Page 1

DVD /CD Rewri table D rive

S E RVICE MANUAL

MODEL: G WA - 4 1 6 4 B /

G WA - 4 1 6 6 B /

G S A - 4 1 6 6 B

P/NO : 3828HS1049D

J u l y, 2005

Printed in Korea

MODEL : GWA-4164B/GWA-4166B/GSA-4166B

Page 2

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................................................3

FEATURES................................................................................................................................................................................4

SPECIFICATIONS...............................................................................................................................................................5~14

LOCATION OF CUSTOMER CONTROLS .......................................................................................................................15~16

DISASSEMBLY.................................................................................................................................................................17~18

1. CABINET and CIRCUIT BOARD DISASSEMBLY..........................................................................................................17

2. MECHANISM ASSY DISASSEMBLY..............................................................................................................................17

EXPLODED VIEW.............................................................................................................................................................19~20

MECHANICAL REPLACEMENT PARTS LIST ................................................................................................................21~23

GLOSSARY.............................................................................................................................................................................24

THE DIFFERENCES OF CD-R/CD-RW DISCS AND GENERAL CD-ROM.....................................................................25~29

1. Recording Layer..............................................................................................................................................................25

2. Disc Specification............................................................................................................................................................25

3. Disc Materials..................................................................................................................................................................26

4. Reading Process of Optical Disc.....................................................................................................................................27

5. Writing Process of CD-R Disc .........................................................................................................................................28

6. Writing Process of CD-RW Disc......................................................................................................................................28

7. Organization of the PCA, PMA and Lead-in Area ...........................................................................................................29

8. Function of PCA and PMA area ......................................................................................................................................30

9. OPC and ROPC ..............................................................................................................................................................30

10. Writing Process of DISC................................................................................................................................................31

THE DIFFERENCES OF DVD-R/RW, DVD+R/RW DISCS AND DVD-ROM....................................................................32~40

1. Recording Layer..............................................................................................................................................................32

2. Disc Specification............................................................................................................................................................33

3. Disc Materials..................................................................................................................................................................33

4. Writing Pulse Waveform of DVD+R.................................................................................................................................36

5. Writing Pulse Waveform DVD+RW.................................................................................................................................38

6. Organization of Inner Drive Area, Outer Drive Area, Lead-in Zone and Lead-out Zone .................................................39

LightScribe MEDIA...........................................................................................................................................................41~44

1. LightScribe Media............................................................................................................................................................41

2. Hardware Block Diagram of LightScribe Label Printing...................................................................................................42

3. MD Assy For LightScribe.................................................................................................................................................43

4. Optical Encoder Assy......................................................................................................................................................44

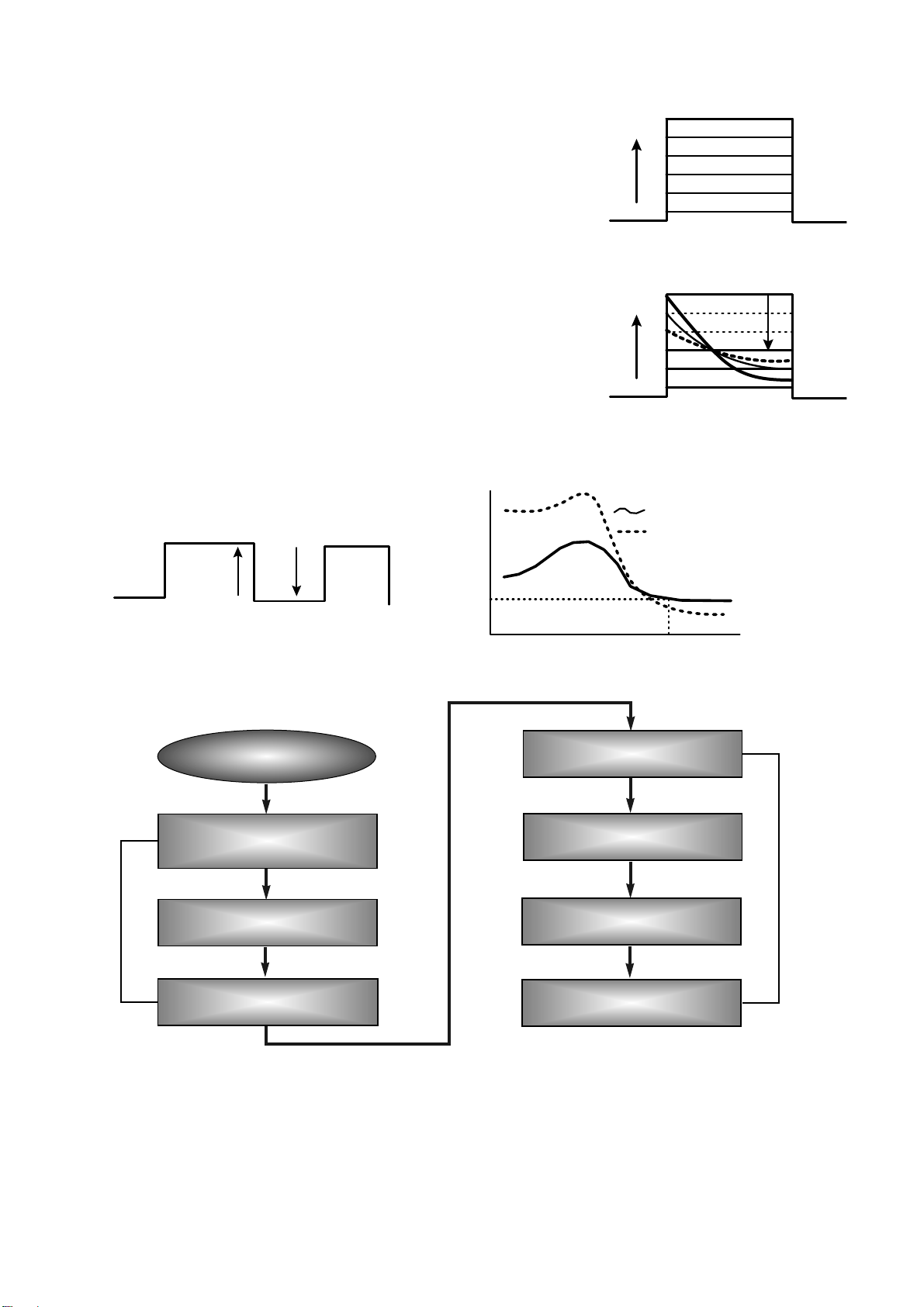

DVD & CD DATA PROCESSING......................................................................................................................................45~48

1. Data Processing Flow......................................................................................................................................................45

2. Copy Protection and Regional Code Management Block ...............................................................................................46

3. About Prevention the DVD-ROm from to be copy...........................................................................................................47

4. About the DVD-ROM Regional Code..............................................................................................................................48

INTERNAL STRUCTURE OF THE PICK-UP....................................................................................................................49~51

1. Block Diagram of the Pick-up..........................................................................................................................................49

2. Pick up Pin Assignment...................................................................................................................................................50

3. Signal detection of the P/U..............................................................................................................................................51

DESCRIPTION OF CIRCUIT.............................................................................................................................................52~56

1. ALPC Circuit....................................................................................................................................................................52

2. Focus/Tracking/Sled Servo Circuit..................................................................................................................................53

3. Spindle Circuit .................................................................................................................................................................55

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION.............................................................................57~74

TROUBLESHOOTING GUIDE..........................................................................................................................................75~91

BLOCK DIAGRAM............................................................................................................................................................92~94

CIRCUIT DIAGRAM..........................................................................................................................................................95~97

PRINTED CIRCUIT BOARD DIAGRAM.........................................................................................................................98~101

ELECTRICAL REPLACEMENT PARTS LIST......................................................................................................................102

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM.

Page 3

3

INTRODUCTION

GSA-4164B series Design Specfications

This service manual provides a variety of service

information.

I

t contains the mechanical structure of the DVD/CD

Rewritable Drive and the electronic circuits in

schematic form. This DVD/CD Rewritable Drive was

manufactured and assembled under our strict quality

control standards and meets or exceeds industry

specifications and standards.

This DVD/CD Rewritable drive is an internal drive

unit designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 700

Mbytes of digital data into CD-R/RW disc, and can

read as much as 700 Mbytes of digital data stored

in a CD-ROM, CD-R and CD-RW disc.

It can write as much as 4.7Gbytes of digital data

into DVD+R/RW disc, and can read as much as

4.7Gbytes of digital data stored in a DVD-ROM,

DVD-R, DVD-RW, DVD+R and DVD+RW disc.

This DVD/CD Rewritable Drive can easily meet

the upcoming MPC level 3 specification, and its

Enhanced Intelligent Device Electronics (E-IDE)

and ATAPI interface allows Plug and play

integration in the majority of today’s PCs without

the need of an additional interface card.

