Page 1

C910 Fi nis her

Setup and User’s Guide

February 2002

www.lexmark.com

Page 2

Edition: February 2002

The following paragraph does not apply to any country where such provisions are inconsistent with local law: LEXMARK INTERNATIONAL,

INC., PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the information herein; these changes will

be incorporated in later editions. Improvements or changes in the products or the programs described may be made at any time.

Comments about this publication may be addressed to Lexmark International, Inc., Department F95/032-2, 740 West New Circle Road, Lexington,

Kentucky 40550, U.S.A. In the United Kingdom and Eire, send to Lexmark International Ltd., Marketing and Services Department, Westhorpe House,

Westhorpe, Marlow Bucks SL7 3RQ. Lexmark may use or distribute any of the information you supply in any way it believes appropriate without incurring

any obligation to you. You can purchase additional copies of publications related to this product by calling 1-800-553-9727. In the United Kingdom and

Eire, call +44 (0)8704 440 044. In other countries, contact your point of purchase.

References in this publication to products, programs, or services do not imply that the manufacturer intends to make these available in all countries in

which it operates. Any reference to a product, program, or service is not intended to state or imply that only that product, program, or service may be

used. Any functionally equivalent product, program, or service that does not infringe any existing intellectual property right may be used instead .

Evaluation and verification of operation in conjunction with other products, programs, or services, except those expressly designated by the

manufacturer, are the user’s responsibility.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries. Other

trademarks are the property of their respective owners.

© Copyright 2002 Lexmark International, Inc.

All rights reserved.

UNITED STAT ES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use, duplication or disclosure by the Government is subject to restrictions

as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 and in applicable FAR

provisions: Lexmark International, Inc., Lexington, KY 40550.

FCC emissions information

The Lexmark C910 finisher has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation. Refer to the

Any questions on this statement should be directed to:

Director of Lab Operations

Lexmark International, Inc.

740 West New Circle Road

Lexington, KY 40550

(859) 232-3000

Lexmark C910 Publications

CD for additional details.

Safety information

• If your product is NOT marked with this symbol

• The power cord must be connected to an electrical outlet that is near the product and easily accessible.

• Refer service or repairs, other than those described in the operating instructions, to a professional service person.

• This product is designed, tested, and approved to meet strict global safety standards with the use of specific Lexmark components. The safety

features of some parts may not always be obvious. Lexmark is not responsible for the use o f other replac ement parts.

• Your product uses a printing process that heats the print media, and the heat may cause the media to release emissions. You must understand

the section in your operating instructions that discusses the guidelines for selecting print media to avoid the possibility of harmful emissions.

, it MUST be connected to an electrical outlet that is properly grounded.

Conventions

It may help you to recognize the caution and warning conventions used in this book. These appear in the left column for easy reference.

CAUTION! A caution identifies something that could cause you harm.

Warning! A warning identifies something that could damage your finisher hardware or software.

Note: A note provides information you may find useful.

Page 3

Table of

contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Unpacking the finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Attaching the docking plate and guide rail . . . . . . . . . . . . . . . .4

Combining the finisher and stand . . . . . . . . . . . . . . . . . . . . . . .6

Attaching the bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Aligning the finisher and printer . . . . . . . . . . . . . . . . . . . . . . .11

Adjusting the wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Attaching the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Attaching the paper jam label . . . . . . . . . . . . . . . . . . . . . . . . .21

Attaching the finisher book sleeve . . . . . . . . . . . . . . . . . . . . .22

Printing a menu settings page . . . . . . . . . . . . . . . . . . . . . . . .23

Using finisher features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Offsetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Stapling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Hole punching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Clearing finisher messages . . . . . . . . . . . . . . . . . . . . . . . . . .35

Solving other problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Printing envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table of contents

iii

Page 4

Lexmark confidential until announced

Hole punch adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Clearing staple jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Electronic emission notices. . . . . . . . . . . . . . . . . . . . . . . . .61

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

iv

Table of contents

Page 5

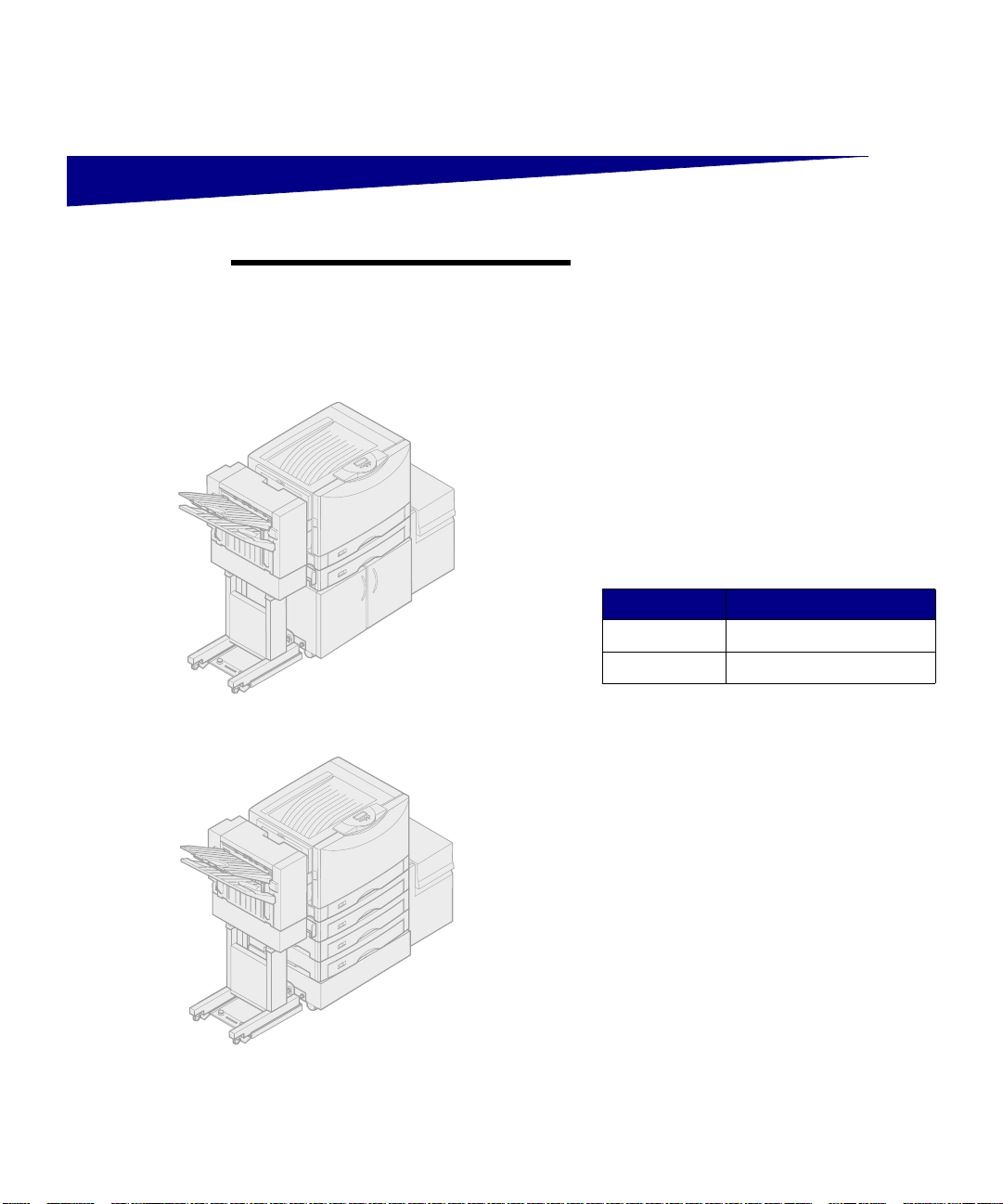

Introduction

Note:

with an optional printer cabinet, or a low

profile printer stand and optional drawers

to install a finisher.

Printer with cabinet, high capacity feeder, and finisher

Your printer must be configured

Your Lexmark™ C910™ printer supports

an optional finisher that adds hole

punching, stapling, and offset functions

to the printer output capabilities.

Your finisher also increases output

capacity. You can stack up to 100 sheets

of 20 lb paper in bin 1 (the top bin) and

1000 sheets in bin 2 (the lower bin).

Depending on the finisher you have

chosen, you can punch 3 or 4 holes in

your print jobs. The number of holes and

their plac ement are set at the factory.

Finisher Part number

3-Hole 12N0784

4-Hole 12N0785

You can corner staple up to 30 sheets of

20 lb pap er. Stapled jobs exit face down

into bin 2.

If you select offsetting, your print jobs

exit into bin 2. Transparencies, card

stock, glossy paper, and labels exit only

into bin 1.

Printer with low profile printer stand, optional drawers,

high capacity feeder, and finisher

Introduction

1

Page 6

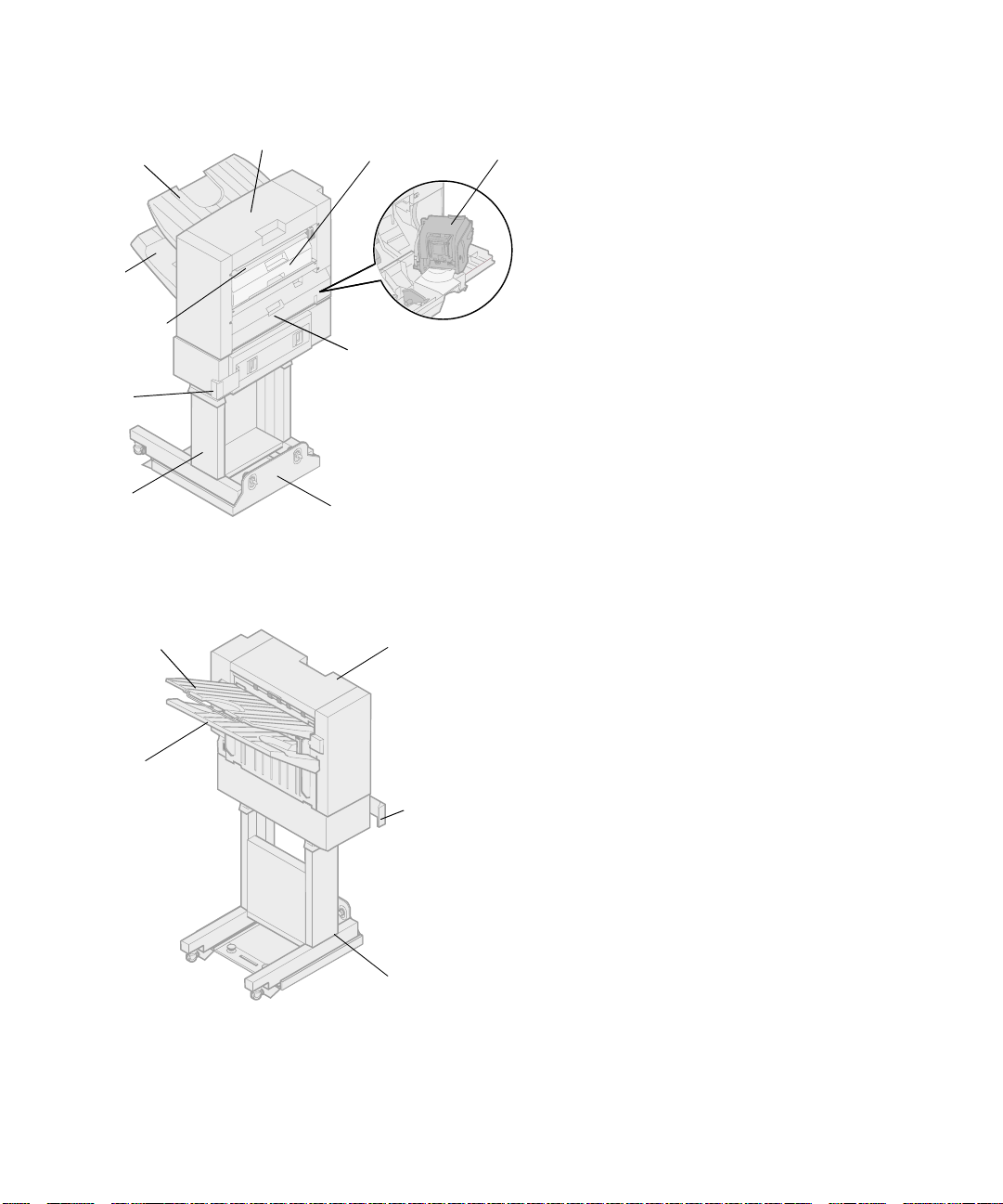

Bin 1

Bin 2

Entry guide

Latch

Top cover

Hole punch box

Stapler door

Stapler

Familiarize yourself with the names and

locations o f items o n the fr ont and r ear of

your new finisher. This will help you

during finisher setup.

