Page 1

MANUAL DEL PROPIETARIO

Secadora de Eléctrica y Gas

Gracias por comprar una secadora Completamente Automática LG.

Por favor lea su manual del propietario cuidadosamente, ya que

le proveerá de instrucciones sobre la segura instalación, manejo

y mantenimiento. Consérvelo para futuras referencias, archive

el modelo y números de serie de su secadora.

/

/

/

/

/

/

☎☎

1-800-243-0000

para el Servicio LG (Atención al Cliente) 24 horas al día, 7 días a la semana

Page 2

P/No.: 3828EL4001A

/

/

/

/

/

/

Electric and Gas Dryer

☎☎

1-800-243-0000

24 HOURS A DAY, 7 DAYS A WEEK FOR LG CUSTOMER SERVICE

Page 3

TABLE OF CONTENTS

PART1. IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS .................................................................3-5

PART2. INITIAL STEPS FOR INSTALLING YOUR DRYER .............................................................................6-11

Positioning the Dryer ...................................................................................................................................6

Procedure for Reversing the Door...............................................................................................................7

Connecting the Exhaust and Venting System.............................................................................................8

Connection of Gas Supply/Electrical Plug Connections for Electric Dryer Only..........................................9

Preparation of the Dryer/Confirming Heat Source Operation/Dryer Airflow ..............................................10

Additional Instructions for Installation of Your Dryer in a Manufactured or Mobile Home .........................11 .

PART3. ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYER ...............................................................12-16

3-Wire Connection with a Power Supply Cord ..........................................................................................14

4-Wire Connection with a Power Supply Cord ..........................................................................................15

Optional 3-wire Connection .......................................................................................................................16

PART4. ELECTRICAL REQUIREMENTS FOR GAS DRYERS ............................................................................17

PART5. GAS REQUIREMENTS AND INSTRUCTIONS........................................................................................18

PART6. EXHAUST REQUIREMENTS AND MAINTENANCE..........................................................................19-20

PART7. FEATURES AND BENEFITS ..............................................................................................................21-26

Using Your Dryer/To use a Sensor Dry Cycle...........................................................................................22

To use a Manual Dryer Cycle/Stopping Your Dryer/Loading ....................................................................23

Cycle Descriptions.....................................................................................................................................24

Options/Modifiers ......................................................................................................................................25

Rack Dry/Beeper/Anti-Bacterial/Custom Programming.............................................................................26

PART8. TROUBLESHOOTING GUIDE ............................................................................................................27-29

LG DRYER LIMITED WARRANTY ........................................................................................................................30

22

Page 4

Part 1 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

!

SEEKING WARRANTY ASSISTANCE

Warranty Service.

Warranty service is available by contacting your nearest LG Service Center and, for warranty period

from the date of purchase, if this dryer is installed and operated according to the instructions in this

manual, LG will repair or replace any of its mechanical or electrical parts if they are defective in

material or workmanship.

The warranty for your dryer is printed the end of this manual.

WARNING!

For your safety, the recommendations in this manual must be followed. To reduce the risk

of fire or explosion, electric shock, or to prevent property damage, personal injury, or

death when using your appliance, follow basic precautions, including the following.

Warranty Restriction:

coverage is effective for only 90 days.

You will need the complete model and serial numbers when requesting information. We recommend

that you staple your sales slip or cancelled check here, because proof of original purchase date is

needed to obtain warranty service. Your dryer’s model and serial numbers are located on the Model

and Serial Number Plate located on the front of the dryer behind the door.

If the dryer is subjected to other than private family use, all warranty

Use the space below to record the model number and serial number of your new LG dryer.

Model No.

Serial No.

Date of Purchase

❈ Staple your receipt hear.

3

3

Page 5

Part 1 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

!

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

to help reduce any risk of electric shock, fire, or other personal or property injury

when using your dryer, please exercise care and follow basic safety precautions,

including the following:

1) Read all instructions before using the appliance.

2) Do not dry articles that have come into contact with

gasoline, dry-cleaning solvents, or other flammable

or explosive substances, as they give off vapors that

could ignite or explode.

3) Do not allow children to play on or in the appliance.

Close supervision of children is necessary when

using the appliance.

4) Before the appliance is removed from service or

discarded, remove the door to the drying

compartment.

5) Do not reach into the appliance if the drum is

moving.

6) Do not install or store this appliance where it will be

exposed to the weather.

7) Do not tamper with controls.

8) Do not repair or replace any part of the appliance or

attempt any servicing unless specifically

recommended in the user-maintenance instructions.

9) Do not use heat to dry articles containing foam

rubber or similarly textured rubber-like materials.

10) Clean lint screen before or after each load.

11) Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of

lint, dust, and dirt.

12) The interior of the appliance and exhaust duct

should be cleaned periodically by qualified service

personnel.

13) Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

load to catch fire.

14) Do not use fabric softners or products to eliminate

static unless recommended by the manufacturer of

the fabric softner or product.

SAVE THESE INSTRUCTIONS

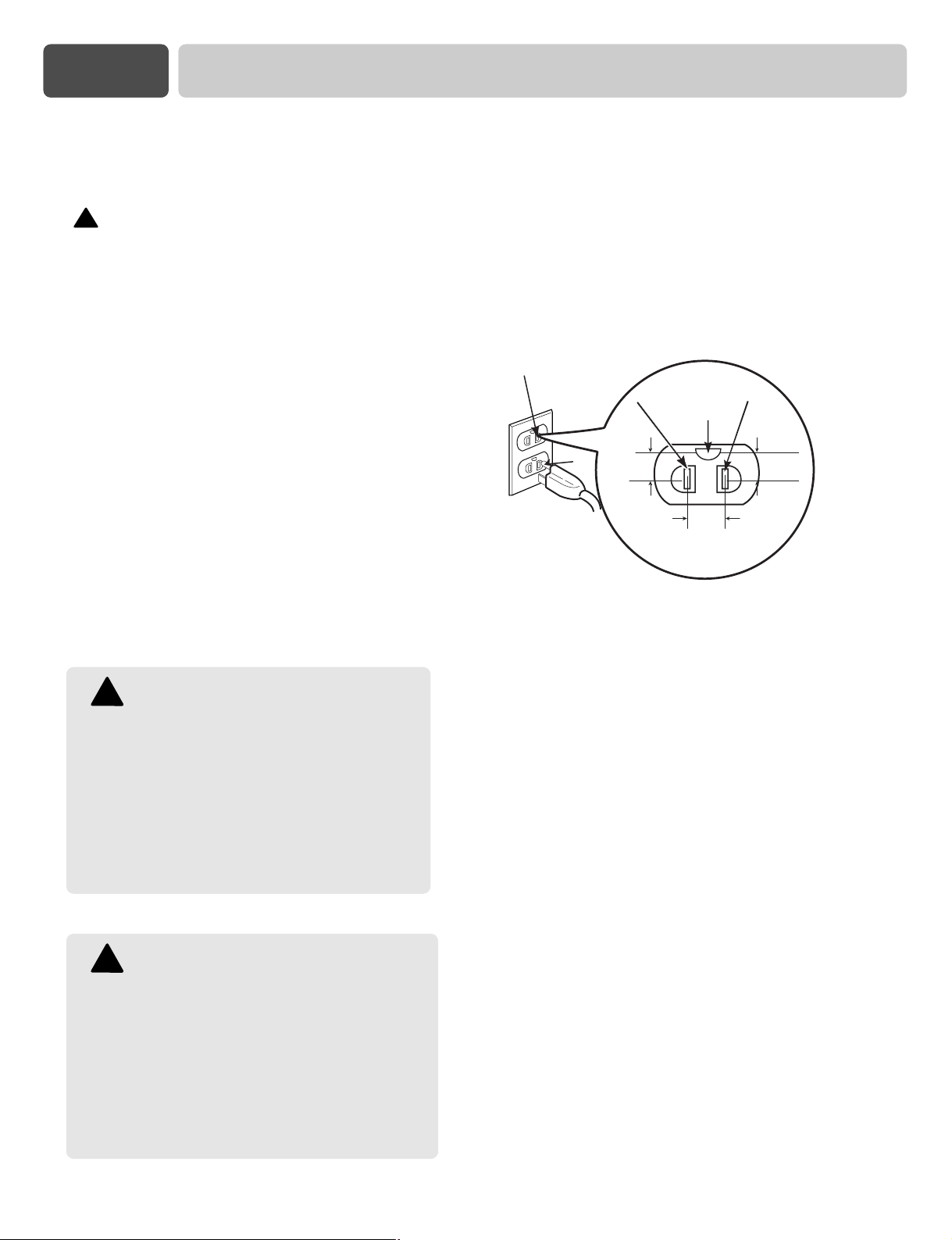

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. This appliance is

equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper connection of the equipmentgrounding conductor can result in a risk of electric

shock. Check with a qualified electrician or service

person if you are in doubt as to whether the appliance is

properly grounded.

4

Do not modify the plug provided with the appliance: if

it will not fit the outlet, have a proper outlet installed by

a qualified electrician.

Page 6

Part 1 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

!

!

!

WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light a match, or cigarette, or

turn on any gas or electrical appliance.

WARNING!

• Do not touch any electrical switches. Do not

use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions carefully.

• If you cannot reach your gas supplier, call the

fire department.

WARNING

To reduce the risk of fire or explosion, electric

shock, property damage, personal injury, or death

when using this appliance, please follow all

instructions and information, including those in

this manual and instructions and information

provided by your gas supplier, including the

following:

• Do not store or use any gasoline, dry-cleaning

solvents, or any other flammable vapors or

liquids in the area surrounding this appliance.

• Do not dry anything that has ever had anything

flammable on it, even after washing.

• No washer can completely remove oil. Do not

dry any articles that have ever had any kind of

oil on them, including cooking oil.

• Keep flammable materials and vapors, such

as gasoline, away from dryer.

• Place dryer at least 18 inches above the floor

for a garage installation.

• Failure to do so can result in death,

explosion or fire.

California Safe Drinking W

T

oxic Enforcement Act

This act requires the governor of California to

publish a list of substances known to the state to

cause cancer, birth defects or other reproductive

harm and requires businesses to warn customers

of potential exposure to such substances.

Gas appliances can cause minor exposure to four

of these substrances, namely benzene, carbon

monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of

natural gas or LP fuels.

Properly adjusted dryers will minimize

combustion. Exposure to these substances can be

minimized further by properly venting the dryer

to the outdoors.

ater and

• Articles containing foam, rubber, rubber like

materials, plastic, or similar materials should be

dried on a clothesline or by using an air cycle.

• Failure to follow these instructions can result in

fire, death, or serious injury.

• A qualified service person or company must

perform installation and service of this

appliance.

5

Page 7

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

5

0

.5

"

(1

2

8

.2

7

cm

)

42"3/4

(108.6 cm)

27"

(68.6 cm)

3

0

"

(7

6

.2

c

m

)

3"

(7.6 cm)

3"

(7.6 cm)

48"

2

(310 cm2)

24"

2

(155 cm2)

31.5"1"

(2.54 cm) (80.01 cm)1"(2.54 cm)

14" max

(35.6 cm)

18"

(45.72 cm)

27"

(68.6 cm)

0"

(0 cm)

0"

(0 cm)

The following instructions will help guide you through the initial steps of setting up your dryer for use.

Please note that every section of this manual provides important information regarding the preparation and

use of your dryer, and it is important that you review this entire manual before proceeding with any

installation or use. More detailed instructions concerning electrical connections, gas connections, and

exhaust requirements are provided at other parts of this manual.

