Page 1

11SP 4247” LCD TV Power specification

Specification

Specification

Rev 1.3

6

Date: 2012. 08. 15

Page 2

11SP 4247” LCD TV Power specification

1. INTRODUCTION

1.1 Scope

This approval is the description related to every electrical and structural specifications

and reliability For Power Supply Unit used on 4247 inch LGE LED TV.

1.2 Customers product related items

Product : Power Supply Unit

Part code : EAY62171601

1.3 Product name

Product name : LGP4247-11SPL

Revision code : 1.3

2. SPECIFICATION

Rev 1.3

2.1 Input Requirements

Nominal Input Voltage AC 100V to AC 240V

Input Voltage Variation AC 90V to AC 264V

Under 3.5Arms . (at 100Vac & Nominal Load)

Input Current

Under 1.5Arms . (at 240Vac & Nominal Load)

Nominal Frequency 50 / 60 Hz

Frequency Variation Range 47 Hz to 63 Hz

Phase Single

Leakage Current 0.7mA_peak. (100Vac ~ 240Vac)

Surge Immunity ±

4kV / 1000ns / 0˚

to 360˚

Hold-up Time More than 20ms at 100Vac and maximum output load

Lightning Surge 2kA Normal, Common Mode

80A zero-peak max

Inrush Current

at cold start and any specified line, load, temperature conditions.

