LEXMARK X7500 Service Manual

• Table of Contents

• Start Diagnostics

• Safety and Notices

LexmarkTM X7500

4036-501

• Trademarks

• Index

Lexmark and Le x m ark with dia mo nd des ig n are

trademarks of Lexmark International, Inc., registered

in the United States and/or other countries.

©

4036-501

Edition: October 2001

The following paragraph does not apply to any country where such provisions are inconsistent with local law:

LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions; therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in later editions. Improvements or changes in the products or the

programs described may be made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22A/032-2, 740 West New Circle Road,

Lexington, Kentucky 40550, U.S.A or e-mail at ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any

of the information you supply in any way it believes appropriate without incurring any obligation to you. You can purchase

additional copies of publications related to this product by calling 1-800-553-9727. In other countries, contact your point of

purchase.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States

and/or other countries.

Other trademarks are the property of their respective owners.

Copyright Lexmark International, Inc. 2001.

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use, duplication or disclosure by the

Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc., Lexington, KY

40550. U.S.A.

U.S.A. P/N 12G9083 Japanese P/N

1234-XXX

Table of Contents

Notices and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv-vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tools Required for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Preparing the scanner for shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Duplex Auto Document Feeder (DADF) Power Principles of Operation . . . . . . . . . . 1-4

DADF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Scanner Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Scanner Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Scanner Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Mechanical Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Scanning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Scanner Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

MFD Controller Cage Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Symptom Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DADF Repair Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Notations in the Removal Replacement text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

DADF Assembly Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

DADF Assembly Paper Skew Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Adjusting the Position of Full Rate/Half Rate Carriages . . . . . . . . . . . . . . . . . . 4-6

Configuring the MFD Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

DADF Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

DADF Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

DADF Front Cover, Handle, and Magnet Removal . . . . . . . . . . . . . . . . . . . . . 4-11

DADF Cushion Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

DADF Exit/Reverse Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

DADF Input Tray Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

DADF Jam Access Door Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

DADF Top Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

DADF Rear Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

iii

1234-XXX

DADF Jam Door Open Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Mylar Paper Guide Strip Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

DADF Left and Right Hinge Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

DADF Controller Card Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

DADF Registration Roll Drive Motor Assembly Removal . . . . . . . . . . . . . . . . 4-26

DADF Main Drive Motor Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

DADF Separator Pad Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

DADF Separator Pad Remov a l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

DADF #1 and #2 Linkage Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Linkage Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Paper Stop Spring and Paper Stop Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

DADF Roller Engagement Shaft Assembly Removal . . . . . . . . . . . . . . . . . . . 4-36

DADF Paper Present Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

DADF Paper Present Indicator Card Assembly Removal . . . . . . . . . . . . . . . . 4-39

Paper Present Sensor Flag Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

DADF Pick Roller with Separator Pad Kit Assembly Removal . . . . . . . . . . . . . 4-41

Registration Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

DADF Gear #3 Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Tension Roller Spring and Tension Roller Removal . . . . . . . . . . . . . . . . . . . . . 4-44

DADF Upper Paper Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

DADF #4 Gear Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Scanner Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

User Interface Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Flatbed Scanner T op Co ver Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . 4-50

Flatbed Center Platen Glass Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Left DADF Platen Glass Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Scanner Main Drive Motor Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Scanner Motor Card Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Flatbed Open Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Registration Sensor Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Plate Switch Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Scanner System Card Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Charge Couple Device Card Assembly Removal . . . . . . . . . . . . . . . . . . . . . . 4-62

Automatic Paper Size Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Full Rate Carriage Lamp Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Cable Assembly-Scan, Rear Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Full Rate Carriage Lamp Cable Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Location Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Wiring Diagrams and Signal Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

DADF Master Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Scanner Master Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

iv

1234-XXX

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintaining Your Multifunction Product (MFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

CleaNing the touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning the scanner bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning the scanner rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning the scanner pick pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: DADF Cover and Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: DADF Cover, Switch, and Hinge (Rear) . . . . . . . . . . . . . . . . . . . . . . . 7-4

Assembly 3: DADF Control Board and DADF Registration Roll Drive Motor Assembly

7-6

Assembly 4: DADF Separator Pad Asm. and Paper Stop . . . . . . . . . . . . . . . . . . 7-8

Assembly 5: DADF Pick Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Assembly 6: DADF Document Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Assembly 7: DADF Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Assembly 8: Scanner Platen Glass and IPS PWB . . . . . . . . . . . . . . . . . . . . . . 7-16

Assembly 9: Scanner Lens Assembly and CCD Card . . . . . . . . . . . . . . . . . . . . 7-18

Assembly 10: Scanner Carriage Motor and Cable . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Assembly 11: Scanner Full Rate and Half Rate Carriage . . . . . . . . . . . . . . . . . 7-22

Assembly 12: Scanner Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Assembly 13: Multifunction Device Controller Cage Electronics. . . . . . . . . . . . . . 7-26

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

v

1234-XXX

vi

4036-501

Notices and Safety Information

Safety Information

• This product is designed, tested and approved to meet strict global safety standards

with the use of specific Lexmark components. The safety features of some parts may

not always be obvious. Lexmark is not responsible for the use of other replacement

parts.

• The maintenance information for this product has been prepared for use by a

professional service person and is not intended to be used by others.

• There may be an increased risk of electric shock and personal injury during

disassembly and servicing of this product. Professional service personnel should

understand this and take necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les normes strictes de

sécurité globale lors de l'utilisation de composants Lexmark spécifiques. Les

caractéristi que s de sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres pièces de rec ha nge.

• Les consignes d'entretien et de réparation de ce produit s'adressent uniquement à

un personnel de maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques

électriques, le personnel d'entretien qualifié devra prendre toutes les précautions

nécessaires.

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in conformità a severi standard di

sicurezza e per l’utilizzo con componenti Lexmark specifici. Le caratteristiche di

sicurezza di alcune parti non sempre sono di immediata comprensione. Lexmark

non è responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate

soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il rischio di subire

scosse elettriche e danni alla persona è più elevato. Il personale di assistenza

autorizzato, deve, quindi, adottare le precauzioni necessarie.

Notices and Safety Information vii

4036-501

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden entworfen und getestet,

um beim Einsatz die weltweit gültigen Sicherheitsanforderungen zu erfüllen. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von Lexmark sind, wird von

Lexmark keinerlei Verantwortung oder Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind ausschließlich für die

Verwendung durch einen Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein

zusätzliches Risiko eines elektrischen Schlags und körperlicher Verletzung. Das

zuständige Fachpersonal sollte entsprechende Vorsichtsmaßnahm en tre ffen.

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para cumplir los más estrictos

estándares de seguridad global usando los componentes específicos de Lexmark.

Puede que las características de seguridad de algunas piezas no sean siempre

evidentes. Lexmark no se hace responsable del uso de otras piezas de recambio.

• La información sobre el mantenimiento de este producto está dirigida

exclusivamente al personal cualificado de mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños personales durante el

desmontaje y la reparación de la máquina. El personal cualificado debe ser

consciente de este peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para satisfazer os padrões globais

de segurança na utilização de componentes específicos da Lexma rk. As funções de

segurança de alguns dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de substituição.

• As informações de segurança relativas a este produto destinam-se a profissionais

destes serviços e não devem ser utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a desmontagem e

manutenção deste produto. Os profissionais destes serviços devem estar avisados

deste facto e tomar os cuidados necessários.

viii Service Manual

4036-501

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal d'acomplir les estrictes

normes de seguretat globals amb la utililització de components específics de

Lexmark. Les característiques de seguretat d'algunes peces pot ser que no sempre

siguin òbvies. Lexmark no es responsabilitza de l'us d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està orientada exclusivament a

professionals i no està destinada a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar durant el procés de

desmuntatge i de servei d’aquest producte. El personal professional ha d’estar-ne

assabentat i prendre les mesures convenients.

