LG HBLG1004R, HBLG8004RA4, HBLG8004R, HBLG8004RB4, L8004RY4 Service Manual

...

LG

Room

Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL: HBLG8004R,HBLG8004RA4,HBLG8004RB4,

HBLG1004R, CL8000ER,M8004R, M8004RY4,

M1004R,L8004R,L8004RY4,L1004R

2 Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions..........................................................................................................................................3

Dimensions .....................................................................................................................................................6

Outside Dimensions...................................................................................................................................6

Product Specifications ..................................................................................................................................7

Installation .......................................................................................................................................................8

Select the Best Location ............................................................................................................................8

Installation Check.......................................................................................................................................8

How to Secure the Drain Pipe....................................................................................................................8

How to Install..............................................................................................................................................9

Operation ......................................................................................................................................................12

Function of Controls .................................................................................................................................12

Disassembly..................................................................................................................................................13

Mechanical Parts......................................................................................................................................13

Air handling Parts.....................................................................................................................................14

Electrical Parts .........................................................................................................................................15

Refrigerating Cycle...................................................................................................................................17

Schematic Diagram.......................................................................................................................................20

Electronic Control Device.........................................................................................................................20

Wiring Diagram.........................................................................................................................................21

Components Location ..............................................................................................................................22

Troubleshooting Guide.................................................................................................................................23

Pipeing System ........................................................................................................................................23

Trou

bleshooting Guide .............................................................................................................................24

Elect

rical Parts Troubleshooting Guide ....................................................................................................26

Electrical Parts .........................................................................................................................................30

Exploded View ..............................................................................................................................................36

Replacement Parts List ................................................................................................................................37

Service Manual 3

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

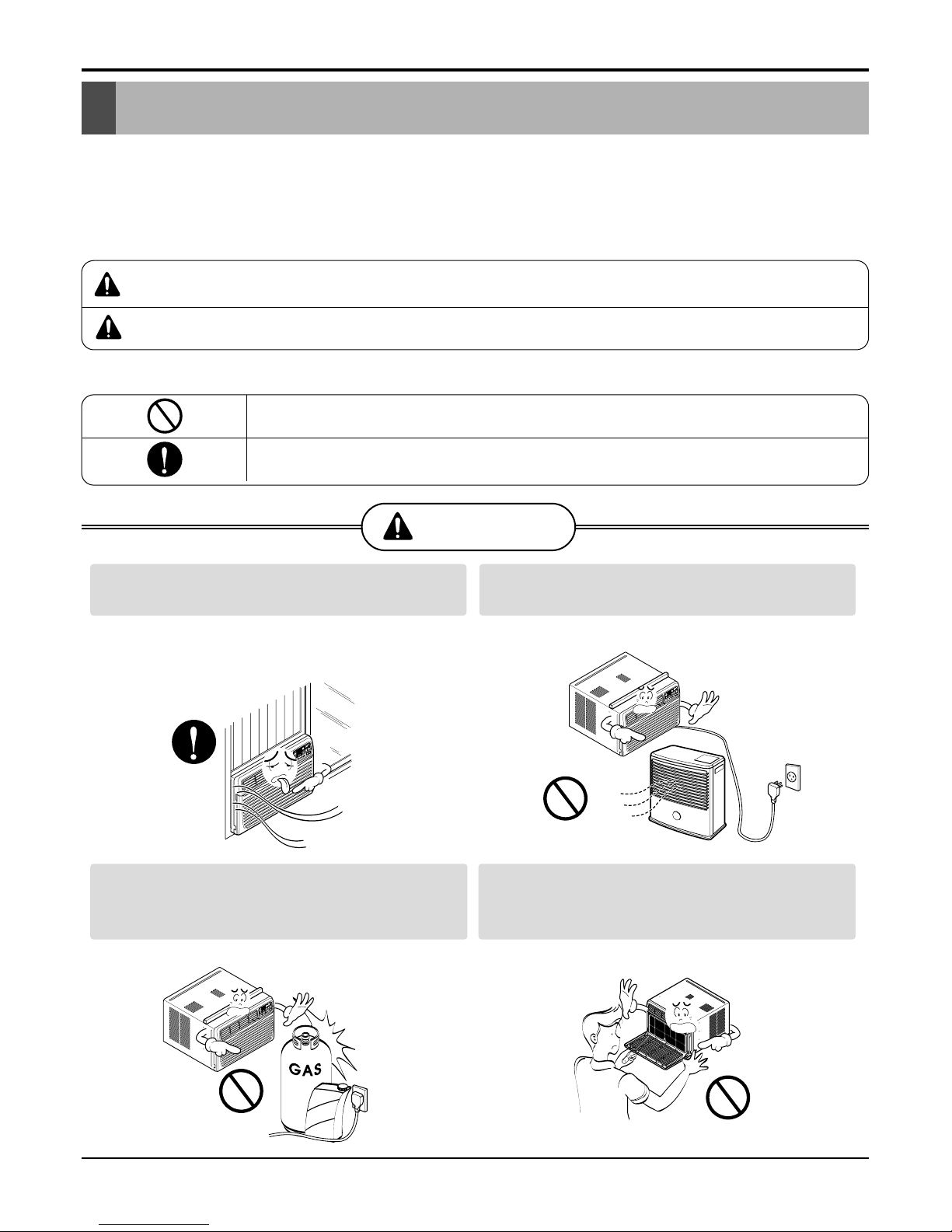

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property only.

Be sure not to do.

Be sure to follow the instruction.

WARNING

Always install the expansion panel(s).

• Improper assembly or installation may cause

incorrect operation, including injury, fire, and

electric shock hazards.

Do not place the power cord near a heater.

• It may cause fire and electric shock.

Do not use the power cord near flammable

gas or combustibles such as gasoline,

benzene, thinner, etc.

• It may cause explosion or fire.

Do not disassemble or modify products.

• It may cause electric shock and failure.

