LG 42LH50 Training Manual

42LH50 Direct View LCD

42LH50 Direct View LCD

1080P

Direct View LCD

Updated February 17th2010

Original: August 2009

OUTLINE

OUTLINE

Section 1

Section 2

Contact Information, Preliminary Matters, Specifications,

LCD Overview, General Troubleshooting Steps,

Signal Distribution, Disassembly Instructions and Voltages

Circuit Board Operation, Troubleshooting of :

• Switch mode Power Supply/Ballast Combination

• Main Board

Internet ConnectionNew

• Ft Control Board

• Side Keys

2

August 2009 42LH50

Overview of Topics to be Discussed

Overview of Topics to be Discussed

42LH50 LCD Direct View Display

This Section will cover Contact Information and remind the Technician of Important Safety Precautions for

the Customers Safety as well as the Technician and the Equipment.

Basic Troubleshooting Techniques which can save time and money sometimes can be overlooked. These

techniques will also be presented.

Section 1

This Section will get the Technician familiar with the Disassembly, Identification and Layout of the LCD

Display Panel.

At the end of this Section the Technician should be able to Identify the Circuit Boards and have the ability

and knowledge necessary to safely remove and replace any Circuit Board or Assembly.

3

August 2009 42LH50

Preliminary Matters (The Fine Print)

Preliminary Matters (The Fine Print)

IMPORTANT SAFETY NOTICE

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons possessing an adequate background in

electrical equipment, electronic devices, and mechanical systems. In any attempt to repair a major Product,

personal injury and property damage can result. The manufacturer or seller maintains no liability for the

interpretation of this information, nor can it assume any liability in conjunction with its use. When servicing this

product, under no circumstances should the original design be modified or altered without permission from LG

Electronics. Unauthorized modifications will not only void the warranty, but may lead to property damage or

user injury. If wires, screws, clips, straps, nuts, or washers used to complete a ground path are removed for

service, they must be returned to their original positions and properly fastened.

CAUTION

CAUTION

To avoid personal injury, disconnect the power before servicing this product. If electrical power is required for

diagnosis or test purposes, disconnect the power immediately after performing the necessary checks. Also be

aware that many household products present a weight hazard. At least two people should be involved in the

installation or servicing of such devices. Failure to consider the weight of an product could result in physical

injury.

4

August 2009 42LH50

(Electrostatic Static Discharge)

ESD Notice

ESD Notice

Today’s sophisticated electronics are electrostatic discharge (ESD) sensitive. ESD can weaken or damage

the electronics in a manner that renders them inoperative or reduces the time until their next failure.

Connect an ESD wrist strap to a ground connection point or unpainted metal in the product. Alternatively,

you can touch your finger repeatedly to a ground connection point or unpainted metal in the product. Before

removing a replacement part from its package, touch the anti-static bag to a ground connection point or

unpainted metal in the product. Handle the electronic control

repackaging a failed electronic control assembly in an anti-static bag, observe these same precautions.

Regulatory Information

Regulatory Information

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate

the receiving antenna; Increase the separation between the equipment and the receiver; Connect the

equipment to an outlet on a different circuit than that to which the receiver is connected; or consult the

dealer or an experienced radio/TV technician for help.

(Electrostatic Static Discharge)

assembly by its edges only. When

5

August 2009 42LH50

Contact Information

Contact Information

Customer Service (and Part Sales) (800) 243-0000

Technical Support (and Part Sales) (800) 847-7597

USA Website (GCSC) aic.lgservice.com

Customer Service Website us.lgservice.com

LG Web Training lge.webex.com

LG CS Academy lgcsacademy.com

LCD-DV:

PLASMA:

Also available on the

Also available on the

Plasma page

Plasma page

32LG40, 32LH30, 37LH55, 42LG60, 42LG70, 42LH20, 42LH40, 42LH50,

42LH90, 42SL80, 47LG90, 47LH85

42PG20, 42PQ20, 42PQ30, 50PG20, 50PS80, 50PS60, 60PS11

Plasma Panel

Alignment Handbook

Published August 2010 by LG Technical Support and Training

LG Electronics Alabama, Inc. 201

Presentations

with Audio/Video

and Screen Marks

http://136.166.4.200

New Training Materials on

New Training Materials on

the Learning Academy site

the Learning Academy site

James Record Road, Huntsville,

AL, 35813.

6

August 2009 42LH50

LCD DIRECT VIEW OVERVIEW

LCD DIRECT VIEW OVERVIEW

Safety and Handling Regulations

1. Approximately 20 minute pre-run time is required before any adjustments are performed.

2. Voltage levels on SMPS are factory adjusted and sealed. VR301 and VR302.

3. Be cautious of electric shock from the Backlight section, it uses high voltage AC. Check

that the Power Supply and Drive Circuits are completely discharged because of residual

current stored before Circuit Board removal.

4. C-MOS circuits are sensitive to static electricity, use caution when dealing with Circuit

boards. Always handle the circuit boards on the outside edges, while wearing a static wrist

strap.

5. Exercise care when making voltage and waveform checks to prevent damaging the unit

and service equipment.

6. Be cautious of lost screws and other metal objects to prevent a possible short in the

circuitry.

Checking Points to be Considered

1. Check the appearance of the Replacement Panel and Circuit Boards for both physical

damage and part number accuracy.

2. Check the model label. Verify model names and board model matches.

3. Check details of defective condition and history. Example: Oscillator failure dead set, etc…

7

August 2009 42LH50

Basic Troubleshooting Steps

Basic Troubleshooting Steps

Define, Localize, Isolate and Correct

•Define

the failure. Use your senses Sight, Smell, Touch and Hearing. Look for burned parts and

check for possible overheated components. Capacitors will sometimes leak dielectric material

and give off a distinct odor. Frequency of power supplies will change with the load, or listen for

relay closing etc. Observation of the front Power LED may give some clues.

•Localize

checked and after giving a thorough examination using your senses the first check should

always be the DC Supply Voltages to those circuits under test. Always confirm the supplies

are not only the proper level but be sure they are noise free. If the supplies are missing check

the resistance for possible short circuits.

•Isolate

Oscilloscope to make a final determination of the failure. Look for correct Amplitude Phasing

and Timing of the signals also check for the proper Duty Cycle of the signals. Sometimes

“glitches” or “road bumps” will be an indication of an imminent failure.

