Page 1

SPECIFICATIONS

1. PICTURE TUBE

Size : 17 inch (Flat Square Tube)

DefIection Angle : 90¡

Neck Diameter : 29.1mm

Transmission : 46%

Dot Pitch : 0.28mm

Face Treatment : AR-ASC (Anti-Reflection and

Anti-Static Coating)

Low Radiation : MPR-II, TCO-95

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level : Low=0~1.2V, High=2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75 ½

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15-pin D-Sub Connector

2-4. Scanning Frequency

Horizontal : 30 ~ 70kHz

Vertical : 50 ~ 160Hz

3. POWER SUPPLY

3-1. Power Range

AC 100~264V (Free Voltage), 50/60Hz, 2.0A Max.

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area : 310 x 230 mm (12.20" x 9.06")

(Available for Full Screen)

4-2. Display Color : Full Colors

4-3. Display Resolution : 1280 x 1024 / 60Hz

(Non-Interlace)

4-4. Video Bandwidth : 110MHz

5. ENVIRONMENT

5-1. Operating Temperature: 15¡C ~ 30¡C (59¡F ~ 86¡F)

(Ambient)

5-2. Relative Humidity : 8%~ 80%

(Non-condensing)

5-3. Altitude : 5,000m

6. DIMENSIONS (with TILT/SWIVEL)

Width : 512mm (20.16 inch)

Depth : 545mm (21.46 inch)

Height : 525mm (20.67 inch)

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 15.90kg (35.06 lbs.)

Gross Weight : 19.00kg (41.89 lbs.)

- 2 -

MODE

NORMAL (ON)

STAND-BY

SUSPEND

OFF

FAULT

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

OUT OF RANGE

POWER CONSUMPTION

less than 105 W

less than 15 W

less than 15 W

less than 15 W

less than 5 W

LED COLOR

GREEN

ORANGE

ORANGE

ORANGE

Page 2

- 4 -

VIDEO

SYNC

C

E

D

F

AB

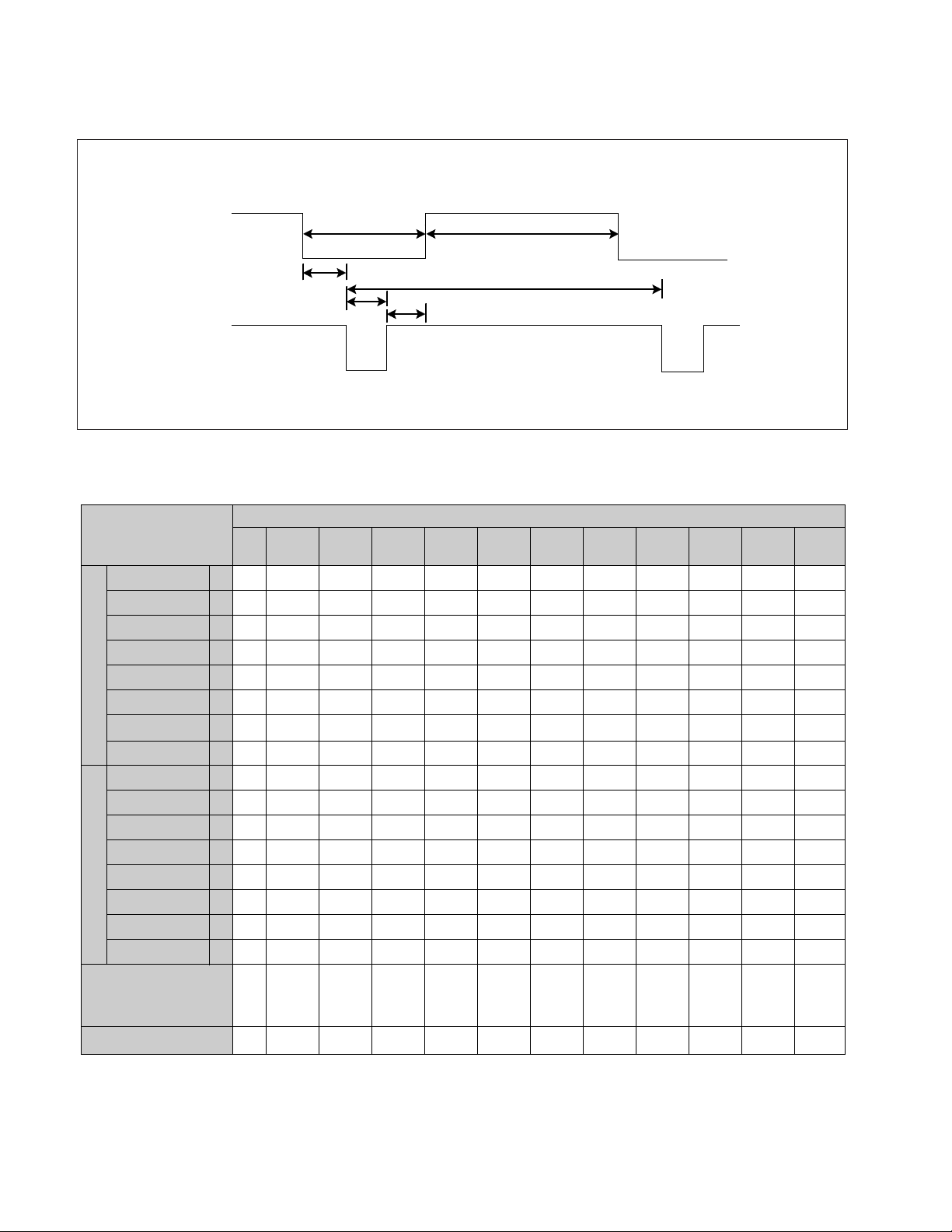

TIMING CHART

MODE

Resolution

Recall

H

O

R

I

Z

O

N

T

A

L

V

E

R

T

I

C

A

L

kHz

µs

µs

µs

µs

µs

µs

Hz

ms

ms

ms

ms

ms

ms

MODE 2

+

46.88

21.33

16.16

5.17

0.32

1.62

3.23

+

75.01

13.331

12.798

0.533

0.021

0.064

0.448

800

x

600

75Hz

Yes

MODE 1

Ñ

37.50

26.67

20.32

6.35

0.51

2.03

3.81

Ñ

74.99

13.335

12.802

0.533

0.026

0.080

0.427

640

x

480

75Hz

Yes

MODE 3

+

53.68

18.63

14.22

4.41

0.57

1.14

2.70

+

85.07

11.775

11.178

0.577

0.018

0.056

0.503

800

x

600

85Hz

Yes

MODE 4

+

68.677

14.561

10.836

3.725

0.508

1.016

2.201

+

85.00

11.764

11.182

0.582

0.014

0.044

0.524

1024

x

768

85Hz

Yes

MODE 5

Ñ

31.47

31.78

25.42

6.36

0.64

3.81

1.91

+

70.08

14.269

12.712

1.557

0.414

0063

1.080

640

x

400

70Hz

Yes

MODE 6

Ñ

31.47

31.78

25.42

6.36

0.64

3.81

1.91

Ñ

59.94

16.684

15.254

1.430

0.318

0.063

1.049

640

x

480

59Hz

Yes

MODE 7

+

37.88

26.40

20.00

6.40

1.00

3.20

2.20

+

60.32

16.579

15.840

0.739

0.026

0.106

0.607

800

x

600

60Hz

Yes

MODE 8

Ñ

43.27

23.11

17.78

5.33

0.89

1.33

3.11

Ñ

85.01

11.763

11.093

0.670

0.023

0.069

0.578

640

x

480

85Hz

Yes

MODE 9

Ñ

49.75

20.10

14.52

5.58

0.55

1.12

3.91

Ñ

74.95

13.407

12.542

0.865

0.021

0.060

0.784

832

x

624

75Hz

Yes

MODE 10

+

60.02

16.66

13.00

3.66

0.20

1.22

2.24

+

75.03

13.328

12.795

0.533

0.017

0.050

0.466

1024

x

768

75Hz

Yes

MODE 11

+

63.98

15.63

11.85

3.78

0.44

1.04

2.30

+

60.02

16.661

16.005

0.656

0.015

0.047

0.594

1280

x

1024

60Hz

Yes

MARK

E

A

B

C

D

F

E

A

B

C

D

F

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

FACTORY PRESET MODE

* Mode 1~Mode 4: Basic Mode (Mode 5~Mode 11: Default Mode)

Page 3

- 8 -

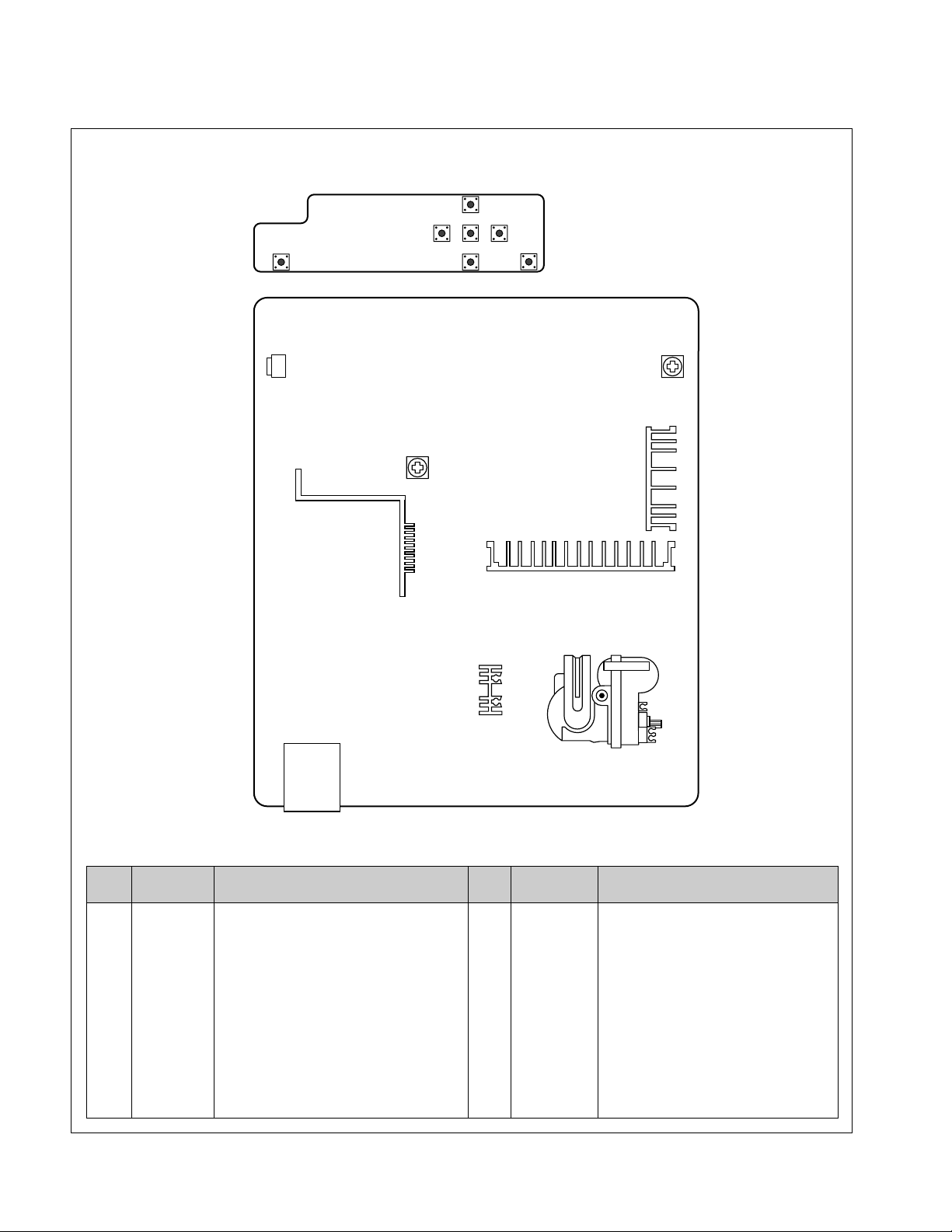

CONTROL LOCATIONS

MAIN

FBT

CONTROL

1

2

3

4

5

7

89

10

6

NO.

1

2

3

4

5

Ref. No.

SW207

SW205

SW206

SW204

SW202

NO.

6

7

8

9

10

Ref. No.

