting temperature will be raised by 1°C 30minutes later and by 2°C 1 hour later.

The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• Heating Mode with the Sleep Mode.

The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

Intake Air temp.

COMP. ON

(SET TEMP. +0.5°C

COMP. OFF

(SET TEMP. -0.5°C

INDOOR FAN SPEED

COMPRESSOR

ON OFF OFFON ON

Low Low Low Low

1°C

1°C

Low

30 minutes

30 minutes

More than

3 minutes

More than

3 minutes

SETTING TEMP. +3°C

(COMPRESSOR OFF)

SETTING TEMP.

(COMPRESSOR ON)

INDOOR FAN SPEED

COMPRESSOR

Med.

ON

ON

ON

Low or OFF Low or OFF Low or OFF

OFF

OFF

OFF

Med. Med.

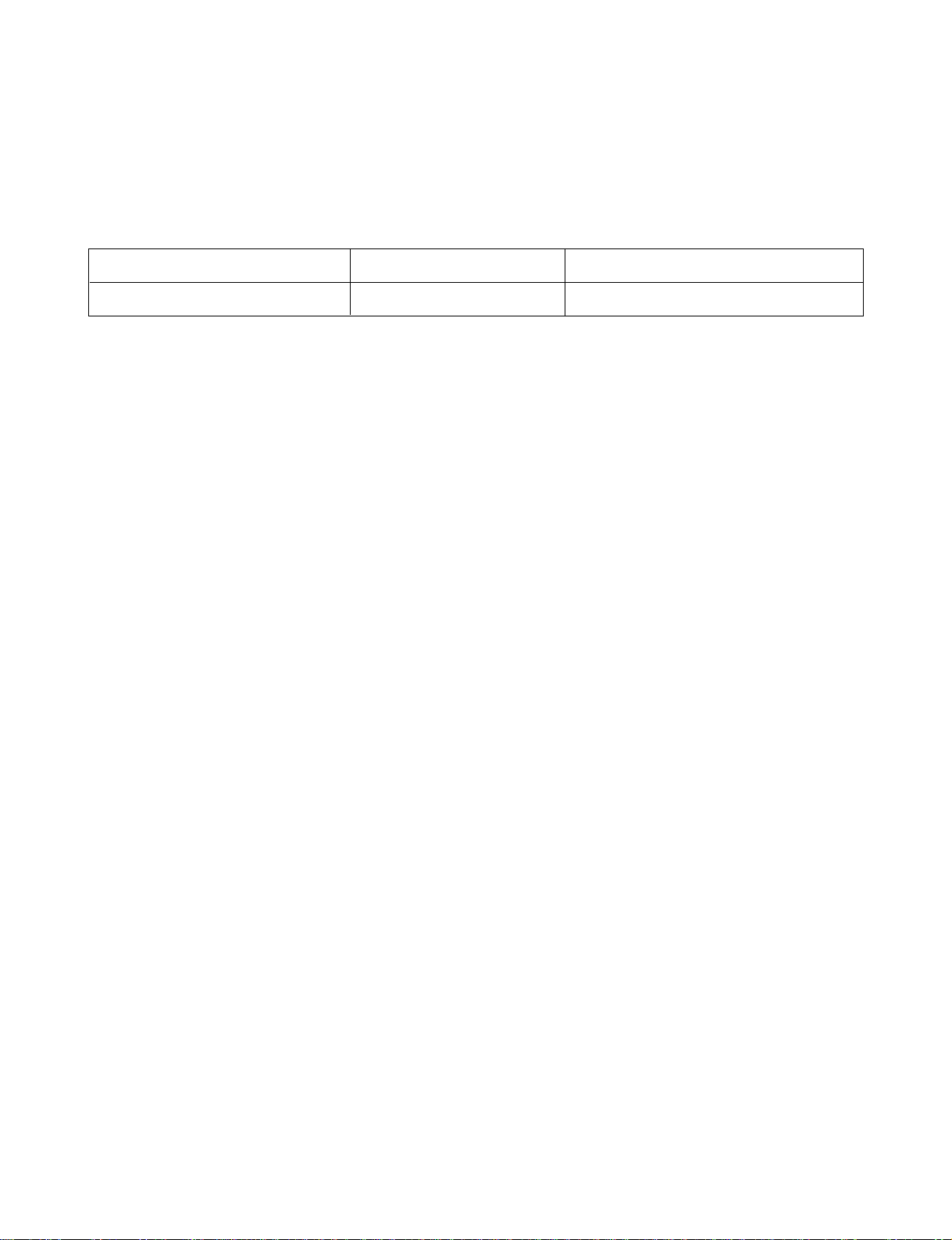

5. Auto Operation

• The operation procedure is as following.

