Page 1

• Table of contents

Edition: May 15, 2007

Lexmark™ E350d, E352dn

4512-420

4512-430

• Start diagnostics

• Safety and notices

•Trademarks

• Index

Lexmark and Lexmark with diamond design are

trademarks of Lexmark International, Inc., registered

in the United States and/or other countries.

Page 2

E

T

L

E

M

i

T

i

p

C

L

y

o

R

e

a

i

t

d

c

u

L

r

P

P

A

©

U

T

a

4512-420, -430

dition: May 15, 2007

he following paragraph does not apply to any country where such provisions are inconsistent with local law:

EXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

ITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

ERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

mplied warranties in certain transacti ons; therefore, this statement ma y not apply to you.

his publi cation could include technical inaccuracies or typographi cal errors. Chang es are periodically made to the

nformation her ein; these changes will be inco rporat ed in later editions . Improvements or changes in the products or the

rograms described may be made at any time.

omments may be addressed to Lexmark Internati onal, Inc., Department D22A/032-2, 740 West New Circle Road,

exington, Kentucky 40550, U.S.A or e-mail at ServiceInfoAndTr aining@Lexmark.com. Lexmark may use or distribute an

f the inf ormati on you supply in any way it believes appropriate without incurring any obligation to you.

eferences in this pub li cation to product s, programs, or services do not imply that the manufacturer intends to make thes

vailable in all countries in whic h it operates. Any reference to a product, program, or service is not intended to state or

mply that only that pr oduct, progr am, or service may be used. Any functi onall y equiv alent product , progr a m, or service tha

oes not infringe any existing intellectual property right may be used instead. Evaluation and verification of operation in

onjunction with other products, programs, or services, except those expressly desi gnated by the manufacturer, are the

ser’s responsibility.

exmark, Lexmark with diamond design, Ma rkNet, and MarkVision are trademarks of Lexmark International, Inc.,

egistered in the United States and/or other countries.

ictureGrade is a trademark of Lexmark Int ernational, Inc.

CL® is a registered trademark of the Hewlett-Packard Company.

ll other trademarks are the property of their respective owners.

2006 Lexmark International, Inc.

All rights reserved.

NITED STATES GOVERNMENT RIGHTS

his software and any accompanying documentation provided under this agreement are commercial comput er software

nd documentat ion developed exclusively at private expense.

P/N 12G9708

Page 3

4512-420, -430

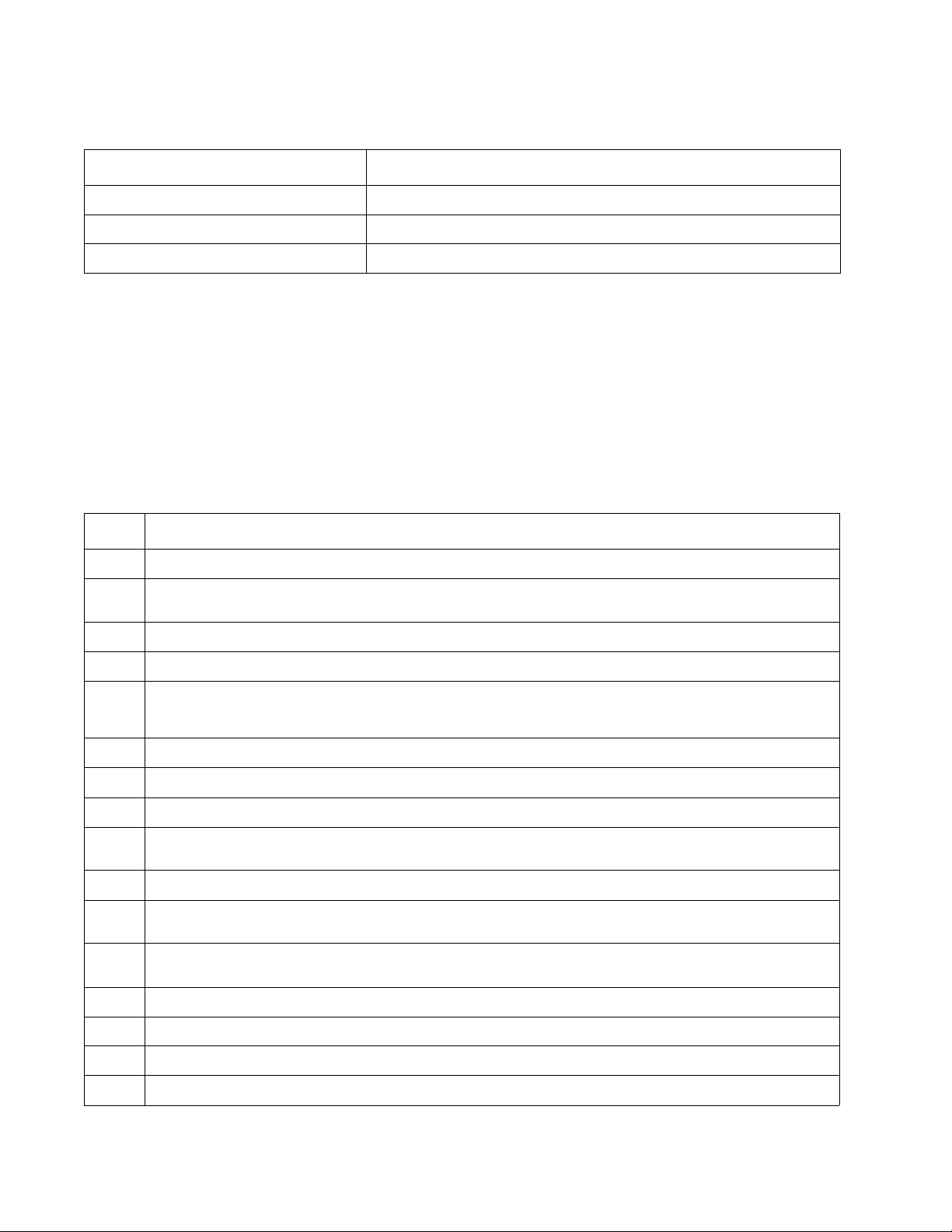

Table of Contents

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Notices and safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Laser notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview of the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Print speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Print quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Media trays and supply capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Connectivity and compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Types of print media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Tips on preventing jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Diagnostics information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview of the operator panel and menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Indicator light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

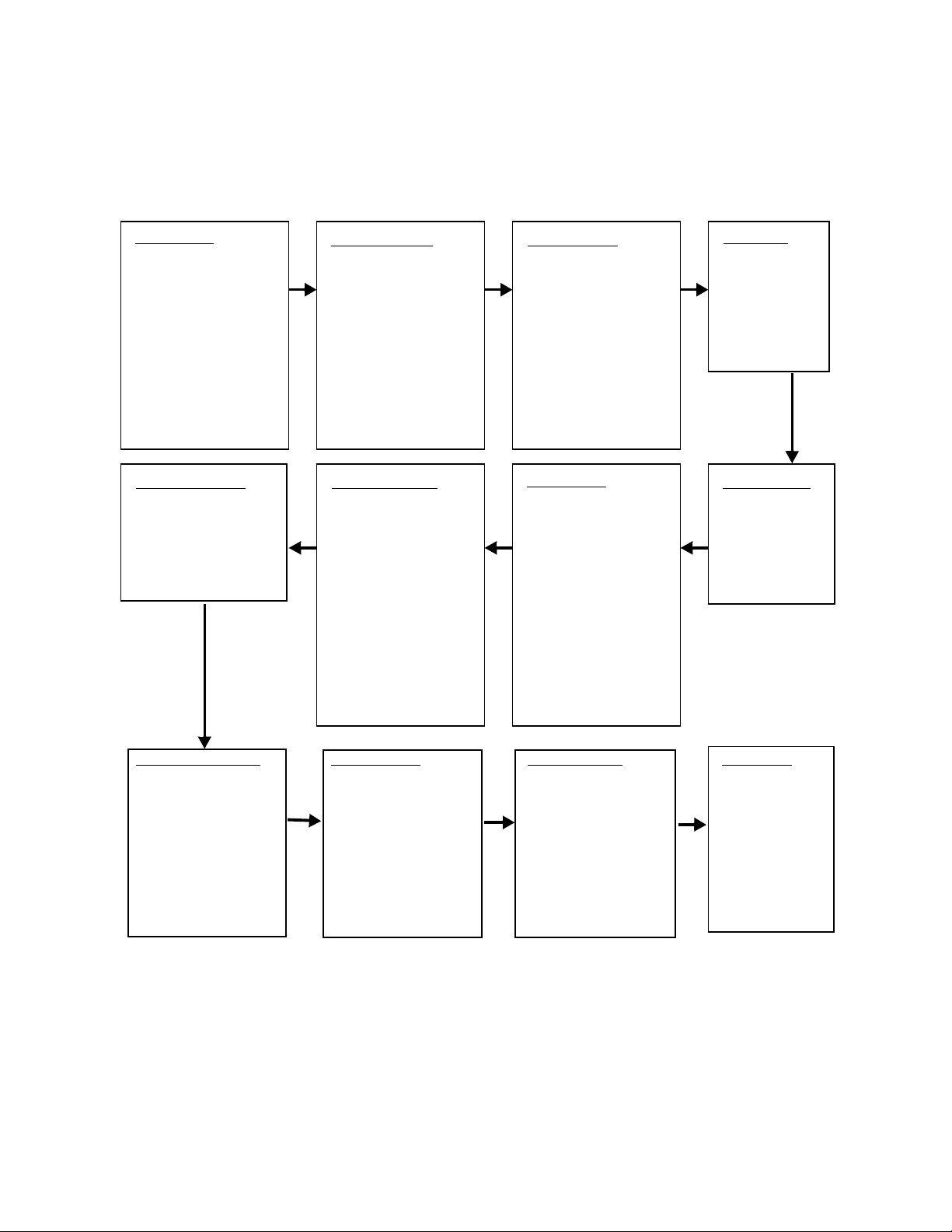

Diagram of the printer menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Messages and error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

User attendance messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Cartridge error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Paper jam error codes (200-series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Service error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

POST symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Printer symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Controller card service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Cooling fan service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Cover interlock switch service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Dead machine service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Fuser service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

LVPS/HVPS service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Main motor service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Operator panel service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Paper feed service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Parallel or USB port service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Print quality service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Printhead service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Transfer roll service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Table of Contents iii

Page 4

4512-420, -430

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Accessing service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printing menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Configuration menu (CONFIG MENU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Entering Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Available menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Maint Cnt Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Reset Maint Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Reset PC Cnt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Print quality pages (Prt Quality Pgs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

PPDS Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Energy Conserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Reduced Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

USB Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Exit Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Diagnostics mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Entering Diagnostics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Available tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Print tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Hardware tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Duplex tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Input tray tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Base sensor test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Printer setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

EP setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Exit Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Locations and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

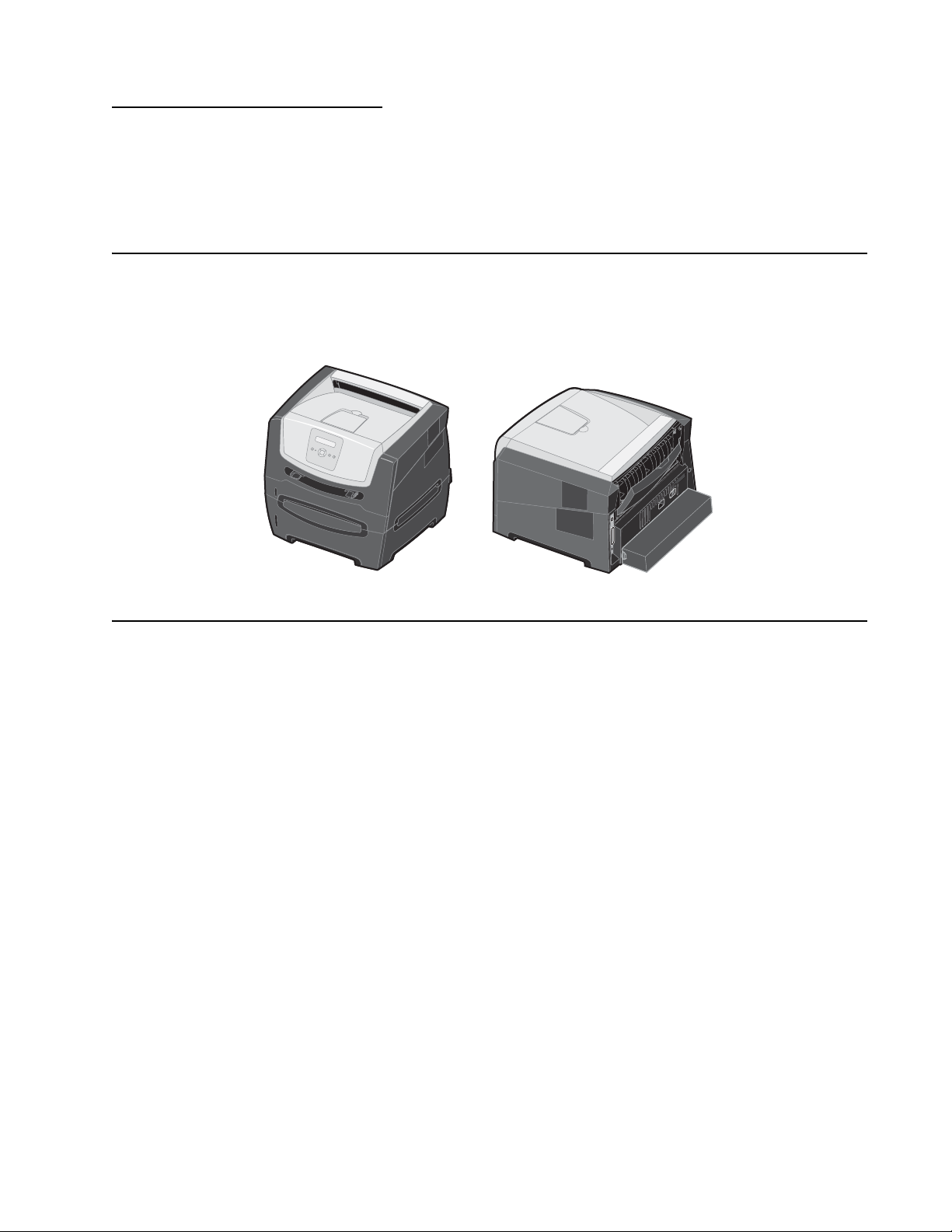

Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Controller card connector pin values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety inspection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Maintenance kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Parts catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Part number index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-5

iv Lexmark™ E350d, E352dn

Page 5

4512-420, -430

Notices and safety information

The following laser notice labels may be affixed to this printer as shown:

Laser notice

The printer is certified in the U .S. to confo rm to the requir ements of DHHS 21 CFR Subchapter J for Class I (1)

laser product s, and elsewhere is certified as a Class I laser product conforming to the requirements of IEC

60825-1.

