Page 1

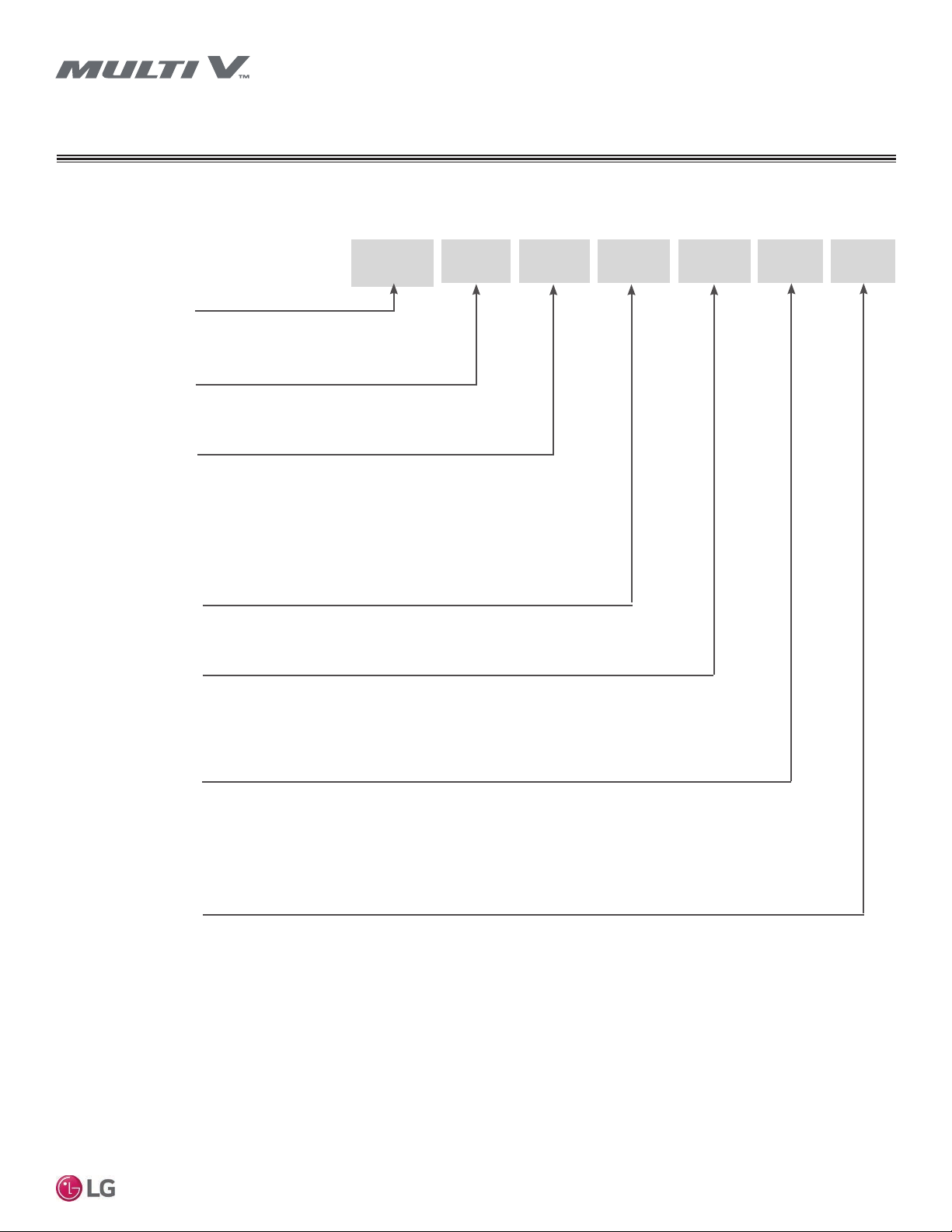

DUCTED INDOOR UNITS

INSTALLATION MANUAL

ARNU073BGA4

ARNU093BGA4

ARNU123BGA4

ARNU153BGA4

ARNU183BGA4

ARNU243BGA4

ARNU283BGA4

ARNU363BGA4

ARNU423BGA4

High-Static Ducted Indoor Units

ARNU283BRA4

ARNU363BRA4

ARNU423BRA4

ARNU483BRA4

ARNU543BRA4

ARNU363B8A4

ARNU423B8A4

ARNU483B8A4

ARNU763B8A4

ARNU963B8A4

Low-Static Ducted Indoor Units

ARNU073BHA4

ARNU093BHA4

ARNU123BHA4

ARNU153BHA4

ARNU183BHA4

ARNU243BHA4

Built-In Ducted Indoor Units

ARNU073B3G4

ARNU093B3G4

ARNU123B3G4

Vertical Air Handler

Indoor Units

ARNU123NJA4

ARNU183NJA4

ARNU243NJA4

ARNU153B3G4

ARNU183B4G4

ARNU243B4G4

ARNU073L1G4

ARNU093L1G4

ARNU123L2G4

ARNU153L2G4

ARNU183L2G4

ARNU243L3G4

ARNU303NJA4

ARNU363NJA4

ARNU423NKA4

ARNU483NKA4

ARNU543NKA4

Page 2

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information, and other

materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc., only in confidence.

Do not throw away, destroy, or lose this manual.

Please read carefully and store in a safe place for future reference.

Content familiarity required for proper installation.

The instructions included in this manual must be followed to prevent prod-

uct malfunction, property damage, injury, or death to the user or other

people. Incorrect operation due to ignoring any instructions will cause

harm or damage. A summary of safety precautions begins on page 4.

For more technical materials such as submittals, engineering

databooks, and catalogs, visit www.lghvac.com.

IM_MultiV_Ducted_IDU_5_16

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

©LG Electronics U.S.A., Inc.

This document, as well as all reports, illustrations, data, information, and other materials are the property of LG Electronics U.S.A., Inc.

Page 3

TABLE OF CONTENTS

Safety Instructions .........................................................................4

Introduction ....................................................................................9

Unit Nomenclature ....................................................................... 11

R410A Refrigerant .......................................................................12

General Data ...............................................................................13

Specications − High-Static BH Chassis ........................................... 13

Specications − High-Static BG Chassis ........................................... 14

Specications − High-Static BG Chassis ........................................... 15

Specications − High-Static BR/B8 Chassis...................................... 16

Specications − Low-Static B3/B4 Chassis ....................................... 18

Specications − Low-Static Ducted L1/L2/L3 Chassis ...................... 19

Specications − Vertical Air Handler NJ Chassis ............................... 20

Specications − Vertical Air Handler NK Chassis .............................. 21

Electrical − High-Static BH/BG/BR/B8 Chassis ................................. 22

Electrical − Low-Static Built-In B3/B4 Chassis .................................. 23

Electrical − Low-Static Ducted L1/L2/L3 Chassis .............................. 24

Dimensions – High-Static Ducted BH Chassis .................................. 25

Dimensions – High-Static Ducted BG Chassis .................................. 26

Dimensions – High-Static Ducted BR Chassis .................................. 27

Dimensions – High-Static Ducted B8 Chassis ................................... 28

Dimensions – Built-In Low-Static Ducted B3/B4 Chassis .................. 29

Dimensions – Low-Static Ducted L1/L2/L3 Chassis .......................... 30

Dimensions – Vertical Air Handler NJ Chassis .................................. 31

Dimensions – Vertical Air Handler NK Chassis.................................. 32

Refrigerant Piping Diagrams ............................................................. 33

Power and Control Wiring ............................................................46

Overview ............................................................................................ 46

Indoor Unit Communication Cable Connections ................................ 47

Indoor Unit Power Cable Connections .............................................. 50

DIP Switch Settings for Gen4 Equipment .......................................... 52

High-Static Ducted BH Chassis ......................................................... 53

High-Static Ducted BG Chassis ......................................................... 55

High-Static Ducted BR Chassis ......................................................... 57

High-Static Ducted B8 Chassis ......................................................... 59

Low-Static Ducted L1 Chassis ........................................................... 61

Low-Static Ducted L2/L3 Chassis ...................................................... 63

Low-Static Built-In B3/B4 Chassis ..................................................... 65

Vertical Air Handler NJ Chassis ......................................................... 67

Vertical Air Handler NK Chassis ........................................................ 69

Optional Wall-Mounted Sensor and Controller .................................. 71

Controls Setup .............................................................................72

Installation Checklist .................................................................... 76

Installation Manual

General Installation Guidelines ....................................................34

Installation ...................................................................................35

Install Ducted IDU Chassis ................................................................ 35

Indoor Unit Dimensions ..................................................................... 36

Duct Connection Dimensions ............................................................ 37

Maintenance Clearances ................................................................... 38

Piping Connections ............................................................................ 39

Refrigerant Piping ........................................................................40

Condensate Piping ......................................................................44

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

3

Page 4

SAFETY INSTRUCTIONS

WARNING

DANGER

WARNING

CAUTION

DANGER

The instructions below must be followed to prevent product malfunction, property damage, injury or death to the user or other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness is classified by the symbols below.

TABLE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Note:

This symbol Indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

INSTALLATION

Don’t use or store ammable gas or combustibles near the unit.

There is risk of re, explosion, and physical injury or death.

Do not install, remove, or re-install the unit by yourself

(end-user). Ask the dealer or an an LG trained service

provider to install the unit.

Improper installation by the user may result in water leakage, re,

explosion, electric shock, physical injury or death.

Multi V Ducted Indoor Units

For replacement of an installed unit, always contact an

LG trained service provider.

There is risk of re, electric shock, explosion, and physical injury or death.

The outdoor unit is shipped with refrigerant and the service

valves closed. Do not open service valves on the unit until

all non-condensibles have been removed from the piping

system and authorization has been obtained from the commissioning agent.

There is a risk of physical injury or death.

Do not run the compressor with the service valves

closed.

There is risk of explosion, physical injury, or death.

Periodically check that the outdoor unit is not damaged.

There is risk of explosion, physical injury, or death.

Replace all control box and panel covers.

If cover panels are not installed securely, dust, water and animals may

enter the unit, causing re, electric shock, and physical injury or death.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Exposure to high concentration levels of refrigerant gas may lead to

illness or death.

4

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Do not install the unit using defective hanging, attaching,

or mounting hardware.

There is risk of physical injury or death.

Wear protective gloves when handling equipment.

Sharp edges may cause personal injury.

Dispose of the packing materials safely.

• Packing materials, such as nails and other metal or wooden parts

may cause puncture wounds or other injuries.

• Tear apart and throw away plastic packaging bags so that children

may not play with them and risk suffocation and death.

Do not install the unit in any location exposed to open

ame or extreme heat. Do not touch the unit with wet hands.

There is risk of re, electric shock, explosion, and physical injury or death.

Install the unit considering the potential for earthquakes.

Improper installation may cause the unit to fall, resulting in physical

injury or death.

Do not change the settings of the protection devices.

If the pressure switch, thermal switch, or other protection device is

shorted and forced to operate improperly, or parts other than those

specied by LG are used, there is risk of re, electric shock, explosion,

and physical injury or death.

If the air conditioner is installed in a small space, take measures to prevent the refrigerant concentration from exceeding safety limits in the event of a refrigerant leak.

Consult the latest edition of ASHRAE (American Society of Heating,

Refrigerating, and Air Conditioning Engineers) Standard 15. If the refrigerant leaks and safety limits are exceeded, it could result in personal

Page 5

SAFETY INSTRUCTIONS

CAUTION

INSTALLATION – CONTINUED

injuries or death from oxygen depletion.

Be very careful when transporting the product.

• Do not attempt to carry the product without assistance.

• Some products use polypropylene bands for packaging. Do not use polypropylene bands to lift the unit.

• Suspend the unit from the base at specified positions.

• Support the unit at a minimum of four points to avoid slippage from rigging apparatus.

• Failure to follow these directions may result in minor or moderate physical injury.

Note:

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated pipe can generate condensate that

may drip and cause a slippery oor condition and/or water damage to

walls.

When installing the unit in a hospital, mechanical room, or

similar electromagnetic eld (EMF) sensitive environment,

provide sufcient protection against electrical noise.

Inverter equipment, power generators, high-frequency medical equipment, or radio communication equipment may cause the air conditioner to

operate improperly. The unit may also affect such equipment by creating

electrical noise that disturbs medical treatment or image broadcasting.

Do not use the product for special purposes such as preserving foods, works of art, wine coolers, or other precision

air conditioning applications. This equipment is designed to

provide comfort cooling and heating.

There is risk of property damage.

Do not make refrigerant substitutions. Use R410A only.

If a different refrigerant is used, or air mixes with original refrigerant, the

unit will malfunction and become damaged.

Do not install the unit in a noise sensitive area.

When connecting refrigerant tubing, remember to allow for

pipe expansion.

Improper piping may cause refrigerant leaks and system malfunction.

Take appropriate actions at the end of HVAC equipment life

to recover, recycle, reclaim or destroy R410A refrigerant according to applicable U.S. Environmental Protection Agency

(EPA) rules.

Periodically check that the outdoor unit is not damaged.

There is a risk of equipment damage.

Install the unit in a safe location where no one can step on or

fall onto it.

attaching, or mounting hardware.

Do not install the unit with defective hanging,

There is risk of unit and property damage.

Install the drain hose to ensure adequate drainage.

There is a risk of water leakage and property damage.

Don’t store or use ammable gas/combustibles near the

unit.

There is risk of product failure.

Always check for system refrigerant leaks after the unit has

been installed or serviced.

Low refrigerant levels may cause product failure

The unit is shipped with refrigerant and the service valves

closed.

non-condensibles have been removed from the piping system and authorization to do so has been obtained from the

com-missioning agent.

Do not open service valves on the unit until all

There is a risk of refrigerant contamination, refrigerant loss and equipment damage.

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

5

Page 6

SAFETY INSTRUCTIONS

DANGER

WARNING

WIRING

High voltage electricity is required to operate this system.

