Page 1

BE–1

–BODY ELECTRICAL BODY ELECTRICAL SYSTEM

BODY ELECTRICAL SYSTEM

BE0DC–01

PRECAUTION

Take care to observe the following precautions when performing inspections or removal and replacement

of body electrical related parts.

1. SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The Lexus LS400 is equipped with an SRS (Supplemental Restraint System) such as the driver airbag and

front passenger airbag. failure to carry out service operation in the correct sequence could cause the SRS

to unexpectedly deployed during servicing, possibly leading to a serious accident. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read the precautionary codices

in the RS section.

2. COMBINATION METER SYSTEM

The cold cathode tube connectors (Connectors ”N”, ”P” and ”Q”) in the combination meter are charged with

high voltage AC current when power is supplied, so do not touch them when they are charged.

3. MICRO COMPUTER PRESET DRIVING POSITION SYSTEM

Power Seat Control System

Power Mirror Control System

Power Tilt and Telescopic Steering System

If the battery negative (–) terminal is disconnected, the preset driving positions stored in memory are erased,

so be sure to note the positions and reset them after the battery terminal is reconnected.

4. AUDIO SYSTEM

! If the battery negative (–) terminal is disconnected, the preset AM, FM 1 and FM 2 stations stored in

memory are erased, so be sure to not the stations and reset them after the battery terminal is reconnected.

! If the battery negative (–) terminal is disconnected, the ”ANTI–THEFT SYSTEM” will operate when the

terminal is reconnected, but the radio, tape player and CD player will not operate. Be sure to input the

correct ID number so that the radio, tape player and CD player can be operated again.

2000 LEXUS LS400 (RM717U)

1864Author!: Date!:

Page 2

BE–2

–BODY ELECTRICAL BODY ELECTRICAL SYSTEM

5. MOBILE COMMUNICATION SYSTEM

If the vehicle is equipped with a mobile communication system, refer to precautions in the IN section.

6. LIGHTING SYSTEM

! Halogen bulbs have pressurized gas inside and require special handling.

They can burst or scatter if scratched or dropped. Hold a bulb only by its plastic or metal case.

Don’t touch the glass part of a bulb with bare hands.

! When high voltage socket of discharge headlight is touched with the light control switch HEAD, high

voltage of 20,000 V is momentarily generated. This might lead to a serious accident.

! Never connect the tester to the high voltage socket of discharge headlight for measurement, as this

leads to a serious because of high voltage.

! When performing operation related to the discharge headlight, make sure to do it in the place with no

water of rain to prevent electric shock, with light control switch OFF, battery terminal removed, connector of light control ECU disconnected.

! When performing operation related to the discharge headlight, make sure to do it after assembling has

been completely over and never light up without a bulb installed.

! Do not light up the discharge headlight using another power source except vehicle’s.

! When there is a defect on the discharge headlight or any shock has been applied to it, replace the light

with a new one.

Even if the light operates normally, there is a possibility that the fail–safe function not works.

2000 LEXUS LS400 (RM717U)

1865Author!: Date!:

Page 3

BE–256

N13360

–

BE0DB–01

INSPECTION

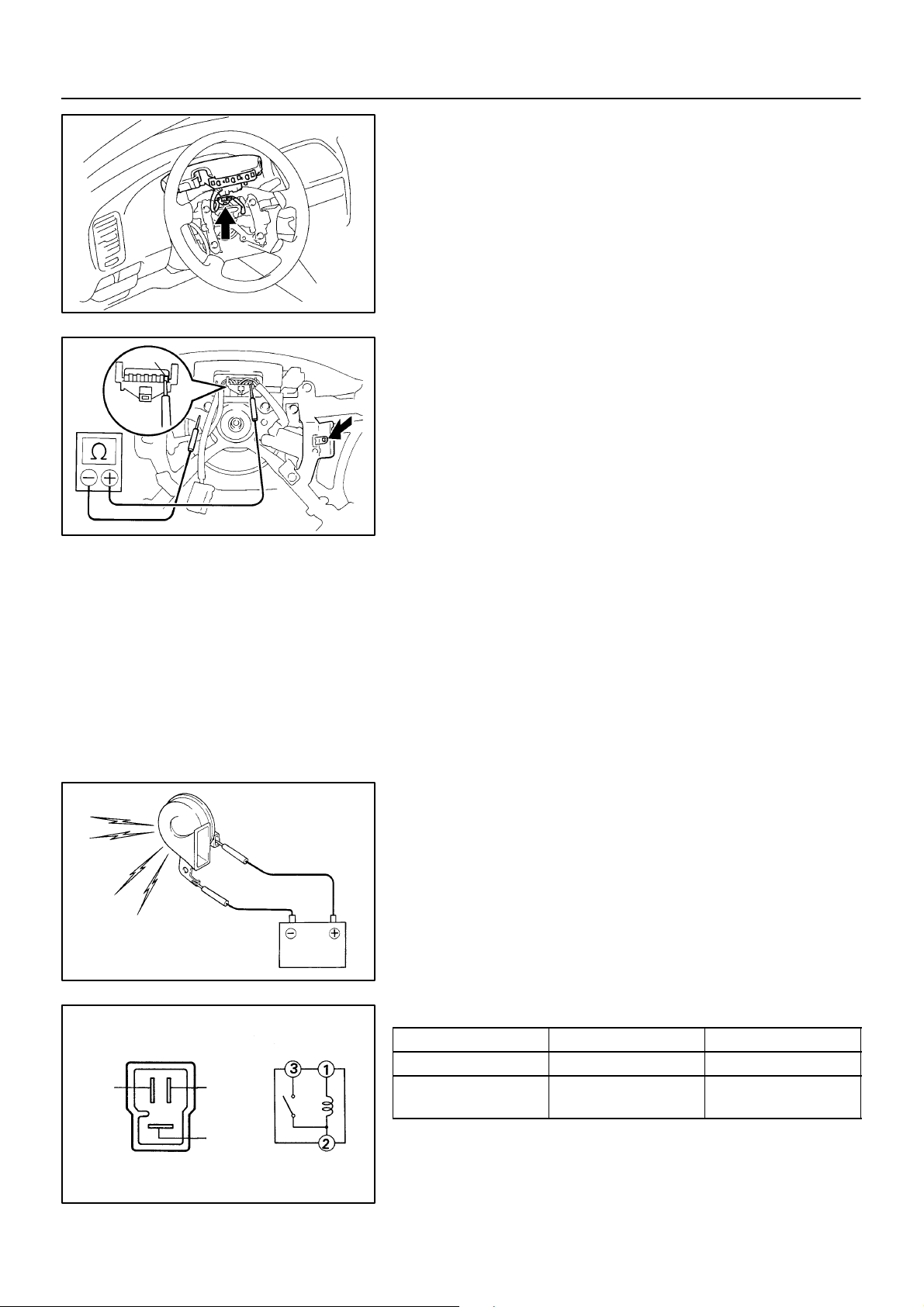

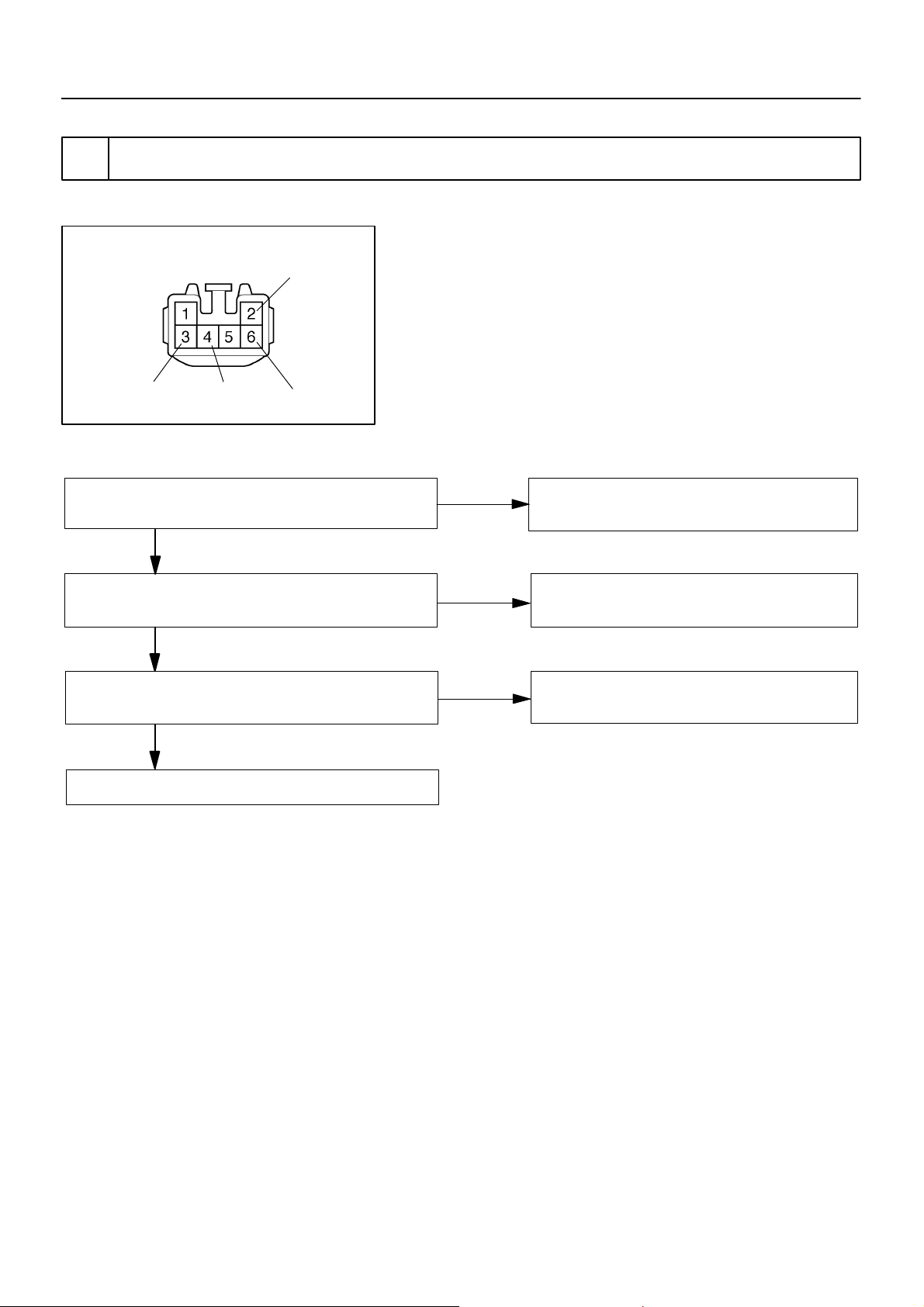

1. INSPECT HORN SWITCH

(a) Disconnect the negative (–) terminal from the battery.

(b) Remove the left and right covers from the steering wheel.

(c) Using a torx socket wrench, loosen the 2 bolts.

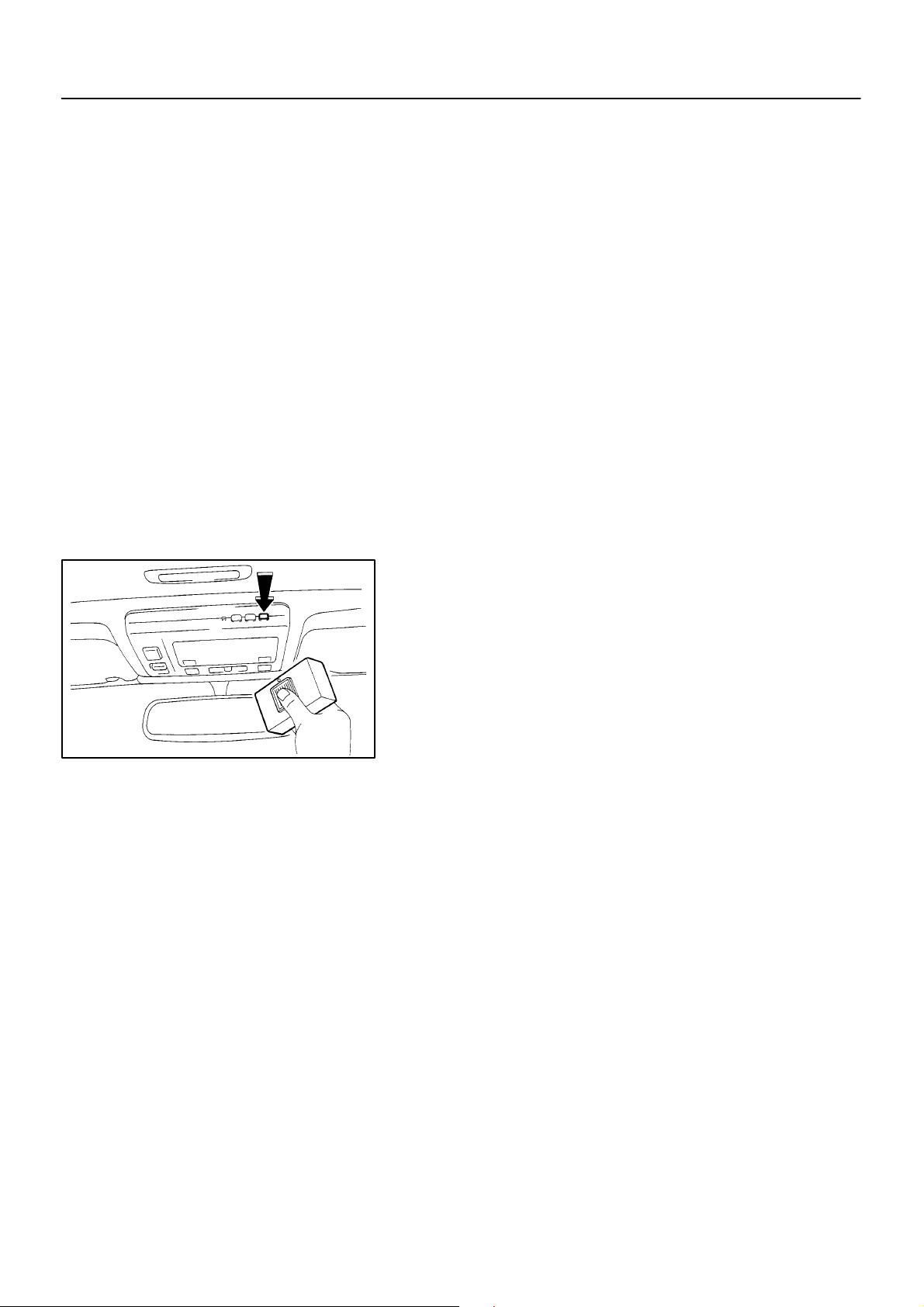

(d) Pull up the horn pad and place it on the steering column,

as shown.

HINT:

Do not disconnect the connector from the horn pad.

6

(e) Disconnect the connector from the slip ring.

(f) Check that there is no continuity between terminal 6 of the

connector and body ground.

(g) Check that there is continuity between terminal 6 of the

connector and body ground when the horn contact plate

is pressed against the steering spoke assembly.

If continuity is not as specified, repair or replace the steering

wheel or wire harness as necessary.

I03247

(h) Install the horn pad in place and using a torx socket

wrench, torque the 2 bolts.

Torque: 7.1 N·m (72 kgf·cm, 62 in.·lbf)

(i) Install the left and right covers.

(j) Connect the negative (–) terminal to the battery.

2. INSPECT HORN OPERATION

Connect the positive (+) lead from the battery to the terminal

and negative (–) lead to the horn body and check that the horn

blows.

If operation is not as specified, replace the horn.

I03248

3. INSPECT HORN RELAY CONTINUITY

Condition Te s te r c o nn e c t i on Specified condition

Constant 1 – 2 Continuity

2

3

1

Z08505

Apply B+ between

terminals 1 and 2.

2 – 3 Continuity

If continuity is not as specified, replace the relay.

2119Author!: Date!:

Page 4

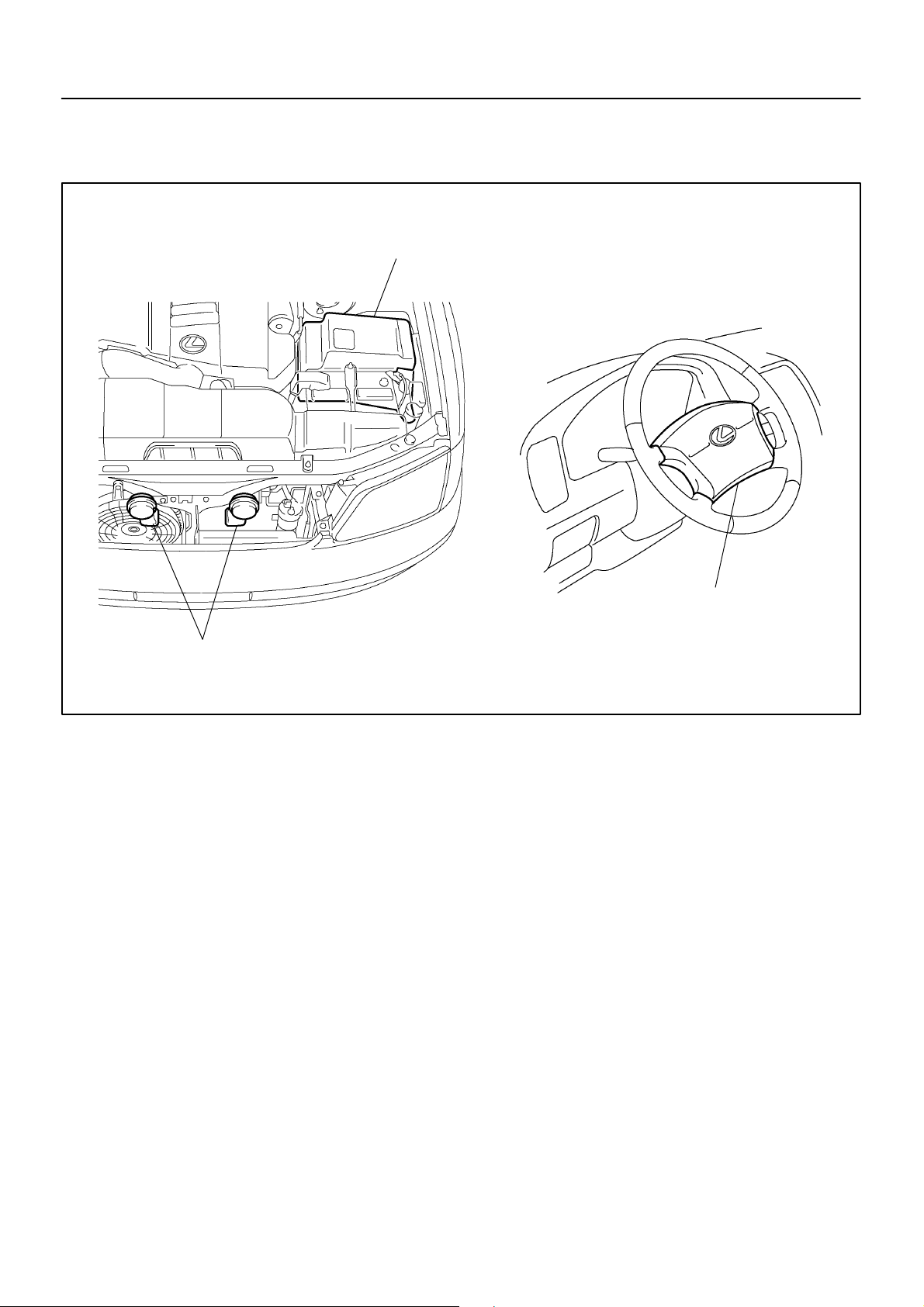

HORN SYSTEM

LOCATION

BE–255

–

BE0DA–01

Engine Room Junction Block

! Horn Relay

! HORN Fuse

Horn

Horn Switch

I03238

2118Author!: Date!:

