Page 1

Color Jetprinter™ 2070

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4090-001

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4090-001

Third Edition (July, 1997)

The following paragraph doesnot apply to theUnited Kingdomor anycountry where such

provisions are inconsistent with local law: LEXMARK INTERNATIONAL,INC. PROVIDES

THIS PUBLICATION “AS IS” WITHOUT WARRANTYOF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimerof expressor implied warrantiesin certain transactions, therefore, this

statement may not apply to you.This publication could include technical inaccuracies or

typographical errors. Changes are periodically made to the information herein; these

changes will be incorporated inlater editionsof thepublication. Improvements or changes

in the products or the programs described in this publication may be made at any time.

Publications are not stocked at the address given below; requests for publications should

be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department D22A/035-3,

740 New Circle Road, Lexington, Kentucky 40550, U.S.A. Lexmark may use or distribute

any of the information you supply in any way it believes appropriate without incurring any

obligation to you.

Lexmark is a trademark of Lexmark International, Inc., registered in the United States

and/or other countries.

Color Jetprinter is a trademark of Lexmark International, Inc.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1995, 1997. All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

Page 3

4090-001

Contents 1

Contents .............................................. iii

Preface ...............................................vi

SafetyInformation..................................... vi

GeneralInformation....................................1-1

Resolution and Print Speed ............................1-1

PowerConsumption..................................1-1

Maintenance Approach................................1-1

Abbreviations....................................1-2

UniqueToolsRequiredForService...................1-2

DiagnosticInformation .................................2-1

Start..............................................2-1

ErrorIndicatorTable...............................2-2

Power-On Self Test (POST) Sequence ................2-2

POSTSymptomTable.............................2-3

SymptomTables .................................2-4

ServiceChecks......................................2-6

EnvelopeFeedServiceCheck.......................2-6

FirstPrintLineServiceCheck.......................2-6

MaintenanceStationServiceCheck..................2-7

Paper Feed Service Check .........................2-8

Paper Path Service Check.........................2-10

ParallelPortServiceCheck........................2-11

PowerServiceCheck.............................2-11

PrintQualityServiceCheck........................2-12

TransportServiceCheck..........................2-14

DiagnosticAids .......................................3-1

EncoderSensorTest.................................3-2

InitializeErrorLog....................................3-3

Paper Sensor Test ...................................3-4

ParallelPortTest....................................3-5

PrintNVRAMContents................................3-6

TestPage..........................................3-7

iii

Page 4

4090-001

RepairInformation......................................4-1

Handling ESD-Sensitive Parts.......................... 4-1

Adjustments........................................ 4-2

RemovalProcedures................................. 4-2

ReleasingPlasticLatches.......................... 4-2

BaseAssemblyRemoval........................... 4-3

CarrierBeltRemoval.............................. 4-3

CarrierFrameAssemblyRemoval ................... 4-4

CarrierTransportMotorRemoval.................... 4-5

Code Module Removal . . .......................... 4-6

Edge Guide Asm and Paper Load Shaft Removal ....... 4-6

EncoderCardRemoval............................ 4-6

EncoderStripRemoval............................ 4-6

ExitDriveBeltRemoval............................ 4-7

ExitRollerRemoval............................... 4-7

FeedArmAssemblyRemoval....................... 4-7

FrontCoverRemoval ............................. 4-8

GutterPadRemoval.............................. 4-8

InsideIdlerGearsRemoval......................... 4-9

LargeFeedRollRemoval......................... 4-10

LargeOutsideGearRemoval...................... 4-11

LeftSideFrameAssemblyRemoval................. 4-12

Maintenance Station Assembly Removal ............. 4-13

Maintenance Wipers and Caps Removal ............. 4-13

Manual Insert Tray Removal ....................... 4-13

MidFrameAssemblyRemoval..................... 4-13

Paper Feed Motor Removal ....................... 4-14

Paper Guide and EOF Flag Assembly Removal . ....... 4-14

Paper Load Door Removal ........................ 4-16

Pick Roll Hub, Shaft and Envelope Bucklers Removal . . . 4-16

Power Supply Removal. . ......................... 4-16

Printhead Cable, Cradle & Paper Deflector Removal .... 4-17

Printhead Carrier Assembly Removal ................ 4-19

Printhead Rubber Backer Removal. . ................ 4-19

RearCoverRemoval............................. 4-20

RightSideFrameAssemblyRemoval................ 4-20

Small Feed Roll Shaft, Rollers & Paper Flap Removal . . . 4-21

StarRollerRemoval ............................. 4-21

SystemBoardRemoval........................... 4-21

ConnectorLocations....................................5-1

SystemBoardConnectors............................. 5-2

EncoderCardConnector........................... 5-3

iv

Page 5

4090-001

PreventiveMaintenance ................................6-1

Lubrication Specifications. . ............................6-1

PartsCatalog .........................................7-1

HowToUseThisPartsCatalog.........................7-1

Assembly1:Covers..................................7-2

Assembly2:Frames..................................7-4

Assembly 3: Paper Feed . . ............................7-6

Assembly4:Electronics...............................7-8

Assembly5:Carrier.................................7-12

Assembly6:CarrierTransport.........................7-14

Assembly 7: Sheet Feeder . ...........................7-16

Assembly 8: Maintenance Station ......................7-18

Index ..................................................1

v

Page 6

4090-001

Preface 2

This manual is divided into the following chapters:

1. General Information contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

2. Diagnostic Information contains error indicator table, symptom

table, and service checks used to isolate failing field replaceable

units (FRUs).

3. Diagnostic Aids contains tests and checks used to locate or

repeat symptoms of printer problems.

4. Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

5. ConnectorLocations uses illustrations to identify theconnector

locations and test points on the printer.

6. Preventive Maintenance contains the lubrication specifications

and recommendations to prevent problems.

7. Parts Catalog contains illustrations and part numbers for individual FRUs.

Safety Information

The maintenance information for this product has been

•

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injur y during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

• The safety features of some parts may not always be

obvious. Therefore, replacement parts must have the

identical or equivalent characteristics as the original parts.

vi

Page 7

4090-001

Sicherheitshinweise

• Die Wartungsinformationen für dieses Produkt wurden zur

Verwendung durch einen Wartungsfachmann entwickelt und

sollten nicht von anderen benützt werden.

• Zusätzliches Risiko eines elektrischen Schlags und

körperlicher Verletzung existiert während des

Auseinandernehmens und der Wartung des Geräts.

Fachpersonal sollte im vollen Verständnis der Lage

entsprechende Vorsichtsmaßnahmen ergreifen.

• Ersatzteile müssen gleiche oder gleichwertige Merkmale wie

die Originalteile aufweisen,da Sicherheitsvorkehrungen nicht

immer offensichtlich sind.

Consignes de Sécurité

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

• Les normes de sécurité de certaines pièces n'étant pas

toujours explicites, les pièces de rechange doivent être

identiques ou conformes aux caractéristiques des pièces

d'origine.

Norme di sicurezza

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale

dell'assistenza autorizzato.

• Durante lo smontaggio e il manutenzionamento di questo

prodotto, è possibile il rischio accresciuto di scosse elettriche

e danni personali. Il personale di assistenza autorizzato,

consapevole di ciò, deve adottare le precauzioni necessarie.

• È possibile che le funzioni di sicurezza dialcunielementinon

siano così ovvie, quindi, i pezzi di ricambio devono avere

caratteristiche identiche o equivalenti a quelle dei pezzi

originali.

Preface vii

Page 8

4090-001

Pautas de Seguridad

• La información sobre el mantenimiento de este producto fue

escrita para el personal de mantenimiento cualificado y no

para cualquier otro usuario.

• Existen mayores riesgos de descargas eléctricas y daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado comprende esto y toma las

precauciones necesarias.

• Los dispositivos de seguridad de algunas partes quizá no

siempre puedan ser reconocidas a simple vista. Por lo tanto,

las partes de reemplazo deben poseer características

idénticas o equivalentes a las partes originales.

Sikkerhedsoplysninger

• Oplysningerne om vedligeholdelse af dette produkt er

forberedt med henblik på professionelt servicepersonale, og

bør derfor ikke benyttes af andre.

• Risikoen for elektrisk stød øges under demontering og

service af dette produkt, hvorfor der børtages de nødvendige

forholdsregler.

• Sikkerhedsforanstaltningerne er ikke altid lige åpenbare for

alle reservedele. Der bør derfor kun anvendes originale

reservedele eller reservedele med samme egenskaber som

de oprindelige.

Informações de Segurança

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto.Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

• Os dispositivos de segurança de algumas peças poderão

não ser sempre suficientemente evidentes. Assim, as peças

sobressalentes devem possuir características idênticas ou

equivalentes às peças originais.

viii

Page 9

4090-001

Chinese Safety Information

Korean Safety Information

Preface ix

Page 10

4090-001

1. General Information

The Color JetprinterTM2070 (4090-001) printer is a personal, near

laser-quality inkjet printer. The print cartridge contains single-unit

customer-replaceable supply items. Dual printheads provide color

and true black printing without changing printheads. The black

cartridge has a total of 104 nozzles and installs on the left. The color

cartridge has a total of 96 nozzles and installs on the right. The

printer is capable of printing in two directions from either cartridge.