To ensure your finisher is Energy Star

compliant, your printer controls the

power to the finisher.

Finisher stand

Bin 1

Bin 2

Guide rail

Front

Top cover

Latch

Finisher stand

Rear

2

Introduction

Page 7

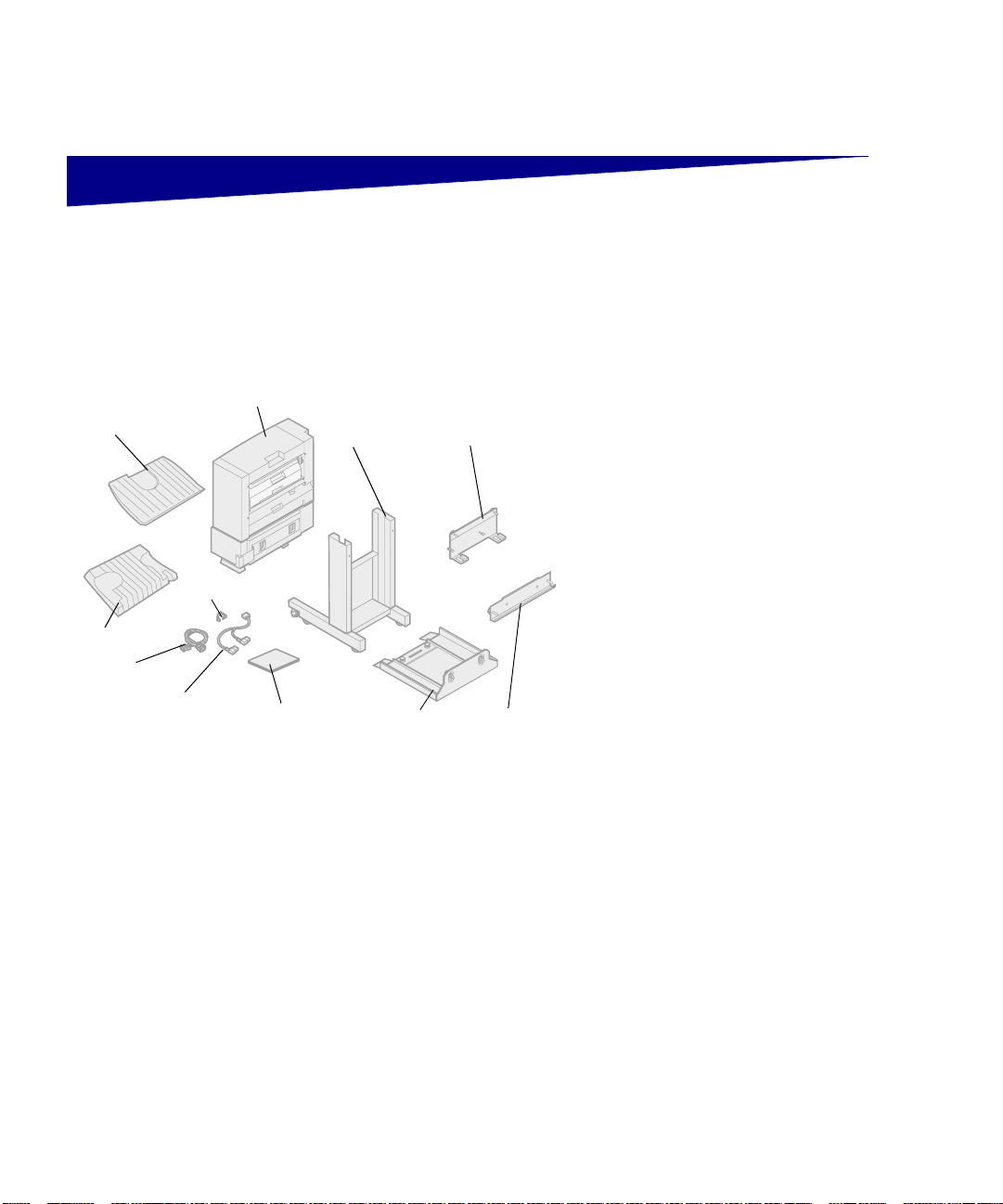

Setup

Output bin 1

Output bin 2

Interface cable

Y–Power cord

Unpacking the finisher

Finisher

Cable holder

Setup and

User’s Guide

Finisher stand

Guide rail

Docking plate

Guide rail

plate

1

Remove all items from the box

and unpack them.

2

Make sure you have all the

following items shown at left.

If any items are missing or damaged,

refer to the

Publications

Lexmark support phone number for your

country.

Save the carton and packing material in

case you need to repack the finisher.

Lexmark C910

CD for the designated

Setup

3

Page 8

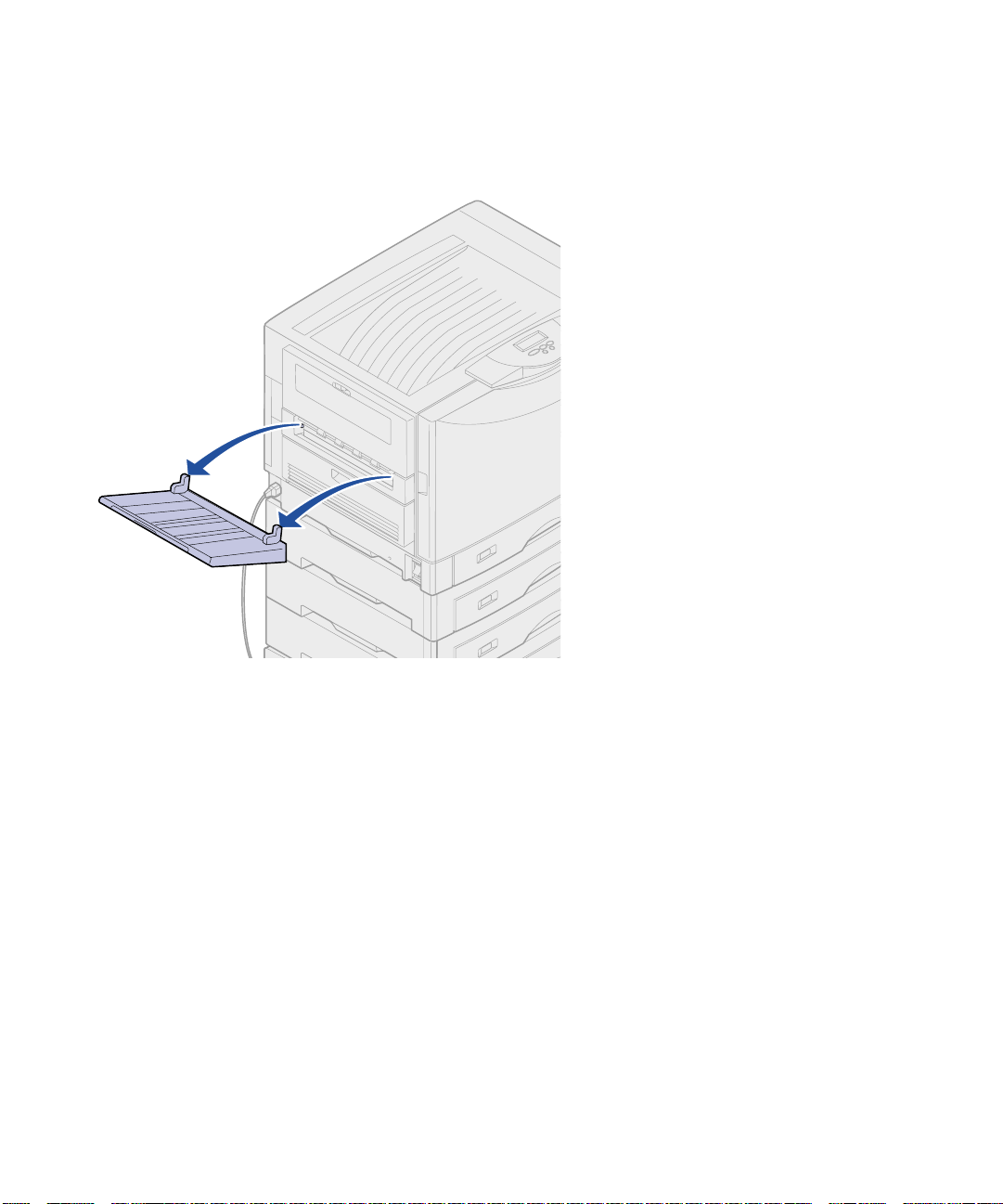

Attaching the docking

plate and guide rail

1

Lift the printer exit tray halfway

and remove.

You will not need the tray when

the finisher is attached. However,

you will need to move the finisher

and reinstall the tray to print

envelope sizes other than C5 or

B5.

4

Setup

Page 9

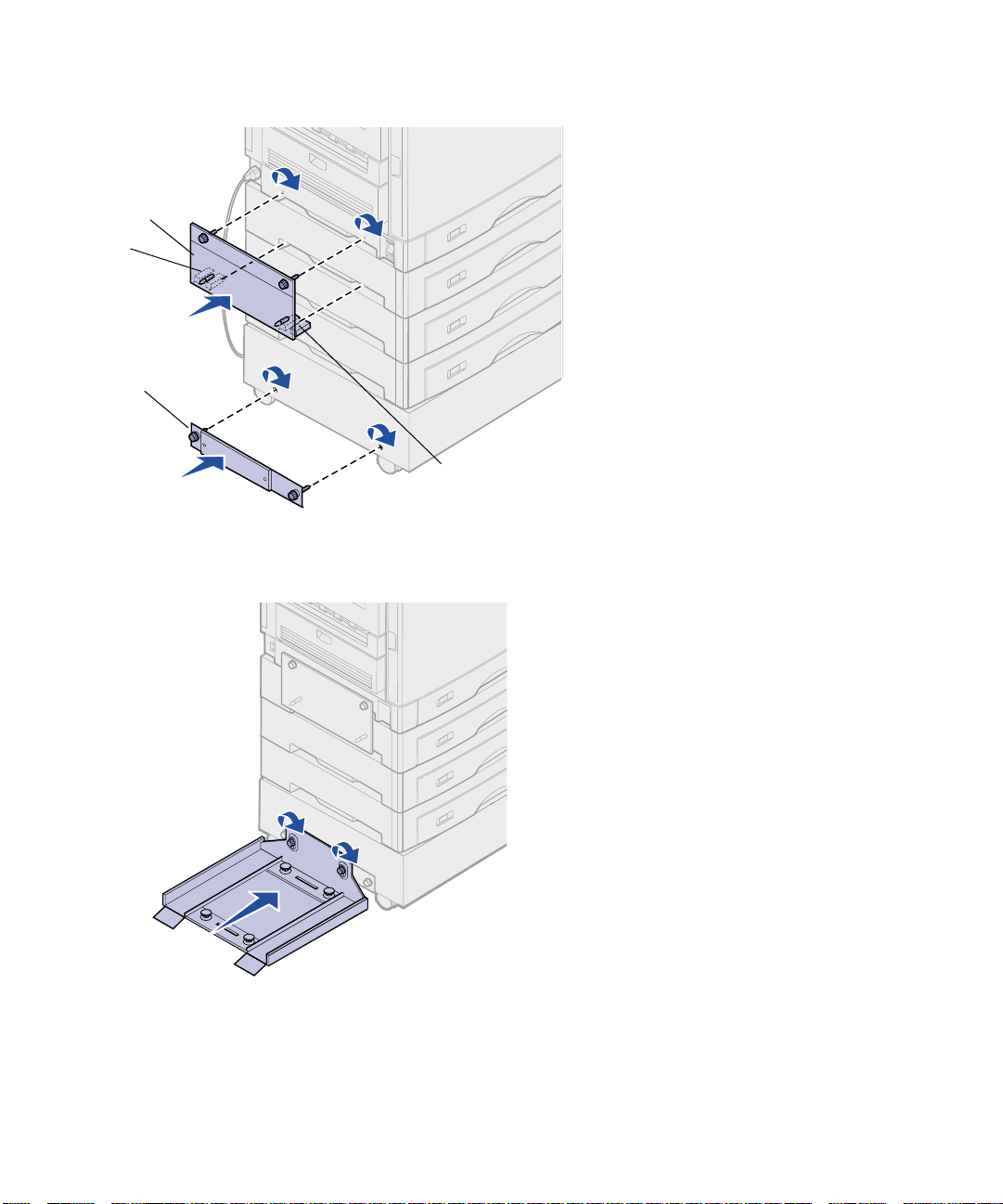

Docking plate

Tab

Guide rail plate

Tab

2

Insert the docking plate tabs into

the printer.

