Page 1

- 1-1 -

[CONTENTS]

SECTION 1.GENERAL

• SERVICING PRECAUTIONS ................................................................................................ 1-2

• ESD PRECAUTIONS............................................................................................................. 1-4

• SPECIFICATIONS...................................................................................................................1-5

SECTION 2. ELECTRICAL

• AUDIO TROUBLESHOOTING GUIDE .................................................................................. 2-1

• DVD TROUBLESHOOTING GUIDE ...................................................................................... 2-5

• DVD DETAILS AND WAVEFORMS ON SYSTEM TESTAND DEBUGGING..................... 2-13

• WIRING DIAGRAM.............................................................................................................. 2-25

• BLOCK DIAGRAMS............................................................................................................. 2-26

• AUDIO PART SCHEMATIC DIAGRAMS ............................................................................. 2-31

• DVD PART SCHEMATIC DIAGRAMS................................................................................. 2-47

• PRINTED CIRCUIT DIAGRAMS ......................................................................................... 2-53

• CIRCUIT VOLTAGE CHART................................................................................................ 2-63

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION .............................................................................. 3-1

• DECK MECHANISM EXPLODED VIEW .............................................................................. 3-3

• PACKING ACCESSOR Y SECTION ...................................................................................... 3-5

SECTION 4. SPEAKER PART .................................................................................. 4-1

SECTION 5. REPLACEMENT PARTS LIST ............................................................. 5-1

Page 2

- 1-2 -

SECTION 1. GENERAL

SERVICING PRECAUTIONS

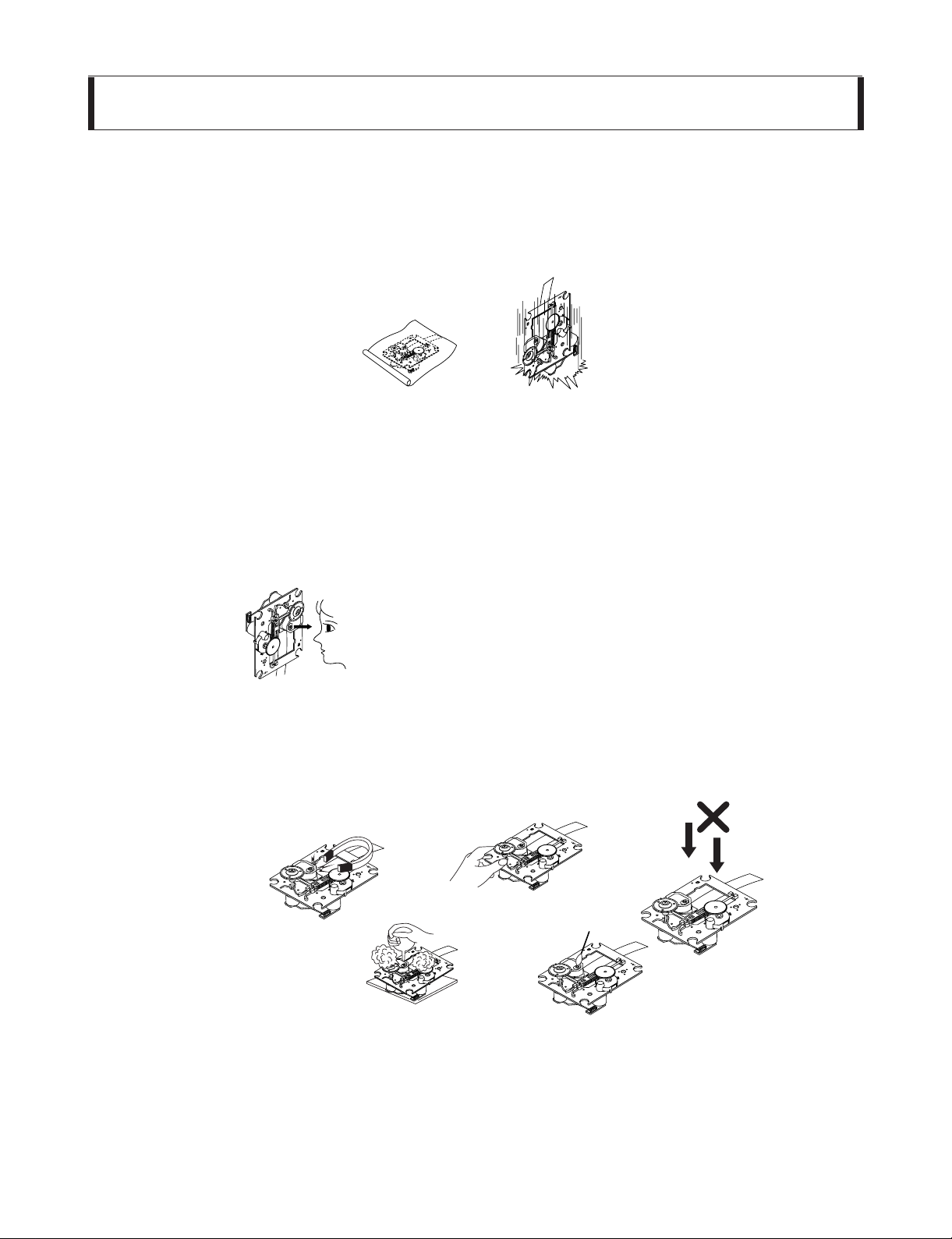

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Conductive Sheet

Cotton swab

Pressure

Pressure

Page 3

- 1-3 -

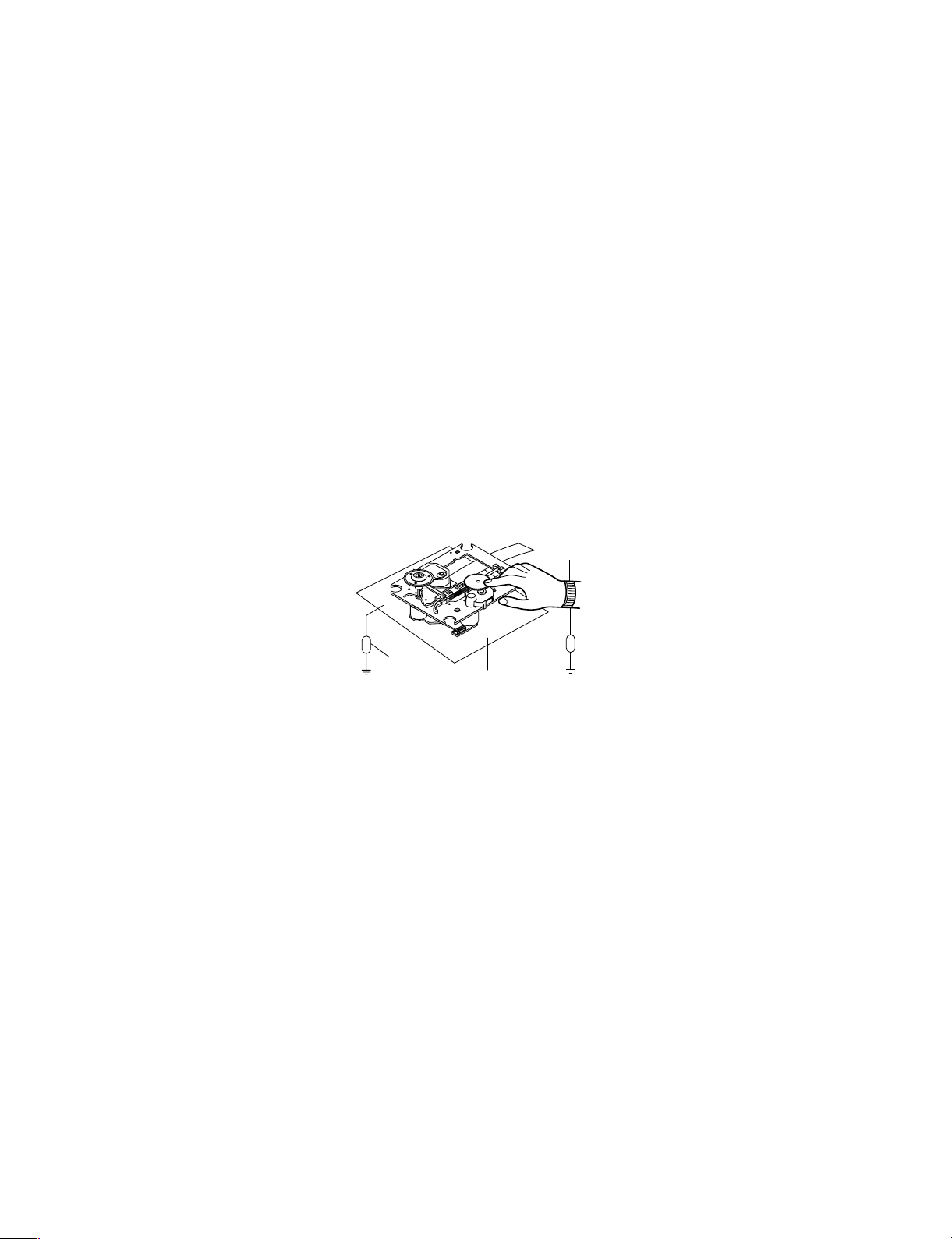

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Resistor

(1 Mohm)

Conductive

Sheet

Resistor

(1 Mohm)

Armband

Page 4

- 1-4 -

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive sur-

face such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNELTO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE ARISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINTWITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANTSAFETY INFORMATION IN SERVICE

LITERATURE.

Page 5

- 1-5 -

SPECIFICATIONS

GENERAL

Power supply Refer to main label

Power consumption Refer to main label

Mass 5.5 kg

External dimensions (W x H x D) 435 x 54 x 350 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

CD/DVD

Laser Semiconductor laser, wavelength 650 nm

Signal system NTSC 525/60

Frequency response (audio) 150 Hz to 18 kHz

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, NOP -6 dB, 20 kHz LPF/A-Filter)

Dynamic range (audio) More than 70 dB

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)

VIDEO

Video input 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 2

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1

S-video output (Y) 1.0 V (p-p), 75 Ω, negative sync., Mini DIN 4-pin x 1

(C) 0.3 V (p-p), 75 Ω

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 ohms, RCA jack x 2

TUNER

FM

Tuning Range 87.5 - 108.0 MHz or 65.0 - 74.0 MHz, 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono)

Frequency Response 150 - 8,000 Hz

AM[MW]

Tuning Range 520 - 1,720 kHz

Intermediate Frequency 450 kHz

AMPLIFIER

Stereo mode 150W + 150W (6Ω at 1 kHz, THD 10 %)

Surround mode Front: 150W + 150W (THD 10 %)

Center*: 150W

Surround*: 150W + 150W (6Ω at 1 kHz, THD 10 %)

Subwoofer*: 250W (4Ω at 30 Hz, THD 10 %)

SPEAKERS

Front/Rear Speaker Center speaker Passive Subwoofer

(LHS-75SGS) (LHS-75SGC) (LHS-75SGW)

Type 2 Way 2 Speaker 2 Way 2 Speaker 1 Way 1 Speaker

Impedance 6 Ω 6 Ω 4 Ω

Frequency Response 145 - 20,000 Hz 120 - 20,000 Hz 50 - 1,500 Hz

Sound Pressure Level 85 dB/W (1m) 85 dB/W (1m) 83 dB/W (1m)

Rated Input Power 150 W 150 W 250 W

Max. Input Power 300 W 300 W 500 W

Net Dimensions (W x H x D) 104 x 235 x 120 mm 220 x 115 x 120 mm 195 x 398 x 419 mm

Net Weight 1.0kg 1.0kg 6.6kg

(* Depending on the sound mode

settings and the source, there may

be no sound output.)