Gasolin

4 Room Air Conditioner

Safety Precautions

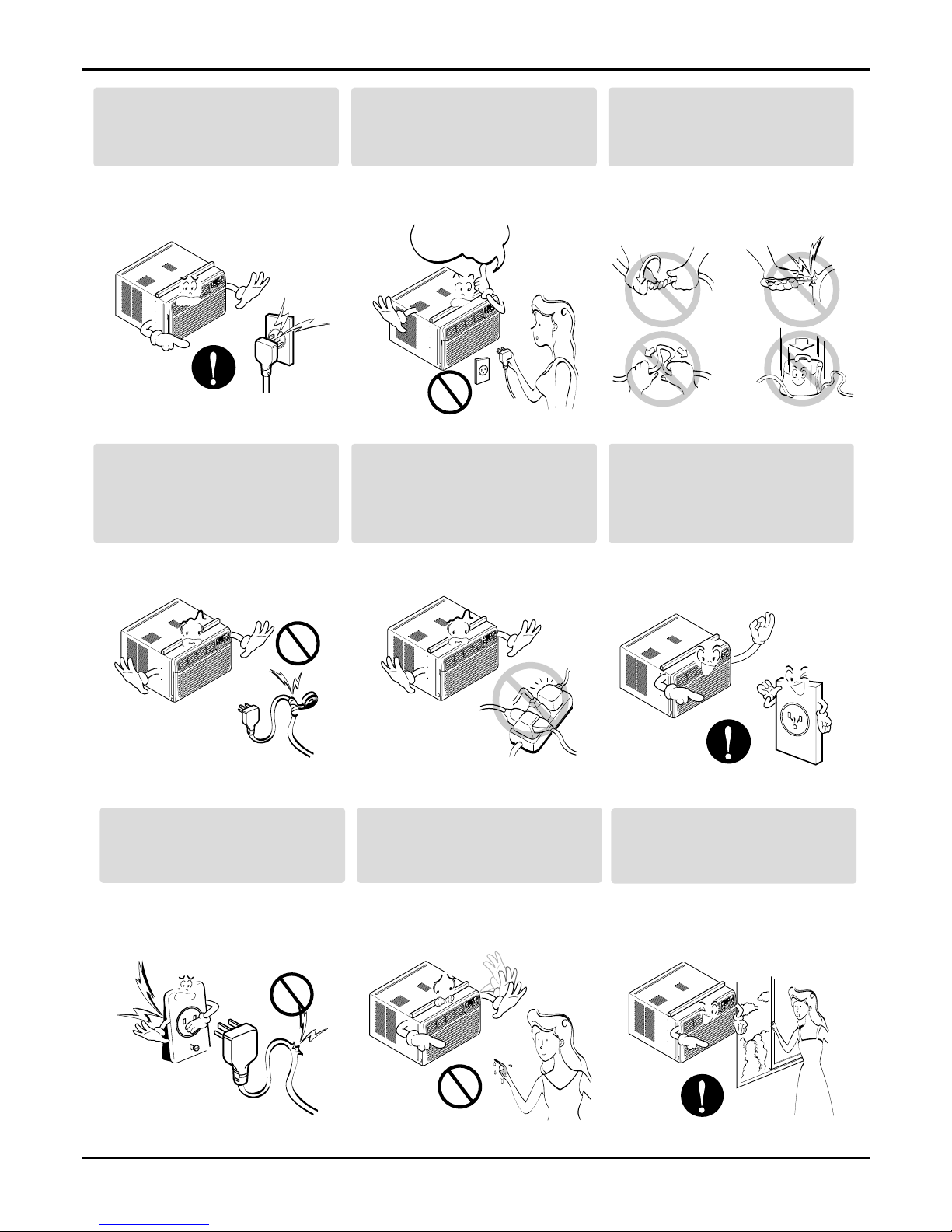

Plug in the power plug

properly.

• Otherwise, it will cause

electric shock or fire.

Do not operate or stop the

unit by inserting or pulling

out the power plug.

• It will cause electric shock or

fire.

Do not damage or use an

unspecified power cord.

• It will cause electric shock or

fire.

Do not modify power cord

length.

• It will cause electric shock or

fire.

Use the air conditioner on a

single outlet circuit.

Do not share the outlet with

other appliances.

• It will cause electric shock or

fire.

Always plug into a

grounded outlet.

• No grounding may cause

electric shock.

Do not use the socket if it is

loose or damaged.

• It may cause fire and electric

shock.

Do not operate with wet

hands or in damp

environment.

• It may cause electric shock.

ON

ON

Ventilate before operating air

conditioner when gas goes

out.

• It may cause explosion, fire,

and burn.

Service Manual 5

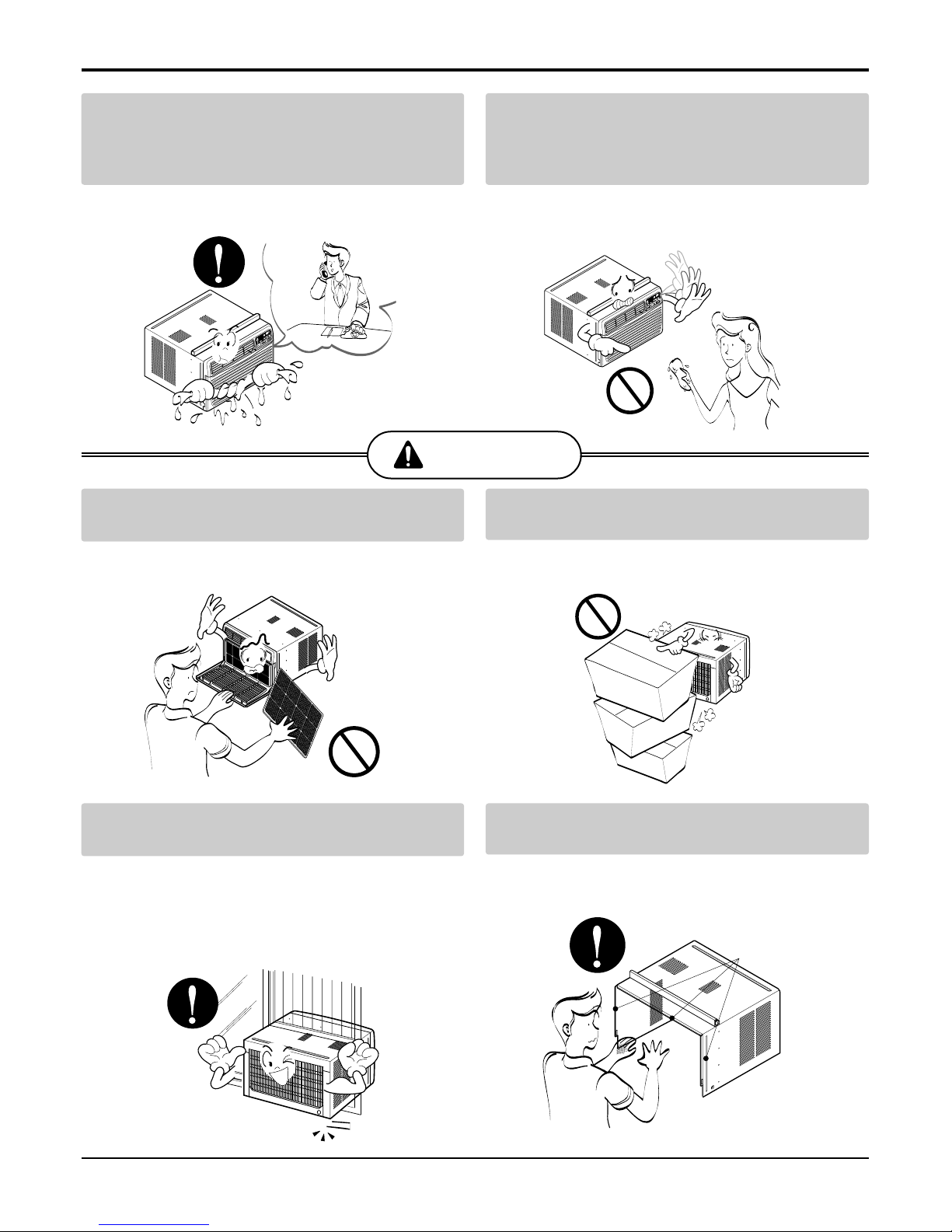

If water enters the product, turn off the the power

switch of the main body of appliance. Contact service center after taking the power-plug out from

the socket.

