Page 1

Revised: March 24, 2006

Lexmark™ 910 Series

Photo Jetprinter™

• Table of Contents

•Start Diagnostics

4110-XXX

• Safety and Notices

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered i n the

United States and/or ot her countries.

Page 2

4110-XXX

Editi on: March 24, 2006

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMAR K INTERNATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING , BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not all o w di sc la im er o f e x pres s o r i mpl i ed wa rr an tie s i n c ertai n t ra ns act ion s; t he refore, t hi s

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the info rmation herein; these changes will be incorpo rated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Le xmark International, Inc., Department D22A/032-2 ,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or e-mail at

ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate withou t incurring any obligation

to yo u.

Lexmark and Lexmark with diam ond design are trademarks of Lexmark International,

Inc. , registered in the Unit ed States and/or other countries. Photo Jetprinter is a

trademark of Lexmark Interational, Inc.

Other trademarks are the property of their respective owners.

© 2004 Copyright Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are

commercial computer software and documentation develope d exclusively at priva te

expense.

U.S.A. P/N 12G9405

Japanese P/N 12G9406

Page 3

4110-XXX

Table of contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Control panel and menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Control panel buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Print quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Maintenance approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power-On Self Test (POST) sequence . . . . . . . . . . . . . . . . . . . . 2-1

POST symptom table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Sym p tom ta b le s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Maintenance station service check . . . . . . . . . . . . . . . . . . . . . . . 2-4

Operator panel button service check . . . . . . . . . . . . . . . . . . . . . . 2-5

LCD assembly display service check . . . . . . . . . . . . . . . . . . . . . . 2-5

Paper feed service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Paper path service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Power service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Print quality service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transport carrier service check . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -12

Catastrophic error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Non-catastrophic error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Self test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Repair informatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Top cover assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Control panel door assembly removal . . . . . . . . . . . . . . . . . . . . . 4-4

Card reader removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Print engine assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Base assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Carrier assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

System board removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -10

Transport carrier motor removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-12

iii

Page 4

4110-XXX

Maintenance station removal . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Card reader door removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

ASF guide with spring removal . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Connector locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

System board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to use the parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Electronics/carrier transport . . . . . . . . . . . . . . . . . . .7-4

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

iv Service Manual

Page 5

4110-XXX

Preface

This manual describes the 910 Series Photo Jetprinter (4110-XXX)

and contains maintenance procedures for service personnel. It is

divided into the following chapters:

1. Gene r al infor m ation contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

2. Diagnostic information contains an error indicator table,

symptom tables, and service checks used to isolate failing field

replaceable units (FRUs).

3. Diagnostic aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair informa tio n provides instructions for making printer

adjustments and removing and installing FRUs.

5. Connector locations uses illustrations to identify the connector

locations and test points on the printer.

6. Preventive maintenance contains the lubrication specifications

and recommendations to prevent problems.

7. Parts catalog conta ins illustrations and part numbers for

individual FRUs.

Preface v

Page 6

4110-XXX

Safety information

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury dur ing disassem bly and ser v icing of this product.

Professional service personnel should understand this and take

necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiqu es. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'aut res

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de m aintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

vi Service Manual

Page 7

4110-XXX

Norme di sicurezza

• Il pr odotto è stato progettato, testato e approvato in conformità a

severi standard di sicurezza e per l’utiliz zo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune parti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Safety i n fo rmat io n vii

Page 8

4110-XXX

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes. Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La in formaci ón sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser conscien te de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outro s component es de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serv iços e não devem s er

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessári os.

viii Service Manual

Page 9

4110-XXX

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

Safe ty inform at ion ix

Page 10

4110-XXX

x Service Manual

Page 11

4110-XXX

1. Gen e r a l in for matio n

The Lexmark™ 910 Series Photo Jetprinter™ (4110-XXX) is a small

personal inkjet printer specifically for standalone photographic

printing. The photoprinter incorporates a new photo control operator

panel into the cover and slots to support the compact flash and

smar t media.

.