The tabs on the bottom of the

docking plate must be inserted

into the handholds on the printer

so the docking plate will be flush

against the printer.

3

Align the thumbscrews on the

docking plate with the holes in the

side of the printer.

4

Tighten the docking plate

thumbscrews.

5

Align the thumbscrews on the

guide rail plate with the holes in

the side of the printer cabinet or

stand.

6

Tighten the guide rail plate

thumbscrews.

7

Align the thumbscrews on the

guide rail with the holes in the

guide rail plate.

8

Tighten the guide rail

thumbscrews.

Setup

5

Page 10

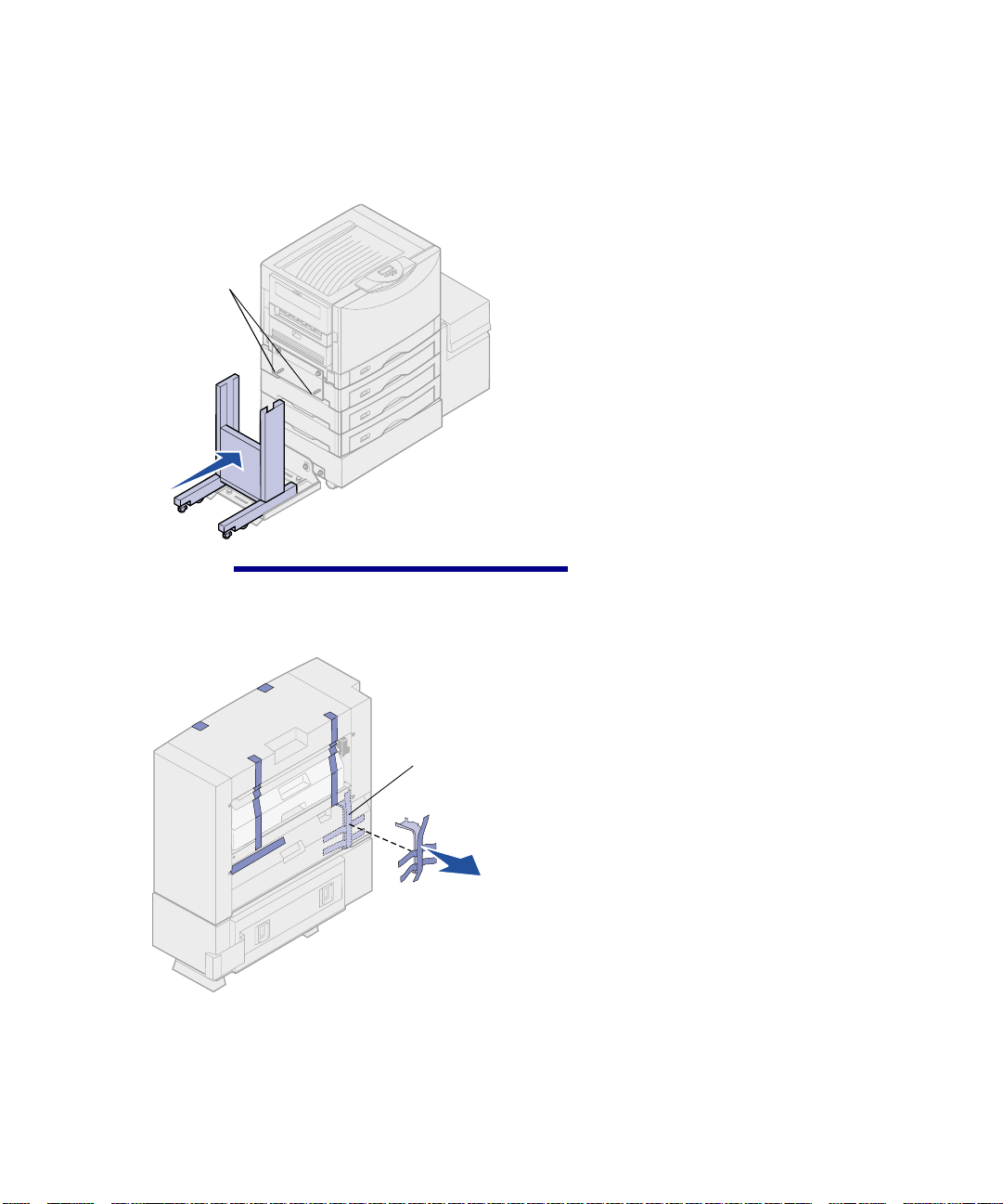

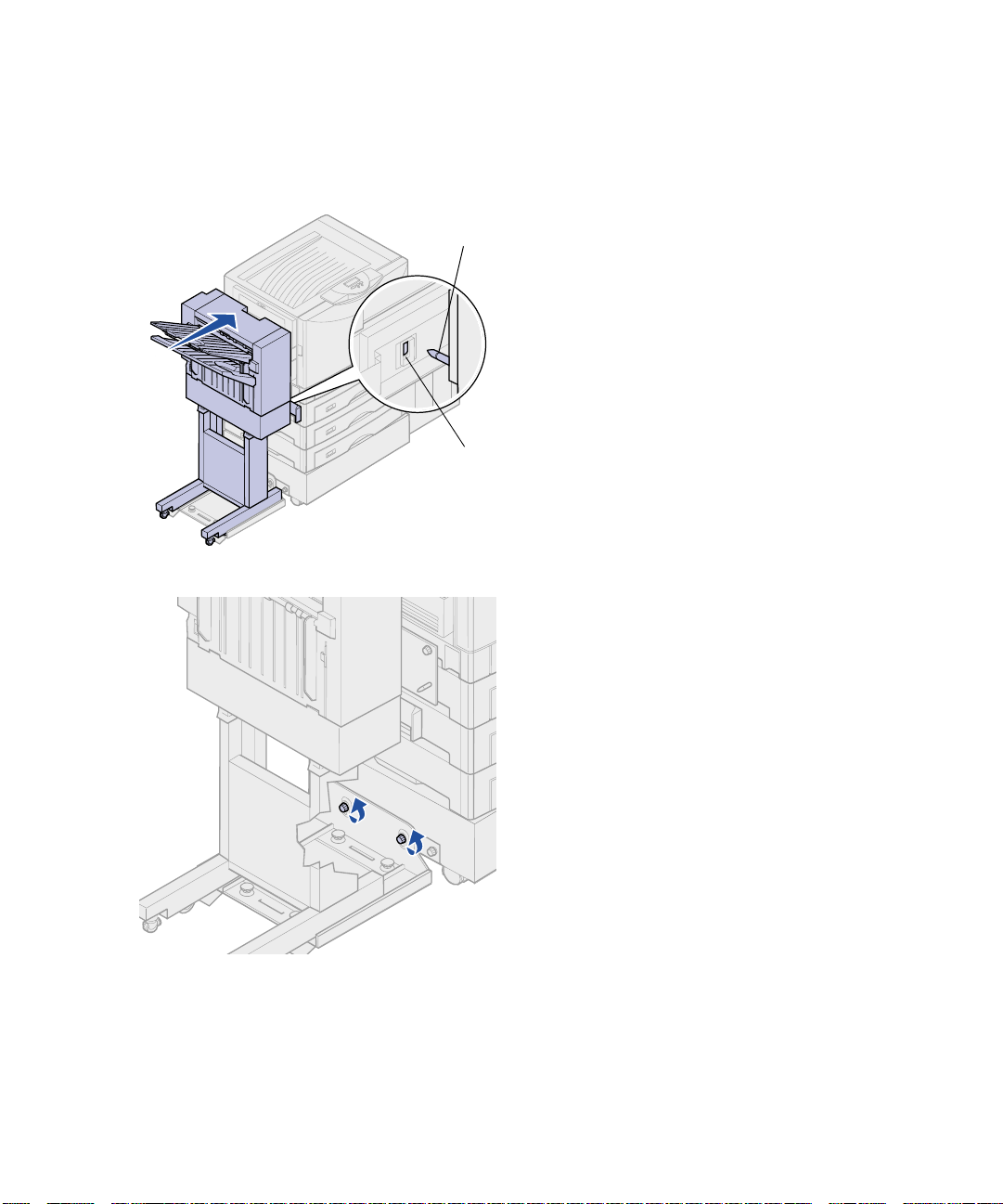

Docking plate pins

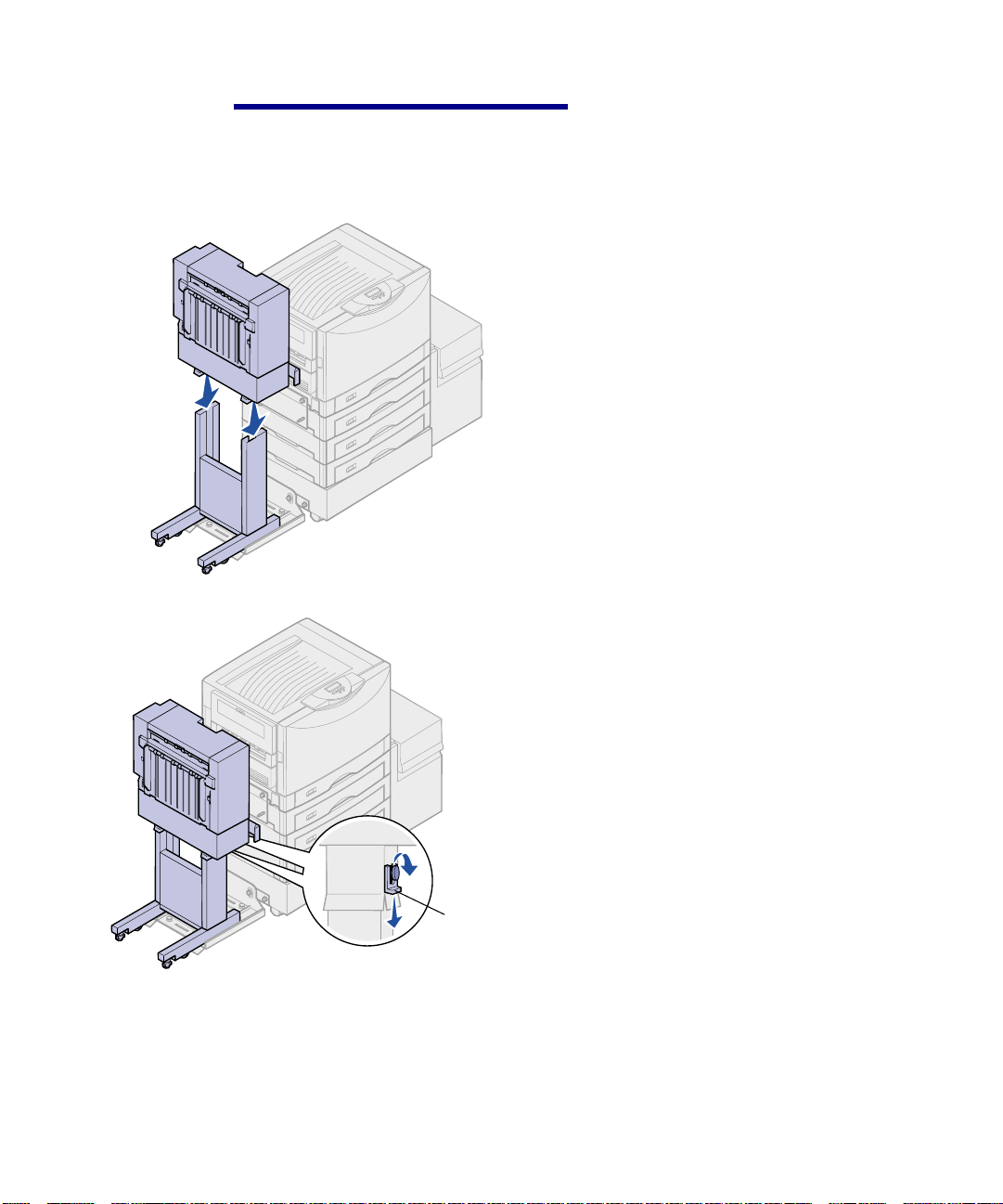

Combining the finisher

and stand

1

Roll the finisher stand onto the

guide rail.

Do not push the stand all the way

up against the printer.

CAUTION!

(42.2 Ibs).

The finisher weighs 19.7 kg

Metal shipping

bracket

2

Remove and discard all shipping

tape, packing material, and the

metal shipping bracket.

