Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PP91B

MODEL : 42PQ301R 42PQ301R-ZB

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

P/NO : MFL60273009 (0906-REV00) Printed in Korea

Page 2

- 2 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CONTENTS

CONTENTS ............................................................................................................................... 2

SAFETY PRECAUTIONS ...........................................................................................................3

SPECIFICATION.........................................................................................................................4

ADJUSTMENT INSTRUCTION ..................................................................................................8

BLOCK DIAGRAM ...................................................................................................................16

EXPLODED VIEW ..................................................................................................................17

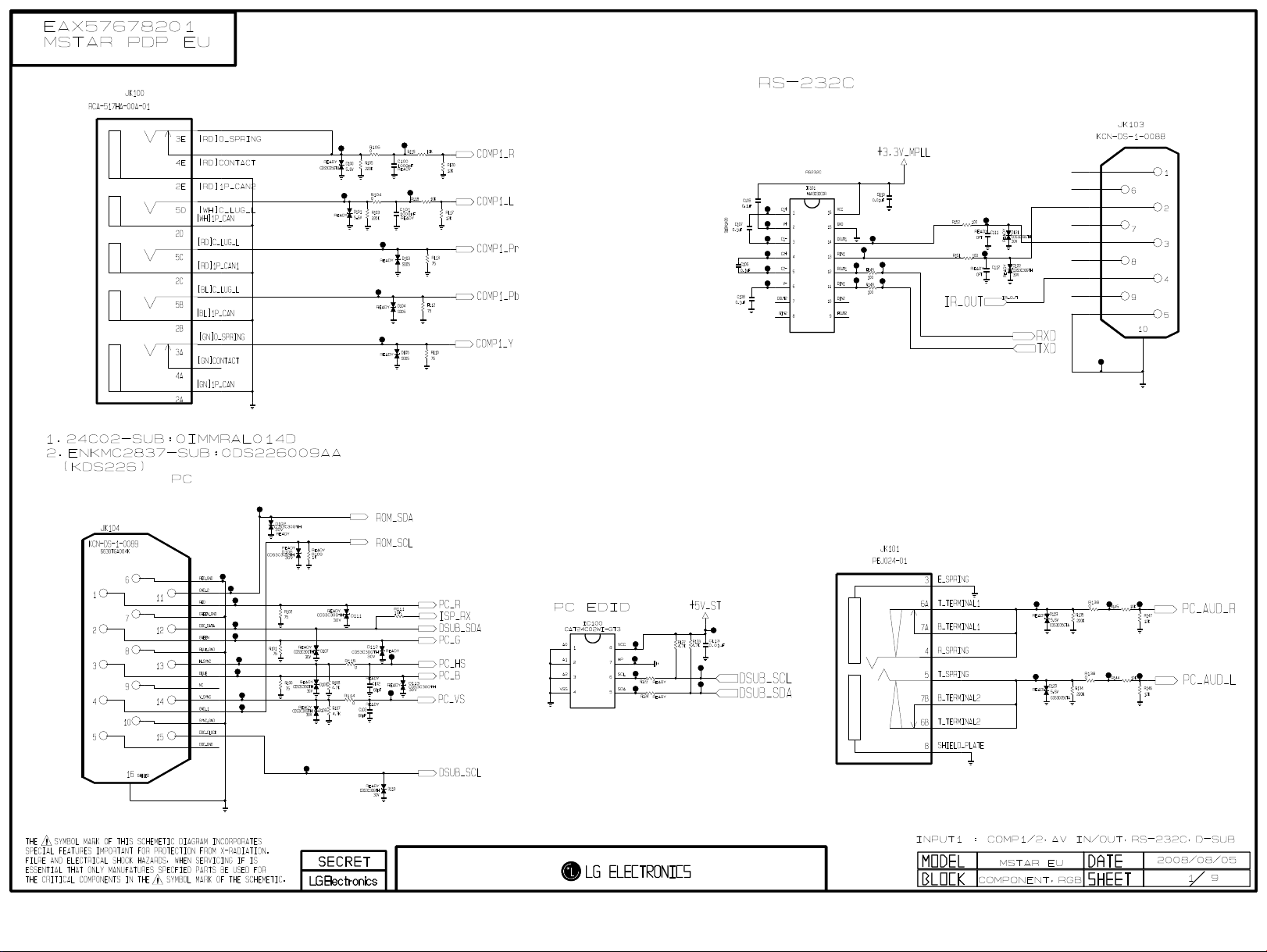

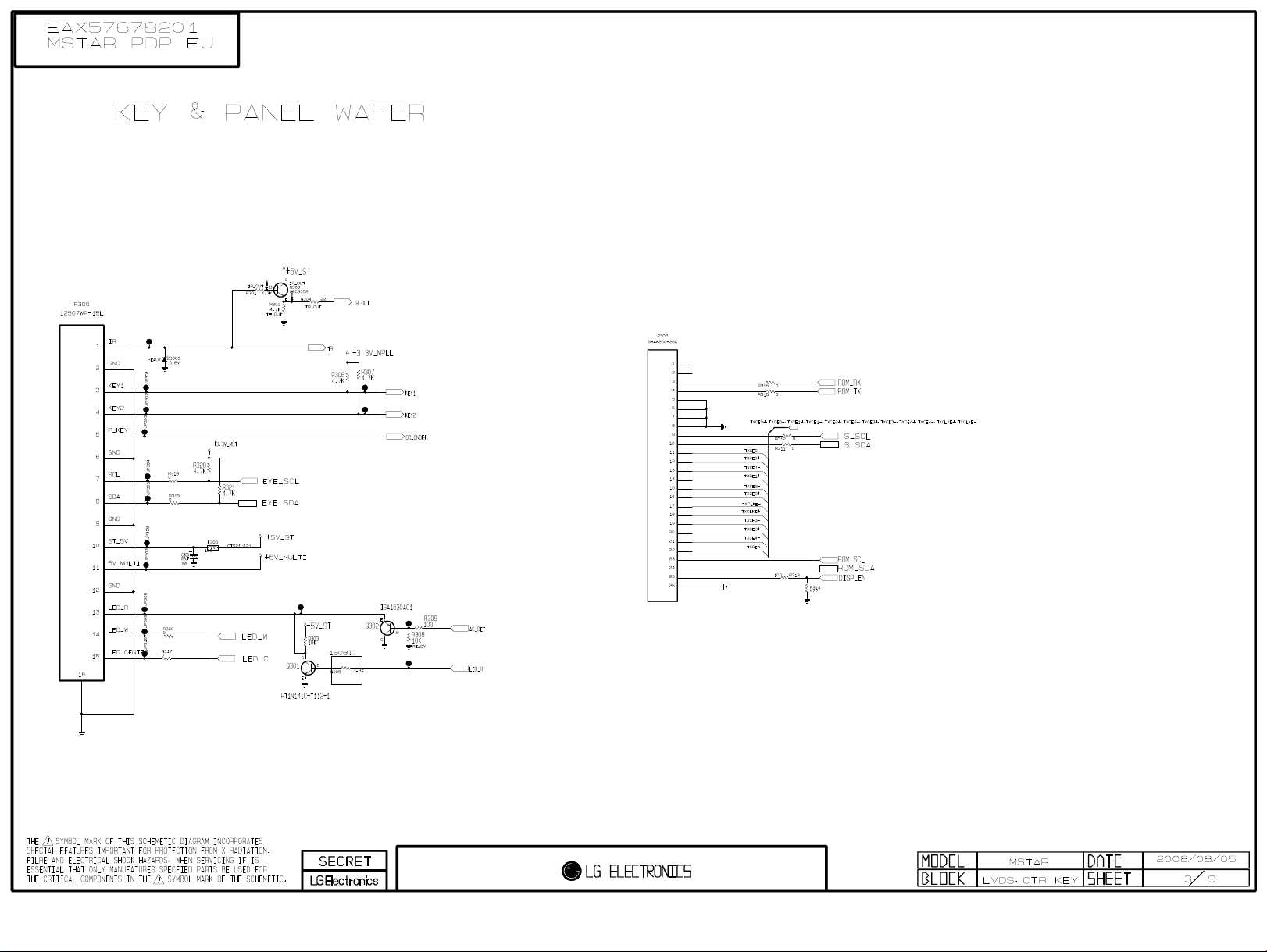

SVC. SHEET ................................................................................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

