Page 1

DVB-T/HDD/DVD RECORDER

SERVICE MANUAL

MODELS : HDR899/1000

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

MODELS : HDR899/1000

SERVICE MANUAL

Website http://biz.lgservice.com

Internal Use Only

Page 2

CONTENTS

SECTION 1.........SUMMARY

SECTION 2.........CABINET & MAIN CHASSIS

SECTION 3.........ELECTRICAL

SECTION 4.........RS-06A LOADER PART

SECTION 5.........REPLACEMENT PARTS LIST

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 3

SECTION 1

SUMMARY

CONTENTS

NEW FUNCTIONS OF HDD/DVD RECORDER .................................................................................1-3

PRODUCT SAFETY SERVICING GUIDELINES FOR HDD/DVD RECORDER PRODUCTS

SERVICING PRECAUTIONS....................................................................................................................1-5

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

SERVICE INFORMATION FOR EEPROM IC SETTING..................................................................1-6

UPGRADE THE MAIN & LOADER PROGRAM.................................................................................1-7

SPECIFICATIONS ........................................................................................................................................1-8

..............1-4

LGE Internal Use Only

1-2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 4

NEW FUNCTIONS OF HDD/DVD RECORDER

• HDMI

HDMI IS THE SPECIFICATION FOR THE HIGH-DEFINITION MULTIMEDIA INTERFACE. HDMI IS PROVIDED

FOR TRANSMITTING DIGITAL TELEVISION AUDIOVISUAL SIGALS FROM HDD-DVD RECODER TO TELEVISION SETS, OTHER VIDEO DISPLAYS. HDMI CAN CARRY HIGH QUALITY MULTI-CHANNEL AUDIO DATA

AND CAN CARRY ALL STANDARD AND HIGH DEFINITION CONSUMER ELECTRONICS VIDEO FORMATS.

CONTENT PROTECTION TECHNOLOGY IS AVAILABLE. HDMI CAN ALSO CARRY CONTROL AND STATUS

INFORMATION IN BOTH DIRECTIONS.

<< OPERATING >>

AUDIO, VIDEO AND AUXILIARY DATA IS TRANSMITTED ACROSS THE THREE TMDS DATA CHANNELS.

THE VIDEO PIXEL CLOCK IS TRANSMITTED ON THE TMDS CLOCK CHANNEL AND USED BY THE

RECEIVER AS A FREQUENCY REFERENCE FOR DATA RECOVERY ON THE THREE TMDS DATA CHANNELS.

VIDEO DATA IS CARRIED AS A SERIES OF 24-BIT PIXELS ON THE THREE TMDS DATA CHANNELS.

TMDS ENCODING CONVERTS THE 8BIT PER CHANNEL INTO THE 10BIT DC-BALANCED.

VIDEO PIXEL RATES CAN RANGE FROM 25MHz TO 165MHz. THE VIDEO PIXELS CAN BE ENCODED IN

EITHER RGB, YCbCr 4:4:4 OR YCbCr 4:2:2 FORAMTS. IN ALL THREE CASES, UP TP 24 BITS PER PIXEL

CAN BE TRANSFERRED.

FAST DUBBING

DUBBING MEANS A COPYING FUNCTION BETWEEN HDD TO DVD DISCS.

COPYING BETWEEN HDD TO DVD IS A COMPLETELY DIGITAL PROCESS AND THEREFORE INVOLVES

NO LOSS OF QUALITY IN THE AUDIO OR VIDEO. SO THIS MEANS THAT COPYING CAN BE CARRIED OUT

AT THE MAXIMUM SPEED POSSIBLE.

<< DUBBING SPEED RATE >>

NORMAL DUBBING : SPEED RATE MAX X1

FAST DUBBING : SPEED RATE MAX X4

WHEN FAST DUBBING FROM HDD TO DVD, THE SPEED OF COPYING DEPENDS ON THE RECODING

MODE AND THE KIND OF USING THE DVD DISC, AND THIS MODE IS NOT AVAILABLE FOR EDITED VIDEO

TITLE IN HDD.

WHEN FAST DUBBING FROM DVD TO HDD, ONLY AVAILABLE WHEN COPYING VR MODE DISC(DVD-RW)

TO HDD, AND ONLY NORMAL DUBBING AVAILABLE WHEN COPYING VIDEO MODE DISC(DVD+RW/RW,

DVD-R) TO HDD.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-3

LGE Internal Use Only

Page 5

PRODUCT SAFETY SERVICING GUIDELINES FOR HDD/DVD RECORDER PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from LG Corporation. All components should

be replaced only with types identical to those in the original circuit and their physical

location, wiring and lead dress must conform to original layout upon completion of

repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component designators and are required to maintain safe performance. No deviations are allowed

without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way, implementation of the latest safety and performance improvement changes into the set is

not delayed until the new service literature is printed.

CAUTION

tomized installations without manufacturer’s approval. Unauthorized modifications will

not only void the warranty, but may lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

: Do not attempt to modify this product in any way. Never perform cus-

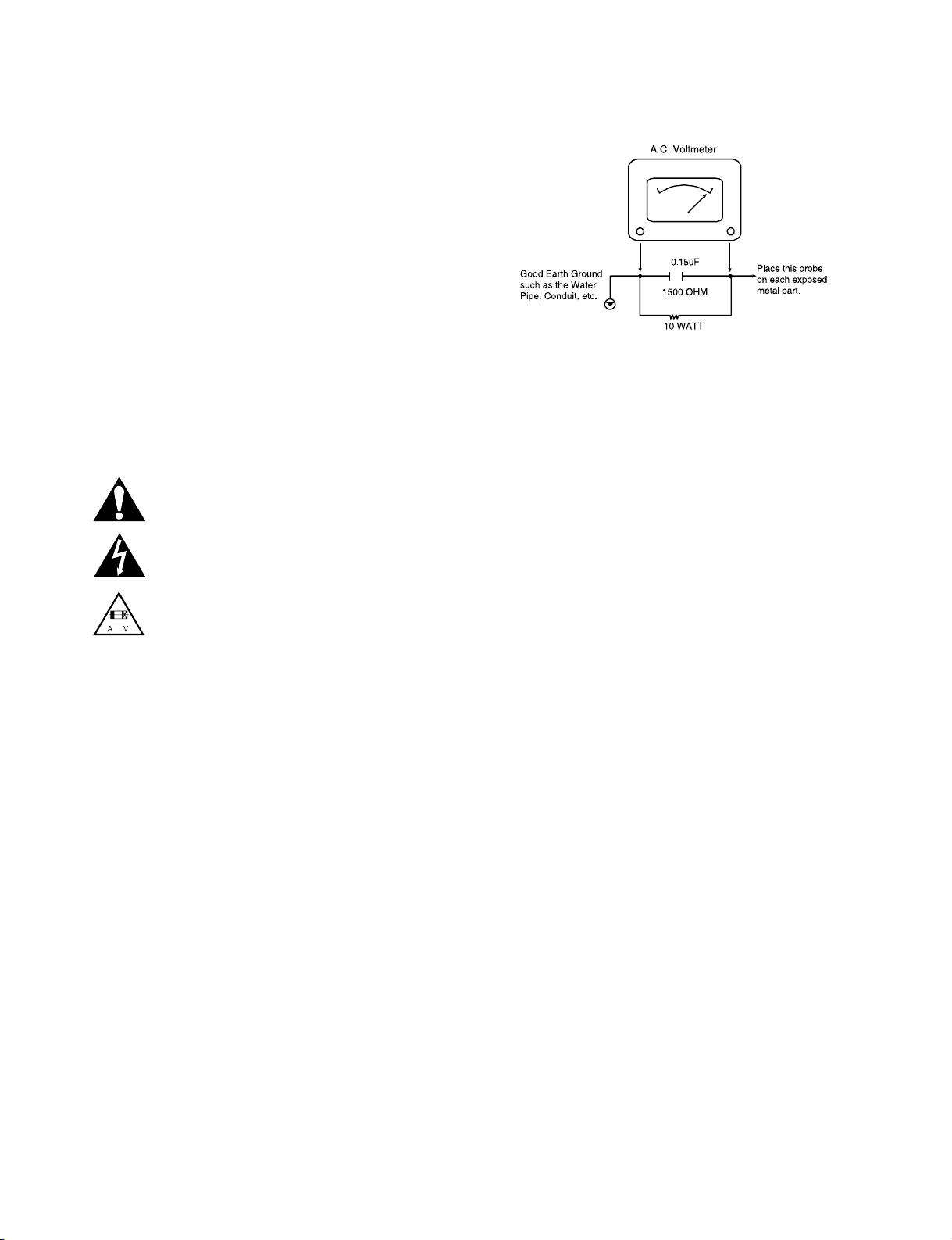

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service literature.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the service personnel to the presence of noninsulated “dangerous voltage” that may be of sufficient magnitude to

constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral triangle is intended to convey to the service personnel the following

fuse replacement caution notice:

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After

the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent component shorts. This is especially important on items trans-ported to and from the

repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

reliefs, power supply cords, and other hardware have been reinstalled per the original design. Be sure that the safety purpose of the polarized line plug has not been

defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components,

for frayed leads or damaged insulation (including the AC cord), and replace if necessary.

5. No lead or component should touch a high current device or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

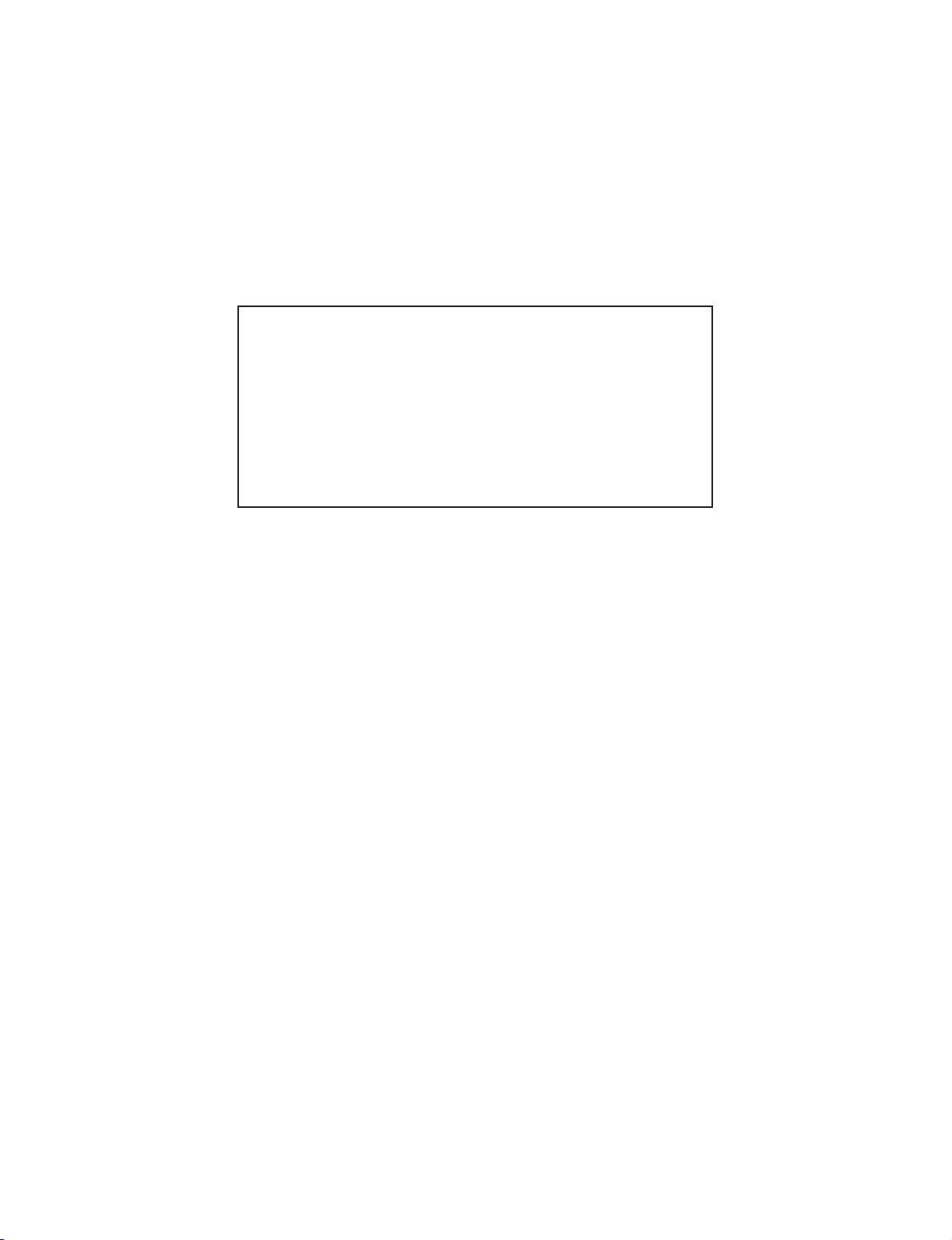

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals, handle and screws) to be sure that set is safe to operate without danger of electrical

shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the

following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by a .15 mfd

150V AC type capacitor between a known good earth ground water pipe, conduit,

etc.) and the exposed metallic parts, one at a time. Measure the AC voltage across

the combination of 1500 ohm resistor and .15 mfd capacitor. Reverse the AC plug

by using a non-polarized adaptor and repeat AC voltage measurements for each

exposed metallic part. Voltage measured must not exceed 0.75 volts RMS. This

corresponds to 0.5 milliamp AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew

is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should also

avoid the use of decorative scarves or other coverings that might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or platform must retain its original feet (or the equivalent thickness in spacers) to provide

adequate air flow across the bottom. Bolts or screws used for fasteners must not

touch any parts or wiring. Perform leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

LGE Internal Use Only

1-4

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 6

SERVICING PRECAUTIONS

CAUTION: Before servicing the HDD / DVD RECORDER covered by this service data and its supplements and addends,

read and follow the SAFETY PRECAUTIONS. NOTE: if

unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in

this publications, always follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the HDD / DVD RECORDER AC power cord

from the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an electrolyt-

ic capacitor.

Caution : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this HDD / DVD

RECORDER or any of its assemblies.

3. Unless specified otherwise in this service data, clean electrical contacts by applying an appropriate contact cleaning

solution to the contacts with a pipe cleaner, cotton-tipped

swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this HDD / DVD RECORDER and

/ or any of its electrical assemblies unless all solidstate

device heat sinks are correctly installed.

6. Always connect the test instrument ground lead to an appropriate ground before connecting the test instrument positive

lead. Always remove the test instrument ground lead last.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil,or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Caution: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

1-5

LGE Internal Use Only

Page 7

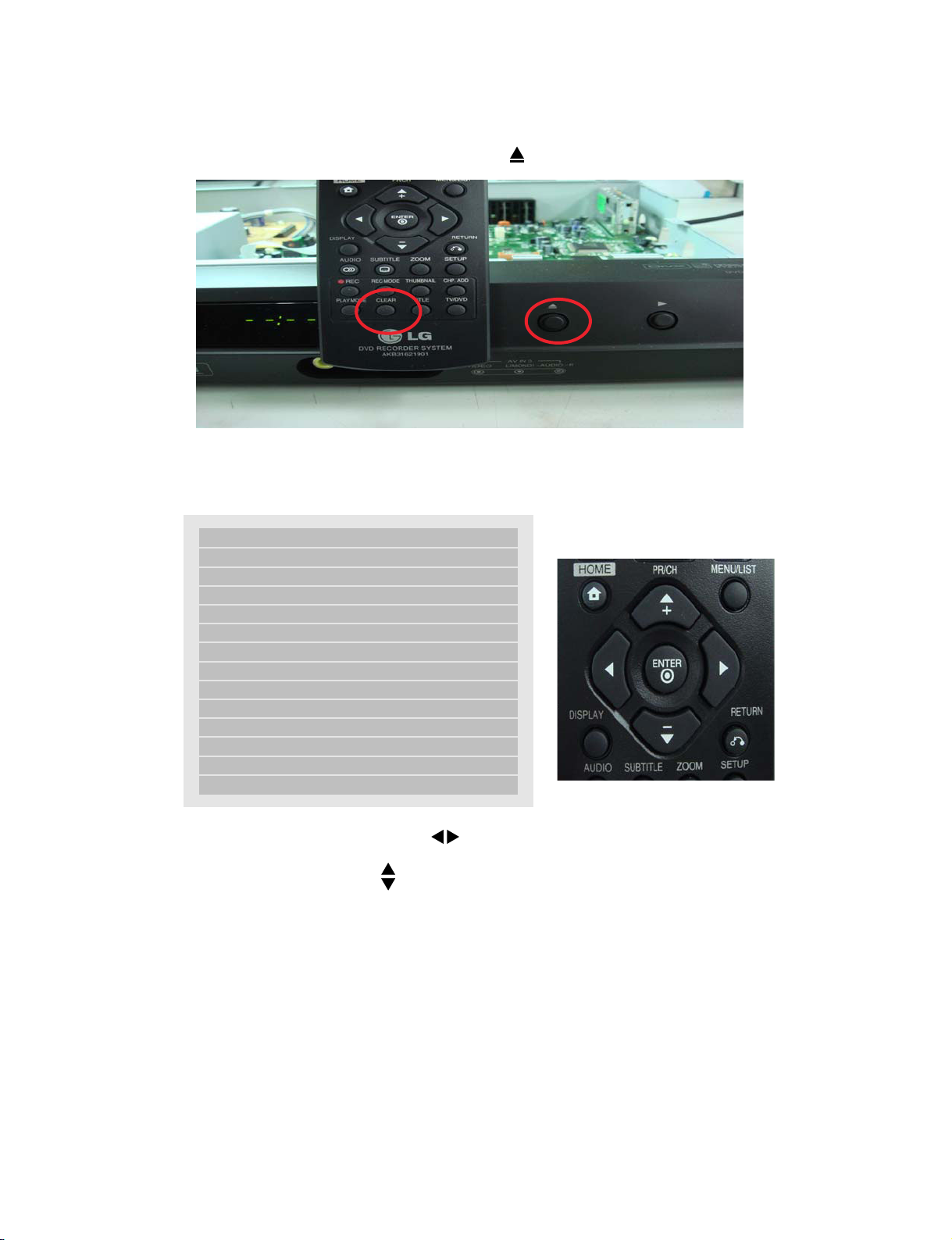

SERVICE INFORMATION FOR EEPROM IC SETTING

1. Please the CLEAR button on the remocon together with OPEN the Front Panel about 6 sec.

The picture on OSD will be bellow ;

Model :

Disc Read Time

DVD 018 Sec OK

CD 021 Sec NG

OP1 : 00 00000000 M : 10.013

OP2 : 00 00000000 E : FF(OR)

OP3 : 00 00000000

OP4 : 00 00000000

OP5 : 00 00000000

OP6 : 00 00000000

OP7 : 00 00000000 Write : OK

OP8 : 00 00000000 E x i t : MP

OP9 : 00 00000000 Move : < >

OPA : 00 00000000 E d i t :

2. To MOVE from OP! to another option. Please button on the remote control.

3. To CHANGE the Option Code. Please button on the remote control.

4. To APPLY the Option Code. After change the option press ENTER button on remote control.

5. To INITIALIZE the system. Press CLEAR button on the remotecontrol together with OPEN on the Front panel

about 2sec.