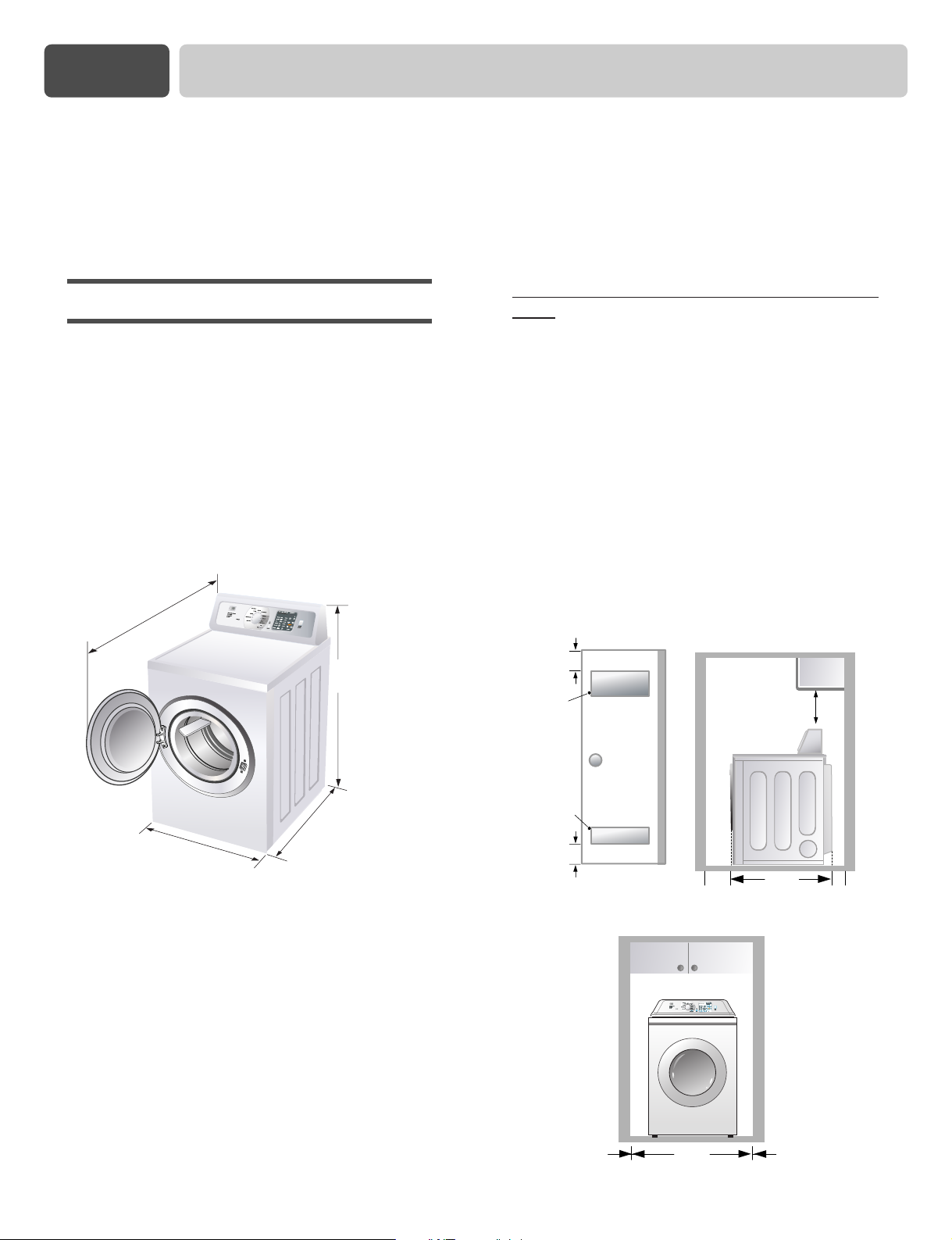

STEP 1: Positioning the Dryer.

Choose a location with a solid floor for your dryer.

Place the dryer at least eighteen inches above the

floor for a garage installation. After placing the

dryer in the desired location, please confirm that the

dryer has the required clearances through reference

to the following information and manual sections on

Exhaust Requirements and Maintenance.

If you are installing your dryer in a manufactured or

mobile home, please refer to STEP 9 below for

additional instructions.

Installing Y

our Dryer in a Closet or Recessed

Area. Following are instructions concerning and the

minimum clearances required for any closet, recessed

area, or customized under-counter installation:

• Additional spacing should be considered for

installation and servicing.

• Additional clearances might be required for wall,

door, and floor moldings.

• Additional spacing of 1 in. (2.5 cm) on all sides of

the dryer is recommended to reduce noise transfer.

• For closet installation with a door, minimum

ventilation openings in the top and bottom of the

door are required. Louvered doors with equivalent

ventilation openings are acceptable. Companion

appliance spacing should also be considered.

* Most installations require a minimum 5

6

(14 cm) clearance behind the dryer for the exhaust

vent with elbow.

1/2 in.

Page 8

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

Once in position, adjust the leveling legs of the dryer

until it is level from left to right and from front to

back. The leveling legs must remain firmly on the

floor and the dryer should not rock. The maximum

slope of the dryer from left to right or from front to

back should not exceed 2.5 cm (1 inch). If the dryer

is not level, and if the slope exceeds 2.5 cm (1 inch),

a load may not tumble properly and internal sensors

may malfunction. Note: Other sections of this

manual also provide important information

concerning the placement of and clearances for your

dryer. Please review this entire manual before

proceeding with any installation.

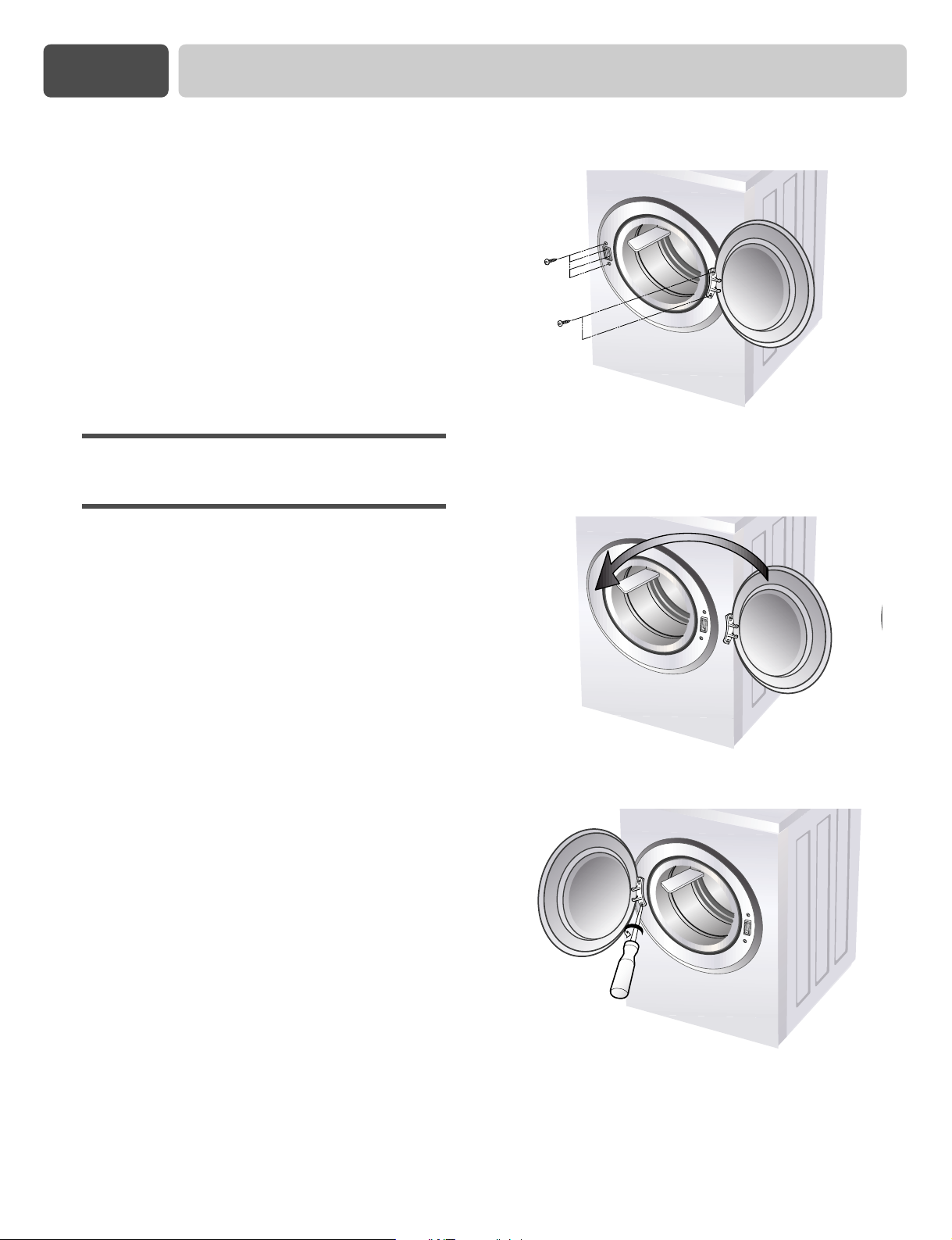

STEP 2: Procedure for Reversing

the Door

1

2

The door on your dryer may be installed to open

either to the left or the right. Follow these

procedures to reverse the direction in which your

door opens:

3

7

Page 9

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

!

Attach

hole

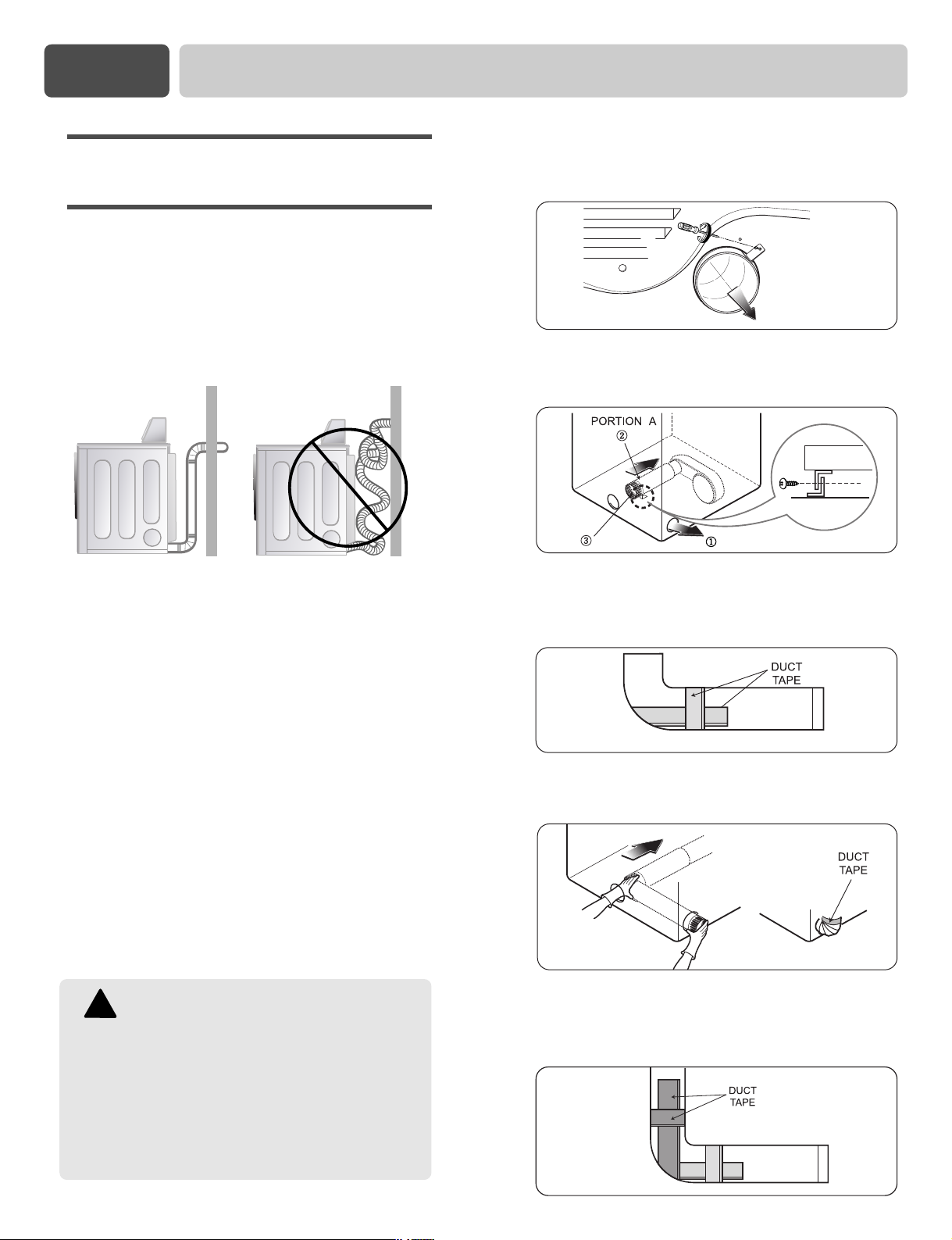

STEP 3: Connecting the Exhaust

and Venting System.

