LG

website:http://biz.LGservice.com

PLASMA

CHASSIS : PD83A

TV

MODEL : 42PG3000

CAUTION

BEFORE SERVICING THE CHASSIS,

IN

READ THE SAFETY PRECAUTIONS

THIS MANUAL.

42PG3000-ZA

CONTENTS

CONTENTS .............................................................................................. 2

SAFETV PRECAUTIONS .......................................................................... 3

SPECIFICATION ........................................................................................ 4

ADJUSTMENT INSTRUCTION ................................................................. 6

TROUBLE SHOOTING ............................................................................ 15

BLOCK DIAGRAM ................................................................................... 24

EXPLODED VIEW .................................................................................. 26

SVC. SHEET .............................................................................................. .

PRINTED CIRCUIT DIAGRAM ................................................................... .

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

- 2 -

LGE Internai Use Only

SAFETY PRECAUTIONS

IMPORTANT SAFETV NOTICE

Many electrical and mechanical parts

Schematic Diagram and Replacement Parts List.

is

essential that these special safety parts should be replaced with the same components

lt

X-RADIATION, Shock, Fire, or other Hazards.

Do

not modify the original design without permission of manufacturer.

General Guidance

An

isolation Transformer should always

servicing of a receiver whose chassis

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting

from electrical shocks.

lt will also protect the receiver and it's components from being

damaged

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor)

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface

extrema care should

Do

by

accidentai

W),

keep the resistor 10mm away from PCB.

not lift the Picture tube by it's Neck.

be

used

shorts

in

in

this chassis have special safety-related characteristics. These parts are identified by

be

used during the

is

not isolated from the

in

persona! injury

of

the

in

this monitor

circuitry

area

that

is

blown, replace

of picture tube,

handling the Picture Tube.

may

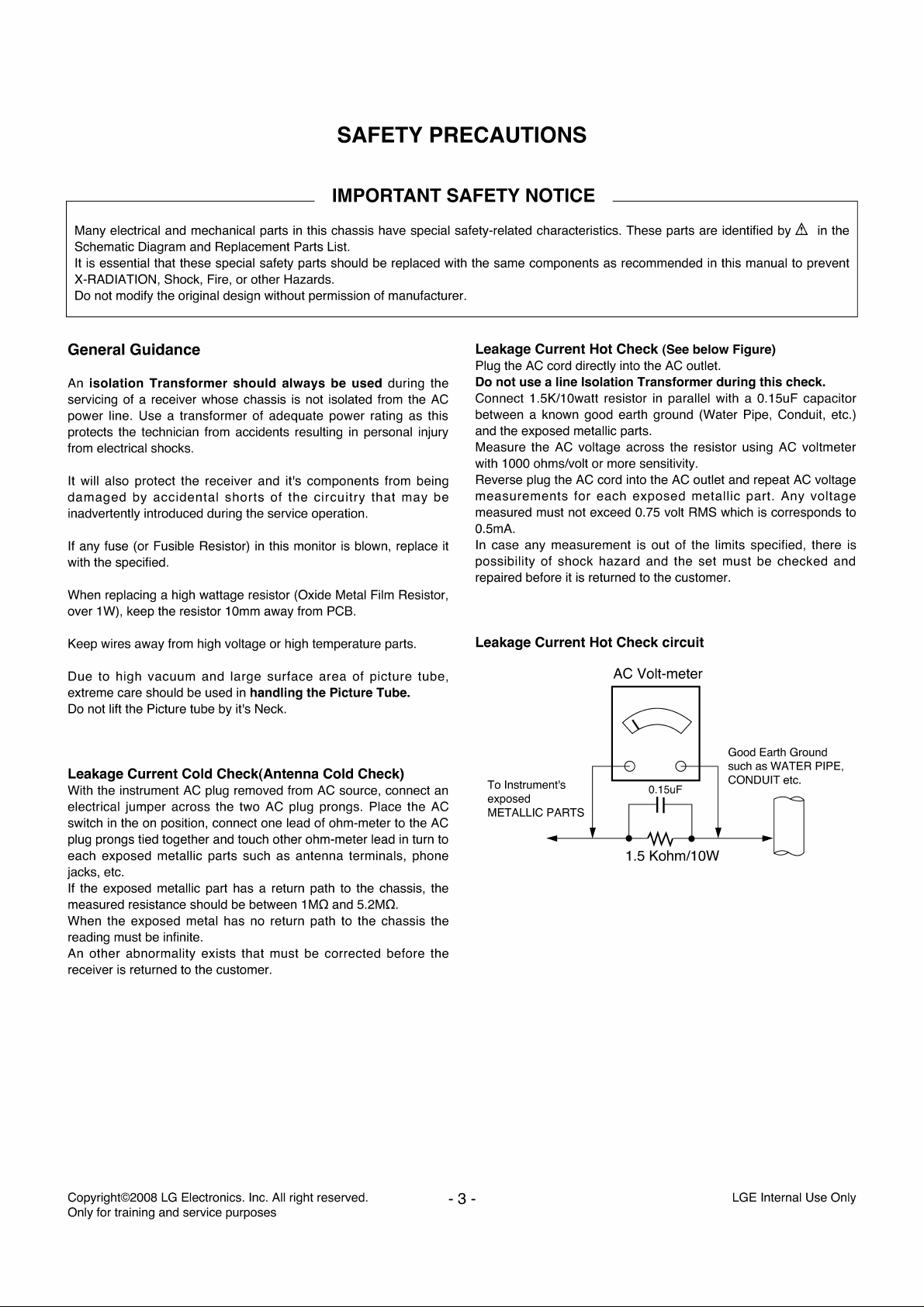

Leakage Current Hot

Plug the

Do

not

use

Connec! 1.5K/10watt resistor

AC

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the

measurements

be

measured must not exceed 0.75 volt

0.5mA.

ln

it

case any measurement

possibility of shock hazard and the set must be checked and

repaired before il

Leakage Current Hot

as

AC

cord directly into the

recommended

Check

in

this manual to prevent

(See below Figure)

AC

outlet.

a line Isolation Transformer during this check.

in

parallel with a 0.15uF capacitor

AC

outlet and repeat

for

each

is

returned

exposed

is

to

Check

AC

Volt-meter

metallic

RMS

out of the limits specified, there is

the customer.

which

part.

is

corresponds to

circuit

.&

AC

Any

in

the

voltage

voltage

Leakage Current Cold Check(Antenna Cold Check)

With the instrument

electrical jumper across the two AC plug prongs. Place the

switch

in

the

plug prongs tied together and touch other ohm-meter lead

each exposed metallic parts such as antenna terminais, phone

jacks, etc.

If the exposed metallic part has a return path

measured resistance should be between 1

When the exposed metal has

reading must be infinite.

An other abnormality exists that must be corrected before the

is

receiver

Copyright©2008

Only for training

returned

AC

plug removed from

on

position, connect one lead of ohm-meter to the

no

return path to the chassis the

to

the customer.

LG

Electronics.

and

service purposes

Inc.

AC

MO

Ali

right reserved.

source, connect an

to

the chassis, the

and 5.2MO.

AC

AC

in

turn

to

Good Earth Ground

such as WATER PIPE,

To lnstrument's

exposed D

METALLIC PARTS

~/\/\.--------..~

1.5

0.15uF

Kohm/1

- 3 -

CONDUIT etc.

OW

LGE

Internai

Use

Only

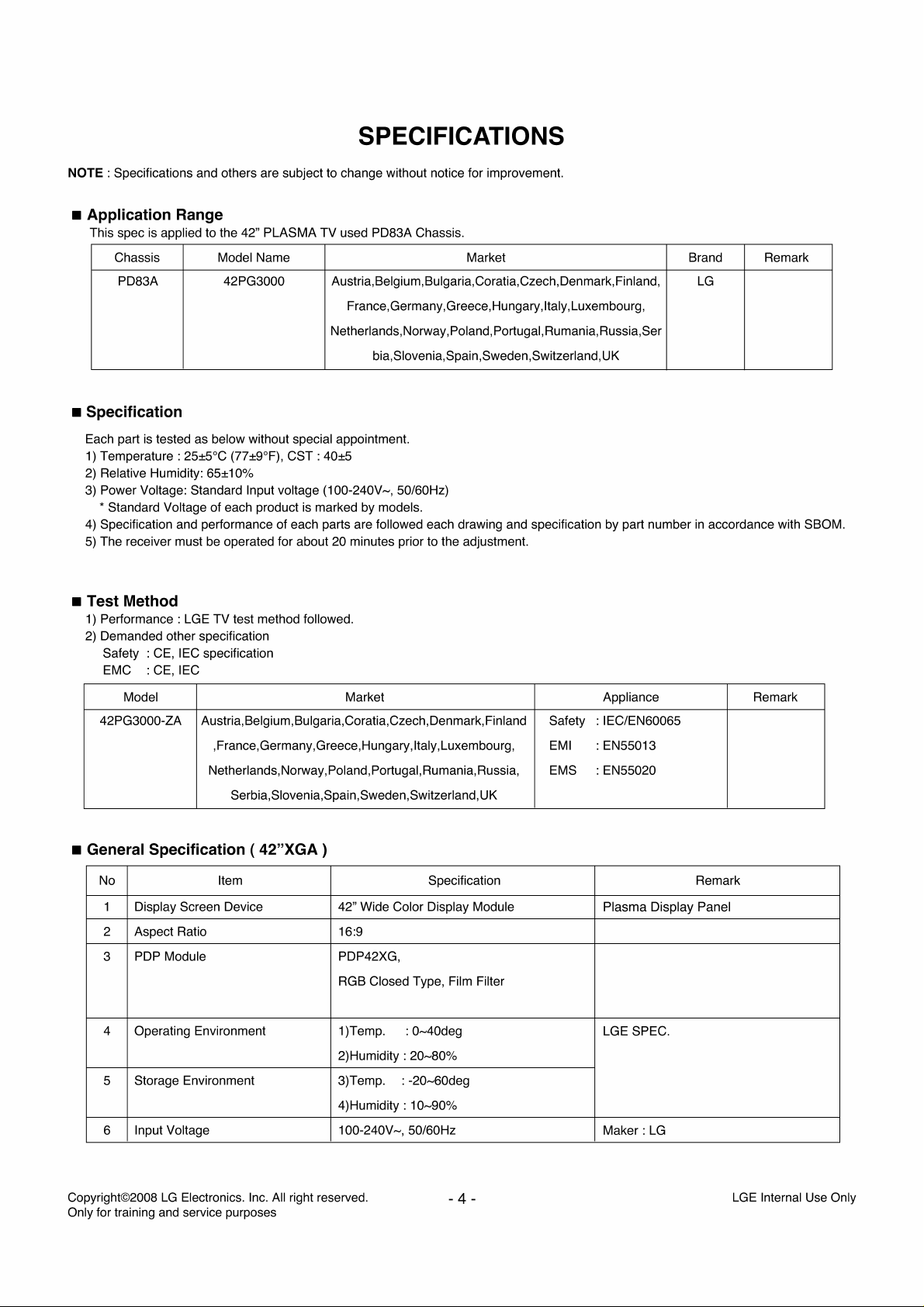

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement.

