Page 1

Website:http://www.LGservice.com [For U.S.A]

www.lg.ca [For Canada]

ELECTRIC & GAS DRYER

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE

TROUBLES CORRECTLY BEFORE OFFERING SERVICE.

MODEL : DLE5911W

DLE2511W

DLE5932W

DLE5932S

DLE2532W

DLE0332W

DLG5911W

DLG2511W

DLG5932W

DLG5932S

DLG2532W

DLG0332W

Page 2

MAR. 2003 PRINTED IN KOREA

P/No.:3828EL3001B

Page 3

2

To avoid personal injury, disconnect power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

!

WARNING !

WHAT TO DO IF YOU SMELL GAS:

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing adequate backgrounds

of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in

personal injury and property damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in connection with its use.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are

removed for service, they must be returned to their original position and properly fastened.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic

control assembly. The new control assembly may appear to work well after repair is

finished, but failure may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted

metal in the appliance.

- OR -

Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground connection

point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

When repackaging failed electronic control assembly in anti-static bag, observe above instructions.

Do not try to light a match, or cigarette, or turn on

any gas or electrical appliance.

Do not touch any electrical switches. Do not use any

phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions

carefully.

If you cannot reach your gas supplier, call the fire

department.

Page 4

3

1. SPECIFICATIONS ..................................................................................................................4

2. FEATURES AND BENEFITS .................................................................................................... 5

3. INSTALLATION INSTRUCTIONS ........................................................................................... 6

4. COLUMBUS DRYER CYCLE PROCESS .................................................................................... 9

5. COMPONENT TESTING INFORMATION ..............................................................................10

6. MOTOR DIAGRAM AND SCHEMATIC..................................................................................13

7. CONTROL LAY - OUT .........................................................................................................14

8. WIRING DIAGRAM ............................................................................................................15

9. DIAGNOSTIC TEST .............................................................................................................16

9-1. TEST 1 120VAC ELECTRICAL SUPPLY..........................................................................17

9-2. TEST 2 THERMISTOR TEST --- MEASURE WITH POWER OFF .......................................18

9-3. TEST 3 MOTOR TEST ................................................................................................19

9-4. TEST 4 MOISTURE SENSOR ....................................................................................20

9-5. TEST 5 DOOR SWITCH TEST ...................................................................................21

9-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE...........................................................22

9-7. TEST 7 GAS VALVE TEST - GAS TYPE.........................................................................23

10. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ...............................................24

11. DISASSEMBLY INSTRUCTIONS .........................................................................................26

12. EXPLODED VIEW ..............................................................................................................32

12-1. CONTROL PANEL & PLATE ASSEMBLY .......................................................................32

12-2. CABINET & DOOR ASSEMBLY...................................................................................33

12-3-1. DRUM & MOTOR ASSEMBLY : ELECTRIC TYPE ........................................................34

12-3-2. DRUM & MOTOR ASSEMBLY : GAS TYPE ...............................................................35

13. REPLACEMENT PARTS LIST ................................................................................................36

CONTENTS

Page 5

Equipped

Temperature

Moisture

Equipped

Adopted

Equipped

27" x 42

3

/

4

" x 28

1

/

3

"

29

1

/

2

" x 44

3

/

4

" x 30

3

/

4

"

On / Off

High / Low / OffHigh / Low / Off

Equipped

Stainless Steel

Equipped

Sensor

35

5

126 / 144

Door Trim

Top Plate

Color

White

Chrome

Silver

Painted

Porcelain

Porcelain

White

Titanium

120V / 240V 60Hz (26A)

POWER SUPPLY

LAMP

HEATER

MOTOR

55

5

59

9

7.3 cu.ft.

Electronic

15W (125mA)

GAS VALVE

13W (110mA) X 2

5400W (22.5A)

55

5

250W (4.5A)

ELECTRICITY

CONSUMPTION

White

Material &

Finishes

DLE2532W

DLE5932S

DLE5932W

DLG2532W

DLG5932S

DLG5932W

ITEM

Child lock

Reversible Door

Interior Light

Product (WXHXD)

Packing (WXHXD)

Audible End of Cycle Beeper

Dryer Rack

Drum

No. of Dry Levels

No. of Dry Option

No. of Programs

DRUM CAPACITY

CONTROL TYPE

No. of Temperature Controls

Weight (lbs): Net / Gross

AC 120V

( GAS TYPE)

AC 240V

( ELECTRIC TYPE)

