LG TRAINING MANUAL

LG TRAINING MANUAL

Steam Dryers DLEX8377*M/DLG8388*M

Fall 2008

Published August 2008 by LG Electronics USA Trainng Center

Copyright © 2008 LG Electronics of Alabama, Inc.

Ph o n e Co n t a C t s :

Contact Number Hours of Operation

Customer Service (800) 243-0000 24/7 - 365 days a year

Technical Support (800) 847-7597 7am-7pm Mon-Fri / Sat 8-2 CST

Parts Sales (888) 393-6484 7am-7pm Mon-Sat CST

Training Center (256) 774-4051 8am-5pm Mon-Fri CST

e b Co n t a C t s :

W

Web Site Address Description

LG USA www.lgusa.com USA sales site

Customer Service us.lgservice.com Customer support

GCSC aic.lgservice.com Service center support

Customer Service Academy www.LGCSAcademy.com Technical training

TRAINING MANUAL

DLEX8377WM

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons possessing an adequate background

in electrical equipment, electronic devices, and mechanical systems. In any attempt to repair a major

appliance, personal injury and property damage can result. The manufacturer or seller maintains no liability

for the interpretation of this information, nor can it assume any liability in conjunction with its use. When

servicing this product, under no circumstances should the original design be modified or altered without

permission from LG Electronics. Unauthorized modifications will not only void the warranty, but may lead

to property damage or user injury. If wires, screws, clips, straps, nuts, or washers used to complete a

ground path are removed for service, they must be returned to their original positions and properly

fastened.

CAUTION

To avoid personal injury, disconnect the power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

Also be aware that many household appliances present a weight hazard. At least two people should be

involved in the installation or servicing of such devices. Failure to consider the weight of an appliance could

result in physical injury.

ESD NOTICE

Some of the electronic components in appliances are electrostatic discharge (ESD) sensitive. ESD can

weaken or damage the electronics in these appliances in a manner that renders them inoperative or

reduces the time until their next failure. Connect an ESD wrist strap to a ground connection point or

unpainted metal in the appliance. Alternatively, you can touch your finger repeatedly to a ground

connection point or unpainted metal in the appliance. Before removing a replacement part from its package,

touch the anti-static bag to a ground connection point or unpainted metal in the appliance. Handle the

electronic control assembly by its edges only. When repackaging a failed electronic control assembly in an

anti-static bag, observe these same precautions.

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or

relocate the receiving antenna; Increase the separation between the equipment and the receiver; Connect

the equipment to an outlet on a different circuit than that to which the receiver is connected; or consult

the dealer or an experienced radio/TV technician for help.

DISCLAIMER

The information in this training manual was accurate at the time of publication. Every effort has been made

to ensure accuracy. Updates, changes, etc. are available via GCSC and LGCSacademy. The information in

this manual is intended for persons with adequate backgrounds in electronics, mechanical, and electronic

servicing. The manufacturer and seller are not to be held responsible for any liability incurred from its use.

COMPLIANCE

The responsible party for this device’s compliance is LG Electronics Alabama, Inc.; 201 James Record Road,

Huntsville, AL, 35813.

DLEX8388WM

Page 1

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

Contents

Important Notices (The Small Print Page) 1

Contents 2

Introduction 3

LCD Control Panel 4

LED Control Panel 5

Safety Notices 6

Warranty Information 7

Specifications 8

Accessories 9

Drying Rack Installation 9

Stacking Kit Installation 10

Makeup Air 11

Pedestal 12

Remote Laundry Monitor Installation 14

Electrical Connection (Electric Dryer Only) 15

Gas Connection (Gas Dryer Only) 18

Dryer Cycle Chart 19

Steam Cycle Information 20

STEAMFRESH™ 20

Reduce Static 20

Easy Iron 20

Display PWB 21

Main Control Board 21

Main Control Board (Photo, with connectors labeled) 22

Schematic (Electric Dryer) 23

Schematic (Gas Dryer) 24

Diagnostic Test Mode 25

Component Testing Procedures 26

Motor Diagram and Schematic 29

Safety Switches 30

Centrifugal Switch 30

Belt Switch 30

Diagnostic Test Procedures 31

Test 1 – AC Electrical Supply 31

Test 2 – Thermistor Test (Power Off) 34

Test 3 – Motor Test 35

Test 4 – Moisture Sensor Test 36

Test 5 – Door Switch Test 37

Test 6 – Heater Switch Test (Electric Dryer Only) 38

Test 7 – Gas Valve Test (Gas Dryer Only) 39

Test 8 – Semiconductor (Sensor) Test 40

continued on next page Æ

DLEX8388WM

Page 2

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

Contents, continued

Gas Conversion (Natural Gas to Propane) 41

Regulator Conversion 42

Orifice Change 42

Gas Pressure Testing 43

Gas Valve Operation 44

Disassembly and Repair Instructions 45

Top Plate (Cover) 45

Panel Drawer (Water Container) 45

Control Panel 46

Front Cabinet 47

Door Reversal 47

Guide Assembly (for Steam Generation) 48

Steam Generator 49

Steam Generator Troubleshooting 50

Main Components 50

Theory of Operation 50

Thermistor Testing 51

Pump Motor Testing 51

Panel Body and Frame 53

Tub Front (Front Bulkhead) 53

Drum, Belt, and Pulley 54

Drum Lamp 55

Vent Replacement (Side Venting Kit) 56

Additional Venting Information 57

Static Pressure Testing and Vent Kit 58

Filter Assembly and Moisture Sensor 59

Rear Bulkhead 59

Air Duct 59

Rollers 60

Blower Housing 61

Exploded Views 62

Parts List 67

Supplementary Materials 70

Serial Number Identification 70

Ohm’s and Watt’s Laws (Chart and Formulae) 71

Temperature Conversion (Chart and Formulae) 72

Service Bulletins 73

DLEX8388WM

Page 3

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

INTRODUCTION

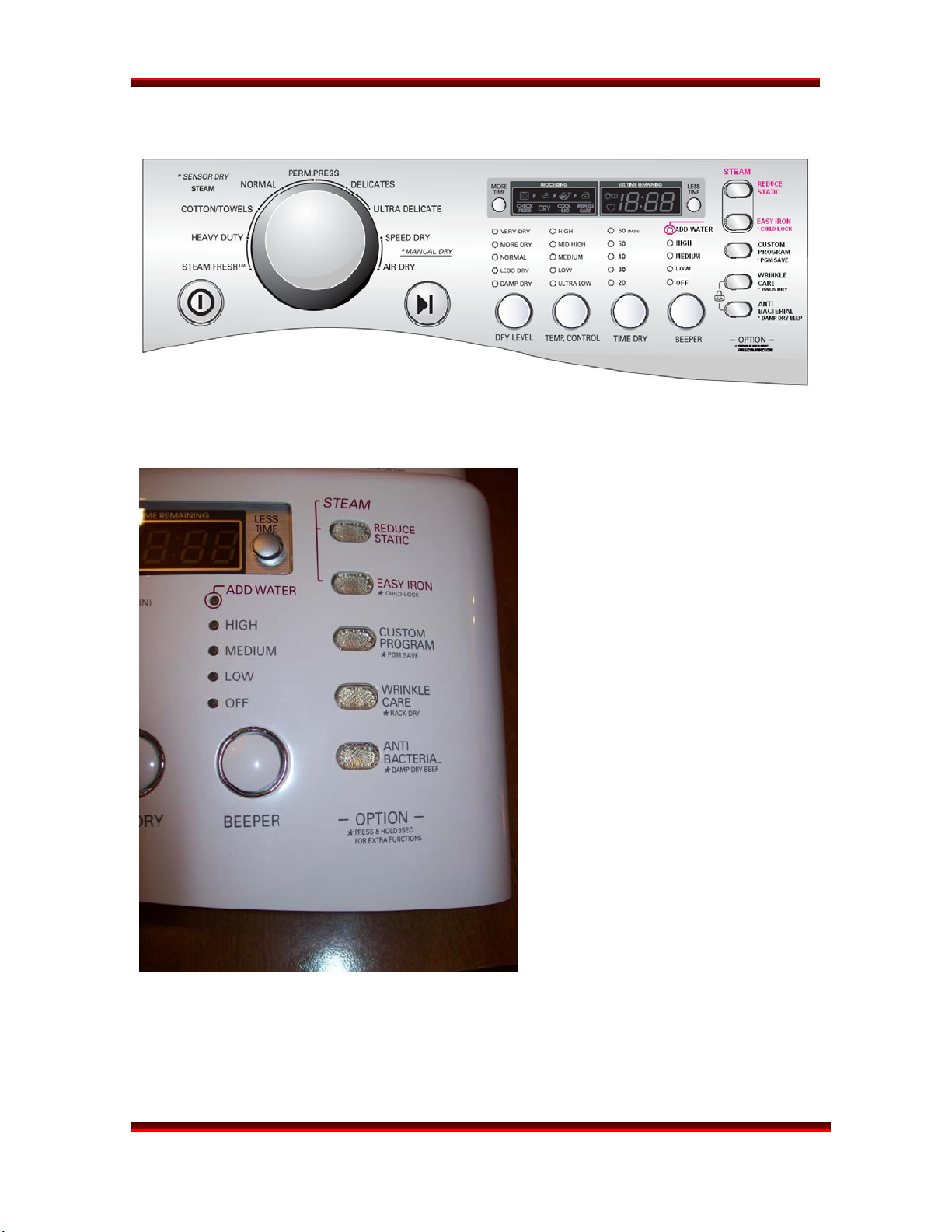

MAIN CONTROL PANEL

The Steam Dryer is available in two models. The top end model includes an LDC control

panel while the next model down has LEDs instead. Both models function similarly. (See

photo, next page.)

The LCD control panel includes a display

window and an array of option buttons.

The steam feature buttons (REDUCE

STATIC and EASY IRON) add these steam

features to the end of any of the sensor

cycles available.

(See complete explanation on page 20.)

DLEX8388WM

1. Cycle selected

2. Approximate time remaining on cycle

3. Progress indicator (%age complete)

4. Child Lock indicator

5. Sensor cycle indicator

6. Indicators – refer to the option buttons

below the window. These buttons allow

the user to override the default settings

on many cycles.

Error messages are displayed in the LCD

window as well.