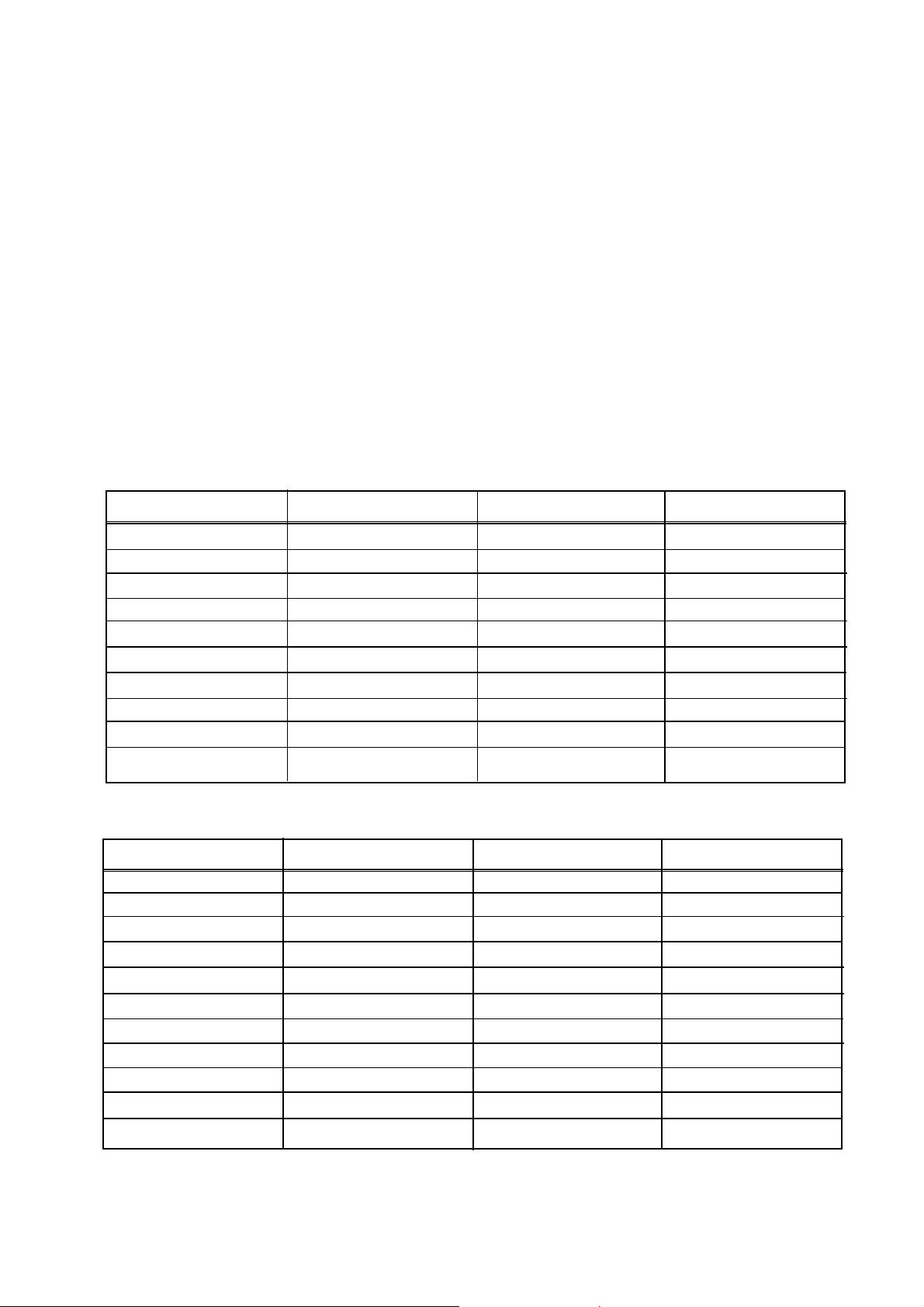

Light Scribe

CD-R

CD-RW

DVD-R

DVD-RW

DVD-R DL

DVD+R

DVD+RW

DVD+R DL

DVD-RAM

GWA-4164B

X

40x w

32x w

16x w

6x w

4x w

16x w

8x w

6x w

X

GWA-4166B

O

40x w

32x w

16x w

6x w

4x w

16x w

8x w

6x w

X

GSA-4166B

O

48x w

32x w

16x w

8x w

4x w

16x w

8x w

6x w

5x w

CD-ROM

CD-R

CD-RW

DVD-ROM

DVD-R

DVD-RW

DVD-R DL

DVD+R

DVD+RW

DVD+R DL

DVD-RAM

GWA-4164B

40x

40x

32x

16x

10x

8x

8x

10x

8x

8x

X

GWA-4166B

40x

40x

32x

16x

10x

8x

8x

10x

8x

8x

X

GSA-4166B

48x

48x

32x

16x

16x

8x

8x

16x

8x

8x

5x

• Write

• Read

Page 4

4

FEATURES

1 General

1) Enhanced IDE (ATAPI) interface.

2) Internal Half-height Drive.

3) CD-R/RW, DVD-R/RW/+R/+R DL(Double Layer)/+RW read and write compatible CD Family and DVDROM read compatible.

4) Buffer Under-run prevention function embedded.

5) 2MB buffer memory.

6) Power loading and power eject of a disc. Bare media loading.

7) MTBF : 100,000 POH

8) Vertical and Horizontal installable.

9) Support LightScribe Direct Label Printing Technology

2. Supported disc formats

1) Reads data in each CD-ROM, CD-ROM XA, CD-I, Video CD, CD-Extra and CD-Text.

2) Reads data in Photo CD (Single and Multi session).

3) Reads standard CD-DA.

4) Reads and writes CD-R discs conforming to “Orange Book Part 2”.

5) Reads and writes CD-RW discs conforming to “Orange Book Parts 3”.

6) Reads data in each DVD-ROM, DVD-R(Ver.1.0, Ver.2.0 for Authoring).

7) Reads and writes in each DVD-R(Ver.2.0 for General), DVD-RW, DVD+R, DVD+R DL, DVD-R DL and

DVD+RW.

8) LightScribe DVD+R conforming to “LightScribe Media Specification”

9) LightScrive CD-R conforming to “LightScribe Media Specification”

3. Supported write method

1) CD-R/RW : Disc at once, Session at Once, Track at once and Packet Write.

2) DVD-R : Disc at Once and Incremental Recording.

3) DVD-RW : Disc at Once, Incremental Recording and Restricted Overwrite.

4) DVD+R : Sequential Recording

5) DVD+R DL(Double Layer)/DVD-R DL(Dual Layer) : Sequential Recording

6) DVD+RW : Random Write

7) LightScribe Label Printing Functions complying with “LightScribe System Specification”

4. Audio

1) 16 bit digital data output through ATA interface.

2) Software Volume Control

3) Equipped with audio line output for audio CD playback.

Page 5

5

SPECIFICATIONS

I. MODEL : GWA-4164B

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium4 1.6GHz (or faster)

(For High speed, 2GHz or faster recommended.)

-128MB Memory or greater

• SUPPORTING OPERATING SYSTEM

2. GENERAL DESCRIPTION

2.1 Applicable disc formats

DVD DVD-ROM: 4.7GB (Single Layer)

8.5GB (Dual Layer)

DVD-R: 3.95GB (Ver.1.0 : read only)

4.7GB (Ver.2.0 for Authoring : read only)

4.7GB (Ver.2.0 for General: read & write)

DVD-RW: 4.7GB (Ver.1.1)

DVD+R: 4.7GB

DVD+R DL: 8.5GB

DVD+RW: 4.7GB

CD CD-ROM Mode-1 data disc

CD-ROM Mode-2 data disc

CD-ROM XA, CD-I, Photo-CD Multi-Session, Video CD

CD-Audio Disc

Mixed mode CD-ROM disc (data and audio)

CD-Extra

CD-Text

CD-R (Conforming to “Orange Book Part2”: read & write)

CD-RW (Conforming to “Orange Book Part3”: read & write)

2.2 Disc diameter..............................................120mm

80mm (Horizontal only)

2.3 Data capacity

• User Data/Block DVD-ROM/R/RW/+R/+RW ...............2,048 bytes/block

CD (Yellow Book)..........................................2,048 bytes/block(Mode 1 & Mode 2 Form 1)

2,336 bytes/block (Mode 2)

2,328 bytes/block (Mode 2 Form 2)

2,352 bytes/block (CD-DA)

2.4 RPC (Regional Playback Control) Phase2, No Region

* Operating System

Window 98 Second Edition (Not supported in

LightScribe)

Windows Millennium Edition(Me) (Not supported in

LightScribe)

Window 2000 Professional

Window XP Home Edition, Professional

* Recording tool

(1) RecordNow (Sonic)

(2) DLA (sonic)

(3) Nero(Ahead)

(4) In CD(Ahead)

(5) Easy CD Creator (Roxio)

(6) Direct CD (Roxio)

Page 6

6

3. DRIVE PERFORMANCE

3.1 Host interface ........................................................X3T13 ATA/ATAPI5/1321D

INF-8090i Rev.5.3

3.2 Read/Write & Rotational speed

<Read> CD-R/ROM, data/CD-I.........................17x ~ 40x (CAV), Approx. 8,100r/min

CD-RW ................................................15x ~ 32x (CAV), Approx. 6,500 r/min

CD-DA (DAE).......................................17x ~ 40x (CAV), Approx. 8,100 r/min

CD-DA (Audio out)/VideoCD ............... 6x ~ 15x (CAV), Approx. 3,130 r/min

DVD-ROM ............Single layer...........6.7x ~ 16x (CAV), Approx. 9,420 r/min

Dual layer..............3.3x ~ 8x (CAV), Approx. 5,180 r/min

DVD-Video(CSS).................................3.3x-8x(CAV)

DVD-R...................3.95GB..................4.2x ~ 10x (CAV), Approx. 5,950 r/min

4.7GB ...................4.2x ~ 10x (CAV), Approx. 5,950 r/min

DVD-RW................4.7GB....................3.3x ~ 8x (CAV), Approx. 4,720 r/min

DVD+R..................4.7GB....................4.2x ~ 10x (CAV), Approx. 5,950 r/min

DVD+R DL.............8.5GB....................3.3x ~ 8x (CAV), Approx. 4,720r/min

DVD+RW...............4.7GB....................3.3x ~ 8x (CAV), Approx. 4,720 r/min

<Write> CD-R....................................................10x, 16x (CLV), 24x, 40x (CAV)

CD-RW ................................................4x (CLV), High speed Disc, 10x (CLV)

Ultra speed Disc 16x(CLV), 24x(ZCLV), 32x(ZCLV)

DVD-R .................................................2x, 4x (CLV), 8x (ZCLV)

DVD-RW..............................................2x, 4x (CLV)

DVD+R DL...........................................2.4x (CLV)

DVD+R ................................................2.4x, 4x (CLV), 8x (ZCLV)

DVD+RW.............................................2.4x, 4x (CLV)

DVD-R DL............................................4x(CLV)

* Rotational speed (CLV, ZCLV)

CD-ROM/R/RW ...................................1x: Approx. 500 (Inside) to 210 r/min (Outside)

DVD-R/RW/ROM/+R/RW....................1x: Approx. 1,390(Inside) ~ 580 r/min(Outside)

* LightScribe Label Printing

Pixel Resolution...................................600DPI

Track Resolution .................................500~1600TPI

Linear Velocity.....................................0.25~0.75m/sec

Laser Power.........................................30~60mW as Objective emission light

of 780nm wavelength

Color....................................................Monochrome

Page 7

3.3 Data transfer rate

3.3.1 Sustained transfer rate

<Read> CD-ROM/R.....................................................2,550 ~ 6,000 kbytes/s (40x) Max.

CD-RW...........................................................2,250 ~ 4,800 kbytes/s (32x) Max.

CD-DA(DAE)..................................................2,550 ~ 6,000 kbytes/s (40x) Max.

DVD-ROM ............Single layer......................9.28 ~ 22.16 Mbytes/s (16x) Max.

Dual layer........................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD-R............................................................5.73 ~ 13.85 Mbytes/s (10x) Max.

DVD-RW ........................................................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD+R...........................................................5.73 ~ 13.85 Mbytes/s (10x) Max.

DVD+R DL.....................................................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD+RW .......................................................4.58 ~ 11.08 Mbytes/s (8x) Max.

<Write> CD-R .....................10x,16x (CLV) .................1.5, 2.4 Mbytes/s (Mode-1)

24x (ZCLV)......................1.8 ~ 3.6 Mbytes/s (Mode-1)

40x(CAV).........................2.4 ~ 6.0 Mbytes/s(Mode-1)

CD-RW..................4x, 10x (CLV) ..................0.6, 1.5 Mbytes/s (Mode-1)

16x (ZCLV)......................1.8 ~ 2.4 Mbytes/s (Mode-1)

24x (ZCLV)......................1.8 ~ 3.6 Mbytes/s (Mode-1)

32x(ZCLV).......................1.8 ~ 4.8 Mbytes/s (Mode-1)

DVD-R...................2x, 4x(CLV), 8x(ZCLV)....2.77, 5.44, 5.44~11.08 Mbytes/s

DVD-RW................1x, 2x, 4x(CLV)................1.38, 2.77, 5.44 Mbytes/s

DVD+R..................2.4x, 4x(CLV) ..................3.32, 5.54 Mbytes/s

8x(ZCLV).........................5.44~11.08 Mbytes/s

DVD-R DL .............4x (CLV) .........................5.44 Mbytes/s

DVD+R DL.....................................................2.4x (CLV) 5.54Mbytes/s

DVD+RW...............2.4x, 4x (CLV) .................3.32, 5.54 Mbytes/s

3.3.2 Burst transfer rate

Ultra DMA Mode 2..........................................33.3 Mbytes/s Max.

Multiword DMA Mode 2..................................16.6 Mbytes/s Max.

PIO Mode 4....................................................16.6 Mbytes/s Max.

3.4 Access time (Random)

* Typical value

DVD-ROM(SL)...............................................140 ms Typ.

(Note 1)

DVD-ROM(DL)...............................................175 ms Typ.

(Note 1)

CD-ROM ........................................................120 ms Typ.

(Note 1)

Note :

1) Average random access time is the typcal value of more than 50 times including latency and error correction time.

Test Disc : DVD : ALMEDIO TDV-520 / TDR-820

CD : ALMEDIO TCDR-701 / HITACH HCD-1

*) Typical value defines a measured value in normal temperature (20 deg.C.) and horizontal position.

