LG FMN0760NL, FMN0960NL, FMN1860NT, FMN1860NV, FMN1260NL Service Manual

...

Free Joint Multi Type

Air Conditioner

SERVICE MANUAL

MODELS

Indoor Unit : FMN0760NL

FMN0960NL

FMN1260NL

FMN1260NFM/B/D

FMN1260NT

FMN1860NT

FMN1860NV

FMN1860NL

Outdoor Unit : FMU4480N6L

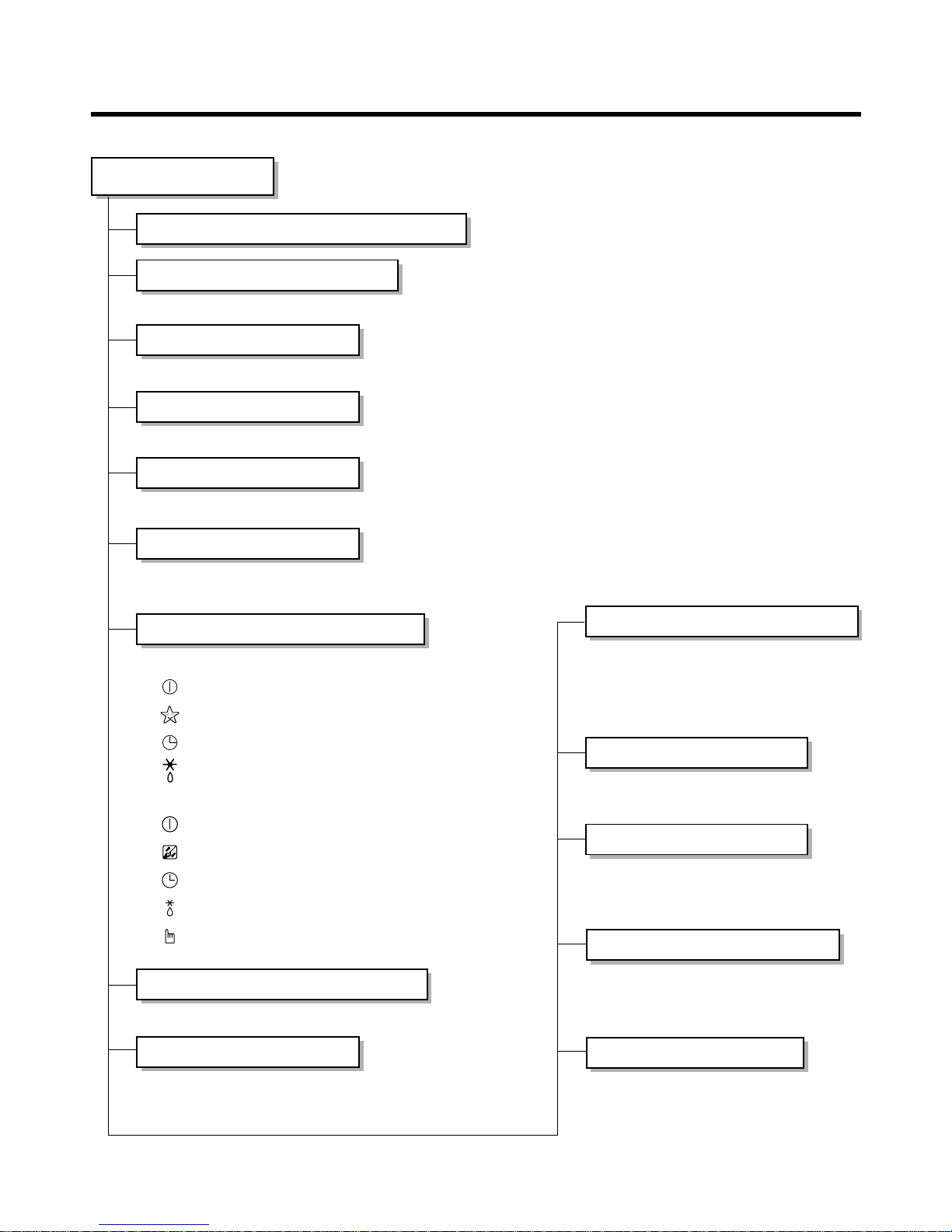

Functions...................................................................................................................................... 3

Product Specifications .................................................................................................................5

Operation Details ..........................................................................................................................7

Dimensions..................................................................................................................................23

Wiring Diagram ...........................................................................................................................27

Self-diagnosis Function .............................................................................................................29

Refrigeration Cycle Diagram......................................................................................................30

Installation of Indoor, Outdoor Unit ..........................................................................................31

Disassembly of the parts ...........................................................................................................70

3-way Valve ..................................................................................................................................76

Cycle Troubleshooting Guide ....................................................................................................81

Electronic Parts Troubleshooting Guide...................................................................................82

Electronic Control Device ..........................................................................................................93

Schematic Diagram...................................................................................................................101

Exploded View and Replacement Parts List...........................................................................107

- 2 -

Contents

- 3 -

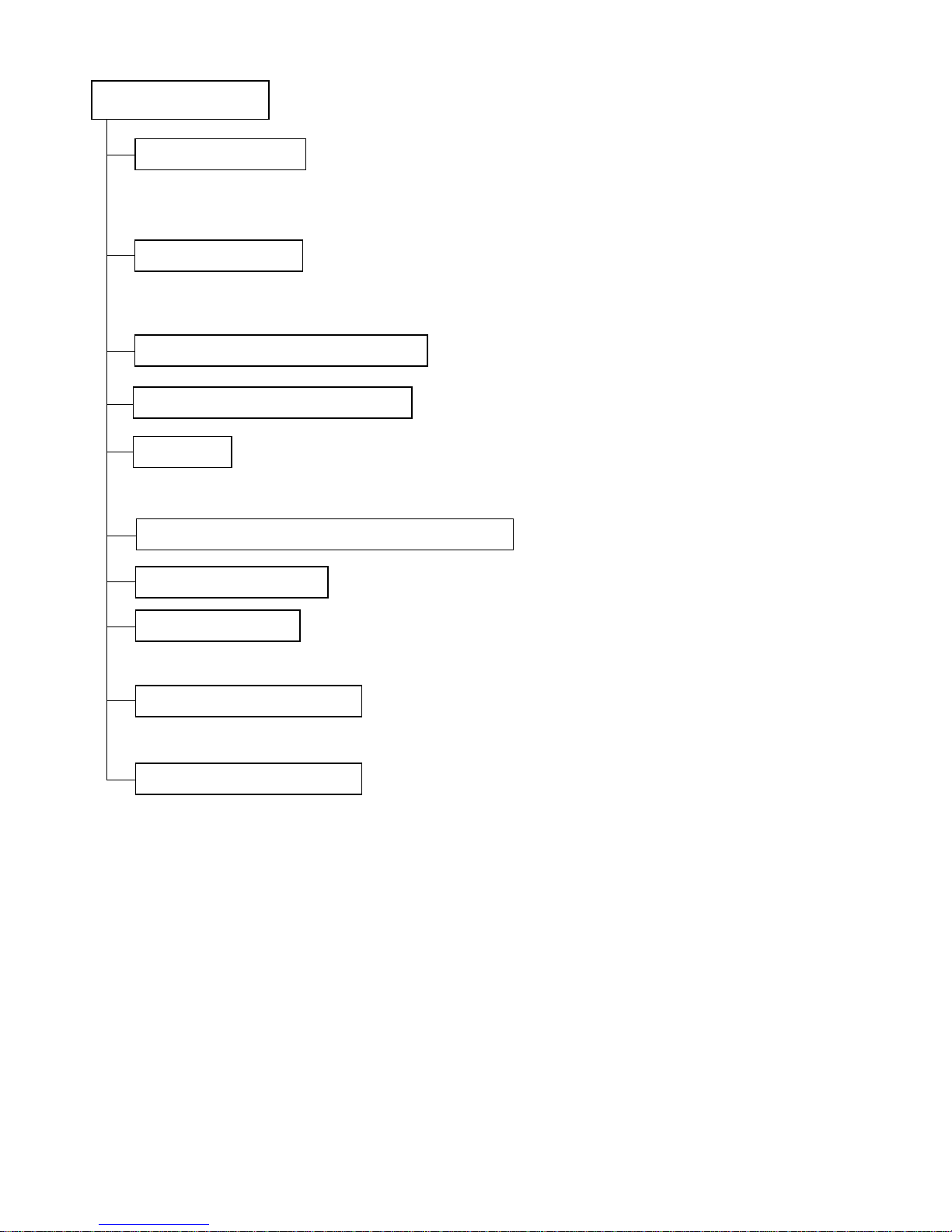

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• Room/Art Cool/Convertible Type Indoor Unit: High, Med, Low, Chaos

• Cassette Type Indoor Unit: High, Mde, Low, Auto

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

• Both the indoor and outdoor fan

stops during deicing.

• Hot start after deice ends.

• The indoor fan stops until the

evaporator piping temperature will be

reached at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

Deice (defrost) control (Heating)

• The fan is switched to intermittent or irregular operation

• The fan speed is automatically switched

from high to low speed.

• Room/Art Cool/Convertible type Indoor Unit

-- Lights up in operation

-- Lights up in Sleep Mode

-- Lights up in Timer Mode

-- Lights up in Deice Mode

• Cassette type Indoor Unit

-- Lights up in Operation

-- Lights up in Filter replacement

-- Lights up in Timer Mode

-- Lights up in Defrost Mode or Hot Start Operation.

-- Operation procedures when the remote control

can't be used.

• Intermittent operation of fan at low speed.

•

The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The louver can be set at the desired position or swing up and down automatically.

• The setting temperature, indoor fan

speed and desired operation mode

are automatically set.

Auto Operation Mode

Hot-start Control (Heating)

- 4 -

• If power is on, it will operate to charge capacitor (330µF/450WV) on controller and power relay will operate after about 2~5sec.

• The final operating freq. of comp. is set the lowest freq. that limited outdoor temp., discharge pipe temp.,

target freq., owing to CT.

• It will be changed the drive voltage of comp. according to operating frequency.

• It is only operated in the heating operation mode except defrosting operation.

• High speed/Low speed

Outdoor Unit

Power relay control

Comp. Freq. control

Overheatng. Protection(Powr module)

Freq. speed control(up/down speed)

V/F control

Total current control (over current protection)

