Page 1

COLOR MONIT OR

SER VICE MANUAL

CHASSIS NO. : CL-18

MODEL: FPD1570, LB680A

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Page 2

CONTENTS

SPECIFICATIONS

1. LCD CHARACTERISTICS

Type : TFT Color LCD Module

Size : 335.0(H) x 273.5(V) x 11.2(D)

Pixel Pitch : 0.243mm x 0.243mm

Color Depth : 8-bit, 16,777,216 colors

Active Video Area : 15.7inch (39.88cm)

(39.832diagnal 311mm x 284.8mm)

Surface Treatment : Anti-Glare, Hard Coating (3H)

Backlight Unit : Two-CCFL (Cold Cathode

Fluorescent Lamp)

2. OPTICAL CHARACTERISTICS

2-1. Viewing Angle by Contrast Ratio

≥

10

Left : 60° typ., 60° min.

Right : 60° typ., 60° min.

Top : 45° typ., 45° min.

Bottom : 45° typ., 45° min.

2-2. Luminance : 200 cd/m

2

typ.

2-3. Angle at Half Luminance

Left : 45° min.

Right : 45° min.

Top : 45° min.

Bottom : 45° min.

2-4. Contrast Ratio : 250 typ.

3. SIGNAL (Refer to the Timing Chart)

3-1. Sync Signal

1) Type : Separate Sync. (Horizontal & Vertical)

2) Input Voltage Level: Low=0~0.8V, High=2.1~5.5V

3) Sync Polarity : Positive or Negative

3-2. Video Input Signal

1) Type : R, G, B Analog

2) Voltage Level : 0~0.714 V

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.714 Vp-p

3) Input Impedance : 75 Ω

3-3. Operating Frequency

Horizontal : 30 ~ 80kHz

Vertical : 56 ~ 85Hz

4. POWER SUPPLY

4-1. Power Adaptor

Input : AC 100~240V, 50/60Hz 1.2A

Output : DC 24V 1.2A

4-2. Power Consumption

5. ENVIRONMENT

5-1. Operating Temperature: 10°C~35°C (50°F~95°F)

(Ambient)

5-2. Relative Humidity : 10%~80%

(Non-condensing)

5-3. Altitude : 0~10,000ft (3,030m)

6. DIMENSIONS (with TILT/SWIVEL)

Width : 370.2mm (14.57'')

Depth : 134.0mm (5.27'')

Height : 387.7mm (15.26'')

7. WEIGHT (with TILT/SWIVEL)

Net. Weight : 4.5kg (9.92 lbs)

Gross Weight : 6.8kg (14.99 lbs)

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 3

TIMING CHART ....................................................... 4

OPERATING INSTRUCTIONS ................................ 5

CONTROL LOCATIONS ......................................... 8

WIRING DIAGRAM ................................................. 8

DISASSEMBLY ....................................................... 9

BLOCK DIAGRAM ................................................. 11

DESCRIPTION OF BLOCK DIAGRAM.............. 12

ADJUSTMENT ...................................................... 13

TROUBLESHOOTING GUIDE .............................. 14

PRINTED CIRCUIT BOARD................................... 20

EXPLODED VIEW...................................................22

REPLACEMENT PARTS LIST ...............................24

PIN CONFIGURATION............................................31

SCHEMATIC DIAGRAM......................................... 36

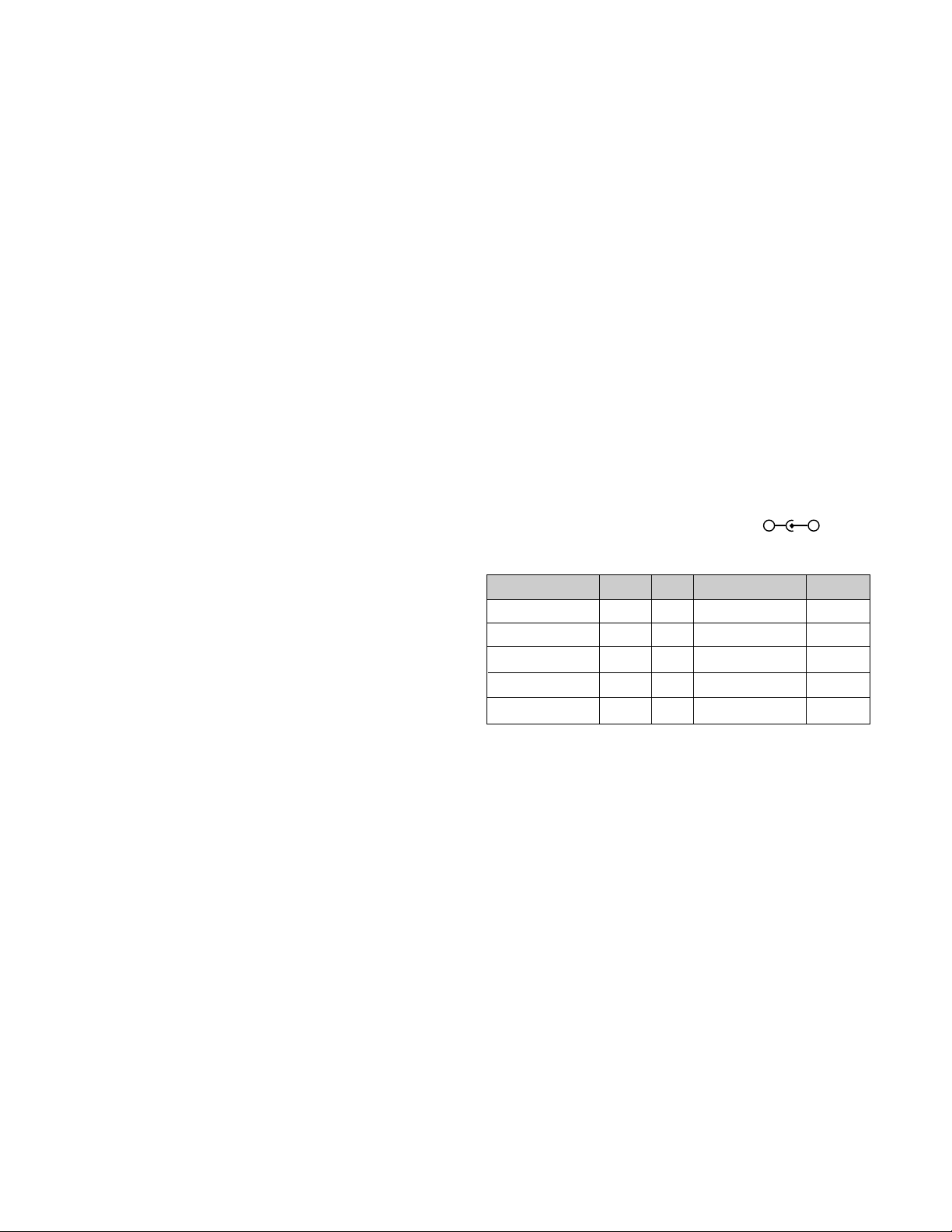

MODE

POWER ON (NORMAL)

STAND-BY

SUSPEND

DPM OFF

POWER OFF

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

-

POWER CONSUMPTION

less than 36 W

less than 3 W

less than 3 W

less than 3 W

less than 3 W

LED COLOR

GREEN

AMBER

AMBER

AMBER

OFF

VIDEO

ACTIVE

OFF

OFF

OFF

-

-

+

Page 3

- 3 -

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and the

replacement parts list. It is essential that these critical

parts should be replaced with the manufacturer’s

specified parts to prevent electric shock, fire or other

hazard.

• Do not modify original design without obtaining written

permission from Gate Way. or you will void the original

parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

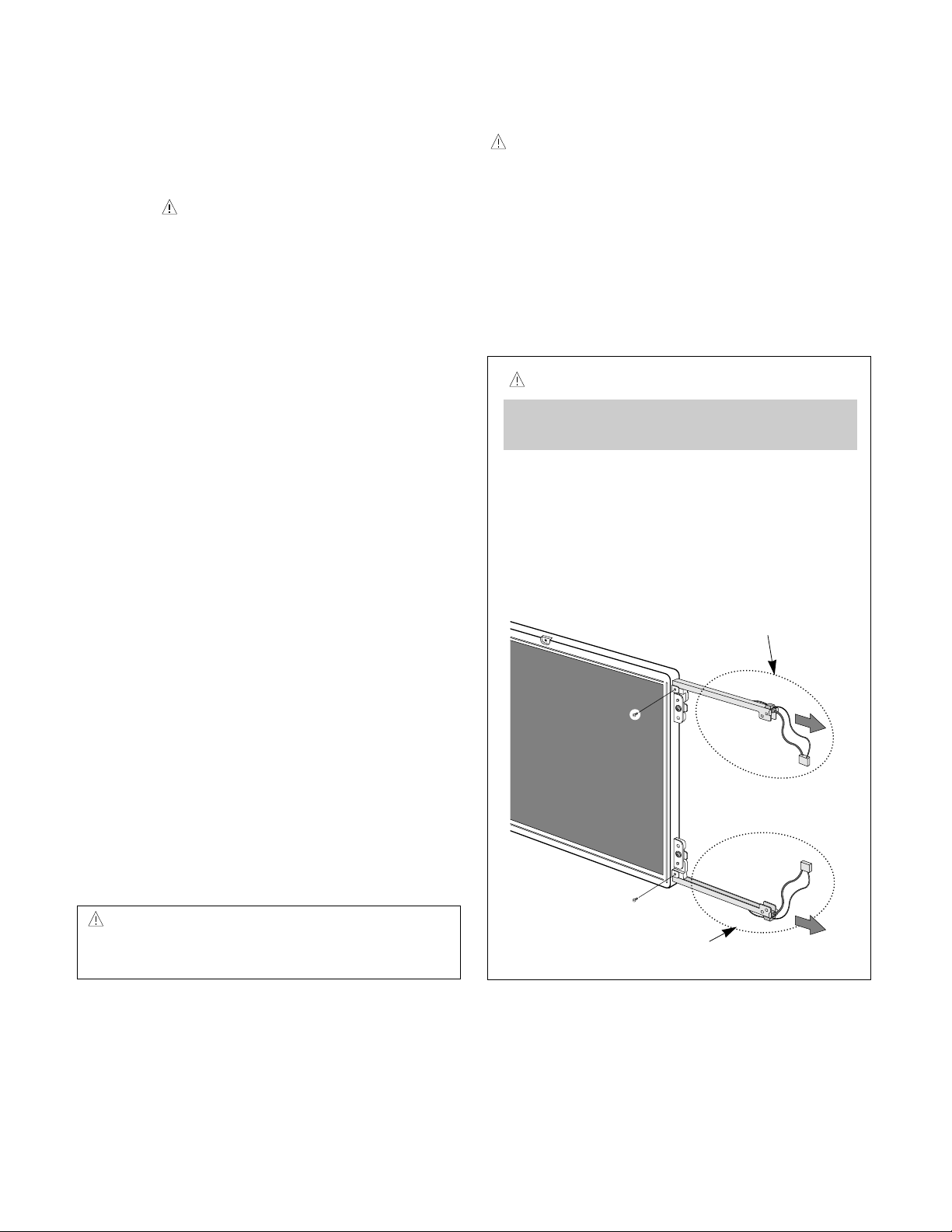

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or

inverter circuit, must disconnect the AC adapter

because high voltage appears at inverter circuit about

650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

PRECAUTION

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

CAUTION

• There is two backlight, must distinguish between

the top (upper) and the bottom (lower), and be

careful of treatment it.

