Page 1

Optra

TM

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

E310/E312

4044-XXX

•Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4044-XXX

Edition: July 2000

The following paragraph does not apply to any country where such provisions are

inconsiste nt with local law: LEXMARK INTERNATIONAL, INC. PROV IDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRE SS OR

IMPLIED , INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not

allow disclaimer of express or implied warranties in certain transactions; therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

A form for reader’s comments is provided at the back of this publication. If the form has

been removed, comments may be addressed to Lexmark International, Inc., Department

D22A/032-2, 740 West New Circle Road, Lexington, Kentucky 40550, U.S.A. Lexmark

may use or distribute any of the information you supply in any way it believes appropriate

without incurring any obligation to you. You can purchase additional copies of publications

related to this product by calling 1-800-553-9727. In other countries, contact your point of

purchase.

Lexmark and Optra are trademarks of Lexmark International, Inc., registered in the United

States and/or other countries.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 2000.

All rights reserved.

UNITED STA TES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DF ARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

Page 3

4044-XXX

Table of Contents

Notices and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Laser Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xv

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Service Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

User Error Message Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Power-On Self Test (POST ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Symptom Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Cooling Fan Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Cover Open Switch Service Check . . . . . . . . . . . . . . . . . . . . . . 2-13

Dead Machine Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Fuser Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Main Motor Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Operator Panel Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Operator Panel Button Service Check . . . . . . . . . . . . . . . . . . . . 2-24

Paper Feed Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Print Quality Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Parallel Port Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Print Quality Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

User Mode Print Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hex Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Restoring Factory Defau lts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Engine Clean Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Toggle Demo/Normal Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Printer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-Sensitive Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

iii

Page 4

4044-XXX

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Screw Identification Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Frame Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Fuser Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

HVPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Interconnect Board (model E310) . . . . . . . . . . . . . . . . . . . . . . . .4-12

Engine/LVPS Board (model E310) . . . . . . . . . . . . . . . . . . . . . . .4-13

Engine/LVPS Board (model E312) . . . . . . . . . . . . . . . . . . . . . . .4-15

Main Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Pick Roll Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Transfer Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Controller Board (model E310/E312) . . . . . . . . . . . . . . . . . . . . . .5-1

Engine/LVPS Board (model E310) . . . . . . . . . . . . . . . . . . . . . . . .5-4

Engine Board (model E312) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

LVPS (model E312). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

High Voltage Power Supply (model E310) . . . . . . . . . . . . . . . . .5-16

High Voltage Power Supply (model E312) . . . . . . . . . . . . . . . . .5-18

Interconnect Board (model E310) . . . . . . . . . . . . . . . . . . . . . . . .5-21

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Assembly 2: Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Assembly 3: Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Assembly 4: Main Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Assembly 5: Paper Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Assembly 6: Electronics (model E310) . . . . . . . . . . . . . . . . . . . .6-20

Assembly 6: Electronics (model E312) . . . . . . . . . . . . . . . . . . . .6-24

Assembly 7: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Assembly 8: Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

iv Service Manual

Page 5

4044-XXX

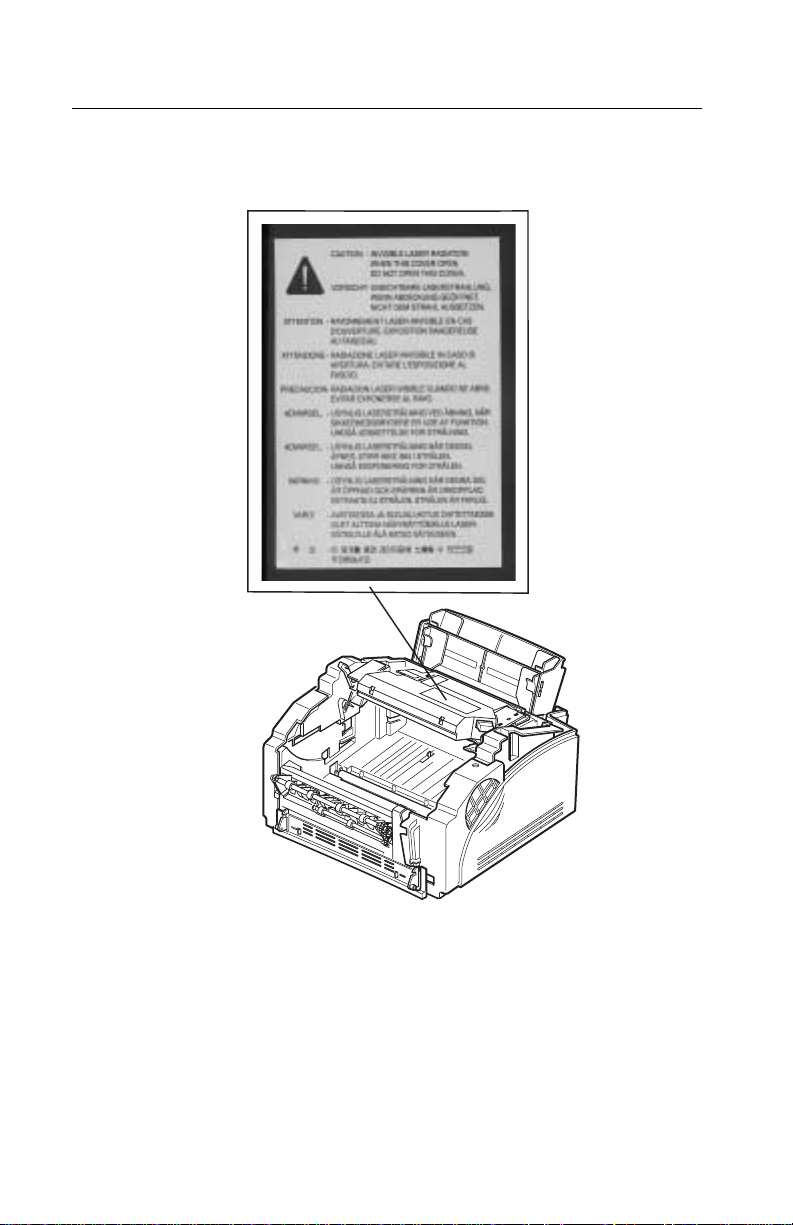

Notices and Safety Information

Laser Notice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and

elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 825.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelength region of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service condition.

v

Page 6

4044-XXX

Laser Advisory Label

vi

Page 7

4044-XXX

Class 1 Laser Statement Label

vii

Page 8

4044-XXX

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Department of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbe tr ie b, bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

Kundendienst Laserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 825 relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des ra yonnements de Classe I .

viii

Page 9

4044-XXX

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della norma CEI 825.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometri. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della classe

1..

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 825 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectada por ningún tipo de radiac ión láser superior al nivel de

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

ix

Page 10

4044-XXX

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformidade com os

requisitos da regulamentação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certificada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 825.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um produto laser da Classe IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. Voor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 825.

Laserprodukten van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebruik, bij onderhoud of

reparatie conform de voorschriften, nooit blootstelling mogelijk is

aan laserstraling boven een niveau zoals voorgeschreven is voor

klasse 1.

x

Page 11

4044-XXX

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser, der nominelt er en 5

milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal drift, brugervedligeholdelse eller

obligatoriske servi c ebet ing el se r.

Huomautus laserlaitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 825 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

xi

Page 12

4044-XXX

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 825.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770795 nanometer. Lasersystemet och skrivaren är utformade så att det

aldrig finns risk för att någon person utsätts för laserstrålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC

825.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut ov er klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceoperasjoner.

xii

Page 13

4044-XXX

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 825.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmet re s. El siste ma làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per sobre d’un nivell de classe I durant una operació normal, durant

les tasques de manteniment d’usuari ni durant els serveis que

satisfacin les condicions prescrites.

xiii

Page 14

4044-XXX

Japanese Laser Notice

Chinese Laser Notice

xiv

Page 15

4044-XXX

Kore an Laser Notice

Safety Inf ormation

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not

always be obvious. Lexmark is not responsible for the use of

other replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injury during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

xv

Page 16

4044-XXX

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation

d'autres pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certai ns risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in

conformità a severi standard di sicurezza e per l’utilizzo con

componenti Lexmark specifici. Le caratteristiche di sicurezza

di alcune parti non sempre sono di immediata comprensione.