Look at the symptom carefully and determine what circuits could be causing

After carefully checking the symptom and determining the circuits to be

To further isolate the failure, check for the proper waveforms with the

•Correct

check the DC Supplies for proper levels. Make all necessary adjustments and lastly always

perform a Safety AC Leakage Test before returning the product back to the Customer.

The final step is to correct the problem. Be careful of ESD and make sure to

8

August 2009 42LH50

42LH50 PRODUCT INFORMATION

42LH50 PRODUCT INFORMATION

This section of the manual will discuss the specifications of the 42LH50

LCD Direct View Display Panel.

9

August 2009 42LH50

Basic Specifications

Basic Specifications

Key Features

• LG NetCast™ Entertainment Access*

• (Netflix®, YouTube™, Yahoo!® Widgets,

• My Media Access CIFS)

• TruMotion 120Hz

• Full HD 1080p HD Resolution

• 70,000:1 Dynamic Contrast Ratio

• 2.7ms Response Time (GTG)

• 500 cd/m2 Brightness

• Wide Color Gamut

• Super IPS Panel

• Wide Viewing Angle

• XD Engine®

• 24p Real Cinema

• ISFccc® Ready

• Picture Wizard

• AV Mode II (Cinema, Sports, Game)

• 60,000 Hour Panel Life (typical)

• NTSC/ATSC Tuners with Clear QAM

10

August 2009 42LH50

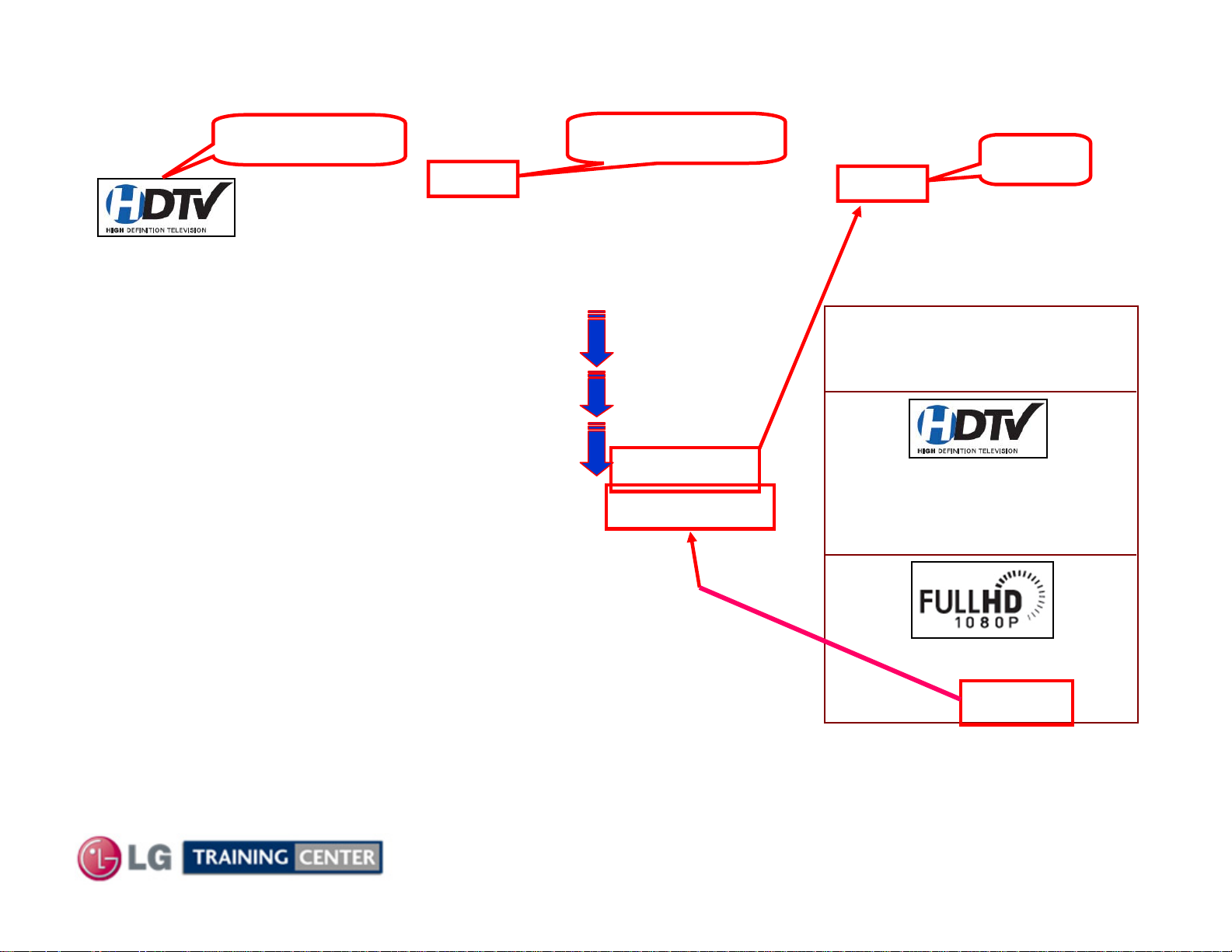

Pixel Count to Resolution Comparisons

Pixel Count to Resolution Comparisons

NTSC

SD

HD

HD

HD

720P Logo

HD RESOLUTION 720p HD Resolution Pixels: 1365 (H) × 768 (V)

High definition television is the highest performance segment of the

DTV system used in the US. It’s a wide screen, high-resolution video

image, coupled with multi-channel, compact-disc quality sound.

720P Panel

FORMATS

480I

480P

1080I

720P

1080P

Interlaced

Progressive

Interlaced

Progressive

Progressive

240 Lines

480 Lines

540 Lines

720 Lines

1080 Lines

768

BASIC

PIXEL COUNTS

720P Panel

1365 (H) × 768 (V)

Possible Frame

Rates:

24FPS

30FPS

60FPS

Interlaced

2 Fields to make a Frame

1080P Panel

Progressive

1920 (H) x 1080 (V)

Each Field is a Frame

Think of sync as the Panels “Refresh Rate”

11

August 2009 42LH50

Basic Specifications (LOGO Familiarization)

Basic Specifications (LOGO Familiarization)

Full HD 1080p Resolution

Displays HDTV programs in full 1920 x 1080p resolution for a more detailed picture.