Class I laser products are not considered to be hazardous. The pri nter contains internally a Class IIIb (3b) laser

that is nominally a 5 milliwatt gallium arsenide laser operati ng in the wavelength region of 770-795 nanometers.

The laser system and printer are designed so there is never any hum an access to laser radiation above a Class

I level during normal operation, user maintenance, or pr escri bed service condition.

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigu ng der USA die Anforderungen der Bestimmung DHHS

(Department of Health and Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1) . In anderen

Ländern gilt der Drucker als Laserprodukt der Klasse I, der die Anforderungen der IEC (International

Electrotechnical Commission) 60825-1 gemäß amtlicher Bestäti gung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des Druckers befindet sich ein Laser der Klasse

IIIb (3b), bei dem es sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen der Länge 770-795

Nanometer ausstrahlt. Das Lasersystem und der Drucker sind so konzipiert, daß im Normalbetrieb, bei der

Wartung durch den Benutzer oder bei ordnungsgemäßer Wartung durch den Kundendienst Laserbestrahlung,

die Klasse I überstei gen würde, Menschen keinesfall s err eicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux pro vis ions DHHS 21 CFR alinéa J concernant

les produits laser de Classe I (1). Pour les autres pa ys: cette imprimante répond aux normes IEC 60825-1

relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comm e des produits non dangereux. Cett e impri m ante est

équipée d’un l aser de Classe IIIb (3b) (arséniure de gallium d’une puissance nomi nale de 5 milliwatts) émettant

sur des longueurs d’onde comprises entre 770 et 795 nanomètres. L’imprimante et son sys tème laser sont

conçus pour impossible, dans des conditions normales d’uti lisation, d’entr etien par l’utilisateur ou de révision,

l’exposition à des rayonnements laser supérieurs à des ray onnements de Classe I .

Avvertenze sui prodotti laser

Questa stampant e è certificata negli St ati Uniti per ess ere conforme ai requisiti del DHHS 21 CFR Sottocapitolo

J per i prodotti las er di classe 1 ed è certificata negli altri Paesi come prodotto laser di classe 1 conf orme ai

requisiti del la norma CEI 60825-1.

I prodotti laser di class e non sono con sider ati pericol osi. La stampan te conti ene al suo in terno un laser di cl asse

IIIb (3b) all’arseniuro di gallio della potenza di 5mW che opera sulla lunghezza d’onda compr esa tra 770 e 795

nanometri. Il sistema laser e la stampante sono stati progettati in modo tale che le persone a contatto con la

stampante, durante il normale funzionam ento, le operazioni di servizio o quelle di assis tenza tecnica, non

ricevano radiazioni laser superiori al livello della classe 1.

Notices and safety information v

Page 6

4512-420, -430

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los requisitos para los productos láser de Clase I (1)

establecidos en el subcapítulo J de la norma CFR 21 del DHHS (Departamento de Sanidad y Servicios) y, en

los demás países, reúne todas las condiciones expuestas en la norma IEC 60825-1 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran pel igrosos. La impre sora contiene en su interior un láser de

Clase IIIb (3b) de arseniur o de galio de func ionamiento nominal a 5 m ilivatios en una longitud de onda de 770 a

795 nanómetros. El sistema láser y la impresora están diseñados de forma que ninguna persona pueda verse

afectada por ningún tipo de radiac ión láser superior al nivel de la Cla se I dur ante su uso normal, el

mantenimiento realizado por el usuario o cualquier otra situaci ón de servic io técnico.

Declaração sobre Laser

A impressora está ce rtific ada nos E. U .A. e m conf ormida de com os requi sito s da reg ulame ntação DHHS 2 1 CFR

Subcapítulo J para a Cla sse I (1) de produt os laser. Em outros locais, está certificada como um prod uto lase r da

Classe I, em conf ormidade com os requisitos da norma IEC 60825-1.

Os produtos lase r da Classe I não sã o conside rados peri gos os. I nternamente , a impr esso ra cont ém um produ to

laser da Classe IIIb (3b), designado laser de arseneto de potássio, de 5 milliwatts ,oper ando numa faixa de

comprimento de onda entre 770 e 795 nanómetros. O sistema e a impressora laser f oram concebidos de forma

a nunca ex ist ir qualquer possiblidade de acesso humano a radiação laser superior a um nível de Classe I

durante a operação normal, a manutenção feita pelo utilizador ou condições de assist ência prescritas .

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een laserprodukt van klas se I. V oor de Verenigde

Staten zijn deze eisen vastgeleg d in DHHS 21 CFR Subchapter J, voor ander e landen in IEC 60825-1.

Laserprodukten van klasse I worden nie t als ongevaarli jk aangemerkt. De printer is v oorzien van een laser van

klasse IIIb (3b), dat wil zeggen een gallium ars enide-laser van 5 milliwatt met een gol flengte van 770-795

nanometer . Het laser gedeelt e en de printer zijn z o ont worpen dat bij normaal gebru ik, bij onde rhoud of re parat ie

conform de voorschriften, nooit blootstelling mogelijk is aan laserstraling boven een niveau zoals

voorg e schreve n is voor klasse 1.

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i overenstemmelse med kravene i IEC 60825-1.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren indeholder internt en Klasse IIIB (3b)-laser, der

nominelt er en 5 milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet 770-795 nanometer.

Lasersystem et og printeren er udformet sål edes, at mennesker aldrig udsættes for en laserstråling over Klasse

I-nive au ved normal drift, brugervedligeholdelse eller ob ligatoriske servicebetingelser.

vi Lexmark™ E350d, E352dn

Page 7

4512-420, -430

Huomautus laserlaitteesta

Tämä kirjoi tin on Yh dysv alloi ssa lu okan I ( 1) lase rlait teide n DHHS 21 CFR Subchapt er J -määrityks en muk ainen

ja muualla luokan I l aserlaitteiden IEC 60825- 1 -määri tyksen mukainen.

Luokan I las e r la itt e id e n e i ka ts o ta ol evan vaarallis ia käyttä jä lle . K irj oi tt im e s sa on si sä i ne n lu oka n IIIb (3 b ) 5

milliwat in galliumarsenidilaser , joka toimii aaltoalueella 770 - 795 nanometriä. Laserj ärjestelmä ja kirjo itin on

suunnitelt u siten, että käyttäj ä ei al tistu luokan I määrityksi ä voimakkaammall e säteilylle kirj oittimen normaalin

toiminnan, käyttäjän tekemien huoltotoimien tai muiden huoltotoimien yhteydessä.

VARO! Av attaessa ja suojalukitus ohitettaessa ol et alttiina näkymätt öm älle lasersäteily ll e. Älä katso

säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad. Betrakta ej stråle n.

Laser-notis

Denna skrivar e är i USA certifier ad att motsvara kraven i DHHS 21 CFR, underparagr af J fö r la serprodukter av

Klass I (1). I andra länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt kraven i IEC 60825-1.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en inbyggd laser av Klass IIIb (3b) som består av

en laserenhet av gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770-795 nanometer.

Lasersystem et och skrivaren är utformade så att det aldrig finns risk för att någon person utsät ts för

laserstrå lning över Klass I-ni vå vid normal användning, underhåll som utförs av användaren eller annan

föreskriv en serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR, underkapittel J, for klasse I (1) laserprodukter, og er

i andre land godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC 60825-1.

Klasse I-l aserprodukter er ikke å betrakte som f arlige. Skriveren inneholder internt en klasse IIIb (3b)-laser, som

består av en gallium-arsenlaser enhet som avgir stråling i bølgel engdeområdet 770-795 nanom eter.

Lasersystem et og skriveren er utformet slik at personer al dri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk , vedlikehol d som utføres av brukeren, eller foreskre vne serviceoperasjoner.

Avís sobre el Làser

Segons ha estat certificat al s Estats Units , aquesta impressor a complei x els req uisit s de DHHS 21 CFR, apartat

J, pels productes làser de classe I (1), i segons ha estat certificat en altres llocs, és un producte làser de classe

I que compleix els requisits d’IEC 60825-1.

Els productes l àser de classe I no es consideren peril losos. Aquesta impr essora conté un làser de cl asse IIIb

(3b) d’arseniür de gal.li, nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona de 770-795

nanòmetres. El sistema làser i la impressora han sigut concebuts de manera que mai hi hagi exposició a la

radiació làser per sobre d’un niv ell de classe I durant una oper ació normal, durant les tasques de manteniment

d’usuari ni durant els serveis que satisfacin les condicions prescrites.

Notices and safety information vii

Page 8

4512-420, -430

viii Lexmark™ E350d, E352dn

Page 9

4512-420, -430

Safety information

• The safety of this product is based on testing and approvals of t he original design and specific

components . The manufacturer is not responsibl e for safety in the event of use of unauthorized

replacement parts .

• The maintenance information for this product has been prepared for use by a professional service person

and is not intended to be used by others.

• There may be an increased risk of electric shoc k and personal injury during disa ssem bly and servicing of

this product . Pro fessional service personnel should understand this and take necessa ry precaut ions.

• CAUTION: When you see th is symbol , ther e is a danger f rom hazard ous v olt age in the area of the

product where y ou ar e working . Unplug the product bef ore you beg in, or use c autio n if t he produc t

must receive power in order to perform the task.

Consignes de sécurité

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'origine et sur des composants particuliers. Le fabricant n'assume

aucune respon sabilité concernant la sécurité en cas d'utilisation de pièces de rechange non agréées.

• Les consignes d'entretien et de répar ati on de ce produit s'adressent uniquement à un personnel de

maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques électriques, le personnel

d'entretien qualifié devra prendre toutes les précautions nécessaires.

• ATTENTION : Ce symbole indique la présence d'une tension dangereuse dans la partie du

produit sur laquelle vous tra vaillez. Débranchez le produit avant de commencer ou f aites preuve

de vigilance si l' exécution de la t âche exige que le produit reste sous tension.

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del progetto originale e dei componenti

specifici. Il produttore non è responsabile per la sicurezza in caso di sostituzion e non autorizzata delle

parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate soltanto al personale di

assistenza autorizzato .

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subi re scosse elettriche e danni al la persona è più elev ato. Il per sonale di assistenza

autorizzato deve, quindi, adottare le precauzioni necessarie.

• ATTENZIONE: Questo simbolo indica la presenza ditensione pericolosa nell'area del prodotto.

Scollegare il pr odotto prima di iniziare o usare caut ela se il prodotto dev e essere alimentato per

eseguire l'intervento.

Safety information ix

Page 10

4512-420, -430

Sicherheitshinweise

• Die Sicherheit di eses Produkts basiert auf Tests und Zulassungen des ursprünglichen Modells und

bestimmter Baut eil e. Bei Verwendung nicht genehmigter Ersatztei le wi rd vom Hersteller kei ne

Verantwortung oder Haft ung für die Sicherheit übernommen.

• Die Wartungsinformationen für dieses Produkt sind ausschließl ich für die V erwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein zusätzliches Risiko eines

elektrischen Schlags und körperlicher Verletzung. Das zus tändige Fachpersonal sollte entsprechende

Vorsichtsmaßn ahm en treffen.

• ACHTUNG: Dieses Symbol weist auf eine gefährliche elektrische Spannung hin, die in diesem

Bereich des Produkts auftreten kann. Zie hen Sie vor den Arbeiten am Gerät den Netzst ecker des

Geräts, bzw. arbeiten Sie mit großer Vorsicht, wenn das Produkt für die Ausfü hrung der Arbeiten

an den Strom angeschlossen sein muß.

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y aprobaciones del diseño original y componentes

específico s. El fabricante no es responsable de la seguridad en caso de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimiento de este producto está dirigida exclusivamente al personal

cualificado de mantenimiento.

• Existe may o r riesg o de descar ga el éctrica y de dañ os person al es duran te e l desmont aj e y la r eparac ión de

la máquina. El personal cualificado debe ser consciente de este peligro y tomar las precauciones

necesarias.

• PRECAUCIÓN: este símbolo indica que el voltaje de la parte del equipo con la que está

trabajando es peligroso. Antes de empezar, desenchufe el equipo o tenga cuidado si, para

trabajar con él, debe conectarlo.

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações do modelo ori ginal e de componentes

específico s. O fabricante não é responsável pela segunrança, no caso de uso de peças de subst it uição

não autorizadas.

• As informações de segurança relativas a este produto dest inam-se a profissionais destes serviços e não

dev em ser ut ilizadas por outras pessoas.

• Risco de choques eléct ricos e ferimentos graves durante a desmontagem e manutenç ão deste produto.

Os profissio nais destes serviços devem estar avis ados deste facto e tomar os cuidados necessários .

• CUIDADO: Quando vir este sí m bolo, existe a possível presença de uma potencial tens ão

perigosa na zona do produto em que está a trabalhar. Antes de começar, desligue o produto da

tomada eléctrica ou s eja cui dado so caso o pro duto te nha d e estar liga do à corrent e eléc trica para

realizar a tarefa necessária.

x Lexmark™ E350d, E352dn

Page 11

4512-420, -430

Informació de Seguretat

• La seguretat d' aquest producte es basa en l'avaluació i apr ovació del disseny original i els compo nents

específics.

El fabricant no es fa responsabl e de les qüestions de

seguretat si s'u tilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest pr oducte està orientada exclusivament a professionals i no està

destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar durant el procés de desmunt atge i de servei

d’aquest producte. El personal professional ha d’estar-ne assabentat i prendre

les mesures con venients.