6

Setup

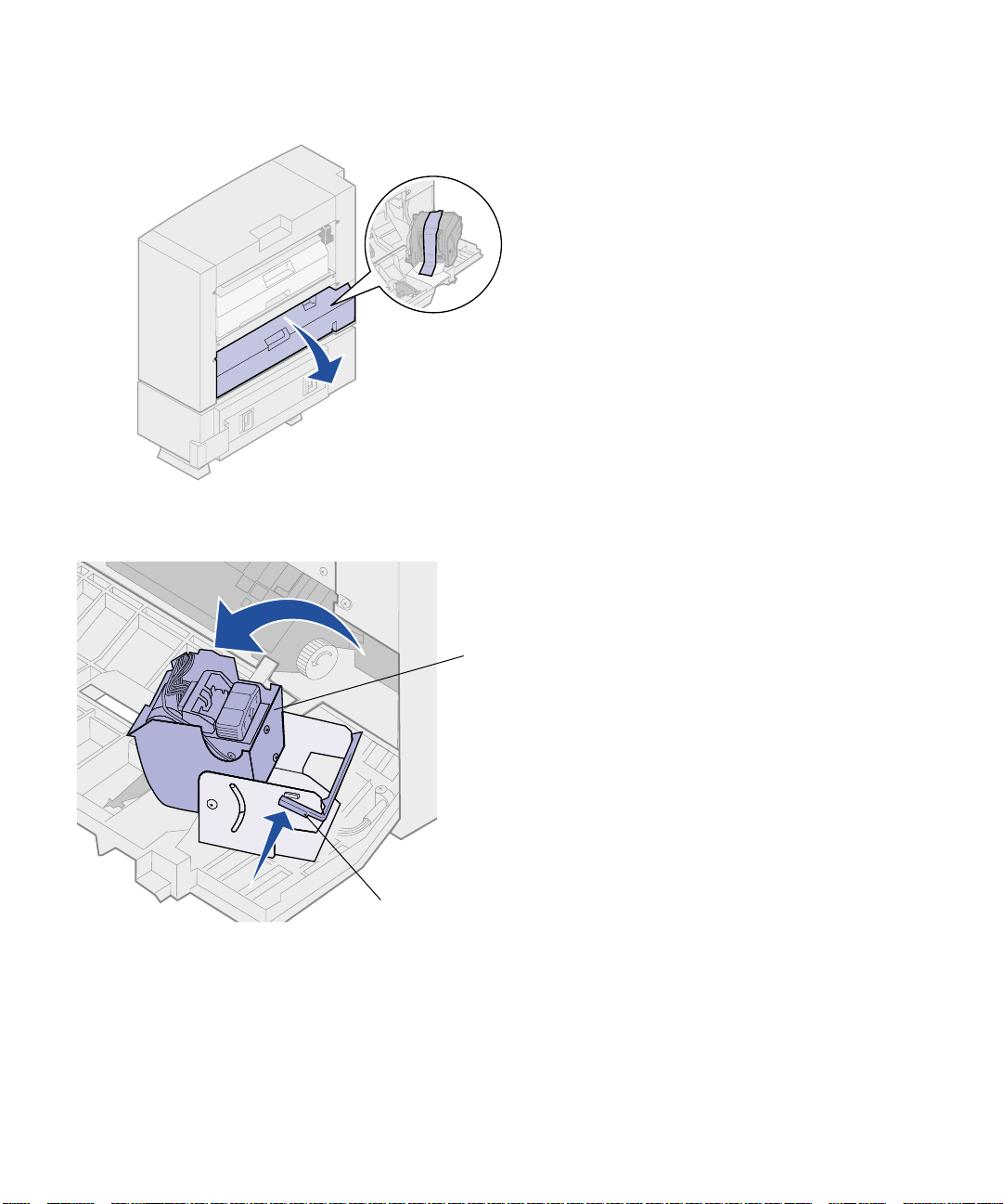

Page 11

Stapler

3

Open the stapler door.

4

Remove all shipping tape and

packing material.

5

Lift the stapler locking lever.

6

Raise the stapler.

7

Remove all shipping tape and

packing material.

Stapler locking lever

Setup

7

Page 12

8

Close the stapler.

9

Close the stapler door.

8

Setup

Page 13

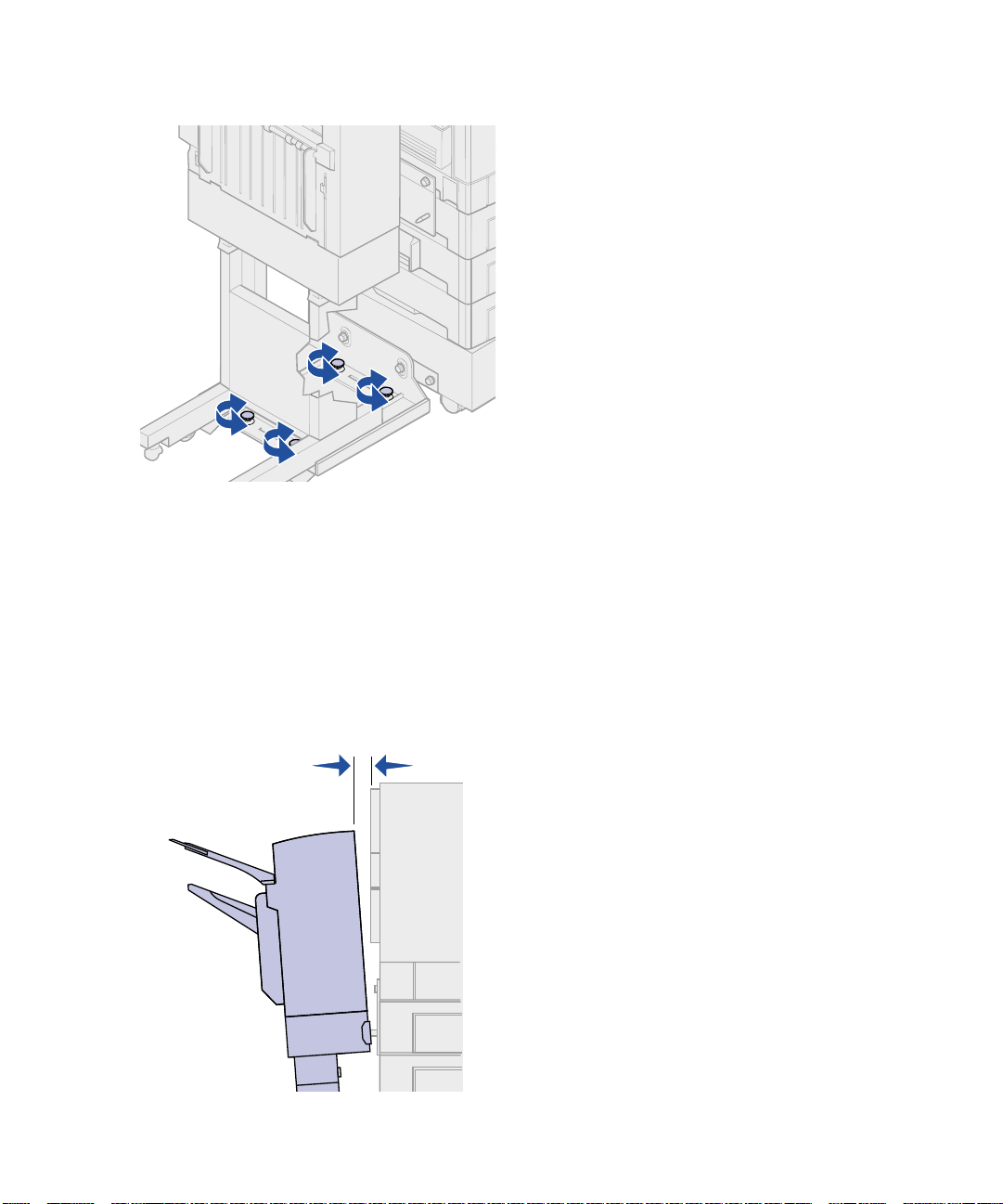

CAUTION!

finisher weighs 26.3 kg (56.9 Ibs) and

requires two people to lift it safely.

When assembled, the

10

Align the two sockets on the

bottom of the finisher with the legs

of the finisher stand.

11

Lower the finisher onto the stand.

12

Remove both thumbscrew

spacers.

13

Tighten the two thumbscrews.

Thumbscrew

spacers

Setup

9

Page 14

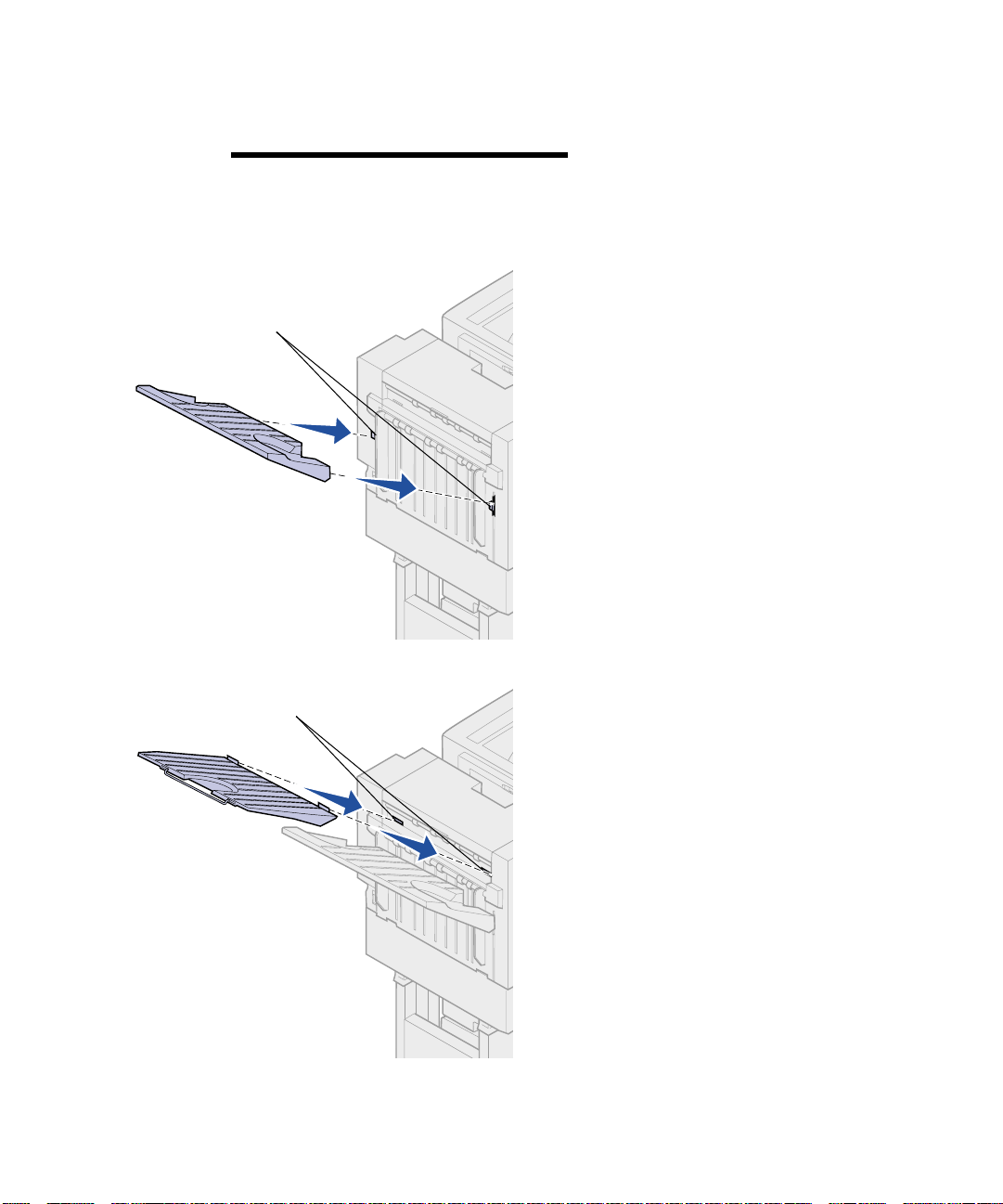

Attaching the bins

Note:

and finisher stand are referred to as the

finisher.

Metal brackets

When assembled, the finisher

Slots

1

Align the slots on bin 2 with the

metal brackets on the rear of the

finisher.

2

Slide the bin down onto the metal

brackets until it is fully seated.

3

Align the tabs on bin 1 with the

slots on the rear of the finisher.

4

Lower the bin until it is fully

seated.