General information 1-1

Page 12

4110-XXX

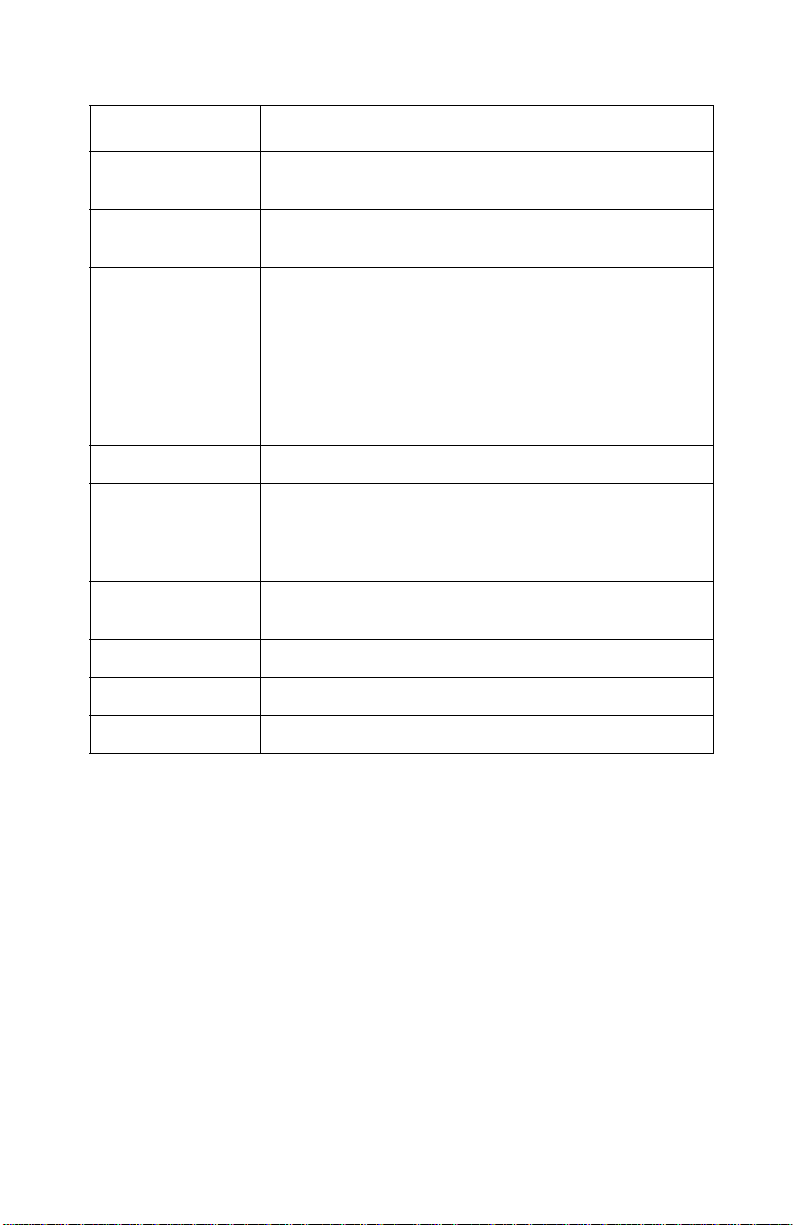

Control panel and men u

Using the control pa nel

The control panel has a blue-LED-backlit power button. The card

reader bezel has a single blue LED to indicate memory card inserted

and memory card activity . As soon as a memory card is inserted and

while the card remains inserted, the LED is lit solid. When the card is

being actively read from or written to, the LED should blink at the

prescribed rate.

Control panel buttons

Buttons Functions

Power Tur ns on power. At power up, the printer turns on the

card reader LED and the co lor gr aphic s LCD . The car d

reader LED is on during power up, changing to of f

when the card reader is accessible for memory card

insertion.

Start Starts the selected operation. Us e this button to select

1-2 Service Manual

color or mono printing from the Phot o m enu.

Page 13

4110-XXX

Buttons Functions

Up arrow

Down arrow

Left arrow

Right arrow

Resize Sets the image siz e of photos in the Photo Selecti on

Number of Prints Changes the number of copies to print.

Rotate Rotates the image in the LCD di splay by 90° CCW f or

Select Selects photos in Photo mode and cancels the

Print Preview Shows how photos will print on the page.

Stop/Clear Cancels a print job bef ore it begins printing.

Menu Enters/exits the menus.

Navigates menu items on the LCD.

Btowses and choose options on the LCD

mode. In Photo Crop mode, the button changes the

zoom of the ROI. The Region of Intere st is a portion of

a photo or an image that is ide ntified by a green

outline . For photos, it is t he portion of the pho to that

displays based on the curre n t phot o size select ion.

Also used with the Resize button when croppi ng

photos and for indicating the regi on to print.

each time the button is pressed. Also used to rotate

the ROI when in the Crop function of the Photo mode

menu.

displayed photo when pres sed again.

General information 1-3

Page 14

4110-XXX

Print qua li ty

Mono print reso lu t ion:

Quick - 300 x 600 dpi

Normal - 600 x 600 dpi

Photo - 1200 x 1200 dpi

Color print resol ut i on:

Quick - 600 x 600 dpi

Normal - 1200 x 1200 dpi

Photo - 4800 x 1200 dpi

Power consumption

Printing - 13.08 Watts

Idle - 8.5 Watts

Sleep - 6.6 Watts

Maintenance approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error indicator charts,

symptom index, service checks, and diagnostic aids to determine

the symptom and repair the failure. Begin with “Start” on page 2-1.

This printer can be serviced without being connected to a host

computer.

After you complete the repair, perf orm tests as needed to verify the

repair.

1-4 Service Manual

Page 15

4110-XXX

Abbreviations

CIS Contact Image Sensor

CSU Customer Setup

EOF End of Forms

ESD E lectr ostatic Discharge

FRU F ield Replac eable Unit

HV High Voltage

LCD Liquid Crystal Display

LED Light-Emitting Diode

LV Low Voltage

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POST Power-On Self Test

ROI Region of Interest

V ac Volts alternating current

V dc Volts direct current

General information 1-5

Page 16

4110-XXX

1-6 Service Manual

Page 17

4110-XXX

2. Diagnostic information

Start

Use the post symptom table, symptom tables, and service checks in this

chapter to determine the printer failure.

Power-On Self Test (POST) sequence

Plug the printer in and check for a correct POST operation by

observing the following:

1. The Power button light turns on.

2. The LCD turns on and displays “Lexmark.”

3. The carrier moves off the maintenance station and then returns.

4. The paper feed motor cycles and then turns off.

Note: After the above sequence occurs, the power button light and

LCD remain on.

If your printer complete s POST with no errors, g o to the “Sympto m tabl es”

on page 2-2

If your printer does not complete POST, locate the sympt om in the following

table and tak e the appropriate actio n.

, locate the symptom and take the appropriate action.

POST symptom table

Symptom Action

No motors run Go to the “Power service chec k” on

page 2-8.

Paper feed gears do not turn Go to the “Paper feed service

check” on page 2-6.

• Carrier does not move

• Carrier slams side frame

• Blank display

• All diamonds displayed af ter POST

• Display diff ic u lt to re ad

• Display OK, buttons do not function

• One or mor e buttons do not f unction

Go to the “Transport carrier service

check” on page 2-10.