In addition to the following warnings, please refer

to manual section on Exhaust Requirements and

Maintenance. IMPORTANT: To reduce the risk of

fire, combustion, and gas accumulation, the dryer

must be vented to the outdoors. Please follow the

following instructions (and all others in this

manual) very carefully.

• Do not use thin plastic or foil ducting.

• Use 4" (10.2 cm) diameter rigid or flexible metal

duct (note: venting materials are not supplied with

the dryer, and you should obtain the venting

materials necessary for proper installation)

• Position the dryer so that the exhaust duct is as

short as possible

• Clean old ducts before installing this dryer

• The male end of each section of exhaust duct must

point away from the dryer

• Use as few elbow joints as possible

• Use duct tape on all duct joints

• Insulate ductwork that runs through unheated

areas in order to reduce condensation and lint

build-up on pipe walls; and

• PLEASE BE AWARE THAT FAILURE TO

EXHAUST THE DRYER CORRECTLY WILL

VOID THE DRYER’S WARRANTY.

■ ALTERNATE EXHAUST DIRECTIONS

1. Remove screw & exhaust duct.

2. Detach and remove the bottom, left, or right

side knockout as desired.

(Right side vent not avilable on gas dryer.)

3. Reconnect the new duct[11 in(28cm)] to the

blower housing, and Fixing the duct to the

base.

4. Pre-assemble 4" elbow with 4" duct.

Wrap duct tape around joint.

WARNING!

• Use a heavy metal vent.

• Do not use a plastic vent.

• Do not use a metal foil vent.

• Failure to follow these instructions can

result in death or fire.

• Clean old ducts before installing this dryer

8

5. Insert duct assembly, elbow first, through the

side opening and connect the elbow to the

dryer internal duct.

Page 10

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

2

3

5

1

4

!

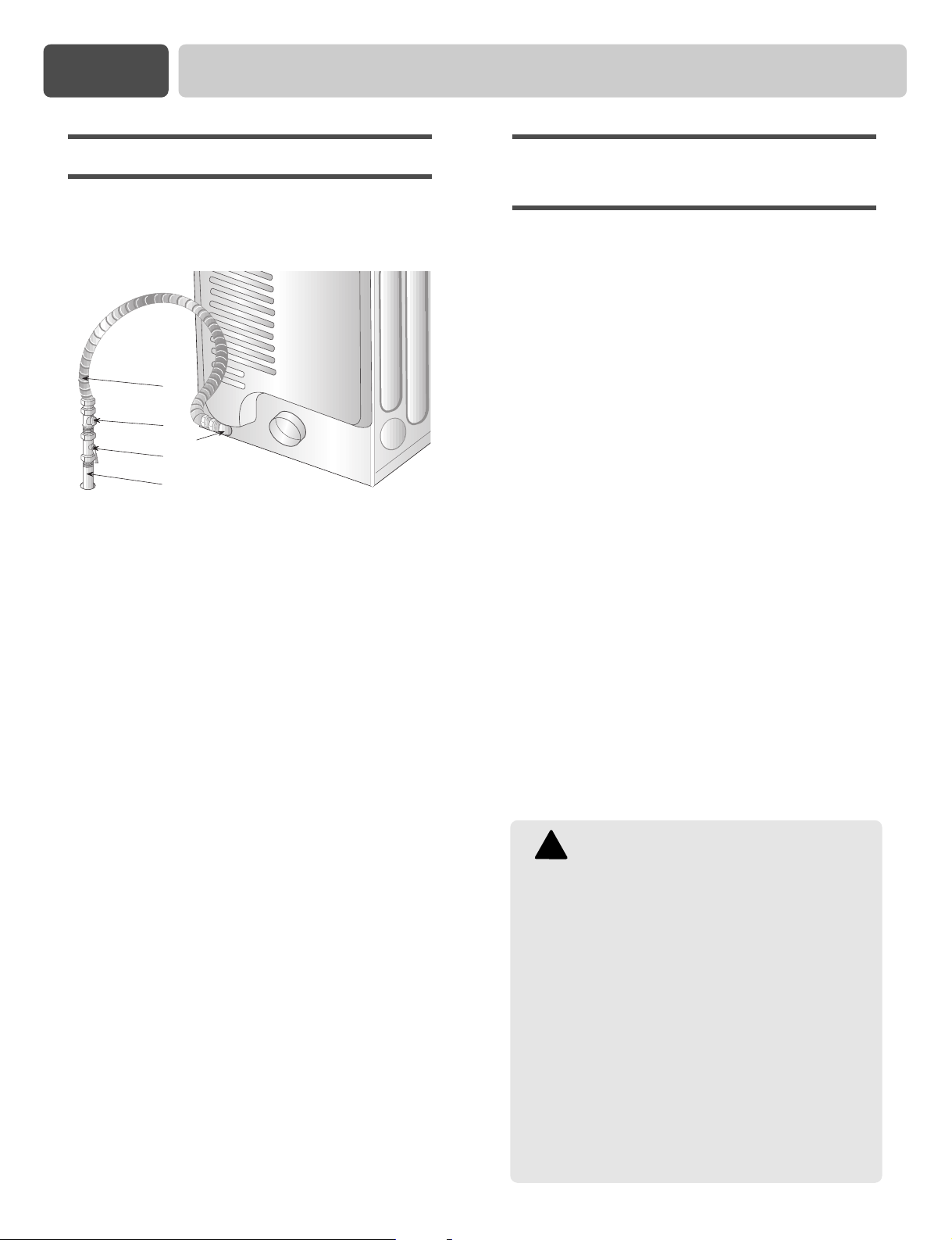

STEP 4: Connection of Gas Supply

STEP 5: Electrical Plug Connections

for Electric Dryer Only.

(Gas dryer only). In addition to the following,

please refer to manual section on Gas Requirements

and Instructions.

Following are several warnings and instructions

concerning making the electrical connection for

electric dryers. More detailed information

concerning the electrical connection is provided at

the manual section entitled Electrical Requirements

For Electric Dryer and it is important that you

thoroughly review that section, and the remainder of

this manual, before taking any steps to install or use

this dryer.

1. Use only a new U.L. listed No. 10 (copper wire

only) three conductor power supply cord kit rated

240 Volts (minimum) 30 Amperes and labeled as

suitable for use in a clothes dryer.

1. New stainless steel flexible connector. Use this type of

connector only if allowed by local codes. Use Design AGA

Certified Connector.

2. 1/8" NPT Pipe Plug (for checking inlet gas pressure)

3. Equipment Shut-Off ValveInstalled within 6’ (1.8 m) of dryer

4. Iron Pipe. Shorter than 20’ (6.1 m)

Use 3/8" pipe. Longer than 20’ (6.1 m) - Use 1/2" pipe.

5. 3/8" N.P.T. Gas Connection

2. Four-wire cord is required for manufactured

(mobile) home installations and use and where

local codes do not allow grounding of this

appliance through neutral.

3. The wiring diagram is provided inside the dryer

control hood. Label all wires prior to

disconnection when servicing the dryer, because

wiring errors can cause serious injury to you and

1. Confirm that the type of gas available in your

laundry room is appropriate for the dryer. The

dryer is prepared for Natural Gas with a 3/8"

NPT gas connection.

2. Remove the shipping cap from the gas

your dryer.

4. For additional instruction on connecting the dryer

to an electrical power source, please refer to this

manual’s section on Electrical Requirements and

Electric Dryer.

connection at the back of the dryer. Make sure

that you don’t damage the threads of the gas

connection pipe when you remove the shipping

cap.

3. Connect the dryer to your laundry room’s gas

supply using a new flexible stainless steel

connector (as noted below, only use a new

stainless steel flexible connector if allowed by

your local codes).

4. Securely tighten all connections between the

dryer and your laundry room’s gas supply. Turn

on your laundry room’s gas supply and check all

pipe connections (both internal and external) for

gas leaks with a non-corrosive leak detection

fluid.

5. For LP (Liquefied Petroleum) gas connection,

refer to this manual’s section entitled Gas

Requirements and Instructions.

• Use a new UL approved 30 amp power

• Use a UL approved strain relief.

• Disconnect power before making electrical

• Connect neutral wire(white or center wire) to

• Ground wire(green or bare wire) must be

• Securely tighten all electrical connections

• See installation instructions for complete

• Failure to do so can result in fire or electrical

WARNING!

supply cord or 10 gauge solid copper wire.

connections.

center terminal.

connected to green ground connector.

instructions.

shock.

9

Page 11

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

1

2

STEP 6: Preparation of the Dryer.

Prior to first use of this appliance, use an allpurpose cleaning product, or a solution of detergent

and water, with a damp clothe to remove from the

inside of the dryer drum/drying compartment any

dust or dirt that may have accumulated inside of the

dryer. Plug in your dryer after reviewing the

following parts on your dryer’s Electrical

Requirements.

STEP 7: Confirming Heat Source

Operation.

Confirming Heat Source in Gas Dryers

Close the door to the dryer drum/drying

compartment and, after completing all steps in this

manual for proper installation of this dryer, start the

dryer on a heat setting, as described more fully in

the operating instructions that accompany the dryer.

After the dryer starts, the igniter will glow red and

the main burner will ignite.