❋ If initial mode is decided, that mode is continued despite of the room temperature changing.

• Auto Operation for Cooling

- 15 -

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation mode

Indoor fan speed are automatically decided by Fuzzy rule.

Setting temperature

Intake-air

temperature

Operation Mode

Over below

21°C24

°

C

Soft Dry

below 21°C

Heating

Over 24°C

Cooling

~

Intake-Air temp.

Setting Temp. +0.5°C

(Compressor OFF)

Setting Temp. -0.5°C

(Compressor ON)

COMPRESSOR ON OFF ON OFF

INDOOR FAN SPEED Fuzzy Speed

Intake-air Temperature Setting Temperature

Over 26°C25°C

Over 24°C~below 26°C Intake air -1°C

Over 22°C~below 24°C Intake air -0.5°C

Over 20°C~below 22°C Intake air temperature

below 20°C20°C

Over 20°C~below 30°C Fuzzy control

below 20°C20°C

over 30°C30°C

Operation Condition

When Auto Operation

initial start

Controlled by

Fuzzy logic

1/f rhythm

Fan Speed Air DirectionControl

When Switch to Auto

Operation

■ Auto Operation for Soft Dry

The Setting temperature will be same that of the current intake-air temperature.

- Compressor ON temperature; Setting temperature +1°C

- Compressor OFF temperature; Setting temperature -0.5°C

■ Auto Operation for Heating

- 16 -

Intake Air temp. below 20°C Over 20°C~below 21°C

Setting temp. 20°C Intake air temperature +0.5°C

- 17 -

6.Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

For 9K, 12K Models

Intake Air temp.

Setting temp. +3°C

(Compressor OFF)

Setting temp.

(Compressor ON)

Selecting

fan speed

Selecting

fan speed

Hot

Start

A

B

A

minimum

10sec.

minimum

10sec.

minimum

10sec.

OFF

COMPRESSOR ON OFF ON OFF

• A point; The indoor pipe temperature to be 35°C.

The indoor fan operates minimum 10sec. even if falls lower than 35°C.

• B point; The indoor pipe temperature to be 35°C.

The indoor fan operates minimum 10sec. even if falls lower than 35°C.

INDOOR FAN SPEED LOW

OFF

LOW LOW OFF

7. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached at 28°C. (BY TEMPERATURE)

• The operation diagram is as following.

PIPE

TEMP 28

°C

INDOOR

FAN SPEED

COMPRESSOR

ON

OFF

LOW

60 sec.

