LG DGS2028EKD, DGS2038EKD, DGS1858EKD, DGS1818EKD, DES2038EKD Service Manual

...

U.S.A Website: http://us.lgservice.com

Canadian Website: http://lg.ca

ELECTRIC & GAS DRYER

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY IN ORDER TO

PROPERLY DIAGNOSE PROBLEMS AND TO SAFELY

PROVIDE QUALITY SERVICE ON THESE DRYERS.

DGS2028EKD DGS2038EKD DGS1828EKD DGS1838EKD

DGS1858EKD DGS1818EKD DES2038EKD

DLE1101W DLG1102W

IMPORTANT SAFETY NOTICE

WARNING !

!

To avoid personal injury, disconnect power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

To reduce the risk of personal injury, adhere to all industry recommended safety procedures including the

use of long sleeved gloves and safety glasses. Failure to follow all of the safety warnings in this manual

could result in property damage, injury to persons or death.

RECONNECT ALL GROUNDING DEVICES

WHAT TO DO IF YOU SMELL GAS:

Do not try to light a match, or cigarette, or turn on

any gas or electrical appliance.

Do not touch any electrical switches. Do not use

any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions carefully.

If you cannot reach your gas supplier, call the fire

department.

2

CONTENTS

1. SPECIFICATIONS ............................................................................................................... 4

2. FEATURES AND BENEFITS .................................................................................................. 6

3. INSTALLATION INSTRUCTIONS .......................................................................................... 6

4. DRYER CYCLE PROCESS ..................................................................................................... 9

5. COMPONENT TESTING INFORMATION ............................................................................10

6. MOTOR DIAGRAM AND SCHEMATIC .............................................................................. 13

7. WIRING DIAGRAM .......................................................................................................... 14

8. FLOW SENSOR FUNCTION ............................................................................................. 15

8-1. FLOW SENSOR ...................................................................................................... 15

8-2. INSTALLATION TEST ................................................................................................ 16

8-3. TROUBLESHOOTING FOR FLOW SENSOR DRYER ................................................... 18

9. DIAGNOSTIC TEST .......................................................................................................... 19

9-1. TEST 1 120V AC ELECTRICAL SUPPLY ..................................................................... 20

9-2. TEST 2 THERMISTOR TEST - MEASURE WITH POWER OFF ....................................... 21

9-3. TEST 3 MOTOR TEST .............................................................................................. 22

9-4. TEST 4 MOISTURE SENSOR ................................................................................... 23

9-5. TEST 5 DOOR SWITCH TEST .................................................................................. 24

9-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE ........................................................ 25

9-7. TEST 7 GAS VALVE TEST - GAS TYPE ...................................................................... 26

9-9. TEST 8 MOTOR ASSEMBLY, DC, PUMP .................................................................... 27

10. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ......................................... 28

11. DISASSEMBLY INSTRUCTIONS .................................................................................... 30

12. EXPLODED VIEW............................................................................................................ 37