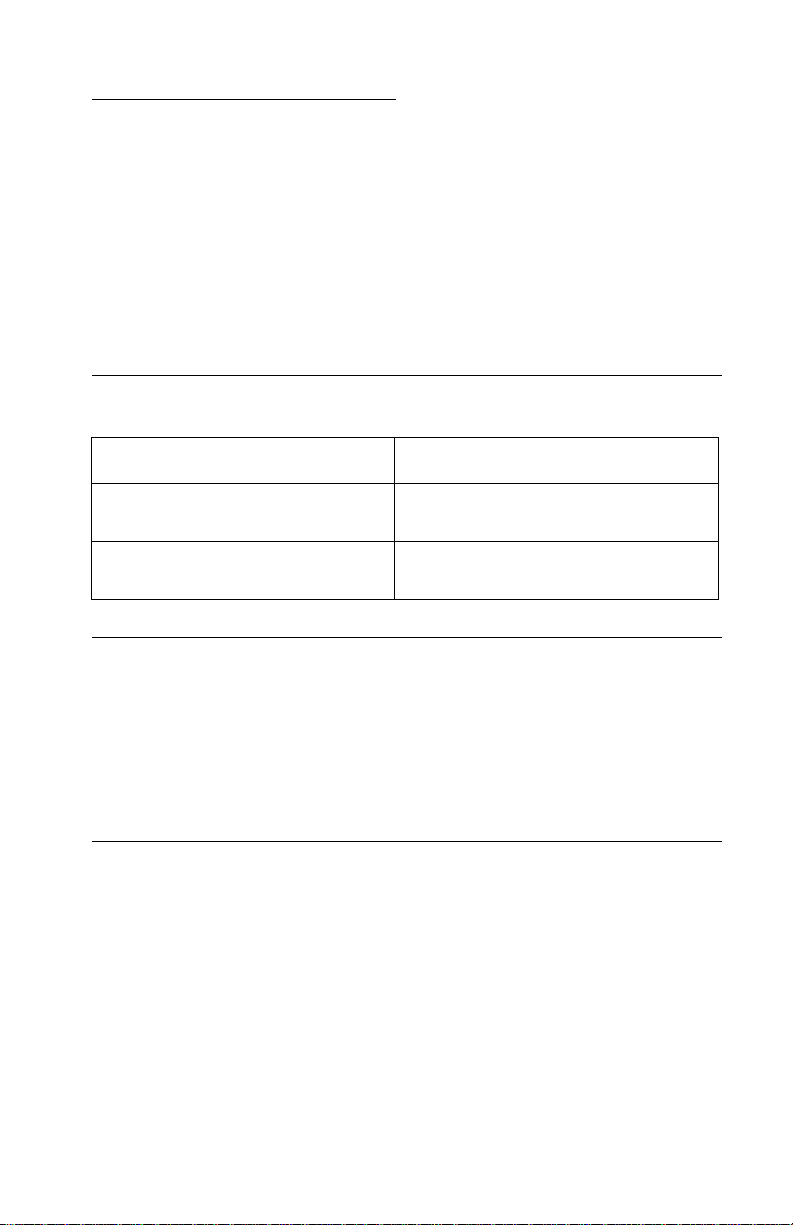

Resolution and Print Speed

Color Black

600 X 300 dpi

600 X 600 (using special paper)

167 cps - Letter Quality

300 cps - Draft

600 X 300 dpi

600 X 600 (using special paper)

230 cps - Letter Quality

300 cps - Draft

Power Consumption

Less than 2 Watts - power off and power to the printer

•

• 7.5 Watts - Idle Mode (power on - not printing)

• 12 Watts - Printing (average)

• 25 Watts - Printing (peak)

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error indicator charts,

symptom index, service checks, and diagnostic aids to determine

the symptom and repair the failure. Begin with “Start” on page 2-1.

This printer can be serviced without being connected to a host

computer. The user is directed, in the Printer Control program, to

perform the head to head and bidirectional alignment adjustments

after replacing a print cartridge.

General Information 1-1

Page 11

4090-001

After you complete the repair, perform tests as needed to verify the

repair.

Abbreviations

CE Customer Engineer

CSU Customer Setup

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POST Power-On Self Test

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

Unique Tools Required For Service

Parallel Wrap Plug P/N 1319128

General Information 1-2

Page 12

4090-001

2. Diagnostic Information

Use the error indicator table, symptom tables, service checks, and

diagnostic aids to determine the failing part.

Start

Service error indications show as a series of flashes of the Power

light. There is a pause between each series of flashes. If your printer

has an error indication, locate the series of flashes in the ’Error

Indicator Table’ on page 2-2 and take the indicated action. Unplug

the printer to clear the error indicator.

If an error indicator appears, go to the error indicator table and take

the indicated action for that error.

The printer also logs the last occurring error. If you think it may have

an intermittent error, or the error indicator lights have been cleared,

you can retrieve the error:

1. Run the ’Print NVRAM Contents’ on page 3-6. The last error

appears at the bottom of the page.

2. Run ’Initialize Error Log’ on page 3-3 to clear the error (the error

may not be the result of a current error).

3. Run the ’Test Page’ on page 3-7. If no error appears, go to

’Power-On Self Test (POST) Sequence’ on page 2-2.

