Page 1

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : AC-05MB

MODEL : 30FS4D 32FS4D-UC

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//biz.lgservice.com

Page 2

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube .

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

!1.5KV: 14-19 inch, 26!1.5KV: 19-21 inch,

29.0

!1.5KV: 25-29 inch, 30.0 ! 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

Any other abnormality that exists must be corrected before the

receiver is returned to the customer.

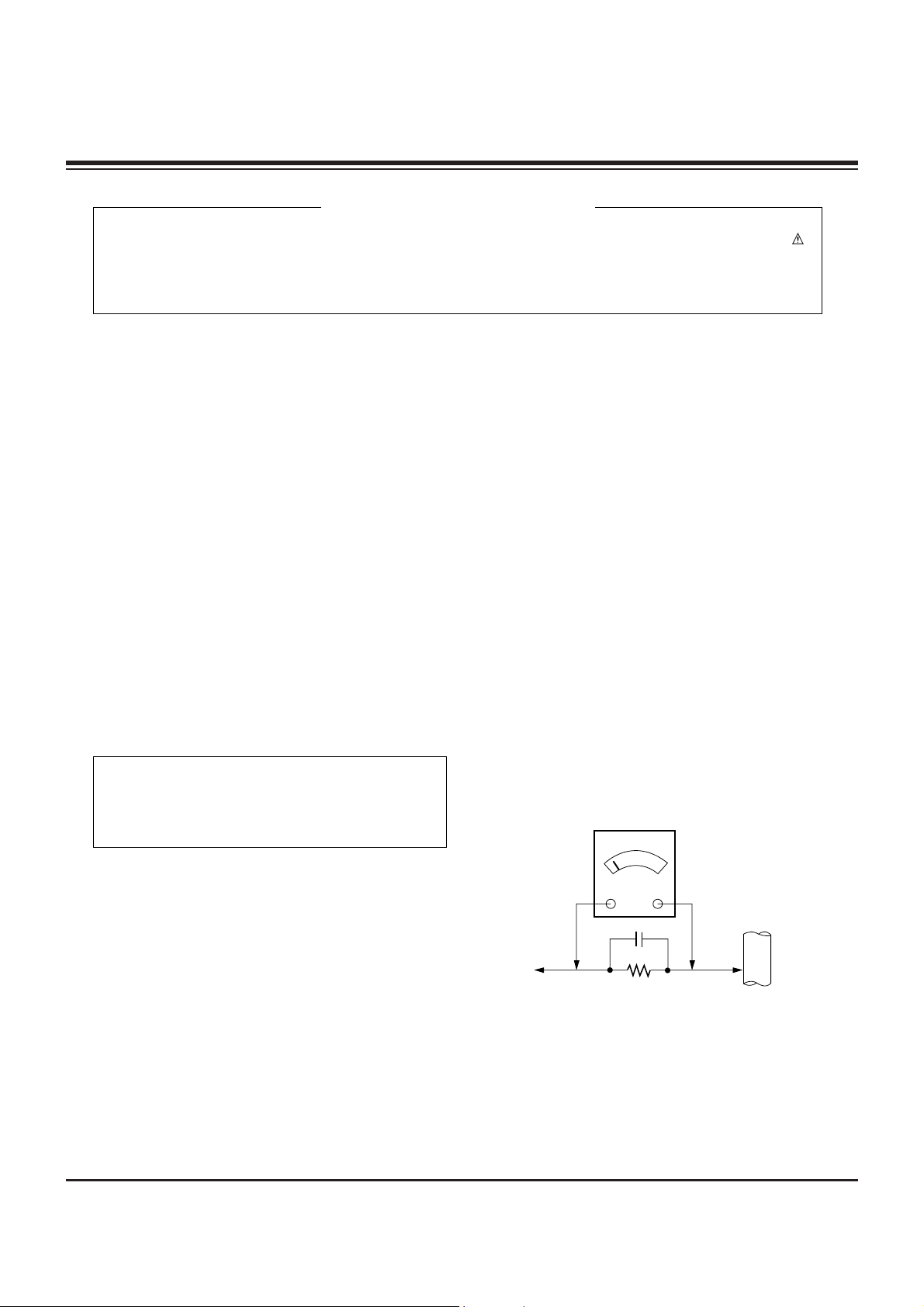

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road

Huntsville, AL 35824

Digital TV Hotline 1-800-243-0000

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

the Replacement Parts List.

IMPORTANT SAFETY NOTICE

0.15uF

To Instrument’s

exposed

METALLIC PARTS

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 3

- 3 -

DESCRIPTION OF CONTROLS...........................................4

SPECIFICATIONS.................................................................9

ADJUSTMENT INSTRUCTIONS ........................................10

PRINTED CIRCUIT BOARDS.............................................22

BLOCK DIAGRAMS............................................................29

EXPLODED VIEW...............................................................32

EXPLODED VIEW PARTS LIST.........................................33

REPLACEMENT PARTS LIST............................................34

SCHEMATIC DIAGRAMS.......................................................

TABLE OF CONTENTS

Page 4

- 4 -

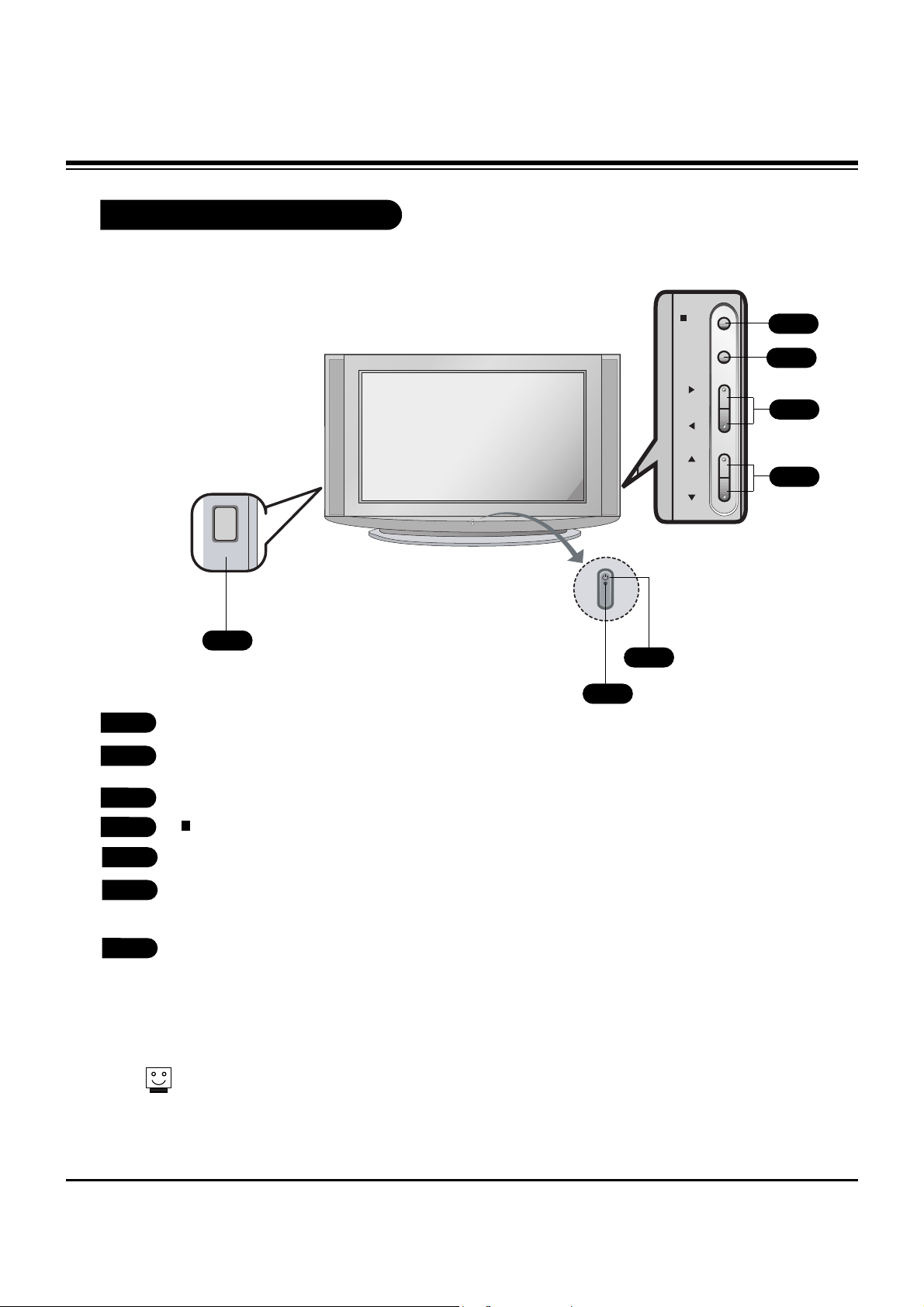

Front Panel Controls

ON/OFF

Standby indicator (Illuminates brightly when the TV is in

standby mode. Dims when the TV is switched on.)

Remote control sensor

TV/VIDEO

MENU

VOL left/ right

Volume(

GG

) button increases the sound level and vol-

ume(

FF

) button decreases the sound level.

CH (Channel) up / down

1

2

3

4

These buttons work just as they do on

your remote control.

5

6

7

ON/OFF

MENU

VOL

CH

TV/

VIDEO

1

2

3

4

5

6

7

DESCRIPTION OF CONTROLS

Page 5

- 5 -

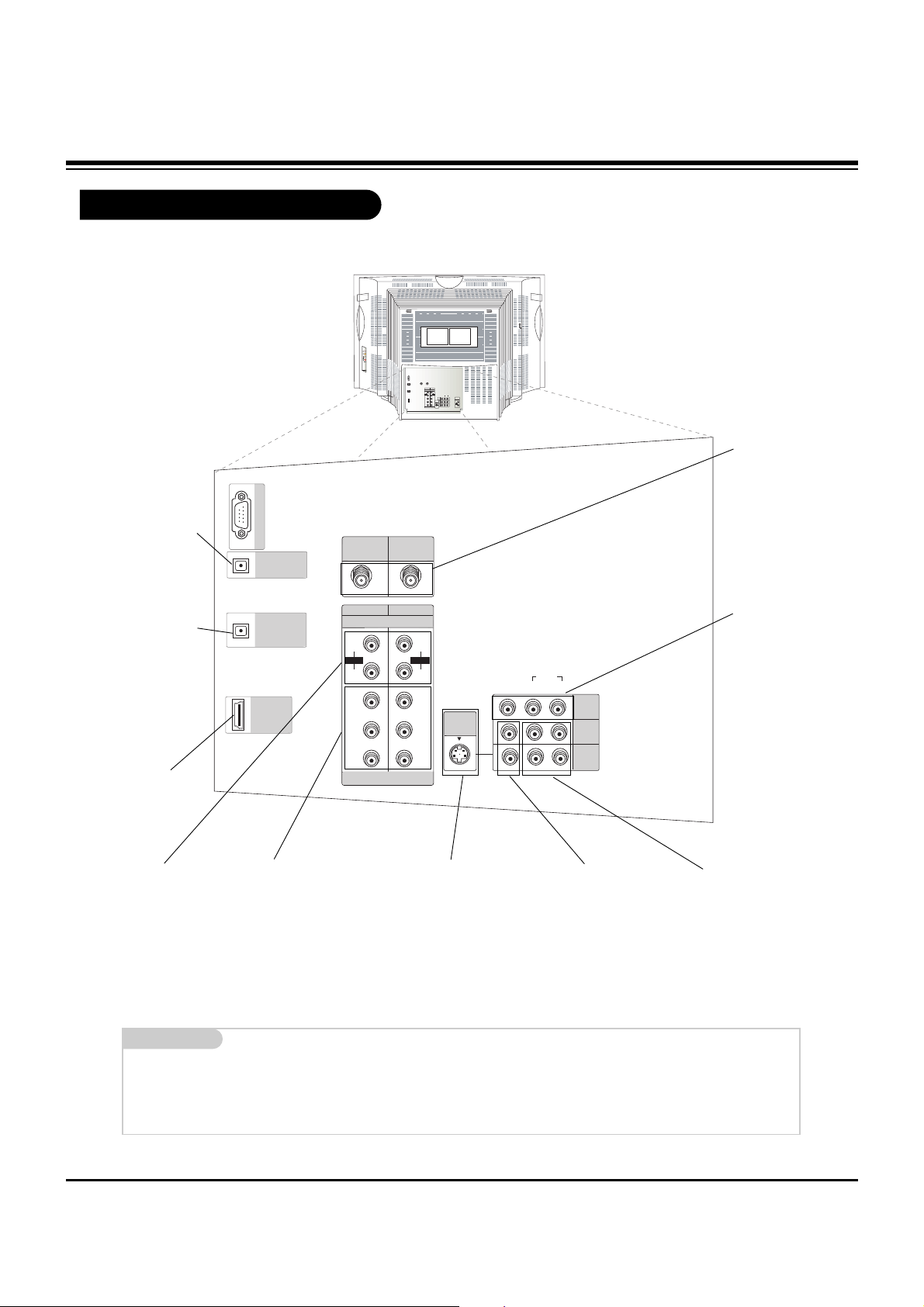

Rear Connections Panel

Mini glossary

JACK A connection on the back of a TV, VCR, or any other A/V device. This includes the RF jack and the Audio/Video jacks that are

color-coded.

SIGNAL Picture and sound traveling through cable, or over the air, to your television screen.