Go to the

service check” on page 2-5

“LCD assembly disp lay

.

Diagnostic information 2-1

Page 18

4110-XXX

Symptom tables

Locate the symptom in the following tables and take the appropriate

action.

Transport carrier problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slam s si de frame

Go to the “Transport carrier service

check” on page 2-10.

Communications problems

Symptom Action

Printer not communicating with

host computer.

Check the USB connec tion (connec tor

J2). If the connection is good and

problem persists, repl ace the system

board. Go to “System board removal”

on page 4-10.

Maintenance station problems

Symptom Action

• F ails to cap the printhead

• F ails to clean the printhead

Go to the “Maintenance station

service check” on page 2-4.

2-2 Service Manual

Page 19

4110-XXX

Paper feed problems

Symptom Action

• Fails to pick pape r

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Paper skews Go to the “Paper path service check”

Go to the “Paper feed service chec k”

on page 2-6.

on page 2-8.

Power prob le ms

Symptom Action

No po we r in printe r Go to t h e “Power service check” on

page 2-8.

Print quality problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

• Fuzzy print

• Carrier moves but does not print

• Printhead drying prematur ely

• Excessive ink flow (Floodi ng)

• Horizontal banding

Go to the “Prin t qu a lit y service c heck ”

on page 2-9.

• Ink smearing

• Vertical streaks on paper

• Print lin e s crow ded

Go to the “Paper feed service chec k”

on page 2-6.

Diagnostic information 2-3

Page 20

4110-XXX

Service checks

Maintenance station service check

The maintenance station has two functions:

1. Cleans the printhead nozzles during the print operation.

2. When the printer is not in use, it seals the printhead to prevent

the nozzles from drying.

Parts / FRUs Action

1 Maintenance

Station Assembly

2 Wiper A worn wiper causes degraded print quality just

3 Cap A worn cap causes the printhead nozzles to dry

As the carrier moves to the right over the

maintenance station, a slot on the bottom of the

carrier engages a tab on the sled of the

maintenance station causing the cap to rise and

seal the printhead. Car rier movement to the le ft

will uncap the printhead. The wiper cleans the

printhead nozzl es as the carrier leav es the

maintenance station. The wiper cleans the

printhead only when the carrier is moving to the

left. There should be no wiping action of the

printhead nozzles when the carrier is moving to

the right. After the cleaning operation is complete,

a tab on the maintenance station engages a tab

on the carrier, causing the wiper to lo wer.

Check the m aintenance station f or worn or brok en

parts.

after a maintenan ce cleaning. Check for loose or

worn wiper.

and clog. Check for loose or worn cap.

2-4 Service Manual

Page 21

4110-XXX

Operator panel button service check

Parts / FRUs Action

1Buttons

System Board

If th e LC D displ ay i s O K , bu t t h e button s do not

function, go to the “POST symptom table” on

page 2-1 and run the button test. If any of the

buttons fail, replace the control panel door

assembly. If the symptom remains, replace the

system board.

LCD assembly display service check

Parts / FRUs Action

1 LCD Assembly

System Board

T o chec k the LCD, go to “POST symptom ta ble” on

page 2-1 and run the LCD test.

If the LCD assembly is blank and the printer

completes POST, check the system board cable

J11 connector. If the connector is correctl y

installed and the problem persists, replace control

panel door assembly. Go to “Control panel door

assembly removal” on page 4-4. If replacing the

control panel door assem bly does not correct the

problem, r eplace the syste m boar d. G o to “System

board removal” on page 4-10.

Diagnostic information 2-5

Page 22

4110-XXX

Paper feed service check

If the printer does not have paper jams, continue with this service

check. If the printer has a paper jam, examine it for the following

before you begin the service check:

• Check the entire paper path for obstructions.

• Be sure not to overfill the sheet feeder.

• Be sure the correct type of paper is being used.

• Check for static in the paper.

Parts / FRUs Action

1 System Board Check for approximately 30 V dc between pi ns 1

and 2 at connector J251 on the system board. If

the volt age is incorrect, replace the system boar d.

Go to “System board removal” on page4-10. If

correct, check for motor pins shorted to the motor

housing. If you f ind a shorted pin, replac e the print

engine assembly. Go to “Print engine assembly

removal” on page 4-6.

2-6 Service Manual

Page 23

4110-XXX

Parts / FRUs Action

2 Paper F eed Motor

Print Engine

Assembly

System Board

A noisy or chattering motor or a motor that fails to

turn, can be caused by:

• An open or short in the motor

• An open or short in the motor driver on the

system board

• A bind in the paper feed mechanism

Check fo r motor pins shorted to the motor

housing. If you fi nd a shorted pin, repl ace the prin t

engine assembly. Go to “Print engine assembly

removal” on page 4-6.

With the paper feed motor cable disconnected

from the system board, check f or approx imately 20

ohms between pins 1 and 2 on the motor cable. If

correct, plug in the printer and check the voltage

reading on connector 251, pins 1 and 2 for

approximately 30 volts. If the voltage reading is

incorrect, replace the system board. Go to

“System board remo val” on page 4-10.

Although the paper feeds in a forw ard direction

only, the paper feed motor turns in two directio ns.

If the paper feed m otor turns in one direction only,

replace the system boar d. Go to “System board

removal” on page 4-10.

Binds in the paper feed motor or gear train can

cause intermittent false paper j am errors. Rem ove

the paper feed motor and check the shaft for

binds. Also check for loose or worn motor gear.

3 Gears Check for binds in the gear train and paper feed

mechanism by rotating the large feed roll by hand.

