Page 1

CUSTOMER : LG ELECTRONICS INC.

DATE : 15.SEP. 2011.

SPECIFICATIONS FOR APPROVAL

PRODUCT NAME : PDP POWER SUPPLY UNIT

MODEL NAME : PSPI-L103A

CUSTOMER P/N : EAY62609701

PRODUCTION FACTROY : LGIT YANTAI (CHINA)

APPROVAL REMARK

RoHS

APPENDIX

0.1 15.SEP.2011

Designed Checked Approved

LG Innotek Co., Ltd.

DOCUMENT No. 11(개A)EP-070

K,S Kimm J,H Park J,S Kang PAGE 41

(30)-4022

Page 2

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

REV.NO : 0.1

PAGE :

Change History of Revision

Revision Date Contents of Revision Change Remark

0.1 ‘11.09.15 1. Load Life time 개선품

2,000Hr)

-

C363 : 470uF 10V KMG

-

C364 : 100uF 16V KMG

-

C701 : 100uF 16V KMG

2. SMD

-

R611,R612,R614~R619,R629_240KΩ

,R630_360KΩ

-

R840_24KΩ,R841,R842_270KΩ,

R843~R850_470KΩ

3. Vs Dead time delay 삭제

-

C805 50V 0.1uF

4. Va

-

R518 : 33KΩ39KΩ

-

R519 : 33KΩ36KΩ

5. Q356 온도

-

R366 : 220Ω470Ω

6. M5V 기동時이상파형

-MICOM Version변경

Version(V0.03V0.06)/Checksum(2B472478)

-

Q367 : KRC103S

-

C379 : 0.1uF 50V

7. Space Holder (Supporter) 추가

-P3 추가

8. 무부하

-

R830 : 470Ω

9. PCB 냄새

-

KB-3152 원판

10. Vs dip test(264Vac)時

-

R816 : 1.8KΩ

Axial 로부품변경

R615,R616_1.2MΩ

R617_68KΩ,R618_51KΩ로변경

R840_15KΩ,R841,R842_150KΩ,

R843,R844_1.2MΩ

Thermer

Detect level 변경

Margin 확보

기동時Vs OVP(Burst

F

820Ω

Issue 개선

삭제

F

적용

1/2W,

1/2W 로

delete

F 변경

F 변경

F

개선

공진

1.2KΩ

(1,000Hr

NXB series로

NXB series로

NXB series로

변경

부품추가

mode 진입不)개선

F

Margin 부족

F

변경

변경

변경

개선

PCB Rev0.6

(30)-4022

Page 3

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

Ⅰ. INTRODUCTION

Ⅱ. SPECIFICATION

Ⅲ. SCHEMATIC

Ⅳ. PART LIST

Ⅴ. PCB LAYOUT

Ⅵ. SAFETY PARTS

INDEX

REV.NO : 0.1

PAGE :

1

Ⅶ. SILICON BONDING

Ⅷ. HEATSINK LAYOUT

Ⅸ. PACKING

Appendix

Ⅰ. Process Flow

Ⅱ. SCHMETIC

“ SCHMETIC 별첨”

Ⅲ. Magnetic Part

Ⅳ. Non-use certificate

“ Non-use certificate 별첨 ”

(30)-4022

Page 4

DOCUMENT No : 11(개A)EP-070

MODEL NAME : PSPI-L103A .

Ⅰ. INTRODUCTION

1. Scope

This approval is the description related to every electrical and structural

specifications and reliability for Power Supply Unit (PSPI-L103A)

used on 50FHD LGE PDP (Plasma Display Panel).

2. Customers product related items

Product : PDP TV向 Power Supply Unit

Part code : EAY62609701

3. LG Innotek product name

Product name : PSPI-L103A

Revision code : 0.1

S P E C I F I C A T I O N

REV.NO : 0.1

PAGE :

2

Ⅱ. SPECIFICATION

1. Input Requirement

Nominal Input Voltage AC100V to AC240V

Input Voltage Variation AC90V to AC264V

Input Current

Nominal Frequency 50 / 60 Hz

Frequency Variation Range 47Hz to 63Hz

Phase Single

Inrush Current

Efficiency

Leakage Current

Impulse Noise Surge ±2kV / 50ns to 1000ns / 0˚

Dip Test

Max 3.7A at 100Vac

Max 1.7A at 240Vac, Norminal Load, 50/60Hz

50A zero-pk max

at cold start and any specified line, load, and temperature

conditions.

More than 85% at the 230Vac Rated load

0.5mA max. (AC264 / 60Hz)

at Nominal Load

100% 1cycle

60% 5cycle

(AC100 ~ 240V, Normal load Ta=25℃)

Judgment

Related Regulation : IEC 61000-4-11, EN61000-4-11

to 360 ˚

Surge Immunity

Electrostatic Discharge 8kV

4kV (Common Mode) : 2 time each polarity

4kV (Normal Mode) : 2 time each polarity

(30)-4022

Page 5

DOCUMENT No : 11(개A)EP-070

2. Output Characteristics

Voltage

Output

PDP

Module

VSC

Board

(Signal

Interface)

Vs

(205V)

Va

(55V)

M5V

(5.2V)

17V - 1.5A 0 ~ 3.0A ±5% 500

5.2V - 1.5A 0.1 ~ 3.0A ±5% 200

STBY

variable

range [V]

200V ~

(Before

RL_ON)

(After RL_ON)

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

CTQ

Rated Current (Min, Max)

Rated

206V

- 1.0A 0.01 ~ 2.0A ±1.5% 300

- 1.5A 0.5 ~ 2.5A ±5% 100

3.5V

5.2V

1.0A 0.1 ~ 1.4A ±1% 500

0.1A

STBY

1.0A 0.1 ~ 2.0A ±5% 200

[Amean]

*note 1

0.07 ~ 0.2A

9mA

Below 0.3W Condition

REV.NO : 0.1

PAGE :

3

Voltage

Regula

tion [V]

±4% 100

Ripple

Voltage

[mVp-p]

※ Module Max Spec : 300W

※ Aging, RQA test condition : Rated Current

※ Voltage Regulation Condition

- When regulation test for 17V, total current of 5.2V+M5V+STBY set upper 2A.