SW203

SW201

VR101

VR701

VR901

Control Function

POWER BUTTON

OSD SELECT/ADJUSTMENT(DOWN)

OSD SELECT/ADJUSTMENT(RIGHT)

SET BUTTON

OSD SELECT/ADJUSTMENT(LEFT)

Control Function

OSD SELECT/ADJUSTMENT(UP)

OSD BUTTON

TCO ADJUSTMENT

HIGH-VOLTAGE ADJUSTMENT

B+ADJUSTMENT

Page 4

- 9 -

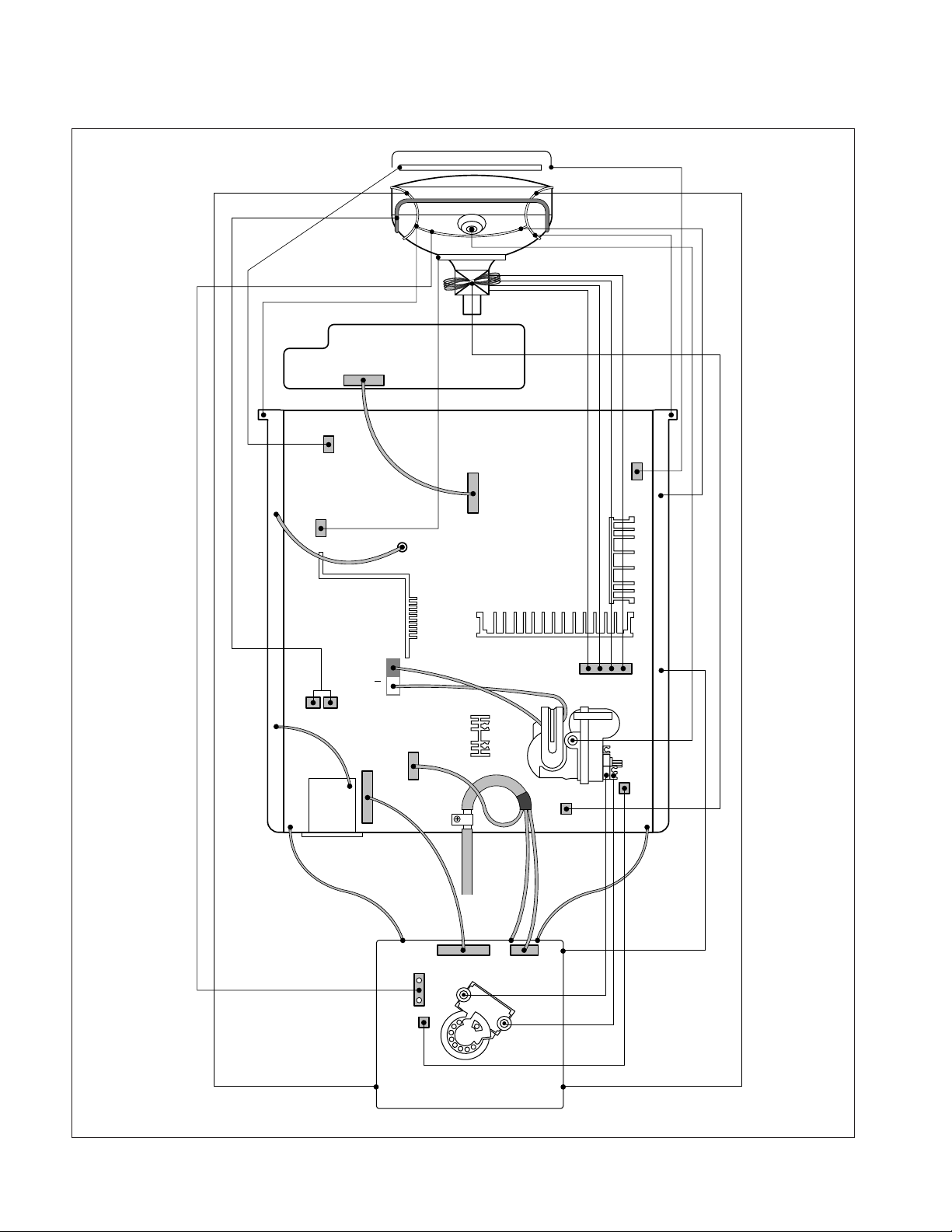

WIRING DIAGRAM

P201

P401

P102

P101

P501

WG2

P301P302

P702

P402

P902 P903

S

+

S

P304

P303

P704

P703

Signal

Cable

AC

Socket

FBT

Page 5

- 10 -

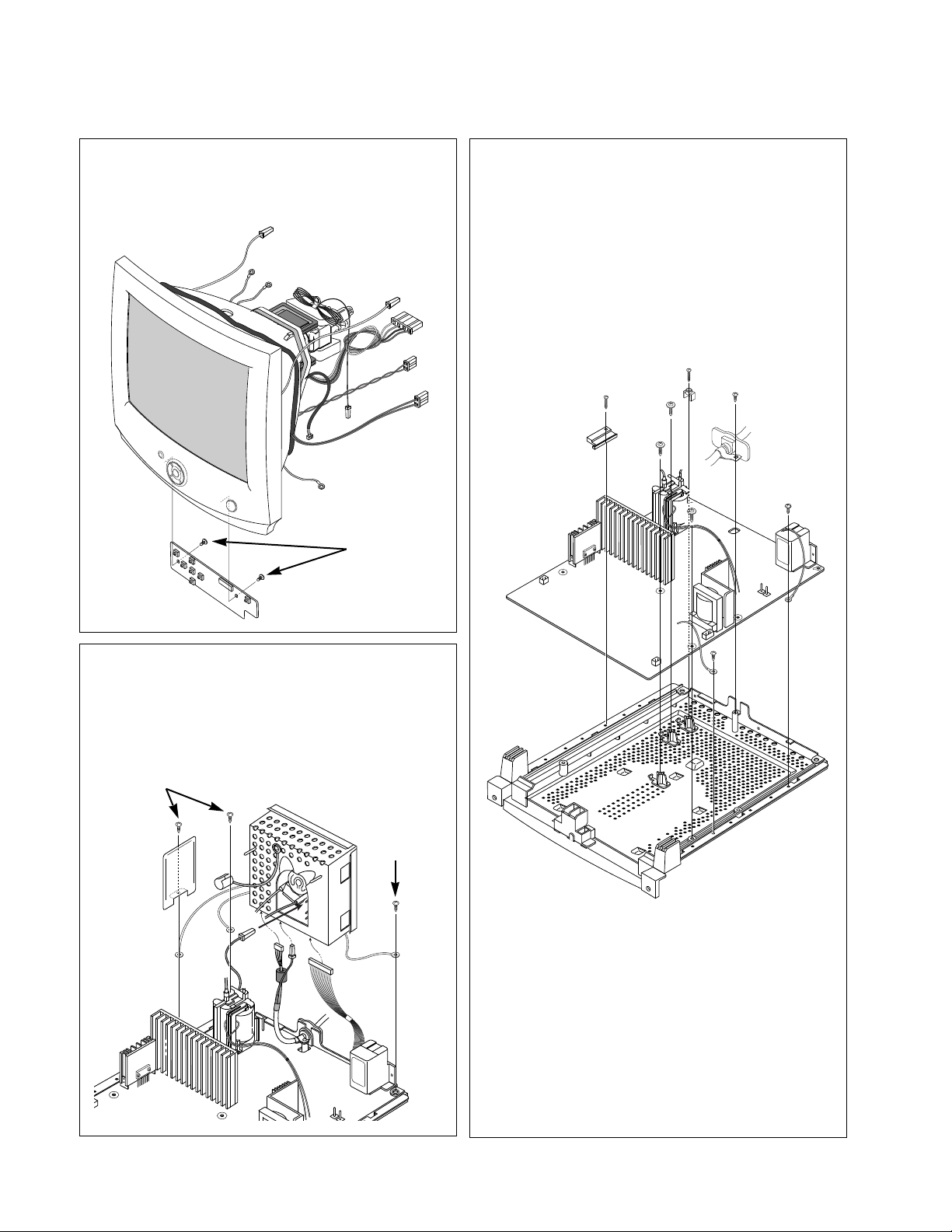

DISASSEMBLY

2. BACK COVER REMOVAL

1) Remove two screw caps (a).

2) Remove four screws (b).

3) Remove signal cable cap (c).

4) Slide the Back Cover away from the Front

Cabinet of the monitor.

(a)

1. TILT/SWIVEL REMOVAL

1) Set the monitor face downward.

2) Pressing the latch (a), carefully remove

the Tilt/Swivel by pulling it upward.

Anode Cap

P701

P102

DY Assembly Screw

P704

P304

P101

P401

P501

P902, P903

(c)

(b)

(b)

(c)

(a)

3. TOTAL CHASSIS ASSEMBLY REMOVAL

1)

Remove connector (a) from the DY Assembly screw.

2) Disconnect P304 (GND Wire) and two pins (b)

from the Video PCB.

3) Carefully separate the CDT Board Assembly

from the CDT neck.

4) Discharge the remaining static electricity

by shorting between the Anode Cap

and the CDT ground.

5) Disconnect the Anode Cap

from the CDT.

6) Disconnect P902, P903

(Degaussing pin),

P701 (DY pin), P101, P102,

P401, P501, and P704

from the Main PCB.

7) Remove two screws (c).

8) Remove the Total Chassis

Assembly from the Main Frame.

(a)

(a)

(b)

(c)

(b)

Page 6

- 11 -

4. CONTROL PCB ASSEMBLY REMOVAL

1) Remove two screws (a).

2) Remove the Control PCB Assembly

from the Front Cabinet.

5. VIDEO PCB ASSEMBLY REMOVAL

1) Disconnect P301, P302, and P303

from the Video PCB.

2) Remove three screws (a).

3) Remove the Video PCB Assembly

from the Interface Assembly.

(a)

(a)

(a)

6. BOTTOM BRACKET REMOVAL

1) Remove three screws (a).

2) Remove five screws (b).

3) Remove the Bottom Bracket.

(b)

(b)

(a)

(a)

(b)

(b)

(a)

P303

P301

(b)

P302

Page 7

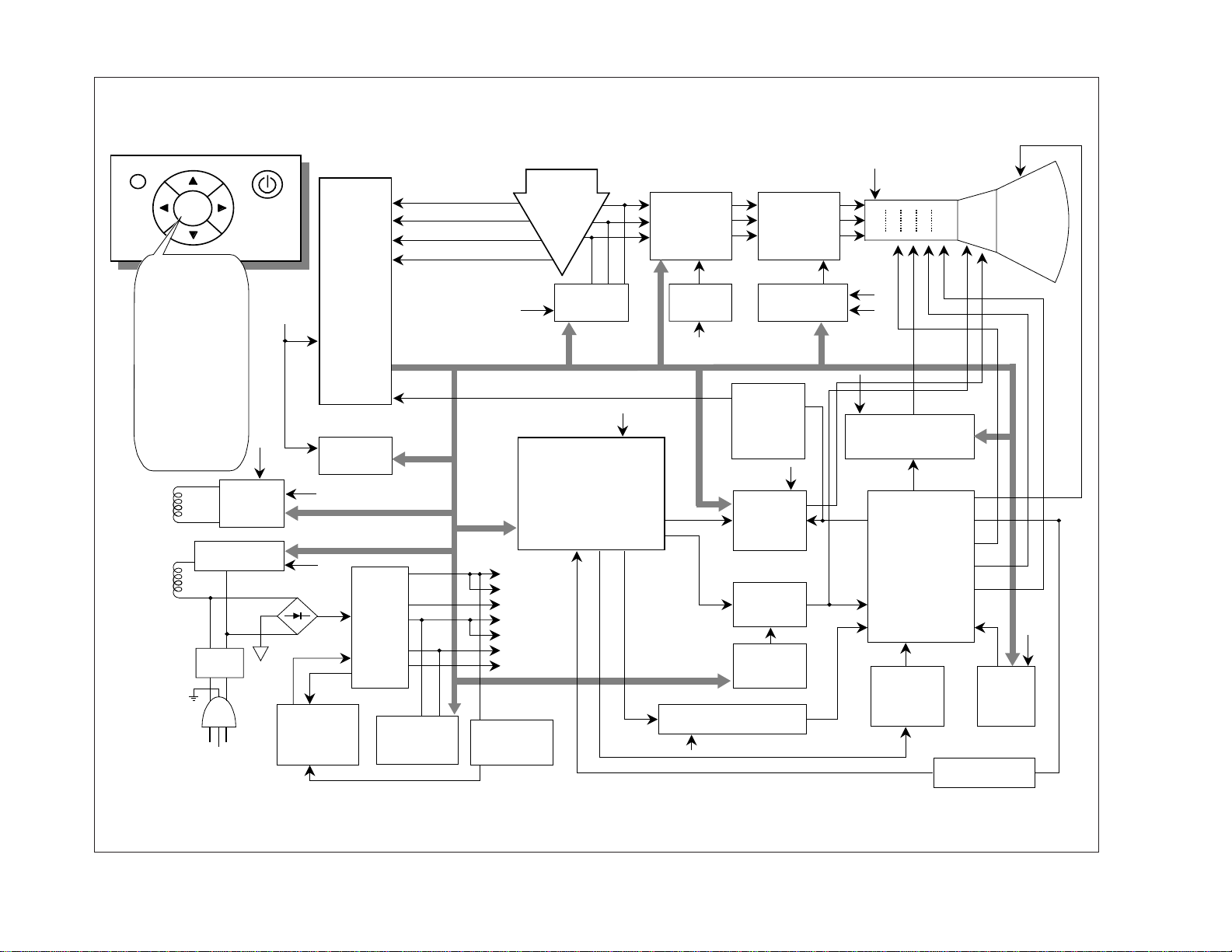

BLOCK DIAGRAM

- 12 -

POWER INPUT

100~240VAC

(50/60Hz)

Line

Filter

Degaussing

Circuit

OSD

ON/

OFF

SET

< OSD Control >

SMPS

TRANS

(T901)

SMPS

CONTROL

(IC901)

DPM

CONTROL

CIRCUIT

160V

125V

70V

15V

12V

6.3V

5V

TILT

Control

Circuit

6.3V

6.3V

E2PROM

(IC402)

H / V POSITION

H / V SIZE

SPCC

TRAPIZODE

PIN BALANCE

PARALLELOGRAM

ROTATION

RECALL

DEGAUSS

DDC OPTION

COLOR CURVE

MOIRE

LANGUAGE

RECALL

VIDEO LEVEL

BRIGHTNESS CONTROL

OSD POSITION

5V

OSD IC

(IC303)

H-Sync Sig

V-Sync Sig

I2C DATA(SDA)

I2C CLOCK(SCL)

VIDEO

PRE-AMP

(IC302)

Signal

Cable

R

G

B

VIDEO

MAIN AMP

(IC303)

8V REG.

