Page 1

MODEL: HT306SF(HT306SF, SH36SF-S, SH36SU-W)SERVICE MANUAL

Internal Use Only

Website http://biz.lgservice.com

DVD HOME CINEMA SYSTEM

SERVICE MANUAL

MODEL: HT306SF

P/NO : AFN75272761 FEBRUARY, 2011

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

(HT306SF, SH36SF-S, SH36SU-W)

Page 2

CONTENTS

SECTION 1 ........SUMMARY

SECTION 2 ........ELECTRICAL

SECTION 3 ........CABINET & MAIN CHASSIS

SECTION 4 ........MECHANISM (DP-15T)

SECTION 5 ........REPLACEMENT PARTS LIST

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

SERVICING PRECAUTIONS .......................................................................................................................... 1-3

ESD PRECAUTIONS ....................................................................................................................................... 1-5

SERVICE INFORMATION FOR EEPROM .................................................................................................... 1-6

HOW TO UPDATE DVD & AUDIO MICOM PROGRAMS ........................................................................... 1-7

SPECIFICATIONS ............................................................................................................................................ 1-8

1-2

Page 4

SERVICING PRECAUTIONS

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort lens.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-3

Pressure

Page 5

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

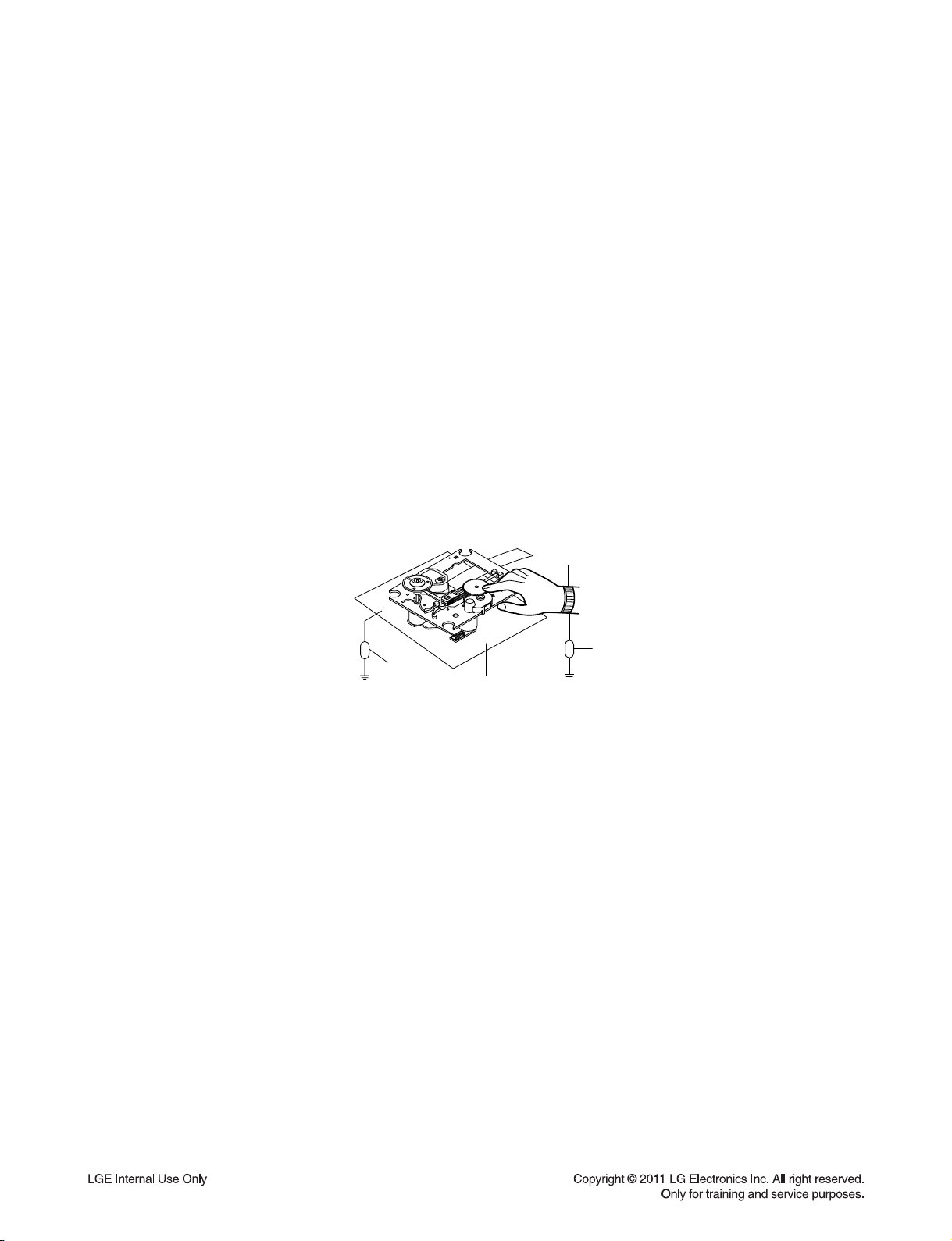

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Resistor

(1 M Ω)

Resistor

(1 M Ω)

Conductive

Sheet

1-4

Page 6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

Page 7

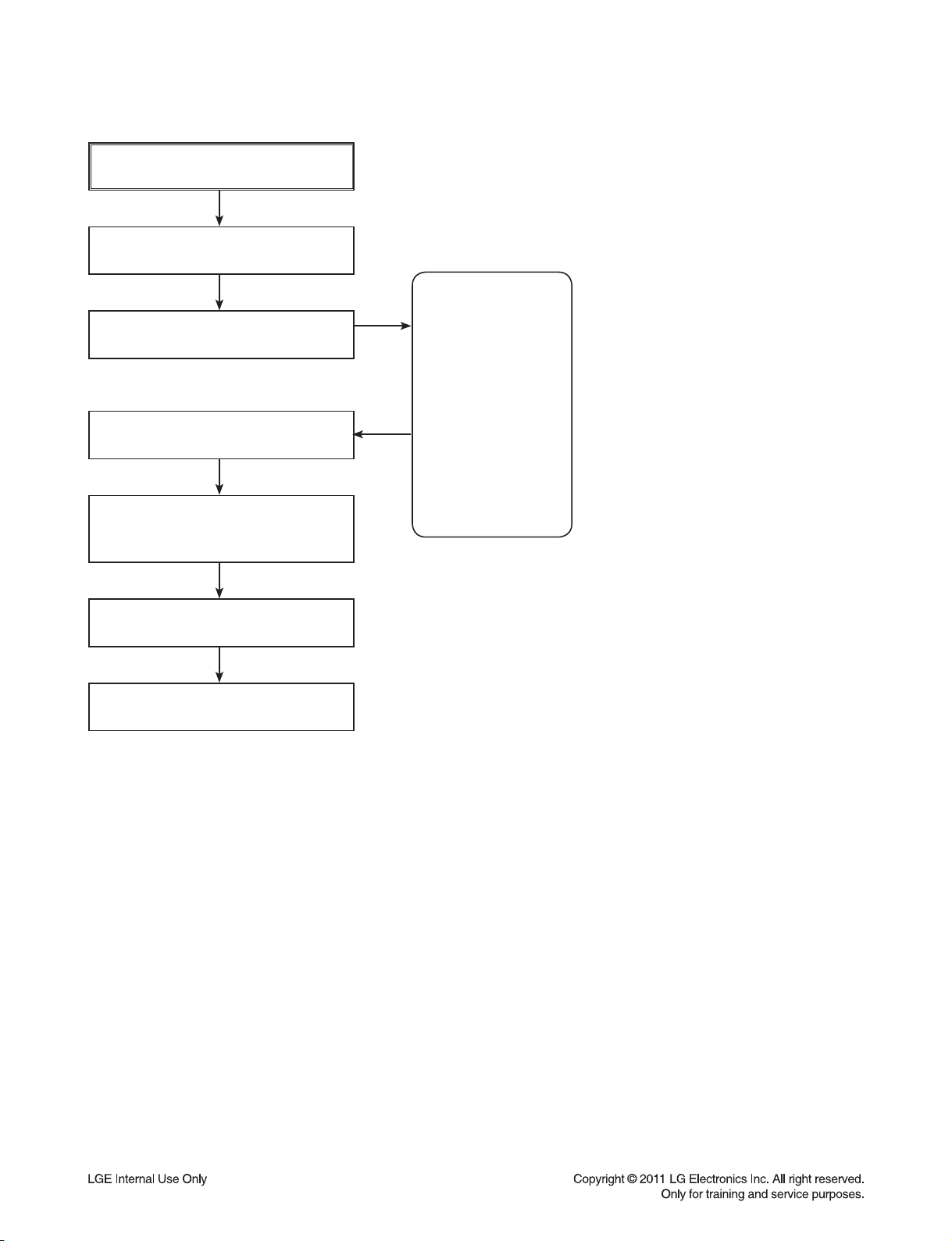

SERVICE INFORMATION FOR EEPROM

POWER ON

DVD LOGO Status (NO Disk status)

Remote control

Pause key-->1-->4-->7-->2 in order.

Press number 0~9, Press character

A~F (1~6 for a while)

▲

Use arrow key (

▲

▲

▲

) to move

to appropriate position and make

changes

Press pause key once

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME

OPT 1

OPT 2

OPT 3

OPT 4

OPT 5

OPT 6

OPT 7

OPT 8

OPT 9

OPT A

HEX

F1

00

D0

29

00

81

A0

30

50

08

Change will be applied when power

OFF-->ON.

1-6

Page 8

HOW TO UPDATE DVD & AUDIO MICOM PROGRAMS

1. The Whole Sequence

1) DVD program download.

2) Power cord out −> in.

3) Audio micom program download.

4) Remote control Pause key ‘

5) Enter into the system information for check the version, options and check sum.

6) Power off −> on.

Attention:

After DVD program download, never input options and check the version before power cord out.