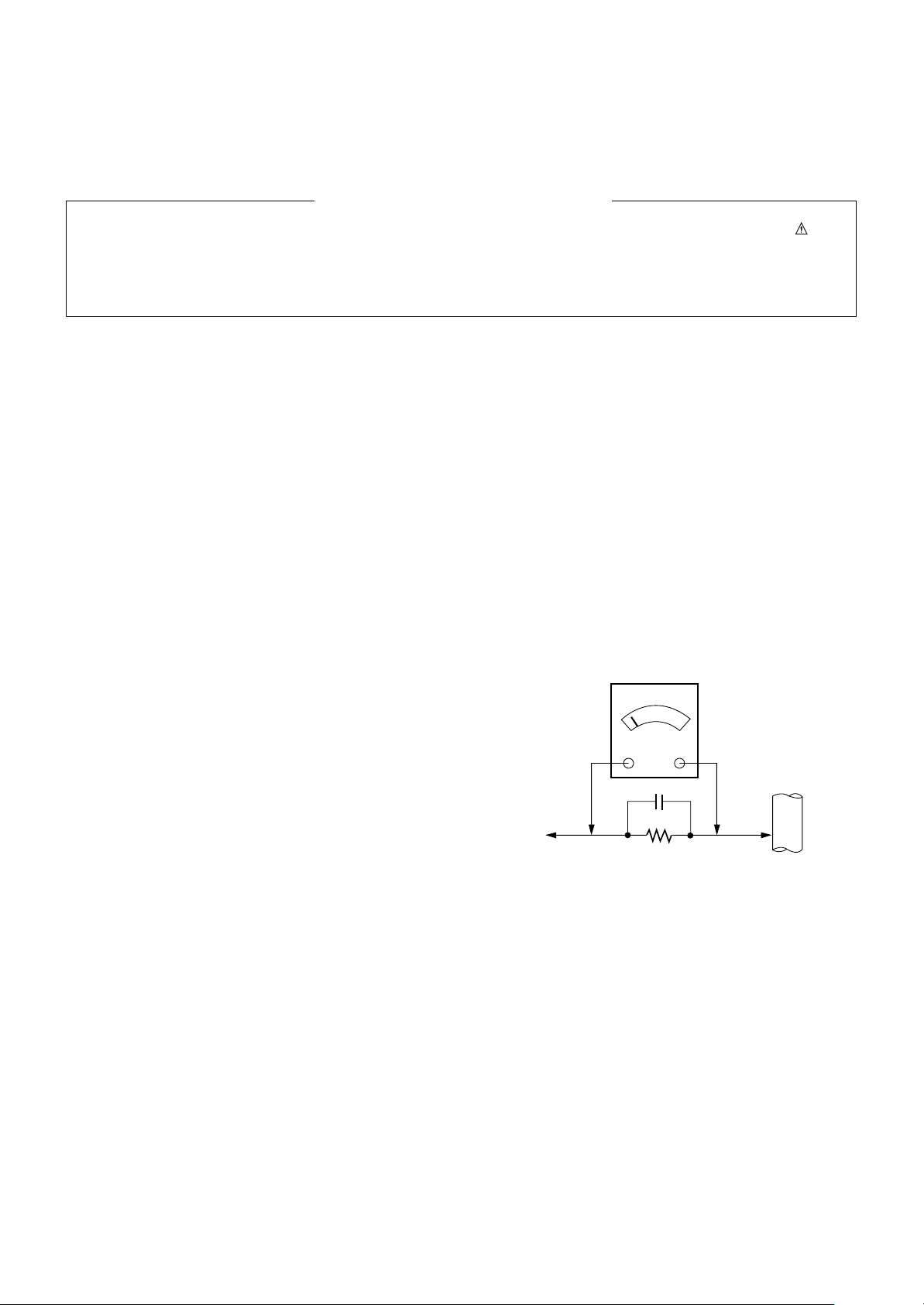

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

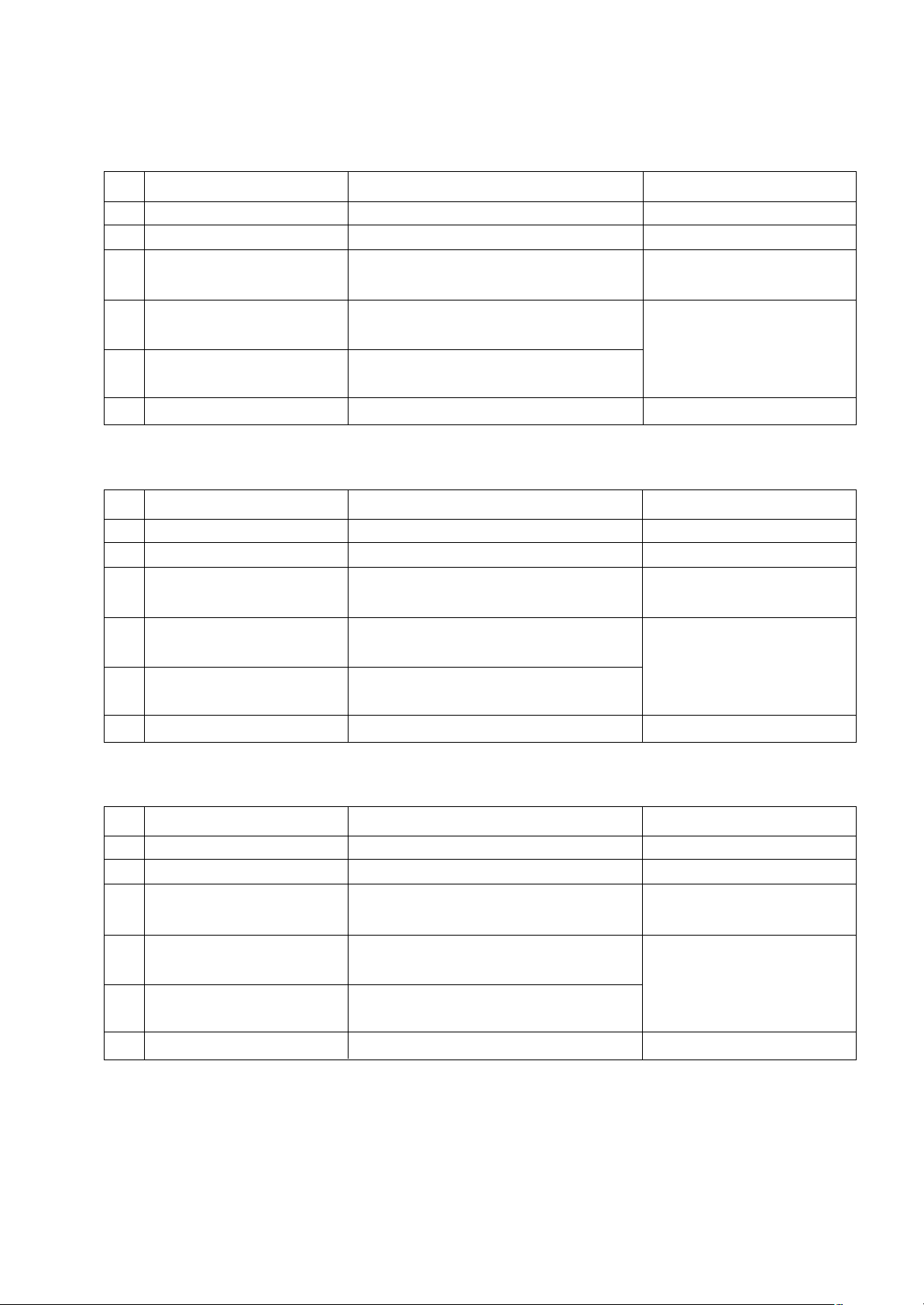

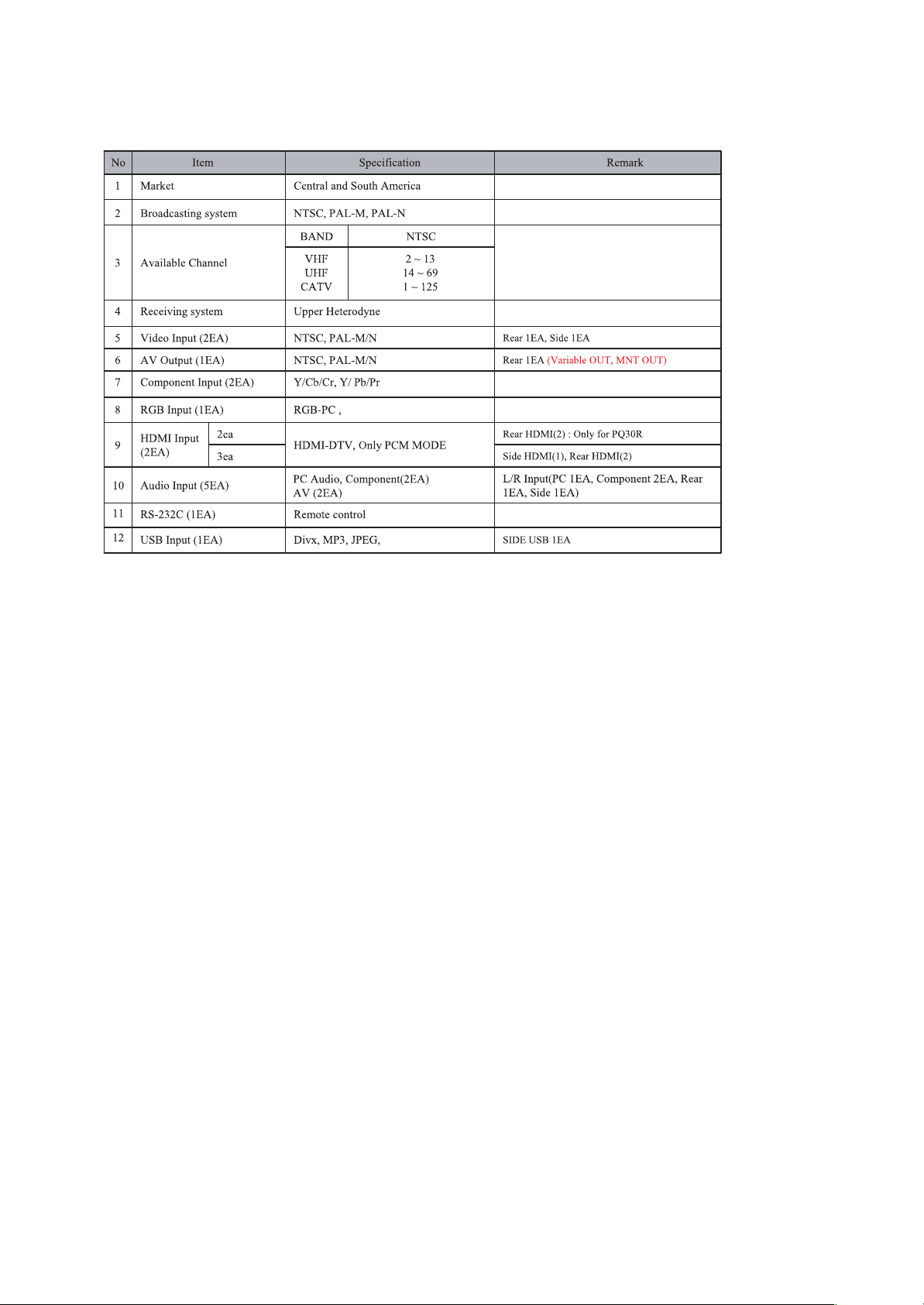

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to PDP TV used PP91A/B/C/D Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

Remark

Safety: IEC/EN60065, EMI: EN55013,

EMS: EN55020

Safety: IEC/EN60065, EMI: CISPR13

Market

EU

NON-EU

Central and South America

Appliance

TEST

TEST

Page 5

- 5 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

V Module Specification

(1) 42” XGA

(2) 50” WXGA

(3) 50” FHD

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

50 inch 16:9 Color plasma Display Module

16:9

PDP50G2####,

RGB Closed(Well) Type

1) Temp. : 0 ~ 55deg

2) Humidity : 20 ~ 80%

3) Temp. : -10 ~ 60deg

4) Humidity : 10 ~ 90%

AC100-240V~, 50/60Hz

PDP

Glass Filter

LGE SPEC.

Maker: LGIT

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

50 inch 16:9 Color plasma Display Module

16:9

PDP50H3####,

RGB Closed Type

1) Temp. : 0 ~ 55deg

2) Humidity : 20 ~ 80%

3) Temp. : -10 ~ 60deg

4) Humidity : 10 ~ 90%

AC100-240V~, 50/60Hz

PDP

Glass Filter

LGE SPEC.

Maker: LGIT

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

42 inch 16:9 Color plasma Display Module

16:9

PDP42G2####,

RGB Closed Type

1) Temp. : 0 ~ 60deg

2) Humidity : 20 ~ 80%

3) Temp. : -20 ~ 60deg

4) Humidity : 10 ~ 90%

AC100-240V~, 50/60Hz

PDP

Glass Filter

LGE SPEC.

Maker: LGIT

Page 6

- 6 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

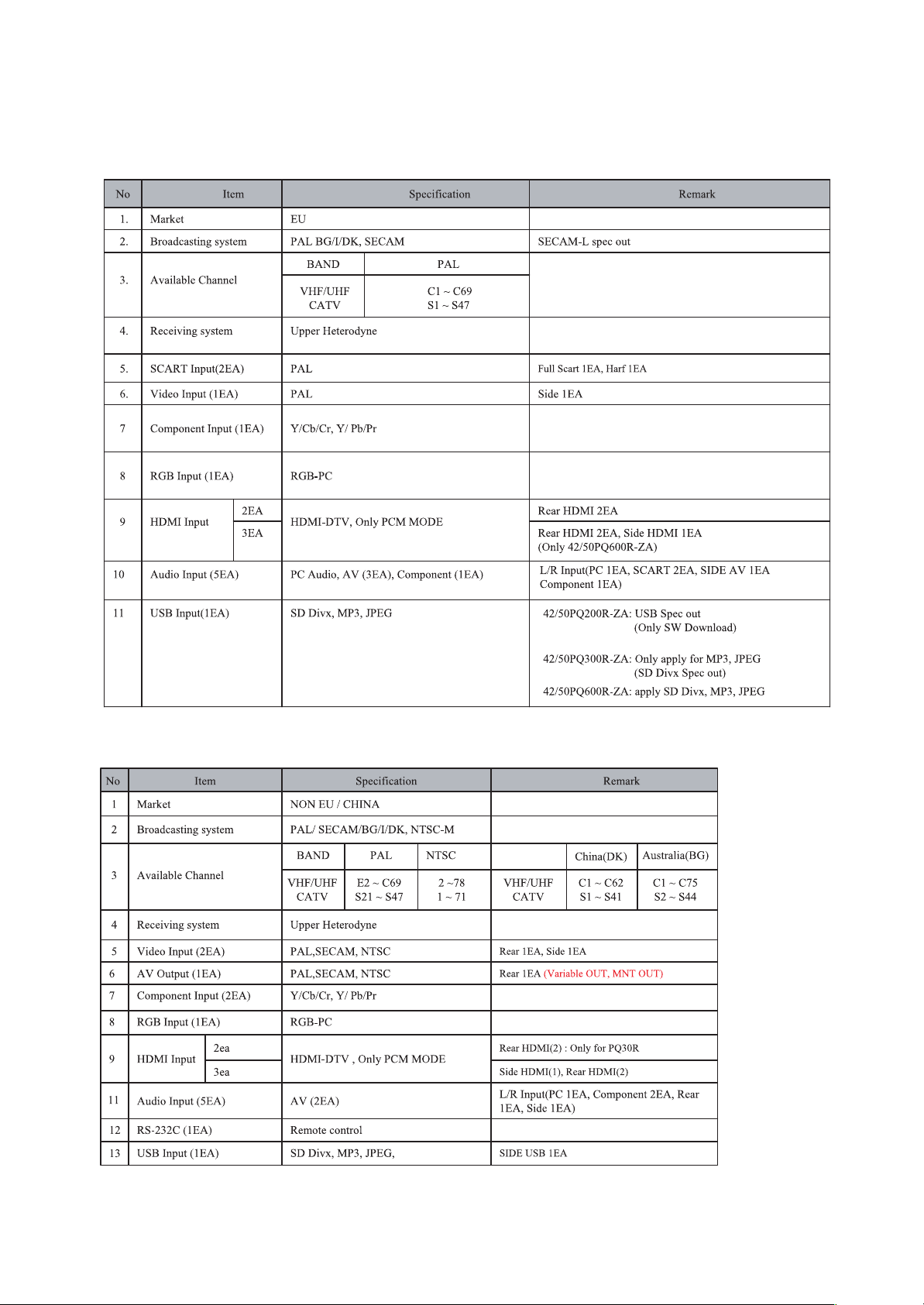

V Model General Specification

(1) EU Spec.(ZA)

(2) NON-EU Spec.(TA)

Page 7

- 7 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(3) Central and South America(MA)

Page 8

- 8 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Range

This spec sheet is applied to all of the PP91A/B chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~240V,

50/60Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15°

- In case of keeping module is in the circumstance of 0°C,

it should be placed in the circumstance of above 15°C for

2 hours

- In case of keeping module is in the circumstance of below

-20°C, it should be placed in the circumstance of above

15°C for 3 hours,.

