LG 29FU1RL, 29FU1RG Schematic

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : CW91A

MODEL : 29FU1RL/RG

MODEL : 29FU1RL/RG-TK

May., 2010

Printed in China

P/NO : MFL62077307

North/ Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

- 2 -

CONTENTS

Contents...................................................................................................................2

Safety Precautions..............................................................................................3

Specifications........................................................................................................4

Adjustment Instructions .................................................................................5

Trouble Shooting.................................................................................................10

Printed circuit board.........................................................................................14

Block Diagram ......................................................................................................16

Exploded View.....................................................................................................18

SVC. Sheet..................................................................................................................

Copyright©2010 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5 ± 1.5KV: 14-19 inch, 26 ± 1.5KV: 19-21 inch,

29.0 ± 1.5KV: 25-29 inch, 30.0 ± 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

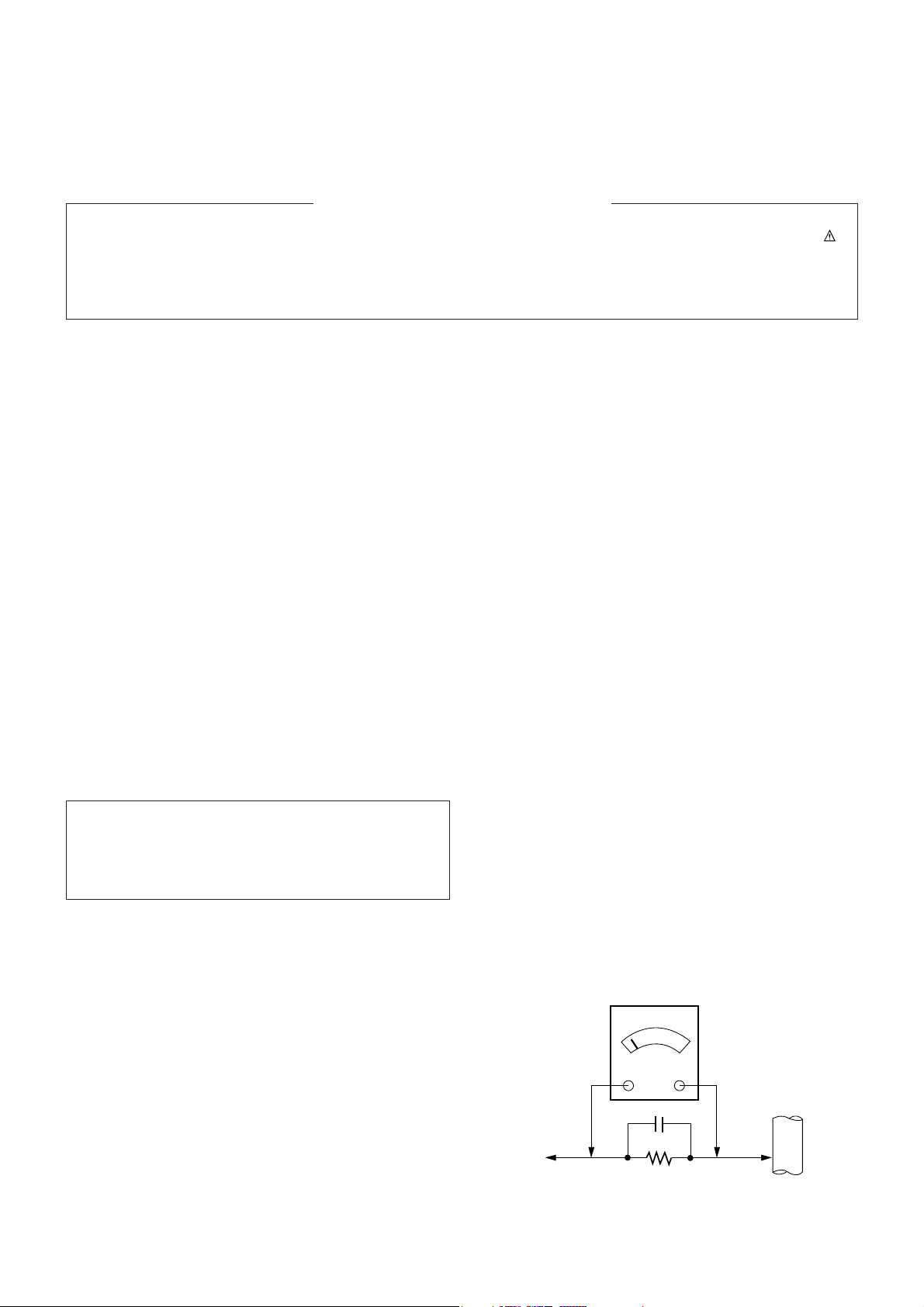

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Copyright©2010 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

- 4 -

V Scope

This specification applies to CTV models based on chassis

CW91A .

V SPECIFIC

Testing should be done at given condition if no condition is specified

1) Ambient Temperature : 25±5

°C (CST 40±5

°

C)

2) Ambient Humidity : 65±10%

3) Input Voltage : Standard input voltage (110~240V ac 50/60Hz)

4) All BOM mentioned component should be same quality standard

as mentioned in specs./ drawing of that particular Part No.

5) Testing should be done after 20 minute heat run.

6) Power Voltage

V Testing and Inspection Method

1) Performance Testing --- According to LG TV Testing Standard

2) Required Regulations