• Application Range

This spec is applied to the 42"

Chassis Model Name Market

PD83A 42PG3000 Austria, Belgiu

• Specification

Each part

1)

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V-, 50/60Hz)

4) Specification and performance of each parts are followed each drawing and specification by part number

5)

is

tested as below without special appointment.

Temperature : 25±5°C (77±9°F), CST : 40±5

* Standard Voltage of each product is marked by models.

The receiver must be operated for about 20 minutes prior to the adjustment.

PLASMA

TV used PD83A Chassis.

m,

Bulgaria, Coratia,Czech, Den mark, Fin land,

France,Germany,Greece,Hungary,ltaly,Luxembourg,

Netherlands,Norway,Poland,Portugal,Rumania,Russia,Ser

bia,Slovenia,Spain ,Sweden,Switzerland, UK

Brand

LG

in

accordance with SBOM.

Re

mark

• Test Method

1)

Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

Model Market

42PG3000-ZA Austria,Belgium,Bulgaria,Coratia,Czech,Denmark,Finland

,France,Germany,Greece,Hungary,ltaly,Luxembourg,

Netherlands, Norway, Poland, Portugal,

Serbia,Slovenia,Spain,Sweden,Switzerland,UK

Ru

mania, Russia,

• General Specification ( 42"XGA )

No Item Specification

1 Display Screen Device 42" Wide Color Display Module

2 Aspect Ratio 16:9

POP Module PDP42XG,

3

RGB Closed Type, Film Filter

4 Operating Environment 1)Temp. :

2)Humidity :

Storage Environment 3)Temp.

5

4)Humidity:

6 Input Voltage 100-240V-, 50/60Hz

0-40deg

20-80%

:-20-60deg

10-90%

Appliance

Safety : IEC/EN60065

EMI : EN55013

EMS : EN55020

Plasma Display Panel

LGE SPEC.

Maker:

LG

Re

mark

Re

mark

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

- 4 -

LGE Internai Use Only

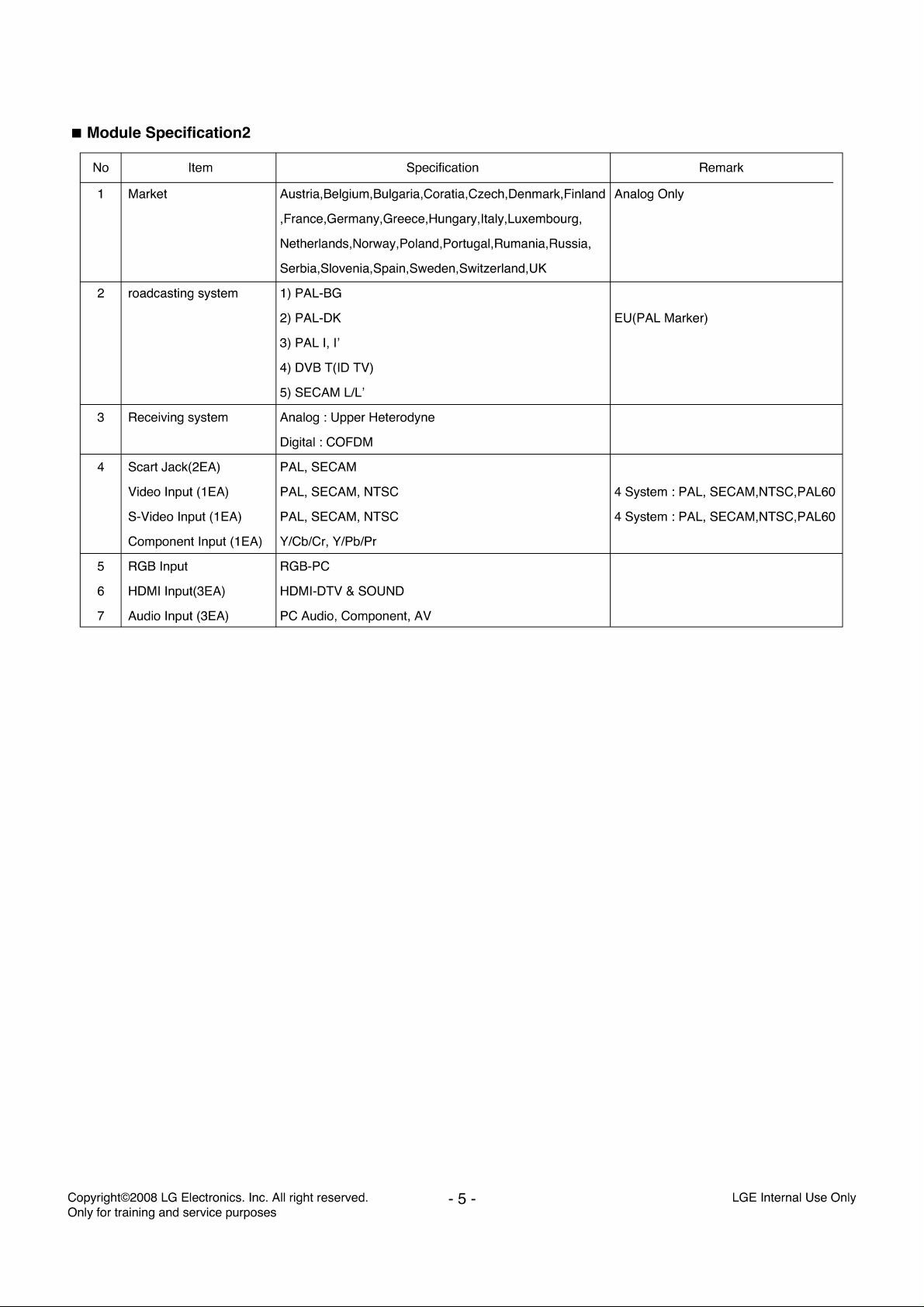

• Module Specification2

No Item Specification

Bu

1 Market Au stria, Belgium,

,France,Germany,Greece,Hungary,ltaly,Luxembourg,

Netherlands, Norway, Po land, Portugal,

Serbia,Slovenia,Spain,Sweden,Switzerland,UK

2 roadcasting system 1) PAL-BG

2) PAL-DK

1,

3) PAL

4) DVB T(ID TV)

5) SECAM

Receiving system Analog : Upper Heterodyne

3

Digital : COFDM

4 Scart Jack(2EA) PAL, SECAM

(1

Video Input

S-Video Input

Component Input

RGB Input RGB-PC

5

HDMI lnput(3EA) HDMI-DTV

6

EA) PAL, SECAM, NTSC

(1

EA) PAL, SECAM, NTSC

(1

EA) Y/Cb/Cr, Y/Pb/Pr

I'

7 Audio Input (3EA) PC Audio, Component,

lgaria, Coratia,Czech, Den mark, Fin land

UL'

& SOUND

AV

Ru

mania, Russia,

Re mark

Analog Only

EU(PAL Marker)

4 System : PAL, SECAM,NTSC,PAL60

4 System : PAL, SECAM,NTSC,PAL60

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

- 5 -

LGE Internai Use Only

ADJUSTMENT INSTRUCTION

1.

Application Object

These instructions are applied all of the 42" PLASMA TV,

PD83A Chassis.

2.

Note

(1)

Because this

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2)

Adjustment must

(3)

The adjustment must be performed

25±5°C of temperature and 65±10% of relative humidity

there

is

(4) The input voltage of the receiver must keep 100-240V-,

50/60Hz.

(5)

The receiver must

to the adjustment.

ln

case of keeping module

should be placed

2hours.

ln

case of keeping module

C,

-20°

15°C for 3hours.

• Alter RGB Full white HEAT-RUN Mode, the receiver must

be operated prior

• Enter into HEAT-RUN MODE

1)

Press the POWER

2)

OSD display and screen display PATTERN MODE.

* Set

is

activated HEAT-RUN without signal generator

this mode.

* Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses

If you turn on a still screen more than 20 minutes, (Especially

digital pattern, cross hatch pattern) alter image may be occur

the black level part of the screen.

3.

AOC Calibration

* Using 'power on' button off the contrai R/C, power on TV.

• Auto adjustment Map(RS-232C)

NO Item CMD1 CMD2 Data o

ADC adjust

Data Read

Default Write

Enter

Adjust Mode

ADC

ADC

Adjust Mode

Adjust Mode Out

- Baud : 115200bps, RS232 Host :

is

nota

hot chassis, it

be

done

in

no specific designation.

be

operated for about 15 minutes prior

in

the circumstance of above 15°C for

it should be placed

to

adjustment.

ON

KEY

to

check PANEL.