• MTBF (Mean Time Between Failure) of a backlight

is about 25,000 hours.

Top (Upper) Backlight Ass’y

(P/N: 6913TZZ003A)

Bottom (Lower) Backlight Ass’y

(P/N: 6913TZZ003B)

IF BRIGHTNESS OF THE LCD MODULE DARKEN,

REPLACE THE BACKLIGHT ONE OR ALL.

Page 4

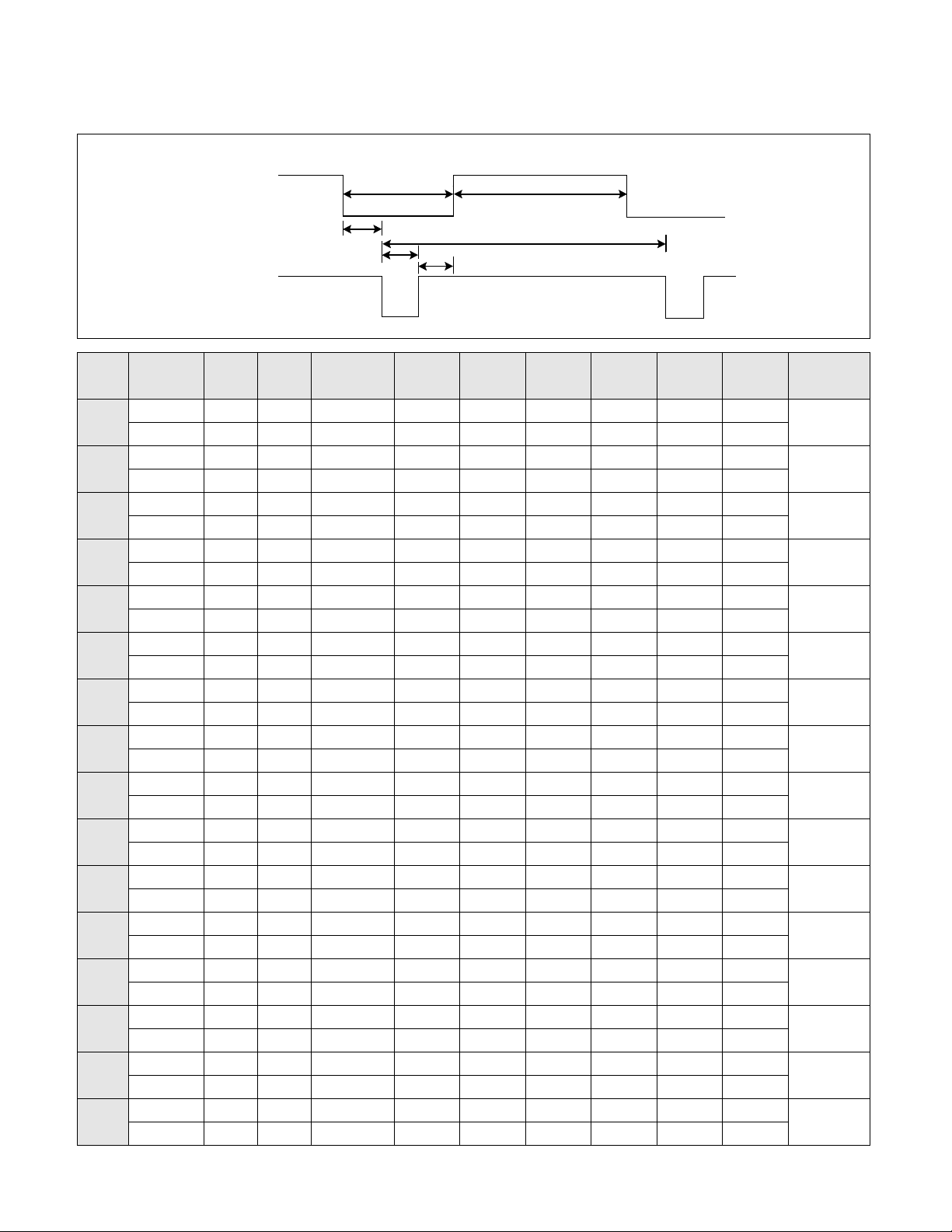

TIMING CHART

- 4 -

VIDEO

SYNC

B

D

C

F

E

A

H / V

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

H (Pixels)

V (Lines)

Sync

Polarity

+

–

–

+

–

–

–

–

–

–

+

+

+

+

+

+

+/–

+/–

–

–

–

–

+

+

+/–

+/–

+/–

+/–

+

+

+

+

Dot

Clock

25.175

28.321

25.175

31.5

36.0

40.0

49.5

56.25

57.283

65.0

78.75

94.5

100.0

92.978

108.0

135.0

Frequency

31.469 KHz

70.8 Hz

31.468 KHz

70.8 Hz

31.469 KHz

59.94 Hz

37.5 KHz

75 Hz

43.269 KHz

85.0 Hz

37.879 KHz

60.317 Hz

46.875 KHz

75.0 Hz

53.674 KHz

85.061 Hz

49.725 KHz

74.55 Hz

48.363 KHz

60.0 Hz

60.123 KHz

75.029 Hz

68.677 KHz

84.997 Hz

68.681 KHz

75.062 Hz

61.805 KHz

65.96 Hz

63.981 KHz

60.02 Hz

79.976 KHz

75.035 Hz

Resolution

640 x 350

720 x 400

640 x 480

640 x 480

640 x 480

800 x 600

800 x 600

800 x 600

832 x 624

1024 x 768

1024 x 768

1024 x 768

1152 x 870

1152 x 900

1280 x 1024

1280 x 1024

Total

Period

( E )

800

449

900

449

800

525

840

500

832

509

1056

628

1056

625

1048

631

1152

667

1344

806

1312

800

1376

808

1456

915

1504

937

1688

1066

1688

1066

Video

Active

Time ( A )

640

350

720

400

640

480

640

480

640

480

800

600

800

600

800

600

832

624

1024

768

1024

768

1024

768

1152

870

1152

900

1280

1024

1280

1024

Blanking

Time

( B )

160

99

180

49

160

45

200

20

192

29

256

28

256

25

248

31

320

43

320

38

288

32

352

40

304

45

352

37

308

42

408

42

Sync

Duration

( D )

96

2

108

2

96

2

64

3

56

3

128

4

80

3

64

3

64

3

136

6

96

3

96

3

128

3

134

4

12

3

144

3

Back

Porch

( F )

48

59

54

35

48

33

120

16

80

25

88

23

160

21

152

27

224

39

160

29

176

28

208

36

144

39

200

31

248

38

248

38

Front

Porch

( C )

16

38

18

12

16

10

16

1

56

1

40

1

16

1

32

1

32

1

24

3

16

1

48

1

32

3

18

2

48

1

16

1

MODE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Page 5

OPERATING INSTRUCTIONS

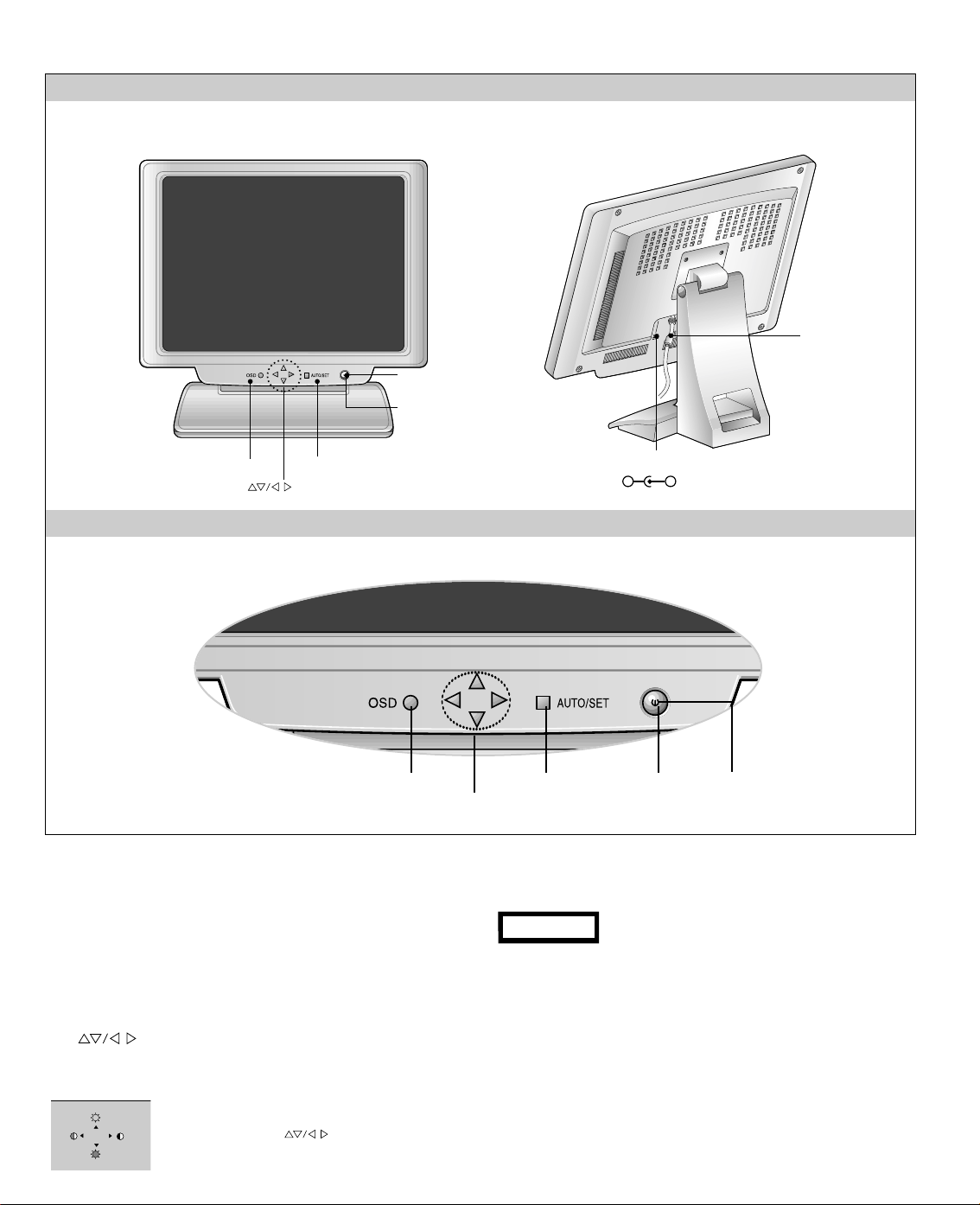

FRONT VIEW REAR VIEW

Front Control Panel

1. Power ON/OFF Button

Use this button to turn the monitor on or off.

2. Power Indicator

This indicator lights up green when the monitor

operates normally; in DPMS (Energy Saving) mode,

-stand-by, suspend, or power off mode -its color

changes to orange.

3. Button

Use these buttons to choose or adjust items in the on screen

display.

4

AUTO/SET Button

Use this button to enter a selection in the on screen display.

5. OSD Button

Use this button to enter or exit the on screen display.