SELECTING

FAN SPEED

HOT-START BY TEMPERATURE

T1

T2

T1

T2

- 18 -

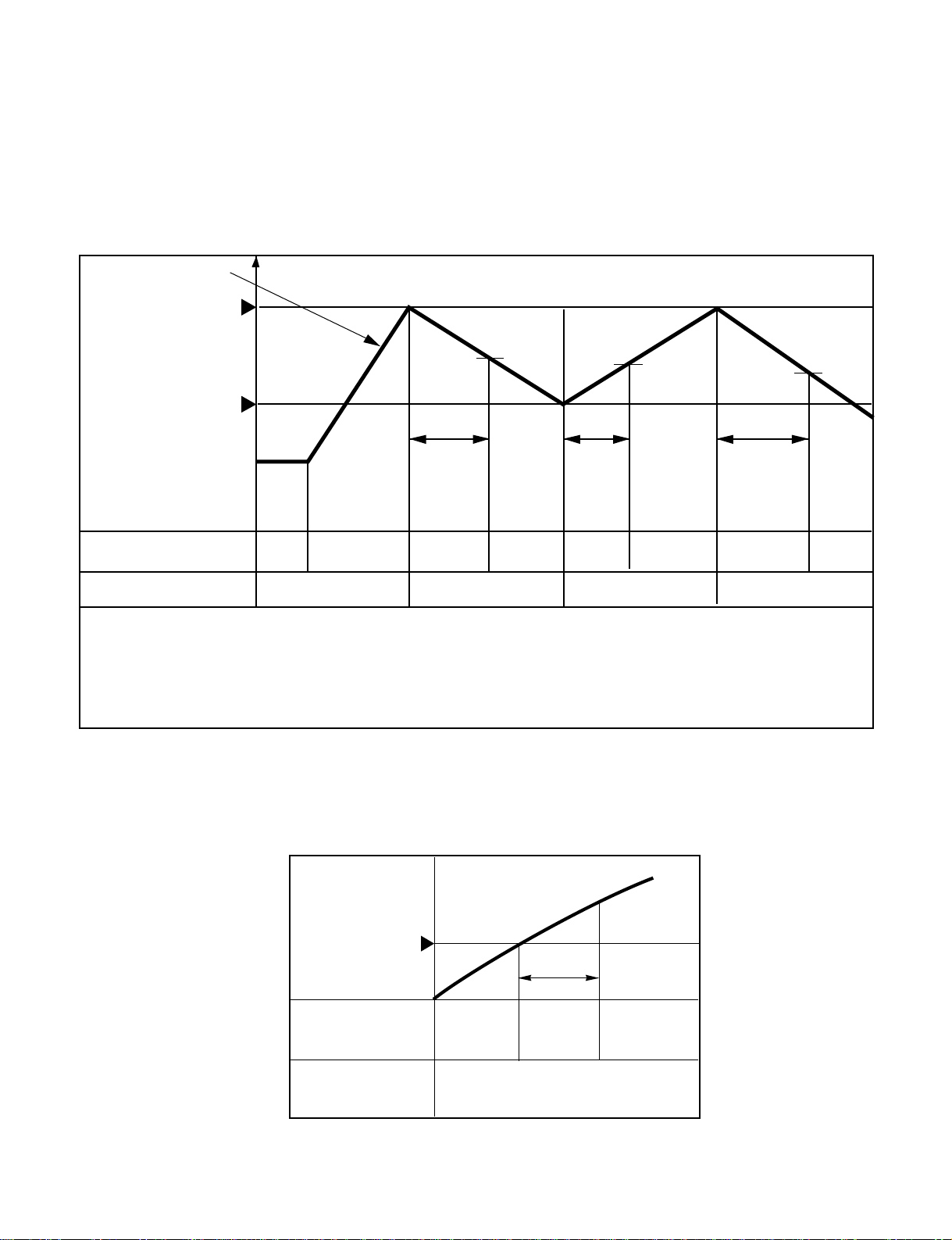

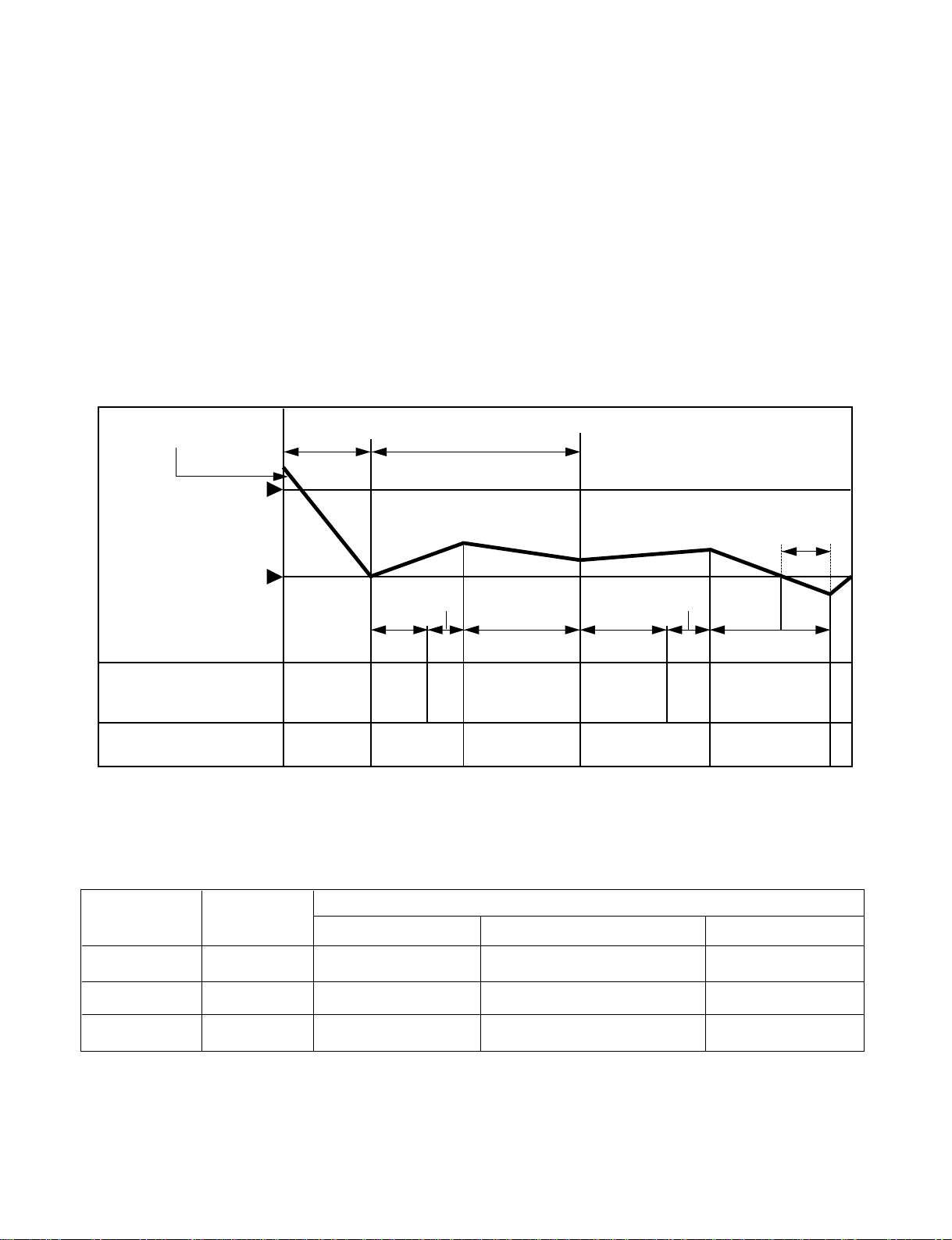

8. Deice Control

• Deicing operation is controlled by timer and sensing the indoor pipe temperature.

• Deicing operation checks the indoor pipe temperature and Intake-air temperature at 25 minutes and 60 minutes

on starting of heating operation, and discriminates by temperature difference.

• When the heating operation passed 25 minutes, the temperature (△T1=TE1–TR1) is checked and memorized

with checking the indoor pipe temperture (TE1) and the indoor Intake-air temperature (TR1).

• When the heating operation passed 60 minutes, deicing operation checks the indoor pipe temperature (TE2)

and the indoor Intake-air temperature (TR2), and checks indoor pipe temperature(TE2), the temperature

difference (△T2=TE2–TR2) and the temperature difference △Td(=△T1–△T2) of △T1, △T2.

If temperature of indoor pipe is below 32°C Deicing function operates at the priority I condition.

If temperature of indoor pipe is over 32°C Deicing function operates at the priority II condition.

If the temperature difference (△Td) become more than the option temperature, deicing operation starts.

• At that time, deicing operation time is decided.

• The deicing operation time starts after deicing operation started.

• If deicing operation start, above heating operation time is reset, so if deicing operation is finished, the heating

operation time is recounted.

• The deicinig time and the operation diagram are as following.

TEMP °C

60 minutes

25 mins

TE1

TE2

25 mins

Heating

Heating

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON(Heating Operation)

ON

ON

OFF

COMPRESSOR

4-WAY VALVE

OUTDOOR FAN

INDOOR FAN

DEICE LED

Deicing

Hot

Start

Pipe Temp.

Intake Air

Temp.

T1-T2=Td Over 3.5°C 3.0~3.5°C 2.5~3.0°C 2.0~2.5°C below 2.0°C

Deicing Time 12mins 11mins 10mins 9mins Heating Operation

TE2 below 30°C 30~31°C 31~32°C Over 32°C

Deicing Time 12mins 11mins 10mins Heating Operation

(DEICING DIAGRAM)

