LG LHS-26-SGS, LHS-26-SHS, LHS-26-SQS, LHT-2660, LHT-2645 Service manual

...

DVD/CD RECEIVER

SERVICE MANUAL

MODELS : LH-T2645(X)/LH-TK2645(X)/LH-T2665(X)/LH-TK2665(X)/LH-T2660(X)/LH-TK2660(X)

SERVICE MANUAL

P/NO : AFN31220002 AUGUST, 2006

MODELS : LH-T2645(X)/LH-TK2645(X)/LHS-26SGS/26SGW

LH-T2665(X)/LH-TK2665(X)/LHS-26SQS/26SQW

LH-T2660(X)/LH-TK2660(X)/LHS-26SHS/26SHW

LH-T2645(X)/LH-TK2645(X)

LH-T2665(X)/LH-TK2665(X)

LH-T2660(X)/LH-TK2660(X)

1-1

[CONTENTS]

SECTION 1. GENERAL

• SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• ESD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

• SERVICE INFORMATION FOR EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

• SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SECTION 2. AUDIO PART

• AUDIO TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

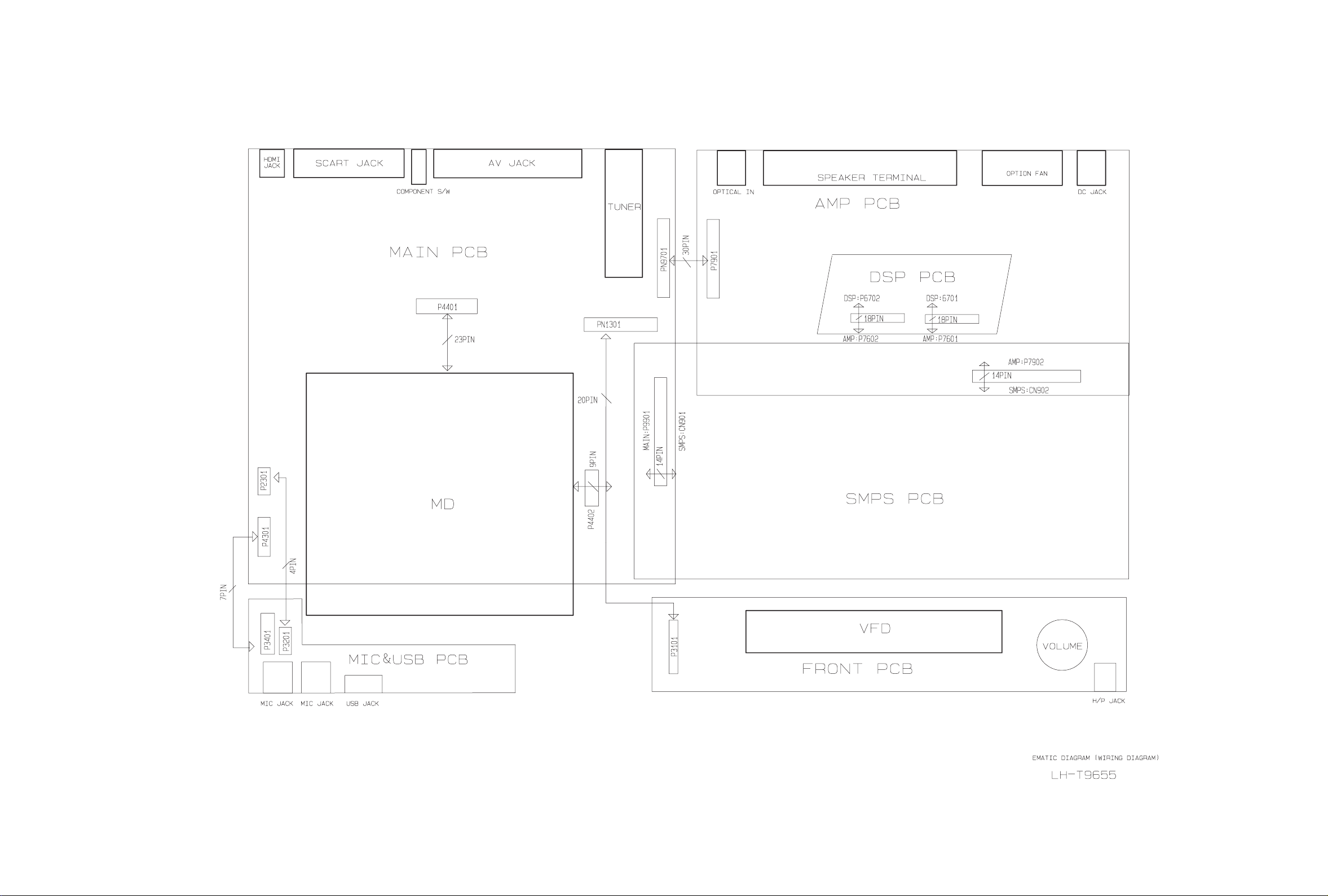

• WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

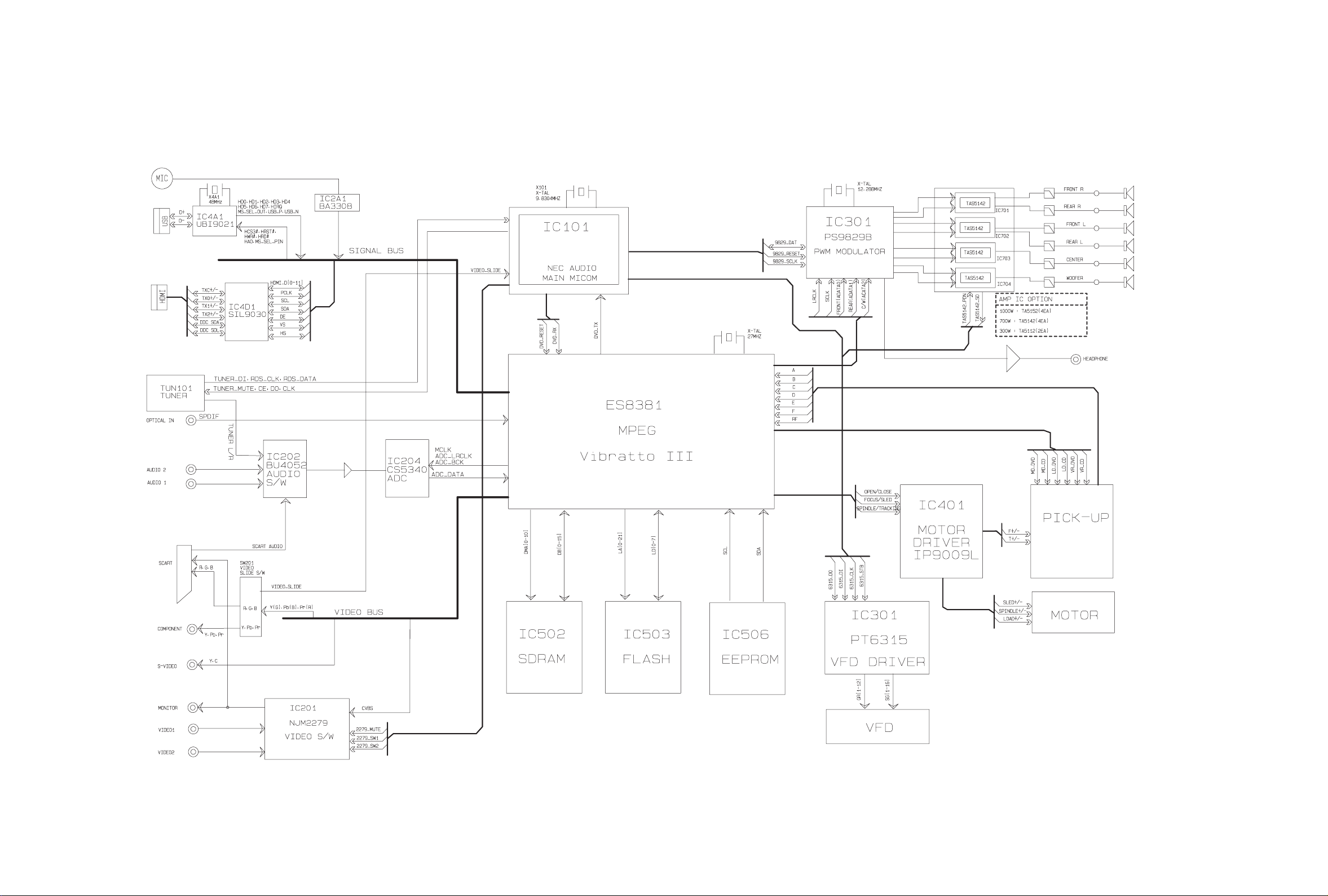

• BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