• PRECAUCIÓ: aquest símbol in dica que el voltatge de la part de l'equip amb la qual esteu

treballan t és perillós . Abans de començar, desendoll eu l'equip oextremeu les precaucions si, per

treballar amb l'equip, l'heu de connectar.

Safety information xi

Page 12

4512-420, -430

Preface

This manual contains maintenance procedures for service personnel. It is divided into t he following ch apters:

1. General information contains a general description of the printer and the maintenance approach used to

repair it. Special tools and test equipment are, as well as general environmental and safety instructions.

2. Diagnostic information contains an error indicator table, symptom tables, and service checks used to

isolate failing field replaceable units (FRUs).

3. Diagnostic aids contains tests and checks used to locate or repeat symptoms of printer problems.

4. Repair information provides inst ructions for maki ng printer adjustments and removing and installing

FRUs.

5. Connector locations uses illustr ations to identify the connector locations and test points on the printer.

6. Preventive maintenance contai ns the lubrication specifications and recommendat ions to prevent

problems.

7. Parts catalog contains illus trations and part numbers for individual FR Us.

Appendix A contains service tips and inf ormati on.

Appendix B contains representative print samples.

Definitions

Note: A note provides addition al i nformation.

Warning: A warning identifies something that might damage the product hardware or software.

CAUTION: A caution identifies something that might cause a servicer harm.

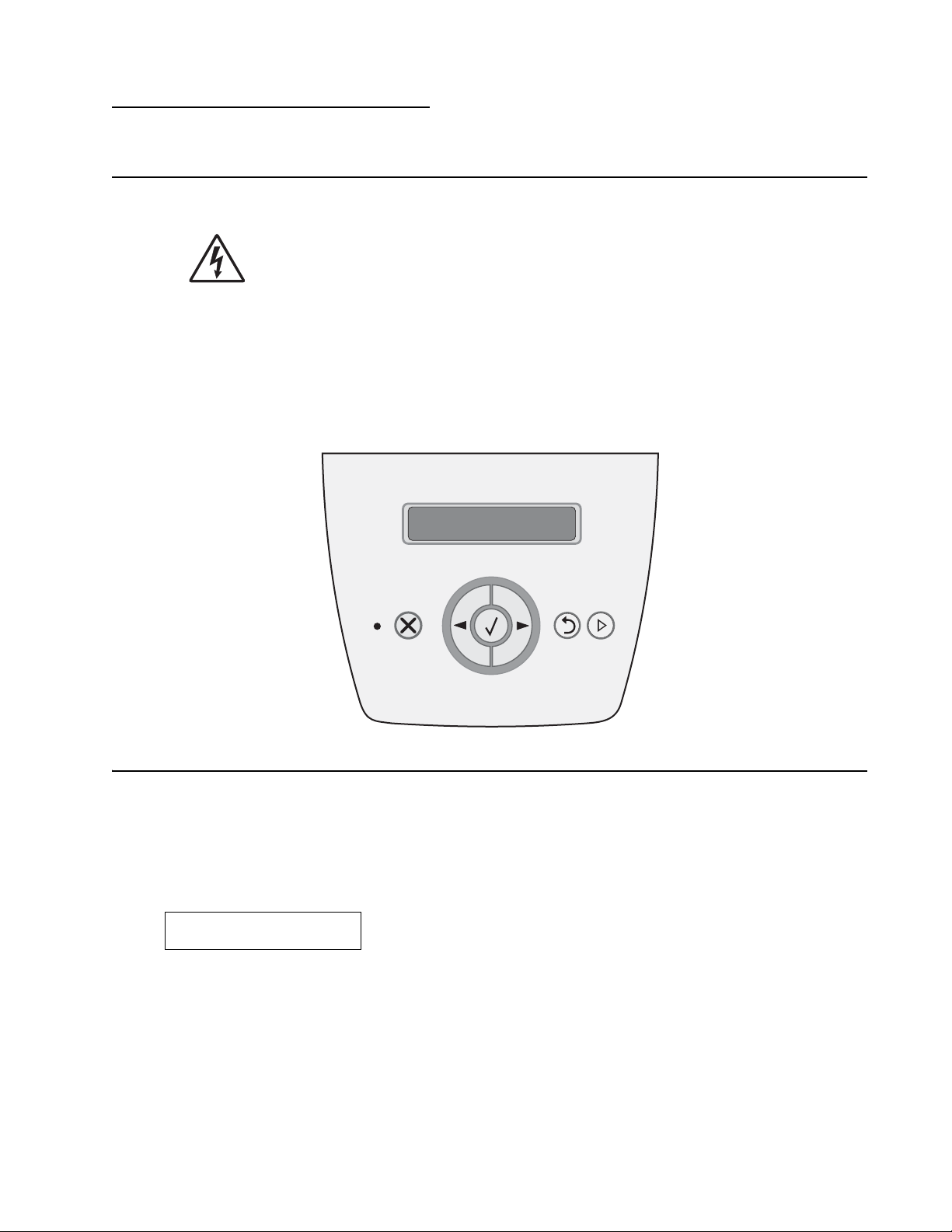

CAUTION: When you see this symbol, there is a danger from hazardous voltage in the area of the

product where you are working. Unplug the product before you begin, or use caution if the product

must receive power in order to perform the task.

xii Lexma rk™ E350d, E352dn

Page 13

4512-420, -430

1. General information

The Lexmark™ E350d and E352dn are monochrome laser printers designed for single users or small

workgroups. This book contains information on E350d and E352dn. For information on E250d and

E250dn, see the 4512-220,-230 service manual.

Model

There are two models: E350d and E352dn. Both models have 32MB memory standard, a parallel USB

connector, INA, ENA option support via USB and/or parallel ports, and prints 35 pages per minute on l ett er-size

media (34 ppm on A4, 29 ppm on legal).

Maintenance approach

The diagnostic information in this manua l le ads to the correct field repla ceable unit (FR U ) or part. Use the error

code charts, symptom ind ex, and service checks to determine the symptom and repair the f ailure. See

“Diagnostics information” on page 2-1 for more inf ormati on. See “Repair information” on page 4-1 to help

identify parts. After completing the repair, perform tests as needed to verify the repair.

General inf ormation 1-1

Page 14

4512-420, -430

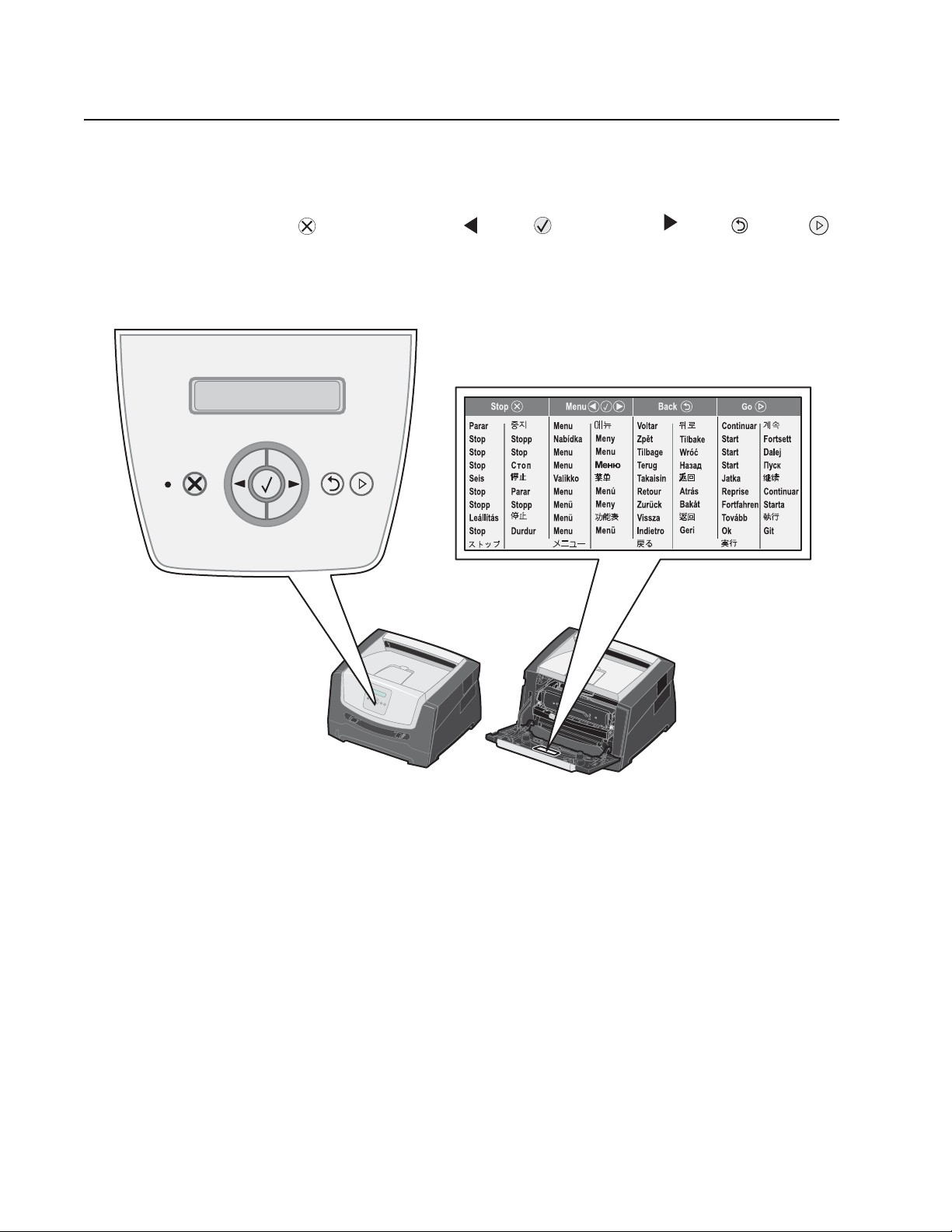

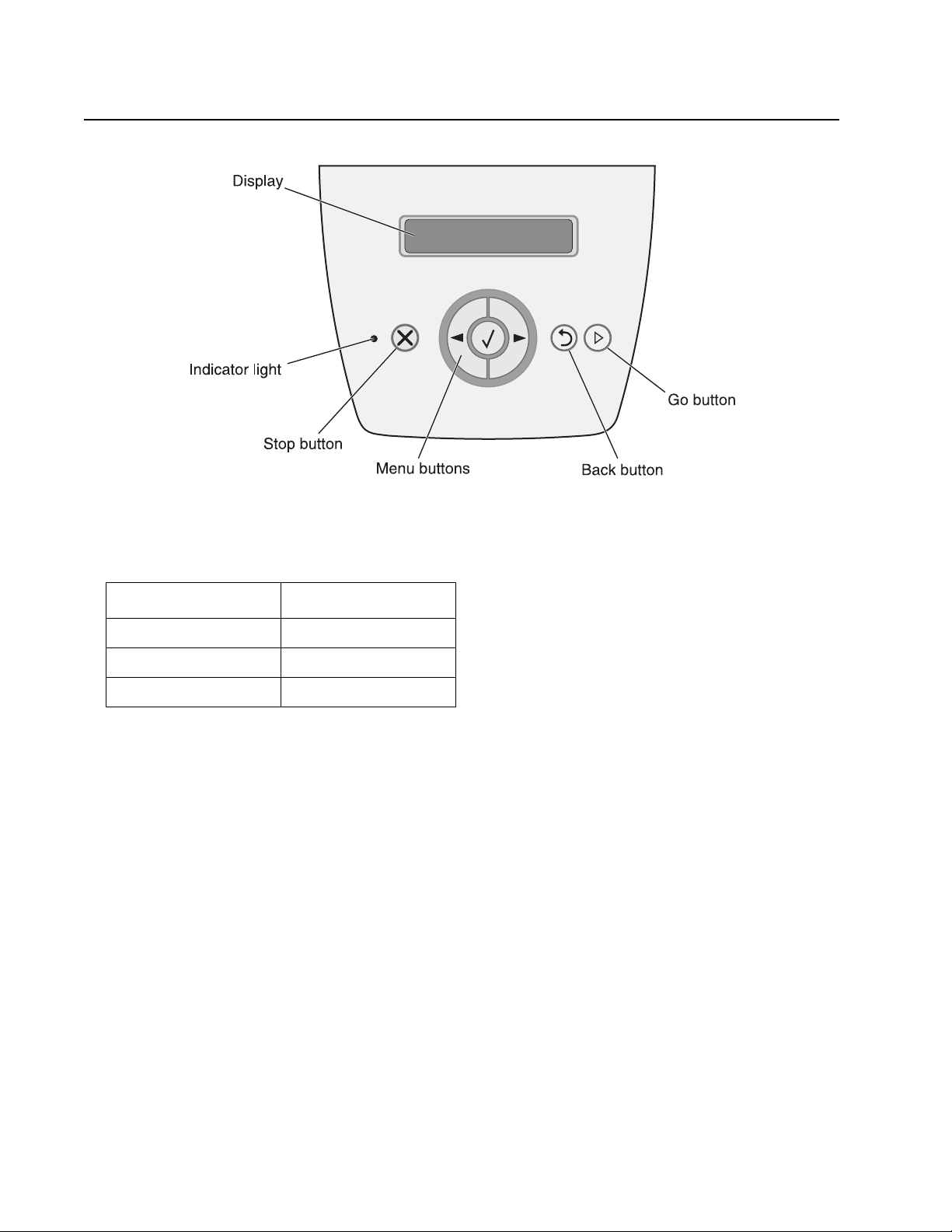

Overview of the operator panel

The operator panel consists of these items:

• A 2-line liquid crystal display (LCD) that shows text

• Six buttons: Stop , Menu (with Left Menu , Select , and Right Menu ), Back , and Go

• An indicator lig ht

A label located on the in side front door shows the operator panel buttons. An additional translated label is

included in the printer box.