Thermistor

Electro sensor

AC 120V

AC 120V

REMARK

4

SPECIFICATIONS

1

Page 6

5

FEATURES AND BENEFITS

2

DLE5911W / DLG5911W

DLE2511W / DLG2511W

DLE5932W / DLG5932W / DLE5932S / DLG5932S

DLE2532W / DLG2532W

Page 7

6

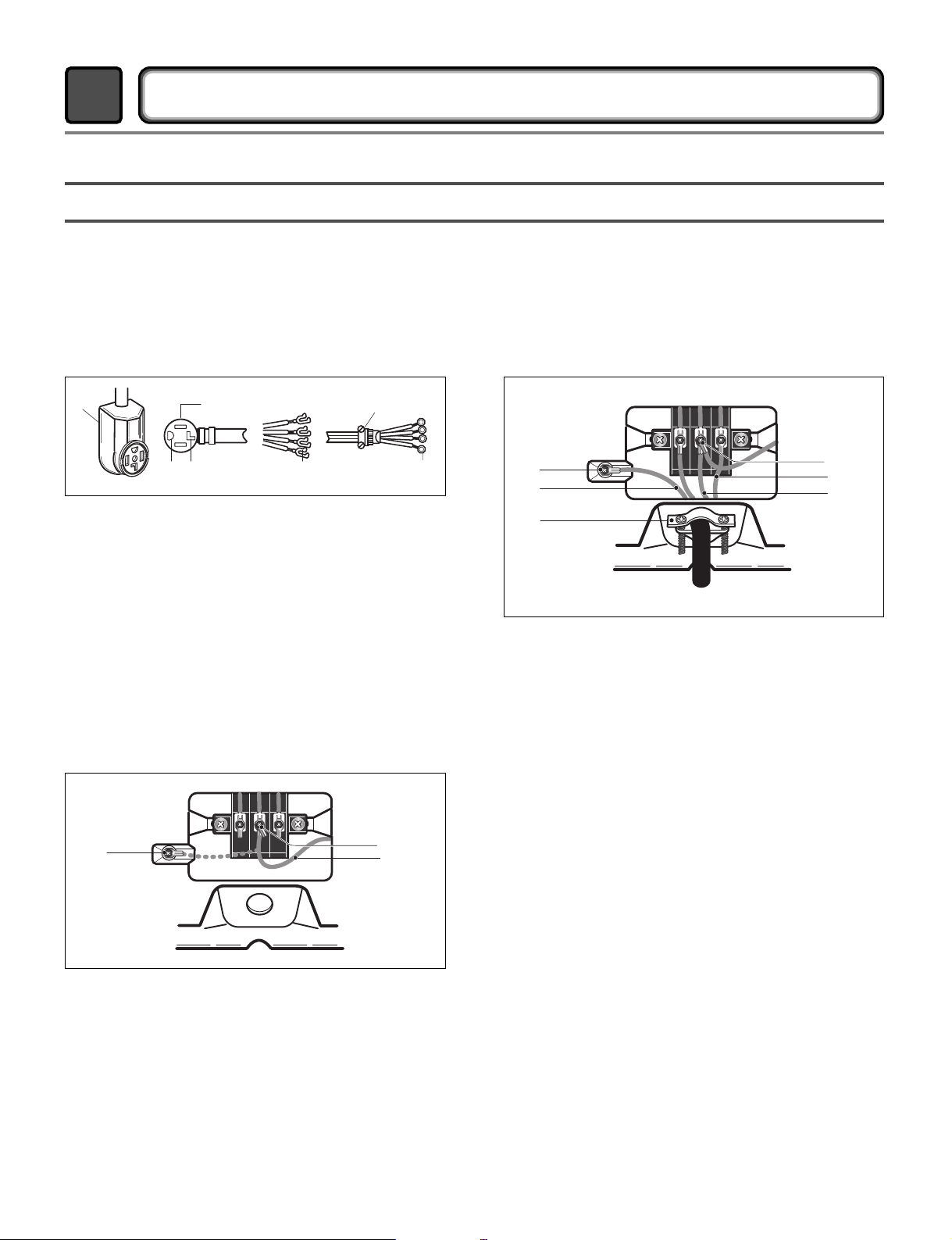

3-1. POWER CORD

INSTALLATION INSTRUCTIONS

3

1) 4-wire connection

1. External ground connector - Dotted line shows

position of NEUTRAL ground wire before being

moved to center terminal block screw

2. Center silver-colored terminal block screw

3. Green wire of harness

1. External ground connector

2. Green or bare copper wire of power supply cord

3. 3/4 in. (1.9 cm) UL-listed strain relief

4. Center silver-colored terminal block screw

5. Neutral grounding wire (green)

6. Neutral wire (white)

5. Connect the other wires to outer terminal block

screws. Tighten screws.

6. Tighten strain relief screws.

7. Insert tab of terminal block cover into slot of dryer

rear panel Secure cover with hold-down screw.

3. Connect ground wire (green or bare) of power

supply cable to external ground conductor screw.

Tighten screw.

4. Connect neutral wire (white or center wire) of

power supply cord to the center, silver colored

terminal screw of the terminal block.

1. 4-wire receptacle (NEMA type 14-30R)

2. 4-prong plug

3. Ground prong

4. Neutral prong

5. Spade terminals with upturned ends

6. 3/4 in. (1.9 cm) UL approved strain relief

7. Ring terminals

1. Remove center terminal block screw.

2. Remove appliance ground wire (green) from

external ground connector screw. Fasten it under

center, silver colored terminal block screw.

IMPORTANT: A 4-wire connection is

required for mobile

homes and where local

codes do not permit the

use of 3 wire connections.