• It will cause electric shock or failure of machine.

Do not clean the air conditioner with water.

• Water may enter the unit and degrade the insulation. It may cause an electric shock.

Never touch the metal parts of the unit when

removing the filter.

• They are sharp and may cause injury.

Do not block the inlet or outlet.

• It may cause failure of appliance or performance

deteriorate.

Ensure that the outer case is not damaged by

age or wear.

• If the outer case is damaged, it must be repaired

or replaced immediately.

Leaving it damaged could result in the air conditioner falling out of the window, creating a safety

hazard.

Be cautious not to touch the sharp edges

when installing.

• It may cause injury.

CAUTION

Safety Precautions

Sharp

edges

6 Room Air Conditioner

Dimensions

Dimensions

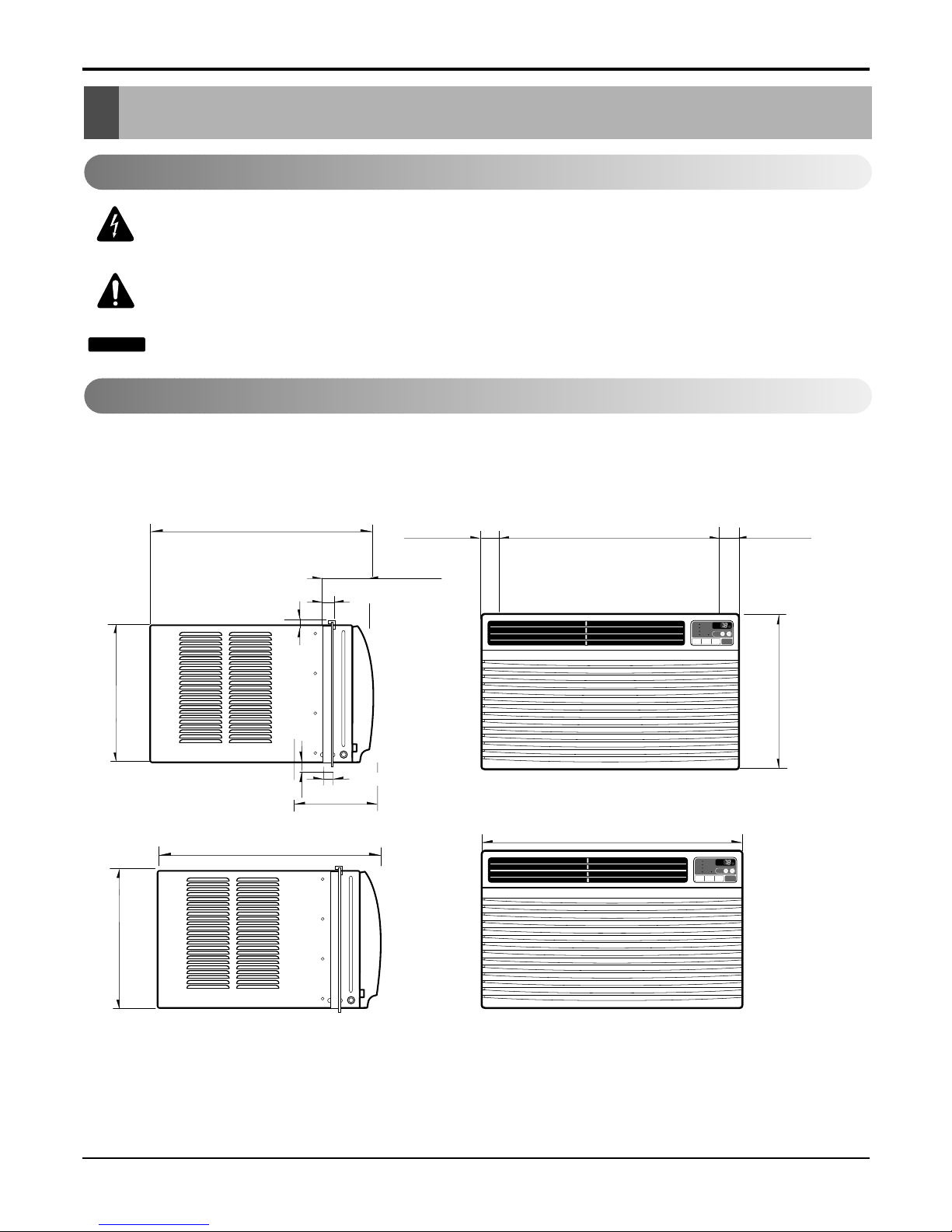

Outside Dimensions

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used in this Manual

497 (19 9/16")

492 (19 3/8")

315 (12 3/8")

30 (1

3

/16")

243.3(9

9/16

")

12

(0.4

1/16

")

22.5(0.8

3/32

")

100.3 (3

27.5 (1

3

/32")

")/

15

16

'

F

TIMER POWERMODE

TEMP

FAN

SPEED

F1 LOW

F2 MED

F3 HIGH

Dry Timer

Fan

Energy

Saver

Cool

'

F

TIMER POWERMODE

TEMP

FAN

SPEED

F1 LOW

F2 MED

F3 HIGH

Dry Timer

Fan

Energy

Saver

Cool

347 (13

21

/

32

")

497 (19 9/16")

42 (1 21/32")

42 (1 21/32")

492 (19 3/8")

315 (12 3/8")