3.5 Data error rate (Measured with 5 retries maximum)

DVD-R/RW/ROM...<10

-12

DVD+R/RW...........<10

-12

CD-ROM/R/RW.....<10

-12

(Mode-1)

<10-9(Mode-2)

Condition : It is assumed that the worst case raw error rate of the disc is 10

-3

3.6 Data buffer capacity .......................................................2Mbytes

7

Page 8

8

3.7 LightScribe Label Printing

* Note (1) DRF Parameters for this spec : LV=250mm/sec, TrackShift=85, Laser Power=34mW

3.7.1 Printing Time

1070TPI * 12cm Entire Disc.......................................less than 36 minutes

800TPI * 12cm Entire Disc.........................................less than 28 minutes

530TPI * 12cm Entire DIsc ........................................less than 20 minutes

3.7.2 Image Contrast complying to the colorimetry standard CIE L*a*b, defined as Delta L(

∆L)

1070TPI * LS CD-R Media (973423 : 795973)...........higher than 28

800TPI * LS CD-R Media (973423 : 795973).............higher than 20

530TPI * LS CD-R Media (973423:795973)...............higher than 12

4. Quality and Reliability

4.1 MTBF..................................................125,000 Power On Hours(Consecutive/Cumulative POH)

Assumption : ..........................Used in a normall office environment at room temperature.

-POH per year.........................3,000

-ON/OFF cycles per year........600

-Operating duty cycle..............20% of power on time (Seek: 5% of operating time)

4.2 Tray cycle test...................................30,000 times

No degeneration in the mechanical part after test

4.3 Actuator mechanism........................1,000,000 full stroke seek

4.4 MTTR (Mean Time To Repair) ...........0.5 h

4.5 Component life .................................5 years or 2,000 h of Laser radiating time

Assumption : ..........................Used in a normall office environment.

5. POWER REQUIREMENTS

5.1 Source voltage

+5V +5% tolerance, less than 100 mVp-p Ripple voltage

+12V +10% tolerance, less than 100 mVp-p Ripple voltage

5.2 Current

Idle (Hold track state)..............+5V DC 0.6A Typ. < 1.0 A Max.

+12V DC 0.5A Typ. < 1.0 A Max.

Write (Active)..........................+5V DC 0.9A Typ. < 1.3 A Max.

+12V DC 0.5A Typ. < 1.2 A Max.

Read (Active)..........................+5V DC 0.6A Typ. < 1.2 A Max.

+12V DC 0.6A Typ. < 1.2 A Max.

Seek (Acess) ..........................+5V DC 0.7A Typ. < 1.2 A Max.

+12V DC 1.0A Typ. < 1.8 A Max.

Label Printing +5V DC 0.7A typ. < 1.0 A max.

+12V DC 0.3A typ. < 0.5 A max.

5.3 Standby

Sleep mode (No disc).............2.5 W Typ. 3.0 W Max.

6. AUDIO PERFORMANCE

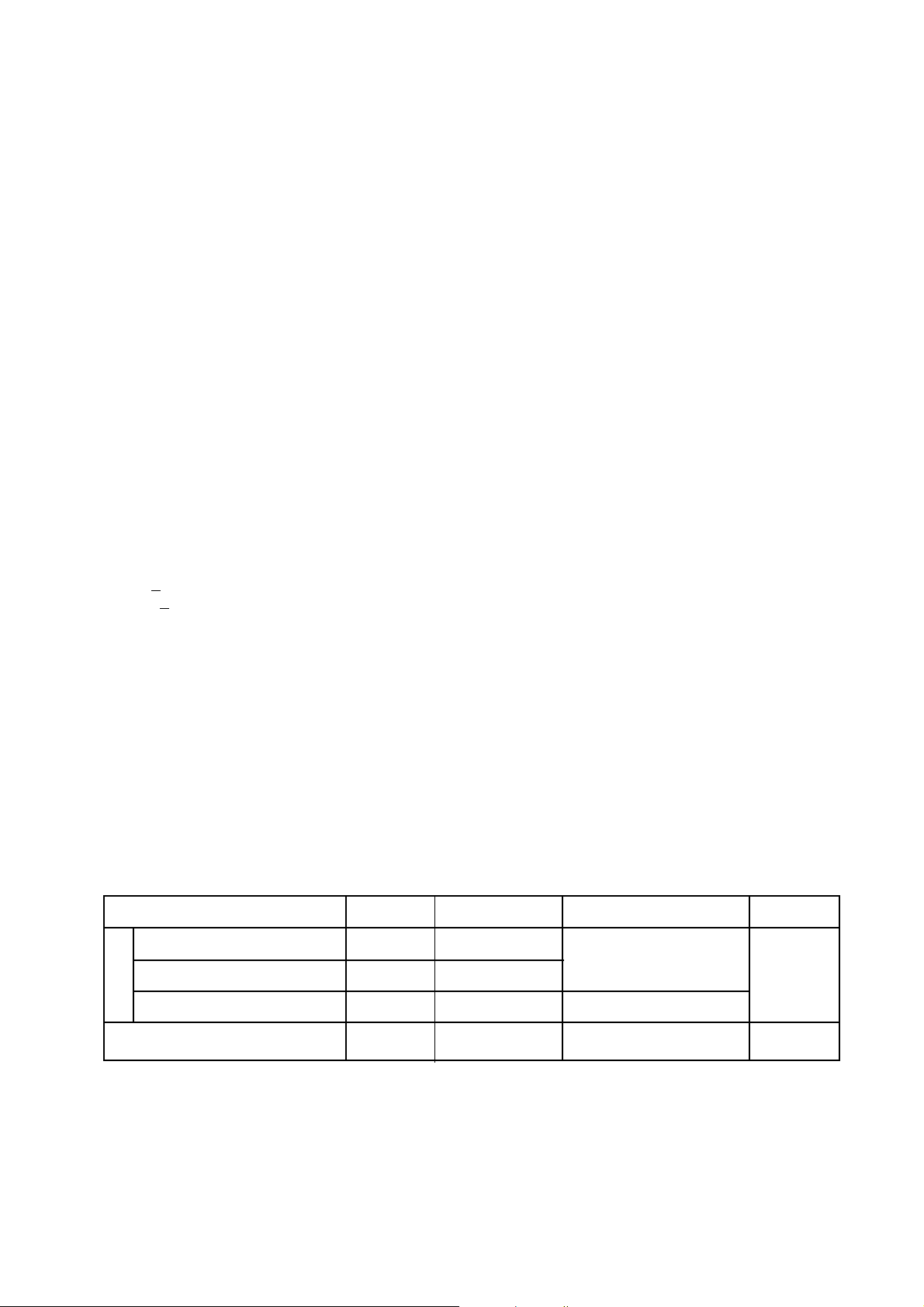

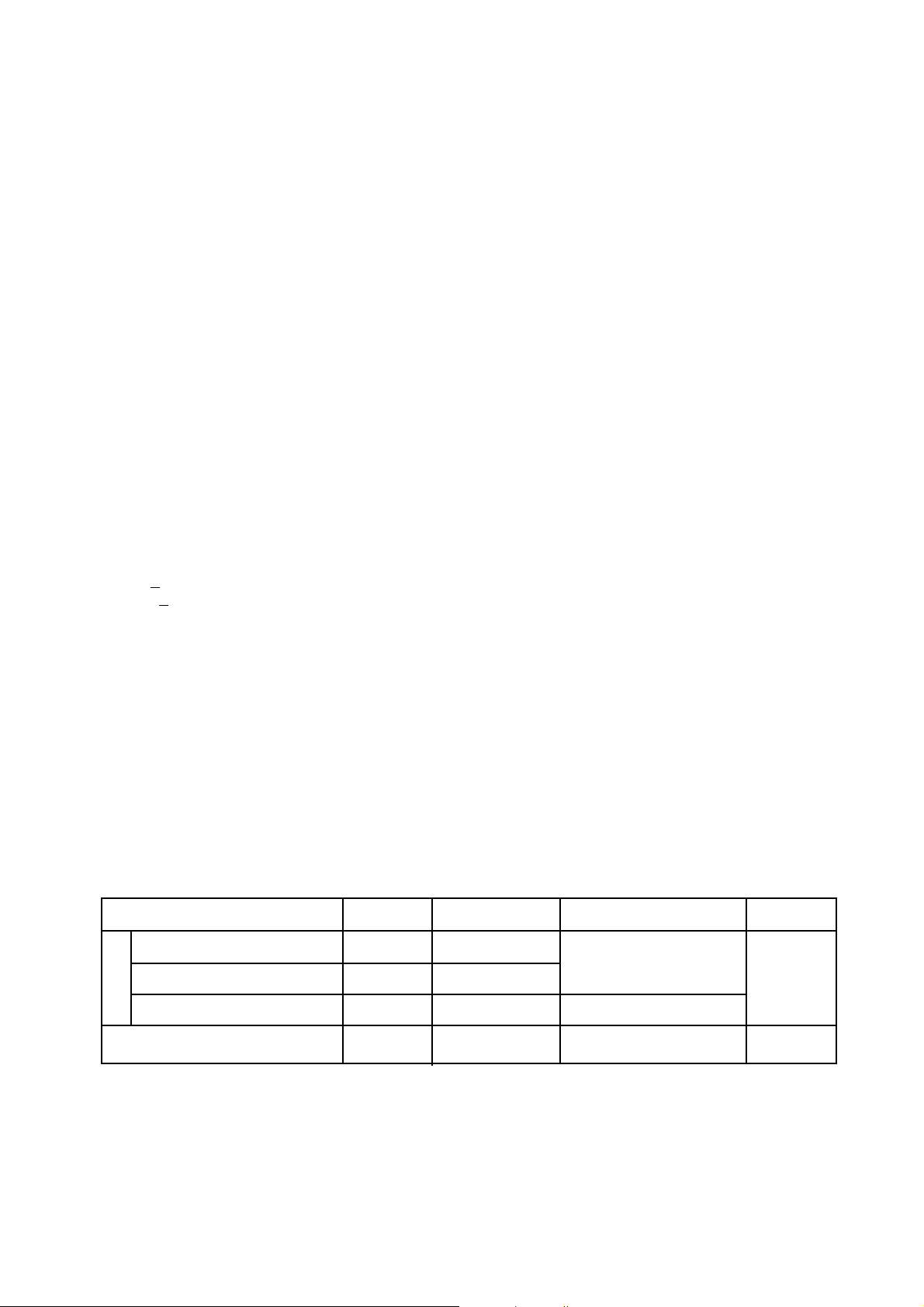

Item Typical Test Signal Test Condition Note

Output Level 0.7 Vrms 1KHz 0 dB No Filter

Frequency response +/-3dB 20-20kHz 0dB at 47kΩ

THD 0.1% 1KHz 0 dB with IHF-A + 20KHz LPF

Headphone output level(Optional) - - - None

AUDIO OUT

Page 9

7. Acoustic noise

Less than 50dB, A scale, at 0.5 m away from the drive

Note : 1. Disc : Less than unbalance 0.3 x10-4Nm

2. Installation : Horizontal

3. Ambient temperature : Normal temperature

4. Except loading, unloading and seek

8. Dimensions

External dimensions (W x H xD) 146x41.3x184.7mm

Front bezel (WxHxD) 148x42x5 mm

9. Mass .................................................880g+/-10g(net)

* Please Contact the friendly staff of LG Service Care at: Website http: //www.LGEservice.com

9

Page 10

10

SPECIFICATIONS

II. MODEL : GWA-4166B

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium4 1.6GHz (or faster)

(For High speed, 2GHz or faster recommended.)