12

August 2009 42LH50

Remote Control

Remote Control

Familiarization

Familiarization

TOP PORTION

BOTTOM PORTION

13

August 2009 42LH50

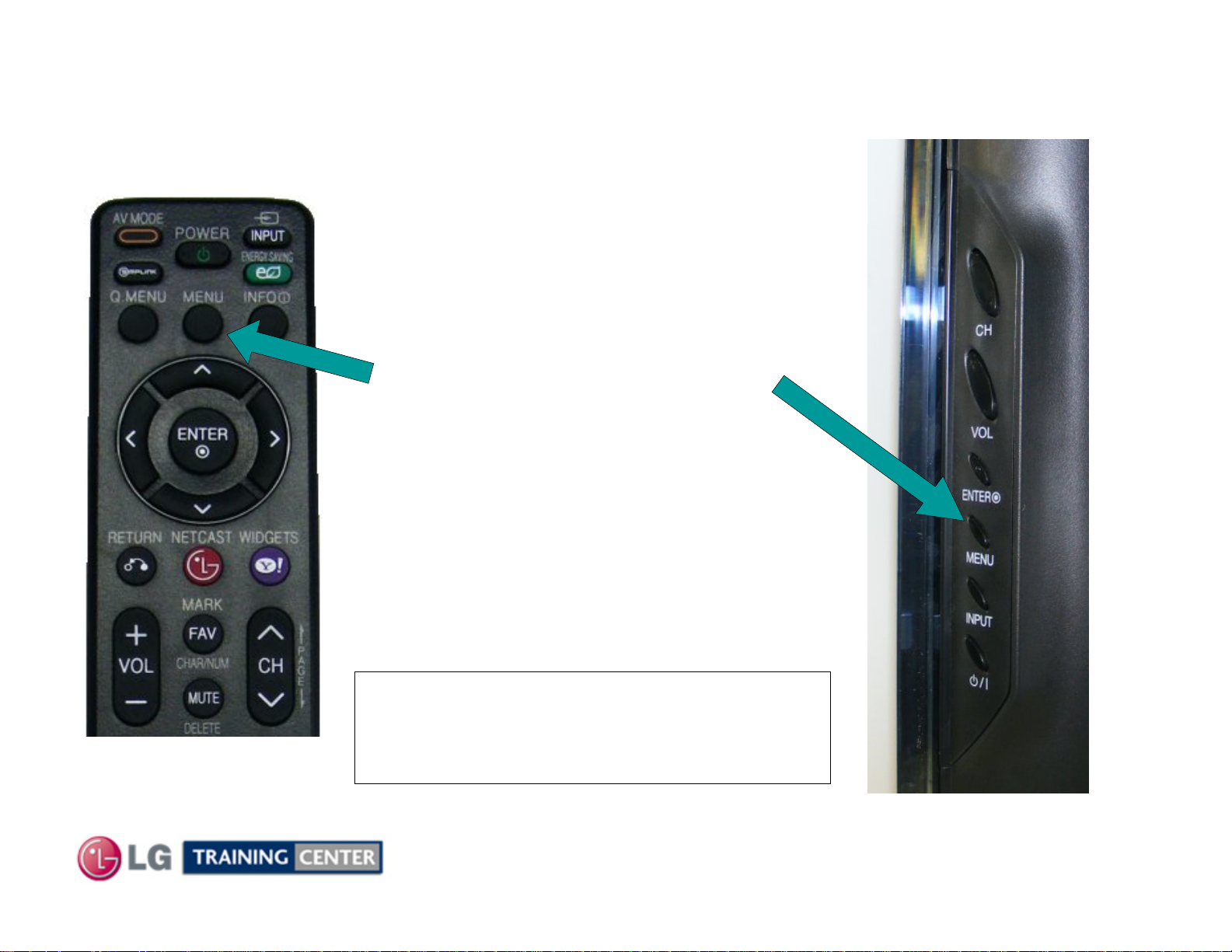

Accessing the Service Menu

Accessing the Service Menu

REMOTE

BOTTOM PORTION

To access the Service Menu.

1) Turn the Set On

2) Simultaneously, Press and

“Hold” the Menu Key on the

Side Key pad and Press and

“Hold” the Menu Key on the

Remote approximately 5

seconds.

3) If Customer’s Menu appears,

continue to hold until it

disappears.

SIDE KEYS

4) The Service Menu appears

Note: If a Password is required to

enter the Service Menu. Enter;