Buttons

OSD Button

AUTO/SET Button

Power Button

Power Indicator

DC Power Connecter

-

+

D-Sub Signal

Connector

15 4

3

2

100

100

<Shortcut Keys>

• Brightness and Contrast can be adjusted directly

without entering the On Screen Display (OSD)

system. Touch the buttons to adjust the

settings and then the OSD button to save all

changes. The Brightness and Contrast functions are

also available in the On Screen Display (OSD) menu.

* AUTO adjustment function

Touch the AUTO/SET button before using OSD menu.

This button is for the automatic adjustment of the

screen position, clock and phase.

Note: Some signal from some graphics boards may

not function properly. If the results are

unsatisfactory, adjust your monitor’s Position, Clock

and Phase manually.

PROCESSING

AUTO CONFIGURATION

Page 6

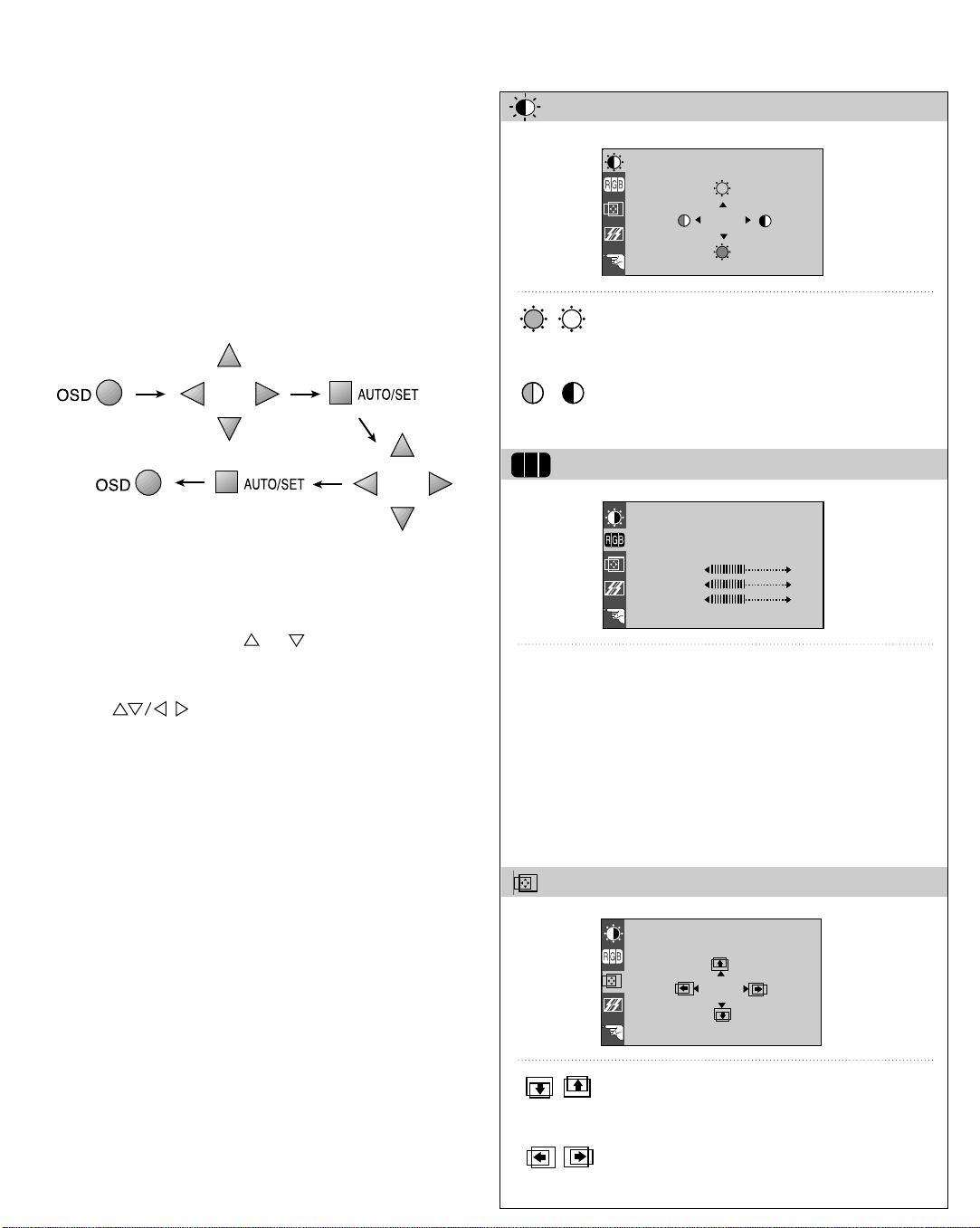

On-Screen-Display (OSD) Control

88

100

BRIGHTNESS CONTRAST

9300K 6500K

COLOR

PRESET

RED

GREEN

BLUE

RGB

61

39

POSITION

To adjust an image size, position, and operating

parameters are quick and easy with the On-ScreenDisplay control system, using the OSD button and the

Adjustment control button. A quick example is given below

to familiarize you with use of the controls.

Example;

Note:

Allow the monitor to stabilize for at least 30 minutes

before making image adjustment.

To make adjustments in the On Screen Display, follow these

steps:

Listed below are icons, icon names, and icon descriptions

of the OSD menu.

BRIGHTNESS CONTRAST

Brightness

Used to adjust the brightness of the

screen.

Contrast

Adjust the display to the contrast

desired.

COLOR

1. Press the OSD Button, then the main menu of the OSD

appears.

2.

To acces a control, use the or Buttons. When the icon

you want becomes highlighted, press the AUTO/SET Button.

3.

Use the Buttons to adjust the item to the desired

level.

4.

Accept the changes by pressing the AUTO/SET Button.

5.

Exit the OSD by Pressing the OSD Button.

PRESET

RED

GREEN

BLUE

POSITION

9300K/ 6500K

To appear the displays color

temperature.

• 9300K:Slightly bluish white.

• 6500K:Slightly reddish white.

To set your own color levels.

To set your own color levels.

To set your own color levels.

Vertical Position

To move image up and down.

Horizontal Position

To move picture image left and right.

Page 7

TRACKING

TRACKING

CLOCK

PHASE

LANGUAGE ENGLISH

FULL

OSD POSITION

48.3kHz / 60.0Hz

PRESET MODE

MODE INFO ON

IMAGE SIZE

SETUP

SETUP

CLOCK

PHASE

To minimize any vertical bars or

stripes visible on the screen

background.The horizontal screen

size will also change.

To adjust the focus of the display.

This item allows you to remove any

horizontal noise and clear or

sharpen the image of characters.

LANGUAGE

To choose the language in which the

control names are displayed.

IMAGE SIZE

This function displays the image in its

original size or enlarged size so as to

fit in the full screen of the LCD panel.

OSD POSITION

To adjust position of the OSD

window on the screen.

MODE INFO

There is information of video modespreset and user modes.

Page 8

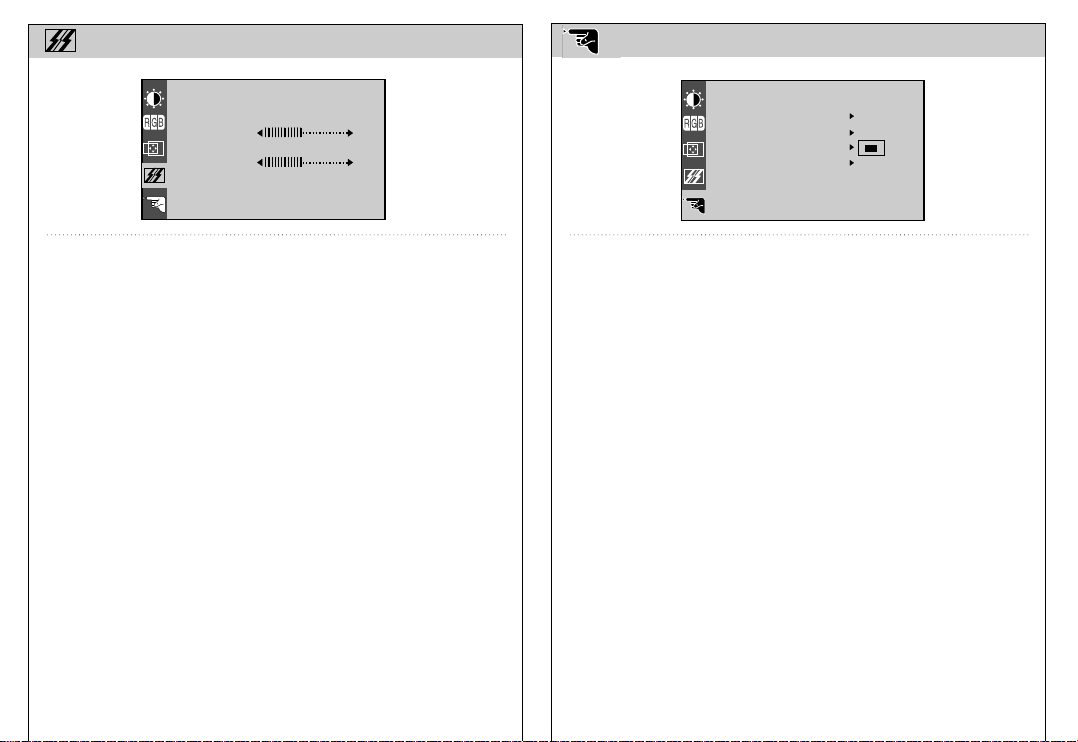

CONTROL LOCATIONS

CN3

J10

J4

J2

CN2

CN1

J301

MAIN PCB

CONTROL PCB

12 5

67

3

4

WIRING DIAGRAM

NO.

1

2

3

4

5

6

7

Ref. No.