-128MB Memory or greater

• SUPPORTING OPERATING SYSTEM

2. GENERAL DESCRIPTION

2.1 Applicable disc formats

DVD DVD-ROM: 4.7GB (Single Layer)

8.5GB (Dual Layer)

DVD-R: 3.95GB (Ver.1.0 : read only)

4.7GB (Ver.2.0 for Authoring : read only)

4.7GB (Ver.2.0 for General: read & write)

DVD-RW: 4.7GB (Ver.1.1)

DVD+R: 4.7GB

DVD+R DL: 8.5GB

DVD+RW: 4.7GB

CD CD-ROM Mode-1 data disc

CD-ROM Mode-2 data disc

CD-ROM XA, CD-I, Photo-CD Multi-Session, Video CD

CD-Audio Disc

Mixed mode CD-ROM disc (data and audio)

CD-Extra

CD-Text

CD-R (Conforming to “Orange Book Part2”: read & write)

CD-RW (Conforming to “Orange Book Part3”: read & write)

2.2 Disc diameter 120mm

80mm (Horizontal only)

2.3 Data capacity

• User Data/Block DVD-ROM/R/RW/+R/+RW ...............2,048 bytes/block

CD (Yellow Book)..........................................2,048 bytes/block(Mode 1 & Mode 2 Form 1)

2,336 bytes/block (Mode 2)

2,328 bytes/block (Mode 2 Form 2)

2,352 bytes/block (CD-DA)

2.4 RPC (Regional Playback Control) Phase2, No Region

* Operating System

Window 98 Second Edition (Not supported in

LightScribe)

Windows Millennium Edition(Me) (Not supported in

LightScribe)

Window 2000 Professional

Window XP Home Edition, Professional

* Recording tool

(1) RecordNow (Sonic)

(2) DLA (sonic)

(3) Nero(Ahead)

(4) In CD(Ahead)

(5) Easy CD Creator (Roxio)

(6) Direct CD (Roxio)

Page 11

11

3. DRIVE PERFORMANCE

3.1 Host interface...........................................................X3T13 ATA/ATAPI5/1321D

INF-8090i Rev.5.3

3.2 Read/Write & Rotational speed

<Read> CD-R/ROM, data/CD-I............................17x ~ 40x (CAV), Approx. 8,100r/min

CD-RW...................................................15x ~ 32x (CAV), Approx. 6,500 r/min

CD-DA (DAE).........................................17x ~ 40x (CAV), Approx. 8,100 r/min

CD-DA (Audio out)/VideoCD.................. 6x ~ 15x (CAV), Approx. 3,130 r/min

DVD-ROM .............Single layer .............6.7x ~ 16x (CAV), Approx. 9,420 r/min

Dual layer................3.3x ~ 8x (CAV), Approx. 5,180 r/min

DVD-Video(CSS)....................................3.3x ~ 8x (CAV)

DVD-R ...................3.95GB....................4.2x ~ 10x (CAV), Approx. 5,950 r/min

4.7GB......................4.2x ~ 10x (CAV), Approx. 5,950 r/min

DVD-RW................4.7GB......................3.3x ~ 8x (CAV), Approx. 4,720 r/min

DVD+R...................4.7GB......................4.2x ~ 10x (CAV), Approx. 5,950 r/min

DVD+R DL.............8.5GB......................3.3x ~ 8x (CAV), Approx. 4,720r/min

DVD+RW...............4.7GB......................3.3x ~ 8x (CAV), Approx. 4,720 r/min

<Write> CD-R ......................................................10x, 16x (CLV), 24x, 40x (CAV)

CD-RW...................................................4x (CLV), High speed Disc, 10x (CLV)

Ultra speed Disc 16x(CLV), 24x(ZCLV), 32x(ZCLV)

DVD-R....................................................2x, 4x (CLV), 8x (ZCLV), 12x, 16x(CAV)

DVD-RW.................................................1x, 2x, 4x (CLV), 6x (ZCLV)

DVD+R DL..............................................2.4x (CLV), 6x, 8x

DVD+R...................................................2.4x, 4x (CLV), 8x (ZCLV), 12x, 16x (CAV)

DVD+RW................................................2.4x, 4x, 8x (CLV)

DVD-R DL ..............................................4x(CLV)

* Rotational speed (CLV, ZCLV)

CD-ROM/R/RW......................................1x: Approx. 500 (Inside) to 210 r/min (Outside)

DVD-R/RW/ROM/+R/RW.......................1x: Approx. 1,390(Inside) ~ 580 r/min(Outside)

* LightScribe Label Printing

Pixel Resolution......................................600DPI

Track Resolution ....................................500~1600TPI

Linear Velocity........................................0.25~0.75m/sec

Laser Power...........................................30~60mW as Objective emission light

of 780nm wavelength

Color ......................................................Monochrome

3.3 Data transfer rate

3.3.1 Sustained transfer rate

<Read> CD-ROM/R.............................................2,550 ~ 6,000 kbytes/s (40x) Max.

CD-RW...................................................2,250 ~ 4,800 kbytes/s (32x) Max.

CD-DA(DAE)..........................................2,550 ~ 6,000 kbytes/s (40x) Max.

DVD-ROM .............Single layer .............9.28 ~ 22.16 Mbytes/s (16x) Max.

Dual layer................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD-R....................................................5.73 ~ 13.85 Mbytes/s (10x) Max.

DVD-RW.................................................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD+R...................................................5.73 ~ 13.85 Mbytes/s (10x) Max.

DVD+R DL..............................................4.58 ~ 11.08 Mbytes/s (8x) Max.

DVD+RW................................................4.58 ~ 11.08 Mbytes/s (8x) Max.

Page 12

<Write> CD-R .....................10x,16x (CLV) .................1.5, 2.4 Mbytes/s (Mode-1)

24x (ZCLV)......................1.8 ~ 3.6 Mbytes/s (Mode-1)

40x(CAV).........................2.4 ~ 6.0 Mbytes/s(Mode-1)

CD-RW..................4x, 10x (CLV) ..................0.6, 1.5 Mbytes/s (Mode-1)

16x (ZCLV)......................1.8 ~ 2.4 Mbytes/s (Mode-1)

24x (ZCLV)......................1.8 ~ 3.6 Mbytes/s (Mode-1)

32x (ZCLV)......................1.8 ~ 4.8 Mbytes/s (Mode-1)

DVD-R...................2x, 4x(CLV), 8x(ZCLV)....2.77, 5.44, 5.44~11.08 Mbytes/s

12x, 16x (CAV)................8.91~16.62 Mbytes/s

8.91~22.16 Mbytes/s

DVD-R dual...........4x(CLV)...........................5.44 Mbytes/s

DVD-RW................1x, 2x, 4x(CLV)................1.38, 2.77, 5.44 Mbytes/s

DVD+R..................2.4x, 4x(CLV) ..................3.32, 5.54 Mbytes/s

8x(ZCLV).........................5.44~11.08 Mbytes/s

12x, 16x (CAV)................8.91~16.62Mbytes/s

8.91~22.16Mbytes/s

DVD+R DL ............2.4x (CLV) ......................5.54 Mbytes/s

6x ....................................8.28 Mbytes/s

8x ....................................5.44~11.08 Mbytes/s

DVD+RW...............2.4x, 4x (CLV) .................3.32, 5.54 Mbytes/s

3.3.2 Burst transfer rate

Ultra DMA Mode 2..........................................33.3 Mbytes/s Max.

Multiword DMA Mode 2..................................16.6 Mbytes/s Max.

PIO Mode 4....................................................16.6 Mbytes/s Max.

3.4 Access time (Random)

* Typical value

DVD-ROM(SL)...............................................140 ms Typ.

(Note 1)

DVD-ROM(DL)...............................................175 ms Typ.

(Note 1)

CD-ROM ........................................................120 ms Typ.

(Note 1)

Note :

1) Average random access time is the typcal value of more than 50 times including latency and error correction time.

Test Disc : DVD : ALMEDIO TDV-520 / TDR-820

CD : ALMEDIO TCDR-701 / HITACH HCD-1

*) Typical value defines a measured value in normal temperature (20 deg.C.) and horizontal position.

3.5 Data error rate (Measured with 5 retries maximum)

DVD-R/RW/ROM...<10

-12

DVD+R/RW...........<10

-12

CD-ROM/R/RW.....<10

-12

(Mode-1)

<10-9(Mode-2)

Condition : It is assumed that the worst case raw error rate of the disc is 10

-3

3.6 Data buffer capacity .......................................................2Mbytes

12

Page 13

13

3.7 LightScribe Label Printing

* Note (1) DRF Parameters for this spec : LV=250mm/sec, TrackShift=85, Laser Power=34mW

3.7.1 Printing Time

1070TPI * 12cm Entire Disc.......................................less than 36 minutes

800TPI * 12cm Entire Disc.........................................less than 28 minutes

530TPI * 12cm Entire DIsc ........................................less than 20 minutes

3.7.2 Image Contrast complying to the colorimetry standard CIE L*a*b, defined as Delta L( ∆L)

1070TPI * LS CD-R Media (973423 : 795973)...........higher than 28

800TPI * LS CD-R Media (973423 : 795973).............higher than 20

530TPI * LS CD-R Media (973423:795973)...............higher than 12

4. Quality and Reliability

4.1 MTBF..................................................125,000 Power On Hours(Consecutive/Cumulative POH)

Assumption : ..........................Used in a normall office environment at room temperature.

-POH per year.........................3,000

-ON/OFF cycles per year........600

-Operating duty cycle..............20% of power on time (Seek: 5% of operating time)

4.2 Tray cycle test...................................30,000 times

No degeneration in the mechanical part after test

4.3 Actuator mechanism........................1,000,000 full stroke seek

4.4 MTTR (Mean Time To Repair) ...........0.5 h

4.5 Component life .................................5 years or 2,000 h of Laser radiating time

Assumption : ..........................Used in a normall office environment.

5. POWER REQUIREMENTS

5.1 Source voltage

+5V +5% tolerance, less than 100 mVp-p Ripple voltage

+12V +10% tolerance, less than 100 mVp-p Ripple voltage

5.2 Current

Idle (Hold track state)..............+5V DC 0.6A Typ. < 1.0 A Max.

+12V DC 0.5A Typ. < 1.0 A Max.

Write (Active)..........................+5V DC 0.9A Typ. < 1.3 A Max.

+12V DC 0.5A Typ. < 1.2 A Max.

Read (Active)..........................+5V DC 0.6A Typ. < 1.2 A Max.

+12V DC 0.6A Typ. < 1.2 A Max.

Seek (Acess) ..........................+5V DC 0.7A Typ. < 1.2 A Max.

+12V DC 1.0A Typ. < 1.8 A Max.

Label Printing..........................+5V DC 0.7A typ. < 1.0 A max.

+12V DC 0.3 A typ. < 0.5 A max.

5.3 Standby

Sleep mode (No disc).............2.5 W Typ. 3.0 W Max.