- When regulation test for each voltage, current of other output set below rated value.

- When regulation test for M5V, it’s reinforced GND

※ The following instruments shall be used for measuring ripple voltage.

1. Probe having impedance ratio of 1:1.

2. Oscilloscope having frequency characteristic of 100MHz or more.

3. Vs ripple voltage is 2000mVp-p, Va ripple voltage is 600mVp-p, STBY(5.2V),5.2V

and M5V ripple voltage is 200mVp-p, STBY(3.5V) ripple voltage is 200mVp-p

at the electric-load and room temperature with metal ground plane.

※ All regulations must satisfy spec. which are recorded in approval.

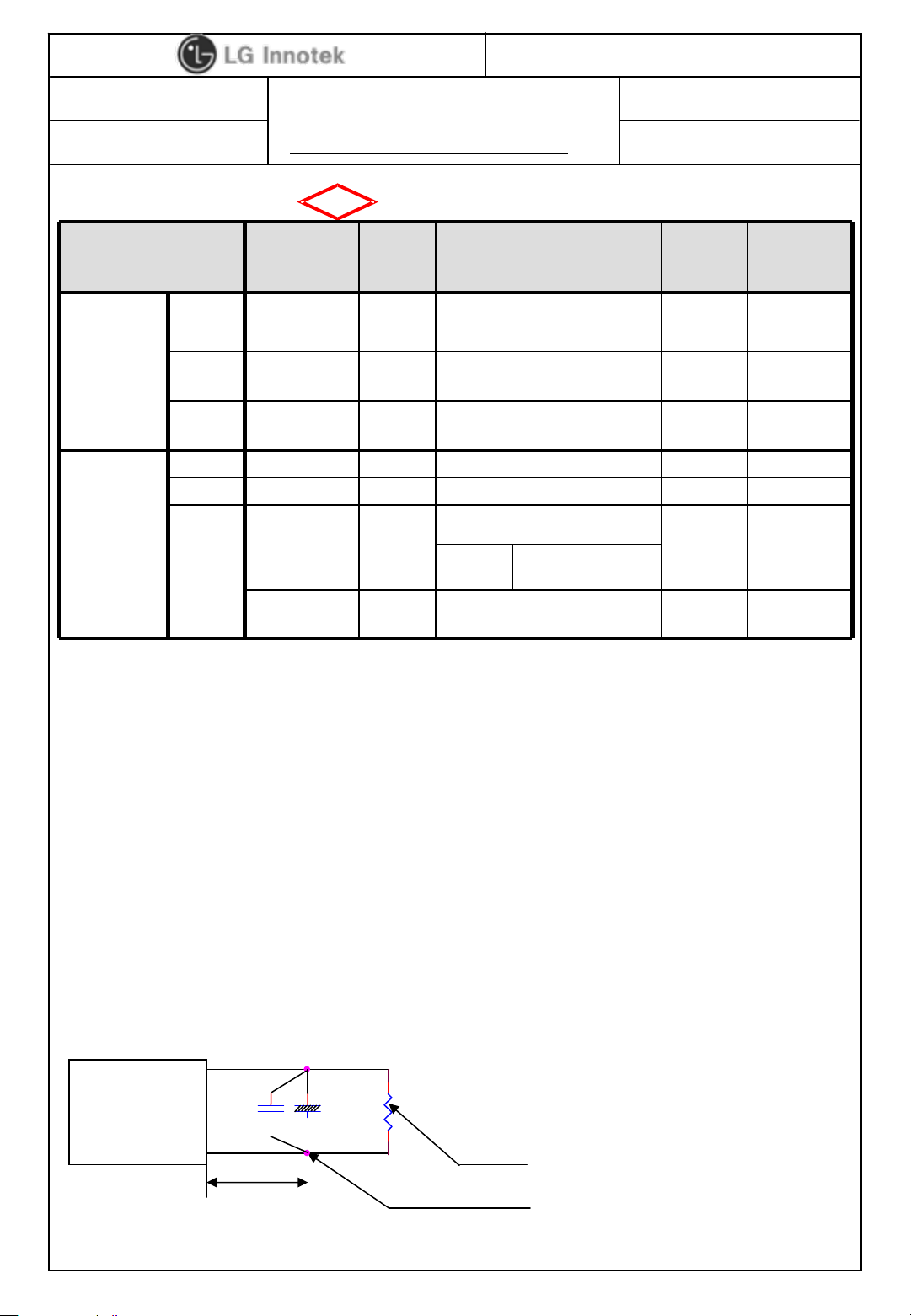

As shown in fig.1 C1(47uF) electrolytic

capacitor and C2 (0.1uF) film capacitor

PSU

C2

+

C1

-

shall be connected between measuring

Load

points when measuring ripple noise.

Fig 1

100mm

Measuring Point

(30)-4022

Page 6

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

3. Environment Requirement

Operating Temperature Range 0 to 70 deg.

Operating Humidity Range 20 to 80 %

Storage Temperature Range -20 to 70 deg.

Storage Humidity Range 10 to 90 %

MTBF

Mean Time Between Failure

Cooling Condition Natural Air

98

㎨

Shock test consists of pivoting the power supply, from one

Shock

edge of it’s bottom side, on a flat surface (such as wood

having thickness of 10mm or more) and allowing the

opposite edge to fall from a height of 50mm to this surface.

The test is performed three times on each edge of the

bottom side of the power supply

440,000hour(Tool_Telcordia Issue 1)

REV.NO : 0.1

PAGE :

4

Under Development Mass Product

Frequency (Hz) 2~200 2~200

Vibration

Acceleration

(Grms)

Time (min) 20 min. /

Direction X, Y, Z

1.04 0.84

축

4. Dielectric Strength Voltage

① Live & Neutral to all Secondary(+ line) : 3.0KVac or 4242Vdc

Dielectric

Strength Voltage

※ Above tests are performed at room temperature in non-condensing atmospheric conditions

※ Frame grounds are connected to secondary circuits.

