LG 32FS4D, 32FS4D-TE Service Manual

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : CD61A

MODEL : 32FS4D

MODEL :

32FS4D-TE

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ..........................................................................3

CONTROL DESCRIPTIONS .................................................................... 4

SPECIFICATIONS .................................................................................... 7

ADJUSTMENT INSTRUCTIONS ............................................................. 8

TROUBLE SHOOTING .......................................................................... 17

PRINTED CIRCUIT BOARD ....................................................................20

BLOCK DIAGRAM ..................................................................................27

EXPLODED VIEW ...................................................................................28

EXPLODED VIEW PARTS LIST ..............................................................29

REPLACEMENT PARTS LIST ................................................................30

SVC. Sheet ..................................................................................................

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An Isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5 ± 1.5KV: 14-19 inch, 26 ± 1.5KV: 19-21 inch,

29.0 ± 1.5KV: 25-29 inch, 30.0 ± 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as antennas,

terminals, etc., to be sure the set is safe to operate without

damage of electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

OK

TVD/A

INPUT

DVD

ARC

EXIT

VOL

TEXT

UPDATE

INDEX

HOLD

SIZE

TIME

REVEAL

MIX

Q.VIEW

MUTE

PR

FAV

LIST

I/II

MENU

SLEEP

GUIDE

MULTI

INFO

VCR

POWER

123

456

789

0

SSM

PSM

?

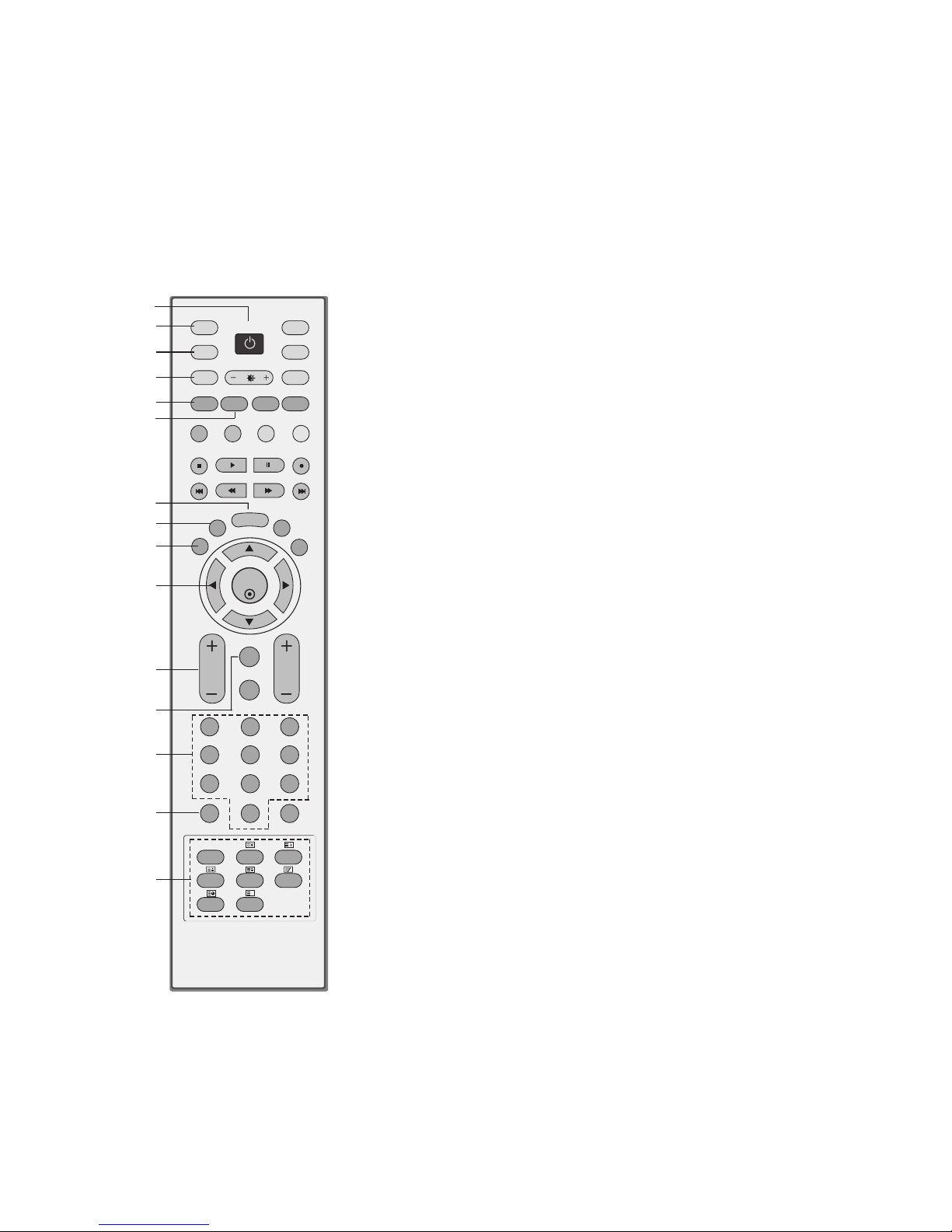

All the functions can be controlled with the remote control handset. Some functions can also be adjusted with the buttons on the

front panel of the set.