6. To exit from the Option Code menu without Initialize the system.

Just turn off the power and turn on again.

LGE Internal Use Only

1-6

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 8

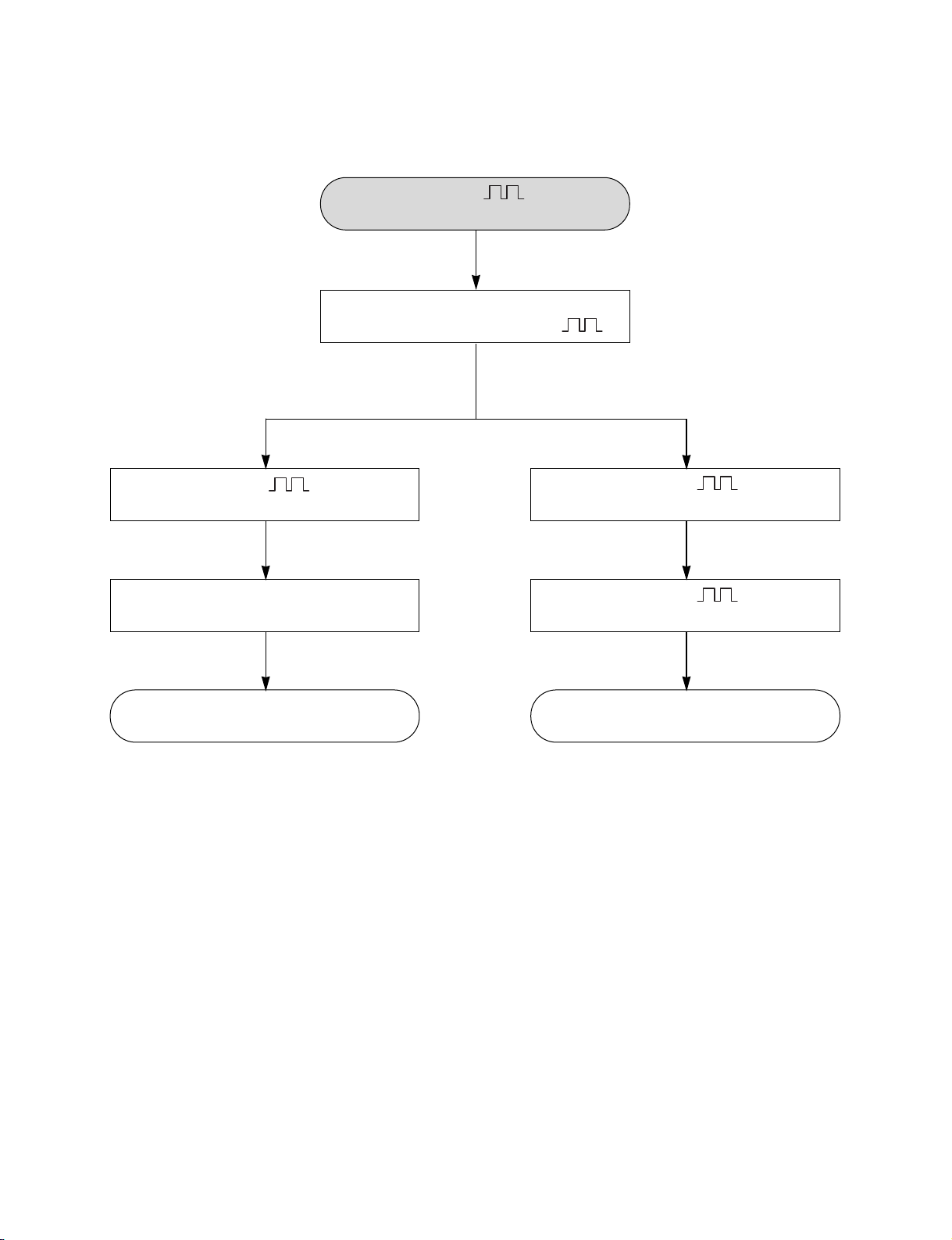

UPGRADE THE MAIN & LOADER PROGRAM

1. MAKING UPGRADE DISC

1) Do Physical format as ISO9660 or JOLIET file

system

2) Don’t care about the CD Volume label

3) Write RH300 B_E & LOADER file on Root

4) Write I_O file on Root

Note) You can’t write steps 3 and 4 on the same disc.

Use the different disc to write another step.

* OPTIONAL PARTS

1) B_E

LG_RH300_UPDATE_PAL.ROM

2) LOADER

DvdS617.rs6, Yas617.din

3) I_O

io_micom_update.hex

2. UPGRADE FLASH (MAIN & LOADER) and I_O

1) Put Upgrde DISC on the Set

2) After Disc Reading, You can see below screen

3) Press ENTER (or OK) KEY.

You can see both current and upgrade version.

4) Press PLAY KEY.

Start upgrading.

5) After upgrading, Automatically open tray.

Eject the Disc.

Reboot the Set

6) Put I_O update disc and repeat 1) ~ 5)

* OPTIONAL PARTS

1) MAIN

ONLY B_E UPGRADE

2) LOADER

ONLY LOADER UPGRADE

3) ALL

B_E & LOADER UPGRADE

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-7

LGE Internal Use Only

Page 9

SPECIFICATIONS

• GENERAL

Power requirements AC 200-240V, 50/60 Hz

Power consumption 30W

Dimensions (approx.) 430 X 49 X 275mm (w x h x d) without foot

Net weight (approx.) 4kg

Operating temperature 5°C to 35°C

Operating humidity 5% to 65%

Television system PAL I, B/G, I/I, SECAM D/K, K1 color system

Recording format PAL

• RECORDING

Recording format DVD Video Recording, DVD-VIDEO

Recordable media HDD (320GB), DVD-RW, DVD-R, DVD+RW,

DVD+R, DVD+R (Double Layer), DVD-RAM

Recordable time DVD (4.7GB): Approx. 1 hour (XP mode),

2 hours (SP mode), 4 hours (LP mode),

6 hours (EP mode), 14 hours (MLP mode)

DVD+R DL (8.5GB): Approx. 3hours (XP mode),

3.8 hours (SP mode), 7.3 hours (LP mode),

9.1 hours (EP mode), 21 hours (MLP mode)

HDD (320GB, MPEG2 Recording):

Approx. 85 hours (XP mode), 165 hours (SP mode),

323 hours (LP mode), 456 hours (EP mode),

935 hours (MLP mode)

Video recording format

Sampling frequency 27MHz

Compression format MPEG2 (VBR supported)

Audio recording format

Sampling frequency 48kHz

Compression format Dolby Digital

• PLAYBACK

Frequency response DVD (PCM 48kHz): 8Hz to 22kHz,

CD: 8Hz to 20kHz

DVD (PCM 96kHz): 8Hz to 44kHz

Signal-to-noise ratio More than 90dB (AUDIO OUT connector)

Harmonic distortion Less than 0.02% (AUDIO OUT connector)

• INPUTS

Dynamic range More than 95dB (AUDIO OUT connector)

ANTENNA IN Antenna input, 75ohms

VIDEO IN 1.0 Vp-p 75ohms, sync negative, RCA jack x 1 / SCART x 2

AUDIO IN 2.0 Vrms more than 47kohms, RCA jack (L, R) x 1 / SCART x 2

DV IN 4 pin (IEEE 1394 standard)

USB IN 4 pin (USB 1.1 standard)

• OUTPUTS

VIDEO OUT 1Vp-p 75Ω, sync negative, SCART x 2

S-VIDEO OUT (Y) 1.0V (p-p), 75Ω, sync negative,

Mini DIN 4-pin x 1(C) 0.3V (p-p) 75Ω

COMPONENT VIDEO OUT (Y) 1.0V (p-p), 75Ω, sync negative,

RCA jack x 1, (PB)/(PR) 0.7V (p-p), 75Ω, RCA jack x 2

HDMI video/audio output 19 pin (HDMI standard, Type A)

Audio output (digital audio) 0.5V (p-p), 75Ω, RCA jack x 1

Audio output (optical audio) 3V (p-p), Optical connector x 1

Audio output (analog audio) 2Vrms (1kHz, 0dB), 600Ω, RCA jack (L, R) x 2 / SCART x 2

LGE Internal Use Only

1-8

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 10

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS .....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION ..................................................................................................2-2

2. DECK MECHANISM SECTION (RS-06A).................................................................................................2-3

3. PACKING ACCESSORY SECTION...........................................................................................................2-4

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-1

LGE Internal Use Only

Page 11

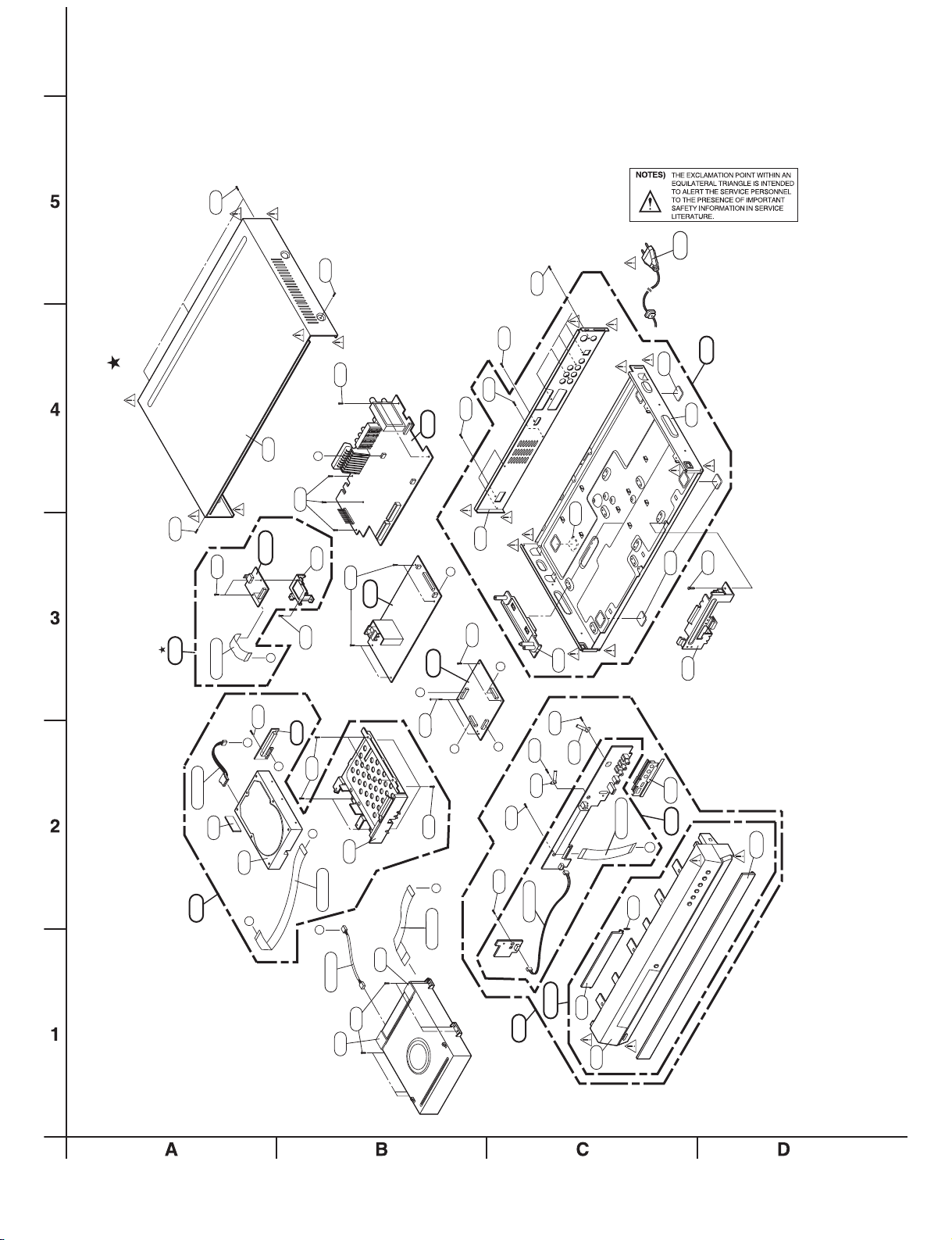

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

462

462

OPTIONAL PARTS

8

250

46

A52

G

465

5

46

300

465

70

4

A44

261

0

26

462

A54

468

CABLE7

CABLE10

261

A26

104

A54A

HDMI

468

BOARD

253

468

I/O BOARD

261

320

A

8

1

46

26

A47

SMPS

468

C

C

8

46

G

E

A53

F

468

F

101

ABLE11

C

A

CABLE6

8

46

261

471

261

410

46

A

ABLE5

C

468

452

275

CABLE1

264

452

A43A

275

285

TIMER

CABLE2

286

73

2

4

27

50

A

D

281

E

MAIN

BOARD

D

B

452

B

452

KEY

A43

280

LGE Internal Use Only

2-2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 12

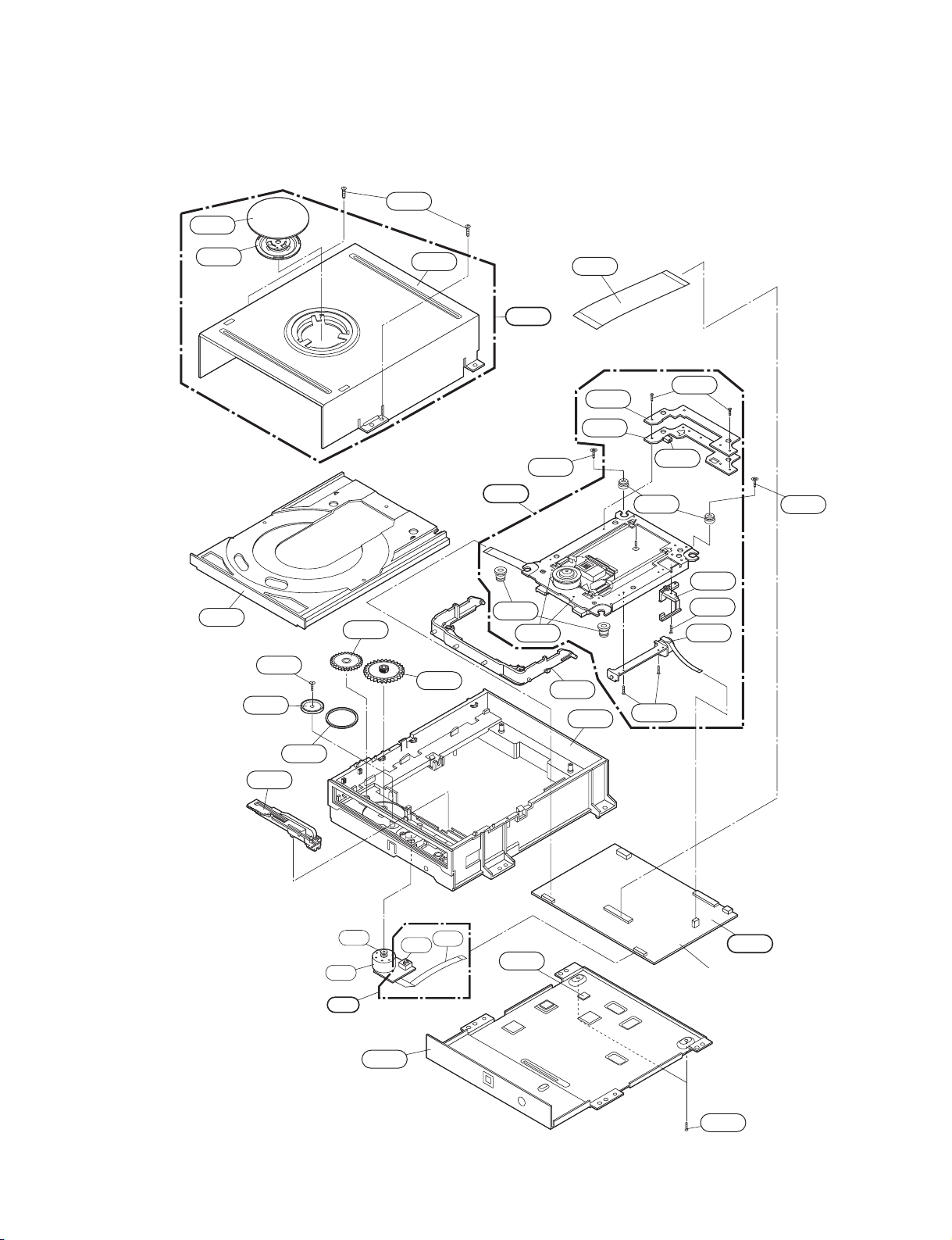

2. DECK MECHANISM SECTION (RS-06A)

1431

1001

RS-06A(DR-11H)

1003

1026

1433

1016

1017

1002

1013

A001

A006

1041

1437

1432

1011

1020

1030

1033

1032

1025

1432

1434

1034

1437

1038

1432

1036

1015

1012

1019

1018

A

0

0

5

1047

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1043

1045

2-3

1046

A46A

M

a

in

C

.

B

.