※ Cut OFF condition : 10mA

for 1 Minute

② Live & Neutral to all Secondary GND : 1.5KVac or 2121Vdc

for 1 Minute.

※ 1.8KVac for 1 seconds (Mass Production)

5. Insulation Resistance

Insulation

Resistance

Insulation resistance shall be 8MΩ

between primary Live, Neutral line and secondary.

~ ∞Ωat 500Vdc after 60sec.

(30)-4022

Page 7

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

6. Burn – in(1h)

AC 110V Input Voltage, Nominal Load, ambient temperature 45℃±5

-

MP 1'st : 24 Hr

MP ~ 2.0 K : 12 Hr

2.0 ~ 5.0 K : 8 Hr

After 5.0 K : 1 Hr ( According to below condition. *note1)

when operating 1Hr Aging, The condition of ELT(양산보증시험) Aging is same

※

as note2 and be tested following note2.

Also result should be written on the forwarding report (출하성적서).

※ 1 Hours Standard (*note1)

Start

30min

AC

Off

/On

REV.NO : 0.1

PAGE :

5

Discharge for 5min.

1h

AC

Off

/On

/Off

Check [30min 간격 이상유무 확인]

* When happened a fault on check process for 30 min intervals and On/Off test ,

Serial No., fault phenomenon and time from Aging start to fault happening are record ed.

※ note2

비고Spec.

구분

구분

시간

시간

On/Off Test

On/Off Test

60 ℃ (58±2℃)Chamber 온도

60 ℃ (58±2℃)Chamber 온도

양산 품(20hr)

양산 품(20hr)

4M변경 품(44hr)

4M변경 품(44hr)

st

st

품(68hr)

품(68hr)

MP 1

MP 1

시험 종료 시

시험 종료 시

On/Off Test 실시

On/Off Test 실시

비고Spec.

동작온도 승인원 기준고온동작 TestTest 항목

동작온도 승인원 기준고온동작 TestTest 항목

Max 80% load 기준승인원 기준Load

Max 80% load 기준승인원 기준Load

2회이상(AC 전원)

2회이상(AC 전원)

On/Off Time : 각 10s

On/Off Time : 각 10s

Lot size

Lot size

0 ~

0 ~

1,000

1,000

1,001 ~

1,001 ~

2,000

2,000

2,001 ~

2,001 ~

3,000

3,000

3,001 ~

3,001 ~

4,000

4,000

4,001 ~

4,001 ~

5,000

5,000

5,001 ~

5,001 ~

6,000

6,000

5

5

20 Hrs

20 Hrs

10

10

44 Hrs

44 Hrs

15

15

201510

201510

251510

251510

302015

302015

302015

302015

353020

353020

MP 1st Lot4M 변경품양산 Lot

MP 1st Lot4M 변경품양산 Lot

Time시료 수Time시료 수Time시료 수

Time시료 수Time시료 수Time시료 수

68 Hrs

68 Hrs

(30)-4022

Page 8

DOCUMENT No : 11(개A)EP-070

7. Interface

Signal Description

RL_ON

M_ON

(Module_ON)

AC_DET

5.2V, 17V

ON/OFF

M5V / Vs Va

ON / OFF

Monitor for

AC input voltage

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

Signal

Direction

Input

Input

Output

HIGH : 5.2V, 17V ON

LOW : 5.2V, 17V OFF

HIGH : M5V / Vs,Va ON

LOW : M5V / Vs,Va OFF

HIGH : Active

LOW : Inactive

REV.NO : 0.1

PAGE :

Active Level

6

High : more

than 2V

Low : Less

than 0.7V

High : more

than 3V

Low : Less

than 0.7V

High : more

than 4V

Low : Less

than 0.7V

•Auto Power turn on System

- If VSC B/D is not connected PSU through 18pin connector, auto power

on mode is operated from PDP Set Signal.

8. Product Safety

Safety Standards to be applied

EMI / RFI Standards to be applied

Design to meet the requirements as follows

UL60065 and IEC/EN60065

Design to meet the requirements as follows

FCC and EN55020 Class B

with 4dB minimum margin.

9. Construction

Weight Less than 670g / PSU

Unit Size 196(W) x 245(D) x 27(H)(with PCB)

1.6mm ~ 3.0 mm under

Lead Length

IC102,IC103,IC352,IC902,IC903 are 4.8mm under

D351,Q356 are 5.5mm under

Height

27mm (with PCB)

TH101,C907,C351 and C502 are Max. 27mm

height (without PCB)

RL103 are Max. 27mm+5mm height (without PCB)

T901 are Max. 29mm height (without PCB)