2.1.1 Power Factor

over than 0.9 at 90 – 264Vac & max load condition

7

Date: 2012. 08. 15

Page 3

11SP 4247” LCD TV Power specification

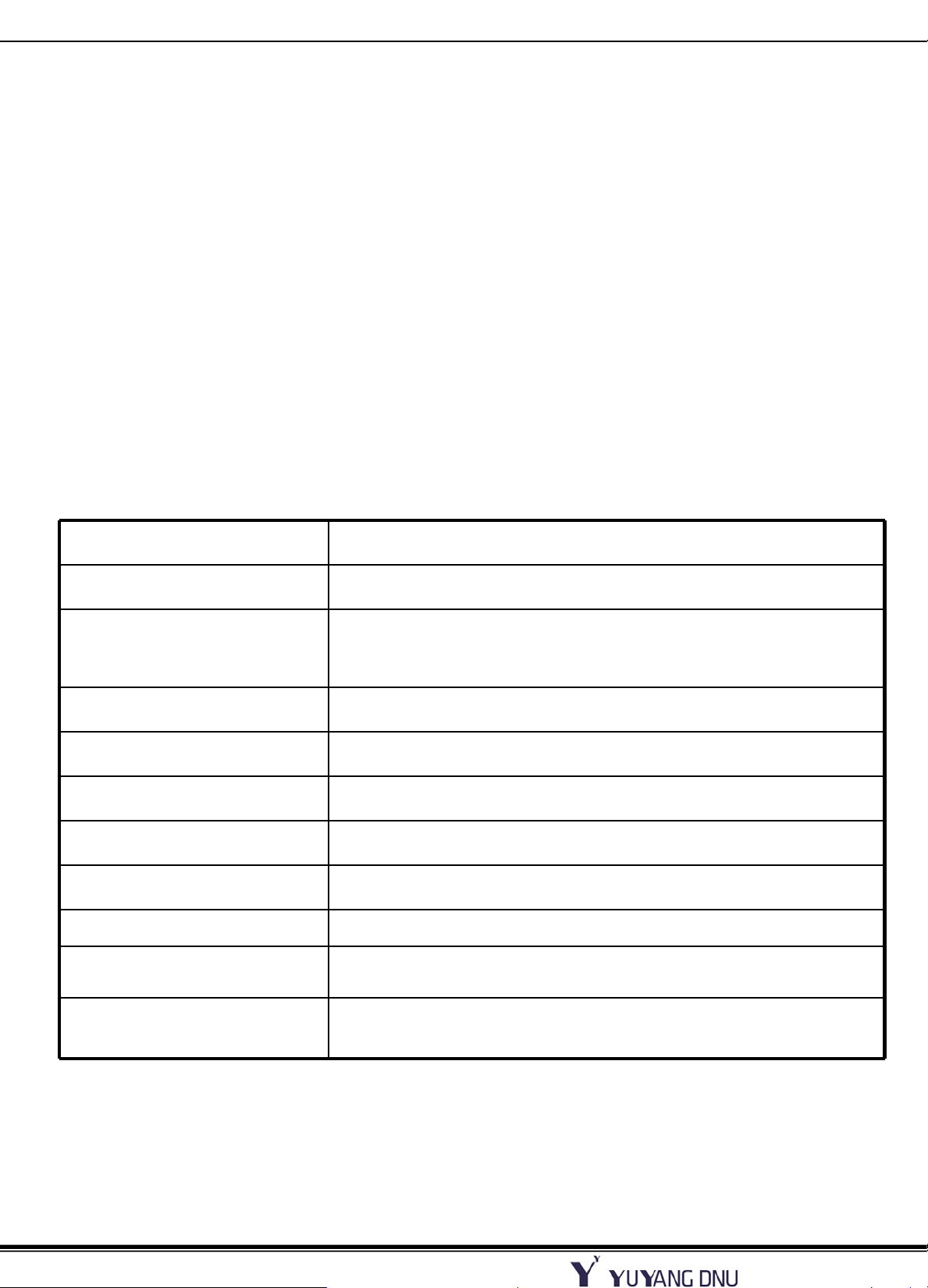

2.2 Power Output Characteristics

Rev 1.3

Output

3.5V

Voltage

Variable range

[V]

0.09W Under(6mA) - -

Rated Current

(Min, Max)

[Amean]

Voltage

Regulation

[V]

Ripple

Voltage

[mVp_p]

3.325V ~ 3.675V

(STBY)

12V 11.4V ~ 12.6V 3 (0.3~3 ±

24V 22.8V ~ 25.2V 4.1 (0.1~4.1) ±

2 (0.001~2) (ON condition) ±

5% 250 mVp_p

5% 350 mVp_p

5% 500 mVp_p

* On Condition : In a moment of Power_ON Signal activated, the current of 3.5V output should be

limited within 40mA(Max) at LCD TV condition for stability.

Do not turn “Power_ON” Signal on at the load condition of 3.5V output, more than 40mA.

* Total regulation for each output circuit includes the results of input voltage variation,

load variation, warm-up drift and temperature change.

* The following instruments shall be used for measuring ripple noise.

1. Probe having impedance ratio of 1:1.

2. Oscilloscope having frequency characteristic of 100MHz or more.

- Test Point : power output each pin

Add Electrolytic Capacitor 47㎌ + 0.1㎌

Power Supply Unit

Output Voltage

700mm

※ Ripple and noise are measured at the end of output cable which are added a 0.1uF ceramic

capacitor and 47uF electrolytic capacitor. ( connected parallel )