Remote control handset

Before you use the remote control handset, please install the batteries. See the next page.

1. POWER

Switches the set on from standby or off to standby.

2. D/A (Digital TV / Analogue TV)

Selects digital or analogue mode.

Switches the set on from standby.

3. INPUT

External input modes rotate in regular sequence: Digital,

Analogue, AV1-3, Component 1-2, HDMI/DVI.

Switches the set on from standby.

4. ARC (Aspect Ratio Control)

Selects your desired picture format.

5. SLEEP

Sets the sleep timer.

6. GUIDE

Shows a programme schedule.

7. MENU

Selects a menu.

8. LIST

Displays the programme table.

9. EXIT

Clears all on-screen displays and returns to TV viewing from

any menu.

10. OK

Accepts your selection or displays the current mode.

DD / EE

or

FF / GG

Adjusts menu settings.

Selects menu item.

11. VOL +/- (Volume Up/Down)

Increases/decreases sound level.

12. Q.VIEW

Returns to the previously viewed programme.

13. NUMBER BUTTONS

Switches the set on from standby or directly select a number.

14. PSM (Picture Status Memory)

Recalls your preferred picture setting.

15. TELETEXT BUTTONS

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

Text button is used to enable teletext services while other buttons are for teletext functions.

2

3

4

5

8

10

11

13

14

15

12

9

1

6

7

- 4 -

CONTROL DESCRIPTIONS

- 5 -

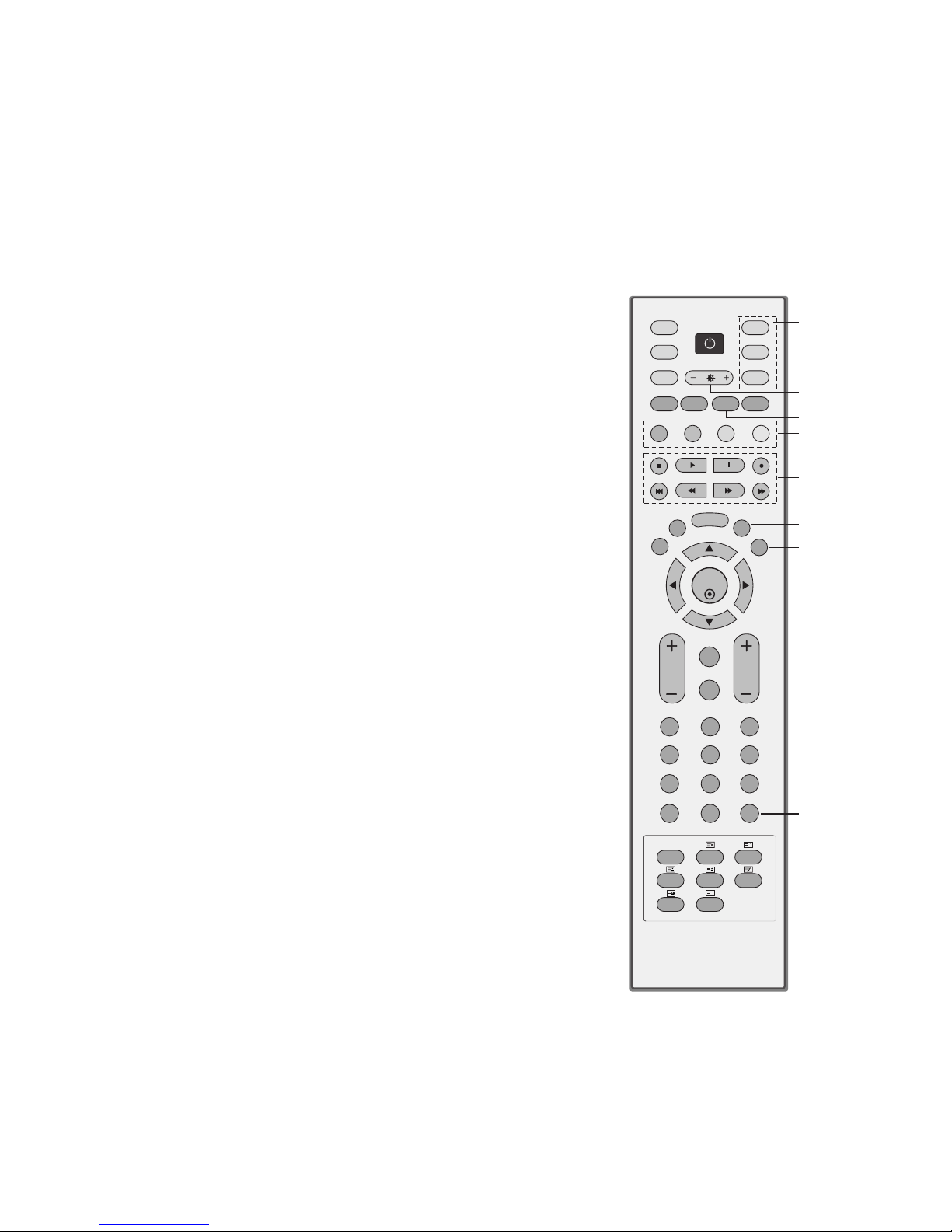

16. TV, DVD, VCR

Selects the remote operating mode: TV, VCR, DVD. Select other

operating modes, for the remote to operate external devices.