(30)-4022

Page 9

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

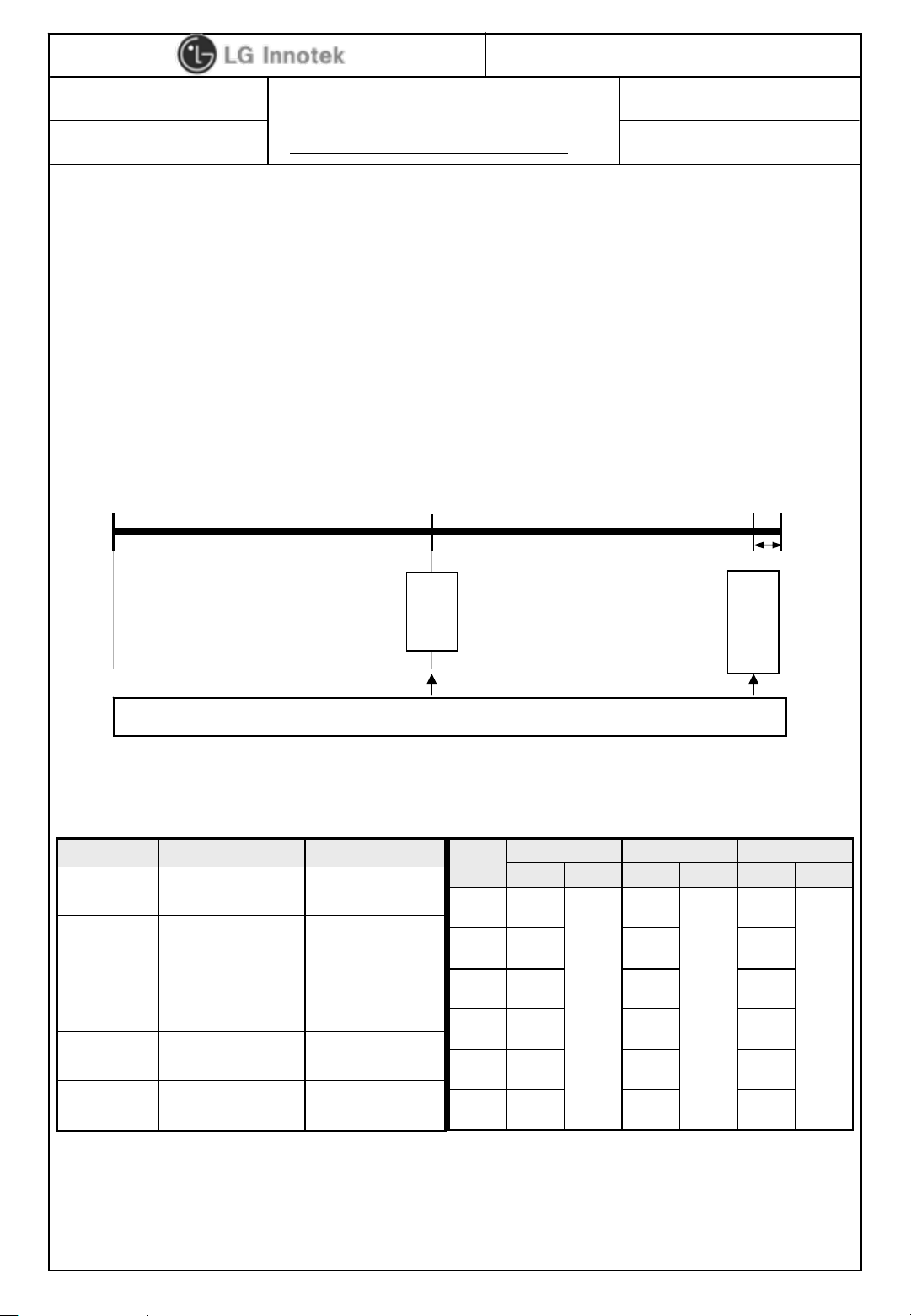

* Construction _ Height limit exception components

T901

REV.NO : 0.1

PAGE :

7

C907

C502

TH101

C351

RL103

(30)-4022

Page 10

DOCUMENT No : 11(개A)EP-070

MODEL NAME : PSPI-L103A .

10. Function of protection

Protection Output Circuit Trip point Notes

Over Current

Under Voltage

Over Voltage

S P E C I F I C A T I O N

CTQ

STBY 2.5A ~ 20A

5.2V 6A ~ 20A

M5V 4.1A ~ 20A

17V 3.1A ~ 8A

Va 2.1A ~ 12A

Vs 1.5A ~ 6A

5.2V 3.5V ~ 4.5V

M5V 3.5V ~ 4.5V

17V 8V ~ 14V

Va 40V ~ 50V

Vs 165V ~ 180V

5.2V 5.5V ~ 9.0V

M5V 5.5V ~ 7.0V

17V 19.5V ~ 28V

Va 60V ~ 70V

Vs 215V ~ 240V

REV.NO : 0.1

PAGE :

8

Shut down

Shut down

Shut down

Shut down

Hiccup or

※ The OCP test of STBY, 5.2V, M5V and 17V should setup current rise slew rate greater than 3.6A/S.

※ This Power Supply has above-mentioned protections.

※ The time for short shall be less than 10sec.

※ PSU should be shutdown by under voltage protection when short circuit test

※ PSU should be wake up normally when AC off-on / Relay off-on / protection removal

※ Short circuit protection between different output terminals is not considered.

※ Trip point for over voltage indicates the operating point when the output voltage

slowly increases.

※ The conditions of Over Current measurement

부하조건

구분

구분

OCP

OCP

(100Vac)

(100Vac)

출력전압 조정

출력전압 조정

(110Vac)

(110Vac)

측정포

측정포

인트

인트

5.2Vst

M5V 1ANom

17V

17V

Va

Va

Vs

Vs

5.2Vst

Nom

Nom Min

5.2Vsc

Nom

-

-

Nom

Nom

Nom

NOMINAL(42HD/50FHD/60FHD :205V )

-

-

NOMINAL(42

NOMINAL(42

M5V

Nom

Nom

NomNom

-

-

Min

부하조건

17V

17V

1A

1ANomNom5.2Vsc

-

-

”

”

/50FHD/60FHD:55V)

0.3A

0.3A

VsVa

VsVa

0.3A

0.3A

0.1A-MINVa

0.1A-MINVa

-0.01AMINVs

-0.01AMINVs

MINMINMIN전출력OVP (100Vac)

MINMINMIN전출력OVP (100Vac)

MINMINMIN전출력UVP (100Vac)

MINMINMIN전출력UVP (100Vac)

10-1. AC Over-voltage Test

1) Over voltage shall test 315Vac~340Vac , Protection should be occur.

2) No fire, shock hazard or explosion sh all occur.