(IC304)

8V

12V

CUT OFF

CONTROL

125V

8V

5V

H/V Sync Processor

( IC701 )

TDA4856

V-OUT

( IC601)

TDA4866

H-OUT

( Q706)

H-Linearity

Correction

DC/DC Converter

X-RAY

Protection

Circuit

FBT

( T701 )

Dynamic

Focus

Circuit

Auto

Beam

Limit

Vertical Blanking,

Brightness Control

- 120V

40V

6.3V

D/D Feed Back

30V

15V

MICOM

(IC401)

SCL / SDA

H/V Sync,

PWM Control

Sig

12V

15V

160V

DY CDT

Heater ( 6.3V )

I2C

I2C

I2C

H/V

Sync

G

1

Screen

Dynamic Focus

Static Focus

H.V

R/G/B

Bias

R/G/B

Contrast

H-DRV

B-DRV

B+

15V

POWER

TILT

COIL

DEGAUSSING

COIL

I2C

VOLTAGE

FEEDBACK

12V

Page 8

DESCRIPTION OF BLOCK DIAGRAM

1. Line Filter & Associated Circuit.

This is used for suppressing noise of power input line

flowing into the monitor and/or some noise generated in

this monitor flowing out through the power input line.

That is to say, this circuit prevents interference between

the monitor and other electric appliances.

2. Degauss Circuit & Coil.

The degauss circuit consists of the degaussing coil, the

PTC(Positive Temperature Coefficient) thermistor(TH901),

and the relay(RL901). This circuit eliminates abnormal

color of the screen automatically by degaussing the

shadow mask in the CRT during turning on the power

switch. When you need to degauss in using the monitor,

select DEGAUSS on the OSD menu.

3. SMPS(Switching Mode Power Supply).

This circuit is working of 90~264V AC(50/60Hz).

The operation procedure is as follows:

1) AC input voltage is rectified and smoothed by the

bridge diodes (D901~D904) and the capacitor (C907).

2) The rectified voltage(DC) is applied to the primary

coil of the transformer(T901).

3) The control IC(IC901) generates switching pulse to

turn on and off the primary coil of the transformer

(T901) repeatedly.

4) Depending on turn ratio of the transformer, the

secondary voltages appear at the secondary coils of

the transformer(T901).

5) These secondary voltages are rectified by each

diode(D902, D922~D924, D926)) and operate other

circuit. (horizontal and vertical deflection, video

amplifier, ...etc.)

4. X-ray Protection.

I

f the high voltage of the FBT reaches up to 29kV (abnormal

state), Q807 operates and IC401(MICOM) pin 11 come to

low level. Then MICOM control IC701 (Deflection controller)

to stop Horizontal drive pulse and stop Horizontal Deflection.

5. Micom(Microprocessor) Circuit.

The operating procedure of Micom(Microprocessor) and

its associated circuit is as follows:

1) H and V sync signal is supplied from the signal cable.

2) The Micom(IC401) distinguishes polarity and

frequency of H and V sync.

3) The Micom sets operating mode and offers the

controlled data. (H-size, H-position, V-size, ... etc.)

4) The controlled data of each mode is stored in itself.

5) User can adjust screen condition by each OSD

function. The data of the adjusted condition is stored

in EEPROM(IC402).

6. Horizontal and Vertical Oscillation.

This circuit generates the horizontal pulse and the vertical

pulse by taking the H and V sync signal.

This circuit consists of the TDA4856(IC701) and the

associated circuit.

7. Oscillating Circuit for D/D Converter.

This circuit generates the saw-tooth wave which has the

horizontal period by taking output of the TDA4856(IC701).

8. D/D(DC to DC) Converter.

This circuit supplies DC voltage to the horizontal

deflection output circuit by decreasing DC 160V which is

the secondary voltage of the SMPS in accordance with

the input horizontal sync signal.

9. Side-Pincushion & Trapezoid Correction Cirucit.

This circuit improves the side-pincushion and the

trapezoid distortion of the screen by mixing parabola and

saw-tooth wave to output of the horizontal deflection D/D

converter which is used for the supply voltage(B+) of the

deflection circuit.

10. Horizontal Deflection Output Circuit.

This circuit makes the horizontal deflection by supplying

the saw-tooth current to the horizontal deflection yoke.

11. High Voltage Output & FBT(Flyback Transformer).

The high voltage output circuit is used for generating

pulse to the primary coil of the FBT(Flyback Transformer

(T701)). A boosted voltage(about 26kV) appears at the

secondary of the FBT and it is supplied to the anode,

focus, and screen voltage of the CRT.

12. H-Linearity Correction Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

13. Vertical Output Circuit.

This circuit takes the vertical ramp wave from the

TDA4856(IC701) and performs the vertical deflection by

supplying the saw-tooth current to the vertical deflection

yoke.

14. Dynamic Focus Output Circuit.

This circuit takes the horizontal and the vertical parabola

waves from the TDA4856(IC701) and amplifies it to

maintain constant focus on center and corners in the

screen.

- 13 -

Page 9

15. H & V Blanking and Brightness Control.

Blanking circuit eliminates retrace line by supplying

negative pulse to the G1 of the CRT. And Brightness

circuit is used for control of the screen brightness by

changing DC level of the G1.

16. Image Rotation (Tilt) Circuit.

This circuit corrects the tilt of the screen by supplying the

image rotation signal to the tilt coil which is attached near

the deflection yoke of the CRT.

17. Video Pre-Amp Circuit.

This circuit amplifies the analog video signal from 0-0.7V

to 0-4V. It is operated by taking the clamp, R, G, B drive

and contrast signal from the Micom(IC401).

18. Video Output Amp Circuit.

This circuit amplifies the video signal which comes from

the video pre-amp circuit and amplified it to applied the

CRT cathode.

- 14 -

Page 10

- 15 -

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

¥ Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then

press

DEGAUSS on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

- Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM compatible PC.

- Set external Brightness and Contrast volume to max position.

1. Adjustment for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust voltage to 160V

±

0.5Vdc with VR901.

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust FBT B+voltage to 140V

±

0.5Vdc with

VR701.

3. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode 1.

2) Run alignment program for StudioWorks 775N,

CB775 on the IBM compatible PC.

3) Power button of the monitor turn off

→ turn on.

4) COMMAND → START → Y(Yes) command.

5) DIST. ADJ. → TILT command.

6) Adjust tilt as arrow keys to be the best condition.

7) DIST. ADJ. → BALANCE command.

8) Adjust balance of side-pincushion as arrow keys to

be the best condition.

9) DIST. ADJ. → BALANCE command.

10)

Adjust parallelogram as arrow keys to be the best

condition.

11)

DIST. ADJ. → FOS. ADJ command.

12)

Adjust V-SIZE as arrow keys to 230±2mm.

13)

Adjust V-POSITION as arrow keys to center of the

screen.

14)

Adjust H-SIZE as arrow keys to 310±2mm.

15)

Adjust H-POSITION as arrow keys to center of the

screen.

16)

Adjust S-PCC (Side-Pincushion) as arrow keys to be

the best condition.

17)

Adjust TRAPEZOID as arrow keys to be the best

condition.

18)

Display from Mode 1 to Mode 4 and repeat above

from number

12)

to

17)

.

19)

PRESET EXIT → Y (Yes) command.

4. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Press the DEGAUSS on the OSD menu for

demagnetization of the CDT.

3) Set Brightness and SUB-Brightness to Max position.

4) Display color 0,0 pattern at Mode 4.

5) COLOR ADJ. → LUMINANCE command of the

alignment program.

6) COLOR ADJ. → BIAS ADJ. command of the

alignment program.

7) Check whether blue color or not at R-BIAS and GBIAS to min position and B-BIAS to 0.3

±

0.05FL.

Check it's not blue color.

8) Adjust R-BIAS and G-BIAS command to x=0.281

±

0.01 and y=0.311±0.01 on the White Balance Meter

with PC arrow keys.

9)

Adjust SUB-Brightness command to 0.4±0.1FL of the

raster luminance.

10)

Display color 15,0 box pattern (70x70mm) at Mode 4.

11)

Set Contrast and SUB-Contrast to max position.

12)

DRIVE ADJ command.

13)

Set B-DRIVE to 2/3 150(96) (decimal) at DRIVE of

the alignment program.

14)

Adjust R-DRIVE and G-DRIVE command to white

balance x=0.281

±

0.003 and y=0.311±0.003 on the

White Balance Meter with PC arrow keys.

ADJUSTMENT

Page 11

- 16 -

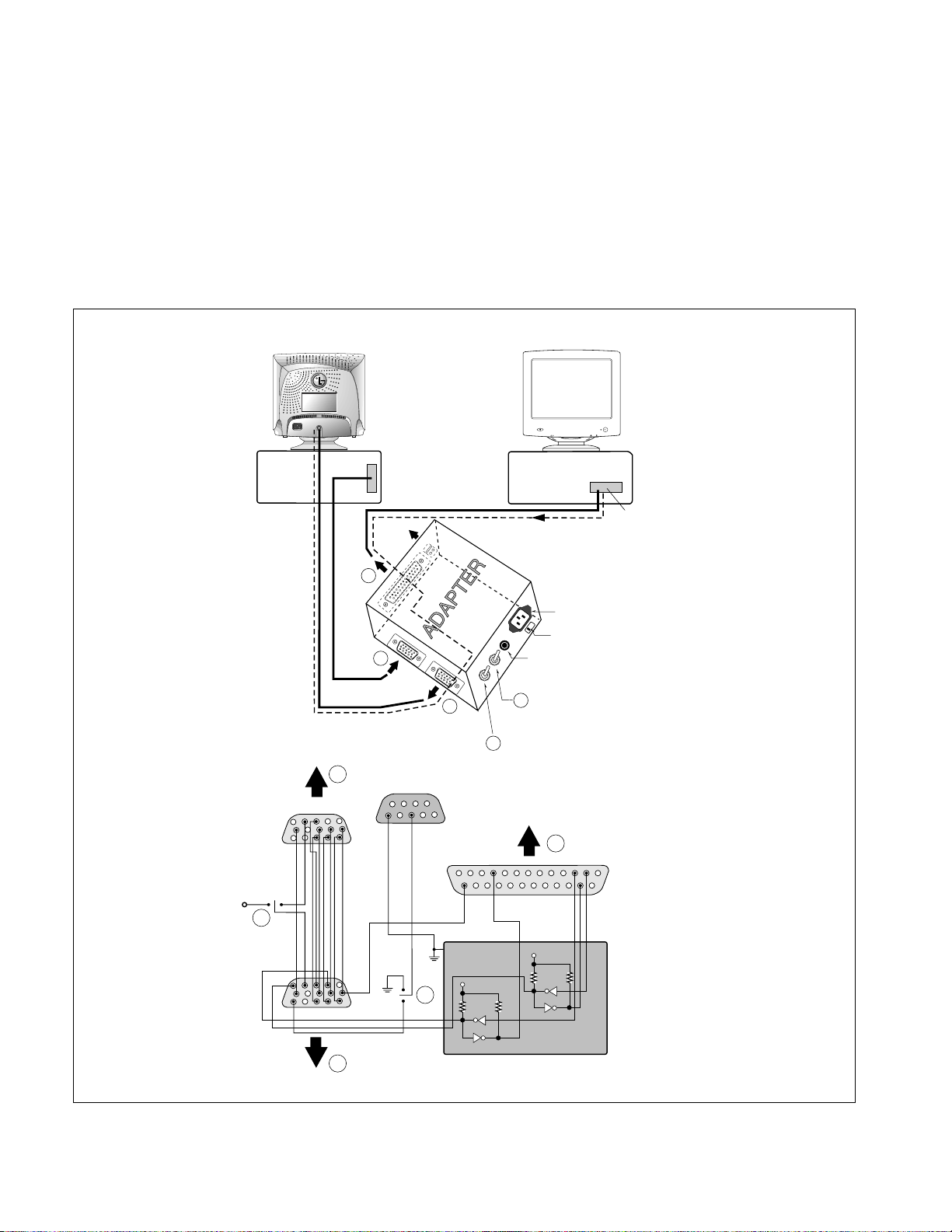

Figure 1. Cable Connection

15)

Adjust SUB-CONTRAST command to 47±2FL of the

color 15,0 box pattern (70x70mm) luminance at

mode 4 and save in color 1.

