Page 1

Supe r Mult i DVD D riv e

S E RVICE MANUAL

MODEL: GSA-4165B/

G S A - 4 1 6 7 B /

G S A - 4 1 6 8 B

P/NO : 3828HS1047G

August 2005

Printed in Korea

MODEL : GSA-4165B/GSA-4167B/GSA-4168B

Page 2

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................................................3

FEATURES............................................................................................................................................................................3~5

SPECIFICATIONS.................................................................................................................................................................6~9

LOCATION OF CUSTOMER CONTROLS .......................................................................................................................10~11

DISASSEMBLY.................................................................................................................................................................12~13

1. CABINET and CIRCUIT BOARD DISASSEMBLY..........................................................................................................12

1-1. Bottom Chassis..........................................................................................................................................................12

1-2. Front Bezel Assy........................................................................................................................................................12

1-3. Cabinet and Main Circuit Board.................................................................................................................................12

2. MECHANISM ASSY DISASSEMBLY..............................................................................................................................12

2-1. Pick-up Unit................................................................................................................................................................12

2-2. Pick-up ......................................................................................................................................................................13

EXPLODED VIEW.............................................................................................................................................................14~15

MECHANICAL REPLACEMENT PARTS LIST ................................................................................................................16~18

GLOSSARY.............................................................................................................................................................................19

THE DIFFERENCES OF CD-R/CD-RW DISCS AND GENERAL CD-ROM.....................................................................20~26

1. Recording Layer..............................................................................................................................................................20

2. Disc Specification............................................................................................................................................................20

3. Disc Materials..................................................................................................................................................................21

4. Reading Process of Optical Disc.....................................................................................................................................22

5. Writing Process of CD-R Disc .........................................................................................................................................23

6. Writing Process of CD-RW Disc......................................................................................................................................23

7. Organization of the PCA, PMA and Lead-in Area ...........................................................................................................24

8. Function of PCA and PMA area ......................................................................................................................................25

9. OPC and ROPC ..............................................................................................................................................................25

10. Writing Process of DISC................................................................................................................................................26

THE DIFFERENCES OF DVD-R/RW, DVD+R/RW DISCS AND DVD-ROM....................................................................27~35

1. Recording Layer..............................................................................................................................................................27

2. Disc Specification............................................................................................................................................................28

3. Disc Materials..................................................................................................................................................................28

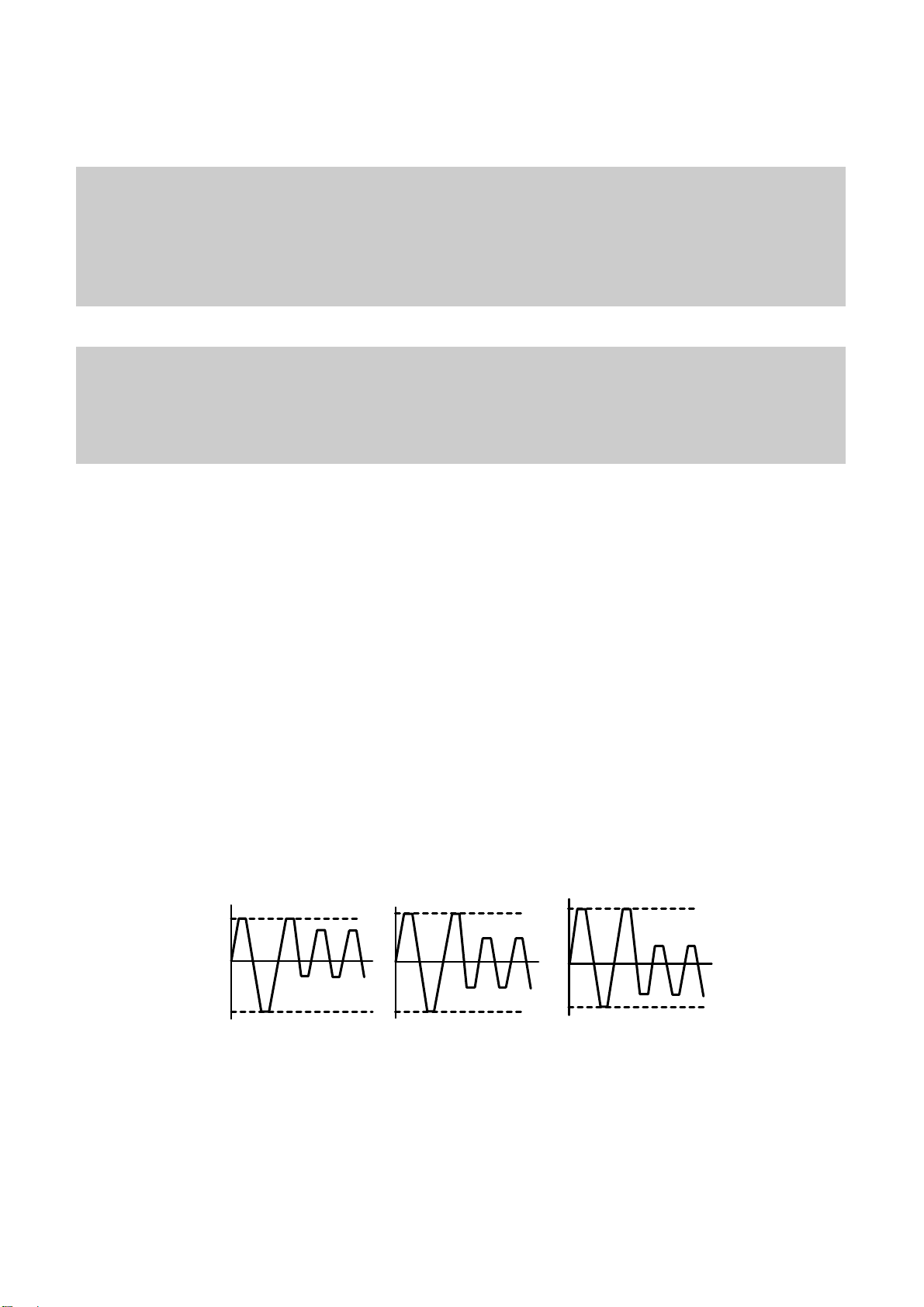

4. Writing Pulse Waveform of DVD+R.................................................................................................................................31

5. Writing Pulse Waveform DVD+RW.................................................................................................................................33

6. Organization of Inner Drive Area, Outer Drive Area, Lead-in Zone and Lead-out Zone .................................................34

LightScribe MEDIA...........................................................................................................................................................36~39

1. LightScribe Media............................................................................................................................................................36

2. Hardware Block Diagram of LightScribe Label Printing...................................................................................................37

3. MD Assy For LightScribe.................................................................................................................................................38

4. Optical Encoder Assy......................................................................................................................................................39

DVD & CD DATA PROCESSING......................................................................................................................................40~43

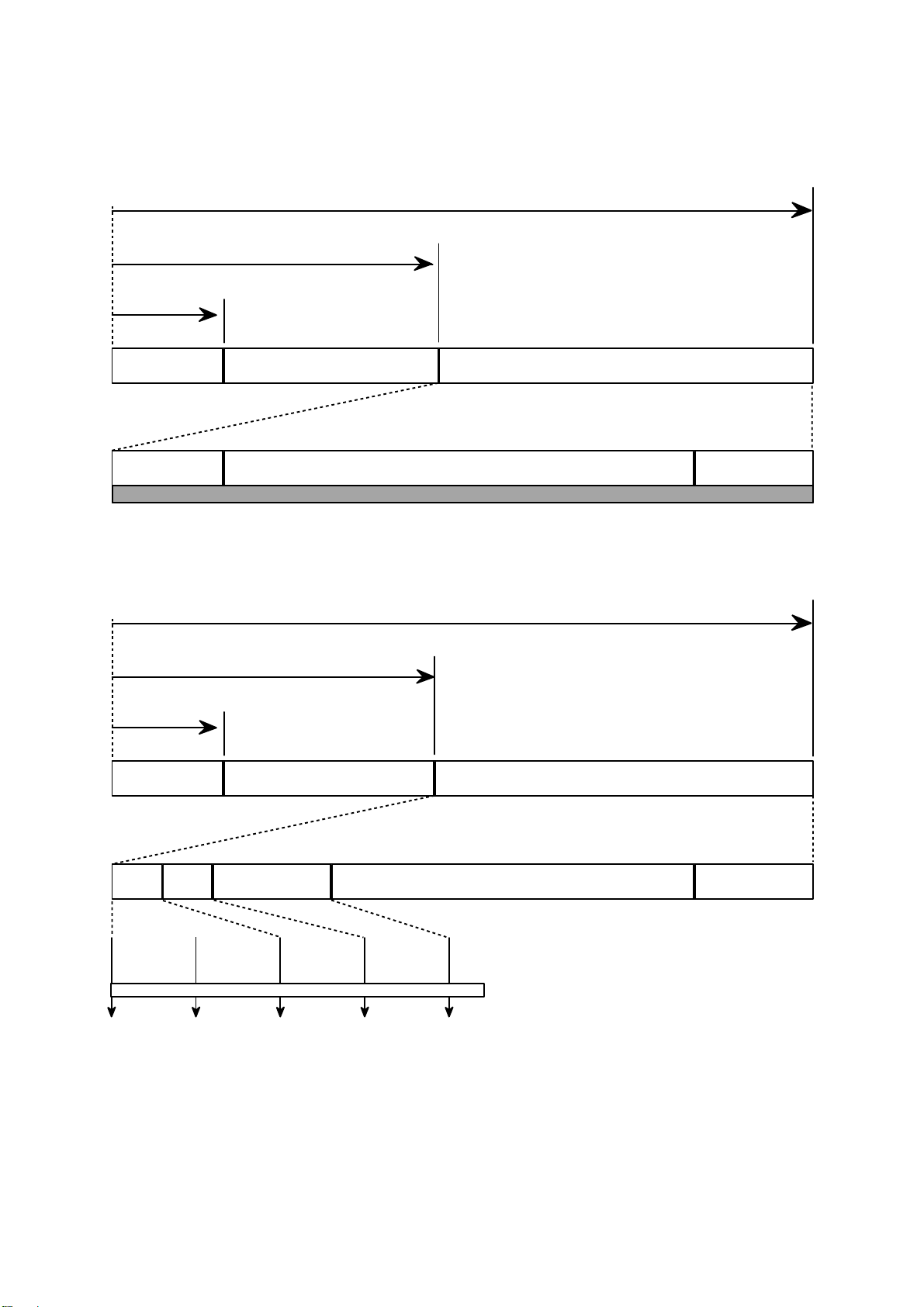

1. Data Processing Flow......................................................................................................................................................40

2. Copy Protection and Regional Code Management Block ...............................................................................................41

3. About Prevention the DVD-ROM from to be copy...........................................................................................................42

4. About the DVD-ROM Regional Code..............................................................................................................................43

INTERNAL STRUCTURE OF THE PICK-UP....................................................................................................................44~46

1. Block Diagram of the Pick-up(HOP-7632TS)..................................................................................................................44

2. Pick up Pin Assignment...................................................................................................................................................45

3. Signal detection of the P/U..............................................................................................................................................46

DESCRIPTION OF CIRCUIT.............................................................................................................................................47~53

1. ALPC Circuit....................................................................................................................................................................47

2. Focus Circuit....................................................................................................................................................................49

3. Tracking & Sled Circuit....................................................................................................................................................50

4. Spindle Circuit .................................................................................................................................................................53

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION.............................................................................55~72

TROUBLESHOOTING GUIDE..........................................................................................................................................73~90

BLOCK DIAGRAM..................................................................................................................................................................91

PRINTED CIRCUIT BOARD DIAGRAM...........................................................................................................................92~96

ELECTRICAL REPLACEMENT PARTS LIST........................................................................................................................97

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM.

Page 3

3

This service manual provides a variety of service

information.

It contains the mechanical structure of the Super

Multi DVD Drive and the electronic circuits in

schematic form. This Super Multi DVD Drive was

manufactured and assembled under our strict quality

control standards and meets or exceeds industry

specifications and standards.

This Super Multi DVD drive is an internal drive unit

designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 700

Mbytes of digital data into CD-R/RW disc, and can

read as much as 700 Mbytes of digital data stored in

a CD-ROM/R/RW disc.

It can write as much as 4.7Gbytes of digital data into

DVD-R/RW/RAM/+R/+RW disc, and can read as

much as 4.7Gbytes of digital data stored in a

DVD-ROM/R/RW/RAM/+R/+RW disc.

It can write as much as 8.5Gbytes of digital data into

DVD+R DL/DVD-R DL disc, and can read as much

as 8.5Gbytes of digital data stored in a DVD-ROM

DL/+R DL/-R DL disc.

This Super Multi DVD Drive can easily meet the

upcoming MPC level 3 specification, and its

Enhanced Intelligent Device Electronics (E-IDE) and

ATAPI interface allows Plug and play integration in

the majority of today’s PCs without the need of an

additional interface card.

INTRODUCTION

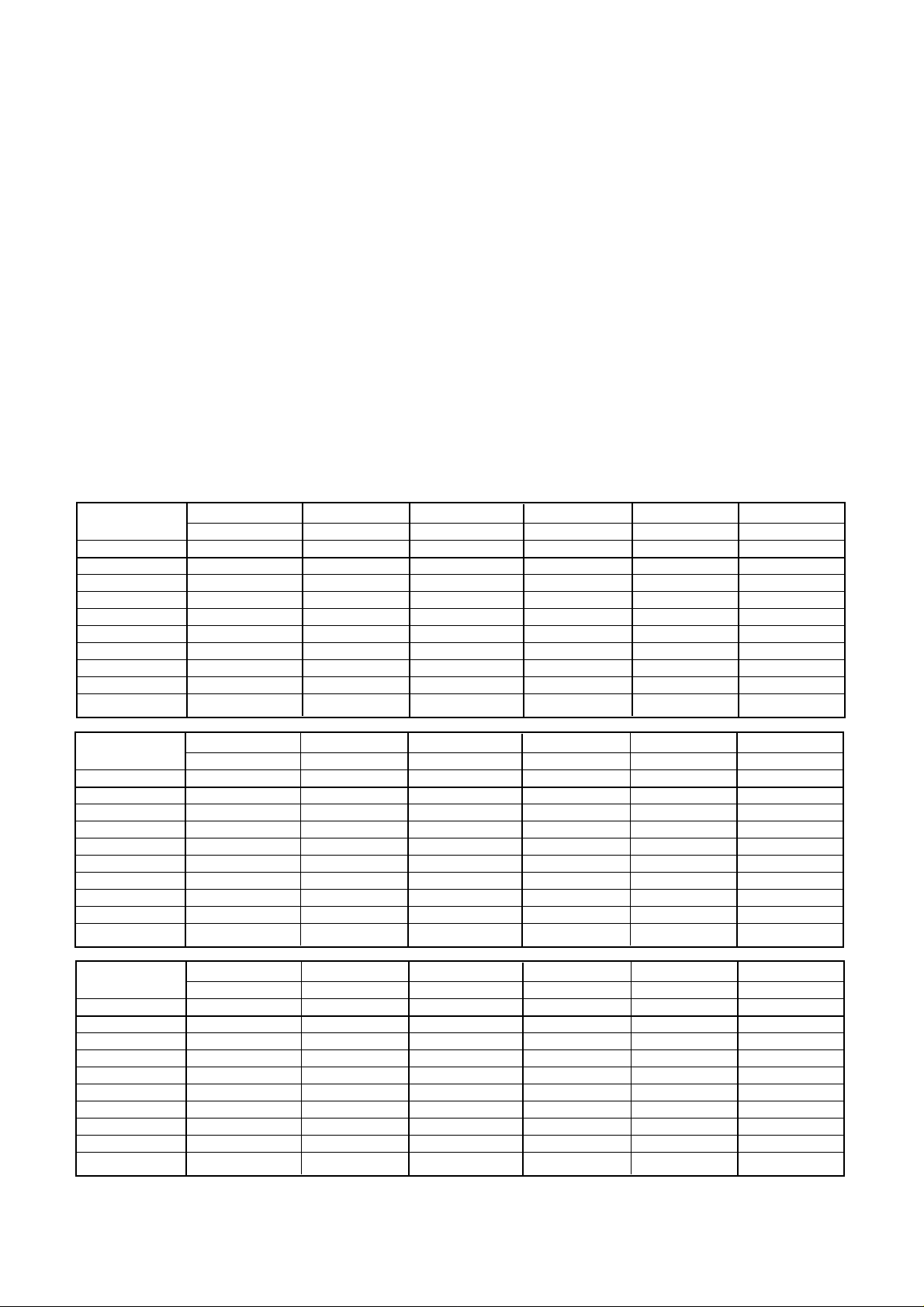

1. Support feature and writable disc

*) Indicated write-in speed is a value at the time of the fastest operation.