Page 6

- 2-1 -

AUDIO TROUBLESHOOTING GUIDE

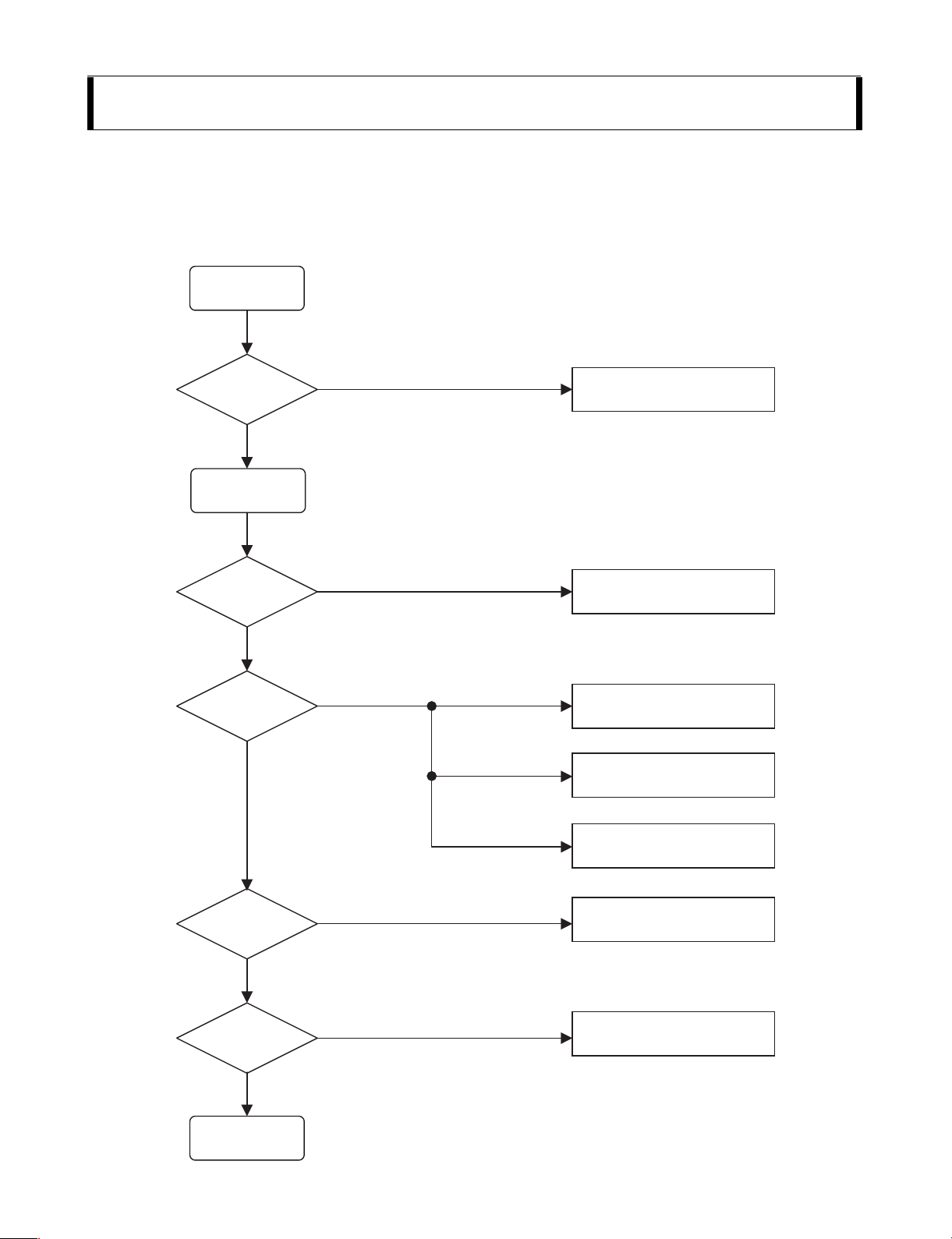

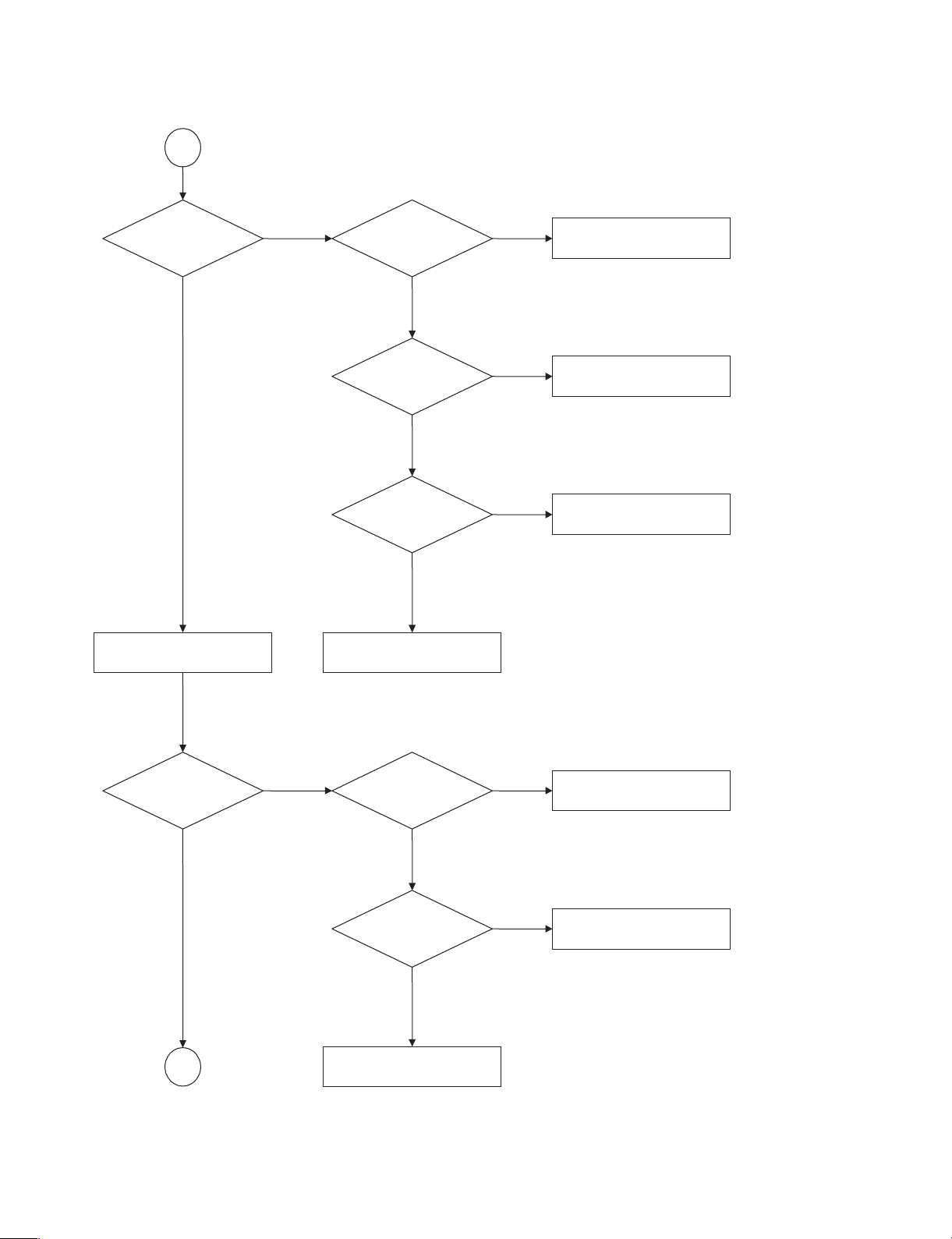

1. POWER CHECK FLOW

SECTION 2. ELECTRICAL

INSERT

WER CORD.

PO

TURN ON

THE RED LED?

YES

TURN PO

IS PO

WER ON.

WER ON?

YES

DOES INITIAL

WORK?

READ

YES

NO

NO

NO

CHECK POWER PLUG

AND POWER SUPPLY CIRCUIT

CHECK POWER SUPPLY CIRCUIT.

CHECK LASER CIRCUIT

CHECK FOCUS CIRCUIT

.

.

.

PLAY?

DOES IT

YES

DOES IT OUTPUT

AUDIO?

YES

OK

NO

NO

CHECK DISC.

CHECK TRACKING SERV

CHECK AUDIO CIRCUIT.

O CIRCUIT.