6. AUDIO PERFORMANCE

Item Typical Test Signal Test Condition Note

Output Level 0.7 Vrms 1KHz 0 dB No Filter

Frequency response +/-3dB 20-20kHz 0dB at 47kΩ

THD 0.1% 1KHz 0 dB with IHF-A + 20KHz LPF

Headphone output level(Optional) - - - None

AUDIO OUT

Page 14

14

7. Acoustic noise

Less than 50dB, A scale, at 0.5 m away from the drive

Note : 1. Disc : Less than unbalance 0.3 x10-4Nm

2. Installation : Horizontal

3. Ambient temperature : Normal temperature

4. Except loading, unloading and seek

8. Dimensions

External dimensions (W x H xD) 146x41.3x184.7mm

Front bezel (WxHxD) 148x42x5 mm

9. Mass .................................................880g+/-10g(net)

* Please Contact the friendly staff of LG Service Care at: Website http: //www.LGEservice.com

Page 15

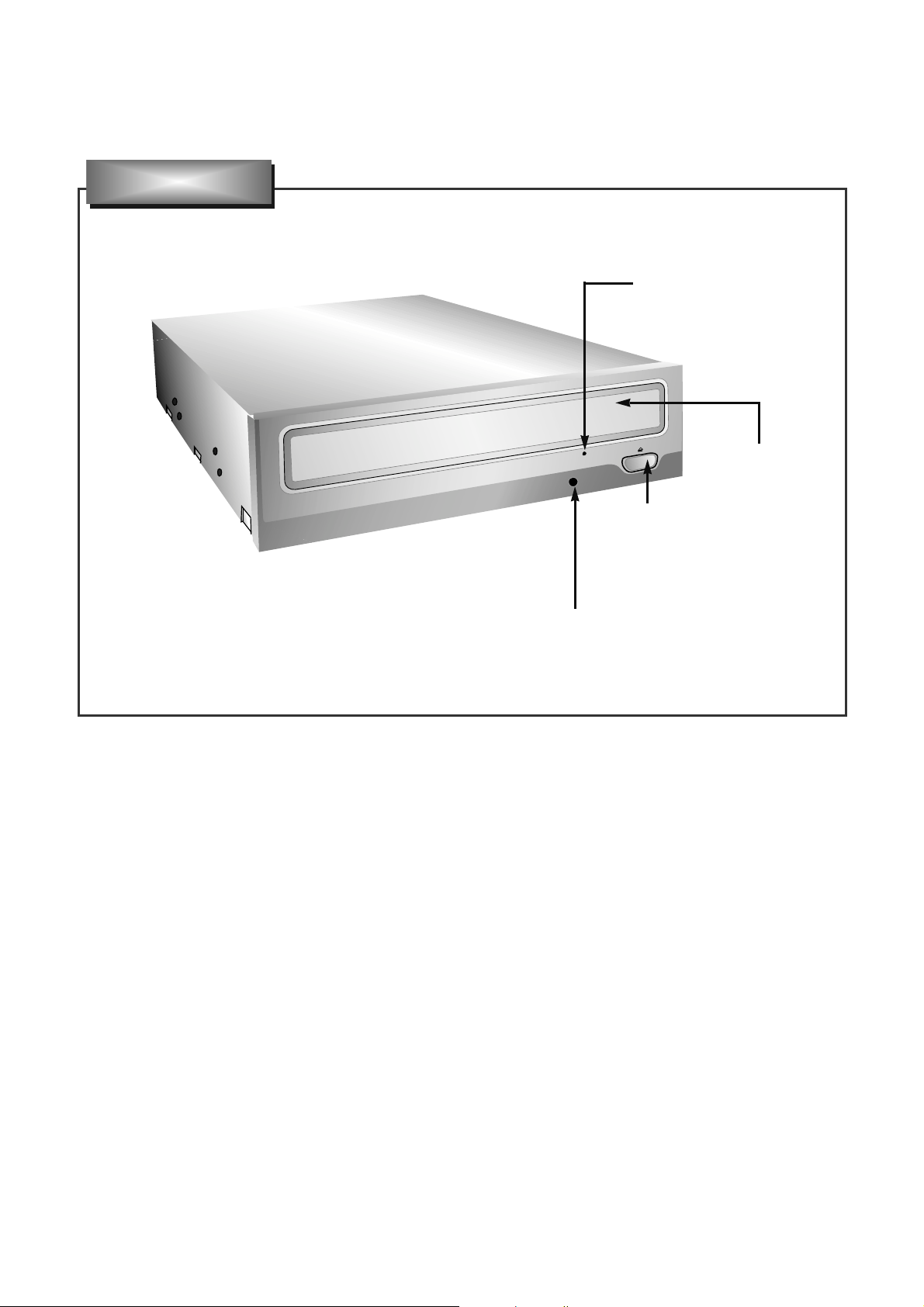

Drive Activity Indicators

Stop/Eject Button

Disc Tray

Emergency Eject Hole

LOCA TION OF CUSTOMER CONTROLS

15

1. Disc tray

This is the tray for the disc. Place the disc on the

ejected disc tray, then lightly push the tray (or

push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray

forcibly. This might cause damage to the loading

section of the drive.

2. Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to

the drive.

3. Emergency Eject Hole

Insert a paper clip here to eject the Disc tray

manually or when there is no power.

4. Drive activity indicator

Green colored LED is used to indicate the

operation of the Drive.

Front Panel

Page 16

16

1. Power Connector

Connects to the power supply (5-and 12-V DC) of

the host computer.

NOTE : Be careful to connect with the proper

polarity. Connecting the wrong way may damage

the system (and is not guaranteed). Usually this

connector can only be attached one-way.

2. IDE Interface Connector

Connect to the IDE (Integrated Device

Electronics) Interface using a 40-pin flat IDE

cable.

NOTE : Do not connect or disconnect the cable

when the power is on, as this could cause a short

circuit and damage the system. Always turn the

power OFF when connecting or disconnecting the

cable.

3. Jumper Connector

This jumper determines whether the drive is

configured as a master or slave. Changing the

master-slave configuration takes effect after

power-on reset.

4. Analog Audio Output Connector

Provides output to a sound card (analog signal).

Generally you need this to play a regular audio

CD.

5. Digital Audio Output Connector

This connector is not supported.

Digital Audio Output

Connector

Jumper Connector

Analog Audio Output Connector

IDE Interface Connector

Power Connector

Rear Panel

Page 17

1. CABINET and CIRCUIT BOARD

DISASSEMBL Y

1-1. Bottom Chassis

A. Release 4 screws (A) and remove the Bottom Chassis

in the direction of arrow (1). (See Fig.1-1)

1-2. Front Bezel Assy

A. Insert and press a rod in the Emergency Eject

Hole and then the CD Tray will open in the direction

of arrow (2).

B. Remove the Tray Door in the direction of arrow

(3) by pushing the stoppers forward.

C. Release 3 stoppers and remove the Front Bezel Assy.

1-3. Cabinet and Main Circuit Board

A. Remove the Cabinet in the direction of arrow (4).

(See Fig. 1-3)

B. When the CD tray has been opened completely, lift

2 points (a) and remove the CD tray while drawing

out simultaneously.

C. Remove the Soldering of the LD- and LD+ (b) for

the Loading Motor, and then remove the Main

Circuit Board.

D. At this time, be careful not to damage the 5

connectors of the Main Circuit Board.

2. MECHANISM ASSY DISASSEMBL Y

2-1. Pick-up Unit

A. Release screws (B).

B. Separate the Pick-up Unit in the direction of arrow (6).

Main

Circuit Board

Cabinet

(4)

(5)

(a)

(b)

Fig. 1-1

Fig. 1-2

DISASSEMBLY

17

Fig. 1-3

Mechanism Assy

Pick-up Unit

(6)

(B)

(B)

Fig. 2-1

(1)

(A)

Bottom Chassis

(A)

(A)

(A)

(3)

Stoppers

Emergency Eject Hole

(2)

Tray Door

Front Bezel Assy

CD Tray

Page 18

2-2. Pick-up

A. Release 1 screw (C) and remove the Pick-up.

Pick-up Unit

Pick-up

(C)

Fig. 2-2

18

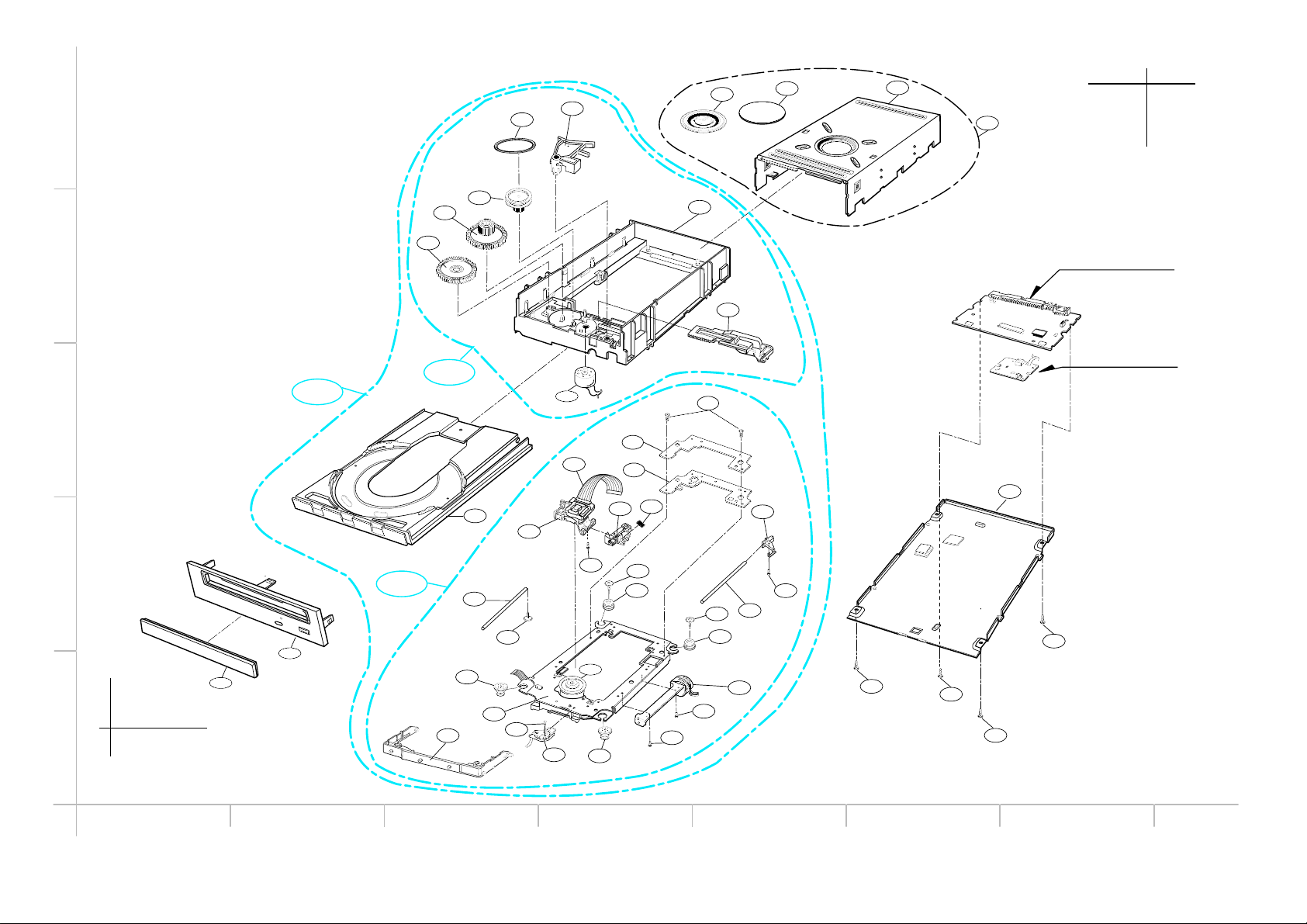

Page 19

030

014

007

A02

A01

A03

021

028

028

452

032

452

020

021

050

430

005

035

004

006

A B C D E F GH

1

2

3

4

5

452

024

481

034

027

026

033

025

430

419

020

453

031

036

453

003

002

010

011

009

008

012

016

015

013

PBM00 (MAIN C.B.A)

PBF00 (FRONT C.B.A)

482

482

482

001

482

19 20

EXPLODED VIEW

Page 20

ATIP Absolute Time in Pre-groove. With an additional modulation of the “Wobble”, the “Groove” contains a time

code information.

Wobble The pre-groove in the Disc is not a perfect spiral but is wobbled.

With : – A typical amplitude of 30 nm

– A spatial peried of 54~64 µm

CW Continuous Wave. The laser light output is at a constant level.

DOW Direct Over-Write. The action in which new information is recored over previously recorded information in

CD-RW disc.

Overwrite

The action in which new information is recorded over previously recorded information.

(Pre-)Groove

The guidance track in which clocking and time code information is stored by means of an FM

modulated wobble.

Land Land is characterized in the following way:

When radial signals are concerned,land is defined as the area between the grooves.

When HF signal are concerned,land is defined as the area between the marks(pits) in tangential

direction.

Hybrid Disc A Multisession disc of which the first Session is mastered. On a hybrid disc, recorded and

mastered information may co-exist.

Mastered Information,stored as pits on the disc during the manufacturing process of the disc.

Information (when making the master)

OPC Optimum Power Control. Procedure is determined optimum recording power according to CD-

R/RW Media in recording start step.

ROPC Running OPC. The purpose is to continuously adjust the writing power to the optimum power

that is required.

When the optimum power may change because of changed conditions of disc and change in

operating temperature.