Notices and Safety Information ix

4036-501

Preface

This manual describes the Lexmark X7500 Scanner (4036-501) and contains

maintenance procedures for service personnel only. It is divided into the following

chapters:

1. General Information contains a general description of the scanner and the

maintenance approach used to repair it. Special tools and test equipment are listed

in this chapter, as well as general environmental and safety instructions.

2. Diagno stic Information contains error indicator tables, and troubleshooting tables

used to isolate failing field replaceable units (FRUs).

3. Diagnostic Aids - this scanner does not contain diagnostic aids.

4. Repair Information provides instructions for making scanner adjustments and

removing and installing FRUs.

5. Connector Locations uses illustrations to identify the connector locations and test

points on the scanner.

6. Preventive Maintenance contains recommendations to prevent problems.

7. Parts Catalog contains illustrations and part numbers for individual FRUs.

x Service Manual

4036-501

1. General Information

The Lexmark X7500 (4036-501) scanner option is a multifunction solution for the

Lexmark W820 printer that adds copy, fax, and monochrome network scanning

capabilities for increased corporate productivity.

With the X7500 scanner option you can:

• Copy:

Up to 45 ppm, scan once print many, duplex in/out, job building, book copy,

reduce/enlarge, brightness adjustment.

• Fax:

33.6 KBS, JBIG, speed dial, memory send, retry, fax server support, memory

send, fax from workstation, LDAP for fax number lookup.

• Scan:

Up to 40 ppm mono simplex scanning, reversing duplex scanning, TIFF, JPEG,

PDF file formats, scan to E-mail, scan to FTP, scan to workstation, LDAP for Email address lookup, ad hoc scanning.

Maintenance Approach

The diagnostic information in this manual leads you to the correct field replaceable unit

(FRU) or part for the scanner. Use the error code tables, service checks, and symptom

tables determine the corrective action necessary to repair a malfunctioning scanner

system.

Tools Required for Service

The removal and replacement procedures described require the following tools and

equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be used)

General Information 1-1

4036-501

Acronyms

ADF Automatic Direction Finder

AGC Automatic Gain Control

AOC Abnormal Operating Condition

APS Automatic Paper Size

CCD Charged Couple Device

CPU Central Processing Unit

DADF Duplex Automatic Document Feeder

DIMM Dual Inline Memory Module

EE-ring

FTP File Transfer Protocol

GND Ground

HDD Hard Disk Drive

I/O Input/Output

JBIG Joint Bitonal Image Group

JPEG Joint Photographic Experts Group

KBS Knowledge Based System

KL Clip

LDA P Lightweight Directory Access Protocol

LVPS Low Voltage Power Supply

MFD Multifunction Device

MFP Multifunction Product

PDF Portable Document Format

PPM Pages Per Minute

PWBA Printed Wiring Board Assembly

ROM Read Only Memory

SScrew

SE System Engineer

TIFF Tagged Image File Format

TTY Teletypewriter

UI User Interface

VAC V olts alternating current

VDC Volts direct current

1-2 Service Manual

4036-501

Preparing the scanner for shipping

The following procedure parks the carriages in a safe position to prevent damage, and

clears memory of customer settings.

1. From the home screen of the scanner system enter the following sequence on the

numeric keypad: **411

2. After a short pause the service engineer (SE) menu is displayed.

3. Press 9 on the numeric keypad to select the scanner menu.

4. Press 1 to select the Carriage Lock Screen.

5. Press the green Start button three times to move the carriage all the way to the left.

6. Press the red Stop button to leave the Carriage lock screen.

7. Press 2 to select the NVM Clear screen.

8. Press Start to clear NVM. The scanner resets.

General Information 1-3

4036-501

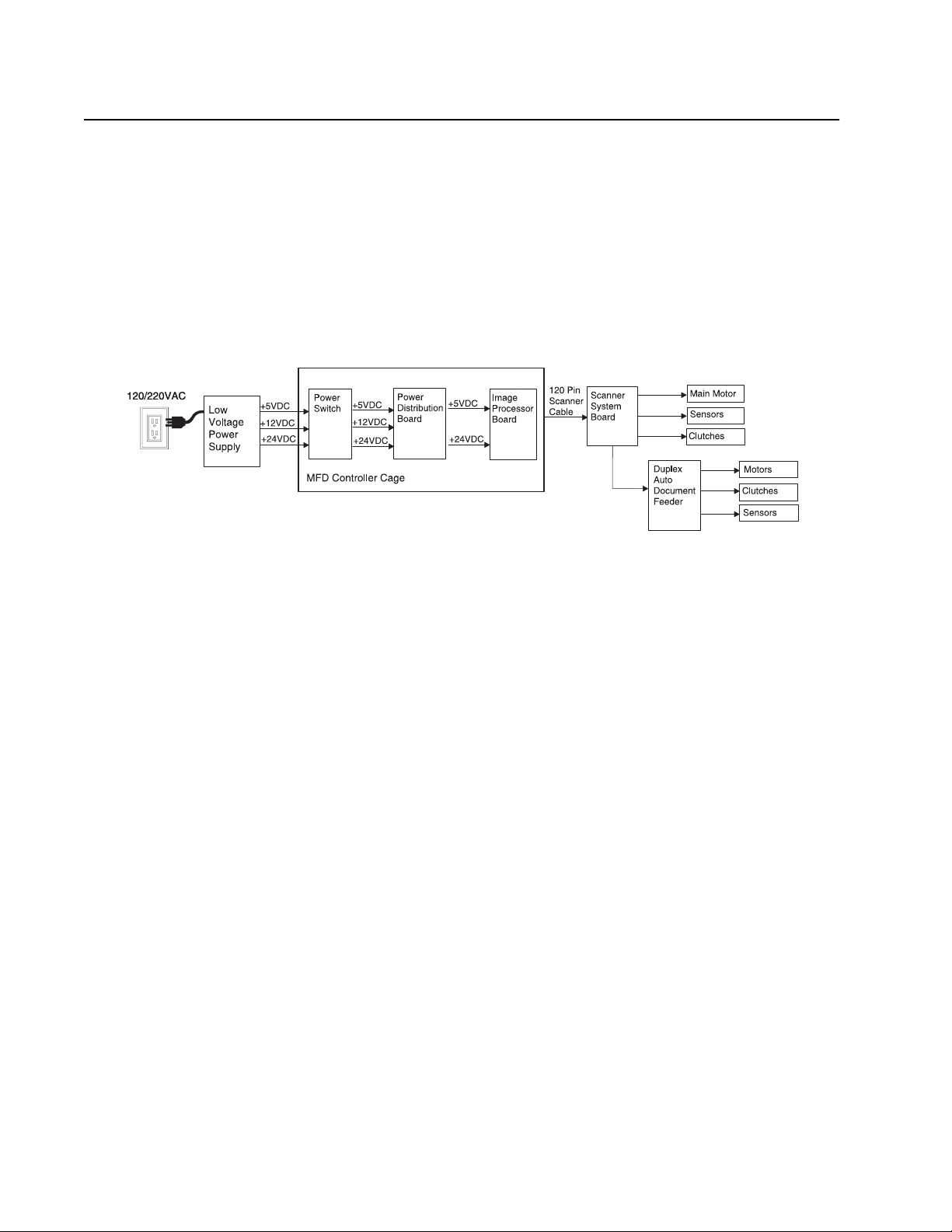

Duplex Auto Document Feeder (DADF) Power Principles of Operation

The power cord carries AC line voltage to the external low voltage power supply (LVPS).