0000

14

August 2009 42LH50

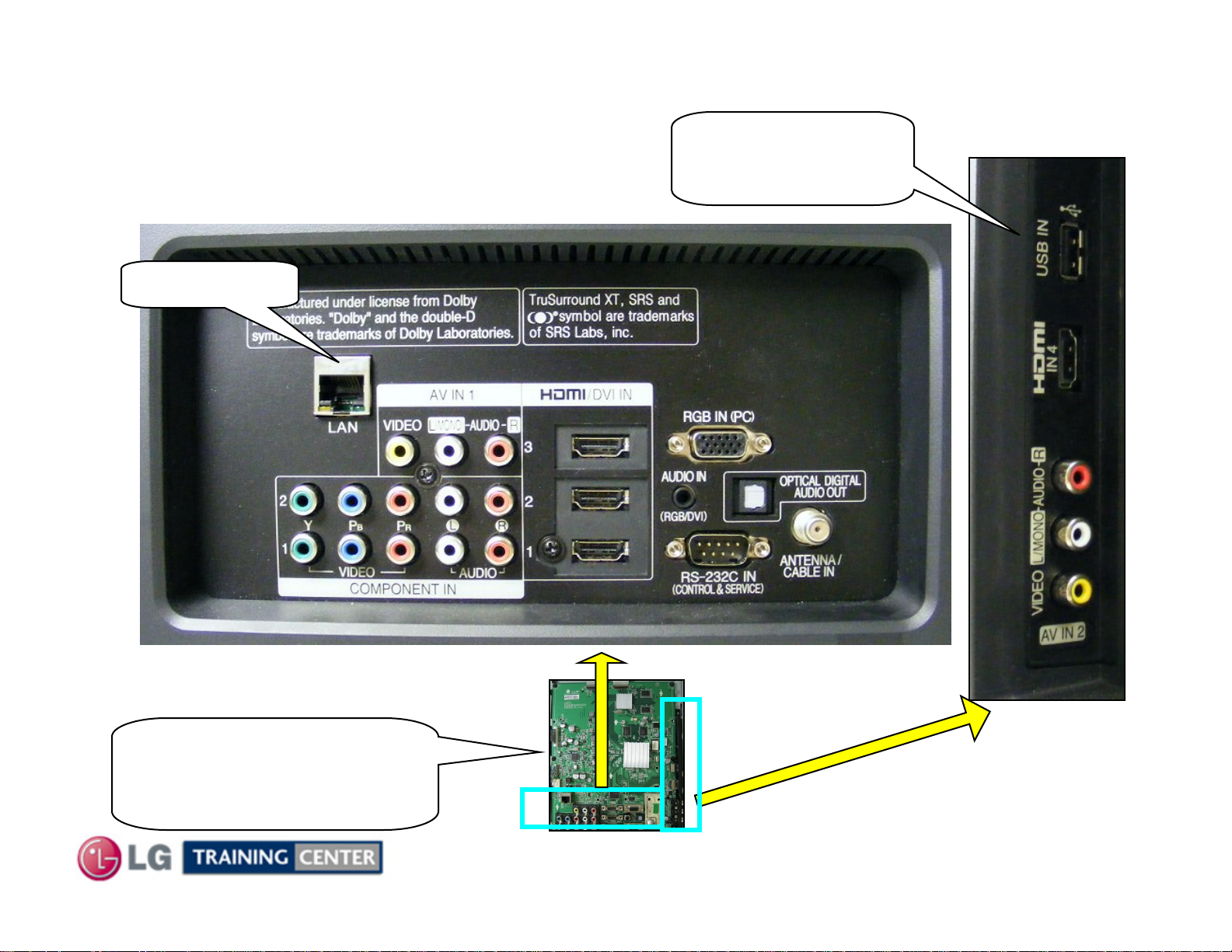

Rear and Side Input Jacks

Rear and Side Input Jacks

Internet Port

Rear In/Out Jacks

USB Port

Software Upgrades

Music, Photos

Side In/Out

MAIN PWB

Rear and Side

Input/Output locations

15

August 2009 42LH50

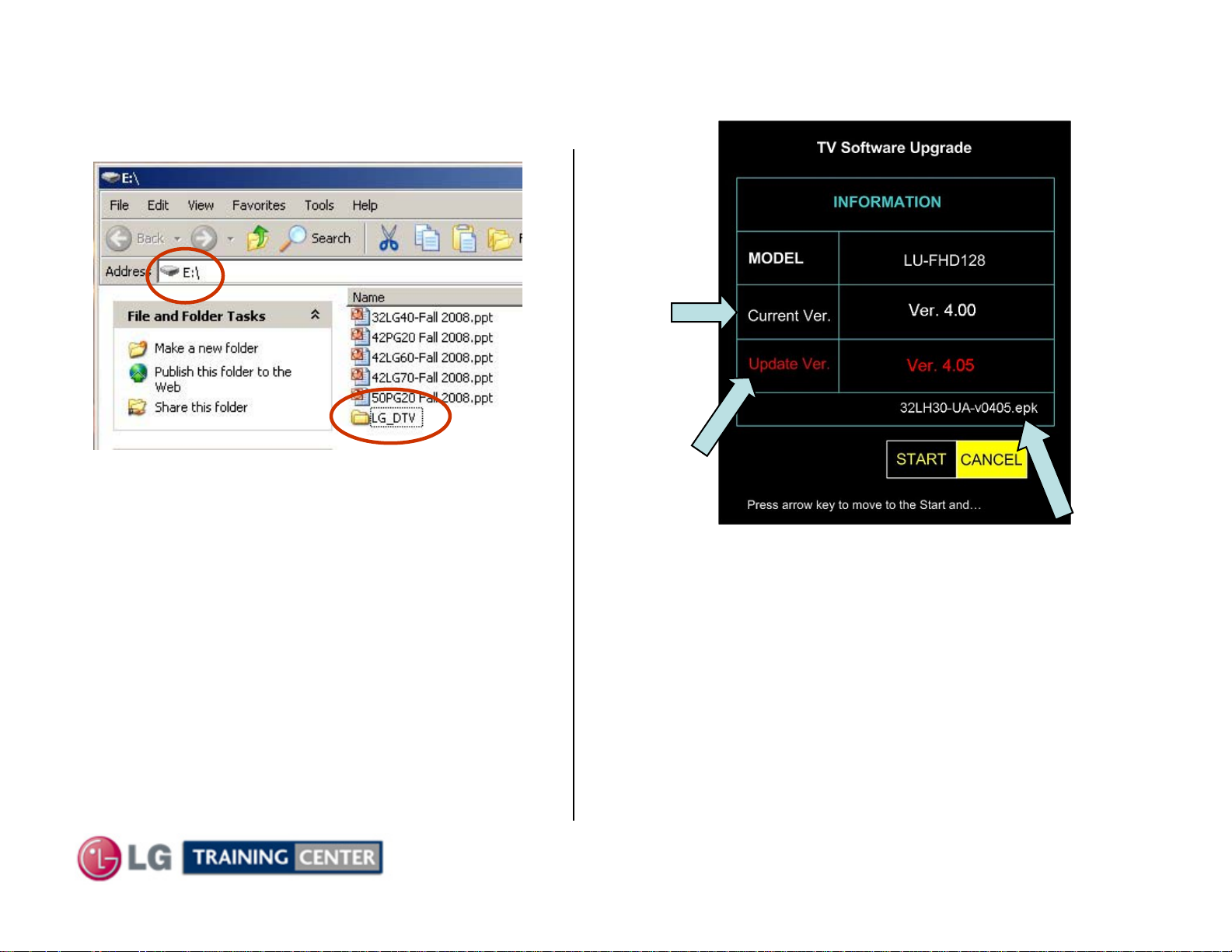

Software Upgrade Procedure

Software Upgrade Procedure

1) Create an LG_DTV folder on the USB Flash Drive

Shows the

Currently

Installed

Version

2) Copy new software (xxx.epk) to "LG_DTV"

folder. Make sure to have correct software file.