CALIBRATION

DIGITAL

AUDIO OUTPUT

OPTICAL

DVD/DTV INPUT

AUDIO

L(MONO)

CABLE

ANTENNA

HDMI/DVI

DIGITAL

AUDIO INPUT

OPTICAL

(DVI)

R

COMPONENT1

(480i/480p/720p/1080i)

COMPONENT2

S-VIDEO

MONITOR

OUTPUT

IN1

IN2

AUDIO

R

AUDIO

AUDIO

INPUT

VARIABLE

AUDIO

S-Video In

A connection available with some highend equipment that

provides even better

picture quality for

Video 1, Front Video.

RF Connectors:

Cable, Antenna

Used to connect

cable or antenna

signals to the television, either directly

or through your

cable box.

Video 1 and 2 Inputs

Connects the video signals from various types

of equipment.

Y, P

B, PR

DVD Component Video and HD

Component Video

Some top-of-the-line DVD players

use what is called “component

video,” for extremely accurate picture reproduction. Refer to your

DVD manual for further information.

Connecting external equipment to your TV.

Monitor Out

Connects to a second TV or Monitor.

Left/Right Audio

Used for stereo sound

from various types of

equipment.

Component Left/Right

Audio

Used for stereo sound

from various types of

equipment.

HDMI/DVI

Used to connect

from a DTV

source.

Digital Audio

Output Optical

Connects to exter-

nal audio equip-

ment like a home

theater system.

Digital Audio Input

Optical

Connects to digital

audio from various

types of equipment.

DESCRIPTION OF CONTROLS

C

A

L

I

B

R

A

T

I

O

N

DIGITAL

AUDIO OUTPUT

OPTICAL

DIGITAL

AUDIO INPUT

OPTICAL

(DVI)

HDMI

/DVI

CABLE ANTENNA

+75 Ω +75 Ω

COMPONENT1

COMPONENT2

(480i/480p/720p/1080i)

(R)

AUDIO

(L)

P

R

PB

Y

DVD/DTV INPUT

CALIBRATION

DIGITAL

AUDIO OUTPUT

OPTICAL

DIGITAL

AUDIO INPUT

OPTICAL

(DVI)

HDMI/DVI

AUDIO

CABLE

ANTENNA

++7575 ΩΩ ++7575 ΩΩ

COMPONENT1

COMPONENT2

(480i/480p/720p/1080i)

RR

RR

AUDIO

AUDIO

AUDIO

LL

LL

VIDEOVIDEO

L(MONO)

RR

VARIABLE

MONITOR

AUDIO

PP

R

R

PP

OUTPUT

S-VIDEO

LL

PP

BB

PP

BB

IN2

INPUT

AUDIO

RR

YY

YY

IN1

DVD/DTV INPUT

(R)

(L)

PR

S-VIDEO

INPUT

PB

Y

VIDEO

AUDIO

L(MONO) R

MONITOR

OUTPUT

IN2

IN1

Page 6

- 6 -

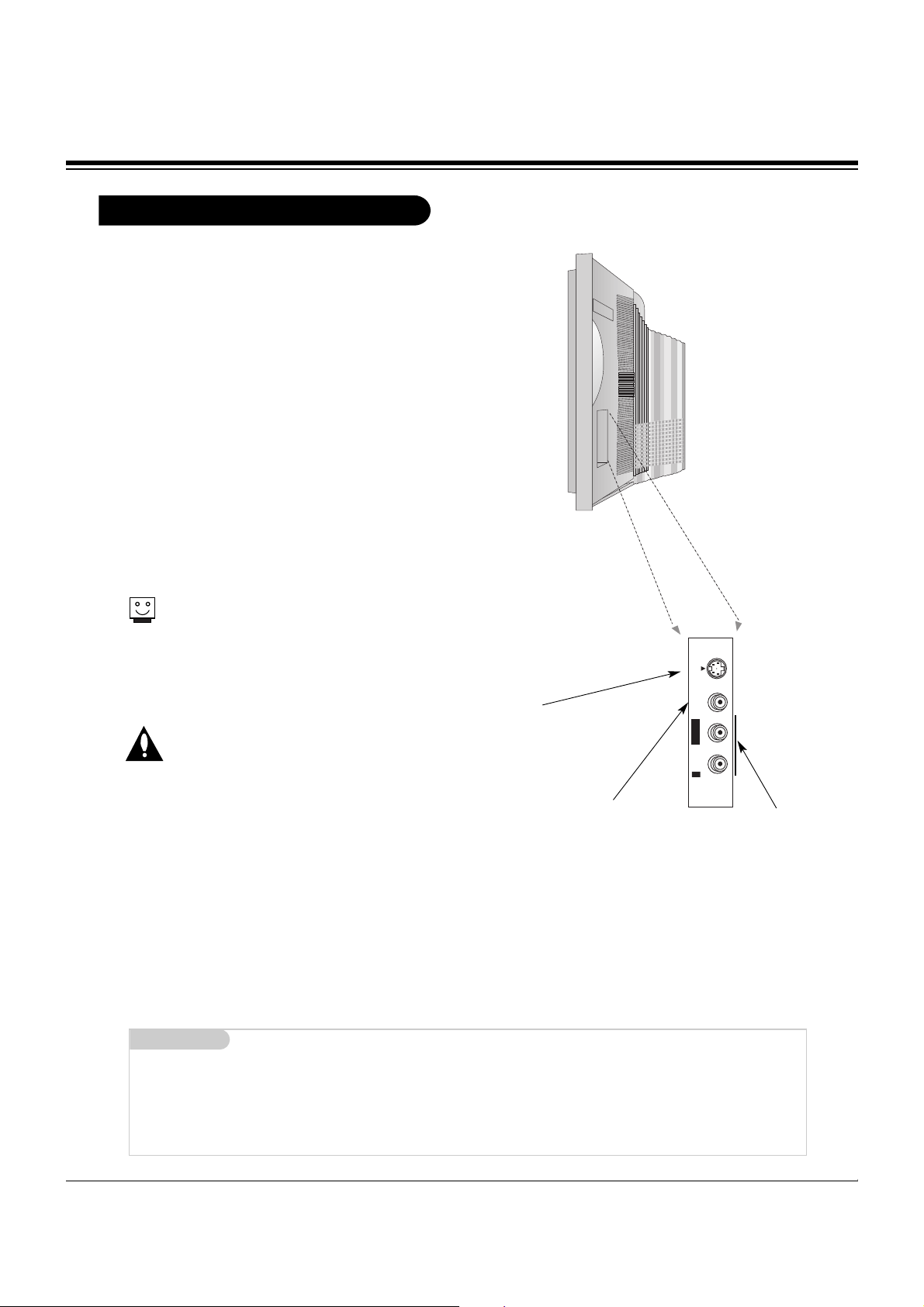

Side Connections Panel

There are four jacks on the lower-right front side

of your TV that make connecting Audio/Video

devices like video games and camcorders very

simple.

The jacks are like those found on the back jack

connection panel. This means that most equipment that connects to those types of jacks on

the rear jackpack, may be connected to the Side

connection panel (FRONT VIDEO).

To use the Side jacks as the signal source,

select them using Input source menu as

described on page 25. They will be named

“FRONT VIDEO” in the Input source menu.

Left/Right Audio

Used for stereo sound

from various types of

equipment.

Video in

Connects the video

signals from any

piece of equipment.

S-Video

A connection available on some very

high-end equipment that provides

better picture quality than video

input.

When you select Front Video

or Front S-Video, the Front

Audio inputs are automatically

selected as well.

Do not connect to both Video

and S-Video at the same time.

Connect either Video or SVideo only.

Mini glossary

A/V CABLES Audio/Video cables. Three cable connector—Right audio (red), Left audio (white), and Video (yellow). A/V cables are used

for stereo playback of videocassettes and for higher quality picture and sound from other A/V devices.

A/V DEVICE Any device that produces video (picture) and/or audio (sound) (VCR, DVD, cable box, or television).

DESCRIPTION OF CONTROLS

FRONT VIDEO Panel

S-VIDEO

VIDEO IN

L/MONO

AUDIO

R

FRONT VIDEO

Page 7

- 7 -

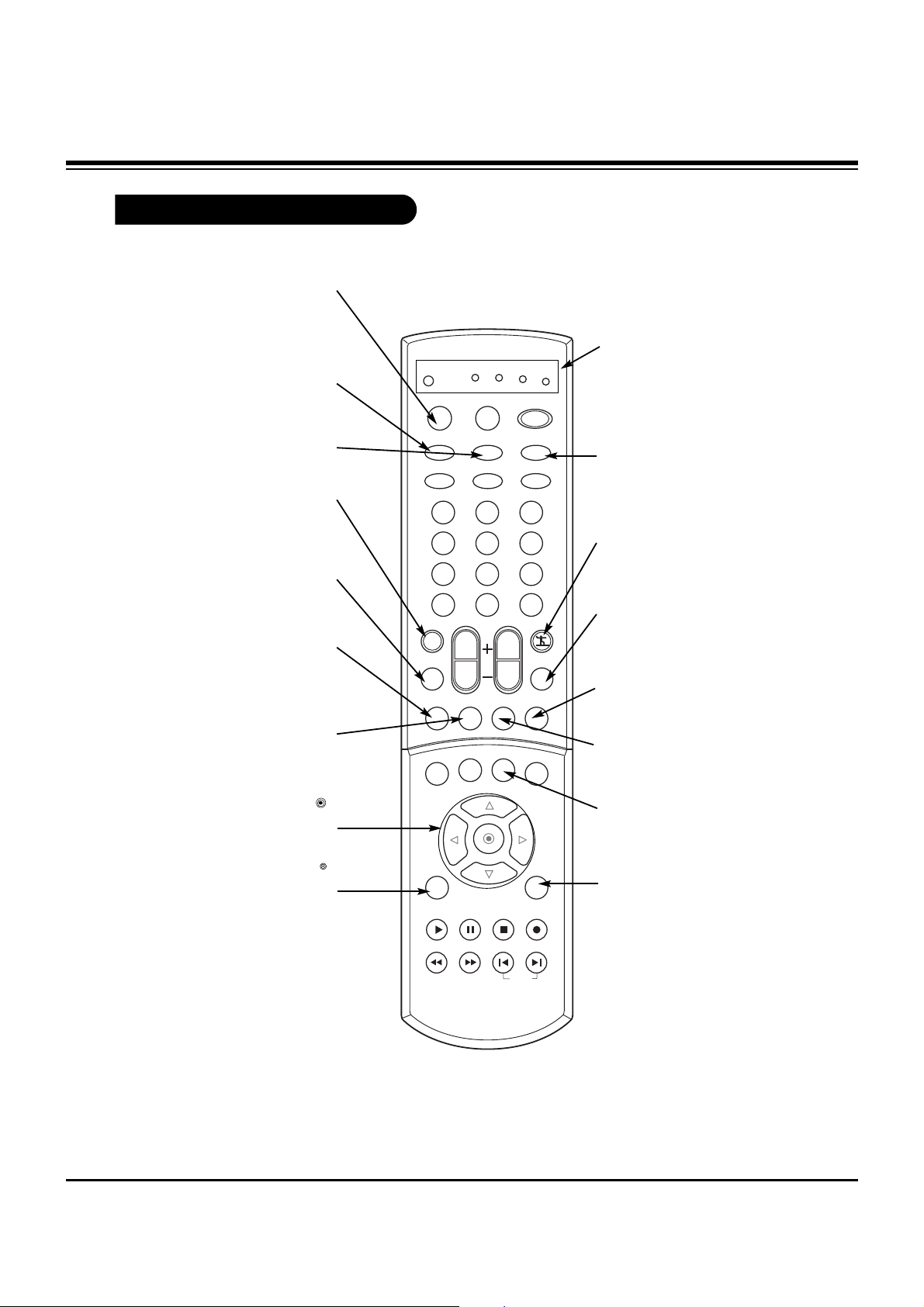

Remote Control Functions in TV Mode

FAV

Use to scroll the FAV channel list.

MENU

Brings up the main

menu to the screen.

EXIT

Clears all on-screen displays and returns to TV

viewing from any menu.

CC

Lets you select a closed caption

mode for displaying captioning

information when provided for

DTV/Analog signal.

EZ PIC

Adjusts the factory preset picture depending on the viewing environment.

SAP

Selects MTS sound: Mono, Stereo,

and SAP in analog mode.

Change the audio language in DTV

mode.

SURROUND

Selects : Off, 3D

EchoSound System and

SRS TruSurround XT.

MUTE

Switches the Mute or the EZ mute.

Mute: The sound is off. EZ mute:

Turns the sound off, and displays the

caption.

THUMBSTICK

(UP/DOWN/LEFT/RIGHT/ )

Allows you to navigate the on-screen

menus and to adjust the system settings

and preferences, by moving to an option

with

F G

and selecting the highlighted

option with .

TV INPUT

Switches TV mode or CATV

mode.

MODE

Selects the remote operating

mode: TV, VCR, Cable, DVD or

Satellite. Select other operating

modes, for the remote to oper-

ate external devices.

TV/VIDEO

Selects: Antenna, Cable,

Video1, Video2, Front video,

Component 1-2 and HDMI/DVI

input sources.

COMP1

Selects the Component 1

input source.

EZ SOUND

Selects the sound appropriate

for the program’s category.

FREEZE

Captures and freezes

the currently-viewed

picture.

RATIO

Changes the aspect ratio.

MODE INDICATOR

LIGHTS

Show active remote mode

every time any button is

pressed.

