LEXMARK Z51 Service Manual

Lexmark Z51 Color Jetprinter™

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4098-001

• Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

4098-00X

Carrier Transport Motor Removal .........................4-4

Encoder Sensor / Temperature Sensor Removal .............4-4

Encoder Strip Removal .................................4-4

Front Cover Removal ..................................4-5

Gear Plate Assembly Removal ...........................4-5

Gutter Pad / Maintenance Station Removal .................4-5

Maintenance Wipers and Caps Removal ...................4-5

Mid Frame / Large Feed Roller / Exit Roller Removal..........4-6

Operator Panel Removal................................4-6

Paper Feed Motor Removal .............................4-7

Power / Parallel / USB Board Removal.....................4-7

Printhead Cable and Cradle Removal......................4-8

Rear Cover Removal...................................4-8

Sheet Feeder Removal .................................4-9

Small Feed Rollers ....................................4-9

Small Feed Roller Holder / EOF Removal...................4-9

Star Wheel Roller Assembly Removal .....................4-9

System Board Removal................................4-10

ConnectorLocations....................................5-1

Connector Locations (cont.) ...............................5-2

Preventive Maintenance .................................6-1

Lubrication Specifications .................................6-1

PartsCatalog ..........................................7-1

How to Use This Parts Catalog .............................7-1

Assembly 1: Covers ......................................7-2

Assembly 2: Frames......................................7-4

Assembly 3: Paper Feed ..................................7-6

Assembly 4: Electronics .................................7-10

Assembly 5: Carrier .....................................7-12

Assembly 6: Carrier Transport .............................7-14

Assembly 7: Maintenance Station ..........................7-16

Index................................................ X-1

iv Service Manual

Preface

This manual describes the Lexmark Z51 Color Jetprinter (4098-001)

and contains maintenance procedures for service personnel. It is

divided into the following chapters:

1. General Information contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

2. Diagnostic Information contains an error indicator table,

symptom tables, and service checks used to isolate failing field

replaceable units (FRUs).

3. Diagnostic Aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

5. Connector Locations uses illustrations to identify the

connector locations and test points on the printer.

6. Preventive Maintenance contains the lubrication specifications

and recommendations to prevent problems.

7. Parts Catalog contains illustrations and part numbers for

individual FRUs.

Preface v

Safety Information

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

vi Service Manual

Norme di sicurezza

• Il prodotto è stato progettato,testato e approvatoin conformità a

severi standard di sicurezza e per l’utilizzo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune

parti non sempre sono di immediata comprensione. Lexmark

non è responsabile per l’utilizzo di parti di ricambio di altri

produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Safety Information vii

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes.Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

viii Service Manual

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

Safety Information ix

x Service Manual

4098-001

1. General Information

The Lexmark Z51 Color JetprinterTMis an electro-mechanical printer

that creates characters and graphics by composing programmed

patterns of ink dots using a printhead and liquid ink. The printhead

uses small heater plates and nozzles to control ink flow and the

formation of characters on the print media. The printhead assembly

and ink supply are combined into a single-unit, print cartridge,

available as a customer replaceable supply item. Dual printheads

provide color and true black printing without changing printheads.

The number and size of inkjets or n ozzles, in the printhead,

determines the overall quality and capability of the printer.The black

cartridge has a total of 208 nozzles and installs on the right. The

color cartridge has a total of 192 nozzles and installs on the left. The

printer is capable of printing in two directions from either cartridge.