1

2

3 4 5 7

6

1

2

3

4

5

6

1

2

3

Page 8

7

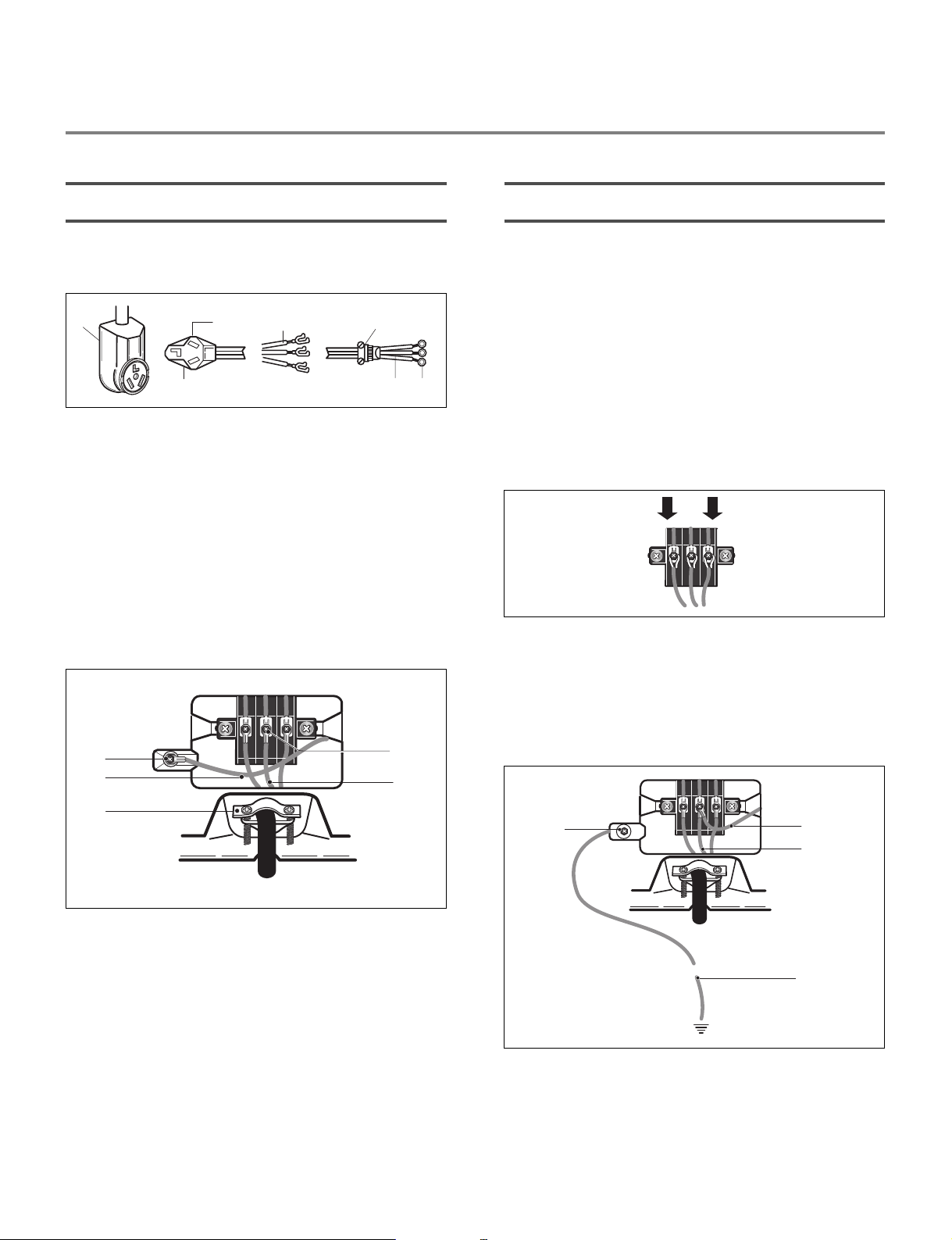

2) 3-wire connection

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

1. Remove center terminal block screw.

2. Remove appliance ground wire (green) from

external ground connector screw. Connect

appliance ground wire and the neutral wire (white

or center wire) of power supply cord/cable under

center, silver colored terminal block screw.

Tighten screw.

3. Connect the other wires to outer terminal block

screws. Tighten screws.

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

3) Optional 3-wire connection

1. Loosen or remove center terminal block screw.

2.

Connect neutral wire (white or center wire) of

power supply cord to the center, silver colored

terminal screw of the terminal block. Tighten screw.

1. External ground connector

2. Neutral grounding wire (green)

3. Center silver-colored terminal block screw

4. Neutral wire (white or center wire)

5. 3/4 in. (1.9 cm) UL-listed strain relief

3. Connect the other wires to outer terminal block

screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer

rear panel. Secure cover with hold-down screw.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer

rear panel. Secure cover with hold-down screw.

6. Connect a separate copper ground wire from the

external ground connector screw to an adequate

ground.

1. External ground connector

2. Neutral grounding wire (green)

3. Neutral wire (white or center wire)

4.