DC peak current control

4 way valve control

Outdoor fan motor control

Discharge pipe temp. control

- 5 -

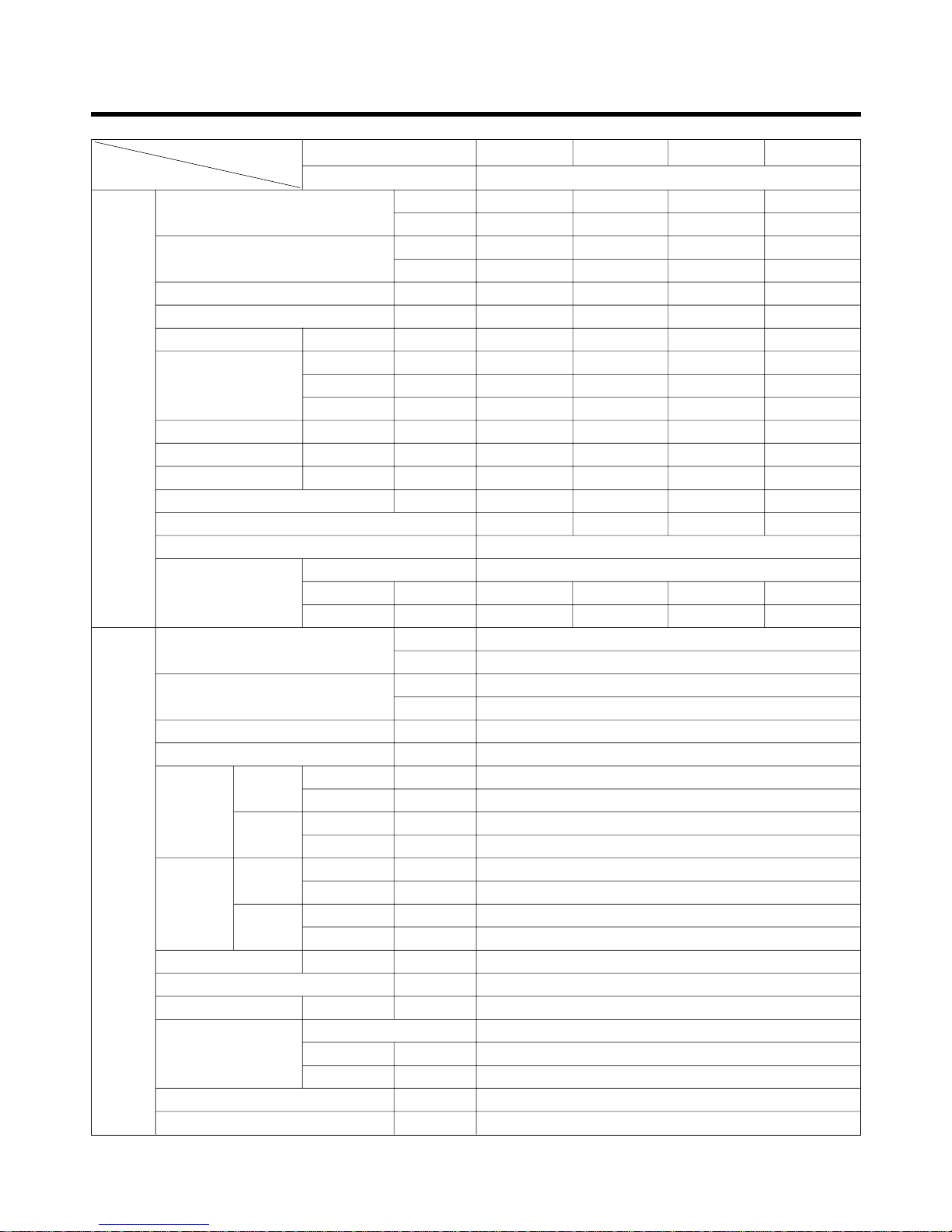

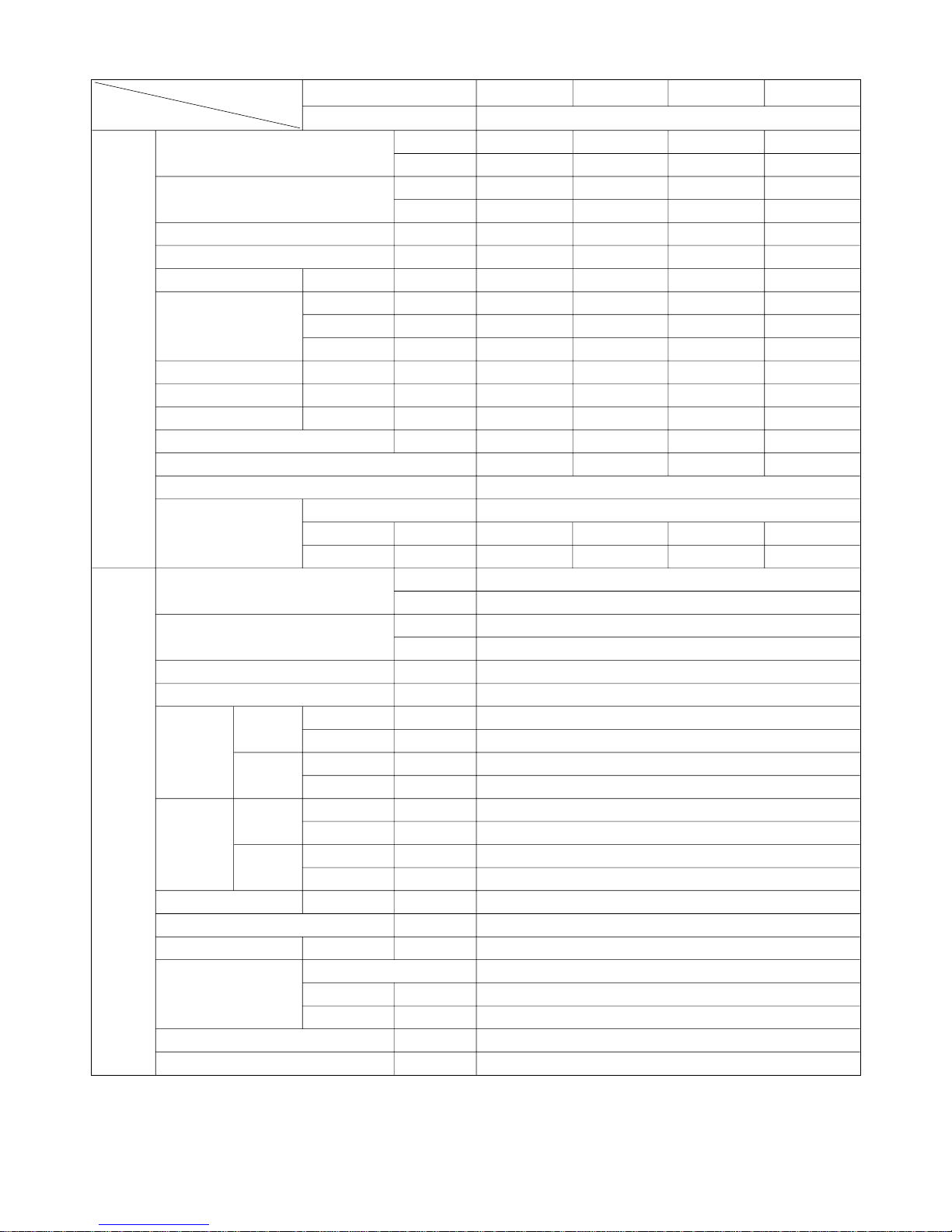

Product Specifications

Indoor

Cooling capacity

[Btu/h]

Unit [W]

Heating capacity

[Btu/h]

[W]

Moisture Removal [l/h]

Power Supply [Ø,V,Hz]

Air Circulation Max [CMM]

High dB[A]

Nosie Level Med dB[A]

Low dB[A]

Input Motor [W]

Runing Current Motor [A]

Demensions WxDxH [mm]

Net Weight [kg]

Air flow Direction Control[Up & Down]

Remocon Type

Type

Pipe Connection Gas inch[mm]

Liquid inch[mm]

Outdoor

Cooling capacity

[Btu/h]

Unit [W]

Heating capacity

[Btu/h]

[W]

Nosie Level dB[A]

Power Supply [Ø, V, Hz]

Cooling

Normal [W]

Input

Max [W]

Heating

Normal [W]

Max [W]

Cooling

Normal [A]

Runing Max [A]

Current

Heating

Normal [A]

Max [A]

Dimensions WxDxH [mm]

Net Weight [kg]

Refrigerant R-22 [g]

Type

Pipe Connection Gas inch[mm]

Liquid inch[mm]

Connection cable [mm

2

]

Power cable [mm

2

]

7,000 9,000 12,000 12,000

2,051 2,638 3,517 3,517

8,000 10,000 13,800 13,800

2,344 2,931 4,044 4,044

1.4 1.7 2.5 1.2

1, 220-240, 50 1, 220-240, 50 1, 220-240, 50 1, 220-240, 50

6.5 7 9 8.3

34 36 39 44

33 34 36 41

30 32 35 34

27 27 28 11

0.14 0.14 0.15 0.12

802 x 165 x 262 802 x 165 x 262 888 x 170 x 287 570 x 137 x 568

77 9 9

Up & Down Up & Down Up & Down Up & Down

L.C.D Wireless

Flare Connection

3/8[9.52] 3/8[9.52] 1/2[12.7] 1/2[12.7]

1/4[6.35] 1/4[6.35] 1/4[6.35] 1/4[6.35]

44,000

12,895

50,600

14,829

63

3, 380 ~ 415, 50

1,900 ~ 4,700

5,150

2,310 ~ 5,700

5,700

3.5 ~ 8.5

8.8

4.0 ~ 9.3

9.3

900 x 370 x 1,225

110

5,300 (at 7.5m)

Flare Connection

3/8[9.52]

1/4[6.35]

0.75, 4wires (Include earth)

3.5, 4wires (Exclude earth)

FMN0760NL FMN0960NL FMN1260NL

FMN1260NFM/B/D

FMU4480N6L

Model

Item

Indoor Unit

Outdoor Unit

- 6 -

Indoor

Cooling capacity

[Btu/h]

Unit [W]

Heating capacity

[Btu/h]

[W]

Moisture Removal [l/h]

Power Supply [Ø,V,Hz]

Air Circulation Max [CMM]

High dB[A]

Nosie Level Med dB[A]

Low dB[A]

Input Motor [W]

Runing Current Motor [A]

Demensions WxDxH [mm]

Net Weight [kg]

Air flow Direction Control[Up & Down]

Remocon Type

Type

Pipe Connection Gas inch[mm]

Liquid inch[mm]

Outdoor

Cooling capacity

[Btu/h]

Unit [W]

Heating capacity

[Btu/h]

[W]

Nosie Level dB[A]

Power Supply [Ø, V, Hz]

Cooling

Normal [W]

Input

Max [W]

Heating

Normal [W]

Max [W]

Cooling

Normal [A]

Runing Max [A]

Current

Heating

Normal [A]

Max [A]

Dimensions WxDxH [mm]

Net Weight [kg]

Refrigerant R-22 [g]

Type

Pipe Connection Gas inch[mm]

Liquid inch[mm]

Connection cable [mm2]

Power cable [mm2]

12,000 18,000 18,000 18,000

3,517 5,275 5,275 5,275

13,800 20,700 19,000 20,700

4,044 6,067 5,567 6,067

1.5 3.3 2.5 2.5

1, 220-240, 50 1, 220-240, 50 1, 220-240, 50 1, 220-240, 50

9.25 13.5 13 14

41 47 44 49

39 45 41 47

37 43 39 45

68 90 60 56

0.29 0.5 0.32 0.25

570 x 570 x 269 570 x 570 x 269 1,080 x 181 x 314 1,200 x 205 x 615

19 19 12 30

Up & Down Up & Down Up & Down Up & Down

L.C.D Wireless

Flare Connection

5/8[15.88] 5/8[15.88] 1/2[12.7] 1/2[12.7]

1/4[6.35] 1/4[6.35] 1/4[6.35] 1/4[6.35]

44,000

12,895

50,600

14,829

63

3, 380 ~ 415, 50

1,900 ~ 4,700

5,150

2,310 ~ 5,700

5,700

3.5 ~ 8.5

8.8

4.0 ~ 9.3

9.3

900 x 370 x 1,225

110

5,300 (at 7.5m)

Flare Connection

3/8[9.52]

1/4[6.35]

0.75, 4wires (Include earth)

3.5, 4wires (Exclude earth)

FMN1260NT FMN1860NT FMN1860NL FMN1860NV

FMU4480N6L

Model

Item

Indoor Unit

Outdoor Unit

Operation Details

1. Room/Art Cool Type Indoor Unit

(1) The Function of main control

• DISPLAY

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled

Defrost Indicator

• Off except when hot start during heating mode operation or while in defrost control

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor

not running, operating with the low airflow speed regardless of the setting.

■ Soft Dry Operation Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification

operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation

• When the intake air temp reaches +3°…above the setting temp, the compressor is turned off. When below

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 26°C, when above 28°C , it

operates with the low or setting airflow speed.

-7-

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C , it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below -5°C after 40 minutes passed from

starting of heating operation and more than 10 minutes operation of compressor.

• Defrost ends after 12 minutes passed from starting of defrost operation or after the outdoor fan operates within max. 2 minutes 30 seconds when the outdoor pipe temperature rises over 12°C even it before 12 minutes.

• The second defrost starts only when the outdoor pipe temperature falls below -5°C after 40 minutes passed

from ending of the first defrost and more than 10 minutes operation of compressor.

■ Fuzzy Operation

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air

temp at that moment as follows.

24°C ≤ Inatake Air Temp ➲ Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C ➲ Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C ➲ Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp +0.5°C

Compressor OFF Temp ➲ Setting Temp – 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C≤ Intake Air Temp ➲ 25°C

24°C≤ Intake Air Temp<26°C ➲ Intake Air Temp – 1°C

22°C≤ Intake Air Temp<24°C ➲ Intake Air Temp – 0.5°C

18°C≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

-8-

-9-

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp – 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air Temp – 1°C

22°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp – 0.5°C

18°C ≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in

dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°C or more above

the setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp

Compressor OFF Temp ➲ Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

20°C≤Intake Air Temp ➲ Intake Air Temp + 0.5°C

Intake Air Temp<20°C ➲ 20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to the

intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

-10-

■ Off-Timer <=> On-Timer Operation

• When the set time is reached after the on/off time is input by the remote control, the on/off-timer operation is

carried out according to the set time.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to

the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

■ Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they are

fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

■ Jet Cool Mode Operation

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the

other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

• The slide switch on the main unit of the appliance should be on the Auto Restarting position in order that the

Auto Restarting operation is available.

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected Airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer (unit of hour)

• Incase the power comes on again after a power failure,

Auto Restarting operation is the function to operate procedures

automatically to the previous operating conditions. (Art Cool Type)

Slide Switch

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

-11-

■ Forced Operation

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide switch

position is switched to the Auto Restarting (or test operation) position or switched from the remote control

position to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position or

the remote control position, the forced operation is canceled and the appliance stops operating.

• In the forced operation mode, the indoor fan is operated at low speed for around 15 sec and then the operation condition is set according to the intake air temperature as follows.

24°C≤Intake Air Temp ➲ Cooling Mode Operation, 22°C, High Speed

21°C≤Intake Air Temp<24°C ➲ Dehumidification Operation, 23°C, High Speed

Intake Air Temp<21°C ➲ Heating Mode Operation, 24°C, High Speed

■ Remote Control Operation Mode

• When the remote control is selected by the slide switch on the main unit, the appliance operates according to

the input by the remote control.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C and higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

- 12 -

2. Cassette Type Indoor Unit

(1) The function of main control

■ Time Delay Safety Control

• 3 min

...

The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 5 sec

...

Vertical air flow direction control louvers open in 5 seconds to prevent noise between louvers and wind.

• 5 sec

...

The 4-way valve is ceased for 5 sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode when compress is off.

While compressor is running, it takes 3~5 seconds to switch.

■ Auto Swing Control

• This function is to swing the louver up and down automatically.

■ Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by Micom Control.