Adhere to the National Electrical Codes and these

instructions when wiring.

Improper connections and inadequate grounding can cause accidental

injury or death.

Always ground the unit following local, state, and National

Electrical Codes.

The information contained in this manual is intended for use

by an industry-qualied, experienced, trained electrician

familiar with the U.S. National Electric Code (NEC) who is

equipped with the proper tools and test instruments.

Failure to carefully read and follow all instructions in this manual can

result in equipment malfunction, property damage, personal injury or

death.

Ensure the unit is connected to a dedicated power source

that provides adequate power.

If the power source capacity is inadequate or the electric work is not performed properly, it may result in re, electric shock, physical injury or death.

Note:

Do not cut, lengthen or shorten the communications and

power cable between any dry contact unit and its connected

Multi V Ducted Indoor Units

indoor unit. Do not install the unit in a location where the communications and power cable cannot be safely and easily connected between the two units. Do not allow strain on this cable.

Poor cable connections can cause equipment malfunction.

Turn the power off at the nearest disconnect before servicing

the equipment.

Electric shock can cause physical injury or death.

Properly size all circuit breakers or fuses.

There is risk of re, electric shock, explosion, physical injury or death.

Refer to local, state, and federal codes, and use power wires

of sufcient current capacity and rating.

Wires that are too small may generate heat and cause a re.

Secure all eld wiring connections with appropriate wire

strain relief.

Improperly securing wires will create undue stress on equipment power

lugs. Inadequate connections may generate heat, cause a re and

physical injury or death.

Properly tighten all power connections.

Loose wiring may overheat at connection points, causing a re, physical

injury or death.

6

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 7

OPERATION

DANGER

WARNING

CAUTION

Do not provide power to or operate the unit if it is ooded

or submerged.

There is risk of re, electric shock, physical injury or death.

Use a dedicated power source for this product.

There is risk of re, electric shock, physical injury or death.

Do not operate the disconnect switch with wet hands.

There is risk of re, electric shock, physical injury or death.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Avoid excessive cooling and periodically perform ventilation

to the unit.

Inadequate ventilation is a health hazard.

Do not touch refrigerant piping during or after operation.

It can cause burns or frostbite.

Do not operate the unit with the panel(s) or protective

cover(s) removed; keep ngers and clothing away from

moving parts.

The rotating, hot, cold, and high-voltage parts of the unit can cause

physical injury or death.

Periodically check power cable and connection for damage.

Cable must be replaced by the manufacturer, its service agent, or similar

qualied persons in order to avoid physical injury and/or electric shock.

Securely attach the electrical cover to the unit.

Non-secured electrical covers can result in burns or electric shock due to

dust or water in the service panel.

Periodically verify the hanging bolts and other hardware

securing the unit have not deteriorated.

If the unit falls from its installed location, it can cause property damage,

product failure, physical injury or death.

If refrigerant gas leaks out, ventilate the area before operating the unit.

If the unit is mounted in an enclosed, low-lying, or poorly ventilated area

and the system develops a refrigerant leak, it may cause re, electric

shock, explosion, physical injury or death.

Do not open the inlet grille of the unit during operation.

Do not operate the unit with the panels or guards removed.

Do not insert hands or other objects through the inlet or

outlet when the unit is powered. Do not touch the electro-

static lter, if the unit includes one. The unit contains sharp,

rotating, hot, and high voltage parts that can cause personal

injury and/or electric shock.

Ensure no power is connected to the unit other than as

directed in this manual. Remove power from the unit before

removing or servicing the unit.

There is risk of unit failure, re, electric shock, physical injury or death.

Do not open the inlet grille of the unit during operation.

Do not operate the unit with the panels or guards removed.

Do not insert hands or other objects through the inlet or outlet with the unit is plugged in. Do not touch the electrostatic

lter, if the unit includes one.

The unit contains sharp, rotating, hot, and high voltage parts that can

cause personal injury and/or electric shock.

Installation Manual

To avoid physical injury, use caution when cleaning or

servicing the air conditioner.

Note:

Clean up the site after installation is nished, and check

that no metal scraps, screws, or bits of wiring have been left

inside or surrounding the unit.

Do not use this equipment in mission critical or specialpurpose applications such as preserving foods, works of art,

wine coolers or refrigeration. This equipment is designed to

provide comfort cooling and heating.

Provide power to the compressor crankcase heaters at least

six (6) hours before operation begins.

Starting operation with a cold compressor sump(s) may result in severe

bearing damage to the compressor(s). Keep the power switch on during

the operational season.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Do not block the inlet or outlet.

Unit may malfunction.

Securely attach the electrical cover to the indoor unit. Non-

secured covers can result in re due to dust or water in the

service panel.

Periodically verify the equipment mounts have not deteriorated.

If the base collapses, the unit could fall and cause property damage or

product failure.

Do not allow water, dirt, or animals to enter the unit.

There is risk of unit failure.

7

Page 8

Multi V Ducted Indoor Units

8

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 9

Ducted Indoor Units

WARNING

This manual describes how to install LG ducted indoor units (IDU)

for Multi V Variable Refrigerant Flow (VRF) heat pump and heat

recovery systems. Table 1 lists the available models. Refer to LG’s

Multi V Indoor Unit Engineering Manual for complete detailed

engineering data and selection procedures.

Safety

Safety of personnel is the primary concern during all procedures.

Read and understand the safety summary at the front of this manual.

Read and understand this installation procedure before beginning

installation. Use the appropriate tools and accessories during installation. Plan your work and do not work alone, if possible. Know how

to obtain emergency medical and fire fighting assistance.

Installation Personnel

This equipment is intended for installation by personnel trained

in the required construction, mechanical, electrical, and/or other

disciplines.

Applicable Codes

Personnel must be familiar with and follow the applicable national,

state, and/or local codes.

INTRODUCTION

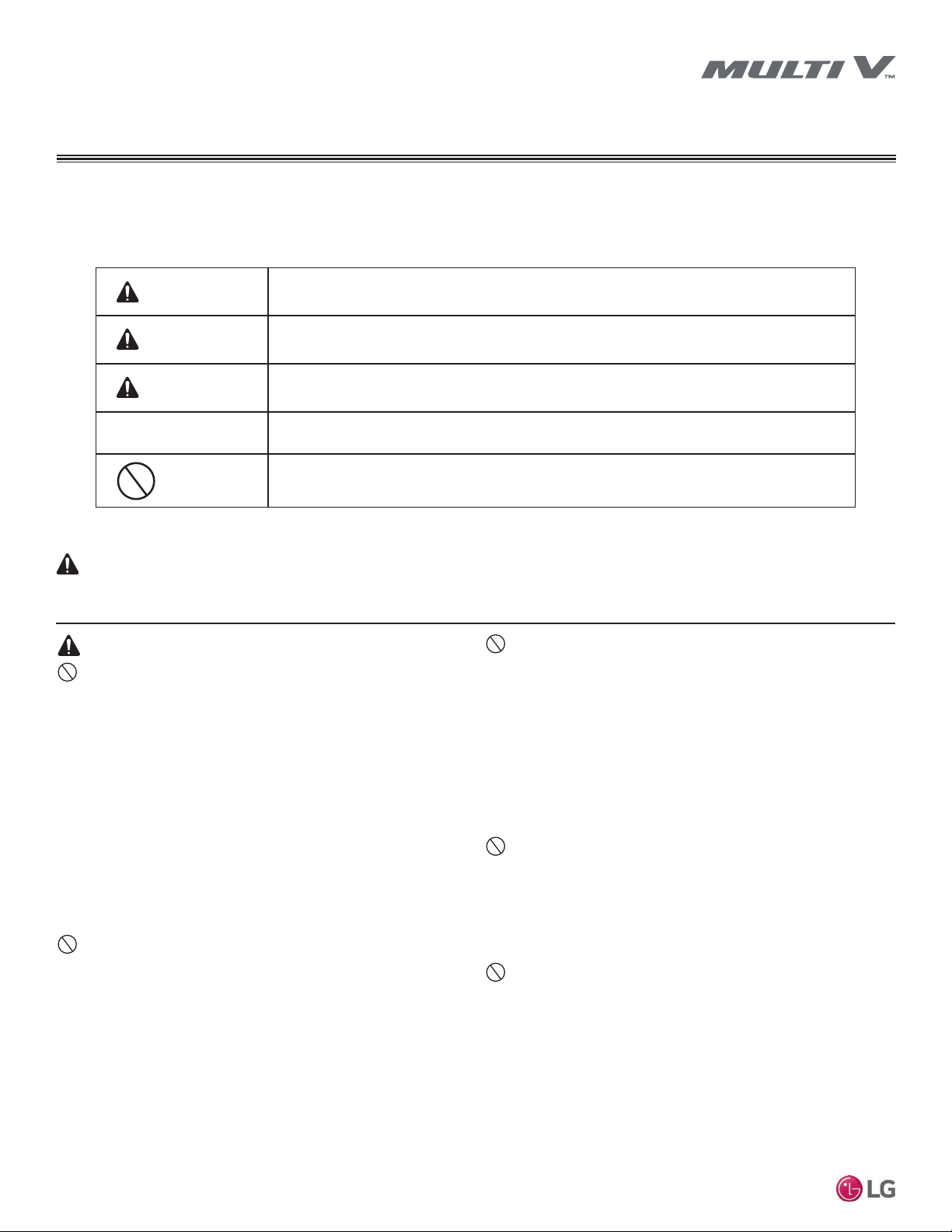

Figure 1: High-Static Ducted, BG/BR/B8/BH Chassis

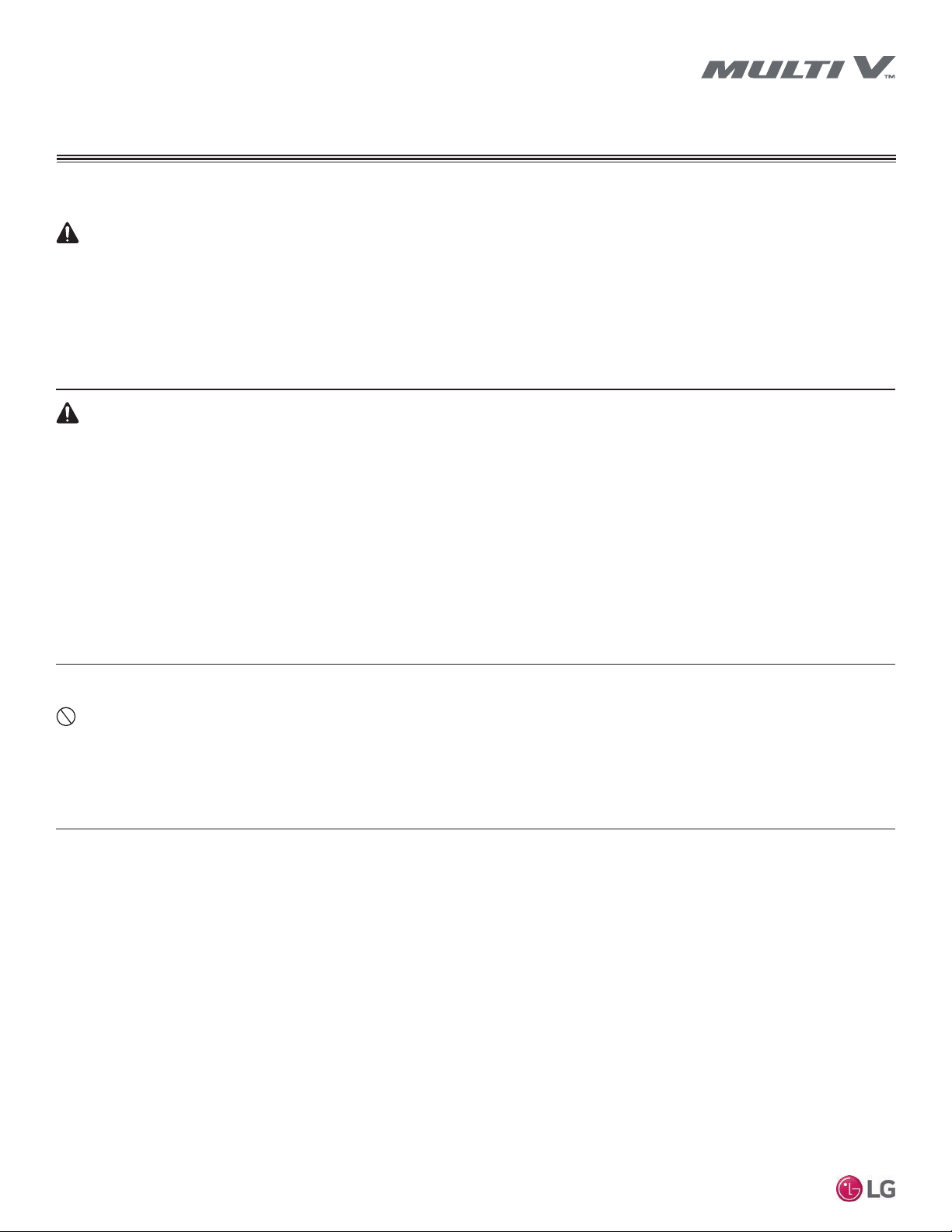

Figure 2: Built-In Ducted, B3/B4 Chassis

Installation Manual

Installation work must be performed by trained personnel and in accordance with national wiring standards and all local or other applicable

codes. Improper installation can result in re, electric shock, physical

injury, or death.

Note:

Please read all instructions before installing this product. Become familiar

with the unit, its components and connections, and the order of installation. Incorrect installation can degrade or prevent proper operation.