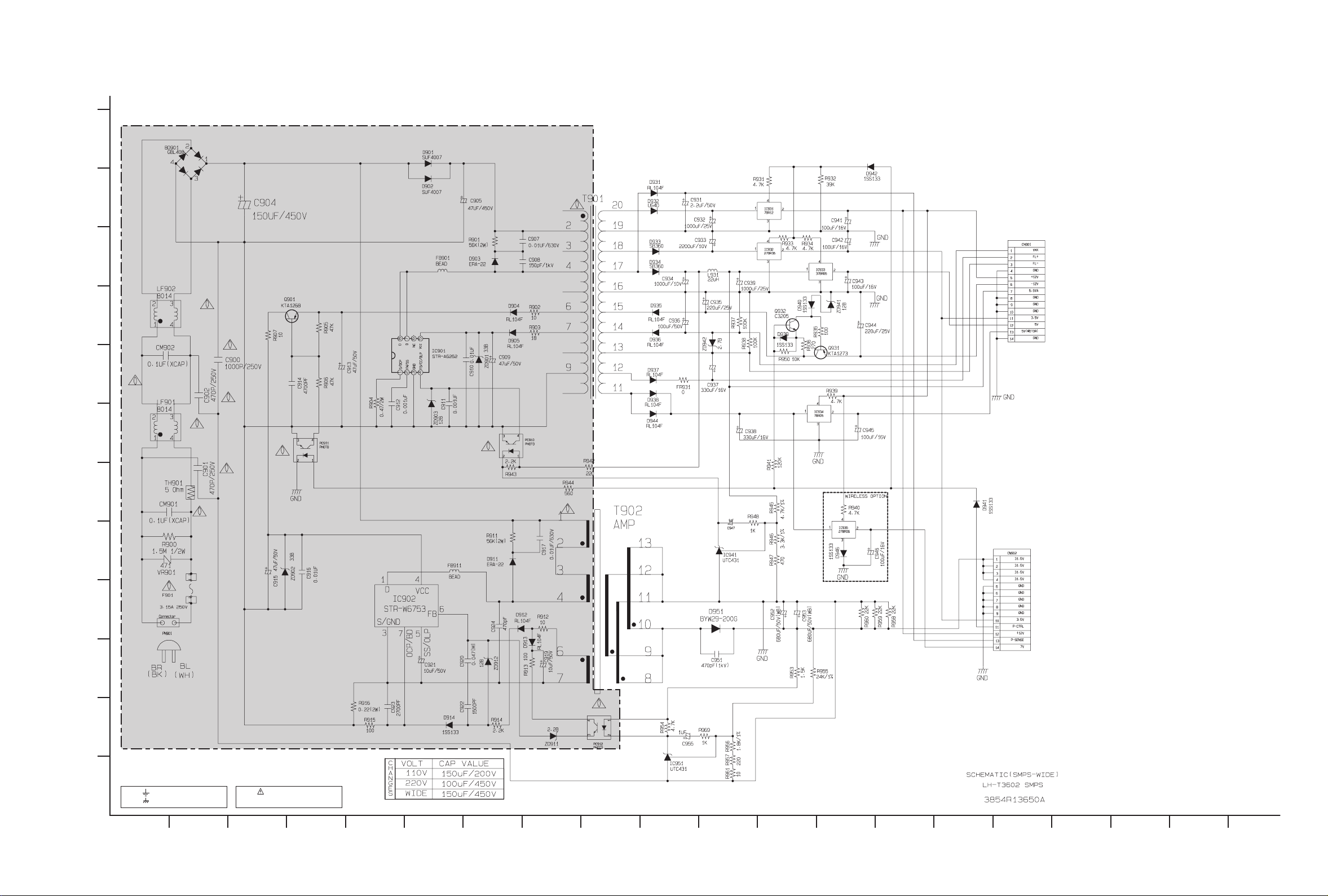

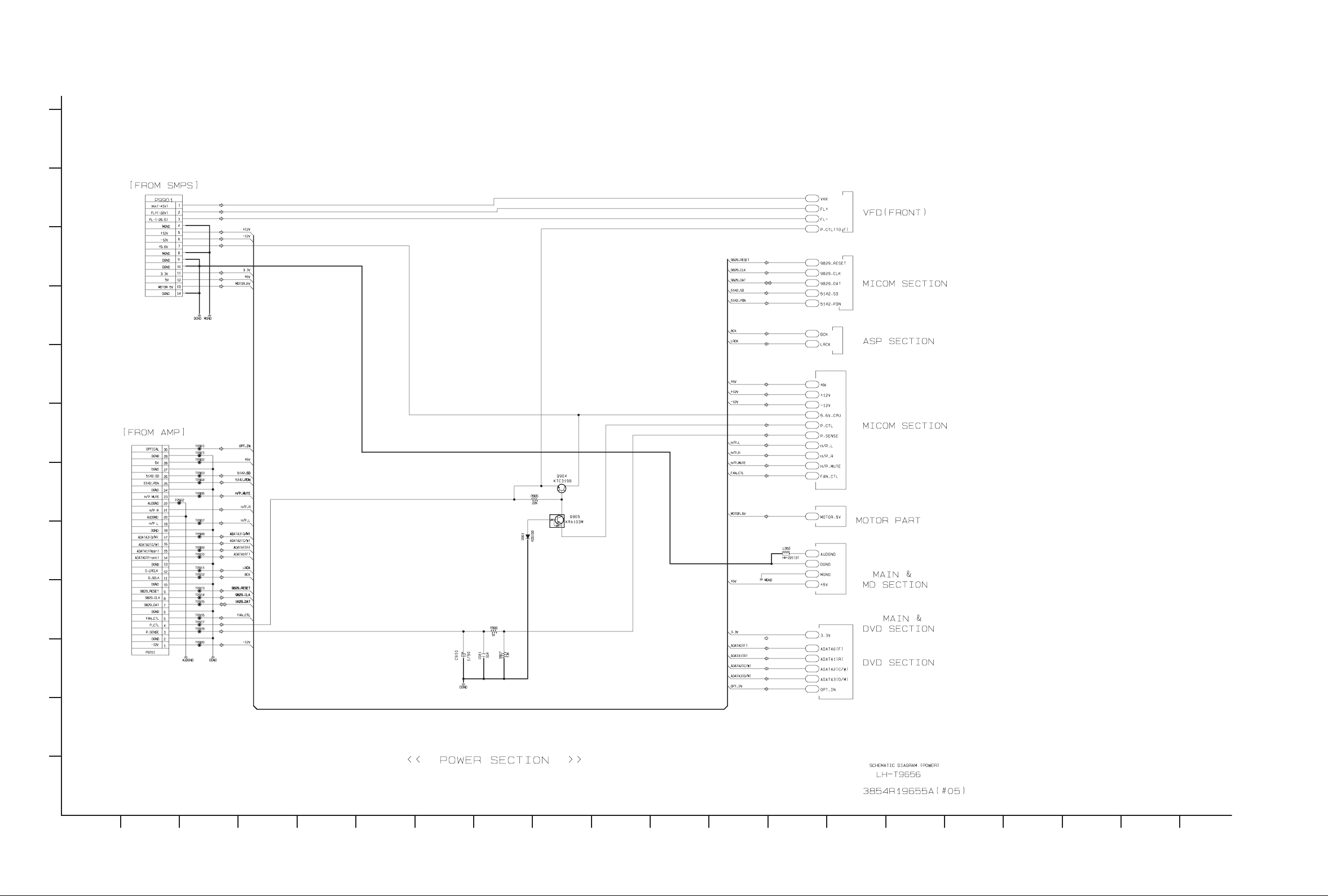

• CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

• PRINTED CIRCUIT DIARGAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

SECTION 3. DVD & AMP PART

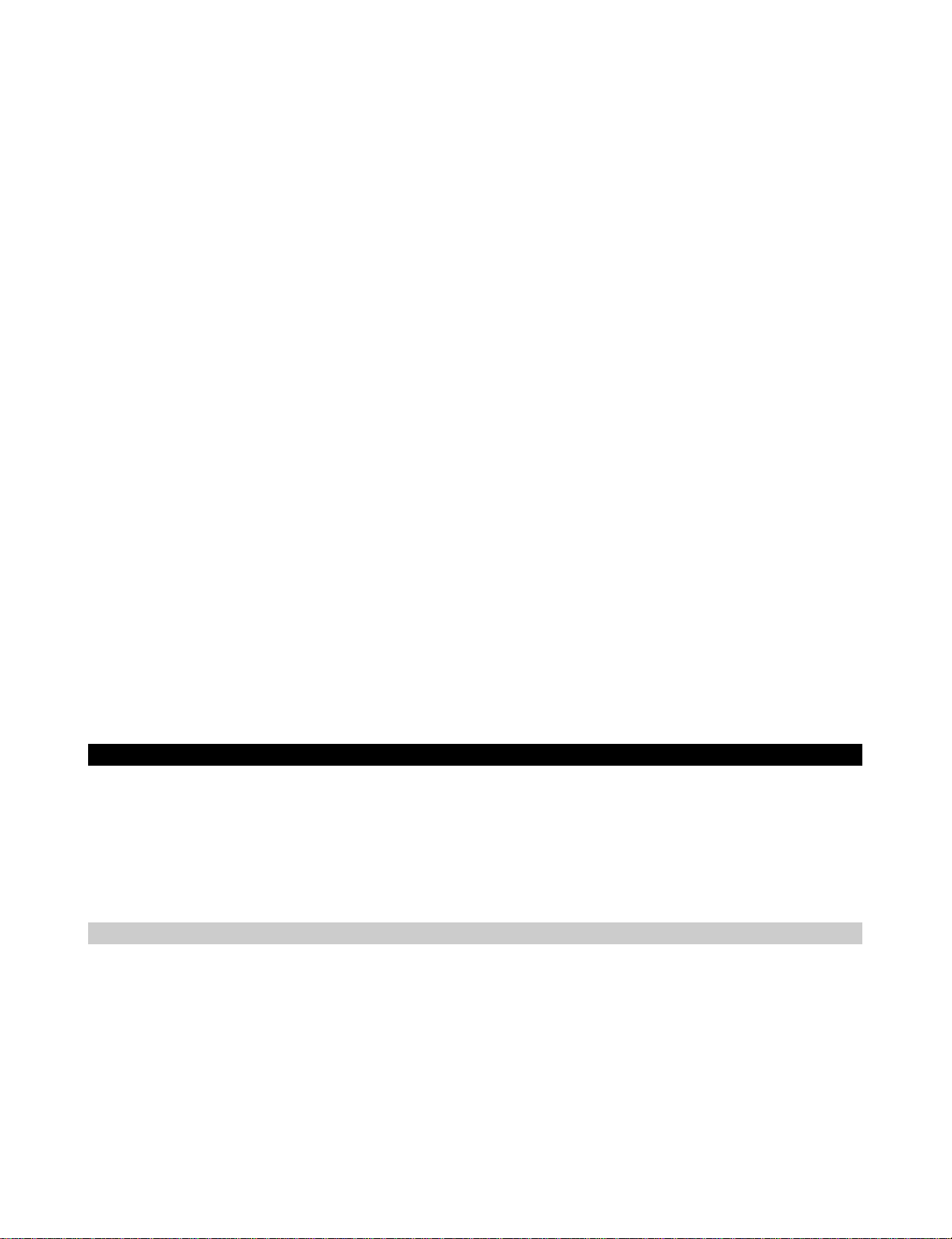

• ELECTRICAL TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

• DVD & AMP CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

• PRINTED CIRCUIT DIARGAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

SECTION 4. EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

SECTION 5. SPEAKER PART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

SECTION 6. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

1-2

SERVICING PRECAUTIONS

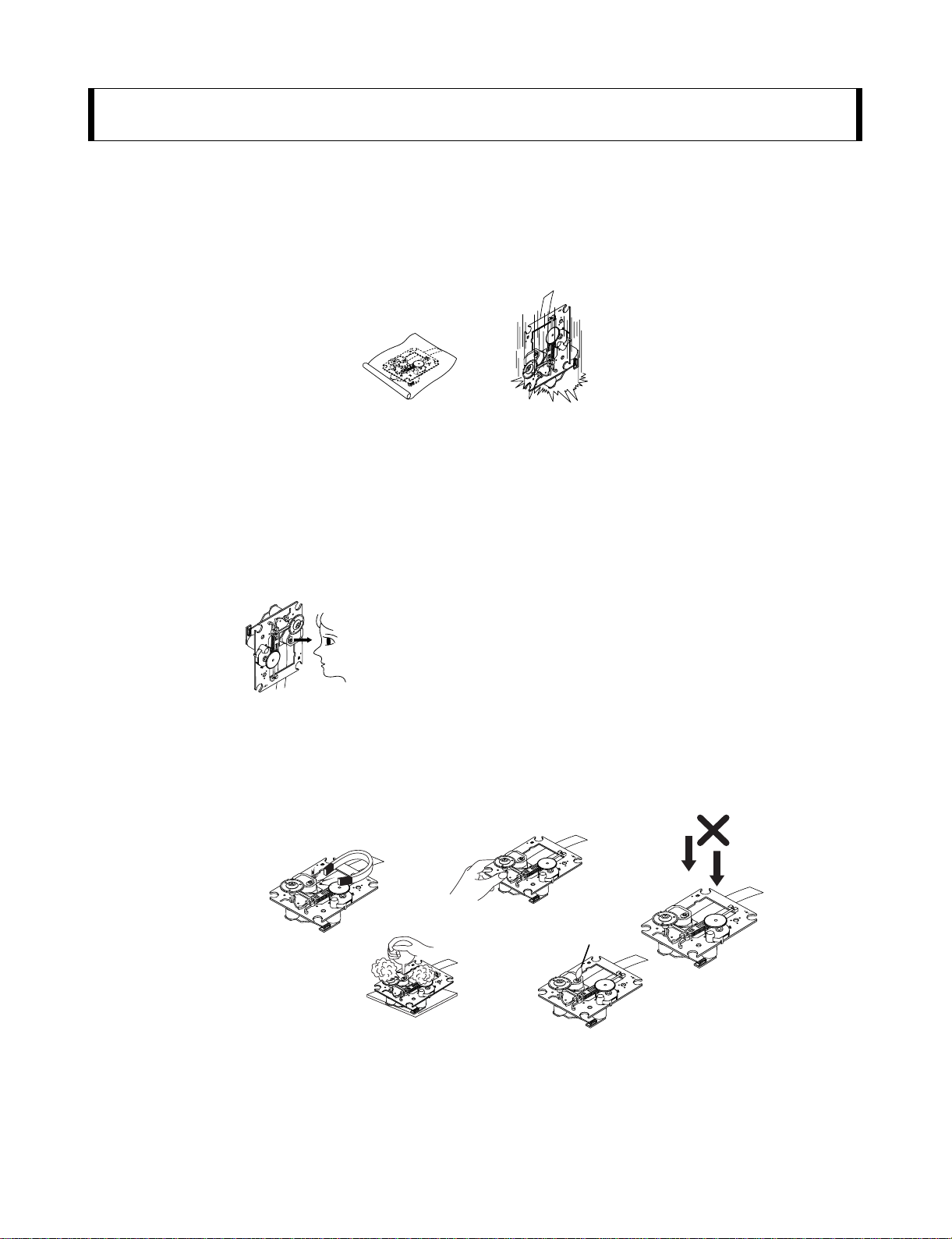

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Conductive Sheet

Cotton swab

Pressure

Pressure

SECTION 1. GENERAL

1-3

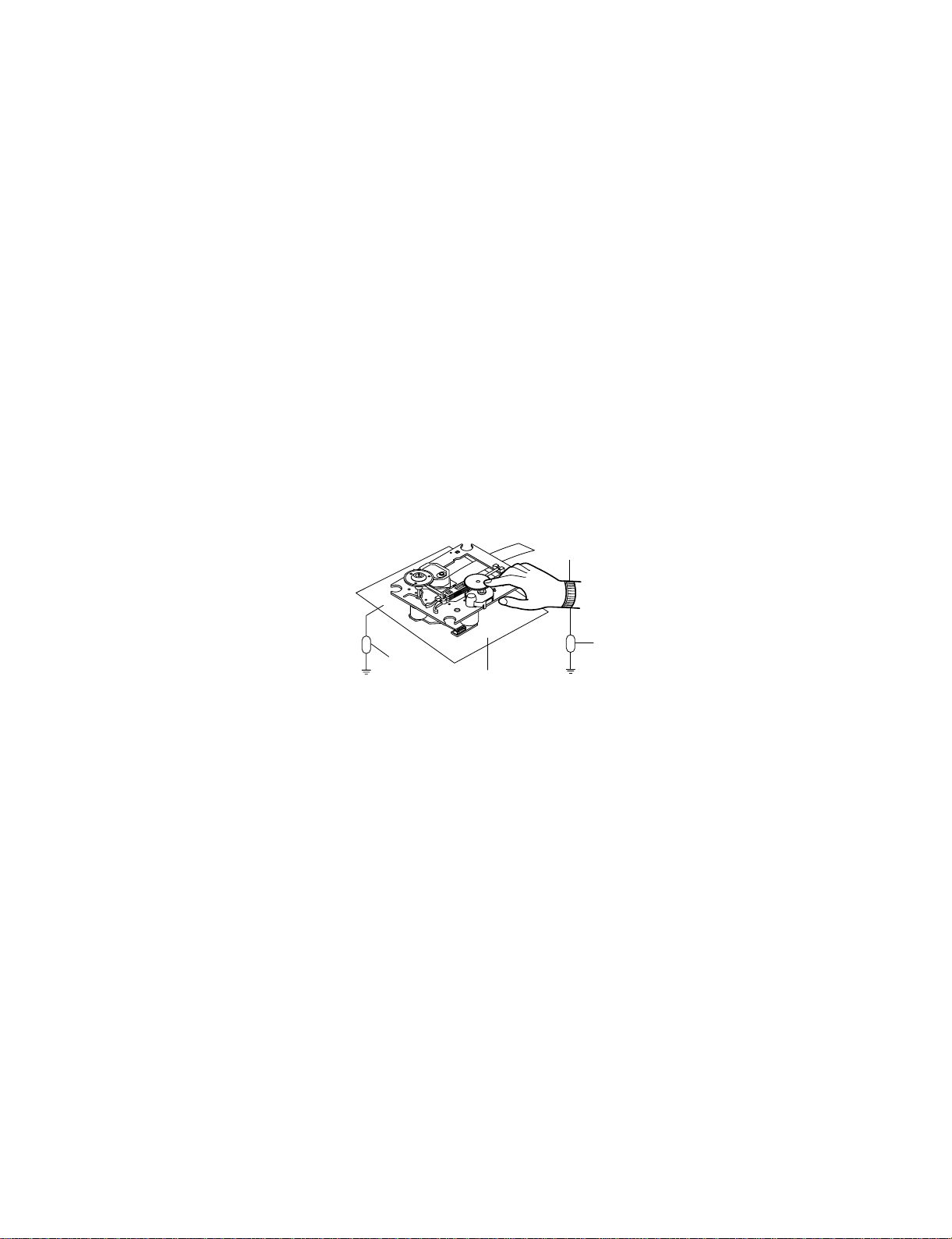

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Resistor

(1 Mohm)

Conductive

Sheet

Resistor