The LVPS converts the 120/220VAC to regulated +5VDC, +12VDC, and +24VDC

voltages. The LVPS sends these voltages to the main power switch in the Multifunction

Device (MFD) controller cage. The voltage is then sent to the power distribution board.

The +5VDC and +24VDC voltages are sent through the image processing board and onto

the scanner through the 120 pin scanner cable. The voltage travels from the scanner

cable into the scanner system board where it passes onto the DADF.

DADF Control

The DADF control card provides the logic and information processing that is necessary

for the DADF to function. Every electrical component within the DADF is connected to the

control card. Sensors in the DADF send status information to the control card. The control

card processes that information, shares it with the MFD controller cage, and compares it

to timing tables stored in ROM. Acting on the results of the processing, the control card

sends commands to the various DADF components

.

1-4 Service Manual

4036-501

General Information 1-5

4036-501

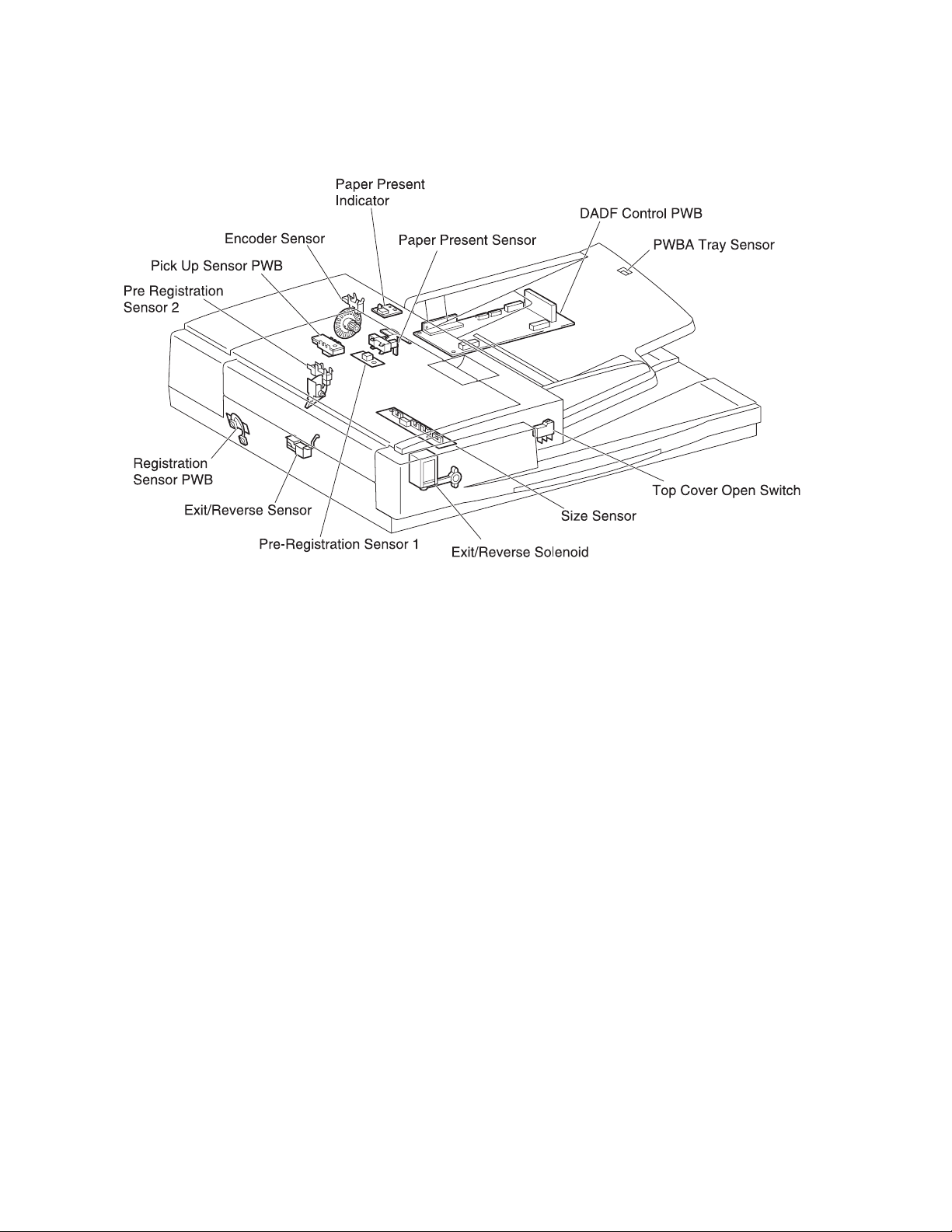

DADF Control Components

• DADF Control Card

The card controls all DADF functions, executes commands sent from the MFD

controller cage, and sends information back to the MFD controller cage.

• Top Cover Open Switch

The switch detects the jam access door assembly in the DADF is either opened or

closed.

• Pre-registration Sensor 1

This sensor detects top of paper and sends a signal for making the paper standby

just before the registration roll.

• Pre-registration Sensor 2

This sensor detects top of paper and sends a signal for making the paper standby

just before the large roll.

• Size Sensor

The sensor detects paper size. The passing paper uses three actuators on the size

sensor card and turns them on and off respectively. The originated signal is

transmitted to the MCU card.

• Encoder Sensor

The sensor detects the number of registration roll drive motor rotations.

• Paper Present Sensor

This sensor detects the paper loaded in the DADF.

• Pick Up Sensor

The sensor detects the existence of paper. This sensor utilizes a timing control of the

paper conveyance as well as analyzes and recognizes the length of paper.

1-6 Service Manual

4036-501

• Registration Sensor

This sensor detects top of paper. The sensor uses the on/off control of the large roll

clutch to match up the timing of paper scanning with the timing of paper convey ance.

• Exit/Reverse Sensor

The sensor detects the paper passing it. This sensor also uses a timing control of

the paper conveyance.

• PWBA Tray Sensor

The tray sensor detects paper length set on the tray as being longer than the

specified length.