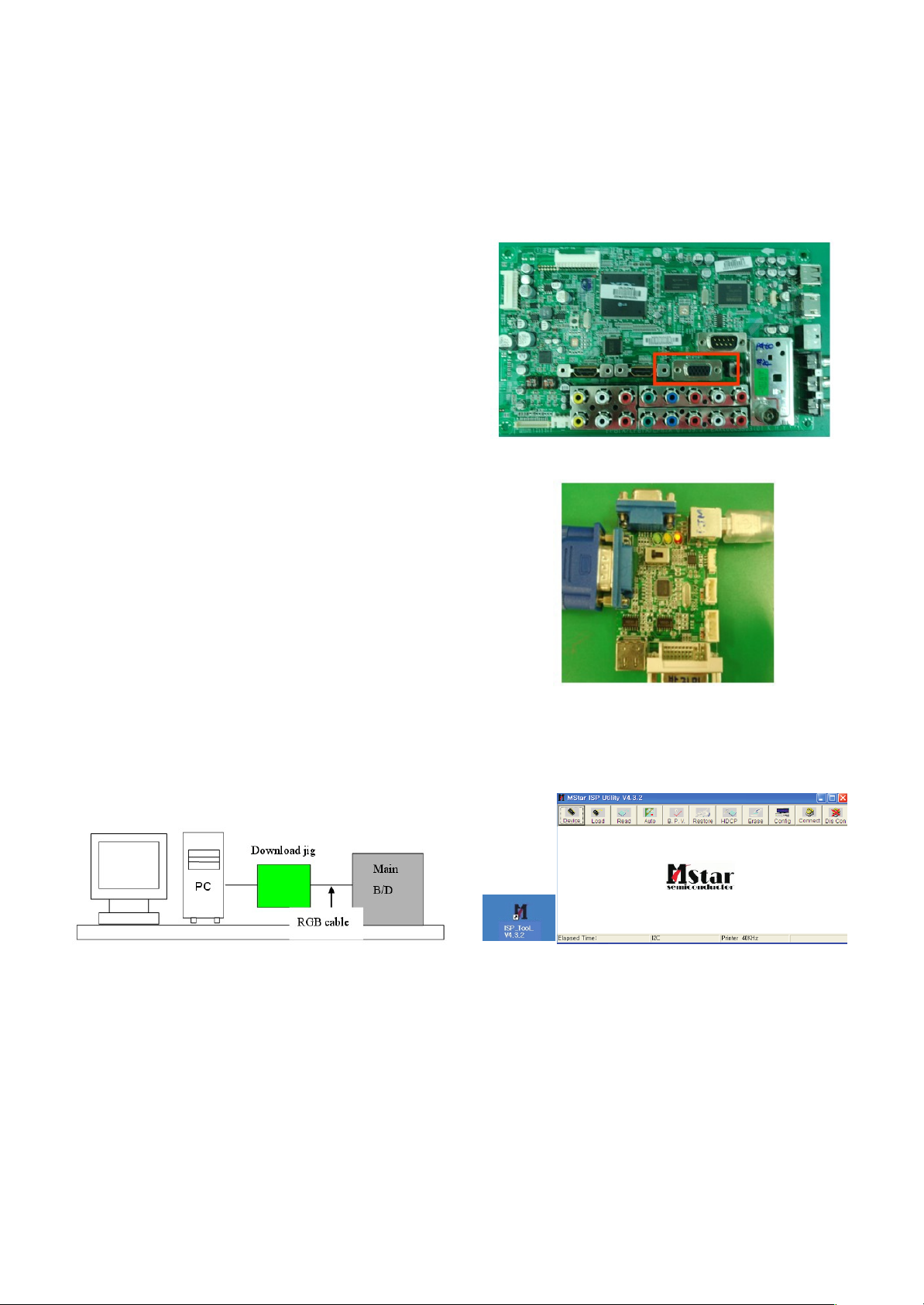

3. S/W Program Download

3-1. Profile

This is for downloading the s/w to the flash memory of the

IC603

3-2. Equipment

(1) PC

(2) ISP_tool program

(3) Download jig

3-3. Connection Structure

3-4. Connection Condition

(1) IC name and circuit number : Flash Memory and IC603

(2) Use voltage : 3.3V (5 pin)

(3) SCL : 15 pin

(4) SDA : 12 pin

(5) Tact time : about 2min and 30seconds

3-5. Download Method (By using MSTAR JIG)

(1) Preliminary Steps

1) Connect the download jig to D-sub jack

2) Connect the PC to USB jack

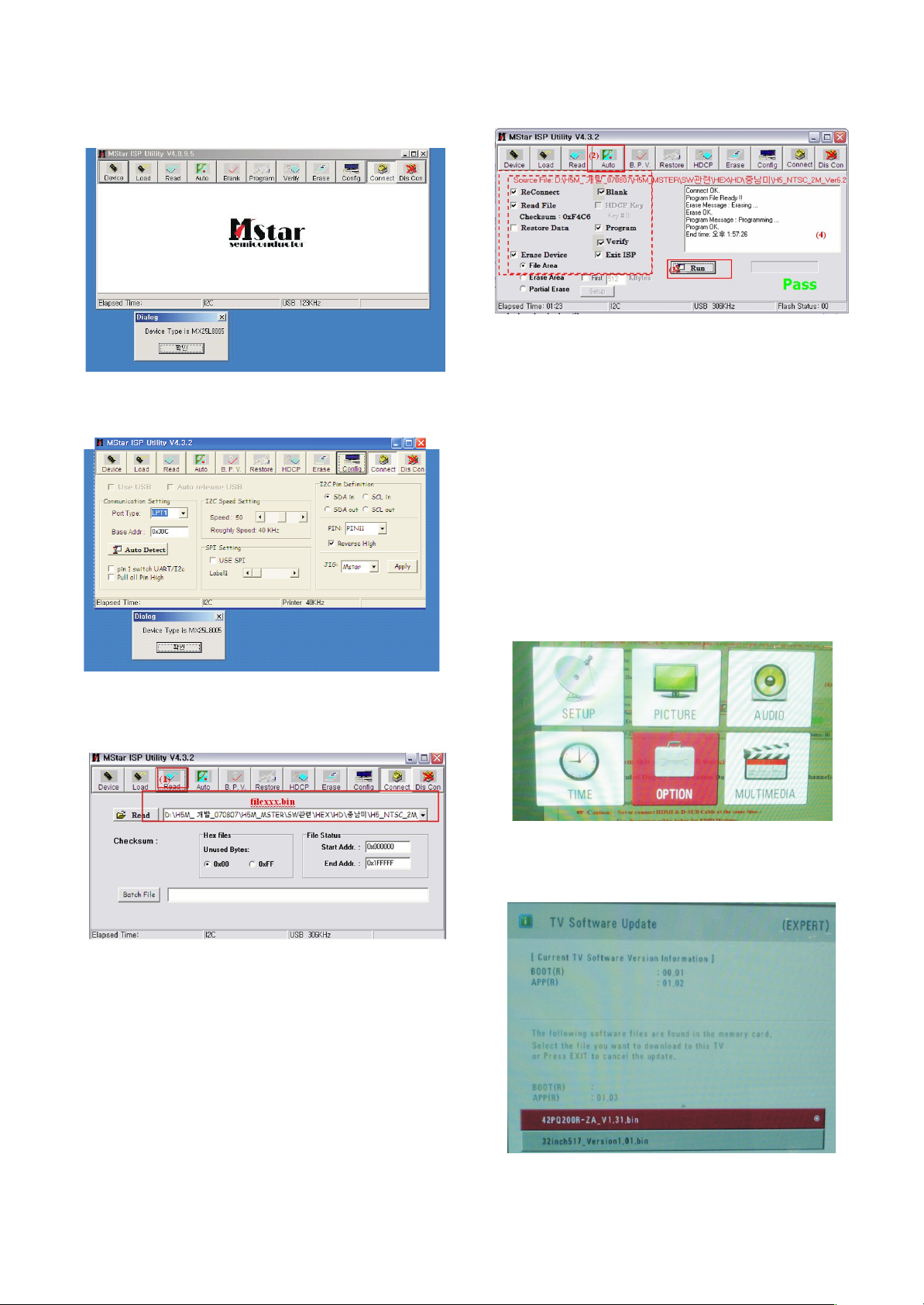

(2) Download Steps

1) Execute ‘ISP Tool’ program in PC, then a main window will

be opened

Double click

Page 9

2) Click the connect button and confirm “Dialog Box”.

3) Click the Config button and Change speed

E2PROM Device setting : over the 350Khz

4) Read and write bin file

Click “(1)Read” tab, and then load download file(XXXX.bin)

by clicking “Read”.

5) Click “Auto(2)” tab and set as below

6) Click “Run(3)”.

7) After downloading, check “OK(4)” message.

3-6. Download Method (By using USB

Memory Stick)

[Caution]

- Using ‘power on’ button of the control R/C, power on TV.

- USB file (EPK) version must be bigger than downloaded

version of main B/D.

(1) Using ‘Power ON’ button of the control R/C, Power on TV.

(2) Insert the USB memory stick to the SET.

(3) Display USB loding message then, push the ‘Exit’ Key of

control R/C

(4) Push the ‘MENU’ Key and move the cusor ‘OPTION’ of

OSD ( Fig. 1)

* Caution: Don’t push the ‘OK’ key.Just cusor is on the

‘OPTION’ menu.

(5) Push the “7” key of control R/C continuously.

Then, Display “TV Software Update” Pop-up menu. (Fig. 2)

- 9 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

( Fig. 1)

( Fig. 2)

Page 10

(6) Select SW file (XXXX.bin) you want, push the “OK” Key.

(7) S/W download process is excuted automatically.

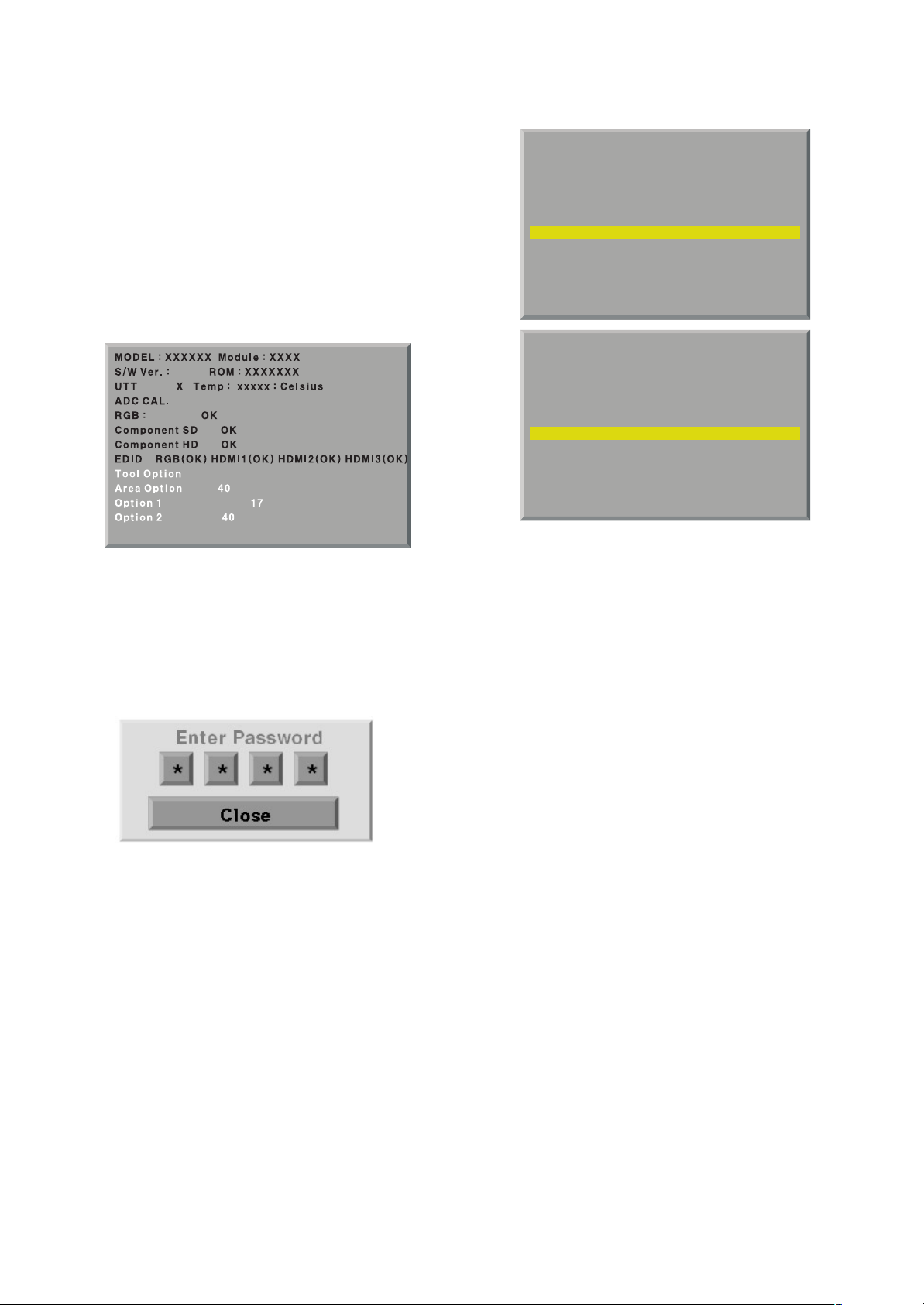

4. PCB Assembly Adjustment Method

4-1. Option Adjustment Following BOM

Tool Option

Area Option

Option 1

Option 2

Option 3(Available for EU & Non EU model)

* Profile: Must be changed the option value because being

different with some setting value depend on module, inch

and market

* Equipment : Adjustment Remote Controller

(1) Push the IN-START key in the Adjust R/C.