17. +/-

Adjusts brightness on screen.

It returns to the default settings brightness by changing mode source.

18. INFO

Shows the present screen information.

19. MULTI

Selects the Component 1-2 or HDMI/DVI modes.

20. COLOURED BUTTONS

They are used as per the indications or functions displayed on

the TV screen in the case of Text displays (Teletext, EPG) and

programme edit.

21. VCR/DVD control buttons

Control some video cassette recorders or DVD players

("RECORD" button is not available for DVD player).

22. I/II

Selects the language during dual language broadcast.

Selects the sound output or the audio mode.

23. FAV (FAVOURITE)

Displays the selected favourite programmes.

24. PR +/- (Programme Up/Down)

Selects a programme.

Switches the set on from standby.

25. MUTE

Switches the sound on or off.

26. SSM (Sound Status Memory)

Recalls your preferred sound setting.

OK

TVD/A

INPUT

DVD

ARC

EXIT

VOL

TEXT

UPDATE

INDEX

HOLD

SIZE

TIME

REVEAL

MIX

Q.VIEW

MUTE

PR

FAV

LIST

I/II

MENU

SLEEP

GUIDE

MULTI

INFO

VCR

POWER

123

456

789

0

SSM

PSM

?

16

17

19

18

20

21

23

24

26

25

22

- 6 -

1. MAIN POWER (ON/OFF)

Switches the set on or off.

2. POWER/STANDBY INDICATOR

illuminates brightly when the set is in standby

mode.

Dims when the set is switched on.

3. MENU

Selects a menu.

4. OK

Accepts your selection or displays the current

mode.

FF / GG

(Volume Down/Up)

Adjusts the volume.

Adjusts menu settings.

DD / EE

(Programme Up/Down)

Selects a programme or a menu item.

Switches the set on from standby.

5. REMOTE CONTROL SENSOR

6. AUDIO/VIDEO IN SOCKETS (AV IN3)

Connect the audio/video out sockets of external equipment to these sockets.

S-VIDEO/AUDIO IN SOCKETS (S-AV)

Connect the video out socket of an S-VIDEO

VCR to the S-VIDEO socket.

Connect the audio out sockets of the SVIDEO VCR to the audio sockets as in AV

IN3.

Front panel

ON/OFF

MENU

OK

VOL

PR

1

Side panel

S-VIDEO

VIDEO

L/MONO RAUDIO

AV IN3

6

2

5

3

4

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

Item

Broadcasting system

Available Channel

Tune IF

Input Voltage

Display Method

Aspect ratio

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

- 7 -

A Scope

This specification can be applied to all the television related to

CD61 Chassis.

A Test and Inspection Method

1) Performance : Follow the Standard of LG TV test

2) Demanded other specification

- Safety: IEC60065, EN60065

- EMC: CISPR 13 Class B

A Test Condition

1) Temperature : 25 ± 5°C (77 ± 9°C)

2) Relative Humidity : 65 ± 10%

3) Power voltage : Standard input voltage(240V~±10%, 50Hz)

* Standard voltage of each product is marked by model.

4) Follow each drawing or spec for spec and performance of

parts,based upon P/N of B.O.M

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

A General Specifications

No.

1

2

3

4

5

6

7

8

9

10

Specification

PAL-B/G, DTV : DVB-T

1) VHF : 01 ~ 12

2) UHF : 20 ~ 75

3) CATV : 02 ~ 44

4) DTV : 06 ~ 12, 7 ~ 69

1) PAL : 38.90MHz(picture)

34.40MHz(sound)

2) DVB-T : 36.125MHz

240V~, 50Hz

CRT

16 : 9(wide)

1) Temp : 0 ~ 45 deg

2) Humidity: ~ 85%

1) Temp : -20 ~ 60 deg

2) Humidity: ~85%

- 8 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions are applied to the CD61A chassis.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of an isolation

transformer will help protect test instruments.

(2) Adjustments must be done in the correct order.

(3) The input voltage of the receiver must remain at

120V±10% while adjusting.

(4) The receiver must be operated for about 20 minutes prior

to the adjustment.

* Never operate the set over 10 minutes with a still picture

because it may cause screen burn.