No

1

2

3

4

5

6

7

8

9

10

Item

Receiving System

Available Channel

Input Voltage

Market

Screen Size

Aspect Ratio

Display Method

Tuning System

Operating Environment

Storage Environment

Remark

China / Indonesia/ Thai/ Vietnam

CIS

L.America/ Philippine/Taiwan

Asia/Middle East/Africa

PAL Model

NTSC Model

Asia

Others

PAL Model

NTSC

Specification

PAL BG.DK.I / NTSC M(AV3.58/4.43)

PAL BG.DK.I / NTSC M(AV3.58/4.43)

SECAM DK

PAL NM / NTSC M(AV3.58)

PAL BG,DK,I / NTSC M(AV3.58/4.43)

SECAM BG,DK,L

VHF : E2 ~ E12

UHF : E21 ~ E69

CATV : S1 ~ S20

HYPER : S21 ~ S41

VHF : 2~13CH(12CH)

UHF : 14~69CH(56CH)

CATV : 1 ~ 125CH(113CH)

AC 220Vac 50/60Hz

AC 110~240V 50/60Hz

Latin America, China, Indonesia

Philippines, Taiwan, Thai, Vietnam,

Asia/Africa,CIS

29 inch Flat / Super slim

4:3

CRT

FVS

FS

1)Temp : 0 ~ 40 deg

2)Humidity : ~ 85 %

3)Temp : -20 ~ 60 deg

4)Humidity : ~ 90 %

V General Specification

Market Place

Middle East/Africa

Band

LG

Standard input Voltage

AC110 ~240V 50/60Hz

Remarks

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

Copyright©2010 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

Market Place

Middle East/Africa/cis

Compliance

Safety : CB(IEC60065)

EMC : CE(EN55020,EN55013)

Remarks

1. Scope of Application

These adjustment instructions are applicable to CW91A

Chassis whether SET(0), SKD(0), or CKD(0).

2. Notes

2.1 Because this is a cold chassis, it is not necessary to use

an isolation transformer. However,operating it using a

transformer between the power supply line and chassis

input to prevent electric shock and to protect the test

instrument.

2.2 All adjustments must be done in correct sequence.

However, for better productivity, it can be changed in a prepermitted range.

2.3 Environment conditions: If not specified, it must be done in

following conditions.

1) Temperature: 25°C ±5°C

2) Humidity : 65%±10%

2.4 Power supply of SET

1) NTSC

Latin America/Philippines Market:100~240V ±10%,50/60Hz

Korea Market : 220V ±10%,60Hz

Taiwan Market : 110V ±10%,60Hz

Japan Market : 100V ±10%,50/60Hz

2) PAL/SECAM

China/Indonesia/Thailand/Vietnam/CIS Market :

100~240V ±10%, 50/60Hz

2.5 If not specified, the receiver must be operated for more

than 20 minutes prior to the adjustment.