Lexmark non è responsabile per l’utilizzo di parti di ricambio

di altri produttori.

xvi

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale di assistenza

autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Page 17

4044-XXX

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit

gültigen Sicherheitsanforderungen zu erfüll en. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen

sind nicht immer offensichtlich. Sofern Teile eingesetzt

werden, die nicht von Lexmark sind, wird von Lexmark

keinerlei Verantwortung oder Haftung für dieses Produkt

übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede

que las características de seguridad de algunas piezas no

sean siempre evidentes. Lexmark no se hace responsable

del uso de otras piezas de recambio.

• La información sobre el mantenimiento de este producto

está dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

xvii

Page 18

4044-XXX

Informações de Segurança

• Este produto foi concebido, testado e aprovado para

satisfazer os padrões globais de segurança na utilização de

componentes específicos da Lexmark. As funções de

segurança de alguns dos componentes podem não ser

sempre óbvias. A Lexmark não é responsável pela u til iz ação

de outros componentes de substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não dev em ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

xviii

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest

producte. El personal professional ha d’estar-ne assabentat i

prendre les mesures convenients.

Page 19

4044-XXX

Chinese Safety Information

Korean Safety Information

xix

Page 20

4044-XXX

xx

Page 21

4044-XXX

1. General Information

This printer is a letter-quality laser page printer designed to attach to

an IBM Personal Computer or other computers compatible with the

IBM Personal Computer (with 386 processor or higher) and

Macintosh Computers via the USB connection.

Product

Name

MT/Model 4044-001 4044-201 4044-2L1 4044-2L2

Speed 8 pages

Base

Memory

Emulations PSLII,

Connectivity Parallel/

Resolution True 600dpi/Image Quality 1200dpi

Starter

Toner

Cartridge

Optra

E310

per minute

2MB 4MB 4MB 2MB

PCL6,

PPDS

USB

6k pages 6k pages 1.5k pages 1.5k pages

Optra

E312

10 pages

per minute

PSLII,

PCL6,

PPDS

Parallel/

USB

Optra

E312L

10 pages

per minute

PSLII,

PCL6,

PPDS

Parallel/

USB

Optra

E312L

10 pages

per minute

PSLII,

PCL6,

PPDS

Parallel/

USB

Options

The following options are available. Some options are not available

in every country. Contact y our point of purchase for options available

in your country.

Memory options of 8MB, 16MB, 32MB and 64MB

Flash memory options of 1MB, 2MB and 4MB

General Information 1-1

Page 22

4044-XXX

Acronyms

CSU Customer Setup

DRAM Dynamic Random Access Memory

EP Electrophotographic Process

EPROM Erasable, Programmable Read-Only

Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LV PS Low Voltage Power Supply

MROM Masked Read Only Memory

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PC Photoconductor

POST Power-On Self Test

ROM Read Only Memory

SIMM Single In-Line Memory Module

SRAM Static Random Access Memory

UPR Used Parts Return

USB Universal Serial Bus

V ac Volts alternating current

V dc Volts direct current

1-2 Service Manual

Page 23

4044-XXX

2. Diagnostic Information

Start

CAUTION: NEVER manually actuate or disable the top cover

interlock switch and the printhead shutter actuator at the same

time. To perform some of the service checks and tests, such as

troubleshooting paper feed problems, you need to actuate the top

cover interlock switch with the covers opened or removed and power

applied to the machine. It is important for personal safety that you

DO NOT, FOR ANY REASON, disable the printhead shutter actuator

when power is on.

Remove power from the printer before you connect or disconnect

any cable or electronic board or assembly for personal safety and to

prevent damage to the printer.

Use the service error code, user error message, symptom table,

service checks, and diagnostic aids in this chapter to determine the

corrective action necessary to repair a malfunctioning printer.

The lights on the operator panel can indicate either a user error

message or service error message. When a service error occurs,

the printer stops printing and all operator panel LEDs blink in a

continuous pattern, indicating a service error, until the printer is

powered off. If all operator panel LEDs are blinking, go to the

Error Codes” on page 2-2

When a user error message occurs, one or two operator panel LEDs

are on solid or blinking. Go to the

page 2-6

If your machine does not have a service error code and does not

complete POST, go to the “POST Symptom Table” on page 2-10. If your

machine completes POST without an error, and you have a

symptom, go to the

your symptom and take the appropriate action.

If a service error code appears while you are working on the

machine, go to the “Service Error Codes” on page 2-2 and take the

indicated action for that error.

.

.

“User Error Message Table” on

“Base Printer Symptom Table” on page 2-10. Locate

Diagnostic Information 2-1

“Service

Page 24

4044-XXX

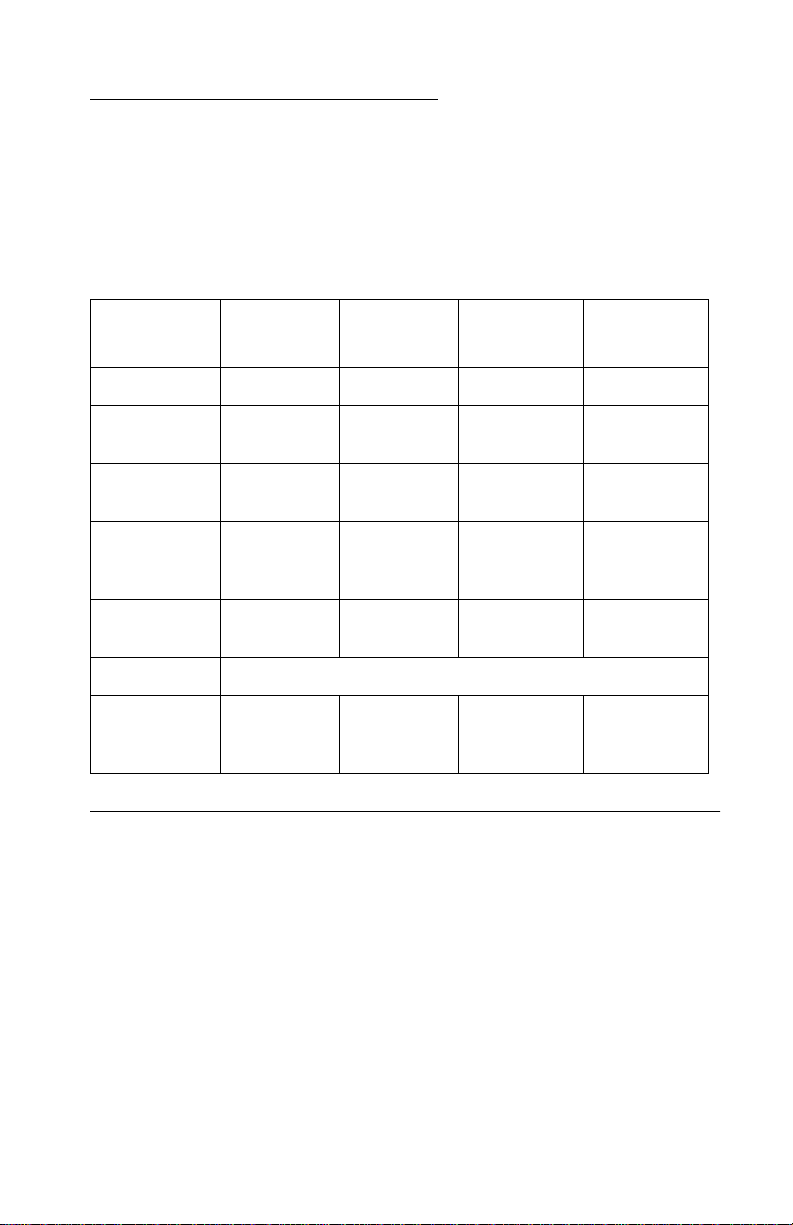

Service Error Codes

Primary Service Error Codes

When a service error occurs the printer stops printing and all

operator panel LEDs blink in a continuous pattern, indicating a

service error, until the printer is powered off.