Jitter The 16 value of the time variation between leading and trailing edges of a specific (I3 … I11) pit

or land as measured by Time Interval Analysis.

Deviation The difference between a fixed value of Pit length and Land length.

TOC Table Of Contents : in the Lead-in Area the subcode Q-channel contains information about the

Tracks on the disc.

Packet A method of writing data on a CD in small increments.

Writing Two kinds of packets can be written : Fixed-length and Variable-length.

Write The shape of the HF write signal used to modulate the power of the laser.

Strategy The Write Strategy must be used for recordings necessary for disc measurements.

Information Wobble, ATIP, Disc Identification, Write Power, Speed Range OPC Parameters, etc are

Area recorded in the Information area of CD-RW Disc

Finalization The action in which (partially) unrecorded or logically erased tracks are finished and the Lead-in

and/or Lead-out areas are recorded or overwritten with the appropriate TOC subcode.

Logical Erase

A method to remove information from a disc area by overwriting it with an EFM signal containing

mode 0 subcode

A logically erased area is equivalent to an unrecorded

Physical Erase

The action in which previously recorded information is erased by overwriting with a CW laser

output.

After a Physical Erase action, the erased area on the CD-RW disc is in the unrecorded state

again.

Session

An area on the disc consisting of a Lead-in area, a Program area, a lead-out area.

Multi session

A session that contains or can contain more than one session composed Lead-in and Lead-out

GLOSSARY

24

Page 21

25

The differences of CD-R/CD-RW discs and General CD-ROM

1.Recording Layer

Recordable CD has a wobbled pre-groove on the surface of disc for laser beam to follow track.

2.Disc Specification

Read-only Disc

CD-R and CD-RW Disc

3~1 1T

1.6um

0.4~0.5 um

(Pit)Groove

Land

Track pitch(p)

Radial Direction

Iw

A

O

a

a

Groove

Land

Radial Error Signal

The Groove wobble

Average center

Actual center

CD-ROM (READ-ONLY DISC)

a=30nm

ITEM CD-ROM CD-R CD-RW

Standard Yellow Book Orange Book II Orange Book III

Record Not available Write once Re-Writeable

Tracking Signal I11/Itop > 0.6 > 0.6 0.55 > M11> 0.70

(HF Modulation)

Read Laser Power(mW) < 0.5 mW < 0.7 mW < 1.0 mW

Jitter < 35 nsec < 35 nsec < 35 nsec

Reflectivity (R

top) 70 % 65 % 15 % ~ 25 %

Remark)

Write Laser Power(mW) 14-65 mW 6-45 mW

Page 22

26

3.Disc Materials

1) CD-ROM disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Organic Dye Layer

Reflective Layer

Protective Layer

Label Printing

2) CD-R disc

Pigment Reflective Layer Color

Phtalocyanine Gold/Silver Yellow/White

Cyanine Gold/Silver Dark Green/Bright Green

Azo Gold/Silver Dark Blue

• It is composed of Silver _ colored aluminum plate and Reflective layer.

• Groove (Pit) of aluminum plate make a track.

• Laser wavelength : 780 nm, Laser Power (Read): 0.5mW

• Signal is detected by the

difference of reflective beam

intensity between “pit” and

“Land” on the disc.

• It is so-called WORM (Write Once Read Many) CD.

• It is composed of polycarbonate layer, Organic dye layer, Reflective layer, and Protective

layer.Gold/Silver Reflective layer is used to enhance the reflectivity

• According to the kinds of Organic dye layer, it is divided by Green CD, Gold CD, Blue CD.

• Laser Wavelength : 780 nm, Laser Power (read) : 0.7 mW

• Recording Power : 8x(14~20mW), 16x(25~35mW)

• When some part of dye layer is exposed to laser heat, it’s color changs black.Therefore, writing and

reading is enabled by the difference of reflectivity between changed part and unchanged part.

• Polycarbonate layer has Pre_Groove which make a Track.

Laser Beam

Pit

Substrate

(Polycarbonate)

Reflective Layer

Protective Layer

Label Printing

Page 23

27

3) CD-RW Disc

4.

Reading process of Optical Disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Recording Layer

Dielectric Layer(TL)

Dielectric Layer(UL)

Protective Layer

Label Printing

• It is composed of polycarbonate layer, alloy(silver, arsenic) layer, aluminum reflectivity layer, protective layer.

• An crystalized alloy layer is transformed into noncrystalized by the laser heat. Therefore, writing and reading

is enabled by the difference of reflectivity.

• It is possible to overwrite about 1000 times.

• Laser Wavelength : 780 nm, Laser Power (Read) : 1.0mW

• Recording Power : Erase (4~18mW), Write (6~45mW)

• When disc rewriting, new data is overwritten previously recorded data.

• Polycarbonate layer has a Pre-Groove which make a track.

Lens

H

D

Beam

Spot

Focusing

Lens

Laser Spot

at Constant

Read Intensity

Reflected

Light

Signal

Laser Spot

Position

(Time)

Previously Recorded Marks

Groove Land Mirror

I

3

I

top

I

11

I

G

I

L

I

0

Numerical aperture: NA=nsinθ,

n: Refractive index

Focus depth : H =

λ

/NA

laser spot diameter : D =

λ

/NA

2

θ

Page 24

28

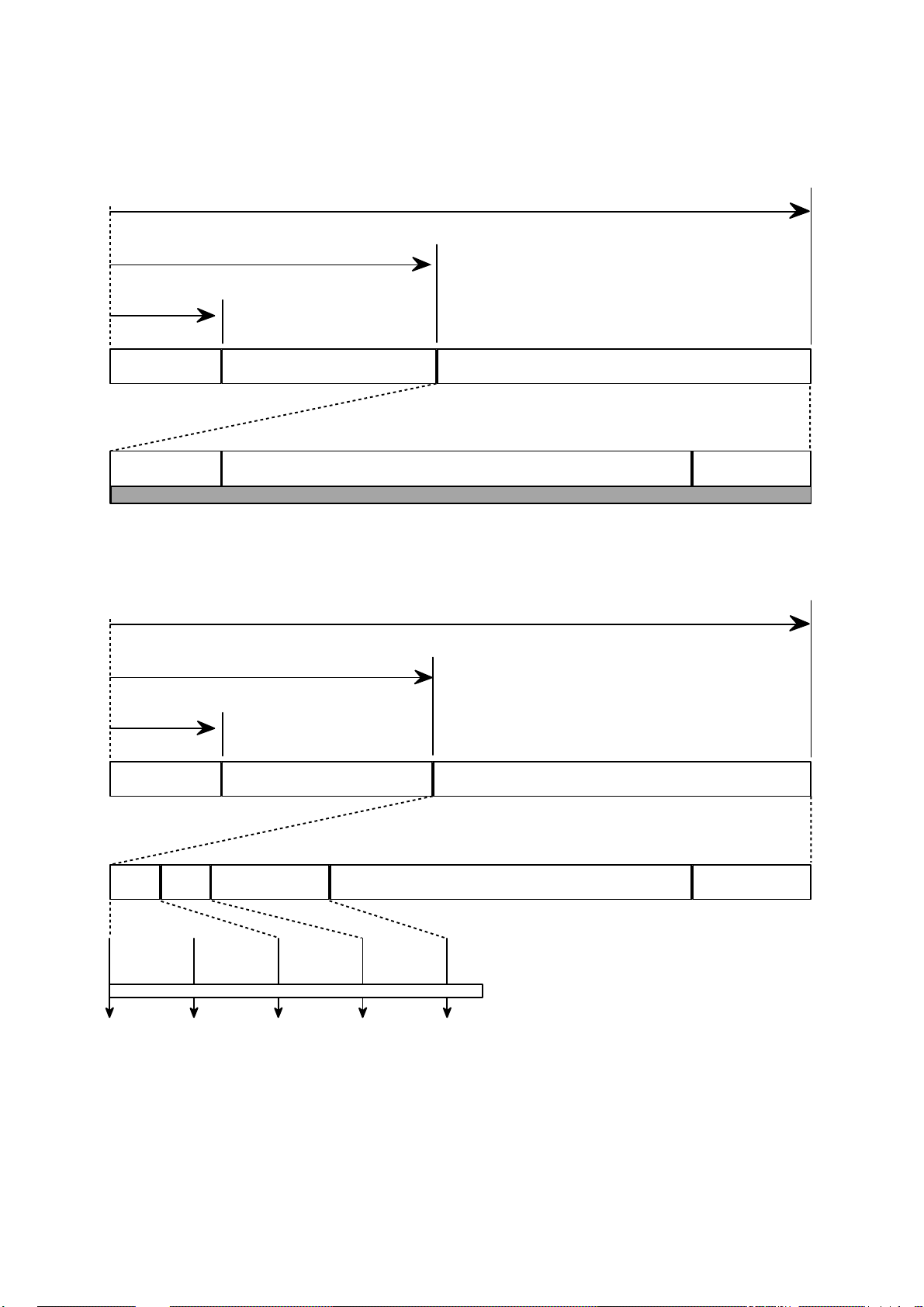

5.Writing Process of CD-R Disc

a b c d e f g

a

b

c

d

e

f

g

Incident

Laser

Power

(Read)

(Read)

(Write)

Laser Spot

Position

(Time)

a b c d e f g

Laser Spot

Position

(Time)

Laser

Spot

Recorded

Mark

Reflected

Light

Signal

Reflected

Light

Signal

Below "ORP"– Mark Too Short

At Optimum Record Power ("ORP")

Above "ORP" – Mark Too Long

Time

6.Writing process of CD-RW Disc

Write Power

Erase Power

Read Power

Groove

Crystal

Amorphous

Amorphous

Recorded state

(lower reflectivity)

Melting/

quenching

Heating/

gradual cooling

Crystal phase

Erased state

(higher reflectivity)

Page 25

29

7.Organization of the PCA, PMA and Lead-in Area

1) Layout of CD-ROM disc

Center hole Clamping and Label Area Information Area

Lead-in Area

Lead-in Area

Diameter 15 mm

Diameter 46 mm

Diameter 120 mm

Program Area

Read Only Disc

Lead-out Area

Program Area Lead-out Area

Center hole

Clamping and Label Area

Information Area

PCA PMA

Test Area Count Area

Diameter 15 mm

Diameter 45 mm

Diameter 120 mm

Unrecorded Disc

Tsl-00:35:65 Tsl-00:15:05

Tsl-00:13:25

Tsl

99:59:74

00:00:00

in out

Test Area : for performing OPC procedures.

Count Area : to find the usable area immediately in T.A

Tsl : start time of the Lead-in Area, as encoded in ATIP

PMA : Program Memory Area

Disc Center

Disc Center

2) Layout of CD-R/RW disc

Page 26

30

8. Function of PCA and PMA area

1) PCA (Power Calibration Area)

• PCA area is used to determine the correct Laser Power for a disc.

– Method 1 : PCA area is divided by a track.

– Method 2 : The previous Calibration value is referred.

– Method 3 : ROPC is used to determine Laser Power value automatically in data writing.

• CD-R Disc can write maximum 99 Tracks but CD-RW Disc can write unlimited tracks because it has a rewritable

function.

2) PMA (Program Memory Area)

• It has a track information (track No, track Start/End time) of every track before writing completed.

– PMA area has the last written point and the next writable point of a disc.

– In case of CD to CD copy, some writer may not write PMA area.

* When Disc is Finalized,

PMA information is transferred to the Lead_In area so that general Driver can read it.

* Because PCA and PMA area exist before Lead-In area, General CD Player or CD-ROM Drive can’t read

these areas.

9. OPC and ROPC

1) OPC (Optimum Power Control)

• This is the first step of writing process, because CD writer has its own laser power value and media have different

writing characteristics,

– This is determined by the Writing characteristic, speed, temperature, and humidity.

– Laser wavelength is determined by the environmental temperature (775~795nm) and Optical Laser Power is

determined by the test and retry.