(1 Mohm)

Armband

1-4

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALLOTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNELTO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINTWITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

SERVICE INFORMATION FOR EEPROM

POWER ON

DVD LOGO Status (NO Disk status)

Remotecontrol

Pause key-->1-->4-->7-->2 in order.

Press number 0~9, Press charater

A~F (1~6 for a while)

Use arrow key ( ) to

move to approprite position and

make changes

Press pause key once

Change will be applied when power

OFF-->ON.

* OPTION

• NTSC model doesn’t have VCR option and use DVD option B~F as VCR option. (only DVD exist)

• PAL model has another separate VCR option. (Both VCR and DVD exist)

NAME HEX

OPT 1 55

OPT 2 41

OPT 3 40

OPT 4 FF

OPT 5 52

OPT 6 05

OPT 7 F8

OPT 8 31

OPT 9 0C

OPT A 00

OPT B 00

OPT C 00

OPT D 00

OPT E 00

OPT F 00

OPT G 00

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

* Refer to page 6-1.

1-6

SPECIFICATIONS

GENERAL

Power supply Refer to main label

Power consumption Refer to main label

Net Weight 3.9 kg

External dimensions (W x H x D) 430 x 57 x 295 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

CD/DVD

Laser Semiconductor laser, wavelength 650 nm

Signal system PAL 625/50, NTSC 525/60

Frequency response (audio) 150 Hz to 18 kHz

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, NOP -6 dB, 20 kHz LPF/A-Filter)

Dynamic range (audio) More than 70 dB

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)

VIDEO

Video input 1.0 V (p-p), 75 Ω, negative sync., RCAjack x 1

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1/ SCART (TO TV)

TUNER

FM

Tuning Range 87.5 - 108.0 MHz or 65.0 - 74.0 MHz, 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono)

Frequency Response 140 - 8,000 Hz

AM [MW]

Tuning Range 522 - 1,620 kHz or 520 - 1,720 kHz

Intermediate Frequency 450 kHz

AMPLIFIER(LH-T26’s)

Stereo mode Front: 30 W + 30 W (THD 10 %)

Centre*: 30 W

Surround*: 30 W + 30 W (6Ω at 1 kHz, THD 10 %)

Subwoofer*: 70 W (8Ω at 30 Hz, THD 10 %)

Input AUX IN, MIC