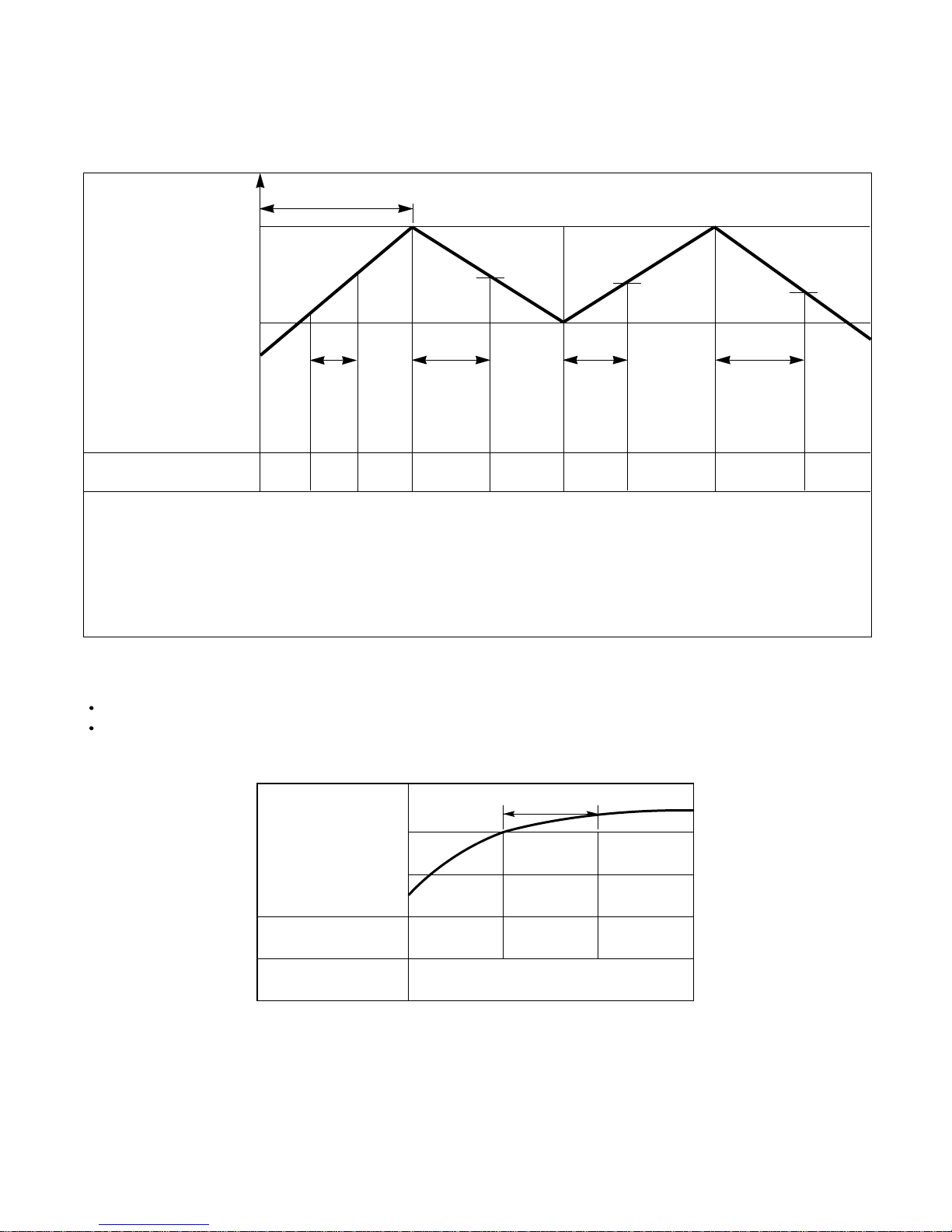

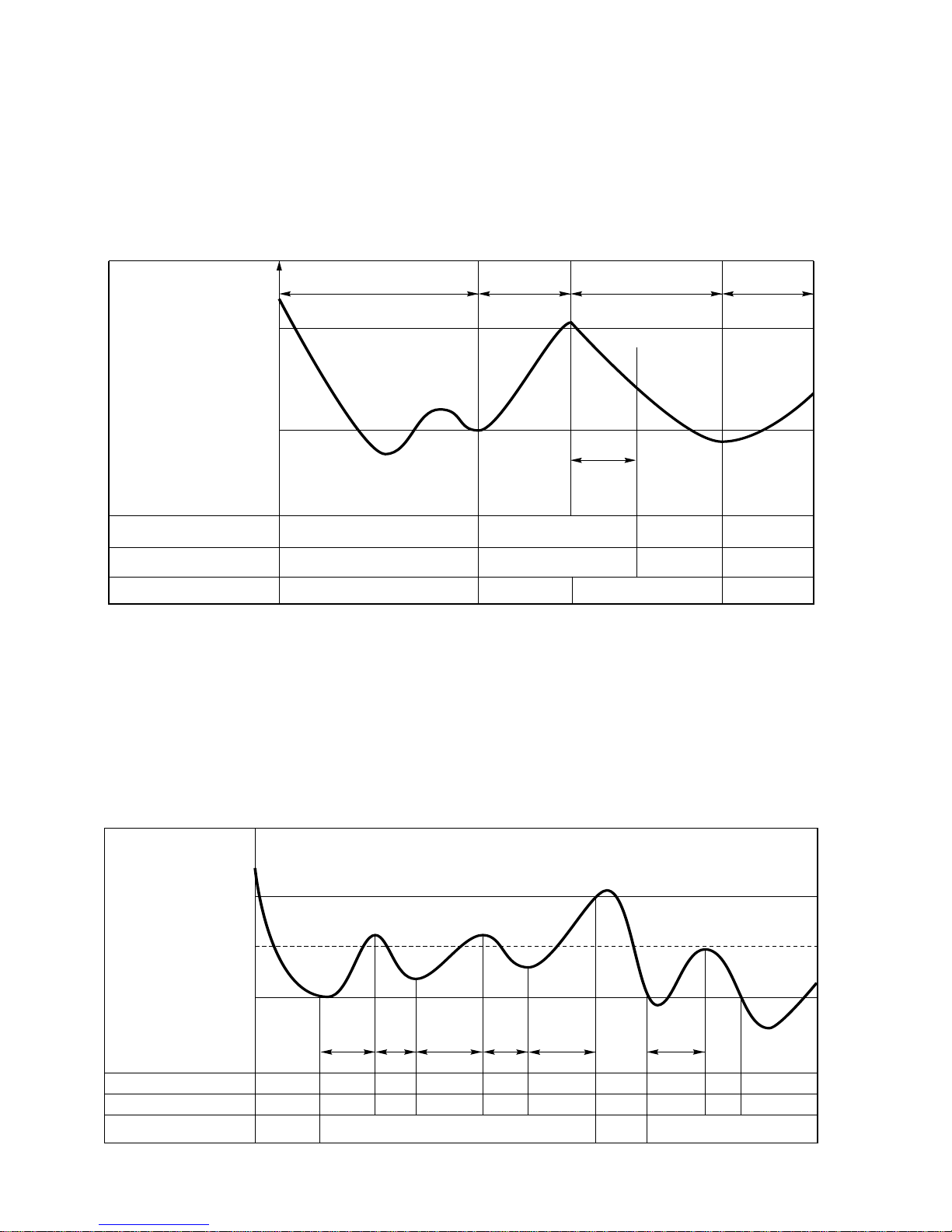

■ Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote

controller and the operation diagram is as following

Intake Air temp.

COMP. ON

(SET TEMP.+0.5°C)

COMP. OFF

(SET TEMP. -0.5°C) More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

INDOOR FAN Low Low

- 13 -

Intake Air temp.

Setting temp.+3°C

(Compressor OFF)

Setting temp.

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

■ Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Hot Start

Low

Selecting

Fan Speed

minimum 3min

Selecting fan

speed

minimum

10sec.

1min

AA

minimum

1min.

minimum

10sec.

B

■ Hot-Start Control

The indoor fan stops until the evaporator piping temperature will be reached to 25°C.

The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN OFF LOW

Selected Fan

ON

22°C

25°C

• A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed, when

it becomes lower than 40˚C fan stops.

• B point; When the indoor Heat-Exchanger temperature is higher than 31°C, fan operates at selected fan

speed, when it becomes lower than 31°C, the fan operates at low speed for 10sec, after 10sec, it

operates at selected fan speed.

- 14 -

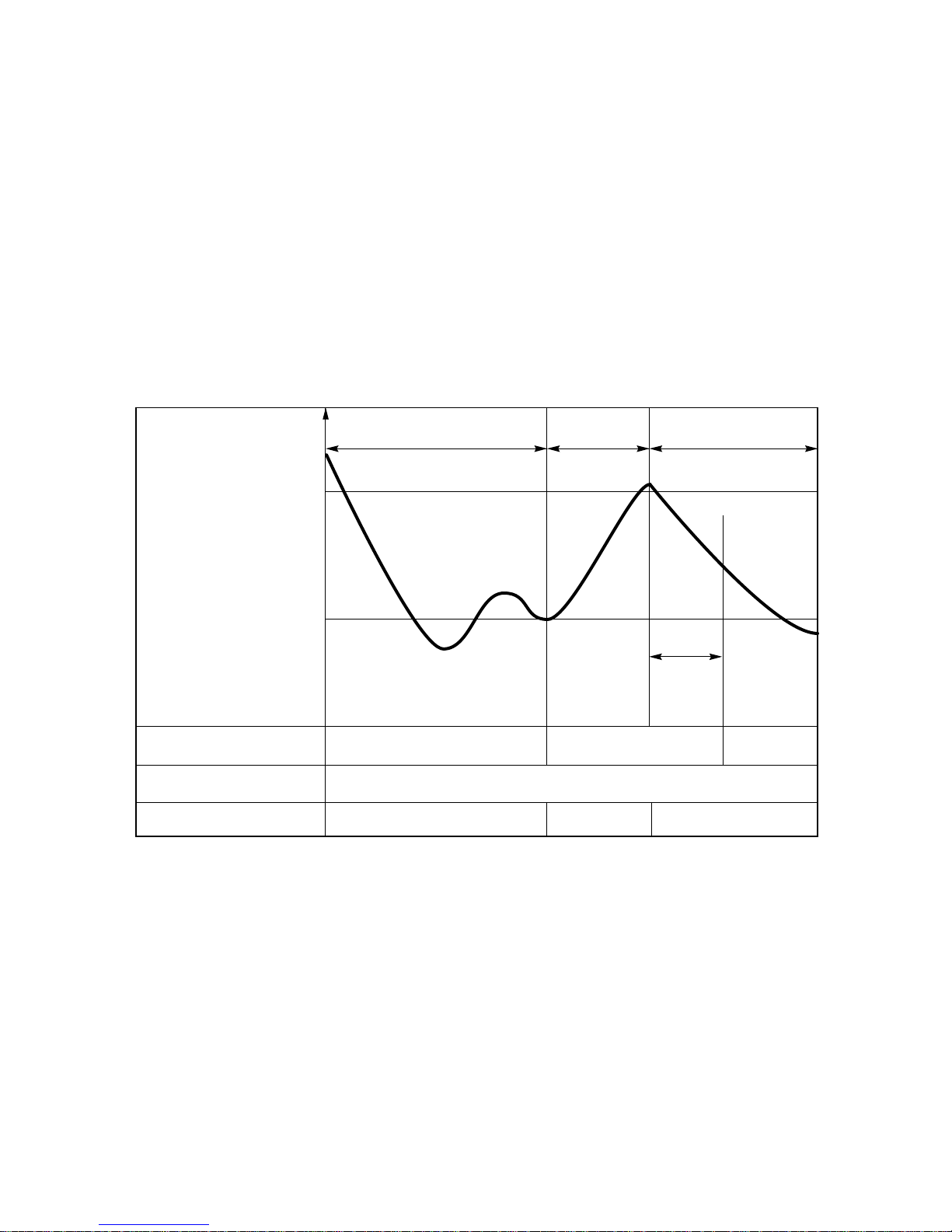

■ Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing, reversed to

cooling cycle to defrost the evaporator pipe of the outdoor unit.

• Defrost control is available 45 min. later since heating mode operation started, and it will not prolong over 10 min.

• Defrost control is carried out according to the following priority order while in heating mode operation.

1st priority : Defrost control is carried out according to the indoor pipe temp 60 min. later since heating mode opera-

tion started.

2nd priority : The temp differences between the indoor pipe temp and the intake air temp 25 min. later(∆T1) and 45

min. later (∆T2) since heating mode operation started are measured, then defrost control is carried out

according to the dirrerence (∆T=∆T1-∆T2)

3rd priority : Defrost control is carried out according to the temp difference (E=TE1-TE2) between the indoor pipe

temperatures of 25 min later(TE1) and 45 min later (TE2) after heating mode operation started.

• When the indoor pipe temp is 41°C or above, defrost control is not carried out even if the condition is one of the

defrost conditions above.

• While in defrost control, the compressor is on and the indoor fan, the outdoor fan, and the 4 way valve are off.

More than 45 minutes

of heating operation

Within

9min. 45sec.

ON OFF

ON

ON

ON OFF

COMPRESSOR

4-WAY VALVE

INDOOR FAN

-6°C ON

12°C OFF

The outdoor

piping Temp.

More than 10 min.

running of compressor

More than 45 minutes

of heating operation

HOT-

START

ON

3. Convertible Type Indoor Unit

(1) The function of main control

■ Time Delay Safety Control

• 3min…The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 5sec…Vertical air flow direction control louvers open in 5 seconds to prevent noise between louvers and wind.