(2) Enter Password number. The value of Password is “0 0 0

0”.

(3) Input the Option Number that was specified in the BOM,

into the Shipping area.

(4) Select “Tool Option/ Area Option” by using

D/E(CH+/-)

key, and press the number key(0~9) consecutively

ex) If the value of Tool Option1 is 4, input the data using

number key “4” (Fig. 3)

Caution: Don’t Push “IN-STOP” key after PCB assembly

adjustment.

(5) EDID D/L Method

After software D/L or PCBA manufacturing, you can

download EDID Data.

When you adjust Tool Option, H6 Model EDID download

process is executed automatically

* If the model don’t have HDMI 3, HDMI 3 will be disappeared

at OSD Window.

Caution: When you adjust tool option, don’t connect HDMI or D-

sub cable.

If you connect some cable, EDID D/L process will be

failed.

(6) Adjustment method

Before PCBA check, have to change the Tool option and Area

option

[ About PDP

After done all adjustments, Press IN-START button and

compare Tool option and Area option value with its BOM, if it

is correctly same then Change “RF mode” and then unplug

the AC cable.

If it is not same, then correct it same with BOM and unplug AC

cable.

For correct it to the model’s module from factory JIG model.

[ Don’t push The IN-STOP KEY after completing the function

inspection.

- 10 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

.

.

3.09

5

.

.

MODEL : XXXXXX Module : XXXX

S/W Ver. : X.XX ROM : XXXXXXX

UTT X Temp : xxxxx : Celsius

ADC CAL.

RGB : OK

Component SD OK

Component HD OK

EDID RGB(OK) HDMI1(NG) HDMI2(NG) HDMI3(NG)

Tool Option 4

Area Option 40

Option 1 17

Option 2 40

.

.

MODEL : XXXXXX Module : XXXX

S/W Ver. : X.XX ROM : XXXXXXX

UTT X Temp : xxxxx : Celsius

ADC CAL.

RGB : OK

Component SD OK

Component HD OK

EDID RGB(OK) HDMI1(OK) HDMI2(OK) HDMI3(OK)

Tool Option 4

Area Option 40

Option 1 17

Option 2 40

( Fig. 3)

Page 11

5. EDID(The Extended Display

Identification Data)

Originally H6(PP91A/B) Model EDID download process is

executed when you adjust Tool Option.

[ Caution

- Use the proper signal cable for EDID Download

- Never connect HDMI & D-SUB Cable at the same time.

- Use the proper cables below for EDID Writing

5-1. Profile: To be possible for plug and play

5-2. Equipment

(1) Adjusting PC with S/W for writing EDID Data.(S/W: EDID

TESTER Ver.2.5)

(2) A Jig for EDID Download

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable.

5-3. Connection Structure

Caution: Never connect HDMI & D-SUB Cable at the same time.

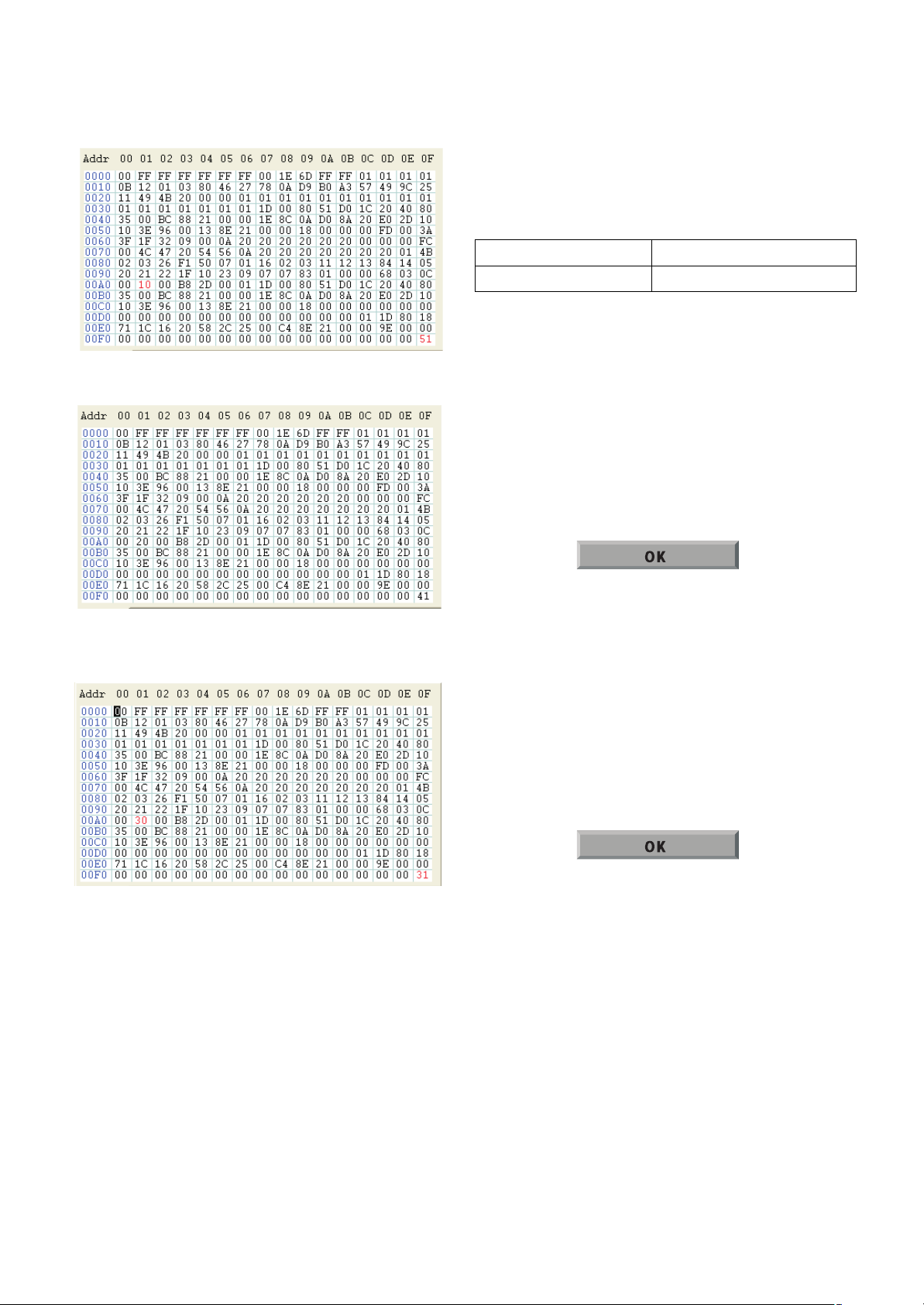

5-4. EDID Data

O WXGA EDID DATA(50inch)

<Analog(RGB) : 128bytes>

<HDMI 1 : 256bytes>

<HDMI 2 : 256bytes>

<HDMI 3 : 256bytes> SIDE HDMI(HDMI 3) is adjusted above

60Tool model

O XGA EDID DATA(42inch)

<Analog(RGB) : 128bytes>

- 11 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Connection Diagram of EDID

Page 12

<HDMI 1 : 256bytes>

<HDMI 2 : 256bytes>

<HDMI 3 : 256bytes> SIDE HDMI(HDMI 3) is adjusted above

60Tool model

6. HDCP(High-Bandwidth Digital

Contents Protection) Download

HDCP download process is deleted in H6 models

In H6 models, it is usimg the EEPROM masking HDCP Key

7. Manual ADC Adjustment

(Component 1, RGB)

[Caution]

- Do not connect external input cable

- Adjustment result is applied to SET On/Off later.

* Adjustment is done using internal ADC, so input signal is not

necessary.

7-1. COMPONENT ADC (SD / HD)

(1) Convert to Component1 input source.

(2) Press ADJ key on R/C for adjustment.

(3) Enter Password number. The value of Password is “0 0 0

0”.

(4) Select “0. ADC calibration” by using

D/E(CH +/-) and press

ENTER(

V).

(5) Start ADC adjustment by using

F/G (VOL +/-) or press

ENTER(

V).

(6) ADC adjustment is executed automatically .

When ADC adjustment is finished, this OSD appear.

7-2. RGB input ADC

Auto RGB Gain/Offset Adjustment

(1) Convert to PC in Input-source

(2) Press ADJ key on R/C for adjustment.

(3) Enter Password number. The value of Password is “0 0 0

0”.

(4) Select “0. ADC calibration” by using

D/E(CH +/-) and press

ENTER(

V).

(5) Start ADC adjustment by using

F/G (VOL +/-) or press

ENTER(

V).

(6) ADC adjustment is executed automatically .

When ADC adjustment is finished, this OSD appear.

Notice : After All mode check, set the Speaker Volume “0”.

- 12 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

RF input

NO SIGNAL or White noise

AV / Component / RGB input

NO SIGNAL

Page 13

Notice : From this sentence, All working is mass production.

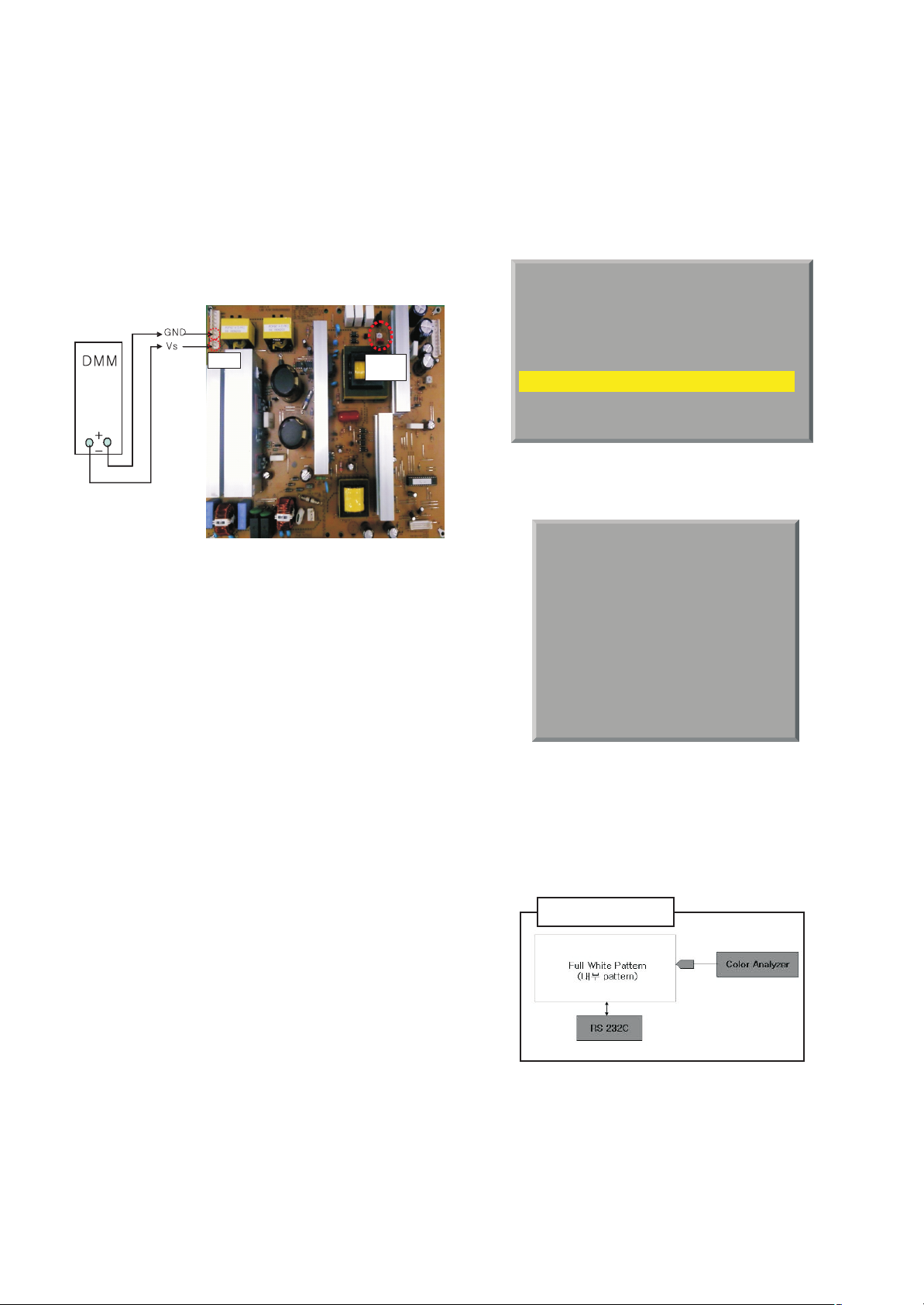

8. POWER PCB Assy Voltage

Adjustment

(Vs voltage Adjustment)

8-1. Test Equipment: D.M.M 1EA

8-2. Connection Diagram for Measuring

Refer to (Fig. 4)

8-3. Adjustment Method

(1) Vs Adjustment

1) Connect + terminal of D. M..M. to Vs pin of P702,

connect -terminal to GND pin of P702.