Page 4

STEAM DRYER

TRAINING MANUAL

INTRODUCTION, continued

MAIN PANEL

DLEX8377WM

New features on the control panel

include the STEAM FUNCTION

BUTTONS and the ADD WATER

warning lamp.

The option buttons are the same on

both types of control panel.

DLEX8388WM

Page 5

STEAM DRYER

TRAINING MANUAL

SAFETY

DLEX8377WM

Check the local laws and regulations concerning the installation and connection of gas. In

most localities, it is illegal to connect gas piping, re-jet or adjust burners, or repair gasfired equipment unless you are licensed and certified so to do. It is the servicer’s

responsibility to comply with all such regulation.

The STEAM GENERATOR operates at a high temperature (hot enough to boil water.)

When servicing the steam generator, let it cool before beginning work. Hot water and

steam can cause severe burns and injuries.

DLEX8388WM

Page 6

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

WARRANTY

Warranty statements vary by product. Be sure to check the warranty that was included

with the product because that is the valid warranty. This statement is generic and for

instructional purposes only.

DLEX8388WM

Page 7

STEAM DRYER

TRAINING MANUAL

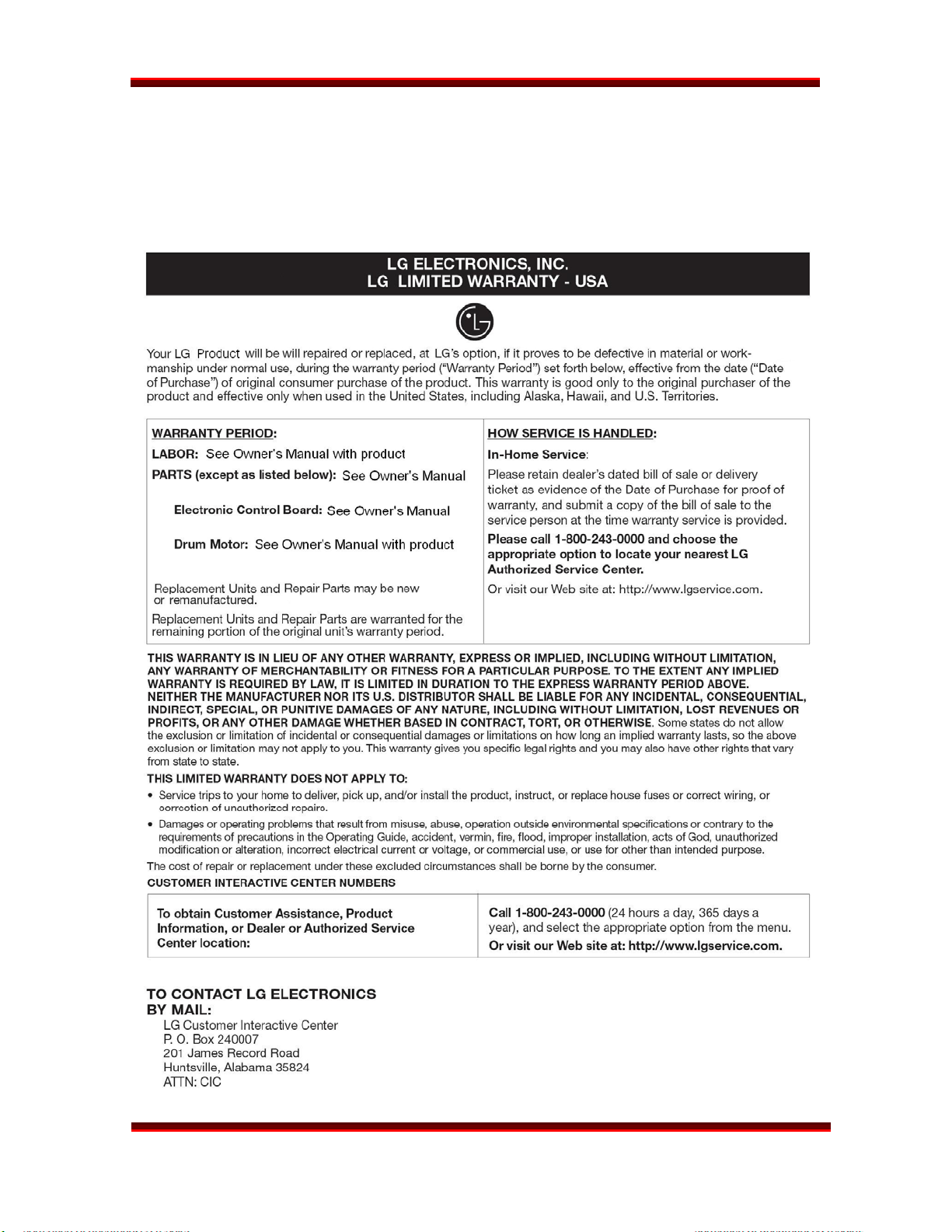

SPECIFICATIONS

DLEX8377WM

Specifications are subject to change without notice.

DLEX8388WM

Page 8

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

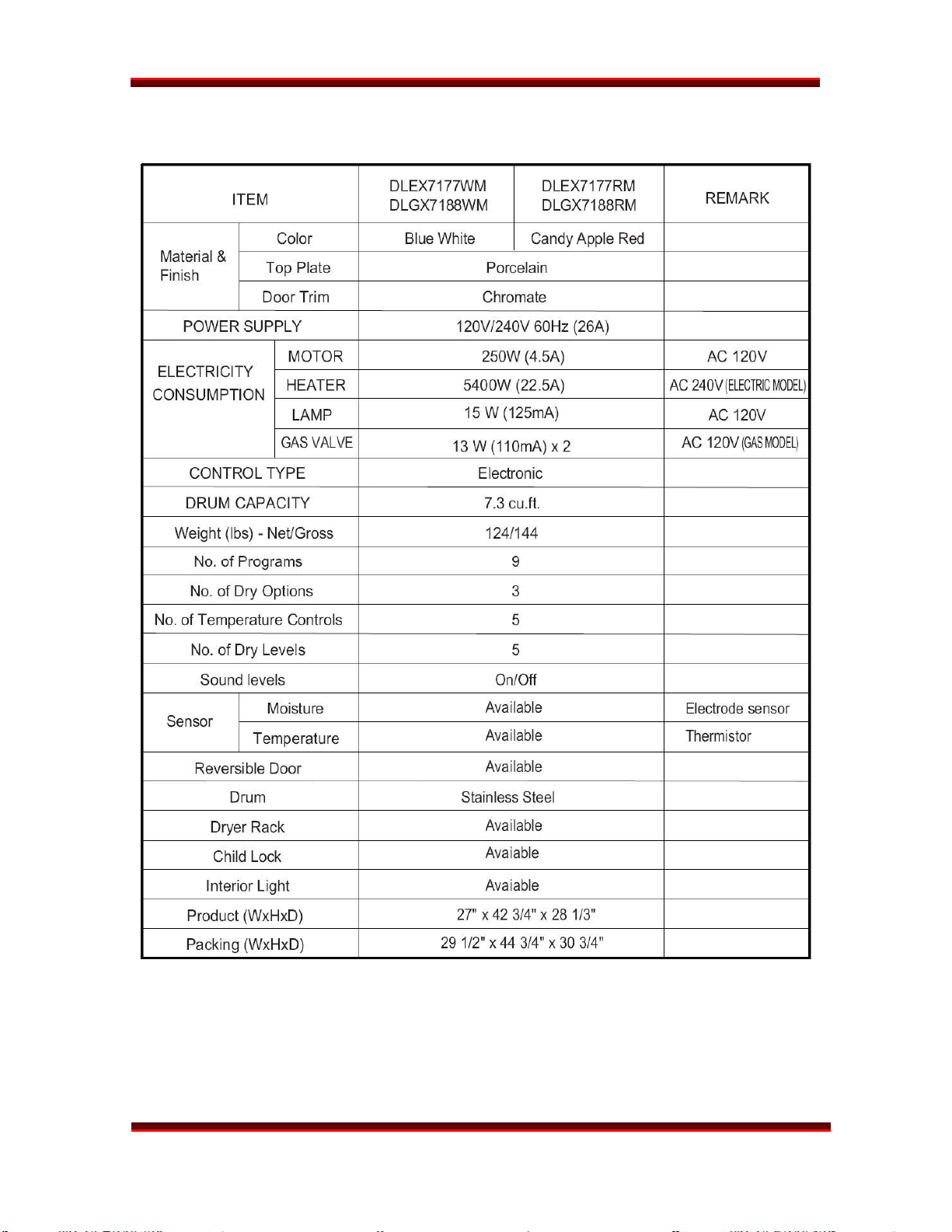

ACCESSORIES

DRYING RACK STACKING KIT PEDESTAL

The DRYING RACK is used to dry items that should not be tumbled, like sweaters, tennis

shoes, etc. It should be removed and stored when not in use. The rack is included with

the dryer. (See installation procedure, below.)

The STACKING KIT is used to stack a dryer on top of a matching washer. (NEVER put a

washer on top of a dryer!) The stacking kit should not be used in situation where there is

the possibility of excessive vibration and movement of the washer, such as in a mobile

home or an upper floor of a frame structure. The stacking kit is available as an optional

purchase. (See installation procedure, page 10.)

The PEDESTAL can be used under either the washer or the dryer. It is possible to stack a

washer and dryer on a pedestal, but the dryer controls may be difficult to reach and the

possibility of vibration and movement is greater. The pedestal is available as an optional

purchase. (See installation procedure, pages 12 ~ 13.) Pedestals are available in heights

of 7¼” and 13”.

DLEX8388WM

INSTALLATION (RACK)

Open the dryer door.

Put the rack in place.

Select RACK DRY (2nd button on right)

Press START.

Be sure the front of the rack is properly

situated in the notches on either side

of the filter. The back should rest on the

drum and allow the drum to rotate.