16)

Display color 15,0 full white patten at Mode 4.

17)

COLOR ADJ. → LUMINANCE → ABL command.

18)

Adjust ABL to 31±1FL of the luminance.

19)

Exit from the program.

5. Adjustment for Focus.

1) Set the Brightness and Contrast to max position.

2) Display H character in full screen at Mode 4.

3) Adjust two Focus control on the FBT that focus

should be the best condition.

220

Monitor to be

adjusted

Video

Signal

Generator

IBM

Compatible PC

Parallel Port

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

E

V-Sync On/Off Switch

(Switch must be ON.)

F

F

A

A

B

B

C

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

Page 12

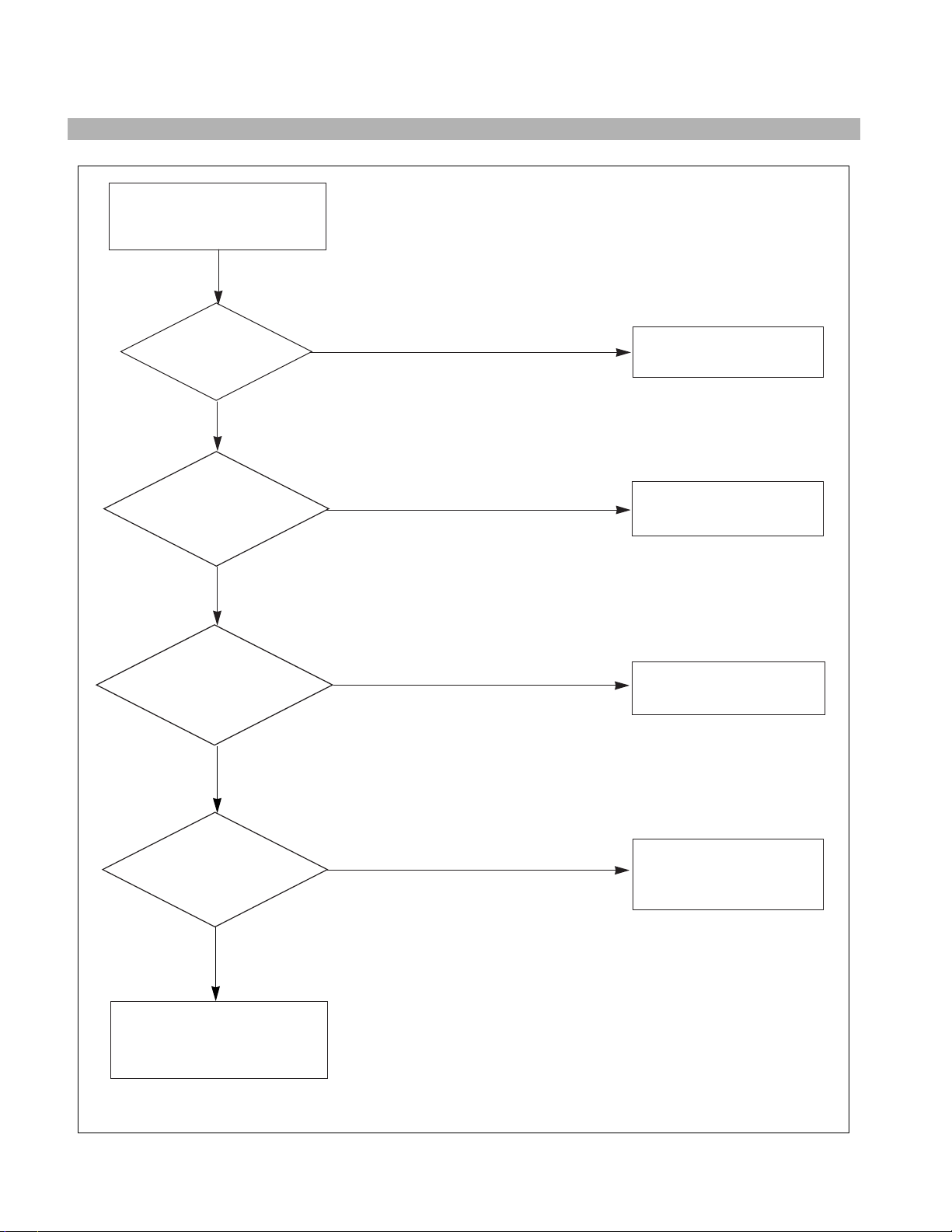

NO POWER

(POWER INDICATOR

OFF)

TROUBLE IN

D901, D902, D903, D904

TROUBLE IN FUSE

(F901)

TROUBLE IN

IC901, IC902

TROUBLE IN

D920, D922, D923,

D924, D926

TROUBLE IN

IC923, IC925, Q922,

Q923, Q924, Q926

CHECK

FUSE OK?

CHECK

C907 VOLTAGE?

(AC120V: 170VDC,

AC220V: 310VDC)

NO

YES

YES

YES

YES

NO

NO

NO

- 17 -

CHECK

IC901 PIN 3

WAVEFORM

(SQUARE WAVE

COMES OUT?)

CHECK

D920, D922, D924,

D923, D926

VOLTAGE?

TROUBLESHOOTING GUIDE

1. NO POWER

Page 13

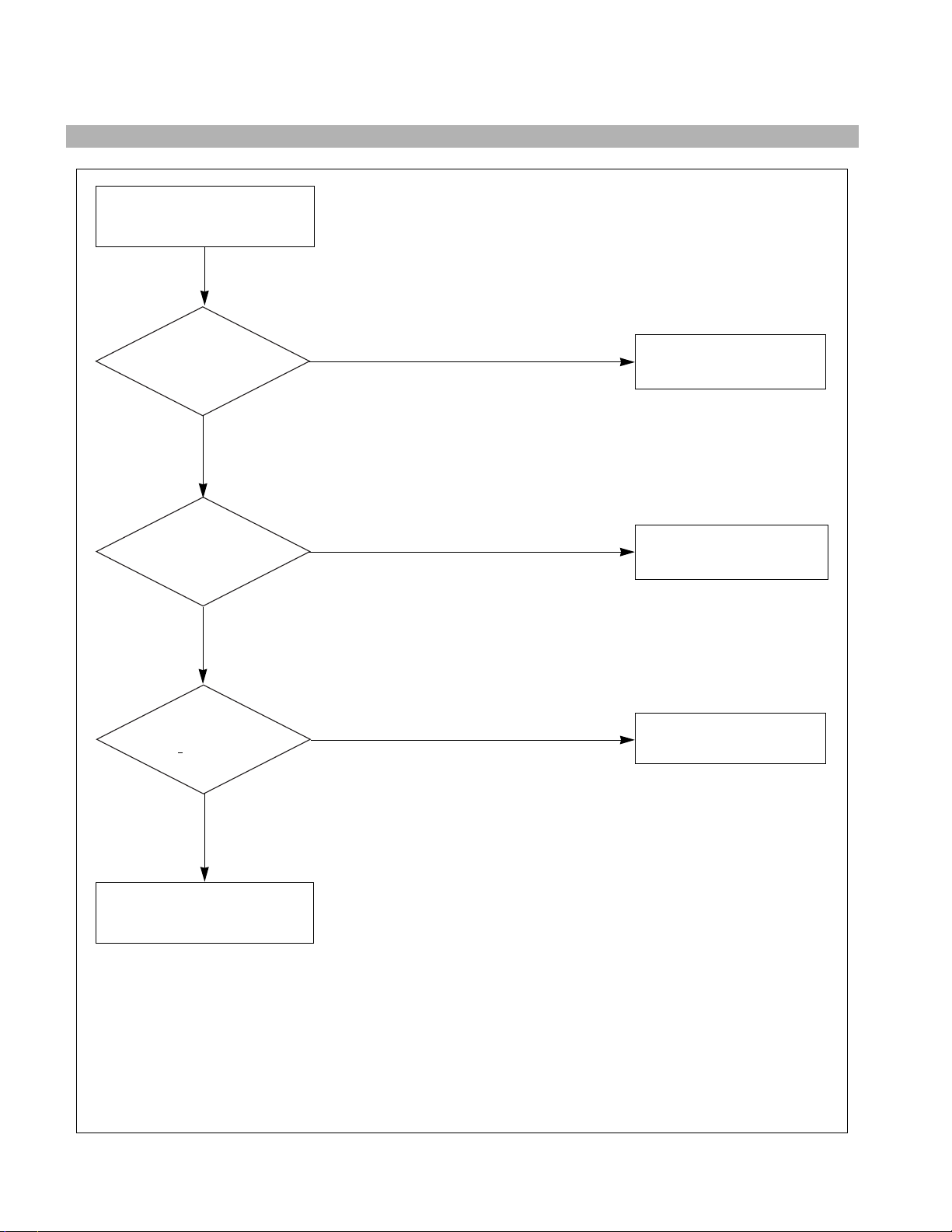

2. NO CHARACTER

- 18 -

NO CHARACTER

CHECK

IC302 PIN 7, 15, 18,

21(8V) ?

CHECK

IC302 PIN 6, 8, 10 ?

CHECK

IC302 PIN 16, 19, 22 ?

CHECK

IC303

PIN 1, 3, 5 ?

CHECK

IC303 PIN 6 (70V)

10 (12V) ?

TROUBLE IN

P302 12V LINE, IC304

TROUBLE IN

PC SIGNAL,

P301 SIGNAL CABLE

TROUBLE IN

IC302

TROUBLE IN

P302 12V LINE/70V LINE

TROUBLE IN IC303

NO

YES

NO

NO

YES

YES

YES

YES

NO

NO

CHECK

R, G, B CATHODE

VOLTAGE?

TROUBLE IN

R338~R341,

R344, R345, L302~L304,

D307~D310, D312, D313

TROUBLE IN

CRT SOCKET

YES

NO

Page 14

NO VIDEO

(POWER INDICATOR ON)

CHECK

POWER INDICATOR

GREEN or ORANGE?

CHECK

D712 ANODE

(-120V)?

CHECK

G1 VOLTAGE?

(

10~20V)

TROUBLE IN

D712

TROUBLE IN

D926, Q925 (6.3V)

TROUBLE IN

Q801~Q806

DPM MODE

(NO H and/or V SYNC)

ORANGE

NO

GREEN

YES

YES

NO

- 19 -

3. NO RASTER

Page 15

- 20 -

4. NO HORIZONTAL DEFLECTION

NO H-DEFLECTION

(ONE VERTICAL LINE)

CHECK

Q706?

CHECK

B+ VOLTAGE

(160V)?

CHECK

T701(FBT) PIN 3

(31KHZ 70V,

69KHZ 140V) ?

CHECK

Q705 COLLECTOR

WAVEFORM?

TROUBLE IN

Q706

TROUBLE IN

160V LINE

TROUBLE IN

Q717, Q718, Q719,

D707

TROUBLE IN

Q705

TROUBLE IN

T701, P701

NO

NO

YES

YES

YES

YES

NO

NO

Page 16

- 21 -

5. TROUBLE IN H-LINEARITY

UNBALANCED OF H-LIN.

CHECK

IC401

PIN 18, 19, 20?

CHECK

Q711~Q716?

CHECK

L703?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q711 ~ Q716

TROUBLE IN

L703

TROUBLE IN

L720, R744

NO

NO

NO

YES

YES

YES

Cs SIGNAL TABLE

HORIZONTAK

FREQUENCY(fH)

30K ~ 39K

39K ~ 47.5K

47.5K ~ 62K

62K ~ 70K

Cs0

L

L

L

H

Cs1

L

L

H

H

Cs2

L

H

H

H

Page 17

- 22 -

6. NO VERTICAL DEFLECTION

NO V-DEFLECTION

(ONE HORIZONTAL LINE)

CHECK

IC601 PIN 3

(15V)?

CHECK

IC601 PIN 7

(40V)?

CHECK

IC701 PIN 12, 13?

TROUBLE IN

R603, Q601~Q603,

15V LINE

TROUBLE IN

HIGH-VOLTAGE OUT

CIRCUIT, D713

TROUBLE IN

IC701

TROUBLE IN

IC601, V-CIRCUIT

NO

NO

YES

YES

YES

NO

3V

Page 18

- 23 -

TROUBLE IN

OSD PERIPHERAL

CIRCUIT

NO OSD

TROUBLE IN

5V LINE

TROUBLE IN

IC601 PIN8 (V-FBP),

T701 40V LINE

TROUBLE IN

IC302, IC301

TROUBLE IN

IC301, IC302

NO

YES

DC 5V

YES

YES

YES

NO

NO

NO

Pin 5

5V

Pin 10

5V

H+V

5V

H+V

CHECK

IC301 B

+

?