G*A-4165B

GSA GMA GWA GRA GCA GDA

Light Scribe x x x x x x

CD-R 48x write 48x write 48x write 48x write 48x write read only

CD-RW 32x write 32x write 32x write 32x write 32x write read only

DVD-R 16x write 16x write 16x write read only 16x write 16x write

DVD-RW 4x or 6x write 4x or 6x write 4x or 6x write read only 4x or 6x write 4x or 6x write

DVD-R DL 4x write 4x write 4x write read only 4x write 4x write

DVD+R 16x write read only 16x write 16x write read only read only

DVD+RW 8x write read only 8x write 8x write read only read only

DVD+R DL 4x or 6x write read only 4x or 6x write 4x or 6x write read only read only

DVD-RAM 5x write 5x write read only read only read only 5x write

G*A-4167B

GSA GMA GWA GRA GCA GDA

Light Scribe xxx xxx

CD-R 48x write 48x write 48x write 48x write 48x write read only

CD-RW 32x write 32x write 32x write 32x write 32x write read only

DVD-R 16x write 16x write 16x write read only 16x write 16x write

DVD-RW 6x write 6x write 6x write read only 6x write 6x write

DVD-R DL 4x write 4x write 4x write read only 4x write 4x write

DVD+R 16x write read only 16x write 16x write read only read only

DVD+RW 8x write read only 8x write 8x write read only read only

DVD+R DL 6x write read only 6x write 6x write read only read only

DVD-RAM 5x write 5x write read only read only read only 5x write

G*A-4168B

GSA GMA GWA GRA GCA GDA

Light Scribe O O O O O O

CD-R 48x write 48x write 48x write 48x write 48x write read only

CD-RW 32x write 32x write 32x write 32x write 32x write read only

DVD-R 16x write 16x write 16x write read only 16x write 16x write

DVD-RW 6x write 6x write 6x write read only 6x write 6x write

DVD-R DL 4x write 4x write 4x write read only 4x write 4x write

DVD+R 16x write read only 16x write 16x write read only read only

DVD+RW 8x write read only 8x write 8x write read only read only

DVD+R DL 6x write read only 6x write 6x write read only read only

DVD-RAM 5x write 5x write read only read only read only 5x write

Page 4

4

FEATURES

1 General

1) Enhanced IDE (ATAPI) interface.

2) Internal Half-height Drive.

3) CD-R/RW, DVD-R/-R DL(Dual Layer)/-RW/RAM/+R/+R DL(Double Layer)/+RW read and write

compatible CD Family and DVD-ROM read compatible.

4) Buffer Under-run prevention function embedded.

5) 2MB buffer memory.

6) Power loading and power eject of a disc. Bare media loading.

7) MTBF : 100,000 POH

8) Vertical and Horizontal installable.

2. Supported disc formats

1) Reads data in each DVD-ROM, DVD-R(Ver. 2.0 for Authoring) and DVD-RAM(Ver.1.0)

2) Reads and writes in each DVD-R(Ver. 2.0 for General), DVD-R DL(Dual Layer), DVD-RW, DVDRAM(Ver.2.2), DVD+R, DVD+R DL(Double Layer) and DVD+RW

3) Reads data in each CD-ROM, CD-ROM XA, CD-I, Video CD, CD-Extra and CD-Text

4) Reads data in Photo CD (Single and Multi session)

5) Reads standard CD-DA

6) Support to read Super Audio CD(Compatible layer in Hybrid type)

7) Reads and writes CD-R discs conforming to “Orange Book Part 2”

8) Reads and writes CD-RW discs conforming to “Orange Book Part 3”

9) Reads DVD-RAM with CPRM and DVD-RW with CPRM

3. Supported write method

1) DVD-R:..................Disc at Once and Incremental Recording

2) DVD-R DL .............Disc at Once, incremental Recording and Layer jump recording

3) DVD-RW:...............Disc at Once, Incremental Recording and Restricted Overwrite

4) DVD-RAM:.............Random Write

5) DVD+R:.................Sequential Recording

6) DVD+R DL: ...........Sequential Recording

7) DVD+RW:..............Random Write

8) CD-R/RW: .............Disc at Once, Session at Once, Track at Once and Packet Write

Page 5

4. Performance

1) Average access time: DVD-ROM 145 ms

(1/3 stroke) CD-ROM 125 ms

2) Write speed: DVD-R 2x, 4x CLV, 8x ZCLV, 16x PCAV

DVD-R DL 2x, 4x CLV

DVD-RW 1x, 2x, 4x, 6x CLV

DVD-RAM 2x, 3x ZCLV (Ver.2.2), 3x-5x PCAV(Ver.2.2)

DVD+R 2.4x, 4x CLV, 8x ZCLV, 12x, 16x PCAV

DVD+R DL 2.4x, 4x, 6x CLV

DVD+RW 2.4x, 4x CLV, 8x ZCLV

CD-R 4x, 8x, 16x CLV, 24x, 32x, 40x, 48x ZCLV

CD-RW 4x, 10x, 16x CLV, 24x, 32x ZCLV

(High Speed: 10x, Ultra Speed: 16x, 24x, 32x)

3) Read speed: DVD-R/RW/ROM/ROM-Dual layer 10x / 8x / 16x / 12x max.

DVD-R DL 8x max.

DVD-RAM (Ver.1.0/2.2) 2x / 2x, 3x ZCLV, 3x-5x PCAV

DVD-Video(CSS Compliant Disc) 8x max. (Single/Dual layer)

DVD+R/+RW 10x / 8x max.

DVD+R DL 8x max.

CD-R/RW/ROM 48x/40x/48x max.

CD-DA (DAE) 40x max.

80mm CD 16x max.

4) Sustained Transfer rate: DVD-ROM 22.16 Mbytes/s (16x) max.

CD-ROM 7,200 kB/s (48x) max.

5) Burst Transfer rate: Ultra DMA Mode2

Multi word DMA Mode2, PIO Mode 4

6) Multimedia MPC-3 compliant

5. Audio

1) 16 bit digital data output through ATA interface

2) Software Volume Control

3) Equipped with audio line output for audio CD playback

*Definition

Transfer Rate:.........1x (DVD) = 1.385 Mbytes/s..........1x (CD) = 150 kB/s

Mbytes/s = 106bytes/s, ................kB/s = 210bytes/s

Capacity:.................MB = 220bytes,.............................kB = 210bytes

5

Page 6

6

SPECIFICATIONS

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium 4 2.4GHz (or faster)

(For High speed, 2.4GHz or faster recommended.)

-128MB Memory or greater

2. SUPPORTING OPERATING SYSTEM

2.1 Applicable disc formats

DVD............................DVD-ROM: 4.7GB (Single Layer)

8.5GB (Dual Layer)

DVD-R DL: 8.5GB

DVD-R: 4.7GB (Ver.2.0 for Authoring : read only)

4.7GB (Ver.2.0 for General: read & write)

DVD-RW: 4.7GB (Ver.1.2)

DVD-RAM: 2.6GB/side (Ver.1.0)

1.46GB/side, 4.7GB/side (Ver.2.2)

DVD+R: 4.7GB

DVD+R DL: 8.5GB

DVD+RW: 4.7GB

CD...............................CD-ROM Mode-1 data disc

CD-ROM Mode-2 data disc

CD-ROM XA, CD-I, Photo-CD Multi-Session, Video CD

CD-Audio Disc

Mixed mode CD-ROM disc (data and audio)

CD-Extra

CD-Text

CD-R (Conforming to “Orange Book Part2”: read & write)

CD-RW (Conforming to “Orange Book Part3”: read & write)

2.2 Writing method

(1) DVD-R/RW...........................Disc at Once

Incremental Recording

Restricted Overwrite (DVD-RW only)

(2) DVD-R DL ............................Disc at Once

Incremental Recording

Layer jump Recording

(3) DVD-RAM/+RW ...................Random Write

(4) DVD+R.................................Sequential Recording

(5) DVD+R DL ...........................Sequential Recording

(6) CD-R/RW .............................Disc at Once (DAO)

Session at Once (SAO)

Track at Once (TAO)

Packet Write

2.3 Disc diameter..............................................120mm

80mm (Horizontal only)

* Operating System

Windows Millennium Edition (Me)

Window 2000 Professional

Window XP Home Edition, Professional

* Recording tool

(1) Nero(Ahead)

(2) In CD(Ahead)

(3) Power Producer Gold (Cyber Link)

Page 7

7

2.4 Data capacity

• User Data/Block DVD-ROM/R/RW/RAM/+R/+RW ......2,048 bytes/block

CD (Yellow Book)..........................................2,048 bytes/block(Mode 1 & Mode 2 Form 1)

2,336 bytes/block (Mode 2)

2,328 bytes/block (Mode 2 Form 2)

2,352 bytes/block (CD-DA)

2.5 RPC (Regional Playback Control) Phase2, No Region

3. DRIVE PERFORMANCE

3.1 Host interface ..................................................................X3T13 ATA/ATAPI5/1321D

INF-8090i Rev.5.3

3.2 Read/Write & Rotational speed

<Write> DVD-R...............................................................2x, 4x(CLV), 8x(ZCLV), 16x(PCAV)

DVD-R DL .........................................................2x, 4x(CLV)

DVD-RW............................................................1x, 2x, 4x, 6x(CLV)

DVD-RAM ...............................Ver. 2.2.............2x, 3x(ZCLV), 3x-5x(PCAV)

DVD+R..............................................................2.4x, 4x(CLV), 8x, 12x, 16x(PCAV)

DVD+R DL ........................................................2.4x, 4x, 6x(CLV)

DVD+RW...........................................................2.4x, 4x(CLV), 8x(ZCLV)

CD-R .................................................................4x, 8x, 16x(CLV), 24x, 32x, 40x, 48x(ZCLV)

CD-RW..............................................................4x, 10x,16x(CLV), 24x, 32x (ZCLV)

(High Speed: 10x, Ultra Speed: 16x, 24x, 32x)

<Read> DVD-ROM...............................Single layer.......6.7x - 16x (CAV), Approx. 9,420 r/min

................................................Dual layer .........5.0x - 12x (CAV), Approx. 7,770 r/min

DVD-R DL...............................8.5GB ...............3.3x - 8x (CAV), Approx 5,180r/min

DVD-Video (CSS) .............................................3.3x - 8x (CAV), Approx. 5,180 r/min

DVD-R.....................................4.7GB ...............4.2x - 10x (CAV), Approx. 5,890 r/min

DVD-RW.................................4.7GB ...............3.3x - 8x (CAV), Approx. 4,720 r/min

DVD-RAM...............................Ver. 1.0/ 2.2......2x/ 2x, 3x (ZCLV)* 3x-5x (PCAV)*

DVD+R....................................4.7GB ...............4.2x - 10x (CAV), Approx. 5,890 r/min

DVD+R DL..............................8.5GB ...............3.3x - 8x (CAV), Approx. 5,180 r/min

DVD+RW ................................4.7GB ...............3.3x - 8x (CAV), Approx. 4,720 r/min

CD-R/ROM, CD-I / Video........(1.2m/s) ............20x - 48x (CAV), Approx. 9,540 r/min

CD-RW ...................................(1.2m/s) ...........16.7x - 40x (CAV), Approx. 8,100 r/min

CD-DA (DAE)..........................(1.2m/s) ...........16.7x - 40x (CAV), Approx. 8,100 r/min

CD-DA (Audio out)..................(1.2m/s) ...........4.0x - 10x (CAV), Approx. 2,030 r/min

* Rotational speed (CLV, ZCLV)

DVD-R/RW/ROM, +R/RW...............................1x: Approx. 1,390(Inside) - 580 r/min(Outside)

DVD-RAM................................Ver. 1.0 ...........1x: Approx. 2,390(Inside) - 1,010 r/min(Outside)

Ver. 2.2...........2x: Approx. 3,250(Inside) - 1,380 r/min(Outside)

CD-R/RW/ROM ...............................................1x: Approx. 500(Inside) - 210 r/min(Outside)

Page 8

3.3 Data transfer rate

3.3.1 Sustained transfer rate

<Write> DVD-R.........................2.77, 5.54, 5.44-11.08 Mbytes/s..................................2x, 4xCLV, 8x ZCLV

9.14-22.16 Mbytes/s....................................................................16x PCAV

DVD-R DL...................2.77, 5.54 Mbytes/s....................................................................2x, 4x CLV

DVD-RW ...............1.385, 2.77, 5.54, 8.31 Mbytes/s ...................................1x, 2x, 4x, 6x CLV

DVD-RAM (Ver.2.2): ...2.77, 4.15, 4.15-6.925 Mbytes/s (w/o Verify) .......2x, 3x ZCLV, 3-5x PCAV

DVD+R........................3.32, 5.54, 8.31-11.08 Mbytes/s..............................2.4x, 4x CLV, 8x ZCLV

8.31-16.62, 9.14-22.16 Mbytes/s ..............................12x ZCLV, 16x PCAV

DVD+R DL ..................3.32, 5.54, 8.31 Mbytes/s..................................................2.4x, 4x, 6x CLV

DVD+RW.....................3.32, 5.54, 8.31-11.08 Mbytes/s.............................2.4x, 4x CLV, 8x ZCAV

CD-R...........................

600, 1,200, 2,400, 2,400-3,600, 2,400-4,800, 2,400-6,000, 2,400-7,200 kB/s (Mode-1)

..........................................4x, 8x, 16x CLV 24x, 32x, 40x, 48x ZCLV

CD-RW........................600, 1500, 2,400, 2,400- 3,600, 2,400-4,800 kB/s (Mode-1)

..........................................4x, 10x, 16x CLV, 24x, 32x ZCLV

<Read> DVD-ROM...................Single layer....9.28 - 22.16 Mbytes/s ...........................................16x max.

....................................Dual layer.......6.86 - 16.62 Mbytes/s ...........................................12x max.

DVD-R ................................................5.73 - 13.85 Mbytes/s ............................................10x max.

DVD-R DL...........................................4.58 - 11.08 Mbytes/s ..............................................8x max.

DVD-RW.............................................4.58 - 11.08 Mbytes/s .............................................8x max.

DVD-RAM ...................Ver. 1.0 ..........2.77 Mbytes/s.........................................................2x ZCLV

....................................Ver. 2.2 ..........2.77, 4.155,4.155-6.93 Mbytes/s..2x, 3x ZCLV, 3-5x PCAV

DVD+R ...............................................5.73 - 13.85 Mbytes/s............................................10x max.

DVD+R DL..........................................4.58 - 11.08 Mbytes/s..............................................8x max.

DVD+RW............................................4.58 - 11.08 Mbytes/s .............................................8x max.

CD-R/ROM .........................................3,000 - 7,200 kB/s..................................................48x max.

CD-RW........................ ......................2,500 - 6,000 kB/s..................................................40x max.

CD-DA (DAE)......................................2,500 - 6,000 kB/s..................................................40x max.

3.3.2 Burst transfer rate

Ultra DMA Mode 2..............................33.3 Mbytes/s max.

Multiword DMA Mode 2 ......................16.6 Mbytes/s max.

PIO Mode 4 ........................................16.6 Mbytes/s max.

3.4 Access time (1/3 stroke)

DVD-ROM...........................................145 ms Typ.*

(Note 1)

DVD-RAM (Ver.2.2)............................165 ms Typ.

CD-ROM.............................................125ms Typ.

(Note 1)

Note :

1) Average random access time is the typcal value of more than 50 times including latency and error correction time.

Test Disc : DVD : ALMEDIO TDV-520 / TDR-820

CD : ALMEDIO TCDR-701 / HITACHI HCD-1

*) Typical value defines a measured value in normal temperature (20 deg.C.) and horizontal position.

3.5 Data error rate (Measured with 5 retries maximum)

DVD-R/RW/ROM/RAM ..................................<10

-12

DVD+R/+RW..................................................<10

-12

CD-R/RW/ROM..............................................<10

-12

(Mode-1)

<10-9(Mode-2)

Condition : It is assumed that the worst case raw error rate of the disc is 10

-3

3.6 Data buffer capacity .......................................................2 Mbytes

8

Page 9

9

4. Quality and Reliability

4.1 MTBF..................................................100,000 Power On Hours(Consecutive/Cumulative POH)

Assumption : ..........................Used in a normall office environment at room temperature.

-POH per year.........................3,000

-ON/OFF cycles per year........600

-Operating duty cycle..............20% of power on time (Seek: 5% of operating time)

4.2 Tray cycle test...................................30,000 times

No degeneration in the mechanical part after test

4.3 Actuator mechanism........................1,000,000 full stroke seek

4.4 MTTR (Mean Time To Repair) ...........0.5 h

4.5 Component life .................................5 years or 2,000 h of Laser radiating time

Assumption : ..........................Used in a normall office environment.