10

Setup

Page 15

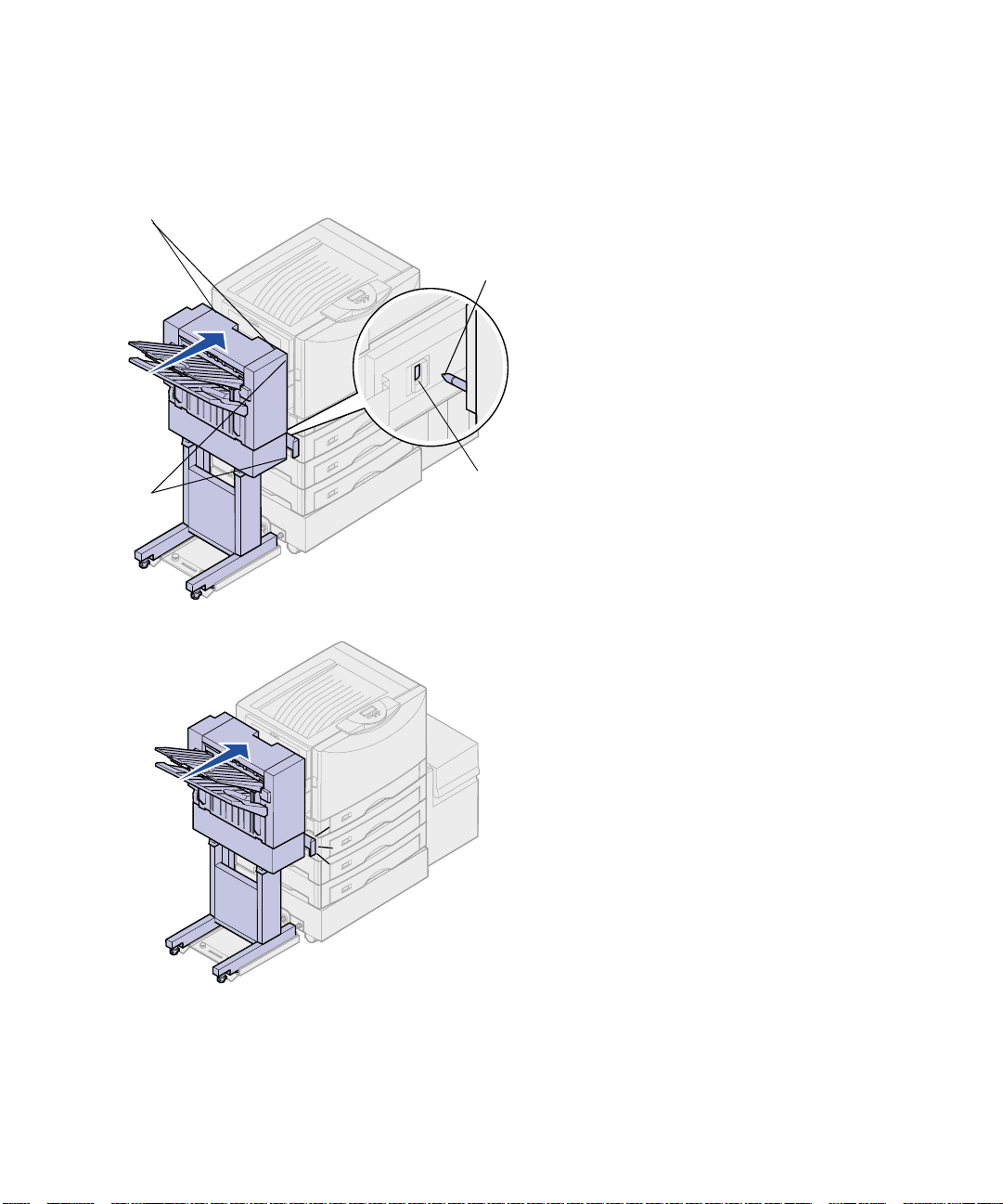

Alignment marks

Aligning the finisher

and printer

Docking plate pin

The following three areas must align

properly to prevent paper jams.

1

The doc ki ng pl at e pi ns must enter

the holes in the finisher.

2

The space between the printer

and finisher must be the same at

the top and bottom of the finisher.

3

The alignment marks on top of the

finisher must align with the edges

of the cover on the side of the

printer.

Spacing

Hole in finisher

4

Roll the finisher toward the printer

until the finisher locks to the

docking plate pins.

You hear a

locks into position.

If the pi ns di d no t go i nto the ho les

in the finisher, see “Lowering or

raising the finisher” on page 12.

Otherwise, go to “Aligning the

sides of the finisher” on page 13.

click

when the finisher

Setup

11

Page 16

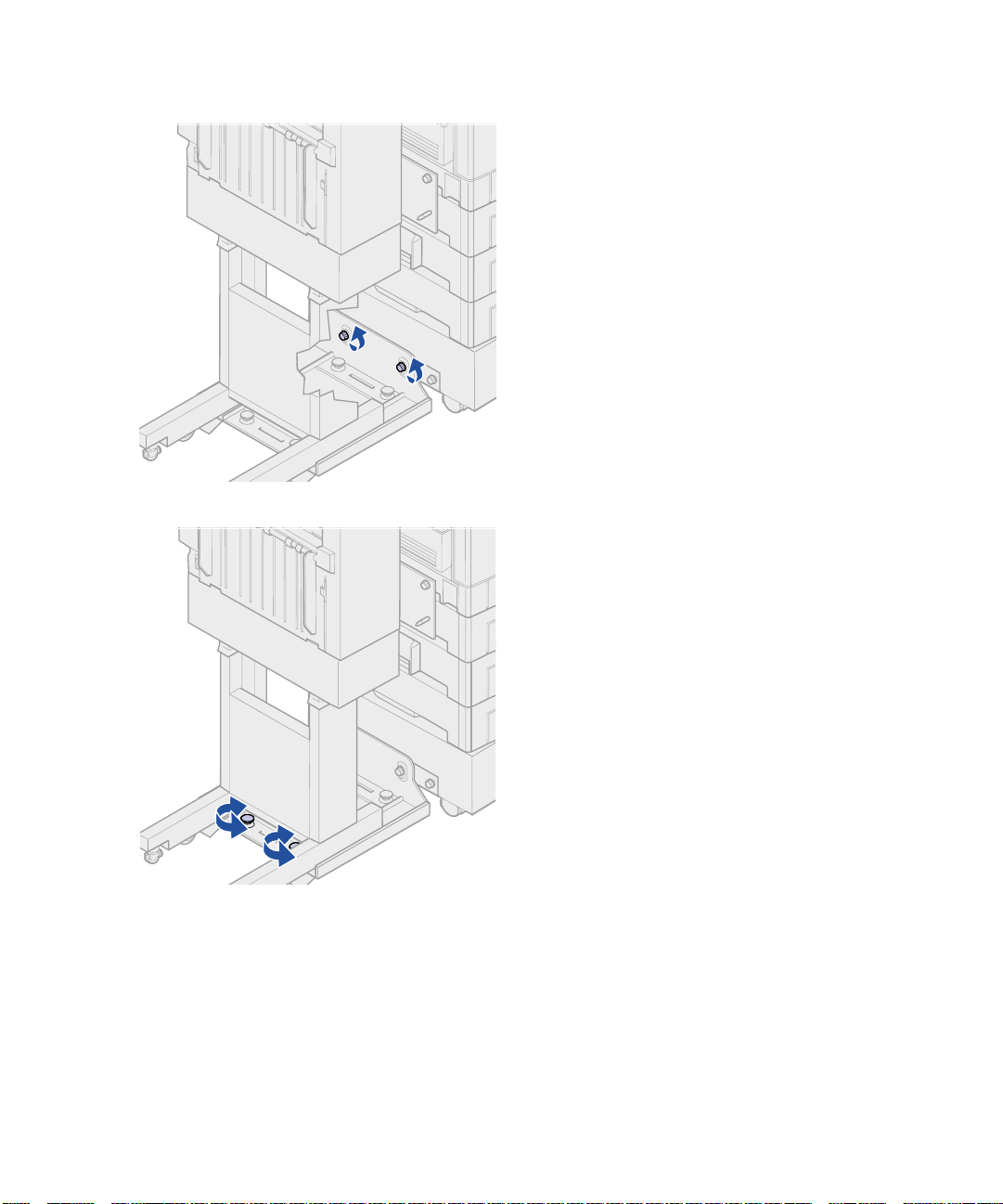

Lowering or raising the

finisher

Pin

Hole in finisher

Follow these instructions if the holes on

the finisher are above or below the pins

on the docking plate.

1

Determine if the pins are above or

below the holes in the finisher.

2

Loosen the guide rail

thumbscrews.

12

Setup

Page 17

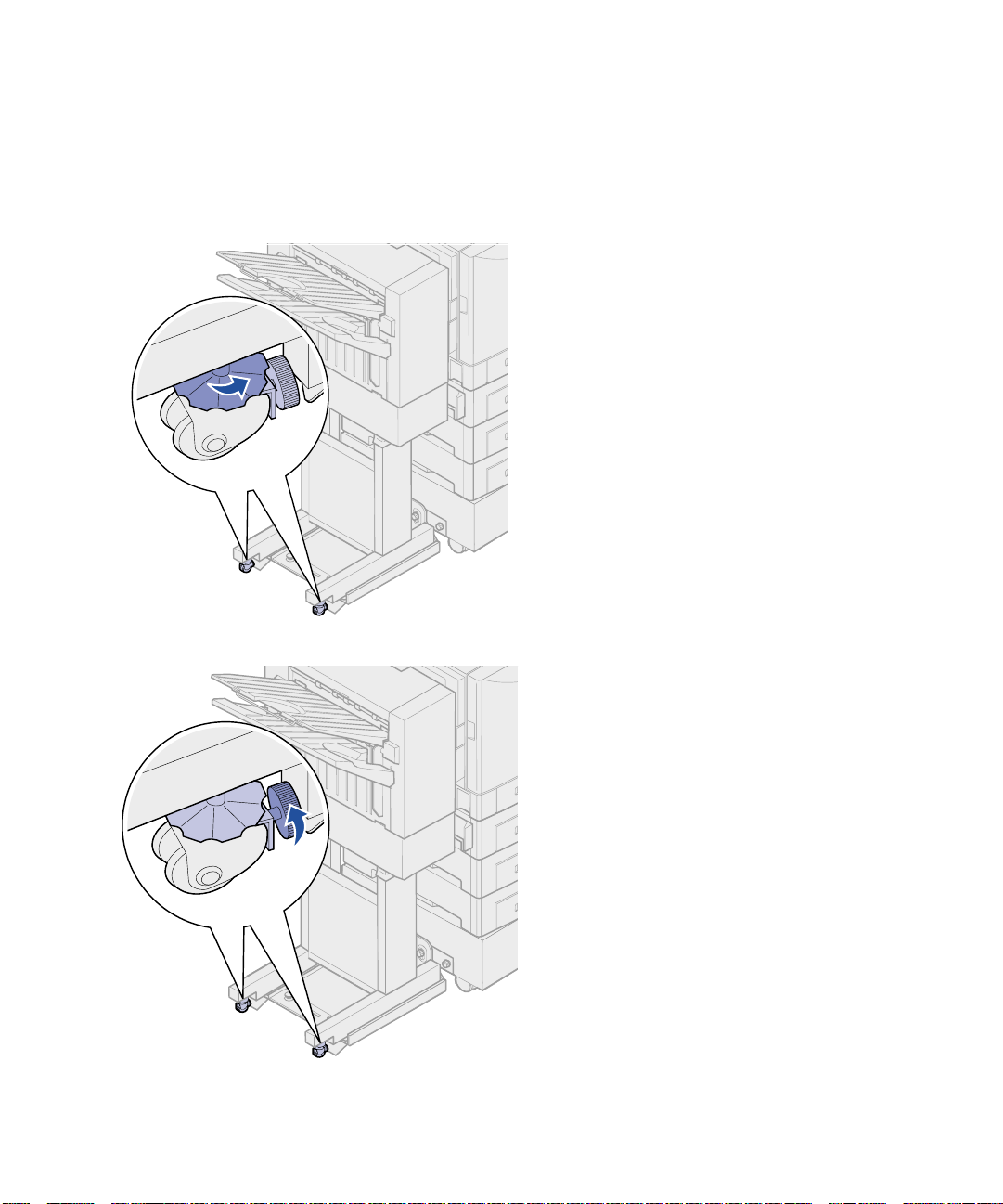

3

Rotate the adjustment knobs as

needed to align the holes in the

finisher with the pins.

To raise the finisher, rotate the

adjustment knobs clockwise.

To lower the finisher, rotate the

adjustment knobs

counterclockwise.

4

Roll the finisher toward the printer

until the finisher locks to the

docking plate pins.

Aligning the sides of the

finisher

You hear a

locks into position.

If the pins go into the holes but the finisher did not lock to the pins, see “Aligning the sides of the finisher” on page 13. Otherwise, go to “Aligning the top of the finisher” on page 15.

Follow these instructions if the distance

between the finisher and printer is not

the same at the top and bottom.

click

when the finisher

Setup

13

Page 18

1

Loosen the guide rail

thumbscrews.