Page 5

BE–254

–

BE0D9–01

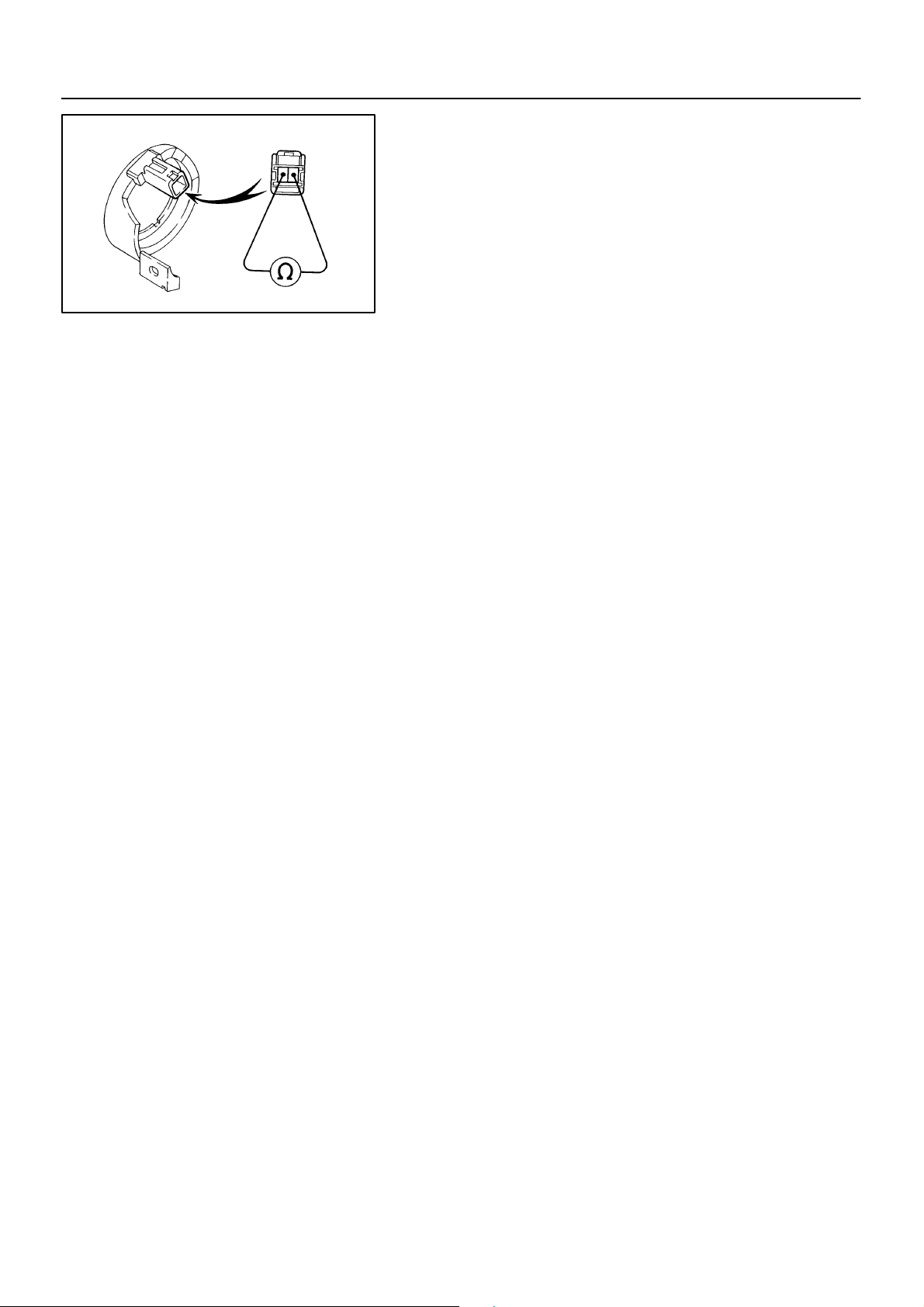

INSPECTION

INSPECTION TRANSPONDER KEY COIL CONTINUITY

Check that there is continuity between terminal 1 and 2.

If continuity is not as specified, replace the coil.

N17185

2117Author!: Date!:

Page 6

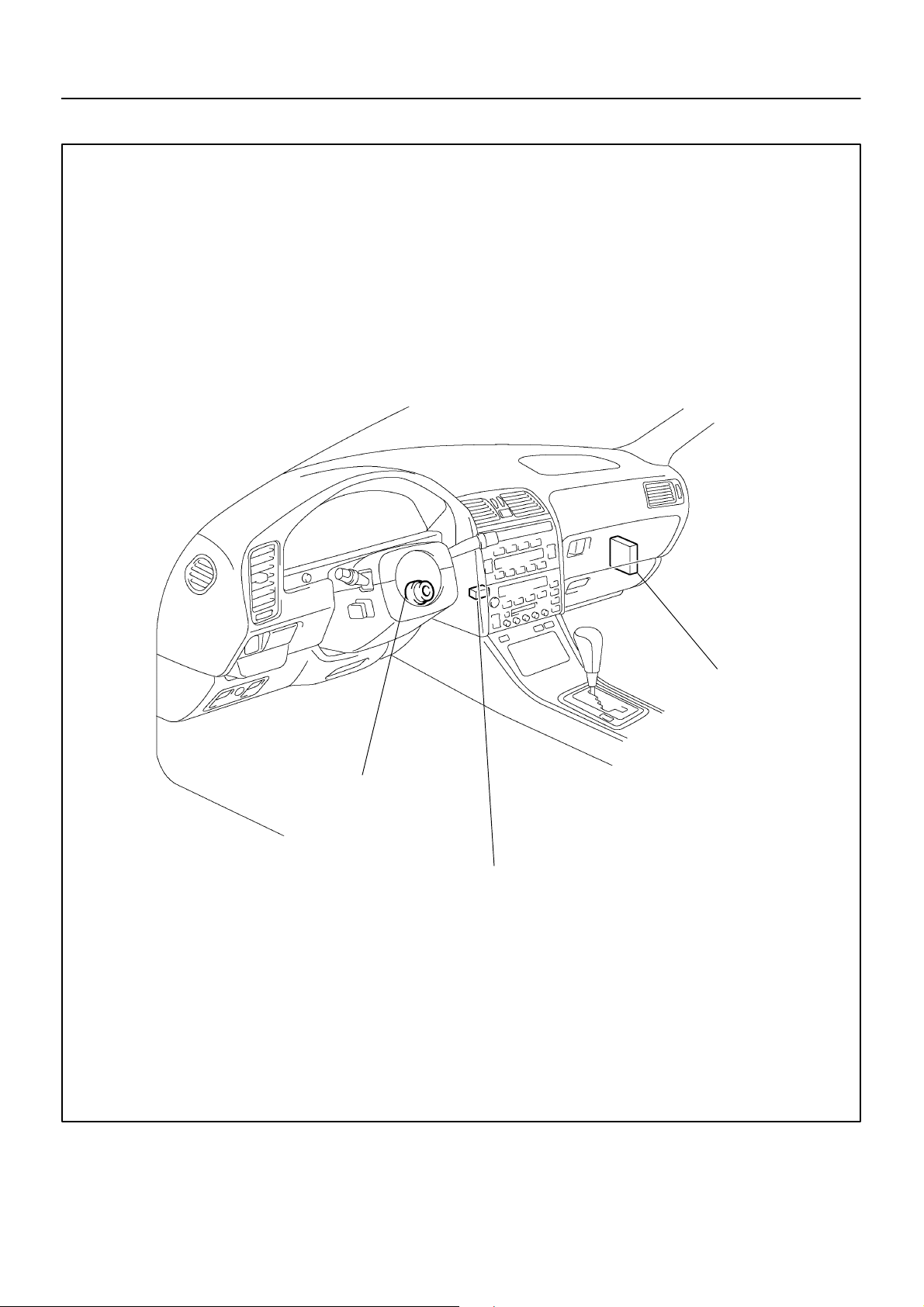

LOCATION

BE–253

–

BE0D8–01

Transponder Key

Coil

ECM

Transponder Key

Amplifier

I03461

2116Author!: Date!:

Page 7

BE–244

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

ENGINE IMMOBILISER SYSTEM

BE0D7–01

REGISTRATION PROCEDURE

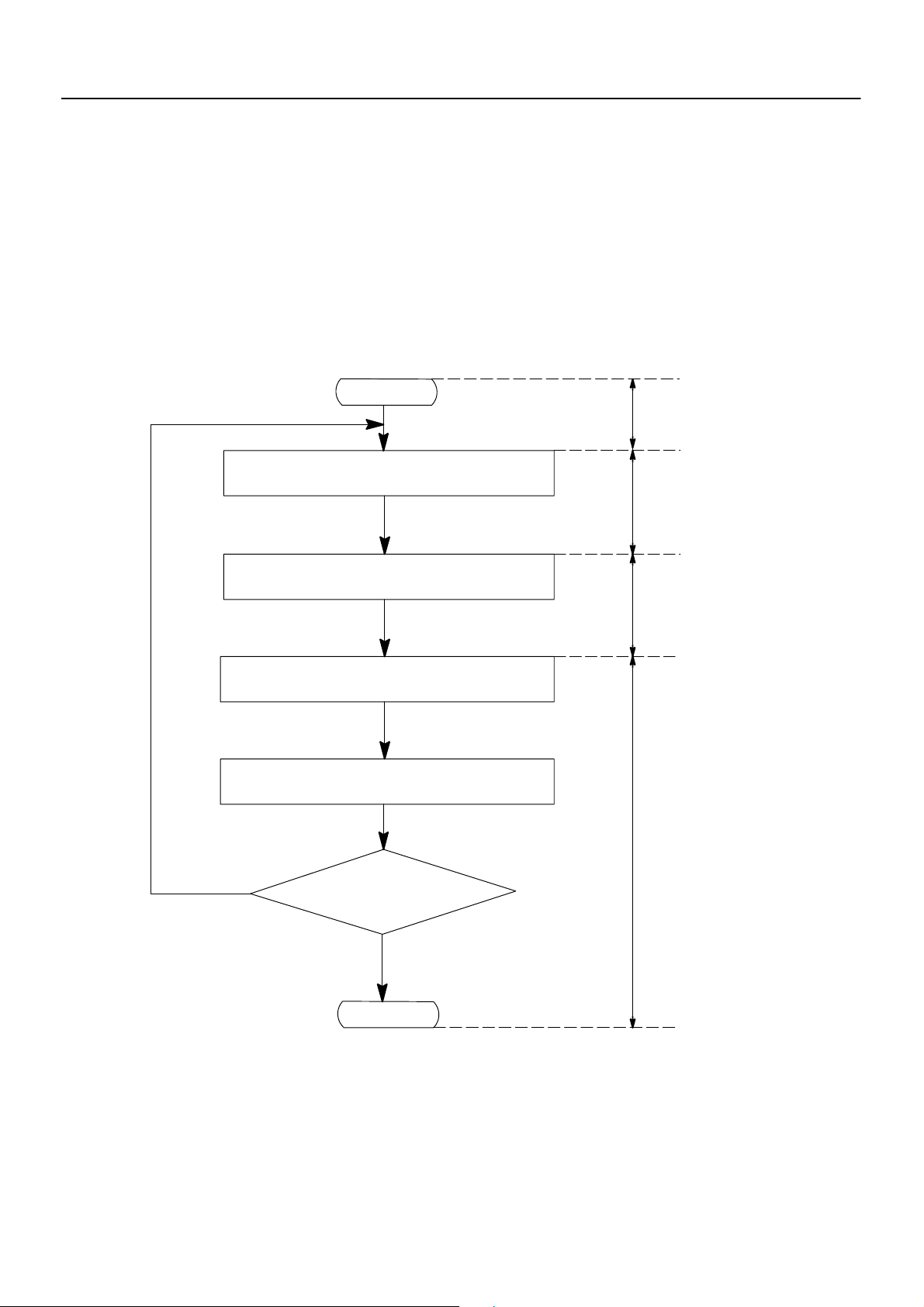

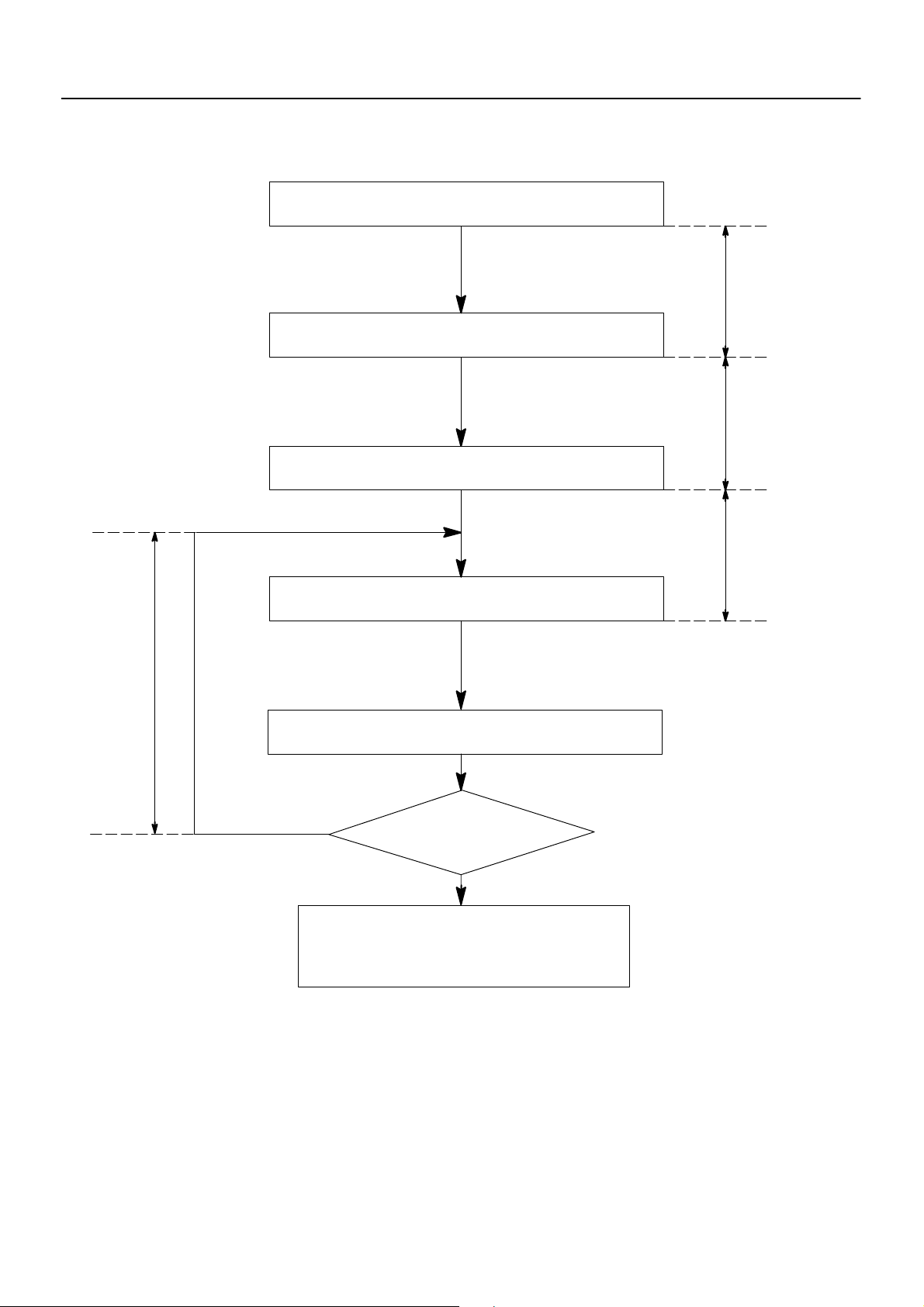

1. KEY REGISTRATION IN AUTOMATIC REGISTRATION MODE

(a) Registration of a new transponder key.

HINT:

! This must be done when you install a new ECM.

! The new ECM is on the automatic key code registration mode. The already fixed number of key codes

for this ECM can be registered.

On this type of vehicle, up to 4 key codes can be registered.

! In the automatic registration mode, the last key registered becomes sub–key.

START

Insert the key in the key cylinder.

Under registration

Registration completion

Remove the key.

Security indicator blinks until the first

key is inserted. The indicator lights up

after the key registration.

Security Indicator ON

Security Indicator

OFF

Yes

2000 LEXUS LS400 (RM717U)

Will you register the

next key?

No

END

Security Indicator ON

(After the last key (sub–key)

has been registered, the indicator goes off.)

2107Author!: Date!:

Page 8

BE–245

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

HINT:

! When a key is not inserted in the key cylinder on the automatic registration mode, the security indicator

always lights on.

! When the immobiliser system operates normally and the key is pull out, the security indicator blinks.

! When key code registration could not be performed on the automatic registration mode, code 2–1 is

output from the security indicator and when inserting the already registered key, code 2–2 is output.

Blinks

1.2 Sec.

0.8 Sec.

0.25 Sec.

0.25 Sec. 0.5 Sec.

Code 2–1 Code2–2

1 Sec.

0.25 Sec.

0.25 Sec.0.5 Sec.

1 Sec.

(b) Automatic registration mode completion

If completing the mode forcibly when more than 1 key code have been registered on the automatic

registration mode, perform the following procedures.

After 1 more key code have been registered with master key, perform step (1) or (2) without pulling

the key out or inserting the already registered key.

(1) Depress and release brake pedal 5 times or more within 15 sec.

(2) With the LEXUS hand–held tester, require automatic registration mode completion.

2000 LEXUS LS400 (RM717U)

2108Author!: Date!:

Page 9

BE–246

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

2. KEY REGISTRATION OF PROCEDURE NEW MASTER KEY AND NEW SUB–KEY ON THIS IS DESCRIBED BELOW

HINT:

Key registration of new master key and new sub–key on this vehicle when new ignition cylinder and key set,

and new lock cylinder set including ignition key cylinder are installed.

