Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PP01A

MODEL : 42PJ350R 42PJ350R-MA

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in Korea

P/NO : MFL62881410(1005-REV02)

Page 2

- 2 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

CONTENTS

CONTENTS ............................................................................................................................... 2

SAFETY PRECAUTIONS ...........................................................................................................3

SPECIFICATION.........................................................................................................................4

ADJUSTMENT INSTRUCTION ..................................................................................................7

BLOCK DIAGRAM ...................................................................................................................15

EXPLODED VIEW ..................................................................................................................16

SVC. SHEET ................................................................................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect

an electrical jumper across the two AC plug prongs. Place the

AC switch in the on position, connect one lead of ohm-meter to

the AC plug prongs tied together and touch other ohm-meter

lead in turn to each exposed metallic parts such as antenna

terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

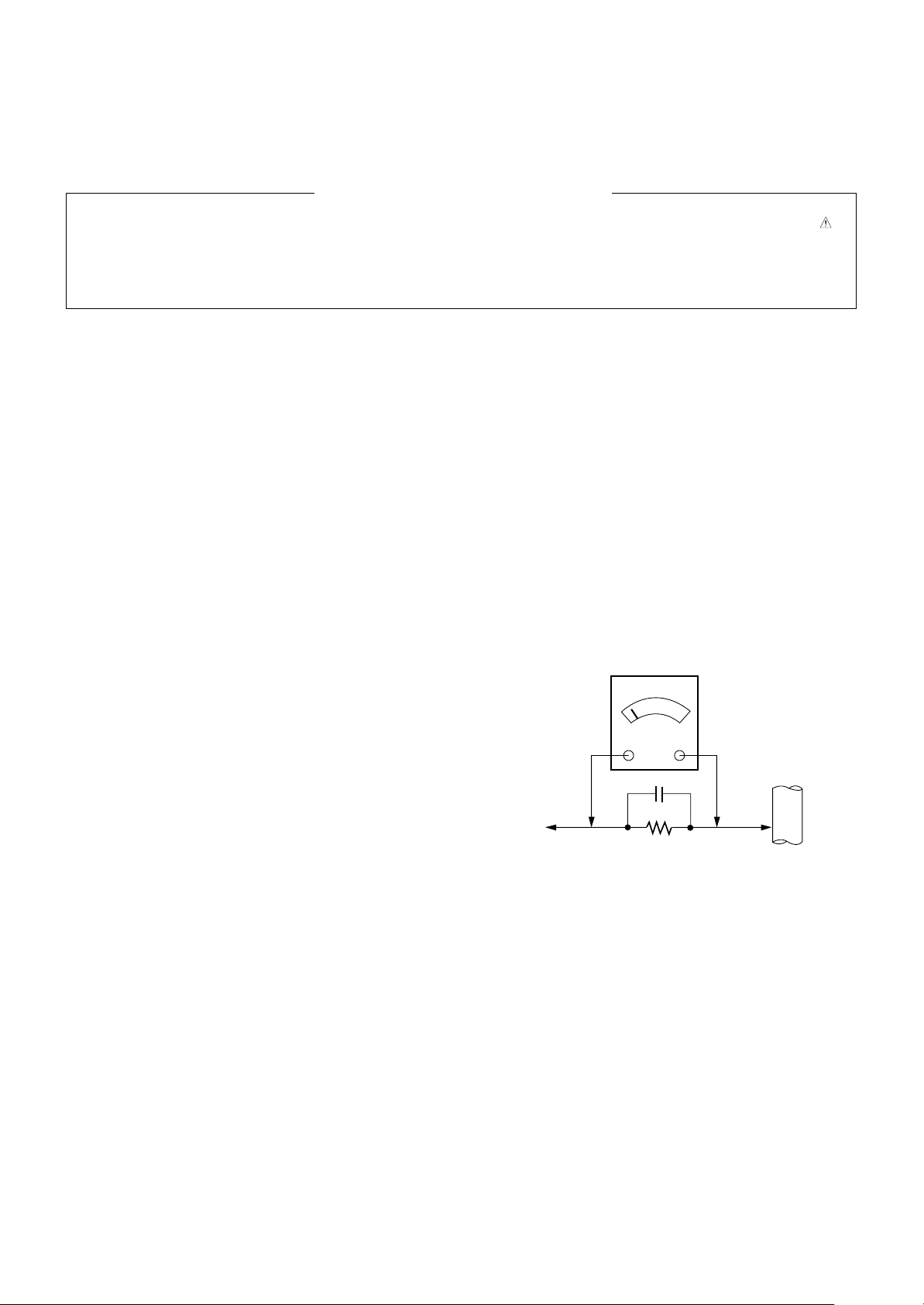

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to PDP TV used PP01A Chassis.

V Specification

Each part is tested as below without special appointment.

(1) Temperature : 25 °C ± 5 °C (77 °F ± 9 °F), CST : 40 ± 5

(2) Relative Humidity: 65 % ± 10%

(3) Power Voltage: Standard Input voltage (100 V - 240 V ~, 50 / 60 Hz)

* Standard Voltage of each product is marked by models.

(4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with

SBOM.

(5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

(1) Performance : LGE TV test method followed.

(2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

V Module Specification

(1) 42” XGA

42PJ350R-MA Central and South America LG

Model Name Market Place Brand

Model Name

42PJ350R-MA

Remark

Safety : IEC/ EN60065, EMI : CISPR13

Market

Central and South America

Appliance

TEST

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No Item Specification Remark

106 cm (42 inch) 16: 9 Color Plasma Display Module

16:9

PDP42T1###,

RGB Closed Type

1) Temp. : 0 deg ~ 60 deg

2) Humidity : 20 % ~ 80 %

3) Temp. : -20 deg ~ 60 deg

4) Humidity : 10 % ~ 90 %

AC 100 V - 240 V, 50 / 60 Hz

PDP

Glass Filter

LGE SPEC.

Maker : LGIT

Page 5

- 5 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

V Model General Specification

(1) Central and South America (MA)

No Item Specification Remark

1 Market Central and South America

2 Broadcasting system NTSC, PAL-M, PAL-N

3 Available Channel BAND NTSC

VHF 2~13

UHF 14~69

CATV 1~125

4 Receiving system Upper Heterodyne

5 Video Input (2EA) PAL,SECAM, NTSC Rear 1EA, Side 1EA

6 Component Input (2EA) Y/Cb/Cr, Y/ Pb/Pr

7 RGB Input (1EA) RGB-PC

8 HDMI Input 2ea HDMI-DTV , Only PCM MODE Side HDMI(1), Rear HDMI(1)

: 42/50PJ250-MA only

3ea Side HDMI(1), Rear HDMI(2)

9 Audio Input (5EA) L/R Input(PC 1EA, Component 2EA,

Rear 1EA, Side 1EA)

10 RS-232C (1EA) Remote control

11 USB Input (1EA) SD DivX, MP3, JPEG, PJ250R Rear USB only for service

Page 6

- 6 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

A Chroma & Brightness (Optical)

(1) (With 38% Filter) 42” T1 module

No Item Min Typ Max Unit Remark

(*) Special Peak Brightness Mode

- 1/ 100 ~ 3/ 100 white window Pattern

60Hz : 315 - cd/ m

2

(typically 1% window size)

50Hz : 315 - Picture Mode : Vivid

1 White peak Brightness - Mode : HDMI

- Resolution : 1920 x 1080 60H

60Hz : 161 60Hz : 173 - cd/ m

2

(*) Normal Mode

50Hz : 148 50Hz : 161

- 25 white window pattern

- Picture Mode : Vivid

2 White average brightness

60Hz : 47 60Hz : 52 - Full White Pattern

50Hz : 46 50Hz : 50

cd/ m

2

- Picture Mode : Vivid

3 Brightness uniformity -10 0 +10

- 85IRE Full White Pattern

- Picture Mode: Vivid

White X 0.270 0.285 0.300 White 216 level pattern

Y 0.278 0.293 0.308 Red/ Green/ Blue : 255 level pattern

Red X 0.635 0.640 -

4 Color

Y 0.318 0.330 0.340

coordinate Green X 0.242 0.300 0.305

Y 0.595 0.600 -

Blue X - 0.150 0.158

Y - 0.060 0.070

5 Contrast ratio at dark room 100,000: 1 1,000,000 :1

- White : 1/ 100 White Window Pattern

( Peak Mode )

- Black : Full Black

- Picture Mode : Vivid

6 Color coordinate uniformity -0.01 Average +0.01

- 85IRE Full White Pattern

- Picture Mode : Vivid

Cool X 0.261 0.276 0.291 - 85IRE Full White Pattern

Y 0.268 0.283 0.298 - Picture Mode : Vivid

7 Colour Medium X 0.270 0.285 0.300 - Warm, Cool : Color Temp. UI 30

Temperature Y 0.278 0.293 0.308 - Medium : Color Temp. UI 0

Warm X 0.298 0.313 0.328

Y 0.314 0.329 0.344

Page 7

- 7 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Range

This spec sheet is applied to all of the PP01A chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep 100 V

~ 240 V, 50 / 60 Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15 °C

- In case of keeping module is in the circumstance of 0 °C,

it should be placed in the circumstance of above 15 °C

for 2 hours

- In case of keeping module is in the circumstance of below

-20 °C, it should be placed in the circumstance of above

15 °C for 3 hours,.

3. S/W Program Download

3-1. Profile

This is for downloading the s/w to the flash memory of the

IC402

3-2. Equipment

(1) PC

(2) ISP_tool program

(3) Download jig

3-3. Connection Structure

3-4. Connection Condition

(1) IC name and circuit number : Flash Memory and IC402

(2) Use voltage : 3.3V (5 pin)