Required Tools (field provided)

• Level

• Screwdriver

• Electrical lineman pliers

• Electric drill

• Holesaw

• Drill

• Flaring tool set

• Tubing cutter

• Tube/pipe reamer

• Torque wrenches

• Allen wrench

• Gas-leak detector

• Thermometer

Required Parts (field provided)

• Pipes - vapor line and liquid line, with insulation

• 3/8” or 1/2” nuts, at washers, and lock/split washers

• 3/8” or 1/2” threaded hanger rods

• Insulated drain hose

• Additional drain hose

• Connecting cable (power and control)

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

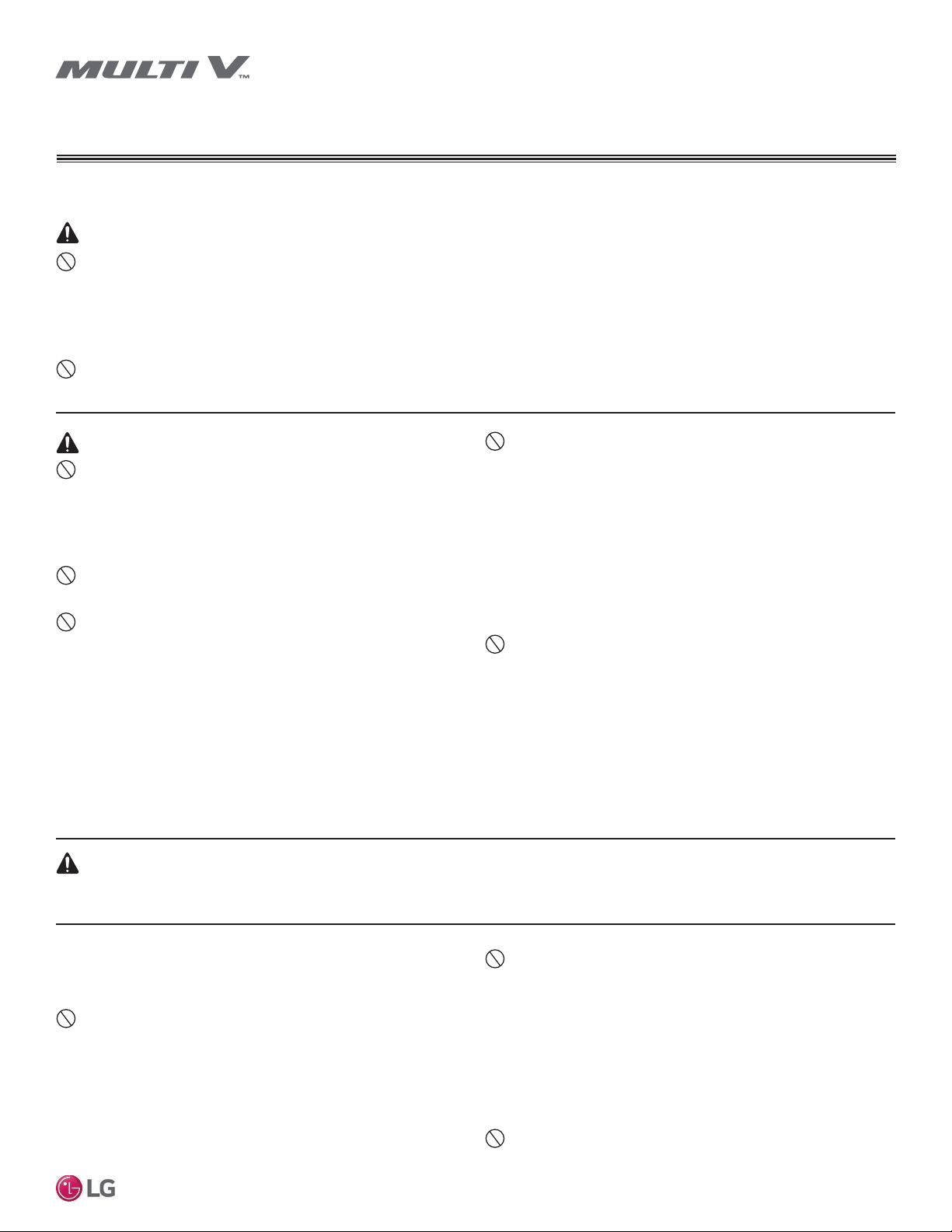

Figure 3: Low-Static Ducted, L1/L2/L3 Chassis

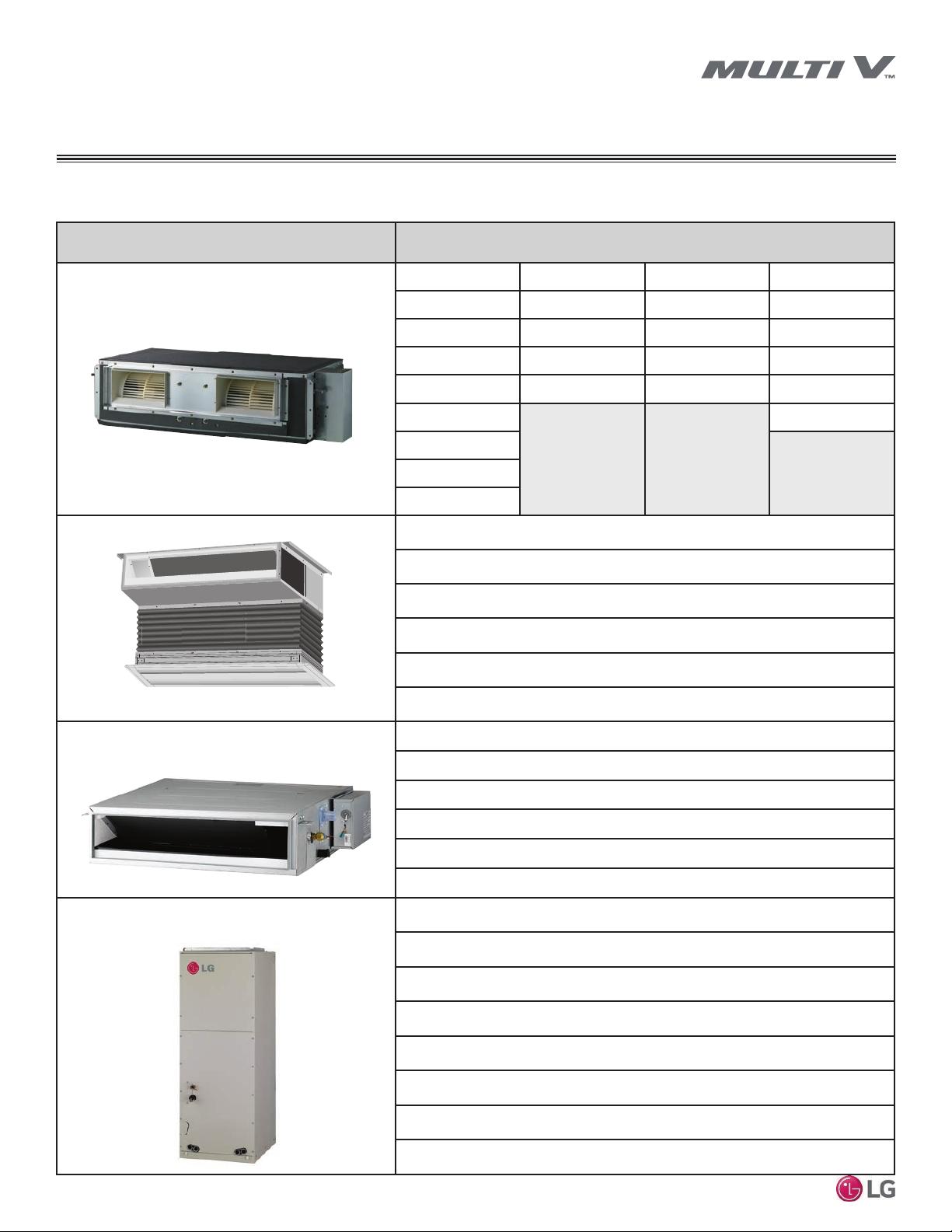

Figure 4: Vertical Air Handler NJ/NK Chassis

9

Page 10

INTRODUCTION

Unit Model Numbers

High-Static Ducted BG/BR/B8

Built-In Ducted B3/B4

Table 1: Multi V Ducted Indoor Units

ARNU073BGA4 ARNU283BRA4 ARNU363B8A4 ARNU073BHA4

ARNU093BGA4 ARNU363BRA4 ARNU423B8A4 ARNU093BHA4

ARNU123BGA4 ARNU423BRA4 ARNU483B8A4 ARNU123BHA4

ARNU153BGA4 ARNU483BRA4 ARNU763B8A4 ARNU153BHA4

ARNU183BGA4 ARNU543BRA4 ARNU963B8A4 ARNU183BHA4

ARNU243BGA4 ARNU243BHA4

ARNU283BGA4

ARNU363BGA4

ARNU423BGA4

ARNU073B3G4

(shown with optional canvas boot and grill)

Multi V Ducted Indoor Units

Low-Static Ducted L1/L2/L3

Vertical Air Handler

ARNU093B3G4

ARNU123B3G4

ARNU153B3G4

ARNU183B4G4

ARNU243B4G4

ARNU073L1G4

ARNU093L1G4

ARNU123L2G4

ARNU153L2G4

ARNU183L2G4

ARNU243L3G4

ARNU123NJA4

ARNU183NJA4

ARNU243NJA4

ARNU303NJA4

ARNU633NJA4

ARNU423NKA4

ARNU483NKA4

ARNU543NKA4

10

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 11

Cassette Indoor Units Nomenclature

UNIT NOMENCLATURE

Family

ARN = Multi V Indoor Unit (Refrigerant R410A)

Type

U = Inverter Heat Pump/Heat Recovery

Nominal Capacity

(Nominal cooling capacity in Btu/h)

07 = 7,500

09 = 9,600

12 = 12,300

15 = 15,400

Electrical Ratings

3 = 208–230V/60Hz/1Phase

Chassis/Model Type

BG = High-Static Ducted

BR = High-Static Ducted

B8 = High-Static Ducted

18 = 19,100

24 = 24,200

28 = 28,000

36 = 36,200

42 = 42,000

48 = 48,000

54 = 54,000

76 = 76,000

B3 = Built-In Ducted

B4 = Built-In Ducted

BH = Built-In Ducted

ARN

96 = 96,000

L1 = Low-Static Ducted

L2 = Low-Static Ducted

L3 = Low-Static Ducted

U 07 3 BG A

NJ = Vertical Air Handler

NK = Vertical Air Handler

4

Installation Manual

Feature

C = Plasma Filter

A = No Plasma Filter

G = Low-Static

Generation

4 = Fourth

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

11

Page 12

R410A REFRIGERANT

WARNING

R410A refrigerant has a higher operating pressure in comparison to R22 refrigerant and, therefore, all piping system materials

installed must have a higher resisting pressure than the materials traditionally used in R22 systems.

R410A refrigerant is an azeotrope of R32 and R125, mixed at 50:50, so the ozone depletion potential (ODP) is 0.

• Do not place the refrigerant cylinder in direct sunlight. Refrigerant cylinder may explode causing severe injury or death.

Note:

• Because R410A is a combination of R32 and R125, the required additional refrigerant must be charged in its liquid state. If the

refrigerant is charged in its gaseous state, its composition changes and the system will not work properly.

• Do not heat piping more than necessary during installation. Piping may become soft and fail when pressurized.

• Do not use any piping that has not been approved for use in high-pressure refrigerant systems. Piping wall thickness must comply

with the applicable local, state, and federal codes for the 551 psi design pressure of R410A. Inadequate piping may fail when

pressurized.

Multi V Ducted Indoor Units

12

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 13

Model No.