Priority I

Priority II

- 19 -

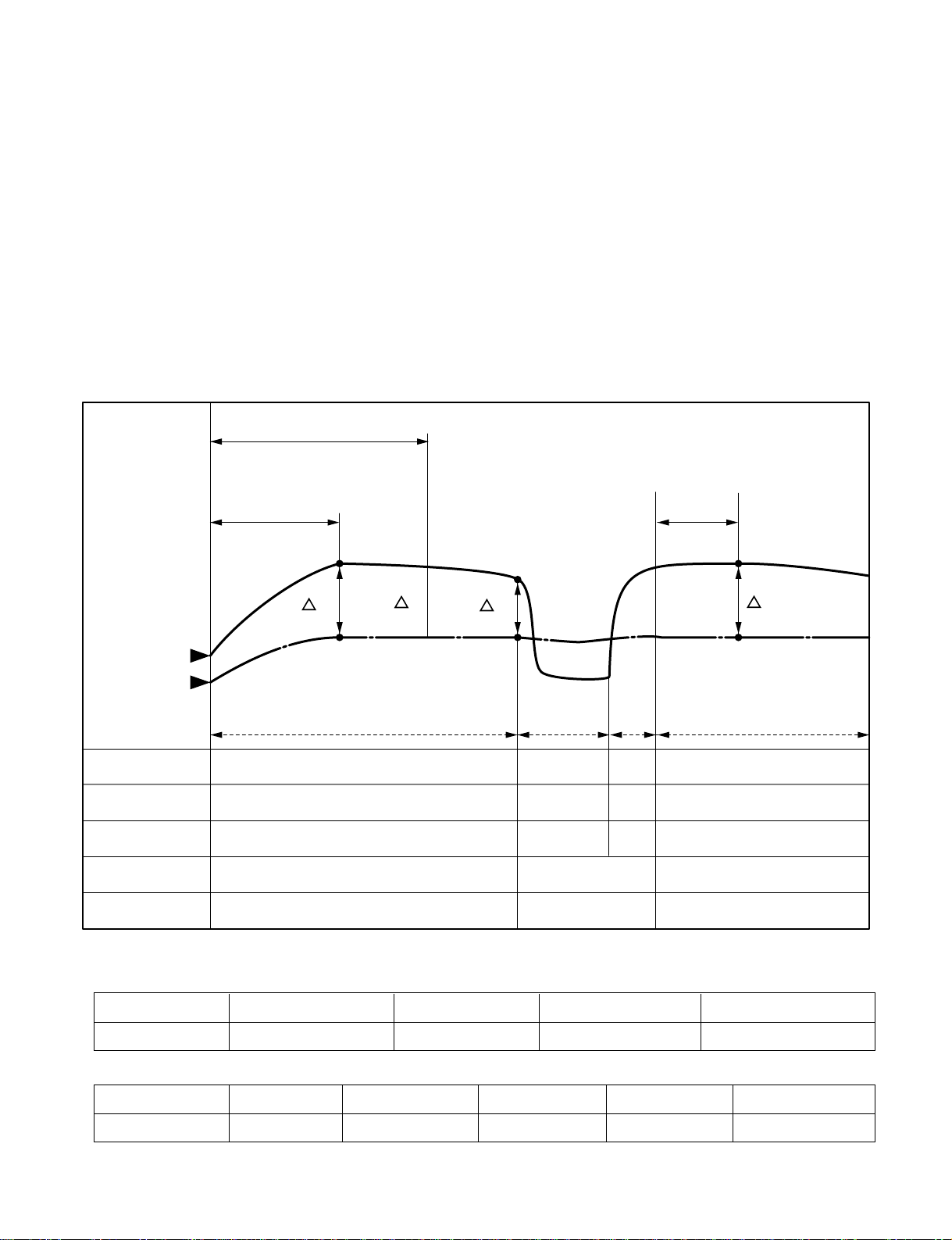

9. Soft Dry Operation.

• During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 1°C, the compressor

OFF temperature is the setting temperature minus 0.5°C.

• When the room temperature rises over the compressor ON temperature, the operation mode is switched to the

cooling mode.

• When the room temperature falls between the compressor ON temperature and OFF temperature, the operation

mode is switched to the Soft Dry Operation.

In this temperature range, 10min. Dry operation, 5.5min operation OFF, 1.5min. only fan operation repeat. During

10min Dry operation, even if the room temperature falls below compressor OFF temperature, 10min(MAX)

Compressor ON from starting of Dry operation which includes 4 min. Compressor ON operation below the compressor OFF temperature.

• In micom dehumidify mode, control of fan speed is as following.

ROOM TEMP.

Operation

Cooling

Dry operation

1.5 minutes

5.5 minutes

10 minutes

1 minutes

2 minutes

maximum

4 minutes

maximum

10 minutes

INDOOR FAN SPEED

ON

ON

ON

OFF

OFF

OFF

LOW

LOW

LOW

LOW

OFF

Selecting

fan speed

COMPRESSOR

SETTING TEMP.+1°C

(COMP. ON)

SETTING TEMP.-0.5°C

(COMP. OFF)

10. Forced operation

• If you lose wireless remote controller, you can operate the unit with forced operation switch.

• The standard conditions are as following.

