Lexus LS 400 2005 User Manual

A T–1

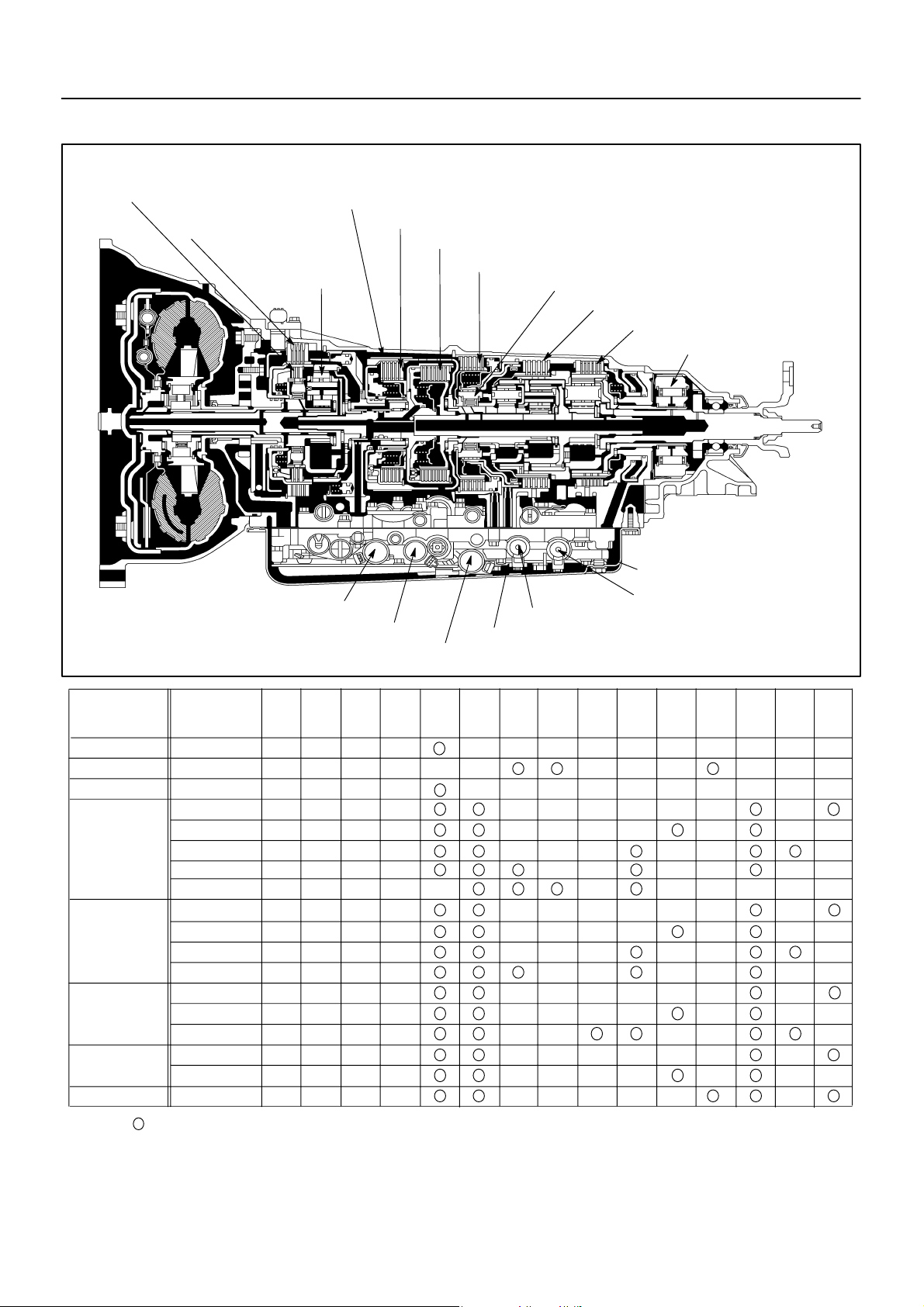

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION SYSTEM

AUTOMATIC TRANSMISSION SYSTEM

AT033–01

PRECAUTION

If the vehicle is equipped with a mobile communication system, refer to the precautions in the IN section.

2000 LEXUS LS400 (RM717U)

1508Author: Date:

AT–2

OPERATION

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION SYSTEM

AT034–01

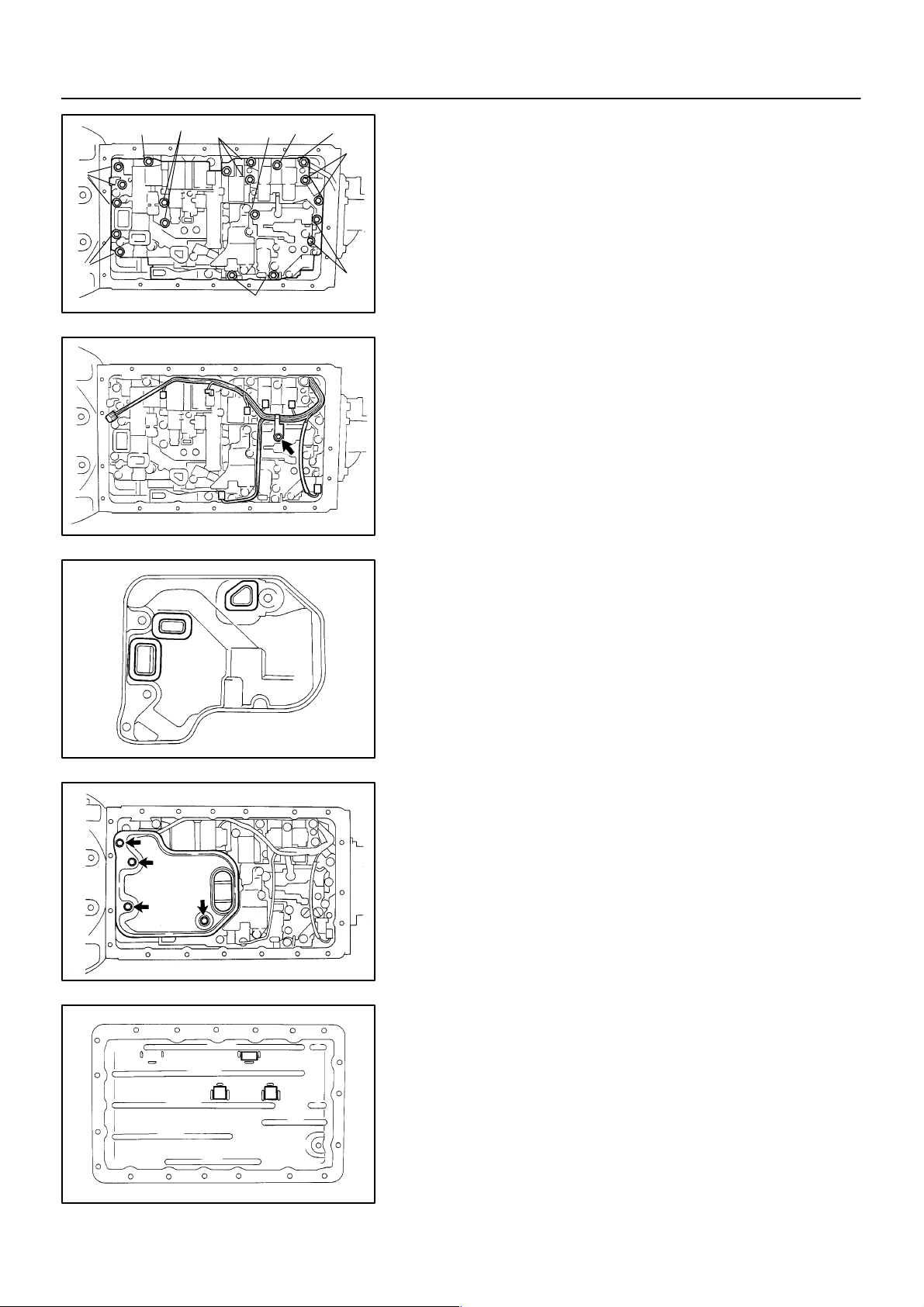

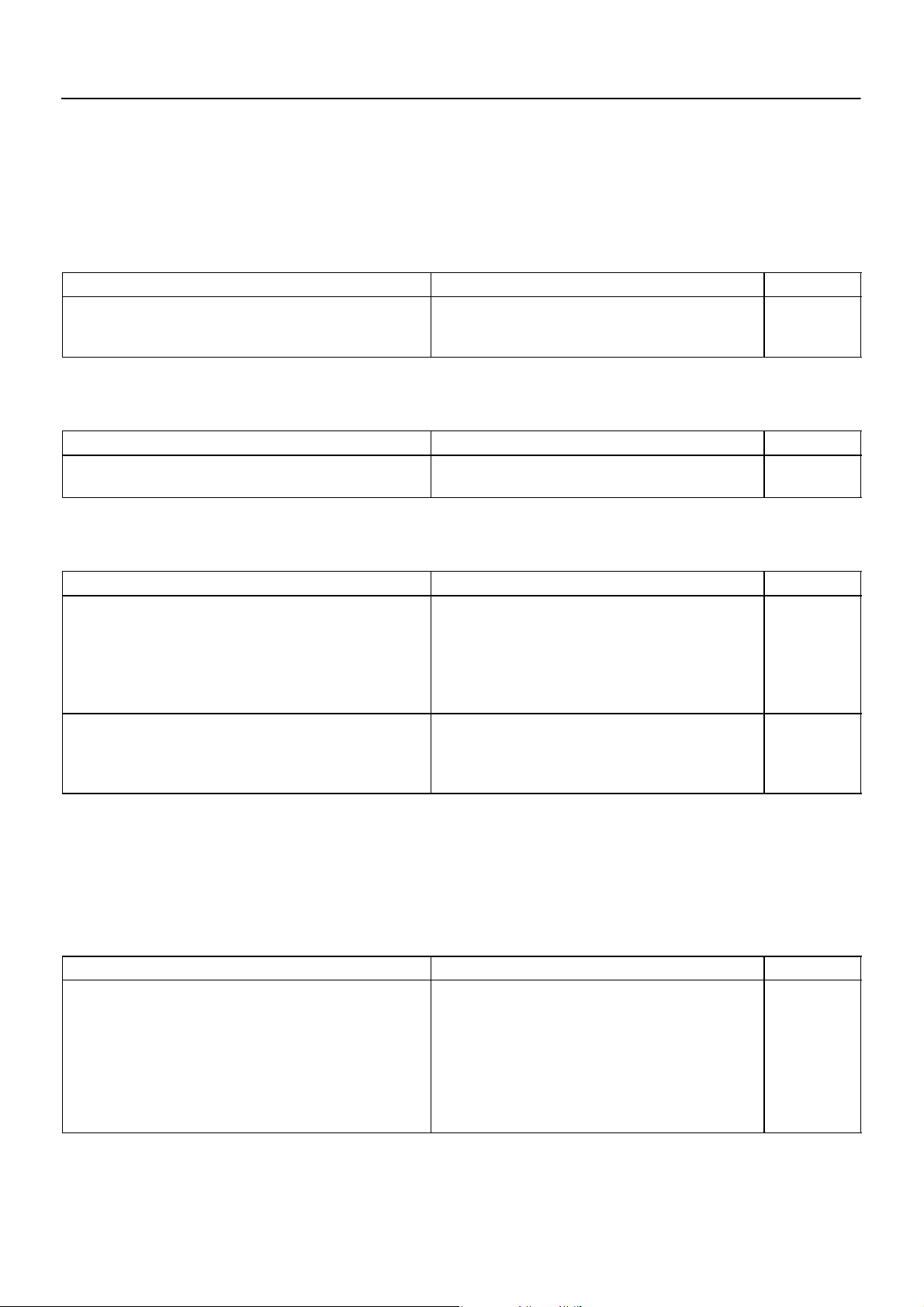

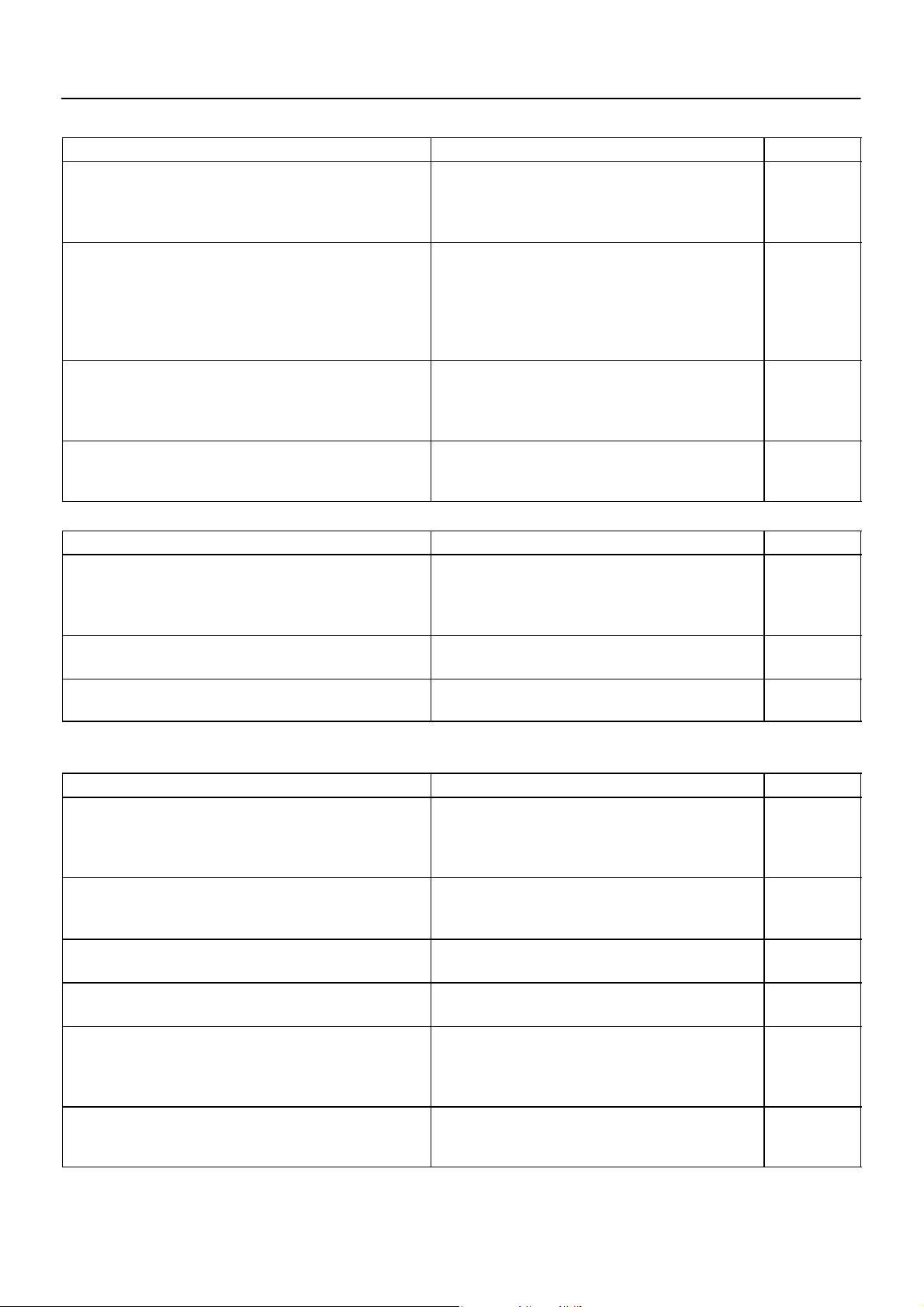

O/D Direct Clutch (C0)

O/D Brake (B0)

Shift Solenoid Valve SLT

3rd Coast Brake (B1)

Direct Clutch (C2)

O/D One–way

Clutch (F0)

Shift Solenoid Valve SLU

Shift Solenoid Valve SLN

Forward Clutch (C1)

3rd Brake (B2)

No.1 One–way Clutch (F1)

2nd Brake (B3)

1st & Reverse Brake (B4)

No.2 One–way Clutch (F2)

Shift Solenoid Valve No.2

Shift Solenoid Valve No.1

Shift Solenoid Valve No.3

Shift Solenoid Valve No.4

D01264

Shift Lever

Position

P

R

N

D

4

3

2

L

Gear

Position

Park

Reverse

Neutral

1st

2nd

3rd

4th

5th

1st

2nd

3rd

4th

1st

2nd

3rd

1st

2nd

1st

: Operating

S1 S2 S3 C0C1C2B0B1B2B3B4F0F1F

ON OFF ON

OFF

ON

OFF

S4

OFF

OFF

OFFON ONONOFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

ON

ON

OFFOFF

ON OFF

ON

OFF

OFF ON

OFF OFF

OFF OFF

OFFON

ON

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

ON

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

2

2000 LEXUS LS400 (RM717U)

1509Author: Date:

–AUTOMA TIC TRANSMISSION EXTENSION HOUSING OIL SEAL

AT–3

D01008

EXTENSION HOUSING OIL SEAL

AT035–01

ON–VEHICLE REPAIR

1. DRAIN ATF

2. REMOVE FRONT EXHAUST PIPE AND HEAT INSULATOR

(See page AT–16)

3. REMOVE PROPELLER SHAFT

(See page PR–3)