A

1439

LGE Internal Use Only

Page 13

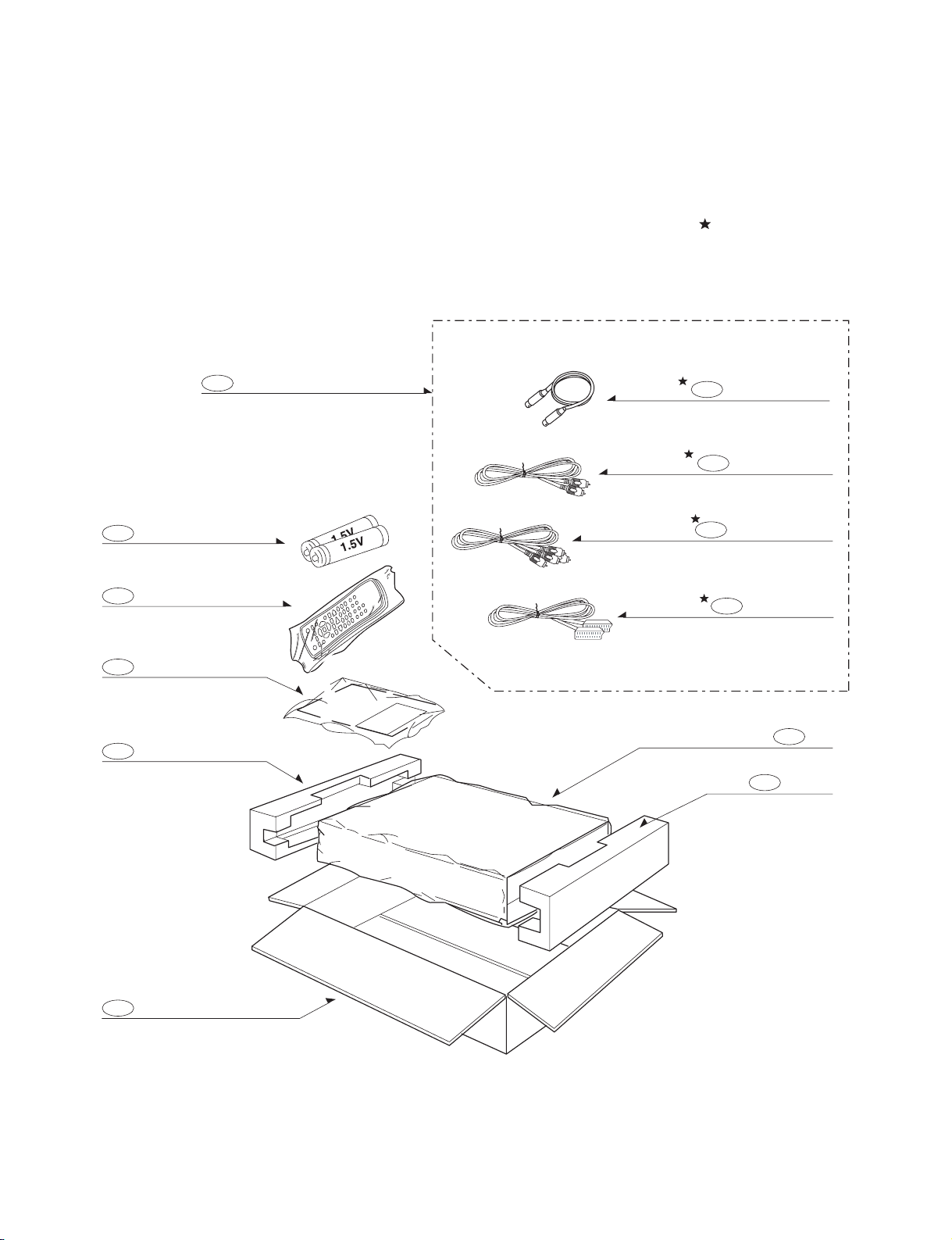

3. PACKING ACCESSORY SECTION

OPTIONAL PARTS

810 Accessory Assembly

808 Battery

900 Remote Control

Instruction Ass'y

801

803 Packing

806 RCA Plug(Black)

Plug Ass'y 1way

811

812

Plug Ass'y 2way

821 SCART Cable

804 Bag

803 Packing

Box

802

LGE Internal Use Only

2-4

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 14

SECTION 3

ELECTRICAL

CONTENTS

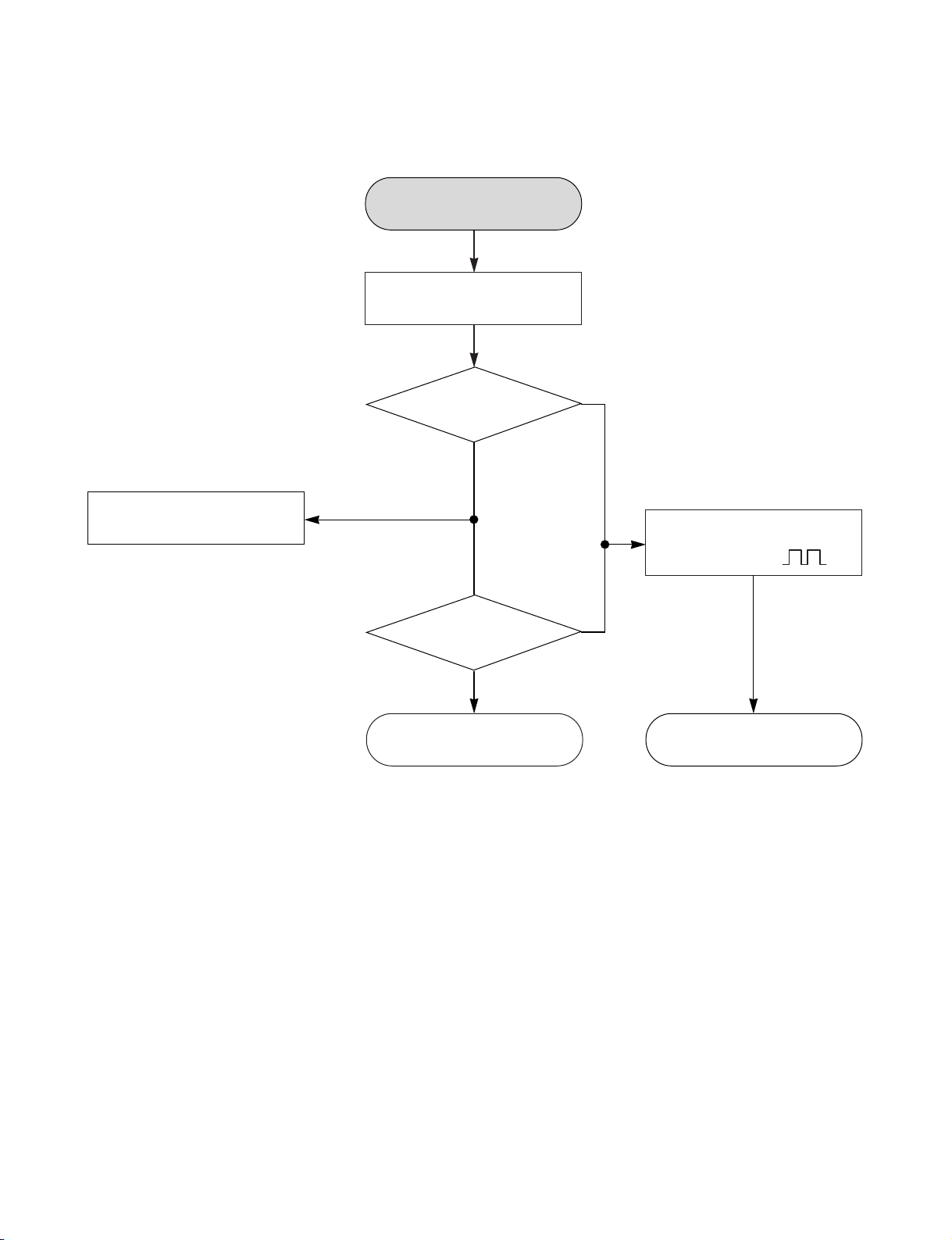

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER SUPPLY ON SMPS BOARD .............3-2

2. POWER SUPPLY ON I/O BOARD ...................3-4

3. SYSTEM CIRCUIT PART ..................................3-9

4. DISC NOT RECOGNIZED.................................3-9

5.

WHEN PLAYING DISC, NO AUDIO OUTPUT

6. NO OPTICAL/DIGITAL OUTPUT ....................3-11

7. NO TUNER AUDIO OUTPUT .........................3-12

8. NO EXTERNAL AUDIO INPUT .......................3-13

9. NO RGB/COMPONENT VIDEO SIGNAL

WHEN PLAY DISC ...........................................3-14

10. NO COMPOSITE/S-VIDEO SIGNAL

WHEN PLAY DISC............................................3-15

11. NO TV, EXTERNAL INPUT VIDEO

SIGNAL..............................................................3-16

12. NO DV (IEEE1394)

INPUT (VIDEO/AUDIO) SIGNAL.....................3-17

...........3-2

..........3-10

WAVEFORMS..........................................................3-18

1. SMPS BLOCK ..................................................3-18

2. SYSTEM BLOCK .............................................3-20

3. VIDEO BLOCK (COLOR BAR INPUT)...........3-23

4. AUDIO BLOCK (1kHz SINEWAVE INPUT)....3-24

5. SERIAL INTERFACE BLOCK

(BETWEEN MAIN AND I/O)............................3-25

6. TUNER BLOCK ................................................3-26

7. HDMI BLOCK ...................................................3-27

WIRING CONNECTION DIAGRAM...............3-28

1. WIRING CONNECTION DIAGRAM 1 ............3-28

2. WIRING CONNECTION DIAGRAM 2 ............3-29

3. WIRING CONNECTION DIAGRAM 3 ............3-30

BLOCK DIAGRAMS.............................................3-31

1. VERALL BLOCK DIAGRAM............................3-31

2. SMPS BLOCK DIAGRAM ...............................3-32

3. POWER MAIN BLOCK DIAGRAM .................3-33

4. POWER I/O BLOCK DIAGRAM......................3-34

5. A/V BLOCK DIAGRAM ....................................3-35

6. AUDIO OUT BLOCK DIAGRAM .....................3-36

7. HDMI BLOCK DIAGRAM ................................3-37

CIRCUIT DIAGRAMS...........................................3-39

1. SMPS 1 CIRCUIT DIAGRAM..........................3-39

2. SMPS 2 CIRCUIT DIAGRAM..........................3-41

3. MPEG CIRCUIT DIAGRAM.............................3-43

4. FLASH/DDR/DV CIRCUIT DIAGRAM............3-45

5. ATAPI, HDMI & USB CIRCUIT DIAGRAM.....3-47

6. I/O, µ-COM CIRCUIT DIAGRAM ....................3-49

7. DECODER & MIC CIRCUIT DIAGRAM.........3-51

8. SCART/RCA CIRCUIT DIAGRAM..................3-53

9. HDMI CIRCUIT DIAGRAM ..............................3-55

10. TIMER CIRCUIT DIAGRAM

11. KEY CIRCUIT DIAGRAM (8 & 9 TOOLS) ......3-59

(8 & 9 TOOLS)