+

Load

Oscilloscope

Measurement point

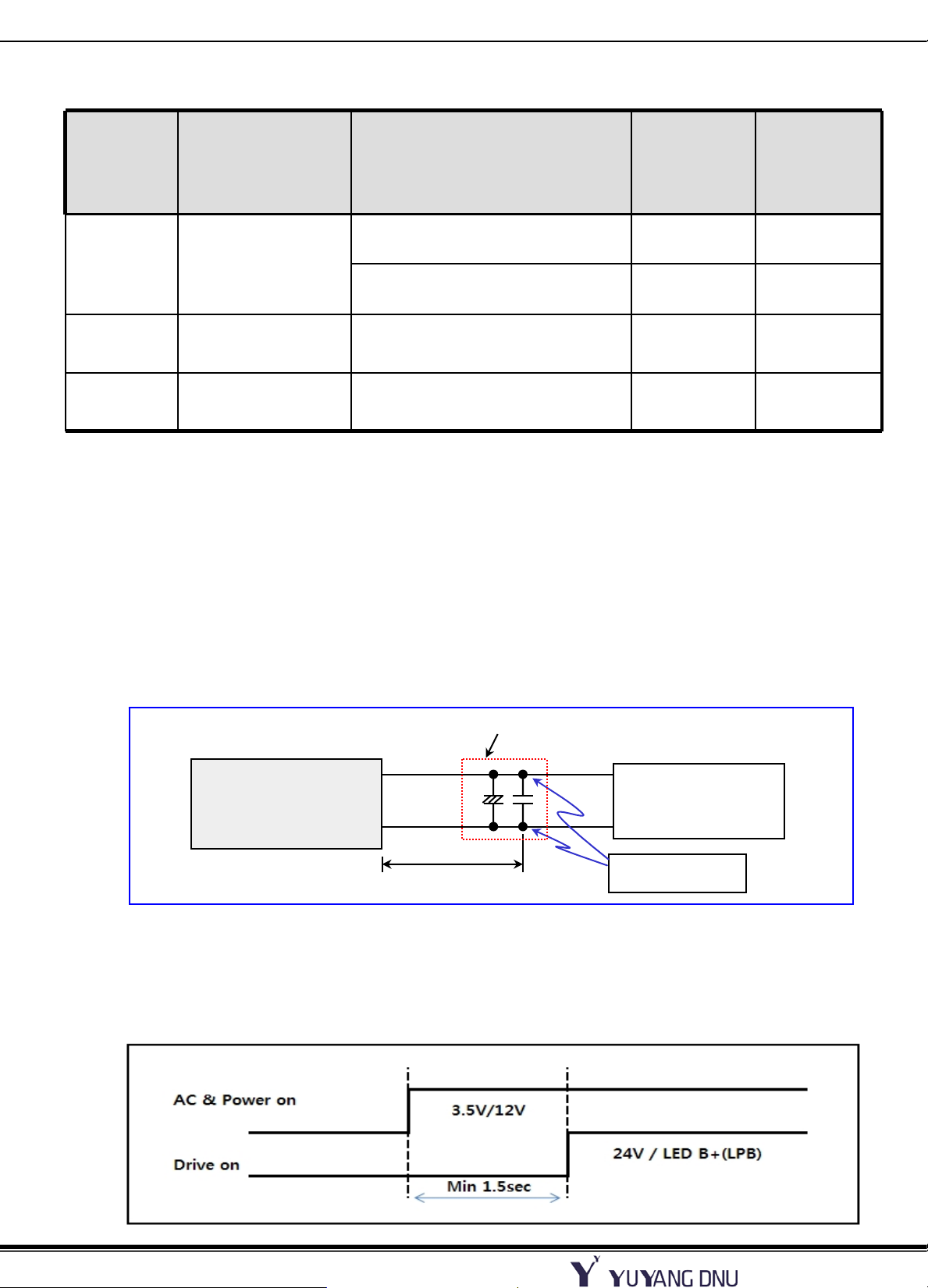

* Power turn on system (Only E/Load condition)

If Main Board is opened, that is electrical load condition,

drive on signal must be turn on after about 1.5s behind power on signal

8

Date: 2012. 08. 15

Page 4

11SP 4247” LCD TV Power specification

2.2.1 Stand By Power Consumption

Output Voltage 3.5V (STBY) 12V 24V

Load [A] 0.006 Don’t Care (Power-Off)

Wattage [W] Less than 0.09Under (230Vac / 50Hz)

2.3 Environment Requirement

Operating Temperature Range -10℃ to 40℃

(60℃:No Hardware Failure, TV SET Condition)

Operating Humidity Range 30 to 85 %

Storage Temperature Range -25 to 85 deg.

Storage humidity Range 5 to 90 %

Rev 1.3

MTBF

50,000 hour

(Mean Time Between Failure)

Cooling Condition Natural Air

Shock 98 ㎨

Shock test consists of pivoting the power supply, from

one edge of it’s bottom side, on a flat surface

(such as wood having thickness of 10mm or more) and

allowing the opposite edge to fall from a height of 50mm

to this surface.