5. POWER REQUIREMENTS

5.1 Source voltage

+5V +5% tolerance, less than 100 mVp-p Ripple voltage

+12V +10% tolerance, less than 100 mVp-p Ripple voltage

5.2 Current

Idle (Hold track state)..............+5V DC .................0.9A typ. .........< 1.0 A max.

+12V DC ...............0.5A typ...........< 1.0 A max.

Write (Active)..........................+5V DC .................1.3A typ. .........< 1.5 A max.

+12V DC................0.9A typ. .........< 1.5 A max.

Read (Active)..........................+5V DC .................1.0A typ. .........< 1.5 A max.

+12V DC................0.9A typ. .........< 1.5 A max.

Seek (Acess) ..........................+5V DC .................1.0A typ. .........< 1.5 A max.

+12V DC ...............1.2A typ. .........< 2.0 A max.

5.3 Standby

Sleep mode (No disc).............1.1 W typ. 1.3 W max.

6. AUDIO PERFORMANCE

Output Level (1kHz, 0dB)........................................................0.7 Vrms typical

Frequency Response..............................................................+/-3dB (20 to 20,000Hz)

Signal to Noise Ratio...............................................................80 dB min. with IHF A and LPF 20 kHz

THD (1kHz, 0dB).....................................................................0.10% max. with LPF 20 kHz

Channel separation(10kHz).....................................................65 dB min.

Condition:................................................................................Load inpedance : 10 kohms

7. Acoustic noise

Less than 50dB, A scale, at 0.5 m away from the drive

Note : 1. Disc : Less than imbalance 0.3 x 10-4Nm

2. Installation : Horizontal

3. Ambient temperature : Normal temperature

4. Except loading, unloading and seek

8. Dimensions

External dimensions (W x H xD) 146 x 41.3 x 165mm(without Bezel)

Front bezel (WxHxD) 148 x 42 x 5 mm

9. Mass .................................................Approx. 0.77+/-0.03 kg

* Which is not provided with Circuit Diagram of this model. Please Contact the friendly staff of LG

Service Care at: Website http: //www.LGEservice.com

Page 10

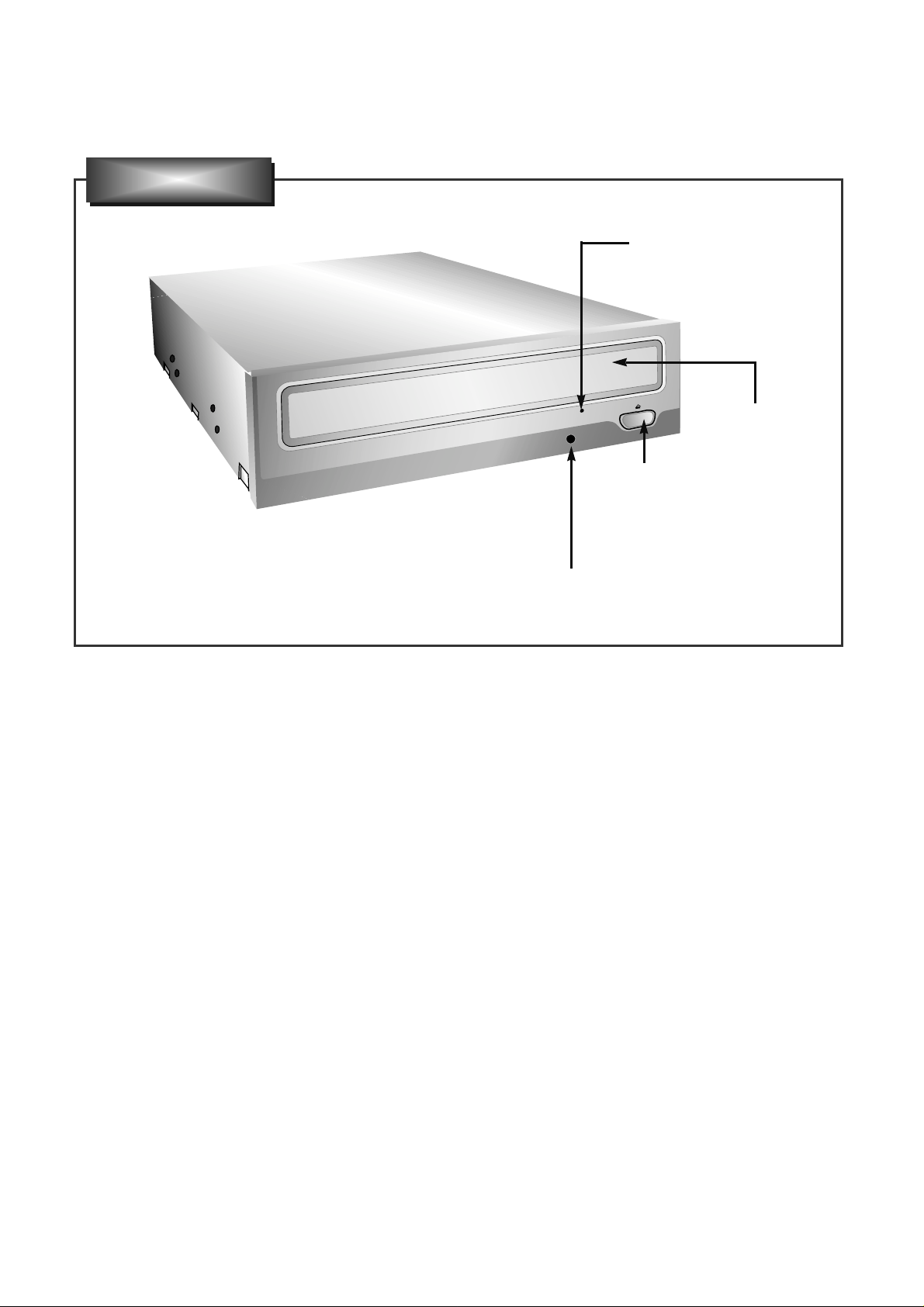

LOCA TION OF CUSTOMER CONTROLS

10

1. Disc tray

This is the tray for the disc. Place the disc on the

ejected disc tray, then lightly push the tray (or

push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray

forcibly. This might cause damage to the loading

section of the drive.

2. Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to

the drive.

3. Emergency Eject Hole

Insert a paper clip here to eject the Disc tray

manually or when there is no power.

4. Drive activity indicator

Two colored LED is used to indicate the operation

of the Drive.

Drive Activity Indicators

Stop/Eject Button

Disc Tray

Emergency Eject Hole

Front Panel

Page 11

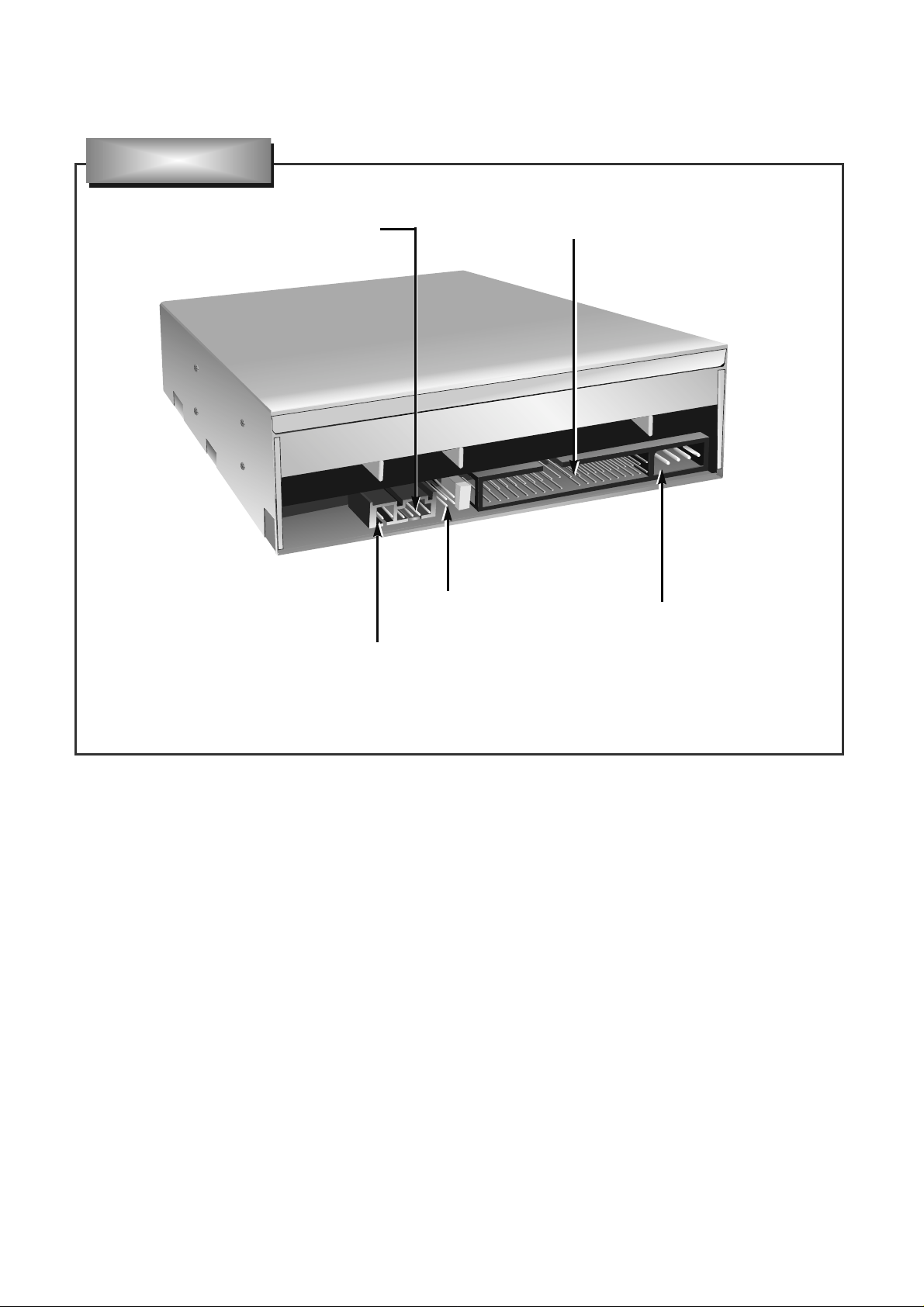

11

1. Power Connector

Connects to the power supply (5-and 12-V DC) of

the host computer.

NOTE : Be careful to connect with the proper

polarity. Connecting the wrong way may damage

the system (and is not guaranteed). Usually this

connector can only be attached one-way.

2. IDE Interface Connector

Connect to the IDE (Integrated Device

Electronics) Interface using a 40-pin flat IDE

cable.

NOTE : Do not connect or disconnect the cable

when the power is on, as this could cause a short

circuit and damage the system. Always turn the

power OFF when connecting or disconnecting the

cable.

3. Jumper Connector

This jumper determines whether the drive is

configured as a master or slave. Changing the

master-slave configuration takes effect after

power-on reset.

4. Analog Audio Output Connector

Provides output to a sound card (analog signal).

Generally you need this to play a regular audio

CD.

5. Digital Audio Output Connector

This connector is not supported.

Digital Audio Output

Connector

Jumper Connector

Analog Audio Output Connector

IDE Interface Connector

Power Connector

Rear Panel

NOTE: The actual drive may be different from this design.

Page 12

1. CABINET and CIRCUIT BOARD

DISASSEMBL Y

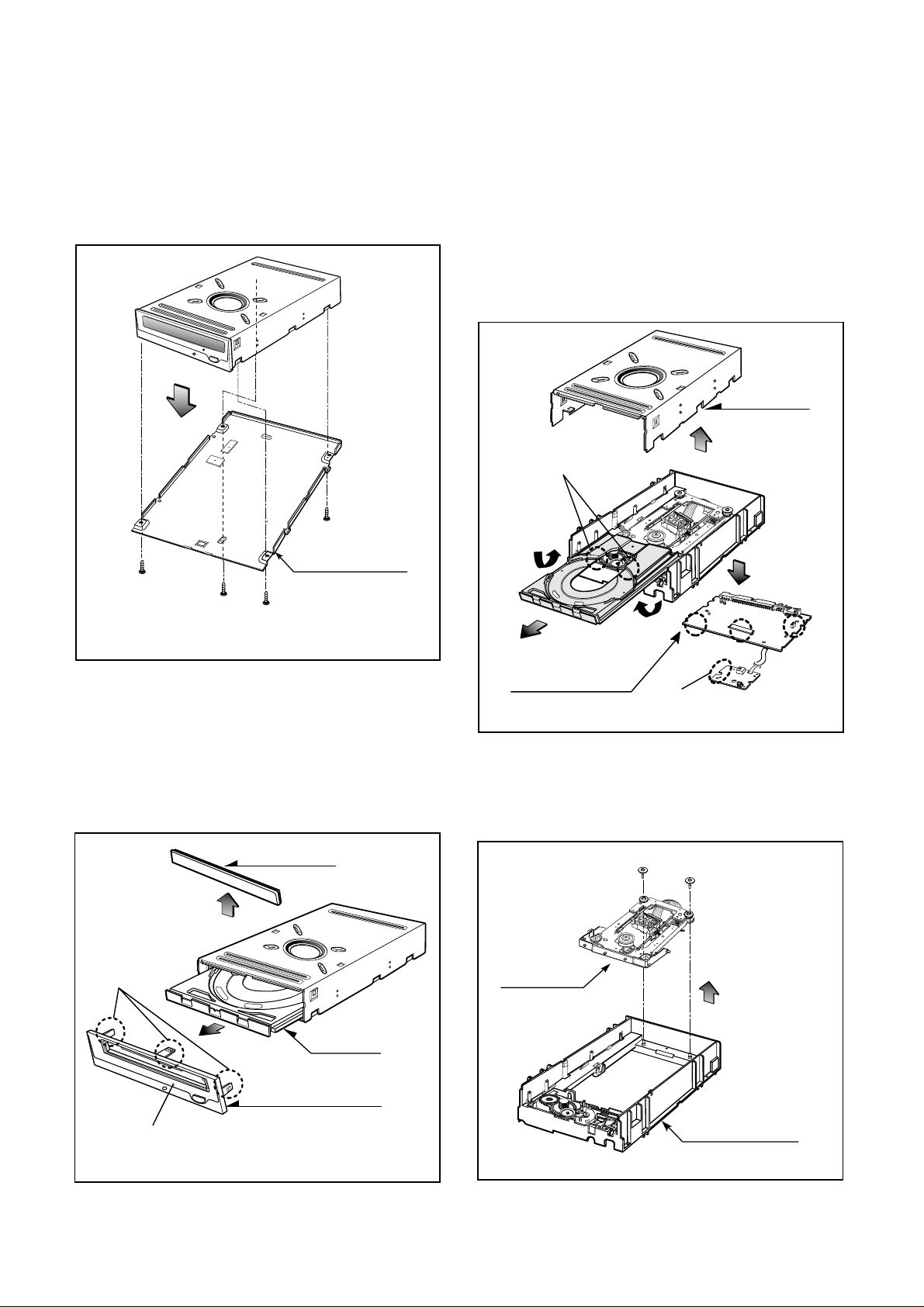

1-1. Bottom Chassis

A. Release 4 screws (A) and remove the Bottom Chassis

in the direction of arrow (1). (See Fig.1-1)

1-2. Front Bezel Assy

A. Insert and press a rod in the Emergency Eject

Hole and then the CD Tray will open in the direction

of arrow (2).

B. Remove the Tray Door in the direction of arrow

(3) by pushing the stoppers forward.

C. Release 3 stoppers and remove the Front Bezel Assy.

1-3. Cabinet and Main Circuit Board

A. Remove the Cabinet in the direction of arrow (4).

(See Fig. 1-3)

B. When the CD tray has been opened completely, lift

2 points (a) and remove the CD tray while drawing

out simultaneously.

C. Remove the Soldering of the LD- and LD+ (b) for

the Loading Motor, and then remove the Main

Circuit Board.

D. At this time, be careful not to damage the 4

connectors of the Main Circuit Board.