If you notice a bind, isolate it by removing one of

the small idler gears on t he inside of the left side

frame. If any worn or binding gears or rollers are

found, repl ace the print engine assembly. Go to

“Print engine assembly removal” on page 4-6.

4 Paper Path Perform the “P aper path service check” on

page 2-8, starting at step 1.

Diagnostic information 2-7

Page 24

4110-XXX

Paper path service check

Examine the printer for the following before you begin this service

check:

• Check the entire paper path for obstructions.

• Be sure the paper guides are not worn or broken and are

positioned against the paper without binding or buckling the

paper.

• Be sure the correct type of paper is being used.

• Be sure the printer is installed on a flat surface.

Parts / FRUs Action

1 Large and Small

Feed Roller s

2 Small Feed Rol ler

Springs

3Exit Roller

Star Rolle rs

Exit Drive Belt

and Tensioner

4 Sheet Feeder Check the following for wear or damage:

5 End-of-Forms

Flag & Spring

Check for wear and binds.

Check for damage.

Check for wear and binds.

• Paper pick assembly

• All parts inside the left and righ t edge guides.

Check for binds or damage.

Power service check

Parts / FRUs Action

1 Power Supply Check vo lt age reading of 30 V dc.

If incorrect voltage or no vol tage, replace the

power supply.

2-8 Service Manual

Page 25

4110-XXX

Parts / FRUs Action

2 Printhead Cable

USB Cable

3 System Board If the symptom has not changed, replace the

Unplug the printer. Disconnec t the pri nthead cab le

and plug in the printer. Look for a symptom

change. Check the failing part for shorts and

replace as necessary. Repeat this procedure for

the USB cable.

system board.

Print quality service check

Parts / FRUs Action

1 Print Cartridge Be sure the printer contains good print cartridges.

2 Printhead Carrier

Assembly

3 Printhead

Cartridge

Reseat the printhead cab le on the system board

and check the following parts for wear or damage:

• Print Cartridge Latch

• Latch Spring

• Carrier

Clean the print nozzles when you suspect the

nozzles are clogged or if the characters ar e not

printing completely. When you clean the print

nozzles, a test li nes pri n t so you can see if the

cleaning process was successful .

To clean the nozzles, go to

page 3-1

down arrow to the clean (nozzle check).

4 Printhead Cable Check the gold-plated contacts , on th e e nd of th e

cable that connect to the carrier, f or di rt and wear.

Use only a clean dry cloth to clean the contacts.

Also check t he ca ble f or d amage . You may need to

remove the cable from the carrier to inspect it.

5 Maintenance

Station

Intermittent nozzl e f ailur es c an be caused b y worn

parts in the maintenance station. Perform the

“Maintenance station service check” on page 2-4,

and then return to this check.

. Enter the self test mode and press the

“Self te s t mode” on

Diagnostic information 2-9

Page 26

4110-XXX

Parts / FRUs Action

6 Paper Feed Ink smudging and sm eari ng can be caused by

paper problems or problems in the paper feed

area.

Check the following:

• Correct typ e of paper is being used.

• Paper f or cu rl or wrinkle s.

• Feed r oll ers for wear, dirt, or looseness.

• Gears for wear or binds.

• Paper path for obst ructions.

7 Transport Blurred print and voids can be caused by

problems in the transport area. Check the

following:

• Transport belt for w ear and f ull engag ement int o

the ca rrie r gr ip.

• Carrier guide rod for wear or dirt.

• Carrier to carrier fr am e engagement should be

lubricated with grease P/N 99A0394.

Lubricate the carrier guid e rod and carrier fr ame

on both sides where the two top bearing

surfaces ri de on the f rame.

• Idler pulley parts for wear, damage, or

looseness.

Transport carrier service check

Parts / FRUs Action

1 Transport Carrier

Motor

Check the motor f or binds, or loos e motor pulley.

Disconnect the t ransport motor J250 from the

system board. Check for approximately 14 ohms

between pins 1 and 2 on the motor cable and for

shorted motor pins. If the reading is incorrect,

replace the print engi ne assembly. Go to “Print

engine assembly removal” on page 4-6.

2-10 Service Manual

If the failure remains, replace the system boa rd.

Go to “System board removal” on page4-10.

Page 27

4110-XXX

Parts / FRUs Action

2 System Board Check connector J250 on the system board and

check for a app rox imat ely 30 V d c on pins 1 and 2.

If incorrect, re place system board. Go to “System

board removal” on page 4-10.

3 Ink Carrier

Assembly

4 Carrier Guide

Rod

5 Tra nsport Carrier

Belt

Idler Pulle y Parts

Carr ie r Frame

6 Printhead Cable Be sure all connect ors are fully seat ed. Check the

7 Maintenance

Station

Check the ink car rier assemb ly.

Clean the carrier rod.

Note: L ubricat e the rod and t he carrier r od bearing

surface.

Check for worn, loose or broken parts. Check for

obstructions blocking carrier movement.

Carrier to carrier frame engagement should be

lubricated with grease P/N 99A0394.

cables for damage.

A problem wi th the mai ntenanc e stat ion c an c ause

carrier mov emen t pro b lems at the ri ght mar gin. Go

to the “Maintenance station service check” on

page 2-4.

Diagnostic information 2-11

Page 28

4110-XXX

Error codes

Catastrophic error

In this state, the printer is in an error mode such that operation

cannot continue. These errors affect the entire printer. The LCD is

on and operating. An error message is displayed on the LCD. The

printer accepts data, but discards it and does not respond.