2.6 Signal: Received the standard color signal. (65dB±1dBuV)

NTSC: LG standard signal means the digital pattern

13CH(480NC).

PAL/SECAM: LG standard signal means the digital

pattern PAL-B/Gz 05CH

2.7 If not specified, APC ON is APC CLEAR (DYNAMIC).

3. Adjustment content

3.1. Screen Voltage Adjustment

3.1.1.Adjustment (Use factory remote control)

(1) Input in the 75Ω cable LG standard signal

(Digital Pattern,480NC)

(2) Press IN-START KEY and ADJ KEY of SVC T/X

generate horizontal line for Screen adjust.

(3).Turn the screen volume on the FBT clockwise until the

horizontal line is visible and turn it counterclockwise until

horizontal line faintly visible.

(Exit screen voltage adjustment by press “Exit” key of SVC

T/X.)

3.2. Purity and Convergence Adjustment

3.2.1. Purity adjustment

(1). Adjustment Preparation

a. Received Red Raster Pattern for purity adjustment (51CH).

b. Demagnetize the CPT and Cabinet with a degaussing coil.

(2). Adjustment

a. Pre-adjust the static convergence(STC) with the 4 and

6-pole magnet.

b. If the horizontal Line is inline with CPT Mark,2-Pole

magnet should direct 3-9 o’clock direction.

c. If not,direct 2-Pole magnet handle toward 6-12 o’clock

direction and adjust the Horizontal Line to fall onto the

mark opening the magnet at an angle.

d.Push the DY(deflection yoke) all the way to the CPT funnel.

e.Turn the purity magnet(2-pole magnet) so that the “green”

color portion of left side and the “blue” color portion on

the right side have equal amount of color.

f.Pull the DY slowly backward and fix it when the whole

screen becomes red.

(The specified torque for fixing DY screw should be 10Kg/cm.)

3.2.2. Convergence adjustment

(1). Necessary Instrument

a. Degaussing Coil

b. Convergence fixing instrument(special tools)

(2). Adjustment Preparation

a. Operate the unit at the least 15 minutes before adjustment.

b. Using degaussing coil,remove the stains on CPT & Cabinet.

c. Received the Cross Hatch Pattern for Convergence (09ch).

d. Let the Contrast in normal luminance level.

(3). Static Convergence (STC) Adjustment

a. Received the Cross Hatch Pattern for Convergence (09ch).

b. Before adjusting Static Convergence(STC),adjust the

focus first seeing to it that the WHITE color picture quality

is sharp enough.

c. Converge the RED vertical line and BLUE vertical line in

unity(same line) by changing the angle between the 2

tabs of 4-pole magnet.

d. Converge the RED horizontal and BLUE horizontal line

unity(same line) by turning the 2 tabs of the 4-pole magnet.

At this time,do not change the angle between the 2 tabs.

e. Converge the R,G,B vertical line in unity(same line) by

changing the angle between the 2 tabs of the 6-pole magnet.

f. Converge the R,G,B horizontal line in unity(same line) by

turning the 2 tabs of the 6-pole magnet. At this time, do not

change the angle between the 2 tabs.

(4). Dynamic Convergence (DYC) Adjustment

a. Y-Axis Adjustment :Adjust convergence of Y-axis(vertical)

by moving the deflection yoke(DY) left and right.

b. X-axis Adjustment : Adjust convergence of X-axis(horizontal)

by moving the deflection yoke(DY) up and down.

3.3. White Balance Adjustment

3.3.1. Necessary Instrument

(1). Auto white balance meter (Low/High Light Pattern generator)

(2). CRT Color Analyzer, CA-100 :1 set

(3). Factory Remote control

3.3.2. Adjustment preparation : Prior to this adjustment, the

Screen Voltage adjustment should be finished.

3.3.3. Auto Adjustment

(1). Adjust using Auto White Balance Meter.

(2).Enter CPU OFF mode by press the “IN-START” &”MUTE”

key of factory remote control in turn before adjustment.

Exit CPU OFF mode by press the “MUTE” key of factory

remote control after adjustment finished.