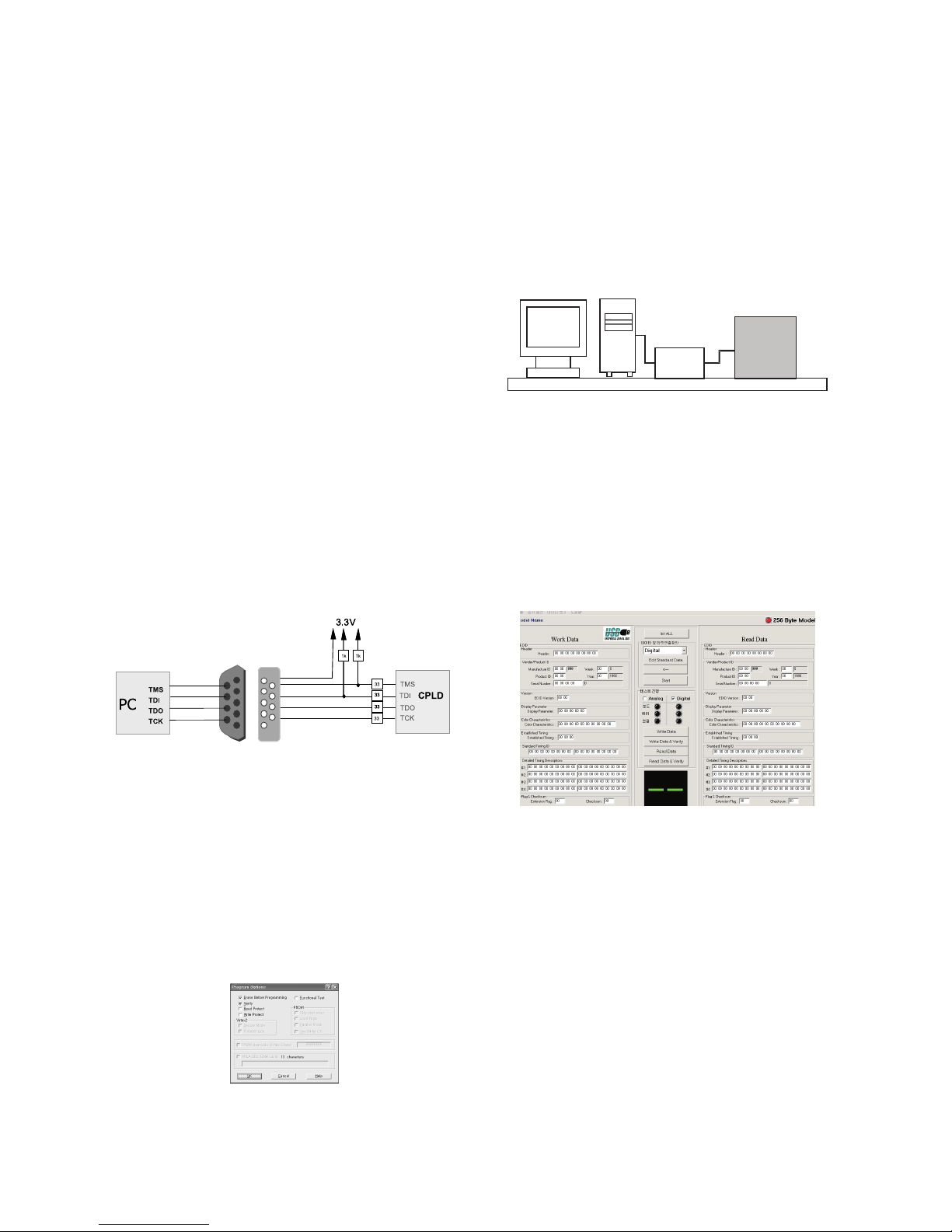

3. CPLD Download

3-1. Required Test Equipments &

Preparation for Adjustment

(1) Connect the PC and memory JIG as shown in <Fig. 1>.

(2) Turn on JIG MAIN POWER SW.

(3) Turn on the PC and monitor, operate the ‘Device

Programming’ software.

3-2. Adjustment Sequence

(1) Once the program is running, [OPTION MODE

SELECTION] is displayed in the window.

Check the “Load configuration File(.cdf, .pdr)” in this window

and click the ‘finish’ button

(2) When the screen displays the “open” window, select the

suitable file(*.cdf) according to model.

(3) IC figure is change to green by clicking it.

(4) Select program options.

(5) Check the [Erase before programming] and [Verify] menu

as shown <Fig. 2> and press the OK button.

(6) At this time, the download starts. The download will finish

in about 10 seconds.

5. EDID Data Input

5-1. Required Test Equipment

(1) PC, Jig for adjusting DDC. (256 bytes write)

(2) S/W for writing DDC(EDID data write & read)

(3) Cable for HDMI EDID Download.

5-2. Setting of Device

5-3. Adjustment

(1) Set devices as above and turn on the PC and JIG.

(2) Open S/W for writing DDC (EDID data write & read).