Grounding path determined by a qualified electrician

1. 3-wire receptacle (NEMA type 10-30R)

2. 3-wire plug

3. Neutral prong

4. Spade terminals with up turned ends

5. 3/4 in. (1.9 cm) UL approved strain relief

6. Ring terminals

7. Neutral (white or center wire)

3

1

2

4

1

2

3

4

1

2

5

76

3

4

5

Page 9

8

3-2. Connect Gas Supply Pipe (Gas Dryer ONLY)

2

3

5

1

4

1. Make certain your dryer is equipped for use with the

type of gas in your laundry room. Dryer is equipped

at the factory for Natural Gas with a 3/8” N.P.T. gas

connection.

2. Remove the shipping cap from the gas connection

at the rear of the dryer. Make sure you do not

damage the pipe thread when removing the cap.

3. Connect to gas supply pipe using a new flexible

stainless steel connector.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. For L.P. (Liquefied Petroleum) gas connection, refer

to section on Gas Requirements.

For further assistance, refer to section on Gas Requirements.

1 New Stainless Steel Flexible Connector - Use

only if allowed by local codes (Use Design

A.G.A. Certified Connector)

2 1/8” N.P.T. Pipe Plug

(for checking inlet gas pressure)

3 Equipment Shut-Off Valve-Installed within 6’

(1.8 m) of dryer

4 Black Iron Pipe

Shorter than 20’ (6.1 m) - Use 3/8” pipe

Longer than 20’ (6.1 m) - Use 1/2” pipe

5 3/8” N.P.T. Gas Connection

Page 10

9

Time

COLUMBUS DRYER CYCLE PROCESS

4

Cycle

Heavy Duty

3Hr

3Hr

Off Time: 6min

On Time: 10sec

Temperature Control for each cycle

High

Medium

High

Medium

Low

Low

Extra

low

(High)

(Medium

High)

Cotton/

Towel

Normal

Perm.

Permanent

Press

Delicate

Ultra

Delicate

Speed dry

Freshen Up

Air dry

-

(Normal)

(Normal)

(Normal)

(Normal)

(Normal)

(Normal)

-

-

-

54min Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

55min

41min

36min

32min

34min

25min

20

min

30

min

(5min)

(5min)

(5min)

(5min)

(5min)

(5min)

(5min)

(5min)

N/A

70±5°C

66±5°C

62±5°C

55±5°C

55±5°C

45±5°C

(70±5°C)

(66±5°C)

No

heater

47±5°C

47±5°C

47±5°C

47±5°C

38±5°C

38±5°C

(47±5°C)

(47±5°C)

N/A

Saturation

Load

Sense

Dry *

Manual

Dry **

Default

Drying

Electro-

sensor

Temp-

Control

Default

time

Temp-

Control **

Cooling Wrinkle care

Conditions of operation and termination

Temp-

erature

Dry

Level

Display

time

Motor

Heater

* Sense dry : “Dry Level” is set by users.

** Manual dry : “Temperature control” is set by users.

Default settings can be adjusted by users.

Page 11

10

When checking the Component, be sure to turn the power off, and do voltage discharge sufficiently.

COMPONENT TESTING INFORMATION

5

CAUTION

Component Test Procedure Check result Remark

1. Thermal cut off

• Check Top Marking :

N130

Measure resistance of terminal

to terminal

Open at 266±12°F

(130±7°C)

Auto reset -31°F (-35°C)

Same shape as Outlet Thermostat.

If thermal fuse is open must

be replaced

Resistance value ∞

Continuity (250°F ) < 1Ω

• Heater caseSafety

• Electric type

2. Hi limit Thermostat

(Auto reset)

Measure resistance of terminal

to terminal

Open at 257±9°F

(125±5°C)

Close at 221±9°F

(105±5°C)

Resistance value ∞

Resistance value < 5Ω

• Heater case Hi limit

• Electric type

3. Outlet Thermostat

( Auto reset)

• Check Top Marking :

N85

Measure resistance of terminal

to terminal

Open at 185±9°F

(85±5°C)

Close at 149±9°F

(65±5°C)

Same shape as Thermal cut off.

Resistance value ∞

Resistance value < 5Ω

• Blow housing Safety

• Electric type

4. Lamp holder Measure resistance of terminal

to terminal

Resistance value :

80Ω ~ 100Ω

6. Idler switch Measure resistance of the

following terminal :

“COM - NC”

1. lever open

Resistance value < 1Ω

2. Lever push (close)

Resistance value ∞

5. Door switch Measure resistance of the

following terminal

1) Door switch knob : open

Terminal : “COM” - “NC” (1-3)

Terminal : “COM” - “NO” (1-2)

2) Door switch push : push

Terminal : “COM” - “NC” (1-3)

Terminal : “COM” - “NO” (1-2)

Resistance value < 1Ω

Resistance value ∞

Resistance value ∞

Resistance value < 1Ω

The state that

Knob is

pressed is

opposite to

Open

condition.

!