2. How to enter into System Information

1) Enter into SETUP menu in NO Disc.

2) Put on cursor [Highlight] 16:9 wide option of TV aspect in SETUP menu.

3) Press follow key in continuous using remote control.

1 −> 3 −> 9 −> 7 −> 1 −> 3 −> 9 −> ENTER

3. How to update program

3-1. How to update MTK DVD program

1) Change the fi lename to download as “LG_(MODEL NAME).ROM”.

[Both Upper and Lower case In fi lename is possible]

Ex.) HT306: “LG_HT306.ROM”

2) Copy the fi le to the formatted USB, and burn it.

3) Move to the USB function, and insert the USB to the set.

The upgrade information will be shown on the screen.

4) Remove the USB, press PLAY key of the remote control.

5) Remove and reconnect the power cable when it changes to logo screen from upgrade information.

Then the upgrade process is completed.

||

’ + ‘1472’ for input options.

3-2. How to update AUDIO MICOM program

1) Change the fi lename to download as “(MODEL NAME)_(Version).HEX”. Only upper cases are permitted.

Ex.) HT306: "HT306_0809262.HEX"

2) Copy the fi le to the root folder of USB storage.

3) Put the USB into the SET, and move to the USB function.

Then the upgradeprocess will be started with the upgrade information.

4) If the upgrade process is complete, the set will be power off automatically with “Complete” message.

1-7

Page 9

SPECIFICATIONS

• GENERAL

Power requirements Refer to main label

Power consumption Refer to main label

Dimensions (W x H x D) Approx. 365 x 58.5 x 307 mm without foot

Net Weight (Approx.) 2.44 kg

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity 5 % to 90 %

• OUTPUTS

VIDEO OUT 1.0 V (p-p), 75 Ω, sync negative, RCA jack x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, sync negative, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

HDMI OUT (video/audio) 19 pin (Type A, HDMI™ Connector)

ANALOG AUDIO IN 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) x 1

PORT. IN 0.5 Vrms (3.5 mm stereo jack)

• SYSTEM

Laser Semiconductor laser, wavelength: 650 nm

Signal system Standard NTSC/PAL color TV system

Frequency response 20 Hz to 20 kHz (48 kHz, 96 kHz, 192 kHz sampling)

Signal-to-noise ratio More than 80 dB

Harmonic distortion 0.05 % at 1 W

Dynamic range More than 85 dB

Bus Power Supply (USB) DC 5 V 500 mA

• AMPLIFIER

Stereo mode 45 W + 45 W (3 Ω at 1 kHz)

Surround mode Front 45 W + 45 W (3 Ω at 1 kHz)

Center 45 W (3 Ω at 1 kHz)

Surround 45 W + 45 W (3 Ω at 1 kHz)

Subwoofer 105 W (4 Ω at 60 Hz)

• TUNER

FM Tuning Range 87.5 to 108.0 MHz or 87.50 to 108.00 MHz

• FRONT SPEAKER (LEFT/ RIGHT)

Type 1 Way 1 Speaker

Impedance Rated 3 Ω

Input Power 45 W

Max. Input Power 90 W

Net Dimensions (W x H x D) 97 x 110 x 80 mm

Net Weight 0.39 kg

• REAR SPEAKER (LEFT/ RIGHT)

Type 1 Way 1 Speaker

Impedance Rated 3 Ω

Input Power 45 W

Max. Input Power 90 W

Net Dimensions (W x H x D) 97 x 110 x 80 mm

Net Weight 0.39 kg

• CENTER SPEAKER

Type 1 Way 1 Speaker

Impedance Rated 3 Ω

Input Power 45 W

Max. Input Power 90 W

Net Dimensions (W x H x D) 97 x 110 x 80 mm

Net Weight 0.39 kg

• SUBWOOFER

Type 1 Way 1 Speaker

Impedance Rated 4 Ω

Input Power 105 W

Max. Input Power 210 W

Net Dimensions (W x H x D) 157 x 325 x 250 mm

Net Weight 3.5 kg

1-8

Page 10

SECTION 2

ELECTRICAL

CONTENTS

ELECTRICAL TROUBLESHOOTING GUIDE ............................................................................................... 2-2

1. POWER SUPPLY CIRCUIT .................................................................................................................... 2-2

2. FRONT CIRCUIT (1/2) ............................................................................................................................ 2-3

3. FRONT CIRCUIT (2/2) ............................................................................................................................ 2-4

4. SYSTEM OPERATION FLOW ................................................................................................................ 2-5

5. TEST & DEBUG FLOW .......................................................................................................................... 2-6

6. AMP PROTECTION .............................................................................................................................. 2-12

7. AUDIO μ-COM CIRCUIT(DVD & AMP) ................................................................................................ 2-13

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING .................................................. 2-14

1. SYSTEM 27 MHZ CLOCK, RESET, FLASH R/W SIGNAL .................................................................. 2-14

2. SDRAM CLOCK .................................................................................................................................... 2-15

3. TRAY OPEN/CLOSE SIGNAL .............................................................................................................. 2-16

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION) .......................................................... 2-17

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION) .......................................................... 2-18

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION) ......................................... 2-18

7. DISC TYPE JUDGEMENT WAVEFORMS ........................................................................................... 2-19

8. FOCUS ON WAVEFORMS................................................................................................................... 2-21

9. SPINDLE CONTROL WAVEFORMS (NO DISC CONDITION) ............................................................ 2-22

10. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING) ................................................... 2-23

11. MT1389MH VIDEO OUTPUT WAVEFORMS ....................................................................................... 2-24

12. DVD & AMP WAVEFORMS MT1389MH .............................................................................................. 2-25

WIRING DIAGRAM ........................................................................................................................................ 2-27

BLOCK DIAGRAMS ...................................................................................................................................... 2-29

CIRCUIT DIAGRAMS .................................................................................................................................... 2-33

1. SMPS CIRCUIT DIAGRAM .................................................................................................................. 2-33

2. MAIN & AMP - 1 CIRCUIT DIAGRAM .................................................................................................. 2-35

3. MAIN & AMP - 2 CIRCUIT DIAGRAM .................................................................................................. 2-37

4. FRONT & POWER KEY CIRCUIT DIAGRAM ...................................................................................... 2-39

5. FRONT JACK CIRCUIT DIAGRAM ...................................................................................................... 2-41

CIRCUIT VOLTAGE CHART ........................................................................................................................ 2-43

PRINTED CIRCUIT BOARD DIAGRAMS .................................................................................................... 2-47

1. MAIN & AMP P.C. BOARD ................................................................................................................... 2-47

2. SMPS P.C. BOARD .............................................................................................................................. 2-51

3. FRONT P.C. BOARD ............................................................................................................................ 2-53

4. POWER KEY P.C. BOARD .................................................................................................................. 2-53

5. FRONT JACK P.C. BOARD .................................................................................................................. 2-53