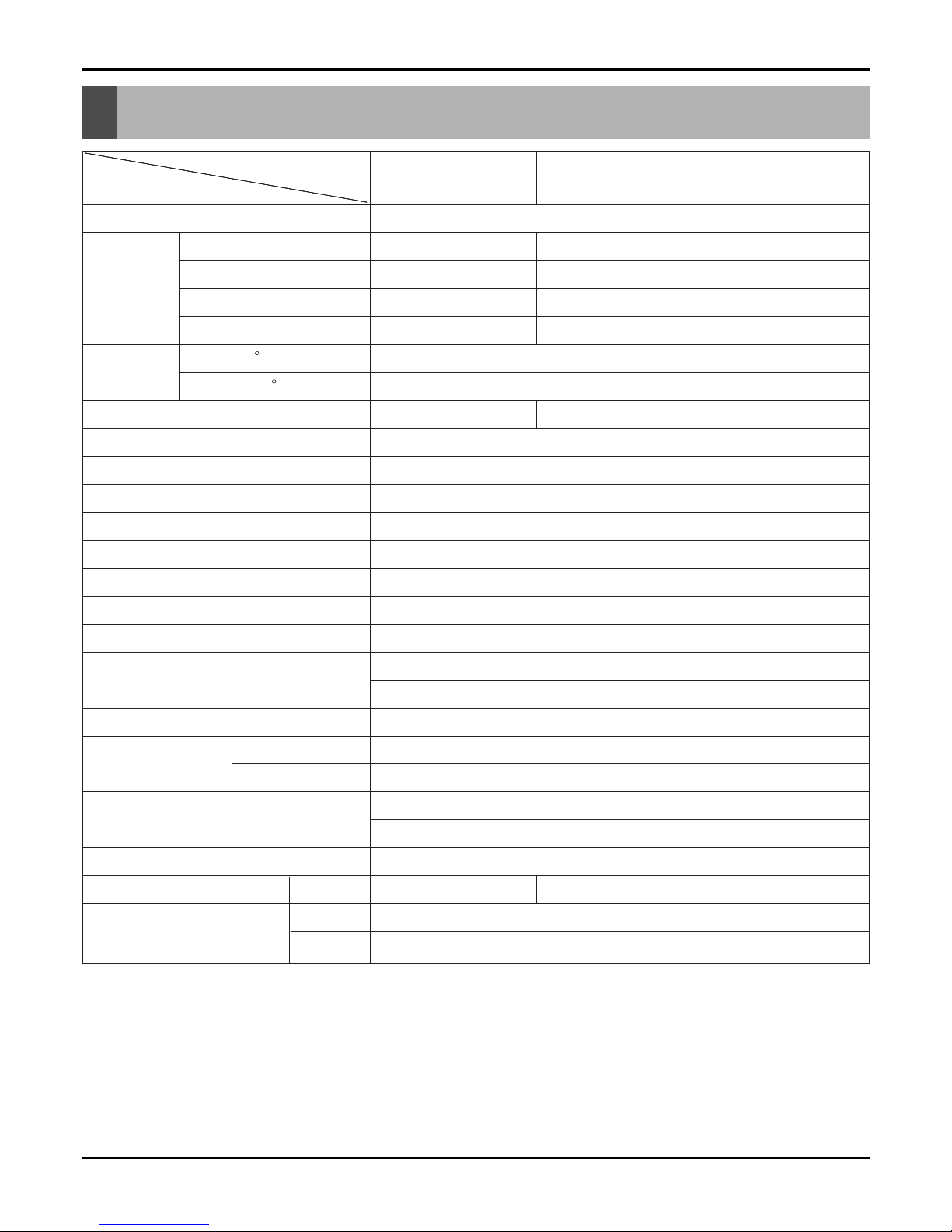

Specfications

Product Specifications

POWER SUPPLY

CAPACITY

POWER SUPPLYPOWER SUPPLY

(BTU/h)CAPACITYCAPACITY

INPUT

(BTU/h)(BTU/h)

POWER SUPPLY

(W)INPUTINPUT

CAPACITY

COOLING

(W)(W)

(BTU/h)

RUNNING CURRENT

COOLINGCOOLING

INPUT

(A)RUNNING CURRENTRUNNING CURRENT

(W)

E.E.R

(A)(A)

COOLING

(BTU/W.h)E.E.RE.E.R

RUNNING CURRENT

INDOOR (

(BTU/W.h)(BTU/W.h)

(A)

C)INDOOR (INDOOR (

E.E.R

OUTDOOR (

C)C)

(BTU/W.h)

C)OUTDOOR (OUTDOOR (

INDOOR (

REFRIGERANT (R-22) CHARGE

C)C)

C)

EVAPORATOR

REFRIGERANT (R-22) CHARGEREFRIGERANT (R-22) CHARGE

OUTDOOR (

CONDENSER

EVAPORATOREVAPORATOR

C)

FAN, INDOOR

CONDENSERCONDENSER

REFRIGERANT (R-22) CHARGE

FAN, OUTDOOR

FAN, INDOORFAN, INDOOR

EVAPORATOR

FAN SPEEDS, FAN/COOLING/HEATING

FAN, OUTDOORFAN, OUTDOOR

CONDENSER

FAN MOTOR

FAN SPEEDS, FAN/COOLING/HEATINGFAN SPEEDS, FAN/COOLING/HEATING

FAN, INDOOR

OPERATION CONTROL

FAN MOTORFAN MOTOR

FAN, OUTDOOR

ROOM TEMP. CONTROL

OPERATION CONTROLOPERATION CONTROL

FAN SPEEDS, FAN/COOLING/HEATING

AIR DIRECTION CONTROL

ROOM TEMP. CONTROLROOM TEMP. CONTROL

FAN MOTOR

CONSTRUCTION

AIR DIRECTION CONTROLAIR DIRECTION CONTROL

OPERATION CONTROL

PROTECTOR

CONSTRUCTIONCONSTRUCTION

ROOM TEMP. CONTROL

COMPRESSOR

PROTECTORPROTECTOR

AIR DIRECTION CONTROL

FAN MOTOR

COMPRESSORCOMPRESSOR

CONSTRUCTION

POWER CORD

FAN MOTORFAN MOTOR

PROTECTOR

DRAIN SYSTEM

POWER CORDPOWER CORD

COMPRESSOR

NET WEIGHT

DRAIN SYSTEMDRAIN SYSTEM

FAN MOTOR

(lbs/kg)NET WEIGHTNET WEIGHT

POWER CORD

OUTSIDE DIMENSION (inch)

(lbs/kg)(lbs/kg)

DRAIN SYSTEM

(W x

OUTSIDE DIMENSION (inch)OUTSIDE DIMENSION (inch)

NET WEIGHT

H(W x(W x

(lbs/kg)

xHH

OUTSIDE DIMENSION (inch)

D) x x(W x (mm)D) D) H (mm)(mm) x

1ø, 115V, 60Hz

D)

8,000

1ø, 115V, 60Hz1ø, 115V, 60Hz

(mm)

8,0008,0008,000 10,0008,0008,000

1ø, 115V, 60Hz

820

10,00010,0008,000

740820820

8,000

1,020740740

10,000

7.3

1,0201,020820

7.07.37.3

740

9.47.07.0

1,020

9.8

9.49.47.3

10.89.89.8

7.0

9.810.810.8

9.4

26.7(DB)* 19.4(WB)**

9.89.89.8

35(DB)* 23.9(WB)**

26.7(DB)* 19.4(WB)**26.7(DB)* 19.4(WB)**

10.8

420g(14.8 oz)

35(DB)* 23.9(WB)**35(DB)* 23.9(WB)**

9.8

410g(14.3 oz)420g(14.8 oz)420g(14.8 oz)

26.7(DB)* 19.4(WB)**

480g(16.9 oz)410g(14.3 oz)410g(14.3 oz)

35(DB)* 23.9(WB)**

2 ROW 11 STACKS, LOUVER-FIN TYPE

480g(16.9 oz)480g(16.9 oz)420g(14.8 oz)

2 ROW 15 STACKS, STRAGHT TYPE

2 ROW 11 STACKS, LOUVER-FIN TYPE2 ROW 11 STACKS, LOUVER-FIN TYPE

410g(14.3 oz)

TURBO FAN

2 ROW 15 STACKS, STRAGHT TYPE2 ROW 15 STACKS, STRAGHT TYPE

480g(16.9 oz)