1-2 Lexmark™ E350d, E352dn

Page 15

4512-420, -430

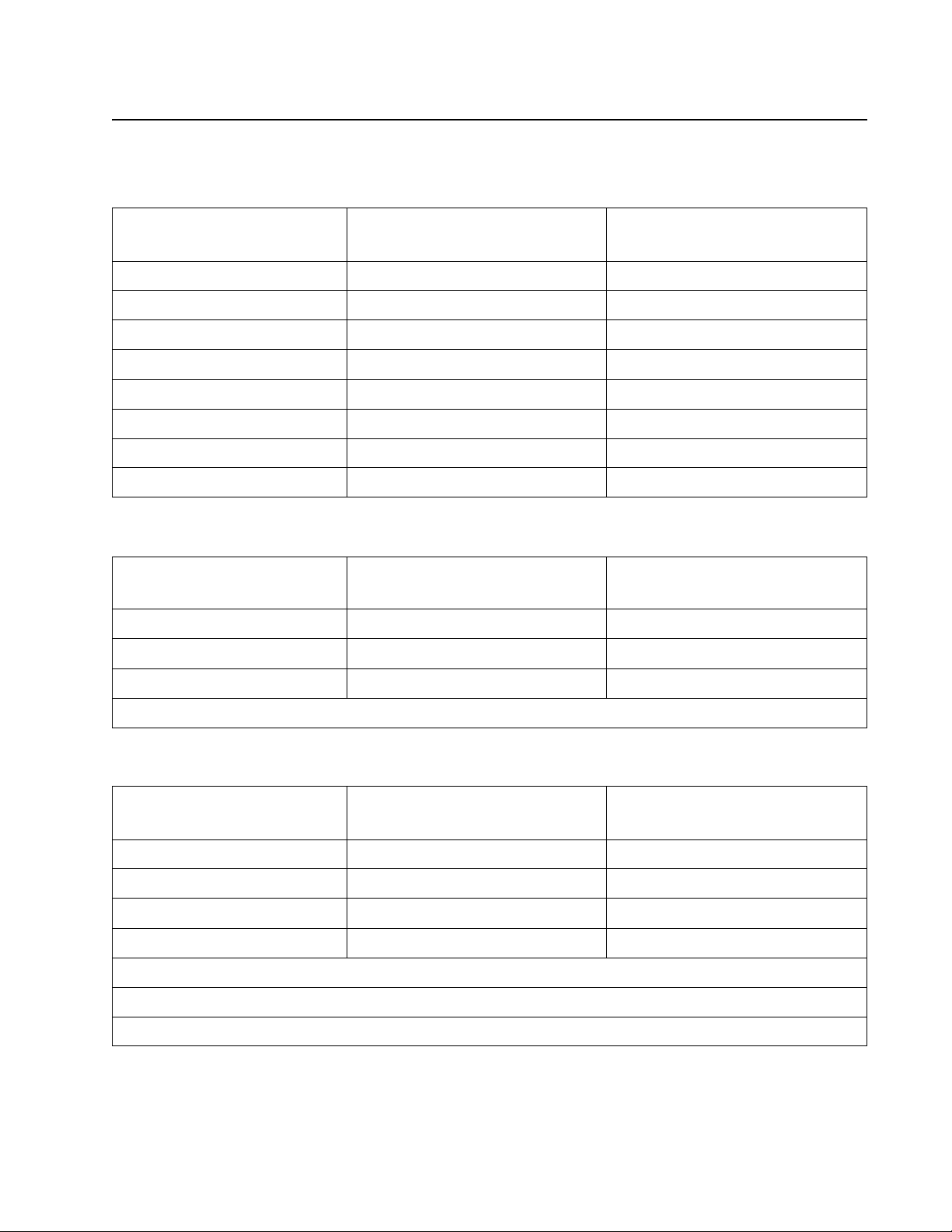

Specifications

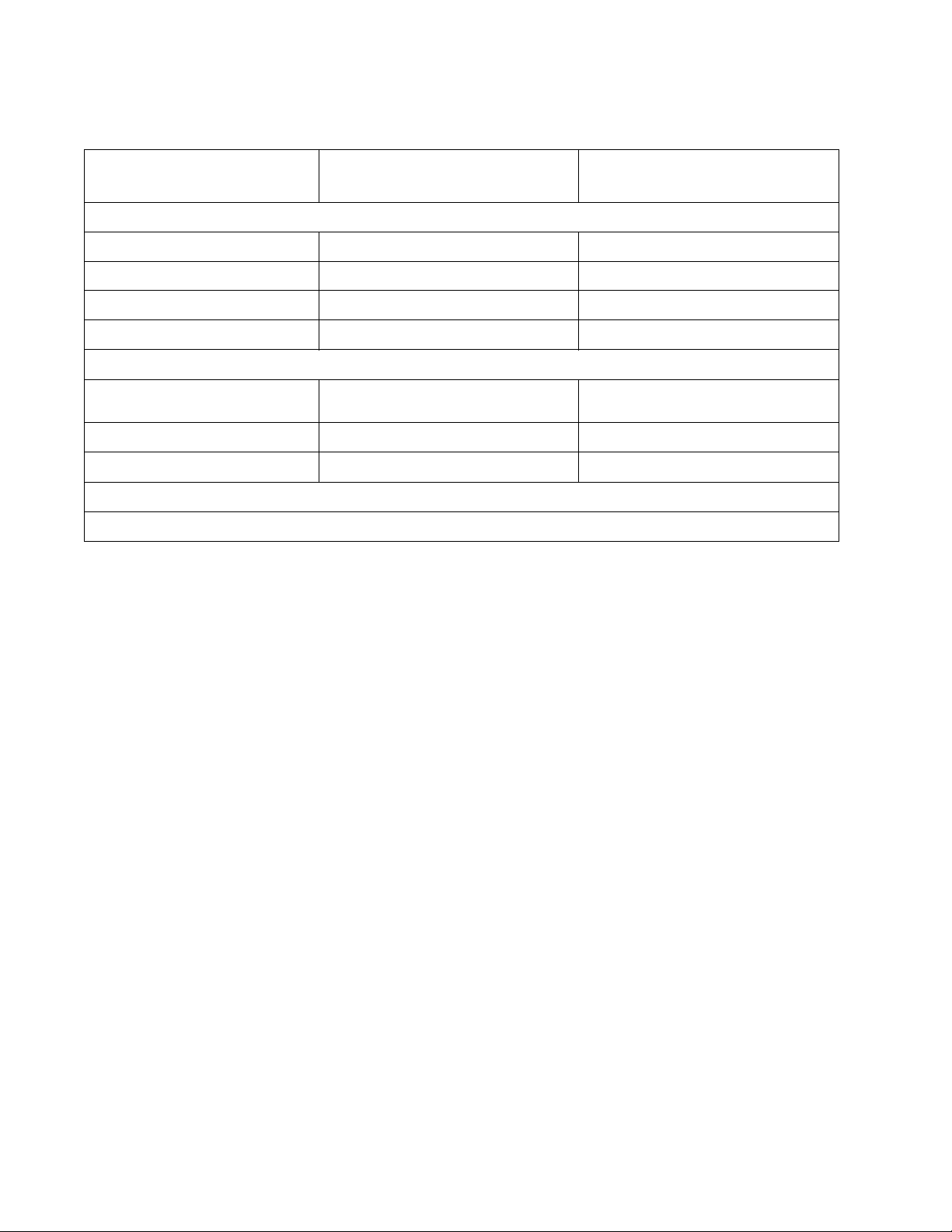

Memory

Item

Standard DRAM 32MB 32MB

Optional SDRAM 32MB ✔✔

Optional SDRAM 64MB ✔✔

Optional SDRAM 128MB ✔✔

Optional SDRAM 256MB n/a n/a

Maximum DRAM 160MB 160MB

Optional flash memory 32MB ✔✔

Optional f ont cards (DBCS) ✔✔

4512-420

Lexmark E350d

4512-430

Lexmark E352dn

Print spee d

Media Size

Letter—8.5 x 11 in. 35 ppm 35 ppm

A4—210 x 297 mm 34 ppm 34 ppm

4512-420

Lexmark E350d

4512-430

Lexmark E352dn

Legal—8.5 x 14 in. 29ppm 29ppm

Speed measured on media from tray 1, simplex, and at 600 x 600 dpi.

Print qua lit y

Resolution

1200 Image qualit y ¹ ✔✔

2400 Image qualit y ² ✔✔

1200 x 1200 dpi ³ ✔✔

600 x 600 dpi ✔✔

¹ 1200 Image quality defined as 600 dpi with 2 bit IET (image enhancement technology) default mode for all models

² 2400 Image quality defined as 600 and 4 bit IET

³ True 1200 dpi at ½ rated speed.

4512-420

Lexmark E350d

4512-430

Lexmark E352dn

General inf ormation 1-3

Page 16

4512-420, -430

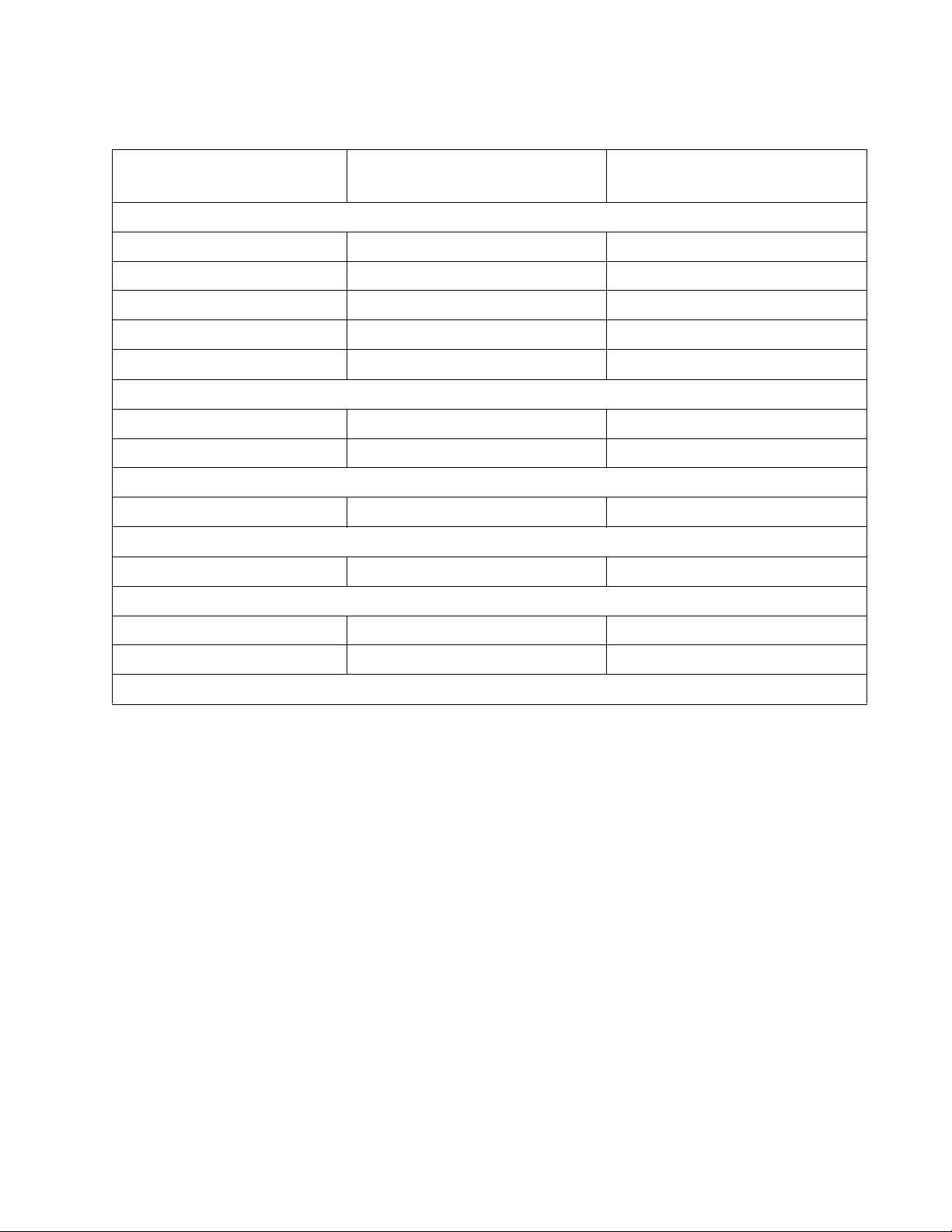

Medi a trays and supply capacity

Item

Available input trays

250-sheet tray ✔✔

550-sheet option drawer ✔✔

550-sheet tray ✔✔

Dust cover ✔✔

Toner and photoconductor

Toner cartridge 1,500 standard pages SWE¹

3,500 standard pages SWE¹

High toner cartridge 9,000 standard pages¹ 9,000 standard pages¹

Photoconductor kit Up to 30,000 ² Up to 30,000 ²

¹ Declared value in accordance with ISO/IEC 1975 2

² Based on approximately 5% coverage, actual yield may vary

4512-420

Lexmark E350d

2,500 standard pages SWE¹

3,500 standard pages SWE¹

4512-430

Lexmark E352dn

1-4 Lexmark™ E350d, E352dn

Page 17

4512-420, -430

Connectivity and compatibility

Item

Data stream emulations

PCL 6 ✔✔

Pos tScri pt 3 ✔✔

HBP ✔✔

PPDS ✔✔

Compatibility Windows/Macintosh/Linux Windows/Macintosh/Linux

Standard local connections

Parallel (IEE 1284 Bi-Di) ✔✔

USB* ✔✔

Standard network connections

Ethernet (10/100 Base TX) n/a ✔

Optional local connections

External print server support ✔✔

Option slots

4512-420

Lexmark E350d

4512-430

Lexmark E352dn

Memory slots (100-pin DIMM) 1 1

Flash memory / option card 2 2

* The E 350d and E352dn products are USB 2.0 certified devices supporting hi-speed (480MB/sec.) data transfer.