Outputs MONITOR, PHONES: (32 Ω, 1.0 V)

SPEAKERS(LHS-26SG)

Satellite Speaker Passive Subwoofer

Type 1 Way 1 Speaker 1 Way 1 Speaker

Impedance 6 Ω 8 Ω

Frequency Response 130 - 20,000 Hz 50 - 1,500 Hz

Sound Pressure Level 83 dB/W (1m) 82 dB/W (1m)

Rated Input Power 30W 70W

Max. Input Power 60W 140W

Net Dimensions 88 x 100 x 95 mm 160 x 350 x 325 mm

Net Weight 0.54 kg 4.12 kg

(* Depending on the sound mode

settings and the source, there may

be no sound output.)

1-7

SPEAKERS(LHS-26SH)

Satellite Speaker Passive Subwoofer

Type 1 Way 1Speakers 1 Way 1Speaker

Impedance 6 Ω 8 Ω

Frequency Response 130 - 20,000 Hz 50 - 1,500 Hz

Sound Pressure Level 130 - 20,000 Hz 50 - 1,500 Hz

Rated Input Power 30W 70W

Max Input Power 60W 140W

Net Dimensions 88 x 100 x 95 mm 160 x 350 x 325 mm

Net Weight 0.54 kg 4.12 kg

SPEAKERS(LHS-26SQ)

Satellite Speaker Passive Subwoofer

Type 1 Way 1 Speaker 1 Way 1 Speaker

Impedance 6 Ω 8 Ω

Frequency Response 130 - 20,000 Hz 50 - 1,500 Hz

Sound Pressure Level 83 dB/W (1m) 82 dB/W (1m)