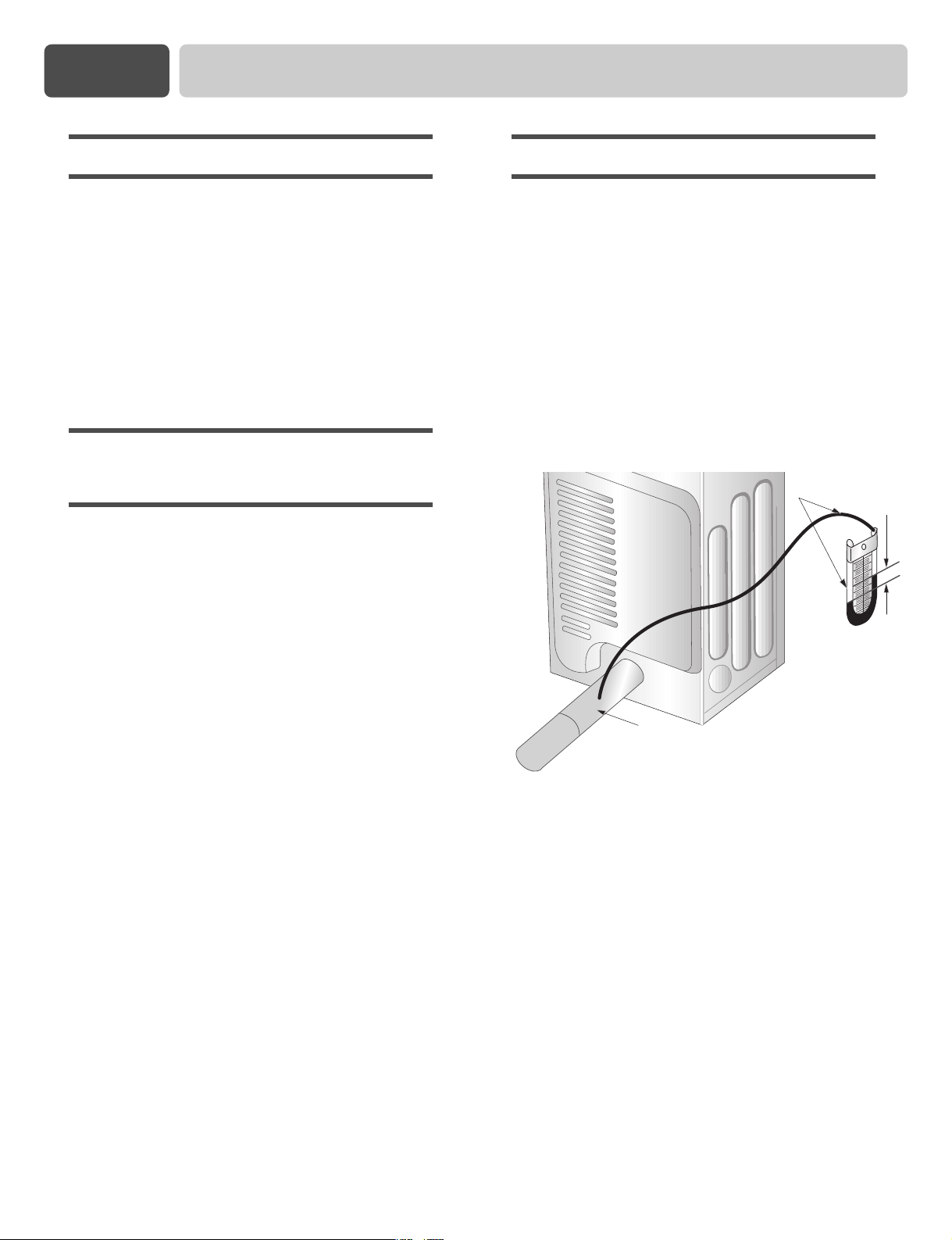

STEP 8: Dryer Airflow.

Effective dryer operation requires appropriate dryer

airflow. The adequacy of the airflow can be

measured by evaluating the static pressure. Static

pressure in the exhaust duct can be measured with a

manometer, placed on the exhaust duct

approximately 2 ft. (60.9 cm) from the dryer. Static

pressure in the exhaust duct should not exceed 0.6

inches (1.5 cm). The dryer should be checked with

the dryer running with no load.

Measuring Static pressure

Warning: If all air is not purged from the gas line,

the gas igniter may go off before the gas and the

main burner have ignited. If this happens, the

igniter will re-attempt gas ignition after

approximately two minutes.

Confirming Heat Source in Electric Dryers

Close the door to the dryer drum/drying

compartment and, after completing all steps in this

manual for proper installation of this dryer, start the

dryer on a heat setting, as described more fully in

the operating instructions that accompany the dryer.

The exhaust air or the exhaust pipe should be warm

after the dryer has been operating for three minutes.

10

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

0.6 inches (1.5 cm)

1 Manometer

2 Exhaust Duct

Page 12

Part 2 INITIAL STEPS FOR INSTALLING YOUR DRYER

!

!

STEP 9: Additional Instructions for

Installation of Your Dryer

in a Manufactured or

Mobile Home.

The following instructions are applicable to

installations of the dryer in a manufactured or

mobile home. Any installation in a manufactured or

mobile home must comply with the Manufactured

Home Construction and Safety Standards Title 24

CFR, Part 32-80 or Standard CAN/CSA0Z240 MH

and local codes and ordinances. If you are

uncertain whether your proposed installation will

comply with these standards, please contact a

service and installation professional for assistance.

The following instructions apply to any installation

of the dryer in a manufactured or mobile home:

1) The gas dryer must be permanently attached to

the floor.

2) The electrical connection for an electric dryer

must be a 4-wire connection. More detailed

information concerning the electrical connection

is provided at the manual section entitled

Electrical Requirements for Electric Dryer

4) Electric dryers may be vented to the outside

using the back, left, right, or bottom panel.

5) Gas dryers may be vented to the outside using the

back, left, or bottom panel. Gas dryer may not be

vented to the outside using the right side panel

because of the burner housing.

6) The dryer exhaust duct must be affixed securely

to the manufactured or mobile home structure,

and the exhaust duct must be made of a material

that will resist fire and combustion, and it is

recommended that you use a rigid or flexible

metal pipe.

7) DO NOT connect the exhaust duct with any other

duct, vent, chimney, or other exhaust duct.

8) Make sure the dryer has adequate access to

outside fresh air to ensure proper operation. The

opening for outside fresh air must be at least 25

2

(163 cm2).

in

9) It is important that the clearance of the duct from

any combustible construction be at least 2 inches

(5 cm), and, when venting the dryer to the

outdoors, the dryer can be installed with a

clearances of 1 inch at the sides and back of the

dryer.

10) Please be aware that venting materials are not

supplied with the dryer. You should obtain the

venting materials necessary for proper

installation.

3) To reduce the risk of combustion and fire, the

dryer must be vented to the outside.

WARNING!

DO NOT connect exhaust ducts with

metal screws or fasteners that extend

into the duct.

DO NOT vent the exhaust duct under the

manufactured or mobile home.

WARNING!

11

Page 13

Part 3 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

!

!

Following are additional instructions regarding electrical connections and requirements for electric dryers.

Important Warning: To help prevent fire, electric shock, serious injury or death, the wiring and grounding

must conform to the latest edition of the National Electrical Code, ANSI/NFPA 70 and all applicable local

regulations. Please contact a qualified electrician to check your home’s wiring and fuses to ensure that your home

has adequate electrical power to operate the dryer.

120V/208V, 60 Hertz, 3-Wire Installation

120V/ 240V, 60 Hertz, 3-Wire Installation

Instructions for Grounding of your Electric

Electric Dryer:

a) Please note that the wiring diagram is provided

inside the dryer control hood.

b) This dryer must be connected to a grounded

metal, permanent wiring system; or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

dryer.

c) The dryer has its own terminal block that must

be connected to a separate branch, 60 Hertz,

single phase circuit, AC (alternating current)

circuit, fused at 30 Amperes (the circuit must be

fused on both sides of the line). ELECTRICAL

SERVICE FOR THE DRYER SHOULD BE

OF MAXIMUM RATE VOLTAGE LISTED

ON THE NAMEPLATE. DO NOT CONNECT

DRYER TO 110, 115, OR 120 VOLT

CIRCUIT. Heating elements are available for

field installation in dryers which are to be

conected to electrical service of different

voltage than that listed on nameplate, such as

208 Volt.

e) The power cord (pigtail) connection between wall

receptacle and dryer terminal block IS NOT

supplied with dryer. Type of pigtail and gauge of

wire must conform to local codes and with

instructions mentioned on the following pages.

f) The method of wiring the dryer is optional and

subject to local code requirements. Refer to

examples on next page.

g) You must select the method by which to wire

your dryer according to local code and ordinance

requirements. Sample methods are included in

the following pages.

WARNING!

Label all wires prior to disconnection

when servicing the dryer, because

wiring errors can cause serious injury

to you and your dryer.

d) If branch circuit to dryer is fifteen feet (4.50 m)

or less in length, use U.L. (Underwriters

Laboratories) listed No. 10 A.W.G. wire

(copper wire only), or as required by local

codes. If over fifteen feet (4.50 m), use U.L.

(Underwriters Laboratories) listed No. 8

A.W.G. wire (copper wire only), or as required

by local codes. Allow sufficient slack in wiring

so dryer can be moved from its normal location

when necessary.

12

Page 14

Part 3 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

Review the following options to determine the appropriate electrical connection

for your home:

3-wire receptacle

(NEMA type10-30R)

Use the instructions at this section if your home has

a 3-wire receptacle (NEMA type 10-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

Use the instructions at this section if your home has

a 4-wire receptacle (NEMA type 14-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

4-wire receptacle

(NEMA type14-30R)

Important: If your local codes or ordinances do not allow the connection of a frame-

grounding conductor to the neutral wire, use the instructions under Option 3: Optional

3-wire connection.

13

Page 15

Part 3 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

d

gf

a

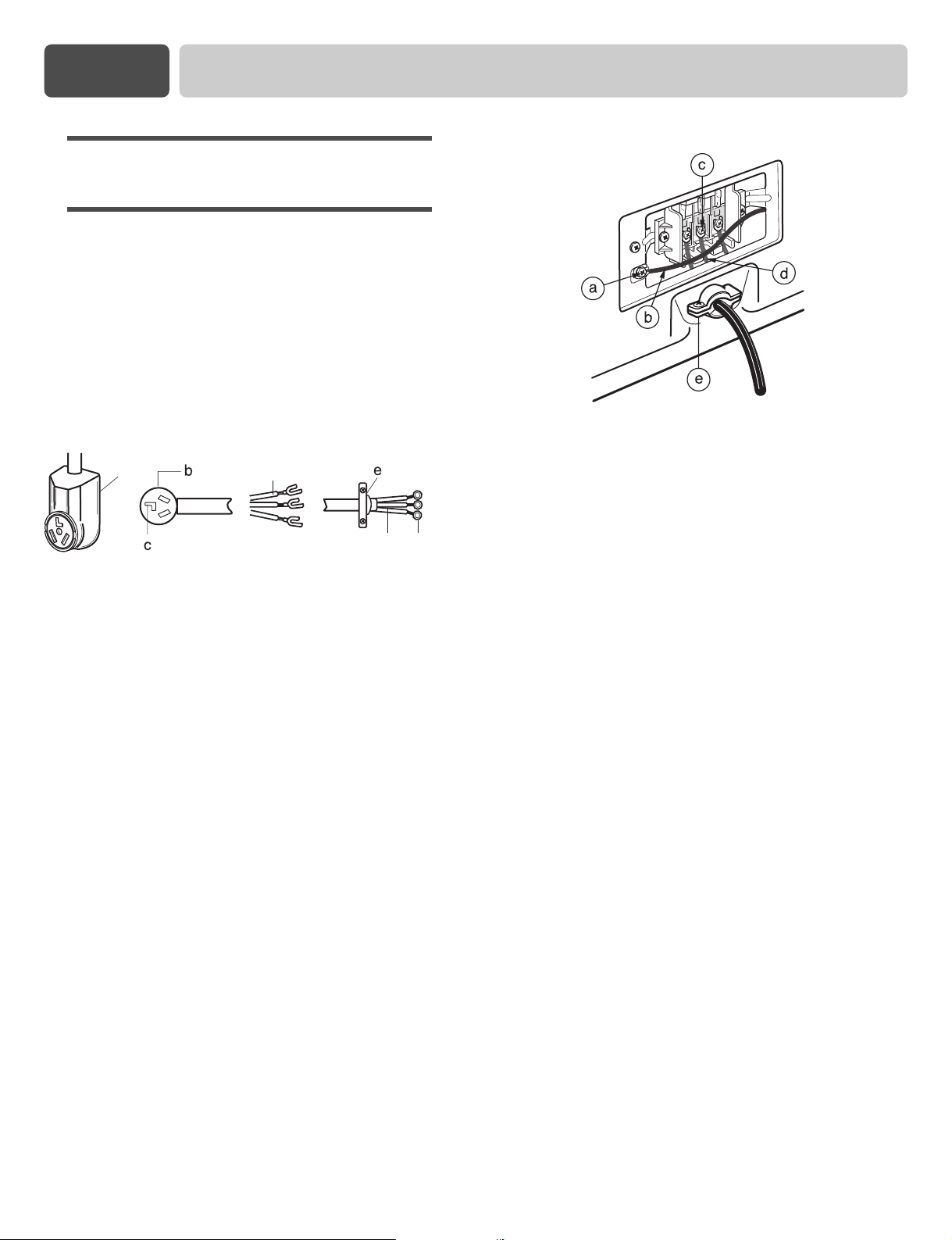

Option 1: 3-Wire Connection with

a Power Supply Cord

lf your local codes or ordinances permit the

connection of a frame-grounding conductor to the

neutral wire, use these instructions. If your local

codes or ordinances do not allow the connection of

a frame-grounding conductor to the neutral wire,

use the instructions under Section 3: Optional

3-wire connection.

a. External ground connector

b. Neutral grounding wire (green)

c. Center silver-colored terminal block screw

d. Neutral wire (white or center wire)

e. 3/4 in. (1.9 cm) UL-listed strain relief

a. 3-wire receptacle (NEMA type 10-30R)

b. 3-wire plug

c. Neutral prong

d. Spade terminals with up turned ends

e. 3/4 in. (1.9 cm) UL approved strain relief

f. Ring terminals

g. Neutral (white or center wire)

1. Loosen or remove center terminal block screw.

2. Connect neutral wire (white or center wire) of

power supply cord to the center, silver colored

terminal screw of the terminal block. Tighten

screw.