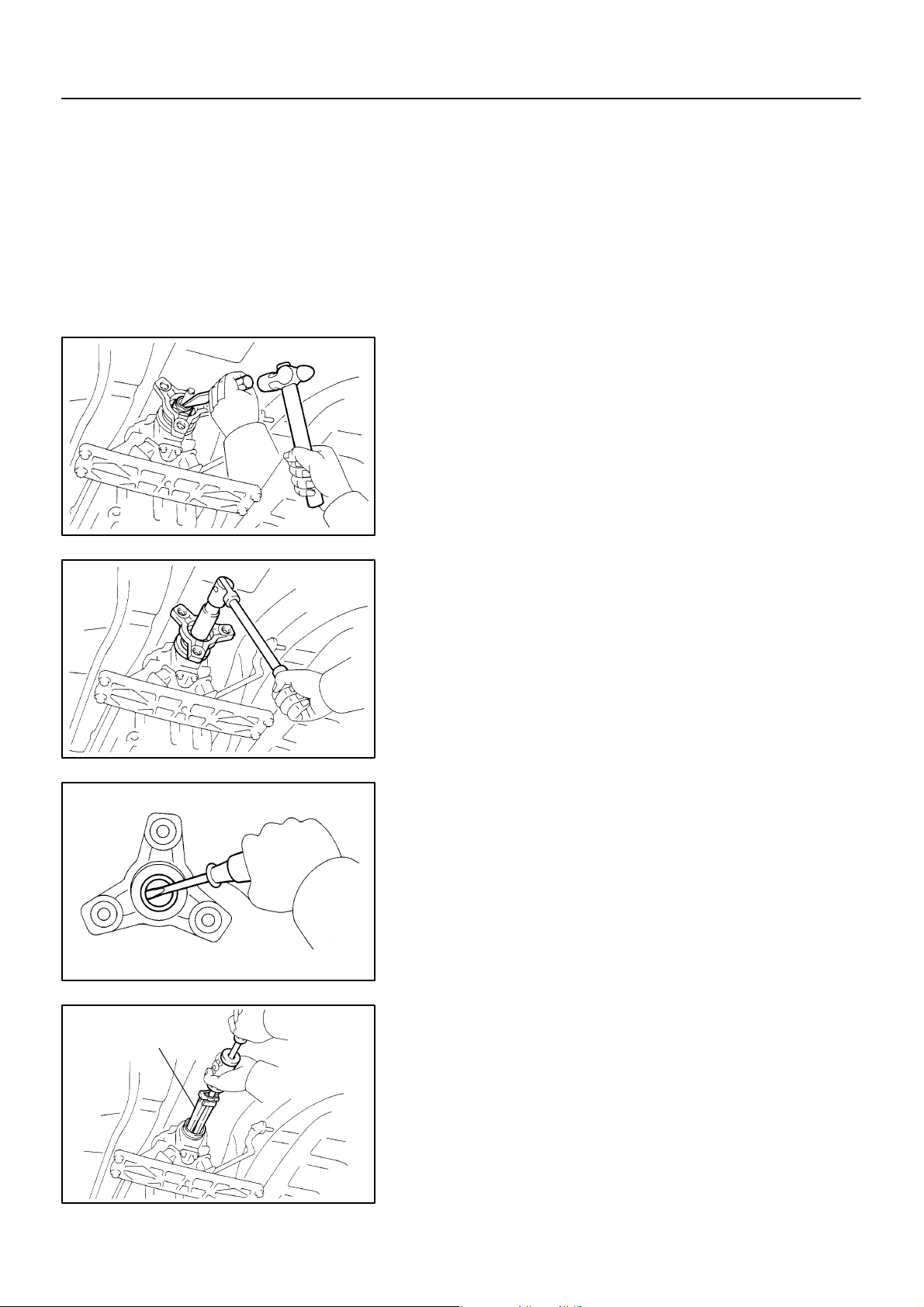

4. REMOVE TRANSMISSION OUTPUT FLANGE

(a) Using a chisel and hammer, loosen the staked part of the

nut.

HINT:

Shift the shift lever to the P position.

(b) Using a 30 mm deeper socket wrench, remove the nut.

(c) Tap the output flange with a plastic hammer to remove it .

SST

D01009

(d) Using a screwdriver, remove the oil seal from the output

flange.

D01010

5. REMOVE EXTENSION HOUSING REAR OIL SEAL

Using SST, remove the oil seal.

SST 09308–00010

D01011

2000 LEXUS LS400 (RM717U)

1510Author: Date:

AT–4

–AUTOMA TIC TRANSMISSION EXTENSION HOUSING OIL SEAL

SST

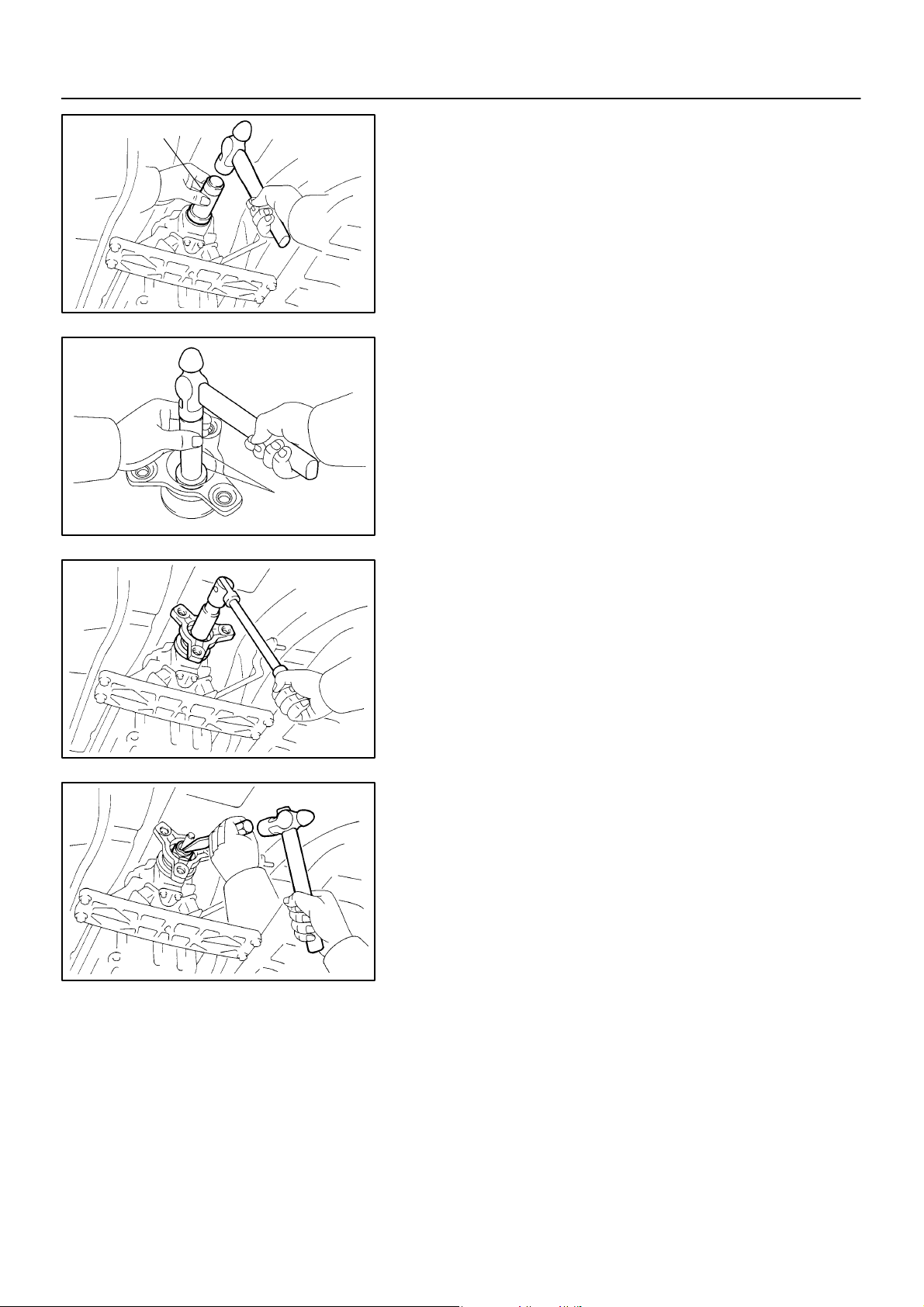

6. INSTALL EXTENSION HOUSING REAR OIL SEAL

(a) Coat the lip of a new oil seal with MP grease.

(b) Using SST and a hammer, drive in the oil seal with the lip

facing downward.

SST 09309–37010

Oil seal depth from flat end: 2.0 mm (0.079 in.)

D01012

7. INSTALL TRANSMISSION OUTPUT FLANGE

(a) Using SST and a hammer, drive in a new oil seal.

SST 09950–60010 (09951–00350), 09950–70010

(09951–07100)

SST

Q08511

(b) Install the output flange.

(c) Using a 30 mm deeper socket wrench, install and torque

a new nut.

Torque: 123 N·m (1,250 kgf·cm, 90 ft·lbf)

HINT:

Shift the shift lever to P position.

D01009

D01008

(d) Using a chisel and hammer, stake the nut.

8. INSTALL PROPELLER SHAFT

(See page PR–9)

9. INSTALL FRONT EXHAUST PIPE AND HEAT INSULATOR

(See page AT–16)

10. FILL AND CHECK FLUID LEVEL

(See page DI–173)

2000 LEXUS LS400 (RM717U)

1511Author: Date:

–AUTOMA TIC TRANSMISSION ATF TEMPERATURE SENSOR

A T–5

ATF TEMPERATURE SENSOR

AT036–01

ON–VEHICLE REPAIR

CAUTION:

When working with FIPG material, you must observe the following items.

Using a razor blade and gasket scraper, remove all the old

FIPG material from the gasket surfaces.

Thoroughly clean all components to remove all the loose

material.

Clean both sealing surfaces with a non–residue solvent.

Apply FIPG in an approx. 1 mm (0.04 in.) wide bead along

the sealing surface.

Parts must be assembled within 10 minutes of application.

Otherwise, the FIPG material must be removed and reapplied.

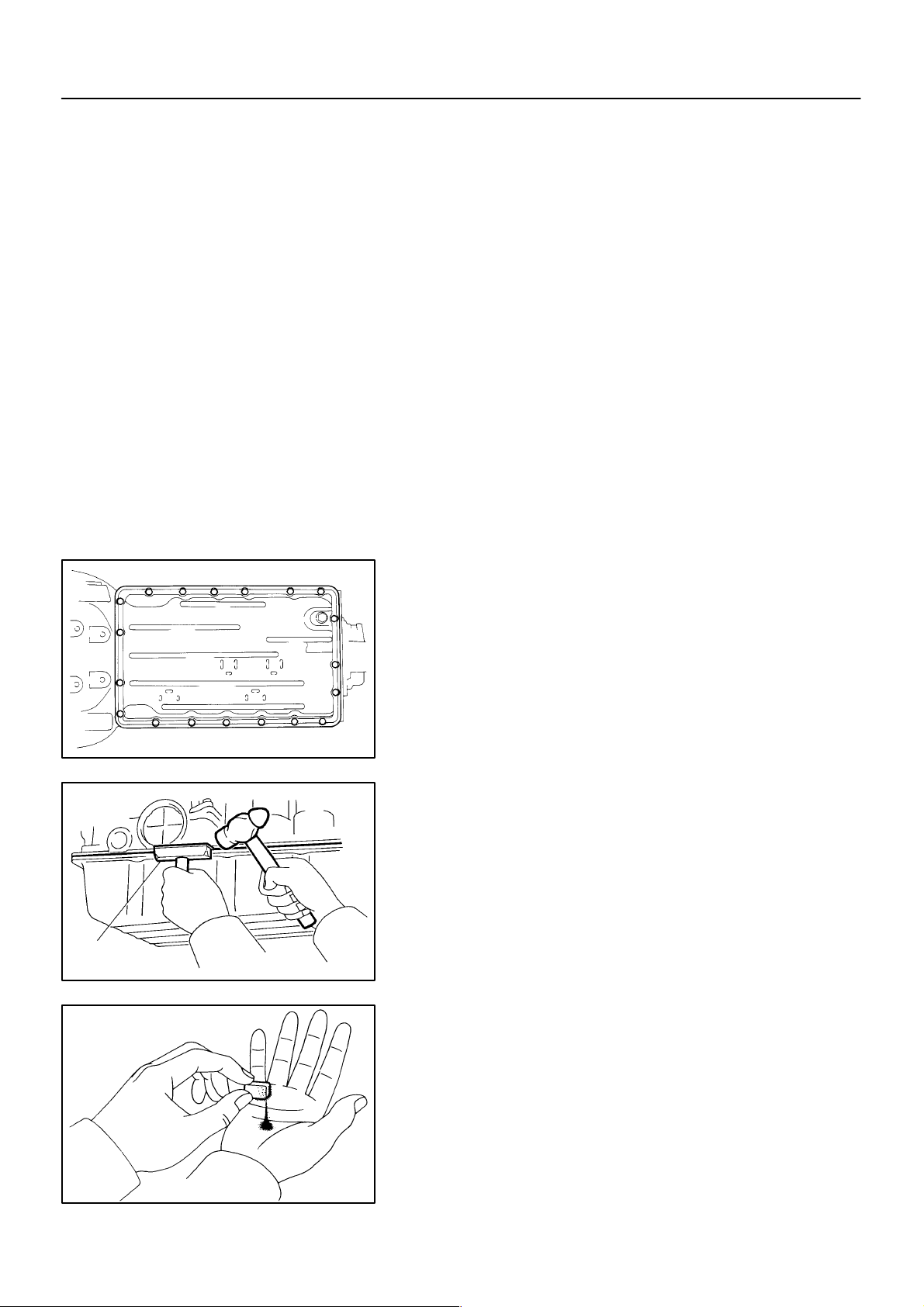

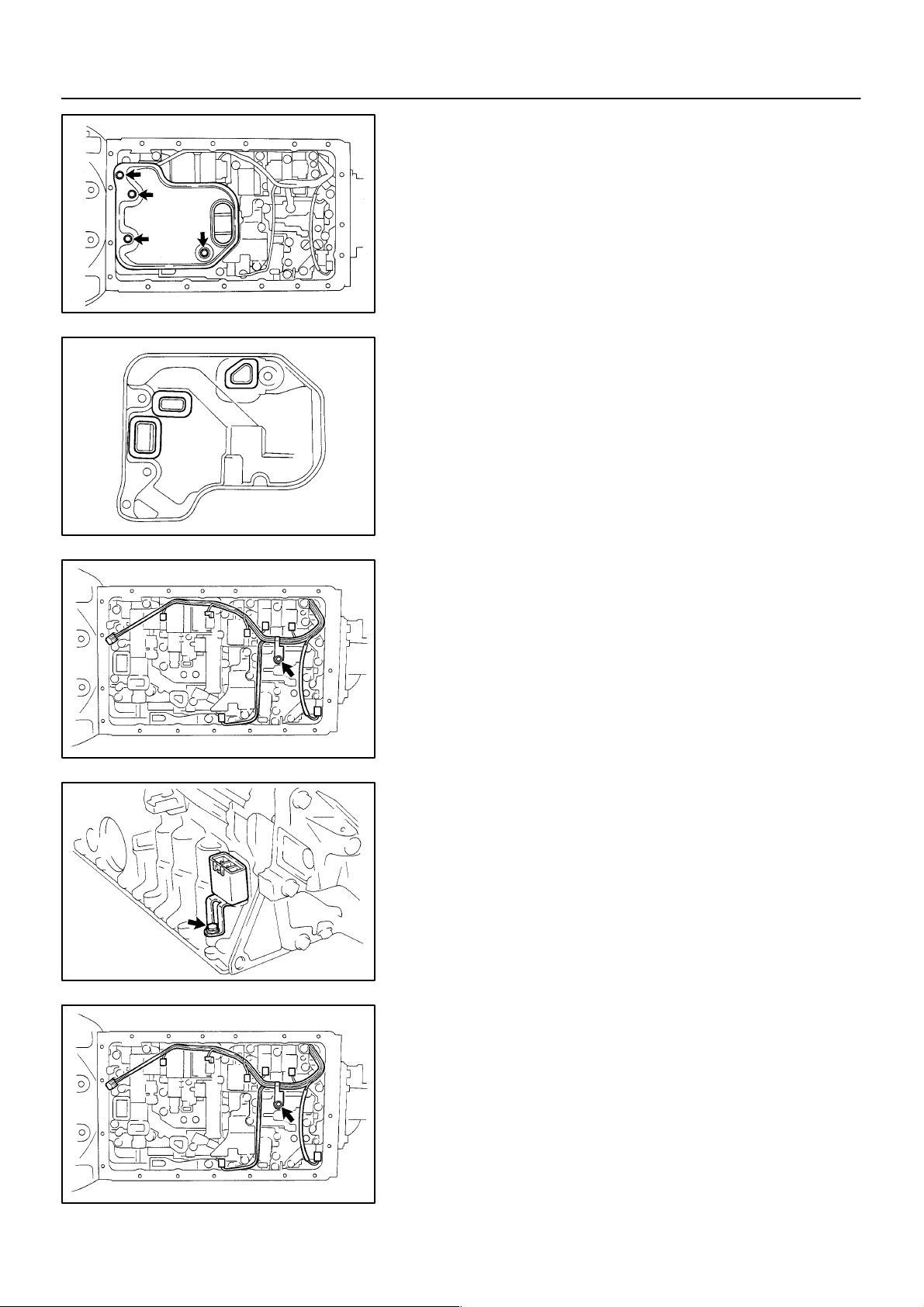

1. REMOVE DRAIN PLUG WITH GASKET AND DRAIN

AT F

2. REMOVE OIL PAN

NOTICE:

Some fluid will remain in the oil pan.