General Information 1-7

4036-501

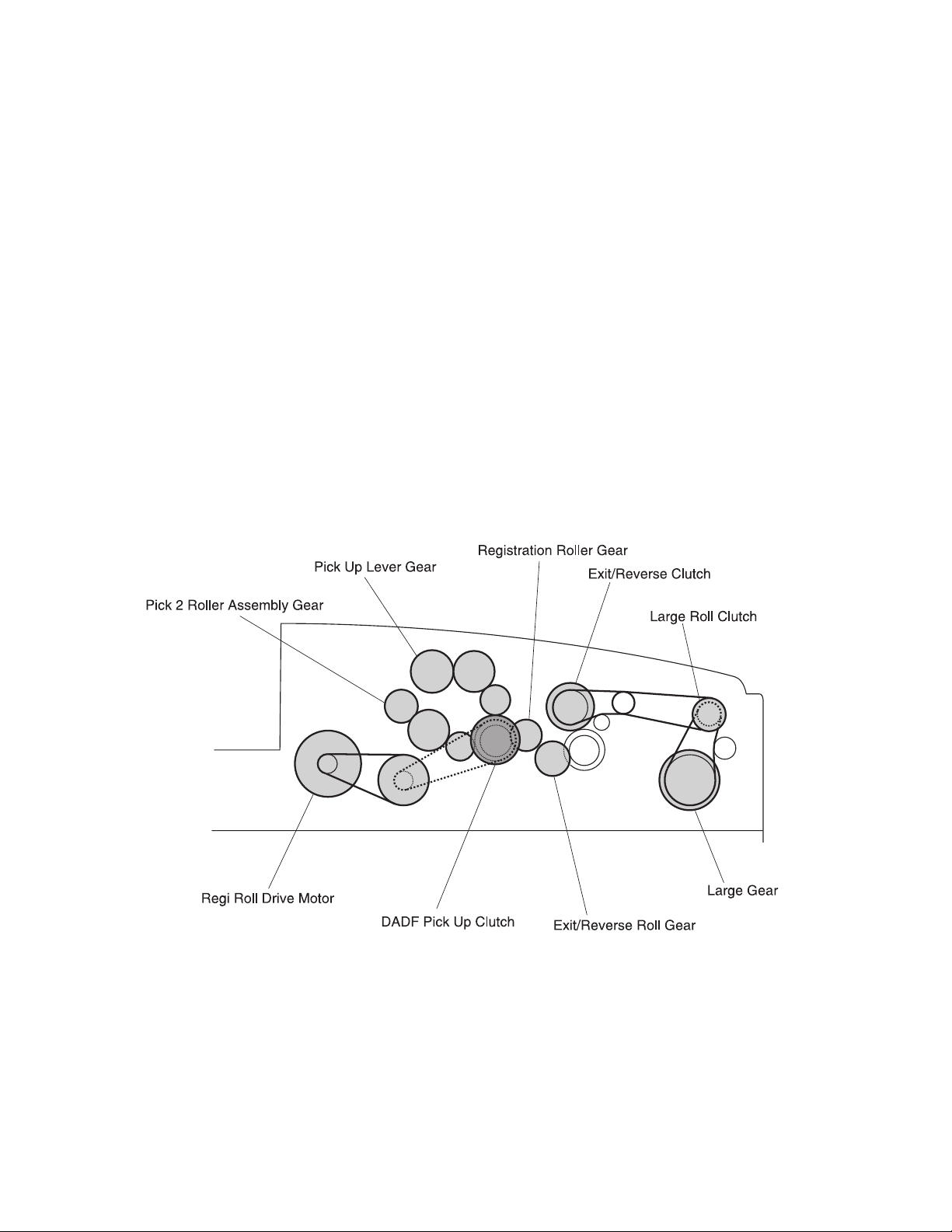

Mechanical Drive

Mechanical drive describes both the rotation of the motor and the action of the gears,

belts, and clutches that are used to transmit and control drive to the various components

throughout the DADF. The major purpose of the drive is to provide the dynamic energy

required for the paper conveyance throughout the DADF.

The registration roll drive motor provides the rotation power with the center gear of the

frame assembly through the belt (6 mm). The center gear of the frame assembly delivers

the rotation power to the gear (23T/48T) through the belt (6 mm). With the rotation of the

gear (23T/48T), the rotation power is distributed to the gears of the registration roll gear

and the pick 2 roller assembly respectively. The DADF pick up clutch distributes the drive

power to the pick up gear when activated, and then the power is delivered to the roller

engagement shaft assembly.

The DADF large roll drive assembly provides the rotation power with the each gear of the

large roll drive motor assembly through the belt (6 mm) and the belt (4 mm). The drive

power is delivered to the pulley 1 through the belt (6 mm) when the DADF large roll clutch

is actuated, and also to the large gear through the belt (6 mm). The further drive power is

delivered to the gear of the exit/reverse roll through the belt (4 mm) when the exit/ reverse

clutch is actuated.

1-8 Service Manual

4036-501

DADF Mechanical Drive Components

The DADF mechanical drive is one major component, with numerous belts, pulleys, and

clutches that transmit drive to the various DADF transport rolls.

• DADF Registration Roll Drive Motor

There is +24VDC on the registration roll drive motor. This motor is part of the DADF

registration roll drive motor assembly.

• DADF Main Drive Motor

There is +24VDC on the step motor. This motor provides drive power to the DADF

main drive motor assembly.

• Pick Up Clutch

The clutch delivers drive power from the roller engagement shaft to the gears.

• Exit/Reverse Clutch

The clutch delivers drive power from the main drive motor to the exit/reverse roll.

• Large Roll Clutch

The clutch delivers drive power from the main drive motor to the large roll.

General Information 1-9

4036-501

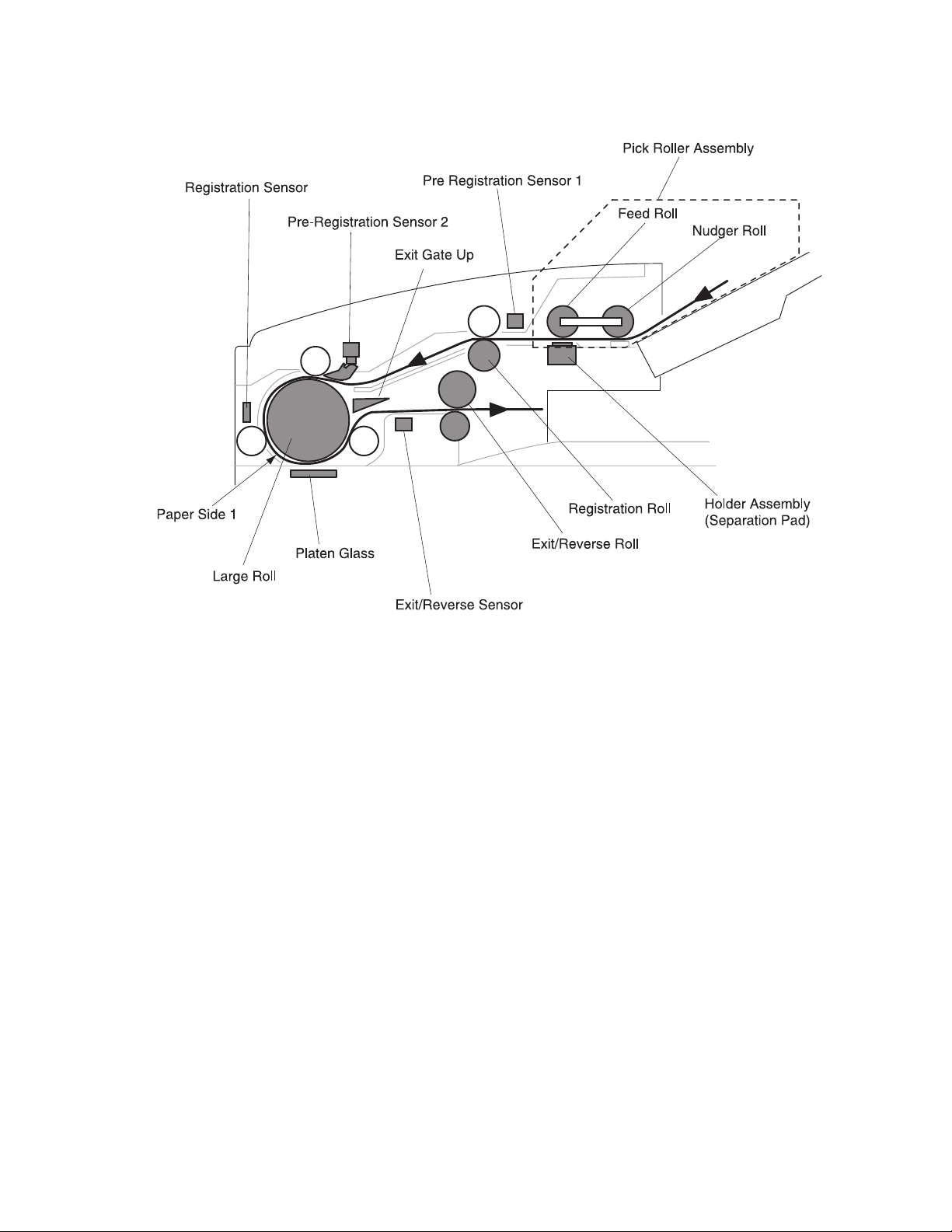

DADF Paper Path

The DADF moves the paper along the paper path using a combination of rolls, solenoids,

clutches and gears. The DADF adjusts the scanning timing to the specified paper

movement speed and fixing the cartridges of the scanner at the DADF position. The