ADC

ad1ust

Parameter

Digital Data

Parameter

(Average)

Ad1ustment

Confirmation

A D 1

A D 2

A

A D

A D

A D 0 0

ln

A

D

D

is

not necessary

the correct order.

in

the circumstance of

is

in

the circumstance of

is

in

the circumstance of below

in

the circumstance of above

on

R/C for adjustment.

mark

Re

0

0

Transfer

1 BByte

(Input resolution Data)

0

3

4 0

To

check

ADC

Assembly

transfer

Adjustment

the

command.

9 9

9 0

PC,

Echo : none.

on

When

ln', Carry the

to

0°c, it

in

line

'Mode

use

in

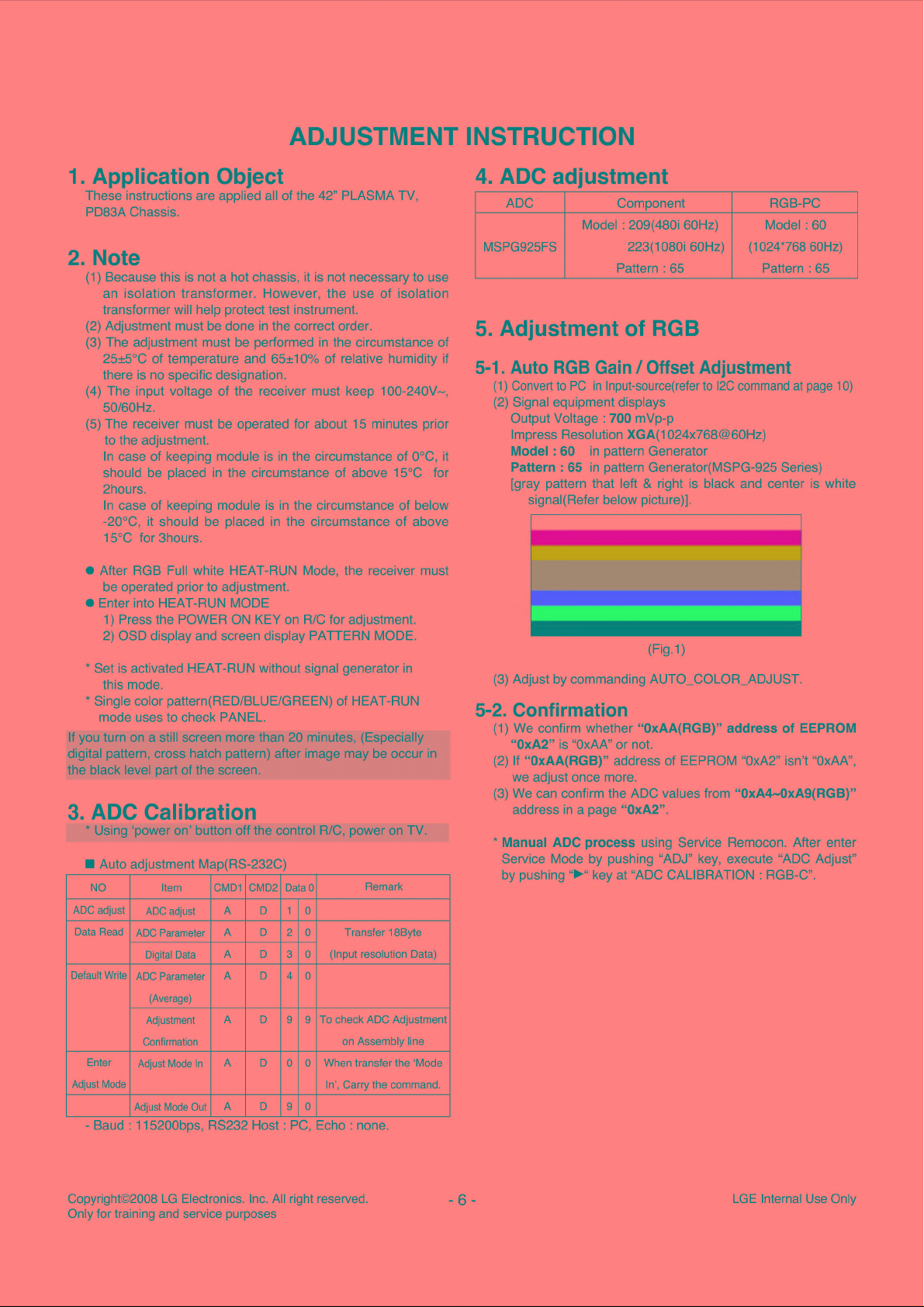

4.

AOC adjustment

ADC Component

Model : 209(480i 60Hz)

MSPG925FS 223(1080i 60Hz)

Pattern : 65 Pattern : 65

5.

Adjustment of RGB

if

5-1.

Auto

RGB

Gain I Offset

(1)

Convert

to

PC

in

lnput-source(refer

(2)

Signal equipment displays

Output Voltage : 700 mVp-p

lmpress Resolution XGA(1024x768@60Hz)

in

Model : 60

Pattern : 65

pattern Generator

in

pattern Generator(MSPG-925 Series)

[gray pattern that left

signal(Refer below picture)].

(3)

Adjust by commanding AUTO_COLOR_ADJUST.

5-2. Confirmation

(1)

We confirm whether "OxAA(RGB)"

is

"OxAA"

"OxA2"

(2)

If

"OxAA(RGB)" address of EEPROM

we adjust once more.

(3)

We can confirm the

address

in

* Manual ADC

Service Mode by pushing "ADJ" key, execute "AOC Adjust"

by pushing

"~"

or not.

AOC

a page "OxA2".

process

key at "ADC CALIBRATION: RGB-C".

RGB-PC

Model:

60

(1024*768 60Hz)

Adjustment

to

12C

command

& right

is

black and center

1)

(Fig.

address

"OxA2"

values from

"OxA4-0xA9(RGB)"

using Service Remocon. After enter

at

page 1 O)

is

of

EEPROM

isn't

white

"OxAA

",

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right

reserved.

- 6 -

LGE

Internai

Use

Only

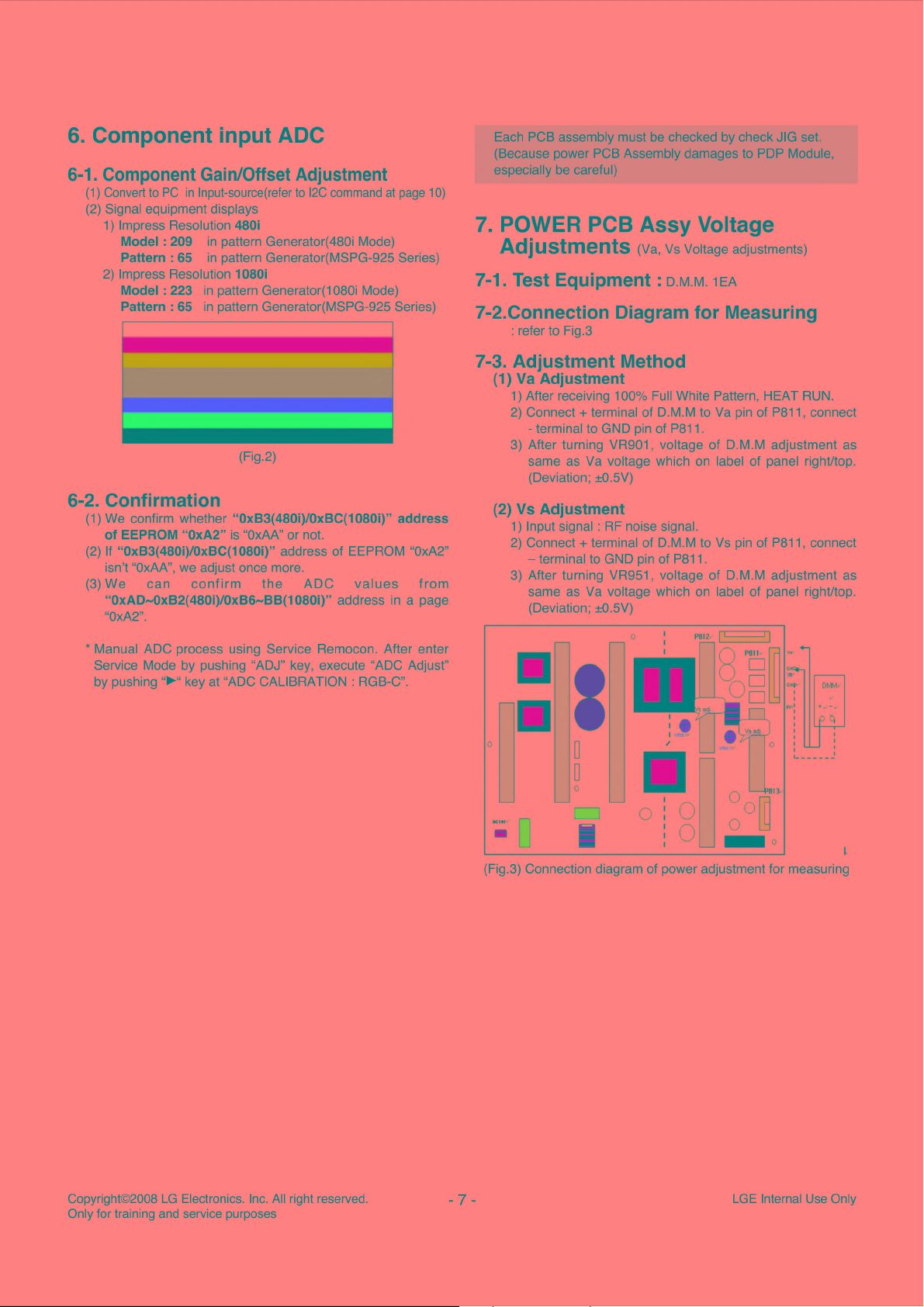

6.