2) After turning VR901, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel right/top (

deviation ; ±0.5V)

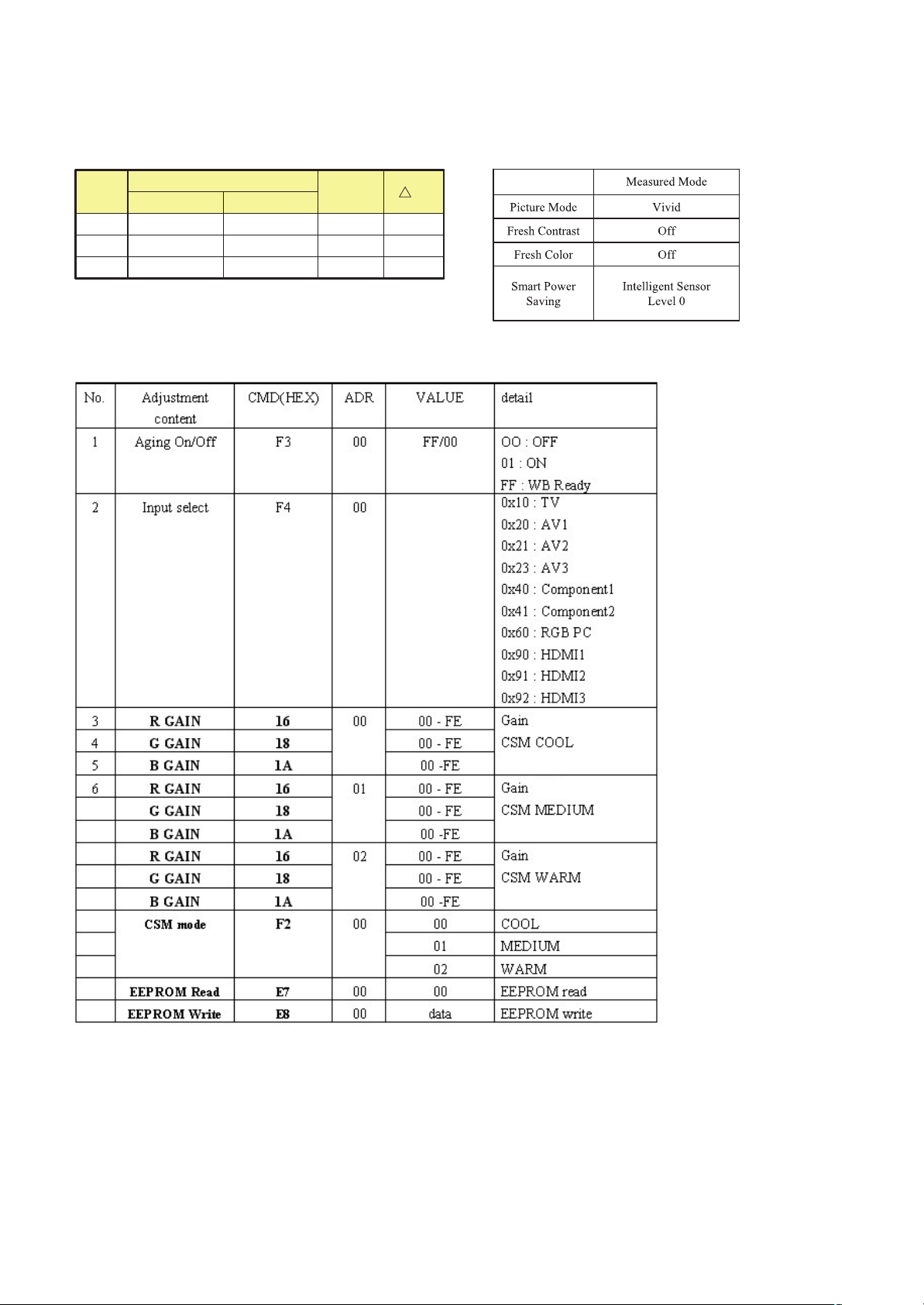

9. Adjustment of White Balance

9-1. Purpose and Principle for Adjustment

of the Color Temperature

(1) Purpose: Adjust the color temperature to reduce the

deviation of the module color temperature.

(2) Principle : To adjust the white balance without the

saturation, Fix the one of R/G/B gain to C0 and decrease

the others.

(3) Adjustment mode: Two modes of Cool, Warm and Medium

9-2. Required Equipment

(1) Remote controller for adjustment

(2) Color Analyzer : CA-100+ or CA-210 or same product

- PLASMA TV(ch : 10)

(3) Auto W/B adjustment instrument(only for Auto adjustment)

- Do the white balance adjustment under the 10LUX

[ Notice: When using the Color Analyzer with PDP,

recommend the CA-100 more than CA-210.

If CA-100 can not available, it is also good to use the CA-210.

(4) PC (for communication through RGB)

(5) Pattern Generator (MSPG-925FA etc.)

-Before white balance, press the ADJ key and select third

row like (Fig. 5)

-To enter White-balance mode, Enter Password Number “0

0 0 0” and select third row.

[ Caution: System control Host should be “DDC” for adjustment.

(6) Adjust W/B DATA, for all CSM, choose ‘COPY ALL’

9-3. Connecting Diagram of Equipment for

Measuring

(For Automatic Adjustment)

(Method 2, using RS-232C, You connect RS-232C Cable)

(1) Enter the adjustment mode of the white balance

- Enter the white balance adjustment mode at the same time

heat-run mode when pushing the power on by power only

key

- 13 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

P811

Vs ADJ

VR901

(Fig. 4)

EZ ADJUST

0. ADC CALIBRATION : TV

1. ADC ADJUST

2. SUB B/C ADJUST

3. W/B ADJUST

4. WHITE PATTERN : OFF

5. EDID D/L

(Fig. 5)

3. W/B ADJUST

Mode : TV

TEMPERATURE : Medium

R-Gain. : 192

G-Gain. : 192

B-Gain. : 192

R-Offset : 128

G-Offset : 128

B-Offset : 128

COPY ALL

(Fig. 6)

Method 2-(RS-232C)

Page 14

- Maintain the white balance adjustment mode with same

condition of Heat-run

- Maintain after AC off/on in status of Heat-run pattern display

(2) Release the white balance adjustment mode

- Release the adjust mode after AC off/on or std-by off/on in

status of finishing the Hear-run mode

- Release the Adjust mode when receiving the aging off

command(F3 00 00) from adjustment equipment)

(3) Enter the adjust mode of white balance

- Enter the white balance adjustment mode with aging

command(F3, 00, FF)

9-4. Adjustment of White Balance for

Manual Adjustment

(method 3)

Adjustment mode: Three modes of Cool, Medium(Vivid) and

Warm

- Equipment : 1) Color analyzer(CA100+, CA210) should be

used in the calibrated ch by CS-1000(PDP :

CH10)

2) Adjustment remocon

- For manual adjustment, it is also possible by the following

sequence.

Operate the zero-calibration of the CA-100+ or CA-210, then

stick sensor to the module when adjusting.

(1) Select white pattern of heat-run by pressing “POWER ON”

key on remote control for adjustment then operate heat run

longer than 5 minutes. (recommend)

(If not executed this step, the condition for W/B will be

different)

(2) Changing to the AV mode by remote control.(Push front-

AV)

(3) Input external pattern(85% white pattern).

(4) Stick sensor to center of the screen and select each items

(Red/Green/Blue Gain and Offset) using

D/E(CH +/-) key

on R/C..

(5) Adjust R/ G/ B Gain using

F/G(VOL +/-) key on R/C.

(6) Adjust three modes of Cool, Medium(Vivid) and Warm as

below figure.

(Fix the one of R/G/B and change the others)

- Push the “VOL + “ key : Cool, Medium, Warm

[

Refer to the below case to know what value is fixed.

[CASE]

First adjust the coordinate much away from the target value(x, y).

1. x, y > target

1) Decrease the R, G.

2. x, y < target

1) First decrease the B gain,

2) Decrease the one of the others.

- In case of decreasing the x, decreasing the R : fix G

- In case of decreasing the y , decreasing the G : fix R

3. x > target , y < target

1) First decrease B, so make y a little more than the target.

2) Adjust x value by decreasing the R

4. x < target , y > target

1) First decrease B, so make x a little more than the target.

2) Adjust x value by decreasing the G

(7) When adjustment is completed, Exit adjustment mode

using EXIT key on R/C.

9-5. Connecting diagram of Equipment for

Measuring

(For Automatic Adjustment)

(method 1, using IIC, You connect RGB Cable)

(1) Enter the adjustment mode of the white balance

- Enter the white balance adjustment mode at the same time

heat-run mode when pushing the power on by power only

key

- Maintain the white balance adjustment mode with same

condition of Heat-run

- Maintain after AC off/on in status of Heat-run pattern display

(2) Release the white balance adjustment mode

- Release the adjust mode after AC off/on or std-by off/on in

status of finishing the Hear-run mode

- push the “power on” key(IIC Mode) on Adjust remotecontroller.

- Release the Adjust mode when receiving the aging off

command(F3 00 00) from adjustment equipment)

(3) Enter the adjust mode of white balance

- Enter the white balance adjustment mode with aging

command(F3, 00, FF)

O Color Temperature & Color Coordinates Setting

- When adjusting the Color Temperature, Color Analyzer CA210(Matrix should be corrected through CH10 of CS-1000)

should be used. When CA-210 have used, it don’t need to fit

the CH10.

- Adjust the Color Temperature based below adjustment color

coordinates.

O Target Value CA-210(LCD : CH 9, PDP : CH10), CA-100(PDP)

- 14 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

+0.0036,500K

Warm

+0.0009,300K

Medium

+0.00011,000K

Cool 0.276±0.002

0.285±0.002 0.293±0.002

0.329±0.002

0.313±0.002

0.283±0.002

YX

uvTemp

Color coordinate

Mode

Method 1-(I2C)

Page 15

(Standard color coordinate and temperature when using the

CA-100+ or CA210 equipment)

O Above optical characteristics are should be measured by

following condition.