12-1. CONTROL PANEL AND PLATE ASSEMBLY .............................................................. 37

12-2. CABINET AND DOOR ASSEMBLY .......................................................................... 38

12-3-1. DRUM AND MOTOR ASSEMBLY: ELECTRIC TYPE ................................................. 39

12-3-2. DRUM AND MOTOR ASSEMBLY: GAS TYPE ........................................................ 40

3

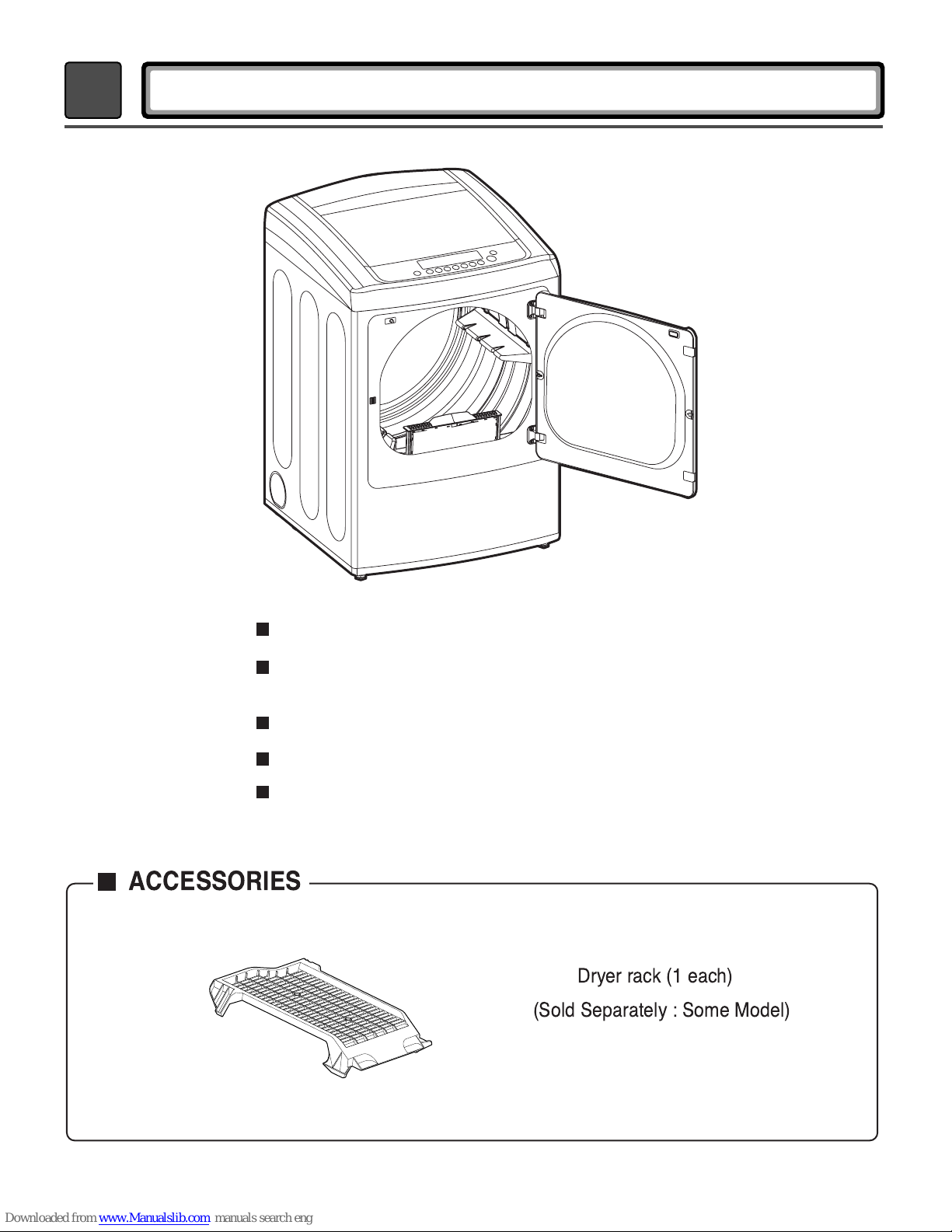

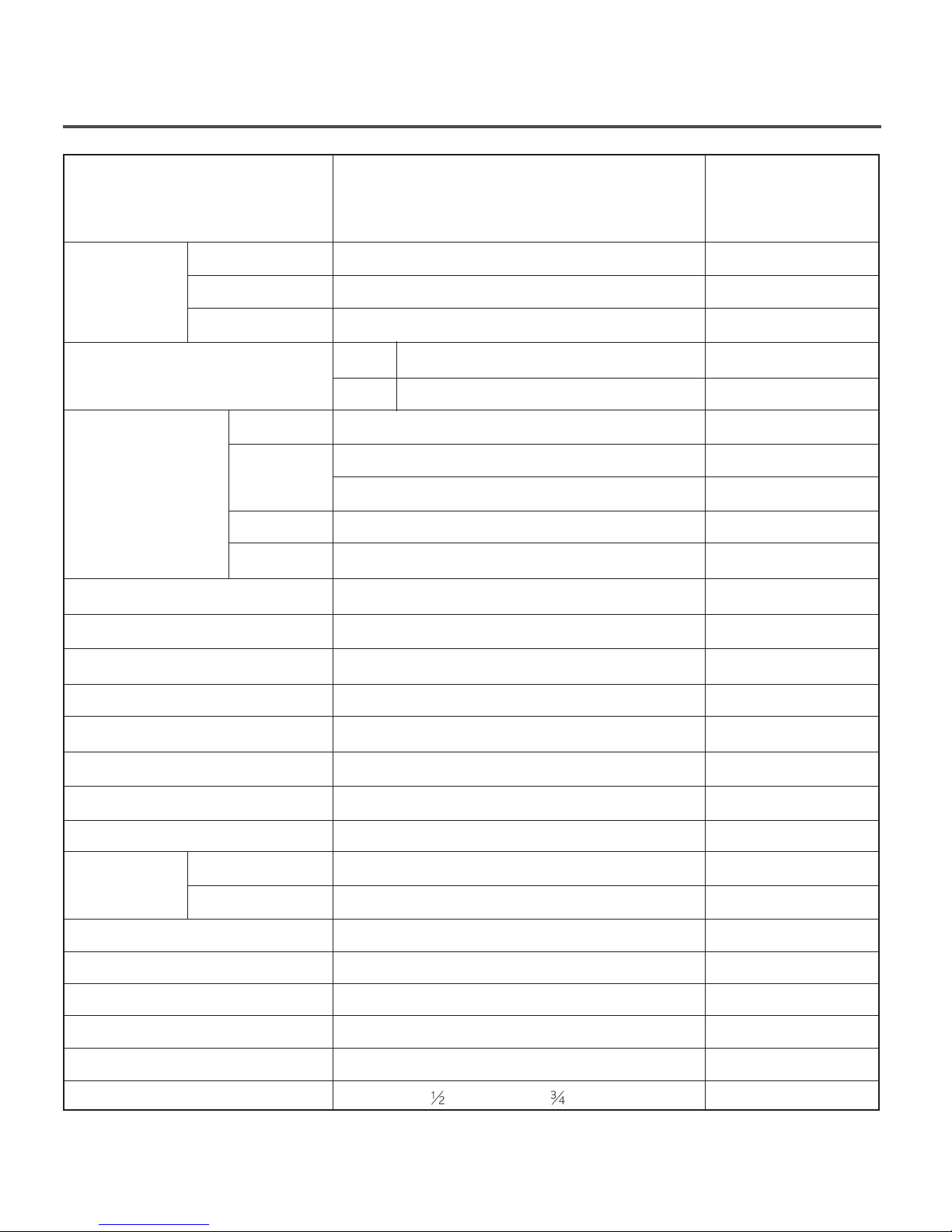

1

SPECIFICATIONS

Name: Electric and Gas Dryer

Power supply: Refer to the rating label on the dryer.

Size: 27” X 403/16” X 29” (inch)

Dryer capacity: IEC 7.3 cu.ft.

Weight: 125.5 (Ibs)

Specifications are subject to change by manufacturer.

ACCESSORIES

Gas: 120 VAC Electric: 240VAC

Dryer rack (1 each)

(Sold Separately : Some Model)

See page 6 of this manual for usage instruction.

4

ITEM

DGS2028EKD DGS2038EKD

DGS1828EKD DGS1838EKD

DGS1858EKD DGS1818EKD

DES2038EKD

DLE1101W DLG1102W

REMARK

Material &

Finish

POWER

SUPPLY