...3-57

• CIRCUIT VOLTAGE CHART ....................3-61

PRINTED CIRCUIT BOARD DIAGRAMS...3-65

1. MAIN P.C.BOARD ............................................3-65

2. I/O P.C.BOARD.................................................3-67

3. POWER P.C.BOARD .......................................3-71

4. TIMER & KEY P.C.BOARD..............................3-73

5. HDMI P.C.BOARD ............................................3-75

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-1

LGE Internal Use Only

Page 15

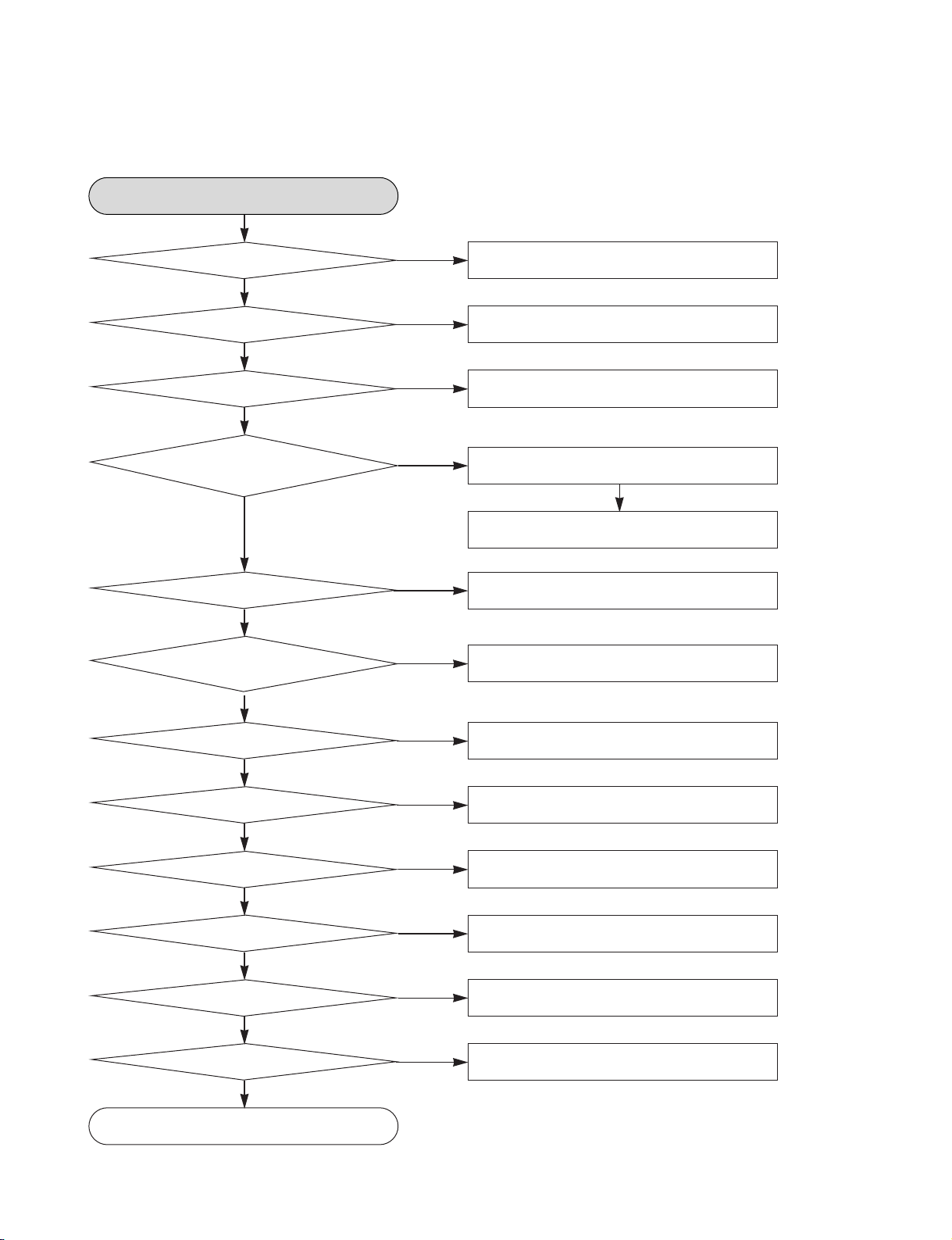

ELECTRICAL TROUBLESHOOTING GUIDE

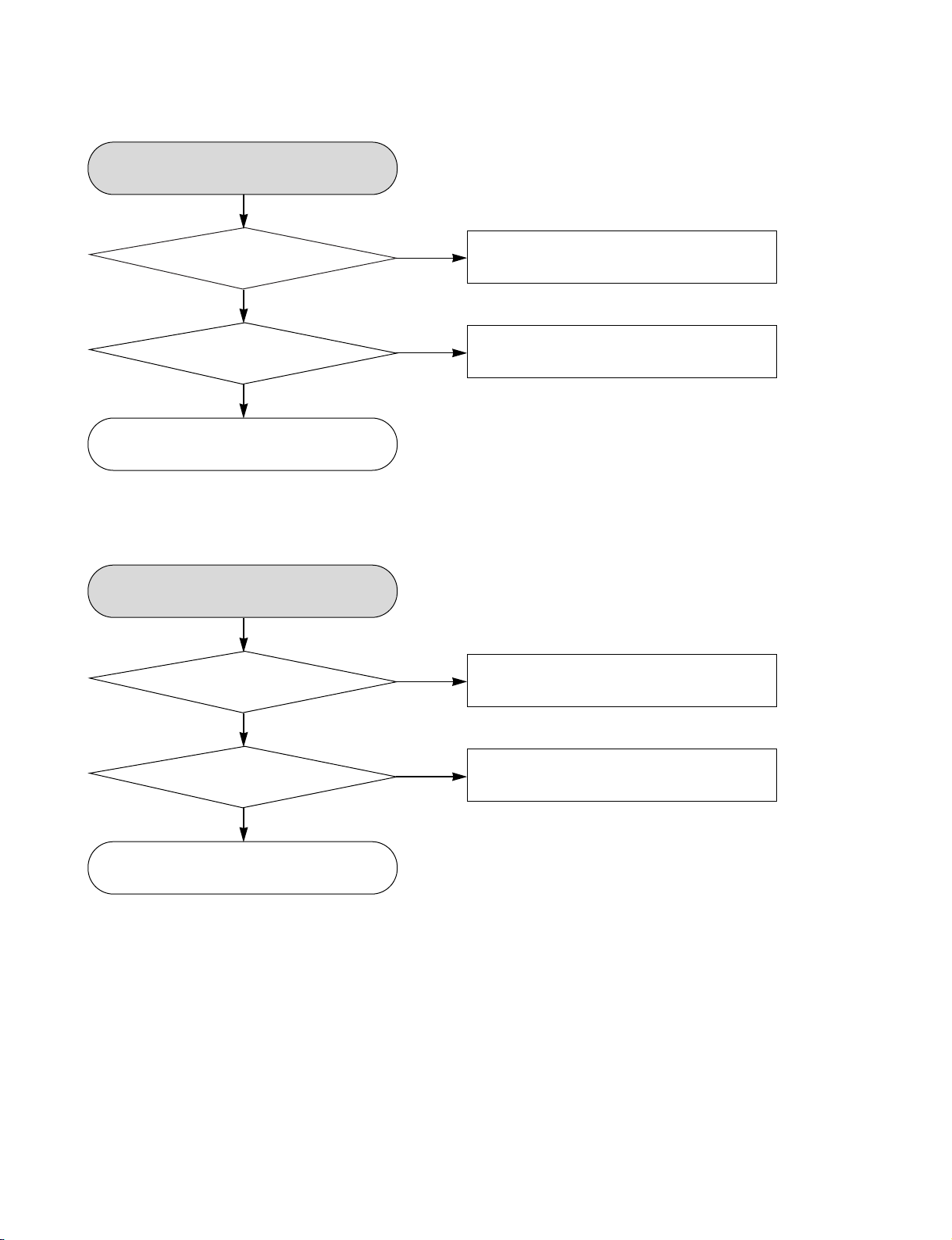

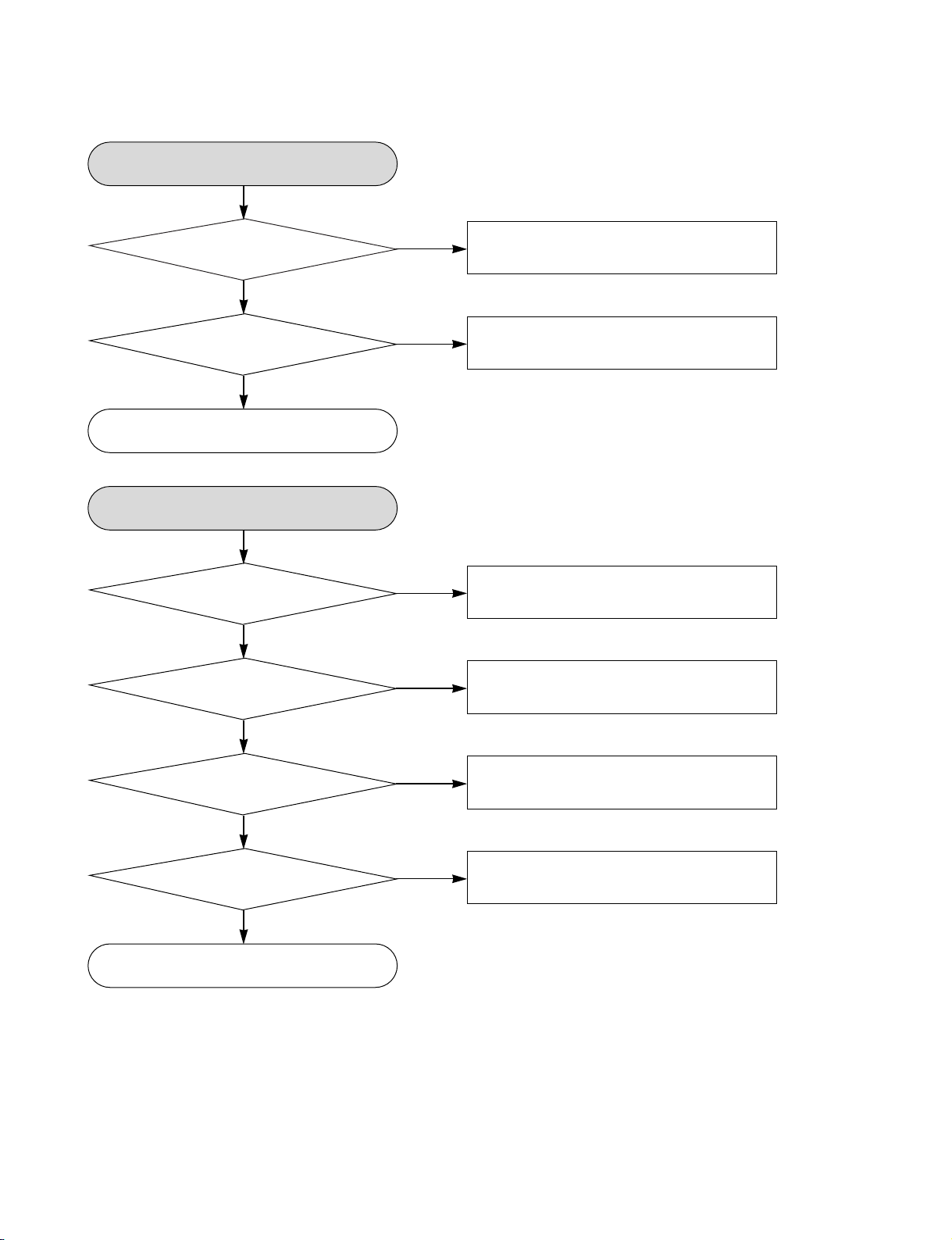

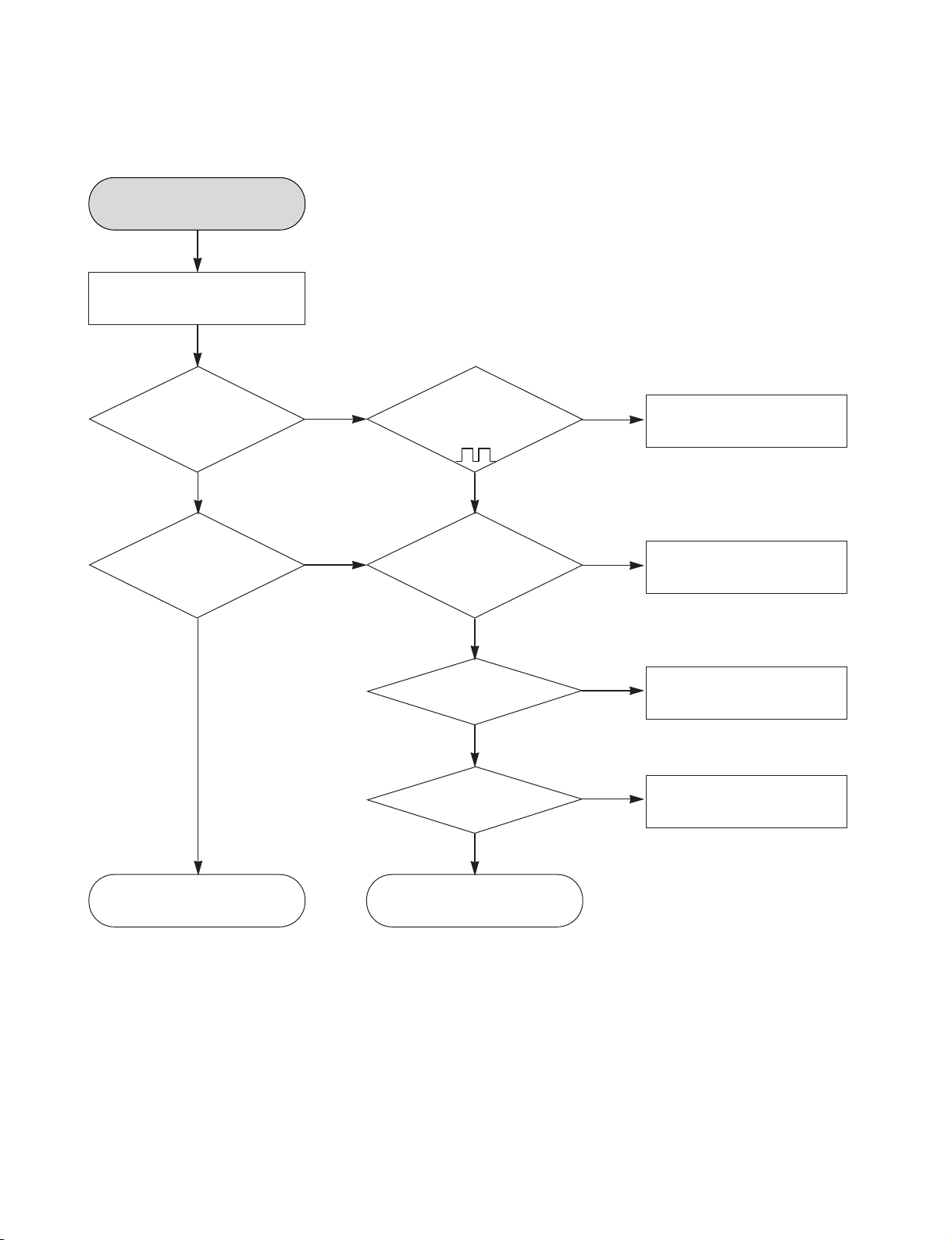

1. POWER SUPPLY ON SMPS BOARD

No 5.3VA

YES

Is the F101 normal? Replace the F101 (Use the same fuse)

YES

Is the BD101 normal? Replace the BD101

YES

Is the TH01 normal? Replace the TH01

YES

NO

NO

NO

Is the Vcc

(10V - 17V) supplied to

NO

Is the D102 normal?

IC101 Pin 6?

NO

YES

Is the D128 normal? Replace the D128

YES

Is there about 2.5V at the

NO

NO

Check or replace the D102

Replace the IC103

IC103 Pin 1?

YES

Is the D121 normal? Replace the D121

YES

Is the D122 normal? Replace the D122

YES

Is the D125 normal? Replace the D125

YES

Is the D124 normal? Replace the D124

NO

NO

NO

NO

Is the D127 normal?

Is the D126 normal? Replace the D126

Power line of I/O PCB is short

LGE Internal Use Only

YES

YES

YES

NO

NO

3-2

Replace the D127

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 16

No 5V for HDD & DVD drive

YES

Is there about 5.5V at

the IC156 Pin 1?

YES

Is there about 4V ~ 5V at

the IC156 Pin 4?

YES

Check the IC156 and replace

No 12V for HDD & DVD drive

YES

Is there about 13.5V at

the IC155 Pin 1?

NO

NO

NO

Check D125 and replace

Check the “PWR CTL‘H’”

signal from µ-COM

Check D124 and replace

YES

Is there about 4V ~ 5V at

the IC155 Pin 4?

YES

Check the IC155 and replace

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

NO

3-3

Check the “PWR CTL ‘H’”

signal from µ-COM

LGE Internal Use Only

Page 17

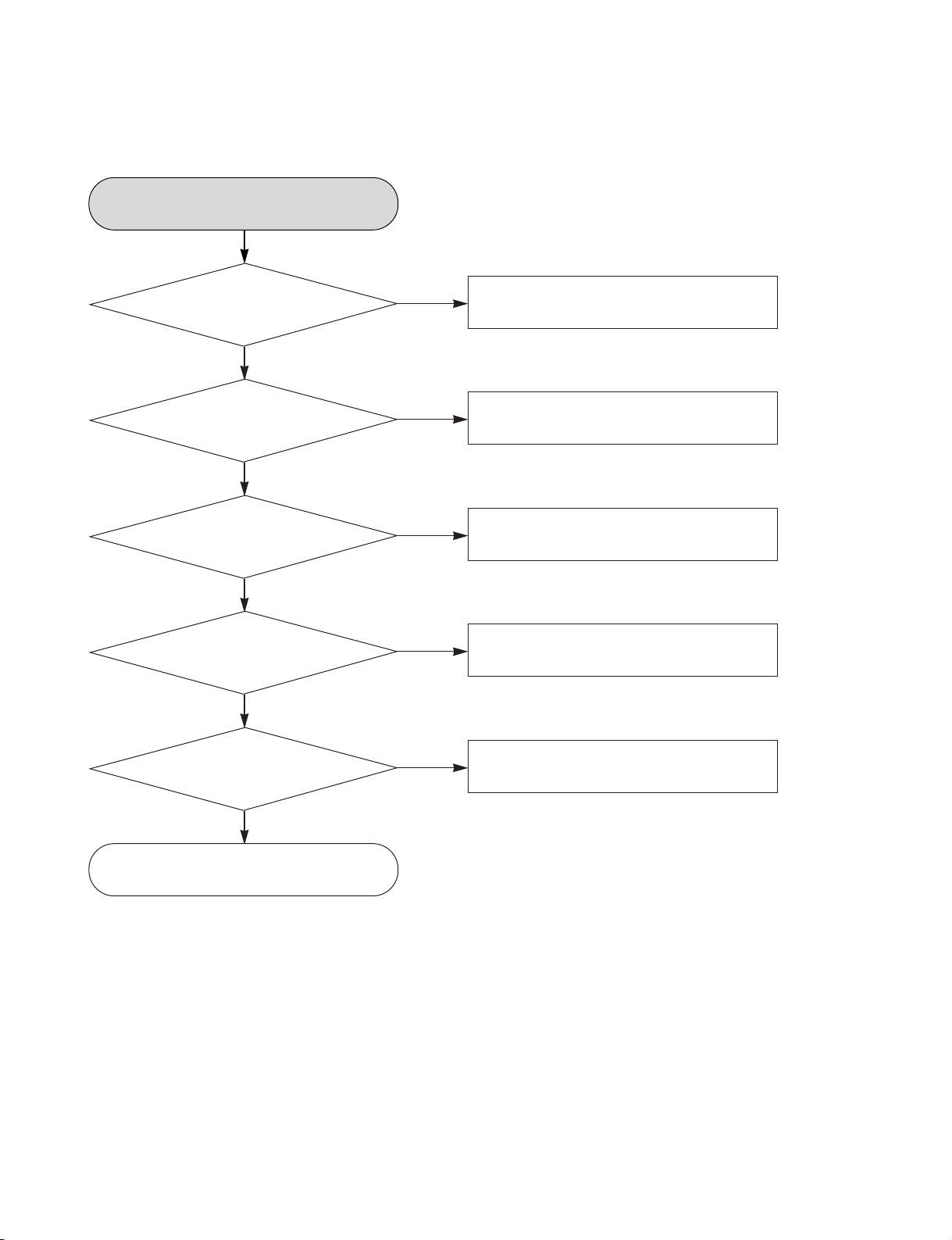

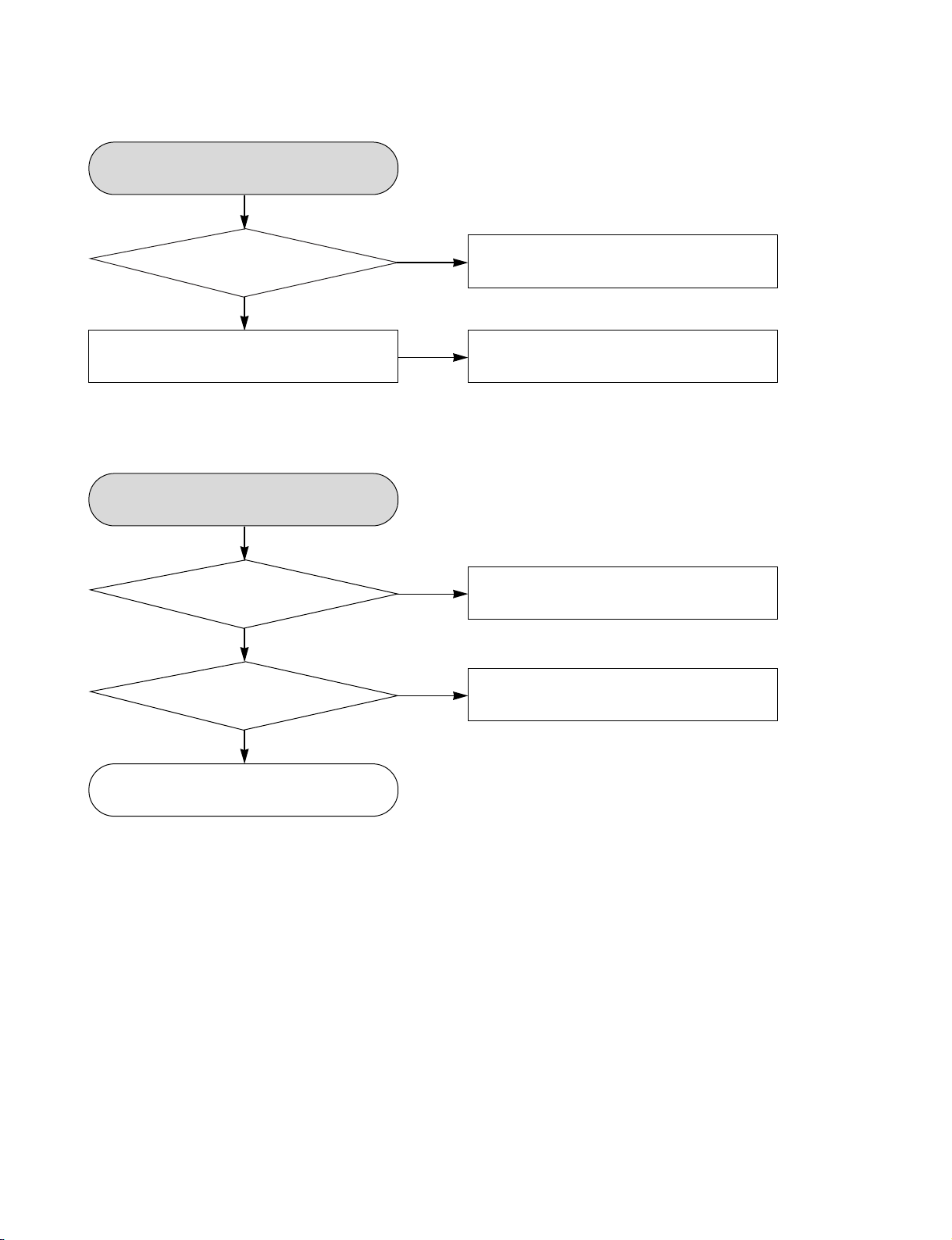

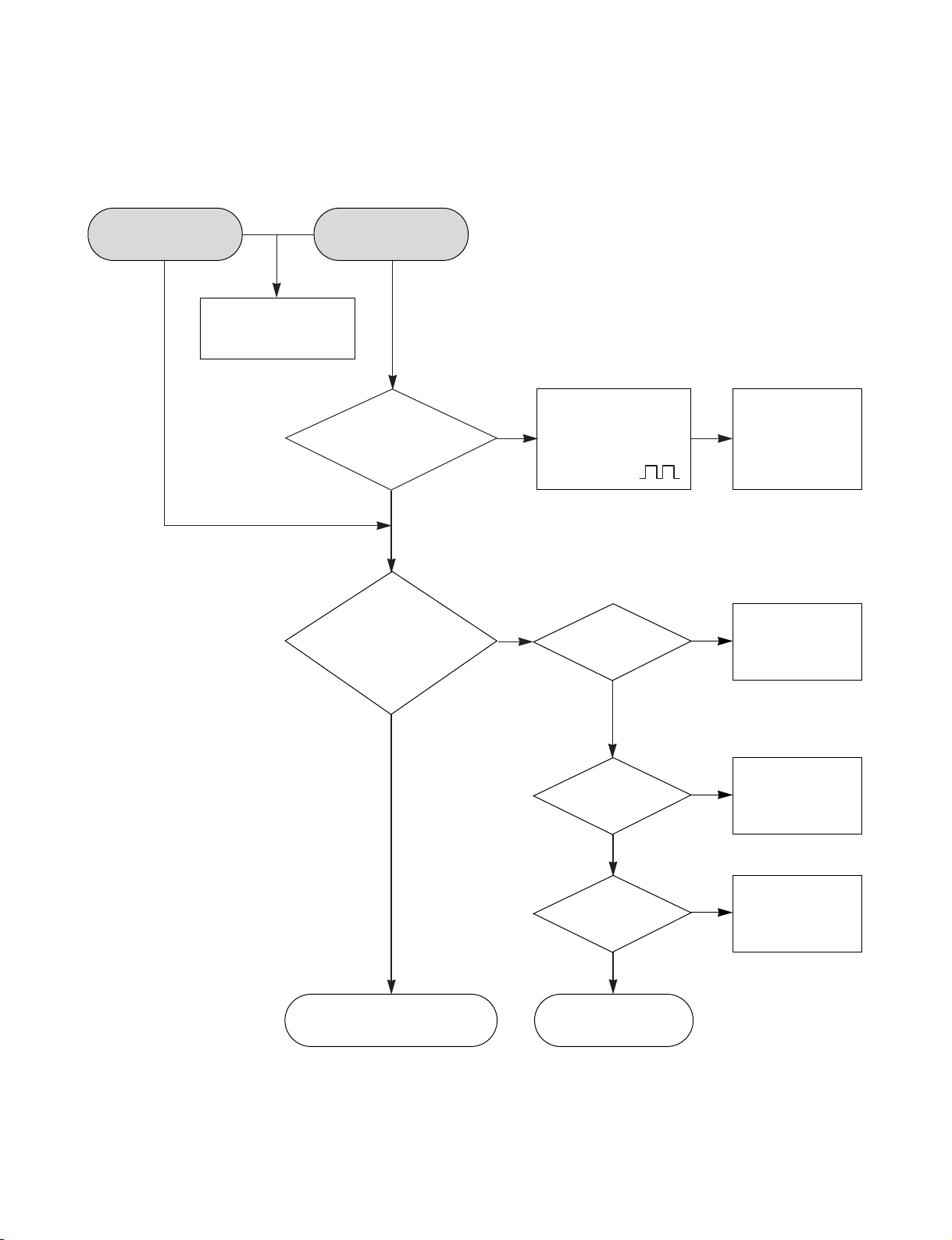

2. POWER SUPPLY ON I/O BOARD

No 12VT

YES

Is the Vcc (14V) supplied to

Q164 collector?

YES

Is there about 12.5V at

ZD151 & Q164 base?