(3) SCL : 15 pin

(4) SDA : 12 pin

(5) Tact time : about 2min and 30seconds

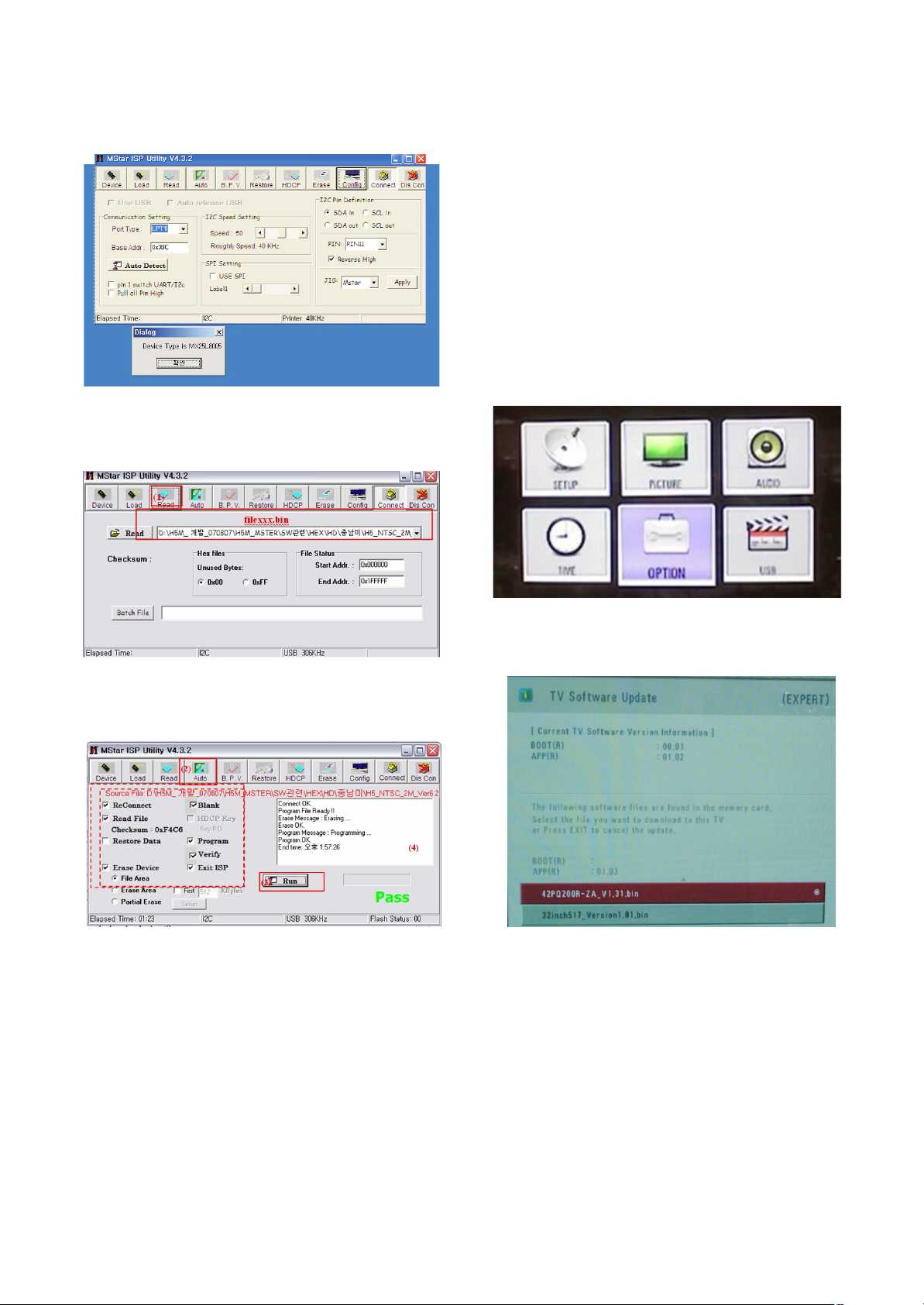

3-5. Download Method (By using MSTAR JIG)

(1) Preliminary Steps

1) Connect the download jig to D-sub jack

2) Connect the PC to USB jack

(2) Download Steps

1) Execute ‘ISP Tool’ program in PC, then a main window

will be opened

2) Click the connect button and confirm “Dialog Box”.

Double click

Page 8

3) Click the Config button and Change speed

E2PROM Device setting : over the 350Khz

4) Read and write bin file

Click “(1)Read” tab, and then load download

file(XXXX.bin) by clicking “Read”.

5) Click “Auto(2)” tab and set as below

6) Click “Run(3)”.

7) After downloading, check “OK(4)” message.

3-6. Download Method (By using USB

Memory Stick)

Caution

- Using ‘power on’ button of the control R/C, power on TV.

- USB file (EPK) version must be bigger than downloaded

version of main B/D.

- It should be only one SW binary file in USB Stick

(1) Using ‘Power ON’ button of the control R/C, Power on TV.

(2) Insert the USB memory stick to the SET.

(3) Display USB loding message then, push the ‘Exit’ Key of

control R/C

(4) Push the ‘MENU’ Key and move the cusor ‘OPTION’ of

OSD ( Fig. 1)

* Caution: Don’t push the ‘OK’ key.Just cusor is on the

‘OPTION’ menu.

(5) Push the “7” key of control R/C continuously.

Then, Display “TV Software Update” Pop-up menu. (Fig. 2)

(6) Select SW file (XXXX.bin) you want, push the “OK” Key.

(7) S/W download process is excuted automatically.

- 8 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

( Fig. 1)

( Fig. 2)

Page 9

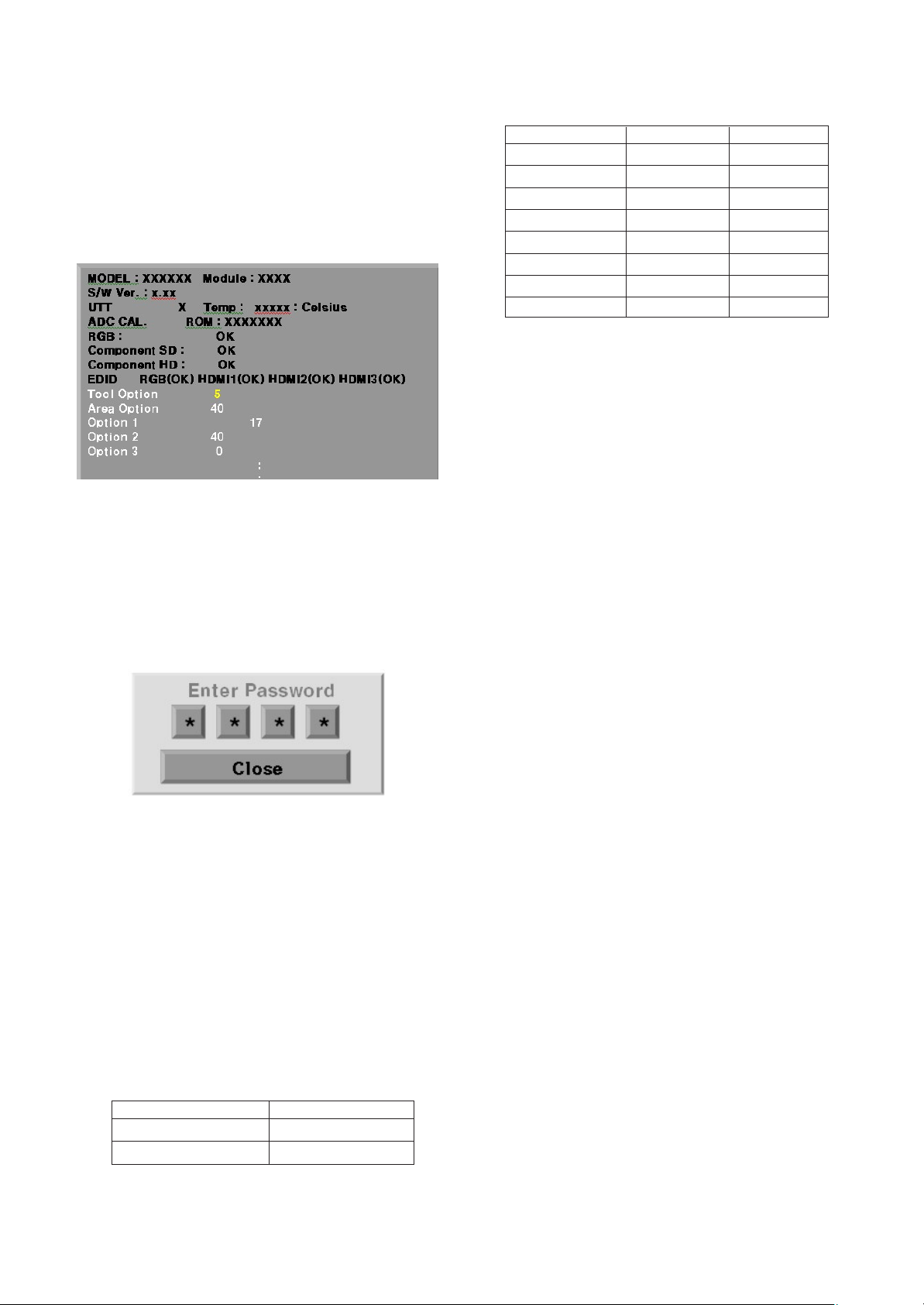

4. PCB Assembly Adjustment Method

4-1. Option Adjustment Following BOM

Tool Option

Area Option

Option 1

Option 2

Option 3(Available for EU & Non EU model)

* Profile: Must be changed the option value because being

different with some setting value depend on module,

inch and market

* Equipment : Adjustment Remote Controller

(1) Push the IN-START key in the Adjust R/C.

(2) Enter Password number. The value of Password is “0 0 0

0”.

(3) Input the Option Number that was specified in the BOM,

into the Shipping area.

(4) Select “Tool Option” by using

D/E(CH+/-) key, and press

the number key(0~9) consecutively

ex) If the value of Tool Option1 is 4, input the data using

number key “4” (Fig. 3)

(5) if it is EU model ( such as 42/50PJ**R-ZA ), select “Area

option” by using

D/E(CH+/-) key , and press the number

key(0~9) consecutively.

ex) If the value of Area Option is 40, input the data using

number key “40” (Fig. 3)

Caution

- Don’t Push “IN-STOP” key after PCB assembly

adjustment.