Page 12

11

Component Test Procedure Check result Remark

7. Heater Measure resistance of the

following terminal

Terminal : 1 (COM) - 2

Terminal : 1 (COM) - 3

Terminal : 2 - 3

Resistance value : 10Ω

Resistance value : 10Ω

Resistance value : 20Ω

• Electric type

8. Thermistor Measure resistance of terminal

to terminal

Temperature condition :

58°F ~ (10~40°C)

58°F ~ 104F (10~40°C)

Resistance value : 10Ω • Heater case -

Hi limit

• Electric type

9. Motor • See Page 13

10. Gas valve

valve 1

valve 2

Measure resistance of the

following terminal

Valve 1 terminal

Valve 2 terminal

Resistance value : > 1.5kg ~

Resistance value :

>

1.5~2.5kg

• Gas type

11. Igniter Measure resistance of terminal

to terminal

Resistance value : 100~800Ω • Gas type

12. Frame Detect Measure resistance of terminal

to terminal

Open at 370°F ((Maximum)

Close at 320°F

Resistance value ∞

Resistance value < 1Ω

• Gas type

Page 13

12

Component Test Procedure Check result Remark

13. Outlet Thermostat

(Auto reset)

• Check Top Marking :

N95

Measure resistance of terminal

to terminal

Open at 203±7°F (95±5°C)

Close at 158±9°F (70±5°C)

Resistance value ∞

Continuity < 1Ω

• Gas type

• Gas funnel

13. Outlet Thermostat

(Manual reset)

• Check Top Marking :

N100

Measure resistance of terminal

to terminal

Open at 212±12°F

(100±7°C)

Manual reset

If thermal fuse is open must

be replaced

Resistance value ∞

Continuity < 1Ω

• Gas type

• Gas funnel

Page 14

13

MOTOR DIAGRAM AND SCHEMATIC

6

Contact On / Off by Centrifugal Switch

STOP MODE

(When Motor does not operate)

RUN MODE

(Motor operates)

When checking Component, be sure to turn Power off, then do voltage discharge sufficiently.

NOTE

Centrifugal switch

Centrifugal switch

(Pull Drive forward)

Page 15

14

CONTROL LAY - OUT

7

PWB ASSEMBLY DISPLAY LAY-OUT

PWB ASSEMBLY LAY-OUT

MODEL DISPLAY AS DIAGNOSTIC TEST

MODEL

DLE5932W/S

DLG5932W

DLE5911W

DLG5911W

OP 1

X

X

X

X

OP 2

X

X

O

O

OP 3

X

O

X

O

OP 4

X

X

X

X

OP 5

X

X

X

X

OP 6

X

X

X

X

6871EC2025F

6871EC2025G

6871EC2025H

6871EC2025J

18:20

19:20

18:21

19:21

OPTION PART

LED

DISPLAY

P/No

Page 16

15

ELECTRIC DRYER WIRING DIAGAM

WIRING DIAGRAM

8

GAS DRYER WIRING DIAGAM

Page 17

16

ACTIVATING THE DIAGNOSTIC TEST MODE

1. Unit must be in Standby (unit plugged in, display off)

2. Press “POWER” while pressing “MORE TIME”, and “LESS TIME” simultaneously.

DIAGNOSTIC TEST

9

Pressing the

“START/PAUSE”

button

CHECKING

ACTION

DISPLAY CHECKING POINT REMARK

None

Once

Electric control

&

Temperature

sensor

Motor

Won’t power up

Defective LED

Thermistor open

Thermistor close

Motor runs

Displays Moisture Sensor Operation:

If moisture sensor is contacted with

damp cloth. The display number is

below 180, in normal condition.

70 ~ 237

Measured

Moisture Value.

Twice

ELECTRIC TYPE

Motor + Heater 1

(1250W)

GAS TYPE

Motor + Valve

Current Temp.

ELECTRIC TYPE :

Heater runs

GAS TYPE :

GAS Valve runs

(Display the Temperature of

Inside drum.)

During check,

If the door is closed.

Motor & Heater Off

+ Lamp Off

70 ~ 237

Return once “1time”

(See test 4) state.

4 times Control Off

Auto Off

3 times

ELECTRIC TYPE

Motor + Heater 1

+ Heater 2

(5400W)

GAS TYPE

Motor Type

Current Temp.

(5 ~ 70)

See test 5

Off

automatically

after 5

minutes

In normal state if displayed

temp. is increasing.

Temperature in 4min : 113°F (45°C)

• Above : 1” on , 1” off beep sound

• Under : 0.5” on, 0.5”

off beep sound

During check,

If the door is open.

Motor & Heater Off

+ Lamp On +

Buzzer beeps five

times

Door switch See test 6

Lamp

See test 1

Display : See page

See test 2

See test 3

See test 4

Gas valve

See test 7

1. This TEST should be used for Factory test /Service test. Do not use this DIAGNOSTIC TEST other than

specified.

2. Activating the Heater manually with the Door open may trip the Thermostat attached to the Heater, therefore do

not activate it manually. (Do not press the door switch to operate the heater while the door is open )

Page 18

17

Test 1

120VAC Electrical supply

Caution

Trouble Symptom

Measurement Condition

When measuring power, be sure to wear insulated gloves, to and avoid an

electric shock.