Page 9

STEAM DRYER

TRAINING MANUAL

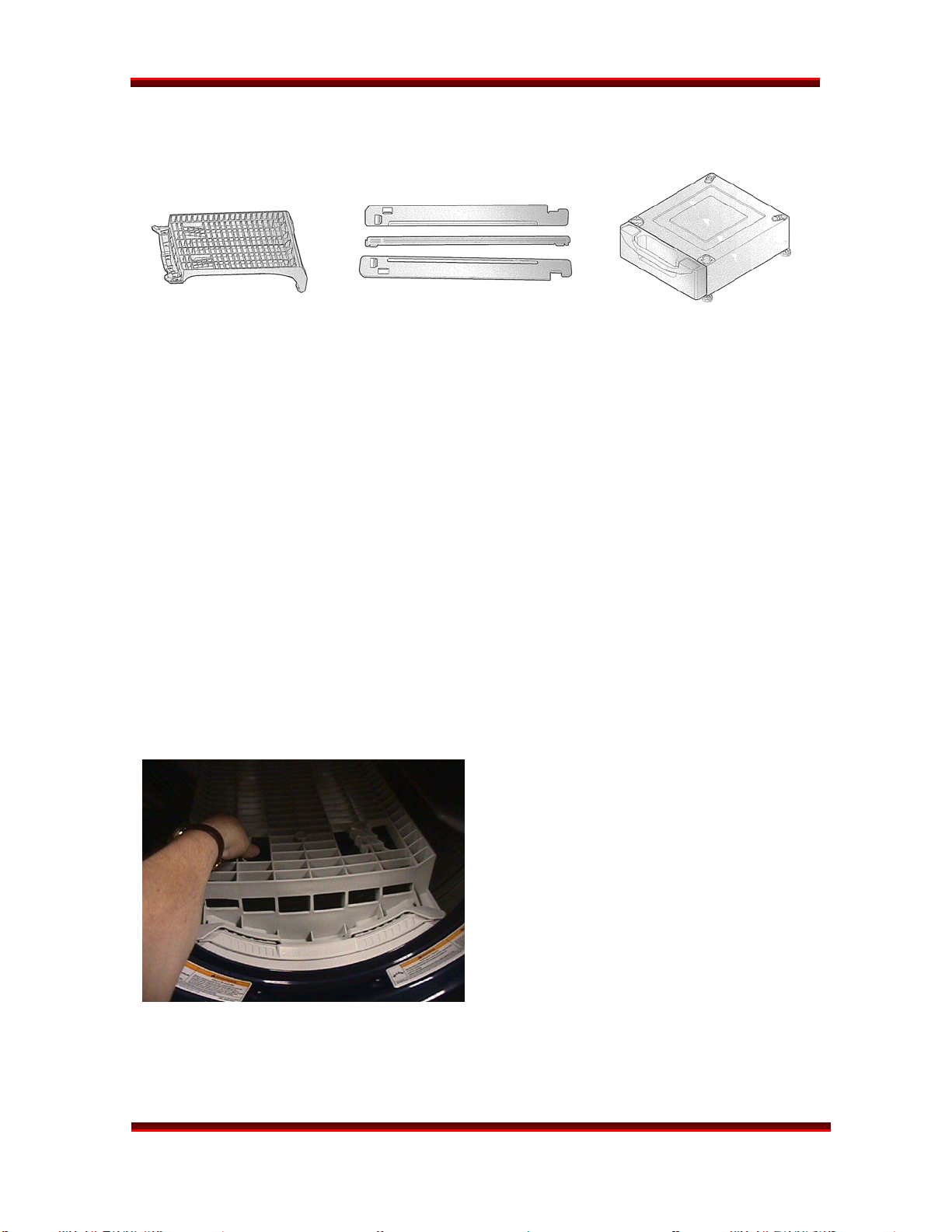

DLEX8377WM

INSTALLATION (Stacking Kit)

WARNING! Do not attempt this alone! At least two people are required to lift the dryer

and place it properly on top of the washer. Failure to observe this warning could result in

serious physical injury and damage to the appliances.

Place the washer on a solid, even floor. If

you plan to use a pedestal, install it now

before going any further.

Peel the protective paper from the

adhesive tape on the side bracket.

Fit the side bracket firmly to the top plate

using the adhesive tape, as shown in the

drawing.

Secure the bracket to the top plate using a

screw, as shown.

Repeat these steps for the other side.

Level the dryer on a firm solid floor and

lock down the adjusters before placing it

on top of the washer.

Lift the dryer on top of the washer it

toward the front of the washer, as shown.

Slide the dryer all the way back to the stop

on the rail.

DLEX8388WM

Page 10

STEAM DRYER

TRAINING MANUAL

INSTALLATION (Stacking Kit) continued

Install the front rail of the stacking kit. Push

the front rail back against the stops on the

side brackets.

Insert a screw to attach the front rail to the

side bracket.

Insert the other screw for the other side.

DLEX8377WM

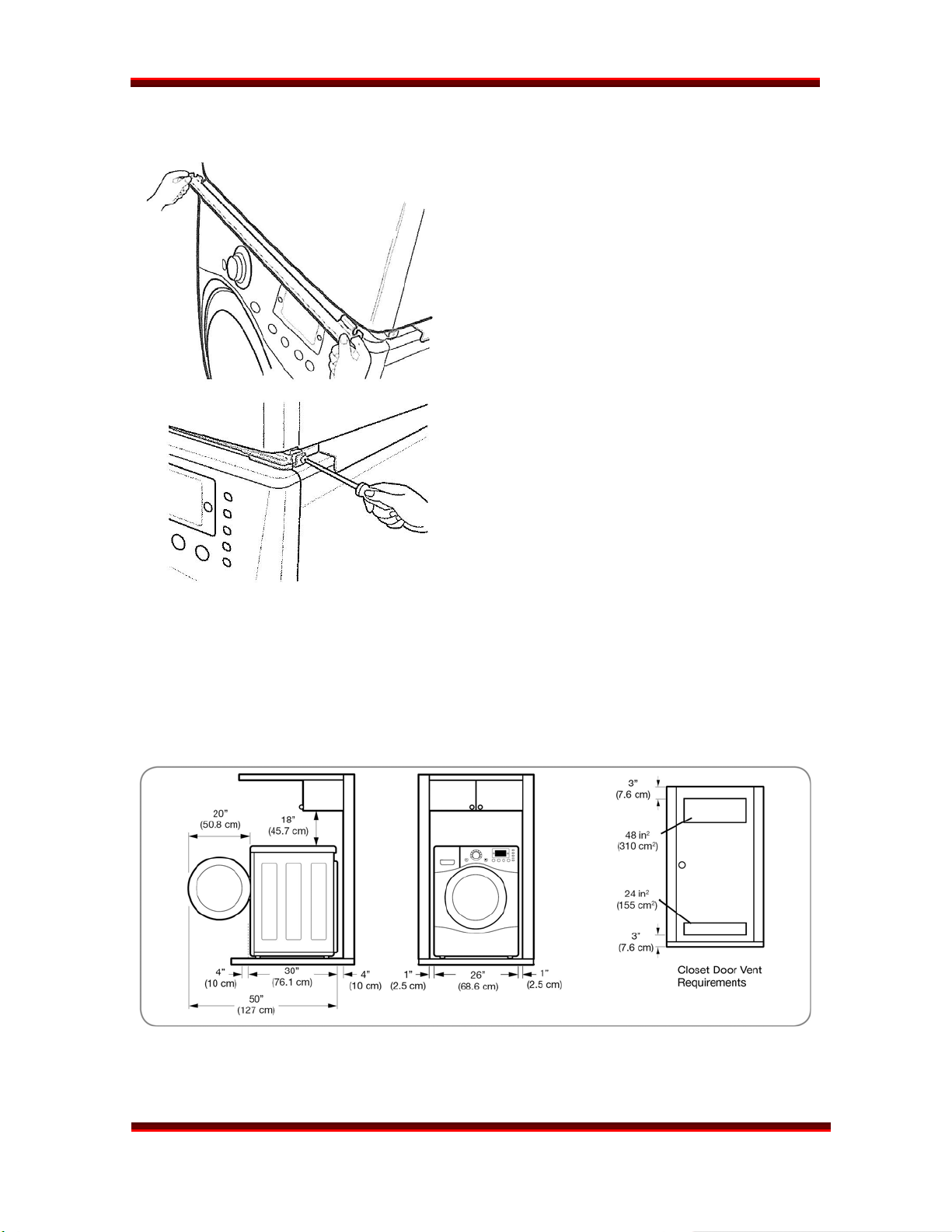

INSTALLATION (Makeup Air)

Minimum clearances must be observed, particularly if the dryer is installed in a closet or a

laundry alcove. The dryer is essentially an air pump moving 150 cfm (cubic feet per

minute) and that air must come from somewhere for the dryer to operate properly.

Additional air must be supplied to support proper combustion.