• Asymmetry and optimum writing Power

– EFM signal Asymmetry is determined by the writing power.

Therefore, Optical Power which has the same value to the preset power value can be estimated by measuring

HF signal Asymmetry on the PCA area.

• Measurement of Asymmetry

* Parameter setting (Beta) : Using AC coupled HF signal before equalization

Beta = (A1+A2)/(A1-A2)

Time

P << Po

Time

P = Po

HF Signal

A1

0

A2

Time

P >> Po

Page 27

31

2) ROPC (Running Optimum Power Control)

• Variable primary factor of Optimum Power

– Change of Power sensitivity on the Disc. (limited to 0.05 *Po)

– Wavelength shift of the laser diode due to the operating temperature change.

– Change of the Spot aberration due to the Disc skew,

Substrate thickness, Defocus.

– Change of Disc or Optics conditions due to the long term OPC

==> It is necessary to adjust continuously to obtain the Optimum Power.

• Principle of Running OPC

– To meet the factors mentioned above,

a horizontal _ direction movement of a curve is uesd.

– Beta = f(B-level) = constant on the Recorded Disc

– Procedure of ROPC

a. Reference B-level is determined during OPC Procedure.

b. During Recording, B-level value is controlled to have a close

Reference B-level value.

c. Normalization of B-level is used to eliminate the effect of reflectivity fluctuation.

==> The reflected B-level value is normalized by the disc reflectivity itself.

CD-R/RW Media

Write Strategy

Determination

PCA Test Area

Program Area

PMA Area

Lead-In Area

Lead-out Area

OPC

PCA Count Area

ROPC

* Recording Capacity of CD-R/RW (74Minute Recording media)

• (2048 Byte/Sector) X (75 Sector/Second) X (60 Second/Minute) X 74 Minute

= 681,984,000 Bytes = 682 Mbytes

• But the actual recording capacity is about 650 Mbytes. (according to the ISO 9660 standard, approximately

30 Mbytes are used to make directory structure and volume names.)

Incident recording pulse

Reflected recording pulse

Sampled timing B

11T

Sample B-level (Write Power)

Level B

Sampled at timing B

Pwo decided by OPC

Recording Power

Level B with Pwo

normalized to recording power

Sample Disc Reflectivity

(Read power)

10. Writing Process of DISC

Page 28

32

The differences of DVD-R/RW , DVD+R/R W discs and DVD-ROM

1.Recording Layer

LPP

(Land Pre-Pit)

DVD+R/RW Disc

DVD-R/RW Disc

0.74

um

3

T

0.4 um

DVD-ROM (Read Only Disc)

Page 29

33

2.Disc Specification

3.Disc Materials

1) DVD-ROM

DVD-ROM

Media T ype

User data capacity

Single-Layer

Read Only

4.7GB

Dual-Layer

Read Only

8.54GB

DVD-R DVD-RW DVD+R DVD+RW

Dye Phase change Dye Phase change

4.7GB 4.7GB 4.7GB 4.7GB

Wavelength

650nm 650nm 650nm 650nm 650nm 650nm

Reflectivity

45~85% 18~30nm 45~85% 18~30% 45~85% 18~30nm

Track pitch

0.74 0.74 0.74 0.74 0.74 0.74

Minimum pit length

0.4 0.44 0.4 0.4 0.4 0.4

Modulation

>0.6 >0.6 >0.6 >0.6 >0.6 >0.6

Channel bit-rate

26.16MHz 26.16MHz 26.16MHz 26.16MHz 26.16MHz 26.16MHz

Wobble Frequency

- - 140KHz 140KHz 817.4KHz 817.4KHz

Addressing

26.16MHz 26.16MHz Wobble & LPP Wobble & LPP Wobble(ADIP) Wobble(ADIP)

Read Power (mW)

0.7 0.1 0.7 0.1

Write Power (mW)

- -

JItter

<8% <8% <8% <8% <9% <9%

++

Bonding layer

Polycarbonate

Semi-reflective

Polycarbonate

Reflective layer

Label

Polycarbonate

Label

Bonding layer

Reflective layer

Polycarbonate

<Single Layer >

<Dual Layer >

Page 30

34

2) Recording format using organic dye material (DVD-R/DVD+R)

* The format that records data through the creation of recorded marks by changing the organic dye material

with a laser beam.

DVD-R

Adhesive layer

Protective layer

Reflective layer

Recording layer(dye)

Disc substrate

DVD+R

Adhesive layer

Protective layer

Reflective layer

Recording layer(dye)

Disc substrate

Adhesive layer

Protective layer

Reflective layer

Dye layer

Substrate

Laser beam

> Disc structure

> Disc structure

[Recording]

Recording is done by changing the organic dye layer and the substrate with a laser when a strong is

applied to a disc, the temperature of the ortanic dye material goes up, the dye is decomposed and the

substrate changes at the same time. At this time, a durable bit is created as is the case with a CD-ROM.

[Playback]

Signals are read with the differences of the reflection of a laser from pits.

Page 31

35

3) Recording format using phase-change recording material (DVD-RW/DVD+RW)

* Data is recorded by changing the recording layer from the amorphous status to the crystalline status, and

played back by reading the difference of the reflection coefficient.

[ Amorphous : Non-crystalline ]

Substrate

Laser beam

Recording data

(Melting/Quick cooling)

Erasing data

(Heating/Gradual cooling)

Data erased state

(High reflection coefficient)

Recorded state

(Low reflection coefficient)

Crystalline status

Amorphous status

DVD-RW

Adhesive layer

Protective layer

Reflective layer

Dielectric layer

Recording layer

(Phase change material)

Dielectric layer

Disc substrate

DVD+RW

Adhesive layer

Protective layer

Reflective layer

Dielectric layer

Recording layer

(Phase change material)

Dielectric layer

Disc substrate

> Disc structure

> Recording principles

[Recording]

When a high-power laser is applied to the recording material, it melts and then becomes amorphous with

a low reflection coefficient when it quickly cools off. When a mid-power laser is applied to heat gradually

the recording material and then gradually cools it off, it becomes crystal with a high reflection coefficient.

[Playback]

A low-power laser is used for playback. The amount of reflected light depends on the status (amorphous

or crystalline) of the recording material. This is detected by an optical sensor.

Page 32

36

4. Writing Pulse Wave Form of DVD+R

For different speed ranges, different write strategies can be used. This document specifies 2 options:

- a pulsed write strategy, where each single mark is created by a number of subsequent separated short

pulses.

- a blocked write strategy, where each single mark is created by one continuous pulse.

1) 1stMethod : Using Pulsed Write Strategy

* 3T :

NRZI

T = 3

2Tw

Ttop

dTtop

dTle

Pb

top

top le

Pp

Channel bits

N = 3 : only the top pulse(T ),

first pulse lead-time dT , dT

NRZI

T > 4

2Tw Tw

Ttop Tmp

Tmp

Tlp

dTtop

dTle

Pb

top

top

le

lp

mp

Pp

Channel bits

N > 4 : the top pulse (T ), multi-pulse (T ) and last pulse (T ),

first pulse lead-time dT , dT

Pp : Actual write power

Pb : Bias Power

* >

4T :

Page 33

37

2) 2stMethod : Using Blocked Write Strategy

NRZI

Channel bits

2Tw

Tw

dT

top

T

top

dT

le

P

p

P

b

T

mp

lp

T

dP

p

0mW

P

c

P

b

1.25T

w

3T mark

4T mark

5T mark

Etc.

dT

top,3

dP

p3

T

top,3

dT

le

1.25T

w

P

c

P

b

1.25T

w

1.25T

w

1.25T

w

dT

top,4

dP

p4

T

top,4

T

lp

T

top,4

T

top,4

T

mp

T

mp

T

lp

T

lpT

mp

N = 3 : T (cm = 3) can be optimized individually.

N > 4 : T (cm 4) + x (N-3) T + T , T = T

P shall be < 0.1mW

top

mp

lp

w

w

top

c

Pp : Actual write power

Pb : Bias Power

dPp : Additional power ( Only be applied for the 3T and 4T marks)

Pc : Cooling power (Especially at higher recording speeds, optimum cooling down of the

recording layer after writing a mark may be

needed.)

>

Page 34

38

5. Writing Pulse Wave Form of DVD+RW

NRZI

Channel bits

2Tw

Tw

Ttop

dTtop

P

p

Pe

T

mp

mp

T

dTera

Pp : Actual write power

Pe : E r as e Powe r

Pb : Bias

Power

Pb

0mW

T

mp

Page 35

6. Organization of the Inner Drive Area, Outer Drive Area, Lead-in Zone and

Lead-out Zone

1) Layout of DVD-ROM disc

39

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Lead-in Zone

Lead-in

Zone

Lead -out

Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Data Zone

Read Only Disc

Lead-out Zone

Data Zone

Outer Drive

Area

Inner Drive

Area

Inner Disc

Test Zone

Outer Disc

Test Zone

Unrecorded Disc

PSN: 23080H 27080H 27480H 28480H 2A480H 30000H 260540H 261940H 262940H

263940H

267940H

in OUT

Disc Center

Rim area

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Disc Center

Rim area

Inner Disc

Count Zone

Outer Disc

Count Zone

2) Layout of DVD+R disc

> Inner Disc Test Zone : for performing OPC procedures.

> Inner Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

> Outer Disc Test Zone : for performing OPC procedures.

> Outer Disc Count Zone : for counting the mumger of OPC algorithm performed in IDT Zone.

Page 36

3) Layout of DVD+RW disc

40

> Inner Disc Test Zone : for performing OPC procedures.

> Inner Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

> Outer Disc Test Zone : for performing OPC procedures.

> Outer Disc Count Zone : for counting the number of OPC algorithm performed in IDT Zone.

Lead-in Zone

Lead -out Zone

Data Zone

Inner Disc

Test Zone

Outer Disc

Test Zone

Unrecorded Disc

PSN: 2A480H 2A7C80H 2DC80H 30000H 260540H 262940H

265940H

266140H

in OUT

Center

hole

1st transition area

2nd transition area

Clamping

Zone

3rd transtion

area

Information Zone

Diameter 15 mm

Diameter 16 mm

Diameter 22 mm

Diameter 33 mm

Diameter 44 mm

Diameter 120 mm

Disc Center

Rim area

Inner Disc

Count Zone

Outer Disc

Count Zone

Page 37

41

LightScribe Media

1. LightScribe Media

Center Hole

Screen Printed Imaging Layer

Clear Protective Coating

Reflective/Thermal Layer

Dye Data Layer

Polycarbonate

Substrate

DiscOD

Label Zone

Control Feature Zone

Clamping/Logo Zone

Page 38

42

2. Hardware Block Diagram of LightScribe Label Printing

Host

PC

(Spindle)

uP

(DSP)

Power

Drive

Analog

Signal

Processor

MECHANISM

Optical

Pick-up

Optical

Encoder

(Sled)

(Track)

(Tilt)

(Focus)

RFOUT

Spindle Motor

Step Motor

Track Actuator

Tilt Actuator

Focus Actuator

Laser Power Reference

Write Strategy Control

Buffer

Memory

SERVO Signals

RF Cell Signals

Laser Power Monitor Signal

Optical FG

CIrcuit

Page 39

43

3. MD Assy For LightScribe

Optical Encoder Unit

OPU ID Movement Range : L=21um

Page 40

44

4. Optical Encoder Assy

Codewheel

Direction of

radial play

CODEWHEEL

OR

CODESTRIP

FFC

3PIN

SIGNAL

PROCESSING

CIRCUITRY

R

V

LED

V

CC

CH A

CH B

CH B

GND

GND

Vcc

OFG

Encoder PCB

PIN 6

VCC

PIN 5

CH A

PIN 4

GND

PIN 3

VLED

PIN 2

GND

PIN 1

CH B

PIN 6

VCC

PIN 5

CH A

PIN 4

GND

PIN 3

VLED

PIN 2

GND

PIN 1

CH B

Optical Encoder IC

Schematic of Enc PCB

Page 41

45

DVD & CD DATA PROCESSING

1.Data Processing Flow

Command

Data

Status

RF EQ & AGC

SERVO

DSP

Encoder & Decoder & CSS

RF data slice EFM demodulator

CiRC error correction

Audio DAC

Buffer/Memory controller

CSS controller

Atapi interface control

Data PLL

Servo ADC

Focus/tracking

control output

Sled control output

CAV Spindle control

P-up

Unit

(LPC-812R)

IC121

RF AMP

(AN22113A)

CD

DVD

IC201

(MN103SA6G)

TE/CSO GEN

FE GEN

IC261 DRAM

IC262

Flash ROM

SRAM

Page 42

46

MN103SA6G

HOST DVD

PLAYER

(EMPEG2 B/D)

Scrambled MPEG Data

Change the "KEY"

KEY Management Control

2. Copy Protection and Regional Code Management Block

Block Diagram

Brief Process

1. Regional Code for DVD Disc

– DVD-ROM drive transfers the regional code of the control data to host by the command of host, the DVD

player of host reads the regional code, and plays title in the case of allowed regional code only.