PROPELLER TYPE FAN WITH SLINGER RING

TURBO FANTURBO FAN

2 ROW 11 STACKS, LOUVER-FIN TYPE

3/3

PROPELLER TYPE FAN WITH SLINGER RINGPROPELLER TYPE FAN WITH SLINGER RING

2 ROW 15 STACKS, STRAGHT TYPE

6 POLES

3/33/3

TURBO FAN

REMOTE CONTROLLER

6 POLES6 POLES

PROPELLER TYPE FAN WITH SLINGER RING

THERMISTOR

REMOTE CONTROLLERREMOTE CONTROLLER

3/3

VERTICAL LOUVER (RIGHT & LEFT)

THERMISTORTHERMISTOR

6 POLES

HORIZONTAL LOUVER (UP & DOWN)

VERTICAL LOUVER (RIGHT & LEFT)VERTICAL LOUVER (RIGHT & LEFT)

REMOTE CONTROLLER

TOP DOWN CHASSIS

HORIZONTAL LOUVER (UP & DOWN)HORIZONTAL LOUVER (UP & DOWN)

THERMISTOR

OVERLOAD PROTECTOR

TOP DOWN CHASSISTOP DOWN CHASSIS

VERTICAL LOUVER (RIGHT & LEFT)

INTERNAL THERMAL PROTECTOR

OVERLOAD PROTECTOROVERLOAD PROTECTOR

HORIZONTAL LOUVER (UP & DOWN)

3 WIRE WITH GROUDING

INTERNAL THERMAL PROTECTORINTERNAL THERMAL PROTECTOR

TOP DOWN CHASSIS

ATTACHMENT PLUG (CORD-CONNECTED TYPE)

3 WIRE WITH GROUDING3 WIRE WITH GROUDING

OVERLOAD PROTECTOR

DRAIN PIPE OR SPLASHED BY FAN SLINGER

ATTACHMENT PLUG (CORD-CONNECTED TYPE)ATTACHMENT PLUG (CORD-CONNECTED TYPE)

INTERNAL THERMAL PROTECTOR

62/28

DRAIN PIPE OR SPLASHED BY FAN SLINGERDRAIN PIPE OR SPLASHED BY FAN SLINGER

3 WIRE WITH GROUDING

71/3262/2862/28

ATTACHMENT PLUG (CORD-CONNECTED TYPE)

62/28 71/3271/32

DRAIN PIPE OR SPLASHED BY FAN SLINGER

19

62/2862/28 62/28

9

19 19

71/32

/

99

62/28

16

//

19

x 12

1616

9 3

x 12x 12/ /

33

16 8

//x 12 x 19

88

3 3

x 19x 19/ /

33

8 8

//x 19

497 x 315 x 492

88

3

HBLG8004R(A4/B4)

L8004R(Y4)/M8004R(Y4)

