Level Pro Sentinel Series Instruction Manual

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

INSTRUCTION MANUAL

WIRELESS REMOTE TANK UNIT

AL R1 R2

ESC

ENTER

MENU

Read carefully the instructions published in this manual before the first use of the level meters. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

TM

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

FCC STATEMENT

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1)This device must not be allowed to cause harmful interference

(2)This device must accept any interference that may cause undesired operation.

Sentinel Series Introduction

Overview

The Sentinel Series is a wireless communication device that provides quick and easy access to

remote information such as storage tank inventory. Intended for supplier-managed inventory

programs, the Sentinel utilizes the latest internet and cellular technology to provide instant access

to inventory information around the globe. Coupled with the Sentinel information web site, the

Sentinel can provide a tremendous advantage over conventional systems for inventory

management, asset control, or information exchange.

For Your Safety

This equipment contains a cellular radio which transmits at several times the power of a hand-held

cellular phone. While it has been tested to comply with applicable FCC regulations and is approved

for use in nonresidential applications, it may still interfere with other electronic equipment.

Therefore its use in certain situations is restricted. Read these installation and operation instructions

carefully. Failure to follow these instructions may be dangerous or illegal. Only qualified service

personnel must install or repair this equipment.

HOW IT WORKS

TANK / SUMP SENTINEL CELLULAR NETWORK SENTINEL 247 ONLINE INVENTORY MANAGER

Fig 1

01

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

Transfer of Data

The Sentinel communicates to the cloud based da

called GSM Short Message Service. This technology allows the unit to transmit digital data to the

data center using the existing network of GSM cellular towers deployed throughout North America.

In order to transmit a data packet, the local GSM cellular carrier must provide SMS (Short Message

Service). Once the data is at the cloud based data center, it may be viewed over the INTERNET

using a standard web browser (i.e. Microsoft Internet Explorer), downloaded to applications such

as Microsoft Excel, or it may be used to trigger events such as an e-mail or text to the inventory

manager or service representative. To access the data provided by the Sentinel unit, a current

monitoring service agreement with Sentinel is required.

Product Highlights

• No telephone line is required for communication.

• No external power source is required.

• Fast, simple installation.

• Flexible sensing technology.

• Fixed monitor

• Readily available r

• Unlimited applications.

ing costs.

eplacement batteries

.

ta center using a wireless cellular technology

INSTALLATION

Safety Precautions

The Sentinel uses Radio Frequency (RF) waves for communication to the nearest cellular tower and

can transmit at several times the power of a hand-held cellular phone.

In general, if you can place a cellular telephone call in the location where you wish to install the unit,

then the Sentinel should be able to communicate properly.

However, because of the inherent characteristics of RF communications, there are certain guidelines

that should be followed when positioning the unit

DO NOT install the Sentinel where hazardous vapors are present.

WARNING!

DO NOT use the Sentinel where blasting is in progress

sensitive electronic components. Be sure to discharge yourself by touching a grounded metal

object before

opening the unit. The unit should be installed in an area free from overhanging metal

structures, large obstructions, or equipment which could generate RF or electrical interference.

DO NOT install the unit below ground level unless provisions are made for an external

antenna. Service may be limited in areas that do not have GSM cellular coverage and support

SMS (Short Message Service). If the unit is installed in an area with poor signal strength, an

external antenna may be required for reliable performance. If you have doubt about the suitability

of a particular location for the Sentinel, or are having difficulty transmitting, please see Sections

3-2 and 3-3. If an external antenna is required, several optional antennas are available. Please

contact Sentinel Customer Service to determine your exact needs

Electrostatic discharge can damage

02

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

Initial Inspection

When you receive the Sentinel unit, thoroughly inspect it for any damage, which may have

occurred during shipping. If there is any damage to the Sentinel, contact the shipping company

as soon as possible.

Locate the packing checklist in the shipping container. Check for any missing items before

you begin installation of the Sentinel.

Note: The Sentinel is shipped with the antenna disconnected. It is located in a separate

area within the shipping carton. Verify that the antenna is present before proceeding.