(a) Remove the 19 bolts.

SST

D00910

(b) Install the blade of SST between the transmission case

and oil pan, cut off applied sealer, and remove the oil pan.

SST 09032 – 00100

NOTICE:

When removing the oil pan, be careful not to damage the oil

pan flange.

Q07487

3. EXAMINE PARTICLES IN PAN

Remove the magnets and use them to collect steel particles.

Carefully look at the foreign matter and particles in the pan and

on the magnets to anticipate the type of wear you will find in the

transmission.

Steel (magnetic) ... bearing, gear and clutch plate wear

Brass (non–magnetic) ... bushing wear

AT0103

2000 LEXUS LS400 (RM717U)

1512Author: Date:

AT–6

–AUTOMA TIC TRANSMISSION ATF TEMPERATURE SENSOR

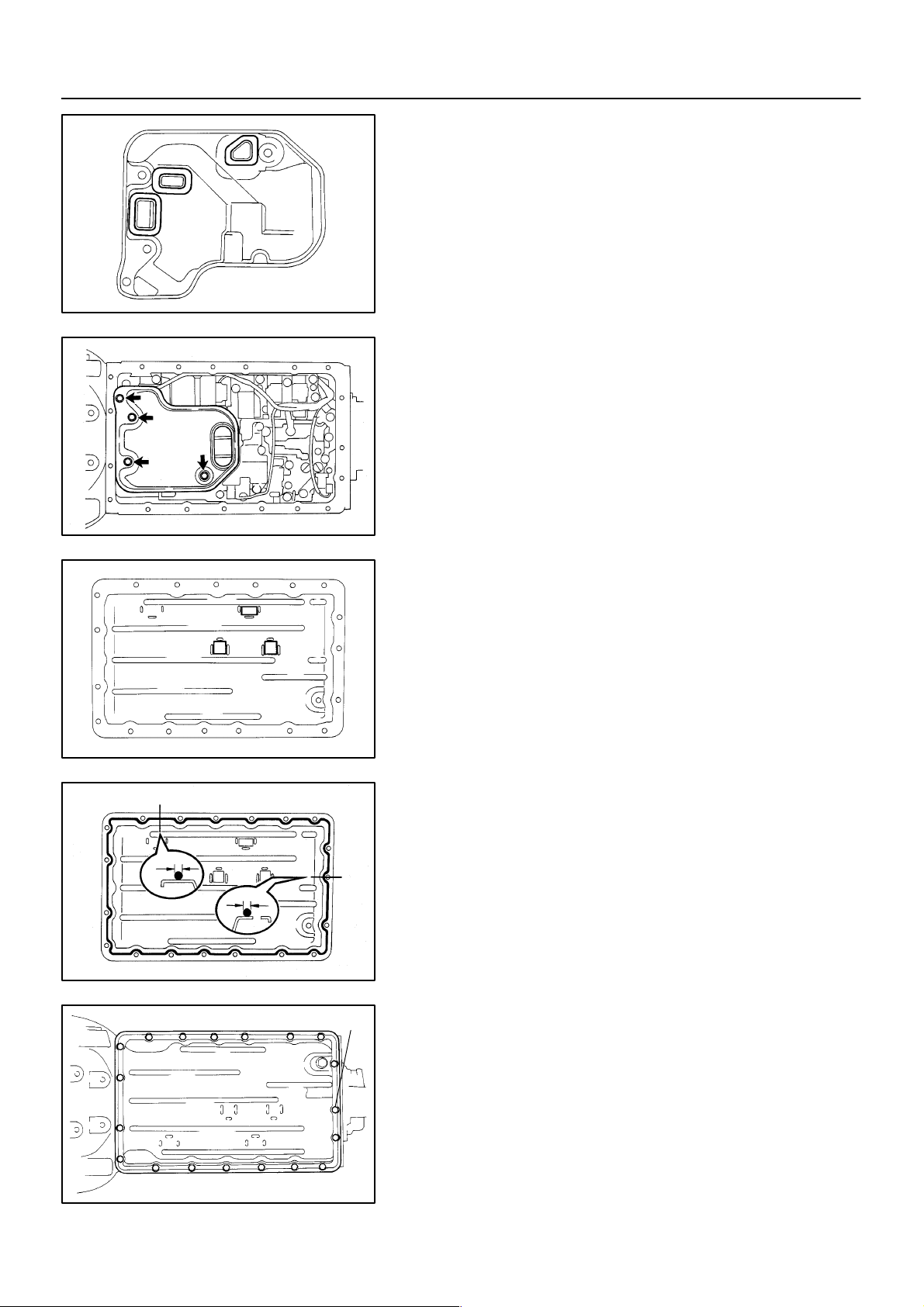

4. REMOVE OIL STRAINER

NOTICE:

Be careful as some fluid will come out of the oil strainer.

(a) Remove the 4 bolts and oil strainer.

D00752

(b) Remove the 3 gaskets from the oil strainer.

D00753

D00909

D00916

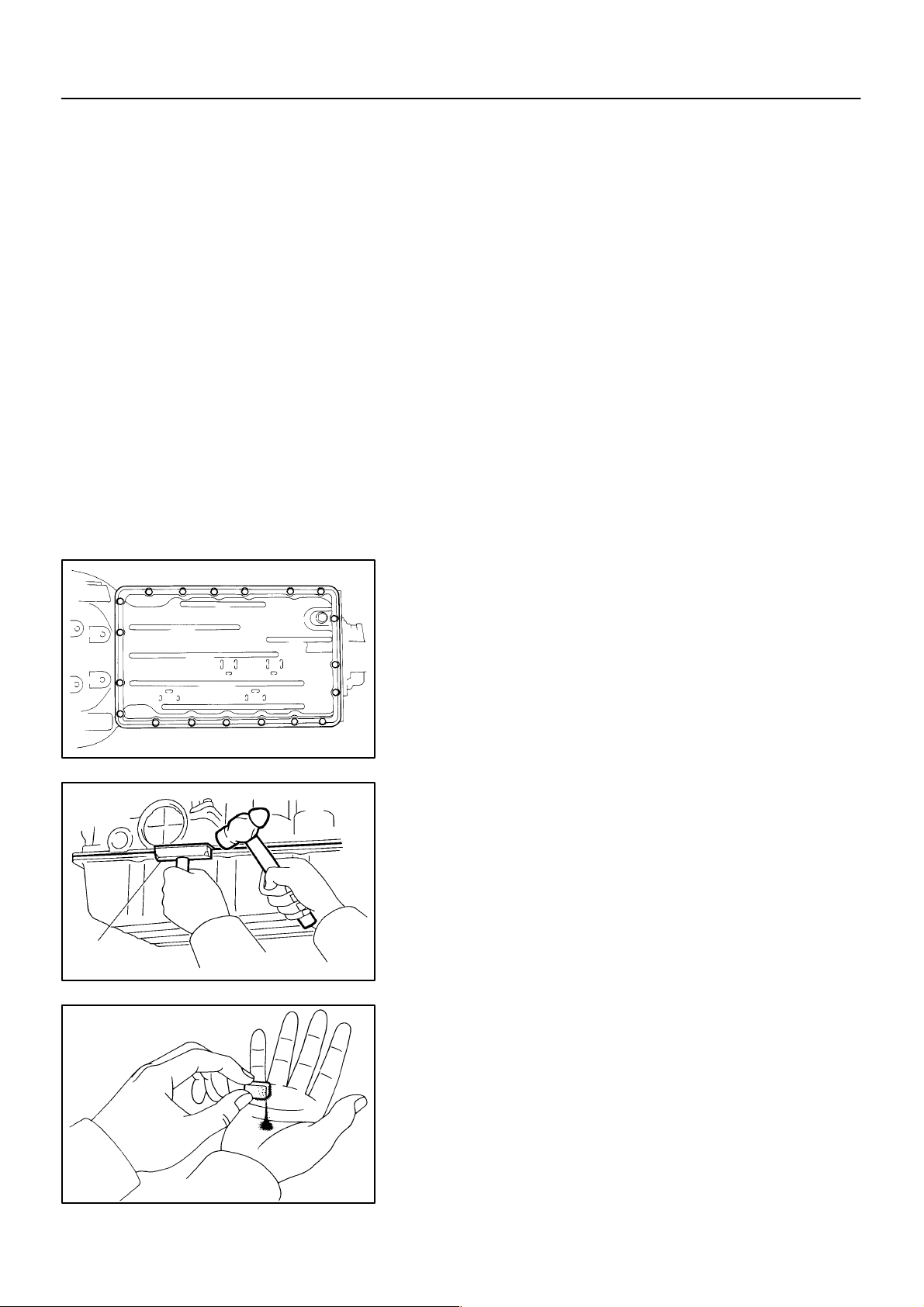

5. REMOVE SOLENOID WIRING WITH ATF TEMPERATURE SENSOR

(a) Disconnect the ATF temperature sensor.

(b) Remove the bolt and clamp.

(c) Disconnect the 7 connectors from the solenoid valves.

(d) Remove the bolt and pull out the solenoid connector.

6. INSTALL SOLENOID WIRING WITH ATF TEMPERATURE SENSOR

(a) Install the solenoid connector with the bolt.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

2000 LEXUS LS400 (RM717U)

(b) Connect the 7 connectors to the solenoid valves.

(c) Install the clamp with the bolt.

Torque: 6.4 N·m (65 kgf·cm, 56 in.·lbf)

(d) Connect the ATF temperature sensor.

D00909

1513Author: Date:

D00753

A T–7

–AUTOMA TIC TRANSMISSION ATF TEMPERATURE SENSOR

7. INSTALL OIL STRAINER

(a) Install 3 new gaskets.

(b) Install the oil strainer with the 4 bolts.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

Seal Breadth 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

D00752

8. INSTALL OIL PAN

(a) Install the 3 magnets in the indications of the oil pan.

D00912

(b) Remove any packing material and be careful not to drop

oil on the contacting surfaces of the transmission case

and oil pan.

(c) Apply FIPG to the oil pan.

FIPG:

Part No. 08826 – 00090, THREE BOND 1281 or

equivalent

D01917

2000 LEXUS LS400 (RM717U)

”A”

D00910

(d) Install the oil pan with the 19 bolts.

Torque: 7.4 N·m (75 kgf·cm, 65 in.·lbf)

HINT:

Replace the only ”A” bolt with a new one.

9. INSTALL DRAIN PLUG WITH NEW GASKET

Torque: 20 N·m (205 kgf·cm, 15 ft·lbf)

10. FILL FLUID AND CHECK FLUID

(See page DI–173)

1514Author: Date:

AT–8

–AUTOMA TIC TRANSMISSION VALVE BODY ASSEMBLY

VALVE BODY ASSEMBLY

AT037–01

ON–VEHICLE REPAIR

CAUTION:

When working with FIPG material, you must observe the following items.

Using a razor blade and gasket scraper, remove all the old

FIPG material from the gasket surfaces.

Thoroughly clean all components to remove all the loose

material.

Clean both sealing surfaces with a non–residue solvent.

Apply FIPG in an approx. 1 mm (0.04 in.) wide bead along

the sealing surface.

Parts must be assembled within 10 minutes of application.

Otherwise, the FIPG material must be removed and reapplied.

1. REMOVE DRAIN PLUG WITH GASKET AND DRAIN

AT F

2. REMOVE OIL PAN

NOTICE:

Some fluid will remain in the oil pan.

(a) Remove the 19 bolts.

SST

D00910

(b) Install the blade of SST between the transmission case

on oil pan, cut off applied sealer, and remove the oil pan.

SST 09032 – 00100

NOTICE:

When removing the oil pan, be careful not to damage the oil

pan flange.

Q07487

3. EXAMINE PARTICLES IN PAN

Remove the magnets and use them to collect steel particles.

Carefully look at the foreign matter and particles in the pan and

on the magnets to anticipate the type of wear you will find in the

transmission.

Steel (magnetic) ... bearing, gear and clutch plate wear

Brass (non–magnetic) ... bushing wear

AT0103

2000 LEXUS LS400 (RM717U)

1515Author: Date:

D00752

AT–9

–AUTOMA TIC TRANSMISSION VALVE BODY ASSEMBLY

4. REMOVE OIL STRAINER

NOTICE:

Be careful as some fluid will come out of the oil strainer.

(a) Remove the 4 bolts and oil strainer.

(b) Remove the 3 gaskets from the oil strainer.

D00753

D00909

D00754

5. REMOVE SOLENOID WIRING

(a) Disconnect the ATF temperature sensor.

(b) Remove the bolt and clamp.

(c) Disconnect the 7 connectors from the solenoid valves.

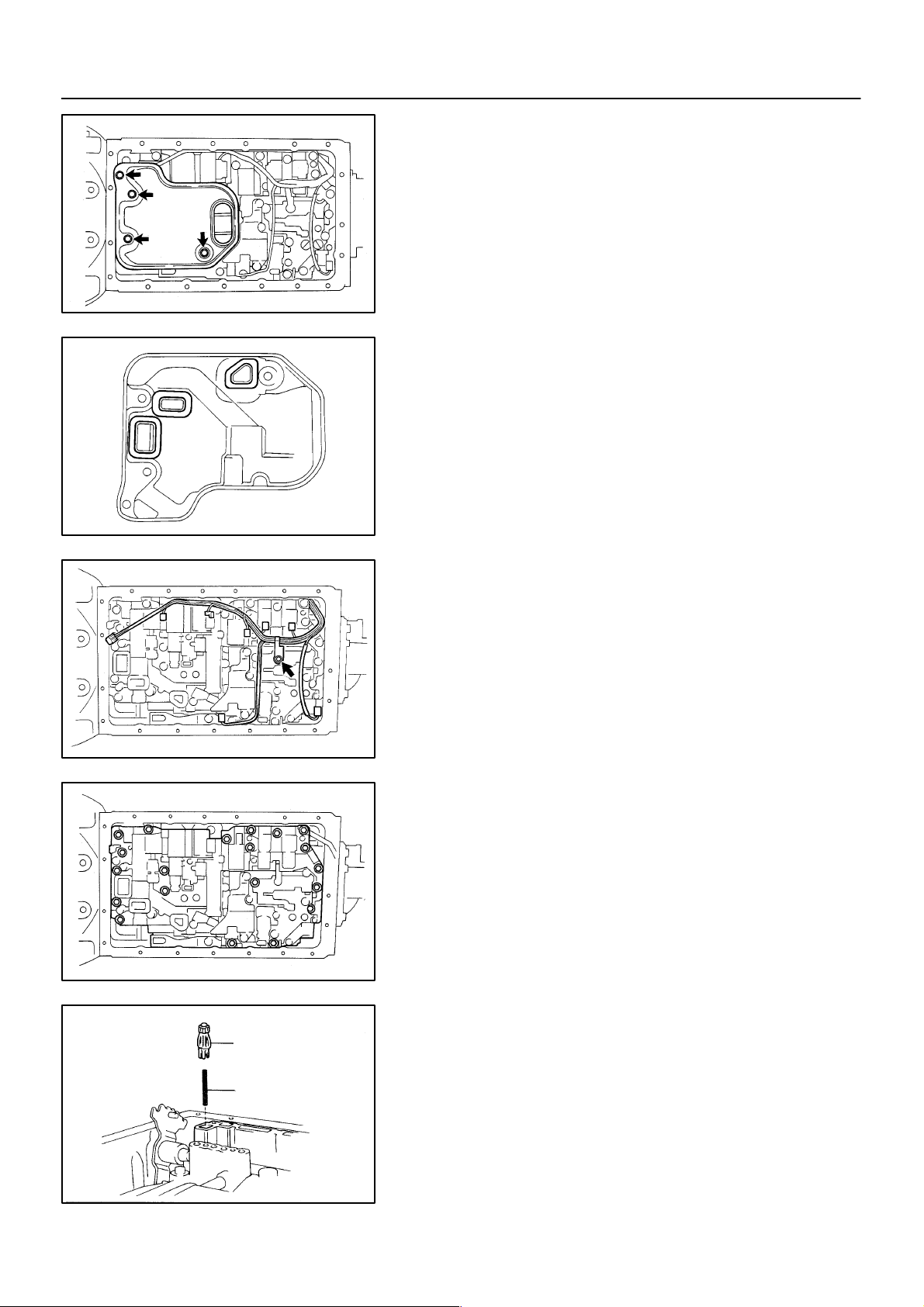

6. REMOVE VALVE BODY

Remove the 21 bolts and valve body.

2000 LEXUS LS400 (RM717U)

Check Ball Body

Spring

D01741

7. REMOVE CHECK BALL BODY AND SPRING

NOTICE:

Do not drop the check ball body and spring.