2. MECHANISM ASSY DISASSEMBL Y

2-1. Pick-up Unit

A. Release screws (B).

B. Separate the Pick-up Unit in the direction of arrow (6).

Main

Circuit Board

Cabinet

(4)

(5)

(a)

(b)

(A)

(A)

(A)

(A)

(1)

Bottom Chassis

Fig. 1-1

Fig. 1-2

DISASSEMBLY

12

Fig. 1-3

Mechanism Assy

Pick-up Unit

(6)

(B)

(B)

Fig. 2-1

(3)

Stoppers

Emergency Eject Hole

(2)

Tray Door

CD Tray

Front Bezel Assy

Page 13

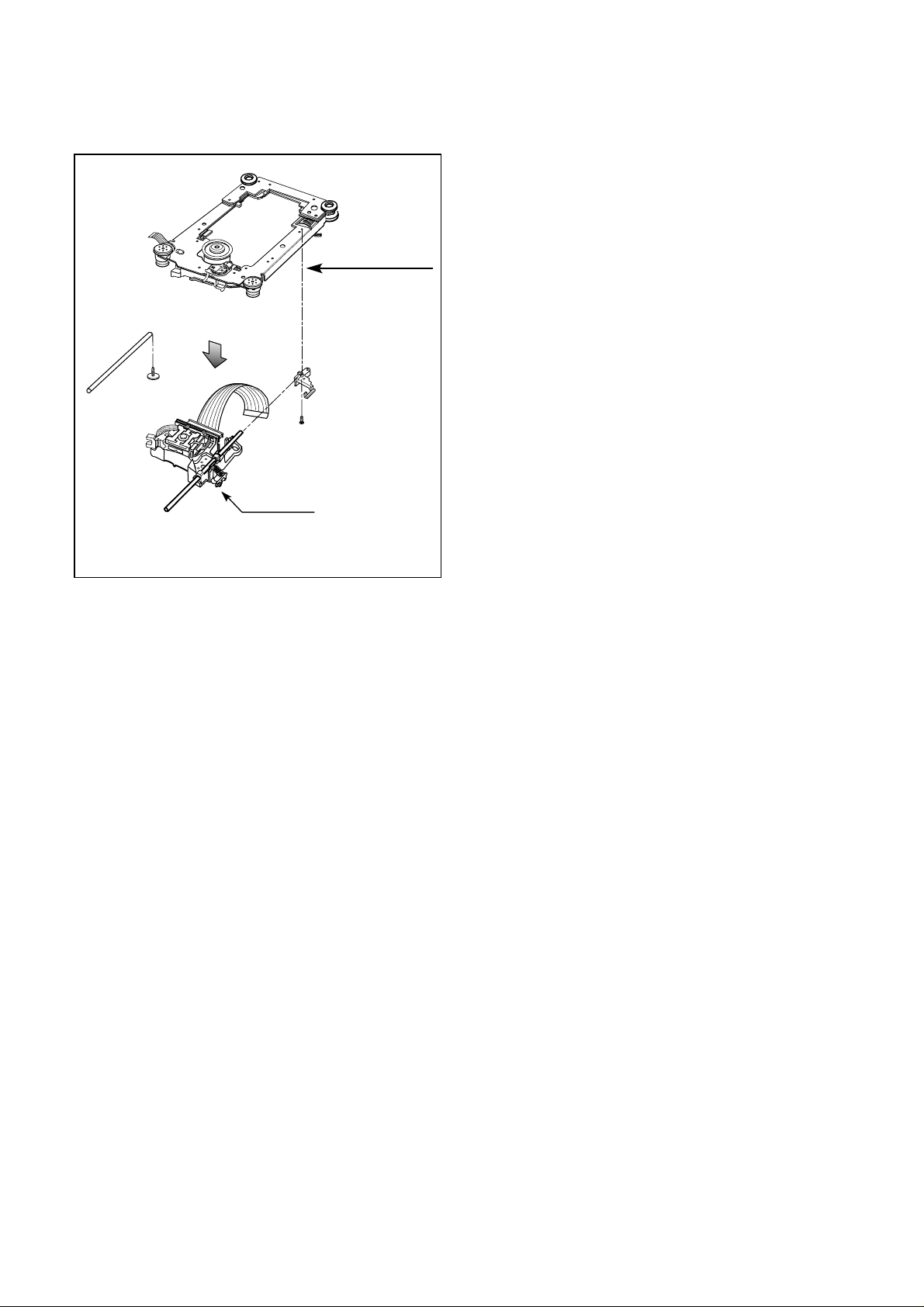

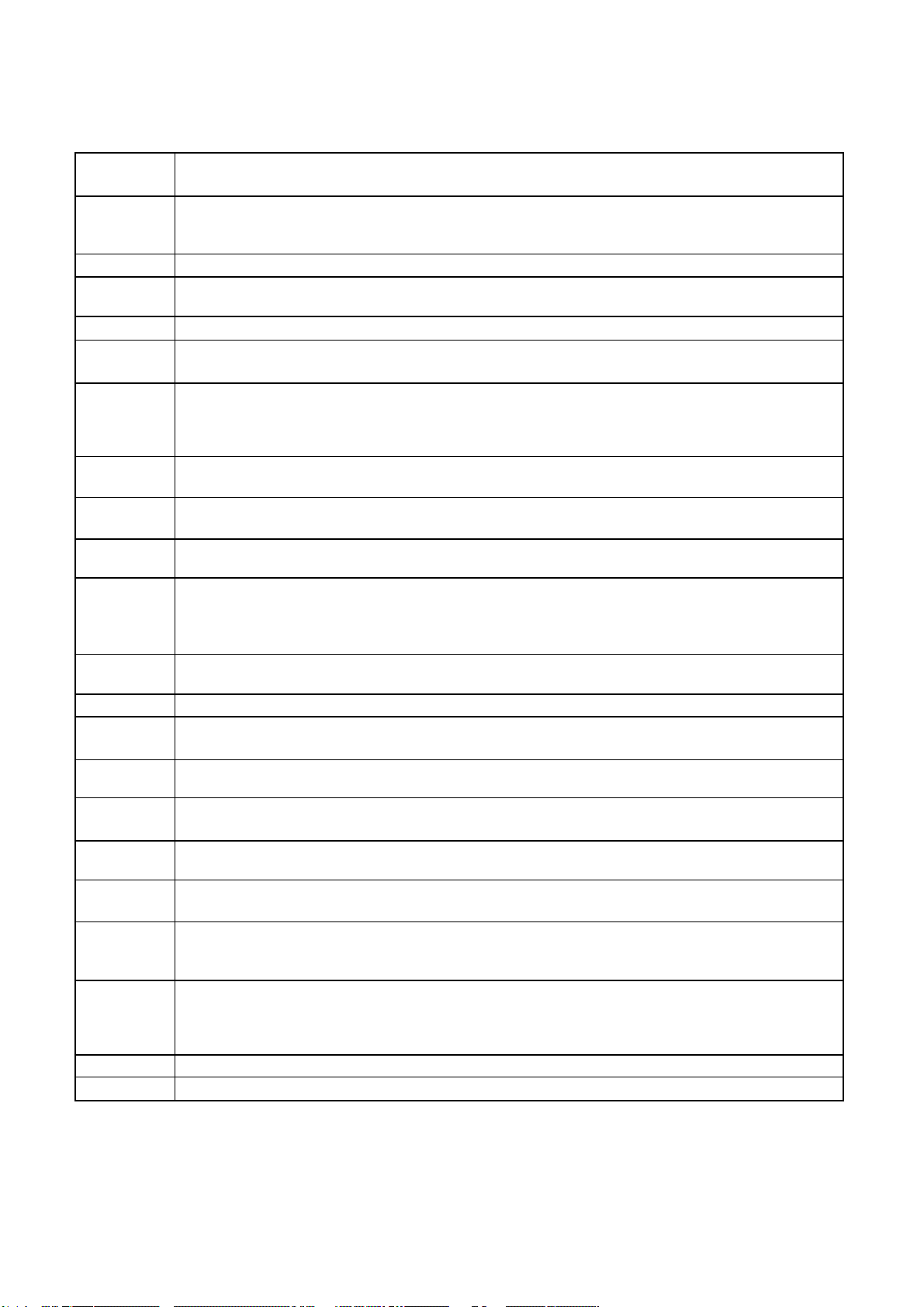

2-2. Pick-up

A. Release 1 screw (C) and remove the Pick-up.

Pick-up Unit

Pick-up

(C)

Fig. 2-2

13

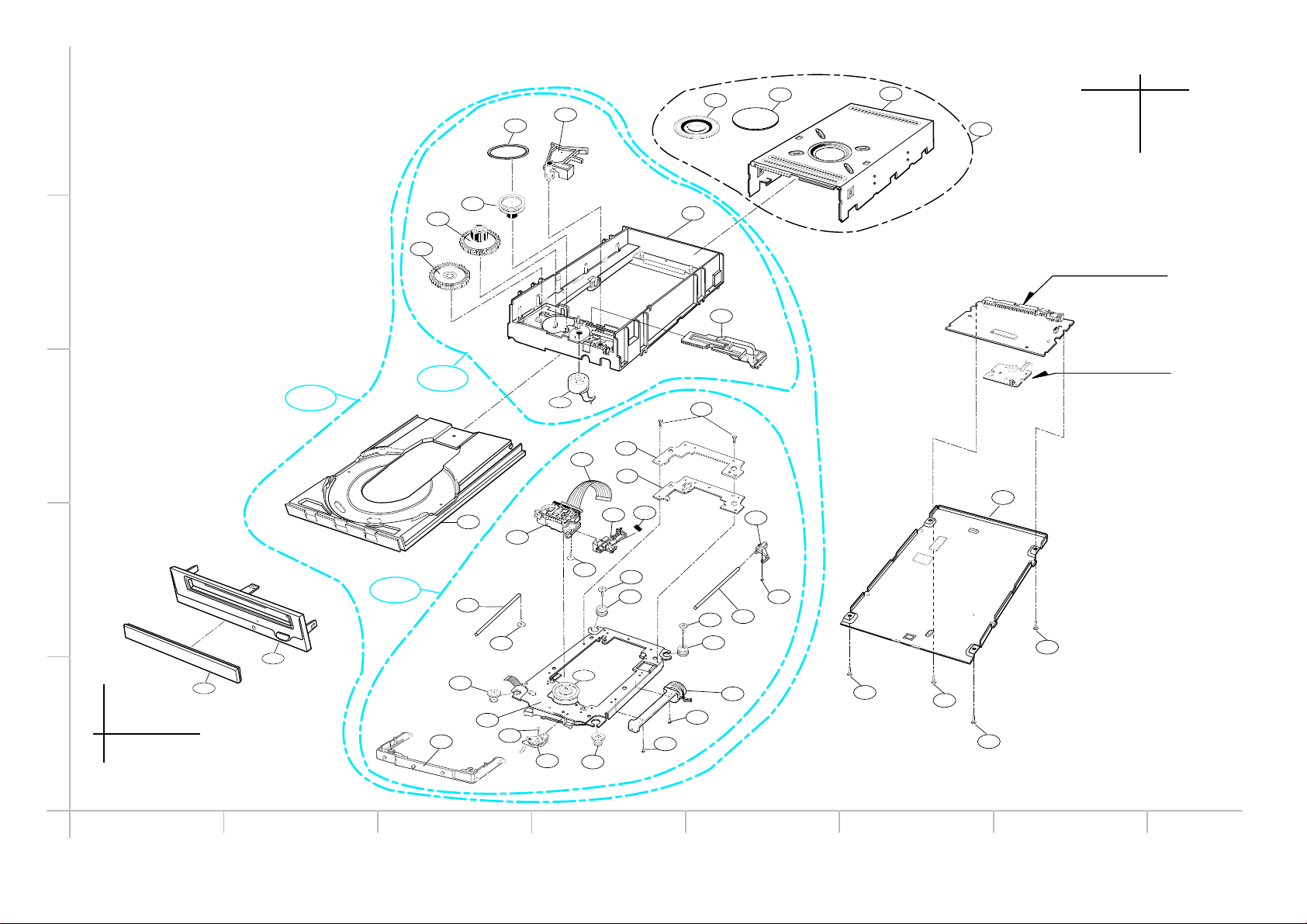

Page 14

030

014

007

A02

A01

A03

021

028

028

452

032

452

020

021

050

430

005

035

004

006

A B C D E F GH

1

2

3

4

5

452

024

481

034

027

026

033

025

430

445

020

453

031

036

453

010

011

009

008

012

016

015

013

PBM00 (MAIN C.B.A)

PBF00 (FRONT C.B.A)

482

482

482

001

482

003

002

(LightScribe only)

14 15

EXPLODED VIEW

Page 15

ATIP Absolute Time in Pre-groove. With an additional modulation of the “Wobble”, the “Groove” contains a time

code information.

Wobble The pre-groove in the Disc is not a perfect spiral but is wobbled.

With : – A typical amplitude of 30 nm

– A spatial peried of 54~64 µm

CW Continuous Wave. The laser light output is at a constant level.

DOW Direct Over-Write. The action in which new information is recored over previously recorded information in

CD-RW disc.

Overwrite

The action in which new information is recorded over previously recorded information.

(Pre-)Groove

The guidance track in which clocking and time code information is stored by means of an FM

modulated wobble.

Land Land is characterized in the following way:

When radial signals are concerned,land is defined as the area between the grooves.

When HF signal are concerned,land is defined as the area between the marks(pits) in tangential

direction.

Hybrid Disc A Multisession disc of which the first Session is mastered. On a hybrid disc, recorded and

mastered information may co-exist.

Mastered Information,stored as pits on the disc during the manufacturing process of the disc.

Information (when making the master)

OPC Optimum Power Control. Procedure is determined optimum recording power according to CD-

R/RW Media in recording start step.

ROPC Running OPC. The purpose is to continuously adjust the writing power to the optimum power

that is required.

When the optimum power may change because of changed conditions of disc and change in

operating temperature.

Jitter The 16 value of the time variation between leading and trailing edges of a specific (I3 … I11) pit

or land as measured by Time Interval Analysis.

Deviation The difference between a fixed value of Pit length and Land length.

TOC Table Of Contents : in the Lead-in Area the subcode Q-channel contains information about the

Tracks on the disc.

Packet A method of writing data on a CD in small increments.

Writing Two kinds of packets can be written : Fixed-length and Variable-length.

Write The shape of the HF write signal used to modulate the power of the laser.

Strategy The Write Strategy must be used for recordings necessary for disc measurements.

Information Wobble, ATIP, Disc Identification, Write Power, Speed Range OPC Parameters, etc are

Area recorded in the Information area of CD-RW Disc

Finalization The action in which (partially) unrecorded or logically erased tracks are finished and the Lead-in

and/or Lead-out areas are recorded or overwritten with the appropriate TOC subcode.

Logical Erase

A method to remove information from a disc area by overwriting it with an EFM signal containing

mode 0 subcode

A logically erased area is equivalent to an unrecorded

Physical Erase

The action in which previously recorded information is erased by overwriting with a CW laser

output.

After a Physical Erase action, the erased area on the CD-RW disc is in the unrecorded state

again.

Session

An area on the disc consisting of a Lead-in area, a Program area, a lead-out area.

Multi session

A session that contains or can contain more than one session composed Lead-in and Lead-out