DLEX8388WM

Page 11

STEAM DRYER

TRAINING MANUAL

REAR FRONT

DLEX8377WM

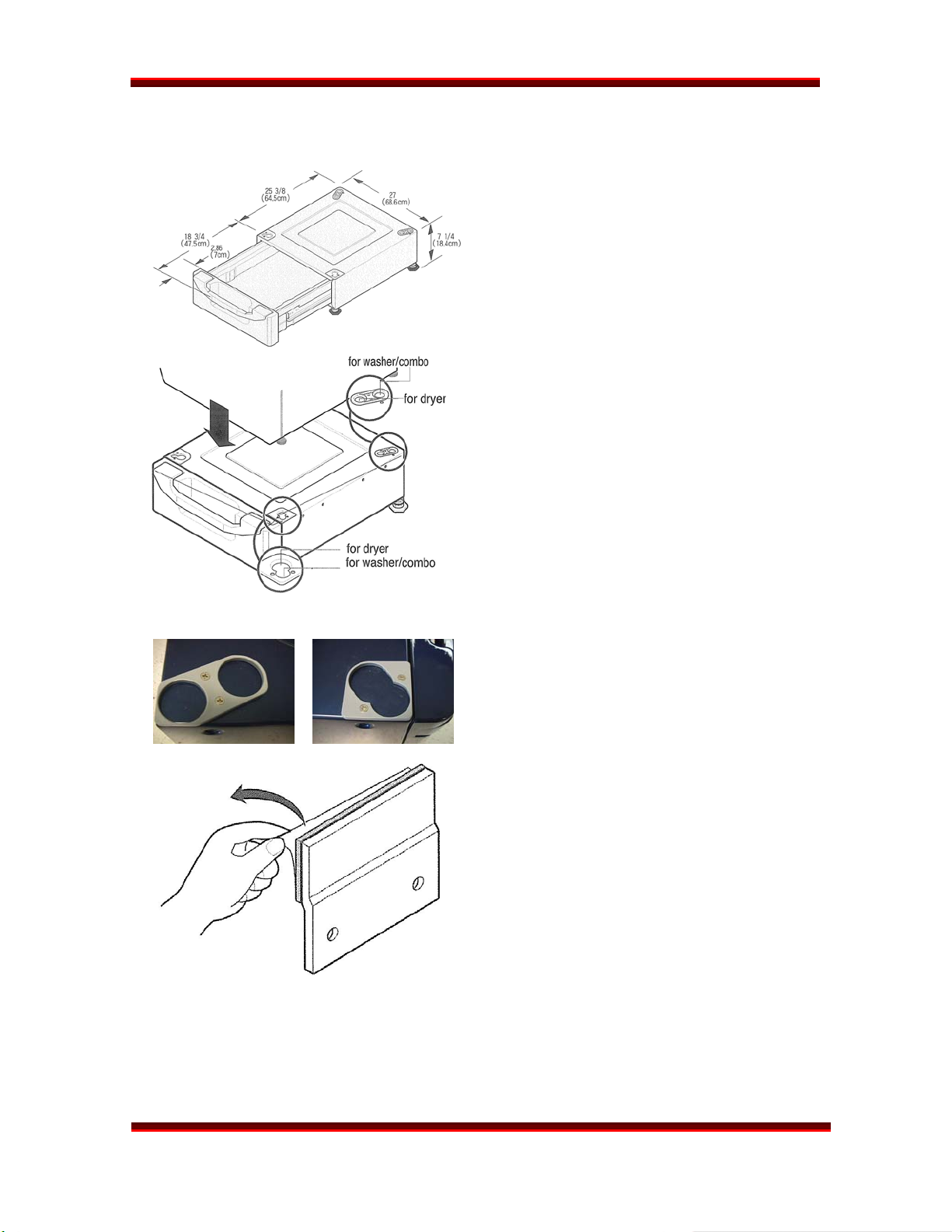

INSTALLATION (Pedestal)

For 27” Pedestals

(Washer, Dryer, and Combo)

Remove the pedestal, installation hardware,

and instructions from the shipping

container.

Level the pedestal on a solid, flat, level

floor. Lock down the rear adjusters, but

leave the front ones free for now.

Set the dryer on the pedestal and level it.

Level it and lock down all four adjusters on

the dryer.

Note which holes are for the washer and

which are for the dryer. If you are stacking

the appliances, the washer should be on

the bottom.

DLEX8388WM

Remove the protective paper from the

adhesive surface of the bracket.

Be particularly careful, because when this

adhesive makes contact, there is no

adjustment possible.

NOTE: Some kits include two sets of

brackets (curved for the dryer and flat

(shown) for the washer.) Use the correct

bracket for your application. The curved

bracket is for clearance of the exhaust vent

when a dryer has been converted to side

venting. (See next page.)

Page 12

STEAM DRYER

TRAINING MANUAL

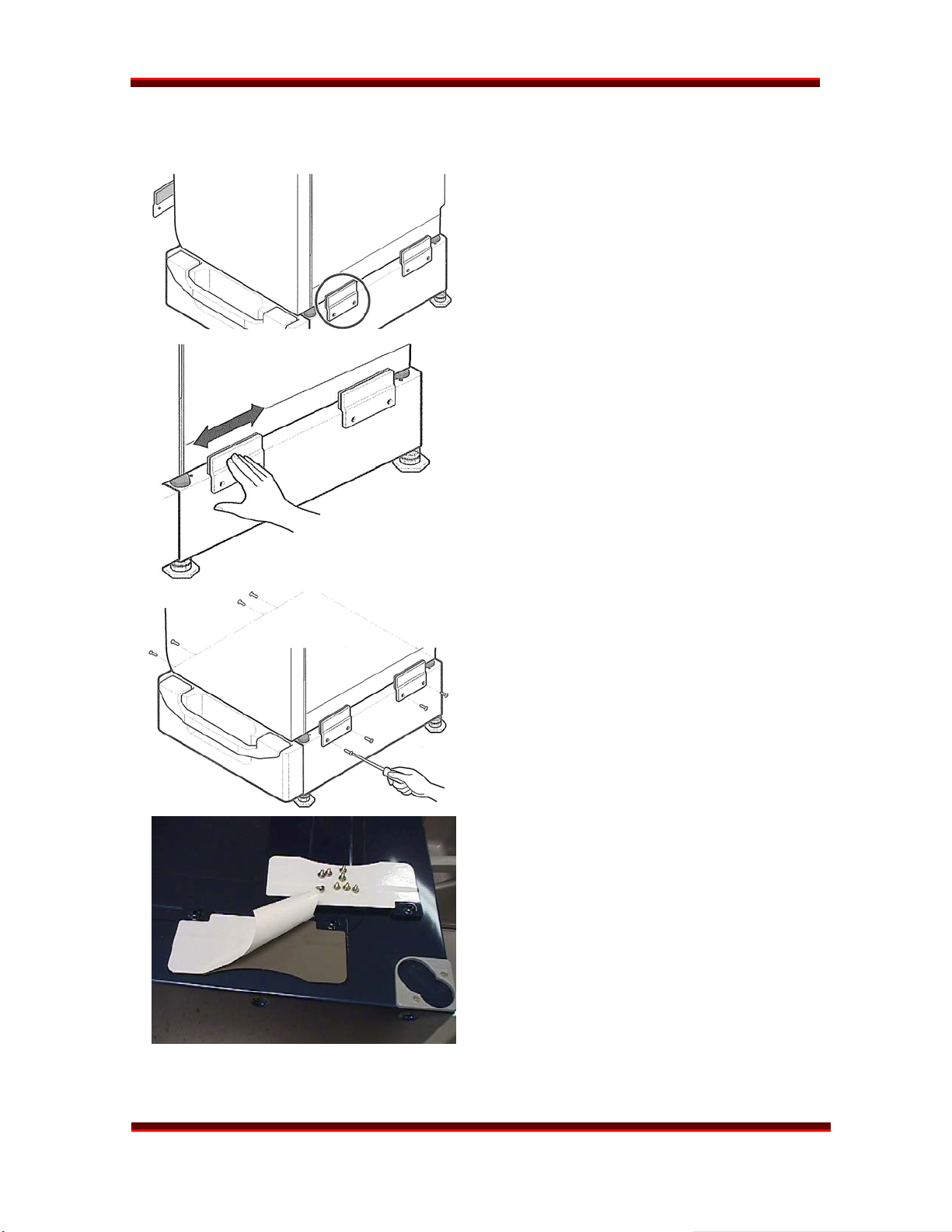

INSTALLATION (Pedestal) continued

Holding the adhesive part of the bracket

away from the dryer, insert the screws and

get them started.

Press the bracket onto the dryer and

tighten the screws.

Press the brackets onto the sides of the

dryer and rub the brackets from side to

side to ensure the total adhesive area is

attached completely.

Tighten all the screws securely.

DLEX8377WM

Lower each leg of the dryer one-fourth turn

with the adjusting wrench to put a little

pressure between the dryer and pedestal

to prevent any motion and rattling.

Push the dryer into place.

Check the level and adjust the front legs of

the pedestal as necessary. Then lock down

the adjusters.

The pedestal kit includes the mounting

plates (with adhesive covered by paper)

and the screws to attach the plates.

Remember, some pedestal kits come with

two sets of brackets. The flat tops are for

washers; the curved tops (shown) are for

dryers. Use the correct brackets for your

application. The curved bracket is for

clearance of the exhaust vent when a dryer

has been converted to side venting.

DLEX8388WM

Page 13

STEAM DRYER

TRAINING MANUAL

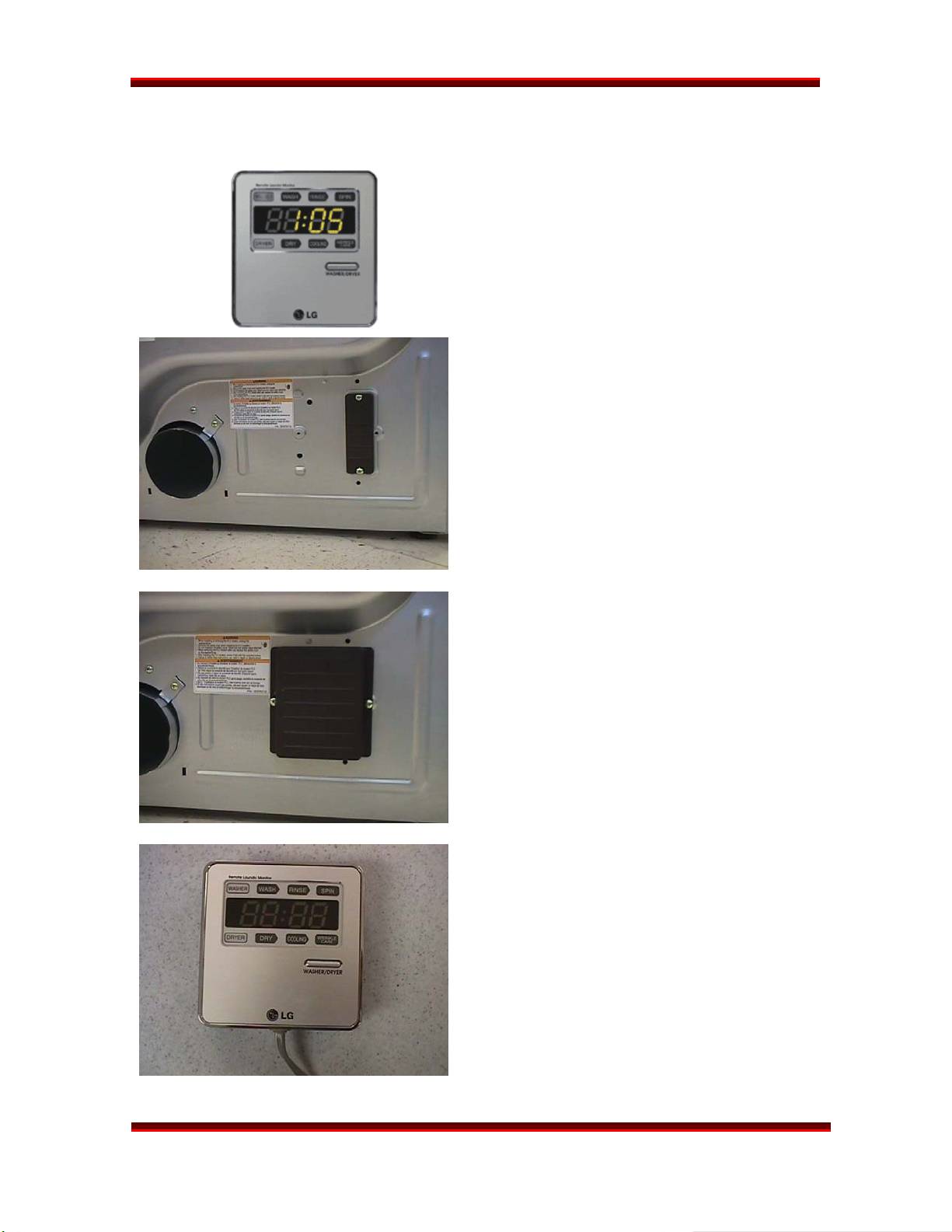

INSTALLATION (Modem and Monitor)

REMOTE MONITOR

The monitor plugs in to any 120 V

outlet in the home. It receives its data

signal via the power lines.