2-1

Page 11

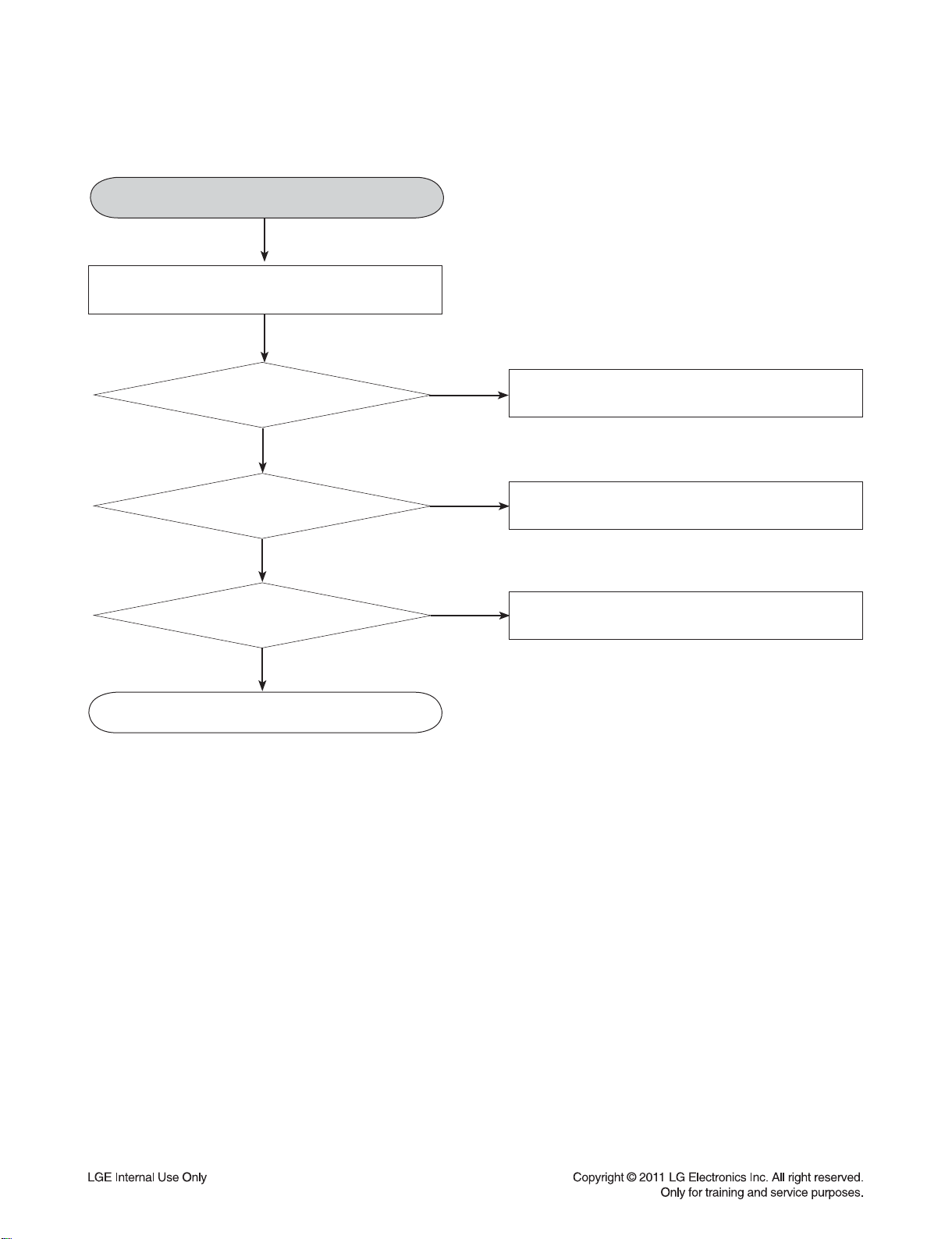

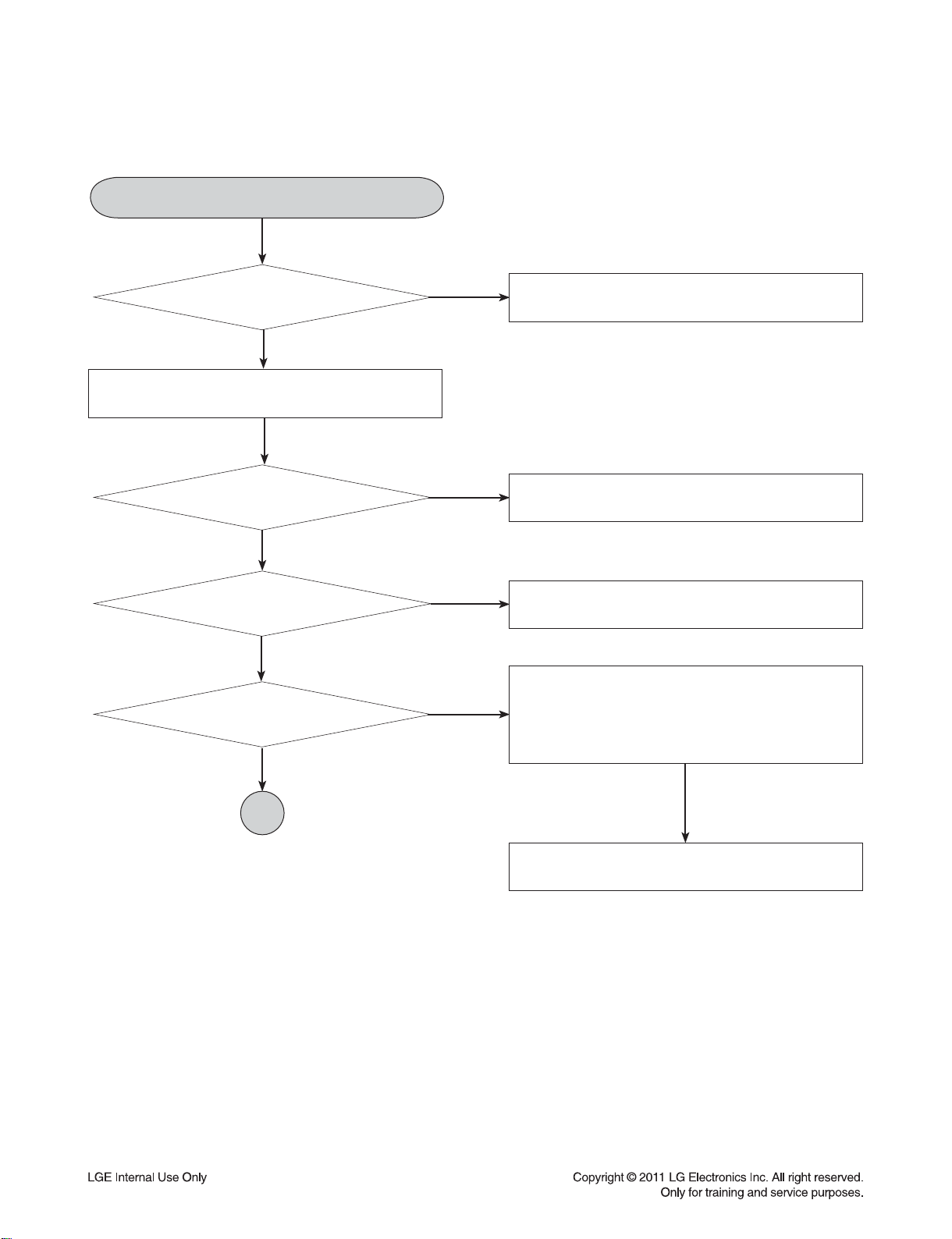

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY CIRCUIT

INSERT POWER CORD.

YES

Turn power on.

YES

Is power on?

YES

Does it play?

YES

Does it output

audio?

YES

OK

NO

Check power supply circuit.

NO

Check tracking servo circuit.

NO

Check audio circuit.

2-2

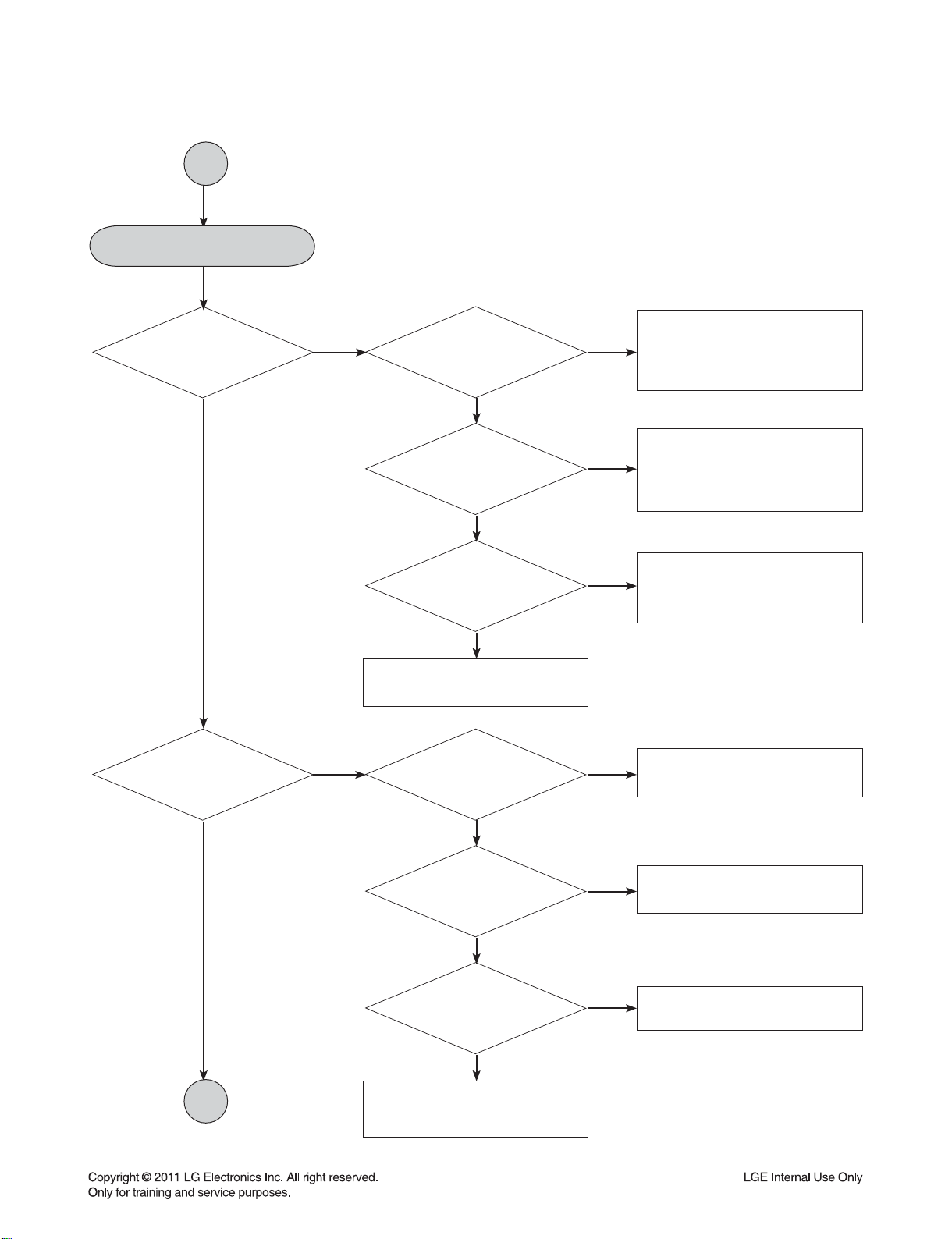

Page 12

ELECTRICAL TROUBLESHOOTING GUIDE

2. FRONT CIRCUIT (1/2)

POWER ON.

YES

Is the Digitron on

correctly?

YES

Check if all

buttons are ok?

YES

Check if the remote

control is ok?

YES

Front B/D ok.

NO

NO

NO

Check if

PN301 is ok?

YES

1

2

Check if the front

power is ok?

YES

Check if

DIS301 is ok?

NO

Reconnect it.

NO

Refer to SMPS part.