In case there is excess RED color at screen voltage

adjustment, adjust it using “Volume -(F)”Key of factory remote

control until the RED color disappear.

- 5 -

ADJUSTMENT INSTRUCTIONS

Copyright©2010 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

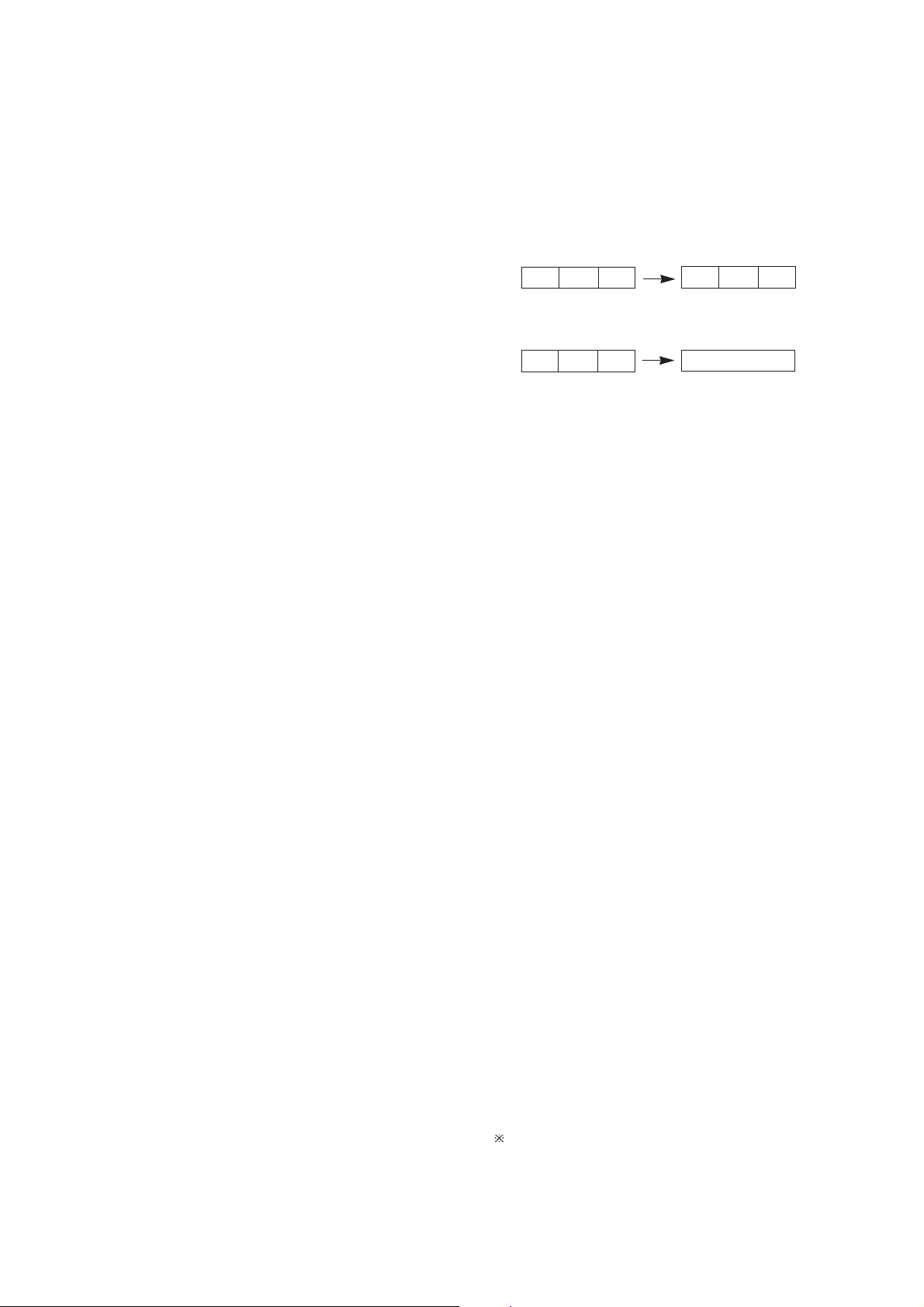

G

RB

G

RB

G

RB

R

3.3.4. Manual Adjustment

(1). Adjust using white balance meter and factory remote control.