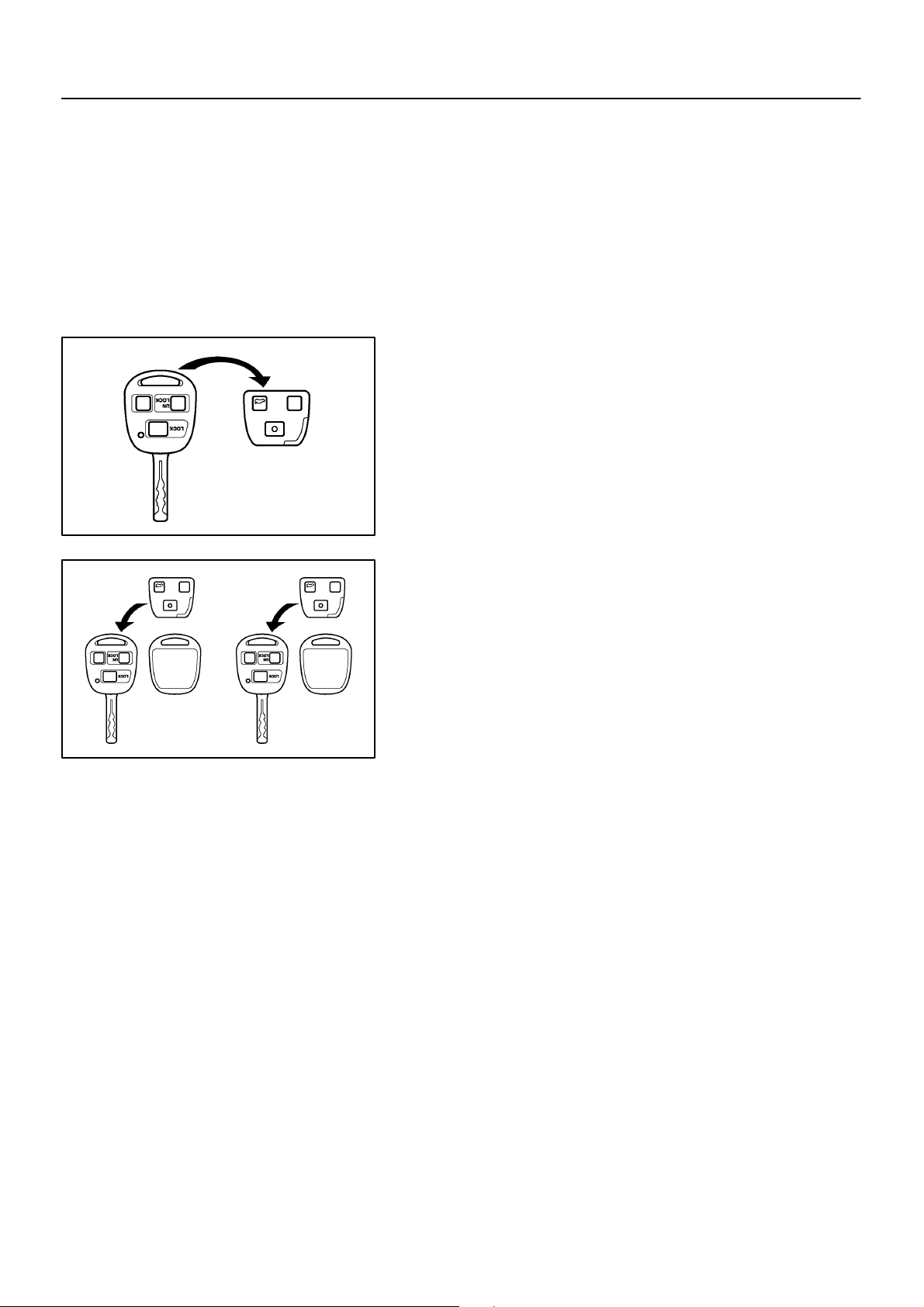

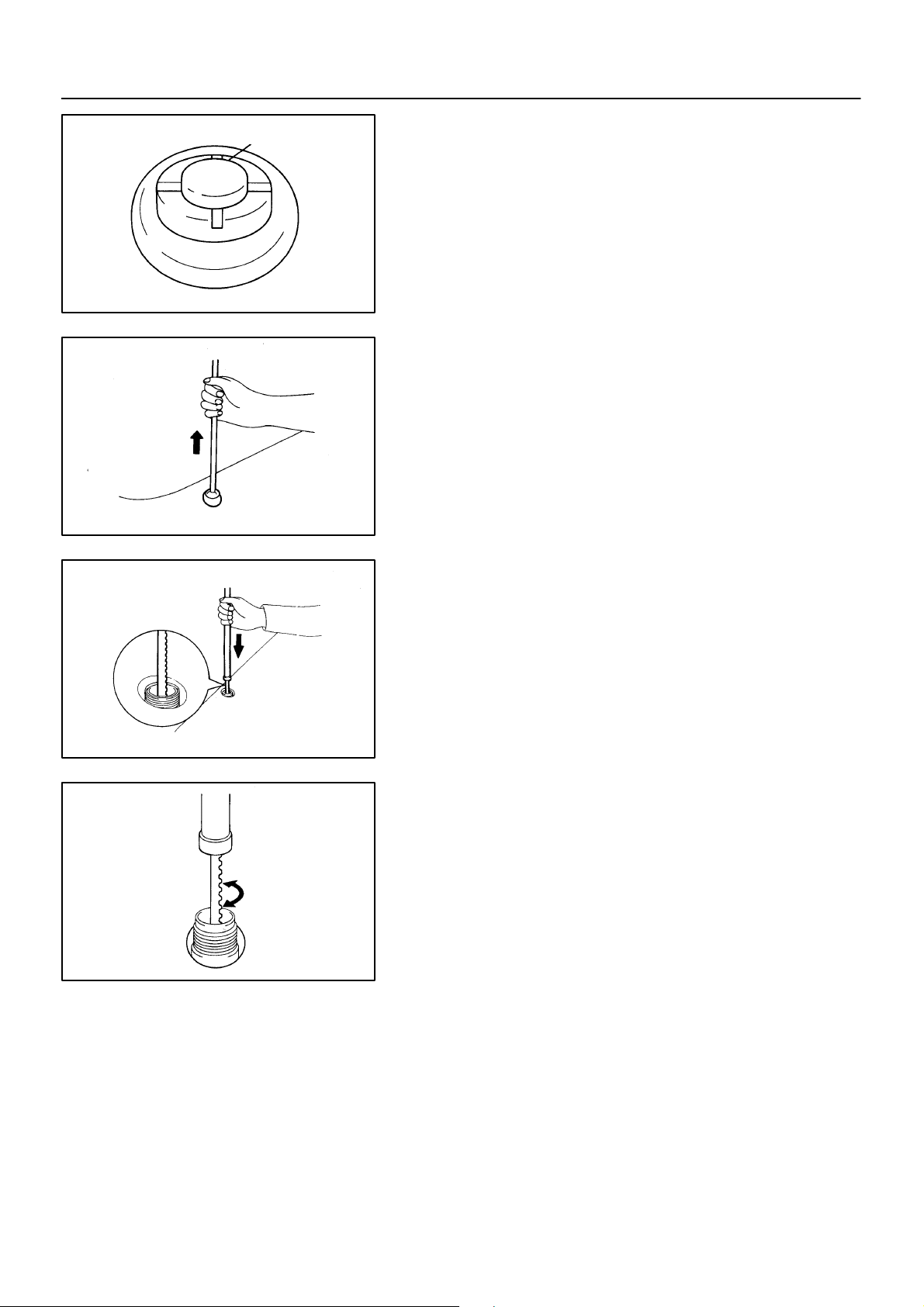

(a) Removing wire–less and immobiliser module from origi-

nal master key.

I04311

I04312

(b) Masking new master key.

After replacing and installing new ignition cylinder, install

removed original modules into new 2 key housing as supply parts.

(c) Registration of supplied new sub–key and /or master key

Register supplied new sub–key and /or master key by using new master key.

(See step 3 and 4)

NOTICE:

In case of replacing with ignition cylinder and key set, door

locks cannot be opened by new ignition keys. Therefore, to

avoid any trouble caused by empty battery of transmitter

of new ignition key, please bring the original key while driving.

2000 LEXUS LS400 (RM717U)

2109Author!: Date!:

Page 10

BE–247

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

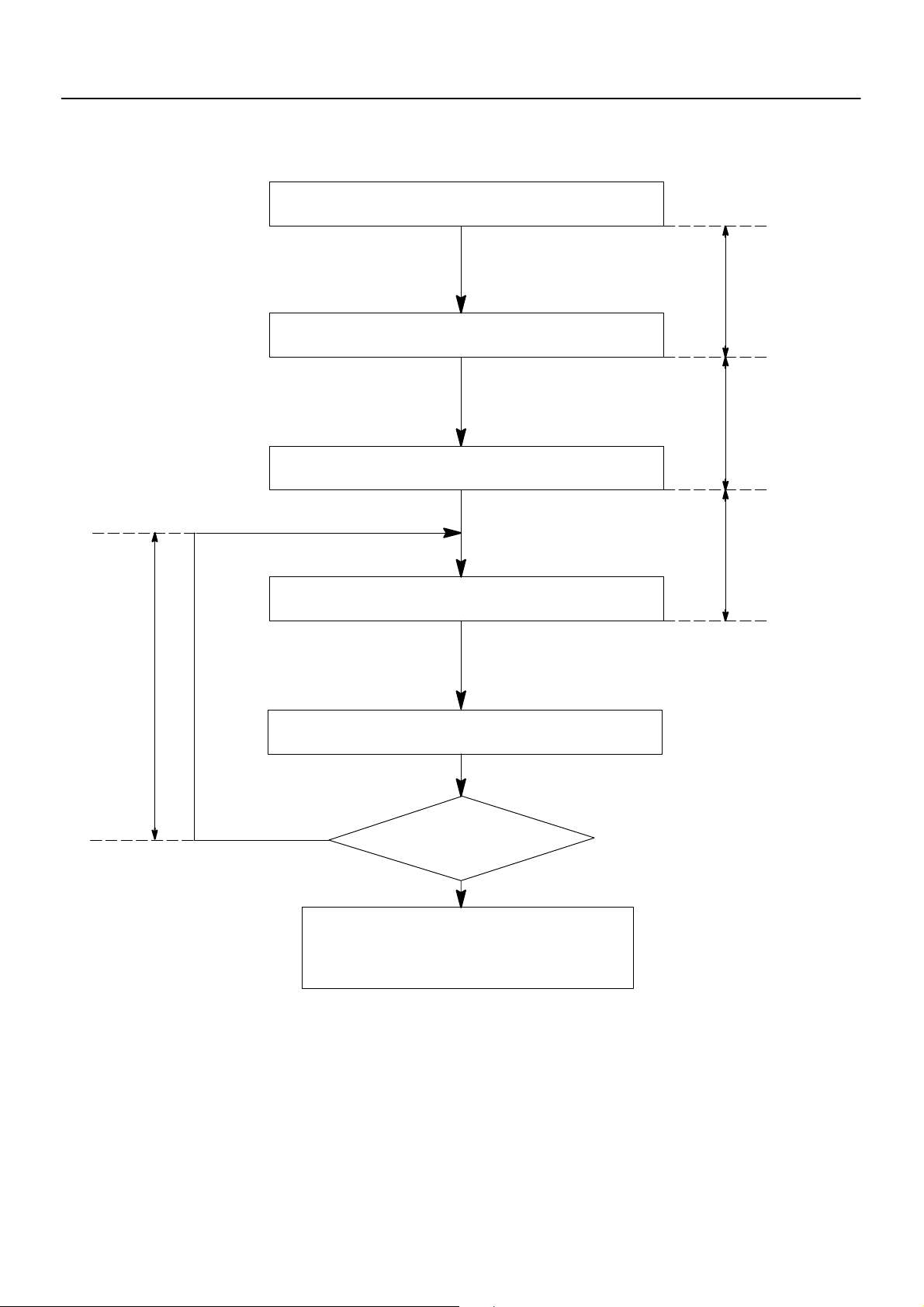

3. REGISTRATION OF ADDITIONAL MASTER KEY

There are 2 ways for registration of additional master key, one way is depressing brake pedal and acceleration pedal and the other way is using LEXUS hand–held tester.

HINT:

! It is possible to register up to 7 master key codes including the already registered key code.

! When any operation time described below is over, registration mode completes.

! When the next procedure is performed while the timer is working, the timer completes counting time,

then next timer starts.

! When replacing ”Ignition Cylinder Key Set” or ”Lock Cylinder Set” and register according to the follow-

ing procedure using the original master key. However, after the registration of the additional master

key, as the original master key and the original sub–key is not necessary any more, so erase registration of those key codes.

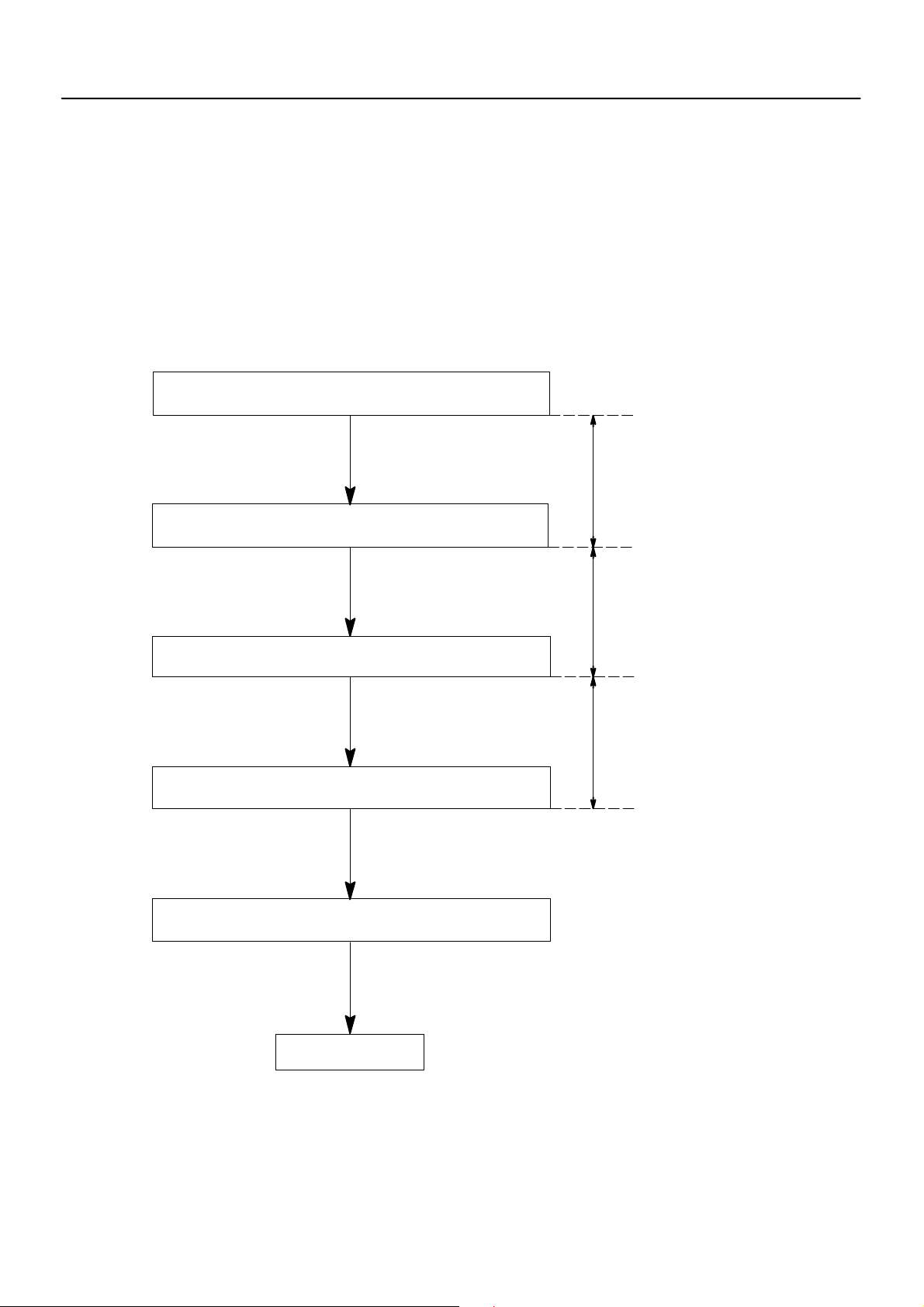

(1) Depressing brake pedal and acceleration pedal:

Insert already registered master key in the key

cylinder

Within 10 sec.

Depress and release the acceleration pedal 5

times.

Depress and release the brake pedal 6 times,

and remove the master key.

Insert key to be registered in key cylinder.

Depress and release the acceleration pedal 1

time. (Security indicator blinks)

After 60 sec. additional master key is registered.

(Security indicator is OFF)

Within 15 sec.

Within 20 sec.

Within 10 sec.

Within 10 sec.

2000 LEXUS LS400 (RM717U)

Yes

The registration mode completes when pulling

out the key and depressing and releasing the

brake pedal once or more within 10 secs. after

indicator has been off or 10 sec. have passed.

Will you register the

next key?

No

2110Author!: Date!:

Page 11

BE–248

(2) Using LEXUS hand–held tester:

Insert already registered master key in the key cylinder.

Using LEXUS hand–held tester select master key registration.

Remove the master key.

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

Within 120 sec.

Within 20 sec.

Within

10 sec.

Within 10 sec.

Insert key to be registered in key cylinder.

(Security indicator blinks)

After 60 sec., additional master key is registered.

(Security indicator OFF)

Yes

Will you register the

next key?

No

The registration mode completes when pulling

out the key and depressing and releasing the

brake pedal once or more within 10 sec. after indicator has been off or 10 sec. have passed.

2000 LEXUS LS400 (RM717U)

2111Author!: Date!:

Page 12

BE–249

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

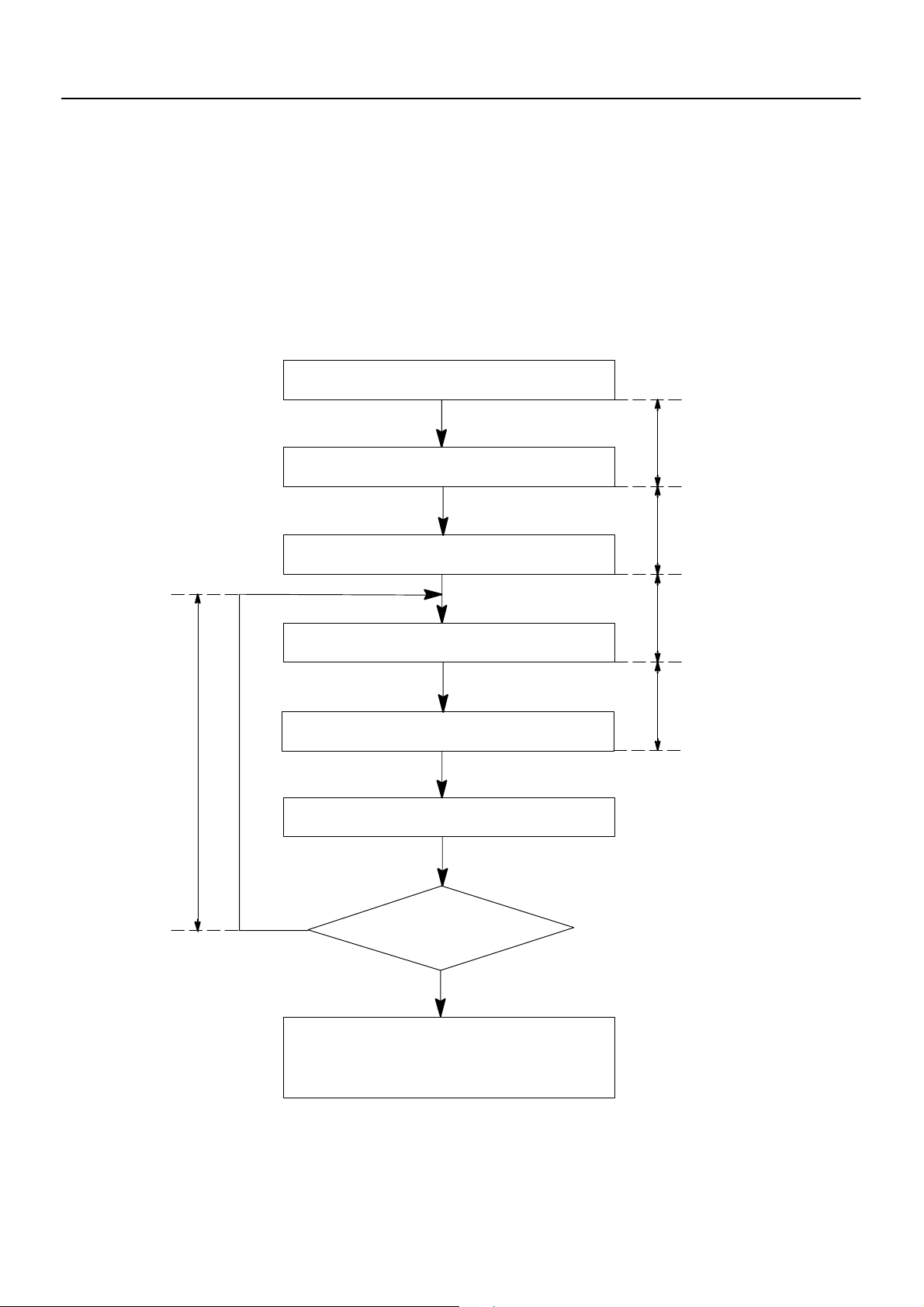

4. REGISTRATION OF ADDITIONAL SUB–KEY

There are 2 ways for registration of additional sub–key, one way is depressing brake pedal and acceleration

pedal and the other way is using LEXUS hand–held tester.

HINT:

! It is possible to register up to 3 sub–key codes including the already registered key code.

! When any operation time described below is over, registration mode completes.

! When the next procedure is performed while the timer is working, the timer completes counting time,

then next timer starts.

(1) Depressing brake pedal and acceleration pedal:

Insert already registered master key in the key

cylinder

Within 10 sec.

Depress and release the acceleration pedal 4

times.

Depress and release the brake pedal 5 times,

and remove the master key.

Insert key to be registered in key cylinder.

Depress and release the acceleration pedal 1

time. (Security indicator blinks)

After 60 sec. additional sub–key is registered.

(Security indicator is OFF)

Within 15 sec.

Within 20 sec.

Within 10 sec.

Within 10 sec.

2000 LEXUS LS400 (RM717U)

Yes

The registration mode completes when pulling

out the key and depressing and releasing the

brake pedal once or more within 10 sec. after indicator has been off or 10 sec. have passed.

Will you register the

next key?