ELECTRICITY

CONSUMPTION

CONTROL TYPE

DRUM CAPACITY

Weight (lbs) - Net

No. of Programs

Color

Top Plate

Door Trim

MOTOR

HEATER

LAMP

GAS VALVE

ELEC.

GAS

Blue White / Stainless Silver

White / Silver / Black

Chrome

120/240V 60Hz (26A)/120/208V 60Hz (23A)

120V/60Hz (11.5A)

250W (4.5A)

5400W (22.5A)

4100W (21A)

15 W (0.2A)

13 W (0.11A) x 2

Electronic

7.3 cu.ft.

124.9/144.4

9 / 12

AC 120V

AC 240V(ELECTRIC MODEL)

AC 208V(ELECTRIC MODEL)

AC 120V

AC 120V(GAS MODEL)

No. of Dry Options

No. of Temperature Controls

No. of Dry Levels

Sound levels

Moisture

Sensor

Temperature

Reversible Door

Drum

Child Lock

Interior Light

Product (WxHxD)

Packing (WxHxD)

27

”x 403/16”

29

1(on/off)

Available

Available

Available

Alcosta

Available

Available

”x 403”

5

6

4

5

x 29”(inch)

x 30

”

(inch)

Electrode sensor

Thermistor

2

Open the door.

Hold the dryer rack

with both hands.

Put the dryer rack into

the drum

Check and be sure that the

front of the rack is properly

seated behind the lint filter.

