Page 1

User’s Guide

Click the document name to open it:

Administrator’s Guide

Roadmap

Setup Guide

2000-Sheet Drawer User’s Guide

High-Capacity Output Stacker

Installation Instructions

Use this document when you have questions about the Lexmark

Optra™ T printer or encounter a problem when using it. This document contains information on loading print material, clearing jams,

and using your printer.

The online Administrator’s Guide on this CD is a complement to this

User’s Guide. If you are not accessing these documents directly

from the CD, the Administrator’s Guide may not be available to you.

See your administrator if you need the Administrator’s Guide.

TIPS

Use the Adobe Acrobat (3.x or higher) icons and

•

table of contents on your screen to navigate and

use this document.

Click the blue text to link to another part of

•

this document or to another document.

You can print all or specific pages of this

•

document.

Home

1User’s Guide

Page 2

Other sources of

information

Drivers, MarkVision and

Utilities CD

Lexmark Web site

In addition to printer drivers and utilities, the Drivers, MarkVision and

Utilities CD includes information about Lexmark printers. After

launching the CD, click View Documentation and then click:

Printer Commands to open the Technical Reference and get

•

details about printer languages and commands, interface

specifications, and memory management.

Special Media to open the Card Stock & Label Guide and get

•

information about choosing the correct print material.

MarkVision™ Printer Utility to open documents providing

•

details about the MarkVision printer management software.

MarkNet™ Print Servers to open documents containing infor-

•

mation about configuring MarkNet print servers.

Access our site on the World Wide Web for updated printer drivers,

utilities, and documentation:

www.lexmark.com

2User’s Guide

Page 3

Trademarks

Trademarks

TrademarksTrademarks

Lexmark and Lexmark with diamond design, MarkNet, MarkVision, and Optra are

trademarks of Lexmark International, Inc., registered in the United States and/or

other countries.

Operation ReSource is a service mark of Lexmark International, Inc.

PCL® is a registered trademark of the Hewlett-Packard Company. PCL 6 is

Hewlett-Packard Company’s designation of a set of printer commands (language)

and functions included in its printer products. This printer is intended to be compatible with the PCL 6 language. This means the printer recognizes PCL 6 commands used in various application programs, and that the printer emulates the

functions corresponding to the commands.

PostScript® is a registered trademark of Adobe Systems Incorporated. PostScript

3 is Adobe Systems’ designation of a set of printer commands (language) and

functions included in its software products. This printer is intended to be compatible with the PostScript 3 language. This means the printer recognizes PostScript

3 commands used in various application programs, and that the printer emulates

the functions corresponding to the commands.

Details relating to compatibility are included in the Technical Reference.

Other trademarks are the property of their respective owners.

3Trademarks

Page 4

Meet the Printer

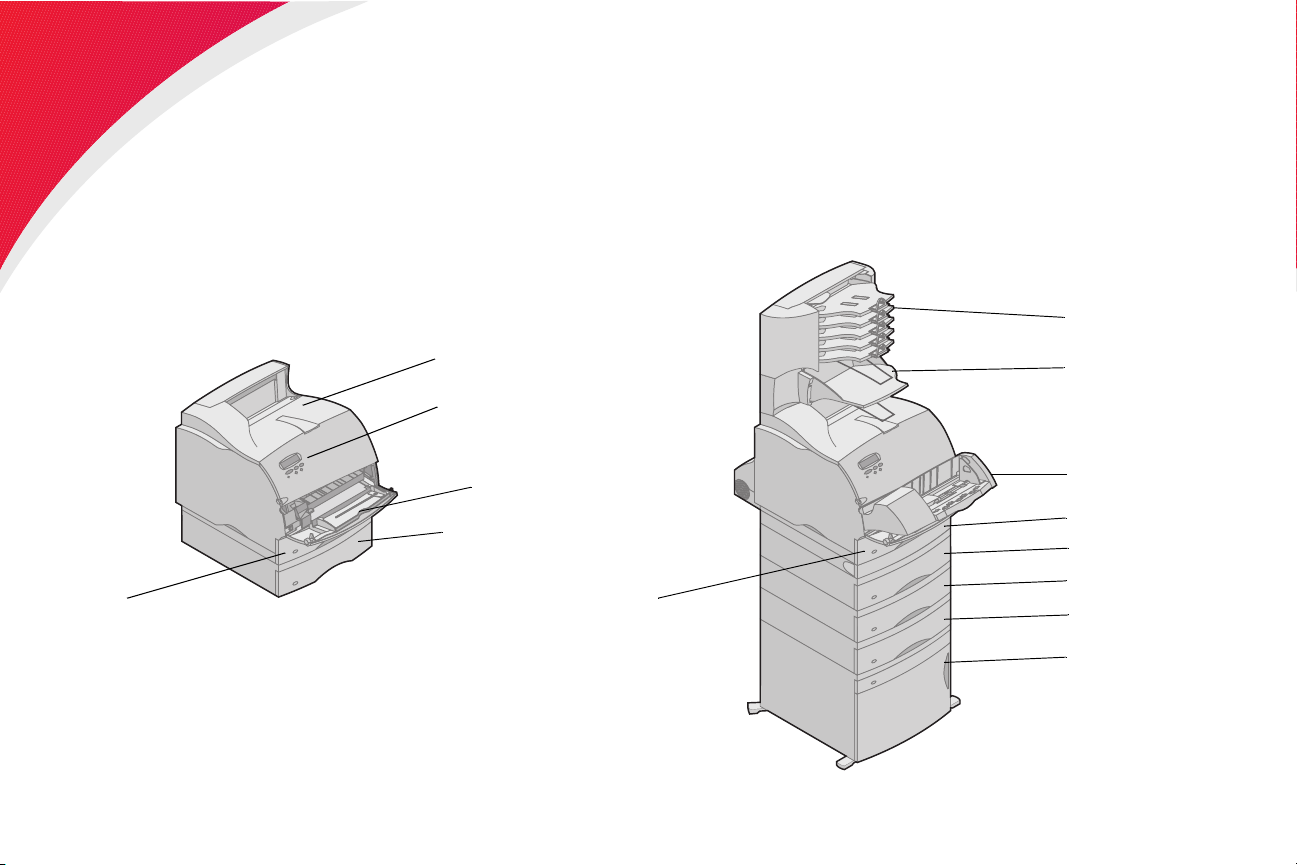

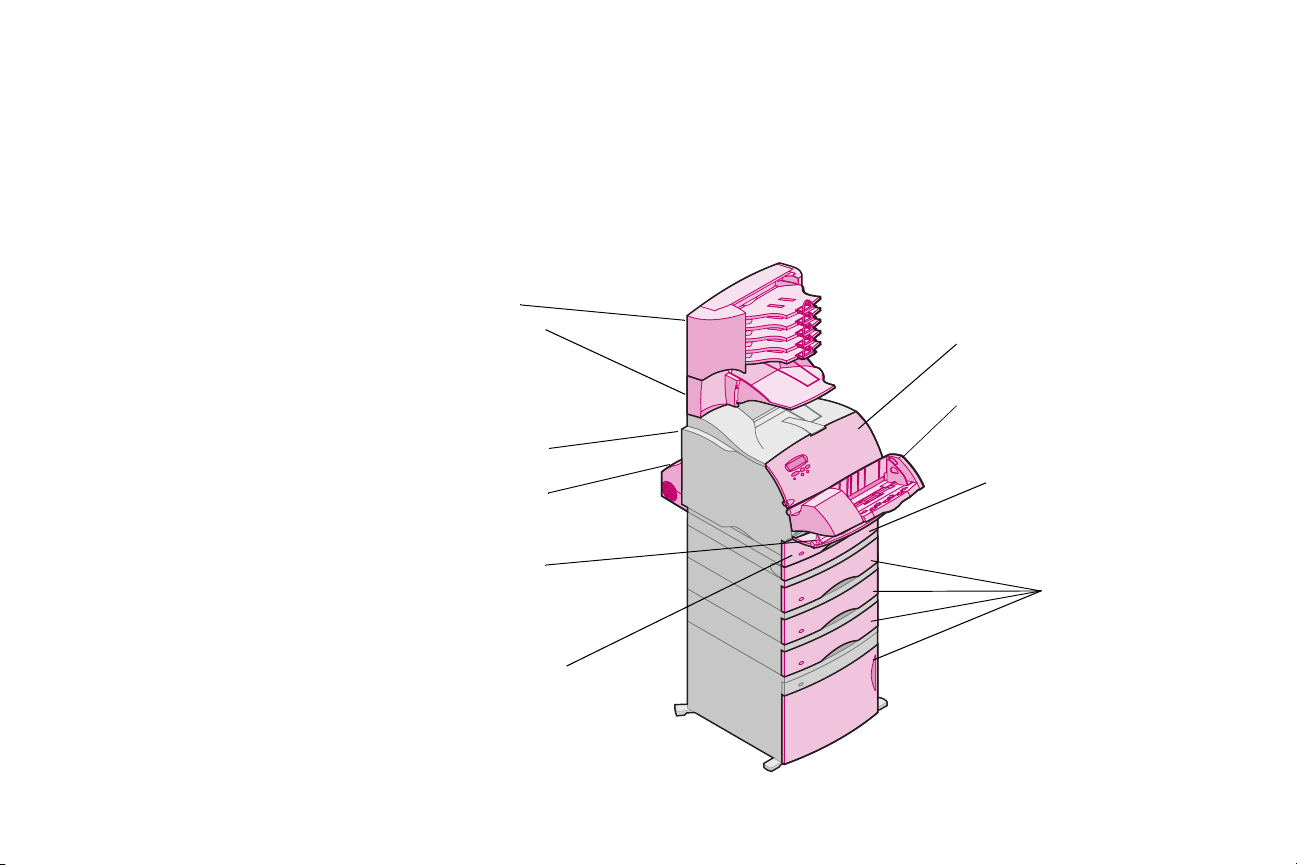

The following illustrations show typically and fully configured printers. If you have attached paper

handling options to your printer, it may look more like the fully configured model. For information on

other possible configurations, refer to the Setup Guide.

Typically configured Fully configured

5-Bin mailbox

Tray 1

(integrated tray)

Standard output bin

Operator panel

Multipurpose Feeder

Tray 2

Tray 1

(integrated tray)

4Meet the Printer

Output expander

Envelope feeder

Duplex unit

Tray 2

Tray 3

Tray 4

Tray 5

(2000-sheet drawer)

Page 5

Using Printer Drivers

The printer drivers, installed on your computer from the Drivers,

MarkVision and Utilities CD that came with your printer, provide you

with powerful control of the printer features from almost any software application. Some of the things you can control include:

• Choosing paper sources

• Changing page orientation

• Choosing different sizes and types of media

• Adjusting the quality of print jobs

• Resetting printer defaults

• Multipage printing

• Changing duplex settings

• Print and Hold functions

You can open the printer driver from most applications:

1

Open the application File menu.

2

Choose Print (or Printer) Setup.

3

In the Printer Setup dialog box, click the Properties, Options,

or Setup button (depending on the application).

5Using Printer Drivers

Page 6

Using the Operator Panel and Menus

This section contains information about using the operator panel,

changing printer settings, and understanding operator panel menus.

You can change most printer settings from your software application

or printer driver. Settings you change from the application or printer

driver apply only to the job you are preparing to send to the printer.

N

: Changes made to printer settings from a software application

OTE

override changes made from the printer operator panel.

If there is a setting you cannot change from your application, use the

printer operator panel or the remote operator panel available from

MarkVision. Changing a printer setting from the printer operator

panel or from MarkVision makes that setting the user default.

6Using the Operator Panel and Menus

Page 7

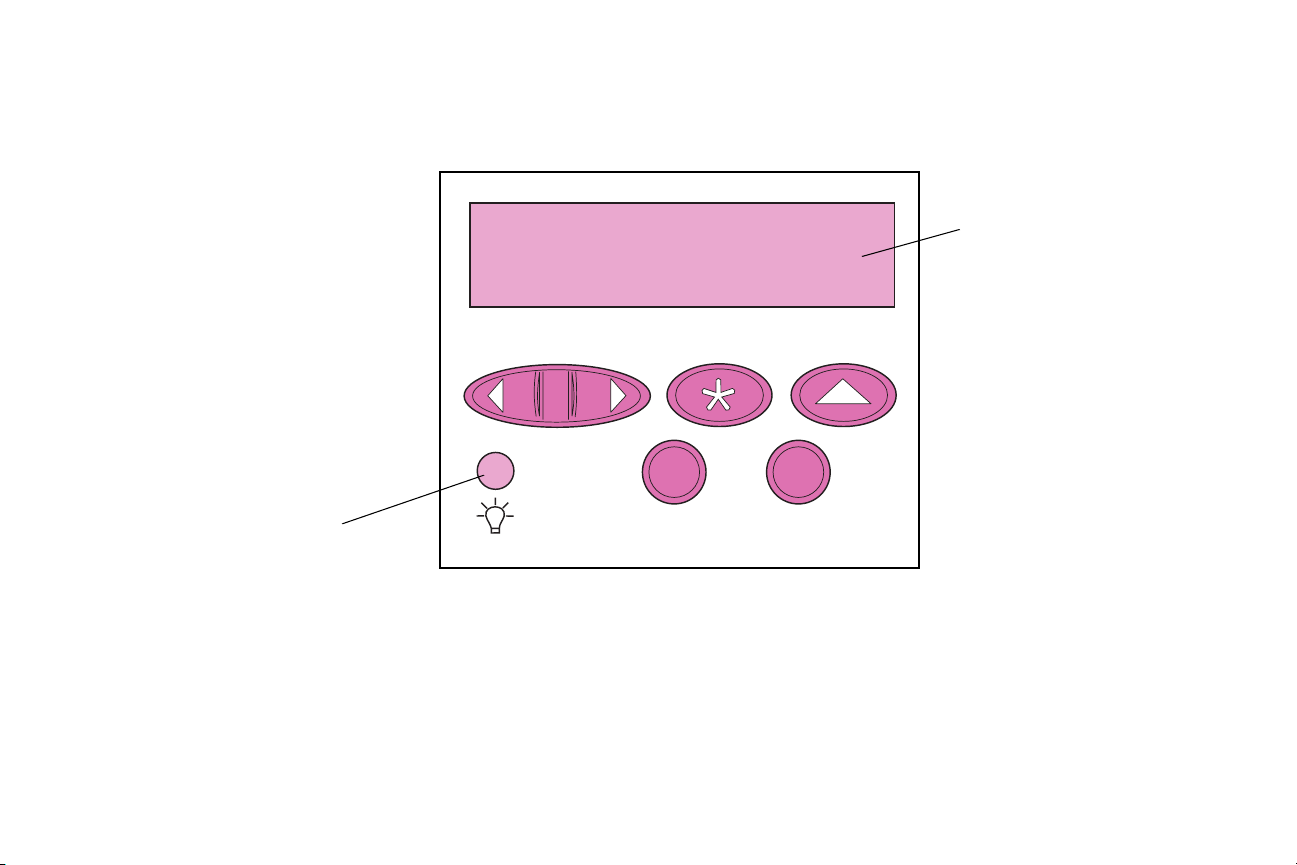

Using the

operator panel

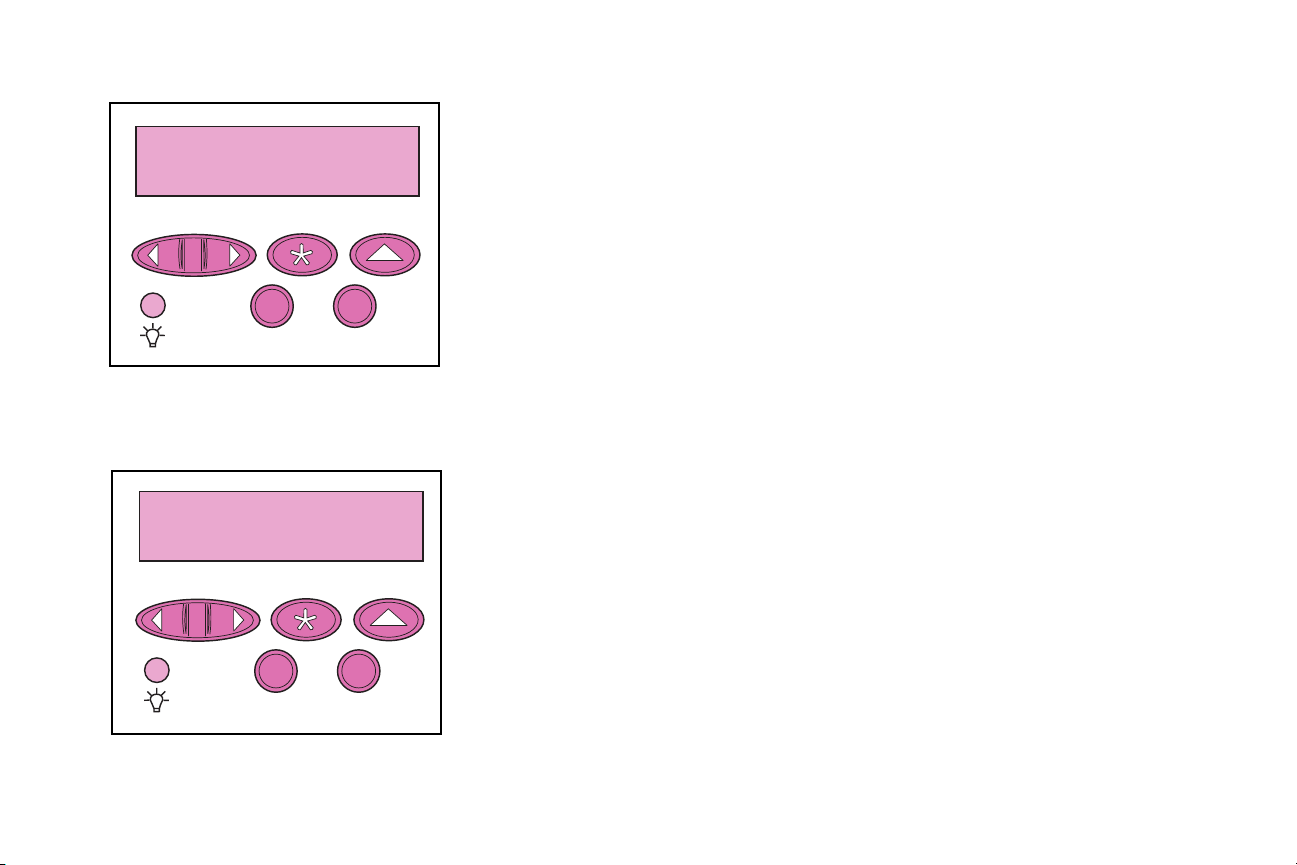

The printer operator panel, on the front left-side of your printer, has

a 2-line by 16-character liquid crystal display (LCD), five buttons,

and one indicator light.