Be sure the dryer is unplugged.

Remove the modem cover.

Save the cover for future use; in the event

you must remove the modem, you can

replace the cover.

DLEX8377WM

AC

Attach the modem to the socket with the

screws provided.

Plug the monitor’s power cord in an outlet

where you can observe it easily. Use the

stand or the wall mount bracket.

Press and hold the button until the display

shows SET.

The dryer can be operated normally

without the modem if the customer does

not wish to purchase it as an option.

DLEX8388WM

Page 14

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

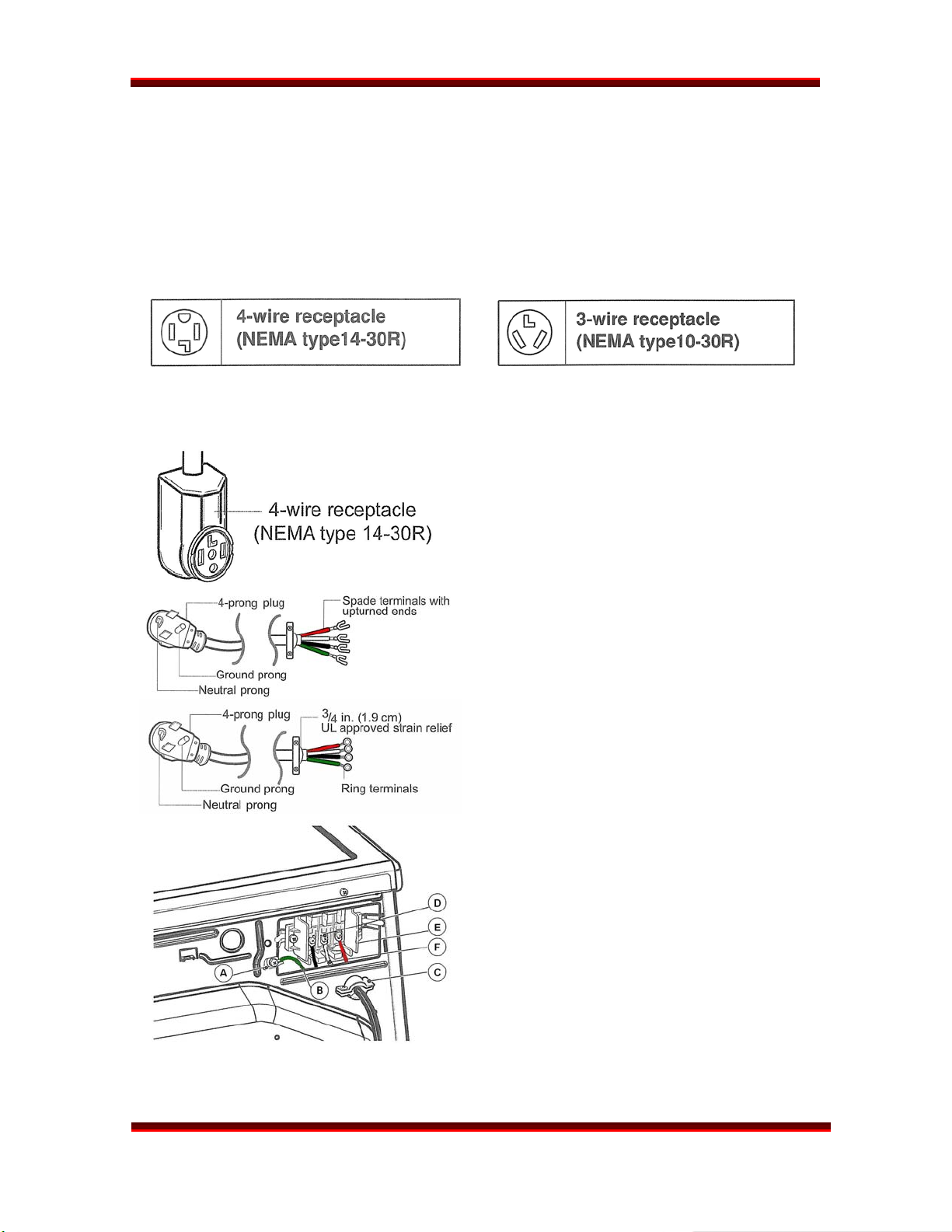

ELECTRICAL CONNECTION (Electric Dryer Only)

PIGTAIL INSTALLATION

Install the appropriate power cord for the outlet available. Grounding through the

neutral conductor is prohibited in new branch-circuits, mobile homes, recreational

vehicles, and where prohibited by local code.

4-wire Connection

The 4-wire receptacle looks like this.

Power cord with spade terminals.

Power cord with ring terminals.

Install a strain relief on the power cord.

Then connect the terminals to the terminal

block, matching the wire colors.

A. Ground screw on chassis

B. Green wire from power cord

C. Strain relief

D. Neutral screw on terminal block

E. Terminal block

F. Neutral wire from power cord

DLEX8388WM

Page 15

STEAM DRYER

TRAINING MANUAL

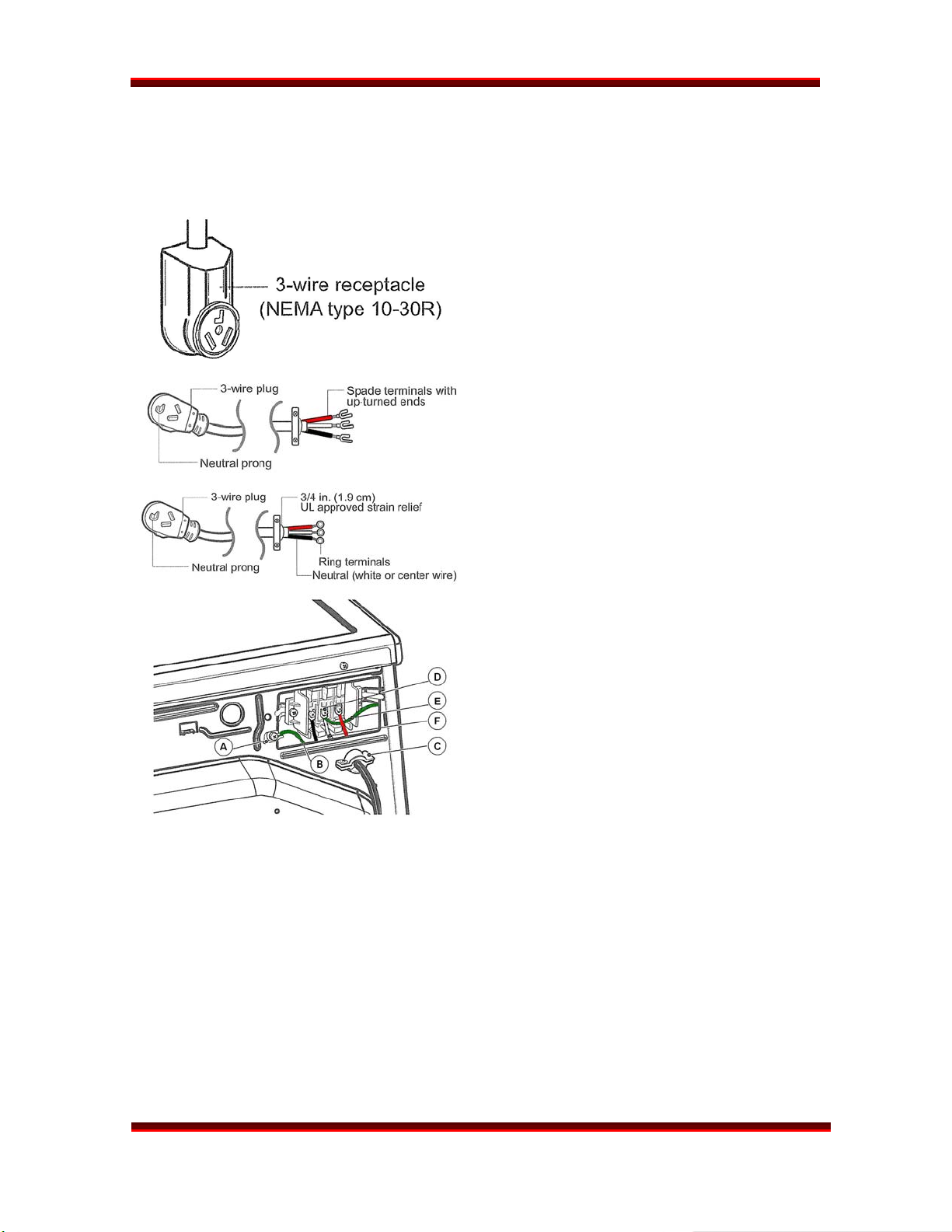

ELECTRICAL CONNECTION (Electric Dryer Only) continued

3-wire Connection

The 3-wire receptacle looks like this.

Power cord with spade terminals.

Power cord with ring terminals.

DLEX8377WM

Install a strain relief on the power cord.

Then connect the terminals to the terminal

block, matching the wire colors. Add a wire

to connect the chassis ground to neutral.