Diagnostic Information 2-1

Page 13

4090-001

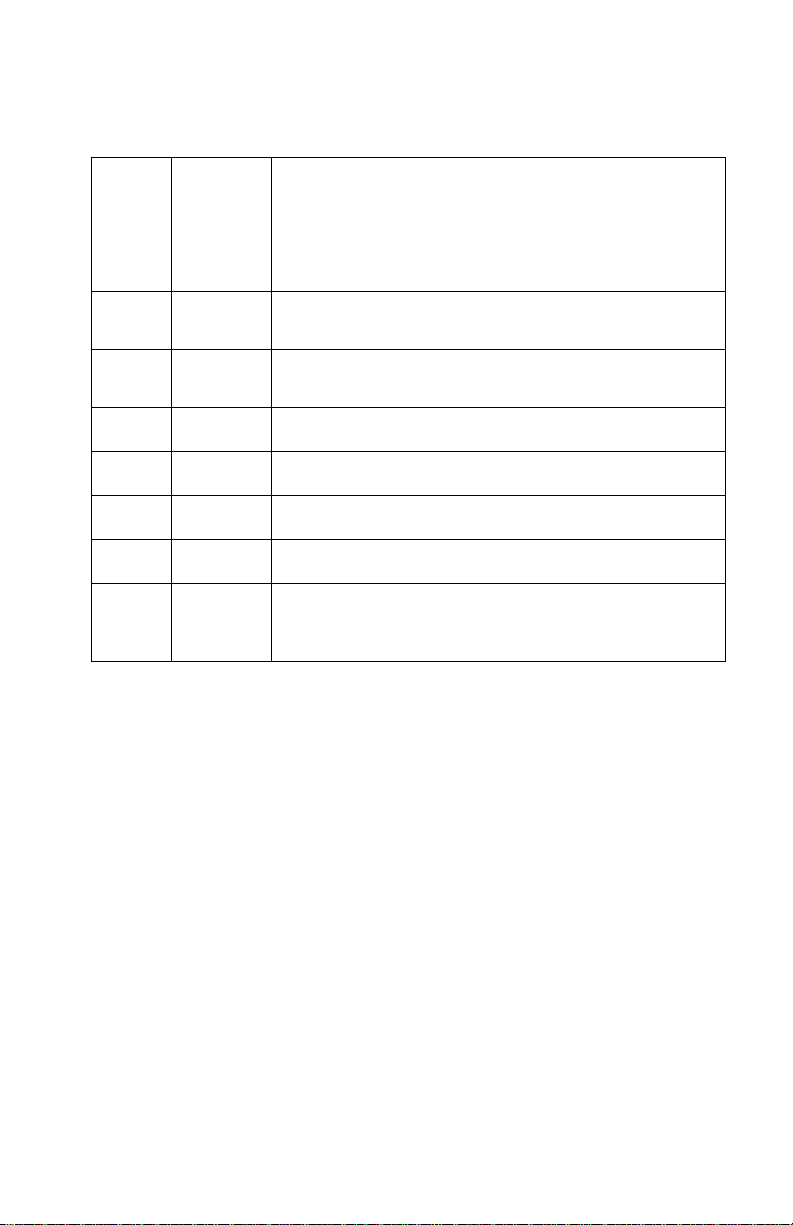

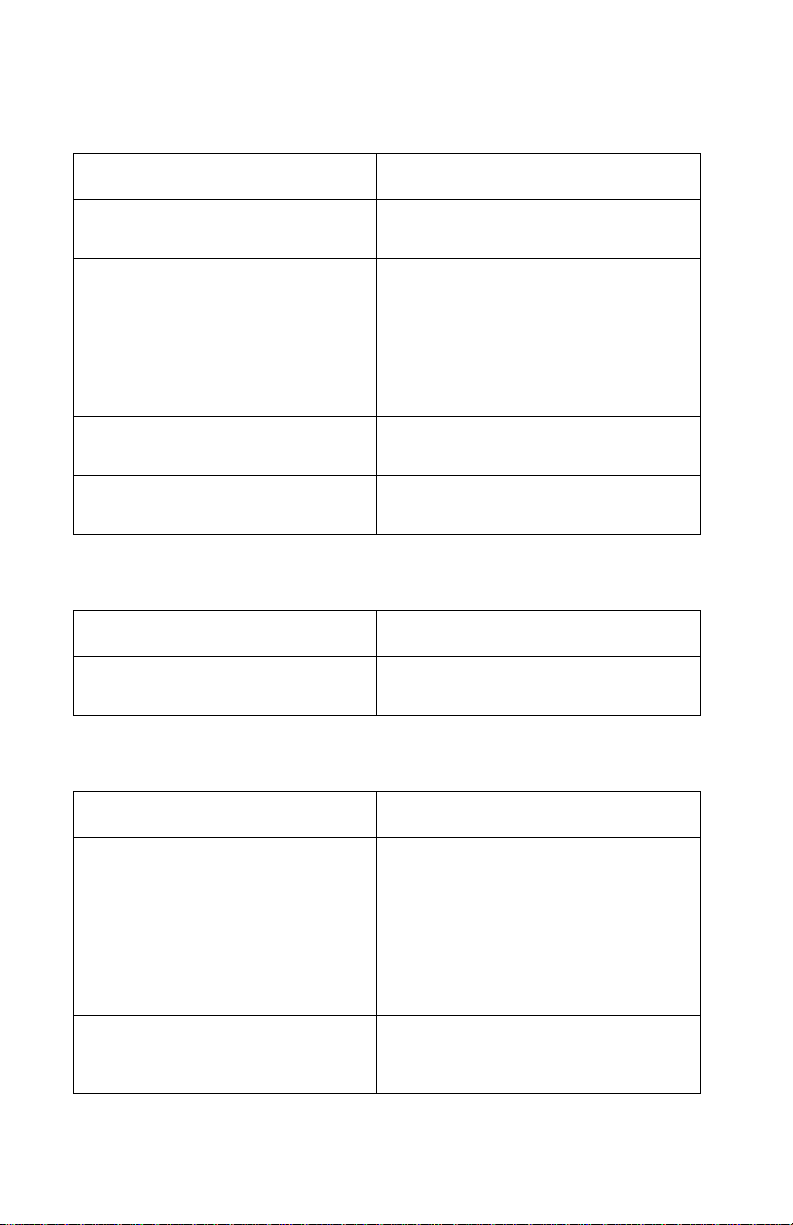

Error Indicator Table

Number

Error

Code

of

Power

Light

Flashes

Action

64

65

66 78

79

81

83

89

127

and

up

7

6

9

1

8

4

10

Replace the Code Module and/or system board.

Replace the Code Module and/or system board.

Replace the Code Module and/or system board.

Go to the ’Transport Service Check’ on page 2-14.

Replace the Code Module and/or system board.

Go to the ’Transport Service Check’ on page 2-14.

Replace the Code Module and/or system board.

Power-On Self Test (POST) Sequence

When you turn the printer on it performs a POST. Turn your printer

on and check for a correct POST operation by observing the

following:

1. The busy light comes on and goes off.

2. The power light comes on.

3. The carrier moves over the maintenance station and seals the

printheads.

4. The paper feed gears turn.

5. All motors stop and the power light stays on.

If your printer completes POST with no errors, go to the ’Symptom

Tables’onpage2-4, locate the symptom and take the indicated

action.

Diagnostic Information 2-2

Page 14

4090-001

If your pr inter does not complete POST, locate the symptom in the

following table and take the indicated action.

POST Symptom Table

Symptom Action

No Powerlight

and no motors

run

Power light,

but no busy

light

Feeds paper Go to the ’First Print Line Service Check’ on page 2-6.

Paper feed

gears do not

turn

Carrier doesn’t

move

Carrier slams

side frame

Go to the ’Power Service Check’ on page 2-11.

Replace the system board.

Go to the ’Paper Feed Service Check’ on page 2-8.

Go to the ’Transport Service Check’ on page 2-14.

Go to the ’Transport Service Check’ on page 2-14.

2-3

Page 15

4090-001

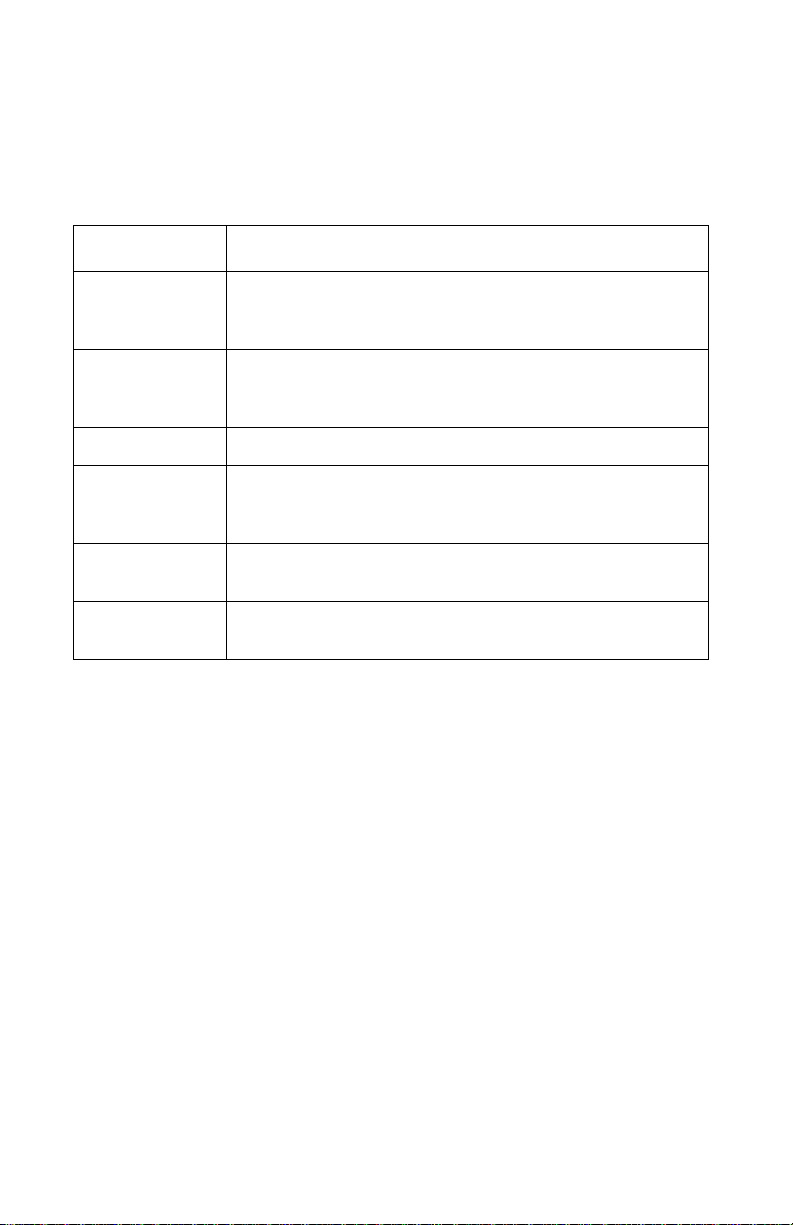

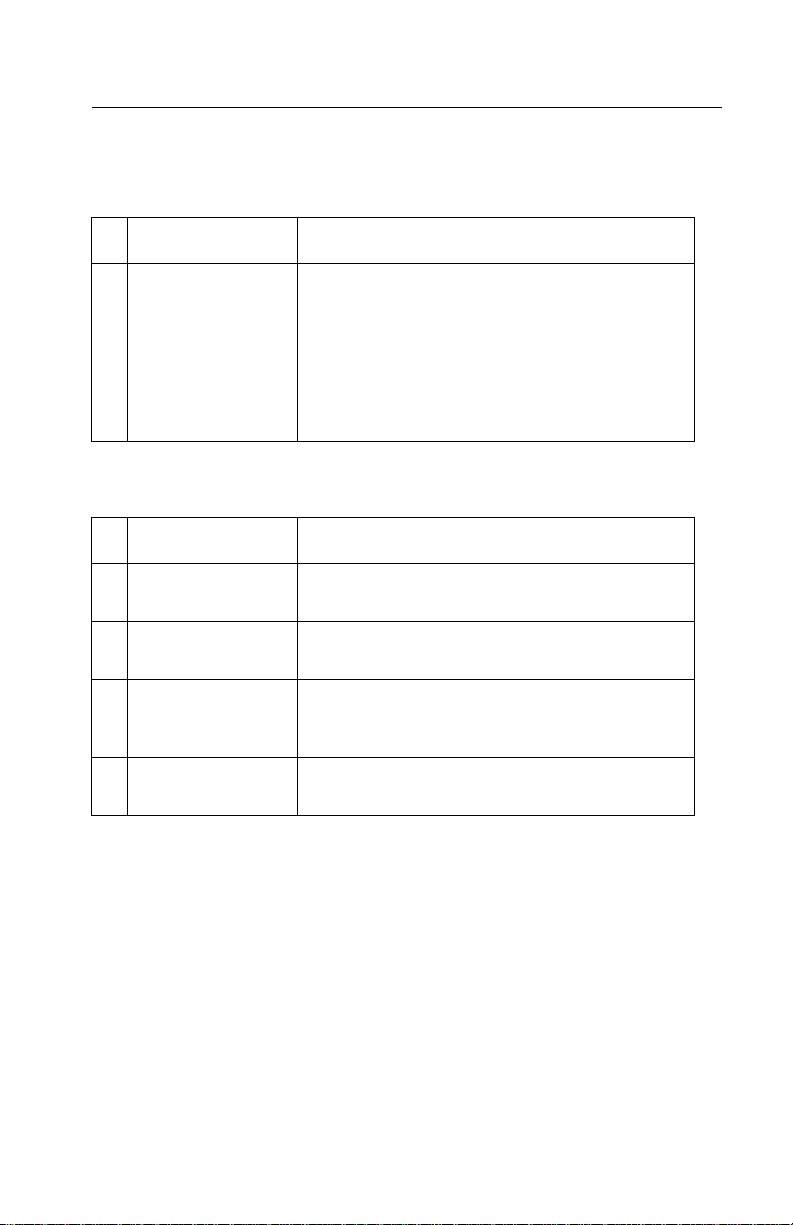

Symptom Tables

Locate the symptom in the following tables and take the appropriate

action.