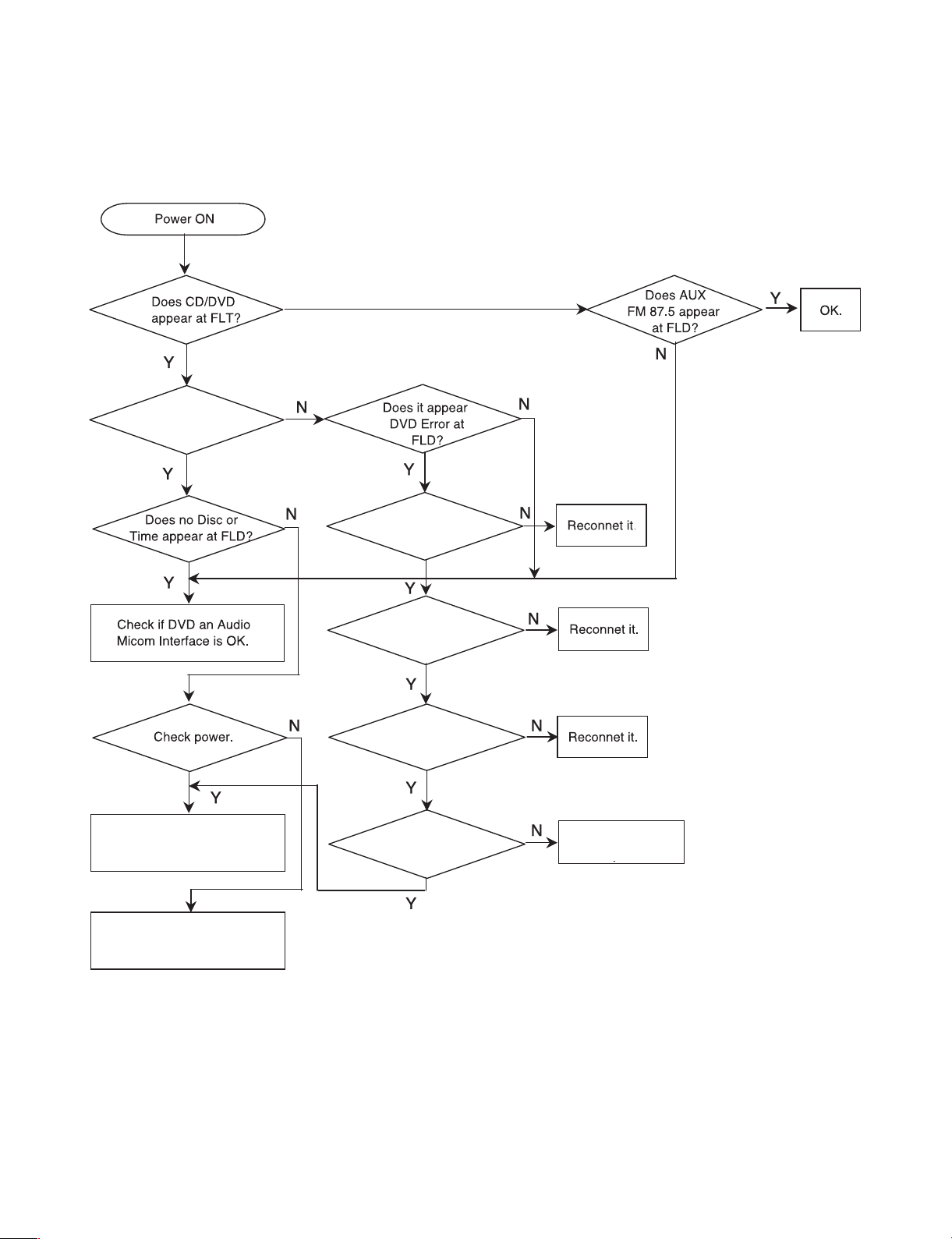

Page 7

- 2-2 -

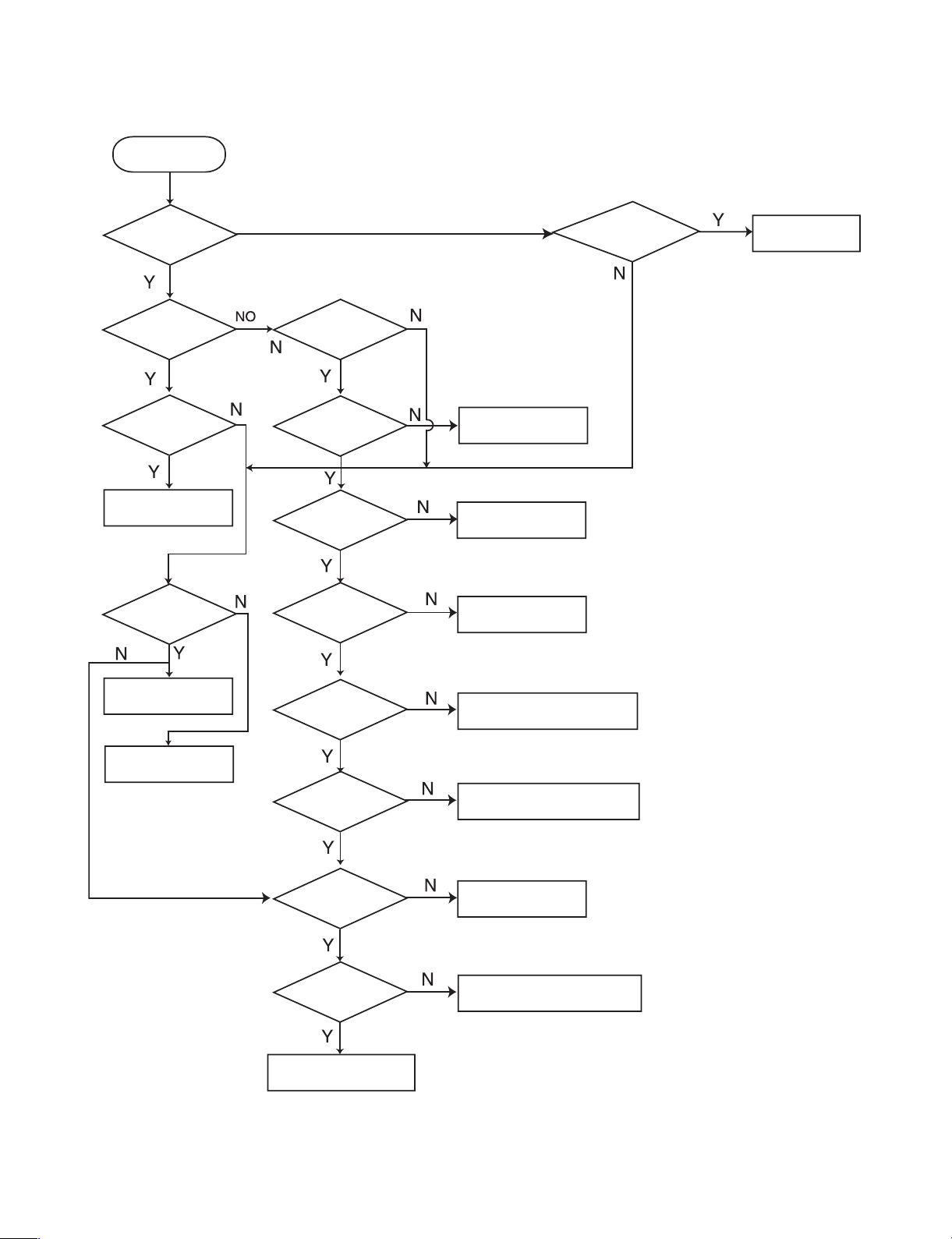

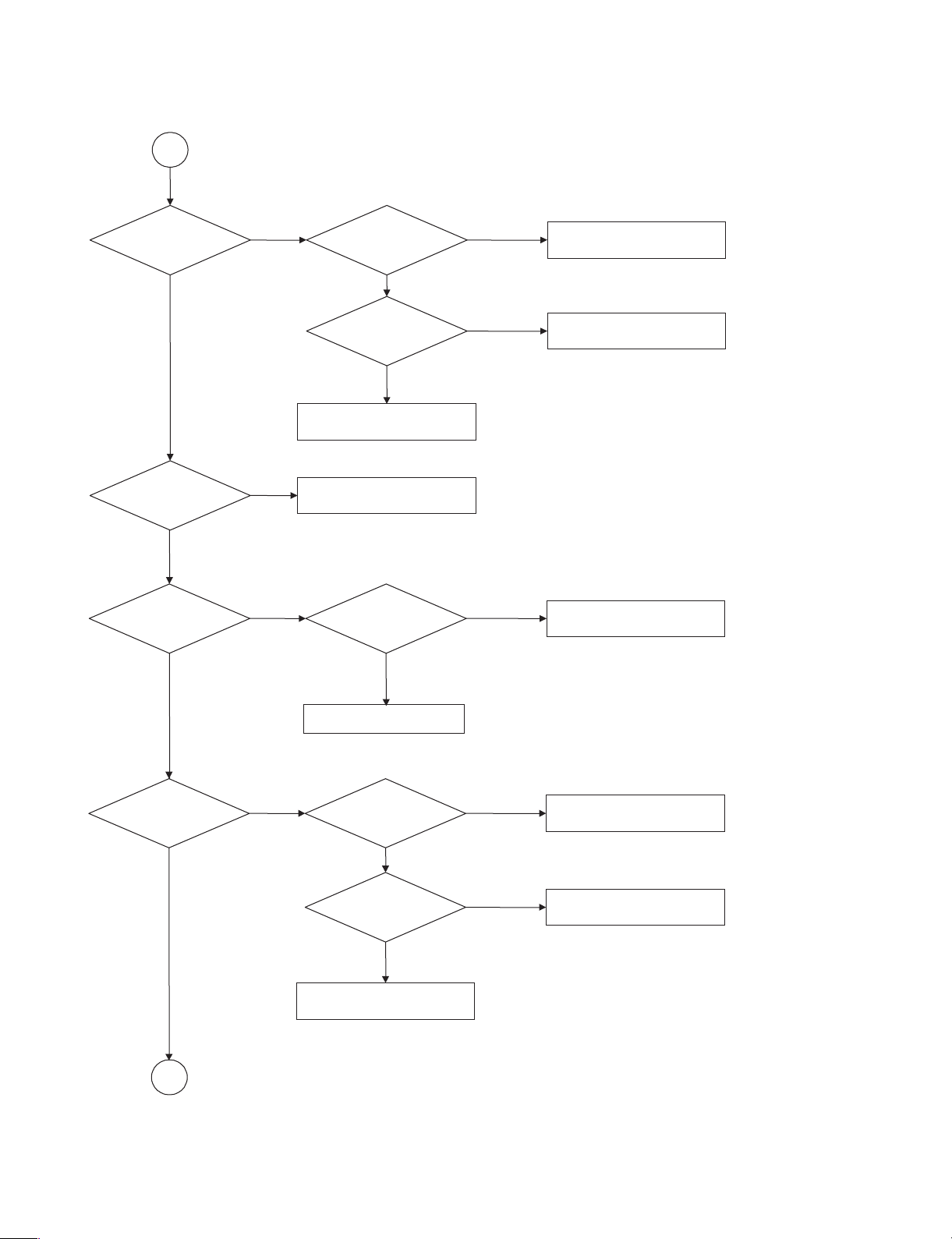

2. AUDIO µ-COM CIRCUIT

POWER ON

Does CD/DVD

appear at FLD?

Does

AV 1/2 FM87.5

appear at FLD?

OK.

Does READING

appear at FLD?

Does no Disc or

Time appear at FLD?

Check if DVD an Audio

Micom Interface is OK.

Check power.

Check DVD Module.

Check SMPS.

Does it appear

DVD Error at

FLD?

Check

Connector(PN902)if

is normally.

Check power part

of Main B/D.

Check oscillator

of x101.

Check if IC101

PIN80 is High.

Reconnect it.

Refer to SMPS

Refer to oscillator

Circuit.

Check DVD Reset Waveform.

Check if IC101

PIN92 is High.

Check if IC101 PIN

31, 32, 51, 88 are high

(5V).

Check if IC101

PIN96 is High.

Replace IC101.

Check IC101 Reset Wavefrom.

Check 5V line.

Check Power section Circuit.