Component input AOC

6-1. Component Gain/Offset Adjustment

(1)

Convert

to

PC

in

lnput-source(refer

(2) Signal equipment displays

lm

press Resolution 480i

1)

in

Model : 209

Pattern : 65

2) lmpress Resolution 1080i

Model:

Pattern : 65

223

pattern Generator(480i Mode)

in

pattern Generator(MSPG-925 Series)

in

pattern Generator(1080i Mode)

in

pattern Generator(MSPG-925 Series)

(Fig.2)

to

12C

command

at

page 1 O)

6-2. Confirmation

(1) We confirm whether "OxB3(480i)/OxBC(1080i)" address

of

EEPROM

If

"OxB3(480i)/OxBC(1080i)" address of EEPROM "

(2)

isn't "

We

(3)

"OxAD-OxB2(480i)/OxB6-BB(1080i)" address

"OxA2".

"OxA2"

OxAA",

we adjust once more.

can

confirm

is "OxAA

the

" or not.

ADC

values

in

OxA2"

from

a page

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

7.

POWER PCB Assy Voltage

(Va,

Vs

Adjustments

7-1. Test

Equipment:

Voltage adjustments)

D.M.M.1EA

7-2.Connection Diagram for Measuring

: refer to Fig.3

7-3. Adjustment Method

(1) Va Adjustment

1)

Alter receiving 100% Full White Pattern, HEAT RUN.

2)

Connec!+

- terminal to GND pin of P811.

3) Alter turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2)

Vs

Adjustment

1)

Input signal : RF noise signal.

2)

Connec!+

~

terminal to GND pin of P811.

3) Alter turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

terminal of D.M.M to Va pin of P811, connect

terminal of D.M.M to Vs pin of P811, connect

* Manual ADC process using Service Remocon. Alter enter

SeNice Mode by pushing "ADJ" key, execute "ADC Adjust"

".,._"

by pushing

key at "ADC

CALIBRATION:

RGB-C".

•

1

•

•

(Fig.3) Connection diagram of power adjustment for measuring

D

D

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 7 -

LGE

Internai

Use

Only

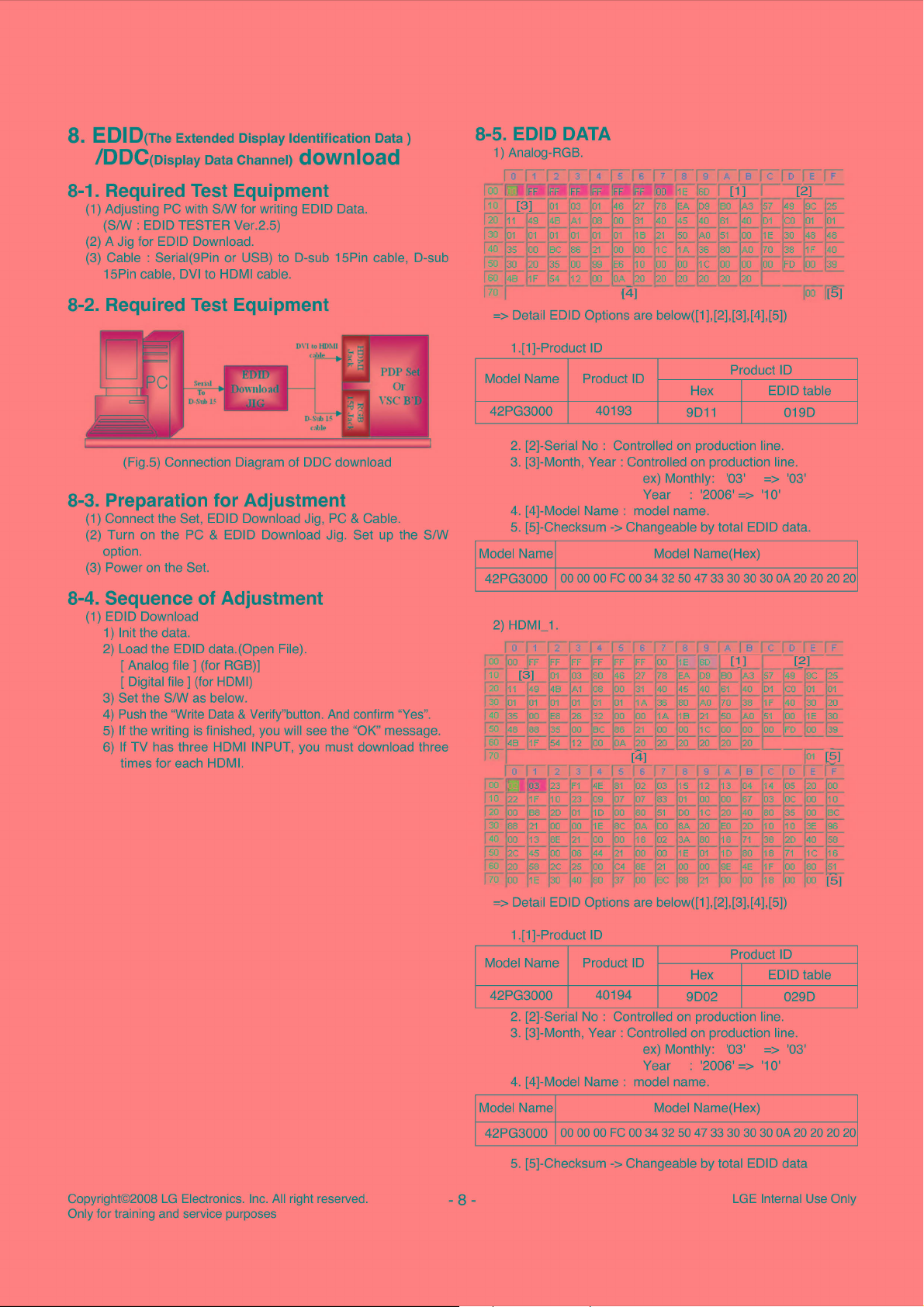

8.

ED I D(The

/DDC(Display

Extended Display Identification Data )

Data Channel) download

8-5. EDID

1)

Analog-RGB.

DATA

8-1. Required Test Equipment

(1) Adjusting

(S/W : EDID TESTER Ver.2.

(2) A Jig for EDID Download.

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cab le,

PC

with S/W for writing EDID Data.

5)

DVI

to H

DMI

cable.

8-2. Required Test Equipment

(Fig.5) Connection Diagram of DDC download

8-3. Preparation for Adjustment

(1) Connect the Set, EDID Download Jig, PC & Cable.

(2) Turn on the

PC

& EDID Download Jig. Set up the S/W

option.

(3) Power on the Set.

8-4. Sequence of Adjustment

(1) EDID Download

1)

lnit the data.

2) Load the EDID data.(Open File).

[ Analog file

[ Digital file] (for HDMI)

3) Set the S/W as below.

4)

Push

5)

If

the writing

6)

If

TV has three HDMI INPUT, you must download three

times for each HDMI.

J (for RGB)]

the "Write Data & Verify"button.

is

finished, you will see the "OK" message.

And

confirm

"Yes".

01

5C

86

21

35

00

99

5,

12

)0

C.."

20

,[4]

=>

Detail EDID Options are below([1],[2],[3],[4],[5])

1.[1

]-Product

Model Name Product

42PG3000

2.

[2]-Serial

3.

[3]-Month, Year : Controlled

ID

ID

40193

No

: Controlled on production line.

Product

Hex

9D11

on

production line.

1

1

ex) Monthly: '03'

Year : '2006'

4.

[4]-Model Name : model name.

5.

[5]-Checksum -> Changeable by total EDID data.

=>

Model Name Model Name(Hex)

42PG3000

00 00 00

FC

00

34

32

50

47

33

30 30 30

2) HDMl_1.

[2]

00 (5]

ID

EDID table

0190

=>

'03'

'10'

OA

20 20 20 20

D F

1§']

57

8 8C 25

CO

Oi

F 40

~o

CO

1E

ü[,

00

rD

c·

01

20

30

39

[2]