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

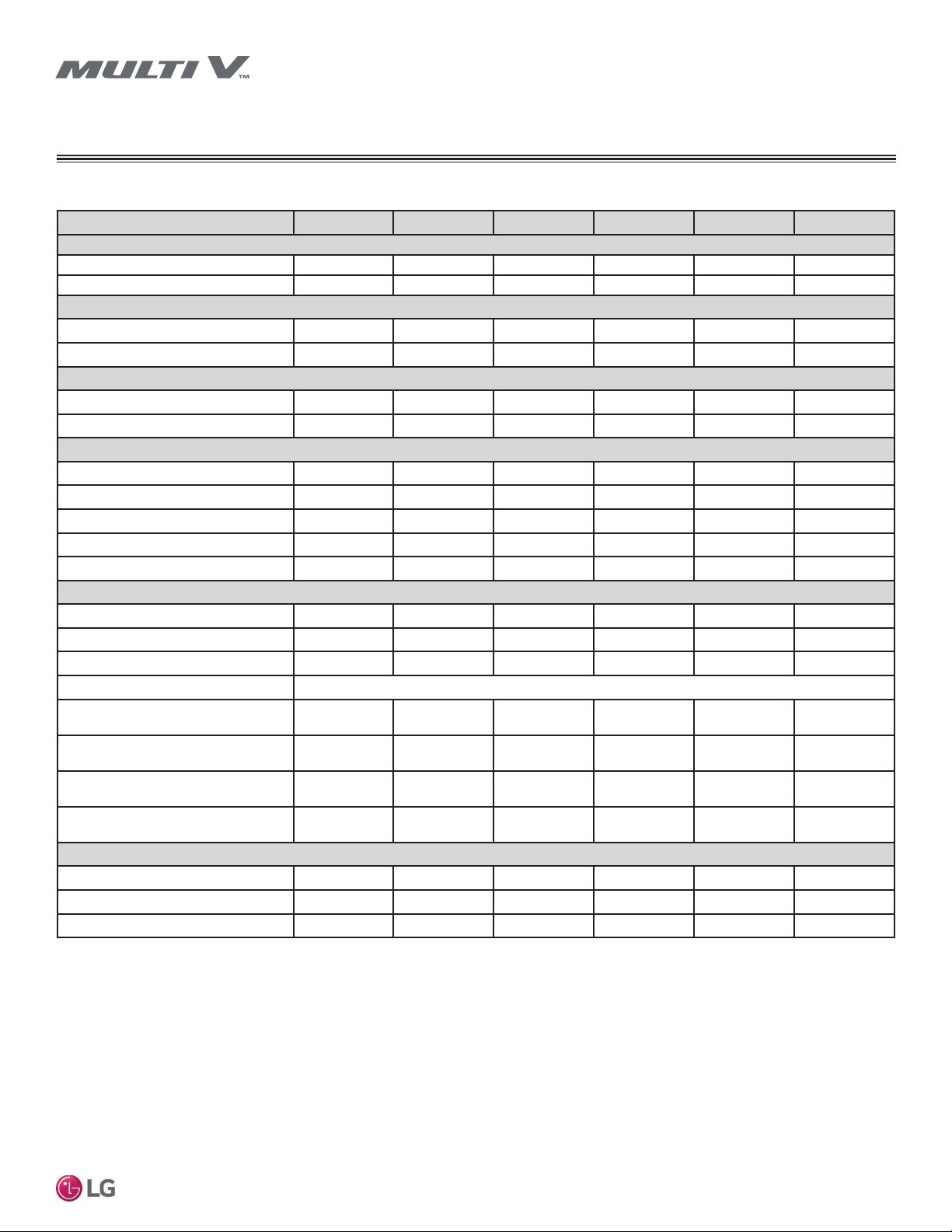

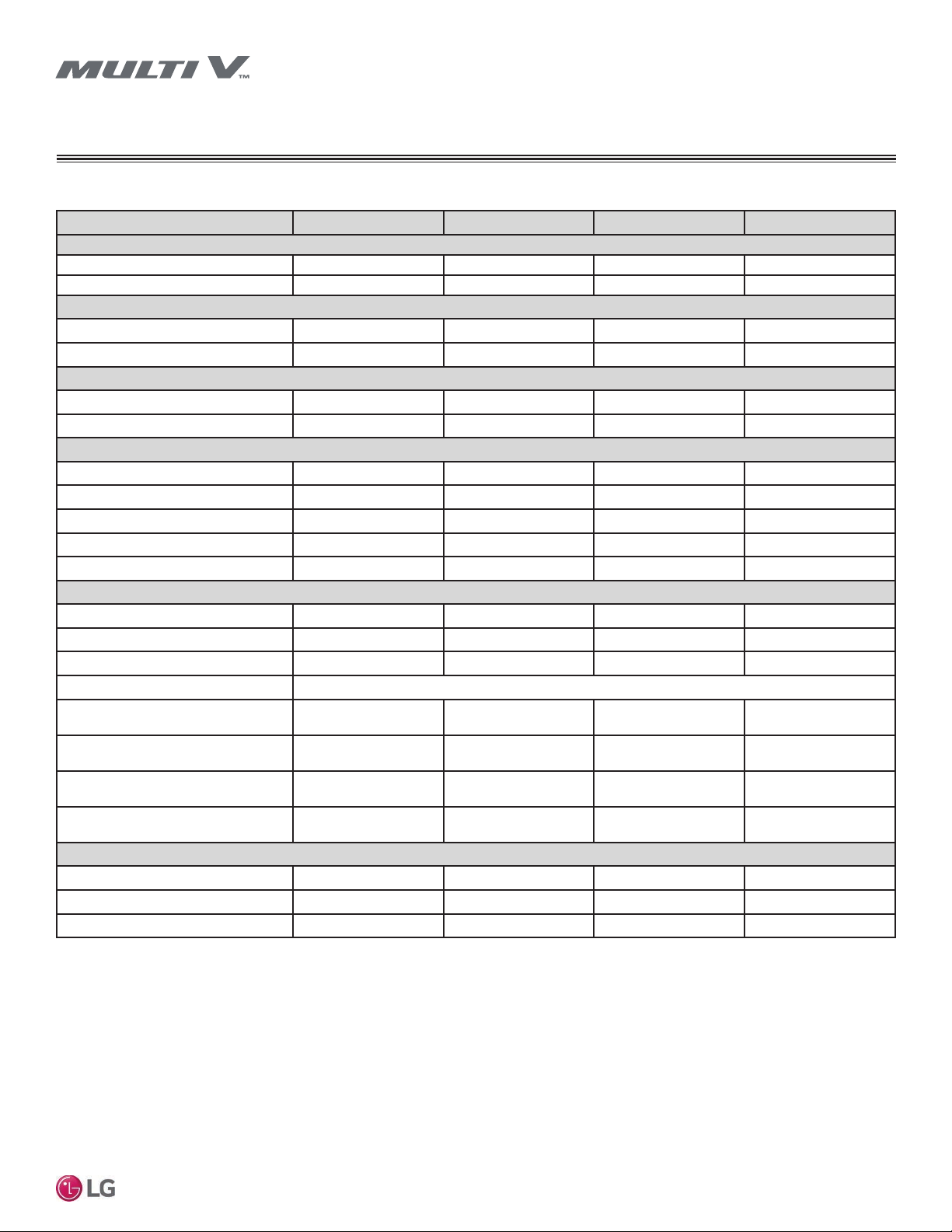

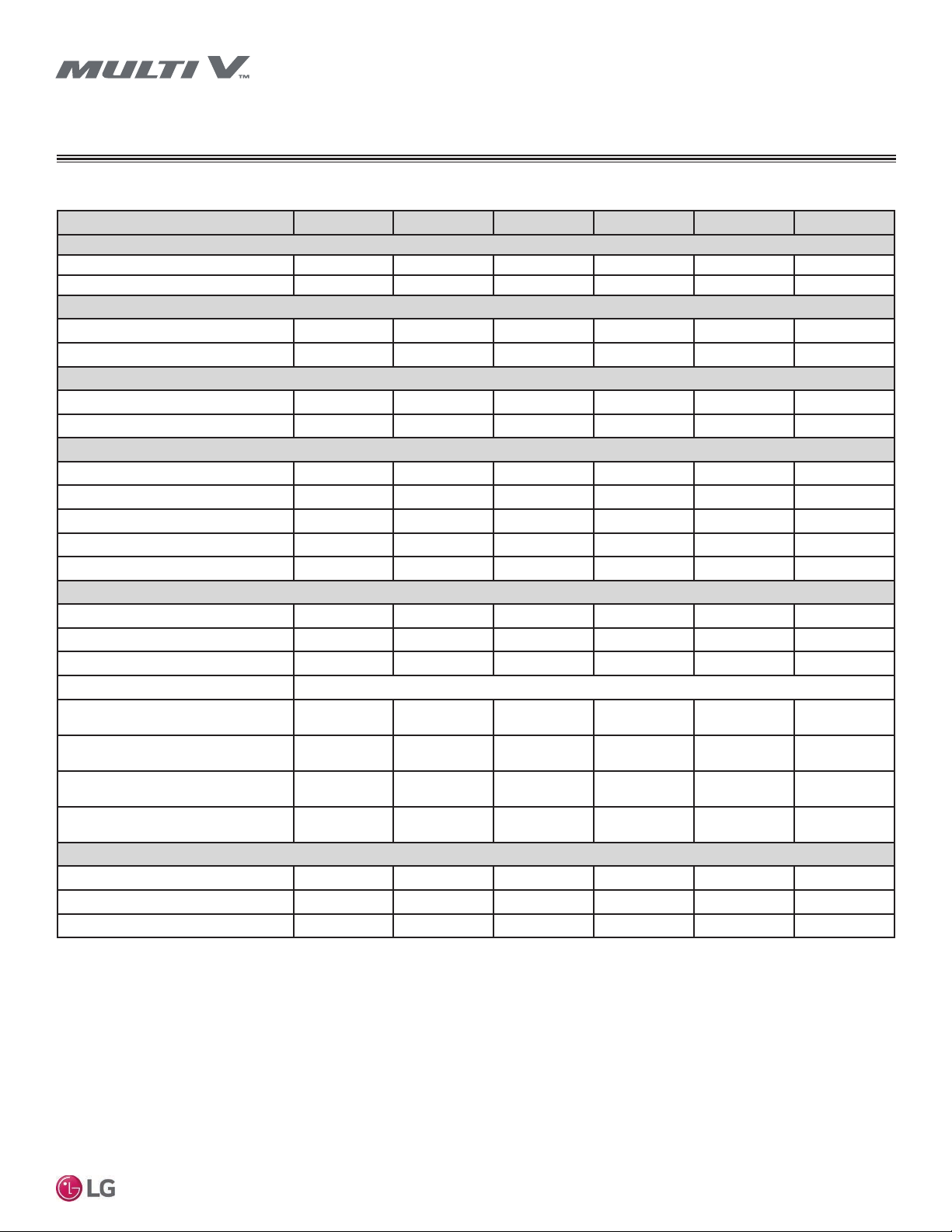

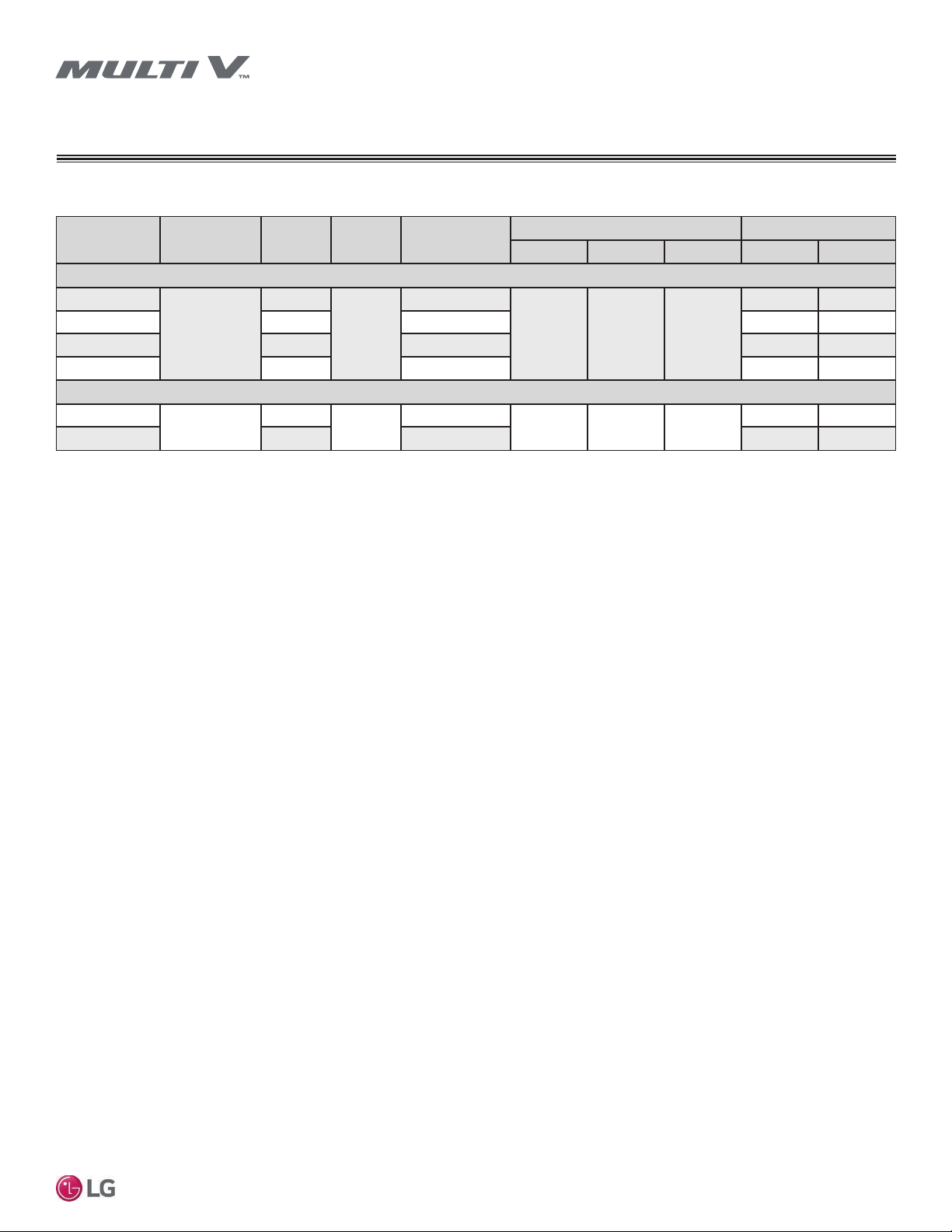

GENERAL DATA

Specications − High-Static BH Chassis

Table 2: High-Static Ducted BH Chassis IDU Specications

ARNU073BHA4 ARNU093BHA4 ARNU123BHA4 ARNU153BHA4 ARNU183BHA4 ARNU243BHA4

7,500 9,600 12,300 15,400 19,100 24,200

150 150 150 150 150 150

8,500 10,900 13,600 17,100 21,500 27,300

150 150 150 150 150 150

76 76 76 76 76 76

59 59 59 59 59 59

R410A R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV EEV

58.4 58.4 58.4 58.4 58.4 58.4

68.3 68.3 68.3 68.3 68.3 68.3

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco Sirocco

1 1 1 1 1 1

2 2 2 2 2 2

Brushless Digitally Controlled / Direct

258 / 222 / 198 258 / 222 / 198 307 / 258 / 198 388 / 357 / 307 466 / 413 / 258 618 / 519 / 445

230 / 205 / 191 286 / 230 / 205 339 / 286 / 230 399 / 339 / 230 459 / 399 / 339 565 / 509 / 459