NO

Check pattern and resoldering

2-3

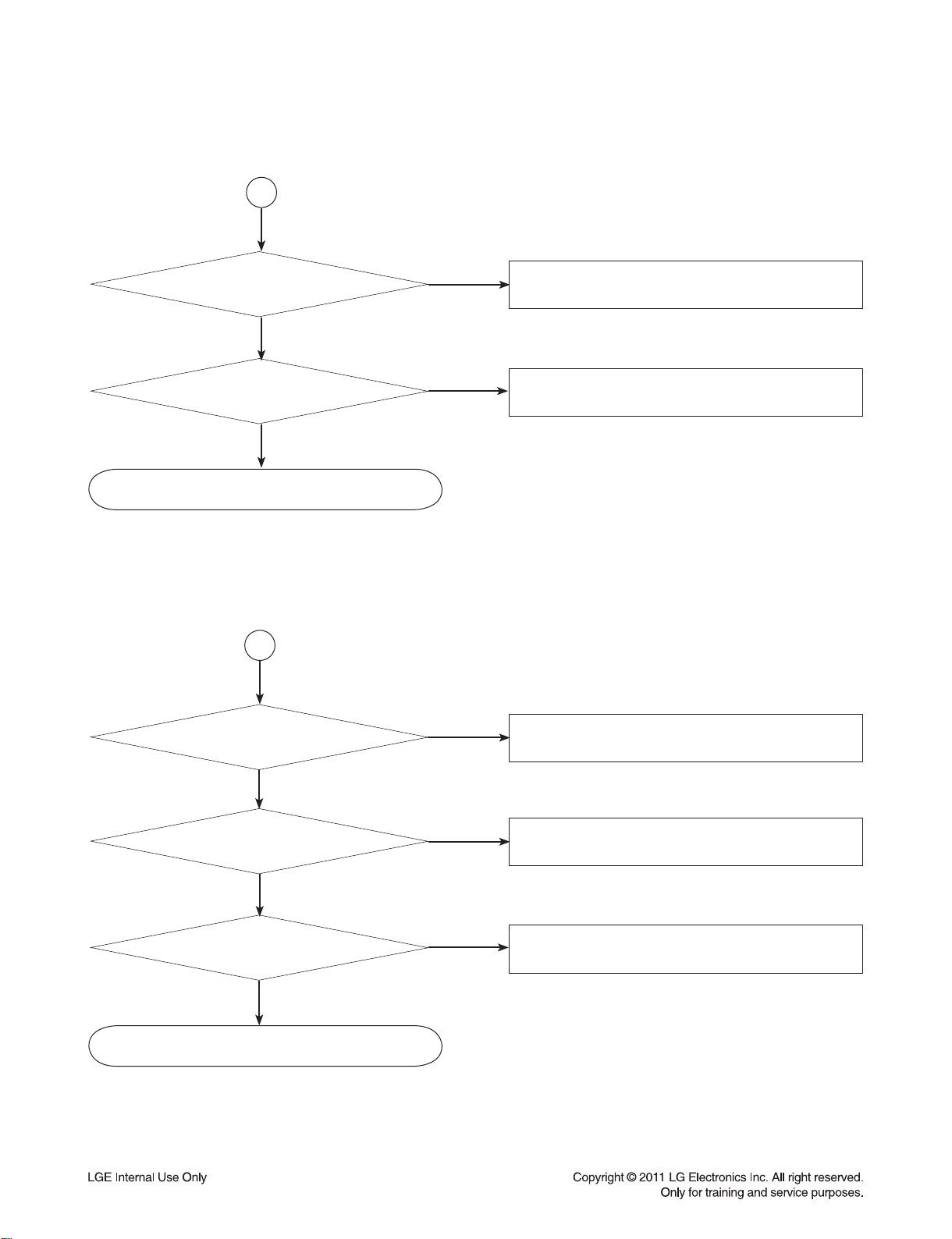

Page 13

ELECTRICAL TROUBLESHOOTING GUIDE

3. FRONT CIRCUIT (2/2)

1

Check if the

power part of the

front is ok?

YES

Check if

R346~R349, R352, R370

ok?

YES

Refer to MICOM circuit.

2

NO

Refer to power(SMPS).

NO

Replace R346~R349, R352, R370.

Check if the

power part of the front

is ok?

YES

Check if the remote

control waveform of PN301

pin5 is ok?

YES

Check if RC301

voltage is ok(3.3 V)?

YES

Resolder or Replace RC301.

NO

Refer to power(SMPS).

NO

Refer to MICOM circuit.

NO

Check RM circuit

2-4

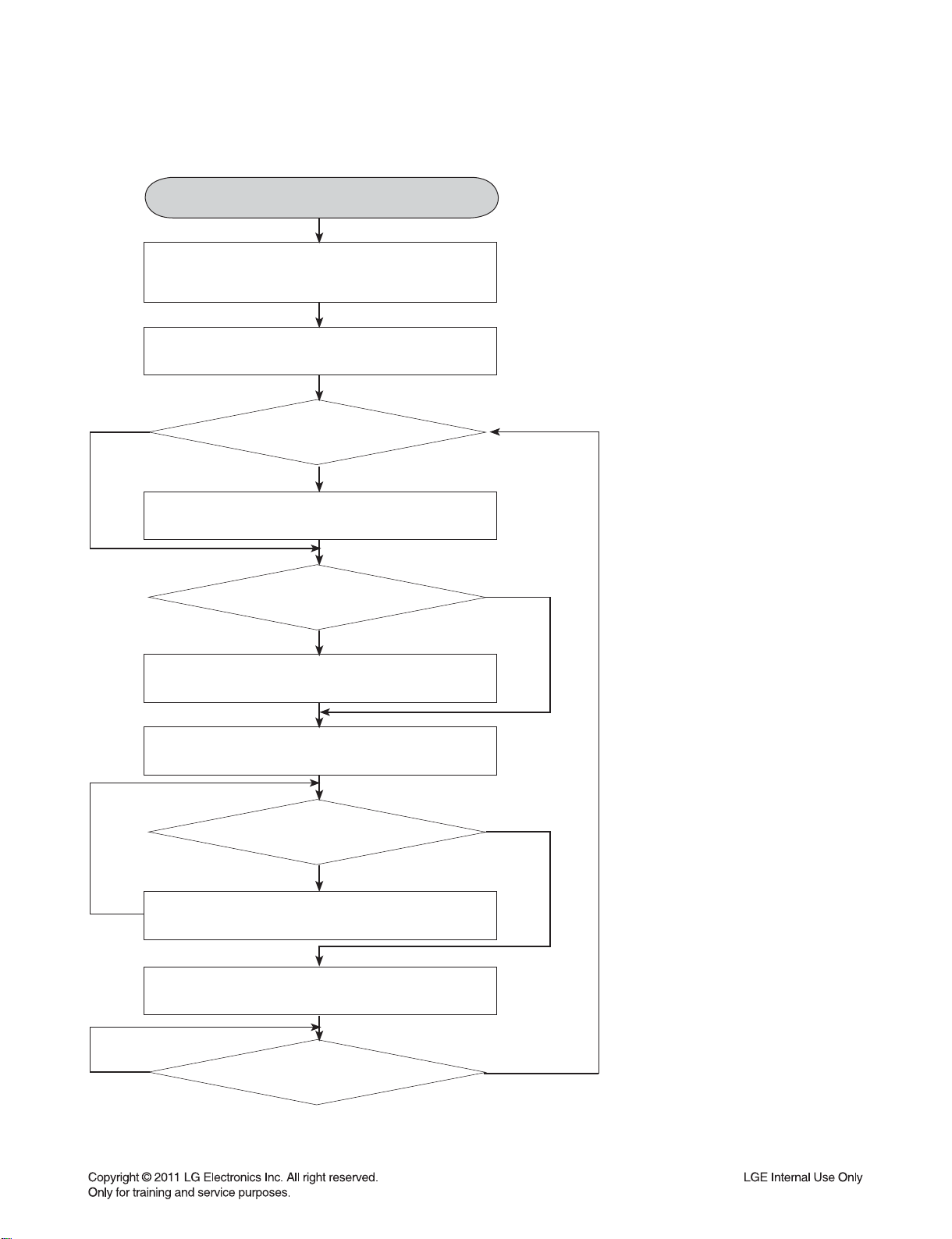

Page 14

ELECTRICAL TROUBLESHOOTING GUIDE

4. SYSTEM OPERATION FLOW

POWER ON.

1. Initializes SERVO, DSP & RISC registers.

2. Write RISC code to SDRAM.

3. Reset RISC.

Show LOGO.

YES

YES

Tray closed?

NO

Tray close to closed position.

SLED at inner

side?

NO

SLED moves to inner position.

1. Judge whether have disc and disc type.

2. Jump to related disc reading procedure.

Recieve

OPEN/ CLOSE

Key?

YES

YES

NO

NO

1. Execute Pressed Key & IR Key.

2. System operation routine loop.

1. Stop Playback & Open Tray.

2. Display tray open message & LOGO.

YES

Receive

CLOSE Key?