• 30sec… The 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

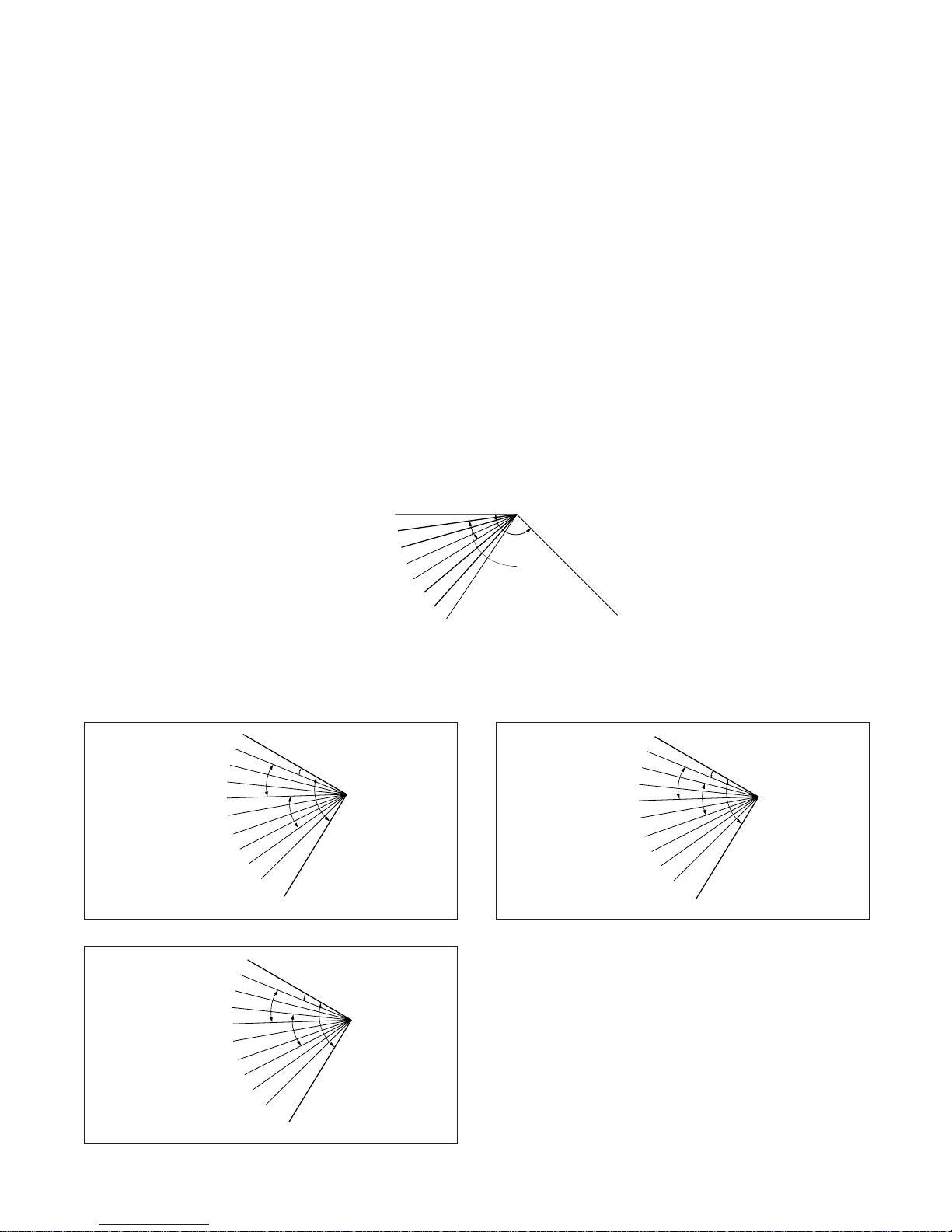

■ Airflow Direction Control

• This function is to swing the louver up and down automatically and to set it at the desired position.

• The procedure is as the following.

1st ; Press the ON/OFF Button to operate the product.

2nd ; Press the Airflow Direction Control Button to swing the louver up and down automatically.

3nd ; Repress the Airflow Direction Control Button to set the louver as the desired position.

MODE 0

1

2

3

4

5

6

7

135°

Cooling

MODE

MODE

MODE

MODE

MODE

MODE

MODE

9

MODE

(CLOSE)

OPEN

135°

12°

Cooling

HeatingHeatingHeating

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

MODE 7

MODE 8

MODE 9

CLOSE

OPEN

135°

12°

Cooling

Heating

Heating

Heating

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

MODE 7

MODE 8

MODE 9

CLOSE

Heating

OPEN

135°

12°

Cooling

Heating

Heating

Heating

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

MODE 7

MODE 8

MODE 9

CLOSE

–15–

※ For Heating Model

• Airflow direction control figure when installed on

the floor.

• Airflow direction control figure when installed

under the ceiling.

3. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as following

4. Cooling or Heating Mode with Sleep Mode Auto Operation

• When selecting the Cooling( ) or the Heating( ) combined with the Sleep Mode Auto Operation( ), the

operation diagram is as following.

■ Cooling Mode with the Sleep Mode

• The setting temperature will be raised by 1°C 30minutes later and by 2°C 1 hour later.

• The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

■ Heating Mode with the Sleep Mode.

• The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

Intake Air temp.

COMP. ON

(SET TEMP.+0.5°C)

COMP. OFF

(SET TEMP. -0.5°C) More than More than

3 minutes 3 minutes

INDOOR FAN Low Low Low Low Low

COMPRESSOR ON OFF ON OFF ON

30 minutes 30 minutes

1°C

1°C

–16–

Setting Temp. +3°C

(Compressor OFF)

Setting Temp.

(Compressor ON)

Indoor Fan Low. Low. Low. Low. Low. Low.

Compressor ON OFF ON OFF ON OFF

Intake Air temp.

COMP. ON

(SET TEMP.+0.5°C)

COMP. OFF

(SET TEMP. -0.5°C) More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

5. Auto Operation

• The operation procedure is as following. (Cooling & Heating Model)

* If initial mode is decided, that mode is continued without the room temperature changing.

* For cooling operation mode over 24°C setting temperature and fan speed are same as cooling only model.

• Auto Operation for Cooling. (Cooling only Model)

–17–

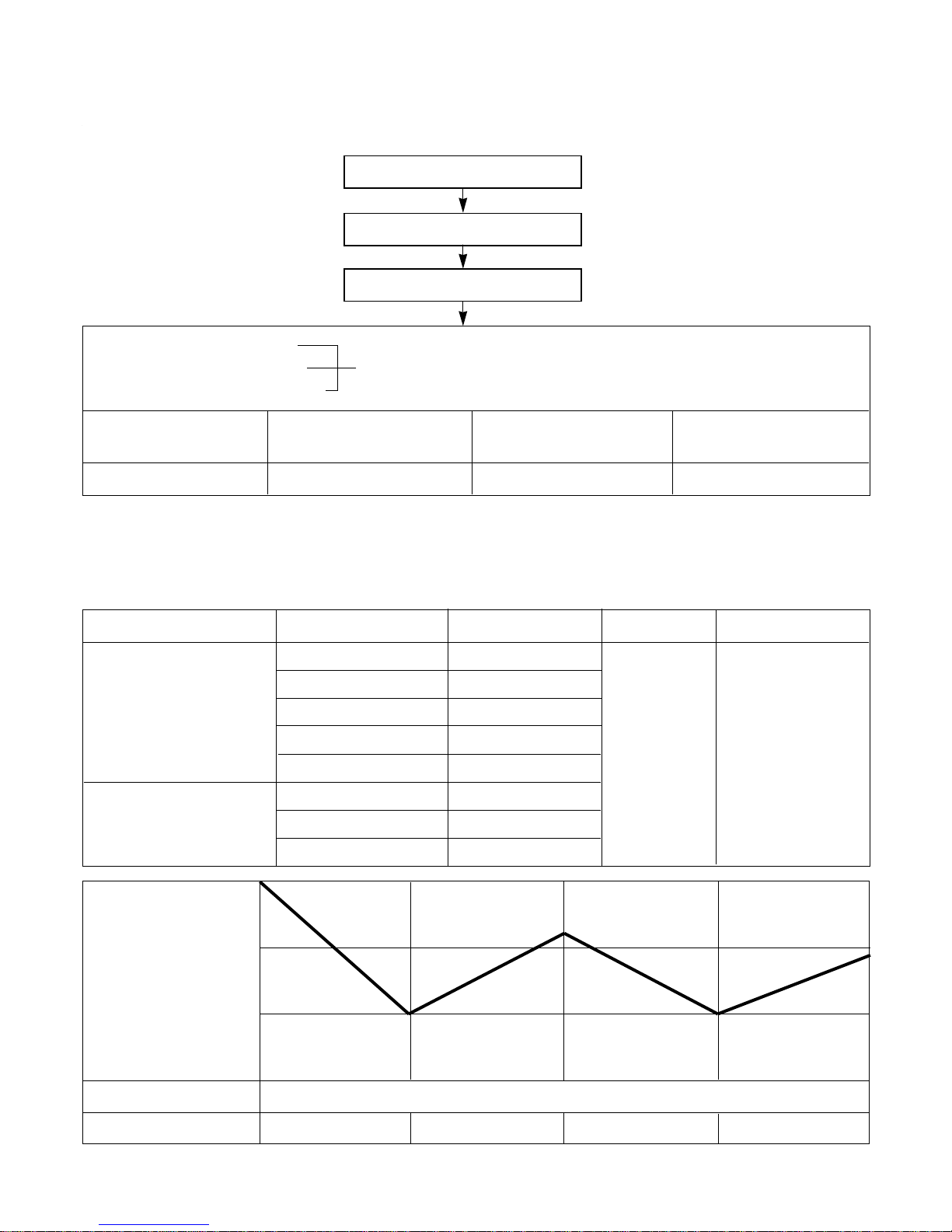

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation mode

Indoor fan speed are automatically decided by Fuzzy rule.

Setting temperature

Intake-air

temperature

Operation Mode Heating Soft Dry Cooling

Operation Condition Intake-air Temperature Setting temperature Fan speed Air Direction Control

Over 26°C25°C

Over 24°C~below 26°C Intake air -1°C

Over 22°C~below 24°C Intake air -0.5°C

Over 20°C~below 22°C intake air temperture

below 20°C20°C

Over 20°C~below 30°C Fuzzy control

below 20°C20°C

over 30°C30°C

below 21°C

below

24°C

~

Over 24°C

Over

21°C

When Auto Operation

initial start

When pressing room temperature setting button

during Auto Operation

Controlled

by Fuzzy logic

In this mode, when

pressing the vertical air diretion control.

Button, louvers

moves to 1/f

rhythm (refer to

page 17)

Intake-Air temp

Setting Temp. +0.5°C

(Compressor OFF)

Setting Temp.-0.5°C

(Compressor ON)

Indoor Fan

Compressor

ON ONOFF OFF

Fuzzy Speed

• Auto Operation for Soft Dry

The Setting temperature will be same as that of the current intake-air temperature.

- Compressor ON temperature; Setting temperature +1°C

- Compressor OFF temperature; Setting temperature -0.5°C

• Auto Operation for Heating.

- Compressor ON temperature; Setting temperature

- Compressor OFF temperature; Setting temperature +3°C

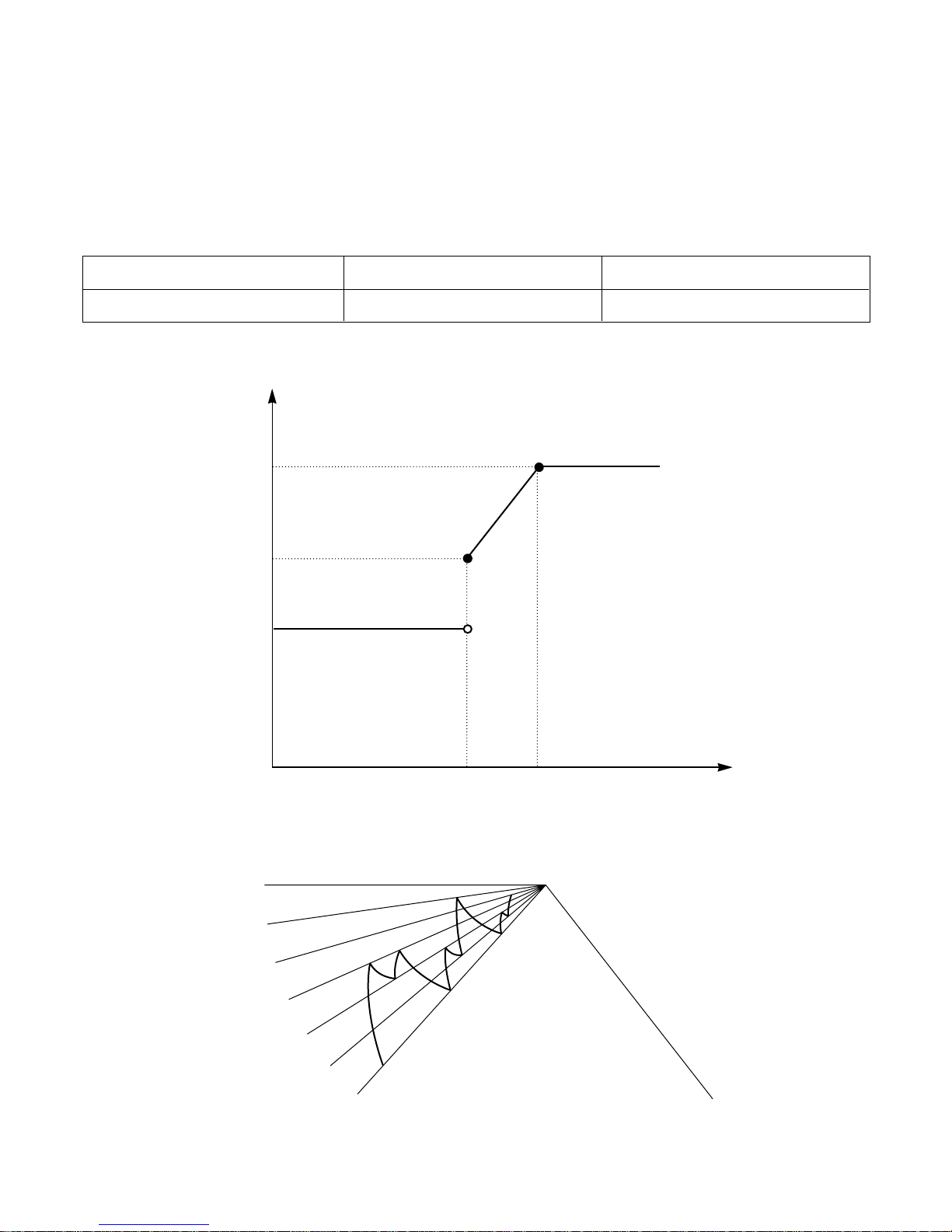

• 1/f rhythm louver operation : In Auto operation mode, when pressing the vertical air direction control button, louver moves as following cycle.

–18–

Intake Air temp. below 20°C over 20℃~below 21°C

Setting temp. 20°C Intake air temp. +0.5°C

21.5°C

20°C

20°C

Intake-Air temp.