- 15 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

+0.0036,500K

Warm

+0.0009,300K

Medium

+0.00011,000K

Cool 0.276±0.002

0.285±0.002 0.293±0.002

0.329±0.002

0.313±0.002

0.283±0.002

YX

uvTemp

Color coordinate

Mode

O DDC Adjustment Command Set

[ R/G/B GAIN max value : C0

Adjustment

Adjustment

Adjustment

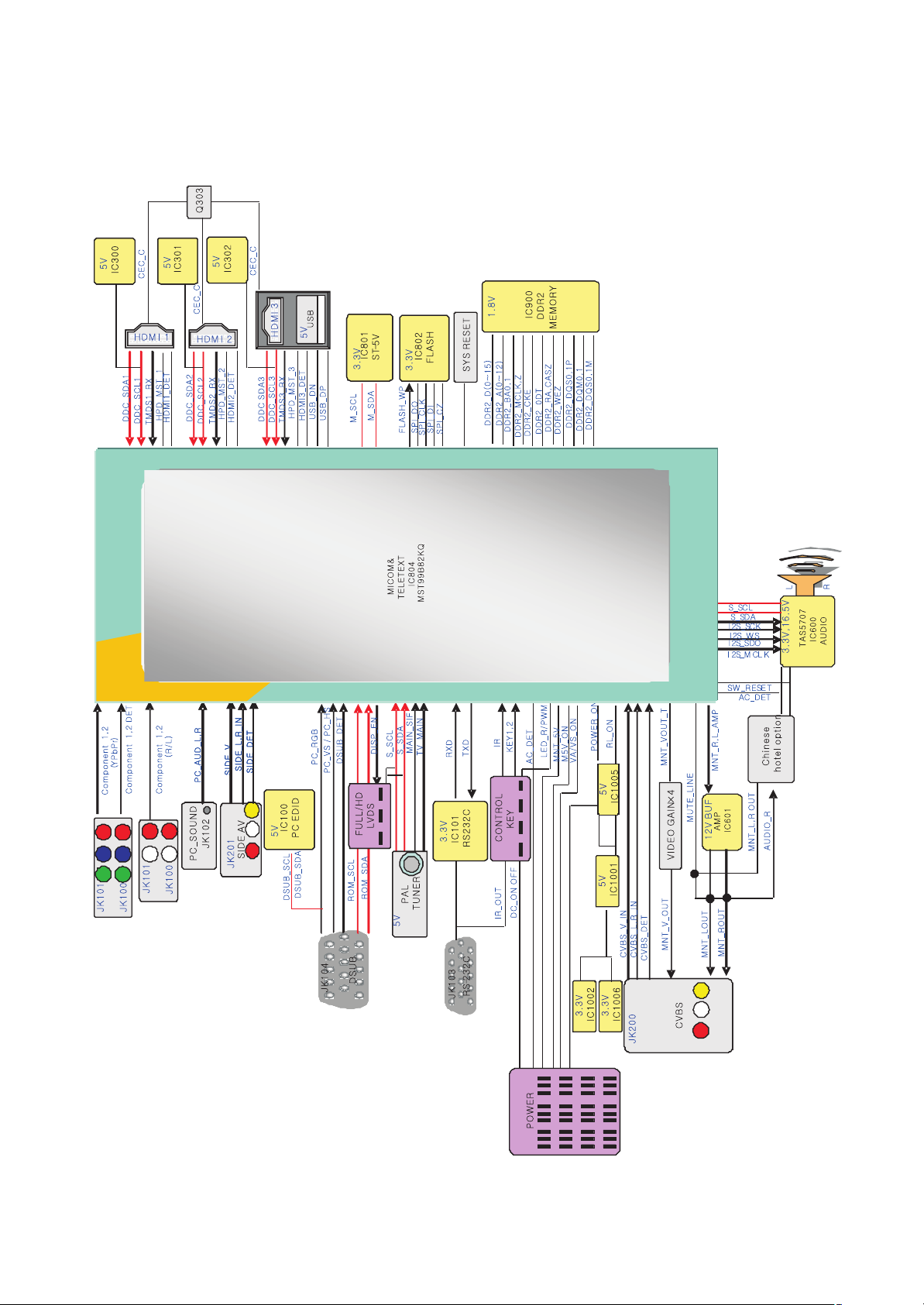

Page 16

- 16 -

LGE Internal Use OnlyCopyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 17

A10

900

901

400

520

590

240

250

300

305

301

303

560

310

330

302

200

120

580

260

270

603

602

601

501

570

A2

LV1

201

203

205

204

206

202

- 17 -

LGE Internal Use Only

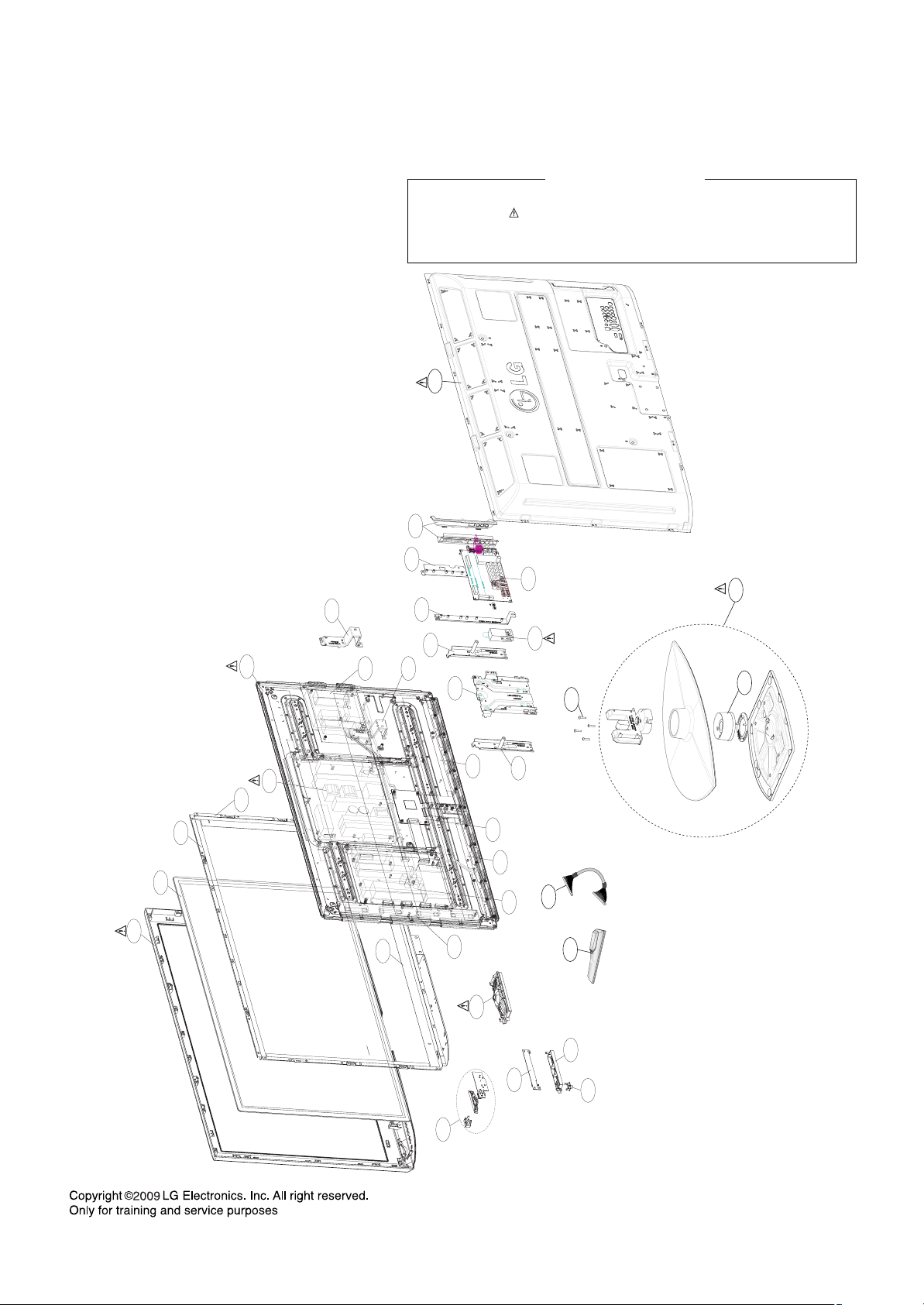

EXPLODED VIEW

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 18

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 19

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 20

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 21

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 22

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 23

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 24

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 25

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 26

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 27

Page 28

PDP TV Repair Process Index

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

No. Symptom (L) Symptom (M) Page Remark

1 No Picture/Sound OK 1

2 No Picture/No sound 2

3 Mal-discharge/Noise/dark picture 3

4 Picture broken/Freezing 4

5 Vertical bar/ Horizontal Bar 5

6

7 Turn off (Instant, under watching) 7

9 E. General function Problem Remote control & Local switch checking 9

A. Picture Problem

No Power (Not turn on) 6

B. Power Problem

8No sound/ Sound distortionC. Sound Problem8

First of all, Check whether there is SVC Bulletin in GCSC System for these model.

Page 29

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

No Picture/Sound OK

Making

Revision

2009. 2 . 1

First of all, Check whether all of cable between board was inserted properly or not.

(Main B/D↔ Power B/D, Power B/D↔ Y-sus B/D,Y-Sus B/D ↔Z-Sus B/D,LVDS Cable,Speaker Cable,IR B/D Cable,,,)

☞A1

Check Module pattern

by using “TILT” key

on SVC R/C

Normal

N

☞A3

Check

Vs, Va

☞A2

Check

Y

Sound

Normal

N

Move

Power problem

Section

Sound

OK

Move

No Picture/No sound

Section

☞A5~A6

Check voltage

Y

Y

. -V

. VSC

. VZB

☞A8~A11

1. Check Y-Sus/ Z-Sus Board

2. Replace defective B/D

Y

N

Check

LVDS Cable

Normal

Replace

Main B/D

Y

Close

N

☞A13

☞A12

Check B+ Voltage

Y

Normal Normal

N

on Power Board

/ Control Board

.Check B+(5V)

N

Move

Power problem

Section

1.Check Control Board

. LED on

Y

. Crystal(X101)

. 1.8V, 3V, 5V FET

. Rom update

2.Replace Control B/D

1/9

<SVC R/C & Pattern>

※Refer to the Module label for each voltage

-VY VSC VZB

1

☞A4

Page 30

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

☞A1

Check Module pattern

by using “TILT” key

on SVC R/C

No Picture/ Sound Ok

Symptom

Normal

Move

Section

A. Picture Problem

No Picture/No Sound

Making

Revision

2009. 2 . 1

2/9

☞A2

Check

Y

Sound

N

Sound

OK

Y

N

Check

LVDS Cable

Normal

Replace

Main B/D

Y

Close

N

☞A26

N

Check IR operation

Normal

Y

Power

LED ON?

N

Repair/Replace

IR B/D

Y

OSD

appear?

Check Input signal

. RF Cable connection

Y

. SCART Cable connection

. HDMI Cable connection

N

. Component Cable …

Latest S/W update

from GCSC

(Firmware Management)

Normal

Close

N

Y

2

Replace

Main B/D

Page 31

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Check

Picture problem

Type

☞A14

Mal-discharge

Symptom

Dot

type

Scan

Type

A. Picture Problem

Mal-discharge/Noise/dark picture

☞A15

Check CTRL ROM Ver.

and

Rom Upgrade

☞A5~A6

Check voltage

Y / VSC

. –V

(Y-Sus B/D)

Normal

Picture?

N

Replace

Y-Sus B/D

Normal

Picture?

Close

☞A16

Check

Y

Y Drive B/D

Replace B/D

Y

&

Making

2009. 2 . 1

Revision

N

Replace

Control board

Normal

Picture?

Y

Close

☞A13

Normal

Picture?

Close

N

1.Check Control B/D

2.Replace Board

Y

☞A17

※Check Discharge resistance (10Ω 2~3ea)

on Power B/D before replace Y Drive B/D

3/9

N

Replace

Module

N

Normal

Picture?

Y

Close

Picture Noise

Dark Picture

Check RF Cable

Connection

Picture mode

Check

setting

Normal

Picture?

Close

Normal

Picture?

Y

Close

N

Check Tuner

& Replace

Y

☞A9(42G2),A11(50G2)

N

1. Check Z-Sus Board

2. Replace Board

Normal

Picture?

Y

Close

N

Replace

Module

3

Page 32

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

☞A21

Check RF Signal level

Normal

Signal?

N

Check RF Cable

Connection

1. Reconnection

2. Install Booster

Normal

Picture?

Y

Close

Y

N

Symptom

A. Picture Problem

Picture broken/Freezing

. By using Digital signal level meter

. By using Diagnostics menu on OSD

( Menu→Setup→Diagnostic)

- Signal strength (Normal : over 50%)

- Signal Quality (Normal: over 50%)

Check whether other equipments have problem or not.

(By connecting RF Cable at other equipment)

→ DVD Player ,Set-Top-Box, Different maker TV etc

Normal

Picture?

Contact with signal distributor

or broadcaster (Cable or Air)

Y

N

Check

S/W Version

SVC

Bulletin?

Y

S/W Upgrade

Normal

Picture?

Y

Making

2009. 2 . 1

Revision

■ Menu→Setup →Booster

Booster menu

N

On→Off: Check

Off→On: Check

Tuner soldering

N

Normal

Picture?

N

Check

Replace

Main B/D

4/9

Y

Close

Close

※ ’09 years new model apply chip tuner

so, chip tuner is soldered on main PCB

[ Chip Tuner: IC500(XC5000) ]

4

Page 33

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

☞A19

Check

defect type

Vertical

Line/Bar

Half

No picture

Symptom

Regular

Vertical

Line / Bar

Irregular

Vertical

Line / Bar

☞A18

1.Check X B/D

2.Replace Board

A. Picture Problem

Vertical bar/ Horizontal Bar

☞A1

Check Module pattern

by using “TILT” key

on SVC R/C

☞A20

Check connection

of Connector

(COF,TCP)

on CTRL B/D , X B/D

1.Connector re-connection

2.Eliminate foreign material on Connector

Normal

Picture?

Normal

N

N

Y

Replace

Module

Normal

Pattern?

☞A13

1.Check CTRL B/D

2.Replace Board

N

☞A13

1.Check CTRL B/D

2.Replace Board

Making

2009. 2 . 1

Revision

Y

Replace

Module

※CTRL B/D: Control board

Normal

Picture?

Close

N

Y

5/9

Check Main B/D

Replace Module

(If Main B/D doesn’t cause)

☞A20

Horizontal

Line/Bar

Check connection

of Connector (FPC)

on Y Drive B/D

Y

Close

☞A16

Y

Normal

N

1.Connector re-connection

2.Eliminate foreign material on FFC

1. Check Y Drive B/D

2. Replace Board

※ H-Line’s Cause is rare CTRL B/D

Normal

Picture?

Y

Close

N

1.Check CTRL B/D

2.Replace Board

Normal

Picture?