3. Connect the other wires to outer terminal block

screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of

dryer rear panel. Secure cover with hold-down

screw.

14

Page 16

Part 3 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

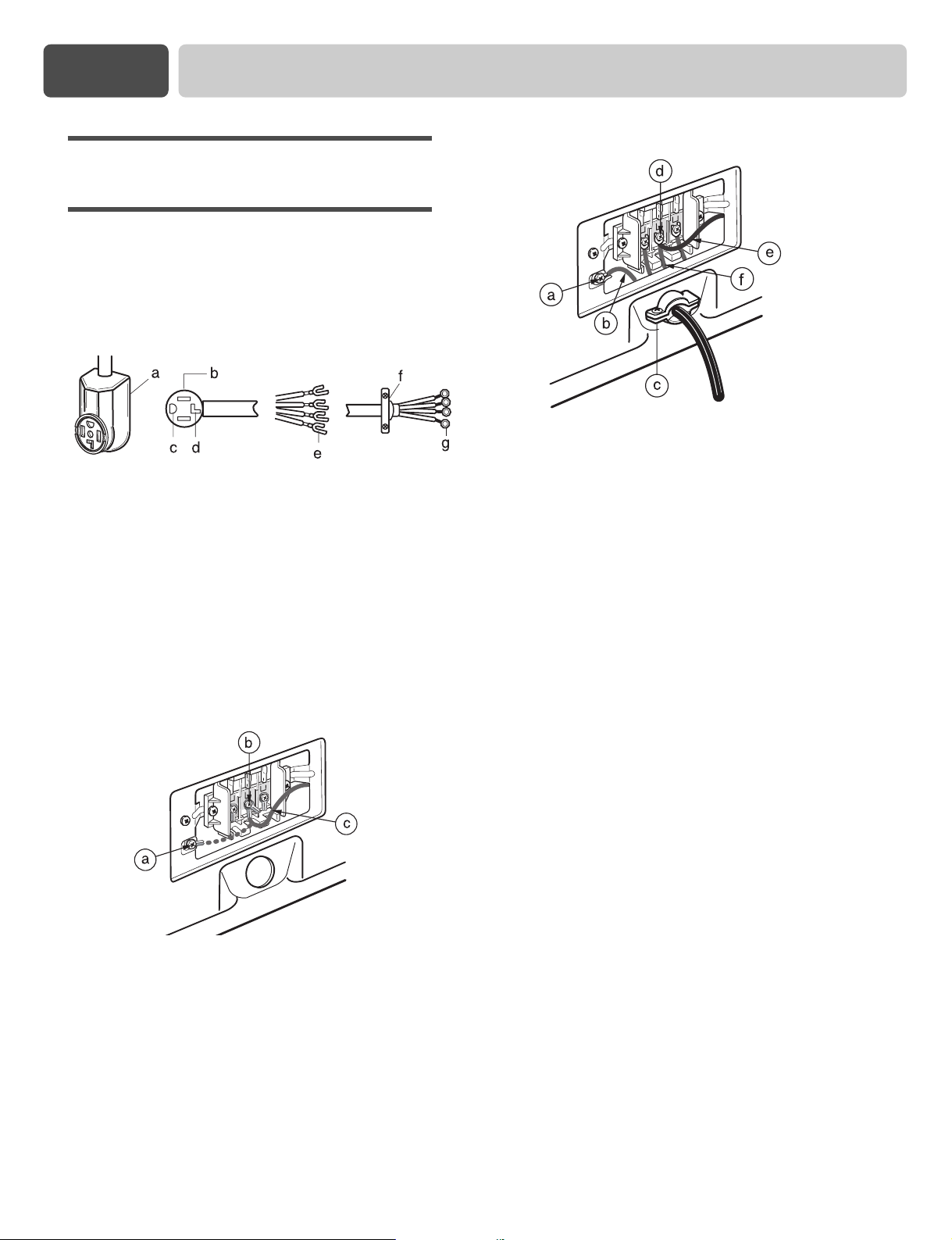

Option 2: 4-wire connection with a

Power supply cord.

• lf your local codes or ordinances do not allow the

use of a 3 wire connection, or you are installing

your dryer in a mobile home, you must use a 4wire connection.

a. External ground connector

b. Green or bare copper wire of power supply cord

c. 3/4 in. (1.9 cm) UL-listed strain relief

a. 4-wire receptable (NEMA type 14-30R)

b. 4-pront plug

c. Ground prong

d. Neutral Prong

e. Spade terminals with upturned ends

f. 3/4 in. (1.9 cm) UL approved strain relief

g. Ring terminals

1. Remove center terminal block screw.

2. Remove appliance ground wire (green) from

external ground connector screw. Fasten it under

the center, silver colored terminal block screw.

d. Center silver-colored terminal block screw

e. Neutral grounding wire (green)

f. Neutral wire (white)

5. Connect the other wires to outer terminal block

screws. Tighten screws.

6. Tighten strain relief screws.

7. Insert tab of terminal block cover into slot of

dryer rear panel. Secure cover with hold-down

screw.

a. External ground connector - Dotted line

shows position of NEUTRAL ground wire

before being moved to center terminal block

screw

b. Center silver-colored terminal block screw

c. Green wire of harness

3. Connect ground wire (green or bare) of power

supply cable to external ground conductor screw.

Tighten screw.

4. Connect neutral wire (white or center wire) of

power supply cord to the center, silver colored

terminal screw of the terminal block.

15

Page 17

Part 3 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

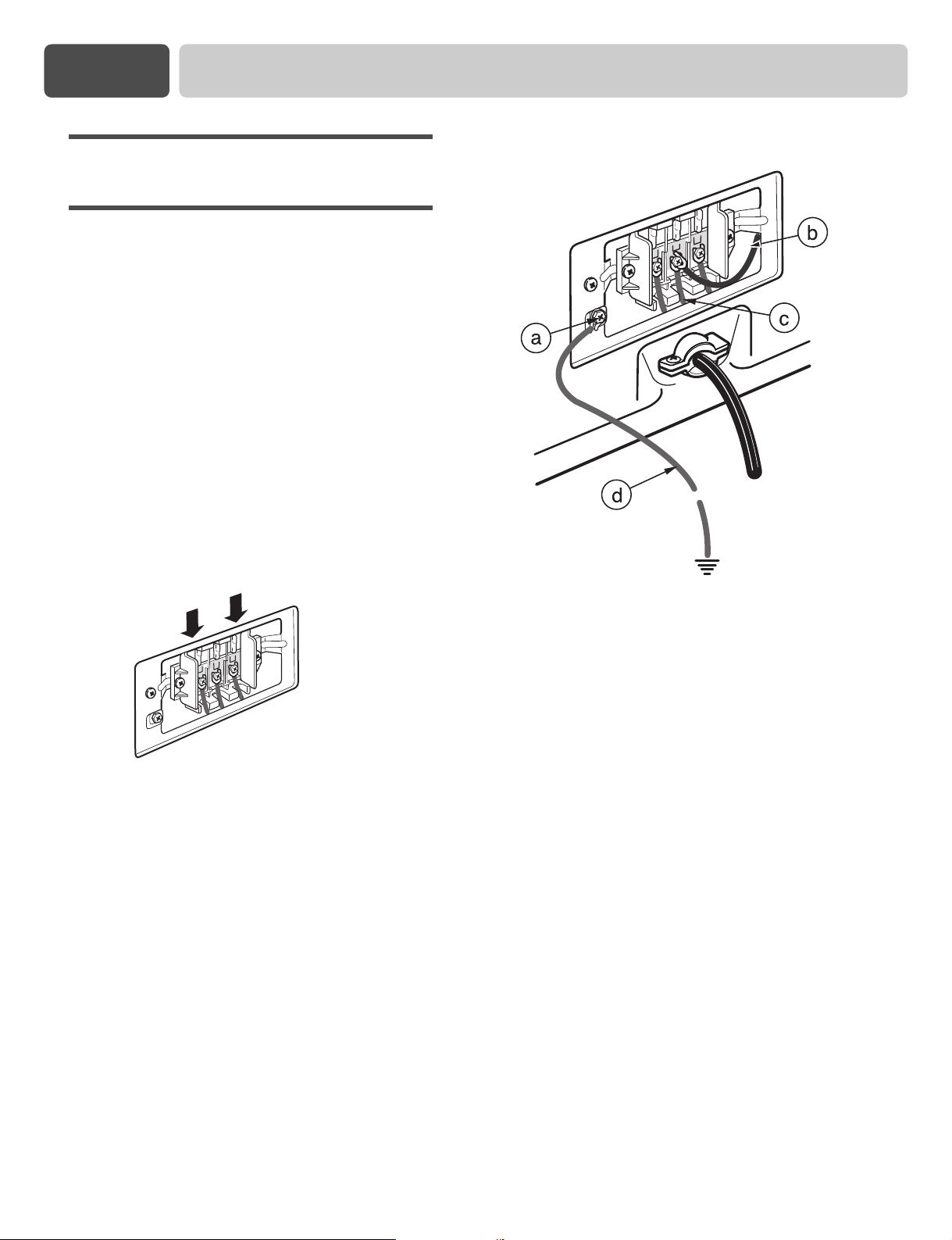

Option 3: Optional 3-wire

connection.

• If your local codes or ordinances do not allow the

connection of a frame-grounding conductor to the

neutral wire, use the instructions under this

section.

1. Remove center terminal block screw.

2. Remove appliance ground wire (green) from

external ground connector screw. Connect

appliance ground wire and the neutral wire (white

or center wire) of power supply cord/cable under

center, silver colored terminal block screw.

Tighten screw.

3. Connect the other wires to outer terminal block

screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of

dryer rear panel. Secure cover with hold-down

screw.

6. Connect a separate copper ground wire from the

external ground connector screw to an adequate

ground.

a. External ground connector

b. Neutral grounding wire (green)

c. Neutral wire (white or center wire)

d. Grounding path determined by a qualified electrician

16

Page 18

Part 4 ELECTRICAL REQUIREMENTS FOR GAS DRYERS

!

!

2

1

3

5

4

V.A.C.

120

+ 12

0

V.A.C.

120

± 12

V.A.C

!

120 Volt, 60 Hertz, with 3-Prong Grounding Plug

Following are additional instructions regarding electrical connections and requirements for gas dryers.

Important Warning: To help prevent fire, electric shock, serious injury or death, the wiring and grounding

must conform to the latest edition of the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and all applicable local regulations. Please contact a qualified electrician to check your home’s

wiring and fuses to ensure that your home has adequate electrical power to operate the dryer.

Electrical Requirements for Your Dryer:

a) Please note that the wiring diagram is provided

inside the dryer control hood. Label all wires

prior to disconnection when servicing the dryer,

because wiring errors can cause serious injury to

you and your dryer.

b) Your dryer is designed to be used on a separate

branch, polarized, three-wire, effectively

grounded, 120 Volt, 60 Hertz, AC (alternating

current) circuit protected by a 15 Ampere fuse,

equivalent fusetron or circuit breaker.

c) Use separately fused circuits for washers and

dryers, and DO NOT operate a washer and a

dryer on the same circuit.