LCD

Light

Printer indicator light

1

Menu

2

5

Go

Select

3

Return

Stop

4

6

The printer indicator light gives information about the status of your

printer. If the light is:

Off - the printer is off

•

On - the printer is on, but idle

•

Blinking - the printer is on and is busy

•

7Using the Operator Panel and Menus

Page 8

Operator panel buttons

Use the five operator panel buttons to open a menu, scroll through a

list of values, change printer settings, and respond to printer messages.

You will find the numbers 1 through 6 beside the operator panel buttons; these numbers are used to enter PIN numbers for Print and

Hold jobs. For more information, see “Using the Print and Hold

Function” on page 106.

The following information describes the functions of each button.

N

: Buttons act upon the information that displays on the second

OTE

line of the operator panel.

Go

Press the Go button to:

Return to the

•

(the

Ready

Exit printer menus and return to the

•

Clear operator panel error messages.

•

Ready

message does not display on the operator panel).

state if the printer is in an offline situation

Ready

state.

If you’ve changed printer settings from the operator panel menus,

press Go before sending a job to print. The printer must display

Ready

for jobs to print.

8Using the Operator Panel and Menus

Page 9

<Menu> Each end of the button has a function. Press

Menu>

or

<Menu

:

When

•

Ready

first menu in the menus.

the menus.

When

•

When the printer is offline:

•

–

–

For menu items with numerical values, such as

•

and hold

Release the button when the number you want displays.

Select Press the

Select the menu displayed on the second line of the operator

•

panel. Depending on the type of menu, this action:

–

–

Save the displayed menu item as the default setting. The

•

printer displays the

item.

Ready

state) and enter the menus.

Busy

Press

Press

Select

displays, to take the printer offline (out of the

Menu>

<Menu

takes you to the last menu in

displays, to take the printer to the

Menu>

<Menu

Menu>

to go to the next item in the menus, or

to go to the previous item in the menus.

to scroll forward, or

<Menu

takes you to the

JOB MENU

Copies

to scroll backward.

button to:

.

, press

Opens the menu and displays the first item in the menu.

Opens the menu item and displays the default setting.

Saved

message and returns to the menu

Clear certain messages from the operator panel.

•

9Using the Operator Panel and Menus

Page 10

Return Press the

menu item.

Return

button to return to the previous menu level or

Stop Press the

temporarily stop all activity and take the printer offline. The operator

panel status message changes to

Press Go to return the printer to the

button at the

Stop

Ready, Busy

Not Ready

Ready, Busy

, or

Waiting

.

, or

message to

Waiting

state.

10Using the Operator Panel and Menus

Page 11

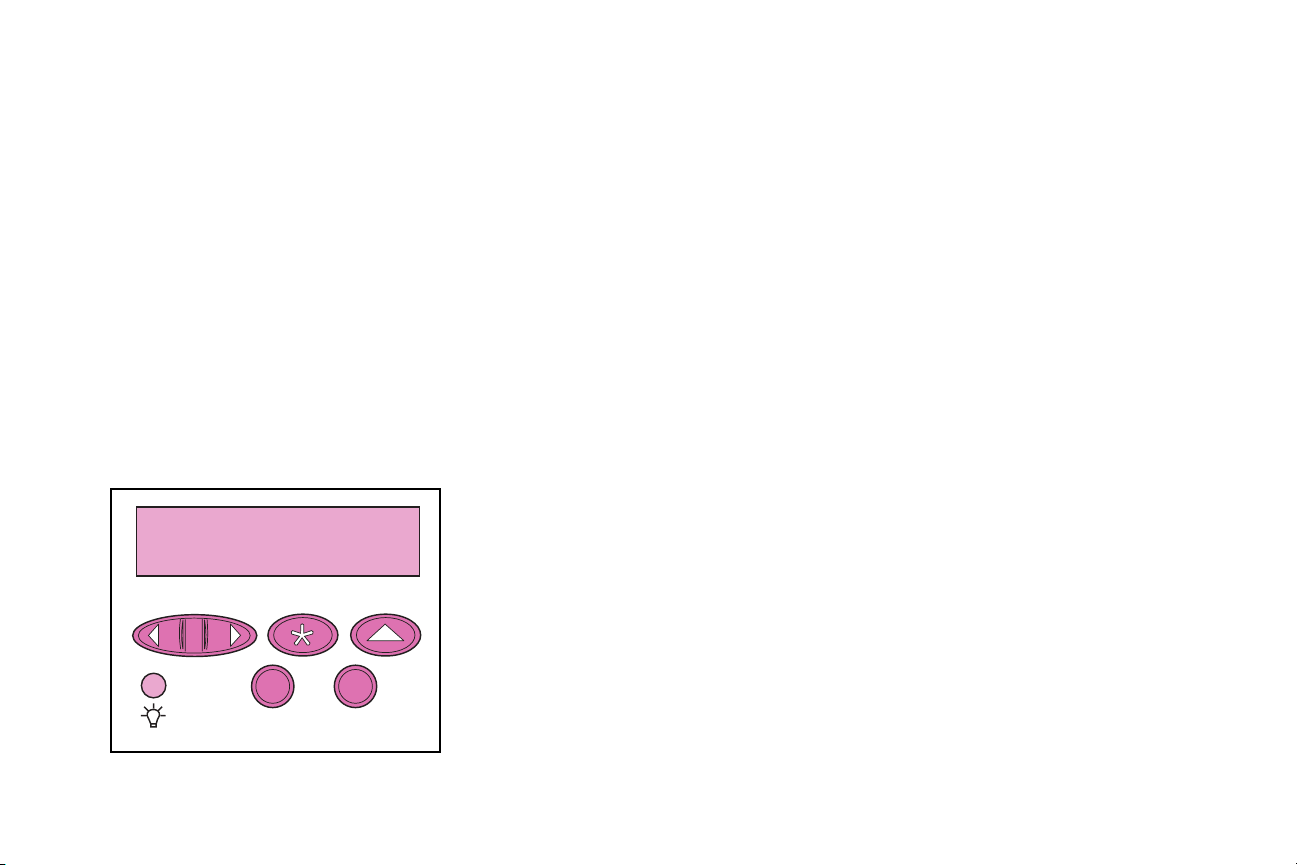

Printer messages

The operator panel displays three types of messages:

N

: Refer to the Administrator’s Guide for a complete listing of all

OTE

printer messages.

Status messages provide information about the current state

•

of the printer.

Attendance messages report printer errors that you must

•

resolve.

Service messages indicate printer failures that may require

•

servicing.

Status messages

Busy PCL

Toner Low

When the

Ready

status message displays, the printer is ready to

receive a print job.

While a job is processing or printing, the

status message dis-

Busy

plays on the first line of the operator panel.

The screen to the left is an example of a message. The printer status displays on the first line of the operator panel. The second line

displays warning messages that give more information about printer

status and possible intervention conditions.

The

used for the print job. The

message identifies the printer language (PCL emulation)

Busy

Toner Low

message warns you that the

print cartridge is low on toner.

11Using the Operator Panel and Menus

Page 12

Attendance messages Attendance messages help you solve printer problems.

For example, if print material is jammed in the printer, the message

201 Paper Jam

201 Paper Jam

Remove Cartridge

displays.

Service messages

A service message indicates a printer failure that may require a service call.

917 Service

Transfer Roll

12Using the Operator Panel and Menus

Page 13

Using the operator panel to

change printer settings

From the operator panel, you can select menu items and associated

values to run your print jobs successfully. You can also use the

panel to alter the setup and operating environment of the printer.

See “Operator panel menus” on page 16 for an explanation of all the

menu items.

You can modify printer settings by:

• Selecting a setting from a list of values.

• Changing an On/Off setting.

• Changing a numerical setting.

To select a new value as a setting:

1

From a Ready status message, press Menu> or <Menu. The

menu names display.

2

Continue to press and release Menu> or <Menu until you

reach the menu you need. Refer to the Administrator’s Guide

for more information on specific menu items and values.

3

Press Select to select the menu or menu item displayed on

the second line of the operator panel.

–

If the selection is a menu, the menu is opened and the first

printer setting in the menu displays.

13Using the Operator Panel and Menus

Page 14

– If the selection is a menu item, the default setting for the

menu item displays. (The current user default setting has

an asterisk (*) beside it.)

Each menu item has a list of values for the menu item. A value

can be:

– a phrase or word to describe a setting

– a numerical value that can be changed

– an On or Off setting

4

5

Press

Press

Menu>

Select

or

<Menu

to move to the value you need.

to select the value on the second line of the

operator panel. An asterisk appears beside the value to

indicate that it is now the user default setting. The new setting

displays for one second, clears, displays the word

Saved

then displays the previous list of menu items.

6

Press

Return

to go back to previous menus. Make additional

menu selections to set new default settings. Press Go if this is

the last printer setting to change.

, and

User default settings remain in effect until you save new settings or

restore the factory defaults. Settings you choose from your software

application can also change or override the user default settings you

select from the operator panel.

14Using the Operator Panel and Menus

Page 15

Example of printing the

menu settings

Complete the following steps to print a list of the current user default

settings and installed printer options.

1 Make sure the printer power is on and the

message displays.

2 Press

Menu>

3 Continue to press and release

UTILITIES MENU.

4 Press

UTILITIES MENU

Select

5 Continue to press and release

Menus

6 Press

The message,

until the page prints the current settings for the menus and a

list of installed options.

If an error message displays, refer to the Administrator’s Guide for

more information.

.

Select

or

<Menu

to display the list of menu items for the

.

to select

Printing Menu Settings,

to enter the menus.

Menu>

Menu>

Print Menus.

Ready

until you see

until you see

displays and remains

status

Print

The printer returns to

15Using the Operator Panel and Menus

Ready

when the page or pages finish printing.

Page 16

Operator panel menus

Standard menus The printer has standard menus that let you configure the printer:

Additional menus Additional menus display if: a language is available for the model or

• Paper

• Finishing

• Utilities

• Job

• Quality

• Setup

• PCL Emul

• Pos tScript

is activated; options, network adapters, and attachments are

installed; or a Print and Hold job is present. These menus include:

• Standard Parallel, Parallel Option 1, and Parallel Option 2

• Standard Serial, Serial Option 1, and Serial Option 2

• Standard Network, Network Option 1, Network Option 2

• USB Option 1, USB Option 2

• Infrared

• LocalTalk

• Fax

• Confidential Job

• Held Jobs

16Using the Operator Panel and Menus

Page 17

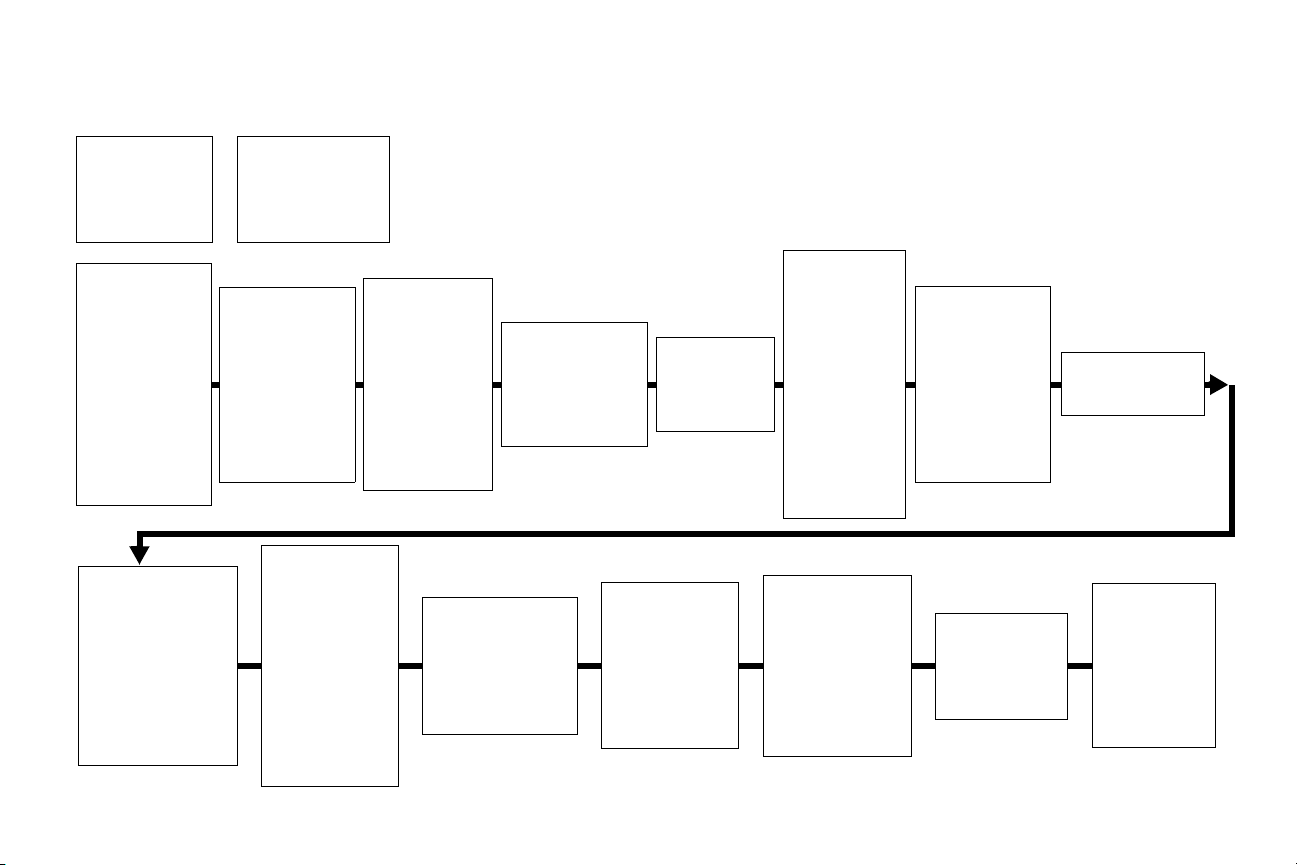

The diagram on page 19 shows the menu items in each menu.

An asterisk (*) next to a value indicates the factory default setting.

Factory defaults may differ for different countries.

Factory defaults are the function settings in effect the first time you

turn your printer on. These remain in effect until you change them.

Factory defaults are restored if you select the Restore value for the

Factory Defaults menu item in the UTILITIES MENU. Refer to the

Administrator’s Guide for more information.

When you select a new setting from the operator panel, the asterisk

moves next to the selected setting to identify it as the current user

default.

User defaults are the settings you select for different printer func-

tions and store in printer memory. Once stored, these settings

remain active until new ones are stored or the factory defaults are

restored.

:

N

OTE

Be aware that settings you choose from your software

application may override the settings you select from the

operator panel.

17Using the Operator Panel and Menus

Page 18

Menus disabled If your printer is configured as a network printer available to a num-

ber of users, it is possible that

press

Menu>

or

<Menu

from the

Menus Disabled

Ready

state. Disabling the menus

prevents users from using the operator panel to inadvertently

change a printer default that has been set by the person managing

the printer. You can still clear messages and select items from the

Job Menu

when printing a job, but you cannot change other printer

settings. You can, however, use your printer driver to override printer

defaults and select settings for individual print jobs.

displays when you

18Using the Operator Panel and Menus

Page 19

Overview of printer menus Menus or menu items in italics only display if the corresponding

option is installed. Capitalized menu items (for example, PAPER

SIZE) have submenus.

HELD JOB

Print All Jobs

Print A Job

Delete All Jobs

Delete A Job

Print Copies

PAPER MENU

Paper Source

PAPER SIZE

PAPER TYPE

CUSTOM TYPES

Output Bin

Configure Bins

Overflow Bin

ASSIGN TYPE/BIN

Substitute Size

Configure MP

Envelope Enhance

PAPER TEXTURE

PAPER WEIGHT

PAPER LOADING

PARALLEL MENU

PARALLEL OPTION x

PCL SmartSwitch

PS SmartSwitch

NPA Mode

Parallel Buffer

Job Buffering

Advanced Status

Protocol

Honor Init

Parallel Mode 1

Parallel Mode 2

CONFIDENTIAL JOB

Print All Jobs

Print A Job

Delete All Jobs

Delete A Job

Print Copies

FINISHING MENU

Duplex

Duplex Bind

Copies

Blank Pages

Collation

Separator Sheets

Separator Source

Multipage Print

Multipage Order

Multipage View

Multipage Border

SERIAL MENU

SERIAL OPTION x

PCL SmartSwitch

PS SmartSwitch

NPA Mode

Serial Buffer

Job Buffering

RS-232/RS-422

RS-422 Polarity

Serial Protocol

Robust XON

Baud

Data Bits

Parity

Honor DSR

UTILITIES MENU

Print Menus

Print Net Setup

Print Net1 Setup

Print Net2 Setup

Print Fonts

Print Directory

Factory Defaults

Format Flash

Defragment Flash

Format Dis k

Job Acct Stat

Hex Trace

NETWORK MENU

NETWORK OPTION x

PCL SmartSwitch

PS SmartSwitch

NPA Mode

Network Buffer

Job Buffering

NETWORK x SETUP

Refer to the Administrator’s Guide for detailed information on menu

items.