Catastrophic error list

Code Name Description Action

0000 NVRAM R/W Error detected in

reading or writing

NVRAM

0001 Memory

Failure

Unable to initialize

memory

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the error

remains, clean the

NVRAM by pressing

the Down button and

Menu button

simultaneously. The

“Self Test Menu”

appears; select Clean

NVRAM. If the error

continues, replac e the

system board.

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the error

remains, clean the

NVRAM by pressing

the Down button and

Menu button

simultaneously. The

“Self Test Menu”

appears; select Clean

NVRAM. If the error

continues, replac e the

system board.

2-12 Service Manual

Page 29

4110-XXX

Code Name Description Action

0002 Hardware

Failure

0003 ROM

Checksum

Error

General hardware

failure (unable to

localize failure to a

specific system)

Corrupted ROM Unplug the printer;

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the err or

remains, clean the

NVRAM by pressing

the Down but ton and

Menu button

simultaneously. The

“Self Test Menu”

appears; sele ct Clean

NVRAM. If the er ror

continues , repl ace the

system board.

wait a few seconds,

then plug the printer

back in and turn the

power on. If the err or

remains, clean the

NVRAM by pressing

the Down but ton and

Menu button

simultaneously. The

“Self Test Menu”

appears; sele ct Clean

NVRAM. If the er ror

continues , repl ace the

system board.

0200 Flash

Programming

Unable to program

flash memory

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the err or

remains, clean the

NVRAM by pressing

the Down but ton and

Menu button

simultaneously. The

“Self Test Menu”

appears; sele ct Clean

NVRAM. If the er ror

continues , repl ace the

system board.

Diagnostic information 2-13

Page 30

4110-XXX

Non-catastrophic error

In this state, an error has occurred, but the printer can continue to

operate. You may need to intervene using a button press, or the

machine may time out and return to the Error! Reference source

not found state, depending upon the error. The printer will continue

to accept and respond to data until its buffers are full . In general, the

entire device is in the non-catastrophic error state, but only the

logical device with the error changes its behavior.

Non-catastrophic error list

Code Name Description Action

1003 Paper

Calibrate

Failure

1201 Print

Incomplete

1202 Data Error Incorrect data has

Failure in initializing or

calibrating DC paper

feed system.

The prin t ca r rier

stopped befor e all of

the data was used.

been sent from the

host PC to the printer.

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the error

remains, check for

voltage

(approximately +5V)

on pin 2 of J15. If

okay, verify voltage at

the Encoder card as

well (same pin at

Encoder card end). If

there is no voltage at

J15-pin 2, change the

system board. If there

is no voltage at the

Encoder card en d, b ut

okay at J15, replace

the print engine.

Resend the print job.

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the error

remains, rep lace USB

cable. If error

continues, replac e the

system board.

2-14 Service Manual

Page 31

4110-XXX

Code Name Description Action

1203 Printhead

Short

1204 Printhead

Programming

1205 Mono TSR

Error

1206 Color Problem in color TSR

1207 Paper System

Error

Short test de t e ct ed

short-circuit in

printhead.

Unable to program

pseudo-random

printhead ID.

Problem is detected in

mono TSR circuit.

Cannot determine

printhead temperature.

circuit; TSR error.

Paper sys tem control

failure detected.

Replace print

cartridge(s).

Replace print

cartridge(s).

Replace print

cartridge(s).

Replace print

cartridge(s).

Clear the paper path.

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If the err or

remains, clean the

NVRAM by pressing

the Down but ton and

Menu button

simultaneously. The

“Self Test Menu”

appears; sele ct Clean

NVRAM. If the er ror

continues , repl ace the

system board.

2200 Scan Carrier

Stall

The scan carrier has

stalled.

Diagnostic information 2-15

Unplug the printer;

wait a few seconds,

then plug the printer

back in and turn the

power on. If error

remains, check all

connections to the

scanner. If

connections are okay

and error continues,

replace the syst em

board.

Page 32

4110-XXX

2-16 Service Manual

Page 33

4110-XXX

3. Diagnostic aids

Self test mode

To enter the Self Test mode press the up arrow and Menu

simultaneously. The Self Test menu screen is displayed.

USB serial number - To view the USB serial number, press and hold

the up arrow and Menu buttons simultaneously . The serial number

is displayed for fi ve seconds. Displa y is then returned to the Self Test

menu.

LCD/LED button test - Verifies the operation of the LCD, the

illumination of the LED’s, and the functionality of the buttons on the

control panel.

Media card test - Tests various memory cards in accordance with

onscreen instructions.

External USB test - Verifies the enumeration with the device

attached to external USB port (DPS port) directly through the USB.

A message is displayed reporting “Success” or “Failure” of test

results. Press Cancel on all message screens to return the display

to the Test menu.

Clean (Nozzle Check) - Prints the Nozzle Cleaning page. Returns to

the Test menu when finished.

NVRAM dump - Prints the contents of the flash NVRAM. Display is

then returned to the Test menu. Press Cancel during printing to stop

the job, eject paper, and return the display to the Test menu.

Clean NVRAM - Clears the non protected area of the Flashemulated NVRAM by restoring values to default or initializing the

values to 0x00s or 0xFFs. When selected, displays a “Clearing”

message. If the function ends successfully a “Success” message is

display e d . Press Cancel on all message screens to return the

display to the Test menu.

SRAM test - Verifies all the address buses and data buses that

connect to the SRAM area work correctly , performs the read/write of

data to the SRAM area with all the address buses and data buses.

Diagnostic aids 3-1

Page 34

4110-XXX

While checking, a “Testing” message is displayed. After that a

“Success” mess age is displayed for three seconds, or a “Failure”

message is displayed until Cancel is pressed.

Media sensor test - The media sensor is read for the current paper

type. A message displays the paper type detected. If no paper is

present, a message indicating “none” is displa yed. Press Cancel on

all message screens to return the display to the Test menu.