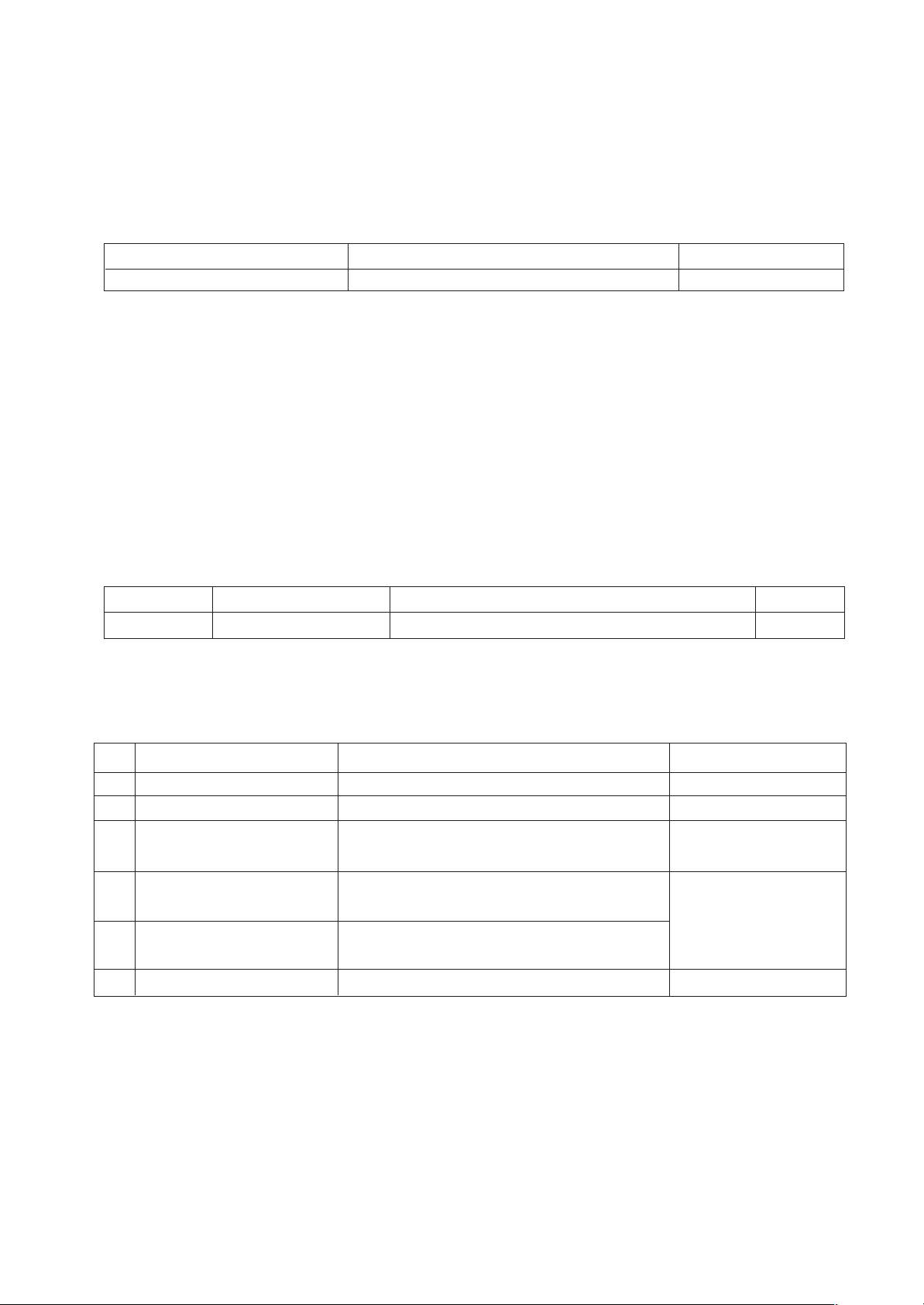

* PP01A/B/C Tool option

(6) EDID D/L Method

After software D/L or PCBA manufacturing, you can

download EDID Data.

When you adjust Tool Option, H6 Model EDID download

process is executed automatically

* If the model don’t have HDMI 3, HDMI 3 will be disappeared

at OSD Window.

Caution

- When you adjust tool option, don’t connect HDMI or Dsub cable.

- If you connect some cable, EDID D/L process will be

failed.

(7) Adjustment method

Before PCBA check, have to change the Tool option and

Area option

[ About PDP

After done all adjustments, Press IN-START button and

compare Tool option and Area option value with its BOM, if

it is correctly same then Change “RF mode” and then

unplug the AC cable.

If it is not same, then correct it same with BOM and unplug

AC cable.

For correct it to the model’s module from factory JIG

model.

[ Don’t push The IN-STOP KEY after completing the function

inspection.

- 9 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

( Fig. 3)

Model Tool option

50PJ250R-TA 16

42PJ250R-ZA 23

CSA Model Tool option Area option

42PJ25*R-M* 1 40

50PJ25*R-M* 2 40

42PJ35*R-M* 3 40

50PJ35*R-M* 4 40

42PJ26*R-M* 5 40

50PJ26*R-M* 6 40

50PK55*R-M* 7 40

60PK55*R-M* 8 40

Page 10

- 10 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

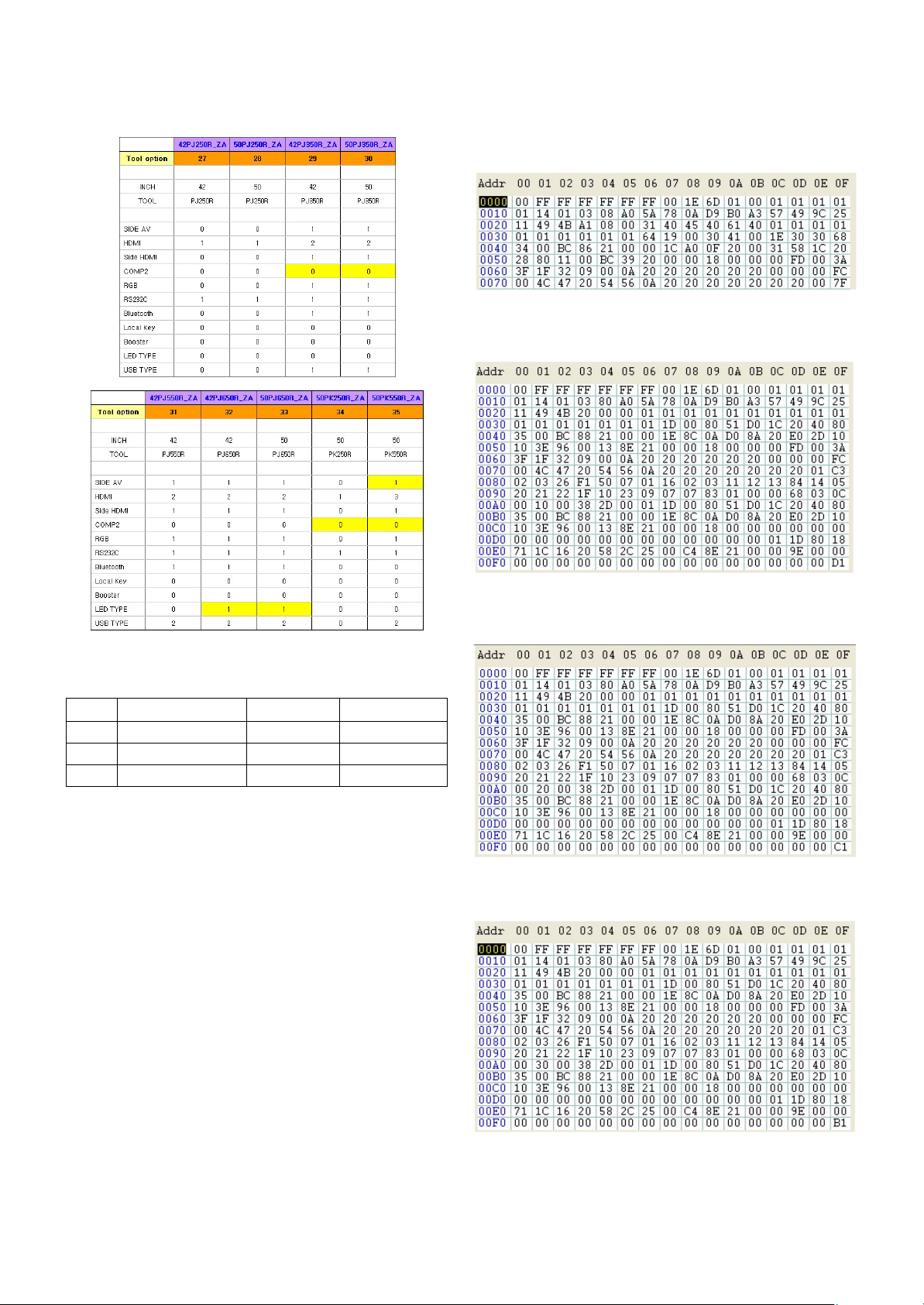

5. EDID(The Extended Display

Identification Data)

Caution

- Never Use the cable( HDMI or D-sub cable) for EDID

Writing.

- Automatically PP01A/B/C Model EDID download process

is executed when you adjust Tool Option.

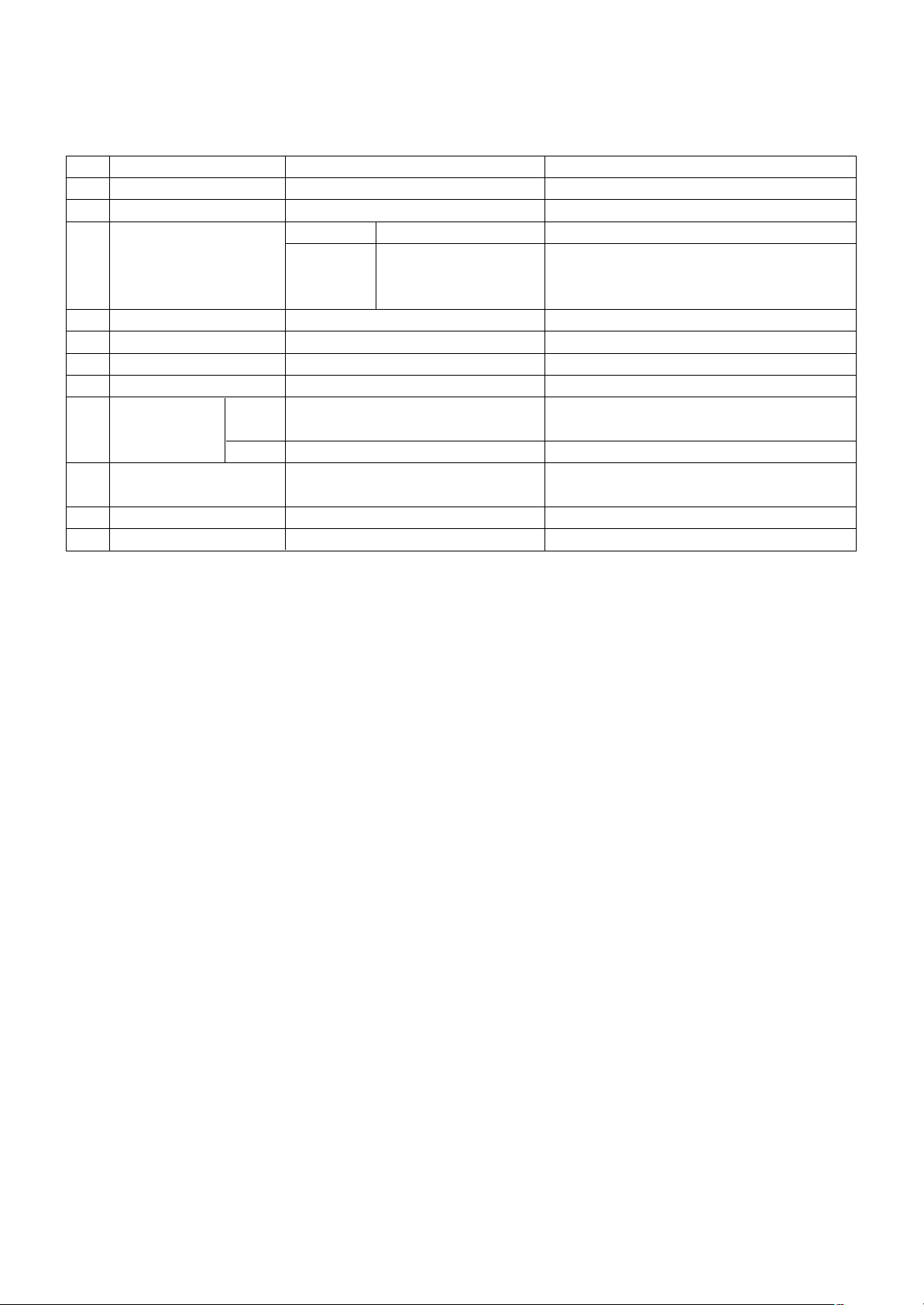

< Jack Layout>

<Tool Option Item>

<CSA AREA>

<NON-EU AREA>

Inch

Tool

SIDE AV 0/1

HDMI 0/1/2/3

Side HDMI 0/1

COMP2 0/1

RGB 0/1

RS232C 0/1

Local Key 0 (7KEY) / 1 (8KEY)

LED TYPE 0 (RED) / 1 (RED/White) / 2 (Reserve)

USB TYPE 0 (NONE) / 1 (PHOTO, MUSIC)

/ 2 (PHOTO, MUSIC, DivX)

Page 11

- 11 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

<EAST EU / CIS AREA>

5-1. EDID Data

O XGA EDID DATA ( 42 inch)

<Analog(RGB) : 128bytes>

<HDMI 1 : 256bytes>

<HDMI 2 : 256bytes>

<HDMI 3 : 256bytes> SIDE HDMI(HDMI 3)

NO Item Condition Hex Data

1 Manufacturer ID GSM 1E6D

2 Version Digital : 1 01

3 Revision Digital : 3 03

Page 12

- 12 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

6. HDCP(High-Bandwidth Digital

Contents Protection) Download

HDCP download process is deleted in PP01A/B/C Chassis

In PP01A/B/C Chassis, it is usi

g the EEPROM masking

HDCP Key

7. Manual ADC Adjustment

(Component 1, RGB)

Caution

- Do not connect external input cable

- Adjustment result is applied to SET On/Off later.