SW301

SW304

SW303

SW306

SW302

SW307

SW305

Control Function

OSD BUTTON

ADJUST LEFT

ADJUST UP

ADJUST DOWN

ADJUST RIGHT

AUTO/SET

POWER SWITCH

Page 9

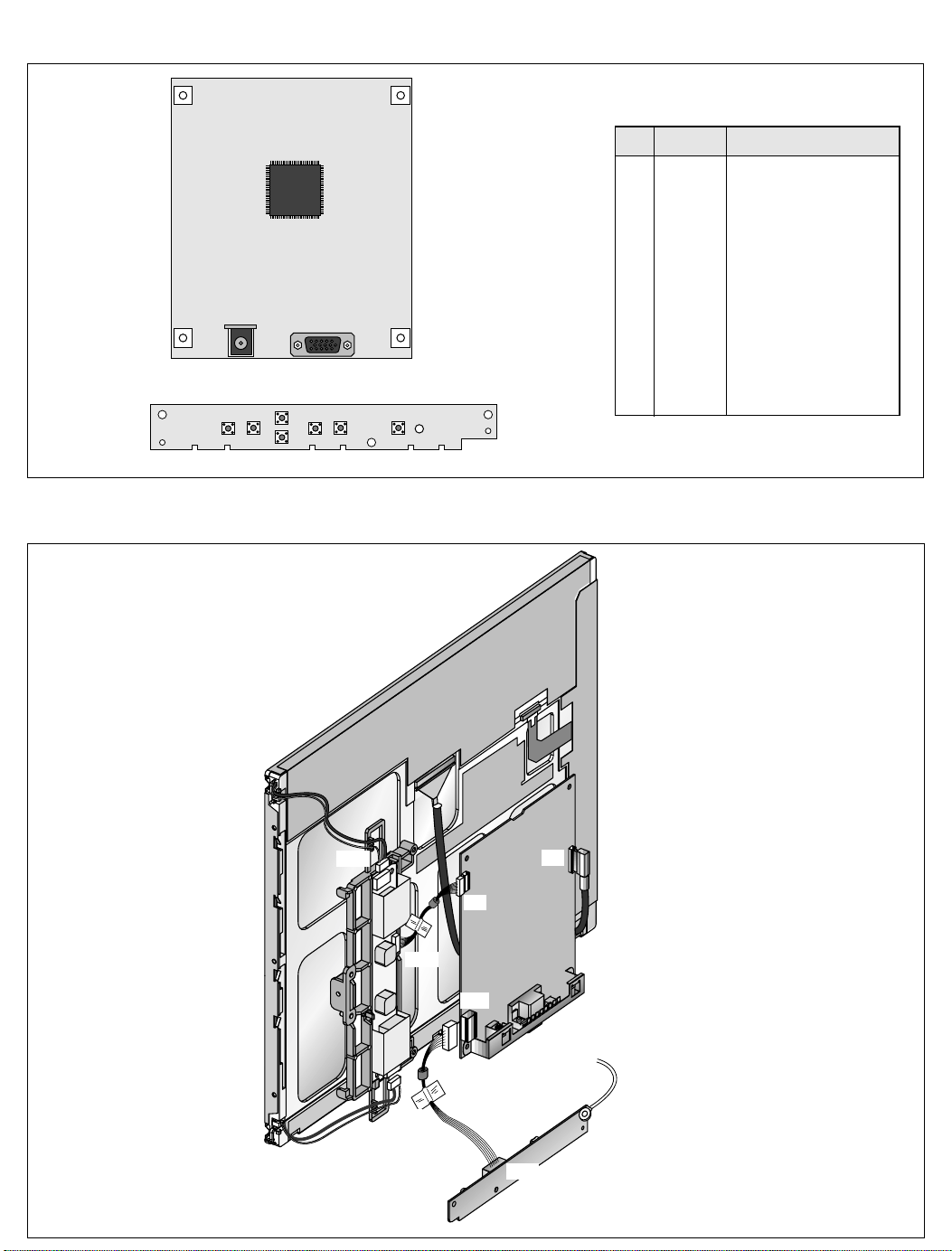

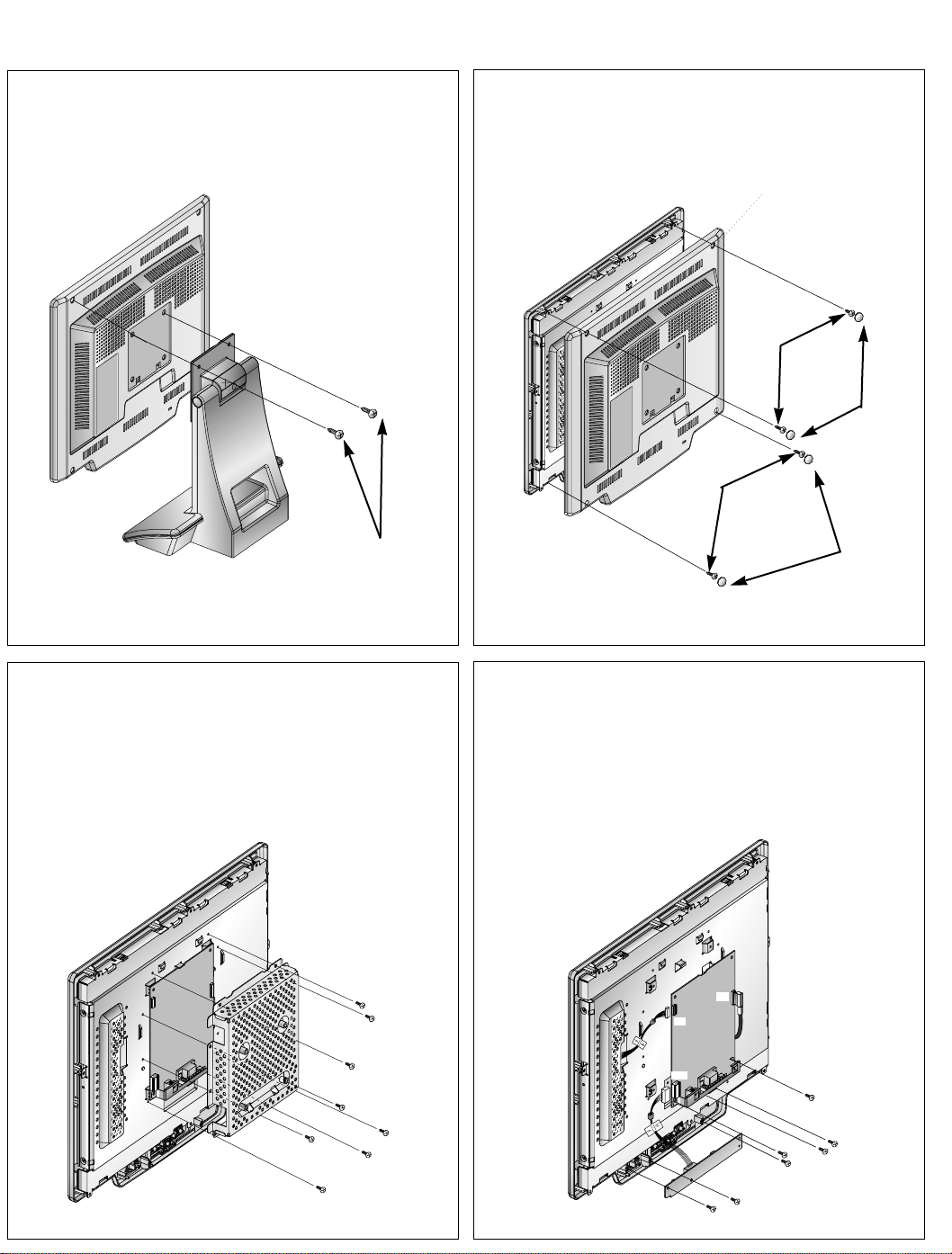

DISASSEMBLY

(a)

(a)

(a)

(a)

(a)

(a)

(a)

(a)

1. TILT/SWIVEL REMOVAL

(1) Remove two screws (a).

(2) Remove the Tilt/swivel.

(a)

2. BACK COVER REMOVAL

(1) Remove four sheet (a) from Back Cover.

(2) Remove four screws (b) from the Back Cover.

(3) Remove the Back Cover.

Back Cover

(b)

(a)

(b)

(a)

3. METAL REAR ASSEMBLY REMOVAL

(1) Remove eight screws (a).

(2) Remove the Metal rear Ass’y.

4. CONTROL, MAIN PCB ASSEMBLY

REMOVAL

(1) Disconnect J2, J4 and J10.

(2) Remove four screws (a).

(3) Remove the Main PCB Ass’y.

(4) Remove three screws (b).

(5) Remove the Control PCB Ass’y.

J2

J4

J10

(b)

(b)

(a)

(b)

(a)

(a)

(a)

Page 10

(b)

(b)

(b)

(b)

(b)

(a)

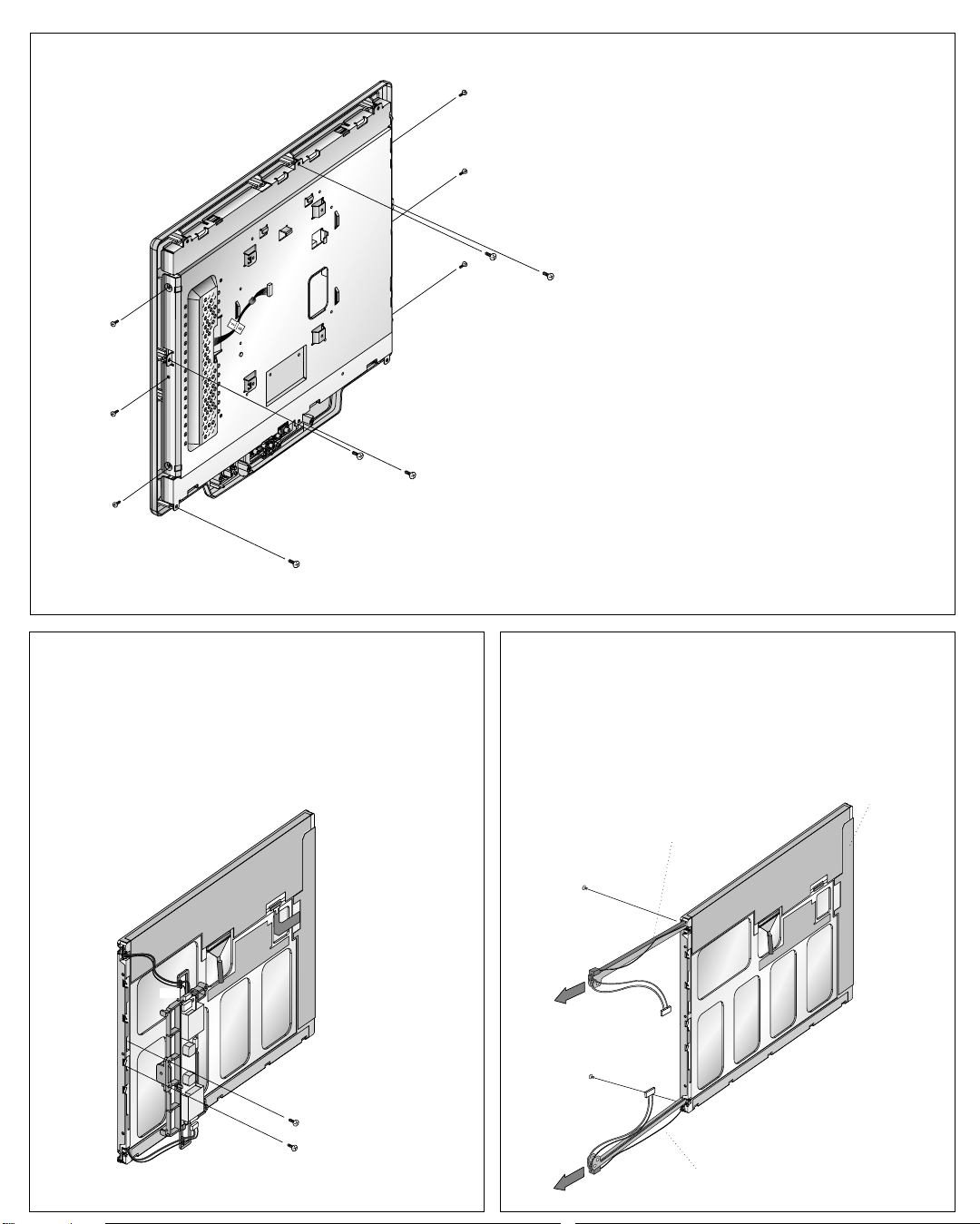

5.METAL FRAME ASSEMBLY

REMOVAL

(1) Remove five screws (a).

(2) Remove six screws (b).

(a)

(3)Remove theMetal Frame Ass’y

(b)

5. INVERYTER REMOVAL

(1) Disconnect CN2,CN3 .

(1) Remove two screws (a).

(2) Remove the Inverter.