No

2112Author!: Date!:

Page 13

BE–250

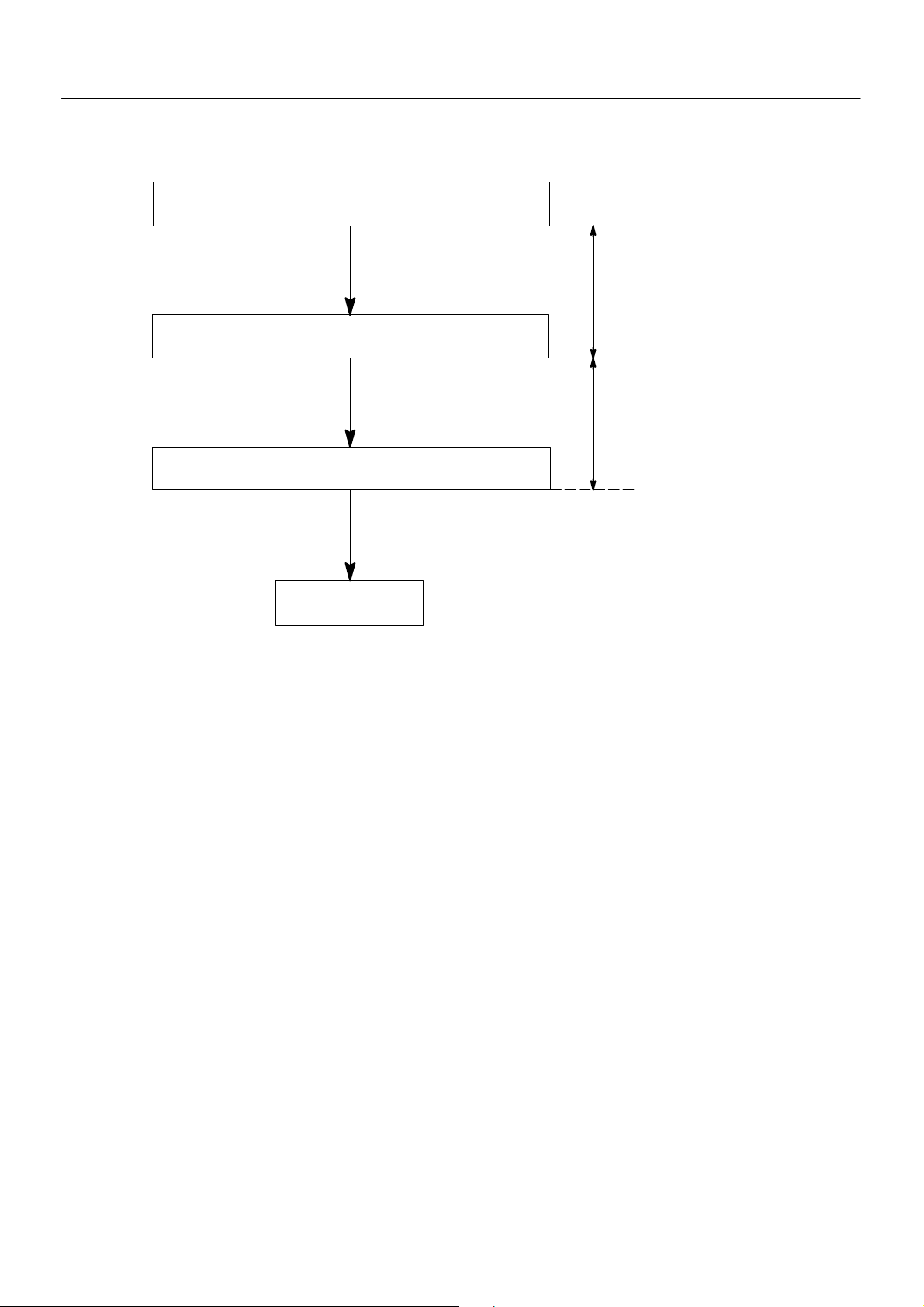

(2) Using LEXUS hand–held tester:

Insert already registered master key in the key cylinder.

Using LEXUS hand–held tester select sub–key registration.

Remove the master key.

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

Within 120 sec.

Within 20 sec.

Within

10 sec.

Within 10 sec.

Insert key to be registered in key cylinder.

(Security indicator blinks)

After 60 sec., additional master key is registered.

(Security indicator OFF)

Yes

Will you register the

next key?

No

The registration mode completes when pulling

out the key and depressing and releasing the

brake pedal once or more within 10 sec. after indicator has been off or 10 sec. have passed.

2000 LEXUS LS400 (RM717U)

2113Author!: Date!:

Page 14

BE–251

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

5. ERASURE OF TRANSPONDER KEY CODE

There are 2 ways for erasure of transponder key code, one way is depressing brake pedal and acceleration

pedal and the other way is using LEXUS hand–held tester.

NOTICE:

Delete all other master and sub–key codes leaving the master key code to use the operation. When

using the key which was used before deletion, it is necessary to register the code again.

HINT:

! When any operation time described below is over, registration mode completes.

! When the next procedure is performed while the timer is working, the timer completes counting time,

then next timer starts.

(1) Depressing brake pedal and acceleration pedal:

1. Insert master key in the key cylinder.

Within 15 sec.

2. Depress and release the acceleration pedal 6 times.

3. Depress and release the brake pedal 7 times.

4. Remove the master key.

5. Leave the vehicle more than 20 sec. without any

operation.

Within 20 sec.

Within 10 sec.

HINT:

If the key cannot be pulled out within 30 sec. from the first brake

depression in the step 3, the key code deletion is canceled.

2000 LEXUS LS400 (RM717U)

END

(Key code erased)

2114Author!: Date!:

Page 15

BE–252

(2) Using LEXUS hand–held tester:

1. Insert master key in the key cylinder.

2. Require key code deletion from hand–held tester.

(Security indicator blinks)

3. Remove the master key.

–BODY ELECTRICAL ENGINE IMMOBILISER SYSTEM

Within 120 sec.

Within 10 sec.

END

(Key code erased)

HINT:

When the key cannot be pulled out in the step 3, key code deletion is canceled.

(Security indicator is OFF.)

2000 LEXUS LS400 (RM717U)

2115Author!: Date!:

Page 16

–

INSTALLATION

1. INSTALL GARAGE DOOR OPENER

(a) Connect the wire harness to the terminal 4 and 5.

(b) Install the 3 screws.

2. INSTALL FRONT PERSONAL LIGHT

(a) Connect the 2 connectors.

(b) Install the 3 screws.

3. INSTALL FRONT PERSONAL LIGHT LENS

BE–243

BE0D6–01

2106Author!: Date!:

Page 17

I03241

I03242

BE–241

–BODY ELECTRICAL GARAGE DOOR OPENER SYSTEM

BE0D5–01

INSPECTION

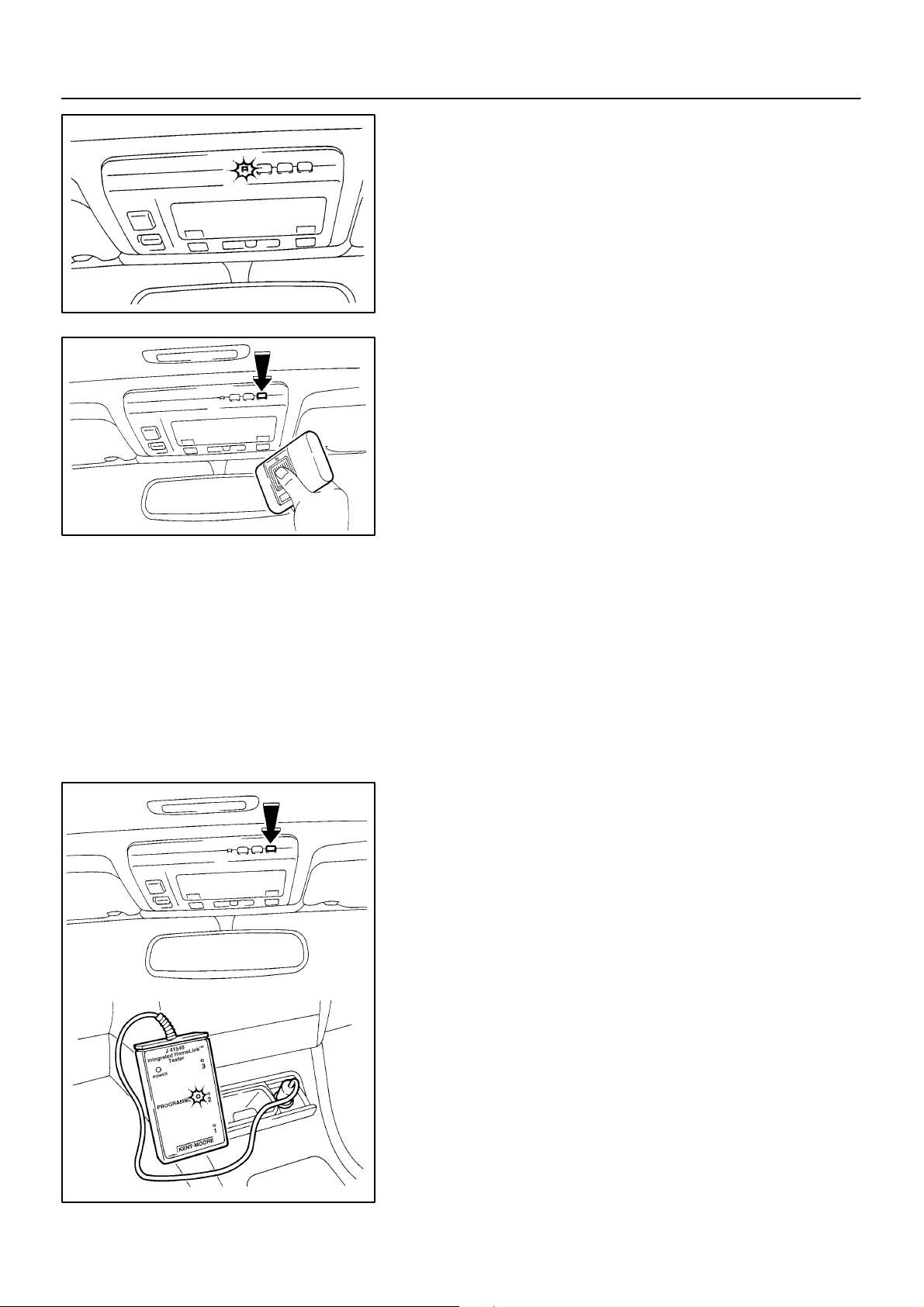

1. INSPECT GARAGE DOOR OPENER

Press the switch and check that each LED (red) lights up.

Even if only one switch is found not to light up, replace it.

2. INSPECT GARAGE DOOR OPENER REGISTRATION

AND TRANSMITTING

HINT:

Use the home link tester made by KENT MORE for this test.

As it is necessary to record the code of the hand held transmitter, customer’s code will be erased. When the inspection completes, please register the customer’s again.

(a) Check that the code of hand held transmitter for inspec-

tion can be recorded.

(See page

If the code can not be registered, replace garage door opener.

2000 LEXUS LS400 (RM717U)

(b) Press the switch which an inspection code has been reg-

istered for and check that LED (green) of the home link

tester lights up.

If the LED (green) does not light up, replace the garage door

opener.

I03244

2104Author!: Date!:

Page 18

BE–242

–BODY ELECTRICAL GARAGE DOOR OPENER SYSTEM

Wire Harness Side

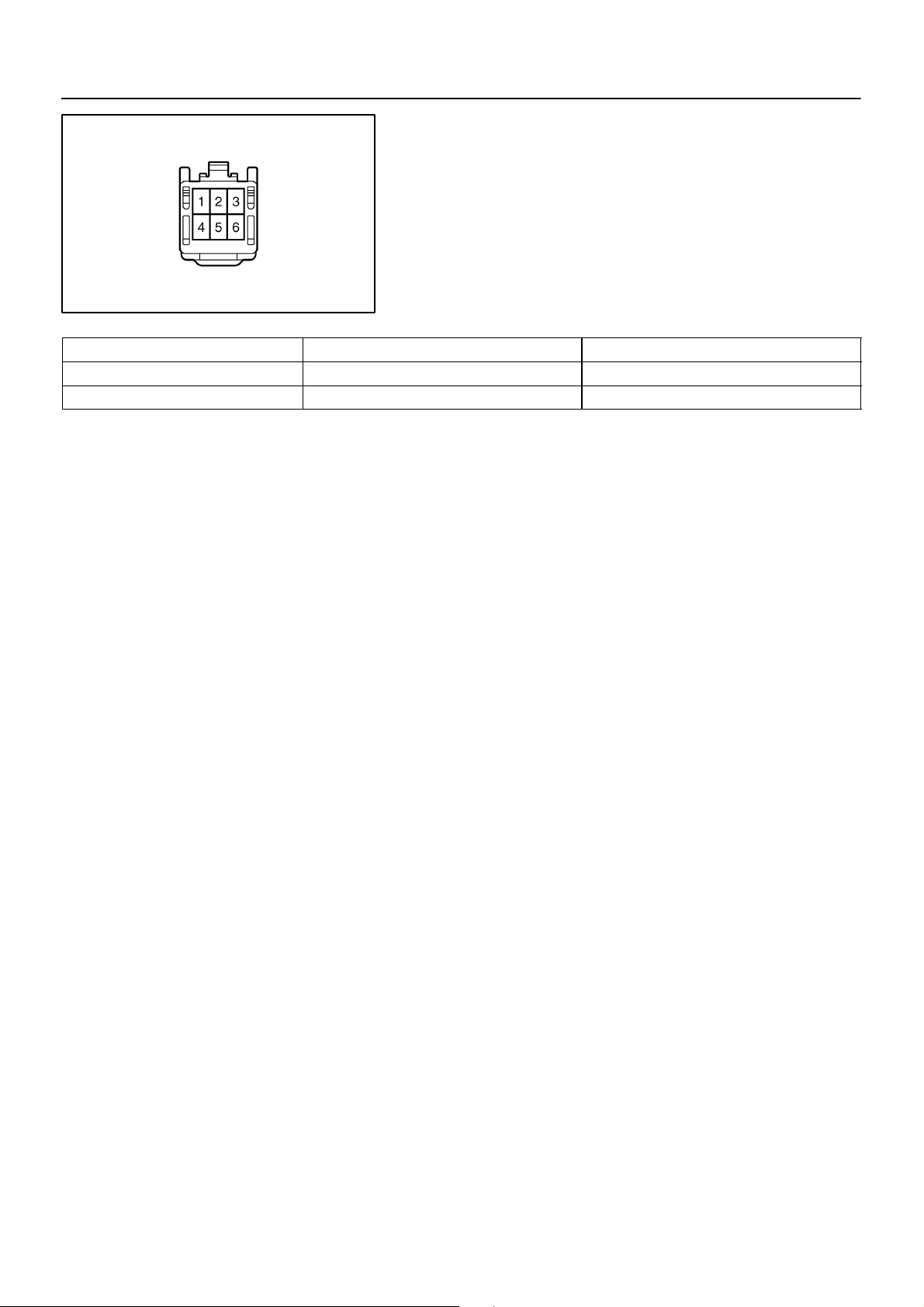

3. INSPECT GARAGE DOOR OPENER CIRCUIT

Disconnect the connector from the switch and inspect the connector on the wire harness side, as shown.

I03432

Te s te r c o nn e c t i on Condition Specified condition

5 – Ground Constant Continuity

4 – Ground Constant Battery positive voltage

2000 LEXUS LS400 (RM717U)

2105Author!: Date!:

Page 19

BE–240

I03419

–

BE0D4–01

REMOVAL

1. REMOVE FRONT PERSONAL LIGHT LENS

2. REMOVE FRONT PERSONAL LIGHT

(a) Remove the 3 screws.

(b) Disconnect the 2 connectors.

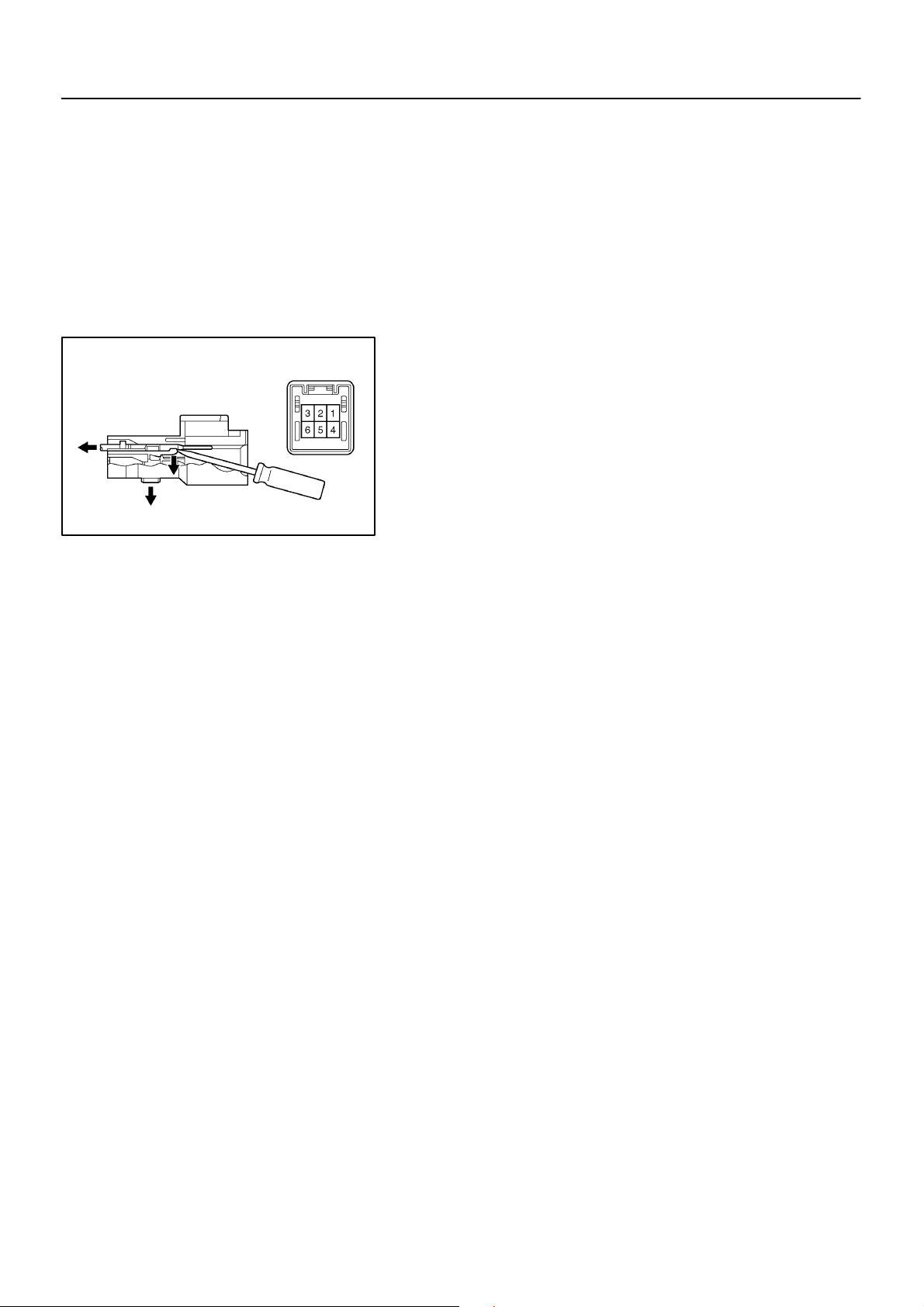

3. REMOVE GARAGE DOOR OPENER

(a) Remove the 3 screws.

(b) Remove the garage door opener connector from the per-

sonal light.

(c) Disconnect the secondary locking device.

(d) Release the locking plug of the terminal 4 and 5, and pull

the terminals out from the rear.

HINT:

Use a small screw driver.