CHECK

IC311 PIN 12

WAVEFORM ?

(ENTER BUTTON MUST BE PRESSED.)

7. TROUBLE IN OSD

CHECK

IC301 PIN 5, 10

WAVEFORM?

CHECK

IC311 PIN 13, 14, 15 ?

Page 19

CHECK

IC401 (MICOM)

PIN 1, 42 (H/V INPUT)

SIGNAL?

CHECK

IC401 PIN 6

WAVEFORM?

CHECK

IC401 (MICOM)

PIN 9, 12 ?

CHECK

B+LINE

(6.3V,15V) ?

CHECK PC,

(PC IS NOT GOING INTO

DPM OFF MODE)

TROUBLE IN

X401

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q922, Q923, Q925, Q926

TROUBLE IN PC

OFF MODE FAILURE

INPUT H/V SYNC SIGNAL

NO H/V SYNC

(NO OFF MODE.)

NO

NO

NO (DPMF: 0V)

DPM TABLE

Mode

Item

NORMAL

STAND-BY

SUSPEND

OFF

DPMS

H

H

H

L

LED

GREEN

ORANGE

ORANGE

ORANGE

DPMF

H

L

L

L

- 24 -

YES

SEE DPM TABLE

YES

YES

5V

6MHz

8. TROUBLE IN DPM

Page 20

CHECK

IC401 PIN 22

(0V)?

CHECK

Q921 COLLECTOR

VOLTAGE?

CHECK

P902, P903?

CHECK

RL901?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q921

TROUBLE IN

P902, P903

TROUBLE IN

RL901

TROUBLE IN

TH902,

DEGAUSSING COIL

NO DEGAUSSING

DC 5V

NO

NO

NO

NO

- 25 -

YES

YES

YES

YES

(DEGAUSS ON THE OSD MENU MUST BE PRESSED.)

9. NO DEGAUSSING

Page 21

- 26 -

10. NO TILT (NO ROTATION)

NO TILT (NO ROTATION)

TROUBLE IN

IC401 (

MICOM)

TROUBLE IN

15V LINE, 6.3V LINE

TROUBLE IN

Q501~Q503

TROUBLE IN

P501, TILT COIL

NO

YES

YES

YES

CHECK

15V LINE

AND 6.3V LINE ?

CHECK

Q503 EMITTER

VOLTAGE ?

NO

NO

CHECK

Q504

WAVE FORM ?

Page 22

- 27 -

PRINTED CIRCUIT BOARD

1. MAIN BOARD (Component Side)

Page 23

- 28 -

2. MAIN BOARD (Solder Side)

Page 24

- 29 -

3. VIDEO BOARD (Component Side)

4. VIDEO BOARD (Solder Side)

Page 25

- 30 -

5. CONTROL BOARD (Component Side)

6. CONTROL BOARD (Solder Side)

Page 26

EXPLODED VIEW

1

11

13

14

15

16

17

30

27

28

29

26-1

26-2

12

B

C

A

18

19

24

25

20

21

22

23

7

2

3

4

5

6

8

9

10

- 32 -

EXPLODED VIEW PARTS LIST

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26-1

26-2

27

28

29

30

A

B

C

Part No.

3091TKC029B

3091TKC029A

2423GC0B85D

339-002H

6631T11005A

6868T17003C

6140TC3001A

4815TKV006E

6871TVH066B

4920TKP015A

4815TKV007J

6174Z-1012B

407-S29H

6200TJB001D

407-T73D

407-T98M

4920TKC003D

6871TST097A

4810TKM031A

4810TKM031B

4810TKK084A

4810TKK060A

431-128A

407-T83A

4950TKS118A

332-102F

3550TKK055A

3550TKK055B

332-102G

3550TKK056A

3809TKC014B

3809TKC014A

3043TKK036A

3141TZZ029B

3141TZZ029A

6871TVT066B

6871TMT095B

6871TMT095A

Description

CABINET ASS'Y, MPR-II, StdioWorks 775N

CABINET ASS'Y, TCO95, StdioWorks 775C

CDT, M41LFQ813X 46NLAA

SCREW ASSÕY, PHP+5x20 BP+GW18

TCO OPEN LOOP WIRE (TCO ONLY)

CRT GROUND WIRE

DEGAUSSING COIL

BRACKET, VIDEO FRONT

PCB ASS'Y, VIDEO

PLATE, HEAT SINK FOR IC303

METAL ASS'Y, VIDEO REAR SHIELD

FBT, FMMTC61

PLATE, HEAT SINK FOR Q719

AC SOCKET

PLATE, HEAT SINK FOR IC901

PLATE, HEAT SINK FOR IC601

COMPRESS, HEAT SINK FOR D704, Q709, Q706

PCB ASS'Y, CONTROL

BRACKET, PCB GUIDE (RIGHT)

BRACKET, PCB GUIDE (LEFT)

BRACKET, PCB HOLDER

HOLDER (PCB)

PIECE HOLDER

TCO SHIELD

METAL, BOTTOM SHIELD

SCREW, PTP+4x20BP

SCREW COVER (RIGHT)

SCREW COVER (LEFT)

SCREW, PTP+4x30

COVER, PIECE REAR

BACK COVER ASSÕY, MPR-II

BACK COVER ASSÕY, TCO95

TILT SWIVEL ASSÕY

CHASSIS ASS'Y, MAIN TOTAL, MPR-II

CHASSIS ASS'Y, MAIN TOTAL, TCO-95

CHASSIS ASS'Y, VIDEO BOARD

PCB ASS'Y, MAIN BOARD, MPR-II

PCB ASS'Y, MAIN BOARD, TCO95

Q'ty

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

2

1

1

4

1

1

1

1

1

1

Material

GE SEA-2 UL94-5V

SPTE-C (t=0.3)

SPTE-C (t=0.3)

AL (t=2.0)

AL (t=2.0)

AL

AL

SBHG1-A (t=1.0)

GE SEA-2 UL94-5V

HIPS 60HR UL 94-HB

Page 27

REPLACEMENT PARTS LIST

CAUTION:BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C401 0CE4766F618 CAPACITOR, AL.ELECTROLYTIC, 47U SMS 16V M FM5 TP5

C402 0CC2200K405 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 22P 50V J SL

C403 0CC2200K405 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 22P 50V J SL

C404 0CK2210K515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 220P 50V K B

C405 0CK2210K515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 220P 50V K B

C406 0CN2210K519 CAPACITOR, TUBULAR(HIGH DIELEC), 220P 50V K B TA52

C407 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C408 0CK1010K515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 100PF 50V K B TR

C409 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C410 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C411 0CK1010K515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 100PF 50V K B TR

C412 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C413 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C501 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C502 0CE1066F618 CAPACITOR, AL.ELECTROLYTIC, 10UF SMS 16V M FL TP5

C503 0CE1066F618 CAPACITOR, AL.ELECTROLYTIC, 10UF SMS 16V M FL TP5

C601 0CE477CH618 CAPACITOR, AL.ELECTROLYTIC, 470UF SHL 25V M FL TP5

C602 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

or C602 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C603 0CE476CN618 CAPACITOR, AL.ELECTROLYTIC, 47UF SHL 100V M FL TP5

C604 181-288P CAPACITOR, POLYESTER, MKT 100V 153JTR PHS86153

C605 0CK3320W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 3300P 500V K B

C701 181-288R CAPACITOR, POLYESTER, MKT 100V 123JTR PHS86123

C702 0CZZTFT001M CAPACITOR, ECQB1H103JM3 103J 50V TP5.0 MATSUSHITA

or C702 181-288N CAPACITOR, POLYESTER, MKT 100V 103JTR PHS86103

or C702 0CQ1031N419 CAPACITOR, POLYESTER, 0.01U 100V J POLY NI TP

C703 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

or C703 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C704 0CZZTFT001F CAPACITOR, ECQB1H332JM3 332J 50V TP5.0 MATSUSHITA

or C704 0CQ3321N419 CAPACITOR, POLYESTER 3300P 100V J POLY NI TP

C705 0CQ1031N419 CAPACITOR, POLYESTER, 0.01U 100V J POLY NI TP

C706 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

or C706 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C707 0CZZTFT002B CAPACITOR, ECQV1H154JZ3 154J 50V TP5.0 MATSUSHITA

or C707 181-288Q CAPACITOR, POLYESTER MKT 100V 154JTR PHS26154

C708 0CE108CF618 CAPACITOR, AL.ELECTROLYTIC, 1000UF SHL 16V M FL TP5

C709 0CK8210W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 820P 500V K B TS

- 33 -

MAIN BOARD

CAPACITORs

Page 28

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C710 0CE1066F618 CAPACITOR, AL.ELECTROLYTIC, 10UF SMS 16V M FL TP5

C711 0CZZTFT001D CAPACITOR, ECQB1H222JM3 222J 50V TP5.0 MATSUSHITA

or C711 0CQ2221N419 CAPACITOR, POLYESTER, 2200PF 100V J PE NI TP

C712 0CE1066F618 CAPACITOR, AL.ELECTROLYTIC, 10UF SMS 16V M FL TP5

C713 0CC2210K415 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 220P 50V J

C714 0CE1076F618 CAPACITOR, AL.ELECTROLYTIC, 100UF SMS 16V M TP(5)

C715 0CZZTFT001M CAPACITOR, ECQB1H103JM3 103J 50V TP5.0 MATSUSHITA

or C715 181-288N CAPACITOR, POLYESTER, MKT 100V 103JTR PHS86103

or C715 0CQ1031N419 CAPACITOR, POLYESTER, 0.01U 100V J POLY NI TP

C716 0CZZTFT002B CAPACITOR, ECQV1H154JZ3 154J 50V TP5.0 MATSUSHITA

or C716 181-288Q CAPACITOR, POLYESTER MKT 100V 154JTR PHS26154

C717 181-309Z CAPACITOR, POLYPROPYLENE, 562H 31.0*17.0*10.0*20.0 1.6KV

C718 0CBZTBU003H CAPACITOR, POLYPROPYLENE, 362J 20.0*12.0*7.0*10.0 800V

C719 0CZZTAB001A CAPACITOR, SM-BP(P)/BP 10UF 50V 13*25 BK5

C720 0CK8210W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 820P 500V K B TS

C721 181-477L CAPACITOR, POLYPROPYLENE, 682J 19.5*12.0*7.0*7.5 250V

C722 181-303G CAPACITOR, POLYPROPYLENE, 334J 31.0*22.0*15.0*20.0 250V

C723 181-305M CAPACITOR, POLYPROPYLENE, 824J 26.0*21.5*13.0*15.0 250V

C724 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C725 181-288D CAPACITOR, POLYESTER, MKT 100V 473JTR PHS26473

C726 181-482W CAPACITOR, POLYPROPYLENE, 304J 19.0*18.5*10.5*7.5 250V

C727 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C728 0CE3344K638 CAPACITOR, AL.ELECTROLYTIC, 0.33UF SRA,SS 50V M FM5

C729 181-482C CAPACITOR, POLYPROPYLENE, 154J 18.0*14.0*8.0*7.5 250V

C730 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C732 181-477U CAPACITOR, POLYPROPYLENE, 333J 19.5*13.0*7.5*7.5 250V

C733 0CE476CQ618 CAPACITOR, AL.ELECTROLYTIC, 47U SHL 200V M FL TP5

C734 181-310A CAPACITOR, AL.ELECTROLYTIC, 10UF SM-BP(D) 5*11 16V M

C735 0CE107CP618 CAPACITOR, AL.ELECTROLYTIC, 100U SHL 160V M FL TP5

C736 0CQ1831N419 CAPACITOR, POLYESTER, 0.018UF 100V J PE NI TP

C737 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C738 0CE1076K618 CAPACITOR, AL.ELECTROLYTIC, 100U SMS 50V M FM5 TP5

C739 0CE476CN618 CAPACITOR, AL.ELECTROLYTIC, 47UF SHL 100V M FL TP5

C740 0CE476CP618 CAPACITOR, AL.ELECTROLYTIC, 47U SHL 160V M FL TP5

C741 0CE2246K618 CAPACITOR, AL.ELECTROLYTIC, 0.22M SMS 50V M FM5 TP(5)

C742 0CZZTFT001M CAPACITOR, ECQB1H103JM3 103J 50V TP5.0 MATSUSHITA

or C742 181-288N CAPACITOR, POLYESTER, MKT 100V 103JTR PHS86103

or C742 0CQ1031N419 CAPACITOR, POLYESTER, 0.01U 100V J POLY NI TP

C743 0CK10302945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.01UF 2KV Z F

C744 0CE4766F618 CAPACITOR, AL.ELECTROLYTIC, 47U SMS 16V M FM5 TP5

C745 0CE108CH618 CAPACITOR, AL.ELECTROLYTIC, 1000UF SHL 25V M FL TP5

C746 0CE3344K638 CAPACITOR, AL.ELECTROLYTIC, 0.33UF SRA,SS 50V M FM5

C747 0CC2210K415 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 220P 50V

C749 0CK56101515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 560P 1KV K B TS