(3) Enter the Model-->Open in the Menu and then select EDID

DATA.

(4) Click the Digital and cancel the ANALOG.

Then connect to turn on the yellow light at the board &

connection.

(5) Click the Write Data & Verify and then download the EDID

DATA.

<Fig. 1 > How to connect the MEMORY JIG and PC

<Fig . 2>

PC

JIG

TV

SET

<Fig . 3>

<Fig . 5>

- 9 -

6. MICOM download

6-1. Required Test Equipment

(1) PC, Jig for MICOM Download

(2) S/W for MICOM Download

(3) Cable for MICOM Download.

6-2. Setting of Device

6-3. Download sequence

(1) Connect the PC Parallel Port to download JIG, and

connect the download JIG to P1700 of Board.

(2) Set PC program for JIG download as shown below.

then operate the download.

<In case of Win ISP 3.0>

(1) Configure the program for download.

1) MCU Select : MTV412M128(Use to MTV416)

2) R/W Option Auto Write(Verify)

3) Jig Option Myson

4) Transmit Speed : Medium

5) Check : blank

6) PORT “ Using Parallel Port(LPT1)

* LPT must be selected to EPP at Rom BIAS.

7) Select the Save Setting.

(2) Click the“Send” button after selecting the Load File and

Loading the Hex File.

7. Focus adjustment

(1) Set the picture mode to “STANDARD”.

(2) Set the screen size to “16:9”.

(3) Receive the PAL CROSS HATCH(PAL 1-7CH) and adjust

the upper Focus volume of FBT for the best focus of

horizontal line A.

(4) Adjust the lower Focus volume of FBT for the best focus of

vertical line A.

(5) Repeat above step 1) and 2) for the best overall focus.

* This adjustment must be done after operating over 10

minutes.

8. Purity & Convergence adjustment

This adjustment should be operated when using the CPT

without ITC.

This adjustment must be done in the order of the following

flowchart.

PC

JIG

TV

SET

<Fig . 5>

<Fig . 7>

configuration of Win ISP V.3.0

Completion of Win ISP V.3.0

<Fig . 6>

Assembling DY to

CPT

CPT Assembling

As preparatory operations before

assembling CPT, wind cotton Tape for

protecting to CPT NECK and DY, CPT

connection parts. At this moment, end

of tape should be over-lapped and

wound in direct route to the NECK.

Let the screen Standard condition.

Operate Heat-Run at least 20

minutes.

Torque is to be 15-18 kg.cm when

fixing DY.

Fix the Magnet to the position as

shown picture below. Be careful not to

make CPT neck shadow while

adjusting DY.

HEAT RUN

Degaussing

STC Pre-Adjustment

PURITY Adjustment

DY Fixing

SCREEN Voltage adj.

W/B Fixing

FOCUS not yet ADJ.

STC not yet ADJ.

DYC not yet ADJ.

2–2mm

The tip of DY

8-1. PURITY adjustment

(1) It makes CPT or CABINET enough to demagnetization.

(2) Receive the signal of red raster.

(3) Loosen fixed screw of DY and closely to CPT funnel part.

(4) Check the center of screen that PURITY MAGNET of CPT

by crossing adjustment. At this time, 4 & 6 pole magnet is

located to magnet of nothing.

(5) Move the DY to make equal red on whole screen and it

does not to make the DY by fixed screw after check a

simple color of Red/Green/Blue and white raster whether

or not it is a pollution of color.

(At this time, take care raster of screen and DY must fixing

in the condition which maintains a horizontality.)

(6) Check the TV set by move direction.

9. CUT-OFF adjustment

(Screen Voltage Adjustment)

9-1. Test equipment

Oscilloscope, 100:1 Probe

9-2. Adjustment

* This adjustment must be operated only at 100Hz DISPLAY

MODE.

(1) Select EZ Adjust 3. CUT-OFF, by pressing the ADJ key on

the SVC Remote control.

When it enters to adjustment mode, the pattern from a

signal generator is being selected, it becomes with Normal

image 16:9 and the CUT-OFF DRIVE data setting 31.

(2) Connect the oscilloscope ground lead to GND on the CPT

board and the probe to the GK pin connector of the CPT

socket.

Using the SCREEN knob on the Fly Back Transformer,

adjust the black level voltage to 160±2V.

10. Deflection adjustment

10-1. 16:9 deflection adjustment

* This adjustment must be operated after changing signal

to Multi signal.

- Adjustment sequence

NTSC H,V adjustment --> HRS correction --> NTSC H,V

re-adjustment(60Hz) --> PAL H,V adjustment(100Hz) -->

PAL H,V adjustment(50Hz) --> PAL(50Hz) 4:3 adjustment

- MULTI 48ch, STANDARD, 16:9 screen is displayed when

Digital pattern is 50/100Hz or PAL B/G(EU05CH) or 60Hz

at H,V adjustment mode.