WARNING!

Do not overload the circuit by operating other

appliances on the same circuit when this

appliance is operating, by using an extension

cord to connect the dryer to the power

source, or by using any adapter to allow

additional cords to connect to the same

outlet.

STANDARD 120 VOLT, 60 HERTZ, 3-WIRE

EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

a) The dryer has a three-prong plug to help guard

against shock. The plug should be plugged

directed into a properly grounded three-prong

receptacle that is rated 120 Volts AC (alternating

current) 15 Amps. This plug, in order to be

properly and fully effective, must be plugged into

a properly installed outlet that is grounded in

accordance with all local codes and ordinances.

WARNING!

DO NOT modify the plug provided with the

dryer. If it does not fit the outlet in your

laundry room, a proper outlet will need to be

installed in your laundry room by a qualified

service person or company.

b) The dryer must be grounded in order to reduce

the risk of electric shock, including a

malfunction or breakdown.

c) If your laundry room does not meet the

specifications required by this manual, or if you

are uncertain whether or not your laundry room

meets these specifications, please have a

qualified service person or company, for example

a qualified electrician or your local electric

company, review your laundry room’s electrical

supply for any problems.

17

Page 19

Part 5 GAS REQUIREMENTS AND INSTRUCTIONS

!

!

!

Following are important instructions and information concerning the requirements for the gas supply and service for

gas dryers. Important Warning: The gas supply and service for a gas dryer must comply with all local codes

and ordinances. In the absence of any local codes or ordinances in your area, the gas supply and service for your gas

dryer must comply with the latest edition of the National Fuel Cas Code, ANSI Z223.1/NFPA 54.

1. Gas supply requirements: Liquefied Petroleum

(L.P.) Gas (2,500 Btu/ft3 (93.1 MJ/m3)) service

must be provided at 10 + 1.5 in. water column

pressure.

2. Important: DO NOT connect the dryer to the

Liquefied Petroleum (LP) Gas service without

converting the gas value.

3. A qualified technician must perform the LP Gas

conversion. Contact your local gas service branch

if you require additional assistance or

information.

4. Isolate the dryer from the gas supply piping

system by closing its individual manual shut-off

valve, during any pressure testing of the gas

supply system at test pressure equal to or less

than 2/1 psi (3.45 kPa).

5. Supply Line Requirements. Your laundry room

must have a rigid gas supply line to your dryer.

In the United States, an individual manual shutoff

valve MUST be installed within at least 6 feet

(1.8m) of the dryer, in accordance with the

National Fuel Gas Coide ANSI Z223.1. A 1/8 in.

N.P.T. pipe plug must be installed as shown.

6. If using a rigid pipe, the rigid pipe should be 1/2

inch IPS. If acceptable under local codes and

ordinances and when acceptable to your gas

supplier, 3/8 inch approved tubing may be used

where lengths are less than 20 feet (6.1m).

Larger tubing should be used for lengths in

excess of 20 feet (6.1m). It is also important that

you use pipe joint compound that is insoluble in

LP gas.

7. To reduce the danger of gas leaks, explosion, and

fire, please follow and observe the following

instructions and WARNINGS:

• Connect the dryer to the type of gas shown on the

nameplate;

• Use new flexible stainless steel connectors;

• Use Teflon tape and pipe joint compound

insoluble in LP gas on all pipe threads;

• Purge gas supply of air and sediment before

connecting the gas supply to the dryer; in order to

prevent gas valve contamination, before tightening

connection between gas supply and dryer, purge

remaining air until odor of gas is identified; and

• DO NOT use an open flame to inspect for gas

leaks; instead, use a non-corrosive leak detection

fluid.

WARNING!

• Use a new AGA or CSA approved gas

DO NOT attempt any disassembly of the

dryer, any disassembly requires the

attention and tools of an authorized and

qualified service person or company.

18

• Install a shut-off valve.

• Securely tighten all gas connections.

• If connected to LP, have a qualified person

• Examples of a qualified person include

• Failure to do so can result in death,

WARNING!

supply line.

make sure gas pressure does not exceed

13 in. water column.

licensed heating personnel, authorized gas

company personnel, and authorized service

personnel.

explosion, or fire.

Page 20

Part 6 EXHAUST REQUIREMENTS AND MAINTENANCE

!

Following are important instructions and information concerning the exhaust requirements for your dryer.

Important Warning: To reduce the risk of fire, combustion, or accumulation of combustible gases, DO NOT

exhaust dryer air into an enclosed and unventilated area, such as an attic, wall, ceiling, crawl space, chimney, gas

vent, or concealed space of a building. To reduce the risk of fire, DO NOT exhaust the dryer with plastic or thin foil

ducting.

Weather Hood

Type

Recommended

4”

(10.2 cm)

Use Only for Short Run

Installations

(10.2 cm)

4”

Number of 90°

Elbows

0

1

2

3

4

0

1

2

3

Maximum length of 4”

(10.2 cm) diameter rigid

metal duct

65 feet (19.8 m)

55 feet (16.8 m)

47 feet (14.3 m)

36 feet (11.0 m)

28 feet (8.5 m)

55 feet (16.8 m)

47 feet (14.3 m)

41 feet (12.5 m)

30 feet (9.1 m)

Maximum length of 4”

(10.2 cm) diameter

flexible metal duct

45 feet (13.7 m)

35 feet (10.7 m)

30 feet (9.1 m)

25 feet (7.6 m)

20 feet (6.1 m)

35 feet (10.7 m)

27 feet (8.2 m)

21 feet (6.4 m)

17 feet (5.2 m)

4

2-1/2”

(6.35 cm)

NOTE : Deduct 6 feet (1.8 m) for each additional elbow.

It is not recommended to use more than 4 90° elbows.

Exhaust Requirements and Instructions:

1. Venting materials are not provided with the dryer

and you should obtain the necessary venting

materials locally. For example, the outer end of

exhaust pipe must have a weather hood with

hinged dampers to prevent back-draft when the

dryer is not in use.

2. The exhaust duct must be four inches (10.2 cm)

in diameter with no obstructions. The exhaust

duct should be kept as short as possible. Make

sure to clean any old ducts before installing your

new dryer.

22 feet (6.7 m)

15 feet (4.5m)

3. Rigid metal duct is recommended. Do not install

flexible duct in concealed spaces.

Non-combustible flexible metal duct is

acceptable. Do not use plastic or thin foil ducting.

4. DO NOT use sheet metal screws on exhaust pipe

joints or other fastening means which extend into

the duct that could catch lint and reduce the

efficiency of the exhaust system. Secure all joints

with duct tape.

5. To maximize operating results, please observe the

duct length limitations noted in the chart above.

19

Page 21

Part 6 EXHAUST REQUIREMENTS AND MAINTENANCE

!

Exhaust and Dryer Maintenance

WARNING!

Disconnect the dryer’s electric power prior

to any cleaning or maintenance.

1. After one year of use, the interior and complete

exhaust system of the dryer should be examined

and cleaned if necessary.

2. You should inspect and clean the exhaust duct at

least yearly.

3. Check the weather hoods frequently to ensure

the dampers are moving freely, that the dampers

are not pushed in and that nothing has been set

against the dampers.

4. A qualified service person or company should be

used to perform this maintenance.

5. A Flexible Metal Vent Kit, available at extra cost,

can be used to exhaust the dryer when it is placed

in hard to reach places. This Kit comes in two

pieces, one of which is attached to the dryer and

the other is attached to the wall exhaust outlet.

Following attachment of the two separate pieces

to the dryer and the wall, the dryer may be

returned to its final position, after which the two

pieces themselves can be connected.

7. Ordinarily, the dryer drum will need no care.

Wipe the exterior of the dryer as required, and

always immediately wipe the exterior of the

dryer in the event any detergent, bleach, or other

washing products is spilled on the dryer, because

these products may cause permanent damage to

the exterior finish of the dryer.

8. Clean the control panel with a damp cloth as

necessary. Warning: spray pre-wash products

may damage the finish of the control panel.

9. Please clean the lint filter either before drying

each load or after drying each load.

10. Always make sure the lint filter is clean before

starting a new load, because a clogged lint filter

may increase drying times.

11. Annually remove the lint filter and attach it to

the vacuum duct. See item #2 above.

12. Please note that the wiring diagram is provided

inside the dryer control hood. Label all wires

prior to disconnection when servicing the dryer,

because wiring errors can cause serious injury

to you and your dryer.

20

Cleaning the Lint Screen

1. Clean the lint filter either before drying each load

or after drying each load. Always make sure the

lint filter is clean before starting a new load,

because a clogged lint filter may increase drying

times.

2. To clean, pull the lint screen straight up and roll

any lint off the screen with your fingers. Do not

rinse or wash screen to remove lint, because wet

lint is hard to remove. Push the lint screen firmly

back into place.

3. Always ensure the lint screen is firmly secured

before running the dryer. Running the dryer with

a loose lint screen may cause overheating and

damage to the dryer and articles being dried.

4. Some articles may shed more lint than other

towels (for example, towels made of synthetic

fibers and natural fibers), causing the lint screen

to become congested more quickly. Remove lint

from the lint screen before and after drying these

articles, such as new towels.

5. In the event lint falls off of the lint screen and

into the dryer during removal, inspect the exhaust

hood and remove any lint.

6. Laundry detergent and fabric softener residue can

build up on the lint screen, causing longer drying

times. The screen is likely blocked if lint falls off

the screen. In order to prevent this type of build

up, and help ensure proper operation of your

dryer, clean the lint screen with a nylon brush

every six months or, if necessary, more

frequently. The lint filter can also be washed as

follows:

a) After rolling the lint off of the screen with your

fingers, wet both sides of the screen with hot or

warm water.

b) Wet a nylon brush with hot water and liquid

detergent and scrub the lint screen with the brush

to remove the buildup of detergent and fabric

softener.

c) Repeat as necessary.

d) After the residue has been removed, rinse screen

with hot water.

e) After drying the lint screen with a clean towel,

firmly replace the lint screen in your dryer.

Page 22

Part 7 FEATURES AND BENEFITS

!

!

Following are instructions for starting and using your new dryer. Please refer to specific sections of this manual for

more detailed information. Important Warning: To reduce the risk of fire, electric shock, or injury to person, read

this entire manual, including the Important Safety Instructions, before operating this dryer.

WARNING!

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any

type of oil on it (including cooking oils).

Items containing foam, rubber, or plastic

must be dried on a clothesline or by using

an Air Cycle. Failure to follow these

instructions can result in death or fire.

■ DLE5911W / DLG5911W

WARNING!

Explosion Hazard

Keep flammable materials and vapors, such

as gasoline, away from dryer.

Do not dry anything that has ever had

anything flammable on it (even after washing).

Failure to follow these instructions can result

in death, explosion, or fire.

■ DLE2511W / DLG2511W

21

Page 23

Part 7 FEATURES AND BENEFITS

DLE5911W/G5911W

DLE5932W/G5932W

DLE0332W/G0332W

DLE5932S/G5932S

DLE2511W/G2511W

DLE2532W/G2532W

■ DLE5932W / DLG5932W / DLE0332W / DLG0332W/ DLE5932S / DLG5932S

■ DLE2532W / DLG2532W

STARTING YOUR DRYER

1. Using Your Dryer

1. Clean lint screen before or after each cycle.

2. Place laundry into dryer and shut door.

See Loading.

3. Turn the knob to select the drying cycle you

want. The preset settings for Sensor Dry Cycles

or Manual Cycles will glow. The estimated or

actual cycle time (in minutes) will show in the

display.

2. To use a Sensor Dry Cycle

• Select an Sensor Dry Cycle.

• Select DRY LEVEL to adjust how dry you want

the load. As the cycle runs, the control senses the

dryness of the load and adjusts the time

automatically for the selected dryness level.