Page 8

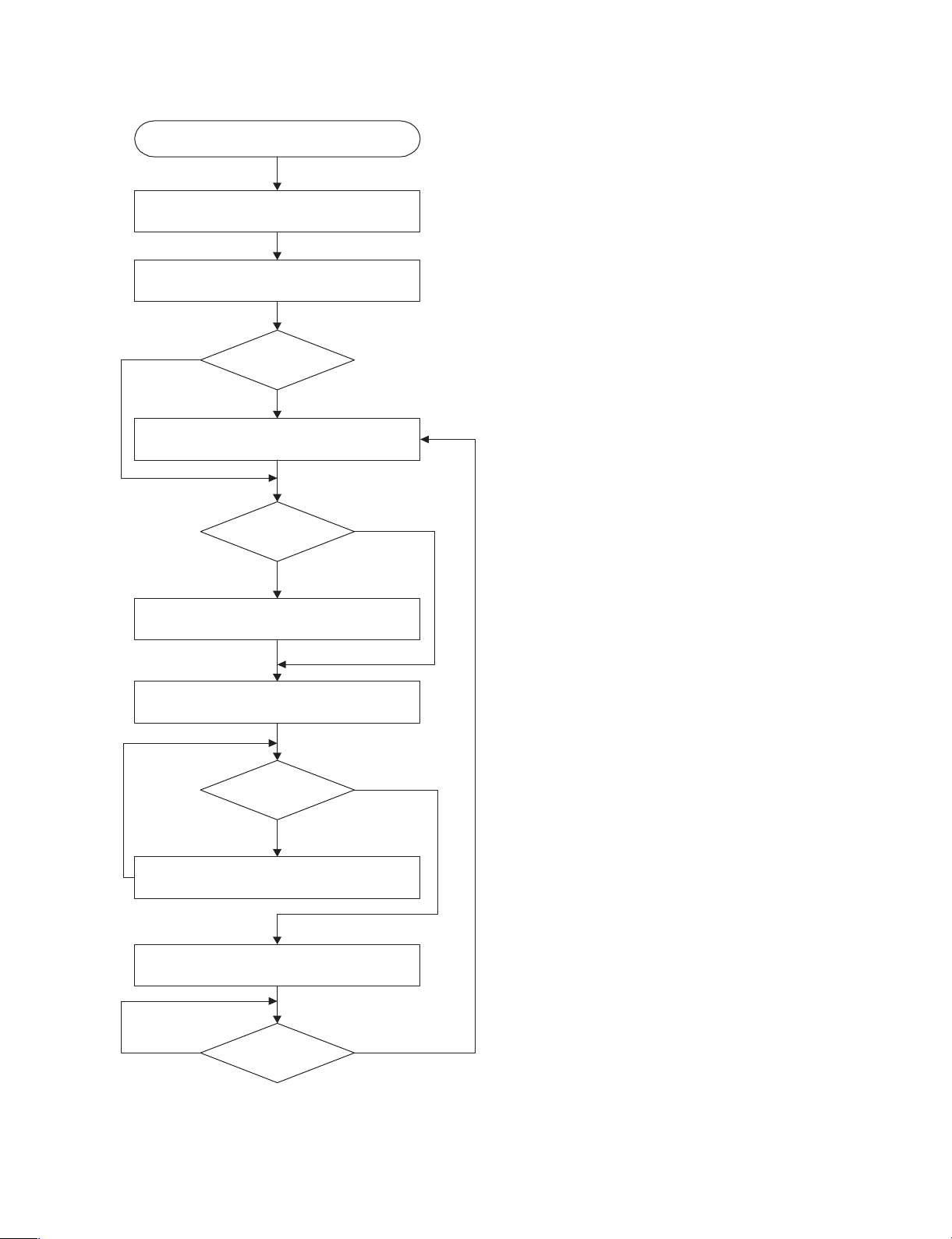

- 2-3 -

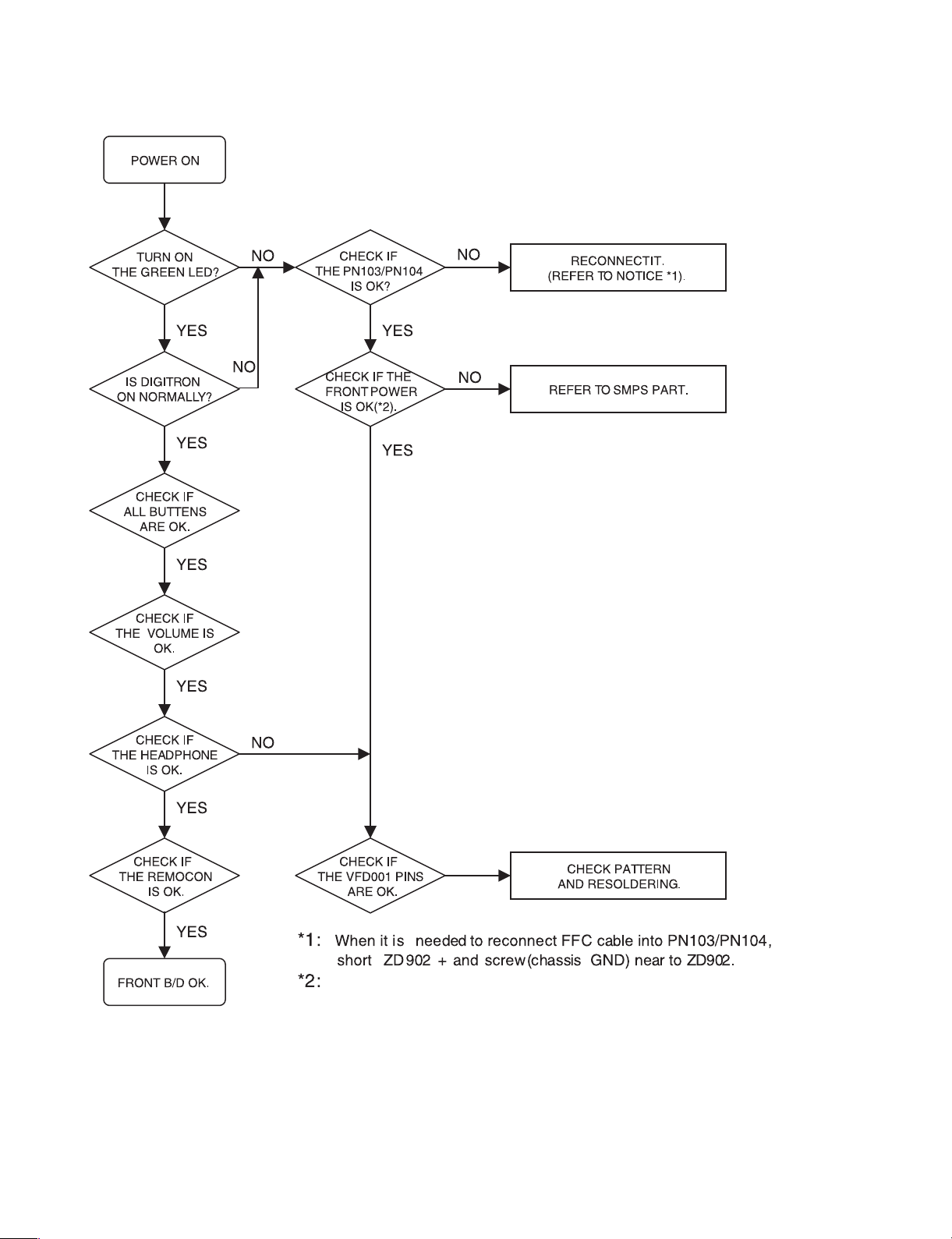

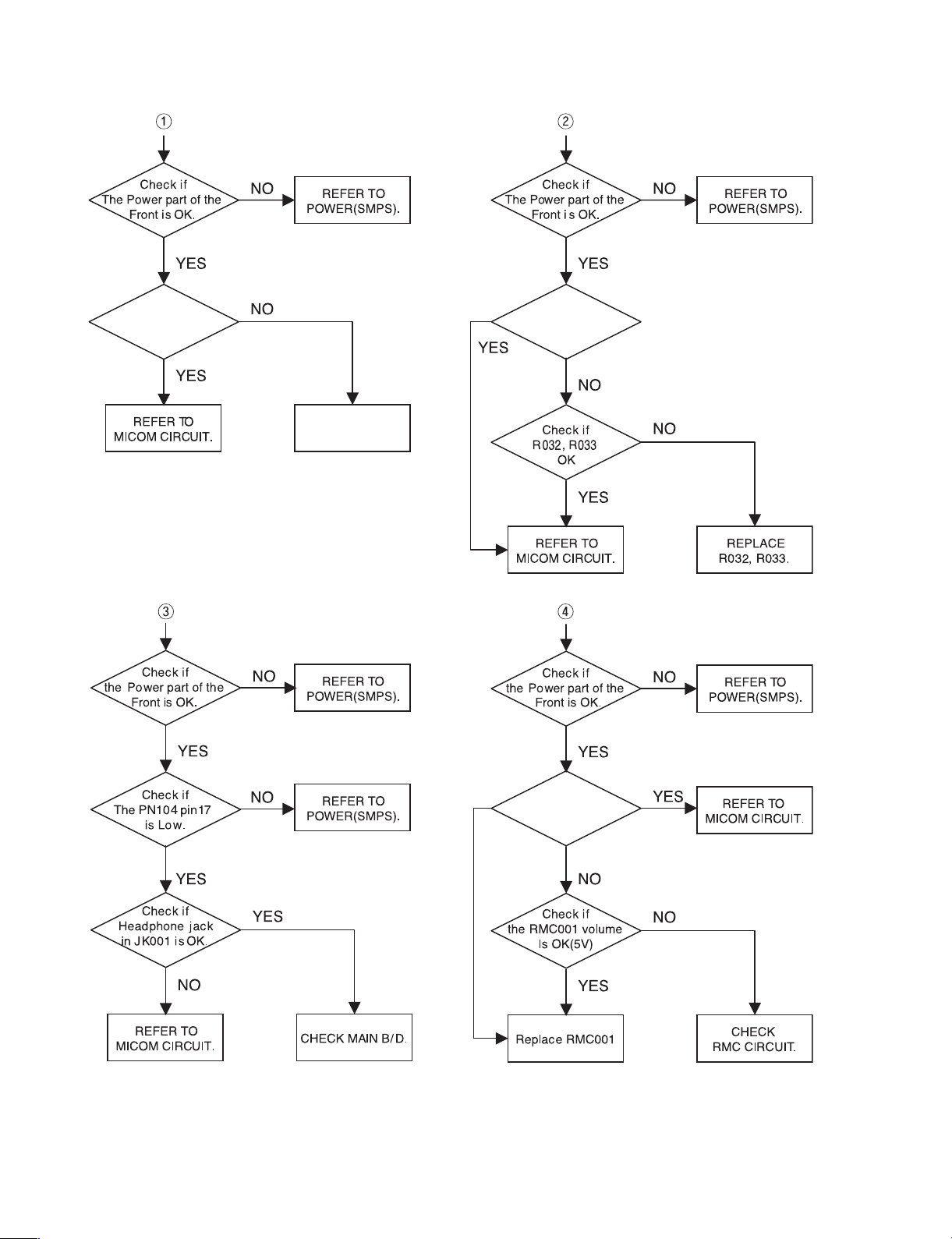

3. FRONT CIRCUIT (1/2)

PIN104 Pins

PIN : -27V

PIN 6 : -18V

PIN7 : -22V

PIN : 5V

Page 9

- 2-4 -

4. FRONT CIRCUIT (2/2)

CHECK

IF R029, R036~R040,

R046~R051

OK.

REPLACE R029,

R036~R040,

R046~R051

Check

if PN104 pins10, 11

Waveform OK.