A. Ground screw on chassis

B. Green wire from power cord

C. Strain relief

D. Neutral screw on terminal block

E. Ground-to-neutral connection

F. Neutral wire from power cord

DLEX8388WM

Page 16

STEAM DRYER

TRAINING MANUAL

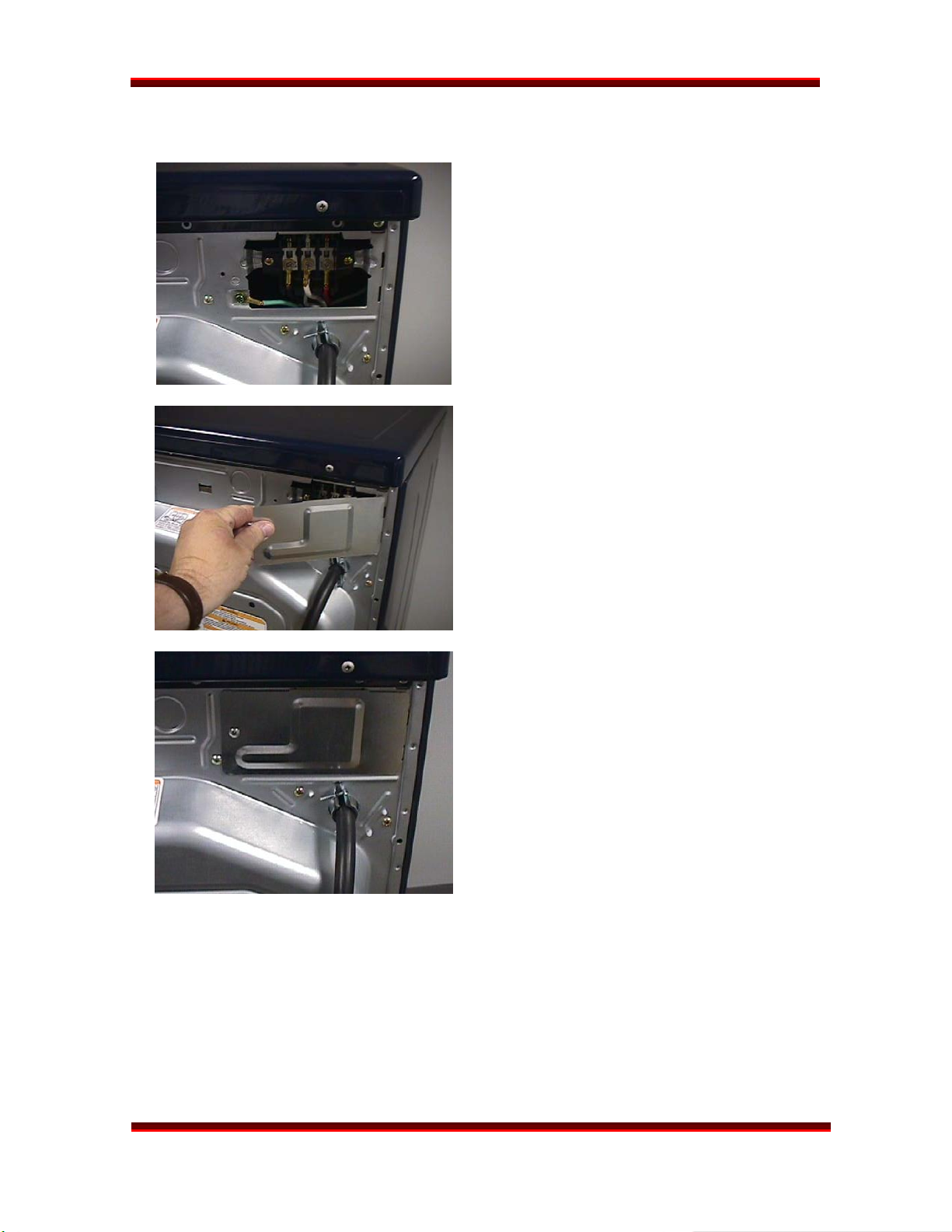

ELECTRICAL CONNECTION (Electric Dryer Only) continued

DLEX8377WM

Be sure to tighten all screws firmly, but do

not strip them or distort the contact area.

You want a secure connection without

damage to the connectors.

Be sure to install a strain relief on the

power cord.

Replace the terminal block cover by

inserting the tabs into the slots and letting

them slide down to engage.

Fold it over to the back of the dryer so it

covers the access to the terminal block. Be

sure no wires are exposed or could touch

any metal surface.

Secure the cover with a screw.

DLEX8388WM

Page 17

STEAM DRYER

TRAINING MANUAL

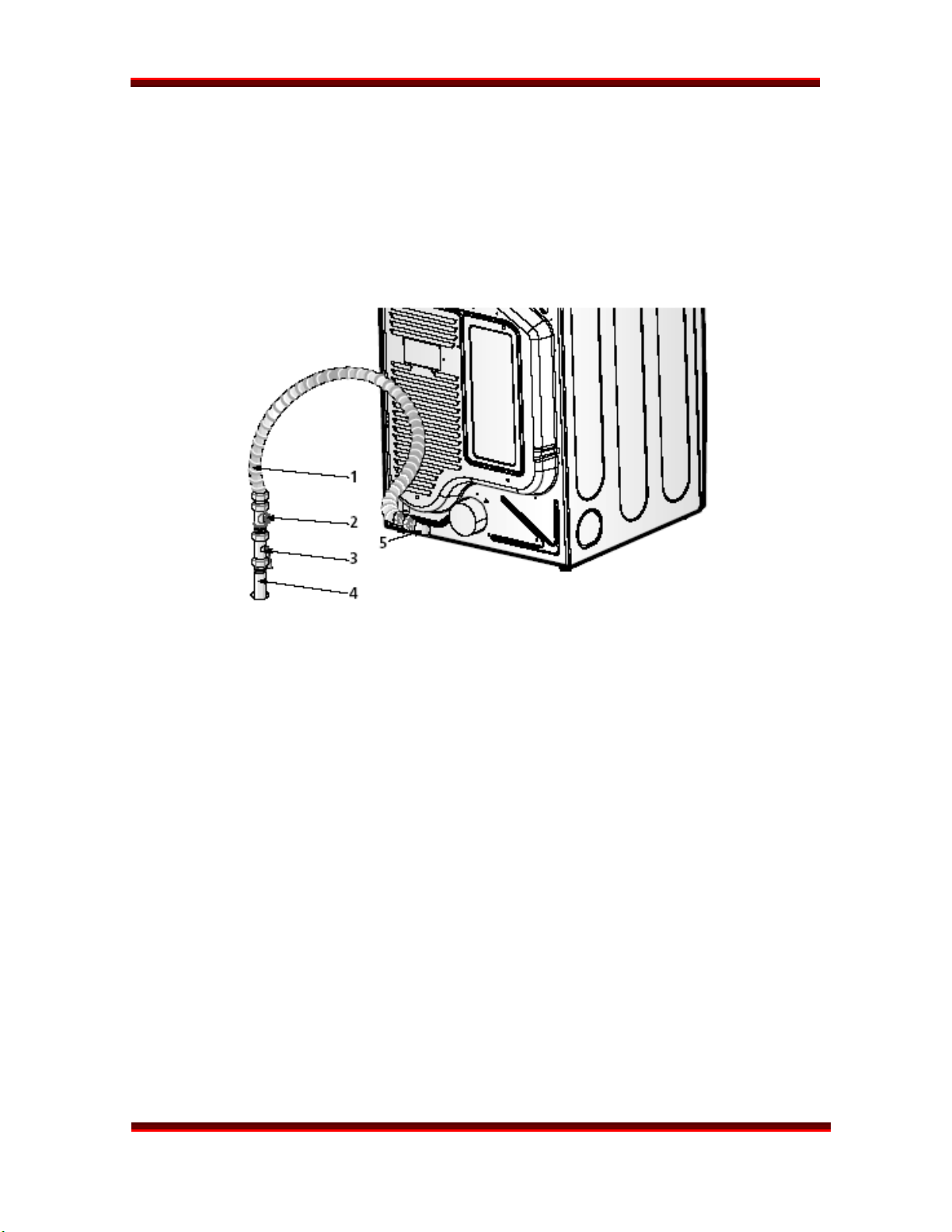

DLEX8377WM

GAS CONNECTION (Gas Dryer Only)

CAUTION! (This warning applies to both natural gas and propane.)

Gas is both flammable and explosive. Use caution when working with gas.

In most locations, installing and connecting gas is restricted to properly trained and

licensed persons.

Always inspect joints and connections for a leak with a soapy solution. If you see bubbles,

turn the gas off and open a window. If you smell gas, turn off the main valve and open a

window.

The gas dryer requires a 120 VAC, single-outlet, dedicated circuit. The cord is installed at

the factory and no user-intervention is required.