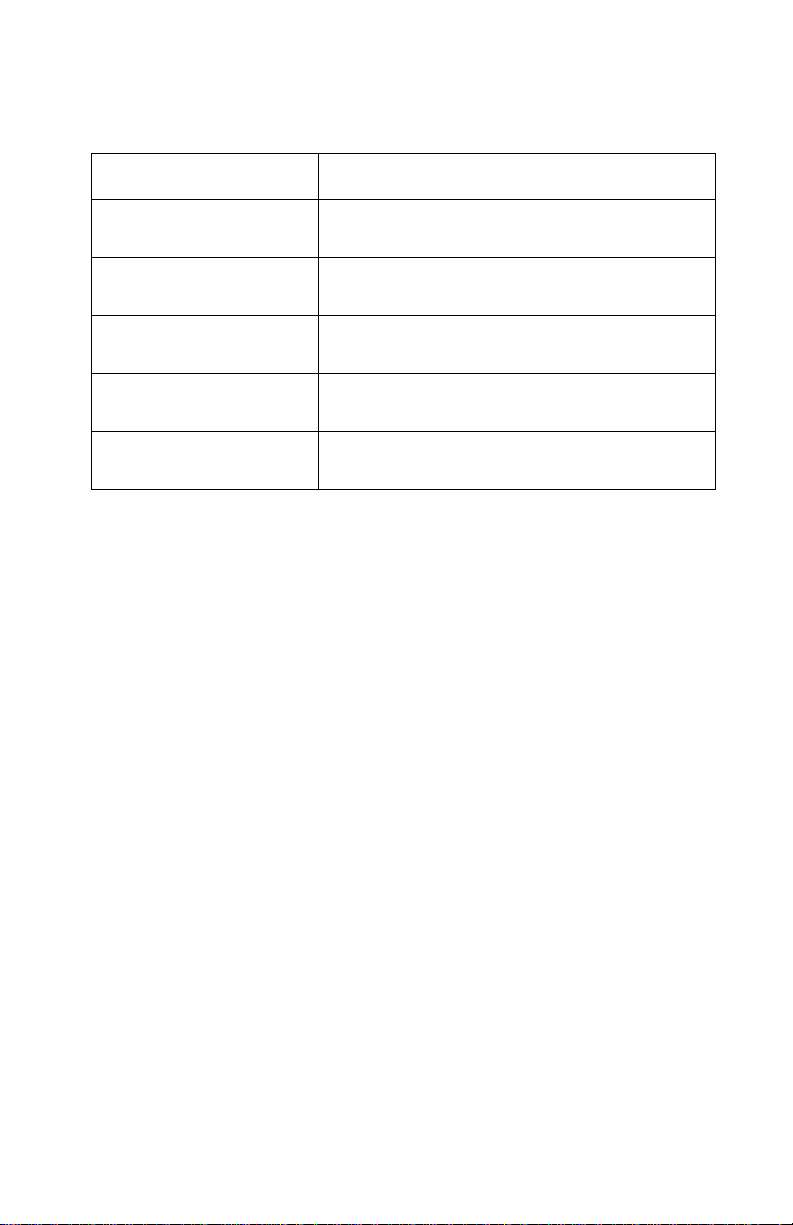

Operator Panel

Buttons Lights

• Left Button - Power

Power On/Off

Right Button - Paper Feed

• Clears a paper jam

• Loads paper when paper is out

Left Light

•On-PowerOn

• Flashing - Printer Error

Right Light - Busy

•On-Busy

• Flashing - Paper Out/Jam

General Information 1-1

4098-001

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the symptom index, service

checks, and diagnostic aids to determine the symptom and repair

the failure. Begin with “Indicator Light Table” on page 2-1.

After you complete the repair, perform tests as needed to verify the

repair.

Abbreviations

EOF End of Forms

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LVPS Low Voltage Power Supply

OEM Original Equipment Manufacturer

V ac Volts alternating current

V dc Volts direct current

LIF Low Insertion Force

USB Universal Serial Bus

FPC Flat Printer Cable

1-2 Service Manual

4098-001

2. Diagnostic Information

Start

Service error indications are a series of Power light flashes. There is

a pause between each series of flashes. If your printer has an error

indicator, locate the series of flashes in the “Error Indicator Table”

on page 2-2. and take the indicated action. Unplug the printer to

clear the error indicator.

The printer also logs the last occurring error. If you think it may have

an intermittent error, or the error indicator lights have been cleared,

you can retrieve the error:

1. Run the“Print NVRAM Contents” on page 3-6 The last error

appears at the bottom of the page.

2. To capture the next error in the error log, run “Clear NVRAM”

on page 3-5 to clear the error.

3. Run the “Print Test Page” on page 3-2.” If no error appears,

go to “Power-On Self Test (POST) Sequence” on page 2-4.”