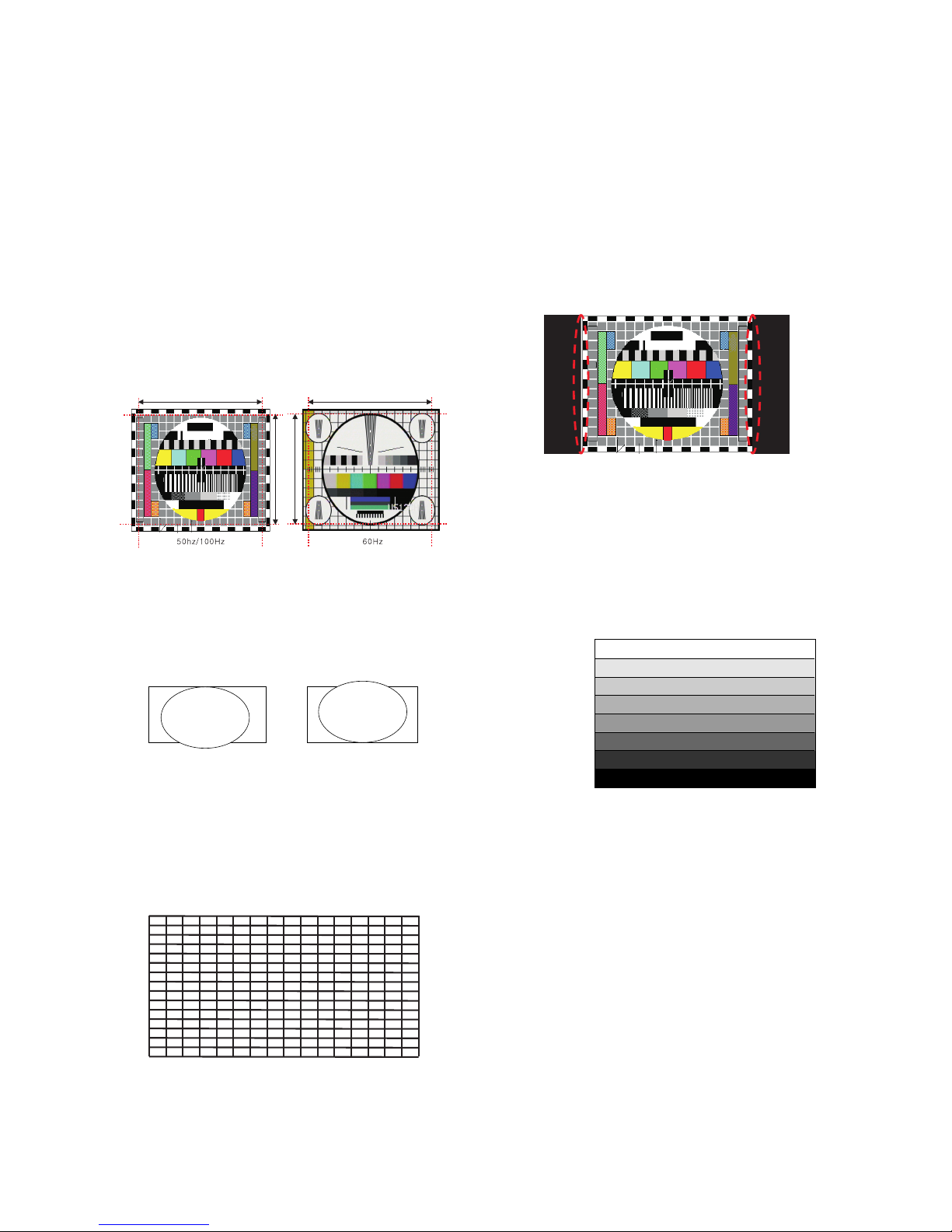

(1) 60Hz Vertical Deflection Size adjustment

1) Select “EZ Adjust 1. Raster, Cent, H/V Size(60Hz)” by

using the ADJ key on the SVC Remote control.

2) Select “V-SIZE” in the adjustment mode.

3) Adjust until the smaller inscribed circle coincides with

the outer frame of screen.

4) Select 95. LO-VLIN or 94. UP-VLIN and adjust until the

larger inscribed circle coincides with the outer frame of

screen.

(2) Raster H-center (H. CENTER) adjustment

: Select “77. H Position” in the adjustment mode and adjust

until left and right screen are symmetrically equal.

(3) Raster V-center (V. CENTER) adjustment

: Select “1. V-Position” in the adjustment mode and adjust

it to position the vertical center line in vertical center of

the CPT.

(4) Vertical Deflection Size Adjustment

1) Reduce “4. H-Size” to verify screen protection

(overscan) on the right and left sides.

2) In the adjustment mode, the third on the 48CH pattern is

to be located in the outer angle as adjusting th H-SIZE.