DLEX8388WM

Page 18

STEAM DRYER

TRAINING MANUAL

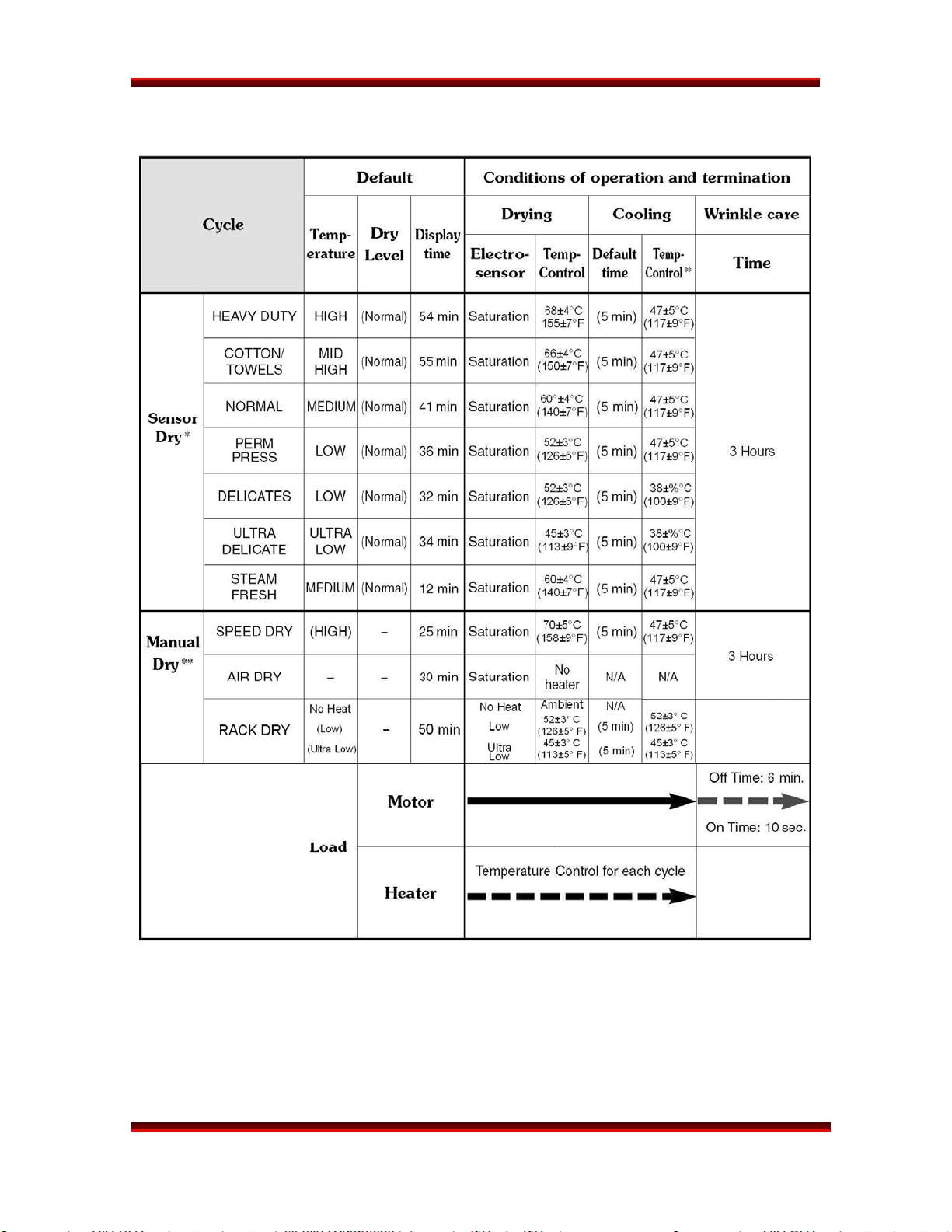

DRYER CYCLE CHART

DLEX8377WM

* SENSOR DRY The dryness level is set by the customer.

** MANUAL DRY The temperature is set by the customer. The maximum drying time

for RACK DRY or SPEED DRY is 1 hour 39 minutes.

The default settings can be overridden by the customer in most cases.

DLEX8388WM

Page 19

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

STEAM CYCLE INFORMATION

The steam dryer is designed to provide the power of steam through the introduction of

steam into almost every drying cycle.

STEAMFRESH™

The STEAMFRESH™ cycle is a 20-minute cycle that tumbles the clothes in a spray of

steam. This cycle is NOT a wash cycle, but is instead designed to refresh clothing that

has been packed away, stored, or otherwise wrinkled and less than freshly laundered. The

steam cycle will refresh from one to five items during its 20-minute run time. The drum

tumbles the clothes while steam sprays through them for the first five minutes. Then the

steam continues while the drum tumbles for 2 seconds once each minute. At that point

(12 minutes in to the cycle,) the steam generator is turned off and the dryer continues

to tumble constantly with the main heater engaged to finish drying the clothes. The main

heater is turned off for the last two minutes of the cycle while the drum continues to

tumble to allow the clothes to cool.

The MORE TIME and LESS TIME buttons are used to adjust the number of items to be

freshened during the STEAMFRESH™ cycle.

The time cannot be adjusted by the user when a sensor dry cycle is engaged.

REDUCE STATIC

The REDUCE STATIC cycle is an add-on to all the regular cycles except AIR DRY or

RACK DRY. When REDUCE STATIC is selected, the main heater is turned off two minutes

before the end of the cycle and the steam generator is energized for the final two

minutes while the drum continues to turn.

EASY IRON

The EASY IRON cycle is an add-on to all the regular cycles except AIR DRY or RACK DRY.

When EASY IRON is selected, the main heater is turned off eight minutes before the end

of the cycle and the steam generator is energized for the final eight minutes while the

drum tumbles for two seconds once a minute.

CHILD LOCK can be engaged only after a cycle has been selected and the START button

has been pressed. CHLD LOCK locks ALL controls, including the POWER button. It

releases at the end of the cycle or in the event of a power failure.

DLEX8388WM

Page 20

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

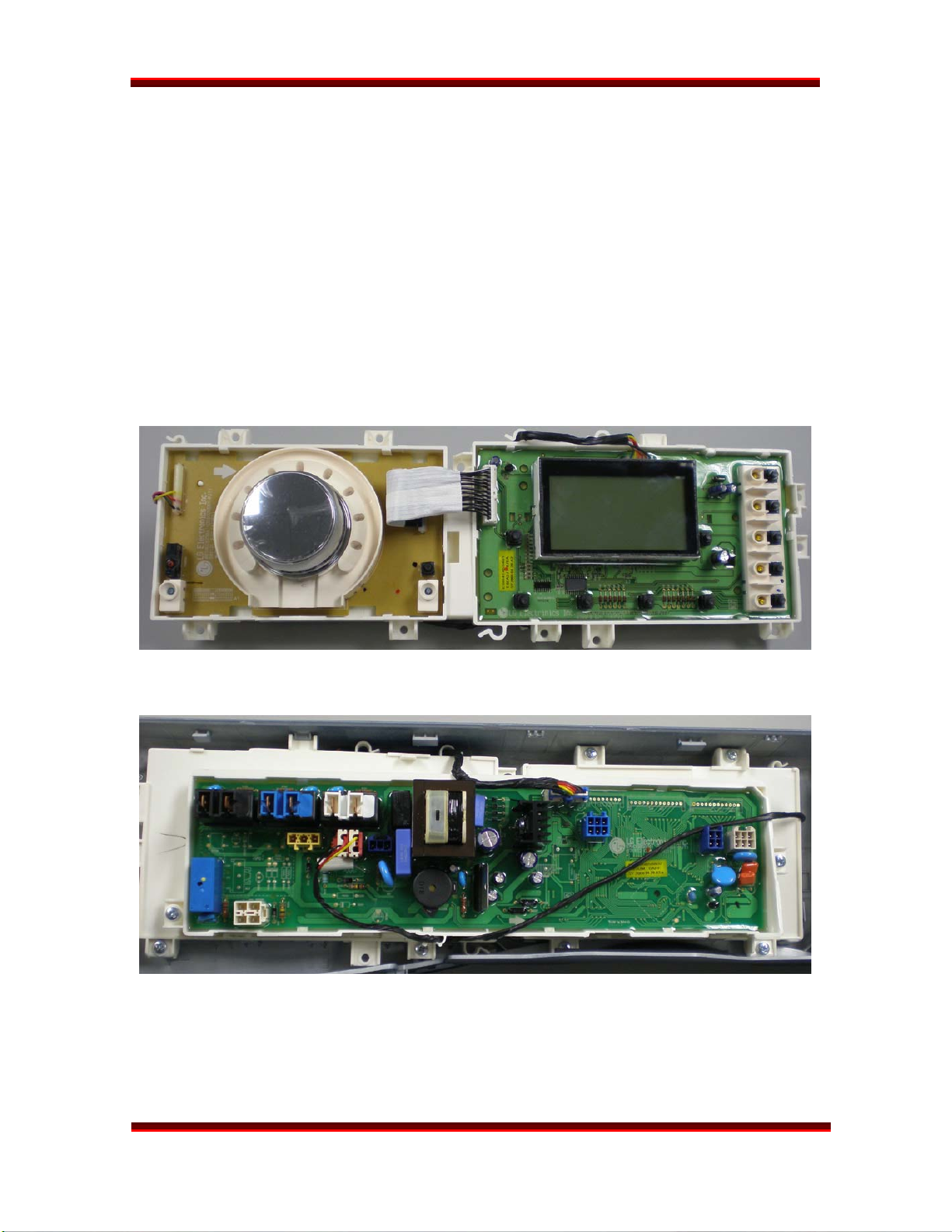

DISPLAY PWB

The display board is actually two boards connected by a ribbon cable. One board holds

the selector knob and cycle indicator LEDs. The other holds the LCD display and

adjustment buttons to override the pre-set cycle selections.

DISPLAY BOARD

The display board includes the LCD display and LEDs that indicate the various cycle and

option information. It is made of two boards that are permanently connected by a ribbon

cable that is soldered to the board at each end. This makes the boards a single unit. The

purpose is to allow the display board to flex to fit inside a curved control panel while

maintaining its integrity as a single board.

MAIN CONTROL BOARD

The main board is attached to the back of the display board in the control panel by two

screws. Many of the components of the dryer can be tested by removing their connector

at the main board.