SETUP MENU

Printer Language

JOB MENU

Cancel Job

CONFIDENTIAL JOB

HELD JOBS

Reset Printer

Print Buffer

Reset Active Bin

INFRARED MENU

Infrared Port

PCL SmartSwitch

PS SmartSwitch

NPA Mode

Infrared Buffer

Job Buffering

Window Size

Transmit Delay

Max Baud Rate

QUALITY MENU

Print Resolution

Toner Darkness

PQET

PictureGrade

Pow e r Saver

Resour ce Save

Download Target

Print Timeout

Wait Time out

Auto Continue

Jam Recovery

Page Protect

Print Area

Display Language

Alarm Control

Toner Alarm

Job Buffer Size

Job Accounting

Job Acct Limit

LOCALTALK MENU

LocalTalk Port

PCL SmartSwitch

PS SmartSwitch

NPA Mode

Job Buffering

LocalTalk Buffer

NPA Hosts

LocalTalk Name

LocalTalk Addr

LocalTalk Zone

PCL EMUL MENU

Font Source

Font Name

Poin t S iz e

Pitch

Symbol Set

Orientation

Lines Per Page

A4 Width

TRAY RENUMBER

Auto CR after LF

Auto LF after CR

USB MENU

PCL SmartSwitch

PS SmartSwitch

NPA Mode

USB Buffer

Job Buffering

POSTSCRIPT MENU

Print PS Error

Font Priority

FAX M ENU

Fax Port

Fax Baud

Fax Data Bits

Fax Pari ty

Fax Bu ffer

Job Buffering

Fax Paper Size

Fax Paper Type

Fax Output Bin

19Using the Operator Panel and Menus

Page 20

Choosing Print Materials

Print materials

Paper specifications

The print quality and feed reliability you get with the printer and

options can vary with the type and size of print material you use.

Guidelines are provided in this section for each type of print material. For information card stock and labels, refer to the Card Stock &

Labels Guide, located on the Drivers, MarkVision and Utilities CD.

Always print samples on the print material you are considering

before buying large quantities.

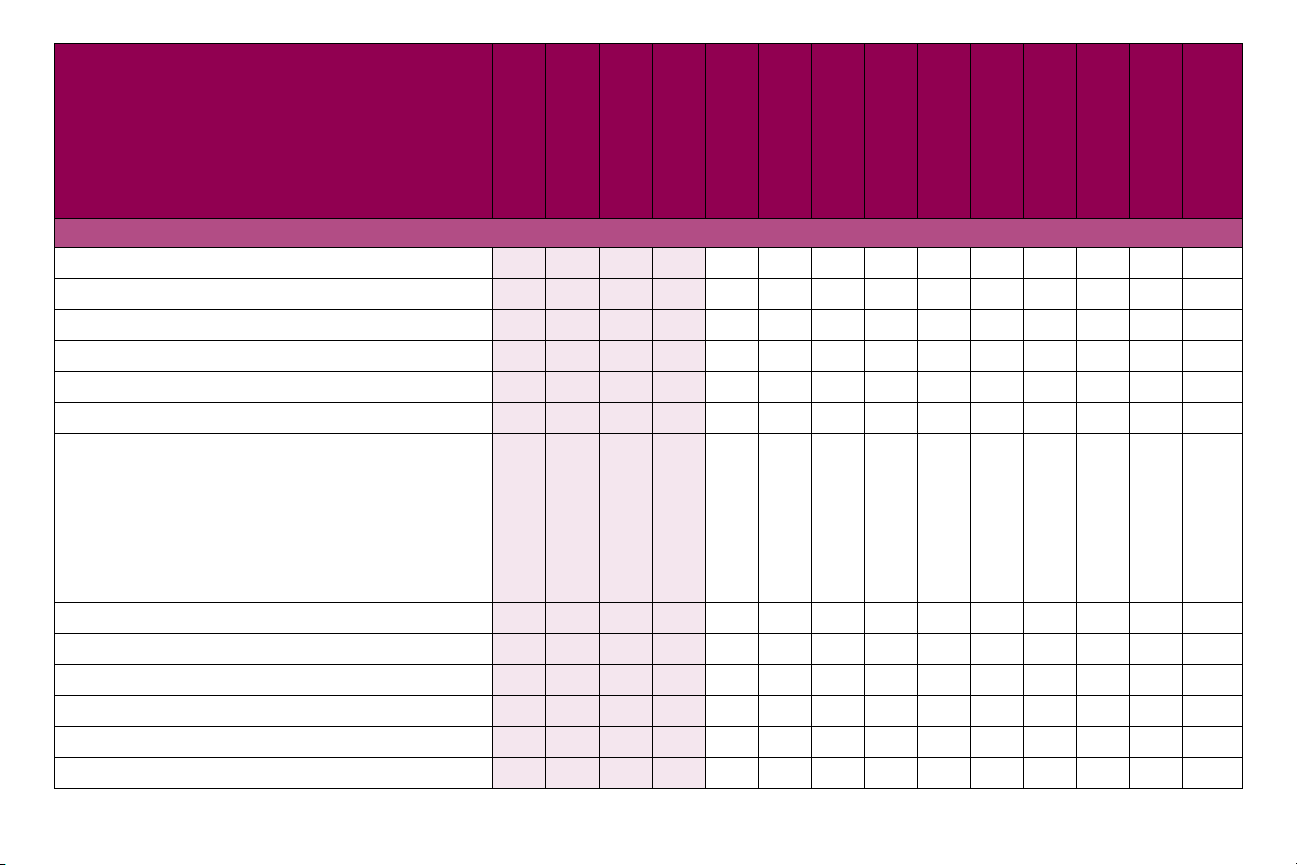

The following tables give information on standard and optional paper

sources, as well as output options, for your printer model, including

the paper sizes you can select from the PAP ER SIZE menu and sup-

ported weights.

:

N

OTE

If you use a paper size not listed, select the next larger size.

20Choosing Print Materials

Page 21

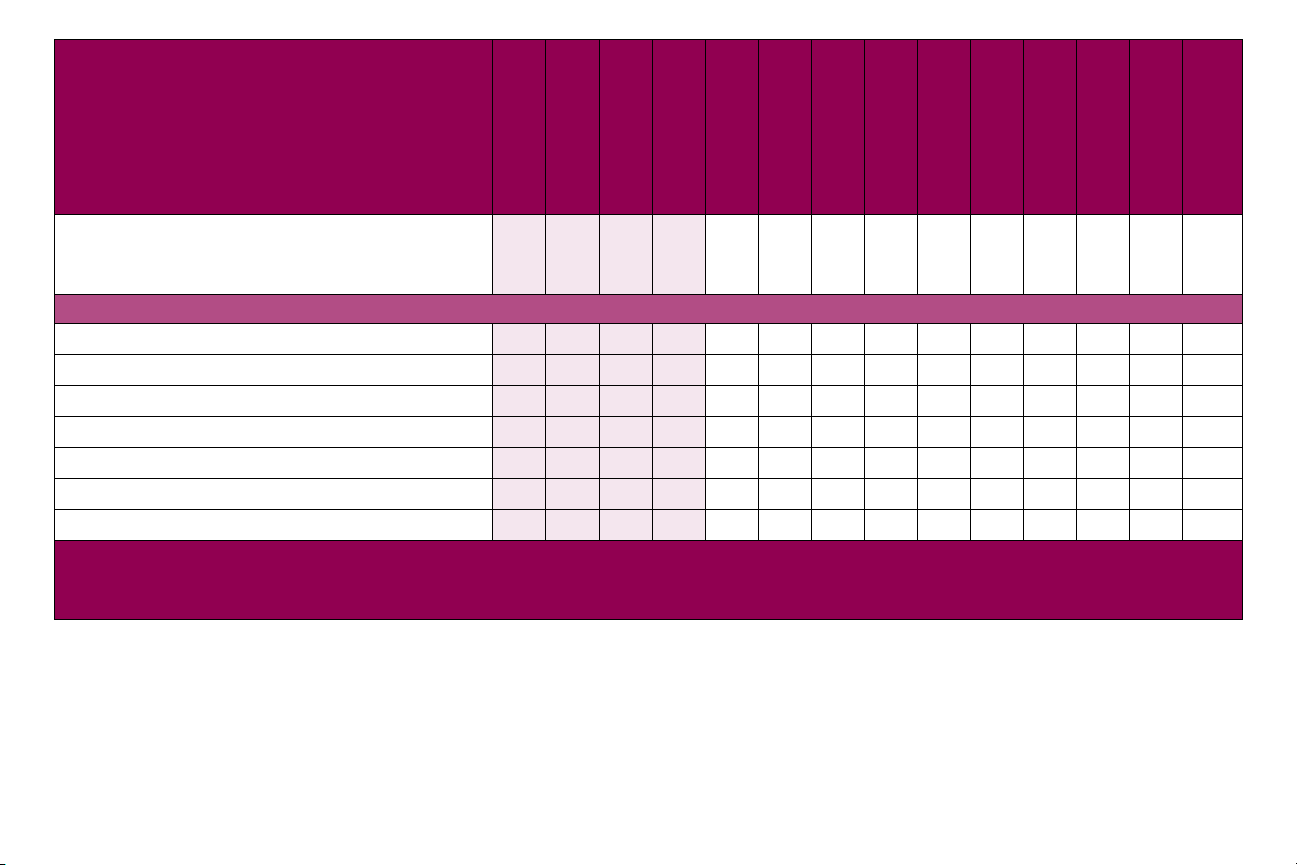

Paper Sizes and Types

Paper Sizes

210 x 297 mm (8.27 x 11.7 in.)

A4

148 x 210 mm (5.83 x 8.27in.)

A5

JIS B5

Letter

Legal

Executive

Universal

7 ¾ Envelope

9 Envelope

10 Envelope

DL Envelope

C5 Envelope

B5 Envelope

182 x 257 mm (7.17 x 10.1 in.)

215.9 x 279.4 mm (8.5 x 11 in.)

215.9 x 355.6 mm (8.5 x 14 in.)

184.2 x 266.7 mm (7.25 x 10.5 in.)

1

139.7 x 210 mm to 215.9 x 355.6 mm

(5.5 x 8.27 in. to 8.5 x 14 in.)

69.85 x 127mm to 229 x 355.6 mm

(2.75 x 5 in. to 9.01 x 14 in.)

148 x 182 mm to 215.9 x 355.6

(5.83 x 7.17 in. to 8.5 x 14 in.)

98.4 x 190.5 mm (3.875 x 7.5 in.)

98.4 x 225.4 mm (3.875 x 8.9 in.)

104.8 x 241.3 mm (4.12 x 9.5 in.)

110 x 220 mm (4.33 x 8.66 in.)

162 x 229 mm (6.38 x 9.01 in.)

176 x 250 mm (6.93 x 9.84 in.)

T616(n) standard tray

T614(n) standard tray

T612(n) standard tray

T610(n) standard tray

250-sheet drawer

500-sheet drawer

Multipurpose tray

2000-sheet drawer

Envelope feeder

Duplex unit

Standard output

Output expander

5-bin mailbox

High-capacity

output stacker

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓ ✓

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓ ✓

✓ ✓ ✓ ✓✓ ✓

✓ ✓ ✓ ✓✓✓

✓✓✓✓ ✓

✓✓✓✓ ✓

✓✓✓✓ ✓

✓✓✓✓ ✓

✓✓✓✓ ✓

✓✓✓✓

21Choosing Print Materials

Page 22

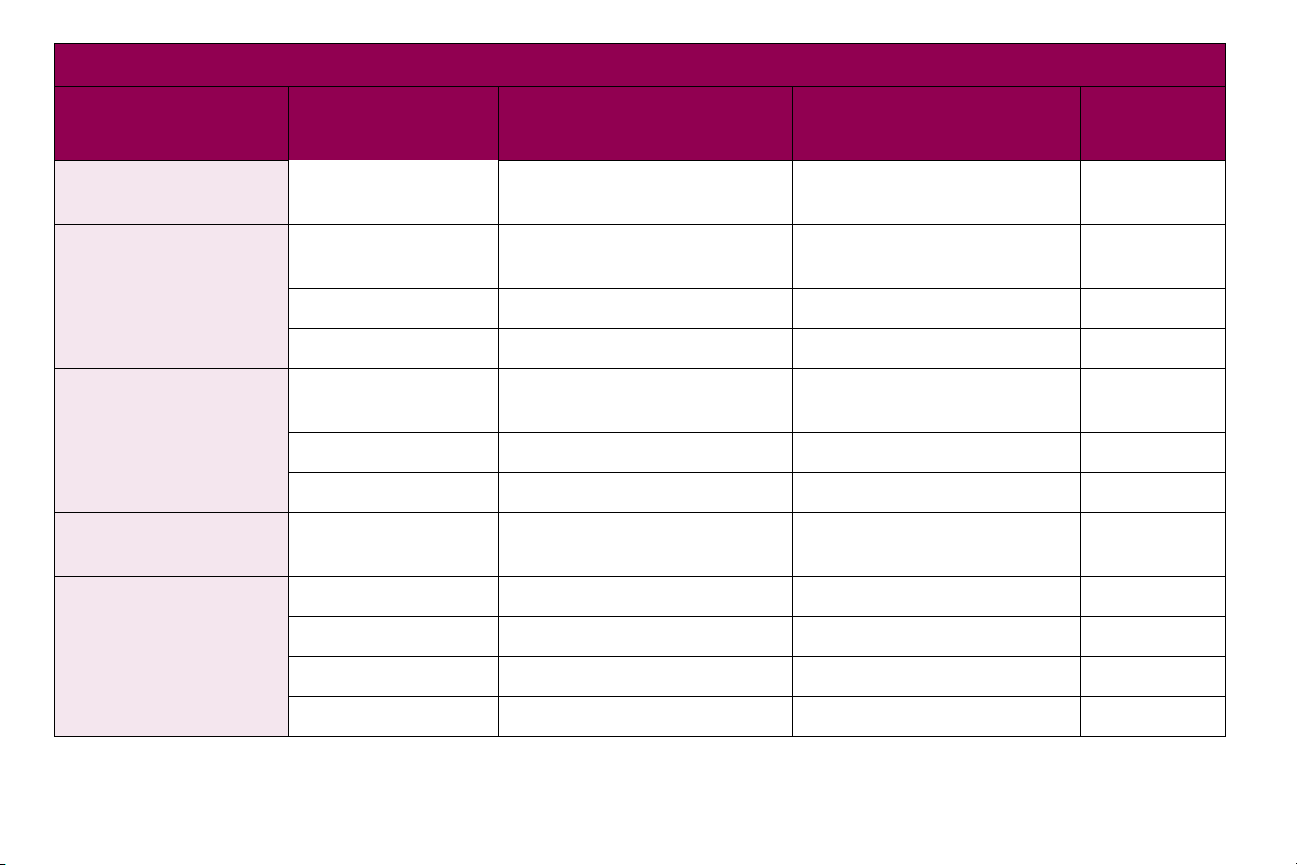

Paper Sizes and Types (Continued)

Other Envelope

98.4x162 mm to 176 x 250 mm

(3.87 x 6.38 in. to 6.93 x 9.84 in.)

1

T616(n) standard tray

T614(n) standard tray

T612(n) standard tray

T610(n) standard tray

250-sheet drawer

500-sheet drawer

Multipurpose tray

2000-sheet drawer

Envelope feeder

Duplex unit

Standard output

Output expander

5-bin mailbox

✓✓✓✓✓

Paper Types

Paper

Card stock

Transparencies

Vinyl labels

Paper labels

Polyester labels

Dual web labels

1

This size setting formats the page for 215.9 x 355.6 mm (8.5 x 14 in.) unless the size is specified by the software application.

2

Label applications require a special label fuser cleaner which precludes duplexing; the label fuser cleaner is included with a special

2

2

2

2

label cartridge for label applications. Refer to the Administrator’s Guide for information on obtaining a label fuser cleaner.