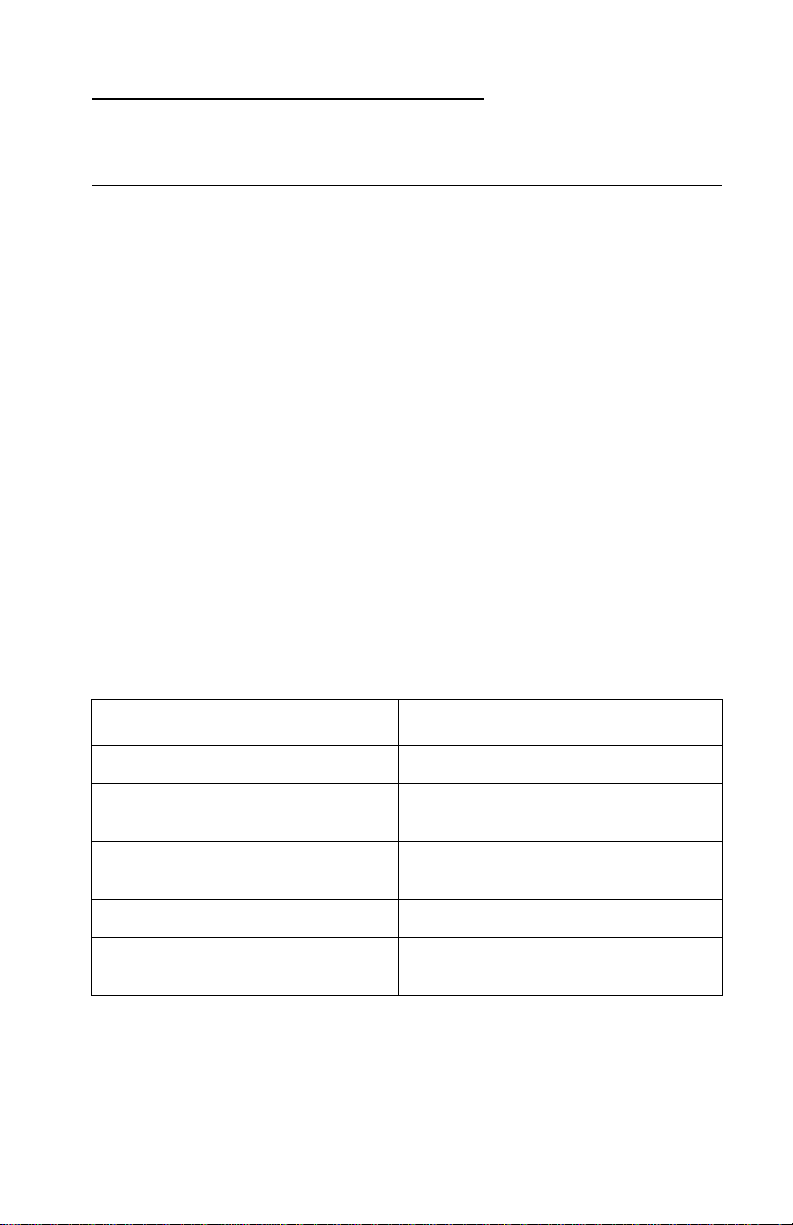

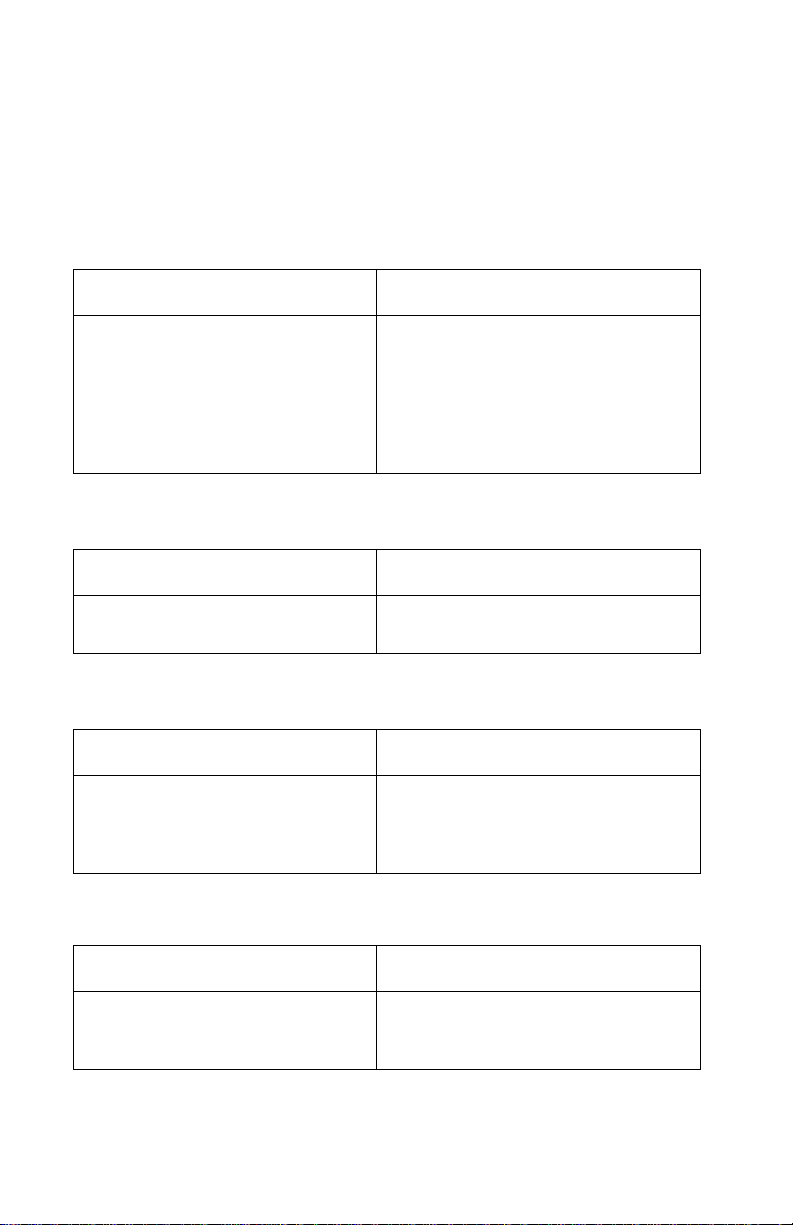

Indicator Light Table

Indicator Light Indicates

Power light on Machine is on.

Power light on and busy light

flashes

Power light and busy light flashes Go to the “Carrier Transport Service

Both lights on at the same time Printer is busy or printing.

Power light flashes See “Error Indicator Table” on

Paper jam or paper out.

Check,”on page 2-8.