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

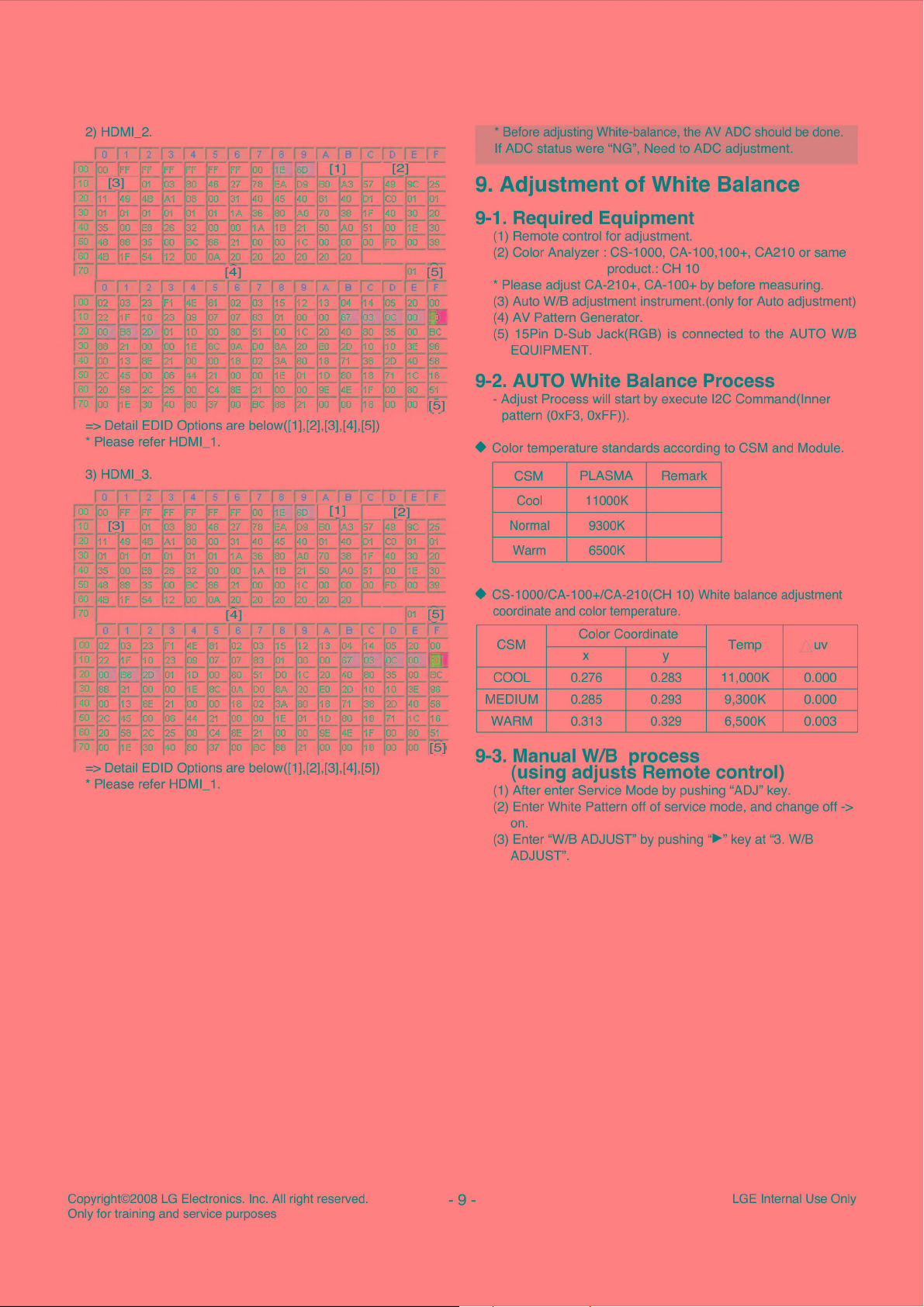

=> Detail EDID Options are below([1],[2],[3],[4],[5])

1.[1]-Product ID

Model Name Product ID

42PG3000

2.

[2]-Serial No : Controlled on production line.

3.

[3]-Month, Year : Controlled on production line.

40194

9D02

ex) Monthly: '03'

Year : '2006'

4. [4]-Model Name : model name.

Model Name Model Name(Hex)

42PG3000

00 00 00

FC

00

34 32

50

5. [5]-Checksum -> Changeable by total EDID data

- 8 -

Hex

47

33 30 30 30

Product

1

1

=> '03'

=>

'1

LGE

Internai

ID

EDID table

029D

O'

OA

20 20 20 20

Use

Only

2)

HDMl_2.

=>

Detail EDID Options are below([1 ],[2],[3],[4],[5])

* Please refer HDMI_

3) HDMl_3 .

1.

* Before adjusting White-balance, the AV

If AOC status were "NG", Need to AOC adjustrnent.

9.

Adjustment of White Balance

AOC

should be done.

9-1. Required Equipment

(1) Remote contrai for adjustment.

(2) Color Analyzer : CS-1000, CA-100, 100+, CA210 or same

product.: CH 10

* Please adjust CA-210+, CA-100+ by before measuring.

(3) Auto W/B adjustment instrument.(only for Auto adjustment)

(4) AV Pattern Generator.

(5) 15Pin D-Sub Jack(RGB) is connected to the AUTO W/B

EQUIPMENT.

9-2. AUTO White Balance Process

- Adjust Process will start by execute

pattern (OxF3, OxFF)).

• Color temperature standards according to GSM and Module .

CSM

Cool 11000K

Normal 9300K

Warm 6500K

PLASMA

Re

mark

12C

Command(lnner

=> Detail EDID Options are below([1],[2],[3],[4],[5])

* Please refer

HDMl_

1.

• CS-1000/CA-1

coordinate

CSM Temp

COOL 0.276 0.283 11,000K

MEDIUM 0.285 0.293 9,300K

WARM 0.313 0.329 6,500K

OO+/CA-21

and

color temperature.

Color Coordinate

X

O(CH

10) White balance adjustment

y

9-3. Manual W/B process

(using adjusts Remote contrai)

(1) Alter enter Service Mode by pushing "ADJ" key.

(2) Enter White Pattern off of service mode, and change off

on.

(3)

Enter "W/B ADJUST" by pushing

ADJUST".

"~"

key

al

"3. W/B

UV

0.000

0.000

0.003

->

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 9 -

LGE

Internai

Use

Only

9-4. Connection Picture of the Measuring

lnstrument(On Automatic contrai)

(1) lnside PATTERN is used when W/B

or

to auto controller

the mode

of

push control R/C IN-ST

White-Balance , the pattern will corne out.

is

controlled. Connect

ART->

Enter

12. EEPROM DATA READ

12-1. Single TABLE

ISTARTI

~

0~

0

ŒJ

Delay

IOOms

0 ~ 0

~0~0

~ 0 ~

01

STOP

1

Full

White

Pattern

RS-232C

Communication

(Fig.6) Auto AV(CVBS) Color Balance Test Pattern

l

CA-210

Col

ANALYZER

TYPE·

or

CA-210

9-5. Auto-contrai interface and directions

(1) Adjust

(2) Measure and adjust after sticking the Color Analyzer(CA-

(3) Aging time

in

the place where the influx of light like floodlight

Jess

around is blocked.(illumination is

100+, CA210) to the side

- After aging start, keep the power on(no suspension of

power supply) and heat-run over 15minutes.

- keep white pattern using inside pattern.

of

the module.

than 10ux)

• Auto adjustment Map(l2C)

-

12C(1

OOK

BPS)

1

O.

Communication START

1

START

* Until

I l 6E 1 1 A 1 1

ACK

BIT goes LOW, Repeat it.

STOP

I l

soMs

1

11. Command form

• Command form use DDC2AB standard communication

protocol.

lsTARTll

sEIIAllsollAIILENIIAllo311AII

1.

LEN:

DATA BYTE

2.

CMD : Command language that monitor executes.

3.

VAL:

FOS DATA

4.

CS : Dada's CHECKSUM that transmit.

5.

DELAY:

6.

A : Acknowledge.

50MS

CMoll

numberto

AlloollAII

send.

VALIIAllcsllAII

STOP

12-2. Command Set

Adjustment CMD

No .

contents (hex)

1 EEPROM READ

2

3

4

5

6

7

8

* To read the appointment Address of

byte

13. EEPROM Data

ADH

(hex)

E?

AO

A2

A4

A6

Write(Serial

ADL

(hex)

0 0-page

80

0

80

0

80

0 3-page

80

13-1. Signal TABLE

1 CMD I LENGTH I ADH I ADL I

CMD

LENGTH : 84h+bytes

ADH : E2PROM Slave Address(AO,A2,A4,A6,A8)

ADL : E2PROM Sub Address low (00-FF)

Data : Write data

CS :

1

:8Eh

Not OOh(Reserved by Buffer To EEPROM)

CMD

+ LENGTH +

DATA_11

ADH + ADL

... 1 DATA_n I CS

13-2. Command Set

No

1

2

EEPROM

Adjust mode

CMD(hex) LENGTH(hex) Description

WRITE

E8

94 16-Byte Write

84+n

0-page

1-page

1-page

2-page

2-page

3-page

E'PROM

+ Data_ 1 +

n-Byte Write

Details

0-?F

80-?F

0-?F

80-?F

0-?F

80-?F

0-?F

80-?F

by 128(80h)-

No

D/L)

I DELA

...

+ Data_n

Read

Read

Read

Read

Read

Read

Read

Read

YI

LG

Copyright©2008

Only for training and service purposes

Electronics.

Inc.

Ali

right reserved.

*

Description

FOS

Default

write : <?mode

Violai, V

_Frequency,

Data

write:

Madel

Name

13-3. Method & Notice

(1) Se rial number D/L is using of scan equipment.

(2) Setting of scan equipment operated by Manufacturing

Technology Group.

(3) Serial number D/L must be conformed when it is produced

in

production line, because serial number D/L

by D-book 4.0.

-

10

-

data>

Sync_Polarity,

and

Serial

write

Htotal,

Number

Hstart,

write

LGE

Vstart,

in

EEPROM,

Internai

0,

Phase

.

is

mandatory

Use

Only

14. Adjustment Command(LENGTH=84)

No

1 FACTORYON

2 FACTORYOFF

3

4 EEPROM Read E7

5

6

7 H POSITION 20

8 V POSITION 30

9

10

11

12 G DRIVE

13 B DRIVE 10

14 R CUTOFF

15 G CUTOFF

16 B CUTOFF

17 BRIGHT

18 CONTRAST

19 AUTO_COLOR_ADJUST

20

21

22

Adjustment Contents CMD(hex)

EO

E2

EEPROM ALL INIT. E4

EEPROM Write

COLORSAVE

(R/G/B cutoff, Drive,

Contrast, Bright)

CLOCK

PHASE 92

R DRIVE 16

CHANGE_COLOR_TEMP

White Pattern

AUTO_INPUT CHANGE

ES

EB

90

18

1A

80

82

84

12

F1

F2

F3

F4

ADR VAL[HEX]

00 00

00 00

00 00

00 00

00 data

00 00

00

00

00

00

00:

cool

01: medium

02:

warm

00:

cool

01:

medium

02:

warm

00 :cool

01: medium

02: warm

00

00

00

00

00

00 02

00

00

00

0,

00-64

00-64

00-64

00-64

00-80

00-80

00-80

00-7F

00-7F

00-7F

00-3F

00-64

0,1,2,3

00,FF

10,20,30,

40,60,90

Description

Factory mode on

Factory mode off

EEPROM Ali clear

EEPROM Read

EEPROM Write by some values

Color Save

They have different range each mode,

FOS Adjustment

Drive adjustment

Offset adjustment

Bright adjustment

Luminance adjustment

Auto COLOR Adjustment

O: Cool

1 : Medium

2:

Warm

3:

User

00: White pattern off

FF: White pattern on

: TV

0

10:

DTV

20:

SCART1

30:

SCART2

40 : Component

60:

RGB

90:

HDMI

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

LGE

Internai

Use

-

11

-

Only

15.