1516Author: Date:

AT–10

–AUTOMA TIC TRANSMISSION VALVE BODY ASSEMBLY

Shift Solenoid

Valve SLN

Shift Solenoid

Valve SLU

Shift Solenoid

Valve SLT

Shift Solenoid

Valve S3

Shift Solenoid

Valve S1

Shift Solenoid Valve S4

Shift Solenoid Valve S2

D00911

8. REMOVE SOLENOID VALVE

(a) Remove the 3 bolts and shift solenoid valve No.1, No.2

and No.3.

(b) Remove the 2 bolts, oil guide plate, lock plate, shift sole-

noid valve SLN and No.4.

(c) Remove the 6 O–rings from each shift solenoid valve.

(d) Remove the bolt, lock plate and shift solenoid valve SLU

and SLT.

9. INSTALL SOLENOID VALVE

(a) Install the shift solenoid valve SLU and SLT and the lock

plate with the bolt.

Torque: 6.4 N·m (65 kgf·cm, 56 in.·lbf)

(b) Coat 6 new O–rings with ATF.

(c) Install the 6 O–rings to the each solenoid valve.

(d) Install the shift solenoid valve SLN, No.4, lock plate and

oil guide plate with the 2 bolts.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

(e) Install the shift solenoid valve No.1, No.2 and No.3 with

the 3 bolts.

Torque:

Shift solenoid valve No.1 and No.3:

6.4 N·m (65 kgf·cm, 56 in.·lbf)

Shift solenoid valve No.2:

10 N·m (100 kgf·cm, 7 ft·lbf)

Pin

2000 LEXUS LS400 (RM717U)

10. INSTALL CHECK BALL BODY AND SPRING

Check Ball Body

Spring

D01741

11. INSTALL VALVE BODY

(a) Align the groove of the manual valve to pin of the lever.

D00913

1517Author: Date:

–AUTOMA TIC TRANSMISSION VALVE BODY ASSEMBLY

AT–11

B

A

B

B

D

A

C

(b) Install the 21 bolts.

B

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

Bolt length:

Bolt A: 23 mm (0.91 in.)

Bolt B: 28 mm (1.10 in.)

Bolt C: 36 mm (1.42 in.)

Bolt D: 55 mm (2.17 in.)

C

C

B

D00754

12. INSTALL SOLENOID WIRING

(a) Connect the 7 connectors to the solenoid valves.

(b) Install the clamp with the bolt.

Torque: 6.4 N·m (65 kgf·cm, 56 in.·lbf)

(c) Connect the ATF temperature sensor.

D00909

13. INSTALL OIL STRAINER

(a) Install 3 new gaskets.

D00753

D00752

D00912

(b) Install the oil strainer with the 4 bolts.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

14. INSTALL OIL PAN

(a) Install the 3 magnets in the indications of the oil pan.

2000 LEXUS LS400 (RM717U)

1518Author: Date:

AT–12

–AUTOMA TIC TRANSMISSION VALVE BODY ASSEMBLY

Seal Breadth 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

D01917

”A”

D00910

(b) Remove any packing material and be careful not to drop

oil on the contacting surfaces of the transmission case

and oil pan.

(c) Apply FIPG to the oil pan.

FIPG:

Part No. 08826 – 00090, THREE BOND 1281 or

equivalent

(d) Install the oil pan with the 19 bolts.

Torque: 7.4 N·m (75 kgf·cm, 65 in.·lbf)

HINT:

Replace the only ”A” bolt with a new one.

15. INSTALL DRAIN PLUG WITH NEW GASKET

Torque: 20 N·m (205 kgf·cm, 15 ft·lbf)

16. FILL FLUID AND CHECK FLUID

(See page DI–173)

2000 LEXUS LS400 (RM717U)

1519Author: Date:

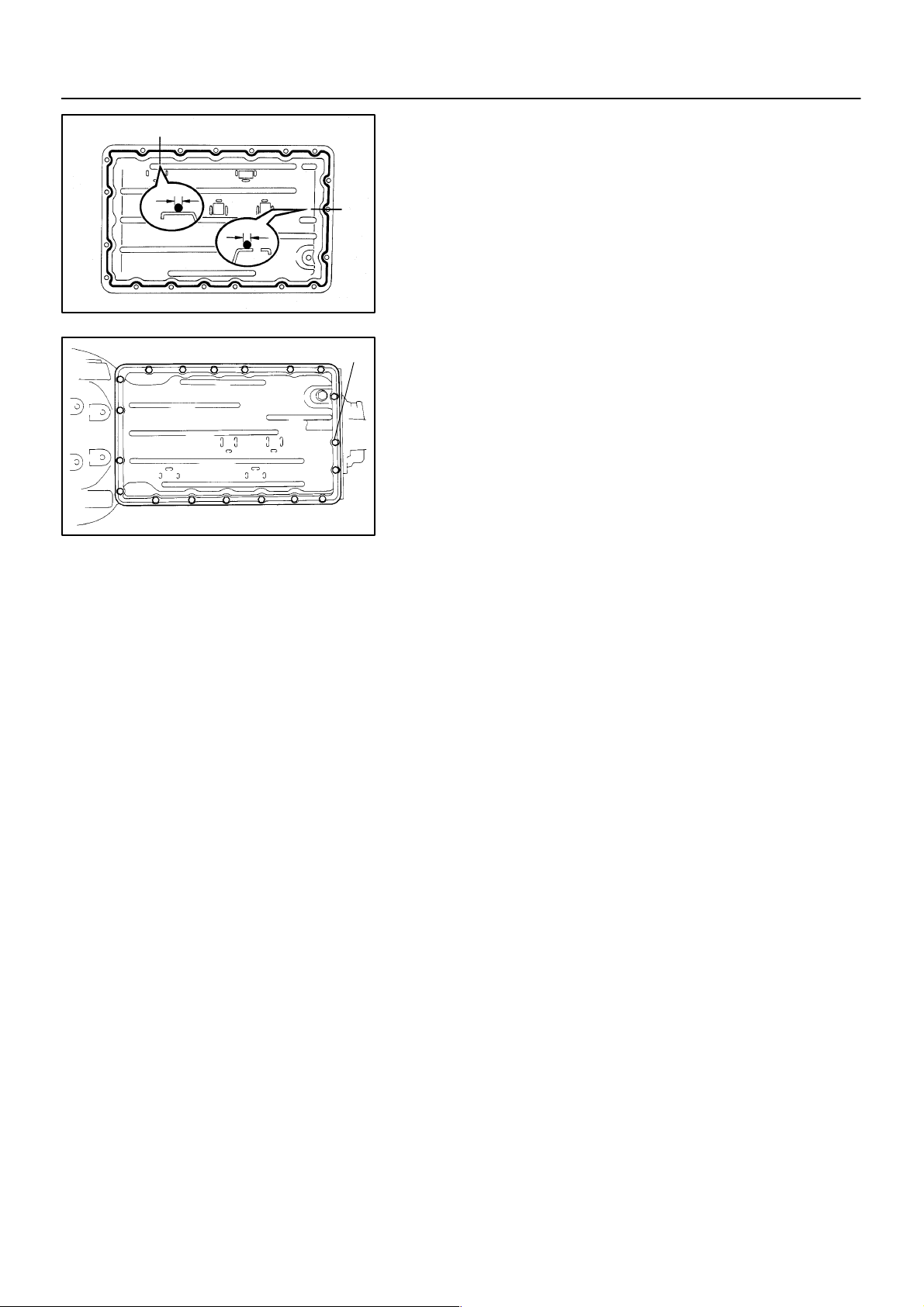

SHIFT LOCK SYSTEM

LOCATION

AT–13

–AUTOMA TIC TRANSMISSION SHIFT LOCK SYSTEM

AT038–01

Key Interlock Solenoid

Stop Light Switch

Shift Lock Override

Button

Shift Lock Solenoid

Shift Lock Control Switch

Shift Lock Control ECU

D01014

2000 LEXUS LS400 (RM717U)

1520Author: Date:

AT–14

A, 3 A, 5 (KLS E)

–AUTOMA TIC TRANSMISSION SHIFT LOCK SYSTEM

INSPECTION

+

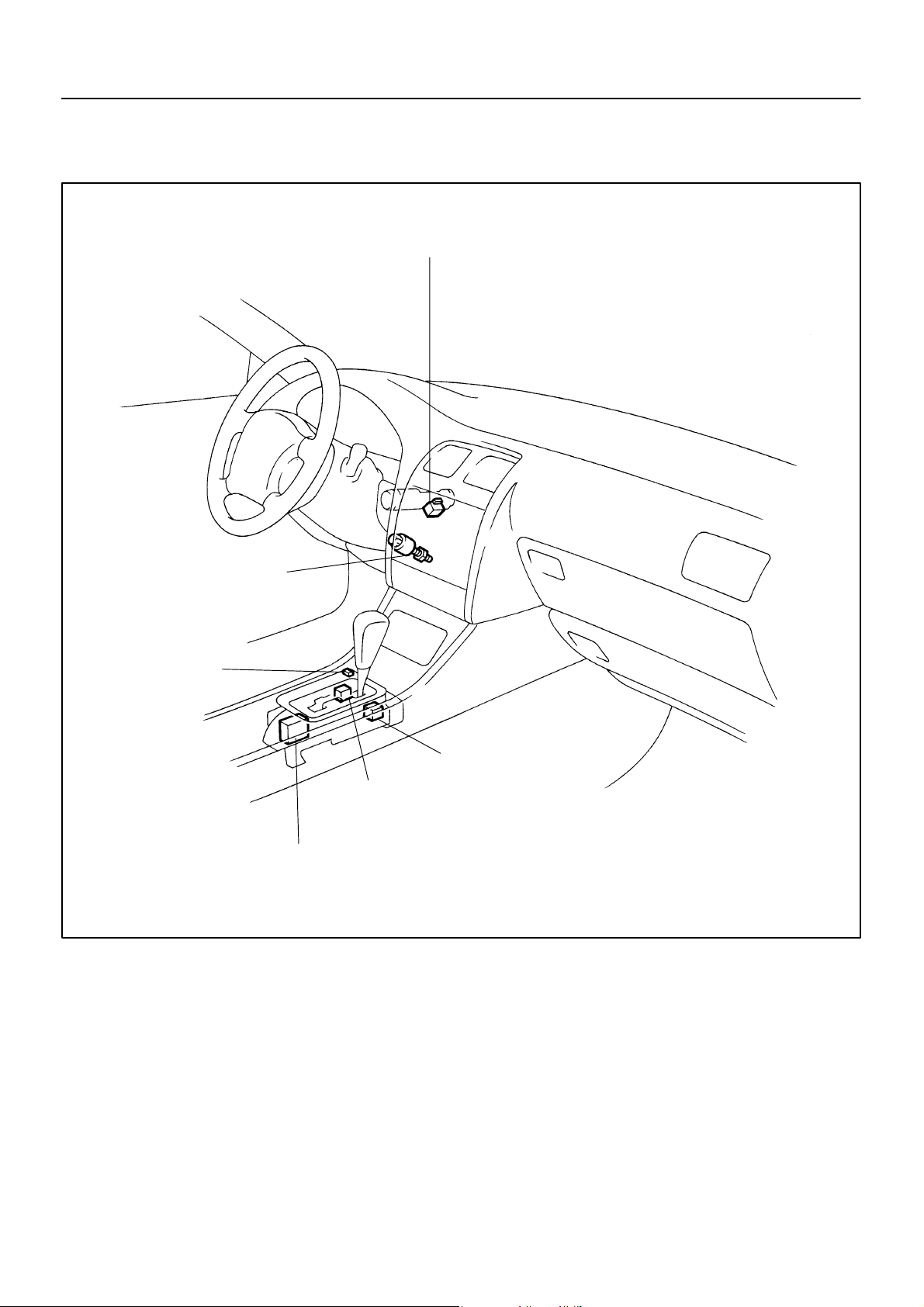

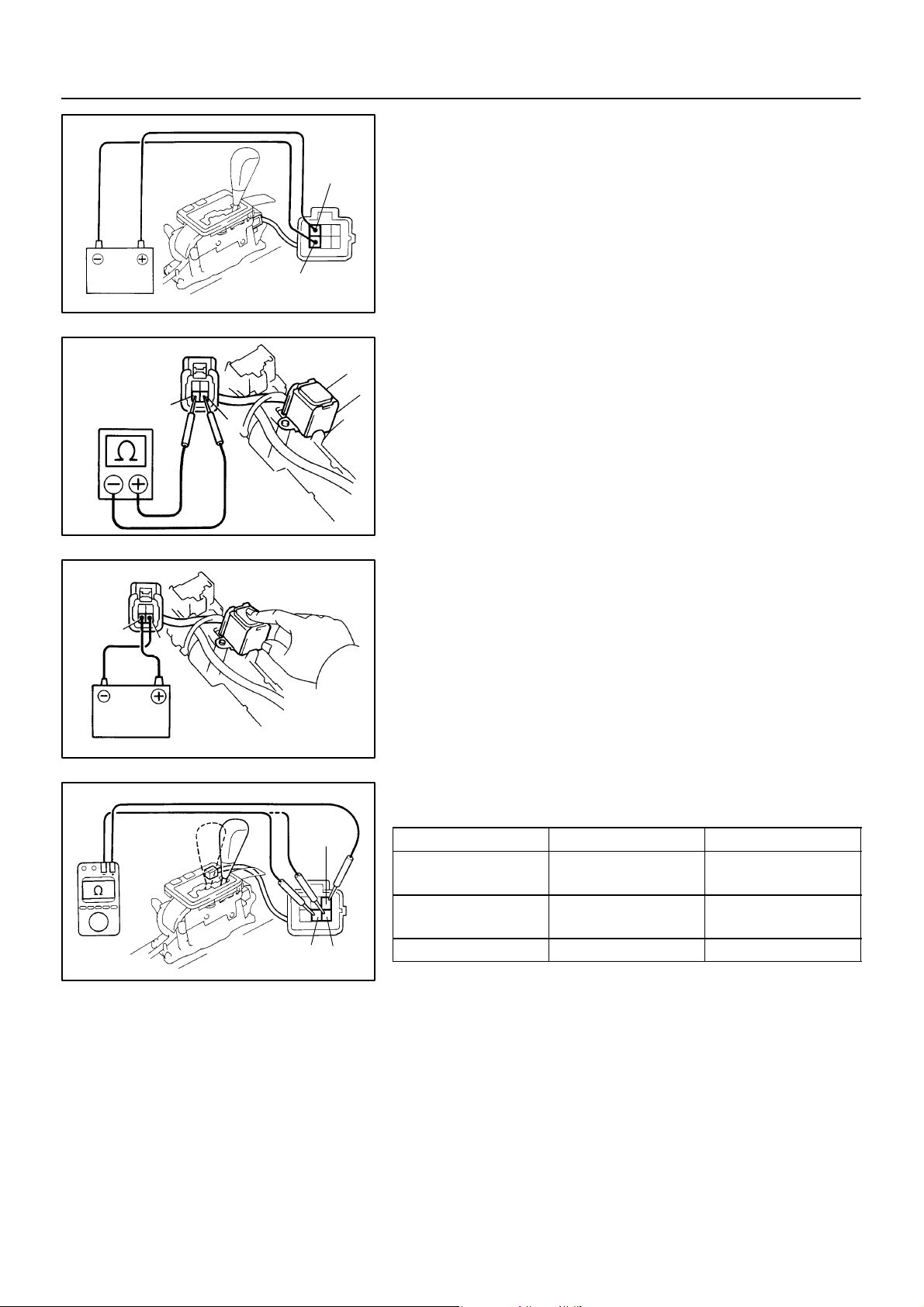

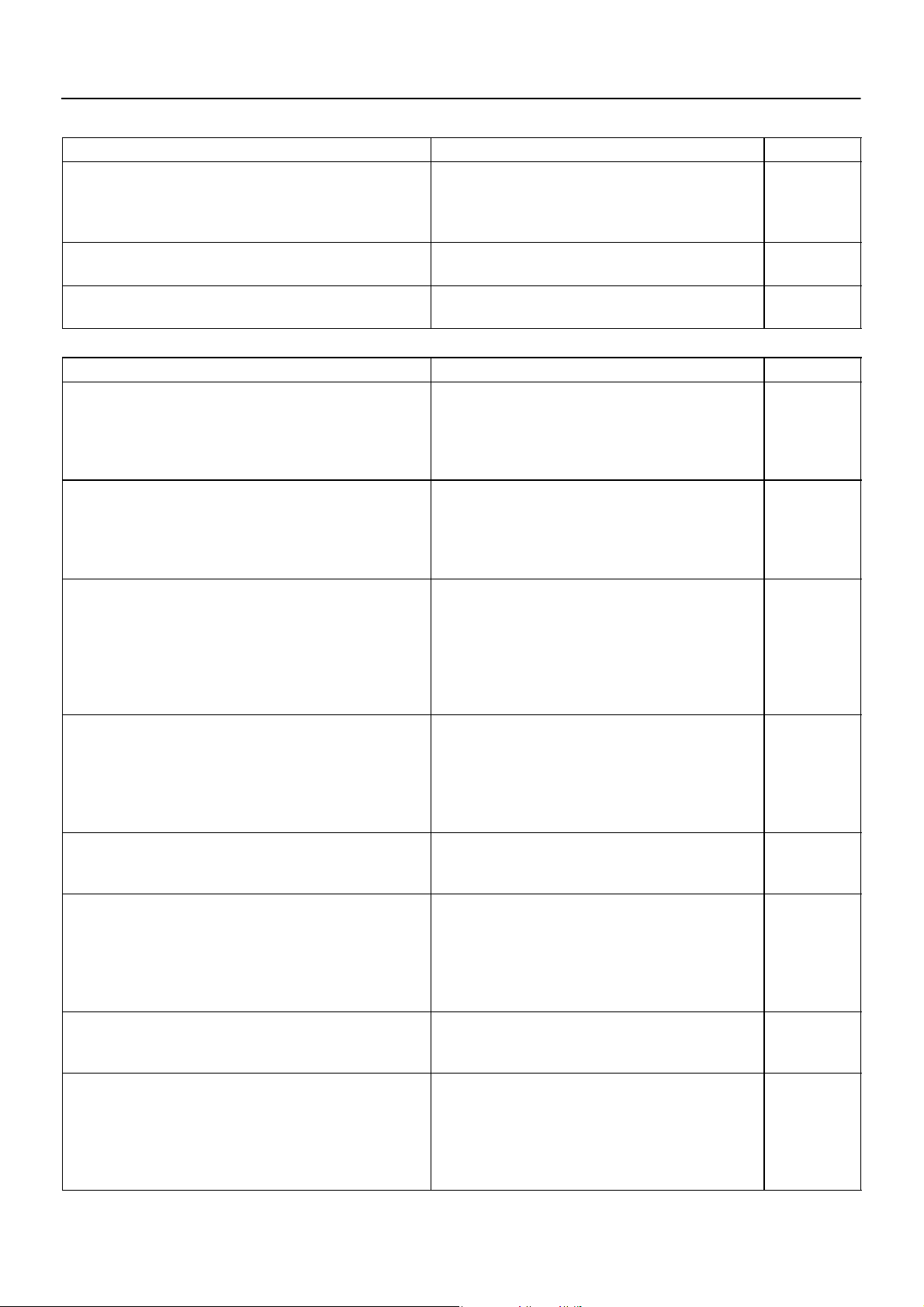

1. INSPECT SHIFT LOCK CONTROL ECU

IG

A

ACC

B

P

SLS

Using a voltmeter, measure the voltage at each terminal.