3) With TV turned on, insert USB flash drive.

4) You can see the message

“TV Software Upgrade” (See figure to right)

5) Cursor left and highlight "START" Button and

push “Enter” button using the remote control.

6) You can see the download progress Bar.

7) Do not unplug until unit has automatically

restarted.

8) When download is completed, you will see

“COMPLETE”.

9) Your TV will be restarted automatically.

Shows the

Software

Version

found on the

USB Flash

Drive

Shows the

Software file found

on the USB Flash

Drive

* CAUTION:

Do not remove AC power or the USB Flash Drive.

Do not turn off Power, during the upgrade

process.

16

August 2009 42LH50

nd

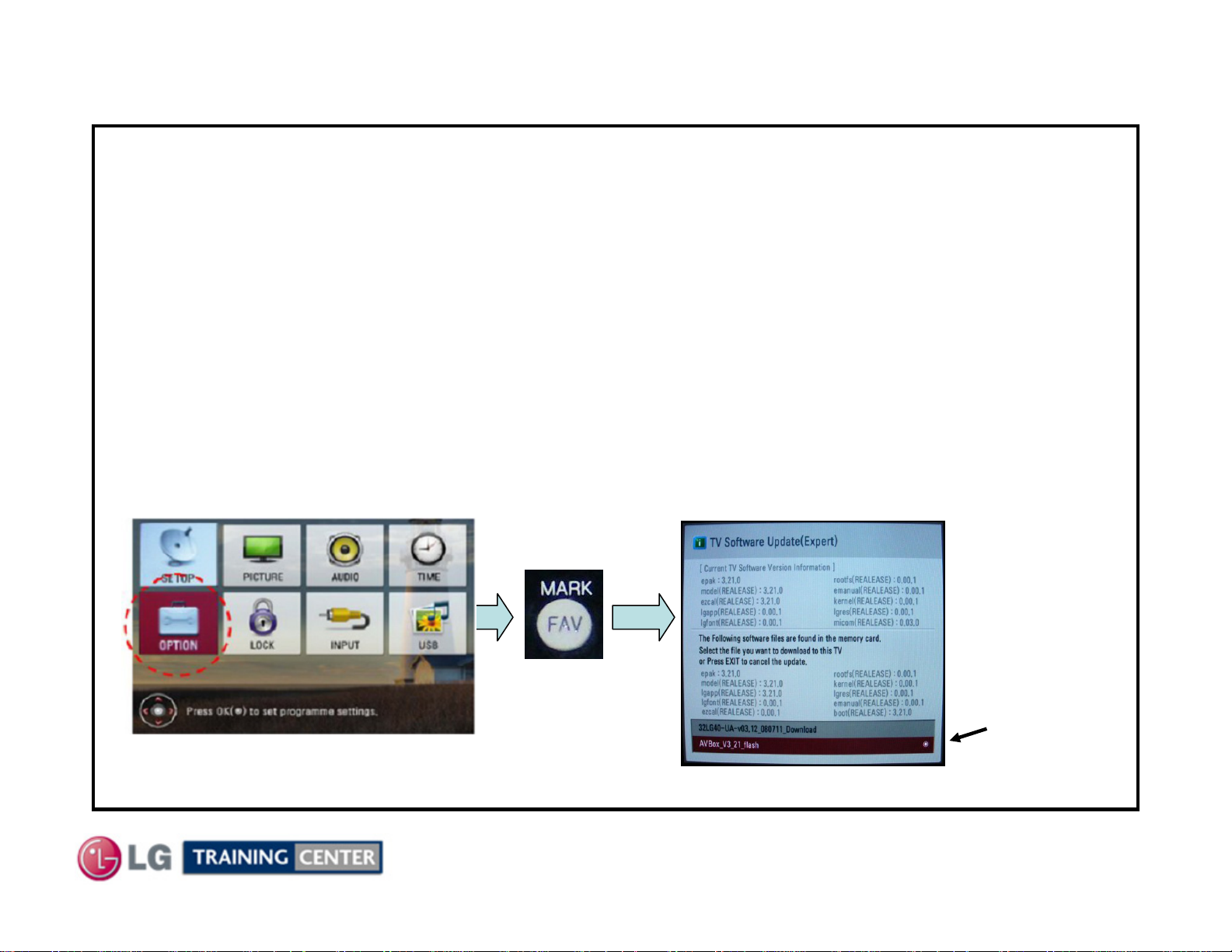

How to Perform a Manual Software Update (2

How to Perform a Manual Software Update (2

1. (Remove all cables).

2. Plug USB Memory (Jump drive) into the USB jack (front input).

The (epk) file must be in a Sub-Folder named “LG_DTV” on the jump drive.

3. Bring up the Customer’s Menu. Highlight the “OPTION” selection. (See Fig 1)

4. Press “FAV/MARK” button on the remote controller 7 times. (See Fig 2)

5. A Pop-Up window appears (See Fig 3). Using Cursor keys, select the correct file.

6. Press the “SELECT” key on the remote.

7. A Progress bar appears indicating that the download is in progress. Same as Automatic Mode.

(Do not remove AC during this time).

8. When the download is complete the TV will automatically restart.

9. Turn off TV and remove AC for 30 seconds.

Re-apply AC and turn the TV on.

nd

Choice)

Choice)

Fig 1

Press 7 times

Fig 2

17

Be very careful.

Make sure you

have selected the

correct

Upgrade File

before pressing

“SELECT”.