Last USB connect speed - The status and/or connection speed of

the USB connection is shown.

Show font - Displays all the characters of the font set in both white

and dark gray. Use the up arrow and down arrow buttons to navigate

through the font set. Press Ca ncel on all message screens to return

the display to the Test menu.

Show strings - This menu item is reserved for future use for

displaying strings available in the machine.

3-2 Service Manual

Page 35

4110-XXX

4. Rep a ir in fo r m a t i on

This chapter explains how to make adjustments to the printer and

how to remove defective parts.

CAUTION: Read the following before handling electronic parts.

When working on the printer, always unplug the printer from the

electrical outlet. High voltage is present in the power supply as long

as it is plugged into the electrical outlet.

Handling ESD-sensitive parts

Many electronic products use parts that are known to be sensitive t o

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual

precautions, such as turning off power before removing logic boards:

• Keep the ESD-sensitive part in its original shipping container

(a special “ESD bag”) until you are ready to install the part into the printer.

• Mak e the few er po ssi b le movem ents with your body t o preven t an increase

of static electricity from clothing fibers, carpets, and furniture.

• Put th e E SD wri st strap on your w rist . C on nect the w ris t band to the system

ground point. This discharges any static electricity in your body to the

printer.

• Hold the ESD-sensitive part by its edge connector shroud (cover); do not

touch its pin s . If y ou are rem oving a plugga ble module , use t he correct tool.

• Do not place the ESD-sensitive part on the printer cover or on a metal

table; if you need to put down the ESD-sensitive part for any reason, first

put it into its special bag.

• Printer covers and metal tables are electrical grounds. They increase the

risk of damage because they make a discharge path from your body

through the ESD-sensitive part. (Large metal objects can be discharge

paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by other

personnel. Install printer covers when you are not working on the printer,

and do not put unprotected ESD-sensitive parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal cabinet

(case).

• Be careful in working with ESD-sensitive parts when cold weather heating

is used because low humidity increases static electricity.

Repair information 4-1

Page 36

4110-XXX

Removal proced ur e s

The following procedures are arranged according to the name of the

printer part discussed. Unplug the power cord before removing any

parts.

Top cover assembly removal

1. Depress tab (A) and remove paper support.

4-2 Service Manual

Page 37

4110-XXX

2. Remove four screws (B).

3. Lift cover and disconnect cables (C) from system board.

Repair information 4-3

Page 38

4110-XXX

4. Release tabs (D) and remove top cover.

Control panel door assembly removal

1. R e m o ve top cover asse m b ly.

2. Disconnect two springs (A) and remove two screws (B).

3. Remove control panel door assembly and cable.

Note: Routing of cables.

4-4 Service Manual

Page 39

4110-XXX

Card reader removal

1. Remove top cover assembly.

2. Remove control panel door assembly.

3. Remove two screws (A).

4. Remove card reader.

Note: Routing of cables.

Repair information 4-5

Page 40

4110-XXX

Print engine assem b l y remo val

1. R e m o ve top cover asse m b ly.

2. Remove eight scre ws (A).

3. Lift and remove exit feed roller assembly (B).

4-6 Service Manual

Page 41

4110-XXX

4. Depress tab (C) on small feed roller.

5. Lift and remove print engine.

Base assembly removal

1. Remove top cover assembly.

2. Remove print engine.

3. Remove base assembly.

Repair information 4-7

Page 42

4110-XXX

Carrier assembly removal

1. R e m o ve top cover asse m b ly.

2. Remove print engine.

3. Remove carrier shaft retainer clips (A).

4. Disconnect carrier cables.

5. Remove carrier shaft out the left side.

4-8 Service Manual

Page 43

4110-XXX

6. Disconnect encoder strip (B).

7. Depress belt tensioner (C) and remove belt (D).

8. Remove the carrier assembly.

Repair information 4-9

Page 44

4110-XXX

System board removal

1. R e m o ve top cover asse m b ly.

2. Remove print engine.

3. Disconnect media sensor from connector J1(A).

4. Remove screw (B) from media sensor bracket.

4-10 Service Manual

Page 45

4110-XXX

5. Pry tab (C) loose with a screwdriver.

6. Remove media sensor bracket.

7. Disconnect all cables from system board.

Repair information 4-11

Page 46

4110-XXX

8. Remove three screws (D).

Warning: When removing the system board, be careful not to

damage the end-of-forms flag (E).

9. Lift and remove system board.

Transport carrier motor removal

1. R e m o ve top cover asse m b ly.

2. Remove print engine.

3. Disconnect transport carrier motor from connector J250.

4. Remove carrier shaft.

5. Depress belt tensioner and remove belt from transport carrier

motor gear.

4-12 Service Manual

Page 47

4110-XXX

6. Remove two screws (A) from transport carrier motor.

7. Remove transport carrier motor.

Repair information 4-13

Page 48

4110-XXX

Maintenance station removal

1. R e m o ve top cover asse m b ly.

2. Remove print engine.

3. Depress three tabs (A).

4-14 Service Manual

Page 49

4110-XXX

4. Release maintenance station from slots (B) by pulling forward

and downward.