497 x 315 x 492497 x 315 x 492

/

CL8000ER

8

HBLG1004R

L1004R/M1004R

CL8000ERCL8000ER

497 x 315 x 492

HBLG1004R

L1004R/M1004R

HBLG1004R

L1004R/M1004R

CL8000ER HBLG1004R

L1004R/M1004R

MODELS

ITEMS

MODELSMODELS

ITEMSITEMS

OPERATING

MODELS

CONDITION

OPERATINGOPERATING

ITEMS

* D

CONDITIONCONDITION

B* D* D

OPERATING

: dry bulbBB

CONDITION

** WB : wet bulb

: dry bulb : dry bulb* D

** WB : wet bulb** WB : wet bulb

B : dry bulb

** WB : wet bulb

Service Manual 7

8 Room Air Conditioner

Installation

Installation

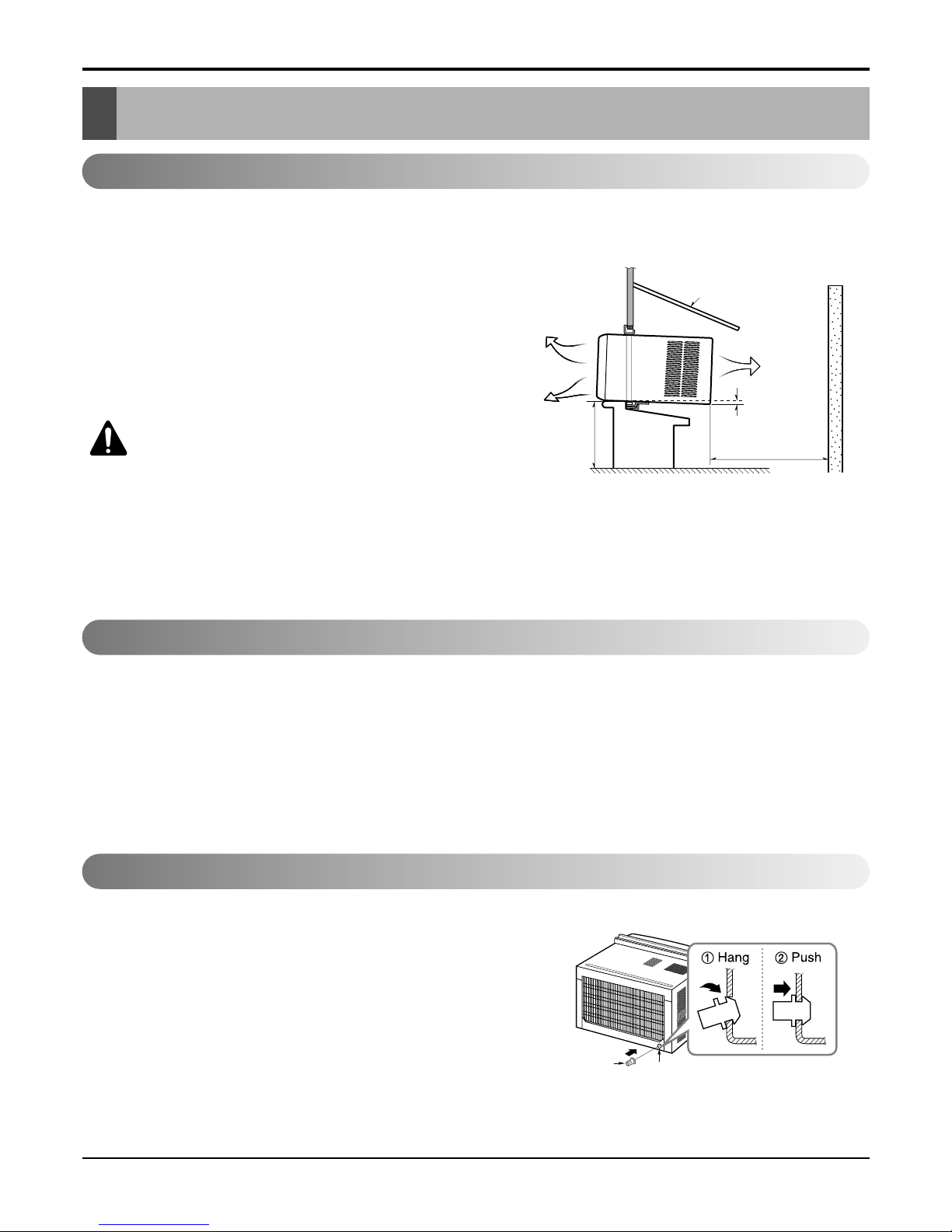

Select the Best Location

Installation Check

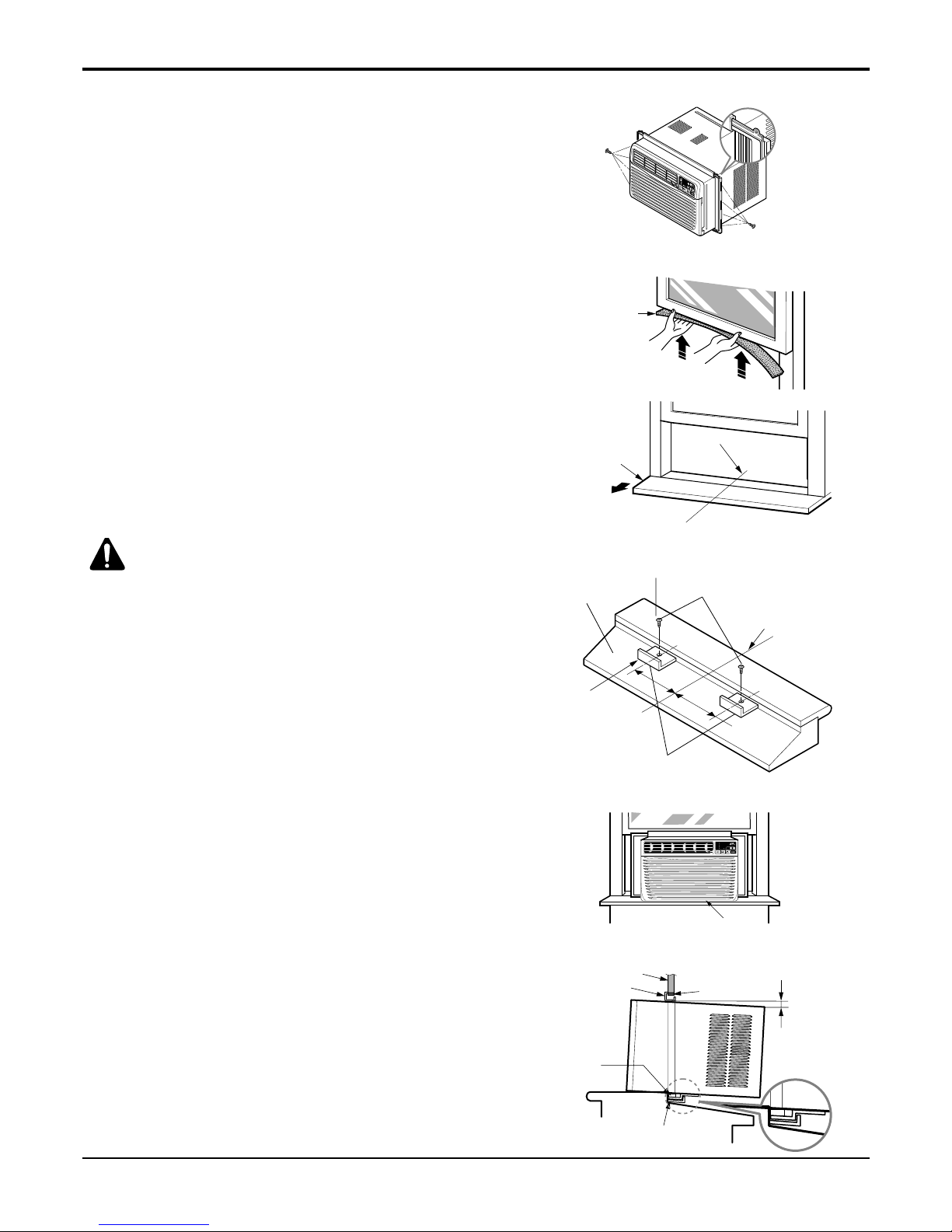

How to Secure the Drain Pipe

1. To prevent vibration and noise, make sure the unit is installed

securely and firmly.

2. Install the unit where the sun does not shine directly on the

unit.

3. The outside of the cabinet must extend outward for at least

12" and there should be no obstacles, such as a fence or

wall, within 20" from the back of the cabinet because it will

prevent heat radiation of the condenser.

Restriction of outside air will greatly reduce the cooling efficiency of the air conditioner.

CAUTION: All side louvers of the cabinet must

remain exposed on the outdside of the structure.

4. Install the unit slanted slightly so the back is slightly lower

than the front (about 1/

4"). This will force condensed water

to the outside.

5. Install the unit with the bottom about 30"~60" above the

floor level.

The setting conditions must be checked prior to initial starting.

The following items are especially important checking points when the installation is finished.

1. Grounding wire (Green or Green and Yellow) is provided in the power cord. The green wire must be grounded.

2. Connect to a single-outlet 15A circuit.

(or 20A circuit for Electric Heater Model)

3. To avoid vibration or noise, make sure the air conditioner is installed securely.

4 Avoid placing furniture or draperies in front of the air inlet and outlet.

In humid weather, excess water may cause the Base Pan to

overflow. To drain the water, remove the Drain Cap and secure

the Drain Pipe to the rear hole of the Base Pan. (Figure. 2)

Figure 2

ABOUT / "

Over 20"

HEAT

RADIATION

FENCE

AWNING

OUTSIDE

INSIDE

COOLED AIR

30"-60"