YES

Is the Vcc (33V) supplied

to Q162 emiter?

YES

Is there about 0V at

Q162 base?

YES

NO

NO

NO

NO

Check D124 on SMPS

board and replace

Check Q164 and replace

Check D126 on SMPS

board and replace

Check Q162 and replace

Is there about 5V at R170

and 0.7V at Q156 base?

Check Q156 and replace

LGE Internal Use Only

YES

NO

3-4

Check the “TIMER_H”

signal from µ-COM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 18

No 5VT

YES

Is the Vcc (5.3V)

supplied to Q155 emiter?

YES

Is there about 0V

at D152 and

Q152 vollector?

YES

Is there about 5V

at R180 and 0.7V

at Q152 base?

YES

Check Q152 and replace

No 33VT

NO

NO

NO

Check 5.3VA on SMPS board

Check Q155 and replace

Check the “TIMER H”

signal from µ-COM

YES

Is the Vcc (33V)

supplied to Q161 emiter?

YES

Is there about 0V at

Q152 collector?

YES

Is there about 5V

at R180 and 0.7V

at Q152 base?

YES

Check Q152 and replace

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

NO

NO

NO

3-5

Check D126 on SMPS

board and replace

Check Q161 and replace

Check the “TIMER H”

signal from µ-COM

LGE Internal Use Only

Page 19

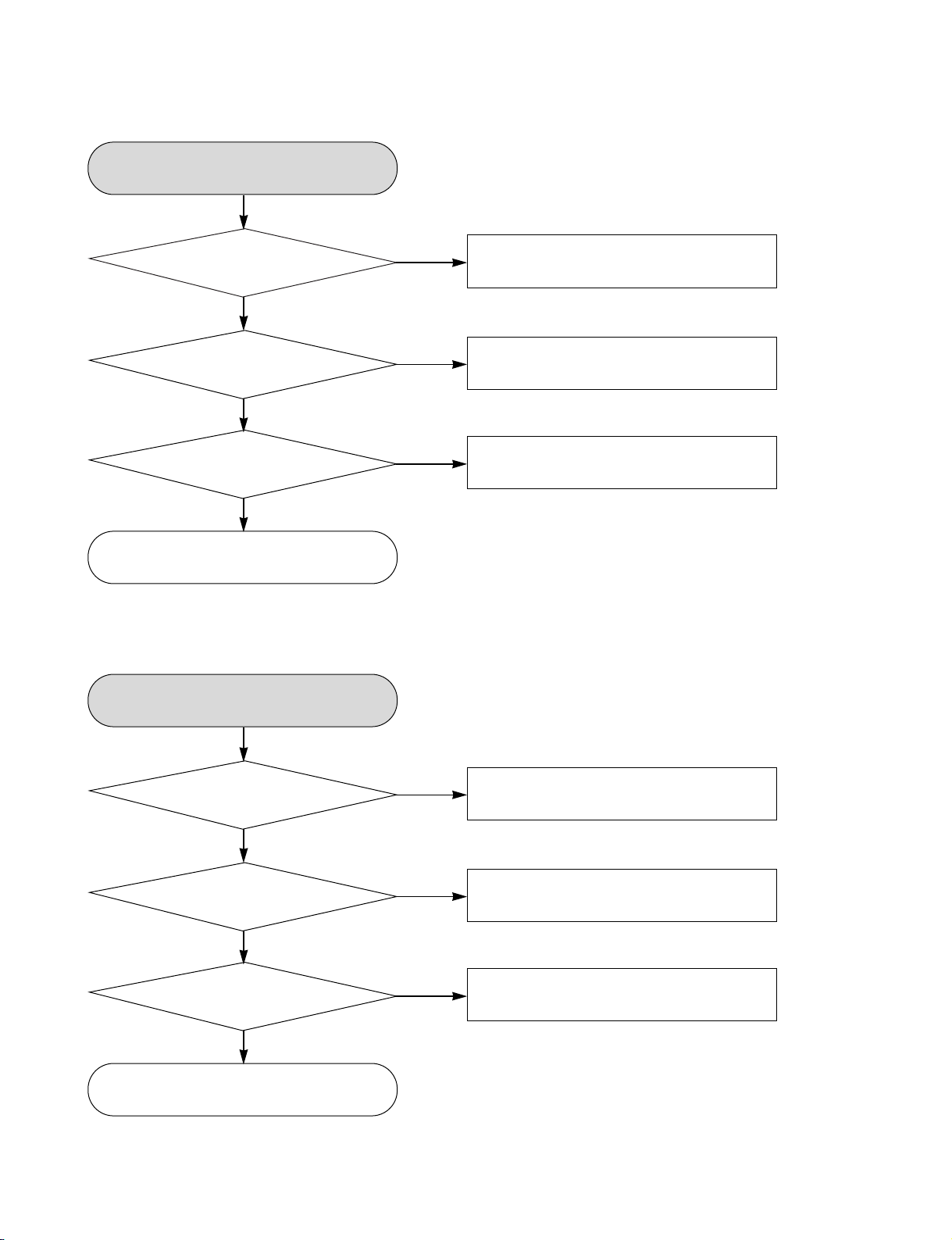

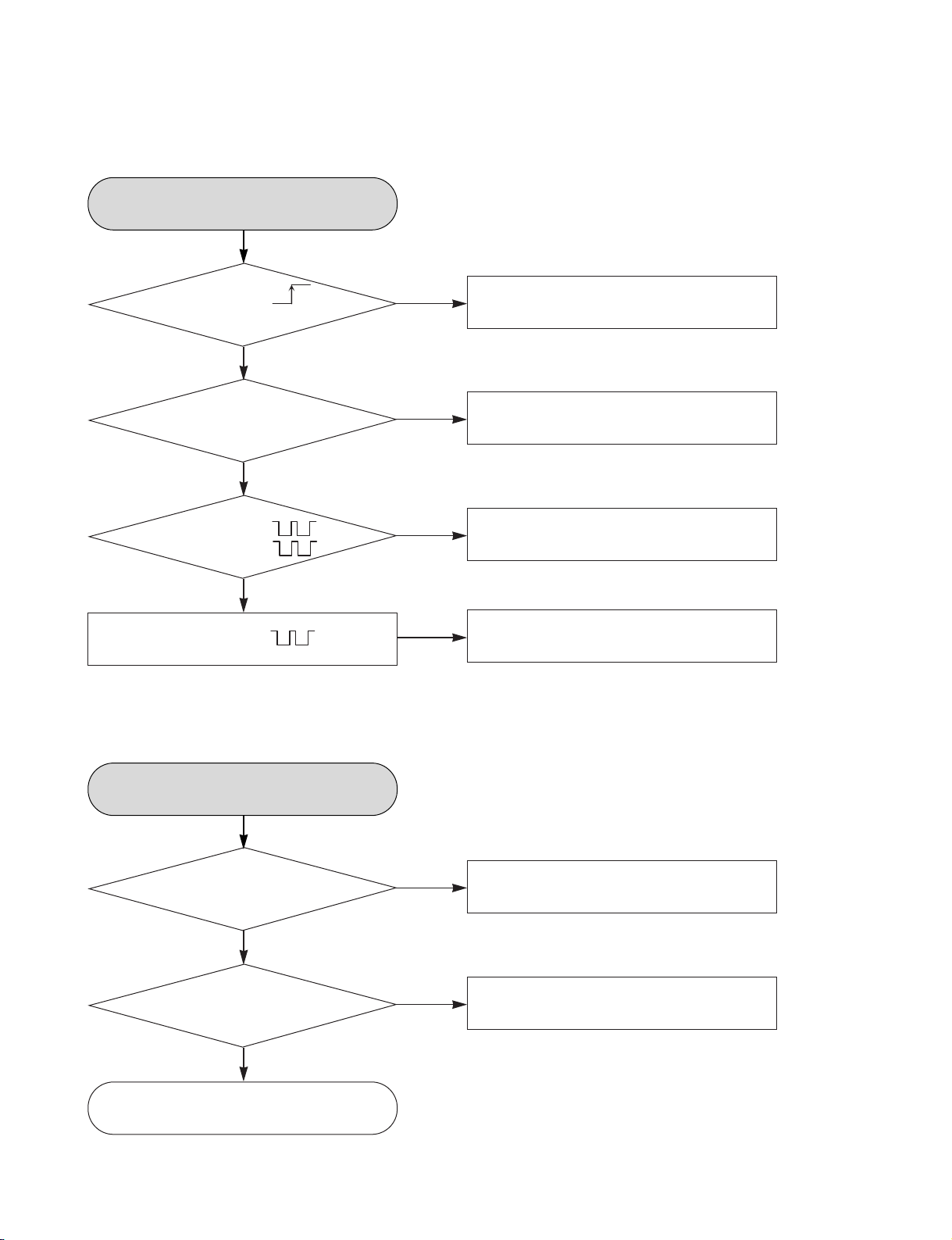

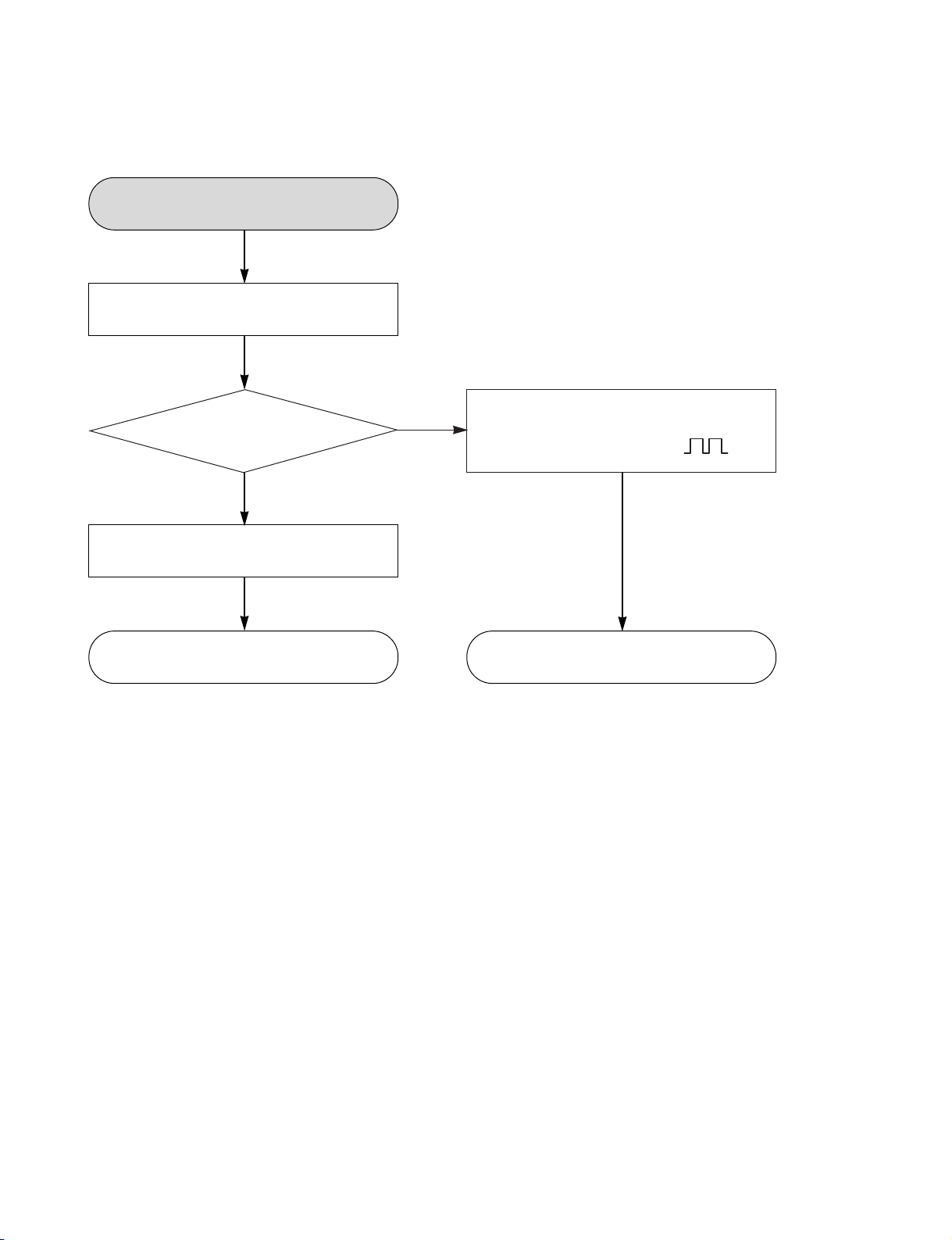

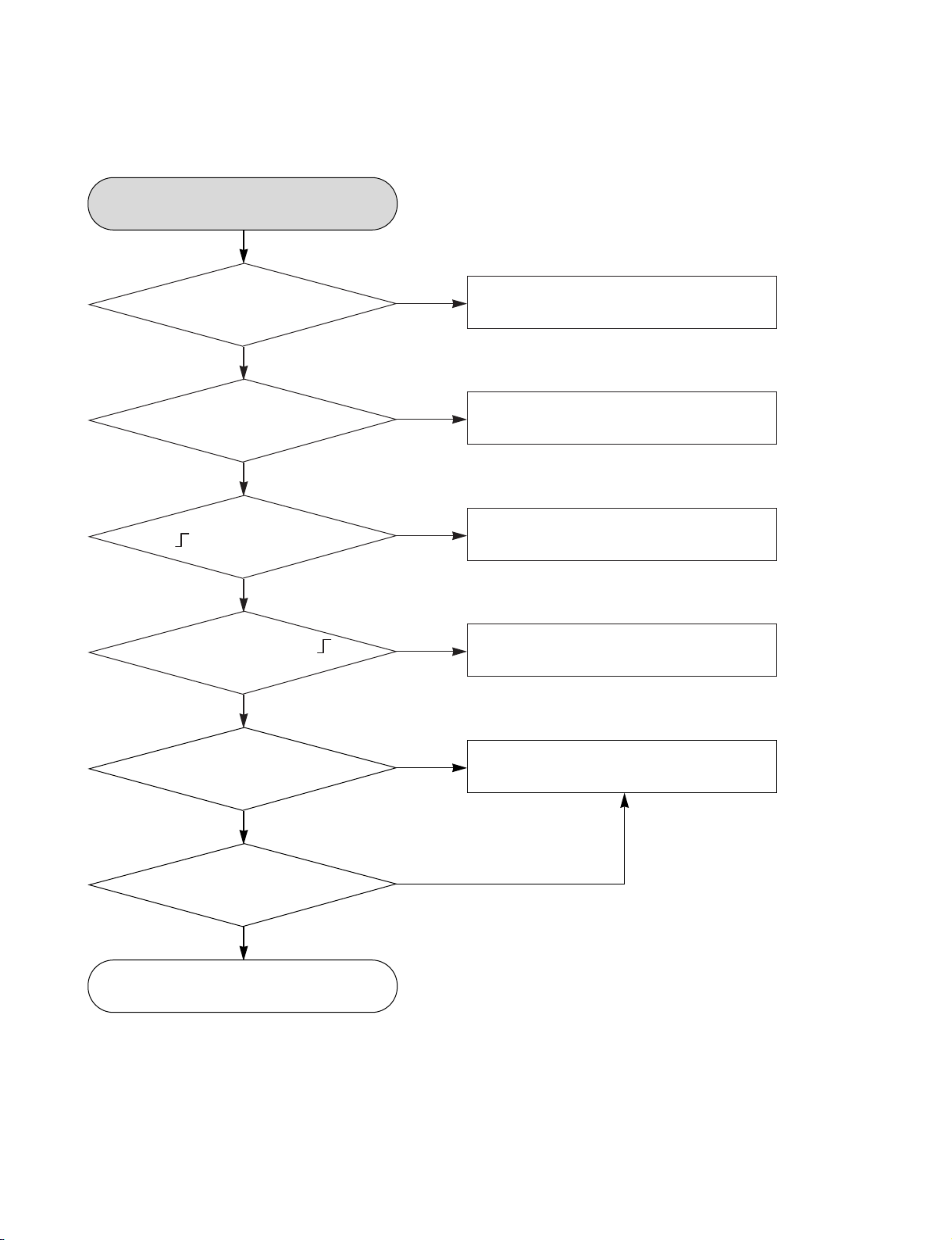

No 5.0VD

YES

Is there about 5.3V at

the IC153 Pin 1?

YES

Is there about 4V ~ 5V at

the IC153 Pin 4?

YES

Check the IC153 and replace

No 2.5V

YES

Is there about 3V ~ 3.8V

at the IC151 Pin 1?

YES

Is there about 4V ~ 5V at

the IC151 Pin 4?

NO

NO

NO

NO

Check 5.3VA on SMPS board

Check the “PWR CTL H”

signal from µ-COM

Check D154 and

D127 on SMPS board

Check the “PWR CTL H”

signal from µ-COM

Check the IC151 and replace

Is there about 3.8V at

the IC152 Pin 1?

Is there about 4V ~ 5V at

the IC152 Pin 4?

Check the IC152 and replace

LGE Internal Use Only

YES

No 3.3V

YES

YES

YES

NO

NO

3-6

Check D127 on SMPS

board and replace

Check the “PWR CTL H”

signal from µ-COM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 20

No SW_5.3VA

YES

Is the Vcc (5.3V)

supplied to Q158 emiter?

YES

Is there about 0V

at R179 and R156?

YES

Check Q158 and replace

No SW_FD(+)

YES

Is the Vcc (FD+) supplied

to Q163 collector?

YES

Is there about 5.3V at

R184 and Q153 collector?

NO

NO

NO

NO

Check 5.3VA on SMPS board

Check the “STANBY H”

signal from µ-COM

Check D121 on SMPS

board and replace

Check Q163 and replace

YES

Is the VCC (5.3V)

supplied to Q153 emiter?

YES

Is there about 0V

at Q153 base?