2103Author!: Date!:

Page 20

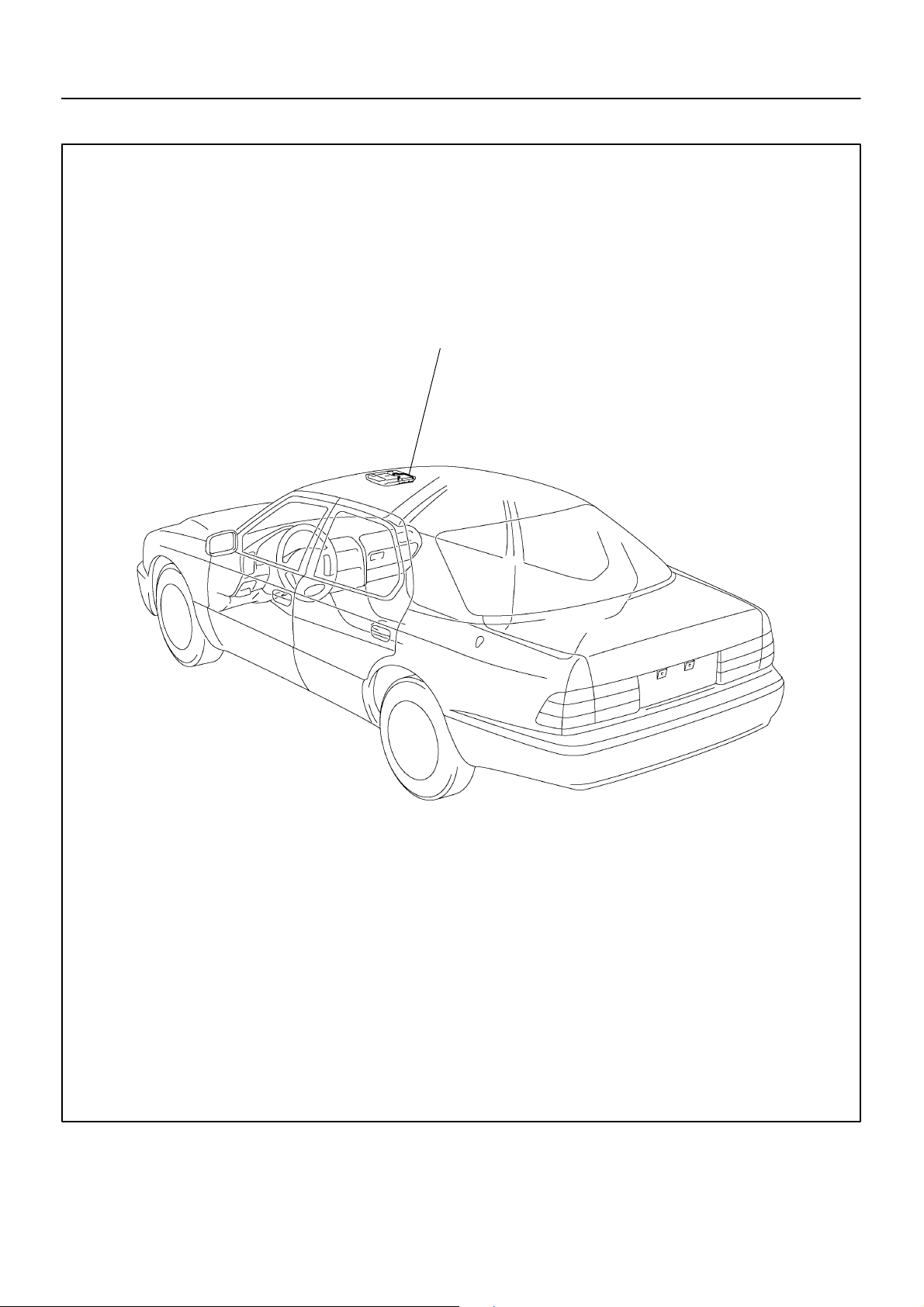

LOCATION

BE–239

–

BE0D3–01

Garage Door Opener

I03403

2102Author!: Date!:

Page 21

BE–236

–BODY ELECTRICAL GARAGE DOOR OPENER SYSTEM

GARAGE DOOR OPENER SYSTEM

BE0D2–01

REGISTRATION PROCEDURE

1. NEW CODE REGISTRATION

NOTICE:

! If pressing the switch of the original transmitter to

register the code, the system might operate.

! When registering the transmitter codes such as for

garage or gate, check that there is nobody around

those places then register.

(a) Press the switch for the item to be registered for 20 se-

conds

HINT:

When transferring to registration mode, LED (red) blinks in 1 Hz

cycle.

(b) In the condition of (a), bring the original transmitter to with-

in 1–inch area around the garage door opener and press

the switch. (code transmitting).

HINT:

When code registration completes correctly, LED (red) blinks in

5.6 Hz cycle.

I03243

2000 LEXUS LS400 (RM717U)

2099Author!: Date!:

Page 22

–BODY ELECTRICAL GARAGE DOOR OPENER SYSTEM

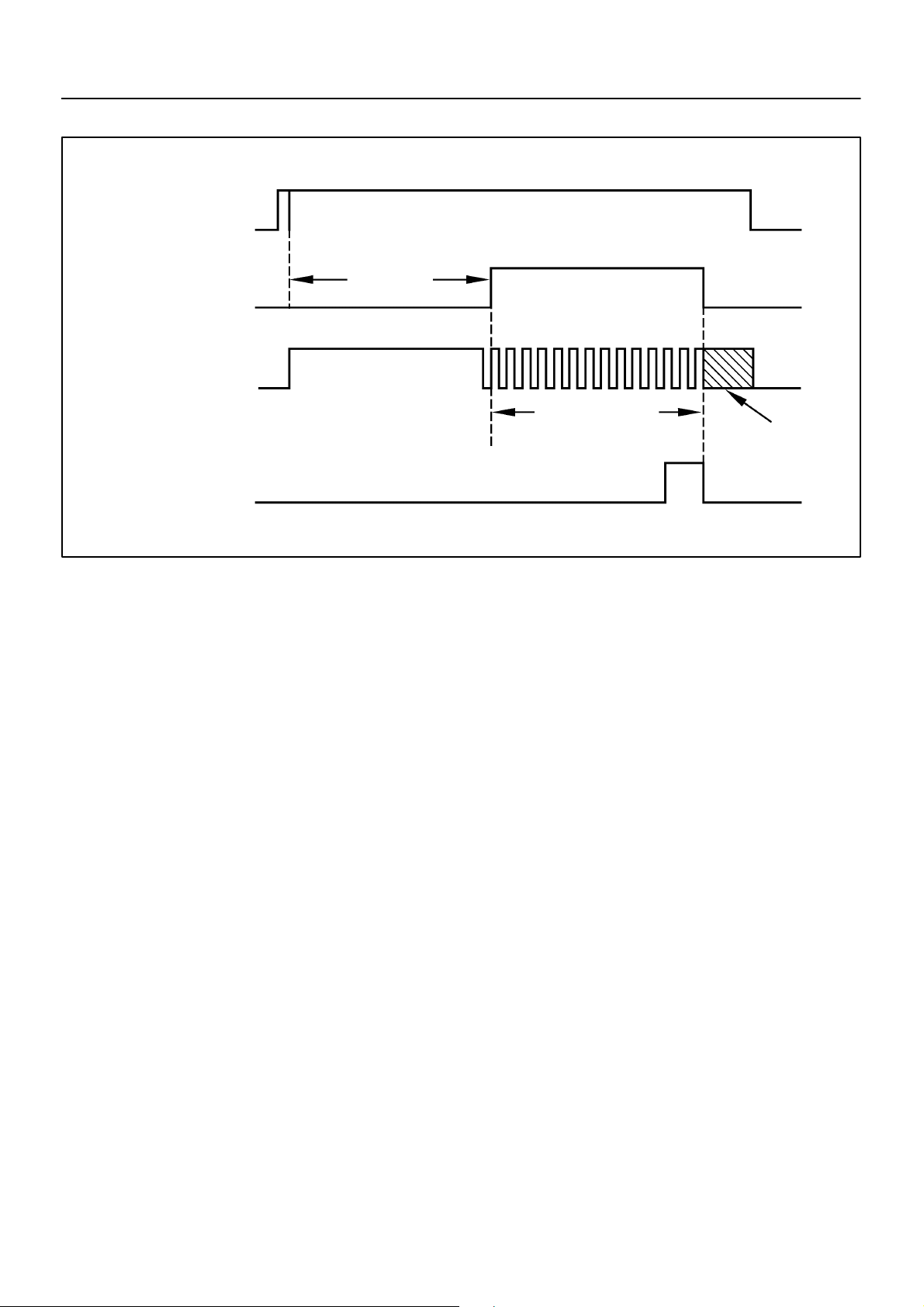

New code registration timing chart

BE–237

GARAGE DOOR

OPENER SWITCH

LEARN MODE

LED

OPERATION

ORIGINAL

TRANSMITTER

PRESSED

RELEASE

ENTER

EXIT

ON

OFF

ON

OFF

20 sec

LED flashes

at a rate of 1 Hz

LED flashes at a

rate of 5.6 Hz

I03487

If a code can not be registered, observe the following conditions.

HINT:

! If the battery of original transmitter is consumed.

! Press the switch of the transmitter repeatedly in registra-

tion mode, as some transmitters stop transmitting for 1 to

2 seconds.

! This system is not applicable to the garage door opener

which had been made before 1982.

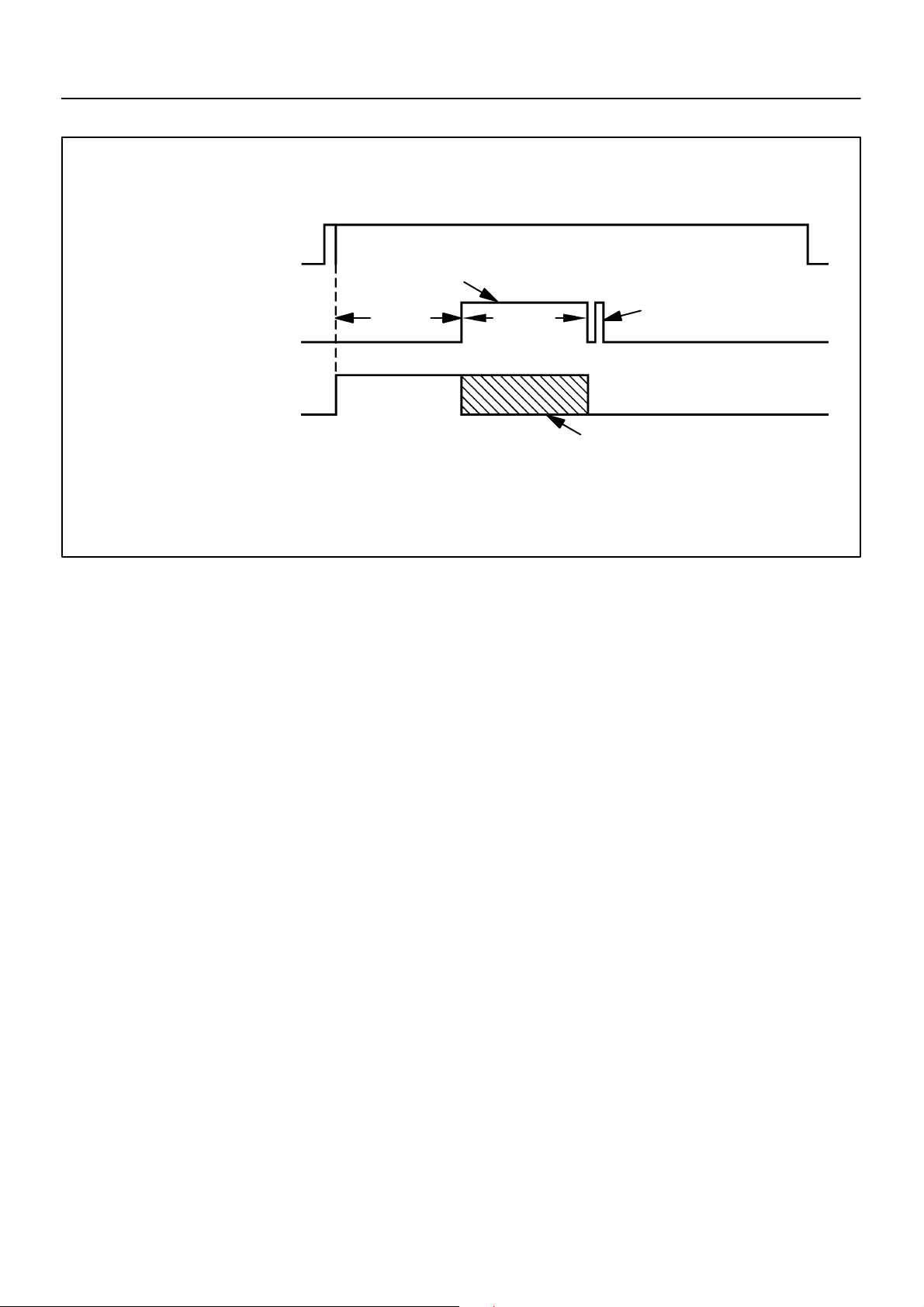

2. CODE DELETION

(a) Press the switches at both ends of garage door opener

simultaneously for 20 seconds.

HINT:

When transferring to deletion mode, LED (red) blinks in 6 Hz

cycle.

(b) When releasing the switch within 10 seconds after trans-

ferring to deletion mode, all the registered codes will be

erased.

HINT:

Press the switch until blinking in 6 Hz cycle stops, so that the

default code for check is set.

2000 LEXUS LS400 (RM717U)

2100Author!: Date!:

Page 23

BE–238

–BODY ELECTRICAL GARAGE DOOR OPENER SYSTEM

Code deletion timing chart

GARAGE DOOR

OPENER SWITCH

(Switch at both end)

CLEAR/DEFAULT

MODE

LED

OPERATION

PRESSED

RELEASE

ON

OFF

ON

OFF

Enter erase mode to erase all 3 channels

20 SEC

10 SEC

LED flashes at a rate of 6 HZ

LOAD DEFAULT

I03488

2000 LEXUS LS400 (RM717U)

2101Author!: Date!:

Page 24

BE–234

–BODY ELECTRICAL CLOCK

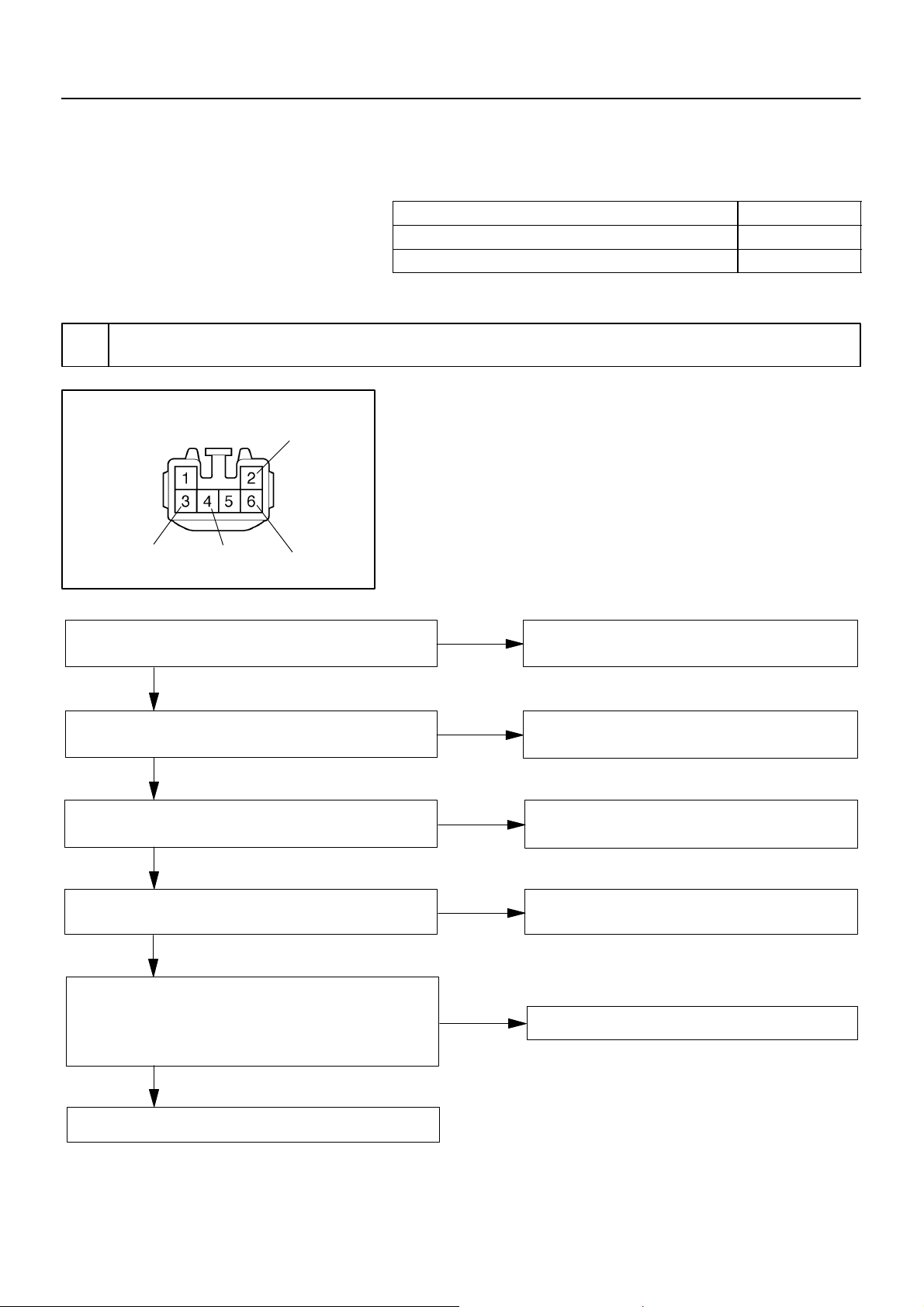

1. PROBLEM No.1

1 CLOCK WILL NOT OPERATE

+B

e–6–1

GND

ACC

IG

I03486

CLOCK

BE0D1–02

TROUBLESHOOTING

HINT:

Problem No.

Clock will not operate 1

Clock loses or gains time 2

± 1.5 seconds / da

(a) Turn the ignition switch ON.

(b) Check that the battery positive voltage is 10 – 16 V.

If voltage is not as specified, replace the battery.

(c) Check that the DOME FR, GAUGE and FR CIG fuses in

not below.

If the fuse is blown, replace the fuse and check for short.

(d) Troubleshoot the clock as follows.

HINT:

Inspect the connector on the wire harness side.

Is there battery positive voltage between terminal

+B and body ground?

Yes

Is there battery positive voltage between terminal

IG and body ground?

Yes

Is there battery positive voltage between terminal

ACC and body ground?

Yes

Is there continuity battery terminal GND and body

ground?

Yes

Is there battery positive voltage between terminal

ILL and body ground when rheostat knob is turned

to any position except fully clockwise? (Taillight

switch ON)

Yes

No

No

No

No

No

Open or short circuit in wire harness between

terminal +B and DOME fuse.

Open or short circuit in wire harness between

terminal IG and GAUGE fuse.

Open or short circuit in wire harness between

terminal ACC and FR CIG fuse.

Open circuit in wire harness between terminal

GND and body ground.

Rheostat light control or wire harness faulty.

Replace clock assembly.

2000 LEXUS LS400 (RM717U)

2097Author!: Date!:

Page 25

2. PROBLEM No.2

2 CLOCK LOSES OR GAINS TIME

IG

+B

e–6–1

GND

ACC

I03486

BE–235

–BODY ELECTRICAL CLOCK

(a) Check that the battery positive voltage is 10 – 16 V.

If voltage is not as specified, replace the battery.

(b) Inspect the error of the clock.

Allowable error (per day): ± 2.0 seconds

If the error exceeds the allowable error, replace the clock assembly.

(c) Check if the clock adjusting button is sticking in position

and has failed to return.

(d) Troubleshoot the clock as follows.

HINT:

Inspect the connector on the wire harness side.

Is there 10 – 16 V between terminal +B and body

ground?

Yes

Is there 10 – 16 V between terminal IG and body

ground?

Yes

Is there 10 – 16 V between terminal ACC and body

ground?

Yes

Adjust or replace clock assembly.

Bellow 10 V

Bellow 10 V

Bellow 10 V

Locate cause and repair, or recharge battery.

Locate cause and repair, or recharge battery.

Locate cause and repair, or recharge battery.

2000 LEXUS LS400 (RM717U)

2098Author!: Date!:

Page 26

Antenna Nut

Twist

BE4671

BE5781

BE5780

BE4674

BE–233

–

BE11Z–01

REPLACEMENT

1. Auto Antenna Models:

REMOVE ANTENNA ROD

HINT:

Do this operation with the battery negative (–) cable connected

to the battery terminal.

(a) Turn the ignition switch to ”LOCK” position.

(b) Remove the antenna nut.