Check

if the Remocon

Waveform of the

PN104 pin16

Page 10

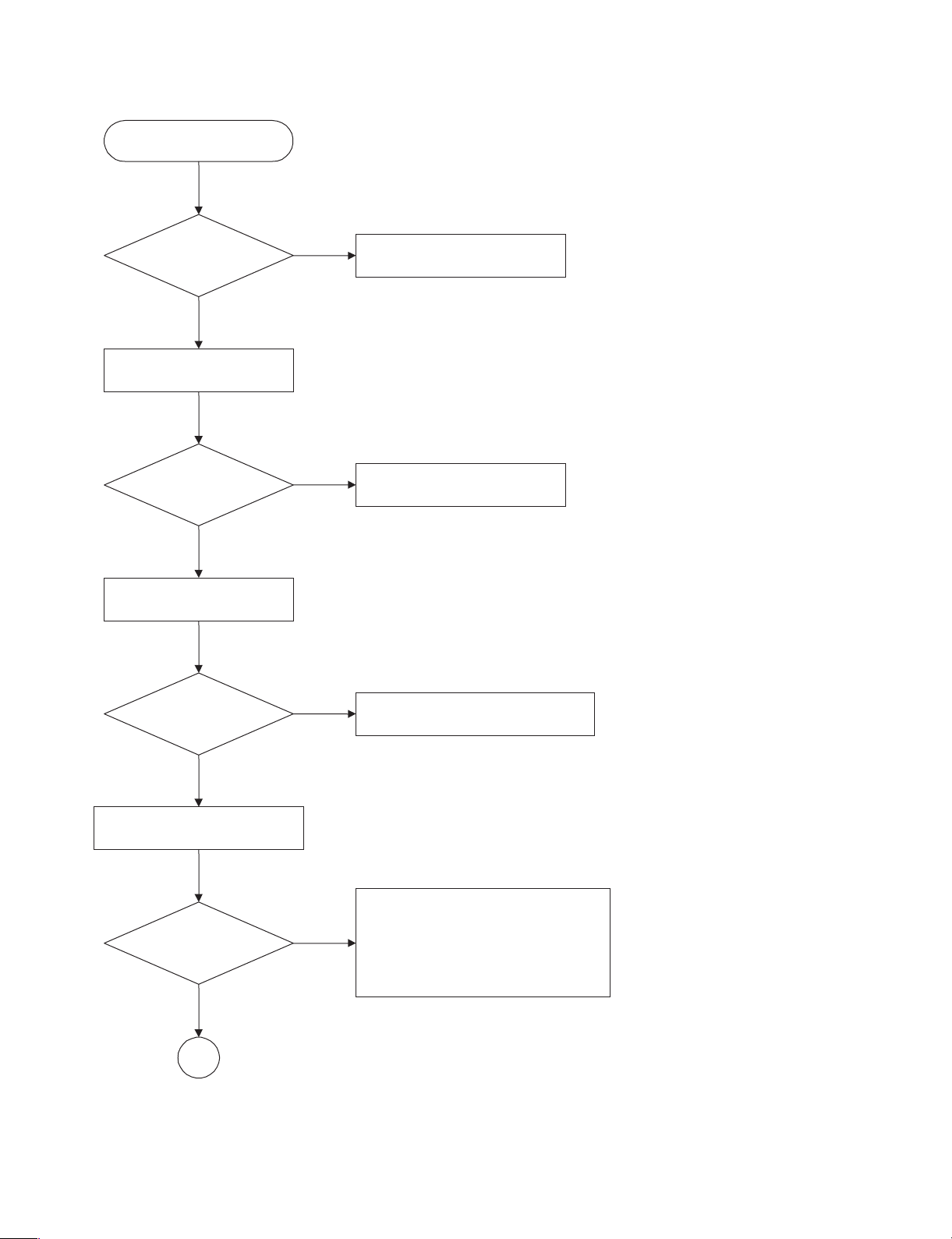

- 2-5 -

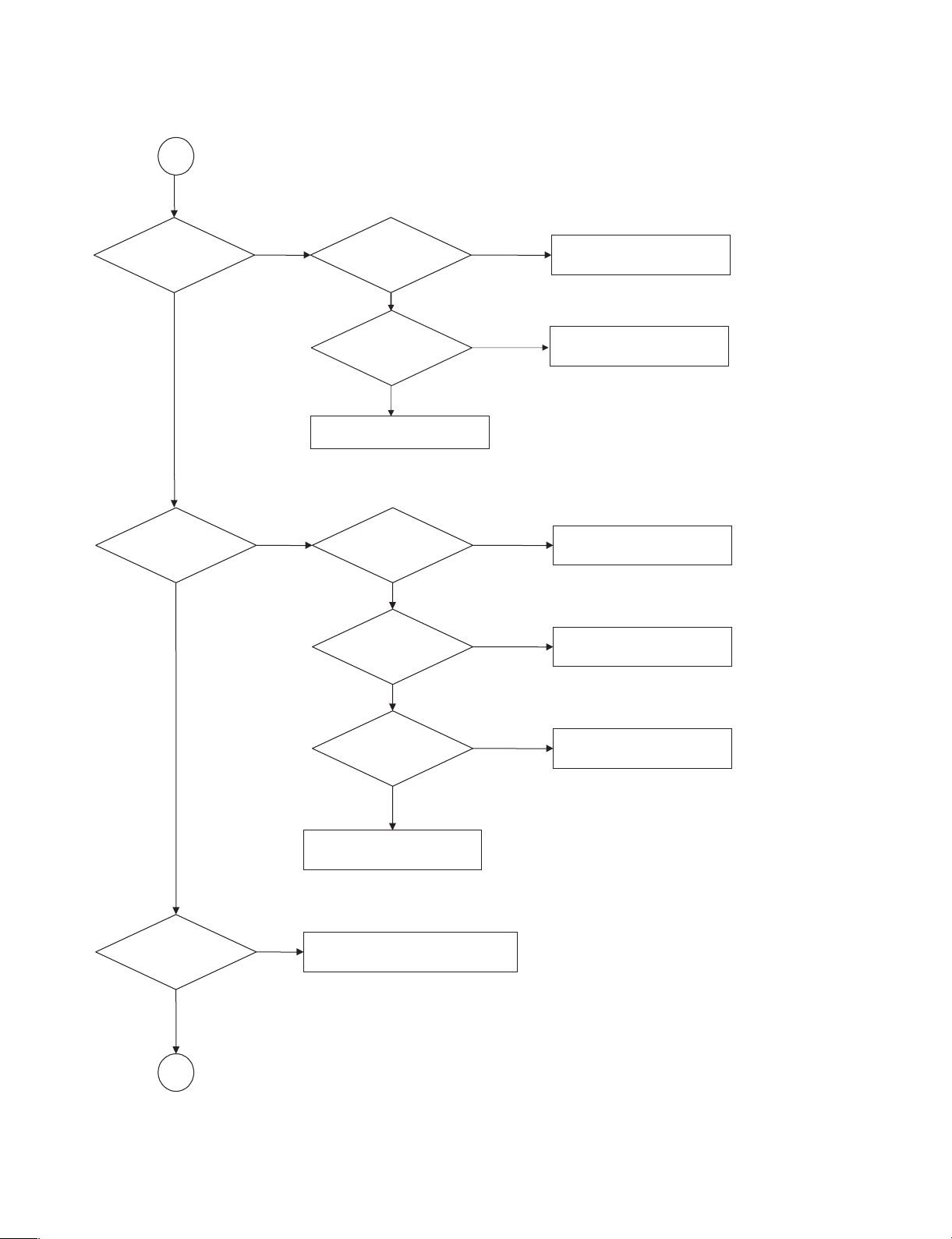

1. POWER CHECK FLOW

DVD TROUBLESHOOTING GUIDE

READING appear at FLD?

Does

Check DVD SECTION

Check

Connector(CN201)

if is normally.

Check

Connector CN202

Check

Connector CN203

Check

voltage each pin for PN902

Check SMPS

board regulator

Check Connector PN902

Page 11

- 2-6 -

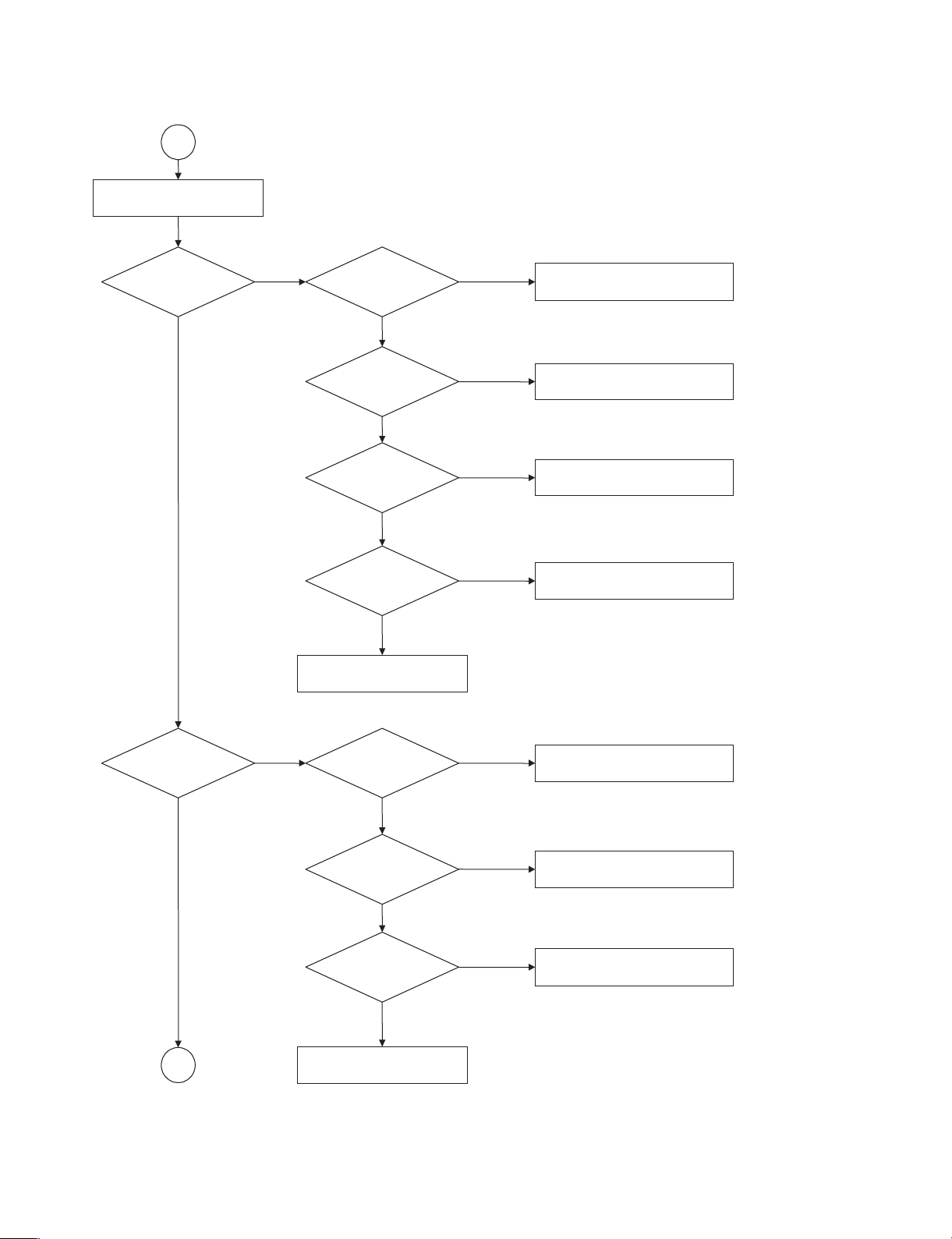

2. SYSTEM OPERATION FLOW

Power On

1. 8032 initializes SERVO, DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

YES

Tray Closed?

NO

Tray Close to Closed position

SLED at Inner

Side ?

NO

SLED Moves to Inner Positi on

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Reci eve

OPEN/CLOSE

Key?

YES

YES

NO

1. Execute Pressed Key & IR Key

2. System operation Routine Loop

1. Stop Playback & Open Tray

2. Display tray open message & LOGO

NO

Receive

CLOSE Key?

YES

Page 12

- 2-7 -

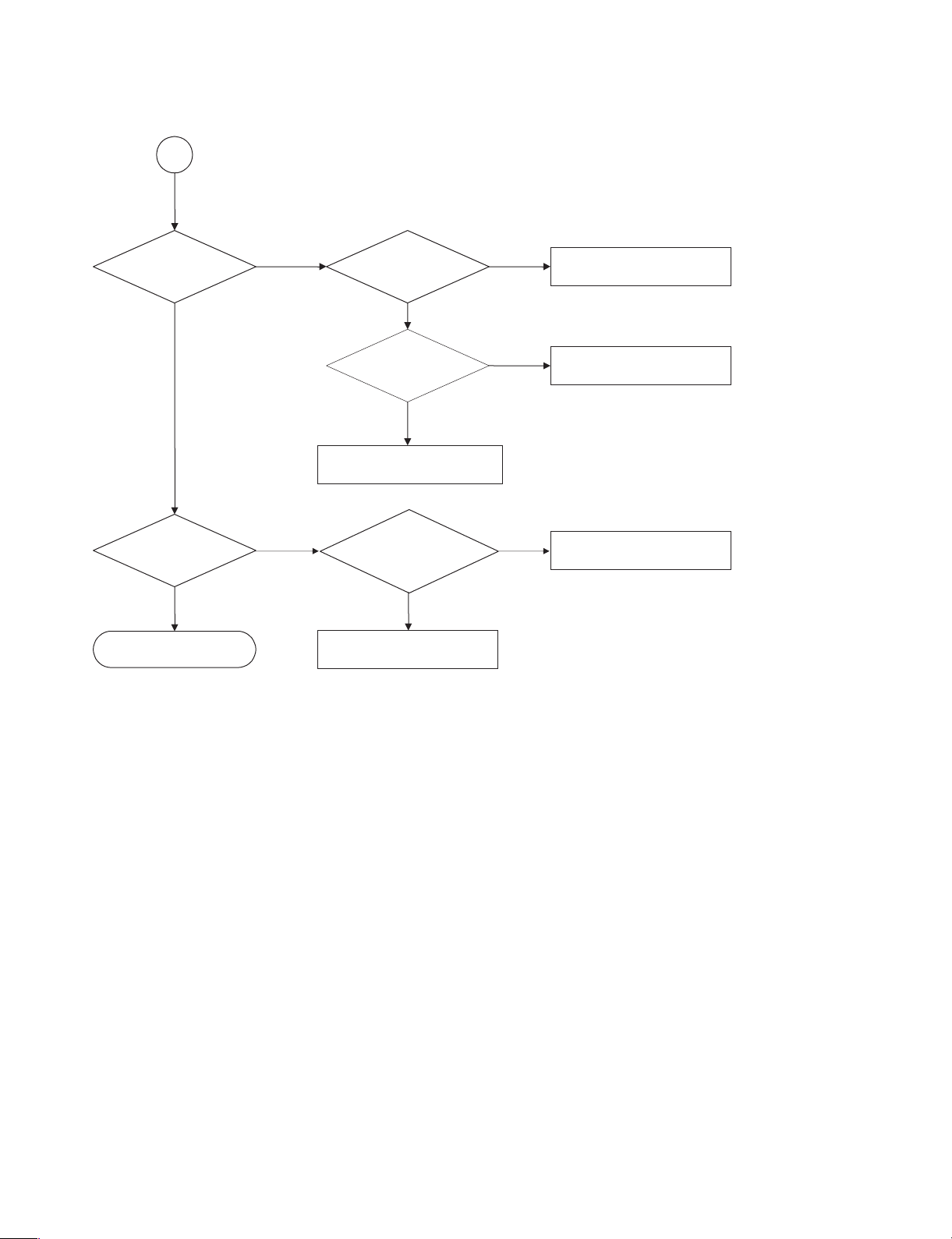

3. TEST & DEBUG FLOW

TEST

Check the AC Voltage

Power PCBA(120V)

YES

Switch on the Power PCBA

Is the DC Voltage

outputs OK?

(5V,3.3V, 8V, 12V, -12V, 11.5V)

YES

Make sure the main PCBA don't

short on VCCs and switch it on.

NO

NO

Replace power PCBA or

AC transformer.

Repair or Replace P ower PCBA

Is 3.3V and 1.8V DC

outputs normal on main

PCBA?

YES

Connect to PC RS232 Cable and

update the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

Check the regulators or related diodes.

1. Check 27MHz system clock.

NO

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

Page 13

- 2-8 -

A

RESET or Power On.

Show LOGO?

NO

Flash Memory operates

properly?

YESYES

SDRAM works properly?

YES

MT1389 VIDEO outputs

properly?

YES

Have TV signal output?

YES

Check AV cable connection

to TV set.

NO

NO

NO

NO

Check connection lines between FLASH

& MT1389 and the FLASH access time

whether is suitable or not.

Check connection lines between

SDRAM & MT1389 and the SDRAM

is damaged.

Check the related circuit of MT1389.

Check the filtering and amp circuit of

TV signal.

Does Tray move

inside when it is not

at closed position?

YES

B

NO NO

Normal TROUT &

TRIN signals?

YES

Normal TRCLOSE &

TROPEN signal?

YES

Normal LOAD+ &

LOADsignal?

YES

Check the cable connection

between main PCBA and loader.

NO

NO

Check the load OPEN & CLOSE

switch

Check the Tray control IO pins on

MT1389 & IP4504.

Check the Tray control amplifying

circuit on Motor driver.

Page 14

- 2-9 -

B

Does

the SLED move

to inner side when it is at

outter position?

YES YES

NO NO

Motor Driver STBY

Pin is High?

Check the connection line of

STBY signal.

Do not put in disc and tray

close.

Optical Lens has

movements for searching

Focus?

Is FMSO DC Level higher

than 1.4V?

YES

SL+ and SL- output

properly?

YES

Check the cable connection with

NO NO

MECHA.

Proper FOSO outputs

to motor driver?