HINT:

Do not disconnect the ECU connector.

+

STP

KLS

P1P2

SPDDOFF E

Terminal Measuring Condition Voltage (V)

A, 1 – A, 5 (ACC – E) IG SW ACC 10 – 14

A, 2 – A, 5 (IG – E) IG SW ON 10 – 14

A, 8 – A, 5 (STP – E) Depress brake pedal 10 – 14

(1) IG SW ACC and shift lever P position Below 1.5

A, 3 – A, 5 (KLS+ – E)

A, 4 – A, 5 (SPD – E)

A, 7 – A, 5 (DOFF – E)

B, 3 – B, 6 (SLS+ – SLS–)

B, 5 – B, 1 (P1 – P)

B, 4 – B, 1 (P2 – P)

(2) IG SW ON and shift lever R, N, D, 3, 2, L position 8.5 – 10.5

(3) IG SW ON and shift lever R, N, D, 3, 2, L position (after 1 second) 7.0 – 8.5

(1) IG SW ON, shift lever D or 3 position and vehicle speed more than 11 km/h

(6.8 mph)

(2) IG SW ON, shift lever D or 3 position and vehicle speed less than 11 km/h

(6.8 mph)

(1) IG SW ON and shift lever D, 3 position 10 – 14

(2) IG SW ON and shift lever P, R, N, 2, L position 0

(1) IG SW ON and shift lever P position 0

(2) IG SW ON and depress brake pedal 8.8 – 12.5

(3) IG SW ON and depress brake pedal (after 20 seconds) 6.5 – 9.2

(4) IG SW ON and shift lever D, 3, 2, L position 0

(1) IG SW ON and shift lever P position 0

(2) IG SW ON and shift lever R, N, D, 3, 2, L position 10 – 14

(1) IG SW ACC and shift lever P position 10 – 14

(2) IG SW ACC and shift lever R, N, D, 3, 2, L position 0

SLS

Z16912

–

AT039–01

Below 2

10 – 14

2000 LEXUS LS400 (RM717U)

6 (SLS

3 (SLS

–)

+)

D01015

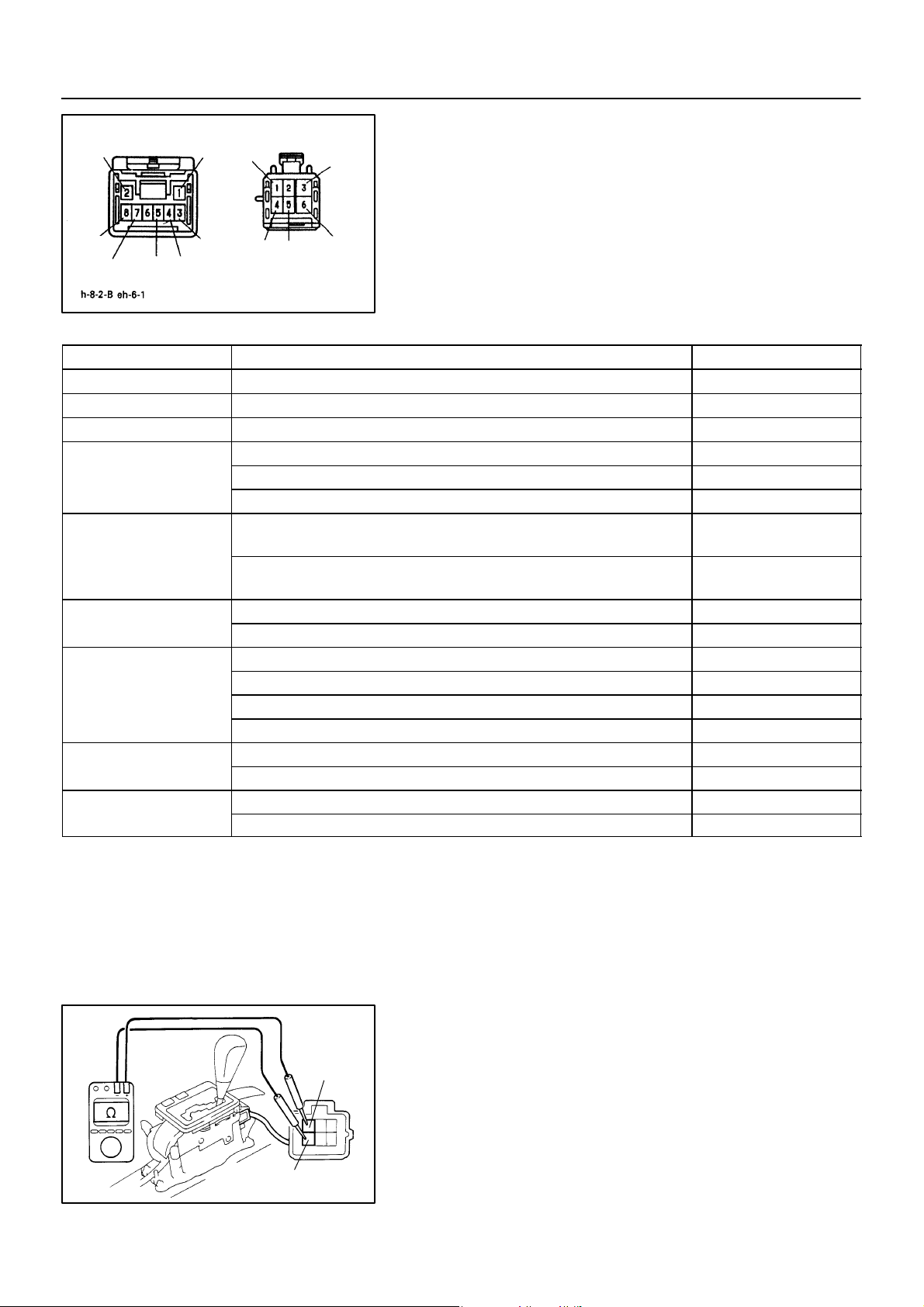

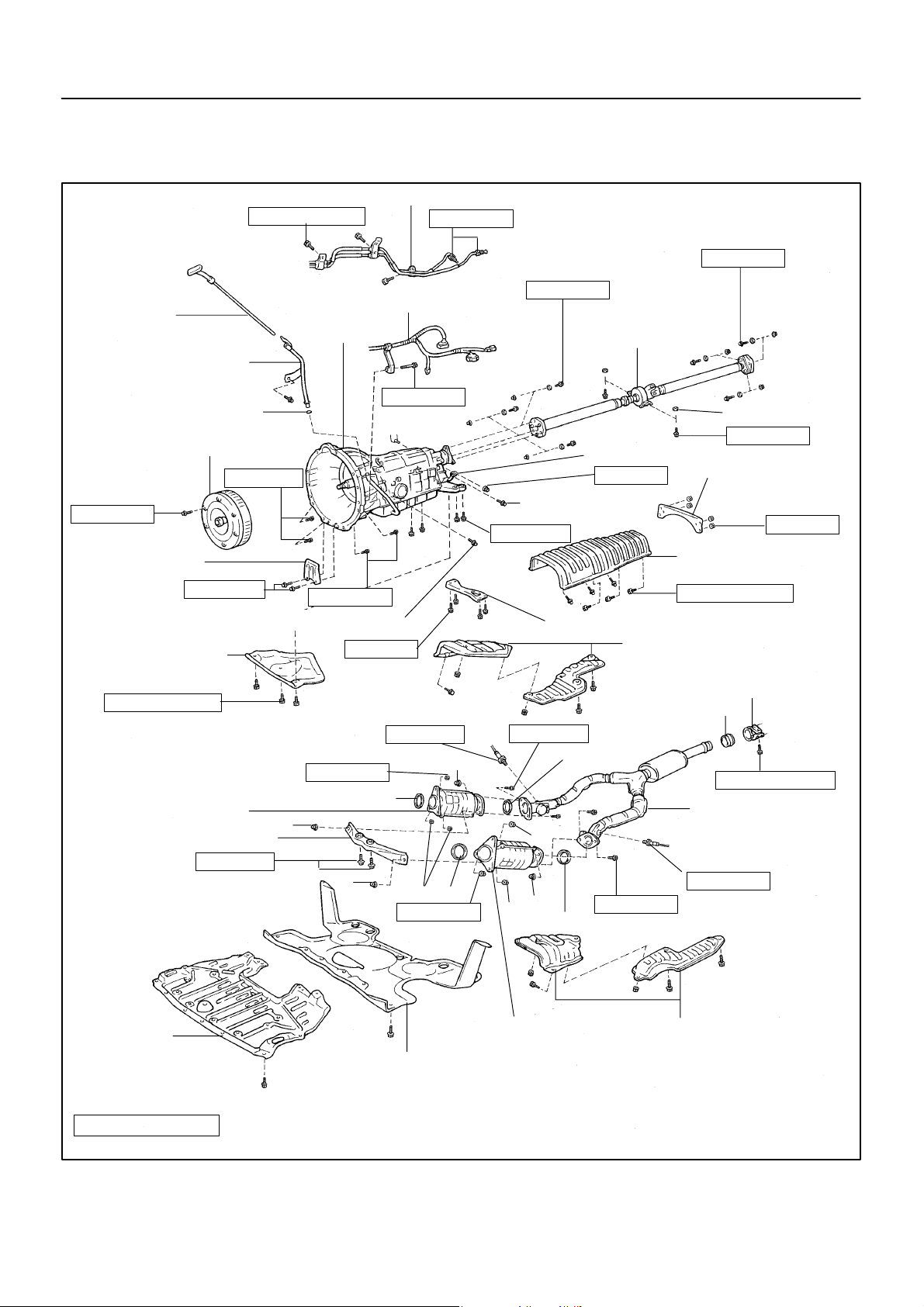

2. INSPECT SHIFT LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Using an ohmmeter, measure the resistance between ter-

minals 3 and 6.

Standard resistance: 20 – 28 Ω

If the resistance is not as specified, replace the solenoid.

1521Author: Date:

AT–15

–AUTOMA TIC TRANSMISSION SHIFT LOCK SYSTEM

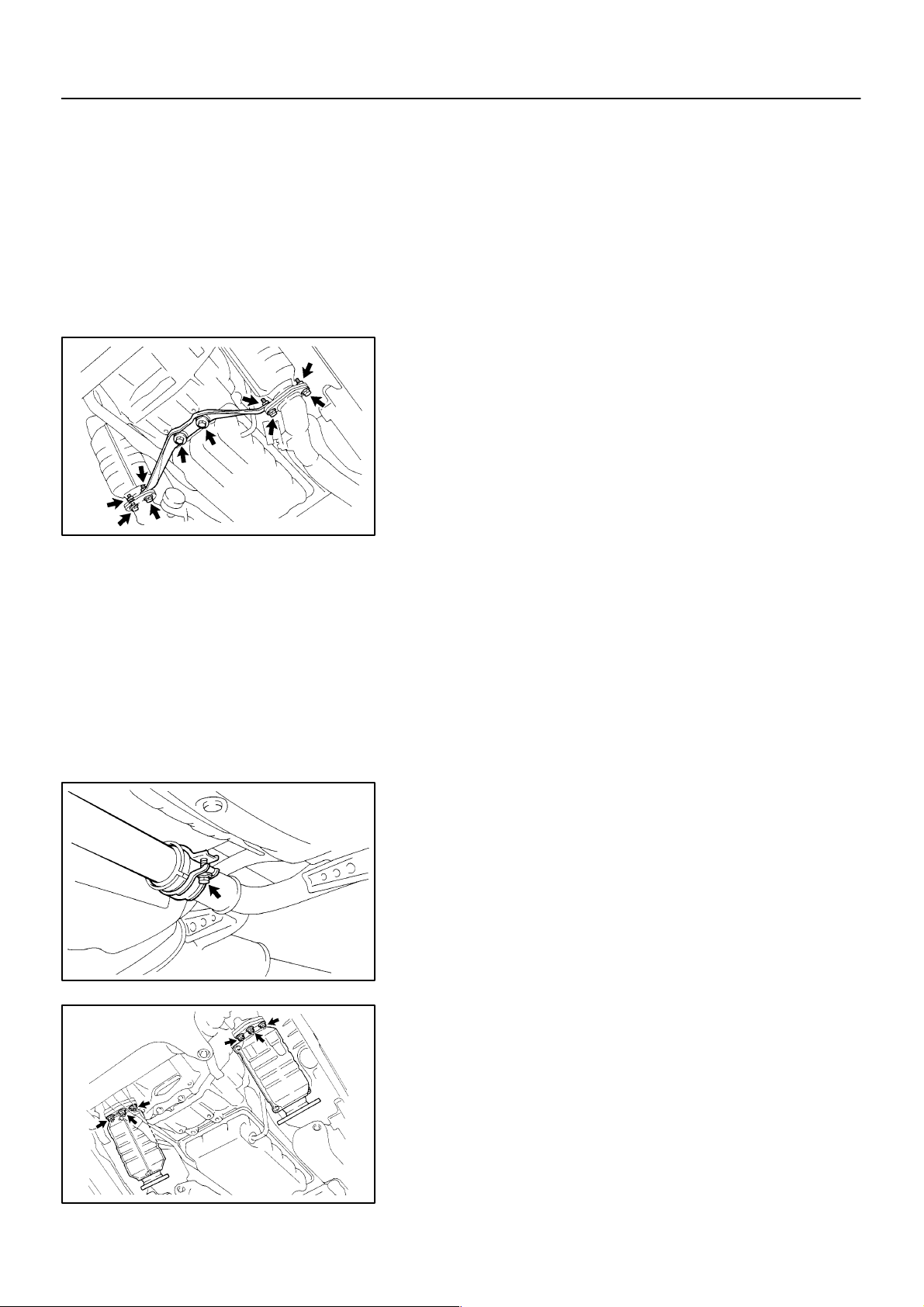

(c) Apply the battery voltage between terminals 3 and 6. At

this time, confirm that the solenoid operates.

If the operation is not as specified, replace the solenoid.

3 (SLS

6 (SLS

+)

–)

D01016

3. INSPECT KEY INTERLOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Using an ohmmeter, measure the resistance between ter-

+

–

minals 3 and 4.

Standard resistance: 12 – 17 Ω

If the resistance value is not as specified, replace the solenoid.

Z16909

(c) Touch the solenoid with your finger and check that the so-

lenoid operation can be felt when battery voltage is applied intermittently to terminals 3 and 4.

+

–

Z16910

If the operation is not as specified, replace the solenoid.