YES

Check Q153 and replace

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

NO

NO

3-7

Check 5.3VA on SMPS board

Check the “STANBY H”

signal from µ-COM

LGE Internal Use Only

Page 21

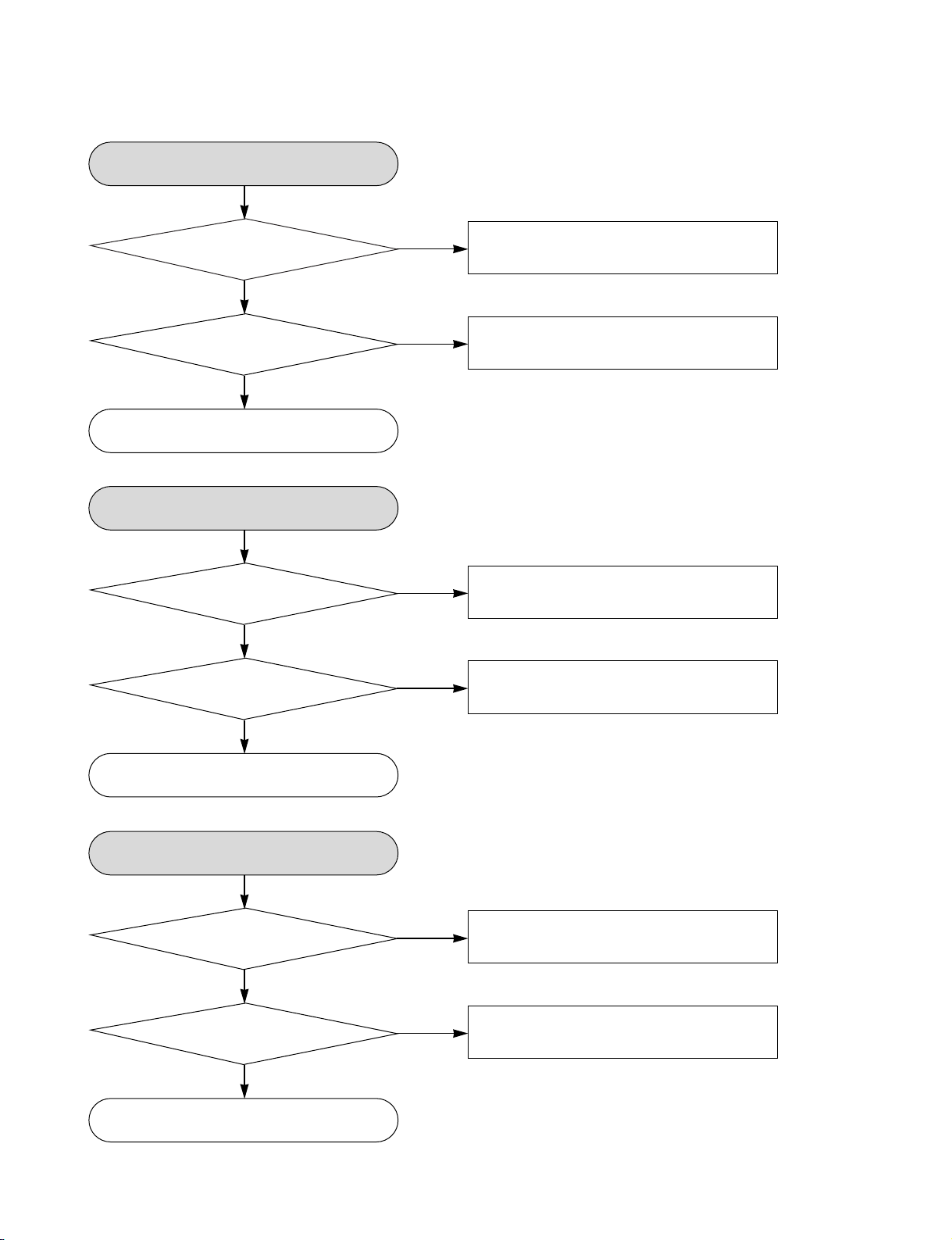

No 1.8V

YES

Is the Vcc (3.3V)

supplied to Pin 3 IC155?

YES

There is 1,8V at IC155 Pin 2, 4

No 1.25V

YES

Is there about 5.3V at

the IC154 Pin 2?

YES

Is there about 4V ~ 5V at

the IC154 Pin 5?

NO

NO

NO

NO

Check 3.3V power supply

IC155 defect

Check 5.3VA on SMPS board

Check the “PWR CTL H”

signal from µ-COM

Check the IC154 and replace

LGE Internal Use Only

YES

3-8

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 22

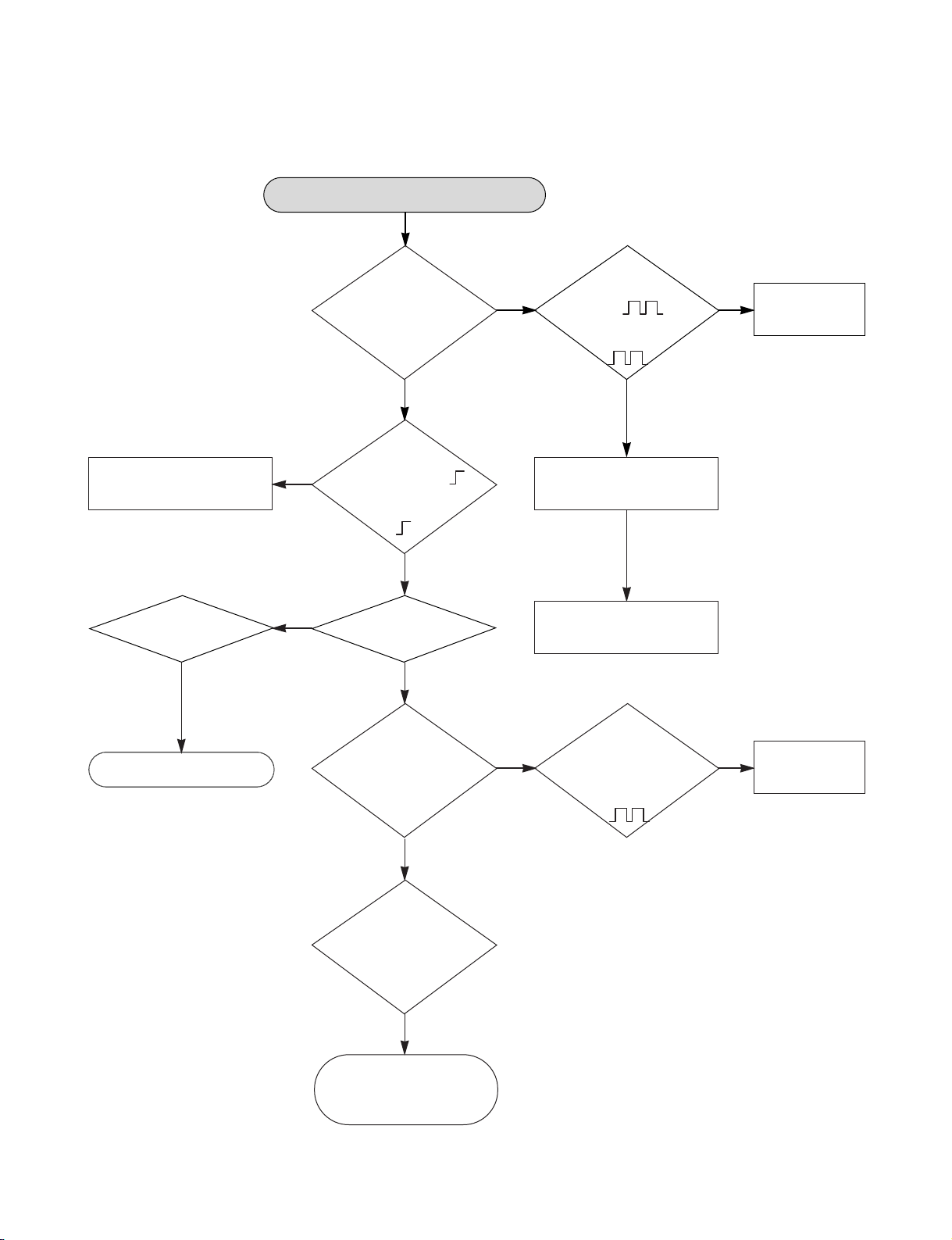

3. SYSTEM CIRCUIT PART

“Please wait” displayed

continue at power on

YES

IC1306 Pin 5 : ?

(/HOST-RESET)

YES

X1101 : Clock oscillated?

(13.5MHz)

YES

AR1105 Pin 3 : ?

IC1201 Pin 32 : ?

YES

R1173, R1174 : ?

4. DISC NOT RECOGNIZED

NO

NO

NO

NO

Check PVM02 Pin 25 IC 701 Pin 19

Replace X1101

Check IC1201 (Flash memory) & IC1101

IC1101 defect

DISC not recognized

Check driver power?

5V, 12V

YES

Check ATAPI connector

YES

Check loader

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

NO

NO

3-9

Check SMPS

Change MEDIA TEST

LGE Internal Use Only

Page 23

5. WHEN PLAYING DISC, NO AUDIO OUTPUT

When playing DISC, no Audio output

IC904 Pin 14, 15 :

Is there a signal?

YES

NO NO

Check

IC904 Pin 5, 6,

7, 8 : .

Pin 3, 4 (Host CLK

& DATA) :

YES

IC1101 defect

Check

Q808, Q809, Q810, Q801

Check

IC902 Pin 8

(12VT)

YES

Replace IC902

NO

IC904 Pin 1, 16

(Z_MUTE R/L) : .

IC701 Pin 24

(A_MUTE_L) :

NO

IC902 Pin 1, 7 :

Is there a signal

IC801 Pin 34, 35,

37, 38 : Is there

a signal?

YES

YES

YES

Check

IC904 Pin 11 (5VD)

YES

Replace IC904

Check

NO NO

IC801 Pin 14

(12V) Pin 30 (5, 3V)

Pin31, 32

(SCL, SDA) :

Replace

IC801

LGE Internal Use Only

L804, L808,

L820, L821 :

Is there a signal?

YES

Check

cable connections &

TV audio mute.

3-10

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 24

6. NO OPTICAL/DIGITAL OUTPUT

R1107 : .

Is there a signal?

PVM02 Pin 1 (SPDIF_OUT) : .

YES

Check

YES

R832 : .

Is there a signal?

YES YES

Check JK803 Pin 2 (5V)

YES YES

Check JK803 &

optical cable connection

C839 : .

Is there a signal?

BD803 : .

Is there a signal?

Check JK802 &

RCA cable connection

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-11

LGE Internal Use Only

Page 25

7. NO TUNER AUDIO OUTPUT

TU701 Pin 16 (SIF) :

Is there a signal?

YES

IC901 Pin 106, 107

Is there a signal?

YES

IC801 Pin 40, 41 :

Is there a signal?

NO

Pin 30 (5, 3V) Pin 31, 32

Check

IC801 Pin 14 (12V)

(SCL, SDA) :

NO

Replace IC801

YES

IC901 Pin 98,

99, 100, 95 (Ain_D0,

AIN_SCLK, AIN_FSYNC,

AIN_MCLK) : Is there

a signal?

YES

When playing DISC,

no audio output

NO

YES

Check Pin 51/

RST_SAA7138

YES

X901 (24.576MHz)

oscillated?

YES

R906, R909

(SCL/SDA)

YES

IC901 defect

NO

NO

NO

Check IC1302

reset circuit

Change X901

Check IC901 power

3.3V & 1.8V

LGE Internal Use Only

3-12

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 26

8. NO EXTERNAL AUDIO INPUT

< AV3 > < AV1/AV2>

C9F3, C9F4 :

Is there a signal?

YES

NO

IC801 pin 2, 3, 5, 6 :

Check

cable connections

& input signal.

IC803 Pin 40, 41 :

AIN_SCLK, AIN_FSYNC,

Is there a signal?

YES

Is there a signal?

YES

IC901

Pin 98, 99,100,

95 (Ain_D0,

AIN_MCLK) :

Is there

a signal?

IC801 Pin 14 (12V)

NO

Pin 30 (5, 3V)

Pin 31, 32

(SCL, SDA) : .

NO

Check Pin 51/

RST_SAA7138

Check

NO

NO

Replace

IC801

Check

IC1302 reset

circuit

YES

When playing DISC,

no audio output

YES

X901

(24.576MHz)

oscillated?

YES

R906, R909

(SCL/SDA)

YES

IC901 defect

NO

NO

Change X901

Check

IC901 power

3.3V & 1.8V

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-13

LGE Internal Use Only

Page 27

9. NO RGB/COMPONENT VIDEO SIGNAL WHEN PLAY DISC

R1160, R1161, R1162 :

Is there a signal?

YES

PVM01 Pin 13, 14, 16 :

Is there a signal?

YES

IC801 Pin 24, 25, 26 :

Is there a signal ?

YES

NO

Check IC801 Pin 14 (12V)

Pin 30 (5, 3V)

Pin 31, 32 (SCL, SDA) : .

Check condition

RGB_Sel_Out & Ypbpr_Mute_L

YES

Check cable connection Replace IC801

YES

LGE Internal Use Only

3-14

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 28

10. NO COMPOSITE/S-VIDEO SIGNAL WHEN PLAY DISC

R1157, 1158, 1159 :

Is there a signal?

YES

PVM01 Pin 18, 19, 20 :

Is there a signal?

YES

IC801 Pin 27, 29, :

Is there a signal?

YES

Check S-VIDEO

cable connection

(S-VIDEO)

(SCART)

IC801 Pin 36, 39, :

Is there a signal?

YES

Check SCART

cable connection

NO

Check IC801 Pin 14 (12V)

Pin 30 (5, 3V) Pin 31, 32

(SCL, SDA) : .

YES

Replace IC801

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-15

LGE Internal Use Only

Page 29

11. NO TV, EXTERNAL INPUT VIDEO SIGNAL

No TV, external input

video signal

No video

signal of external

input AV3

(Front

RCA input)

YES

R905 :

Is there a signal?

NO

Check

cable connection &

input signal

When cable

NO

connecting tuner

and rear SCART 1, 2

no TV video signal

(AV1/2)

C843, C863, C864 :

Is there a signal?

IC 801 Pin 42 :

Is there a signal?

YES

YES

YES

IC801 Pin 14

NO

(12V) Pin 30

(5, 3V) Pin 31,

32 (SCL, SDA)

Check

: .

YES

Replace

IC801

Check no RGB / Component / Composite /

LGE Internal Use Only

IC901 Pin (56, 57, 58,

61,62, 63, 64, 65) VIND2-VIND9

is there a signal .

YES

S-VIDEO signal when play DISC

3-16

Check Pin 51

/RST_SAA7138

YES

X901

(24.576MHz)

oscillated?

YES

R906,

R909 (SCL/SDA), L917

(VinCLK)

YES

NONO

NO

NO

Check

IC1302 reset

circuit

Change

X901

Check

IC901 power

3.3V & 1.8V

IC901 defect

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 30

12. NO DV (IEEE1394) INPUT (VIDEO/AUDIO) SIGNAL

Check DV_Jack connection

YES

DV-mode switching?

YES

IC1401 power 3.3V

YES

IC1401 Pin 37 : “High”

& X401 (24.576MHz)

oscillated ?

YES

IC1401 pin 15 : “High” .

Is there a signal?

YES

NO

NO

NO

NO

Change to DV-mode.

using remote control

Check power 3.3V on I/O board

Check IC1302 reset circuit

Check DV cable

IC1401

Pin 1, 27, 28, 29, 30 :

Is there a signal?

YES

IC1401 Pin 2, 3 :

Is there a signal?

NO

IC101 defect

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

NO

YES

3-17

Replace IC1401

LGE Internal Use Only

Page 31

1. SMPS BLOCK

1

< Switching waveform of IC101,

when power is on >

WAVEFORMS

1

2

< Both ends waveform of D128,

when power is on (feedback 5.3VA) >

2

LGE Internal Use Only

3-18

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 32

3

3

< Both ends waveform of D124,

when power is on (12VA) >

4

4

< Both ends waveform of D125,

when power is on (5.5VA) >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-19

LGE Internal Use Only

Page 33

2. SYSTEM BLOCK

1

Frequency=13.5MHz

< Main Clock >

1

IC1101

2

< DDR RAM Clock >

LGE Internal Use Only

Frequency=198MHz

3-20

2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 34

3

< DDR Bank Address >

4

5

6

5

4

< DDR RAS & CAS >

6

< DDR Write Enable >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-21

3

LGE Internal Use Only

Page 35

7

8

IC1101

7

LGE Internal Use Only

< 12C_SDA >

3-22

8

< 12C_SCL >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 36

3. VIDEO BLOCK (COLOR BAR INPUT)

1

< CVBS_OUT >

2

1

2

3

< Y_OUT >

4

5

3

6

< C_OUT >

4

5

6

< G/Y_OUT >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

< R/PR_OUT >

3-23

< B/PR_OUT >

LGE Internal Use Only

Page 37

4. AUDIO BLOCK (1kHz SINEWAVE INPUT)

1

2

3

4

1

2

< AOUT_FSYNC >

< AOUT_SCLK >

3

4

LGE Internal Use Only

< AOUT_D0 >

3-24

< AOUT_MCLK >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 38

5. SERIAL INTERFACE BLOCK (BETWEEN MAIN AND I/O)

1

2

3

1

< SIO_SPI_CLK >

2

< SIO_SPI_MOSI >

3

< SIO_SPI_MISO >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-25

LGE Internal Use Only

Page 39

6. TUNER BLOCK

1

IC901

1

< SIF >

LGE Internal Use Only

3-26

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 40

7. HDMI BLOCK

1

1

1

576i/576p mode : 27MHz 720p/1080i mode : 74.25MHz

< VOUT_CLK >

2

< VOUT_CLK >

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-27

< VOUT_CLK >

2

IC1701

LGE Internal Use Only

Page 41

WIRING CONNECTION DIAGRAM

USB

V_IN

//

A_IN

DV

1. WIRING CONNECTION DIAGRAM 1

: FFC

X pin

X pin

X pin

o Bíd

: Bíd t

X pin

X pin

n

: Harness

: Bíd i

X pin

Half Nim

TUNER

Optical

S Video

Coaxial

Composite

SCART1/2

Junction Bíd

Junction Bíd

5pin

4pin

30pin

I/O BOARD

4pin

30pin

30pin

40pin

5pin

40pin

HDD

A_IN

//

V_IN

USB

DV

Timer

HDMI

40pin

16pin

16pin

SMPS

4pin

40pin

30pin

30pin

40pin

4pin

MAIN BíD

40pin

30pin(New)

RS-03

LOADER

Option BíD

KARAOKE

30pin

RW DRIVER

±

DVD

2pin

Sub timer

LGE Internal Use Only

3-28

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 42

2. WIRING CONNECTION DIAGRAM 2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-29

LGE Internal Use Only

Page 43

3. WIRING CONNECTION DIAGRAM 3

LGE Internal Use Only

3-30

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 44

BLOCK DIAGRAMS

PMV

PMV0

1. OVERALL BLOCK DIAGRAM

ARD

Timer BO

TPA+

TPA-

DV

+

TPB

K

JAC

-

TPB

NKON

PHY_LI

Q

S

PHY_LRE

PHY_LP

IC1401

TSB41AB

]

K

PHY_DATA[7:0]

PHY_CTL[1:0

PHY_CL

VOUT_CLK

1

PMH10

IC1101

DMN8653

VO_D[15:0]

SCL

SDA

LSI

AOUT_MCLKOUT

AOUT_IEC958

HDMI

HDMI

RT2_RX

UA

UART2_TX

UART2_RTS

UART2_CTS

SO

VIDEO_INT

INTERFACE

INTERFACE

CEC

SIO_SPI_MOSI

SIO_SPI_CLK

SIO_SPI_CS0

SIO_SPI_MI

SPI_CS

SPI_CLK

T

UAR

PMX03

PC DEBUGGING

Register

SPI_MOSI

SPI_MISO

NEC

MICOM

IC701

R

I/O BOARD

/RST_PHY

/RST_TDA9984

/RST_SAA7138

IC901

SAA7138

AV DECODE

ARD

TTC-90

IC1201

FLASH

MX29LV640M

MEMORY

HD[15:0]