Cooling Model

Heat pump Model

Room Temp ≥ 24°C21°C ≤Room Temp 24°C Room Temp 21°C

Operation Mode Cooling Cooling Soft Dry Heating

Indoor Fan Speed

High High Low High

Setting Temp. 22°C22°C Room Temp. 24°C

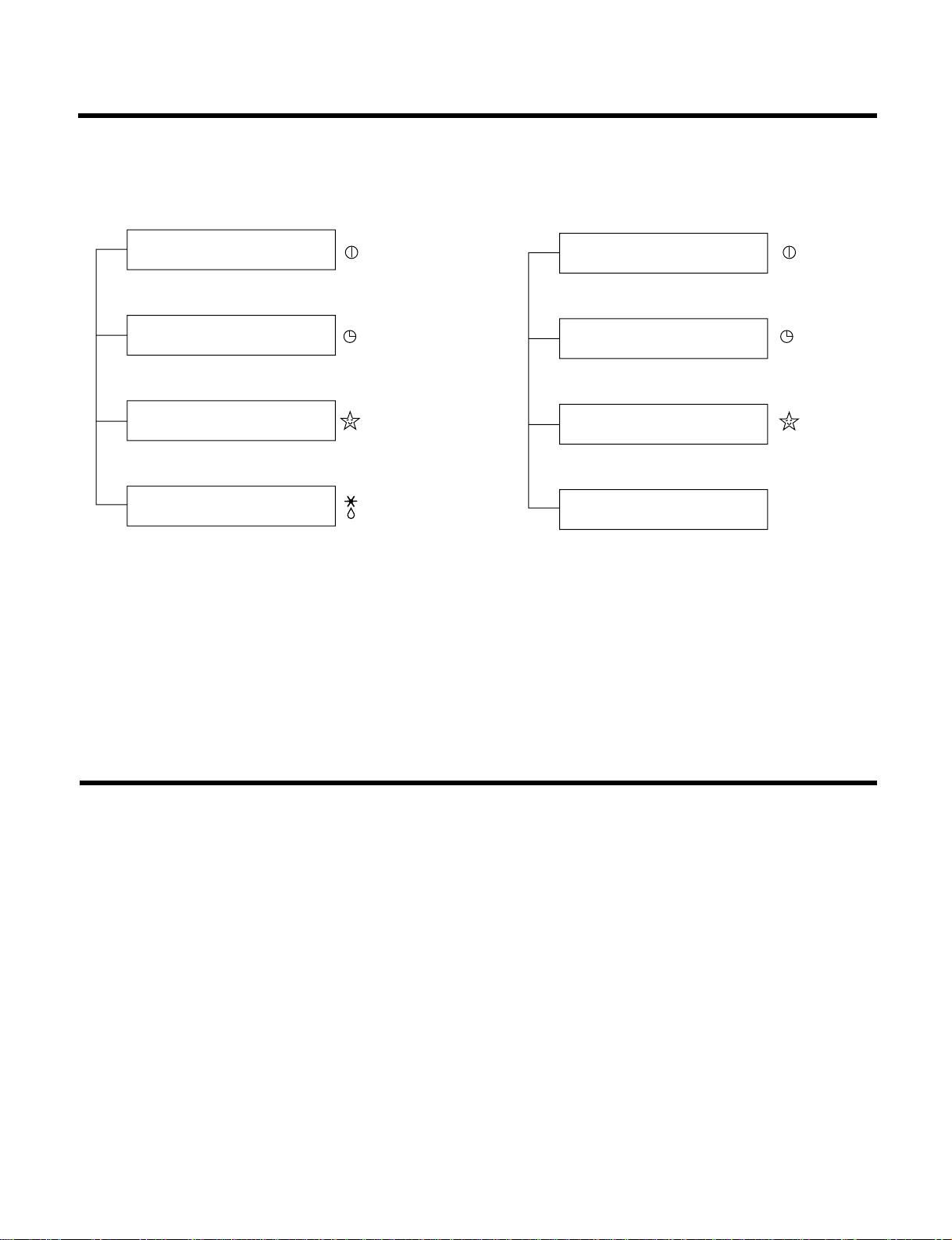

1. Heating Model 2.Cooling Model

1. Protection of the eveporator pipe from frosting

If the temperature of the indoor pipe is below 0°C after 7 mins from starting the compressor, the compressor

and the outdoor fan is stopped, and then after 3 mins delay of the compressor and the temperature of the indoor

pipe is over 7°C, the compressor and the outdoor fan is reoperated.