(2). Enter white balance adjustment mode by press “IN-START”

key of factory remote control.

(3). Use the CHD, CHE key to choose adjustment item.

(4). Use the VOLF,VOLG Key to change item data.

(5). Adjustment Procedure

a. Make the picture luminance 45Ft-L by change the

“CONTRAST” and “BRIGHTNESS”.

b. Adjust X data of high light with R DRIVE and Y data of high

light with B DRIVE to have color temperature as shown below.

c. Make the picture luminance 4.5Ft-L by change the

“CONTRAST” and “BRIGHTNESS”.

d. Adjust X data of low light with R BIAS and Y data of low light

with B BIAS to have color temperature as shown below.

e. Repeat steps a~d until both low and high light have same

reading as shown below.

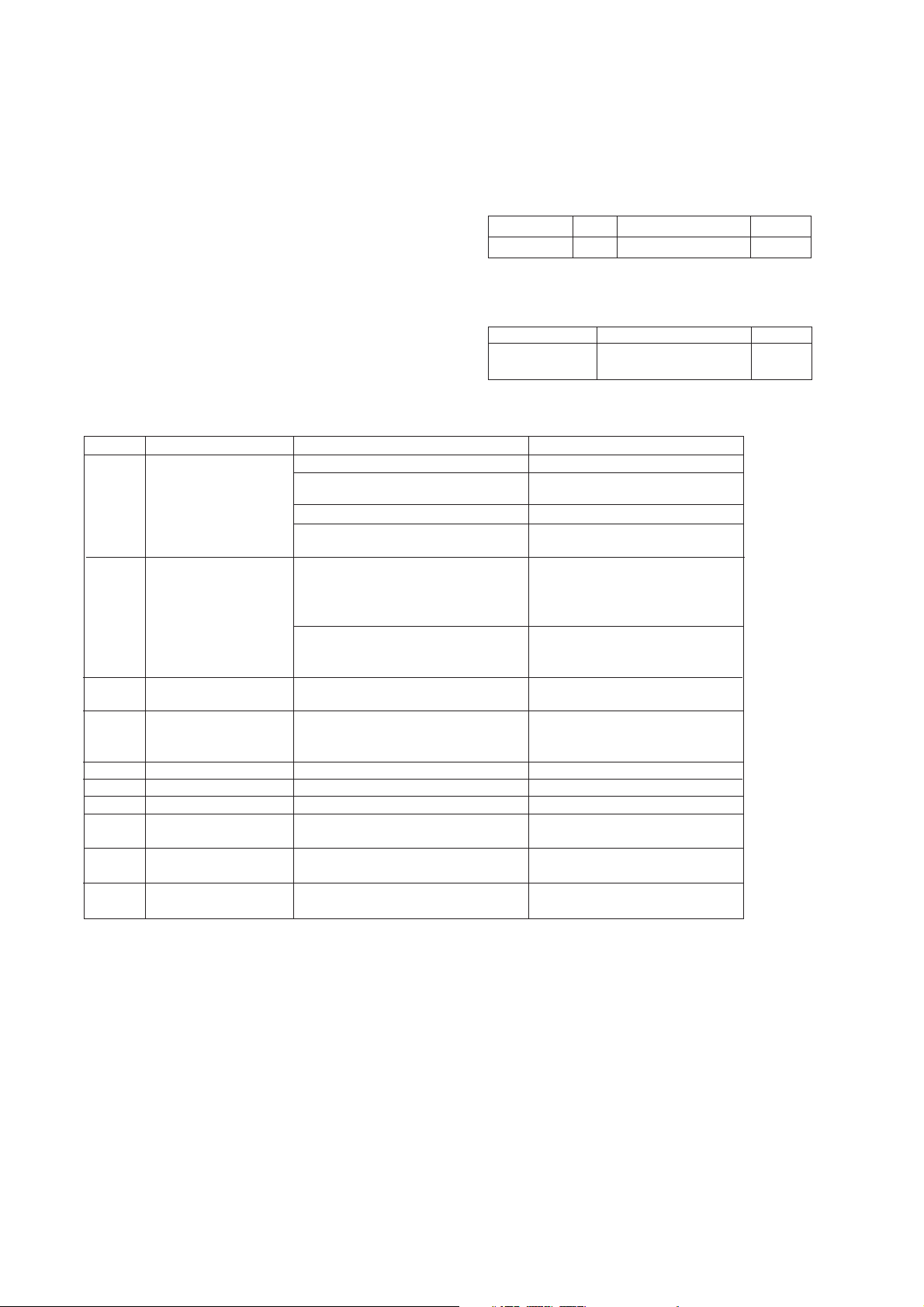

3.3.5. CW91A WHITE BALANCE IIC PARAMETER

(1) W/B auto adjust machine setting Table

(2) White balance IIC Parameter (Address)

(3) Color coordinate

Tolerance Range : Adjust within

±5 for each X,Y coordinate

(4) White Balance default setting data

3.5. Focus Voltage Adjustment

Adjustment must be done after operating the TV set receiver

sufficiently.

3.5.1. Adjustment Preparation

Received the LG standard pattern (PAL :Digital

Pattern,480NC,13CH, NTSC: Crosshatch pattern, Ch.09 )

and set the picture condition on “APC ON” (CLEAR) mode.

3.5.2. Adjustment Turn the focus volume on the FBT upper

direction to have the best focus vertical line and horizontal

line as shown below.

3.6. SUB-BRIGHTNESS Adjustment (Do not adjust)