DADF also allows the scanner to scan page 2 of the paper following page 1 using the

gate change mechanism of the duplex function.

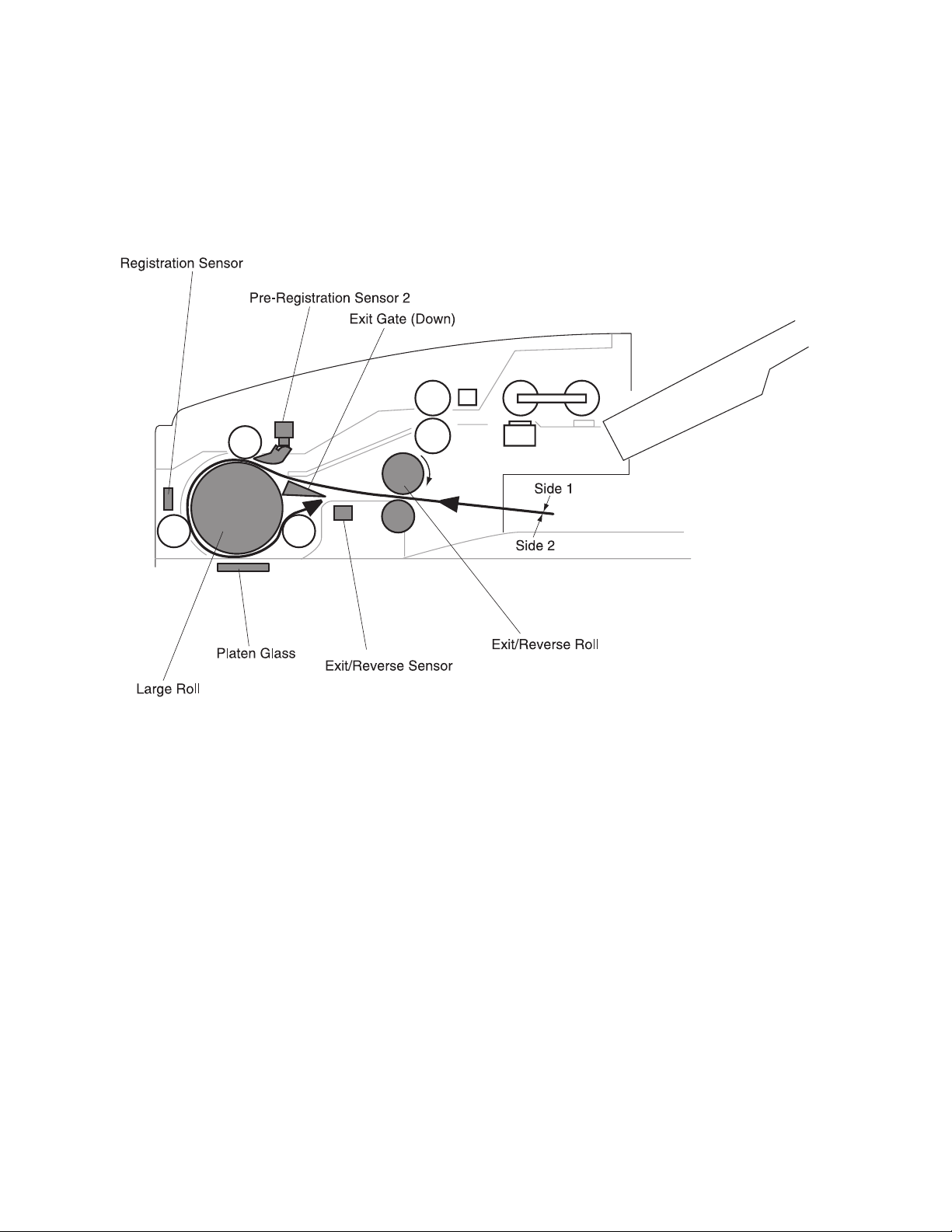

1. Simplex Paper Path

• The rotation of the nudger roll, moves the paper on the DADF tray to the feed

roll.

• The paper moves to the registration roll by the rotation of the feed roll.

• When the pre–registration sensor 1, located just in front of the registration roll,

detects the passing of the top of the paper, the paper movement is interrupted

for the specified time to synchronize with the paper feed timing.

• The paper restarts toward the registration roll.

• After passing on the DADF upper paper guide, the top of the paper reaches and

actuates the paper present sensor of the pre-registration sensor.

• At the position just in front of the large roll, the paper movement is interrupted

again for the specified time to synchronize with the paper feed timing.

• The paper is moved to the DADF platen glass by rotation of the large roll.

• Along the way, the DADF registration sensor card interrupts the movement for

the specified time to synchronize with the scanning timing of the scanner.

• The sensor restarts to move the paper to the platen glass by the rotation of the

large roll.

• The image of the paper is scanned at the platen glass.

• After scanning, the paper passes the gate through the lower path and is moved

to the exit/reverse roll.

• The rotation of the exit/reverse roll discharges the paper onto the DADF output

tray.