FEATURES AND BENEFITS

3

INSTALLATION INSTRUCTIONS

6

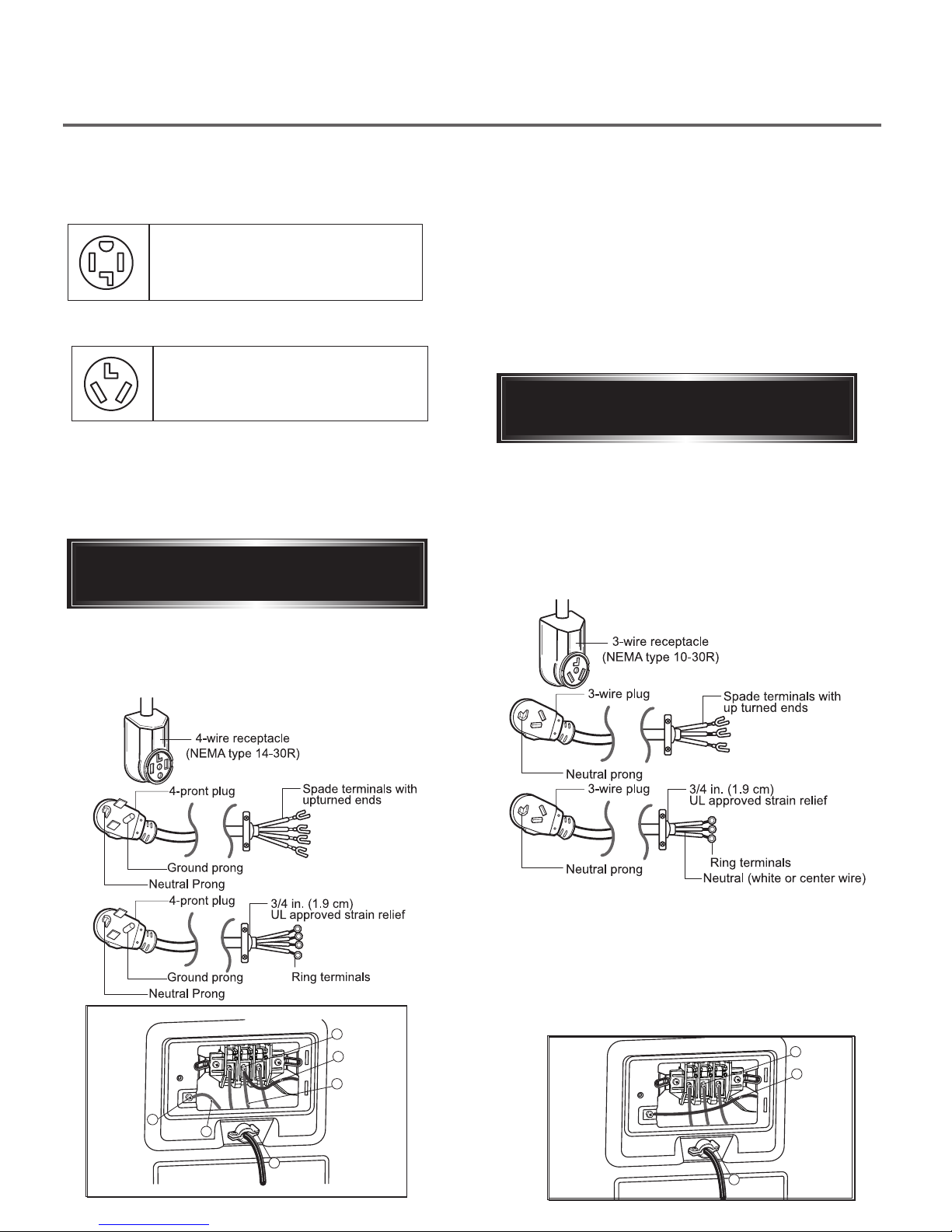

Review the following options to determine

the appropriate electrical connection for

your home:

4-wire receptacle

(NEMA type14-30R)

Use the instructions under option 1 if your home

homehas a 4-wire receptacle (NEMA type 14-30R).

3-wire receptacle

(NEMA type10-30R)

Use the instructions under option 2 or 3 if your

home has a 3-wire receptacle (NEMA type 10-30R).

Use option 2 if local codes and ordinances permit

the connection of a chassis ground to the neutral

connector. If this is not permitted, use option 3.

Option 1: 4-wire connection with

a Power supply cord.

1. Connect the neutral wire (white) of the power

cord to the center terminal block screw.

2. Connect the red and black wires to the left and

right terminal block screws.

3. Connect the ground wire (green) of the power

cord to the external ground screw. Remove the

neutral ground wire of appliance and connect it to

center screw.

4. Make sure that the strain relief screw is tightened

and that all terminal block nuts are tight and the

power cord is in the right position.

Option 2: 3-Wire Connection with

a Power Supply Cord

lf your local codes or ordinances permit the

connection of a frame-grounding conductor to the

neutral wire, use these instructions. If your local

codes or ordinances do not allow the connection of

a frame-grounding conductor to the neutral wire,

use the instructions under Section 3: Optional

3-wire connection.

• If your local codes or ordinances do not allow the

use of a 3 wire connection, or you are installing

your dryer in a mobile home, you must use a 4wire connection.

D

E

F

1. Connect the neutral (white or center) wire (B) to

the center, silver colored, screw (A) and tighten

securely.

2. Connect the other two power cord wires (red and

black) to the left and right terminal block screws

and tighten securely.