General inf ormation 1-5

Page 18

4512-420, -430

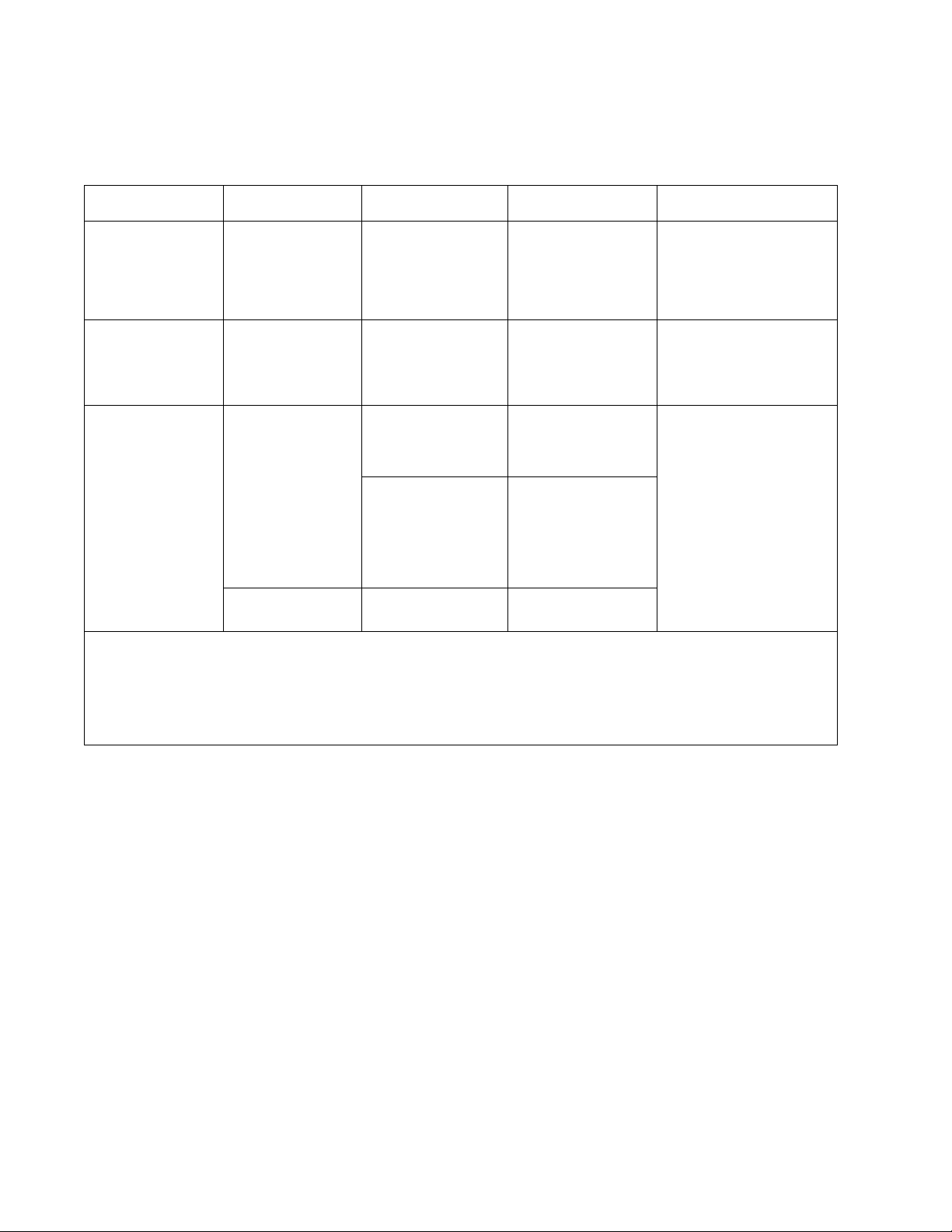

Types of print media

Ensure trays are properly loaded. Never mix media types withi n a tray.

Source Sizes Types Weight Input capacity* (sheets)

Input tra y 1

(250-sheet tr ay)

2nd Drawer option

(550-sheet drawer)

Manual feeder A4, A5, A6 (grain

* Capacity for 20 lb print media, unless otherwise noted.

** Use for occasional printing only.

A4, A5, A6 (grain

long only), JIS B5,

letter, legal,

executive, folio,

statement,

Universal¹

A4, A5, JIS B5,

letter, legal,

executive, folio,

statement,

Universal¹

long only), JIS B5,

letter, legal,

executive, folio,

statement,

Universal¹

7 3/4, 9, 10, DL,

C5, B5

Plain paper, bind,

letterhead,

transparencies,

paper labels (single

sided only)

Plain paper, bond,

letterhead,

transparencies,

paper tables (si nglesided only)

Plain paper,

transparencies,

paper labels (singlesided only)

Card stock² • 120–163 g/m²

Envelopes 75 g/m² (20 lb)

60–90 g/m²

(16–24 lb)

60–90 g/m²

(16–24 lb)

60–163 g/m²

(16–43 lb)

(16–43 lb)

Index Bristol

• 75–163 g/m²

(46–100 lb)

Tag

• 250 paper

• 50 labels**

• 50 transparencies

• 550 paper

• 50 tables **

• 50 transparencies

1

¹ Universal size ranges:

– Manual feeder: 76–216 x 127–356 mm (3.0–8.5 x 5.0–14.0 in.) (includes 3 x 5 in. cards)

² Grain short is recommende d. Use rear exit for best results.

1-6 Lexmark™ E350d, E352dn

Page 19

4512-420, -430

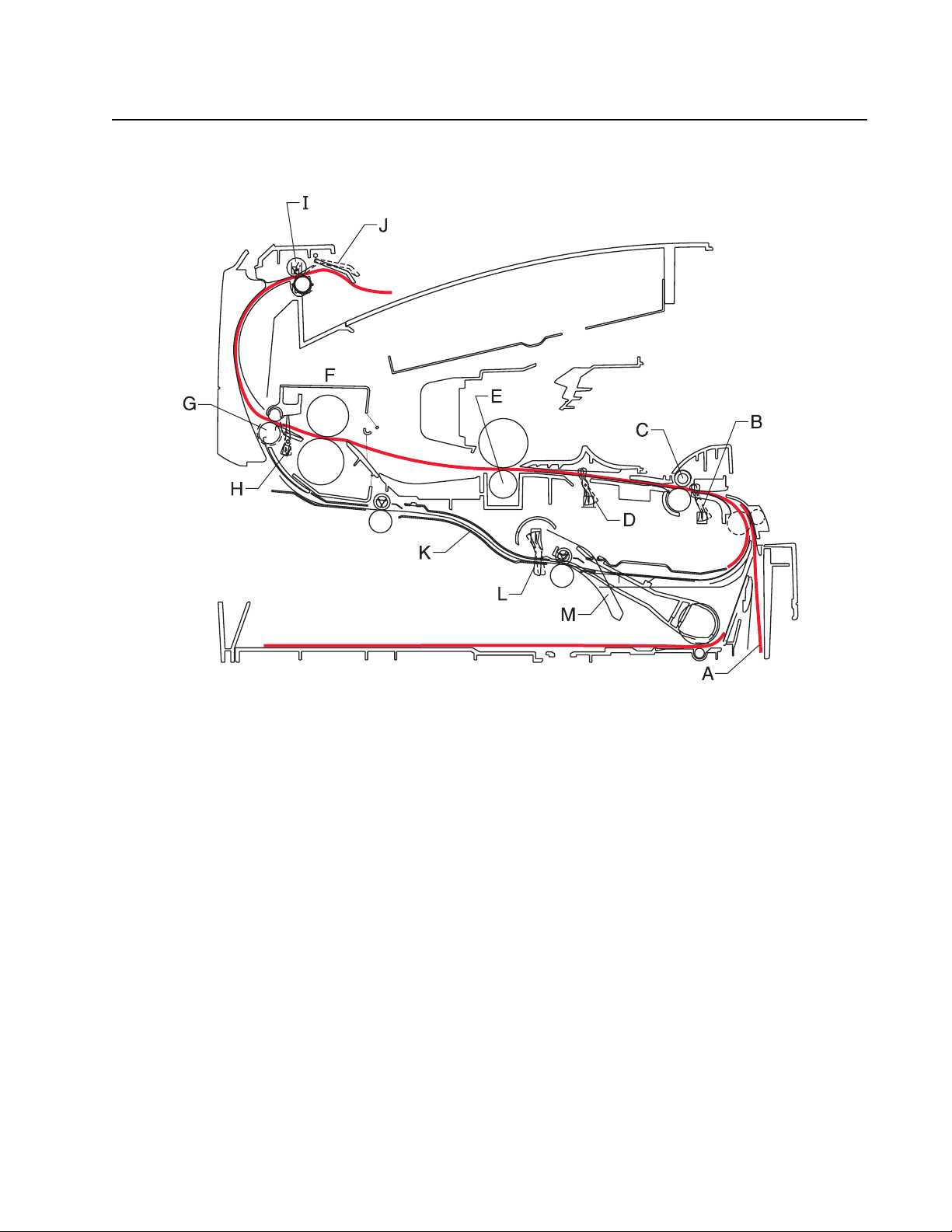

Tips on preventing jams

Paper path

*Measurement s are approximate paper lengths (millimeters)

**Sensors are measured at rotation/position which they are tripped

A Paper path A-B 117.8

B Manual feed sensor B-C 9.6

C Upper end feed rolls C-D 60.5

D Input sensor D-E 49.0

E Transf er roll E-F 110.7

F Fuser F-G 26.9

G Fuser exit rolls G-H 6.2

H Fuser exit sensor H-I 127.2

I Exit rolls I-J 26.4

J Exit sensor I-K 217.4

K Duplex unit K-L 102.5

L Duplex sensor L-M 16.2

M Auto compensator M-B 178.9

General inf ormation 1-7

Page 20

4512-420, -430

Most paper jams can be avoided by correctly loading paper and specialty media in the printer.

The following hints can help prevent paper jams:

• Use only the recommended print media.

• Do not overload the print media sourc es . Make sure the stac k height does not exc eed the maximum hei ght

indicated by the stack line on the labels in the sources.

• Do not load wrinkled, creased, damp, or curled print medi a.

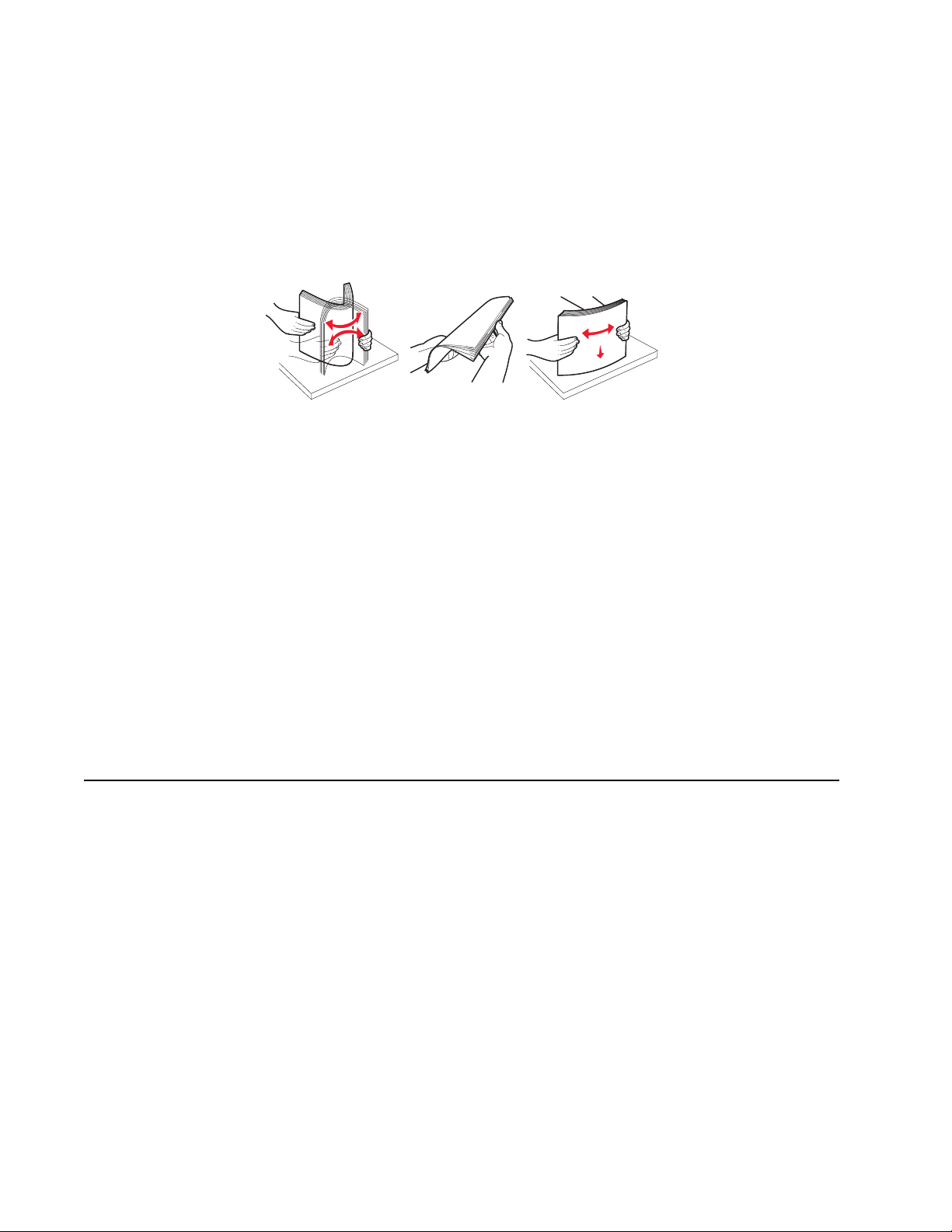

• Flex, fan, and straighten pri nt media before loading it. If jams do occur with the pri nt media, try feeding one

sheet at a time through the manual feeder.

• Do not mix print media sizes, weights, or types in the same print media source.

• Push all trays in firmly after loading the m.

Note: Make sure the media stack is below the maximum media fill indicators on the 250-sheet tray before

pushing the tr ay into the printer.

• Make sure paper guides are positioned before loading the paper or specialty media.

• Do not remove trays while a job is printing.

• Before loading transparencies, fan the stack to prevent sheets from sticking together.

• Do not use envelopes that:

– Have excessive curl

– Are stuck together

– Are damaged in any way

– Contain windows, holes, perforations, cutouts, or embossments

– Have metal clasps, string ties, or metal folding bars

– Have postage stamps attached

– Have any exposed adhesive when the flap is in the seale d position

• Use only recommended media. Refer to the Card Stock & Label Guide available on the Lexmark Web site

at www .l exmark.com for more information about whi ch media provides optimum results for the curr ent

printing environment.