* Adjustment is done using internal ADC, so input signal is not

necessary.

7-1. COMPONENT input ADC (SD / HD),

RGB input ADC

(1) Press ADJ key on R/C for adjustment. Need not convert

input mode.

(2) Enter Password number. The value of Password is “0 0 0

0”.

(3) Select “0. ADC calibration” by using D/E(CH +/-) and press

ENTER(V).

(4) Start ADC adjustment by using F/G(VOL +/-) or press

ENTER(V).

(5) Both component and RGB ADC adjustment are executed

automatically

When ADC adjustment is finished, this OSD appear.

Notice : After All mode check, set the Speaker Volume “0”.

Caution : Don’t Press the Power Key on Remote Controller.

Just AC Power Off. ( Not DC off )

Notice : From this sentence, All working is mass production.

8. POWER PCB Assy Voltage

Adjustment

(Vs voltage Adjustment)

8-1. Test Equipment: D.M.M 1EA

8-2. Connection Diagram for Measuring

Refer to (Fig. 4)

8-3. Adjustment Method

(1) Vs Adjustment

1) Connect + terminal of D. M..M. to Vs pin of P811,

connect -terminal to GND pin of P811.

2) After turning VR901, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel right/top

( deviation ; ±0.5V)

(2) Va Adjustment

1) Connect + terminal of D. M..M. to Va pin of P811,

connect -terminal to GND pin of P811.

2) After turning VR502, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top

( deviation ; ±0.5V)

RF input

NO SIGNAL or White noise

AV / Component / RGB input

NO SIGNAL

(Fig. 4)

Page 13

- 13 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

8-4. Adjustment of Area option.

(1) Area Option Adjustment following BOM

(Including SKD models )

Tool Option

Area Option

Option 1

Option 2

Option 3 ( Available for EU & Non EU model )

* Profile : Must be changed the option value because being

different with some setting value depend on module,

inch and market

* Equipment : Adjustment Remote Controller

1) Push the IN-START key in the Adjust R/C.

2) Enter Password number. The value of Password is “0 0

0 0”.

3) Input the Area Option Number that was specified in the

BOM, into the Shipping area.

4) Select “Area Option” by using

D/E(CH+/-) key, and

press the number key(0~9) consecutively

ex) If the value of Area Option 40, input the data using

number key “40” (Fig. 3)

Caution:

- Although it is SKD model, adjust area option in SET

assemmbly process.

- Don’t Push “IN-STOP” key after PCB assembly

adjustment.

9. Adjustment of White Balance

9-1. Required Equipment

(1) Remote controller for adjustment

(2) Color Analyzer ( CS-1000, CA-100,100+,CA-210 or same

produc : CH 10 (PDP)

lease adjust CA-210, CA-100+ by CS-1000 before

measuring

(3) Auto W/B adjustment instrument(only for Auto adjustment)

9-2. AUTO White Balance Process.

Before Adjust of White Balance, Please press POWER ONLY

key

Adjust Process will start by execute RS232C Command.

O CS-1000/CA-100+/CA-210(CH 10) White balance adjustment

coordinates and color temperature.

9-3. Manual W/B process (using adjusts

Remote control)

(1) Enter ‘PICTURE RESET’ on Picture Mode, then turn off

Fresh Contrast and Fresh colour in Advanced Control

(2) After enter Service Mode by pushing “ADJ” key,

(3) Enter White Pattern off of service mode, and change off ->

on.

(4) Enter “W/B ADJUST” by pushing “G ” key at “3. W/B

ADJUST”.

(5) Adjust W/B DATA, for all CSM, choose ‘COPY ALL’

* Gain Max Value is 192. So, Never make any Gain Value

over 192 and please fix one Value on 192, between R, G

and B.

.

.

CSM Color Coordinate Temp Color Coordinate

xy

Cool 0.276 0.283 11000K 0.002

Medium 0.285 0.293 9300K 0.002

Warm 0.313 0.329 6500K 0.002

Min Tpy Max

R-GAIN 0 192 192

G-GAIN 0 192 192

B-GAIN 0 192 192

Page 14

- 14 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

* Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked. (Illumination is less than 10ux).

(2) Measure and adjust after sticking the Color Analyzer (CA-

100+, CA210 ) to the side of the module.

(3) Aging time

- After aging start, keep the Power on (no suspension of

power supply) and heat-run over 5 minutes

*Above optical characteristics are should be measured by

following condition.

O DDC Adjustment Command Set

Measured Mode

Picture Mode Vivid

Fresh Contrast Off

Fresh Color Off

Smart Power Saving Off

Adjustment

Adjustment

Adjustment

Page 15

- 15 -

LGE Internal Use OnlyCopyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 16

- 16 -

LGE Internal Use Only

EXPLODED VIEW

Copyright ©2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

200

120

305

300

400

580

301

302

303

304

202

240

520

207

206

204

203

201

501

590

570

602

601

604

900

205

910

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

A10

A9

LV1

A12

A21

A2

Page 17

EAX61365502(BPR)

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

H6 Revolution Circuit Diagram

[ Slim Jack : EAG59023302 ]

+5V_HDMI_1

BOT_HDMI

BOT_HDMI

YKF45-7058V

JK100

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R101

1K

C

B

Q100

E

BOT_HDMI

RT1C3904-T112

2SC3875S

DDC_SDA1

DDC_SCL1

CEC

TMDS1_RXC-

TMDS1_RXC+

TMDS1_RX0-

TMDS1_RX0+

TMDS1_RX1-

TMDS1_RX1+

TMDS1_RX2-

TMDS1_RX2+

BOT_HDMI

R104

10K

HPD_MST_1

[ Slim Jack : EAG59023301_SCREW ]

+5V_HDMI_2

R102

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

YKF45-7054V

JK101

[ Slim Jack : EAG42463001]

JACK_GND

20

19

HPD

18

+5V_POWER

17

DDC/CEC_GND

16

SDA

15

SCL

14

NC

13

CEC

12

CLK-

11

CLK_SHIELD

10

CLK+

9

DATA0-

8

DATA0_SHIELD

7

DATA0+

6

DATA1-

5

DATA1_SHIELD

4

DATA1+

3

DATA2-

2

DATA2_SHIELD

1

SIDE_HDMI

DATA2+

KJA-ET-0-0032

JK102

[ SIDE HDMI ]

1K

C

E

Q101

RT1C3904-T112

2SC3875S

DDC_SDA2

DDC_SCL2

CEC

TMDS2_RXC-

TMDS2_RXC+

TMDS2_RX0-

TMDS2_RX0+

TMDS2_RX1-

TMDS2_RX1+

TMDS2_RX2-

TMDS2_RX2+

+5V_HDMI_3

R100

C

1K

SIDE_HDMI

E

R103

10K

B

B

Q102

RT1C3904-T112

2SC3875S

SIDE_HDMI

DDC_SDA3

DDC_SCL3

CEC

TMDS3_RXC-

TMDS3_RXC+

TMDS3_RX0-

TMDS3_RX0+

TMDS3_RX1-

TMDS3_RX1+

TMDS3_RX2-

TMDS3_RX2+

R105

10K

SIDE_HDMI

HPD_MST_2

HPD_MST_3

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

INPUT

[ Slim Jack : 6630TGA004Q ]

JK110

SPG09-DB-010

6

1

11

7

2

12

8

3

13

9

4

14

10

5

15

16

JK103

PEJ027-01

3

6A

7A

4

5

7B

6B

JK106

PPJ235-01

5A

4A

3A

4B

3C

4C

5C

HDMI CEC

Q103

BSS83

D

CEC

CAT24C02WI-GT3

A0

A1

A2

VSS

G

S

B

1

2

3

4

R145

75

R152

10K

R146

220K

R153

10K

R147

220K

+3.3V_MPLL

R106

56K

MMBD301LT1G

D103

30V

D104

10V

IC100

CEC_C

VCC

8

WP

7

SCL

6

SDA

5

R123

220K

R124

220K

R158

12K

R159

12K

C101

0.01uF

25V

R111

75

R125

10K

R126

10K

+5V_ST

R112

75

R114

100

R115

100

R129

R122

4.7K

4.7K

R128

68

R120

4.7K

R127

68

R121

C104

4.7K

68pF

R113

75

R130

12K

R131

12K

SIDE_VIN

SIDE_LIN

SIDE_RIN

+5V_HDMI_1

C102

R116

R119

0.01uF

10K

10K

25V

DDC_SCL1

DDC_SDA1

R132

10K

C103

68pF

PC_AUD_L

PC_AUD_R

+5V_ST

A1CA2

D100

KDS184S

[ Slim Jack : 6630G00001E ]