Mounting a 100 Series Submersible Level Sensor

Differential Pressure Sentinels operate by measuring the pressure (weight) of the liquid the sensor is

submerged into. This pressure is proportional to the density of the liquid.

The opening on the end of the sensor contains an exposed diaphragm which responds to changes

in liquid pressure as the tank is filled or emptied with product. This measured pressure is compared

against atmospheric pressure, and is converted to a readable signal by a microprocessor in the

Sentinel. Please note that the sensor and sensor cable must be clean when installed, to avoid

contamination of the contents of the tank. These tanks are inspected for product contamination,

and the Sentinel installation cannot compromise the product in the tank.

Care must be taken before and during installation to not strike the sensor against any stationary

surface. This can frequently occur during installation of the probe into the tank. Shock may damage

the probe causing it to fail prematurely.

DO NOT install the sensor in a liquid that is susceptible to freezing or at the bottom

with water in it that may freeze. If the liquid freezes, it will damage the probe which will not be

covered under warranty.

WARNING!

DO NOT install the sensor in a tank with a mechanical agitator

DO NOT drop or strike the sensor against a solid object. This may damage the sensor or cause

a shift in the output of the probe.

of a tank

DO NOT kink the probe cable. This could restrict the breather tube in the cable and cause

fluctuating readings.

DO NOT install the sensor where sludge or sediment can clog the probe opening. If necessary,

suspend the sensor above the maximum level of the sediment.

DO NOT use the Sentinel housing to screw the unit into the tank. Use only the wrench flats on

the bottom fitting.

03

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

Mounting an Sentinel Unit

The Sentinel Unit comes standard with a 3/4 inch female NPT connection on the bottom of the

housing for direct connection into standard instrumentation. The wiring will pass thru this 3/4

inch connection to the terminal strip.