D

E

DESCRIPTION OF CONTROLS

CABLE

VCR

TV

MODE

TV INPUT

*

TV/VIDEO

HDMICOMP2

1 2 3

4 5 6

7 8 9

DASH(-)

MUTE

EZ SOUND

RATIO

INFO

MENU EXIT

PLAY

REW

0

VOL

TIMER CC

PAUSE

STOP

FF

CH

SKIP

DVD

SAT

POWER

COMP1

FRONT

FLASHBK

FAV

EZ PIC

SURROUNDFREEZE SAP

SIGNAL

RECORD

Page 8

- 8 -

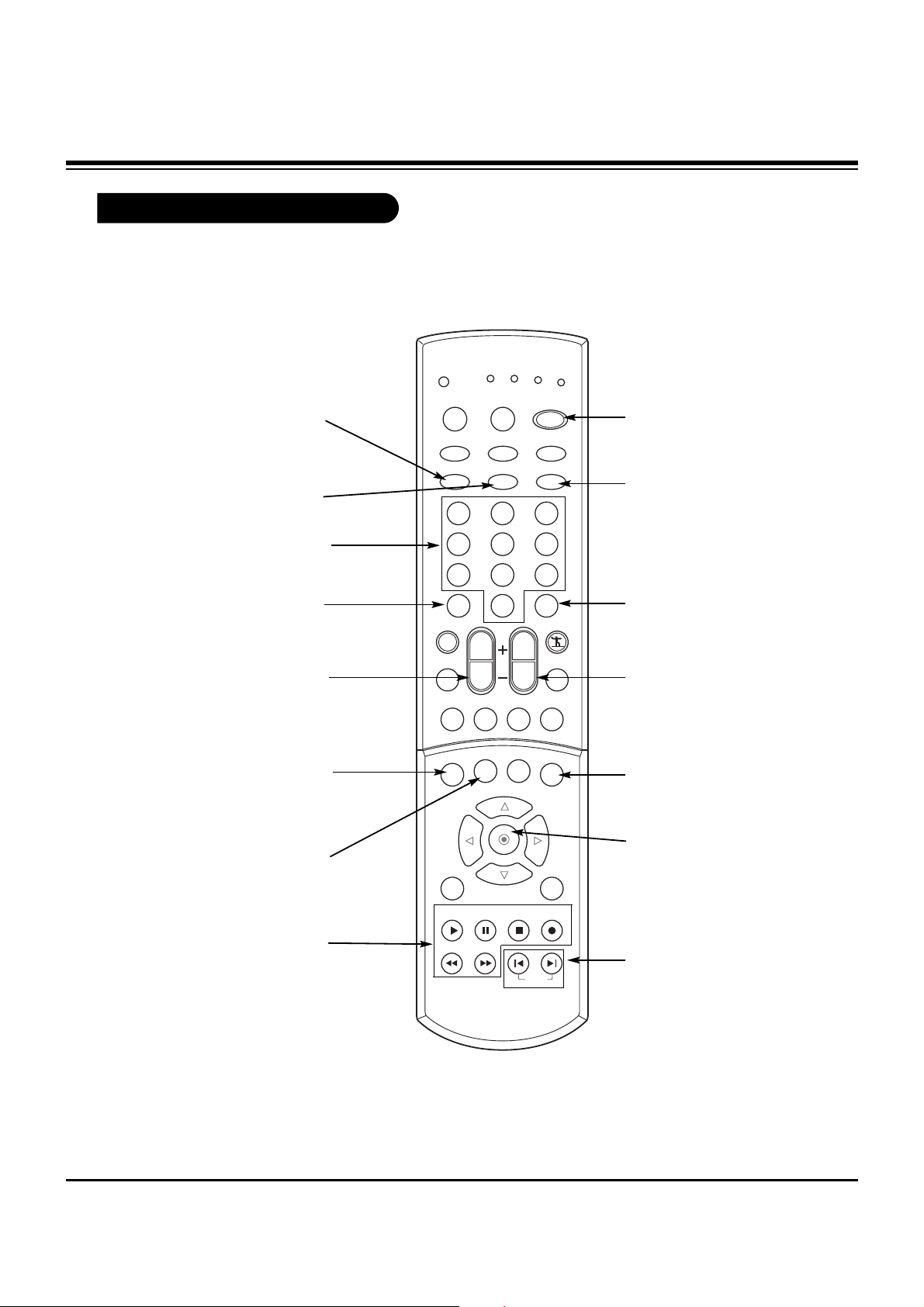

Remote Control Functions in TV Mode

POWER

Turns your TV or any other

programmed equipment on

or off, depending on mode.

CHANNEL UP/DOWN

Scrolls through available channels

present in EZ Scan memory.

NUMBER KEYPAD

For direct channel selection and

programming functions.

ENTER

When in the menu system

and other on-screen displays, selects highlighted

options.

RECORD, PAUSE, REW,

FFWD, PLAY, STOP

Control the functions on your VCR.

VOLUME UP/DOWN

Increases/decreases the sound

level.

INFO

When you watch the TV, displays

information on top of the screen.

Not available in Component 1-2

and HDMI/DVI.

SKIP LEFT/RIGHT

Playing CDs: Selects

songs.

Playing DVDs: Selects

movie chapters.

COMP2

Selects the Component 2 input

source.

HDMI

Selects the HDMI input source.

DASH(-)

Is used to enter a program

number for multiple program

channels such as 2-1,2-2,etc.

FLASHBK

Tunes to the previous channel

viewed.

TIMER

Lets you select the amount

of time before your TV

turns itself off automatically.

SIGNAL

Displays the digital signal

strength.

FRONT

Selects the front video

input source.

DESCRIPTION OF CONTROLS

VCR

TV

MODE

TV INPUT

TV/VIDEO

1 2 3

4 5 6

7 8 9

DASH(-)

MUTE

EZ SOUND

VOL

RATIO

TIMER CC

INFO

HDMICOMP2

*

0

CABLE

DVD

SAT

POWER

COMP1

FRONT

FLASHBK

FAV

EZ PIC

CH

SURROUNDFREEZE SAP

SIGNAL

MENU EXIT

PLAY

PAUSE

STOP

REW

FF

RECORD

SKIP

Page 9

- 9 -

Model 32FS4D-UC

Horizontal Size (inches) 36.14

Height (inches) 16.51

Thickness (inches) 23.13

Weight (pounds) 114.9

Power requirement AC 120V~ 60Hz

Television system American TV Standard, NTSC-M, Integrated ATSC tuner, 64 & 256 QAM

Television Channel VHF: 2 - 13

UHF: 14 - 69

CATV: 1 - 135

CADTV: 1 - 135

DTV: 2 - 69

Power consumption (W) 180W

Antenna 75 ohm external terminal for VHF/UHF

Audio Output (W) 7.5W x 2

Supplied accessories Remote control, batteries 2 size AA(Alkaline battery)

Screen Aspect Ratio 16 : 9

External input ports Video/Audio input (3 set)

Video output (1 set)

S-Video input (2)

Component input (2 set)

HDMI/DVI input (1)

Digital audio optical input (DVI)(1)

Digital audio optical output (1)

Calibration port (1)

Cable/Antenna port

Design and specifications are subject to change without prior notice.

Product Specifications

SPECIFICATIONS

Page 10

- 10 -

1. Application Object

These instructions are applied to the AC-05MB chassis.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of an isolation

transformer will help protect test instruments.

(2) Adjustments must be done in the correct order.

(3) The input voltage of the receiver must remain at

120V±10% while adjusting.

(4) The receiver must be operated for about 20 minutes prior

to the adjustment.

[ Never operate the set over 10 minutes with a still picture

because it may cause screen burn.

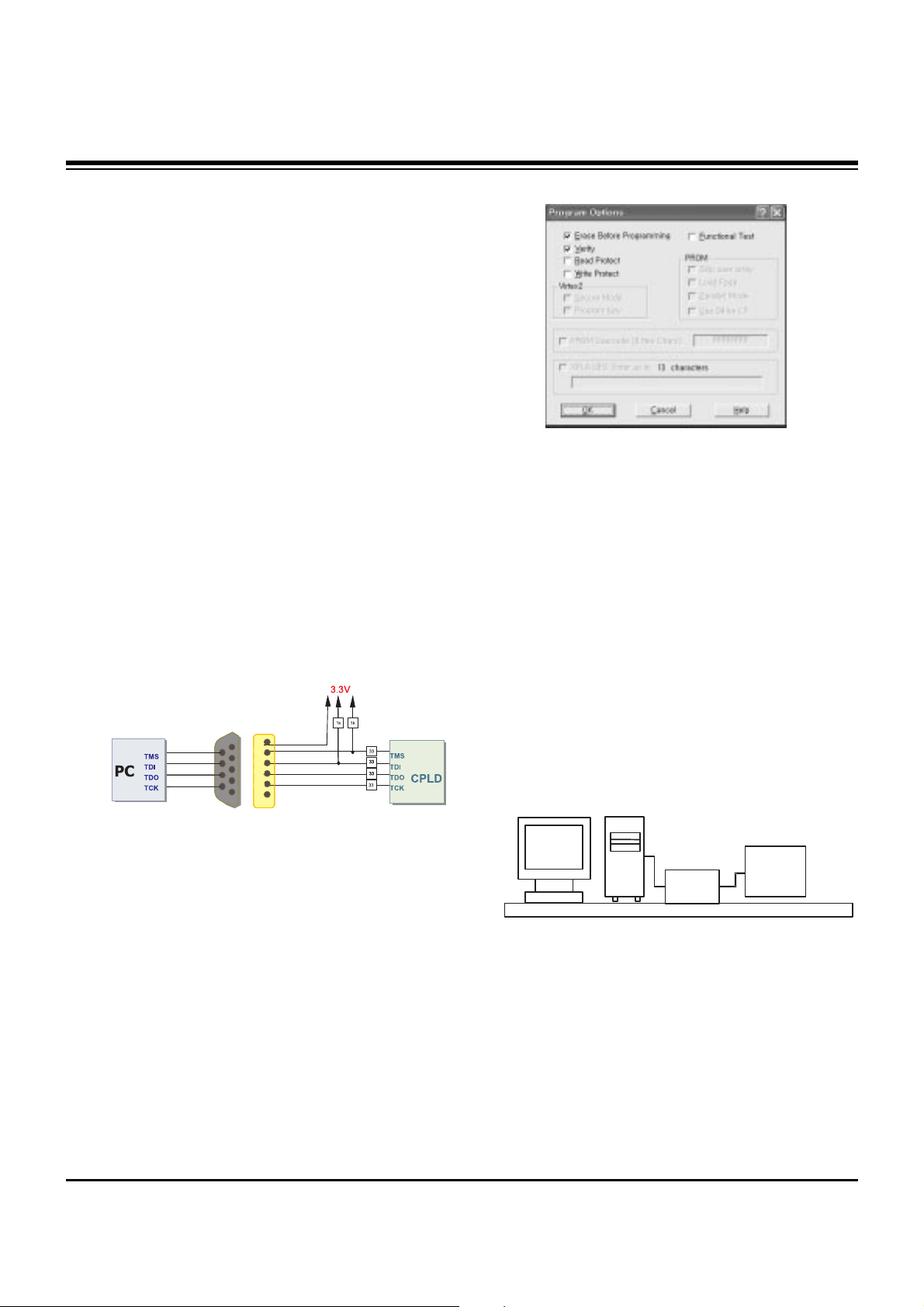

3. CPLD Download

3-1. Required Test Equipments &

Preparation for Adjustment

(1) Connect the PC and memory JIG as shown in <Fig. 1>.

(2) Turn on JIG MAIN POWER SW.

(3) Turn on the PC and monitor, operate the ‘Device

Programming’ software.

3-2. Adjustment Sequence

(1) Once the program is running, [OPTION MODE

SELECTION] is displayed in the window.

Check the “Load configuration File(.cdf, .pdr)” in this

window and click the finish button

(2) When the screen displays the open window, select the

suitable file(*.cdf) according to model.

(3) IC figure is change to green by clicking it.

(4) Select program options.

(5) Check the [Erase before programming] and [Verify] menu

as shown <Fig. 2> and press the OK button.

(6) At this time, the download starts. The download will finish

in about 10 seconds.

4. Hold down Operation Check

(1) This check step is implemented during the frame assembly

process.

(2) Check method: Short circuit the R1471 of Main2 JP

display part and check if it switches to ST-BY. (Install 30K

resistances in parallel to the R1471 on jig.)