This adjustment must be done after the White balance

Adjustment

3.6.1. Adjustment preparation

(1).NTSC

-. Received LG standard Mono scope pattern (CH14).

-. Set the picture condition on “APC ON” (CLEAR) mode.

(2). PAL

-. Received PAL B/G 5CH pattern.

-. Set the picture condition on “PSM ON” (DYNAMIC) mode.

3.6.2. Adjustment

(1). Press the “ADJ” key of the factory remote control twice to

enter to “SUB-BRIGHTNESS” adjustment mode.

(2). NTSC MODEL: Change the Sub-Brightness data by

pressing the VOLF,VOLG KEY so that the number 1 in

gray scale of mono scope pattern almost disappear.

In the ultra slim, Do until the number “1” completely

disappear. (See figure 2)

(3). PAL MODEL: Change the Sub-Brightness data by

pressing the VOLF,VOLG KEY so that the 1th, 2th

Black Level in gray scale of PAL B/G 05CH pattern have

a little bit of difference. (See figure 3)

Program

Sub Add

Start Bit

Stop Bit

Offset

Polarity

EPRom_S

(R)_Amp

Win31_wb TWB

20

5

0

0

1

72

(R)_Cut

Win31_wb TWB

17

5

0

0

1

6A

G_Amp

Win31_wb TWB

21

5

0

0

0

68

- 6 -

Program

VCD Slave

Win31_wb

TWB

8A

Eeprom_Slave

Win31_wb

TWB

A2

Speed1Delay

30

VDC IC

EEPROM

NAME MAKER

NOTE

Algorithm

Speed/Plus

2

22

2

G_Cut

Win31_wb TWB

18

5

0

0

0

6B

ITEM

EU N-EU PhilippinesTaiwan

Latin

America

288

295

9000

X

Y

Color

Temperature

282

288

10000

267

276

13000

268

273

13000

266

282

13000

Copyright©2010 LG Electronics.Inc. All right reserved.

Only for training and service purposes.