✓ ✓ ✓ ✓✓✓✓✓ ✓✓✓✓✓

✓ ✓ ✓ ✓✓✓✓ ✓✓✓ ✓

✓ ✓ ✓ ✓✓✓✓ ✓✓ ✓

✓ ✓ ✓✓✓✓ ✓✓ ✓

✓ ✓ ✓ ✓✓✓✓ ✓✓ ✓

✓ ✓ ✓ ✓✓✓✓ ✓✓ ✓

✓ ✓ ✓ ✓✓✓✓ ✓✓ ✓

High-capacity

output stacker

22Choosing Print Materials

Page 23

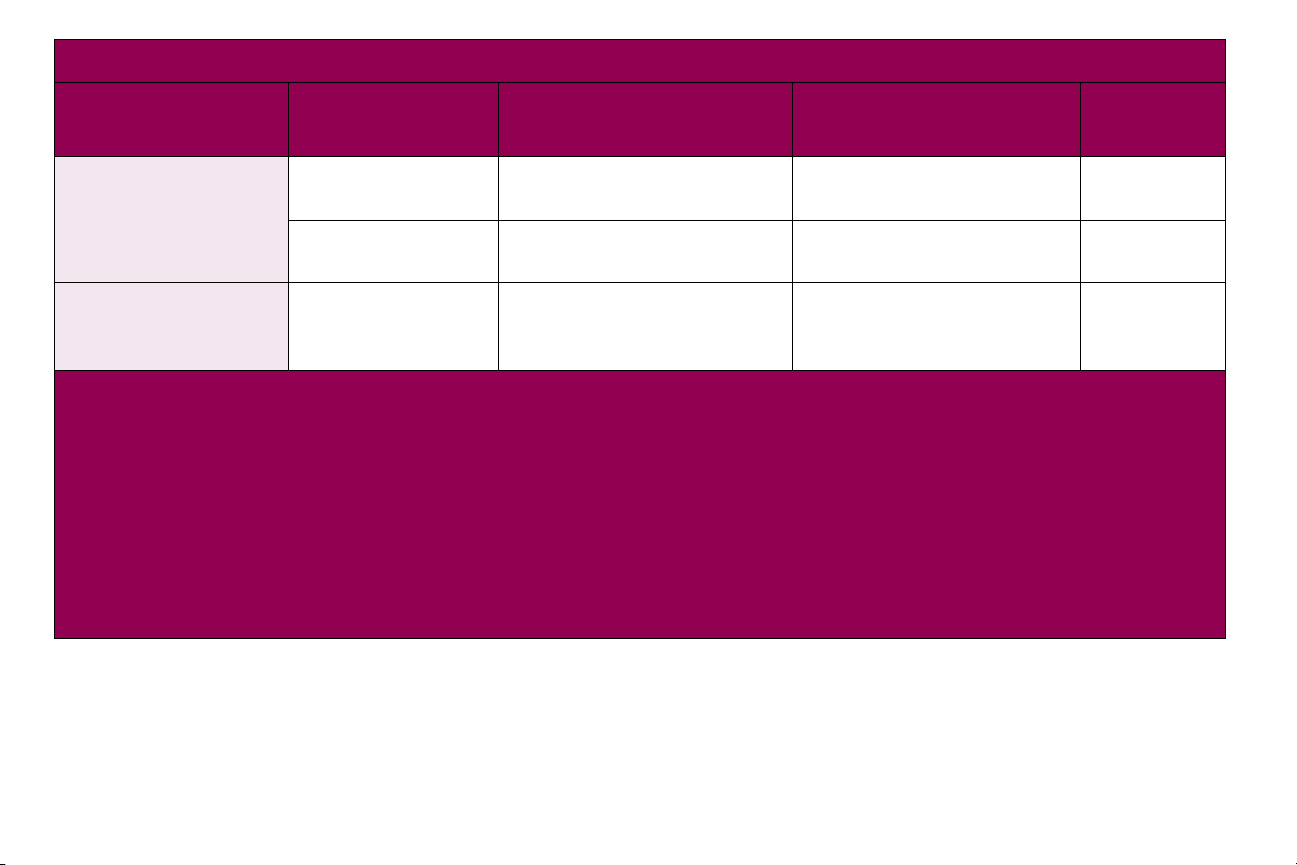

Media Weight for Paper Sources

Material Typ e

Paper

Xerographic or

business paper

Card stock-upper limit

(grain long)

1

Index Bristol 163 g/m2 (90 lb) 120 g/m2 (67 lb) N/A

Ta g 1 63 g / m2 (100 lb) 120 g/m2 (74 lb) N/A

Cover 176 g/m2 (65 lb) 135 g/m2 (50 lb) N/A

Card stock-upper limit

(grain short)

1

Index Bristol 199 g/m2 (110 lb) 163 g/m2 (90 lb) N/A

Ta g 2 03 g / m2 (125 lb) 163 g/m2 (100 lb) N/A

Cover 216 g/m2 (80 lb) 176 g/m2 (65 lb) N/A

(37 to 39 lb bond)

Laser printer

transparencies

Labels-upper limit

6

Paper 180 g/m2 (48 lb bond) 163 g/m2 (43 lb bond) N/A

Dual-web paper 180 g/m2 (48 lb bond) 163 g/m2 (43 lb bond) N/A

Polyester 220 g/m2 (69 lb bond) 220 g/m2 (69 lb bond) N/A

Vinyl

7, 8

– Integrated tray5

– Optional 500-sheet drawer

60 to 176 g/m2 grain long

(16 to 47 lb bond)

138 to 146 g/m

2

(37 to 39 lb bond)

– Multipurpose feeder

– Optional 250-sheet drawer

60 to 135 g/m2 grain long

(16 to 36 lb bond)

138 to 146 g/m

2

(37 to 39 lb bond)

Envelope

feeder

N/A

N/A

300 g/m2 (92 lb liner) 260 g/m2 (78 lb liner) N/A

23Choosing Print Materials

Page 24

Media Weight for Paper Sources (Continued)

Material Typ e

Integrated forms

Pressure sensitive

area

Paper base

(grain long)

Envelopes

Sulfite, wood-free

2

– Integrated tray5

– Optional 500-sheet drawer

140 to 175 g/m

75 to 135 g/m

(20 to 36 lb bond)

N/A 60 to 105 g/m

or up to 100%

cotton bond

Notes:

1

For 60 to 176 g/m2 paper, grain long fibers are recom-

mended; grain short is preferred for heavier papers.

2

The pressure sensitive area must enter the printer first.

3

100% cotton content maximum weight is 24 lb bond.

4

28 lb bond envelopes are limited to 25% cotton content.

5

The duplex unit supports the same weights and types as

the printer, except for transparencies and envelopes.

– Multipurpose feeder

– Optional 250-sheet drawer

2

2

140 to 175 g/m

75 to 135 g/m

2

2

Envelope

feeder

N/A

N/A

(20 to 36 lb bond)

2

(16 to 28 lb bond)

3, 4, 9

75 to 90

(20 to 24 lb

bond)

6

Dedicated label printing requires a special label fuser

cleaner which precludes duplex printing.

7

Vinyl labels are not supported by Optra T616(n).

8

Information on whether your vinyl label converter has

passed Lexmark's criteria is available at Lexmark's Web

site (www.lexmark.com); search for "converter listing”. Or

use Lexmark’s Automated FAX system (LEXFAX).

9

Envelopes fed from the multipurpose tray only.

g/m

2

24Choosing Print Materials

Page 25

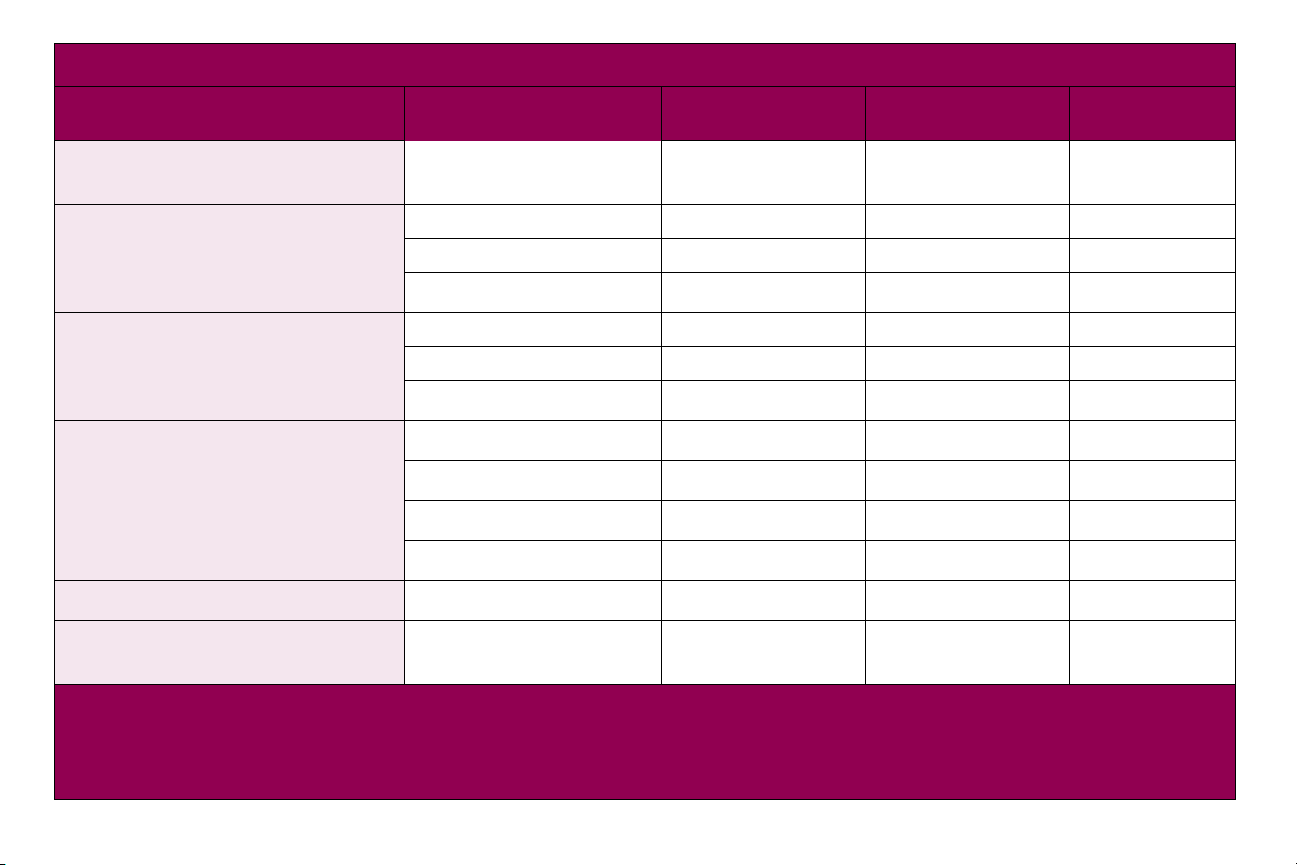

Material Type Output expander

1

3

Paper

(grain long)

Card stock-upper limit

(grain long)

Weight for Output Options

High-capacity

Xerographic or

business paper

60 to 176 g/m

(16 to 47 lb bond)

Index Bristol 163 g/m

Ta g 1 6 3 g / m

output stacker

2

60 to 176 g/m

2

(16 to 47 lb bond)

2

(90 lb) 163 g/m2 (90 lb) see note 1

2

(100 lb) 163 g/m2 (100 lb) see note 1

5-bin mailbox

60 to 120 g/m

(16 to 32 lb bond)

Cover 176 g/m2 (65 lb) 176 g/m2 (65 lb) see note 1

2

Card stock-upper limit

(grain short)

Labels-upper limit

Integrated forms

Envelopes

Not recommended.

2

Vinyl labels are not supported by Optra T616(n).

Index Bristol 199 g/m2 (110 lb) 199 g/m2 (110 lb) see note 1

Ta g 2 0 3 g / m

2

(125 lb) 203 g/m2 (125 lb) see note 1

Cover 216 g/m2 (80 lb) 216 g/m2 (80 lb) see note 1

2

Paper 180 g/m

(48 lb bond) 180 g/m2 (48 lb bond) see note 1

Dual-web paper 180 g/m2 (48 lb bond) 180 g/m2 (48 lb bond) see note 1

Polyester 220 g/m2 (69 lb bond) 220 g/m2 (69 lb bond) see note 1

2, 3

Vinyl

Sulfite, wood-free or up

300 g/m2 (92 lb liner) 300 g/m2 (92 lb liner) see note 1

175 g/m

2

175 g/m

2

see note 1

Supported Supported see note 1

to 100% cotton bond

Information on whether your vinyl label converter has

passed Lexmark's criteria is available at Lexmark's web

site (www.Lexmark.com); search for "converter listing'. Or

use Lexmark’s Automated FAX system (LEXFAX).

25Choosing Print Materials

Page 26

Print material

characteristics

Weight The printer can automatically feed paper weights from 60 to

Curl Curl is the tendency of paper to curve at its edges. If curl is exces-

For detailed information, refer to the Card Stock & Label Guide

located on the Drivers, MarkVision and Utilities CD.

The following paper characteristics affect print quality and reliability.

We recommend that you keep these guidelines in mind when evaluating new paper stock.

131 g/m2 (16 to 35 lb bond) grain long. Paper lighter than 60 g/m2

(16 lb) might not be stiff enough to feed properly, causing paper

jams. For best performance, use 75 g/m2 (20 lb bond) grain long

paper. If you want to print on print materials narrower than 182 x 257

mm (7.2 x 10.1 in.), the basis weight must be greater than or equal

to 90 g/m2 (24 lb bond).

sive, it can cause paper feeding problems. Curl usually occurs after

the paper passes through the printer, where it is exposed to high

temperatures. Storing paper unwrapped in humid conditions, even

in the paper tray, can contribute to paper curling.

Smoothness The degree of smoothness of paper directly affects print quality. If

the paper is too rough, the toner does not fuse to the paper properly,

resulting in poor print quality. If the paper is too smooth, it can cause

paper feeding problems.

26Choosing Print Materials

Page 27

Moisture content The amount of moisture in the paper affects both print quality and

the ability of the printer to feed the paper properly. Leave the paper

in its original wrapper until you are ready to use it. This limits the

exposure of the paper to moisture changes that can degrade its performance.

Grain direction Grain refers to the alignment of the paper fibers in a sheet of paper.

Grain is either grain long, running the length of the paper; or grain

short, running the width of the paper.

For 60 to 176 g/m2 (16 to 47 lb bond) paper, grain long fibers are

recommended. For papers heavier than 176 g/m2 (47 lb bond), grain

short is preferred. For the multipurpose feeder, 60 to 135 g/m2 (16 to

36 lb bond) paper, grain long fibers are recommended. For the multipurpose feeder, papers heavier than 135 g/m2 (36 lb bond) grain

short is preferred.

Fiber content Most high-quality xerographic paper is made from 100% chemically

pulped wood. This content provides the paper with a high degree of

stability resulting in fewer paper feeding problems and better print

quality. Paper containing fibers such as cotton possess characteristics that can result in degraded paper handling.

27Choosing Print Materials

Page 28

Paper guidelines

To help avoid paper jams or poor print quality:

• Always use new, undamaged paper.

• Do not use paper that you have cut or trimmed yourself.

• Do not mix paper sizes, weights, or types in the same paper

source since mixing results in paper jams.

• Do not use coated papers.

• Do not forget to change the Paper Size setting when you use a

source that does not support auto size sensing.

• Make sure the Paper Type, Paper Texture, and Paper Weight

settings are correct (refer to the Administrator’s Guide for

detailed information about these settings).

• Make sure the media is properly loaded in the paper source.

28Choosing Print Materials

Page 29

Recommended papers To ensure the best print quality and feed reliability, use 75 g/m

(20 lb) xerographic paper. Business papers designed for general

business use may also provide acceptable print quality.

Always print several samples before buying large quantities of any

type of paper. When choosing any papers, consider the weight, fiber

content, and color of the paper.

The laser printing process heats paper to high temperatures of

212oC (414oF). Use only papers that are able to withstand these

temperatures without discoloring, bleeding, or releasing hazardous

emissions. Check with the manufacturer or vendor to determine

whether the paper you’ve chosen is acceptable for laser printers.

2

29Choosing Print Materials

Page 30

Preprinted forms and letterhead Use the following guidelines when selecting preprinted forms and

letterhead paper for the printer:

Use grain long papers for best results.

•

Use only forms and letterhead printed using an offset litho-

•

graphic or engraved printing process.

Choose papers that absorb ink, but do not bleed.

•

Avoid papers with rough or heavily textured surfaces.

•

Use papers printed with heat-resistant inks designed for use

•

in xerographic copiers. The ink must withstand temperatures

of 212oC (414oF) without melting or releasing hazardous

emissions. Use inks that are not affected by the resin in the

toner or the silicone in the fuser. Inks that are oxidation-set or

oil-based should meet these requirements. Latex inks might

not meet these requirements. If you are in doubt, contact your

paper supplier.

30Choosing Print Materials

Page 31

Unsatisfactory papers The following papers are not recommended for use with the printer:

Some chemically treated papers used to make copies without

•

carbon paper, also known as carbonless papers

Coated papers (erasable bond)

•

Multiple-part forms or documents

•

Preprinted papers that require a registration (the precise print

•

location on the page) greater than ±0.09 in., such as optical

character recognition (OCR) forms. In some cases, you can

adjust registration with your software application to successfully print on these forms.

Preprinted papers with chemicals that may contaminate the

•

printer

Preprinted papers that can be affected by the temperature in

•

the printer fuser

Rough-edged or curled papers

•

Synthetic papers

•

Thermal papers

•

Less than 75 g/m

•

Recycled papers containing more than 25% post consumer

•

2

(20 lb) recycled paper

waste that do not meet DIN 19 309

31Choosing Print Materials

Page 32

Storing paper Properly storing the paper you buy helps ensure trouble-free print-

ing. Use the following guidelines:

For best results, store paper in an environment where the

•

temperature is approximately 21oC (70oF) and the relative

humidity is 40%.

Store cartons of paper on a pallet or shelf, rather than directly

•

on the floor.

If you store individual packages of paper out of the original

•

carton, make sure they rest on a flat surface so the edges do

not buckle or curl.

Do not place anything on top of the paper packages.

•

32Choosing Print Materials

Page 33

Envelope guidelines

When printing on envelopes:

• Use only new, undamaged envelopes.

• Make sure the glue is not exposed.

• Remember that a combination of high humidity (over 60%)

and the high printing temperatures may seal the envelopes.

• Be sure to select Env Feeder or MP Feeder as the paper

source and set the correct envelope size.

The laser printing process heats envelopes to a temperature of

200oC (392oF). Use only envelopes that are able to withstand these

temperatures without sealing, excessive curling, wrinkling, or releasing hazardous emissions. If you have any doubts about the envelopes you are considering using, check with the envelope supplier.

For best performance, use envelopes made from 75 g/m2 (20 lb

bond) paper. You can use up to 105 g/m2 (28 lb bond) weight for the

multipurpose feeder or 105 g/m2 (28 lb bond) weight for the envelope feeder as long as the cotton content is 25% or less. Envelopes

with 100% cotton content must not exceed 90 g/m

2

(24 lb bond)

weight.

33Choosing Print Materials

Page 34

To minimize jams, do not use envelopes that:

Have excessive curl or twist

•

Are stuck together

•

Are damaged in any way

•

Contain windows, holes, perforations, cutouts, or embossing

•

Use metal clasps, string ties, or metal folding bars

•

Have an interlocking design

•

Have postage stamps attached

•

Have any exposed adhesive when the flap is in the sealed or

•

closed position

Have nicked edges or bent corners

•

Have rough, cockle, or laid finishes

•

34Choosing Print Materials

Page 35

Label guidelines

The printer can print on many labels designed for use with laser

printers. These labels are supplied in letter-size and A4-size sheets.

When printing on labels:

• Be sure to select Labels in the PA P ER TYPE menu in the

PA PE R MENU (refer to the Administrator’s Guide for detailed

information about these settings).