YES

2-5

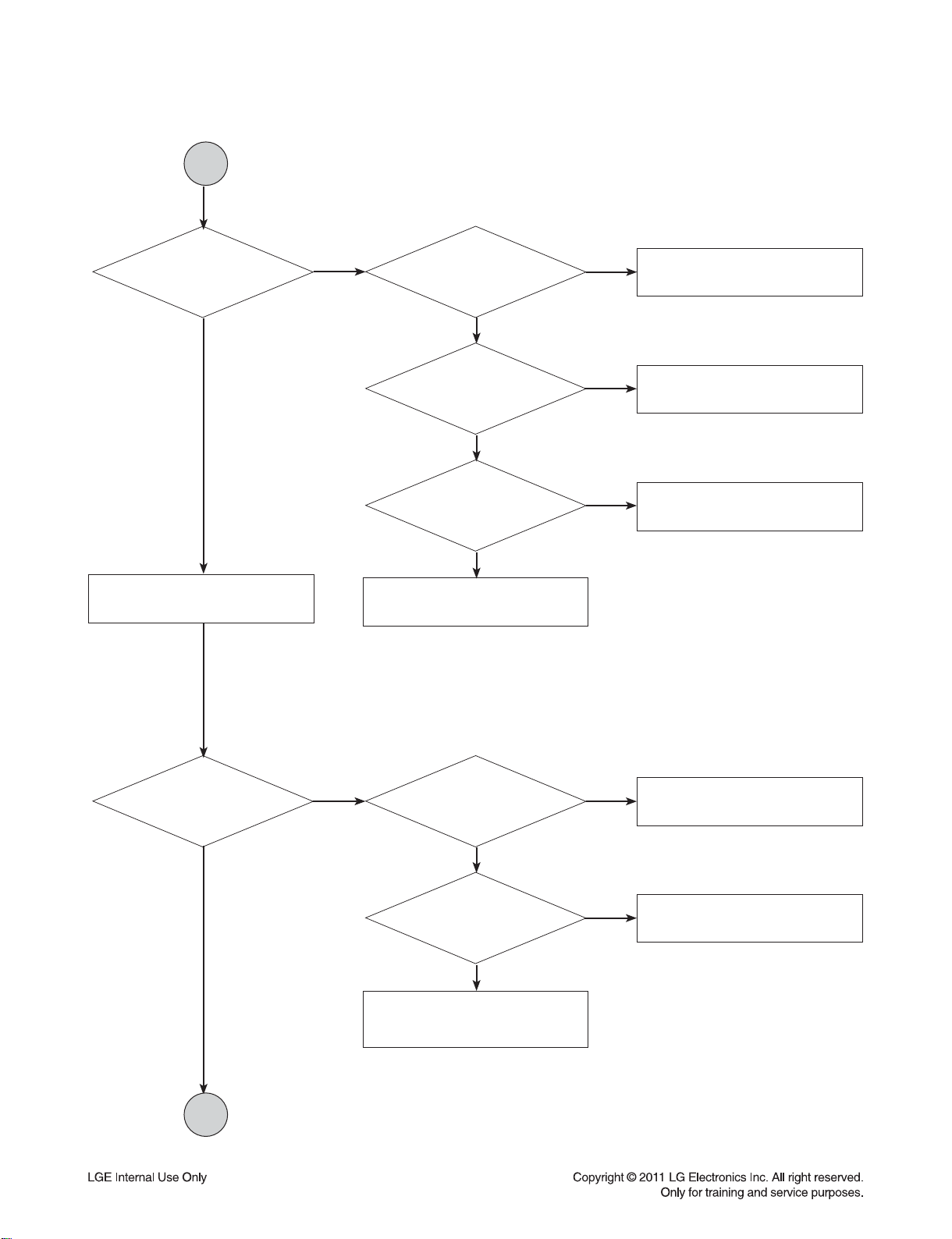

Page 15

ELECTRICAL TROUBLESHOOTING GUIDE

5. TEST & DEBUG FLOW

TEST.

YES

Check the

AC voltage Power PCBA (110 V

or 220 V).

YES

Switch on the Power PCBA.

YES

Are the

DC Voltage outputs OK? (12 V, 3.3 V,

5 V, 7 V, 34 V).

YES

Are 3.3 V and

5 V DC outputs normal on main

PCBA?

YES

Update

FLASH successfully?

YES

NO

NO

NO

NO

Check the POWER PART.

Check the POWER PART.

Check the regulators or diode.

1. Check 27 MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,

RWR.

4. Check FLASH Memory related circuit.

NO

A

Replace FLASH.

2-6

Page 16

ELECTRICAL TROUBLESHOOTING GUIDE

A

YES

Power On.

YES

Show LOGO?

YES

Does Tray

move inside when it

is not at closed

position?

NO

NO

Flash

Memory operates

properly?

YES

SDRAM

works properly?

YES

MT1389MH

VIDEO outputs

properly?

YES

Check AV cable

connection to TV set.

Normal

OPEN_SW,

CLOSE_SW

signal?

Check connection lines

NO

NO

NO

NO

between FLASH & MT1389MH

and the FLASH access time

whether is suitable or not.

Check connection lines

between SDRAM(IC503) &

MT1389MH and the SDRAM

is damaged.

Check the related circuit of

MT1389MH IC501 pins138,

142, 144, 145.

Check the load OPEN &

CLOSE switch.

B

YES

YES

Normal

TROPEN & TRCLOSE

signal?

YES

Normal

LOAD+ & LOAD-

signal?

YES

Check AV cable connection

between main PCBA and

loader. (MECHA)

2-7

NO

Check the Tray control IO pins

on MT1389MH.

NO

Check the Tray control MOTOR

& SERVO circuit IC400.

Page 17

ELECTRICAL TROUBLESHOOTING GUIDE

B

YES

Does

the SLED move to inner

side when it is at outer

position?

YES

Do not put in disc

and close tray.

NO

Motor

Driver M_STBY

pin is high?

YES

Motor

Driver M_STBY

pin is High?

YES

SLED+ and

SLED- output

properly?

YES

Check the cable connection

with MECHA.

NO

NO

NO

Check the connection line of

M_STBY.

Check the related circuit of

SLD.

Check the amp circuit on

motor driver.

Optical Lens

has movements for

searching Focus?

YES

C

NO

Proper

Focus outputs

to motor driver?

YES

Proper F+ & F-

outputs?

YES

Check cable connection with

pick-up head.

2-8

NO

NO

Check Focus connection on

MT1389MH

Check the amp circuit on motor

and motor driver.

driver.

Page 18

ELECTRICAL TROUBLESHOOTING GUIDE

C

YES

Laser

turns on when

reading disc?

YES

Put disc in?

YES

Disc ID is correct?

NO

NO

NO

DVDLD or

CDLD output

property?

YES

Collector

voltage of power transistor

is OK?(Q403, Q405)

YES

Check cable connection

between transistor output and

pick-up head.

Laser off.

Proper

RF signal on

MT1389MH.

NO

NO

NO

Check the laser power circuit

on MT1389MH and

connecting to power transistor.(Q403, Q405).

Check the related circuit on

laser power transistor.

Check the related circuit on

MT1389MH RF signal.

YES

Does spindle rotate?

YES

D

NO

YES

Check the RF connection

between AM5890 and MT1389MH.

Proper

SPINDLE signal on

MT1389MH.

YES

SPNP

SPNN output

properly?

YES

Check the cable connection

between spindle and main

PCB.

2-9

NO

NO

Check the SPINDLE related

circuit on MT1389MH.

Check the spindle control amp

circuit of motor driver.

Page 19

ELECTRICAL TROUBLESHOOTING GUIDE

D

YES

Focus on ok?

YES

Track On OK?

YES

NO

NO

Proper

signals on A, B, C,

D of MT1389MH.

YES

Proper

CD_DVDCT signal on

MT1389MH.

YES

Check CD_DVDCT connection

between AM5890 and

MT1389MH.

Proper

CD_DVDCT signal on

MT1389MH.

YES

Proper

TRACK signal

on MT1389MH.

NO

NO

NO

NO

Check connections between

MT1389MH and pick-up head.

Check the related circuit on

MT1389MH CD_DVDCT.

Check the related circuit on

MT1389MH.

Check the TRACK connection

on MT1389MH and motor driver.

Disc Playback?

YES

E

NO

YES

T+ & T- output

properly?

YES

Check cable connection

on pick-up head.

Check RF signal waveform.

2-10

NO

Check the tracking control amp

circuit on motor driver.

Page 20

ELECTRICAL TROUBLESHOOTING GUIDE

E

YES

Normal Audio

output when disc

playback?

YES

TEST END.

NO

PWM IC

received correct data

stream?

YES

Normal

PWM IC out?(IC602).

YES

Check Digital Amp circuit

(IC701, IC702).

NO

NO

Check connection between

IC602 BCK, LRCK, ADATA0.

Check the related circuit of

PWM.(Check Audio out

pins28, 31, 33, 34, 37, 39, 42).

2-11

Page 21

ELECTRICAL TROUBLESHOOTING GUIDE

6. AMP PROTECTION

"PROTECTION" appears on the FLD.

YES

After unplug power cord, connect again.

YES

Power on.

YES

"PROTECTION"

appears continuously on the FLD.

YES

Is the IC101 pin54

"LOW" signal(0 V)?

YES

Is the Q701 and

Q702 normal?

YES

Replace TI AMP IC(IC701, IC702)

NO

OK.

NO

Replace IC101.

NO

Replace the Q701 and Q702.

2-12

Page 22

ELECTRICAL TROUBLESHOOTING GUIDE

7. AUDIO μ-COM CIRCUIT(DVD & AMP)

Power On.

YES

Does

CD/DVD appear at

FLD?

YES

Does

Reading appear

at FLD?

YES

Does

no Disc or Time

appear at

FLD?

YES

Check

if DVD and audio

CD insert is

OK.

NO

NO

Does

it appear DVD Error

at FLD?

YES

Check

power part of Main

B/D.

YES

Check

oscillator of

X101.

YES

Does Aux,

Scart, opt and FM 87.5

appear at FLD.

NO

NO

Refer to SMPS.

NO

Refer to oscillator circuit.

YESNO

OK

NO

Check Power.

YES

Check DVD Module.

Check SMPS.

NO

Check

if IC101 pin5

is high.

YES

Check

if IC101 pin9, 36, 59 are

high(5 V).

YES

Check

if IC101 pin49

is high.

YES

Replace IC101.

NO

NO

NO

Check IC101 reset

waveform.

Check 3.3 V line.

Check power section

2-13

circuit.

Page 23

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

4

1

2

3

1. SYSTEM 27 MHz CLOCK, RESET, FLASH R/W SIGNAL

1)

MT1389MH

2)

MT1389MH

main clock is at 27 MHz(X500)

1

FIG 1-1

reset is high active.