Press and release the operator panel button to display the service

error code. Locate the blinking LEDs in the following table and

the indicated action

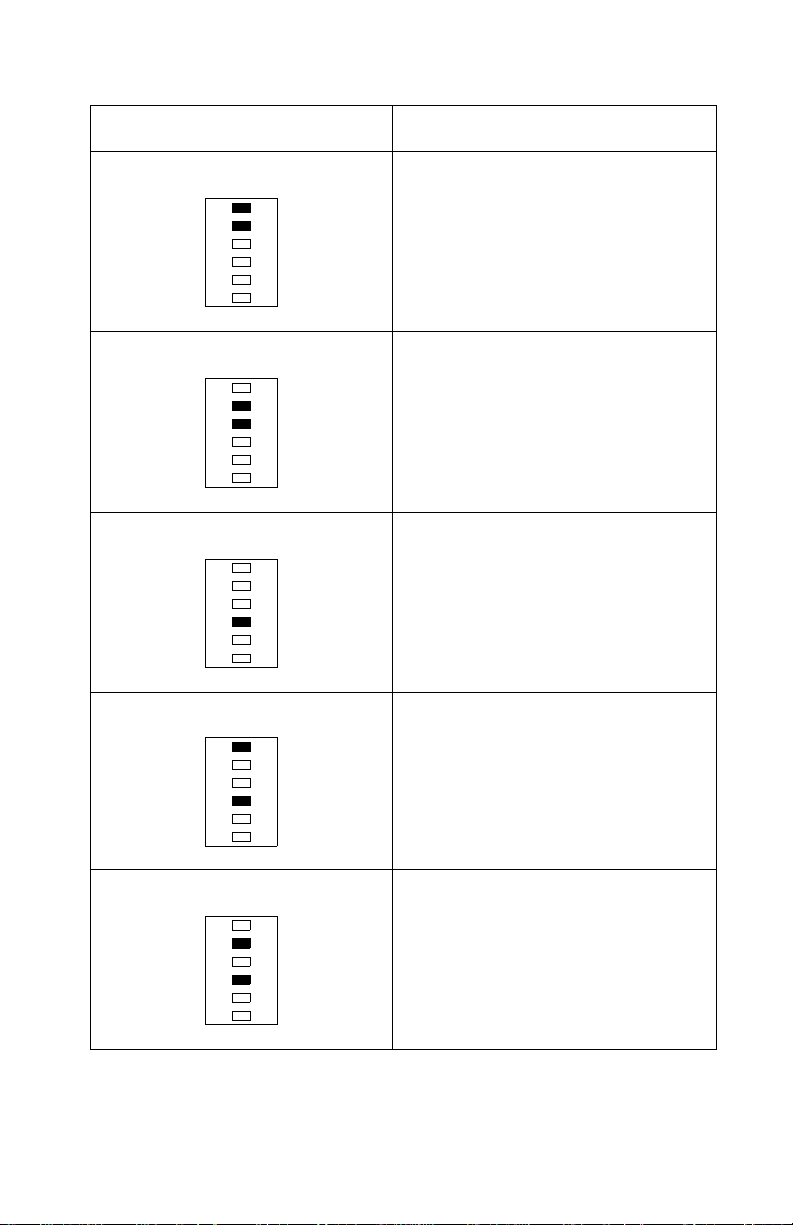

Blinking Operator Panel LED Action

Software Service Error Code Run the Printer Diagnostic Test to

.

diagnose between the R O M SIMM

and the controller board. If no other

error code displays after the test

completes, replace the controller

board.

take

Fuser Failure Error Press and release the operator

Laser Diode Failure Inspect the printhead cable and

panel button to view the secondary

service error code. Go to

“Secondary Service Error Codes” on

page 2-5.

replace as necessary. Replace the

printhead assembly. If this does not

correct t he problem, replace the

engine/LVPS board.

2-2 Service Manual

Page 25

4044-XXX

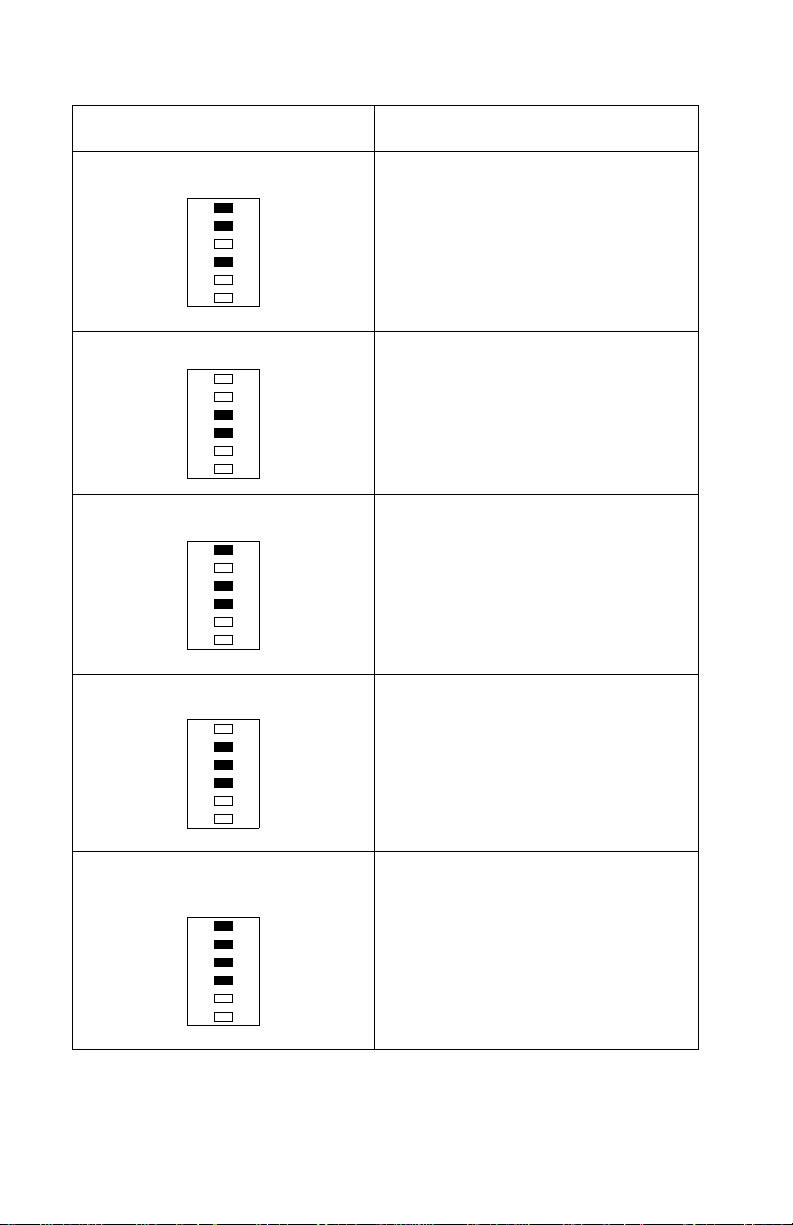

Blinking Operator Panel LED Action

Mirror Motor Failure Inspect the printhead cable and

Optional Memory Error Replace the op tional m emory SIMM.

ROM Checksum Error Replace the ROM SIMM. If this does

Base Memory Error Replace the controller board

replace as necessary. Replace the

printhead assembly. If this does not

correct the problem, replace the

engine/LVPS board.

If this does not correct the problem,

replace the controller board.

not correct the problem, replace the

controller board.