Rated Input Power 30W 70W

Max. Input Power 60W 140W

Net Dimensions 88 x 100 x 95 mm 160 x 350 x 325 mm

Net Weight 0.54 kg 4.12 kg

2-1

SECTION 2. AUDIO PART

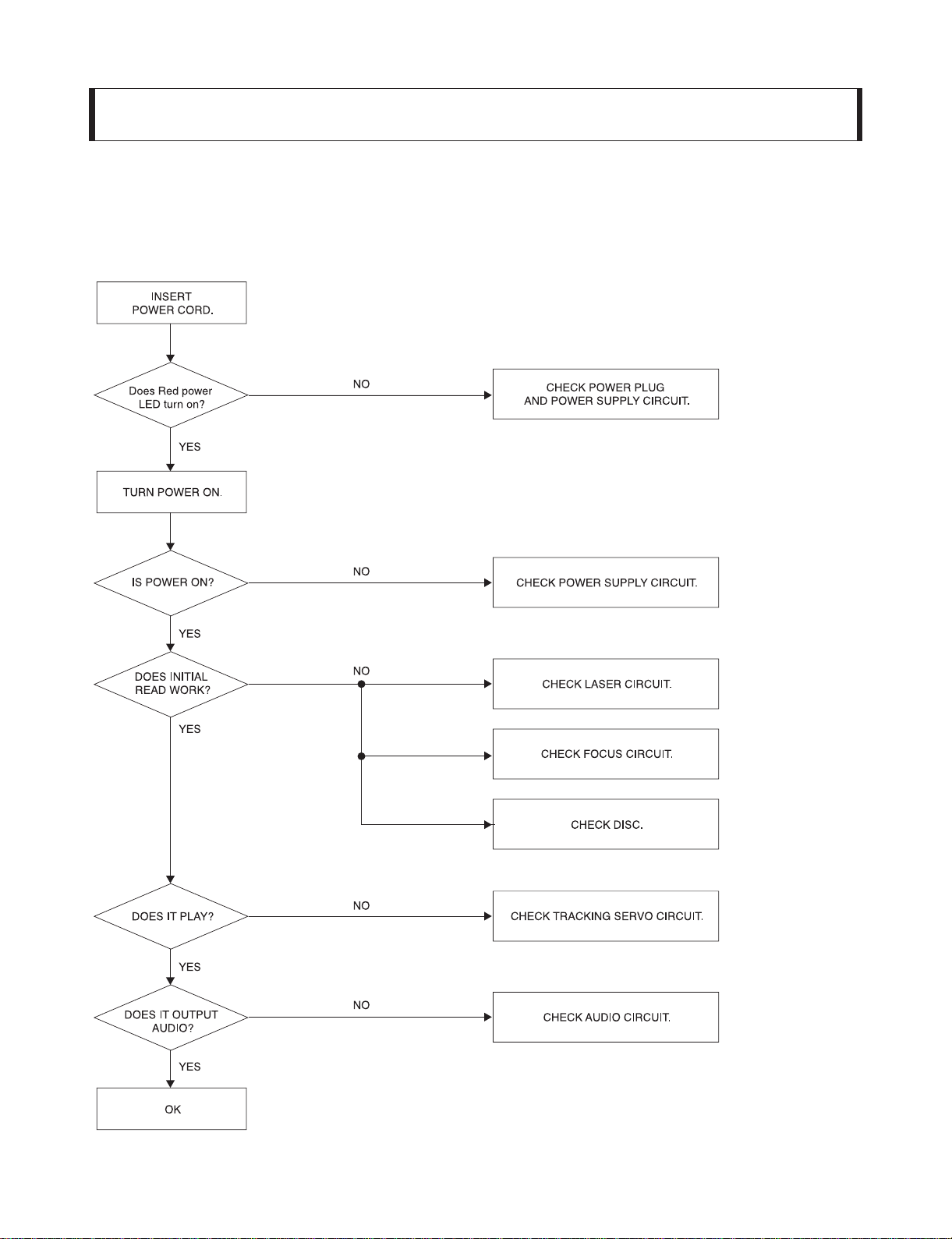

AUDIO TROUBLESHOOTING GUIDE

1. POWER SUPPLY CIRCUIT

2-2

2. FRONT CIRCUIT (1/2)

THE P1301 IS OK?

CHECK IF

CHECK IF

THE DIS301 IS OK?

P1301

Short 1pin of CN901 with 4pin of CN901 in SMPS part.

PIN1

PIN2

PIN3

PIN12

: -41 VKK

: -22 FL+

: -26.5 FL-

: +5.0

2-3

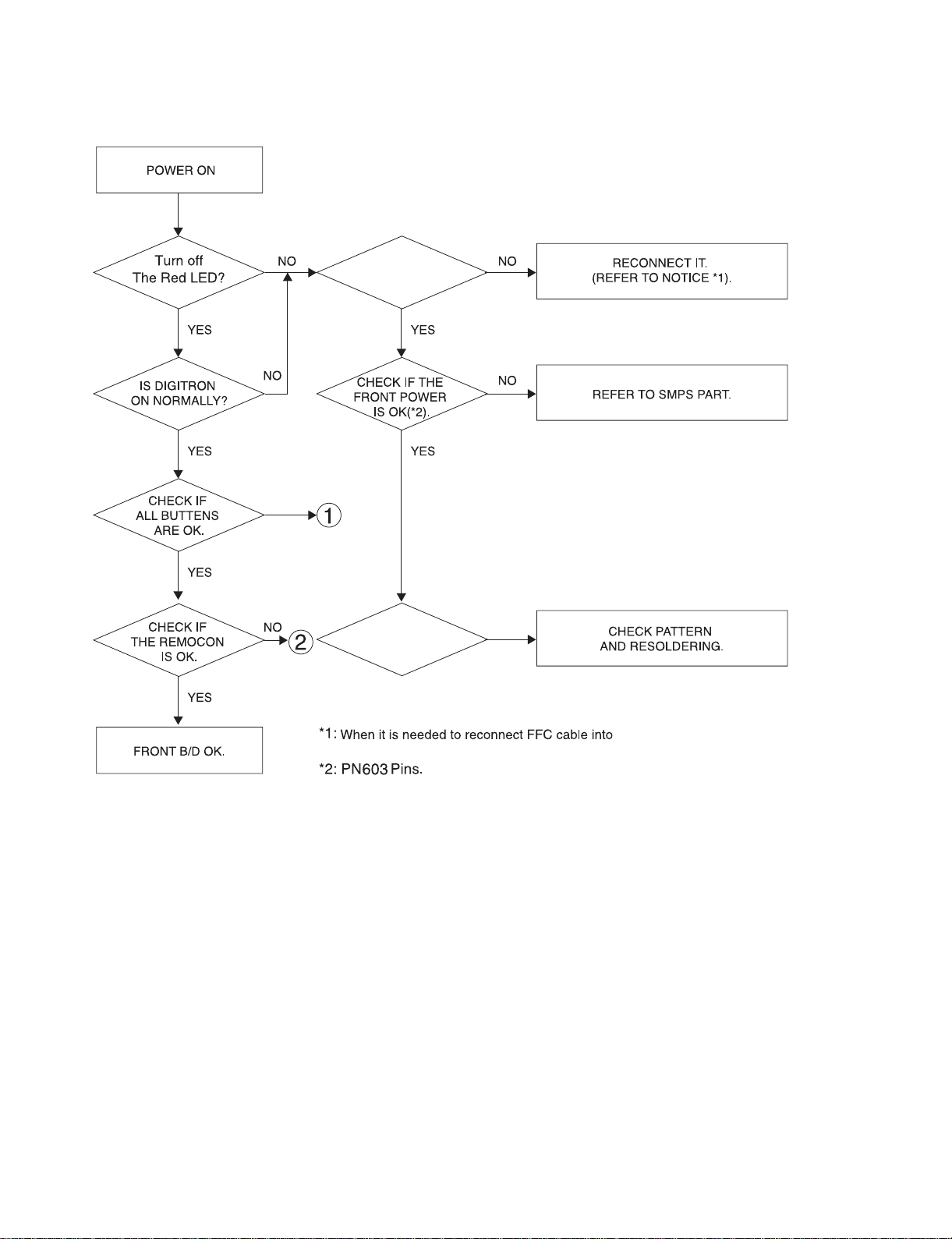

3. FRONT CIRCUIT (2/2)

CHECK IF

R345 ~ R350, R154

OK.