Set

lnformation(Serial

15-1.

Check

(1) Push the menu button in

- Select the

the

STATION->

serial

Diagnostics->

No & Model

number & Model

DTV

mode.

To

set.

name)

name

16. SET factoring condition

(1) This

adjustment

(2) Push

the IN-

the factory shipment.

is setting factory

STOP

key

of

shipment

adjustment

remote controller before

mode.

(2)

Check

~

the Serial

CH

34

CH

36

CH

38

54

.....

Number

No

Power Off

1

Volume Level

2

Main Picture Input

3

Main Las! Channel

4

Mute Off

5

ARC 16:9

6

SETUP

7

(DTV&ATV) Manual Tuning

,.

••

___

.

@

PICTURE Aspect Ratio

8

AUDIO Auto Volume Off

9

Time Clock

10

OPTION Menu Lanquaqe

11

LOCK Lock System Off

12

Item

Auto Tuninq

Proqramme Set

Booster

Software Update

Diagnostics Engineering

Cl Information

Picture Mode Vivid 100

Balance

Sound Mode

Off time Off

Ontime

Sleep Timer

Auto Sleep Off

Time zone

Audio Lanquaqe

Lançiuaçie

Subtitle

Hard of hearinq

Country

Input label

KeyLock

ID

Set

Factorv Reset Off

Set Password New

Block Proqram TV /DTV /Radio

Parental Guidance Off

Condition

15

Antenna

NA

ON

OFF

Diaqnostics

16

:9

Contras!

Briqhtness

Col or

Sharpness

Tint ColorTemp

Advanced Control Fresh Con.

Picture reset

0

Standard 120Hz

--

--

Off

Off

Off

Off

1

* * * *

Confirm

* * * *

Re mark

DTV&ATV

50

60

50

Fresh col.

Noise

Reduction

Film (3:2)

Black level

200Hz

500Hz

1.2Khz

3Khz

7.5Khz

12Khz

User contrai

0

Medium

On

On

On

Off

50

50

50

50

50

50

50

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

- 12 -

LGE Internai Use Only

(4) Click "Read" tab, and then load download file(XXXX.bin)

by clicking "Read"

JI

D~ • ~,G

V.

·-,el

•

11

D

2. USB DOWNLOAD

- Put a * .bin to USB Stick and Tu

(1) Put the USB Stick to the USB socket

rn

on TV

~

Checksum

u

....

,cd8.,tu

'""

• ~

111

..

'.:l·

'.

1_:

)L

lSP

'

6

~

~

Co

nfig

Re

sto

re

HDCP

Era

se

m

Connec! D1s

Flash_J

Pass

F

lash

Stat

USB

3J5t'.Hz

~~~~

us:

~~~

~~

,.

w.,~

(5) Click "Auto" Button, select the check box, and then Click

"Run" Button.

D

evic

e L

oad

Read AUto 8 P V

~

G)ReadFile

Ghects

R

Multi Flashes

oileArea

1 Elapsed

eGonnect

um.

estore

Data

AIICh

ip

EraseAr

Partial Erase

Time: 04.1

~~~~~~~~~~~~~

: OzB43 4

ea

1 1

Blank

(E)Progra

Veri(y

(2)

En t

2C

(6) After downloading, check "OK" message.

in

(2) Automatically detecting update file

* If your downloaded program version

USB Stick

in

USB Stick is Low,

it didn't work.

But

your

downloaded

ver

sion

is

High, USB

data

is

automatically detecting .

(3) Show the message "Copying files from memory"

9

Con

(4) Updating is staring.

(5) Updating Completed, The TV will restart automatically.

After tu

rn

on TV, Please press 'IN-STOP' button on ADJ

Remote-control.

IF

you don't have ADJ R/C,

*

enter 'Fac

tory

Reset' in

OPTION MENU.

When

TV

(6)

turn on,

check

the

Updated

version

on

Diagnostics MENU.

lC

(7) Updating Completed, The TV will restart automatically.

After turn on TV, Please press 'IN-STOP' button on ADJ

Remote-control.

* IF you

don't

hav

e ADJ R/C,

enter

'Factory

Reset'

OPTION MENU.

(8) When

on, check the

Updated

version

TV

turn

Diagnostics MENU.

E~GINEERING JIAGNOSTICS

CH0028

CH

00111

CHOOJO

CH0031

in

on

Copyright©2008

Only

for

training

LG Elec

tronics.

and

service purposes

Inc.

Ali rig

ht reserved.

- 14 -

LGE

Int

ernai Use Only

1. Power Board

TROUBLE SHOOTING GUIDE

1-1. The whole flowchart which it follows

Start check

Doesn't the

screen whole corne

out?

No

Doesn't the Yes No No

low pressure output

corne out?

No

Yes

•

>---------••<

ls it identical

with Power Off

1 . Check the Power Off

condition.

3. Check the St-by 5V 4. Check the

signal circuit. signal circuit. signal.

in

voltage output state

No

ls the Interface

signal operated?

2.

Check the Interface

signal condition.

5V

Monitor

5.

Check the VSC RL-ON

Doesn't the

high tension output

corne out?

No

Does

high tension

output voltage

occur?

No

Manufacture enterprise

rneaning of a passage

DroR

Yes

•

7.

Yes

________.

does

Check the VSC Vs-ON

signal

Whenthe

Y, Z B/D

input

Power

output voltage

9.

Board Output high

Module

connector

Yes •

Check the Power

tension circuit

Board

occur?

is

remove,

hightension

Drop

No

8.

Check the Vs, Va

voltage output circuit.

No

------>-

Doesn't the

input connector is

removed, does outpu

voltage drop

occur?

Yes+

10. Check the Z B/D

Module output circuit

Doesn't the

VSC low pressure

output corne out?

6.

Check the VSC low

pressure output

No

input

removed,

11

. Check the Y B/D

Module output circuit

hen

Z

B/D

connector

voltage

ccurs?

Yes +

th

Module

does

Drop

No

is

output

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 15 -

LGE

Internai

Use

Only

1-2. 42" Power Board Structure

0

liCtll

-

0

D

0

0

rr

• ~

/

P812 ,

,.._

__

__.

(..-...)

o

P8l

l

§s

( D

wl

lll

_Q

·ad

0

1

1 1

·------

813

or

_)

0

rn

- 0

DMM

+ -

-

P811

P812

V

-S

V-S

NC

GND

GND

V-A

V-A

GND

M

SV

MSV

V

-S

V-S

NC

GND

GND

V-A

V-A

GND

M

SV

MSV

IDDDDDDD

1 2 3

I

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc.

Ali

right reserved.

- 16 -

LGE Internai Use Only

2. No Power

(1) Symptom

1)

Doesn't minute discharge at module.

2) Non does not corne

(2) Check following

in

into the front LED.

0

ls plug

in

power cord?

~~~~~~~~~~~~~

i

Yes

ls the Line Filter and Power

Board Cable connected?

tes

ls the Fuse(F801) on

Power Board normal?

tes

ls the Power Board and 22P of

VSC Board Cable connected?

tes

After the cable connect is removed

to Power Board, authorized the AC

voltage marking on manual.

When ST-BY 5V is not operated,

replace Power Board.

1--------

------------------->

------------------->

No

_________ > Plug

No

No

No

in

power cord.

Connectthe

Replace the Fuse.

Cable.

------------------> Connec! the Cable.

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 17 -

LGE

Internai

Use

Only

3.

Protect Mode

(1) Symptom

1)

After once shining,

from module.

2)

The Rely falls.(The sound

3)

lt

is

converted with the color where the front LED

is

red

from green.

(2) Check following

it

does not discharge minutely

is

audible "click")

•

ls the Power Board

normal?

t Yes

ls

the each connector

normal?

t Yes

ls the Y-Board

normal?

t Yes

ls the Z-Board

normal?

t Yes

ls

the X-Board

normal?

t Yes

ls

the Ctrl Board

normal?

No

----•

No

----•

No

----•

No

----•

No

----•

No

----•

ls

output the normality Low/High

voltage except Stand-by 5V?

Alter connecting well each connector,

the normality it operates?

ls

the Fuse(FS202)

normal?(ln case of open

ls

the output voltage alter remove

P801

connect of Z-B/D normal?

ls

the output voltage normal alter

remove P211,

X-B/D?

ls

the output voltage normal alter

remove P161, P162 connector of Ctrl-

P311

B/D?

on

Y-B/D

is

replace)

connector of

__

~-o-

• Replace Power

Yes

..

Yes

Yes

ls the output voltage

normal after remove

..

P201

..

After remove

Yes

Yes

Replace Right X-B/D

..

Alter remove

Replace Left X-B/D

..

Board.

Replace the

connector.

connector of

Y-B/D?

Replace

Z-Board.

Replace

X-Board.

Yes

..

P311

output voltage normality:

P211

output voltage normality:

Replace

Y-Board.

VSC Board normal?

ls

the COF of

Copyright©2008

Only for training

• Yes

ls the

t Yes

X,

normal?

LG

Electronics.

and

service purposes

Y,

----•

Z

----•

Inc.

No

No

ls

the output voltage normal after

remove P801?

Alter crisis COF of each board, check the normality operates.

If

in

case normality operates, correspondence COF Fail

Ali

right

reserved.

- 18 -

Yes

..

P801

After remove

operation: Replace VSC Board

is

replace the module.

normal

LGE

Internai

Use

Only

4.

No Raster

(1) Symptom

1)

No OSO and image occur at screen.