NVRAM Failure Error Replace the controller board

Diagnostic Information 2-3

Page 26

4044-XXX

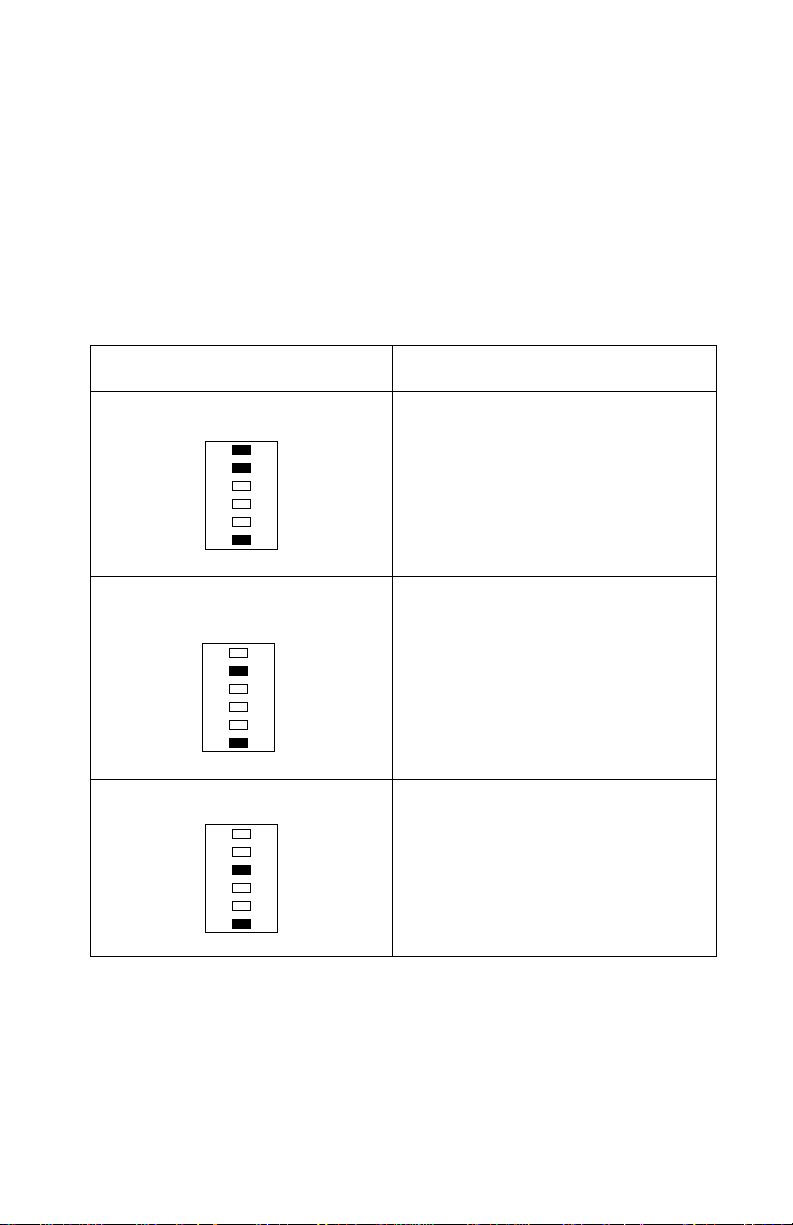

Blinking Operator Panel LED Action

ASIC Register Failure Error Replace the controller board

ASIC SRAM Failure Error Replace the controller board

Flash Memory Failure Error Replace the ROM SIMM w/Flash. If

Font Checksum Fai lure Error Replace the ROM SIMM. If this does

Engine/LVPS Board

Communications Failure Error

this does not correct the problem,

replace the controller board.

not correct the problem, replace the

controller board.

Replace the engine/LVPS board

2-4 Service Manual

Page 27

4044-XXX

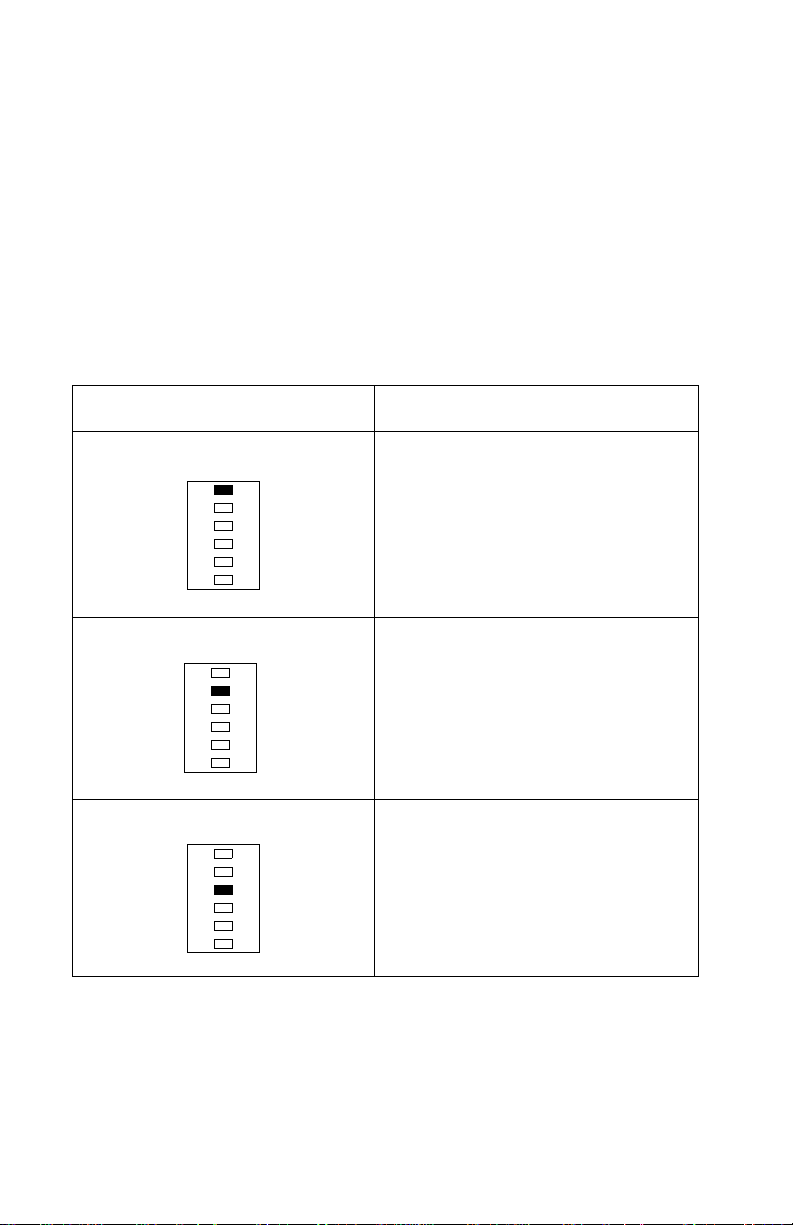

Secondary Service Error Codes

For some service error codes, a second service error code is used

to further describe the error. When a service error occurs, pressing

the operator panel button after viewing the primary service error

code displays the secondary service error code. The following table

contains the secondary service error codes.

Blinking Operator Panel LED Action

Fuser Failure - Over Temperature Go to the “Hot Fuser Service Check”

Fuser Failure - Under

Temperature

Fuser Failure - Thermistor Open Go to the “Fuser Service Check” on

on page 2-21.

Go to the “Cold Fuser Service

Check” on page 2-17.

page 2-17.

Diagnostic Information 2-5

Page 28

4044-XXX

User Error Messag e Table

Primary User Error Message Table

When a user error message occurs the printer stops printing and

one or two operator panel LEDs are on solid or blinking until the

printer is powered off. Locate the printer’s LED Status in the

following table and take the indicated action.

User Error Message LED Status Action

Paper Jam Paper Jam on solid Open cover and clear

Load Manual Paper/

Envelope

Load Paper/Load

Envelope

Load Paper b links and

Press Button on solid

Load Paper on solid

and Press Button on

solid

any paper jams . Close

the top cover. If the

error message is still

present, go to

the“Paper Feed

Service Check” on

page 2-24.

Load media into the

manual slot and push

the operator panel

button to resume

printing one sheet or

do an operator panel

reset by pressing and

holding the operator

panel button for more

than three seconds.

Load media in the

appropriate paper tra y

and push the operat or

panel button to

resume printing or do

an operato r panel

reset by pressing and

holding the operator

panel button for more

than three seconds.

Top Cover Open Error on solid Close the top cover. If

the error LED remains

on solid and POST

does not continue, go

to the “Cover Open

Switch Service

Check” on page2-13.

2-6 Service Manual

Page 29

4044-XXX

User Error Message LED Status Action

Memory Full/Complex

Page/Resolution

Reduction Warning/

Font Error/ Resource

Save Off Deficient

Memory

Flash Memory Full Error blinks and Press

Error on solid and

Press Button on solid

Button on solid

The printer memory is

full or the page is too

complex to print. The

printer is forced to

reduce the resolution

of a formatted page to

300 dpi before

printing, or the printer

is unable to maintain

the required data

transfer rate. Go to the

“Secondary User

Error Message Table”

on page 2-8.

This condition only

occurs when the

Flash memory is full.

Diagnostic Information 2-7

Page 30

4044-XXX

Secondary User Error Message Table

Press and release the operator panel button two times to display the

user secondary error LED status. Each press and release action

must be performed within a half second. Locate the printer’s LED

status in the following table and take the indicated action.

User Error Message LED Status Action

Complex Page Ready, Error, and

Press Button on solid

Memory Full Ready, Data, Error,

and Press Button on

solid

Resolution Reducti on Ready, Data blinking

and the Error, Press

Button on solid

Switch the printing

mode to a different

printing mode using

the Lexmark driver f or

Windows, or push the

operator panel button

to resume printing, or

do an operator panel

reset by pressing and

holding the operator

panel button for more

than three seconds.

Change the printing

mode to Quick P rint

Plus or reduce the

complexity of the job

or the resolution, or

push the operator

panel button to

resume printing, or do

an operato r panel

reset by pressing and

holding the operator

panel button for more

than three seconds.

Switch from the GL/2

or raster mode to

Quick Print Plus m ode

using the Lexmark

driver for Wind o ws, or

press the operator

panel button to

resume printing, or do

an operato r panel

reset by pressing and

holding the operator

button for more than

three seconds.