Close

N

Replace

Module

Y

5

Page 34

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Check

Power LED

. Stand-By: Red

. Operating: Green

Check Power cord

was inserted properly

☞A27

Mechanical Power switch

on Local control of TV

☞A22

Symptom

Power LED

ON?

N

Check & Repair

Normal

?

Check ST-BY 5V

on Power Board

Y

N

B. Power Problem

No Power (Not turn on)

☞A26

DC Power on

Y

by pressing Power Key

On Remote control

Normal

Close

※ ’09 years new model apply mechanical power switch

to reduce power consumption in stand-by status.

If mechanical power switch off

→ Doesn’t turn on by remote control

→ Doesn’t appear LED light

Close

N

Y

Check

R/C IR Operation

Making

Revision

Normal

2009. 2 . 1

Y

N

Repair/Replace

6/9

IR B/D

Normal

Voltage?

Y

N

☞A22

Check

AC DET Signal

on Power B/D

Normal

Signal?

N

☞A23

Check Power B/D

Replace Power B/D

☞A22

Y

Check

RL_ON Signal

on Power B/D

☞A22

Normal

Signal?

Check Main B/D

Replace Main B/D

Y

N

Check

the other pin’s

Output voltage

on Power B/D

Normal

Y

Close

N

Power B/D

Replace

6

Page 35

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

※ To check Power B/D Protection

Instant

Turn off

Turn off

Under watching

Turn on after pull out connector

between Power B/D & Y-Sus

“Off Timer”

Set?

“Off timer”

Function off

B. Power Problem

Turn off (Instant, under watching)

Power LED

Green?

☞A23

Check Power B/D

Replace Power B/D

☞A24

N

Y

Check

Power Off History

N

RCU Off

KEY Off

2HOUR Off

NO Signal Off

Don’t appear

Power Off History

Y

Making

2009. 2 . 1

Revision

☞A8~A11

1. Check Y-Sus/ Z-Sus Board

(especially Short or Open)

2. Replace defective B/D

This is not problem

Normal operation

Move

No Power problem

Section

7/9

7

Page 36

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

1.No sound( If HDMI Input only have no sound, upload EDID data)

Check

“Speaker ON/Off” setting

in OSD Menu

2.Sound distortion & sound drop

Check Input signal

→Cable connection

→Cable open

-RF & external

(HDMI,SCART,,,)

Symptom

Normal

Sound?

Normal

Sound?

Y

Close

Y

Close

N

No sound/ Sound distortion

☞A25

N

AVL off/on

Clear voiceⅡ off/on

Check Speaker

jack connection

& Speaker Cable open

Check

Normal

Sound?

Close

Y

C. Sound Problem

Making

Revision

Normal

Sound?

Y

Close

Problem in all input

N

Problem in only DTV(Case 1)

Problem in external input(Case 2)

N

(SCART,HDMI,,,)

SVC

Bulletin?

N

☞A22

Check 17V

(Audio IC B+)

on Power B/D

2009. 2 . 1

Y

Check Audio IC Short

Replace Main B/D

Apply

SVC Bulletin

(S/W Upgrade etc)

Normal

voltage?

N

Y

Normal

Sound?

N

☞A23

Check Power B/D

Replace Power B/D

8/9

Close

Y

Check whether Problem happen

in same output of other equipments or not.

(By connecting same output cable of other equipment)

→ DVD Player ,Set-Top-Box, different maker TV etc

Normal

Sound?

Y

Explain customer that

Cause is RF Signal’s problem (Case 1)

Cause is Equipment’s problem (case 2)

N

8

SVC

Bulletin?

Y

Apply

SVC Bulletin

(S/W Upgrade etc)

Normal

Sound?

Check Audio IC

Replace Main B/D

Y

NN

Close

Page 37

Repair Process

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

1. Remote control(R/C) operating error

Check R/C itself

Operation

Check R/C Operating

When turn off light

in room

If R/C operate,

Explain the customer

cause is interference

from light in room.

Symptom

Normal

operating?

N

Check & Replace

Baterry of R/C

operating?

Replace R/C

Y

Normal

N

Remote control & Local switch checking

☞A26

Check & Repair

Cable connection

Connector solder

Close

D. General Function Problem

Normal

operating?

Y

Close

☞A26

N

Check B+ 5V

On Main B/D

Making

2009. 2 . 1

Revision

☞A26

Normal

Voltage?

N

Y

Check IR

Output signal

☞A12

Check 5v on Power B/D

Replace Power B/D or

Replace Main B/D

(Power B/D don’t have problem)

9/9

Replace

Main B/D

Normal

Signal?

N

Repair/Replace

IR B/D

Y

2. Local(Mechanical) switch operating error

Check R/C

Operation

Normal

operating?

N

Move

Power problem

Section

☞A27

Check & Repair

Y

Cable connection

Connector solder

Normal

operating?

Y

Close

☞A28

Check & Replace

N

Assembly status

(Key PCB + tool )

9

Normal

operating?

Y

Close

☞A27

N

Check Key

Output signal

Replace

Main B/D

Normal

Signal?

N

Repair/Replace

Local switch B/D

Y

Page 38

PDP TV Repair Process Reference data Index

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

No. Symptom Detail Page Remark

1

2

3

4

Check Module pattern by Tilt key A1

Audio check method

Check Va, Vs on Power Board

PDP Module Label Information

A2

A3

A4

Check & Adjust –VY,VSC,VZB voltage

5

6 Fuse Checking Method A7

7 Y-Sus Board Checking Method(42G2) A8

8 Z-Sus Board Checking Method(42G2) A9

9 Y-Sus Board Checking Method(50G2) A10

10 Z-Sus Board Checking Method(50G2) A11

11 Check 5V, 12V on Power B/D A12

12 Control Board Checking Method(42G2/50G2) A13

Picture Problem

- 42G2 –VY,VSC(Y-Sus) / VZB(Z-Sus)

- 50G2 –VY,VSC(Y-Sus) / VZB(Z-Sus)

A5

A6

13 Mal discharge Symptom Picture A14

14 PDP Module Rom Ver. Checking method A15

15 Y Drive B/D Checking method A16

16 Check Discharge resistor on Power B/D A17

17 (Half picture) X- B/D Checking method(42/50G2) A18

Next page Continued

Page 39

PDP TV Repair Process Reference data Index

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

No. Symptom Detail Page Remark

18

19 Connector Type on PDP Module A20

20 RF Signal level Checking method A21

21 Check voltage on Power board A22

22

23 Check Power off History A24

24 Speaker cable checking method A25

25

26 Check Local switch operating A27

27 Check Local switch assembly status A28

Picture Problem

Power Problem

Sound Problem

General Function Problem

Defect type cause by PDP Module A19

Power board Checking Method A23

Check Remote control IR operation A26

Page 40

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

Item

A. Picture Problem

Check Module pattern by Tilt key

Making

Revision

2009. 2 . 1

A1

Tilt Key

You can see 20 types patterns by using TILT Key on SVC Remote controller (except Old model)

< CHECK Item >

1. Dead pixel 2.Image sticking 3.Mal discharge 4.Module defect (V-Line/Bar, H-Line/Bar,,,)

5. In case of no picture, you can judge defect cause (Module or Main B/D)

- If patterns appear, defect cause is Main B/D

A1

Page 41

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

Audio check method

Making

Revision

Jack for Speaker connection

2009. 2 . 1

A2

1.Check Audio output by using oscilloscope

GND ↔ R+ or R- or L+ or L-

Audio output waveform

2.Check whether speaker jack was inserted properly or not.

A2

Page 42

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Y-Sus Board

Va, Vs on Y-Sus B/D Va, Vs on Power B/D

Symptom

Check Va, Vs on Power Board

PDP Module Label

Power Board

Z-Sus Board

Control Board

Main Board

A. Picture Problem

Making

2009. 2 . 1

Revision

▶ Check Va & Adjust Va Voltage

(Refer to the Module label for Va specification)

▶ Check Vs & Adjust Vs Voltage

(Refer to the Module label for Vs specification)

A3

Check Va, Vs

Va Adjustment

(VR502)

Vs Adjustment

(VR901)

A3

Page 43

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

①

②

③

④

⑤

⑥

-Vy Vsc Vzb

Symptom

⑦

A. Picture Problem

PDP Module Label Information

PDP Module Label Information.

⑧

Making

Revision

2009. 2 . 1

A4

⑨⑩

⑪

⑫

⑬

⑭

⑮

A4

Page 44

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

Check & Adjust –VY,VSC,VZB voltage

Voltage Check & Adjustment : 42G2

<Module Label>

-VY VSC VZB

1. -Vy (-175V) on Y-Sus B/D

. Check Point: R201

. Adjustment Point: VR502

A. Picture Problem

Y-Sus Board

Making

Revision

2009. 2 . 1

A5

Fuse

2. Vsc (140V) on Y-Sus B/D

- Check Point: R520 –J263

- Adjustment Point: VR501

-VYAdjustment

VSCAdjustment

A5

Page 45

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Voltage Check & Adjustment : 42G2

<Module Label>

-VY VSC VZB

Symptom

Check & Adjust –VY,VSC,VZB voltage

Adjustment Point

A. Picture Problem

Making

Revision

Z-Sus Board

2009. 2 . 1

A5

3. VZB (80V) on Z-Sus B/D

. Check Point: R50↔J221

A5

Page 46

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

Check & Adjust –VY,VSC,VZB voltage

Voltage Check & Adjustment : 50G2

<Module Label>

-VY VSC VZB

1. -Vy (-185V) on Y-Sus B/D

. Check Point: R201

. Adjustment Point: VR502

A. Picture Problem

Making

Revision

Y-Sus Board

2009. 2 . 1

A6

Fuse

2. Vsc (135V) on Y-Sus B/D

- Check Point: R202

- Adjustment Point: VR501

A6

-VYAdjustment

Vsc Adjustment

ⓒ LG Electronics. Inc.2009

Page 47

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Voltage Check & Adjustment : 50G2

<Module Label>

-VY VSC VZB

Symptom

Check & Adjust –VY,VSC,VZB voltage

A. Picture Problem

Making

Revision

Fuse

2009. 2 . 1

A6

Z-Sus Board

3. VZB (80V) on Z-Sus B/D

. Check Point: R271↔J125

. Adjustment Point: VR200

Adjustment Point

A6

ⓒ LG Electronics. Inc.2009

Page 48

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

Fuse Checking Method

< Fuse check >

< DMM mode >

Pic. 2.Pic. 1.

Making

Revision

2009. 2 . 1

A7

1) Sound comes, the fuse is OK.

2) If Fuse is defects, it should check again voltage of 5V, Va, Va after replacing the fuse.

3) In case there are no voltage of 5V, Va, Vs, the board is failure, it need to replace the board.

A7

ⓒ LG Electronics. Inc.2009

Page 49

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Check Method

① Check whether there is short between Vs & GND of P201 Connector

② Check FUSE open

③ Check voltage of Diode , FET by using Digital Multi Meter

HS1

SUS UP/Down FET & Diode

Q11~Q16 FET(6ea)

D11 , D12 Diode(2ea)

▣ Measuring Method

Symptom

Y-Sus Board Checking Method(42G2)

HS2

PASS/ER UP/Down FET , Diode

Q21~Q23 FET(3ea)

D21~D24 Diode(4ea)

A. Picture Problem

Making

2009. 2 . 1

Revision

HS1 HS2

A8

Fuse

<Specification>

Position

HS1

HS2

Fuse

Diode FET

Circuit No.Direction

Q16Q15D11,12Q11~Q14

0.3~0.4V0.4~0.5V0.3~0.4V0.3~0.4VForward

OL(Overload)Reverse

D21~D24Q21~Q23

0.3~0.4V0.4~0.5VForward

OL(Overload)Reverse

A8

ⓒ LG Electronics. Inc.2009

Page 50

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Check Method

① Check 5V, 15V input voltage on P2 Connector

② Check VS input voltage on P3 Connector

③ Check voltage of Diode , FET by using Digital Multi Meter)

HS1

HS1

Q506 Q505 D506 Q504 Q503 D505

▣

Measuring Method

Symptom

Z-Sus Board Checking Method(42G2)

HS2

HS2

D501 D502 Q501 Q502 D503 D504

A. Picture Problem

Making

Revision

HS1

2009. 2 . 1

A9

HS2

Diode

<Specification>

Position

HS1

HS2

FET

P3

P2

ClassifyDirection

DiodeFET

0.3~0.4V0.4~0.5VForward

OL(Overload)Reverse

0.3~0.4V0.3~0.4VForward

OL(Overload)Reverse

A9

ⓒ LG Electronics. Inc.2009

Page 51

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Check Method

① Check whether there is short between Vs & GND of P201 Connector

② Check FUSE open

③ Check voltage of Diode , FET by using Digital Multi Meter

HS1 HS2 HS3

Q31,Q32,Q34 FET(3ea)