• Select the desired Options.

• Press START/PAUSE

NOTE: DRY LEVEL selections can only be made

while using Sensor Dry Cycles. Selecting MORE

Dry or LESS Dry automatically adjusts the sensed

time needed.

22

Page 24

Part 7 FEATURES AND BENEFITS

3. To use a Manual Dry Cycle

• Select a Manual Dry Cycle.

• Press MORE TIME or LESS TIME until the

desired drying time is displayed. Tap MORE

TIME or LESS TIME and the time will change by

1 minute intervals.

NOTE: The MORE TIME or LESS TIME

feature can be used with Manual Dry, Time Dry,

and Rack Dry Cycles.

• Press TEMP. CONTROL until the desired

temperature indicator glows.

• (OPTIONAL STEP) If desired, select OPTIONS.

For more details, see Options.

• Press START/PAUSE. Be sure the door is closed.

• If you do not press START/PAUSE within 10

minutes of selecting the cycle, the dryer

automatically shuts off.

• If you wish to end your drying cycle after pressing

START/PAUSE, press START/PAUSE again.

Child Lock

This feature allows you to lock your settings to

prevent children from changing them. You can also

use the child lock feature to prevent unintended

cycle or option changes during dryer operation.

To enable the Child Lock feature:

Press and hold RACK DRY and ANTI

BACTERIAL for 2 seconds. A single BEEP Tone is

heard, and CL is displayed. To unlock, press and

hold RACK DRY and ANTI BACTERIAL for 2

seconds. The indicator light turns off.

5. Loading

Properly loading your dryer can lower your utility

bill and prolong the life of your garments.

Loading suggestions

Load the dryer by the amount of space items take

up, not by their weight.

Do not overload the dryer. This causes uneven

drying and wrinkling.

4. Stopping Your Dryer

To stop your dryer at any time

Press START/PAUSE or open the door.

Pausing or Restarting

To pause the dryer at any time

Open the door or press START/PAUSE once.

To restart the dryer

Close the door. Press START/PAUSE.

NOTE: Drying will continue from where the cycle

was interrupted if you close the door and press

START within 10 minutes. If the cycle is

interrupted for more than 10 minutes, the dryer will

shut off. Select new cycle settings before restarting

the dryer.

Following are sample loads for Super Capacity

Dryers:

Heavy Work Clothes

4 jeans

4 workpants

4 work shirts

Towels

10 bath towels

10 hand towels

Mixed Load

3 sheets (1 king, 2 twin)

4 pillowcases

3 shirts

3 blouses

2 sweatpants

2 sweatshirts

14 wash cloths

9 T-shirts

9 shorts

10 handkerchiefs

23

Page 25

Part 7 FEATURES AND BENEFITS

6. Cycle Descriptions

Select the drying cycle that matches the type of load

you are drying.

(See Sensor Dry or Manual Preset Cycle Settings

charts.)

Sensor Dry Cycles allow you to match the cycle to

the load you are drying. Each cycle dries certain

fabrics at the recommended temperature. A sensor

detects the moisture in the load and automatically

adjusts the drying time for optimal drying

Sensor Dry Cycle

• Heavy Duty

Use this cycle to get high heat for heavy fabrics

such as jeans, corduroys, or work clothes.

• Cotton/Towels

Use this cycle to get medium-high heat for drying

denims and towels.

• Normal

Use this cycle to get medium heat for drying

sturdy fabrics such as work clothes, casual clothes,

and cotton jerseys.

• Perm. press

Use for permanent press and synthetic items.

• Delicate

Use this cycle to get low heat for drying synthetic

fabrics, washable knit fabrics, and no-iron

finishes.

• Ultra Delicate

Use this cycle to get ultra low heat to gently dry

items such as lingerie, exercise wear, or sheer

curtains.

Sensor Dry Preset Cycle Settings

Sensor Dry

Cycles Load Type

HEAVY DUTY

Heavyweight, jeans

COTTON/TOWELS

Denim pants, towel

NORMAL

Corduroys, work clothes

PERM. PRESS

Permanent press,

synthetics

DELICATE

Sheets, lingerie, blouses

ULTRA DELICATE

Exercise wear, sheer

curtains, lace

* Estimated Time with SENSOR DRY LEVEL

(Normal) setting.

Manual Cycles

Use Manual Cycles to select a specific amount of

drying time and a drying temperature. When a

Manual Cycle is selected, the ESTIMATED TIME

REMAINING display shows the actual time

remaining in your cycle. You can change the actual

time in the cycle by pressing MORE TIME or LESS

TIME.

• Speed Dry

Use this cycle for drying small loads or loads that

need a short drying time.

Temp.

High

Medium

High

Medium

Low

Low

Ultra

Low

Time*

(Minutes)

54

55

41

36

32

34

24

• Freshen Up

Use this cycle to remove wrinkles from items,

such as clothes packed in a suitcase or items

wrinkled from being left in the dryer too long.

• Air Dry

Use the Air Dry Modifier for items that require

drying without heat such as rubber, plastic and

heat-sensitive fabrics.

Page 26

Part 7 FEATURES AND BENEFITS

• Time Dry

Use this cycle to complete drying if items are still

damp after an Sensor Dry Cycle. Time dry is also

useful for drying heavyweight and bulky items,

such as bedspreads and work clothes.

Manual Preset Cycle Settings

8. Modifiers

Use Modifiers to select temperatures for the Manual

Cycles. Press TEMP. CONTROL until the desired

temperature setting glows. Temperature modifiers

cannot be used with the Sensor Dry Cycles.

Manual Dry

Cycles Load Type

SPEED DRY

SMALL LOADS

FRESHEN UP

Remove Wrinkles

AIR DRY

Temp.

High

Medium

High

Air Dry

Default Time*

(Minutes)

25

20

30

7. Options

You can customize your cycles by selecting options.

Damp Dry Beep

Select DAMP DRY BEEP to alert you that your

clothes are approximately 80% dry. This is useful

when you want to remove lightweight items in a

mixed load to prevent overdrying or remove

partially dry items that may need ironing.

NOTE: The Damp Dry Beep is only available with

the Sensor Dry Cycles.

WRINKLE CARE

WRINKLE CARE prevents wrinkles that form

when you cannot unload the dryer promptly at the

end of a cycle. During this option, the dryer will

periodically tumble.

• Press WRINKLE CARE to get up to 3 hours of

heat-free, periodic tumbling at the end of a cycle.

• Stop WRINKLE CARE at any time by pressing

WRINKLE CARE or opening the dryer door.

NOTE: If you do not select WRINKLE CARE, the

dryer stops after cool down.

When using Air Dry

This chart shows examples of items that can be

dried using AIR DRY.

Type of Load Default Time*

(Minutes)

Foam rubber-pillows,

padded bras, stuffed toys

Plastic-Shower curtains,

tableclothes

Rubber-backed rugs

Olefin, polypropylene,

sheer nylon

Reset cycle to complete drying, if needed.

• Check to see that coverings are securely stitched.

• Shake and fluff pillows by hand periodically

during the cycle.

• Dry item completely. Foam rubber pillows are

slow to dry.

NOTE: Air Dry is not available with Sensor Dry

Cycles.

20 - 30

20 - 30

40 - 50

10 - 20

25

Page 27

Part 7 FEATURES AND BENEFITS

9. Rack Dry

The dryer rack is shipped in place in your dryer.

Remove and discard any packing material before

use.

The RACK DRY is designed for use with items that

you do not want to tumble dry, including sweaters

and similar items. The heated dryer rack allows the

heated air inside the dryer to flow in a concentrated

pattern, allowing effective and consistent drying.

Use RACK DRY to select the desired time.

To use the RACK DRY:

• Open dryer door.

• Do not remove the lint screen.

• Place dryer rack over the bottom of the dryer door

opening. Rest the rack on the dryer back ledge.

Push down on the frame front to secure over lint

screen.

• Select RACK DRY and MORE TIME or LESS

TIME. Reset time as needed to complete drying.

Refer to the following table.

• Select the desired temperature setting to match the

fabrics in your load by pressing TEMP. CONTROL

(Air Dry-Ultra Low-Low). Items containing foam,

rubber, or plastic must be dried on a clothesline or by

using the Air Dry temperature setting. Refer to the

following table.

• Start the dryer.

10. Beeper

The BEEPER controls the volume of the beep that

is made when you press any of the buttons on the

control panel and the termination of any cycle is

indicated.

Press BEEPER to adjust the sound level or turn off

the signal.

• Place wet items on top of the rack. Allow space

around items for air to circulate. The rack does not

move, but the drum will rotate. Make sure items

do not hang over the edges or between rack grill.

• Close the door.

NOTE: Check the lint screen and remove any lint

accumulated from items dried on the rack.

Suggested Items

for Rack Drying

Washable wool items

(block to shape and

lay flat on rack)

Stuffed toys (cotton

or polyester fiber

filling)

Stuffed toys (foam

rubber filled)

Temperature

Setting

Low 20

Low/Ultra

Low

Air Dry/

Ultra Low

Suggested

Time*

(Minutes)

20/30

50/30

11. Anti Bacterial

This option can only be used with the HEAVY

DUTY, COTTON/TOWELS, and NORMAL cycles.

This option reduces certain types of bacteria. The

ANTI BACTERIAL process produces high

temperature during the cycle.

NOTE: Do not use this cycle on delicate fabrics.

12. Custom Programming

Set up your favorite combination of settings and

save them here for one-touch recall.

To store a CUSTOM PROGRAM.

1. Select a cycle

2. Change DRY LEVEL and TEMP. CONTROL.

Foam rubber pillows

Tennis shoes

* Reset time as needed to complete drying.

26

Air Dry

Air Dry

50

20

3. Select OPTIONS you want.

4. Press and hold the CUSTOM PROGRAM.

To recall your stored CUSTOM PROGRAM

Press CUSTOM PROGRAM pad, then press

START/PAUSE.

Page 28

Part 8 TROUBLESHOOTING GUIDE

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

1.Problem:My Dryer Won ’t Start

Question What to Do

• Is the dryer plugged in?

• Is the fuse blown, or is the circuit

breaker tripped?

Confirm that the dryer’s plug is securely and completely pushed into the laundry

room’s power outlet

Check your home’s or laundry room’s fuse box/circuit breaker box and replace the

fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally use two

fuses or breakers.)

2.Problem:My Dryer Doesn ’t Heat

Question What to Do

• Is the fuse blown, or is the circuit

breaker tripped?

• Is the gas supply or service

blocked or off?

If the fuse is blown or the circuit breaker tripped, the dryer might tumble but not

heat. Check your home’s or laundry room’s fuse box / circuit breaker box and

replace the fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally

use two fuses or breakers.)

Confirm that the house gas shutoff and the dryer gas shutoff are both fully open.

3.Problem:There are Greasy Spots on My Clothes

Question What to Do

• Did you follow the instructions on

your fabric softener product?

• Are you drying clean and dirty

clothes together?

• Were your clothes entirely clean?

Confirm and follow the instructions provided with your fabric softener product.

Make sure to use your dryer to dry only clean items, because dirty items can soil

clean clothes placed in the same load or later placed in the dryer drum.

Stains on dried clothes are actually stains that weren’t cleansed during the washing

process. Please review and confirm that you are following your washing

instructions and that the clothes are being completely cleaned.

27

Page 29

Part 8 TROUBLESHOOTING GUIDE

4.Problem:There is Lint on my Clothes

Question What to Do

• Is your lint filter full?

• Did you properly sort your load of

laundry?

• Do your clothes have excess static

electricity?

• Did you overload your dryer?

• Did you place any paper, tissue, or

other similar material in the load?

Please refer to the manual section on cleaning the lint filter, and please confirm that the

lint filter is clean. It is important that the lint filter is clean before each new load of

laundry.

In order to reduce the amount of lint in a load of laundry, sort lint producers (like a

fuzzy white cotton towel) separately from clothes that might catch lint (such as a pair

of black linen pants).