2-8 Service Manual

Page 31

4044-XXX

User Error Message LED Status Action

Font Error Data blinking and

Resource Save Off

Deficient Memory

Error, Pre ss Button on

solid

Ready blinking and

Error, Pre ss Button on

solid

The print command is

requesting a font that

is not present or

installed. The user

must select a di ff erent

font or try turning the

Best Fit setting on and

retry the print

command.

The printer lacks

sufficient memory to

enable Resource

Save. It is

recommended that

the user install

additional memory or

set each link buffer to

the Auto va lue.

Power-On Self Test (POST)

When you turn the printer On, it performs a Power-On Self Test.

Check for correct POST functioning of the base printer by observing

the following:

1. All LEDs turn on solid.

2. All LEDs turn off.

3. The cooling fan and fuser lamp turn on.

Note: The fuser lamp turns off once the thermistor reaches

operating temperature. As the temperature drops, the lamp

turns back on automatically.

4. The LEDs begin to turn on then off sequentially.

5. Once the fuser has reached operating temperature, the main

motor turns on and the pick roller shaft assembly rotates to

home position.

6. The Ready LED turns on solid while the Data LED blinks.

7. The engine/LVPS board checks the status of the input and exit

paper feed sensors.

8. The main motor turns off.

9. The Data LED turns off.

Diagnostic Information 2-9

Page 32

4044-XXX

Symptom Ta bles

POST Symptom Table

Symptom Action

The main motor, cooling fan and

fuser do not come on.

POST completes except one or

more LEDs do not come on.

None of the LEDs come on. Go to the “Operator Panel Service

Main motor does not come on. Go to the “Main Motor Service

Fan does not come on. Go to the “Cooling Fan Ser v ice

Fuser lamp does not come on. Go to the “Cold Fuser Service

Fuser lamp never turns off. Go to the “Hot Fuser Service Check”

The paper feed picks and tries to

feed paper.

Go to “Cover Open Switch Service

Check” on page 2-13.

Go to the“Operator Panel Service

Check” on page 2-23.

Check” on page 2-23.

Check” on page 2-21.

Check” on page 2-12.

Check” on page 2-17.

on page 2-21.

Go to the “Paper Feed Service

Check” on page 2-24.

Base Printer Symptom Table

Symptom Action

Dead Machine (no power) Go to the “Dead Machine Service

Fan noisy or not working Go to the “Cooling Fan Servi ce

Fuser parts melted Go to the “Hot Fuser Service Check”

Fuser lamp doesn’t light Go to “Cold Fuser Service Check” on

Toner not fused to the paper Go to “Cold Fuser Service Check” on

Check” on page 2-14.

Check” on page 2-12.

on page 2-21.

page 2-17.

page 2-17.

2-10 Service Manual

Page 33

4044-XXX

Symptom Action

Blank page Go to “Blank page” on page 2-28.

Black page Go to “Black page” on page 2-29.

Heavy background Go to “Heavy background” on

page 2-30.

Light pri nt Go to “Light print” on page 2-33.

White or black lines or bands Go to “White or black lines or bands”

on page 2-34.

Toner on back of page Go to “Toner on back of page” on

Incorrect characters print Go to “Incorrect characters print” on

Pap er jams Go to “Paper Feed Service Check”

Main Motor noisy or does not

move

Paper never picks Go to “Paper never picks” on

Paper feeds continuously Go to “Paper picks during POST

Pap er skew Go to “Paper Feed Service Check”

Printer not communicating with

host

Paper wrinkled or bent Go to “Paper "trees", wrinkles,

Top cover will not close Go to “Cover Open Switch Service

page 2-34.

page 2-34.

on page 2-24.

Go to “Main Motor Service Check”

on page 2-21.

page 2-27.

and/or continuously” on page 2-25.

on page 2-24.

Go to “Parallel Port Service Check”

on page 2-35.

stacks poorly or curls” on page 2-28.

Check” on page 2-13.

Operator panel button does not

respond

Operator panel LEDs do not light

or very dim

Go to “Operator Panel Button

Service Check” on page 2-24.

Go to “Operator Panel Service

Check” on page 2-23.

Diagnostic Information 2-11

Page 34

4044-XXX

Service Checks

Note: All service checks which involve measuring voltages of the

circuit boards (except the controller board) must be performed with

the engine/LVPS to controller board cable disconnected and the

printer positioned on its left side. This provides the servicer access

to the various circuit boards underneath the printer while supplying

necessary power to the rest of the printer.

Cooling Fan Service Check

FRU Action

Model E310

Interconnect Board

Cooling Fan

FRU Action

Model E312

Engine Board

Cooling Fan

Make sure moto r cable is properly

seated in location CN408 on the

interconnect board. Disconnect the

cable and check connector-pin

CN408-3 for +24 V dc. If the voltage

is not present, replace the

interconnect board. If the voltage is

present, replace the cooling fan.

Make sure moto r cable is properly

seated in location C N3 on the engine

board. Disconnect the cable and

check connector-pin CN3-1 for +24

V dc. If the voltage is not present,

replace the engine board. If the

voltage is present, replace the

cooling fan.

2-12 Service Manual

Page 35

4044-XXX

Cover Open Switch Service Check

Note: Make sure a toner cartridge is installed and the cover closes

all the way, engaging the cover open switch lever. The lever can

easily be positioned incorrectly if the top cover has been removed

and replaced.

FRU Action

Models E310 & E312

Cover Open Switch

Model E310

HVPS

Engine/LVPS Board

Make sure the cover open switch

cable is properly seated in CN2 of

the HVPS. Disconnec t the cabl e and

check the switch for continuity. Push

the cover open switch lever down to

engage the switch and close the

circuit. If the circuit does not close,

replace the switch.

Measure the volta ge at CN2-3 of the

HVPS. It measures +24 V dc. If

voltage is present at CN2-3, check

for continuity between CN2-1 and

CN1-2. If continuity does not exist,

replace the HVPS. If continuity does

exist, check the HVPS to engine/

LVPS board cable for continuity.

Replace if defective. If voltage is not

present at CN2-3, chec k the voltage

at CN1-1. It measures +24 V dc. If it

does, replace the HVPS. If it does

not, check the voltage at CN2-2 of

the engine/LVPS board. It measures

+24 V dc. If it does, replace the

HVPS to engine/LVPS board cable.

Diagnostic Information 2-13

Page 36

4044-XXX

FRU Action

Model E312

HVPS

Model E312

HVPS to Engine Board Cable

E312

Engine Board

Measure the voltages at CN2 of the

HVPS. CN2-3 measures +5 V dc

and CN2-4 measures +24 V dc. If

the correct voltage is present, check

the continuity between the following

connector locations:

CN2-3 - CN1-17

CN2-3 - CN1-19

CN2-4 - CN1-2

CN2-4 - CN1-4

If any location does not measure

continuity, replace th e HVPS.

Replace the cable if it does not

measure continuity.

Go to the “Engine Board (model

E312)” on page -9. Measure the

voltages on CN11. If an y voltages

are incorrect, replace the engine

board.

Dead Machine Service Check

Note: Check the AC line voltage. The voltage should be within the

following limits:

100 V ac - 127 V ac for the low voltage model printer

200 V ac - 240 V ac for the high voltage model printer

FRU Action

Model E310 & E312

LVPS Fuse

Check the fuse on the LVPS for

continuity. Replace with the

appropriate fuse if blown. If a fuse

blows again after being rep laced,

install a new fuse and go to “Engine/

LVPS Board (model E310)” on

page 5-4 and check the engine/

LVPS board output.

2-14 Service Manual

Page 37

4044-XXX

FRU Action

Model E310

Engine/LVPS Board

Power Switch

Model E310

LVPS to Interconnect Board

Cable

Model E310

Interconnect Board

Disconnect the ca bles from C N2 and

CN5 and leav e the cab les conn ected

to the power switch attached. With

the prin ter position ed on its left side

and the engine/LVPS board

positioned on a flat surface, turn the

power switch on and check the AC

line voltage at connector CN201. If

no voltage is present, replace the

power switch. If line voltage is

present, measure the voltages at

connectors CN2 and CN5. Go to

the“Engine/LVPS Board (model

E310)” on page 5-4 and check for

correct voltage measurements.

Replace the engine/LVPS board if

any of the voltage measurements

are incorrect.

Check the continuity of the LVPS to

interconnect board cable. Replace

the cable if it does not measure

continuity.