2. Management of DVD Disc for the scrambled of data

(1) DVD-ROM and DVD player of host generate the “KEY 1” respectively, transfer to opposite part, the

“KEY 2” is received, recognizes the data transfer or not with this value, and generates the bus key

encoded the data.

(2) Encoded “Disc Key” and “Title Key” host is transfer with the bus Key.

(3) DVD player of host reads the key value, and uses the value to restore the scrambled data.

* Refer to the next page for the details.

Page 43

47

3. About Prevention the DVD-ROM from to be copy

A data is able to encode and record in the disc, if a copyright holder wants to prevent the disc from copying.

In case of a disc enhanced movie of 3 titles......

DISC KEY (2048 Bytes) is used to encode the whole contents in the disc and TITLE

KEY (5 Bytes) is used to encode the title respectively.

So, the data is encoded and stored in a disc through the unknown algorithms

with a disc key and title key. (At this time, the disc key and title key are stored

in a disc.)

…As above, the disc is able to copy when the disc key and title key are

opened.

Then, ROM-DRIVE encodes the disc key and title key and transfers to MPEG2 board.

If you want to play the disc prevented from the copy......

First of all, ROM-DRIVE and MPEG-2 board identify with each other through the procedure as described

below.

1. Drive and host gives and takes the ID of 2bit. This ID is AGID (Authentication Grant ID).

The various decoder boards are attached to the host, in these, AGID sets the MPEG-2 board and drive.

2. After the AGID is set, MPEG-2 board generates the challenge key (10 Byte) and transfers to drive. The

board and drive generate key 1 (5Byte) with the challenge key respectively. (Of course, the Algorithm

generating the key 1 is not known.)

3. Compare with the generated key 1, if it corresponds each other, the first step of authentication is

completed. This is a course to identify the MPEG-2 board with a drive.

4. The second step of authentication is a course to identify a drive with the MPEG-2 board.

The dirve generates a challenge key and transfers it to the MPEG-2 board. The dirve and MPEG-2 board

generate the key 2 (5Byte) with the challenge key, compare with each other, and if it corresponds and the

secondary step of authentication is completed.

5. As above, the identification is completed.

6. The dirve and MPEG-2 board generate the Bus key with the key 1 and key 2 and own it.

7. Dirve encodes the disc key and title key with this Bus key and transfers to the MPEG-2 board.

8. The MPEG-2 board reads the encoded disc key and title key with the Bus key only.

9. MPEG-2 board lets data read from the drive to decode with the read disc key and title key and makes into

the video signal by decoding.

ROM-DRIVE

AGID

HOST

MPEG-2

BOARD

Challenge key

encoded disc key, title key

Page 44

48

4.About the DVD-ROM Regional Code

DISC ROM - DRIVE MPEG-2 BOARD VGA CARD

MONITOR

1

CAN

U.S.A

MIX

CUB

BHS

PRI. VIR

1

BMG

GRL

2

2

ZAF

ISO

SWZ

FIN

POI

FST

LTU

BIR

UKR

TUR

FGY

JRN

TKM

AFG

PAK

CHN

MMR

MNG

RUS

KOR

JPN

HKG

MAC

TWN

PHL

6

3

2

1

5

5

4

1

MDI

MNP

GUM

PLW

PNG

NZL

AUS

4

The disc has

the regional

code of 8 bit.

Example)

The disc

manufactured

in the U.S.A,

has the

number one.

Transfer to

MPEG-2 board

reading the

regional code.

Receiving

data from the

MPEG-2

board and

output

through the

monitor

If the board is setting to the regional

code 1 for the U.S.A. ...

Check the received regional code to

number 1, all or not, transfer the

data to VGA card in accordance with

only a case among the three case.

Regional code

Page 45

INTERNAL STRUCTURE OF THE PICK-UP

1.Block Diagram of the PICK-UP(LPC-812R)

49

7

RF- SW

EF3

C

VC

VCC

D

GND

RF+

EF2

B

A

EF1

EF4

VREF

VCC

GND

STB

SW

OUT

NC

CW

CW

CDO

DVDO

IN

ENA E3

VCC

SEL

DVD_LD CD_LD

VCC

OSC

NE4E4NE3

CXA2694N

PD4CI

CP0076AH

8

1

VC(PDIC)

2

VCC(PDIC)

3

GND(PDIC)

4

EF4

5

EF1

6

A

7

B

8

EF2

9

EF3

10

C

11

D

12

SW(PDIC)

13

RF+

14

RF-

15

SW(FM)

16

VCC(FM)

17

GND(FM)

18

VREF(FM)

19

FM_OUT

20

TEMP

21

GND

Themester

22

W1DISN

23

W1DIS

24

W2DISN

25

W2DIS

26

W3DISN

27

W3DIS

28

OSCEN

29

GND

30

GND

31

VCC

32

W3SET

33

W2SET

34

W1SET

35

RSET

36

OUTSET

37

ENABLE

38

VCC

39

GND

40

F+

Focus

Actuator

TILT

TRACK

41

F-

42

TILT+

43

TILT-

44

T+

45

T-

9

10

11

12

13

14

6

5

4

3

2

1

10 1

2

3

4

5

9

8

7

6

13

6

NE2

5

E2

4

ER

3

RFA

2

RFB

1

OUTB

14

RSA

15

GND

16

RSB

17

OUTA

18

12

19

VCC

20IR21I222

I3

I4

23

24

11

10

9

8

7

Page 46

2.Pick up Pin Assignment

50

No. Pin Name Signal Description

45 T- Tracking Actuator drive signal44 T+ Tracking Actuator drive signal+

43 Tilt- Tilting Actuator drive signal42 Tilt+ Tilting Actuator drive signal+

41 F- Focusing Actuator drive signal40 F+ Focusing Actuator drive signal+

39 GND(LDD) Ground connection for LDD

38 VCC(LDD) Power supply for LDD

37 ENABLE Disables output current regardless of OUTEN(ENABLE Low:No lout)

36 OUTSEL High:selects DVD LD, Low:CD LD

35 RSET Input voltage for current amplifier

34 W1SET Input voltage for current amplifier

33 W2SET Input voltage for current amplifier

32 W3SET Input voltage for current amplifier

31 VCC(LDD) Power supply for LDD

30 GND(LDD) Ground connection for LDD

29 GND(LDD) Ground connection for LDD

28 OSCEN TTL control for Oscillator Enable (High Enable)

27 W3DIS LVDS control for output current (High Enable)

26 W3DISN LVDS control for output current (Low Enable)

25 W2DIS LVDS control for output current (High Enable)

24 W2DISN LVDS control for output current (Low Enable)

23 W1DIS LVDS control for output current (High Enable)

22 W1DISN LVDS control for output current (Low Enable)

21 GND(FPD) Ground connection for PDIC, FPD, TEMP

20 TEMP Output voltage for controlling temperature

19 FPD-OUT APC amplifier output

18 VREF(FPD) APC amplifier reference voltage output

17 GND(TEMP) Ground connection for PDIC, FPD, TEMP

16 VCC(FPD) Power supply for FPD

15 SW2(FPD) FPD output gain Select (High : CD, Low:DVD)

14 RF- Signal PDIC RF negative differential output

13 RF+ Signal PDIC RF positive differential output

12 SW1(PDIC) PDIC output gain Select (L/M/H)

11 D Signal PDIC output D

10 C Signal PDIC output C

9 EF3 Signal PDIC output EF3

8 EF2 Signal PDIC output EF2

7 B Signal PDIC output B

6 A Signal PDIC output A

5 EF1 Signal PDIC output EF1

4 EF4 Signal PDIC output EF4

3 GND(PDIC) Ground connection for PDIC, FPD, TEMP, LDD

2 VCC(PDIC) Power supply for PDIC(+5V)

1 VC(PDIC) Reference voltage input for PDIC)

Page 47

3.Signal detection of the P/U

1) Focus Error Signal ==> (A+C)-(B+D)

This signal is generated in RF IC (IC121 : AN22113A) and controls the pick-up’s up and down to focus on

Disc.

2) Tracking Error Signal (DPP Method) ==> {(A+D)-(B+C)}- k x {(EF1+EF4)-(EF2+EF3)}

This signal is generated in RF IC (IC121 : AN22113A) and controls the pick-up’s left and right shift to find

to track on Disc.

3) RF Signal ==> (A+B+C+D)

This signal is converted to DATA signal in DSP IC (IC201 : MN103SA6G).

51

Pick-Up module

Photo Diode

Tracking

Focusing

Infrared Iaser

k[(F+H) - (E+G)]

(A+D) - (B+C)

(A+D) - (B+C) - k[(F+H) - (E+G)]

Offset

TE

Tp

Sub2

Main

Tp/2

Sub1

T rac k Center

F,E

D,C

A,B

H,G

Page 48

52

MN103SA6G

Write

Strategy

IC 201

CN 101

Optical

Pick-up

LPC-812R

LD PD

LDD

Serial

I/F

D/A

D/A

D/A

D/A

D/A

D/A

M

P

X

IC 121 AN22113A

APC

19

A/D

ADSC

S/H

Signal

FM

123

VPD

127

FPDM

124

VREFPD

40 41

42

SH1

SH2SH3

VGA

LPF

Ave

Erase

Space

VGA

S/H2

S/H3

S/H1

DESCRIPTION OF CIRCUIT

1. ALPC (Automatic Laser Power Control) Circuit

1-1. Block Diagram

1-2. ALPC (Automatic Laser Power Control) Circuit Operation

The ALPC block detects the laser output power of the front monitor. The power signal detected with the PD for front monitor

detection is input the voltage from the VPD pin(123Pin) or the FPDM pin(127Pin), the reference signal of the input signal is

input from the VREFPD pin(124Pin). The ALPC block generates the singals from the input laser power signals in the

following detection systems. This block has four detection paths:All average value path, multi pulse average/peak value

detection path, erase/bottom value detection path, space/playback power value detection path.

Page 49

53

2.Focus/Tracking/Sled Servo Circuit

2-1. Focus, Tracking & Sled Servo Process

F

E

DC

AB

H

G

Pick-up

Focus Error

Detector

Focus Error

Detector

A,B,C,D

A,B,C,D

E,F,G,H

A,B,C,D

E,F,G,H

IC121 AN22113A

FE

TE

IC201

Servo Control

MN103SA6G

TE FE

A/D

D

A

C

SLED

COMPENSATOR

A/D

PARALLEL

DIGITAL

COMPENSATOR

SDRV

60

64

66

67

STEP2

STEP1

IC301 BD7956FS

29

30

M

Stepping Motor

Logic

A+

37 38 40 39

A- B- B+

Tracking Focusing

Actuator

T- T+ F- F+

5

4

LEVEL SHIFT

FDRV

TDRV