GLOSSARY

19

Page 16

20

The differences of CD-R/CD-RW discs and General CD-ROM

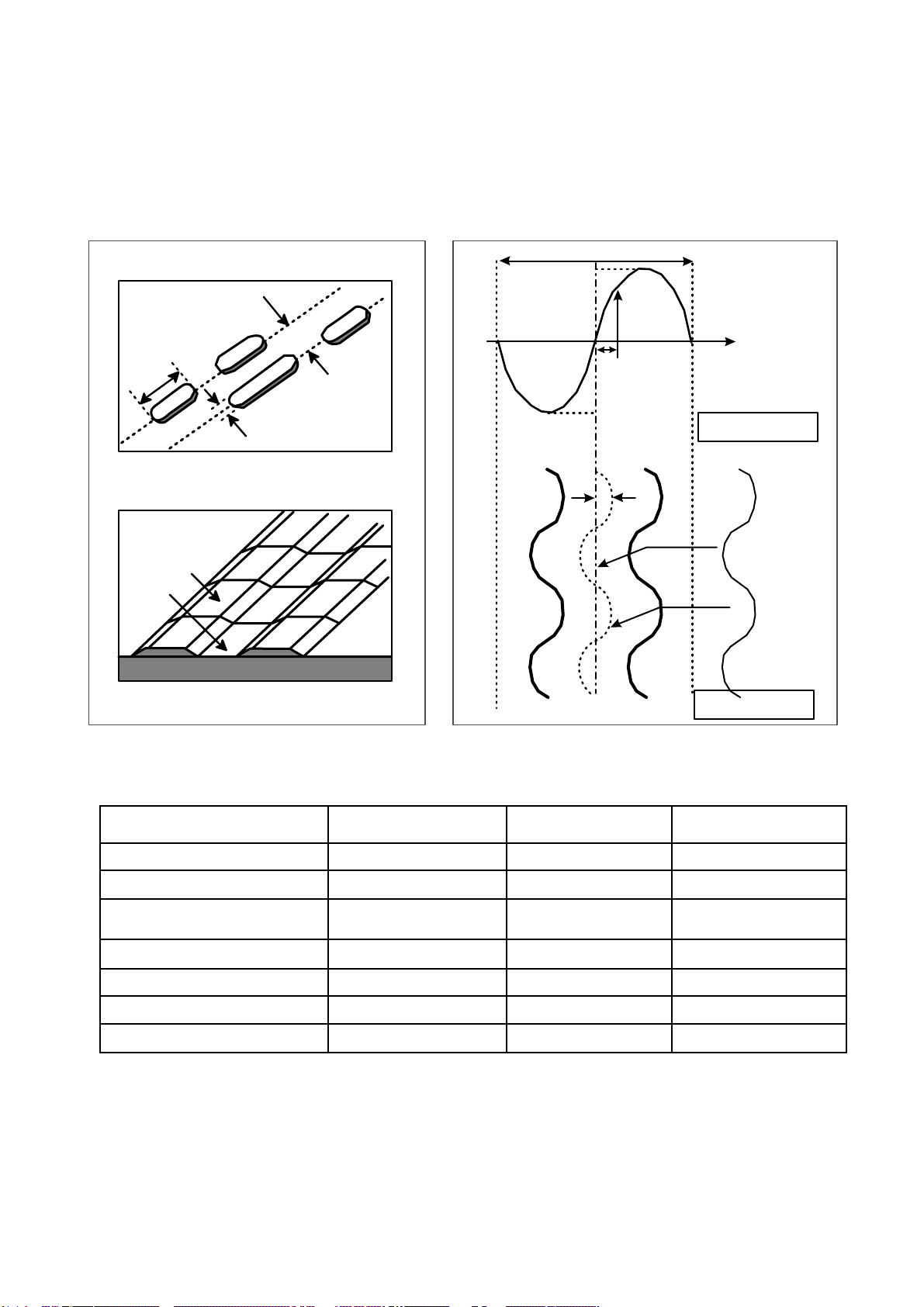

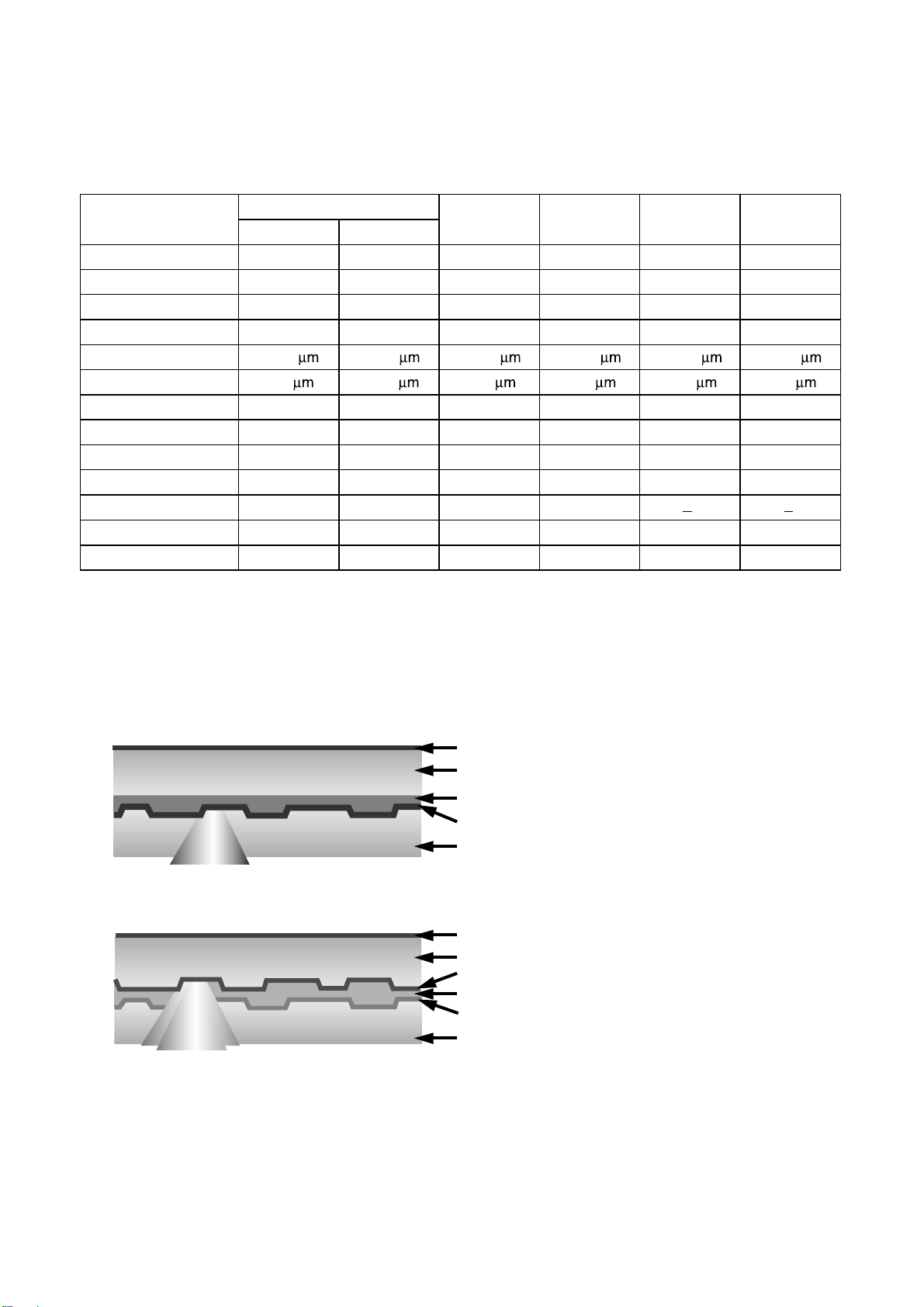

1.Recording Layer

Recordable CD has a wobbled pre-groove on the surface of disc for laser beam to follow track.

2.Disc Specification

Read-only Disc

CD-R and CD-RW Disc

3~1 1T

1.6um

0.4~0.5 um

(Pit)Groove

Land

Track pitch(p)

Radial Direction

Iw

A

O

a

a

Groove

Land

Radial Error Signal

The Groove wobble

Average center

Actual center

CD-ROM (READ-ONLY DISC)

a=30nm

ITEM CD-ROM CD-R CD-RW

Standard Yellow Book Orange Book II Orange Book III

Record Not available Write once Re-Writeable

Tracking Signal I11/Itop > 0.6 > 0.6 0.55 > M11> 0.70

(HF Modulation)

Read Laser Power(mW) < 0.5 mW < 0.7 mW < 1.0 mW

Jitter < 35 nsec < 35 nsec < 35 nsec

Reflectivity (R

top) 70 % 65 % 15 % ~ 25 %

Remark)

Write Laser Power(mW) 14-65 mW 6-45 mW

Page 17

21

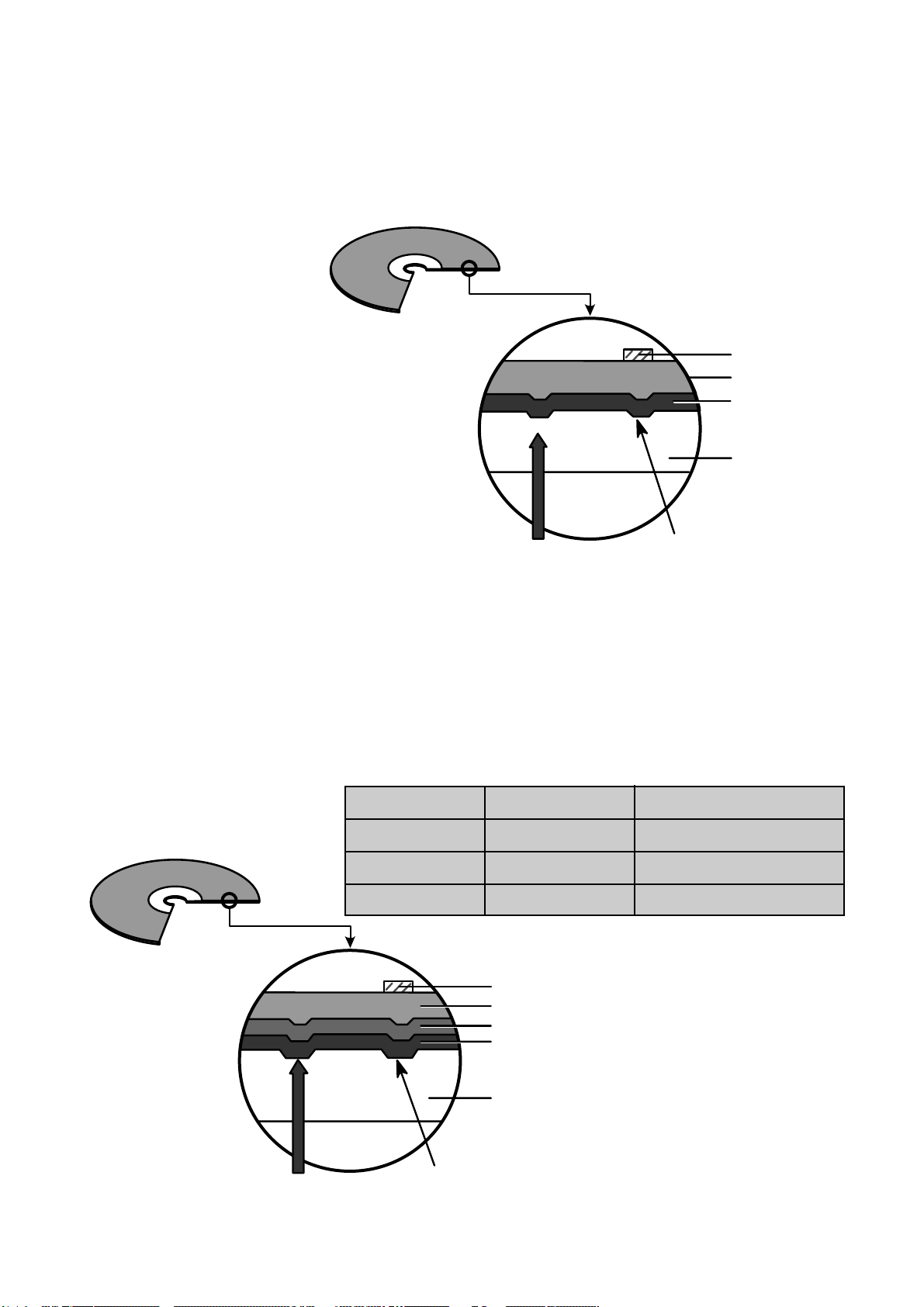

3.Disc Materials

1) CD-ROM disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Organic Dye Layer

Reflective Layer

Protective Layer

Label Printing

2) CD-R disc

Pigment Reflective Layer Color

Phtalocyanine Gold/Silver Yellow/White

Cyanine Gold/Silver Dark Green/Bright Green

Azo Gold/Silver Dark Blue

• It is composed of Silver _ colored aluminum plate and Reflective layer.

• Groove (Pit) of aluminum plate make a track.

• Laser wavelength : 780 nm, Laser Power (Read): 0.5mW

• Signal is detected by the

difference of reflective beam

intensity between “pit” and

“Land” on the disc.

• It is so-called WORM (Write Once Read Many) CD.

• It is composed of polycarbonate layer, Organic dye layer, Reflective layer, and Protective

layer.Gold/Silver Reflective layer is used to enhance the reflectivity

• According to the kinds of Organic dye layer, it is divided by Green CD, Gold CD, Blue CD.

• Laser Wavelength : 780 nm, Laser Power (read) : 0.7 mW

• Recording Power : 8x(14~20mW), 16x(25~35mW)

• When some part of dye layer is exposed to laser heat, it’s color changs black.Therefore, writing and

reading is enabled by the difference of reflectivity between changed part and unchanged part.

• Polycarbonate layer has Pre_Groove which make a Track.

Laser Beam

Pit

Substrate

(Polycarbonate)

Reflective Layer

Protective Layer

Label Printing

Page 18

22

3) CD-RW Disc

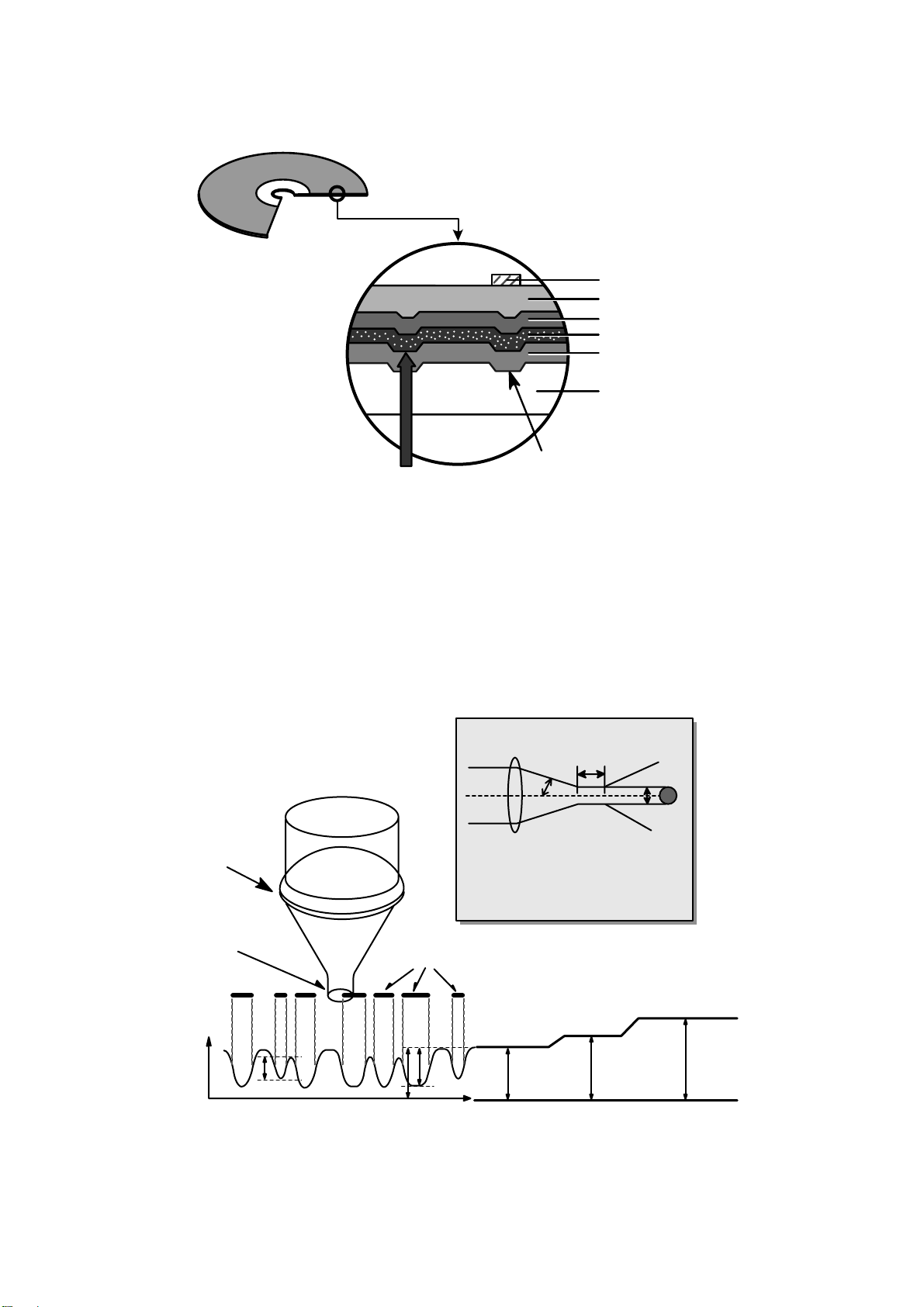

4.

Reading process of Optical Disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Recording Layer

Dielectric Layer(TL)

Dielectric Layer(UL)

Protective Layer

Label Printing

• It is composed of polycarbonate layer, alloy(silver, arsenic) layer, aluminum reflectivity layer, protective layer.

• An crystalized alloy layer is transformed into noncrystalized by the laser heat. Therefore, writing and reading

is enabled by the difference of reflectivity.

• It is possible to overwrite about 1000 times.

• Laser Wavelength : 780 nm, Laser Power (Read) : 1.0mW

• Recording Power : Erase (4~18mW), Write (6~45mW)

• When disc rewriting, new data is overwritten previously recorded data.

• Polycarbonate layer has a Pre-Groove which make a track.