Power Cord in

P_CTL

DVD_RST

RESET_IN

2

3

4

FIG 1-2

2-14

Page 24

3) Flash R/W enable signal during download(Downloading)

6

5

7

SF_DI

5

SF_DO

6

FIG 1-3

2. SDRAM CLOCK

1)

MT1389MH

DCLK = 93 MHz, Vp-p=2.2, Vmax=2.7 V

SDCLK

main clock is at 27 MHz(X500)

7

FIG 2-1

2-15

Page 25

3. TRAY OPEN/CLOSE SIGNAL

8

9

11

10

1) Tray open/close waveform

OPENSW

CLOSESW

OPEN

CLOSE

FIG 3-1

3) Tray open waveform

OPENSW

2) Tray close waveform

OPENSW

8

CLOSESW

9

OPEN

10

CLOSE

11

FIG 3-2

8

8

9

10

11

CLOSESW

9

OPEN

10

CLOSE

11

FIG 3-3

2-16

Page 26

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

13

12

14

15

SLD

M-STBY

SL+

SL-

FIG 4-1

12

13

14

15

2-17

Page 27

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION)

17 18

16

2119 20

FOD

F+

F-

16

17

18

FIG 5-1

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION)

MDI1

DVDLD

CDLD

FIG 6-1

19

20

21

2-18

Page 28

7. DISC TYPE JUDGEMENT WAVEFORMS

22

24

23

F+

PU_DET

RF

FIG 7-1 (DVD)

F+

PU_DET

22

23

24

23 : This signal can see using special debug program

22

23

RF

24

FIG 7-2 (DVD)

2-19

Page 29

F+

22

24

23

22

PU_DET

RF

F+

PU_DET

RF

23

24

FIG 7-3 (CD)

23 : This signal can see using special debug program

22

23

24

FIG 7-4 (CD)

2-20

Page 30

8. FOCUS ON WAVEFORMS

26

27 28

25

25 : This signal can see using special debug program

PU_DET

FOD

F+

F-

PU_DET

FOD

F+

F-

25

26

27

28

FIG 8-1 (DVD)

25

26

27

28

FIG 8-2 (CD)

2-21

Page 31

30

29

31

9. SPINDLE CONTROL WAVEFORMS (NO DISC CONDITION)

FIG 9-1

SPIND

29

SP-

30

SP+

31

2-22

Page 32

10. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING)

32

35

34

33

PU_DET

32

TRO

33

T-

34

T+

35

FIG 10-1(DVD)

32 : This signal can see using special debug program

PU_DET

32

TRO

33

FIG 10-2(CD)

T-

34

T+

35

2-23

Page 33

11. MT1389MH VIDEO OUTPUT WAVEFORMS

36

37

1) Full colorbar signal(COMPOSITE)

CVBS

FIG 11-1

2) Y

36

Y_G

37

FIG 11-2

2-24

Page 34

12. DVD & AMP WAVEFORMS MT1389MH

1)

• FL+ : R640

3)

• WF- : R642

5)

or

WF+ : R643

38

40

2)

39

• RL+ : R641

4)

41

• C+ : R644

6)

• FR+ : R645

42

43

• RR+ : R646

43

42

41

40

39

38

2-25

Page 35

MEMO

2-26

Page 36

WIRING DIAGRAM

CN851

HDMI

CN402

23PIN

JK202

COMPONENT

CVBS

AUX

JK201 TU100

SCART

CN401

9PIN

CN202

Tuner

18PIN

12 PIN

JK701

SPK TERMINAL

CN103

MAIN+AMP PCB

PN901

16 PIN

B’d to B’d

PWR KEY PCB

MD

CN301

PN202

VOLUME

PN301

CN901

SMPS PCB

FRONT JACK PCB

PORTABLE IN

VFD

FRONT PCB

MIC 1,2USB

PN302

2-27 2-28

Page 37

6

BLOCK DIAGRAMS

1. BLOCK DIAGRAM-1

I/O Board

Composite

Component

Front

Scart

Aux-IN

Portable

R,G,B

CVBS

Y, Pb, Pr

2CH A

2CH A

2CH A

ADC

CS5345

CVBS

MCLK, LRCK, BCK

AD_DATA

Karaoke model: 4M

Non karaoke: 2M

MM1692

6dB up

CVBS

Y/G,

Pb/B,

Pr/R

SPI

FLASH

SPI_CS,CLK,DI,KO

SDRAM

DMA[0..11],DB[0..15]

EEPROM

MPEG

MT1389MH

(176PIN)

DSCK#,CKE,CS0#,RAS0#

SCI, SDA

w~t

tvk|sh{vy

\WP

z`_

Ow

syjsrSGzjsr

myvu{Ohkh{hWP

ylhyOhkh{hXP

jV~Ohkh{hYP

kVtOhkh{hZP

A,B,C,D,E,F,RF

MDI

CDDVDCT,VRCD,VRDVD

CDLD, DVDLD

OPEN/CLOSE

FOCUS/SLED

SPINDLE/TRACKING

M_STBY

sRVTSGmyRVT

m

RVTSGy

ys

jl

~vvmly

yR

u{lyRVT

RVT

MOTOR

(AM5890)

VT

DRIVE

IC

{hz\Z\Y

wGh

kljrGGtljohupzt

/('s)s7s

6

2$'s63,1'/(s

/

P/UP

M

2CH A

EEPROM

Tuner

ST_IND

TUNER_CLK

TUNER_DAT

RDS_CLK

RDS_DAT

CE,CLK,DI

,DO, MRST#

MICOM

CLK,DI,DO

USBP, USBN

S4308

TX0, TX1, TX2, TXC

j

l

j

USB CON

Analog MIC

MIC

I/F

oktp

2-29 2-30

Page 38

2. BLOCK DIAGRAM-2

Tuner

MPEG

TUNED

ST_IND

TUNER_CLK

TUNER_DAT

RDS_CLK

RDS_DAT

DVD_CLK

DVD_DI

DVD_DO

DVD_RST

DVD_CE

MICOM

PWM_RST

PWMT_CLK

PWM_DAT

TAS5352

AMP_PDN

AMP_SD

AMP_PROTECT

PS9850B

OP-AMP

MIC

EEPROM

MIC_DET

P_SENSE

EEP_CLK

EEP_DAT

VFD

DRIVER

VFD_DO

VFD_STB

VFD_CLK

RMC

RCU_IN

VOL_UP

VOL_DN

KEY

VOL &

KEY

ADC_RST

ADC_CLK

ADC_DAT

RESET

DBGP0

DBGP1

D/L CNT

CS5346

DBGP2

2-31 2-32

Page 39

CIRCUIT DIAGRAMS

1. SMPS CIRCUIT DIAGRAM

12

11

10

9

8

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES IDENTICAL

TO THOSE IN THE ORIGINAL CIRCUIT. SPECIAL

COMPONENTS ARE SHADED ON THE SCHEMATIC

FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety.

Replace only with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

7

6

5

4

3

2

CAUTION:

1

A

Danger if fuse is incorrectly replaced.

Replace only with the type identical to fuse rating

and(or) model name described in main label.

B C D E F G H I J K L M N O P Q R ST

Warning

Parts that are shaded are critical with

respect to risk of fire or electrical shock.

EBY61269201, REV1.1

2010. 11. 25

SMPS

2-33 2-34

Page 40

2. MAIN & AMP - 1 CIRCUIT DIAGRAM

12

6

11

10

5

37

36

9

8

7

1

2119 20

23

4

25

32

7

6

16 26

5

4

3

24

10

11

12

14

15

22

27

18

28

13

33

29

30

31

34

3517

8

9

2

1

: WAVEFORM NUMBER

A

BCDEFGH I J KLMNOPQRST

EBY61070501(#1), REV2.13

MAIN & AMP

2011. 02. 08

2-35 2-36

Page 41

3. MAIN & AMP - 2 CIRCUIT DIAGRAM

12

11

10

9

8

3

2

7

6

43

42

5

41

40

4

39

38

3

2

1

: WAVEFORM NUMBER

A

BCDEFGH I J KLMNOPQRST

EBY61070501(#2), REV2.13

MAIN & AMP

2011. 02. 08

2-37 2-38

Page 42

4. FRONT & POWER KEY CIRCUIT DIAGRAM

12

11

10

9

8

7

6

POWER KEY

EBY61051201, REV2.4

2010. 11. 25

5

4

3

2

1

EBY61070601, REV2.1

A

B C D E F G H I J K L M N O P Q R ST

FRONT

2010. 11. 25

2-39 2-40

Page 43

5. FRONT JACK CIRCUIT DIAGRAM

12

11

10

9

8

7

6

5

4

3

2

1

A

B C D E F G H I J K L M N O P Q R ST

FRONT JACK

EBY61070701, REV2.3

2010. 11. 25

2-41 2-42

Page 44

CIRCUIT VOLTAGE CHART

1. IC'S VOLTAGE

Pin No. Specification EE Mode (V) Playback Mode (V)

IC101 MICOM (LC87F5M64A)

9(VDD2) 2.8~5.5 3.479 3.475

36(VDD3) 2.8~5.5 3.479 3.476

59(VDD1) 2.8~5.5 3.479 3.476

IC103 EEPROM (M24C16)

8(VCC) 1.8~5.5 3.48 3.475

IC104 DETECT

1(VCC) - 3.643 3.636

IC105 DETECT

1(VCC) - 3.476 3.469

IC201 ADC (CS5346)

5(VLC) 3.13~5.25 3.244 3.227

14(VA) 4.75~5.25 4.979 4.962

30(VA) 4.75~5.25 - -

36(VLS) 3.13~5.25 3.244 3.227

46(VD) 3.13~3.47 3.244 3.227

IC301 VFD (ET16315)

13(VDD) 4.5~5.5 3.491 3.485

43(VDD) 4.5~5.5 3.491 3.486

30(VEE) VDD-35 -20.75 -20.82

IC400 MOTOR IC (AM5890S

8(VCC1) 4.3~13.2 4.993 4.95

19(VCC2) 4.3~Vcc1 4.993 4.952

20(VCCD) 0~12 3.1 -

IC501 (MT1389FE/MH With HDMI)