• Do not load labels together with paper or transparencies in

the same paper tray; combining print materials can cause

feeding problems.

• Do not load partial sheets with areas exposed by missing

labels; this can cause labels to peel off during printing, resulting in a paper jam and contamination of your printer and your

cartridge with adhesive, and could void your printer and cartridge warranties.

• Avoid using labels that may release hazardous emissions

when heated.

:

N

OTE

Labels are one of the most difficult print materials for laser

printers. A special fuser cleaner should be used for label

applications to optimize feed reliability. Refer to the

Administrator’s Guide for information on obtaining a label

fuser cleaner.

35Choosing Print Materials

Page 36

After continuously printing approximately 10,000 page sides of

labels (or each time you replace the print cartridge), complete the

following steps to maintain printer feeding reliability:

1 Print 5 sheets of paper.

2 Wait approximately 5 seconds.

3 Print 5 more sheets of paper.

For detailed information on label printing, characteristics, and

design, refer to the Card Stock & Label Guide, available on the Driv-

ers, MarkVision and Utilities CD or the Lexmark Web site, at

www.lexmark.com.

36Choosing Print Materials

Page 37

Card stock guidelines

Card stock is single ply, and has a large array of properties. The orientation of paper fibers, moisture content, thickness, and texture

can all affect printing on card stock. See page 23 for information on

the preferred weight for the grain direction of print materials.

When printing on card stock:

• Be sure to select Card Stock in the PAP ER TYPE menu in the

PA PE R MENU (refer to the Administrator’s Guide for detailed

information about these settings).

• Be aware that preprinting, perforation, and creasing can sig-

nificantly affect the print quality and cause paper handling or

jamming problems.

• Avoid using card stock that may release hazardous emissions

when heated.

37Choosing Print Materials

Page 38

After printing approximately 10,000 page sides of card stock (or

each time you replace the print cartridge), complete the following

steps to maintain printer feeding reliability:

1 Print 5 sheets of paper.

2 Wait approximately 5 seconds.

3 Print 5 more sheets of paper.

For more information, refer to the Card Stock & Label Guide, avail-

able on the Drivers, MarkVision and Utilities CD or the Lexmark

Web site, at www.lexmark.com.

38Choosing Print Materials

Page 39

Transparency guidelines

The printer can print directly on transparencies designed for use in

laser printers. Print quality and durability depend on the transparency used. Always print samples on the transparencies you are considering before buying large quantities.

The Paper Type setting should be set to Transparency to help pre-

vent jams (refer to the Administrator’s Guide for detailed information

about this setting). Check with the manufacturer or vendor to determine whether your transparencies are usable with laser printers that

heat transparencies to 180oC (356oF) or 212oC (414oF), depending

on the setting. Use only transparencies that are able to withstand

these temperatures without melting, discoloring, offsetting, or

releasing hazardous emissions. For detailed information, refer to the

Card Stock & Label Guide, which is available on the Drivers,

MarkVision and Utilities CD.

Transparencies can be fed automatically from the multipurpose

feeder and all standard and optional trays, except the 2000-sheet

drawer, for all printer models.

Be careful when you handle transparencies. Fingerprints on the surface of the transparency cause poor print quality.

39Choosing Print Materials

Page 40

Tray linking

Tray linking enables the automatic linking feature for trays when you

use the same size and type of print material in multiple paper

sources (trays).

For example, if you have loaded two optional trays with the same

size print material and both are set to the same paper type; then

when one tray becomes empty, the printer automatically selects

print material from the other tray since the printer sees the trays as

linked.

If you use different print material in the trays, each source with a different print material must have the PAPER TYPE set to a unique

value to disable the automatic linking feature (refer to the Adminis-

trator’s Guide for detailed information about tray linking). For exam-

ple, if you did not make sure all trays have the same type when they

are linked, you could send a report to print and if you have letterhead paper loaded into one tray, you could print the report on letterhead paper.

40Choosing Print Materials

Page 41

Paper loading

Proper paper loading helps prevent paper jams and ensure troublefree printing.

Do not remove paper trays while a job is printing or

played on the operator panel. Doing so may cause a paper jam.

Before loading paper, you need to know the recommended print

side of the paper you’re using. This information is usually indicated

on the paper package.

If you want to load the:

“Paper tray” go to page 44

“Multipurpose feeder” go to page 47

“Envelope feeder” go to page 61

“2000-sheet drawer” go to page 68

Busy

is dis-

41Choosing Print Materials

Page 42

Tips for avoiding paper jams

By carefully selecting print materials and loading them properly, you

should be able to avoid most paper jams. If jams do occur, follow the

steps outlined in “Clearing Jams” starting on page 69. If jams occur

frequently, make sure you are following these tips to avoid jams.

• See “Loading Print Materials” on page 43 to load paper prop-

erly. Make sure the adjustable guides are positioned correctly.

• Do not overload the paper trays. Make sure the paper is under

the paper capacity mark on the inside of the paper tray.

• Do not remove paper trays while print jobs are in process.

• Flex, fan, and straighten the paper before loading it.

• Fan stacks of labels or transparencies before loading them

into trays or the multipurpose feeder. If jams do occur using

the multipurpose feeder, try feeding one sheet at a time.

• Do not load wrinkled, creased, damp, or highly curled paper.

• Do not mix paper types in one tray.

• Use only recommended print materials. See “Print materials”

on page 20.

• Make sure the recommended print side is face down for sim-

plex printing when loading all trays.

• Keep print materials stored in an acceptable environment.

See “Moisture content” on page 27.

42Choosing Print Materials

Page 43

Loading Print Materials

This section provides information about loading the various input

options. For information on a particular option, click the option

name:

“Paper tray” on page 44

•

“Multipurpose feeder” on page 47

•

“Envelope feeder” on page 61

•

“2000-sheet drawer” on page 68

•

43Loading Print Materials

Page 44

Length guide

lever

Paper size

indicators

Paper tray

Squeeze here

Length

guide

Complete these instructions to load print materials into any of the

standard or optional trays. All paper trays are loaded the same way.

1 Remove the paper tray.

2 Squeeze the width guide lever and slide the width guide to the

far right side of the tray.

3 Squeeze the length guide lever and slide the length guide to

the correct position for the size paper you are loading.

Width

guide

44Loading Print Materials

Page 45

. 4

Squeeze

here

Paper capacity

mark

Width

guide

Place the paper into the paper tray with the recommended

print side face down for single-sided printing and face up for

double-sided printing.

capacity mark (fill line)

Squeeze the width guide lever and slide the width guide to the

5

Do not fill paper above the paper

.

left until it lightly rests against the edge of the paper stack.

Adjust the knob to show the size of the paper currently

6

loaded.

Knob

N

OTE

This setting serves as a visual reminder only; it

:

has no effect on the operation of the printer.

Reinstall the tray.

7

45Loading Print Materials

Page 46

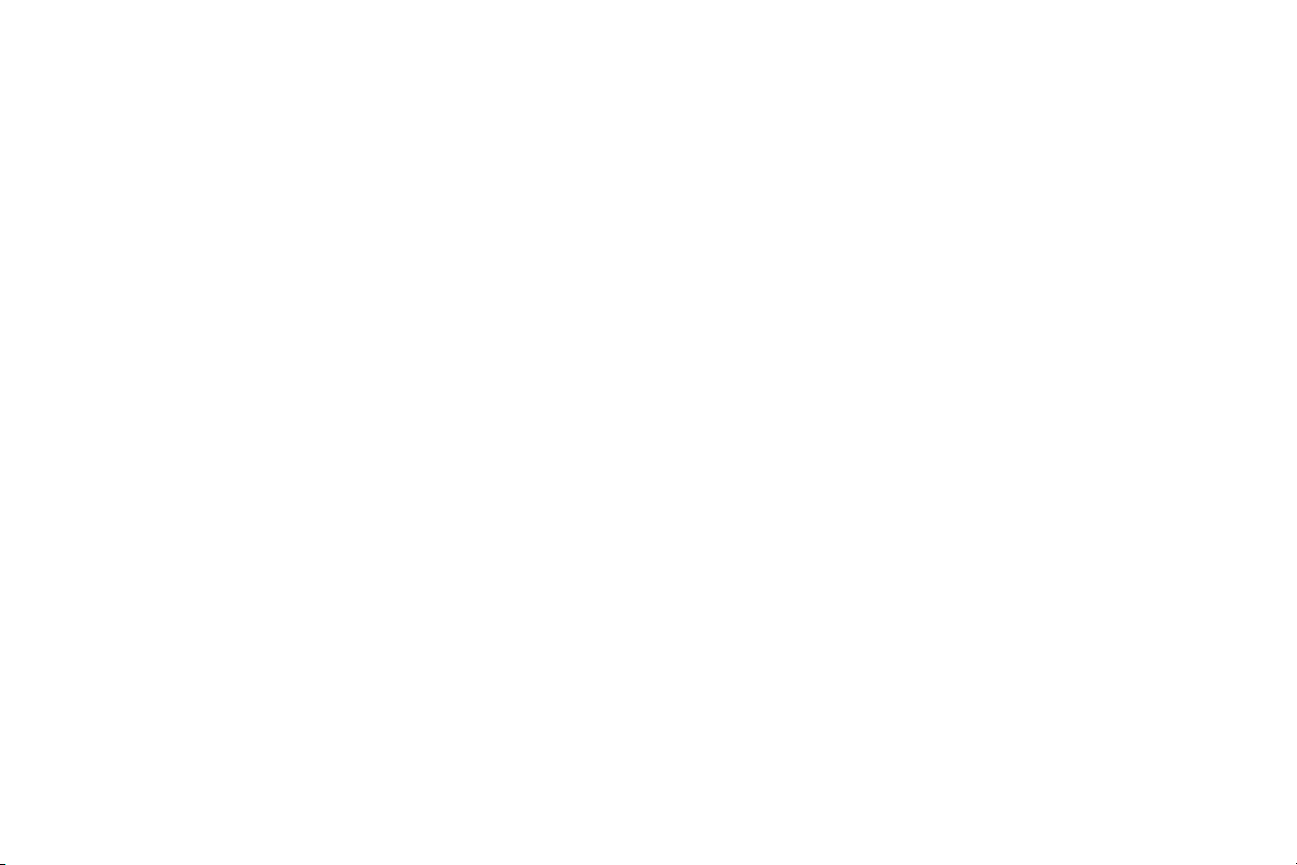

Loading letterhead paper

For

simplex

printed design side

(single-sided) printing on letterhead paper, place the

face down

with the top edge of the page nearest

the knob for the paper size indicator.

For

side

N

OTE

duplex

face up

printing on letterhead paper, place the printed design

with the top of the page nearest the length guide.

The printer has a

:

Paper Loading

menu setting that allows

simplex (single-sided) printing on letterhead (or other

preprinted media) that has been

printing

Guide

. For more information, refer to the

.

loaded specifically for duplex

Administrator’s

46Loading Print Materials

Page 47

Multipurpose feeder

The multipurpose feeder can hold several sizes and types of paper,

such as transparencies, post cards, note cards, and envelopes. It is

useful for single page printing on letterhead, colored paper, or other

special paper.

Multipurpose feeder guidelines

Capacity

The maximum stack height for any print material is 10 mm (0.4 in.).

The multipurpose feeder can hold about:

100 sheets of 75 g/m2 (20 lb) paper

•

12 envelopes

•

75 transparencies

•

Print material dimensions

The multipurpose feeder accepts only print material within the following dimensions:

Width –

•

Length –

•

69.85 mm (2.75 in.) to 229 mm (9.01 in.)

127 mm (5 in.) to 355.6 mm (14 in.)

47Loading Print Materials

Page 48

Trouble-free operation

•

Load only one size of paper or envelopes at a time in the multipurpose feeder.

• To achieve the best possible print quality, use only high-quality

print media that is designed for use in laser printers. For more

guidelines on paper, see “Print materials” on page 20.

• To prevent paper jams, do not add paper when there is still

paper in the multipurpose feeder. This applies to other types

of print materials, too.

• Print material should be loaded face up with the top of the

print material going into the multipurpose feeder first.

• Do not place objects on the multipurpose feeder. Also, avoid

pressing down or applying excessive force on it.

:

N

OTE

The multipurpose feeder may be used with the optional

envelope feeder installed.

48Loading Print Materials

Page 49

Opening the

multipurpose feeder

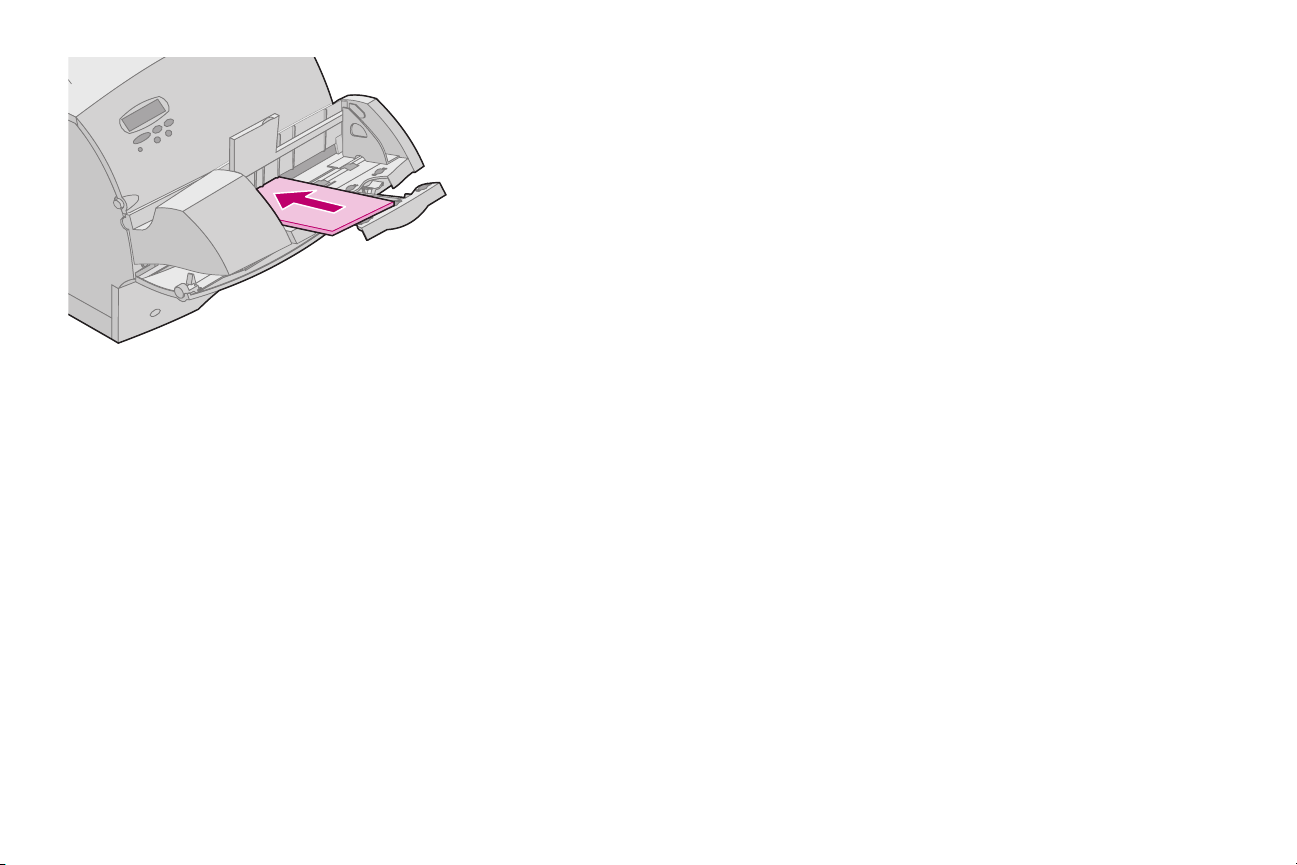

1

Push the lower release latch as shown. The multipurpose

feeder door drops open and stops in place.

2 Locate the metal bar in the recessed area on the

multipurpose feeder and pull it out far enough to accomodate

the paper you will be using.

49Loading Print Materials

Page 50

Loading the

multipurpose feeder

Proper loading helps prevent paper jams and ensure trouble-free

printing.

Do not remove any paper tray while a job is printing from the multipurpose feeder or

may cause a paper jam.

Never add print materials to the multipurpose feeder while the

printer is printing from the multipurpose feeder. Doing so may cause

a paper jam.

Before loading paper, you need to know the recommended print

side of the paper you are using. This information is usually indicated

on the paper package.

is displayed on the operator panel. Doing so

Busy

50Loading Print Materials

Page 51

1 Notice the icons on the multipurpose feeder surface. These

icons show you how to load the multipurpose feeder with

paper, how to turn an envelope for printing, and how to load

letterhead paper for simplex and duplex printing.

Simplex

Letterhead

Duplex

Letterhead

Envelope

N

OTE

The printer has a

:

Paper Loading

menu setting

that allows simplex (single-sided) printing on

letterhead (or other preprinted media) that has

been loaded specifically for duplex printing. For

more information, refer to the Administrator’s

Guide.

2 Slide the colored paper width guide to the far right on the

multipurpose feeder.

51Loading Print Materials

Page 52

3 Prepare the print material for loading.

For paper and envelopes:

.

–

Flex paper or fan envelopes back and forth. Do not fold or

crease the paper. Straighten the edges on a level surface.

N

OTE

If envelopes jam while printing, try reducing the

:

number of envelopes in the multipurpose feeder.

For transparencies:

–

Hold the transparencies by the edges and avoid touching

the print side. Fan the stack of transparencies to prevent

feeding failures. Be careful not to scratch or leave fingerprints on the print sides.

52Loading Print Materials

Page 53

. 4

Stack height limiter

Use the print materials stack height limiter as a guide for stack

height when loading print materials.

Load one type of print material in the multipurpose feeder.

5

mix types. See the following directions to load each type

not

of print material.