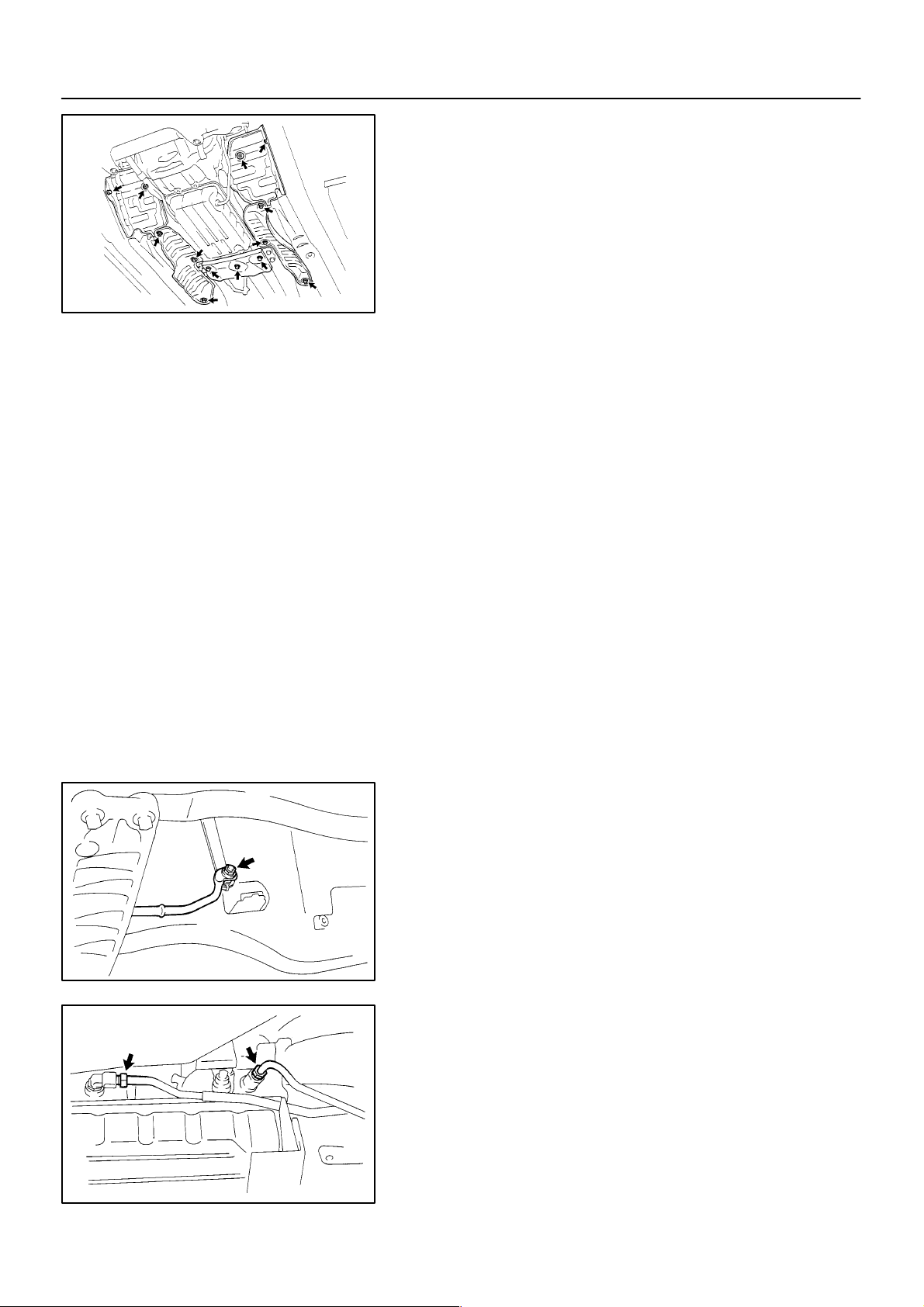

4. INSPECT SHIFT LOCK CONTROL SWITCH

Inspect that there is continuity between each terminal.

5 (P1)

1 (P)

4 (P2)

D01017

Shift position Tester condition Specified value

P position (Shift lever at

left side)

P position (Shift lever at

right side)

R, N, D, 3, 2, L position 4 – 1 (P2 – P) Continuity

5 – 1 (P1 – P) Continuity

5 – 1 (P1 – P)

4 – 1 (P2 – P)

Continuity

If the continuity is not as specified, replace the switch.

2000 LEXUS LS400 (RM717U)

1522Author: Date:

AT–16

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

AUTOMATIC TRANSMISSION UNIT

COMPONENTS

Oil Cooler Pipe

Level Gauge

Filler Pipe

O–Ring

Torque Converter Clutch

48 (490, 35)

x6

Flywheel Housing

Under Cover

18 (185, 13)

Engine Rear Mounting

Member Bracket Plate

5.4 (55, 48 in.·lbf)

4.9 (50, 43 in.·lbf)

Wire Harness and Connector

Transmission

72 (730, 53)

37 (380, 27)

37 (380, 27)

Plug for Line Pressure Test

13 (130, 9)

Oxygen Sensor

44 (450, 32)

x6

26 (270, 20)

44 (450, 32)

79 (805, 58)

79 (805, 58)

Propeller Shaft

Adjusting Washer

37 (375, 27)

Shift Control Rod

13 (130, 9)

Plug for Accumulator

Rear Center Floor

Crossmember Brace

Back Pressure Test

Heat Insulator

5.4 (55, 48 in.·lbf)

Front Center Floor Crossmember Brace

Heat Insulator

Clamp

Gasket

43 (440, 32)

AT03A–01

13 (130, 9)

RH Front TWC

Pipe Support Bracket

43 (440, 32)

Engine Under

Cover

N·m (kgf·cm, ft·lbf)

Non–reusable part

62 (630, 46)

Gasket

Front Suspension Protector

: Specified torque

62 (630, 46)

LH Front TWC

See page EM–120

Front Exhaust Pipe

Oxygen Sensor

44 (450, 32)

43 (440, 32)

Gasket

Heat Insulator

D00996

2000 LEXUS LS400 (RM717U)

1523Author: Date:

D00997

A T–17

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

AT03B–01

REMOVAL

1. REMOVE LEVEL GAUGE

2. RAISE VEHICLE

NOTICE:

Make sure that the vehicle is securely supported.

3. REMOVE ENGINE UNDER COVER

4. REMOVE FRONT SUSPENSION PROTECTOR

5. REMOVE FRONT EXHAUST PIPE

(a) Disconnect the 2 heated oxygen sensors.

Torque: 44 N·m (450 kgf·cm, 32 ft·lbf)

HINT:

At the time of installation, please refer to the following items.

Before installing the heated oxygen sensor, twist the sen-

sor wire counterclockwise 3 and 1/2 turns.

After installing the heated oxygen sensor wire is not

twisted. If it is twisted, remove the heated oxygen sensor

and reinstall it.

(b) Remove the 4 bolts, nuts and 2 gaskets from the LH and

RH front TWC.

Torque: 43 N·m (440 kgf·cm, 32 ft·lbf)

HINT:

At the time of installation, please refer to the following item.

Replace the used nuts and gaskets with new ones.

(c) Remove the 2 bolts and support bracket.

Torque: 43 N·m (440 kgf·cm, 32 ft·lbf)

2000 LEXUS LS400 (RM717U)

(d) Remove the pipe clamp set bolt and gasket.

(See page EM–120)

HINT:

At the time of installation, please refer to the following item.

Replace the used gasket with a new one.

(e) Remove the front exhaust pipe.

D00998

6. REMOVE LH AND RH FRONT TWC

Remove the 6 nuts, 2 gaskets, LH and RH front TWC.

Torque: 62 N·m (630 kgf·cm, 46 ft·lbf)

HINT:

At the time of installation, please refer to the following item.

Replace the used nuts and gaskets with new ones.

D00999

1524Author: Date:

AT–18

D01000

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

7. REMOVE HEAT INSULATOR AND ENGINE REAR

MOUNTING MEMBER BRACKET PLATE

(a) Remove the 4 nuts, 6 bolts and heat insulators.

(b) Remove the 3 bolts and bracket plate.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

8. REMOVE BOLT AND FILLER PIPE

HINT:

At the time of installation, please refer to the following item.

Replace the used O–ring with a new one.

9. REMOVE HEAT INSULATOR

Remove the 6 bolts and heat insulator.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

10. REMOVE CROSSMEMBER BRACE

(a) Remove the 4 bolts and front center floor crossmember

brace.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

(b) Remove the 4 nuts and rear center floor crossmember

brace.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

11. REMOVE PROPELLER SHAFT

(See page PR–3)

2000 LEXUS LS400 (RM717U)

12. REMOVE SHIFT CONTROL ROD

Remove the nut and disconnect the rod.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

D01001

13. DISCONNECT OIL COOLER PIPE

(a) Loosen the 2 union nuts from the transmission.

Torque: 44 N·m (450 kgf·cm, 32 ft·lbf)

NOTICE:

Be careful no to damage the oil cooler pipe.

D01002

1525Author: Date:

D01003

A T–19

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

(b) Disconnect the 3 set bolts of the clamp.

Torque: 4.9 N·m (50 kgf·cm, 43 in.·lbf)

(c) Disconnect the 2 oil cooler pipes from the transmission.

14. REMOVE TORQUE CONVERTER CLUTCH MOUNTING BOLT

(a) Remove the 2 bolts and flywheel housing under cover.

Torque: 18 N·m (185 kgf·cm, 13 ft·lbf)

D01004

D01005

Q03721

(b) Turn the crankshaft to gain access to each bolt.

(c) Hold the crankshaft pulley nut with a wrench and remove

the 6 bolts.

Torque: 48 N·m (490 kgf·cm, 35 ft·lbf)

HINT:

At the time of installation, please refer to the following item.

First install black colored bolt and then the 5 other bolts.

15. SUPPORT TRANSMISSION WITH JACK

2000 LEXUS LS400 (RM717U)

16. REMOVE ENGINE REAR MOUNTING 4 SET BOLTS

Torque: 26 N·m (270 kgf·cm, 20 ft·lbf)

D01006

1526Author: Date:

AT–20

Q06925

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

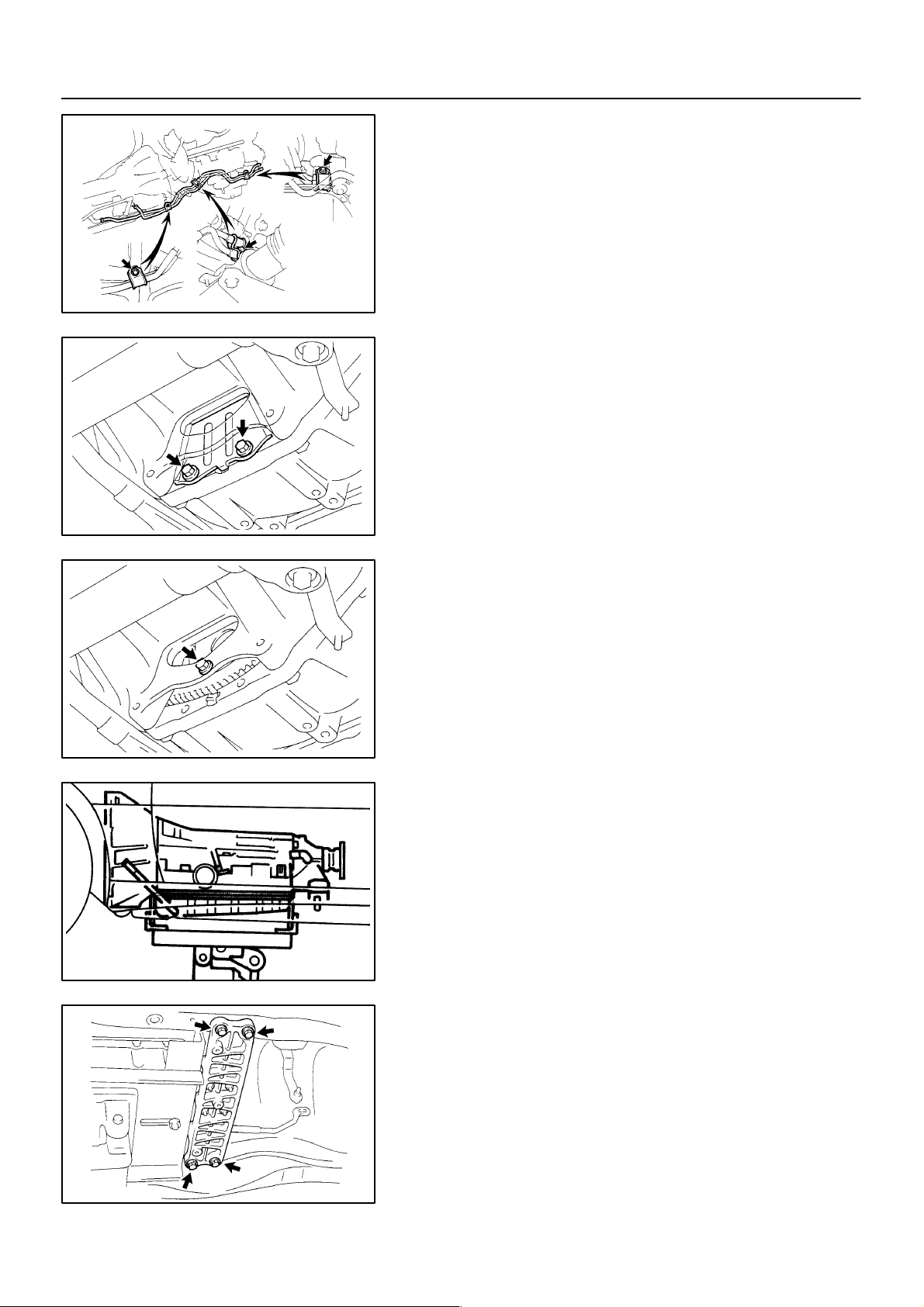

17. DISCONNECT CONNECTORS AND WIRE HARNESS

(a) Tilt down the transmission.

NOTICE:

Take care so that the cooling fan does not come in contact

with the fan shroud.

(b) Disconnect the following connectors:

(1) O/D direct clutch speed sensor connector

(2) Vehicle speed sensor connector

(3) Park/neutral position switch connector

(4) Solenoid connector

(c) Disconnect the wire harness from the clamp on transmis-

sion.

17 mm Head

Bolt

17 mm Head Bolt

14 mm Head Bolt

18. REMOVE TRANSMISSION

Remove the 10 bolts and transmission.

Torque:

14 mm head bolt: 37 N·m (380 kgf·cm, 27 ft·lbf)

17 mm head bolt: 72 N·m (730 kgf·cm, 53 ft·lbf)

Q03099

HINT:

At the time of installation, please refer to the following item.

Lift the engine front side.

Q06924

2000 LEXUS LS400 (RM717U)

1527Author: Date:

D01007

A T–21

–AUTOMA TIC TRANSMISSION AUTOMA TIC TRANSMISSION UNIT

AT03C–01

INSTALLATION

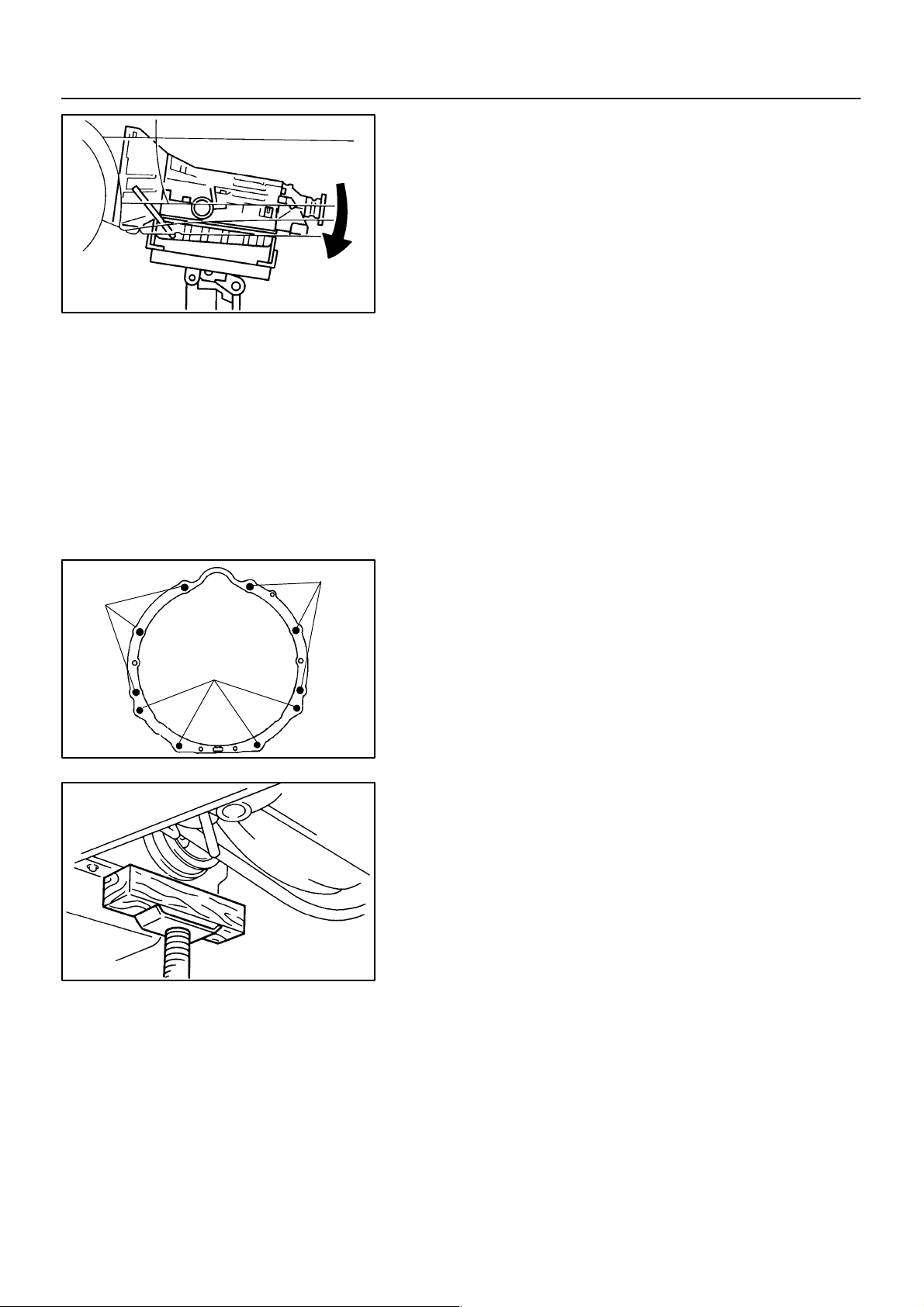

1. CHECK TORQUE CONVERTER CLUTCH INSTALLATION

Using calipers and a straight edge, measure from the installed

surface of the torque converter clutch to the front surface of the

transmission housing.