Setting temp.

20.5°C

21°C

MODE0

MODE1

MODE2

MODE3

MODE4

MODE5

MODE6

MODE9

(CLOSED)

End

Start

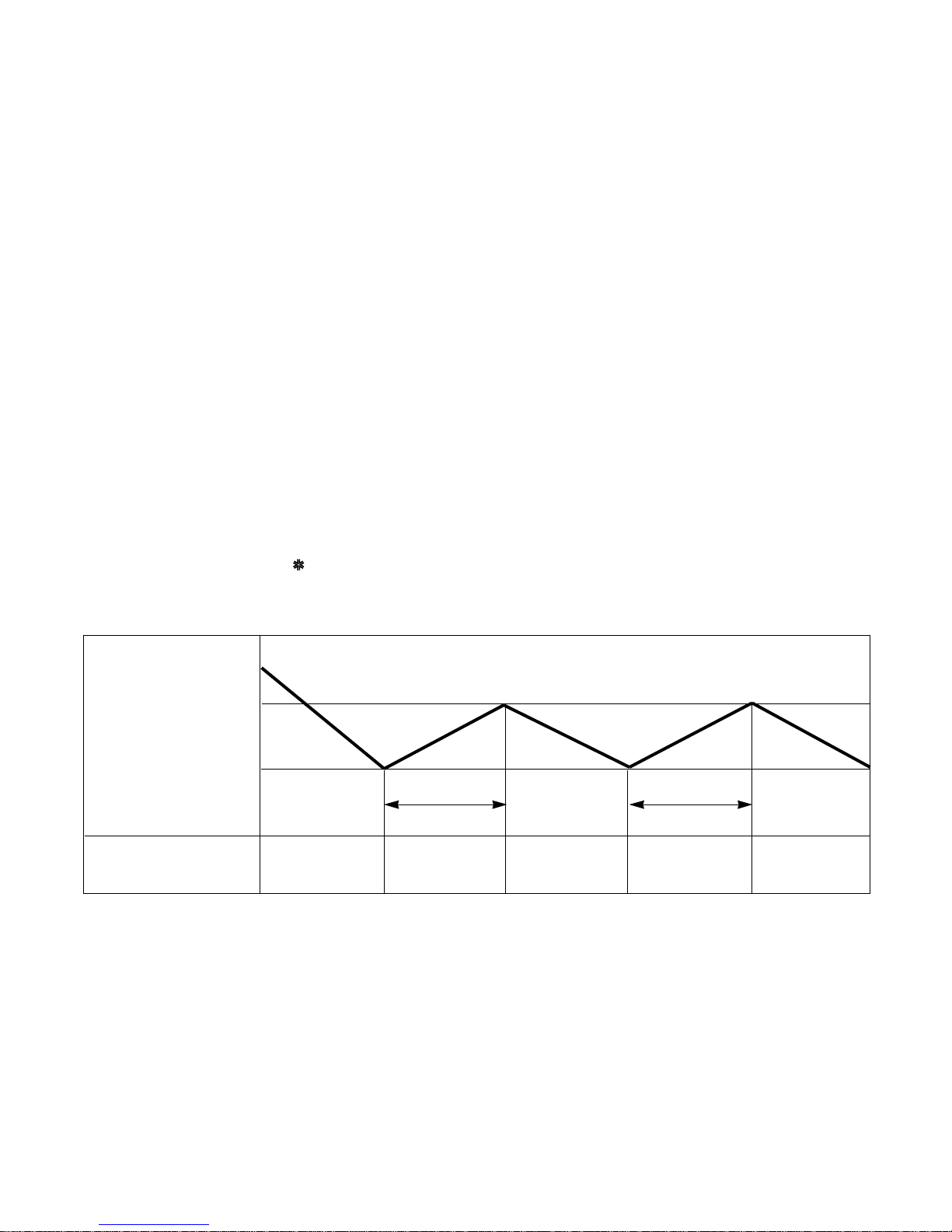

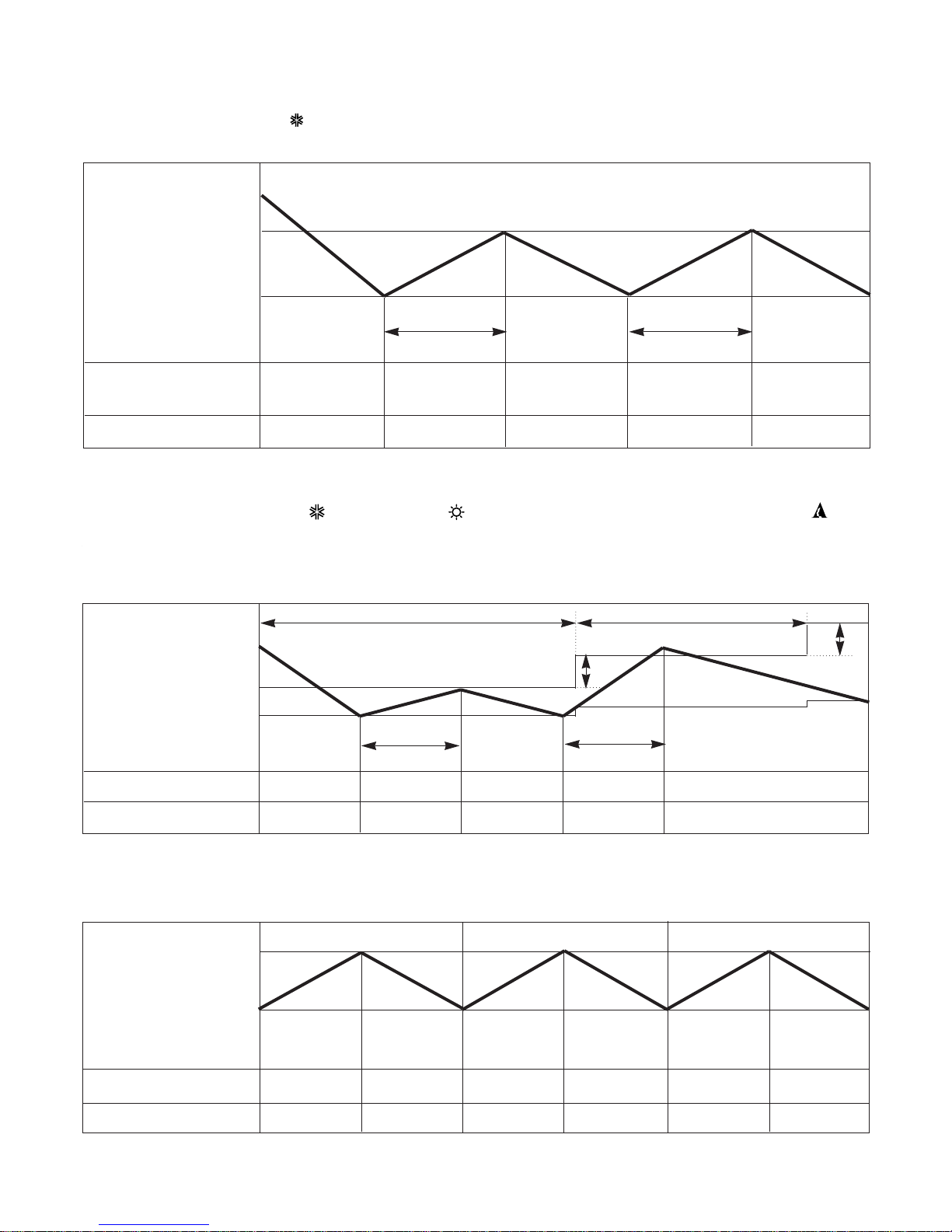

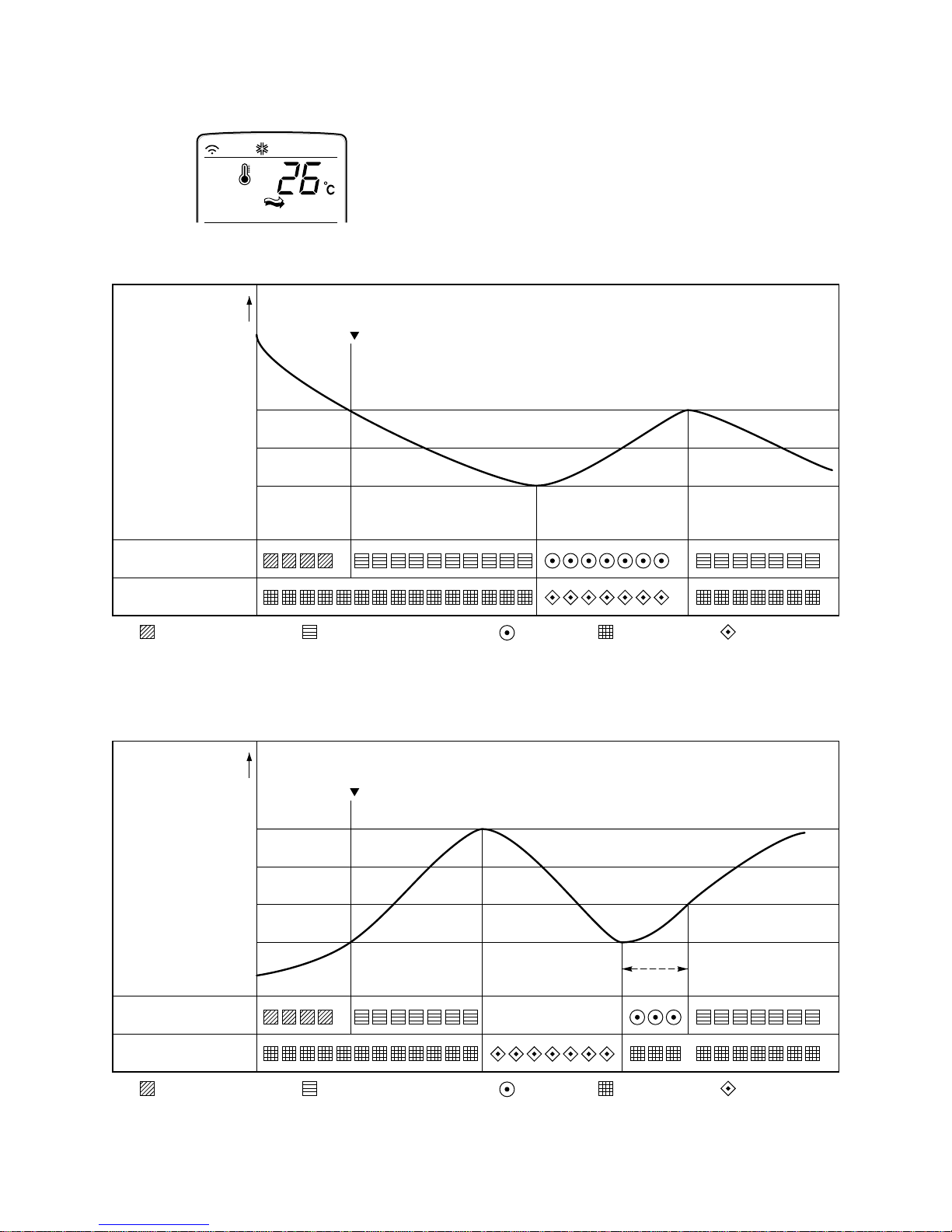

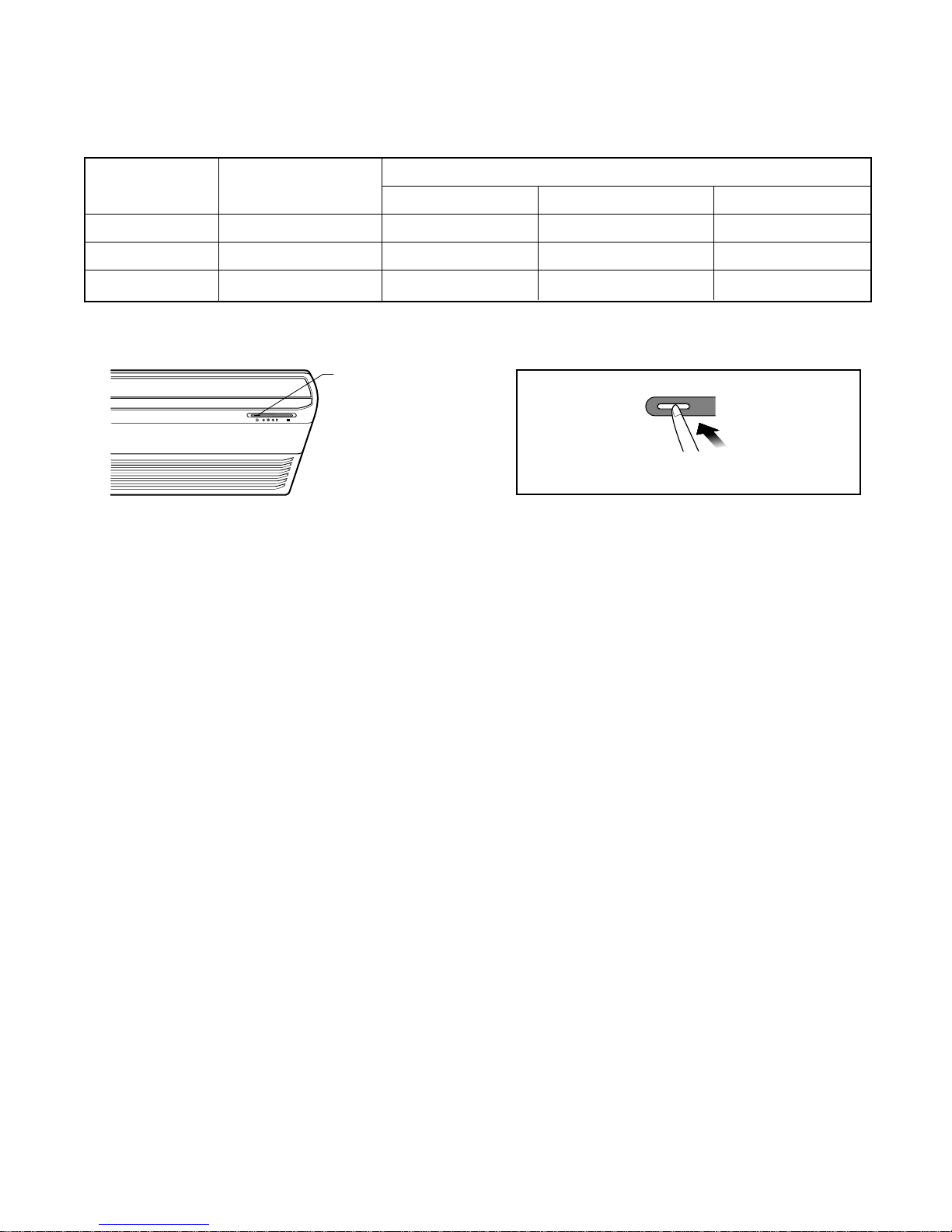

6. Natural wind by CHAOS logic

–19–

For more fresh feeling than other fan speed mode, press

the indoor fan Speed Selector and set to CHAOS mode.