Repair information 4-15

Page 50

4110-XXX

Card reader door removal

1. Depress two tabs (A).

2. Lift and remove.

4-16 Service Manual

Page 51

4110-XXX

ASF g uide with spring removal

1. Flex ASF guide and remove tab (A) from hole.

Repair information 4-17

Page 52

4110-XXX

2. Remove guide and spring.

3. When reinstalling, ensure the spring goes back into hole (B).

4-18 Service Manual

Page 53

4110-XXX

5. Connector locations

System board

Connector Description

J1

J2

J3

J6

J7

J8

J9

J11

J12

J15

J250

J251

S1

Media Sensor Pins 1 & 3 - 5 Vol ts

USB

Carrier

Card Reader/PictBridge Pin 2 - 5 Volts

Carrier

Carrier

Card Reader/PictBridge

Control Pane l/ LCD

Card Reader/PictBridge

Paper Feed Encoder Dial

Tran sport Carrier Motor Pins 1 & 2 - 30 Volts

Paper F eed Motor Pins 1 & 2 - 30 Vol ts

Access Door Sensor

Approximate

voltage

PS1

EOF

Connector locations 5-1

Page 54

4110-XXX

5-2 Service Manual

Page 55

4110-XXX

6. Preventive maintenance

This chapter contains the lubrication specifications. Follow these

recommendations to prevent problems and maintain optimum

performance.

Lubrication specifications

Lubricate only when parts are replaced or as needed, not on a

scheduled basis. Use grease P/N 99A0394 to lubricate the following:

• All gear mounting studs.

• The left and right ends of the large feed roller at the side frames.

• Both ends of the sheet feeder pick roll shaft at the side frames.

• The carrier to carrier frame engagement.

• The carrier guide shaft, and carrier guide shaft bearings.

• Both ends of the exit roller shaft.

Preventive maintenance 6-1

Page 56

4110-XXX

6-2 Service Manual

Page 57

4110-XXX

7. Parts catalog

How to use the parts catalog

• SIMIL AR ASSEMBLIE S: If tw o a sse mblies contain a majority of

identical parts, they are shown on the same list. Common parts

are shown by one index number. Parts pertaining to one of the

other assemblies are listed separately and identified by

description.

• NS: (Not Shown) in the Asm-Index column indicates that the

part is procurable but is not shown in the illustration.

Parts cata log 7-1

Page 58

4110-XXX

Assembl y 1: Co ver s

7-2 Service Manual

Page 59

4110-XXX

Assembly 1: Covers

AsmIndex

1-1 56P2757 1 Cover, control panel Dutch (001, 003)

1-1 56P2758 1 Cover, control panel English (001, 003)

1-1 56P2759 1 Cover, control panel French (001, 003)

1-1 56P2760 1 Cover, control panel German (001, 003)

1-1 56P2761 1 Cover, control panel Greek (001, 003)

1-1 56P2762 1 Cover, control panel Italian (001, 003)

1-1 56P2763 1 Cover, control panel Japanese (001,

1-1 56P2764 1 Cover, control panel Korean (001, 003)

1-1 56P2765 1 Cover, control panel Polish (001, 003)

1-1 56P2766 1 Cover, control panel Port/Brazil (001,

1-1 56P2767 1 Cover, control panel S. Chinese (001,

1-1 56P2768 1 Cover, control panel Spanish (001, 003)

1-1 56P2769 1 Cover, control panel T. Chinese (001,

1-1 56P2770 1 Cover, control panel Russian (001, 003)

1-2 56P2754 1 Door, card reader access (001, 003)

1-3 56P2612 1 Paper support (001, 003)

1-4 56P2753 1 Panel, control with LCD and door (001,

1-5 56P2772 1 Guide, ASF with spring (0 01, 003)

1-6 56P2755 1 Cover, top assembl y (001, 003)

1-7 56P2751 1 Base, printer assem bly (001)

1-7 56P3841 1 Base, printer assem bly (003)

NS 56P2796 1 Pad, ink (001, 003)

NS 56P2771 1 Badge, P915 model number (001, 003)

NS 7373900 1 Plain package B/M includes: carton,

NS 7373997 1 Plain package B/M includes: carton,

NS 7374001 1 Plain package B/M includes: carton,

Part

Number

Units Description

003)

003)

003)

003)

003)

cushion, set , and se aling tape USA (001,

003)

cushion, set, and sealing tape EMEA

(001, 003)

cushion, se t, and sea ling tape APG (001,

003)

Parts cata log 7-3

Page 60

4110-XXX

Assembly 2: Electronics/carrier transport

7-4 Service Manual

Page 61

4110-XXX

Assembly 2: Electronics/carrier transport

AsmIndex

2-1 56P2750 1 Board, system (001, 003)

2-2 21G0175 1 Print engine (001, 003)

2-3 13D0400 1 Power suppl y 120V (001, 003)

2-4 56P2752 1 Card reader (001)

2-4 56P3842 1 Card reader (003)

2-5 56P2611 1 Complete carrier with belt and cable

2-6 56P2617 1 Maintenance station (001, 003)

NS 13D0401 1 Power suppl y HV 220V (001, 003)

NS 13D0403 1 Power supply LV 100V LAD (001, 003)

NS 13D0402 1 Power suppl y 100V (001, 003)

NS 21B0101 1 Cord, line UK/Ireland/Hong Kong

NS 21B0102 1 Cord, line Germany/Isreal/Russia/

NS 21B0103 1 Cord, line Argentina (0 03)

NS 21B0104 1 Cord, line Aust ralia (003)

NS 21B0105 1 Cord, line South Africa (003)

NS 21B0106 1 Cord, line Peru (only) (003)

NS 21B0107 1 Cord, line China (003)

NS 21B0108 1 Cord, line Kor ea (003)

NS 21B0109 1 Cord, line India (003)

Part

Number

Units Description

(001, 003)

(003)

Poland/Spain/Chile /Asia (003)