Fig 3

August 2009 42LH50

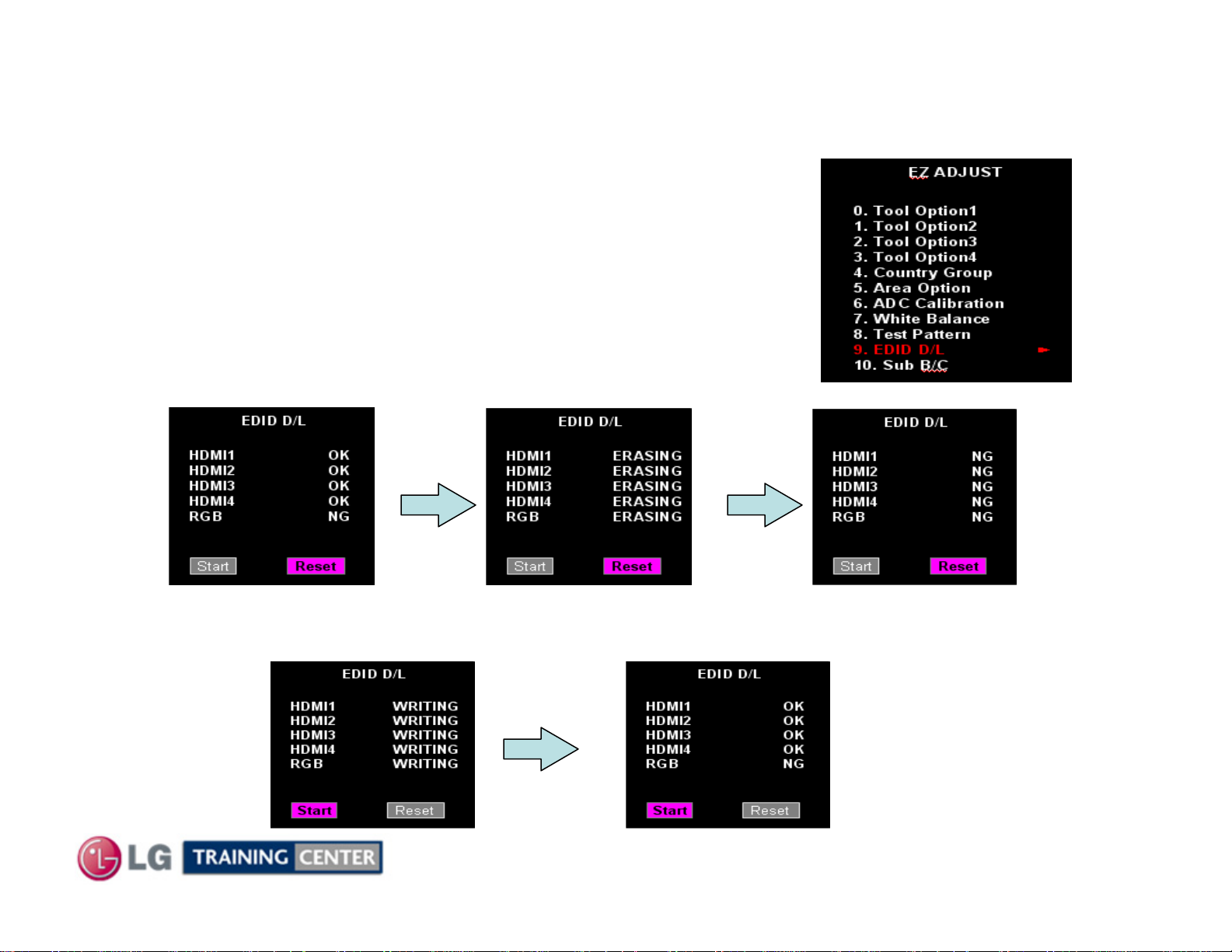

How to Upgrade EDID Data

How to Upgrade EDID Data

Caution : Before upgrading EDID data, the Software Upgrade should have

already been performed.

Remove all cables for the Television.

1. Press the ADJ key on the Service Remote to display EZ ADJUST Menu.

(See Figure A on the right)

2. Using the cursor down key, Highlight EDID D/L selection and press “SELECT”

on the remote. (See Figure A)

3. A “Pop-Up” screen showing the EDID status as OK appears. (See Figure B)

4. Using the Cursor keys, Highlight “RESET” and press “SELECT”.

(See Figures C and D)

The EDI Data is first Erased and the status is shown as NG.

Fig B Fig C Fig D

Fig A

5. Highlight “START” and press “Select” to download and update EDID. (See Figure E through F)

First the EDID Data is written into memory.

Fig E Fig F

Then the Status is shown as OK

18

August 2009 42LH50

42LH50 Product Dimensions

42LH50 Product Dimensions

There must be at least 4 inches of Clearance on all sides

Wattage

Average 197W

Stand By 0.22W

42LH50 Dimensions

41-3/8"

1051.6mm

7-7/8"

200mm

3-5/8"

91.4mm

25-7/8"

657.9mm

28-5/16"

718.8mm

2-3/8"

60.96mm

16-3/4"

425mm

4-1/16"

103.8mm

20-11/16"

518mm

12-15/16"

327.8mm

12-15/16"

327.8mm

Center

8-7/8"

225mm

8-13/16"

224mm

7-7/8"

200mm

Model No.

Serial No.

Label

Remove 4 screws to

remove stand for

wall mount

Weight without Stand: 37.9 lb

Weight with Stand: 41.9 lb

19-15/16"

506mm

19

11-11/16"

297.1mm

DISASSEMBLY AND TROUBLESHOOTING SECTION

DISASSEMBLY AND TROUBLESHOOTING SECTION

Disassembly:

This section of the manual will discuss Disassembly, Layout and Circuit

Board Identification, of the 42LH50 LCD Direct View Television.

Upon completion of this section the Technician will have a better understanding of

the disassembly procedures, the layout of the printed circuit boards and be able to

identify each board.

Troubleshooting:

This section of the manual will also discuss troubleshooting.

Upon completion of this section the Technician will have a better understanding of

how to diagnosis and resolve problems.

20

August 2009 42LH50

Removing the Back Cover

Removing the Back Cover

Remove the 23 screws indicated.

Pay attention to the size and type of screw

as there are many different types.

Putting in an improper screw when

reassembling may Cause damage.

The Stand and its bottom two screws do not need to be removed before removing the back.