3. Tighten the strain relief screws (C) securely.

A

B

a

b

C

7

C

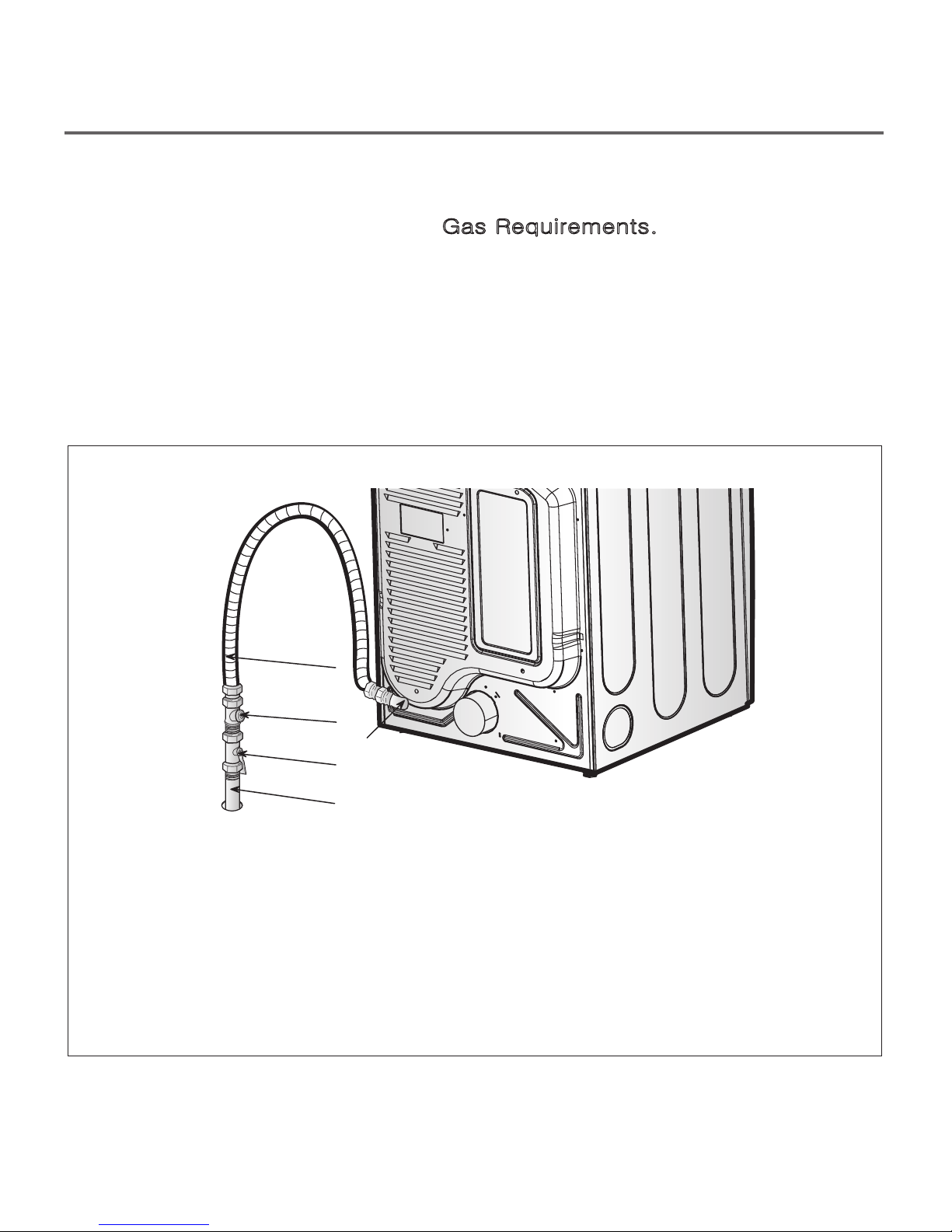

Connect Gas Supply Pipe (Gas Dryer ONLY)

For further assistance, refer to section on

Gas Requirements.

1. Make certain your dryer is equipped for use with the

type of gas in your laundry room. Dryer is equipped

3

at the factory for natural gas with a

/8” N.P.T. gas

connection.

2. Remove the shipping cap from the gas connection

at the rear of the dryer. Make sure you do not

damage the pipe thread when removing the cap.

1

3. Connect to gas supply pipe using a new flexible

stainless steel connector.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. For LP (Liquefied Petroleum) gas connection, refer

to section on Gas Requirements.

2

5

3

4

1 New Stainless Steel Flexible Connector

- Use only if allowed by local codes (Use

Design A.G.A. Certified Connector)

1

8

/

”NPT Pipe Plug (for checking inlet gas

2

pressure)