Reconnect the LVPS to the

interconnect board cable. Go to

“Interconnect Board (model E310)”

on page 5-21 and measure voltages

on the following connectors on the

interconnect board:

Model E312

Power Switch

CN401/CN402/CN403/CN404/

CN405/CN407/CN408

If any of the measured voltages are

incorrect, replace the interconnect

board.

Place the printer on its rear side.

Position the LVPS board on a flat

surface with all the cables

connected. Turn the printer power

switch to the on position. Check the

AC line voltage at power switch

connector CN501. If no voltage is

present, replace the pow er switch

Diagnostic Information 2-15

Page 38

4044-XXX

FRU Action

Model E312

LVPS Board

Model E312

Engine Board

Disconnect the LVPS cable from

connector CN7 on the en gine bo ard.

Go to the “LVPS (model E312)” on

page -14. Check the voltage

measurements at co nne ctor C N503.

If any voltage measurements are

incorrect, replace the LVPS.

Reconnect the LVPS cable to

connector CN7 on the en gine bo ard.

Disconnect all other cables from the

engine board. Go to the “Engine

Board (model E312)” on page -9.

Check the voltage measurements at

each connector. If any voltages are

incorrect, replace the engine board.

If all voltages are correct, reconnect

all the cables to the engine board

one at a time. Check the voltage

meausrements on the engine board

each time you connect a cable. If a

voltage measurement is incorrect

after connecting one of the cables,

replace the FRU that you connected.

2-16 Service Manual

Page 39

4044-XXX

Fuser Servic e Check

Cold Fuser Service Check

When toner is partially fused to the paper, it is usually caused by low

fuser temperature.

Avoid handling the lamp as much as possible as it is easily broken.

Be careful not to touch the glass housing with bare hands as skin

contains acids that can weaken the glass.

The line voltage to the printer must be within the following limits:

100 V ac - 127 V ac for the low voltage model printer

200 V ac - 240 V ac for the high voltage model printer

Turn the printer off and wait a few minutes for the fuser lamp to cool.

Turn the machine on and observe the lamp turning on during POST .

You can see the lamp with the left side cover and fuser wire cover

removed.

Diagnostic Information 2-17

Page 40

4044-XXX

The fuser lamp does light

FRU Action

Model 310

Thermistor

Model 312

Thermistor

If the fuser lamp comes on and a

fuser failure LED error code displ ays,

be sure the thermistor is contacting

the hot roll and the thermistor cable

is firmly seated in c on nec tor C N1 on

the L VPS board. Check fo r excessiv e

toner buildup on the surface of the

thermistor. Clean or replace as

necessary. Turn the printer off and

disconnect the t hermistor c ab le fro m

CN1 on the LVPS board. Measure

the resistance of the thermistor

between CN1-1 and CN1-2. The

resistance measures approximately

225K ohms when cool. Replace the

thermistor as necessary.

If the fuser lamp comes on and a

fuser failure LED error code displ ays,

be sure the thermistor is contacting

the hot roll and the thermistor cable

is firmly seated in connector CN10

on the engine board. Check for

excessive toner buildup on the

surface of the thermistor. Clean or

replace as necessary. Turn the

printer off and disconnect the

thermistor cable from CN10 on the

engine board. Measure the

resistance of the thermistor betw een

CN10-1 and CN10-3. Th e resistance

measures appro ximatel y 225K ohm s

when cool. Replace the thermistor

as necessary.

Models E310 & E312

Fuser Lamp

2-18 Service Manual

Make sure the correct vo lta ge lam p

is installed. The voltage rating is

stamped on one of the lamp

contacts.

Page 41

4044-XXX

The fuser lamp does not light

FRU Action

Model E310

Fuser Lamp

Lamp Cable

Thermistor

LVPS

Tur n the printer off and disconnect

the fuser lamp wires from the fuser.

Check for continuity across the fuser

lamp wire contacts. If there is

continuity, go to step 1: Continuity.

If there is no continuity, go to

step 2: No Continuity.

Step 1: Continuity

Measure the voltage at connector

CN202 on the LVPS. It should match

the line voltage. If it does not,

replace the LVPS. If line voltage is

present, check the fuser lamp cable

for continuity. Replace if

defective.Make sure the fuser

thermistor is correctly connected to

CN1 on the LVPS. If the problem

persists, disconnect the thermistor

cable from CN1 on the LVPS board

and measure the vol tag e between

CN1-1 and ground. The voltage

measures approximately 3.9 V dc. If

the voltage is incorrect, replace the

LVPS. If correct, replace the

thermistor.

Step 2: No Continuity

Check the thermal fuse f or contin uity .

If incorrect, replac e the t hermal fuse .

If correct, replace the lamp.

Diagnostic Information 2-19

Page 42

4044-XXX

FRU Action

Model E312

Fuser Lamp

Lamp Cable

Thermistor

LVPS

Turn the printer off and disconnect

the fuser lamp wires from the fuser.

Check fo r contin uity acros s the fuse r

lamp wire contacts. If there is

continuity, go to step 1: Continuity.

If there is no continuity, go to

step 2: No Continuity.

Step 1: Continuity

Measure the voltage at connector

CN502 on the LVPS. It should match

the line voltage. If it does not,

replace the LVPS. If line voltage is

present, check the fuser lamp cable

for continuity. Replace if

defective.Make sure the fuser

thermistor is correctly connected to

CN10 on the engine board. If the

problem persists, disconnect the

thermistor cable from CN1o on the

engine board and measure the

voltage between CN10-1 and

ground. The voltage measures

approximately 3.9 V dc. If the voltag e

is incorrect, replace the engine

board. If correct, replace the

thermistor.

Step 2: No Continuity

2-20 Service Manual

Check the thermal fuse f or contin uity .

If incorrect, replace the thermal f use.

If correct, replace the lamp.

Page 43

4044-XXX

Hot Fuser Service Check

FRU Action

Model E310

Fuser Thermistor

Model E312

Fuser Thermistor

Models E310 & E312

Fuser Lamp

Disconnect the the rmistor cable from

the LVPS. Measure the resistance

across CN1-1 and CN1-2 of the

thermistor cable. Replace the

thermistor if the resistance is low er

than 1k ohm or shorted.

Disconnect the the rmistor cable from

the engine board. Measure the

resistance across CN10-1 and

CN10-3 of the thermistor cable.

Replace the thermistor if the

resistance is lower than 1k ohm or

shorted.

Make sure the correct voltage fuser

lamp is insta lled. Replace if

necessary.

Main Motor Service Che ck

FRU Action

Model E310

Interconnect Board

Main Motor

Main Motor Cable

Check the in terconnec t board f or the

following voltages:

CN405-3 +24 V dc

CN405-4 +24 V dc

If these voltages are not correct,

replace the interconnect board. If

these voltag es are correct, check the

main motor cable for continuity. If

continuity exists on each wire,

replace the main motor. If continuity

does not exist on one or more of the

wires, replace the cable.

Diagnostic Information 2-21

Page 44

4044-XXX

FRU Action

Model E312

Engine Board

Main Motor

Main Motor Cable

Check the engine board for the

following voltages:

CN2-3 +24 V dc

CN2-4 +24 V dc

If these voltages are not correct,

replace the engine board. If these

voltages are co rrec t, ch eck the main

motor cable for continuity. If

continuity exists on each wire,

replace the main motor. If continuity

does not exist on one or more of the

wires, replace the cable.

2-22 Service Manual

Page 45

4044-XXX

Operator Panel Service Check

Inspect the operator panel cable for damage. Make sure the cable is

plugged in securely.

Run POST and check each LED for proper operation.

FRU Action

Models E310 & E312

Operator Panel

Operator Panel Cable

Models E310 & E312

Operator Panel

Operator Panel Cable

Controller Board

If more than one LED does not turn

on or an individual LED stays on

solid during POST, check the

operator panel cable for continuity.

Replace if defective. If the cable

measures continuity, replace the

operator panel.

If all LEDs are dim and operate

erratically during POST or all LEDs

come on and stay on solid during

POST, replace the following FRUs

one at a time in the order shown:

Controller Board

Operator Panel

Operator Panel Cable

If none of the LEDs come on, make

sure the cable is properly connected

to the operator panel and the

controller board. Disconnect the

cable and check it for continuity.

Replace if necessary. If the cable

measures continuity, measure the

followi ng v oltag es wit h the printer on

at idle:

U5-1: Ground

U5-2: +5 V dc

U5-3: +5 V dc

U5-5: +5 V dc

U5-6: Ground

If these voltages are not correct,

replace the controll er bo ard. If thes e

voltages are correct, replace the

operator panel.