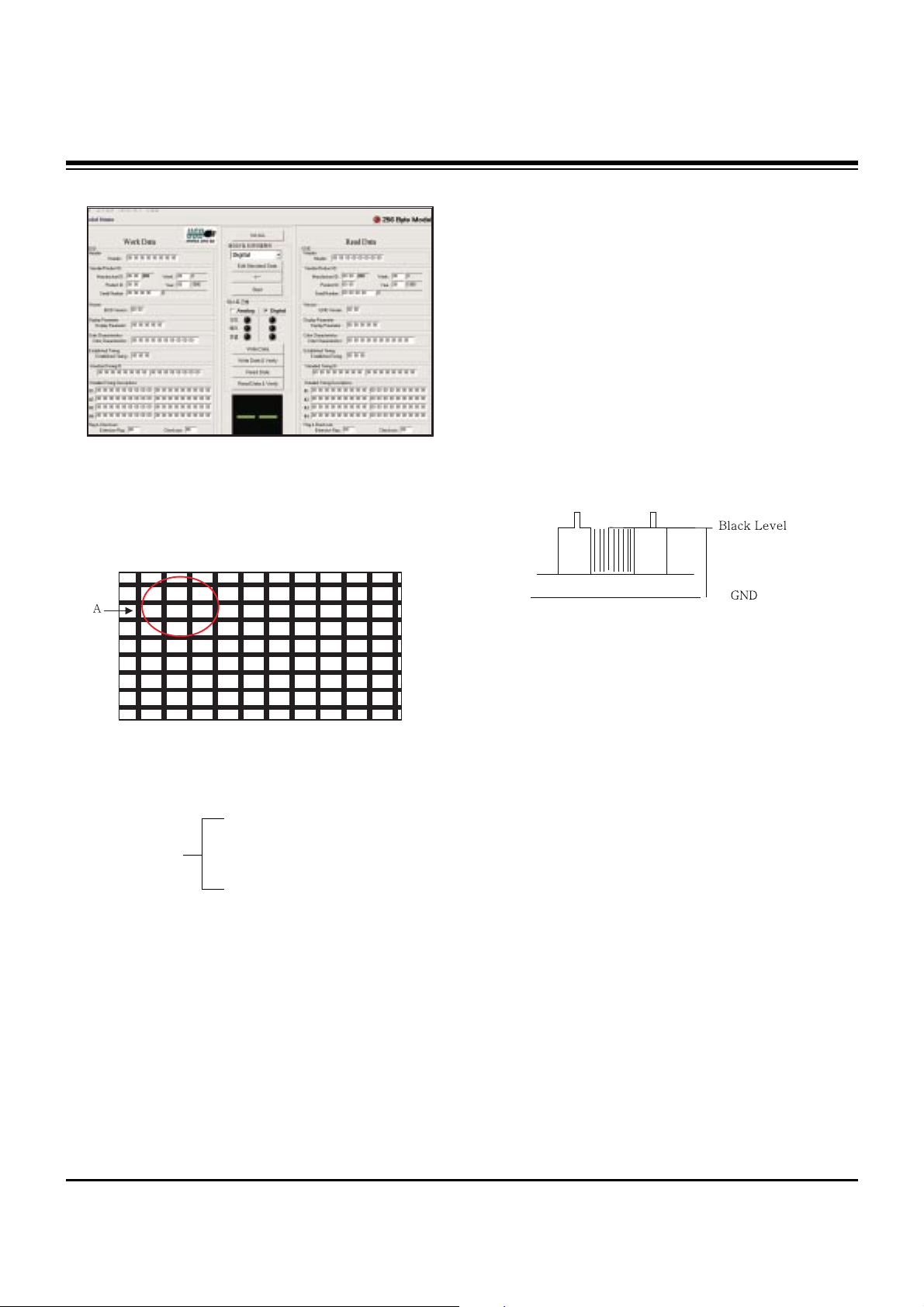

5. EDID Data Input

5-1. Required Test Equipment

(1) PC, Jig for adjusting DDC. (256 bytes write)

(2) S/W for writing DDC(EDID data write & read)

5-2. Setting of Device

5-3. Adjustment

(1) Set devices as above and turn on the PC and JIG.

(2) Open S/W for writing DDC (EDID data write & read).

(3) Enter the Model-->Open in the Menu and then select EDID

DATA.

(4) Click the Digital and cancel the ANALOG.

Then connect to turn on the yellow light at the board &

connection.

(5) Click the Write Data & Verify and then download the EDID

DATA.

ADJUSTMENT INSTRUCTIONS

<Fig. 1 > How to connect the MEMORY JIG and PC

<Fig . 2>

PC

JIG

TV

SET

<Fig . 3>

Page 11

- 11 -

6. Focus Adjustment

(1) Set Picture condition to “Normal”.

CONTRAST : 100

BRIGHT : 60

Normal TINT : 60

COLOR : 0

SHARPNESS : 60

(2) Set the Aspect ratio to Wide Mode.

(3) Receive a Cross Hatch Pattern, adjusting the FOCUS

Knob on the flyback transformer for the best focus in the

area designated “A” above.

[ Heat run over 15 minutes before adjustment.

7. CUT-OFF Adjustment

(Screen Voltage Adjustment)

7-1. Test equipment

Oscilloscope, 100:1 Probe

7-2. Adjustment

(1) Select EZ Adjust 3. CUT-OFF, by pressing the ADJ key on

the SVC Remote control.

When it enters to adjustment mode, the pattern from a

signal generator is being selected, it becomes with Normal

image 16:9 and the CUT-OFF DRIVE data setting 31.

(2) Connect the oscilloscope ground lead to GND on the CPT

board and the probe to the GK pin connector of the CPT

socket.

Using the SCREEN knob on the Flyback Transformer,

adjust the black level voltage to 170±2V.

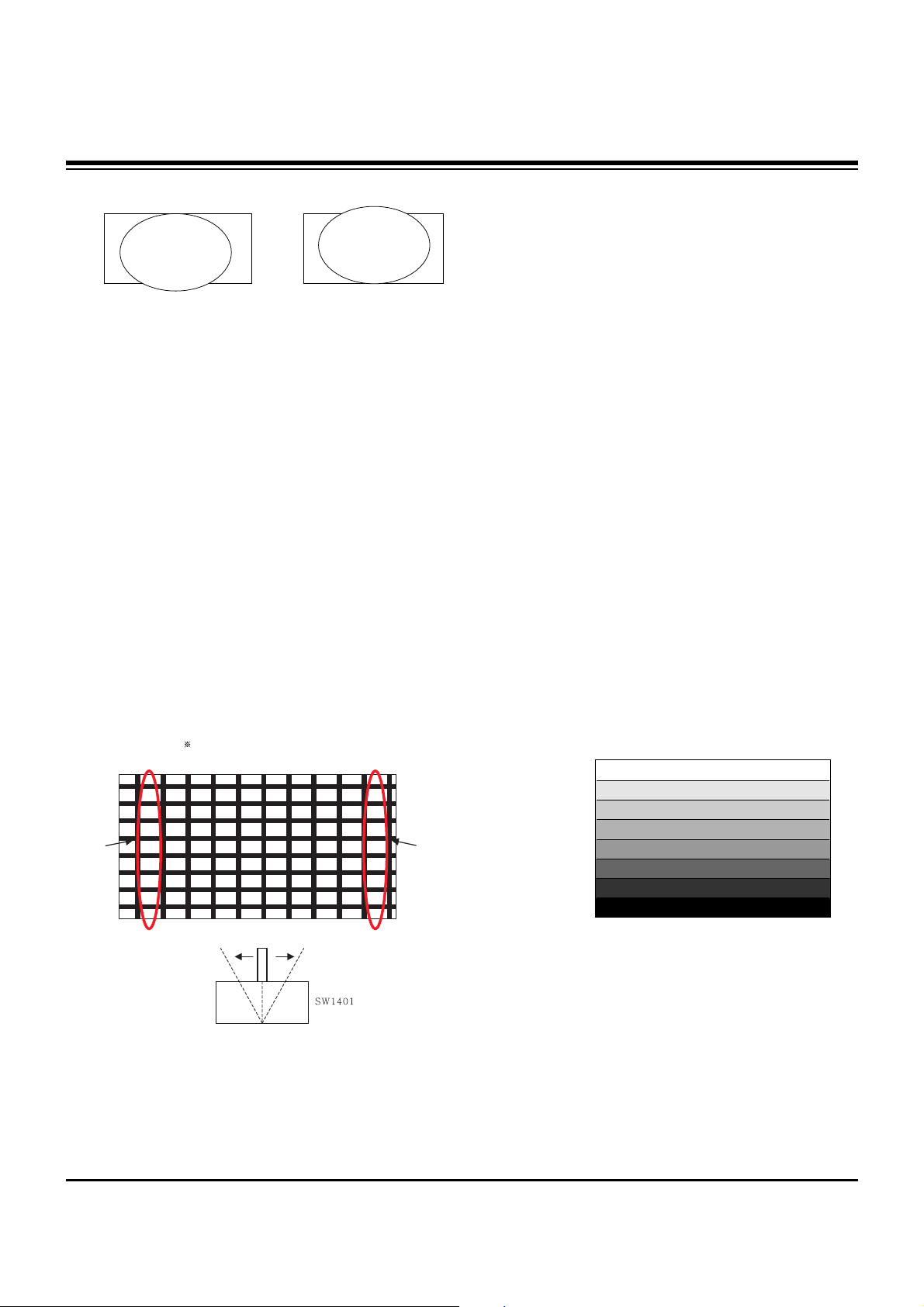

8. Deflection Adjustment

8-1. Preliminary Steps

Select EZ Adjust 1. Raster, Cent, H/V Size by using the ADJ

key on the SVC Remote control.

In the adjustment mode a Digital Pattern signal, NORMAL,

16:9 Screen is displayed.

8-2. Raster V-Center(V.Center) Adjustment

Select 62. V-Postition in the adjustment mode and adjust it to

position the vertical center line in vertical center of the CPT.

8-3. Vertical Deflection Size Adjustment

(Overscan : 10%)

(1) Select 59. V-SIZE in the adjustment mode.

(2) Adjust until the smaller inscribed circle coincides with the

outer frame of screen.

(3) Select 95. LO-VLIN or 94. UP-VLIN and adjust until the

larger inscribed circle coincides with the outer frame of

screen.

ADJUSTMENT INSTRUCTIONS

170±2V

<Fig . 6> CUT-OFF Adjustment

(SCREEN voltage adjustment OSCILLOSCOPE,

100:1 PROBE, VOLTS/DIV : 0.5V/DIV SEC/DIV : 5us,

The TRIGGER MODE it puts in the TV-H)

<Fig . 4>

<Fig . 5>

Page 12

- 12 -

8-4. Raster H-center(H.CENTER) Adjustment

Select 77. H Postion in the adjustment mode and adjust until

left and right screen are symmetrically equal.

8-5. Horizontal Deflection Size Adjustment

(1) Reduce 66 H-Size to verify screen protection (overscan)

on the right and left sides.

(2) Adjust the horizontal size, using a test pattern.

8-6. Horizontal Pincushion Adjustment

(1) Select EZ Adjust 2. Pin-Cushion(16:9) by pressing the ADJ

key on the SVC Remote control.

In the adjustment mode a Cross-Hatch Pattern, 16:9

Screen is displayed.

(2) Select PIN-PHASE, PIN-AMP, AFC-BOW, AFC-ANGLE,

UP-CPIN, LO-CPIN in the adjustment mode and adjust

until there is no Pincushion distortion or trapezoid distortion

on the screen.

8-7. HRS Switch Adjustment

(1) Change the Cross Hatch Pattern.

(2) If the linearity size width of A is narrow on the A or B,

change the SW1401 to the right.

And if the B is narrow, change the SW1401 to the left to

make the size width as same as A and B.

* If the neutral condition is alike, not to change, put the

position.

(3) Readjust the “1.Raster, Cent, H/V Size“ by pressing the

ADJ key of adjustment remote control.

(4) Readjust the “2.Pin-Cushion(16:9)“ by pressing the ADJ

key of adjustment remote control.

8-8. Pincushion Adjustment (4:3 Mode)

(1) Change the Digital Pattern.

(2) Select EZ Adjust 3. Pin-Cushion(4:3) by pressing the ADJ

key on the SVC Remote control.

In the adjustment mode a Digital Pattern signal, NORMAL,

4:3 Screen is displayed.

(3) 4:3 Pin cushion Adjustment

Adjust the 4 adjustment item to be straight without distortion

left/right line of 4:3 Screen

1) 4 Adjustment Item: Pin-Amp, Pin-Phase, Up-Cpin, LoCpin

2) Initial Data of 4 Adjustment Item: 0

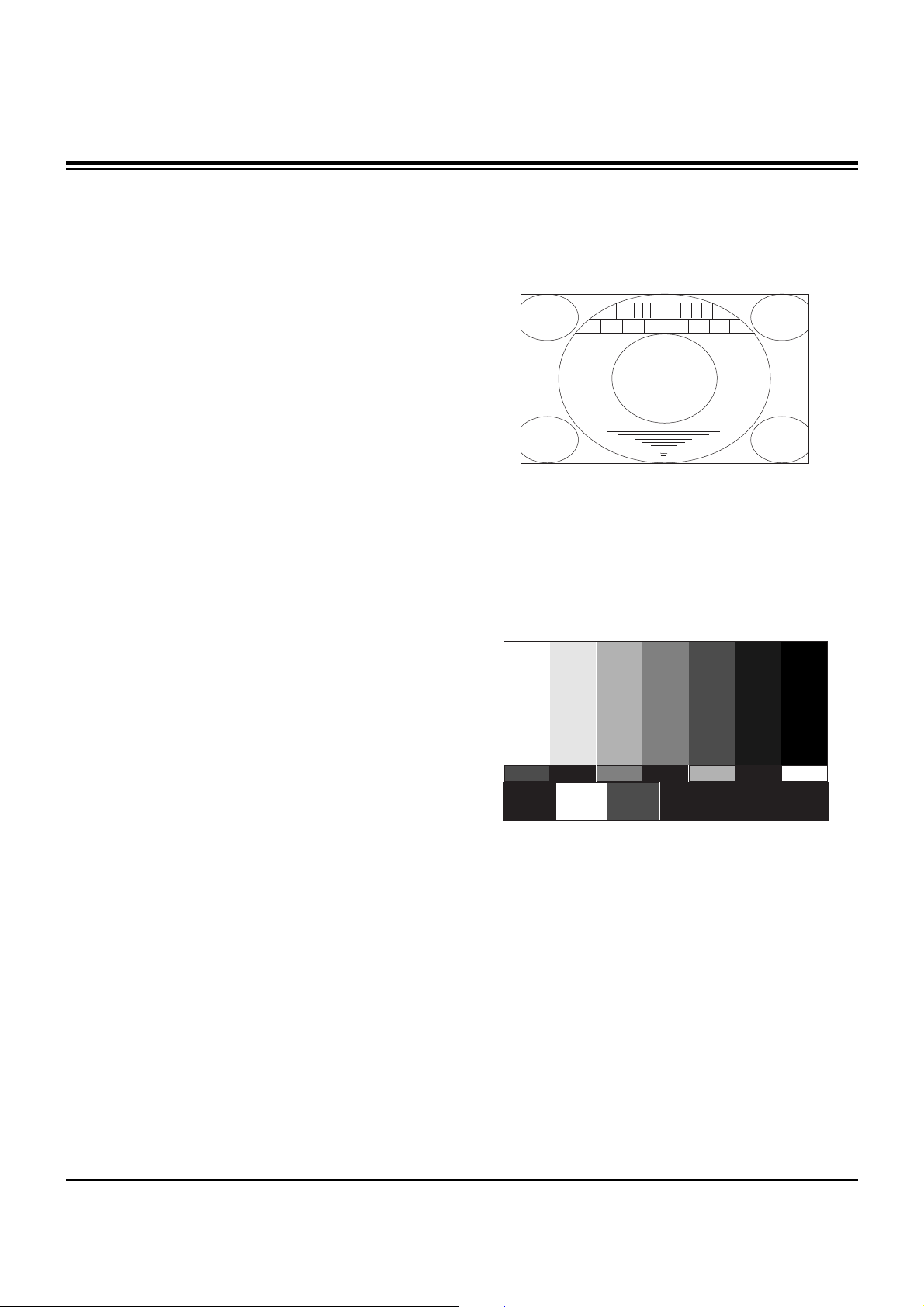

9. Component MST3000 Offset/Gain

Adjustment

9-1. Test Equipment

801GF(802B, 802F, 802R) Pattern Generator or MASTER

Pattern Generator

9-2. Preliminary Steps

(1) Turn the power supply on.