REPLACE

R345 ~ R350, R154.

Check if

the Remocon

waceform of the

P3101 pin 10

is OK

Check if

the RM301

voltage is OK(5V)

Resoldering or

Replace RM301

2-4 2-5

WIRING DIAGRAM

2-6 2-7

BLOCK DIAGRAM

2-8 2-9

CIRCUIT DIAGRAMS

1. SMPS(POWER) CIRCUIT DIAGRAM

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

NOTE) Warning

NOTE) Parts that are shaded are critical

NOTE) With respect to risk of fire or

NOTE) electricial shock.

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

2-10 2-11

2. POWER INTERFACE CIRCUIT DIAGRAM

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

2-12 2-13

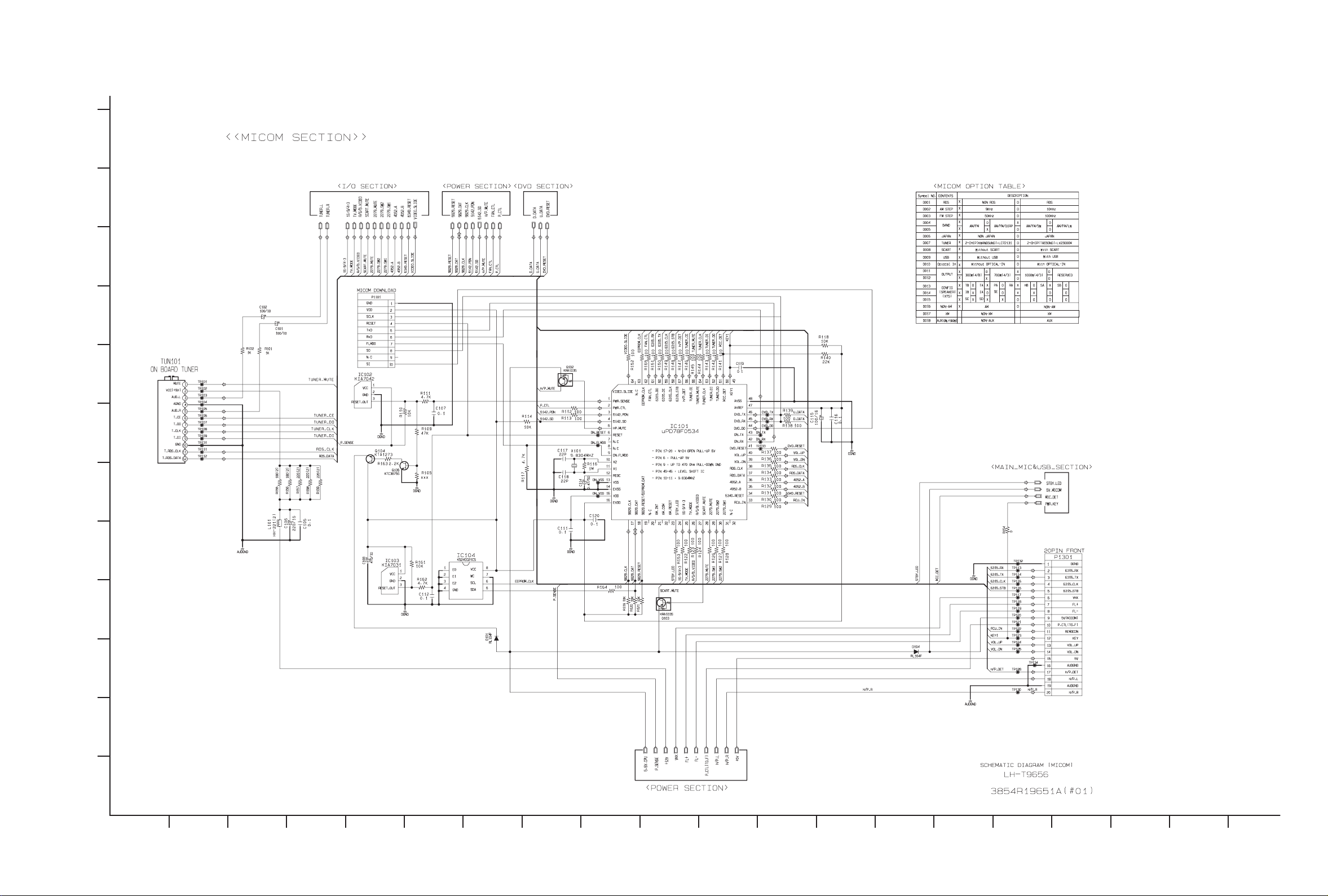

3. µ-COM(MAIN) CIRCUIT DIAGRAM

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

2-14 2-15

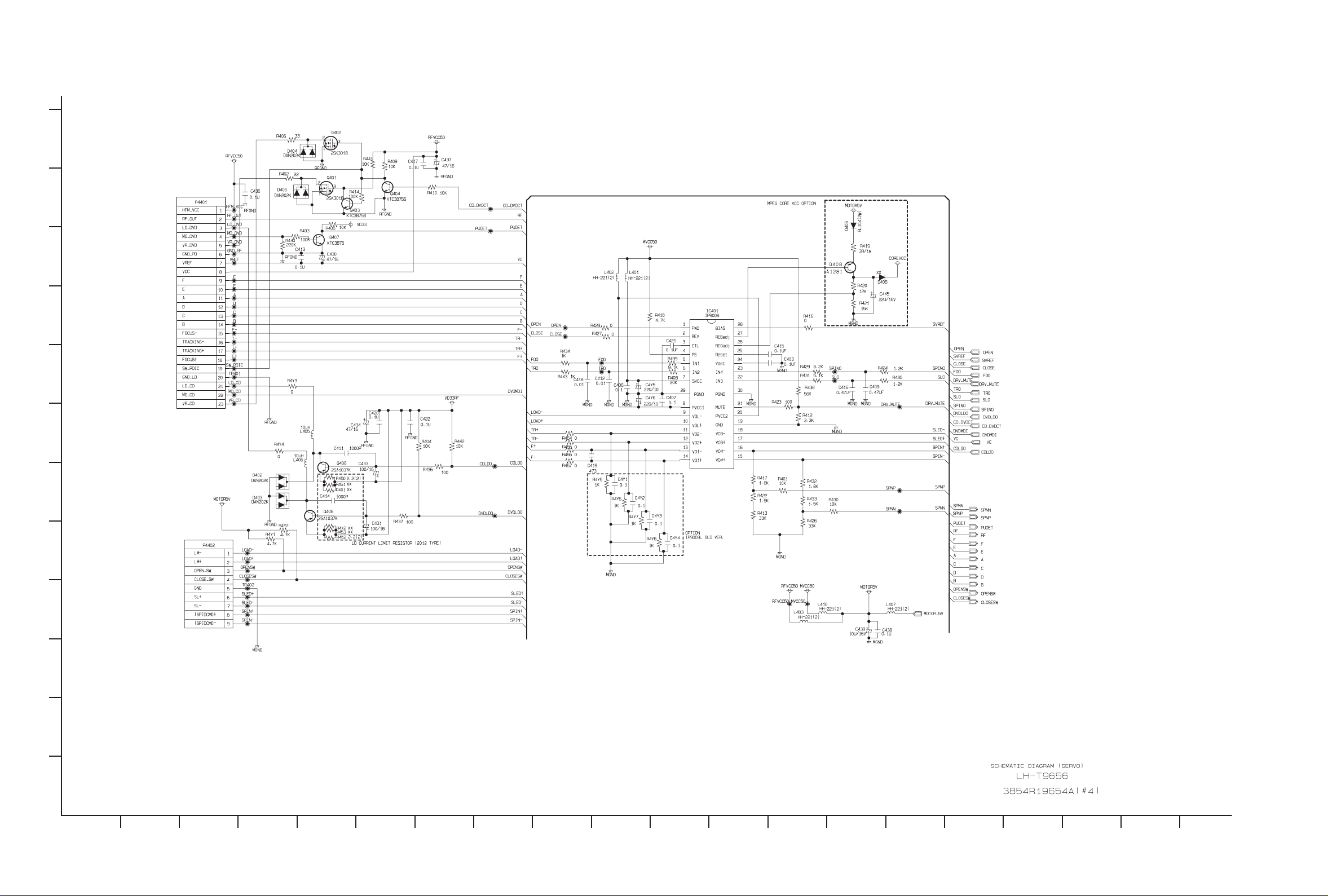

4. SERVO CIRCUIT DIAGRAM

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

2-16 2-17

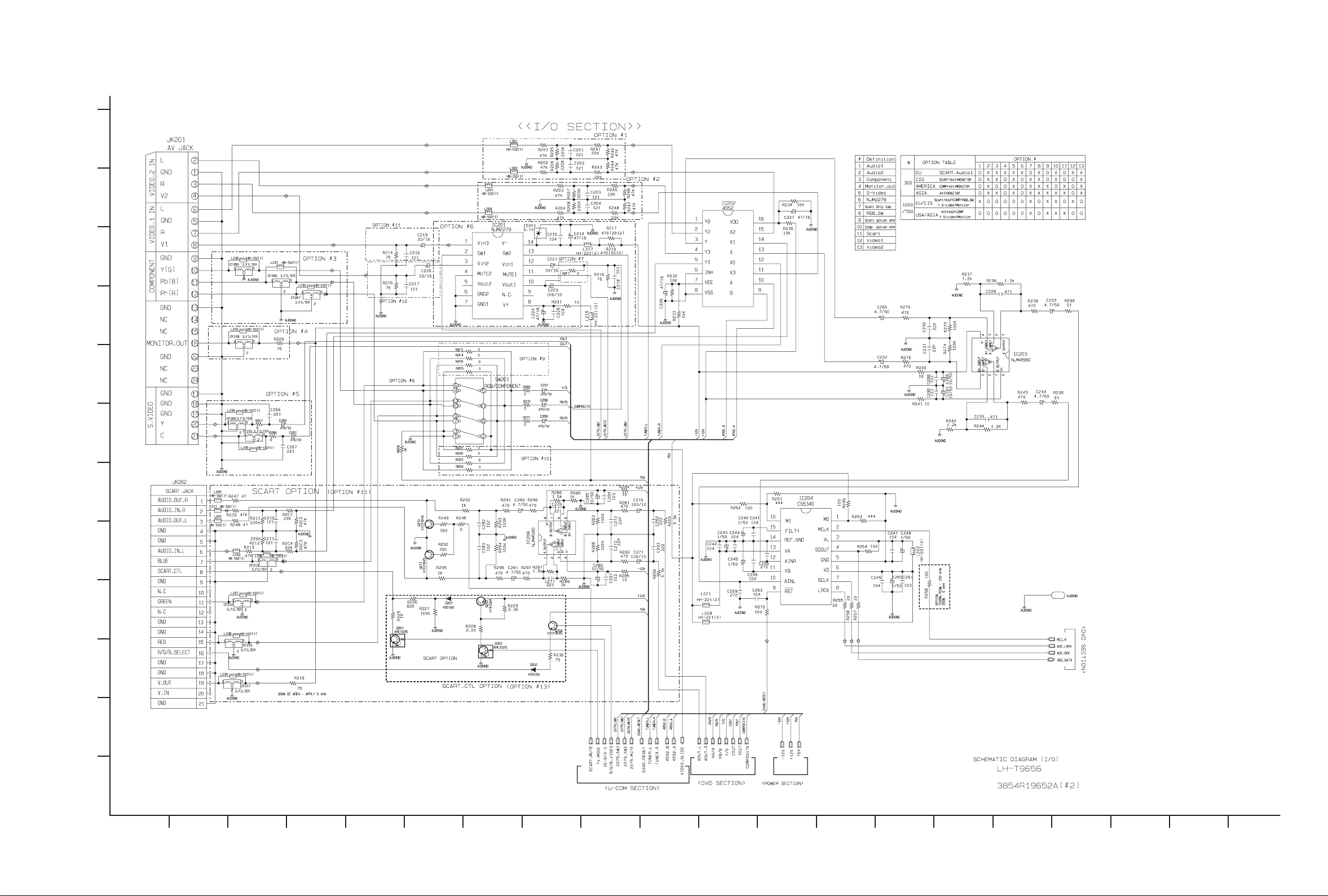

5. I/O CIRCUIT DIAGRAM

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

2-18 2-19

6. MIC CIRCUIT DIAGRAM

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Loading...

Loading...