In this mode, the wind blows like natural breeze by automatically changing fan speed according to the CHAOS

logic.

Intake Air temp.

OUTDOOR FAN/COMP.

INDOOR FAN

: Setting fan speed : LOW

Cooling on temp.

(Setting temp.+0.5)

Setting CHAOS Natural wind

Setting temp.

Cooling off temp.

(Setting temp.-0.5)

: CHAOS Natural wind

: COMP ON : COMP OFF

GRAPH of Natural wind by the CHAOS logis (During Cooling operation)

Intake Air temp.

30sec

OUTDOOR FAN/COMP.

INDOOR FAN

: Setting fan speed : LOW

Heating off temp.

(Setting temp.+3.0)

Setting CHAOS Natural wind

Heating on temp.

(Setting temp.)

: CHAOS Natural wind

: COMP ON : COMP OFF

GRAPH of Natural wind by the CHAOS logis (During Heating operation)

LOW OR STOP

–20–

7. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as

following.

• For Heating Model

INDOOR FAN

4-WAY VALVE

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

26°C

28°C

Indoor piping temp.

Intake Air temp.

Setting temp. +3.0˚C

(Compressor OFF)

Setting temp.

(Compressor ON)

minimum

1min.

minimum

3min.

Fan

Stops

Low

Fan

Low Fan Low Fan Fan StopSelected Fan

Selected

Fan

Low

Fan

Selected

Fan

minimum

3min.

minimum

30sec.

minimum

1min.

OUTDOOR FAN

COMPRESSOR

8. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached to 28℃.

• During heating operation, if piping temperatures falls below 26°C fan stops.

• The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

: Selected Fan : Low Fan : Fan Stop

28°C

(22˚C)

26°C

(20˚C)

–21–

9. Deice Control

• Deicing operation is controlled by timer and sensing the outdoor piping temperature.

• The first deicing starts only when the outdoor pipe temperature falls below -6°C after 45(30) minutes passed

from starting of heating operation.

• Deicing ends after 10(6) minutes passed from starting of deice operation or when the outdoor pipe temperature

rises over 12°C even if before 10(6) minutes.

• The second deicing starts only when the outdoor pipe temperture falls below -6°C after 45(30) minutes passed

from ending of the first deicing.

More than 45(30) minutes

of heating operation

Within

10(6) minutes

DeicingDeicing

ON OFF

ON ON

ON

ON OFF OFF

COMPRESSOR

4-WAY VALVE

INDOOR FAN

-6°C

DEICE ON

12°C

DEICE OFF

The outdoor

piping Temp.

ON

More than 45(30) minutes

of heating operation

HOT-

START

ON

OFF

ON

INDOOR FAN

Low Fan Low Fan

Intake Air temp.

Setting temp. +1.0˚C

(Compressor ON)

Setting temp. -0.5˚C

(Compressor OFF)

Setting temp.

2min.58sec. 2min.58sec.

10min. 10min.7min.

Within 7min.

CoolingCooling

OUTDOOR FAN

COMPRESSOR

Selected

Fan

Selected

Fan

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFFONON

OFF

OFF

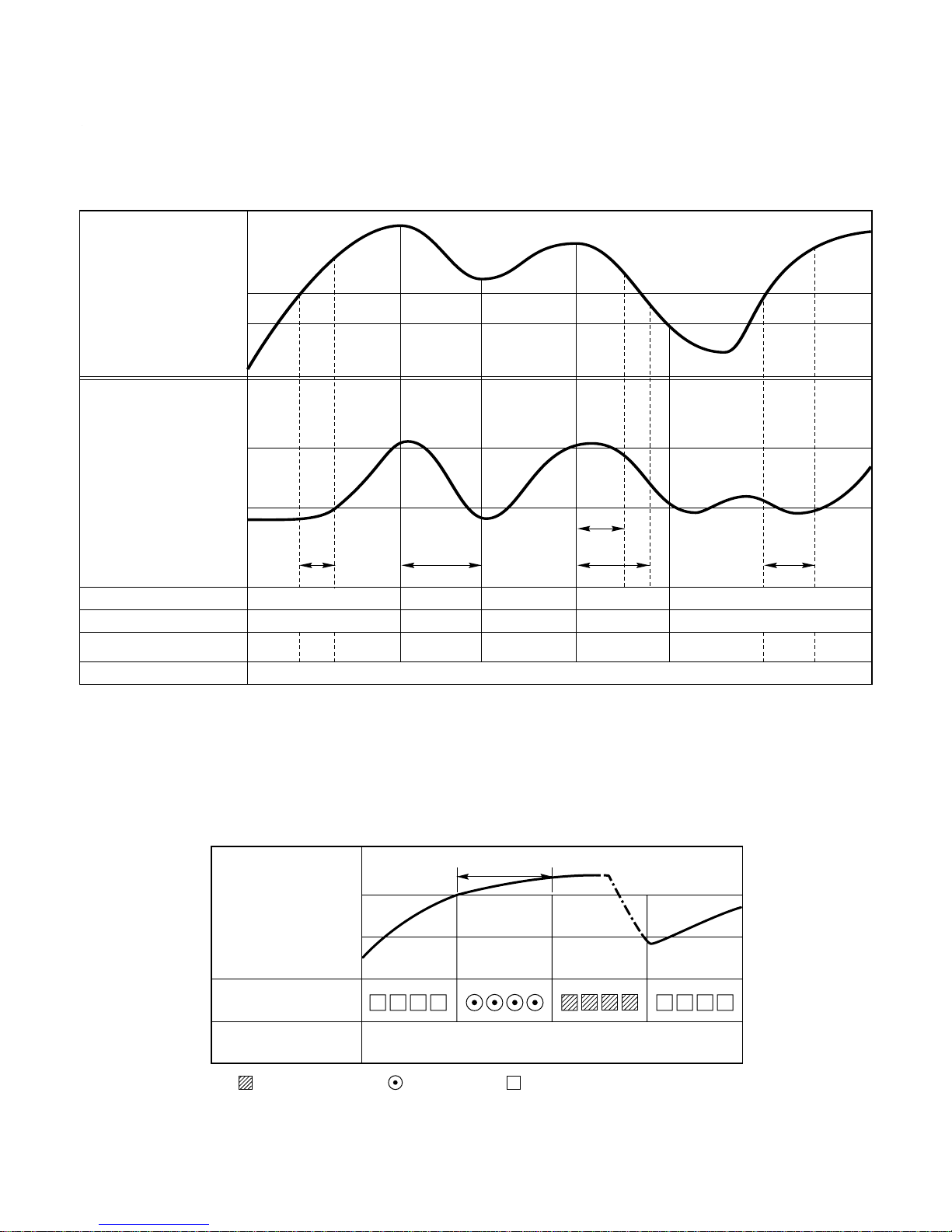

10. Soft Dry Operation

• During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 1°C, the compressor

OFF temperature is the setting temperature minus 0.5°C.

• When the room temperature rises over the compressor ON temperature, the operation mode is switched to the

cooling mode.

• When the room temperature falls between the compressor ON temperature and OFF temperature, the operation mode is switched to the Soft Dry Operation.

In this temperature range, 10min. Dry Operation, 7min operation OFF. During 10min Dry operation, if the room

temperature falls below compressor OFF temperature, Compressor OFF.

• In micom dehumidify mode, control of fan speed is as following.

12. Protection of the evaporator pipe from frosting

If the temperature of the indoor coil is below 0°C after 7 minutes from starting the compressor, the

compressor and the outdoor fan is stopped, and then after 3 minute delay of the compressor and

the temperature of the indoor coil is over 7°C, the compressor and the outdoor fan is reoperated.

Indoor fan operates at low speed (comp. OFF) or at selected speed (comp. ON)

13. Inlet grille open

Once the inlet grille is opened during operation of the unit, the unit automatically stops operation and the

lamps will be turned-off. But memorized functions are still available.

When the inlet grille is closed again, the unit become waiting state for operation. From then, the unit can be

operated by forced operation button or Start/Stop button of remote controller.

14. Test Operation

• When pressing forced operation switch about 3 seconds, the unit operates in cooling mode at high speed fan

regardless of room temperature and resets in 18 min.

• During test operation, if remote controller signal is received, the unit operates as remote controller sets.

15. Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance should be on the automatically operates in the mode

on the memory.

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer(unit of hour)

–22–

11. Forced operation

• If you lose wireless remote controller, you can operate the unit with forced operation switch.

• The standard conditions are as following.

• Unit operates in low fan mode for first 15 seconds, then switched to proper operation mode according to

intake Air temperature.

Heat pump Model

Room Temp≥ 24

°C

21°C〈Room Temp≤24

°C

Room Temp 〈21

°C

Operation Mode Cooling Cooling Soft Dry Heating

FAN Speed High High Soft Dry Rule High

Setting Temp. 24°C22°C Air Intake Temperature 24°C

Cooling Model

R

Forced

Operation Button

Press the Forced Operation Button.

•Press the Forced Operation Button once

again to stop operation.