(30)-4022

Page 11

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

11. Input / output Pin Assignment

AC Input

SK101

1 AC

2 AC

Wafer YAW396-02M1

PSU VSC Board

1 17V 2 17V

3 GND 4 GND

5 5V 6 5V

7 5V 8 Error_DET

9 GND 10 GND

11 GND 12 GND

13 STBY 14 STBY

15 RL_ON 16 AC DET

17 M_ON 18 AUTO_GND

Wafer

P813

SMAW200-H18S2

REV.NO : 0.1

PAGE :

9

PSU PDP Module

Pin P811

1 Vs

2 Vs

3 NC

4 GND

5 GND

6 Va

7 M5V

Wafer YAW396-H73FD

SK101

2 1

7~15 mm

7 6 5 4 3 2 1

P811

P813

18 2

7~15mm

(30)-4022

Page 12

DOCUMENT No : 11(개A)EP-070

12. Power Sequence

AC IN

AC_DET

5V

STBY5.2V

RL_ON

M_ON

5.2V,17V

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

90%

Max. 150ms

AC-OFF

REV.NO : 0.1

PAGE :

10

DC-OFF

3.5V

90%

M5V

Va

Vs

Max. 150ms

Ton

Min. 200ms

Max.300ms

10%

10%

90%

Min 50ms / Max 200ms

90%

Min 50ms / Max 200ms

Toff

90%

10%

Min.2000ms

※ * RL_ON, M_ON signal is come from VSC B’d, So, Sequence spec related RL_ON,

M_ON is just guide spec for PDP Buyer. Measured data can’t be judged OK or NG.

Va, Vs 전압이 10% 이하 일 경우에만 상기의 Ton , TVaR , TVsR 에 meet 할수있다.

Toff 시간은 AC 전원으로 (플러그 해제) off 한 경우는 제외된다,

※ M_ON은 RL_ON 이후 Max50ms이전에 입력 되었을 경우로 한다

(30)-4022

Page 13

DOCUMENT No : 11(개A)EP-070

13. Block Diagram

AC INPUT(90~264V)

EMI Filter

L/F * 3EA

Relay

250Vac 10A

Rectifier

(600V 15A)

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

STBY

Trans

EER2828

Control IC

STR-

W6052S

MBRB2060CT

10V 3300UF

REV.NO : 0.1

PAGE :

AOD484

25V 1UF

AOD484

10V 470UF

AOD484

16V 100UF

MBRD10200CT

AP9575GS

50V 220UF*2

25V 220UF

11

STBY

5.1V

M5V

17V

Control IC

R2A20112

Multi V Level

Vs V Level

Va V Level

RL On/VS On

EER2820 * 2

TK12A60U * 2

MURF1060CT

450V 120uF * 2

AC Det

PFC

MICOM

MC81F4216D

Control IC

NCP1397B

5V(STBY5V)ON

Va

Multi ON

/Vs ON

PFC ON

Multi1차

Vs/Va Trans

(LLC Resonant)

EER3944

TK12A60D * 2

SDURF1040CTR

F/B

SDURF1040CT

250V 150UF

TK13A25D

MBRF10200CT

80V 330UF

100V 33UF

VS

VA

(30)-4022

Page 14

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

14. Electrical characteristics

No. Test Item Test method

1 Intermittent

Operation stability

test

2 Low temperature

operation

3 Low temperature

Storage test

Leave at low

temperature

The switching regulator shall ON-OFF for 20,000 time at an

interval of 10 sec at typical load, after that electrical characteristics

shall be satisfied.

The switching regulator is left at the operating guarantee minimum

temperature for 2 hours without applying electricity.

After that power shall be turned on, and then the electrical

characteristics shall be satisfied.

The switching regulator is left at minimum storage temperature for

96 hours or more.

Then the switching regulator is left at a room temperature and

humidity for 1hour or more, after that electrical characteristics shall

be satisfied.

REV.NO : 0.1

PAGE :

12

4 Heat cycle storage

test

The switching regulator is 10 consecutive temperature cycle that

shown below is performed and then leave them at room temperature

and humidity for 1 hour or more.

After that, electrical characteristics shall be satisfied.

Time Temperature

30 minutes 25℃

30 minutes 25 ℃→-20 ℃

60 minutes Minimum storage temperature(-20 ℃)

30 minutes -20 ℃→25 ℃

30 minutes 25 ℃

30 minutes 25 ℃→70 ℃

60 minutes Maximum storage temperature (70 ℃)

30 minutes 70 ℃→25 ℃

(30)-4022

Page 15

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

No. Test Item Test method

5 Heat shock Test Heat shock test performed under following conditions without

applying electricity and then leave them at room temperature and

humidity for 1hour or more.

After that, electrical characteristics shall be satisfied.

Condition : -20℃(120minutes), 70℃(120 minutes),

Switching time : 4minutes(±1minutes), 10 cycle

REV.NO : 0.1

PAGE :

13

15. Mechanical characteristics

No. Test Item Test method

1 Appearance There shall be no contaminant or dirt on the switching regulator

which has adverse effect on electrical characteristics.

There shall be no excessive unevenness or scratches on the plated

or painted surface.

2 Vibration

Frequency

(Hz)

Acceleration

(Grms)

Time (min) 20 min. /

Direction X, Y, Z

After that electrical characteristics shall be satisfied.

There shall be no damage to appearance and construction.

3 Shock Shock : 98m/s^2

On the oak more than 10mm thickness with the flat face, raise the

one side for 50mm, and it carries out each side free fall for three

sides.

There shall be no damage to appearance and construction.

Under Development Mass Product

2~200 2~200

1.04 0.84

축

(30)-4022

Page 16

DOCUMENT No : 11(개A)EP-070

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A .

16. Sound noise characteristics

PSU NOISE MEASURE POINT

PSU NOISE MEASURE POINT

PSU NOISE MEASURE POINT

PSU

★ ★ ★

CTQ

at a distance of 60

cm to noise source

REV.NO : 0.1

PAGE :

14

4189 mic

anechoic room 內

PSU NOISE SPEC.

PSU NOISE SPEC.

PSU NOISE SPEC.

22.5dB(A) /20.0u Pa2.00E-5 Pa

Each Frequency

(1/1 octave, A-weighting, to 1khz~16khz Total overall)

Measure Location : Anechoic Room

Measure Condition : at a distance of 60 cm to mic.

full white pattern, at AC 110V/220V

The Max Specification : measure 3 points,

at PSU center and left & right on the outside..

17. Micom Definitions

V0.06A-2478

F4216D

YYWW

※ Version : V0.06A

Checksum : 2478

(30)-4022

Page 17

DOCUMENT No : 11(개A)EP-070

MODEL NAME : PSPI-L103A .