2)

lt

maintains the condition where the front LED

(2)

Check

following

is

green.

0

Does minute discharge

At Module?

Yes

1 f

ls the L VDC cable

normal?

Yes

1 f

ls the IC100(LGE7383C)

Output normal?

No

-----•

No

-----•

No

-----•

ls the VAVS on?

YES

Check the POP Module

Reconnect the L VOS

'

cable in P400

Replace the VSC.

NO

-----•

ls output the normality

Low/High voltage except

stand-by

SV?

NO Replace the Power

----•

board

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 19 -

LGE

Internai

Use

Only

5.

ln

case of occurring strange screen into specific mode

5-1.

ln

case the OSD does not displayed

(1) Symptom

1)

LED is green.

2) The minute discharged continuously becomes Accomplished from module.

(2) Check following

0

ls the L VOS cable

normal?

Yes

, ,

ls the VSC Board

normal?

Yes

, ,

ls the Ctrl Board of

Module normal?

No

-----•

No

-----•

No

-----•

ls the L VOS cable

connected?

:

No

1

1

Re-insert the Cable inserts.

Operates ?(LGE7383C)

'

Does the IC100

1

,

No

1

1

Replace IC100

'

(LGE7383C)

Replace Ctrl B/D.

Yes

Yes

..

Replace the cable.

-

Replace hte VSC B/D

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

LGE

Internai

Use

-

20

-

Only

5-2.

ln

case of does't display the screen into specific mode

(1) Symptom

1) The screen does not

(RF, AV, Component, RGB, DVI).

(2) Check following

1)

Check

the all input mode should become normality display.

(3)

ln

case of becomes unusual display from

ls the

Tuner

become

normal?

the display from specific input mode

No

--------

Yes

BlockA

RF

ls the

Tuner

1

f No

Re-insert the Cable .

mode

Cable connected?

i-

--

iil!

1

1 - -

1 - -

1 - jillll!illl

1 - - -

ls the Input voltage, IIC Communication

CVBS

and

output normal?

Replace the

No

Tuner

.

~'s_t_h_e_1c_1_o_o_(L_G_E_7_3_8_3_C_)

(4)

ln

ls the Video input

Jack(JK700, 707)normal?

(5)

ln

ls theR,G,B input and H,V Sync

normal? _ Communication? _

the case of becomes unusual display from side S-video/AV mode

of

• Yes

Same

as Black A

the case of becomes unusual display from Component, RGB mode

of the JK701,703 normal?

Yes

Same

as Block A

the

~

__

AV

- - - -

~~..,

~-ls_n_o_rm-al_t_h_e_ln_p_u_t

No

..,

Check

the input source and Cable

---~~---1

~-----------~

Check

the input source

_vo_l_ta_g_e_,

_11c_~- ___

-~~

___

..,

~I

__

R

__ i -~h-l~-~

ep

ace e ·

Copyright©2008

Only for training and service purposes

LG

Electronics.

Inc.

Ali

right reserved.

-

21

-

LGE Internai Use Only

(6) ln the case of becomes unusual display from HDMI mode

~1-s-th_e_v_id_e_o_in_p_u_to_f_t_he~--~~•~I

_ HDMI

~---n_o_rm_a_l?_.

Jack

normal? _

.Yes

ls the TDMS(IC902) No ls the Input and Output signal,IIC No 1

Same

.Yes

as

--~

Black A

- - - -

___

c_h_e_ck-th_e_in_p_u_t_so_u_rc_e

-•

'----C_om_m_u_n_ic_at_io_n_n_o_rm_al_?

__

__

(7) ln the case of becomes unusual display from SCART1 mode

ls the Video input od

Jack(JK601) normal? .

.Yes

Same

as

Black A

AN

--~-~•1

~-----------~

Check

the input source

~

_,

- - - - - -

-•

~--R_e_p_la_ce_th_e_i_c_. _ _.

(8) ln the case of becomes unusual display from SCART2 mode

ls the Video input od

Jack(J600) normal?

.Yes

Same

as

Black A

AN

--~-~•1

~-----------~

Check

the input source

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

- 22 -

LGE Internai Use Only

6.

ln

case of

(1) Symptom

1)

LED is Green.

2) Screen display but sound

(2) Check following

no

sound

is

not output.

Yes

Ali input(mode) is no

sound?

________________________________

i No

Only HDMI is No

Sound?

Yes

-----.-

Download

the EDID data

i No

Only RF is no sound?

-----.-

the Tuner IN/OUT

Yes Check

i No

Only AV/component/PC

input is no sound? the Sound IN/OUT

-~-e~._

Check

ls the speaker On

._

ls the speaker Cable

normal?

IC1000 operates

menu?

i YES

Yes

normal?

it

No

-----.-

No

----.-

No

-----.-

Set on speaker

Check the Speaker

Cable.

Replace the IC1000

(NTP3000A)

in

menu.

Copyright©2008

Only for training

LG

Electronics.

and

service purposes

Inc.

Ali

right reserved.

- 23 -

Replace the VSC B/D

LGE

Internai

Use

Only

0

:::,

'<~

ô

~

-

el.@

:::,

-·

:::,

lO

m r

6.

(/)

(D

~

:S.

()

(D

TI

C

-a

0 -

(/):::,

(D

(/)

()

0

~-

lO

:::,-

[\.)

0

0

CD

G)

m

-

(D

Q.

~

0

~-

()

!'.fl

,,

~

(0

3:

iil

(/)

(D

<

(D

o.

1\)

+:>-

r

G)

m

:::,

iii

:l

flè.

C

(/)

(D

0

::,

'<

DTV/MNT V OUT

SC2

CVBS

IN

SC1_R/G/B

SC1_TV_VOUT

DSUB

..

R/G/B

DSUB_HIV

_SYNC

PC_UR_IN

-,

<

~

:,

1

CD

Il

[)

COMP _ Y/Pb/Pr

UR

1

IN

cEc

TMDS

HPD

COMP

~

rr~

• .

•

i.....!...

~EPROM 1 §PROM I IEEPROM

DTV/MNT

SC1_L/R_IN

@~

BOOSTER

AGC_SPEED

TV_CVBS

SIF

TU_TS

1

REMOTE

1, 2, 3

SC2

UR

IN

_L/R_OUT

SC1. CVBS

TV_LIR_OUT

IN

MM1731

(IC700)

0

1

DATA

GJ

r--

MDS351

(IC902)

___.

____.

!

PAG

OMS

PD

a....:._-----~

5V

..

_HDMl_

KIA7427

(IC101)

1

+

EEPROM

LGE7363C

(IC100)

_,()()({)

(/)

~

~

Ul"lH

1 1 1 1l

(/)

~

![

1

0

;i,-

;i,-0 '1l_

-, 0

~

i[

l

Cl

Slot

(PBOO

Cl

CD

,a1

-

Kl;7S232FU

1,

2,

3

(IC802)

Il

)

~

(IC302)

r

NTP300A

IC902

1

(/)

"

-

;i,-

i°

0

m

_

..,

~

C

-,

I11

in

:::

1

JJ

m

(/)

m

_

..,

()

>

P1100

iil

CSN

1

.iil

CSN

2

1

l~DATA[O

1 ~DATA[1731J

LED

G/R&l~1

KEY1/2

~

SIDE_

Y,

C_IN

SIDE_L,R_IN

SIDE

CVBS

USB

1

DM/DP

-!l~(L)

P1000

16]

~

IN

~I

Flash

Flash

~I

1

~

256Mb

~

1

256Mb

LVDS

LVA_ [0:4]

P401

SP

4MB

4MB

DDR

DDR

(R)

Memory

(IC303)

Memory

(IC304)

Memory

(IC300)

Memory

(IC301)

POP

Panel

1

ê

m

r

0

0

C

"

-

)>

C)

lJ

)>

s:

0

:::,

--o

'< '<

ô

~

~@

-·

~-

:::,

(0

m'

6.

(/)

(D (D

;;_

()

(D

TI

C

-a

0:::,

(/)

(D

(/)

()

0

t.6·

:::,-

[\.)

0

0

OJ

G)

IJJ

8-

0

:::,

o·

(f)

:_

()

.

~

(0

3:

iil

(/)

(D

<

(D

o.

1\)

(Jl

Power

P1100

+5V_ST(6A)

1•

0

MOSFET

(01102)

~---

POWER_

ON/OFF1

Stand-by

+5V

1

+5V_GENERAL

+5V_CI

AZ1085S-3.3V

IC1105

1

1+3.3V _ VDDP

Û

AZ1085S

IC1102

1

AZ1117D

(IC1103)

_ST

I +

1.25V _ST

1

+3.3V_TU 1 0.003

1

+3.3V_CI

5000hm

BEAD

AZ1117D

0.001

(IC1104)

AZ1117D

(IC1108)

A

A

1

+3.3V_VDDP

+3.3V _AVDD _MPLL

+3.3V_IR

+3.3V_AVDD_OTG

+3.3V _AVDD _ADC

+3.3V _AVDD _MEMPLL

+1

.25V_VDDC

+ 1.25V _AVDD _DVI

B

1

+1

.B_

AMP

1

G)

'

:::,

iii

:l

flè.

C

(/)

(D

0

:::,

-<'

m

1

li

11

P

12V(1A)

+16V(1.3A)

5000~m

BEAD

+12V_SC

1

KA7809ERTM

(IC1109)

1

KIA7805AF

(IC1110)

1

+5V_TU

1

AZ1117D

(IC1107)

1

+3.3V_AVDD_S1F

+3.3V

AVDD

+3.3V _AVDD _LPLL

AU

1

1

+3.3V _AVDD

1

+2.5V_DDR

+2.5V _ VDD_DDR

1

5000hm

BEAD

0.055

A

0.04A

1

IC1000(AMP)_PVDD

EXPLODED VIEW

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved.