(2) Enter the Component mode.

(3) Receive the “1080I” Format, “Hoz30Bar” Pattern of the

Video Pattern Generator.

(4) Certainly, adjust the output signal in state of 700mVp-p

±10mV.

ADJUSTMENT INSTRUCTIONS

L-LIN U-LIN

A(Left) B(Right)

This screen is reflected picture

at the position of worker

RightLeft

Neutrality

<Fig . 7>

<Fig . 8>

100% White

100% Yellow

100% Cyan

30% Gray

30% Gray

100% Red

100% Blue

Black

<Fig . 9> 1080I Format, Hoz30Bar Pattern

Page 13

- 13 -

9-3. ADC Offset Adjustment

(1) After receiving a signal press the ADJ Key on the SVC

Remote Control repeatedly to acess the Adjustment mode.

(2) Adjustment will set the automatically by pressing the

“8.MST3000-Set” of adjustment item.

(3) After finishing the adjustment, output the “MST3000-OK”

OSD on the screen.

10. White Balance Adjustment

10-1. Preparation for Adjustment

(1) Perform the Screen Voltage Adjustment first.

(2) The White Balance it executes from automatic adjustment

hour Normal image condition.

(3) Start adjustments from initial setting of R.DRIVE=31,

G.DRIVE=31, B.DRIVE=31, R.CUT=31, G.CUT=31,

B.CUT=31.

(4) For manual adjustment, refer to the following procedure.

10-2. Adjustment

(1) Receive the White Pattern.

(2) Set screen size to wide mode(16:9).

(3) Select EZ Adjust 2.White Balance by pressing IN-START

Key on the SVC Remote control.

(4) Adjustment

1) Using the SVC Remote control, set the DCOL value of

CXA2150 to the “0”.

2) Set an image with Normal image.

3) Adjust R-DRIVE and B-DRIVE data so the color

coordinates in High light are the values in Table below.

(Bright Level : 35fl)

4) Adjust “CONTRAST” and “BRIGHT” so the bright level is

4.5±0.5F.L.

5) Adjust R-CUT and B-CUT data so the color coordinates

in Low light are the values in Table below.

6) Repeat 2)~ 5) until the color coordinates in High and

Low color satisfies the Table.

7) Check the adjusted color coordinates with the white

balance meter.

High Light : x=287

!

3, y=293!3

Low Light : x=287

!

3, y=293!3

Color temperature : 9,000K!

1000(-5MPCD)

11. Sub Bright, TINT, COLOR

Adjustment

11-1. Sub Bright Adjustment

(1) Select EZ Adjust 5. Sub Bright pressing ADJ key on the

SVC Remote control.

(2) Adjust to the point where “2” is not visible.

(3) Completed the adjustment, exit the adjustment mode using

ADJ Key.

11-2. Sub COLOR, TINT Adjustment

(1) Select EZ Adjust 6. Sub Tint, Color pressing ADJ key on

the SVC Remote control.

(2) Select SUB COLOR and adjust the 1 and 1’ portion not to

be classified.

(3) Select SUB TINT and adjust the 3 and 3’ portion not to be

classified.

(4) Completed the adjustment, exit the adjustment mode using

ADJ Key.

ADJUSTMENT INSTRUCTIONS

WHITE

B M C WBK BK BK

1

1'

3

3'

GREEN

MAGENTA

CYAN BLUERED

YELLOW

0 12 34 5 76 8 9

US14CH

Page 14

- 14 -

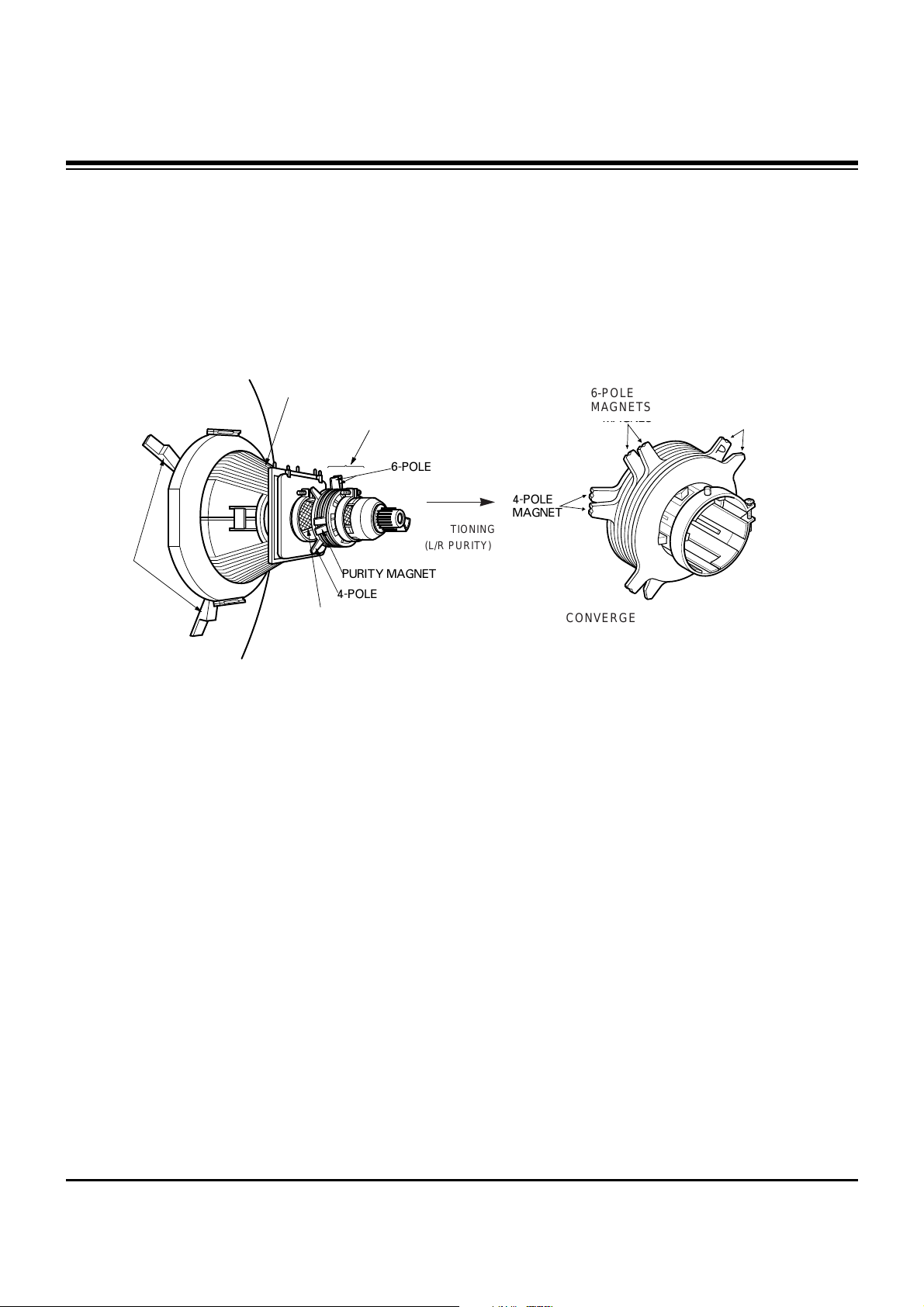

PURITY & CONVERGENCE ADJUSTMENT

Caution:

Convergence and Purity have been factory aligned. Do not

attempt to tamper with these alignments.

However, the effects of adjacent receiver components, or

replacement of picture tube or deflection yoke may require the

readjustment of purity and convergence.

¯ Purity Adjustment

This procedure DOES NOT apply to bonded yoke and picture

tube assemblies.

The instrument should be at room temperature (60 degrees F or

above) for six (6) hours and be operating at low beam current

(dark background) for approximately 20 to 30 minutes before

performing purity adjustments.

CAUTION: Do not remove any trim magnets that may be

attached to the bell of the picture tube.

1. Remove the AC power and disconnect the internal

degaussing coil.

2. Remove the yoke from the neck of the picture tube.

3. If the yoke has the tape version beam bender, remove it and

replace it with an adjustable type beam bender (follow the

instructions provided with the new beam bender)

4. Replace the yoke on the picture tube neck, temporarily

remove the three (3) rubber wedges from the bell of the

picture tube and then slide the yoke completely forward.

5. Reconnect the internal degaussing coil.

6. Position the beam bender locking rings at the 9 o'clock

position and the other three pairs of tabs (2,4 and 6 pole

magnets) at the 12 o'clock position.

7. Perform the following steps, in the order given, to prepare the

receiver for the purity adjustment procedure.

a. Face the receiver in the "magnetic north" direction.

b. Externally degauss the receiver screen with the television

power turned off.

c. Turn the television on for approximately 10 seconds to

perform internal degaussing and then turn the TV off.

d. Unplug the internal degaussing coil. This allows the

thermistor to cool down while you are performing the purity

adjustment. DO NOT MOVE THE RECEIVER FROM ITS

"MAGNETIC NORTH" POSITION.

e. Turn the receiver on and obtain a red raster by increasing

the red bias control (CW) and decreasing the bias controls

for the remaining two colors (CCW).

f. Attach two round magnets on the picture tube screen at 3

o'clock and 9 o'clock positions, approximately one (1) inch

from the edge of the mask (use double-sided tape).

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

RUBBER

WEDGES

GLASS CLOTH TAPE

PURITY MAGNET

6-POLE

4-POLE

4-POLE

MAGNET

CONVERGENCE MAGNET ASSEMBLY

6-POLE

MAGNES

PURITY MAGNET(2-POLE)

X-AXIS YOKE

POSITIONING

(L/R PURITY)

6-POLE

MAGNETS

CONVERGENCE MAGNET ASSEMBLY

Page 15

- 15 -

8. Referring to above, perform the following two steps:

a. Adjust the yoke Z-axis to obtain equal blue circles.

b. Adjust the appropriate beam bender tabs to obtain correct

purity (four equal circles).

9. After correct purity is set, tighten the yoke clamp screw and

remove the two screen magnets.

10. Remove the AC power and rotate the receiver 180 degrees

(facing "magnetic south").

11. Reconnect the internal degaussing coil.

12. Turn the receiver on for 10 seconds (make sure the receiver

came on) to perform internal degaussing, and then turn the

receiver off.

13. Unplug the internal degaussing coil.

14. Turn the receiver on and check the purity by holding one (1)

round magnet at the 3 o'clock and a second round magnet at

9 o'clock position. If purity is not satisfactory, repeat steps 8

through 14.

15. Turn off the receiver and reconnect the internal degaussing coil.

¯ Convergence Adjustment

Caution: This procedure DOES NOT apply to bonded yoke and

picture tube assemblies.

Do not use screen magnets during this adjustment

procedure. Use of screen magnets will cause an

incorrect display.

1. Remove AC power and disconnect the internal degaussing coil.

2. Apply AC Power and set the brightness to the Picture Reset

condition. Set the Color control to minimum.

3. Make horizontal line.

4. Adjust the Red, Green and Blue Bias controls to get a dim

white line.

5. Restore the screen by removing the horizontal line.

6. Reconnect the internal degaussing coil and apply AC power.

7. Turn the receiver on for 10 seconds to perform internal

degaussing and then turn the receiver off again.

8. Unplug the internal degaussing-coil.

9. Turn the receiver on, connect a signal generator to the VHF

antenna terminal and apply a crosshatch signal.

Caution: During the convergence adjustment procedure, be

very careful not to disturb the purity adjustment tabs.

Purity should be confirmed before proceeding with the

convergence adjustments.

Note:

Make sure the focus is set correctly on this instrument

before proceeding with the following adjustment.