If you previously lowered or raised

the guide rail plate, the

thumbscrews will already be

loose.

2

Rotate the rear adjustment knobs

to equally align the top and bottom

of the finisher with the printer.

To move the top of the finisher

closer to the printer, rotate the

adjustment knobs clockwise.

14

Setup

To move the top of the finisher

away from the printer, rotate the

adjustment knobs

counterclockwise.

3

Roll the finisher toward the printer

until the finisher locks to the

docking plate pins.

You hear a

locks into position.

click

when the finisher

Page 19

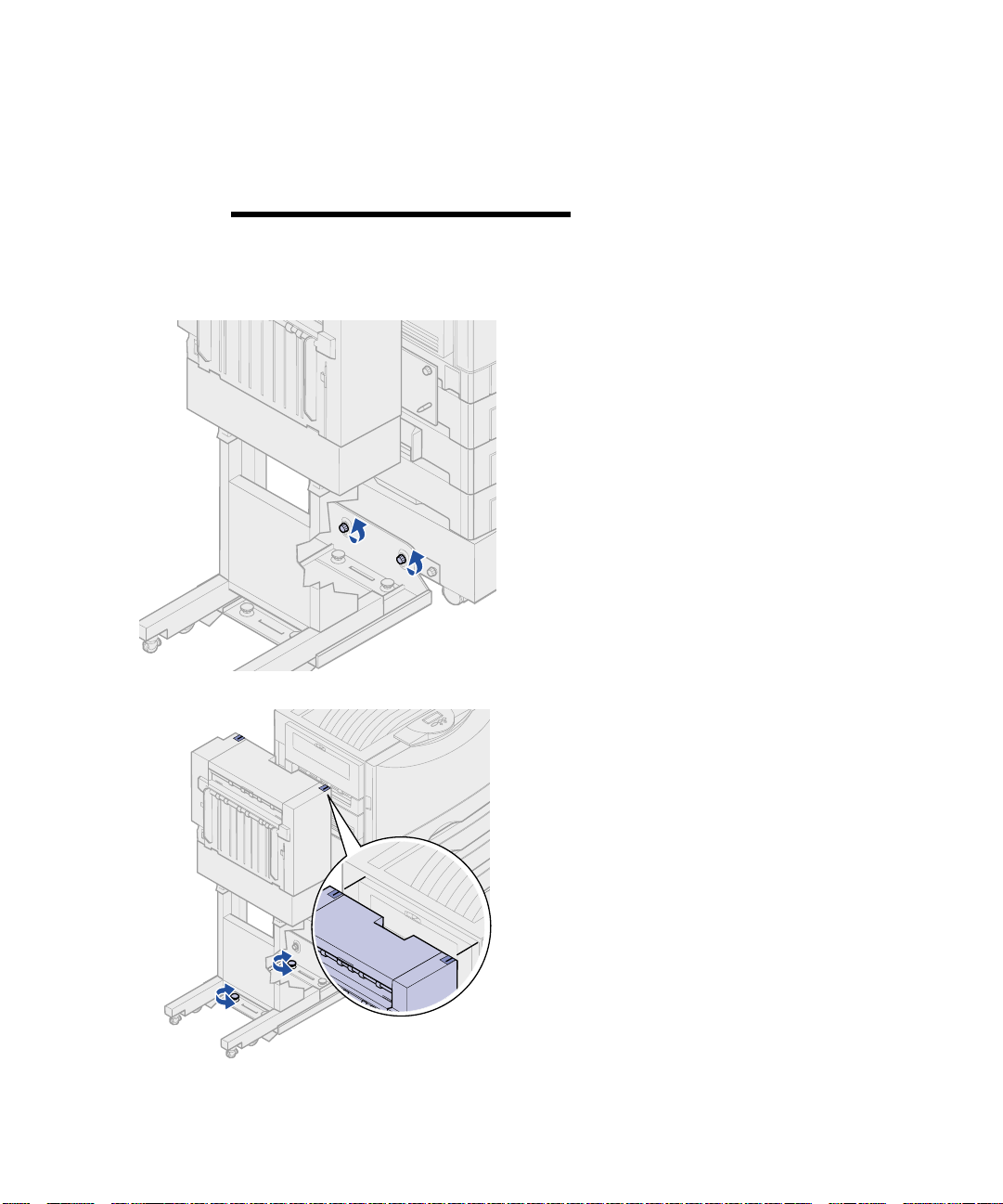

Aligning the top

of the finisher

Follo w t hese i nstruct ions i f the align ment

marks on top of the finisher are not

aligned with the edges of the cover on

the side of the printer.

Note:

finisher, recheck printer and finisher top

alignment.

Any time you move the printer or

1

Loosen the guide rail

thumbscrews.

If you made previous adjustments,

the thumbscrews will already be

loose.

2

Rotate the adjustment knobs as

needed to raise or lower the side

of the finisher.

To raise the finisher, rotate the

adjustment knobs clockwise.

To lower the finisher, rotate the

adjustment knobs

counterclockwise.

3

Tighten the guide rail

thumbscrews.

4

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

click

when the finisher

Setup

15

Page 20

Adjusting the wheels Adjust the wheels on the end of the

finisher so the stand will remain aligned

when moved.

To adjust and lock the wheels:

1

Rotate the left and right upper

adjustment knobs on the rear

wheels until the wheels touch the

floor.

To lower the wheels, rotate the

adjustment knobs clockwise.

2

Turn the wheels until the locking

knobs are aligned with the finisher

base.

16

Setup

3

Rotate the locking knobs

counterclockwise until they

contact the finisher base.

Page 21

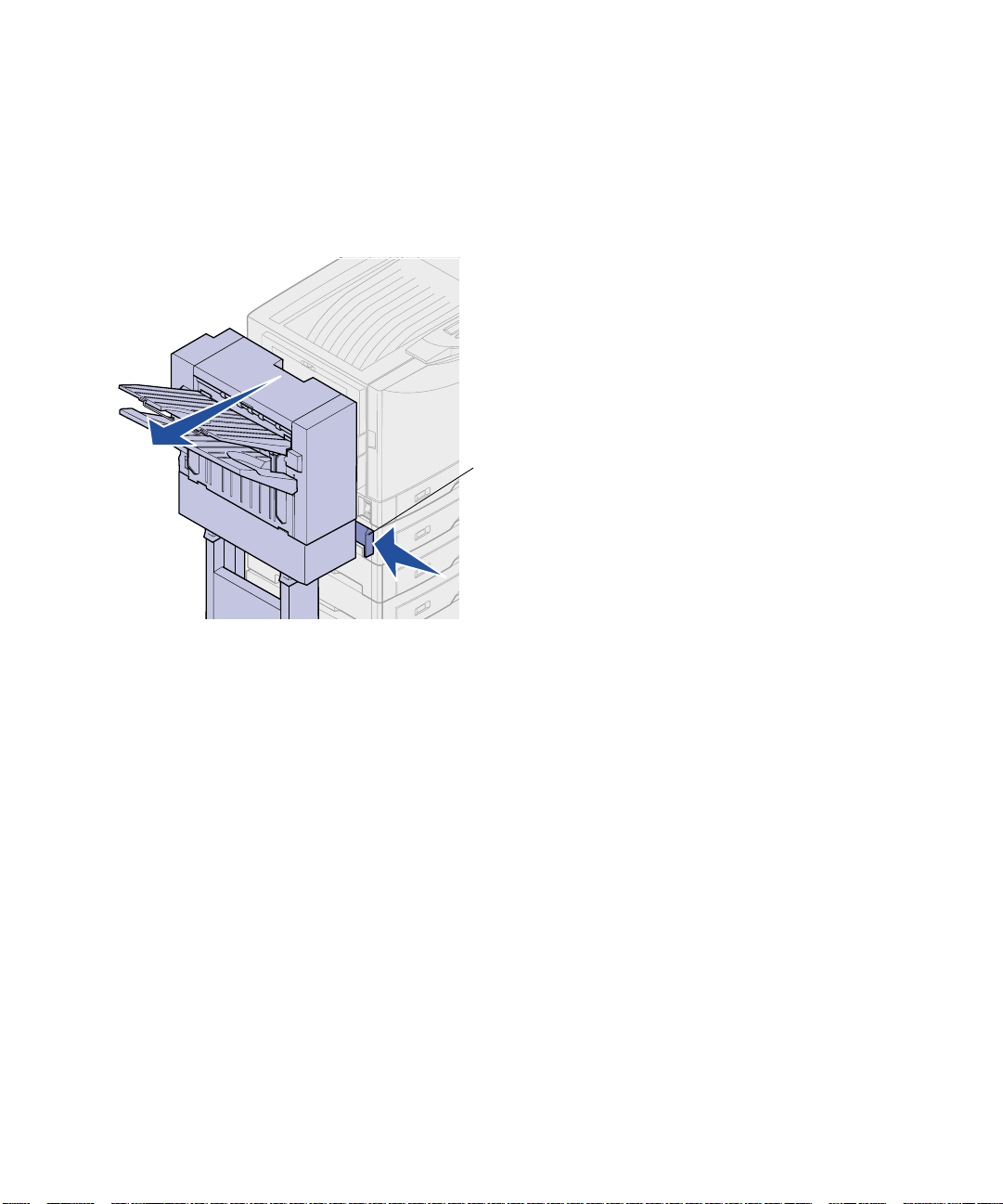

Attaching the cables Your finisher comes with an interface

cable and Y–

cable connects the finisher to the printer,

and the Y

power to the finisher and printer.

1

2

3

4

Latch

power cord. The interface

–

power cord provides electrical

Turn the printer off.

Push the latch in and hold it.

Roll the finisher away from the

printer.

Release the latch.

Setup

17

Page 22

Interface cable

CAUTION!

turned off before continuing.

Make sure the printer is

1

Plug the interface cable into the

bottom connector on the back of

the printer.

2

Tighten the thumbscrews.

3

Plug the interface cable into the

connector on the side of the

finisher.

The plug will be on a slight angle

when connected.

18

Setup

4

Tighten the thumbscrews.

Page 23

Power cable

1

Unplug the power cord from the

side of the printer.

Set the cord aside.

2

Plug the straight Y–power cord

connector into the socket on the

side of the finisher.

3

Plug the angled connector of the

Y–

power cord into the socket on

the side of the printer.

4

Connect the previously removed

printer power cord to the Y–

cord.

Setup

power

19

Page 24

5

Remove the protective paper from

the back of the cable holder.

6

Firmly press the adhesive-backed

cable holder onto the back of the

top optional drawer.

7

Place the finisher interface cable

and power cord into the cable

holder.

8

Close the cable holder .

9

Turn the printer on.

20

The finisher does not have a

power switch. Power is controlled

by the printer.

Setup

Page 25

Attaching the paper

jam label

Place the adhesive label that came with

your finisher over the left side of the

printer paper jam label inside the printer.

1

Open the front door.

2

Remove the protective paper as

shown.

Setup

21

Page 26

3

Firmly press the label as shown.

4

Close the front door.

22

Setup

Attaching the

finisher book sleeve

The adhesive sleeve that came with your

finisher is a handy place to store this

finisher book.

1

Remove the protective paper as

shown.

Page 27

2

Firmly press the sleeve onto the

area as shown.

Printing a menu

settings page

Note:

the operator panel and changing menu

settings, refer to your printer publications

CD.

UTILITIES MENU

1

Menu

For more information about using

Select

Go

3

5

2

Return

Stop

4

6

Print the menu settings page to review

the default printer settings and to verify

that printer options are installed

correctly.

1

Press

Utilities Menu, and then press

Select

2

Press

Menus, and then press

print the page.

The message Printing Menus

is displayed.

3

Verify the finisher is installed.

The finisher will be listed under

“Installed Features.” If it is not

listed, turn the printer off, unplug

the interface cable and power

cord, and then reinstall them.

4

Store this book in the sleeve.

until you see

Menu

.

until you see Print

Menu

Select

to

Setup

23

Page 28

Using finisher features

Output bins There are two output bins on your

finisher.

You can send the following types of

media to bin 1:

•

•

•

•

•

•

•

•

•

•

Plain paper

Bond paper

Card stock

Transparencies

Glossy paper

Labels

C5 and B5 envelopes

Letterhead

Preprinted paper

Colored paper

24

Using finisher features

You can only send A4 or letter paper to

bin 2. The following types of paper can

be sent to bin 2:

•

Plain paper

•

Bond paper

•

Letterhead

•

Preprinted paper

•

Colored paper

Page 29

Offsetting You can offset each print job or each

copy of a print job, making it easier to

separate the documents stacked in the

output bin.

The finisher stacks all offset print jobs in

bin 2. The amount of offset is

approximately 23 mm (0.9 in.).