(c) Press the ”AM, FM” buttons on the radio receiver, and si-

multaneously turn the ignition switch to ”ACC” position.

HINT:

! The rod will extend fully and be released form the motor

antenna.

! After removing the antenna rod, leave the ignition switch

as ”ACC”.

NOTICE:

To prevent body damage when the antenna rod is released,

hold the rod while it comes out.

2. IAuto Antenna Models:

NSTALL ANTENNA ROD

(a) Insert the cable of the rod until it reaches the bottom.

HINT:

! When inserting the cable, the teeth on the cable must face

toward the rear of the vehicle.

! Insert the antenna approx. 300 mm (11.8 in.).

(b) Wind the cable to retract the rod by turning the ignition

switch to ”LOCK” position.

HINT:

! If the ignition switch is already in ”LOCK” position, do step

1 (c) first, then turn the ignition switch to ”ACC” position.

! In case the cable is not wound, twist it, as shown in the

illustration.

! Even if the rod has not retracted fully, install the antenna

nut and inspect the antenna rod operation. It will finally retract fully.

(c) Inspect the antenna rod operation by pushing the radio

wave band select buttons.

2096Author!: Date!:

Page 27

BE–232

–

BE11Y–01

INSPECTION

1. Auto Antenna Models:

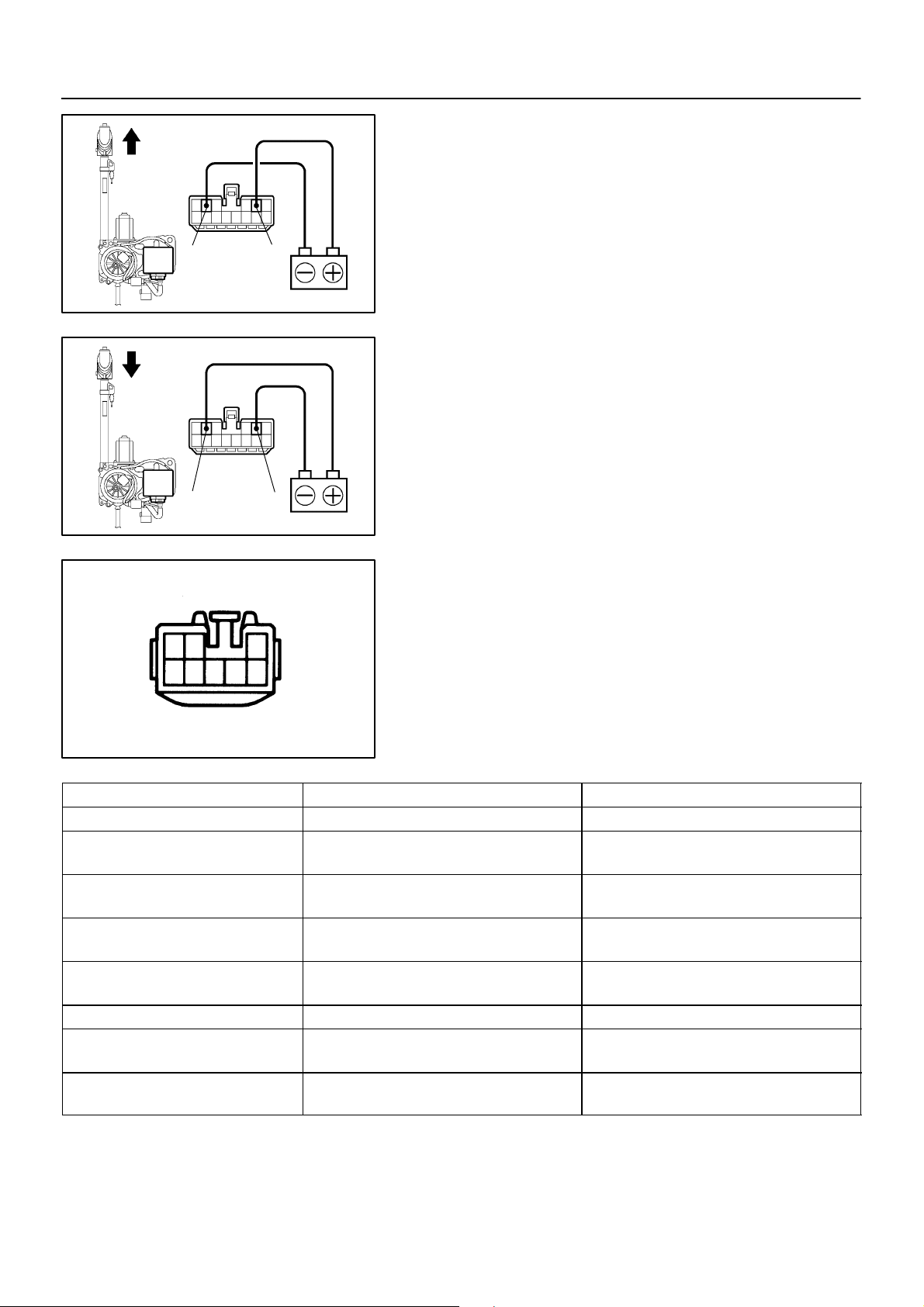

INSPECT ANTENNA MOTOR

(a) Connect the positive (+) lead from the battery to terminal

2 and the negative (–) lead to terminal 5.

(b) Check that the motor turns (moves upward).

25

I05587

25

I05580

NOTICE:

These tests must be done quickly (within 3 – 5 seconds) to

prevent the coil from burning out.

(c) Then, reverse the polarity, check that the motor turns the

opposite way (moves downward).

NOTICE:

These tests must be done quickly (within 3 – 5 seconds) to

prevent the coil from burning out.

Wire Harness Side

213

45 768

Te s te r c o nn e c t i on Condition Specified condition

7 – Ground Constant Continuity

1 – Ground

1 – Ground

2 – Ground

2 – Ground

3 – Ground Constant Battery voltage

5 – Ground

5 – Ground

2. Auto Antenna Models:

INSPECT ANTENNA MOTOR CONTROL RELAY CIRCUIT

Disconnect the connector from the relay and inspect the connector on wire harness side, as shown in the chart below.

Z08688

Ignition switch ACC or ON,

and radio switch ON and Others

Ignition switch ACC or ON,

and radio switch ON and AM

Ignition switch ACC or ON,

and radio or tape or CD switch OFF

Ignition switch ACC or ON,

and radio or tape or CD switch ON

Ignition switch ACC or ON,

and radio switch OFF

Ignition switch ACC or ON,

and radio switch ON

No voltage

Battery voltage

No voltage

Battery voltage

No voltage

Battery voltage

2095Author!: Date!:

Page 28

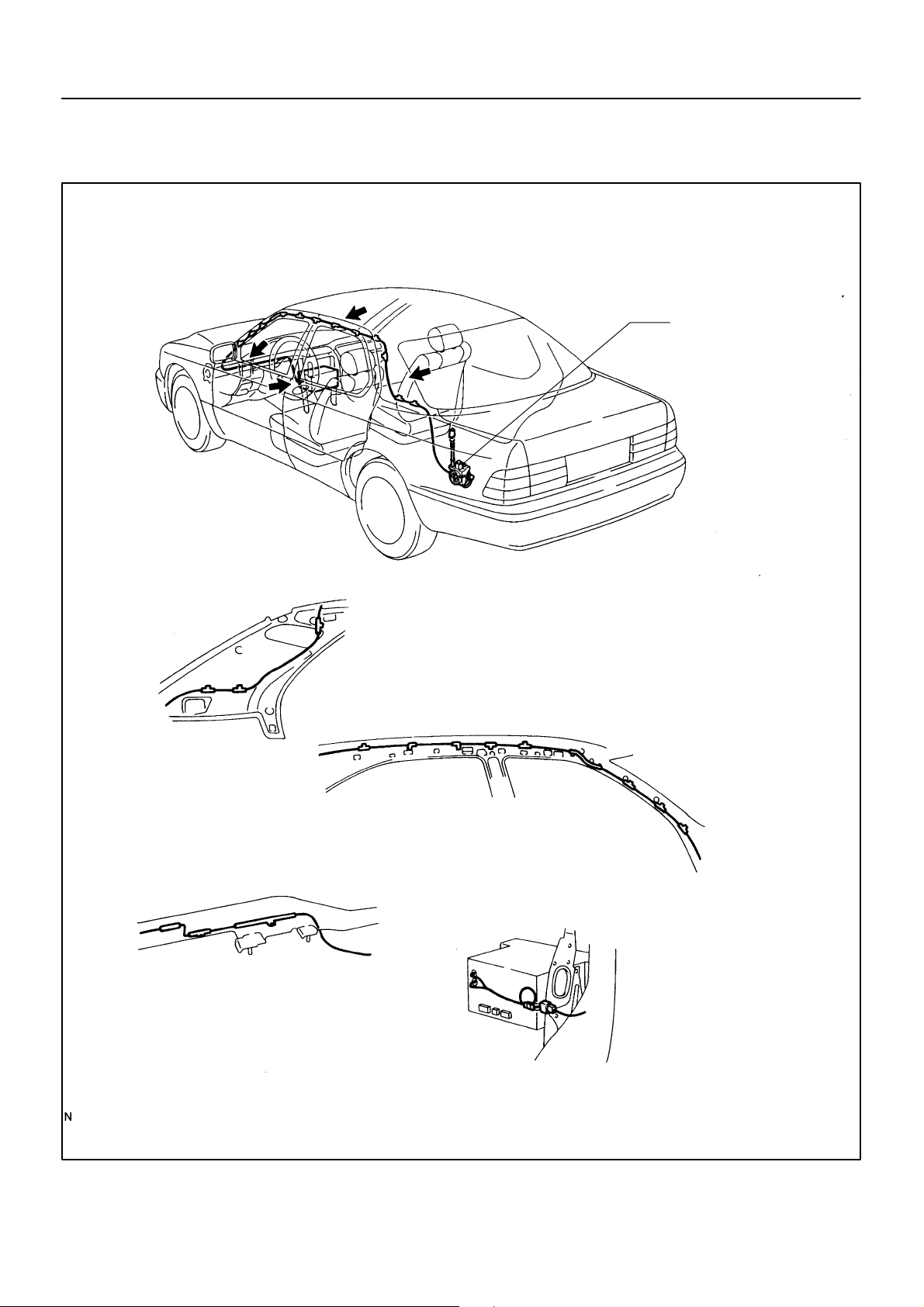

ANTENNA

LOCATION

BE–231

–

BE11X–01

B

View ”A”

C

A

D

View ”B”

Antenna

View ”C”

View ”D”

I10507

2094Author!: Date!:

Page 29

BE–226

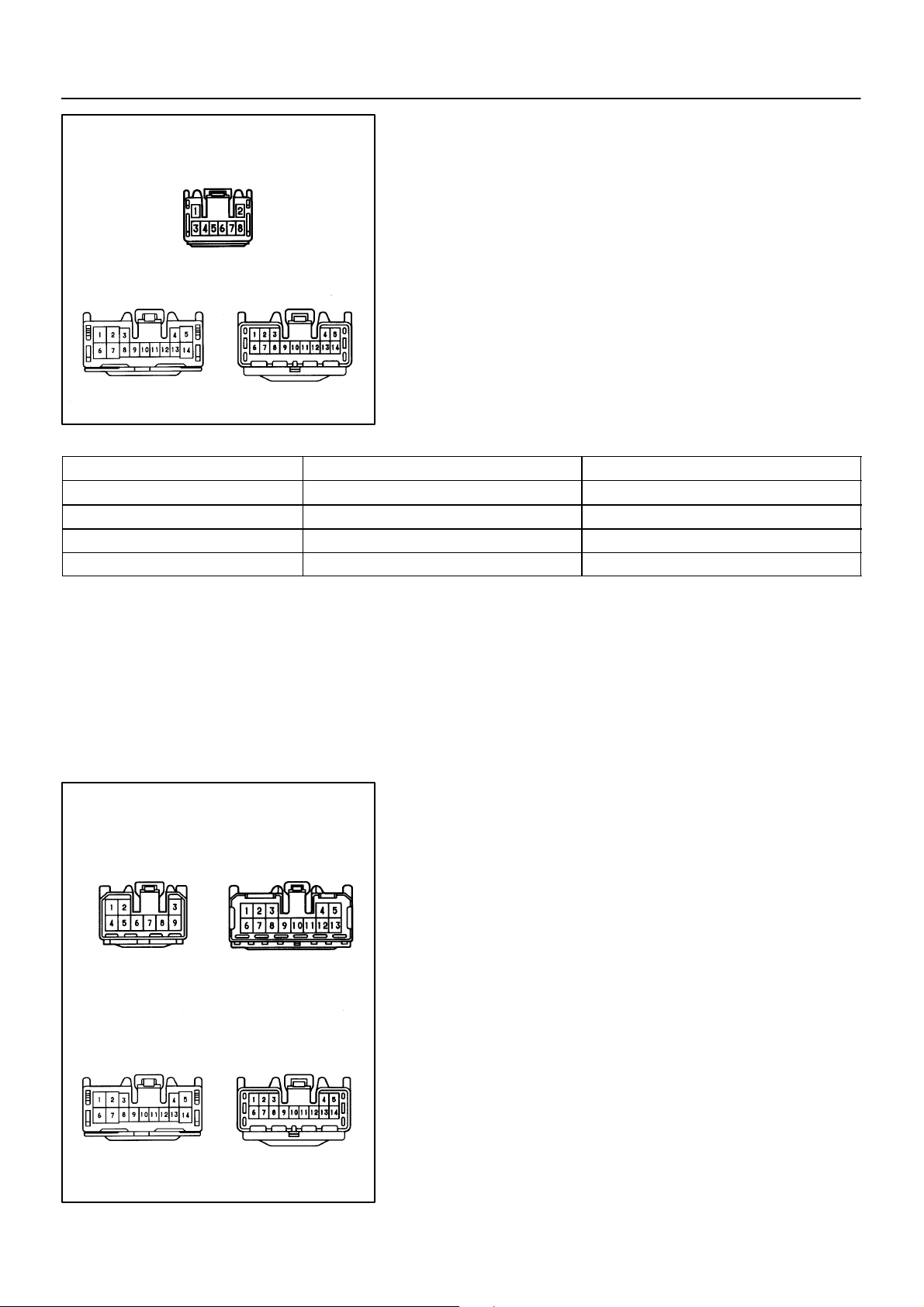

Wire Harness Side

Connector ”A”

Connector ”B” Connector ”C”

Te s te r c o nn e c t i on Condition Specified condition

B14 – Ground Constant Continuity

B6 – Ground Ignition switch position ACC or ON Battery positive voltage

B6 – Ground Ignition switch position LOCK No voltage

B1 – Ground Constant Battery positive voltage

–BODY ELECTRICAL AUDIO SYSTEM

BE0D0–01

INSPECTION

1. Nakamichi made:

INSPECT RADIO RECEIVER ASSEMBLY CIRCUIT

Disconnect the connectors from the radio receiver assembly.

And inspect the connector on the wire harness side, as shown.

Z14756

If circuit is not as specified, inspect the circuits connected to other parts.

HINT:

Check the wire harness between radio receiver assembly and

the CD auto changer, between radio receiver assembly and

power amplifier.

Wire Harness Side

Connector ”A” Connector ”B”

Connector ”C”

e–9–1 e–13–1–A

eh–14–1 h–14–1–A

2000 LEXUS LS400 (RM717U)

Connector ”D”

2. Nakamichi made:

INSPECT POWER AMPLIFIER CIRCUIT

Disconnect the connector from the power amplifier and inspect

the connector on the wire harness side, as shown.

Z14757

2089Author!: Date!:

Page 30

–BODY ELECTRICAL AUDIO SYSTEM

Te s te r c o nn e c t i on Condition Specified condition

A4 – Ground Constant Continuity

A5 – Ground Constant Battery positive voltage

A6 – Ground Ignition switch position ACC or ON Battery positive voltage

D6 – Ground

Ignition switch position ACC or ON

Radio, Tape or CD switch ON

Battery positive voltage

If circuit is not as specified, inspect the circuits connected to other parts.

BE–227

Wire Harness Side

h–14–1–A

Te s te r c on n e c t i on t o

terminal number

5 – Ground Constant Battery positive voltage

4 – Ground Ignition switch LOCK No voltage

4 – Ground Ignition switch ACC or ON Battery positive voltage

3. Nakamichi made:

INSPECT CD AUTO CHANGER CIRCUIT

Disconnect the connectors from the controller and inspect the

connector on the wire harness side, as shown.

Z14758

Condition Specified condition

If circuit is not as specified, inspect the circuits connected to other parts.

HINT:

Since the signals to and from the AP+, AP–, SGND, GND1 terminals are serial signals, they cannot ordinarily be measured

with a tester.

2000 LEXUS LS400 (RM717U)

2090Author!: Date!:

Page 31

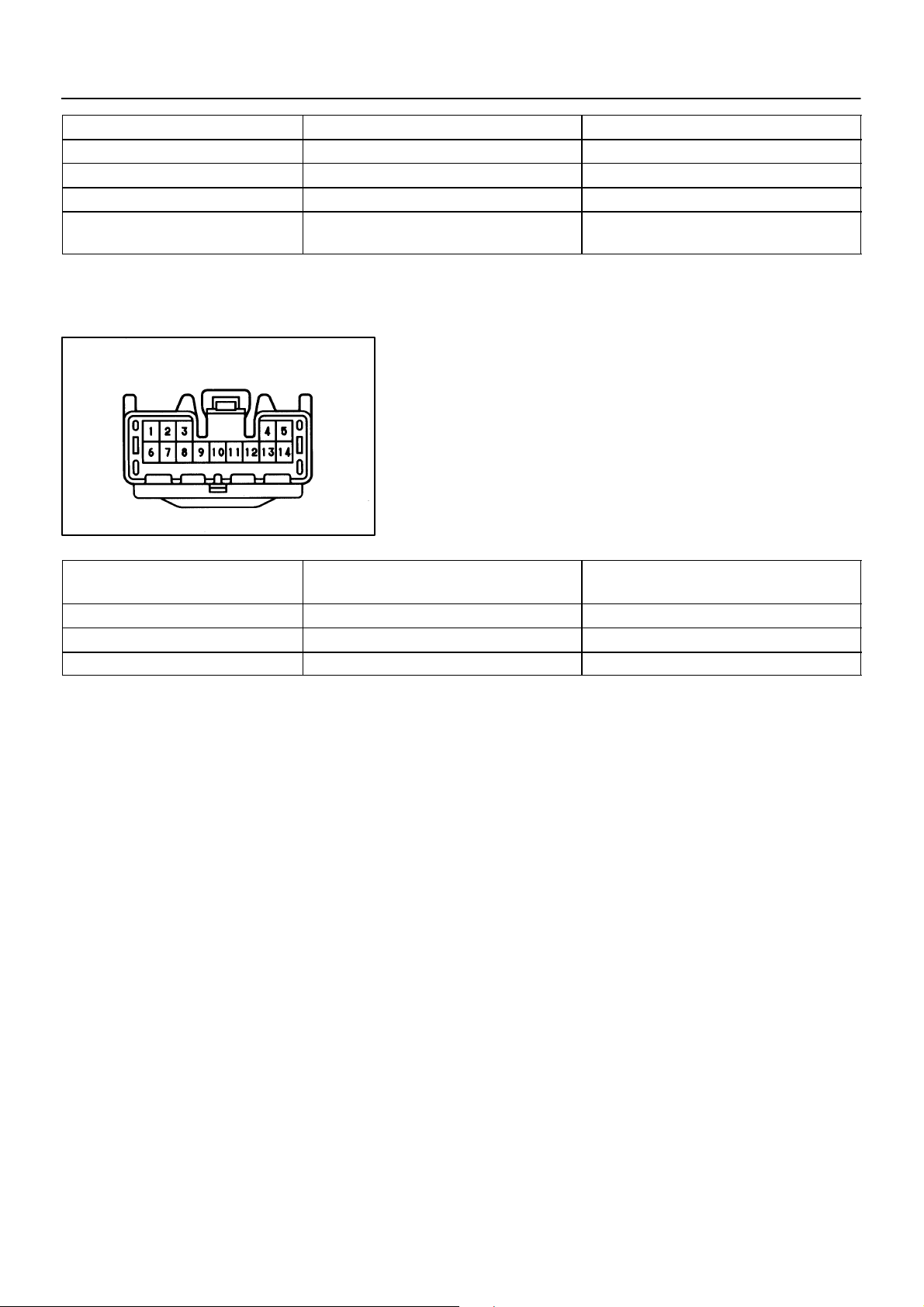

BE–228

–BODY ELECTRICAL AUDIO SYSTEM

Wire Harness Side

Connector ”A”

Connector ”B”

Te s te r c o nn e c t i on Condition Specified condition

B1 – Ground Constant Continuity

A6 – Ground Ignition switch position ACC or ON Battery positive voltage

A6 – Ground Ignition switch position LOCK No voltage

A1 – Ground Constant Battery positive voltage

4. Pioneer made:

INSPECT RADIO RECEIVER ASSEMBLY CIRCUIT

Disconnect the connectors from the radio receiver assembly.