Lens

H

D

Beam

Spot

Focusing

Lens

Laser Spot

at Constant

Read Intensity

Reflected

Light

Signal

Laser Spot

Position

(Time)

Previously Recorded Marks

Groove Land Mirror

I

3

I

top

I

11

I

G

I

L

I

0

Numerical aperture: NA=nsinθ,

n: Refractive index

Focus depth : H = λ/NA

laser spot diameter : D =

λ

/NA

2

θ

Page 19

23

5.Writing Process of CD-R Disc

a b c d e f g

a

b

c

d

e

f

g

Incident

Laser

Power

(Read)

(Read)

(Write)

Laser Spot

Position

(Time)

a b c d e f g

Laser Spot

Position

(Time)

Laser

Spot

Recorded

Mark

Reflected

Light

Signal

Reflected

Light

Signal

Below "ORP"– Mark Too Short

At Optimum Record Power ("ORP")

Above "ORP" – Mark Too Long

Time

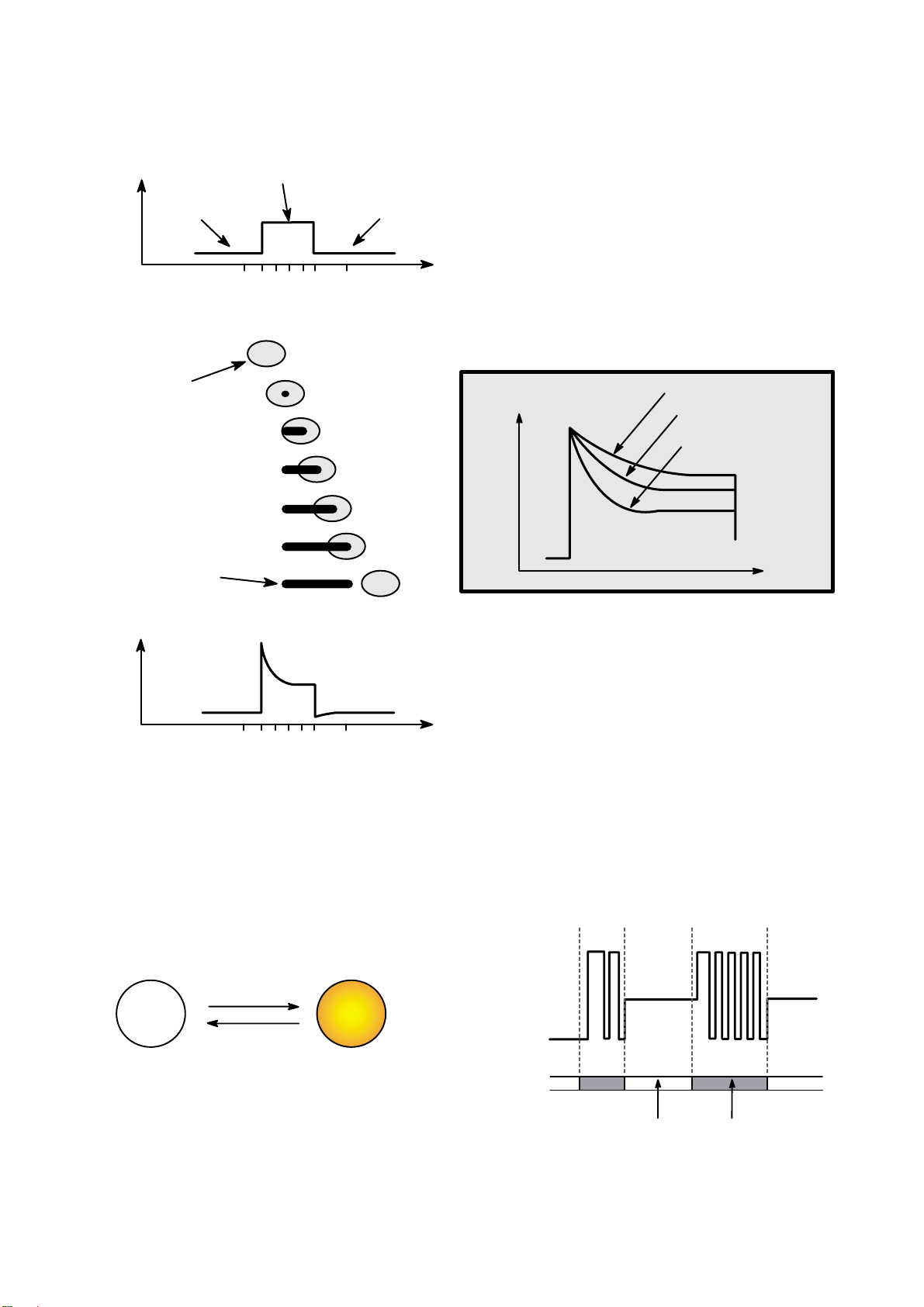

6.Writing process of CD-RW Disc

Write Power

Erase Power

Read Power

Groove

Crystal

Amorphous

Amorphous

Recorded state

(lower reflectivity)

Melting/

quenching

Heating/

gradual cooling

Crystal phase

Erased state

(higher reflectivity)

Page 20

24

7.Organization of the PCA, PMA and Lead-in Area

1) Layout of CD-ROM disc

Center hole Clamping and Label Area Information Area

Lead-in Area

Lead-in Area

Diameter 15 mm

Diameter 46 mm

Diameter 120 mm

Program Area

Read Only Disc

Lead-out Area

Program Area Lead-out Area

Center hole

Clamping and Label Area

Information Area

PCA PMA

Test Area Count Area

Diameter 15 mm

Diameter 45 mm

Diameter 120 mm

Unrecorded Disc

Tsl-00:35:65 Tsl-00:15:05

Tsl-00:13:25

Tsl

99:59:74

00:00:00

in out

Test Area : for performing OPC procedures.

Count Area : to find the usable area immediately in T.A

Tsl : start time of the Lead-in Area, as encoded in ATIP

PMA : Program Memory Area

Disc Center

Disc Center

2) Layout of CD-R/RW disc

Page 21

25

8. Function of PCA and PMA area

1) PCA (Power Calibration Area)

• PCA area is used to determine the correct Laser Power for a disc.

– Method 1 : PCA area is divided by a track.

– Method 2 : The previous Calibration value is referred.

– Method 3 : ROPC is used to determine Laser Power value automatically in data writing.

• CD-R Disc can write maximum 99 Tracks but CD-RW Disc can write unlimited tracks because it has a rewritable

function.

2) PMA (Program Memory Area)

• It has a track information (track No, track Start/End time) of every track before writing completed.

– PMA area has the last written point and the next writable point of a disc.

– In case of CD to CD copy, some writer may not write PMA area.

* When Disc is Finalized,

PMA information is transferred to the Lead_In area so that general Driver can read it.

* Because PCA and PMA area exist before Lead-In area, General CD Player or CD-ROM Drive can’t read

these areas.

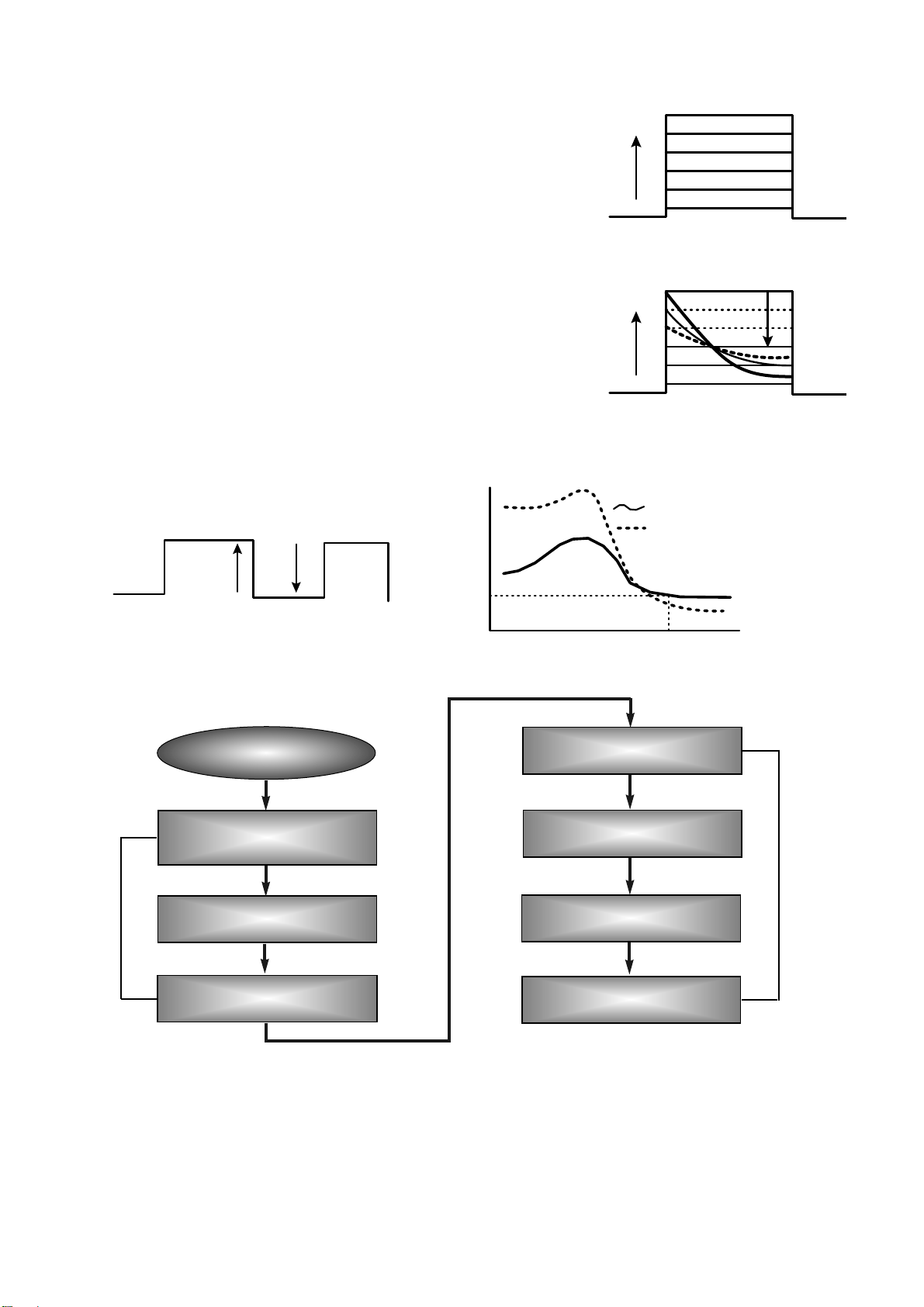

9. OPC and ROPC

1) OPC (Optimum Power Control)

• This is the first step of writing process, because CD writer has its own laser power value and media have different

writing characteristics,

– This is determined by the Writing characteristic, speed, temperature, and humidity.

– Laser wavelength is determined by the environmental temperature (775~795nm) and Optical Laser Power is

determined by the test and retry.

• Asymmetry and optimum writing Power

– EFM signal Asymmetry is determined by the writing power.

Therefore, Optical Power which has the same value to the preset power value can be estimated by measuring

HF signal Asymmetry on the PCA area.

• Measurement of Asymmetry

* Parameter setting (Beta) : Using AC coupled HF signal before equalization

Beta = (A1+A2)/(A1-A2)

Time

P << Po

Time

P = Po

HF Signal

A1

0

A2

Time

P >> Po

Page 22

26

2) ROPC (Running Optimum Power Control)

• Variable primary factor of Optimum Power

– Change of Power sensitivity on the Disc. (limited to 0.05 *Po)

– Wavelength shift of the laser diode due to the operating temperature change.

– Change of the Spot aberration due to the Disc skew,

Substrate thickness, Defocus.

– Change of Disc or Optics conditions due to the long term OPC

==> It is necessary to adjust continuously to obtain the Optimum Power.

• Principle of Running OPC

– To meet the factors mentioned above,

a horizontal _ direction movement of a curve is uesd.

– Beta = f(B-level) = constant on the Recorded Disc

– Procedure of ROPC

a. Reference B-level is determined during OPC Procedure.

b. During Recording, B-level value is controlled to have a close

Reference B-level value.

c. Normalization of B-level is used to eliminate the effect of reflectivity fluctuation.

==> The reflected B-level value is normalized by the disc reflectivity itself.

CD-R/RW Media

Write Strategy

Determination

PCA Test Area

Program Area

PMA Area

Lead-In Area

Lead-out Area

OPC

PCA Count Area

ROPC

* Recording Capacity of CD-R/RW (74Minute Recording media)

• (2048 Byte/Sector) X (75 Sector/Second) X (60 Second/Minute) X 74 Minute

= 681,984,000 Bytes = 682 Mbytes

• But the actual recording capacity is about 650 Mbytes. (according to the ISO 9660 standard, approximately

30 Mbytes are used to make directory structure and volume names.)

Incident recording pulse

Reflected recording pulse

Sampled timing B

11T

Sample B-level (Write Power)

Level B

Sampled at timing B

Pwo decided by OPC

Recording Power

Level B with Pwo

normalized to recording power

Sample Disc Reflectivity

(Read power)

10. Writing Process of DISC

Page 23

27

The differences of DVD-R/RW , DVD+R/R W discs and DVD-ROM

1.Recording Layer

LPP

(Land Pre-Pit)

DVD+R/RW Disc

DVD-R/RW Disc

0.74

um

3

T

0.4 um

DVD-ROM (Read Only Disc)

Page 24

28

2.Disc Specification

3.Disc Materials

1) DVD-ROM

DVD-ROM

Media T ype

User data capacity

Single-Layer

Read Only

4.7GB

Dual-Layer

Read Only

8.54GB

DVD-R DVD-RW DVD+R DVD+RW

Dye Phase change Dye Phase change

4.7GB 4.7GB 4.7GB 4.7GB

Wavelength

650nm 650nm 650nm 650nm 650nm 650nm

Reflectivity

45~85% 18~30nm 45~85% 18~30% 45~85% 18~30nm

Track pitch

0.74 0.74 0.74 0.74 0.74 0.74

Minimum pit length

0.4 0.44 0.4 0.4 0.4 0.4

Modulation

>0.6 >0.6 >0.6 >0.6 >0.6 >0.6

Channel bit-rate

26.16MHz 26.16MHz 26.16MHz 26.16MHz 26.16MHz 26.16MHz

Wobble Frequency

- - 140KHz 140KHz 817.4KHz 817.4KHz

Addressing

26.16MHz 26.16MHz Wobble & LPP Wobble & LPP Wobble(ADIP) Wobble(ADIP)

Read Power (mW)

0.7 0.1 0.7 0.1

Write Power ( mW)