You can select the following values from

the Finishing Menu using your printer

driver or the printer operator panel.

Value Output

None* Stacks all sheets directly on

Between

Copies

Between

Jobs

Values marked by an asterisk (*) are the

factory def au lt set t in gs.

top of each other.

Offsets each copy of a print

job.

Offsets each print job.

Using finisher features

25

Page 30

Stapling The stapler is located insi de the stap ler

door. You can corner staple 20 —28 lb

plain paper. The finisher stacks up to 30

stapled sets face down in bin 2.

The maximum number of sheets you can

staple is:

Paper weight Maximum

20 lb paper

30 sheets

24 lb paper

28 lb paper

Stapling more than the maximum number

of sheets may cause the stapler to jam.

You can select the following values from

the Finishing Menu using your printer

driver or the printer operator panel.

Value Output

Off*

On

Values marked by an asterisk (*) are the

factory def au lt set t in gs.

The message Load Staples appears

on the printer operator panel if the

stapler is empty or Insert Staple

Cartridge if the staple cartridge has

been removed. When the stapler has

been filled and reinstalled, the printer

clears the message.

Does not staple print jobs.

Staples each print job.

25 sheets

20 sheets

26

Using finisher features

Page 31

Latch

Use the following steps to remove the

stapler holder and add more staples:

1

Push the latch in and hold it.

2

Roll the finisher away from the

printer.

3

Release the latch.

4

Open the stapler door.

Stapler

Using finisher features

27

Page 32

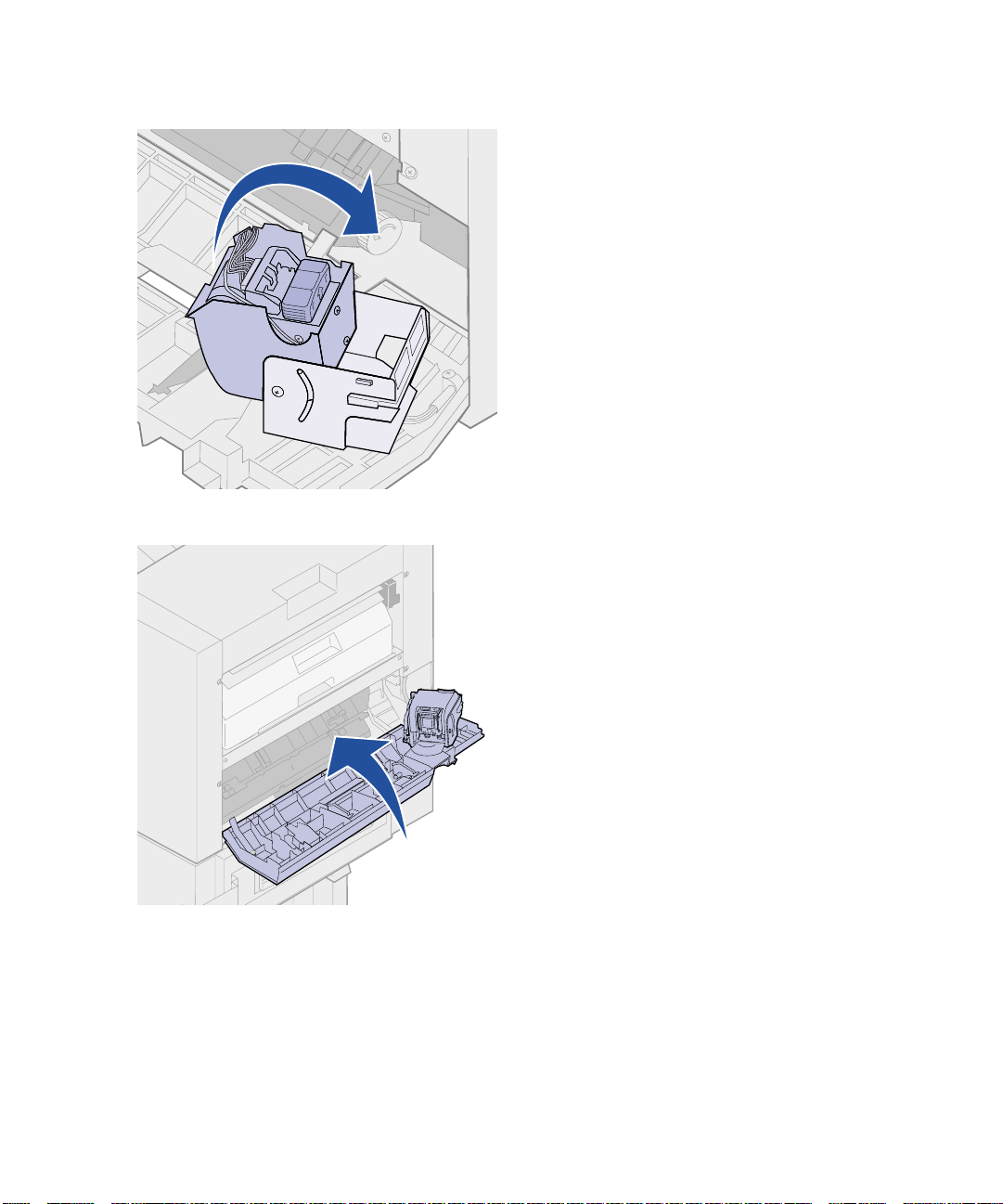

Stapler

Stapler locking lever

5

Lift the stapler locking lever.

6

Rotate the stapler up.

7

Pull the staple holder from the

stapler.

28

Using finisher features

Page 33

8

Pull the empty staple cartridge

from the staple holder.

9

Discard the cartridge.

10

Remove the new staple cartridge

from its packaging.

Part number Description

11K3188 C910/T62x

Staple Cartridge

Note:

cartridge until after the cartridge has

been inserted into the holder.

Leave the tape on the staple

11

Insert the new cartridge.

12

Remove the tape from the

cartridge.

Using finisher features

29

Page 34

13

Insert the staple holder into the

stapler.

Push down until the staple holder

is fully seated.

14

Rotate the stapler to its closed

position.

30

Using finisher features

Page 35

15

Close the stapler door.

16

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

click

when the finisher

Using finisher features

31

Page 36

Hole punching Depending on the finisher you have, you

can punch 3 or 4 holes in your print jobs.

The finisher can stack hole punch print

jobs in bin 1 or bin 2. You cannot hole

punch transparencies, card stock, glossy

paper, or labels.

Value Output

Off*

Does not punch holes in

printed output.

On

Values marked by an asterisk (*) are the

factory def au lt set t in gs.

As the finisher punches holes, it deposits

discarded bits of paper in the hole punch

box. When the finisher has punched

15,000 sheets, the message Empty

Hole Punch Box appears on the printer

operator panel.

Use the following steps to empty the box:

1

2

3

Punches holes in every

printed page.

Push the latch in and hold it.

Roll the finisher away from the

printer.

Release the latch.

32

Latch

Using finisher features

Page 37

Handle

4

Lift the finisher entry guide

handle.

5

Lift the hole punch box, rotate the

bottom outward and then remove

it.

6

Release the handle.

7

Empty the box.

8

Lift the handle.

9

Place the top of the box in the

finisher and then rotate the bottom

of the box into the finisher.

10

Release the handle.

Using finisher features

33

Page 38

11

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

12

Check the printer operator panel

display.

If you emptied the box before the

Empty Hole Punc h Box

message appeared, press

until you see Supplies Menu on

the display and select Replace

Supplies, and then select Box

and select Replaced.

The Ready message appears.

click

when the finisher

Menu

34

Using finisher features

Page 39

Troubleshooting

This section helps you clear messages

that appear on the printer operator

panel, clear paper and stapler jams, and

resolve other finisher problems that may

occur.

Message Solution

Bin <x> Full

Close Finisher

Door

alternates with

Check Finisher

Installation

Empty Hole

Punch Box

Insert Hole

Punch Box

Load Staples

Remove the stack of paper from the specified bin. Press Go to clear the message and

continue printing.

Note: If you assigned the bin a name, the bin name is displayed instead of the bin

number.

Close the finisher top cover.

(or)

Make sure the finisher is flush against the printer.

You must empty the ho le pun ch box to continue printi ng. For instructions on emptying the

box, see “Hole punching” on page32. Press Go to clear the message and continue

printing.

The hole punch box is missing. Place the box in the finisher to clear the message.

You must replace the staple cartridge if you want to continue stapling. You can press Go

to clear the message and contin ue printin g witho ut stapl ing. F o r inst ructions on rep lacing

the staple cartridge, see “Stapling” on page 26.

Clearing finisher

messages

Messages appear on the printer operator

panel to inform you of the status of your

finisher. The following table e xplains how

to clear the messages.

Insert Staple

Cartridge

The staple holder is missing. Place the holder in the stapler to clear the message.

Troubleshooting

35

Page 40

Message Solution

210 Staple Jam

Check Area H

alternates with

Clear Staple Job

From Finisher

Requested Env

Not Supported

This message indicates a staple jam has occurred inside the finisher. Open the stapler

door, remove the paper from accumulator area, and clear the staple jam.

For information on removing the paper from the accumulator, see “Accumulator area” on

page 51. For information on clearing the staple jam, see “Clearing staple jams ” on

page 56.

This message indicates a request to print an envelope other than C5 or B5 was sent to

the printer with the finisher attached. The message displays for 5 seconds and then is

removed. The printer prints the information for the nonsupported envelope onto the print

media in tray 1.

Note: You receiv e thi s m es s age if you are trying to print envelope siz e s other than C5 or

B5 with the finisher attached to the printer. To print envelopes other than C5 or B5, see

“Printing envelopes” on page 38.

Solving other problems

Symptom Cause Solution

Paper frequently

jams in the finisher.

The finisher and printer are

misaligned.

The printer and finisher have

been moved.

Properly align the finisher with the printer. Refer to

“Aligning the sides of the finisher” on page13 and

“Aligning the top of the finisher” on page 15 for

instructions.

Use the following table to find

solutions to other problems with the

optional finisher.

The printer does not

print to the

requested output

bin.

The paper jam

message will not

clear.

36

Troubleshooting

You are trying to staple, hole

punch, or offset print jobs on

print media other than paper.

The finisher cables are not

connected properly.

Your printer driver and the

operator panel settings are

different.

You are trying to send a print

job to the wrong output bin.

The cover is not close d, the

finisher is not against the

printer, or there is paper

somewhere in the paper path .

Restrict use of the finisher to plain paper. You cannot

hole punch transparencies, card stock, labels, or

envelopes.

Check the cable connections. Refer to “Attaching the

cables” on page 17 for instructions on connecting the

finisher to the printer.

Make sure your printer driver is set to dir ect the output

to the bin you want.

Printer settings selected fro m a so ftw are ap plica tion or

driver override default settings selected from the

operator panel.

Card stock, transparencies, and hole punch jobs are

sent to bin 1. Stapled jobs are sent to bin 2.

Open and close the top cover and make sure the

finisher is locked onto the docking pins. Recheck the

finisher and printer for additional jams.

Page 41

Symptom Cause Solution

Pages are not stapled.

Punched holes are not

in the proper position.

You cannot print

requested envelopes.

You are trying to staple too

many sheets.

The staple cartridge is empty. Install a new staple cartridge. See “Stapling” on

The stapler is jammed. Check the stapler for a staple jam. See “Clearing

The printer and finisher are not

aligned properly.

You hole punched a printed job

on different finishers.

You are trying to print envelope

sizes other than C5 or B5 with

the finisher attached to the

printer.

Reduce the number of pages in the staple job.

The finisher can staple up to 30 sheets of 20 lb paper.

If you attempt to staple a larger stack of paper, the

finisher ejects the stack without stapling it.

page 26 for instructions.

staple jams” on page 56 for instructions.

Align the top of the finisher with the printer. See

“Aligning the top of the finisher” on page 15 for

instructions.

Move the alignment of the finisher to compensate for

the hole punch diffe r en ce. See “Hole punch

adjustment” on page 44 for instructions.

Move the finisher away from the printer. Reinstall the

printer exit tray. Turn the printer off. Wait 15 seconds

and turn the printer on. Resend the envelope print job.

Troubleshooting

37

Page 42

Printing envelopes You can print C5 or B5 envelopes on

your printer and send them to bin 1. If

you try to print envelopes other than C5

or B5 and have the finisher attached to

the printer, you receive the Requested

message.

Latch

Env Not Supported

The message displays for 5 seconds and

then is removed. The printer prints the

information for the nonsupported

envelope onto the print media in tray 1.

To print envelopes other than C5 or B5:

1

Push the latch in and hold it.

2

Roll the finisher away from the

printer.

3

Release the latch.

38

Troubleshooting

Page 43

4

Align the holes on the exit tray

tabs with the pins on the side of

the printer.