No power was applied to Controller. (LED, Display off)

With Dryer Power On; Connector linked to Controller.

Check the outlet, is the voltage

110V ~ 125V AC?

YES

NO

• Check the fuse

or circuit breaker.

Check if the voltage measured between

Connector “RD3-

” (Black) linked to the

Controller and “WH3- ”(White) is

110V ~ 125V?

YES

NO

• Check if Power

Cord is properly

connected.

• Reconnect the

controller.

Replace controIler.

Check if the Controller wire is

disconnected.

Check if Terminal Block and Power Cord

are connected (Check Plug ).

- Does Power Cord N( Natural) line match

to Terminal Center N(Natural) line?

YES

NO

L (Black) L (Led)

N(White)

Page 19

18

Test 2

Thermistor Test --- Measure with Power Off

Caution

Trouble Symptom

Measurement Condition

Before measuring resistance, be sure to turn Power off, and do voltage discharge.

(When discharging, contact the metal plug of Power cord with the Ground.)

During Diagnostic Test, tE1 and tE2 Error occur.

During operation, Heater would not turn off, or remains on.

Difference between actual and sensed temperature is significant.

After turning Power off, measure the resistance.

Check if resistance is in the range of Table 1

when measuring 6pin connector Pin

(Blue wire) and Pin (Red wire) connected

to Controller.

NO

YES

• Check if Control

and 6Pin

connector is

properly

connected.

• Replace

Controller.

Check Harness-linking connector.

Take 6pin Connector from

the Controller.

Table 1. Resistance for Thermistor Temperature.

Check if resistance is in the range of Table 1

when measuring resistance between

terminals after separating Harness

From Thermistor assembly Connector.

YES

NO

• Replace

Thermistor.

Air TEMP.

[°F (°C)]

50°F (10°C)

60°F (16°C)

70°F (21°C)

80°F (27°C)

18.0

14.2

11.7

9.3

90°F (32°C)

100°F (38°C)

110°F (43°C)

120°F (49°C)

7.7

6.2

5.2

4.3

130°F (54°C)

140°F (60°C)

150°F (66°C)

160°F (71°C)

2.9

3.0

2.5

2.2

RES.

[kΩ]

Air TEMP.

[°F (°C)]

RES.

[kΩ]

Air TEMP.

[°F (°C)]

RES.

[kΩ]

Page 20

19

Test 3

Motor test

Caution

Trouble Symptom

Measurement Condition

Before measuring resistance, be sure to turn Power off, and do voltage discharge.

(When discharging, contact the metal plug of Power cord with earth line.)

Drum will not rotate; No fan will function; No Heater will work.

Turn the Dryer’s Power Off, then measure resistance.

Is resistance below 1Ω between Idler Switch

terminals?

YES

NO

Does Idle Switch attached to Motor Bracket

operate Level by drum belt?

(Not operating Lever is normal.)

YES

• Replace Idler

Switch.

• Check Idler Assembly.

• Drum Belt cuts off

• Drum Belt takes off

from

• Motor Pulley.

Is resistance below 3Ω between Connector

“WH3-

” (White wire) and “BL2- ” (Yellow wire)?

Measure while door is closed.

YES

NO

• Check if Door flame

presses door switch

knob.

• Check Door Switch.

• Check Harness

connection.

Is resistance below 3Ω between Connector

“BL2-

” (Yellow wire) and “BL2- ” (Brown wire)?

NO

YES

• Replace Control.

(Relay check)

• Check Controller

connector.

Is resistance below 1Ω between terminals

of Outlet Thermostat attached to blower housing?

YES

NO

• Replace Outlet

• Thermostat.

(Refer to

‘Component’)

Is resistance below 3Ω between Connector

“WH3-

”

(White wire) and “BL2-

” (Brown wire)?

Measure while door is closed.

NO

YES

• Replace Control.

(Relay check)

• Check Controller

connector.

• Check Motor.

(Refer to ‘Motor Diagram & Check’)

•

Check if Control Connector is contacted.

Idler Switch Lever

Idler Switch

Page 21

20

Test 4

Moisture sensor

Caution

Trouble Symptom

Measurement Condition

Before measuring resistance, be sure to turn Power off, and do voltage discharge.

(When discharging, contact the metal plug of Power cord with earth line.)

Degree of dryness does not match with Dry Level.

Turn the Dryer’s Power Off, then measure resistance.

Normal Condition

Damping cloth

Metal or Wire

Table 2. IMC Ratio and Display Value / Voltage (IMC : Initial Moisture Content)

IMC

70% ~ 40%

40% ~ 20%

10% ~ Dried clothes

50 ~ 130

100 ~ 20

205 ~ 240

2.5V

2.0V ~ 4.0V

Over 4.0V

Weight after removing from

Washing Machine

Damp Dry

Completely-dried clothes

Display Value

Voltage(DC) (between 6Pin terminal )

Remark

Short with metal to 6pin connector’s Pin

(BLUE wire) and Pin (ORANGE wire)

to Controller.

When measuring resistance in Electric load,

is resistance below 1Ω?