Carrier Transport Problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams side frame

Go to the ’Transport Service Check’

on page 2-14.

Communications Problems

Symptom Action

Printer not communicating with

host computer.

Go to the ’Parallel Port Service

Check’ on page 2-11.

Maintenance Station Problems

Symptom Action

• Fails to cap the printhead

• Fails to clean the printhead

Go to the ’Maintenance Station

ServiceCheck’onpage2-7.

Op Panel

Symptom Action

Paper feed button does not

operate

Busy light does not come on Replace the system board.

Replace the system board.

Diagnostic Information 2-4

Page 16

4090-001

Paper Feed Problems

Symptom Action

Paper fails to stop at first print line Go to the ’First Print Line Service

Check’ on page 2-6.

• Fails to pick paper

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Envelopes fail to feed Go to the ’Envelope Feed Service

Paper skews Go to the ’Paper Path Service

Go to the ’Paper Feed Service

Check’ on page 2-8.

Check’ on page 2-6.

Check’ on page 2-10.

Power Problems

Symptom Action

No power in printer, no Power

light, no motors

Go to the ’Power Service Check’ on

page 2-11.

Print Quality Problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

•Fuzzyprint

• Carrier moves but does not

print

• Printhead drying prematurely

• Vertical alignment off

Go to the ’Print Quality Service

Check’ on page 2-12.

• Ink smearing

• Vertical streaks on paper

• Print lines crowded

2-5

Go to the ’Paper Feed Service

Check’ on page 2-8.

Page 17

4090-001

Service Checks

Envelope Feed Service Check

FRU Action

1 Envelope Guide Be sure the envelope guides have been turned

to the envelope load positions.

Be sure the envelope guides are against the

envelopes.

Perform the ’Paper Feed Service Check’ on

page 2-8.

First Print Line Service Check

FRU Action

1End-of-Forms

Flag

2End-of-Forms

Sensor

3 System Board Perform the ’PaperSensor Test’ on page 3-4 to

4 Feed Arm

Assembly

Check the flag for binds or damage.

Check the sensor for dirt.

check the end-of-forms sensor on the system

board.

Check all parts of the feed arm assembly for

binds, wear,or damage.

Diagnostic Information 2-6

Page 18

4090-001

Maintenance Station Service Check

The maintenance station has two functions:

1. Cleans the printhead nozzles during the print operation.

2. Seals the printhead when it is not being used to prevent the

nozzles from drying.

FRU Action

1 Maintenance

Station Assembly

2 Wiper A worn wiper causes degraded print quality just

3 Cap A worn cap causes the printhead nozzles to dry

As the carrier moves to the right over the

maintenance station, a slot on the bottom of the

carrier engages a tab on the sled of the

maintenance station causing the caps to rise and

seal the printheads. Carrier movement to the left

will uncap the printheads. The wipers clean the

printhead nozzles as the carrier leaves the

maintenance station. The wipers clean the

printheads only when the carrier is moving to the

left. There should be no wiping action of the

printhead nozzles when the carrier is moving to

the right. After the cleaning operation is complete,

a tabon the maintenancestation engages atab on

the carrier, causing the wipers to lower.

Check the maintenance station for worn or broken

parts.

after a maintenance cleaning. Check for loose or

worn wiper.

and clog. Check for loose or worn cap.

2-7

Page 19

4090-001

Paper Feed Service Check

If your printer does not have paper jam problems, continue with the

service check. If your printer does have a paper jam problem,

examine it for the following before you begin the ser vice check:

• Check the entire paper path for obstructions.

• Be sure there is not too much paper in the sheet feeder.

• Be sure the correct type of paper is being used.

• Check for static in the paper.

FRU Action

1 System Board With J5 disconnected and power on, check for

+30 V dc between J5-1 and ground, and between

J5-2 and ground on the system board. If the

voltage is not present, check for motor pins

shorted to the motor housing. If you find a shorted

pin, replace the motor. If you still havea failure

after replacing the motor, replace the system

board.

Diagnostic Information 2-8

Page 20

4090-001

FRU Action

2 Paper Feed Motor A noisy or chattering motor or a motor that fails to

turn, can be caused by:

• An open or short in the motor

• An open or short in the motor driver on the

system board

• A bind in the paper feed mechanism

With the paper feed motor cable disconnected

from the system board, check for 5 to 10 ohms

between pin 1 and 4 on the motor cable.

If the reading is incorrect, replace the motor.

Checkfor motorpins shorted to themotor housing.

If you find a shorted pin, replace the motor.If the

failure remains, replace the system board.

Although the paper feeds in a forward direction

only, the paper feed motor turns in two directions.

If the paper feed motor turns in one direction only,

replace the system board.

Binds in the paper feed motor or gear train can

cause intermittent false paper jam errors. Remove

the paperfeed motorand check the shaft forbinds.

Also check for loose or worn motor gear.

3 Gears Check for binds in the gear train and paper feed

4 Feed Arm

Assembly

5 Paper Path Perform the ’Paper Path Service Check’ on page

mechanism by rotating the large feed roll byhand.

If you notice a bind, isolate it by removing one of

the small idler gears on the inside of the left side

frame. Replace any worn or binding gears or

rollers.

At the beginning of the paper feed operation, the

paper feed motor reverses momentarily to allow

the feed arm pawl to drop off the home position

notch in the left side frame.If the pawl fails to drop

off the notch, check the feed arm assembly for

binds, and worn or broken parts.

2-10,startingatStep1.

2-9

Page 21

4090-001

Paper Path Service Check

Examine the printer for the following before you begin this service

check:

• Check the entire paper path for obstructions.

• Be sure the paper guides are not worn or broken and are posi-

tioned against the paper without binding or buckling the paper.

• Be sure the correct type of paper is being used.

• Be sure the printer is installed on a flat surface.

FRU Action

1 Large and Small

Feed Rollers

2 Small Feed Roller

Springs

Paper Guide

Paper Flap

3 Exit Rollers

Star Rollers

Exit Drive Belt

4 Sheet Feeder Check the following for wear or damage:

5End-of-Forms

Flag & Spring

Check for wear and binds.

Check for damage.

Check for wear and binds.

• Pick Rollers

• Envelope Bucklers

• All parts inside the left and right edge guides.

Check for binds or damage.

Diagnostic Information 2-10

Page 22

4090-001

Parallel Port Service Check

FRU Action

1 Parallel Port Run a test page to be sure the printer can print.

Run the ’Parallel Port Test’ on page 3-5.Ifthetest

fails, replace the system board.

Power Service Check

FRU Action

1 Power Supply Disconnect J3 from the system board and check

the following voltages on the power supply cable:

• J3-1toGND=+5Vdc

• J3-3 to GND = +30 V dc

• J3-5 to GND = +13.5 V dc

• J3-6toGND=+5Vdc

• J3-8toGND=+5Vdc

If you do not have correct voltage, replace the

power supply. Be sure to unplug the printer before

you reconnect the power supply to the system

board.

3 Printhead Cable

Parallel Cable

Encoder Card

4 System Board If the symptom has not changed, replace the

Turn off the printer. Disconnect one of the

printhead cablesand turn on the printer.Look fora

symptom change. Check the failing part for shorts

and replace as necessary. Repeat this procedure

for the parallel cable and the encoder card.

system board.

2-11

Page 23

4090-001

Print Quality Service Check

FRU Action

1 Print Cartridge Be sure the printer contains good print cartridges.

2 Printhead Carrier

Assembly

3 System Board

Printhead Cable

Rubber Backer

Reseat the printhead cables in the system board

and check the following parts for wear or damage:

• Print Cartridge Latch

• Latch Spring

•Carrier

•Performthe’Test Page’on page 3-7. Look for a

break in the diagonal line of the test pattern. A

broken line indicates one or more print nozzles

are not working. Run the test again to verify the

failure. If there are even breaks in the diagonal

line similar to the pattern shown below, replace

the system board.

If there is a single break or random breaks in the

diagonal line check the following:

• Check the gold-plated contacts, on the end of

the cable that connect to the carrier, for dirt and

wear. Use only a clean dry cloth to clean the

contacts. Also check the cable for damage. You

mayneedtoremovethecablefromthecarrier

to inspect it.

• A worn rubber backer results in poor contact

between the printhead cable and the print

cartridge. Check the rubber backer for wear.

4 Maintenance

Station

Intermittent nozzle failures can be caused by worn

parts in the maintenance station. Perform the

’Maintenance Station Service Check’ on page 2-7,

then return to this check.

Diagnostic Information 2-12

Page 24

4090-001

FRU Action

5 Paper Feed Ink smudging and smearing can be caused by

paper problems or problems in the paper feed

area.

Check the following:

• Correct type of paper is being used. Also check

the paper for curl or wrinkles.

• Feed rollers for wear,dirt, or looseness.

• Gearsforwearorbinds.

• Paper path for obstructions.

6 Transport Blurred printand voids canbe caused byproblems

in the transport area. Check the following:

• Transport belt for wear.

• Carrier guide rod for wear or dirt.

• Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301.

Do not lubricate the carrier guide rod or

carrier bearing surfaces.