2. Thermistor Cut Off of Short

Cut Off/Short : Blinks on and off the operation mode LED. (0.5 sec ON/3 sec OFF)

Display Function

- 20 -

Self-diagnosis Function

Operation Indicator

• Cooling, Soft Dry, Fan, Heating

• Timer Mode

• Sleep Mode

• Hot-start, Deice

Timer Indicator

Sleep Timer Indicator

Deicer Indicator

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Outdoor unit operation

• Cooling, Soft Dry, Fan, Heating

• Timer Mode

• Sleep Mode

• Outdoor Unit Operating or not

OUT

DOOR

- 21 -

Installation

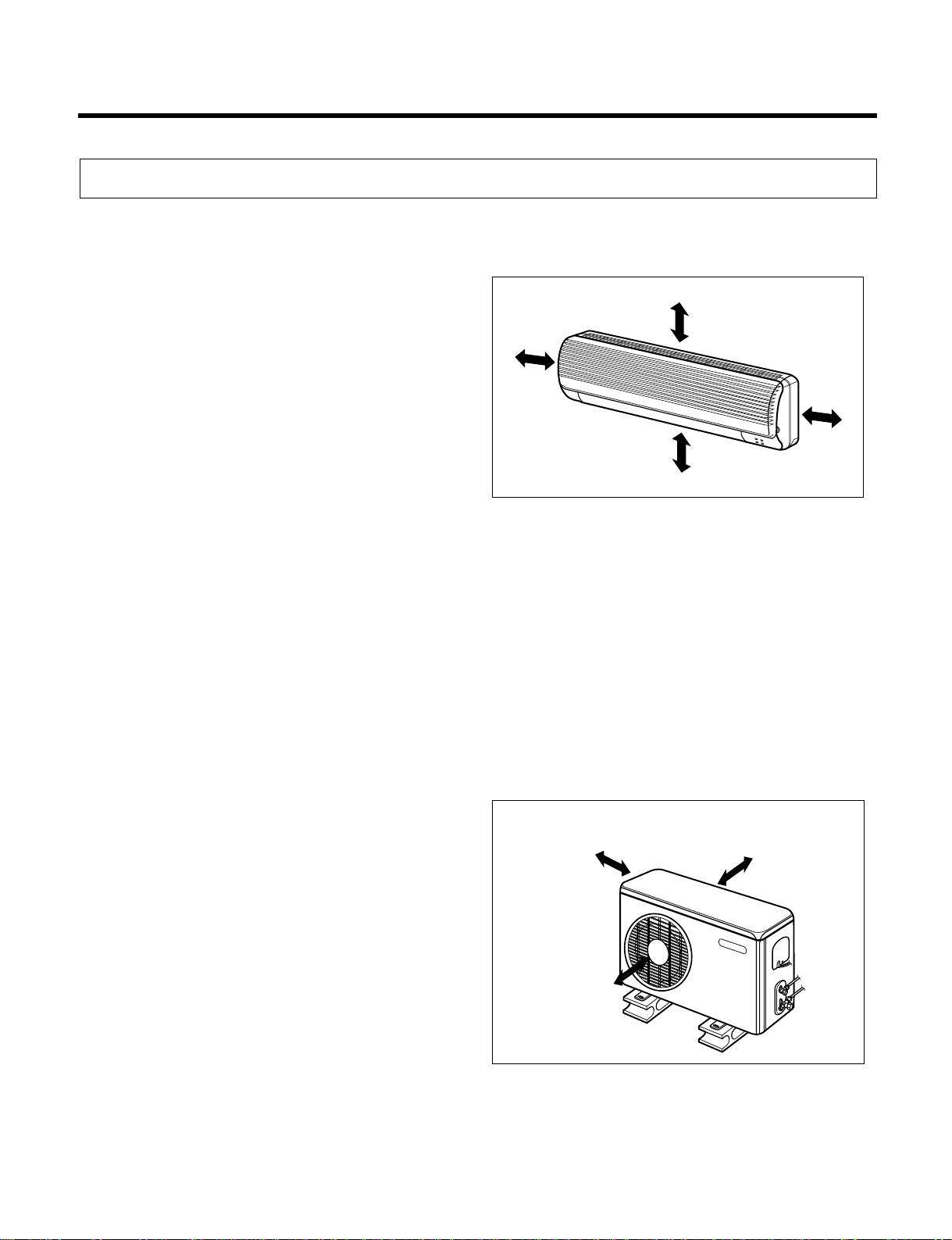

1. Installation of Indoor, Outdoor unit

1) Selection of the best location

1. Indoor unit.

2. Outdoor unit.

•

There should not be any heat source or steam near

the unit.

• There should not be any obstacles to prevent the air

circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consid-

eration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat radiation from the condenser is not restricted.

• There should not be any animals or plants which

could be affected by hot air discharged.

• Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.