(5) HRS switch adjustment(only 60Hz display mode)

- 10 -

160 – 2V

<Fig . 8> CUT-OFF adjustment

<Fig . 10> CUT-OFF adjustment

A

B

Actual screen size

(a)

(b)

<Fig . 9>

A(Left) B(Right)

F

F

Right

Left

Neutrality

SW1401

<Fig . 11> MULTI CH48

L-LIN U-LIN

- 11 -

1) Initial switch(SW1401) is located in neutrality.

2) Reduce by forth~fifth of H-SIZE and then check the

things rolled the screen occurs.If not, you locate the

switch in neutrality.

If the things rolled A(the left) occurs, move SW1401 to

the right.

If the things rolled B(the right) occurs, move SW1401 to

the left.

(6) Re-adjust 60Hz H,V SIZE and POSITION after adjusting

HRS.

(7) 60Hz PINCUSION adjustment

: Adjust PIN-PHASE, PIN-AMP, AFC-BOW, AFC-ANGLE,

UP-CPIN, LO-CPIN to be straight without pin cushion

distortion and trapezoid distortion in “1.Raster,Cent,H/V

Size(60Hz)” adjustment mode.

(8) Vertical, horizontal deflection adjustment of 50, 100Hz

1) Select “2.V-SIZE” in adjustment mode.

2) As shown above <Fig. 12>(a), adjust large circle with the

dotted line of screen, though to do width dotted line size.

3) To be up and down symmetry, adjust the larger one than

outer angle of the screen with 5.LO-VLIN or 6.UP-VLIN.

(9) Raster H-center & Horizontal deflection adjustment

1) Select 3. H Position in the adjustment mode and adjust

until left and right screen are symmetrically equal.

2) With“4. H-SIZE”, adjust the screen size as shown above

dotted line rate of <Fig . 12>(a).

(10) 50, 100Hz PINCUSION adjustment

* This adjustment must be operated after changing signal

to PAL B/G or Multi signal.

1) Adjust “2.Raster, Cen, H/V Size(100Hz)” by pressing

“ADJ” button on the SVC remote control.

2) Adjust “3.Pin-Cushion(100Hz)” by pressing “ADJ” button

on the SVC remote control.

3) Adjust “4.Raster,Cent,H/V Size(50Hz)” by pressing

“ADJ” button on the SVC remote control.

4) Adjust “5.Pin-Cushion(50Hz)” by pressing “ADJ” button

on the SVC remote control.

10-2. 4:3 deflection adjustment(only 50Hz)

1) Adjust “6. 4:3 Pin-Cushion(50Hz)” by pressing “ADJ”

button on the SVC remote control.

2) Adjust the Pin-cushion data to be vertical line a left/right

line of 4:3 screen (ARC).

11. Component MST3000 Offset/Gain

Adjustment

11-1. Test Equipment

801GF(802B, 802F, 802R) Pattern Generator or MASTER

Pattern Generator

11-2. Preliminary Steps

(1) Turn the power supply on.

(2) Enter the Component 1 mode.

(3) Receive the “1080I” Format, “Hoz30Bar” Pattern of the

Video Pattern Generator.

(4) Certainly, adjust the output signal in state of 700mVp-p

±10mV.

11-3. ADC Offset Adjustment

(1) After receiving a signal press the ADJ Key on the SVC

Remote Control repeatedly to access the Adjustment

mode.

A

B

Actual screen size

(a)

(b)

<Fig . 12>

<Fig . 14>

<Fig . 13>

L-LIN

U-LIN

100% White

100% Yellow

100% Cyan

30% Gray

30% Gray

100% Red

100% Blue

Black

<Fig . 16> 1080I Format, Hoz30Bar Pattern

<Fig . 15> 1080I Format, Hoz30Bar Pattern

(2) Adjustment will set the automatically by pressing the

“8.MST3000-Set” of adjustment item.

(3) After finishing the adjustment, output the “MST3000-OK”

OSD on the screen.

12. White Balance Adjustment

(Only 100Hz Display mode)

12-1. Preparation for Adjustment

(1) Perform the Screen Voltage Adjustment first.

(2) Change the automatic image mode to “STANDARD/ W/B

MEDIUM”.

(3) Start adjustments from initial setting of R.DRIVE=31,

G.DRIVE=31, B.DRIVE=31, R.CUT=31, G.CUT=31,

B.CUT=31.

(4) For manual adjustment, refer to the following procedure.

12-2. Adjustment(manual)

(1) Receive the White Pattern.

(2) Set screen size to wide mode(16:9).

(3) Select “2.White Balance” by pressing IN-START button on

the SVC Remote control.

(4) Adjustment

1) Using the SVC Remote control, set the DCOL value of

CXA2150 to the “0”.

2) Set an image with STANDARD/ W/B MEDIUM.

3) Adjust R-DRIVE and B-DRIVE data so the color

coordinates in High light are the values in Table below.

(Bright Level : 35fl)

4) Adjust “CONTRAST” and “BRIGHT” so the bright level is

4.5±0.5F.L.