YES

NO

When contacting cloth to Electro load:

1. Is the measurement within the range of Table 2

during Diagnostic Test?

2. Is the measurement within the range of Table 2

when measuring the voltage in 6pin connector’s

Pin

(BLUE wire) and Pin (ORANGE wire)?

YES

NO

• Replace Control

and Check.

• Check Electro Load

and

• Harness Connector.

• Check Harness-

linking connector.

Take 6pin Connector from

the Controller.

Page 22

21

Test 5

Door switch test

Caution

Trouble Symptom

Measurement Condition

Before measuring resistance, be sure to turn Power off, and do voltage discharge.

(When discharging, contact the metal plug of Power cord with earth line.)

Door Opening is not sensed.(During operation, when opening Door, Drum motor and

Heater run continuously; Door Close is not sensed.

(Drum motor will not operate. Display will flash at 0.5 second intervals.)

After turning Dryer Power Off, measure resistance.

Check Controller.

Check Harness-linking connector.

Measure while Door is closed. Check if

resistance is below 250Ω between “WH3-

”

(White wire) and “RD3-

”(Black wire)

Connector WH3, RD3 after taking WH3, RD3

out from Controller.

NO

YES

• Door switch

Check (Refer to

Component

testing.)

Measure while Door is open. Check if

resistance is 300~60Ω between “WH3-

”

(White wire) and “RD3-

” (Black wire)

Connector WH3, RD3 after taking WH3, RD3

out from Controller.

YES

NO

• Check Lamp.

(When opening

Lamp, replace then

measure again.)

• Door switch

Check(Refer to

Component

testing.)

Measure while Door is open. Check if

resistance is below 1Ω between “BL2-

”

(Yellow wire) and “WH3- ” (White wire) after

taking Connector WH3, BL2 out from Controller.

NO

YES

• Door switch

Check (Refer to

Component

testing.)

Measure while Door is closed. Check if

resistance is below 1Ω between “BL2-

”

(Yellow wire) and “WH3- ” (White wire) after

taking Connector WH3, BL2 out from Controller.

YES

NO

• Door switch

Check (Refer to

Component

testing.)

Page 23

22

Test 6

Heater switch test - Electric Type

Caution

Trouble Symptom

Measurement Condition

Before measuring resistance, be sure to turn Power off, and do voltage discharge.

(When discharging, contact the metal plug of Power cord with earth line.)

While operating, Heating will not work.

Drying time takes longer.

After turning Power off, measure the resistance.

Check Controller.

Check Harness-linking Connector.

Check Motor. Check if the value of measured

resistance is below 1Ω between terminal

and at RUN condition.

YES

NO

• Check Motor and

replace it.

1. Is resistance between Heater terminal

and below 18 ~ 22Ω?

2. Is resistance between Heater terminal

and below 18 ~ 22Ω?

3. Is resistance between Heater terminal

and below 9 ~ 11Ω?

YES

NO

• Replace Heater.

Check if the value of measured resistance is

below 1Ω between terminal TH2 (Safety Thermostat).

YES

NO

• Replace TH2

(Safety Thermostat)

.

Check if the value of measured resistance is below

1Ω between terminal TH3 (HI-Limit Thermostat).

YES

NO

• Replace TH3

(HI-Limit Thermostat)

.

TH3

TH2

Page 24

23

Test 7

GAS Valve test - Gas Type

Caution

Trouble Symptom

Measurement Condition

When measuring power, be sure to wear insulated gloves, to avoid electric shock.

While operating, Heating will not work.

Drying time takes longer.

With dryer power on

• Harness check

• Controller change

When measuring terminal resistance on “Valve 1”,

“Valve 2”, Value is more than1.5 ~ 2.5kΩ?

(Measure after Off )

NO

YES

• Change Valve

• Check thermostat

Hi limit Safety

Igniter operates?

(after 1 min, Igniter becomes reddish)

YES

NO

• Check Igniter &

Frame detect

When measuring Valve 2 voltage, Value is more

than AC 90V? (10 sec after Igniter off)

NO

YES

• Check Gas

connection or

Gas supply

When measuring Valve 1 voltage,

More than AC 90V?

YES

NO

Power On & Start (Normal Cycle)

NO

Igniter

Valve 2

Valve 1

Page 25

24

After Natural Gas Setting, applying Propane Gas Orifice or wrong use of Natural Gas

Orifice will result in fire. Conversion must be made by a qualified technician.

Initially

, Natural Gas mode is set. Propane Gas Orifice is on sale as a Service

Part to authorized servicers only.

CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS)

10

Warning

STEP 1 : VALVE SETTING

Full open

“Change screw”

STEP 2 : ORIFICE CHANGE

Orifice

Gas type

Natural Gas

Propane Gas

Marking

NCU

PCU

Shape

Orifice P/No

4948EL4001B

4948EL4002B

Close

“Change screw”

Remove 2 screws.

Disassemble the pipe assembly.

Replace Natural Gas orifice with Propane Gas orifice.

Kit contents : Orifice (Dia. = 1.613mm, for Propane Gas)

: Replace Label

: Instruction sheet

!