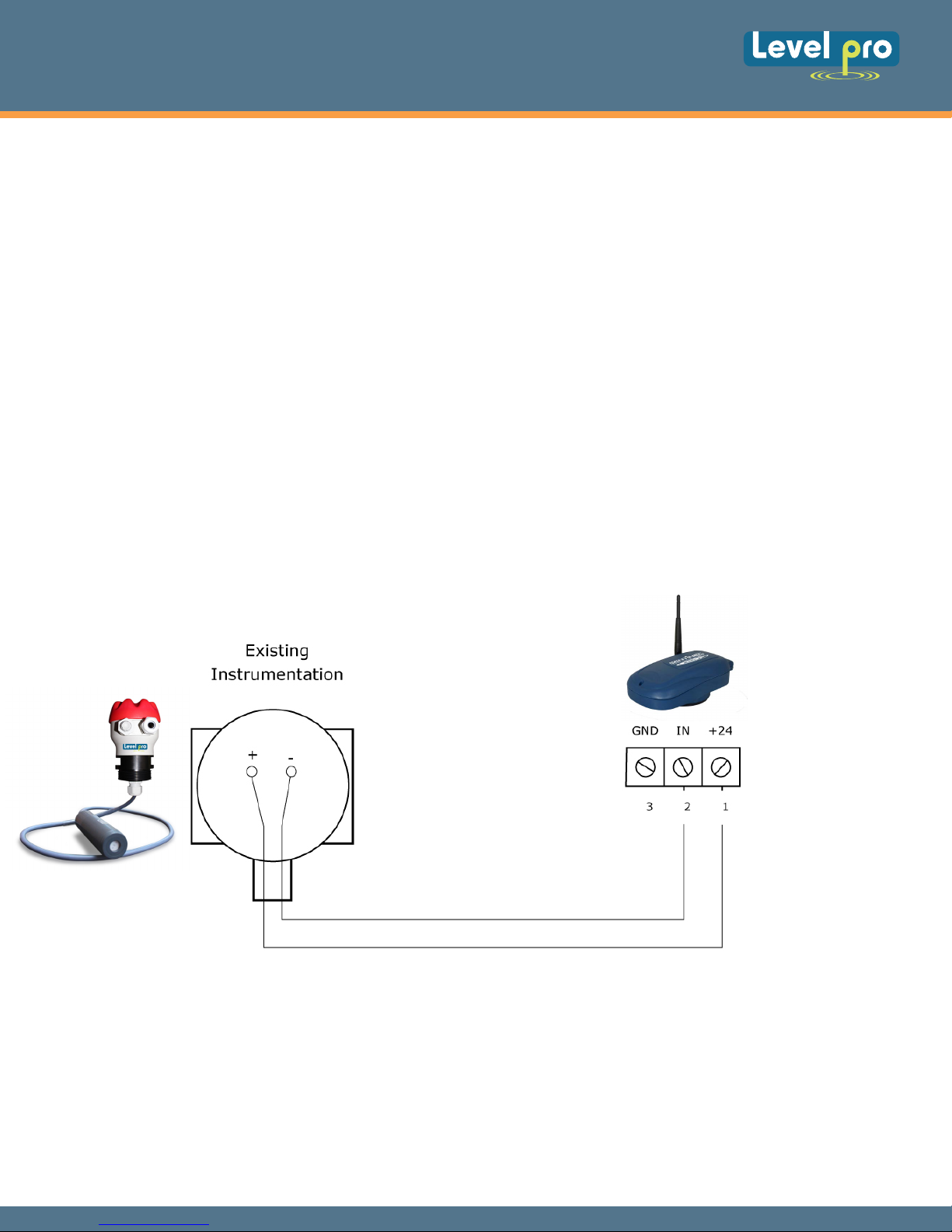

Wiring the Current Loop

The wiring for the current loop passes through the bottom of the housing, thru the hole in

the electronics board, and connects at terminal strip J3. Refer to Figure 8.

Sentinel Unit Providing Current Loop

In this scenario, the Sentinel is providing the power for the sensor thru the current loop.

Typically the Sentinel is mounted directly to the sensor using a 3/4-inch NPT connection. The

Sentinel can supply no more than 24 VDC to the sensor. Please note the return wire is connected to

JP3 – 2 (IN), and not to GND. The electronics of the Sentinel unit route the return to ground

internally.