3 Equipment Shut-Off Valve

-Installed within 6’(1.8 m) of dryer

4 Black Iron Pipe

Shorter than 20’ (6.1 m) – Use ” pipe

Longer than 20’ (6.1 m) – Use ” pipe

3

8

5 ” NPT Gas Connection

/

8

3

8

/

1

2

/

4

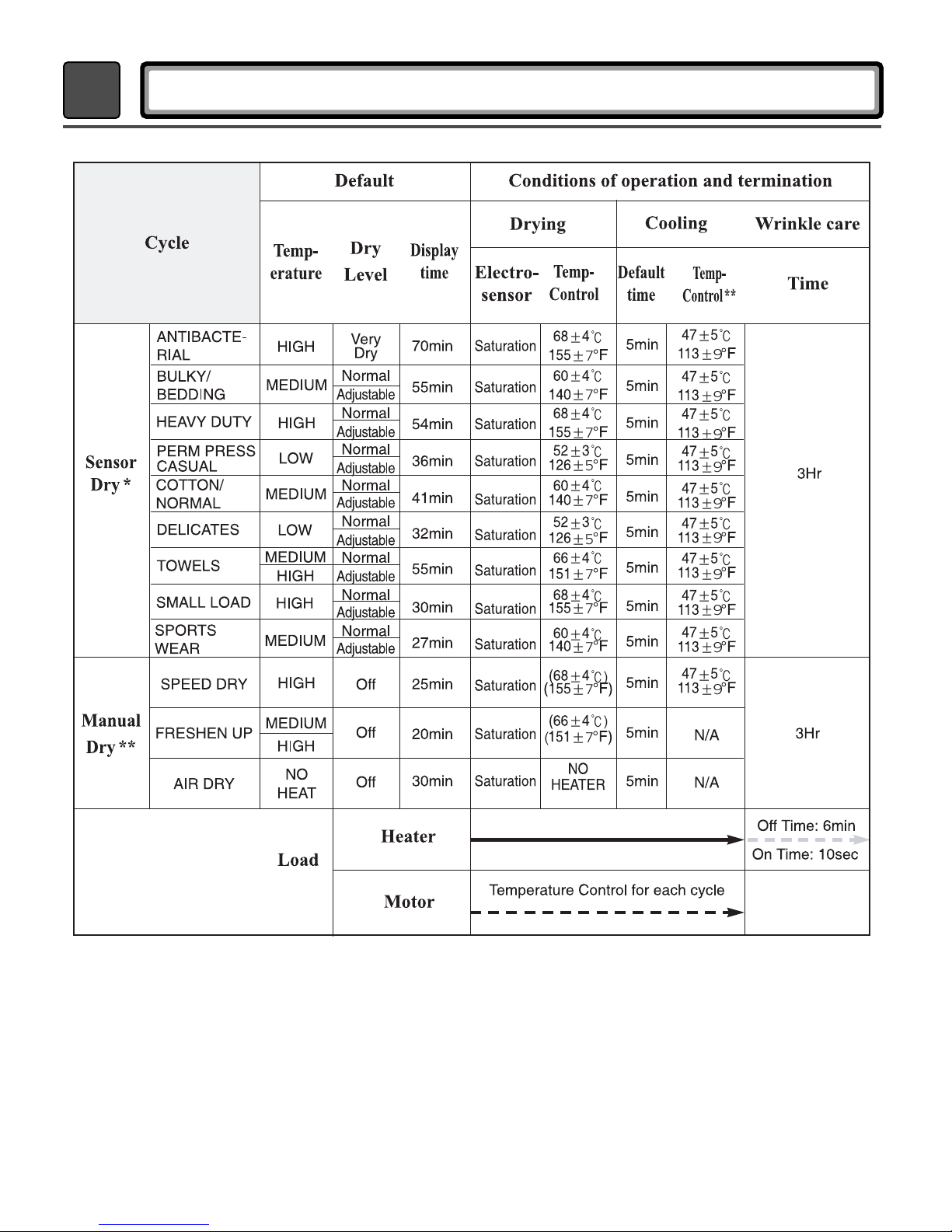

DRYER CYCLE PROCESS

* Sensor dry: Dry Level is set by users.

** Manual dry: Temperature control is set by users.

Default settings can be adjusted by users.