C750 0CE2256K618 CAPACITOR, AL.ELECTROLYTIC, 2.2U SMS 50V M FM5 TP5

C751 0CE1066F618 CAPACITOR, AL.ELECTROLYTIC, 10UF SMS 16V M FL TP5

- 34 -

Page 29

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C752 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C753 0CQ5621N419 CAPACITOR, POLYESTER, 5600P 100V J POLY NI TP

C754 0CK2710W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 270P 500V

C755 0CK10201515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 1000P 1KV K B TS

C756 0CK1040K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.1UF 50V Z F TR

C801 0CE477CF618 CAPACITOR, AL.ELECTROLYTIC, 470UF SHL 16V M FL TP5

C802 0CE4756P618 CAPACITOR, AL.ELECTROLYTIC, 4.7U SMS 160V M FM5 TP5

C803 0CE4756P618 CAPACITOR, AL.ELECTROLYTIC, 4.7U SMS 160V M FM5 TP5

C804 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C805 0CE1066K618 CAPACITOR, AL.ELECTROLYTIC, 10M SMS 50V M FM5

C806 181-288P CAPACITOR, POLYESTER, MKT 100V 153JTR PHS86153

C807 0CE1056P618 CAPACITOR, AL.ELECTROLYTIC, 1U SMS 160V M FM5 TP5

C907 181-124R CAPACITOR, AL.ELECTROLYTIC, 220UF SMG(25.4*40) 400V M

C908 181-308V CAPACITOR, POLYPROPYLENE, 393J 20.0*21.0*13.5*10.0 630V

C909 0CK10101515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 100PF 1KV K B TR

C910 0CE1076H618 CAPACITOR, AL.ELECTROLYTIC, 100M SMS 25V M FM5 TP(5)

C911 0CK8210W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 820P 500V K B TS

C913 0CKZTTA003C CAPACITOR, CERAMIC (HIGH DIELECTRIC), SC E 472M

or C913 0CKZTTA001C CAPACITOR, CERAMIC (HIGH DIELECTRIC), 1307-486E

C920 0CK56101515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 560P 1KV K B TS

C921 0CE4766F618 CAPACITOR, AL.ELECTROLYTIC, 47U SMS 16V M FM5 TP5

C922 0CE227CQ650 CAPACITOR, AL.ELECTROLYTIC, 220UF SHL 200V M FM7.5

C923 0CE107CN618 CAPACITOR, AL.ELECTROLYTIC, 100UF SHL 100V M FL TP5

C925 0CE108CH618 CAPACITOR, AL.ELECTROLYTIC, 1000UF SHL 25V M FL TP5

C926 0CE108CF618 CAPACITOR, AL.ELECTROLYTIC, 1000UF SHL 16V M FL TP5

C927 0CE1056P618 CAPACITOR, AL.ELECTROLYTIC, 1U SMS 160V M FM5 TP5

C929 0CE4766F618 CAPACITOR, AL.ELECTROLYTIC, 47U SMS 16V M FM5 TP5

C930 0CE477CF618 CAPACITOR, AL.ELECTROLYTIC, 470UF SHL 16V M FL TP5

C931 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

or C931 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C932 0CC8200K415 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 82P 50V J NP0

D401 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D501 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D502 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D701 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D702 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D703 0DR400500AA DIODE, RECTIFIER, SB40-05J BK SANYO TO-220ML 50V 4A

D704 0DD300000AB DIODE, RECTIFIER, FMP-3FU BK SANKEN TO3PF 1500V 5A

D705 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D705 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D706 0DR359150AA DIODE, RECTIFIER, BY359F-1500 BK PHILIPS SOD100 1500V

D707 0DD200009AJ DIODE, RECTIFIER, RL2Z V(1) TP SANKEN A-TMD 200V 2A

D708 0DR100009EA DIODE, RECTIFIER, RGP10G[CHN] TP G.I DO204AL 400V 1A

D711 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

- 35 -

DIODEs

Page 30

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

D712 0DR100009EA DIODE, RECTIFIER, RGP10G[CHN] TP G.I DO204AL 400V

D713 0DR100009DB DIODE, RECTIFIER, RGP10D[CHN] TP G.I DO204AL 200V 1A

D714 0DD400709CB DIODE, RECTIFIER, UF4007 TP G.I DO204AL 1000V 1A 30A

D715 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D716 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D716 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D717 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D717 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D718 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D718 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D723 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D730 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D731 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D732 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A

or D732 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D734 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D735 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D736 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D737 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D738 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D801 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D802 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D803 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D803 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D804 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D804 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D805 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D805 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D807 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D901 0DR153999AB DIODE, RECTIFIER, 1N5399GP TP G.I DO204AC 1000V 1.5A

D902 0DR153999AB DIODE, RECTIFIER, 1N5399GP TP G.I DO204AC 1000V 1.5A

D903 0DR153999AB DIODE, RECTIFIER, 1N5399GP TP G.I DO204AC 1000V 1.5A

D904 0DR153999AB DIODE, RECTIFIER, 1N5399GP TP G.I DO204AC 1000V 1.5A

D906 0DD400709CB DIODE, RECTIFIER, UF4007 TP G.I DO204AL 1000V 1A 30A

D907 0DR100009DB DIODE, RECTIFIER, RGP10D[CHN] TP G.I DO204AL 200V 1A

D910 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D911 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D919 0DR140059DA DIODE, RECTIFIER, 1N4005TB52 TP LITEON DO41 600V 1A 40A

or D919 0DD400509AA DIODE, RECTIFIER, 1N4005 GP TP G.I DO204AL 600V

D920 0DD300009AC DIODE, RECTIFIER, RU3AMV(1) TP SANKEN R-TMD 600V 1.5A

D921 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D922 0DD200009AH DIODE, RECTIFIER, RU2AMV(1) TP SANKEN R-TMD 600V 1.1A

D923 0DR100009DB DIODE, RECTIFIER, RGP10D[CHN] TP G.I DO204AL 200V 1A

D924 0DD540200AA DIODE, RECTIFIER, UF5402 (19C2-409) BK G.I DO201AD 200V

D926 0DD150009CB DIODE, RECTIFIER, RGP15D TP G.I DO204AC 200V 1.5A 50A

D928 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

- 36 -

Page 31

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

D929 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D931 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

ZD401 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD402 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD403 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD404 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD405 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD406 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD407 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD408 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD409 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD410 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V

ZD704 0DZ180009AG DIODE, ZENER, MTZJ18B TP ROHM-K DO34 500MW 18V 5MA

ZD705 0DZ510009AB DIODE, ZENER, MTZ5.1B TP ROHM-K DO34 500MW 5.1V 20MA

ZD706 0DZ180009AG DIODE, ZENER, MTZJ18B TP ROHM-K DO34 500MW 18V 5MA

ZD801 0DZ180009AG DIODE, ZENER, MTZJ18B TP ROHM-K DO34 500MW 18V 5MA

ZD802 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V 5MA

ZD803 0DZ620009BB DIODE, ZENER, MTZJ6.2B TP ROHM-K DO34 0.5W 6.2V 5MA

IC401 0IZZTSZ027A IC[HYBRID ], CB775 MICOM ASSY, (1)CB775 MICOM ASSY

IC402 0ISG240860A IC, SGS-THOMSON, M24C08-BN6 8DIP BK 8K SERIAL IIC BUS

or IC402 0IAL240800A IC, ATMEL, AT24C08, 8D EEOROM(8K, IIC)

IC601 0IPH486650A IC, PHILIPS, TDA4866/V5 SIL9P BK VERTICAL DEFLECTION IC

IC701 0IPH485600A IC, PHILIPS, TDA4856 SDIP32 BK IIC DEFLECTION CONT. IC

IC901 0ISK665413B IC, SANKEN, STR-F6654A[LF1351] 5P BK SWITCHING

IC902 0ILI817000E IC, LITEON, LTV-817M B 4P BK PHOTO COUPLER CTR(130-260)

or IC902 0ISH123200B IC, LITEON, LTV-817M B 4P BK PHOTO COUPLER CTR(130-260)

IC921 0IKE431000B IC, SHARP, PC123 FY2

IC923 0ISS780500F IC, SAMSUNG ELECTRONICS, KA7805

IC925 0ISS781200F IC, SAMSUNG ELECTRONICS, KA7812

L702 150-518N COIL, CHOKE, DR14*20 180UH 0.12*25MM 57.5T

L703 150-L05N COIL, LINEARITY, DR14*15 14*6T 5.6UH 0.12*30MM 17.5T

L704 125-155K CORE (CIRC),BEAD, BFS3550A0FG SAMWHA 3.5*5.0MM

L705 150-985K COIL, CHOKE, DR14*20 2.8MH 0.35MM 235.5T D/D CHOKE

L901 6200TLT002A FILTER(CIRC), LINE, RING 19*6*13H 1.0MH 0.5MM 22T CB770

Q401 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI

or Q401 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q501 0TR471009AA TRANSISTOR, KSD471AC-Y TP SAMSUNG TO92 NPN

or Q501 0TR320209AA TRANSISTOR, KTC3202-TP-Y (KTC1959), KEC

Q502 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q502 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

- 37 -

COILs & COREs

ICs

TRANSISTORs

Page 32

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

Q503 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q503 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q504 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q504 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q601 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q602 0TR928009AB TRANSISTOR, KSA928A-Y TP SAMSUNG TO92L PNP

or Q602 0TR127309AA TRANSISTOR, KTA1273-Y(KTA966A) TP KEC

Q603 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q704 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q704 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q705 0TR200009AB TRANSISTOR, KTC200-Y TP KEC TO92 NPN

Q706 0TR252700AB TRANSISTOR, BU2527AX BK PHILIPS SOT339 H-OUT TR

Q707 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q707 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q708 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

Q709 0TR141300AB TRANSISTOR, KTD1413 BK KEC TO220IS NPN

Q710 0TR130050BA TRANSISTOR, KSE13005F-A BK SAMSUNG TO220 NPN

Q711 0TF650000AA FET, IRF650A BK SAMSUNG 200V 25A TO220

Q712 0TF124000AB FET, FS12KMA-4A BK MITSUBISHI 200V 12A TO220FN

or Q712 0TF630000CA FET, IRFS630A BK SAMSUNG 200V 6.5A

Q713 0TF124000AB FET, FS12KMA-4A BK MITSUBISHI 200V 12A TO220FN

or Q713 0TF630000CA FET, IRFS630A BK SAMSUNG 200V 6.5A

Q714 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q714 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q715 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q715 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q716 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q716 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q717 0TR471009AA TRANSISTOR, KSD471AC-Y TP SAMSUNG TO92 NPN

or Q717 0TR320209AA TRANSISTOR, KTC3202-TP-Y (KTC1959), KEC

Q718 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q718 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q719 0TF963000BA FET, SFS9630 BK SAMSUNG -200V -4.4A TO220

Q720 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q720 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q721 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q721 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q722 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q722 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q723 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q723 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q724 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q724 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q725 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q725 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q726 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

- 38 -

Page 33

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

Q729 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q730 0TR564009AB TRANSISTOR, KSB564AC-YTA TP SANSUNG TO92 PNP

or Q730 0TR127009AA TRANSISTOR, KTA1270-Y(KTA562TM), TP, KEC

Q731 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q731 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q801 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q802 0TR101309CC TRANSISTOR, KSA1013-YTA TP SAMSUNG TO92L PNP

or Q802 0TR127509AC TRANSISTOR, KTA1275-Y(KTA1013) TP, KEC

Q803 0TR231009AA TRANSISTOR, KSC2310-Y TP SAMSUNG TO92L NPN

or Q803 0TR302609AB TRANSISTOR, KTC3206-Y, TP(KTC2229), KEC

Q804 0TR910009AA TRANSISTOR, KSA910-YTA TP SAMSUNG TO92L PNP

or Q804 0TR102409AB TRANSISTOR, KTA1024-Y(KTA949) TP, KEC

Q805 0TR910009AA TRANSISTOR, KSA910-YTA TP SAMSUNG TO92L PNP

or Q805 0TR102409AB TRANSISTOR, KTA1024-Y(KTA949) TP, KEC

Q806 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q806 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q807 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q808 0TR231009AA TRANSISTOR, KSC2310-Y TP SAMSUNG TO92L NPN

or Q808 0TR302609AB TRANSISTOR, KTC3206-Y, TP(KTC2229), KEC

Q920 0TR233009AA TRANSISTOR, KSC2330-O TP SAMSUNG TO92L NPN

or Q920 0TR320709AA TRANSISTOR, KTC3270, TP(KTC2482), KEC

Q921 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q921 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q922 0TR928009AB TRANSISTOR, KSA928A-Y TP SAMSUNG TO92L PNP

or Q922 0TR127309AA TRANSISTOR, KTA1273-Y(KTA966A) TP KEC

Q923 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q923 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q924 0TR233009AA TRANSISTOR, KSC2330-O TP SAMSUNG TO92L NPN

or Q924 0TR320709AA TRANSISTOR, KTC3270, TP(KTC2482), KEC

Q925 0TR928009AB TRANSISTOR, KSA928A-Y TP SAMSUNG TO92L PNP

or Q925 0TR127309AA TRANSISTOR, KTA1273-Y(KTA966A) TP KEC

Q926 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q926 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815) TP, KEC