NO

NO

Check the related circuit of

FMSO.

Check the amp circuit on motor

driver.

Check FOSO connection on

MT1389 and motor dirver.

YESYES

Proper F+ & F- outputs?

YES

C

Check cable connect on with

pick-up head.

NO

Check the amp circuit on motor

dirver.

Page 15

- 2-10 -

C

Laser turns on when

reading disc?

YES

Put disc in? Laser off

YES

Disc ID is correct?

NO

NO

NO

LD01 or LD02 output

properly?

Collector voltage of

power transistor is OK?

Check cable connection between

transistor ouput and pick-up

head.

Proper RFL signal

on MT1389?

YES

YES

YES

NO

NO

NO

Check the laser power circuit

on MT1336 and connecting to

power transistor.

Check the related circuit on

laser power transistor

Check the related circuit

on MT1389 RFL signal.

YES

Does spindle rotate?

YES

D

NO

Check LDO1 & LDO2 signal

Proper DMSO signal on

MT1389

YES

SP+ & SP- output

properly?

YES

Check the cable connection

between spindle and main PCBA.

NO

NO

Check DMSO related

circuit on MT1389.

Check the spindle control

amp circuit of motor

driver.

Page 16

- 2-11 -

D

YES

Focus ON OK?

YES

Track On OK?

YES

NO NO

NO

Proper signals on

A,B,C,D of MT1389

YES

Check FEO signal

on MT1389

YES

Check FOSO signal on MT1389

Normal TEO Signal on

MT1389?

YES

Properly TRSO signal

on MT1389?

YES

NO

NO

NO

Check connections between

MT1389 and pick-up head.

Check the FOSO connection on

MT1389 and motor driver.

Check the related

circuit on MT1389

Check the TRSO

connection on MT1389

and motor dirver.

Disc is play ?

YES

E

NO

T+ & T- output

properly?

YES

Check cable connection on

pick-up head.

Check RFO & RFLVL signal waveform.

NO

Check the tracking control

amp circuit on motor

driver.

Page 17

- 2-12 -

E

Normal Audio output

when disc playback?

YES

Normal IR.VFD & Front

pannel key functions?

YES

TEST END

NO NO

NO

Audio PWM IC received

correct data stream?

YES

Normal Audio PWM IC

out?

YES

Check Audio filter,amplify,mute

IR.VFD Front pannelkey & MT1389

Check the cable connection on

circuit.

Communications between

is normally?

YES

Front pannel.

NO

NO

Check connection between MT1379

& Audio PWM IC.

Check the related

circuit of Audio PWM IC.

Check communication lines on

MT1389.

Page 18

- 2-13 -

DVD DETAILS AND WAVEFORMS ON SYSTEM

TEST AND DEBUGGING

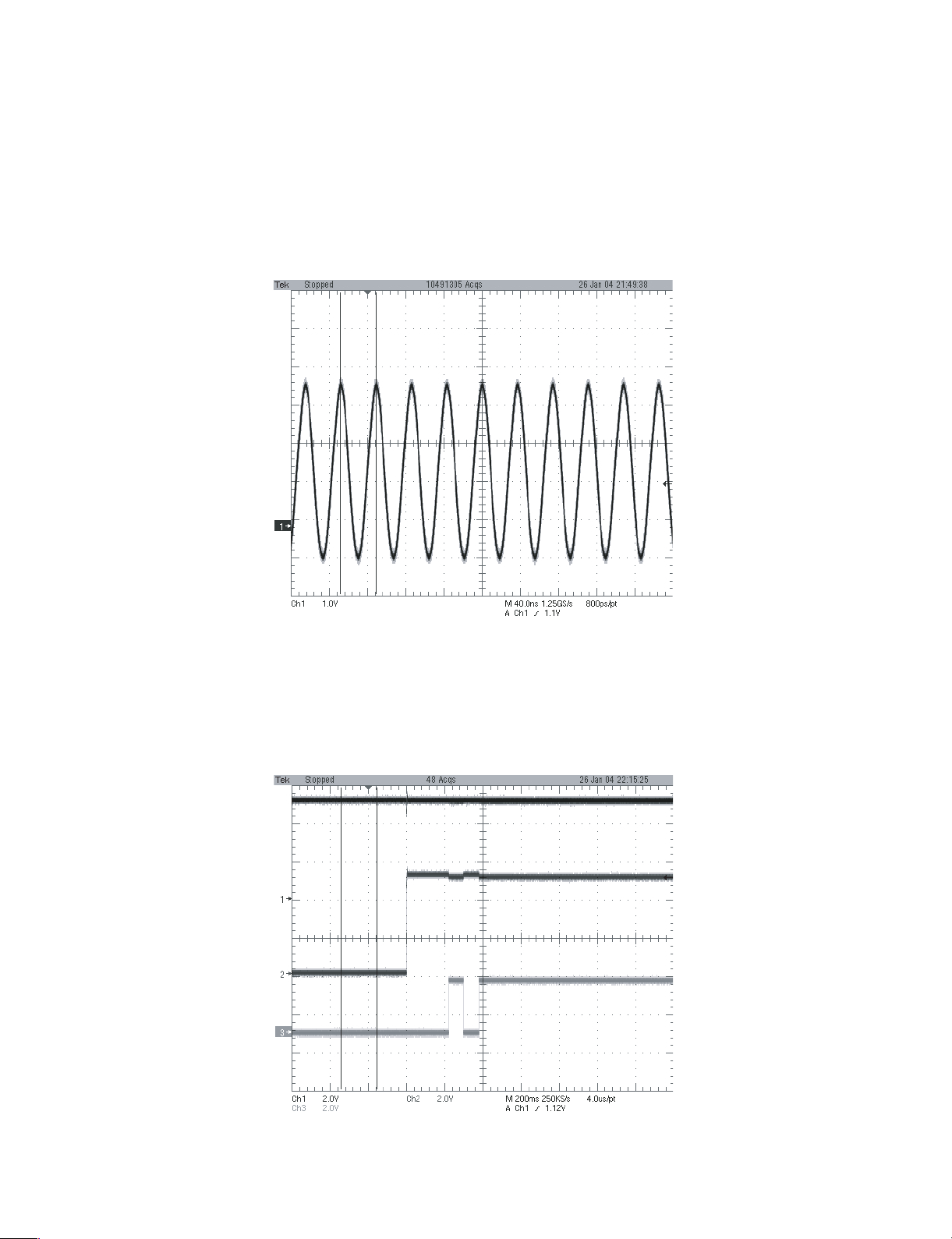

1. SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1) MT1389 main clock is at 27MHz(X601)

2) MT1389 reset is high active

FIG 1-1

FIG 1-2

Page 19

- 2-14 -

3) RS232 waveform during procedure(Downloading)

4) Flash R/W enable signal during download(Downloading)

FIG 1-3

FIG 1-4

Page 20

- 2-15 -

2. SDRAM CLOCK

1) MT1389 main clock is at 27MHz(X601)

3. TRAY OPEN/CLOSE SIGNAL

FIG 2-1

FIG 3-1

Page 21

- 2-16 -

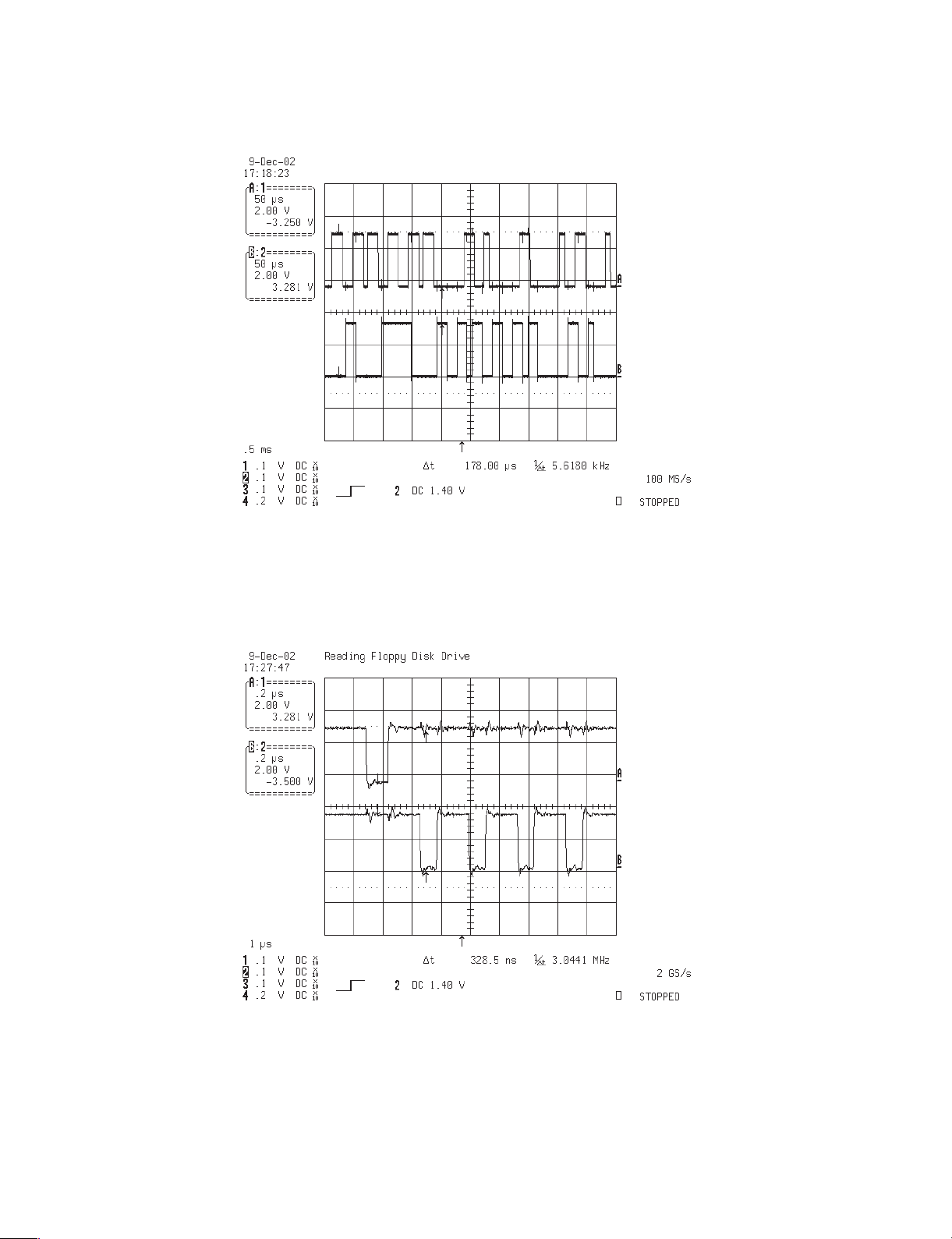

4. SLED CONTROL RELATED SIGNAL

(NO DISC CONDITION)

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 4-1

FIG 5-1

Page 22

- 2-17 -

6. LASER POWER CONTROL RELATED SIGNAL

(NO DISC CONDITION)

7. DISC TYPE JUDGEMENT WAVEFORM

FIG 6-1

FIG 7-1

Page 23

- 2-18 -

FIG 7-2 (DVD)

FIG 7-3 (CD)

Page 24

- 2-19 -

8. FOCUS ON WAVEFORM

FIG 7-4 (CD)

FIG 8-1 (DVD)

Page 25

- 2-20 -

FIG 8-2 (CD)

9. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

FIG 9-1

Page 26

- 2-21 -

10. TRACKING CONTROL RELATED SIGNAL

(System checking)

FIG 10-1 (DVD)

FIG 10-2 (CD)

Page 27

- 2-22 -

11. MT1389 AUDIO OPTICAL AND COAXIAL INPUT

(SPDIF)

12. MT1389 VIDEO OUTPUT WAVEFORM

1)100%

FIG 11-1 (DVD)

FIG 12-1

Page 28

- 2-23 -

2) COMPOSITE VIDEO SIGNAL

13. MT1389 AUDIO OUTPUT TO PWM IC

FIG 12-2

ADAT0~3

FIG 13-1

Page 29

- 2-24 -

14. AUDIO OUTPUT FROM PWM IC

FIG 14-1

Page 30

- 2-25 -

WIRING DIAGRAM

Page 31

- 2-26 -

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

5V

MEMORY SLOT

IC603

M12L64164A

SD33

JK601

HDMI OUT

CONNECTO

3.3V-D1

HDMI PCB ASSY

3.3V-D1,1.8V-D1

ASSY

(7 IN 2)