0.23 0.23 0.23 0.23 0.23 0.23

0.31 0.31 0.31 0.31 0.31 0.31

1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

1 1 1 1 1 1

Installation Manual

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

13

Page 14

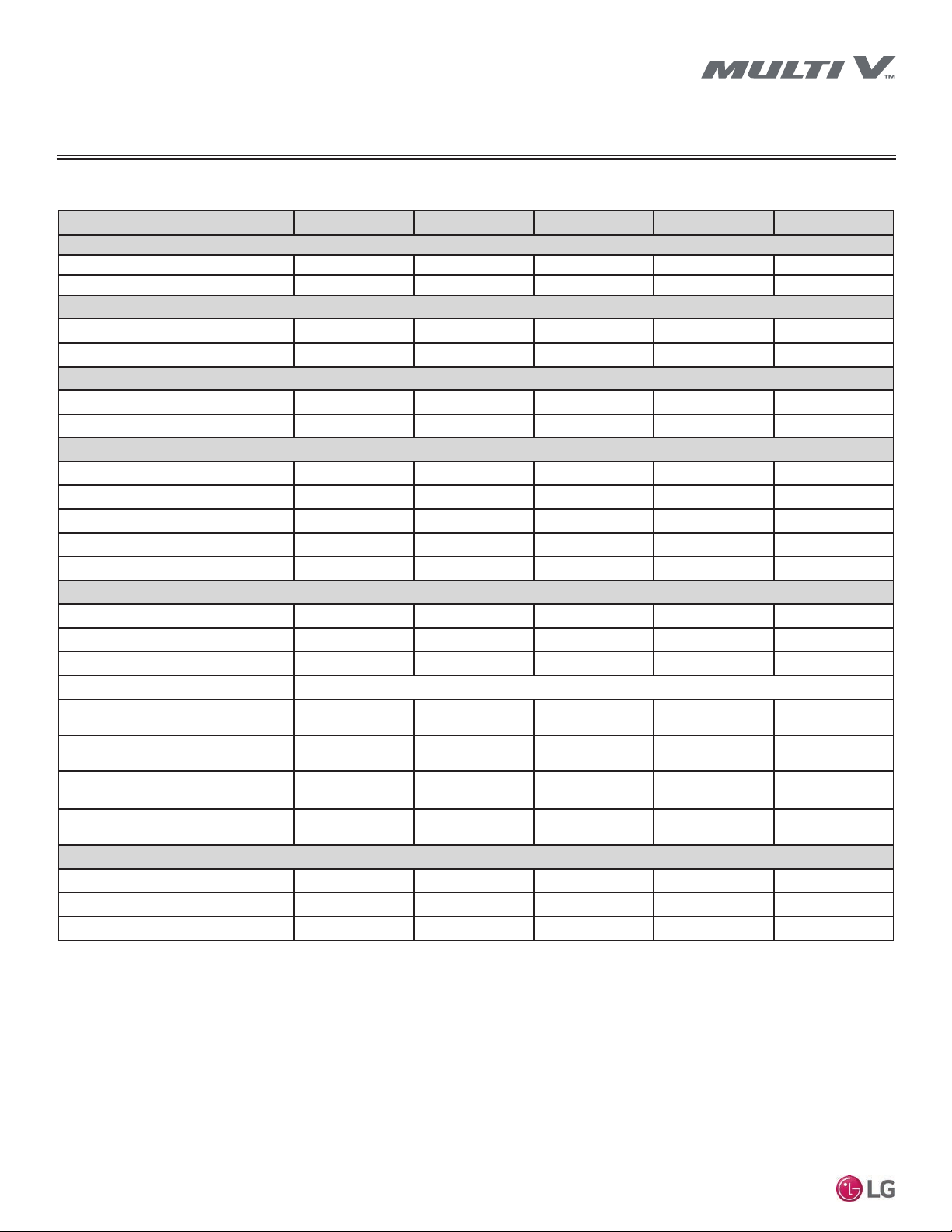

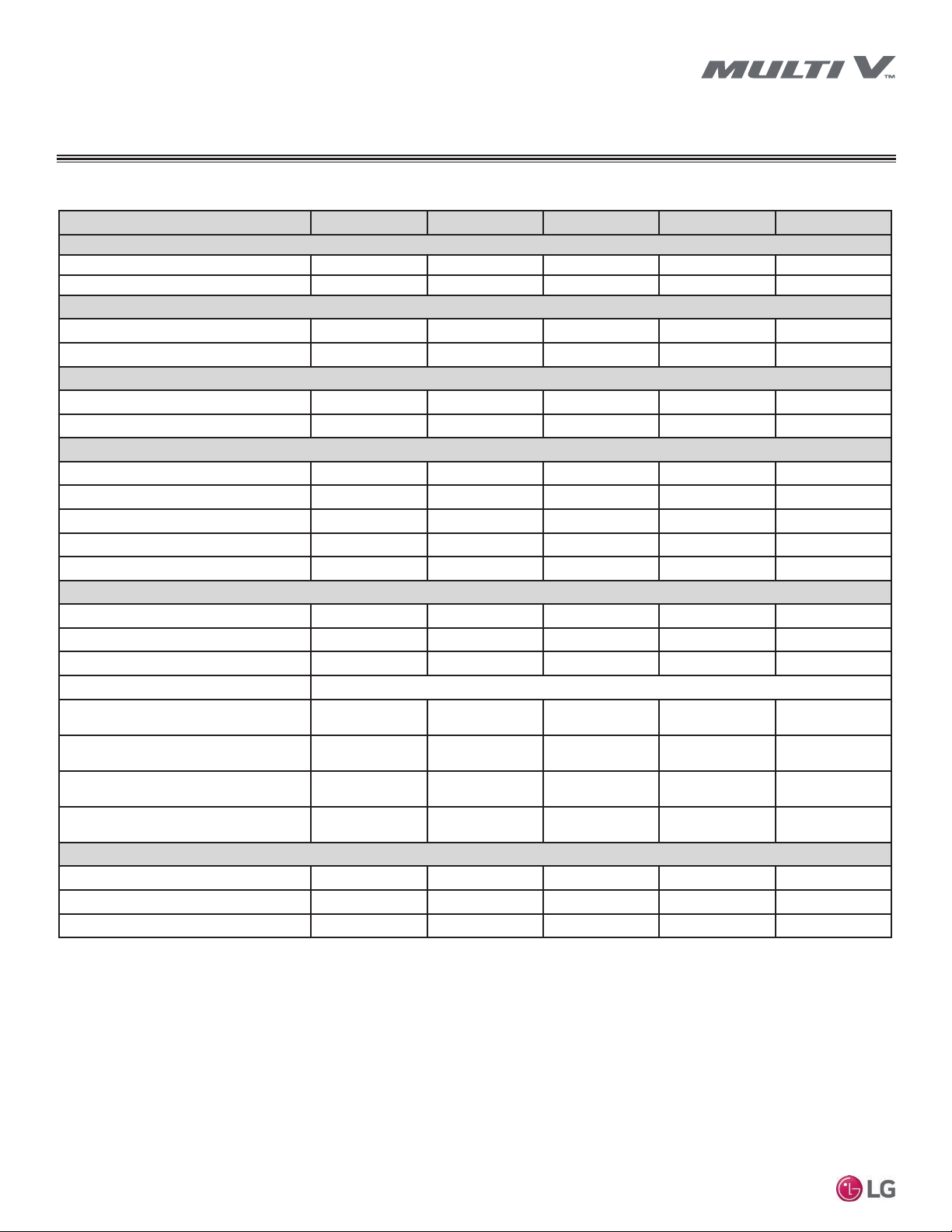

GENERAL DATA

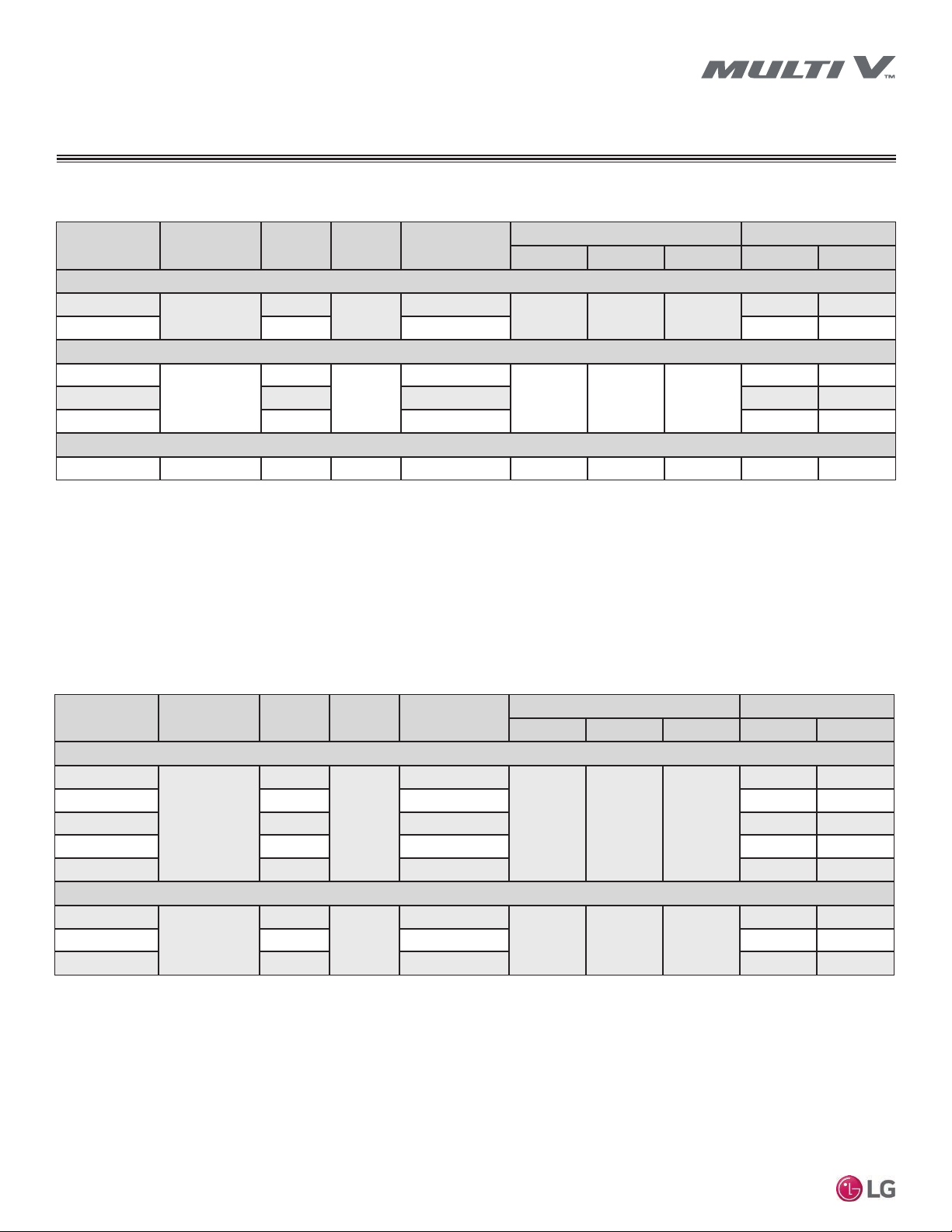

Specications − High-Static BG Chassis

Table 3: High-Static BG Chassis IDU Specications

Model No. ARNU073BGA4 ARNU093BGA4 ARNU123BGA4 ARNU153BGA4 ARNU183BGA4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Multi V Ducted Indoor Units

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

7,500 9,600 12,300 15,400 19,100

450 450 450 450 450

8,500 10,900 13,600 17,100 21,500

450 450 450 450 450

76 76 76 76 76

59 59 59 59 59

R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV

83.8 83.8 83.8 83.8 83.8

94.8 94.8 94.8 94.8 94.8

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco

1 1 1 1 1

2 2 2 2 2

516 / 484 / 434 533 / 484 / 434 586 / 533 / 484 477 / 427 / 318 547 / 470 / 427

441 / 406 / 332 452 / 406 / 332 477 / 427 / 332 487 / 417 / 293 537 / 487 / 417

0.15 0.15 0.15 0.23 0.23

0.23 0.23 0.23 0.31 0.31

3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare

5/8 Flare 5/8 Flare 5/8 Flare 5/8 Flare 5/8 Flare

1 1 1 1 1

Brushless Digitally Controlled / Direct

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

14

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 15

Table 2: High-Static BG Chassis IDU Specications – continued

Model No. ARNU243BGA4 ARNU283BGA4 ARNU363BGA4 ARNU423BGA4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