1-10 Service Manual

4036-501

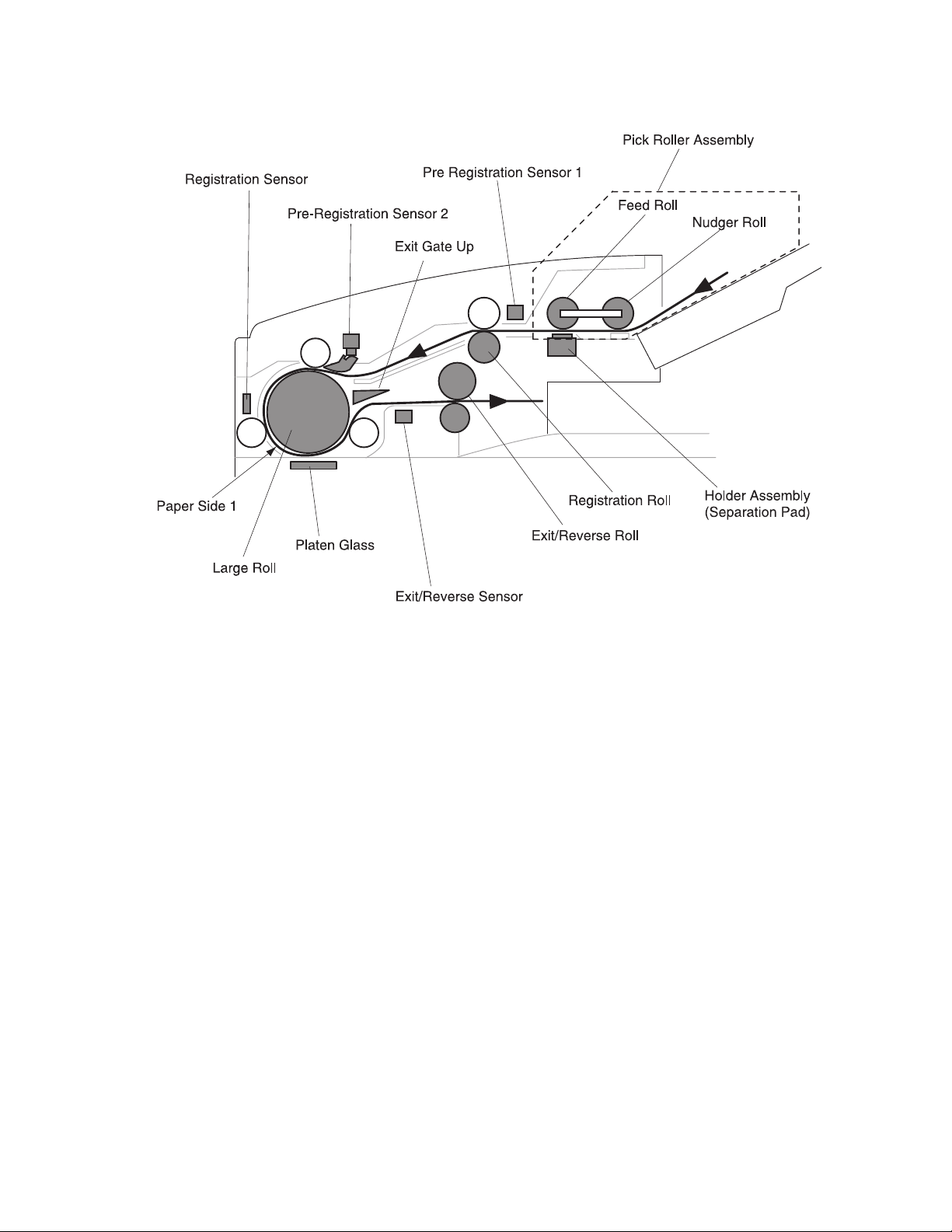

2. Duplex Paper Pa th

Note: The duplex paper path may be able to utilize two operational patterns due to its

mechanical configuration design. Those patterns are described in this section.

General Information 1-11

4036-501

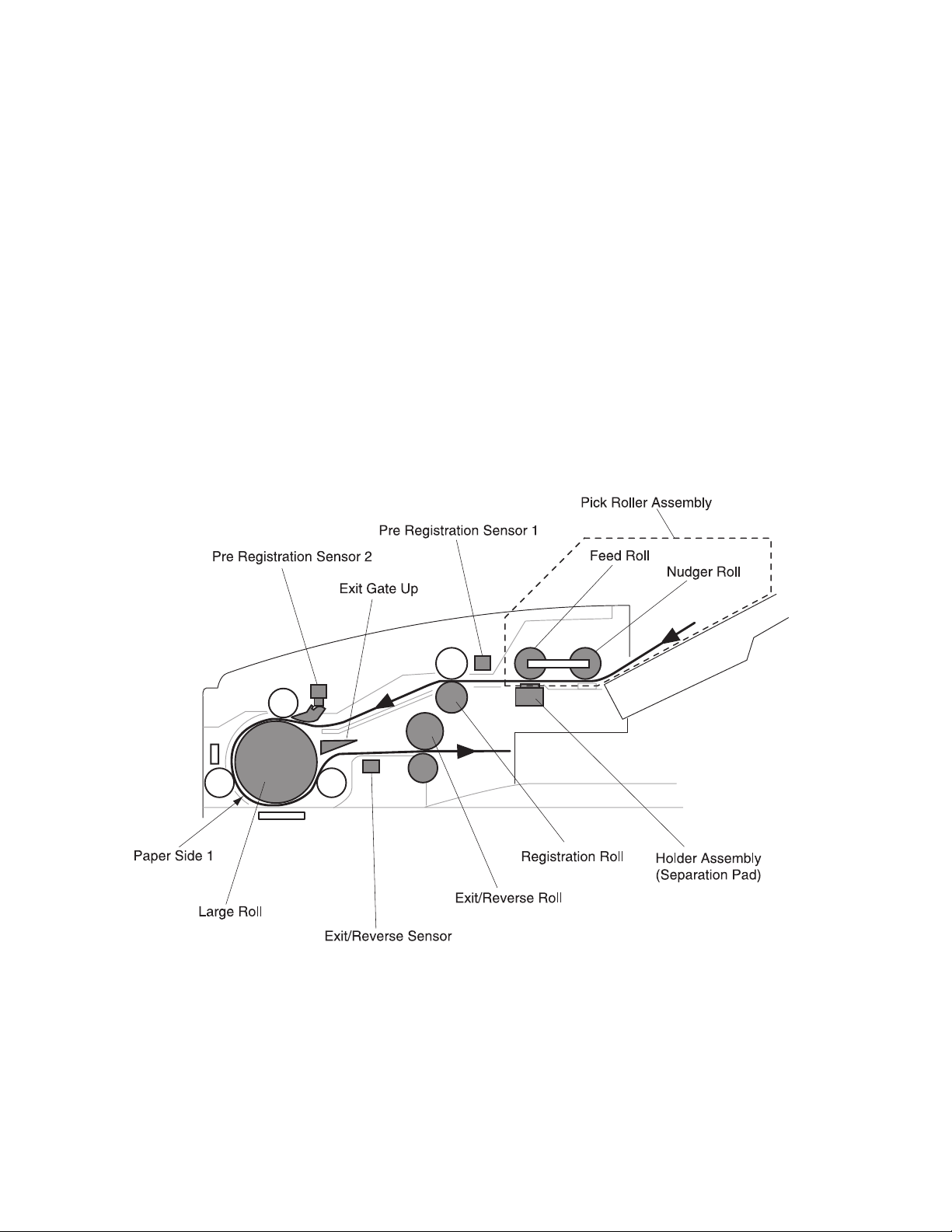

Operational Pattern 1

Step 1: Scan of side 1

• The rotation of the nudger roll moves the paper on the DADF tray to the feed

roll.

• The paper moves to the registration roll by the rotation of the feed roll and the

pad in the DADF individual separator pad.

• When the pre-registration sensor 1, located just in front of the registration roll,

detects the passing of the top of the paper, the paper movement is interrupted

for the specified time to synchronize with the paper feed timing.

• The paper restarts toward the registration roll.

• After passing the DADF upper paper guide, the top of the paper reaches and

actuates the paper present sensor flag of the pre–registration sensor 2.

• At the position just in front of the large roll, the paper movement is interrupted

again for the specified time to synchronize with the paper feed timing.

• The paper is moved to the DADF platen glass by rotation of the large roll.

• The DADF registration sensor card interrupts the movement for the specified

time to synchronize with the scanning timing of the scanner.

• The scanner restarts to move the paper to the platen glass by rotation of the

large roll. Utilizing the combined mechanism of the large roll rotation and the

scanner full rate carriage, side 1 of the paper is scanned.

• After scanning, the paper passes the gate through the lower path and moves to

the exit/reverse roll.

• Along the way, the timing of the exit/reverse sensor detects the pass of the top

of the paper.

• The paper is stopped by the exit/reverse roll and the reverse roll.