12MHz

USB_M, USB_P

DCS#, DRAS#, DCAS#,

BA[0:1], SDCLK, SDCKE

64Mb, SDRAM

DDC CLK,DATA

+5V

R

HOT PLUG DET

DATA0~2/+-

IC602

64Mb, SDRAM

HY57V643220CT

13.5MHz

X601

DQ0~31

DAD0~10

IC601

FLI2301

RESOLUTION UP

UP

PICK

M

MOTOR

SPINDLE

A29LV800TA-70

DV33

1M, 8BIT FLASH

DWE#

DQ[00:15]

DQM[0:1]

MA[00:11]

HDMI

IC603

SIL9190

3.3v-D1, 3.3V-M

IC605

MM1234

SWITCHING IC

AV33, DV33

Y,Pb,Pr

FDATA0~7

M_VSYNC, M_HSYNC

LOADING

SLED

(Resolution up)

LOAD+, LOAD-

M

MOTOR

M

MOTOR

IC602

A[00:21]

SPDIF

TX0+,TX0-, TX1+,TX1-,

TX2+,TX2-, TXC+,TXC-,

F+, F-, T+, T-

SP+, SP-

SL+, SL-

AD[0:7]

AV33, DV33

IC606

KS24C021CS

2Kb,

EEPROM

DV33

CN601

RS-232

TXD

PCE#, PRD#, PWR#

IC601

AMCLK

SCL,SDA

LIMIT

SCL

RXD

X601

27MHz

MT1389FE

MPEG & DSP

CD : RFO, A, B, C, D, E, F

DVD : RFO, A, B, C, D

Y,Pb,Pr(Analog)

Y,Pb,Pr(Analog or Digital)

SDA

ALRCK, ABCK

REG_ 12V

IC303

V1P4

TROUT, TRIN, ADIN

V2.0, MDI1

AVCC, APC

LD01, LD02, IOA,

TUNER_L, R

TROPEN, TRCLOSE, TRSO, FOSO, DMSO, FMSO, STBY

DVD_DATAOUT

DVD_CE, DVD_CLK, DATAIN

ADATA

AMCLK

BU4052

X101

12.5MHz

DVD_RESET

AUDIO S/W

JK002

JK003

JK004

AV2_AUDIO L, R_VIDEO

AV2_L, R

4052_SW1,SW2

REG_5VA

IC101

JK503

OPT.

TMP88CU77F

SPDIF

AUDIO MICOM

REG_5VA

FRONT

REAR

RIN, LIN

C/SW

ALRCK, ABCK

DN_MIX

IC305

IC304,

OPAMP

V_MUTE1

V_MUTE2

COMPONET-OUT

COAXIAL IN

IC302

CS42516

CODEC & DIR

AV1_L, R

PS9829_DATA

JK501

AV1-IN

COAXIAL IN

AV1 AUDIO_L, R_VIDEO

PS9829_CLK, RESET, PDN

510_PDN

510_FAULT, TH_WAR

Y, Pb, Pr

MONITOR OUT

AV1_VIDEO

AV2_VIDEO

REG_3.3VA

SL+/

JK502

S-VIDEO

MM1623XFBE

VIDEO 6dB AMP

C+/

FL+/

REG_3.3VA, 34.5VA

L703

L.P.F

Y_OUT, C_OUT

IC605

IC301

PS9829

L702

IC502

V_MUTE1

X301

MODULAT

8CH. PWM

STA510

IC701, IC702

IC703, IC704

L708

S/W

VIDEO

NJM2244

CVBS

V_MUTE2

12.288MHz

OR

FR+/

SW+/

LL705

LL706

JK001

H/PHONE

HEAD PHONE L, R

IC501

H/PHONE+/

SR+/

OPAMP

L710,L711,L712

P_DI

MUTE

IC201

IP4504A

MOTOR DRIVER

RVCC2, +P8V

TUN101

OPTION

RDS_CLK, DATA

P_CE, P_CLK, P_DO

RADIO TUNER MODULE

REG-9V

C

F.L

R.L

SW

JK701

F.R

R.R

SPEAK ER TERMINAL

Page 32

- 2-27 -

2. SMPS BLOCK DIAGRAM

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

TO I/O

5.3VA

(PSV01)

RECTIFIER &

SMOOTING BLOCK

(D927,C931,L925,C932)

C925)

RECTIFIER &

(D921,C921,L921

SMOOTING BLOCK

T901

!

!

SNUBBER

3.8VA

13VA

GND

GND

(IC956,R950,C953)

(IC953,R947,C928)

12V REG & S/W Block

12VT REG & S/W Block

RECTIFIER &

SMOOTING BLOCK

(D922,C922,L922,C926)

BLOCK

(D901,C905,R901)

GND

33VA

33V S/W Block

(Q923,R943,R934)

RECTIFIER &

SMOOTING BLOCK

54

DRIVE & S/W BLOCK

FL-

FL+

-29VA

R945,C920)

5.0VD S/W Block

5.0VT S/W Block

(Q920,R942,R944

(Q924,R940,R935,R936

FEED-BACK

(D925,C929,)

RECTIFIER &

(D923,C923,L923)

SMOOTING BLOCK

7

C909,C910,R906,

(IC901, D902, D903,

!

2

ZD901,ZD902)

D934,C934)

BLOCK

PHOTO COUPLER

TIMER ‘H’ Block

(R930,R931,

(PC910)

PWR CTL Block

(Q926,R964,R965)

(Q925,R956,R957)

R926,R927,

R928,C930)

(IC941)

ERROR AMP

T902

!

RESET

BLOCK

GND

P-con

35.5V

TO AMP

(PSW01)

(L951,C953,C954)

REGULATION BLOCK

RECTIFIER &

SMOOTING BLOCK

1

(D905,D906)

DRIVE & S/W BLOCK

P-sen

(R951,R952)

RECTIFIER &

(D91,C951,C952)

SMOOTING BLOCK

5

4

C919,ZD912)

(IC902,R919,

C916, C917,C918,

BLOCK

R949,R950,

(R946,R947,

FEED-BACK

(PC912)

PHOTO COUPLER

!

R955,C943)

(IC942)

ERROR AMP

TH901

BD901

+

C903,C904

1

!

3

8

BLOCK

(CM901,L902,

NOISE FILTER

3

2

Y-CAP

C900

!

!

Y-CAP

C901,C902

!

FUSE

L901, CM902)

(F901)

BR BL

(BK)(WH)

Page 33

- 2-28 -

3. SERVO Block Diagram

EEP

ROM

SCL, SDA

PRD#, PWR#

PCE#

MT1389

DVDPLAYER

X601

27MHz

X-TAL

AD[0:7]

ROM

FLASH

A[0:20]

IC601

ONE CHIP

RS232C(MTK)

RXD, TXD

MA[0:11]

DQM0 ,DQM1

WE#,CAS#,RAS#

CS#,BA0,BA1

SDCLK

SDCKE

IC603

SDRAM

DQ[0:15]

4M x 16bit

ALPC

LD0 1, LDO 2, IOA

MDI 1

TRCLOSE

ADIN

IC201

IP4504

STBY,V1P4

FOSO,TRSO,FMSO

DMSO,,TROPEN

Motor Driver

V20, PICKSEL

DVD: A,B,C,D, RFO

CD: A,B,C,D, E, F,RFO

LIMIT,TRIN,TROUT

F+, F-, T+, T-

SL+, SL-

SP+, SP-

LOAD+, LOAD-

UP

PICK

M/D

Page 34

- 2-29 -

4. MPEG & MEMORY Block Diagram

VIDEO

Interface

IC606

EEPROM

Y2(Y),Y3(Color)

Y4(Y),Y5(Cb),Y6(Cr)

ASPECT(16:9)

SCL,SDA

ACLK,ALRCK,ABCK

MUTE,VSCK,VSDA

e

AUDIO

Interfac

ASPDIF

ASTB,SCL,SDA

ASDTA[0:3]

AD[0:7]

A[0:20]

IC602

PWR,PCE,PRD

(16 M )

IC603

SDRAM

64M

FLASH MEMORY

CS,DCKE,MA[0:10]

DCLK,WE,CAS,RAS

DQ[0:15]

DQM0,DQM1

M_REQ

VFD_TXD

VFD_SCK

MT1389

SCKO,TXDO,M-REQ

IC601 (MPEG + DSP + RF)

X601

27MHz

VFD_RXD

URST,S_REQ

AUDIO MICOM

Page 35

- 2-30 -

5. VIDEO & AUDIO Block Diagram

M

A/V

JACK

CVBS

HDMI BOARD

COMPONENT(Y.Pb.Pr)

Amp

IC605

VIDEO 6dB

REAR R

FRONT R

SUPER VIDEO (Y/C)

IC701 Digital

POWER IC

REAR L

FRONT L

IC702 Digital

POWER IC

CENTER

WOOFER

IC303, IC704

Digital POWER IC

5.1CH BOARD

IC301

IC

PWM

(5.1CH)

MODULATOR

FDATA

[0:7]

(Y/C)

(Y.Pb.Pr)

MPEG

ACLK

LRCK

PEG

ADATA2

ADATA1

ADATA3

Page 36

Page 37

- 3-5 -

• PACKING ACCESSORY SECTION

811

PLUG ASS'Y 1WAY(YELLOW)

826

FILTER(CIRC)

808

BATTERY

900

REMOCON

SHEET

804

812

PLUG ASS'Y 2WAY

824

ANTENNA LOOP(AM)

825

ANTENNA (FM)

OWNER'S MANUAL

801

PACKING, CASING

803A

PACKING, CASING

803B

803C

PACKING, CASING

PACKING, CASING

803

802

BOX

Page 38

- 4-1 -

SECTION 4. SPEAKER PART

1. WOOFER SPEAKER SECTION

• MODEL: LHS-75SGW

950

952

A900

954

953

959

955

951

957

958

Page 39

- 4-2 -

2. SPEAKER CENTER SECTION

• MODEL: LHS-75SGC

A700

755

758

754

750

751

753

756

759

756

Page 40

- 4-3 -

3. SPEAKER REAR/FRONT SECTION

• MODEL: LHS-75SGS

A800

859

855

850

851

853

857

854

856

858

Page 41

Page 42

2-31 2-32

AUDIO PART SCHEMATIC DIAGRAMS

• SMPS-1 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 43

• SMPS-2 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

2-33 2-34

Page 44

2-35 2-36

• MICOM SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 45

2-37 2-38

• I/O SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 46

2-39 2-40

• AMP SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 47

2-41 2-42

• FRONT SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 48

2-43 2-44

• H/PHONE SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 49

2-45 2-46

• AV2 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 50

2-47 2-48

DVD PART SCHEMATIC DIAGRAMS

• MPEG SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 51

2-49 2-50

• DSP SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 52

2-51 2-52

• SERVO SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 53

3-53 3-54

PRINTED CIRCUIT DIAGRAMS

• MAIN P.C. BOARD (TOP SIDE)

Page 54

3-55 3-56

• MAIN P.C. BOARD (BOTTOM SIDE)

Page 55

2-57 2-58

• FRONT P.C.BOARD (TOP SIDE)

• FRONT P.C.BOARD (BOTTOM SIDE)

Page 56

2-59 2-60

• H/PHONE P.C.BOARD (TOP SIDE)

• H/PHONE P.C.BOARD (BOTTOM SIDE)

• AV JACK P.C.BOARD (TOP SIDE)

• AV JACK P.C.BOARD (BOTTOM SIDE)

Page 57

2-61 2-62

• POWER P.C.BOARD

LOCATION GUIDE

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 58

2-63 2-64

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

12).IC703(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

13).IC704(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

11).IC702(STA510)

10

2 17.7

3 17.7

4 34.5

50

60

7 34.5

8 17.7

9 17.7

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

19 0

20 NC

21 NC

22 NC

23 NC

24 4.93

25 0

26 NC

27 NC

28 NC

29 NC

30 NC

31 NC

32 NC

33 NC

34 NC

35 NC

36 NC

37 NC

38 0

39 0

40 0

41 4.94

42 NC

43 NC

44 NC

45 NC

46 NC

47 NC

48 0

49 0

50 NC

51 3.26

52 0

53 3.26

54 0

55 0

56 NC

57 NC

58 NC

59

1.66(12.288MHz)

60 0.32

61 0.32

62 0

63 NC

64 NC

6).IC303(BU4052)