ISP_RX

DSUB_SDA

DSUB_SCL

ROM_SDA

PC_R

PC_G

PC_B

ROM_SCL

PC_HS

PC_VS

6A

5A

4A

7B

5B

7C

5C

5D

4E

5E

6E

PPJ234-01

JK105

EU

IC101

CAT24C02WI-GT3

A0

1

A1

2

A2

3

VSS

4

JK111

SPG09-DB-009

1

6

2

7

3

8

4

9

5

10

NONE_EU

PPJ239-01

JK107

VCC

8

WP

7

R133

SCL

100

6

R134

SDA

100

5

6J

5J

4J

7K

5K

7L

5L

5M

4N

[RD2]CONTACT

5N

[RD2]O-SPRING_2

6N

[RD2]E-LUG

6D

[GN1]E-LUG

5D

[GN1]O-SPRING

4D

[GN1]CONTACT

7E

[BL1]E-LUG-S

5E

[BL1]O-SPRING

7F

[RD1]E-LUG-S

5F

[RD1]O-SPRING_1

4F

[RD1]CONTACT_1

5G

[WH1]O-SPRING

4H

[RD1]CONTACT_2

5H

[RD1]O-SPRING_2

6H

[RD1]E-LUG

+5V_HDMI_2

R135

10K

DDC_SDA2

NONE_RGB

NONE_RGB

NONE_RGB

NONE_RGB

R136

C109

10K

0.01uF

25V

DDC_SCL2

R142 100

R143 100

R144 100

R150 100

R543 100

R544 100

C100

0.01uF

25V

R137

75

NONE_EU

R138

75

NONE_EU

R148

NONE_EU

10K

NONE_EU

R140

220K

R149

10K

NONE_EU

R141

220K

NONE_EU

R165

75

R166

75

R167

75

R168

220K

R169

220K

+5V_ST

A1CA2

D101

KDS184S

R174

10K

R175

10K

R109

100

NONE_EU

VSS

R110

100

12K

NONE_EU

A0

A1

A2

ROM_SDA

ROM_SCL

DSUB_SDA

DSUB_SCL

EYE_SCL

EYE_SDA

MAX3232CDR

VCC

16

GND

15

DOUT1

14

RIN1

13

ROUT1

12

DIN1

11

DIN2

10

ROUT2

9

100

R118

100

R117

NONE_EU

R154

R139

12K

75

R155

R178

12K

R179

12K

IC102

CAT24C02WI-GT3

1

2

3

4

IC103

IR_OUT

COMP1_Y

COMP1_PB

COMP1_PR

COMP1_L

COMP1_R

COMP2_Y

COMP2_PB

COMP2_PR

COMP2_L

COMP2_R

VCC

8

WP

7

SCL

6

SDA

5

+3.3V_MPLL

C105

0.1uF

C1+

1

V+

2

3

4

5

6

7

8

TXD

RXD

SIDE_HDMI

SIDE_HDMI

C1-

C2+

C107

C2-

0.1uF

V-

DOUT2

RIN2

+5V_HDMI_3

R160

100

R161

100

C108

0.1uF

C106

0.1uF

R162

10K

SIDE_HDMI

DDC_SDA3

NONE_EU

PPJ241-01

SIDE_HDMI

C110

R163

0.01uF

10K

25V

SIDE_HDMI

SIDE_HDMI

DDC_SCL3

NONE_EU

JK113

PPJ231-01

JK116

4

3

5

+5V_ST

A1CA2

D102

KDS184S

4

5

7

8

6

[RD]R_OUT

[WH]L_OUT

[WH]GND

EU

JK114

PSC008-02

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

SHIELD

EU

JK115

PSC008-02

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

SHIELD

AV_DET

AV_DET

R537

EU

1K

EU

R530

470K

EU

R531

R534

1K

470K

EU

EU

+3.3V_MST

R526

3K

EU

R536 22

EU

C

Q500

2SC3875S(ALY)

EU

E

R528

470K

R529

470K

R538

5.6K

EU

R532

0

R533

1K

NONE_HOTEL

R539

0

R535

1K

NONE_HOTEL

EU

C113

10uF

C

E

C

E

B

C115 220uF

HOTEL

R540

0

HOTEL

C111

10uF

16V

C

Q502

2SC3875S(ALY)E

HOTEL

C

E

R503

220K

R504

220K

EU

EU

R500

0

NONE_EU

R505

10K

R506

10K

R507

20K

EU

R508

R509

220K

R510

220K

R514

12K

R515

12K

3K

EU

R520

R516

75

EU

R517

75

EU

R518

75

EU

R524

R519

75

EU

SC1_RIN

SC1_LIN

SC1_ID

SC1_B

SC1_G

SC1_R

1K

EU

R525

3K

EU

B

R527 75

SC1_VIN

75

R511

10K

R512

10K

R513

10K

EU

EU

R521

EU

12K

EU

R522

12K

EU

3K

EU

R523

SC2_RIN

SC2_LIN

SC2_ID

[ EAG41945401 ]

R501

EU

0

NONE_EU

R502

75

R542

75

EU

SC2_VIN

EU

C116

100uF

16V

MNT_VOUT

1234

USB DOWN STREAM

JK112

KJA-UB-4-0004

5

H6 R 2009/11/05

16V

B

Q505

2SC3875S(ALY)

EU

C112

10uF

16V

EU

B

Q503

2SC3875S(ALY)

EU

R541

3K

EU

C

Q501

2SC3875S(ALY)

E

EU

16V

EU

B

C114

10uF

16V

NONE_HOTEL

B

Q504

2SC3875S(ALY)

R180

5.1

R181

5.1

1 4INPUT

TV_ROUT

MUTE_LINE

TV_LOUT

MUTE_LINE

SC1_FB

TV_VOUT

SPK_R+_HOTEL

AUDIO_R

MNT_ROUT

MUTE_LINE

SPK_R-_HOTEL

MNT_LOUT

MUTE_LINE

+5V_MULTI

USB_DN

USB_DP

Page 18

EAX61365502(BPR)

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

H6 Revolution Circuit Diagram

Power Block

KEY/IR Interface

LVDS Block

P202

SMAW200-H26S1

+5V_ST

CB3216PA501E

C200

22uF

16V

+17V_TI

+5V_ST

+3.3V_MPLL

RL_ON/POWER_ON

L200

C2

SMAW200-H18S1

1

3

5

7

9

11

13

15

17

R207

100K

C202

C8

10uF

16V

16mA

VIN

25V

0.01uF

C201

R200

10K

P200

2

4

6

8

10

12

14

16

18

19

R4

C1

C210

0.01uF

C204

READY

D1

ZD201

READY

IC200

AP2121N-3.3TRE1

2

3

MAX 300mA

1

GND

R201

10K

B

100

R236

R203 100

IC201

MP2305DS

BS

1

IN

2

SW

3

GND

4

L1

L202

22uH

VOUT

C206

22uF

R202

10K

C

Q200

RT1C3904-T112

E

12mA

16V

C20 7

22u F

16V

+17V_TI

C205

0.01uF

25V

M5V_ON

RL_ON/POWER_ON

SS

8

EN

7

C215

COMP

6

4700pF

FB

5

R1

C5

C213

C9

READY

+3.3V_MPLL

25V

0.01uF

C209

1420mA

25V

0.01uF

C211

3.2A / P-CHANNEL

+5V_MULTI

R226

4.7K

+5V_ST

AC_DET

C221

0.1uF

C6

READY

R2

C217

R213

3.6K

50V

10K

R208

R215

68K

R3

C218

22uF

16V

3225

Q201

RTR030P02

S D

G

R231

100

ERROR_DET

L201

MLB-201209-0120P-N2

120-ohm

C223

R216

READY

C7

C222

100uF

16V

MAIN SUB MICOM

MAIN I2C PULL UP

RS232C-TRANCEIVER

CEC LEVEL SHIFT

READY

R5

V=0.923X(1+R1/R3)=7.2V

THE RECOMMANDED VALUE OF R3 IS 10K

AZ1117H-ADJTRE1(EH11A)

INPUT

C224

OUTPUT

0.1uF

16V

C214

100uF

16V

R248

0

READY

IC202

3

1420mA

2

C216

0.01uF

25V

1

C208

100uF

16V

ADJ/GND

C212

0.01uF

25V

R217

110

1/10W

1%

TYPICAL 3A

AZ1085S-3.3TR/E1

INPUT

3

C229

C2

10uF

16V

IC203

R243

100K

1

ADJ/GND

C8

+5V_MULTI

R225

330

1/10W

1%

L203

CBC3225T330KR

OUTPUT

2

R4

C1

C231

0.01uF

C230

READY

D1

ZD200

READY

USB

1391mA

GND

BS

IN

SW

C225

100uF

16V

C219

100uF

16V

MP2305DS

1

2

3

4

L803

10uH

IC204

L1

SEPARATE GND

R1

0

R2

0

R3

0

R4

0

R5

0

R6

0

R7

0

R8

0

+5V_TU

356mA

85mA

C220

0.01uF

25V

SS

8

EN

7

C232

COMP

6

5

C5

C233

4700pF

FB

50V

R1

C238

C9

READY

CGND1

CGND2

CGND3

CGND4

TUNER

MAIN IC : 4 PAGE

IC205

AZ1117H-ADJTRE1(EH11A)

INPUT

3

1

MAX 1A

2

OUTPUT

READY

C7

C235

0.1uF

C6

READY

R2

R245

3.6K

R246

R244

10.5K

3.9K

1%

1%

R3

C234

22uF

16V

3225

P203

12507WS-12L

13

GND

+3.3V_MST

R212

R211

36

1/10W

1%

75

1%

25V

0.01uF

C227

+1.2V_MST

MAIN IC CORE

OUT:1.27V

ADJ/GND

C226

47uF

16V

C236

R247

READY

R5

V=0.923X(1+R1/R3)=1.266V

THE RECOMMANDED VALUE OF R3 IS 10K

930mA

C237

100uF

16V

IR

1

GND

2

KEY1

3

KEY2

4

RED_LED

5

GND

6

SCL

7

SDA

8

GND

9

3.3V_MPLL

10

3.3V_MST

11

WHITE_LED

12

59mA

DDR2 & Vref

+3.3V_MPLL

1.899V

+1.8V_DDR

+3.3V_MPLL

R220

10K

R221

4.7K

+3.3V_MST

0

R21 0

LED_W

R223

10K

+3.3V_MST

R222

4.7K

+5V_ST

0

R22 8

READY

IR

HOTEL

+3.3V_MPLL

KEY1

KEY2

R230

100

C

EYE_SCL

EYE_SDA

BUZZ_PWM

12507WS-08L

HOTEL OPTION

+5V_ST

C

R224

4.7K

KDS1 84S

HOTEL

Q202

B

R240

10K

A2

A1

D200

2SC3052

E

R227

4.7K

HOTEL

HOTEL

R232

22

LED_R

LED_BL

IR_OUT

Buzzer ready

+5V_MULTI

D201

1N4148W

READY

READY

R241

100

B

R242

10K

READY

C

Q203

2SC3875S(ALY)

READY

E

LEAD+

LEAD-

DUMMY

READY

BU2

SMT-5030D

1

2

3

Hotel Option

HOTEL

P204

9

1

2

3

4

5

6

7

8

+17V_TI

C228

0.1uF

HOTEL

R209

1K

READY

SPK_R+_HOTEL

SPK_R-_HOTEL

AUDIO_R

SW_RESET

AC_DET

HD

ROM_TX

P_SCL

TXCE0- TXCE0+

TXCE1- TXCE1+

TXCE2- TXCE2+

TXCLKE- TXCLKE+

TXCE3- TXCE3+

TXCE4- TXCE4+

ROM_SCL

DISP_EN

R21 9

R218 100

470

ROM_SCL

ROM_SDA

P_SCL

DISP_EN

P_SDA

ROM_RX

ROM_TX

1

3

5

7

9

11

13

15

17

19

21 22

23 24

25 26

27

TXCE0-

TXCE0+

TXCE1-

TXCE1+

TXCE2-

TXCE2+

TXCLKE-

TXCLKE+

TXCE3-

TXCE3+

TXCE4-

TXCE4+

TXCO0-

TXCO0+

TXCO1-

TXCO1+

TXCO2-

TXCO2+

TXCLKO-

TXCLKO+

TXCO3-

TXCO3+

TXCO4-

TXCO4+

2

4

6

8

10

12

14

16

18

20

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TF05-51S

P201

FHD

ROM_RX

P_SDA

ROM_SDA

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

H6 R

2009/11/05

2 4Key / Power

Page 19

EAX61365502(BPR)

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

H6 Revolution Circuit Diagram

Audio Amp

AVSS

Tuner(7mm)

R302

0

Separate DGND AND AVSS

+3.3V_AVDD

C300

AVSS

R300

1K

C301

1000pF

50V

10uF 16V

I2S_MCLK

AC_DET

I2S_WS

I2S_SCK

I2S_SDO

A_SDA

A_SCL

SW_RESET

C304

0.1uF

R304

22

C302

0.1uF

R305

22

R306

22

R307

22

AVSS

C306

4.7uF

10V

This parts are Located

on AVSS area.