More than

5 cm

More than 5 cm

More than

5 cm

More than eye-level

More than 10 cm

More than 10 cm

More than 70 cm

- 22 -

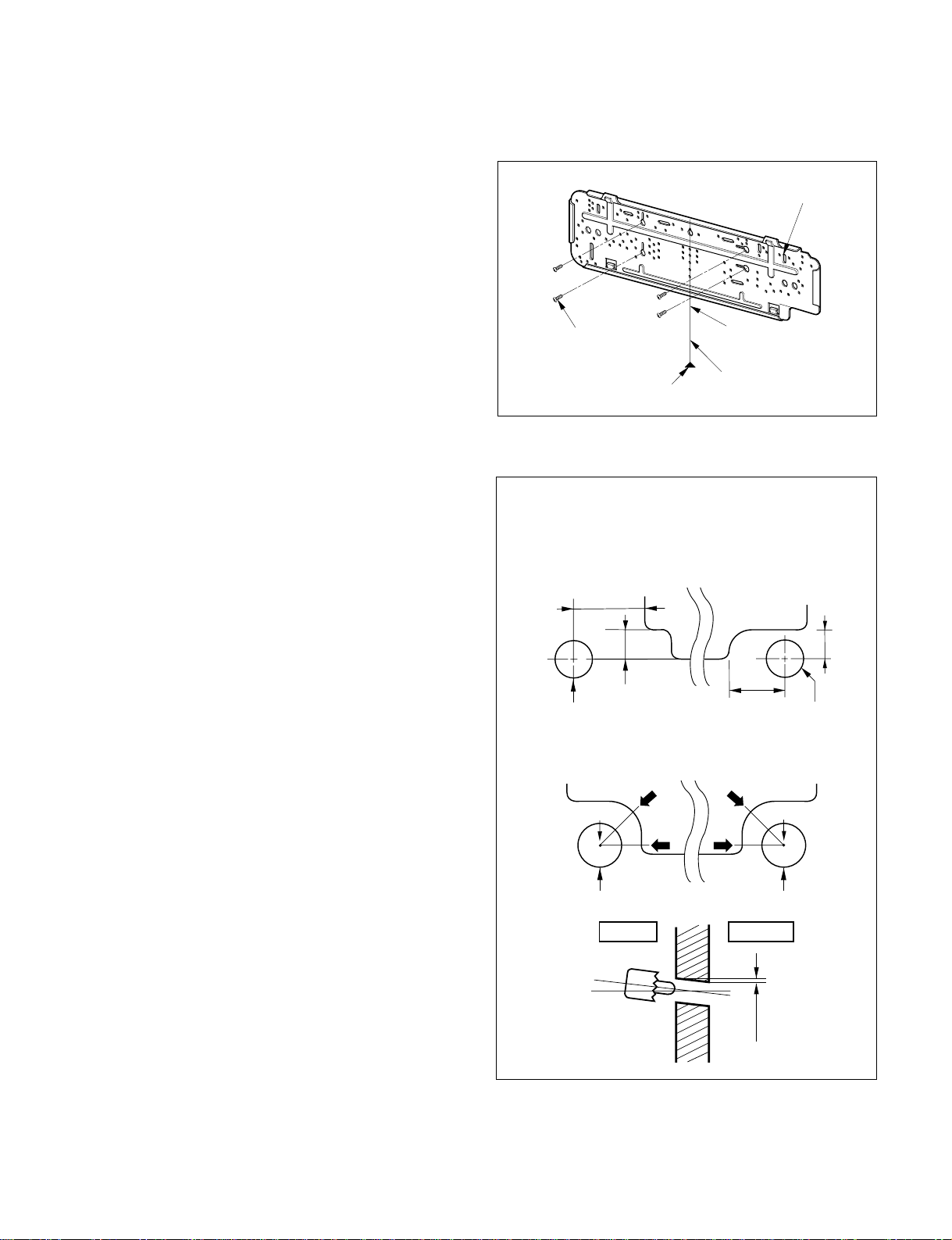

2) Indoor Unit Installation

The mounting wall should be strong and solid enough

to prevent it from the vibration.

1. Mount the installation plate on the wall with

four Type "A" screws.

• Always mount the Installation plate horizontally by

aligning the marking-off line with using the thread

and a level.

2. Drill the piping hole with 70mm dia. holecore

drill.

• Drill the piping hole at either the right or the left and

the hole should be slightly slant to the outdoor side.

Type "A" screw

Installation Plate

marking-off line

Thread

Weight

The lower left and right side of Installation

Plate

Left rear piping

Left rear piping

Right rear piping

Right rear piping

Indoor

Center

Center

<7K, 9K BTU>

<11K, 12K, 14K BTU>

Outdoor

WALL

80mm

20mm

ø70mm

A

50mm

ø70mm

A

20mm

A

A

ø70mm ø70mm

5~7mm

Loading...

Loading...