Diagnostic Information 2-23

Page 46

4044-XXX

Operator Panel Button Service Check

FRU Action

Models E310 & E312

Operator Panel

Operator Panel Cable

Disconnect the operator panel from

the operator panel cabl e . Check the

continuity between U5-1 and U5-2

on the operator panel as you press

the operator panel button. As the

button is pressed, continuity is

present. Replace the operator panel

if continuity is not present. If

continuity is present, replace the

operator panel cabl e .

Paper Feed Service Check

Paper Jam error indication during POST

FRU Action

Models E310 & E312

Exit Sensor Flag

Models E310 & E312

Input Paper Feed Sensor

If the exit sensor flag is not resting

within the paper exit sensor during

POST, the printer displays a paper

jam message. M ake sure the flag is

operating freely and correctly

installed.

Make sure the input paperfeed

sensor is working properly. A stuck

or incorrectly installed sensor

causes this error.

2-24 Service Manual

Page 47

4044-XXX

Paper picks during POST and/or continuously

FRU Action

Models E310 & E312

Pick Roller Clutch

Solenoid

Check the pick roller clutch for wear.

The solenoid interac ts with the

clutch controlling motion of the pick

roller. If the cam surface of the pick

roller clutch assembly is worn, the

solenoid ma y not sto p the pick roller

from rotating. Repla ce the pick roller

clutch assembly if necessary. Make

sure the spring on the solenoid is

properly installed. If the spring is

improperly installed or missing, the

pick roller will continuously pick

paper.

Paper picks but stops about an inch down the page

FRU Action

Models E310 & E312

Roller Guides

Check for correct position of roller

guides on pick roller assembly.

Paper picks but stops half way through the printer

FRU Action

Model E310

Input Paper Feed Sensor

Interconnect Board

Make sure the input paper feed

sensor is working properly. Check for

a broken or stuck flag on the input

paper feed sensor. Check to make

sure the cable is seated on the

CN401 connector on the

interconnect board. Disconnect the

cable and check for the following

voltages:

CN401-3 +5 V dc

CN401-4 Ground

If these voltages are not correct,

replace the interconnect board. If

correct, replace the in put paper feed

sensor.

Diagnostic Information 2-25

Page 48

4044-XXX

FRU Action

Model E312

Input Paper Feed Sensor

Engine Board

Make sure the input paper feed

sensor is working properly. Check for

a broken or stuck flag on the input

paper feed sensor. Check to make

sure the cable is seated on the CN6

connector on the engine board.

Disconnect the cable and check for

the following v oltages:

CN6-3 +5 V dc

CN6-4 Ground

If these voltages are not correct,

replace the engine board. If correct,

replace the input paper feed sensor.

2-26 Service Manual

Page 49

4044-XXX

Paper never picks

FRU Action

Models E310 & E312

Pap er Tray

Model E310

Pick Roller Solenoid

Model E312

Pick Roller Solenoid

Make sure the p ape r t ray is correc tly

installed. The black mylar guide

sheet in the front of the tray must be

positioned in the paper path just

behind the pick rol ler a ss em bly. This

guide sheet can easily block the

paper path if installed incorrectly.

Make sure solenoid is installed

correctly and its cab le is plugged into

CN402 on the interconnect board. If

installation is correc t, disco nnect the

solenoid and check CN402-1 for

+24 V dc. If the voltage is present,

replace the solenoid. If the vo ltage is

not present, replac e the interco nnect

board.

Make sure solenoid is installed

correctly and its cab le is plugged into

CN4 on the engine board. If

installation is correc t, disco nnect the

solenoid and check CN4-1 for

+24 V dc. If the voltage is present,

replace the solenoid. If the vo ltage is

not present , replace the engine

board.

Paper occasionally picks or picks multiple sheets at once

FRU Action

Models E310 & E312

Pick Roller Assembly

Models E310 & E312

Paper Separator Assembly

Models E310 & E312

Pick Roller Pad Assembly

Check pick roller assembly for wear.

Replace as necessary.

Check the friction pad on the paper

separator for signs of wear. Replace

as necessary.

Check the friction pad on the pick

roller pad assembly for signs of

wear. Replace as necessary.

Diagnostic Information 2-27

Page 50

4044-XXX

Paper "trees", wrinkles, stacks poorly or curls

FRU Action

Models E310 & E312

Transfer Roller

This problem is most likely due to a

worn transfer roller. A worn transfer

roller causes the printer to run h otter

than required for the media being

printed. Excessive heat can cause

paper treeing problems, poor

stacking or curl.

Print Quality Service Check

Blank page

FRU Action

Models E310 & E312

Toner Car tridge

Printhead

Printhead Cable

HVPS

Engine/LVPS Board (Model E310)

Engine Board (Model E312)

Remove the toner cartridge and

gently shake the assembly to evenly

distribute the toner.

Blank pages can be caused by a

defective printhead assembly, high

voltage power supply or engine/

LVPS board. Disconnect the

printhead cable from the HVPS and

measure the signals on connectors

CN3 and CN4. Go to the “High

V oltage P ower Su pply (model E310 )”

on page 5-16 in the connector

locations chapter and check the

voltage measurements. If the

voltages are correct, check the

printhead cable for continuity. If the

cable measures continuity, replace

the printhead. If the cable does not

measure continuity, replace the

cable. If the voltage measurements

are not correct, replace the HVPS. If

the problem still exists, replace the

engine/LVPS board on the model

E310 or the engine board on the

model E312.

2-28 Service Manual

Page 51

4044-XXX

Black page

Note: Incorrect laser exposure or incorrect charging of the

photoconductor causes an all black page.

FRU Action

Models E310 & E312

HVPS Contacts

Model E310

Engine/LVPS Board

HVPS Cable

HVPS

Model E312

Engine Board

HVPS Cable

HVPS

Check the contacts for

contamination and correct

installation. Replace as necessary.

Make sure the HVPS to engine/

LVPS cable is correctly installed.

Disconnect the cable and measure

the signals on CN2 of the engine/

LVPS board. Go to “Engine/LVPS

Board (model E310)” on page 5-4

and check the voltage

measurements. If the voltages are

not correct, replace t he engine/LVPS

board. If the voltages are correct,

check the HVPS to engine/LVPS

cable f o r co nti n ui ty. If the cable does

not measure continuity, replace the

cable. If the cable measures

continuity, replace the HVPS.

Make sure the HVPS to engine

board cable is correctly installed.

Disconnect the cable and measure

the signals on CN11 of the engine

board. Go to the “Engine Board

(model E312)” on page-9. Check

the voltage measurements. If the

voltages are not cor rect, replace the

engine board. If the voltages are

correct, check the HVPS to engine

board cable for continuity. If the

cable does not measure continuity,

replace the cable. If the cable

measures continuity, replace the

HVPS.

Diagnostic Information 2-29

Page 52

4044-XXX

Heavy background

Poor dev elopment or poorly charged toner particles cause excessive

background. This is more noticeable as the toner cartridge nears

end of life.

FRU Action

Models E310 & E12

Toner Car tridge

Model E310

HVPS Contacts

HVPS Board

Engine/LVPS Board

Model E312

HVPS Contacts

HVPS Board

Engine Board

Make sure toner cartridge is

correctly installed and the high

voltage contacts are clean. If the

cartridge is installed correctly, try a

new cartridge.

Check the contacts for correct

installation and co ntamination where

contact is made with the toner

cartridge and HVPS Board. Clean as

necessary. If this does not correct

the problem, replace the following

FRUs one at a time in the order

shown:

HVPS Board

Engine/LVPS Board

Check the contacts for correct

installation and co ntamination where

contact is made with the toner

cartridge and HVPS Board. Clean as

necessary. If this does not correct

the problem, replace the following

FRUs one at a time in the order

shown:

HVPS Board

Engine Board

2-30 Service Manual

Page 53

4044-XXX

Partial blank image/white spots (no periodic pattern)

FRU Action

Toner Cartridge Remove the toner cartridge and

Fuser Backup Roller Springs Check left and right backup roller

Paper Make sure recommended paper is

gently shake the assembly to evenly

distribute the toner. If toner cartridge

is low, try a new one.

springs and backup roller to ensure

adequate e ven pressu re is applied to

the fuser hotroll.

being used.

Variation in image density horizontally across page

FRU Action

Toner Cartridge The charge roll in the toner cartridge

Transfer Roller Bearing Assembly

Transfer Roller

may have an unbalanced pressure

against the PC drum. Try a new

toner cartridge.