– “Paper” on page 54

– “Envelopes” on page 55

– “Transparencies” on page 56

– “Letterhead (Single-sided printing)” on page 57

– “Letterhead (Duplex printing)” on page 57

Do

53Loading Print Materials

Page 54

Paper

Load paper with the left edge of the stack against the stack

height limiter and with the recommended print side face up.

For information on selecting paper, see “Paper guidelines” on

page 28.

54Loading Print Materials

Page 55

Envelopes

Load envelopes with the flap side down. The stamp area and

flap are on the left side. The end of the envelope with the

stamp area enters the multipurpose feeder first.

:

N

OTE

Do not feed stamped envelopes. The stamp is

shown for placement only.

W

ARNING

:

Never use envelopes with clasps, snaps, windows,

coated linings, or self-stick adhesives. These

envelopes may severely damage the printer.

For information on printing on envelopes, see “Envelope

guidelines” on page 33.

55Loading Print Materials

Page 56

Transparencies

Load transparencies with the left edge of the stack against the

stack height limiter.

For information on printing on transparencies, see “Transpar-

ency guidelines” on page 39.

56Loading Print Materials

Page 57

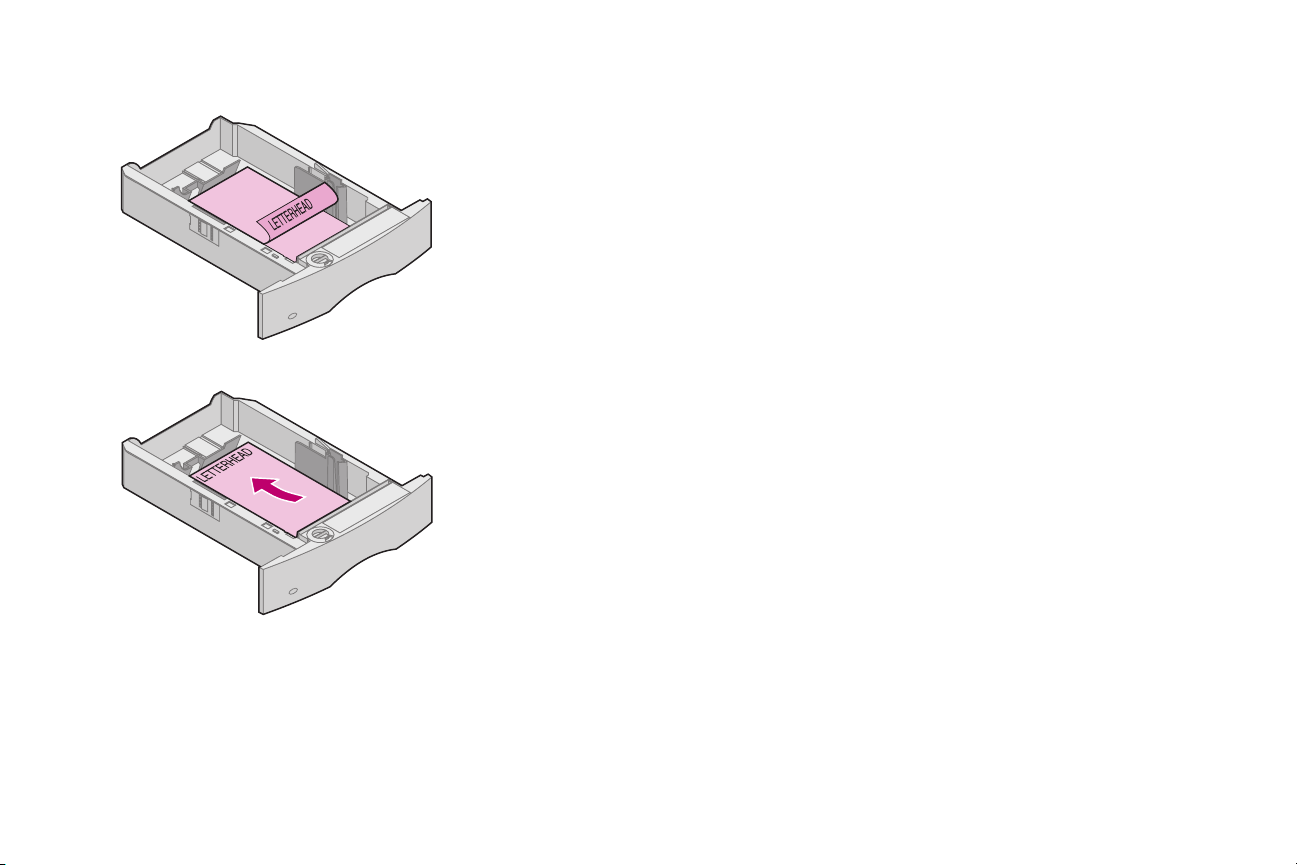

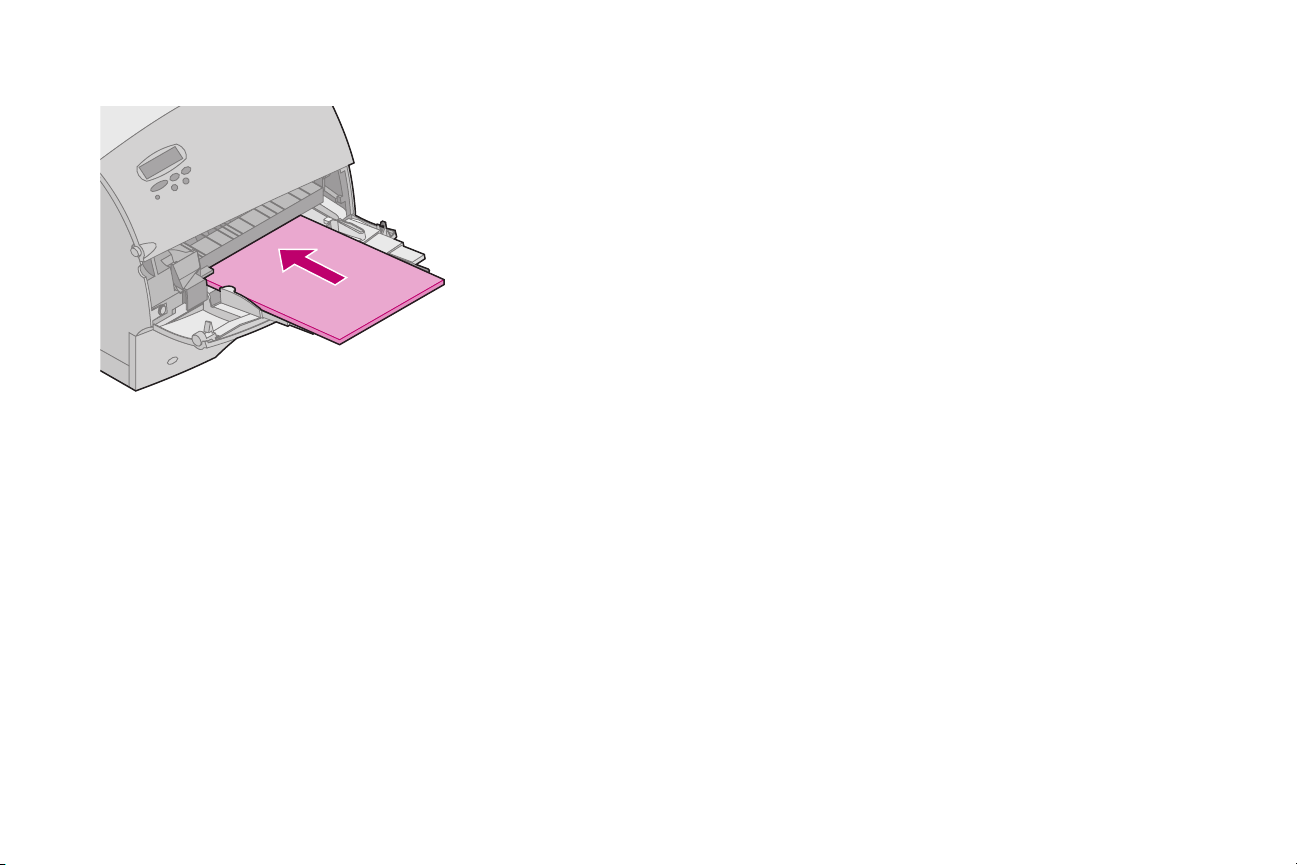

Letterhead (Single-sided printing)

Load letterhead paper for single-sided printing with the design

face up. The top edge of the sheet with the logo should enter

the printer first.

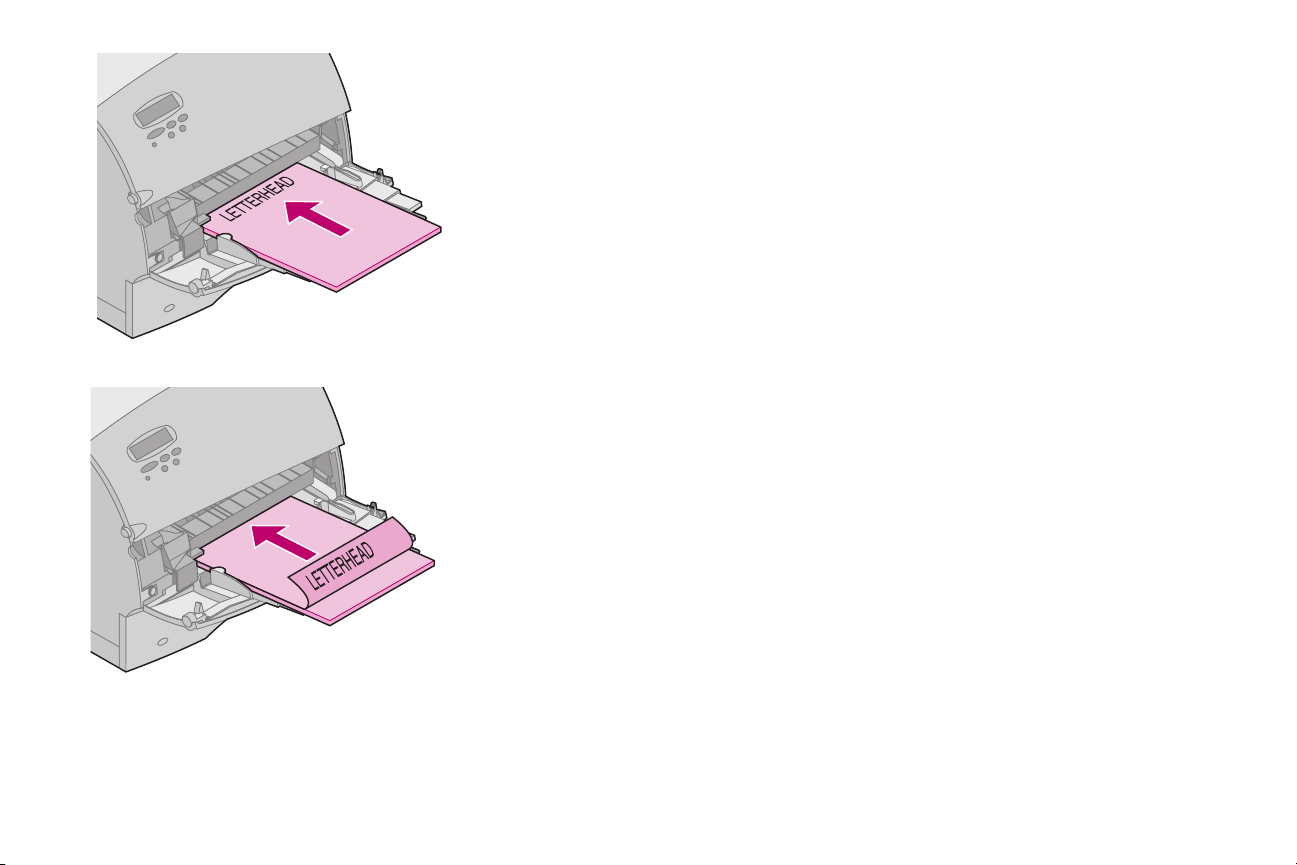

Letterhead (Duplex printing)

Load letterhead paper for duplex printing with the design face

down. The top edge of the sheet with the logo should enter

the printer last.

:

N

OTE

See “Choosing Print Materials” on page 20 for

information on selecting types of print materials.

N

:

OTE

The printer has a

Paper Loading menu setting

that allows simplex (single-sided) printing on

letterhead (or other preprinted media) that has

been loaded specifically for duplex printing. For

more information, refer to the Administrator’s

Guide.

57Loading Print Materials

Page 58

6 Slide the print material into the multipurpose feeder as far as it

will go. Do not force it. Forcing causes buckling of the print

material.

7 Make sure you have not loaded too much print material. The

stack should fit loosely under the stack height limiter. The

print material buckles if you load a stack that is too deep or

push the stack in too far.

8 Slide the paper width guide to the left until it lightly touches

the stack of print material. Do not bend the print material.

58Loading Print Materials

Page 59

Using the multipurpose feeder After loading print material in the multipurpose feeder, select the

paper source from your software application, and then select the

paper size and type from both your software application and from

the printer operator panel.

To set the printer operator panel:

1 Make sure the

Feeder Size)

is set to the correct size paper, envelope, or other

PAP E R SIZE

for the multipurpose feeder

(MP

print material you are loading (refer to the Administrator’s

Guide for detailed information about this setting).

2 Make sure the

Feeder Typ e

) is set to the correct value for the print material

PAP E R TYPE

for the multipurpose feeder (

you are loading (refer to the Administrator’s Guide for detailed

information about this setting).

3 Press

N

OTE

to return to

Go

Software settings may override operator panel

:

Ready

.

settings.

MP

59Loading Print Materials

Page 60

Closing the multipurpose feeder

Remove print material from the multipurpose feeder.

1

2 Push the metal bar straight back to collapse the multipurpose

feeder to its short-length position.

3 Close the multipurpose feeder door.

60Loading Print Materials

Page 61

Envelope feeder

Guidelines

Load only one size of envelopes at a time in the envelope

•

feeder.

To achieve the best possible print quality, use only high-quality

•

print material that is designed for use in laser printers. For

more information, see “Envelope guidelines” on page 33.

Do not place objects on the envelope feeder. Also, avoid

•

pressing down or applying excessive force on it.

61Loading Print Materials

Page 62

Loading the envelope feeder The envelope support has three positions:

Fully closed (pushed in toward printer) for short envelopes

•

Extended to the middle position for medium-length envelopes

•

Fully open (extended to its full length) for long envelopes

•

1 Gently adjust the envelope support for the size you are

loading.

62Loading Print Materials

Page 63

2 Slide the attached envelope weight up.

3 Flip the envelope weight over and back toward the printer. It

stays in place.

4 Slide the envelope edge guide to the far right.

63Loading Print Materials

Page 64

5 Flex a stack of envelopes back and forth.

6 Straighten the edges on a level surface. Press down the

corners to flatten them. Fan the envelopes. This prevents the

edges of the envelopes from sticking together and helps them

feed properly.

N

OTE

When you load envelopes, do not exceed the

:

maximum stack height of 64.7 mm (2.55 in.).

The envelope feeder holds a maximum of 85

2

envelopes (75 g/m

, 20 lb bond).

64Loading Print Materials

Page 65

7 Load the stack of envelopes with the address side up and flap

side down. The flap side edge of the envelope should be

facing the left side of the envelope feeder. Make sure the

envelopes at the bottom of the stack slide into the envelope

feeder slightly more than the ones at the top of the stack.

N

OTE

N

OTE

W

ARNING

Do not try to load more envelopes by forcing

:

them under the envelope feeder weight. This

results in jams.

Do not feed stamped envelopes.

:

Never use envelopes with clasps, snaps, windows,

:

coated linings, or self-stick adhesives. These

envelopes may severely damage the printer. See

“Envelope guidelines” on page 33 for more

information.

65Loading Print Materials

Page 66

8 Slide the envelope edge guide to the left until it lightly touches

the side of the stack. Make sure the envelopes do not buckle.

9 Rotate the envelope weight back toward you and lower it to

the stack.

66Loading Print Materials

Page 67

Using the envelope feeder After loading envelopes in the envelope feeder, select the paper

source from your software application, and then select the paper

size and type from both your software application and from the

printer operator panel.

To set the printer operator panel:

1 Make sure the

Feeder Size

) is set to the correct envelope size you are

PAP E R SIZE

for the envelope feeder (

Env

loading (refer to the Administrator’s Guide for detailed

information about this setting)

2 Press

N

OTE

to return to

Go

Software settings may override operator panel

:

Ready

.

.

settings.

If the printer experiences an envelope jam while printing, see “260

Paper Jam Check Env Feeder” on page 96 for information on how to

clear the jam.

67Loading Print Materials

Page 68

2000-sheet drawer

For information on loading the 2000-sheet drawer, refer to the

2000-Sheet Drawer User’s Guide.

68Loading Print Materials

Page 69

Clearing Jams

By carefully selecting print materials and loading them properly, you

should be able to avoid most paper jams. If paper jams do occur, follow the steps outlined in this section. If paper jams occur frequently,

make sure you see “Tips for avoiding paper jams” on page 42.

To resolve the paper jam attendance messages, you must clear all

paper from the paper path.

Press Go

page that jammed if

Auto setting does not guarantee the page will print.

to resume printing. The printer prints a new copy of the

Jam Recovery is set to On or Auto; however, the

Possible paper jam areas

“Paper jam areas” on page 70 shows the path the paper travels

through the printer and the options. The path varies depending on

the paper source and paper exit selection (output bin). The jam

areas are shown, too.

69Clearing Jams

Page 70

Paper jam areas

Note:

If a jam occurs in the

multipurpose feeder, you receive a

250 Paper Jam

message. The

shown here for a jam in the optional

envelope feeder. Both types of jams

occur in the same manner.

attendance

260 Paper Jam

is

201 Paper Jam

200 Paper Jam

260 Paper Jam

Note: 27x Paper Jam

any output option: output expanders

(shown in illustration), 5-bin

mailboxes, or high-capacity output

stacker. x indicates the output option

depending on how many you

installed. Jam areas shown may

occur in any output option.