21

August 2009 42LH50

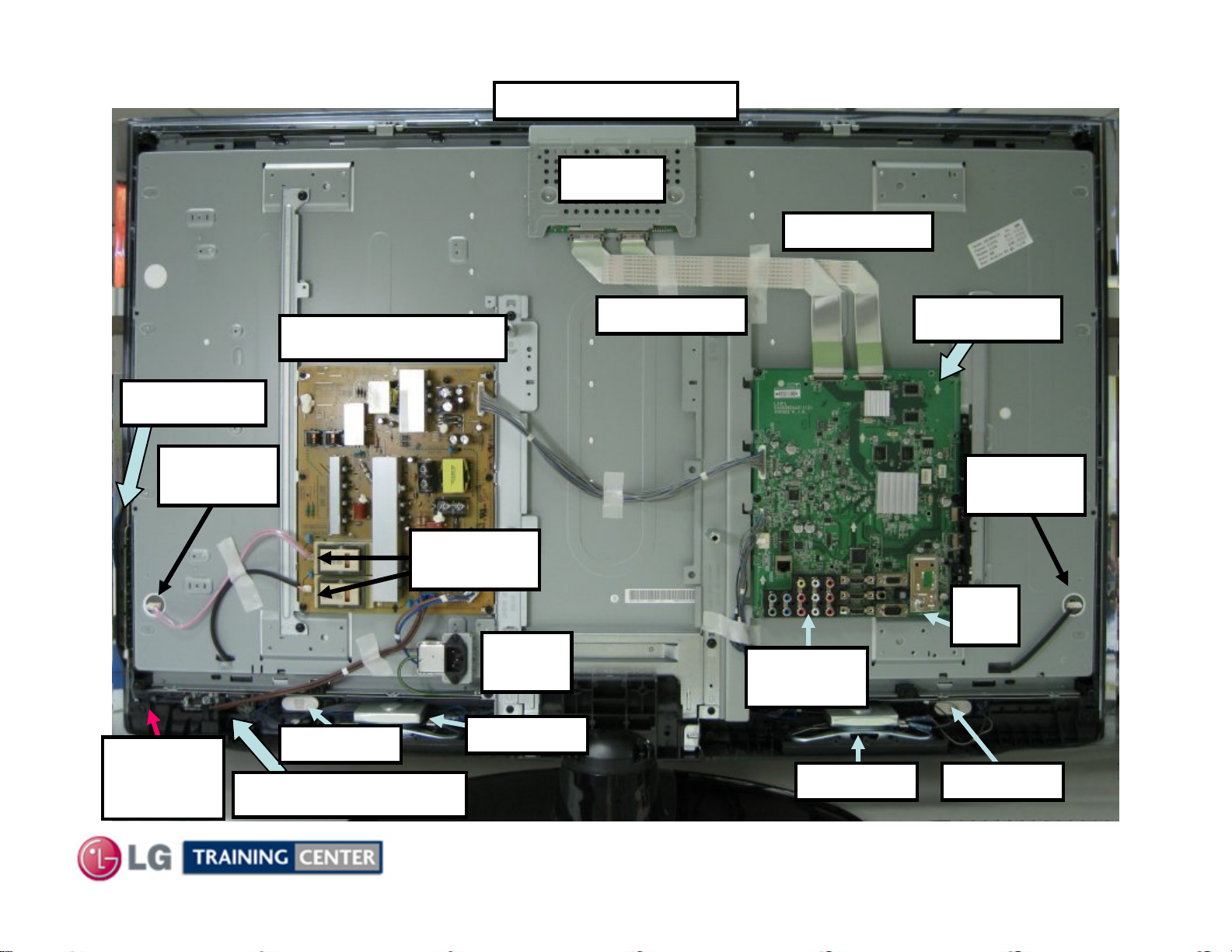

Circuit Board Layout

Circuit Board Layout

T-CON p/n EAT60663701

T-CON

LVDS Cable

Side Keys

Backlight

Connection

Master

Power

Switch

POWER SUPPLY

Backlight

Connections

Tweeter R

Ft IR/LED Control

AC

Input

Speaker R

LVDS Cable

Rear

Inputs

Speaker L

Main PWB

Backlight

Connection

RF

Input

Tweeter L

22

August 2009 42LH50

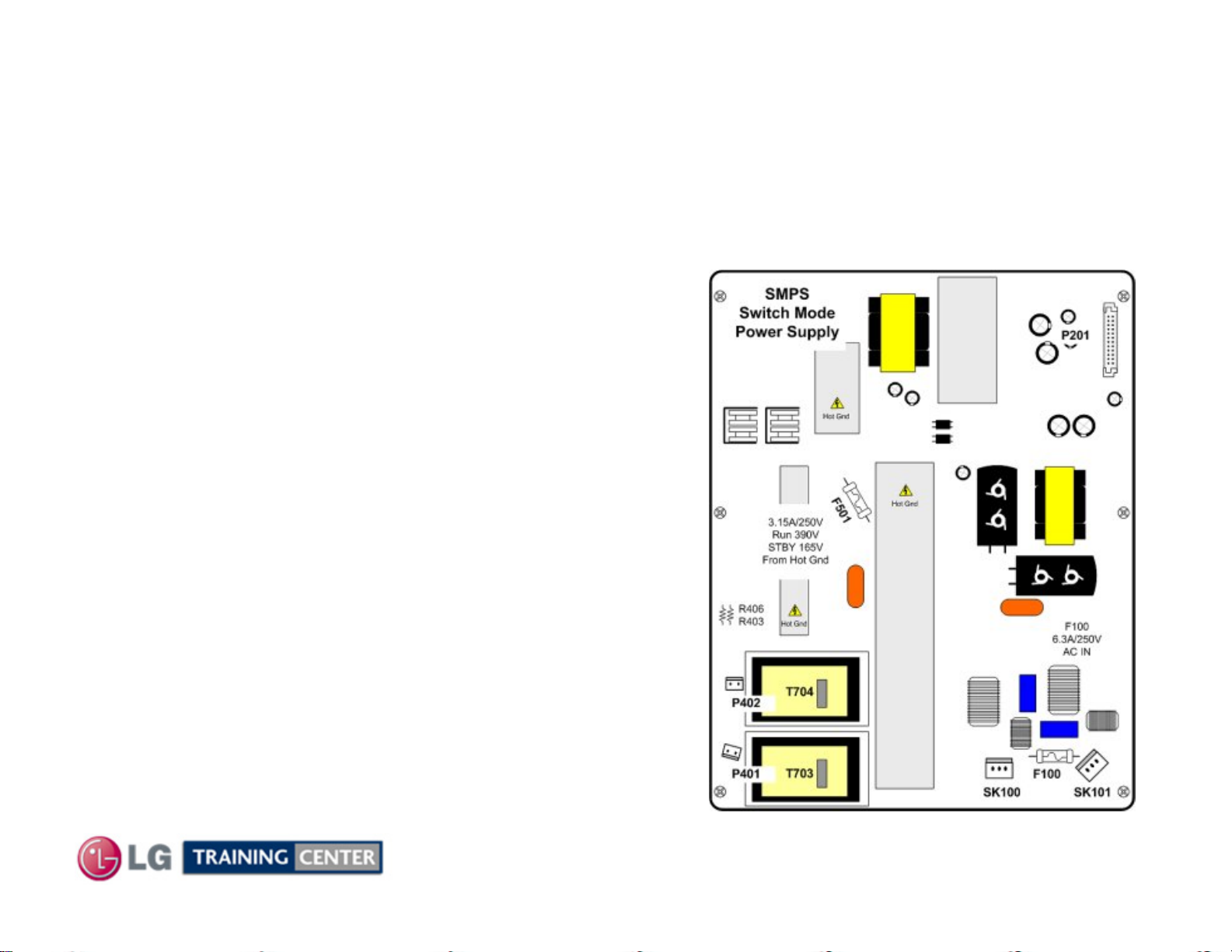

POWER SUPPLY SECTION

POWER SUPPLY SECTION

Note: If the Master Power Switch is off, this power supply is completely off.

This switch mode power supply has the ballast section built in.

The power supply develops Stand By 5V, 12V and 24V for the Main board.

This power supply draws a little less that 1 watt during stand

by mode. The fuse F501 reads 73VDC (from hot ground)

during this time. When the controller chip (on the back)

receives the PWR-ON command via P201 Pin 19, the primary

section increases its current supplying ability. The Primary