LGE Internal Use Only

LOW

LIGHT

HIGH

LIGHT

ITEM

BLO-R(R CUT)

BLO-G(G CUT)

BLO-B(B CUT)

RG(R DRIVE)

GG(G DRIVE)

BG(B DRIVE)

Default setting data

PAL NTSC

32

32

32

32

32

32

32

32

32

32

32

32

remark

Fixed

Fixed

Range

0~63

0~63

0~63

0~63

0~63

0~63

US 51CH

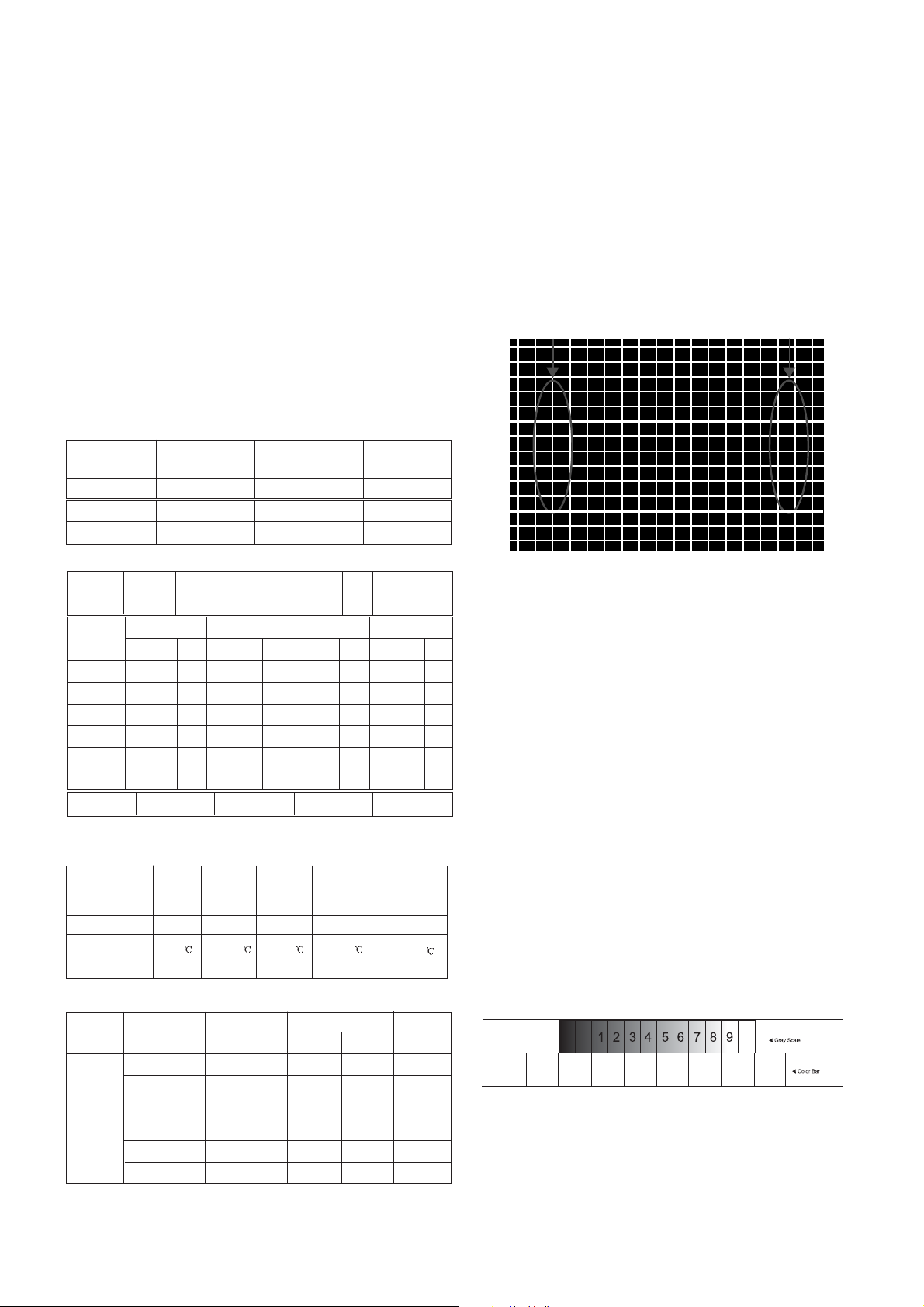

[Fig 1] Cross-Hatch Pattern(NTSC:US 51CH, PAL:C-8 CH)

[figure 2] MONO SCOPE Pattern signal

Loading...

Loading...