D32~D36 Diode(4ea)

▣ Measuring Method

Symptom

Q22,Q23 FET(2ea)

D21 Diode(1ea)

Y-Sus Board Checking Method(50G2)

Q11~Q13, Q16~Q18 FET (6ea)

D11 Diode (1ea)

A. Picture Problem

Making

Revision

Fuse

2009. 2 . 1

A10

HS3

HS1

<Specification>

Position

HS1

HS2

HS3

FET Diode

Circuit No.Direction

D32~D36Q34Q31,32

0.4~0.5V0.3~0.4V0.4~0.5VForward

OL (Overload)Reverse

D21Q22,23

0.3~0.4V0.3~0.4VForward

OL(Overload)Reverse

Q16~Q18D11Q11~Q13

0.4~0.5V0.3~0.4V0.3~0.4VForward

OL(Overload)Reverse

A10

HS2

Fuse

ⓒ LG Electronics. Inc.2009

Page 52

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Check Method

① Check 15V input voltage on P100 Connector

② Check 5V,VS input voltage on P101 Connector

③ Check FUSE open

④ Check voltage of Diode , FET by using Digital Multi Meter)

D301 D302 Q301 Q303 D305

D303 Q304 D306

▣

Measuring Method

Symptom

HS200

HS200

Z-Sus Board Checking Method(50G2)

HS201

HS201

Q318 Q315 Q313 Q312

Q317 Q314 Q311

A. Picture Problem

Making

Revision

2009. 2 . 1

A11

P101

Fuse

D311D312

HS200

HS2

HS201

Diode

FET

<Specification>

Position

HS200

HS201

ClassifyDirection

OL(Overload)Reverse

0.5V~0.6V

OL(Overload)Reverse

P100

DiodeFET

0.3V~0.4V0.4V~0.5VForward

D311,312Q313~Q318Q311~312

0.3V~0.4V0.3V~0.4VForward

A11

ⓒ LG Electronics. Inc.2009

Page 53

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Measure 5V voltage

Symptom

Power Board

P813

A. Picture Problem

Check 5V, 12V on Power B/D

P1100

▣ Measure 12V voltage

Making

Revision

2009. 2 . 1

A12

Pin Map

Power B/D↔Main B/D

(P813) (P1100)

P813

A12

ⓒ LG Electronics. Inc.2009

Page 54

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

▣ Checking Method

① Check input voltage(5V of P101) on Control B/D

② Check LED On

③ If LED light doesn’t appear, check Crystal X101 output

④ Check 3.3V, 5V,1.8V FET

⑤ Check MCM at VS_DA by using Multi meter

Check Crystal(X101)

③

Symptom

Control Board Checking Method(42G2/50G2)

Check oscillation of Crystal

(Normal: 100 MHZ, 1.6v)

A. Picture Problem

Check Crystal(X101)

④

Making

Revision

GND

3.3 V

1.8 V

5 V

2009. 2 . 1

A13

Check MCM

⑤

MCM Check point

(+)VS_DA / (-) GND

(Normal: 3.3V )

A13

Check LED On

②

Check Input voltage

①

ⓒ LG Electronics. Inc.2009

Page 55

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Dark picture caused by Mal-discharge

▣

Symptom

Dot type Mal-discharge symptom

▣

A. Picture Problem

Mal discharge Symptom

Scan type Mal-discharge symptom

▣

Making

Revision

2009. 2 . 1

A14

A14

Page 56

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Check by using Rom Label on control board

▣

Check by using SVC Remocon

▣

Press “In-start”→Press” 0000”

Select Panel option →Pop up Module Rom ver.

→

Symptom

PDP Module Rom Ver. Checking method

A. Picture Problem

Making

Revision

Rom ver. Label

2009. 2 . 1

※Refer to the Module Rom upgrade manual

for Rom upgrade.

A15

USB Type Jig

A15

Page 57

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

◆ Y Drive board

42G2 50G2

Scan IC

Input

connecter

A. Picture Problem

Y Drive B/D Checking method

< In case that Y Drive is ok >

. Diode

- Forward: 0.7V

- Reverse: O.L

Input

connecter

▶ Scan IC output checking method

1. Fixed Red Probe(“-”) at one pin of any Input connector

2. Check all pin of output connector(6ea) by using Black probe

If DMM display value as the below,there is no problem.

ÎNormal : Forward (0.7V ~ 0.8V), Reverse( O.L)

If Y Drive have defect (short) , DMM display almost 0v.

※ DMM(Digital Multi Meter)

Making

Revision

2009. 2 . 1

A16

(Red Probe”-”)

Output connecter

(Black Probe”+”)

Check all pin on output connector by using Black probe

A16

Page 58

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

Check Discharge resistor on Power B/D

Check Discharge resistor (10Ω/22Ω 2~3ea)

on Power B/D before replace Y Drive B/D

Making

Revision

2009. 2 . 1

A17

42” (Maker: LGIT,Sanken) 42” (Maker: Lite On) 50” HD(Maker: LGIT,Sanken)

A17

Page 59

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

◆ Half /partly No picture (or abnormal picture)

1) Check Va input voltage

( P233,P232, P311: Power connector of the X B/D)

2) check connectors between CTRL B/D and X B/D

3) To replace the X B/D.

4) Be sure the connection of TCP after X B/D replacing

※ Relation between screen and X B/D

. Left No Picture( Picture1) ↔ Check/Replace Right X B/D

. Right No picture (Picture2) ↔ Check/Replace Left X B/D

Y-Sus B/D

Symptom

(Half picture) X- B/D Checking method(42G2)

Control B/D

A. Picture Problem

Half

No picture

Partly

no Picture

(abnormal)

Check Connector (TCP,FFC) connection on Board

Making

Revision

abnormal

2009. 2 . 1

A18

Picture2Picture1

Va Input

XL (Left X B/D) XR (Right X B/D)

X B/D

A18

Page 60

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

◆ Half /partly No picture (or abnormal picture)

1) Check Va input voltage

( P122: Power connector of the X B/D)

2) check connectors between CTRL B/D and X B/D

3) To replace the X B/D.

4) Be sure the connection of TCP after X B/D replacing

※ Relation between screen and X B/D

. Left No Picture( Picture1) ↔ Check/Replace Right X B/D

. Right No picture (Picture2) ↔ Check/Replace Left X B/D

Y-Sus B/D

Symptom

(Half picture) X- B/D Checking method(50G2)

Control B/D

A. Picture Problem

Half

No picture

Partly

no Picture

(abnormal)

Check Connector (TCP,FFC) connection on Board

Making

Revision

abnormal

2009. 2 . 1

A18

Picture2Picture1

Va Input

XL (Left X B/D) XR (Right X B/D)XC (Center X B/D)

X B/D

Connector XC↔XRConnector XL↔XC

A18

Page 61

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

Defect type cause by PDP Module

Making

Revision

2009. 2 . 1

First of all, Check whether all of cable between board was inserted properly or not.

Next, Check whether there is foreign material on connector.

1. Check connection

Regular vertical lines

Vertical lines or Bar

(CTRL B/D, X B/D)

2. Check CTRL B/D

3. Replace CTRL B/D

1. Check connection

(CTRL B/D, X B/D)

2. Check CTRL B/D

3. Replace CTRL B/D

A19

To actiondefects descriptionSymptom picture

1. Check connection

(CTRL B/D, X B/D)

Many irregular vertical lines

2. Check CTRL B/D

3. Replace CTRL B/D

1. Check connection

(Y-Sus B/D ↔Panel)

Horizontal Line or Bar

2. Check Y-Sus B/D

3. Replace Y-Sus B/D

A19

Page 62

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

1. Check foreign & Connection status

2. Check bad soldering

on Chip resistance

▣ Defect symptom

Symptom

COF Type

96 Out Put

A. Picture Problem

Connector Type on PDP Module

TCP Type

192 Out Put

TCP (Tape Carrier Package) is film

for IC connect with Electrode pattern

(Direct Bonding) on X B/D

Making

Revision

Connector to connect between

Electrode PAD Of PANEL and

Y Drive B/D,Z-Sus B/D

2009. 2 . 1

A20

FPC Type

A20

Page 63

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

A. Picture Problem

RF Signal level Checking method

Making

Revision

2009. 2 . 1

A21

◆ MENU Æ SETUP Æ Diagnostics

1. Check whether Signal Strength, Signal Quality is over 50% or not.

2. If Signal Strength, Signal Quality is under 50%,install the Booster to increase signal level.

A21

Page 64

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

Pin Map

Power B/D↔Main B/D

(P813) (P1100)

B. Power Problem

Check voltage on Power board

Checking Order

Checking Order

No.

Checking

Point

Making

Revision

2009. 2 . 1

A22

RemarkSpec

A22

1

KEY-ON

2

3

4

5

6

7

Check the other pin’s output

Low

(GND Value)

5VSTBY 5V

High(3.3V~5V)AC DET

High(3.3V~5V)RL_ON

High(3.3V~5V)M5V_ON

High(3.3V~5V)Vs-ON

Mechanical switch on

Page 65

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

Fuse

▣ Checking Method

B. Power Problem

Power board Checking Method

Power B/D↔ Y-Sus B/D

Va adjust

Vs adjust

Making

Revision

P811Pin

VS1

VS2

NC3

GND4

GND5

Va6

Va7

GND8

M5V9

M5V10

Va Voltage ADJ

◆ Check 5V,Va,Vs voltage

→ For Voltage specification,

2009. 2 . 1

A23

refer to the PDP Module Label.

◆ Adjust Va,Vs voltage.

① Check soldering status on each major component.

② Check there is problem on major component or not by eye.

(CONDENSER, FET, IC, Resistor)

③ Check FUSE.

④ Check 5V,Va,Vs voltage

※ PSU Maker: 1)LG IT 2)Sanken 3)Lite-On

※ If happen Power board Protection,

check whether there is Short or Open on Y-SUS, Z-SUS B/D or not.

A23

Vs Voltage ADJ

- value

Adjust way

+ value

Page 66

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Check Power off History by using SVC Remocon

▣

Press “In-start”→Press” 0000”→Select “Power Off History”→Pop up Module Rom ver.

Symptom

Check Power off History

B. Power Problem

Making

Revision

2009. 2 . 1

A24

LAST HISTORY 1~5

RCU OFF

KEY OFF

2HOUR OFF

NO SIGNAL OFF

A24

Appear Power off history 5ea.

(1 is the latest history)

Power off by Remote control

Mechanical power switch off

After turn on by OnTimer, There is no operation for 2hours

In case that there is no signal for 15minutes

Page 67

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

C. Sound Problem

Speaker cable checking method

Making

Revision

Jack for Speaker connection

2009. 2 . 1

A25

1.Check whether speaker jack was inserted properly on Mian B/D side & speaker side or not.

2. Check whether speaker cable have problem (disconnection wire) or not.

Speaker

A25

Page 68

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Symptom

D. General function defect

Check Remote control IR operation

IR

GND

KEY1

KEY2

KEY-ON

GND

SCL-Sub/AMP

SDA-Sub/AMP

GND

+5V ST

(+5V-Multi)

( +3.3V-CI )

GND

LED-Red

LED-Green

IR Board

Making

Revision

2009. 2 . 1

A26

IR Board for XXPQ20/30xx

IR Board for XXPQ60xx

▣ Checking method

1.Check connector was inserted properly

on Main board and IR board.

2. Check +5V ST Voltage at Pin10

3. Check whether appear voltage on multi meter

when operate remote control.

※ Test Condition for case 3

→ Check Point: Pin 1( IR)

→ TV: power on status

→ Multi meter: Select DC 10V

A26

Page 69

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

~PQ60xx

~PQ20/30xx

Symptom

D. General function defect

Check Local switch operating

SCL-Sub/AMP

SDA-Sub/AMP

(+5V-Multi)

( +3.3V-CI )

LED-Green

Local switch Board

▣ Checking method

IR

GND

KEY1

KEY2

KEY-ON

GND

GND

+5V ST

GND

LED-Red

Making

Revision

2009. 2 . 1

A27

Vol-Vol+CH-CH+

Local switch Board for XXPQ20/30xx

Local switch Board for XXPQ60xx

Enter Menu Input

Mechanical

Power

1.Check connector was inserted properly

on Main board and local switch board.

2. Check Key-on signal is low(GND Value, Mechanical switch on)

[ If mechanical switch off status, Key-on is high(5v) ]

3. Check whether appear voltage on multi meter

when operate Local switch.

※ Test Condition for case 3

→ Check Point: Pin 2,3( Key1,Key2)

→ TV: power on status

→ Multi meter: Select DC 10V

4. Check bad solder & assembly status on Tactical power switch

A27

Page 70

Repair Process-Reference data

Copyright ⓒ 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PDP TV

Check Local KEY assembly status

Symptom

D. General function defect

Check Local switch assembly status

Making

Revision

2009. 2 . 1

A28

A28

XXPQ20/30xx

XXPQ60xx

Loading...

Loading...