DLEX8388WM

Page 21

STEAM DRYER

TRAINING MANUAL

DLEX8377WM

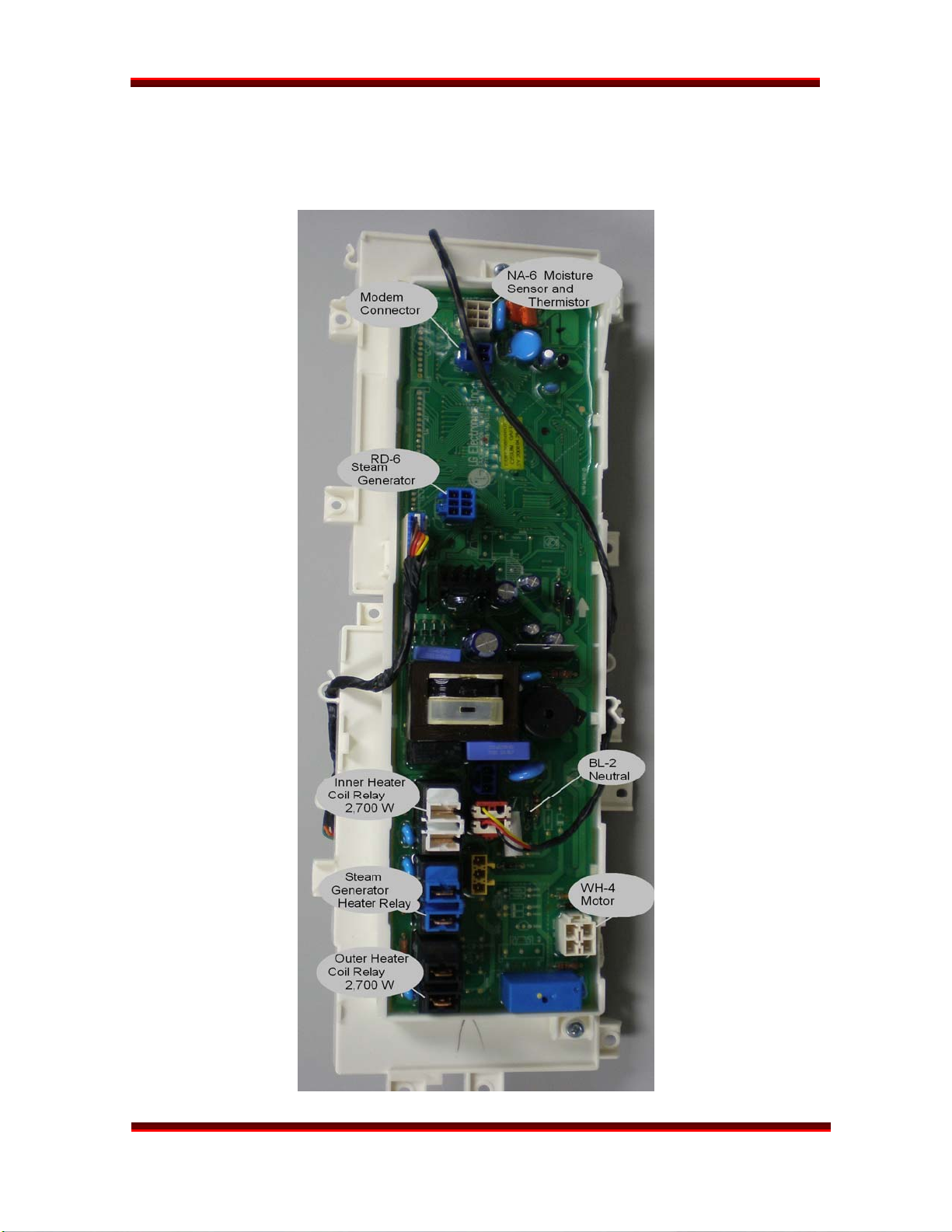

MAIN PWB

The main board includes the relays that operate electric heaters and gas valves.

The gas and electric models have a different main board.

DLEX8388WM

Page 22

STEAM DRYER

TRAINING MANUAL

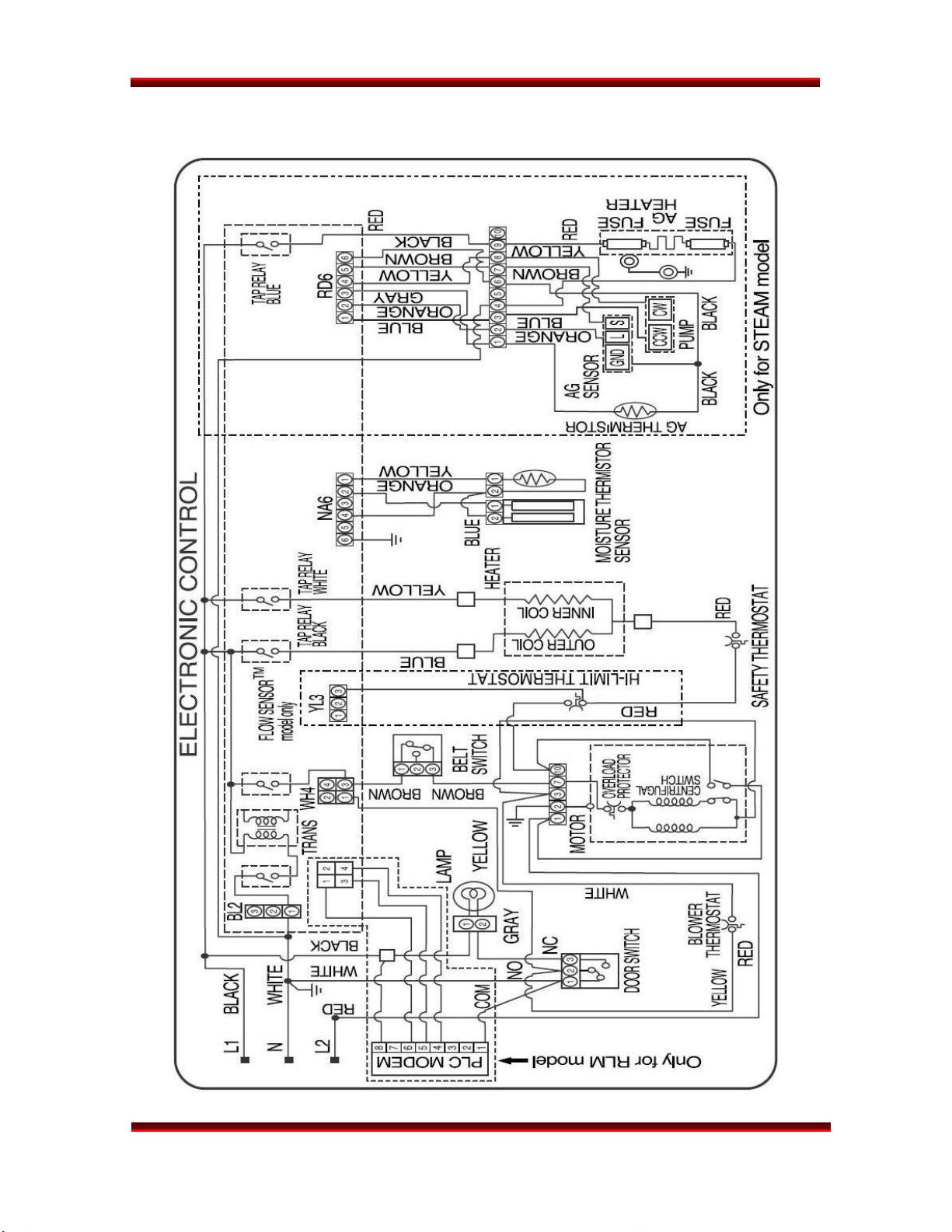

SCHEMATIC – ELECTRIC DRYER

DLEX8377WM

DLEX8388WM

Page 23

STEAM DRYER

TRAINING MANUAL

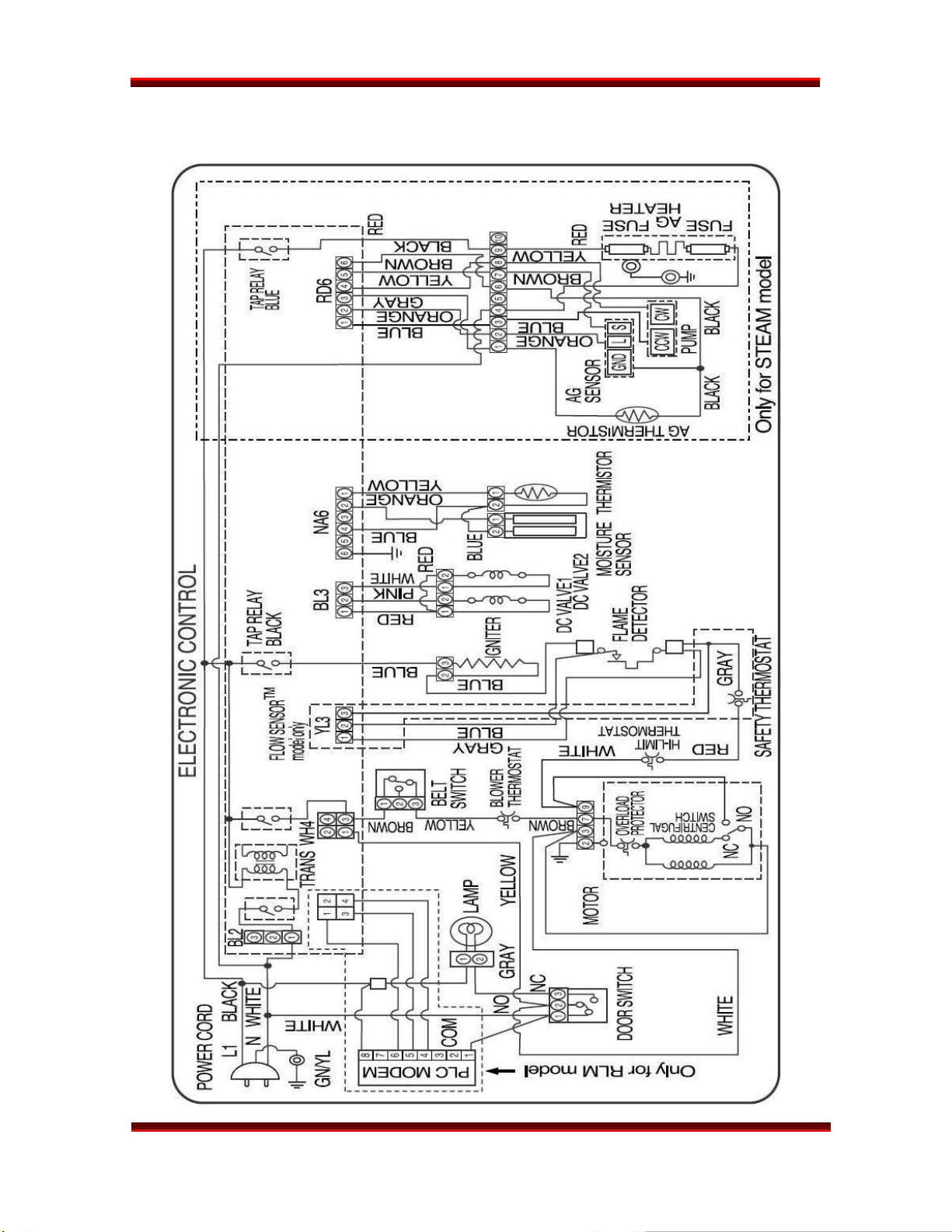

SCHEMATIC – GAS DRYER

DLEX8377WM

DLEX8388WM

Page 24

STEAM DRYER

Loading...

Loading...