CN3

(a)

(a)

(a)

6. BACKLIGHT REMOVAL

(1) Remove two screws (a).

(2) Remove the Backlight from the LCD Module.

LCD Module

Top (Upper) Backlight Ass’y

(a)

CN2

(a)

(a)

(a)

Bottom (Lower) Backlight Ass’y

Page 11

D-SUB

Video Controller

MX88L282

LVDS

(LVDS83)

LVDS

(LVDS83)

Memory

(KM416S102BT)

H-Sync

A/D

converter

AD9884

M-CLK

Out - CLK

DE ,H/V Sync out

R,G,B odd

Out - CLK

DE ,H/V Sync out

R,G,B Even

LCD Module

R,G,B

differential

L VDS:Low Voltage Differential Signaling

Data 48 BitAddress

H-Sync

R,G,B

3.3V

3.3V

3.3V

ADC CLK

ADC CLK

R,G,B

even, odd

Micom

68HC08-BD48

Inverter CTL

Module CTL

V-Sync

Power CTL

H-Sync

3.3V

Inverter

24V

DC-DC

Converter

3.3V

Reg.

3.3V

24V Input

5.0V

5.0V

Video Signal

3.3V

3.3V

Page 12

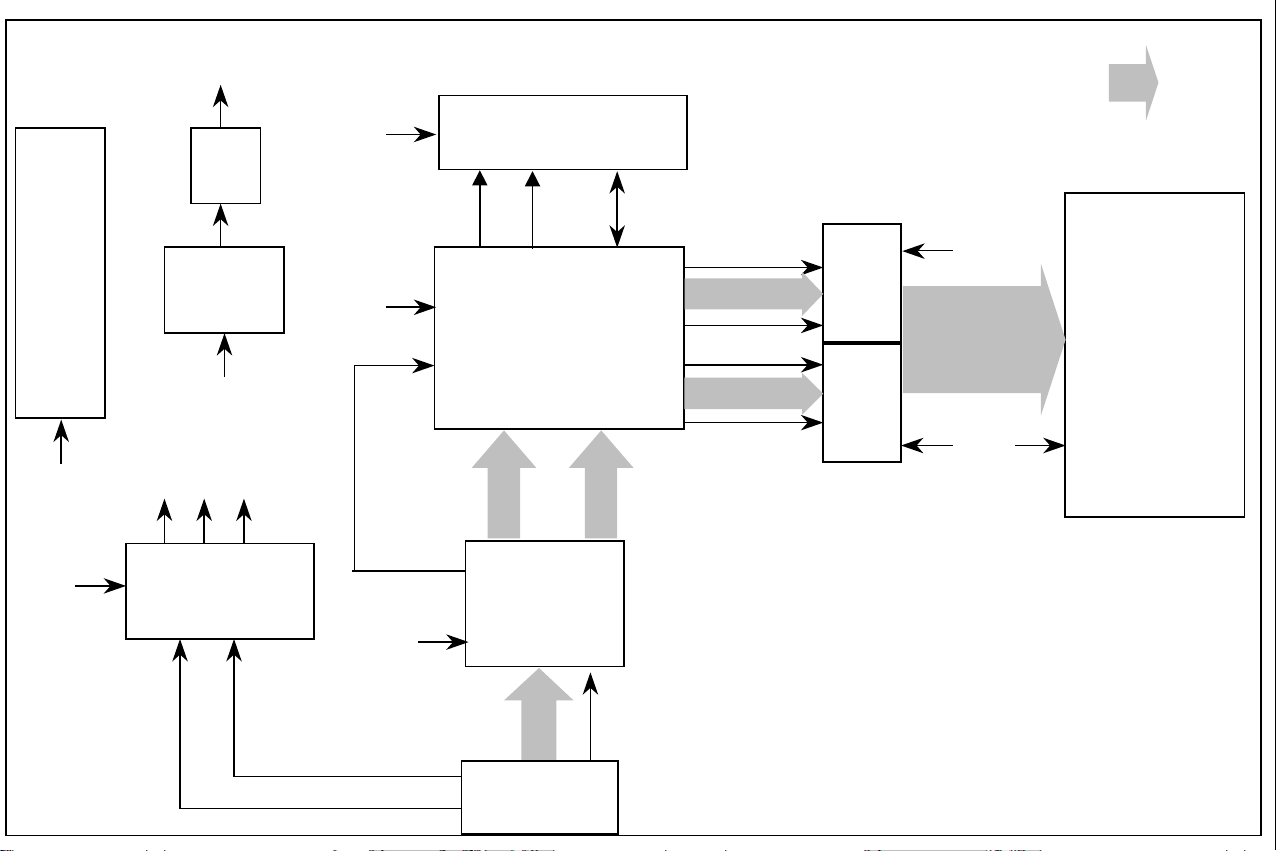

DESCRIPTION OF BLOCK DIAGRAM

- 12 -

1. Pre-amp/ ADC / PLL Part.

This part amplifies the level of video signal for the digital conversion and converts from the analog video signal to the

digital video signal using a pixel clock.

The pixel clock for each mode is generated by the PLL.

The range of the pixel clock is from 25MHz to 135MHz.

2. Video Controller Part.

This part consists of the Scaler and frame buffers which converts frame rate of input signal to 60Hz frame rate.

The Scaler gets the video signal converted analog to digital, interpolates input to 1280 X 1024 resolution signal and

outputs 8-bit R, G, B signal to transmitter.

3. Display Data Transmitter Part.

This part transmit digital signal from the Scaler to the receiver of module.

4. Power Part.

This part consists of the DC/DC converter and several 3.3V regulators .

The DC/DC converter coverts 24V to be entered power adapter to 5V.

5V, output of DC/DC converter, supply to the micom and 3.3V regulators.

The output voltage of 3.3V regulator supply to IC of each part.

5. MICOM Part.

This part consists of EEPROM IC which stores control data, Reset IC and the Micom.

The Micom distinguishes polarity and frequency of the H/V sync are supplied from signal cable.

The controlled data of each mode is stored in EEPROM.

6. Inverter

The inverter converts from 24V to AC 700Vrms and drive back-light lamp of module.

Page 13

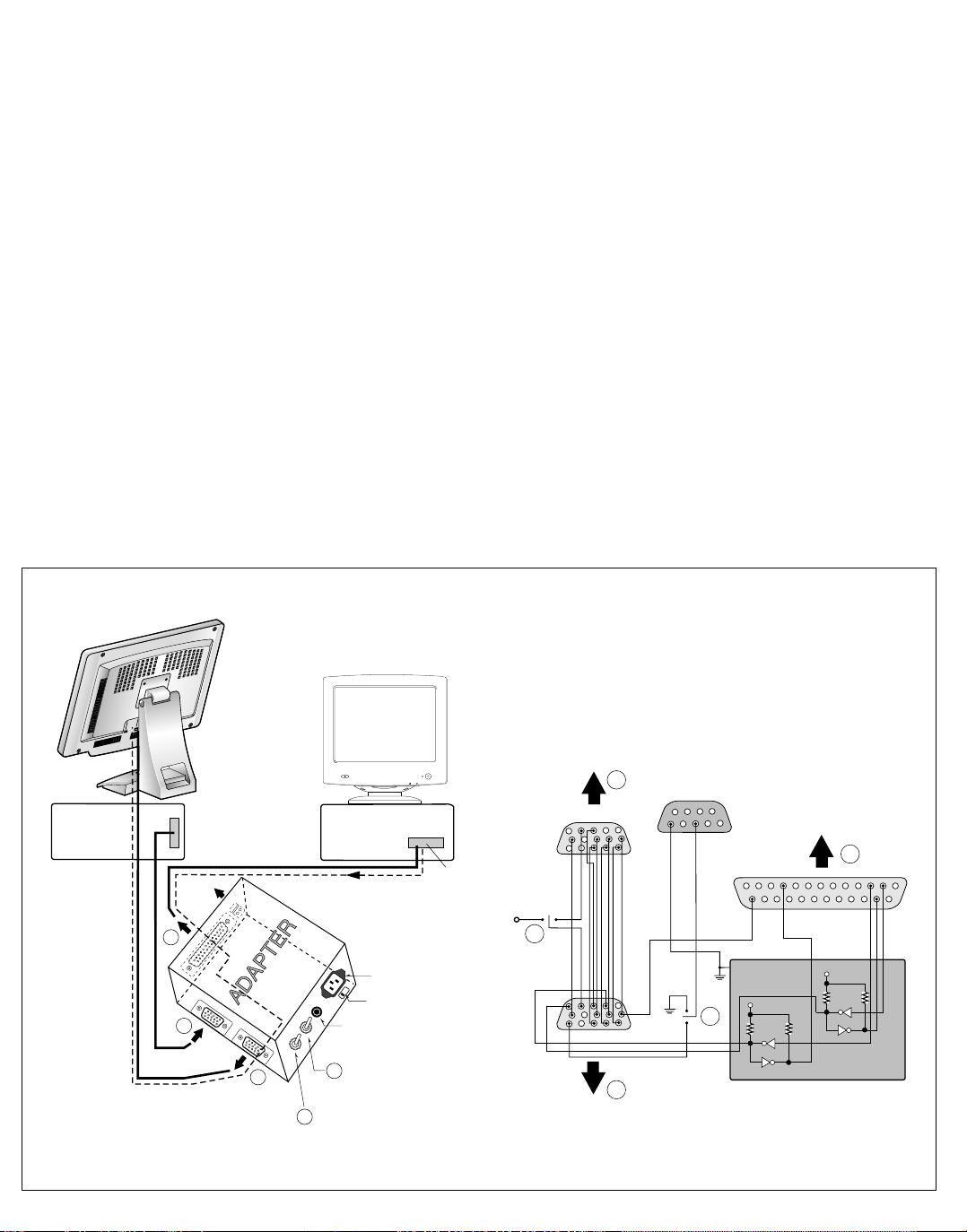

ADJUSTMENT

220

IBM

Compatible PC

PARALLEL PORT

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

E

V-Sync On/Off Switch

(Switch must be ON.)

F

F

A

A

B

B

C

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several minor adjustment may be required.

Adjustment should be following procedure and after

warming up for a minimum of 10 minutes.

Alignment appliances and tools.

- IBM Compatible PC

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- E(E)PROM with each mode data saved.

- Alignment Adapter and Software.

1. Adjustment for Factory Preset Mode

1) Run alignment program for FPD1570 on the IBM

compatible PC.

2) Select EEPROM all clear command and Enter.

3) Display cross hatch pattern at Mode 1.

4) Select COMMAND PRESET START command.

5) Select FOS DEFAULT command and Enter.

6) Press "Y" key, it will automatically save all FOS data

to EEPROM.

2. Adjustment for White Balance

1) Display color 0,0 pattern at Mode 13.

2) Set External Bright to MAX position and Contrast to

MAX Position.

3) Select PRESET START

→ BIAS CAL command

and Enter.

4) No attempt to manually adjust, BIAS data is automatically adjusted and saved to the EEPROM.

5) Display color 15,0 pattern at Mode 13.

6) Select DRIVE CAL command and Enter.

7) Color 1 (9300K) and Color 2 (6500K) are

automatically adjusted and saved to the EEPROM.

8) Select PRESET EXIT command and Enter.

Figure 1. Cable Connection

Page 14

TROUBLESHOOTING GUIDE

NO POWER

(POWER INDICATOR OFF)

1. NO POWER

CHECK U15

INPUT VOLTAGE

(24V) ?