12.75

20

32.75

40

5NC

60

7 -6.25

80

90

10 0

11 0

12 2.75

13 2.75

14 NC

15 0

16 5.95

7).IC304(UTMC4580)

12.84

22.84

32.84

4 -12.31

52.84

62.84

72.84

8 11.68

8).IC305(UTMC4580)

12.86

22.86

32.86

4 -12.32

52.86

62.86

72.86

8 11.69

9).IC501(UTMC4580)

10

20

30

4-11.42

50

60

70

8 11.23

9).IC502(NJM2244M)

12.04

24.82

31.97

44.82

52.82

64.76

72.06

80

10).IC701(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

10 17.7

9 4.95

10 0

11 3.27

12 4.95

13 0

14 0.9

15 0

16 4.91

17 0

18 4.91

19 0

20 4.95

3).IC103(KIA7042)

1 5.1

20

3 5.1

20).IC201(IP4504)

1 1.37

2 2.56

3 2.52

4 2.61

5 2.41

6 2.44

7 2.46

80

9 1.42

10 4.35

11 0

12 0

13 3.94

14 3.94

15 3.19

16 4.7

17 3.9

18 4

19 7.9

20 1.42

21 1.62

22 1.39

23 3.25

24 4.91

25 2.58

26 2.39

27 2.52

28 2.49

4).IC301(PS9829)

10

20

3 2.44

4 4.92

5 3.28

6 2.42

71

80

90

55 -23

56 -23

57 -23

58 -23

59 -23

60 -23

61 -23

62 -23

63 -23

64 -23

65 -23

66 2.5

67 0

68 0

69 4.9

70 4.9

71 0

72 4.8

73 4.8

74 4.8

75 4.4

76 0

77 0

78 0

79 4.8

80 3.9

81 0

82 0

83 0

84 4.8

85 4.8

86 4.8

87 -26

88 4.9

89 1.8

90 0

91 1.8

92 4.8

93 4.35

94 0

95 0

96 5.1

97 4.9

98 0.3

99 0.3

100 0

2).IC102(74HCT244)

10

2 2.48

30

4 2.47

50

6 1.5

70

8 3.27

Volt (V)

MODE

PIN NO.

IC101

(AUDIO MICOM)

10

21.04

34.75

40

50

60

7 4.9

8 4.9

9 4.9

10 4.9

11 2.4

12 4.9

13 0

14 0

15 0

16 0.6

17 5.1

18 0

19 0

20 0

21 0

22 4.9

23 4.9

24 5.1

25 0

26 0

27 5.1

28 0

29 0

30 0

31 5.1

32 4.9

33 -23.4

34 -23.4

35 -23.4

36 -23.4

37 -23.4

38 -23.4

39 -23.4

40 -23.4

41 -23.4

42 -23.4

43 -23.4

44 -23.4

45 -23.4

46 -23.4

47 -23.4

48 -23.4

49 -23.4

50 -23

51 4.88

52 -23.7

53 -23

54 -23

Volt (V)

MODE

PIN NO.

IC102

(74HCT244)

Volt (V)

MODE

PIN NO.

IC103

(KIA7042)

IC201

(IP4504)

IC301

(PS9829)

Volt (V)

MODE

PIN NO.

10 3.28

11 0

12 0

13 2.44

14 0

15 0

16 0

17 0

18 0

19 1.63

20 1.63

21 0

22 3.28

23 1.23

24 1.23

25 1.23

26 1.23

27 NC

28 0

29 3.28

30 NC

31 NC

32 NC

33 NC

34 2.44

35 0

36 NC

37 NC

38 0

39 3.28

40 1.63

41 1.63

42 2.44

43 0

44 0

45 1.63

46 1.63

47 3.28

48 1.63

49 1.63

50 0

51 1.63

52 1.63

53 0

54 1.63

55 1.63

56 3.28

57 0

58 1.63

59 1.63

60 0

61 1.63

62 1.63

63 0

64 0

Volt (V)

MODE

PIN NO.

IC302

(CS42516)

65 3.28

66 2.44

67 1.63

68 1.63

69 0

70 1.63

71 1.63

72 3.28

73 0

74 1.63

75 1.63

76 3.28

77 0

78 0.5

79 0.5

80 2.44

81 0

82 3.28

83 3.28

84 0

85 0

86

1.65(12.288MHz)

87 3.28

88 NC

89 NC

90 NC

91 2.44

92 0

93 NC

94 3.28

95 0

96 4.92

97 NC

98 NC

99 NC

100 NC

1NC

2NC

3NC

43.27

50

64.93

70.65

80

9 0.2

10 0.11

11 0

12 4.93

13 2.83

14 2.83

15 2.83

16 2.83

17 2.75

18 0

Volt (V)

MODE

PIN NO.

IC303

(BU4052)

Volt (V)

MODE

PIN NO.

IC304

(UTMC4580)

IC305

(UTMC4580)

IC501

(UTMC4580)

IC502

(NJM2244M)

IC701

(STA510)

Volt (V)

MODE

PIN NO.

IC702

(STA510)

Volt (V)

MODE

PIN NO.

IC703

(STA510)

IC704

(STA510)

Volt (V)

MODE

PIN NO.

IC601

(MT1389)

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

10

2 1.67

3 1.67

4 1.67

5 1.67

6 1.67

7 1.67

8 1.99

92

10 2

11 2

12 1

13 1

14 1

15 1

16 1

17 1

18 2

19 2

20 0.18

21

22 2.34

23 3.21

24 3.2

25 1.55

26 1.93

27 0

Volt (V)

MODE

PIN NO.

28 2.71

29 2

30 1.37

31 1.32

32 1.33

33 1.33

34 2.8

35 2.78

36 2.34

37 2.04

38 1.33

39 0

40 1.37

41 1.37

42 1.4

43 0

44 1.57

45 1.57

46 3.28

47 2.84

48 3.28

49 0

50 3.24

51 0

52 2

53 2.12

54 1.89

55 1.76

56 1.45

57 1.72

58 2.23

59 1.5

60 0.02

61 0

62 0

63 1.7

64 0

65 3.1

66 3.27

67 0.27

68 0.62

69 0.65

70 3

71 1.3

72 1.8

73 3.27

74 1.71

75 2.51

76 0

77 0

78 2.08

79 0

80 3.27

81 1.53

82 1.52

Volt (V)

MODE

PIN NO.

83 1.23

84 0.96

85 0

86 1.3

87 1.68

88 1.32

89 0

90 1.17

91 1.34

92 0.31

93 1.88

94 0

95 1.8

96 3.22

97 1.8

98 2.51

99 2.51

100 3.25

101 3.25

102 3.27

103 3.27

104 2.5

105 1.3

106 2.51

107 3.27

108 3.27

109 0

110 3.9

111 2.52

112 2.6

113 1.93

114 0.02

115 1

116 0

117 1.25

118 1.07

119 0

120 1.82

121 2.35

122 1.8

123 1.14

124 1.13

125 1.27

126 1.33

127 3.27

128 1.3

129 1.4

130 1.3

131 1.2

132 1

133 1

134 0

135 1.2

136 3.28

137 2

Volt (V)

MODE

PIN NO.

138 3.1

139 2.7

140 3.1

141 3.27

142 2.57

143 1.54

144 0

145 1.6

146 0.06

147 0.6

148 0

149 1.95

150 2

151 1.46

152 1.8

153 0.37

154 1.48

155 3.27

156 1.66

157 1.7

158 0

159 0

160 0

161 0

162 1.43

163 0

164 1.45

165 1.59

166 1.43

167 3.27

168 3.27

169 0.77

170 0

171 2.8

172 2.9

173 1.8

174 3.28

175 0

176 3.28

177 3.26

178 0

179 2.89

180 0

181 0.8

182 3.28

183 0.13

184 3.12

185 0.13

186 3.12

187 0.13

188 0

189 3.27

190 1.23

191 1.23

192 2.28

CIRCUIT VOLTAGE CHART

Page 59

2-65 2-66

1 300V

2 GND

3 20V

4 0 ~ 6.5V

5 0 ~ 5V

1 5.6V

25V

3 GND

4 2.5V

1 13V

2 12V

3 GND

4 3.3V

1 4.5V

2 3.3V

3 GND

4 2.5V

1 12V

2 GND

38V

1 2.5V

2 GND

3 4.8V

1 2.5V

2 GND

3 30V

52 0

53 1.1

54 0

17).IC604(LD1117A)

13.27

2 1.8

30

18).IC605(MM1623)

1 4.9

22.33

3 4.9

4 1.1

50

6 1.5

70

82.37

90

10 1.47

11 0

12 2.33

13 4.9

14 2.33

15 0

16 2.39

17 0

18 2.39

19 0

20 1.88

21 1.76

22 0

23 1.74

24 0

25 0

26 0

27 2.38

28 4.9

19).IC606(EEPROM)

10

20

30

40

5 3.2

6 3.2

70

8 3.2

1 GND

2 1 ~ 5V

3 GND

4 0 ~ 6V

5 GND

6 300V

7 12V

8 0 ~ 6V

46 0

47 0

48 0.45

13.27

2 1.2

33.26

41.07

5 1.4

60.12

71.09

81.33

93.27

10 0.96

11 0.7

12 0

13 0.8

14 3.27

15 2

16 3.2

17 2.8

18 3.1

19 2.8

20 2

21 1.72

22 0.06

23 1

24 1.91

25 1.97

26 1.58

27 3.27

28 0

29 1.6

30 1.5

31 1.5

32 1.5

33 0.03

34 0.03

35 0.04

36 NC

37 1.6

38 1.6

39 2

40 NC

41 0

42 1.2

43 3.26

44 1.2

45 0.9

46 0

47 1.5

48 1.5

49 3.26

50 1.3

51 1.3

248 1.9

249 0

250 1

251 1

252 1.6

253 1.53

254 1.5

255 0.9

256 3.2

1 0.4

2 0.8

3 0.8

43

5 2.8

6 0.7

7 0.9

8 1.7

90

10 0

11 3.2

12 3.9

13 3.27

14 3.27

15 1.5

16 0

17 0.3

18 1.9

19 2.5

20 2.3

21 1.4

22 1.9

23 2.2

24 1.95

25 2

26 0

27 0

28 0

29 1.6

30 1.1

31 1.7

32 1

33 1.1

34 0.11

35 1.1

36 0.16

37 3.27

38 1.5

39 1

40 1.5

41 1.2

42 1.3

43 1.2

44 1.4

45 2.09

Volt (V)

MODE

PIN NO.

IC101

(AUDIO MICOM)

193 0

194 0.48

195 3.28

196 0.69

197 0

198 2.9

199 3.27

200 0.5

201 0

202 0.71

203 0.69

204 3.28

205 2.9

206 4.2

207 2.9

208 1.48

209 1.3

210 1.64

211 1.58

212 3.28

213 1.63

214 1.63

215 1.63

216 0

217 1.21

218 1.15

219 1.2

220 0.07

221 1.82

222 1.2

223 0

224 0

225 1.64

226 0

227 1.82

228 0.67

229 0.84

230 1.4

231 1.41

232 0

233 0

234 3.24

235 1.81

236 1.66

237 1.66

238 1.56

239 3.24

240 1.4

241 0

242 1.7

243 1.1

244 3.24

245 1.59

246 1.37

247 1.3

Volt (V)

MODE

PIN NO.

IC602

(FLASH ROM)

Volt (V)

MODE

PIN NO.

IC603

(SDRAM)

IC604

(LD1117A)

IC605

(MM1623)

IC606

(EEPROM)

IC901

Volt (V)

MODE

PIN NO.

Volt (V)

MODE

PIN NO.

IC902

IC902

IC922

IC923

IC924

IC941

IC942

Page 60

3-1 3-2

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION

NOTE) Refer to “SECTION 5 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

A43

A50

452

A42

274

A49

283

292

452

463

255

463

A26

252

A60

463

A47

463

A40

463

250

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

463

279

280

A49A

452

261

261

260

463

253

266

261

A44

463

468

264

300

265

267

A46

463

263

468

Page 61

3-3 3-4

• DECK MECHANISM EXPLODED VIEW

003

004

005

006

038

434

013

012

049

008

010

011

014

054

434

052

055

044

017

045

431

435

046

048

061

019

030

020

431

058

431

021

059

024

050

022

023

026

057

434

043

042

434

056

051

027

025

007

001

436

002

435

016

039

040

041

060

434

009

037

034

047

433

438

432

036

437

032

035

033

062

028

029

015

A26

031

018

434

Loading...

Loading...