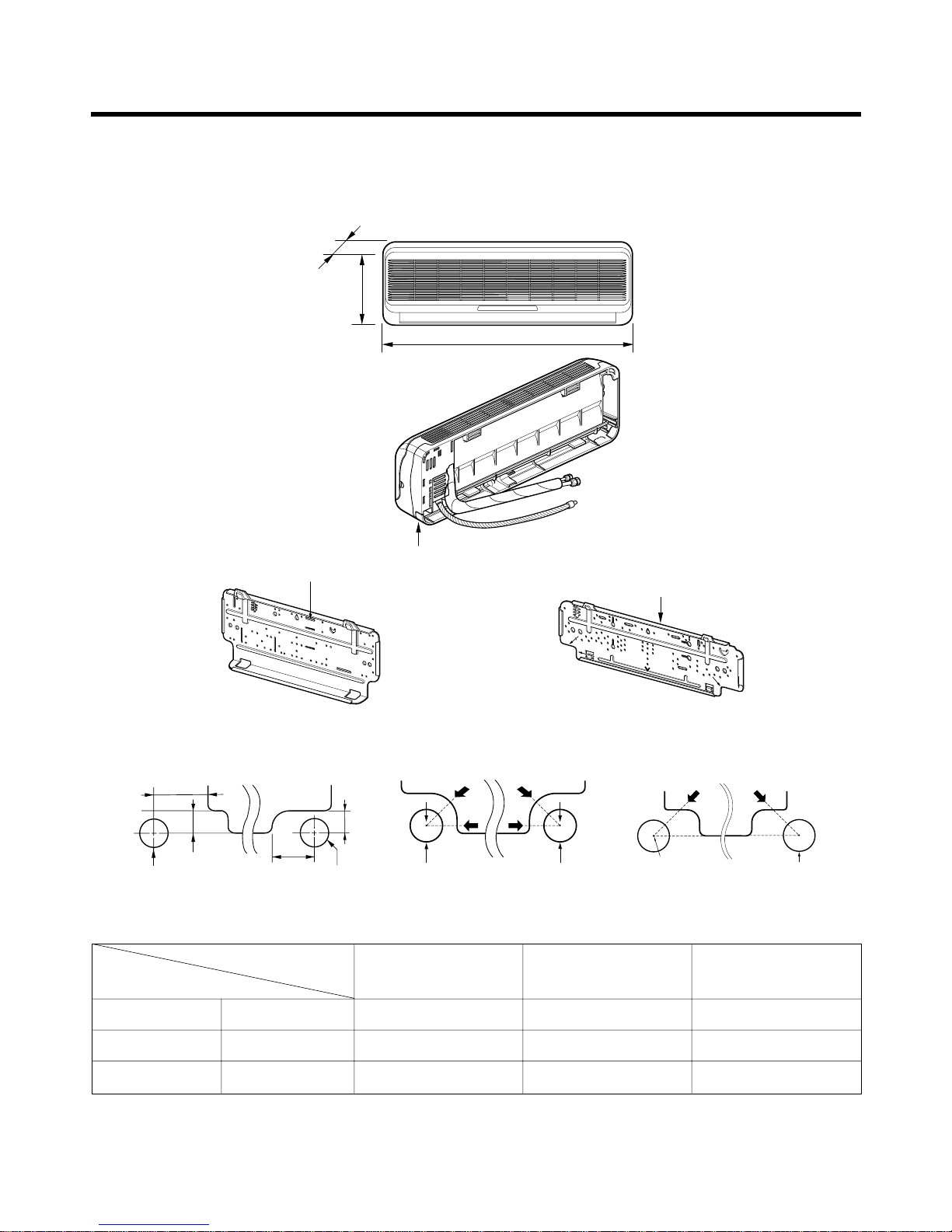

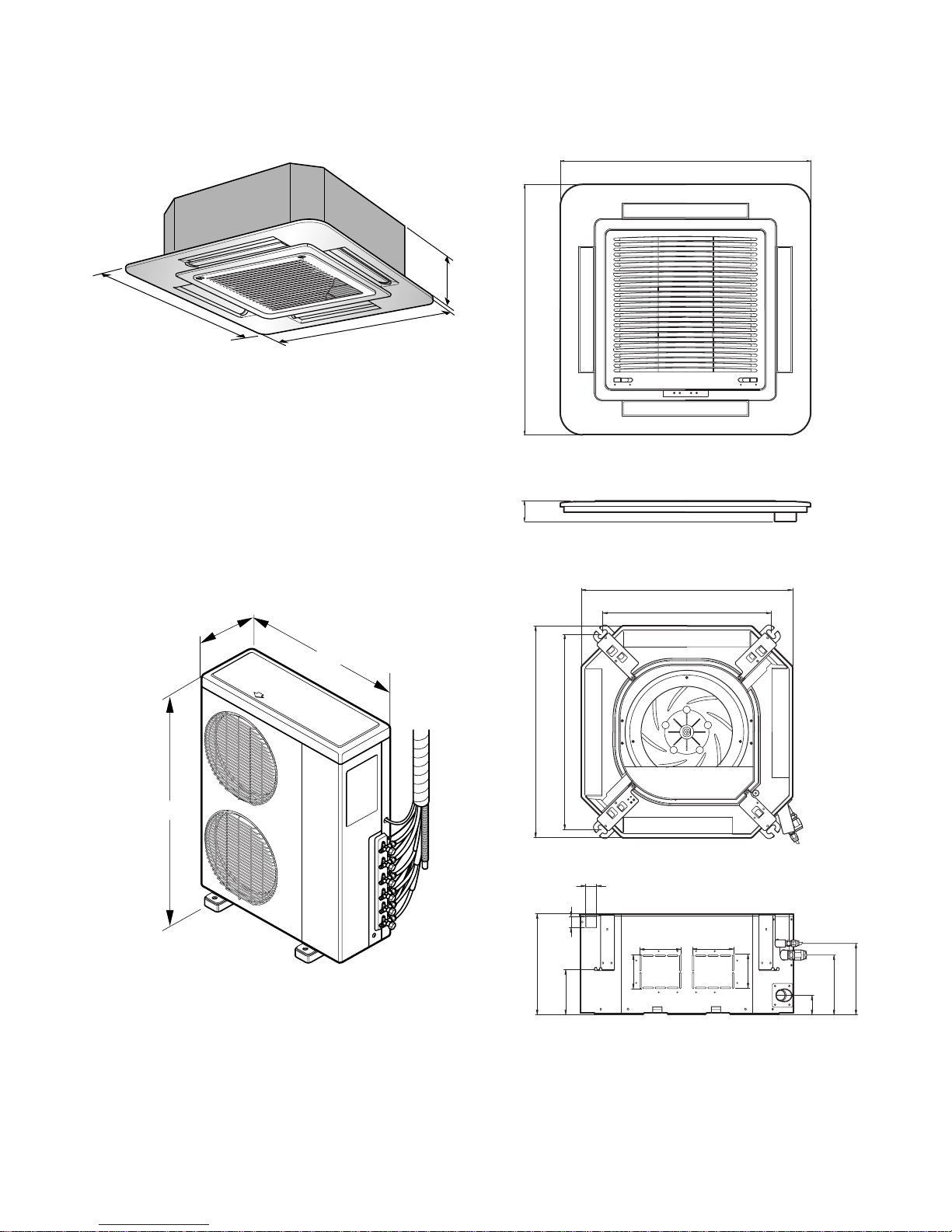

1. Indoor Unit

• Room Type Indoor Unit

- 23 -

Dimensions

Installation plate

Installation plate

D

H

W

Tubing hole cover

FMN1860NLFMN1260NLFMN0760NL, FMN0960NL

ø70mm ø70mm

A

A

A

A

Left rear piping Right rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

Left rear piping Right rear piping

Left rear piping Right rear piping

Hole Center

ø70mm

"D"

"C"

W mm 802 888 1,080

H mm 262 287 314

D mm 165 170 181

FMN0760NL

FMN0960NL

FMN1260NL FMN1860NL

MODEL

DIM

- 24 -

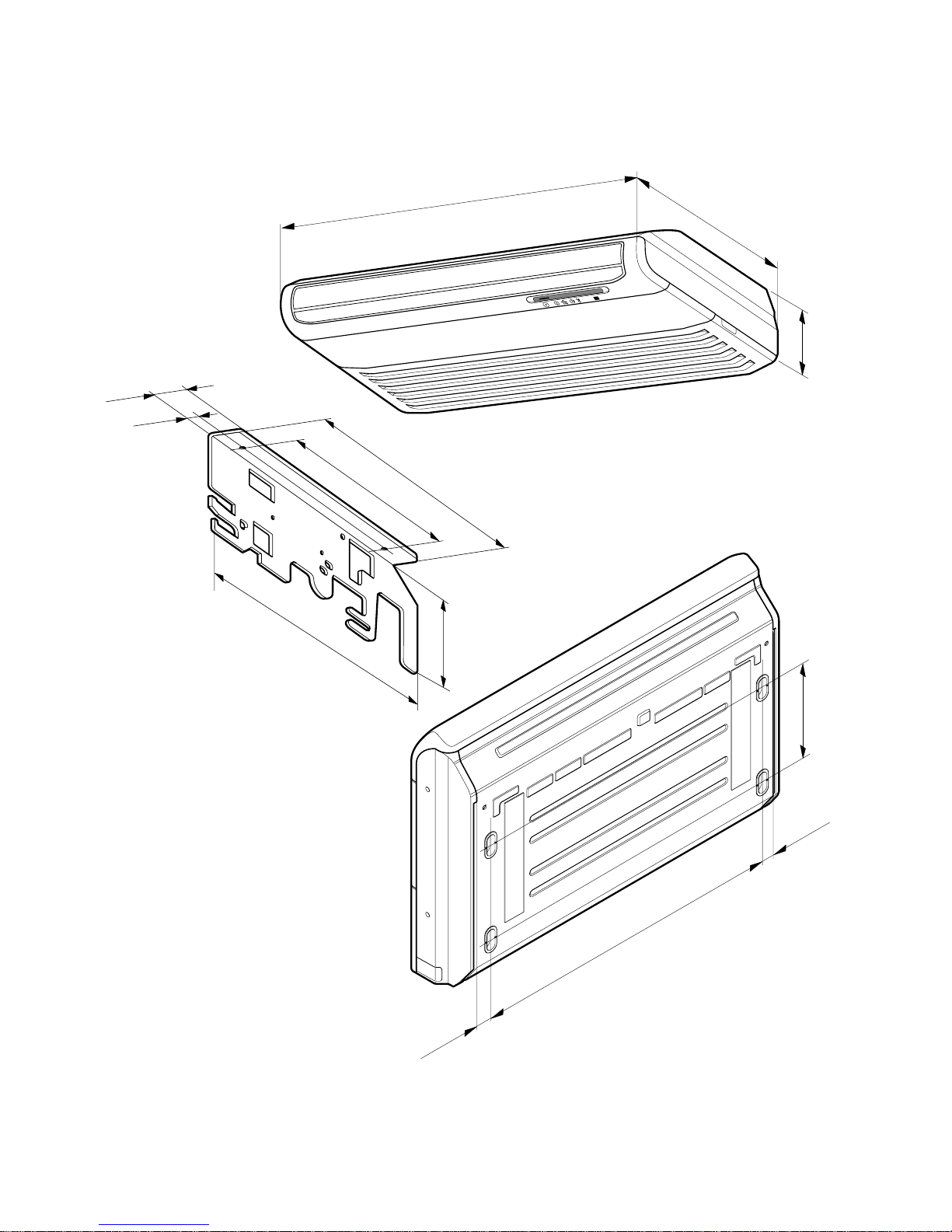

• Art Cool Type Indoor Unit

Pipe Hole

Fix Hole

Hanger Hole

H

W

D

MODEL

DIM Unit

W mm 570

H mm 568

D mm 137

INDOOR UNIT

- 25 -

• Convertible Type Indoor Unit

250mm

36mm

36mm

1076mm

1200mm

205mm

615mm

392mm

265mm

468mm

R

63mm

38mm

175mm

(Installation Plate)

(Rear Side)

- 26 -

• Cassette Type Indoor Unit

269

67055

570

269

190.5

160

52

90

90

120.4

30

521

670

570

450

40

110 110

670

670

CLOSE OPEN OPEN CLOSE

900

1,225

370

2. Outdoor Unit

- 27 -

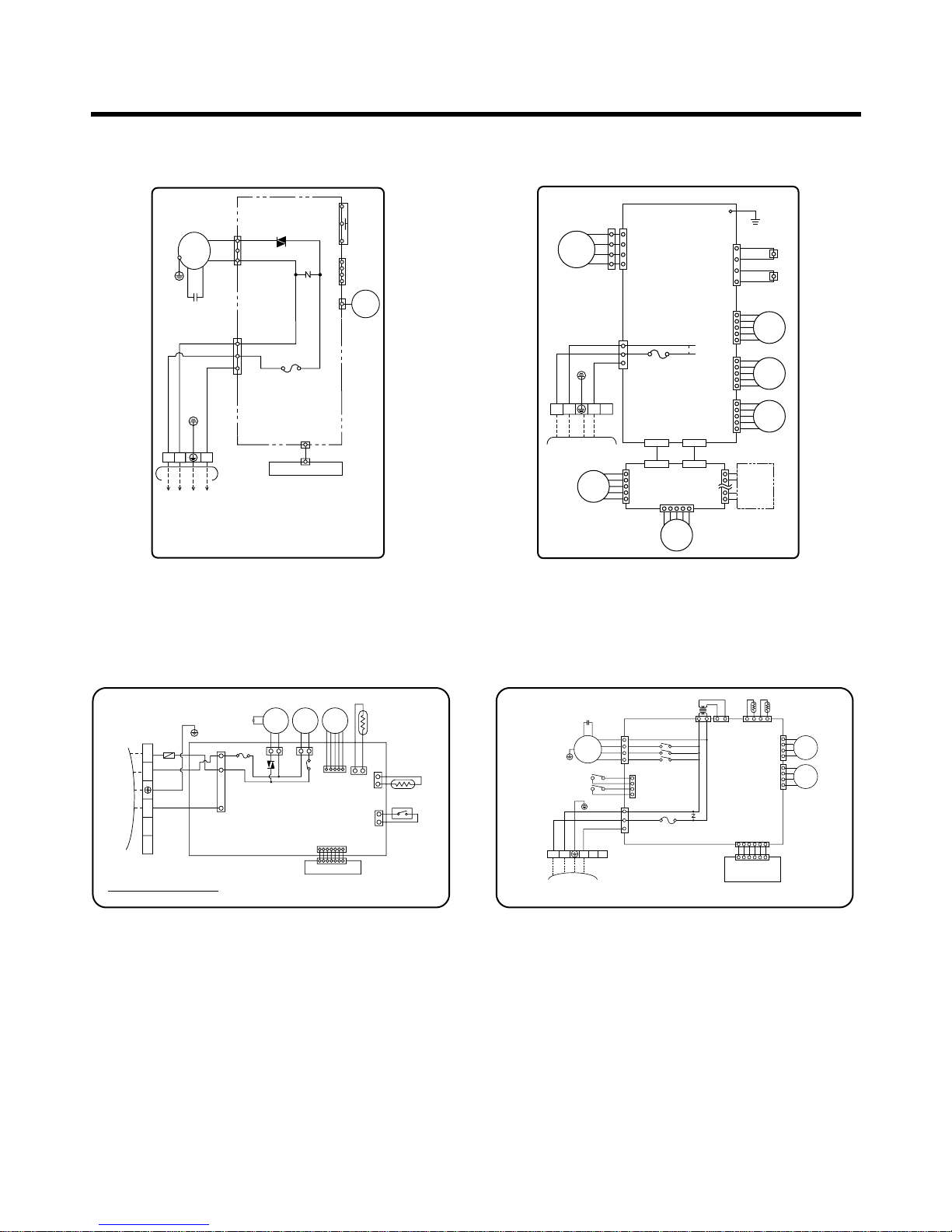

Wiring Diagram

1. Room Type Indoor Unit 2. Art Cool Type Indoor Unit

3. Cassette Type Indoor Unit 4. Convertible Type Indoor Unit

3854A20023B

INDOOR WIRING DIAGRAM

CN-DISP1

CN-U/D

FUSE

AC250V/T2A

CN-TH

SSR

SH-CAPA.