Q928 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

Q929 0TR114009AB TRANSISTOR, DTC114ES TP ROHM-K SPT NPN

R401 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R402 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R403 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R404 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R405 0RD2001Q609 RESISTOR, FIXED CARBON FILM, 2K 1/4W(3 5% TA52

R406 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R407 0RD3301Q609 RESISTOR, FIXED CARBON FILM, 3.30K 1/4W(3 5% TA52

R408 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R409 0RD1801Q609 RESISTOR, FIXED CARBON FILM, 1.80K 1/4W(3 5% TA52

- 39 -

RESISTORs

Page 34

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R410 0RD1801Q609 RESISTOR, FIXED CARBON FILM, 1.80K 1/4W(3 5% TA52

R411 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R413 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R414 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R421 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R422 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R423 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R424 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R425 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R427 0RD5602Q609 RESISTOR, FIXED CARBON FILM, 56K 1/4W(3 5% TA52

R428 0RD1003Q609 RESISTOR, FIXED CARBON FILM, 100K 1/4W(3 5% TA52

R430 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R431 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R432 0RD5602Q609 RESISTOR, FIXED CARBON FILM, 56K 1/4W(3 5% TA52

R434 0RD0332Q609 RESISTOR, FIXED CARBON FILM, 33 1/4W(3 5% TA52

R435 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R436 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R437 0RD5100Q609 RESISTOR, FIXED CARBON FILM, 510 1/4W(3 5% TA52

R438 0RD5100Q609 RESISTOR, FIXED CARBON FILM, 510 1/4W(3 5% TA52

R501 0RD0471A609 RESISTOR, FIXED CARBON FILM, 4.7 OHM 1/2 W (7.0) 5% TA52

R502 0RD0202A609 RESISTOR, FIXED CARBON FILM, 20 OHM 1/2 W (7.0) 5% TA52

R503 0RD8201Q609 RESISTOR, FIXED CARBON FILM, 8.20K 1/4W(3 5% TA52

R504 0RD1500Q609 RESISTOR, FIXED CARBON FILM, 150 1/4W(3 5% TA52

R505 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R506 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R507 0RD1601Q609 RESISTOR, FIXED CARBON FILM, 1.60K 1/4W(3 5% TA52

R508 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R601 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R602 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R603 0RN0390G609 RESISTOR, FIXED METAL FILM, 0.39 1/4W 5 TA52

R604 0RD0101A609 RESISTOR, FIXED CARBON FILM, 1 OHM 1/2 W (7.0) 5% TA52

R605 0RD0102A609 RESISTOR, FIXED CARBON FILM, 10 OHM 1/2 W (7.0) 5% TA52

R606 0RD1000A609 RESISTOR, FIXED CARBON FILM, 100 OHM 1/2 W (7.0) 5%

R607 0RN5101F409 RESISTOR, FIXED METAL FILM, 5.10K 1/6W 1% TA52

R608 0RD2700A609 RESISTOR, FIXED CARBON FILM, 270 OHM 1/2 W (7.0) 5%

R609 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R610 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R611 0RD9100A609 RESISTOR, FIXED CARBON FILM, 910 OHM 1/2 W (7.0) 5%

R612 0RN5101F409 RESISTOR, FIXED METAL FILM, 5.10K 1/6W 1% TA52

R701 0RD4702Q609 RESISTOR, FIXED CARBON FILM, 47K 1/4W(3 5% TA52

R702 0RD4702Q609 RESISTOR, FIXED CARBON FILM, 47K 1/4W(3 5% TA52

R703 0RD1202Q609 RESISTOR, FIXED CARBON FILM, 12K 1/4W(3 5% TA52

R704 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R705 0RD2402Q609 RESISTOR, FIXED CARBON FILM, 24K 1/4W(3 5% TA52

R706 0RN2701F409 RESISTOR, FIXED METAL FILM, 2.70K 1/6W 1% TA52

R707 0RN1801F409 RESISTOR, FIXED METAL FILM, 1.80K 1/6W 1% TA52

- 40 -

Page 35

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R708 0RN1101F409 RESISTOR, FIXED METAL FILM, 1.10K 1/6W 1% TA52

R709 0RD2202Q609 RESISTOR, FIXED CARBON FILM, 22K 1/4W(3 5% TA52

R710 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R711 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R712 0RD5602Q609 RESISTOR, FIXED CARBON FILM, 56K 1/4W(3 5% TA52

R713 0RD4301Q609 RESISTOR, FIXED CARBON FILM, 4.30K 1/4W(3 5% TA52

R714 0RD1502Q609 RESISTOR, FIXED CARBON FILM, 15K 1/4W(3 5% TA52

R715 0RD3002Q609 RESISTOR, FIXED CARBON FILM, 30K 1/4W(3 5% TA52

R716 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R717 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R718 0RD5102Q509 RESISTOR, FIXED CARBON FILM, 51K OHM 1/4 W (3.4) 2%

R719 0RN3601F409 RESISTOR, FIXED METAL FILM, 3.6K 1/6W 1 TA52

R720 0RD0471Q609 RESISTOR, FIXED CARBON FILM, 4.70 1/4W(3 5% TA52

R721 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R722 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R723 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R724 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R725 0RD0102Q609 RESISTOR, FIXED CARBON FILM, 10 1/4W(3 5% TA52

R726 0RX9102J609 RESISTOR, SMALL FIX METAL FILM OXIDE, 91K OHM 1 W 5%

R727 0RX0432K607 RESISTOR, SMALL FIX METAL FILM OXIDE, 43 OHM 2 W 5%

R728 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R729 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R730 0RD3000A609 RESISTOR, FIXED CARBON FILM, 300 OHM 1/2 W (7.0) 5%

R731 0RD0271A609 RESISTOR, FIXED CARBON FILM, 2.7 OHM 1/2 W (7.0) 5%

R732 0RD0472A609 RESISTOR, FIXED CARBON FILM, 47 OHM 1/2 W (7.0) 5%

R733 0RD6801Q609 RESISTOR, FIXED CARBON FILM, 6.80K 1/4W(3 5% TA52

R734 0RD1802Q609 RESISTOR, FIXED CARBON FILM, 18K 1/4W(3 5% TA52

R735 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R736 0RN1003F409 RESISTOR, FIXED METAL FILM, 100K 1/6W 1 TA52

R737 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R738 0RN1503F409 RESISTOR, FIXED METAL FILM, 150K 1/6W 1% TA52

R739 0RN2202F409 RESISTOR, FIXED METAL FILM, 22K 1/6W 1% TA52

R740 0RN1503F409 RESISTOR, FIXED METAL FILM, 150K 1/6W 1% TA52

R741 0RD8202A609 RESISTOR, FIXED CARBON FILM, 82K OHM 1/2 W (7.0) 5%

R742 0RD3002Q609 RESISTOR, FIXED CARBON FILM, 30K 1/4W(3 5% TA52

R743 0RD8200Q609 RESISTOR, FIXED CARBON FILM, 820 1/4W(3 5% TA52

R744 0RD2200A609 RESISTOR, FIXED CARBON FILM, 220 OHM 1/2 W (7.0) 5%

R745 0RD4702Q609 RESISTOR, FIXED CARBON FILM, 47K 1/4W(3 5% TA52

R746 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R747 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R748 0RD4702Q609 RESISTOR, FIXED CARBON FILM, 47K 1/4W(3 5% TA52

R749 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R750 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R751 0RD4702Q609 RESISTOR, FIXED CARBON FILM, 47K 1/4W(3 5% TA52

R752 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R753 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

- 41 -

Page 36

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R754 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R756 0RD0472Q609 RESISTOR, FIXED CARBON FILM, 47 1/4W(3 5% TA52

R757 0RD0472Q609 RESISTOR, FIXED CARBON FILM, 47 1/4W(3 5% TA52

R758 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R759 0RN0270H609 RESISTOR, FIXED METAL FILM, 0.27 1/2W 5 TA52

R760 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R761 0RD1502Q609 RESISTOR, FIXED CARBON FILM, 15K 1/4W(3 5% TA52

R762 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R763 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R764 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R765 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R766 0RD8202Q609 RESISTOR, FIXED CARBON FILM, 82K 1/4W(3 5% TA52

R767 0RD2701Q609 RESISTOR, FIXED CARBON FILM, 2.70K 1/4W(3 5% TA52

R768 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R769 0RN6202F409 RESISTOR, FIXED METAL FILM, 62KOHM 1/6 W 1% TA52

R770 971-0016 WIRE, JUMP, TIN HDC 0.60H

R771 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R772 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R773 0RD3002Q609 RESISTOR, FIXED CARBON FILM, 30K 1/4W(3 5% TA52

R774 0RD3602Q609 RESISTOR, FIXED CARBON FILM, 36K 1/4W(3 5% TA52

R775 0RD8202Q609 RESISTOR, FIXED CARBON FILM, 82K 1/4W(3 5% TA52

R777 0RD2703A609 RESISTOR, FIXED CARBON FILM, 270K OHM 1/2 W (7.0) 5%

R778 0RD5603A609 RESISTOR, FIXED CARBON FILM, 560K OHM 1/2 W (7.0) 5%

R779 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R780 0RX9102J609 RESISTOR, SMALL FIX METAL FILM OXIDE, 91K OHM 1 W 5%

R781 0RD2403A609 RESISTOR, FIXED CARBON FILM, 240K OHM 1/2 W (7.0) 5%

R782 0RD2002A609 RESISTOR, FIXED CARBON FILM, 20K OHM 1/2 W (7.0) 5%

R783 0RD5103Q609 RESISTOR, FIXED CARBON FILM, 510K 1/4W(3 5% TA52

R784 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R785 0RD3000Q609 RESISTOR, FIXED CARBON FILM, 300 1/4W(3 5% TA52

R786 0RD5602Q609 RESISTOR, FIXED CARBON FILM, 56K 1/4W(3 5% TA52

R787 0RD8202Q609 RESISTOR, FIXED CARBON FILM, 82K 1/4W(3 5% TA52

R788 0RD6801Q609 RESISTOR, FIXED CARBON FILM, 6.80K 1/4W(3 5% TA52

R789 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R790 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R795 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R796 0RD1303A609 RESISTOR, FIXED CARBON FILM, 130K OHM 1/2 W (7.0) 5%

R797 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R798 0RD1202Q609 RESISTOR, FIXED CARBON FILM, 12K 1/4W(3 5% TA52

R799 0RD5603A609 RESISTOR, FIXED CARBON FILM, 560K OHM 1/2 W (7.0) 5%

R801 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R802 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R803 0RD1003Q609 RESISTOR, FIXED CARBON FILM, 100K 1/4W(3 5% TA52

R804 0RD3002Q609 RESISTOR, FIXED CARBON FILM, 30K 1/4W(3 5% TA52

R805 0RD4700Q609 RESISTOR, FIXED CARBON FILM, 470 OHM 1/4 W (3.4) 5% TA52

R806 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

- 42 -

Page 37

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R807 0RD1803Q609 RESISTOR, FIXED CARBON FILM, 180K 1/4W(3 5% TA52

R808 0RD1004Q609 RESISTOR, FIXED CARBON FILM, 1M OHM 1/4 W (3.4) 5% TA52

R809 0RD1003Q609 RESISTOR, FIXED CARBON FILM, 100K 1/4W(3 5% TA52

R810 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R811 0RD1503Q609 RESISTOR, FIXED CARBON FILM, 150K 1/4W(3 5% TA52

R812 0RD1004Q609 RESISTOR, FIXED CARBON FILM, 1M OHM 1/4 W (3.4) 5% TA52

R813 0RD5603Q609 RESISTOR, FIXED CARBON FILM, 560K 1/4W(3 5% TA52

R814 971-0016 WIRE, JUMP, TIN HDC 0.60H

R815 0RD4700Q609 RESISTOR, FIXED CARBON FILM, 470 OHM 1/4 W (3.4) 5%

R816 0RN1102F409 RESISTOR, FIXED METAL FILM, 11K 1/6W 1% TA52

R817 0RD2001Q609 RESISTOR, FIXED CARBON FILM, 2K 1/4W(3 5% TA52

R818 0RN1802F409 RESISTOR, FIX METAL FILM, 18K 1/6W 1% TA52

R820 0RD3001Q609 RESISTOR, FIXED CARBON FILM, 3K 1/4W(3 5% TA52

R821 0RD2002Q609 RESISTOR, FIXED CARBON FILM, 20K 1/4W(3 5% TA52

R822 0RD2201Q609 RESISTOR, FIXED CARBON FILM, 2.20K 1/4W(3 5% TA52

R823 0RD4700Q609 RESISTOR, FIXED CARBON FILM, 470 OHM 1/4 W (3.4) 5%

R902 0RMZTWD001A RESISTOR, CEMENT, 4.7 OHM 5 W 5% B RWR

R903 0RD3302A609 RESISTOR, FIXED CARBON FILM, 33K OHM 1/2 W (7.0) 5%

R904 0RD3302A609 RESISTOR, FIXED CARBON FILM, 33K OHM 1/2 W (7.0) 5%

R905 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R906 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R907 0RB0150J609 RESISTOR, FIX WIRE-WOUND PRECISION, 0.15 OHM 1W 5%