And inspect the connector on the wire harness side, as shown.

I03482

If circuit is not as specified, inspect the circuits connected to other parts.

HINT:

Check the wire harness between power amplifier and the CD

auto changer, between radio receiver assembly and power amplifier.

Wire Harness Side

Connector ”A”

Connector ”C”

Connector ”E”

2000 LEXUS LS400 (RM717U)

Connector ”B”

Connector ”D”

5. Pioneer made and LEXUS navigation system:

INSPECT POWER AMPLIFIER CIRCUIT

Disconnect the connector from the power amplifier and inspect

the connector on the wire harness side, as shown.

I03483

2091Author!: Date!:

Page 32

–BODY ELECTRICAL AUDIO SYSTEM

Te s te r c o nn e c t i on Condition Specified condition

B7 – Ground Constant Continuity

B4 – Ground Constant Battery positive voltage

C12 – Ground Ignition switch position ACC or ON Battery positive voltage

If circuit is not as specified, inspect the circuits connected to other parts.

BE–229

Wire Harness Side

Te s te r c on n e c t i on t o

terminal number

5 – Ground Constant Battery positive voltage

12 – Ground Ignition switch LOCK No voltage

12 – Ground Ignition switch ACC or ON Battery positive voltage

6. Pioneer made and LEXUS navigation system:

INSPECT CD AUTO CHANGER CIRCUIT

Disconnect the connectors from the controller and inspect the

connector on the wire harness side, as shown.

I03484

Condition Specified condition

If circuit is not as specified, inspect the circuits connected to other parts.

HINT:

Since the signals to and from the AP+, AP–, SGND, GND1 terminals are serial signals, they cannot ordinarily be measured

with a tester.

2000 LEXUS LS400 (RM717U)

2092Author!: Date!:

Page 33

BE–230

–BODY ELECTRICAL AUDIO SYSTEM

Wire Harness Side

Connector ”A”

Connector ”B” Connector ”C”

Te s te r c o nn e c t i on Condition Specified condition

B2 – Ground Constant Continuity

B1 – Ground Ignition switch position ACC or ON Battery positive voltage

B1 – Ground Ignition switch position LOCK No voltage

B4 – Ground Constant Battery positive voltage

7. LEXUS navigation system:

INSPECT RADIO RECEIVER ASSEMBLY CIRCUIT

Disconnect the connectors from the radio receiver assembly.

And inspect the connector on the wire harness side, as shown.

I03485

If circuit is not as specified, inspect the circuits connected to other parts.

HINT:

Check the wire harness between power amplifier and the CD

auto changer, between radio receiver assembly and power amplifier.

8. INSPECT GLASS PRINTED ANTENNA

(Use same procedure as for ”INSPECT DEFOGGER WIRES”

on page BE–116)

9. REPAIR GLASS PRINTED ANTENNA

(Use same procedure as for ”REPAIR DEFOGGER WIRES” on

page BE–116)

2000 LEXUS LS400 (RM717U)

2093Author!: Date!:

Page 34

LOCATION

BE–225

–

BE0CZ–01

Engine Room Junction Block

! DOME Fuse

! RADIO No.1 Fuse

Tweeter

Speaker

Ignition Switch

Tweeter Speaker

Instrument Panel

Junction Block

! RADIO No.2 Fuse

Power Amplifier

Front Door Speaker

Rear Door Speaker

CD Auto

Changer

Radio Receiver

Assembly

Front Door Speaker

Rear Door Speaker

Woofer Speaker

I03405

2088Author!: Date!:

Page 35

BE–207

–BODY ELECTRICAL AUDIO SYSTEM

BE0CY–01

TROUBLESHOOTING

NOTICE:

When replacing the internal mechanism (computer part) of the audio system, be careful that no part

of your body or clothing comes in contact with the terminals of the leads from the IC, etc. of the replacement part (spare part).

HINT:

This inspection procedure is a simple troubleshooting which should be carried out on the vehicle during system operation and was prepared on the assumption of system component troubles (except for the wires and

connectors, etc.).

Always inspect the trouble taking the following items into consideration.

! Open or short circuit of the wire harness

! Connector or terminal connection fault

Problem No.

Radio No power coming in. 1

Power coming in, but radio not operating. 2

Noise present, but AM – FM not operating. 3

Either speaker does not work. 4

Either AM or FM does not work. 5

Reception poor (Volume faint). 5

Few preset tuning bands. 5

Sound quality poor. 6

Cannot set station select button. 7

Preset memory disappears. 7

Ta p e P l a y er Cassette tape cannot be inserted. 8

Cassette tape inserts, but no power. 9

Power coming in, but tape player not operating. 10

Either speaker does not work. 11

Sound quality poor (Volume faint). 12

Ta p e j a m me d , m al f u n ct i o n wi t h ta p e s pe e d or a u to – r e v er s e . 13

Cassette tape will not eject. 14

CD Player CD cannot be inserted. 15

CD inserts, but no power. 16

Power coming in, but CD player not operating. 17

Sound jumps. 18

Sound quality poor (Volume faint). 19

Either speaker does not work. 20

CD will not eject. 21

Amplifier No power coming in. 22

Either speaker does not work. 23

Noise Noise produced by vibration or shock while driving. 24

Noise produced when engine starts. 25

Noise occurs 26

2000 LEXUS LS400 (RM717U)

2070Author!: Date!:

Page 36

BE–208

1

Radio NO POWER COMING IN

–BODY ELECTRICAL AUDIO SYSTEM

Is tape player operating normally?

Yes

Radio receiver assembly faulty.

No

No

Check if RADIO No.2 fuse is OK.

Replace fuse.

Yes

Is ACC applied to radio receiver assembly?

No

ACC wire harness faulty.

Yes

Check if DOME fuse is OK?

No

Replace fuse.

Yes

Is +B applied to radio receiver assembly?

No

+B wire harness faulty.

Yes

Check if GND (wire harness side) to radio is

No

GND faulty.

OK?

Yes

Radio receiver assembly faulty.

2 Radio POWER COMING IN, BUT RADIO NOT OPERATING

If radio side faulty

Is tape player operating normally?

Yes

Go to No. 23.

No

Is there continuity in speaker wire harness?

No

Speaker wire harness faulty.

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Function OK?

Yes

speaker faulty.

No

Radio receiver assembly faulty.

3 Radio NOISE PRESENT, BUT AM–FM NOT OPERATING

Go to No. 23

Radio receiver assembly faulty.

If radio side faulty

Radio receiver

assembly faulty.

V06272

2000 LEXUS LS400 (RM717U)

2071Author!: Date!:

Page 37

–BODY ELECTRICAL AUDIO SYSTEM

4 Radio EITHER SPEAKER DOES NOT WORK

BE–209

Is tape player operating normally?

No

Is hiss produced by non–functioning speaker?

No

Check if GND to power amplifier is OK?

Yes

Are +B and +B2 applied to power amplifier?

Yes

Is AMP applied to power amplifier?

Yes

Is there continuity in wire harness? (Radio receiver

to power amplifier)

Yes

Is there continuity in speaker wire harness?

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Functions OK?

Yes

Yes

No

No

No

No

No

Yes

Radio receiver assembly faulty.

Radio receiver assembly faulty.

GND fault.

+B and +B2 wire harness faulty.

Check the radio receiver assembly.

Wire harness faulty.

Speaker wire harness faulty.

Speaker faulty.

No

Radio receiver assembly faulty.

2000 LEXUS LS400 (RM717U)

V06273

2072Author!: Date!:

Page 38

BE–210

–BODY ELECTRICAL AUDIO SYSTEM

5 Radio

FEW PRESET TUNING BANDS

Problem with radio wave signals or location?

(See page BE–203)

No

Are both AM and FM defective?

Yes

Go to No.28

If radio side faulty

Is tape player operating normally?

No

Temporarily install another speaker. Functions

OK?

No

Radio receiver assembly faulty.

EITHER AM OR FM DOES NOT WORK, RECEPTION POOR (VOLUME FAINT),

Yes

No

Yes

Yes

Poor signals, poor location.

Radio receiver assembly faulty.

Radio receiver assembly faulty.

Speaker faulty.

6

Radio SOUND QUALITY POOR

Is sound quality always bad?

Yes

Is tape player operating normally?

No

Is speaker properly installed?

Yes

Temporarily install another speaker. Functions

OK?

6–A.

Is sound quality bad in certain areas only?

No

No

Yes

No

Yes

No

Yes

Go to step 6–A.

If radio side faulty

Go to No.28.

Radio receiver

assembly faulty.

Install properly.

Speaker faulty.

Radio receiver assembly faulty.

Poor signals, poor location.

Radio receiver assembly faulty.

2000 LEXUS LS400 (RM717U)

V03663

2073Author!: Date!:

Page 39

BE–211

–BODY ELECTRICAL AUDIO SYSTEM

7 Radio CANNOT SET STATION SELECT BUTTON, PRESET MEMORY DISAPPEARS

Can cassette tape be inserted in tape player?

Yes

Radio receiver assembly faulty.

No

No

Check if DOME and RADIO No.2 fuses are OK.

Replace fuse.

Yes

Are ACC and +B applied to radio receiver assem-

No

ACC and +B wire harness faulty.

bly?

Yes

Check if GND (wire harness side) to radio is OK.

No

GND faulty.

Yes

Radio receiver assembly faulty.

8 Tape Player CASSETTE TAPE CANNOT BE INSERTED

Is there a foreign object inside tape player? Remove foreign object.

Yes

No

Is auto search button of radio operating normally?

No

Check if DOME and RADIO No.2 fuses are OK.

Yes

Are ACC and +B applied to radio receiver assembly?

No

ACC and +B wire harness faulty.

Yes

No

Yes

Radio receiver assembly faulty.

Replace fuse.

Check if GND (wire harness side) to radio receiver

assembly is OK?

No Yes

GND faulty.

Radio receiver

assembly faulty.

2000 LEXUS LS400 (RM717U)

V06275

2074Author!: Date!:

Page 40

BE–212

–BODY ELECTRICAL AUDIO SYSTEM

9 CASSETTE TAPE INSERTS, BUT NO POWER

Tape Player

Is tape operating normally?

No

Check if DOME and RADIO No.2 fuses are OK.

Yes

Is ACC applied to radio receiver assembly?

No

ACC wire harness faulty.

10 POWER COMING IN, BUT TAPE PLAYER NOT OPERATINGTape Player

Functions OK if different cassette tape inserted?

No

Is radio operating normally?

Yes

No

Yes

Yes

Yes

Radio receiver assembly faulty.

Replace fuse.

Radio receiver assembly faulty.

Cassette tape faulty.

Radio receiver assembly faulty.

No

Is there continuity in speaker wire harness?

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Functions OK?

No

Radio receiver assembly faulty.

No

Yes

Speaker wire harness faulty.

Speaker faulty.

2000 LEXUS LS400 (RM717U)

V06276

2075Author!: Date!:

Page 41

–BODY ELECTRICAL AUDIO SYSTEM

BE–213

11

Tape Player

EITHER SPEAKER DOES NOT WORK

Check if RADIO No.1 and RADIO No.2 fuses are

OK.

Yes

Is radio operating normally?

No

Check if GND to power amplifier is OK.

Yes

Are +B and +B2 applied to power amplifier?

Yes

Is AMP applied to power amplifier?

Yes

Is there continuity in wire harness? (Radio receiver

to power amplifier)

Yes

Temporarily install another woofer speaker.

Functions OK?

No

Yes

No

No

No

No

Yes

Replace fuse.

Radio receiver assembly faulty.

GND faulty.

+B and +B2 wire harness faulty.

Check the radio receiver assembly.

Wire harness faulty.

Woofer speaker faulty.

No

Is there continuity in speaker wire harness?

Yes

Te mp or ar il y i ns ta ll a no the r po we r am pli fi er.

Functions OK?

Yes

Power amplifier faulty.

No

No

Speaker wire harness faulty.

Radio receiver assembly faulty.

2000 LEXUS LS400 (RM717U)

V06277

2076Author!: Date!:

Page 42

BE–214

–BODY ELECTRICAL AUDIO SYSTEM

Tape Player

SOUND QUALITY POOR (VOLUME FAINT)12

Functions OK if different cassette tape inserted?

No

Operates normally after cleaning the heads?

(See page BE–203)

No

Is radio operating normally?

No

Is speaker properly installed?

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Functions OK?

No

Radio receiver assembly faulty.

Yes

Yes

Yes

No

Yes

Cassette tape faulty.

Head dirty.

Radio receiver assembly faulty.

Install properly.

Speaker faulty.

TAPE JAMMED, MALFUNCTION WITH TAPE SPEED OR AUTO–REVERSETape Player13

Functions OK if different tape (less than 120 mins.)

is inserted?

No

Is there a foreign object inside tape player?

No

Operates normally after cleaning the heads?

(See page BE–203)

No

Radio receiver assembly faulty.

Yes

Yes

Yes

Cassette tape faulty.

Remove foreign object.

Head dirty.

2000 LEXUS LS400 (RM717U)

V03671

2077Author!: Date!:

Page 43

–BODY ELECTRICAL AUDIO SYSTEM

BE–215

14 Tape Player

Is tape player operating normally?

CASSETTE TAPE WILL NOT EJECT

No

Cassette tape jammed.

Yes

Is auto search button of radio operating normally?

Yes

Radio receiver assembly faulty.

No

Check if DOME fuse is OK? Replace fuse.

No

Yes

Is +B applied to radio receiver assembly?

Yes

Radio receiver assembly faulty.

No

+B wire harness faulty.

CD CANNOT BE INSERTED15 CD Player

Yes

Is CD already inserted?

Eject CD.

No

Is 3.2 in. (8 cm) disc being used?

No

Is auto search button of radio operating normally?

Yes

Is +B applied to CD auto changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Temporarily install another CD auto changer.

Functions OK?

Yes

No

No

No

No

No

No

Use 4.7 in. (12 cm) disc.

Check if RADIO No.1 and

RADIO No.2 fuses are OK?

No

Replace

fuse.

Yes

+B wire harness faulty.

ACC wire harness faulty.

GND wire harness faulty.

Wire harness faulty. (to radio receiver assembly)

Radio receiver assembly faulty.

Yes

CD auto changer faulty.

2000 LEXUS LS400 (RM717U)

V06279

2078Author!: Date!:

Page 44

BE–216

–BODY ELECTRICAL AUDIO SYSTEM

CD INSERTS, BUT NO POWER16 CD Player

Is radio operating normally?

Yes

Is +B applied to CD auto changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK.

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Temporarily install another CD auto changer.

Functions OK?

Check if RADIO No.1 and RADIO No.2 fuses are

No

OK?

NoYes

Replace fuse.

No

+B wire harness faulty.

No

ACC wire harness faulty.

GND wire harness faulty.

No

Wire harness faulty. (to radio receiver assembly)

No

No

Radio receiver assembly faulty.

Yes

CD auto changer faulty.

2000 LEXUS LS400 (RM717U)

V06280

2079Author!: Date!:

Page 45

–BODY ELECTRICAL AUDIO SYSTEM

BE–217

17

CD Player

POWER COMING IN, BUT PLAYER NOT OPERATING

Is CD inserted correct side up?

Yes

Is 3.2 in. (8 cm) disc being used?

No

Functions OK if different CD inserted?

No

Is radio operating normally?

Yes

Is temperature inside luggage compartment hot?

No

Does sudden temperature changer occur inside

luggage compartment?

No

No

Yes

Yes

No

Yes

Yes

Insert correctly.

Use 4.7 in. (12 cm) disc.

CD faulty.

Go to step 17–B.

Protective circuit in operation.

Formation of condensation due to temp.

change.

Go to step 17–A.

17–A.

Is +B applied to CD changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Temporarily install another CD auto changer.

Functions OK?

Yes

CD auto changer faulty.

No

+B wire harness faulty.

No

ACC wire harness faulty.

GND wire harness faulty.

No

Wire harness faulty. (to radio receiver assembly)

No

Radio receiver assembly faulty.

No

2000 LEXUS LS400 (RM717U)

V06281

2080Author!: Date!:

Page 46

BE–218

17–B.

Is there continuity in speaker wire harness?

Yes

–BODY ELECTRICAL AUDIO SYSTEM

No

Speaker wire harness faulty.

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Functions OK?

Yes

Go to step 17–A.

SOUND JUMPS18 CD Player

Does sound jump only during strong vibration?

No

Is CD auto changer properly installed?

Yes

Functions OK if different CD inserted?

No

Does sudden temperature changer occur in luggage compartment?

Yes

Yes

No

Yes

Yes

speaker faulty.

Jumping caused by vibration.

Install properly.

CD faulty.

Formation of condensation due to temp.

change.

No

Is +B applied to CD auto changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Temporarily install another CD auto changer.

Functions OK?

Yes

CD auto changer faulty.

No

+B wire harness faulty.

No

ACC wire harness faulty.

GND wire harness faulty.

No

Wire harness faulty. (to radio receiver assembly)

No

Radio receiver assembly faulty.

No

2000 LEXUS LS400 (RM717U)

V06282

2081Author!: Date!:

Page 47

BE–219

–BODY ELECTRICAL AUDIO SYSTEM

SOUND QUALITY POOR (VOLUME FAINT)19 CD Player

Functions OK if different CD inserted?

No

Is radio operating normally?

No

Is speaker properly installed.

Yes

Temporarily install another speaker. Functions

OK?

No

Is +B applied to CD auto changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Yes

No

Yes

No

No

No

CD faulty.

Install properly

Speaker faulty.

+B wire harness faulty.

ACC wire harness faulty.

GND wire harness faulty.

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Temporarily install another CD auto changer.

Functions OK?

Yes

CD auto changer faulty.

Wire harness faulty.

No

(to radio receiver assembly)

Radio receiver assembly faulty.

No

2000 LEXUS LS400 (RM717U)

V03678

2082Author!: Date!:

Page 48

BE–220

–BODY ELECTRICAL AUDIO SYSTEM

EITHER SPEAKER DOES NOT WORK20 CD Player

Is radio operating normally? Go to step 20–A.

Yes

No

Yes

Is power amplifier operating normally?

Go to step 20–A.

No

Yes

Is hiss produced by non–functioning speaker?

Go to step 20–A.

No

Is there continuity in speaker wire harness?

No

Speaker wire harness faulty.

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Yes

Speaker faulty.

Functions OK?

No

Go to step 20–A.

20–A

Is +B applied to CD auto changer? +B wire harness faulty.

No

Yes

Is ACC applied to CD auto changer?

No

ACC wire harness faulty.

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Te mp or ar il y i ns ta ll a no the r CD a ut o cha ng er ?

Functions OK?

Yes

CD auto changer faulty.

GND wire harness faulty.

No

Wire harness faulty. (to radio receiver assembly)

No

Radio receiver assembly faulty.

No

2000 LEXUS LS400 (RM717U)

V06283

2083Author!: Date!:

Page 49

–BODY ELECTRICAL AUDIO SYSTEM

BE–221

CD Player

CD WILL NOT EJECT21

Is auto search button of radio operating normally?

Yes

Is +B applied to CD auto changer?

Yes

Is ACC applied to CD auto changer?

Yes

Check if GND (wire harness side) to CD auto

changer is OK?

Yes

Is there continuity in CD auto changer wire harness? (to radio receiver assembly)

Yes

Check if RADIO No.1 and RADIO No.2 fuses are

No

OK?

Yes

No

Replace fuse.

No

+B wire harness faulty.

No

ACC wire harness faulty.

GND wire harness faulty.