27x Paper Jam

202 Paper Jam

may occur in

Note: 24x Paper Jam

occur in any of the paper trays,

including the 2000-sheet

drawer. x indicates the tray

depending on how many trays

are installed. Jams can occur

between 2 or 3 trays, on the

incline surface of a tray, or

between a tray, the duplex unit,

and the printers integrated tray.

may

250 Paper Jam

230 Paper Jam

24x Paper Jam

230 Paper Jam

70Clearing Jams

Page 71

Accessing paper

jam areas

Rear door of:

5-bin mailbox,

output expander,

high-capacity

output stacker

(not shown)

Printer rear door

You open doors and covers, remove paper trays, and remove

options to access paper jam areas. If your printer has a multipurpose feeder, it is visible when the lower front door is opened. See

the following illustration for the location of paper sources and possible paper jam areas.

Upper front door

Envelope feeder

Duplex rear door

Lower front door

(down when envelope

feeder is installed)

Integrated input tray

Duplex front access

cover

Paper trays

71Clearing Jams

Page 72

200 and 201 Paper Jam

Remove Cartridge

A 200 attendance message indicates the paper is jammed in the

area under the print cartridge. This requires removing the print cartridge from the printer. With a 201 attendance message, the jam is

farther back in the printer, so you need to reach in farther to grasp

the paper.

N

: To resolve the paper jam attendance messages, you must

OTE

clear all paper from the paper path.

1

Open the upper and lower front doors of the printer.

2

While grasping the print cartridge by the hand grip, pull the

print cartridge up toward the upper front door, and then pull it

straight out toward you. Lay it aside.

N

: Do not leave the print cartridge exposed to light

OTE

for extended periods.

C

AUTION

: The rear portion of the inside of the printer is hot.

72Clearing Jams

Page 73

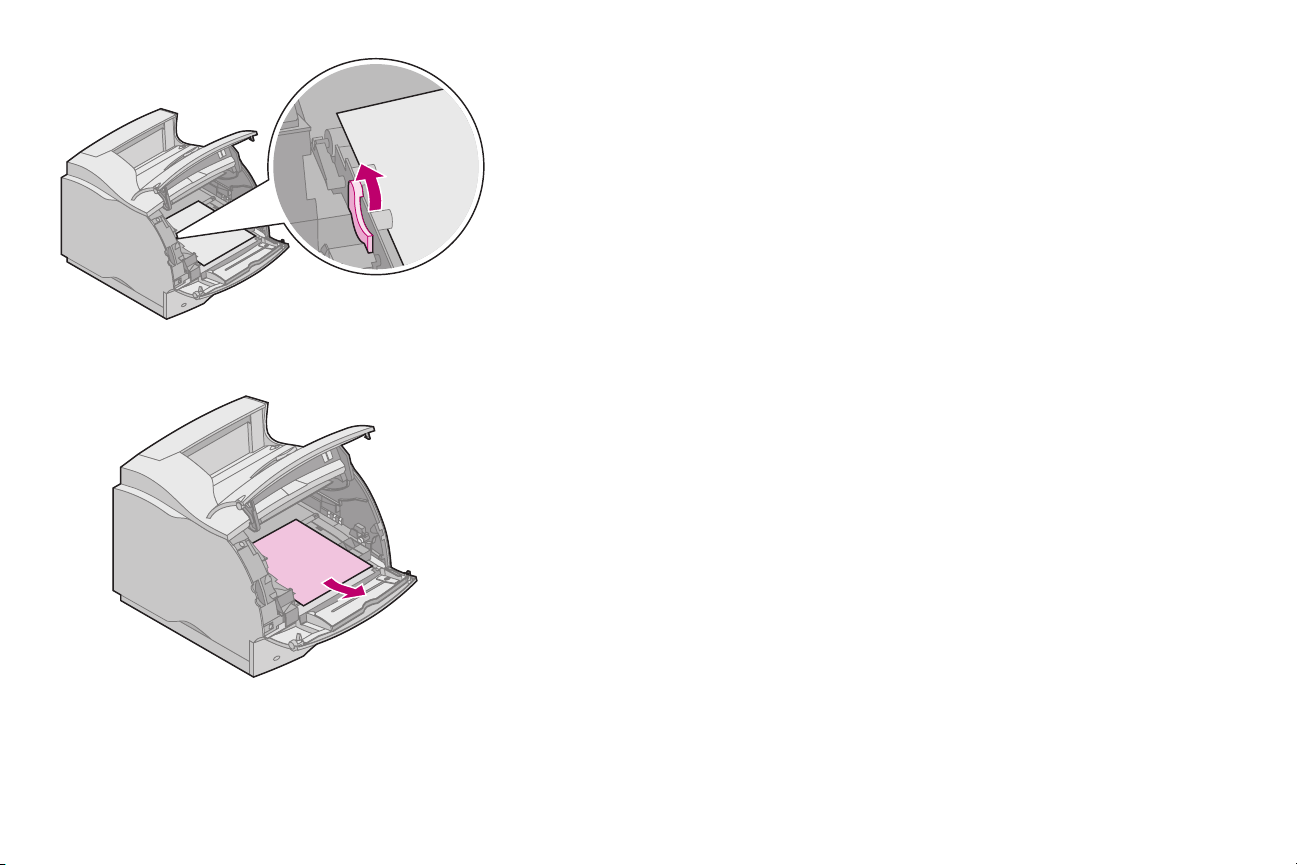

3 Locate and gently push the feed roller release lever back to

release the pressure on the paper.

4 Pull the paper up and toward you. Reinstall the print cartridge.

5 Close the upper and lower front doors.

N

OTE

If there is resistance to the paper, and it does not

:

move immediately when you pull, stop pulling.

You need to access the paper from the rear

door. See “202 Paper Jam Open Rear Door” on

page 74 for more information.

73Clearing Jams

Page 74

202 Paper Jam

Open Rear Door

Jams in the following areas result in a 202 attendance message.

Jams in these areas require opening the printer rear door. See the

appropriate area for the paper jam:

“Before reaching the standard output bin” on page 75

•

“While exiting to the standard output bin” on page 77

•

N

:

OTE

To resolve the paper jam attendance messages,

you must clear all paper from the paper path.

74Clearing Jams

Page 75

Before reaching the standard

output bin

The paper jammed before it exited into the standard output bin or

when it entered the duplex unit to print on the second side of a page.

1 Locate the rear door handle and pull it toward you.

The rear door opens and drops back toward you.

2 Determine how to remove the paper based on what part of the

paper is visible:

– “If the middle section of paper is visible” go to page 76

– “If the end of the paper is visible” go to page 76

– “If there is resistance to the paper” go to page 76

75Clearing Jams

Page 76

If the middle section of paper is visible

–

Grasp the paper on both sides and gently pull the paper

straight out toward you.

:

N

OTE

If paper is still in the fuser area, open the upper

front door to release the fuser rollers and free

the paper for removal.

If the end of the paper is visible

–

Pull the paper straight out toward you.

If there is resistance to the paper

–

If the paper does not move immediately when you pull, stop

pulling. Remove the print cartridge, and then return to the

back of the printer at the rear door area. Pull the paper out.

3

Close the rear door.

76Clearing Jams

Page 77

While exiting to the standard

output bin

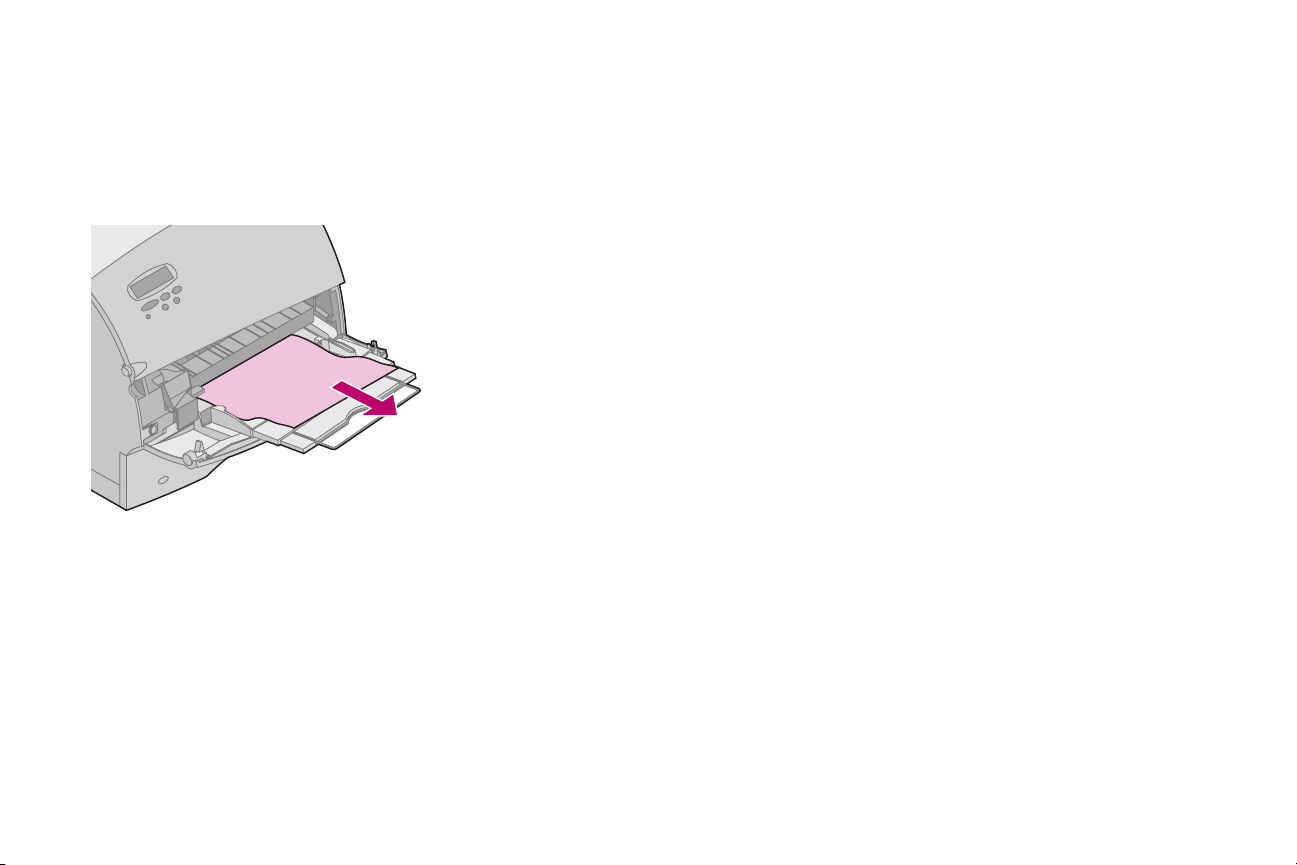

The paper jammed as it exited the standard output bin.

1 Pull the paper straight out. If there is resistance to the paper,

and it does not give immediately when you pull, stop pulling.

Continue with the next step.

2 Open the upper front door to release the fuser rollers.

3 Pull the paper straight out.

N

OTE

Usually with a jam located in this area, there is

:

another jam behind the rear door of the printer.

See

“Before reaching the standard output

bin” on page 75

remove this type of jam.

77Clearing Jams

for instructions on how to

Page 78

230 Paper Jam

Check Duplex

Jams in the following three areas result in a 230 attendance message. See the appropriate area for the paper jam:

“Paper path area in front of duplex unit” on page 79

•

“Inside the duplex unit” on page 81

•

“Back of the duplex unit” on page 82

•

(The page may be entering the duplex unit, inside the duplex

unit, or exiting the duplex unit to go back to the printer to exit

after printing.)

N

:

OTE

To avoid tearing paper when removing the duplex front

access cover, pull it out gently and slowly.

You must check all of the areas to make sure you clear the 230

attendance message.

N

:

OTE

To resolve the paper jam attendance messages, you must

clear all paper from the paper path.

78Clearing Jams

Page 79

Paper path area in front of

duplex unit

This type of jam can occur under an error number different from

230 Paper Jam

The leading edge of the paper is jammed in the pass-through area

where paper crosses in the front of the duplex unit.

, but you must open the duplex front access cover.

1 Locate the recessed areas on each side of the duplex front

access cover.

2 Pull the duplex front access cover straight out from the duplex

unit. The edge of the paper is visible.

79Clearing Jams

Page 80

3 Pull the paper straight up and out.

Since you already have the duplex front access cover pulled

out, continue with the following section.

80Clearing Jams

Page 81

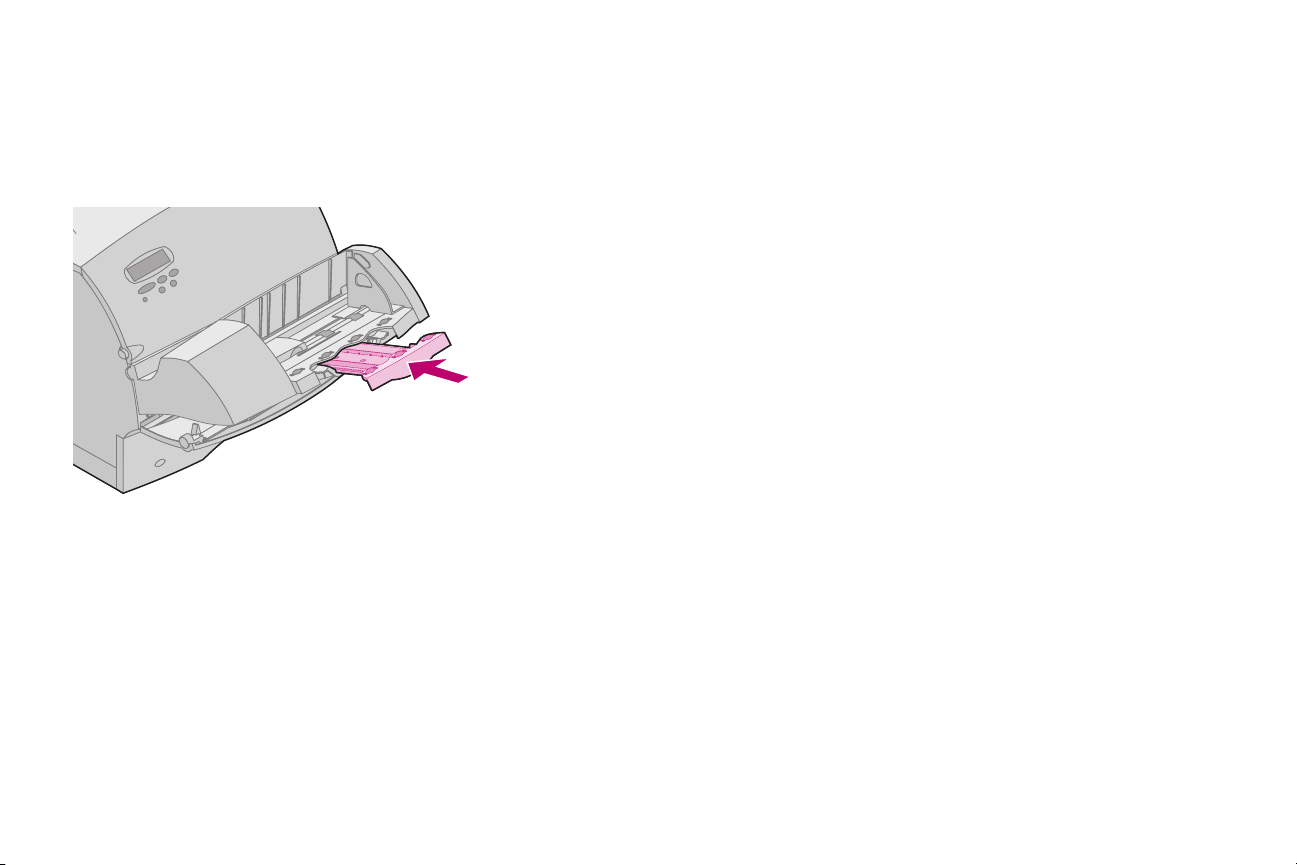

Inside the duplex unit Up to two sheets of paper are lying behind the duplex front access

cover inside the duplex unit.

1 Remove the integrated tray from the printer to give you more

(inside view of duplex unit)

clearance.

2 Locate sheets of paper lying in the duplex front access cover

and pull the paper out toward you.

3 Slide the duplex front access cover back into the duplex unit.

Make sure it snaps into place.

4 Slide the integrated tray back into the printer.

81Clearing Jams

Page 82

Back of the duplex unit

Push the button as shown. The duplex rear door opens.

1

2 Raise the duplex rear door. It remains in place.

3 Look under the rear door for the edge of the paper. Determine

how it is jammed:

If a short piece is visible inside the duplex unit next to the

–

inner wall, grasp it and pull it out. If you cannot grasp it, see

“Inside the duplex unit” on page 81 for instructions.

If only a short piece of paper is visible toward the rear of

–

the printer, do not pull it out; it may be easier to access

from inside the printer. See “200 and 201 Paper Jam

Remove Cartridge” on page 72 for instructions to remove

the paper. However, if most of the paper is visible, continue

with the following.

82Clearing Jams

Page 83

– Pull the paper up and out toward you if the paper is in this

position.

– Pull down and out if the paper is in this position.

83Clearing Jams

Page 84

4 Close the duplex rear door by pressing the center of the door.

Make sure it snaps into place.

84Clearing Jams

Page 85

24x Paper Jam

Check Tray x

Jams in the following four areas result in a 24x attendance message. x represents the tray number where the jam has occurred.

Paper jams in trays may occur at the following locations. See the

appropriate area for the paper jam:

“On the incline surface of a tray or between two trays” on

•

page 86

“Between three trays” on page 88

•

(This may happen if you are using legal-size paper in the trays

or if you have an optional 250-sheet drawer installed with

other optional drawers.)

“Between tray, duplex unit, and integrated tray” on

•

page 90

“2000-sheet drawer” on page 94

•

To avoid tearing print materials when opening trays, pull the trays

out gently and slowly.

N

:

OTE

To resolve the paper jam attendance messages, you must

clear all paper from the paper path.