• Idler pulley parts for wear, damage, or

looseness.

• Encoder strip for wear or dirt.

7 Alignment Uneven vertical lines can be adjusted by

performing the bidirectional alignment. The user is

directed, through the Printer Control program, to

perform thehead to head and bidirectional printing

alignments, when replacing a print cartridge.

2-13

Page 25

4090-001

Transport Service Check

FRU Action

1 Transport Motor Check the motor for binds, or loose motor pulley.

Disconnect the transport motor (J4) from the

system board. Check for 8 to 18 ohms between

pins 1 and 2 on the motor cable. If the reading is

incorrect, replace the motor.

Checkfor motorpins shorted to themotor housing.

If youfind a pinshorted to thehousing, replace the

motor. If the failure remains, replace the system

board.

2 System Board Turn the printer off and disconnect J4 from the

3 Carrier Guide Rod Clean the carrier rod.

4 Transport Belt

Idler Pulley Parts

Carrier Frame

5 Encoder Strip Check for wear and dirt.

6 Printhead Cable

Encoder Strip

Encoder Card

System Board

7 Maintenance

Station

system board. Turn the printer on and check for a

pulse of 6 to 8 V dc between J4-1 and ground as

the printer goes through POST.

Note: Do not lubricate the rod or the carrier rod

bearing surface.

Check for worn, loose or broken parts. Check for

obstructions blocking carrier movement.

Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301.

Be sure connector J2 is fully seated. Check the

cable for damage.

Perform the ’Encoder Sensor Test’ on page 3-2.If

you cannot enter the test, replace the system

board.

A problemwith the maintenance station can cause

carrier movementproblems atthe right margin. Go

to the ’Maintenance Station Service Check’ on

page 2-7.

Diagnostic Information 2-14

Page 26

4090-001

3. Diagnostic Aids

Use these diagnostic test procedures to verify a repair. There are

two ways to enter test procedures, each procedure will indicate the

method to use:

Procedure 1:

• Press and hold the Paper Feed button while turning the

printer on. Release the button when the printer completes

POST.

Procedure 2:

• Turn the printer off.

• Use a two pin jumper on connector J6 as indicated, then turn

the printer on. The test begins when the power button is

pressed.

Note: You can use the two pin jumper on J7 to perform the tests.

Remember to return the jumper to J7 when the test is finished.

A two pin jumper is also available in the parts packet:

1367169 and 69G4188.

Diagnostic Aids 3-1

Page 27

4090-001

Encoder Sensor Test

This test disables the printer motors to allow you to manually move

the carrier to verify the encoder is working correctly.

To run the test:

1. Turn the printer off and place a two pin jumper on connector J6

as shown below. (Pins 1 & 2)

2. Press and hold the Paper Feed button while turning the

printer on, to star t the test. Release the button when the printer

completes POST. Turn power off or unplug the printer to stop

the test.

The power light flashes as the carrier is moved. The busy light

remains on for right to left, and blinks for left to right movement. With

no carrier movement, the busy light indicates the direction of the last

move. If the test fails, power off the printer and remove the carrier

assembly without unplugging the printhead cable.

Power on the printer and check for +5 V dc at pins 1, 2 and 3 of the

encoder card connector.

1. If voltage is not present, check the printhead cable for opens to

the encoder card. If the printhead cable is good, replace the

system board.

2. If voltage is present, check the sensor on the encoder card by

monitoring pin 3 of the encoder card connector as you pass a

piece of paper through the sensor. The voltage should go from

+5 V dc to 0 V dc. Turn the power off and back on to make this

check again. If the voltage at pin 3 does not change, replace the

encoder card. If the symptom remains, replace the printhead

cable.

Diagnostic Aids 3-2

Page 28

4090-0014090-001

Initialize Error Log

This test allows you to track new errors.

Use this procedure to reset the error log to zero. The error log is

especially helpful in diagnosing intermittent or difficult problems.

To run the test:

1. Turn the printer off and place a two pin jumper on connector J6

as shown below. (Pins 1 & 2)

2. Place a sheet of paper in the manual feed slot and press and

hold the paper feedbutton.Errors stored in NVRAM are erased.

Turn power off or unplug the pr inter to stop the test.

3-3

Page 29

4090-001

Paper Sensor Test

This test checks the paper sensor on the system board.

During the test, the power light remains on. The Busy light reflects

the paper sensor status in the following manner:

• On - paper is in sensor

• Off - paper is not in sensor

To run the test:

1. Turn the printer off and place a two pin jumper on connector J6

as shown below. (Pins 3 & 4)

2. Press and hold the Paper Feed button while turning the

printer on, to star t the test. Release the button when the printer

completes POST. Turn power off or unplug the printer to stop

the test.

Diagnostic Aids 3-4

Page 30

4090-0014090-001

Parallel Port Test

This test performs a wrap around test between the printer parallel

port and the parallel port test connector.

This test requires a parallel port wrap plug. Install the wrap plug in

the parallel port before you start the test.

To run the test:

1. Turn the printer off and place a two pin jumper on connector J6

as shown (Pins 3 & 4).

2. Attach the wrap plug to the parallel port.

3. Turn the printer on.

The power light blinks while the test runs. The busy light turns on if

the test is successful. The busy light blinks or turns off if the test

fails.

3-5

Page 31

4090-001

Print NVRAM Contents

This test prints the contents of NVRAM in hexadecimal format.

To run the test:

1. Turn the printer off and place a piece of paper in the manual

paper slot.

2. Press and hold the Paper Feed button while turning the

printer on. Release the button when the printer completes

POST.

The test prints English for easy recognition. The following appears

on the right side of the printout:

• Device ID

The following appears below the printout:

• Code Level

• Last Error

• Page Count

• Code Level Date

Diagnostic Aids 3-6

Page 32

4090-0014090-001

Test Page

This test prints the test page.

To run a complete test page of black and color patterns, be sure the

print cartridges are in good condition. Install a blackprint cartridge in

the left side of the printhead cradle and a color print cartridge in the

right side.

To enter the test:

1. Turn the printer off.

2. Ensure the manual paper slot is empty.

3. Press and hold the Paper Feed button while turning the

printer on. Release the button when the printer completes

POST.

The test page will contain the following:

• Code level and date

• Nozzle test pattern for both cartridges

• Bidirectional alignment pattern

• Vertical and horizontal test patterns

• Purge test for both cartridges

3-7

Page 33

4090-001

4. Repair Information

This chapter explains how to make adjustments to the printer and

how to remove defective parts.

Note: Read the following before handling electronic parts. When

working on the printer, always unplug the printer from the wall outlet.

High voltage is present in the power supply as long as it is plugged

into the wall outlet.

Handling ESD-Sensitive Parts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual precautions, such as turning off power before removing logic boards:

• Keepthe ESD-sensitive part in its original shipping container(a special

“ESD bag”) until you are ready to install the part into the printer.

• Make the least-possible movements with your body to prevent an

increase of static electricity from clothing fibers, carpets, and furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to the

system ground point. This discharges any static electricity in your body

to the printer.

• Hold the ESD-sensitive part by its edge connector shroud (cover); do

not touch its pins. If you are removing a pluggable module, use the correct tool.

• Do not place the ESD-sensitive part on the printer cover or on a metal

table; if you need to put down the ESD-sensitive part for any reason,

first put it into its special bag.

• Printer covers and metal tables are electrical grounds. They increase

the risk of damage because they make a discharge path from your

body through the ESD-sensitive part. (Large metal objects can be discharge paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by other

personnel. Install printer covers when you are not working on the

printer, and do not put unprotected ESD-sensitive parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal cabinet

(case).

• Be extracareful in working with ESD-sensitiveparts when cold weather

heating is used because low humidity increases static electricity.

Repair Information 4-1

Page 34

4090-001

Adjustments

The user is directed, in the Printer Control program, to perform the

head toheadand bidirectional alignment adjustments afterreplacing

a print cartridge.

Removal Procedures

The following procedures are arranged according to the name of the

printer part discussed. Unplug the power cord before removing any

parts.

Releasing Plastic Latches

Many of the parts are held in place with plastic latches. The latches

break easily; releasethemcarefully.Toremove suchparts, pressthe

hook end of the latch away from the part to which it is latched.

4-2

Hook

Never apply excessive force

when releasing the hook.

Page 35

4090-001

Base Assembly Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Disconnect the power supply connector at the system board.

4. Remove the two screws from the maintenance station

assembly. Pull up the right side of the mid frame assembly and

pull forward and remove the maintenance station assembly.

5. Remove the two screws securing the carrier frame to the base

cover.

6. Slide the printer off the base cover.

Carrier Belt Removal

1. Remove the front cover.

2. Remove the carrier assembly.

3. Push the idler pulley to the right to release the tension on the

belt and remove the belt.

Repair Information 4-3

Page 36

4090-001

Carrier Frame Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the base assembly.

4. Disconnect the paper feed motor connector from the system

board.

5. Remove the fourscrews[A] securing the carrier frame to the left

and right side frames and remove the carrier frame assembly.

4-4

Page 37

4090-001

Note: During reassembly:

1. Be sure the small feed roll spring extensions [B] are in the

groves of the small feed roll arms.

2. Be sure the short extensions of the two paper flap springs are

trapped under the carrier frame [C].

Carrier Transport Motor Removal

1. Remove the front cover.

2. Disconnect the transport motor connector from the system

board.

3. Remove the belt from the transport motor pulley.

4. Remove the two screws securing the transport motor to the

carrier frame and remove the motor. Note the routing of the

motor cable.