24,200 28,000 36,200 42,000

450 450 450 450

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

27,300 31,500 40,600 43,800

450 450 450 450

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

76 76 76 76

59 59 59 59

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

R410A R410A R410A R410A

EEV EEV EEV EEV

83.8 83.8 83.8 83.8

94.8 94.8 94.8 94.8

2 x 18 2 x 18 2 x 18 2 x 18

Fan

Type

Motor

Housing

Sirocco Sirocco Sirocco Sirocco

1 1 1 1

2 2 2 2

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

671 / 576 / 547 893 / 770 / 622 1,003 / 894 / 770 1,130 / 1,003 / 961

671 / 537 / 487 915 / 851 / 770 1,141 / 1,024 / 894 1,218 / 1,141 / 1,084

0.23 0.31 0.31 0.31

0.31 0.39 0.39 0.39

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare

5/8 Flare 5/8 Flare 5/8 Flare 5/8 Flare

1 1 1 1

GENERAL DATA

Specications − High-Static BG Chassis

Installation Manual

Brushless Digitally Controlled / Direct

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

15

Page 16

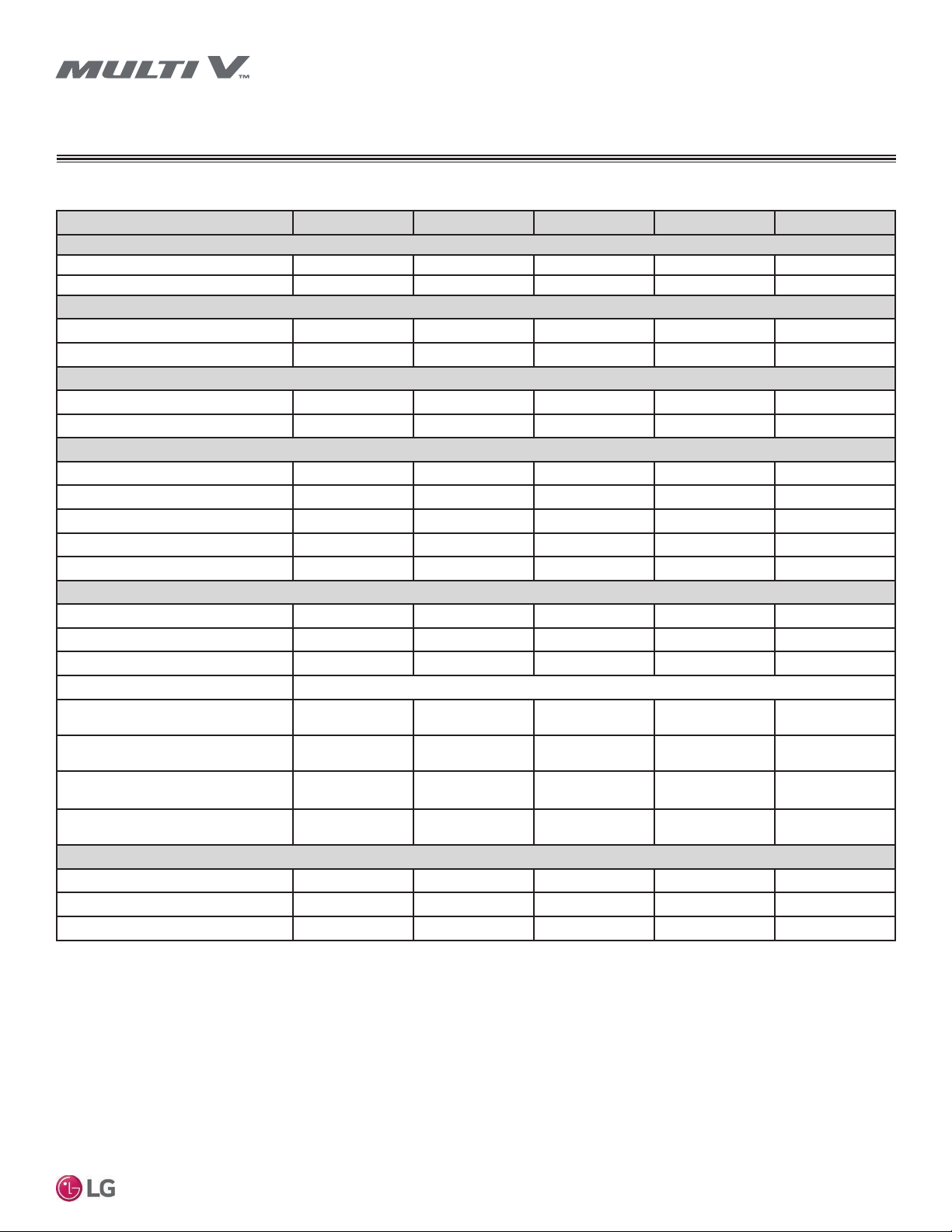

GENERAL DATA

Specications − High-Static BR/B8 Chassis

Table 4: High-Static BR Chassis IDU Specications

Model No. ARNU283BRA4 ARNU363BRA4 ARNU5423BRA4 ARNU483BRA4 ARNU543BRA4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

Multi V Ducted Indoor Units

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

28,000 36,200 42,000 48,100 54,000

450 450 450 450 450

31,500 40,600 43,800 51,200 61,400

450 450 450 450 450

76 76 76 76 76

59 59 59 59 59

R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV

112 112 112 11 2 112

132 132 132 132 132

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco

2 2 2 2 2

2 2 2 2 2

1,151 / 1,105 / 1,074 1,430 / 1,151 / 1,105 1,497 / 1,430 / 1,151 1,568 /1,395 / 1,183 1,819/1,678/1,395

1,278 / 1,134 / 1,007 1,381 / 1,176 / 1,049 1,490 / 1,381 / 1,176 1,582/ 1,434 / 1,176 1,801/1,582/1,434

0.39 0.39 0.39 0.39 0.39

0.55 0.55 0.55 0.55 0.55

3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare

5/8 Flare 5/8 Flare 5/8 Flare 5/8 Flare 5/8 Flare

1 1 1 1 1

Brushless Digitally Controlled / Direct

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

16

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 17

Model No. ARNU363B8A4 ARNU423B8A4 ARNU483B8A4 ARNU763B8A4 ARNU963B8A4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

Table 5: High-Static B8 Chassis IDU Specications

36,200 42,000 48,100 76,400 95,900

800 800 800 800 800

40,600 43,800 51,200 86,000 107,500

800 800 800 800 800

76 76 76 76 76

59 59 59 59 59

R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV

192 192 192 192 192

222 222 222 222 222

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco

2 2 2 2 2

2 2 2 2 2

Brushless Digitally Controlled / Direct

1,896 / 1,748 / 1,550 1,963 / 1,786 / 1,589 2,048 / 1,846 / 1,670 2,050 / 1,766 / 1,766 2,684 / 2,260 / 2,260

1,730 / 1,317 / 1,066 1,914 / 1,458 / 1,123 2,019 / 1,518 / 1,200 2,260 / 1,766 / 1,766 2,542 / 2,260 / 2,260

0.35 0.35 0.35 0.59 0.59

0.70 0.70 0.70 0.87 0.87

3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare 3/8 Flare

3/4 Brazed 3/4 Brazed 3/4 Brazed 3/4 Flare 7/8 Flare

1 1 1 1 1

Installation Manual

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

17

Page 18

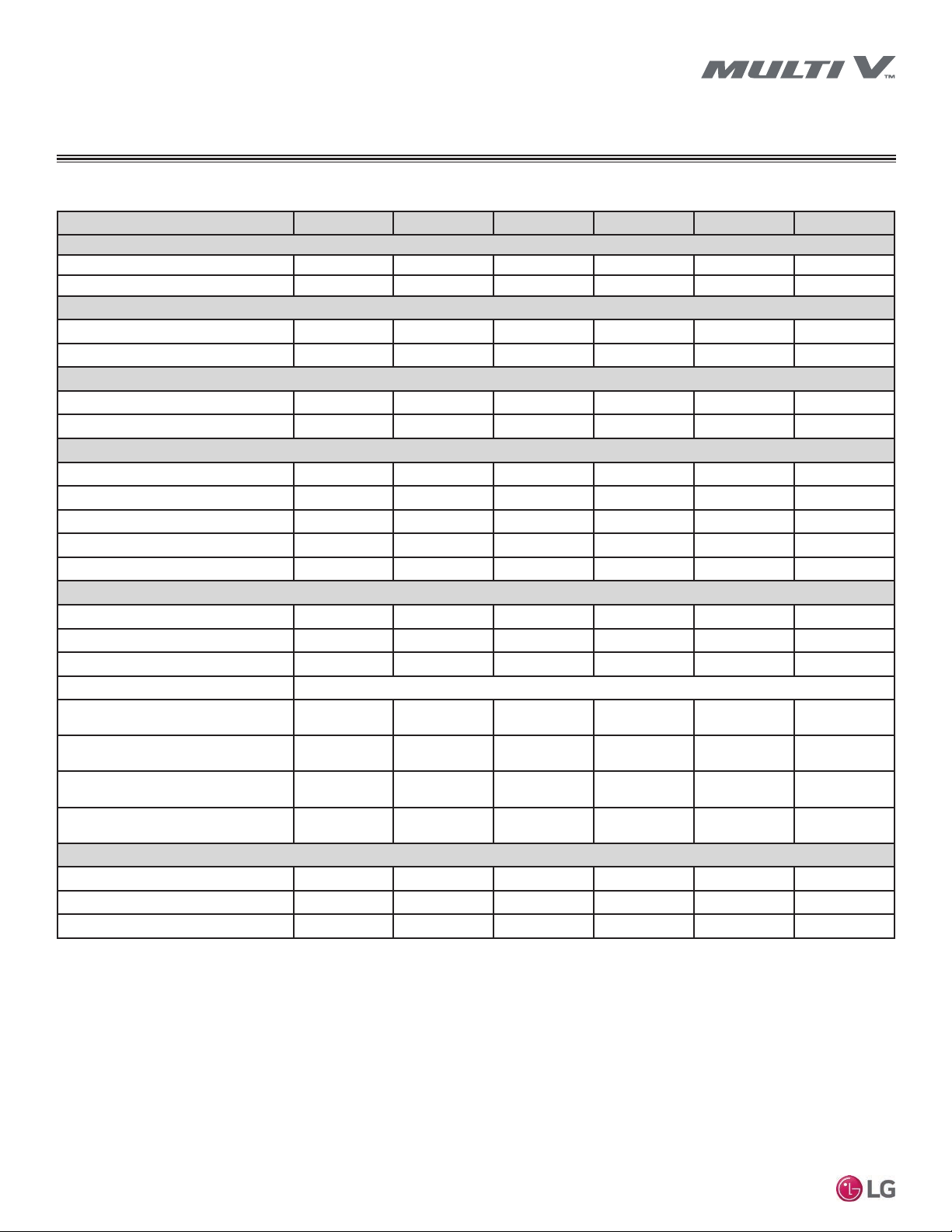

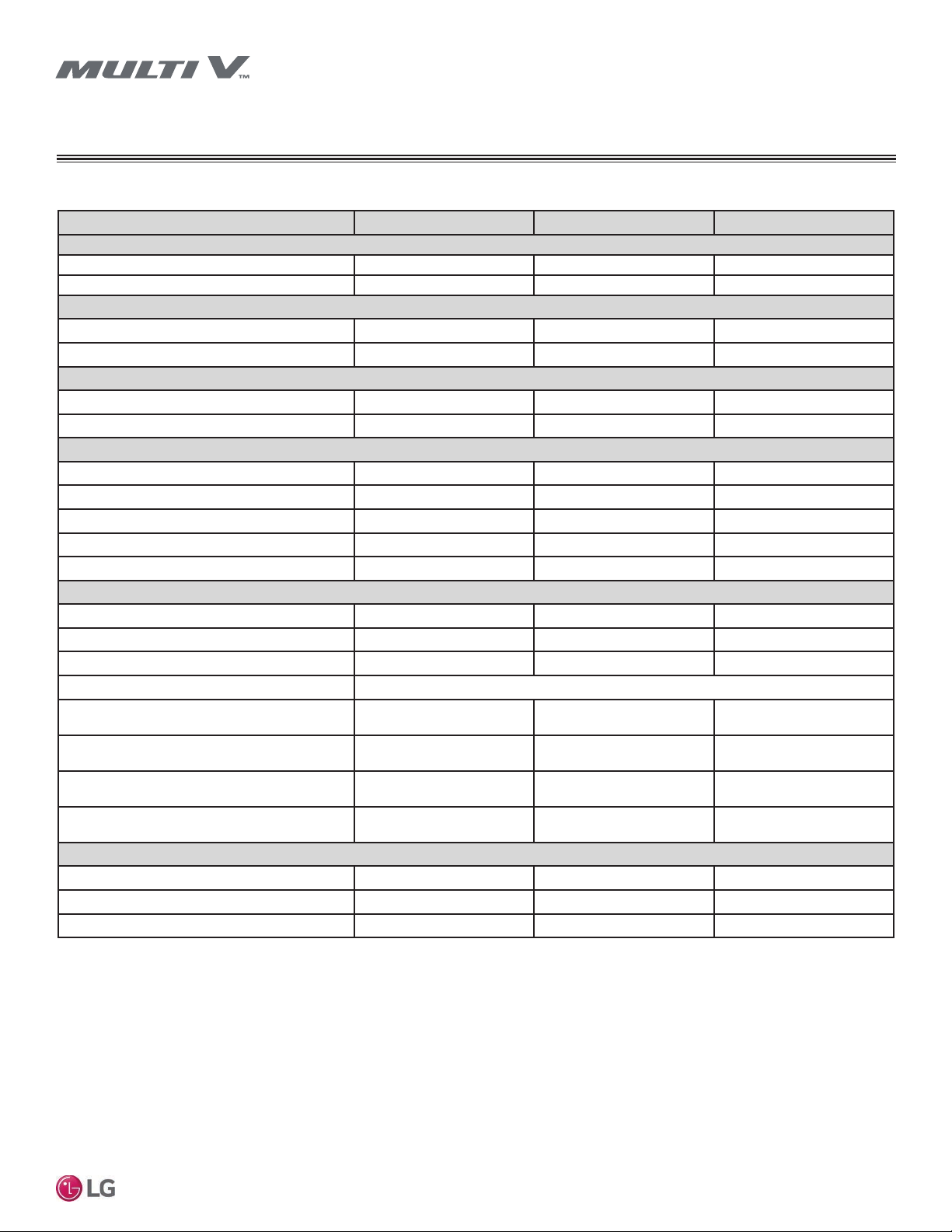

GENERAL DATA

Specications − Low-Static B3/B4 Chassis

Table 6: Low-Static Built-In B3/B4 Chassis IDU Specications

Model No. ARNU073B3G4 ARNU093B3G4 ARNU123B3G4 ARNU153B3G4 ARNU183B4G4 ARNU243B4G4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

Multi V Ducted Indoor Units

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

7,500 9,600 12,300 15,400 19,100 24,200

85 85 85 85 85 115

8,500 10,900 13,600 17,100 21,500 27,300

85 85 85 85 85 115

76 76 76 76 76 76

59 59 59 59 59 59

R410A R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV EEV

46.3 46.3 46.3 46.3 57.3 57.3

53.3 53.3 53.3 53.3 67.2 67.2

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco Sirocco

2 2 2 2 2 2

3 3 3 3 4 4

283 / 229 / 194 318 / 247 / 212 353 / 283 / 229 388 / 353 / 283 494 / 424 / 353 600 / 530 / 353