Tools

The remov al and adjustment procedures require the fo ll owing tools and equipment :

• Spring hook

• Needle nose pliers

• Volt-ohmmeter

• #1 and #2 Phillips screwdr ive r

• Slotted screwdriver

1-8 Lexmark™ E350d, E352dn

Page 21

4512-420, -430

Acronyms

ACM Autocompensator Mechanism (or paper feed)

ADC Analog-to-digital Converter

ASIC Application Speci fic Integrated Circuit

CBM Complete Bill Of Material

DEV Development Roll (of print cartridge/photoconductor

DIMM Dual In-Line Memory Module

ENA External Network Adapter

FRU Field Repl ac e a ble Unit

HBP Host Based Printing

HVPS High Voltage Power Supply

LCD Liquid Crystal Diode

LED Light Emitting Diode

LSU Laser Scanning Unit

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

PC Photoconductor

PCL Printer Control Language

POR Power-On Reset

POST Power-On Self Test

PPDS Per sonal Prin ter Data St ream

PRC People’s Republic of China

TAR Toner Add Roll

SDR Synchronous Dynamic RAM

SWE Shipped With Equipment

USB Universal Serial Bus

V ac Volts alternating current

V dc Volts direct current

system)

General inf ormation 1-9

Page 22

4512-420, -430

1-10 Lexmark™ E350d, E352dn

Page 23

4512-420, -430

2. Diagnostics information

Start

CAUTION: Un plug power from the printer before connecting or disconnecting any cab le,

assembly, or elect roni c card. This is a precaution fo r personal safety and t o prev ent damage to the

printer.

This chapter contains the codes and diagnostic tools to aid in providing corrective action for a malfunctioning

printer . To determine the corrective action to repai r a printer, look for the following information:

• A description of a problem, see “Symptom tables” on page 2-15.

• Information from the operator panel of the printer.

– Models E350d and E352dn ha ve an operator panel with messages. See “Overview of the

operator panel and menus” on page 2-2.

Power–On Self Test (POST) sequence

The foll owing is an example of the events that occur during the POR sequence when the printer is turned on.

1. Diamonds are displayed on the operator panel.

2. While code is being loaded into DRAM, dots scroll across the operator panel.

3. A screen is displayed wi th th e memory and processor speed. A typical example of this message is:

*

32 Mb 366 Mhz

4. Performing Self Test is dis playe d.

5. Busy is displayed.

6. Close Door will be displayed if the cover is open.

7. Any cartridge err ors, such as Defective Cartridge, are displayed.

8. Applicable maintenance messages are displayed.

9. Applicable toner low mess ages are display ed.

10. The printer displays Ready.

Diagnostics information 2-1

Page 24

4512-420, -430

Overview of the operator panel and menus

Indicator light

The indicator light gives information about the status of the printer.

If the light is The printer is

Off Off

On On, but idle

Blinking On and busy

2-2 Lexmark™ E350d, E352dn

Page 25

4512-420, -430

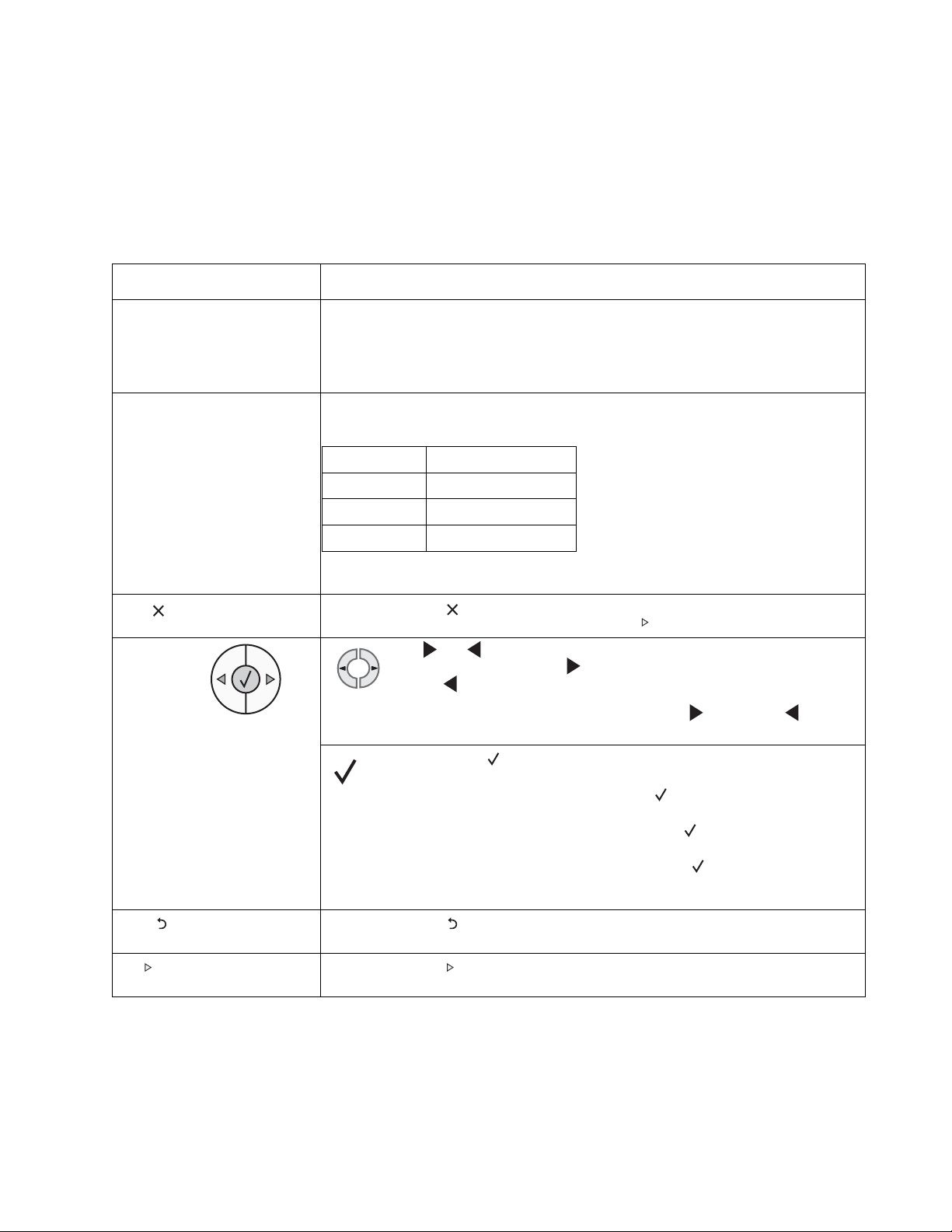

Buttons

Use the six operat or panel buttons to open a men u, scr oll through a list of values, change printe r set tings, and

respond to printe r messages.

Note: Buttons act on the information di splayed on the second line of the operator panel.

The use of the buttons and the layout of the display are desc ribed in the following table:

Button or control panel item Function

Display The display shows messages describing the current state of the printer and indicating

Indicator li ght A green LED is used on the di splay, including the printer status.

Stop Press and release to stop the mechanical operation of the printer. The Not Ready

Menu buttons The and butt ons are used to enter a menu gr oup . Once a m enu gro up

possible printer problems that must be resolved.

The top line of the displ ay is the header line. It will display the current status and the

Supplies (Warnings) status. This is where printer status, supplies messages, and

show -m e screen s are vi ew ed .

If the light is The printer is

Off Off

On On, but idle

Flashing On and busy

message will appear. Operation will resume when is pressed.

is active, press and release to step to the next selection, or press and

release to step to the previous selection.

These buttons can also be used to automatic all y increase or decrease the

desired number of copies.

Press and release to initiate acti on on a selection.

Selects the menu selection displayed on the second lin e o f th e display. If a

menu is displayed such as Paper Menu, then opens t he menu and displays

the first printer setting contained in the men u.

If a menu item such as Paper Source is displayed, then opens the item and

displays the default setting.

If a menu item such as Manual Feeder is displayed, then saves the selection as

the new default setting fo r Paper Source. The printer will display the Saved message

momentarily and then return to the menu item level .

Back Press and release to return to the previous menu group. If at the top of the menu

Go Press and release to place the printer in the Ready state af ter an of f line sit uatio n (to

group , the button functions as a Go button.

exit menus, to clear most messages).

Diagnostics information 2-3

Page 26

4512-420, -430

Diagram of the printer menus

Not all menus or selections will be available on all models or in all situations. These are accessed through the

driver.

Paper Menu

Paper Source

Pape r S i z e

Pape r Type

Custom Types

Universal S etup

Substitute Size

Paper Texture

Pape r Weig h t

Paper Loading

PostScript Menu

Print PS Error

Finishing Menu

Duplex

Dupl ex B i n d

Copies

Blank Pages

Collation

Separator Sheets

Separator Sour ce

Multipage Print

Multipage Order

Multipage View

Multipage Border

PCL Emul Menu

Font Source

Font Name

Pitch

Symbol Set

Orientation

Lines pe r Page

A4 Width

Tray Renumber

Auto CR after LF

Auto LF after CR

Utilities Menu

Quick Demo

Print Menus

Print Stats

Print Net Setup

Print Fonts

Print Demo

Factory Defaults

Hex Trace

Setup Menu

Eco-Mode

Quiet Mode

Print er La ng uage

Power Saver

Resource Save

Print Timeout

Wait Timeout

Auto C o ntinue

Jam Recovery

Page Protec t

Print area

Display Language

Toner Alarm

Job Menu

Reset Printer

Quality Menu

Print Resolution

Toner Darkness

Small Font Enh.

PPDS (if activated)

Orientation

Lines pe r Page

Lines pe r inch

Page Format

Character Se

Best Fit

Tray 1 Renumber

Auto CR after LF

Auto LF after CR

2-4 Lexmark™ E350d, E352dn

Parallel Menu

Std Parallel

Network Menu

Standard Network

USB Menu

Standa r d US B

Page 27

4512-420, -430

Messages and error codes

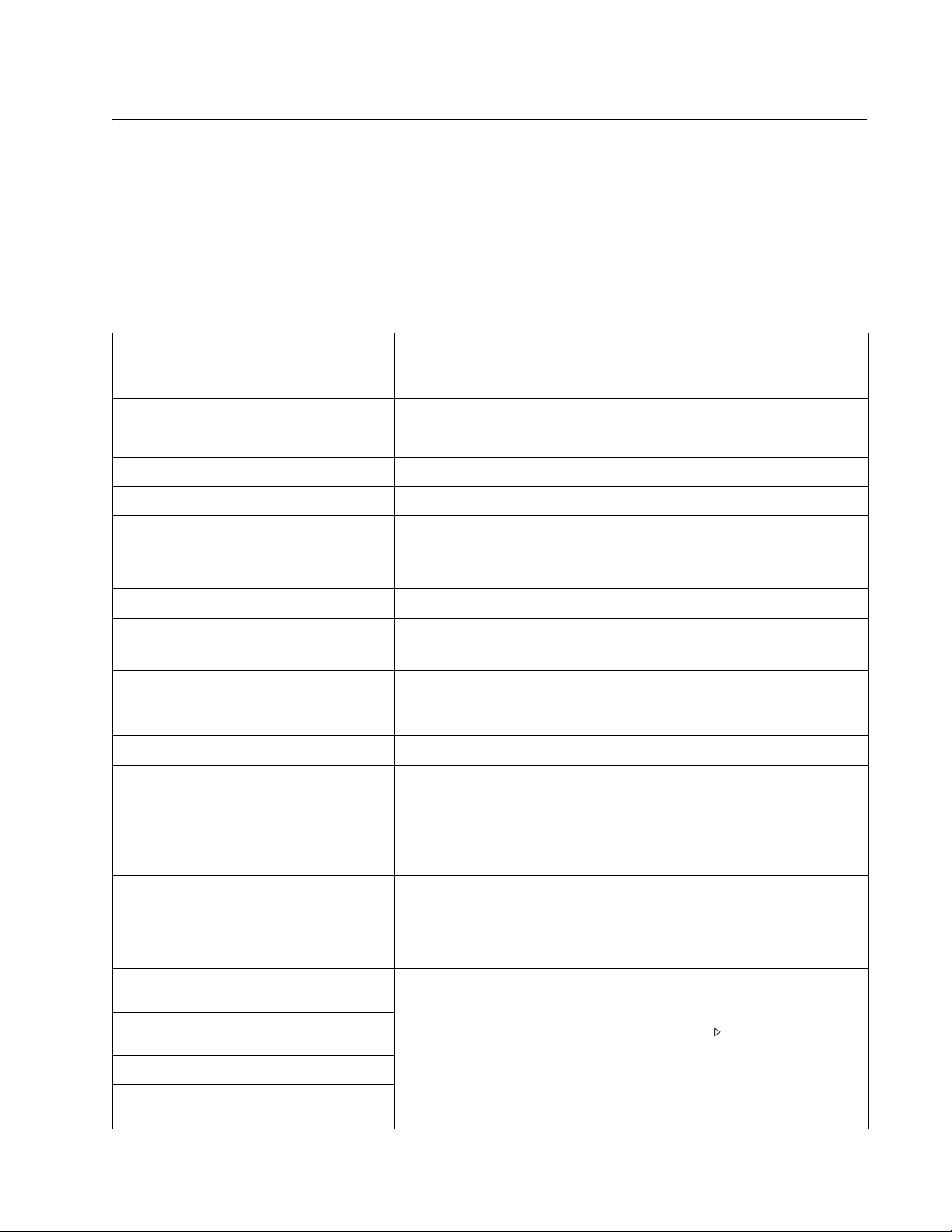

User attendance messages

The printer control panel displa ys m essages describing the cur rent state of the printer and indicates possible

printer problems that must be resolv ed. This topic provides a list of all printer messages, expla ins what they

mean, and tells how to clear the messages.

The foll owing table lists the messages in alphanumerical order. A message can also be located using the index.

User attendance messages

Message Action

Activa ti ng De mo Mode Wait for the message to clear.

Activa ti ng Me nu Changes Wait for the message to clear.

Activating/Deactivating PPDS Wait for the message to clear.

Busy Wait for the message to clear, or cancel the prin t job.

Cancel li ng Jo b Wait for the message to clear.

Change Cart ri dge Invali d Ref ill The printer has detected an unsupported refilled cartridge. Remove the

Close do or Close the specified door to clear the message.

Deacti va tin g Demo Mode Wait for the message to cl ear.