fuse F501 now reads 390V.

12V is routed out P201 pins 5 and 6 and

24V is routed out P201 pins 1 and 2.

Internally, the power supply also sends B+ (390V) voltage to

the Ballast section but it is not turned on at this time.

When the power supply receives the INV-ON command via

P201 pin 20, it is routed to the driver for the ballast (on the

back of the board). The driver now starts to deliver drive

information to the output FETs (on the far left hand heat sink)

which in turn switch the primary sides of the two ballast

transformers T703 and T704. They output 1.2Kv (48Khz)

pulses to the backlights via P401 and P402.

23

August 2009 42LH50

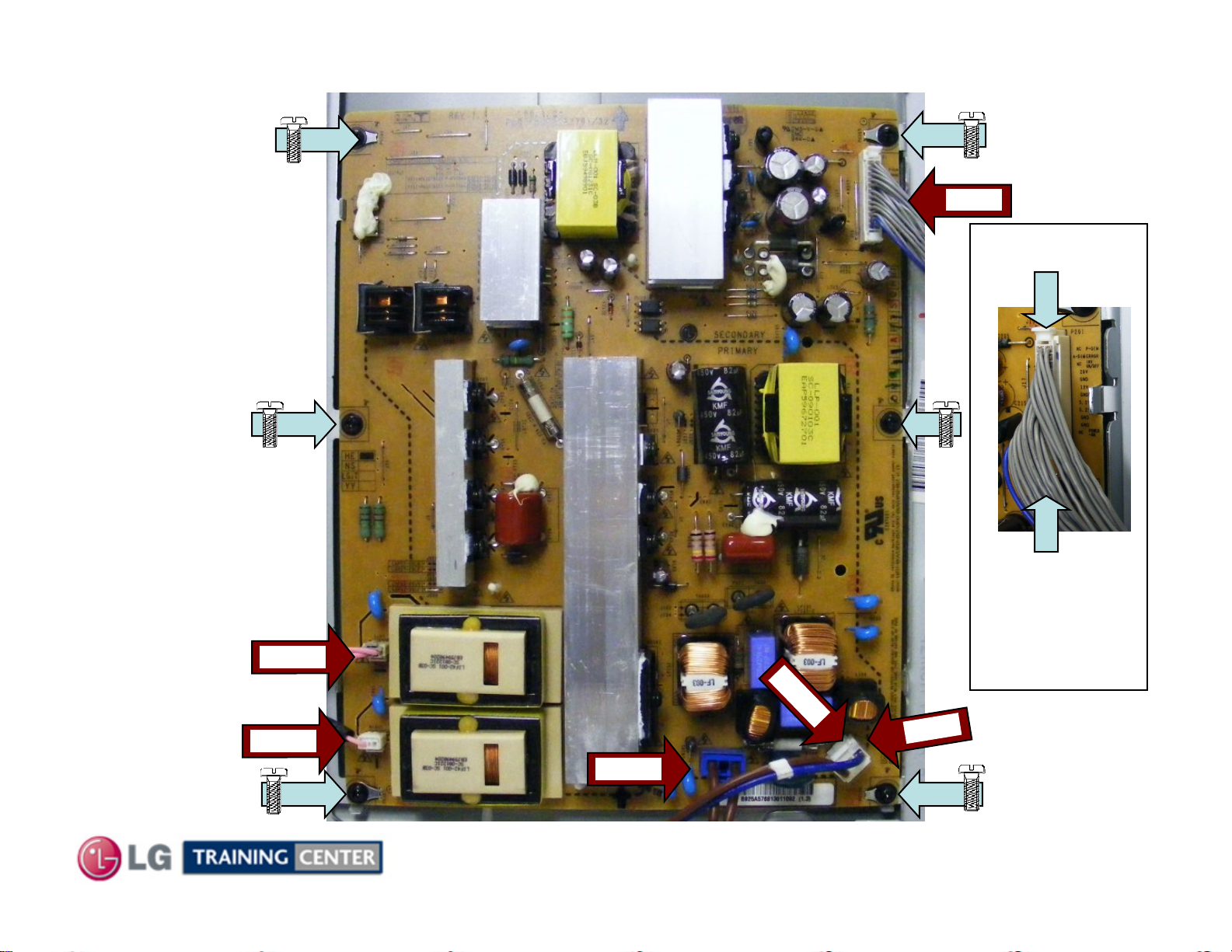

Power

Power

Supply PWB

Supply PWB

Removal

Removal

P201

Disconnect

P201, P401,

P402, AC In

SK101 and

SK102.

Remove the 6

screws indicated

by the arrows

w/screw.

P402

P401

SK

P201

Press in

Two tabs

to release

lock

1

0

1

In

C

A

SK102

24

August 2009 42LH50

Loading...

Loading...