18. Bar code Specification

2~3mm

8 mm

LB81E626097010001(0.1)

LB81E626097010001(0.1)

S P E C I F I C A T I O N

40 mm min

34mm min

REV.NO : 0.1

PAGE :

2~3mm

5mm min

Label Form

15

※

Bar Code Size는

그림의

size보다

Manufacturing code

Manufacturing Year

Manufacturing Month

Manufacturing Date

Manufacturing Line

LG Part No.

Serial. No.

Approval sheet

Version

그림의

줄일수는

size가

최소size이며, 업체

없음.

기준및PCB공간에

L (L : LGIT)

B (9:2009,A:2010,B:2011,…)

8 (1,2,3,… 10:O, 11:N, 12:D)

1 (1~9, … A:10, B:11, C:12, … X)

A~D : Gwangju

E~N or 0~9 : Yantai(china)

62609701 (EAY62609701)

0001 (10Digit, 0001~9999)

(0.1)

따라

변경할수

I,O Except

있으나,

RemarkBarcode SpecificationCode

Barcode type : 93 code

Barcode length : 17 digit

Label size : 8 X 36 mm (minimize)

※ BARCODE PRINTING : DO NOT ERASE, WHEN RUB BY HAND.

(30)-4022

Page 18

DOCUMENT No : 11(개A)EP-070

Ⅲ.SCHEMATIC

※ APPENDIX 참고

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A.

REV.NO : 0.1

PAGE :

16

Page 19

DOCUMENT No : 11(개A)EP-070

※ APPENDIX 참고

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A.

REV.NO : 0.1

PAGE :

17

Page 20

DOCUMENT No : 11(개A)EP-070

※ APPENDIX 참고

S P E C I F I C A T I O N

MODEL NAME : PSPI-L103A.

REV.NO : 0.1

PAGE :