YES

CHECK

5VST VOLTAGE

(5V) ?

YES

CHECK

U4 PIN 6.

IS THIS PIN

OSCILLATED?

NO

NO

NO

TROUBLE IN

ADAPTOR or

INVERTER

TROUBLE IN

U15

TROUBLE IN

U4 or X2

YES

TROUBLE

SOMEWHERE ELSE

Page 15

NO RASTER

2. NO RASTER

CHECK

J4 PIN 10

(24V) ?

YES

CHECK

J4 PIN 5 (5V) ?

YES

CHECK

U4 PIN 42

H. PULSE ?

YES

CHECK

U5 PIN 117

H.PULSE?

YES

NO

NO

NO

NO

TROUBLE IN

POWER ADATER

TROUBLE IN

INON PATTERN

TROUBLE IN

U106, U105, U101,

U109

TROUBLE IN

U5

CHECK

U5 PIN 115

AD CLOCK ?

YES

NO

TROUBLE IN

U5

Page 16

YES

CHECK

U1 PIN 254

DOT CLOCK ?

YES

CHECK

MEMORYCLK

U6, U7, U8

PIN 35 ?

YES

CHECK

U1 PIN 93, 94

DOT CLOCK ?

YES

NO

NO

NO

CHECK

ADC-CLK PATTERN

TROUBLE IN

U1

TROUBLE IN

U1

CHECK

U1 PIN 124

D26 (H.PULSE) ?

YES

NO

TROUBLE IN

U1

Page 17

YES

CHECK

U2, U11 PIN 27

H.PULSE ?

YES

CHECK

U2, U11 PIN 28

V.PULSE ?

YES

CHECK

U2, U11 PIN 31

DOT CLOCK?

YES

CHECK

U2, U11 PIN 30

H.PULSE?

NO

NO

NO

NO

TROUBLE IN

U1

TROUBLE IN

U1

TROUBLE IN

U1

TROUBLE IN

U1

YES

TROUBLE IN

LCD MODULE

Page 18

NO DOT CLOCK

YES

3. NO CLOCK (CLOCK GENERATOR)

CHECK

U5Vcc

3.3V ?

CHECK

U5 PIN 115

CLOCK ?

YES

NO

NO

TROUBLE IN

U23

TROUBLE IN

U5

Page 19

TROUBLE IN DPM

CHECK

U617 (MICOM)

PIN 1, 42 (H/V INPUT)

SIGNAL ?

YES

4. TROUBLE IN DPM

NO

TROUBLE IN

U17

CHECK

U4 PIN 6

WAVEFORM

(24MHz) ?

YES

CHECK

U4 PIN 26

(5V) ?

YES

TROUBLE IN PC

NO

NO

TROUBLE IN

X2

TROUBLE IN

SIGNAL CABLE

Page 20

C66

C62

C47

R13

R20

J2

U23

U20

U19

U13

R12

C150

C209

C35

R15

C1

C49

R101

C65

C201

R104

U2

BA18

C151

C153

C152

U11

C175

C174

CA17

C50

BA36

R103

C193

C194

R100

C64

R64R63

L5

C235

L24

C234

L6

C99

J5

BA19

BA20 BA21 BA22 BA23 BA24 BA40 BA41

BA43BA42

BA45

BA44

X1

CA11

CA18

BA30

BA33

R76

C73

C74

60

50

D5

C3

R98

C198

C195

C63

R102

R62

C233

R66

R65

Model:LB680A Ver:1.3

U8

P/N:6870T285A10

Date:2000.09.20

BA7

120

110

100

90

70

R16

C15

CA12CA15

C13

BA27BA35

70

30

D4

D3

ZD2

ZD1

BA8

BA9

140

130

6050

CA16CA9

BA29RA32

90

80

20

U6

BA12

BA11

BA10

160 150

40

30

CA10CA13

BA26BA34

U5

100

51

10

BA14

BA13

BA15

170

2010

CA14

CA7

BA28

BA31

L3

120

110

C72

125

D1

D2

BA16

BA17

U1

1

CA8

BA25

C67

C96

R92

D6

J3

R94

U7

BA3

C101

C181

BA1

210

200

BA37BA38

230

220

BA39

C60

255

R24

U3

R91

C196

Q7Q3

R93

Q8

C197

C95

C184

BA5

BA4BA6

C190

C177

C42

ZD3

R37

R27R31

R26

R36

L1

U17

J1

C89

C48

C59

C127

U14

U10

R30

U9

L7

Q6

R52

R59

R32

R60

U24

U16

U12

C61

C31

R50

R49

R83

C56

C55

C32

X2

R84

Q2

R68

C36

Q5

R58

C37

L26

C57

C38

C40

Q4

C58

L9

U15

R80C30

R47

Q1

R48

L12

L13

C192

C135

J4

1

C41 L27

L23

C188

ZD6

U4

L4

J10

1. MAIN BOARD (Component Side)

Page 21

C186C51

C118

C204

R1

C24

C27

R14

C25

C230

C229

C53

C129

C128

C126

C21

C5

L2

C142

C143

L8

C103

C26

C166

C167

C168

C54

C52

C124C123

C133

C131

C130

C125

C136

C140

C137

C146

C145

C155

C156

C149

C154

C160

C169

C170

C173

C172

C171

C83

C94

C93

C92

R23

C110

C134

C122

C144

C139

C138

C147

C141

C23

C158

C157

C148

C163 C161

C164

C162

C165

C17

C85

R74

C88

C90

C91

C117C120

C114C116

C121

C16

C19

C14

C22

C20

C159

C18

C81

C79

R73C87

C86

C84

R18

R19

C11

C70

C77

C76

C78

C80

C82

R90

C111

C115

C112

C98

C97

C102

R8

R7

L10

C9

R17

R10

R11

C12

C68

C75

C69

C71

C203

R97

R96

C109

C108

C105

C104

C107

C106

C8

R4

C4

R9

C6

R6

C7

C10

R2

R67

R21

R78

C202

R110

C182

C180

C100

R3

R5

R130

R132

R56

R55

R53

R38

R135

R133

R45

R46

R61

C33

R109

R108

R89

R99

C224

R111

C39

R88

C113C183

R70

C119

C176

R54

R25

R77

R125

R42

R41

R43

R44

R126

R121

R28

C132

C231

C178

C179

C200

R86

R85

R82

R35

R87

R39

R40

C191

R29

R33

R34

R57

R51

R95

C2

C232

R22

C199

R81

R79

R75

R69

R72

C189

C187

C185

R124

C46

C45

C44

C43

C34

C29

C28

L17 L16

R71

2. MAIN BOARD (Solder Side)

Page 22

EXPLODED VIEW

1

2 3

4

5

A

8

9

10

10-1

13

12

7

6

EXPLODED VIEW PARTS LIST

Ref. No.

1

2

3

4

5

6

7

8

9

10

10-1

11

12

13

A

Part No.

3091TKL021C

6304TLT157A

6632Z-1502D

6871TST198A

4951TKS062A

6871TMT213A

6631T11010E

4951TKK044A

3809TKL016C

5410TKK020B

332-113F

3043TKK070B

332-105F

6634TBZ009E

3313TL5022A

Description

CABINET ASS’Y, LB680A G/WAY 3090TKL019A PC+ABS, 12446B

LCD , LGPHILIPS TFT LCD LM157E2-A2, 15.7” 1280x1024 W/O I

INVERTER, NMC1502 15.1”

PWB(PCB)ASS’Y, SUB LB680A XAGT BRAND CONTROL

METAL ASS’Y, FRAME LB680A

PWB(PCB)ASS’Y, MAIN LB680A XGWC G/WAY CL-18 TOTAL

CONNECTOR ASS’Y, 30P H-H 140MM UL-20276 LB680A

METAL ASS’Y, REAR LB680A

BACK COVER ASS’Y, LB680A 017A G-WAY, 12446B

INSULATION, PVC SHEET LB680

SCREW, PVP+3x12(MSWR/FZMY)

TILT SWIVEL ASS’Y, LG680, (G/WAY, 12446B)

SCREW, PVS+4x10(MSWR/FZMW)

ADAPTER, AC-DC, PSCV360107 SAMSUNG 100-240V 24V 1.5A FOR G/WAY

MAIN TOTAL ASS’Y, LB680A G/WAY CL-18

Page 23

REPLACEMENT PARTS LIST

CAUTION: BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

MAIN BOARD

CAPACITORs

C1 0CH8107F611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 16V M 85STD(CYL) R/TP

C2 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C3 0CH6150K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 15PF 50V J NP0 2012 R/TP

C4 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C5 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C6 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C7 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C8 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C9 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C10 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C11 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C12 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C13 0CH6150K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 15PF 50V J NP0 2012 R/TP

C14 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C15 0CH6150K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 15PF 50V J NP0 2012 R/TP

C16 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C17 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C18 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C19 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C20 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C21 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C22 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C23 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C24 0CH6560K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 56PF 50V J NP0 2012 R/TP

C25 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C26 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C27 0CH6560K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 56PF 50V J NP0 2012 R/TP

C28 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C29 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C30 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C31 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C32 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C33 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C34 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C35 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C36 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C37 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C38 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C39 0CH6101K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 100PF 50V J NP0 2012 R/TP

C40 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C41 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C42 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C43 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C44 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C45 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C46 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C47 0CZZTAT002B CAPACITOR, SVP, SANYO 10V 47UF M REEL OS-CON

C48 0CZZTAT002B CAPACITOR, SVP, SANYO 10V 47UF M REEL OS-CON

C49 0CZZTAT002B CAPACITOR, SVP, SANYO 10V 47UF M REEL OS-CON

C50 0CH8107F611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 16V M 85STD(CYL) R/TP

C51 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C52 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C53 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C55 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C56 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C57 0CH6221K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 220PF 50V J NP0 2012 R/TP

C58 0CH6221K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 220PF 50V J NP0 2012 R/TP

C59 0CZZTAT002B CAPACITOR, SVP, SANYO 10V 47UF M REEL OS-CON

C60 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

Page 24

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C61 0CH8106J691 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 10UF 35V M 105STD (CYL) R/TP

C62 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C63 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C64 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C65 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C66 0CH6102K406 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 1000PF 50V J SL 2012 R/TP

C67 0CH8107F611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 16V M 85STD(CYL) R/TP

C68 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C69 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C70 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C71 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C72 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C73 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C74 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C75 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C76 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C77 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C78 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C79 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C80 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C81 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C82 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C83 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C84 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C85 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C86 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C87 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C88 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C89 0CH8107F611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 16V M 85STD(CYL) R/TP

C90 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C91 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C92 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C93 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C94 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C95 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C96 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C97 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C98 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C100 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C101 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C102 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C103 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C104 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C105 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C106 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C107 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C108 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C109 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C111 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C112 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C113 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C114 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C115 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C116 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C117 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C118 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C119 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C120 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C121 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C122 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C123 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C124 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C125 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C126 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C127 0CZZTAT002D CAPACITOR, SVP, SANYO 10V 270UF M REEL OS-CON

C128 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C129 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C130 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C131 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

Page 25

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C132 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C133 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C134 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C135 0CH8107J611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 35V M 85STD(CYL) R/TP