Page 26

25

GAS IGNITION

START

GAS IGNITION

ON

ON OFF

OFF ON

CLOSE

VALVE 1

IGNITER

VALVE 2

FRAME

DETECT

OPEN

GAS VALVE STRUCTURE

GAS VALVE FLOW

START KEY PUSH

DRYING

“VALVE 1” ON

“VALVE 2” ON

IGNITE ON

FRAME DETECT OPEN

IGNITE OFF

IGNITE

TEMPERATURE ABOUT

370”F

GAS IGNITION

FRAME DETECT CLOSE

“VALVE 2” OFF

NO

NO

YES

YES

Page 27

26

Disassemble and repair the unit only after pulling out power plug from the outlet.

DISASSEMBLY INSTRUCTIONS

11

1.

Remove 3 screws on the rear Panel.

2.

Pull the control panel forward.

3.

Open the cover protect.

4.

Disconnect connectors.

5.

Remove 5 screws.

6.

Disassemble the controller assembly.

Page 28

27

1.

Push backward using an opener and lift

the top plate.

7cm

7cm

1.

Open the top plate.

2.

Open the door, Remove 2 screws.

3.

Remove 2 screws form upper side.

4.

Pull the Cover Cabinet.

5.

Disconnect the door switch connector.

Page 29

28

1.

Open the top plate.

2.

Remove Cover Cabinet.

3.

Disconnect the door lamp and electro

sensor connector.

4.

Remove 4 screws.

5.

Disassemble the Tub Drum [Front].

1.

Open the top plate.

2.

Remove the Cover Cabinet and

Tub drum [front].

3.

Disengage belt from motor and idler pulleys.

4.

Carefully remove Drum out through front of dryer.

-1

-2

-1

1.

Open the door.

2.

Remove the screw holding the drum lamp shield

in place.

3.

Slide the shield up and remove.

4.

Remove the bulb and replace with a 15 watt,

120 volt candelabra-base bulb.

5.

Replace the lamp shield and screw.

Page 30

29

1.

Remove screw & exhaust duct.

PORTION “A”

DUCT

TAPE

DUCT

TAPE

DUCT

TAPE

3.

Reconnect the new duct[11 in(28cm)] to the

blower housing, and attach the duct to the base.

2.

Detach and remove the bottom, left or right side

knockout as desired.

4.

Pre-assemble 4" elbow with 4" duct.

Wrap duct tape around joint.

5.

Insert duct assembly, elbow first, through the side

opening and connect the elbow to the dryer

internal duct.

Page 31

30

1.

Remove the filter.

2.

Remove 3 screws.

3.

Pull the grill.

4.

Disconnect electro sensor.

1.

Open the top plate.

2.

Remove the Cover Cabinet and Tub Drum [Front].

3.

Remove the Drum assembly.

4.

Remove 2 screws and cover(Air guide).

5.

Remove the bolt and washer.

6.

Pull the fan.

7.

Disconnect the motor clamp and motor.

1.

Open the top plate.

2.

Remove the Cover Cabinet and Tub Drum [Front].

3.

Remove the Drum assembly.

4.

Remove 7 screws.

5.

Pull the Tub Drum [Rear] towards the front.

Page 32

31

1.

Open the top plate.

2.

Remove the Cover Cabinet.

3.

Remove filter and 2 screws.

4.

Pull the air duct towards the front.

1.

Open the top plate.

2.

Remove the Cover Cabinet and Tub Drum [Front].

3.

Remove the Drum assembly and Tub Drum [Rear].

4.

Disconnect Air duct from the Tub Drum [Front].

5.

Remove the roller from the Tub Drum [Front]

and Tub Drum [Rear].

Page 33

A120

A140

A570

A215

A150

A130

A210

A110

A600

A211

32

EXPLODED VIEW

12

12-1. Control Panel & Plate Assembly

Page 34

12-2. Cabinet & Door Assembly

A310

A700 A800

A520

A540

A330

A300

A305

A340

A320

A535

A450

A420

A500

A510

A430

A212

A460A410

A400

33

Page 35

34

12-3-1. Drum & Motor Assembly : Electric Type

F120

F130

F110

K640

K120

K140

K400

F200

K310

K610

K33

0 K340

K130

K222

K100

K221

K210

K240

F140

K510

K515

K650

K651

K600

K251

K520

K550

K560

K320

K620

K530

K230

K350

K540

K251

K360

K250

K250

Page 36

35

12-3-2. Drum & Motor Assembly : Gas type

M210

M180

M160

M170

M171

M140

M141

M240

M150 M220

M230

M250

M110

M181

M190

K640

K120

K140

K400

F200

K310

K610

K33

0 K340

K130

K100

K221

K222

K210

K240

K510

K650

K251

K520

K515

K550

K560

K320

K620

K530

K230

K350

K540

K600

K651

K251

K360

K250

K250

M171 : Propane Gas orifice

M170 : Natural Gas orifice

Page 37

36

REPLACEMENT PARTS LIST

13

Page 38

37

Loading...

Loading...