1

4

Figure 1

Drain Pipe

Drain Cap

Service Manual 9

Installation

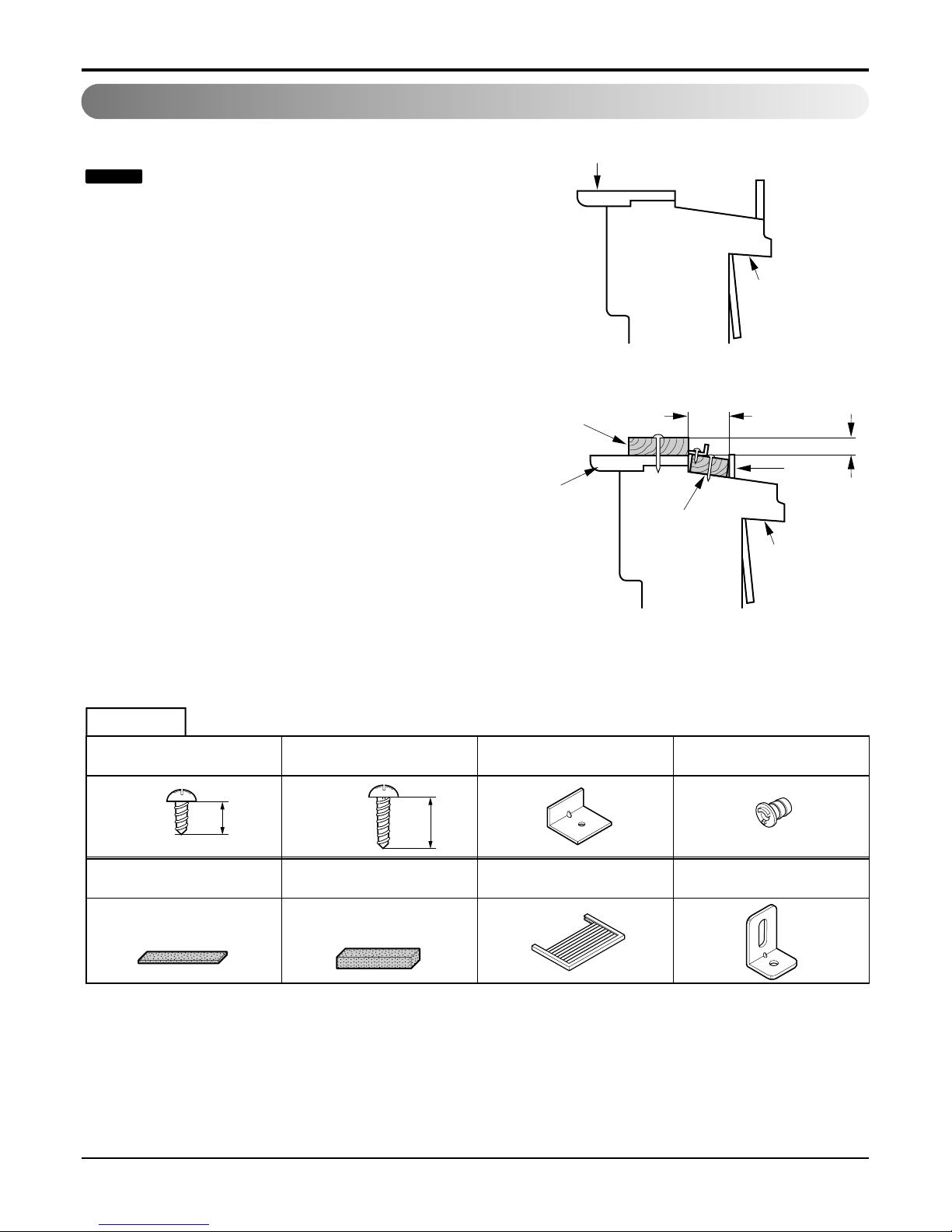

How to Install

Window Requirements

All supporting parts should be secured to

firm wood, masonry, or metal.

1. This unit is designed for installation in standard double

hung windows with actual opening widths of 22" to 36".

The upper and lower sash must open sufficiently to allow

a clear vertical opening of 13" from the bottom of the

sash to the window stool.

2. If storm window presents interference, fasten a 2" wide

wood strip to the inner window sill across the full width of

the sill. The wood strip should be thick enough to raise

the height of the window sill so that the unit can be

installed without interference by the storm window

frame. See Figure. 4. Top of wood strip should be

approximately 3/4" higher than the storm window frame

(STORM WINDOW FRAME) or wood strip (OUTDOORS) to help condensation to drain properly to the

outside.

3.

Install a second wood strip (approximately 6" long by 11/2"

wide and same thickness as first strip) in the center of the

outer sill flush against the back off the inner sill. This will

raise the L bracket as shown Figure. 4.

4. If the distance between STORM WINDOW FRAME and

WOOD STRIP MOUNTED ON TOP OF INNER SILL is

more than 1", two of wood strip are not necessary.

Installation

NOTICE

OUTDOORSINDOORS

INNER

SILL

OUTER

SILL

INNER

SILL

WOOD STRIP MOUNTED

ON TOP OF INNER SILL

WOOD STRIP

FOR

L

BRACKET

3/4"

CLEARANCE

1" MAX.

STORM

WINDOW

FRAME

OUTDOORSINDOORS

OUTER

SILL

Figure 3

Figure 4

HARDWARE

TYPE E: 1EA

(SASH SEAL)

(Not adhesive backed)

TYPE D: 1EA

(SEAL STRIP)

(Adhesive backed)

TYPE F: 2EA

(GUIDE PANEL)

TYPE C: 3EA

(L BACKET)

TYPE A: 11EA

(SHORT SCREW)

10mm

TYPE B: 5EA

(WOOD SCREW)

16mm

TYPE G: 1EA

(SUPPORT BACKET)

DRAIN PIPE

10 Room Air Conditioner

Installation

BEFORE INSTALLATION

1. Insert the guide panels into the guides of the air conditioner.

Fasten the curtains to the unit with screws (TYPE A) as

shown Figure. 5.

2.

Cut the adhesive-backed seal strip (TYPE D) to the window

width.

Remove the backing from the seal strip and attach the seal

strip to the underside of the bottom window. (

Figure

. 6)

NOW START INSTALLATION

1. LOCATING UNIT IN WINDOW

Open the window and mark center line on the center of the

inner sill, as shown in Figure. 6.

2. ATTACH L BRACKET

a. Install the L brackets behind the inner window sill, with

the short side of bracket as shown.

Use the 2 screws (TYPE A) provided.

b. The bracket helps to hold unit securely in place. Be sure

to place bracket edge flush against back of inner sill. See

Figure. 7.

CAUTION:

During the following step, hold

unit firmly until window sash is lowered to top

channel behind side panel frames. Personal injury or

property damage may result if unit falls from window.

3. INSTALL THE AIR CONDITIONER IN THE WINDOW

a. Carefully lift the air conditioner and slide it into the open

window. Make sure the bottom guide of the air conditioner drops into the notches of the

L bracket. See Figure. 8.

IMPORTANT :

When the air conditioner drops into the L bracket, the air con-

ditioner will be centered in window opening as shown in

Figure. 9.

b. While steadying the air conditioner, carefully bring the

window sash down behind the upper guide of the air conditioner, as shown in Figure. 10.

ROOM SIDE

CENTER LINE

INNER SILL

SEAL STRIP

(TYPE D)

OUTSIDE

INSIDE

L

BRACKET

OUTER SILL

SHORT SIDE

INNER SILL

TYPE A

8"

8"

CENTER LINE

SEAL

WINDOW FRAME

BOTTOM

GUIDE

ABOUT

1/4"

L

BRACKET

UPPER GUIDE

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Type A

Type A

C enter L ine

F

TEMP

F1 LOW

F2 MED

F3 HIGH

Dry Timer

Fan

Energy

Saver

Cool

Service Manual 11

Installation

4. SECURE THE GUIDE PANELS

Extend the guide panels (TYPE F) to fill the window

opening using 4 screws (TYPE B) to secure them, as

shown in Figure. 11.

5. INSTALL THE SASH SEAL AND SASH LOCK

a. Cut the sash seal (TYPE E) to the window width. Stuff

the sash seal between the glass and the window to

prevent air and insects from getting into the room, as

shown in Figure. 11.

b. Fasten the L bracket using a (TYPE A) screw, as

shown in Figure. 11.

6. Window installation of room air conditioner is now

completed. See ELECTRICAL DATA for attaching

power cord to electrical outlet.