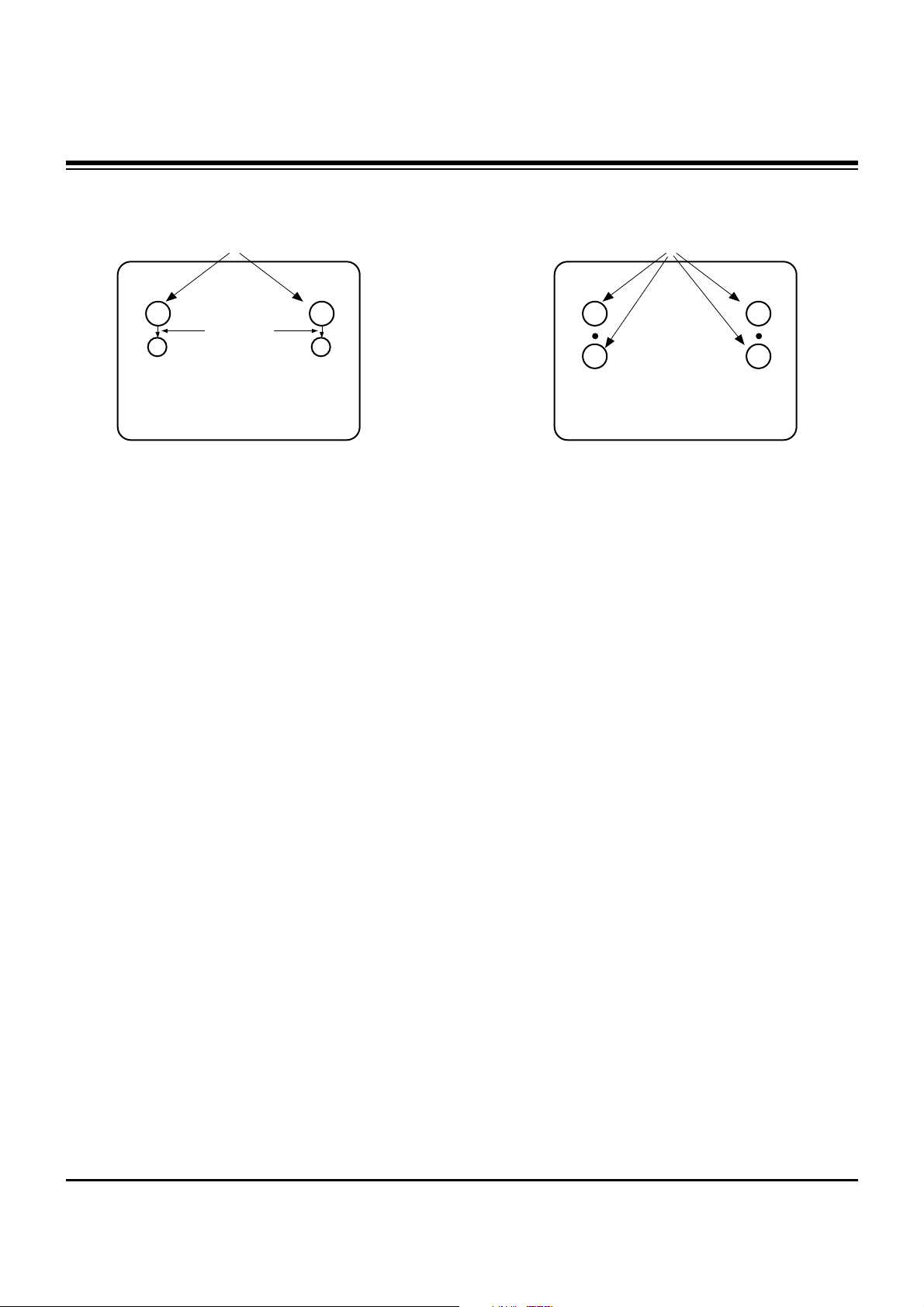

10. Converge the red and blue vertical lines to the green vertical

line at the center of the screen by performing the following

steps (below TABLE).

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in opposite directions from the 12 o'clock

position to converge the red and blue vertical lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in opposite directions form the 12 o'clock

position to converge the red and blue (now purple)

vertical lines with the green vertical line.

11. Converge the red and blue horizontal with the green line at

the center of the screen by performing the following steps.

(below TABLE)

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in the same direction (keep the spacing

between the two tabs the same) to converge the red and

blue horizontal lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in same direction (keep the spacing between

the two tabs the same) to converge the red and blue (now

purple) horizontal lines with the green horizontal line.

c. Secure the tabs previsouly adjusted by locking them in

place with the locking tabs on the beam bender.

MAGNETS

RED RED

1.ADJUST YOKE Z-AXIS FIRST

TO GET EQUAL BLUE

COLOR CIRCLES

2 .ADJUST BEAM BENDER 2 POLE

MAGNET TO GET FOUR EQUAL

COLOR CIRCLES

PURITY & CONVERGENCE ADJUSTMENT

Page 16

- 16 -

RING

PAIRS

4

POLE

ROTATION DIRECTION

OF BOTH TABS

OPPOSITE

SAME

OPPOSITE

SAME

MOVEMENT OF RED

AND BLUE BEAMS

B B

RR

OR

OR

B R B R

OR

B

R

B

R

B R

OR

B

R

6

POLE

12. While watching the 6 o'clock positions on the screen, rock the

front of the yoke in a vertical (up/down) direction to converge

the red and blue vertical lines. (Fig upper left)

13. Temporarily place a rubber wedge at the 12 o'clock position

to hold the vertical position or the yoke.

14.

Check the 3 o'clock and 9 o'clock areas to confirm that the red

and blue horizontal lines are converged.

If the lines are not converged, slightly offset the vertical tilt of the

yoke (move the rubber wedge if necessary) to equally balance the

convergence error of the horizontal lines at 3 o'clock and 9 o'clock

and the vertical lines at 6 o'clock and 12 o'clock.

15. Place a 1.5 inch piece of glass tape over the rubber foot at

the rear of the 12 o'clock wedge.

16. While watching the 6 o'clock and 12 o'clock areas of the

screen, rock the front of the yoke in the horizontal (left to

right) motion to converge the red and blue horizontal lines.

(Fig. upper right)

17. Temporarily place a rubber wedge at the 5 o'clock and 7

o'clock positions to hold the horizontal position of the yoke.

18. Check the 3 o'clock and 9 o'clock areas to confirm that the

red and blue vertical lines are converged. If the lines are not

converged, slightly offset the horizontal tilt of the yoke (move

the temporary rubber wedges if necessary) to equally

balance the convergence error of the horizontal lines at 6

o'clock and 12 o'clock and the vertical lines at 3 o'clock and 9

o'clock.

19. Using a round magnet confirm purity at the center, right and

left sides and corners. See Purity Adjustment Procedure.

20. Reconfirm convergence and apply a 1.5 inch piece of glass

tape over the rubber foot at the rear of the 5 o'clock and the 7

o'clock wedges.

RED

BLUE

RED BLUE

BLUE

RED

GREEN

GREEN

BLUE RED

GREEN

GREEN

ADJUSTMENT

VIEWING

AREA

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

ADJUSTMENT

VIEWING

AREA

RED

RED

GREEN

TV

SCREEN

LEET/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

UP/DOWN ROCKING OF THE YOKE CAUSES

OPPOSITE ROTATION OF RED AND BLUE

RASTERS

LEFT/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

PURITY & CONVERGENCE ADJUSTMENT

Page 17

- 17 -

12. Service Mode Adjustment Data

(SVC Remote control ‘ADJ’ Key)

(1) Raster, Center, H/V_Size Data

(2) Pin-Cushion Data

ADJUSTMENT INSTRUCTIONS

NO OSD DATA

1 V-POSITION 26

2 V-SIZE 20-->25

3 H-POSITION 33

4 H-SIZE 27

5 UP-VLIN 5

6 LO-VLIN 4

7 PIN-AMP 30

8 PIN-PHASE 22

9 UP-CPIN 35

10 LO-CPIN 36

11 AFC-BOW 32

12 AFC-ANGLE 30

NO OSD

[16:9 Mode]

DATA

1 V-POSITION 26

2 V-SIZE 20

3 H-POSITION 33

4 H-SIZE 27

5 UP-VLIN 5

6 LO-VLIN 4

7 PIN-AMP 30

8 PIN-PHASE 22

9 UP-CPIN 35

10 LO-CPIN 36

11 AFC-BOW 32

12 AFC-ANGLE 30

NO OSD

[4:3 Mode]

DATA

1 Pin_Amp 0

2 Pin_Phase 0

3 Up_CPin 0

4 Lo_CPin 0

Page 18

- 18 -

(3) W/B Data

(4) SUB-BRIGHT: 20-->18

(5) SUB-TINT/COLOR

SUB-TINT: 12

SUB-COLOR: 8

ADJUSTMENT INSTRUCTIONS

NO OSD DATA

1 R-DRIVE 31

2 G-DRIVE

31(Fix.)

3 B-DRIVE 31

4 R-CUTOFF 31

5 G-CUTOFF

31(Fix.)

6 B-CUTOFF 31

Page 19

- 19 -

ADJUSTMENT INSTRUCTIONS

13. Service Mode Adjustment Data

(SVC Remote control ‘IN-START’ Key)

(1) CXA2150

NO ITEM

Initial

Data

Initial

Data

Initial

Data

NO ITEM NO ITEM

* SYSTEM RF/AV/480i/480p: 2

HD 720p/1080i: 3

SHP-F0 SD:1, HD: 0

* LTI_LEV: Digital Preset Mode: 3

Other Mode: 2

Page 20

NO ITEM

Initial

Data

NO ITEM

Initial

Data

NO ITEM

Initial

Data

NO ITEM

Initial

Data

- 20 -

ADJUSTMENT INSTRUCTIONS

(2) TeckWell IC(TW9919)

(3) NEC IC(uPD64011)

Page 21

- 21 -

NO ITEM

Initial

Data

NO ITEM

Initial

Data

ADJUSTMENT INSTRUCTIONS

(4) MST3000(ADC_IC)

Page 22

- 22 -

PRINTED CIRCUIT BOARD

MAIN(TOP)

Page 23

- 23 -

PRINTED CIRCUIT BOARD

MAIN(BOTTOM)

Page 24

- 24 -

POWER

PRINTED CIRCUIT BOARD

Page 25

- 25 -

DIGITAL(TOP)

PRINTED CIRCUIT BOARD

Page 26

- 26 -

DIGITAL(BOTTOM)

PRINTED CIRCUIT BOARD

Page 27

- 27 -

PRINTED CIRCUIT BOARD

V-FOCUS

SIDE A/V

POWER S/W

Page 28

- 28 -

PRINTED CIRCUIT BOARD

CONTROL

CPT

LED/IR

Page 29

- 29 -

BLOCK DIAGRAM

–

Page 30

- 30 -

BLOCK DIAGRAM

Page 31

- 31 -

NOTES

Page 32

- 32 -

EXPLODED VIEW

112

913

170

150

510

501

550

503

943

400

300

101

120

310

570

600

580

540

174

530

520

560

504

331

330

320

Page 33

- 33 -

EXPLODED VIEW PARTS LIST

101 4810V01503A BRACKET,CRT 32FS3D AC05MA HIPS 40AF .

112 6335932003A CPT ASSEMBLY,W76ERS270XV1 N(+0.40G) 0G TINT DOUBLE

6335932003B CPT,ITCW76ERS270XV1 L 32INCH SUPER-SLIM 0.50G 4/3

120 6400VA0025F SPEAKER,FULLRANGE C163A01K1452 8OHM 15/20W 86DB OTHERS 32FS2D

150 EAP30771101 Coil,Degaussing 32INCH SUPER SLIM AT 110V ADD SPONGE

170 6868900001A EARTH,CRT 32INCH 2POINT TIN WIRE BRAID 144TS 32FS1D

174 64109UH002A POWER CORD,LP-208RW+YFH800-02 2400MM HOUSING BLACK

300 30919E0029B CABINET ASSEMBLY,32FS4D-UC NO BRAND

310 5020V01110A BUTTON,CONTROL 32FS2D-NA ABS, HF-380 6KEY .

320 320-062E SPRING,KNOB

330 5020V01111A BUTTON,POWER 32FS2D-NA ABS, HF-380 1KEY .

331 4810V01272B BRACKET,32FS2D AC05MA ABS, AF-303S POWER, BRACKET

400 3809900135B BACK COVER ASSEMBLY,32FS4D-UC

501 4810V01239A BRACKET,BOARD 32FS2D AC05MA HIPS 40AF .

503 4811V00359J BRACKET ASSEMBLY,REAR AV 32FS2D-UC AC05MB SUPER SLIM

504 351-008A LINK,POWER S/W FOR MC-97A CHASSIS

510 6871VSMZZ4D PCB Assembly,Sub CPT M.I AC05MB 32FS4D-UC AUSLLA CPT B/D

520 68719MM061B PCB ASSEMBLY,MAIN AC05MB 32FS2D-UC AUXLLAX M/I

68719MM061C PCB Assembly,MAIN1 M.I AC05MB 32FS4D-UC CANADA ACCLLA M/I

530 68719DM006A PCB ASSEMBLY,MAIN2 M.I AC05MB 32FS4D-UC AUSLLA MAIN2 ASSY

540 68719SM122A PCB ASSEMBLY,SUB AC05MA 32FS2D-NA AKRLLA HRS/CS

550 68719SM170B PCB ASSEMBLY,SUB AC05MA 32FS2D-UC AKRLLA DIGITAL NEC

560 68719SM153A PCB ASSEMBLY,SUB POWER M.I AC05MB 32FS2D-UB AUSLLAX POWER SW

570 68719SM067A PCB ASSEMBLY,SUB AC05MA 32FS2D AKRLLAK CONTROL

580 68719SM068B PCB ASSEMBLY,SUB AC05MA 32FS4D AKRLLAK LED/PRE AMP

600 68719SM121A PCB ASSEMBLY,SUB AC05MA 32FS2D-NA AKRLLA SIDE A/V

943 1PTF0403116 SCREW TAP TITE(P),TRUSS HEAD

No.

Part No.