C136 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C137 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C138 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C139 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C140 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C141 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C142 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C143 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C144 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C145 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C146 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C147 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C148 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C149 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C150 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C151 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C152 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C153 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C154 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C155 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C156 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C157 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C158 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C159 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C160 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C161 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C162 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C163 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C164 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C165 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C166 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C167 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C168 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C169 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C170 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C171 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C172 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C173 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C174 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C175 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C176 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C177 0CH8106J691 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 10UF 35V M 105STD (CYL) R/TP

C178 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C179 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C180 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C181 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C182 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C183 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C184 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C185 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C186 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C187 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C189 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C190 0CZZTAT002D CAPACITOR, SVP, SANYO 10V 270UF M REEL OS-CON

C191 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C192 0CH8107J611 CAPACITOR, CHIP, [AL. ELECTROLYTIC], 100UF 35V M 85STD(CYL) R/TP

C193 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C194 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C195 0CH6100K116 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 10PF 50V D NP0 2012 R/TP

C196 0CH6101K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 100PF 50V J NP0 2012 R/TP

C197 0CH6101K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 100PF 50V J NP0 2012 R/TP

C198 0CH6150K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 15PF 50V J NP0 2012 R/TP

C199 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C200 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C201 0CH6150K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 15PF 50V J NP0 2012 R/TP

Page 26

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C202 0CH6680K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 68PF 50V J NP0 2012 R/TP

C203 0CH6680K416 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 68PF 50V J NP0 2012 R/TP

C204 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C209 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C224 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C229 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C230 0CH3103K516 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 10000PF 50V K B 2012 R/TP

C231 0CH3104K566 CAPACITOR, CHIP, [CERAMIC LD-LESS HD], 0.1UF 50V K X 2012 R/TP

C232 0CH6102K406 CAPACITOR, CHIP, [CERAMIC LD-LESS TC], 1000PF 50V J SL 2012 R/TP

CA7 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA8 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA9 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA10 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA11 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA12 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA13 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA14 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA15 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA16 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA17 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

CA18 0CHZTTA001A CAPACITOR, CHIP, 10F 50V F 3216 4ARRAY REEL TDK

DIODEs

D1 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

D2 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

D3 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

D4 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

D5 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

D6 0DS226009AA DIODE, SWITCHING, KDS226 TP KEC SOT-23 80V 300MA 2A 4NS 0.5UA

ZD1 0DZ560009DA DIODE, ZENER, UDZ S 5.6B TP ROHM-K SOD323 200MW 5.6V 5MA .PF

ZD2 0DZ560009DA DIODE, ZENER, UDZ S 5.6B TP ROHM-K SOD323 200MW 5.6V 5MA .PF

ZD3 0DZ560009DA DIODE, ZENER, UDZ S 5.6B TP ROHM-K SOD323 200MW 5.6V 5MA .PF

ZD6 0DR340009AA DIODE, RECTIFIER, MBRS340 TP FAIRCHILD NON 40V 3A 80A .SEC 2MA

ICs

U1 0IMR882820B IC, MACRONIX , MX88L282FC 256PQFP BK SXGA LCD INTEGRATION

U2 0ITH638300A IC, THINE MICROSYSTEMS, THC63LVDM83A,LVDS(THINE)

U3 0IMP240800A IC, MICRO CHIP TECHNOLOGY, 24LC08BT/SN 8P SOIC TP EEPROM

U4 0IZZTSZ109A IC, DRAWING, MC68HC08BD48 42PIN,SDIP BK MCU(BD48) FLASH ROM

U5 0IAD988414A IC, ANALOG DEVICE, AD9884AKS-140 128P MQFP ST ANALOG DEVICES

U6 0IEB121616A IC, ELITE MEMORY TECHNOLOGY, M12L16161A-7T 50P TSOP ST

U7 0IEB121616A IC, ELITE MEMORY TECHNOLOGY, M12L16161A-7T 50P TSOP ST

U8 0IEB121616A IC, ELITE MEMORY TECHNOLOGY, M12L16161A-7T 50P TSOP ST

U9 0IKE704200J IC, KEC, KIA7042AF SOT-89 TP 4.2V VOLTAGE DETECTOR

U11 0ITH638300A IC, THINE MICROSYSTEMS, THC63LVDM83A,LVDS(THINE)

U12 0ISS781200J IC, SAMSUNG ELECTRONICS, KA78M12R 3P,D-PAK TP VOL. REGULATOR

U13 0IPMGSJ001A IC, POWER MANAGEMENT, EZ1086CM-3.3 SEMTECH TO-263 R/TP 1.5A

U14 0ISS780500H IC, SAMSUNG ELECTRONICS, KA78M05-R 3P,D-PAK TP 5V 0.5A

U15 0INS259650A IC, NATIONAL SEMICONDUCTOR, LM2596-5V 5LEAD,TO263(S) TP 3A 5V S/D

U16 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

U17 0IMO741420B IC, MOTOROLA, MC74HCT14ADR2 14P,SOIC TP LEVEL CONVERTER

U19 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

U20 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

U23 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

U24 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

COILs & COREs

L1 6210TCE001C CORE (CIRC), BEAD, HB-1T3216-500JT CERATEC 3216MM CHIP-BEAD

L2 6210TCE001E CORE (CIRC), BEAD, HB-1M2012-800JT CERATEC 2012MM R/TP

L3 6210TCE001K CORE (CIRC), BEAD, HB-1H2012-260JT CERATEC 2012MM R/TP

L4 6210TCE001G CORE (CIRC), BEAD, HH-1M3216-501 CERATEC 3216MM R/TP

L5 6210TCE001K CORE (CIRC), BEAD, HB-1H2012-260JT CERATEC 2012MM R/TP

L6 6210TCE001K CORE (CIRC), BEAD, HB-1H2012-260JT CERATEC 2012MM R/TP

L7 6210TCE001C CORE (CIRC), BEAD, HB-1T3216-500JT CERATEC 3216MM CHIP-BEAD

L8 6210TCE001E CORE (CIRC), BEAD, HB-1M2012-800JT CERATEC 2012MM R/TP

L9 6200TEZ003D FILTER(CIRC), CAPACITOR, TPRH1207-330M BOAM 33UH,SMD CHOKE

Page 27

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

L10 6210TCE001R CORE (CIRC), BEAD, HB-1S2012-400JT CERATECH 2012MM R/TP

L12 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

L13 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

L16 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

L17 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

L23 6210TCE001G CORE (CIRC), BEAD, HH-1M3216-501 CERATEC 3216MM R/TP

L24 6210TCE001K CORE (CIRC), BEAD, HB-1H2012-260JT CERATEC 2012MM R/TP

L26 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

L27 6210TCE001D CORE (CIRC), BEAD, HB-1M2012-601JT CERATEC 2012MM R/TP

TRANSISTORs

Q1 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EPI. SILICON TR

Q2 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EPI. SILICON TR

Q3 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EPI. SILICON TR

Q5 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EPI. SILICON TR

Q6 0TF492509AA FET, SI4925DY TP TEMIC 30V 6.1A SO-8

Q7 0TR390409AE TRANSISTOR, KST3904-MTF TP SAMSUNG SOT23 GEN. PURPOSE TR

Q8 0TR390409AE TRANSISTOR, KST3904-MTF TP SAMSUNG SOT23 GEN. PURPOSE TR

RESISTORs

R1 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R2 0RH2201D622 RESISTOR, CHIP, 2.2K 1/10W P-TYPE TAPPING

R3 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R4 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R5 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R6 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R7 0RH0472D622 RESISTOR, CHIP, 47 1/10W 5 D.R/TP

R8 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R9 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R11 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R12 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R13 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R14 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R15 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R16 0RH1004D622 RESISTOR, CHIP, 1.0M 1/10W 5 D.R/TP

R17 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R18 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R19 0RH0222D622 RESISTOR, CHIP, 22 1/10W 5 D.R/TP

R20 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R21 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R22 0RH1003D622 RESISTOR, CHIP, 100K 1/10W 5 D.R/TP

R24 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R25 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R26 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R27 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R28 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R29 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R30 0RH3302D622 RESISTOR, CHIP, 33K 1/10W 5 D.R/TP

R31 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R33 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R34 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R35 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R36 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R37 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R38 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R39 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R40 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R41 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R42 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R43 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R44 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R45 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R46 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R47 0RH2700D622 RESISTOR, CHIP, 270 1/10W 5 D.R/TP

R48 0RH2700D622 RESISTOR, CHIP, 270 1/10W 5 D.R/TP

R49 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R50 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

Page 28

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R51 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R52 0RH6802D622 RESISTOR, CHIP, 68K 1/10W 5 D.R/TP

R53 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R54 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R55 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R56 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R57 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R59 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R61 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R62 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R63 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R64 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R65 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R66 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R67 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R68 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R69 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R70 0RH1003D622 RESISTOR, CHIP, 100K 1/10W 5 D.R/TP

R71 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R72 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R73 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R74 0RH1500D622 RESISTOR, CHIP, 150 1/10W 5 D.R/TP

R75 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R76 0RH1501D622 RESISTOR, CHIP, 1.5K 1/10W 5 D.R/TP

R77 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R78 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R79 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R80 0RH1004D622 RESISTOR, CHIP, 1.0M 1/10W 5 D.R/TP

R81 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R82 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R85 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R86 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R87 0RH1201D622 RESISTOR, CHIP, 1.2K 1/10W 5 D.R/TP

R88 0RH1501D622 RESISTOR, CHIP, 1.5K 1/10W 5 D.R/TP

R89 0RH1501D622 RESISTOR, CHIP, 1.5K 1/10W 5 D.R/TP

R90 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R91 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R92 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R93 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R94 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R95 0RH1003D622 RESISTOR, CHIP, 100K 1/10W 5 D.R/TP

R96 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R97 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R98 0RH0102D622 RESISTOR, CHIP, 10 1/10W 5 D.R/TP

R99 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R100 0RH0102D622 RESISTOR, CHIP, 10 1/10W 5 D.R/TP

R101 0RH0102D622 RESISTOR, CHIP, 10 1/10W 5 D.R/TP

R102 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R103 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R104 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R108 0RH4700D622 RESISTOR, CHIP, 470 1/10W 5 D.R/TP

R109 0RH2201D622 RESISTOR, CHIP, 2.2K 1/10W P-TYPE TAPPING

R110 0RH4702D622 RESISTOR, CHIP, 47K 1/10W 5 D.R/TP

R111 0RH2702D622 RESISTOR, CHIP, 27K 1/10W 5 D.R/TP

R121 0RH1003D622 RESISTOR, CHIP, 100K 1/10W 5 D.R/TP

R124 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R125 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R126 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R130 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R132 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R133 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R135 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

OTHERs

J1 6612TAH002A JACK, AC/DC POWER DC-001 UNITOP DC-001 2.0MM (UNITOP)

X1 6202TST001A CRYSTAL, SX-1 SUNNY ,SMS, 14.31818MHZ ,30PPM, 18PF, TP

X2 6202TST001E CRYSTAL, SX-1 SUNNY CHIP 24MHZ 30PPM 20PF BK

RA32 6210TCE002C CORE (CIRC), BEAD, HB-4T3216-201JT CERATECH 3216MM R/TP

Page 29

MODEL: FPD1570 DATE: 2000. 10. 11.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMAR

CONTROL BOARD

R301 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R302 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R303 0RD1601Q609 RESISTOR, FIXED CARBON FILM, 1.60K 1/4W(3 5% TA52