9

10

5

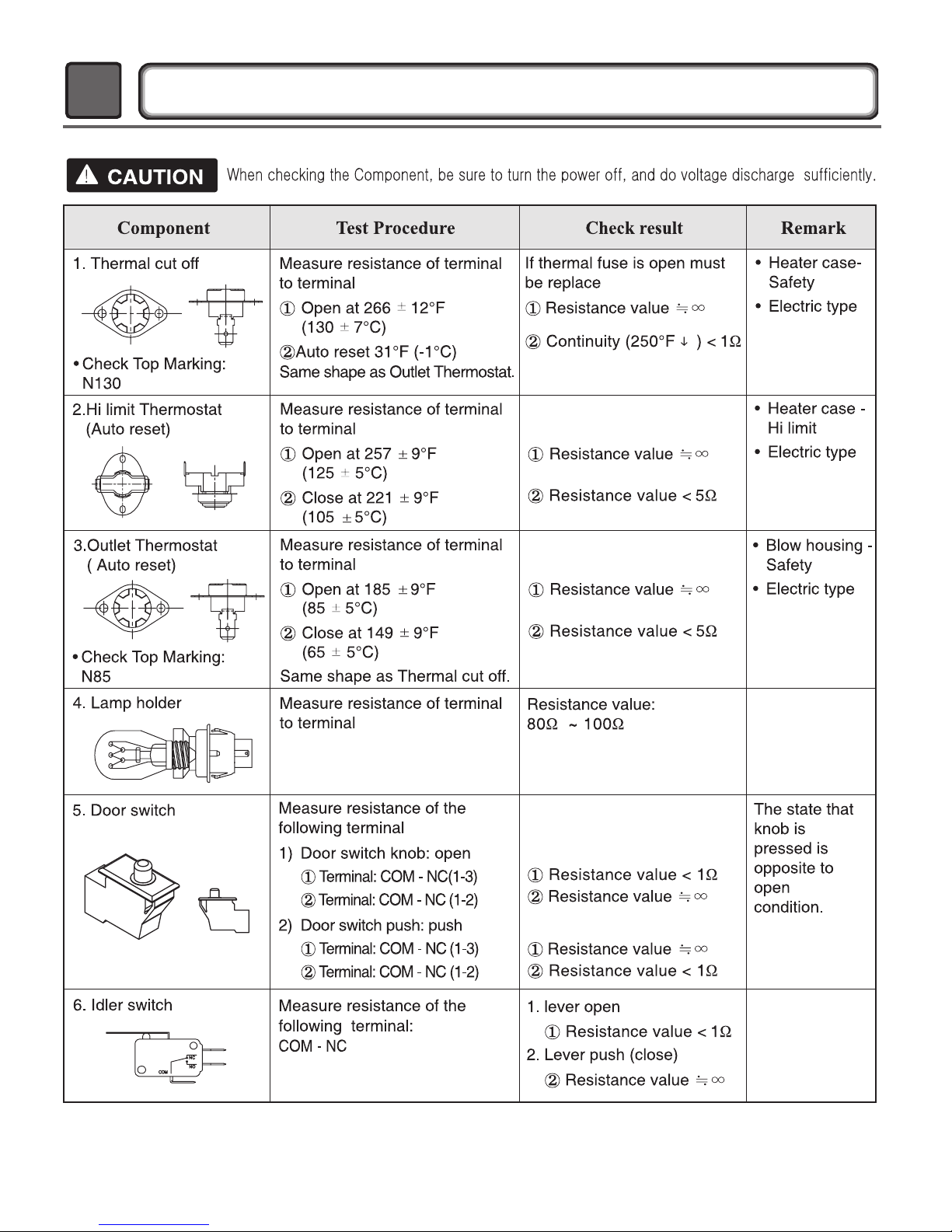

COMPONENT TESTING INFORMATION

5

Component Test Procedure

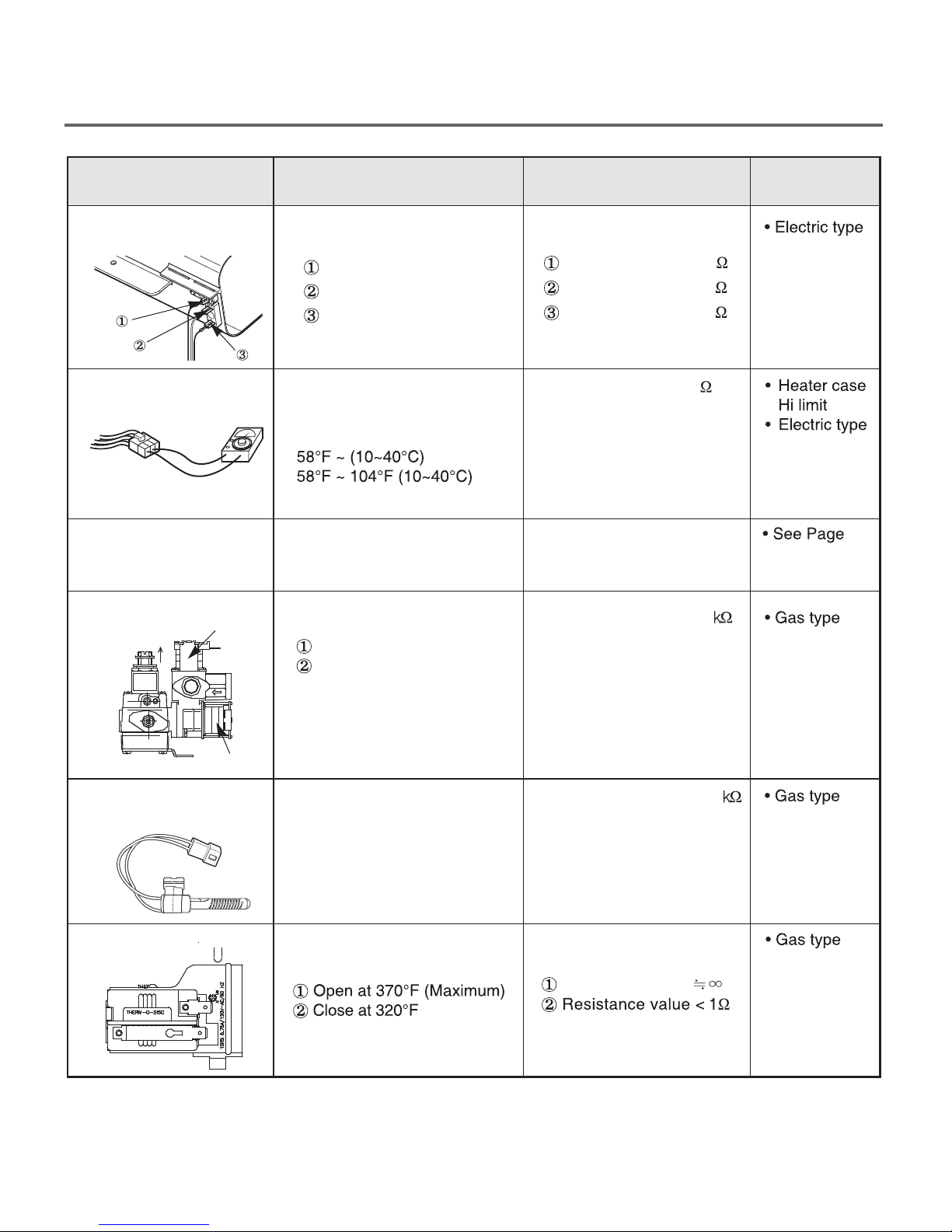

7. Heater

8. Thermistor

9. Motor

10. Gas valve

valve 1

Measure resistance of the

following terminal

Terminal: 1 (COM) - 2

Terminal: 1 (COM) - 3

Terminal: 2 - 3

Measure resistance of terminal

to terminal

Temperature condition:

Measure resistance of the

following terminal

Valve 1 terminal

Valve 2 terminal

Check result

Resistance value: 10

Resistance value: 10

Resistance value: 20

Resistance value: 10

Resistance value:1.5~2.5

Remark

13

11. Igniter

5318EL3001

12. Frame Detect

valve 2

Measure resistance from

terminal to terminal.