Description

Page 34

- 34 -

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC805

IC806

IC807

IC831

IC900

IC901

IC901

IC902

IC902

IC903

Q100

Q102

Q104

Q1106

Q1203

Q1204

Q1205

Q1206

Q1208

Q1211

Q1402

Q1406

Q1407

Q1408

Q1409

Q1410

Q1504

Q1505

Q1601

Q1604

Q1605

Q1606

Q1607

Q1610

Q1901

Q1902

Q1903

Q1904

Q1905

Q1906

Q1907

Q1920

Q1921

Q203

Q204

Q206

0ISH092100B

0ISH122100B

0IPMG00006A

0ILI817000G

0IPRPNE008A

0IPRPFA015B

0IPH612000B

0IPH612000B

0IPMGSG018C

0IPH612000B

0TR102008AA

0TR387500AA

0TR387500AA

0TR319809AA

0TR150400BA

0TR387500AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TF200000AA

0TR319809AA

0TR126609AA

0TRTH10007A

0TR127409AB

0TRKE10013A

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR102009AM

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR319809AA

0TR319809AA

0TR387500AA

0TR322800AB

0TRFC10001A

0TR387500AA

0TR150400BA

0TR387500AA

PQ09RD21 4SIP

PQ12RD21 4SIP

STR-F6458(LF1352) SANKEN 5PIN

LTV817M-VB 4P

UPD64011BGM-8ED-A NEC 160

FMS6400CS1X SOIC 8P

TDA6120Q/N2 13P

TDA6120Q/N2 13P

LD1086DT15TR 2P 1.5V 1.5A

TDA6120Q/N2 13P VIDEO OUT AMP

KRA102S R/TP KEC SOT23 CHIP TR

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

KTC3198(KTC1815) TO92 50V

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

KTC3198(KTC1815) TO92 50V

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

IRFIBC20G BK I.R 600V

KTC3198(KTC1815) TO92 50V

KTA1266-Y(KTA1015) TO92 PNP

2SC5858 TO3P VCBO 1700V

KTA1274-Y TO-92L

KTD1047 TO3P 160V 12A

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

KRA102S SOT23 -50V -0.1A

KTC3198(KTC1815) TO92 50V

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

KTC3198(KTC1815) TO92 50V

KTC3198(KTC1815) TO92 50V

CHIP 2SC3875S(ALY) BK KEC

KTC3228-Y(KTC2383), BK KEC

KSC5042F-YDTU TO220F 1500V

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

LOCA. NO PART NO DESCRIPTION

IC100

IC101

IC102

IC103

IC103

IC104

IC105

IC106

IC107

IC109

IC110

IC1201

IC13

IC14

IC1401

IC1504

IC1505

IC1506

IC1602

IC17

IC18

IC19

IC200

IC202

IC203

IC2302

IC314

IC315

IC405

IC500

IC501

IC502

IC503

IC504

IC504

IC601

IC601

IC602

IC607

IC610

IC701

IC702

IC801

IC802

IC803

IC804

0IMCRSS016A

0ISH323422A

0ISH323422A

0IMMR00141A

0ISJ156612A

0IMMR00141A

0IKE702900D

0IPH741400E

0IMP242560A

0IMCRPH026B

0IMCRSG010A

0ISO206900A

0ISH052100C

0IMCRKE018A

0ISA784600A

0IKE780500Q

0ISS455880A

0ISA164500B

0ISA428200A

0IFA753307A

0IFA754207A

0IMCRAL006A

0ICTMLG009C

0IMMRHY033B

0IMMRHY033B

0IPRPM3021A

0IPRPXL001B

0ICTMLG013A

0ILNRIS002A

0ICB841500B

0IMCRSO007A

0IKE358000P

0IMCRFA003A

0IKE782400C

0IMCRFA014A

0IKE780500P

0IMMRAL014B

0IMCRMN027E

0ICTMLG019A

0IMMRCS012B

0IMMR00229A

0IPMGSH019A

0IPMGSK003A

0ILI817000G

0ISK135000A

0IKE780500Q

S3C44BOX01-EDRO LQFP-160 TRAY CPU

PQ3RF23 4P(TO-220) 3.3V

PQ3RF23 4P(TO-220) 3.3V

HY57V641620ETP-6 54PIN

SC15661T-2.5TR 3P TO-220-3L

HY57V641620ETP-6 54PIN

KIA7029AP-0.3TO15V 2.9V 400MW

74HC14D 14SOP

24LC256-I/SM 8P 256K IIC SERIAL EEPROM

PA9516APW PHILIPS 16P

ST3232CDR SOP16 R/TP RS232

CXA2069Q QFP64 BK I2C BUS AV S/W

PQ05RD21 4SIP

KIA78R05API KEC 4P TO220 ST 5V 1A

7846 SIP,10P BK V-OUT IC

KIA7805API 3P TO-220 5V

KA4558D 8SOP OP AMP

LB1645N 10SIP MOTOR DRIVE IC

LA4282-(E) 12P 2CH 10W AUDIO AMP

KA75330ZTA 3P,TO-92 TP 3.3V

KA75420ZTA 3P,TO-92 TP 4.2V

AT24C16AN-10SU-2.7 8P EEPROM

LGDT1102C HD2.3 SBGA-432P

HY57V643220DTP-6 86P

HY57V643220DTP-6 86P

MST3385M-LF-80 128PIN

XC9572XL-10TQ100C XILINX TQ100

LGDT1901A LG IC 24P

EL8401ISZ-T7 14PIN

CS8415A-CZR 28P

CXA2150Q SONY 64P

KIA358F 8P

KA2903 FAIRCHILD 8SOP

KIA7824API 3 ST REGULATOR .

74F04SCX FAIRCHILD 14P

KIA78L05BP(AT) 3P 5V,150MA

AT24C02N-10SI-2.7 8P

MSP4440G QA B8 80P

LGDT3303 LG IC 100P

CAT24WC08W-T(MST3000) 8P

M12L16161A-5TG 16MBIT 50PIN

PQ018EZ02ZPH(PB-FREE)

STR-A6351 8 DIP ST SMPS 1 CHIP

LTV817M-VB 4P

SE135N(LF12) 3P 135V ERROR AMP

KIA7805API 3P TO-220 ST REGULATOR 5V

IC

RUN DATE : 2006.5.15

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

TRANSISTOR

Page 35

- 35 -

LOCA. NO PART NO DESCRIPTION

Q207

Q208

Q212

Q213

Q215

Q503

Q504

Q505

Q506

Q507

Q508

Q509

Q510

Q511

Q515

Q516

Q600

Q601

Q601

Q602

Q603

Q603

Q604

Q604

Q605

Q606

Q801

Q802

Q803

Q804

Q840

Q900

Q901

Q901

Q902

Q903

Q904

Q905

Q970

Q971

Q972

Q973

D100

D14

D1401

D1401

D1402

D1409

D1410

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR830009BA

0TR830009BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR322709AA

0TR421009CA

0TR322709AA

0TR319809AA

0TR319809AA

0TR150400BA

0TR150400BA

0TR319809AA

0TR126609AA

0TR322709AA

0TR322709AA

0TR127409AB

0TR127409AB

0TR322709AA

0TR394400AA

0TR153500AA

0DD184009AA

0DD060009AC

0DD150009CE

0DD150009CE

0DD150009CE

0DD060009AC

0DD060009AC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

BSS83 NON N-CHANNEL S/W TR

BSS83 NON N-CHANNEL S/W TR

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SC3875S(ALY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

KTC3227 Y, (KTC1627A)

BF421(TAPING) TO-92

KTC3227 Y, (KTC1627A)

KTC3198(KTC1815) TO92 50V

KTC3198(KTC1815) TO92 50V

CHIP 2SA1504S(ASY) BK KEC

CHIP 2SA1504S(ASY) BK KEC

KTC3198(KTC1815) TO92 50V

KTA1266-Y(KTA1015) TO92 PNP

KTC3227 Y, (KTC1627A)

KTC3227 Y, (KTC1627A)

KTA1274-Y TO-92L

KTA1274-Y TO-92L

KTC3227 Y, (KTC1627A)

2SC3944A TO220 180V

2SA1535A TO220 -180V

KDS184 - 85V - 300MA

TVR06J 600V 250NSEC GP15J 600V

GP15J 600V

GP15J 600V

TVR06J 600V 250NSEC TVR06J 600V 250NSEC -

LOCA. NO PART NO DESCRIPTION

D1415

D1419

D1420

D1426

D1429

D1430

D1433

D1501

D1601

D1604

D1605

D1606

D1609

D1901

D1903

D1904

D1905

D1907

D1908

D1909

D1913

D1914

D505

D511

D514

D600

D610

D804

D805

D810

D811

D813

D815

D816

D817

D819

D820

D821

D822

D823

D824

D825

D840

D841

D842

D843

D901

D904

D907

D908

D970

0DD300009AC

0DR500000CA

0DR360000AA

0DD140009AA

0DD400509AA

0DZ120009BG

0DD400509AA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DR210009AC

0DR210009AC

0DD060009AC

0DR210009AC

0DR210009AC

0DD060009AC

0DZ100009AE

0DR210009AC

0DR210009AC

0DS113379BA

0DS113379BA

0DS113379BA

0DD184009AA

0DD226239AA

0DD414809ED

0DD414809ED

0DD060009AC

0DD060009AC

0DD100009AM

0DD260000BB

0DD420000BB

0DD100009AM

0DD606000AA

0DD100009AM

0DD420000BB

0DR360000AA

0DD420000BB

0DD420000BB

0DD420000BB

0DR010009AA

0DD100009AM

0DD060009AC

0DD060009AC

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD060009AC

RU3AMV(1) 600V 1.5A 50A 0.4US

FMQ-G5GS TO3P 1700V 10A 50A

FMG-36S 2.2V 100NSEC 1.0MA

EK14 V(1) 40V 1.5A 40A 0.2US 5MA

1N4005 DO204AL 600V 1A 30A - 5UA

ZENERS,GDZJ12B

1N4005 DO204AL 600V 1A 30A - 5UA

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

BAV21 DO35 200V 0.2A 1A

BAV21 DO35 200V 0.2A 1A

TVR06J 600V 250NSEC BAV21 DO35 200V 0.2A 1A

BAV21 DO35 200V 0.2A 1A

TVR06J 600V 250NSEC ZENERS,MTZJ10C

BAV21 DO35 200V 0.2A 1A

BAV21 DO35 200V 0.2A 1A

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

1SS133 T-72 DO34 90V

KDS184 - 85V - 300MA

KDS226

1N4148 TP GRANDE

1N4148 TP GRANDE

TVR06J 600V 250NSEC TVR06J 600V 1400MV 10UA 25A

EU1ZV(1) 200V 0.25A 15A 0.4US

BRIDGE D2SBA60(STK)

D4L20U SHINDENGEN

EU1ZV(1) 200V 0.25A 15A 0.4US

RBV606 600V 6A 150A NA 10UA

EU1ZV(1) 200V 0.25A 15A 0.4US

D4L20U SHINDENGEN

FMG-36S 2.2V 100NSEC 1.0MA

D4L20U SHINDENGEN

D4L20U SHINDENGEN

D4L20U SHINDENGEN

EG01C 1000V 0.5A 10A

EU1ZV(1) 200V 0.25A 15A 0.4US

TVR06J 600V 250NSEC TVR06J 600V 250NSEC KDS226

KDS226

KDS226

KDS226

TVR06J 600V 250NSEC -

REPLACEMENT PARTS LIST

DIODE

Page 36

- 36 -

LOCA. NO PART NO DESCRIPTION

D971

D972

D973

LD1101

ZD100

ZD101

ZD11

ZD12

ZD1401

ZD1417

ZD501

ZD503

ZD504

ZD505

ZD601

ZD700

ZD840

ZD841

C006

C007

C100

C101

C102

C103

C104

C105

C106

C107

C108

C109

C110

C110

C1101

C1103

C111

C111

C112

C113

C114

C115

C116

C117

C118

C118

C119

C119

C120

C120

C1200

C1201

0DD060009AC

0DD060009AC

0DD060009AC

0DD000000BA

0DRSE00038A

0DRSE00038A

0DZ620009AK

0DZ510009BF

0DZ120009BG

0DZ510009AK

0DZ120009AF

0DZ620009AK

0DZ510009BF

0DZ560009AH

0DZ820009BF

0DZ910009BD

0DZ300009BB

0DZ330009CC

0CE4763F618

0CN1020K519

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CC220CK41A

0CC220CK41A

0CK821CK56A

0CE477DD618

0CN1030F679

0CE4763F618

0CK104CF56A

0CE477DD618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CE106SF6DC

TVR06J 600V 250NSEC TVR06J 600V 250NSEC TVR06J 600V 250NSEC SA5711-B(DL-1LO(S))