- -

JItter

<8% <8% <8% <8% <9% <9%

++

Bonding layer

Polycarbonate

Semi-reflective

Polycarbonate

Reflective layer

Label

Polycarbonate

Label

Bonding layer

Reflective layer

Polycarbonate

<Single Layer >

<Dual Layer >

Page 25

29

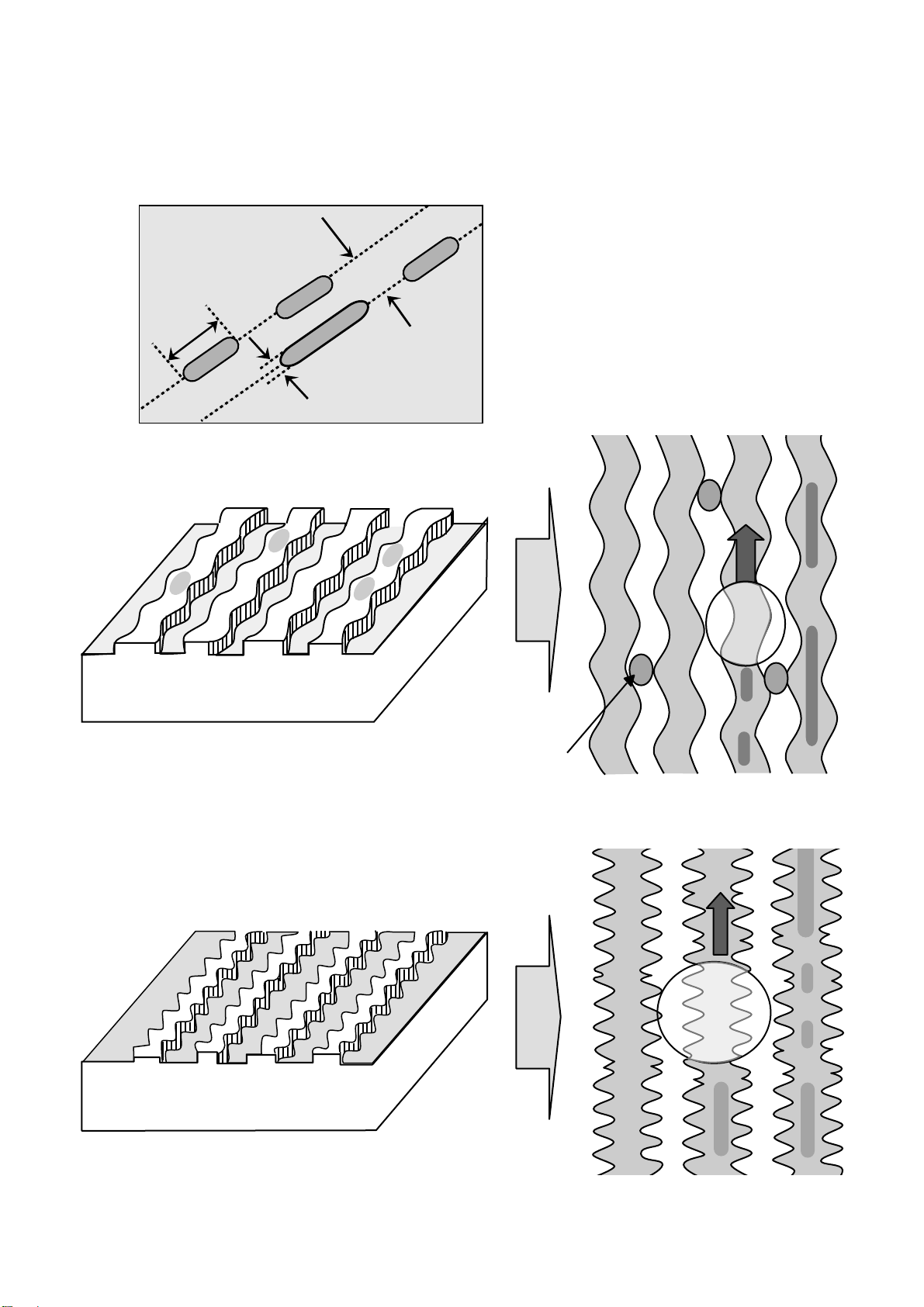

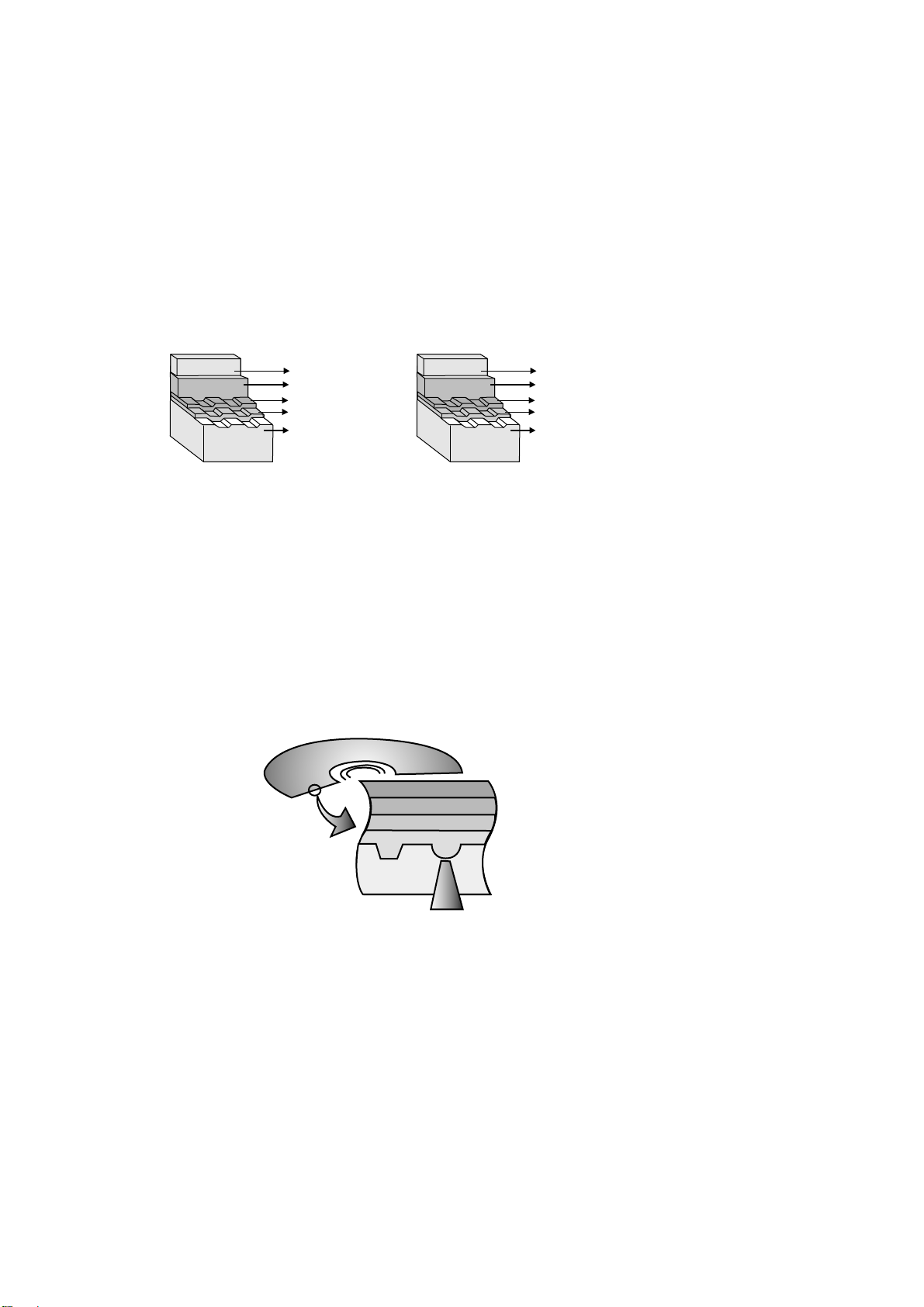

2) Recording format using organic dye material (DVD-R/DVD+R)

* The format that records data through the creation of recorded marks by changing the organic dye material

with a laser beam.

DVD-R

Adhesive layer

Protective layer

Reflective layer

Recording layer(dye)

Disc substrate

DVD+R

Adhesive layer

Protective layer

Reflective layer

Recording layer(dye)

Disc substrate

Adhesive layer

Protective layer

Reflective layer

Dye layer

Substrate

Laser beam

> Disc structure

> Disc structure

[Recording]

Recording is done by changing the organic dye layer and the substrate with a laser when a strong is

applied to a disc, the temperature of the ortanic dye material goes up, the dye is decomposed and the

substrate changes at the same time. At this time, a durable bit is created as is the case with a CD-ROM.

[Playback]

Signals are read with the differences of the reflection of a laser from pits.

Page 26

30

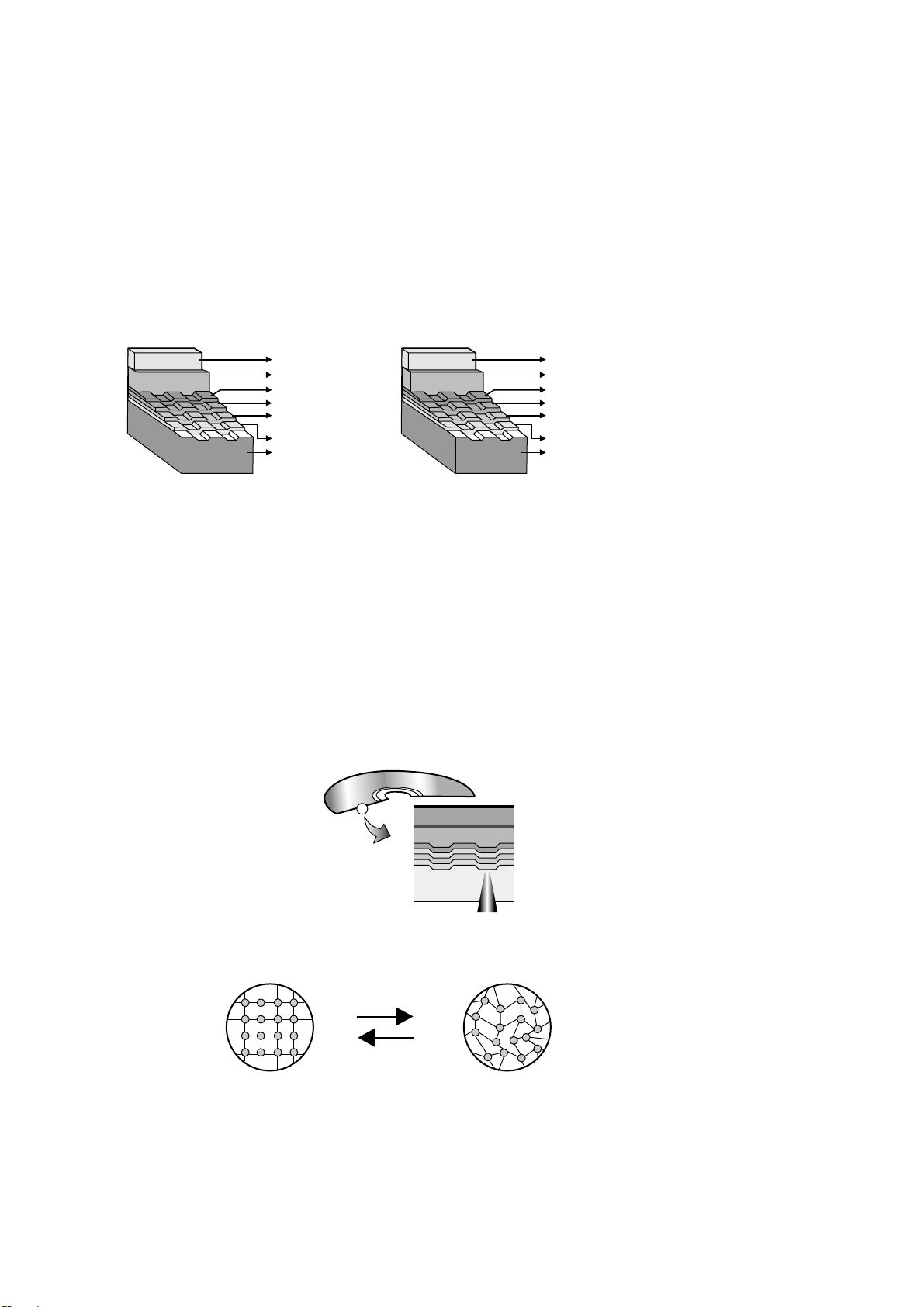

3) Recording format using phase-change recording material (DVD-RW/DVD+RW)

* Data is recorded by changing the recording layer from the amorphous status to the crystalline status, and

played back by reading the difference of the reflection coefficient.

[ Amorphous : Non-crystalline ]

Substrate

Laser beam

Recording data

(Melting/Quick cooling)

Erasing data

(Heating/Gradual cooling)

Data erased state

(High reflection coefficient)

Recorded state

(Low reflection coefficient)

Crystalline status

Amorphous status

DVD-RW

Adhesive layer

Protective layer

Reflective layer

Dielectric layer

Recording layer

(Phase change material)

Dielectric layer

Disc substrate

DVD+RW

Adhesive layer

Protective layer

Reflective layer

Dielectric layer

Recording layer

(Phase change material)

Dielectric layer

Disc substrate

> Disc structure

> Recording principles

[Recording]

When a high-power laser is applied to the recording material, it melts and then becomes amorphous with

a low reflection coefficient when it quickly cools off. When a mid-power laser is applied to heat gradually

the recording material and then gradually cools it off, it becomes crystal with a high reflection coefficient.

[Playback]

A low-power laser is used for playback. The amount of reflected light depends on the status (amorphous

or crystalline) of the recording material. This is detected by an optical sensor.

Page 27

31

4. Writing Pulse Wave Form of DVD+R

For different speed ranges, different write strategies can be used. This document specifies 2 options:

- a pulsed write strategy, where each single mark is created by a number of subsequent separated short

pulses.

- a blocked write strategy, where each single mark is created by one continuous pulse.

1) 1stMethod : Using Pulsed Write Strategy

* 3T :

NRZI

T = 3

2Tw

Ttop

dTtop

dTle

Pb

top

top le

Pp

Channel bits

N = 3 : only the top pulse(T ),

first pulse lead-time dT , dT

NRZI

T > 4

2Tw Tw

Ttop Tmp

Tmp

Tlp

dTtop

dTle

Pb

top

top

le

lp

mp

Pp

Channel bits

N > 4 : the top pulse (T ), multi-pulse (T ) and last pulse (T ),

first pulse lead-time dT , dT

Pp : Actual write power

Pb : Bias Power

* > 4T :

Page 28

32

2) 2stMethod : Using Blocked Write Strategy

NRZI

Channel bits

2Tw

Tw

dT

top

T

top

dT

le

P

p

P

b

T

mp

lp

T

dP

p

0mW

P

c

P

b

1.25T

w

3T mark

4T mark

5T mark

Etc.

dT

top,3

dP

p3

T

top,3

dT

le

1.25T

w

P

c

P

b

1.25T

w

1.25T

w

1.25T

w

dT

top,4

dP

p4

T

top,4

T

lp

T

top,4

T

top,4

T

mp

T

mp

T

lp

T

lpT

mp

N = 3 : T (cm = 3) can be optimized individually.

N > 4 : T (cm 4) + x (N-3) T + T , T = T

P shall be < 0.1mW

top

mp

lp

w

w

top

c

Pp : Actual write power

Pb : Bias Power

dPp : Additional power ( Only be applied for the 3T and 4T marks)

Pc : Cooling power (Especially at higher recording speeds, optimum cooling down of the

recording layer after writing a mark may be

needed.)

>

Page 29

33

5. Writing Pulse Wave Form of DVD+RW

NRZI

Channel bits

2Tw

Tw

Ttop

dTtop

P

p

Pe

T

mp

mp

T

dTera

Pp : Actual write power

Pe : E r as e Powe r

Pb : Bias

Power

Pb

0mW

T

mp

Page 30

6. Organization of the Inner Drive Area, Outer Drive Area, Lead-in Zone and

Lead-out Zone

1) Layout of DVD-ROM disc

34

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Lead-in Zone

Lead-in

Zone

Lead -out

Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Data Zone

Read Only Disc

Lead-out Zone

Data Zone

Outer Drive

Area

Inner Drive

Area

Inner Disc

Test Zone

Outer Disc

Test Zone

Unrecorded Disc

PSN: 23080H 27080H 27480H 28480H 2A480H 30000H 260540H 261940H 262940H

263940H

267940H

in OUT

Disc Center

Rim area

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Disc Center

Rim area

Inner Disc

Count Zone

Outer Disc

Count Zone

2) Layout of DVD+R disc

> Inner Disc Test Zone : for performing OPC procedures.

> Inner Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

> Outer Disc Test Zone : for performing OPC procedures.

> Outer Disc Count Zone : for counting the mumger of OPC algorithm performed in IDT Zone.

Page 31

3) Layout of DVD+RW disc

35

> Inner Disc Test Zone : for performing OPC procedures.

> Inner Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

> Outer Disc Test Zone : for performing OPC procedures.

> Outer Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

Lead-in Zone

Lead -out Zone

Data Zone

Inner Disc

Test Zone

Outer Disc

Test Zone

Unrecorded Disc

PSN: 2A480H 2A7C80H 2DC80H 30000H 260540H 262940H

265940H

266140H

in OUT

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Disc Center

Rim area

Inner Disc

Count Zone

Outer Disc

Count Zone

Page 32

36

LightScribe Media

1. LightScribe Media

Center Hole

Screen Printed Imaging Layer

Clear Protective Coating

Reflective/Thermal Layer

Dye Data Layer

Polycarbonate

Substrate

DiscOD

Label Zone

Control Feature Zone

Clamping/Logo Zone

Page 33

37

2. Hardware Block Diagram of LightScribe Label Printing

Host

PC

(Spindle)

uP

(DSP)

Power

Drive

Analog

Signal

Processor

MECHANISM

Optical

Pick-up

Optical

Encoder

(Sled)

(Track)

(Tilt)

(Focus)

RFOUT

Spindle Motor

Step Motor

Track Actuator

Tilt Actuator

Focus Actuator

Laser Power Reference

Write Strategy Control

Buffer

Memory

SERVO Signals

RF Cell Signals

Laser Power Monitor Signal

Optical FG

CIrcuit

Page 34

38

3. MD Assy For LightScribe

Optical Encoder Unit

OPU ID Movement Range : L=21um

Page 35

39

4. Optical Encoder Assy

Codewheel

Direction of

radial play

CODEWHEEL

OR

CODESTRIP

FFC

3PIN

SIGNAL

PROCESSING

CIRCUITRY

R

V

LED

V

CC

CH A

CH B

CH B

GND

GND

Vcc

OFG

Encoder PCB

PIN 6

VCC

PIN 5

CH A

PIN 4

GND

PIN 3

VLED

PIN 2

GND

PIN 1

CH B

PIN 6

VCC

PIN 5

CH A

PIN 4

GND

PIN 3

VLED

PIN 2

GND

PIN 1

CH B

Optical Encoder IC

Schematic of Enc PCB

Page 36

40

DVD & CD DATA PROCESSING

1.Data Processing Flow

Command

Data

Status

RF EQ & AGC

SERVO

DSP

Encoder & Decoder & CSS

RF data slice EFM demodulator

CiRC error correction

Audio DAC

Buffer/Memory controller

CSS controller

Atapi interface control

Data PLL

Servo ADC

Focus/tracking

control output

Sled control output

CAV Spindle control

P-up

Unit

(HOP-7632TS)

IC101

RF AMP

(R2S35002)

CD

DVD

IC301

(R8J32007)

TE/CSO GEN

FE GEN

DRAM

U-COM

SRAM

IC302

Flash ROM

Page 37

41

R8J32007

HOST DVD

PLAYER

(EMPEG2 B/D)

Scrambled MPEG Data

Change the "KEY"

KEY Management Control

2. Copy Protection and Regional Code Management Block

Block Diagram

Brief Process

1. Regional Code for DVD Disc

– DVD-ROM drive transfers the regional code of the control data to host by the command of host, the DVD

player of host reads the regional code, and plays title in the case of allowed regional code only.