page 2-2

Diagnostic Information 2-1

4098-001

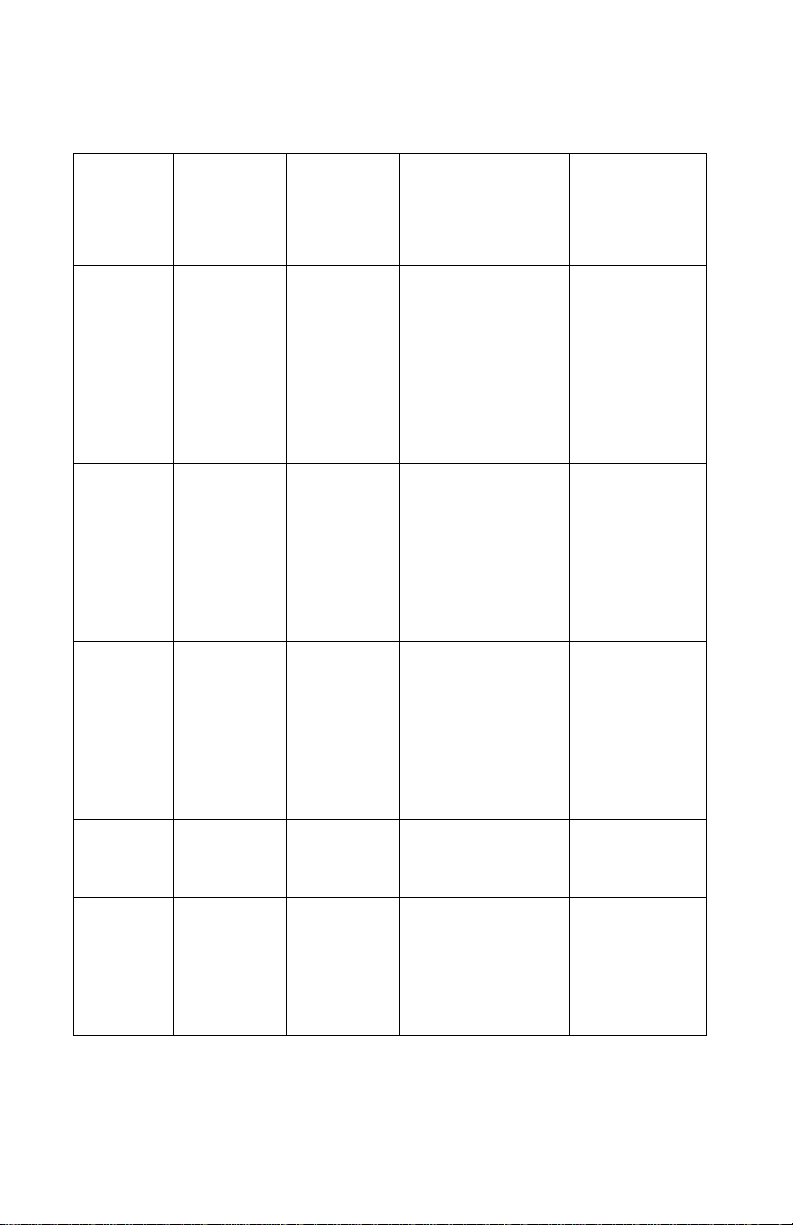

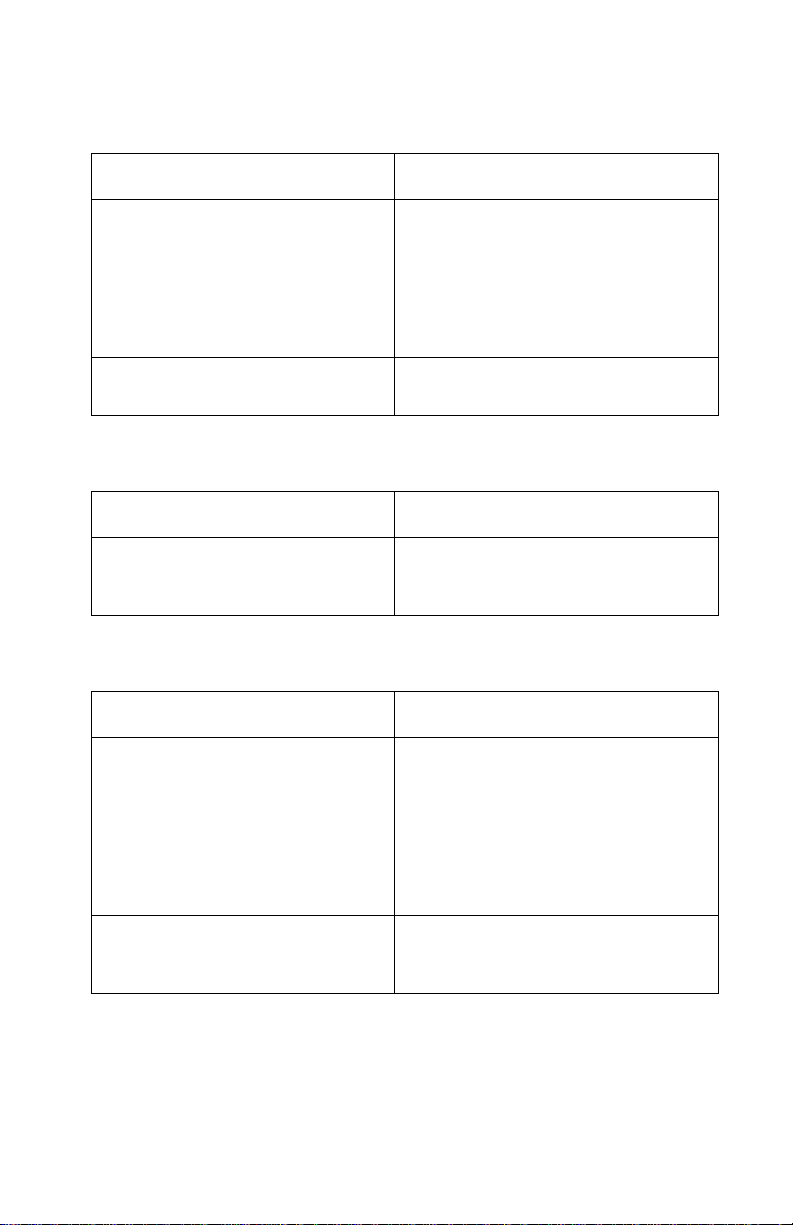

Error Indicator Table

Number

of Power

Light

Flashes

Service

Error

(Logged)

281Carrier stall No carrier emitter

393Data error Incorrect data has

489Print

Error

Name

incomplete

Error Description Action

signals received,

carrier not moving

been sent from the

host PC to the

printer

Carrier stopped

before print data

all used

Goto“Carrier

Transport

Service

Check” on

page 2-8.

Ensure the

driver is

installed

correctly.

Check the

system board

and cable. If

OK, check

printhead

cables.

Replace as

needed.

Check system

board and

cable. If OK,

check

printhead

cables.

Replace as

needed.

664,66thru78Exception

765Address

2-2 Service Manual

Error

Error

Illegal instruction

from

microprocessor

16/32 bit item on

odd address

boundary

Replace

system board

Replace

system board.

See“System

Board

Removal” on

page 4-10.