The test is performed three times on each edge of the

bottom side of the power supply

2.4 Dielectric Strength Voltage and Insulation Resistance

Dielectric

Strength Voltage

AC-DC 1.5K VAC 3 SEC 10 mA.

Between Primary and All Secondary Circuits.

Safety

Insulation

Resistance

Insulation resistance shall be more than 8M ohm (at DC 500V)

Between Primary Live, Neutral line and Secondary.

* Above tests are performed at room temperature in non-condensing atmospheric

conditions

* Frame grounds are connected to secondary circuits.

2.5 Burn-in

More than 0.5 hours at 45℃(±5℃), Normal input voltage.

AC on/off must be test 1 time after burn-in.

80% Load of specification.

9

Date: 2012. 08. 15

Page 5

11SP 4247” LCD TV Power specification

2.6 Interface

Appellation Explanation Signal Direction Action

Rev 1.3

POWER ON Vcc Circuit ON/OFF Input

2.7 Product Safety

Safety

Design to meet the requirements as follows

Safety Standards to be applied

UL60950, IEC60950, IEC60065 and 60950

Design to meet the requirements as follows

EMI/RFI Standards to be applied

FCC and EN55020, EN55013 Class B

with 4dB minimum margin.

2.8 Construction

Weight Less than 1.0kg

Unit Size 290(W) X 240(D) X 12.9(H)

Hi : Vcc ON

Low : Vcc OFF

2.9 Function of protection

Trip point

Protection Output Circuit

Min Max

STBY 3.5V 3.0A 6.0A Auto Re-start

Over Current

12V 8.0A 28.4A Latch

24V 5.0A 14.2A Latch

STBY 3.5V - Auto Re-start

Short Circuit

12V - Latch

24V - Latch

* This Power Supply has above-mentioned protections.

* Short circuit protection between different output terminals is not considered.

* Trip point for over voltage indicates the operating point when the output voltage

slowly increases.

* The conditions of Over Current measurement

Multi output(3.5V,12V,24V) is nominal load state except an over current

measurement.

Notes

10

Date: 2012. 08. 15

Page 6

11SP 4247” LCD TV Power specification

2.10 Sound Noise Characteristics.

PSU Noise Specification

22.5 dB(a) / 20.u Pa 2.0E-5 Pa

(1/1 octave, A-weighting, to 1khz ~ 16khz Total overall

Measure Location : Anechoic Room

Measure Condition : At a distance of 60cm mic

Full white pattern, at AC 110V/220V

The max specification

(measure 3 points, at PSU center and left & right on the side)

Rev 1.3

11

Date: 2012. 08. 15

Page 7

11SP 4247” LCD TV Power specification

2.11 Connector Specification

2.11.1 Connectors Usage

Rev 1.3

P201

Type : SMAW200-H24S2

Maker : YEON-HO

Pin No. Signal Pin No. Signal

1 POWER-ON 2 24V

3 24V 4 24V

5 GND 6 GND

7 GND 8 GND

9 3.5V 10 3.5V

11 3.5V 12 3.5V

13 GND 14 GND

15 GND 16 N.C

17 12V 18 INV ON/OFF

19 12V 20 A-DIM

P202

Type : 20010WR-H14B/C

Maker : YEON-HO

Pin No. Signal

1 24V

2 24V

3 24V

4 24V

5 24V

6 GND

7 GND

8 GND

9 GND

10 GND

21 12V 22 P-DIM

23 N.C 24 ERROR

SK100

Type : 90011WR-H03D

Maker : YEON-HO

Pin No. Signal

1 LIVE

2 F.G

3 NEUTRAL

11 ERROR

12 INV ON/OFF

13 A-DIM

14 P-DIM

12

Date: 2012. 08. 15

Page 8

11SP 4247” LCD TV Power specification

Rev 1.3

2.12 PCB Dimension.

4.5mm

4.5mm

240

290

4.5mm

4.5mm

9.0mm

(Tolerance ±0.5mm)