-

26

1~

'-

-

-

LGE Internai Use Only

SPDIF

OPTIC

.JACK

Cl

BUF

TS

CLKBUF

TS

DATA[O],BUF T SYNC,TU

ERROR & BUF

74LVC541A(PW)

ICSOO

+5V_CI_Vs

.

TS

VAL

TU

TS

DATA[1-7]

1

0067972-0SOLF

~rta,»_

PCM

D[3]

THEL§YMBOL

SPECIAL

FILRE

ESSENTIAL

THE

DDR

MARK

FEATURES

IMPORTANT

AND

ELECTRICAL

THAT

ONLY

CRITICAL

COMPONENTS

MEMORY

,go1

'I:1,

,;;T

T

sro sro

DQM1

M_WE

L...J-------,-+------,

M_CAS L...J-------,-+------,

M_RAS L...J-------,-+------,

OF

THIS

SCHEMETIC

FOR

PROTECTION

SHOCK

HAZARDS,

MANUFATURES

IN

TH~

,1, ,1, ,1, ,1, ,1,

GI° GI° GI°

+2.SV_DDR

IC300

DIAGRAM

INCORPORATES

FROM

WHEN

SERVICING

SPECFIED

PARTS

SYMBOL

MARK

OF

,L

b,

GI°sI;'"J'"'

X-RADIATION.

IF

IS

BE

USED

FOR

THE

SCHEMETIC.

+2.5V_DDR

1

mil = 0.0254

20

mil = 0.508

40

mil=

ADDRESS

TOTAL

DDR1 & DDR2

1.016

LENGTH < 3000

different

mm

mm

mm

mil

(76.2mm)

length

range=+/-

+2.5V_DDR +2.5V_DDR

25

mil

IC301

(max+/-

THEL§YMBOL

SPECIAL

FILRE

ESSENTIAL

THE

FEATURES

AND

ELECTRICAL

THAT

CRITICAL

MARK

OF

THIS

IMPORTANT

SHOCK

ONLY

MANUFATURES

COMPONENTS

SCHEMETIC

FOR

PROTECTION

HAZARDS.

SPECFIED

IN

TH~

SYMBOL

DIAGRAM

WHEN

PARTS

MARK

INCORPORATES

FROM

X-RADIATION

SERVICING

IF

BE

USED

OF

THE

SCHEMETIC

IS

FOR

HDMI

50

mil)

MADR[10J ,------,-------1---1--"=a

MADR[O]

,------,

__

MADR[1]

MADR[2]

MADR[3]

THEL§YMBOL

SPECIAL

FILRE

ESSENTIAL

THE

Copyright©2008 LG Electronics. Inc. Ali right reserved

Only for training and service purposes

____,-+------,

,------,-------,-+------,

=-------,-+------,

=-------,-+------,

MARK

OF

FEATURES

IMPORTANT

AND

ELECTRICAL

THAT

ONLY

CRITICAL

MANUFATURES

COMPONENTS

THIS

SCHEMETIC

SHOCK

IN

FOR

HAZARDS,

TH~

DIAGRAM

PROTECTION

WHEN

SPECFIED

PARTS

SYMBOL

MARK

INCORPORATES

FROM

X-RADIATION.

SERVICING

IF

BE

USED

OF

THE

SCHEMETIC

IS

FOR

MADR[10]

,-,_

MADR[O]

,-,_

MADR[1]

,-,_

MADR[2]

,-,_

MADR[3]

=,--------1-+-------,

___

W.::'.:":'.:'..!

___

I+-------,

___

I+-------,

___

I+-------,

THEL§YMBOL'"MARK

SPECIAL

FILRE

AND

ESSENTIAL

THE

CRITICAL

FEATURES

ELECTRICAL

THAT

ONLY

COMPONENTS

OF

THIS

SCHEMETIC

IMPORTANT

SHOCK

MANUFATURES

IN

FOR

PROTECTION

HAZARDS,

SPECFIED

TH~

SYMBOL

DIAGRAM

WHEN

PARTS

MARK

INCORPORATES

FROM

X-RADIATION.

SERVICING

IF

IS

BE

USED

OF

THE

SCHEMETIC.

FOR

+3.3V _ VDDP

_ST

LGE Internai Use Only

Module

001

·21D;001

:25l·009·10D

THE2'sYMB0L

SPECIAL

FILRE

ESSENTIAL

THE

SW

SDA

3.3V

001

17ALLVA_OP

001.16ALLVA

001.16AL

LVA_2

001·1sL>.lVA_CKP

001:15ALLVA

001·15ALLVA_4P

PC_SER_DAT

FEATURES

AND

ELECTRICAL

THAT

CRITICAL

R40Q

100

1P

p

3P

oom

t

R401

MARK

OF

THIS

SCHEMETIC

IMPORTANT

SHOCK

ONLY

MANUFATURES

COMPONENTS

IN

PANNEL

-

-

0

DIAGRAM

FOR

PROTECTION

HAZARDS,

WHEN

SPECFIED

TH~

SYMBOL

P400

SMW200-26C

2

4

6

8

10

12

14

16

18

20

22

24

26

INCORPORATES

FROM

X-RADIATION.

SERVICING

OF

BE

THE

IF

USED

SCHEMETIC.

PARTS

MARK

WAFER

1

~

3

~

5

7

9

11

13

15

17

19

21

23

25

IS

FOR

R402

R403

100

QROM

-A_2M

- LVA_CKM01

DL

i

R404

R405

27K

SW_SCL_3.3V

LVA_OM

001:17AL

LVA_1M

00116AL

00116AL

LVA

3M

001.15AL

LVA_

4M

001

PC_SER_CL.Koo6·3A

100

i

'

MSD2379AO

L

IC100

E7363C-LF

IC100

LGE7363C-L

IR/CONTROL

UOO-\i,1,,0

L401·,i),,O

L402-:Jv,

o

L403-w.0

uo1-·1 o

'M

L405-~0

""'

16AL

ISAL

DISP_EN

001·211

'Don·t

<>Ar

PIN8_RE_1

t:,ea,,.,,.,,ea

0604

5t,ate

;,;

turned

on(PIN_RE_2)

POVVER

TUNER+5V

B/D

+C1119

1l~JF

+5V_+12V

Stand-by

TUNER

+3

3V

+1

.25V

MST

Core

Cl

+3.3V

+1

.SV

+2.5V_DDR

[SCART

SC

ART

PIN

8]

THEJsYMBOL

SPECIAL

FILRE

ESSENTIAL

THE

Copyright©2008 LG Electronics. Inc. Ali right reserved

Only for training and service purposes

FEATURES

AND

ELECTRICAL

THAT

CRITICAL

MARK

OF

THIS

IMPORTANT

SHOCK

ONLY

MANUFATURES

COMPONENTS

SCHEMETIC

FOR

HAZARDS,

IN

TH~

DIAGRAM

PROTECTION

WHEN

SPECFIED

SYMBOL

MARK

INCORPORATES

FROM

X-RADIATION

SERVICING

PARTS

BE

USED

OF

THE

SCHEMETIC.

L604'1 0 L611'1

THEJsYMBOL

SPECIAL

IF

IS

FOR

FILRE

ESSENTIAL

THE

FEATURES

AND

ELECTRICAL

THAT

CRITICAL

MARK

OF

IMPORTANT

ONLY

COMPONENTS

0

'M 'M

THIS

SCHEMETIC

FOR

PROTECTION

SHOCK

HAZARDS,

MANUFATURES

IN

TH~

DIAGRAM

WHEN

SPECFIED

SYMBOL

INCORPORATES

FROM

X-RADIATION.

SERVICING

PARTS

BE

MARK

OF

THE

IF

IS

USED

FOR

SCHEMETIC.

5.

19V / 10.91V_ 1 Kohm(LOAD)

LGE Internai Use Only

Analog

RGB

SwitchlNG

COMPONE

NT

RS232C

TUNER

':?~T~O_N

_: ~~

~~C-

_ _ _ _

USE

ONL

Y FO_R

_?~~A~

USB

5V

CONTROL

__

THE,/j,YMBOL

SPECIAL

FILRE

AND

ESSENTIAL

THE

CRITICAL

MAIN(TOP)

MARK

FEATURES

ELECTRICAL

THAT

ONLY

COMPONENTS

OF

THIS

SCHEMETIC

IMPORTANT

FOR

SHOCK

MANUFATURES

IN

THl1i',

PROTECTION

HAZARDS,

SPECFIED

SYMBOL

DIAGRAM

WHEN

PARTS

MARK

INCORPORATES

FROM

X-RADIATION.

SERVICING

IF

BE

USED

OF

THE

SCHEMETIC.

IS

FOR

MAIN(BOTTOM)

D

,_

'""''

PRINTED CIRCUIT BOARD

Qsc

o,

9,

1

'[,S

$ _l'lllll

___

l!i~"'W

THE&YMBOL

SPECIAL

FEATURES

FILRE

AND

ESSENTIAL

THE

CRITICAL

~

c5

tn

..

o~·

111si-•••

MARK

OF

IMPORTANT

ELECTRICAL

THAT

ONLY

MANUFATURES

COMPONENTS

THIS

SCHEMETIC

SHOCK

IN

0

FOR

PROTECTION

HAZARDS,

SPECFIED

THl1i',

SYMBOL

D

DIAGRAM

WHEN

PARTS

MARK

0

ao,

.

c;:i.:

'

INCORPORATES

FROM

X-RADIATION.

SERVICING

IF

IS

BE

USED

OF

THE

SCHEMETIC.

FOR

Control B/D(TOP)

1,

1..1..:-~;~I

Control B/D(BOTTOM)

PREAMP B/D(TOP)

I'-.

_,_

[o]

Q

li

[o]

ls

[o]

1,

[o]

;~;

Copyright©2008

Only for training and service purposes

LG

Electronics. Inc. Ali right reserved

PREAMP B/D(BOTTOM)

LGE Internai Use Only

Loading...

Loading...