85Clearing Jams

Page 86

On the incline surface of a tray

or between two trays

If your paper is being fed from any of the standard or optional trays,

the paper may jam:

Along the incline surface of the tray where the paper feeds out

•

of the tray.

Between feed rollers in the pass-through area where paper

•

crosses in the front of two trays.

You see the difference as soon as you pull the tray out.

1 Pull the paper tray half way out of the support unit.

2 Look for paper in the paper tray and remove it based on how it

is jammed:

If the paper is lying on the incline or wall surface at the front

–

of the tray, pull the paper straight out.

86Clearing Jams

Page 87

– If the paper is between two trays, when you pull the tray out

of the support unit, the top edge of the paper springs out

toward you. Pull the paper straight up, and then out.

3

Slide the paper tray back into the support unit.

N

: If you do not see one end of the print material,

OTE

the jam has occurred between three trays. See

“Between three trays” on page 88 to remove the

jam.

87Clearing Jams

Page 88

Between three trays This type of jam may occur if you are using legal-size paper in the

trays or if you have a 250-sheet drawer installed with other optional

drawers.

1 Pull the paper tray out of the support unit. If only a short piece

of the paper is visible, do not pull down to remove the paper.

2 Gently slide the paper tray back into the support unit.

3 Pull the paper tray out of the support unit that is above the tray

you just pulled out and closed.

88Clearing Jams

Page 89

4 Look for the leading edge of the paper. Most of the paper

should be visible now.

5 Pull the paper in either direction, up or down. If it does not pull

easily one way, try the other way.

6 Slide the paper tray back into the support unit.

N

OTE

With this type of jam, there may be another jam

:

under the print cartridge. Remove the print

cartridge and look for a paper jam. Remove any

jammed paper and reinstall the print cartridge.

89Clearing Jams

Page 90

Between tray, duplex unit, and

integrated tray

N

OTE

To avoid tearing paper when opening the duplex front access

:

cover, pull the duplex front access cover out gently and

slowly.

1 Pull the paper tray out of the support unit. If only a short piece

of the paper is visible, do not pull down to remove the paper.

90Clearing Jams

Page 91

2 Pull the duplex front access cover straight out from the duplex

unit.

Duplex

front

access

cover

3 Pull the integrated tray out of the printer.

If you see the edge of the paper in the integrated tray:

–

Pull the paper down and out.

a

Slide the paper tray all the way into the printer. In this

b

case the paper is not trapped in the printer feed rollers.

Slide the duplex front access cover back into the duplex

c

unit. Make sure it snaps into place.

91Clearing Jams

Page 92

– If you do not see the edge of the paper in the integrated

tray:

Push the integrated tray back into the printer.

a

Open the upper and lower front doors of the printer.

b

Remove the print cartridge. You should see the leading

c

edge of the paper now.

Locate and gently push the feed roller release lever back

d

to release the pressure on the paper.

Pull the paper up and toward you.

.

e

92Clearing Jams

Page 93

.

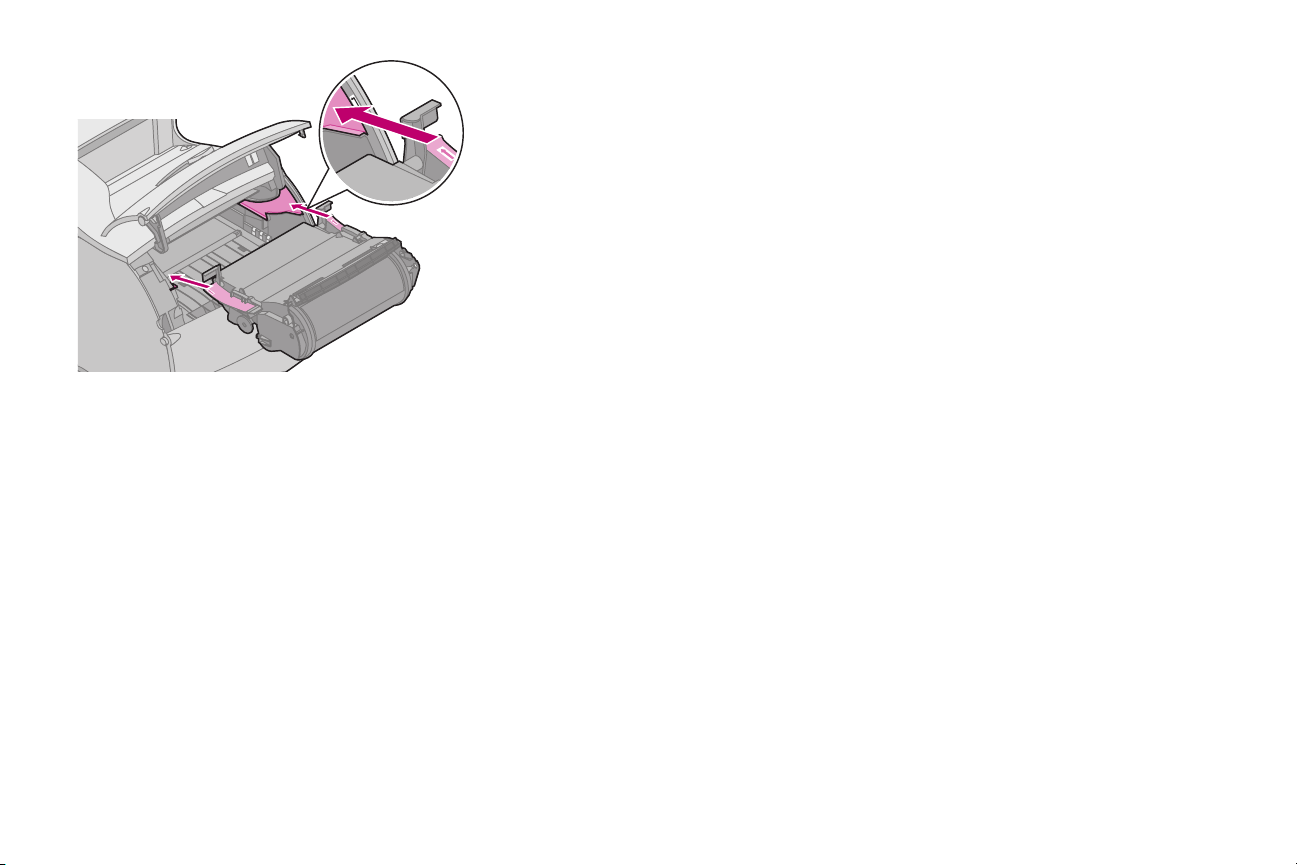

f Reinstall the print cartridge:

Align the slides on the print cartridge with the slots on

the print cartridge cradle and use the colored arrows

inside the printer for placement. Guide the print cartridge down as it drops and snaps into place.

g Close the upper and lower front doors of the printer.

h Slide the paper tray all the way into the printer.

93Clearing Jams

Page 94

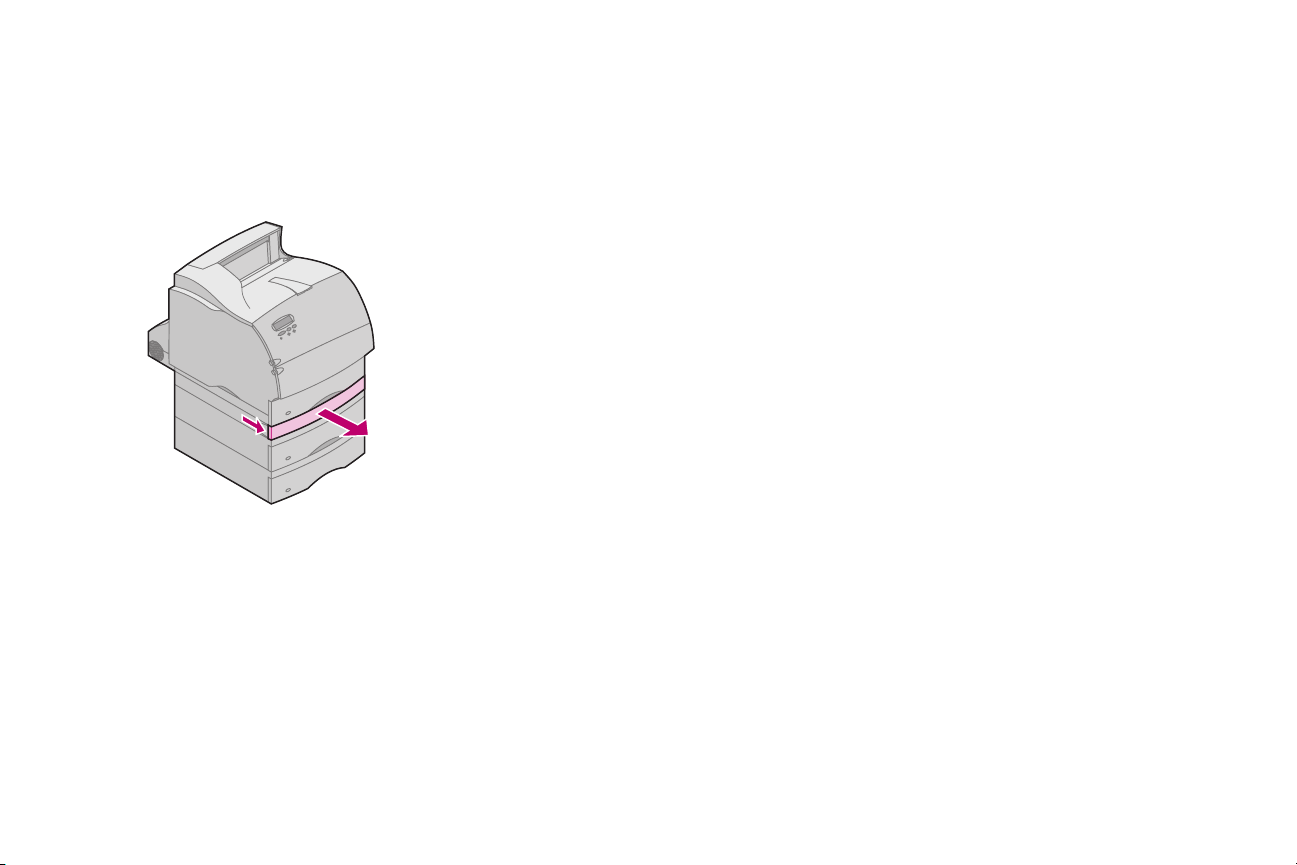

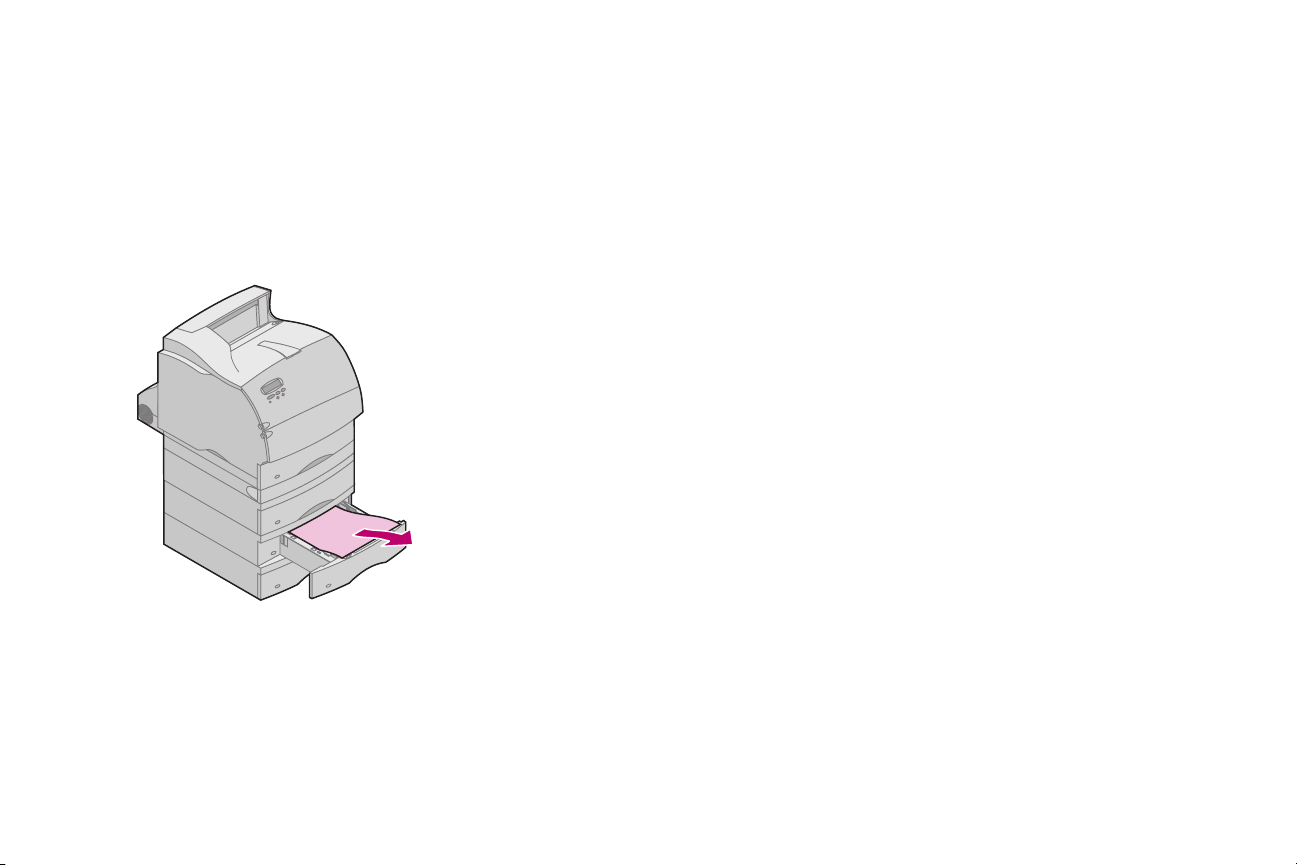

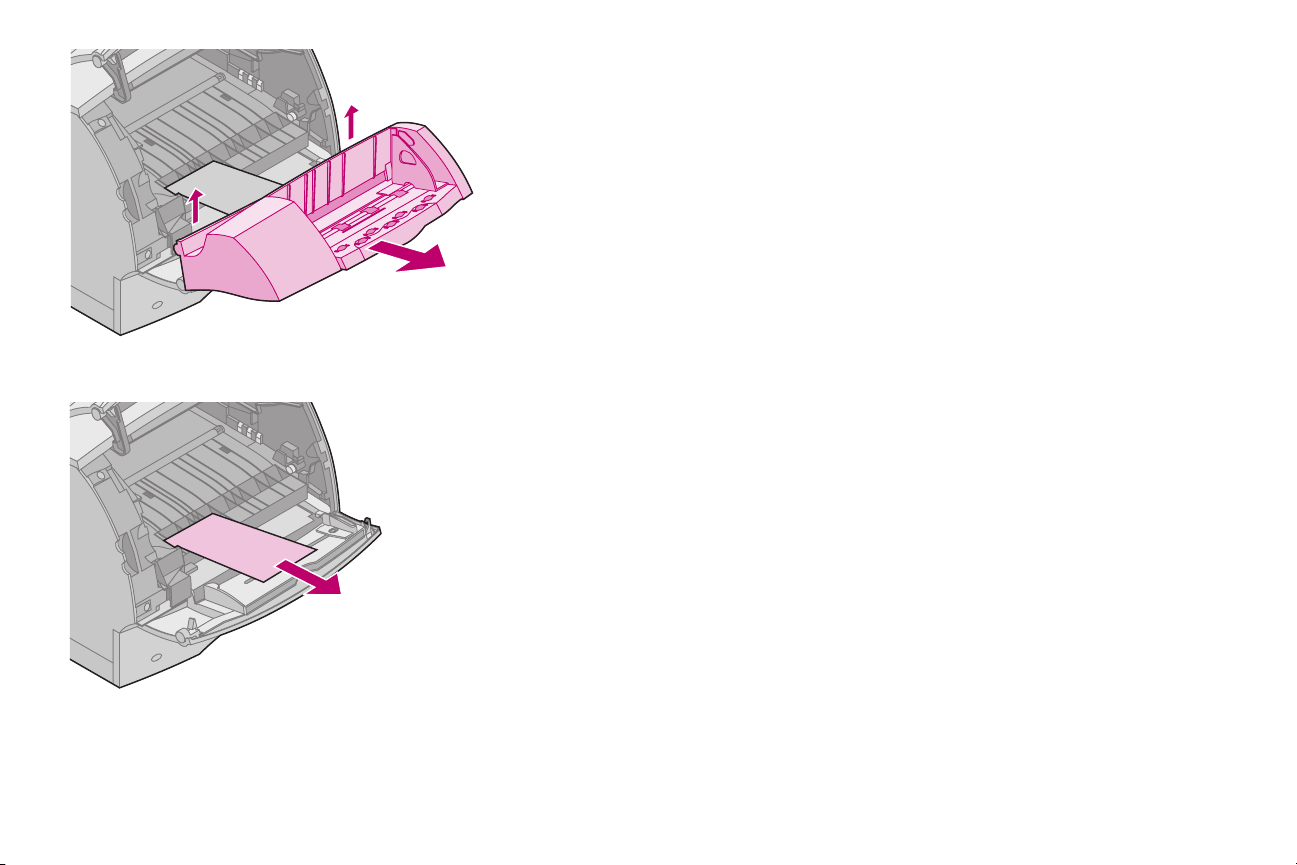

2000-sheet drawer 1 Open the loading door.

2 Press the elevator down button.

3 Remove the paper jam and clear all paper from the paper

path of the drawer and printer.

4 Check to see if the stack of paper is neat and aligned.

5 Close the door.

6 Allow a few seconds for the elevator to reach the top.

Elevator down

button

7 Select

94Clearing Jams

to resume printing.

Go

Page 95

250 Paper Jam

Check MP Feeder

To avoid tearing print materials, pull the jammed print material out

gently and slowly.

N