5) Adjust R-CUT and B-CUT data so the color coordinates

in Low light are the values in Table below.

6) Repeat 3)~ 5) until the color coordinates in High and

Low color satisfies the Table.

7) Check the adjusted color coordinates with the white

balance meter.

High Light : x=287

±3, y=293±3

Low Light : x=287

±3, y=293±3

Color temperature : 9,000K

±1000(-5MPCD)

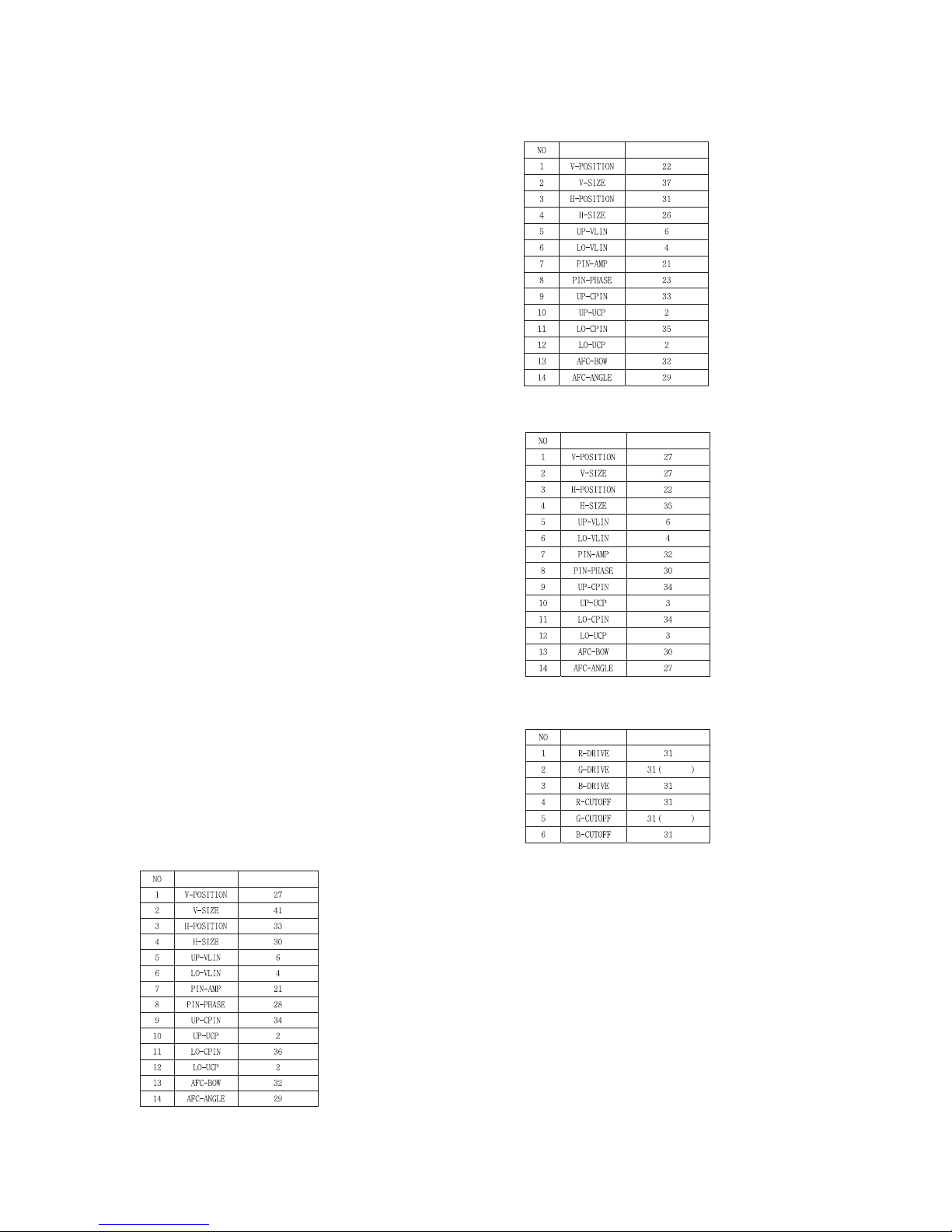

13. Service mode data 1(ADJ button)

13-1. Raster, Center, H/V_Size & 16:9 Pin-

cushion DATA

(1) 50Hz

(2) 100Hz

(3) 60Hz

13-2. W/B DATA(STANDARD)

13-3. SUB-BRIGHT

17(100Hz)/ 30(50Hz)/ 47(60Hz)

13-4. SUB-TINT/COLOR

SUB-TINT : 6

SUB-COLOR : 2

- 12 -

ITEM

DATA

ITEM

DATA

ITEM

DATA

ITEM

DATA

Fixing

Fixing

- 13 -

14. Service mode data2

(IN-START button)

14-1. CXA2150(50Hz)

R_CUTOFF

UP_CPIN

Initial data Initial data Initial data

Loading...

Loading...