• The paper movement is stopped at the time when the end of the paper passes

on the exit/reverse sensor.

1-12 Service Manual

4036-501

General Information 1-13

4036-501

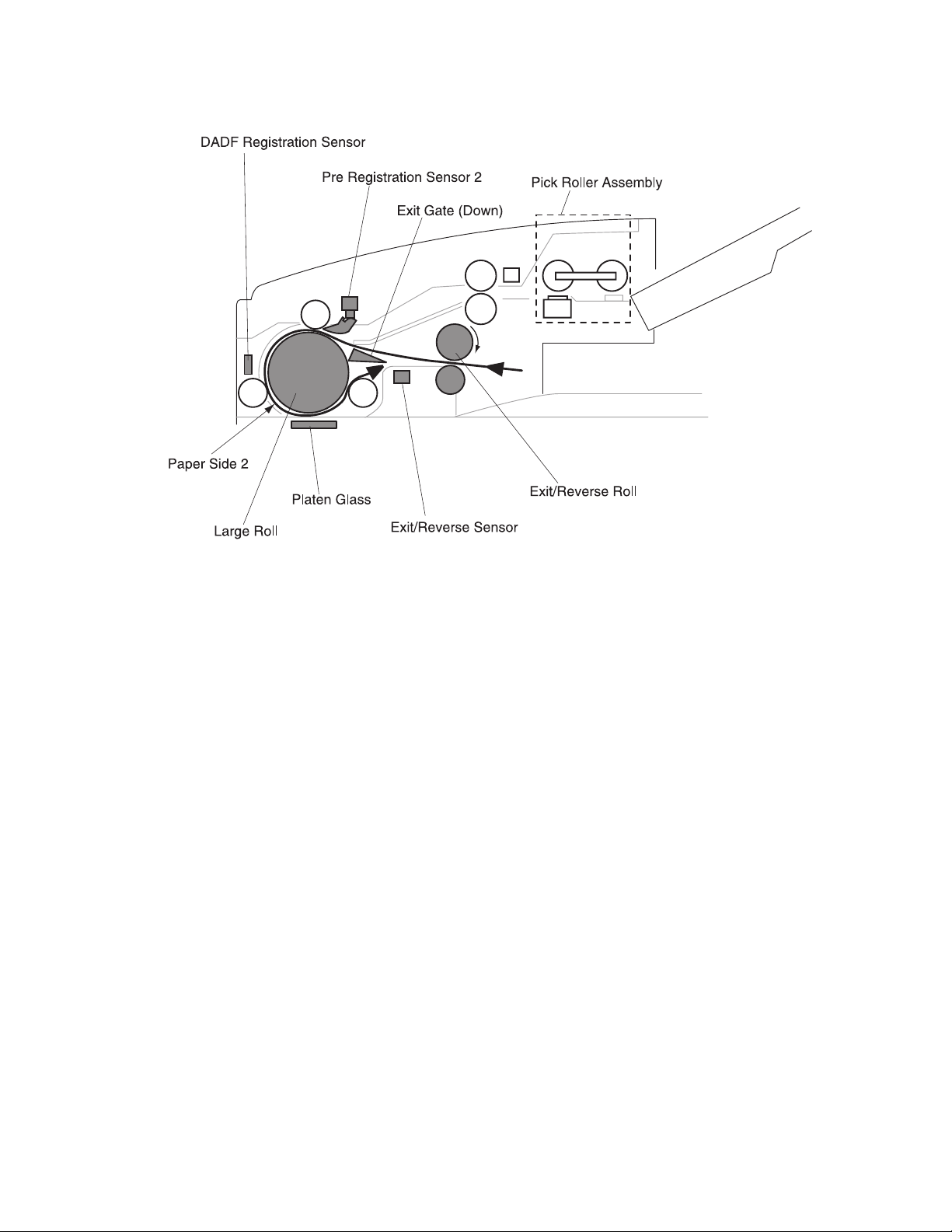

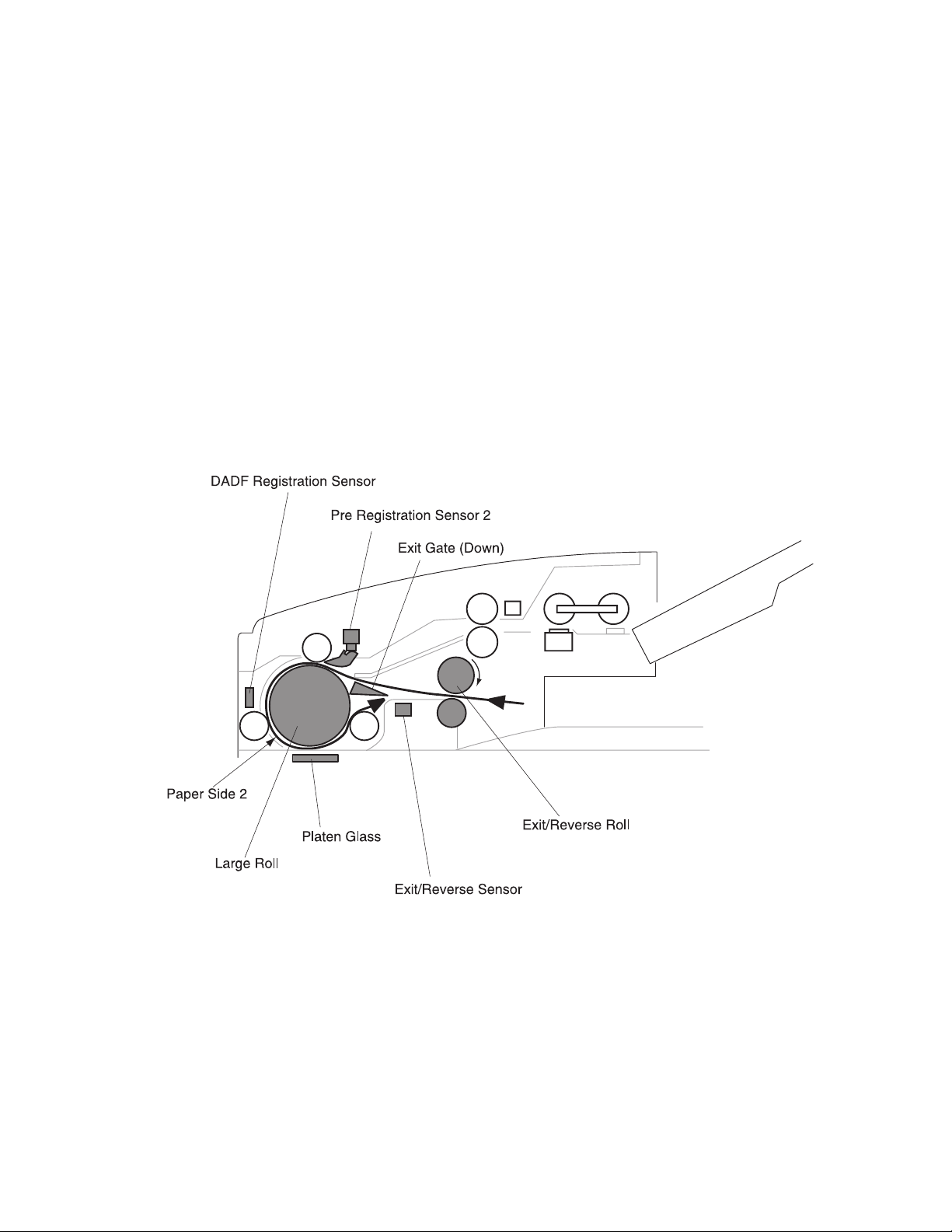

Step 2: Scan of side 2

• The paper is re–fed to the large roll by the counterclockwise rotation of the

exit/reverse roll.