Correct distance: More than 17.1 mm (0.673 in.)

If the distance is less than the standard, check for an improper

installation.

2. INSTALL TRANSMISSION

Installation is in the reverse order of removal.

(See page AT–17)

HINT:

After installation, check and inspect items as follows.

Adjust the shift lever position. (See page DI–173)

Check fluid level. (See page DI–173)

Do the road test. (See page DI–173)

2000 LEXUS LS400 (RM717U)

1528Author: Date:

AT–22

–AUTOMA TIC TRANSMISSION TORQUE CONVERTER CLUTCH AND DRIVE PLATE

TORQUE CONVERTER CLUTCH

SST

Lock

Free

AT5436

AND DRIVE PLATE

AT03D–01

INSPECTION

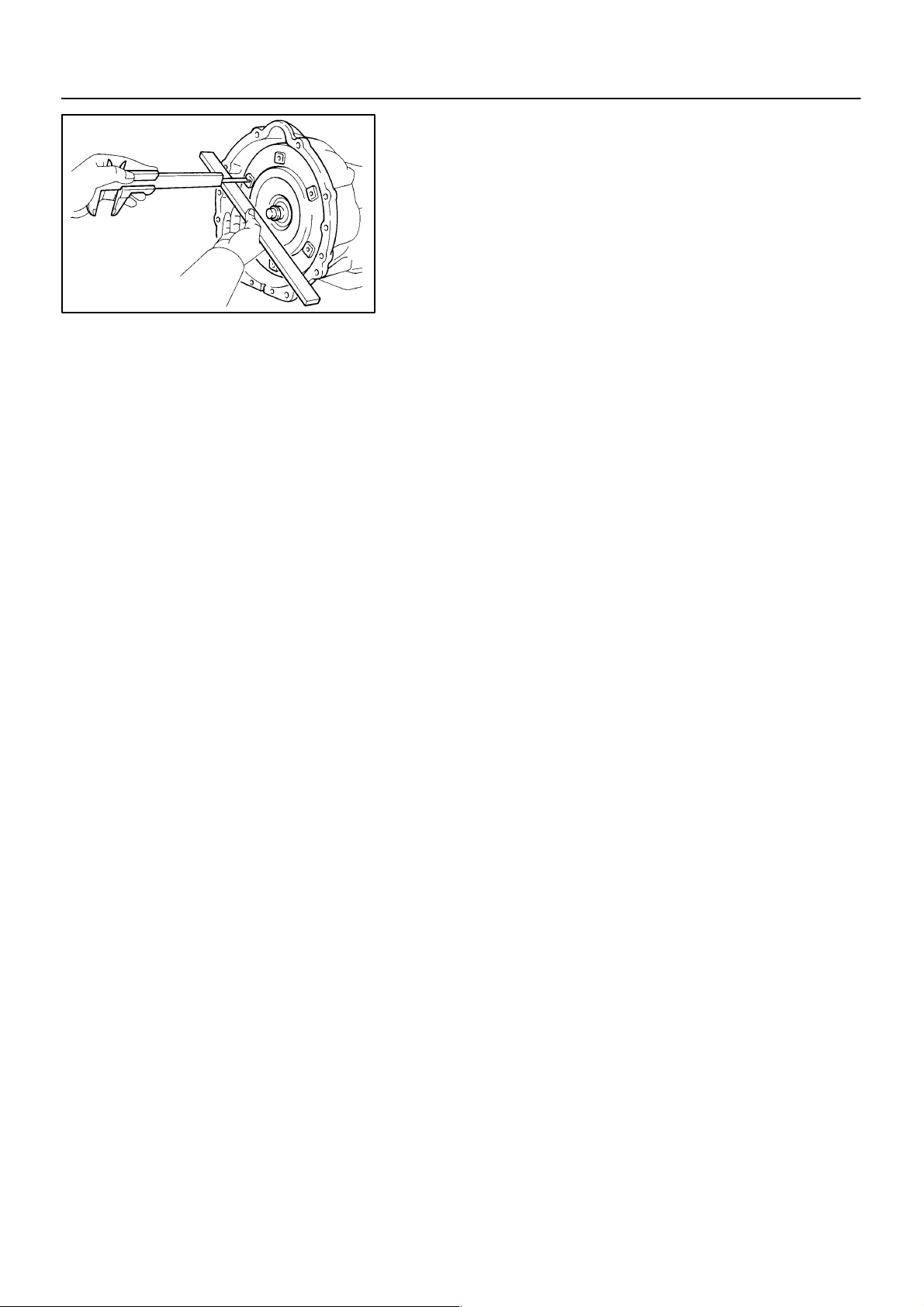

1. INSPECT ONE–WAY CLUTCH

(a) Install SST so that it fits in the notch of the converter hub

and outer race of the one–way clutch.

SST 09350–30020 (09351–32020)

(b) Press on the serrations of starter with a finger and rotate

it.

Check if it rotates smoothly when turned clockwise and

locks up when turned counterclockwise.

AT5437

Q03546

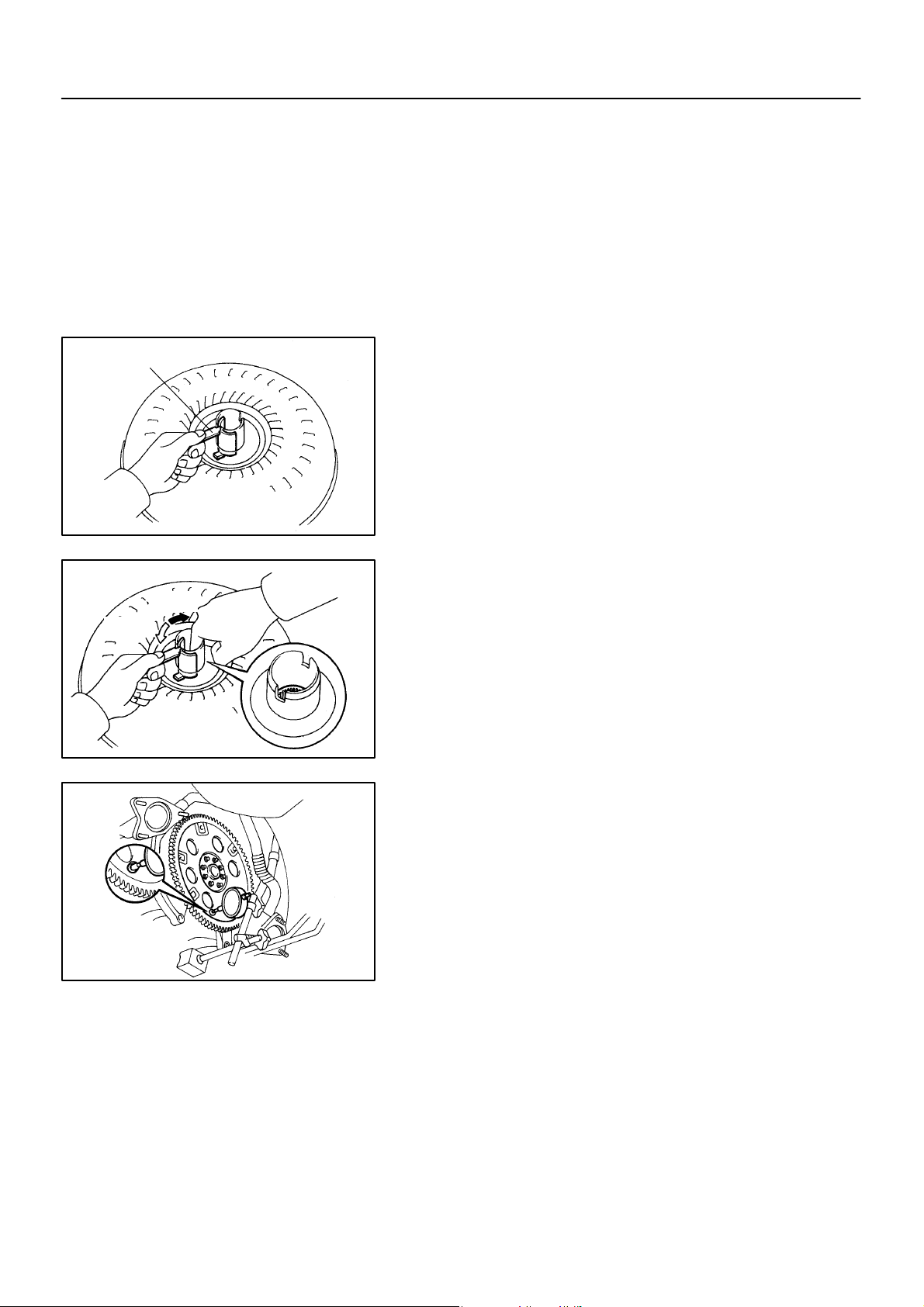

2. MEASURE DRIVE PLATE RUNOUT AND INSPECT

RING GEAR

Set up a dial indicator and measure the drive plate runout.

Maximum runout: 0.20 mm (0.0079 in.)

If runout exceeds 0.20 mm (0.0079 in.) or if the ring gear is damaged, replace the drive plate. If installing a new drive plate, note

the orientation of spacers and tighten the bolts.

Torque: 83 N·m (850 kgf·cm, 61 ft·lbf)

2000 LEXUS LS400 (RM717U)

1529Author: Date:

AT4184

AT–23

–AUTOMA TIC TRANSMISSION TORQUE CONVERTER CLUTCH AND DRIVE PLATE

3. MEASURE TORQUE CONVERTER CLUTCH SLEEVE

RUNOUT

(a) Temporarily mount the torque converter clutch to the drive

plate. Set up a dial indictor.

Maximum runout: 0.30 mm (0.0118 in.)

If runout exceeds 0.30 mm (0.0118 in.), try to correct by reorienting the installation of the torque converter clutch.

If excessive runout cannot be corrected, replace the torque

converter clutch.

HINT:

Mark the position of the torque converter clutch to ensure correct installation.

(b) Remove the torque converter clutch.

2000 LEXUS LS400 (RM717U)

1530Author: Date:

BE–1

–BODY ELECTRICAL BODY ELECTRICAL SYSTEM

BODY ELECTRICAL SYSTEM

BE0DC–01

PRECAUTION

Take care to observe the following precautions when performing inspections or removal and replacement

of body electrical related parts.

1. SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The Lexus LS400 is equipped with an SRS (Supplemental Restraint System) such as the driver airbag and

front passenger airbag. failure to carry out service operation in the correct sequence could cause the SRS

to unexpectedly deployed during servicing, possibly leading to a serious accident. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read the precautionary codices

in the RS section.

2. COMBINATION METER SYSTEM

The cold cathode tube connectors (Connectors ”N”, ”P” and ”Q”) in the combination meter are charged with

high voltage AC current when power is supplied, so do not touch them when they are charged.

3. MICRO COMPUTER PRESET DRIVING POSITION SYSTEM

Power Seat Control System

Power Mirror Control System

Power Tilt and Telescopic Steering System

If the battery negative (–) terminal is disconnected, the preset driving positions stored in memory are erased,

so be sure to note the positions and reset them after the battery terminal is reconnected.

4. AUDIO SYSTEM

If the battery negative (–) terminal is disconnected, the preset AM, FM 1 and FM 2 stations stored in

memory are erased, so be sure to not the stations and reset them after the battery terminal is reconnected.

If the battery negative (–) terminal is disconnected, the ”ANTI–THEFT SYSTEM” will operate when the

terminal is reconnected, but the radio, tape player and CD player will not operate. Be sure to input the

correct ID number so that the radio, tape player and CD player can be operated again.

2000 LEXUS LS400 (RM717U)

1864Author: Date:

BE–2

–BODY ELECTRICAL BODY ELECTRICAL SYSTEM

5. MOBILE COMMUNICATION SYSTEM

If the vehicle is equipped with a mobile communication system, refer to precautions in the IN section.

6. LIGHTING SYSTEM

Halogen bulbs have pressurized gas inside and require special handling.

They can burst or scatter if scratched or dropped. Hold a bulb only by its plastic or metal case.

Don’t touch the glass part of a bulb with bare hands.

When high voltage socket of discharge headlight is touched with the light control switch HEAD, high

voltage of 20,000 V is momentarily generated. This might lead to a serious accident.

Never connect the tester to the high voltage socket of discharge headlight for measurement, as this

leads to a serious because of high voltage.

When performing operation related to the discharge headlight, make sure to do it in the place with no

water of rain to p r e v e n t e l e c tric shock, with light control switch OFF, battery terminal removed, connector of light control ECU disconnected.

When performing operation related to the discharge headlight, make sure to do it after assembling has

been completely over and never light up without a bulb installed.

Do not light up the discharge headlight using another power source except vehicle’s.

When there is a defect on the discharge headlight or any shock has been applied to it, replace the light

with a new one.

Even if the light operates normally, there is a possibility that the fail–safe function not works.

2000 LEXUS LS400 (RM717U)

1865Author: Date:

BE–3

–BODY ELECTRICAL TROUBLESHOOTING

BE0DD–04

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

The table below will be useful for you in troubleshooting these electrical problems. The most likely causes

of the malfunction are shown in the order of their probability. Inspect each part in the order shown, and replace the part when it is found to be faulty.

POWER OUTLET

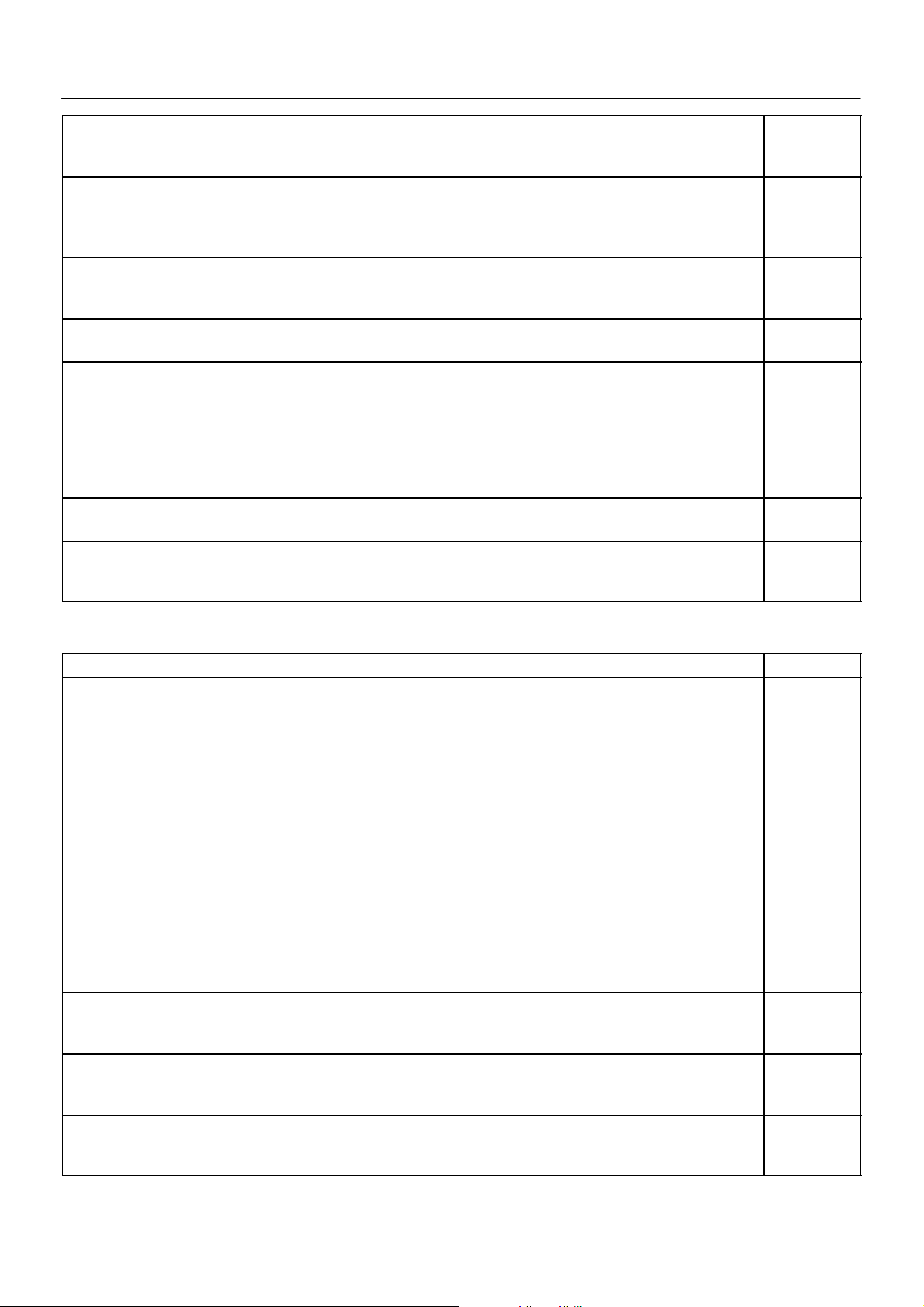

Symptom Suspect Area See page

1. Battery

Electric power source cannot be taken out of the power outlet

IGNITION SWITCH:

This system uses the multiplex communication system, so check diagnosis system of the multiplex communication system before you proceed with troubleshooting.