SDC15 TVS SOT23 12.8V

SDC15 TVS SOT23 12.8V

ZENERS,GDZJ6.2B

ZENERS,GDZ5.1B

ZENERS,GDZJ12B

ZENERS,GDZJ5.1B

ZENERS,MTZJ12B

ZENERS,GDZJ6.2B

ZENERS,GDZ5.1B

ZENERS,GDZJ5.6B

ZENERS,GDZJ8.2B

Zeners,GDZJ9.1B

ZENERS,MTZJ30B

ZENERS,MTZJ3.3B

47UF SRE,SE 16V 20% FL TP 5

1000PF D 50V 10% B(Y5P) TA52

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

22pF 5% 50V

22pF 5% 50V

820PF 1608 50V 10% R/TP X7R

470UF STD 10V 20% FL TP 5

10000PF D 16V 20% X5R TA52

47UF SRE,SE 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

470UF STD 10V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20%

LOCA. NO PART NO DESCRIPTION

C1204

C1205

C1208

C121

C121

C1216

C1217

C122

C1220

C1227

C1228

C1229

C123

C123

C1232

C1233

C1234

C1235

C124

C125

C125

C126

C126

C127

C129

C130

C131

C1313

C1314

C1315

C132

C132

C1328

C133

C134

C135

C136

C140

C140

C1401

C1401

C1402

C1403

C1405

C1406

C1412

C1413

C1414

C1415

C1416

C1417

0CE105DK618

0CE105DK618

0CE105DK618

0CK103CK56A

0CE477DD618

0CE105DK618

0CE105DK618

0CK103CK56A

0CE105DK618

0CE226DF618

0CE226DF618

0CE106DF618

0CK103CK56A

0CK104DK56A

0CE226DF618

0CE477DF618

0CE475DK618

0CE475DK618

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CE105SK6DC

0CE105SK6DC

0CE105SK6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE105SK6DC

0CE477DD618

0CE106SF6DC

0CK104CF56A

0CK104CF56A

0CE108DD618

0CE108DD618

0CE105SK6DC

0CE476DD618

0CK47201510

0CE228DH61A

0CK47201510

181-010M

0CQ3341N401

0CQ2731N509

181-010F

181-013S

0CE108BH618

181-091D

0CE227BK618

0CF2241N5AA

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

0.01UF 1608 50V 10% R/TP X7R

470UF STD 10V 20% FL TP 5

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

0.01UF 1608 50V 10% R/TP X7R

1UF STD 50V 20% FL TP 5

22UF STD 16V 20% FL TP 5

22UF STD 16V 20% FL TP 5

10UF STD 16V 20% FL TP 5

0.01UF 1608 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

22UF STD 16V 20% FL TP 5

470UF STD 16V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

10UF MVG 16V 20%

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

1UF MVG 50V 20% SMD R/TP

1UF MVG 50V 20% SMD R/TP

1UF MVG 50V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

1UF MVG 50V 20% SMD R/TP

470UF STD 10V 20% FL TP 5

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

1000UF STD 10V 20% FL TP 5

1000UF STD 10V 20% FL TP 5

1UF MVG 50V 20% SMD R/TP

47UF STD 10V 20% FL TP 5

4700PF D 1KV 10% B(Y5P) R

2200UF STD 25V 20% FL TP 7.5

4700PF D 1KV 10% B(Y5P) R

PP 630V 0.018UF J

0.33UF D 100V 5% PE FM5

0.027UF D 100V 10% PE TP5

PP 0.15UF 400V 5% FM NON

MPP 400V 0.62UF J

1000UF KME TYPE 25V 20% FL TP 5

1nF 10%

220UF KME TYPE 50V 20% FL TP 5

0.22UF D 100V 10% MPS TP 7.5

REPLACEMENT PARTS LIST

CAPACITOR

Page 37

- 37 -

LOCA. NO PART NO DESCRIPTION

C1418

C1418

C1421

C1423

C1426

C1427

C1429

C143

C1431

C1432

C1434

C1435

C1436

C1437

C1438

C144

C1440

C1441

C1442

C1443

C1444

C1445

C1447

C1448

C145

C1450

C1501

C1502

C1508

C1509

C1521

C1525

C1526

C1527

C1528

C1530

C1602

C1604

C1605

C1607

C1608

C1610

C1614

C1616

C1620

C1623

C1628

C1631

C1636

C1637

C1639

181-010F

181-010E

181-010C

0CK1020K515

0CE107DK618

181-014Z

181-033V

0CC121CK41A

0CE106DK618

0CE226DR630

181-091W

181-091W

181-091T

181-009D

181-015M

0CC331CK41A

0CK3320W515

181-010M

181-010G

181-0641

0CE685BK652

0CE107BK618

0CE106DH618

0CQ1041N509

0CC331CK41A

181-014S

0CE107BK618

0CE475DK618

0CE106DK618

0CQ1041N509

0CE105DK618

0CK104DK56A

0CE226DK618

0CK1030K945

0CE107BK618

0CE107DH618

0CE106DF618

0CE226DF618

0CE226DF618

0CE108DF618

0CE226DF618

0CE226DF618

0CQ1031N509

0CQ1031N509

0CE107DF618

0CE107DH618

0CE107DF618

0CE108DK61A

0CQ1041N509

0CQ1041N509

0CE228DJ650

PP 0.15UF 400V 5% FM NON

PP 400V 0.12UF J

PP 0.08UF 400V 5% FM 7.5MM

1000PF D 50V 10% B(Y5P) TR

100UF STD 50V 20% FL TP 5

BUP 0.0033UF 1.6KV 5%,-5%

1KV B 222K FL10

120pF 5% 50V

10UF STD 50V 20% FL TP 5

22UF STD 250V 20% FM5 BULK

R 470PF 2KV 10%,-10% R/TP TP7.5

R 470PF 2KV 10%,-10% R/TP TP7.5

R 4700PF 1KV 10%,-10% R/TP TP10

PP 200V 0.068UF J

MPP 1600V 0.01UF H

330PF 1608 50V 5% R/TP NP0

3300PF D 500V 10% B(Y5P) TR

PP 630V 0.018UF J

PP 400V 0.01UF K

CE 6.8UF 50V 5% M (16*35.5)

6.8UF KME TYPE 50V 20% FM7.5 BP(S)

100UF KME TYPE 50V 20% FL TP 5

10UF STD 25V 20% FL TP 5

0.1UF D 100V 10% PE TP5

330PF 1608 50V 5% R/TP NP0

0.0022UF 2KV 5%,-5% FM METP

100UF KME TYPE 50V 20% FL TP 5

4.7UF STD 50V 20% FL TP 5

10UF STD 50V 20% FL TP 5

0.1UF D 100V 10% PE TP5

1UF STD 50V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

22UF STD 50V 20% FL TP 5

0.01UF D 50V 80%,-20% F(Y5V) TR

100UF KME TYPE 50V 20% FL TP 5

100UF STD 25V 20% FL TP 5

10UF STD 16V 20% FL TP 5

22UF STD 16V 20% FL TP 5

22UF STD 16V 20% FL TP 5

1000UF STD 16V 20% FL TP 5

22UF STD 16V 20% FL TP 5

22UF STD 16V 20% FL TP 5

0.01UF D 100V 10% PE TP5

0.01UF D 100V 10% PE TP5

100UF STD 16V 20% FL TP 5

100UF STD 25V 20% FL TP 5

100UF STD 16V 20% FL TP 5

1000UF STD 50V 20% FL TP 7.5

0.1UF D 100V 10% PE TP5

0.1UF D 100V 10% PE TP5

2200UF STD 35V 20% FM7.5 BULK

LOCA. NO PART NO DESCRIPTION

C1641

C1645

C1646

C1647

C1648

C1650

C1660

C17

C18

C1801

C19

C1902

C1905

C1906

C1907

C1911

C1912

C1915

C1916

C1917

C1923

C1926

C1928

C1929

C1930

C1940

C1952

C1953

C1955

C1956

C20

C200

C201

C202

C203

C204

C205

C206

C207

C208

C209

C210

C211

C212

C213

C214

C215

C215

C216

C217

C218

0CE228DJ650

0CE105DK618

0CE105DK618

0CE105DK618

0CE105DK618

0CK104DK56A

0CE476DD618

0CE108DF618

0CE108DF618

0CQZVBK002D

0CK104DK56A

0CK104DK56A

0CE108BF618

0CK104DK56A

0CE107BF618

0CK47202510

0CK47102515

0CE106BR618

0CE108BF618

0CE107BF618

0CE106BR618

0CE107BF618

0CE107BF618

0CE108BF618

0CK1040K945

0CE107BF618

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE107DD618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE226SF6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK103CK56A

0CK103CK56A

0CK104CF56A

0CK104CF56A

0CE106DF618

0CK104CF56A

0CK104CF56A

0CK104CF56A

2200UF STD 35V 20% FM7.5 BULK

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

1UF STD 50V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

47UF STD 10V 20% FL TP 5

1000UF STD 16V 20% FL TP 5

1000UF STD 16V 20% FL TP 5

A.C 275V 0.47UF K (S=22.5)

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

1000UF KME TYPE 16V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

100UF KME TYPE 16V 20% FL TP 5

4700PF D 2KV 10% B(Y5P) R

470PF D 2KV 10% B(Y5P) TR

10UF KME TYPE 250V 20% FL TP 5

1000UF KME TYPE 16V 20% FL TP 5

100UF KME TYPE 16V 20% FL TP 5

10UF KME TYPE 250V 20% FL TP 5

100UF KME TYPE 16V 20% FL TP 5

100UF KME TYPE 16V 20% FL TP 5

1000UF KME TYPE 16V 20% FL TP 5

0.1UF D 50V 80%,-20% F(Y5V) TR

100UF KME TYPE 16V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

100UF STD 10V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

22UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.01UF 1608 50V 10% R/TP X7R

0.01UF 1608 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

REPLACEMENT PARTS LIST

Page 38

- 38 -

LOCA. NO PART NO DESCRIPTION

C218

C219

C22

C220

C221

C222

C222

C223

C224

C225

C226

C227

C227

C228

C229

C23

C230

C231

C232

C233

C234

C235

C236

C237

C238

C239

C240

C2400

C2401

C241

C241

C242

C243

C244

C244

C245

C246

C246

C247

C247

C248

C248

C249

C249

C250

C251

C252

C252

C253

C253

C254

0CE106DF618

0CK103CK56A

0CE477BF618

0CK103CK56A

0CK104CF56A

0CK104CF56A

0CE106DF618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE106DF618

0CK104CF56A

0CK104CF56A

0CQ1041N509

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CK104CF56A

0CE475DK618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE475DK618

0CK104CF56A

0CK104CF56A

0CE475DK618

0CK104CF56A

0CE475DK618

0CK104CF56A

0CE106DF618

0CK104CF56A

0CE106DF618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE106DF618

0CK104CF56A

0CE106DF618

0CK104CF56A

10UF STD 16V 20% FL TP 5

0.01UF 1608 50V 10% R/TP X7R

470UF KME TYPE 16V 20% FL TP 5

0.01UF 1608 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF D 100V 10% PE TP5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

100UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

4.7UF STD 50V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

4.7UF STD 50V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

4.7UF STD 50V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

4.7UF STD 50V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

10UF STD 16V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

LOCA. NO PART NO DESCRIPTION

C255

C256

C257

C258

C259

C260

C2600

C2601

C2602

C2603

C2604

C2605

C2607

C2608

C2609

C261

C2610

C2611

C2612

C2613

C2614

C262

C2621

C2623

C2626

C2627

C2628

C263

C2631

C2632

C264

C265

C2650

C2651

C2652

C2653

C266

C2660

C2661

C2662

C2663

C2664

C2665

C267

C268

C2683

C269

C27

C270

C271

C272

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK473CH56A

0CK153CK56A

0CK473CH56A

0CK473CH56A

0CC220CK41A

0CC220CK41A

0CK104CF56A

0CE106SF6DC

0CE106SF6DC

0CK104CF56A

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE106SF6DC

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK473CH56A

0CK153CK56A

0CK473CH56A

0CK473CH56A

0CK104CF56A

0CK473CH56A

0CK473CH56A

0CK473CH56A

0CK473CH56A

0CK473CH56A

0CK473CH56A

0CK104CF56A

0CK104CF56A

0CK103CK56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

15000PF 1608 50V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

22pF 5% 50V

22pF 5% 50V

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

15000PF 1608 50V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.047UF 1608 25V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.01UF 1608 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

REPLACEMENT PARTS LIST

Page 39

- 39 -

LOCA. NO PART NO DESCRIPTION

C273

C274

C275

C276

C277

C278

C279

C28

C280

C281

C282

C283

C284

C285

C286

C287

C288

C289

C29

C290

C291

C292

C293

C294

C295

C296

C297

C298

C299

C30

C348

C351

C353

C354

C370

C371

C38

C384

C385

C386

C387

C39

C42

C422

C423

C424

C425

C426

C427

C428

C429

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE105DK618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE108DD618

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CK104CF56A

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CK104CF56A

0CE106SF6DC

0CK104CF56A

0CE108BF618

0CE105DK618

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0CE107SF6DC

0CK104CF56A

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

1UF STD 50V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

1000UF STD 10V 20% FL TP 5

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 1608 16V 10% R/TP X7R

1000UF KME TYPE 16V 20% FL TP 5

1UF STD 50V 20% FL TP 5

100UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

100UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

100UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

100UF MVG 16V 20% SMD R/TP

0.1UF 1608 16V 10% R/TP X7R

LOCA. NO PART NO DESCRIPTION

C43

C437

C439

C44

C440

C442

C443

C445

C446

C447

C448

C449

C45

C450

C469

C47

C48

C500

C501

C501

C502

C502

C503

C503

C504

C504

C505

C505

C506

C506

C507

C507

C508

C508

C509

C509

C510

C510

C511

C512

C513

C514

C515

C516

C517

C518

C519

C520

C520

C521

C523

0CE477DD618

0CE226SF6DC

0CE226SF6DC

0CK104DK56A

0CE226SF6DC

0CE106SF6DC

0CK104CF56A

0CC560CK41A

0CC560CK41A

0CC560CK41A

0CC560CK41A

0CC560CK41A

0CK104DK56A

0CC560CK41A

0CC331CK41A

0CE107DD618

0CK104DK56A

0CK104DK56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CK104DK56A

0CK104CF56A

0CE227DF618

0CK104DK56A

0CE107SF6DC

181-064P

0CK104CF56A

0CK473CH56A

0CE476DK618

0CK104CF56A

0CE107DF618

0CK103CK56A

0CK104DK56A

0CK103CK56A

0CE475DK618

181-007H

0CK104CF56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE105DK618

0CK103CK56A

0CK104DK56A

0CE107DF618

0CE226DF618

470UF STD 10V 20% FL TP 5

22UF MVG 16V 20% SMD R/TP