18

Page 21

5V_MI

C731

0.47uF

D601

Q706

C

B

C724

E

2SD2114KW

D702

1N4148W

RL103

50V

DG5D1-0-2

4

3

0.1uF

R742

4.7K5%1/8W

R746

4.7K

1/8W

RL2

5%

30PDA60-FA7

D602

MURF1060CT

A1

A2

C

2

1

1/4W1%620K

1/4W1%620K

1/4W1%620K

R106

150K

1/8W

LF101

50uH

CY104

330pF

CY105

1%

Q605

KTD1347

C

15V

ZD601

R10 3

240 K

1/8 W

E

B

D60 8

1N4 148 W

D307

GPP10J-E3

600V

C311

0.1uF

50V

1%

C625

0.1uF

330pF

50V

VCC2

LF104

50uH

R105

R10 4

150K

240 K

1/8W

1/8 W

1%

1%

D609

1N4007

VCC1

R628

2.7K

1/8W

5%

C312

2200pF

1KV

D/ST

1

VCC

4

C307

33uF

50V

NXB

YAW396-02M

SK101

5V_MI

AC_DET

PFC_ON

T10A H -250V

F101

2

1

R631

1K

1/8W

5%

4

3

1

2

MULTI_INPUT

VA1 01

IC102

PC-17K1C

IC103

PC-17K1C

12mH

LF102

INR 14D 62 1K- AM OTE CH

VCC2

R125

1

R124

2

4

3

1 2

10K

1.8K

1/8W

1/8W

D304

5%

5%

SB140A

34

40V

R3052W5%

0.33

IC101

KIA431BM

C108

R101

R102

R108

R107

150K

1/8W

1%

50V

IC301

STR-W6052S

3

S/OCP

BR

7

GND

5

6

FB/OLP

10V

ZD303

CY1 03

100 0pF

250 V

CX106

0.47uF

275V

CY1 02

100 0pF

250 V

C112

R119

51K

1/8W

R120

91K

1%

0.01uF

1%

1/8W

C309

2200pF

50V

0.15uF

K

R

C113

A

0.047uF

50V

C301

0.1uF

50V

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

R301

75K2W5%

D10 3

C303

100uF

50V

LXV

1KV

1N4 007

VCC

D305

1N4007

1KV

R307

10K

1

P101

ZD301

15V

KTC3198-Y

5%

1/8W

ZD302

TH101

15-ohm

VCC1

Q301

132

18V

P102

R304

1/8W

1%

1/8W

17V

3.0A

C356

1uF

25V

STBY_ON

C363

470uF

10V

NXB

6.3 X11

31

R615

R616

R617

R618

1.2M

1.2M

68K

51K

STBY

2.0A

1/2W

1/2W

3.0A

1/8W

1/8W

5V

PFC

1%1%

1%

1%

5

3

2

1

L60 1

EE2 820

6

8

10

1

A

1KV

D303

UF4007

5%

10K

1/8W

C308

100uF

50V

LXV

C302

1000pF

50V

AC1

2

4

3

AC2

1

3

5 8

6

4

3

D101

D15XB60-7000

C

1

T301

EER2828

IC352

PC-17K1C

C601

1uF

500V

R624

33K

1/8W

1%

R632

3M

1/8W

5%

C619

C352

R

R358

R360

18

1W

5%

0.1uF

OPEN

C

50V

C607

220pF

50V

R353

4.7K

1/8W

1

C351

3300uF

10V

NXB

R385

OPEN

C373

OPEN

1%

R627

33K

1/8W

1%

P301

P302

OPEN

R626

51K

P304

1

P307

1

1

1

P310

1%

R354

18K

1/8W

R359

12K

1/8W

1%

1%

R356

10K

1/8W

C608

C624

0.1uF

2.2uF

12

11

10

9

1

2

R351

R352

50V

50V

D352

MBRD10U200CT

A1

A2

C368

680pF

2KV

P3051P306

D351

MBRS2060CT

A2

C

A1

C362

330pF

2KV

390

1/8W

1%

K

IC351

A

1.8K

1/8W

5%

KIA2431AS

1

R366

470

1/8W

1%

C358

OPEN

C606

0.47uF

50V

1/8W

P311

R601

33K

1/8W

1%

C605

1/8W1%

R625

680K

0.47uF

50V

1%

1

5V_MI

C

E

Q358

KRC103S

B

C365

220uF

50V

NXB

C354

0.1uF

50V

ZCD-M

ZCD-S

TM

VREF

SGND

RAMP

RT

COMP

R361

100K

1/8W

5%

STBY_SAVE

5

6

IC601

R2A20112ASP

1

2

3

4

5

6

7

8

R367

7.5K5%1/8W

5%

R368

7.5K

1/8W

C377

220uF

50V

NXB

C355

0.1uF

50V

Q357

2SA1504S

C369

2200pF

50V

Q352

AP40T03GH

D

G

Q353

AP40T03GH

D

G

B

16

15

14

13

12

11

10

9

C375

0.1uF

50V

3

8

S

S

C

E

VCC

GD-M

PGND

GD-S

OCP-M

OCP-S

SS

FB

E

C

C372

OPEN

ZD352

2

1

10

D603

1N4148W

6.8

R610

R369

KTC3875SY(ALY)

16V

Q362

KRC103S

B

ZD353

16V

5%

1/8W

C613

0.47uF

50V

39K

1/8W

L60 2

EE2 820

R605

5%

R381

C

E

200

Q359

100K

5%

1/8W

R623

220

Q356

AP9575GS

S

13K

R373

C

E

1/8W

5%

Q363

KRC103S

B

Q603

TK12A60U

D

G

S

1

B

C610

1uF

25V

R380

4.7K5%1/8W

C

E

P308

C359

0.1uF

50V

Q367

KRC103S

1

MULTI_ON

R379

4.7K

1/8W

5%

B

D604

1N4148W

6.8

R606

C611

50V

100uF

LXV

MULTI_ON

C379

0.1uF

50V

1/8W

5%

P309

M5V_ON

1/8W

C612

2200pF

50V

G

1/8W

C357

0.1uF

50V

R603

1%

5%

R382

68K

B

47K

1/8W

C623

0.47uF

50V

D

C361

0.1uF

50V

R370

47K

C

E

1/8W

C374

0.1uF

50V

5%

R60 75W5%

0.035

P303

5%

1/8W

Q364

KRC103S

5%

U-Power 50"PV1

R604

200

5%

1/8W

R622

1

KTC3875SY(ALY)

D

TK12A60U

R608

220

C615

2200pF

50V

R374

G

6.3 X11

Q601

G

68K

5%

1/8W

1/8W

1%

10K

5%

1/8W

6.8 V

Q35 1

AP4 0T0 3G H

S

ZD354

C370

0.1uF

50V

C364

470uF

10V

NXB

R61 35W5%

Q360

ZD3 51

16V

D

S

0.035

VCC

C

E

R357

M5V

2.5A

C366

0.022uF

B

MMSD4148T1G

100K

1/8W

Q366

C

KRC103S

E

5%

C617

450V

D353

100V

B

C618

120uF

120uF

450V

C620

2200pF

50V

R376

5.6K

1%

1/8W

1%

R377

1.2K

R375

50V

270K

1/8W

R383

1/8W

5%

R378

5.1K

1/8W

1%

47K

5%

1/8W

Q365

C

KRC103S

B

C367

0.1uF

50V

C378

E

0.1uF

50V

2011. 09. 03

R620

15K

R6211K1%

C371

220uF

25V

NXB

PFC/STBY/Multi

Page 22

5V_MI

R718

30

1/8W

5%

5.1V

ZD704

C701

100uF

16V

NXB

6.3 X11

M5V

M5V_ON

MULTI_ON

PFC_ON

AC_DET

VS_ON

RL2

STBY_SAVE

STBY_ON

R757

2.7K

1/10W

R728

390

1/10W

5%

1%

R725

1K

1/10W

5%

R750

1K

1/10W

5%

R751

4.7K

5%

1/10W

R726

10K

1/10W

R752

5%

4.7K

5%

1/10W

6

5

R753

1K

1/10W

5%

4

25036WS-06B

EC1/SCK/EXT2/AN2/R04

PWM1O/T1O/SI/EXT3/AN3/R05

EC2/SO/EXT4/AN4/R06

[SDATA]T2O/EXT5/AN5/R07

VREF/EXT6/R10

[SCLK]PWM2O/EXT7/AN6/R11

RXD/R14

TXD/R15

AN10/R25

VDD

IC701

MC81F4216D

1

2

3

4

5

6

7

8

9

10

R03/AN1/EXT1/T0O/PWM0O

20

R02/AN0/EXT0/EC0

19

SXOUT/R01/EXT11

18

SXIN/R00/EXT10

17

VSS

16

RESETB/R35/VPP

15

14

13

12

11

XIN/R34

XOUT/R33

R27/AN12

R26/AN11

R736

1/10W

10K

5%

R733

100K

5%

1/10W

R760

22K

1/10W

1%

10K

1/10W

Q702

2SC3875S(ALY)

C

B

E

R732

R731

20K

1/10W

1000pF

R777

1K

1/10W

5%

50V

5%

5%

47K

1/10W

C713

R722

1K

1/10W

5%

R719

220K

M_ON_IN

VS_DET

1/10W

5%

AUTO_GND

AC_ON

VA_DET

ERROR_DET

R734

2.2K

C714

1/10W

50V

1000pF

5%

R735

R723

5.6K

1/10W

1%

D710

MMSB414B

D704

MMSB414B

R737

220K

1/10W

5%

5%

P701

1

2

3

17V

5V

STBY

RL_ON

M_ON_IN

R727

47K

1/10W

5%

C715

1000pF

SMAW200-H18T-S

17V

1

GND

3

5V

5

5V

7

GND

9

GND

11

STBY

13

15

M_ON

17

50V

P813

2

4

6

8

10

12

14

16

18

C708

17V

GND

5V

ERROR_DET

GND

GND

STBY

AC_ONRL_ON

AUTO_GND

50V

0.1uF

R758

2.7K

C716

0.1uF

50V

1%

1/10W

17V

5V

ERROR_DET

STBY

AC_ON

AUTO_GND

P811

YAW396-H73FD

1

VS

2

VS

NC

4

GND

5

GND

6

VA

7

M5V

8

VA

M5V

C750

0.1uF

50V

0.022uF

5V

17V

ZD702

24V

50V

R748

100

1/10W

5%

ZD703

7.5V

C741

0.1uF

50V

R747

100

C702

1/10W

5%

R740

10K

50V

1000pF

R755

5.6K

R745

10K

1/10W

5%

5%

1/10W

1%

R756

5.1K

1/10W

1/10W

R741

10K

1/10W

1%

R743

18K

1/10W

1%

Q703

2SC3875S(ALY)