C316

C313

0.047uF

TESTOUT

R308

200

1%

18K

R309

OSC_RES

DVSS_1

VR_DIG

4700pF

R313

470

AVDD

13

14

MCLK

15

16

17

18

PDN

19

LRCLK

20

SCLK

21

SDIN

22

SDA

23

SCL

24

+3.3V_DVDD

C315

10uF 16V

R314

470

AVSS

4700pF

C320

C319

PLL_FLTM

PLL_FLTP

11

12

AVSS

10

VR_ANA

TAS5709PHPR

25

27

DVDD

RESET26STEST

C318

1000pF

C317

0.1uF

DVSS_2

22K

0.047uF

R315

OC_ADJ

SSTIMER

7

8NC9

IC300

28

29

30

GND

AGND31VREG

1uF

C32 7

C321 2200pF

BST_A

GVDD_OUT_1

5

6

32

BST_D

GVDD_OUT_2

C328

1uF

C322

0.1uF

C332

0.033uF

50V

OUT_A

PVDD_A_1

PVDD_A_2

2

3

4

33

34

OUT_D

PVDD_D_135PVDD_D_2

0.033uF

C331

50V

C333

C341

0.1uF

C307

100uF

25V

0.1uF

1

48 PGND_AB_2

47 PGND_AB_1

46 OUT_B

45 PVDD_B_2

44 PVDD_B_1

43 BST_B

42 BST_C

41 PVDD_C_2

40 PVDD_C_1

39 OUT_C

38 PGND_CD_2

37 PGND_CD_1

36

C303

C337

C340

100uF

0.1uF

25V

0.1uF

C325

100uF

25V

C326

100uF

25V

+17V_TI

+17V_TI

50V

0.033uF

C353

+17V_TI

C355

0.1uF

2S

1S 1F

50V

0.033uF

C359

2S

1S 1F

EAP61008401

SPK_R-

SPK_R+

SPK_LSPK_L+

+3.3V_MST

L308

AD-9060

2F

EAP61008401

L307

AD-9060

2F

C363

0.68uF

L310

120-ohm

L309

120-ohm

C364

0.68uF

C369

0.1uF

C370

0.1uF

C366

0.1uF

C367

0.1uF

+3.3V_AVDD

+3.3V_DVDD

C373

0.01uF

R322

3.3

R323

3.3

C374

0.01uF

C371

0.01uF

R320

3.3

R321

3.3

C372

0.01uF

SPK_L+

SPK_L-

SPK_R+

SPK_R-

P300

SMAW250-H04R

1

2

3

4

13

TU300-*1

TAFJ-S001D

SHIELD

13

1

2

3

4

5

6

7

8

9

10

11

12

NC_1

PAL EU Tuner

NC_2

+B[5V]

RF_AGC

MOPLL_AS

SCL

SDA

NC_3

SIF

NC_4

VIDEO

GND

TU300

TAFJ-Z001D

1

2

3

4

5

6

7

8

9

10

11

12

SHIELD

NC_1

NC_2

+B[5V]

RF_AGC

MOPLL_AS

SCL

SDA

NC_3

SIF

NC_4

VIDEO

GND

13

TU300-*2

TAFJ-H001F

SHIELD

R301

4.7K

10

11

12

1

2

3

4

5

6

7

8

9

NC_1

NC_2

+B[5V]

RF_AGC

MOPLL_AS

SCL

SDA

NC_3

SIF

NC_4

VIDEO

GND

L300

BLM18BD102SN1D

EU

C305

27pF

R303

READY

C314

0.1uF

50V

B

C308

27pF

+5V_TU

+5V_TU

C309

0.1uF

R312

330

R311

330

R310

0

L301

120 -oh m

R318

270

R319

270

E

Q301

ISA1530AC1

C

R316

100

EU

S_SCL

S_SDA

MAIN_SIF

C323

READY

R343

0

EU

C312

4.7uF

35V

EU

C

B

Q300

E

2SC3875S(ALY)

EU

TV_MAIN

B

R317

R354

180

EU

IF_AGC_SEL

10K

EU

TV_VOUT

E

Q304

ISA1530AC1

EU

C

+1.8V_DDR

C395

0.1uF

16V

VDDL

J1

H8

VSSQ1

H2

VSSQ2

F8

VSSDL

J7

F2

E7

VSSQ3

VSSQ4

VSSQ5D8VSSQ6D2VSSQ7A7VSSQ8B8VSSQ9

DDR Memory for Main IC

+1.8V_DDR

1K

R324

C382

1K

0.1uF

R325

Close to DDR2 IC

C380

C383

0.1uF

0.1uF

C381

C384

0.1uF

0.1uF

DDR2_A[0]

DDR2_A[1]

V_REF

A1

A0

M3

M8

DDR2_A[0-12]

Hynix

VREF

J2

Samsung

VREF

A10/AP

LDQS

UDQS

LDQS

UDQS

NC_4

NC_5

NC_6

NC_1

NC_2

NC_3

VSSDL

VDDL

K4T51163QG-HCE7

J2

A0

M8

A1

M3

A2

M7

A3

N2

A4

N8

A5

N3

A6

N7

A7

P2

A8

P8

A9

P3

M2

A11

P7

A12

R2

BA0

L2

BA1

L3

CK

J8

CK

K8

CKE

K2

ODT

K9

CS

L8

RAS

K7

CAS

L7

WE

K3

F7

B7

LDM

F3

UDM

B3

E8

A8

L1

R3

R7

A2

E2

R8

J7

J1

IC303-*1

+1.8V_DDR

DQ0

G8

DQ1

G2

DQ2

H7

DQ3

H3

DQ4

H1

DQ5

H9

DQ6

F1

DQ7

F9

DQ8

C8

DQ9

C2

DQ10

D7

DQ11

D3

DQ12

D1

DQ13

D9

DQ14

B1

DQ15

B9

VDD_5

A1

VDD_4

E1

VDD_3

J9

VDD_2

M9

VDD_1

R1

VDDQ_10

A9

VDDQ_9

C1

VDDQ_8

C3

VDDQ_7

C7

VDDQ_6

C9

VDDQ_5

E9

VDDQ_4

G1

VDDQ_3

G3

VDDQ_2

G7

VDDQ_1

G9

VSS_5

A3

VSS_4

E3

VSS_3

J3

VSS_2

N1

VSS_1

P9

VSSQ_10

B2

VSSQ_9

B8

VSSQ_8

A7

VSSQ_7

D2

VSSQ_6

D8

VSSQ_5

E7

VSSQ_4

F2

VSSQ_3

F8

VSSQ_2

H2

VSSQ_1

H8

DDR2_BA0

DDR2_DQM1

DDR2_DQM0

DDR2_DQS1M

DDR2_DQS0M

56

56

R341

NC6

UDQS

NC3

NC2

R8

E2

NC4

NC5

NC1

R7

A2

LDQS

A8

L1

R3

E8

R340

56

R339

UDM

B3

56

R338

LDM

F3

DDR2_DQS1P

DDR2_DQS0P

56

R336

56

R337

LDQS

UDQS

F7

B7

DDR2_RASZ

DDR2_CASZ

DDR2_WEZ

WE

RAS

CAS

CS

K3

K7

L7

L8

DDR2_ODT

ODT

K9

DDR2_MCLK

DDR2_CKE

DDR2_MCLKZ

READY

R342

CK

CKE

CK

K8

K2

J8

DDR2_BA1

BA0

BA1

L2

L3

DDR2_A[11]

DDR2_A[10]

DDR2_A[12]

A10/AP

A11

A12

P3

M2

P7

R2

DDR2_A[9]

DDR2_A[8]

DDR2_A[7]

A9

A8

A7

P8

P2

DDR2_A[4]

DDR2_A[6]

DDR2_A[5]

A5

A6

A4

N3

N7

N8

DDR2_A[2]

DDR2_A[3]

A2

A3

M7

N2

IC303

H5PS5162FFR-S6C

B2

VSSQ10

P9

VSS1N1VSS2J3VSS3E3VSS4A3VSS5

G9

VDDQ1G7VDDQ2G3VDDQ3G1VDDQ4E9VDDQ5C9VDDQ6C7VDDQ7C3VDDQ8C1VDDQ9

A9

R1

VDD1M9VDD2J9VDD3E1VDD4A1VDD5B9DQ15B1DQ14D9DQ13D1DQ12D3DQ11D7DQ10

VDDQ10

C2

DQ9C8DQ8F9DQ7F1DQ6H9DQ5H1DQ4H3DQ3H7DQ2G2DQ1G8DQ0

C385

0.1uF

C386

0.1uF

C387

0.1uF

V_REF

C388

0.1uF

C389

0.1uF

+17V_TI

L302

120-ohm

C324

0.1uF

2SC3875S(ALY)

MNT_LOUT

MNT_ROUT

2SC3875S(ALY)

Gaim Amp for MNT out

+17V_AMP

Q302

Q303

+17V_AMP

C

B

C390

E

6800pF

R326

4.7K

+17V_AMP

C

E

6800pF

R327

4.7K

50V

B

C391

50V

1K

R328

MNT_L_AMP

+17V_AMP

MNT_R_AMP

1K

R329

R330

15K 1/16W

33pF

C392

R332

5.6K

5.6K

R335

6.8K

C393

33pF

1/16W

R33115K

5%

5%

R334

6.8K

R333

IC302

LM324D

1

1

2

2

3

3

4

4

5

5

6

6

7

7

+17V_AMP

1K

C397

6800pF

50V

EU

C398

6800pF

50V

EU

B

R352

4.7K

EU

R353

4.7K

B

C

Q305

2SC3875S(ALY)

EU

E

+17V_AMP

C

Q306

2SC3875S(ALY)

EU

E

EU

TV_LOUT

TV_ROUT

14

14

13

12

11

10

9

8

13

12

11

10

9

8

R348 10K

R344

6.8K

R347

EU

33pF

C394

EU

R346

5.6K

EU

EU

5.6K

EU

EU

C396

33pF

EU

R349 10K

1K

R350

EU

TV_L_AMP

TV_R_AMP

R345

6.8K

EU

EU

R351

AMP :GAIN X 4

+1.8V_DDR

DDR2_D[14]

DDR2_D[13]

DDR2_D[15]

DDR2_D[10]

DDR2_D[12]

DDR2_D[11]

DDR2_D[9]

DDR2_D[8]

DDR2_D[7]

DDR2_D[4]

DDR2_D[6]

DDR2_D[5]

DDR2_D[1]

DDR2_D[2]

DDR2_D[3]

DDR2_D[0]

DDR2_D[0-15]