REMOVAL FROM WINDOW

Trun the air conditioner off, disconnect the

power cord, remove the L bracket and the

screws installed through the top and bottom

of the guide panels, and save for reinstallation later. Close the guide panels. keeping a

firm grip on the air conditioner, raise the

sash, and carefully tilt the air conditioner

backward, draining any condensate water.

Lift the air conditioner from the window ad

remove the sash seal from between the windows.

NOTICE

Figure 11

Type B

Sash Seal

(Type F)

L Bracket

Type A

12 Room Air Conditioner

Operation

Operation

• Designed for COOLING ONLY.

• Powerful and quiet cooling.

• Top-down chassis for the simple installation and service.

• Low air-intake, top cooled-air discharge.

• Built-in adjustable Thermistor

• Washable one-touch filter

• Compact size

• Equipped with reliable and efficient rotary

compressor.

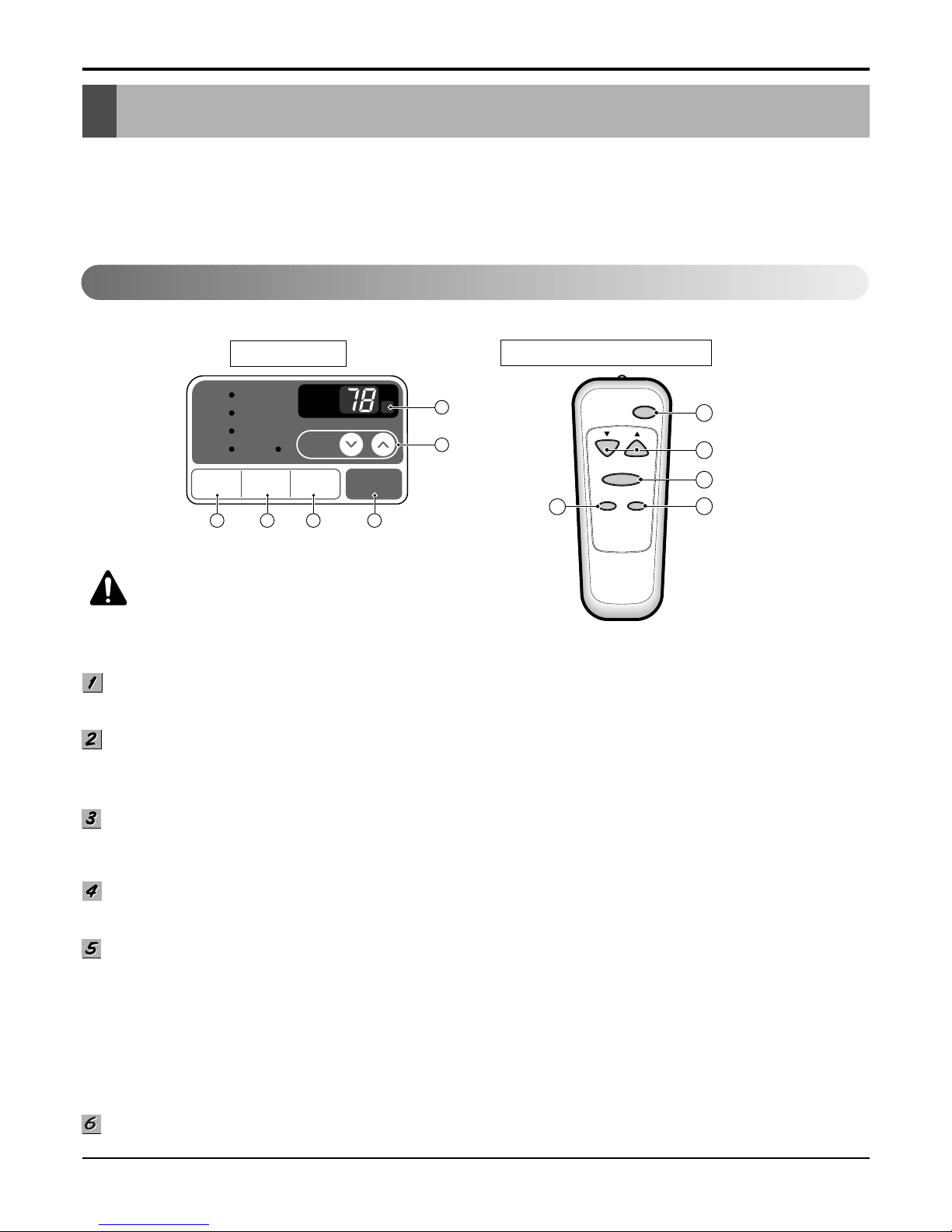

REMOTE CONTROL

DISPLAY

'

F

TIMER POWERMODE

TEMP

FAN

SPEED

F1 LOW

F2 MED

F3 HIGH

Dry Timer

Fan

Energy

Saver

Cool

Power

Temp

Fan Speed

Timer Mode

1

2

3

4

5

1

2

6

3 45

PRECAUTION:

The Remote Control unit will not

function properly if strong light strikes the sensor window

of the air conditioner or if there are obstacles between the

Remote Control unit and the air conditioner.

POWER BUTTON

To turn the air conditioner ON, push the button. To turn the air conditioner OFF, push the button again.

This button takes priority over any other buttons.

ROOM TEMPERATURE SETTING BUTTON

This button can automatically control the temperature of the room. The temperature can be set within a range of 60°F to

86°F by 1°F. (16°C to 30°C by 1°C)

Select the lower number for lower temperature of the room.

OPERATION MODE SELECTION BUTTON

Every time you push this button, it will shift among COOL, ENERGY SAVER, FAN and DRY.

-

Energy Saver: If Energy Save mode is selected, the fan stops when the compressor stops cooling.a

Approximately every 3 minutes the fan will turn on and check the room air to determine if cooling is needed.

FAN SPEED SELECTOR

Every time you push this button, it is set as follows.

(Hi [F3] ➔ Low [F1] ➔ Med [F2] ➔ Hi [F3] ➔ Low [F1] ➔...)

ON/OFF TIMER BUTTON

You can set the time when the unit will turn on or turn off automatically by pressing the timer button. If the unit is operating,

this button controls the time it will be turned off. If the unit is off state, this button controls the time it will start. Every time

you push this button, the remaining time will be set as follows.

- Stopping operation

(1Hour ➔ 2Hours ➔ 3Hours ➔ 4Hours ➔ 5Hours ➔ 6Hours ➔ 7Hours ➔ 8Hours ➔ 9Hours ➔ 10Hours ➔ 11Hours ➔

12Hours ➔ 0Hour ➔ 1Hour ➔ 2Hours ➔... )

- Starting operation

(1Hour ➔ 2Hours ➔ 3Hours ➔ 4Hours ➔ 5Hours ➔ 6Hours ➔ 7Hours ➔ 8Hours ➔ 9Hours ➔ 10Hours ➔ 11Hours ➔

12Hours ➔ off ➔ 1Hour ➔ 2Hours ➔ ... )

REMOCON SIGNAL RECEIVER

Function of Controls

Loading...

Loading...