LP100

Junction Box

Sentinel

100 Series

Fig 2

Providing Current Loop Power

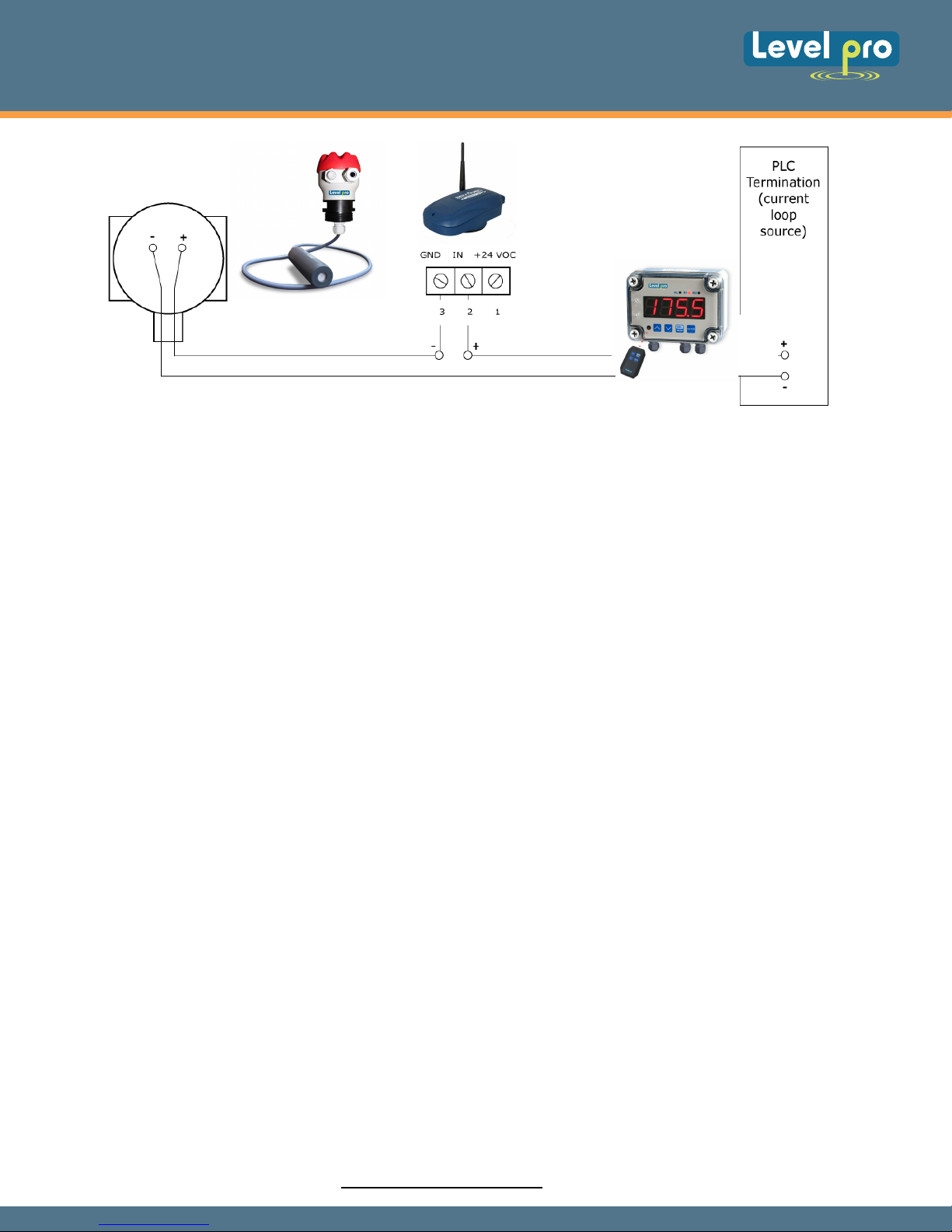

Sentinal Unit Placed in Series with Existing Current Loop

Power (Between +24VDC and existing instrumentation)

In this scenario, the Sentinel is wired into an existing, established current loop on the

positive side (between the current loop source and the instrumentation).

04

Sentinel Series | Telemetry

Tank | Sump Liquid Level Monitoring

LP100 Junction Box

100 Series

Sentinel Installed in an Existing Current Loop

4 Unit Activation

4.1 Verifying GSM Signal Strength

During installation, you can determine your GSM signal suitability by operating a GSM

cellular phone and confirming its operation capability by placing a call.ti

4.3 Establishing Communication

Sentinel

TVL Series

Display

Fig 3

Once all tank preparation has been completed, the Sentinel is properly mounted to the

tank, the GSM SMS (Short Message Service) is available, signal strength has been

verified, and the number of callouts per day has been properly set, it is now time to

establish communications with the Icon Process Controls Data Center.

1) Open the top cover of the Sentinel opened by loosening the screw at the front of the lid

using a 3/16” flat screwdriver. Insert the two batteries into the battery holders at the insidefront of the housing and connect the optional extended life battery pack if present (J7). Refer

to Figure 4 ( Next Page )

2) Verify that the Prophet’s antenna is pointing straight up.

3) Press the white button on the right side of the unit. A green LED

inside front of the housing.

4) The green LED will flash fast (half second ON, half second OFF).

5) Once a cellular network is found, the green LED will flash slow (one second ON, one

second OFF).

6) The green LED will go to solid ON for about 60 seconds while the unit is

transmitting data to the Levelpro® Data Center.

7) After a successful transmission, the green LED will flash and then go out. The

Sentinel is now in sleep mode, and will remain in sleep mode until the next scheduled

transmission time or until the white button is pressed again.

will light up at the

8) If the data transmission was not successful, a red LED will light and the green LED will

flash an error code. Refer to Section 8-1 of this manual for information on the error codes.

9) Contact Icon Process Controls Customer Service at 1-905.469.9283 to verify a

successful data transmission, and to verify tank information.

10) Secure the top cover. Do not over tighten the screw.

05

Loading...

Loading...