See comments below under There is static in my clothes after drying.

Divide your larger load into smaller loads.

Sometimes a person might forget to take a piece of paper or a tissue out of the pocket

of a pair of pants, and this paper, tissue, or similar material can cause excess lint in a

load of laundry. Confirm that the pockets of pants, shirts, and other articles of clothing

are empty before washing and drying.

5.Problem:There is static in my clothes after drying

Question What to Do

• Did you use fabric softener?

• Did you over dry the load of

laundry?

• Are you drying synthetic, permanent

press, and blends?

Try using a fabric softener to reduce static electricity.

Over-drying a load of laundry can cause a build up of static electricity. Try

using a fabric softener or adjust your settings and use a shorter drying time.

These materials can cause static to build up in a load of dried clothes. Try

using a fabric softener.

6.Problem:The drying time is not consistent

Question

• Are you using consistent heat

settings and consistent load sizes?

The drying time for a load will vary depending on the heat setting, the type of heat

used (electric, natural, or LP gas), the size of the load, the type of fabrics, the wetness

of the clothes, and the condition of the exhaust ducts and lint filer.

What to Do

28

Page 30

Part 8 TROUBLESHOOTING GUIDE

7.Problem:It takes too long for my clothes to dry

Question What to Do

• Did you properly sort your loads of

laundry?

• Are you drying large loads of heavy

fabrics?

• Are the dryer controls properly set?

• Is the lint filter clean before each

new load of laundry?

• Are the exhaust ducts clear and

properly configured?

• Is the fuse blown, or is the circuit

breaker tripped?

• Did you overload your dryer?

• Did you under load your dryer?

Separate heavy weight items from light weight items when creating loads.

Heavy fabrics take longer to dry because they tend to retain more moisture. To help

reduce and maintain more consistent drying times for large and heavy fabrics,

separate these items into smaller loads of a consistent size.

Use the appropriate control settings for the type of load you are drying.

Please confirm that the lint filter is clean prior to each new load of laundry.

Confirm through review of the appropriate sections of this manual that the exhaust

venting ductwork is properly configured. Confirm that the venting is free of

obstructions. Confirm that the outside wall dampers are moving freely, that the

dampers are not pushed in, and that nothing has been set against the dampers.

Check your home’s or laundry room’s fuse box/circuit breaker box and replace the

fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally use two

fuses or breakers.)

Divide your larger load into a number of smaller loads.

If you are only drying a handful of items, add a few extra pieces to help ensure

proper tumbling action.

8.Problem:My clothes are wrinkled

Question What to Do

• Are you over drying your laundry?

• Are you removing your laundry

from the dryer soon after the

drying cycle is complete?

Over drying a load of laundry can lead to wrinkled clothes. Try a shorter drying

time, and remove items while they still retain a slight amount of moisture.

Remove your laundry from the dryer after the drying cycle ends and either hang or

fold the items.

9.Problem:My clothes are shrinking

Question What to Do

• Are you following the care

instructions for your garment?

To avoid shrinkage, please carefully follow the care and use instructions for your

garment, because some fabrics will naturally shrink when washed. Other fabrics

can be washed but will shrink when dried in a dryer.

29

Page 31

30

LG DRYER LIMITED WARRANTY – USA

1-800-243-0000

1-800-243-0000

Page 32

CONTENIDO

PARTE 1 GARANTÍA E INSTRUCCIONES DE SEGURIDAD IMPORTANTES. ..................................................3-5

PARTE 2 PASOS INICIALES PARA LA INSTALACIÓN DE SU SECADORA...................................................6-11

Colocación de la Secadora............................... .........................................................................................6

Procedimiento para la Invertir Puerta.........................................................................................................7

Conexión del Sistema de Escape y Ventilación................................. ........................................................8

Conexión del Suministro de Gas / Conexiones Eléctricas para Secadoras Eléctricas Solamente... .........9

Preparación de la Secadora / Confirmación de la Operación de la Fuente de Calor /

Flujo de Aire en la Secadora. ........................... ........................... ............ ........................... .................10

Instrucciones Adicionales para la instalación de su Secadora en una Casa Prefabricada o Móvil. ........11

PARTE 3. REQUERIMIENTOS ELÉCTRICOS PARA SECADORA ELÉCTRICA............................................12-16

Conexión de 3 Alambres con un Cordón de Alimentación......................................................................14

Conexión de 4 Alambres con un Cordón de Alimentación......................................................................15

Conexión de 3 Alambres Opcional..........................................................................................................16

PARTE 4. REQUERIMIENTOS ELÉCTRICOS PARA SECADORAS A GAS........................................................17

PARTE 5. REQUERIMIENTOS E INSTRUCCIONES SOBRE EL GAS.................................. ...............................18

PARTE 6. REQUERIMIENTOS Y MANTENIMIENTO SOBRE EL ESCAPE........................ ............................19-20

PARTE 7. CARACTERÍSTICAS Y BENEFICIOS............................................................... ...............................21-26

Uso de su Secadora Para usar un Ciclo de Auto Secado.......................................................................22

Para usar un Ciclo de Secado Manual Para Detener su Secadora / Carga ....... ...................................23

Descripción de los Ciclos.............................................................................. ..........................................24

Operaciones / Modificadores...................................................................................................................25

Secado en Parrilla Alarma Anti-Bacterial / Programación Personalizada ...............................................26

PARTE 8. GUÍA PARA LA SOLUCIÓN DE PROBLEMAS.............................................. .................................27-29

GARANTÍA LIMITADA DE LA SECADORA LG.................................. ........................ .........................................30.

2

Page 33

Part 1

!

GARANTÍA E INSTRUCCIONES DE SEGURIDAD IMPORTANTES

BÚSQUEDA DE ASISTENCIA SOBRE LA GARANTÍA

Servicio de Garantía. La garantía de su secadora está impresa al final de este manual. El

servicio de garantía está disponible contactando su Centro de Servicio LG más cercano y por el

período de garantía desde la fecha de compra, si esta secadora es instalada y operada de acuerdo con

las instrucciones en este manual, LG reparará o remplazará cualquiera de sus partes mecánicas o

eléctricas si están defectuosas en el material o en la fabricación.

ADVERTENCIA!

este manual. Para reducir el riesgo de incendio o explosión, o choque eléctrico, o para

prevenir daños a la propiedad, lesiones personales, o muerte cuando use su artefacto, siga

las precauciones básicas, incluyendo las siguientes.

Restricción de la Garantía : Si la secadora es utilizada para otro propósito que no sea el uso

familiar privado, toda cobertura de la garantía es efectiva por sólo 90 días.

Usted necesitará el número de modelo y de serie completos cuando solicite información. Le

recomendamos engrapar su recibo o cheque cobrado aquí, debido que necesitará sustentar la fecha de

su compra original para obtener el servicio de la garantía. Los números de modelo y de serie de su

secadora están ubicados en una placa que se encuentra en la parte frontal de su secadora detrás de la

puerta.

Utilice el siguiente espacio para anotar el número de modelo y de serie de su nueva secadora LG.

Modelo No.

No. de Serie

Para su seguridad, debe seguir las recomendaciones de

Fecha de Adquisición

❈ Engrape su recibo aquí.

3

3

Page 34

Part 1

!

GARANTÍA E INSTRUCCIONES DE SEGURIDAD IMPORTANTES

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

ADVERTENCIA!

Para ayudar a reducir el riesgo de choque eléctrico, incendio, o lesión personal o

daño a la propiedad cuando use su secadora, por favor sea precavido y siga las

precauciones de seguridad básicas, incluyendo las siguientes:

1) Lea todas las instrucciones antes de usar el artefacto.

2) No seque artículos que hayan estado en contacto con

gasolina, solventes para lavado en seco, o cualquier

otra sustancia inflamable o explosiva, ya que

despiden vapores que pueden incendiarse o explotar.

3) No permita que los niños jueguen sobre o dentro del

artefacto Es necesario que supervise de cerca a los

niños cuando utiliza el artefacto.

4) Antes de que el artefacto sea removido del servicio o

desechado, quite la puerta del compartimiento de

secado.

5) No meta la mano en el aparato si el tambor está en

movimiento.

6) No instale o almacene este artefacto donde esté

expuesto a la intemperie.

7) No fuerce los controles.

8) No repare o reemplace ninguna pieza del artefacto ni

intente darle servicio a menos que esté

específicamente recomendado en las instrucciones de

mantenimiento para el usuario

9) No use calor para secar artículos que contengan hule

espuma o materiales de textura similares al hule.

10) Limpie la malla para pelusas antes o después de

cada carga.

11) Mantenga el área alrededor de la abertura de escape

y las áreas adyacentes libres de acumulación de

pelusa, polvo y sucio.

12) El interior del artefacto y el ducto de escape deben

ser limpiados periódicamente por personal de

servicio calificado.

13) No coloque artículos que hayan sido expuestos a

aceite de cocina dentro de la secadora. Artículos

contaminados con aceite de cocina pueden

contribuir a una reacción química causante de

incendiar una carga.

14) No use suavizantes de telas o productos para

eliminar la estática a menos que sea recomendado

por el fabricante de estos productos.

GUARDE ESTAS INSTRUCCIONES

INSTRUCCIONES DE CONEXIÓN A TIERRA

Este artefacto debe estar conectado a tierra. En caso de

mal funcionamiento o avería, la conexión a tierra

reduce el riesgo de choque eléctrico al proveer una ruta

de menor resistencia a la corriente eléctrica. Este

artefacto está equipado con un cordón que contiene un

conductor equipo-tierra y un enchufe con conexión a

tierra. El enchufe debe ser conectado a un tomacorriente

adecuado, debidamente instalado y conectado a tierra

de acuerdo con todos los códigos locales y ordenanzas.

ADVERTENCIA- Una incorrecta conexión del

conductor equipo-tierra puede resultar en un riesgo de

choque eléctrico.

4

Verifique con un electricista calificado o un técnico de

servicio si tiene alguna duda si el artefacto está

debidamente conectado a tierra.

No modifique el enchufe suministrado con el artefacto;

si éste no encajase en el tomacorriente, haga que le

instalen un tomacorriente adecuado por un electricista

calificado.

Page 35

Part 1

!

!

!

GARANTÍA E INSTRUCCIONES DE SEGURIDAD IMPORTANTES

QUE HACER EN CASO DE OLER

GAS:

• No intente encender un fósforo, o cigarrillo, o

encender ningún artefacto a gas o eléctrico.

• No toque ningún interruptor eléctrico. No use

ningún teléfono en su casa o edificio.

• Evacue la habitación, edificio o el área de

todos los ocupantes.

• Llame inmediatamente a su proveedor de gas

desde el teléfono de un vecino. Siga

cuidadosamente las instrucciones de su

proveedor de gas.

• Si no puede contactar a su proveedor de gas,

llame al departamento de bomberos.

ADVERTENCIA!

• Mantenga los materiales y vapores

inflamables, como la gasolina, lejos de la

secadora.

• Coloque la secadora al menos 18 pulgadas

sobre el piso para instalación en el garaje.

• Si no cumple con estas instrucciones puede

resultar en muerte, explosión o incendio.

ADVERTENCIA

Para reducir el riesgo de incendio o explosión,

choque eléctrico, daño a la propiedad, lesiones

personales, o muerte cuando use este artefacto, por

favor siga todas las instrucciones e información,

incluyendo las de este manual y las instrucciones e

información suministradas por su proveedor de

gas, incluyendo las siguientes:

• No almacene o use gasolina, solventes para

lavado en seco, o cualquier otro vapor o líquido

inflamable en el área adyacente a este artefacto.

• No seque nada que alguna vez haya tenido

contacto con algo inflamable, aún después de

lavarlo.

• Ninguna lavadora puede remover completamente

el aceite. No seque ningún artículo que haya

tenido contacto con cualquier clase de aceite,

incluyendo aceite de cocinar.