Symptom Suspect Area See page

Ignition switch is not set to each position.

KEY UNLOCK WARNING SWITCH:

This system uses the multiplex communication system, so check diagnosis system of the multiplex communication system before you proceed with troubleshooting.

2. RR CIG Fuse (Instrument panel J/B)

3. Wire Harness

1. Ignition switch

2. Power source circuit

BE–33

BE–23

Symptom Suspect Area See page

Key unlock warning system does not operate.

(The buzzer does not sound when the driver’s door is opened with

the ignition OFF and key inserted)

Key unlock warning system does not operate.

(The buzzer sounds when the ignition key is ACC or ON)

1. Key Unlock Warning Switch

2. Door Courtesy Switch

3. Driver Door ECU

4. Multiplex Communication Circuit

5. Body ECU

6. Wire Harness

1. Ignition Switch

2. RADIO No.2 Fuse (Instrument Panel J/B)

3. GAUGE Fuse (Instrument Panel J/B)

4. Wire Harness

BE–33

BE–70

DI–727

DI–838

DI–661

BE–33

HEADLIGHT AND TAILLIGHT SYSTEM:

This system uses the multiplex communication system, so check diagnosis system of the multiplex communication system before you proceed with troubleshooting.

HINT:

To inspect the bulb and light control ECU, replace them with the ones working normally and judge whether

they work normally or not.

(AUTOMATIC LIGHT CONTROL SYSTEM)

Symptom Suspect Area See page

1. ECU–IG Fuse (Instrument Panel J/B)

2. DOME Fuse (Engine Room J/B)

”Automatic light control system” does not operate.

3. Automatic Light Control Sensor

4. Light Control Switch

5. Door Courtesy Switch

6. Body ECU

7. Driver Door ECU

8. Wire Harness

BE–38

BE–38

BE–70

DI–661

DI–727

2000 LEXUS LS400 (RM717U)

1866Author: Date:

BE–4

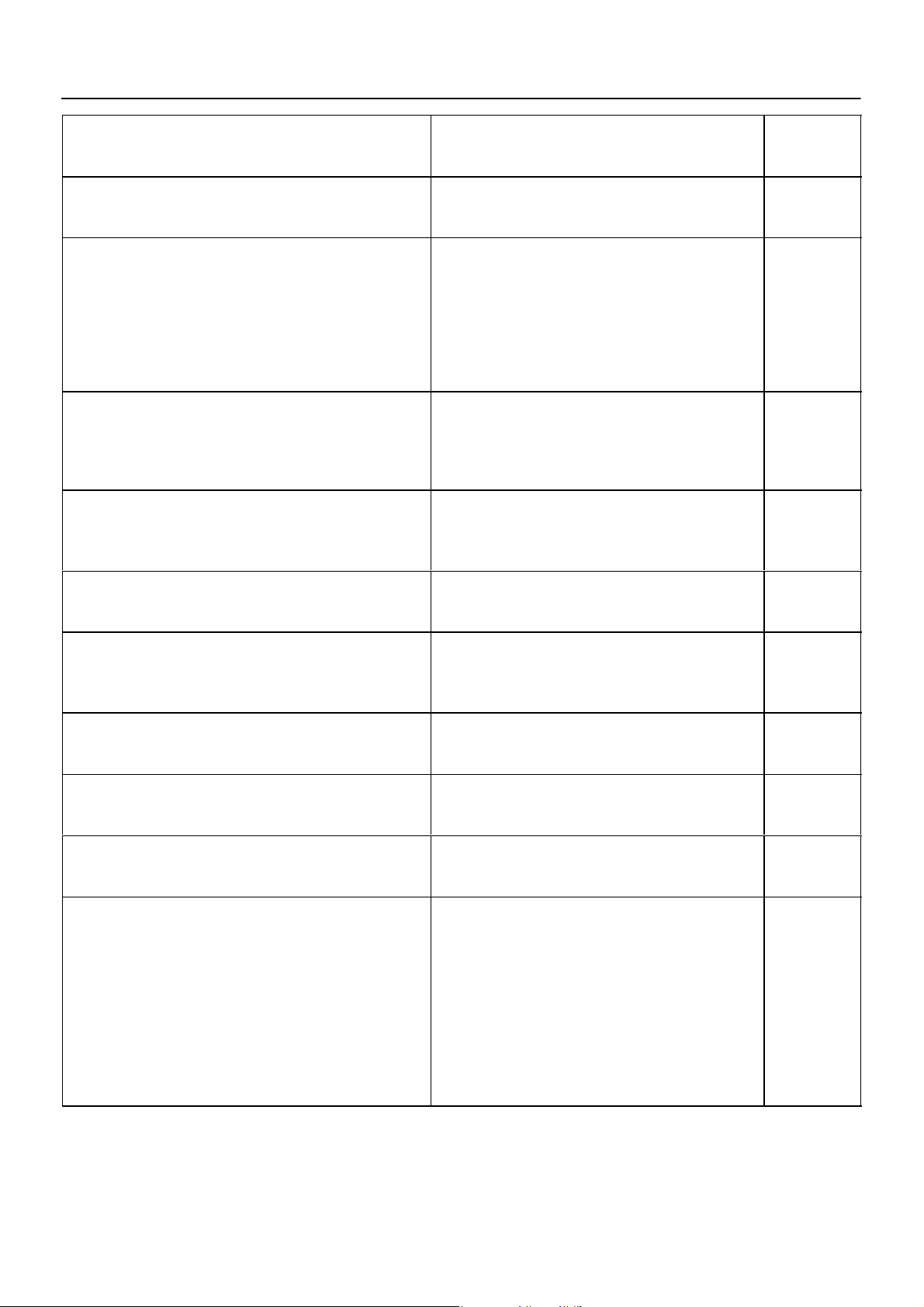

(AUTO TURN OFF SYSTEM)

Symptom Suspect Area See page

Auto turn–off system does not operate when the driver’s door is

opened.

Headlight and taillight does not come on.

Headlight and taillight stays on.

(USA)

Symptom Suspect Area See page

Only one headlight comes on.

(Headlight main)

Only one headlight comes on.

(Headlight sub)

”LO–Beam” does not light.

”HI–Beam” does not light.

(Headlight main and sub)

”HI–Beam” does not light.

(Headlight main or sub)

”Flash” does not light.

(Headlight main and sub)

”Flash” does not light.

(Headlight main or sub)

Headlight does not come on.

(Headlight main and sub)

–BODY ELECTRICAL TROUBLESHOOTING

1. Drivers Door Courtesy Switch

2. Driver Door ECU

3. Multiplex Communication Circuit

4. Body ECU

1. Body ECU

2. Wire Harness

1. Body ECU

2. Wire Harness

1. H–LP Fuse (LH–LWR) (Engine Room No.1 R/B)

2. H–LP Fuse (RH–LWR) (Engine Room No.1 R/B)

3. Headlight Main Bulb

4. *Light Control ECU

5. Wire Harness

1. H–LP Fuse (LH–UPR) (Engine Room J/B)

2. H–LP Fuse (RH–UPR) (Engine Room J/B)

3. Headlight Sub Bulb

4. *Light Control ECU

5. Wire Harness

1. H–LP Fuse (LH–LWR) (Engine Room No.1 R/B)

2. H–LP Fuse (RH–LWR) (Engine Room No.1 R/B)

3. Headlight Dimmer Relay (Engine Room J/B)

4. Headlight Dimmer Switch

5. Headlight Main Bulb

6. *Light Control ECU

7. Wire Harness

1. H–LP Fuse (LH–UPR) (Engine Room J/B)

2. H–LP Fuse (RH–UPR) (Engine Room J/B)

3. Headlight Dimmer Relay (Engine Room J/B)

4. Headlight Dimmer Switch

5. *Light Control ECU

6. Wire Harness

1. Headlight Main or Sub Bulb

2. *Light Control ECU

3. Wire Harness

1. H–LP Fuse (LH–UPR) (Engine Room J/B)

2. H–LP Fuse (RH–UPR) (Engine Room J/B)

3. Headlight Dimmer Relay (Engine Room J/B)

4. Headlight Dimmer Switch

5. *Light Control ECU

6. Wire Harness

1. Headlight Main or Sub Bulb

2. *Light Control ECU

3. Wire Harness

1. Headlight Control Relay (Engine Room J/B)

2. Headlight Dimmer Relay (Engine Room J/B)

3. Light Control Switch

4. Body ECU

5. *Light Control ECU

6. Wire Harness

BE–70

DI–727

DI–838

DI–661

DI–661

DI–661

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

DI–661

BE–38

2000 LEXUS LS400 (RM717U)

1867Author: Date:

–BODY ELECTRICAL TROUBLESHOOTING

BE–5

Headlight does not come on.

(Headlight main or sub)

Headlight is flicker.

Headlight is dark.

Only one taillight comes on.

Taillight does not come on.

(Headlight is normal)

Taillight does not come on.

(Headlight does not light)

Rear combination light does not come on.

*: HID Type

CANADA:

1. Headlight Main or Sub

2. *Light Control ECU

3. Wire Harness

1. Headlight Main or Sub Bulb

2. Headlight Dimmer Relay (Engine Room J/B)

3. *Light Control ECU

4. Wire Harness

1. Headlight Main or Sub Bulb

2. *Light control ECU

3. Wire Harness

1. Taillight Bulb

2. Wire Harness

1. TAIL Fuse (Instrument Panel J/B)

2. GAUGE Fuse (Instrument Panel J/B)

3. Taillight Control Relay (Instrument Panel J/B)

4. Light Failure Sensor

5. Light Control Switch

6. Body ECU

7. Wire Harness

1. Light Control Switch

2. Wire Harness

1. Light Failure Sensor

2. Wire Harness

3. Bulb

BE–38

BE–38

BE–38

BE–38

BE–38

BE–76

BE–38

DI–661

BE–38

BE–76

Symptom Suspect Area See page

Only one headlight comes on.

(Headlight main)

Only one headlight comes on.

(Headlight sub RH)

Only one headlight comes on.

(Headlight sub LH)

”LO–Beam” does not light (All).

(Headlight main)

”LO–Beam” does not light (One side).

(Headlight main)

”HI–Beam” does not light (All).

(Headlight main)

1. H–LP Fuse (LH) (Engine Room R/B No.1)

2. H–LP Fuse (RH) (Engine Room R/B No.1)

3. Headlight Main Bulb

4. *Light Control ECU

5. Wire Harness

1. H–LP Fuse (LH–UPR) (Engine Room J/B)

2. H–LP Fuse (RH–UPR) (Engine Room J/B)

3. Daytime Running Light No.3 Relay

4. Headlight Sub Bulb

5. *Light Control ECU

6. Wire Harness

1. H–LP Fuse (LH–UPR) (Engine Room J/B)

2. H–LP Fuse (RH–UPR) (Engine Room J/B)

3. Headlight Sub Bulb

4. *Light Control ECU

5. Wire Harness

1. Headlight Dimmer Switch

2. *Light Control ECU

3. Wire Harness

1. Headlight Main Bulb

2. *Light Control ECU

3. Wire Harness

1. Headlight Dimmer Switch

2. *Light Control ECU

3. Wire Harness

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

2000 LEXUS LS400 (RM717U)

1868Author: Date:

BE–6

–BODY ELECTRICAL TROUBLESHOOTING

”HI–Beam” does not light (One side).

(Headlight main)

”Flash” does not light.

(Headlight main)

Headlight does not come on.

(Headlight main)

Headlight does not come on.

(Headlight sub)

Headlight does not come on with light control switch in HEAD.

(Headlight main)

Headlight does not go out with light control switch in OFF.

(Headlight main

Headlight is flicker.

Headlight is dark.

Taillight does not come on with light control switch in T AIL.

(Headlight main)

Taillight does not go out with light control switch in OFF.

(Headlight main)

Headlight do not come on with engine running and light control

switch in OFF.

(Headlight main)

*: HID Type

1. Headlight Main Bulb

2. *Light Control ECU

3. Wire Harness

1. Headlight Dimmer Switch

2. *Light Control ECU

3. Wire Harness

1. Headlight Control Relay (Engine Room J/B)

2. Daytime Running Light Relay

3. Headlight Dimmer Switch

4. Light Control Switch

5. Body ECU

6. Wire Harness

7. *Light Control ECU

8. Headlight Main Bulb

1. Headlight Dimmer Relay (Engine Room J/B)

2. Daytime Running Light Relay

3. Daytime Running Light No.4 Relay

4. *Light Control ECU

5. Wire Harness

1. Light Control Switch

2. Body ECU

3. *Light Control ECU

4. Wire Harness

1. Headlight Control Relay (Engine Room J/B)

2. *Light Control ECU

3. Wire Harness

1. Headlight Main or sub Bulb

2. Headlight Dimmer Relay (Engine Room J/B)

3. *Light Control ECU

4. Wire Harness

1. Headlight Main or Sub Bulb

2. *Light control ECU

3. Wire Harness

1. Taillight Control Relay (Instrument Panel J/B)

2. Light Control Switch

3. Wire Harness

1. Taillight Control Relay (Instrument Panel J/B)

2. Light Control Switch

3. Wire Harness

1. ECU–B Fuse (Engine Room J/B)

2. GAUGE Fuse (Instrument Panel J/B)

3. DRL Fuse (Engine Room R/B No.1)

4. Daytime Running Light Relay

5. Daytime Running Light No.3 and No.4 Relay

6. Body ECU

7. Generator L Terminal

8. Parking Brake Switch

9. Brake Fluid Level Warning Switch

10. *Light Control ECU

11. Wire Harness

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

DI–661

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

DI–661

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

BE–38

DI–661

BE–98

BE–98

BE–38

2000 LEXUS LS400 (RM717U)

1869Author: Date:

HEADLIGHT BEAM LEVEL CONTROL SYSTEM

Symptom Suspect Area See page

Beam axis is not controlled. (It is not initialized.)

Headlight Beam Level Control System does not operate.

Beam axis is not controlled. (It is initialized.)

Headlight Beam Level Control System does not operate.

Controlled angle of head light is nnusual. (The angle is controlled.)

Beam axis position is not stable during driving.

FOG LIGHT SYSTEM

–BODY ELECTRICAL TROUBLESHOOTING

1. PWR–IG Fuse (Engine Room J/B)

2. Headlight Beam Level Control Actuator

3. Headlight Beam Level Control ECU

4. Wire Harness Side

1. Headlight Beam Level Control ECU

2. Power Source Circuit

3. Height Control Sensor

4. Suspension ECU

5. Headlight Beam Level Control ECU

6. Wire Harness Side

1. Height Control Sensor

2. Suspension ECU

3. Headlights

4. Wire Harness Side

1. ABS System

2. Headlights

3. Wire Harness Side

BE–7

BE–52

BE–52

BE–52

BE–19

DI–251

IN–32

BE–52

DI–251

IN–32

Symptom Suspect Area See page

1. FOG Fuse (Instrument Panel J/B)

Fog light does not light up with light control SW HEAD

(Headlight is normal.)

Fog light does not light up with light control SW HEAD

(Headlight does not light).

Only one light does not light up.

2. Fog Light Relay (Instrument Panel J/B)

3. Fog Light Switch

4. Wire Harness

1. *1 Other Parts

2. Wire Harness

1. Bulb

2. Wire Harness

*1: Inspect Headlight System

TURN SIGNAL AND HAZARD WARNING SYSTEM

Symptom Suspect Area See page

1. Hazard Warning Switch

”Hazard” and ”Turn” do not light up.

The flashing frequency is abnormal.

Hazard warning light does not light up.

(Turn is normal)

Hazard warning light does not light up in one direction.

*1 Turn signal does not light up.

*2 Turn signal does not light up.

2. Turn Signal Switch

3. Turn Signal Flasher

4. Wire Harness

1. Bulb

2. Turn Signal Switch

3. Wire Harness

1. HAZ Fuse (Engine Room J/B)

2. Wire Harness

1. Hazard Warning Switch

2. Wire Harness

1. Ignition Switch

2. TURN Fuse (Instrument Panel J/B)

3. Turn Signal Switch

4. Wire Harness

1. TURN Fuse (Instrument Panel J/B)

2. Turn Signal Switch

3. Wire Harness

BE–56

BE–38

BE–59

BE–38

BE–59

BE–38

BE–59

BE–33

BE–38

BE–38

2000 LEXUS LS400 (RM717U)

1870Author: Date:

Loading...

Loading...