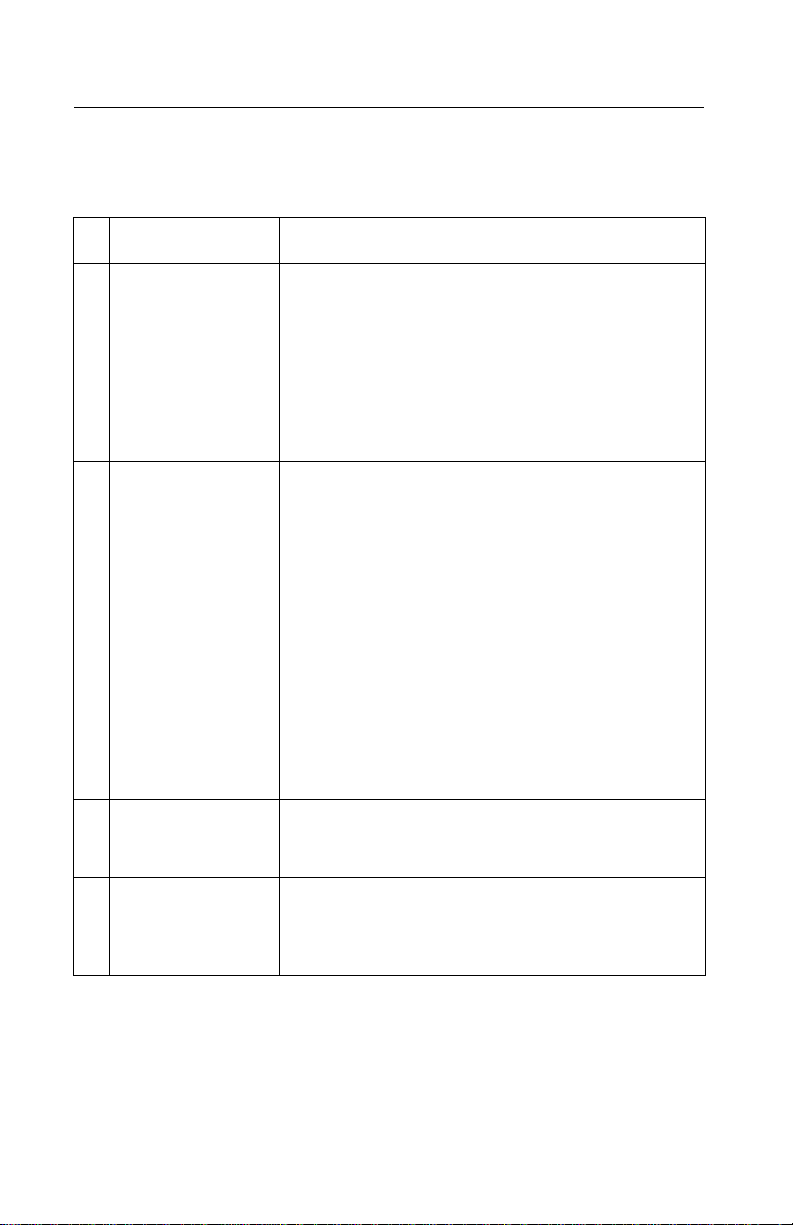

4098-001

Number

of Power

Light

Flashes

8 None NVRAM

979Error xxxxx Replace

11 91 Error xxxxx Replace

12 92 Short error Short test

Service

Error

(Logged)

Error

Name

error

Error Description Action

Error detected in

reading or writing

NVRAM

detected short

circuit in printhead

Replace

system board.

See “System

Board

Removal,”on

page 4-10.

system board.

See “System

Board

Removal” on

page 4-10.”

system board

Check and

replace

printhead and

cable as

needed.IfOK,

replace the

system board.

13 94 Head

Select

15 96 USB error Error in USB

None 31,32,33 Watchdog No action

Install head ID and

print command

head ID do not

match

hardwaredetected

or invalid result

occurred in USB

code

Replace

printheads.

Check system

board cable. If

OK, check

system board

and power/

parallel/USB

board.

Replace as

needed.

Note: There are seven reserved error code power light flashes (5,

10, 14, and 16) that haveno code names. If any reserved codes are

received, unplug and re-plug the printer.

Diagnostic Information 2-3

4098-001

Power-On Self Test (POST) Sequence

Tur n the printer on and check for a correct POST operation by

observing the following:

1. The power light come on.

2. The carrier moves to the left to wipe the printheads.

3. The carrier movesto the right over the maintenance station and

seals the printheads.

4. The paper feed gears turn.

5. All motors stop and the power light stays on.

If your pr inter completes POST with no errors, go to the “Symptom

Tables” on page 2-6, locate the symptom and take the indicated

action.