IC1301

HD[15:0]

HD[15:

HD[15:0]

0]

HA[21:6]

LATCH

Address

74LVT16373

E5_ALE

E5_ALE

/RST_HOST

IC701 MICOM

/RST_E5/FLASH

IC1101

DMN8653

LSI

]

WEn

CS0

/E5_OE

/E5_

HA[5:1][23:22

/E5_L

/E5_OE

/E5_CS0

/E5_LWEn

HA[5:1][23:22]

VFD

FLD_CLK/ENA/DATA

F_CVBS/AL/AR

01

1

IC701

Display

RMC/KEY0/KEY1

NEC

5.3VA/SW5.3VA

-29A/FD+/FD-

PMV

PMV0

I/O BOARD

MICOM

CS3

/E5_

Timer BO

ARD

Timer BO

USB

JACK

USB_VCC

5VD

USB_D-

USB_D+

IC1501

USB_PWR_EN

TPS2052

USB_OCS

1:0]

1

#1

E5_SDRAM_DQ[15:0]

E5_SDRAM_DQM[

E5_SDRAM_CLK

E5_SDRAM_DQS[1:0]

E5_SDRAM_A[13:0]

E5_SDRAM_CLK

160CE-5

IC1202

HYB25D512

#

E5_SDRAM_WE#

E5_SDRAM_CAS

DDR

E

E5_SDRAM_RAS#E5_SDRAM_CLK

E5_SDRAM_BA[1:0]

SDRAM

G2995

IC1204

VREF

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-31

ATAPI1_D[15:0]

DY

/RST_ATAPI1

ATAPI1_DIOR_L

ATAPI1_IORDY

ATAPI1_ADD[4:0]

ATAPI1_DMARQ

ATAPI1_DIOW_L

ATAPI1_INTRQ

ATAPI1_DMAACK_L

INTERFACE

LOADER

PML07

ATAPI2_D[15:0]

/RST_ATAPI2

ATAPI2_DIOR_LATAPI2_IOR

ATAPI2_ADD[4:0]

ATAPI2_DMARQ

ATAPI2_DIOW_L

ATAPI2_INTRQ

ATAPI2_DMAACK_L

INTERFACE

HDD

PML08

LGE Internal Use Only

Page 45

2. SMPS BLOCK DIAGRAM

-28V

FD(-)

FD(+)

P1701

14VA

5V

33VA

3.8VA

5.3VA

PWR CTL

P1D01

12V

RECTIFIER &

R191,R131,ZD121

SMOOTHING BLOCK

D121,FR121,C120,R181,

RECTIFIER &

D122,C122,R122

SMOOTHING BLOCK

D125,C121

5V RECTIFIER &

SMOOTHING BLOCK

14V RECTIFIER &

T101

SMOOTHING BLOCK

3.8V RECTIFIER &

D124,C123,L123,C133

SMOOTHING BLOCK

D127,C124,L124,C134

33V RECTIFIER &

SMOOTHING BLOCK

D126,C126,R147,ZD122

101

D128D130,C125,

5.3V RECTIFIER &

SMOOTHING BLOCK

C156

5V REG &

IC156,R156,

S/W BLOCK

BLOCK

FEEDBACK

L125,C135

IC102

PHOTO COUPLER

12V REG &

IC155,R155,

S/W BLOCK

C143

R141,R142,

R143,R144,

R145,R146,

IC103

ERROR AMP

C155

BD101

LGE Internal Use Only

BLOCK

SNUBER

C103

TH01

105,C106

C

D101,R104,

BLOCK

NOISE FILTER

R101,L101

V101,C101,C102,

BLOCK

DRIVE & S/W

3-32

ZD101,ZD103,

R109,C104,C107,

IC101,D102,R105,

C108,C109, BC

F101

FUSE

113

C

BR BL

Y CAP

H)

(BK)(W

!

C112

Y CAP

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 46

3. POWER MAIN BLOCK DIAGRAM

14VA

33VA

33VD

5.

3VA

5.

3VA

SW

_5

VA

3.

8VA

3.

3V

ST

PW

R_CTL_H

ST

LD

PW

R_CTL_H

PW

R_CTL_H

2.

5V

1.

8V

5V_HDD

12V_HDD

1.

5V

SW

_12VA

5.

0VD

_12VA

SW

33VD

ANDBY_H

ST

.3VA

_5

SW

R_CTL_H

PW

ANDBY_H

ST

25V

1.

DCDC CONVERTOR

R_CTL_H

PW

O

LD

3VA

5.

R_CTL_H

PW

8V

3V

1.

3.

5V

2.

0VD

5.

12V_HDD

5V_HDD

IO

TR Circuit

14VA

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

33VA

3VA

5.

3-33

8VA

3.

SMPS

LGE Internal Use Only

Page 47

4. POWER I/O BLOCK DIAGRAM

g

8

VP

e

M

A

(

g

A

8

uner

P

NJ

-CO

uner

C+

.SW

od Buffer

For

M1510

dB AMP

0

17

udio DAC

713

itron

i

Jack

O

LGE Internal Use Only

l

n

ull UP

For Si

WR Fail

T6315

3-34

UNER

oost

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 48

5. A/V BLOCK DIAGRAM

FRONT

CK

I/O

B

_

_

T

_

_

A

M

MI

JA

CK

_

A

A

_

AT

A

_

A

HDMI

JACK

A

C

_12VA

C+_DET_H

EU2_V_OUT

EU2_A_OUT_L

EU2_A_OUT_R

RGB_SEL_OUT

R_IN

G_IN

B_IN

EU1_V_OUT

EU1_A_OUT_L

EU1_A_OUT_R

SCART_H

SCART 1 SCART 2 (Decorder)

R_SCART_OUT

G_SCART_OUT

B_SCART_OUT

GND

EUEUEU

t

R circu

EU2_V_IN

EU2_A_IN_L

I

GB

OU

GB

JIG_ENA

EU2_A_IN_R

EEPROM

IO MICO

I2C_CLK

I2C_DATA

TU_V_OUT

TU_R_A_OUT

T

ST

OST

T

R_IN

TU_L_A_OUT

MM176

EN

ST

G_IN

IN

I

LD

LD

I2C_CL

I2C_DA

SAA7138

1

_RTN_0

RMC_IN

UNER

SIF

SECAM_AM

TR circuit

Y_OUT

Pr_OUT

Pb_OUT

Y_RCA_OUT

Pb_RCA_OUT

Pr_RCA_OUT

Y, C

COAXIAL

A_L_OUT

A_R_OUT

A_OUT_L

A_OUT_R

COAXIAL

OPTICAL

OARD

B

MIC BOARD

I/O

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CK

C JA

MI

SW_V_OUT

SW_A_OUT_R

AOUT_SCLK

AOUT_FSYNC

AOUT_D0

AOUT_MCLK

HOST_DATA_INHOST_ENA

SPDIF_OUT

AOUT_MCLK

SW_A_OUT_L

AIN_MCLKOUT

AIN_FSYNC, AIN_SCLK

AIN_D0, VIN[2:9]

MV3

VO_D[0:15]

VOUT_CLK

I2C_SCL,

MAIN BOARD

I2C_SDA

HDMI_CEC

V_INT, V_CLK

AD9389_INT

SCL, SDA

USB+,

F_A_R_IN

USB-

F_A_L_IN

USB_5V

F_CVBS_IN

FLD

DRIVER

TIMER BOARD

JACK

TPA+,

TPA-

FRONT

TPB+,

TPB-

LGE Internal Use Only

Y, C

R,G,B

Y,Pb,Pr

Y, C

R,G,B

Y,Pb,Pr

CVBS_OUT

A_OUT_L

A_OUT_R

DAC

AUDIO

MIC_IN

JACK

HDMI BOARD

MIC_DET

HDMI

3-35

Page 49

6. AUDIO OUT BLOCK DIAGRAM

904

AUDI

DAC

PCM178

PMV01

PVM

802

803

D.

di

o O

801

AV

S/

MM1763

(

SCART/RCA(A

)1)

(

)SCART(AV2)

MPEG

ENC/DEC

901

A.D

SAA713

MI

801

ALC

BA3308

903

OPAMP

VR801

10K

D2A

CN801

PVK0

Mono

NTSC

Option

TUNER

Circuit

V1

A

JK802

Coaxial RCA L /R Out

Optical

JK803

COM

MI

SPDIF_OUT

A_MUTE

R

L /

Z_MUTE

MUTE

Circuit

O

IC904

AUDI

DAC

L / R_OUT

DAC

PCM178

R

L /

A_OUT

IC902

0

LTER

FI

OPAMP

IC901

IC801

T

TES

SUB DAC

AC

8

A.D

SAA713

W

S/

AV

MM1763

MIC

R_OUT

L /

IC903

OPAMP

L / R out

SCART/RCA

AV2

L / R out

SCART

LGE Internal Use Only

ut

o O

Audi

MCLK

D.

MAIN I / O

I2S

S/PDIF)

IEC60958(

PVM

PMV01

AO_MCLK

AO_IEC958

01

AO_SCLK

AO_FSYNC

MPEG

ENC/DEC

3-36

AO_DO

D2A

ALC

IC801

Copyright © 2008 LG Electronics. Inc. All right reserved.

BA3308

MIC

MIC_IN

PVK0

1

CN801

10K

VR801

MIC

Only for training and service purposes

Page 50

7. HDMI BLOCK DIAGRAM

TXclkp

TXclkn

TX0p

RxSense

TMDS block

keys

OTP memory

HDCP block

TX0n

HDMI

Serializer

HDCP

TX1p

TX1n

TX2p

processing

TX2n

EXT_

swing

I2C DDC interface

Registers

Down-

4:4:4 to

sampler

(1)

4:2:2

I2C

slave

DDC

master

DSCL DSDA SCL SDA

packet

insertion

Data island

ACR

Info Frame

Audio content

HDMI packet insertion

FIFO

Audio

capture

CTS/N

processing

Audio processing

VHREF generatior

Null & ACP

PLL block

Clock

Management

converter

Color space

Up-

sampler

3x8 bit YCbCr/RGB 4:4:4

2x12 bit YCbCr 4:4:2

input

Video

Video processing

(1) Can be bypassed

(1)

RGB to YUV

YUV to RGB

To

4:4:4

4:2:2

4:2:2

Up-Scaler

2x12 bit

data

capture

YCbCr

WS

ACLK

AP[3..0]

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

MCLK

SPDIF

AUX

PCLK

3-37

VSYNC

HSYNC

DE

VA[7..0]

VB[7..0]

VC[7..0]

LGE Internal Use Only

Page 51

MEMO

LGE Internal Use Only

3-38

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 52

CIRCUIT DIAGRAMS

A B C D E F G H I J K L M N O P Q R ST

RH300'S

No Power

BD101,R101 is Defective

FD(+)FD(-) No Power

D121 is Defective

-28VA No Power

D122 is Defective

14VA No Power

D125 is Defective

No Power

D102 is Defective

3.8VA No Power

D127 is Defective

5V No Power

D125 is Defective

5.6VA No Power

D123 is Defective

S/W Error

IC101 is Defective

Switching Error

IC102,IC103 are Defective

No Power

F101 is Defective

5.3VA No Power

D128 is Defective

5V No Power

IC155 is Defective

5V No Power

IC156 is Defective

1. SMPS 1 CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTE :

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT. SPECIAL

COMPONENTS ARE SHADED ON THE SCHEMATIC

FOR EASY IDENTIFICATION. THIS CIRCUIT DIAGRAM

MAY OCCASIONALLY DIFFER FROM THE ACTUAL

CIRCUIT USED. THIS WAY, IMPLEMENTATION OF THE

LATEST SAFETY AND PERFORMANCE IMPROVEMENT CHANGES INTO THE SET IS NOT DELAYED

UNTIL THE NEW SERVICE LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter during Play mode.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-39 3-40