Parts cata log 7-5

Page 62

4110-XXX

7-6 Service Manual

Page 63

4110-XXX

Index

A

abbreviations 1-5

B

buttons

1-3

menu

number of prints

1-2

power

print preview

1-3

resize

1-3

rotate

1-3

select

1-2

start

stop/clear

1-3

1-3

1-3

C

connector locat ions 5-1

connectors

system board

5-1

D

diagnostic information 2-1

E

error codes

catastrophic error

non-catastrophic error

ESD-sensitive parts

2-12

2-14

4-1

G

general information 1-1

H

how to use the parts catalog 7-1

L

lubrication specifications 6-1

M

maintenance approach 1-4

P

part number index X-3

parts catalog

covers

7-2

electronics

POST

2-1

power consumption

preventive maintenance

print quality

7-4

1-4

6-1

1-4

R

removals

ASF guide with spring

base assembly

card reader

card reader door

carrier assembly

maintenance stati on

print engine assembly

system board

top cover assembly

transport carrier motor

repai r in fo rmation

handling ESD-sensiti ve parts

4-7

4-5

4-16

4-8

4-14

4-10

4-2

S

safet y in formation vi

self test mode

service checks

LCD assembly display

maintenance stati on

operator panel button

paper feed

paper path

power

print quality

transport carrier

symptom table (POST)

symptom tables

communications problems

maintenance stati on problems

3-1

2-4

2-6

2-8

2-8

2-9

2-10

2-1

4-17

4-6

4-12

4-1

2-5

2-5

2-2

2-2

Index X-1

Page 64

4110-XXX

paper feed proble ms 2-3

power problems

print quality problems

2-3

2-3

X-2 Service Manual

Page 65

4110-XXX

Part number index

P/N Description Page

13D0400 Power supply 120V (003) . . . . . . . . . . . . . . . . . . . . 7-5

13D0401 Power supply HV 220V (001, 003) . . . . . . . . . . . . . 7-5

13D0402 Power supply 100V (001, 003) . . . . . . . . . . . . . . . . 7-5

13D0403 Power supply LV 100V LAD (001, 003). . . . . . . . . 7-5

21B0101 Cord, line UK/Ireland/Hong Kong (003). . . . . . . . . 7-5

21B0102 Cord, line Germany/Isreal/Russia/Poland/Spain/Chile/

Asia (003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

21B0103 Cord, line Argentina (003) . . . . . . . . . . . . . . . . . . . . 7-5

21B0104 Cord, line Australia (003) . . . . . . . . . . . . . . . . . . . . 7-5

21B0105 Cord, line South Africa (003). . . . . . . . . . . . . . . . . . 7-5

21B0106 Cord, line Peru (only) (003). . . . . . . . . . . . . . . . . . . 7-5

21B0107 Cord, line China (003) . . . . . . . . . . . . . . . . . . . . . . . 7-5

21B0108 Cord, line Korea (003) . . . . . . . . . . . . . . . . . . . . . . . 7-5

21B0109 Cord, line India (003). . . . . . . . . . . . . . . . . . . . . . . . 7-5

21G0175 Print engine (001,003) . . . . . . . . . . . . . . . . . . . . . . . 7-5

56P2611 Complete carrier w/belt and cable (001, 003) . . . . . 7-5

56P2612 Paper support (001, 003) . . . . . . . . . . . . . . . . . . . . . 7-3

56P2617 Maintenance station (001, 003) . . . . . . . . . . . . . . . . 7-5

56P2750 Board, system (001,003). . . . . . . . . . . . . . . . . . . . . . 7-5

56P2751 Base, printer assembly (001) . . . . . . . . . . . . . . . . . . 7-3

56P2752 Card reader (001) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

56P2753 Panel, control with LCD and door (001, 003) . . . . . 7-3

56P2754 Door, card reader access (001, 003) . . . . . . . . . . . . . 7-3

56P2755 Cover, top assembly (001, 003) . . . . . . . . . . . . . . . . 7-3

56P2757 Cover, control panel Dutch (001, 003). . . . . . . . . . . 7-3

56P2758 Cover, control panel English (001, 003). . . . . . . . . . 7-3

56P2759 Cover, control panel French (001, 003) . . . . . . . . . . 7-3

56P2760 Cover, control panel German (001, 003) . . . . . . . . . 7-3

56P2761 Cover, control panel German (001, 003) . . . . . . . . . 7-3

56P2762 Cover, control panel Italian (001, 003). . . . . . . . . . . 7-3

56P2763 Cover, control panel Japanese (001, 003). . . . . . . . . 7-3

56P2764 Cover, control panel Korean (001, 003). . . . . . . . . . 7-3

X-

3

Page 66

4110-XXX

56P2765 Cover, control panel Polish (001, 003) . . . . . . . . . . 7-3

56P2766 Cover, control panel Port/Brazil (001, 003) . . . . . . 7-3

56P2767 Cover, control panel S. Chinese (001, 003). . . . . . . 7-3

56P2768 Cover, control panel Spanish (001, 003) . . . . . . . . . 7-3

56P2769 Cover, control panel T. Chinese (001, 003). . . . . . . 7-3

56P2770 Cover, control panel Russian (001, 003) . . . . . . . . . 7-3

56P2771 Badge, P915 model number (001, 003). . . . . . . . . . 7-3

56P2772 Guide, ASF with spring (001, 003) . . . . . . . . . . . . . 7-3

56P2796 Pad, ink (001, 003) . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

56P3841 Base, printer assembly (003) . . . . . . . . . . . . . . . . . . 7-3

56P3842 Card reader (003). . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7373900 Plain package B/M USA (001, 003) . . . . . . . . . . . . 7-3

7373997 Plain package B/M EMEA (001, 003). . . . . . . . . . . 7-3

7374001 Plain package B/M APG (001, 003) . . . . . . . . . . . . 7-3

X-4 Service Manual

Loading...

Loading...