Measure resistance of termina

to terminal

11

Resistance value:100~800

Resistance value

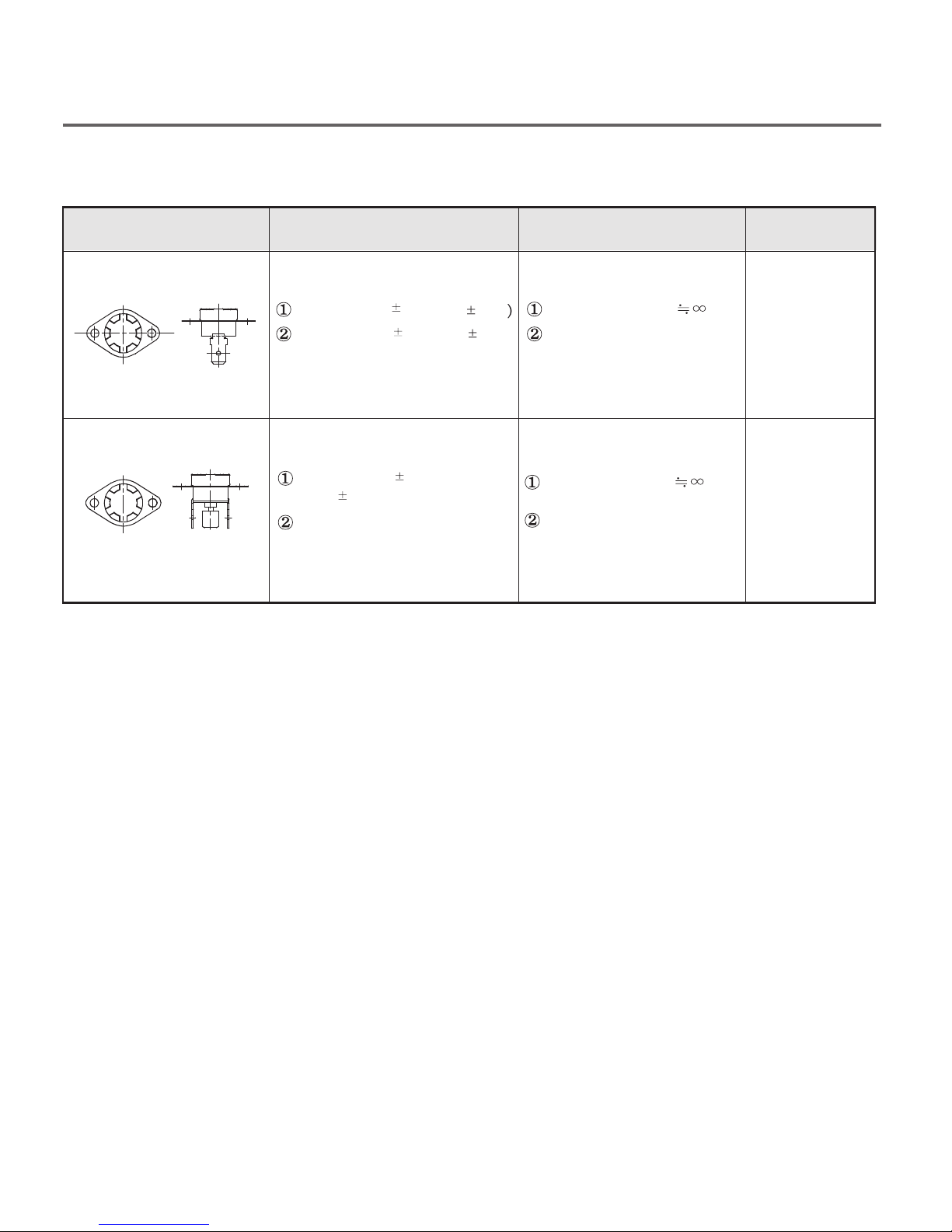

Component Test Procedure

Check result

Remark

13. Outlet Thermostat

(Auto reset)

• Check Top Marking:

N95

14. Outlet Thermostatt

(Manual reset)

• Check Top Marking:

N110

Measure resistance of terminal

to terminal

Open at 203

Close at 159 9°F (70 5°C)

Measure resistance of terminal

to terminal

Open at 212

(110

Manual reset

7°C)

7°F (95 5°C

12°F

Resistance value

Continuity < 1

If thermal fuse is open must

be replaced

Resistance value

Continuity < 1

Ω

Ω

• Gas type

• Gas funnel

• Gas type

• Gas funnel

12

Loading...

Loading...