BR

YL

OR

BK

CN-POWER CN-FAN

ZNR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

STEP

MOTOR

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

TO OUTDOOR UNIT

PILLAR

TERMINAL

BR

BL

YL

1(L) 2(N

)

3

INDOOR WIRING DIAGRAM

CONNECT

PCB ASSY

DISPLAY

PCB

ASSY

MAIN PCB ASSY

CN-GND

CN-TH1CN-UDCN-LR1CN-LR2

CN-MOTOR2

CN-POWER

CN-D1

FUSE

250V 3.15A

CN-D2

BK

WH

YL

RD

FAN

MOTOR

STEP

MOTOR

STEP

MOTOR

STEP

MOTOR

STEP

MOTOR

STEP

MOTOR

TO OUTDOOR UNIT

BR

BL

GN/YL

RD

1(L) 2(N)

3854A20219A

34

Z

CAPACITOR

BR YL

CN-FAN

CN-POWER

RY-L

RY-M

RY-H

CN-TRANS

CN-UP/DOWN 1,2

TRANSFORMER

THERMISTOR

CN-TH

MAIN PCB

ASSY

OR

RD

RDBLBR

BL

BK

DOOR S/W 1,2

FUSE T3.15A

MOTOR

GN/YL

GN/YL

TO OUTDOOR UNIT

1(L)2(N)

4

3854A20220A

INDOOR WIRING DIAGRAM

CN-DISP

DISPLAY PCB

ASSY

TERMINAL

BLOCK

STEP

MOTOR

STEP

MOTOR

56

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

STEP

MOTOR

ROOM

SENSOR

PIPE

SENSOR

FLOAT S/W

CN - DISP

DISPLAY PCB

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20221A

BR

YL

BK

OR

BL

BL

BR

RD

GN/YL

BL

3(L) 4(N) 5 6 7

FUSE T3.15A

FUSE

250V 5A

- 28 -

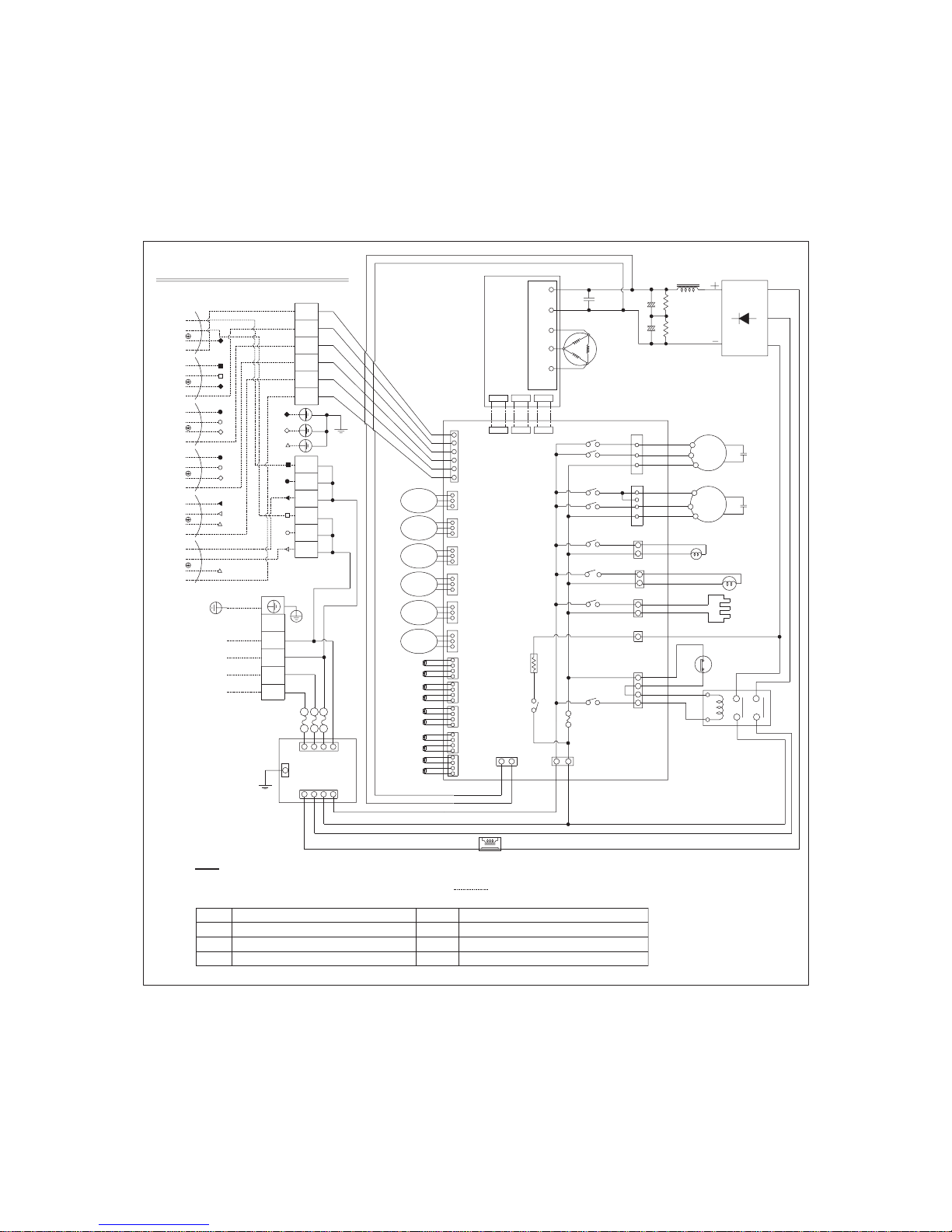

5. Outdoor Unit (FMU4480N6L)

REACTOR

DIODE

BRIDGE

SUB

MOTOR

BL

OR

BK

B

CAPACITOR

BR

YL

BK

MOTOR

OR

BK

BL

A

CAPACITOR

YL

BR

CRANKCASE HEATER

BK

BK

BR

BR

63H

COIL

4WAY

U

IPM

W V

WH

BL

N

RD

BK

RD

CN-IPM

RY-FAN1(HIGH)

RY-FAN1(LOW)

PCB

ASM

GATE1

CN-

CN-

CN-DATA

GATE2

CN-SV

RY-4WAY

RY-FAN2(HIGH)

RY-SV

CN-HEAT

CN-AC

CN-4WAY

RY-HEAT

YL

BL

WH

C

LEV

B

LEV

A

LEV

YL

BL

PTC

F

LEV

LEV

E

LEV

D

WH

RY-FAN2(LOW)

P

BK

WH

WH

GN/YL

T

BL

N

BK

S

T

N

WH

WH

52F

YL

YL

CN-PWR

FUSE

RY-COMP

CN-POWER

250V 5A

BK WH

CN-DC

RY-START

CT

BK RD

(CONNECTING WIRE)

WIRING OF FIELD

FUSE

500V 25A

R

BR

IN

BRBL

WH

OUT

BK

R

3%%c 4W 380-415V

POWER INPUT

50HZ

WH : WHITE

RD : RED

GN/YL : GREEN/YELLOW

NOTE

BR : BROWN

OR : ORANGE

BK : BLACK

BL : BLUE

S

BK

NOISE

FILTER

100K,2W

100K,2W

GAS

BY-PASS

0.27uF

800V

CN-FAN2

CN-LEV3 CN-LEV2 CN-LEV1

TH-A

TH-B

CN-LEV6 CN-LEV5 CN-LEV4

CN-FAN1

Outdoor Unit Wiring Diagram

B

C

A

D

E

E

C

D

B

A

BL

OR

RD

YL

BR

F

1(L)

2

3

1

1

2

F

YL

1

4

1

1

B

UNIT

2(N)

3(A)

1(L)

UNIT

A

1(L)

2(N)

2

5

2

2

5

2

UNIT

D

2(N)

1(L)

UNIT

C

3(C)

1(L)

2(N)

3(B)

2(N)

1(L)

2(N)2(N)

4

6

5

3

3

3

6

3

UNIT

F

3(F)

2(N)

UNIT

E

3(E)

1(L)

1(L)

2(N)

1(L)

3(D)

3854A20012H

TH-D

TH-F

TH-E

TH-C

CN-TH2CN-TH4 CN-TH3CN-TH5

TH-AIR

TH-PIPE

TH-DIS

TH-SUC

THERMISTOR FOR OUTAIR TEMP.

THERMISTOR FOR SUCTION PIPE TEMP.

THERMISTOR FOR PIPE TEMP.

THERMISTOR FOR DISCHARGE PIPE TEMP.

63H

52F

TH-A

A LEV

MAGNETIC SWITCH

THERMISTOR FOR A PIPE TEMP.

HIGH PRESSURE SWITCH

LINEAR EXPANSION VALVE FOR A PIPE

TH-PIPE

TH-AIR

TH-SUC

TH-DIS

CN-TH1

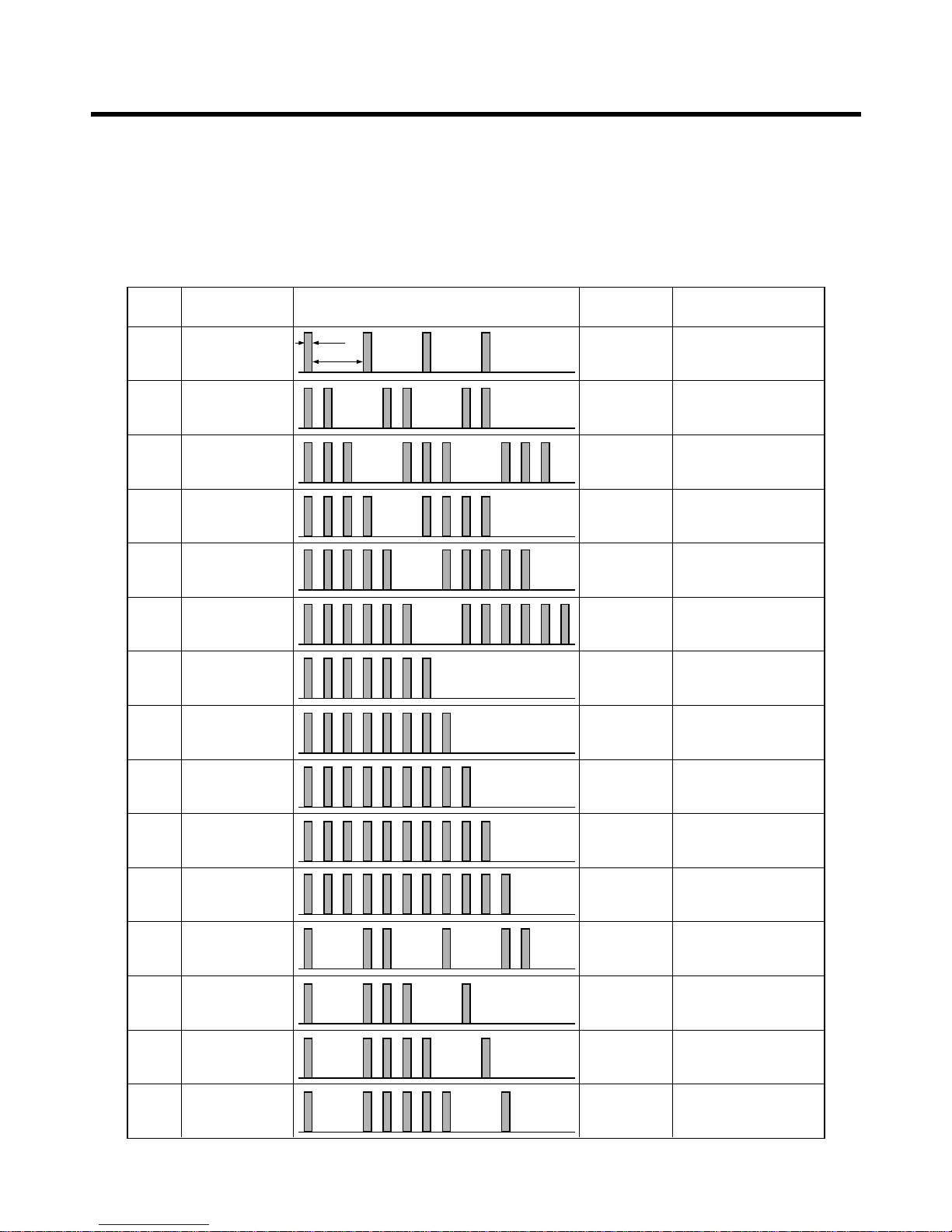

■ Error Indicator

• The function is to self-diagnoisis airconditioner and express the troubles identifically if there is any trouble.

• Error mark is ON/OFF for the operation LED of evaporator body in the same manner as the following table.

• If more than two troubles occur simultaneously, primarily the highest trouble fo error code is expressed.

• After error occurrence, if error is released, error LED is also released simultaneously.

• To operate again on the occurrence of error code 15, be sure to pull out power cord and then re-insert.

• Having or not of error code is different from Model.

- 29 -

Self-diagnosis Function

ERROR

CODE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CONTENTS

Indoor

Thermistor

open/short

Operation

OFF

Same as

above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Same as

above

Operation

OFF

Outdoor

Thermistor

open/short

Drain pump

Error

Poor

Communication

Fire alarm

Response

Difference

Operation

DC

Low Voltage

Excessive

Capacity

Discharge Temp.

Error

Incorrect Wiring

(U.V.W)

Connecting Wire/

Pipe Error

IBM Error

CT Current

Wired Remocon

Communication

Error

• Operation ON

• Signal on For

5 Seconds

• Stop the indoor Fan

When indoor thermistor

is error.

• Operates by Outdoor

Micom Control.

• Stop the operation

High Voltage/Power

Error/Condenser

Temp. Error

LED DISPLAY OPERATION

NO DISPLAY

CASE

- 30 -

Refrigeration Cycle Diagram

1. FM-4480N6L (Cooling & Heating modes)

A

B

C

D

E

F

Heat Exchanger

Indoor Unit

Outdoor Unit

3-WAY

Valve

Heat Exchanger

4-WAY

Valve

Comp

ex)

LEV

Cooling & Deice

Heating

INDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

B(Length)

D(Length)

A(Height)

C(Height)

9.52mm(3/8") 6.35mm(1/4")

12.7mm(1/2") 6.35mm(1/4") 7.5 7.5 25 25

15.88mm(5/8") 6.35mm(1/4")

Pipe Size

GAS LIQUID

Max. length

(m)

Additional

Refrigerant (g/m)

Max. Elevation

(m)

Standard Length

(m)

** A, B mean indoor unit higher located than outdoor unit.

C, D mean outdoor unit higher located than indoor unit.

For installation over rated distance, 25g of refrigerant should be added for each meter in Heat pump Model.

ex) When installed at a distance of 15m, 75g of refrigerant should be added in Heat pump Model.

(15 – 7.5) x 25g = 187.5g

(Rated performance for refrigerant line length of : 7.5m)

Loading...

Loading...