Check the springs in the left and

right transfer roller bearings. The

bearing assemblies should support

the transfer roller, applying even

pressure to the PC drum. Replace

either or both transfer roller bearing

assemblies if the springs show signs

of damage or fatigue. Inspect the

transfer roller for signs of wear or

damage and replace as necessary.

Diagnostic Information 2-31

Page 54

4044-XXX

Periodic irregularity down pa ge

FRU Action

PC Drum (Toner Cartridge)

Distance Between Irregularity

94.5 mm

Charge Roller (Toner Cartridge)

Distance Between Irregularity

37.8 mm

Supply Roller (Toner Cartridge)

Distance Between Irregularity

40.1 mm

Develo per Ro ll er

(Toner Cartridge)

Distance Between Irregularity

46.1 mm

Transfer Roller

Distance Between Irregularity

46.0 mm

Hot Roll

Distance Between Irregularity

56.7 mm

The PC drum or gear driving the PC

drum may be contaminated or

damaged. Inform the customer to

replace the toner cartridge.

The charge roller or gear driving the

charge roller may be contaminated

or damaged. Inform the customer to

replace the toner cartridge.

The supply roller or gear driving the

supply roller may be contaminated or

damaged. Inform the customer to

replace the toner cartridge.

The supply roller or gear driving the

developer roller may be

contaminated or damaged. Inform

the customer to replace the toner

cartridge.

The transfer rol ler or gear driving the

transfer roller may contaminated or

damaged. Inspect the roller and

gear. Replace as necessary.

The hot roll of the fuser or gear

driving the hot roll may be

contaminated or damaged. Inspect

the hot roll and gear. Replace or

clean as necessary.

Backup Roller

Distance Between Irregularity

69.1 mm

2-32 Service Manual

The backup roller of the fuser may

be contaminated or damaged.

Inspect and replace as necessary.

Page 55

4044-XXX

Poor fusing of image

FRU Action

Fuser Lamp The fuser may not be operating at

Paper Make sure recommended paper is

the proper temperature to fuse the

toner to the paper . Go to the “Cold

Fuser Service Check” on page 2-17.

being used.

Light print

FRU Action

Toner Cartridge Make sure the toner cartridge is

installed correctly and is not low on

toner. If the problem continues,

install a new toner cartridge.

Transfer Roller

HVPS Contact (Transfer Roller)

HVPS Board

Check the transfer roller for signs of

toner buildup and contamination.

Inspect the HVPS contact (transfer

roller) for contamination. Inspect the

HVPS board for contamination

where it meets the HVPS contacts. If

all components appear free of

contamination, replace the following

FRUs one at a time in the order

shown:

Transfer Roller

HVPS Contact (Transfer Roller)

HVPS Board

Diagnostic Information 2-33

Page 56

4044-XXX

White or black lines or bands

FRU Action

Toner Car tridge

Paper Feed Drive Gears

Banding appears as light or dark

horizontal lines on a uniformly gray

page or on a page with a large area

of graphics . Bandin g is prima rily due

to a variation in the speed of the

paper as it feeds through the printer

especially in the developer and

transfer process. Inspect the toner

cartridge and paper feed

components, especially the drive

gears, for signs of wear, debris,

binds or damage.

Toner on back of page

FRU Action

Print Cartridge Inspect the overall paper path for

signs of spilled toner. Gently clean

the contaminated areas with a soft

cloth or compressed air.

Fuser Hot Roll

Backup Roller

The fuser hot roll can c ause tone r on

the back of the paper if toner is

building up on the hot roll. This

buildup may transfer to the backup

roller, later transferring to the

backside of the paper. Inspect the

hot roll and back up roll er for signs of

contamination and replace as

necessary.

Transfer Roller A transfer roller contaminated with

toner can cause toner to transfer to

backside of printed pages. Inspect

the transfer roller for contamination

and replace as necessary.

Incorrect characters print

Make sure the correct printer driver software is installed. Incorrect

software can cause incorrect characters to print and the image may

not fit the page.

2-34 Service Manual

Page 57

4044-XXX

Parallel Port Service Check

1. Perform a print test to make sure the printer prints correctly.

2. Be sure the printer cable is designed for bidirectional printing.

3. Be sure the user application is set up correctly. Improper set up

can prevent establishing a communication link with the printer.

4. Try enabling the parallel port pull-up resistors. Go to

Mode 1” on page 3-8

resistors. If the printer still does not print, disable the resistors.

5. If the internal print test page prints correctly, the user

application/printer driver is set up correctly and the correct bidirectional parallel cable is installed, yet the printer still fails to

print on command from the host, replace the controller board.

. Try printing a test page after enabling

“Parallel

Diagnostic Information 2-35

Page 58

4044-XXX

2-36 Service Manual

Page 59

4044-XXX

3. Diagnostic Aids

This chapter explains the tests and procedures you can run to

identify printer failures and verify that repairs have corrected the

problem.

Memory Test

The following tests run sequentially when performing this test:

Standard Memor y Test

Optional Memory Test

The memory test runs automatically during POST if a different size

optional memory SIMM is installed since the last printer power on.

Perform the following steps to run the Memory Test:

1. Turn the printer off.

2. Open the top cover.

3. Press and hold the operator panel button as you turn on the

printer. Release the button once the Error LED comes on solid.

4. Close the top cover.

5. If all the diagnostic tests run correctly, the Data LED blinks. If a

test fails, the Error LED pattern for the service error code displays on the operator panel. Go to the “Service Error Codes” on

page 2-2 and take the indicated action for that error.

Diagnostic Test

Once the memory test is complete, the diagnostic test pages can be

printed by briefly pressing the operator panel button. Two pages are

printed. The first page is a listing of various printer settings and code

level. The second page is used to inspect registration. If the printer

requires a registration adjustment, you must contact your next level

of support to obtain the software utility that enables you to adjust

registration.

Diagnostic Aids 3-1

Page 60

4044-XXX

Print Quality Test

There are three print quality test pages. The first page displays the

installed printer base code level and user default settings for the

following:

Top Margin Offset

Left Margin Offset

Printer Page Count

Installed Memory

PQET Setting (on/off)

Toner Saver (on/off)

Print Resolution

Print Darkness

The next two test pages are used to evaluate print quality. One test

page is gray and the other is black. Perform the following steps to

print the second test page:

1. Turn the printer off.

2. Open the top cover.

3. Turn the printer power on.

4. When the Error LED comes on solid, double-click the operator

panel button.

5. Once the Error and Press Button LEDs start blinking, close the

top cover.

6. The Ready LED comes on solid and the Error and Press Button

LED continue blinking.

7. Double-click the operator button four times. The Ready and

Data LEDs come on solid while the Error and Press Button

LEDs continue blinking.

8. Perform a long button press until all LEDs come on solid.

9. The test pages are printing.

10. When the test pages have finished printing, the Ready LED

comes on solid and the Data LED goes off.

Note: After the print quality test pages print, the printer automatically returns to the Ready mode.

3-2 Service Manual

Page 61

4044-XXX

User Mode Print Test

The User Mode Print Test Page displays the user default values ,

installed options, printer features, various typefaces, and the

installed printer base code level.

1. Turn the printer power on. The Ready LED comes on solid

(printer is in the ready state).

2. Press and release the operator panel button.

3. The Ready LED comes on solid and the Data LED blinks indicating the printer is busy.

4. The test page prints and the operator panel Ready LED comes

on solid and the Data LED turns off.

5. The printer returns to the Ready mode.

Configuration Mode

The configuration mode gives the ability to set the following printer

functions through the operator panel:

Parallel Port Settings

Enable Port

NPA Mode

Protocol

Mode 1

Mode 2

Strobe Adjust

USB Settings

Enable Port

NPA Mode

PPDS Activated

Auto CRLF/LFCR

Diagnostic Aids 3-3

Page 62

4044-XXX

Operator Panel Configuration Mode Button Definition

Term Description Result

Brief Button Press Press the operator

Long Button Press Press and hold the

Double-Click Button

Press

panel button no l onger

than three seconds.

operator panel button

for more than three

seconds.

Press and release the

operator panel button

two times. Each press

and release action

must be performed

within a half second.

This action moves

through the configuration mode settings.

This action selects

and saves the setting

for the menu item displayed. To indicate

that the setting is

saved, all LEDs blink

once.

This action moves

through the configuration mode menu.

Perform the following steps to enter the configuration mode:

1. Turn the printer power off.

2. Open the top cover.

3. Turn the printer power on.

4. When the Error LED comes on solid, double-click the operator

panel button.