283 / 229 / 194 318 / 247 / 212 353 / 283 / 229 388 / 353 / 283 494 / 424 / 353 600 / 530 / 353

0 0 0 0 0 0

0.08 0.08 0.08 0.08 0.08 0.08

1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

1 1 1 1 1 1

Brushless Digitally Controlled / Direct

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

18

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

Page 19

Model No. ARNU073L1G4 ARNU093L1G4 ARNU123L2G4 ARNU153L2G4 ARNU183L2G4 ARNU243L3G4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

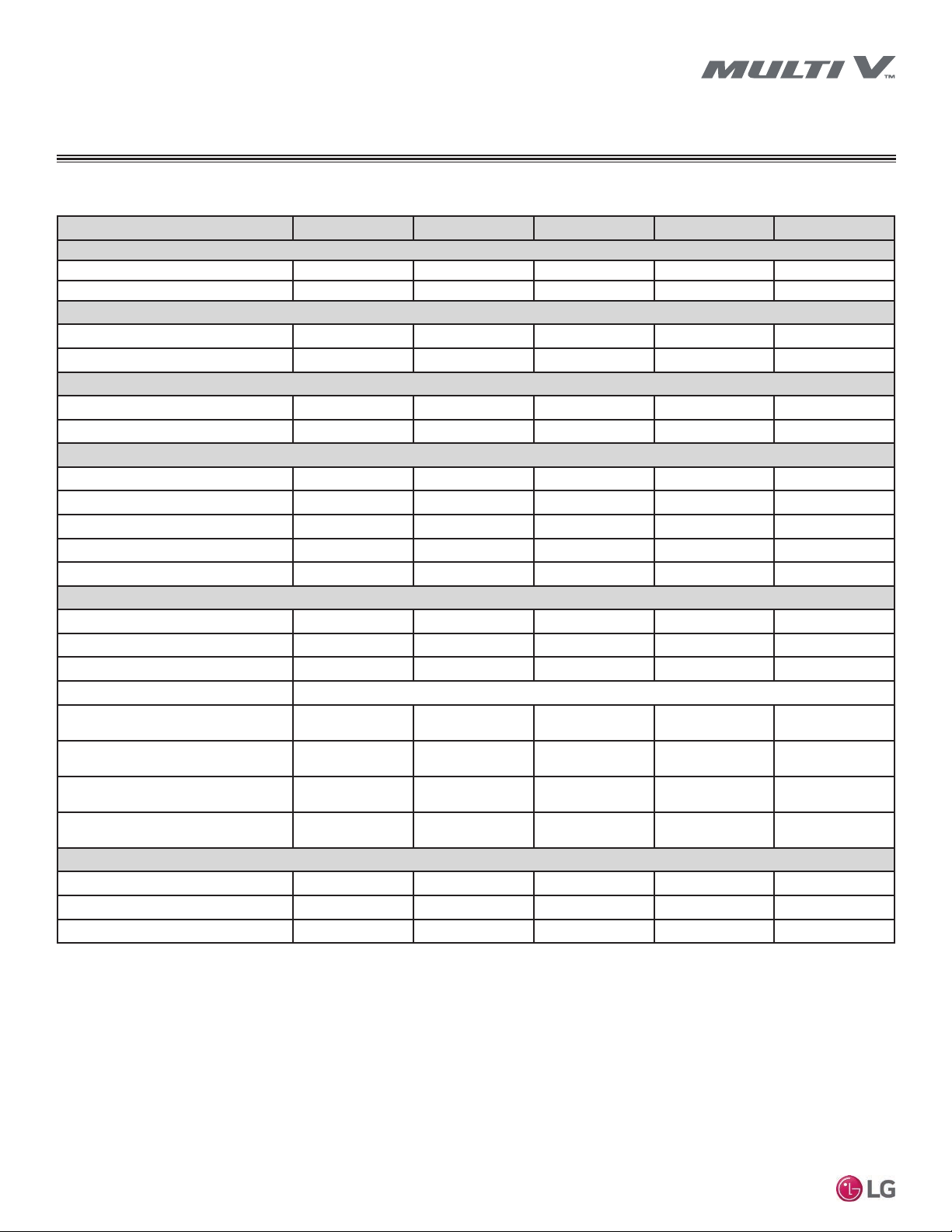

GENERAL DATA

Specications − Low-Static Ducted L1/L2/L3 Chassis

Table 7: Low-Static Ducted L1/L2/L3 Chassis IDU Specications

7,500 9,600 12,300 15,400 19,100 24,000

40 40 85 85 85 115

8,500 10,900 13,600 17,100 21,500 27,300

40 40 85 85 85 115

76 76 76 76 76 76

59 59 59 59 59 59

R410A R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV EEV

38.6 38.6 50.7 50.7 50.7 59.5

47.4 47.4 60.6 60.6 60.6 68.3

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco Sirocco

1 1 2 2 2 2

2 2 3 3 3 4

Brushless Digitally Controlled / Direct

270 / 230 / 200 320 / 250 / 200 360 / 310 / 250 450 / 360 / 310 530 / 450 / 360 710 / 570 / 430

270 / 230 / 200 320 / 250 / 200 360 / 310 / 250 450 / 360 / 310 530 / 450 / 360 710 / 570 / 430

0 0 0 0 0 0

0.1 0.1 0.1 0.1 0.1 0.1

1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 1/4 Flare 3/8 Flare

1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 1/2 Flare 5/8 Flare

1 1 1 1 1 1

Installation Manual

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

19

Page 20

GENERAL DATA

Specications − Vertical Air Handler NJ Chassis

Table 8: Vertical Air Handler NJ Chassis IDU Specications

Model No. ARNU123NJA4 ARNU183NJA4 ARNU243NJA4 ARNU303NJA4 ARNU363NJA4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

Multi V Ducted Indoor Units

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

12,000 18,000 24,000 30,000 36,000

80 80 120 178 228

13,500 20,000 27,000 34,000 40,000

80 80 120 178 228

76 76 76 76 76

59 59 59 59 59

R410A R410A R410A R410A R410A

EEV EEV EEV EEV EEV

117 117 117 117 121

140 140 140 140 144

2 x 18 2 x 18 2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco Sirocco Sirocco

1 1 1 1 1

1 1 1 1 1

530 / 480 / 380 580 / 530 / 480 710 / 640 / 480 880 / 800 / 630 990 / 880 / 800

530 / 480 / 380 580 / 530 / 480 710 / 640 / 480 880 / 800 / 630 990 / 880 / 800

0.3 0.3 0.3 0.3 0.3

0.5 0.5 0.5 0.5 0.5

1/4 Flare 1/4 Flare 3/8 Flare 3/8 Flare 3/8 Flare

1/2 Flare 1/2 Flare 5/8 Flare 5/8 Flare 5/8 Flare

1 1 1 1 1

Brushless Digitally Controlled / Direct

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

20

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

Page 21

Model No. ARNU423NKA4 ARNU483NKA4 ARNU543NKA4

Cooling Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Heating Mode Performance

Capacity (Btu/h)

Power Input1 (W)

Entering Mixed Air

Cooling Max. (°F WB)

Heating Min. (°F DB)

Unit Data

2

Refrigerant Type

Refrigerant Control

Net Unit Weight (lbs.)

Shipping Weight (lbs.)

Communication Cable4 (No. x AWG)

Fan

Type

Motor

Housing

Motor/Drive

Airflow Rate H/M/L (CFM)

Standard Mode

Airflow Rate H/M/L (CFM)

High Mode (Factory Set)

External Static Pressure (in. wg)

Standard Mode

External Static Pressure (in. wg)

High Mode (Factory Set)

Piping

Liquid Line (in., O.D.)

Vapor Line (in., O.D.)

Condensate Line (in., I.D.)

Specications − Vertical Air Handler NK Chassis

Table 9: Vertical Air Handler NK Chassis IDU Specications

42,000 48,000 54,000

260 330 366

46,000 54,000 60,000

260 330 366

76 76 76

59 59 59

R410A R410A R410A

EEV EEV EEV

165 165 165

181 181 181

2 x 18 2 x 18 2 x 18

Sirocco Sirocco Sirocco

1 1 1

1 1 1

Brushless Digitally Controlled / Direct

1,250 / 1,100 / 1,000 1,400 / 1,260 / 1,000 1,475 / 1,400 / 1,260

1,250 / 1,100 / 1,000 1,400 / 1,260 / 1,000 1,475 / 1,400 / 1,260

0.3 0.3 0.3

0.5 0.5 0.5

3/8 Flare 3/8 Flare 3/8 Flare

5/8 Flare 5/8 Flare 5/8 Flare

1 1 1

GENERAL DATA

Installation Manual

1

Power Input is rated at high speed.

2

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or

destroy R410A refrigerant according to applicable regulations (40 CFR Part 82, Subpart F)

under section 608 of CAA.

3

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded and

must comply with applicable local and national codes. Ensure the communication cable

is properly grounded at the master outdoor unit only. Do not ground the ODU−IDU communications cable at any other point.

EEV: Electronic Expansion Valve

Power wiring is field supplied and must comply with the applicable local and national

codes. Power Supply (V/Hz/Ø): 208-230/60/1

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

This unit comes with a dry nitrogen charge.

This data is rated 0 ft above sea level, with 25 ft of refrigerant line per indoor unit and a 0 ft

level difference between outdoor and indoor units. All capacities are net with a combination ratio between 95-105%.

Cooling capacity rating obtained with air entering the indoor coil at 80ºF dry bulb (DB) and

67ºF wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

21

Page 22

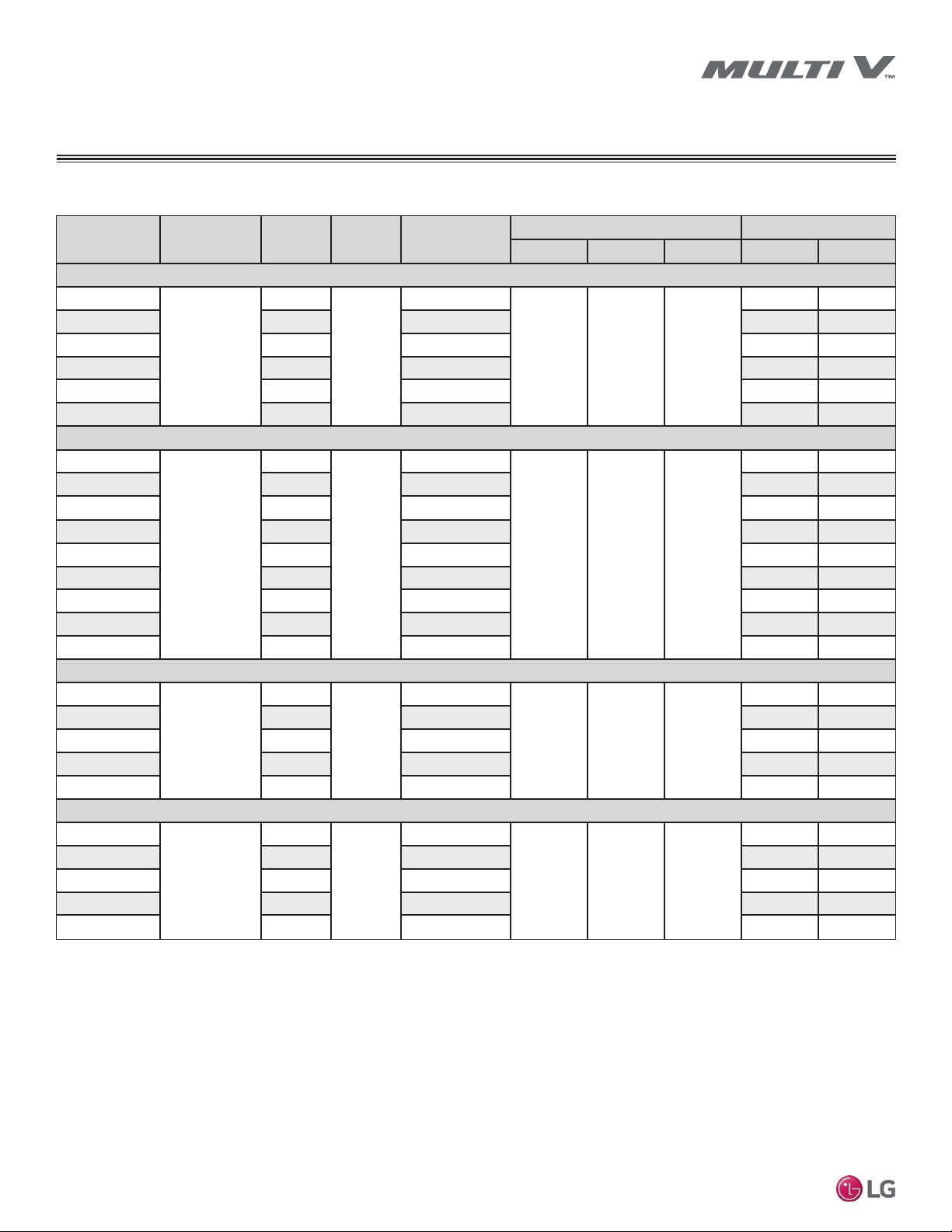

GENERAL DATA

Electrical − High-Static BH/BG/BR/B8 Chassis

Table 10: High-Static BH/BG/BR/B8 Chassis Indoor Unit Electrical Data.