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

Tuner / Amp / DDR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

H6 R

2009/11/05

3 4Tuner/Amp/DDR

Page 20

EAX61365502(BPR)

Copyright © 2010 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

H6 Revolution Circuit Diagram

Main Flash Memory

IC402

+3.3V_MST

+3.3V_MST

SPI_CZ

SPI_DO

C400

0.01uF

R401

4.7K

25V

W25X64VSFIG

HOLD

VCC

NC_1

NC_2

NC_3

NC_4

CS

DO

1

2

3

4

5

6

7

8

CLK

16

DIO

15

NC_8

14

NC_7

13

NC_6

12

NC_5

11

GND

10

WP

9

+3.3V_MST

R411

4.7K

SPI_CLK

SPI_DI

FLASH_WP

HDMI_2

Main EEPROM

IC400

AT24C64CN-SH-T

A0

1

A1

2

A2

3

GND

4

+3.3V_MST

VCC

8

WP

7

SCL

6

SDA

5

C404

0.01uF

25V

M_SCL

M_SDA

Close to IC as close as

possible with width trace

C406 0.1uF

0.1uF

C407

0.1uF

C408

HDMI_1

HDCP EEPROM

+3.3V_MST

IC401

R400

4.7K

+5V_MULTI

CAT24WC08W-T

A0

A1

A2

VSS

MNT_VOUT

GAIN X 4

1

2

3

4

VCC

8

WP

7

SCL

6

SDA

5

Vout Amp

E

Q400

EU

C

C402

0.1uF

B

220

R404

EU

R408

100

R409

100

M_SCL

M_SDA

+5V_MULTI

R406

470

EU

C

E

75

R407

EU

Q401

EU

R488

30K

EU

15K

R489

EU

MNT_VOUT_T

C478

10uF

EU

B

MStar Reset

C401

0.1uF

C403

4.7uF

10V

D401

KDS181

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

Main

+3.3V_MPLL

R405

33K

R410

22

C405

0.1uF

16V

SYS_RESET

+3.3V_MST

TMDS2_RXCTMDS2_RXC+

TMDS2_RX0TMDS2_RX0+

HPD_MST_2

TMDS2_RX1TMDS2_RX1+

TMDS2_RX2TMDS2_RX2+

TMDS1_RXCTMDS1_RXC+

TMDS1_RX0TMDS1_RX0+

TMDS1_RX1TMDS1_RX1+

TMDS1_RX2TMDS1_RX2+

HPD_MST_1

PC_B

PC_G

PC_R

SC1_B

COMP1_PB

COMP1_Y

SC1_G

COMP1_PR

SC1_R

COMP2_PB

COMP2_Y

COMP2_PR

SC1_VIN

SIDE_VIN

SC2_VIN

TV_MAIN

MNT_VOUT_T

MAIN_SIF

SIDE_LIN

SIDE_RIN

MNT_L_AMP

MNT_R_AMP

TV_L_AMP

TV_R_AMP

1/16W

AR400

1/16W

AR401

1/16W

AR402

1/16W

AR403

C410 0.1uF

EU

R479 0

R480

EU

R481

EU

10

10

10

10

0

0

R413 47

R412

R485 22K

C474 0.01uF

EU

EU

C411

C409

0.1uF

10uF

+3.3V_MST

R424 47

R427 470

R425 47

R426 47

R415 47

R416 47

R417 47

R418 47

R419 470

R420 47

R421 47

R431 47

R432 47

R433 470

R434 47

R422 47

R423 47

R482 47

EU

R429

R428

R430 47

C413 0.01uF

47

C417 2.2uF

C418

22K

22K

C414 0.01uF

C475 0.01uF

R414

R486

EU

EU

C412

10uF

SUB MICOM

+3.3V_MPLL

SD Divx_NON RM/SRS

R436

390

C421 0.047uF

C440 1000pF

C422 0.047uF

C423 0.047uF

C424 0.047uF

C425 0.047uF

C426 0.047uF

C427 0.047uF

C441 1000pF

C428 0.047uF

C429 0.047uF

C430 0.047uF

C431 0.047uF

C442

1000pF

C432 0.047uF

C433 0.047uF

C434 0.047uF

C473 0.047uF

EU

C435 0.047uF

47

47 C436 0.047uF

C437 0.047uF

C419 0.1uF

0.1uF

C420

2.2uF

100

R438

R437 100

EU

R483 100

100

R484

EU

22K

C416 0.01uF

R435

C439 0.1uF

C438

C415

1000pF

0.1uF

Close to IC

with width trace

RXBCKN

RXBCKP

RXB0N

RXB0P

HOTPLUGB

RXB1N

RXB1P

AVDD_33_1

RXB2N

RXB2P

RXACKN

RXACKP

RXA0N

RXA0P

AVDD_33_2

RXA1N

RXA1P

GND_1

RXA2N

RXA2P

HOTPLUGA

VCLAMP

BIN1P

SOGIN1

GIN1P

RIN1P

BIN0P

GIN0P

SOGIN0

RIN0P

AVDD_33_3

GND_2

BIN2P

GIN2P

SOGIN2

RIN2P

CVBS6

CVBS5

CVBS4

CVBS3

CVBS2

CVBS1

VCOM1

CVBS0

VCOM0

AVDD_33_4

CVBSOUT

GND_3

SIF0P

SIF0M

VDDC_1

AUVRM

AUOUTL2

AUOUTR2

AUOUTL1

AUOUTR1

C443

4.7uF

REXT

REFP

REFM

BINM

GINM

RINM

AUL5

AUR5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

SC1_FB

SC1_ID

IR

PC_VS

PC_HS

CEC_C

SYS_RESET

GPIO140

IRIN

HSYNC0

VSYNC0

HSYNC1

VSYNC1

CEC

HWRESET

250

251

252

253

254

255

256

SCART H\V SYNC

scart RGB INPUT

S-VIDEO

SCART_CVBS

SCART_AUDIO out

SCART_AUDIO IN

65

AUL066AUR067AUL168AUR169AUL270AUR271AUL372AUR3

C444

C4492.2uF

C4462.2uF

C4482.2uF

C4472.2uF

C4452.2uF

2.2uF

SC1_LIN

SC1_RIN

COMP1_L

COMP2_L

COMP1_R

2.2uF

EU

COMP2_R

SC2_LIN

ISP_RX

RL_ON/POWER_ON

RXD

LED_R

TXD

R442

R440100

R441100

R439

100

100

XIN

GPIO134

GPIO135

GPIO138

GPIO139

244

245

246

247

248

249

73

74

76

AUL475AUR4

AUCOM

GND_477AUVRP78AUVAG

C4772.2uFEUC476

C451

C450

2.2uF

2.2uF

PC_AUD_L

PC_AUD_R

SC2_RIN

+3.3V_MST

+3.3V_MST

C45420pF

12MHz

1M

X400

R444

KEY2

R443

100

0.1uF

KEY1

AC_DET

R445

100

100

R446

SC2_ID

4.7K

C45520pF

R448 100

TXD

R449

100

5%

R45 1

RXD

22

1/1 0W

R450

5%

R452 4.7K

M_SCL

M_SDA

MUTE_LINE

R455

22

R45 4

1/1 0W

I2S_OUT

I2S_SCK

I2S_SDO

1K

25V

0.01uF

C456

I2S_MCLK

I2S_WS

R45 7 22

C452

I2S_IN_SD

I2S_OUT_MCK

I2S_OUT_WS

VDDP_5

GND_16

VDDC_7

I2S_OUT_BCK

I2S_OUT_SD

SPDIFO

UART2_RX/I2CM_SDA

UART2_TX/I2CM_SCK

UART1_RX/GPIO86

UART1_TX/GPIO87

GND_17

GND_18

USB0_DM

USB0_DP

SAR0

SAR1

SAR2

SAR3

AVDD_MPLL

XOUT

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

3.3V

5V

5V5V

IC403

LGE4767A (Matrix SD Divx_ Non RM_NON SRS)

5V

82

84

DDCDA_CK85DDCDA_DA86DDCDB_CK87DDCDB_DA

DDC_SDA1

DDC_SCL1

DSUB_SCL

DSUB_SDA

5V

88

GPIO2089VDDP_190VDDC_3

DDC_SDA2

DDC_SCL2

DDC_SDA3

DDC_SCL3

ROM D/L

RX,TX

91

RXCCKN95RXCCKP

UART2_RX92UART2_TX93DDCDC_CK

R453 100

ROM_RX

ROM_TX

FLASH_WP

94

96

97

RXC0N98RXC0P99GND_6

DDCDC_DA

10

AR4 04

1/1 6W

TMDS3_RX0+

TMDS3_RXC+

TMDS3_RX0-

TMDS3_RXC-

HDMI_3

RXC1N

79

80

GND_5

AVDD_AU

C453

0.01uF

25V

81

VDDC_2

DDCA_CK83DDCA_DA

4.7K

R458 4.7K

R456

DDR2_A[3]

S_SCL

S_SDA

SW_RESET

DDR2_CKE

R460

100

R45 9 22

R461 56

A_MADR[3]

A_MCLKE

VDDC_6

I2S_IN_WS/GPIO67

I2S_IN_BCK/GPIO68

217

218

219

220

221

3.3V

100

101

102

103

104

RXC1P

RXC2N

RXC2P

AVDD_DM

HOTPLUGC

AR4 05101/1 6W

TMDS3_RX2+

TMDS3_RX1+

TMDS3_RX2-

TMDS3_RX1-

DDR2_A[7]

DDR2_A[12]

DDR2_A[9]

56

AR406

A_MADR[5]

A_MADR[9]

A_MADR[12]

A_MADR[7]

212

213

214

215

216

105

106

107

108

109

SCK

SDI

USB1_DM

USB1_DP

HPD_MST_3

USB_DN

USB_DP

SPI_CLK

SPI_DI

FLASH

USB PART

T2

DDR2_A[1]

DDR2_A[10]

DDR2_A[5]

56

AR408

A_MADR[1]

A_MADR[10]

AVDD_DDR_6

209

210

211

3.3V

110

111

112

SDO

SCZ

PWM0

AR4 07

22

SPI_CZ

SPI_DO

DDR2_A[11]

DDR2_BA0

DDR2_BA1

DDR2_WEZ

AR409

A_MADR[11]

A_WEZ

A_BADR[1]

A_BADR[0]

205

206

207

208

113

114

115

116

PWM1

PWM2

PWM3

LVA4P

TXCE0-

100

100

1/1 6W

R462

R490

LED_W

LED_BL

MOVING

LED

DDR2_A[8]

56

A_MADR[6]

A_MADR[8]

203

204

117

118

LVA4M

LVA3P

LVA3M

TXCE1-

TXCE0+

DDR2_A[0-12]

DDR2_A[0]

DDR2_A[2]

DDR2_A[4]

DDR2_A[6]

56

AR410

A_MADR[0]

A_MADR[2]

A_MADR[4]