Defragmenting Flash DO NOT POWER

OFF

Disabling Menus Wait for the message to clear.

Enabling Menus Wait for the message to clear.

Flushing Buffer Wait for the message to clear.

Format ti ng Fl ash DO NOT POWE R

OFF

Invali d Eng in e Code Download valid engine code to the printer.

Invali d Sta nd ard Networ k Cod e The code in an internal pri nt server is not val id. The printer cannot re ceive

indicated print cartridge, and install a new one.

Warning: Do not turn the printer off while this mess age is display ed.

Wait for the message to clear.

Note: The printer settings cannot be changed from the contr ol panel while

the m e nus are disabl ed .

Warning: Do not turn the printer off while this mess age is display ed.

Wait for the message to clear.

and process jobs until valid code is programmed into the internal print

server. Download valid code to the internal print server.

Note: The network code can be downloaded whi le this message is

displayed.

Load manual feeder with <Custom

Type>

Load manual feeder with <Custom

String>

Load manual feeder with <size>

Load manual feeder with <size>

<type>

• Load the specifi ed med ia i n the manual feed tr ay or multipurpose

feeder.

• To ignore the manual feed request and print on media already

installed in one of t he input sources, press .

If the printer fi nds a tray that has media wi th the correct media type

and size, it feeds media from that t ray. If the printer cannot find a

tray with the correct media type and size, it prints on whatever

medi a i s in s t a l led in t h e defaul t i n pu t sour c e.

• Cancel the current job.

Diagnostics information 2-5

Page 28

4512-420, -430

User attendance messages (Continued)

Message Action

Load <src> with <Custom Type

Name>

Load <src> with <Custom String>

Load <src> <size>

Load <src> <type> <size>

Maintenance Replace the maintenance items and, if necessary, reset the printer

Menus Di sab le d The printer menus are disabled. The printer settings cannot be changed

Network A network in ter face is the active communication li nk.

Networ k Car d Bu sy An internal print server (also called an internal network adapter or INA) is

Not Read y The printer i s not ready to rece iv e or process dat a. Someone p res sed to

Parallel A parallel interface is the active com m unication link.

Perfor mi ng Se lf Test The printer is running the series of start-up tests it performs after it is

• Load the input source with the correct type and siz e med ia.

• Cancel the current job.

maintenance cou nter.

from the control panel.

Note: A job can still be canceled.

Contact a system support person.

being reset. Wait for the message to clear.

take the printer offline. Press to make the printer ready to receive jobs.

turned on. Wait for the message to cl ear.

Power Sa ver • Send a job to print.

• Press to warm the printer to normal operating temperature and

display the Ready message.

Printing Directory List The printer is processing or print ing a directory of all files sto red in flash

Printing Font List The printer is processing or printing a list of all available fonts for the

Printing Menu Settings The printer is processing or printing the menu settings page. Wait for the

Printing Device Statistics The printer is printing statist ical information about the printer. Wait for the

Printing Quality Test Pages The print er is formatting and printi ng the Print Quality Test, which consists

Prog Engine Code

DO NOT POWER OFF

Progra m Fla sh

DO NOT POWER OFF

memory. Wait for the message to clear.

specified printer language. Wait for the message to cl ear.

message to clear.

message to clear.

of 4 pages. Page 1 contains a mixtur e of graphics and te xt, pages 2 and 3

contain only gr aphics, and page 4 is a blank page. If Duplex is tu rned on,

then the pages are duplexed; oth erwise they are simplexed. Wait for the

message to clear.

The printer is progr am ming new engine code. Wait for the mess age to

clear and the printer to reset.

Warning: Do not turn the printer off while this mess age is display ed.

The printer is storing resources, such as fonts or macros, in flash memory.

Wait for the message to clear.

Warning: Do not turn the printer off while this mess age is display ed.

2-6 Lexmark™ E350d, E352dn

Page 29

4512-420, -430

User attendance messages (Continued)

Message Action

Prog System Code

DO NOT POWER OFF

Ready Send a job to print.

Remove Paper Standard Bin The standard output bin i s ful l.

Resetting Maint Cnt Valu The printer is resetting the counter that tracks wear on the fuser.

Resett in g PC Cn t Value The printer is resetting the counter that tracks wear on the photoconductor.

Resetting the Printer Wait for the message to clear.

Res Redu ced The printer is reduci ng the resolution of a page in the current jo b from 600

Restoring Factory Defaults Wait for the message to clear.

The printer is progr am ming new system code. W ait for the mess age to

clear and the printer to reset.

Warning: Do not turn the printer off while this mess age is display ed.

dots per inch (dpi) to 300 dpi to prevent a 38 Memory Full error. Res

Reduced remains on the display while the job prints.

Note: When factory def ault settings are rest ored:

• All downloaded resources (fonts, macros, symbol sets) in the

printer memory are deleted.

• All menu settings return to the factory default except:

– The Display Language setting in the Setup Menu

– All settings in the Parallel Menu, Network Menu, and

USB Menu

Std Bin Ful l The standard bin is full.

Toner Lo w • Replace the toner cartridge.

• Press to clear the mes sage and continue printing.

Tray <x> Missing Insert the tray into the printer.

USM The printer is processi ng data through the specified USB port.

Waiting The printer has received a page of data to print , but is wai ting f or an End of

Job command, a Form Feed command, or additional data.

• Press to print the contents of the buffer.

• Cancel the current job.

Diagnostics information 2-7

Page 30

4512-420, -430

Cartridge error messages

Error Description

31 Defec tiv e ca rtridge

32 Unsup por te d print cart rid ge

33 Inval id re fi ll

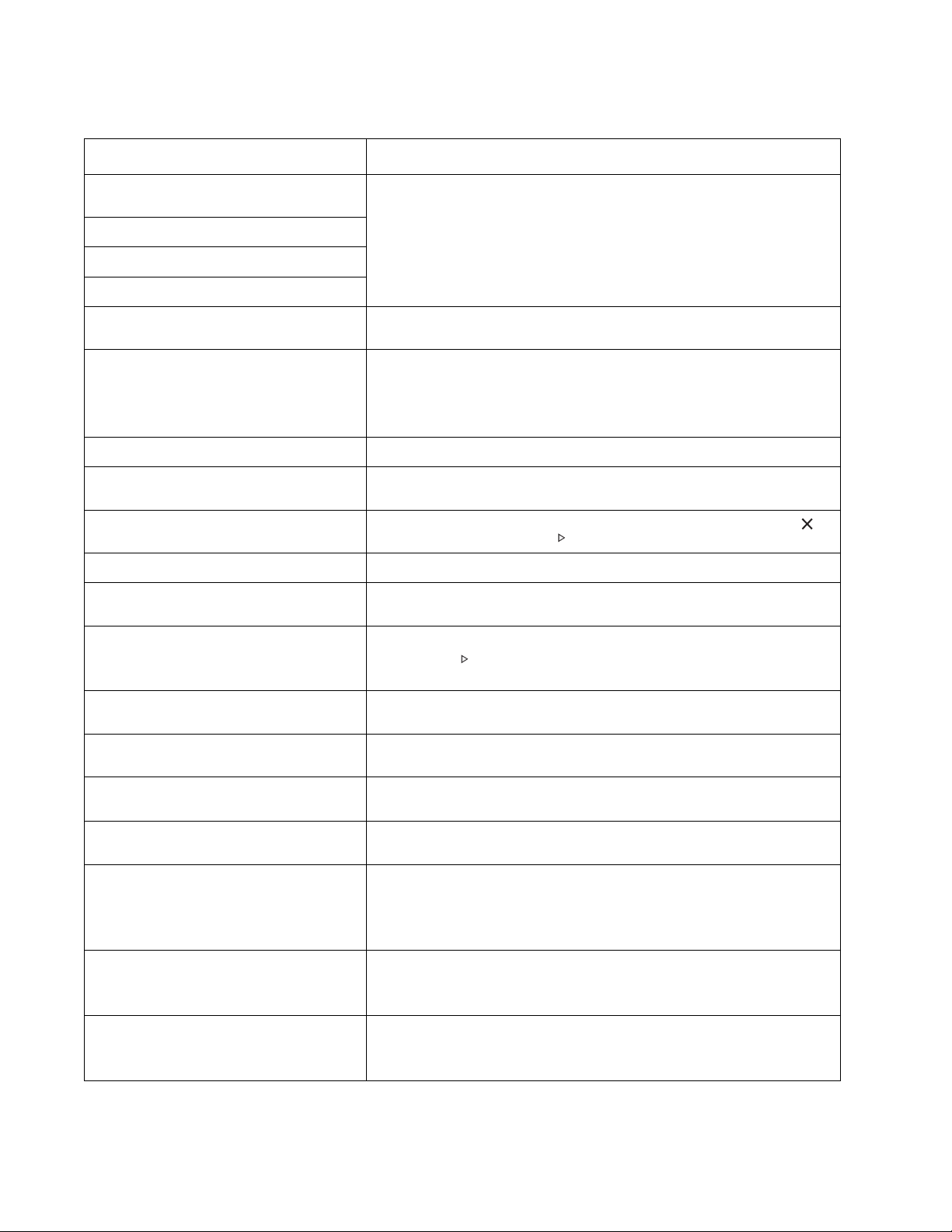

Paper jam error codes (200-series)

Note: The Event log (See “Event log” on page 3-21) will list any of these er rors that have occ urred.

Repeating jams or jam messages can be caused by any of the following:

• Fau lty/contaminated pick solenoids or worn cams of the solenoids.

• Faulty/contaminated flags or springs.

• Debris in the paper path.

• Media not of the specifi ed length.

Paper jam error codes (200-series)

Error Description

200.00 Paper jam around input sensor.

200.01 Classic input jam. The media is too long ov er the input sensor. Possible causes include multi-sheet feed, tray

200.02 The main input sensor never became uncovere d fro m the sheet ahead.

200.03 The video never started on the page at the input sensor within two inches after hitting the input sensor

200.04 The media at the input sensor before interrupt occurred - not enough time elapsed since the printhead started

200.06 Imaged page not expected page (bounc y passthru sensor)

200.08 Media reached the input sensor before the EP was ready

200.09 Transfer servo never started

200.12 Media detected at manual feeder sensor when not expected. Possible causes include user insert of media

200.13 The input sensor is covered when th e media is not expected (media in machine during warm-up)

200.14 Trailing edge cleared m anual feed, but did not success ful ly debounce the sensor. Potential causes are a small

200.15 UNRECOVERABLE NO GAP JA M. Engine detected no gap at the manual feeder sensor, attempted to open

size sensing problem, and media slippage.

to expect the printhead mirror motor loc k. Possible causes include bouncy sensor or exceptionally fast pick perhaps due to media pre-s taged in the source tray.

when motor is running or pre-staged media in the tray.

gap or a bouncy manual feed sensor.

the gap by stopping the feed rolls, but no trailing edge was ever seen at th e input sensor.

200.16 Transport motor error detected

200.17 Took too long to ramp up transport motor

200.18 Manual feeder sensor never became uncovered from the sheet ahead.

200.19 The media never reached the input sensor, but was detected at manual feeder sensor.

2-8 Lexmark™ E350d, E352dn

Page 31

4512-420, -430

Paper jam error codes (200-series) (Continued)

Error Description

200.20 The media is too long over the manual feeder sensor. Possible causes include multi-shee t f eed, media size

200.22 FAILED SMALL GAP OR NO GAP JAM RECOVERY. Engine detected small gap or no gap at the manua l

200.23 Laser Servo never started due to potential conflict with the tr ansfer servo. Possible cause s: sl ow or missing

200.24 The measured gap at the input sensor is too small to meet the video delivery requirements. (There i s not

200.26 The trail ing edge never cleared the input sensor when f eeding out the media that was detected during warm-

200.27 Printhead Driver: Mirror motor fel l out of lock condit ion after the media at t he input sensor - more time el apsed

200.28 First writing line of a page at the dev eloper nip, b ut laser servo cleanup is not co mplete. Likely pre staged

200.29 Printhead drive control out of range due to an external event beyond what the control is designed to handle.

200.30 Narro w media sensor covered during warm-up.

200.32 Media more than 14 inches too long over the manual feeder sensor. Possible causes include multi-sheet feed

(length) problem, pre-staged media in the tray.

feeder senso r , opene d the gap b y s toppi ng the feed rolls, but nev er sa w the l eading ed ge of th e seco nd pag e at

the input sensor.

transport motor positi onal feedback, or the media is transf erred too quick ly t o the input sensor.

enough time since prior image finished to start new image)

up.

since the printhead than the expected stab le lock time, but less than the printhead jitter-stab le specification.

Mirror motor fell out of lock condit ion after media at the input se nsor - more time elapsed since the printhead

than expected stable lock time, but less than the pri nthead jitter-stab le specification.

media or a fast paper feed.

Probable causes: ESD or noise on hsync signal.

or pre-staged media in the tray.

200.33 Page from tray 1 did not reach the input sensor after multiple attempts. Page did make it out of the t ray at least

200.34 Timed out waiting for page from tr ay 1 to reach the input sensor after multiple pick attempts, but the page was

200.35 Failed to create hsync during auto alignment

200.36 Lost hsyncs during auto alignment

200.37 Timeout on data collection during auto align me nt

200.38 Interpage servo gap is sma ll er than expected f or printhead offset target evaluat ion

201.00 Paper jam between input and exit sensor

201.01 Transport motor identificati on failed to identify either motor after two tries.

201.02 Exit sensor never made by leading edge of page. Also known as internal jam.

201.03 Video never started on the page at the input sensor within two inches after hitting the input sensor

201.05 Restart attempted after an internal jam without the cover open/close event. It is likely that the jam was never

201.25 Exit sensor never made by leading edge of media when feeding out the media th at was detected during wa rm-

201.26 Page at fuser nip before fuser started ramping tow ard desired temperatu re. Indicates code may be receiving

as far as the manual feeder sensor. Possible cause is that the page stalled at the alignment gate.

later detected at the input sen sor while w ait ing for any page(s ) ahead to clear t he pap er path. P ossi b le caus e is

that the page is delayed at the alignment gate.

cleared.

up.

more hall interrupts than intended

Diagnostics information 2-9

Page 32

4512-420, -430

Paper jam error codes (200-series) (Continued)

Error Description

201.27 Page at fuser nip before fuser reached acceptable operating temperature. Page arrived at fuser earli er than

202.00 Paper jam around exit sensor.

202.01 Exit sensor never broke on the trailing edge of the sheet at the exit sensor.

202.02 Exit sensor never broke from sheet ahead of page heading toward the exi t sensor.

202.06 Exit sensor bounced

202.13 Exit sensor covered, media not expected (media not i n mac hine during warm-up)

202.25 Exit sensor ne v er bro k e from the sheet ahead of th e page heading to w ard the e xit sens or when f eeding out the

202.26 Trailing edge never cleared e xit sensor when feeding out media that was detected duri ng warm-up.

202.32 Long media or shingled multi f eed stopped before sendi ng to duplex.

231.00 Duple x jam while reve rsi ng into the device

231.01 Duple x sensor never made by leading edge reversing into the duplex.

231.02 Bouncy dupl ex sensor never made.

232.00 Duple x jam while staging in the de vice

232.01 Duple x sensor never broke by the sheet ahea d after reversing into the duplex.

232.02 Page in duplex ahead of current reversing page never staged.

expected, so it was probably staged

media detected during warm-up.