If your pr inter does not complete POST, locate the symptom in the

“POST Symptom Table” on page 2-5 and take the indicated

action.

2-4 Service Manual

4098-001

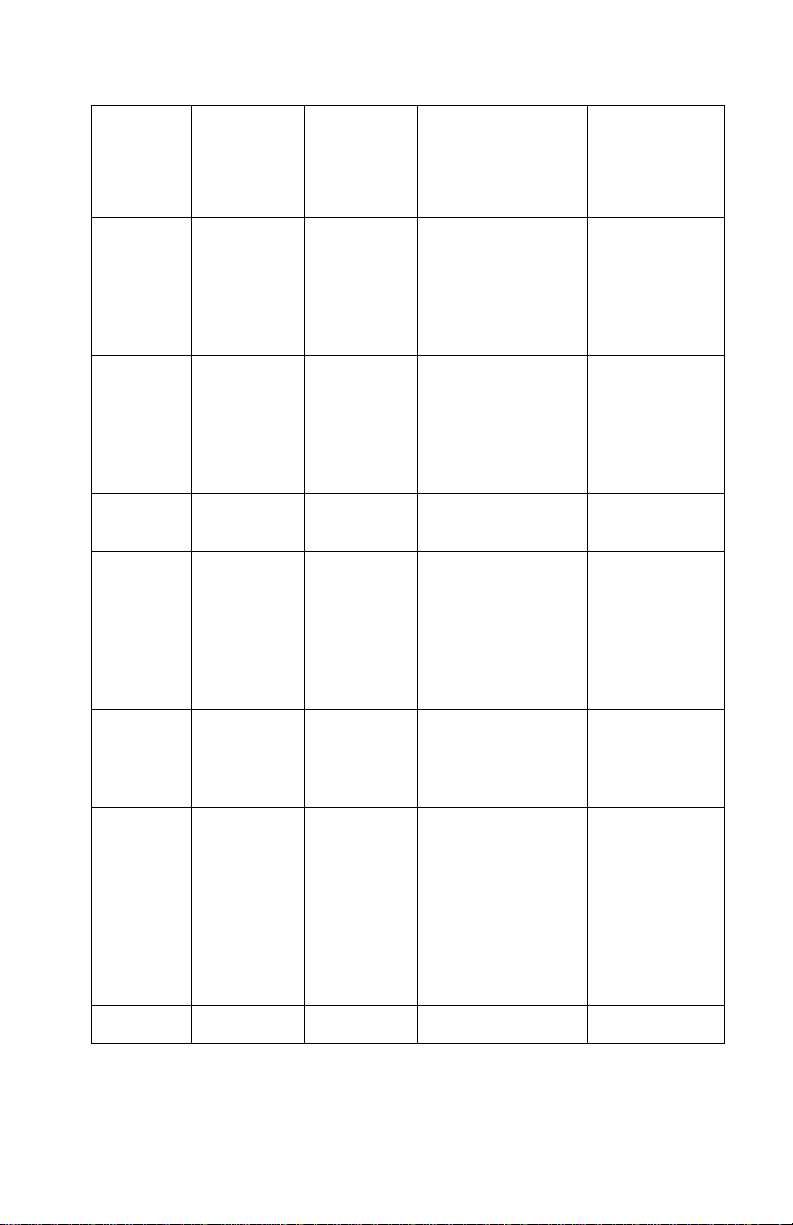

POST Symptom Table

Symptom Action

No power light and no

motors run

Paper feed gears do not

turn

Carrier does not move Go to the “Carrier Transport Service Check”

Carrierslamssideframe Gotothe“Carrier Transport Service Check”

No busy light Replace the operator panel, or the system

Go to the “Power Service Check” on

page 2-13.

Go to the “Paper Feed Service Check” on

page 2-11.

on page 2-8.

on page 2-8.

board.

Diagnostic Information 2-5

4098-001

Symptom Tables

Locate the symptom in the following tables and take the indicated

action.

Carrier Transport Problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams side frame

• Carrier does not move to

cartridge load position when

opening access door

Go to the “Carrier Transport

Service Check” on page 2-8.

Maintenance Station Problems

Symptom Action

• Fails to cap the printheads

• Fails to clean the printheads

Go to the “Maintenance Station

Service Check” on page 2-10.

Operator Panel Problems

Symptom Action

• Power or Paper Feed buttons

do not operate

• Power or Busy lights do not

come on

Replace the operator panel, or the

system board.