Repair Information 4-5

Page 38

4090-001

Code Module Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Gently pry the Code Module from the system board noting the

position of the notch in the module. The notch is down.

Edge Guide Asm and Paper Load Shaft Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the paper load door and manual insert tray.

4. Remove the pick roll hub, shaft and envelope bucklers.

5. Remove the two screws from the right side frame.

6. Work the paper load shaft out of the side frames.

7. Pull up the bottom of the edge guides to separate them from the

top of the back plate and remove the assembly from the frames.

Note: When reinstalling, be sure the edge guide springs are turned

to the inside to maintain spring tension on the guides.

Encoder Card Removal

1. Remove the front cover.

2. Remove the printhead carrier assembly.

3. Disconnect the printhead cable from the encoder card.

4. Remove the screw from the encoder card and remove the card.

Encoder Strip Removal

1. Remove the front cover.

2. Remove the carrier assembly.

3. Gently release the tension on the encoder strip by flexing the

encoder strip tensioner and remove the encoder strip.

Note: When reinstalling the encoder strip, make sure the ends of

the strip are centered in their mounting notches and the strip does

not bind in the encoder card on the carrier.

4-6

Page 39

4090-001

Exit Drive Belt Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the carrier frame assembly.

4. Remove the paper load door and manual insert tray.

5. Remove the small feed roll shaft.

6. Unlatch the left side of the exit roller shaft and work the belt off

the exit roller pulley.

7. Pull up the four clips securing the mid frame to the large feed

roll and work the mid frame out of both side frames.

8. Spread the right side frame apart far enough to allow removalof

the exit drive belt.

Exit Roller Removal

1. Remove the front cover.

2. Remove the two screws from the star roller assembly and

remove the assembly.

3. Unlatch the left side of the exit roller and remove the exit drive

belt from the exit roller pulley.

4. Remove the exit roller.

Feed Arm Assembly Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the C-clip from the feed arm and remove the assembly.

Repair Information 4-7

Page 40

4090-001

Front Cover Removal

1. Place a screwdriver in slot [A] and release the cover latches.

2. Slide the cover forward and off the printer.

To reassemble:

1. Slide the cover over the matching pieces on the bottom cover.

2. Press in both sides opposite the cover latches until they latch.

Gutter Pad Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the base assembly.

4. Scrape the old gutter pad off the base.

4-8

Page 41

4090-001

Inside Idler Gears Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the printer from the base assembly.

4. Remove the paper feed motor.

5. Gently pry the two idler gears from the left side frame. Be

careful not to break the locking tabs [A].

Repair Information 4-9

Page 42

4090-001

Large Feed Roll Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the carrier frame assembly.

4. Using a small screwdriver, break the four prongs off the

compound idler gear and remove the idler gear.

5. Remove the large feedroll from the mid frame by pulling it out of

the four mounting clips. Spread the right side frame and remove

the large feed roll.

Note: Install the compound idler gear after the printer is installed in

the base assembly.

4-10

Page 43

4090-001

Large Outside Gear Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the paper load door and manual insert tray.

4. Remove the C-clip from the feed arm assembly and remove the

feed arm assembly.

5. Remove the C-clip from the left side of the pick roll shaft.

6. Pull the pick roll shaft out far enough to remove the large gear.

Note: Gently pull the feed arm guide [A] on the left side frame

forward, then remove the large gear.

Repair Information 4-11

Page 44

4090-001

Left Side Frame Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the carrier frame assembly.

4. Remove the paper load door and manual insert tray.

5. Using a small screwdriver, break the four prongs off the

compound idler gear [A] and remove the idler gear.

6. Remove the two screws [B] securing the left side frame to the

back plate. Slide the left side frame off the back plate. Note the

relationship of the parts.

Note: Install a new compound idler g ear [A] after the printer is

installed in the base assembly.

B

4-12

A

Page 45

4090-001

Maintenance Station Assembly Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the two screws from the maintenance station

assembly, lift up the right side of the mid frame assembly and

slide the maintenance station assembly forward, out of the

printer.

Maintenance Wipers and Caps Removal

1. Remove the front cover.

2. Push the carrier to the left away from the maintenance station.

3. Gently pull the caps and wipers off their mountings.

Note: When reinstalling the caps, be sure the cap is positioned with

the locking tabs to the left and right before pushing them down on

their mounting posts. Be sure the wipers are completely seated.

Manual Insert Tray Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the paper load door.

4. Spread the right side frame away from the manual insert tray

until the pins in the insert tray clear the frame.

5. Remove the manual insert tray from the left side frame.

Mid Frame Assembly Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the carrier frame assembly.

4. Remove the paper load door and manual insert tray.

5. Remove the small feed roll shaft.

6. Unlatch the left side of the exit roller shaft and work the belt off

the exit roller pulley.

7. Pull up the four clips securing the mid frame to the large feed

roll and work the mid frame out of both side frames.

Repair Information 4-13

Page 46

4090-001

Paper Feed Motor Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the base assembly.

4. Remove the two screws securing the paper feed motor and

remove the motor. Note the routing of the motor cable.

Paper Guide and EOF Flag Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the printhead carrier assembly.

4. Remove the carrier frame assembly.

5. Remove the encoder strip.

6. Remove the system board.

7. Remove the three small feed roll springs.

8. Push the locking tabs [A] to the rear and pull the paper guide

down and out of the carrier frame.

4-14

A

Page 47

4090-001

Note: During reassembly:

1. Be sure the small feed roll spring extensions [B] are in the

groves of the small feed roll arms.

2. Be sure the short extensions of the two paper flap springs are

trapped under the carrier frame [C].

Repair Information 4-15

Page 48

4090-001

Paper Load Door Removal

Spread the left side frame where it joins the paper load door and

remove the door.

Pick Roll Hub, Shaft and Envelope Bucklers Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the paper load door and manual insert tray.

4. Slide the left paper guide to the right.

5. Remove the C-clip from the left side of the pick roll shaft.

6. Pull the pick roll shaft out to the left and remove the pick roll

shaft, hubs and envelope bucklers.

Note: During reassembly, be sure the pick roll hubs are in the slots

at the bottom of the paper guides and the rolls are centered on the

pick pads.

Power Supply Removal

Note: When working on the printer, always unplug the printer from

the wall outlet. High voltage is present in the power supply as long

as it is plugged into the wall outlet.

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the base assembly.

4. Turn the base over, pull out on the latches, slide the power

supply forward and off the base assembly.

4-16

Page 49

4090-001

Printhead Cable, Cradle & Paper Deflector Removal

1. Remove the front cover.

2. Remove the printhead carrier assembly.

3. Disconnect the printhead cablefrom the encoder card. Note the

routing of the cable under the retaining clip on the carrier.

4. Separate the cradle from the printhead carrier assembly by

pushing out the cradle latches [A].

5. Feed the folded end of the printhead cable through the opening

in the carrier assembly and remove the cable.

Note: Use the illustration to assemble thecarrier parts in the correct

sequence.

Repair Information 4-17

Page 50

4090-001

Note: Be sure the cable is secured under the three retaining clips

[B] on the back of the carrier.

B

4-18

Page 51

4090-001

Printhead Carrier Assembly Removal

1. Remove the front cover.

2. Unlock the two printhead cable connectors and disconnect the

printhead cable from the system board.

3. Remove the retainer from the right end of the carrier guide rod.

4. Slide the carrier guide rod to the left, out of the pr inter.

5. Lift the carrier out of the printer.

Printhead Rubber Backer Removal

1. Remove the front cover.

2. Remove the printhead carrier assembly.

3. Separate the cradle from the printhead carrier assembly by

pushing out the cradle latches [A].

4. Remove the rubber backer and paper deflector from under the

printhead carr ier cable.

Note: Use the illustration to assemble thecarrier parts in the correct

sequence.

Repair Information 4-19

Page 52

4090-001

Rear Cover Removal

1. Remove the front cover.

2. Place a screwdriver in slot [A] and release the cover latches.

A

3. Slide the cover up and off the printer.

4. To reassemble, place the cover over the tabs in the bottom

cover and press down until the coverlatches. Be sure the

parallel connector snaps do not get trapped behind the cover.

Right Side Frame Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the carrier frame assembly.

4. Remove the paper load door and manual insert tray.

5. Remove the two screws securing the right side frame to the

back plate.Slide the right side frame off the backplate. Note the

relationship of the parts.

4-20

A

Page 53

4090-001

Small Feed Roll Shaft, Rollers & Paper Flap Removal

1. Remove the front cover.

2. Remove the r ear cover.

3. Remove the carrier frame assembly.

4. Spread the left and right side frames apart far enough to

remove the small feed roll shaft assembly.

Boss Paper Guide Feature

Due to occasional paper buckling at the bottom edge of the page, a

new featurehas been added to the paper guide to stabilize the small

feed roll shaft. Install the new style paper guide and match the small

feed roll assembly. The new small feed roll FRU is cut out in the

paper flap allowing the new feature to contact the small feed roll

shaft.

Star Roller Removal

1. Remove the front cover.

2. Remove the two screws from the star roller assembly and

remove the assembly.

System Board Removal

1. Remove the front cover.

2. Unlock the two printhead cable connectors and disconnect the

printhead cables from the system board.

3. Disconnect the other cables from the system board.

4. Gently release the tension on the encoder strip by flexing the

encoder strip tensioner and remove the encoder strip from the

left side only.

5. Remove the three screws securing the system board to the

carrier frame and remove the system board. Note the routing of

the paper feed motor cable.