1 (AVDD12_2) - 1.856 1.852

2 (AVDD33_1) - 3.165 3.147

12 (AVDD33_2) - 3.164 3.147

22 (VDD33_USB) - 3.165 3.147

25(VDD12_USB) - 1.855 1.844

38 (DVDD33) - 3.22 3.202

57 (DVDD33) - 3.22 3.202

67 (DVDD33) - 3.219 3.202

79 (DVDD12) - 1.843 1.824

92 (DVDD33) - 3.219 3.202

101 (DVDD33) - 3.22 3.202

109 (DVDD12) - 1.843 1.82

114 (AVDD33_12) - 3.075 3.06

119 (AVDD12_C) - 1.879 1.874

125 (AVDD12_D) - 1.879 1.874

140 (DACVDDB) - 0 0

142 (DACVDDA) - 0.312 0.572

151 (AADVDD) - 3.164 3.149

163(ADACVDD1) - 3.165 3.148

164(ADACVDD2) - 3.165 3.148

Pin No. Specification EE Mode (V) Playback Mode (V)

165 (AVDD12) - 1.856 1.849

IC502 Flash (W25Q168)

8(VDD) 2.7~3.6 3.221 3.199

IC503 SDRAM (HY57V64)

1(VDD) 3.0~3.6 3.223 3.209

3(VDDQ) 3.0~3.6 3.223 3.209

9(VDDQ) 3.0~3.6 3.223 3.208

14(VDD) 3.0~3.6 3.223 3.209

27(VDD) 3.0~3.6 3.223 3.209

43(VDDQ) 3.0~3.6 3.223 3.209

49(VDDQ) 3.0~3.6 3.223 3.209

IC602 PWM (PS9850)

16(VDD_IO) 2.97~3.63 3.264 3.255

21(VDD_CORE) 1.08~1.32 1.253 1.255

24(VDD_IO) 2.97~3.63 3.264 3.256

29(VDD_IO) 2.97~3.63 3.264 3.256

32(VDD_IO) 2.97~3.63 3.264 3.256

35(VDD_IO) 2.97~3.63 3.264 3.256

40(VDD_IO) 2.97~3.63 3.264 3.256

43(VDD_CORE) 1.08~1.32 1.253 1.252

48(VDD_IO) 2.97~3.63 3.264 3.256

57(VDD_CORE) 1.08~1.32 1.252 1.252

59(VDDA) 1.08~1.32 1.255 1.254

61(VDD_VIN2) 2.20~3.30 3.264 3.255

64(VDD_VIN1) 2.20~3.30 3.264 3.255

IC701 AMP (TAS5352)

1(GVDD_B) 10.8~13.2 12.22 12.1

21(VDD) 10.8~13.2 12.26 12.15

22(GVDD_C) 10.8~13.2 12.21 12.11

23(GVDD_D) 10.8~13.2 12.21 12.11

26(PVDD_D) 0~52.5 34.8 34.8

27(PVDD_D) 0~52.5 34.8 34.8

32(PVDD_C) 0~52.5 34.8 34.8

35(PVDD_B) 0~52.5 34.8 34.8

40(PVDD_A) 0~52.5 34.8 34.8

41(PVDD_A) 0~52.5 34.8 34.8

44(GVDD_A) 10.8~13.2 12.22 12.11

2-43 2-44

Page 45

2. CAPACITOR'S VOLTAGE

Loca. No

C106 220 10V 3.45V 0V 3.45V 6.55V 3.45V 0V 3.45V 6.55V

C114 100 10V 3.45V 0V 3.45V 6.55V 3.45V 0V 3.45V 6.55V

C122 220 10V 3.69V 0V 3.69V 6.31V 3.7V 0V 3.7V 6.3V

C124 47 16V 4.98V 0V 4.98V 11.02V 4.98V 0V 4.98V 11.02V

C127 47 16V 12.18V 0V 12.18V 3.82V 12.24V 0V 12.24V 3.76V

C133 47 16V 3.45V 0V 3.45V 12.55V 3.45V 0V 3.45V 12.55V

C145 10 16V 3.08V 0V 3.08V 12.92V 3.08V 0V 3.08V 12.92V

C146 100 16V 3.28V 0V 3.28V 12.72V 3.29V 0V 3.29V 12.71V

C228 1 50V 1.4V 0V 1.4V 48.6V - - 0V 50V

C229 100 16V 11.47V 0V 11.47V 4.53V 11.53V 0V 11.53V 4.47V

C230 22 50V 1.97V 0V 1.97V 48.03V 1.97 0 1.97V 48.03V

C231 100 16V 2V 1.88V 0.12V 15.88V 1.99V 1.87V 0.12V 15.88V

C241 22 50V 2.46V 0V 2.46V 47.54V 2.47V 0V 2.47V 47.53V

C243 47 16V 4.95V 0V 4.95V 11.05V 4.95V 0V 4.95V 11.05V

C264 10 16V 4.97V 0V 4.97V 11.03V 4.97V 0V 4.97V 11.03V

C265 10 16V 3.23V 0V 3.23V 12.77V 3.23V 0V 3.23V 12.77V

C267 47 16V 4.2V 0V 4.2V 11.8V 4.95V 0V 4.95V 11.05V

C268 10 16V 2.48V 0V 2.48V 13.52V 2.48V 0V 2.48V 13.52V

C274 470 10V 1.61V 0.8V 0.81V 9.19V 2.03V 1.15V 0.88V 9.12V

C275 470 10V 2.3V 1.37V 0.93V 9.07V 2.31V 1.33V 0.98V 9.02V

C276 470 10V 2.31V 1.4V 0.91V 9.09V 2.32V 1.36V 0.96V 9.04V

C282 470 10V 1.6V 0.91V 0.69V 9.31V 2.02V 1.27V 0.75V 9.25V

C2D1 220 6.3V 1.02V 0V 1.02V 5.28V 4.98V 0V 4.98V 1.32V

C2D3 4.7 50V 0.32V 0.18V 0.14V 49.86V 0.58V 0.31V 0.27V 49.73V

C2D4 4.7 50V 0.42V 0.25V 0.17V 49.83V 0.49V 0.25V 0.24V 49.76V

C309 220 6.3V 3.36V 0V 3.36V 2.94V 3.37V 0V 3.37V 2.93V

C332 47 35V 0V -15.55V 15.55V 19.45V 0V -15.43V 15.43V 19.57V

C333 47 35V 0V -17.91V 17.91V 17.09V 0V -17.81V 17.81V 17.19V

C3A1 47 16V 3.47V 0V 3.47V 12.53V 3.47V 0V 3.47V 12.53V

C3A2 47 35V 0V -20.52V 20.52V 14.48V 0V -20.4V 20.4V 14.6V

C417 47 16V 3.21V 3.14V 0.07V 15.93V 3.2V 2.29V 0.91V 15.09V

C418 47 16V 3.21V 3.14V 0.07V 15.93V 3.2V 3.02V 0.18V 15.82V

C420 47 16V 4.98V 0V 4.98V 11.02V 4.94V 0V 4.94V 11.06V

C421 47 16V 4.98V 0V 4.98V 11.02V 4.94V 0V 4.94V 11.06V

C422 47 16V 1.86V 0V 1.86V 14.14V 1.88V 0V 1.88V 14.12V

C423 100 10V 4.96V 0V 4.96V 5.04V 4.96V 0V 4.96V 5.04V

C427 47 16V 1.4V 0V 1.4V 14.6V 1.42V 0V 1.42V 14.58V

C553 10 16V 1.28V 1.02V 0.26V 15.74V 1.24 1.02 0.22V 15.78V

C554 10 16V 1.25V 1.06V 0.19V 15.81V 1.26 1.05 0.21V 15.79V

C555 100 10V 3.21V 0V 3.21V 6.79V 3.2V 0V 3.2V 6.8V

C556 100 10V 1.85V 0V 1.85V 8.15V 1.86V 0V 1.86V 8.14V

C557 100 16V 1.82V 0V 1.82V 14.18V 1.84V 0V 1.84V 14.16V

C558 100 10V 3.16V 0V 3.16V 6.84V 3.15V 0V 3.15V 6.85V

Value

Capacitor

(uF)

Voltae

Spec

(+) (-) Gap Margin (+) (-) Gap Margin

EE Mode Playback Mode

Loca. No

C560 100 16V 1.53V 0V 1.53V 14.47V 1.48V 0V 1.48V 14.52V

C561 100 10V 1.34V 0V 1.34V 8.66V 1.33V 0V 1.33V 8.67V

C563 10 16V 3.22V 0V 3.22V 12.78V 1.28V 1.03V 0.25V 15.75V

C564 10 16V 3.22V 0V 3.22V 12.78V 3.21V 0V 3.21V 12.79V

C565 10 16V 3.21V 0V 3.21V 12.79V 3.2V 0V 3.2V 12.8V

C613 10 16V 1.24V 0V 1.24V 14.76V 1.25V 0V 1.25V 14.75V

C646 10 16V 0.16V 0V 0.16V 15.84V 0.14V 0V 0.14V 15.86V

C702 47 50V 12.17V 0V 12.17V 37.83V 12.22V 0V 12.22V 37.78V

C708 10 16V 12.11V 0V 12.11V 3.89V 12.17V 0V 12.17V 3.83V

C723 470 50V 37.2V 0V 37.2V 12.8V 37.35V 0V 37.35V 12.65V

C729 470 35V 37.2V 18.4V 18.8V 16.2V 37.35V 18.58V 18.77V 16.23V

C730 470 35V 18.4V 0V 18.4V 16.6V 18.58V 0V 18.58V 16.42V

C731 470 35V 18.4V 0V 18.4V 16.6V 18.58V 0V 18.58V 16.42V

C732 470 35V 37.2V 18.4V 18.8V 16.2V 37.35V 18.58V 18.77V 16.23V

C746 470 50V 37.2V 0V 37.2V 12.8V 37.35V 0V 37.35V 12.65V

C749 47 50V 12.17V 0V 12.17V 37.83V 12.22V 0V 12.22V 37.78V

C753 10 16V 12.11V 0V 12.11V 3.89V 12.17V 0V 12.17V 3.83V

C768 470 35V 37.2V 18.4V 18.8V 16.2V 37.35V 18.58V 18.77V 16.23V

C770 470 35V 18.5V 0V 18.5V 16.5V 18.58V 0V 18.58V 16.42V

C782 470 35V 37.2V 18.4V 18.8V 16.2V 37.35V 18.58V 18.77V 16.23V

C783 470 35V 18.4V 0V 18.4V 16.6V 18.58V 0V 18.58V 16.42V

C784 470 35V 19.8V 0V 19.8V 15.2V 18.58V 0V 18.58V 16.42V

C785 470 35V 37.2V 18.5V 18.7V 16.3V 37.36V 18.58V 18.78V 16.22V

C7A7 470 50V 37.2V 0V 37.2V 12.8V 37.35V 0V 37.35V 12.65V

C7A8 470 50V 37.2V 0V 37.2V 12.8V 37.35V 0V 37.35V 12.65V

Value

Capacitor

(uF)

Voltae

Spec

(+) (-) Gap Margin (+) (-) Gap Margin

EE Mode Playback Mode

2-45 2-46

Page 46

PRINTED CIRCUIT BOARD DIAGRAMS

1. MAIN & AMP P.C. BOARD

(TOP VIEW)

2-47 2-48

Page 47

MAIN & AMP P.C. BOARD

(BOTTOM VIEW)

2-49 2-50

Page 48

2. SMPS P.C. BOARD

(TOP VIEW)

(BOTTOM VIEW)

NOTE) Warning

Parts that are critical with respect to risk

of fire or electrical shock.