Model Voltage Range MCA MOP Rated Amps (A)

Power Supply Power Input (W)

Hz Volts Phase Cooling Heating

BH Units

ARNU073BHA4

ARNU093BHA4 1.32 1.06 150 150

ARNU123BHA4 1.32 1.06 150 150

ARNU153BHA4 1.32 1.06 150 150

ARNU183BHA4 1.32 1.06 150 150

ARNU243BHA4 1.32 1.06 150 150

187-253

1.32

15

1.06

150 150

60 208-230 1

BG Units

ARNU073BGA4

ARNU093BGA4 3.3 2.65 450 450

ARNU123BGA4

ARNU153BGA4 3.3 2.65 450 450

ARNU183BGA4 3.3 2.65 450 450

ARNU243BGA4 3.3 2.65 450 450

ARNU283BGA4 3.3 2.65 450 450

ARNU363BGA4 3.3 2.65 450 450

ARNU423BGA4 3.3 2.65 450 450

187-253

3.3

3.3 2.65 450 450

15

2.65

450 450

60 208-230 1

BR Units

ARNU283BRA4

ARNU363BRA4 4.4 3.5 450 450

ARNU423BRA4 4.4 3.5 450 450

Multi V Ducted Indoor Units

ARNU483BRA4 4.4 3.5 450 450

ARNU543BRA4 4.4 3.5 450 450

187-253

4.4

15

3.5

450 450

60 208-230 1

B8 Units

ARNU363B8A4

ARNU423B8A4 6.5 5.2 800 800

ARNU483B8A4 6.5 5.2 800 800

ARNU763B8A4 6.5 5.2 800 800

ARNU963B8A4

187-253

6.5

15

6.5 5.2 800 800

5.2

800 800

60 208-230 1

MCA : Minimum Circuit Ampacity.

MOP : Maximum Overcurrent Protection.

22

Units are suitable for use on an electrical system where voltage supplied to unit terminals is within the listed range limits.

Select wire size based on the larger MCA value.

Instead of fuse, use circuit breaker.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 23

Electrical − Low-Static Built-In B3/B4 Chassis

Table 11: Low-Static Built-In B3/B4 Chassis Electrical Data.

GENERAL DATA

Model Voltage Range MCA MOP Rated Amps (A)

Power Supply Power Input (W)

Hz Volts Phase Cooling Heating

B3 Units

ARNU073B3G4

ARNU093B3G4 1.0 0.76 85 85

ARNU123B3G4 1.0 0.76 85 85

ARNU153B3G4 1.0 0.76 85 85

187-253

1.0

15

0.76

85 85

60 208-230 1

B4 Units

ARNU183B4G4

ARNU243B4G4 1.2 0.97 115 115

MCA : Minimum Circuit Ampacity.

MOP : Maximum Overcurrent Protection.

187-253

1.2

Units are suitable for use on an electrical system where voltage supplied to unit terminals is within the listed range limits.

Select wire size based on the larger MCA value.

Instead of fuse, use circuit breaker.

15

0.97

60 208-230 1

115 115

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

23

Page 24

GENERAL DATA

Electrical − Low-Static Ducted L1/L2/L3 Chassis

Table 12: Low-Static Ducted L1/L2/L3 Chassis Electrical Data.

Model Voltage Range MCA MOP Rated Amps (A)

Power Supply Power Input (W)

Hz Volts Phase Cooling Heating

L1 Units

ARNU073L1G4

ARNU093L1G4 0.5 0.4 40 40

208-230

0.5

15

0.4

60 208-230 1

40 40

L2 Units

ARNU123L2G4

ARNU153L2G4 1.0 0.76 85 85

ARNU183L2G4 1.0 0.76 85 85

208-230

1.0

15

0.76

85 85

60 208-230 1

L3 Units

ARNU243L3G4 208-230 1.2 15 0.97 60 208-230 1 115 115

MCA : Minimum Circuit Ampacity.

MOP : Maximum Overcurrent Protection.

Units are suitable for use on an electrical system where voltage supplied to unit terminals is within the listed range limits.

Select wire size based on the larger MCA value.

Instead of fuse, use circuit breaker.

Table 13: Vertical Air Handler NJ/NK Chassis Electrical Data.

Model Voltage Range MCA MOP Rated Amps (A)

Multi V Ducted Indoor Units

NJ Units

ARNU123NJA4

ARNU183NJA4 1.4 1.12 228 228

ARNU243NJA4 1.4 1.12 228 228

ARNU303NJA4 1.4 1.12 228 228

ARNU363NJA4 1.4 1.12 228 228

208-230

1.4

1.12

15

Power Supply Power Input (W)

Hz Volts Phase Cooling Heating

228 228

60 208-230 1

NK Units

ARNU423NKA4

ARNU483NKA4 2.3 1.8 366 366

ARNU543NKA4 2.3 1.8 366 366

MCA : Minimum Circuit Ampacity.

MOP : Maximum Overcurrent Protection.

208-230

2.3

15

Units are suitable for use on an electrical system where voltage supplied to unit terminals is within the listed range limits.

Select wire size based on the larger MCA value.

Instead of fuse, use circuit breaker.

1.8

366 366

60 208-230 1

24

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 25

GENERAL DATA

a

Dimensions – High-Static Ducted BH Chassis

Installation Manual

Note - All dimensions have

tolerance of ± 0.25 in.

= Center of gravity

C

ent

e

r o

f

G

r

av

i

t

y

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

25

Page 26

GENERAL DATA

Dimensions – High-Static Ducted BG Chassis

Multi V Ducted Indoor Units

26

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 27

GENERAL DATA

Dimensions – High-Static Ducted BR Chassis

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

27

Page 28

GENERAL DATA

Dimensions – High-Static Ducted B8 Chassis

Multi V Ducted Indoor Units

28

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Page 29

GENERAL DATA

Dimensions – Built-In Low-Static Ducted B3/B4 Chassis

With Suction Grill

A2 C2

With Suction Grill

& Suction Canvas

B2

22-5/8

9-13/16

With Suction Grill

& Suction Canvas

15-1/8

7-7/16

With Suction Grill

A1

15-1/4

24-5/16

With Suction Grill

7-1/2

2-1/2

8-1/2

10-7/8

1

Drain

Power Connection

2-3/8

Supply Air

Installation Manual

Liquid

Vapor

Return Air

C3

A3

Accessory

PBSGB30 35-13/16

PBSGB40 46-13/16 14-1/8

B3

A2 B2 C2

Model

7-1/2

19-11/16 (Max)

With Suction Grill & Suction Canvas

14-1/8 2-3/16

2-3/16

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ARNU073B3G4

ARNU093B3G4

ARNU123B3G4

ARNU153B3G4

ARNU183B4G4

ARNU243B4G4

Accessory A3 B3 C3

PBSC30 32-5/16

PBSC40

32-5/8

43-5/16

43-5/16 1-9/16 to 9-13/1610-11/16

A1

Unit: inches

Note: All measurements

have a tolerance of ±1/4 in.

1-9/16 to 9-13/1610-11/16

29

Page 30

GENERAL DATA

Dimensions – Low-Static Ducted L1/L2/L3 Chassis

7-1/2

3-15/16

3-1/16

4-1/16

11-1/2

2-5/8

Multi V Ducted Indoor Units

Vapor Pipe Connection

Liquid Pipe Connection

Drain Pipe Connection

Power Supply Connection

27-9/16

7-1/2

24-3/4

13/166-1/16

5-5/16 1-3/8

8-11/16

13/16

L1 : 14-7/16

L2 : 22-1/16

L3 : 29-3/4

Top

Top

Top

D

C

Air Outlet

Air Inlet

L1 : 2-15/16

L2 : 3-1/16

B

A

L3 : 3-3/16

30

t

e

n

e

C

i

t

f

r

r

y

v

o

a

G

Unit: inches

Note: All measurements

have a tolerance of ±1/4 in.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

ARNU073L1G4

ARNU093L1G4

ARNU123L2G4

ARNU153L2G4

ARNU183L2G4

ARNU243L3G4

ABCD

30-1/2

27-9/16

28-7/8 26

38-3/8 35-7/16 36-3/4 33-7/8

46-1/4

43-5/16

44-5/8 41-3/4

Page 31

Supply Air

opening

48-11/16

GENERAL DATA

Dimensions – Vertical Air Handler NJ Chassis

SIDE VIEW

21-1/4

18

1-5/8

1-9/16

7/8” Wiring

knockouts

Installation Manual

1-9/16 1-15/16

2-1/16

18

17

12-1/8

21-1/4

TOP VIEW

Return Air

opening

1-15/16

7/8” Wiring

knockouts

2-1/8

1-11/16” Wiring

knockouts

49-5/16

48-11/16

2-9/16

14-5/16

1-1/2

4-11/16

Liquid pipe

Vapor pipe

Drain connection

for upflow application

BOTTOM VIEW

Drain connection

for horizontal

application

Unit: inches

Note: All measurements

FRONT VIEW

have a tolerance of ±1/4 in.

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

9-15/16

1-9/16

13

31

Page 32

GENERAL DATA

Dimensions – Vertical Air Handler NK Chassis

Supply Air

opening

55-3/16

21-1/4

25

24

Multi V Ducted Indoor Units

12-1/8

Return Air

opening

25

1-9/16

21-1/4

1-5/8

1-15/16

2-1/16

7/8” Wiring

knockouts

2-3/16

1-11/16” Wiring

knockouts

1-9/16

55-13/16

7/8” Wiring

knockouts

55-3/16

2-9/16

1-1/2

14-1/4

SIDE VIEW

Liquid pipe

Vapor pipe

Drain connection

for upflow application

32

Unit: inches

Note: All measurements

have a tolerance of ±1/4 in.

4-11/16

Drain connection

for horizontal

application

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

16-15/16

20

FRONT VIEW

1-9/16

Page 33

GENERAL DATA

Refrigerant Piping Diagrams

Figure 5: High-Static Ducted BG/BR/BH, Low-Static Ducted L1/L2L3/B3/B4, and Vertical Air Handler NJ/NK Refrigerant Piping Diagram

lndoor Unit

Vapor

Flare Nut

Vapor

Line

Liquid Line

Flare Nut

Line

Liquid Line

Refrigerant Pipes

to Outdoor Unit

Refrigerant Pipes

to Outdoor Unit

Th3

Heat Exchanger

TH3

Sirocco Fan

Heat Exchanger

EEV

Filter

Th2

Sirocco Fan

Filter

Th1

Figure 6: High-Static Ducted B8 Refrigerant Piping Diagram

EEV

Filter

TH2

Check

Valve

Solenoid Valve

Filter

TH1

lndoor unit

Flare Nut

Flare Nut

Cooling

Heating

Th1 = Thermistor, Return Air

Th2 = Thermistor, Pipe In

Th3 = Thermistor, Pipe Out

EEV = Electronic Expansion Valve

Cooling

Heating

Th1 = Thermistor, Return Air

Th2 = Thermistor, Pipe In

Th3 = Thermistor, Pipe Out

EEV = Electronic Expansion Valve

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

33

Page 34

GENERAL INSTALLATION GUIDELINES

CAUTION

DANGER

Location Selection

To avoid the possibility of re, do not install the unit in an area where combustible gas may generate, ow, stagnate, or leak. Failure to do so will

cause serious bodily injury or death. Before beginning installation, read the safety summary at the beginning of this manual.

Note:

Select a location for installing the wall-mounted indoor unit (IDU) that meets the following conditions:

• Where there is enough structural strength to bear the weight of the unit.

• Operating sound from the unit will not disturb occupants.

• Include enough space for service access.

• Include space for drainage to ensure condensate ows properly out of the unit when it is in cooling mode.

• Use a level indicator to ensure the unit is installed on a level plane.

• Include space for drainage to ensure condensate ows properly out of the unit when it is in cooling mode

Note:

The unit may be damaged, may malfunctioin, and/or will not operate as designed if installed in any of these conditions:

Do not install the unit near a heat or steam source (Figure 7) , or where considerable amounts of oil, iron powder, or flour are used.

These materials may generate condensate, cause a reduction in h eat exchanger efficiency, or malfuction of the condensate drain. If this is

a potential problem, install a ventillation fan large enough to vent out these materials

Do not install the unit where it will be subjected to direct thermal radiation from other heat sources.

Do not install the unit in an area where combustible gas may generate, flow, stagnate, or leak. There is the possibility of fire.

Do not install the unit in a location where acidic solution and spray (sulfur) are often used.

Do not use the unit in environments where oil, steam, or sulfuric gas are present.

Do not install additional ventilation products on the chassis of the unit.

Do not install the unit near high-frequency generator sources.

Multi V Ducted Indoor Units

Installing in an Area Exposed to Unconditioned Air

In some installation applications, areas (floors, walls) in some

rooms may be exposed to unconditioned air. The room may be

above or next to an unheated garage or storeroom. To counter

this condition:

• Verify that carpet is or will be installed (carpet may increase

the temperature by three (3) degrees.

• Install radiant heat or another type of heating system to

the oor.

• Add insulatiion between the oor joists.

Figure 7: Installing Near a Heat or Steam Source

Indoor Unit

Include enough

distance

Heat or steam source

Install a ventilation fan

with sufficient capacity

Unpack and Inspect for Freight Damage

Table 2 lists shipping and net weights. To help avoid personnel injury and unit damage, use at least two people when carrying a unit by hand.

Note:

Do not unpack the unit and remove protective materials until ready to install. Before opening the shipping container, check the container labeling to verify the unit received is the correct unit. Verify the unit capacity, type, and voltage. Refer to the Nomenclature chart on page 11. Before

unpacking, carefully move packaged unit to a work area near installation location. After opening, if unit is damaged, repack unit as it was shipped.

RETAIN ALL PACKING MATERIALS. In general, freight damage claims will be denied if the original packing materials are not retained for the claims

adjustor to inspect. File a freight claim and order a replacement unit.

1. Place the box on a solid surface right side up.

2. Cut the white reinforced nylon straps, open the top of the box, and fold back all four flaps.

34

Due to our policy of continuous product innovation, some specifications may change without notification.