R908 0RD2001Q609 RESISTOR, FIXED CARBON FILM, 2K 1/4W(3 5% TA52

R909 0RD3003Q609 RESISTOR, FIXED CARBON FILM, 300K 1/4W(3 5% TA52

R910 0RD1003A609 RESISTOR, FIXED CARBON FILM, 100K OHM 1/2 W (7.0) 5%

R911 0RD1003A609 RESISTOR, FIXED CARBON FILM, 100K OHM 1/2 W (7.0) 5%

R912 180-465A RESISTOR, CEMENT, 0.56 OHM 5W 5% B RWR

R913 0RN0390G609 RESISTOR, FIXED METAL FILM, 0.39 1/4W 5 TA52

R914 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R915 0RD6200Q609 RESISTOR, FIXED CARBON FILM, 620 1/4W(3 5% TA52

R916 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R918 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R919 0RD3003Q609 RESISTOR, FIXED CARBON FILM, 300K 1/4W(3 5% TA52

R921 0RD0182A609 RESISTOR, FIXED CARBON FILM, 18 OHM 1/2 W (7.0) 5% TA52

R922 0RD1501Q609 RESISTOR, FIXED CARBON FILM, 1.50K 1/4W(3 5% TA52

R923 0RN7502G409 RESISTOR, FIXED METAL FILM, 75 KOHM 1/4 W 1% TA52

R924 0RN7502G409 RESISTOR, FIXED METAL FILM, 75 KOHM 1/4 W 1% TA52

R925 0RN0220H609 RESISTOR, FIXED METAL FILM, 0.22 1/2W 5% TA52

R926 0RN2201F409 RESISTOR, FIXED METAL FILM, 2.20K 1/6W 1% TA52

R927 0RN0220H609 RESISTOR, FIXED METAL FILM, 0.22 1/2W 5% TA52

R928 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R929 0RX4700J609 RESISTOR, SMALL FIX METAL FILM OXIDE, 470 OHM 1 W 5%

R930 0RD4701Q609 RESISTOR, FIXED CARBON FILM, 4.70K 1/4W(3 5% TA52

R931 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R932 0RD1003Q609 RESISTOR, FIXED CARBON FILM, 100K 1/4W(3 5% TA52

R933 0RD1501Q609 RESISTOR, FIXED CARBON FILM, 1.50K 1/4W(3 5% TA52

- 43 -

Page 38

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R934 0RD5603Q609 RESISTOR, FIXED CARBON FILM, 560K 1/4W(3 5% TA52

R935 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R936 0RD1503A609 RESISTOR, FIXED CARBON FILM, 150K OHM 1/2 W (7.0) 5%

R938 0RD5602Q609 RESISTOR, FIXED CARBON FILM, 56K 1/4W(3 5% TA52

R939 0RD0472Q609 RESISTOR, FIXED CARBON FILM, 47 1/4W(3 5% TA52

VR701 180-035G VOLUME, EVN-DJAA03B13 (MEC),1KB

VR901 180-035D VOLUME, EVN-DJAA03B32 (MEC),300B

F901 131-040C FUSE,TIME LAG, 3.15A 250V HBC UL/CSA TRIAD

P401 6602T20002J WAFER, 35362-1010 MOLEX 2.0mm S/T

P401-P201

6631T20004A CONNECTOR ASSY, 10P H-H 220MM UL1061 AWG 26 TWI

P402 6602T20002E WAFER, 35362-0610 MOLEX 2.0mm S/T

P501 6602T25008B WAFER, SMW250-03 YEONHO 2.5MM LOCK S/T

P701 366-112D WAFER, BW-504LG BAEEUN 2.36mm S/T

P702 6602T20002P WAFER, 35362-1510 MOLEX 2.0mm S/T

P702-P302

6631T20009A CONNECTOR ASSY, 15P H-H 180MM UL1061 AWG 26 TWI CB770

P703 366-167A WAFER, BW-501S BAEEUN 2.36mm H=17MM

P704 366-167A WAFER, BW-501S BAEEUN 2.36mm H=17MM

P902 366-167A WAFER, BW-501S BAEEUN 2.36mm H=17MM

P903 366-167A WAFER, BW-501S BAEEUN 2.36mm H=17MM

PG1 302-987A SHIELD, TERMINAL EARTH

PG2 302-987A SHIELD, TERMINAL EARTH

RL901 141-040A RELAY, JW2HN-DC5V MATSUSHITA 250VAC 5A 5V 106MA

SC901 6200TJB001D FILTER(CIRC), EMI, 02ME4E2 DELTA 25MH BLACK

SG701 165-004A SPARK GAP, AG20PT 152F-L3N/S-23 HANDOK RADIAL BULK

T701 6174Z-1012B FBT (FLY BACK TRANSFORMER), FMMTC61

T702 6170TCZ002A

TRANSFORMER, HORIZONTAL DRIVER, EE2519,2.9MH D/FOCUS

T703 6170TCZ001A TRANSFORMER, SMPS, H-DRIVE,EI2218,3.8MH

T901 6170TMZ056A TRANSFORMER, SMPS, EER4045 195UH 16PIN CB770 NY/JS .

TH901 6322TB090AA THERMISTOR, PTC, PT11P62D090Q290 DAEWOO +30%/-20%

WG2 387-P91A CONNECTOR ASSY, UL1015 AWG22

X401 6202TTB001A CRYSTAL, HC-49/U SUNNY E 6.000000MHZ 30PPM 16PF BK

CONN 6631T11005A CONNECTOR ASSY, TCO OPEN LOOP WIRE (UL 101522 CS560)

C301 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

C302 0CE1076D618 CAPACITOR, AL.ELECTROLYTIC, 100M SMS 10V M FM5

C303 0CZZTFT001Z CAPACITOR, ECQB1H104JM3 104J 50V TP5.0 MATSUSHITA

C306 0CZZTFT001X CAPACITOR, ECQB1H683JM3 683J 50V TP5.0 MATSUSHITA

or C306 181-288K CAPACITOR, POLYESTER, MKT 100V 683JTR PHS26683

C307 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z

C308 0CE1076D618 CAPACITOR, AL.ELECTROLYTIC, 100M SMS 10V M FM5

C309 0CK2230K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.022UF 50V Z

C310 0CN2230H949 CAPACITOR, TUBULAR(HIGH DIELEC), 22000P 25V Z FTA52

- 44 -

OTHERs

VIDEO BOARD

CAPACITORs

Page 39

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C311 0CK2230K945 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.022UF 50V Z

C312 0CE1076F618 CAPACITOR, AL.ELECTROLYTIC, 100UF SMS 16V M TP(5)

C313 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C314 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C315 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C316 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C317 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C318 0CE476CN618 CAPACITOR, AL.ELECTROLYTIC, 47UF SHL 100V M FL TP5

C319 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C320 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C321 0CE4766F618 CAPACITOR, AL.ELECTROLYTIC, 47U SMS 16V M FM5 TP5

C323 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C324 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C325 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C327 181-288G CAPACITOR, POLYESTER, MKT 100V 334JTR PHS26334

C329 0CK10301510 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.01M 1KV

C330 0CK10301510 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 0.01M 1KV

C331 0CC4700W405 CAPACITOR, CERAMIC (TEMP. COMPENSATE), 47PF 500V

C333 0CK2220K515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 2200P 50V

C334 0CK3320W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 3300P 500V

C335 0CE336CP630 CAPACITOR, AL.ELECTROLYTIC, 33U SHL 160V M FM5

C336 0CK3320W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 3300P 500V

C337 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C339 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C340 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C341 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C342 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C343 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C344 181-288E CAPACITOR, POLYESTER, MKT 100V 474JTR PHS 26474

C348 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C350 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C351 0CH6102K406 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 1000PF 50V J SL

C352 0CH6102K406 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 1000PF 50V J SL

C353 0CN1020K519 CAPACITOR, TUBULAR(HIGH DIELEC), 1000P 50V K B TA52

C354 0CK5610W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 560P 500V K B

C355 0CK5610W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 560P 500V K B

C356 0CK5610W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 560P 500V K B

C357 0CE2266F618 CAPACITOR, AL.ELECTROLYTIC, 22M SMS 16V M FM5

C359 0CE2266F618 CAPACITOR, AL.ELECTROLYTIC, 22M SMS 16V M FM5

C370 0CH3104K946 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 100000PF 50V Z F

C371 0CE1066N618 CAPACITOR, AL.ELECTROLYTIC, 10M SMS 100V M FM5 TP5

C372 0CN1040K949 CAPACITOR, TUBULAR(HIGH DIELEC), 0.1M 50V Z F TA52

C373 0CK1020W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 1000P 500V

C374 181-288B CAPACITOR, POLYESTER, MKT 100V 104JTR PHS26104

C375 0CK3320W515 CAPACITOR, CERAMIC (HIGH DIELECTRIC), 3300P 500V

- 45 -

Page 40

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

D301 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D302 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D303 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D304 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D305 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D306 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D307 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D308 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D309 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D310 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D311 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D312 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D313 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D314 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D315 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D316 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D317 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

D318 0DS113309AA DIODE, SWITCHING, 1SS133, TP, ROHM, KOREA DO34 90V

IC301 0IMO454520A IC, MOTOROLA, LSC4545P2 16,DIP BK OSD

IC302 0IPH488600A IC, PHILIPS, TDA4886 SDIP24 BK 120MHZ VIDEO PREAMP IC

IC303 0INS240700A IC, NATIONAL SEMICONDUCTOR, LM2407T 11P BK MONO.

IC304 0ISS780800A IC, SAMSUNG ELECTRONICS, KA7808 (KA7808C) REGULATOR

L301 0LA1000K119 INDUCTOR, AXIAL LEAD, 100UH K 2.3*3.4 TP

L302 0LA0560K119 INDUCTOR, AXIAL LEAD, 0.56UH K 2.3*3.4 TP

L303 0LA0560K119 INDUCTOR, AXIAL LEAD, 0.56UH K 2.3*3.4 TP

L304 0LA0560K119 INDUCTOR, AXIAL LEAD, 0.56UH K 2.3*3.4 TP

Q301 0TR390409CA TRANSISTOR, 2N3904 TP SAMSUNG TO92 NPN

Q302 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q302 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815), TP KEC

Q303 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q303 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815), TP KEC

Q304 0TR945009AA TRANSISTOR, KSC945C-Y TP SAMSUNG TO92 NPN EPI.

or Q304 0TR319809AA TRANSISTOR, KTC3198-Y(KTC1815), TP KEC

Q305 0TR231009AA TRANSISTOR, KSC2310-Y TP SAMSUNG TO92L NPN

or Q305 0TR320609AB TRANSISTOR, KTC3206-Y, TP(KTC2229), KEC

Q306 0TR231009AA TRANSISTOR, KSC2310-Y TP SAMSUNG TO92L NPN

or Q306 0TR320609AB TRANSISTOR, KTC3206-Y, TP(KTC2229), KEC

Q307 0TR231009AA TRANSISTOR, KSC2310-Y TP SAMSUNG TO92L NPN

or Q307 0TR320609AB TRANSISTOR, KTC3206-Y, TP(KTC2229), KEC

- 46 -

DIODEs

TRANSISTORs

COILs & COREs

ICs

Page 41

MODEL: S/W775N, S/W775C DATE: 1998 .12. 23.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

R301 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R302 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R303 0RH0752D622 RESISTOR, CHIP, 75 1/10W 5 D.R/TP

R304 0RD1801Q609 RESISTOR, FIXED CARBON FILM, 1.80K 1/4W(3 5% TA52

R305 0RD1501Q609 RESISTOR, FIXED CARBON FILM, 1.50K 1/4W(3 5% TA52

R306 0RD5601Q609 RESISTOR, FIXED CARBON FILM, 5.60K 1/4W(3 5% TA52

R307 0RD1004Q609 RESISTOR, FIXED CARBON FILM, 1M OHM 1/4 W (3.4) 5% TA52

R308 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R309 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R310 0RD1002Q609 RESISTOR, FIXED CARBON FILM, 10K 1/4W(3 5% TA52

R311 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R312 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R313 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R314 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

R315 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R316 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52

R317 0RD0221Q609 RESISTOR, FIXED CARBON FILM, 2.20 1/4W(3 5% TA52

R318 0RD1000Q609 RESISTOR, FIXED CARBON FILM, 100 1/4W(3 5% TA52