2-51 2-52

Page 49

3. FRONT P.C. BOARD

4. POWER KEY P.C. BOARD

(TOP VIEW)

(BOTTOM VIEW)

(TOP VIEW)

(BOTTOM VIEW)

5. FRONT JACK P.C. BOARD

(TOP VIEW)

(BOTTOM VIEW)

2-53 2-54

Page 50

SECTION 3

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS ......................................................................................................................................... 3-3

1. CABINET AND MAIN FRAME SECTION ................................................................................................. 3-3

2. DECK MECHANISM SECTION (DP-15T) ................................................................................................ 3-5

3. SPEAKER SECTION ................................................................................................................................ 3-7

3-1. FRONT/ REAR/ CENTER SPEAKER (SH36SF-S) ............................................................................. 3-7

3-2. PASSIVE SUBWOOFER (SH36SU-W) ............................................................................................... 3-8

4. PACKING ACCESSORY SECTION ......................................................................................................... 3-9

3-1

Page 51

MEMO

3-2

Page 52

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

284

A43

A50

273

PN302

463

CABLE1

C

275

A47

A

463

463

462

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

250

B

A

B

C

463

MAIN

283

279

284

282

463

PN202

A41

E

472

FRONT JACK

263

SMPS

262

261

D

E

A46

300

470

465

D

A44

260

261

3-3 3-4

Page 53

2. DECK MECHANISM SECTION (DP-15T)

MEMO

001

A02

013

017

435

015

439

018

015B

015A

014

002

003

A01

020

016

026

A03

019

440

012

442

037

012

010

012A

442

3-5 3-6

Page 54

3. SPEAKER SECTION

3-1. FRONT/ REAR/ CENTER SPEAKER (SH36SF-S)

850

851

A800 Front SPK

A600 Rear SPK

A700 Center SPK

852

854

853

856

856

855

856

WIRE80 Front SPK Wire (3M)

WIRE70 Center SPK Wire (3M)

WIRE60 Rear SPK Wire (7M)

3-7

Page 55

3-2. PASSIVE SUBWOOFER (SH36SU-W)

A900

3-8

Page 56

4. PACKING ACCESSORY SECTION

808 Battery

801 Owner’s Manual

803 Packing

804 Bag

803A Speaker Packing

803B Speaker Packing

825 FM Antenna

900 Remote Control

803 Packing

803D Speaker Packing

803C Speaker Packing

802 Box

3-9

Page 57

MEMO

3-10

Page 58

SECTION 4. MECHANISM (DP-15T)

[CONTENTS]

DECK MECHANISM PARTS LOCATIONS

• Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

• Top View(without Tray Disc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

• Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

DECK MECHANISM DISASSEMBLY

1. Main Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1-1. Clamp Assembly Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1-1-1. Plate Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1-1-2. Magnet Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1-1-3. Clamp Upper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2. Tray Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

3. Base Assembly Sled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3-1. Gear Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3-2. Gear Middle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3-3. Gear Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4. Rubber Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Frame Assembly Up/Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

6. Belt Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

7. Gear Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

8. Gear Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

9. Guide Up/Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

10. PWB Assembly Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

11. Base Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

EXPLODED VIEW

1. DECK MECHANISM EXPLODED VIEW (DP-15T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-1

Page 59

DECK MECHANISM PARTS LOCATIONS

• Top View

• Top View(without Tray Disc)

• Bottom View

Procedure

Starting No.

1

1

1, 2

1, 2, 3

1, 2, 3, 4

1

1, 6

1, 2, 6

1, 2, 6, 8

1, 2, 6, 8, 9

1, 2, 7

1, 2, 7

1, 2

1, 2 ,13

1, 2, 13, 14

1, 2, 7, 12,

13, 14

1, 2, 13

1, 2, 7, 12, 13,

14, 15, 16, 17

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Parts Fixing Type

Main Base

Clamp Assembly

Disc

Plate Clamp

Magnet Clamp

Clamp Upper

Tray Disc

Base Assembly Sled

Gear Feed

Gear Middle

Gear Rack

Rubber Rear

Frame Assembly

Up/Down

Belt Loading

Gear Pulley

Gear Loading

Guide Up/Down

PWB Assembly

Loading

Base Main

4 Screws,

1 Connector

1 Locking Tabs

1 Screw

1 Screw

1 Locking Tab

1 Locking Tab

1 Locking Tab

1 Hook

2 Screw

2 Locking Tabs

Disass

embly

Bottom

Bottom

Figure

4-1

4-1

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-2

Note

When reassembling, perform the procedure in

reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

Page 60

PLATE CLAMP

MAGNET CLAMP

CLAMP UPPER

DECK MECHANISM DISASSEMBLY

TRAY DISC

MAIN BASE

DISC CLAMP ASSEMBLY

HOLDER

(Fig. A)

BASE MAIN

1. Main Base (Fig. 4-1)

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the

Holder Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise

direction and then lift up the Plate Clamp.

1-1-2. Magnet Clamp

1-1-3. Clamp Upper

BASE MAIN

LEVER

BASE MAIN

BOTTOM SIDE VIEW

Fig. 4-2Fig. 4-1

2. Tray Disc (Fig. 4-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the

Lever(B) in direction of arrow so that the Tray

Disc is ejected about 15~20mm.

2) Pull the Tray Disc until it is separated from the

Base Main completely.

4-3

Page 61

RUBBER DAMPER

RUBBER DAMPER

Distinguish upper and

lower sides

(Assemble with care)

RUBBER DAMPER

Distinguish upper and

lower sides

(Assemble with care)

BASE PU

GENERAL PICK UP ASSEMBLY

GEAR RACK

SPINDLE MOTOR ASSEMBLY

3. Base Assembly Sled (Fig. 4-3)

1) Release 4 Screw(S2).

2) Disconnect the FFC Connector(C1)

3-1. Gear Feed

3-2. Gear Middle

3-3. Gear Rack

(S2)

(S2)

RUBBER DAMPER

Fig. 4-3

4. Rubber Rear (Fig. 4-3)

4-4

Page 62

GEAR LOADING

GUIDE UP/DOWN

SCREW INSERTION

TORGUE CONTROL

(800gf DOWN)

GUIDE UP/DOWN

GEAR PULLEY

(L4)

BELT LOADING

(A)

(L5)

FIG. (A)

PWB ASSEMBLY LOADING

BASE MAIN

(B)

(C)

(B)

FIG. (C)

(S5)

(A)

GUIDE UP/DOWN

Fig. 4-4

(H1)

(C2)

(A)

(B)

FIG. (B)

GUIDE UP/DOWN

(L6)

(L6)

BASE MAIN

(S4)

(S4)

UP/DOWN FRAME ASSEMBLY

5.

Frame Assembly Up/Down (Fig. 4-4)

Note

Put the Base Main face down(Bottom Side)

1) Release the screw(S4)

2) Unlock the Locking Tab(L3) in direction of arrow

and then lift up the Frame Assembly Up/Down to

separate it from the Base Main.

Note

• When reassembling move the Guide Up/Down

in direction of arrow(C) until it is positioned as

Fig.(C).

• When reassembling insert (A) portion of the Frame

Assembly Up/Down in the (B) portion of the Guide

Up/Down as Fig.(B)

6. Belt Loading(Fig. 4-4)

Note

Put the Base Main on original position(Top Side)

7. Gear pulley (Fig. 4-4)

1) Unlock the Locking Tab(L4) in direction of arrow(B) and

then separate the Gear Pulley from the Base Main.

8. Gear Loading (Fig. 4-4)

9. Guide Up/Down (Fig. 4-4)

1) Move the Guide Up/Down in direction of arrow(A) as

Fig.(A)

2) Push the Locking Tab(L5) down and then lift up the

Guide Up/Down to separate it from the Base Main.

Note

When reassembling place the Guide Up/Down as Fig.(C)

and move it in direction arrow(B) until it is locked by the

Locking Tab(L5). And confirm the Guide Up/Down as Fig.(A)

10. PWB Assembly Loading (Fig. 4-

4)

Note

Put the Base Main face down(Bottom Side)

1) Release 1 Screws(S5)

2) Unlock the Loading Motor (C2) from the Hook (H1) on

the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the PWB

Assembly Loading from the Base Main.

11. Base Main(Fig. 4-4)

4-5

Page 63

DECK MECHANISM EXPLODED VIEW (DP-15T)

001

A02

017

013

435

015

439

018

015B

015A

014

440

002

003

A01

020

016

026

A03

019

4-6

442

012

037

012

010

012A

442

Loading...

Loading...