PCB : 1.6mm

SMD Holder : 2.5mm (Tolerance ±0.4mm)

Lead cutting : 2.3mm

(Except T101, L601 Body : 2.3mm+0.5mm , GH : 2.5mm +0.5mm)

13

Date: 2012. 08. 15

Page 9

11SP 4247” LCD TV Power specification

2.13 Apply to the Eyelet point.(LGP4247-11SPL)

Apply to the Eyelet point 2.0Φ

Apply to the small Eyelet point 1.6Φ

EL39,EL40,EL41,EL42,EL45,EL46,EL47,EL48,EL49,EL50,EL51,EL52,EL58,EL59 (32EA)

: EL1,EL2,EL9,EL10,EL19,EL20,EL29,EL30,EL35,EL36,EL37,EL38,EL53,EL54,EL55,EL56,EL61 (17EA)

: EL3,EL4,EL5,EL6,EL7,EL8,EL11,EL12,EL15,EL16,EL17,EL18,EL21,EL22,EL31,EL32,EL33,EL34,

Rev 1.3

14

Date: 2012. 08. 15

Page 10

11SP 4247” LCD TV Power specification

2.14 Electrical Characteristics

No. Test Item Test method

Rev 1.3

Intermittent

1

Operation stability

Test

Low temperature

2

operation

Low temperature

3

Storage test Leave

At low temperature

The switching regulator shall ON/OFF for 20,000 time at an

Interval of 10 sec at maximum load, after that electrical

Characteristics shall be satisfied.

The switching regulator is left at the operating guarantee

Minimum temperature for 2 hours without applying electricity.

After that power shall be turned on, and then the electrical

Characteristics shall be satisfied.

The switching regulator is left at minimum storage

Temperature for 96 hours or more.

Then the switching regulator is left at a room temperature and

humidity for 1 hour or more, after that electrical characteristics

shall be satisfied.

The switching regulator is 10 consecutive temperature cycle that

shown below is performed and then leave them at room

temperature and humidity for 1 hour or more.

After that, electrical characteristics shall be satisfied.

Time Temperature

Heat cycle storage

4

test

5 Heat shock test

30 minutes 25℃

30 minutes 25℃ -> -20℃

60 minutes Minimum storage temperature (-20℃)

30 minutes -20℃ -> 25℃

30 minutes 25℃

30 minutes 25℃ -> 70℃

60 minutes Maximum storage temperature (70℃)

30 minutes 70℃ -> 25℃

Heat shock test performed under following conditions without

applying electricity and then leave them at room temperature and

humidity for 1 hour or more.

After that, electrical characteristics shall be satisfied.

Condition : -45℃(30minutes), 120℃(30minutes),

Switching time : Less than 5 minutes, 200 cycles.

15

Date: 2012. 08. 15

Page 11

11SP 4247” LCD TV Power specification

2.15 Mechanical Characteristics

No. Test Item Test method

There shall be no contaminant or dirt on the switching regulator

which has adverse effect on electrical characteristics.

1 Appearance

There shall be no excessive unevenness or scratches on the

plated or painted surface.

While applying electricity :

Vibration frequency : 5 ~ 100Hz

Acceleration : 4.9 m/s∧2

Vibration in X,Y,Z direction for 30 minutes

Rev 1.3

2 Vibration

3 Shock

While applying electricity :

Vibration frequency : 5 ~ 100Hz

Acceleration : 14.7 m/s∧2

Vibration in X,Y,Z direction for 30 minutes

After that electrical characteristics shall be satisfied.

There shall be no damage to appearance and construction.

Shock : 98 m/s∧2

On the oak more than 10mm thickness with the flat face, raise

the one side for 50mm, and it carries out each side free fail for

three sides.

There shall be no damage to appearance and construction.

16

Date: 2012. 08. 15

Loading...

Loading...