C

B

E

C755

1%

50V

1000pF

R713

R744

1.6K

1%

R724

5.1K

5.6K

1N4148W_DIODES

1/10W

1/10W

1%

1/10W

D703

1%

R739

5.6K

1/10W

1%

C778

50V

1000pF

R717

2.2K

1/10W

5%

R714

100K

1/10W

5%

R712

10K

1/10W

5%

Q701

C

2SC3875S(ALY)

B

E

R738

VA701

Chip Varistor

R701

RL_ON

20K

1/10W

C712

5%

50V

1000pF

5%

47K

1/10W

C710

VS

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

2011. 09. 03U-Power 50"PV1

2 3Micom

Page 23

MULTI_INPUT

F801

T4A H-250V

PFC

D805

MUR160RLG

600V

5%

R823

10

ZD803

1/8W

15V

C813

0.1uF

50V

VCC

14HB15

3

4

RT

CTIMER

1%

330

R833

1/8W

C818

22uF

50V

1/8W 1%

1%

R812

11K

1/8W

R831

6.8K5%1/8W

1.2K

R816

1/8W

1%

R828

IC801

1.2K

NCP1397

R820

10K

1%

1/8W

C809

22uF

50V

VBOOT

16

1

CSS[DIS]

1/8W

1%

R818

R819

6800

1/8W

1%

MUPPER

2

FMAX

1M

12

RB160M-30

GND11MLOWER

10

6FB5BO7DT8

R825

4.7K

1/8W

1%

R824821/8W

C807

330nF

50V

D801

R801

51

1/8W

5%

RB160M-30

R803

51

1/8W

5%

C808

0.1uF

50V

FAULT

9

SKIP/DISABLE

C811

0.47uF

50V

1%

820

R830

D802

1/8W

D

Q801

G

TK12A60D

S

5%

R802

20K

1/8W

D

R8051M1/2W

R806

2.2

1/2W

5%

1/8W

5%

C802

0.022uF

1250V

VCC

C804

10uF

50V

1%

R810

D803

16

C820

270pF

2KV

MMSD4148T1G

R838

8.2K

1/8W

5%

C815

0.01uF

50V

C806

0.068uF

50V

1/8W 1%

R807

1001W5%

D804

MMSD4148T1G

R815

100K

1/8W

5%

R839

IC802

KIA431BM

1K

1/8W

K

A

Q802

G

TK12A60D

S

5%

R804

20K

1/8W

VCC3

C810

0.01uF

50V

C803

10uF

50V

C825

0.1uF

50V

R808

47K

1/8W

5%

C805

R809

10K

1/8W

1%

OPEN

15V

ZD804

R826

20K

C826

1uF

25V

1%

5%

R

C824

0.1uF

50V

T901

EER3944_50T4R4

1

2

3

4

5

6

7

8 9

R844

1.2M

R843

1.2M

R842

150K

R841

150K

C823

0.1uF

50V

R840

15K

1/2W

1/2W

1/8W

1/8W

1/8W

A1

C

1/8W

1/8W

A2

FCF 10A 40

1%

1%

D90 1

C

C506

22uF

100V

VSFB_PC

VR901

20K

R901

R902

R903

R904

R905

R906

47K

47K

47K

33K

33K

2.7K

C502

330uF

80V

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1%

1/8W

C903

0.022uF

400V

R909

1K

1/8W

5%

C904

OPEN

R512

24K

1/8W

VSFB_PC

C907

150uF

250V

C905

0.1uF

50V

R

ZD501

22V

R515

24K

1/8W

5%

C507

0.1uF

50V

K

A

R511

5%

56K

IC901

R507

5.1K

1/8W

B

KIA431

1/4W

5%

5%

C

Q504

KRC103S

E

C908

OPEN

Q501

2SK2508

SGD

47K

R51 7

1N4148W_DIODES

D508

ZD503

5%

R501

33K

1/8W

C

KTC3207

Q502

E

ZD502

7.5V

5%

1/8 W

2

15V

B

D506

1N4148W

R516

6.8K5%1/8W

C505

100pF

3

Q503

KTC3198-Y

1

D507

1N4148W_DIODES

R504

C501

100V

10nF

150K

1/8W

1%

R510

820

1/8W

1%

R502

27K

1%

1/8W

50V

R503

8.2K

1/8W

1%

10K

VR502

R505

27K

1%

R506

9.1K

1/8W

1/8W

1%

R9081K1%

1%

1%

1%

1%

R907

1K

1/8W

1%

1%

100K

TH501

1%

R518

39K

1/8W

R519

36K

1/8W

1%

1%

1/8W

R520

1.3K

R918

39K

1/8W

1%

C503

33uF

100V

R919

33K

1/8W

1%

R920

33K

1/8W

1%

R921

33K

1/8W

1%

R514

1/8W

R922

33K

VS_DET

1/8W

1%

R513

24K

1%

1/8W

24K

1%

16

15

14

13

12

11

10

IC902

PC-17K1C

4

3

MULTI_INPUT

1%

1%

1%

1%

1%

VCC3

R827

2.7K1%1/8W

4

3

IC903

PC-17K1C

1

2

D902

FRF10A40

D509

1KV

UF4007

D504

FMX-22S(SP)

A2

A1

R917

STBY

1K

1/8W

5%

VS_ON

17V

R910

6800

1

R911

2

1.2K

203V 1.4A

VA

55V 2.0A

VA_DET

VS

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

CY999

680pF

250V

2011. 09. 03U-Power 50"PV1

3

3VS/VA

Loading...

Loading...