R304 0RD1601Q609 RESISTOR, FIXED CARBON FILM, 1.60K 1/4W(3 5% TA52

R305 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R306 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

S301 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S302 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S303 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S304 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S305 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S306 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

S307 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL 160G

ZD301 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V 5MA 26MM

ZD302 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V 5MA 26MM

LED301 0DL571300AA LED “SPR571MVW3 TP ROHM GREEN/RED “”10,10MCD”””

MISCELLANEOUS

LCD 6304TLT157A LCD(LIQUID CRYSTAL DISPLAY) “LGPHILIPS TFT LCD LM157E2-A2 15.7””

P/CORD 6410TEW003C POWER CORD SP023+IS14 I-SHENG VDE/SEMKO 1870MM WALL 85964

INVERTER 6632Z-1502D INVERTER “NMC1502 15.1”” (CHOI JEONG GYU)”

ADAPTER 6634TBZ009E ADAPTER AC-DC, PSCV360107A SAMSUNG 100-240V 24V 1.5A FOR G/WAY

S/CABLE 6866TD9001L SIGNAL CABLE UL 2990-9C(7.5) DT 1870MM COOL GRAY 3C LB680A DM

Page 30

Pin Configurations

MX88L281

MX88L282

128 GNDP

127 GNDP

126 GOUT1/OSDG0

125 GOUT0/OSDB0

124 LDTG

123 LVSYNC

122 LHSYNC

121 VDDP

120 RA0

119 RA1

118 RA2

117 RA3

116 RA4

115 RA5

114 RA6

113 RA7

112 GND

111 GA0

110 GA1

109 GA2

108 GA3

107 GA4

106 GA5

105 GA6

104 GA7

103 BA0

102 BA1

101 BA2

100 BA3

99 BA4

98 BA5

97 BA6

96 BA7

95 GNDP

94 LCKA

93 LCKB

92 VDDP

91 RB0

90 RB1

89 RB2

88 RB3

87 RB4

86 RB5

85 RB6

84 RB7

83 VDD

82 GB0

81 GB1

80 GB2

79 GB3

78 GB4

77 GB5

76 GB6

75 GB7

74 BB0

73 BB1

72 BB2

71 BB3

70 BB4

69 BB5

68 BB6

67 BB7

66 GNDP

65 GNDP

GNDP 193

GNDP 194

WE# 195

CAS# 196

RAS# 197

DQM0 198

DQM1 199

GND 200

GNDP 201

MD15 202

MD14 203

MD12 204

MD11 205

VDDP3V 207

MD10 208

MD9 209

MD8 210

MD7 211

MD6 212

MD5 213

MD4 214

MD3 215

MD2 216

MD1 217

MD0 218

GNDP 219

AD0 220

AD1 221

AD2 222

AD3 223

AD4 224

SBCS#/AD5 225

SBDATA/AD6 226

SBCLK/AD7 227

CPUA15/BCS# 228

VDDP 229

ALE 230

GND 231

WR# 232

RD# 233

TMCLK 234

RST# 235

GPIOA0 236

GPIOA1 237

GPIOA2 238

GPIOA3 239

GPIOA4 240

GPIOA5 241

GOUT2/PLLREF 242

GPOU3/PLLRET 243

PLLREF/GPIOA6 244

PLLRET/GPIOA7 245

TDCLK/CSYNC 246

FBLCKSEL 247

HSYNC1 248

VSYNC1 249

PCSEL# 250

CLAMP 251

VDD 252

DCLKB 253

DCLKA 254

GNDP 255

GNDP 256

64 VDDP

63 AVDD

62 AVDD

61 XI

60 XO

59 AGND

58 AGND

57 GNDP

56 PIXINB16

55 PIXINB17

54 PIXINB18

53 PIXINB19

52 PIXINB20

51 PIXINB21

50 PIXINB22

49 PIXINB23

48 GND

47 PIXINB8

46 PIXINB9

45 PIXINB10

44 PIXINB11

43 PIXINB12

42 PIXINB13

41 PIXINB14

40 PIXINB15

39 PIXINB0

38 PIXINB1

37 PIXINB2

36 PIXINB3

35 PIXINB4

34 PIXINB5

33 PIXINB6

32 PIXINB7

31 VDDP

30

ADCCLK2/DE

29 ADCCLK1

28 GNDP

27 PIXINA16

26 PIXINA17

25 PIXINA18

24 PIXINA19

23 PIXINA20

22 PIXINA21

21 PIXINA22

20 PIXINA23

19 VDD

18 PIXINA8

17 PIXINA9

16 PIXINA10

15 PIXINA11

14 PIXINA12

13 PIXINA13

12 PIXINA14

11 PIXINA15

10 GND

9 PIXINA0

8 PIXINA1

7 PIXINA2

6 PIXINA3

5 PIXINA4

4 PIXINA5

3 PIXINA6

2 PIXINA7

1 VDDP

192 VDDP3V

191 MA0

190 MA1

189 MA2

188 MA3

187 MA4

186 MA5

185 MA6

184 MA7

183 MA8

182 MA9

181 GNDP

180 MCLK

179 VDDP3V

178 CKE

177 MD16

176 MD17

175 MD18

174 MD19

173 MD20

172 MD21

171 MD22

170 MD23

169 CS0#

168 GND

167 MD24

166 MD25

165 MD26

164 MD27

163 MD28

162 MD29

161

MD30

160 MD31

159 GNDP

158 MD32

157 MD33

156 MD34

155 MD35

154 MD36

153 MD37

152 MD38

151 MD39

150 MD40

149 DQM3

148 DQM2

147 VDDP3V

146 MD41

145 MD42

144 MD43

143 MD44

142 MD45

141 MD46

140 MD47

139 GNDP

138 OSDBLINK

137 OSDB1

136 OSDG1

135 OSDR1

134 OSDCS#

133 OSDCLK

132 OSDDATA

131 GOUT4/OSDINT

130 VDD

129 VDDP

MX88L282 256PQFP BK XGA LCD INTEGRATION CHIP

Page 31

Chip Block Diagram

PIXOUT - A

(RGB)

Color

conversion

Scale Down

with

SmartScaling

Technology

DRAM

controller

Scale up

with

SmartScaling

Technology

Auto-tracking

Auto-position

Auto-gain

SDRAM/SGRAM

g

correction

Brightness

Contrast

control

RGB/YUV

PIXINA

PIXINB

(RGB or

YUV or

YCrCb)

(RGB24)

OSD MUX

Odd/Even

Mux

Dithering

OSD

PIXOUT - B

(RGB)

OSD

De-Interlace

CPU I/F

System Block Diagram for LCD monitor

Composite

S-Video

PC (RGB)

Video

Decoder

Pre-AMP

Video (YUV)

ROM

ADC

ADC

PLL

SDRAM or

SGRAM

FPD MONITOR

CONTROLLER

8/16 bit uP

GENERATOR

18/24 bit RGB

18/24 bit RGB

H/V Sync,

CLK and DE

OSD

LVDS or

PanelLink

Transmitter

FPD

Panel

Page 32

VSYNC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

XTAL**

PTA5/PWM13

PTA6/PWM14

PTA3/PWM11

PTA4/PWM12

PTC5/ADC5

PTC4/ADC4

PTB7/PWM7

PTB6/PWM6

PTA7/PWM15

EXTAL**

RST

IRQ

PTB5/PWM5

VDD

VSS

VDD3

21

PTE0/SOG/TCH0

PD1/D-**

PD0/D+**

PTA1/PWM9

PTA0/PWM8

PTA2/PWM10

PTD6*/IICSDA*

PTD5*/IICSCL*

PTD3*/DDCSCL*

VSS1

PTD2*/DDCSDA*

HSYNC

PTB3/PWM3

PTB4/PWM4

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

41

PTB0/PWM0

PTB1/PWM1

PTB2/PWM2

42

PTD4/CLAMP

PTC2/ADC2

PTC1/ADC1

PTC0/ADC0

PTE1/HSYNO

PTE2/VSYNO

PTC3/ADC3

42-PIN SDIP

*: +5V open-drain

MC68HC908BD48

**: +3.3V port

else: +5V port

MC68HC908BD

Page 33

PTB0/PWM0

PTB1/PWM1

PTB2/PWM2

PTB3/PWM3

PTB4/PWM4

PTB5/PWM5

OSCILLATOR

AND DIVIDE

BY 4

EXTAL** XTAL**

CORE

TIMER

(COP)

1,024 bytes

RAM

48K bytes

FLASHROM

PTA0/PWM8

PTA1/PWM9

PTA2/PWM10

PTA3/PWM11

PTA4/PWM12

PTA5/PWM13

PTA6/PWM14

PTA7/PWM15

DATA

DIR

REG

PORT

A

REG

PTD0/D+**

PTD1/D-**

PTC0/ADC0

PTC1/ADC1

PTC2/ADC2

PTC3/ADC3

DATA

DIR

REG

PORT

B

REG

IRQ

Pulse

Width

Modulation

(PWM)

SYNC

PROCESSOR

VDD

VSS

STACK POINTER

COND CODE REG V 1 1 I N Z CH

INDEX REG X

CPU CONTROL ALU

68HC08 CPU

ACCUM

PROGRAM COUNTER

CPU REGISTERS

DDC12AB

/IIC

PORT

D

REG

DATA

DIR

REG

PTD6*/IICSDA*

PTD5*/IICSCL*

DDC

*: +5V open-drain

8-bit ADC

USB

Multi-master

IIC

RST

INDEX REG H

PTB6/PWM6

PTB7/PWM7

DATA

DIR

REG

PORT

C

REG

USB

HSYNC

VSYNC

TIMER

PTC4/ADC4

MMIIC

PTD2*/DDCSDA*

PTD3*/DDCSCL*

PTD4/CLAMP

PORT

E

REG

DATA

DIR

REG

SP

Timer

PTE0/SOG/TCH0

PTE1/HSYNCO

PTE2/VSYNCO

PTC5/ADC5

VDD3

SP

**: +3.3V port

else: +5V port

BLOCK DIAGRAM FOR MC68HC908BD

Page 34

- 35 -

SI4925DY Dual P-Channel 30-V (D-S) Rated MOSFET

EZ1086 1.5AMP POSITIVE VOLATAGE REGULATOR

S1

G1

S2

G2

D1 D1

D2 D2

Pin Configuration

P-Channel MOSFET

TO-220

TO-263

123 1

PIN1FUNCTION

ADJ/GND

2

OUTPUT

3

TAB IS OUTPUT

INPUT

23

Pin Configuration

BLOCK DIAGRAM

PARTSTYPE

PARTSTYPE

BA033FP

KA78M05R

KA78M12R

1. INPUT

2. GND

3. OUTPUT

1

3

2

1. Vcc

2. GND

3. OUT

1

3

2

KSC1623

1. BASE

2. EMITTER

3. COLLECTOR

2

3

1

Regulator

Transistor

SO-8

S1

1

2

G1

S2

3

G2

4

8

D1

7

D1

6

D2

5

D2

Page 35

1. AD9884 (PRE-AMP/PLL/ADC)

Page 36

2. VIDEO PROCESS

Page 37

3. LVDS

Page 38

4. MEMORY

Page 39

5. MICOM

Page 40

6. POWER GEN.

Page 41

7. CONNECTOR & JACKS

Loading...

Loading...