• After the paper passes the gate through the upper path and at the timing when

the top of the paper actuates the paper present sensor flag of the pre–

registration sensor 2, the movement is interrupted for the specified time to

synchronize the paper feed timing and then restarted.

• The paper is moved toward the DADF platen glass.

• The paper it is interrupted to synchronize the feed timing with the scanning

timing of the scanner by the command signal sent from the DADF registration

sensor card.

• Paper is conveyed on to the platen glass by the rotation of the large roll, and

side 2 of the paper is scanned at the platen glass.

• After scanning, paper is moved toward the exit/reverse roll passing the gate

through its lower path.

• Paper movement is interrupted for a specified time when the end of the paper

passes on the exit/reverse sensor.

1-14 Service Manual

4036-501

General Information 1-15

4036-501

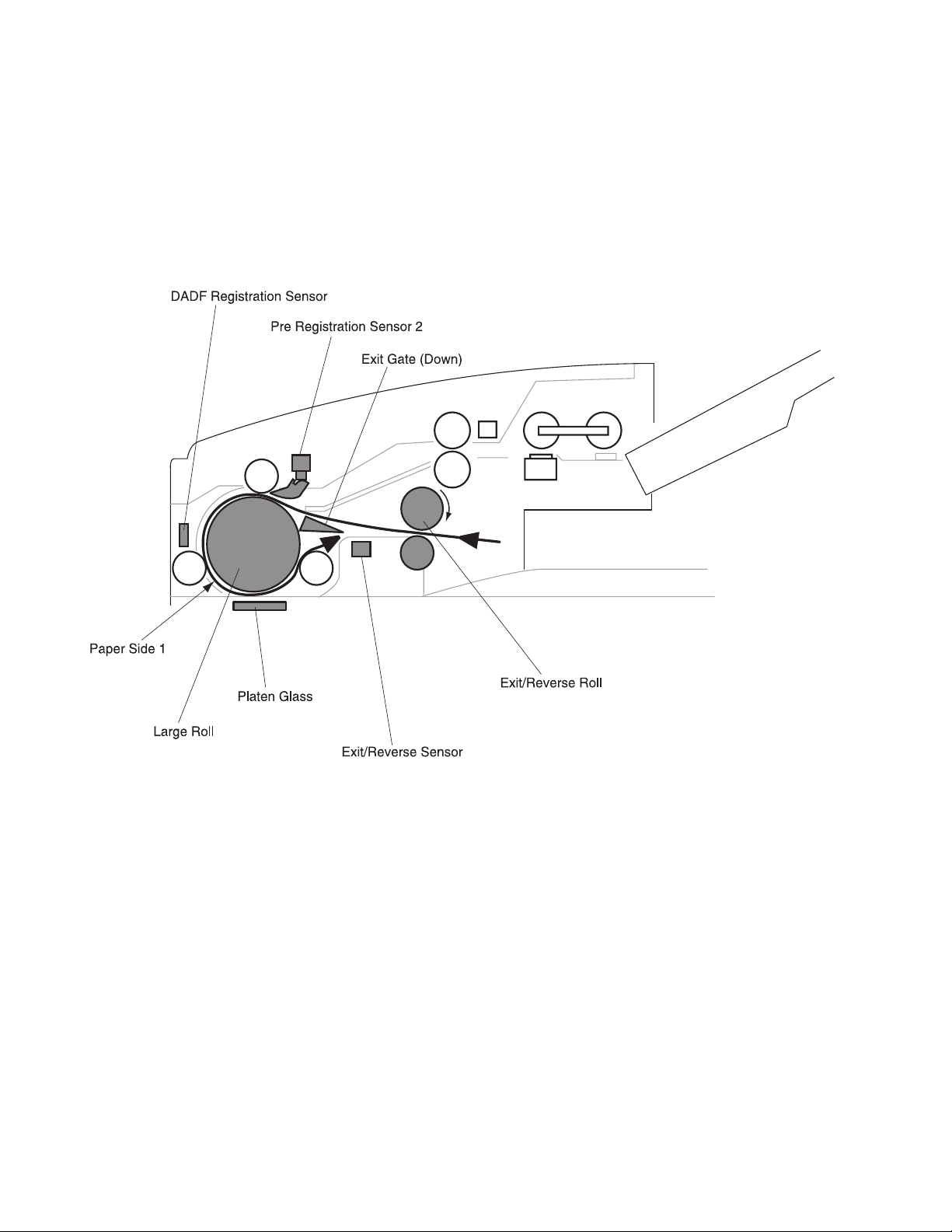

Step 3: High speed reverse rotation

• The paper is re–fed to the large roll by the counterclockwise rotation of the

exit/reverse roll.

• After passing over the upper side of the exit gate, the paper actuates the pre-

registration sensor #2. Movement of the paper is then interrupted for a specific

amount of time to synchronize paper feed timing.

1-16 Service Manual

• The paper moves toward the DADF platen glass. The rotation of the

exit/reverse roll stops.

• The paper moves toward the exit/reverse roll by the rotation of the large roll

passing the gate through the lower path.

• Passing the exit/reverse sensor, paper discharges to the DADF output tray by

the rotation of the exit/reverse roll.

4036-501

General Information 1-17

4036-501

Operational Pattern 2

Step 1: High speed paper feed

• The rotation of the nudger roll causes the paper on the DADF tray to feed into

the feed roll.

• A sheet of paper moves to the registration roll by the rotation of the feed roll.

When the pre-registration sensor 1, located just in front of the registration roll,

detects the passing the top of the paper, the paper movement is interrupted for

the specified time to synchronize with the paper feed timing.

• After the timing adjustment, the paper restarts toward the registration roll.

• After passing the chute, the paper moves by the rotation of the large roll

through the lower path of the gate toward the exit/reverse roll.

• When the exit/reverse sensor detects the passing of the top of the paper, the

paper is nipped by the exit/reverse roll.

• The paper movement is interrupted for a specified time when the end of the

paper passes to the exit/reverse sensor.

1-18 Service Manual

4036-501

Step 2: Scan of side 2

• The paper is re–fed to the large roll by the counterclockwise rotation of the

exit/reverse roll.

• After passing over the upper side of the exit gate, the paper actuates the pre-

registration sensor #2. Movement of the paper is then interrupted for a specific

amount of time to synchronize paper feed timing.

• The paper moves toward the DADF platen glass. The paper is interrupted to

synchronize the feed timing with the scanning timing of the scanner by the

command signal sent from the DADF registration sensor card.

• The paper moves to the platen glass by the rotation of the large roll. Side 2 of

the paper is scanned at the platen glass.

• After scanning, the paper moves toward the exit/reverse roll passing the gate

through the lower path. The paper is nipped by the exit/reverse roll.

• The paper movement is interrupted for a specified time when the end of paper

passes on the exit/reverse sensor.

General Information 1-19

4036-501

Step 3: Scan of side 1

• The paper is re–fed into the large roll by the CW rotation of the exit/reverse roll.

• After passing over the upper side of the exit gate, the paper actuates the pre-

registration sensor #2. Movement of the paper is then interrupted for a specific

amount of time to synchronize paper feed timing.

1-20 Service Manual

Loading...

Loading...