2. Management of DVD Disc for the scrambled of data

(1) DVD-ROM and DVD player of host generate the “KEY 1” respectively, transfer to opposite part, the

“KEY 2” is received, recognizes the data transfer or not with this value, and generates the bus key

encoded the data.

(2) Encoded “Disc Key” and “Title Key” host is transfer with the bus Key.

(3) DVD player of host reads the key value, and uses the value to restore the scrambled data.

* Refer to the next page for the details.

Page 38

42

3. About Prevention the DVD-ROM from to be copy

A data is able to encode and record in the disc, if a copyright holder wants to prevent the disc from copying.

In case of a disc enhanced movie of 3 titles......

DISC KEY (2048 Bytes) is used to encode the whole contents in the disc and TITLE

KEY (5 Bytes) is used to encode the title respectively.

So, the data is encoded and stored in a disc through the unknown algorithms

with a disc key and title key. (At this time, the disc key and title key are stored

in a disc.)

…As above, the disc is able to copy when the disc key and title key are

opened.

Then, ROM-DRIVE encodes the disc key and title key and transfers to MPEG2 board.

If you want to play the disc prevented from the copy......

First of all, ROM-DRIVE and MPEG-2 board identify with each other through the procedure as described

below.

1. Drive and host gives and takes the ID of 2bit. This ID is AGID (Authentication Grant ID).

The various decoder boards are attached to the host, in these, AGID sets the MPEG-2 board and drive.

2. After the AGID is set, MPEG-2 board generates the challenge key (10 Byte) and transfers to drive. The

board and drive generate key 1 (5Byte) with the challenge key respectively. (Of course, the Algorithm

generating the key 1 is not known.)

3. Compare with the generated key 1, if it corresponds each other, the first step of authentication is

completed. This is a course to identify the MPEG-2 board with a drive.

4. The second step of authentication is a course to identify a drive with the MPEG-2 board.

The dirve generates a challenge key and transfers it to the MPEG-2 board. The dirve and MPEG-2 board

generate the key 2 (5Byte) with the challenge key, compare with each other, and if it corresponds and the

secondary step of authentication is completed.

5. As above, the identification is completed.

6. The dirve and MPEG-2 board generate the Bus key with the key 1 and key 2 and own it.

7. Dirve encodes the disc key and title key with this Bus key and transfers to the MPEG-2 board.

8. The MPEG-2 board reads the encoded disc key and title key with the Bus key only.

9. MPEG-2 board lets data read from the drive to decode with the read disc key and title key and makes into

the video signal by decoding.

ROM-DRIVE

AGID

HOST

MPEG-2

BOARD

Challenge key

encoded disc key, title key

Page 39

43

4.About the DVD-ROM Regional Code

DISC ROM - DRIVE MPEG-2 BOARD VGA CARD

MONITOR

1

CAN

U.S.A

MIX

CUB

BHS

PRI. VIR

1

BMG

GRL

2

2

ZAF

ISO

SWZ

FIN

POI

FST

LTU

BIR

UKR

TUR

FGY

JRN

TKM

AFG

PAK

CHN

MMR

MNG

RUS

KOR

JPN

HKG

MAC

TWN

PHL

6

3

2

1

5

5

4

1

MDI

MNP

GUM

PLW

PNG

NZL

AUS

4

The disc has

the regional

code of 8 bit.

Example)

The disc

manufactured

in the U.S.A,

has the

number one.

Transfer to

MPEG-2 board

reading the

regional code.

Receiving

data from the

MPEG-2

board and

output

through the

monitor

If the board is setting to the regional

code 1 for the U.S.A. ...

Check the received regional code to

number 1, all or not, transfer the

data to VGA card in accordance with

only a case among the three case.

Regional code

Page 40

INTERNAL STRUCTURE OF THE PICK-UP

1.Block Diagram of the PICK-UP(HOP-7632TS)

44

45

16 15 14 13 12 11 10

26 27 28 29 30 31 32

917

8

7

6

5

4

3

2

1

Tilt-

C3

R1

R4

CD-LD

DVD-LD

R2

FB2

FB1

CD-VR

DVD-VR

GND

EF4

EF1

VA

VB

VEF2

VREP

VRFN

VD

VCC

VS

VC2

VEF3

SW

C15

C14

C6

C5

C9

C10

Rth

R7

R8

R14

Rd

C12

C13

FB3

C2

C1

IC2(LDD)

IC2(FM)

IC3(OEIC)

VSO

18

OUT2

19

OUT2

20

VSO

21

VSO

22

GND

23

OUT1

24

OUT1

25

VSO

NCNCBUSY

SEN

SDIO

SCLK

MON1

VSL

CLK

CLKB

GND

GND

NRZB

NRZ

RWB

VSA

RSETENAGND

ISLOP

IAPC

Rfreq

SLG

44

Tilt+

43

TR-

42

TR+

41

AF-

40

AF+

39

GND(FM)

38

FM

37

VREF

36

SEL

35

VCC(FM)

34

ENA

33

IAPC

32

SLG

31

VSA5

30

VSL25

29

CLK

28

CLKB

27

GND(LDD)

26

NRZB

25

NRZ

24

GND(LDD)

23

MONITOR

22

RWB

21

SDIO

20

SCLK

19

BUSY

18

SEN

17

VSO

16

Vcc(FM)

15

GND(OEIC,TEMP)

14

RF-

13

RF+

12

E2+F2

11

C

10

A

9

E1+F1

8

E4+F4

7

D

6

B

5

E3+F3

4

GAINSW

3

Vc(OEIC)

2

Vcc(OEIC)

1

GND(OEIC,TEMP)

5

4

2

1

6

7

7

F4

F1

F3

F2

E4 E1

DA

BC

E3

E2

8

9

10

11

12

13

14

6

5

4

3

2

1

3

Behind View

DVD-LD : 1st Vendor : Rd = 82k

DVD-LD : 2nd Vendor : Rd = 5.6k

8

Page 41

45

2.Pick up Pin Assignment

No. Signal Name I/O Signal Description

1 GND(OEIC,TEMP) Ground for OEIC

2 Vcc(OEIC) I Power supply for OEIC

3 Vc(OEIC) I Reference voltage input for OEIC

4 GAINSW I OEIC output gain control (High:Low gain, Middle:Middle gain, Low:High gain)

5 E3+F3 O Single OEIC output EF3

6 B O Single OEIC output B

7 D O Single OEIC output D

8 E4+F4 O Single OEIC output EF4

9 E1+F1 O Single OEIC output EF1

10 A O Single OEIC output A

11 C O Single OEIC output C

12 E2+F2 O Single OEIC output EF2

13 RF+ O Single OEIC RF positive differential output

14 RF- O Single OEIC RF negative differential output

15 GND(OEIC.TEMP) O Ground for OEIC and TEMP

16 TEMP O Output voltage for controlling temperature

17 VSO I Supply voltage for the output drivers only

18 SEN I Serial control enable (H=enable, L=disable)

19 BUSY O Goes high when serial transfer to timing menory is active

20 SCLK I Serial control clock

21 SDIO I/O Serial data for parameters and control ; in/out

22 RWB I Write enable for NRZ laser data (L=write, H=read)

23 MONITOR O Monitor output

24 GND(LDD) Ground connection for LD Driver-IC

25 NRZ I NRZ laser data (H=mark, L=space) (LVDS+)

26 NRZB I NRZ laser data (H=mark, L=space) (LVDS-)

27 GND(LDD) Ground connection for LD Driver-IC

28 CLKB I CLOCK for NRZ code input (LVDS-)

29 CLK I CLOCK for NRZ code input(LVDS+)

30 VSL25 I Supply voltage for 2.5V logic

31 VSA5 I Supply voltage for PLL only

32 SLG I Land/groove input serects the power register set (H=land, L=groove)

33 IAPC I A low inpedance current input ; 100xIAPC frow to the output

34 ENA I Fast chip enable input

35 VCC(FM) I Power supply for FM

36 SEL I Low: selects DVDFMOUT

High: selects CDFMOUT

37 VREF I APC amplifier reference voltage input

38 FM O APC amplifier output

39 GND(FM) Ground connection for FM

40 AF+ I Focusing Actuator drive signal+

41 AF- I Focusing Actuator drive signal42 TR+ I Tracking Actuator drive signal+

43 TR- I Tracking Actuator drive signal44 Tilt+ I Tilting Actuator drive signal+

45 Tilt- I Tilting Actuator drive signal-

Page 42

3.Signal detection of the P/U

1) Focus Error Signal ==> (A+C)-(B+D)

This signal is generated in RF IC (IC101 : R2S35002) and controls the pick-up’s up and down to focus on

Disc.

2) Tracking Error Signal (DPP Method) ==> {(A+D)-(B+C)}- k x {(EF1+EF4)-(EF2+EF3)}

This signal is generated in RF IC (IC101 : R2S35002) and controls the pick-up’s left and right shift to find

to track on Disc.

3) RF Signal ==> (A+B+C+D)

This signal is converted to DATA signal in DSP IC (IC301 : R8J32007).

46

Pick-Up module

Photo Diode

Tracking

Focusing

Infrared Iaser

k[(F+H) - (E+G)]

(A+D) - (B+C)

(A+D) - (B+C) - k[(F+H) - (E+G)]

Offset

TE

Tp

Sub2

Main

Tp/2

Sub1

T rac k Center

F,E

D,C

A,B

H,G

Page 43

47

WGATE

RFPDSH

Optical

Pick-up

LD

Driver

Write

Strategy

FsDAC

WDAC

IAPC

R160

LPF

&

Gain

WFPDSH

FMON

RWAPC

buffe

r

2.5VREF

Buffer

S/H

B/H

+

-

13

S/H MU

X

AM

P

APCDAC

(REDA/WRDA)

SCLK, SDATA, WDEN

12

9

9

8

10

28

29

126

127

CN101

IC101 (R2S35002))

IC301 (R8J32007)

BCNT

5

6

TCPH

32

134

175

R106

R105

C106

25,26,28

120,121,123

108

C105

DESCRIPTION OF CIRCUIT

1. ALPC (Automatic Laser Power Control) Circuit

1-1. Block Diagram

Page 44

48

1-2. ALPC (Automatic Laser Power Control) Circuit

ALPC function DVD/CD anlaog front-end IC(IC101 R2S35002) is for constant power control purpose. Based on the

accurate power sensor(FMON) in P/U, ALPC feedback loop maintains constant power level against laser diode’s

temperature variation.

The ALPC loop amplifies(10x) the FMON signal to enhance the accuracy of read power level control. Swithching of

amplification is made by combination of a logical WGATE signal and a logical RWAPC signal.

There are two set of APCDAC, which are used at different term to monitor different power level. Generally, the one is used

at reading and the other one is used at writing. The logical WGATE signal which is switched between reading and writing

changes the two APCDAC.

The ALPC loop supplies same currency (IAPC) to Laser Diode Driver(LDD) during reading and writing.

There is another ALPC which controls Full-Scale-DAC (FsDAC). FsDAC determines scale of WDAC of Laser Diode Driver.

MPU monitors write-power level of FMON signal and changes FsDAC directly to maintain constant write-power level. There

are two write power signal. The one is based on S/H signal and the other one is based on B/H(Bottom-Hold) signal. The

write power levels are monitored as digital levlels which are converted by built-in Anlog-Digital Converter in DSP. The MPU

monitors each write power level and calculates proper setting of FsDAC, and changes value through serial interface

between LDD and DSP.

Page 45

49

2.Focus Circuit

2-1. Block Diagram

Disc

Motor unit

Optical

Pick-up

HOP-7632TS

A,B,C,D

A,B,C,D

(EF1~EF4)

(A+C)-(B+D)

(A+C)-(B+D)+K[(EF1+EF3)-(EF2+EF4)]

HAVC

LS

to

V14

FE

FE

FE

R102

C405

R103

C406

GND

GND

ADC

Focusing

Compensator

DAC

FOD

FOD

R329

R2S30202FP

IC601

FACT+

FACT-

FACT+

FACT-

IC101

R2S35002

IC301

R8J32007

EN1

EN2

CTL1

CTL2

C335

REF

1.65V

FOIN

A+B+C+D

LPF G

HAVC

LS

to

0.8V

PE

PE

3

LPF G

2

169

170

180

40

42

20

21

34

35

2-2. Focus Servo

The aim of Focus Servo is to maintain the distance between object lens of P/U and disc surface, so that the

detected RF signal(A, B, C, D, EF1, EF2, EF3, EF4) can be maximized.

Focus Error Signal(FE) generates from focus error detection block in RF IC(R2S35002) using Conventional

Astigmatism Detection method, Differential Astigmatism Detection method.

Focus Gain and path can be changed at the RF IC(R2S35002) according to the disc, and the resulting output

FE(R2S35002 2pin) is input to DSP IC(R2S35002 169pin).

The Focus Search operation is using FE, PE Signal, therefore check FE, PE signals when Focusing is failed.

The role of DSP IC(R8J32007) is Focus Digital Controller. The operation path is as follows;

FE Signal is input to DSP IC(R8J32007 169pin), and after A/D Conversion, Digital Equalizer Block and D/A

Conversion in R8J32006FP, the output signal FOD(R8J32007 180pin) is input to Drive IC(R2S30202FP 40pin).

The drive output signal FACT+/FACT- generated according FOIN(R2S30202FP 40pin), and drives focus

actuator in the P/U unit.

Page 46

50

3. Tracking & Sled Circuit

3-1-1. Block Diagram (T racking Following)

Disc

Motor unit

Optical

Pick-up

HOP-7632TS

A,B,C,D

(EF1~EF4)

TE

TE

R101

C101

GND

TE

ADC

Tracking

Compensator

DAC

TRD

TACT+

TACT-

IC101

R2S35002

IC301

R8J32007

MPPO

(A+D)-(B+C)

G

HAVC

LS

to

V14

1

173

181

L

P

F

L

P

F

SPPO

(A+D)-(B+C)-K[(EF1+EF4)-(EF2+EF3)]

Sled

Compensator

DAC

SL2

183

SL1

182

A+

AB+

B-

SLED MOTOR

Unit

(CN601)

TRD

R330

IC601

R2S30202FP

TACT+

TACT-

EN1

EN2

CTL1

CTL2

REF

C604

1.65V

TOIN

39

42

20

21

36

37

SL2

2

SL13

SL1IN

SL2IN

A-

B-

8

10

A+

B+

6

9

SL2N

SL1N

SL2P

SL1P

C336

1.65V

C338

C337

R372

1.65V

R374

R373

R332

R331

Page 47

3-1-2. Block Diagram (Seek)

51

Disc

Motor unit

Optical

Pick-up

HOP-7632TS

SUMF

RFIP

RFIN

(EF1~EF4)

A,B,C,D

TACT+

TACT-

IC101

R2S35002

MPPO

(A+D)-(B+C)

G

HAVC

LS

to

V14

1

L

P

F

L

P

F

SPPO

[(EF1+EF4)-(EF2+EF3)]

A+

A-

B+

B-

SLED MOTOR

Unit

A+B+C+D

G

HAVC

LS

to

V14

L

P

F

L

P

F

38

79

80

81

EQ

MIRR

DET

AGC

TOP

HOLD

63 62

BOTTOM

HOLD

-

+

-

+

TE1

MIRRTOPH MIRRBOTH

C128

GND

MIRR

VREF1

VREF1

SL2

D

A

C

Tracking

Compensator

IC301

R8J32007

173

Sled

Compensator

A

D

C

149

M

U

X

Short

Seek

Algorithm

Loog

Seek

Algorithm

D

A

C

182

181

183

TRD

SL1

Track Counter

and Timer

R101

C101

GND

MIRR

TE1

TE

IP2MIRR

C127

GND

Page 48

52

3-2-1. Tracking Servo

The aim of tracking servo is to make laser beam trace the data track on disc.

Tracking Error(TE) Signal is generated from tracking error detected block in R2S35002 using DPP(Differential

Push-Pull) Method and DPD (Differential Phase Detection) Method.

DPP Method uses not only main beam(A, B, C, D) but also side beam(EF1~EF4) for correcting DC offset

generated in Push-Pull Method.

The remaining procedure of TE signal processing in R8J32007 is similar to Focus Servo.

The role of DSP IC(R8J32007) is Tracking Digital Controller.

TE Signal is input to DSP IC(R8J32007 173pin), and after A/D Conversion, Digital Equalizer Block and D/A