233.00 Duple x jam while picking from the device

233.01 Page in duplex never pick ed.

233.02 Feed error picking from the duplex.

233.03 Paper never reached the input sensor, but was dete cted at the manual fee d sensor.

234.01 Duple x sensor covered duri ng warm-up.

235.01 Inv alid duplex medi a

241.00 Paper jam near tray 1.

241.10 Second pic k attempt failed fr om Tray 1

241.12 Second pic k from manual feeder, tray 1, or feeder f ailed when the media was in the source while other sheets

241.16 Failed to feed fro m tray 1. Pages in the paper path hav e been fl ushed to the output bin.

241.17 MISIDENTIFIED SMALL GAP JA M. Engine detected small gap at the man ual feeder sensor, attempted to

241.18 MISIDENTIFIED NO GAP JAM. Engine detected no gap at the manual feeder sensor, attempted to open the

241.19 Second pic k attempted fai led from Tray 1, no pages printed since calli ng a 241.10 or a prior 241.19.

were committed to the paper path.

open the gap by stopping the feed rol ls, traili ng edge was seen at the input sensor, m anual feeder sensor is no

longer covered.

gap by stopping the feed rolls, t railing edge was seen at the input sensor , manual feeder sensor is no longer

covered.

242.00 Paper jam near tray 2.

2-10 Lexmark™ E350d, E352dn

Page 33

4512-420, -430

Paper jam error codes (200-series) (Continued)

Error Description

242.01 Took too long to ramp up dc feed motor

242.08 Receiv ed lots of dc feed interrupts before losi ng them

242.10 Second pic k attempt failed fr om Tray 2

242.12 Second pic k from manual feeder, tray 1, or feeder f ailed when media was in the source, other sheets were

242.16 Failed to feed fro m tray 2. Pages in the paper path hav e been fl ushed to the output bin.

251.00 Paper jam near the manual feeder.

251.10 Second pic k attempt failed fr om manual feeder.

251.11 Failed to feed fro m manual feeder. Pages in the paper path have been f lushed to the output bin.

251.12 Second pic k from manual feeder, tray 1, or feeder f ailed when media was in the source while the other sheets

251.19 Media never reached the input sensor from the manual feeder.

committed to the paper path.

were committed to the paper path.

Diagnostics information 2-11

Page 34

4512-420, -430

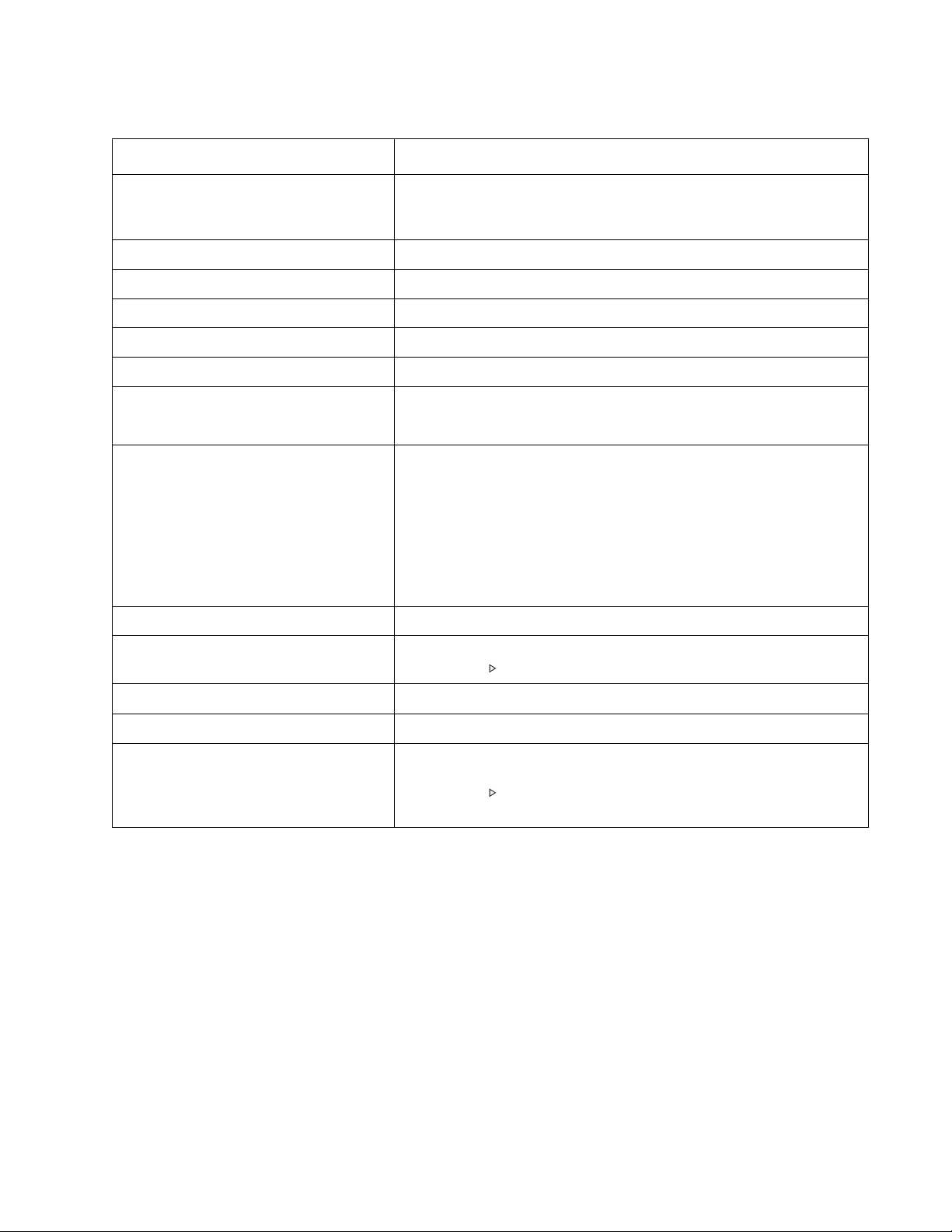

Service error codes

Service error codes are gener ally non-recoverable except in an intermittent condi tion when the printer can be

put into POR to temporarily recover fro m the error condition.

Service error codes (9xx)

Error Description

Engine software service errors

902.xx Engine software error

Transfer service errors

917.00 Transfer service error

917.01 Transfer servo result too low.

Fuser service errors

920.00 Under temperature during steady state control.

920.01 Fuser took too long to heat up after transitioning to new enhanced mode.

920.02 Fuser fell too far below des ir ed temperature while printing.

920.03 Fuser too cool whi le checking for slope change.

920.04 Fuser too cool when heating to desired temperatur e after slope change.

920.05 Fuser under temperature while printing

920.06 Fuser under temperature while printing

920.07 Fuser under temperature while printing

920.08 Fuser temperature did not increase after IR recovery.

920.20 Belt fuser unde r temperature during steady st ate control. This can occur in prin ti ng or standby modes .

921.00 Under temperature during standby control.

921.01 Fuser temperature did not reach standb y temperature after two attempts

922.00 Fuser failed to ramp to target temperature

922.01 Fuser did not reac h standby temperature in time (standby control)

922.07 Media reached fuser nip and fuser is under temperature

922.08 Fuser warm-up failure (motor start conditi on)

922.09 Fuser warm-up failure (compres sion set)

922.20 Belt fuser failed to reach the preheat temperature for the motor to start during warm-up.

922.21 Belt fuser was under temperature when the media reached the fuser nip.

923.00 Fuser is over temperature.

923.01 Fuser is over temperature. This applies to the fuser and belt fusers.

924.00 Open thermistor check.

924.01 Open thermistor chec k failure . This applies to the fuser and belt fusers.

2-12 Lexmark™ E350d, E352dn

Page 35

4512-420, -430

Service error codes (9xx) (Continued)

Error Description

924.02 Open thermistor check failure. The ADC failed to converge. Possible noisy thermistor signal. This applies to the

Fan service errors

927.00 Service fan error

927.03 Main fan took too long to ramp up

927.04 Main fan is under speed or stalled during sp eed adjustment state

927.05 Main fan overspeed during speed adjustment state.

927.06 Main fan capture data is invalid and speed control is at maximum in fan control idle state

927.07 Main fan capture data is invalid and speed control is at maximum in fan control adjustment state.

Printhead service errors

931.00 No first hsync

931.01 No first hsync

932.00 Lost hsyncs

932.01 Lost hsyncs

933.00 Printhead boost signal fai lure

935.10 Printhead s w eep error, s wept through Hz range wi thout finding the resonant fr equency

fuser and belt fusers.

935.11 Printhead s w eep error, autosweep hw state

935.12 Printhead s w eep error, coa rse sweep state

935.13 Printhead s w eep error, init fine sweep state

935.14 Printhead s w eep error, fine sweep state

935.15 Printhead s w eep error, che ck prelim amp state

935.16 Printhead s w eep error, ena ble amp Kp state

935.17 Printhead s w eep error, amp Kp f ailed to conv erge

935.18 Printhead s w eep error, ena ble amp Ki state

935.19 Printhead s w eep error, amp Ki failed to conv erge

935.20 Printhead s w eep error, ena ble offset control ler state

935.21 Printhead sweep error , load scan regs state

935.22 Printhead sweep error, fwd and rev capture times differ by too much

935.23 Printhead sweep error, check sweep accuracy state

935.24 Printhead s w eep error, reserved

935.25 Printhead sweep error , detected resonant frequency out of expected range

935.26 Printhead s w eep error, timed out waiting for end of sweep

Transport motor service errors

Diagnostics information 2-13

Page 36

4512-420, -430

Service error codes (9xx) (Continued)

Error Description

936.01 No lock detected at normal motor start

936.02 No lock detected at motor start for motor ID

936.03 No halls detected at motor start

936.04 Fa il ed to stop within timeout

936.05 Stall detected during speed control

937.00 Main transport motor lost lock

937.01 Main transport motor lost lock, detected by engine control

937.02 Overspeed detected during posit ion control

937.03 Oversp eed detected during speed control

Power supply service errors

940.00 LVPS service error

940.01 Line frequency outside allowed range of 45Hz-64Hz

940.02 Line frequency below 43Hz

940.03 No zero cross detected on belt fuser model

2-14 Lexmark™ E350d, E352dn

Page 37

4512-420, -430

Symptom tables

POST symptom table

Symptom Action

The main motor, cooling fan, and fuser do no t come

on.

POST completes, but the LCD does not come on. See “Operator panel service check” on page 2-21.

Main motor does not come on. See “Main motor service check” on page 2-20.

Fan does not come on. See “Cooling fan service check” on page 2-18.

Fuser does not cycle. See “Fuser service check” on page 2-19.

Fuser does not turn on and off. See “Fuser service check” on page 2-19.

The paper feed picks and tries to feed media. See “Paper feed service checks” on page 2-21.

Note: Investigate any displayed codes before proceeding with these sym ptoms. For example, a missing toner cartridge will

prevent PO S T from completing.

See “Cover interlock switch service check” on page 2-18.

Diagnostics information 2-15

Page 38

4512-420, -430

Printer symptom table

Symptom Action

Fan noisy or fan not working. See “Cooling fan service check” on page 2-18.

Fuser parts melted. See “LVPS/HVPS service check” on page 2-20.

Toner not fused to the media. See“Fuser service check” on page 2-19 or “Solving print

Paper jams. See “Paper feed service checks” on page 2-21.

Main motor noisy or not moving. See “Main motor service check” on page 2-20.

Media ske w. See “Paper feed service checks” on page 2-21.

Printer not communicating with host. See “Parallel or USB port service check” on page 2-23.

Front access cover wil l not close. See “Cover interlock switch service check” on page 2-18.

Operator panel button not responding. See “Operator panel service check” on page 2-21.

Operator panel lights are off or very dim. See “Operator panel service check” on page 2-21.

Blank page. See “Blank page” on page 2-24.

Black page. See “Black page” on page 2-25.

Heavy background. See “Heavy background” on page 2-25.

Light print. See “Light print” on page 2-27.

White or black lines or bands. See “White or black lines or bands” on page 2-27.

Toner on back of page. See “Toner on back of page” on page 2-27.

Media never picks. See “Media never picks” on page 2-22.

quality problems” on page 3-28.

Media feeds continuously. See “Media picks during POST and/or continuously” on

Media wrinkled or bent. See “Media “trees,” wrinkles, stacks poorly, or curls” on

Dead machine (no power). See “Dead machine service check” on page 2-19.

Print quality problems

• Light print

• Blurred characters

• Toner on both sides of media

• Toner not fused

• Streaks

• Blank pages

page 2-21.

page 2-23.

See “Solving print quality problems” on page 3-28.

2-16 Lexmark™ E350d, E352dn

Page 39

4512-420, -430

Service checks

Service checks which involve measuring voltages on the LVPS/HVPS (low voltage power supply/

high voltage power supply board) should be performed with the pri nter positioned on its back side.

Note: When making voltage readings, always use frame ground unless another ground is

specified. See the wiring diagram in the back of the book for more information.

Controller card service check

Controller card service check

FRU Action

Controller card