GND_15

199

200

201

202

PCM

119

120

121

122

LVA2P

LVACKP

LVACKM

TXCLKE-

TXCE2+

TXCE2-

TXCE1+

HD LVDS

DDR2_CASZ

DDR2_RASZ

DDR2_ODT

AR411

56

25V

0.01uF

C457

AVDD_MEMPLL

MVREF

A_ODT

A_RASZ

A_CASZ

195

196

197

198

3.3V

3.3V

3.3V

123

124

125

126

LVA2M

LVA1P

LVA1M

LVA0P

LVA0M

TXCE4-

TXCE3+

TXCE3-

TXCLKE+

V_REF

GND_14

B_MCLKZ

193

194

192

B_MCLK

191

B_MDATA[5]

190

B_MDATA[2]

189

B_MDATA[0]

188

B_MDATA[7]

187

AVDD_DDR_5

186

B_MDATA[13]

185

B_MDATA[10]

184

GND_13

183

B_MDATA[8]

182

B_MDATA[15]

181

AVDD_DDR_4

180

B_DDR2_DQSB[1]

179

B_DDR2_DQS[1]

178

GND_12

177

VDDP_4

176

AVDD_DDR_3

175

B_DDR2_DQSB[0]

174

B_DDR2_DQS[0]

173

GND_11

172

B_DDR2_DQM[0]

171

B_DDR2_DQM[1]

170

AVDD_DDR_2

169

B_MDATA[14]

168

B_MDATA[9]

167

GND_10

166

B_MDATA[12]

165

B_MDATA[11]

164

AVDD_DDR_1

163

B_MDATA[6]

162

B_MDATA[1]

161

GND_9

160

B_MDATA[3]

159

B_MDATA[4]

158

VDDC_5

157

VDDP_3

156

GPIO58

155

GPIO57

154

5V

GPIO56

153

GPIO55

5V

152

GPIO54

151

GPIO53

150

GPIO52

149

GPIO51

148

GND_8

147

GPIO152/I2C_OUT_SD3

146

GPIO151/I2C_OUT_SD2

145

GPIO150/I2C_OUT_MUTE

144

VDDC_4

143

GND_7

142

AVDD_LPLL

141

LVB0M

140

LVB0P

139

LVB1M

138

LVB1P

137

LVB2M

136

LVB2P

135

LVBCKM

134

LVBCKP

133

LVB3M

132

LVB3P

131

LVB4M

130

LVB4P

129

127

128

VDDP_2

TXCE4+

+1.8V_DDR

TXCLKO+

TXCLKO-

C458

0.01uF

25V

+1.2V_MST

22

R471

22

R472

AR414

56

AR415

56

AR412

56

AR413

56

C459

0.01uF

25V

100

R464

100

R465

READY

100

R466

100

R469

R470 22

R467 22

100

R403

22

R447

22

R463

TXCO4+

TXCO4TXCO3+

TXCO3-

TXCO2+

TXCO2TXCO1+

TXCO1TXCO0+

TXCO0-

+3.3V_MST

[MODE SELECTION]

R473

READY

1K

R474

1K

+1.2V_MST

Close to IC as close as possible

C462

C460

0.01uF

25V

0.01uF

25V

C464

0.01uF

25V

C466

0.01uF

25V

C468

0.01uF

25V

C470

0.01uF

25V

C472

0.01uF

25V

+1.8V_DDR

C471

C461

0.1uF

C463

0.1uF

C465

0.1uF

C467

0.1uF

C469

0.1uF

0.1uF

Close to IC as close as possible

DDR2_MCLKZ

DDR2_MCLK

DDR2_DQS1M

DDR2_DQS1P

DDR2_DQS0M

DDR2_DQS0P

DDR2_DQM0

DDR2_DQM1

DISP_EN

ERROR_DET

EYE_SCL

EYE_SDA

IF_AGC_SEL

A_SCL

A_SDA

M5V_ON

P_SCL

P_SDA

FHD LVDS

DDR2_D[5]

DDR2_D[2]

DDR2_D[0]

DDR2_D[7]

DDR2_D[13]

DDR2_D[10]

DDR2_D[8]

DDR2_D[15]

DDR2_D[14]

DDR2_D[9]

DDR2_D[12]

DDR2_D[11]

DDR2_D[6]

DDR2_D[1]

DDR2_D[3]

DDR2_D[4]

R478 4.7K

R477 4.7K

R468 4.7K

R487 4.7K

DDR2_D[0-15]

MATRIX_ONLY MP3

RXBCKN

246

247

248

249

250

251

252

253

254

255

256

1

RXBCKP

2

RXB0N

3

RXB0P

4

HOTPLUGB

5

RXB1N

6

RXB1P

7

AVDD_33_1

8

RXB2N

9

RXB2P

10

RXACKN

11

RXACKP

12

RXA0N

13

RXA0P

14

AVDD_33_2

15

RXA1N

16

RXA1P

17

GND_1

18

RXA2N

19

RXA2P

20

HOTPLUGA

21

REXT

22

VCLAMP

23

REFP

24

REFM

25

BIN1P

26

SOGIN1

27

GIN1P

28

RIN1P

29

BINM

30

BIN0P

31

GINM

32

GIN0P

33

SOGIN0

34

RINM

35

RIN0P

36

IC403-*1

AVDD_33_3

37

GND_2

38

BIN2P

39

GIN2P

40

SOGIN2

41

RIN2P

42

CVBS6

43

CVBS5

44

CVBS4

45

CVBS3

46

CVBS2

47

CVBS1

48

VCOM1

49

CVBS0

50

VCOM0

51

AVDD_33_4

52

CVBSOUT

53

GND_3

54

SIF0P

55

SIF0M

56

VDDC_1

57

AUL5

58

AUR5

59

AUVRM

60

AUOUTL2

61

AUOUTR2

62

AUOUTL1

63

AUOUTR1

64

65

73

74

AUL066AUR067AUL168AUR169AUL270AUR271AUL372AUR3

AUL475AUR4

AUCOM

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

76

79

80

81

82

84

88

91

94

96

97

100

101

102

103

104

105

106

107

108

109

110

111

112

SCK

SDI

SDO

SCZ

GND_477AUVRP78AUVAG

GND_5

VDDC_2

GPIO2089VDDP_190VDDC_3

AVDD_AU

DDCA_CK83DDCA_DA

DDCDA_CK85DDCDA_DA86DDCDB_CK87DDCDB_DA

UART2_RX92UART2_TX93DDCDC_CK

PWM0

RXC0N98RXC0P99GND_6

RXC1N

RXC1P

RXC2N

RXC2P

RXCCKN95RXCCKP

AVDD_DM

USB1_DM

USB1_DP

DDCDC_DA

HOTPLUGC

B_MCLKZ

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

192

B_MCLK

191

B_MDATA[5]

190

B_MDATA[2]

189

B_MDATA[0]

188

B_MDATA[7]

187

AVDD_DDR_5

186

B_MDATA[13]

185

B_MDATA[10]

184

GND_13

183

B_MDATA[8]

182

B_MDATA[15]

181

AVDD_DDR_4

180

B_DDR2_DQSB[1]

179

B_DDR2_DQS[1]

178

GND_12

177

VDDP_4

176

AVDD_DDR_3

175

B_DDR2_DQSB[0]

174

B_DDR2_DQS[0]

173

GND_11

172

B_DDR2_DQM[0]

171

B_DDR2_DQM[1]

170

AVDD_DDR_2

169

B_MDATA[14]

168

B_MDATA[9]

167

GND_10

166

B_MDATA[12]

165

B_MDATA[11]

164

AVDD_DDR_1

163

B_MDATA[6]

162

B_MDATA[1]

161

GND_9

160

B_MDATA[3]

159

B_MDATA[4]

158

VDDC_5

157

VDDP_3

156

GPIO58

155

GPIO57

154

GPIO56

153

GPIO55

152

GPIO54

151

GPIO53

150

GPIO52

149

GPIO51

148

GND_8

147

GPIO152/I2C_OUT_SD3

146

GPIO151/I2C_OUT_SD2

145

GPIO150/I2C_OUT_MUTE

144

VDDC_4

143

GND_7

142

AVDD_LPLL

141

LVB0M

140

LVB0P

139

LVB1M

138

LVB1P

137

LVB2M

136

LVB2P

135

LVBCKM

134

LVBCKP

133

LVB3M

132

LVB3P

131

LVB4M

130

LVB4P

129

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

PWM1

PWM2

PWM3

LVA4P

LVA4M

LVA3P

LVA3M

LVA2P

LVA2M

LVA1P

LVA1M

LVA0P

LVA0M

LVACKP

LVACKM

VDDP_2

GND_14

AVDD_MEMPLL

MVREF

A_ODT

A_RASZ

A_CASZ

A_MADR[0]

A_MADR[2]

A_MADR[4]

GND_15

A_MADR[6]

A_MADR[8]

A_MADR[11]

A_WEZ

A_BADR[1]

A_BADR[0]

A_MADR[1]

A_MADR[10]

AVDD_DDR_6

A_MADR[5]

A_MADR[9]

A_MADR[12]

A_MADR[7]

A_MADR[3]

A_MCLKE

VDDC_6

I2S_IN_WS/GPIO67

I2S_IN_BCK/GPIO68

I2S_IN_SD

I2S_OUT_MCK

I2S_OUT_WS

VDDP_5

GND_16

VDDC_7

I2S_OUT_BCK

I2S_OUT_SD

SPDIFO

UART2_RX/I2CM_SDA

UART2_TX/I2CM_SCK

UART1_RX/GPIO86

UART1_TX/GPIO87

GND_17

GND_18

USB0_DM

USB0_DP

SAR0

SAR1

SAR2

SAR3

AVDD_MPLL

XOUT

XIN

GPIO134

GPIO135

GPIO138

GPIO139

GPIO140

IRIN

HSYNC0

VSYNC0

HSYNC1

VSYNC1

CEC

HWRESET

LGE4766A (Matrix Only MP3_NON SRS)

+3.3V_MST

+3.3V_MST

XIN

GPIO134

GPIO135

GPIO138

GPIO139

GPIO140

IRIN

HSYNC0

VSYNC0

HSYNC1

VSYNC1

CEC

HWRESET

MATRIX BASIC

RXBCKN

245

246

247

248

249

250

251

252

253

254

255

256

1

RXBCKP

2

RXB0N

3

RXB0P

4

HOTPLUGB

5

RXB1N

6

RXB1P

7

AVDD_33_1

8

RXB2N

9

RXB2P

10

RXACKN

11

RXACKP

12

RXA0N

13

RXA0P

14

AVDD_33_2

15

RXA1N

16

RXA1P

17

GND_1

18

RXA2N

19

RXA2P

20

HOTPLUGA

21

REXT

22

VCLAMP

23

REFP

24

REFM

25

BIN1P

26

SOGIN1

27

GIN1P

28

RIN1P

29

BINM

30

BIN0P

31

GINM

32

GIN0P

33

SOGIN0

34

RINM

35

IC403-*2

RIN0P

36

AVDD_33_3

37

GND_2

38

BIN2P

39

GIN2P

40

SOGIN2

41

RIN2P

42

CVBS6

43

CVBS5

44

CVBS4

45

CVBS3

46

CVBS2

47

CVBS1

48

VCOM1

49

CVBS0

50

VCOM0

51

AVDD_33_4

52

CVBSOUT

53

GND_3

54

SIF0P

55

SIF0M

56

VDDC_1