Printer Communication Table

Symptom Action

• Not able to print TestPage Check the USB cable and system

board cable connections. If OK,

replace Power/Parallel/USB board

2-6 Service Manual

4098-001

Paper Feed Problems

Symptom Action

• Fails to pick paper

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Paper skews Go to the “Paper Path Service

Go to the “Paper Feed Service

Check” on page 2-11.

Check,”on page 2-13.

Power Problems

Symptom Action

No power in machine, motors do

not operate and lights do not

come on

Go to the “Power Service

Check,”on page 2-13.

Print Quality Problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

• Blurredprint

• Carrier moves, but no print

• Printhead dries prematurely

• Colors print incorrectly

• Vertical alignment off

Go to the “Print Quality Service

Check,”on page 2-14.

• Ink smearing

• Vertical streaks on paper

• Print lines crowded

Go to the “Paper Feed Service

Check” on page 2-11.

Diagnostic Information 2-7

4098-001

Service Checks

Carrier Transport Service Check

FRU Action

1 System Board Unplug the printer and disconnect the carrier

transport motor connector (J5) from the system

board. Plug in the printer and check for

approximately +30 V dc between (J5-1) and

ground at the system board. If the voltage is

incorrect, replace the system board. If the voltage

is correct, check for carrier transport motor pins

shorted to the housing. If a short is detected,

replace the carrier transport motor.

2 Carrier Transport

Motor

3CarrierGuide

Shaft

4 Carrier Transport

Belt

Idler Pulley Parts

Carrier Frame

Check the motor for binds, or loose motor pulley.

A noisy or chattering motor or a motor that fails to

turncanbecausedby:

• An open or short in the motor.

• An open or short in the motor driver on the

system board.

• A bind in the carrier transport mechanism.

With the carrier transport motor cable

disconnected from the system board, check for

zero to ten (0 - 10) ohms between pins J5-1 and

J5-2 on the motor. If the readings are incorrect,

replace the motor.

Clean the carrier shaft. Lubricate the shaft and the

carrier shaft bearing surfaces with grease (P/N

99A0394)

Check for worn, loose or broken parts. Check for

obstructions blocking carrier movement. Lubricate

the carrier to carrier frame engagement with

grease (P/N 99A0394)

2-8 Service Manual

4098-001

FRU Action

5 Encoder Strip

Encoder Card

Printhead Cable

System Board

6 Maintenance

Station

7 Operator Panel

Operator Panel

Cable

System Board

Check the encoder strip for proper installation.

Check the strip for wear,dirt and grease. Be sure

the carrier cable is fully seated in connector J10

and the cable is seated in the encoder card. Check

the cable for damage.

Perform the “Encoder Sensor Test” on

page 3-4. If you cannot enter the test, replace the

system board.

A problem with the maintenance station can cause

carrier movement problems at the right margin. Go

to the “Maintenance Station Service Check,”on

page 2-10.

If the carrier does not move when the access cover

is opened, check the actuator arm for binds. If the

arm is working correctly, check the operator panel

cable is fully seated in J16 at the system board

and in the operator panel. Check the continuity of

the cable at pins 3 and 4. If the cable is good,

replace the system board or operator panel.

Diagnostic Information 2-9

4098-001

Maintenance Station Service Check

The maintenance station has three functions:

1. Wipes the printhead nozzles to clear them of dirt.

2. Provides a place for the printheads to spit all nozzles keeping

them clear prior to printing.

3. Seals the printheads when not in use to prevent the nozzles

from dr ying.

FRU Action

1 Maintenance

Station Assembly

2 Wipers Worn wipers cause degraded print quality just after

3 Caps Worn caps cause the printhead nozzles to dry and

As the carrier moves to the right over the

maintenance station, a tab on the bottom of the

carrier engages a tab on the sled of the

maintenance station causing the caps to rise and

seal the printhead. Carrier movement to the left

uncaps the printheads. The wipers clean the

printhead nozzles as the carrier leaves the

maintenance station. The wipers clean the

printheads only when the carrier is moving to the

left. There should be no wiping action of the

printhead nozzles when the carrier is moving to

the right. After the printheads are wiped, a tab on

the carrier engages a tab on the maintenance

station and wipers are lowered. The carrier will

then move to the right over the felt pad where they

will spit all nozzles.

Check the maintenance station for worn or broken

parts.

a printhead maintenance cleaning. Check forloose

or worn wipers.

clog. Check for loose or worn caps.

2-10 Service Manual

Loading...

Loading...