Note: The head to head and bidirectional printing alignments willbe

reset to factory defaults. The user, through the Printer Control

program, is directed to perform these alignments. When reinstalling

the system board, itiseasier to insert the printhead cables inthetwo

connectors prior to installing the board.

Repair Information 4-21

Page 54

4090-001

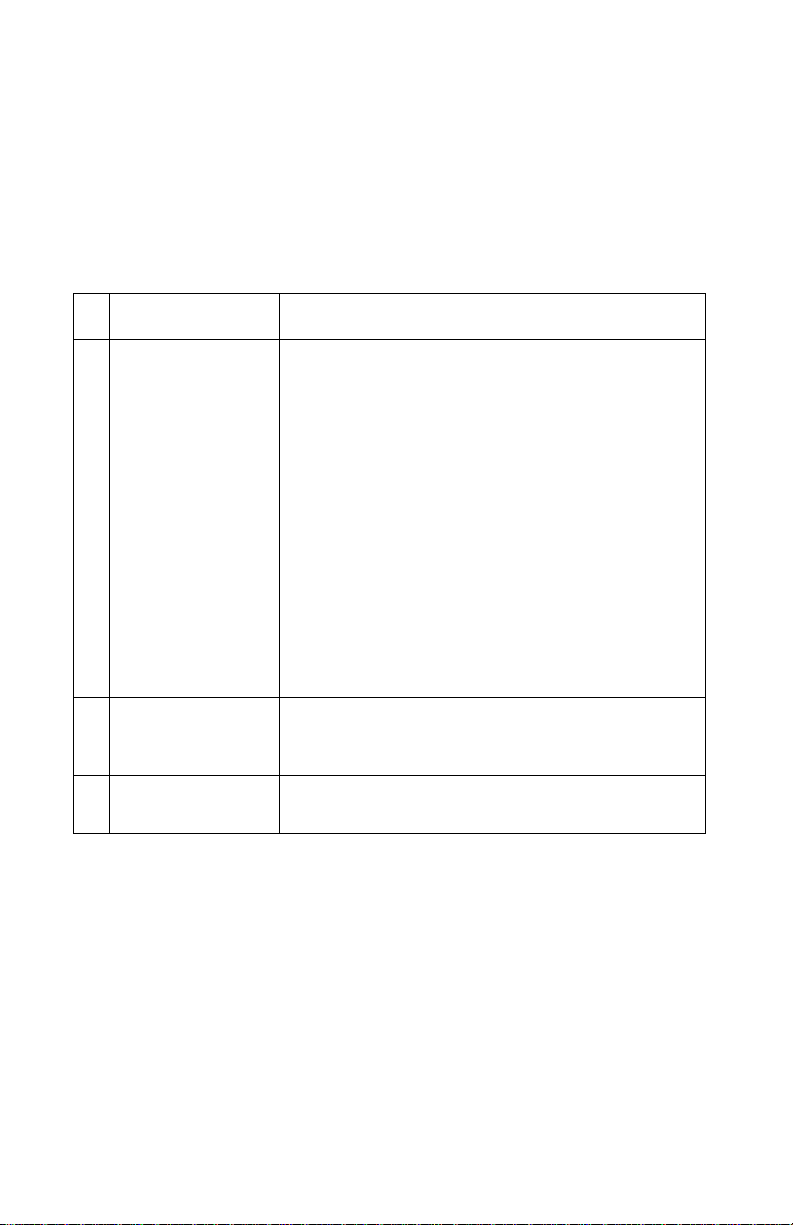

5. Connector Locations

The printer is shipped with the jumper pin setting in the following

static position. Be sure the jumper is installed on the correct pins.

Communications Jumper J7 pin 2 and 3.

Connector Locations 5-1

Page 55

4090-001

System Board Connectors

Connector Locations 5-2

Page 56

4090-001

Connector Connector Names

J1

J2

J3

J4

J5

J6

J7

J8

SW1

SW2

S1

U20

Printhead Cable 1

Printhead Cable 2

PowerSupply

Transport Motor

Paper Feed Motor

Test Jumper

Communications Jumper

Parallel Port

Paper Feed Switch

Power Switch

EOF Sensor

Code Module

Encoder Card Connector

5-3

Page 57

4090-001

6. Preventive Maintenance

This chapter contains the lubrication specifications. Follow these

recommendations to prevent problems and maintain optimum

performance.

Lubrication Specifications

Lubricate only when parts are replaced or as needed, not on a

scheduled basis. Use grease P/N 1329301 to lubricate the following:

• All gear mounting studs.

• The left and right ends of the large feed roller at the side frames.

• Both ends of the sheet feeder pick roll shaft at the side frames.

• The carrier to carrier frame engagement.

Do not lubricate the carrier guide rod, or carrier guide rod bearings.

Preventive Maintenance 6-1

Page 58

4090-001

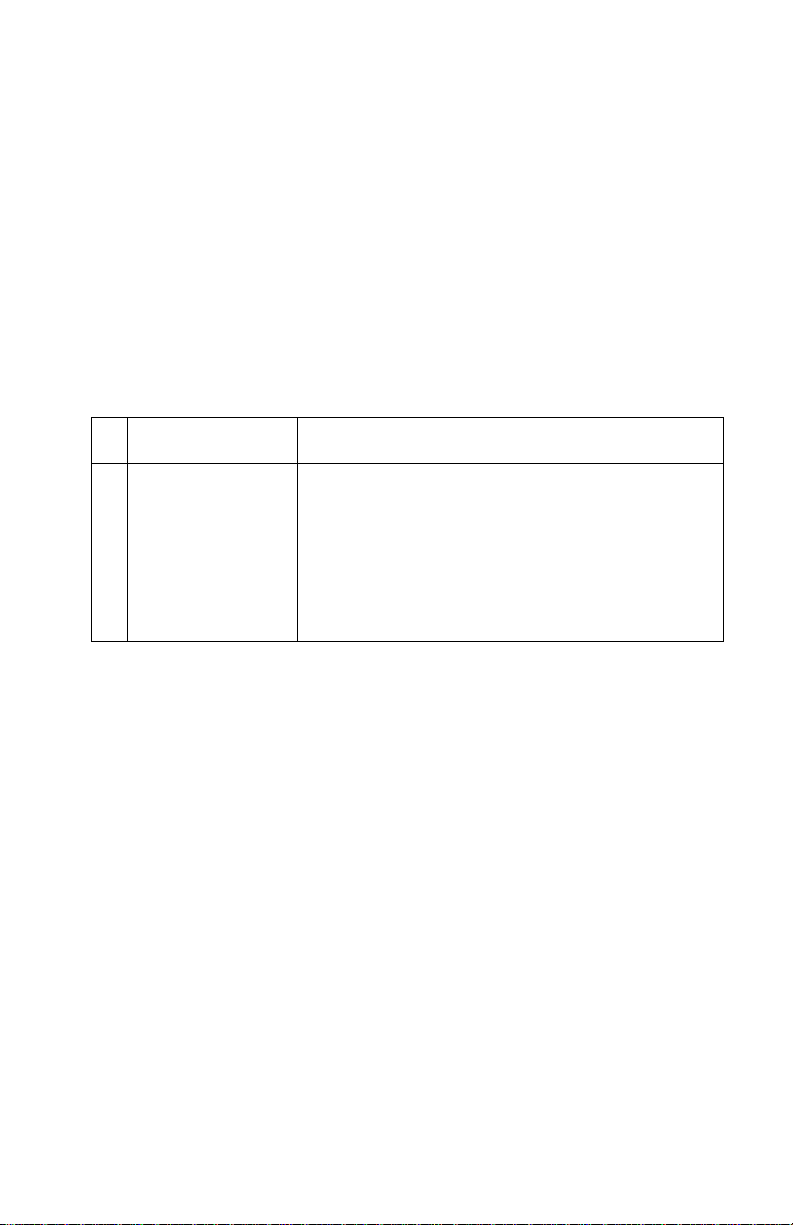

7. Parts Catalog

How To Use This Parts Catalog

•

SIMILAR ASSEMBLIES: If two assemblies contain a majori ty of

identical parts, they are broken down on the same list. Common

parts are shown by one index number. Parts peculiar to one or

the other of the assemblies are listed separately and identified

by description.

• NS: (Not Shown) in the Asm-Index column indicates that the

part is procurable but is not pictured in the illustration.

• PP: in the parts descriptions column indicates the part is

available in the listed parts packet.

Parts Catalog 7-1

Page 59

4090-001

Assembly 1: Covers

Parts Catalog 7-2

Page 60

4090-001

AsmIndex

1 -1 70G0594 1 Base Asm includes Exit Tray, Gutter

-2 70G0595 1 FrontCover Asm,Access Cover,Button

-3 69G4118 1 Rear Cover

-4 69G4119 1 Gutter Pad, Base Asm

N/S 70G0591 1 Replaceable Package B/M (US)

N/S 70G0592 1 Replaceable Package B/M (Non - US)

Part

Number

Units Description

Pad, Feet

& LED Lens

Includes:(Carton, Cushion Set,Sealing

Tape)

Includes:(Carton, Cushion Set,Sealing

Tape)

7-3

Page 61

4090-001

Assembly 2: Frames

Parts Catalog 7-4

Page 62

4090-001

AsmIndex

2 -1 69G4120 1 Left Side Frame Sub-Asm without

-2 70G0574 1 Mid Frame with Star Rollers

-3 69G4121 1 Right Side Frame

-4 69G4122 1 Carrier Frame

-5 69G4188 4 Screw, Frame Mounting (PP)

Part

Number

Units Description

Gears

Also order gears B/M 69G4127

7-5

Page 63

4090-001

Assembly 3: Paper Feed

Parts Catalog 7-6

Page 64

4090-001

AsmIndex

3 -1 69G4074 1 Paper Guide Asm includes EOF

-1 70G3039 1 Paper Guide Asm includes EOF

-2 13A1196 1 Small Feed Roll Shaft Roll B/M

-3 70G0574 1 Star Roller Asm

-4 70G0575 1 Large Feed Roll Asm (includes

-5 70G0576 1 Paper Feed Motor, Motor Gear,

-6 69G4127 1 Gears B/M

-7 69G4398 1 Feed Arm Asm

Part

Number

Units Description

Flag, Spring (Old style - works

with old or new small feed roll).