5

Attach the printer exit tray to the

printer.

6

Turn the printer off.

Troubleshooting

39

Page 44

7

Loosen the interface cable

thumbscrews.

8

Unplug the interface cable from

the connector on the side of the

finisher.

9

Turn the printer on.

10

Resend the envelope print job to

the printer.

When you are finished printing

envelopes complete the following steps:

40

Troubleshooting

Page 45

1

Lift the printer exit tray halfway

and remove.

2

Turn the printer off.

Troubleshooting

41

Page 46

3

Plug the interface cable into the

connector on the side of the

finisher.

The plug will be on a slight angle

when connected.

4

Tighten the thumbscrews.

5

Turn the printer on.

42

Troubleshooting

Page 47

6

Roll the finisher toward the printer

until the finisher locks to the

docking plate pins.

You hear a

locks into position.

click

when the finisher

Troubleshooting

43

Page 48

Hole punch adjustment You can adjust the hole punch alignment

by approximately 4 mm (

adjustment is useful when you want to

center the punched holes onto the paper

or if you hole punched a printed job on

different finishers.

3

/16 in.). This

Note:

used for both three and four hole punch

finishers.

The following procedures are

1

Verify the alignment of the printer

and finisher is correct.

If the alignment is not correct, see

“Aligning the top of the finisher” on

page 15 for instructions, and then

print and hole punch another

sheet of paper and see if an

adjustment is needed.

If an adjustment is needed,

continue with step 2.

2

Using a sheet of paper previously

punched from the finisher, fold the

paper so the bottom punched hole

is aligned with the top punched

hole.

Bottom edge is

below top edge

44

Troubleshooting

Bottom edge is

above top edge

3

Determine if the edge of the

bottom of the page is below or

above the top edge of the page.

Page 49

4

Loosen the guide rail

thumbscrews.

Note:

knobs more than three complete turns

from their starting position. Adjustments

greater than three turns may cause

paper jams.

Do not move the adjustment

5

Rotate both adjustment knobs as

shown, the same amount to raise

or lower the side of the finisher.

A half turn of the knob moves the

position of the hole approximately

one third to one half the distance

of the punched hole.

To move the bottom of the paper

down, rotate the knobs clockwise.

To move the bottom of the paper

up, rotate the knobs

counterclockwise one quarter

turn.

Troubleshooting

45

Page 50

6

Tighten the guide rail

thumbscrews.

7

Print and punch another piece of

paper.

8

Repeat steps 2 and 3. If the holes

are not aligned repeat steps 3

through 8.

Clearing paper jams By carefully selecting and loading paper,

you can avoid most paper jams. For

information on avoiding paper jams, refer

to the

Lexmark C910 Publications

CD.

200 Paper Jam

Check Area I

200 Paper Jam

Check Area H

46

Troubleshooting

200 Paper Jam

Check Area G

When a finisher paper jam occurs, the

200 Paper Jam Check Area <x>

message appears on the printer operator

panel. The illustration at the left identifies

the areas you must check to clear a

finisher paper jam. Refer to your printer’s

Quick Reference

information about clearing jams in the

printer.

You must clear the jam and then press

to resume printing. The Jam

Go

Recovery menu item in the Setup Menu

determines whether the printer reprints

the jammed page. Refer to your printer’s

publications CD for information about the

Jam Recovery menu item.

or publications CD for

Page 51

To clear:

Jam message See page

Check Area G

Check Area G

Check Area H

Check Area I

This message indicates a jam in the

input area of the finisher. To clear

area G:

1

Open the finisher top cover and

remove any jams.

2

Close the top cover.

3

Press Go.

You must clear any printer paper

jams before the printer will resume

printing. For instructions on

clearing printer paper jams, refer

to your printer’s

or publications CD.

47

48

53

Quick Reference

Troubleshooting

47

Page 52

Check Area H

Latch

This message indicates a paper jam

inside the finisher. You need to check

both the upper access area and

accumulator area. To clear area H:

1

Push the latch in and hold it.

2

Roll the finisher away from the

printer.

3

Release the latch.

4

Remove any jams from the

finisher entry guide.

48

Entry guide

Troubleshooting

Page 53

Handle

Upper access area

1

Lift the finisher entry guide

handle.

2

Lift the hole punch box, rotate the

bottom outward and then remove

it.

3

Release the handle.

4

Lift the jam access cover.

Jam access

cover

Troubleshooting

49

Page 54

Knob

5

Remove any jams from the

finisher.

Rotate the knob to move the

paper into the access cover area.

6

Release the jam access cover .

7

Lift the finisher entry guide

handle.

8

Place the top of the box in the

finisher, and then rotate the

bottom of the box into the finisher.

50

Troubleshooting

9

Release the handle.

Page 55

Accumulator area

1

Open the stapler door.

2

Remove any jams from the

accumulator.

Rotate the accumulator knob

counterclockwise to move the

paper down.

Accumulator

knob

Troubleshooting

51

Page 56

3

Close the stapler door.

4

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

5

Press Go.

You must clear any printer paper

jams before the printer will resume

printing. For instructions on

clearing printer paper jams, refer

to your printer’s

or publications CD.

click

when the finisher

Quick Reference

52

Troubleshooting

Page 57

Check Area I

This message indicates a jam in one of

the output areas of the finisher. To clear

area I:

1

Open the finisher top cover and

remove any jams.

2

Close the top cover.

3

Push the latch in and hold it.

4

Roll the finisher away from the

printer.

Latch

5

Release the latch.

Troubleshooting

53

Page 58

6

Open the stapler door.

7

Remove any jams from the

accumulator.

Rotate the accumulator knob

counterclockwise to move the

paper down.

54

Troubleshooting

Accumulator

knob

Page 59

8

Close the stapler door.

9

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

10

Press Go.

You must clear any printer paper

jams before the printer will resume

printing. For instructions on

clearing printer paper jams, refer

to your printer’s

or publications CD.

click

when the finisher

Quick Reference

Troubleshooting

55

Page 60

Clearing staple jams If your print job is not stapled, make sure

you have selected the Staple value from

the Finishing Menu of your printer driver

or the printer operator panel.

If the correct menu value has been

selected and the job does not staple, or

you received a 210 Staple Jam Check

Area H message, use the following

steps to remove and clear the stapler:

1

Push the latch in and hold it.

2

Roll the finisher away from the

printer.

3

Release the latch.

Latch

4

Open the stapler door.

56

Stapler

Troubleshooting

Page 61

Stapler

Stapler locking lever

5

Lift the stapler locking lever.

6

Rotate the stapler up.

7

Remove the staple holder from

the stapler.

Troubleshooting

57

Page 62

8

Lift the staple holder arm.

9

Remove any staples from the end

of the staple holder.

58

Troubleshooting

10

Lower the staple holder arm until it

locks to the staple holder.

Page 63

11

Insert the staple holder into the

stapler.

Push the staple holder down until

it is fully seated.

12

Rotate the stapler to its closed

position.

Troubleshooting

59

Page 64

13

Close the stapler door.

14

Roll the finisher toward the printer

until the finisher locks to the

docking pins.

You hear a

locks into position.

15

Press Go.

click

when the finisher

60

Troubleshooting

Page 65

Electronic emission notices

Federal Communications

Commission (FCC)

compliance information

statement

Note:

FCC regulations on el ectromagneti c

interference f or a Class A computi ng

device, use a properly shielded and

grounded cable. Use of a substitute

cable not properly shielded and

grounded ma y res ult in a v iolation of

FCC regulations.

To assure compliance with

Industry Canada

compliance statement

Avis de conf ormit é aux

normes d’Industrie

Canada

This finisher h as been teste d and found to comply with the l imits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

The FCC Class A limits are designed to provide reasonable protection

against harmful interf erence when the e quipment is op erat ed in a comme rcial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interferenc e, in which case the u ser will b e requ ired to co rrect the interf erence

at their own expense.

The manufacturer is not responsible for any radio or television interference

caused by using other than recommended cables or by unauthorized

changes or modifications to this equipment. Unauthorized changes or

modifications could void the user's authority to operate this equipment.

This Class A digital apparatus meets all requirements of the Canadian

Interferenc e-C au sing Equi pm ent Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

European Community

(EC) directives

conformity

This product is in conformity with the protection requirements of EC Council

directives 89/336/EEC and 73/23/EEC on the approximation and

harmonization of the laws of the Member States relating to electromagnetic

compatibility and safety of electrical equipment designed for use within

certain voltage limits.

Electronic emission notices

61

Page 66

Warning! When a print server is

installed, this is a Class A product.

In a domestic environment, this

product may cause radio

interference, in which case, the user

may be required to take adequate

measures.

CISPR 22 WARNING: This is a Class A product. In a domestic environment, this

A declaration of conformity with the requirements of the directives has been

signed by the Director of Manufacturing and Technical Support, Lexmark

International, S.A., Boigny, France.

This product satis fies t he Class A limi ts of EN 5502 2 a nd sa f ety require ments

of EN 60950.

product may cause radio int erfere nce, in whic h case the user ma y be required

to take adequate measures.

AVERTISSEMENT: Ce produit appartient à la classe A. Dans un

environnement résidentiel, ce produit risque de provoquer des interférences

radio, auquel cas l'utilisateur devra prendre les mesures adéquates.

AVVERTENZA: Questo prodotto appartiene alla Classe A. In ambiente

domestico, questo prodotto può causare interferenze radio, nel qu al caso è

necessario adottare adeguate precauzioni.

W ARNUNG: Bei diesem Gerät handelt es sich um ein Produkt der Klasse A.

In Wohngebieten kann dieses Gerät Störungen des Radio- und

Fernsehempfangs verursachen. Der Benutzer muß in diesem Fall geeignete

Maßnahmen ergreifen.

ADVERTENCIA: Este es un producto de Clase A. En un entorno doméstico,

este producto puede causar interferencias de radio, en cuyo caso, se

solicitará al usuario que adopte las medidas oportunas.

Japanese VCCI notice

The United Kingdom

Telecommunications Act

1984

62

Electronic emission noti ce s

AVISO: Este produto pertence à classe A. Em um ambiente doméstico, ele

pode causar interferências em transmissões de rádio. Nesse caso, será

necessário que o usuário adote as medidas adequadas.

This apparatus is ap proved under the approval number N S/G /12 34/J /10 00 03

for the indirect connections to the public telecommunications systems in the

United Kingdom.

Page 67

Index

A

alignment, hole punch 44

attaching

bins 10

cables 17

docking plate 4

finisher 11

finisher book sleeve 22

finisher stand 9

guide rail 4

guide rail plate 4

paper jam label 21

B

bins

attaching 10

capacities 1

messages 35

output 24

C

cabinet 1

cables

interface 18

power 19

CD

publications 3

Clear Staple Job From Finisher 36

clearing

messages 35

paper jams 46

stapler jam 56

cord, power 19

D

docking plate 5

E

emptying the hole punch box 32

Energy Star 2

envelope printing 38

F

FCC emissions information ii

finisher

aligning 11

stand 9

view, front and rear 2

G

guide rail 4

guide rail plate 4, 5

Index

63

Page 68

H

O

hole punching 32

alignment 44

capacities 32

emptying the hole punch box 32

I

installation verification 23

installing

bins 10

staple cartridge 26

introduction 1

J

jam

label 21

paper 46

stapler 56

L

label, paper jam 21

Load Staples 26

offsetting 25

options

drawers 1

low profile printer stand 1

printer cabinet 1

other problems 36

output bins

attaching 10

capacities 1

supported paper types 24

P

paper jam label 21

paper jams 46

paper weights 26

printer stand 1

printing envelopes 38

problems

finisher 36

frequent jams 36

other problems 36

solving 36

publications CD 3

M

maximum stapled sheets 26

menu settings page 23

messages 35

210 Staple Jam 36

Bin <x> Full 35

Check Finisher Installation 35

Close Finisher Door 35

Empty Box 32

Empty Hole Punch Box 35

Insert Hole Punch Box 35

Insert Staple Cartridge 35

Load Staples 26, 35

Requested Env Not Supported 35

64

Index

R

replacing a staple cartridge 26

S

safety information

located on inside front cover

sleeve, finisher book 22

solving problems 36

stand

finisher 9

printer 1

staple cartridge, replacing 26

staple jam 56

stapling 26

Page 69

T

troubleshooting 35

V

verify finisher installation 23

Index

65

Page 70

P/N 12N0467

E.C. 2N0016

Lexmark and Lexmark with diamond de sign are trademarks of Lexmark International, Inc.,

registered in the United States and/or other countries.

© 2002 Lexmark International, Inc.

740 West New Circle Road

Lexington, Kentucky 40550

www.lexmark.com

Loading...

Loading...