LGE Internal Use Only

Page 53

2. SMPS 2 CIRCUIT DIAGRAM

LGE Internal Use Only

3-41 3-42

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 54

3. MPEG CIRCUIT DIAGRAM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-43 3-44

LGE Internal Use Only

Page 55

4. FLASH/DDR/DV CIRCUIT DIAGRAM

LGE Internal Use Only

3-45 3-46

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 56

5. ATAPI, HDMI & USB CIRCUIT DIAGRAM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-47 3-48

LGE Internal Use Only

Page 57

6. I/O, µ-com CIRCUIT DIAGRAM

LGE Internal Use Only

3-49 3-50

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 58

7. DECODER & MIC CIRCUIT DIAGRAM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-51 3-52

LGE Internal Use Only

Page 59

8. SCART/RCA CIRCUIT DIAGRAM

LGE Internal Use Only

3-53 3-54

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 60

9. HDMI CIRCUIT DIAGRAM

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-55 3-56

LGE Internal Use Only

Page 61

10. TIMER CIRCUIT DIAGRAM (8 & 9 TOOLS)

LGE Internal Use Only

3-57 3-58

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 62

11. KEY CIRCUIT DIAGRAM (8 & 9 TOOLS)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3-59 3-60

LGE Internal Use Only

Page 63

• CIRCUIT VOLTAGE CHART

PIN EE MODE PB MODE

IC105 G5627

1 5.23V 5.23V 5.21V

2 0.8V 0.8V 0.8V

30V 0V 0V

4 0.8V 0.8V 0.8V

5 2.56V 2.56V 2.56V

60V 0V 0V

7 1.36V 1.36V 1.36V

8 5.23V 5.23V 5.21V

IC701 uPD78F0535GK

1 5.23V 5.23V 5.23V

20V 0V 0V

30V 0V 0V

4 5.22V 5.21V 5.21V

50V 0V 0V

6 5.24V 5.24V 5.23V

7 2.67V 2.66V 2.66V

8 2.38V 2.35V 2.34V

90V0V0.01V

10 3.21V 3.24V 3.21V

11 2.6V 2.65V 2.64V

12 2.53V 2.53V 2.53V

13 0V 0V 0V

14 0V 0V 0V

15 5.23V 5.24V 5.23V

16 5.24V 5.24V 5.24V

17 5.17V 5.16V 5.16V

18 5.17V 5.17V 5.17V

19 0V 0V 0V

20 3.67V 3.68V 3.69V

21 5.28V 5.27V 5.27V

22 0V 0V 0.01V

23 5.21V 5.2V 5.2V

24 5.21V 5.2V 5.2V

25 5.23V 5.22V 5.22V

26 0V 0.08V 0.08V

27 0V 0.09V 0.09V

28 5.23V 5.22V 5.22V

29 5.11V 5.1V 5.1V

30 0V 0V 0.01V

31 0V 0.02V 0.02V

32 0V 0.01V 0.01V

33 4.85V 4.83V 4.83V

34 0V 0.01V 0.02V

35 0V 0.01V 0.01V

36 0V 0.01V 0.01V

37 0V 0.01V 0.01V

38 4.93V 4.93V 4.93V

39 0V 0V 0.01V

40 0V 0.01V 0.01V

41 4.95V 4.94V 4.95V

42 5.21V 5.21V 5.21V

43 0V 0.01V 0.01V

44 0.74V 0.74V 0.75V

45 0V 0V 0V

46 5.17V 5.16V 5.16V

47 5.28V 5.28V 5.28V

48 0V 0V 0V

49 5.24V 5.27V 5.27V

50 2.64V 2.64V 2.64V

51 2.48V 2.47V 2.47V

52 2.65V 2.64V 2.64V

53 0V 0V 0V

54 0V 0V 0V

55 0V 0V 0V

56 0V 0V 0V

REC MODE

PIN EE MODE PB MODE

57 5.23V 5.23V 5.23V

58 5.07V 5.06V 5.27V

59 0V 0.01V 0V

60 0.4V 0.42V 0V

61 5.28V 5.27V 5.27V

62 5.19V 5.19V 5.19V

63 0V 0V 0V

64 0V 0V 0V

IC703 S524A60X51-SCTO

10V 0V 0V

20V 0V 0V

30V 0V 0V

40V 0V 0V

5 5.17V 5.17V 5.17V

6 5.16V 5.15V 5.16V

70V 0V 0V

8 5.28V 5.28V 5.28V

10V 0V 0V

2 3.09V 3.08V 3.08V

3 5.07V 5.06V 5.07V

40V 0V 0V

50V0V0.01V

60V0V0.01V

70V 0V 0V

8 5.28V 5.28V 5.27V

9 3.68V 3.68V 3.67V

10 0V 0V 0V

11 5.28V 5.28V 5.27V

12 3.22V 3.22V 3.22V

13 0V 0V 0V

14 5.28V 5.27V 5.28V

1 1.09V 1.09V 1.08V

2 6.93V 6.93V 6.94V

3 6.93V 6.93V 6.94V

4 1.09V 1.09V 1.08V

5 6.94V 6.93V 6.94V

6 6.94V 6.93V 6.94V

7 1.59V 1.59V 1.59V

8 6.93V 6.93V 6.93V

9 6.94V 6.93V 6.93V

10 1.09V 1.09V 1.09V

11 6.93V 6.93V 6.93V

12 6.94V 6.93V 6.93V

13 2.42V 2.42V 2.42V

14 12.06V 12.06V 12.08V

15 1.57V 1.67V 1.57V

16 0V 0V 0V

17 1.56V 1.66V 1.56V

18 2.45V 2.45V 2.45V

19 1.55V 1.64V 1.54V

20 9.97V 9.96V 9.96V

21 2.42V 2.42V 2.42V

22 2.42V 2.42V 2.42V

23 0V 0V 0V

24 0V 0V 0V

25 0V 0.01V 0V

26 2.08V 2.27V 2.08V

27 2.11V 2.31V 2.11V

28 2.12V 2.33V 2.12V

29 2.49V 2.49V 2.49V

30 5.1V 5.1V 5.09V

31 5.16V 5.16V 5.16V

32 5.17V 5.17V 5.17V

33 0V 0V 0V

IC704 74HCT125

IC801 MM1763

REC MODE

PIN EE MODE PB MODE

34 6.47V 6.48V 6.48V

35 6.47V 6.48V 6.47V

36 2.13V 2.34V 2.14V

37 6.48V 6.47V 6.47V

38 6.47V 6.47V 6.47V

39 2.13V 2.34V 2.13V

40 6.46V 6.46V 6.46V

41 6.46V 6.46V 6.46V

42 1.6V 1.61V 1.6V

REC MODE

IC901 SAA7138

10V0.01V 0V

20V 0V 0V

3 1.82V 1.82V 1.82V

40V 0V 0V

5 3.28V 3.28V 3.28V

60V 0V 0V

7 3.26V 3.26V 3.26V

8 0.57V 0.57V 0.57V

9 0.57V 0.57V 0.57V

10 0.57V 0.57V 0.57V

11 1 V 1V 1V

12 0V 0V 0V

13 3.26V 3.26V 3.26V

14 0.4V 0.41V 0.41V

15 0.56V 0.56V 0.56V

16 0.56V 0.56V 0.56V

17 0.99V 0.99V 0.99V

18 1.82V 1.82V 1.82V

19 0V 0V 0V

20 2.11V 2.11V 2.11V

21 3.26V 3.27V 3.27V

22 0V 0V 0V

23 0V 0V 0V

24 0V 0V 0V

25 0V 0V 0V

26 3.26V 3.26V 3.26V

27 0.44V 0.44V 0.44V

28 0.56V 0.56V 0.56V

29 0.89V 0.89V 0.89V

30 0.98V 0.98V 0.98V

31 0V 0V 0V

32 3.26V 3.26V 3.26V

33 1.01V 1.01V 1.01V

34 1.01V 1.01V 1.01V

35 0.57V 0.57V 0.58V

36 0.57V 0.57V 0.57V

37 0.57V 0.57V 0.57V

38 0.99V 1V 1V

39 0V 0V 0V

40 0V 0.01V 0V

41 3.28V 3.28V 3.28V

42 0V 0.01V 0.01V

43 3.28V 3.28V 3.28V

44 3.27V 3.2V 3.22V

45 3.15V 3.15V 3.14V

46 0V 0.01V 0.01V

47 0V 0.01V 0.01V

48 1.8V 1.8V 1.8V

49 0V 0V 0V

50 0.05V 0.05V 0.05V

51 3.28V 3.29V 3.27V

52 0V 0V 0V

53 0.88V 0.88V 0.88V

54 0.87V 0.87V 0.88V

55 1.83V 1.83V 1.83V

56 1.4V 1.4V 1.4V

PIN EE MODE PB MODE

57 1.34V 1.33V 1.32V

58 1.38V 1.37V 1.36V

59 3.29V 3.29V 3.28V

60 0V 0V 0V

61 1.57V 1.62V 1.61V

62 1.47V 1.47V 1.46V

63 1.23V 1.23V 1.22V

64 1.13V 1.14V 1.14V

65 1.35V 1.32V 1.32V

66 3.03V 3.03V 3.03V

67 3.29V 3.29V 3.29V

68 0V 0V 0V

69 1.8V 1.8V 1.8V

70 0V 0V 0V

71 2.74V 2.74V 2.74V

72 1.58V 1.5V 1.53V

73 1.4V 1.42V 1.42V

74 1.32V 1.33V 1.33V

75 1.37V 1.37V 1.36V

76 1.53V 1.53V 1.56V

77 3.29V 3.29V 3.29V

78 0V 0V 0V

79 1.48V 1.47V 1.48V

80 1.23V 1.24V 1.24V

81 1.14V 1.15V 1.15V

82 1.35V 1.34V 1.34V

83 0V 0V 0V

84 1.75V 1.75V 1.75V

85 3.29V 3.29V 3.29V

86 0V 0V 0V

87 3.29V 3.29V 3.29V

88 3.29V 3.29V 3.29V

89 3.29V 3.29V 3.29V

90 1.8V 1.8V 1.8V

91 0V 0V 0V

92 3.29V 3.29V 3.29V

93 3.29V 3.29V 3.29V

94 3.29V 3.29V 3.29V

95 1.66V 1.65V 1.65V

96 3.29V 3.29V 3.29V

97 0V 0V 0V

98 1.65V 1.64V 1.64V

99 1.66V 1.64V 1.65V

100 1.24V 1.24V 1.24V

101 0V 0V 0V

102 3.28V 3.28V 3.28V

103 0.47V 0.47V 0.47V

104 0.47V 0.47V 0.47V

105 0.47V 0.47V 0.47V

106 1.64V 1.64V 1.64V

107 1.64V 1.64V 1.64V

108 3.29V 3.29V 3.29V

109 1.64V 1.64V 1.64V

110 1.64V 1.64V 1.64V

111 0V 0V 0 V

112 0 V 0V 0V

113 1.63V 1.63V 1.63V

114 3.12V 3.12V 3.12V

115 0 V 0V 0V

116 3.29V 3.29V 3.29V

117 0 V 0V 0V

118 1.8V 1.8V 1.81V

119 0 V 0V 0V

120 1.62V 1.62V 1.62V

121 1.62V 1.62V 1.62V

122 1.62V 1.62V 1.62V

REC MODE

PIN EE MODE PB MODE

123 1.62V 1.62V 1.62V

124 1.62V 1.62V 1.62V

125 1.62V 1.62V 1.62V

126 1.62V 1.62V 1.62V

127 1.62V 1.62V 1.62V

128 1.62V 1.62V 1.62V

REC MODE

IC902 NJM4580

1 5.99V 6.02V 6.02V

26V6.02V 6.02V

3 5.98V 6V 6V

40V 0V 0V

5 5.98V 6.01V 6V

66V6.02V 6.02V

76V6.02V 6.02V

8 12.03V 12.08V 12.08V

IC904 PCM1780

1 4.8V 0.01V 4.87V

2 3.21V 3.23V 3.22V

3 3.08V 3.1V 3.08V

40V0.01V 0V

5 1.66V 1.67V 1.66V

6 1.63V 0.01V 1.63V

7 1.63V 1.64V 1.64V

8 1.63V 1.64V 1.63V

90V 0V 0V

10 0V 0V 0V

11 4.88V 4.88V 4.87V

12 0V 0V 0V

13 2.44V 2.44V 2.43V

14 2.38V 2.37V 2.37V

15 2.39V 2.38V 2.38V

16 4.88V 0V 4.87V

IC1701 TDA9983A

10V 0V 0V

20V 0V 0V

30V 0V 0V

40V 0V 0V

5 1.64V 1.64V 1.64V

6 1.66V 1.67V 1.66V

70V 0V 0V

80V 0V 0V

90V 0V 0V

10 0V 0V 0V

11 0 V 0V 0V

12 0V 0V 0V

13 3.27V 3.29V 3.27V

14 0V 0V 0V

15 0V 0V 0V

16 1.82V 1.81V 1.82V

17 3.27V 3.29V 3.27V

18 0V 0V 0V

19 4.92V 4.91V 4.92V

20 4.92V 4.91V 4.92V

21 0V 0V 0V

22 0V 0V 0V

23 3.27V 3.29V 3.27V

24 2V 2.01V 2V

25 0V 0V 0V

26 0V 0V 0V

27 0V 0V 0V

28 3.27V 3.29V 3.27V

29 0V 0V 0V

30 0V 0V 0V

31 0V 0V 0V

32 0V 0V 0V

33 0V 0V 0V

INFORMATION :

1. Voltage Check using W/S

2. EE Mode : Check with signal C2

3. Playback Mode : Check with DVD TEST DISC KDV-N chapter 2

4. Record Mode: Check with recording signal C2 using DVD -RW

Brand : Victor, VR Mode MLP

PIN EE MODE PB MODE

34 3.27V 3.29V 3.27V

35 0V 0V 0V

36 0V 0V 0V

37 0V 0V 0V

38 3.27V 3.29V 3.27V

39 0V 0V 0V

40 0V 0V 0V

41 0V 0V 0V

42 3.26V 3.27V 3.26V

43 3.19V 3.13V 3.19V

44 3.16V 3.17V 3.16V

45 1.82V 1.81V 1.82V

46 0V 0V 0V

47 0V 0V 0V

48 3.27V 3.29V 3.27V

49 0V 0V 0V

50 0V 0V 0V

51 0V 0V 0V

52 0V 0V 0V

53 0V 0V 0V

54 0V 0V 0V

55 0V 0V 0V

56 0V 0V 0V

57 0V 0V 0V

58 0V 0V 0V

59 1.82V 1.81V 1.82V

60 0V 0V 0V

61 0V 0V 0V

62 0V 0V 0V

63 0V 0V 0V

64 0V 0V 0V

65 0V 0V 0V

66 1.62V 1.62V 1.62V

67 0V 0V 0V

68 0V 0V 0V

69 0V 0V 0V

70 0V 0V 0V

71 3.26V 3.29V 3.27V

72 0V 0V 0V

73 0V 0V 0V

74 1.82V 1.81V 1.82V

75 0V 0V 0V

76 0V 0V 0V

77 0V 0V 0V

78 0V 0V 0V

79 0V 0V 0V

80 0V 0V 0V

REC MODE

LGE Internal Use Only

3-61 3-62

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 64

NO

PIN NAME

EE PB REC

MODE MODE MODE

IC401 TSB41AB1 IEEE1394-DV Input

IC401

1 PHY_CLK 1.78 1.71 1.73

2 PHY_CTL0 0.01 0.01 0.01

3 PHY_CTL1 0.01 0.01 0.01

4 PHY_DATA0 0.01 0.01 0.01

5 PHY_DATA1 0.01 0.01 0.01

6 PHY_DATA2 0.01 0.01 0.01

7 PHY_DATA3 0.01 0.01 0.01

8 PHY_DATA4 0.01 0.01 0.01

9 PHY_DATA5 0.01 0.01 0.01

10 PHY_DATA6 0.01 0.01 0.01

11 PHY_DATA7 0.01 0.01 0.01

12 1394_PD 0.01 0.01 0.01

13 PHY_LPS 3.26 3.26 3.26

14 GND 0.01 0.01

15 PHY_LINKON 0.01 0.01 0.01

16 PC0 0.01 0.01 0.01

17 PC1 0.00 0.01 0.01

18 PC2 0.01 0.01 0.01

19 ISO 3.27 3.27 3.27

20 CPS 3.15 3.15 3.15

21 DVDD21 3.27 3.27 3.27

22 TESTM 3.27 3.27 3.27

23 SE 0.01 0.01 0.01

24 SM 0.01 0.01 0.01

25 AVDD25 3.27 3.27 3.27

26 GND 0.00 0.00 0.00

27 TPB- 1.77 1.56 1.56

28 TPB+ 1.77 1.77 1.77

29 TPA- 1.80 1.84 1.84

30 TPA+ 1.77 1.77 1.77

31 TPBIAS 1.82 1.82 1.82

32 AGND32 0.00 0.00 0.00

33 RO 0.00 0.10 0.01

34 RI 1.21 1.21 1.21

35 AVDD35 3.27 3.27 3.27

36 GND 0.00 0.00 0.00

37 /RST_PHY 3.26 3.26 3.26

38 FILTER0 0.01 0.01 0.01

39 FILTER1 1.28 1.29 1.29

40 PLLVDD 3.28 3.27 3.27

41 PLLGND 0.00 0.00 0.01

42 XI 1.50 1.50 1.50

PIN NAME

NO

43 XO 1.50 1.50 1.50

44 DVDD44 3.28 3.28 3.27

45 DVDD45 3.28 3.27 3.27

46 GND 0.00 0.00 0.01

47 GND 0.00 0.00 0.01

48 PHY_LREQ 0.01 0.01 0.01

IC1201 39FV6402B_SST_8MB FLASH MEMORY

1 HA16 0.09 0.08 0.08

2 HA15 0.09 0.08 0.08

3 HA14 0.09 0.08 0.08

4 HA13 0.09 0.08 0.08

5 HA12 0.09 0.08 0.08

6 HA11 0.09 0.08 0.08

7 HA10 0.09 0.08 0.08

8 HA9 0.09 0.08 0.08

9 HA20 0.09 0.08 0.08

10 HA21 0.09 0.08 0.08

11 /E5_LWEn 3.27 3.26 3.26

12 /RST_FLASH 3.25 3.23 3.23

13 HA22 0.02 0.00 0.00

14 HA19 3.25 3.23 3.23

15 HA18 (0.02) 0.00 0.00

16 HA8 (0.02) 0.08 0.08

17 HA18 0.10 0.08 0.08

18 HA8 0.10 3.28 0.08

19 HA7 0.10 0.08 0.08

20 HA6 0.10 0.08 0.08

21 HA5 3.27 3.26 3.26

22 HA4 3.27 3.26 3.26

23 HA3 3.27 3.26 3.26

24 HA2 3.27 3.26 3.26

25 HA1 3.27 3.26 3.26

26 /E5_CS0 3.27 3.26 3.26

27 VSS 0.02 0.00 0.00

28 /E5_OE 3.27 3.26 3.26

29 HD0 0.02 0.01 0.00

30 HD8 0.02 0.00 0.01

31 HD1 0.02 0.01 0.00

32 HD9 0.02 0.01 0.01

33 HD2 0.02 0.01 0.01

34 HD10 0.02 0.01 0.01

35 HD3 0.02 0.01 0.01

36 HD11 0.02 0.01 0.01

EE PB REC

MODE MODE MODE

IC201

NO

37 VCC 3.28 3.28 3.28

38 HD4 0.02 0.01 0.01

39 HD12 0.02 0.01 0.01

40 HD5 0.02 0.01 0.01

41 HD13 0.02 0.00 0.00

42 HD6 0.02 0.01 0.01

43 HD14 0.02 0.01 0.01

44 HD7 0.02 0.01 0.01

45 HD15 0.02 0.01 0.01

46 VSS 0.02 0.01 0.01

47 V33_STB 3.28 3.28 3.28

48 HA17 0.20 0.08 0.08

IC1202 K4H5116380-UCCC DDR SDRAM

1 VDD 2.43 2.43 2.41

2 SDRAM_DQ0 1.11 1.06 1.11

3 VDDQ 2.43 2.43 2.41

4 SDRAM_DQ1 1.13 1.08 1.12

5 SDRAM_DQ2 1.10 1.04 1.09

6 VSSQ 0.00 0.00 0.00

7 SDRAM_DQ3 1.12 1.08 1.15

8 SDRAM_DQ4 1.12 1.09 1.12

9 VDDQ 2.43 2.41 2.41

10 SDRAM_DQ5 1.09 1.20 1.00

11 SDRAM_DQ6 1.09 1.20 1.06

12 VSSQ 0.00 0.00 0.00

13 SDRAM_DQ7 1.05 1.20 0.98

14 NC 0.00 0.00 0.00

15 VDDQ 2.43 2.46 2.41

16 SDRAM_DQS0 1.20 1.23 1.19

17 SDRAM_A13 1.10 1.22 1.08

18 VDD 2.43 2.46 2.41

19 NC 0.00 0.00 0.00

20 SDRAM_DQM0 0.45 0.56 0.56

21 SDRAM_WE# 1.22 1.88 1.79

22 SDRAM_CAS# 1.74 1.85 1.66

23 SDRAM_RAS# 1.79 1.87 1.77

24 /CS 0.00 0.00 0.00

25 NC 0.00 0.00 0.00

26 SDRAM_BA0 1.22 1.24 1.20

27 SDRAM_BA1 1.22 1.24 1.21

28 SDRAM_A10 1.12 1.22 1.11

29 SDRAM_A0 1.13 1.22 1.11

30 SDRAM_A1 1.14 1.22 1.11

PIN NAME

EE PB REC

MODE MODE MODE

IC202

PIN NAME

NO

31 SDRAM_A2 1.14 1.22 1.12

32 SDRAM_A3 1.15 1.23 1.19

33 VDD 2.43 2.47 2.42

34 VSS 0.00 0.01 0.01

35 SDRAM_A4 1.20 1.23 1.19

36 SDRAM_A5 1.20 1.23 1.19

37 SDRAM_A6 1.21 1.23 1.19

38 SDRAM_A7 1.22 1.23 1.20

39 SDRAM_A8 1.21 1.23 1.19

40 SDRAM_A9 1.20 1.23 1.20

41 SDRAM_A11 1.14 1.22 1.10

42 SDRAM_A12 1.13 1.22 1.10

43 NC 0.00 0.00 0.00

44 SDRAM_CLKE 1.85 1.88 1.84

45 SDRAM_CLK1 1.24 1.26 1.23

46 SDRAM_CLK#1 1.14 1.21 1.18

47 SDRAM_DQM1 0.58 0.56 0.56

48 VSS 0.00 0.00 0.00

49 VREF 1.23 1.25 1.22

50 NC 0.00 0.00 0.00

51 SDRAM_DQS1 1.20 1.23 1.19

52 VSSQ 0.00 0.00 0.00

53 NC 0.00 0.01 0.00

54 SDRAM_DQ8 1.13 1.19 1.12

55 VDDQ 2.43 2.47 2.42

56 SDRAM_DQ9 1.13 1.19 1.11

57 SDRAM_DQ10 1.12 1.17 1.06

58 VSSQ 0.00 0.00 0.00

59 SDRAM_DQ11 1.11 1.19 1.17

60 SDRAM_DQ12 1.15 1.20 1.11

61 VDDQ 2.43 2.47 2.41

62 SDRAM_DQ13 1.07 1.20 1.07

63 SDRAM_DQ14 1.09 1.20 1.06

64 VSSQ 0.00 0.00 0.01

65 SDRAM_DQ15 1.07 1.21 1.03

66 VSS 0.00 0.00 0.00

IC1204 G2995

1NC 0.00 0.00 0.00

2 GND 0.00 0.00 0.00

3 VSENSE 1.20 1.24 1.20

4VREF 1.22 1.25 1.22

5 VDDQ 2.41 2.46 2.42

6AVIN 2.40 2.46 2.41

EE PB REC

MODE MODE MODE

IC204

NO

7 PVIN 2.40 2.47 2.42

8VTT 1.20 1.24 1.20

1 GND 0.03 0.03 0.03

2 HA6 0.09 0.09 0.09

3 HA7 0.09 0.09 0.09

4 GND 0.03 0.03 0.03

5 HA8 0.09 3.27 0.09

6 HA9 0.09 0.09 0.09

7 V33_STB 3.28 3.28 3.28

8 HA10 0.09 0.09 0.09

9 HA11 0.09 0.09 0.09

10 GND 0.03 0.03 0.03

11 HA12 0.09 0.09 0.09

12 HA13 0.09 0.09 0.09

13 HA14 0.09 0.09 0.09

14 HA15 0.09 0.09 0.09

15 GND 0.03 0.03 0.03

16 HA16 0.09 0.09 0.09

17 HA17 0.09 0.09 0.09

18 V33_STB 3.28 3.28 3.28

19 HA18 0.09 0.09 0.09

20 HA19 0.09 0.09 0.09

21 GND 0.03 0.03 0.03

22 HA20 0.09 0.09 0.09

23 HA21 0.09 0.09 0.09

24 GND 0.03 0.00 0.00

25 E5_ALE 0.03 0.03 0.03

26 HD15 0.03 0.03 0.03

27 HD14 0.03 0.03 0.03

28 GND 0.03 0.03 0.03

29 HD13 0.03 0.03 0.03

30 HD12 0.03 0.03 0.03

31 V33_STB 3.28 3.28 3.28

32 HD11 0.03 0.03 0.03

33 HD10 0.03 0.03 0.03

34 GND 0.03 0.03 0.03

35 HD9 0.03 0.03 0.03

36 HD8 0.03 0.03 0.03

37 HD7 0.03 0.03 0.03

38 HD6 0.03 0.03 0.03

39 GND 0.03 0.03 0.03

40 HD5 0.03 0.03 0.03

PIN NAME

EE PB REC

MODE MODE MODE

IC1301 74LVT16373ADGG

IC1301

PIN NAME

NO

41 HD4 0.03 0.03 0.03