See “Boss Paper Guide Feature”

on page 4-21.

Flag,Spring(Newstyle,works

with new small feed roll only). See

“Boss Paper Guide Feature” on

page 4-21.

and Paper Flap

(part of Mid Frame)

Small Compound Idler Gear)

Toroid

-8 69G4188 2 C-Clip (PP)

-9 69G4188 3 Spring, Small Feed Roll (PP)

-10 69G4188 2 Screw,Paper Feed Motor Mounting (PP)

-11 70G0577 1 ExitRoller

-12 70G0579 1 ExitDrive Belt

7-7

Page 65

4090-001

Assembly 4: Electronics

Parts Catalog 7-8

Page 66

4090-001

AsmIndex

Part

Number

Units Description

4 -1 70G2695 1 System Board, W/O Code Module

If code module in old board is labeled:

70G0830 through 70G0835;

70G0841 through 70G0845,70G2562,

70G2587, 70G2598, 70G2599, order

new code module 70G3000.

-2 70G0581 1 Power Supply with Ground Plane,

Insulator, Cover

-3 1339526

1342514

1339520

1339520

1342514

1342514

1342534

1339526

1342534

1342514

1342514

1339525

1342514

1339519

1342514

1339520

1339520

1339520

1342514

1342514

1339521

1339524

1342514

1339520

1342514

1339520

1342514

1342536

1342514

1339517

1339523

1339520

1339520

1339522

1339519

1342536

1342514

1PowerCord,U.S.

Power Cord, Argentina

Power Cord, Austria

Power Cord, Belgium

Power Cord, Bolivia

Power Cord, Brazil (LV)

Power Cord, Brazil (HV)

Power Cord, Canada

Power Cord, Chile

Power Cord, Columbia

Power Cord, Costa Rica

Power Cord, Denmark

Power Cord, Ecuador

Power Cord, Egypt

Power Cord, El Salvador

Power Cord, Finland

Power Cord, France

Power Cord, Germany

Power Cord, Guatemala

Power Cord, Honduras

Power Cord, Israel

Power Cord, Italy

Power Cord, Mexico

Power Cord, Netherlands

Power Cord, Nicaragua

Power Cord, Norway

Power Cord, Panama

Power Cord, Paraguay

Power Cord, Peru

Power Cord, Saudi Arabia

Power Cord, South Africa

Power Cord, Spain

Power Cord, Sweden

Power Cord, Switzerland

Power Cord, United Kingdom

Power Cord, Uruguay

Power Cord, Venezuela

7-9

Page 67

4090-001

Assembly 4: Electronics (continued)

Parts Catalog 7-10

Page 68

4090-001

AsmIndex

4 -4 70G3000 1 Code Module

-5 69G4188 5 Screw, System Board Mounting

NS 69G4188 1 Screw, Ground Jumper Mounting

NS 69G4188 2 Jumper, 2-Pin (PP)

Part

Number

Units Description

(PP)

(PP)

7-11

Page 69

4090-001

Assembly 5: Carrier

Parts Catalog 7-12

Page 70

4090-001

AsmIndex

5 -1 70G0585 1 Printhead Carrier B/M

-2 70G0586 1 Printhead Cable (Folded)

-3 70G0587 1 Rubber Backer

-4 69G4157 1 Carrier Guide Rod

-5 69G4156 1 Encoder Card Asm

-6 69G4188 1 Screw, Encoder Card Mounting

-7 69G4188 1 Retainer Right, Carrier Guide Rod

-8 69G4188 1 E-Ring, Carrier Guide Rod (PP)

-9 70G0588 1 Printhead Cartridge Interlock Key

Part

Number

Units Description

(PP)

(PP)

B/M

7-13

Page 71

4090-001

Assembly 6: Carrier Transport

4

2

1

6

3

5

Parts Catalog 7-14

Page 72

4090-001

AsmIndex

6 -1 69G4158 1 Carrier Transport Motor & Pulley

-2 69G4159 1 Carrier Belt

-3 69G4403 1 Encoder Strip

-4 69G4163 1 Idler Pulley Tension Asm

-5 69G4188 2 Screw, Carrier Transport Motor

-6 69G4188 1 Tensioner, Encoder Strip (PP)

Part

Number

Units Description

Mounting (PP)

7-15

Page 73

4090-001

Assembly 7: Sheet Feeder

Parts Catalog 7-16

Page 74

4090-001

AsmIndex

7 -1 69G4166 1 Right Edge Guide & Width Adjust

-2 69G4167 1 Left Edge Guide

-3 69G4131 1 Upper Paper Support

-4 1367469 1 Pick Roll & Paper Load Shaft B/M

-5 1367463 2 Pick Roll Hub Asm

-6 1367019 1 Envelope Buckler B/M, Left & Right

-7 69G4169 1 Back Plate

-8 69G4164 1 Paper Load Door Asm

-9 69G4165 1 Manual Insert Tray

-10 69G4127 1 Gear, Paper Load (Gears B/M)

-11 69G4188 1 E-Ring (PP)

-12 69G4188 4 Screw, Side Frame (PP)

-13 69G4188 1 Spring, Left Paper Load (PP)

Part

Number

Units Description

Strip

Includes Left Edge Guide

-14 69G4188 1 Spring, Right Paper Load (PP)

7-17

Page 75

4090-001

Assembly 8: Maintenance Station

Parts Catalog 7-18

Page 76

4090-001

AsmIndex

8 -1 70G0589 1 Maintenance Station Asm

-2 70G0590 1 Wiper and Cap B/M (one of each)

-3 69G4188 1 Screw, Maintenance Station

Part

number

Units Description

Mounting (PP)

7-19

Page 77

4090-001

Index 3

A

Abbreviations 1-2

Adjustments 4-2

Assemblies

1 Covers

2Frames7-4

3 Paper Feed 7-6

4 Electronics 7-8

5 Carrier 7-12

6 Carrier Transport 7-14

7 Sheet Feeder 7-16

8 Maintenance Station 7-18

7-2

C

Connector Locations 5-1

Connectors

System Board

5-2

D

Diagnostic Aids 3-1

Diagnostic Information 2-1

E

Error Indicator Table 2-2

ESD-Sensitive Parts 4-1

G

General Information 1-1

L

Lubrication Specifications 6-1

M

Maintenance Approach 1-1

P

Parts Catalog 7-1

Plastic Latches 4-2

POST

Sequence

Symptom Table 2-3

Power Consumption 1-1

Preventive Maintenance 6-1

Problems

Carrier Transport

Communications 2-4

Maintenance Station 2-4

Paper Feed 2-5

Power 2-5

Print Quality 2-5

2-2

2-4

R

Removals

Base Assembly

Carrier Belt 4-3

Carrier Frame 4-4

Carrier Transport Motor 4-5

Code Module 4-6

Edge Guide Asm 4-6

Encoder Card 4-6

Encoder Strip 4-6

Envelope Bucklers 4-16

EOF Flag Asm 4-14

Exit Drive Belt 4-7

Exit Roller 4-7

Feed Arm Assembly 4-7

Front Cover 4-8

Gutter Pad 4-8

Inside Idler Gears 4-9

Large Feed Roll 4-10

Large Outside Gear 4-11

Left Side Frame 4-12

Maintenance Caps 4-13

Maintenance Station 4-13

Maintenance Wipers 4-13

Manual Insert Tray 4-13

Mid Frame Assembly 4-13

Paper Deflector 4-17

Paper Feed Motor 4-14

Paper Flap 4-21

Paper Guide 4-14

4-3

X-1

Page 78

4090-001

Removals Continued

Paper Load Door

Paper Load Shaft 4-6

Pick Roll Hub 4-16

Pick Roll Shaft 4-16

Power Supply 4-16

Printhead Cable 4-17

Printhead Carrier 4-19

Printhead Cradle 4-17

Printhead Rubber Backer 4-19

Rear Cover 4-20

Right Side Frame 4-20

Small Feed Roll Shaft 4-21

Small Feed Rollers 4-21

Star Roller 4-21

System Board 4-21

Repair Information 4-1

4-16

S

Safety Information vi

Service Checks

Envelope Feed

First Print Line 2-6

Maintenance Station 2-7

Paper Feed 2-8

Paper Path 2-10

Parallel Port 2-11

Power 2-11

Print Quality 2-12

Transport 2-14

Start 2-1

Symptom Table (POST) 2-3

Symptom Tables 2-4

2-6

T

Tests

Encoder Sensor

Initialize Error Log 3-3

Parallel Port 3-5

Print NVRAM Contents 3-6

Test Page 3-7

Tools 1-2

X-2

3-2

Loading...

Loading...