No

Wire harness faulty. (to radio receiver assembly)

No

Temporarily install another CD auto changer.

Functions OK?

Yes

CD auto changer faulty.

Amplifier

NO POWER COMING IN22

Are +B and +B2 applied to power amplifier?

Yes

AMP fuse is OK?

Yes

Is ACC applied to power amplifier?

Yes

Is there continuity in wire harness? (Radio receiver

to power amplifier)

Yes

Check if GND to body is OK.

Radio receiver assembly faulty.

No

No

No

No

No

No

Power amplifier faulty.

Replace fuse.

Power amplifier.

Wire harness faulty.

GND faulty.

Yes

Radio receiver assembly faulty.

2000 LEXUS LS400 (RM717U)

V06285

2084Author!: Date!:

Page 50

BE–222

–BODY ELECTRICAL AUDIO SYSTEM

EITHER SPEAKER DOES NOT WORK23 Amplifier

Is power amplifier operating normally?

No

Is hiss produced by non–functioning speaker?

No

Is there continuity in speaker wire harness?

Yes

Te mp or ar il y i ns ta ll a no the r sp ea ke r.

Functions OK?

No

Power amplifier faulty.

NOISE PRODUCED BY VIBRATION OR SHOCK WHILE DRIVING24 Noise

Is speaker properly installed?

Yes

Yes

No

Yes

No

Radio receiver assembly faulty.

Radio receiver assembly faulty.

Speaker wire harness faulty.

Speaker faulty.

Install properly.

Yes

No

Is each system correctly installed?

Install properly.

Yes

With vehicle stopped, lightly tap each system.

Yes

Each system faulty.

Is noise produced?

No

Noise produced by static electricity accumulating in the vehicle body.

2000 LEXUS LS400 (RM717U)

V06286

2085Author!: Date!:

Page 51

BE–223

–BODY ELECTRICAL AUDIO SYSTEM

NOISE PRODUCED WHEN ENGINE STARTS25 Noise

Whistling noise which becomes high– pitched when

accelerator strongly depressed, disappears shortly

after engine stops.

No

Whining noise occurs when A/C is operation.

No

Scratching noise occurs during sudden acceleration, driving on rough roads or when ignition switch

is turned on.

No

Clicking sound heard when horn button is pressed,

then released. Whirring/grating sound when

pushed continuously.

No

Murmuring sound, stops when engine stops.

No

Tick–tock noise, occurs in co–ordination with blinking of flasher.

No

Alternator noise.

Yes

Yes

Yes

Yes

A/C noise.

Fuel gauge noise.

Horn noise.

Yes

Ignition noise.

Yes

Turn signal noise.

Noise occurs during window washer operation.

No

Scratching noise occurs while engine is running

and continues a while even after engine stops.

No

Scraping noise in time wiper beat.

No

Other type of noise.

Yes

Yes

Yes

Washer noise.

Engine coolant temp. gauge noise.

Wiper noise.

2000 LEXUS LS400 (RM717U)

V06356

2086Author!: Date!:

Page 52

BE–224

26 Noise NOISE OCCURS

–BODY ELECTRICAL AUDIO SYSTEM

Does the noise occur only in the radio?

Yes

Does the noise occur in a particular place?

No

Is there any additional installation part

around the glass imprinted antenna?

(Sun shade film, telephone antenna etc.)

No

Does the noise occur even pulling out the

antenna cord from the radio?

No

Does the noise occur even pulling out the

antenna terminal on the glass surface?

No

Isn’t there any adhesive (Butyl rubber)

stuck on the bases of the antenna

terminal, defogger terminal and bus bar?

No

(It occurs in the cassette

and CD.)

Yes

Yes

An electric environment.

Does the noise stop by removing it?

Yes

Influence of the film or the noise radiation

of the additional installation part.

Yes

Yes

Yes

Check the radio.

Mixing into the antenna cable.

Failure of glass installation.

Muse plane the butyl rubber.

Refer to No.25.

No

Does the noise occur even pulling out

the defogger terminal?

No

Check the grounding of the antenna,

antenna cord, coke coil, and noise filter.

(See page BE–203)

OK

Does the condition get better by exchanging

the choke coil?

No

Does the condition get better by exchanging

the antenna cord.

No

Radiate directly to the antenna from the

generation source.

Yes

NG

Yes

Yes

Interfering noise from the defogger line

and choke coil.

Grounding failure.

Exchange the choke coil.

Exchange the antenna cord.

2000 LEXUS LS400 (RM717U)

V08552

2087Author!: Date!:

Page 53

BE–202

–BODY ELECTRICAL AUDIO SYSTEM

AUDIO SYSTEM

DESCRIPTION

1. RADIO WAVE BAND

The radio wave bands used in radio broadcasting are as follows:

Frequency

Designation

Radio wave

Modulation method

LF: Low frequency MF: Medium Frequency HF: High Frequency VHF: Very High Frequency

30 kHz

300 kHz

LF

AM FM

Amplitude modulation

2. SERVICE AREA

There are great differences in the size of the service area for AM

and FM monaural. Sometimes FM stereo broadcasts cannot be

received even through AM can be received in very clearly.

Not only does FM stereo have the smallest service area, but it

FM (Stereo)

FM (Monaural)

AM

also picks up static and other types of interference (”noise”)

easily.

3 MHz 30 MHz 300 MHz

MF

HF

BE0CX–03

VHF

Frequency modulation

Fading

Ionosphere

BE2818

3. RECEPTION PROBLEMS

Besides the problem of static, there are also the problems

called ”fading”, ”multipath” and ”fade out”. These problems are

caused not by electrical noise but by the nature of the radio

waves themselves.

(1) Fading

Besides electrical interference, AM broadcasts are

also susceptible to other types of interference, especially at night. This is because AM radio waves

bounce off the ionosphere at night. These radio

waves then interfere with the signals from the same

transmitter that reach the vehicle’s antenna directly.

This type of interference is called ”fading”.

BE2819

2000 LEXUS LS400 (RM717U)

2065Author!: Date!:

Page 54

–BODY ELECTRICAL AUDIO SYSTEM

BE–203

Multipath

Fade Out

(2) Multipath

One type of interference caused by the bounce of

radio waves off of obstructions is called ”multipath”.

Multipath occurs when a signal from the broadcast

transmitter antenna bounces off buildings and

mountains and interferes with the signal that is received directly.

BE2820

(3) Fade Out

Because FM radio waves are of higher frequencies

than AM radio waves, they bounce off buildings,

mountains, and other obstructions. For this reason,

FM signals often seem to gradually disappear or

fade away as the vehicle goes behind a building or

other obstruction. This is called ”fade out”.

BE2821

4. NOISE PROBLEMS

(a) Questionnaire for noise:

It is very important for noise troubleshooting to have good

understanding of the claims from the customers, so that

make the best use of following questionnaire and diagnose the problem accurately.

AM

FM

Noise occurs at a specific place.

Noise occurs when listening to

faint broadcasting.

Noise occurs only at night.

Noise occurs while driving and

at a specific place.

Strong possibility of foreign noise.

There is a case that the same program is broadcasted

from each local station and that may be the case you are

listening different station if the program is the same.

Strong possibility of the beat from a distant broadcasting.

Strong possibility of multipath noise and fading noise

caused by the changes of FM waves.

HINT:

In the case that the noise occurrence condition does not meet

any of the above questionnaire, check based on the ”Trouble

Phenomenon”.

Refer to above descriptions for multipath and fading.

2000 LEXUS LS400 (RM717U)

2066Author!: Date!:

Page 55

BE–204

–BODY ELECTRICAL AUDIO SYSTEM

(b) Matters that require attention when checking:

! Noise coming into the radio usually has no harm for

practical use as the noise protection is taken and it

is hardly thinkable for an extremely loud noise to

come in. When extremely loud noise comes into the

radio, check if the grounding is normal where the

antenna is installed.

! Check if all the regular noise prevention parts are

properly installed and if there is any installation of

non–authorized parts and non–authorized wiring.

! If you leave the radio under out of tune (not tuning),

it is easy to diagnose the phenomenon as noise occurs frequently.

Noise

Noise

to Radio

Battery

Glass Printed Antenna

Noise

Signal

Noise

Noise

Choke Coil

Radio

N21545

(c) Antenna and noise:

Electronic signal received by the antenna will reach to the

radio transmitting through the core wire of the coaxial

cable. Any noise wave other than radio wave is mixed into

this core wire, that naturally causes noise in the radio and

poor sound quality. In order to prevent these noises from

mixing into the radio, the core wire inside the coaxial cable

is covered with a mesh wire called shield wire. This shield

wire shelters the noise and transmits it to the ground, thus

preventing noise from mixing in.

If this shield wire has grounding failure, that causes noise.

(d) Choke coil and noise:

The choke coil is connected in the rear window defogger

circuit. This is connected so to prevent noise from mixing

into the radio by making the noise current included in the

power source of the rear window defogger flow to the

ground.

Noise

2000 LEXUS LS400 (RM717U)

N21546

2067Author!: Date!:

Page 56

–BODY ELECTRICAL AUDIO SYSTEM

BE–205

Antenna

Ter mi n al

Plug (Main)

1

3 4

Plug (Sub)

(Main)

Antenna

Terminal

(Sub)

I04609

(e) Antenna code continuity check and grounding point:

HINT:

During troubleshooting, in case that the antenna code continuity check, grounding check and grounding check of the choke

2

coil are needed, please check referring to the following illustration.

Te r mi n a l c o n ne c t i o n Normal condition

(1) ↔ (2) Continuity

(3) ↔ (4) No continuity

5. COMPACT DISC PLAYER

Compact Disc Players use a laser beam pick–up to read the digital signals recorded on the CD and reproduce analog signals

of the music, etc.

HINT:

Never attempt to disassemble or oil any part of the player unit.

Do not insert any object other than a disc into the magazine.

NOTICE:

CD players use an invisible laser beam which could cause

hazardous radiation exposure. Be sure to operate the player correctly as instructed.

Example :

Head

Pinch Roller

2000 LEXUS LS400 (RM717U)

Capstan

N17398

BE4331

6. Tape Player/Head Cleaning:

MAINTENANCE

(a) Raise the cassette door with your finger.

Next, using a pencil or similar object, push in the guide.

(b) Using a cleaning pen or cotton applicator soaked in clean-

er, clean the head surface, pinch rollers and capstans.

7. CD Player/Disc Cleaning:

MAINTENANCE

If the disc gets dirty, clean the disc by wiping the surface from

the center to outside in the radial directions with a soft cloth.

NOTICE:

Do not use a conventional record cleaner or anti–static preservative.

2068Author!: Date!:

Page 57

BE–206

–BODY ELECTRICAL AUDIO SYSTEM

8. OUTLINE OF AVC–LAN

(a) What is AVC–LAN?

AVC–LAN is the abbreviation, which stands for Audio Visual Communication–Local Area Network.

This is a unified standard co–developed by 6 audio manufactures associated with Toyota Motor Corporation.

The Unified standard covers signals, such as audio signal, visual signal, signal for switch indication

and communication signal.

(b) Objectives

Recently the car audio system has been rapidly developed and functions have been changed drastically. The conventional system has been switched to the multi–media type such as a navigation system. At the same time the level of customers needs to audio system has been heightened. This lies

behind this standardization.

The concrete objectives are explained below.

! When products by different manufactures were combined together, there used to be a case

that malfunction occurred such as sound did not come out. This problem has been resolved

by standardization of signals.

! Various types of after market products have been able to add or replace freely.

! Thanks to the above (2), each manufacture has become able to concentrate on developing

products in their strongest field. This has enabled many types of products provided inexpensively.

! Conventionally, a new product developed by a manufacture could not be used due to a lack

of compatibility with other manufactures products. Thanks to this new standard, users can

enjoy compatible products provided for them timely.

The above descriptions are the objectives to introduce AVC–LAN. By this standardization, development of

new products will no longer cause systematic errors. Thus, this is very effective standard for a product in the

future.

HINT:

! When +B short or GND short is detected in AVC–LAN circuit, communication stops. Accordingly the

audio system does not function normally.

! When audio system is not equipped with a navigation system, audio head unit is the master unit.

! The car audio system using AVC–LAN circuit has a diagnosis function.

! Each product has its own specified numbers called physical address. Numbers are also allotted to

each function in one product, which are called logical address.

2000 LEXUS LS400 (RM717U)

2069Author!: Date!:

Page 58

ON

BE–201

–

BE0CW–01

INSPECTION

1. INSPECT FUEL LID OPENER SWITCH CONTINUITY

(a) Check that there is continuity between terminals with the

switch ON (Lever pulled).

(b) Check that there is no continuity between terminals with

the switch OFF (Lever free).

If continuity is not as specified, replace the switch assembly.

N13319

2. INSPECT FUEL LID OPENER SOLENOID OPERATION

(a) Apply battery positive voltage to the terminals.

(b) Check that the solenoid operates in the open direction.

If operation is not as specified, replace the solenoid.

N06769

2064Author!: Date!:

Page 59

BE–200

FUEL LID OPENER SYSTEM

LOCATION

–

BE0CV–01

Fuel Lid Opener Switch

Instrument Panel Junction Block

! FUEL OPN Fuse

Fuel Lid Opener Solenoid

I03237

2063Author!: Date!:

Page 60

Z14905

BE–197

–BODY ELECTRICAL SEAT HEATER SYSTEM

BE0CU–01

INSPECTION

1. INSPECT SEAT HEATER SWITCH CONTINUITY

Condition Te s te r c o nn e c t i on Specified condition

OFF – No continuity

ON (Left) 8 – 9 – 11 Continuity

ON (Right) 8 – 11 – 13 Continuity

Illumination 10 – 12 Continuity

If continuity is not as specified, replace the switch or bulb.

2. INSPECT SEAT HEATER SWITCH INDICATOR

(a) Connect the positive (+) lead from the battery to terminal

11 and the negative (–) lead to terminal 8.

(b) Push the switch and check that the indicator light lights

up.

If operation is not as specified, replace the switch.

Wire Harness Side

Te s te r c on n e c t i on t o

terminal number

8 – Ground Constant Continuity

9 – Ground Constant * Continuity

13 – Ground Constant * Continuity

11 – G round Ignition switch turned to ON Battery positive voltage

N13349

3. INSPECT SEAT HEATER SWITCH CIRCUIT

Disconnect the switch connector and inspect the connector on

the wire harness side, as shown.

Z14753

Condition Specified condition

*: There is resistance because this circuit is grounded through

the relay coil.

If circuit is not as specified, inspect the circuits connected to other parts.

2000 LEXUS LS400 (RM717U)

2060Author!: Date!:

Page 61

BE–198

Z08901

–BODY ELECTRICAL SEAT HEATER SYSTEM

4. INSPECT ENGINE MAIN RELAY CONTINUITY

Condition Te s te r c o nn e c t i on Specified condition

Constant

Apply B+ between

terminals 1 and 3.

1 – 3

2 – 4

4 – 5 Continuity

Continuity

If continuity is not as specified, replace the relay.

5. INSPECT ENGINE MAIN RELAY CIRCUIT

Remove the relay and inspect the connector on the junction

block side, as shown.

BE4730

Te s te r c o nn e c t i on Condition Specified condition

2 – Ground Constant Continuity

3 – Ground Constant Continuity

1 – Ground Ignition switch ON Battery positive voltage

5 – Ground Constant Battery positive voltage

If circuit is not as specified, inspect the circuits connected to other parts.

2000 LEXUS LS400 (RM717U)

2061Author!: Date!:

Page 62

–BODY ELECTRICAL SEAT HEATER SYSTEM

BE–199

Seat Cushion Side

6. Seat Cushion:

INSPECT SEAT HEATER CONTINUITY

(a) Heat the thermostat with a light.

(b) Inspect the seat heater continuity between terminals.

Connector ”A”

Connector ”B”

Te s te r c o nn e c t i on Condition Specified condition

A2 – B3 Constant Continuity

A1 – B1 Seat heater temperature bellow 25°C (77°F) Continuity

B1 – B2 Seat heater temperature bellow 25°C (77°F) Continuity

A1 – B2 Seat heater temperature bellow 25°C (77°F) Continuity

A1 – B1

B1 – B2

A1 – B2

Z14754

Seat heater temperature above

55°C (131°F)

Seat heater temperature above

45°C (113°F)

Seat heater temperature above

45°C (113°F)

No continuity

No continuity

No continuity

If continuity is not as specified, replace the seat cushion pad.

Seat Back Side

Te s te r c o nn e c t i on Condition Specified condition

1 – 3 Constant Continuity

2 – 3 Constant Continuity

2000 LEXUS LS400 (RM717U)

7. Seat Back:

INSPECT SEAT HEATER CONTINUITY

Inspect the seat heater continuity between terminals, as

shown.

Z14755

If continuity is not as specified, replace the seat back pad.

2062Author!: Date!:

Page 63

BE–196

SEAT HEATER SYSTEM

LOCATION

–

BE0CT–01

Engine Room Junction Block

! FR S/HTR Fuse

! Engine Main Relay

Seat Heater

(Seat Back)

Seat Heater

(Seat Cushion)

Seat Heater Switch

I03404

2059Author!: Date!:

Page 64

BE–194

–BODY ELECTRICAL ELECTRO CHROMIC MIRROR SYSTEM

BE0CS–01

INSPECTION

1. INSPECT ELECTRO CHROMIC INNER MIRROR OPERATION

(a) Connect the positive (+) lead from the battery to terminal

1 and the negative (–) lead to terminal 4.

(b) Connect the positive (+) leaf from the voltmeter to terminal

2 and the negative (–) lead to terminal 3.

(c) Shine an electric light on the mirror, and check that there

is battery positive voltage and mirror surface becomes

”bright” to ”dark”.

If operation is not as specified, replace the inner mirror.

Wire Harness Side

Te s te r c o nn e c t i on Condition Specified condition

4 – Ground Constant Continuity

1 – Ground Ignition switch LOCK or ACC No voltage

1 – Ground Ignition switch ON Battery positive voltage

N16074

2. INSPECT ELECTRO CHROMIC INNER MIRROR CIRCUIT

Disconnect the connector from the mirror and inspect the connector on the wire harness side, as shown.

If circuit is not as specified, inspect the circuits connected to other parts.

Z14965

2000 LEXUS LS400 (RM717U)

2057Author!: Date!:

Page 65

–BODY ELECTRICAL ELECTRO CHROMIC MIRROR SYSTEM

BE–195

”Bright”

”Dark”

”Bright”

”Dark”

w/o Memory

w/ Memory

4

3

N17035

I04603

3. INSPECT ELECTRO CHROMIC OUTER MIRROR OPERATION

w/o Driving position memory:

(a) Disconnect the outer mirror connector.

(b) Connect the positive (+) lead from the dry through battery

to terminal 2 and the negative (–) lead to terminal 1, then

check that the mirror surface become ”dark”.

(c) Reconnect to the dry through battery by the reverse order,

then check that the mirror surface become ”bright”.

If operation is not as specified, replace the mirror assembly.

4. INSPECT ELECTRO CHROMIC OUTER MIRROR OPERATION

w/ Driving position memory:

(a) Disconnect the outer mirror connector.

(b) Connect the positive (+) lead from the dry through battery

to terminal 4 and the negative (–) lead to terminal 3, then

check that the mirror surface become ”dark”.

(c) Reconnect to the dry through battery by the reverse order,

then check that the mirror surface become ”bright”.

If operation is not as specified, replace the mirror assembly.

2000 LEXUS LS400 (RM717U)

2058Author!: Date!:

Page 66

–

ELECTRO CHROMIC MIRROR SYSTEM

LOCATION

Ignition Switch

BE–193

BE0CR–01

Instrument Panel

Junction Block

! ECU–IG Fuse

Electro Chromic Inner Mirror

I03408

2056Author!: Date!:

Page 67

Slider

Upward

4

Downward

1

4

BE–187

–BODY ELECTRICAL POWER SHOULDER BELT ANCHORAGE SYSTEM

BE0CQ–01

(b)(a)

1

INSPECTION

1. INSPECT DRIVER’S HEIGHT ADJUSTABLE ANCHOR

MOTOR AND SENSOR OPERATION

(a) Connect the positive (+) lead from the battery to terminal

4 and the negative (–) lead to terminal 1, and check that

the slider moves upward.

(b) Reverse the polarity and check that the slider moves

downward.

N13338